Patents

Literature

7378 results about "Nondestructive testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nondestructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing. NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art. Innovations in the field of nondestructive testing have had a profound impact on medical imaging, including on echocardiography, medical ultrasonography, and digital radiography.

Multi-parameter X-ray computed tomography

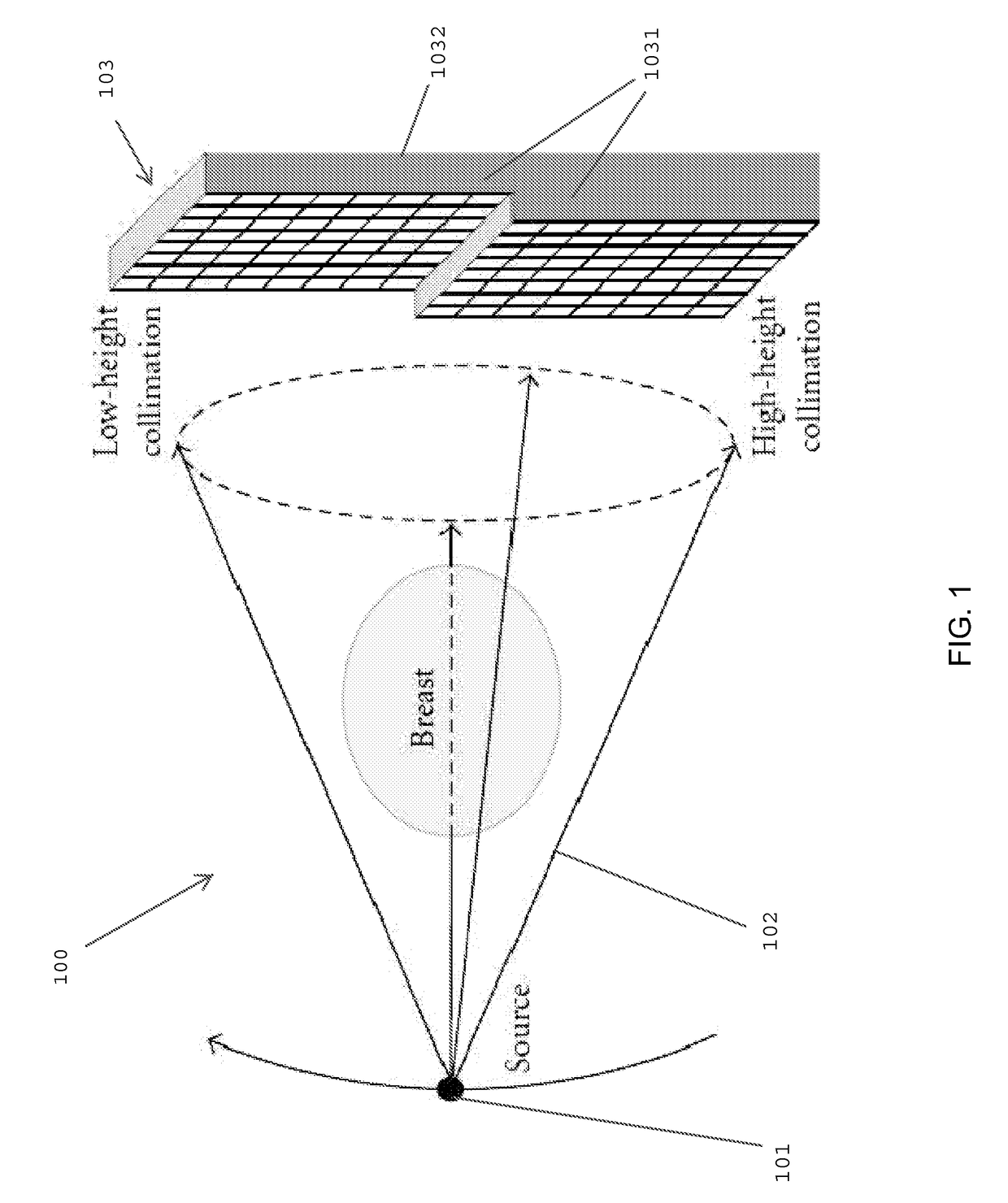

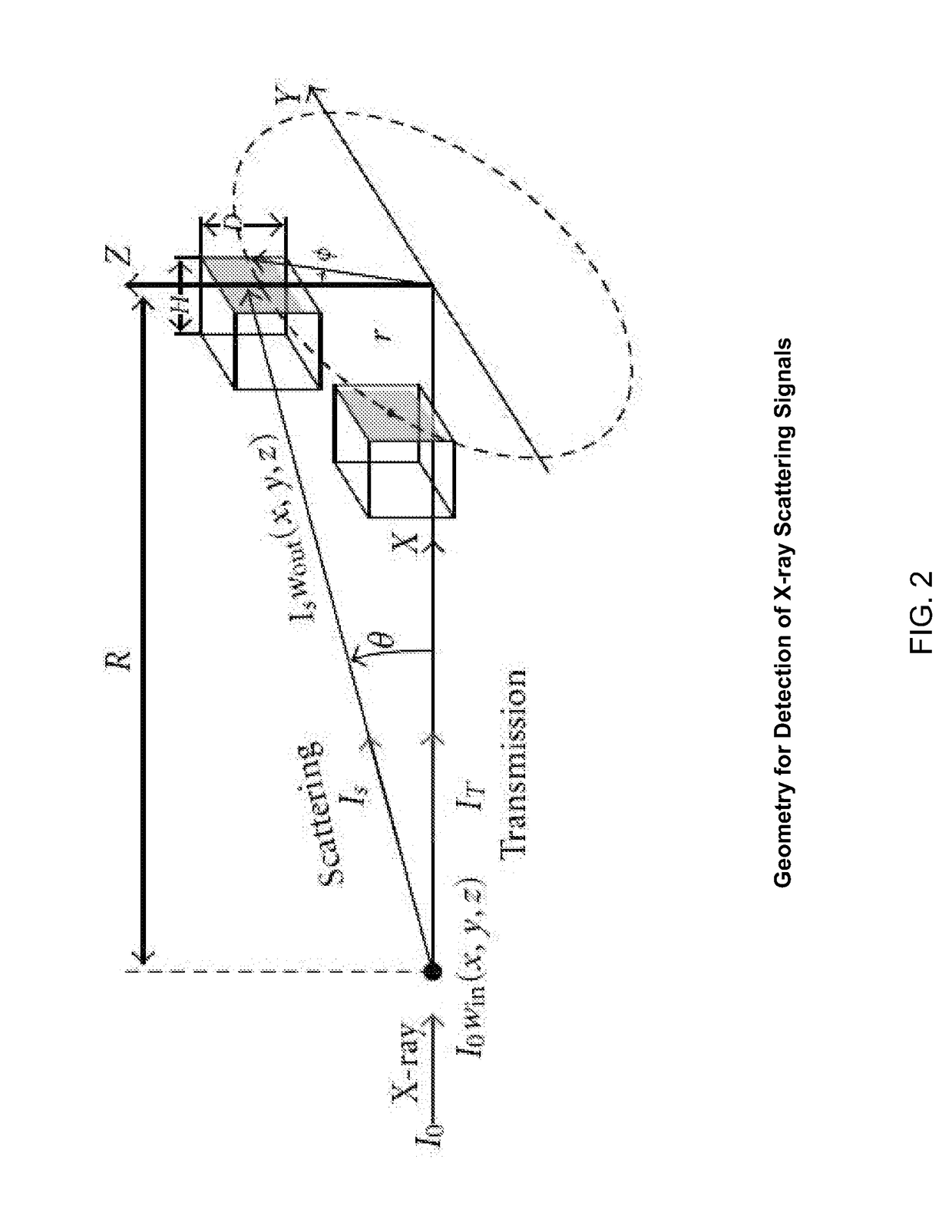

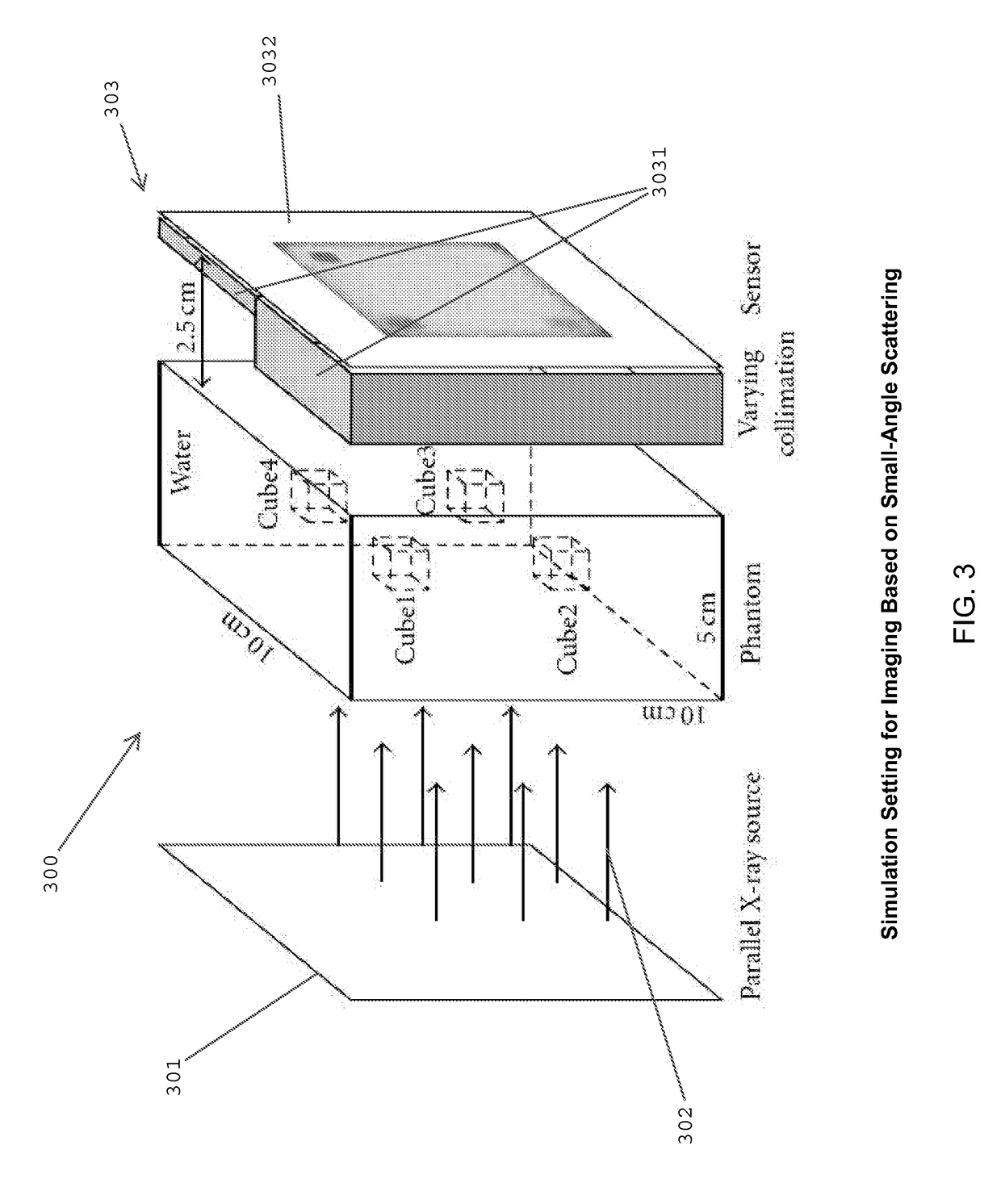

ActiveUS8121249B2Eliminate crosstalkIncrease sampling rateRadiation/particle handlingTomographyData setX-ray

Owner:VIRGINIA TECH INTPROP INC

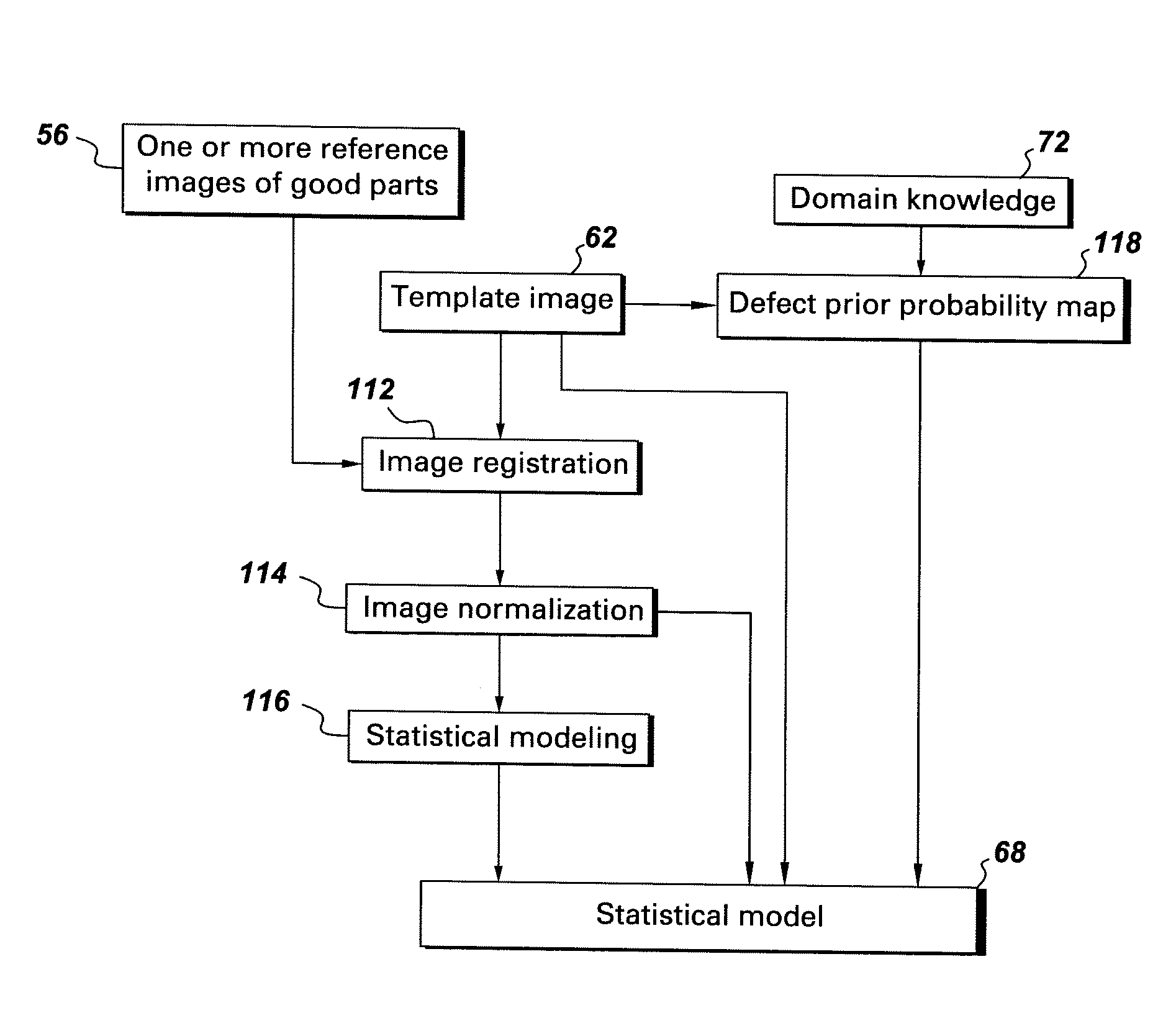

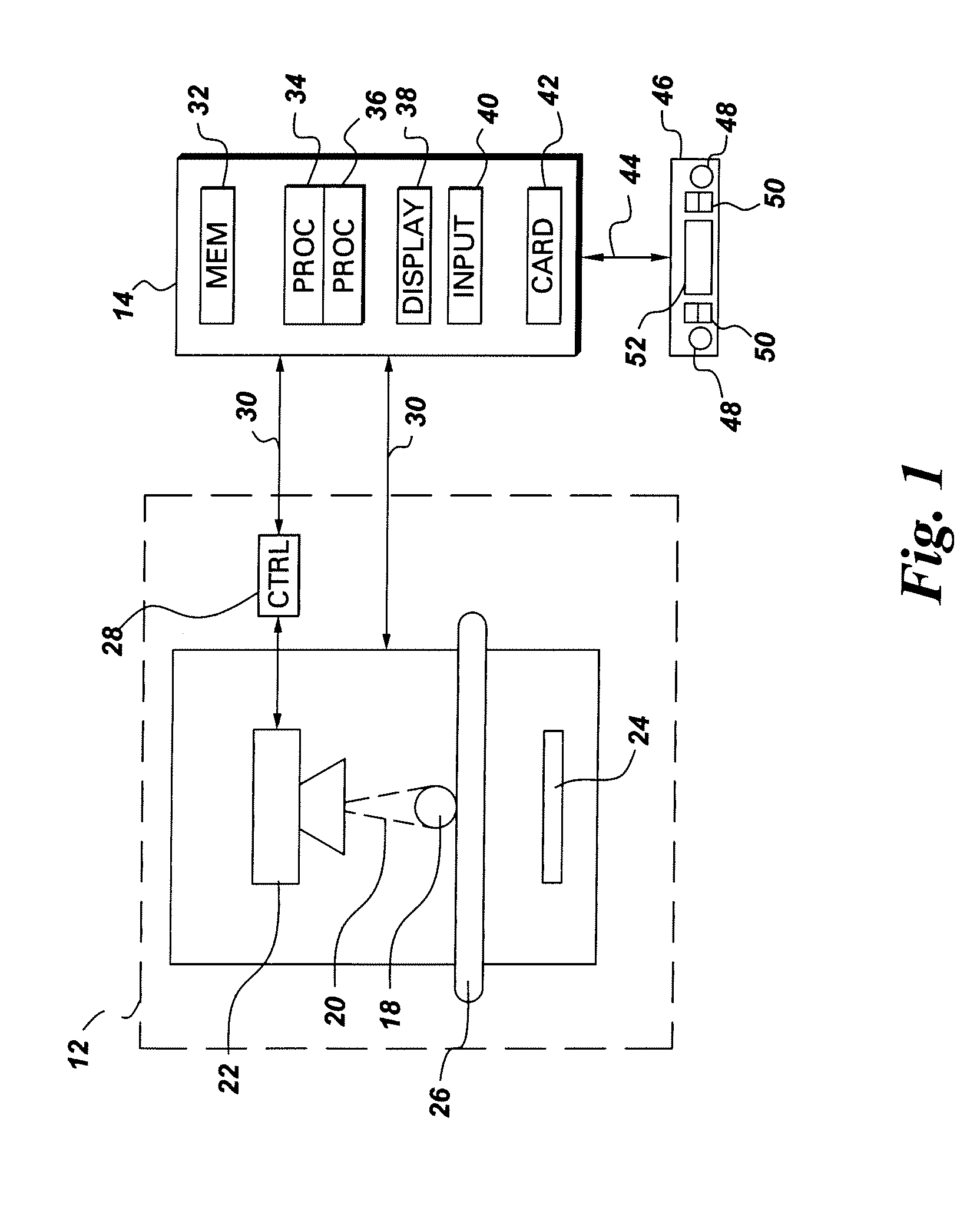

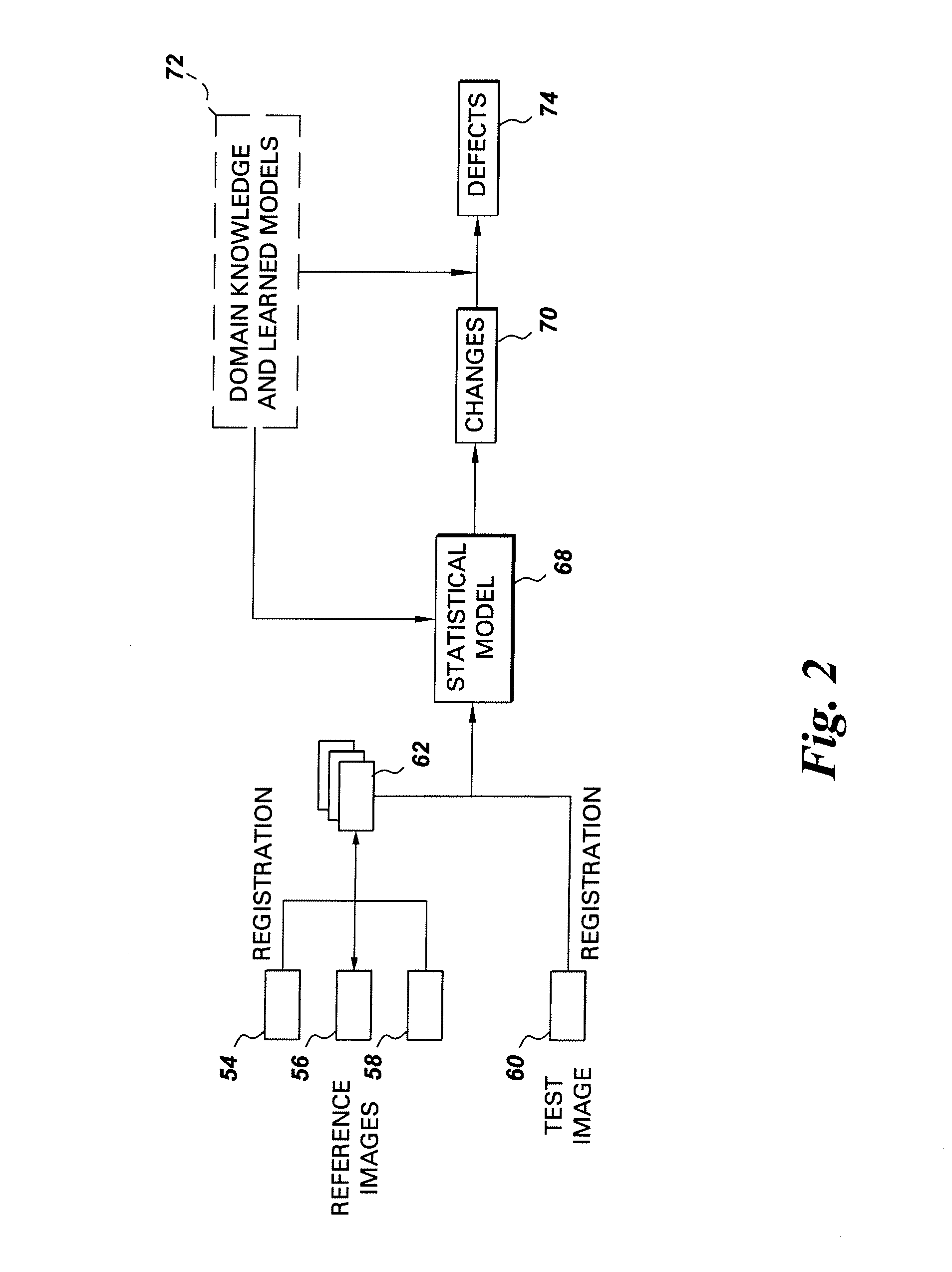

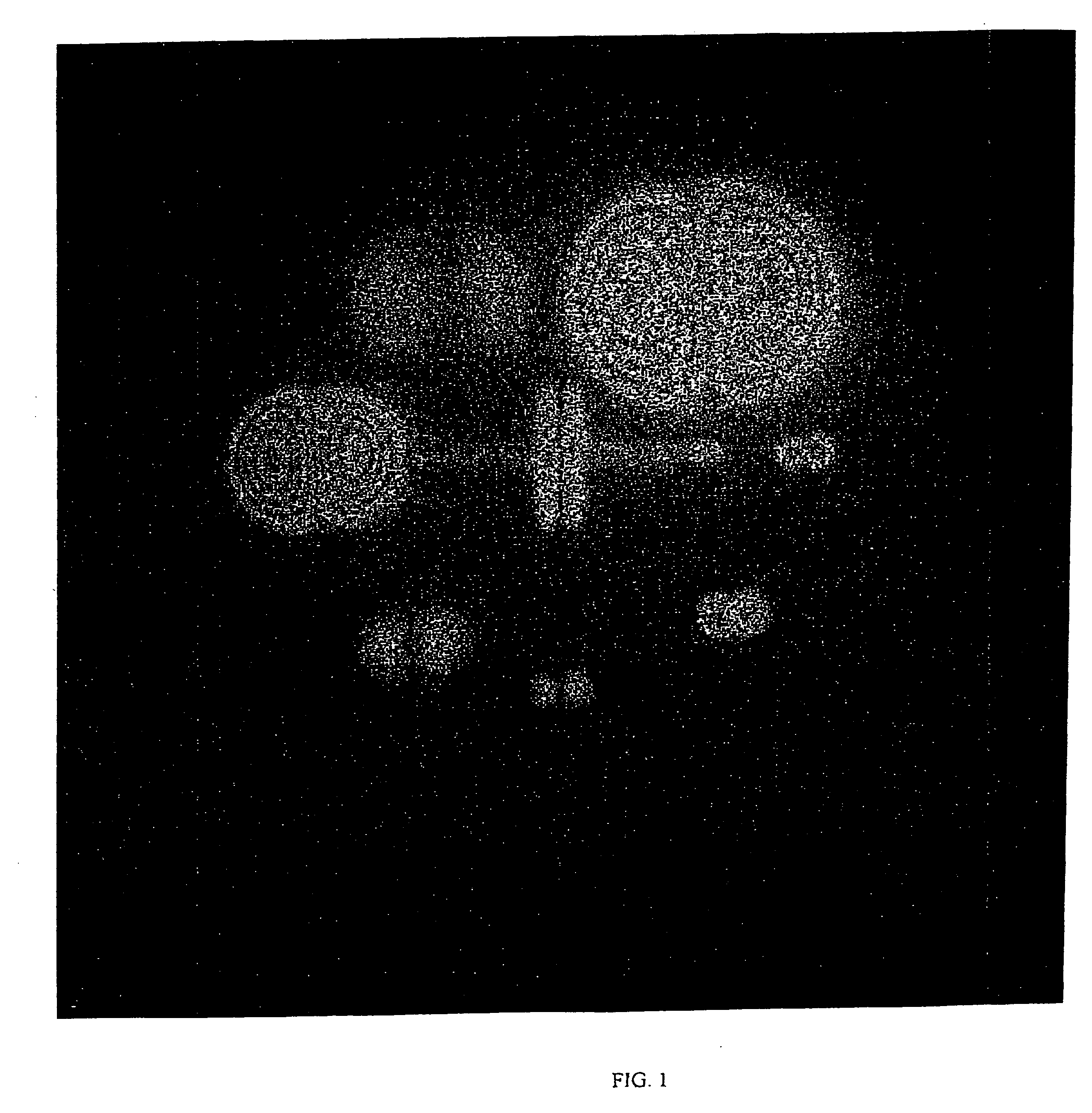

Method and System for Identifying Defects in NDT Image Data

An anomaly detection method includes acquiring image data corresponding to nondestructive testing (NDT) of a scanned object. The NDT image data comprises at least one inspection test image of the scanned object and multiple reference images for the scanned object. The anomaly detection method further includes generating an anomaly detection model based on a statistical analysis of one or more image features in the reference images for the scanned object and identifying one or more defects in the inspection test image, based on the anomaly detection model.

Owner:GENERAL ELECTRIC CO

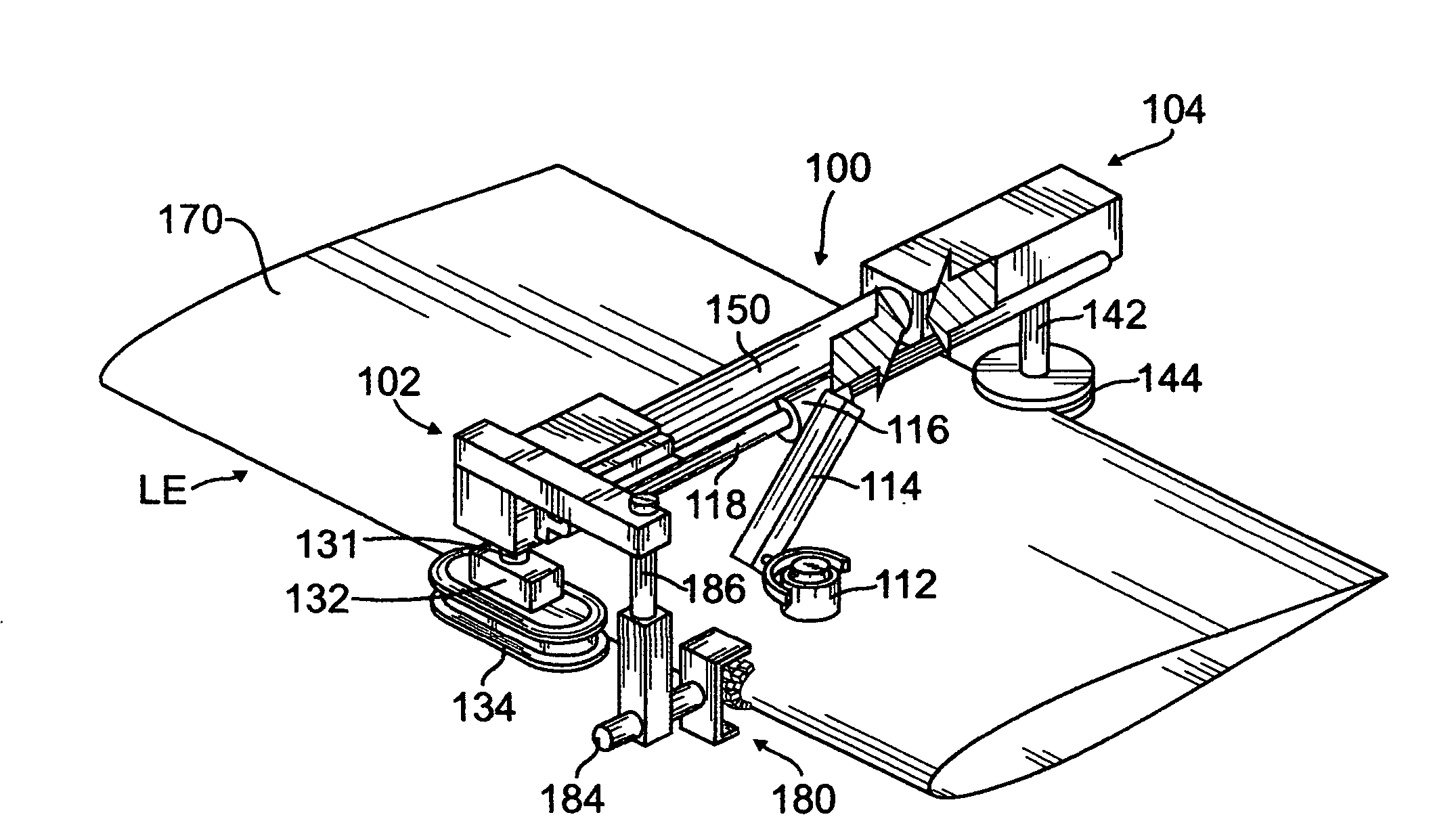

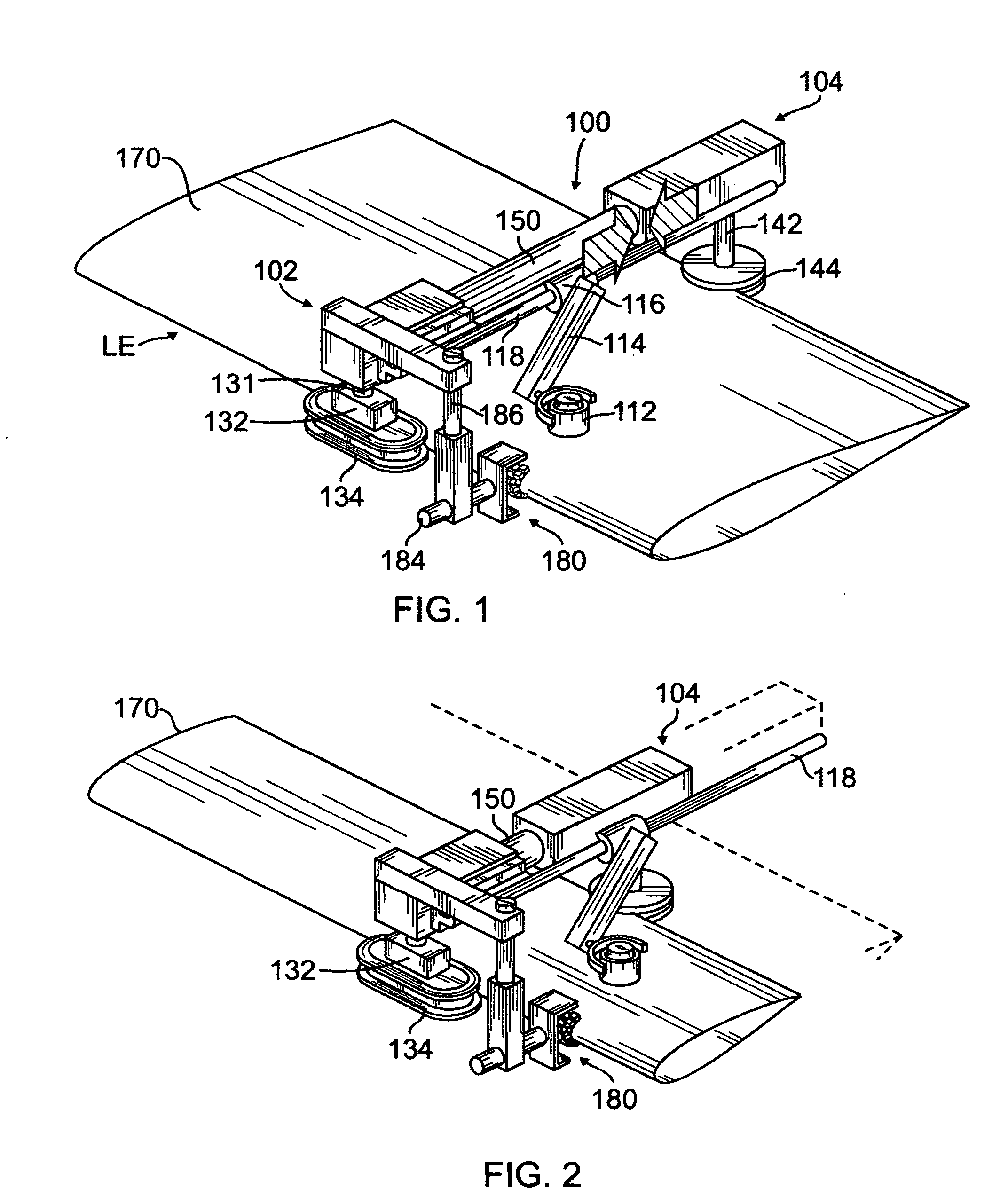

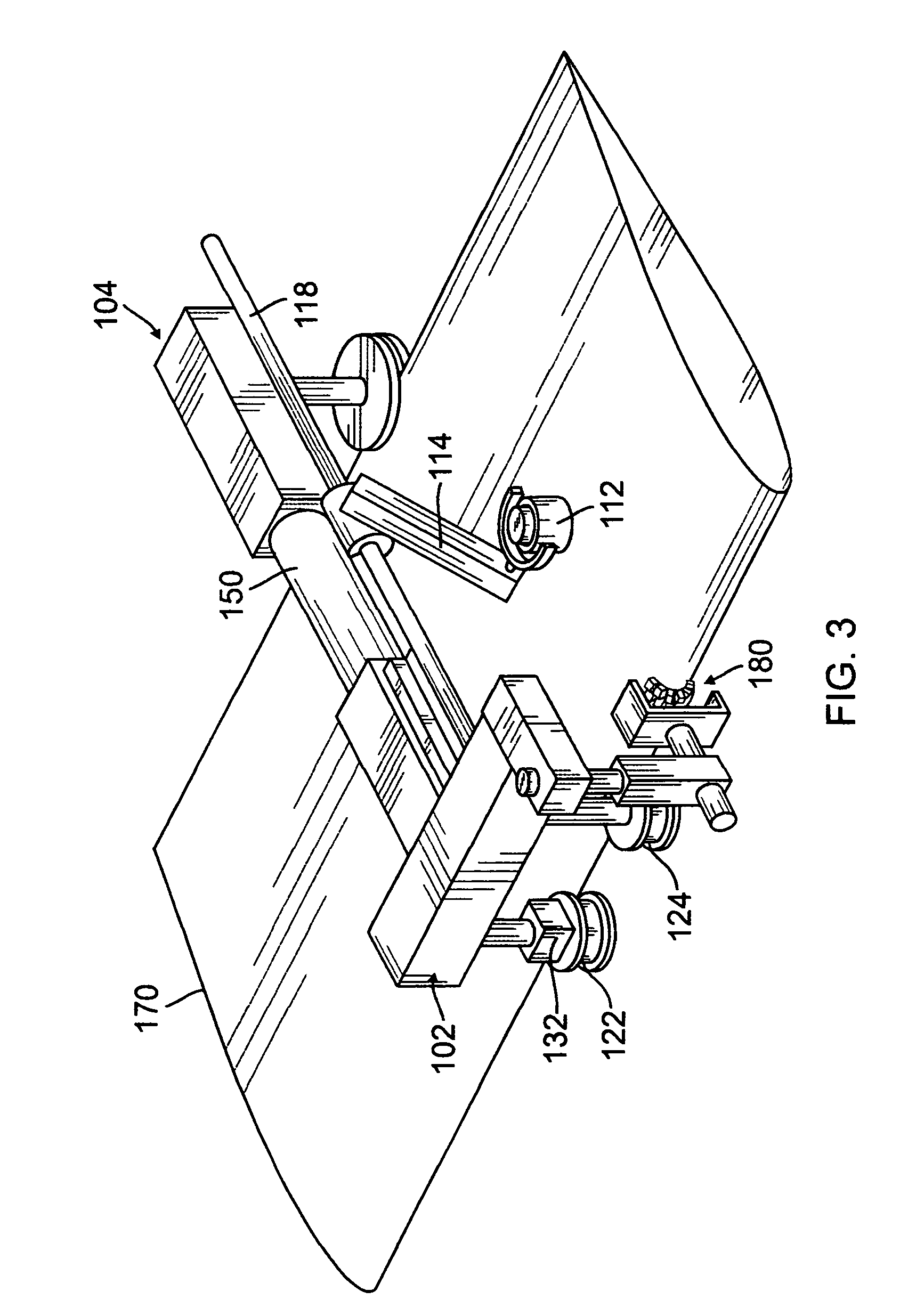

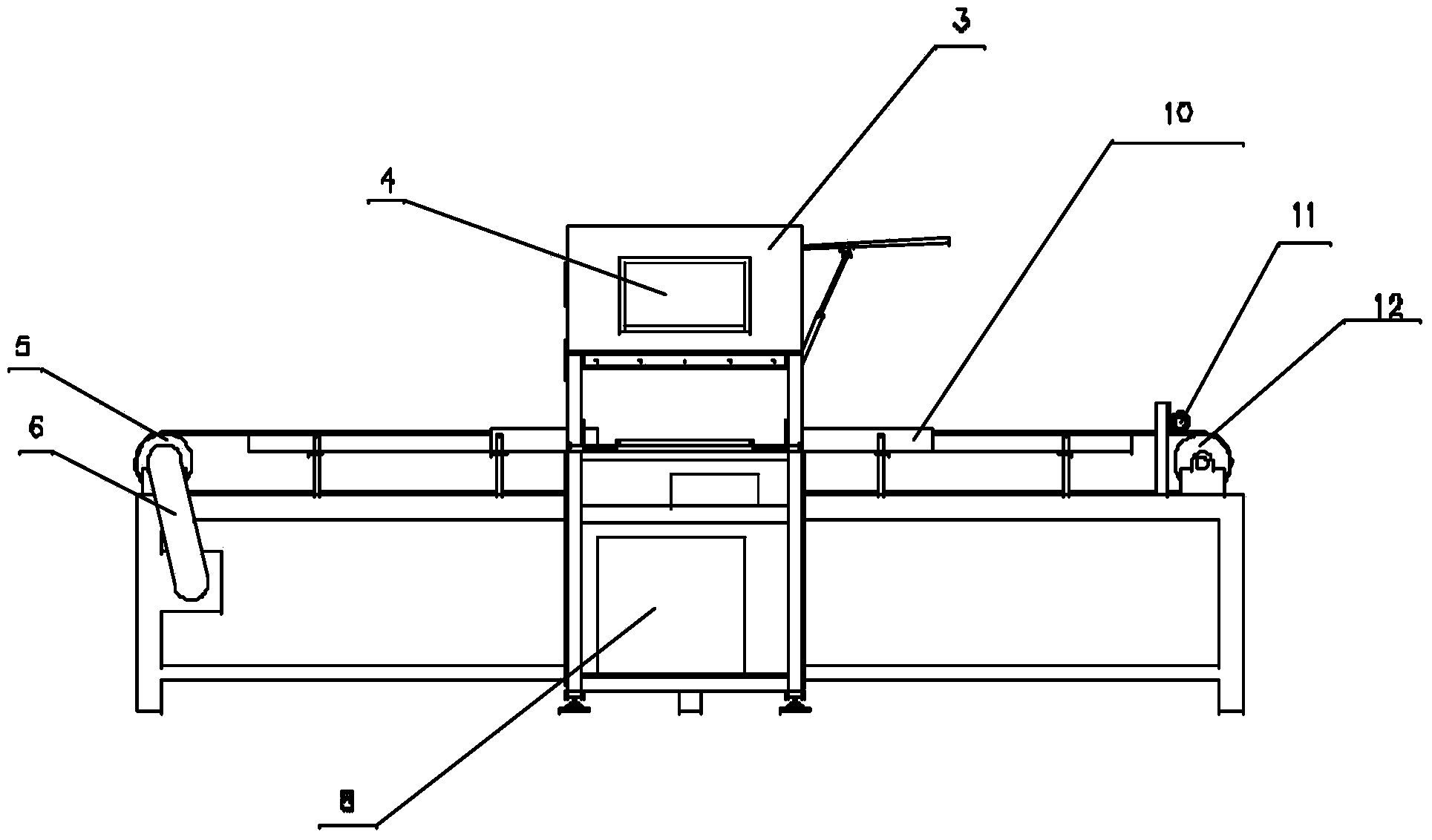

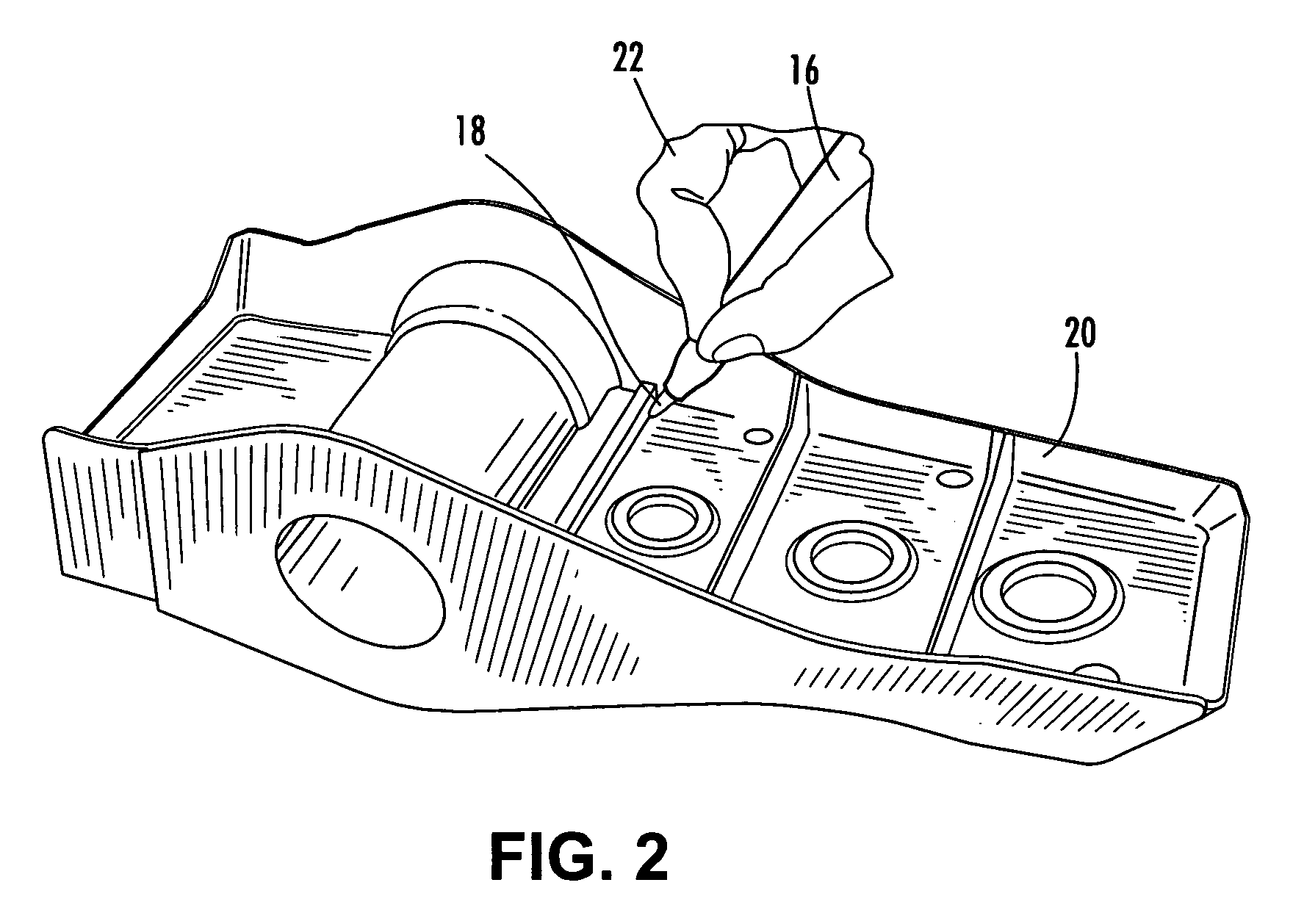

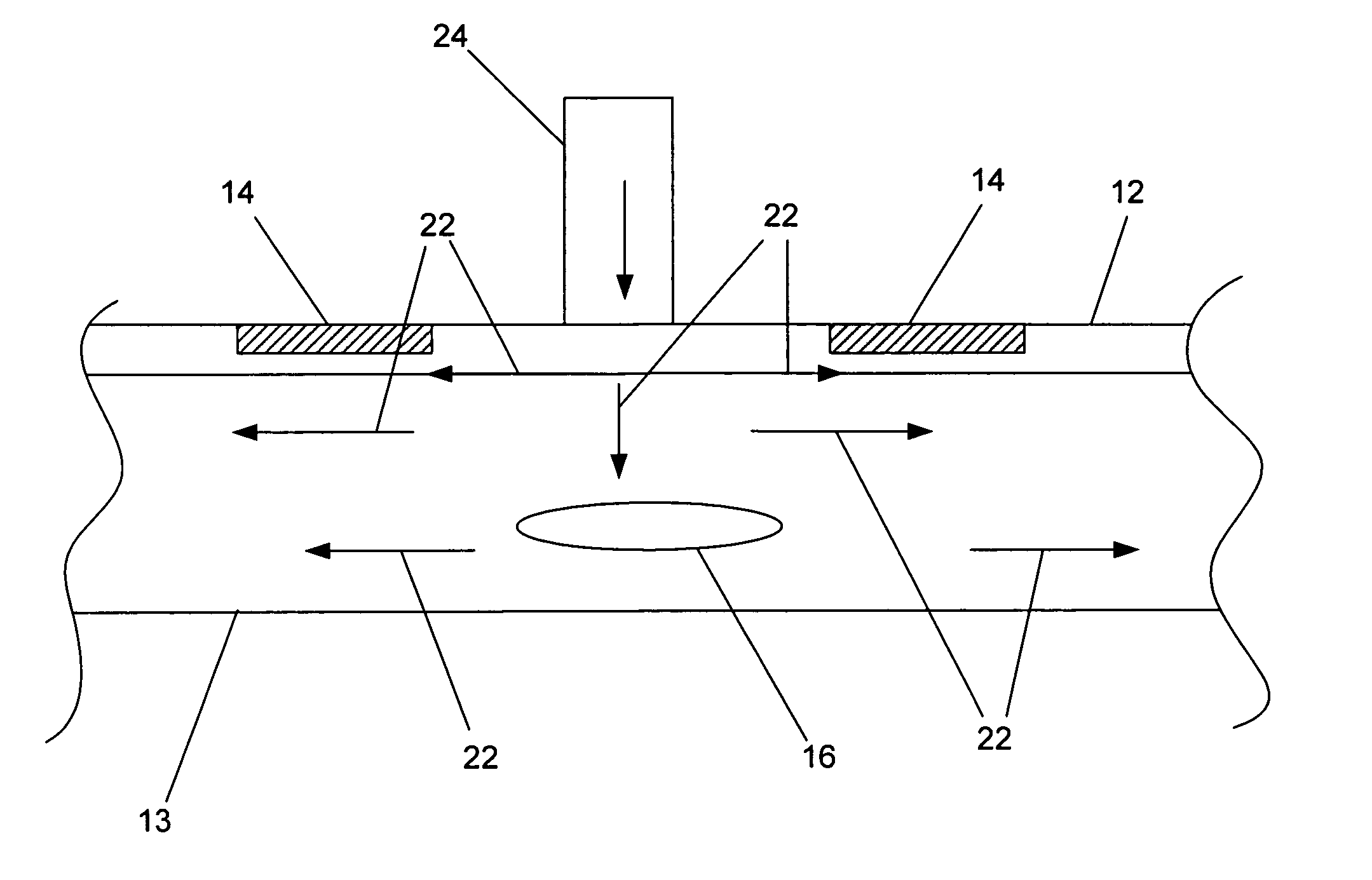

Crawling automated scanner for non-destructive inspection of aeropace structural elements

ActiveUS20110178727A1Material analysis using sonic/ultrasonic/infrasonic wavesBlade accessoriesAviationLeading edge

Apparatus for non-destructive inspection of structural elements or workpieces, in particular those having an airfoil configuration, that moves a scanning sensor across the width (span) of a structural element or workpiece for the purpose of detecting structural damage. In one embodiment, the apparatus simultaneously traverses the length (chord) of the structural element or workpiece. In another embodiment, the apparatus includes a guide rail that encompasses the structural element or workpiece and the scanning sensor travels along the guide rail from a first location at an upper rear region, to the front, of the structural element or workpiece, and then around the leading edge toward the lower rear region. The apparatus includes a processor and a display device to display the processed, sensed, information.

Owner:THE BOEING CO

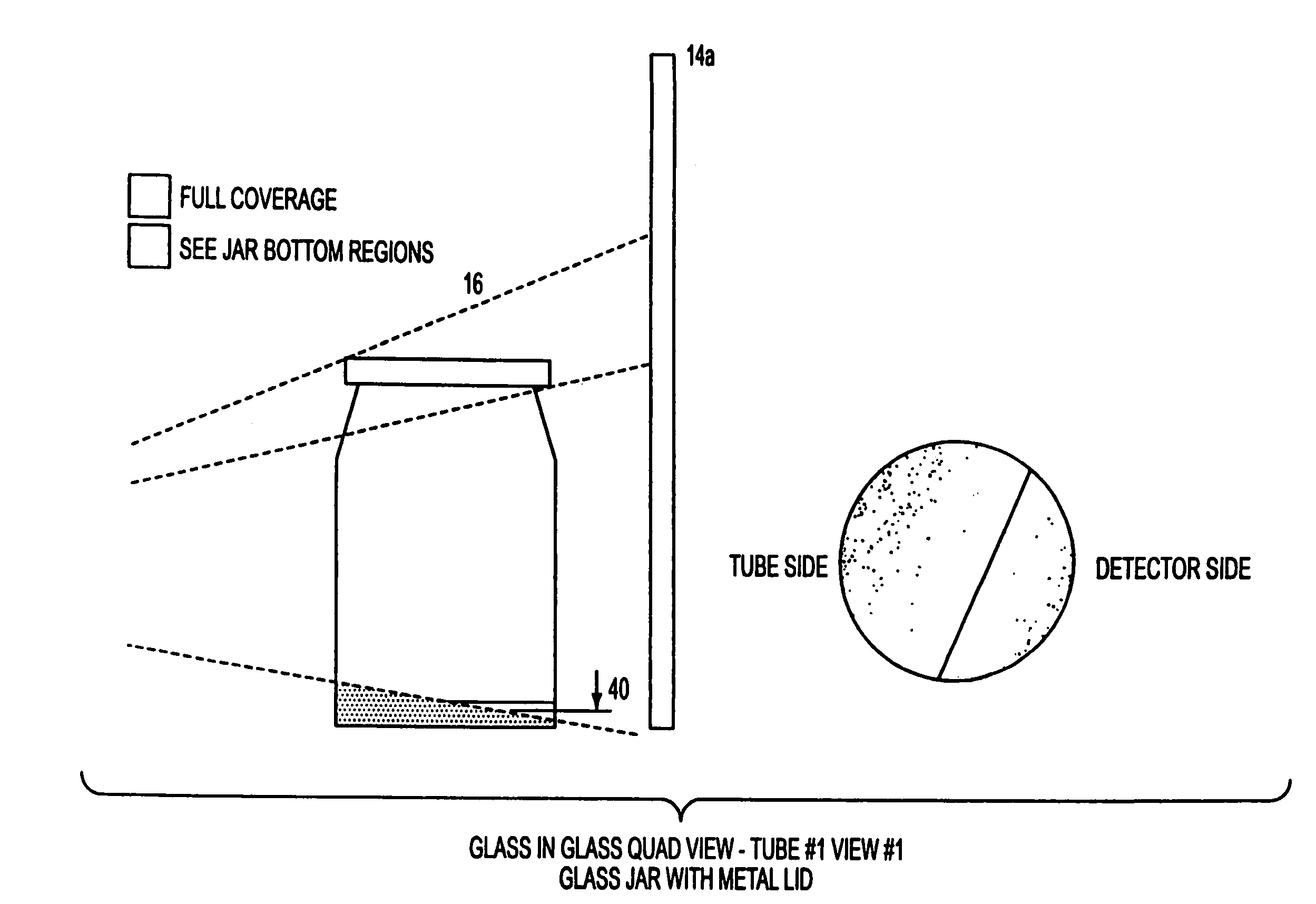

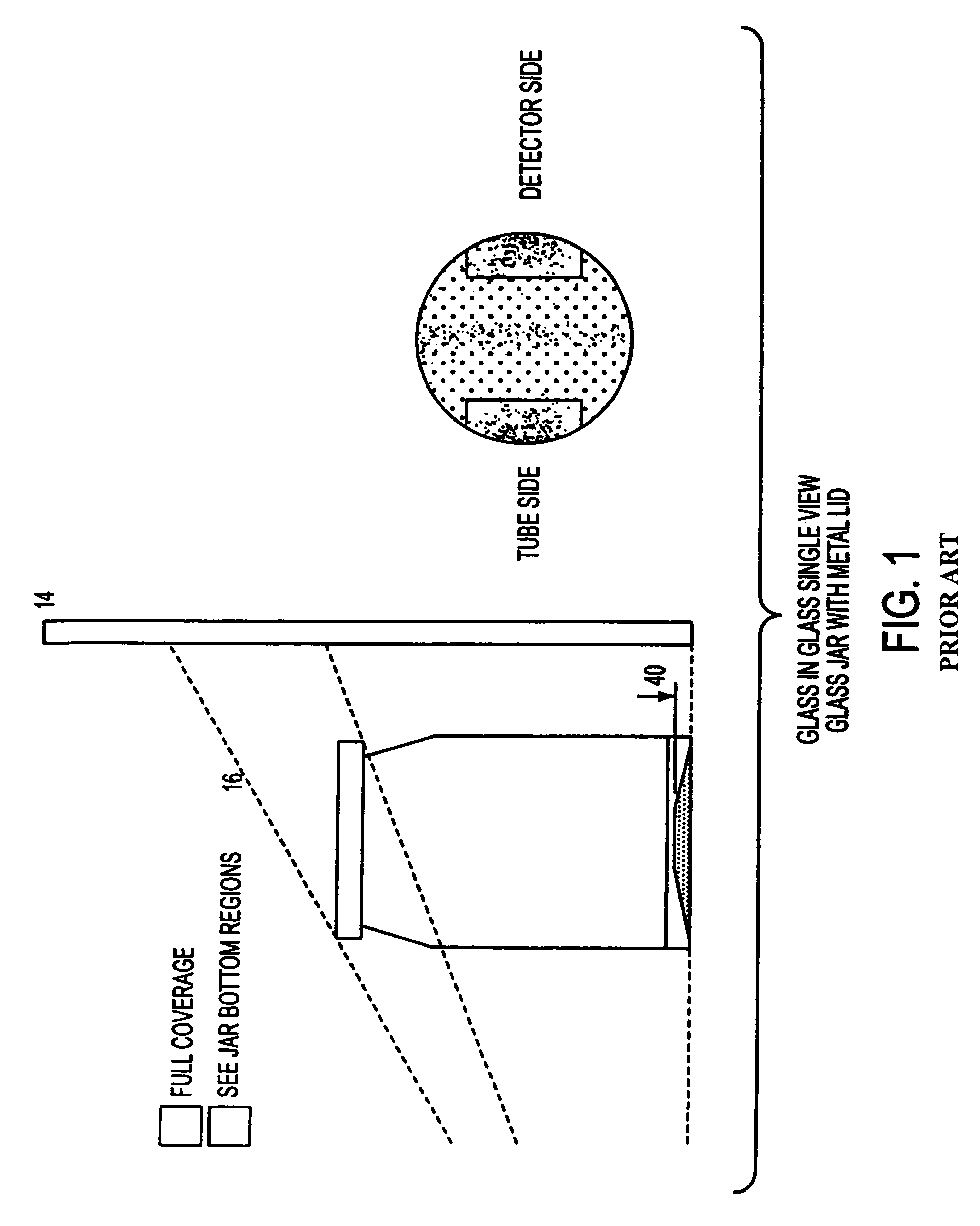

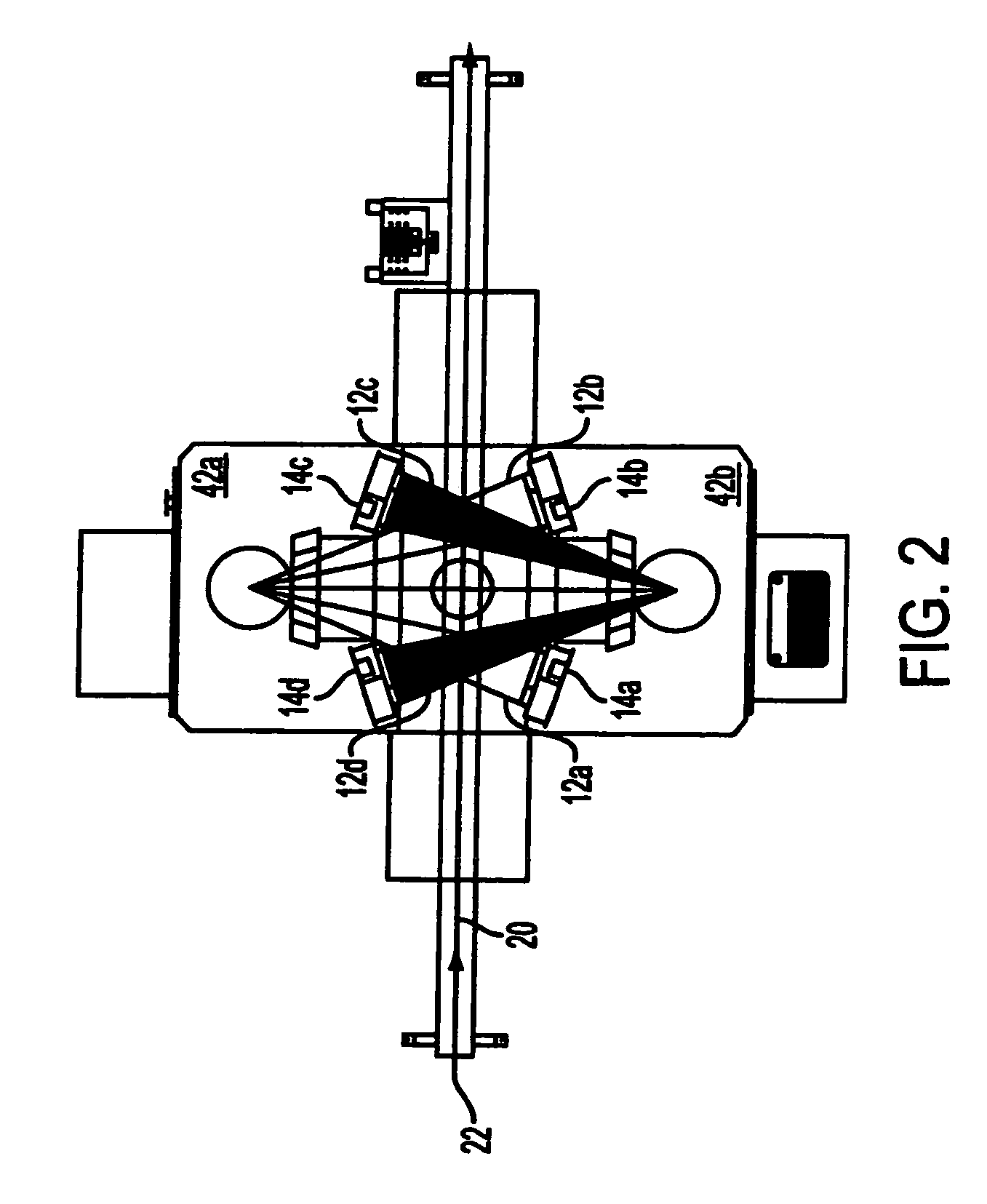

Non-destructive inspection of material in container

InactiveUS7164750B2Using wave/particle radiation meansMaterial analysis by transmitting radiationNon destructiveX-ray

An apparatus and method for non-destructive inspection of materials housed in containers involves orienting an X-ray beam emitter and detector to direct and detect an X-ray beam at an angle substantially parallel to a sloped surface of the container to be inspected. A first X-ray apparatus is located opposite a second X-ray apparatus, and both the first and second X-ray apparatus are adapted to provide two X-ray beams. This arrangement provides for imaging of the entire area of a sloped portion of the container without any shadow or hidden spots.

Owner:METTLER TOLEDO INC

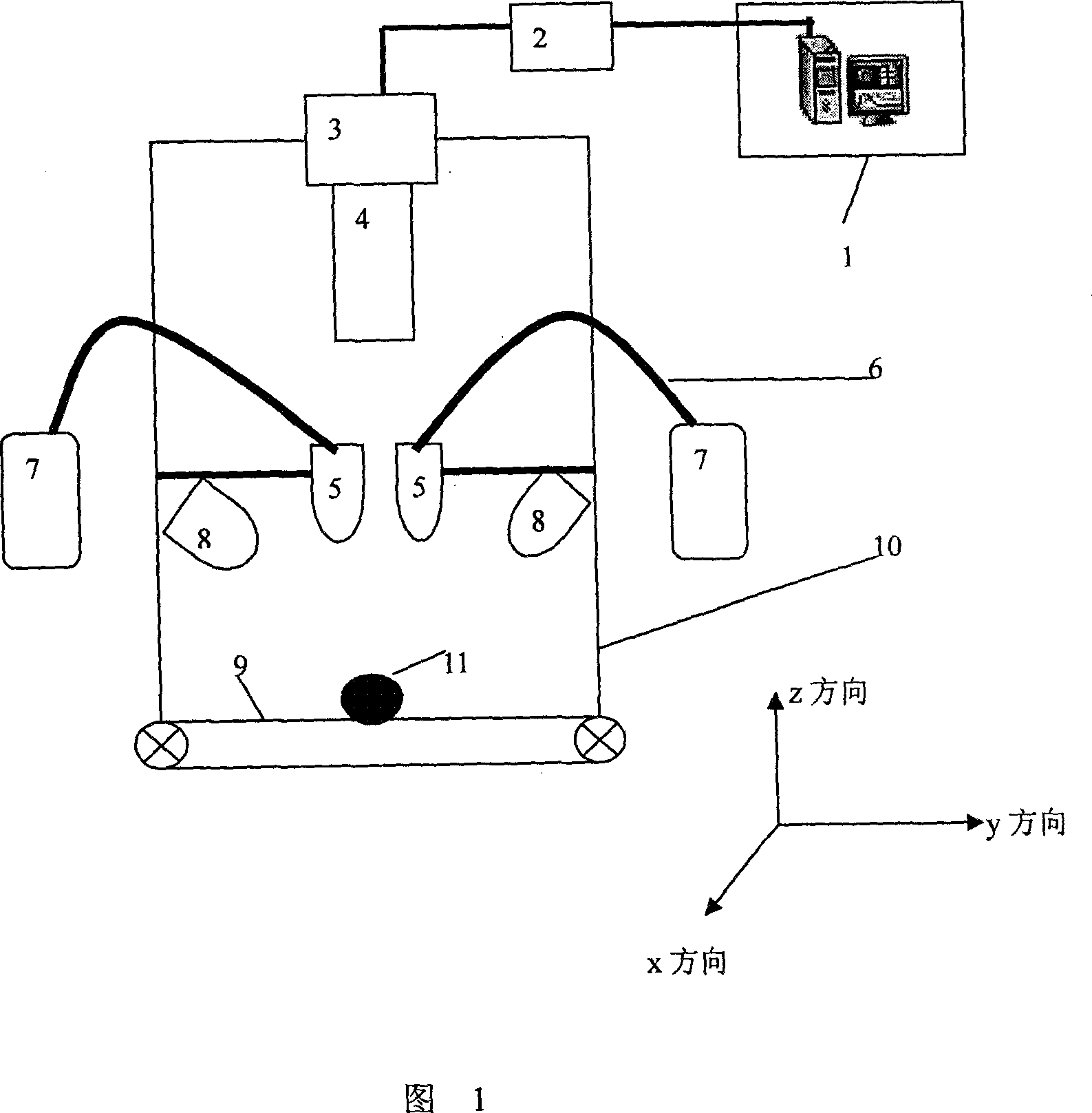

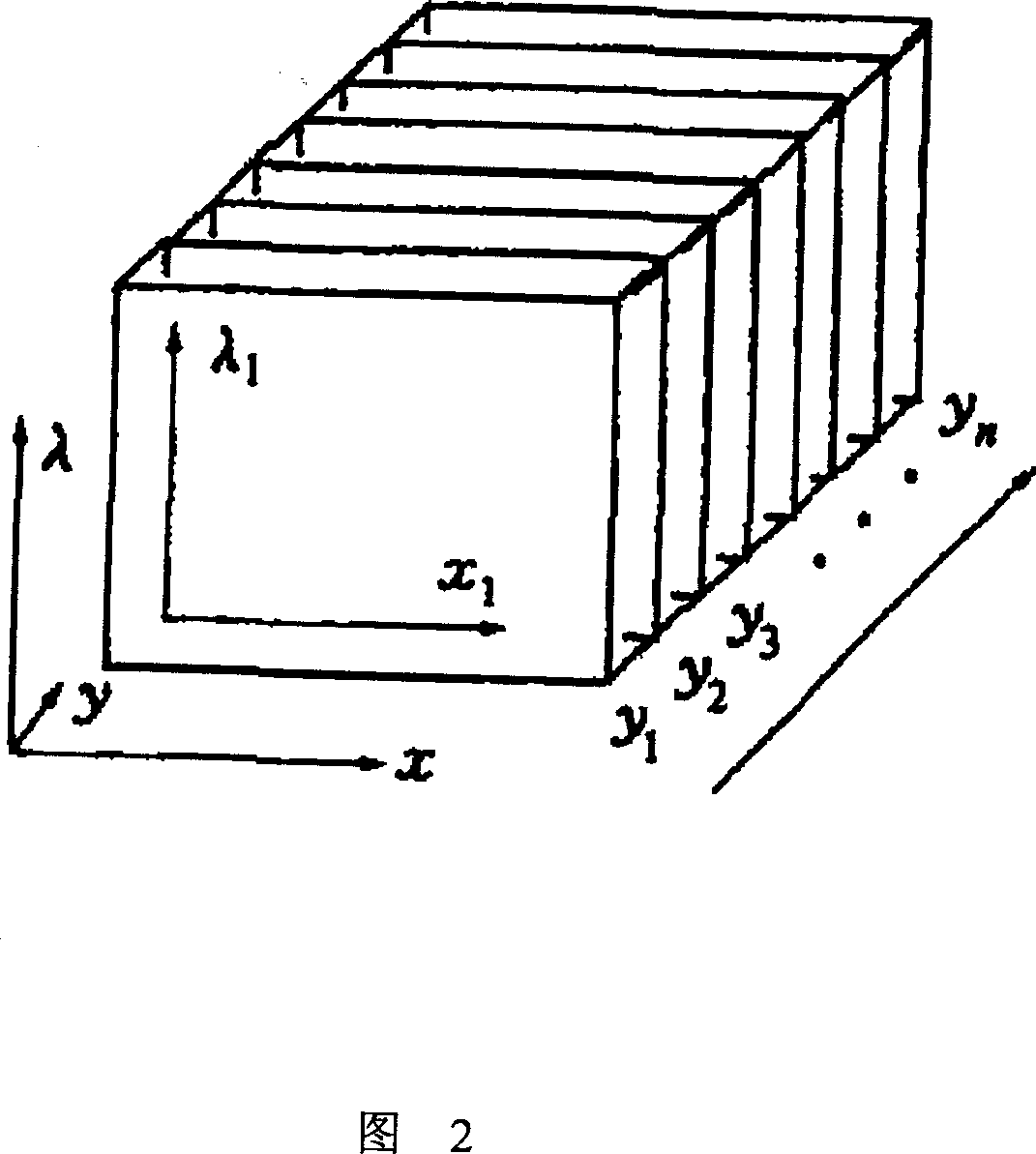

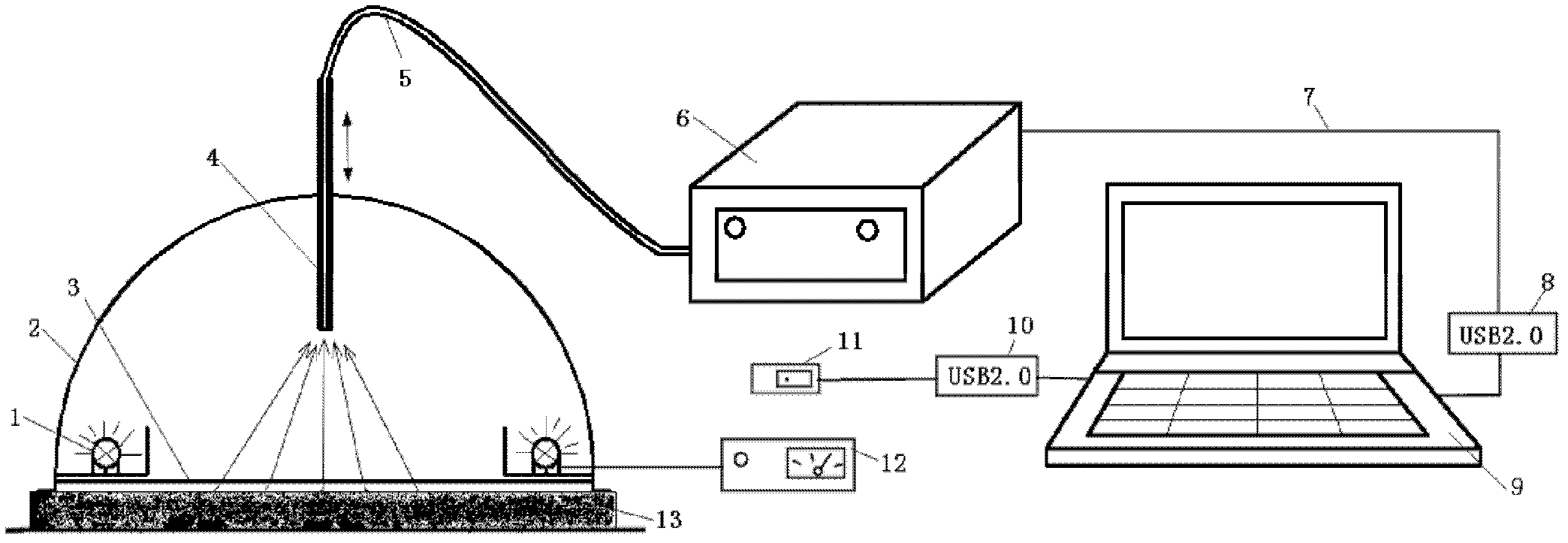

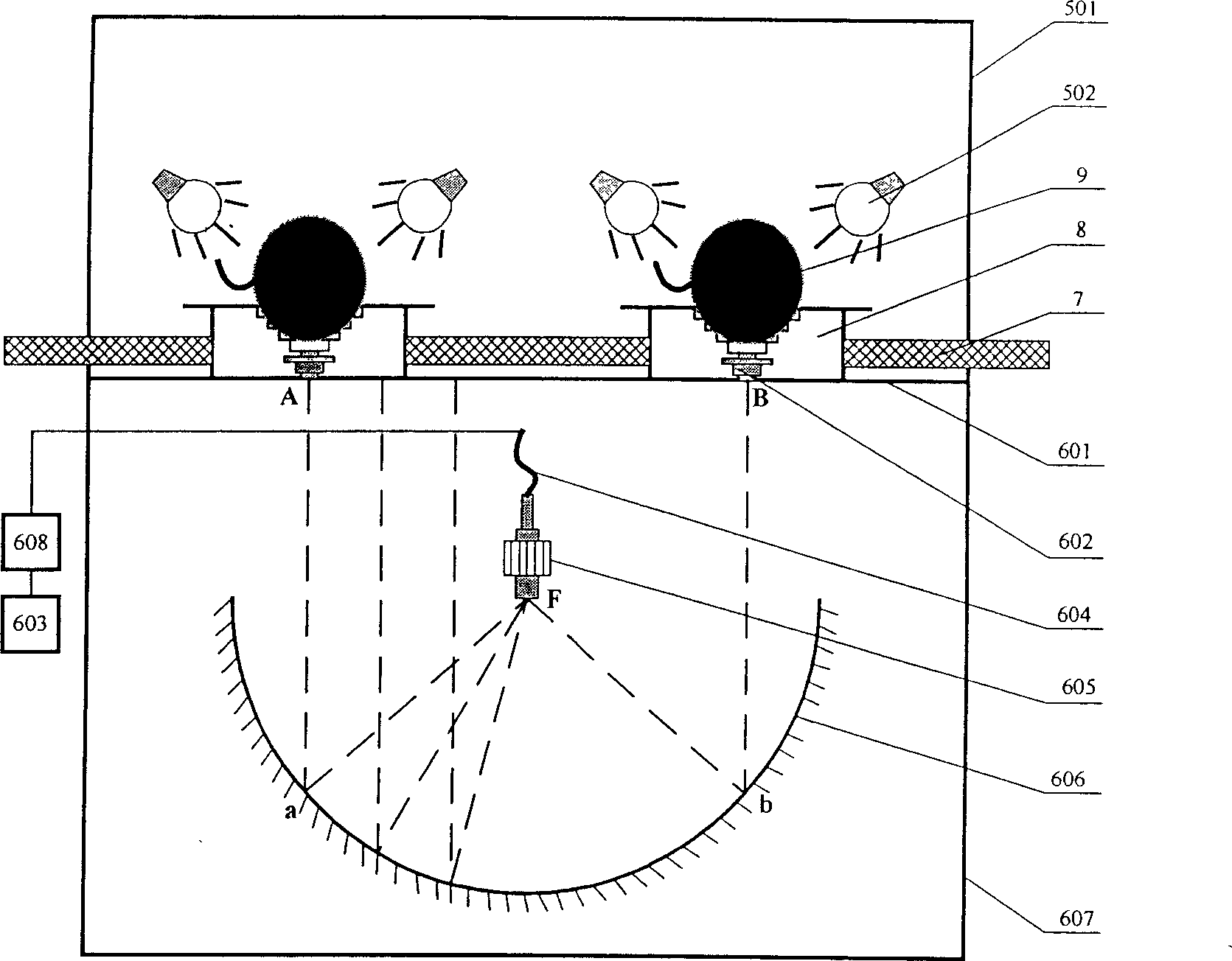

Non-destructive detection method and device for agricultural and animal products based on hyperspectral image technology

InactiveCN1995987AWith artificial intelligenceGuaranteed sampling qualityImage analysisMaterial analysis by optical meansNon destructiveAnimal product

The invention relates to high optical spectral image technique without harm to agricultural products. It can reflect the appearance of the agriculture products like color, shape, texture, dimension, scar and son on, and internal features like hardness, protein content and connected with knowledge base and experience of experts to make judgment. It can make quick, accurate, timely judgment of products, controlling the overall production with guarantee of the agriculture quality.

Owner:JIANGSU UNIV

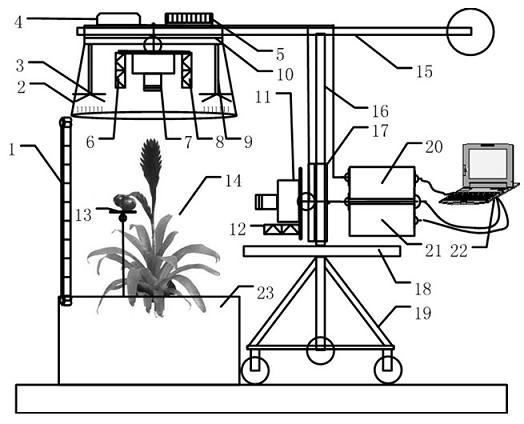

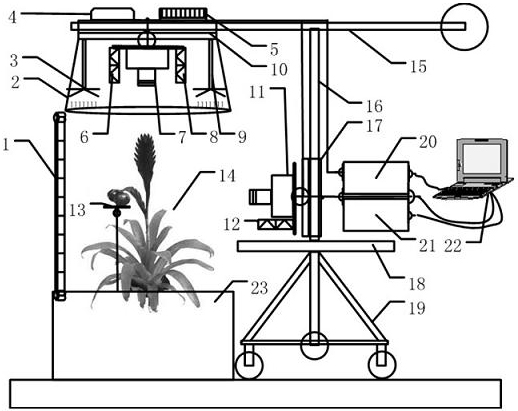

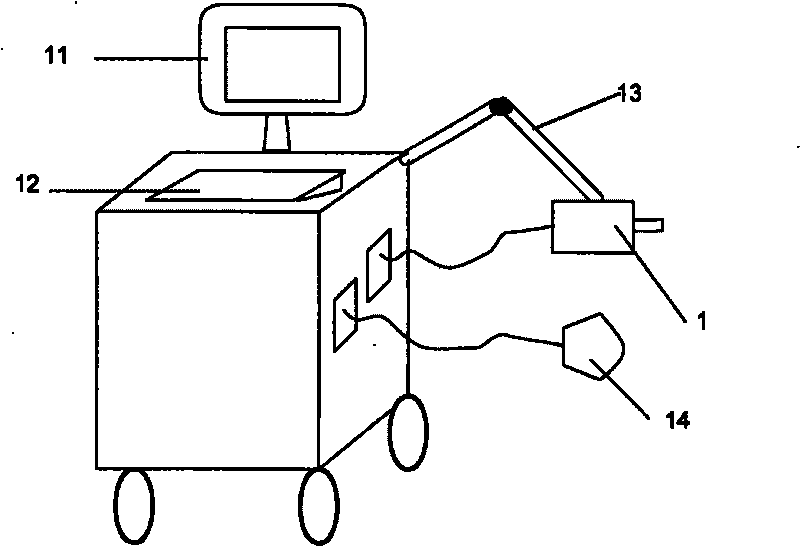

Nondestructive detection device and method for facility crop growth information

ActiveCN102384767AGrasp the state of growthImprove acquisitionMeasurement devicesPotassiumCharacteristic space

The invention discloses a nondestructive detection device and a nondestructive detection method for facility crop growth information, and belongs to the technical field of monitoring of facility crops. The device comprises a growth information sensing system, an electric control mechanical rocker arm and a control computer; the control computer drives the electric control mechanical rocker arm to be positioned at a detection position, and controls the growth information sensing system; reflection spectrums of nitrogen, phosphorus, potassium and moisture of crops, multispectral images, canopy temperature characteristic, multispectral morphological characteristics of canopies, stalks, plants and fruits, fruit quality information, and information of environmental illumination, temperature and humidity are acquired by using a multispectral imager and sensors of infrared temperature, irradiance, environmental temperature and humidity and load; nutrient and moisture characteristic spaces are acquired by optimizing and compensating the nutrient and moisture characteristics of the crops; and growth vigor information of canopy area, stalk thickness, fruit quality, plant height and the like is acquired by extracting the multispectral morphological characteristics of the crops, and comprehensive acquisition and nondestructive detection of the growth information of the crops are realized by combining nutrient, moisture and growth vigor characteristics.

Owner:JIANGSU UNIV

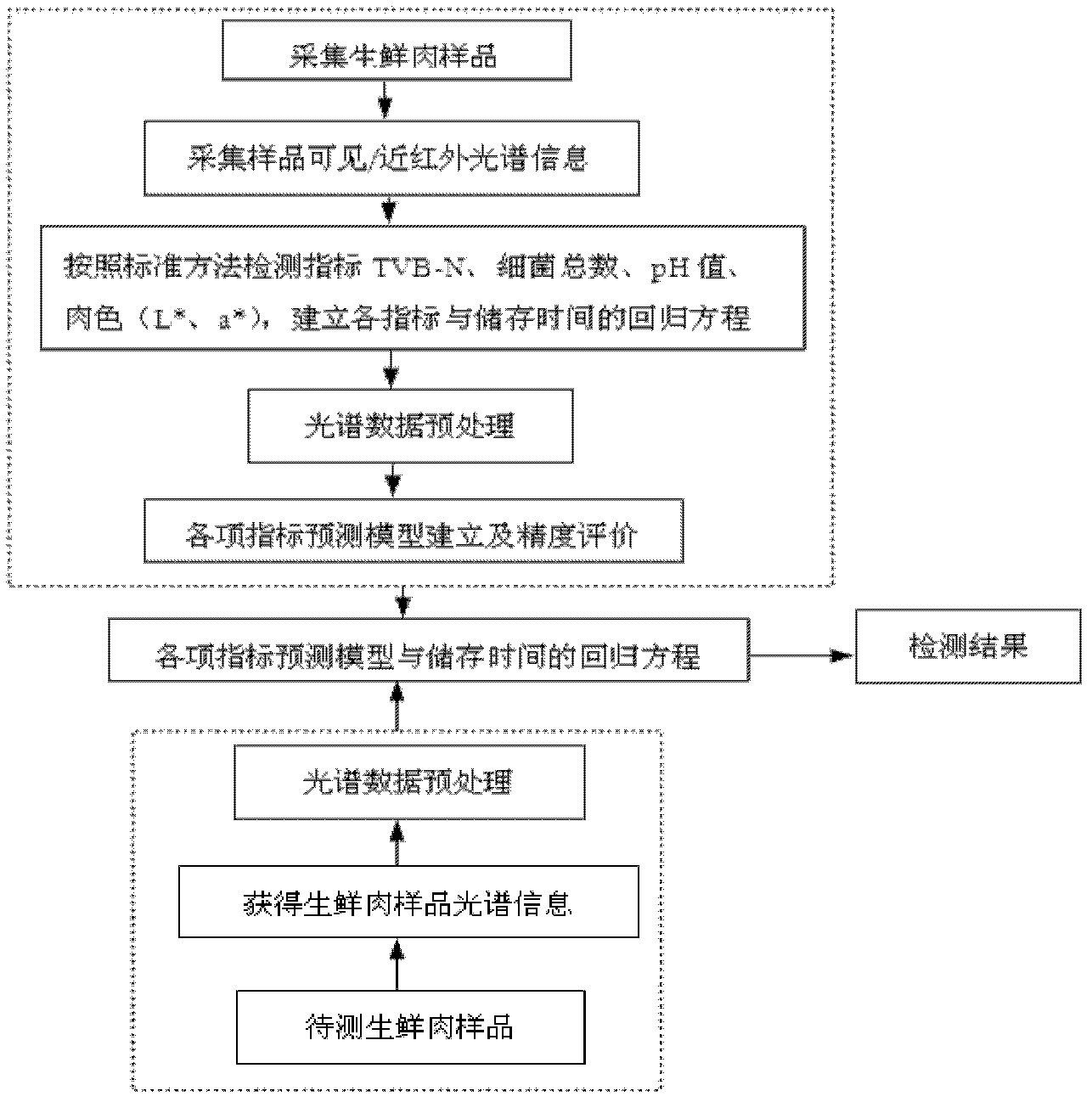

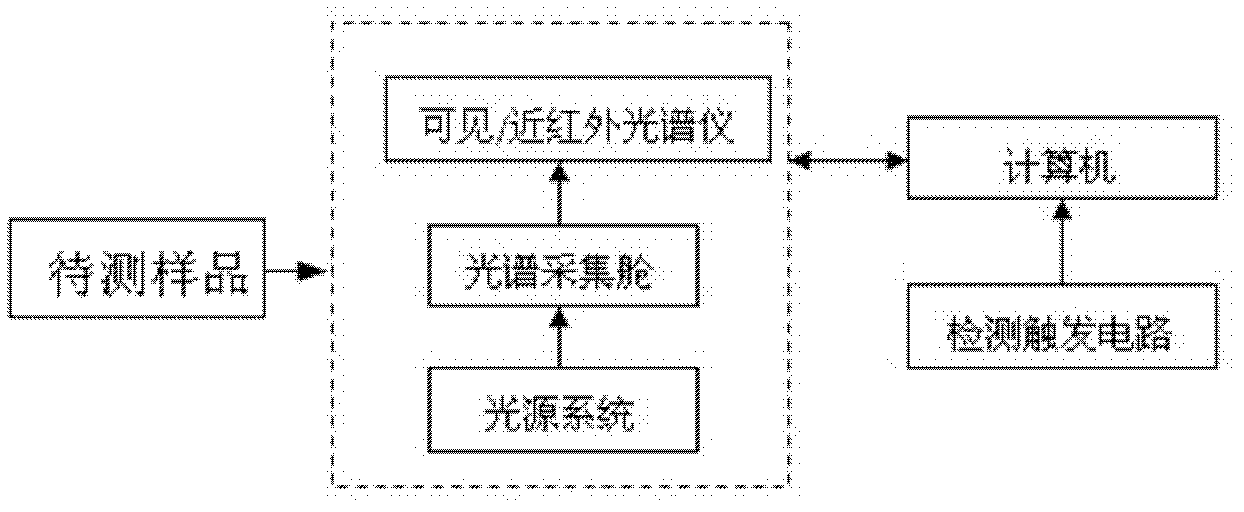

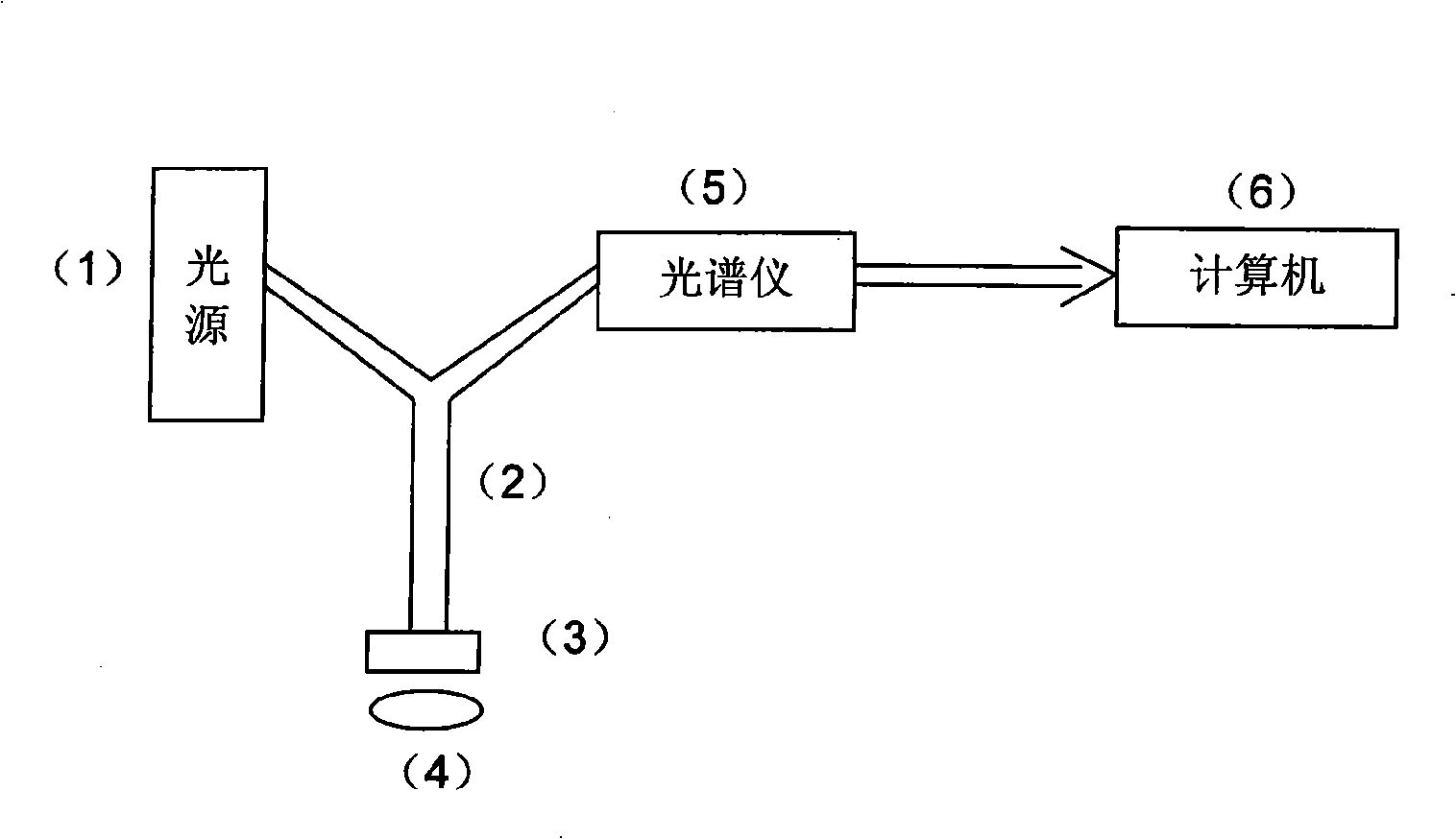

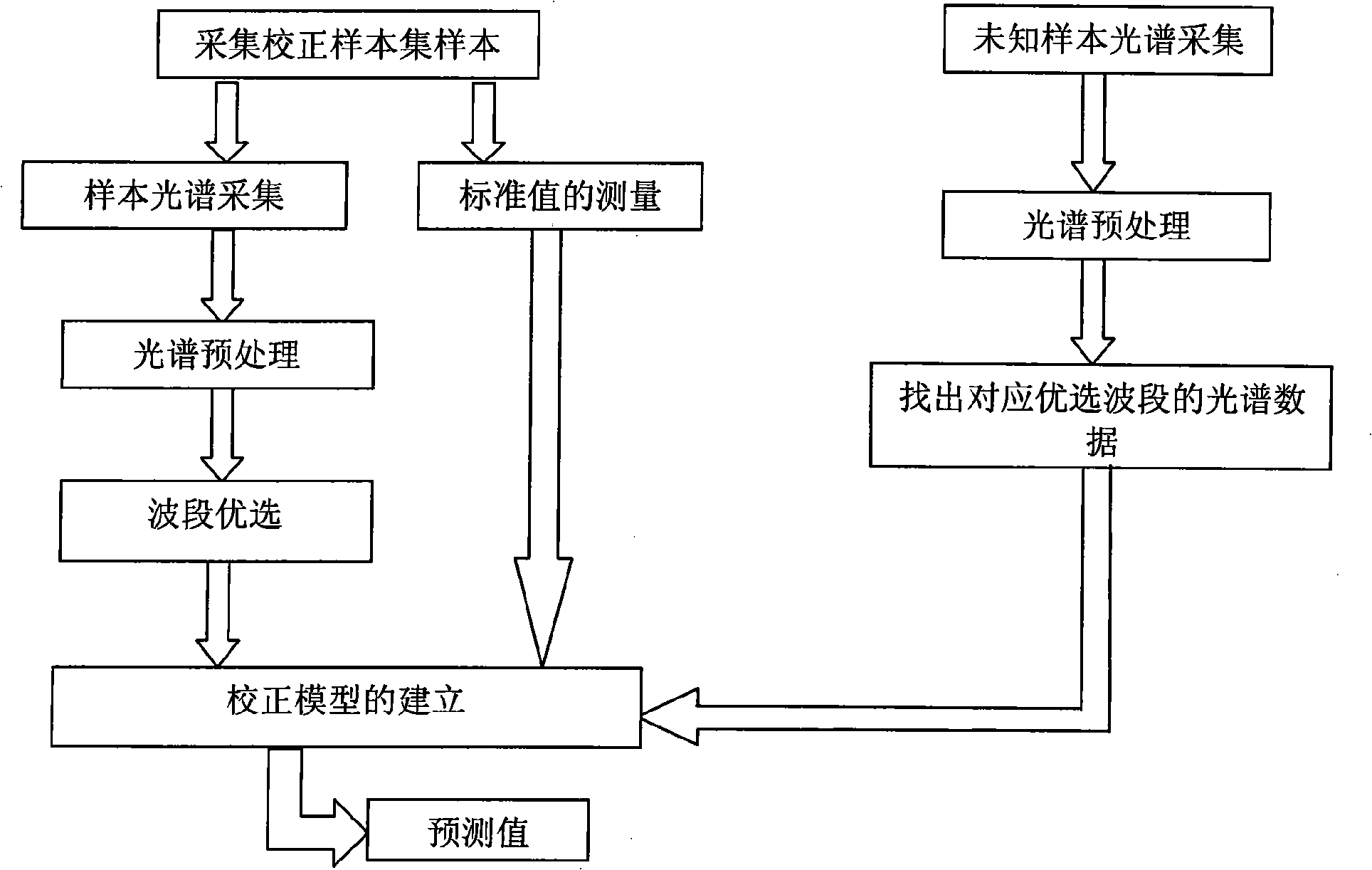

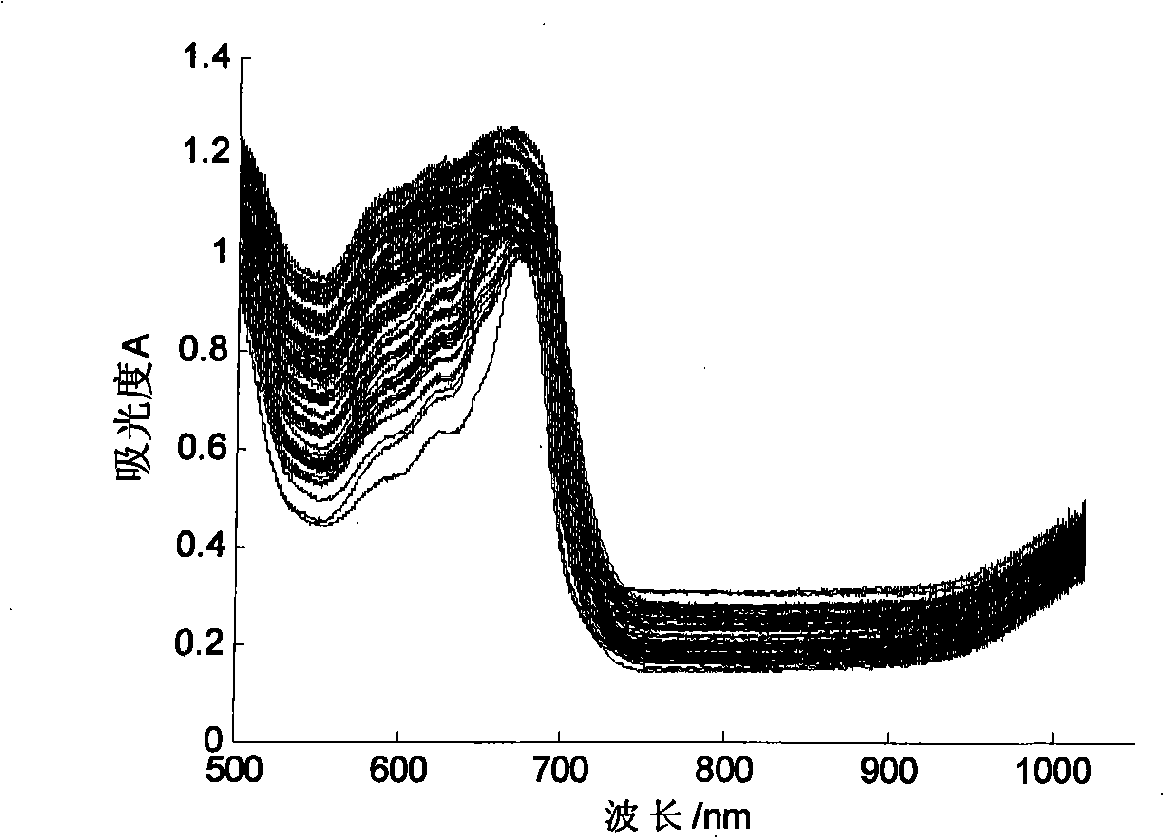

Method and system for quick lossless evaluation on freshness of fresh beef

ActiveCN102507459AHigh degree of intelligenceShort detection timeColor/spectral properties measurementsAdditive ingredientNitrogen

The invention discloses a method and system for quick lossless evaluation on multiple indexes of freshness of fresh beef by applying a visible / near infrared spectrum technology, belonging to the technical field of lossless detection of food. According to the invention, a mathematical prediction model is established between spectral information capable of reflecting fresh beef ingredients and physical state information, and multiple indexes of the freshness of the fresh beef, and the whole detection system is constructed on the basis of the mathematical prediction model, so that the system can be used for accurately and reliably detecting multiple unknown indexes of the freshness of the fresh beef (volatile basic nitrogen (TVB-N), pH value, total bacterial count and beef color (CIE color parameters L* and a*) and the like simultaneously, and predicating the storage time of the beef; furthermore, the freshness of the beef is graded comprehensively by combining multiple indexes, so that the quick lossless detection and evaluation on the freshness of the fresh beef are realized.

Owner:CHINA AGRI UNIV

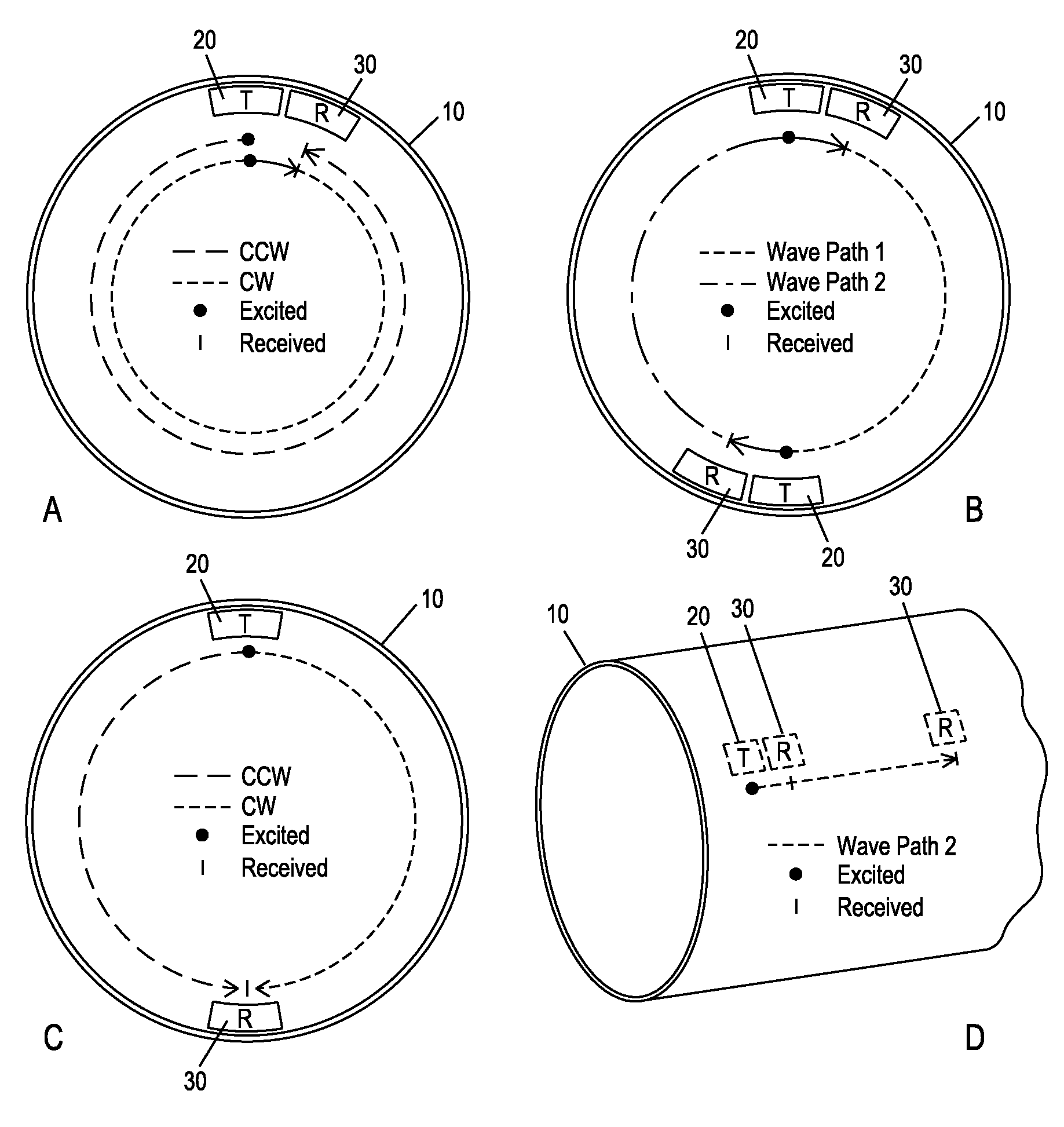

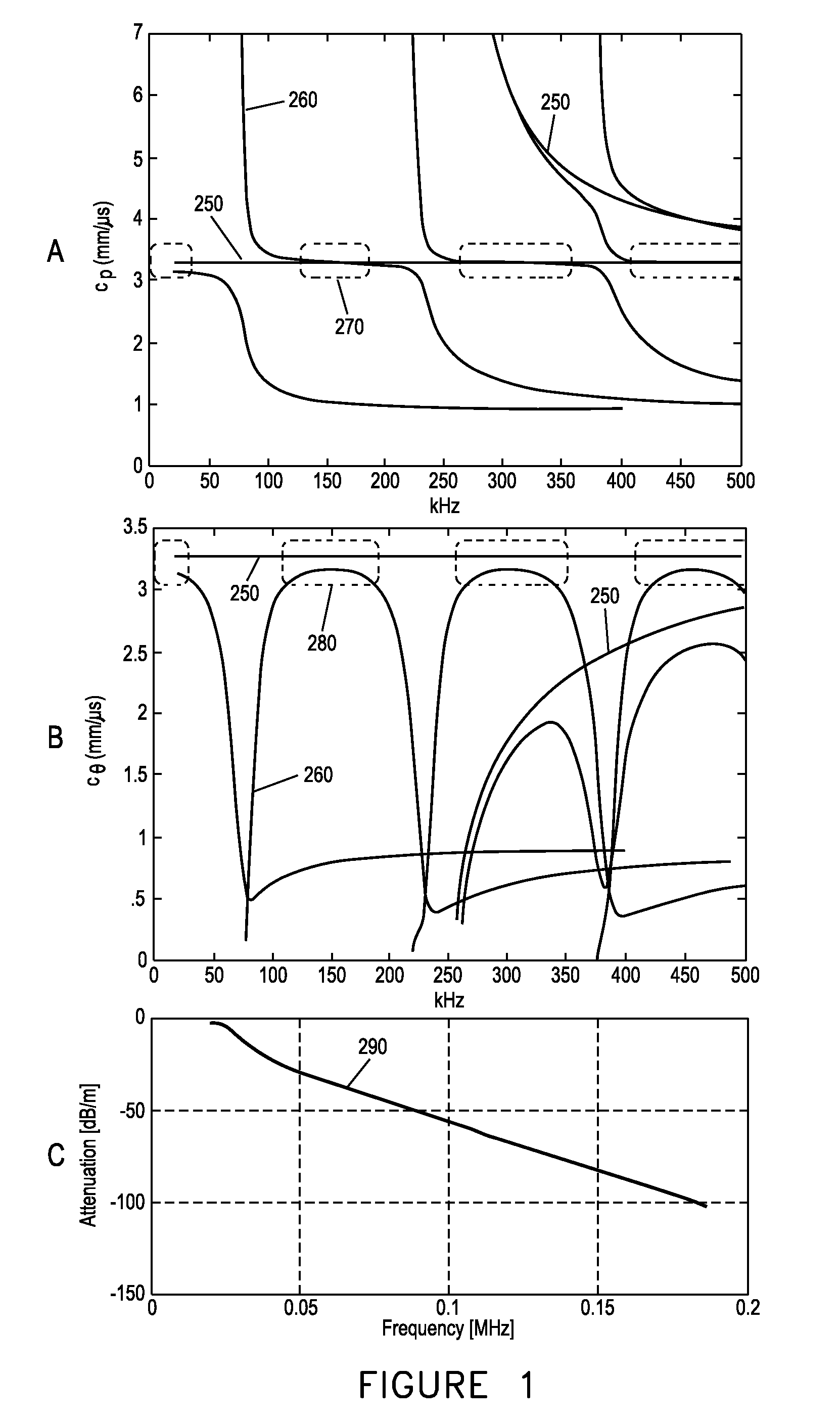

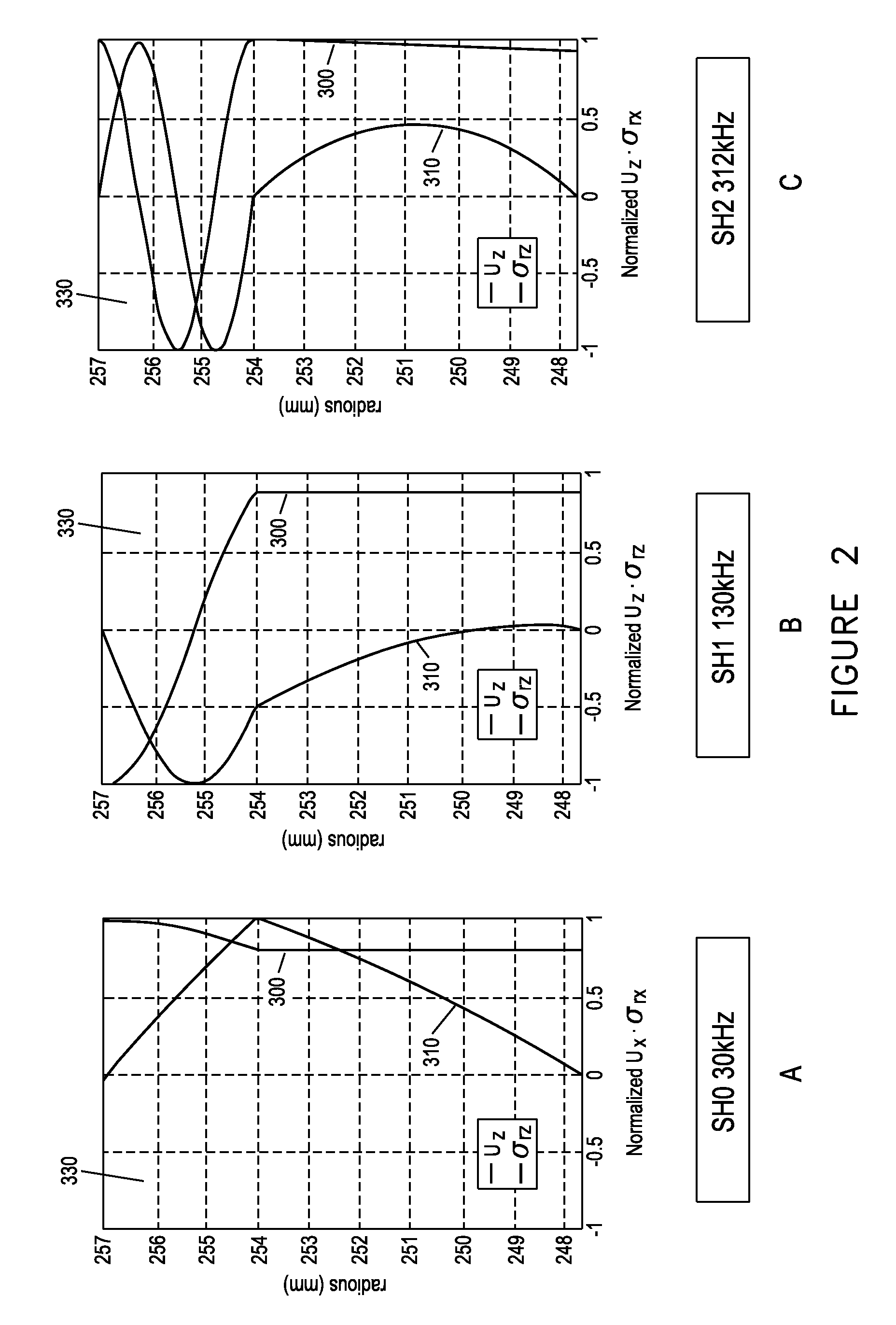

Guided waves for nondestructive testing of pipes

ActiveUS20090150094A1Reliable methodThe method is accurate and reliableAnalysing solids using sonic/ultrasonic/infrasonic wavesFlow propertiesTransducerNondestructive testing

A method for the nondestructive testing of pipeline, and internal or external coatings, using guided ultrasonic waves excited from the inside or outside diameter, wherein at least two transducers are employed to send and receive ultrasound, wherein a data normalization scheme is employed to account for transducer variability, and wherein the hardware arrangement has a number of pulser channels and a number of receiver channels for the collection and storage of signals.

Owner:FUKUOKA BROADCASTING CORPORATION

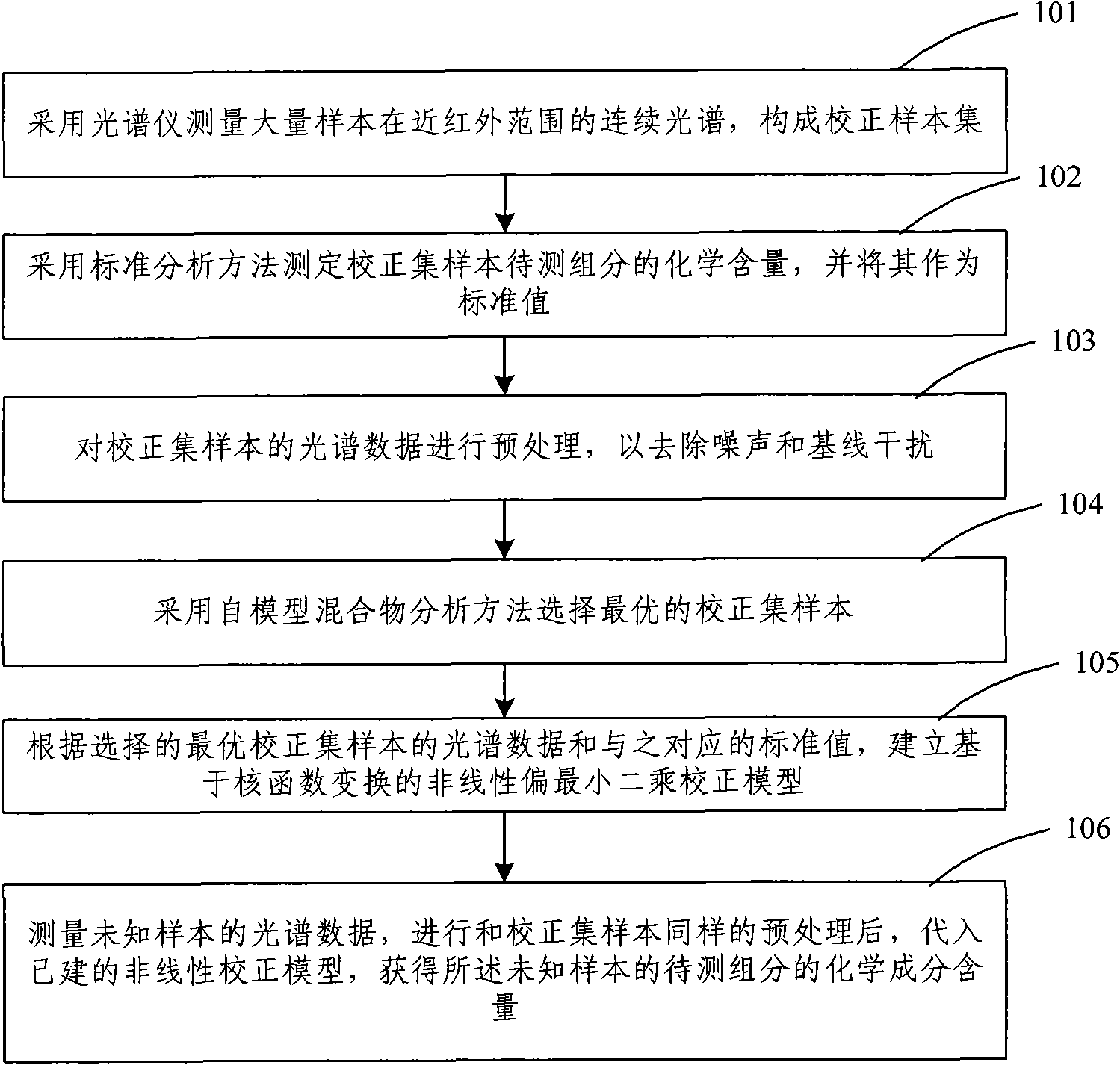

Near infrared spectrum nondestructive testing method and device for material component content

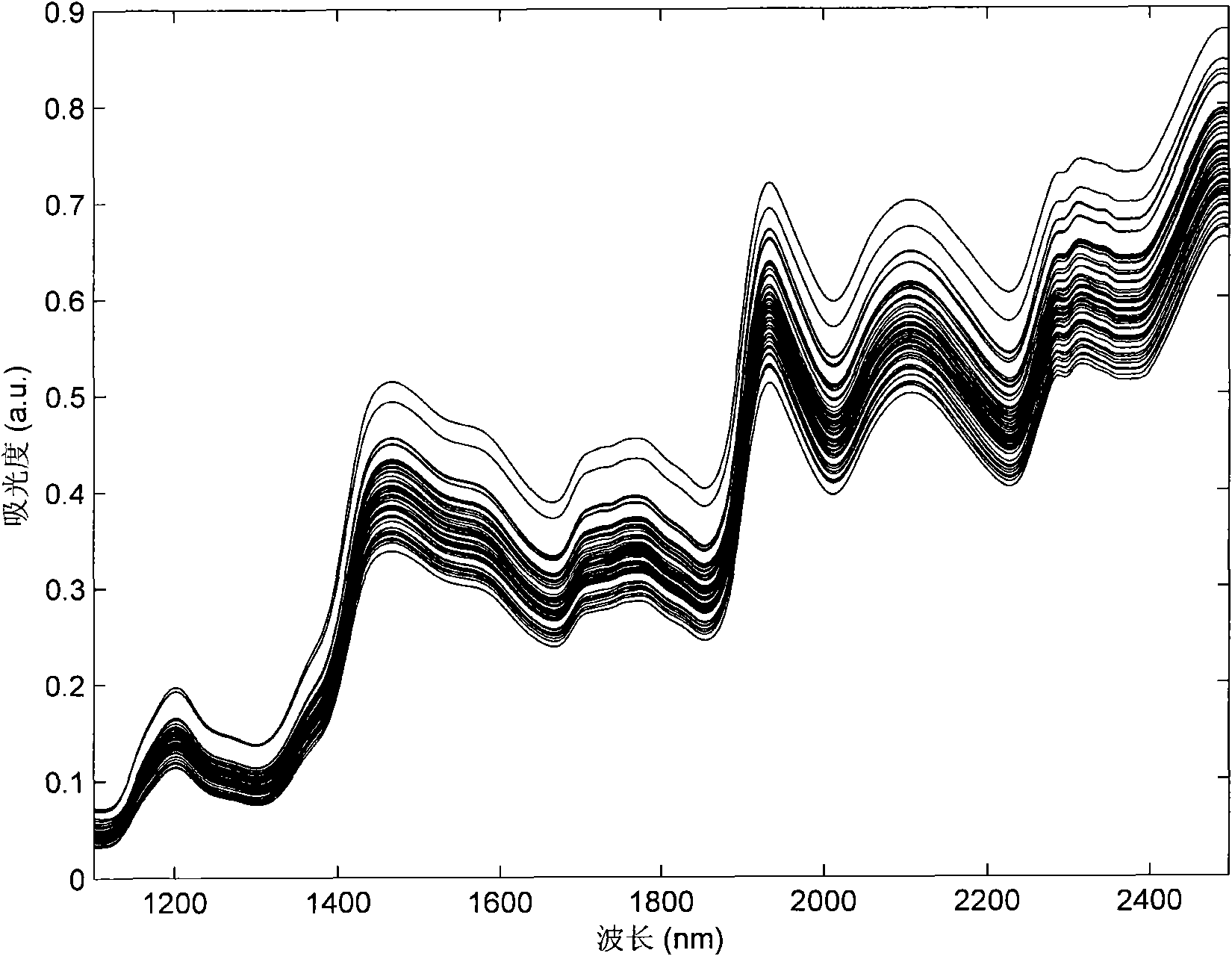

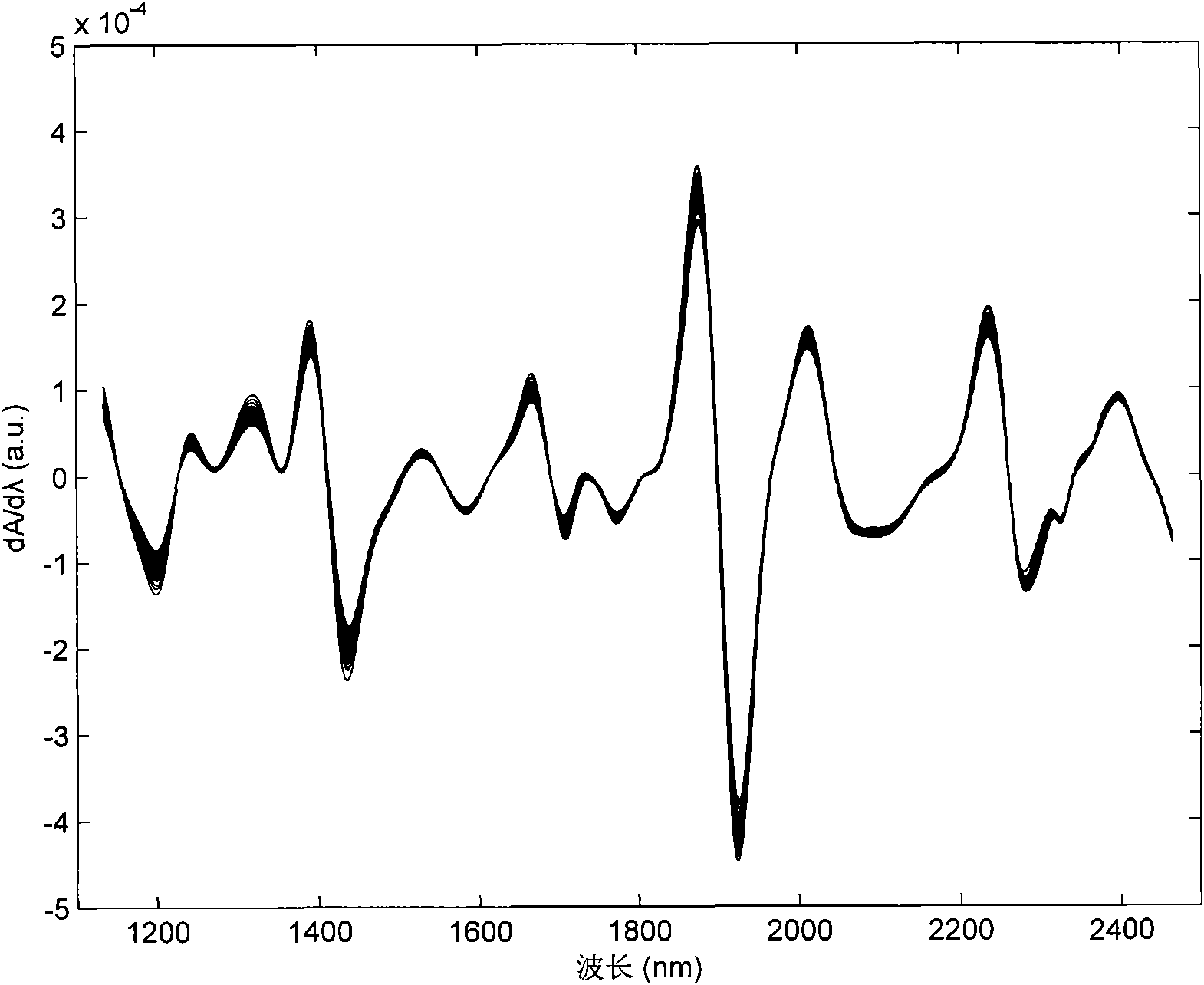

InactiveCN101915744AReduce complexityImprove modeling efficiencyColor/spectral properties measurementsInfraredNonlinear calibration

The invention discloses a near infrared spectrum nondestructive testing method and a near infrared spectrum nondestructive testing device for material component content. The method comprises the following steps of: collecting calibration set samples by using a spectrometer, pretreating a spectrum, selecting an optimal calibration sample set through sample optimization and establishing a nonlinear calibration model by using the optimal calibration sample set, collecting spectrum samples with unknown component content by using the spectrometer, pretreating the spectrum in a mode which is the same as that of pretreating the calibration set samples, and detecting the component content of the unknown sample through the established nonlinear calibration model. The method and the device can effectively solve the problems of complex calibration model, slow training speed and difficult hardware implementation in the conventional near infrared nondestructive testing method for the material component content and obviously improve the accuracy and stability of a nondestructive testing result of the material component content.

Owner:BEIHANG UNIV

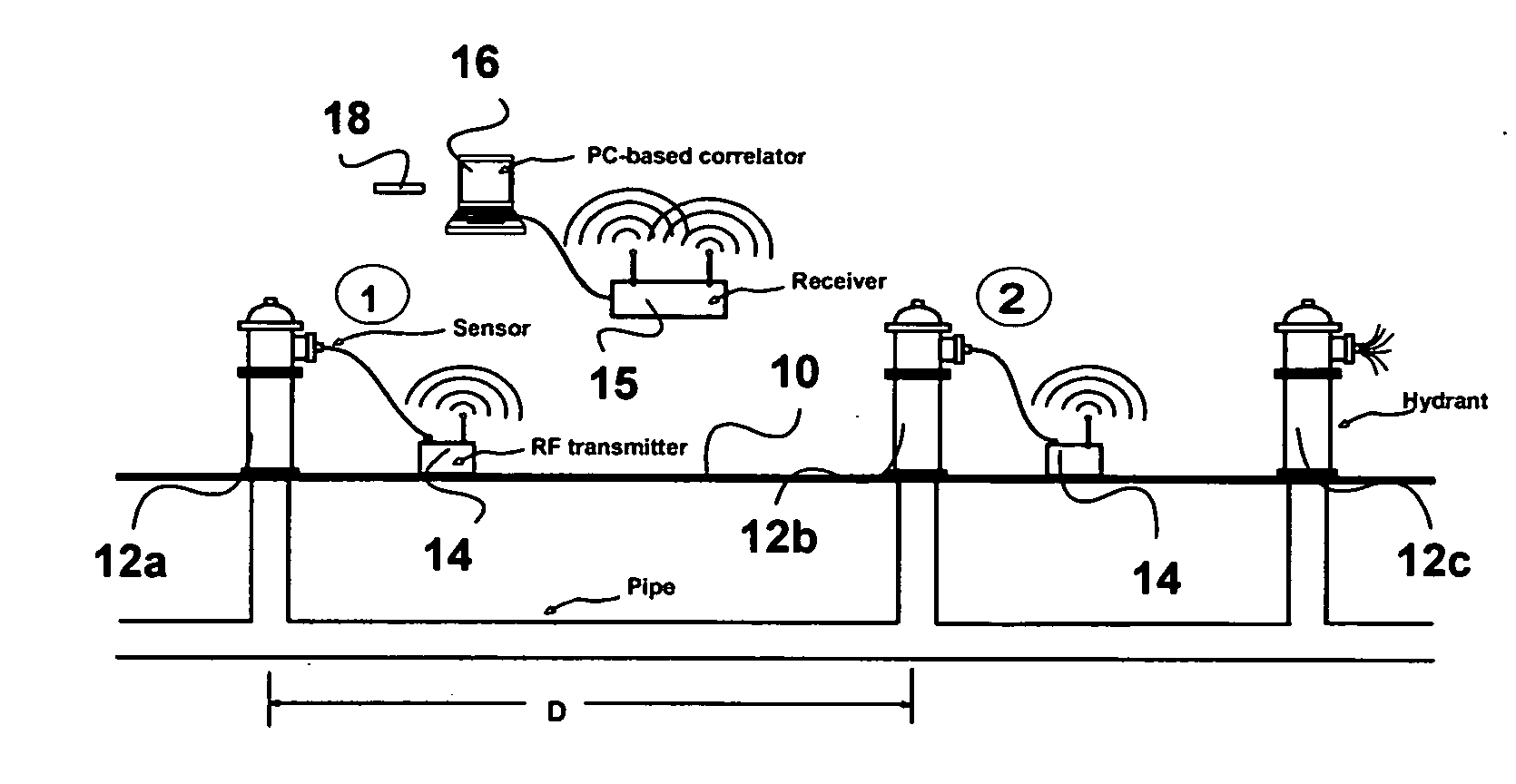

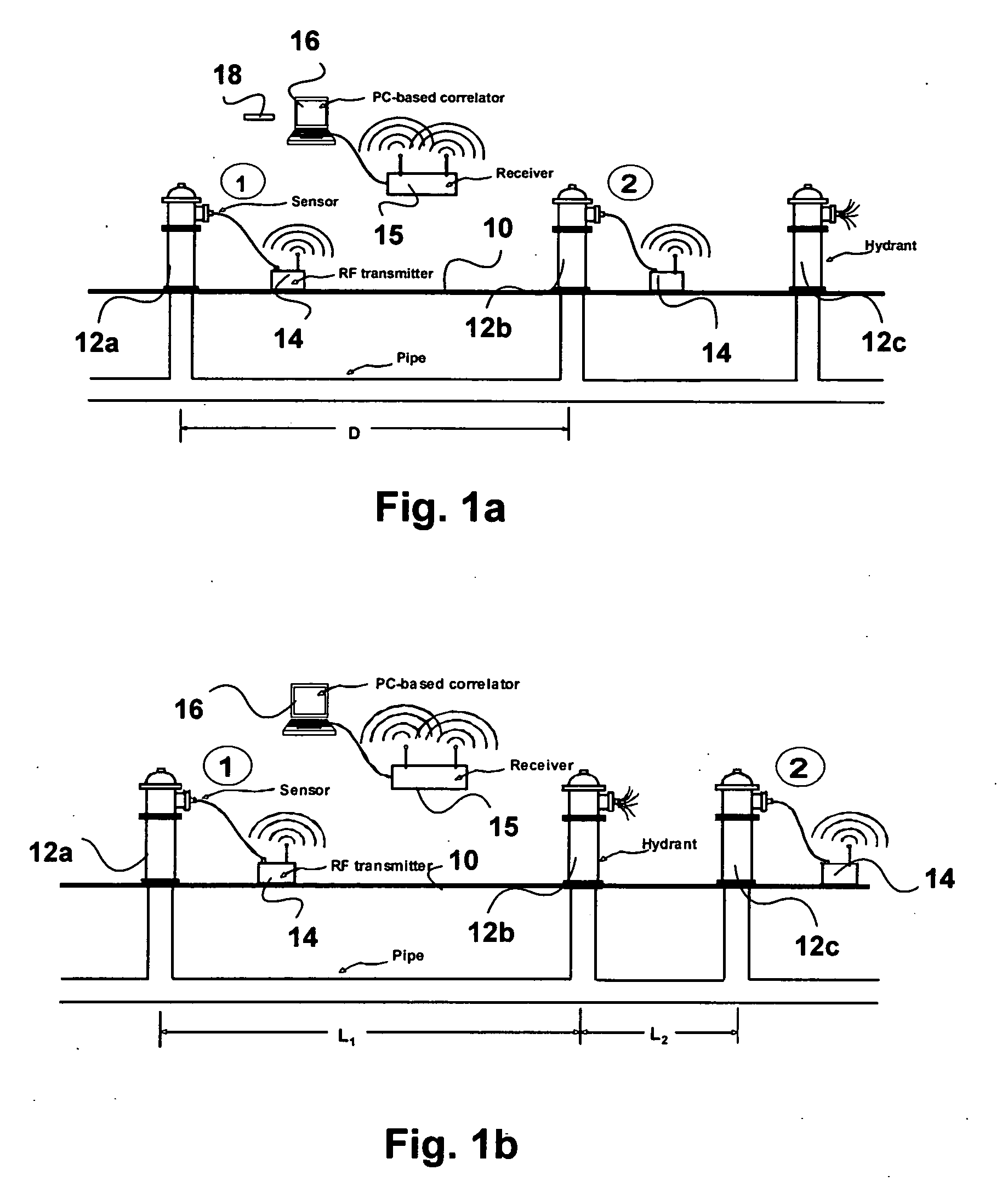

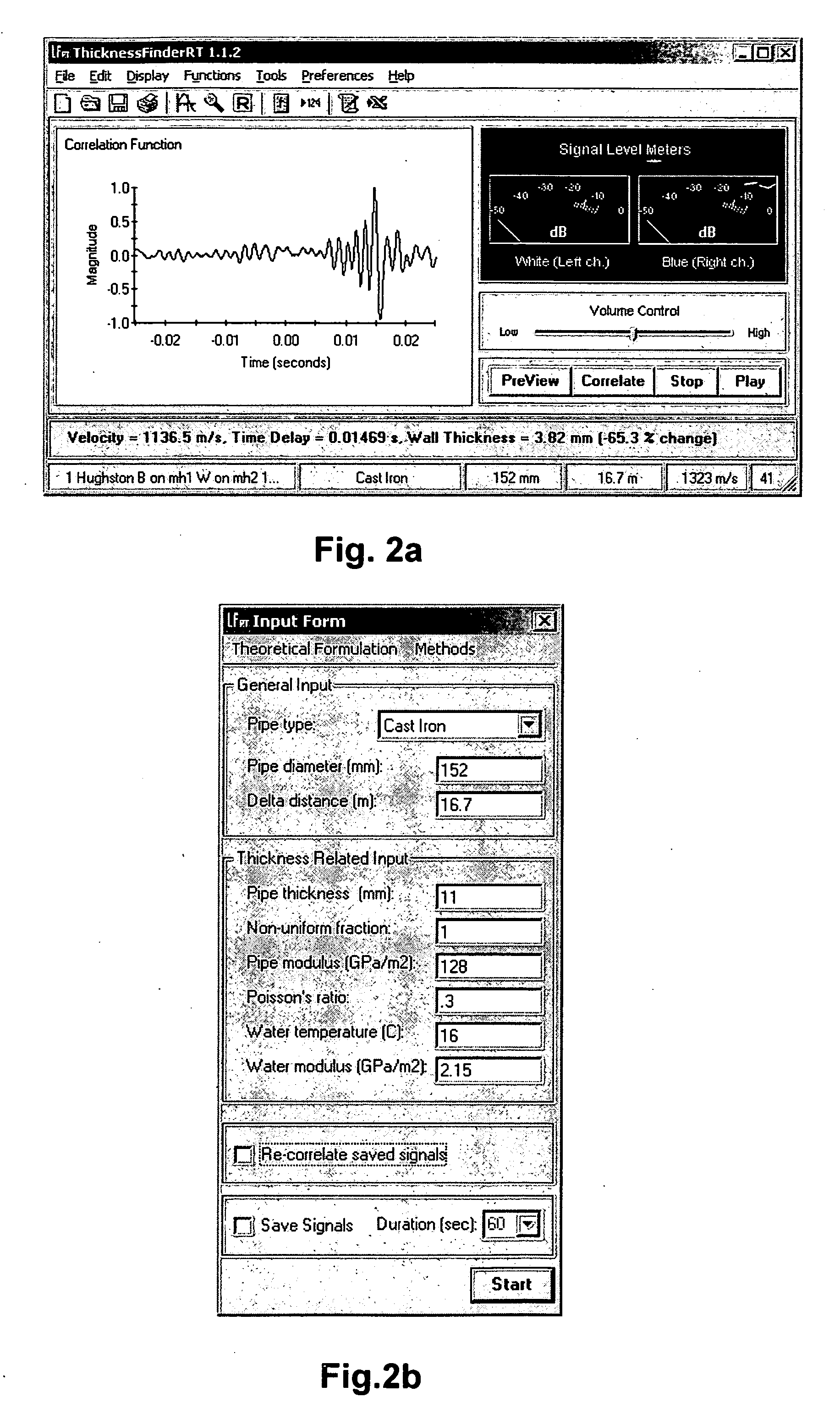

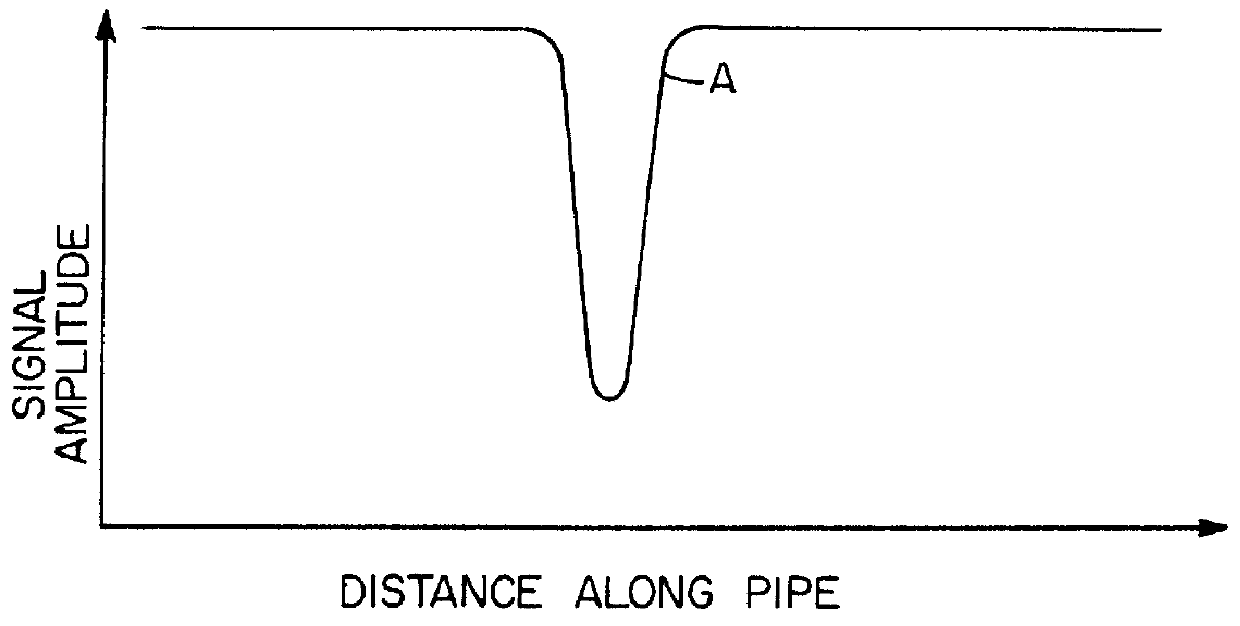

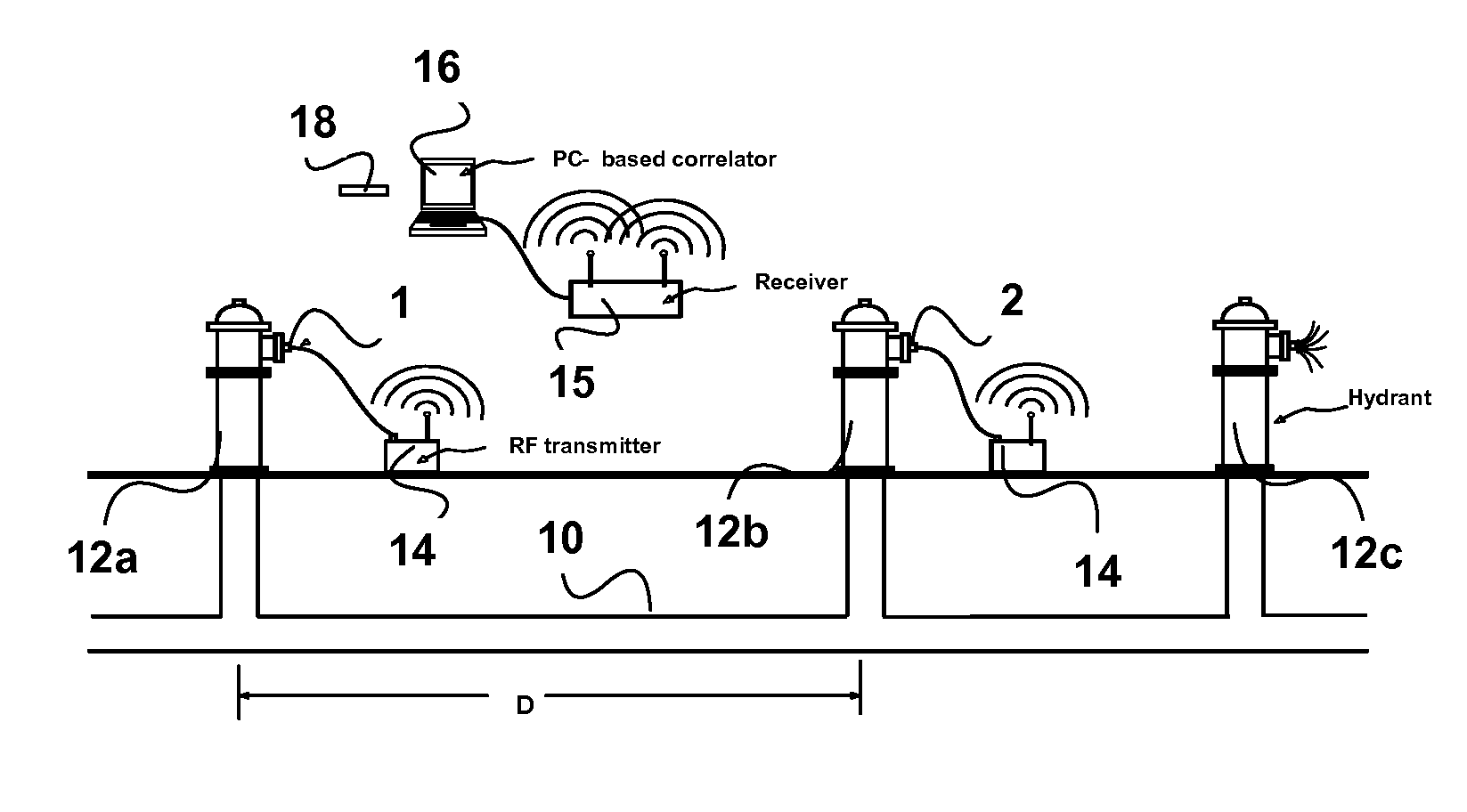

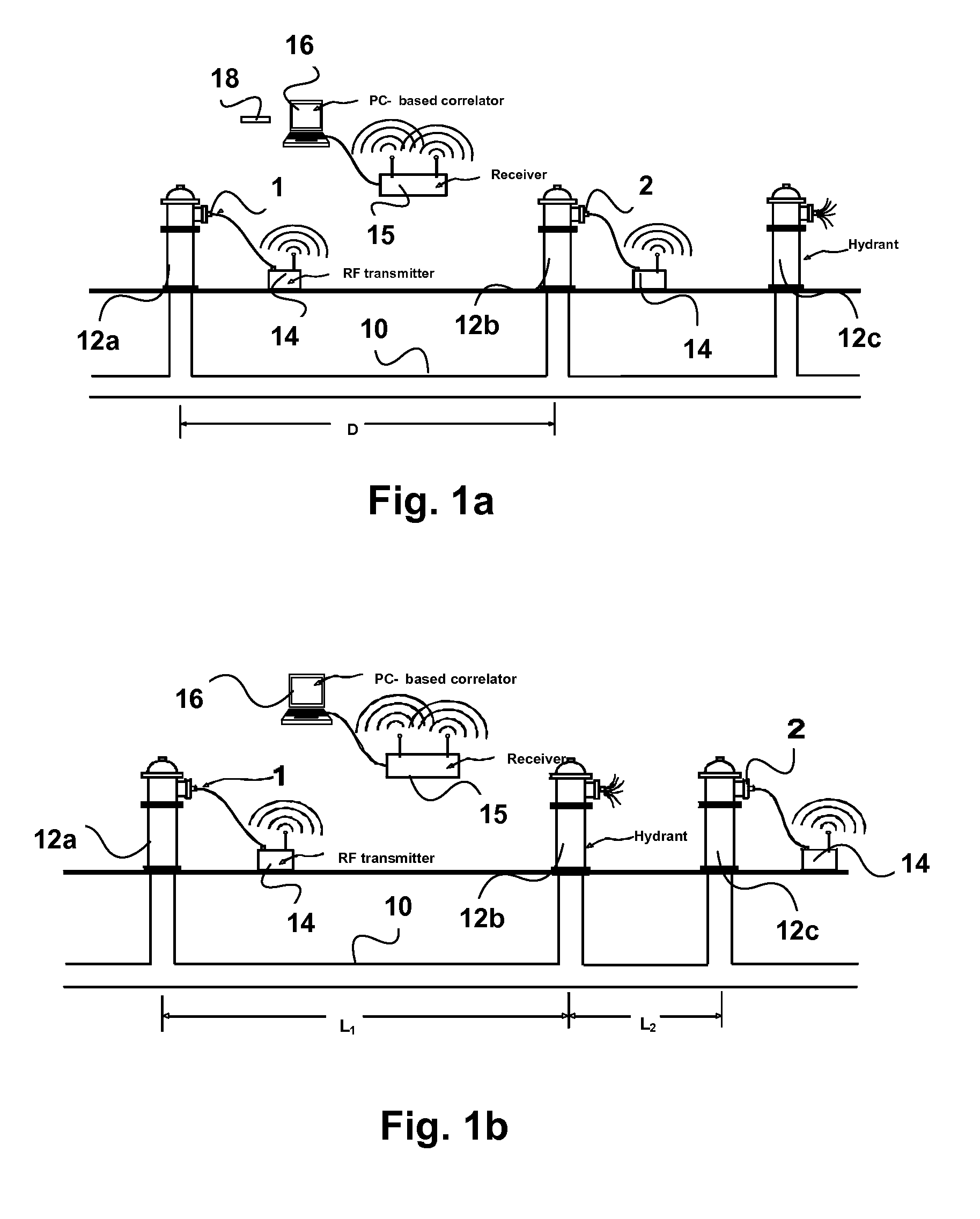

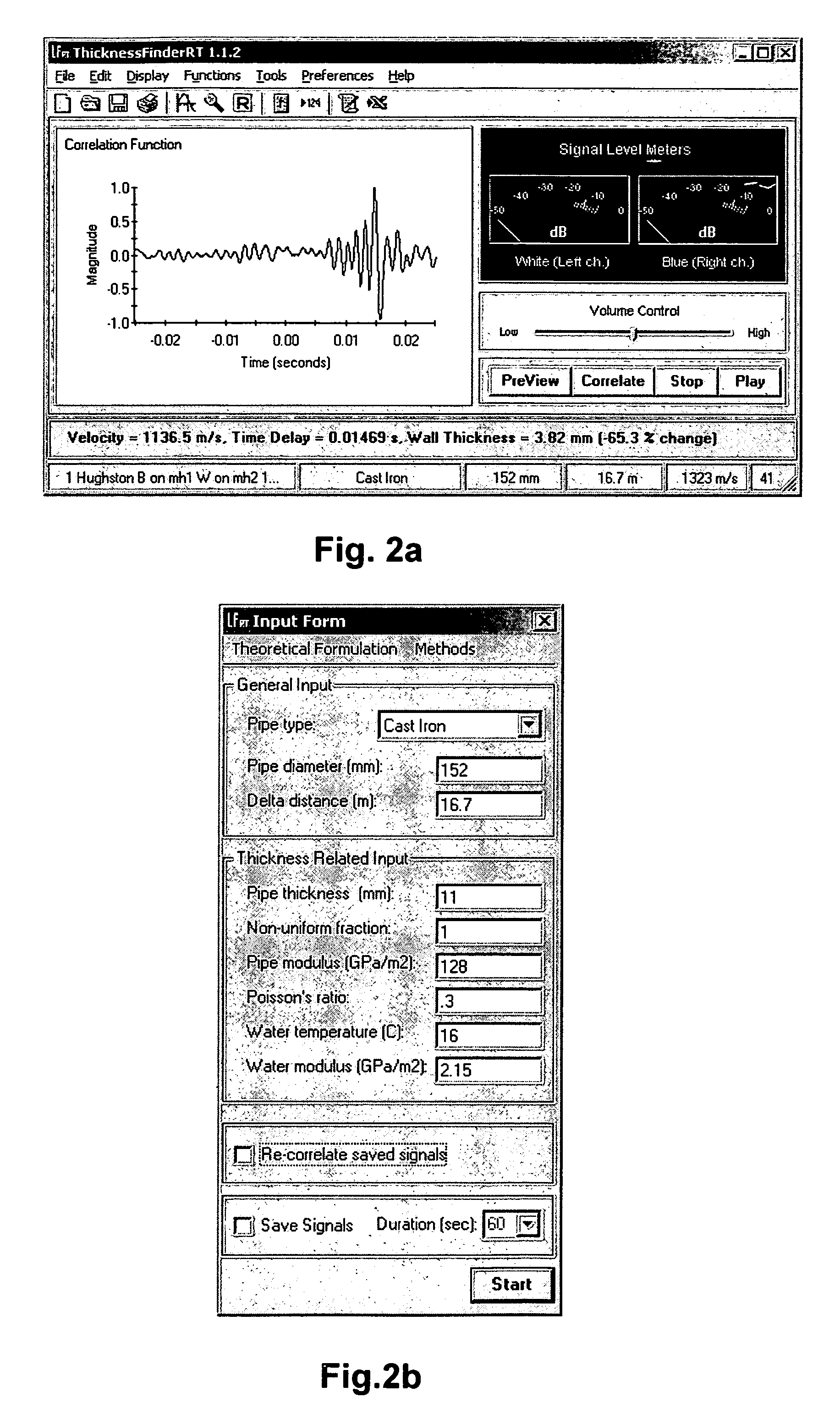

Non-destructive testing of pipes

ActiveUS20060283251A1Easy to measureEasy to calculateAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveEngineering

To perform a non-destructive condition assessment of a pipe carrying a fluid, an actual value representative of the propagation velocity of an acoustic disturbance propagating between two longitudinally separated points on the pipe is determined. A corresponding predicted value for the propagation velocity is computed as a function of at least one wall thickness parameter of the pipe by using a theoretical model for the propagation of acoustic waves in the pipe that assumes said pipe has a finite wall thickness with a predetermined circumferential thickness profile. The wall thickness parameter is then computed by matching the actual value with the predicted value, for example, by substituting the actual value in a formula predicting the theoretical value.

Owner:MUELLER INT LLC

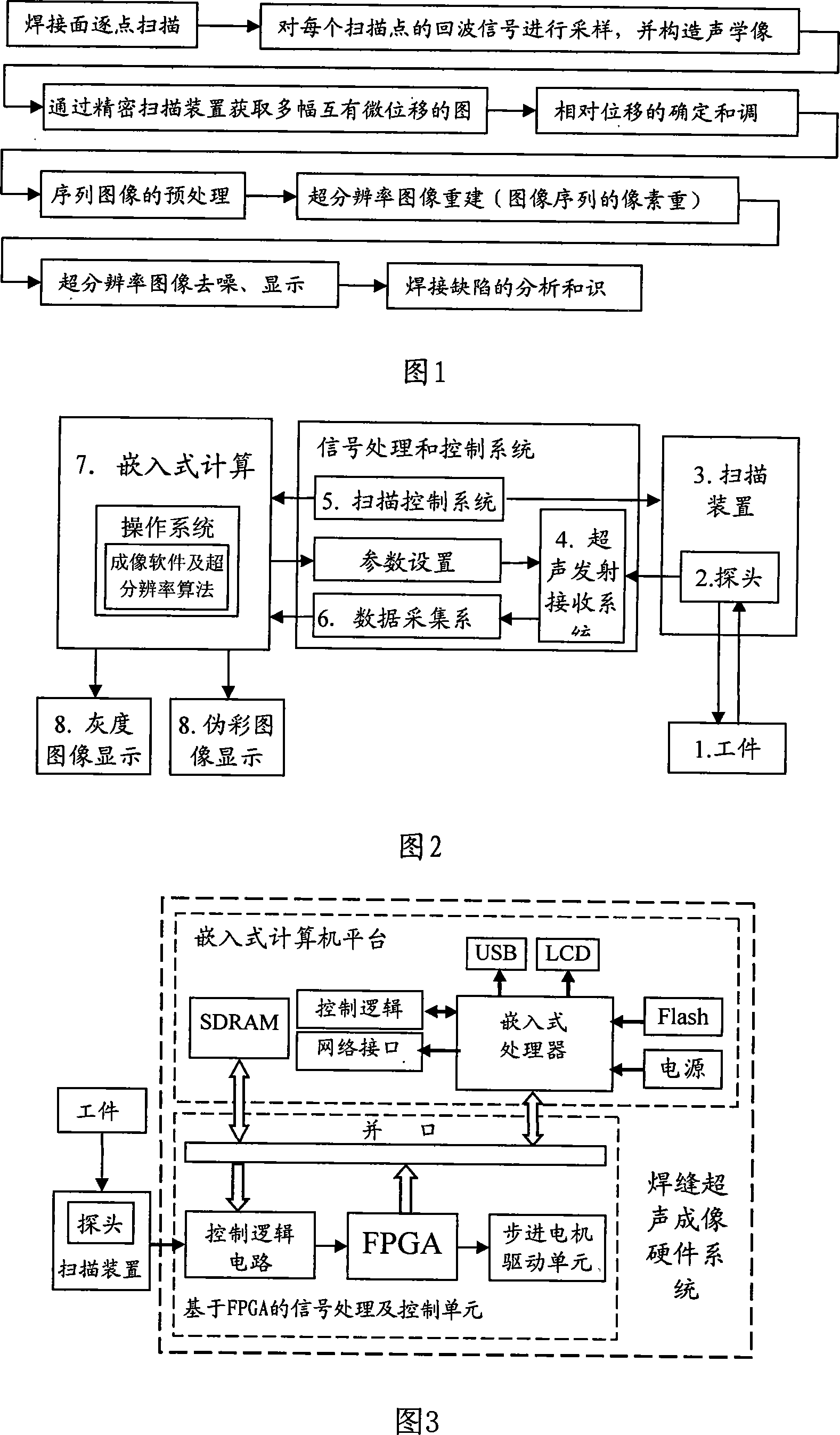

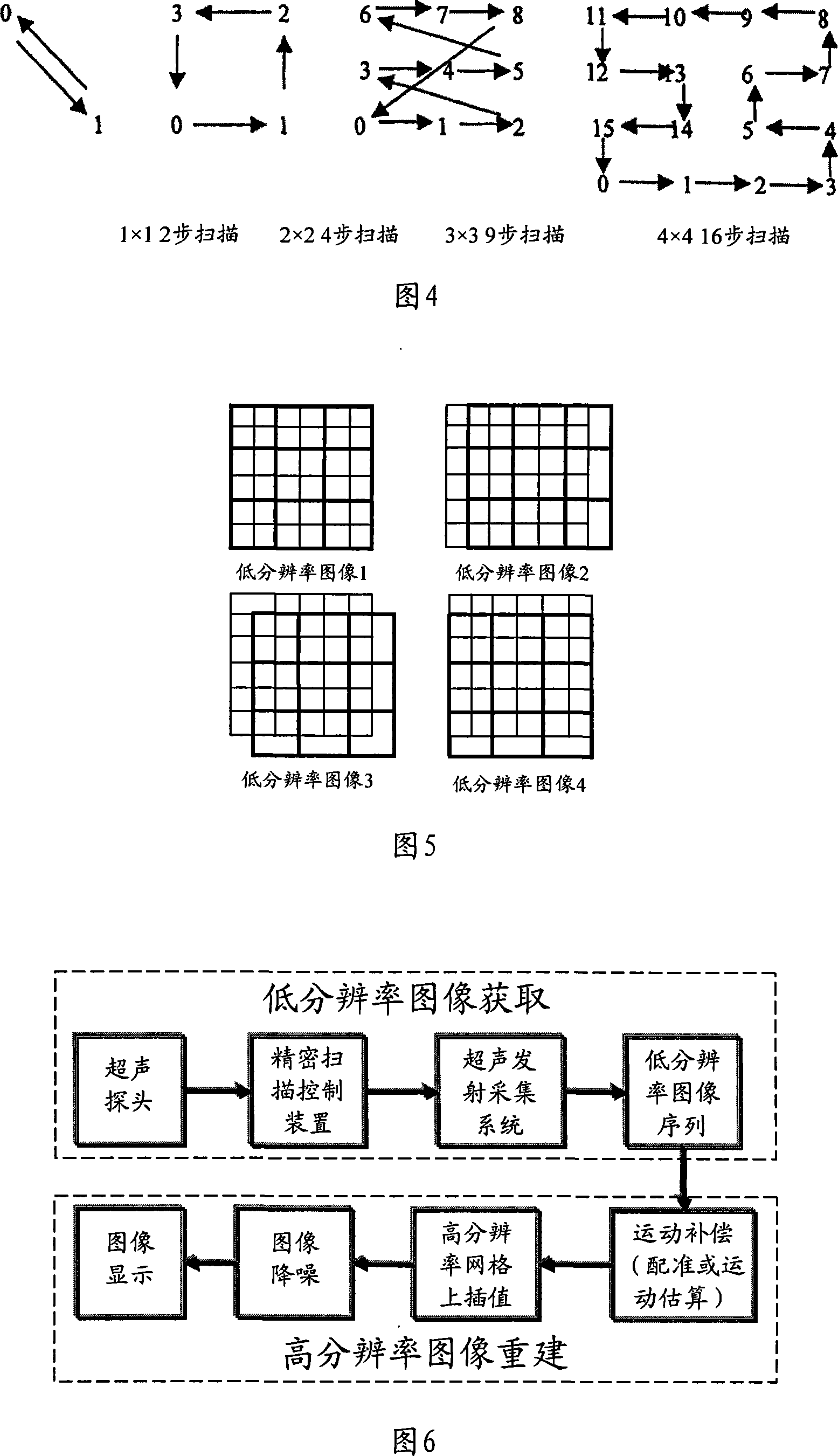

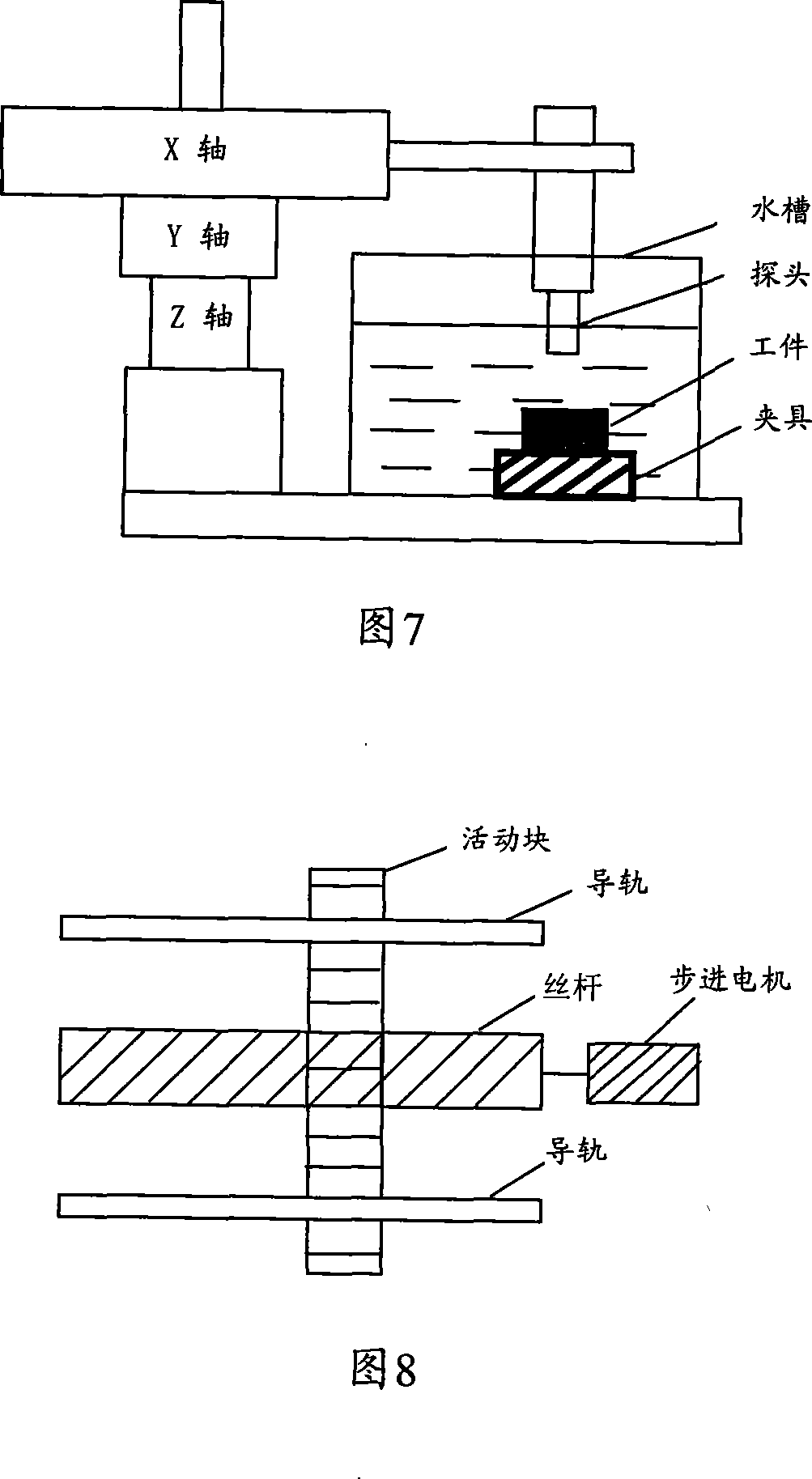

High-resolution welding seam supersonic image-forming damage-free detection method and detection system

InactiveCN101101277AImprove performancePrecise positioningAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound imagingSonification

The invention discloses a high clear weld ultrasound imaging undamaged detection method and detection system, firstly dong point by point scanning with leach focusing probe to welding seam, and sampling detecting signal of ultrasound reflect echo for every bit, composing the ultrasonic scanning image of welding line section, and then realizing to rebuild super-resolution of image by gathering tiny scanning image and multigraph rebuilding super-resolution image. The invention can breach resolution limited of existing equipment of ultrasound imaging, it improves greatly recognizability of equipment of ultrasound imaging for the small bug of welding line by multi-framing rebuilding high resolution and high quality image from fall quality image in the scene.

Owner:SOUTH CHINA UNIV OF TECH

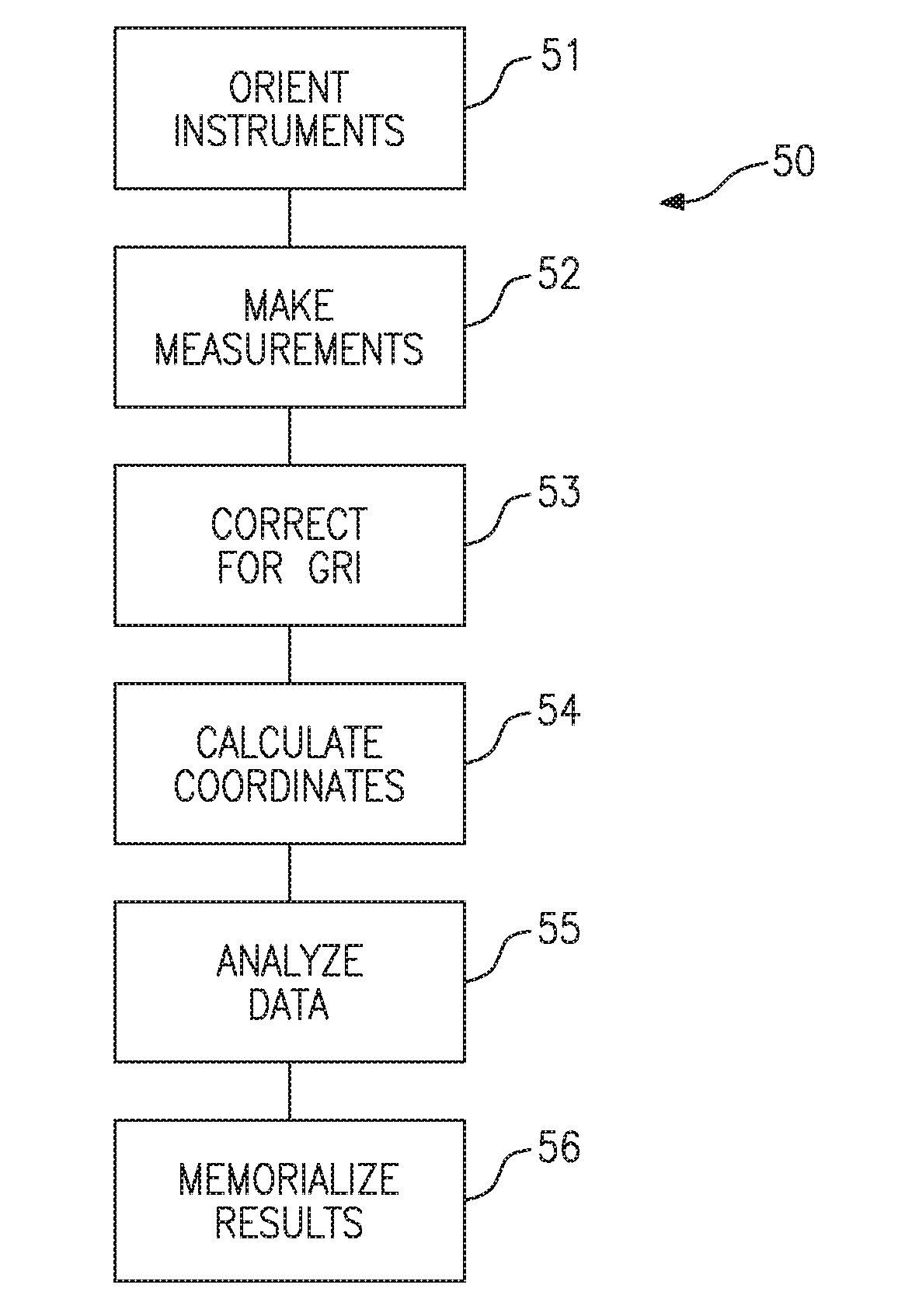

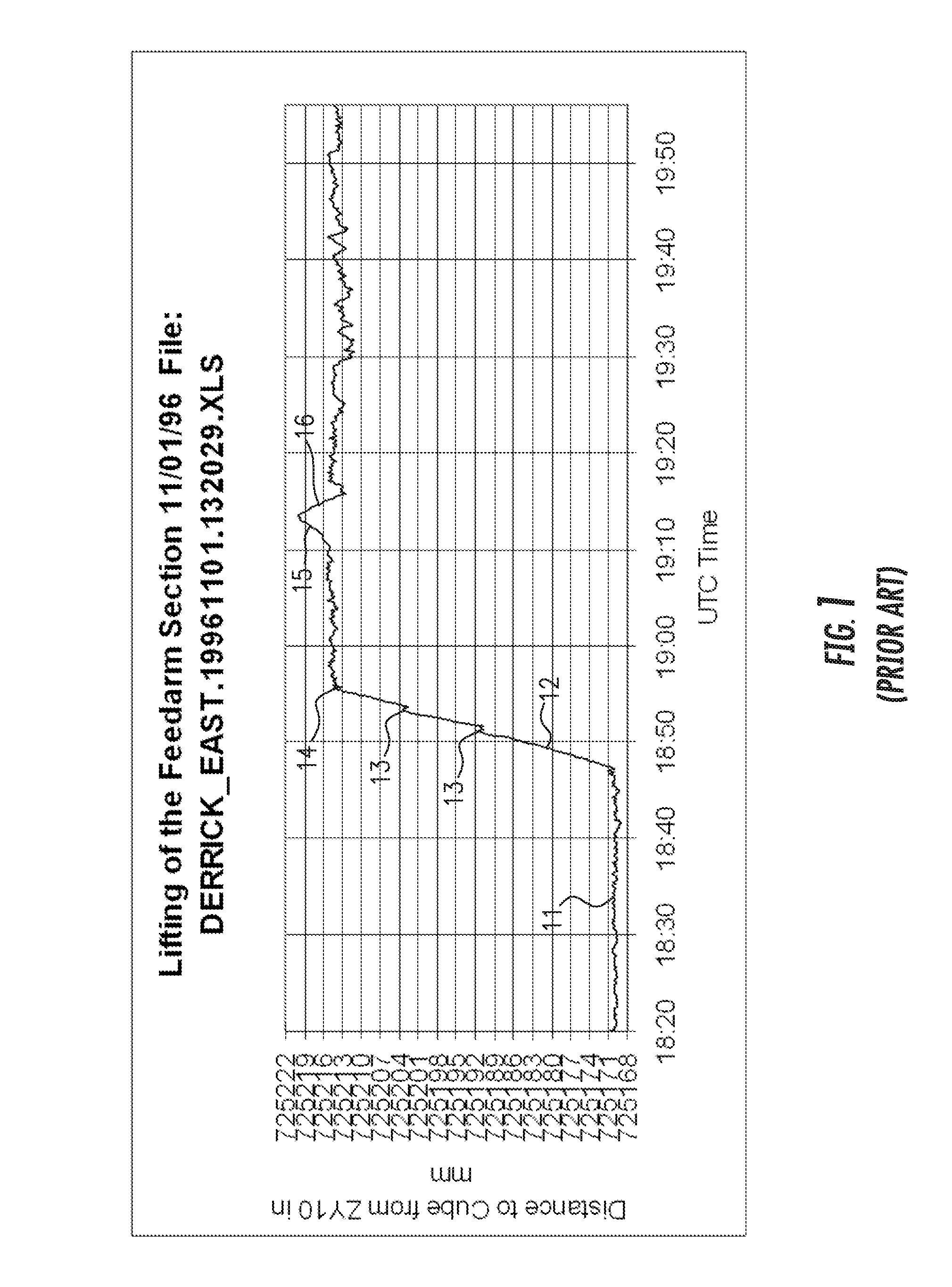

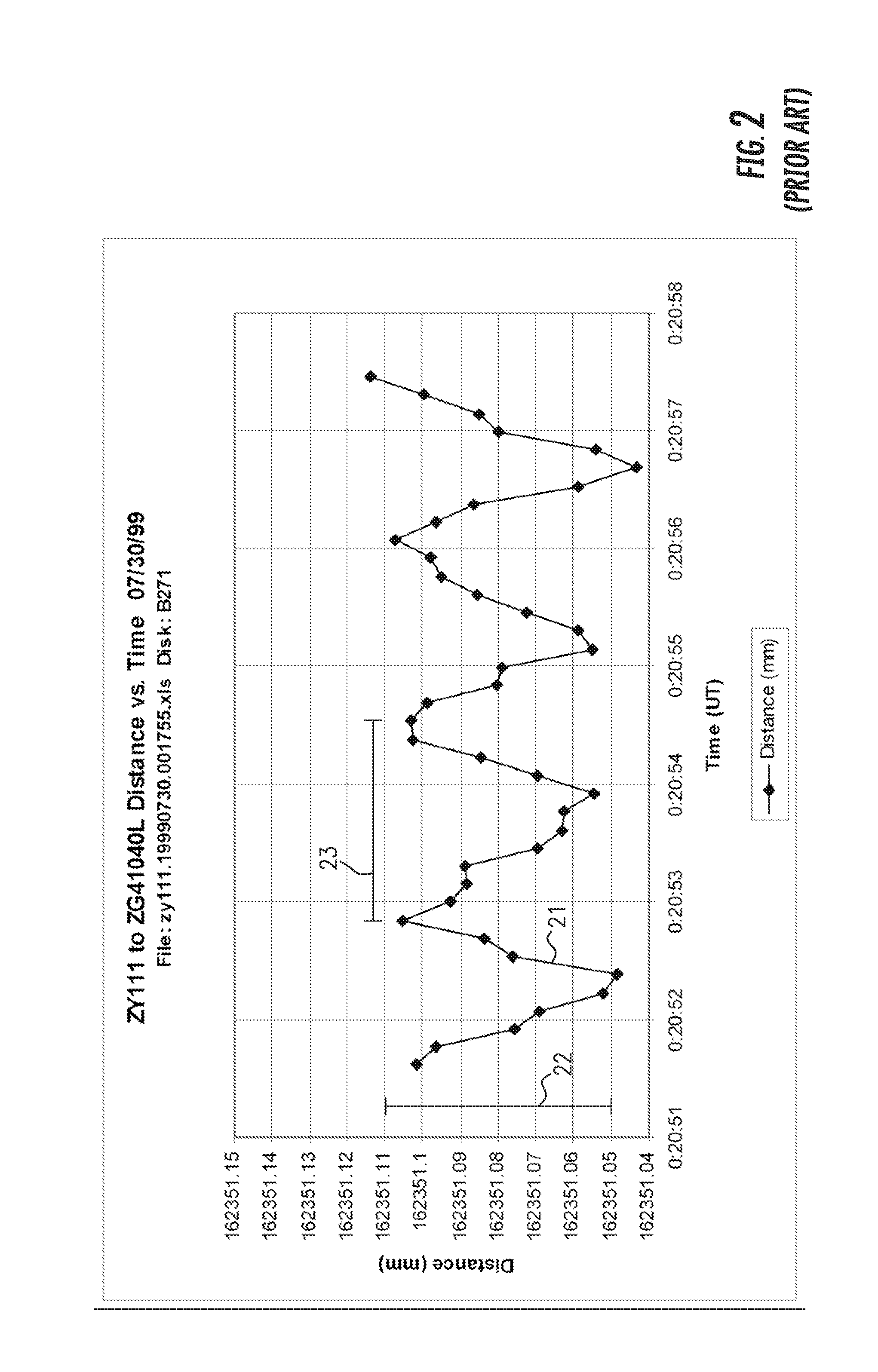

Methods for measuring and modeling the process of prestressing concrete during tensioning/detensioning based on electronic distance measurements

Methods are disclosed for nondestructive testing and measuring the structural health of prestressed concrete structures, such as slabs, columns, girders, bridges, towers, elevated storage tanks, silos, cooling towers, wind power generation towers, liquefied gas storage tanks, nuclear power containment buildings, and the like. Measurements are made as the structure undergoes tensioning and detensioning operations. By measuring actual movements of cardinal points on the structure, in an absolute three-dimensional coordinate system, and comparing the measurements to a model—as tension on a tendon is changed—a margin of safety is assured. High accuracy measurements are made by electronic distance measurement (EDM) instruments over hundreds of meters, which yield coordinates of cardinal points with an uncertainty of the order of one part per million. The methods are proposed as possible alternatives to prior failures of post-tensioned concrete, including the Las Lomas Bridge, the Kapiolani Interchange On-Ramp, Turkey Point Unit 3 Nuclear Power Plant, and Crystal River Unit 3 Nuclear Power Plant. An extensive review of the most closely related prior arts is included.

Owner:SOPHIE LIN TRUSTEE OF THE JOHN MICHAEL PAYNE FAMILY TRUST +1

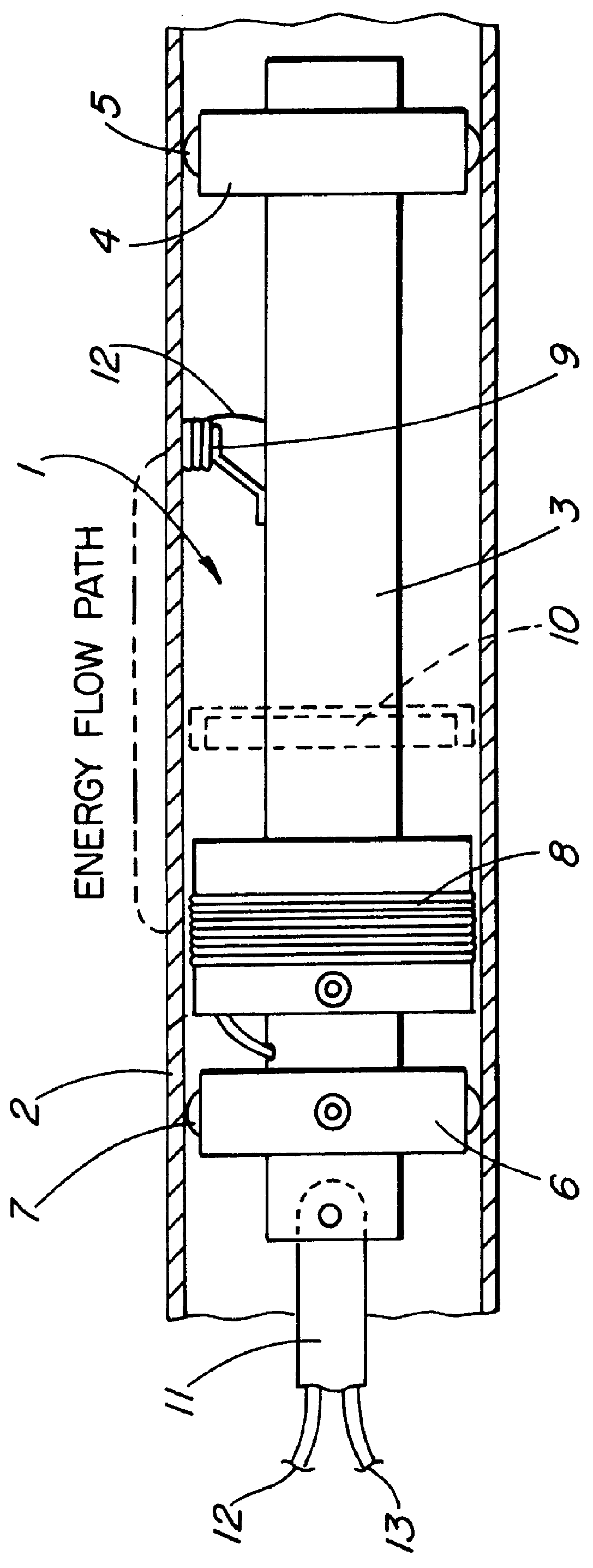

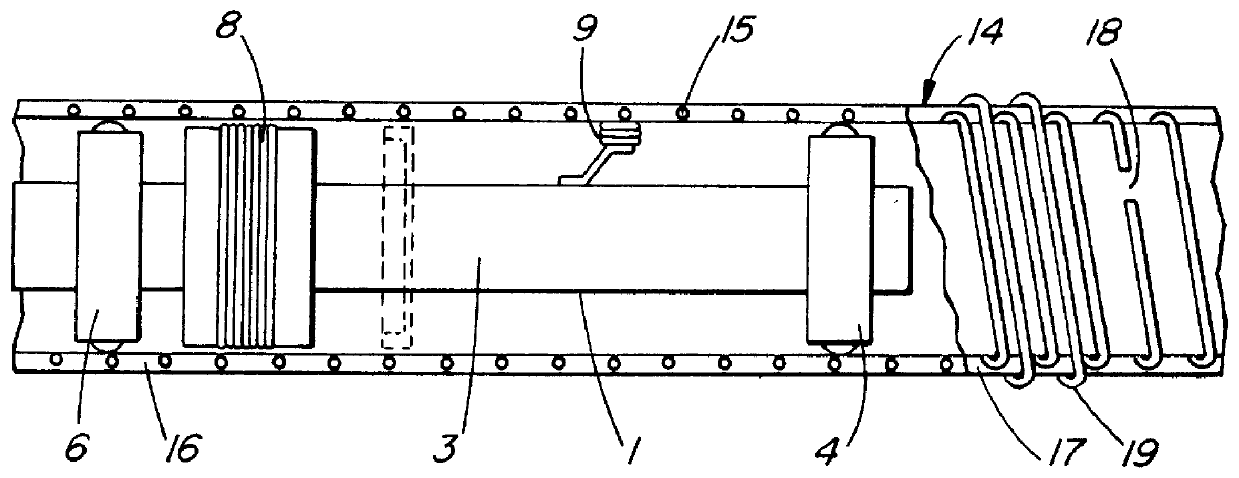

Electromagnetic method for non-destructive testing of prestressed concrete pipes for broken prestressing wires

InactiveUS6127823AImprove energy transferMagnetic property measurementsMaterial magnetic variablesNon destructivePre stress

A method for detecting breaks in a prestressed wire, rod or bar embedded in concrete surrounding a metal pipe is described. A remote field eddy current probe is traversed axially internally through the pipe so as to create an energy flow path externally of the pipe and a transformer coupling through the pipe, and generate a signal in a detector coil axially spaced from an exciter coil. As the exciter coil traverses the wire, rod or bar containing the break a signal change is generated, regardless of the radial position of the detector coil relative to the break.

Owner:THE PRESSURE PIPE INSPECTION COMPANY

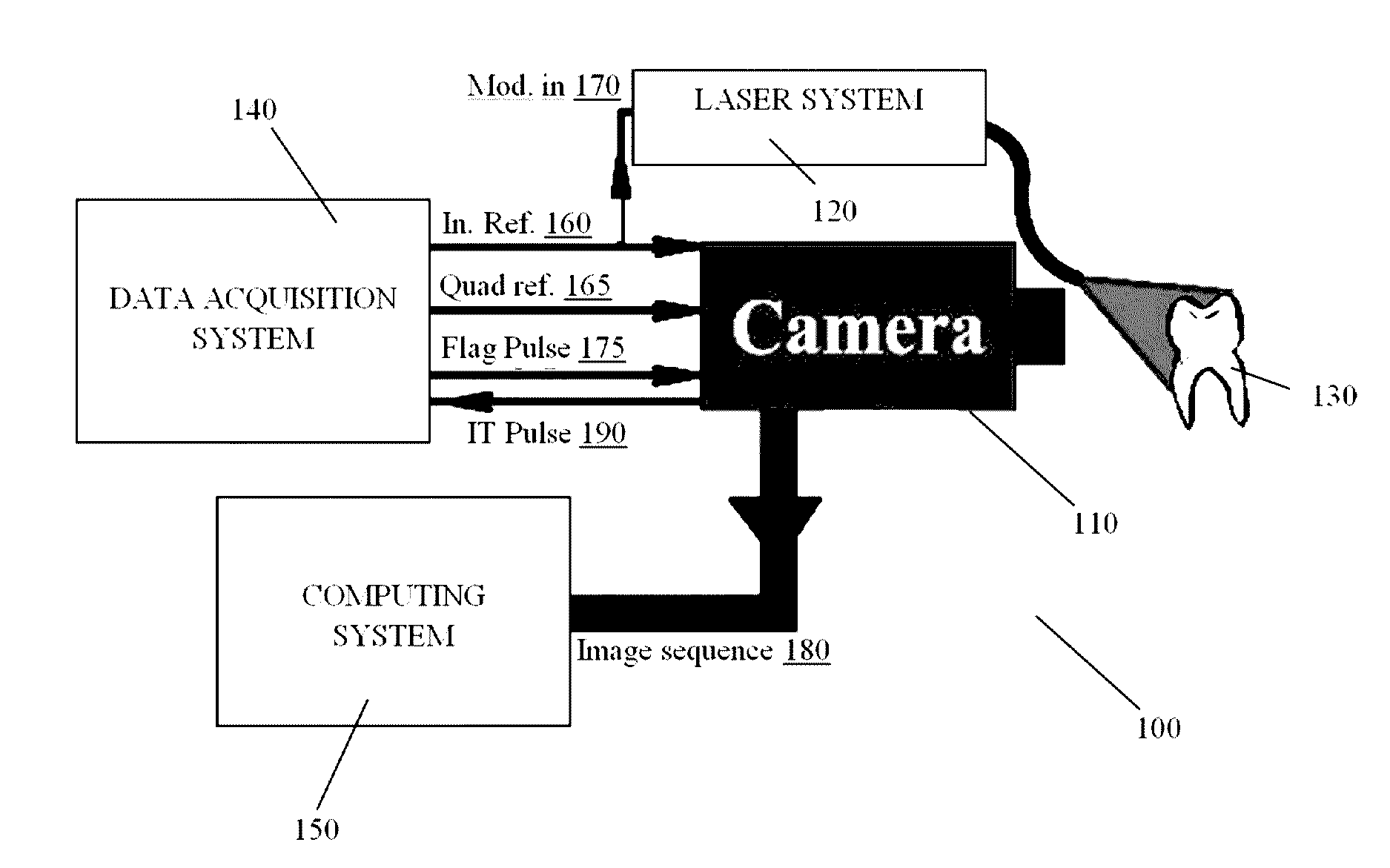

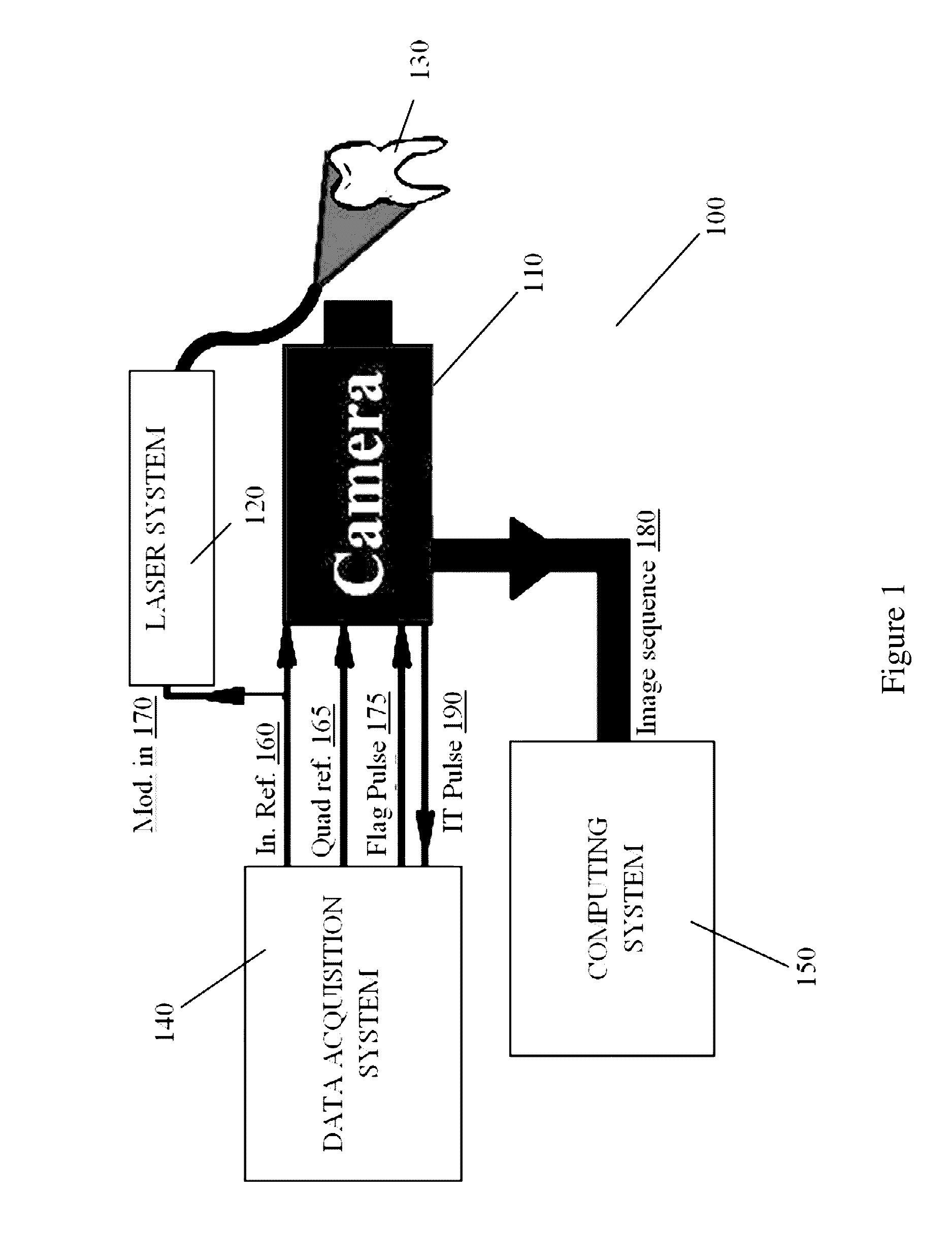

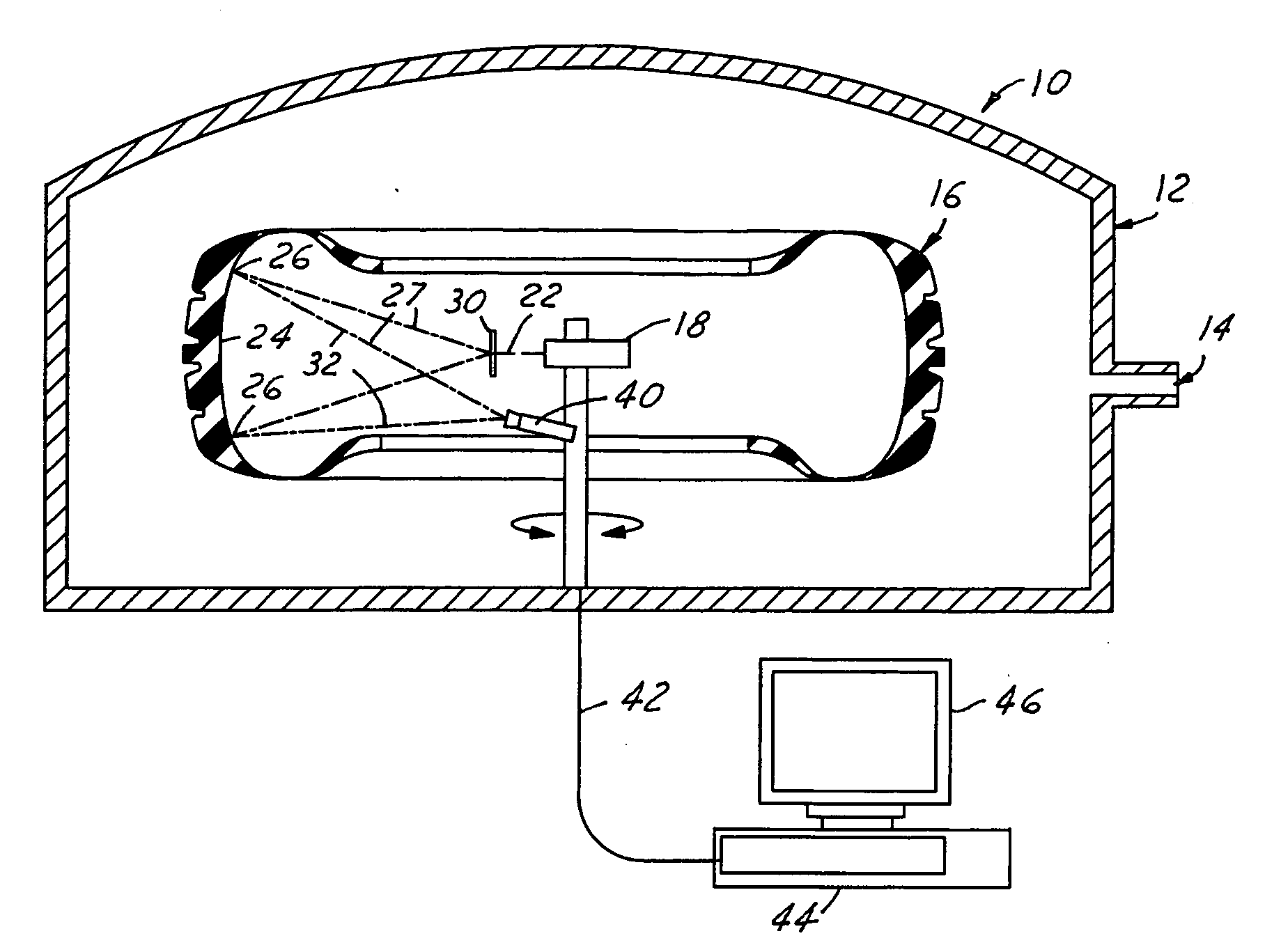

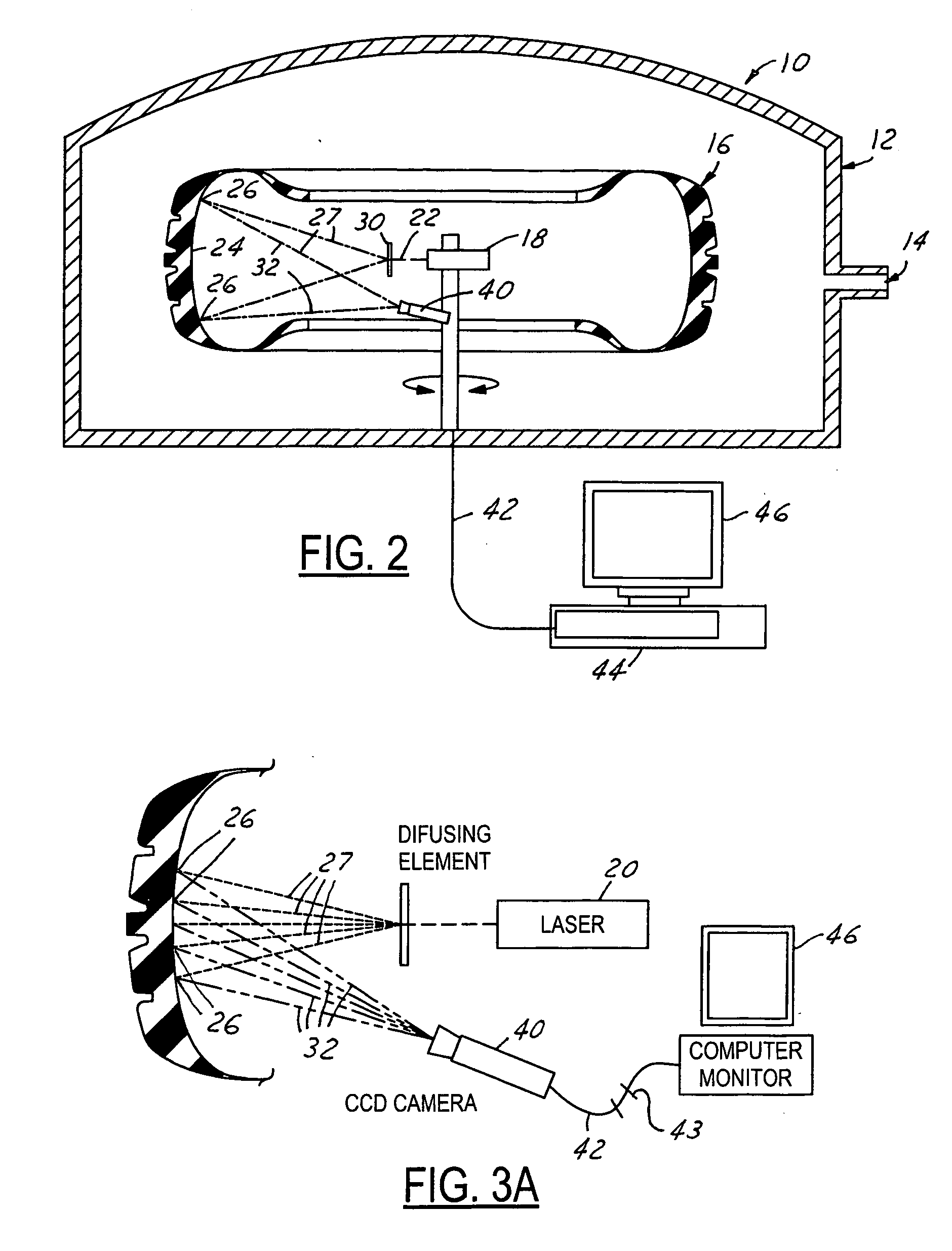

Systems and methods for thermophotonic dynamic imaging

Owner:MANDELIS ANDREAS +2

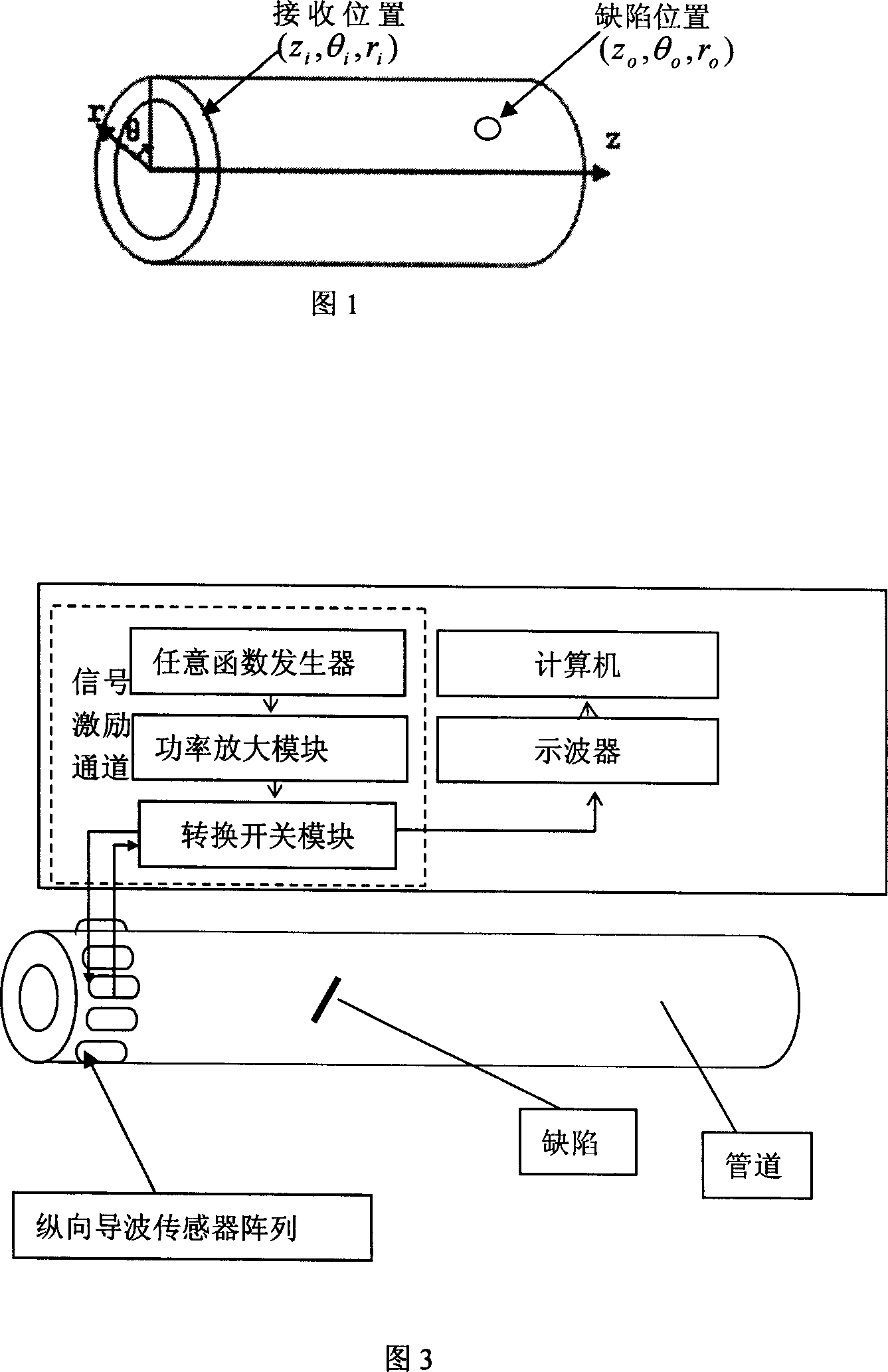

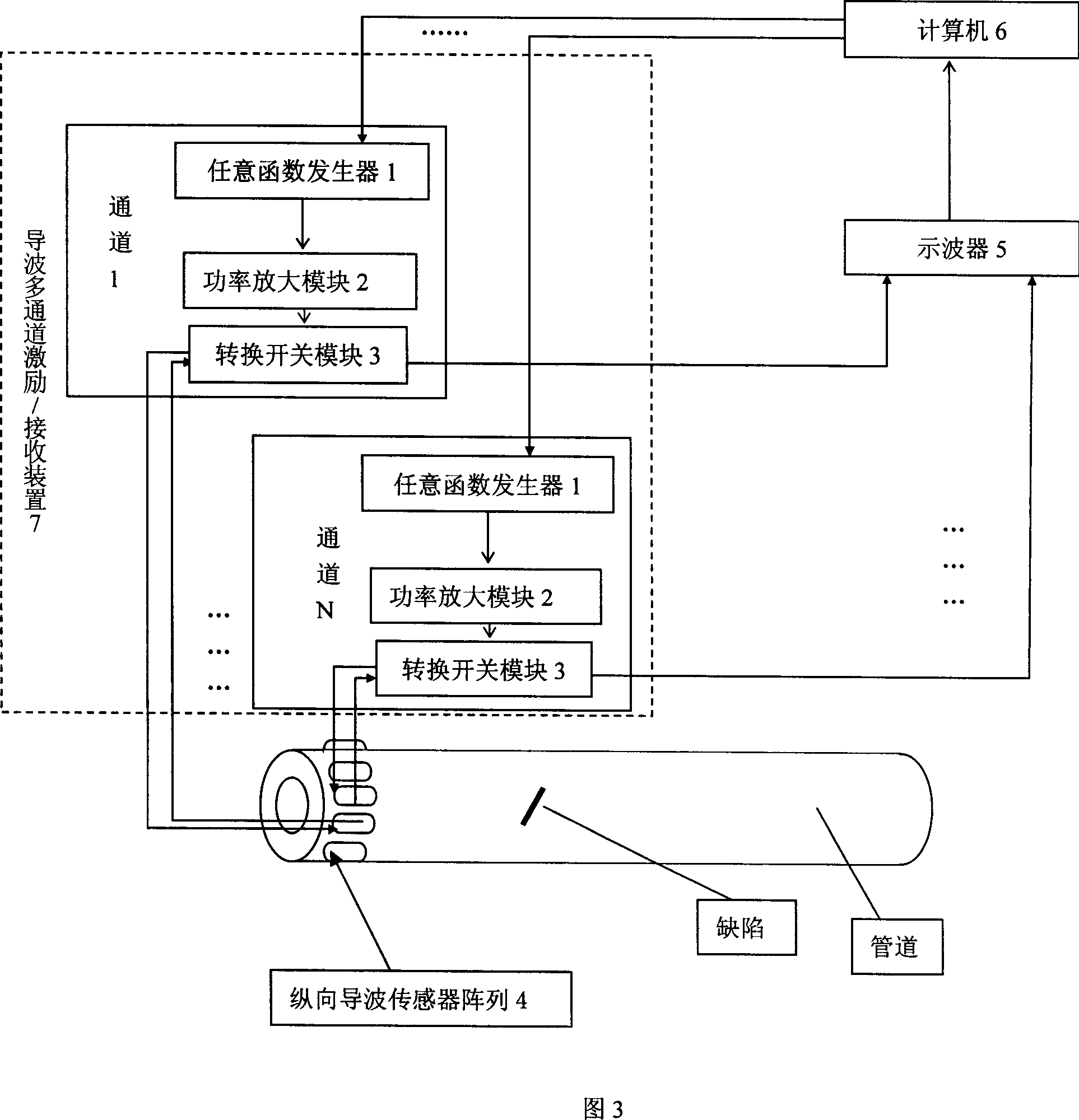

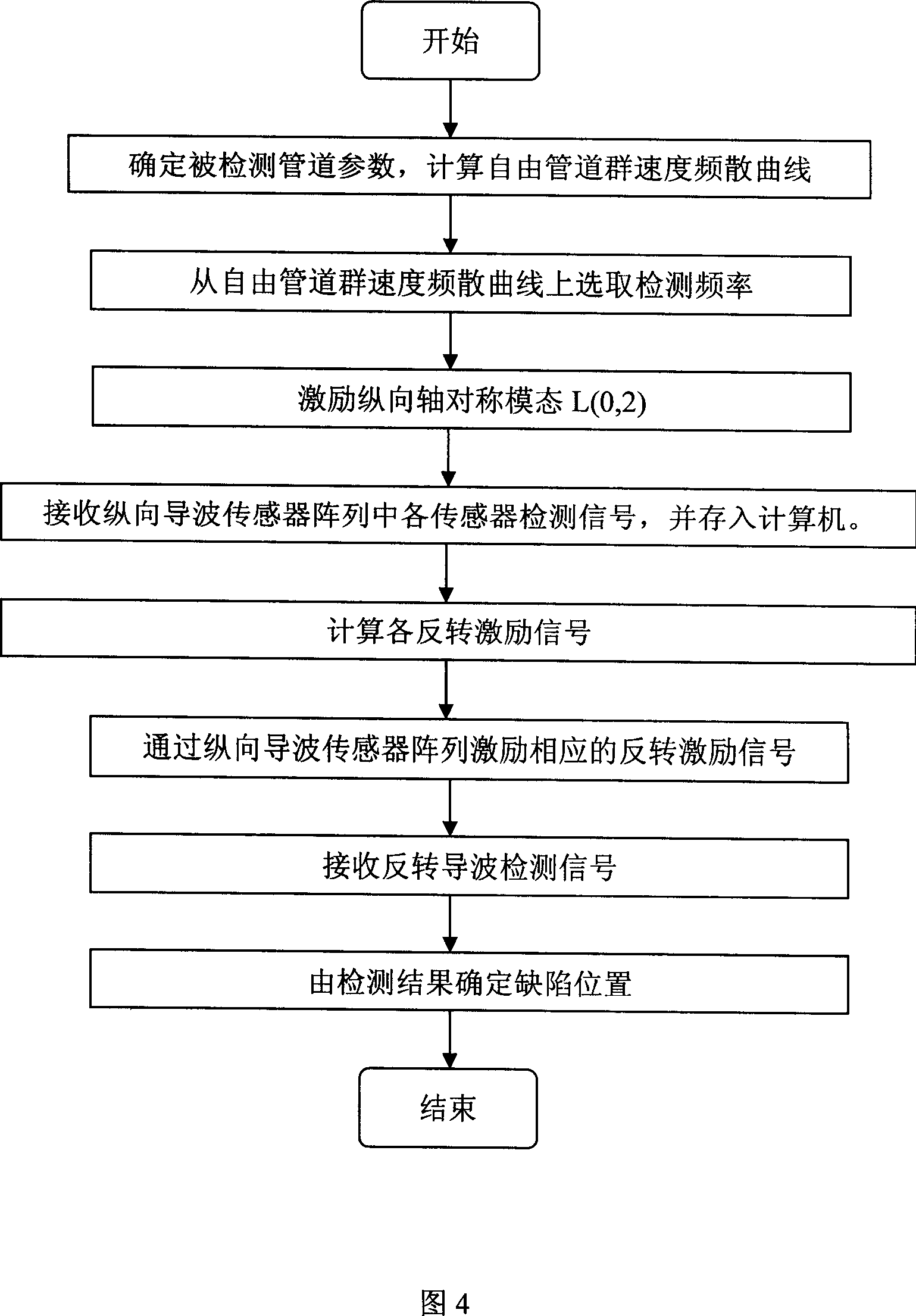

Supersonic guide-wave time reversion detection apparatus and method for defect of pipeline

ActiveCN1978977AImprove readabilityImprove detection abilityPipeline systemsSonificationWave detection

The invention relates to pipeline defect ultrasound guided wave time reversal detection device and method. The method includes the following steps: selecting detecting frequency according to the detected pipeline corresponding free hollow column structure group velocity dispersion curve; inputting the frequency into the arbitrary function generator to generate center frequency used as single sound signal; sending the signal to each passage of exciting / receiving set to transducer unit; exciting longitudinal axis symmetry guided wave modal; sending the reflected signal to the computer and gaining reversal excitation signal by time reversal; repeatedly exciting guided signal to detect. The invention realize space and time focus for guided wave detection, greatly improve detection capability for little defect.

Owner:BEIJING UNIV OF TECH

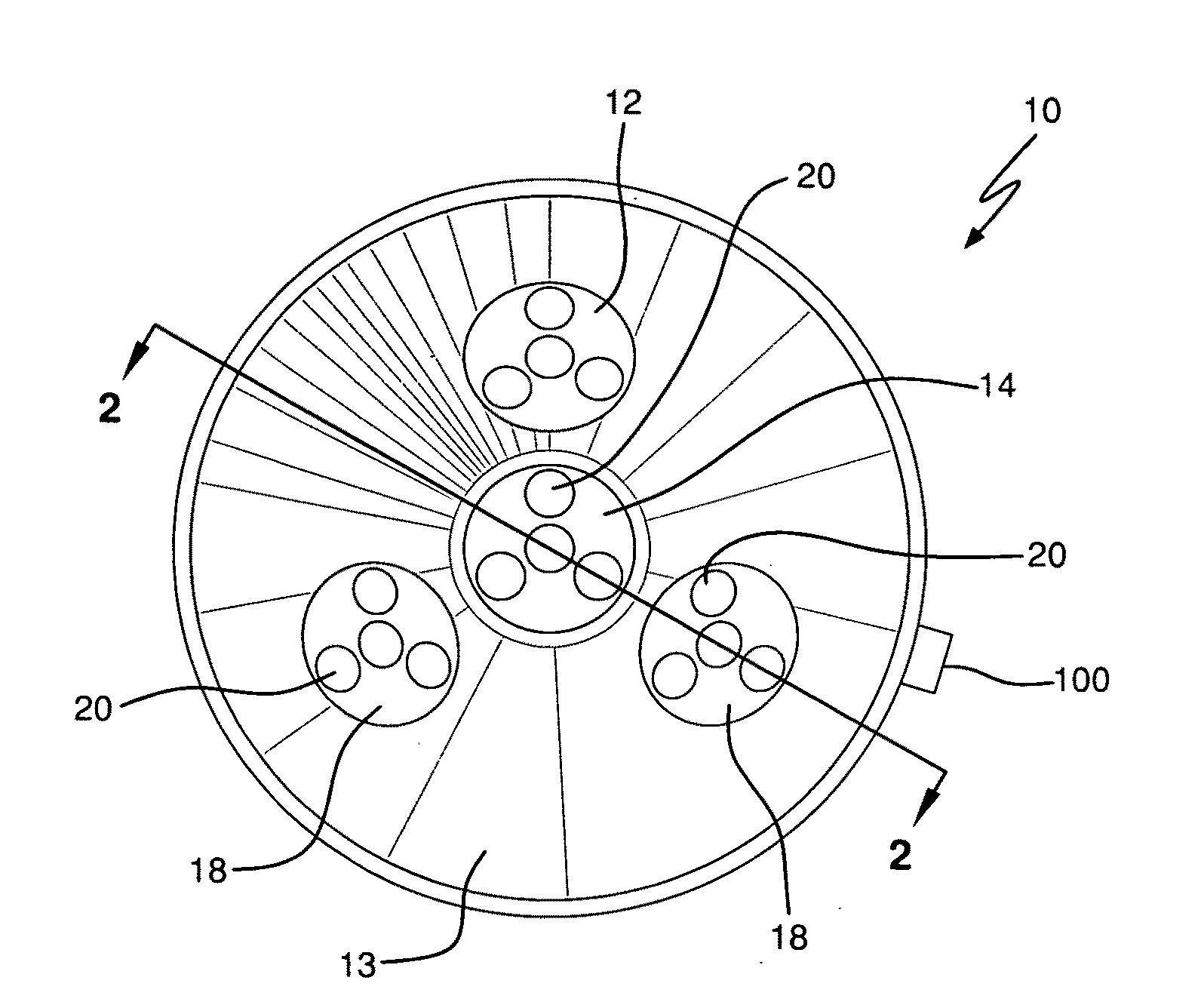

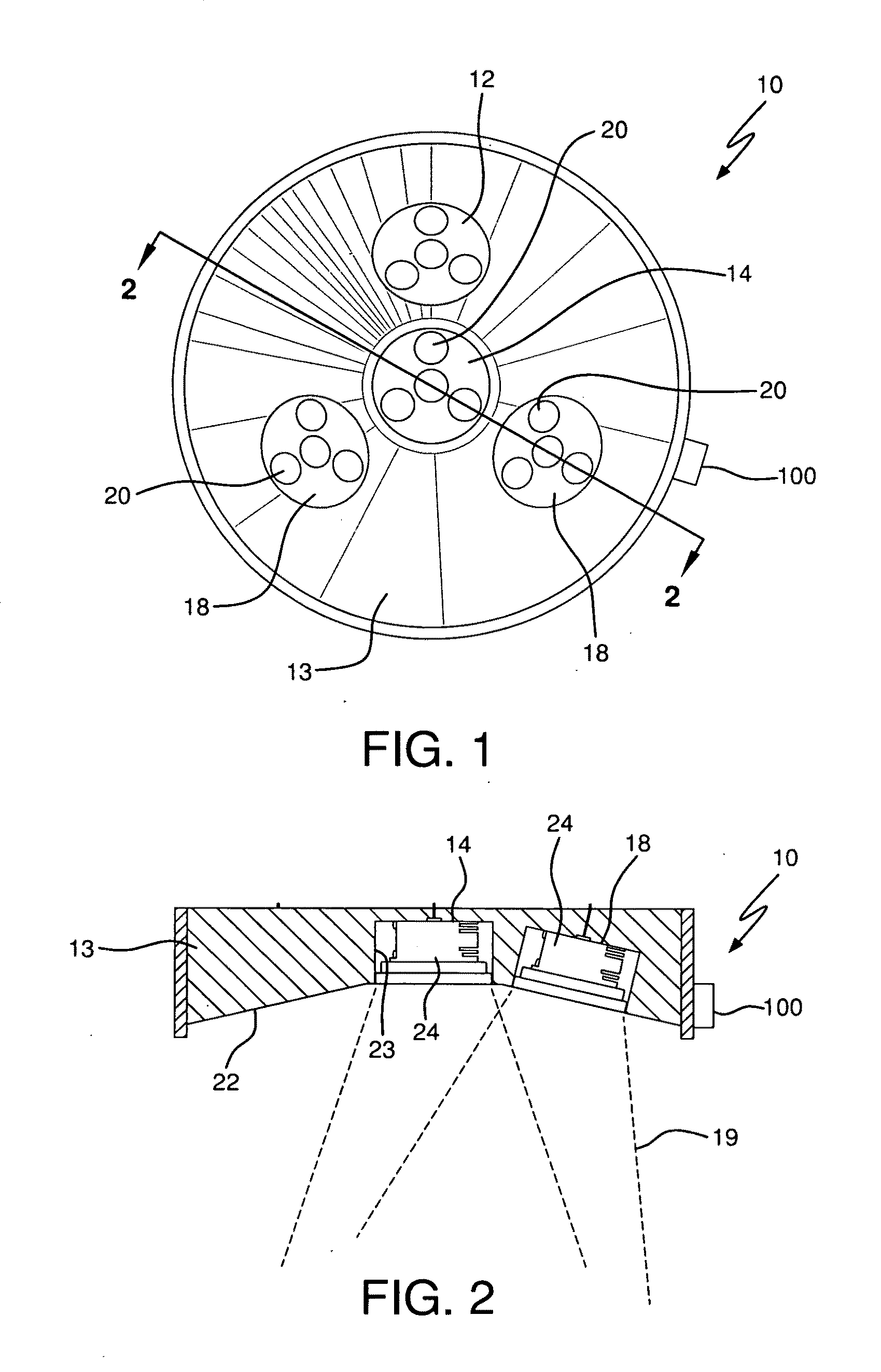

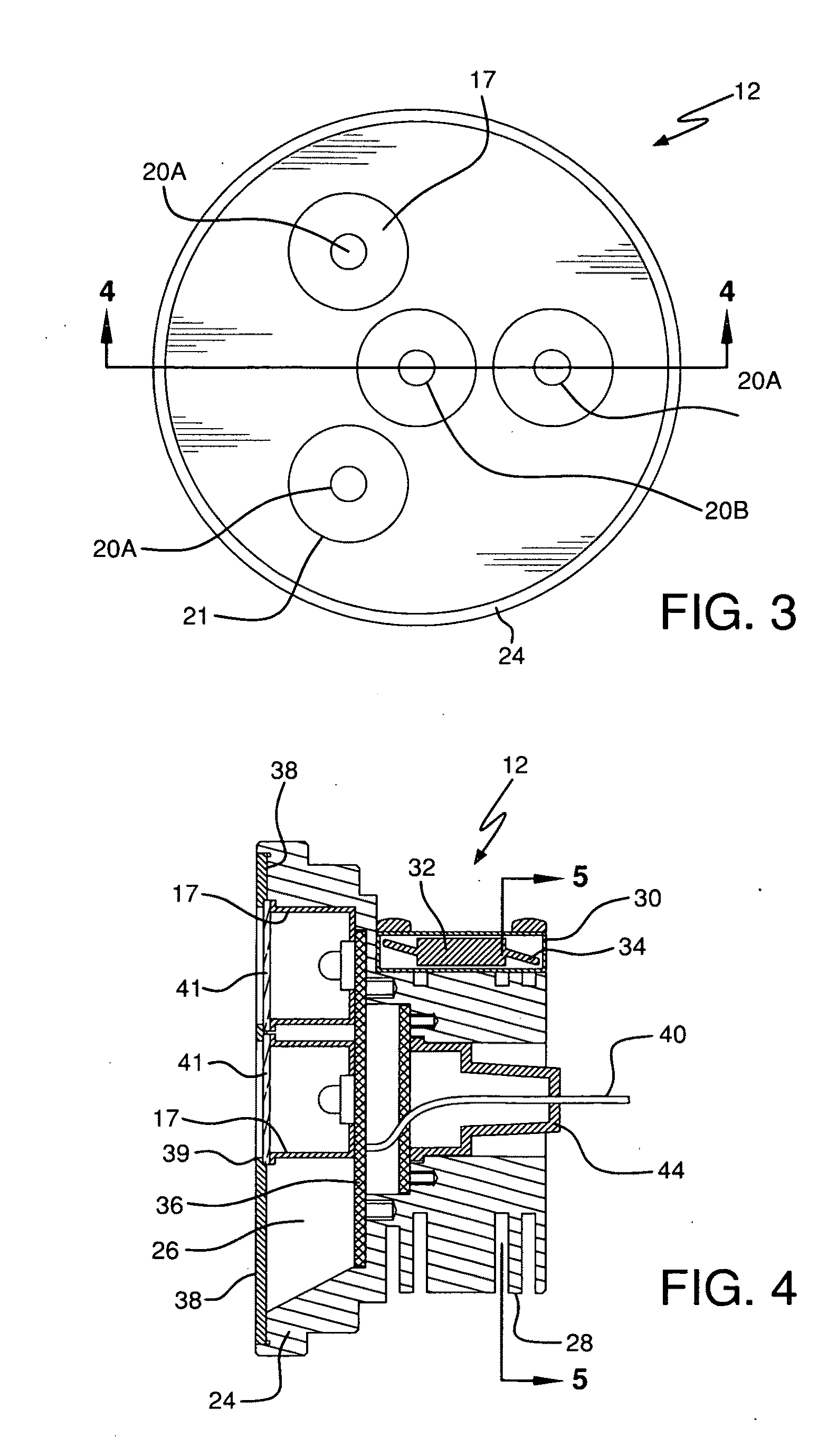

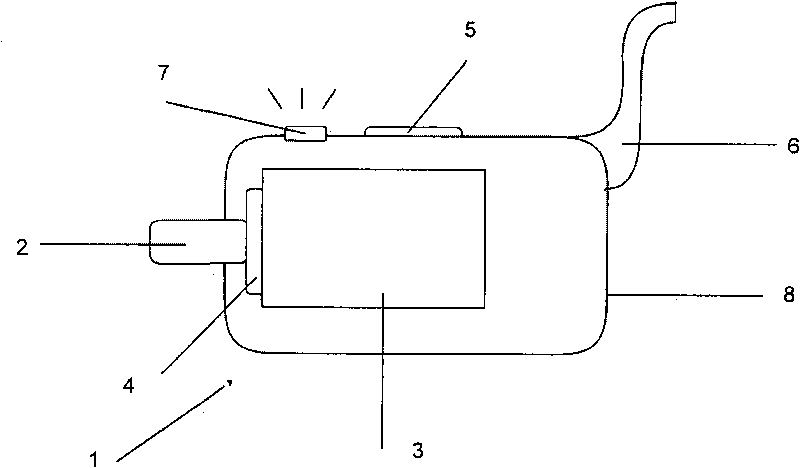

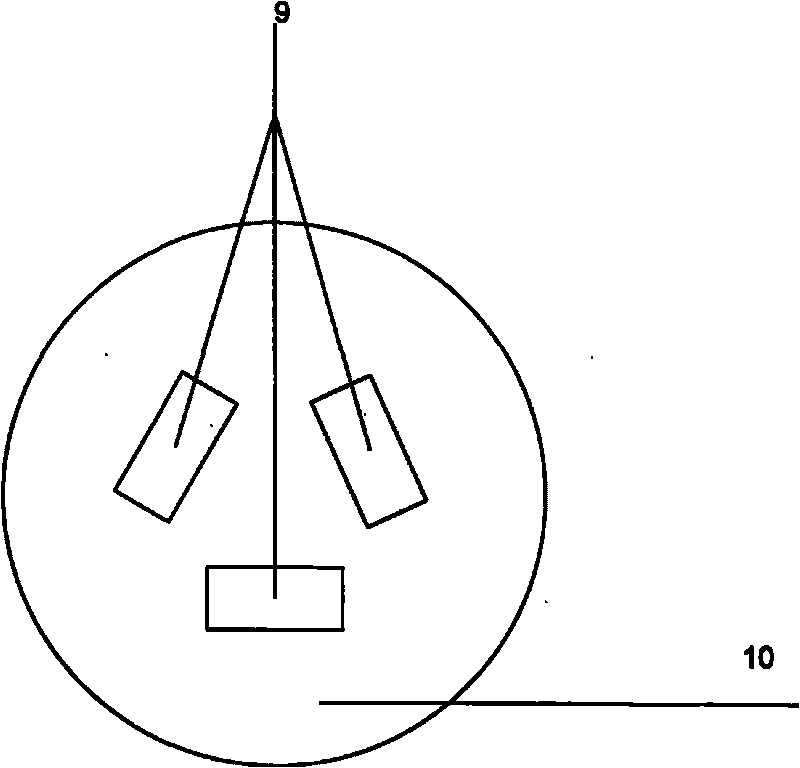

Modular lamp head and assembly for non-destructive testing

A lamp module for use in non-destructive testing and inspection. The module including a module body with a front and rear end, and a side wall. The module body includes a mounting chamber located within the side walls. A plurality of LEDs are mounted within the chamber and oriented to so as to emit light out of the front end of the body. At least one LED emits light having a wavelength selected to produce fluorescence of an illuminated material. A fan is mounted to the body to dissipate heat generated by the LEDs when the fan is activated. Electrical connectors extend out of the body and are electrically connected to the LEDs and the fan for supplying current. The module can be installed in various structures or systems, including in a luminaire, an overhead light housing or a track light system.

Owner:SPECTRO UV LLC

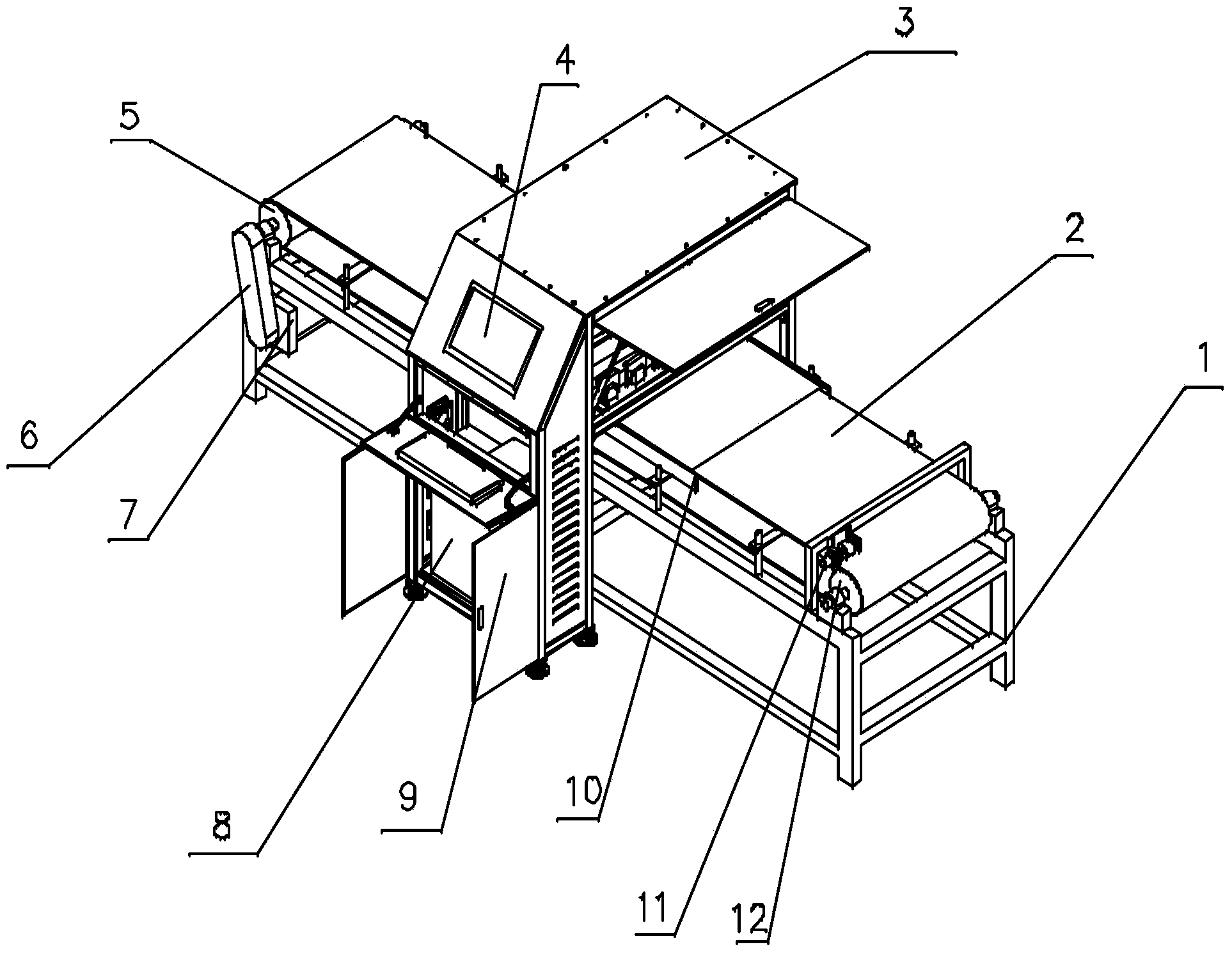

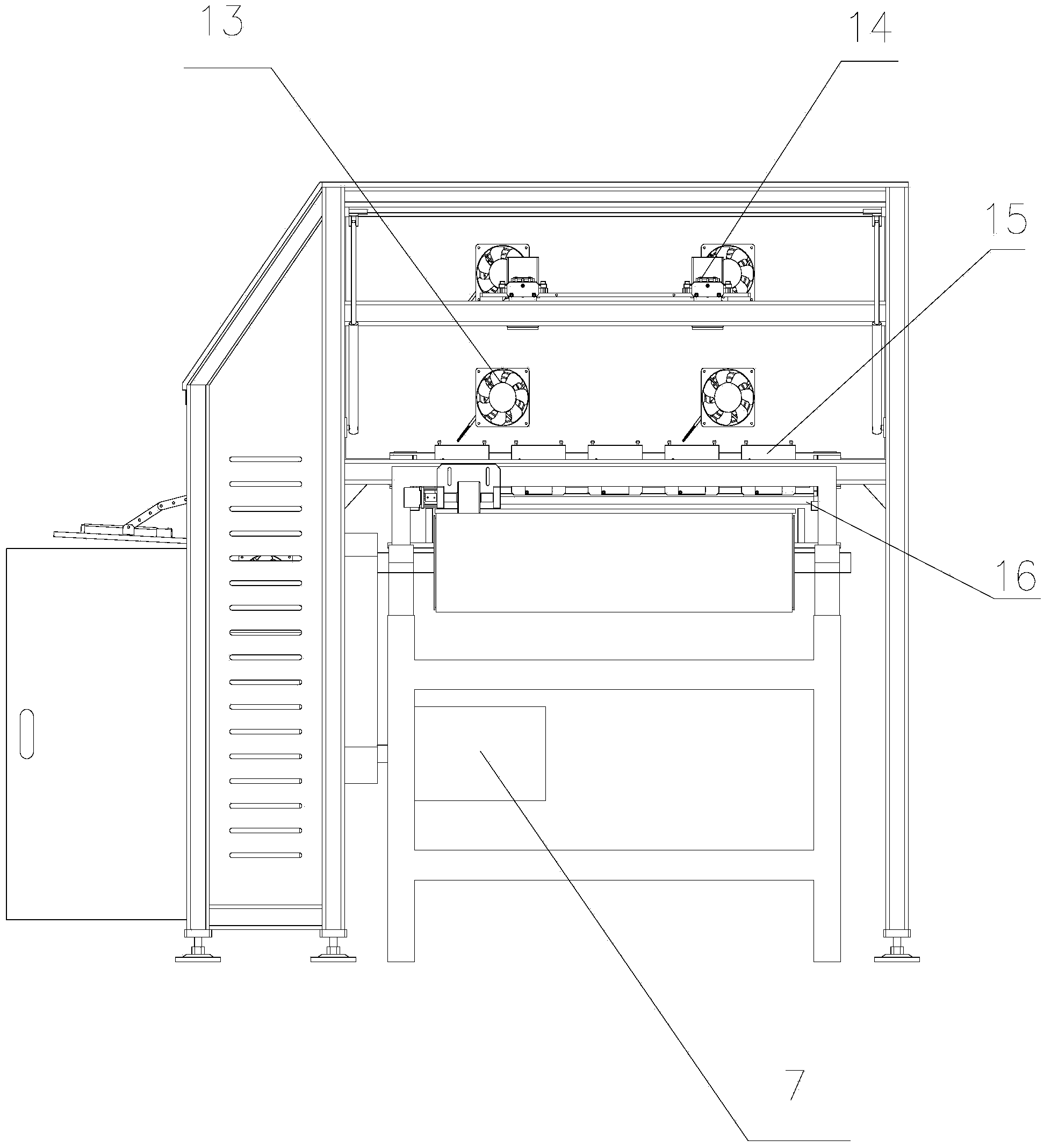

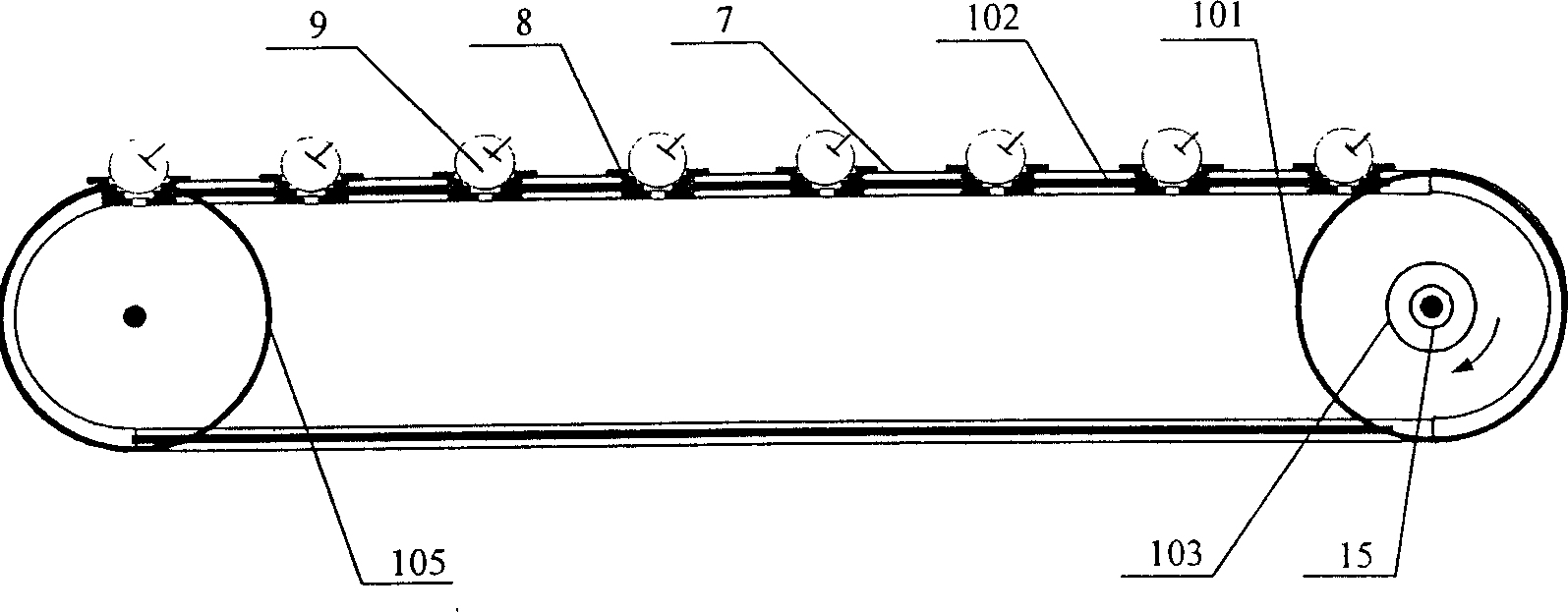

Nondestructive ceramic detection device and detection method thereof

InactiveCN104111260ASimple structureEasy maintenanceMaterial analysis by optical meansUsing optical meansDrive wheelEngineering

The invention discloses a nondestructive ceramic detection device and a detection method thereof. The detection device comprises a rack and an engine cover, wherein the engine cover stretches across the middle of the rack in a portal frame mode; a driving wheel and a driven wheel are respectively mounted at two ends of the rack; a motor is arranged on a framework on one side of the rack; the driving wheel is connected with the motor through a synchronous belt; a fan is mounted on one transverse side of the engine cover; a control cabinet is mounted on one vertical side of the engine cover; the lower half part of the control cabinet is of cabinet type; a detection host is arranged in the cabinet; a linear CCD (Charge Coupled Device) camera is arranged on a first cross beam in the engine cover; a linear light source is arranged under the linear CCD camera; a plurality of laser displacement sensors are arranged on a second cross beam of the engine cover. The detection device is simple in structure, convenient to maintain and capable of effectively avoiding artificial detection error; meanwhile, according to the detection method, the detection process is simple and quick, the detection result is accurate and the detection efficiency is high.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

Non-destructive testing and imaging

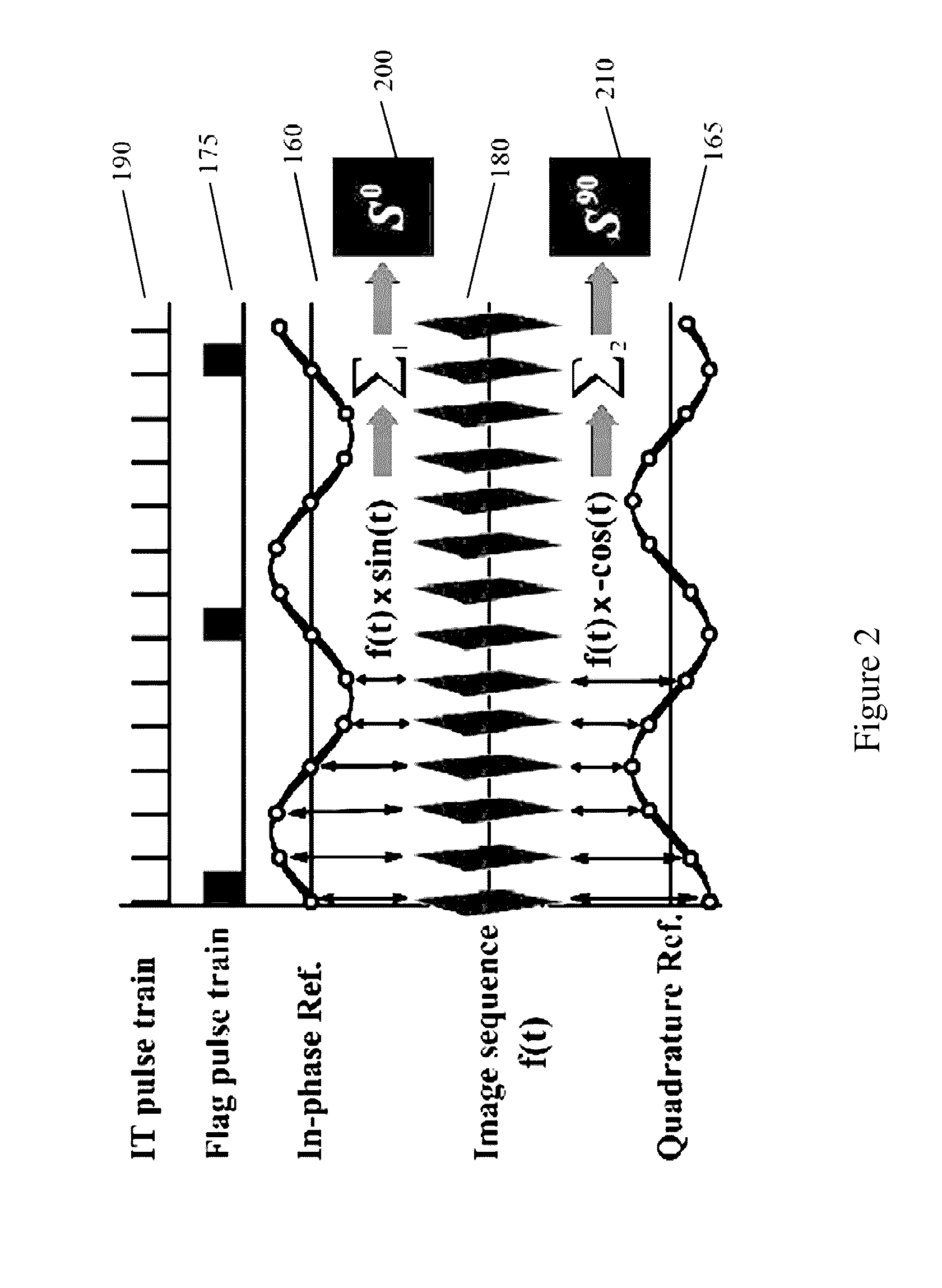

InactiveUS20050264796A1Optically investigating flaws/contaminationUsing optical meansNon destructivePixel value difference

A method of non-destructive testing includes non-destructively testing an object over a range of test levels, directing coherent light onto the object, directly receiving the coherent light substantially as reflected straight from the object, and capturing the reflected coherent light over the range of test levels as a plurality of digital images of the object. The method also includes calculating differences between pixel values of a plurality of pairs of digital images of the plurality of digital images, and adding the pixel value differences of the plurality of pairs of digital images to yield at least one cumulative differential image.

Owner:RAVEN ENG

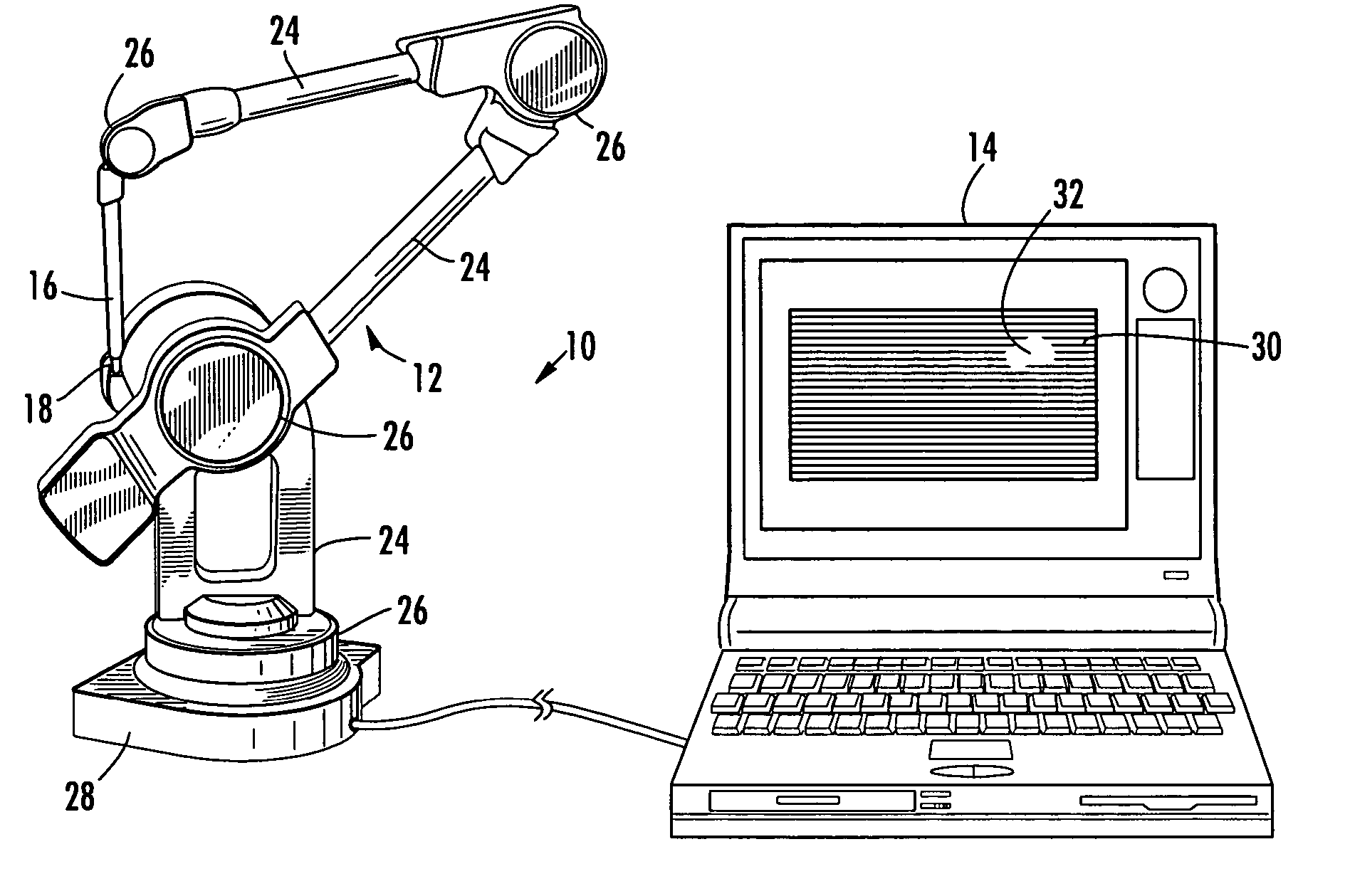

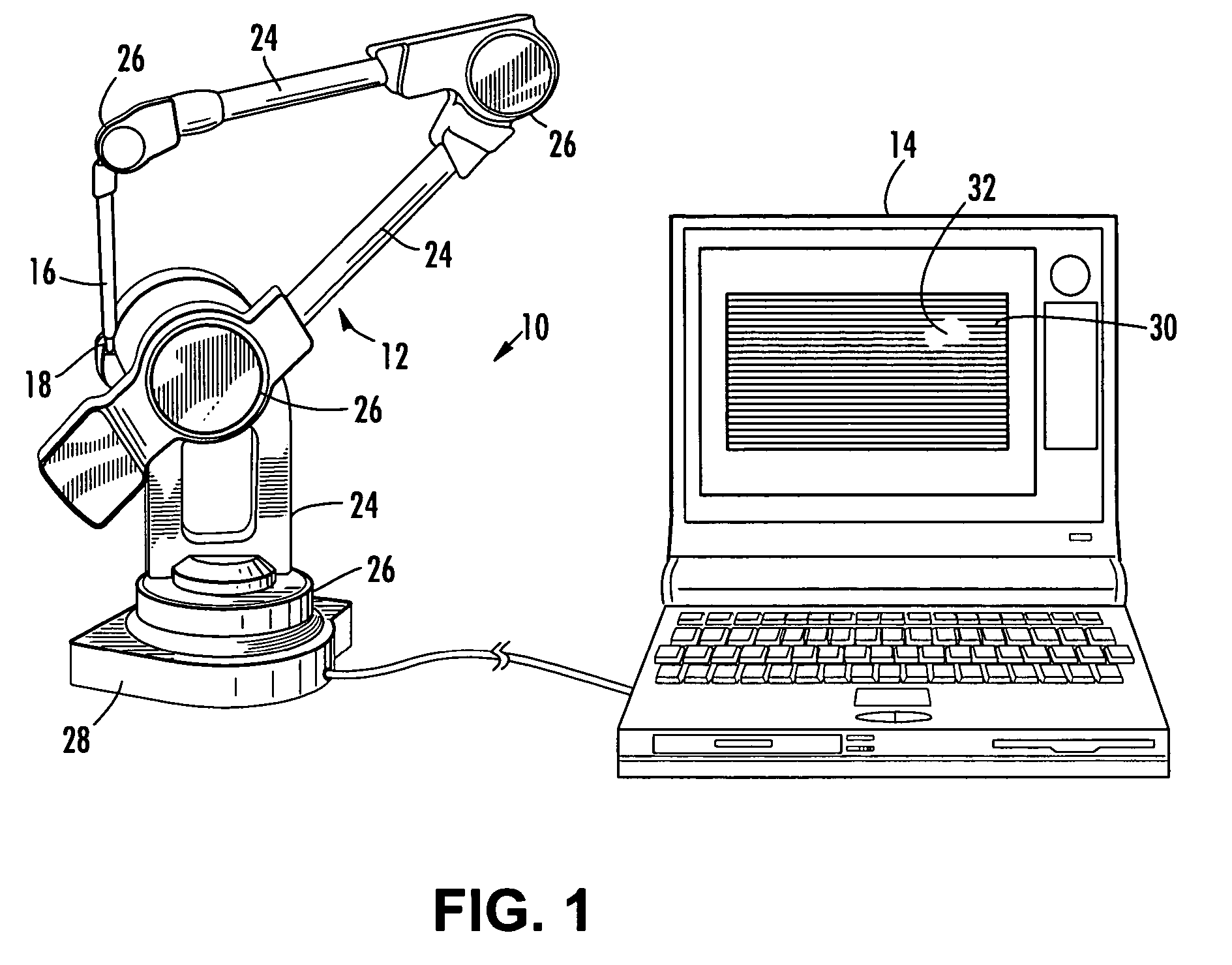

Inspection system using coordinate measurement machine and associated method

ActiveUS20050276466A1Improve detection rateImprove reliabilityImage enhancementImage analysisNon destructiveData acquisition

A system and method for identifying defects in a workpiece are provided. The system includes a sensor for non-destructive testing. The system also includes a movable arm carrying the sensor and being pivotally attached to a base. The movable arm includes at least one pivotable joint between the base and the sensor, and is capable of being moved such that the sensor acquires data indicative of a workpiece as the sensor travels proximate to the workpiece. A data acquisition system is capable of communicating with the sensor to create an image of at least a portion of the workpiece based on the data acquired by the sensor.

Owner:THE BOEING CO

Non-destructive testing of pipes

ActiveUS7328618B2Easy to measureEasy to calculateAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveEngineering

To perform a non-destructive condition assessment of a pipe carrying a fluid, an actual value representative of the propagation velocity of an acoustic disturbance propagating between two longitudinally separated points on the pipe is determined. A corresponding predicted value for the propagation velocity is computed as a function of at least one wall thickness parameter of the pipe by using a theoretical model for the propagation of acoustic waves in the pipe that assumes said pipe has a finite wall thickness with a predetermined circumferential thickness profile. The wall thickness parameter is then computed by matching the actual value with the predicted value, for example, by substituting the actual value in a formula predicting the theoretical value.

Owner:MUELLER INT LLC

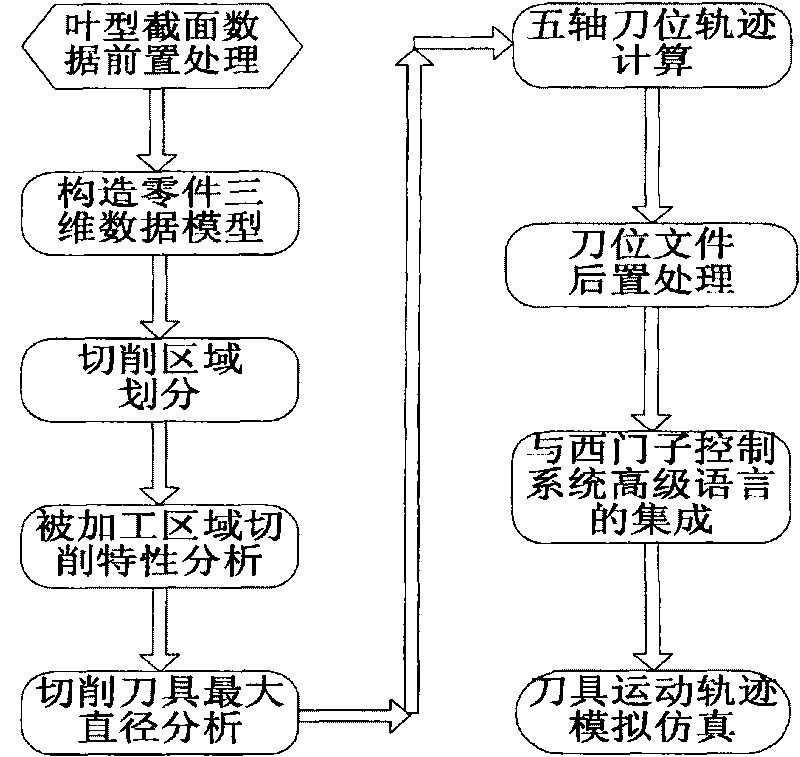

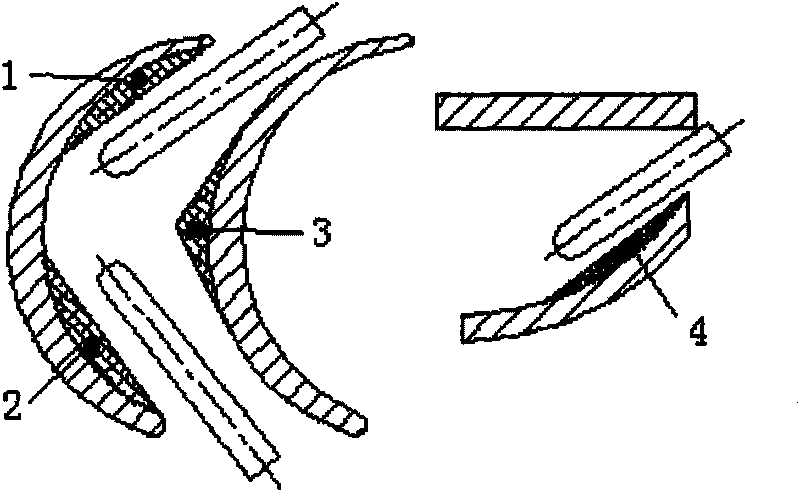

Numerically controlled drilling and milling processing method for runner of blisk of engine

InactiveCN101733618AImprove processing efficiencyShorten the manufacturing cyclePositioning apparatusNumerical controlAngular degreesEngineering

The invention provides a numerically controlled drilling and milling processing method for a runner of a blisk of an engine. The main technical flow before drilling and milling the runner comprises the following steps: lathing each surface of a blank, performing nondestructive testing, lathing inner and outer cavities of the blisk, finely milling a needed periphery and an axial benchmark, drilling and boring an angular datum hole, drilling and milling the runner and inspecting. A part and a fixture are in peripheral seam allowance fit to limit a radial degree of freedom of the part; an end face gland and a central pull bar axially limit an axial degree of freedom of the part; and a precise positioning pin angularly limits an angular degree of freedom of the part. The method has the advantages that: by applying the drilling and milling processing method to a part machining process of the blisk of the engine having the material removing rate of over 90 percent, the method improves the processing efficiency, shortens the manufacturing period of the product, and provides a new technical means for removing a large amount of remainder materials of the blisk; and the processing of a high-temperature alloy, a titanium alloy and other difficult-to-process materials shows that the material is more difficult to process, the removing rate is bigger and the effect is more obvious.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

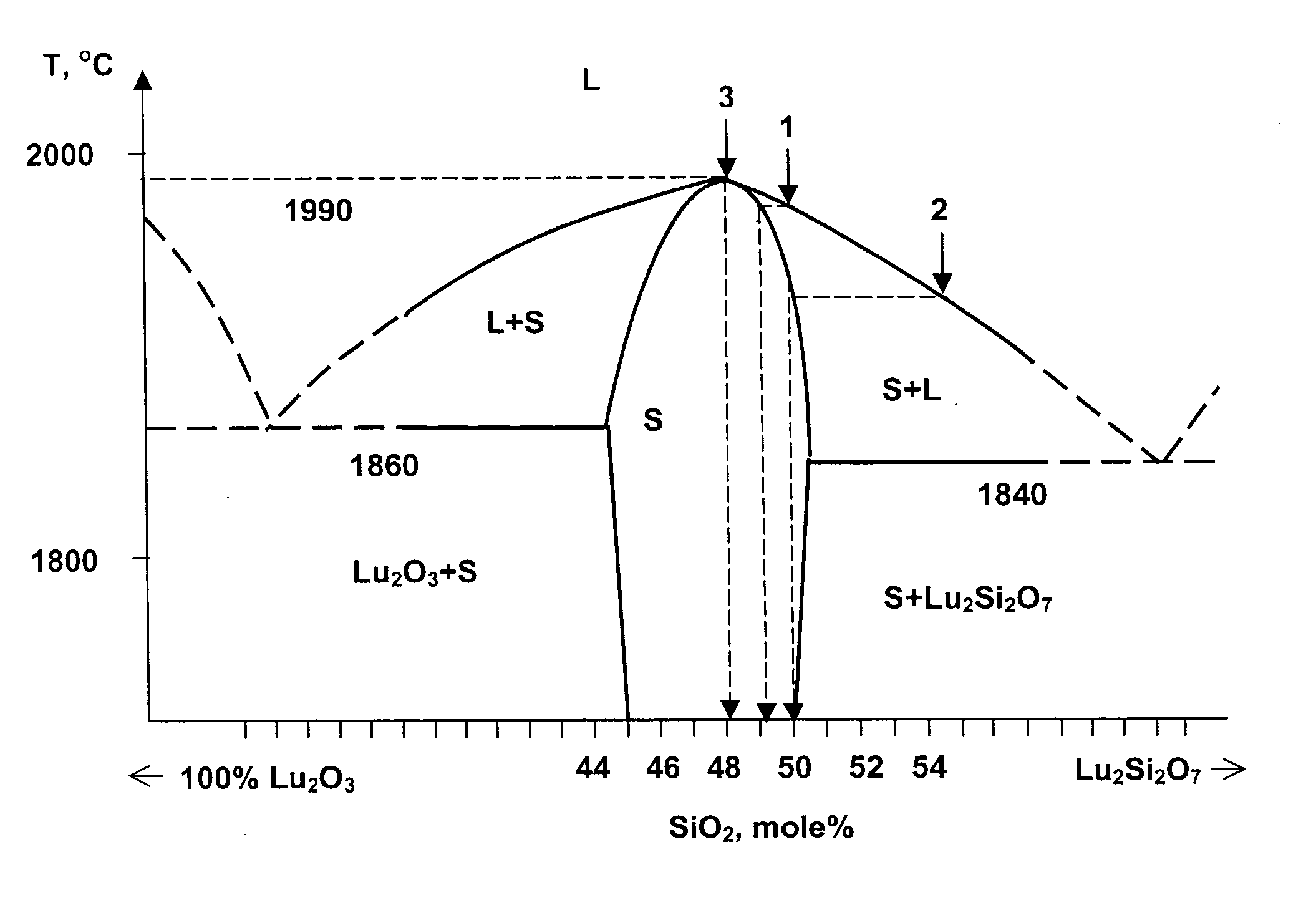

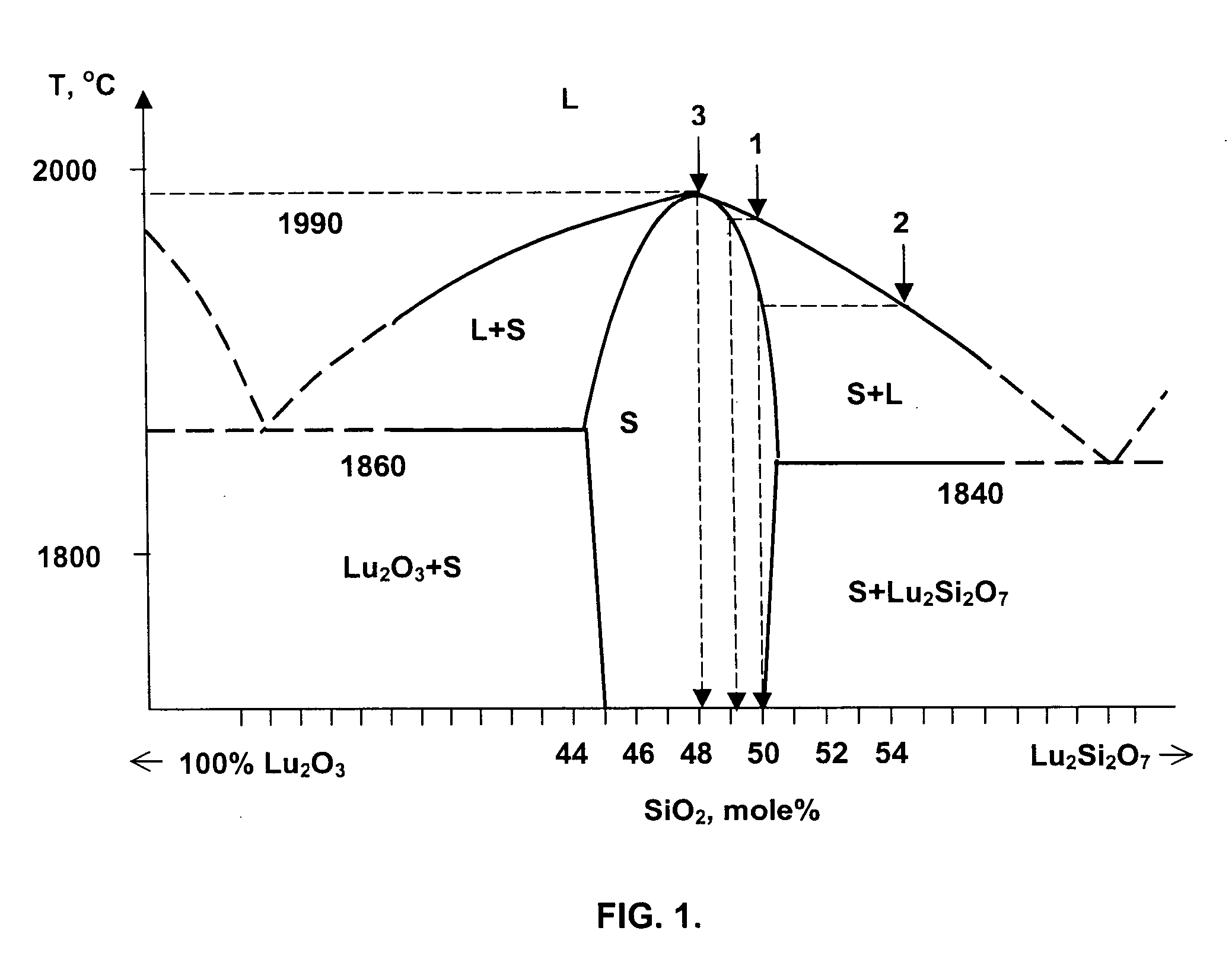

Scintillation substances (variants)

ActiveUS20060086311A1Reduce manufacturing costHigh light yieldPolycrystalline material growthBy pulling from meltFractographyLutetium

Inventions relate to scintillation substances and they may be utilized in nuclear physics, medicine and oil industry for recording and measurements of X-ray, gamma-ray and alpha-ray, nondestructive testing of solid states structure, three-dimensional positron-emission tomography and X-ray computer tomography and fluorography. Substances based on silicate comprising lutetium and cerium characterised in that compositions of substances are represented by chemical formulae CexLu2+2y−xSi1−yO5+y, CexLiq+pLu2−p+2y−x−zAzSi1−yO5+y−p, CexLiq+pLu9.33−x−p−z□0.67AzSi6O26−p, where A is at least one element selected from group consisting of Gd, Sc, Y, La, Eu, Tb, x is value between 1×10−4 f.units and 0.02 f.units., y is value between 0.024 f.units and 0.09 f.units, z is value does not exceeding 0.05 f.units, q is value does not exceeding 0.2 f.units, p is value does not exceeding 0.05 f.units. Achievable technical result is the scintillating substance having high density, high light yield, low afterglow, and low percentage loss during fabrication of scintillating elements.

Owner:ZECOTEK HLDG INC

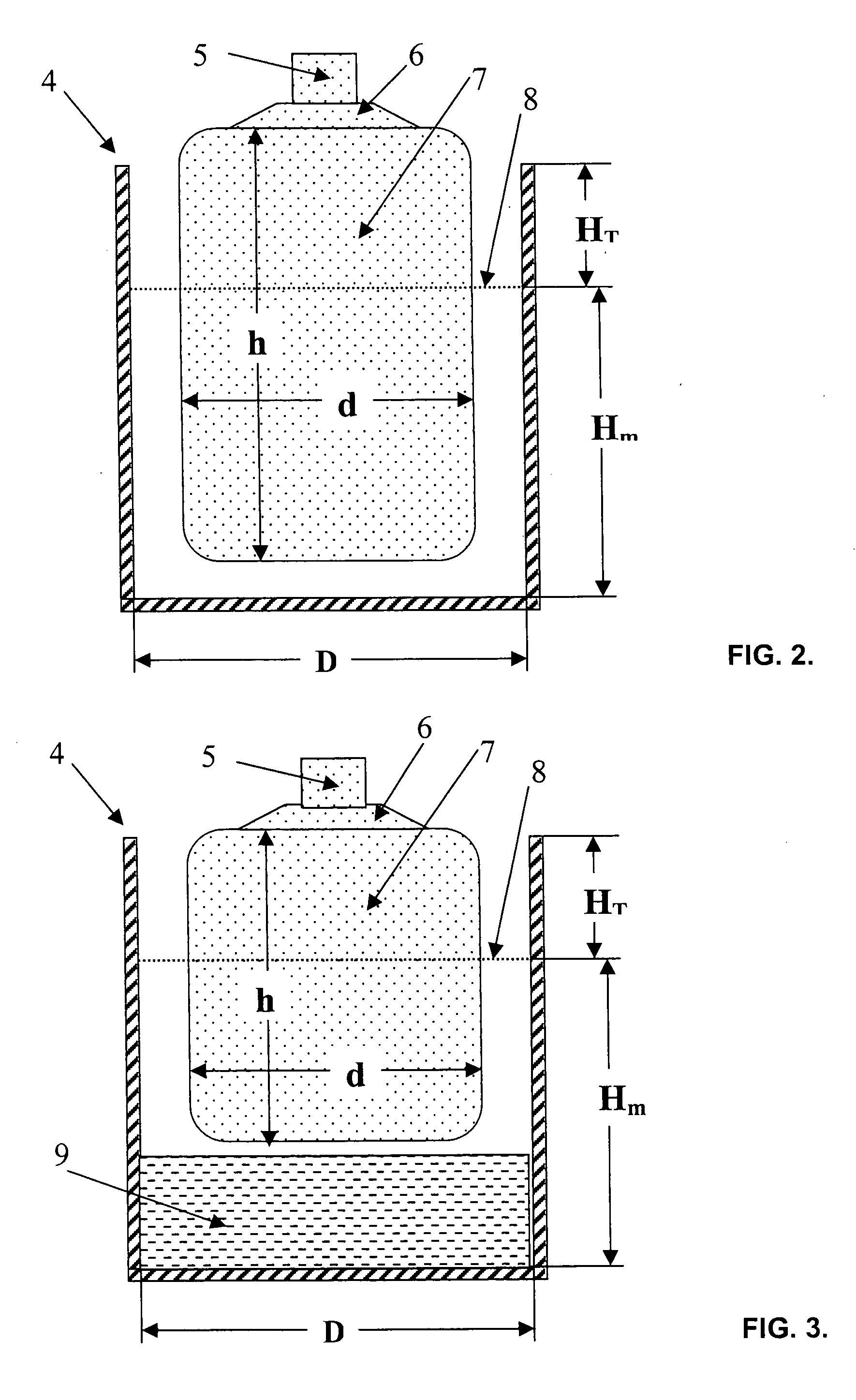

Method and apparatus for non-destructive testing of fruit internal quality based on optical properties

InactiveCN1837788AHigh precisionImprove detection accuracyUsing optical meansColor/spectral properties measurementsNon destructiveOptical property

This invention relates to a method and apparatus for non-destructive testing of fruit internal quality based on optical properties. The device comprises a send unit, an analysis and process unit to evaluate the fruit referred to a stored quality prediction model, a signal control unit to send the fruit position and size information to the detection system with command format, an illumination system to provide stable and optimal-strength light, a detection system to obtain and send the transmitted spectrum information for fruit inner quality to the analysis and process unit, a fruit grade-outlet, a size detection device, and a coder. This invention improves on-line detection speed and precision.

Owner:ZHEJIANG UNIV

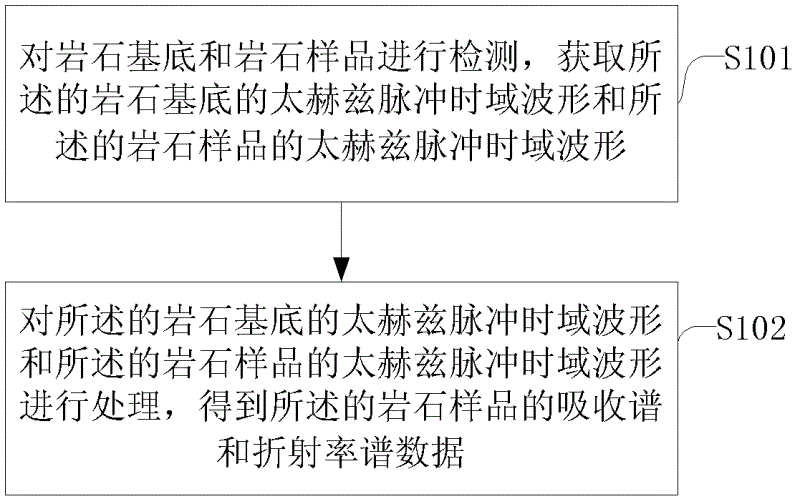

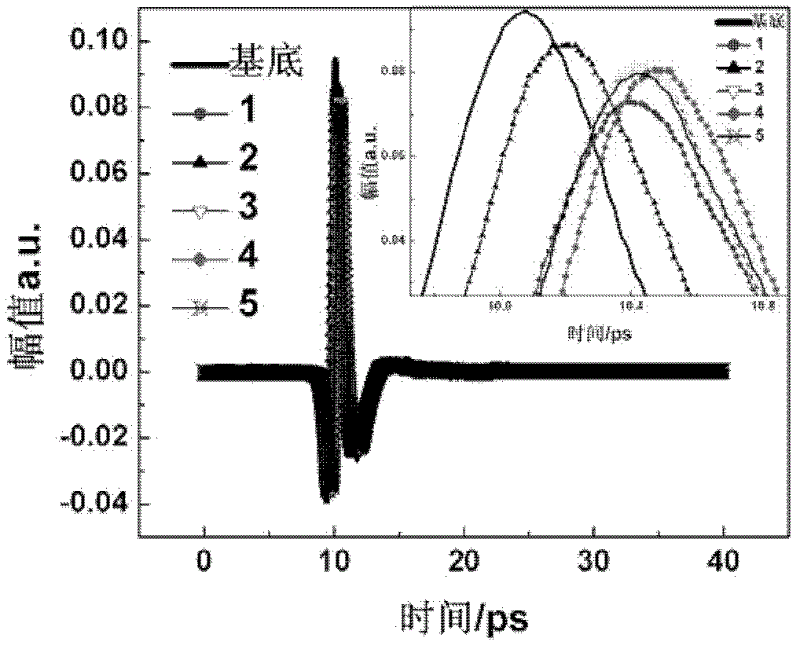

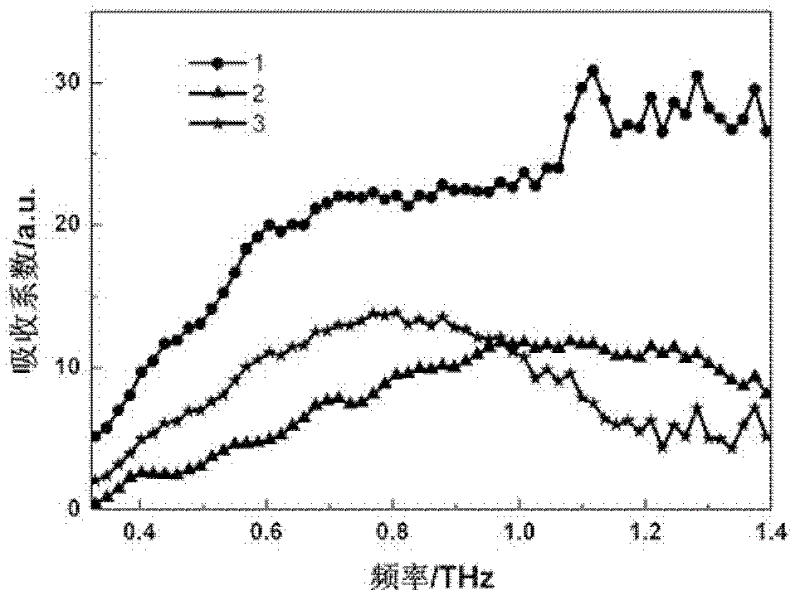

Method and system for measuring rock optical parameters based on Terahertz time-domain spectroscopy

InactiveCN102621083AQuick checkNon-destructive testingPhase-affecting property measurementsColor/spectral properties measurementsRefractive indexTerahertz pulse

The invention relates to a method and a system for measuring rock optical parameters based on Terahertz time-domain spectroscopy. The method comprises the steps of: detecting a rock substrate and a rock sample, and obtaining the Terahertz time-domain waveform of the rock substrate and the Terahertz time-domain waveform of the rock sample; processing the Terahertz time-domain waveform of the rock substrate and the Terahertz time-domain waveform of the rock sample, and obtaining the absorption spectrum and the refractive index spectrum data. The method and the system for measuring rock optical parameters based on the Terahertz time-domain spectroscopy provided by the invention have the advantages that the fast and nondestructive detection can be carried out on the rock, the operation of the detection method is easy, the data processing is simple, and the repeatability is good.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

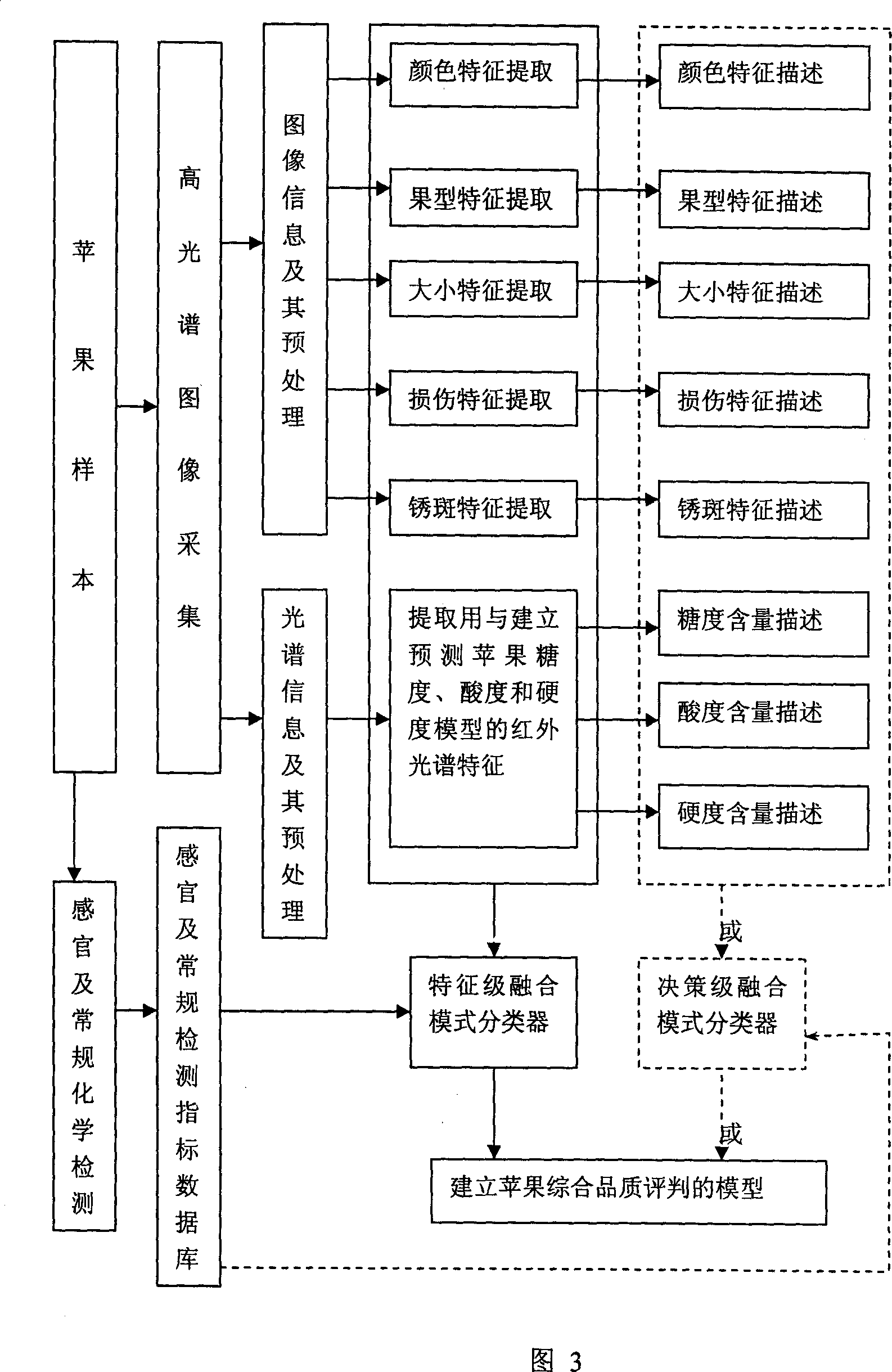

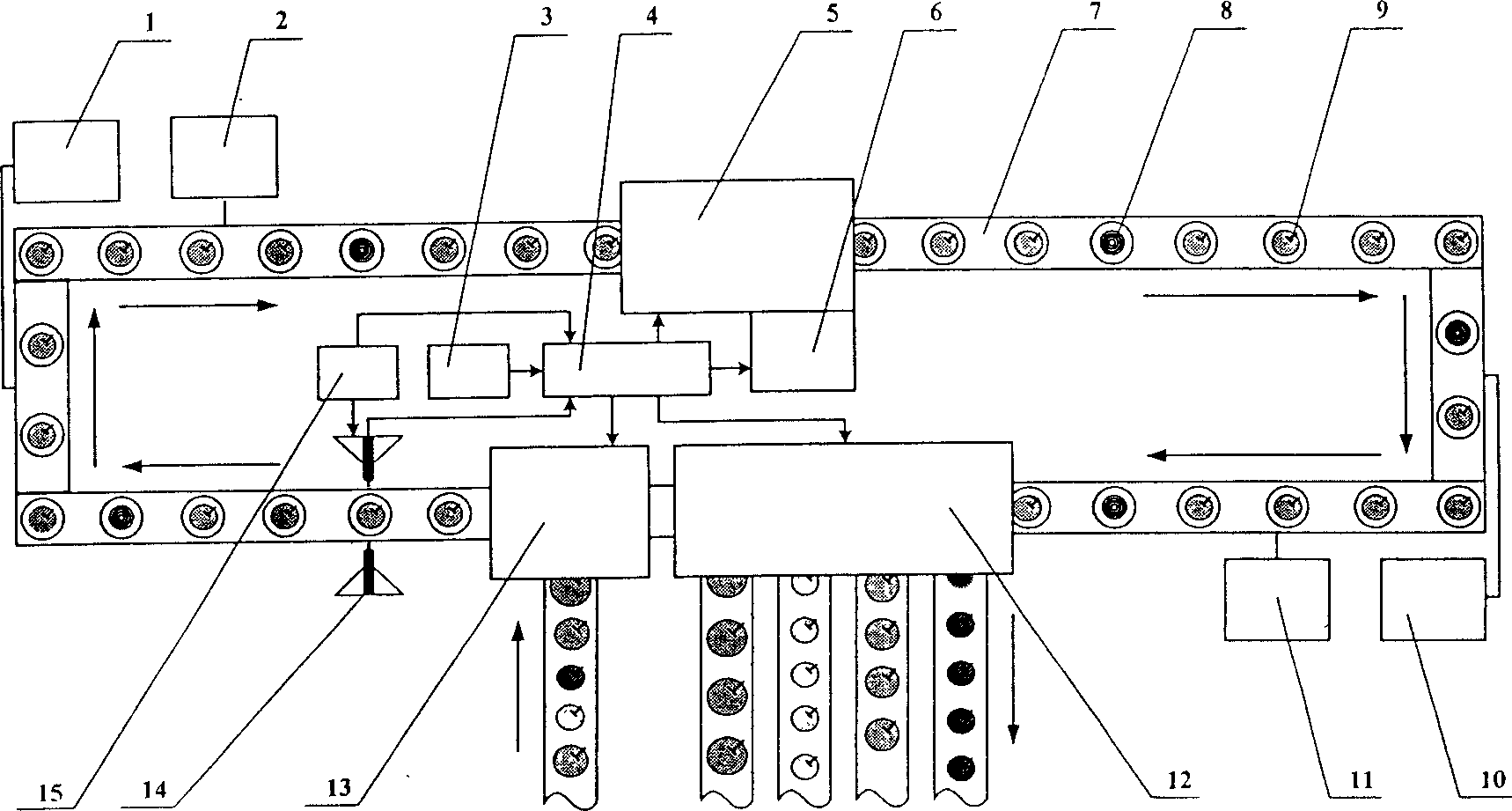

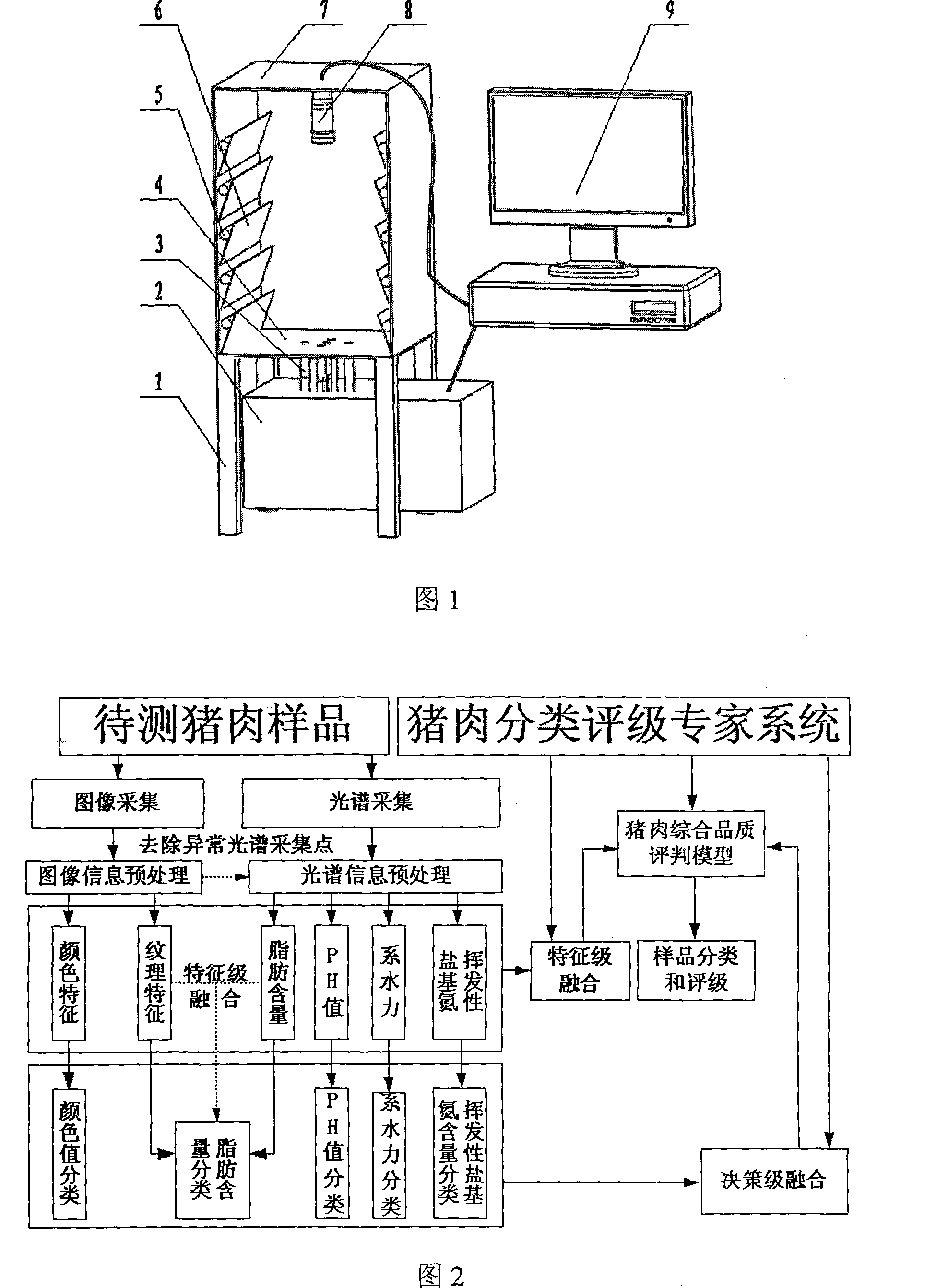

Method and apparatus for nondestructively testing food synthetic quality

ActiveCN101251526AFast NDTThe detection process is fastMaterial analysis by optical meansTesting foodFood materialFood classification

The invention discloses a non-destructive inspection method for the comprehensive quality of food and a device thereof, wherein image information reflecting characteristics of an inspected object, such as color, texture, size and shape, etc. is acquired by a machine vision system, and spectral information reflecting physical and chemical indexes of the sample such as moisture, sugar, protein, lipid and PH value, etc. is obtained by a spectrographic detection system, and the acquired image information and the spectral information undergo the preprocessing on the data layer and the information integration on the characteristic layer or the decision layer; together with a built food classification grading expert system, the quality of the inspection object is comprehensively graded. The invention comprehensively utilizes the light image information and the spectral information to inspect the appearance and inner quality of food, thereby the invention can make a quick, convenient, non-destructive and objective inspection on the comprehensive quality of food; the method and the device are widely used to classify food materials, monitor the food processing and grade the food, etc., which ensures the quality of food and contributes to the good quality and low price of food.

Owner:ZHEJIANG UNIV

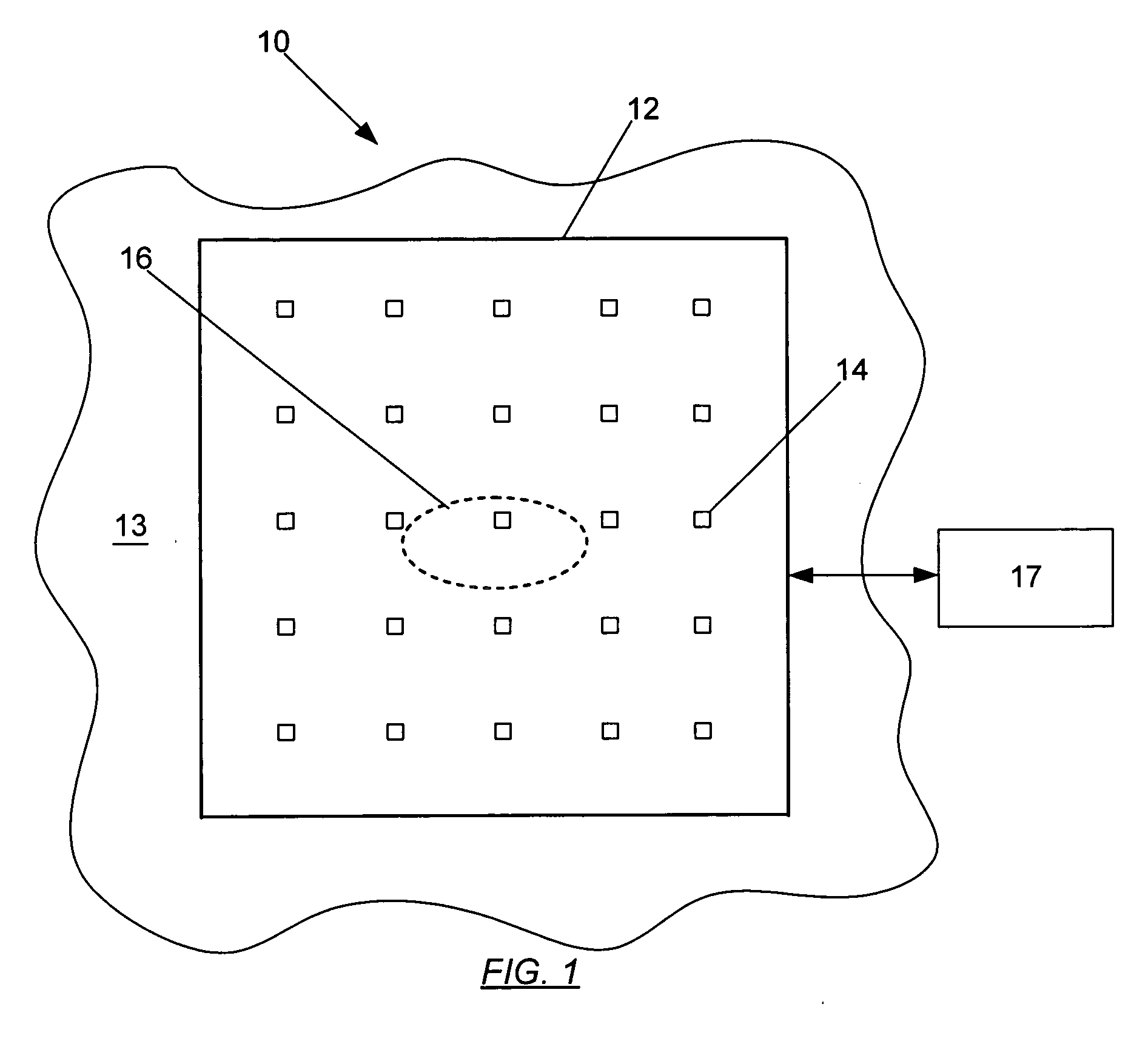

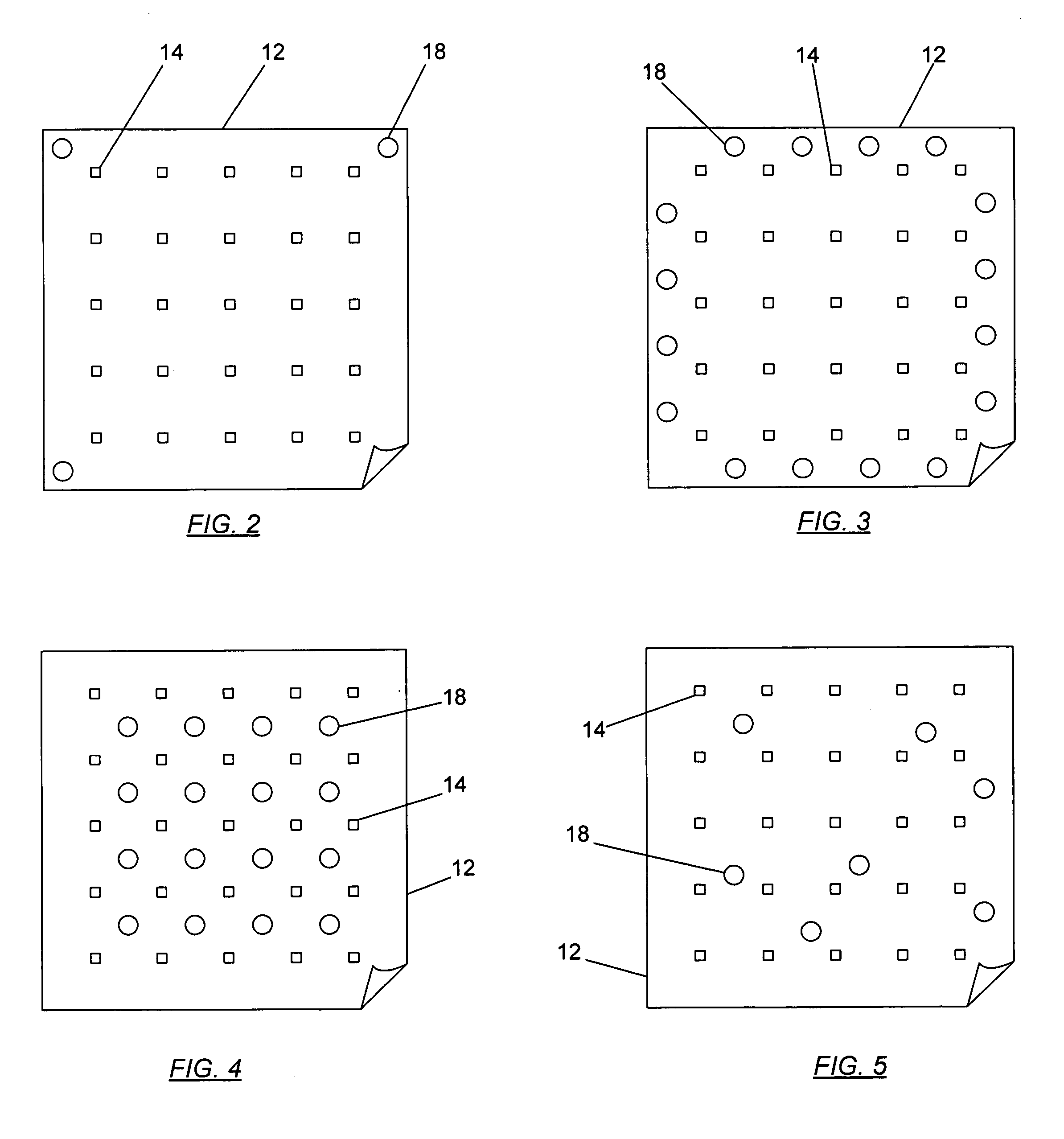

Non-destructive inspection system and associated method

ActiveUS20070017297A1Low costStructure moreAnalysing solids using sonic/ultrasonic/infrasonic wavesElasticity measurementNon destructiveProximate

An assembly, system, and method for identifying defects in a structure are provided. The assembly includes a structure of a metallic or composite material, and a flexible sheet of material positioned adjacent to the structure. The assembly also includes a plurality of non-destructive sensors secured to the flexible sheet, and a mechanism operable to impact the flexible sheet or proximate to the flexible sheet to generate stress waves within and along a surface of the structure. The system further provides a data acquisition system capable of communicating with the sensors such that the data acquisition system generates feedback indicative of at least a portion of the structure based on data from the stress waves acquired by the sensors.

Owner:THE BOEING CO

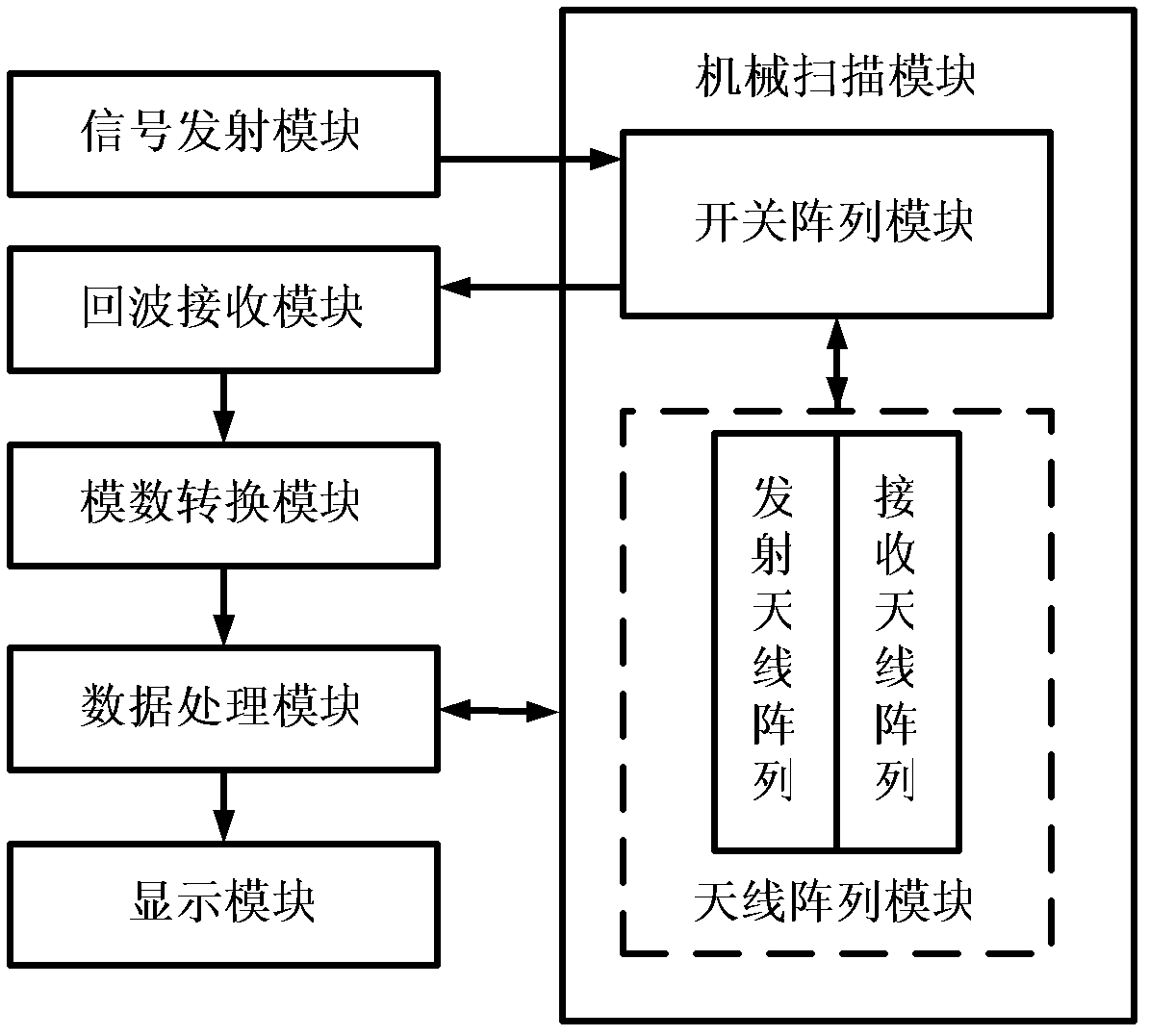

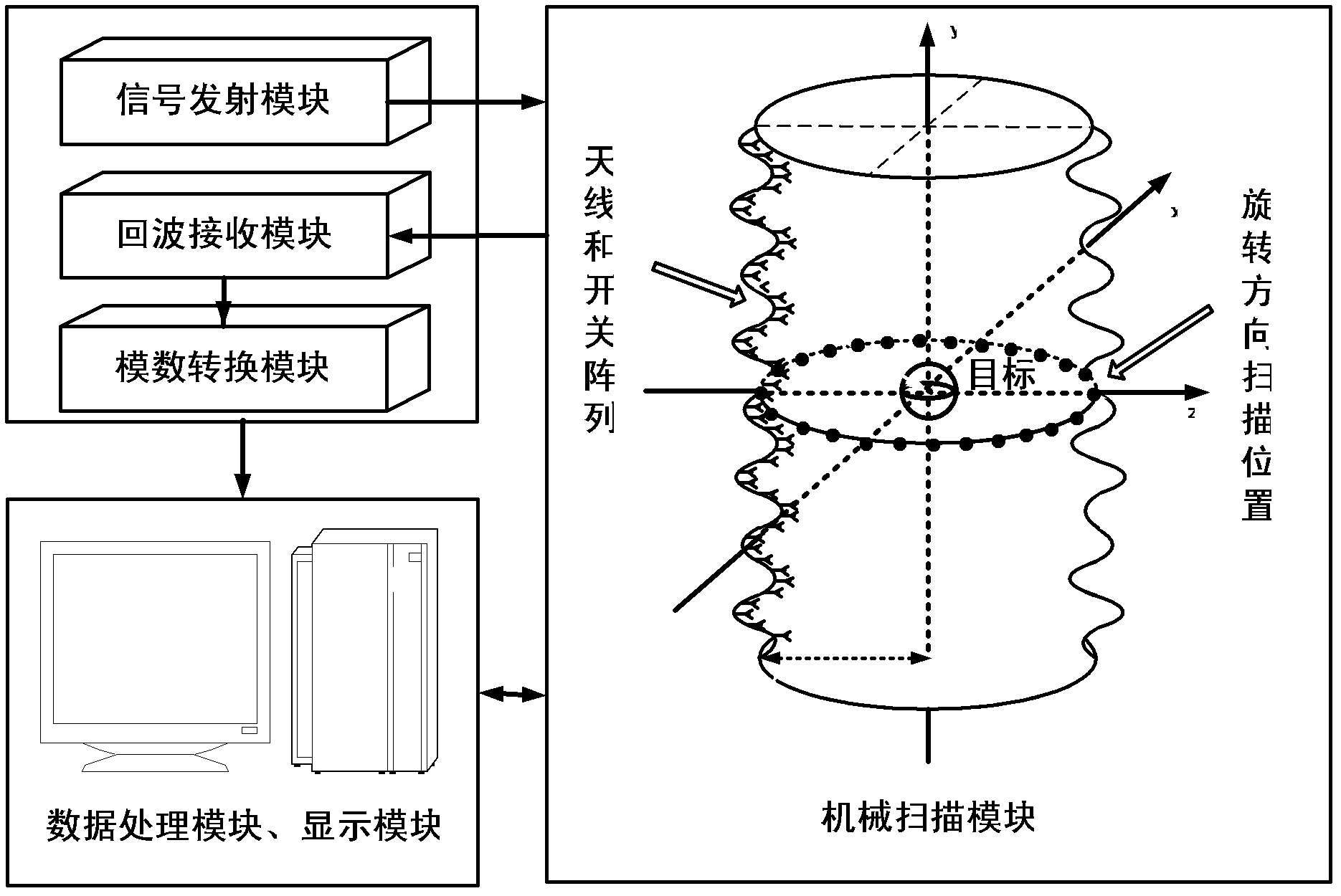

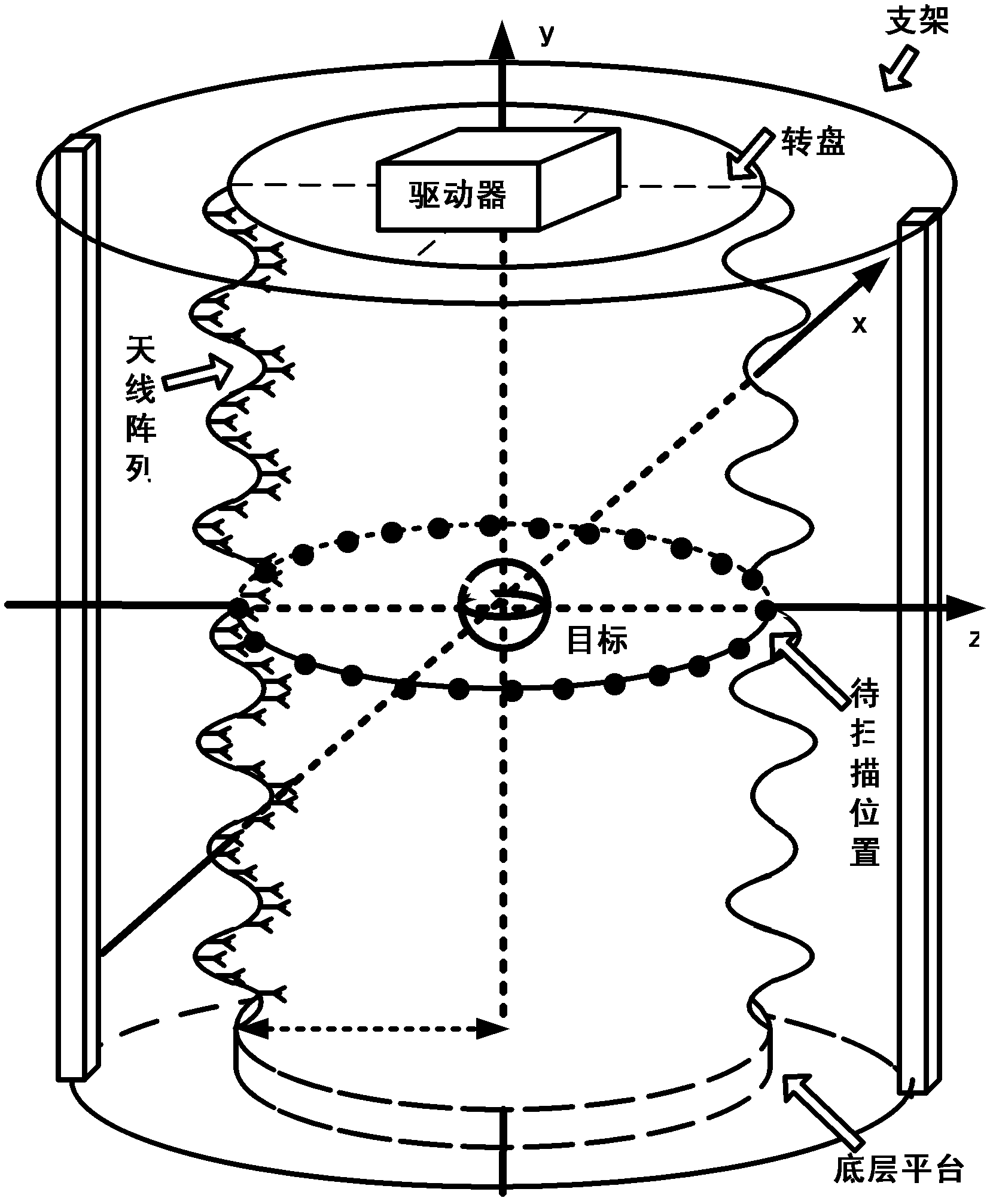

Microwave three-dimensional imaging method based on rotary antenna array

ActiveCN103018738AIncrease flexibilityImprove acquisition efficiencyRadio wave reradiation/reflectionArray elementDigital signal

The invention discloses a microwave three-dimensional imaging method based on a rotary antenna array, and relates to a microwave imaging technology. The method comprises the following steps of: generating an electromagnetic signal by a signal transmitting module; driving an antenna array module which is distributed in a straight line form or a curved line form to rate by a mechanical scanning module, meanwhile, controlling the antenna array module by a switch array module to transmit an electromagnetic signal at the same time, and receiving a signal which is reflected back from an observation target by a back wave receiving module; converting a reflecting signal into a digital signal by an analogue-digital conversion module; and using the digital signal as back wave data acquired by an array element position of the corresponding antenna array; imaging the back wave data by a data processing module to acquire a three-dimensional complex image of the observation target; and displaying the three-dimensional complex image of the observation target by a display module. The imaging method disclosed by the invention is used for application fields of human body surface microwave image acquisition and safe detection, three-dimensional data acquisition of a human body and action based on actual circumstances, nondestructive testing, radar target imaging diagnosis and the like.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Method and device for ultrasonic and nondestructive detection ofelasticity of viscoelastic medium

ActiveCN101699280AReduce computing timeReduce complexityAnalysing solids using sonic/ultrasonic/infrasonic wavesHealth-index calculationSonificationLow frequency vibration

The invention relates to a method and a device for the ultrasonic and nondestructive detection of the elasticity of a viscoelastic medium, which belong to the technical field of nondestructive measurements. The method comprises the following steps of: using an ultrasonic probe to produce low-frequency vibration on a medium to be detected, emitting ultrasonic waves to the medium to be detected and acquiring an ultrasonic signal returned from the medium to be detected; selecting an ultrasonic signal range for calculating the elasticity of the medium to be detected; using the selected ultrasonic signal to calculate the transmission speed of an elastic wave produced by the low-frequency vibration in the medium and further calculating the medium elasticity according to the obtained transmission speed of the elastic wave. The device comprises an ultrasonic wave energy converter contact, a vibrator fixing the ultrasonic wave energy converter contact and a control device. In the method and device, motion compensation of the ultrasonic probe is not required, so that calculation time is shortened; meanwhile, position detection is carry out without a position sensor, so that the system complexity and cost are lowered.

Owner:BEIJING SONICEXPERT MEDICAL TECH CO LTD +1

Nondestructive detection method for physiological index of plant leaf

InactiveCN101403689AImprove forecast accuracyImprove adaptabilityColor/spectral properties measurementsExtensibilityBiology

The invention discloses a nondestructive testing method used for testing the physiological indexes of plant leaves on the basis of invisible-near infrared spectrum, which can carry out the quick and multi-parameter testing on the content of compositions such as chlorophyll, nitrogen, lutein, water and the like simultaneously. The method carries out spectrum collection on calibration samples, subsequently preprocesses the spectrum data, preferably selects the waveband, establishes the calibration model between the spectrum value and the standard value of the content of plant component, and collects the spectrums of the unknown samples; after the spectrum data is pre-processed, the selected waveband data are substituted in the calibration model so as to predict the content of the component to be measured; the technical proposal of the invention adopts full-spectrum information; the measured parameters have strong extensibility and the prediction precision and the model adaptability of the calibration model are improved; the trans-reflective measurement type adopted by the method adopts the spectrum sensitiveness and has stronger adaptability on the leaf type; and the improved wavelet analysis method can simultaneously eliminate the noise of the leaf spectrum data and carries out benchmark line calibration pre-processing on the leaf spectrum and can effectively improve the prediction precision.

Owner:BEIHANG UNIV

Microinjection apparatus integrated with size detector

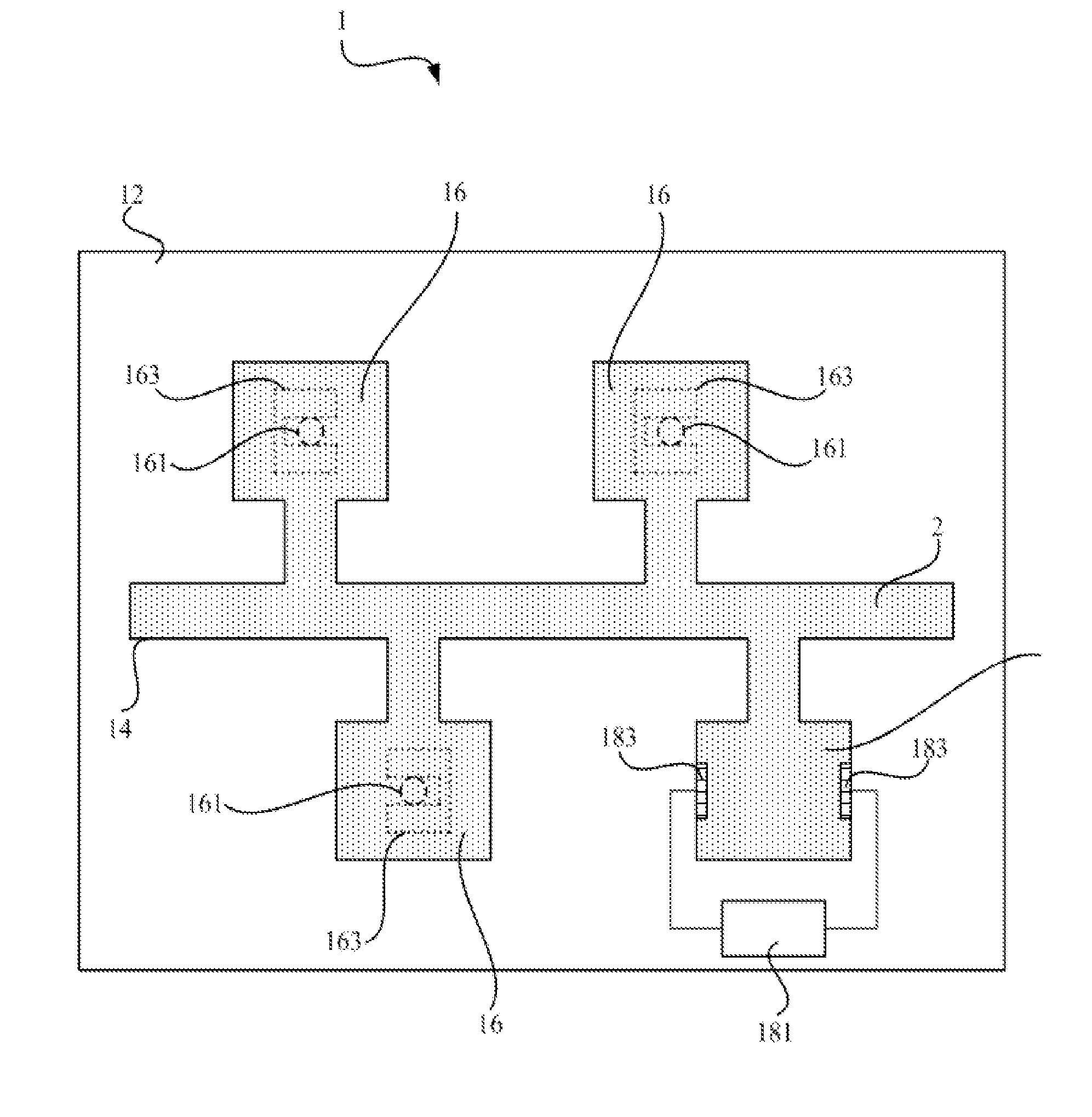

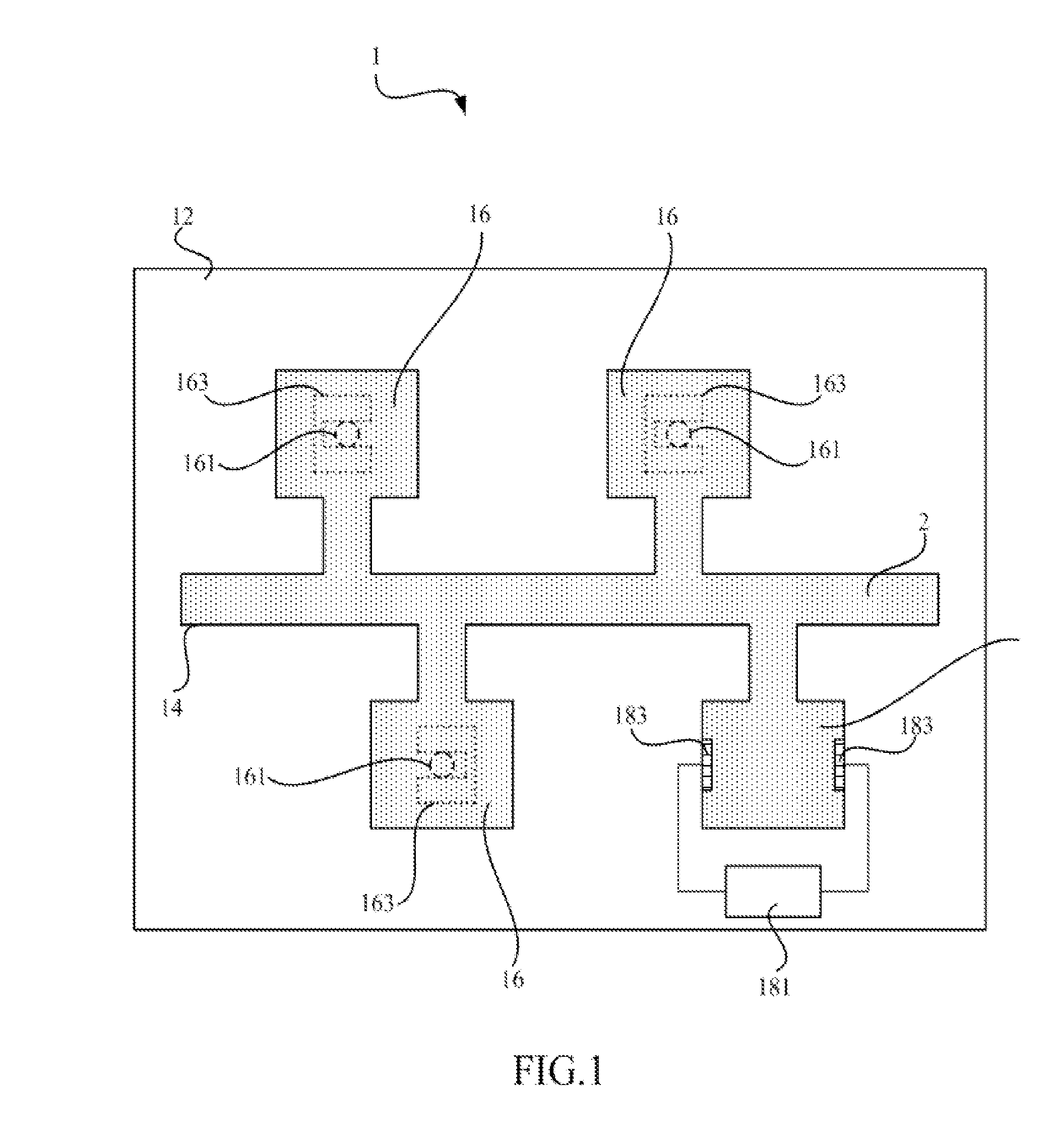

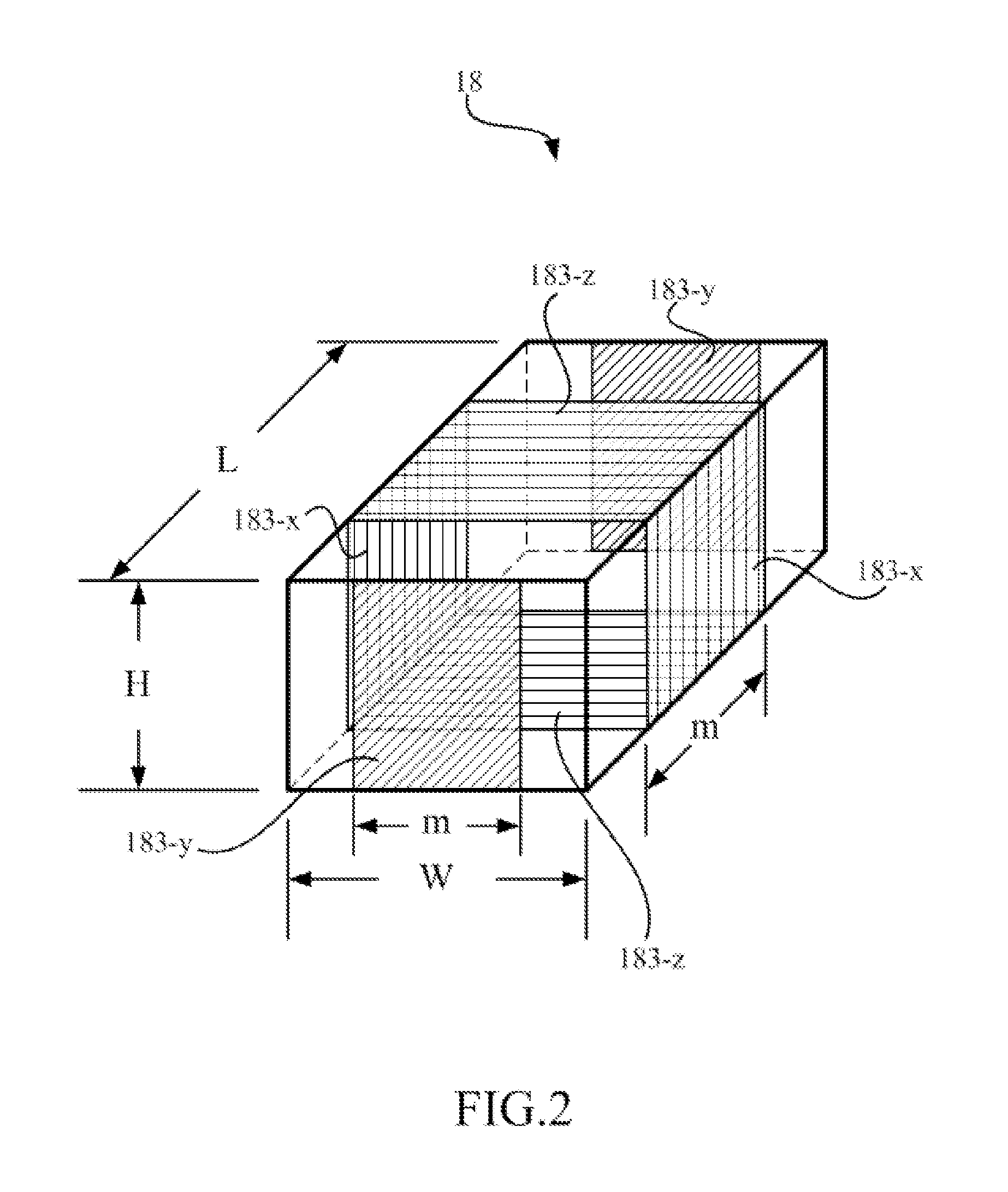

InactiveUS20070153032A1Low costShorten the timePrintingNondestructive testingElectrical and Electronics engineering

The invention provides a microinjection apparatus for a fluid. The microinjection apparatus includes a substrate, a manifold, a fluid chamber, a dummy chamber, a detecting device, and a pair of parallel conductive plates. The manifold is formed on the substrate and supplies the fluid chamber and the dummy chamber, also formed on the substrate, with the fluid. In addition, the pair of parallel conductive plates are formed on a pair of opposite inner walls of the dummy chamber, and electrically connected to the detecting device. By applying the pair of parallel conductive plates and the detecting device provided in the invention, the size of the fluid chamber and the fluid-filled condition relative to the fluid chamber can be indirectly detected by non-destructive testing. Furthermore, the cost of and the time of testing also can be prominently saved.

Owner:BENQ CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com