Patents

Literature

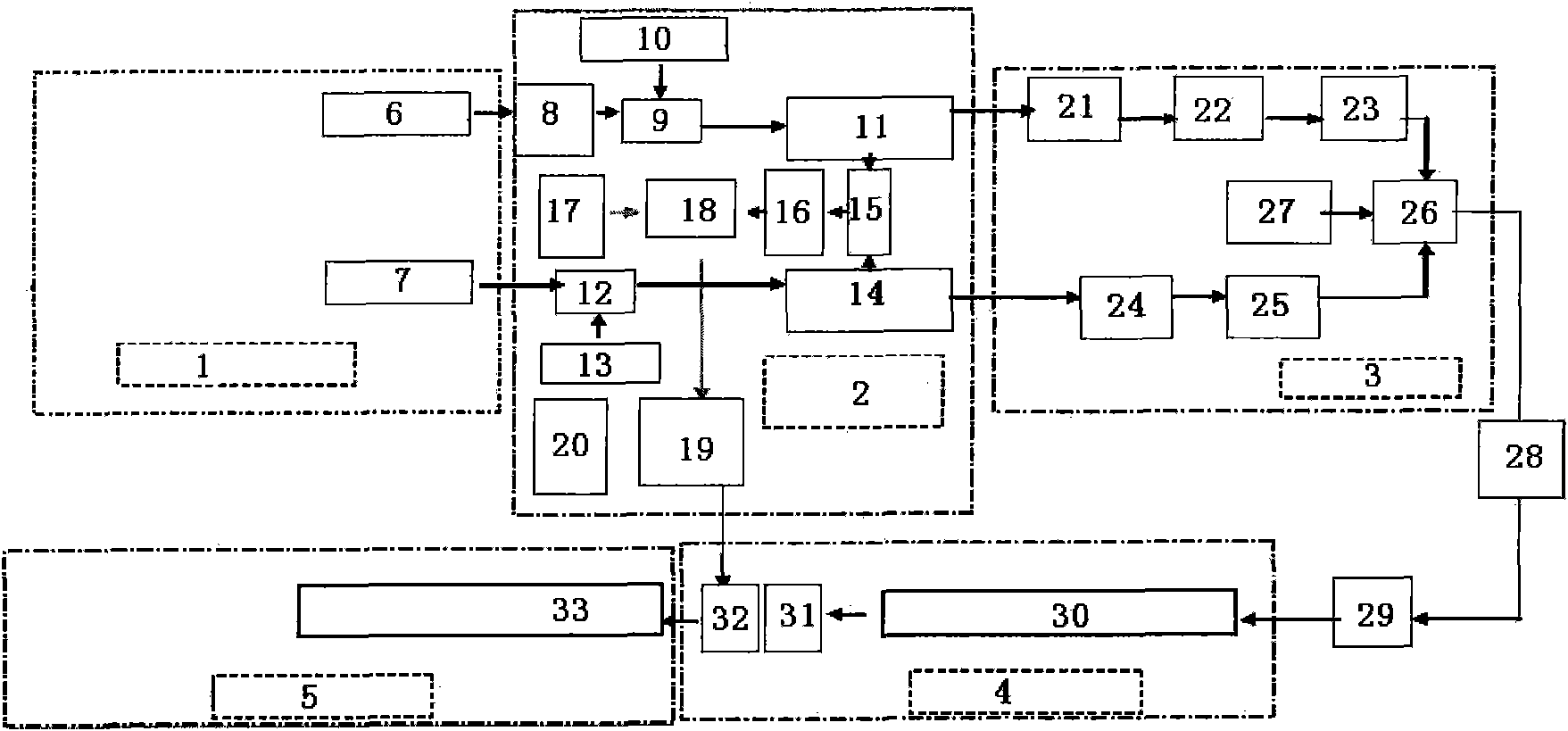

1392 results about "Internal quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internal quality is about the design of the software. This is purely the interest of development. If Internal quality starts falling the system will be less amenable to change in the future. Hence the need for refactoring, clear coding, relentless testing, and the like.

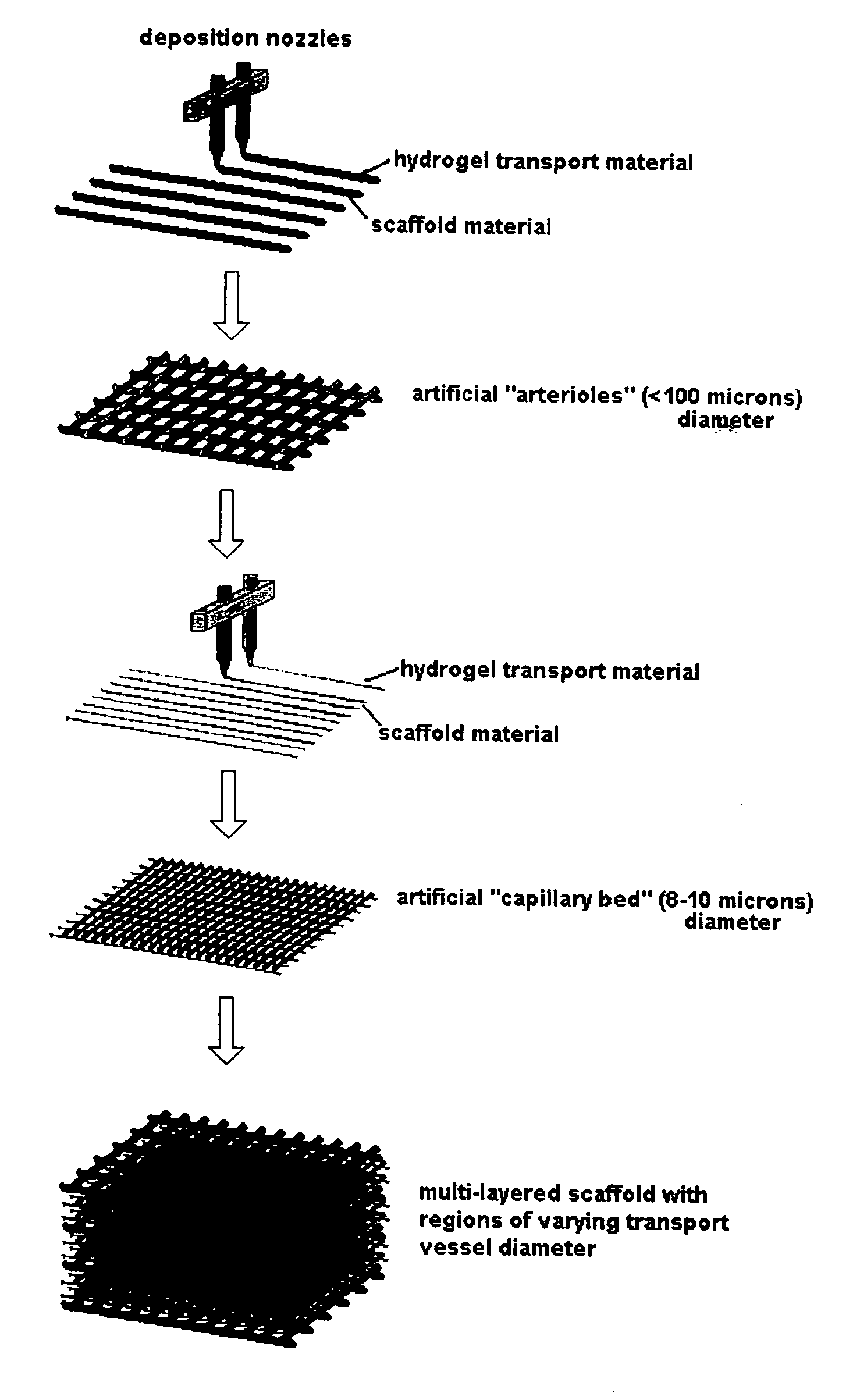

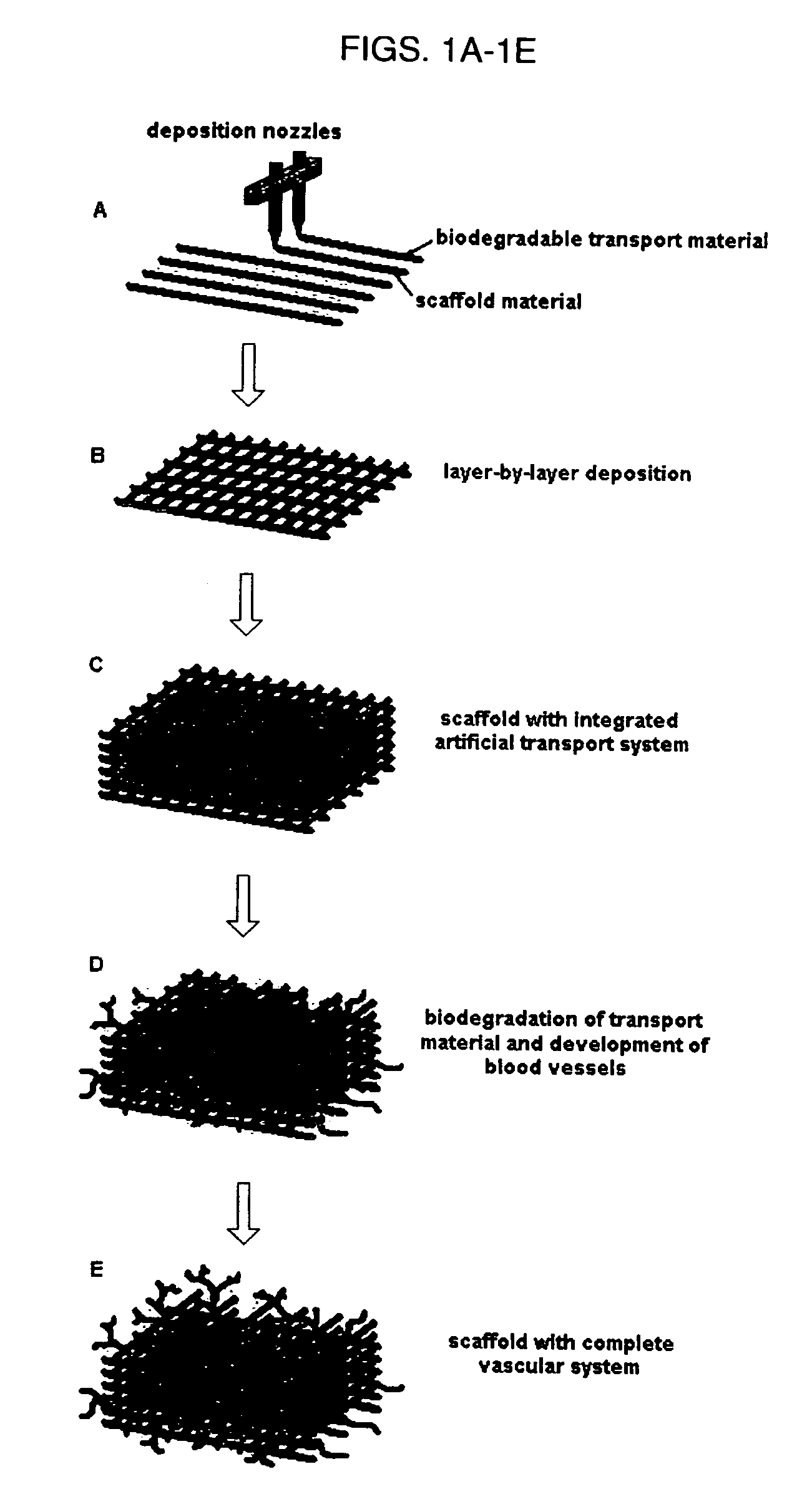

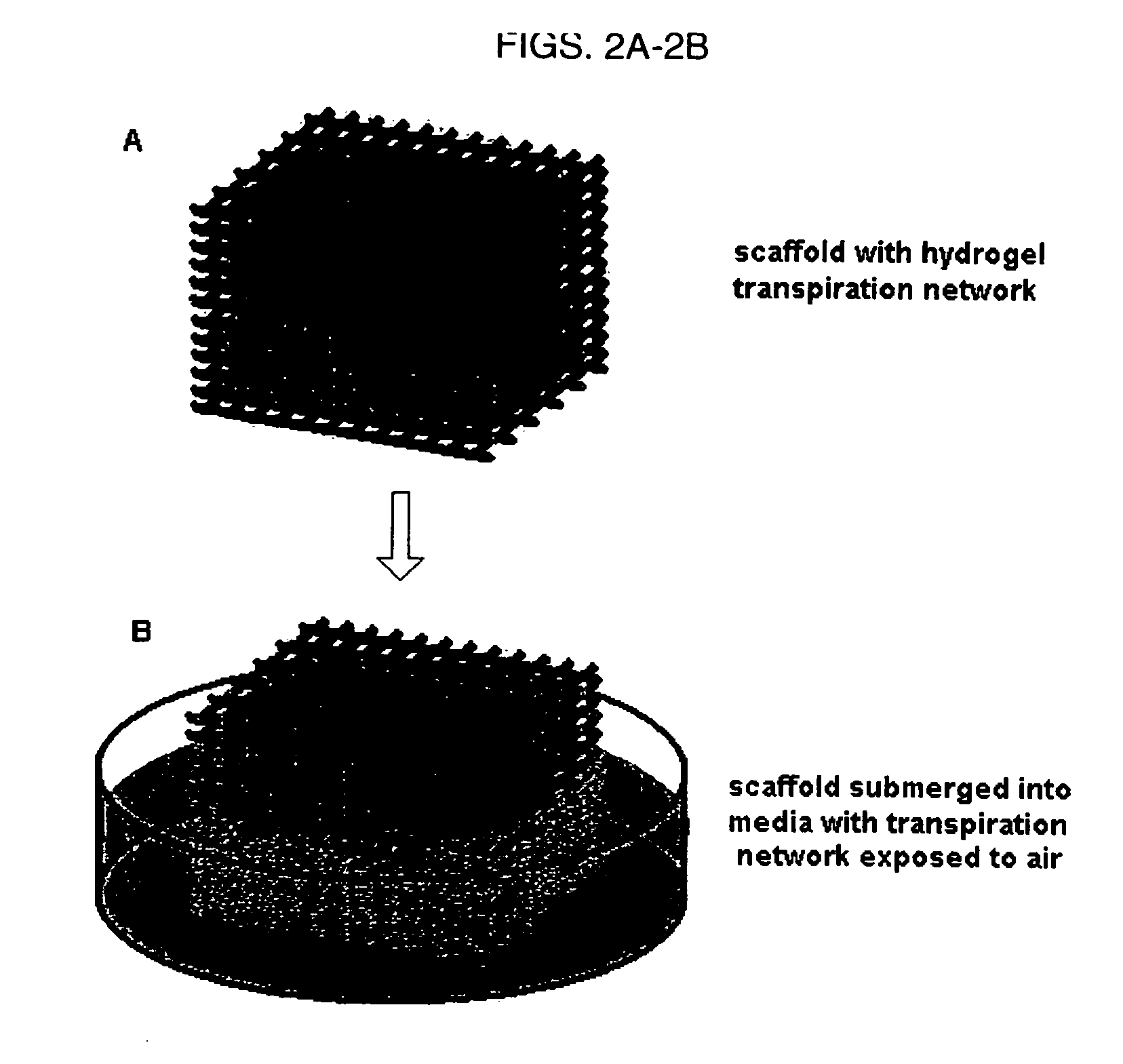

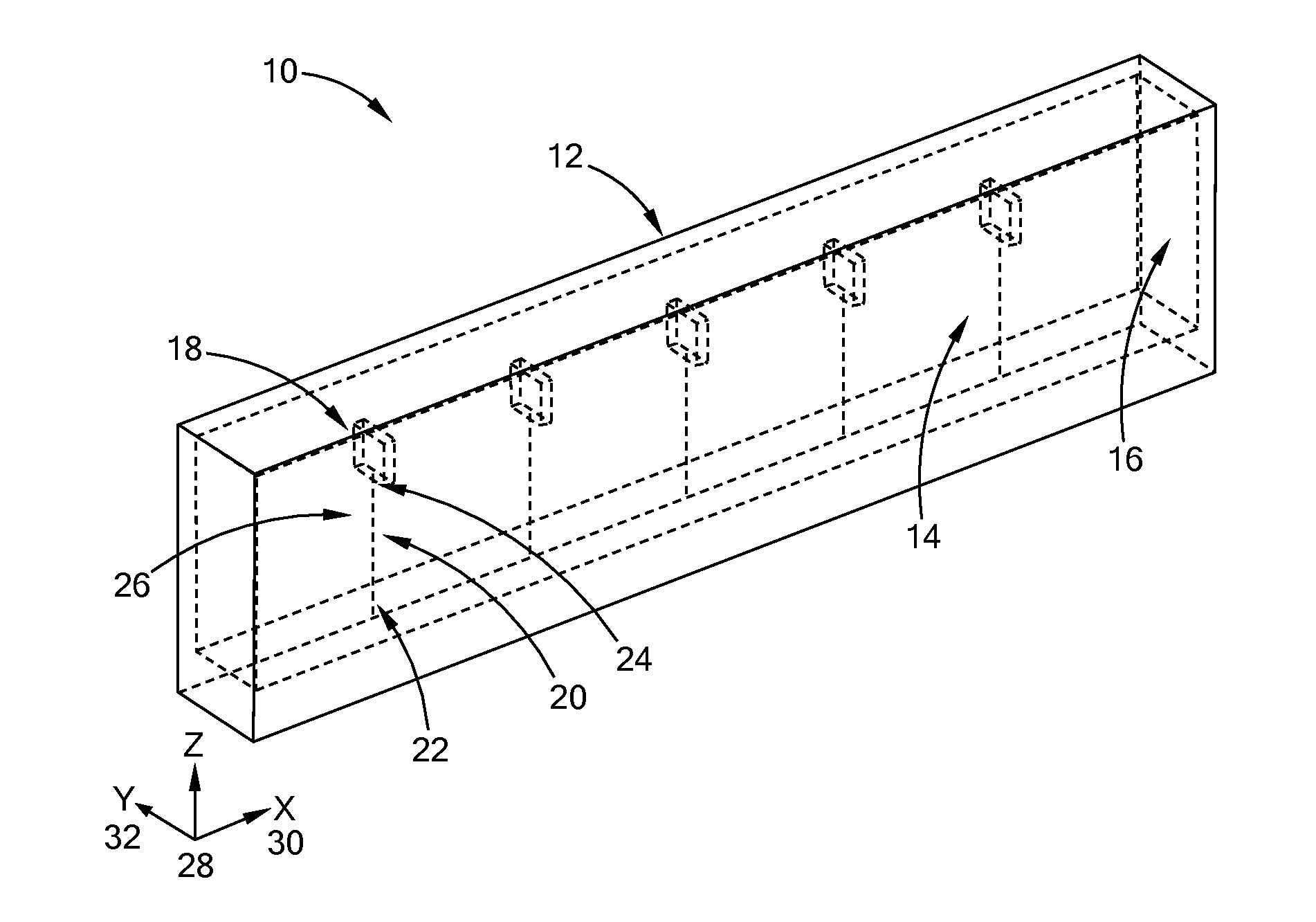

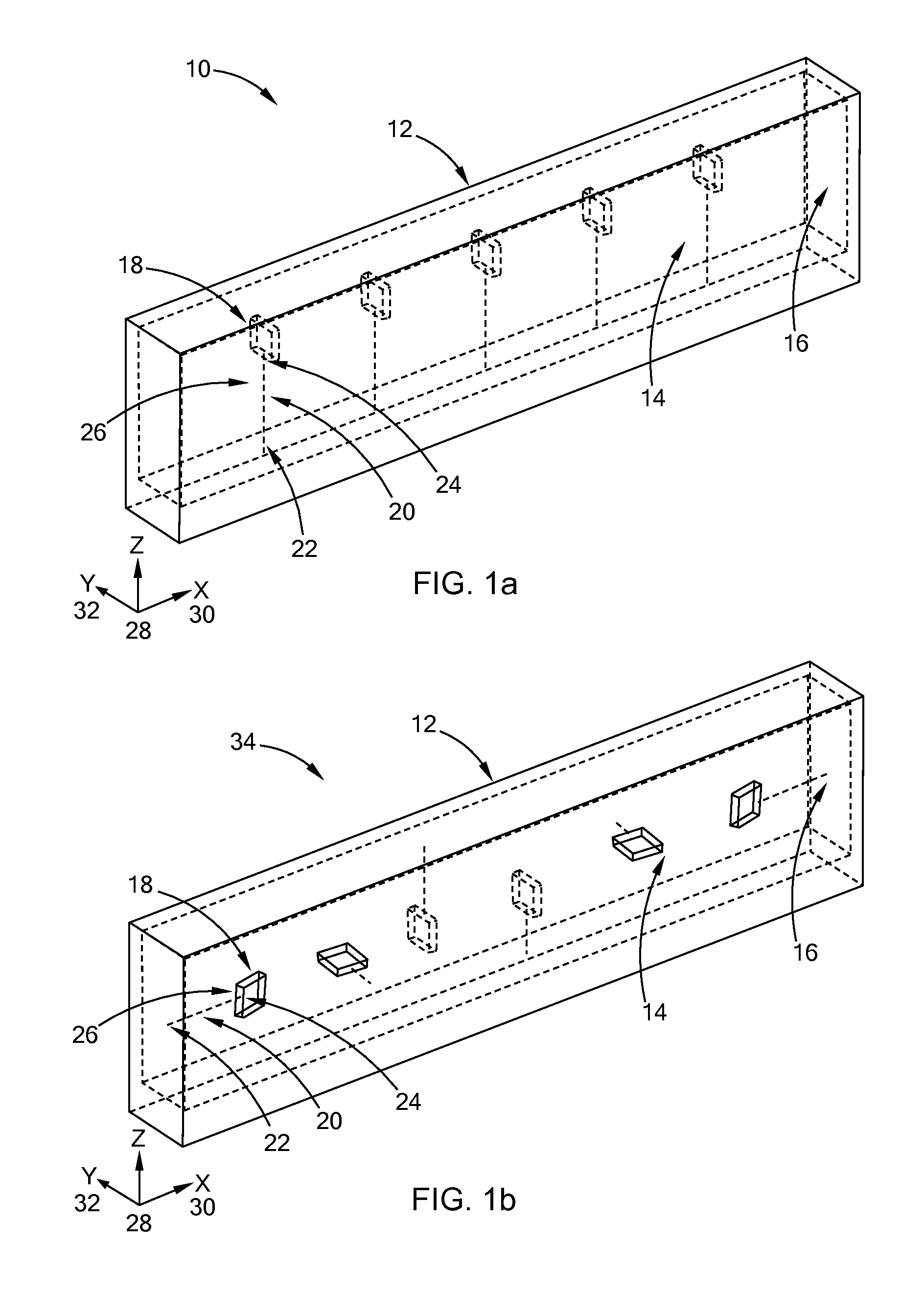

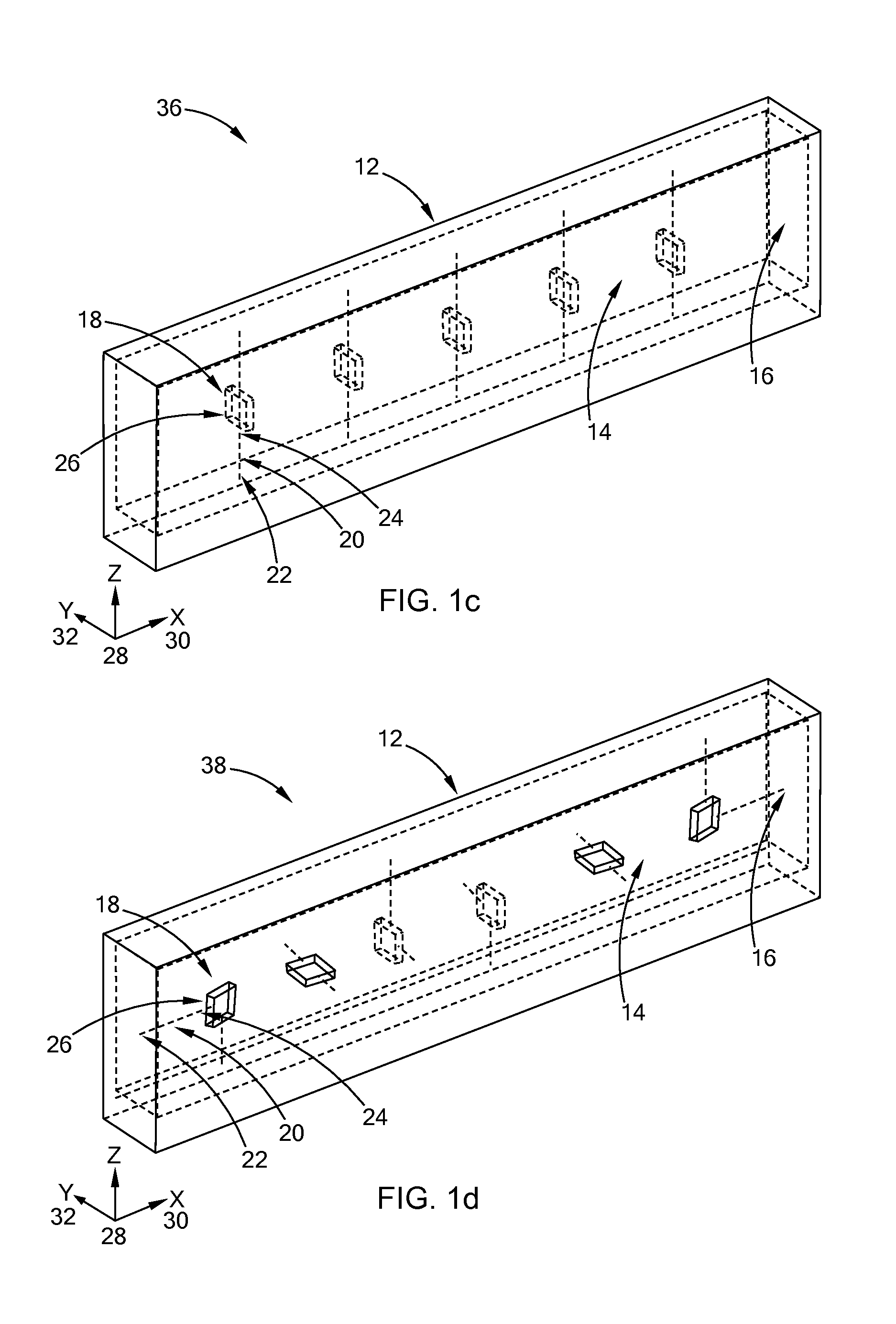

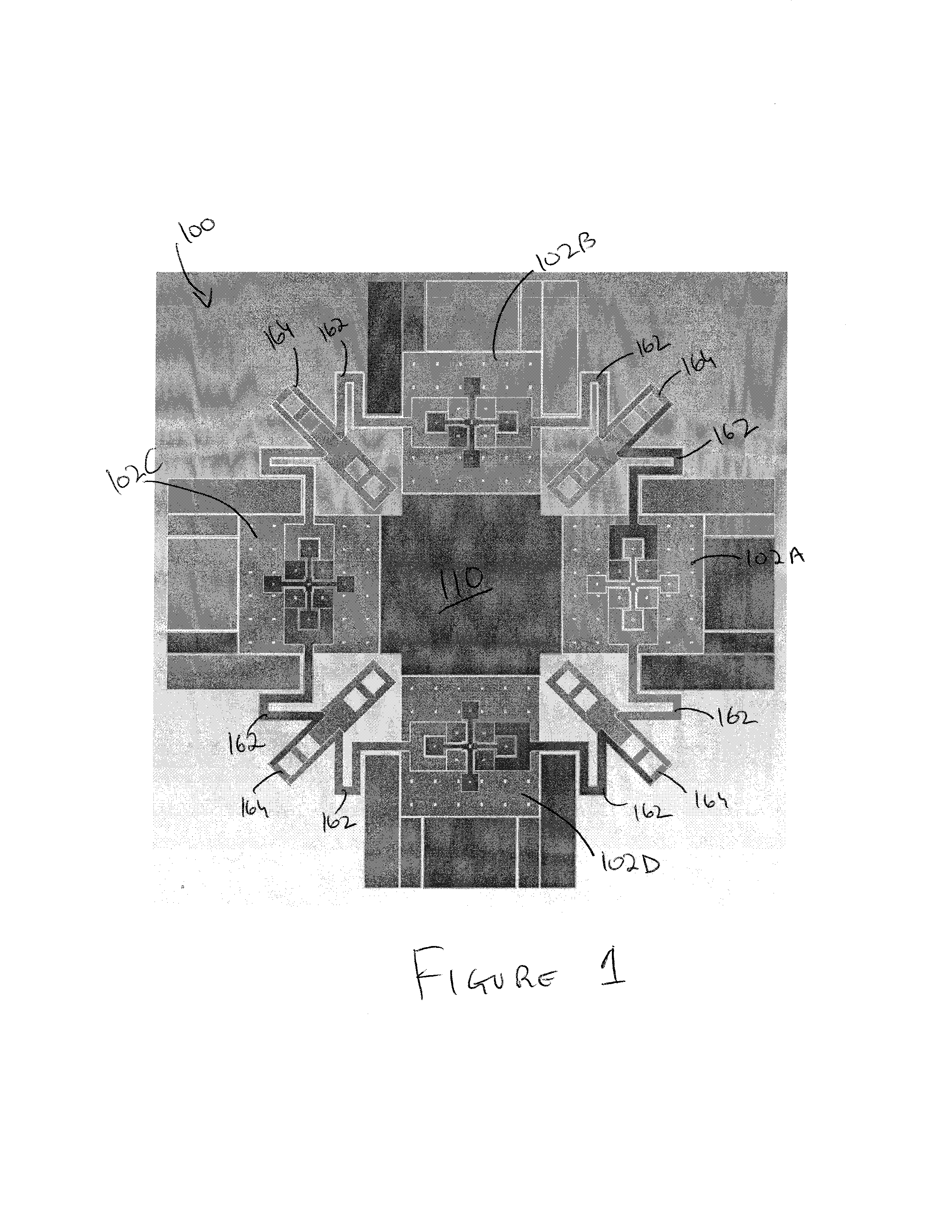

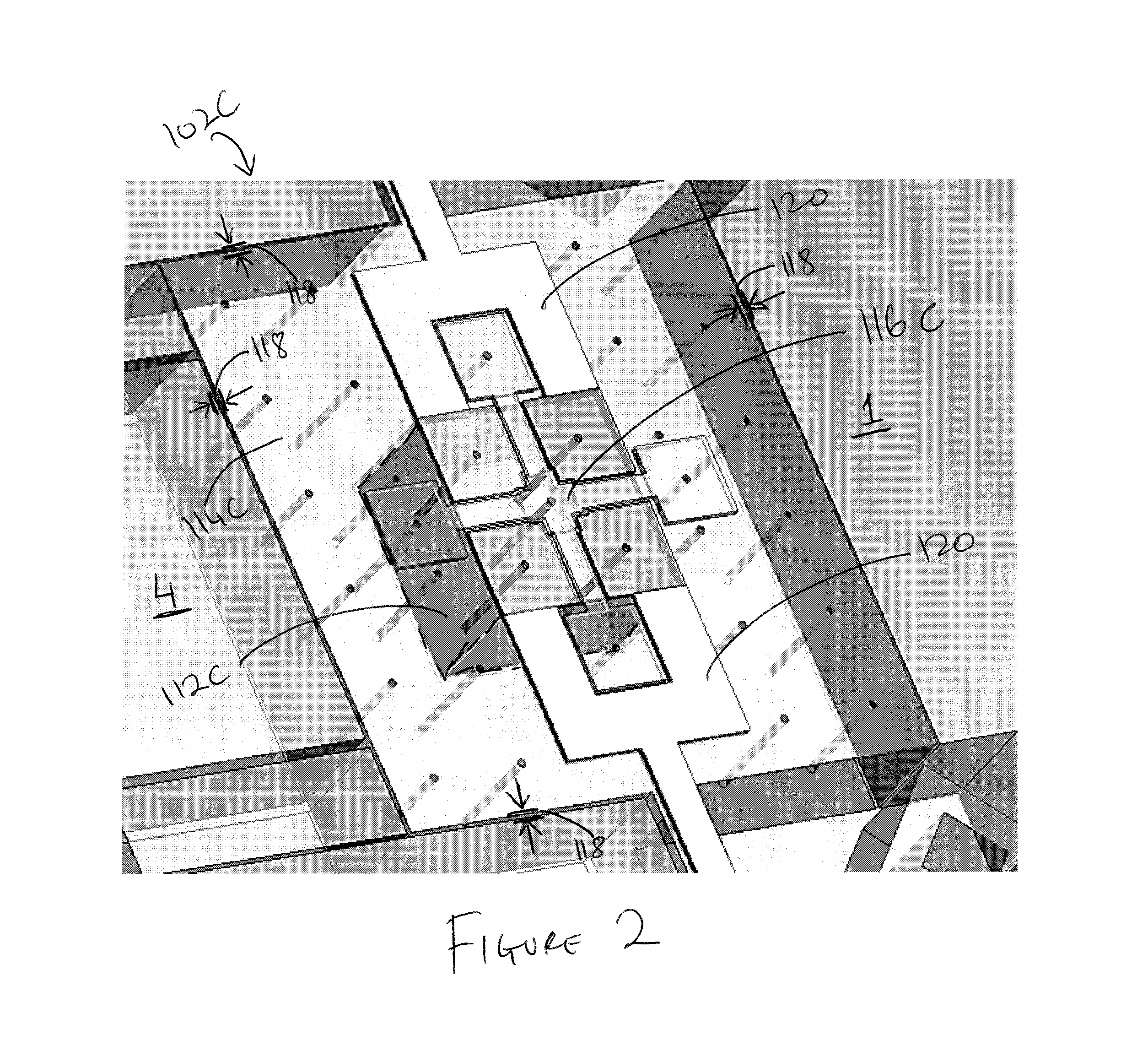

Method for creating an internal transport system within tissue scaffolds using computer-aided tissue engineering

ActiveUS20060195179A1Promote circulationFacilitated DiffusionTissue cultureBlood vesselsTransport systemEngineering

An artificial tissue including an internal mass transport network having a plurality of channels, wherein the channels are designed to substantially mimic naturally occurring vascular network and a method for creating an internal transport system within a tissue scaffold to improve circulation, diffusion, and mass transport properties by utilizing computer-aided tissue engineering (CATE). The artificial tissue has the internal mass transport network of channels embedded, deposited, or molded within a scaffold, wherein the channels are made from a biodegradable transporting material and the scaffold is made from a scaffold material. The artificial tissue of the invention includes a basic circulatory system embedded within the tissue scaffold. This system provides mass transport throughout the entire scaffold and degrades after the new circulatory system develops.

Owner:DREXEL UNIV

Method for preparing tobacco sheet and application thereof

ActiveCN101637298AGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

Surface iron scale control method for middle sheet billet continuous casting and rolling steel plate

InactiveCN101012528AReduce generationGood removal effectTemperature control deviceWork treatment devicesThin slabEnergy conservation

The invention discloses a controlling method of iron oxide sheet of rolled band steel surface of middle-thin board blank, which is characterized by the following: controlling component; proceeding heat load directly; heating to remove phosphor; rolling under high temperature; forcing to cool; controlling Si content in the steel; eliminating red ferric oxide on the surface of heat roll steel; fitting for the steel with not more than 0.18%C, not more than 0.20% Si, not more than 1.50% Mn, not more than 0.015% P, not more than 0.01% S and Nb, V and Ti.

Owner:ANGANG STEEL CO LTD

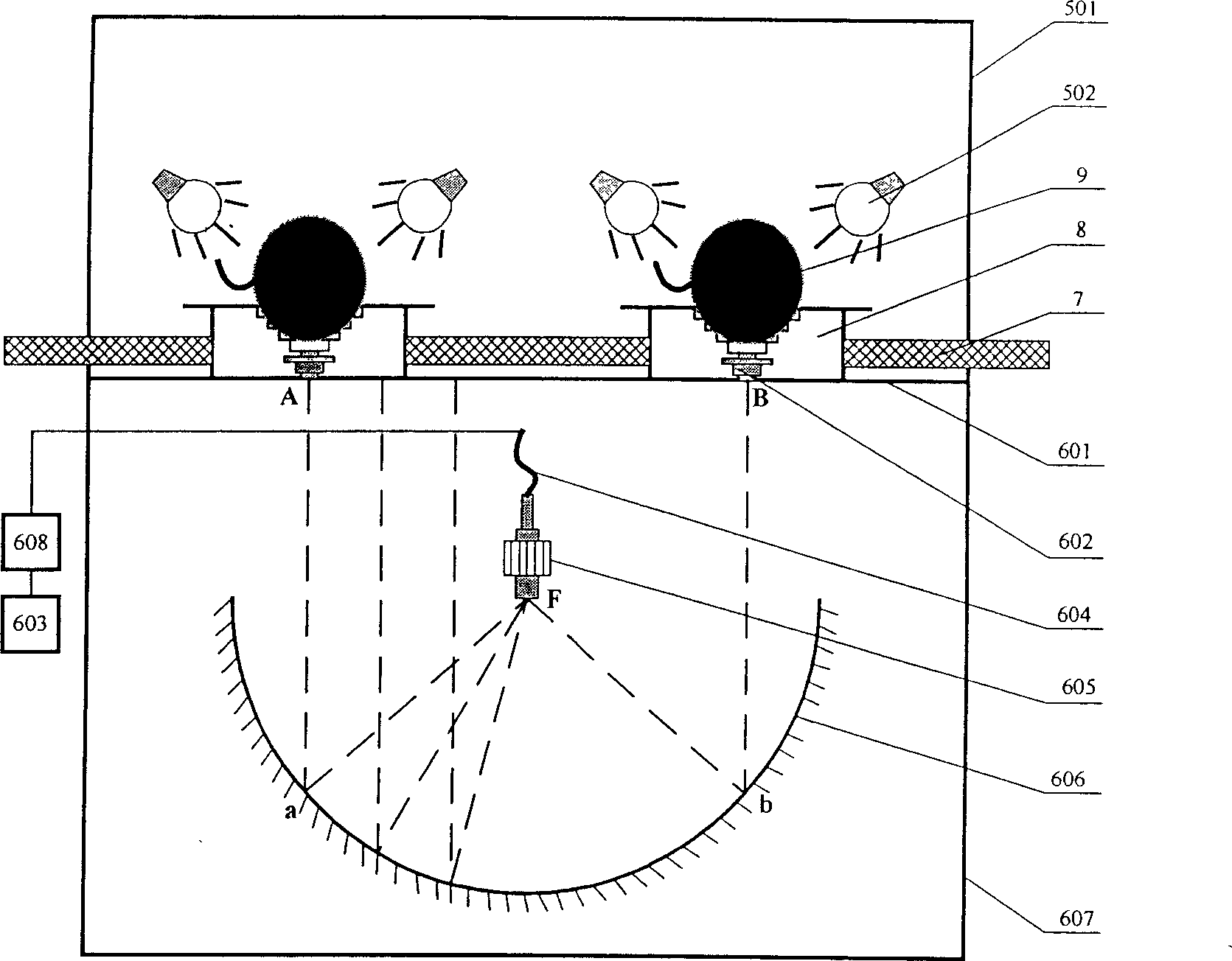

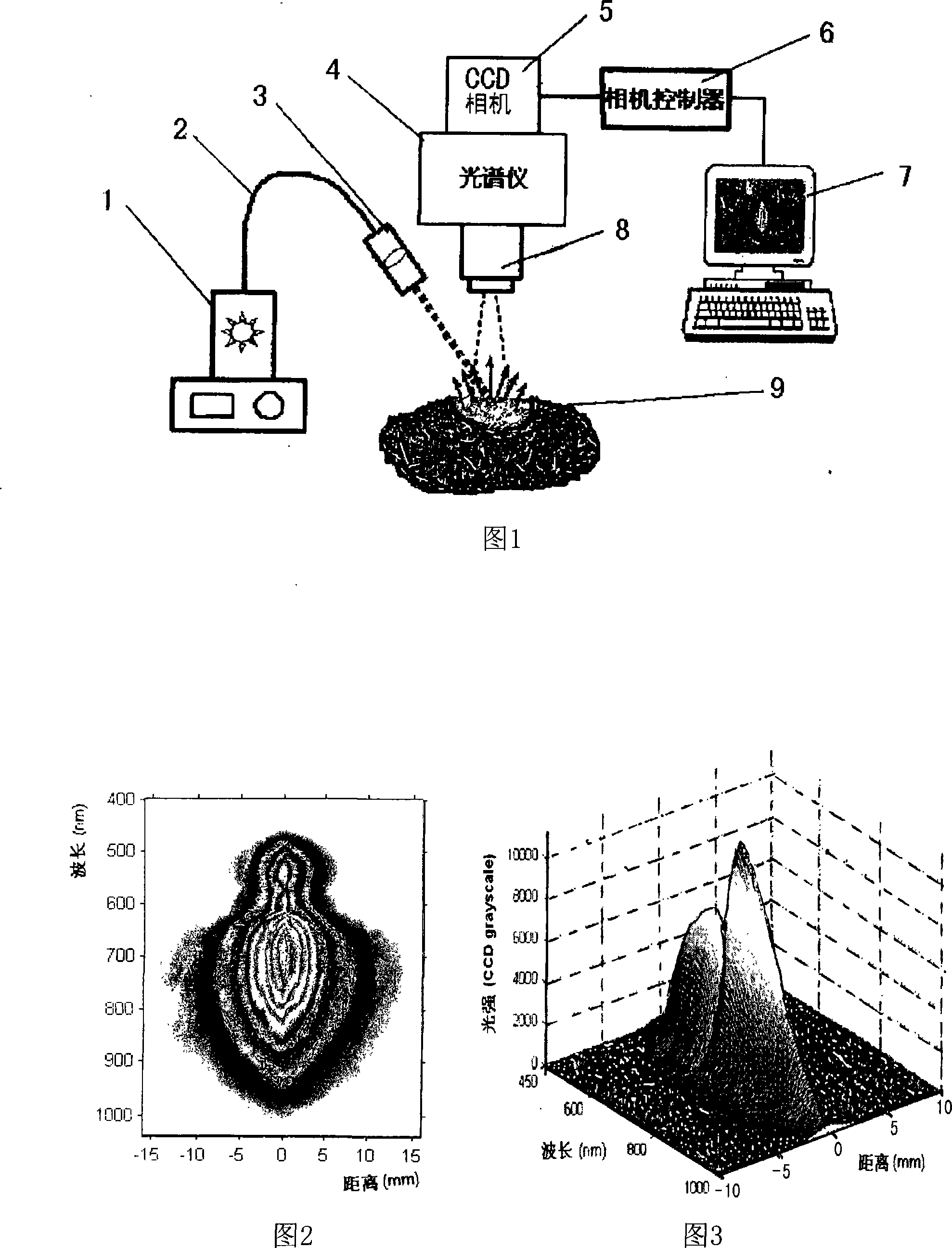

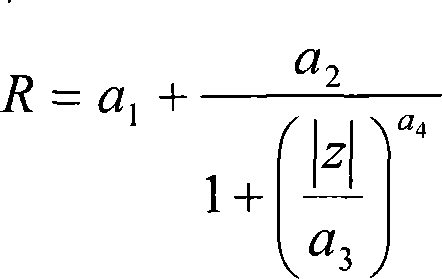

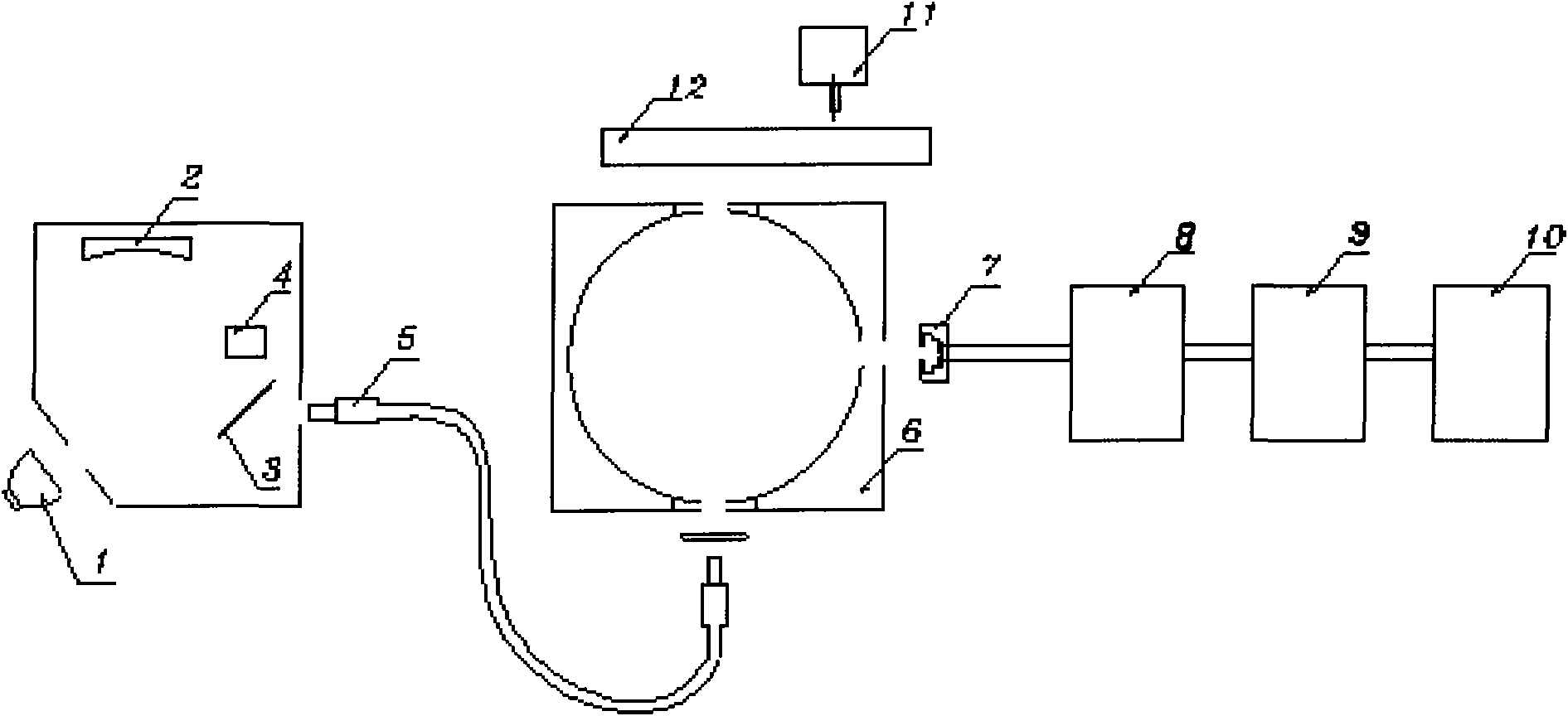

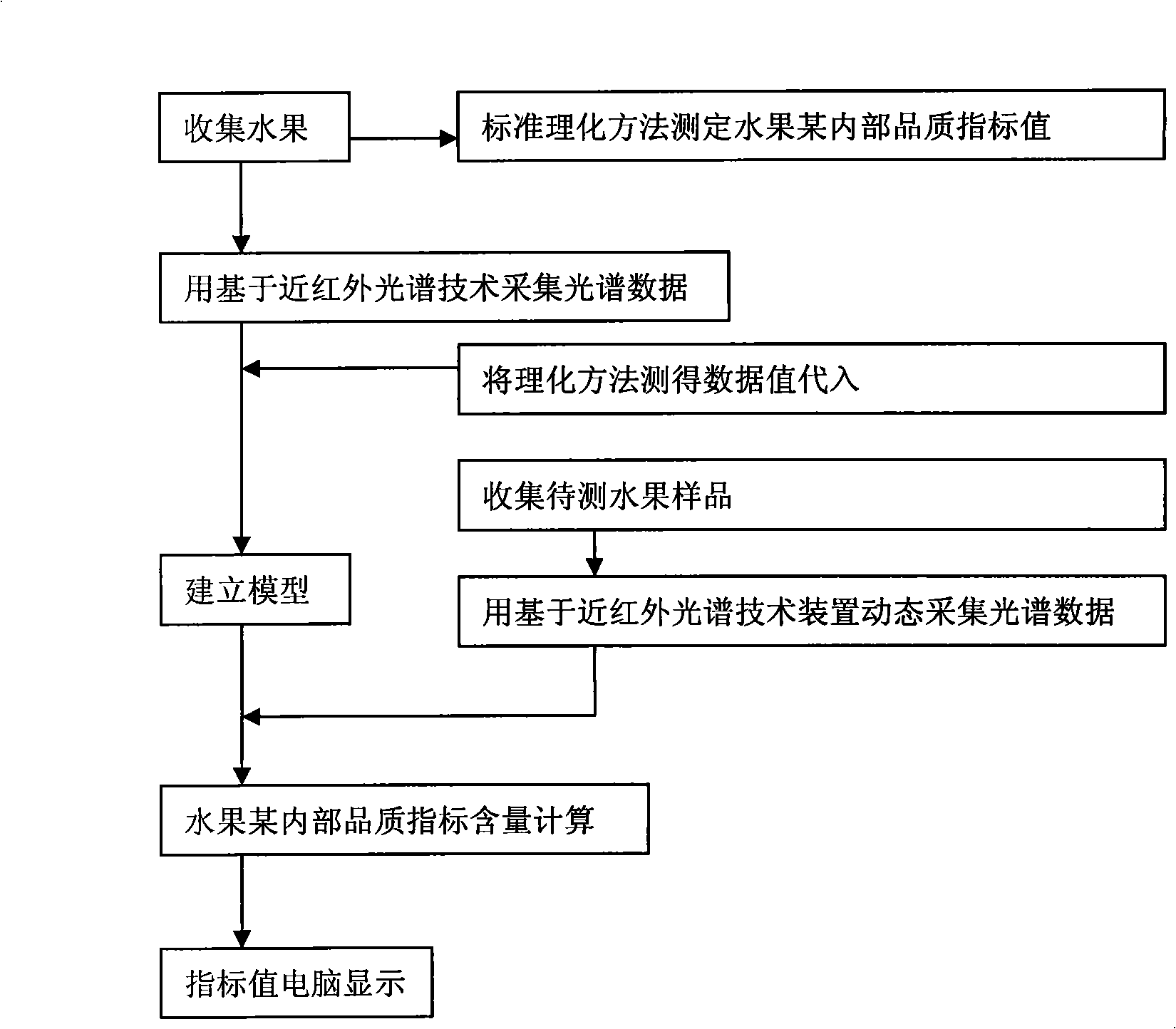

Method and apparatus for non-destructive testing of fruit internal quality based on optical properties

InactiveCN1837788AHigh precisionImprove detection accuracyUsing optical meansColor/spectral properties measurementsNon destructiveOptical property

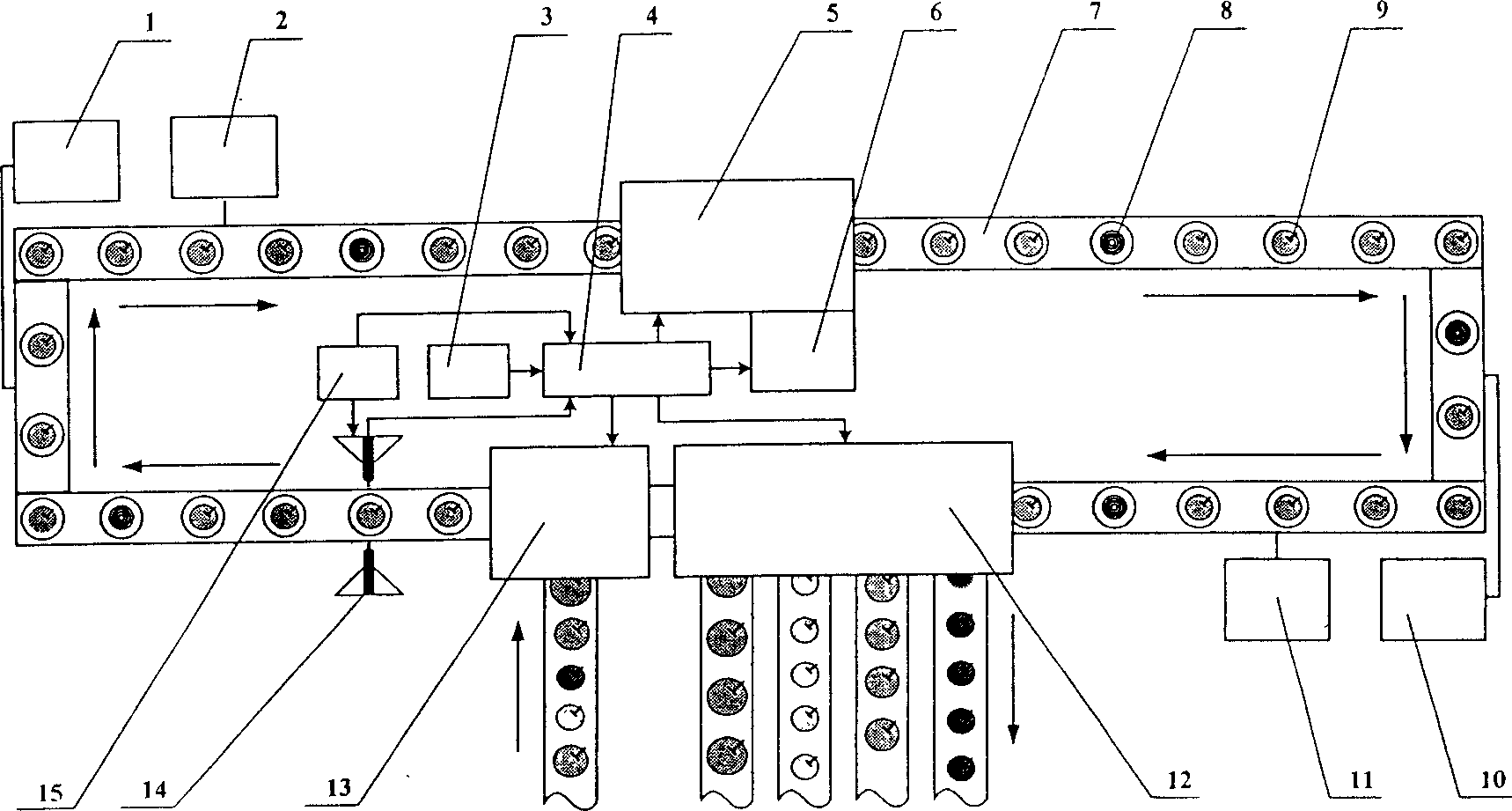

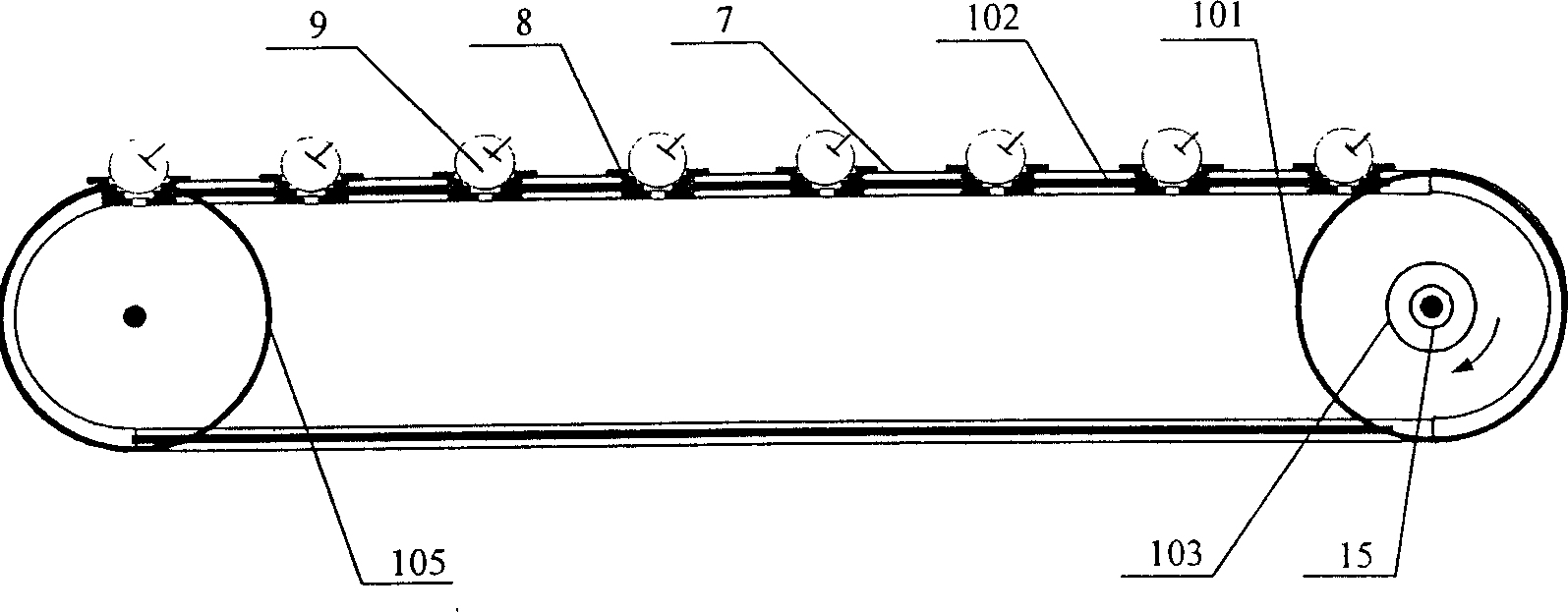

This invention relates to a method and apparatus for non-destructive testing of fruit internal quality based on optical properties. The device comprises a send unit, an analysis and process unit to evaluate the fruit referred to a stored quality prediction model, a signal control unit to send the fruit position and size information to the detection system with command format, an illumination system to provide stable and optimal-strength light, a detection system to obtain and send the transmitted spectrum information for fruit inner quality to the analysis and process unit, a fruit grade-outlet, a size detection device, and a coder. This invention improves on-line detection speed and precision.

Owner:ZHEJIANG UNIV

Cigarette perfuming agent and its preparation method and application

InactiveCN101215805AImprove qualityMellow tasteNon-fibrous pulp additionNon-macromolecular adhesive additivesAluminum foilInternal quality

The invention discloses a cigarette flavor enhancer and a process for preparation and the application, the flavor enhancer agent is mixed by flavor materials with stronger volatility and outstanding characteristic and plant extraction which has promoting effect to the smoking of cigarette, the improvement of the internal quality is firstly achieved by cigarette packing material through the invention, and the process comprises coating flavor enhancer agent on the surface of aluminum foil inner lining paper according to the proposition which is 0.01%-5%, or adding into the existing adhesive agent for aluminum foil liner paper according to the proposition which is 0.01%-5%, making full use of the characters that aluminum foil liner paper directly contacts with cigarettes, continuously decorating and improving the smoking of cigarette, and covering imperfect breath of the existing aluminum foil liner paper itself. The invention can have a good connection with the existing cigarette technique and equipment, and production can be achieved by the invention without adjusting the existing equipment. The invention has the advantages of reasonable process, convenient operation and low production cost, which has an excellent application prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

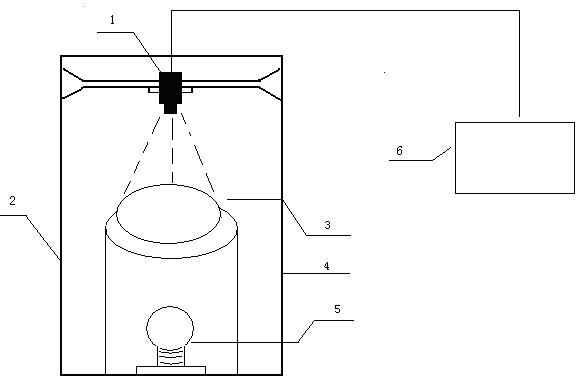

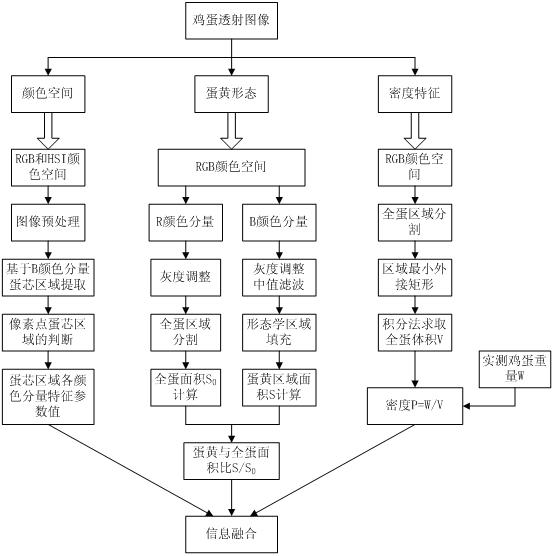

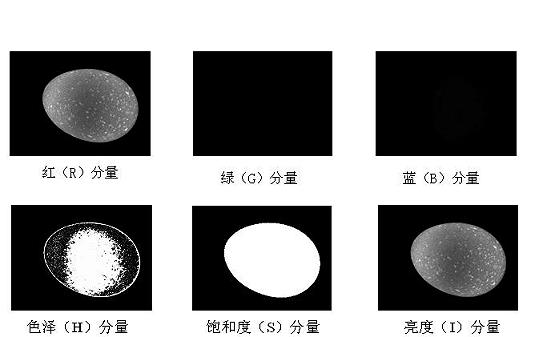

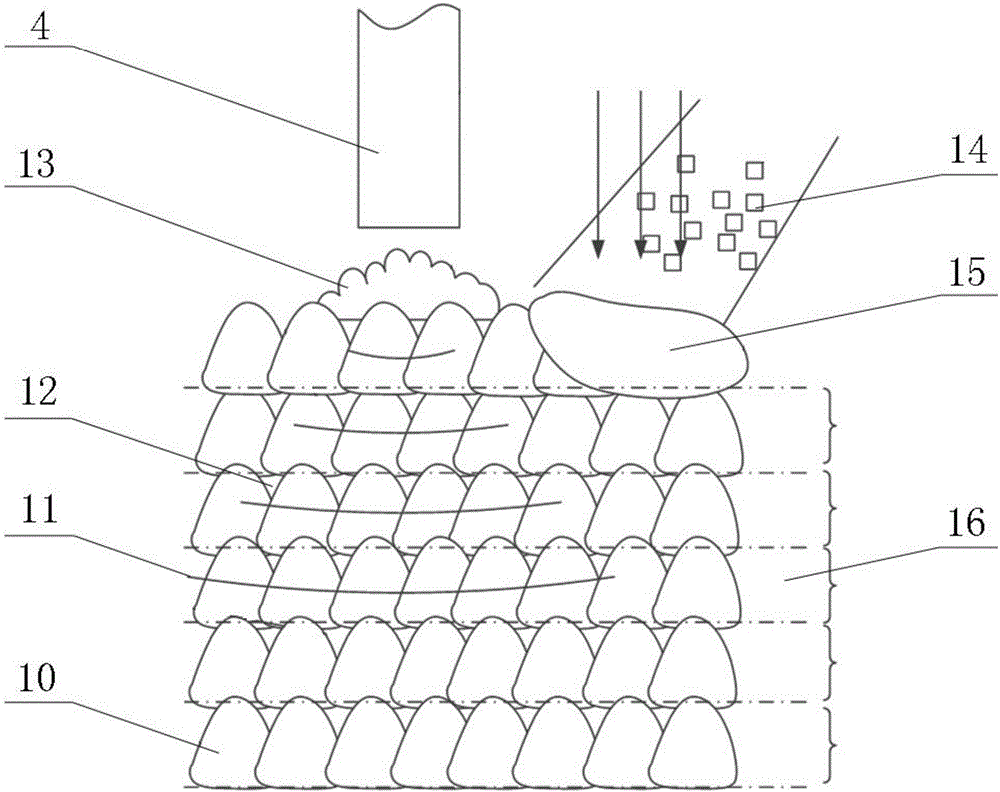

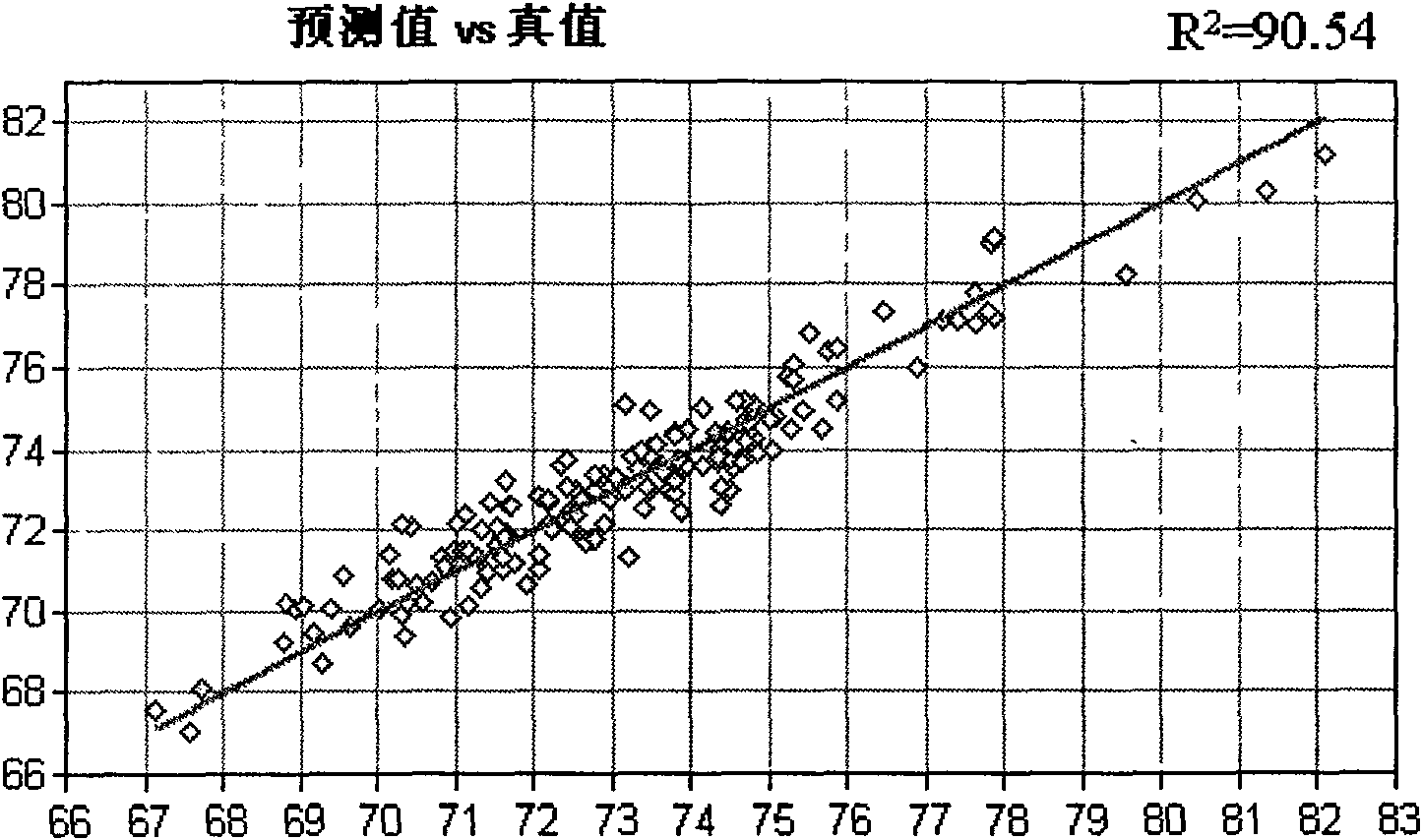

Machine vision technology based method for rapidly detecting egg freshness

InactiveCN102147402AImprove robustnessReduce complexityTesting eggsCharacter and pattern recognitionYolkEggshell

The invention relates to a machine vision technology based method for rapidly detecting egg internal quality, belonging to non-destructive testing technologies for agricultural and animal products. According to the method, a machine vision technology is used for acquiring characteristics on three aspects including a color space, an eggshell shape and an egg density from an egg transmission image so as to comprehensively judge the freshness characteristic of the egg. The machine vision technology based method specifically comprises the steps: acquiring the transmission image of an egg under a certain illumination condition, transmitting the transmission image to a computer through image acquisition equipment, acquiring the information on the three aspects including the color space, an egg yolk area and the egg density from the acquired egg image, fusing and screening the information on the three aspects, and finally obtaining a detection result of the egg freshness by means of a multi-variable analysis model in a standard library, wherein the information on the three aspects including the color space, the egg yolk area and the egg density is in one-to-one correspondence to three phenomena of diluted concentrated egg white, enlarged egg yolk area and raised gas cell height which are expressed under an egg freshness drop condition. In addition, grading can be carried out according to standards so that the egg freshness can be detected more objectively and accurately.

Owner:JIANGSU UNIV

A low-cost precision casting method for titanium alloy and titanium-aluminum alloy

InactiveCN102294436AIncrease contentControl quality costFoundry mouldsFoundry coresPolyvinyl alcoholTitanium alloy

The invention relates to a method for precisely casting a titanium alloy and a titanium aluminum alloy with low cost, which relates to a method for precisely casting the titanium alloy and the titanium aluminum alloy, and solves the technical problem that cast pieces have low surface quality and internal quality in the conventional method for lowering the cost of precisely casting the titanium alloy and the titanium aluminum alloy by using electrically-fused alumina and silica sol. The method comprises the following steps of: preparing a surface layer binder from zirconium sol, silica sol, a wetting agent JFC, n-octyl alcohol, polyvinyl alcohol and latex; adding calcium carbonate, alumina, titanium dioxide and zirconia to prepare a surface layer coating; preparing a shell surface layer; preparing a shell back layer by a universal method for precisely casting the titanium alloy; dewaxing and sintering to obtain a shell; and casting the titanium alloy or the titanium aluminum alloy by using the shell so as to obtain a titanium alloy cast piece or a titanium aluminum alloy cast piece. Compared with a precise casting method by purely using a zirconium-based binder and a zirconia fireproof material, the method has the advantage that raw material cost is lowered by 30 to 70 percent and the method can be used for civil titanium alloy cast pieces and titanium aluminum alloy cast pieces for common aviation.

Owner:HARBIN SHITAI NEW MATERIAL TECH & DEV

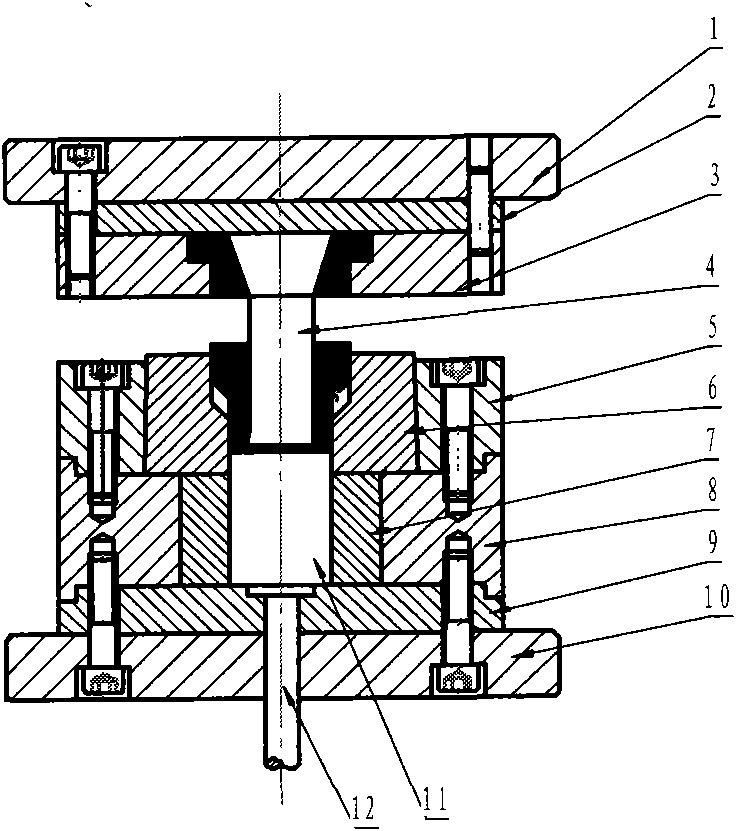

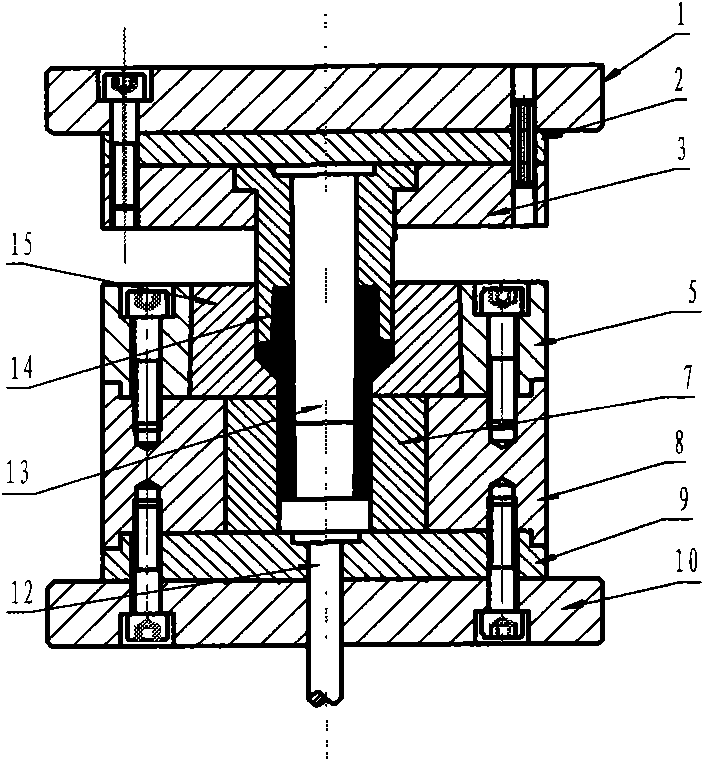

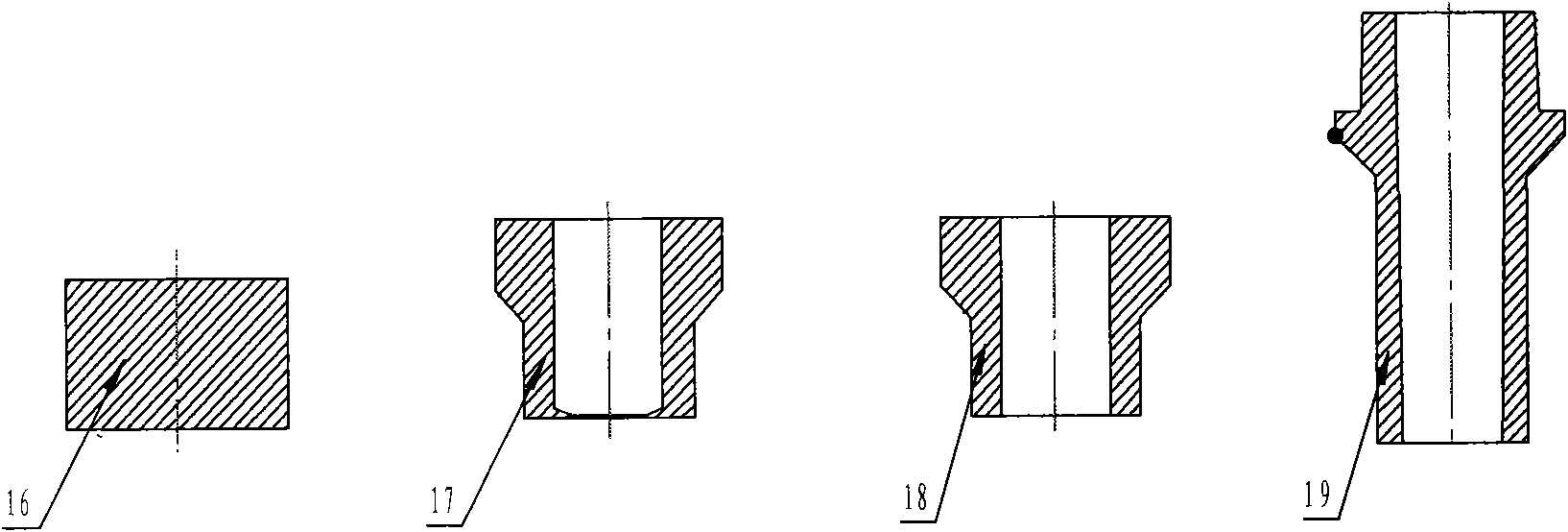

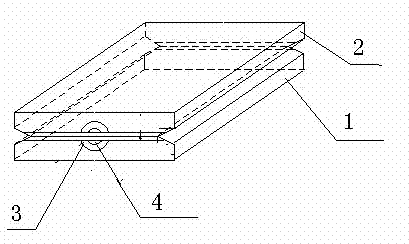

Extrusion forming process of thin-wall long pipe-shaped part blank with flange and mould

InactiveCN101829698AImprove internal qualityHigh dimensional accuracyExtrusion diesMaterials scienceForming processes

The invention belongs to extrusion forming technologies for non-ferrous metal materials and relates to a precise extrusion forming process of a thin-wall long pipe-shaped part blank with a flange. The forming process comprises two steps of primary backward extrusion and secondary forward extrusion, wherein in the step of primary backward extrusion, a primary backward extrusion convex mould (6) is utilized to match with a primary backward extrusion concave mould to together with a piece pusher (11) as an auxiliary for obtaining a primary backward extrusion pipe blank (17) with a web; a secondary forward extrusion convex mould consisting of a forward extrusion convex mould (14) and a mandrel (13) and a secondary forward extrusion concave mould (15) are utilized to carry out the secondary forward extrusion; and the secondary forward extrusion convex mould is placed into a primary backward extrusion pipe blank (18) and moves downwards to extrude the primary backward extrusion pipe blank (18) to obtain a secondary forward extrusion pipe blank (19) so as to finish a secondary forward extrusion process. The internal quality, the size precision and the material utilization rate of the produced thin-wall long pipe-shaped part blank with the flange are greatly improved; and meanwhile, the production efficiency is improved, and the production cost is reduced.

Owner:HENAN UNIV OF SCI & TECH

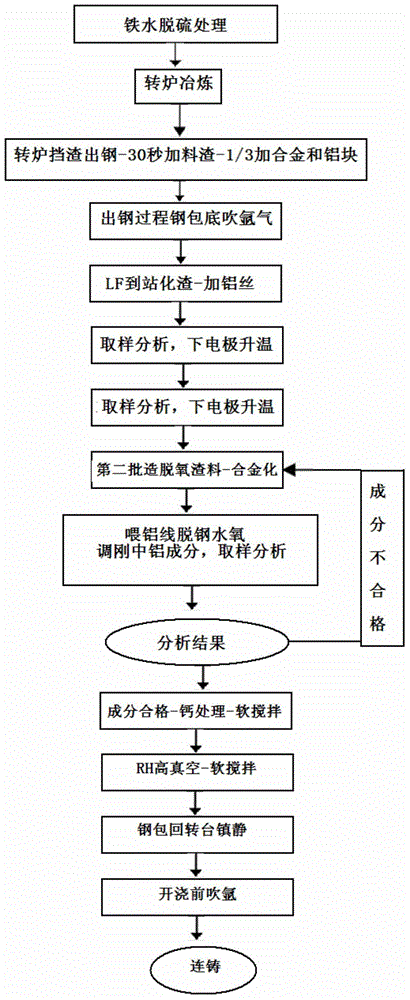

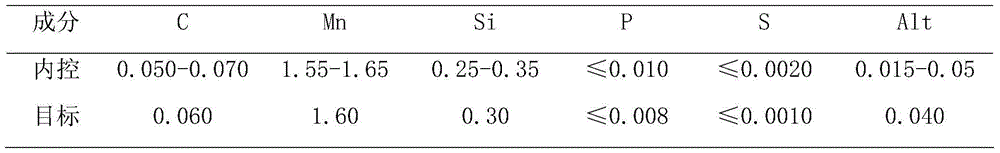

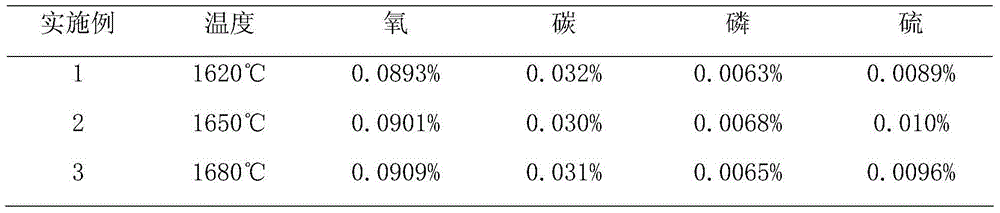

High-cleanliness pipeline steel smelting process

ActiveCN104630418ASolve the difficulty of cleanliness controlQuality improvementManufacturing convertersSulfurNon-metallic inclusions

The invention discloses a high-cleanliness pipeline steel smelting process. The process route comprises molten iron pouring, molten iron pretreatment, converter smelting, tapping, deoxidizing, alloying, LF refining furnace, treating with calcium, RH vacuum furnace and continuous casting and is characterized by comprising the following specific steps: firstly, converter smelting process; secondly, refining furnace smelting process; and thirdly, continuous casting process. The invention belongs to a steel-making process in the field of metallurgy and relates to a method for smelting and controlling a high-cleanliness pipeline steel. By molten iron desulphurization pretreatment, optimizing a converter tapping and deoxidizing system and a slagging system, LF refining furnace deep deoxygenation and reducing slag manufacturing processes, RH high-vacuum-degree degassing and inclusion removal process, the pouring is protected by the continuous casting in the whole process so that the composition of a casting billet is uniform, the contents of harmful elements such as S, P, O, N and H are low, the non-metallic inclusions are effectively controlled, the casting billet is good in internal quality and the production of high value-added ultra-low sulfur steel is ensured.

Owner:NANJING IRON & STEEL CO LTD

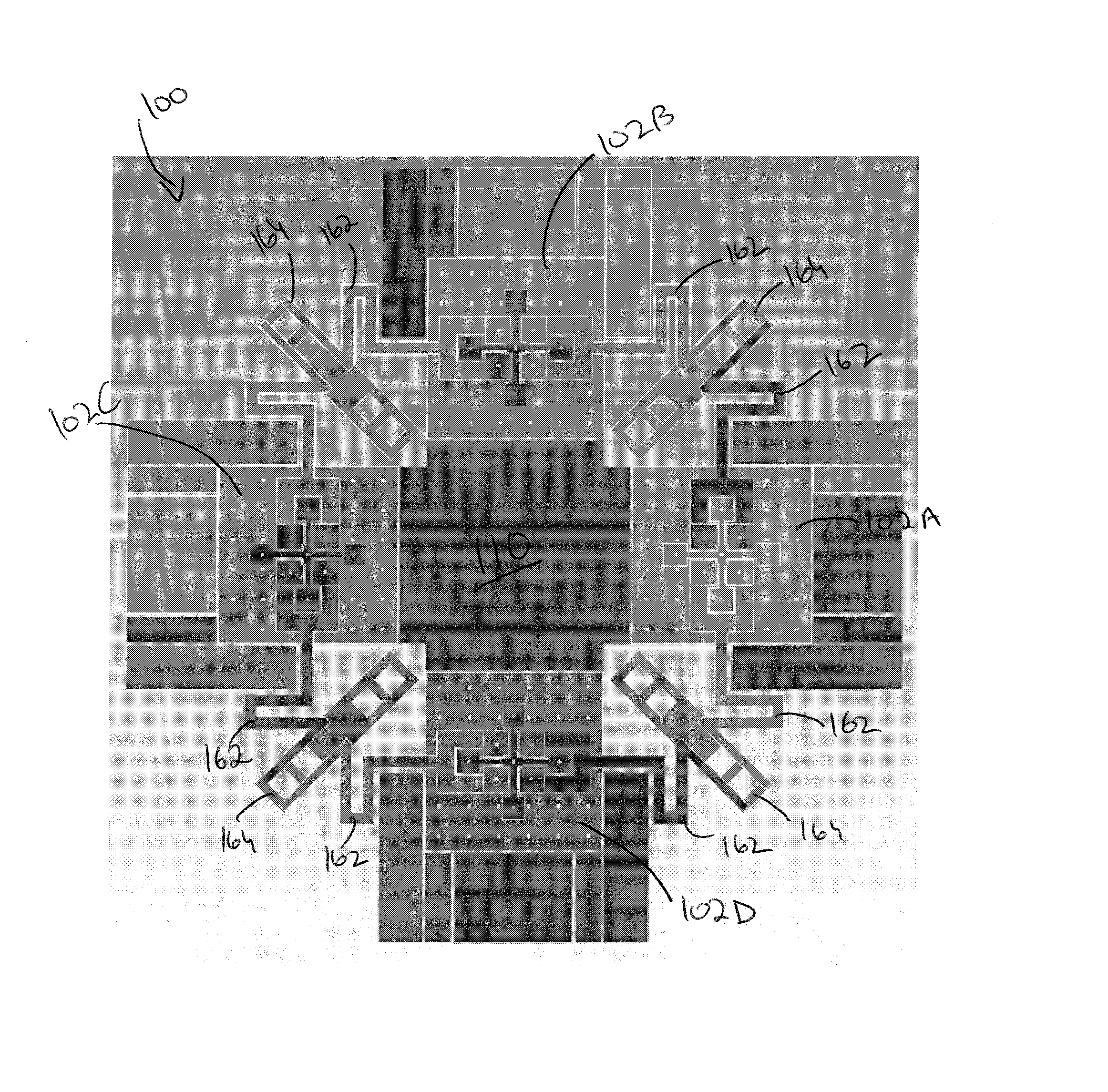

Acoustic metamaterials

ActiveUS20140027201A1Superior vibro-acoustic damping propertyEasy constructionSound proofingSound producing devicesEngineeringAcoustic metamaterials

Metamatenal members for absorbing sound and pressure, and modular systems built of metamaterial members are provided. The metamaterial member includes an outer mass. The outer mass can have a cavity formed therein in which a stem coupled to an inner mass is disposed, or the outer mass can be solid and contain an inner mass embedded therein. The inner mass can include an inner core and an outer shell. Multiple metamaterial members can be attached to form a modular system for absorption of sound and pressure.

Owner:WAYNE STATE UNIV

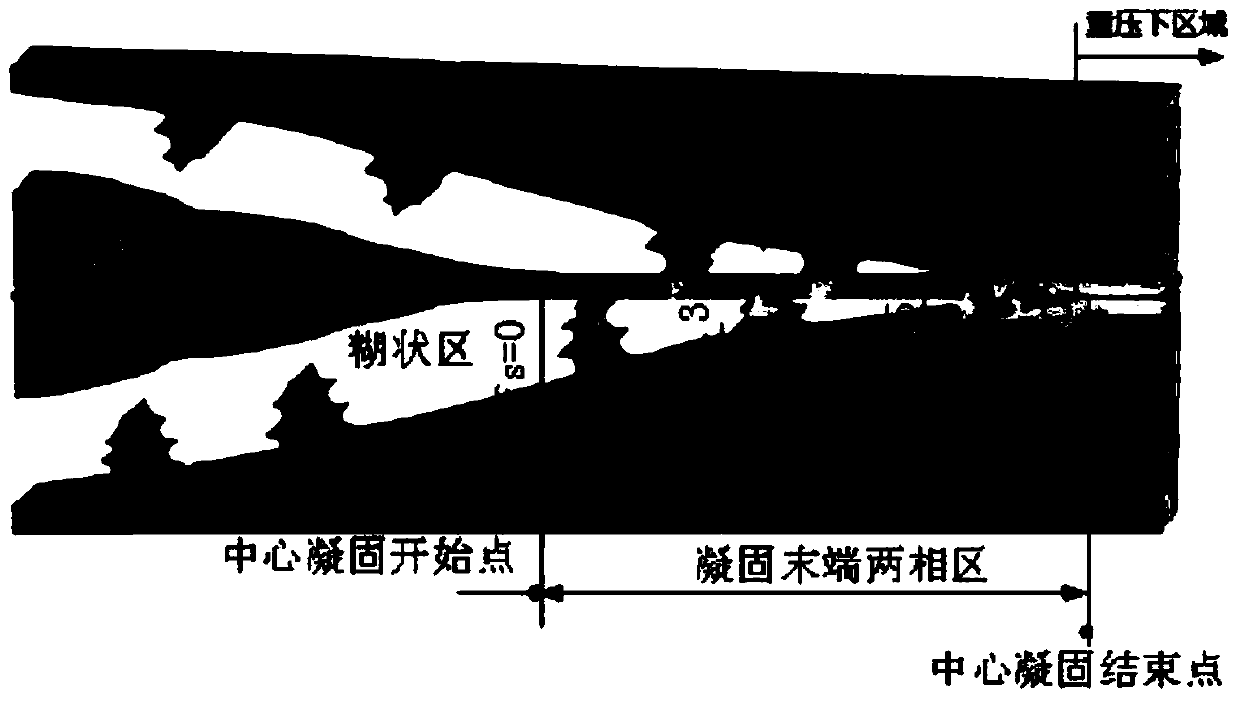

Method for improving center density of continuous cast slabs of high-level building steel

The invention discloses a method for improving center density of continuous cast slabs of high-level building steel. In the continuous casting process, the drawing speed of a casting machine is controlled to be 0.75 m / min-0.90 m / min; solidification tail end heavy reduction is adopted; dynamic secondary cooling control is adopted, and meanwhile, soft reduction and heavy reduction are adopted for carrying out reduction according to the distribution solid phase rate; and the superheat degree of tundish molten steel is controlled to range from 20 DEG C to 30 DEG C. According to the method, technical measures of stabilizing the drawing speed of the casting machine, reducing the superheat degree of tundish, carrying out secondary cooling dynamic control, carrying out solidification tail end heavy reduction control and the like are mainly applied comprehensively to reduce center porosity of the cast slabs of the high-building steel, then the center density of the cast slabs is improved, and internal quality of rolled materials is improved. For the cast slabs produced through the method, after implementation is carried out, the effect is better than that of an existing soft reduction technology, the center density is higher, the overall quality is better, and the use requirement of the high-building steel can be met better.

Owner:TANGSHAN IRON & STEEL GROUP +2

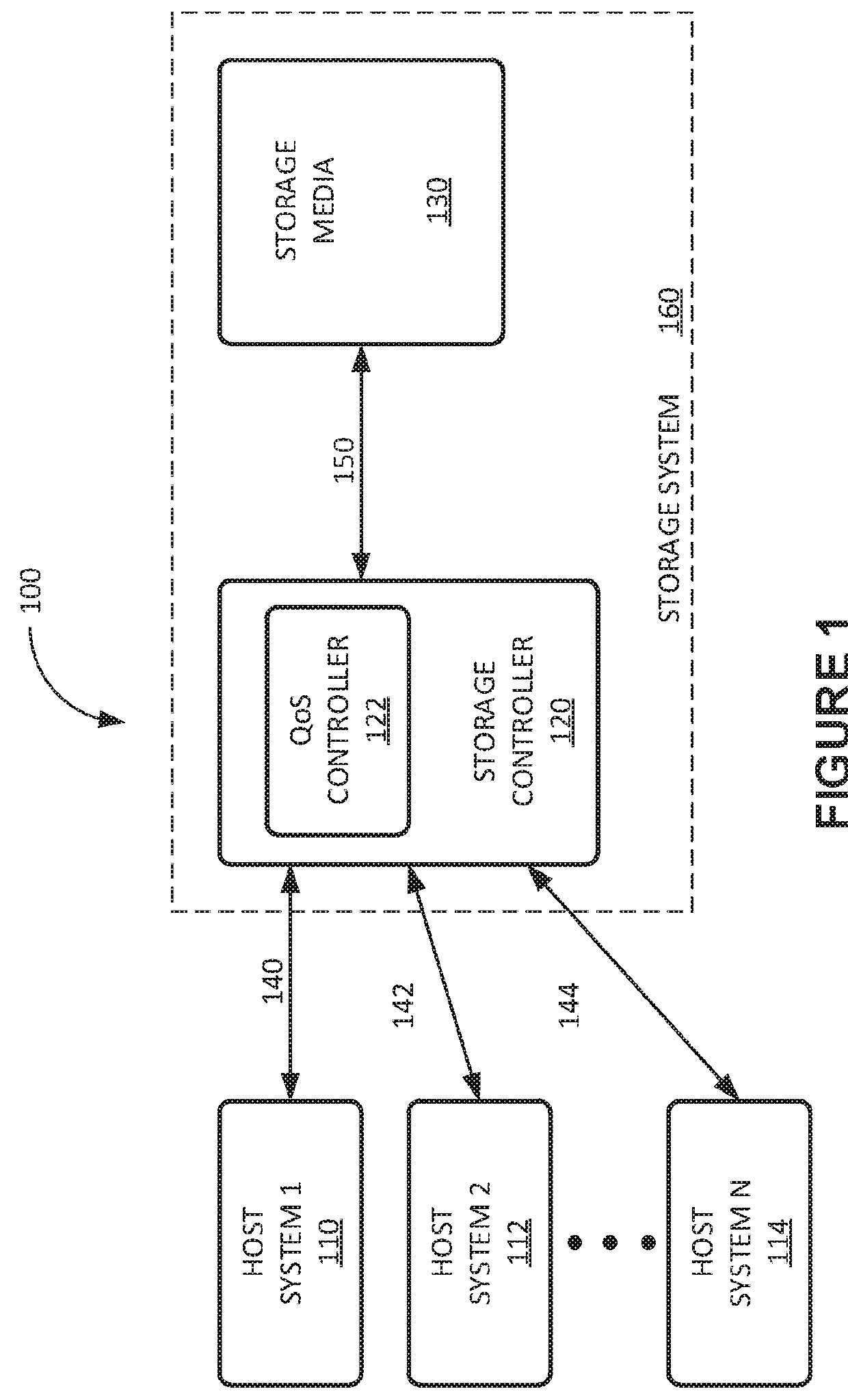

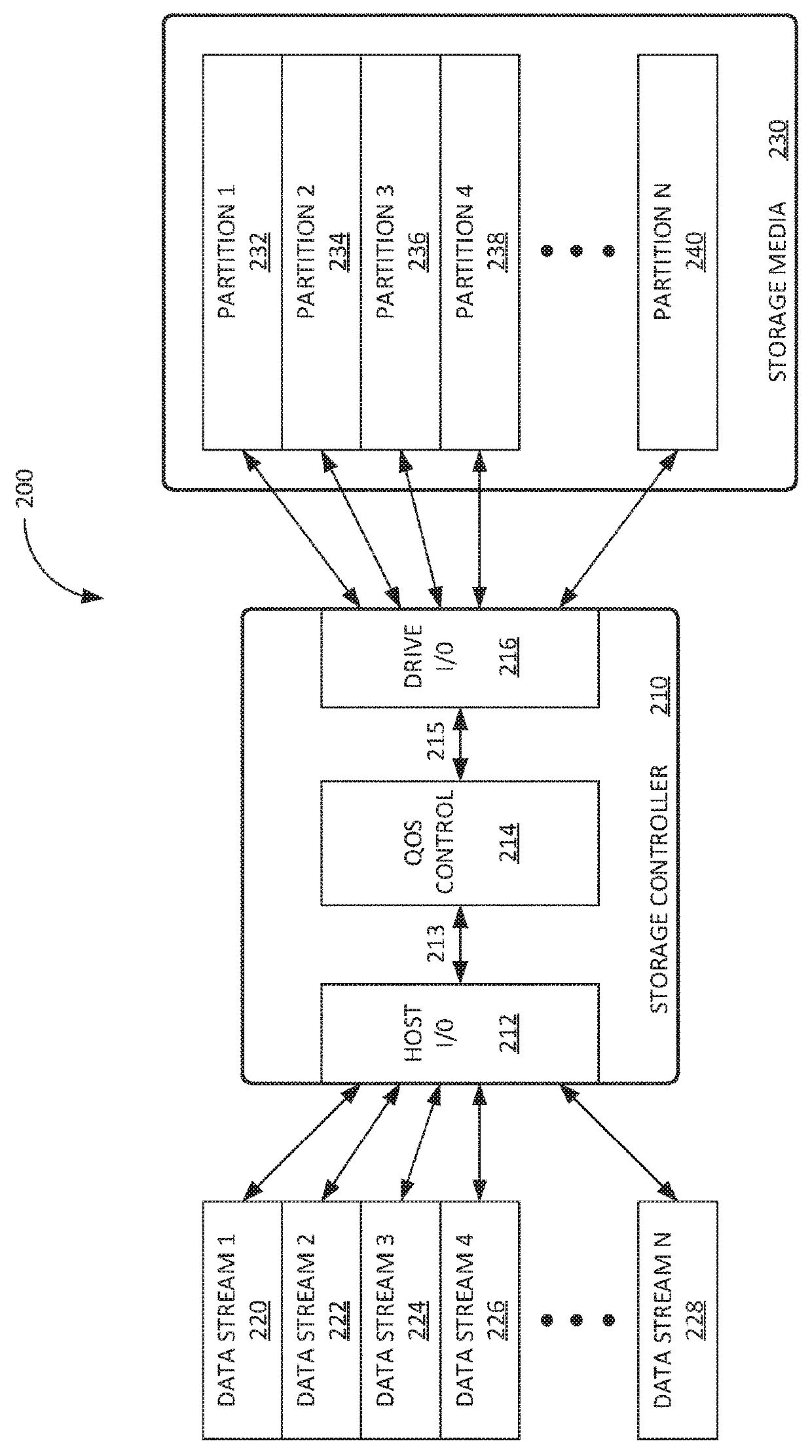

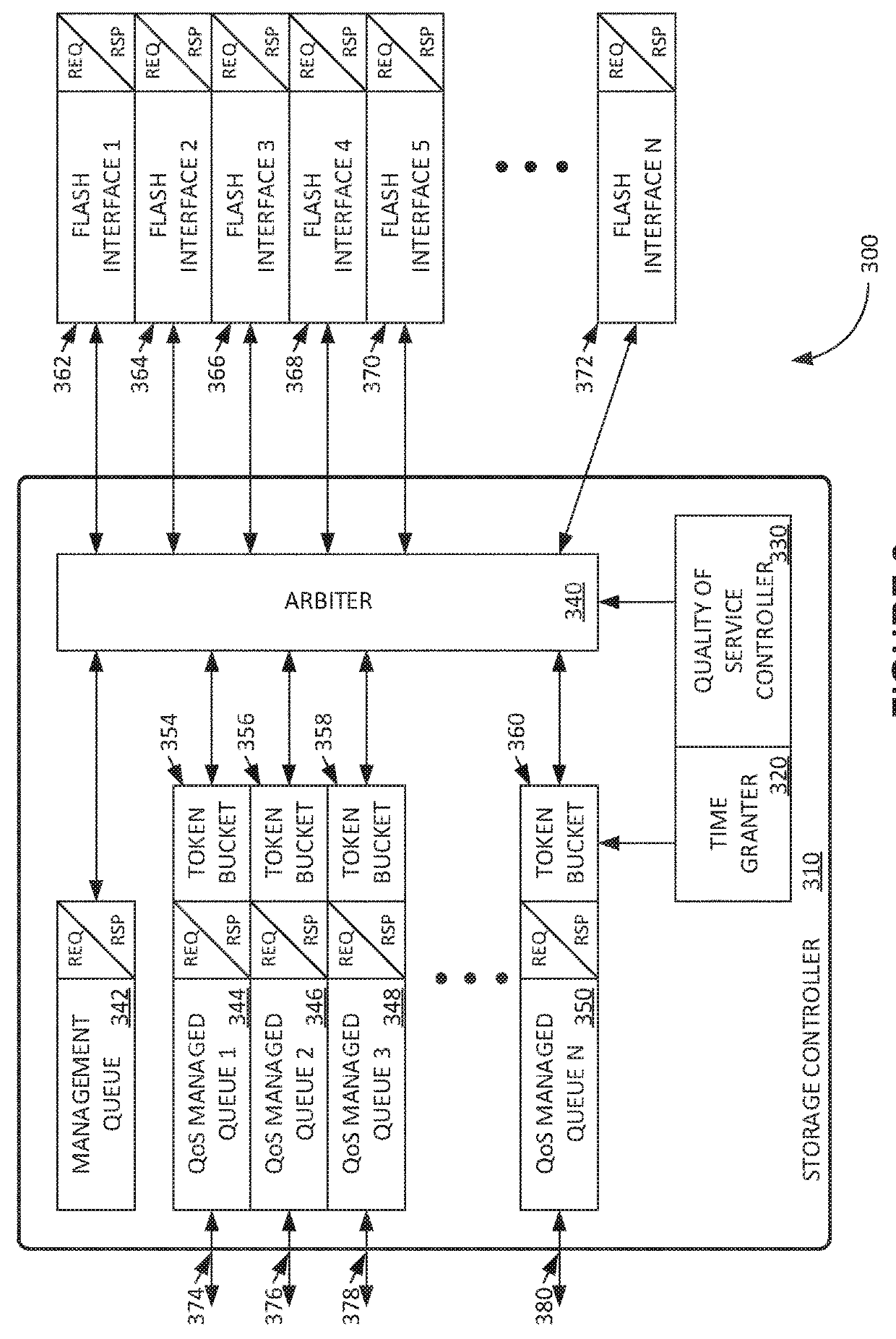

Drive-level internal quality of service

ActiveUS20180275923A1Input/output to record carriersData switching networksService-level agreementData stream

A storage controller is provided. The storage controller includes a host interface, a drive interface, and a quality of service control module coupled with the host interface and the drive interface. The QoS module includes read and write queues for each data stream, each queue associated with corresponding token buckets, and an arbiter, configured to receive requests from the read and write queues, and to service the read and write queues in an order at least partially determined by a quantity of tokens in each token bucket. The QoS module also includes a quality of service measurement module, configured to measure quality of service levels for each of the read and write queues, and a bandwidth allocation manager, configured to allocate tokens to each token bucket at a rate corresponding to the service level agreements and the measured quality of service level for each of the read and write queues.

Owner:BURLYWOOD LLC

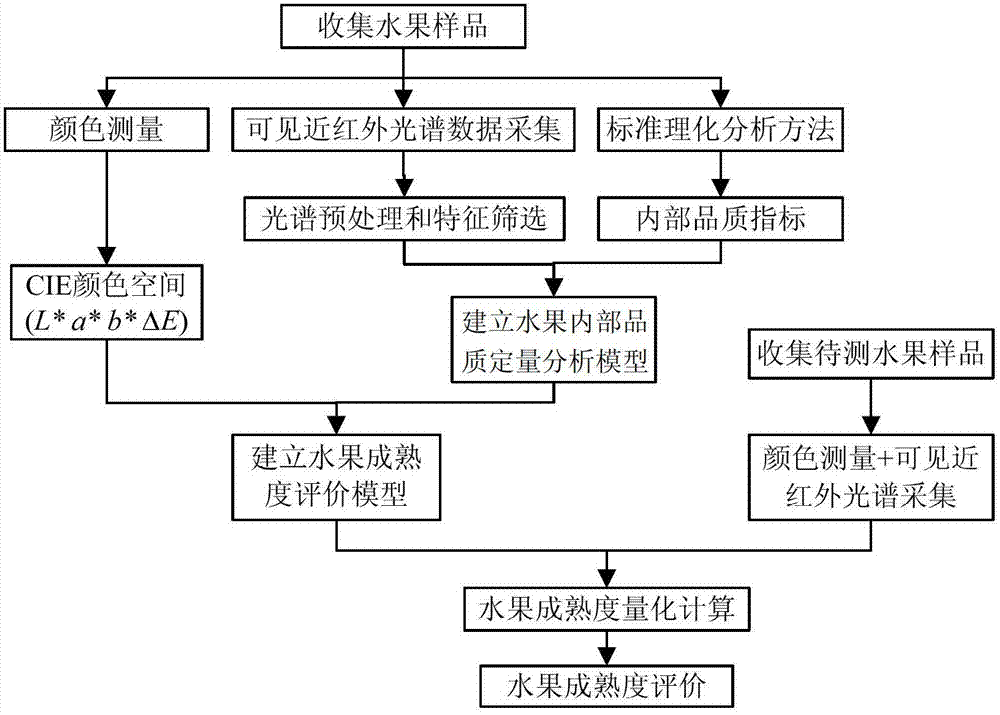

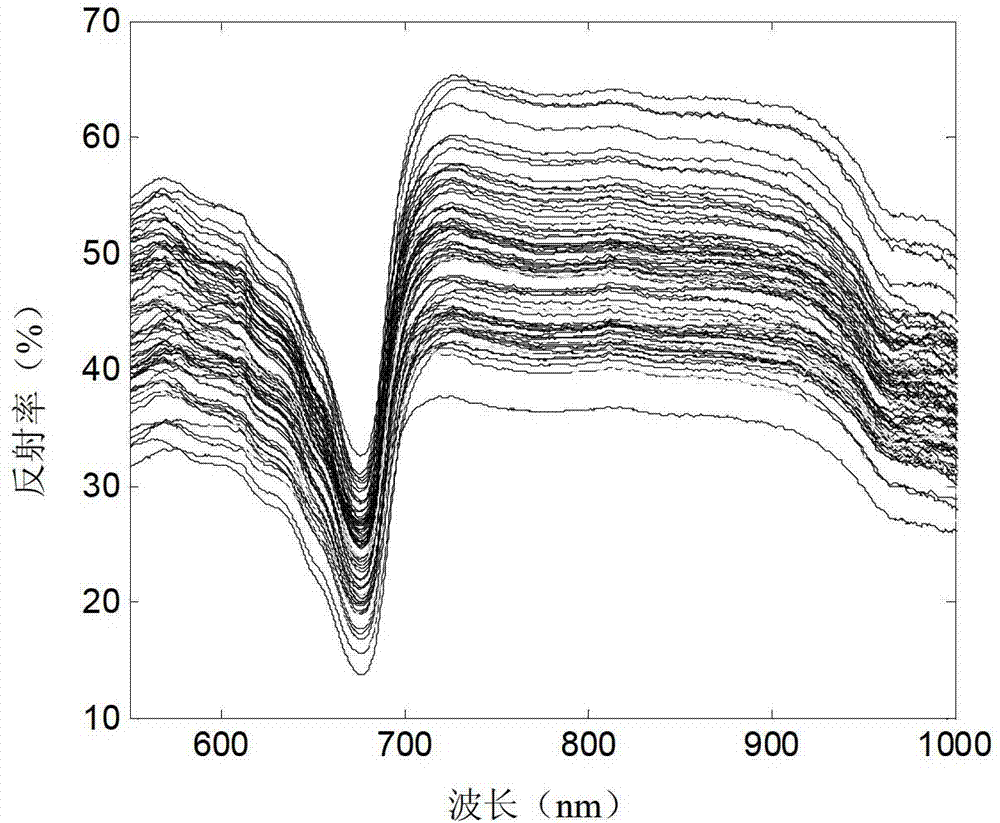

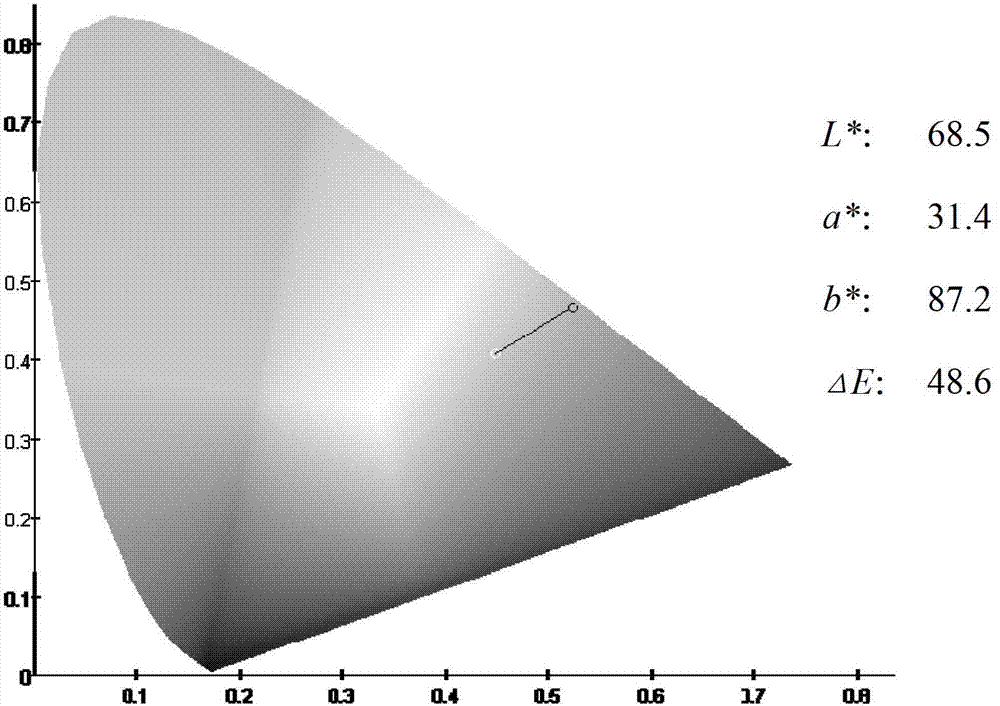

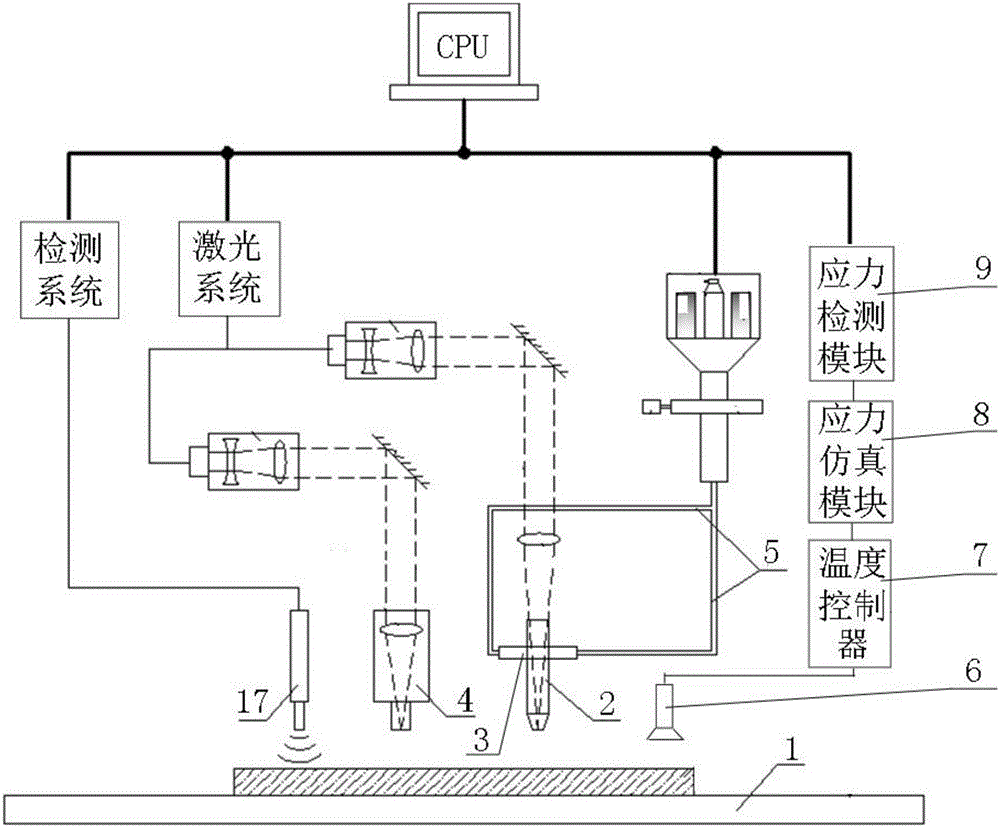

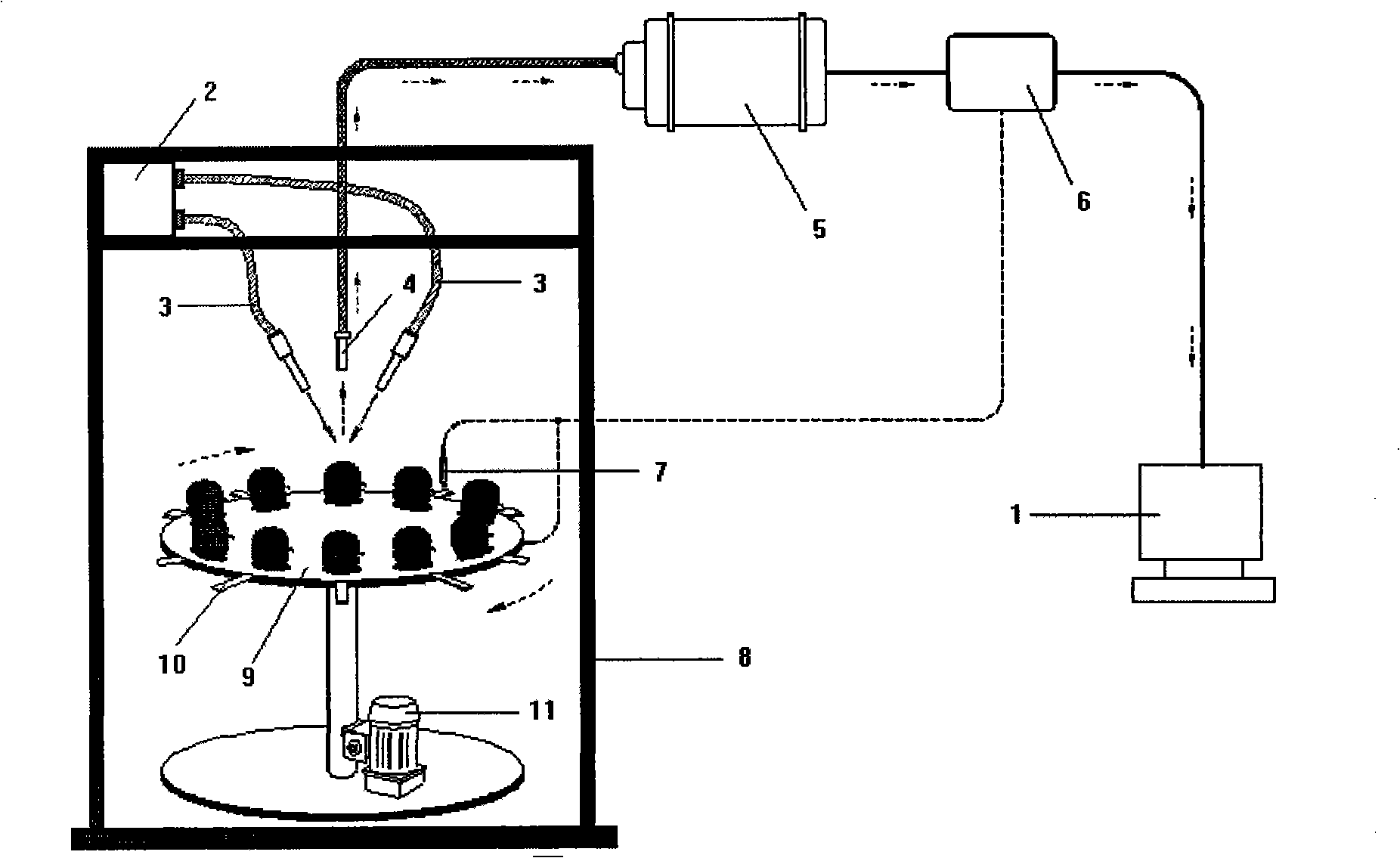

Fruit maturity degree evaluation method based on spectrum and color measurement

ActiveCN102818777AImprove objectivityStrong timelinessColor/spectral properties measurementsMultivariate calibrationVisible near infrared

The invention relates to a fruit maturity degree evaluation method based on spectrum and color measurement. The method comprises the following steps that (1) the degrade division is carried out on a certain fruit, and the color measurement parameter, the visible near infrared spectroscopy and the internal quality evaluation index of each grade of fruit are determined; (2) firstly, the visible near infrared spectroscopy and the internal quality evaluation index are combined, a fruit internal quality quantitative analysis model is built by adopting a multivariate calibration method, then, the color measurement parameter is fused, the fruit maturity degree degrade is used as the standard reference, and a fruit maturity degree evaluation model is built by using a machine learning method; and (3) the visible near infrared spectroscopy and the color measurement parameter of fruit samples to be evaluated are determined and are respectively input into the fruit internal quality quantitative analysis model and the fruit maturity degree evaluation model, and a computer carries out intelligent degrade evaluation on the fruit maturity degree. The fruit maturity degree evaluation method is simple, the fruit damage is avoided, and accuracy and high efficiency are realized.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

Method for controlling center porosity of large section heavy rail steel casting blank

The invention relates to the technical field of ferrous metallurgy, in particular to a method for controlling the center porosity of a large section heavy rail steel casting blank. The method comprises the following steps of controlling the superheat degree of medium-package molten steel; controlling the pulling speed in the normal pouring process; pressing down the final solidification end in the pouring process; setting the stirring strength and stirring frequency of electromagnetic stirring of a crystallizer; setting the stirring strength and stirring frequency of electromagnetic stirring at the final solidification end; controlling the cooling water yield and the secondary cooling specific water yield of the crystallizer. The center porosity of the large section heavy rail steel casting blank produced by adopting the method can be effectively controlled, and the remaining internal quality of the casting blank can be effectively guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Composite manufacturing method of ultra-thick steel plate

InactiveCN102240894AOvercome the problems existing in the production of extra-thick steel plates above 100mmThe internal quality of the product is goodSheet steelHydrogen

The invention relates to a composite manufacturing method of an ultra-thick steel plate, which adopts a method of high-temperature hydrogen reduction and hot rolling for producing an ultra-thick steel plate and belongs to the field of steel rolling in the metallurgical industry. The technical scheme is as follows: the composite manufacturing method sequentially comprises the following process steps: preparing a base material and a covering material; carrying out surface treatment on the base material and the covering material; carrying out welding and combined blanking on the side part of a composite surface; carrying out high-temperature hydrogen reduction; vacuumizing and sealing a composite cavity; heating and rolling; carrying out hot straightening; cooling and inspecting; and collecting and warehousing the finished product. The composite manufacturing method has the following benefits: the ultra-thick steel plate with the thickness of greater than 100mm can be manufactured by the composite manufacturing method, stratification and cracking can be avoided during shearing, drilling and other processing operations, the method overcomes the problems existing in the production of ultra-thick steel plates with the thickness of greater than 100mm in the background art, and the composite manufacturing method has the characteristics of good internal quality of the product, reasonable process steps, high efficiency, low investment, convenient operation process and the like.

Owner:HEBEI IRON & STEEL GRP

Downstream type tobacco-dryer exit tobacco-shred water control method

InactiveCN101356992AMaintain normal productionEasy to processTobacco preparationTemperature controlPulp and paper industry

The invention discloses a method for controlling moisture of tobacco shreds at an outlet of a parallel-flow tobacco dryer, and relates to a production control method in the tobacco industry. The method is characterized in that: in a production phase, the required value of the moisture of the tobacco shreds at the outlet is taken as a target, the precedence of control and adjustment is determined according to the opening degree of a moisture draining air door and a hot wind air door, the temperature of hot wind and the temperature of a wall; the overall principle is firstly controlling and adjusting the parameters which have little impact on the internal quality of the tobacco shreds and the smoking and then controlling and adjusting the parameters which have great impact on the internal quality of the tobacco shreds and the smoking; the sequence is as follows: (1) first the opening degrees of the moisture draining air door and the hot wind air door are controlled and adjusted; (2) then the hot wind temperature is controlled and adjusted; (3) and finally the wall temperature is controlled and adjusted. The method for controlling moisture content of tobacco shreds has the advantage that the wall temperature is basically kept constant in the production process, which is beneficial to stabilizing and unifying the inner quality and style of the tobacco products. The method can provide a technical means for individualized production and classification processing of the cigarettes.

Owner:WUHAN TOBACCO GROUP

Vibratory tuning fork based six-degrees of freedom inertial measurement MEMS device

ActiveUS9003882B1Facilitated releaseAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTuning forkEngineering

A high-Q, mode-matched, vibratory tuning fork based MEMS device, capable of sensing rotational and translational motion around three axes, and processes of fabrication are disclosed herein. In one embodiment, a MEMS device has first and second proof masses actuated along a first axis, and a third and fourth proof masses actuated along a second orthogonal axis. Each of the proof masses includes an inner mass mechanically coupled to an outer frame. A plurality of electrodes sense rotational or translational motion along the three orthogonal axes.

Owner:GEORGIA TECH RES CORP

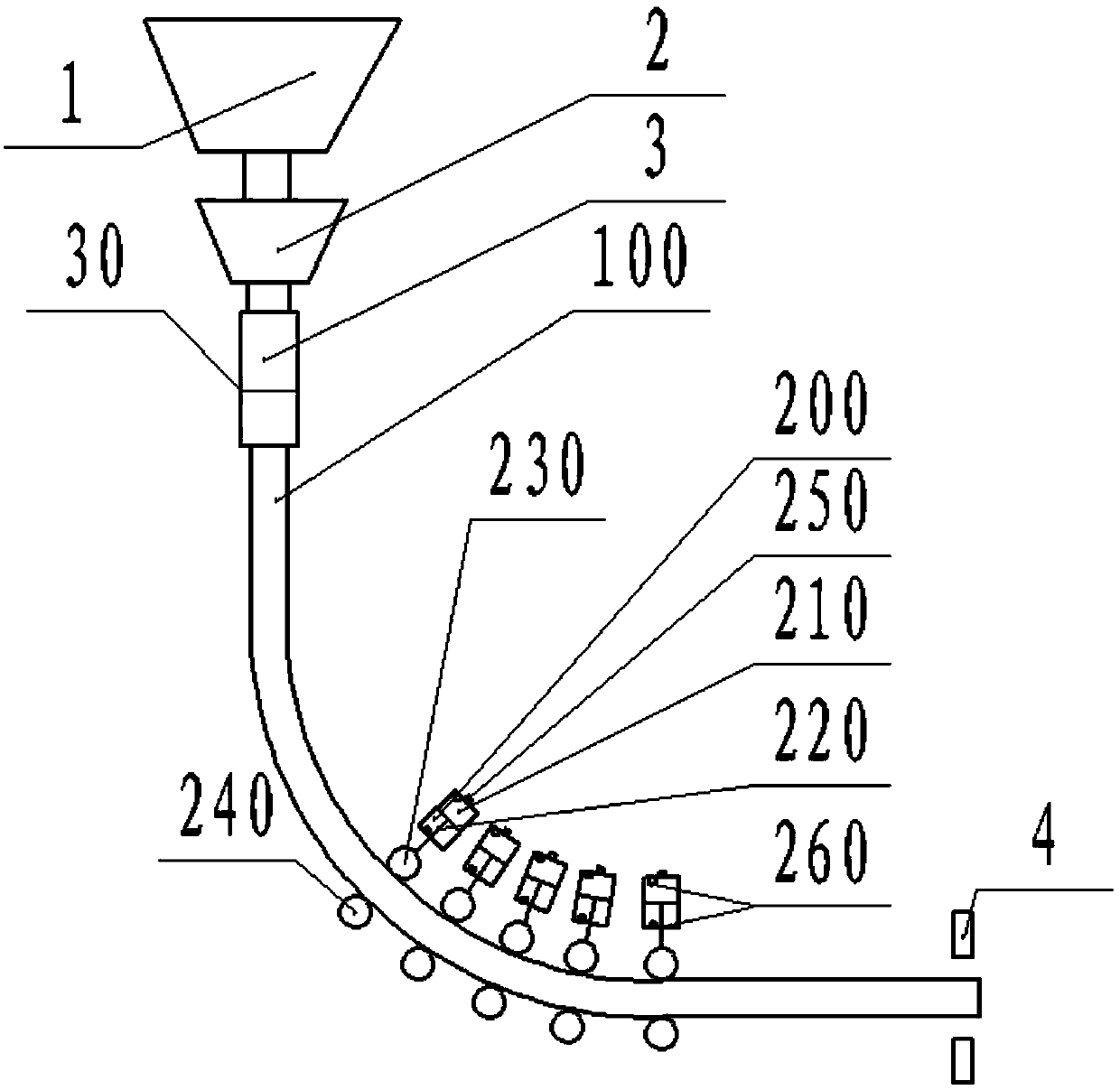

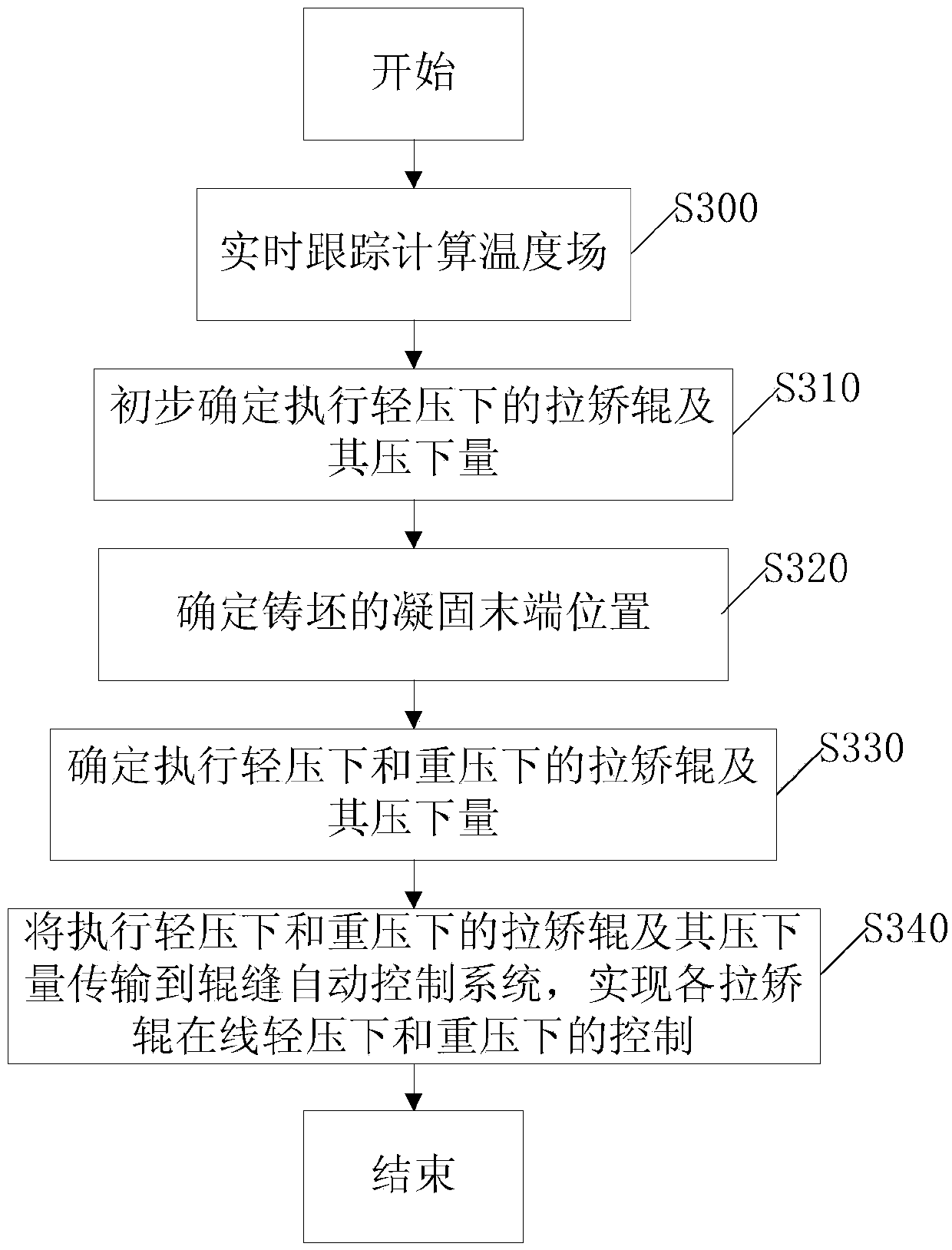

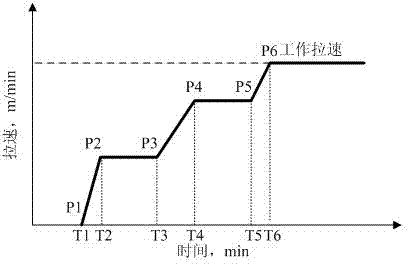

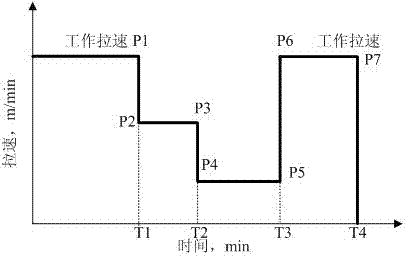

Online control method for continuous casting of small square billet through dynamic soft press and heavy press

The invention provides an online control method for continuous casting of a small square billet through dynamic soft press and heavy press. The method comprises the steps that a casting temperature field is tracked and calculated in real time; a pulling-straightening roller conducting soft press and the press degree of the pulling-straightening roller conducting soft press are primarily determined; the position of the solidification tail end is determined; a pulling-straightening roller conducting soft press and heavy press and the press degree of the pulling-straightening roller conducting soft press and heavy press are determined; the pulling-straightening roller conducting soft press and heavy press and the press degree of the pulling-straightening roller conducting soft press and heavy press are transmitted to an automatic roller gap control system, so that the press degree of online soft press and the press degree of online heavy press of each pulling-straightening roller are controlled remotely. The press degree of online soft press and the press degree of online heavy press of the pulling-straightening rollers are controlled online, and therefore the internal quality problems such as center segregation, loosening and shrinkage of a continuous casting slab can be effectively solved, the press efficiency is improved, and the press effect is stabilized.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Method for increasing flaw detection yield of continuous casting sheet head billet and tail billet

ActiveCN103586433AImprove internal qualityImprove the qualified rate of flaw detectionMetallurgyContinuous casting

The invention discloses a method for increasing the flaw detection yield of a continuous casting sheet head billet and a tail billet. The flaw detection yield of the head billet and the tail billet is increased by improving internal quality of casting billets in the casting process and after the casting stopping process and optimizing technological operation. According to the method, through technological optimization and control under the unstable state condition, the internal quality of the head billet and the internal quality of the tail billet are improved, and then the flaw detection yield of steel sheets is increased. The method is suitable for the field of sheet billet continuous casting, and has significant economical value and practical significance in improving the quality of the casting billets under the continuous casting billet unstable state condition, and especially in improving the quality of variety steel and the material yield.

Owner:NANJING IRON & STEEL CO LTD

Ultra-optical spectrum image-forming system and testing methods of meat product tenderness nondestructive testing

InactiveCN101178356AEstablish automatic detection technologyExact physical propertiesComputation using non-denominational number representationColor/spectral properties measurementsValidation methodsMathematical model

The invention discloses an ultra-spectral imaging system and a detection method for the nondestructive detection of meat tenderness, which pertains to the technical field of nondestructive detection of foods. The ultra-spectral imaging system includes an image collection device which consists of an infrared CCD digital camera, an ultra-spectral spectrograph and a second lens, the ultra-spectral spectrograph, a light source supply system, a computer and so on. The detection method is that the whole system is arranged in a closed light shielding compartment, so as to prevent the external light interference. The image collection device collects the ultra-spectral image data, the computer uses an original image processing method and the mathematical algorithms to extract the image characteristics from the ultra-spectral image and establish a mathematical model, and the invention uses a cross return validation method to further establish a forecast evaluation model to be measured. The invention can obtain the measurement performances and rules of the ultraspectral imaging system for the different meat by the analysis of the characteristics of the ultraspectral images of the meat to be measured, the invention can realize the internal quality and safety evaluation of the meat products which can not achieved by the pervious artificial methods in a non-contact mode, which is rapid, convenient and safe.

Owner:中玺赫(北京)科技有限公司

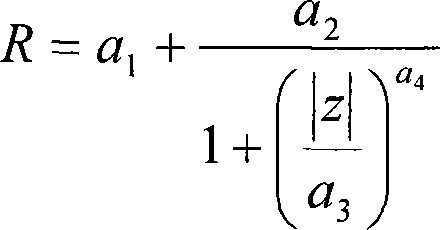

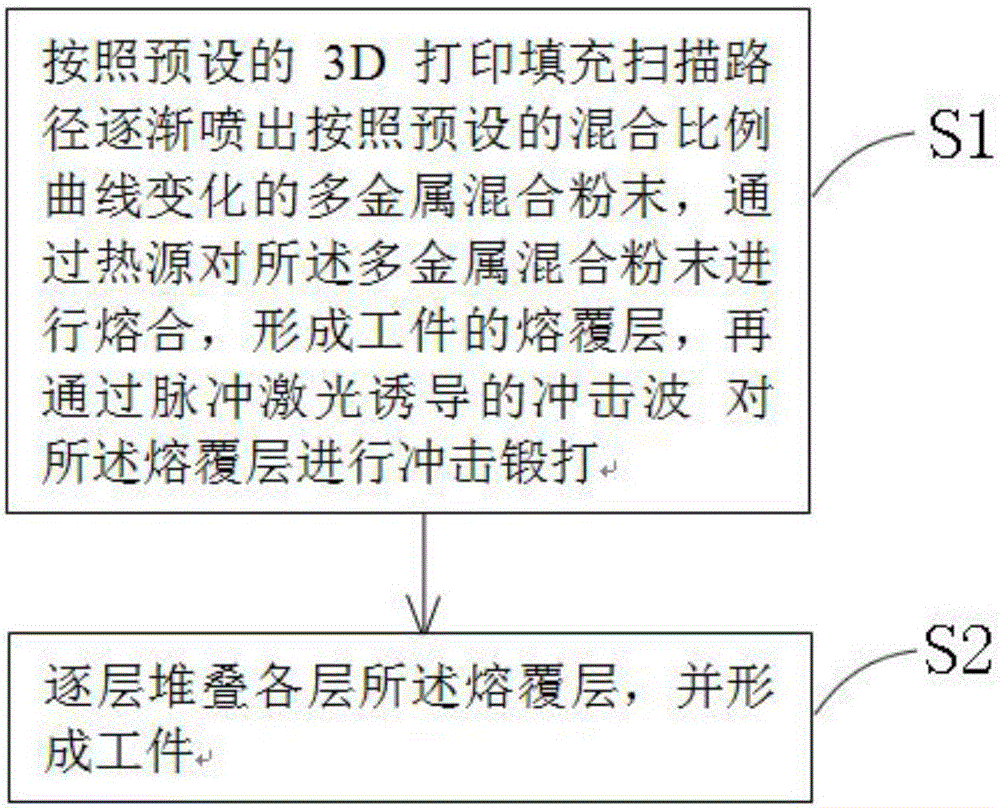

Metal-gradient-material laser-shock-forging composite additive manufacturing method and device

ActiveCN106825574AEven metal ratio transitionQuality improvementAdditive manufacturing apparatusIncreasing energy efficiencyShock waveAdditive layer manufacturing

The invention discloses a metal-gradient-material laser-shock-forging composite additive manufacturing method and device. The method includes: gradually spraying multi-metal mixed powder, which changes according a preset mixing proportion curve, according to a 3D printing filling scanning path, using a heat source to fuse the metal mixed powder to form the cladding layers of a workpiece, and using shock waves induced by pulse laser to impact and forge the cladding layers; stacking the cladding layers layer by layer, and forming the workpiece. The metal-gradient-material laser-shock-forging composite additive manufacturing method and device has the advantages that the cladding layer forming using the heat source to fuse the mixed metal powder and the cladding layer impacting and forging using the pulse laser are performed at the same time and are coordinated to manufacture a metal part, shaping and reinforcing are completed in one step in an efficient and high-quality manner, defects such as air pores, non-fusion and shrinkage cavities of the cladding layers are eliminated, and part internal quality is increased.

Owner:GUANGDONG UNIV OF TECH

Casting and forging combined technique of aluminum alloy linkage rod

InactiveCN101486087AEnsure billet qualitySimplify the traditional die forging processEngine componentsRheniumRare-earth element

The invention discloses technology for casting and forging an aluminum alloy connecting rod, wherein an aluminum alloy composition of the connecting rod is adjusted by addition of rare earth element in casting technology, and the addition of the rare earth element is 2 to 5 percent of an aluminum liquid; the aluminum alloy connecting rod is guaranteed to comprise the following compositions: 88 to 94 percent of aluminum, 3.8 to 4.9 percent of copper, 0.5 to 1.5 percent of silicon, 0.4 to 1.2 percent of manganese, 0.4 to 1.0 percent of magnesium, 0.8 to 1.8 percent of rhenium and 0.4 to 0.14 percent of iron; and a casting head is not cut off and reheated in the casting technology and taken as one part or a scrapped part of a forged piece, and casting afterheat is utilized for forging. The technology simplifies the prior die forging technology, improves reasonable floatation, the streamline and mechanical properties of casting metals, improves a metallurgical structure close to the casting head on the forged piece, and has the effects of high technological utilization rate of materials, shortened technological process and energy conservation and consumption reduction. Moreover, the casting and forging technology can obviously improve the internal quality and the mechanical properties of casting blanks, and the production cost of the casting blanks is lower than that of the prior die forging.

Owner:DANYANG RONGJIA PRECISION MACHINERY

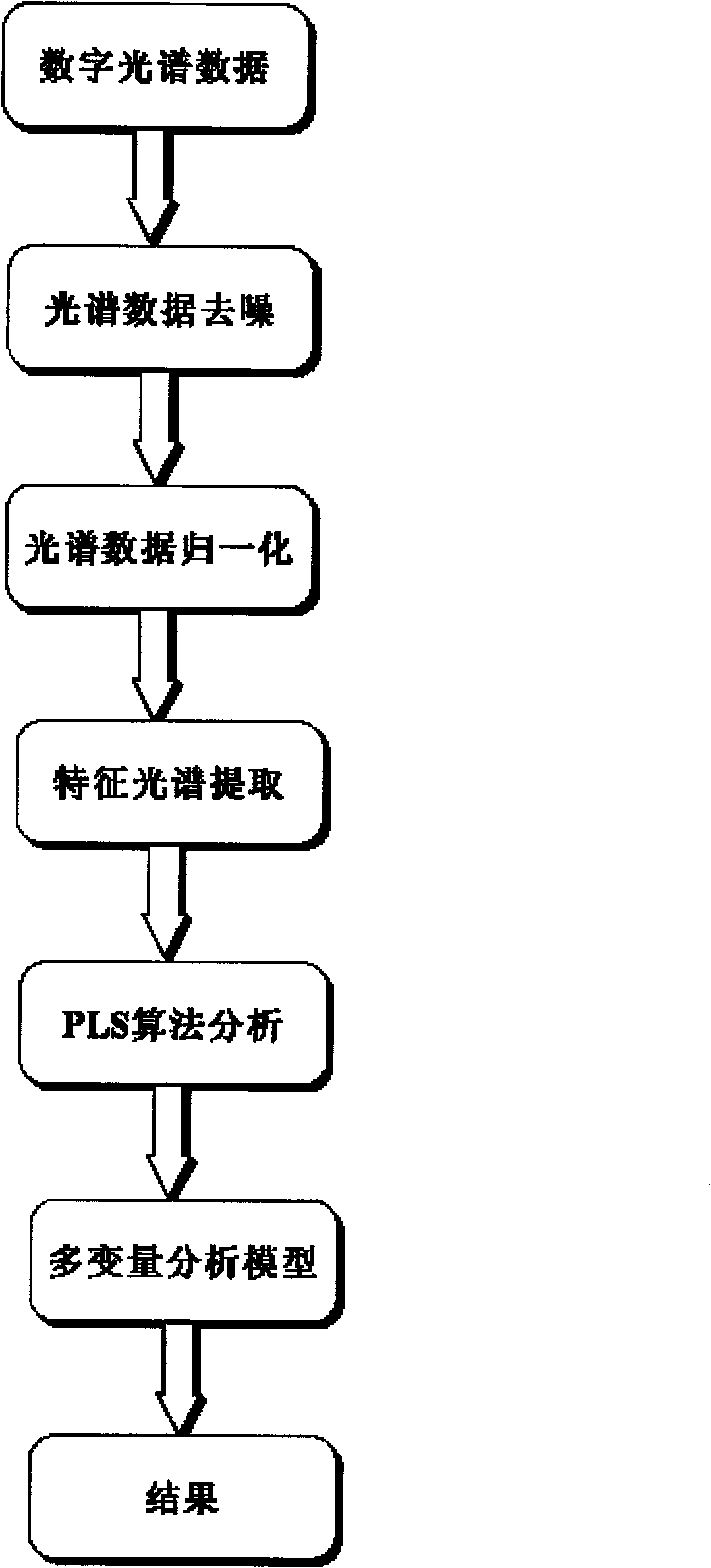

Method for rapidly detecting tea quality through near infrared technology

ActiveCN101620180AEasy to detectAvoid human interferenceScattering properties measurementsTea leafInternal quality

The invention relates to a method for rapidly detecting the tea quality through a near infrared technology, which comprises the following steps: irradiating prismatic near infrared light onto detected tea to acquire all the spectral information contained within a near infrared range; preprocessing the acquired spectral information and analyzing the features of the spectral information to find out the relativity of the spectral information and the tea quality, and predicting the internal quality of the tea through a model acquired through analysis. When in detection, a tea sample does not need preprocessing, the internal quality of the tea can be rapidly and conveniently detected, the interference of human factors in a manual evaluation process can be avoided, and a result is more objective and accurate.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH +1

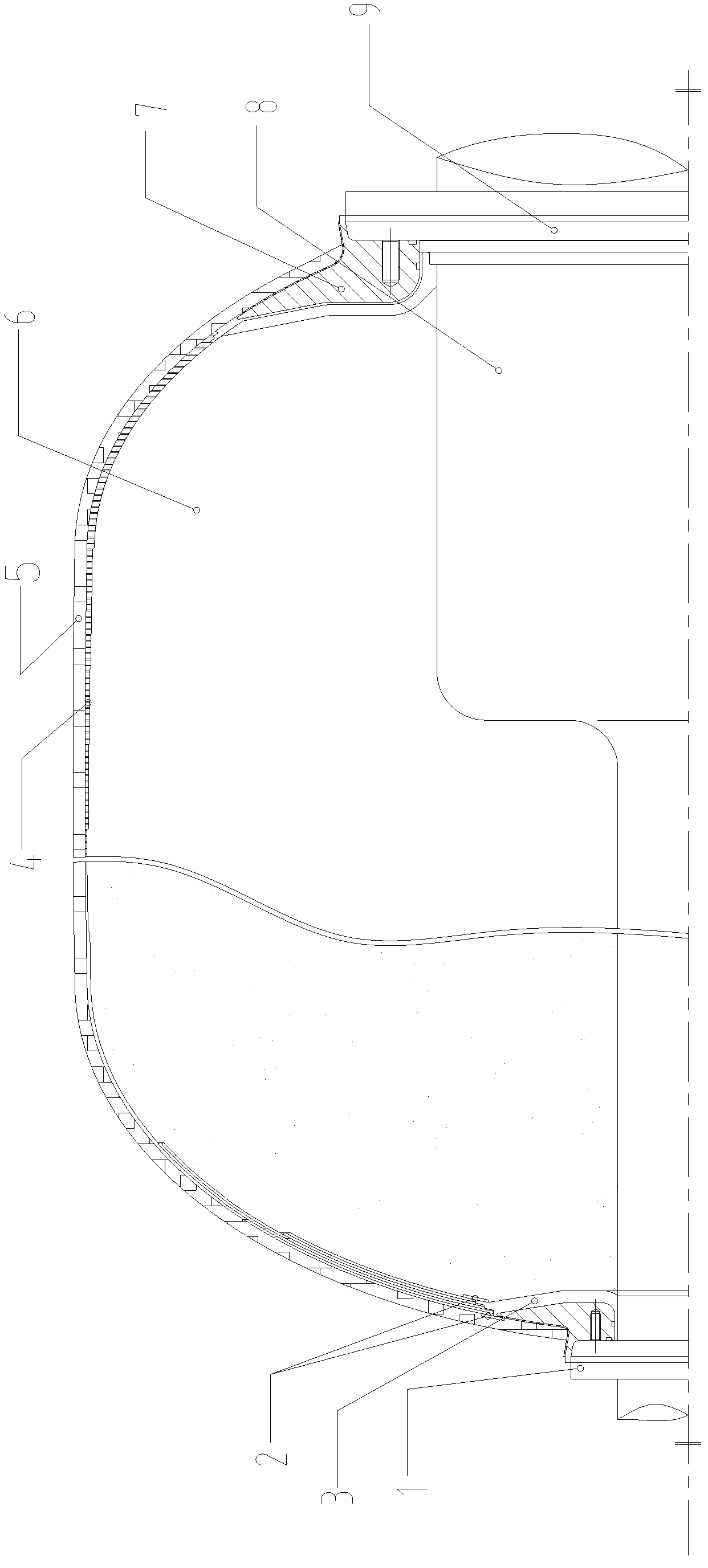

Manufacturing method for manual patch of heat insulating layer of filament winding engine shell

The invention discloses a manufacturing method for a manual patch of a heat insulating layer of a filament winding engine shell. By controlling the preparation environment of the manual patch, an appropriate adhesive is selected, a multilayer patching method is adopted to reduce the film thickness of a single-layer manual patch and patch size, then a fiber yarn is used for preloading pressure, and the heat insulating layer is repaired to increase the internal mass and shape structure size of the heat insulating layer after curing, thus manufacturing the manual patch. The manufacturing method solves the problems of high film hardness, poor self-adhesion and mutual viscosity, and high patching difficulty of an EPDM material, the thickness of the heat insulating layer meets the design requirements, and an EPDM anatomical layer is compact and smoothly passes engine ground test assessment for a few times.

Owner:航天科工火箭技术有限公司

Large-scale roller press squeeze roll forging technique

InactiveCN101134224AForged cavity defectReduce generationMetal-working apparatusFurnace typesIngotMaterials science

The present invention discloses one technological process of forging extrusion roll for large rolling press, and the process of making integral extrusion roll forging includes two upsetting and drawing-out steps. The first upsetting and drawing-out step increases forging ratio and improves the steel ingot structure through making the center of the steel ingot in three way compression stress state, eliminating inside hole type fault and reducing cracks by means of controlling the technological parameters. The second upsetting and drawing-out step controls the forms of inclusions in steel, avoids flaky inclusions and new forging fault and forges to the required product sizes. The technological process has high forging inside quality and facilitates the forging of large extrusion roll.

Owner:CITIC HEAVY INDUSTRIES CO LTD

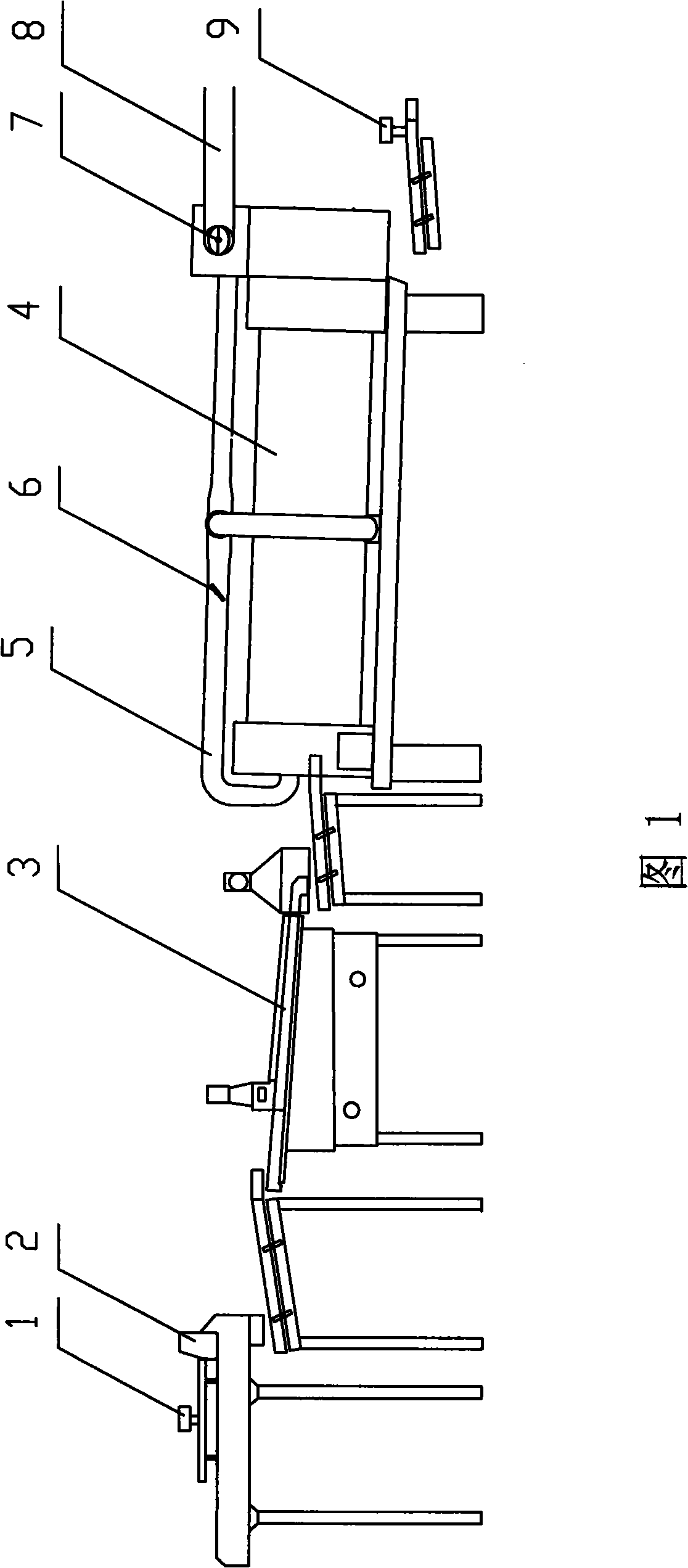

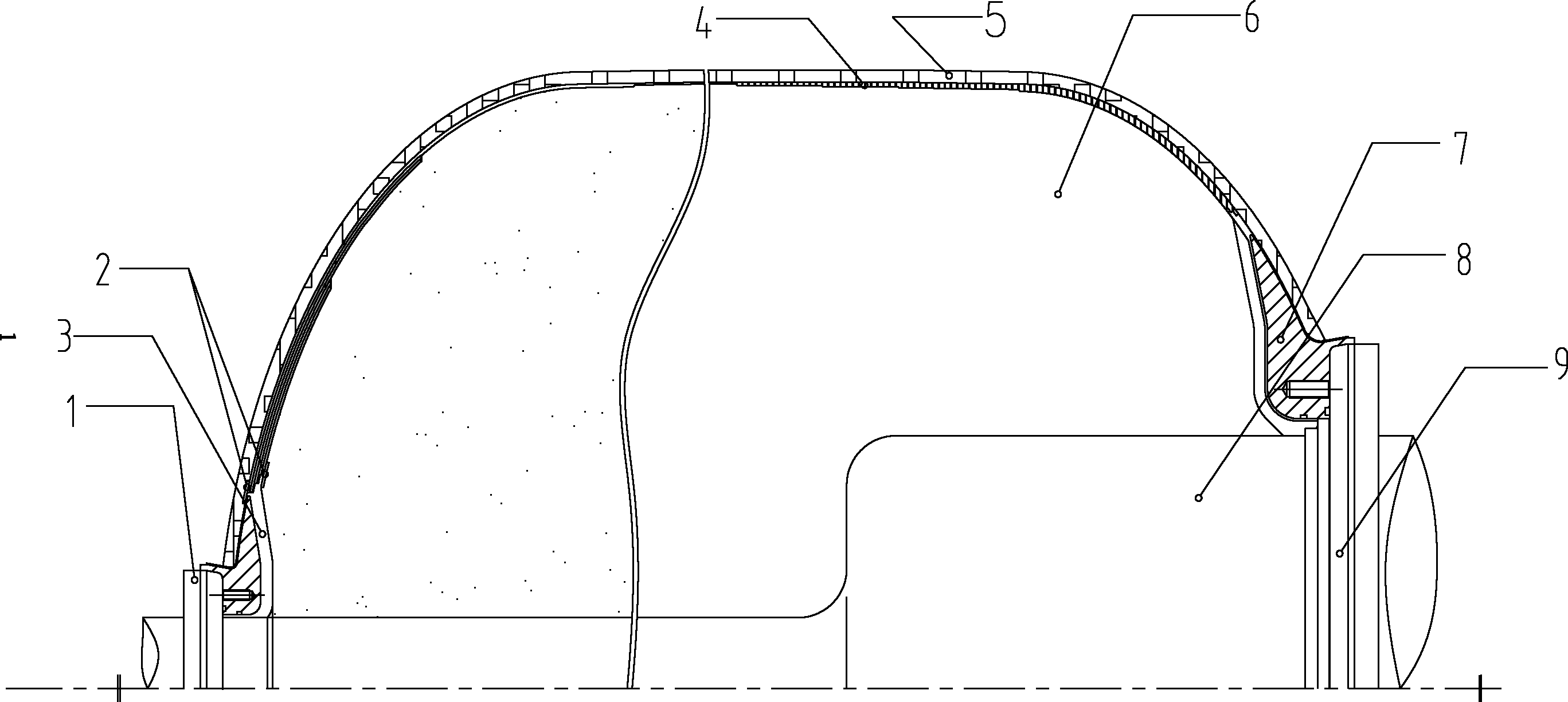

Fruit internal quality on-line checking method and apparatus based on near infrared spectra technology

InactiveCN101308086AImprove objectivityGood repeatabilityColor/spectral properties measurementsTesting foodNear infrared spectraStandardization

The invention relates to a fruit internal quality on-line detection method and an apparatus thereof. The detection method comprises: implementing the spectral scanning to the fruit to be detected and collecting a near infrared spectrum of the fruit to be detected; and putting acquired spectrum signals into a pre-established model and getting the internal quality index of the fruit to be detected. The detection apparatus includes a spectrum collection device and a computer; wherein, the spectrum collection device is used in spectral scanning to the fruit to be detected and collection of near infrared spectrum signals of the fruit to be detected so as to transmit the signals to the computer; and the computer is used for putting the received spectrum signals into the pre-established model for data analysis so as to obtain the internal quality index of the fruit to be detected. The method applies the optical detection means based on near infrared to the detection process of fruit internal quality, and can release the labor force, and the method also has advantages of high detection precision, good consistency of results and high degree of automation, and creates the conditions for the standardized classification of internal quality of fruit products.

Owner:JIANGSU UNIV

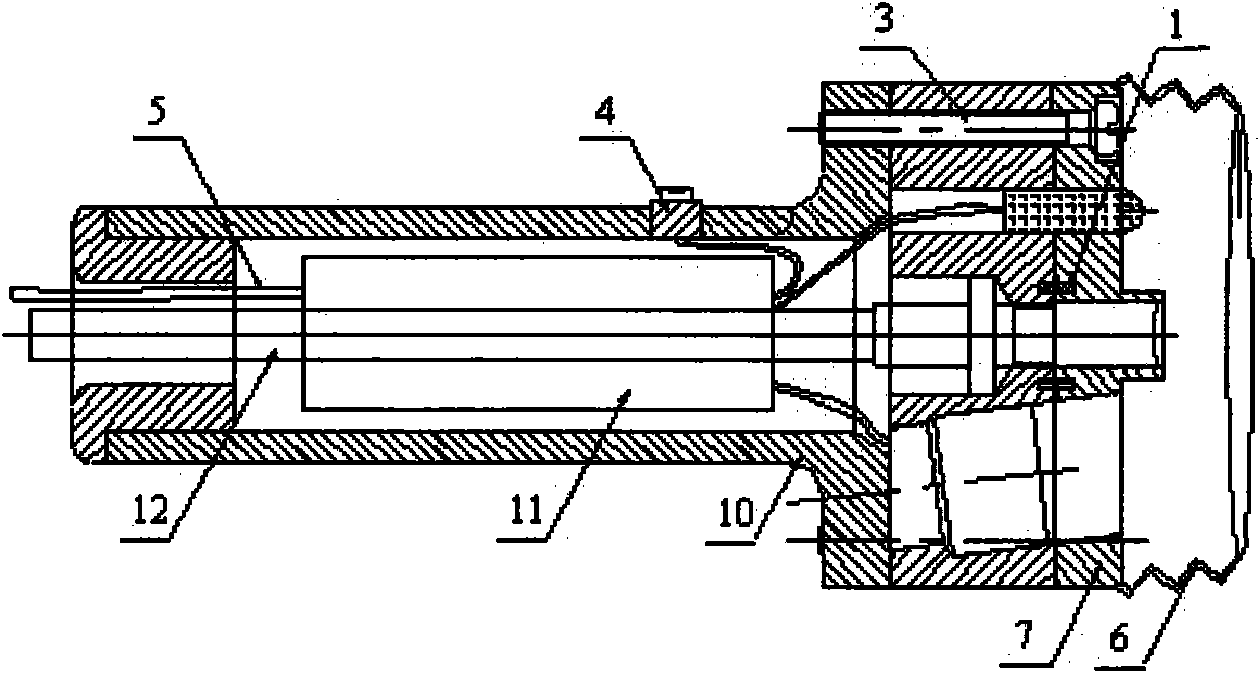

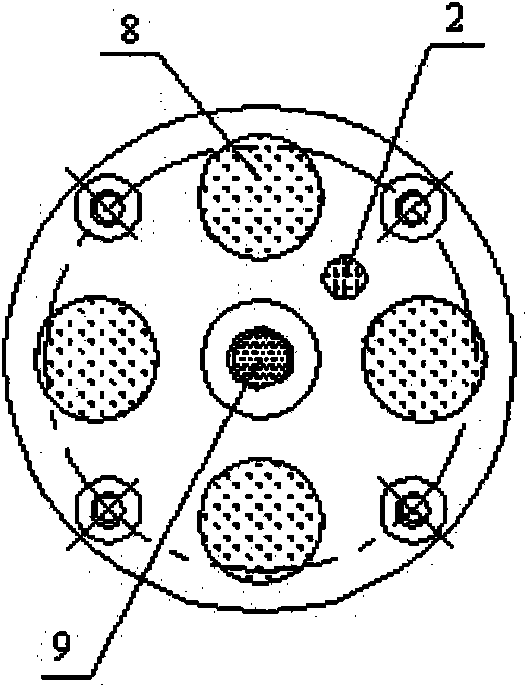

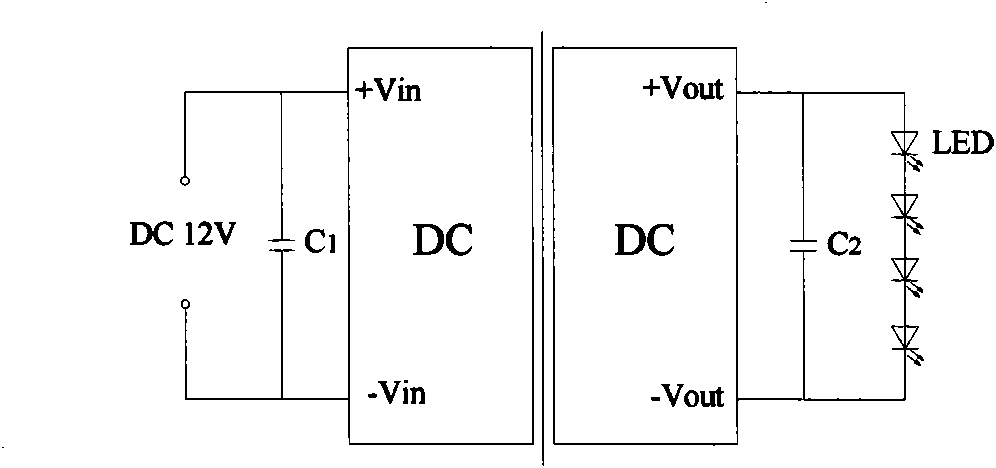

Handheld near-infrared probe for nondestructive internal quality testing of fruit and detection method

InactiveCN101799401AEasy to collectImprove final detection efficiencyPoint-like light sourceScattering properties measurementsHand heldWavelength

The invention relates to a handheld near-infrared probe for nondestructive internal quality testing of fruit and a detection method. The optical fiber probe consists of four LED light sources with different waverlengths, a detection optical fiber, an automatic sampling control system, a light source stabilizing circuit, a digital temperature and humidity sensor, a circular lug boss, a darkening ring, a soft rubber ring, a switch, a circuit box and a shell. The probe has the characteristics of high stability, simple structure, low cost and spectra collecting controllability, and can be widely used for on-line monitoring and on-site sampling of fruit. A voice system and a wireless transmission system can be used for realizing the humanization and easy operation of equipment and effectively expand application space.

Owner:EAST CHINA JIAOTONG UNIVERSITY

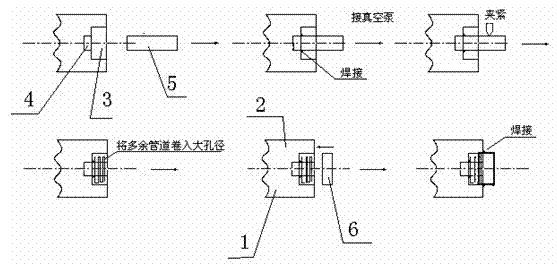

Method for creating an internal transport system within tissue scaffolds using computer-aided tissue engineering

An artificial tissue including an internal mass transport network having a plurality of channels, wherein the channels are designed to substantially mimic naturally occurring vascular network and a method for creating an internal transport system within a tissue scaffold to improve circulation, diffusion, and mass transport properties by utilizing computer-aided tissue engineering (CATE). The artificial tissue has the internal mass transport network of channels embedded, deposited, or molded within a scaffold, wherein the channels are made from a biodegradable transporting material and the scaffold is made from a scaffold material. The artificial tissue of the invention includes a basic circulatory system embedded within the tissue scaffold. This system provides mass transport throughout the entire scaffold and degrades after the new circulatory system develops.

Owner:DREXEL UNIV

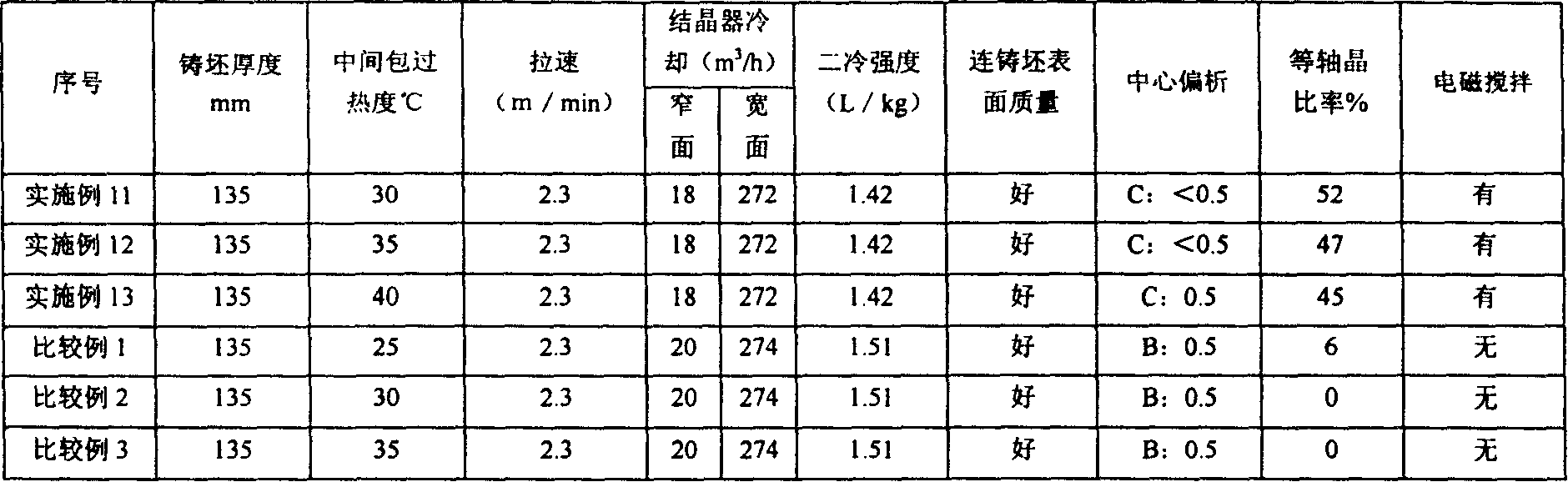

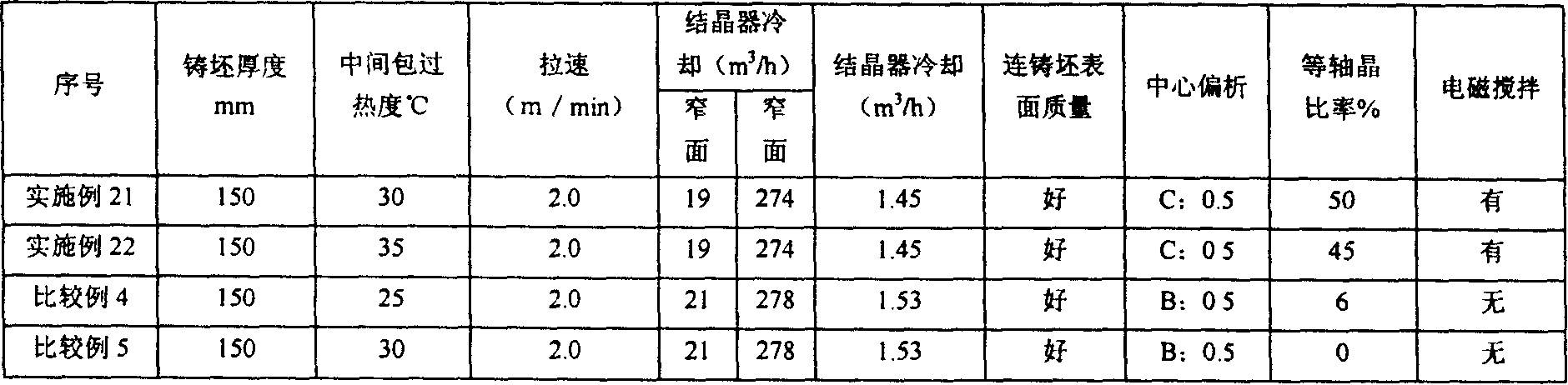

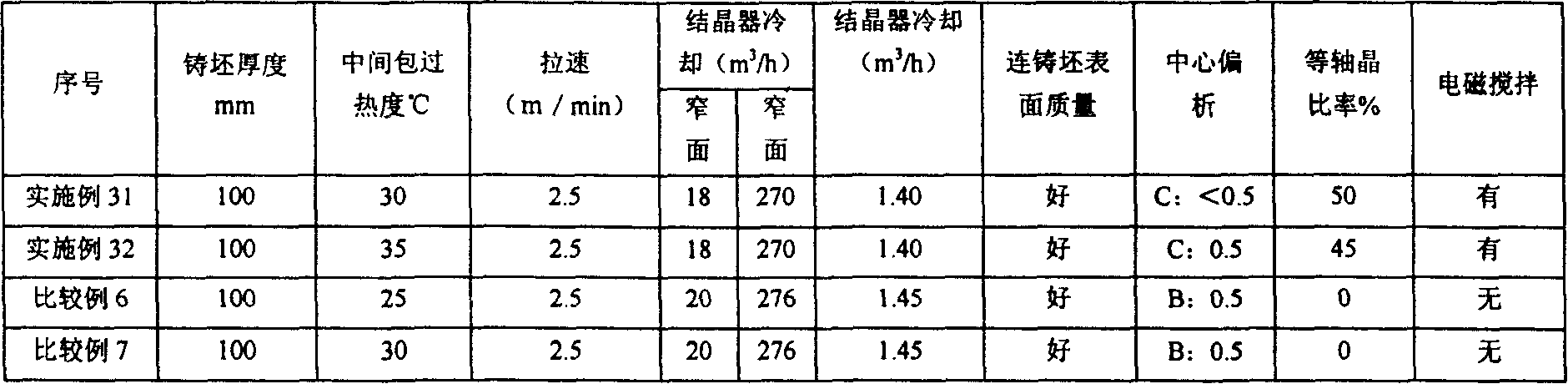

Continuous casting method for increasing equal thickness continuous casting plate billet equal axial crystal rate in non-oriented silicon steel

InactiveCN101164720AImprove mechanical propertiesImprove dynamic conditionsSiliconElectromagnetic stirring

The present invention provides a continuous casting method capable of increasing non-oriented silicon steel medium-thickness continuous cast slab equiaxial crystal rate. It is characterized by that it adopts a medium-thickness slab continuous casting machine, in the continuous casting second cooling zone it adopts a roller electromagnetic stirring equipment. The casting billet size of continuous casting machine is 100-150mmX850-1550mm, pouring speed is 1.5-3.5m / min, the cooling pattern: the narrow edge of crystallizer is 14-25m3 / h, the wide edge of crystallizer is 250-290m3 / h and second cooling intensity is 1.3-1.8L / kg. The described electromagnetic stirring equipment includes 2-4 pairs of introroller built-in traveling wave magnetic field type electromagnetic stirring devices which are assembled into two groups and mounted.

Owner:ANGANG STEEL CO LTD

Method for increasing yield and improving quality of continuously cropped flue-cured tobacco

InactiveCN102919038APromote decompositionSimple structureFertilising methodsHorticultureGreen manureIntermediate Grade

The invention provides a method for increasing yield and improving quality of continuously cropped flue-cured tobacco. The method combines planting and turning over and pressing green manure with applying decomposing agents and microbial fertilizer. When the green manure is turned over and pressed in spring, the decomposing agents are applied; a base fertilizer includes both special tobacco compound fertilizer and the microbial literalizer, so that green manure can give a full play in improving the soil, increasing yield and improving quality of tobacco. Therefore, the method is a simple, effective and practical method for increasing yield and improving quality of the continuously cropped flue-cured tobacco leaves. The yield of the tobacco leaves is increased by 15.2%-19.8%, both the appearance quality and the internal quality of tobacco leaves are improved, and the high and intermediate-grade tobacco yield is increased by 7.5%-10.5%.

Owner:SOUTHWEST UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com