Patents

Literature

36results about How to "Reduce central porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

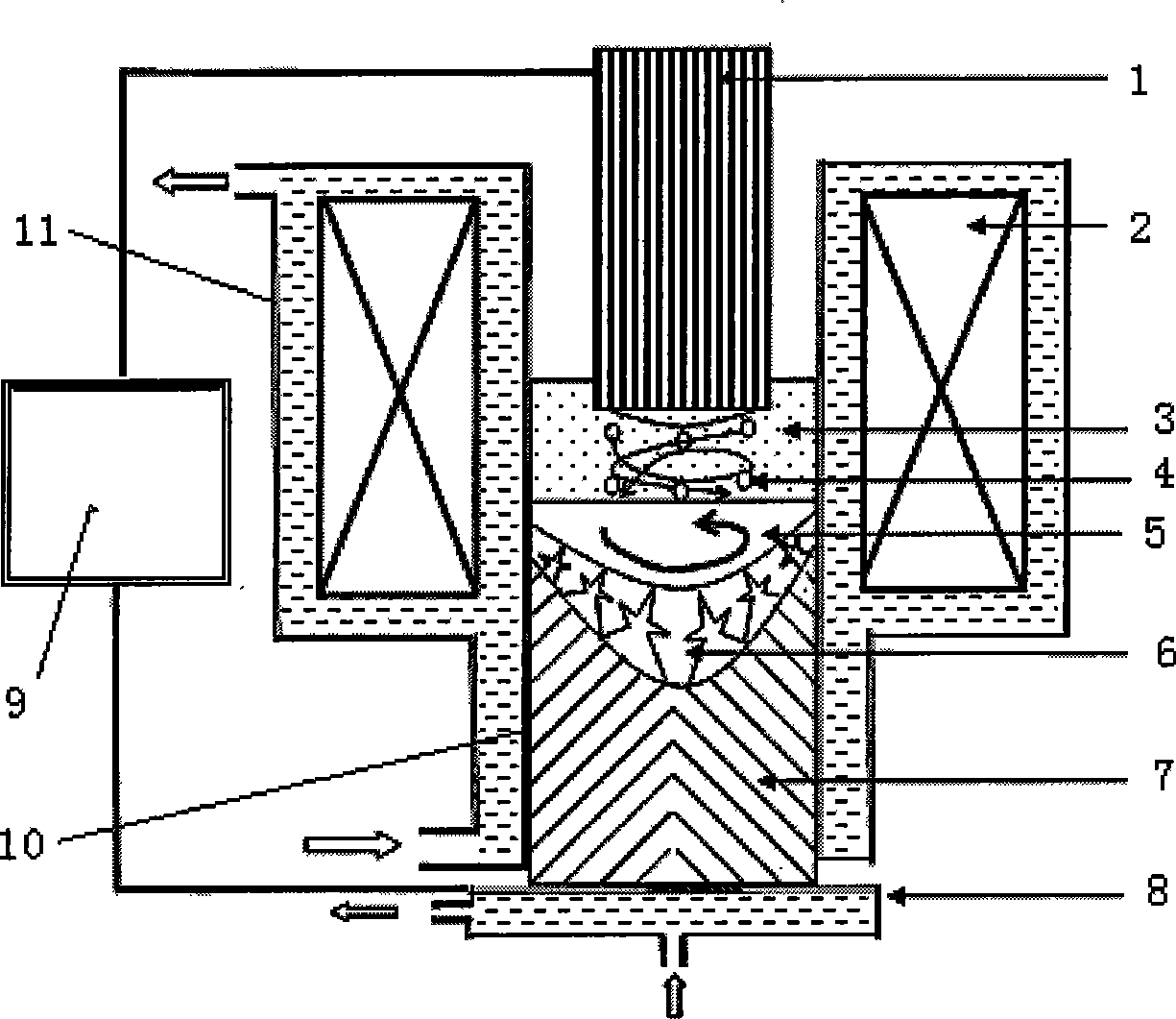

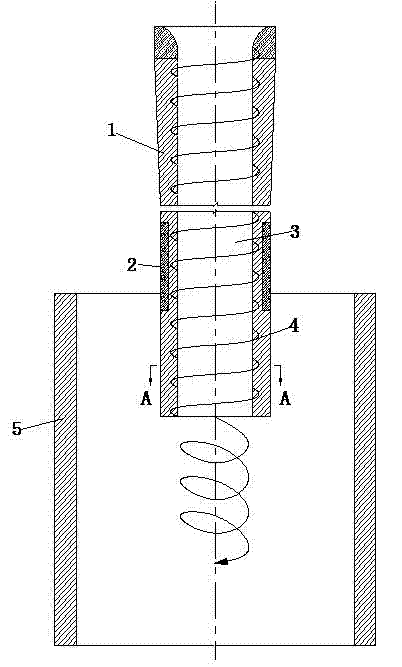

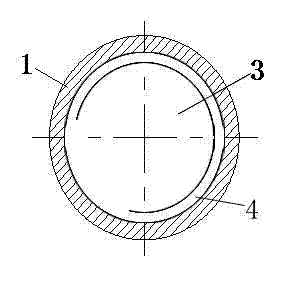

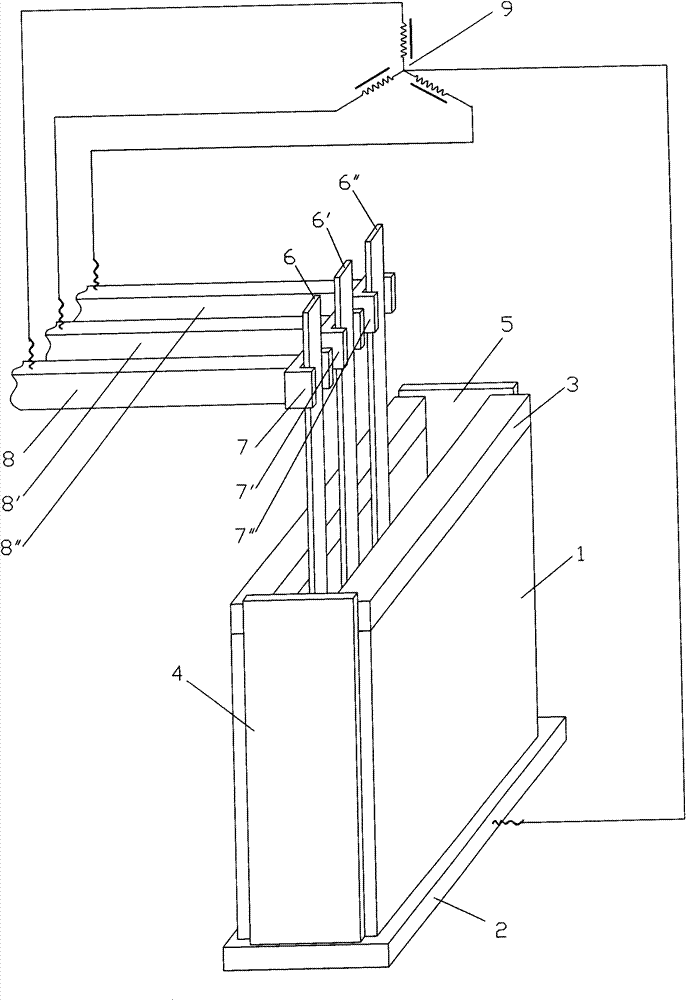

Electroslag smelting casting device with additional electromagnetic stirring and method

The invention relates to an electroslag casting device additionally provided with electromagnetic stirring and a method thereof. The electroslag casting device belongs to the technical field of special steel electroslag metallurgy and comprises a crystallizer, a crystallizer water jacket and an electromagnetic stirrer; an annular magnet is sleeved on the outer wall of the crystallizer and positioned at the middle-upper part of the crystallizer, a loop is wound on an iron core of the annular magnet, an electromagnetic stirrer water jacket is arranged at the periphery of the annular electromagnet, and the electromagnetic stirrer water jacket is communicated with the crystallizer water jacket; a melting consumable electrode forms molten steel drops which then enter a slag layer; the molten steel drops fall down in a spiral line way in the slag layer under the action of the rotary electromagnetic field and then enter a steel ingot liquid tank; the steel ingot liquid tank raises continuously and also enters into an effective magnetic field action region of the electromagnetic stirrer; and meanwhile, electric current in the molten steel is acted with the rotary magnetic field to produce the electromagnetic force which then drives the molten steel to rotate. The invention has simple equipment, and has the obvious functions of improving the surface quality, the subsurface quality and the solidifying tissue of a casting blank and the isometric crystal ratio, and lightening the internal defects, such as the center segregation, the center looseness, and the like.

Owner:NORTHEASTERN UNIV

Method for manufacturing super-thick super-huge single steel ingot

ActiveCN102029378AReduce central porosityReduced tendency to center segregationSteel platesChemical composition

The invention discloses a method for manufacturing a super-thick super-huge single steel ingot. In the invention, two original blanks are placed on a chassis in parallel, the upper parts of the two original blanks are respectively provided with a dead head, two side baffles are respectively arranged at two sides of the original blanks and the dead heads to form a solidification area to be melted; a consumable electrode is inserted in the solidification area to be melted, steel on the consumable electrode is slowly melted in the solidification area to be melted by using the traditional electroslag remelting technology, the steel is solidified at the same time of being melted till the solidification area to be melted is completely filled with the steel melted from the consumable electrode, and the two original blanks are welded together. Compared with electroslag remelting, the method has low production cost and high production efficiency; the internal quality of the super-thick super-huge single steel ingot manufactured with the method disclosed in the invention is higher than that of a super-huge single steel ingot manufactured with a die casting technology and continuous casting, and especially, the trends of center dispersion and center segregation can be reduced greatly. The method can be used for producing the super-thick super-huge single steel ingots, and the super-thick super-huge single steel ingots which are of a structure having different chemical components along thickness direction and can be used for manufacturing composite steel plates.

Owner:BAOSHAN IRON & STEEL CO LTD

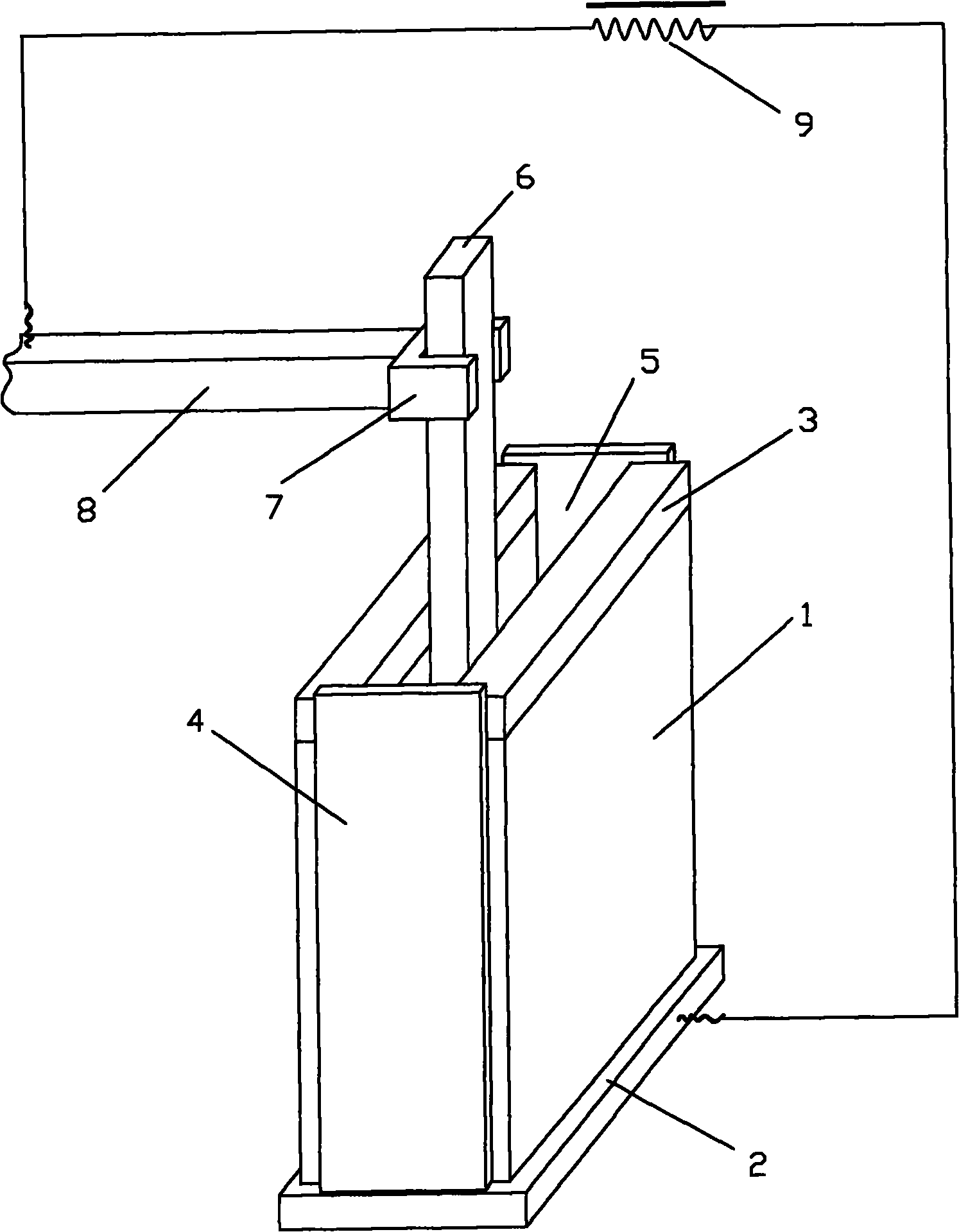

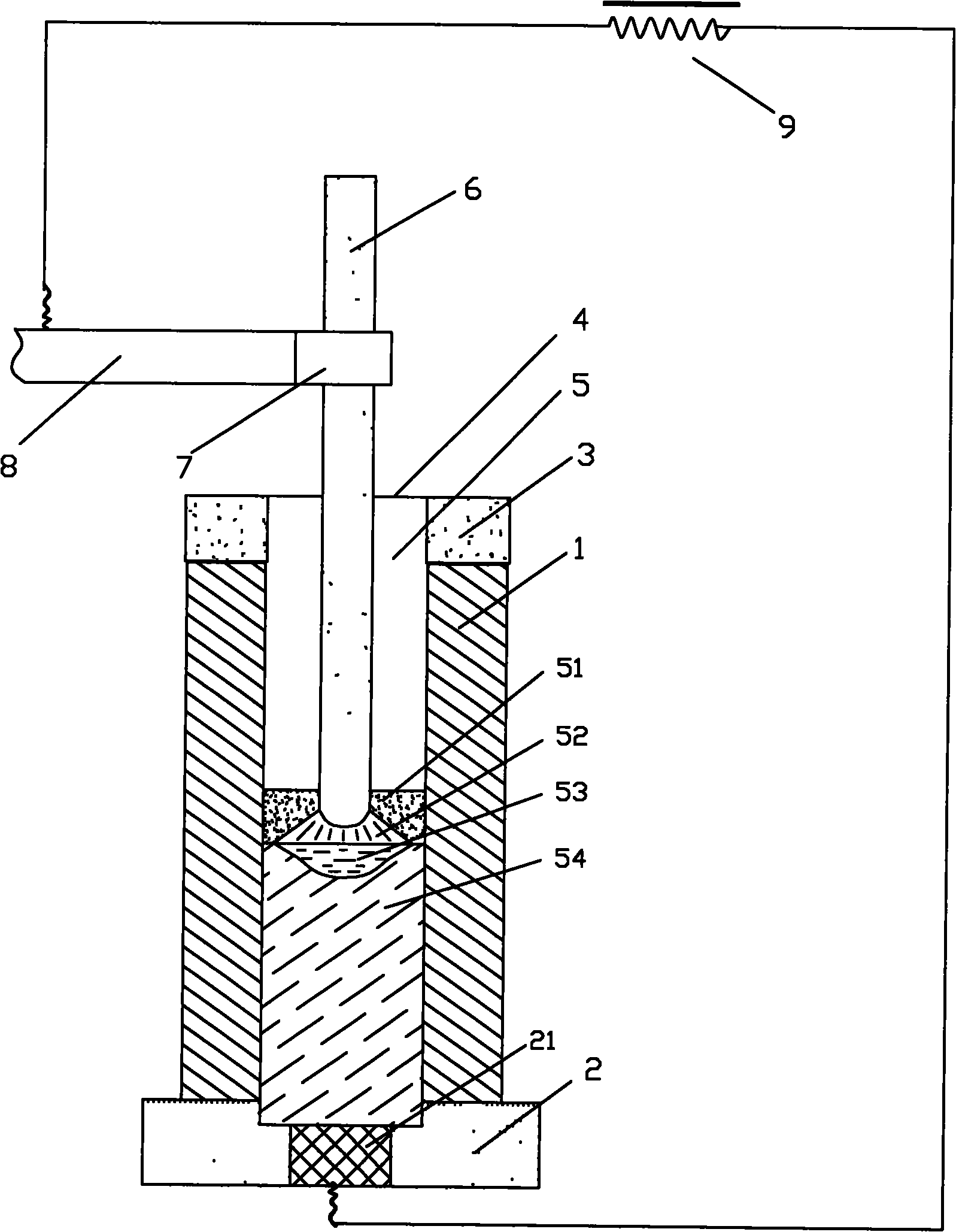

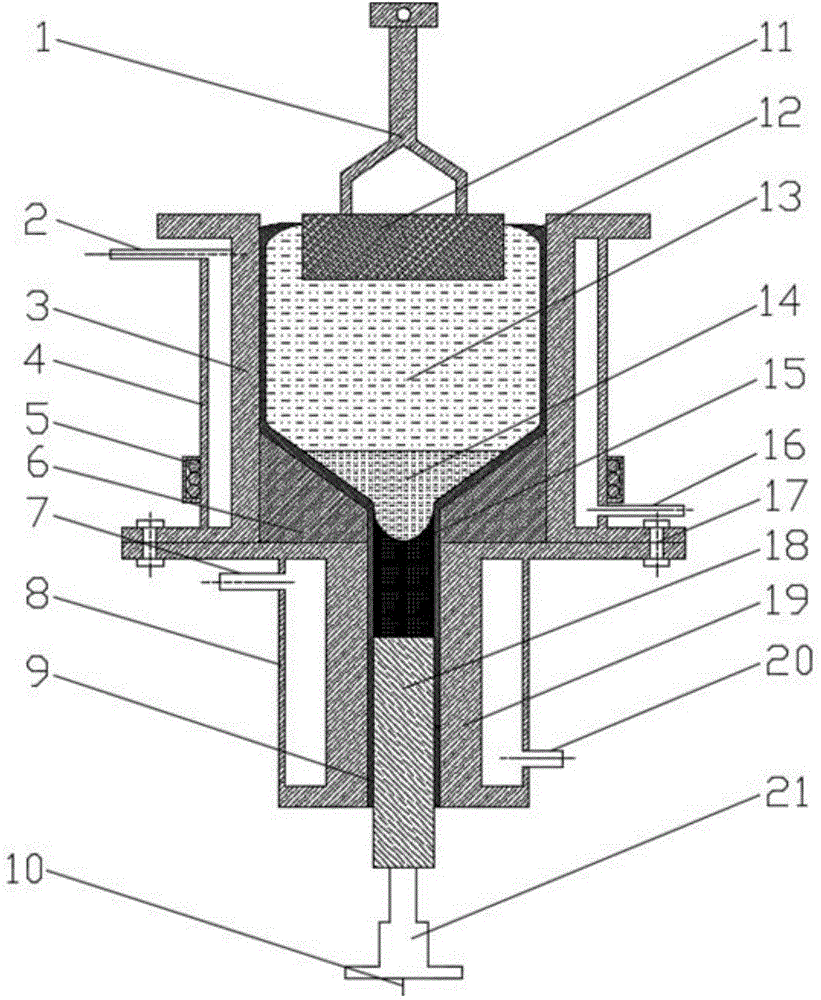

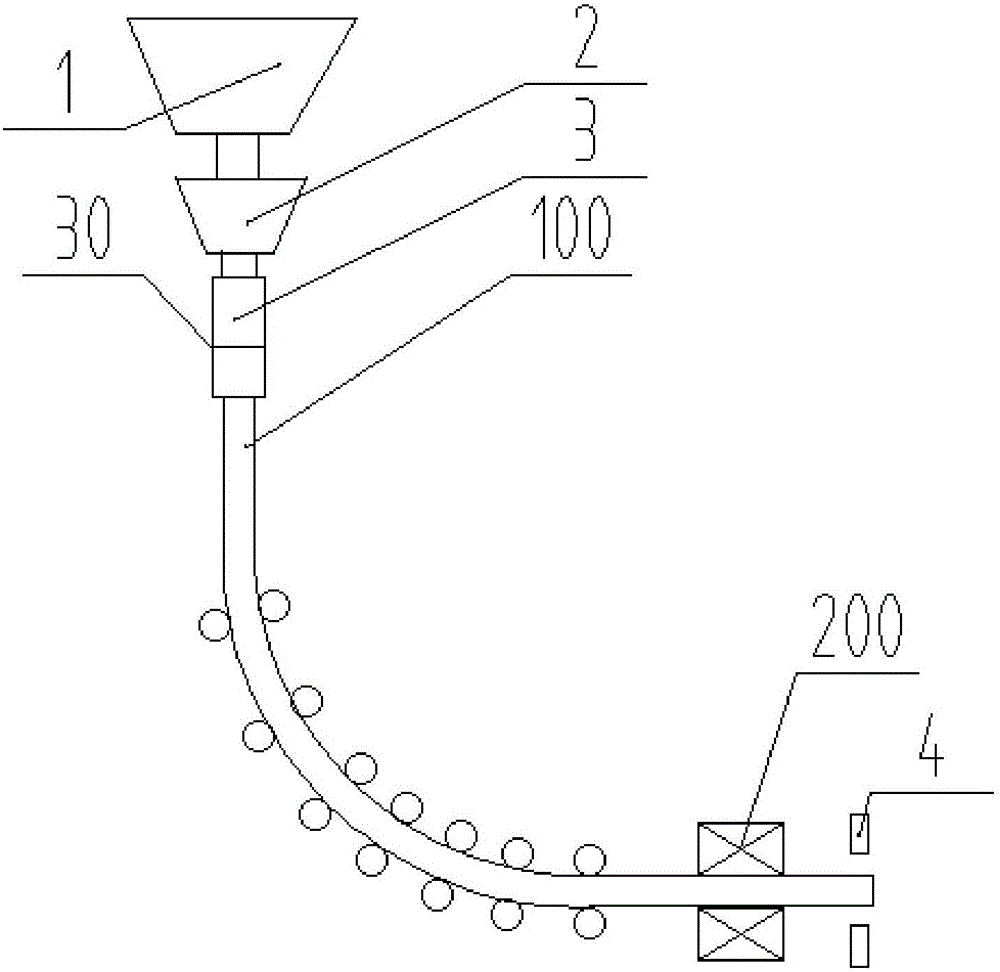

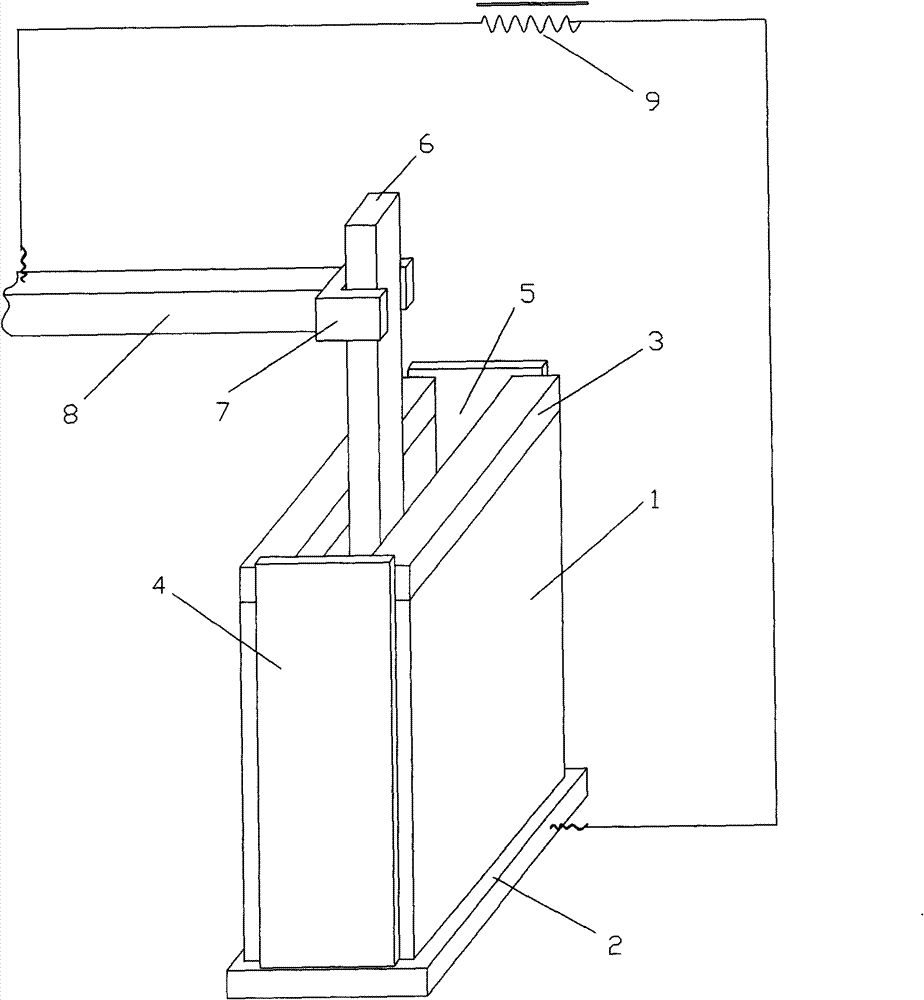

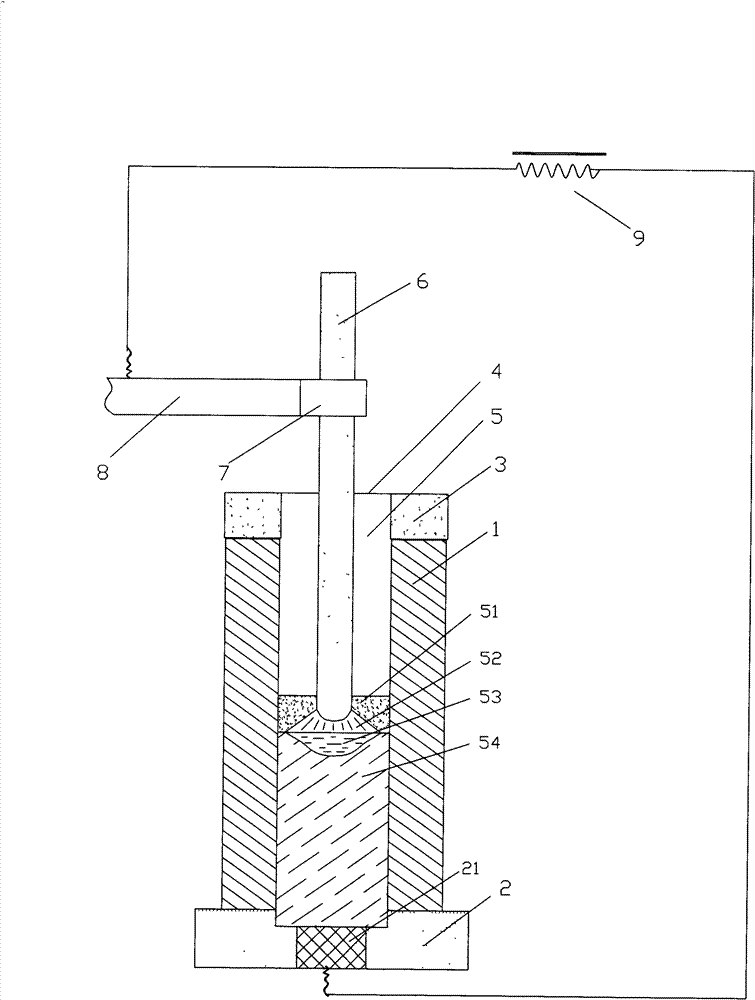

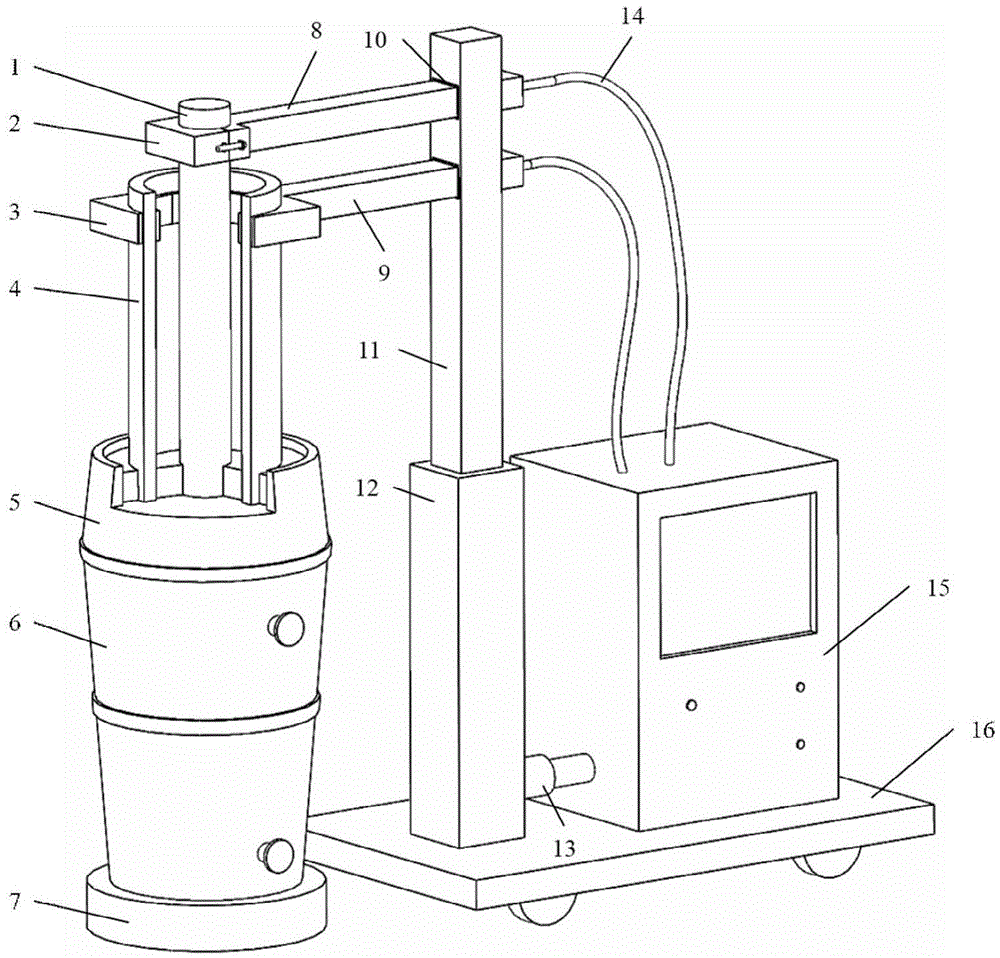

Method and device for preparing rare-earth metal through lower cathode electrolysis and in-situ ingot casting synchronization

The invention relates to a method and a device for preparing rare-earth metal through lower cathode electrolysis and in-situ ingot casting synchronization. The device comprises an electrolysis furnace and an ingot casting furnace which are arranged on a machine frame, wherein a carbon anode is hung at a hearth opening of the electrolysis furnace through an anode conducting rod and is communicated with a positive electrode of a power supply; the anode conducting rod is fixedly arranged on an automatic ascending and descending feeding device arranged on the machine frame; the lower part of a hearth of the electrolysis furnace is provided with a funnel-shaped insulation inner liner; an upper cooling water jacket is arranged outside the furnace wall of the electrolysis furnace; the lower part of the outer side of the upper cooling water jacket is provided with an electromagnetic stirring device; an ingot casting cavity is arranged on the ingot casting furnace; the ingot casting cavity is centered with an outlet of the funnel-shaped insulation inner liner; the lower part of the ingot casting cavity is provided with a sliding ingot guide rod in a matched way; the bottom of the ingot guide rod is connected with an ingot drawing rod and is communicated with the cathode of the power supply through a conducting wire; a lower cooling water jacket is arranged outside the furnace wall of the ingot casting furnace. Constant-voltage or constant-current electrolysis is carried out under the conditions that the temperature is 900 to 1200 DEG C, the voltage is 5 to 30V, and the current is 1000 to 10000A. The rare-earth metal can be continuously and automatically prepared.

Owner:JIANGXI UNIV OF SCI & TECH

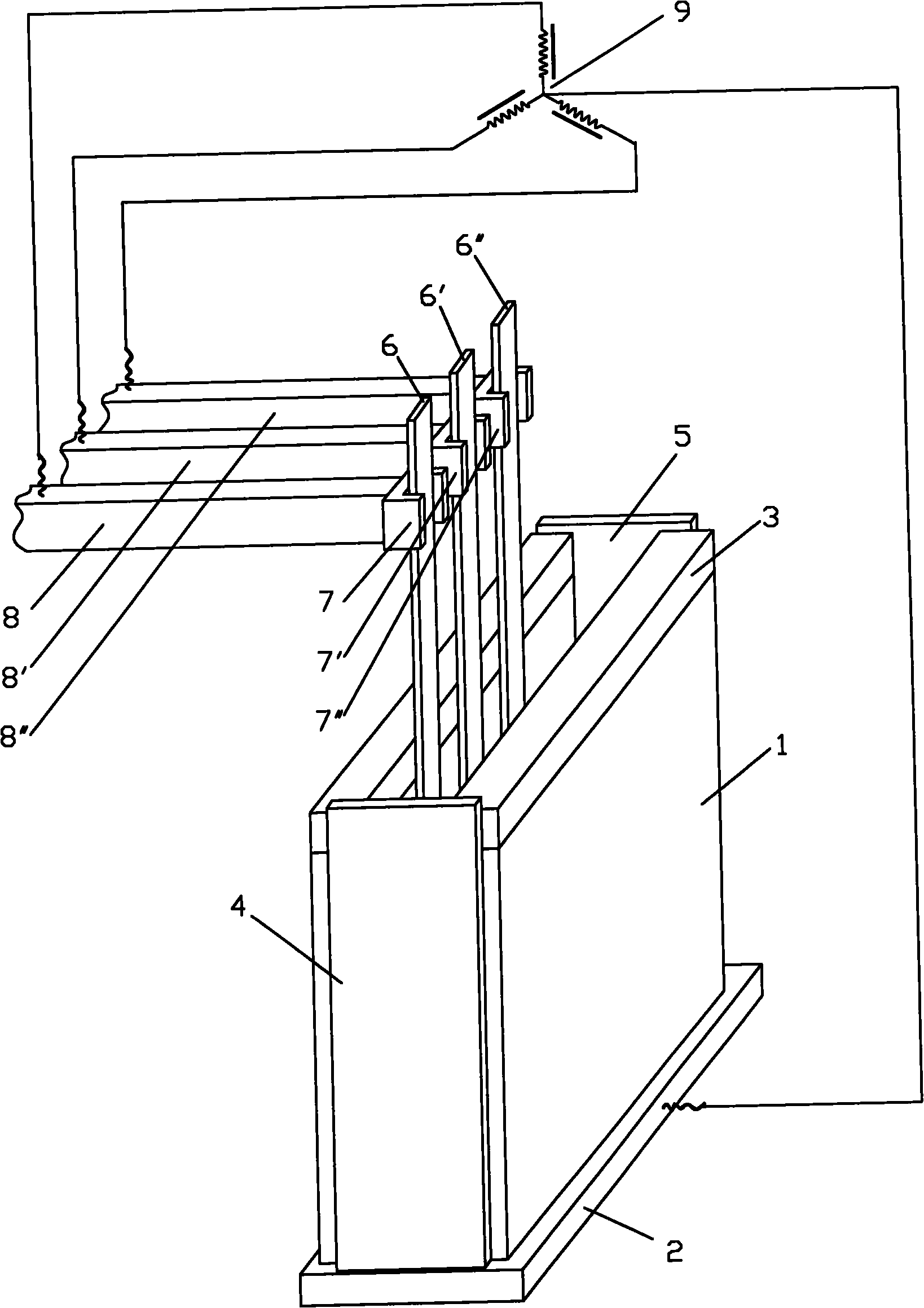

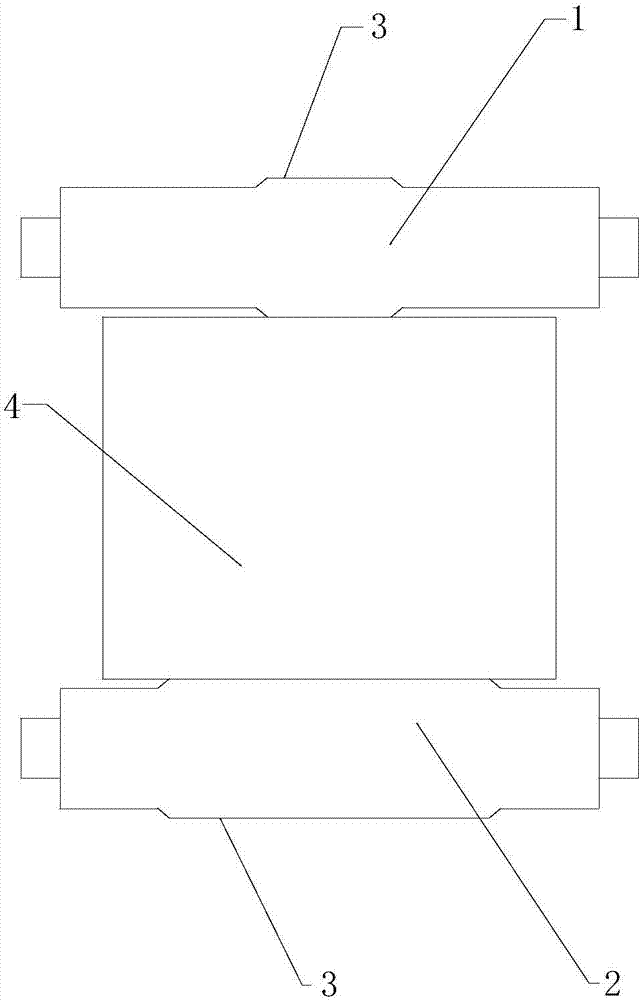

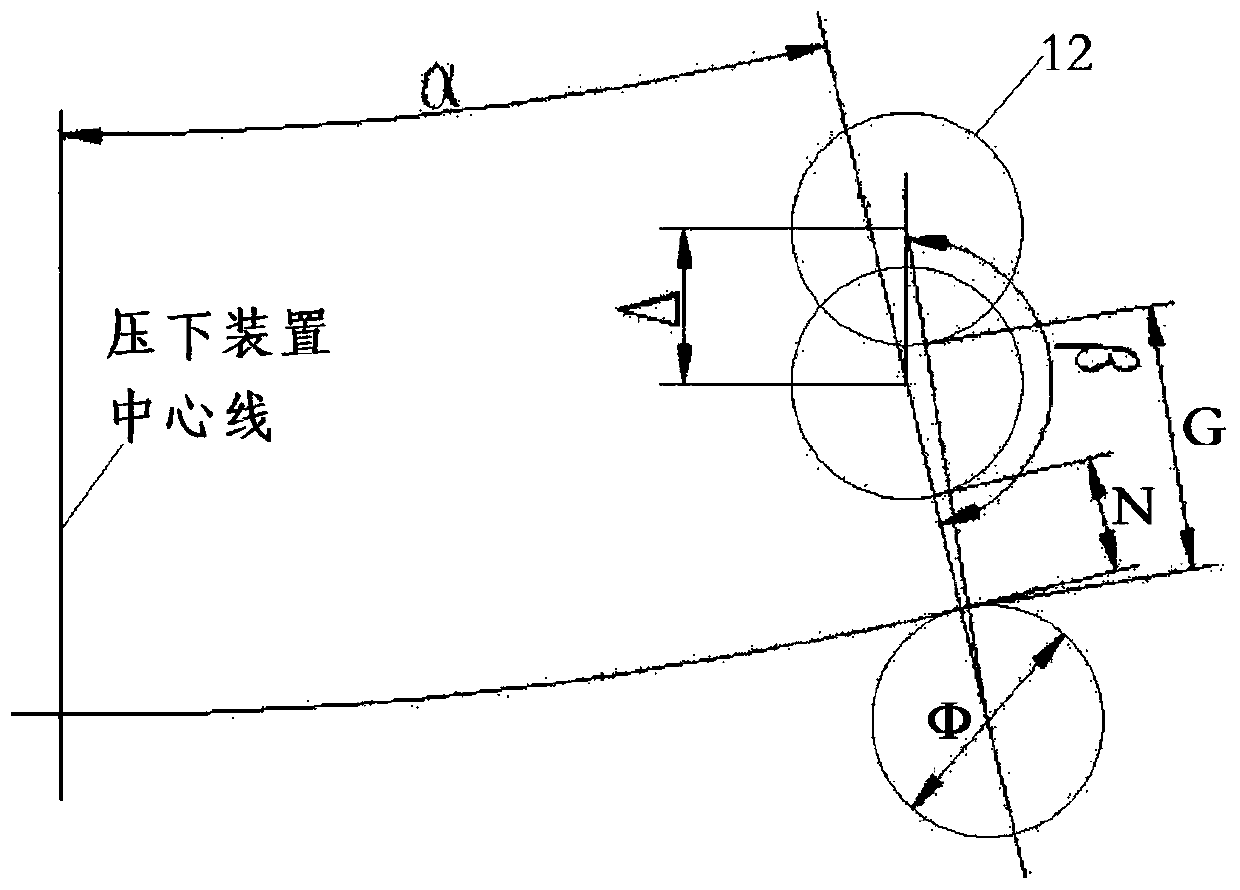

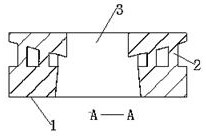

Secondary-cooling reduction convex foot roll structure for bloom and reduction technology

The invention discloses a secondary-cooling reduction convex foot roll structure for bloom and a reduction technology, and particularly relates to a secondary-cooling reduction convex foot roll structure for bloom and a reduction technology in the technical field of iron and steel metallurgy. The secondary-cooling reduction convex foot roll structure for the bloom comprises reduction-area upper foot rolls and reduction-area lower foot rolls, the reduction-area lower foot rolls are located under the reduction-area upper foot rolls, a boss is arranged in the middle of each reduction-area upper foot roll, a boss is arranged in the middle of each reduction-area lower foot roll, and the bosses of the reduction-area lower foot rolls are longer than the bosses of the reduction-area upper foot rolls. According to the secondary-cooling reduction-area reduction technology for the bloom, multiple groups of reduction-area upper foot rolls and reduction-area lower foot rolls are arranged, and the reduction quantity of the reduction-area upper foot rolls is gradually increased in the blank drawing direction. Therefore, the center segregation and center porosity problems of a continuous casting blank of the bloom can be effectively solved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for producing low-alloy and large-size square steel by continuously casting and continuously rolling

ActiveCN101549353AReduce central porosityReduce center cracksRoll force/gap control deviceTemperature control deviceSlow coolingPorosity

The invention provides a method for producing low-alloy and large-size square steel by continuously casting and continuously rolling. The process flow is as follows: molten iron pretreatment, converter smelting, refining, continuously casting, heating, continuously rolling and slow-cooling; the converter tapping temperature is 1640-1670 DEG C; after the LF refining is performed to the molten steel, the refining is performed in a VD or RH refining device for 20-40 minutes, the small flow soft argon blowing is performed to the molten steel during the late period of refining for 5 or more minutes, and the molten steel temperature is controlled between 1540 DEG C and 1570 DEG C after the refining is finished; the superheat degree of the tundish molten steel is controlled within 25 DEG C, the casting speed is 0.5-0.9 m / min, the width and the length of the cross section of the casting billet are respectively 280-320 mm and 380-420 mm; and the charging temperature of the casting billet is 700-800 DEG C, the tapping temperature is 1050-1180 DEG C and the total time of heating is 3 hours or more; the initial rolling temperature is 1050-1160 DEG C, the finishing temperature is 850 DEG C or higher, and the length and the width of the square steel are both 130-160 mm; and the stacking for slow-cooling is performed by using the waste heat of the square steel. The invention reduces the central porosity and the central cracks inside the steel casting billet and eases the influence of the residual stress in the steel billet to the internal structure of the square steel in the temperature reduction process, thereby reducing the central cracks in the process of continuously rolling the square steel and improving the qualification rate of flaw detection.

Owner:ANGANG STEEL CO LTD

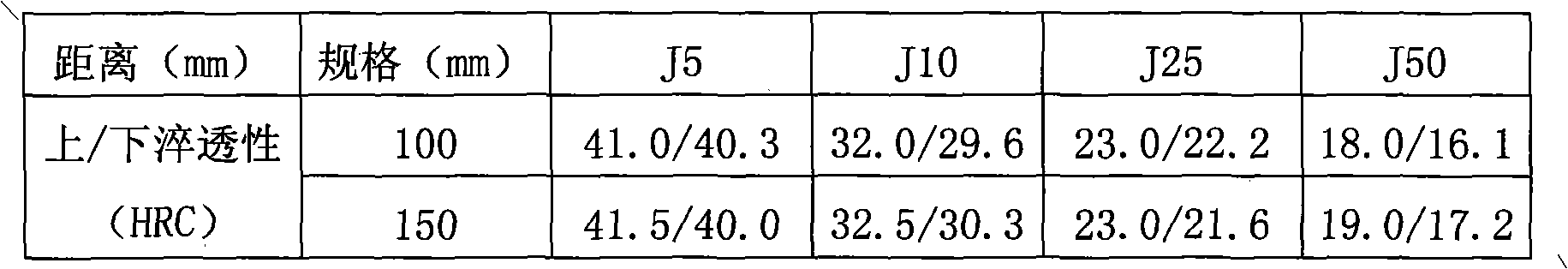

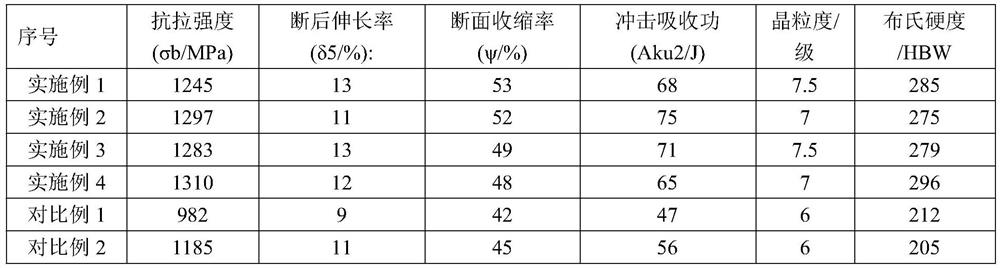

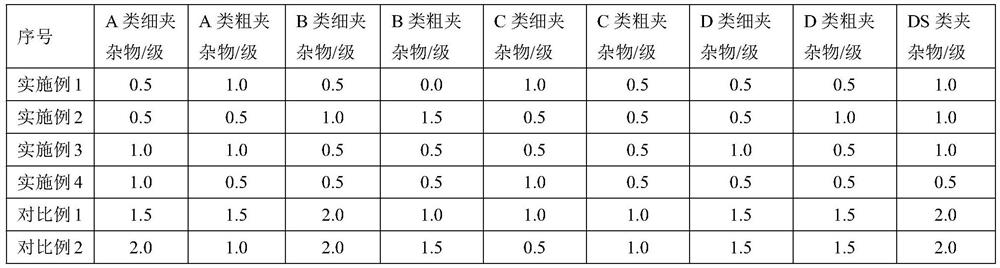

High-quality alloy steel bar and production process thereof

ActiveCN101948986AImprove low-magnification qualityImprove hardenabilityUltimate tensile strengthImpurity

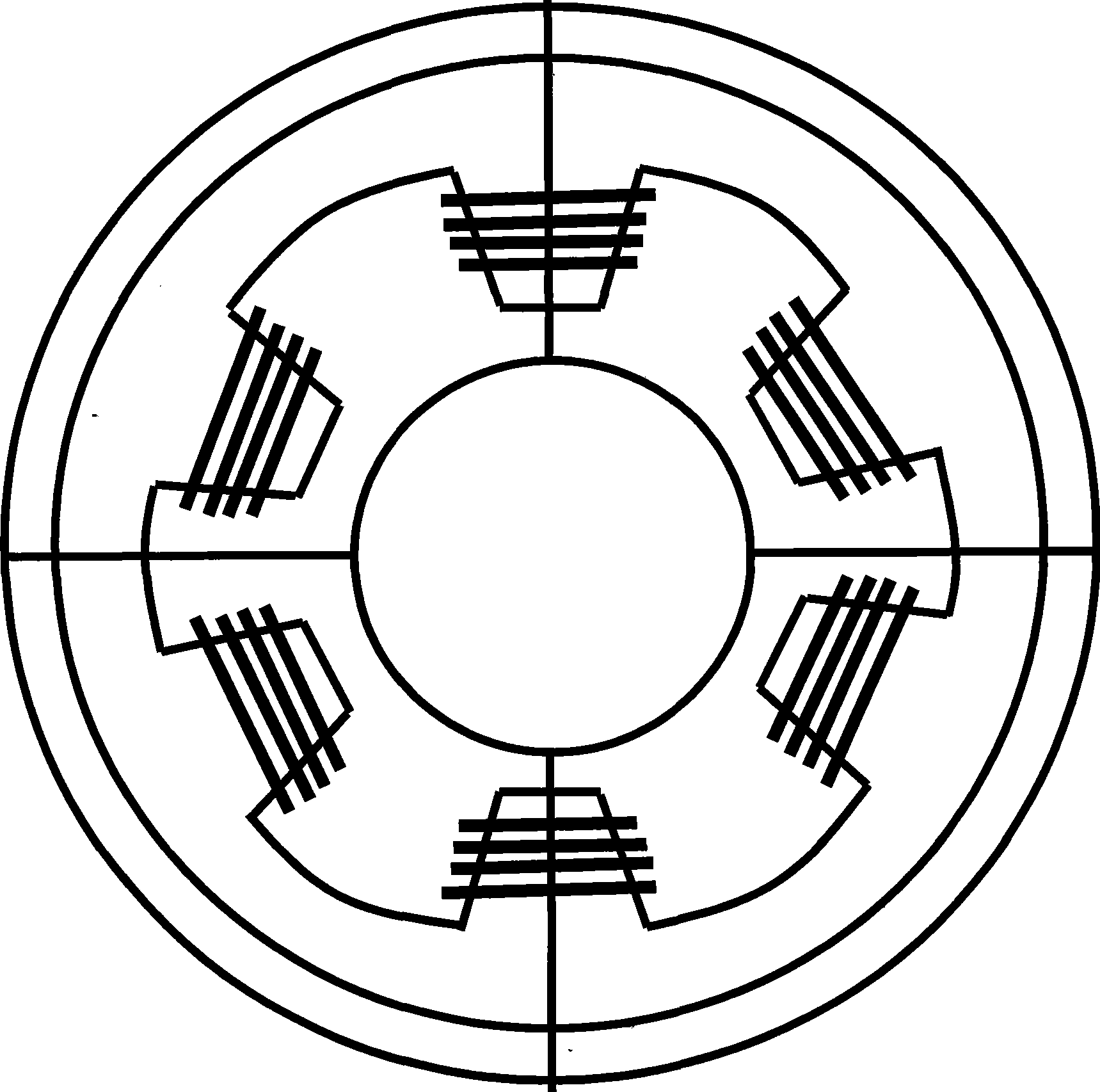

The invention belongs to the field of alloys, in particular to a high-quality alloy steel bar and a production process thereof. The high-quality alloy steel bar comprises the following components in percentage by weight: 0.10 to 0.50 percent of C, 0.10 to 1.50 percent of Cr, 0.50 to 1.50 percent of Mn, 0.010 to 0.015 percent of Ti, less than or equal to 0.40 percent of Si, less than or equal to 0.035 percent of P, less than or equal to 0.035 percent of S, 0.020 to 0.050 percent of Al, less than or equal to 0.020 percent of N, less than or equal to 0.03 percent of Mo, 0.05 to 0.50 percent of V, less than 0.030 percent of Ni, less than or equal to 0.090 percent of Cu, less than or equal to 0.0018 percent of B, less than or equal to 0.0014 percent of O and the balance of Fe and inevitable impurities. In the process, a crystallizer electromagnetic stirring mode is adopted, the current intensity of crystallizer electromagnetic stirring equipment is 0 to 550A, the frequency of the crystallizer electromagnetic stirring equipment is 2 to 4Hz, the solidified end section is slightly rolled and the rolling reduction is 3 to 9 millimeters. In the invention, the internal quality of casting blanks can be improved obviously, and the central looseness and composition segregation of the cast blanks can be reduced.

Owner:NANJING IRON & STEEL CO LTD

C110 steel graded petroleum casing pipe containing rare earth and production method thereof

The invention discloses a C110 steel graded petroleum casing pipe containing rare earth. The petroleum casing pipe is prepared from the following components in percentage by weight: 0.27 to 0.30 percent of C, 0.15 to 0.30 percent of Si, 0.35 to 0.50 percent of Mn, 1.35 to 1.45 percent of Cr, 0.60 to 0.70 percent of Mo, 0.02 to 0.04 percent of V, 0.10 to 0.20 percent of Ni, 0.02 to 0.05 percent ofAl, 0.02 percent of Re, less than or equal to 0.020 percent of P and less than or equal to 0.005 percent of S. The invention further discloses a production method of the petroleum casing pipe. According to the petroleum casing pipe and the production method thereof, inner tissues of the petroleum casing pipe are uniform and chemical components are not segregated; the SSC resistance of the petroleum casing pipe is improved; the obtained petroleum casing pipe has good quality, the service life is prolonged, the transportation safety of a pipeline is increased and requirements on social development are easy to met.

Owner:BAOTOU IRON & STEEL GRP

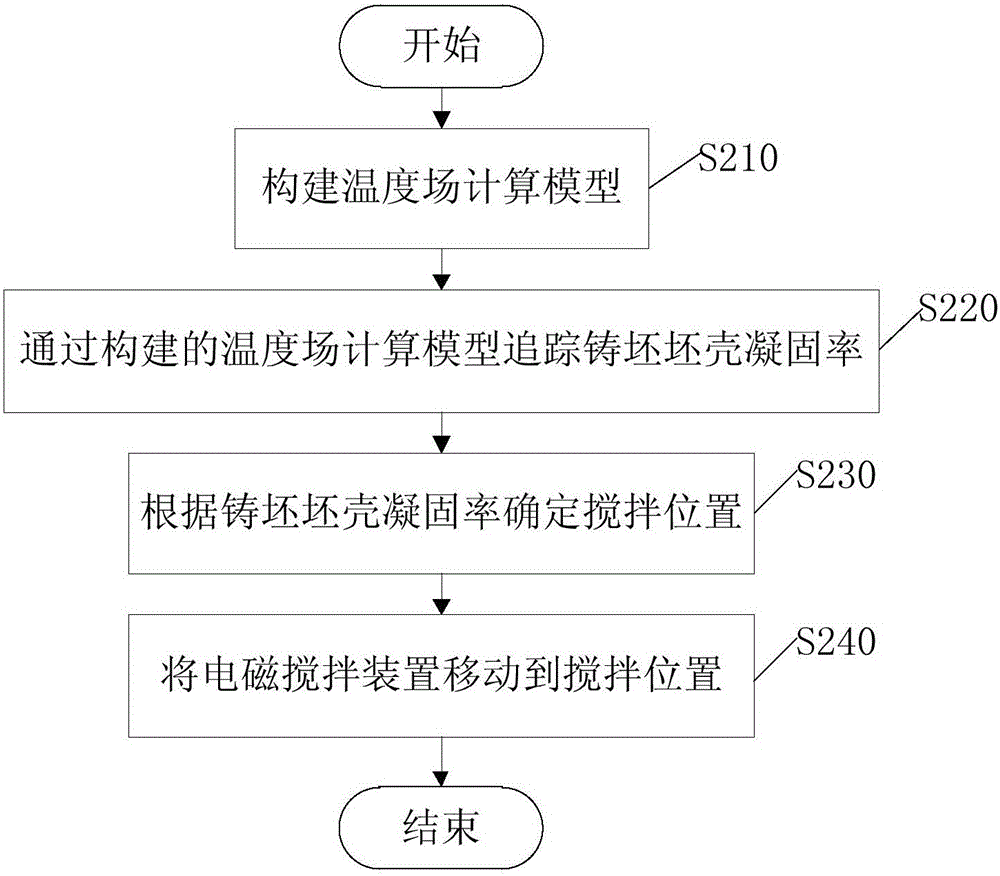

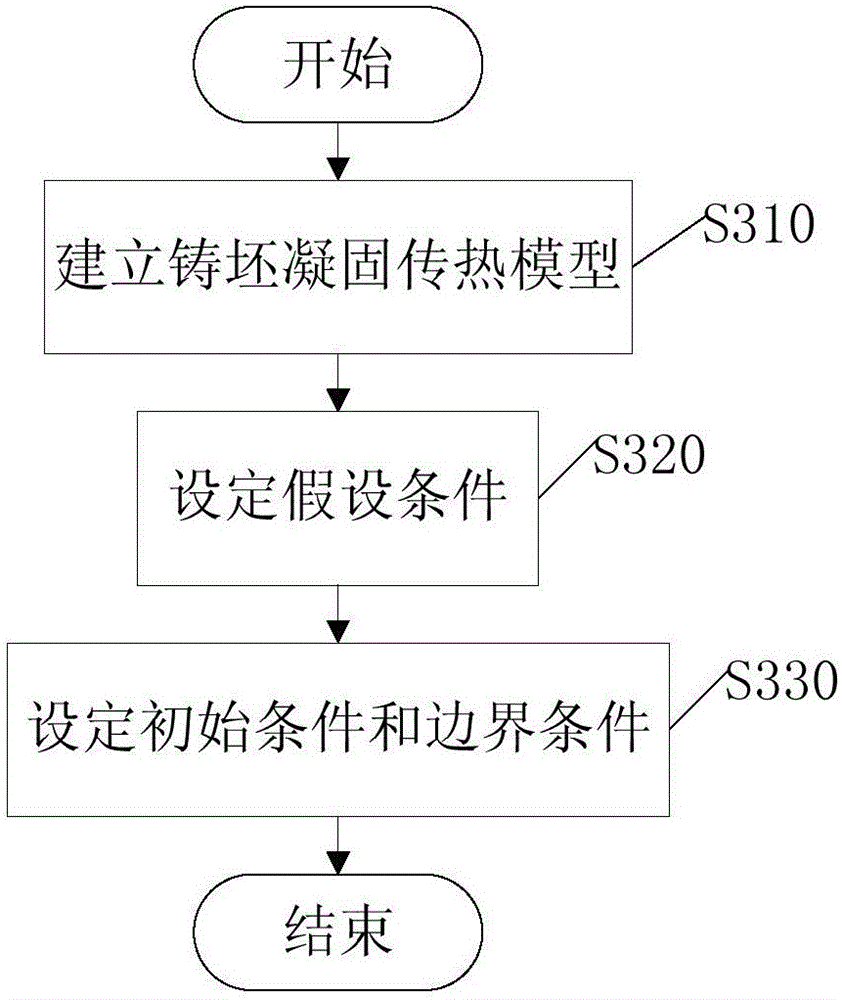

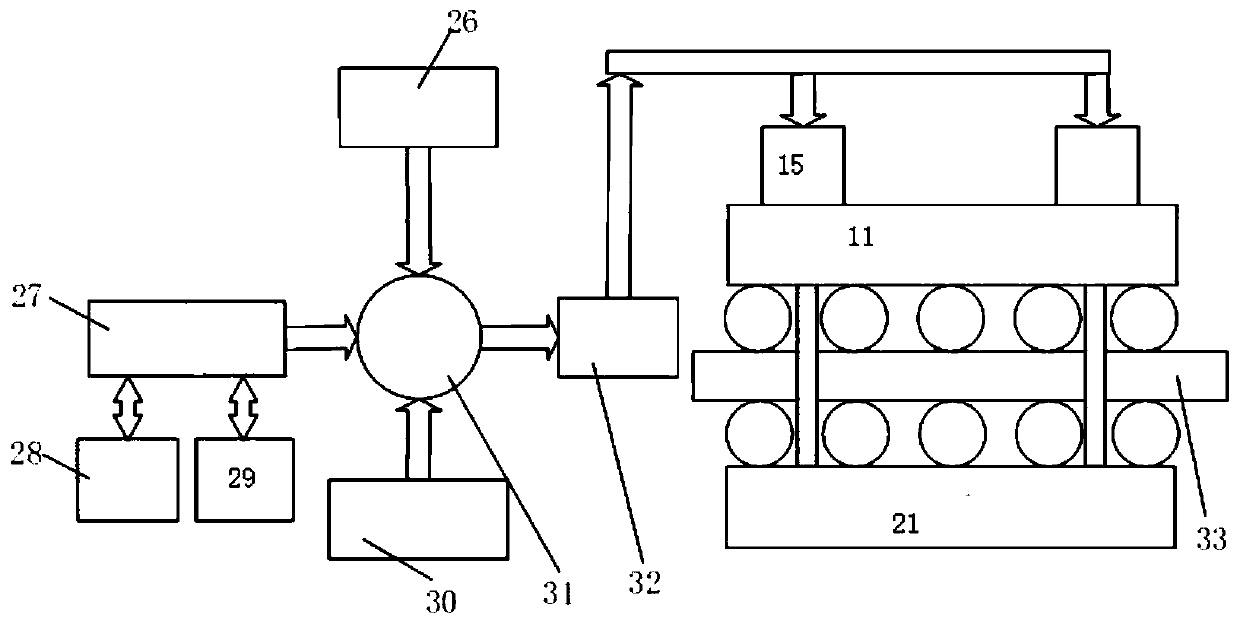

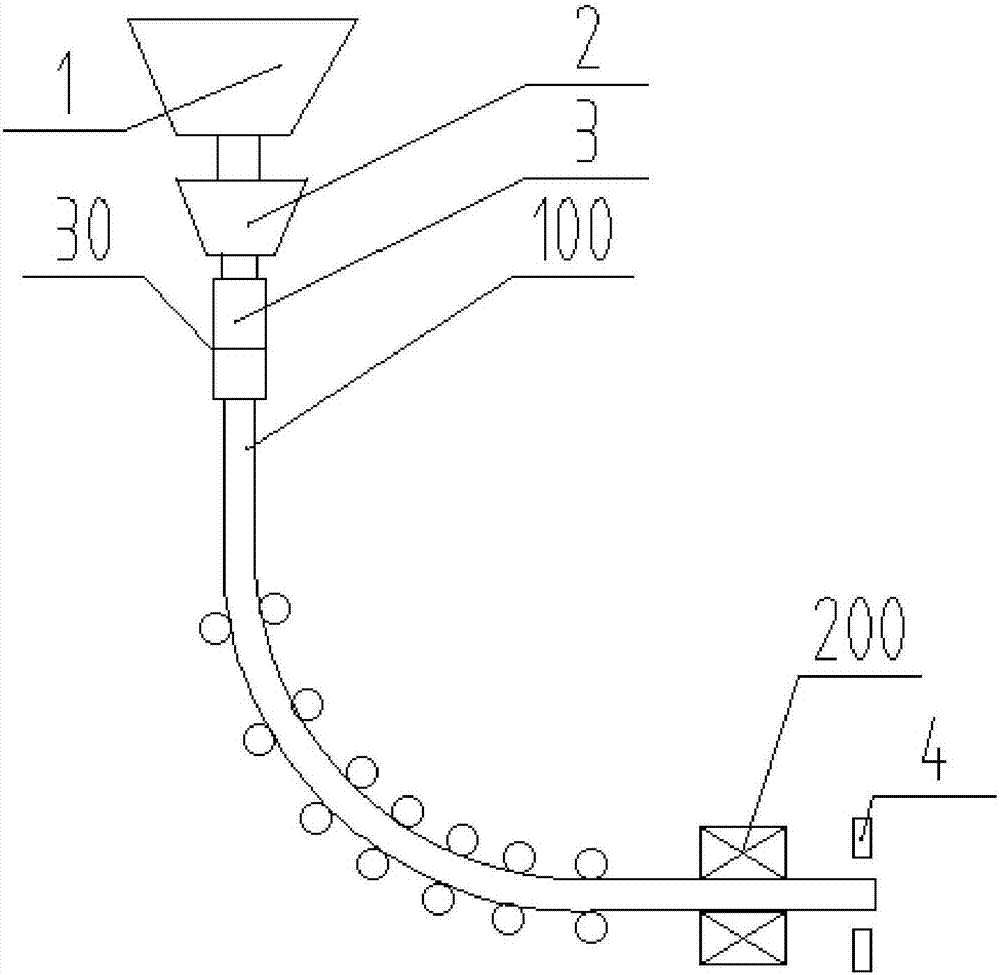

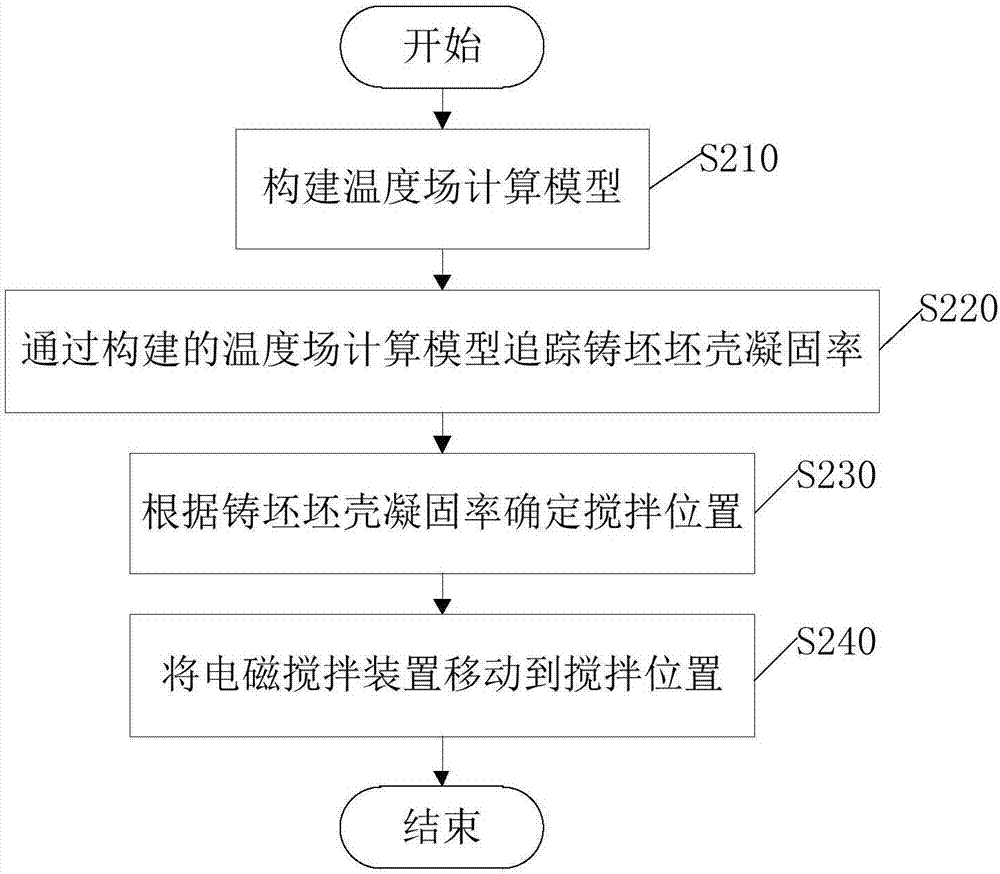

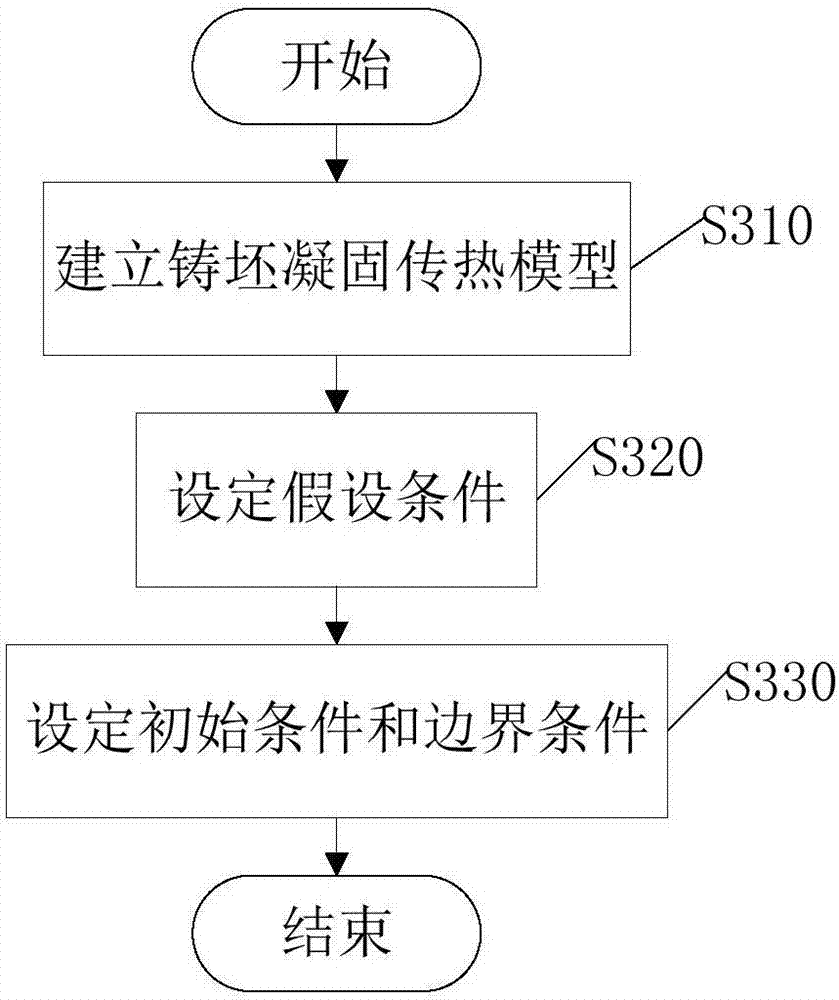

Electromagnetic stirring control method and system for continuous casting

ActiveCN105127390AReduce central porosityReduce center segregationElectromagnetic stirringElectromagnetic field

The invention provides an electromagnetic stirring control method and system for continuous casting. The method comprises the steps that a temperature field calculation model is built; the casting blank shell solidification rate is tracked through the temperature field calculation model; a stirring position is determined according to the casting blank shell solidification rate, wherein the position where the casting blank shell solidification rate is 45%-70% is determined as the stirring position; an electromagnetic stirring device is moved to the stirring position to apply an electromagnetic field to a casting blank. The system comprises an inputting unit, a model building unit, a tracing unit, a determining unit and a moving device; the inputting unit is used for inputting a technological parameter of continuous casting production, the model building unit is used for building the temperature field calculation model, the tracing unit is used for tracing the casting blank shell solidification rate according to the input technological parameter and the temperature field calculation model, the determining unit is used for determining the position where the casting blank shell solidification rate is 45%-70% as the stirring position, and the moving device is used for moving the electromagnetic stirring device to the stirring position. According to the electromagnetic stirring control method and system for continuous casting, a temperature field, the stirring device and the moving device are combined, electromagnetic stirring on the casting block at the best stirring position is achieved, and the internal quality of the casting blank is improved.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

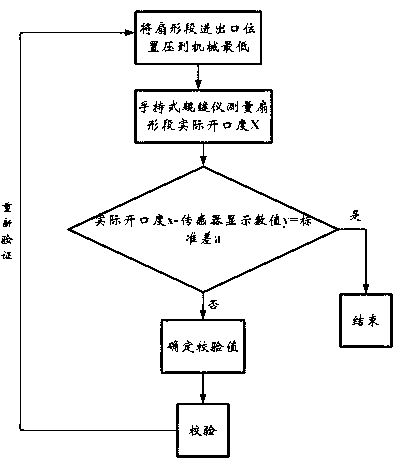

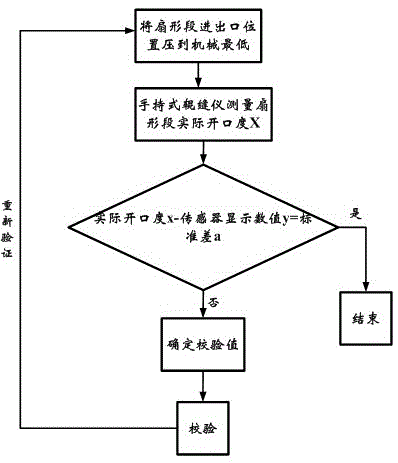

On-line calibration method for opening of wide and thick plate continuous casting machine soft-reduction segment

The invention belongs to the field of wide and thick plate continuous casting machine soft-reduction process in steel production, and particularly relates to an on-line calibration method for the opening of a wide and thick plate continuous casting machine soft-reduction segment. The on-line calibration method is mainly characterized by including the steps: pressing both an inlet and an outlet of the segment to the mechanical lowest position; measuring the actual opening of the segment; comparing the opening; determining a calibration value; calibrating the opening in an on-line manner; and calibrating the opening again. The on-line calibration method has the advantages that by the aid of the on-line calibration method for the opening of the segment, the opening of the segment can be accurately calibrated, a preset soft-reduction scheme can be accurately implemented to obviously improve the low power quality of a casting blank, the rate of blank samples with deviation within 0.5mm from a set roll gap can reach 100%, the rate of blank samples without deviation from the set roll gap can reach 87.60%, center line shrinkage and middle cracks are eliminated, and center segregation and center porosity are decreased.

Owner:JIGANG GRP

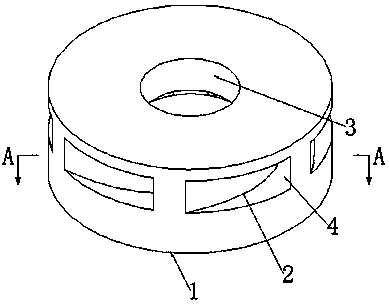

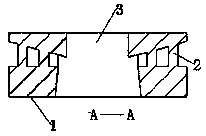

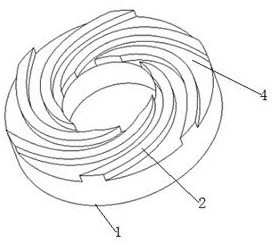

Straight-through submerged nozzle with stirring effect

ActiveCN102764867APromote homogenizationPromotes diffuse distributionMelt-holding vesselsMolten steelMechanical property

The invention belongs to the technical field of continuous casting of the iron and steel industry, and particularly relates to a submerged nozzle device with a stirring effect for square billet and round billet continuous casting molds. The submerged nozzle device comprises a vertically through tubular body, an inner cavity is defined by the body, a slag line is sleeved outside the side wall of the body, and connected spiral grooves are arranged on the inner surface of the side wall of the body. Cleanliness and the mechanical property of molten steel are improved, and the submerged nozzle device has the advantages of simple structure, remarkable effect, low cost and suitability for popularization.

Owner:江苏华滋能源工程有限公司

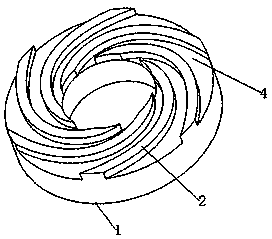

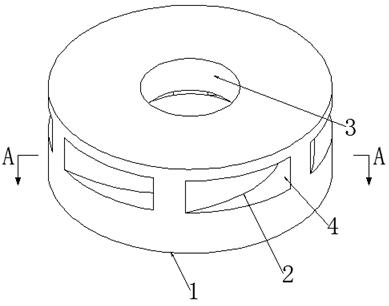

Swirl generator with submersed nozzle, tundish and application

The invention discloses a swirl generator with a submersed nozzle, a tundish and application. The swirl generator with the submersed nozzle comprises a swirl generator body and a step hole formed in the center of the top end of the swirl generator body, wherein a plurality of blades are arranged on the top of the swirl generator body; the curvature of one end of each blade is consistent to the curvature of the excircle of the swirl generator body; the curvature of the end, which is away from the excircle of the swirl generator body, of each blade is consistent with the curvature of the hole wall of the step hole; and a swirl cavity is formed between every two blades. The swirl generator with the submersed nozzle has the beneficial effects that the swirl generator is simple in structure andreasonable in design, homogeneity of distribution of inner flow fields of the submersed nozzle is improved, thus, stability of flowing of liquid steel in a crystallizer is improved remarkably, and the quality of a steel product is improved favorably.

Owner:CHONGQING UNIV

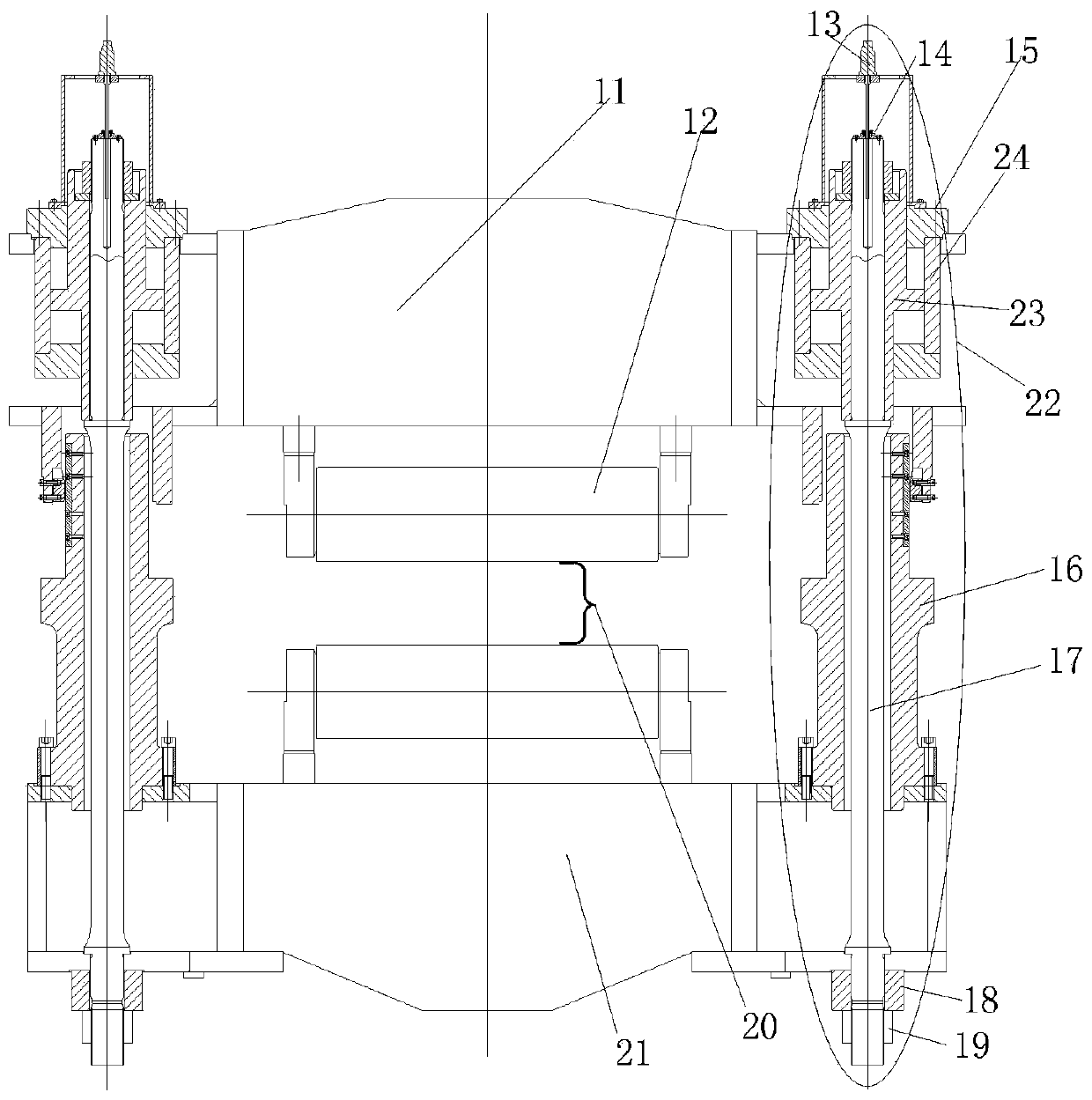

Gap-free large screwdown device for roller gap and using method thereof

PendingCN110181013AEliminate segregationReduce central porosityGeometric CADSpecial data processing applicationsHydraulic cylinderMechanical engineering

The invention discloses a gap-free large screwdown device for a roller gap and a using method thereof. The device comprises a lower frame assembly frame, wherein a plurality of sets of flexible rod frames are connected to the lower frame assembly frame, and each set of flexible rod frames comprises two flexible rods which are positioned on two parallel sides of a lower frame; the upper end of eachflexible rod is connected with a hollow hydraulic cylinder, and the bottom of a piston of each hollow hydraulic cylinder is connected with the corresponding flexible rod; an upper frame assembly frame is detachably connected between the hollow hydraulic cylinders, and a displacement sensing device is further connected to the top of each hollow hydraulic cylinder; a guide roller is connected abovethe lower frame assembly frame; and another guide roller is connected below the upper frame assembly frame. By using the novel flexible rods as support, the influence of the gap between the devices on the detected roller gap is avoided, the roller gap can be remotely and accurately controlled, and the product quality is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

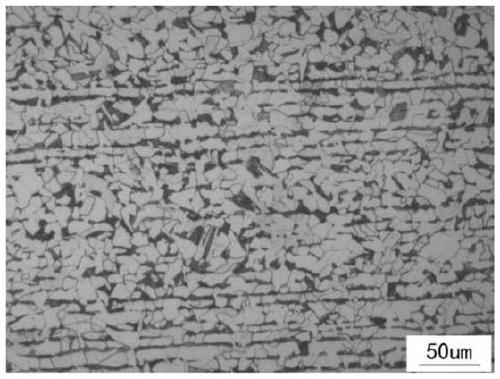

Method for Improving Center Density of Steel Continuous Casting Slabs Used in High-Rise Buildings

The invention discloses a method for improving the center density of steel continuous casting billets for high-rise buildings. During the continuous casting process, the casting machine casting speed is controlled to be 0.75m / min ~ 0.90m / min; the solidification end is pressed under heavy pressure; Dynamic secondary cooling control is adopted, while light pressing and heavy pressing are used to press according to the distributed solid phase ratio; the superheat of the molten steel in the tundish is controlled to 20°C to 30°C. This method mainly uses technical measures such as stabilizing the casting machine speed, reducing the superheat of the tundish, dynamic control of secondary cooling, and control under heavy pressure at the solidification end to reduce the center porosity of the high-construction steel cast slab, thereby improving the center density of the cast slab. Improve the internal quality of rolled products. The cast slab produced by this method is better than the existing light reduction technology after implementation. The center density is higher and the overall quality is good, which can well meet the usage requirements of high-grade construction steel.

Owner:TANGSHAN IRON & STEEL GROUP +2

Steel continuous casting method

The invention provides a steel continuous casting method. By means of the method, segregation-free center-porosity-free casting blanks with high internal quality can be efficiently obtained by striking the casting blanks under proper conditions so as to make the casting blanks vibrate. According to the steel continuous casting method, at least one pair of striking and vibrating devices is arranged on the two sides of the short edge faces of a casting blank containing unset parts when the casting blank with a rectangular cross section is cast through the manufacturing method; while the casting blank is cast, vibration is applied to the casting blank by continuously striking the short edge faces of the casting blank; and by striking the short edge faces, a displacement delta (x) curve of the long edge faces of the casting blank in the thickness direction of the casting blank and intersection points of lines when the displacement delta (x) is equal to 0.10 mm, which are defined in the formula (1) and the formula (2) below, are generated, and the short edge faces are struck by adjusting the vibration energy, the distance between shafts of guide rollers and the unset thickness, so that the distance between the intersection point, away from the original point, of the intersection points and the struck positions of the short edge faces of the casting blank in the width direction of the casting blank is 200 mm or above.

Owner:QINGDAO TAIWEI MACHINE TOOL

Method for producing low-alloy and large-size square steel by continuously casting and continuously rolling

ActiveCN101549353BReduce central porosityReduce crackingRoll force/gap control deviceTemperature control devicePorosityAlloy

The invention provides a method for producing low-alloy and large-size square steel by continuously casting and continuously rolling. The process flow is as follows: molten iron pretreatment, converter smelting, refining, continuously casting, heating, continuously rolling and slow-cooling; the converter tapping temperature is 1640-1670 DEG C; after the LF refining is performed to the molten steel, the refining is performed in a VD or RH refining device for 20-40 minutes, the small flow soft argon blowing is performed to the molten steel during the late period of refining for 5 or more minutes, and the molten steel temperature is controlled between 1540 DEG C and 1570 DEG C after the refining is finished; the superheat degree of the tundish molten steel is controlled within 25 DEG C, the casting speed is 0.5-0.9 m / min, the width and the length of the cross section of the casting billet are respectively 280-320 mm and 380-420 mm; and the charging temperature of the casting billet is 700-800 DEG C, the tapping temperature is 1050-1180 DEG C and the total time of heating is 3 hours or more; the initial rolling temperature is 1050-1160 DEG C, the finishing temperature is 850 DEG C or higher, and the length and the width of the square steel are both 130-160 mm; and the stacking for slow-cooling is performed by using the waste heat of the square steel. The invention reduces the central porosity and the central cracks inside the steel casting billet and eases the influence of the residual stress in the steel billet to the internal structure of the square steel in the temperature reduction process, thereby reducing the central cracks in the process of continuously rolling the square steel and improving the qualification rate of flaw detection.

Owner:ANGANG STEEL CO LTD

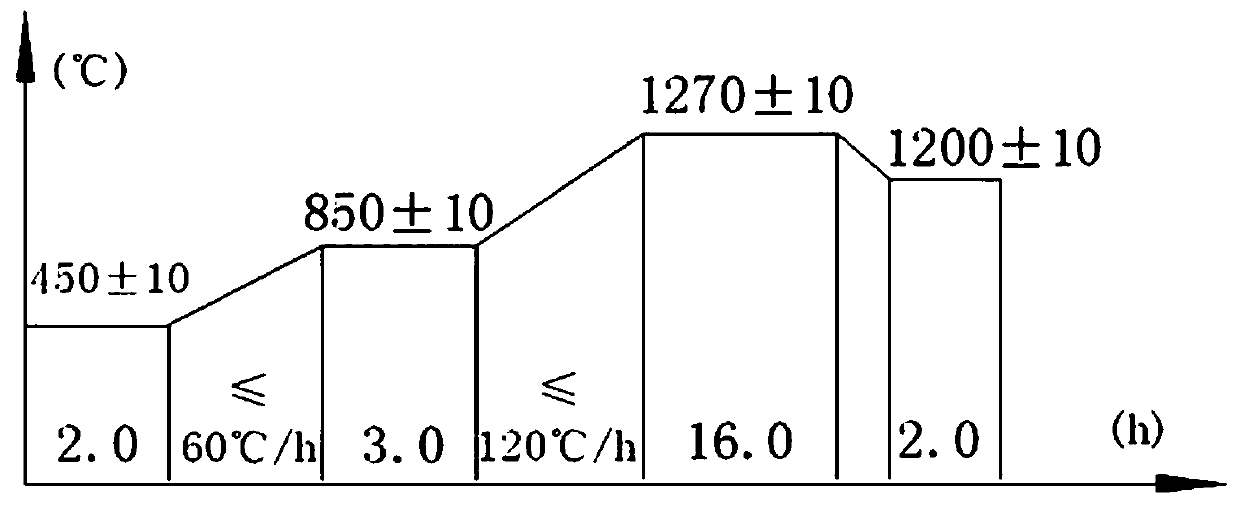

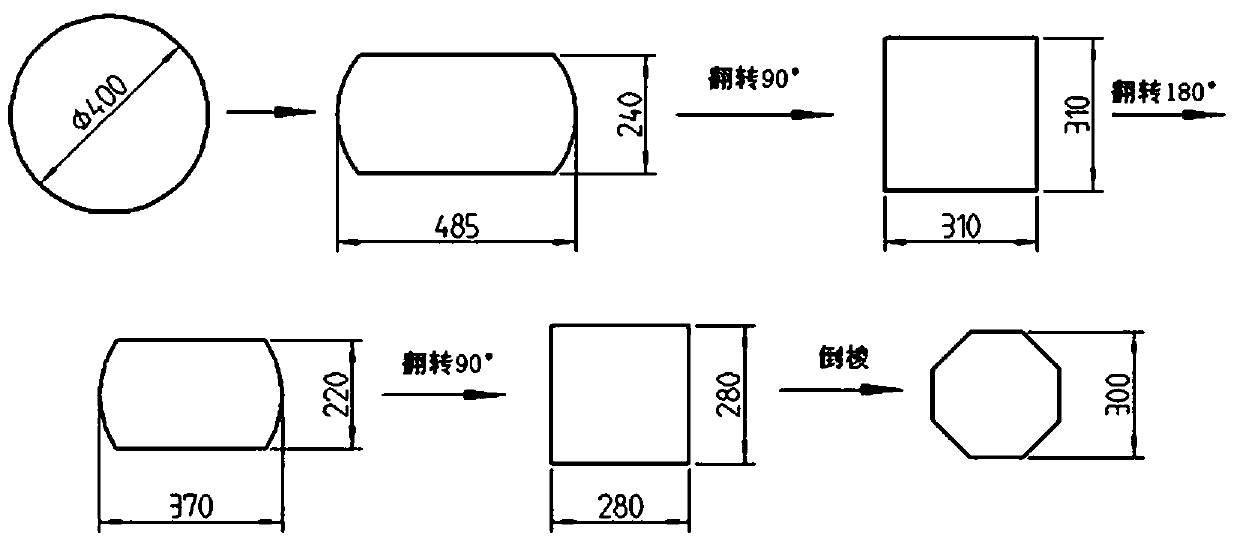

Forging method of H13 steel vertical continuous casting round billet

ActiveCN111250641AReduce central porosityEliminate carbide liquidationForging/hammering/pressing machinesRadial forgingContinuous casting

The invention relates to a forging method of an H13 steel vertical continuous casting round billet. The method comprises the following steps: the continuous casting billet is subjected to heat preservation in a furnace of 450+ / -10 DEG C, the temperature is raised to 850+ / -10 DEG C at the speed of less than or equal to 60 DEG C / h and raised to 1270+ / -10 DEG C at the speed of less than or equal to 120 DEG C / h, the continuous casting billet is air-cooled for 20+ / -5 min, put into a furnace of 1200+ / -10 DEG C furnace for insulation and pulled up on an oil press for four passes, the first-pass reduction rate is 35-45%, then the continuous casting billet is turned over by 90 degrees for second pass, the reduction rate of the second pass is 30-40%, the continuous casting billet is turned over by 180 degrees for third pass, the reduction rate of the third pass is 25-35%, the continuous casting billet is turned over by 90 degrees for fourth pass, the reduction rate of the fourth pass is 20-30%,the blank is chamfered after the fourth pass is finished, put into a furnace of 1000-1150 DEG C for heat preservation, discharged from the furnace and sent to a radial forging machine for reciprocating forging, the last pass is a finishing pass, the drawing and beating speed is 1.3-1.5 m / min, the other passes are the main deformation passes, the reduction rate is 15-30%, and the drawing and beating speed is greater than or equal to 6 m / min. The yield of the continuous casting round billet is improved, the cost is reduced, and the problems of flaw detection and center loosening are solved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

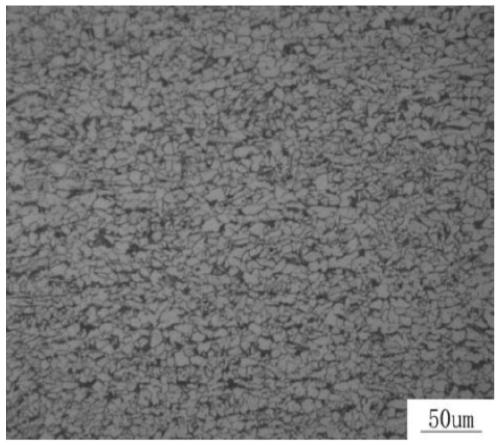

A production method for reducing dendrite segregation of hot-rolled coil q345b

The invention discloses a production method capable of reducing dendritic segregation of a hot rolled coiled plate Q345B. The production method is characterized in that the hot rolled coiled plate Q345B comprises the following chemical components of, by weight, 0.06-0.12% of C, 0.4-0.59% of Mn, 0.06-0.15% of Si, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 0.005-0.030% ofAls, 0.6-1.0% of Cr and the balance iron and unavoidable impurities. With respect to the matching ratios of the components, the contents of Mn and C are reduced, Cr is added and is used to exert solution strengthening and grain refining functions in steel, and a part of Mn and C is replaced, so that dendritic crystals and center segregation behaviors of manganese and carbon are weakened obviouslyunder the condition that the mechanical properties of strip steel are not affected, ferrite grains are refined, the spacing between pearlite pieces is reduced, the toughness and cold-working propertyof the steel are improved, the banded structure level of the rolled strip steel is lowered, the structure is refined, and the strength and mechanical property which meet the requirements are obtained.

Owner:天铁热轧板有限公司

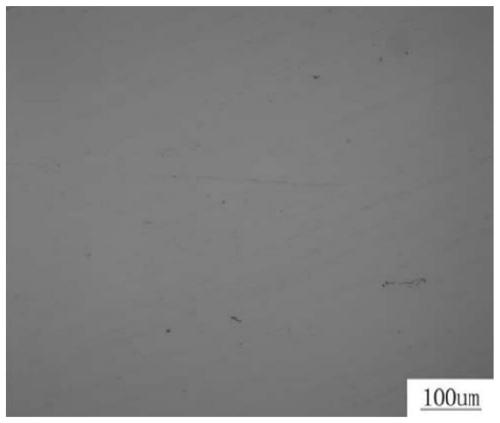

A kind of nickel-brass tape and preparation method thereof

The invention discloses a nickel brass strip. The nickel brass strip comprises, by weight percentage, 67%-73% of Cu, 2%-4.5% of Ni, 0.003%-0.015% of P, not larger than 0.01% of Pb, not larger than 0.012% of Fe and the balance Zn and inevitable impurities. According to the nickel brass strip, by optimizing the components and the content of the nickel brass strip, the corrosion resistance and wear resistance of the nickel brass strip are improved remarkably. The invention further provides a manufacturing of the nickel brass strip.

Owner:中色正锐(山东)铜业有限公司

A method for on-line verification of the opening degree of the fan-shaped segment under light reduction for wide and thick plate continuous casting machine

The invention belongs to the field of wide and thick plate continuous casting machine soft-reduction process in steel production, and particularly relates to an on-line calibration method for the opening of a wide and thick plate continuous casting machine soft-reduction segment. The on-line calibration method is mainly characterized by including the steps: pressing both an inlet and an outlet of the segment to the mechanical lowest position; measuring the actual opening of the segment; comparing the opening; determining a calibration value; calibrating the opening in an on-line manner; and calibrating the opening again. The on-line calibration method has the advantages that by the aid of the on-line calibration method for the opening of the segment, the opening of the segment can be accurately calibrated, a preset soft-reduction scheme can be accurately implemented to obviously improve the low power quality of a casting blank, the rate of blank samples with deviation within 0.5mm from a set roll gap can reach 100%, the rate of blank samples without deviation from the set roll gap can reach 87.60%, center line shrinkage and middle cracks are eliminated, and center segregation and center porosity are decreased.

Owner:JIGANG GRP

Method for manufacturing super-thick super-huge single steel ingot

ActiveCN102029378BReduce central porosityReduced tendency to center segregationMetallurgyDie casting

The invention discloses a method for manufacturing a super-thick super-huge single steel ingot. In the invention, two original blanks are placed on a chassis in parallel, the upper parts of the two original blanks are respectively provided with a dead head, two side baffles are respectively arranged at two sides of the original blanks and the dead heads to form a solidification area to be melted;a consumable electrode is inserted in the solidification area to be melted, steel on the consumable electrode is slowly melted in the solidification area to be melted by using the traditional electroslag remelting technology, the steel is solidified at the same time of being melted till the solidification area to be melted is completely filled with the steel melted from the consumable electrode, and the two original blanks are welded together. Compared with electroslag remelting, the method has low production cost and high production efficiency; the internal quality of the super-thick super-huge single steel ingot manufactured with the method disclosed in the invention is higher than that of a super-huge single steel ingot manufactured with a die casting technology and continuous casting,and especially, the trends of center dispersion and center segregation can be reduced greatly. The method can be used for producing the super-thick super-huge single steel ingots, and the super-thicksuper-huge single steel ingots which are of a structure having different chemical components along thickness direction and can be used for manufacturing composite steel plates.

Owner:BAOSHAN IRON & STEEL CO LTD

Electromagnetic stirring control method and system for continuous casting

ActiveCN105127390BQuality improvementReduce central porosityElectromagnetic shieldingElectromagnetic field

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

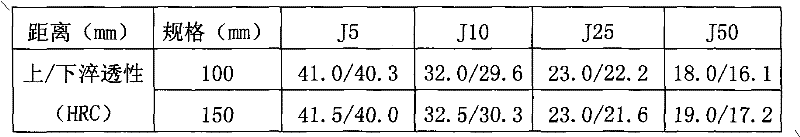

High-strength and high-toughness wind power gear steel and preparation method thereof

ActiveCN114855090AAvoid cloggingImprove purityProcess efficiency improvementSteelmakingTemperature control

The gear steel comprises the following chemical components in percentage by mass: 0.12 to 0.23 percent of C, 0.17 to 0.42 percent of Si, 1.7 to 2.5 percent of Mn, 0.4 to 1.25 percent of Cr, 0.5 to 1.45 percent of Mo, 0.35 to 0.75 percent of Ni, 0.1 to 0.35 percent of V, 0.002 to 0.007 percent of B, less than or equal to 0.015 percent of P, less than or equal to 0.015 percent of S, less than or equal to 0.01 percent of Cu, less than or equal to 0.015 percent of Al, less than or equal to 0.008 percent of Ti, less than or equal to 0.02 percent of N, less than or equal to 0.002 percent of O and the balance of Fe and inevitable impurity elements. The preparation method comprises the procedures of molten steel smelting, refining and deoxidizing, continuous casting, rolling, quenching and tempering which are conducted in sequence, the soft argon blowing time in the refining and deoxidizing procedure is larger than or equal to 30 min, the final secondary cooling water amount in the continuous casting procedure is controlled to be 0.5-0.9 L / kg steel, and through steelmaking component control, temperature control, slag charge control, refining and deoxidizing control, argon blowing control, alloy optimization control and low residual element control, the production efficiency of the steel is improved. And through the controlled rolling and controlled cooling process, the transverse performance, ductility, toughness and compactness are guaranteed, the overall hardness, tensile strength, yield strength and impact toughness are improved, the strength and toughness of the wind power gear steel are both considered, and the tooth breaking risk is avoided.

Owner:JIANGSU YONGGANG GROUP CO LTD

Production method capable of reducing dendritic segregation of hot rolled coiled plate Q345B

The invention discloses a production method capable of reducing dendritic segregation of a hot rolled coiled plate Q345B. The production method is characterized in that the hot rolled coiled plate Q345B comprises the following chemical components of, by weight, 0.06-0.12% of C, 0.4-0.59% of Mn, 0.06-0.15% of Si, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 0.005-0.030% ofAls, 0.6-1.0% of Cr and the balance iron and unavoidable impurities. With respect to the matching ratios of the components, the contents of Mn and C are reduced, Cr is added and is used to exert solution strengthening and grain refining functions in steel, and a part of Mn and C is replaced, so that dendritic crystals and center segregation behaviors of manganese and carbon are weakened obviouslyunder the condition that the mechanical properties of strip steel are not affected, ferrite grains are refined, the spacing between pearlite pieces is reduced, the toughness and cold-working propertyof the steel are improved, the banded structure level of the rolled strip steel is lowered, the structure is refined, and the strength and mechanical property which meet the requirements are obtained.

Owner:天铁热轧板有限公司

High-quality alloy steel bar and production process thereof

ActiveCN101948986BImprove low-magnification qualityImprove hardenabilityUltimate tensile strengthInternal quality

The invention belongs to the field of alloys, in particular to a high-quality alloy steel bar and a production process thereof. The high-quality alloy steel bar comprises the following components in percentage by weight: 0.10 to 0.50 percent of C, 0.10 to 1.50 percent of Cr, 0.50 to 1.50 percent of Mn, 0.010 to 0.015 percent of Ti, less than or equal to 0.40 percent of Si, less than or equal to 0.035 percent of P, less than or equal to 0.035 percent of S, 0.020 to 0.050 percent of Al, less than or equal to 0.020 percent of N, less than or equal to 0.03 percent of Mo, 0.05 to 0.50 percent of V, less than 0.030 percent of Ni, less than or equal to 0.090 percent of Cu, less than or equal to 0.0018 percent of B, less than or equal to 0.0014 percent of O and the balance of Fe and inevitable impurities. In the process, a crystallizer electromagnetic stirring mode is adopted, the current intensity of crystallizer electromagnetic stirring equipment is 0 to 550A, the frequency of the crystallizer electromagnetic stirring equipment is 2 to 4Hz, the solidified end section is slightly rolled and the rolling reduction is 3 to 9 millimeters. In the invention, the internal quality of casting blanks can be improved obviously, and the central looseness and composition segregation of the cast blanks can be reduced.

Owner:NANJING IRON & STEEL CO LTD

A kind of rare earth-containing C110 steel grade petroleum casing and production method thereof

Owner:BAOTOU IRON & STEEL GRP

Method for continuously casting steel

The invention provides a method for continuously casting steel. By means of the method, segregation-free center-porosity-free casting blanks with high internal quality can be efficiently obtained by striking the casting blanks under proper conditions so as to make the casting blanks vibrate. According to the method for continuously casting steel, at least one pair of striking and vibrating devices is arranged on the two sides of the short edge faces of a casting blank containing unset parts when the casting blank with a rectangular cross section is cast through the manufacturing method; while the casting blank is cast, vibration is applied to the casting blank by continuously striking the short edge faces of the casting blank; and by striking the short edge faces, a displacement delta (x) curve of the long edge faces of the casting blank in the thickness direction of the casting blank and intersection points of lines when the displacement delta (x) is equal to 0.10 mm, which are defined in the formula (1) and the formula (2) below, are generated, and the short edge faces are struck by adjusting the vibration energy, the distance between shafts of guide rollers and the unset thickness, so that the distance between the intersection point, away from the original point, of the intersection points and the struck positions of the short edge faces of the casting blank in the width direction of the casting blank is 200 mm or above.

Owner:QINGDAO XINHEYI IND & TRADE CO LTD

Preparation method of high-quality plastic mold steel extra-thick plate continuous casting master billet

Owner:TANGSHAN IRON & STEEL GROUP +2

A large-scale steel ingot electroslag thermal capping device and method with evenly distributed heat source

A large steel ingot electroslag thermal capping device and method with uniform heat source distribution. The device includes a hydraulic fixed support, a hydraulic transmission rod, a lifting arm, a control cabinet, a trolley, an upper clamper, a lower clamper, an upper electrode cross arm, The lower electrode cross arm and the double-layer graphite electrode pair; the inner graphite electrode of the double-layer graphite electrode pair is a solid columnar shape, and the outer graphite electrode is a hollow tubular shape. The two electrodes are coaxially aligned and inserted into the liquid preheater in the riser box. In the slag; the upper electrode cross arm and the lower electrode cross arm are connected to the lifting arm and connected to the control cabinet; the inner graphite electrode is held by the upper holder, and the upper holder is connected to the upper electrode cross arm; The outer graphite electrode is held by a lower holder, which is connected to the lower electrode cross arm. The invention increases the metal yield, improves the uniformity of the chemical composition of the steel ingot and the purity of the steel, improves the solidification conditions in the center of the steel ingot, has high heating efficiency and good heating effect, improves the utilization rate of the riser molten steel, and improves the utilization rate of the steel ingot.

Owner:NORTHEASTERN UNIV LIAONING

A submerged nozzle swirl generator, tundish and application

ActiveCN111482588BSimple structureReasonable designMelt-holding vesselsStructural engineeringMechanics

The invention discloses a submerged nozzle swirl generator, a tundish and its application, comprising a swirl generator body with a stepped hole at the center of the top of the swirl generator body, and a top center of the swirl generator body Several blades are provided, one end of the blade is consistent with the curvature of the outer circle of the swirl generator body, and the end of the blade away from the outer circle of the swirl generator body is consistent with the curvature of the wall of the stepped hole, Moreover, a swirl cavity is formed between two pairs of the blades. Beneficial effects: the structure is simple, the design is reasonable, and the uniformity of the flow field distribution inside the submerged nozzle is improved, thereby significantly improving the stability of the molten steel flow in the crystallizer, thereby helping to improve the quality of steel products.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com