Patents

Literature

813 results about "Pipeline transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pipeline transport is the long-distance transportation of a liquid or gas through a system of pipes—a pipeline—typically to a market area for consumption. The latest data from 2014 gives a total of slightly less than 2,175,000 miles (3,500,000 km) of pipeline in 120 countries of the world. The United States had 65%, Russia had 8%, and Canada had 3%, thus 75% of all pipeline were in these three countries.

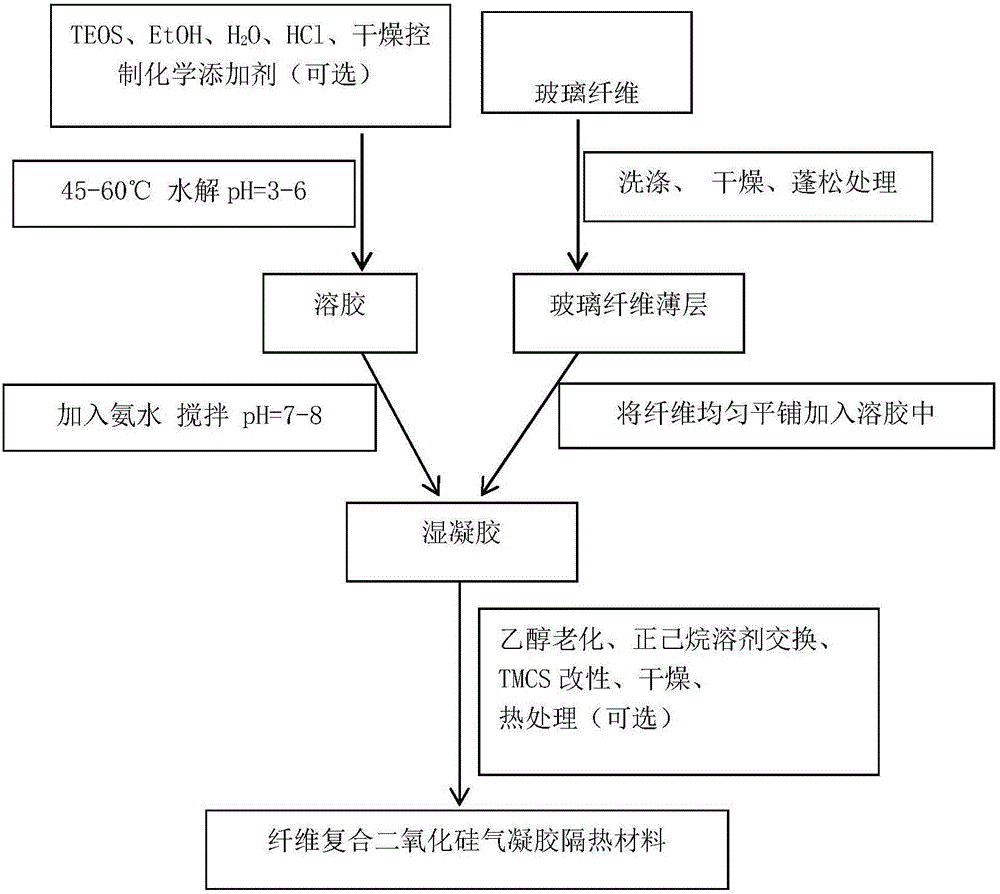

Method for preparing silicon dioxide silica aerogel composite material by drying in atmosphere pressure

InactiveCN101318659ALow thermal conductivityIncrease added valueSilicaThermal insulationPipeline transport

The invention discloses a method for preparing a silicon dioxide aerogel composite material at the condition of normal pressure and drying, which comprises the steps as following: (1) silicon dioxide sol and a reinforcing material are compounded and placed statically to form plural gel, and then ageing treatment is carried out to the plural gel; (2) a modifying agent is used for the hydrophobic modification of the aged plural gel, and then ambient pressure drying is carried out for the modified plural gel to obtain the silicon dioxide aerogel composite material at the condition of normal pressure and drying. The silicon dioxide aerogel composite material prepared by the method of the invention has extremely low coefficient of heat conductivity, which greatly increases the added value of the reinforcing materials such as corpus fibrosum, the product can be widely applied to thermal insulation and sound insulation of buildings, thermal insulation and sound insulation in the industrial pipeline transportation, and the like, and expands the application field of silicon dioxide and the corpus fibrosum.

Owner:绍兴纳诺气凝胶新材料研发中心有限公司 +2

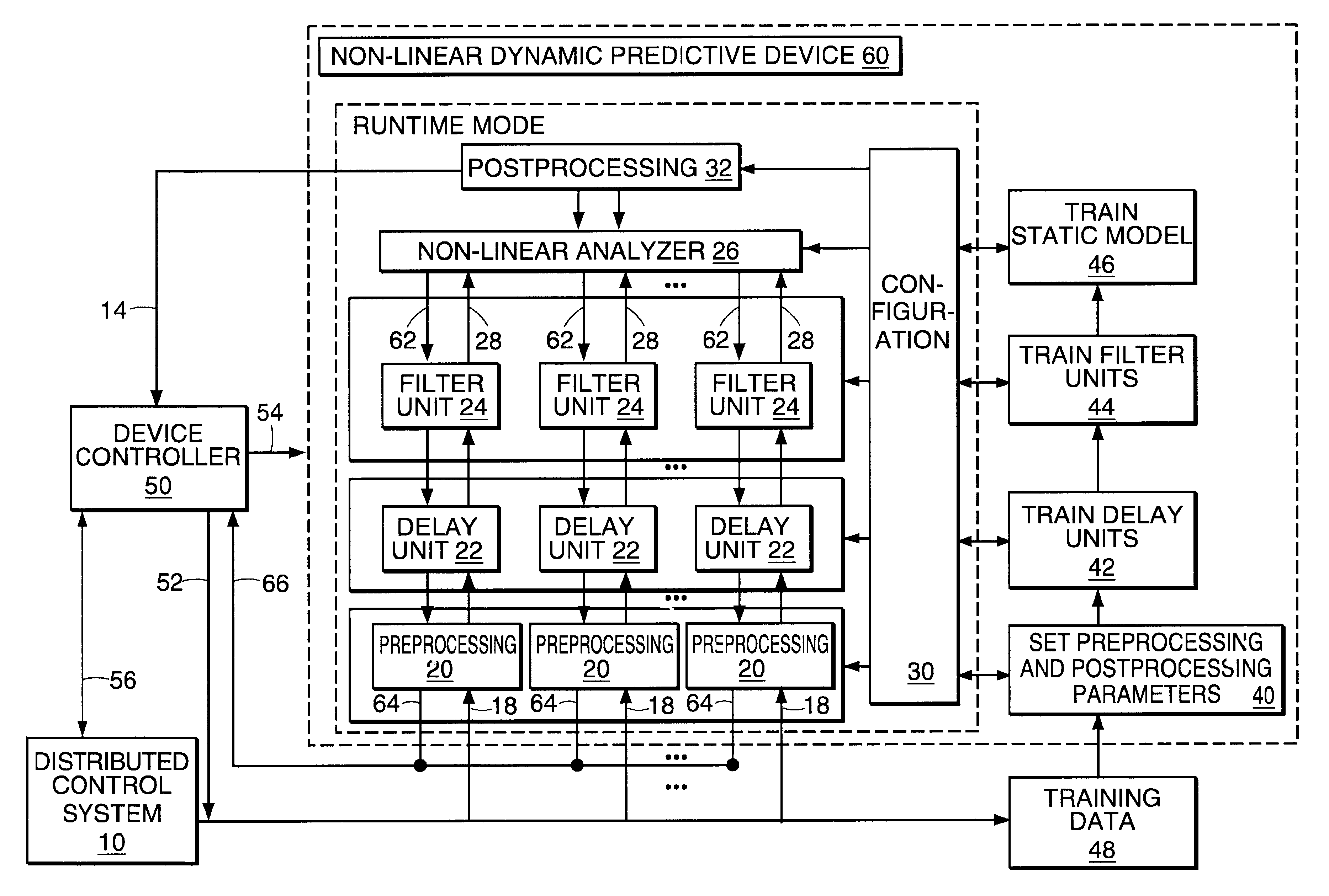

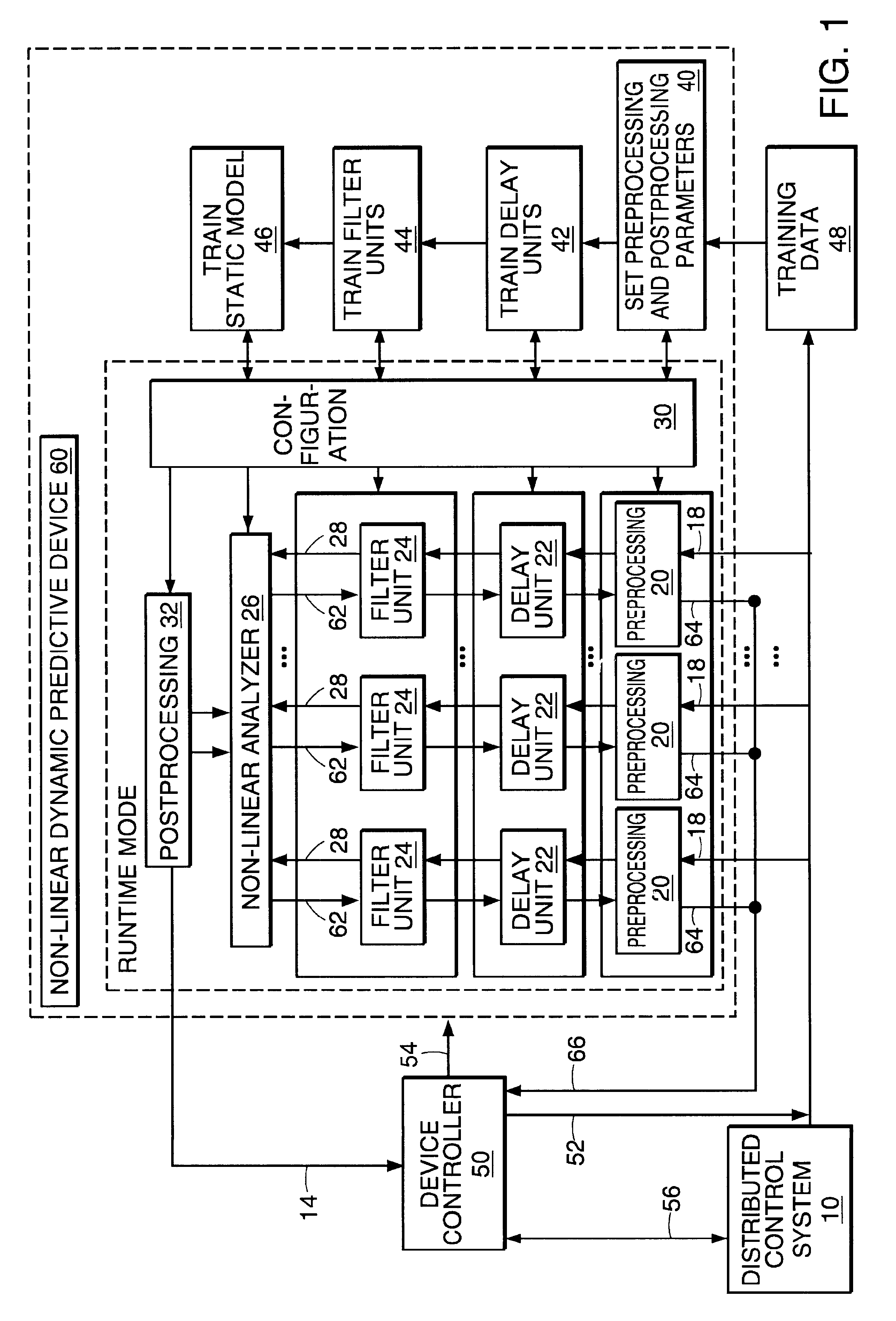

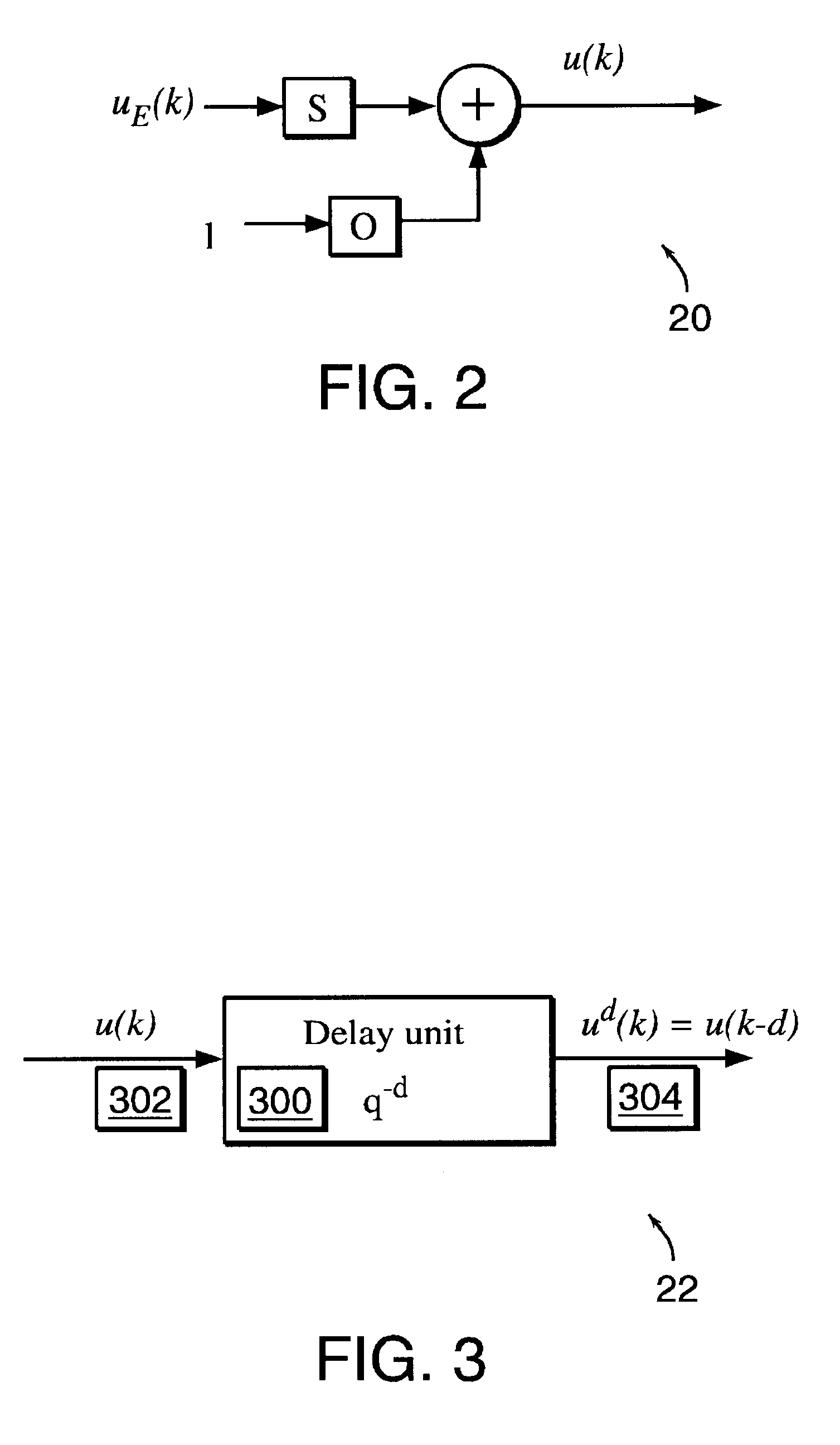

Non-linear dynamic predictive device

InactiveUS6453308B1Improve accuracyFast computerSimulator controlElectric testing/monitoringHorizonDead time

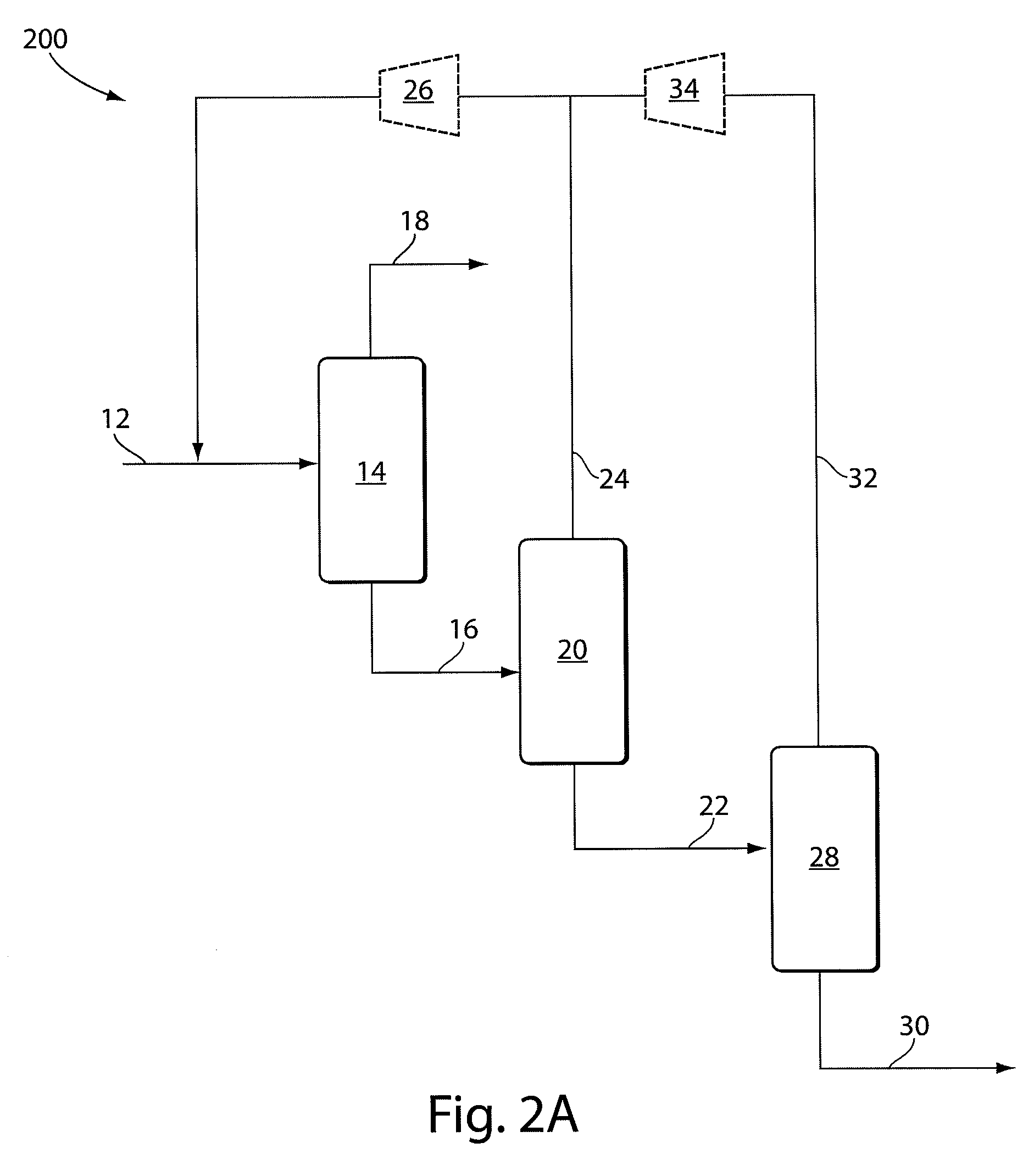

A non-linear dynamic predictive device (60) is disclosed which operates either in a configuration mode or in one of three runtime modes: prediction mode, horizon mode, or reverse horizon mode. An external device controller (50) sets the mode and determines the data source and the frequency of data. In prediction mode, the input data are such as might be received from a distributed control system (DCS) (10) as found in a manufacturing process; the device controller ensures that a contiguous stream of data from the DCS is provided to the predictive device at a synchronous discrete base sample time. In prediction mode, the device controller operates the predictive device once per base sample time and receives the output from the predictive device through path (14). In horizon mode and reverse horizon mode, the device controller operates the predictive device additionally many times during base sample time interval. In horizon mode, additional data is provided through path (52). In reverse horizon mode data is passed in a reverse direction through the device, utilizing information stored during horizon mode, and returned to the device controller through path (66). In the forward modes, the data are passed to a series of preprocessing units (20) which convert each input variable (18) from engineering units to normalized units. Each preprocessing unit feeds a delay unit (22) that time-aligns the input to take into account dead time effects such as pipeline transport delay. The output of each delay unit is passed to a dynamic filter unit (24). Each dynamic filter unit internally utilizes one or more feedback paths that are essential for representing the dynamic information in the process. The filter units themselves are configured into loosely coupled subfilters which are automatically set up during the configuration mode and allow the capability of practical operator override of the automatic configuration settings. The outputs (28) of the dynamic filter units are passed to a non-linear analyzer (26) which outputs a value in normalized units. The output of the analyzer is passed to a post-processing unit (32) that converts the output to engineering units. This output represents a prediction of the output of the modeled process. In reverse horizon mode, a value of 1 is presented at the output of the predictive device and data is passed through the device in a reverse flow to produce a set of outputs (64) at the input of the predictive device. These are returned to the device controller through path (66). The purpose of the reverse horizon mode is to provide essential information for process control and optimization. The precise operation of the predictive device is configured by a set of parameters. that are determined during the configuration mode and stored in a storage device (30). The configuration mode makes use of one or more files of training data (48) collected from the DCS during standard operation of the process, or through structured plant testing. The predictive device is trained in four phases (40, 42, 44, and 46) correspo

Owner:ASPENTECH CORP

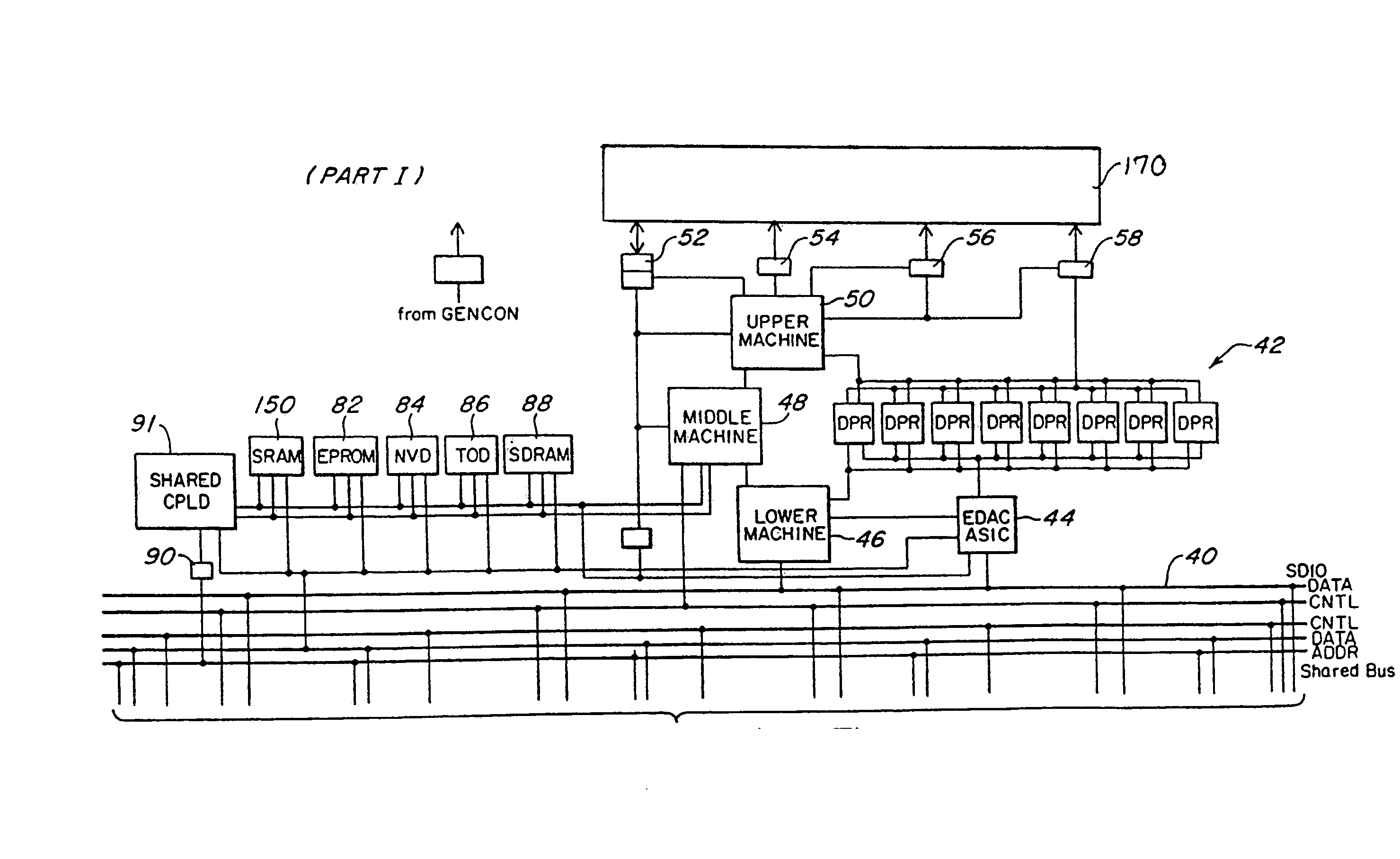

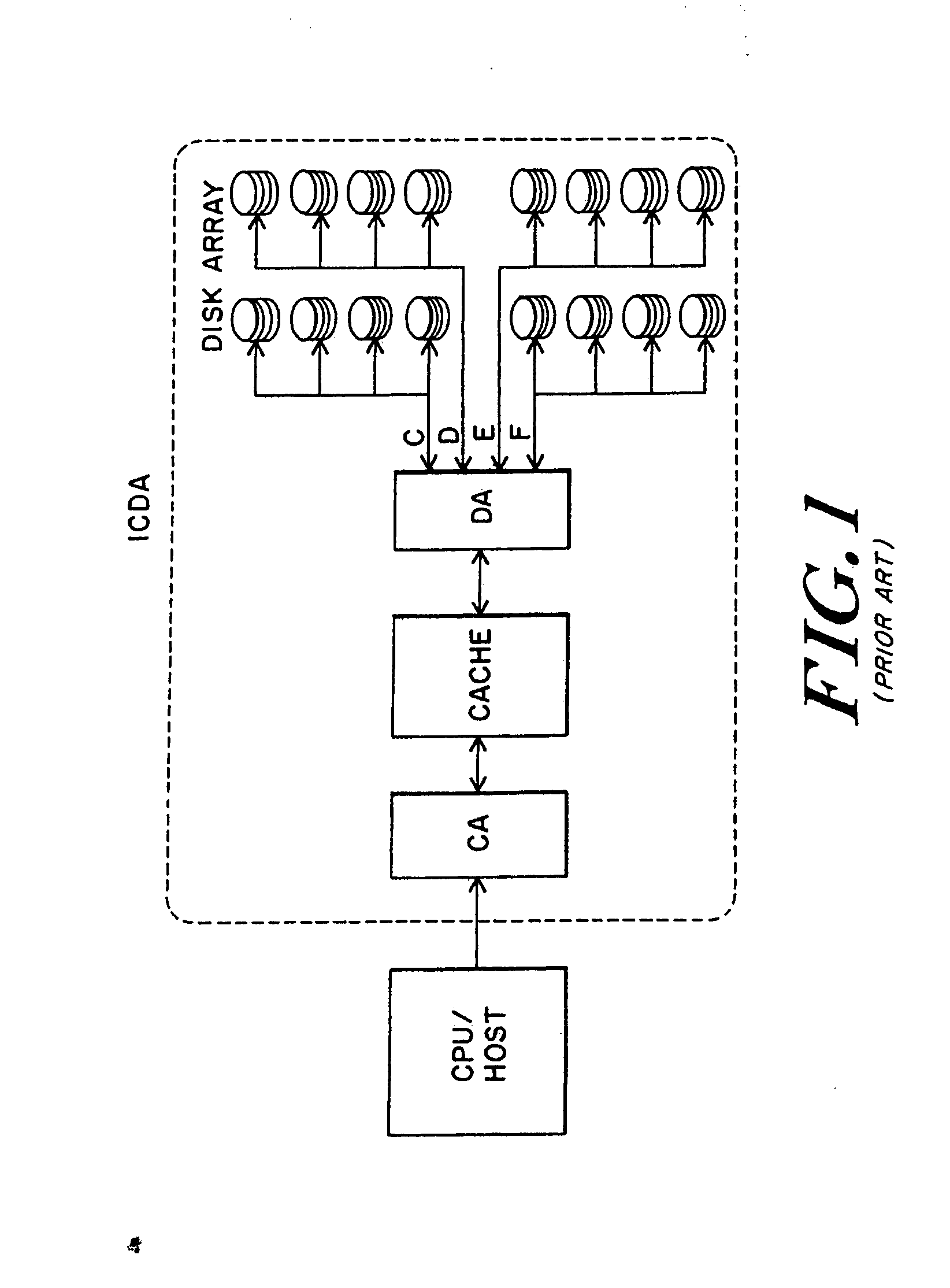

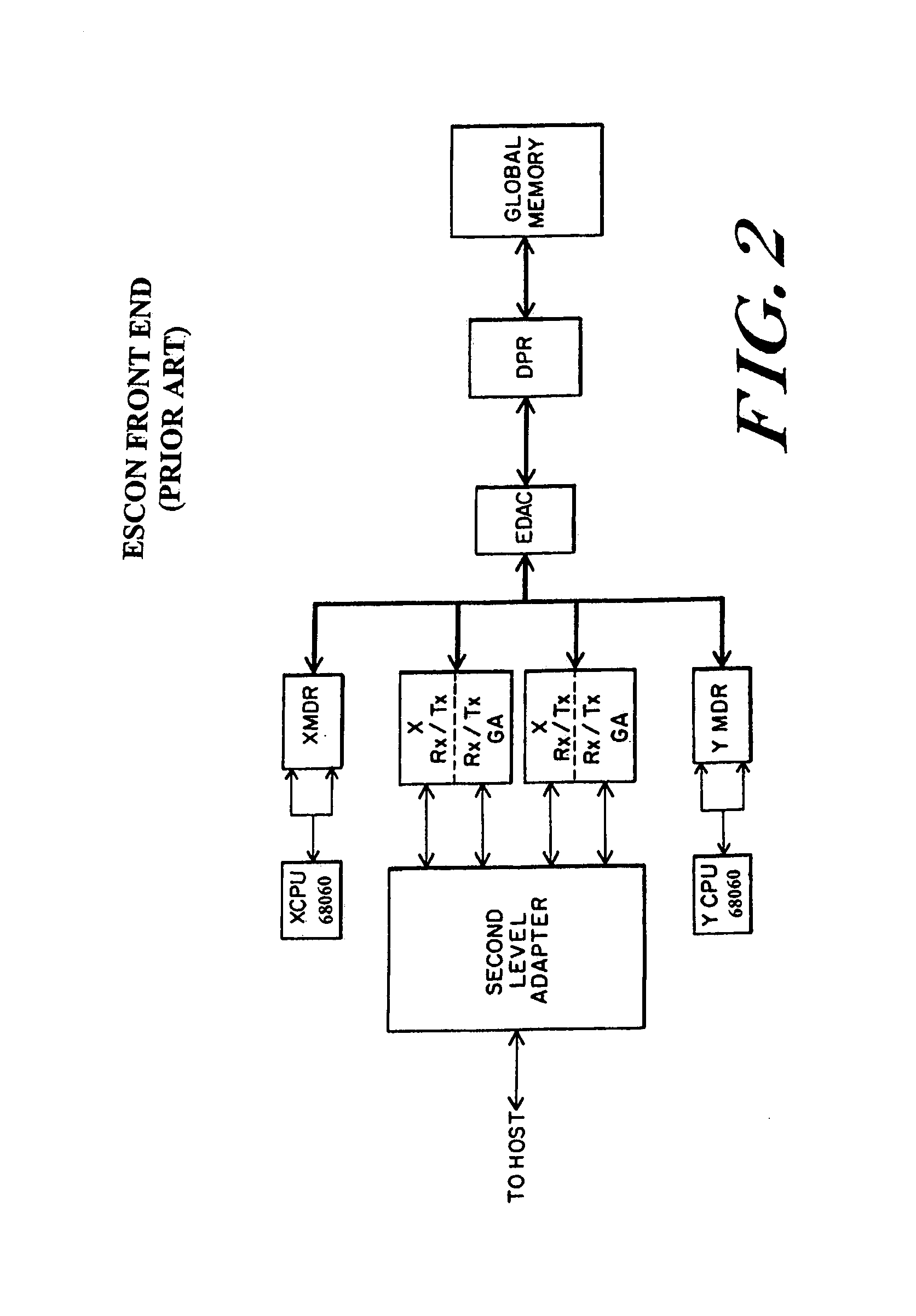

Messaging mechanism for inter processor communication

InactiveUS20070271572A1Easy to operateMinimizing affectionMultiprogramming arrangementsMultiple digital computer combinationsComputer hardwareESCON

An apparatus and method are provided for connecting a host Enterprise System Connection Architecture (ESCON) Input / Output (I / O) interface to a cache of a data storage system. The apparatus includes (a) a set of at least 4 pipelines, each pipeline being coupled on a first end to the host ESCON I / O interface and being coupled on a second end to the cache, (b) a plurality of line processors, each line processor controlling one or more of the pipelines of the set of pipelines, and (c) in each pipeline, a protocol engine, the protocol engine configured to distinguish user data from frame header data and separate the user data from the frame header data for transport over the pipeline.

Owner:EMC IP HLDG CO LLC

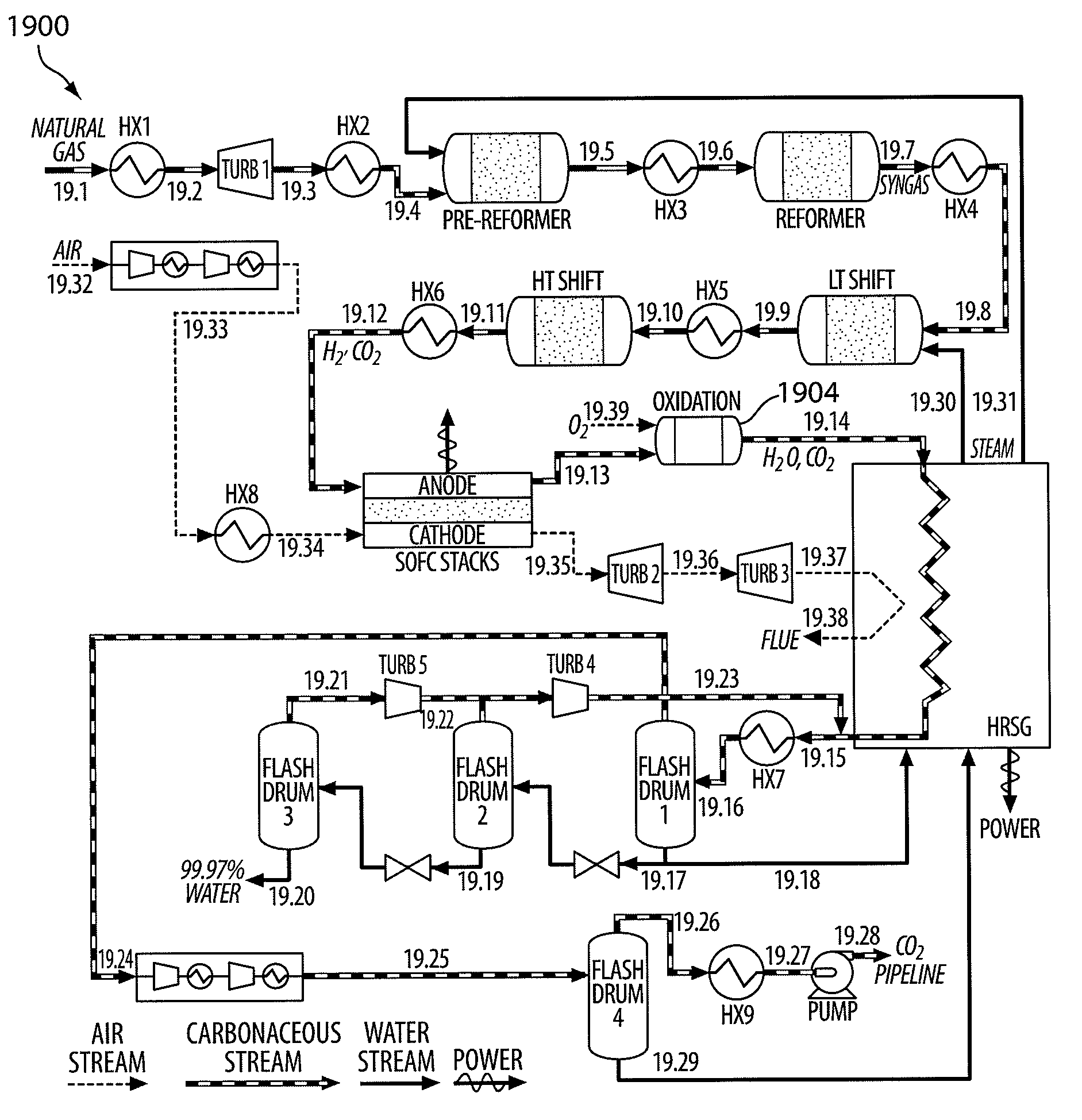

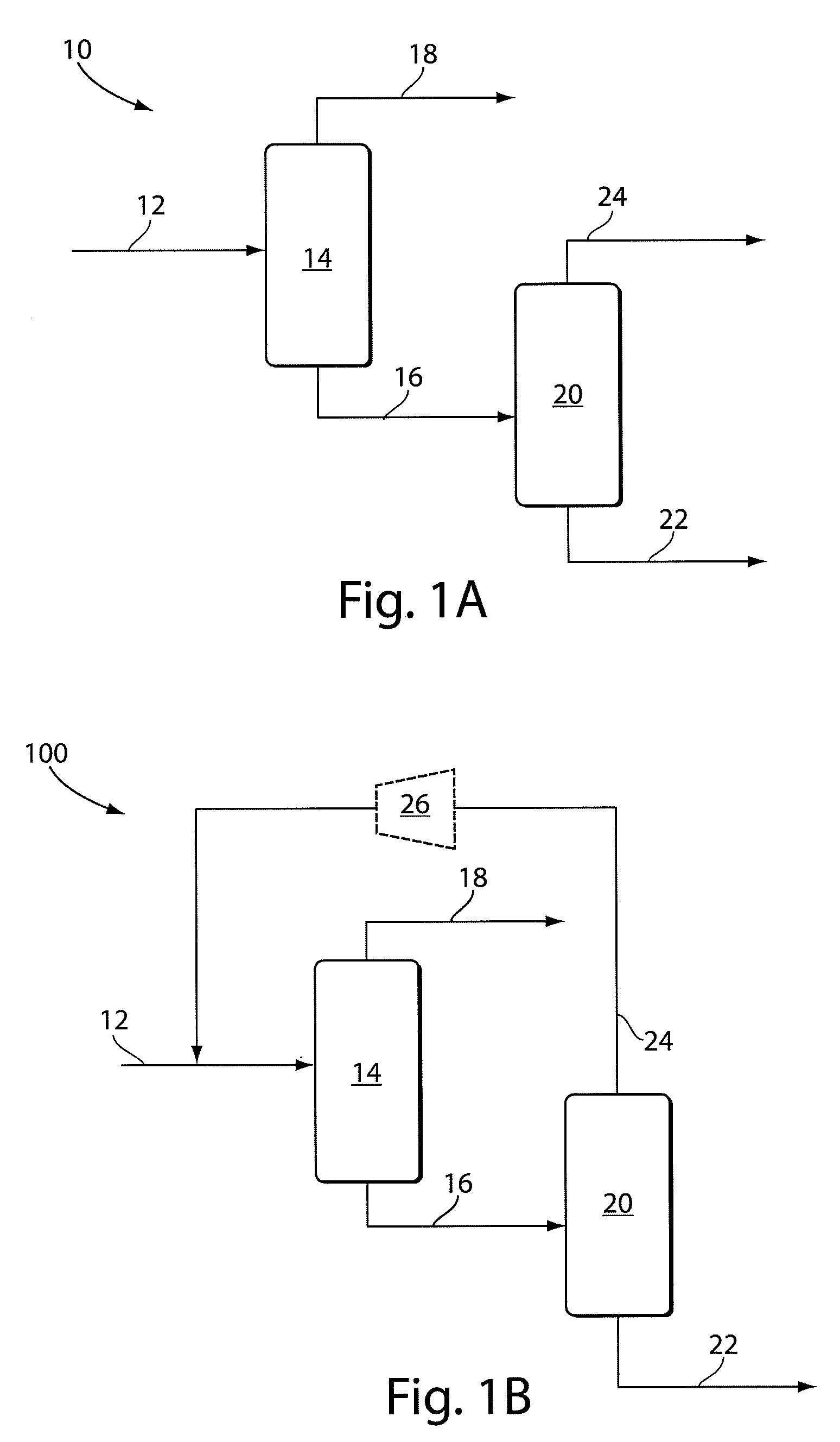

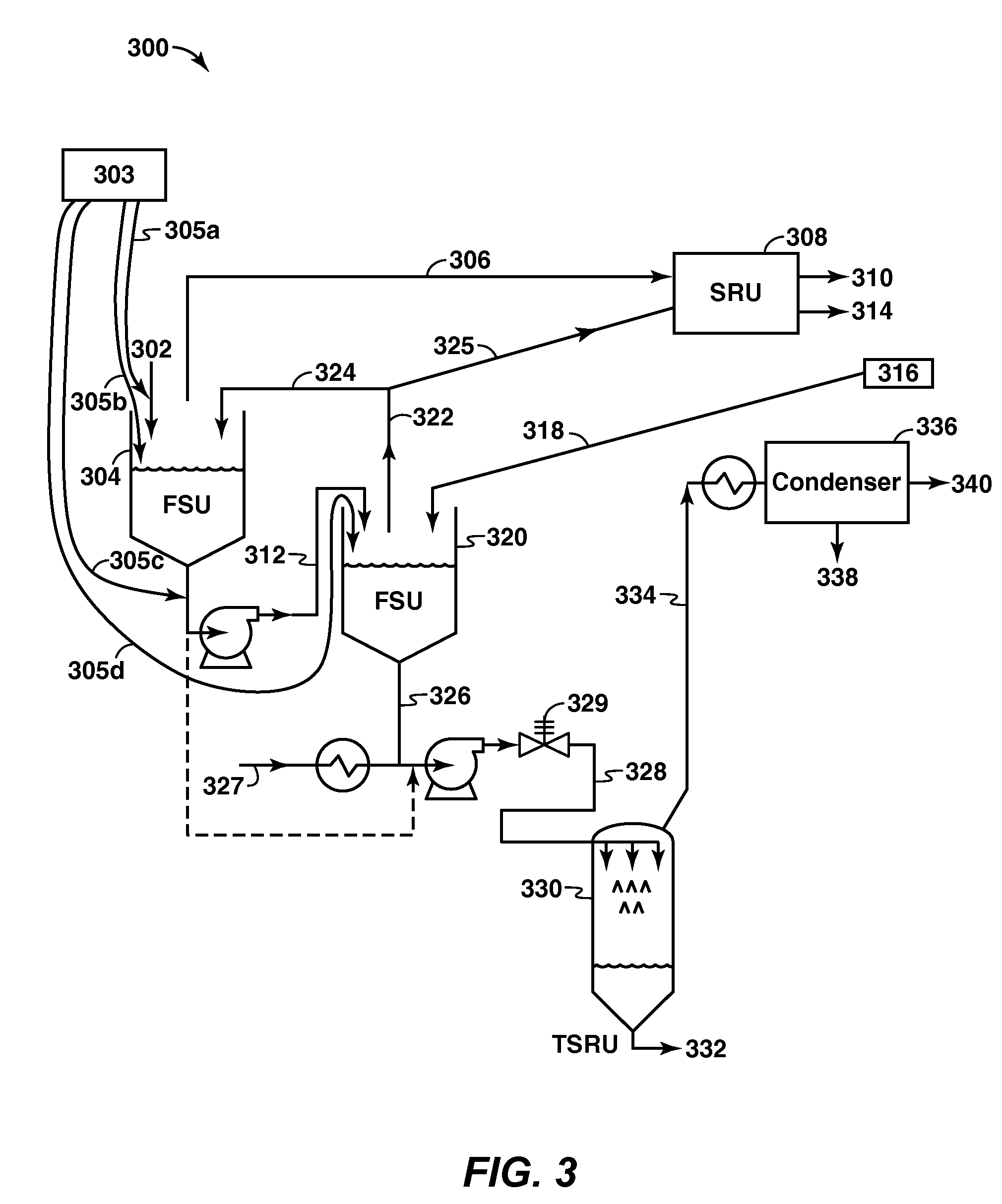

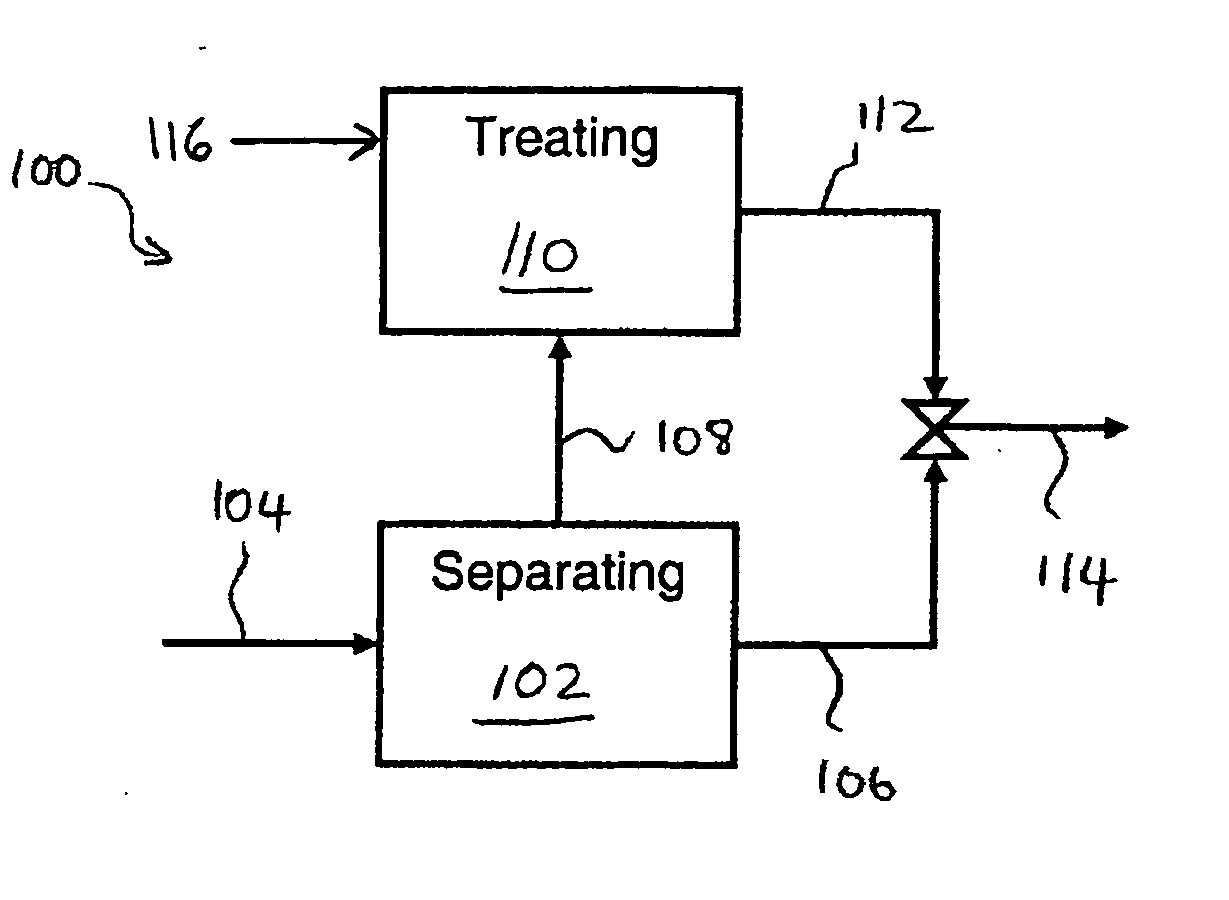

Systems and methods for the separation of carbon dioxide and water

Systems and methods for the separation and capture of carbon dioxide from water are generally described. In some embodiments, a vapor stream containing carbon dioxide and water is separated using a cascade of at least two flash drums. Additional flash steps may be incorporated to remove atmospheric gases, such as nitrogen and argon, from the feed. Carbon dioxide may be condensed and pressurized at purities suitable for pipeline transport and eventual storage in geological formations. In addition, water may be recovered at high purity.In some embodiments, fuel cells may be used in combination with fuel reforming or gasification to produce syngas. Certain aspects of the invention involve innovations related to the combined reforming and fuel cell process, that, in certain embodiments, do not depend upon water and carbon dioxide separation. It should be understood, however, that the invention is not limited to the applications described above, and may be used with any suitable system in which the separation of carbon dioxide and water is desired.

Owner:MASSACHUSETTS INST OF TECH

Process for increasing the transport flow rate of oil from producing wells

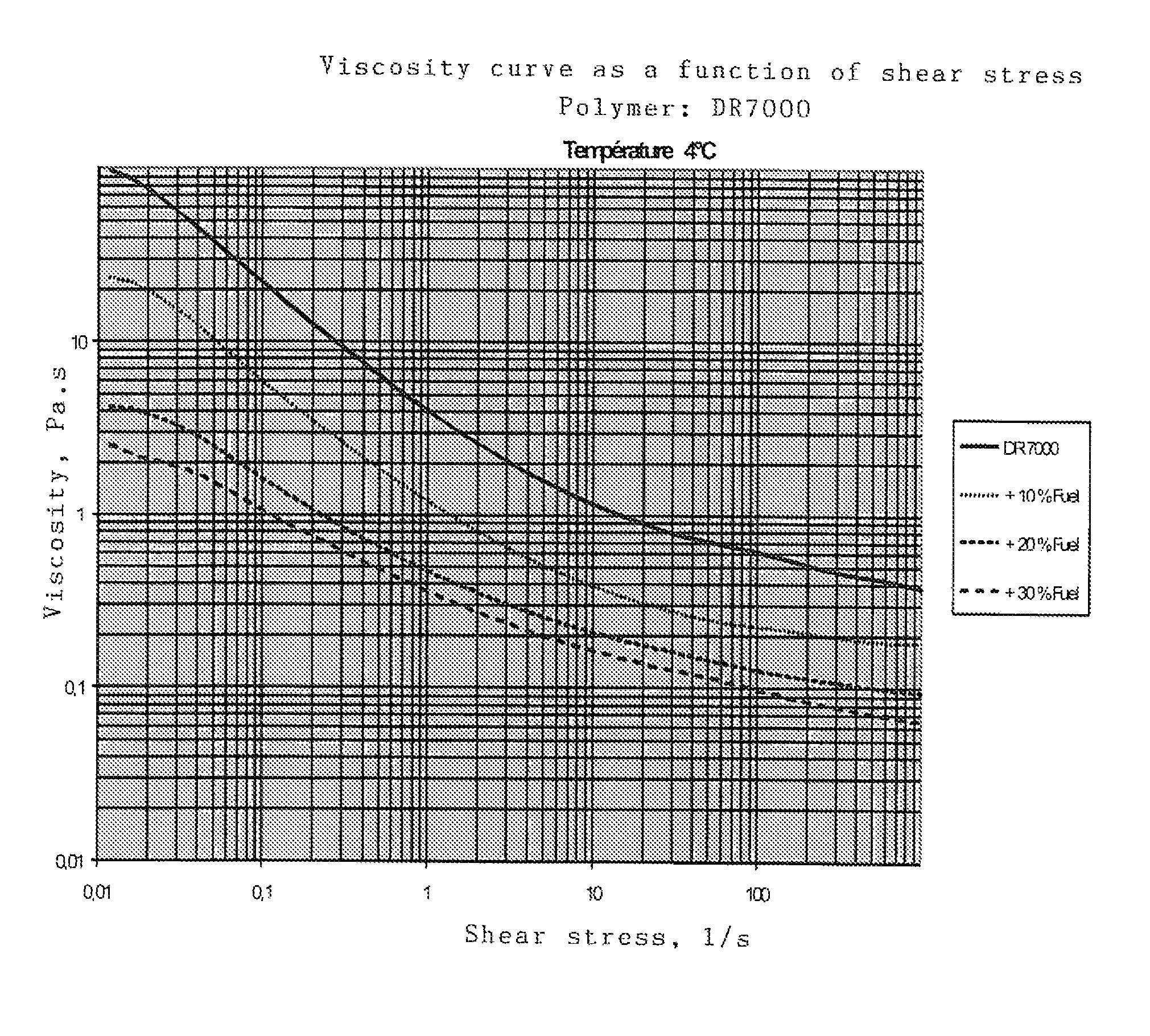

InactiveUS8517104B2Low viscosityIncrease injection rateFluid removalPipeline systemsEmulsionPipeline transport

A process for increasing, on an existing installation, the amount of water-soluble polymer in an emulsion injected into pipelines transporting oil produced at offshore oil wells, includes before injection, diluting the emulsion with fuel oil found on the platform or Floating Production Storage & Offloading unit (FPSO).

Owner:S P C M SA

Upgrading Bitumen In A Paraffinic Froth Treatment Process

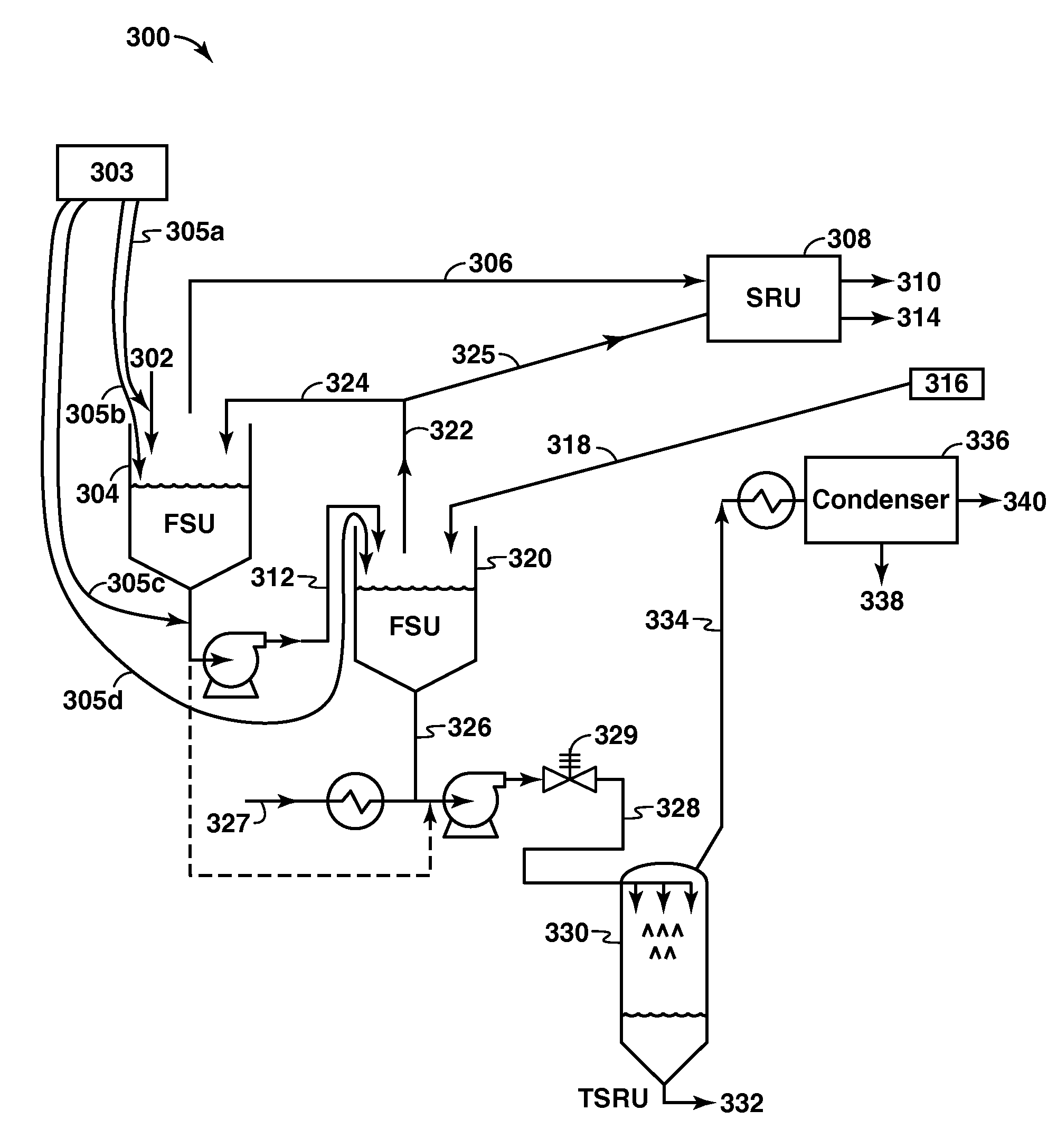

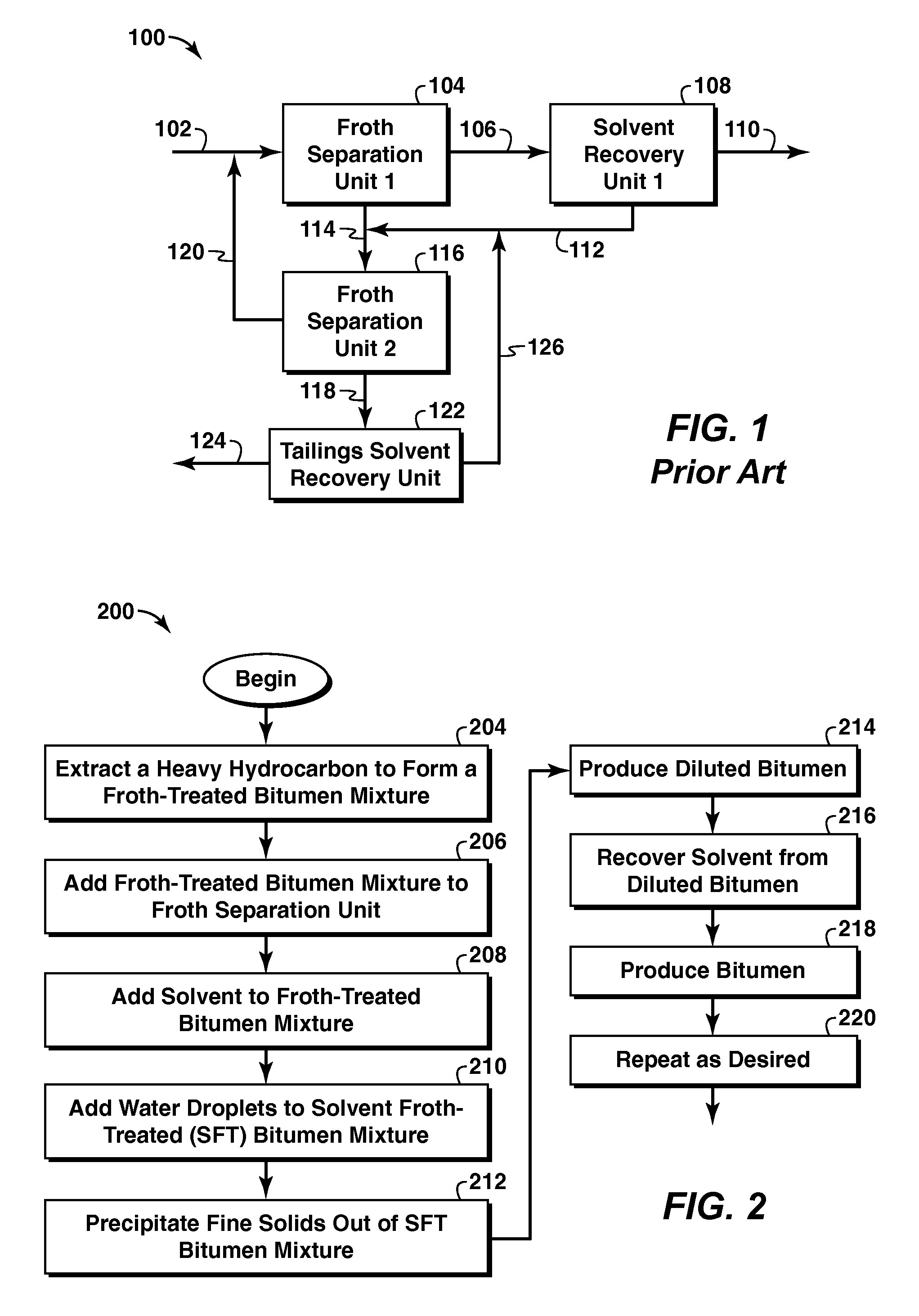

ActiveUS20090200209A1Increase settlement rateWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionParaffin waxPipeline transport

The invention relates to an improved bitumen recovery process. The process includes adding water to a bitumen-froth / solvent system containing asphaltenes and mineral solids. The addition of water in droplets increases the settling rate of asphaltenes and mineral solids to more effectively treat the bitumen for pipeline transport, further enhancement, refining, or any other application of reduced-solids bitumen.

Owner:EXXONMOBIL UPSTREAM RES CO

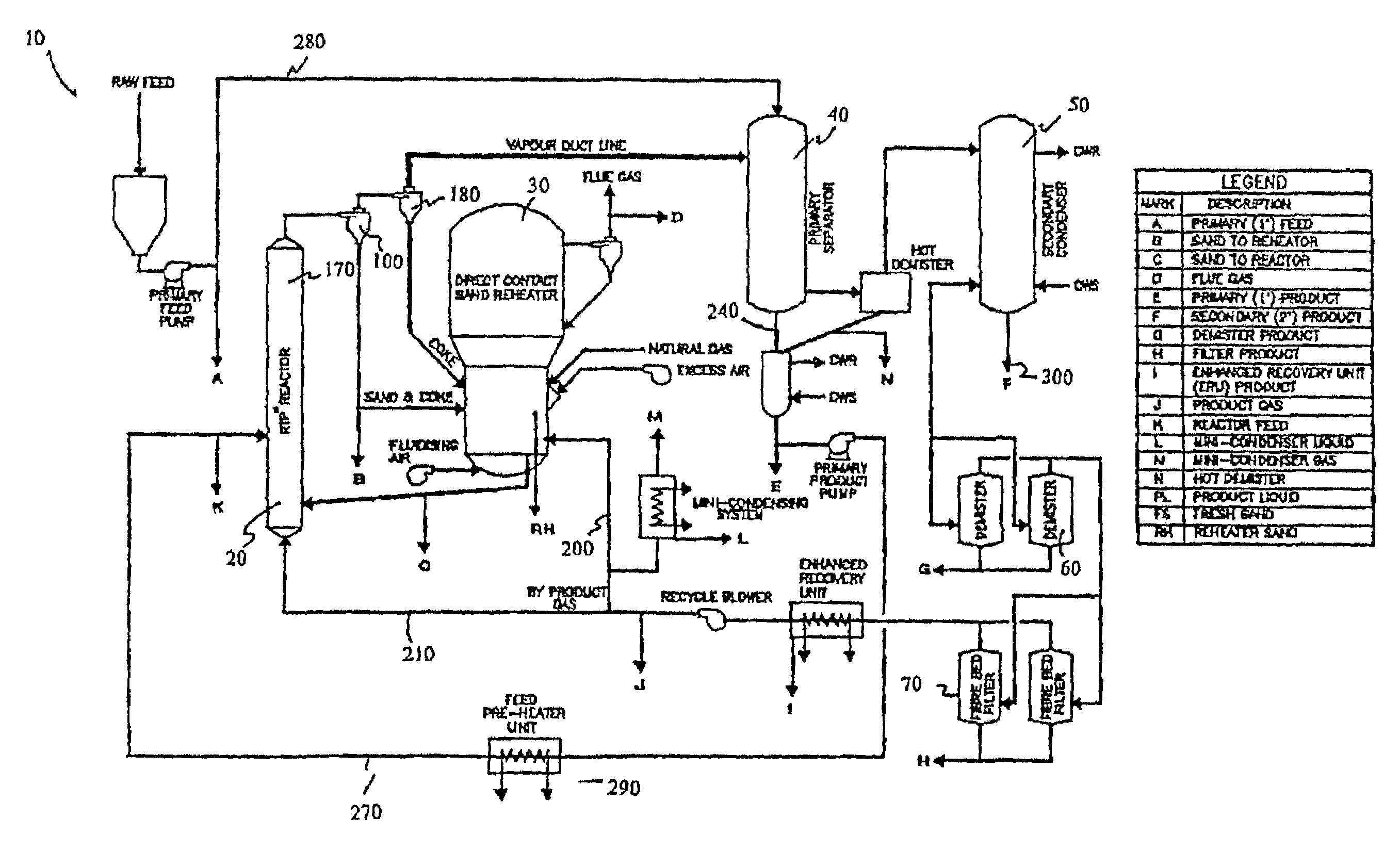

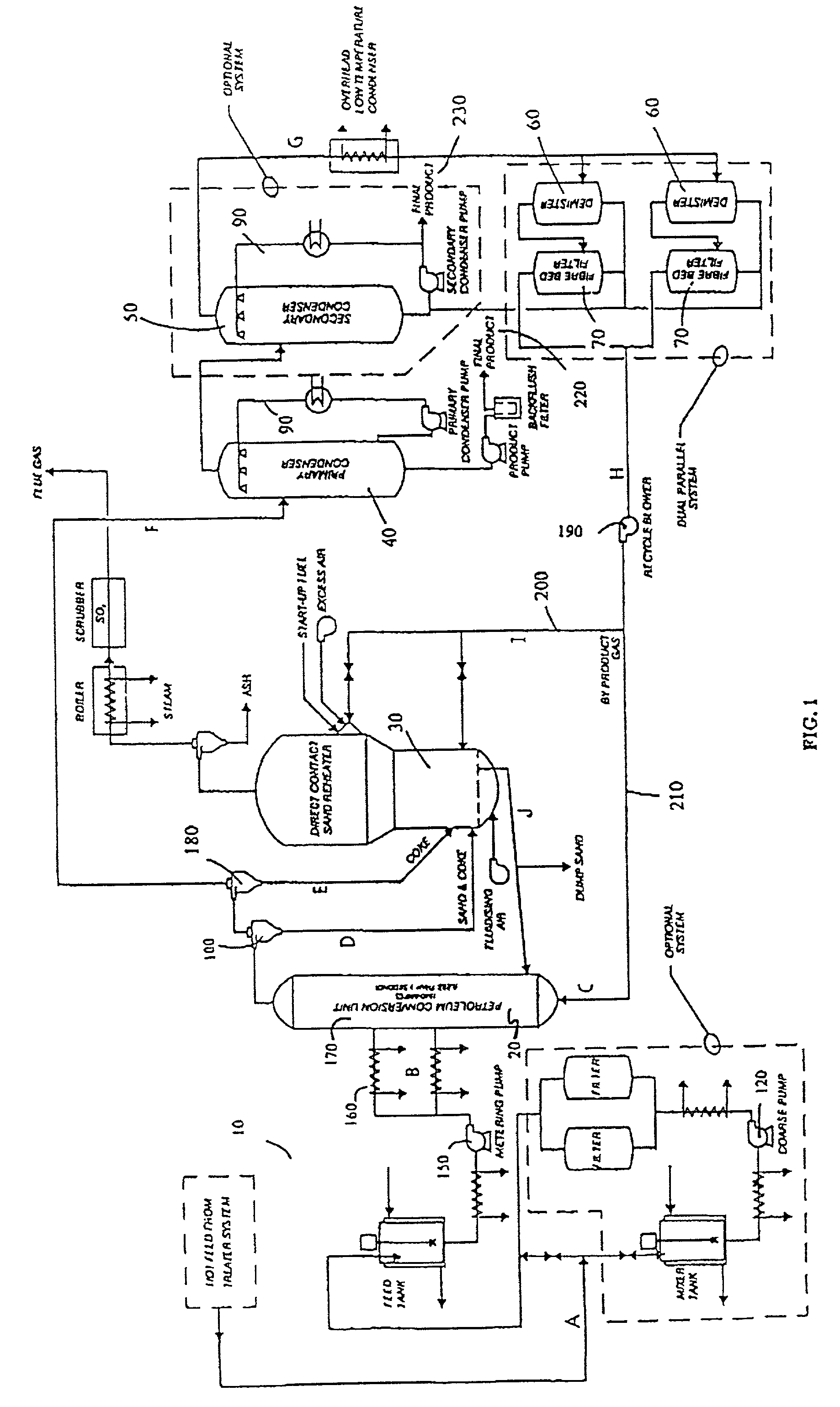

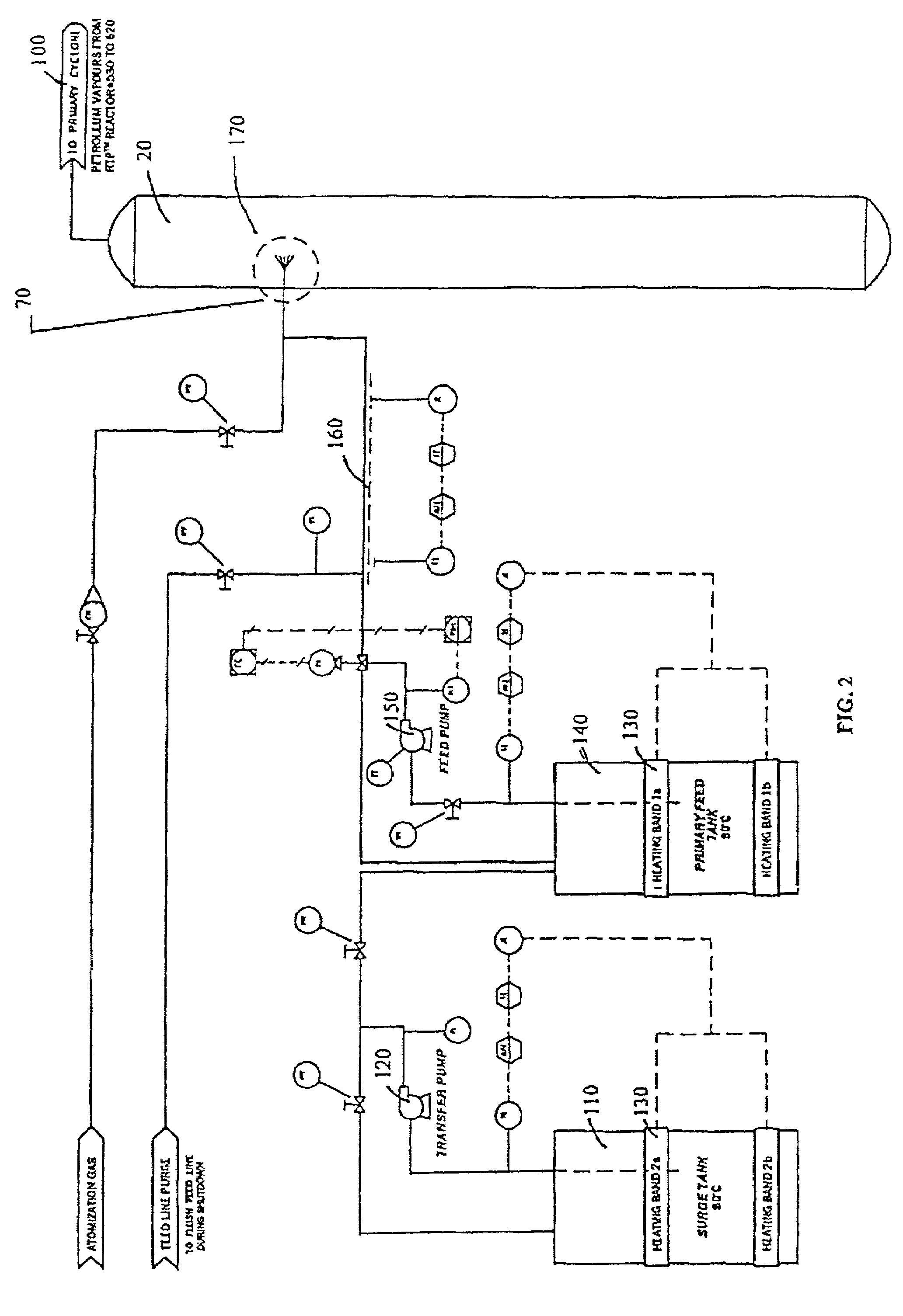

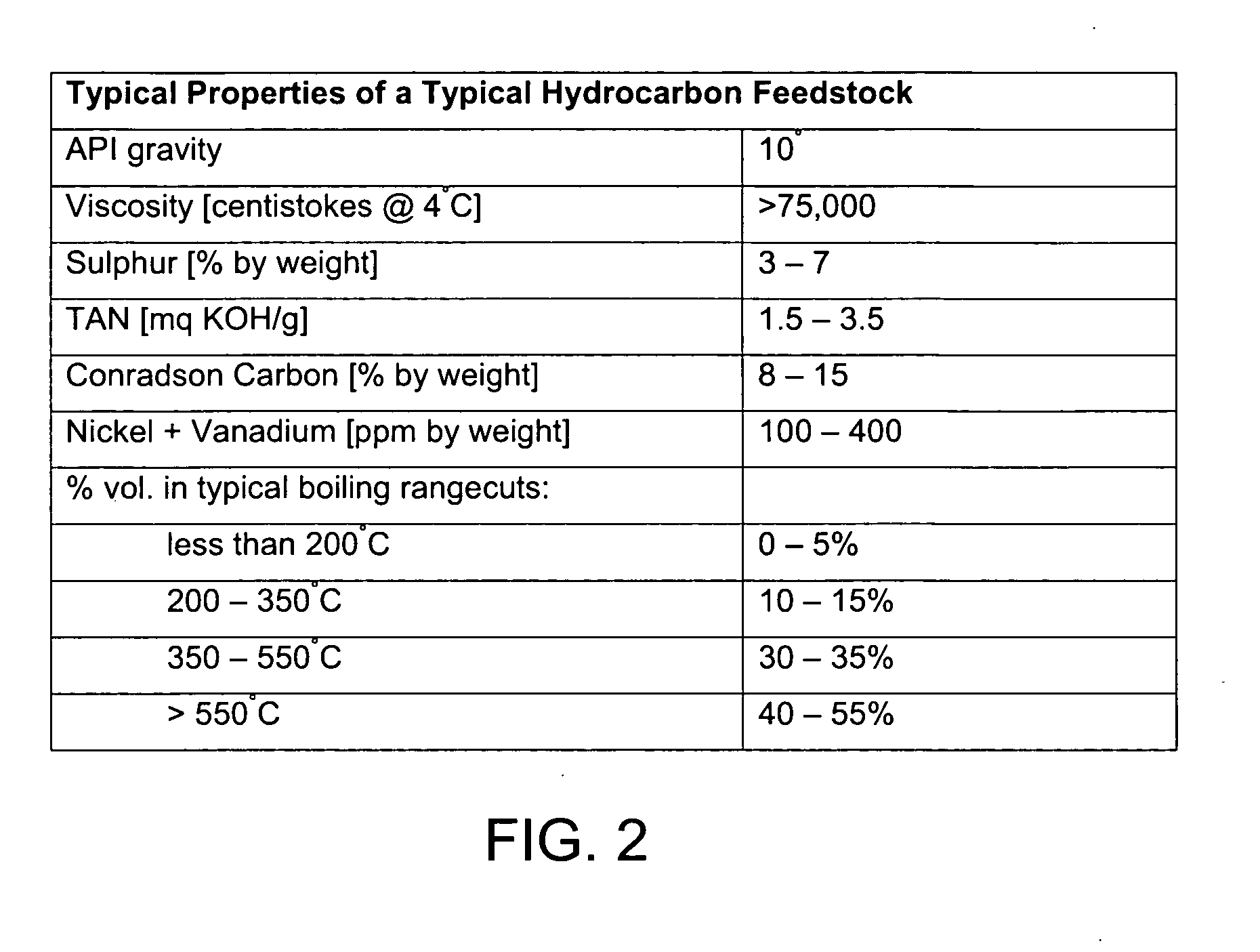

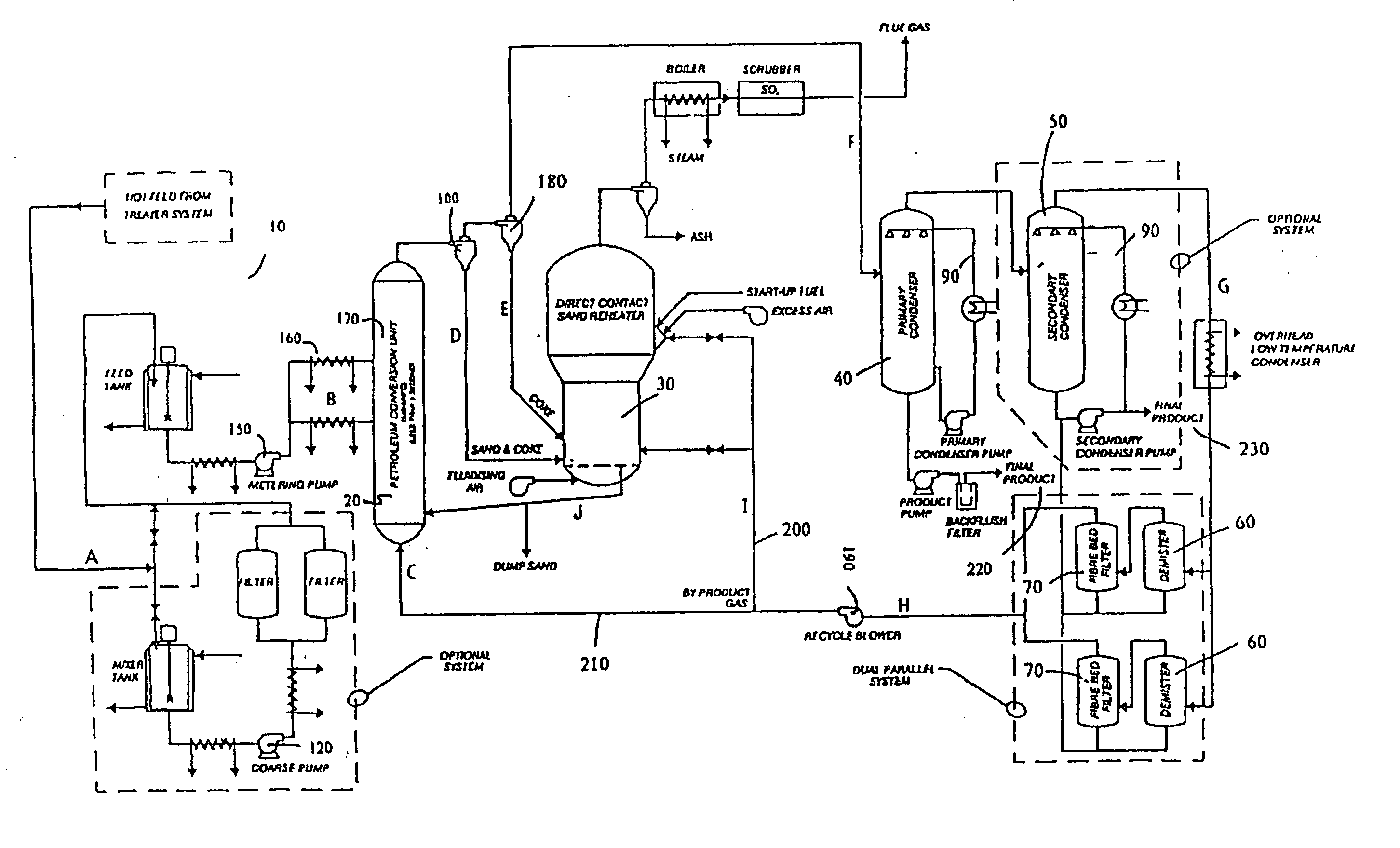

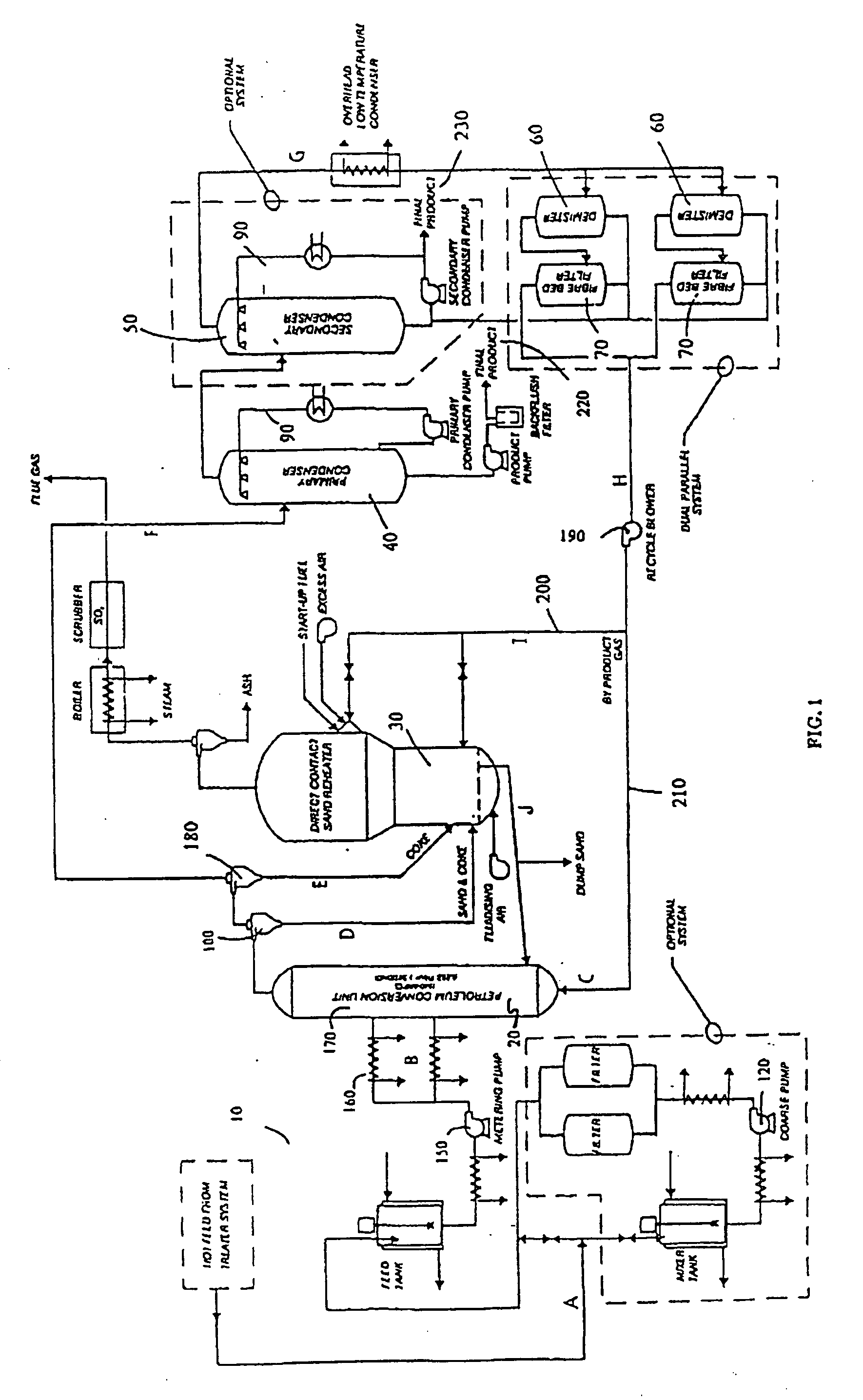

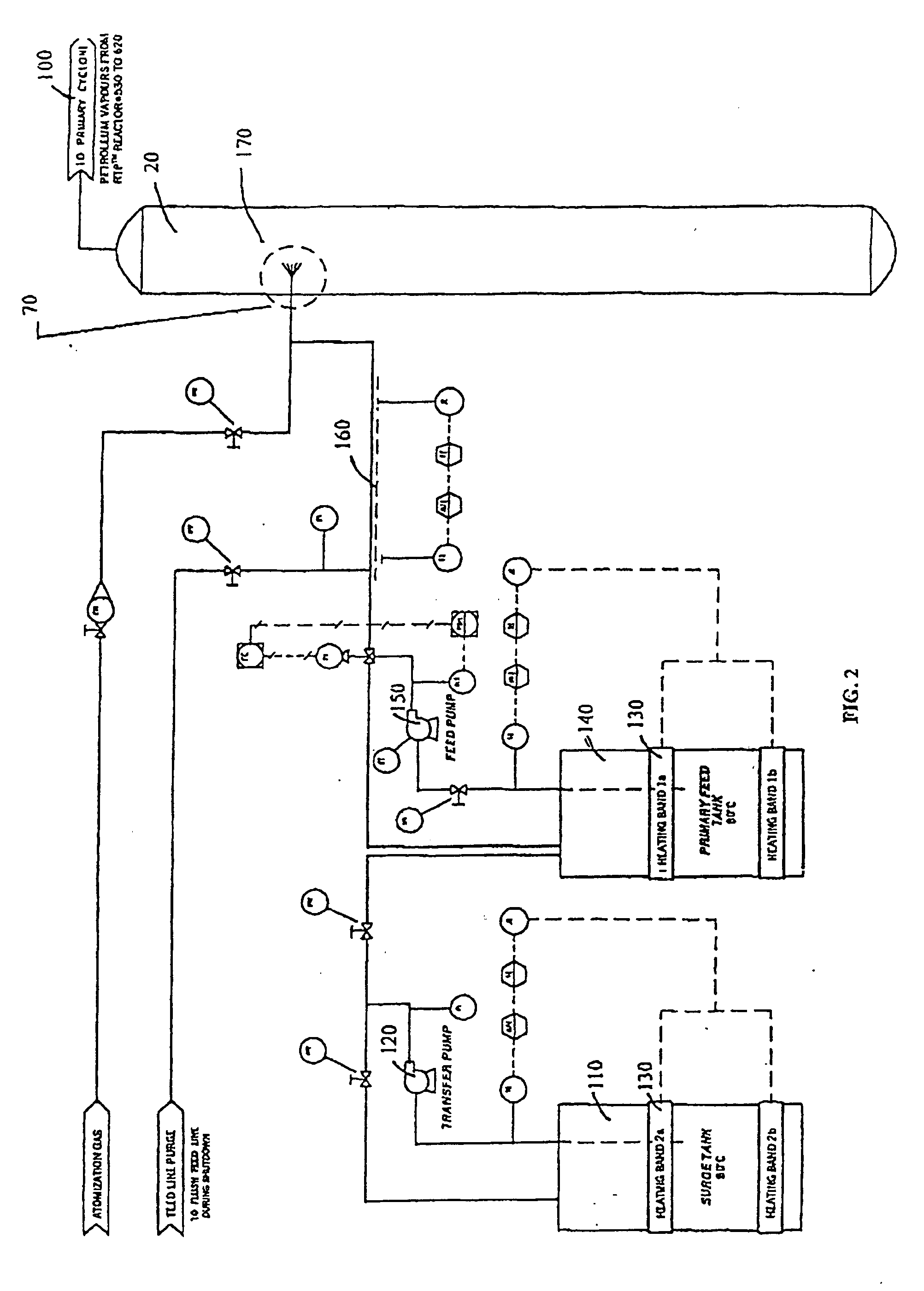

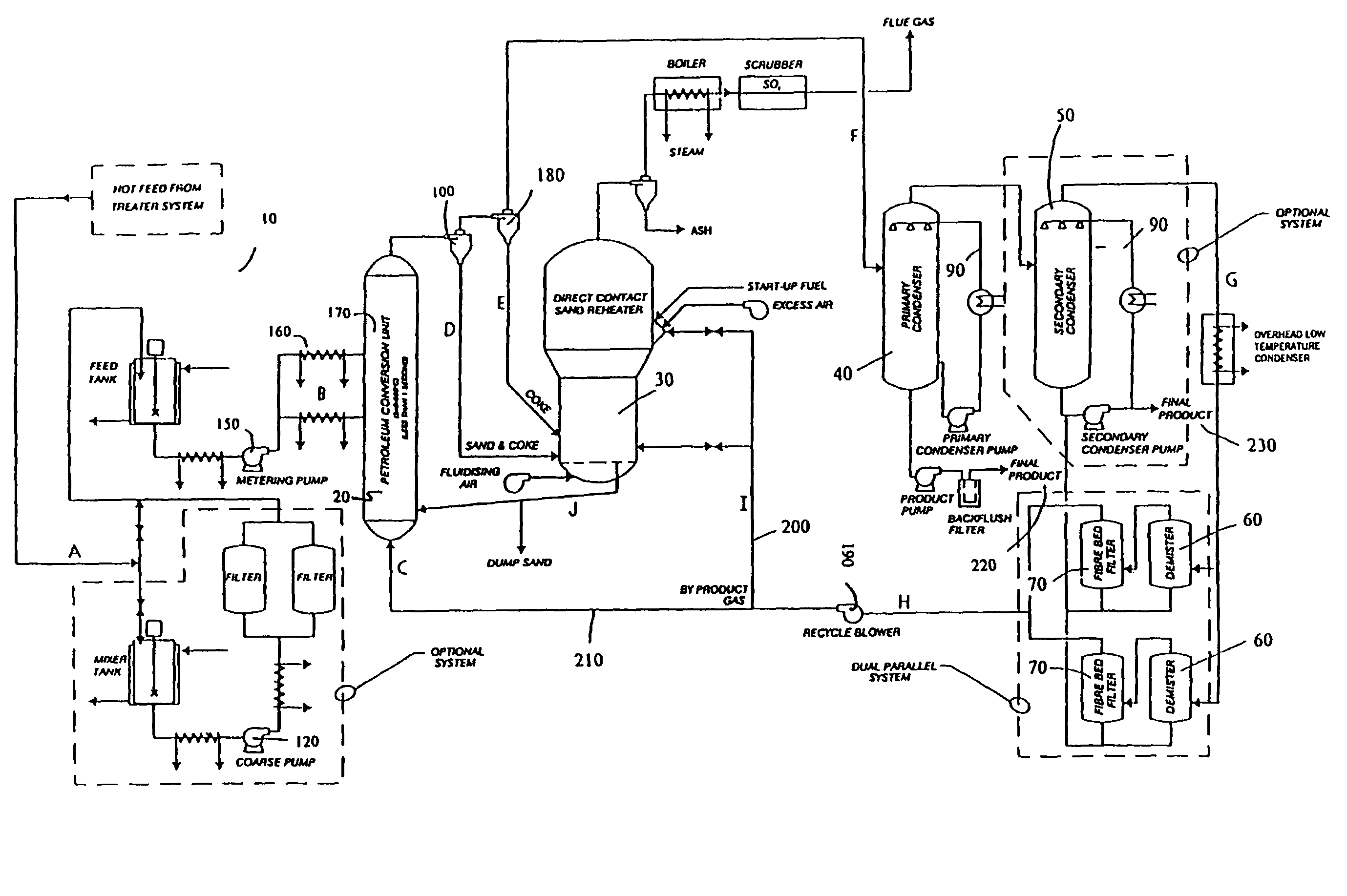

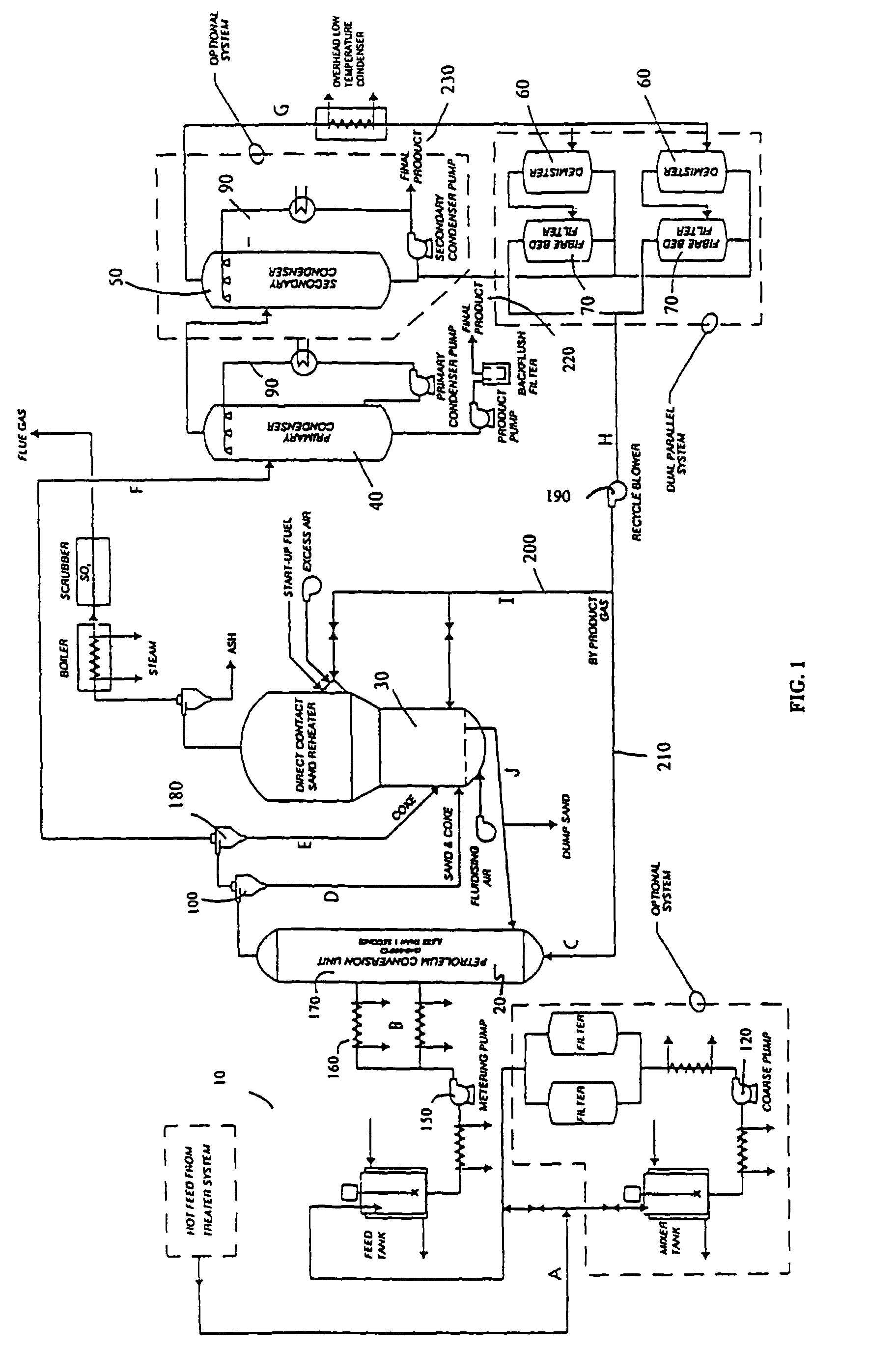

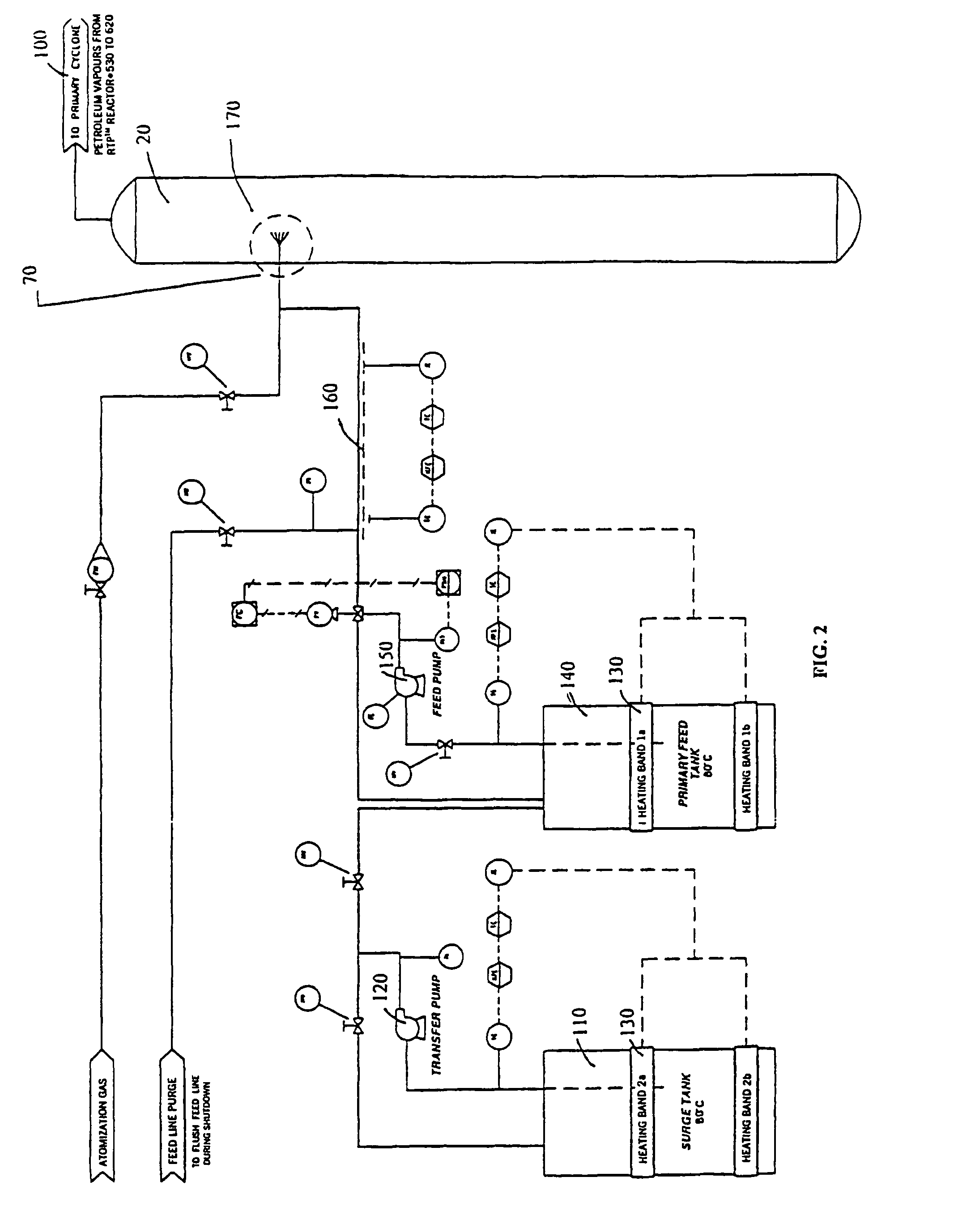

Products produced form rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS7270743B2Upgrade and reduce viscosityRapid heat treatmentThermal non-catalytic crackingLiquid organic insulatorsParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The process of the present invention provides for the preparation of a partially upgraded feedstock exhibiting reduced viscosity and increased API gravity. This process selectively removes metals, salts, water and nitrogen from the feedstock, while at the same time maximizes the yield of the liquid product, and minimizes coke and gas production. Furthermore, this process reduces the viscosity of the feedstock in order to permit pipeline transport, if desired, of the upgraded feedstock with little or no addition of diluents. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream. This invention also pertains to the products produced by the method.

Owner:IVANHOE HTL GASOLINEEUM

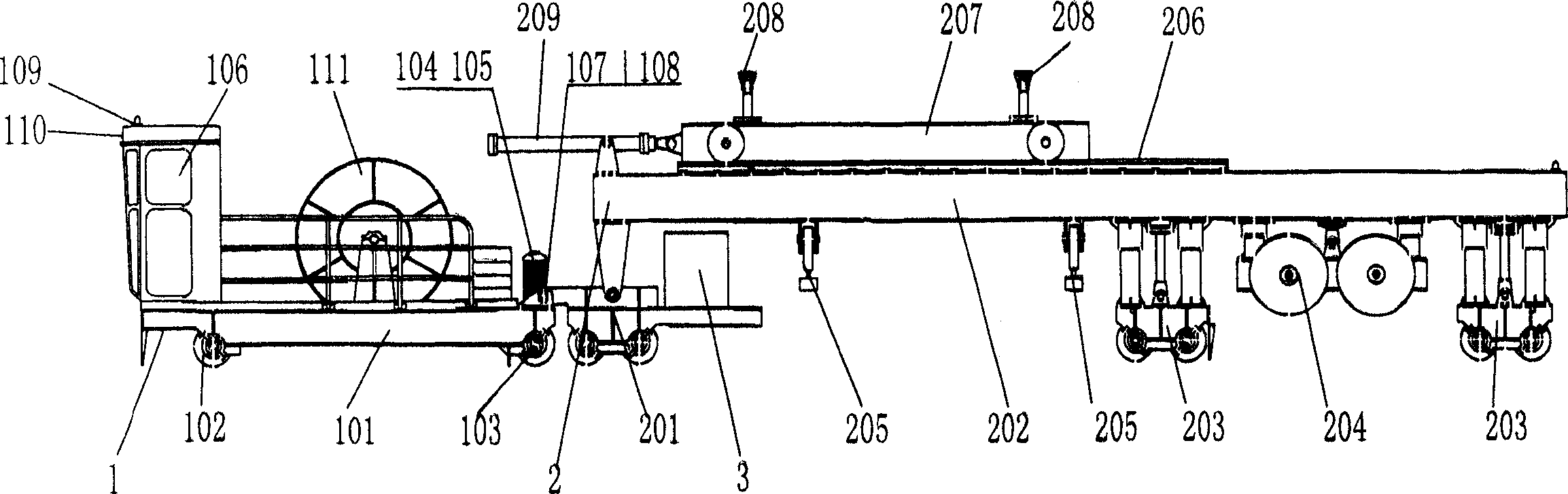

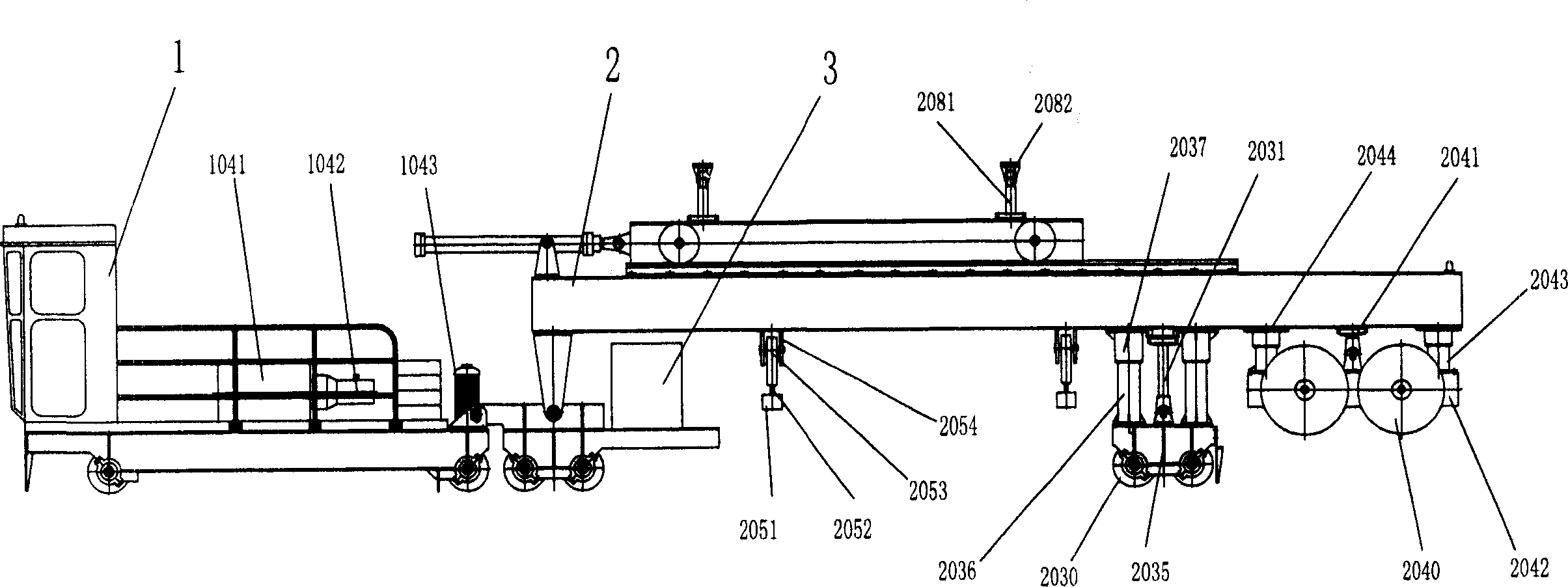

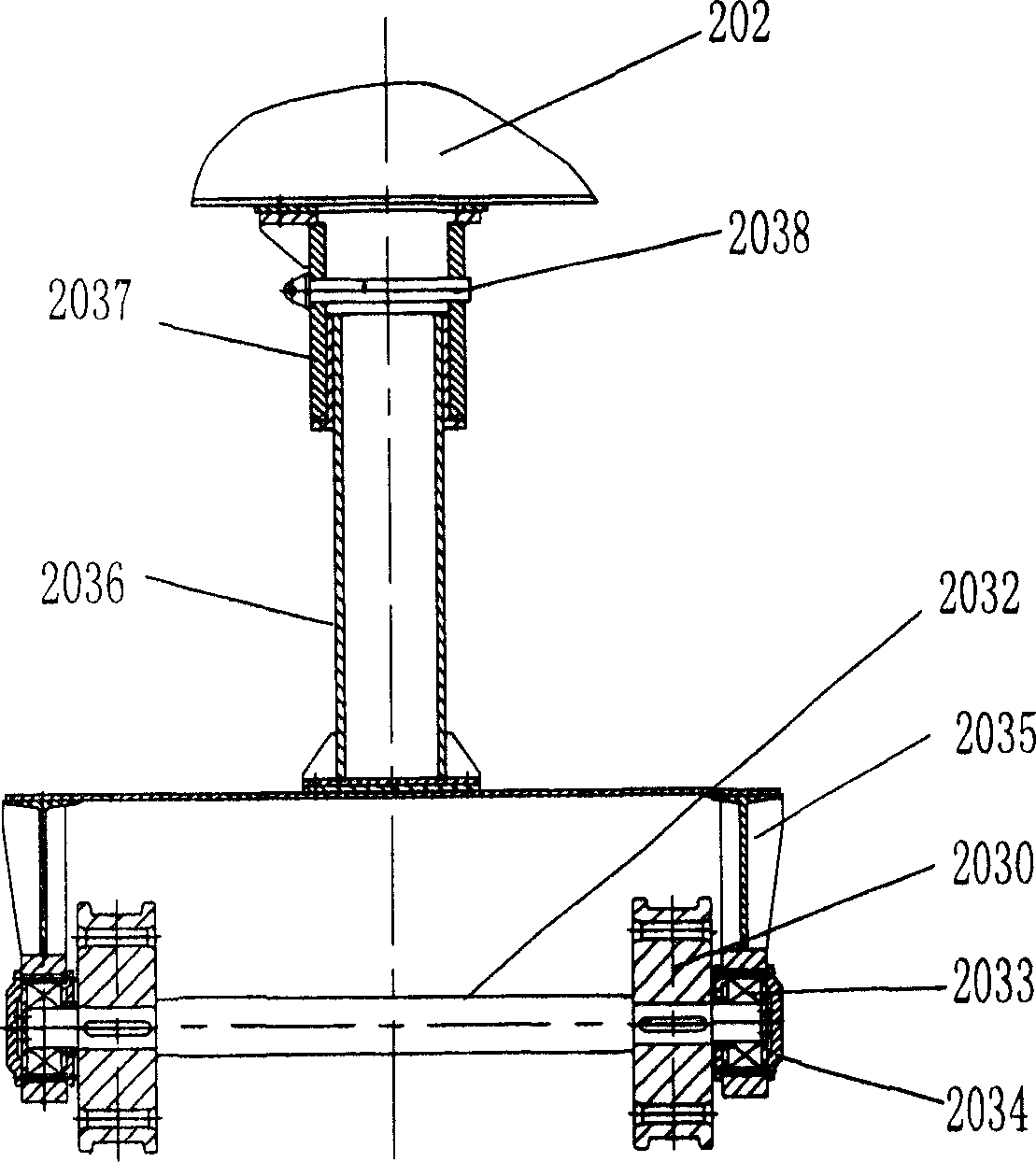

Tunnel pipe transporting mounting vehicle

InactiveCN1380212ACompact structureGuaranteed uptimeEarth drilling and miningWagons/vansDrive wheelPressure transmission

The tunnel pipe trasporting installation vehicle is formed from tractor truck, pipe-carrying vehicle and electric and hydraulic control system. The tractor truck in cludes chassis, driven wheel groupand driving wheel group, power device and speed reducer, cabin, track-cleaning device, warning signal light and headlight; the pipe-carrying vehicle includes front wheel group, front platform, pipe-carrying vehicle beam, lifting wheel group, lifting tyre group, supporting device, pipe-carrying carriage on the pipe-carrying vehicle beam and pipe-carrying lifting device; the described hydraulic control system includes tractor truck static pressure transmission system and hydraulic control system of pipe-carrying vehicle. Said vehicle is compact in structure, stable in operation, can transport, lift and install large-diameter PCCP pipe.

Owner:TAIYUAN HEAVY IND

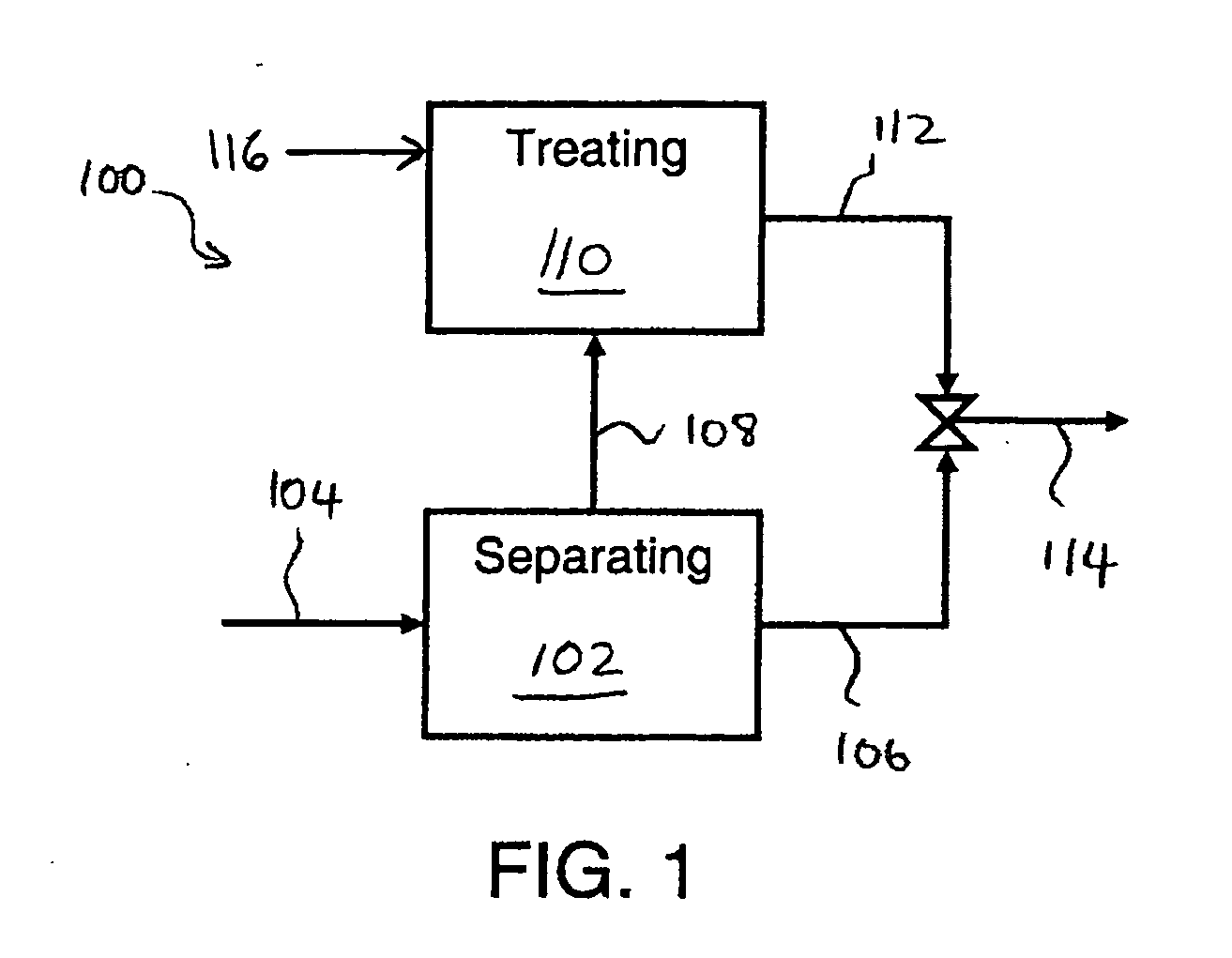

Process for treating a heavy hydrocarbon feedstock and a product obtained therefrom

InactiveUS20070108098A1Thermal non-catalytic crackingCatalytic crackingAPI gravityPipeline transport

A process for treating a heavy hydrocarbon feedstock is disclosed. The process involves separating the feedstock into a residue component and a light component, the residue component having a lower API gravity than the light component and treating at least a portion of the light component to produce a synthetic transport diluent suitable for combining with at least a portion of the residue component to produce a product which meets applicable criteria for pipeline transport.

Owner:STATOIL CANADA

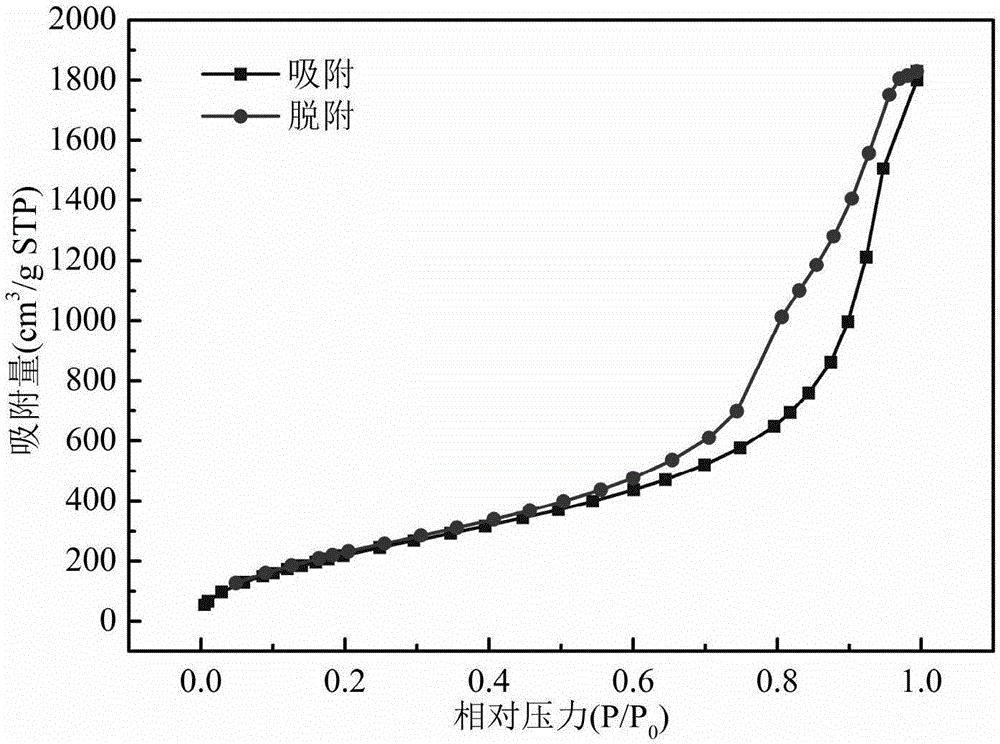

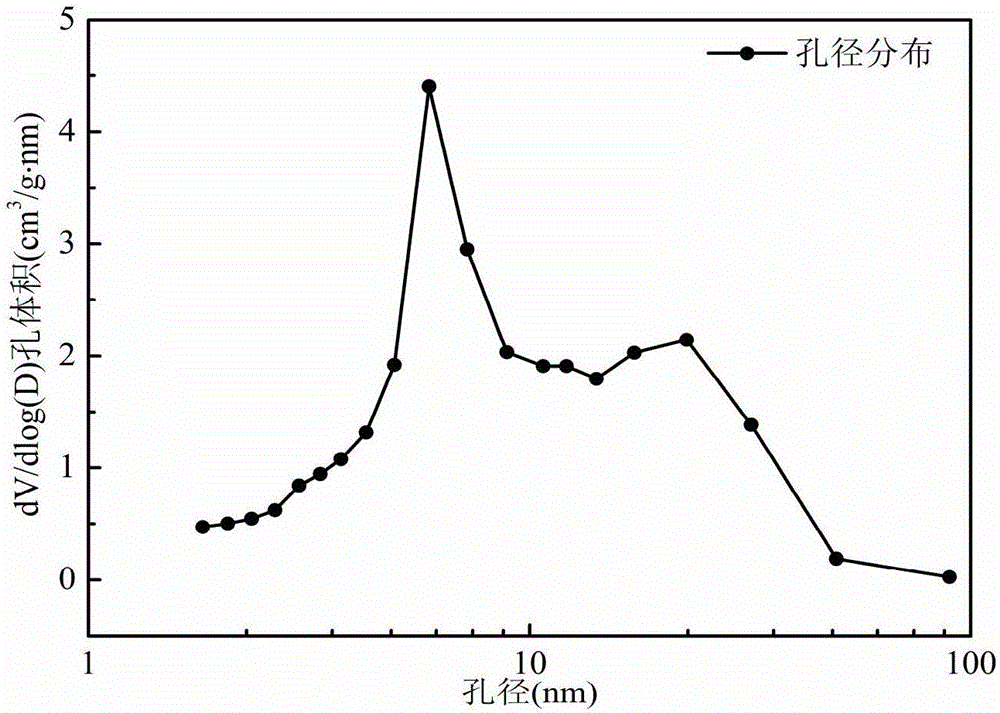

Fiber and silicon dioxide aerogel composite heat insulation material and preparation method thereof

The invention discloses a fiber and silicon dioxide aerogel composite heat insulation material and a preparation method thereof. The fiber and silicon dioxide aerogel composite heat insulation material has thermal conductivity of 0.020 to 0.040W / m.K, porosity of 80 to 90 percent, density of 0.10 to 0.18g / cm<3>, a specific surface area of 800 to 1,000m<2> / g, a hydrophobic angle of 120 to 170 degrees and an aperture distribution of 2 to 50nm. According to the prepared heat insulation material, the thermal property of aerogel is maximally reserved, the mechanical performance of the aerogel is improved, the material has certain strength and toughness, the compressive strength of the material is 0.3 to 5MPa, and the bending strength is 0.5 to 1.5Mpa. A preparation process is simple, short in period, low in equipment cost and safe in production, and the prepared material has high heat insulation performance, has the advantages of low thermal conductivity, low density, environment friendliness, safety, nontoxicity, flame retardancy, anticorrosion and the like compared with an ordinary inorganic heat-preservation material, and can be applied to a heat insulation material for pipeline transportation, a firefighting material and the like.

Owner:UNIV OF SCI & TECH OF CHINA

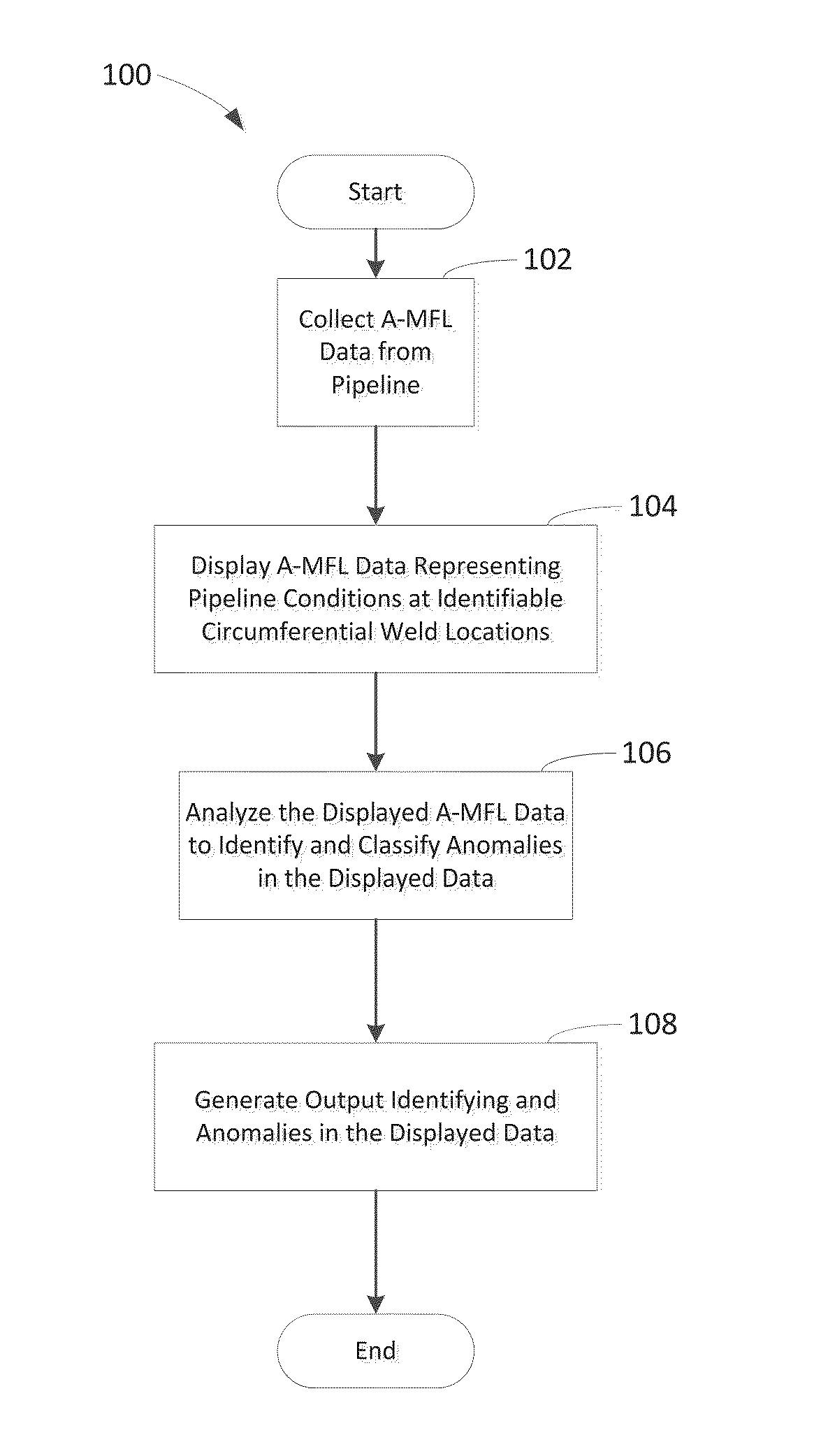

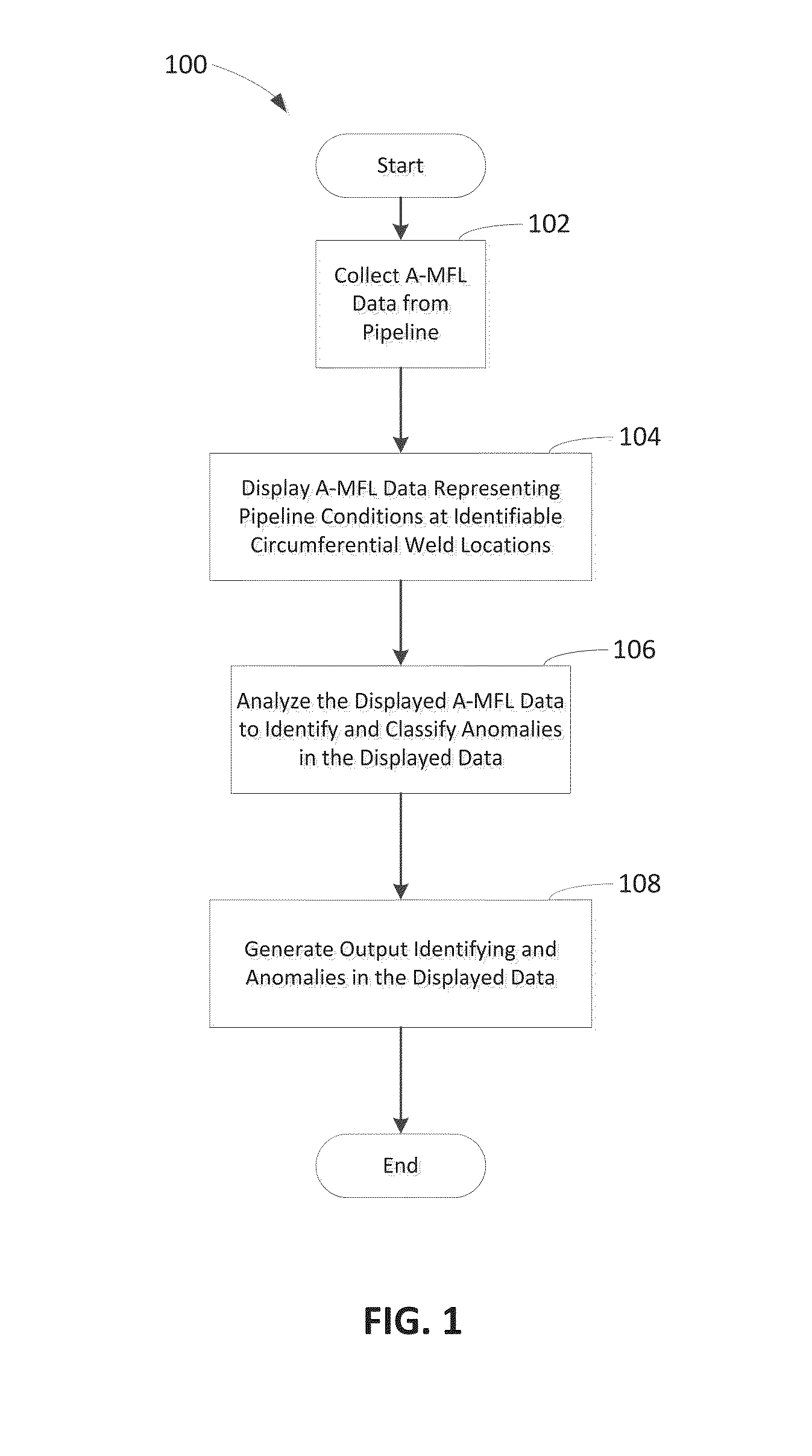

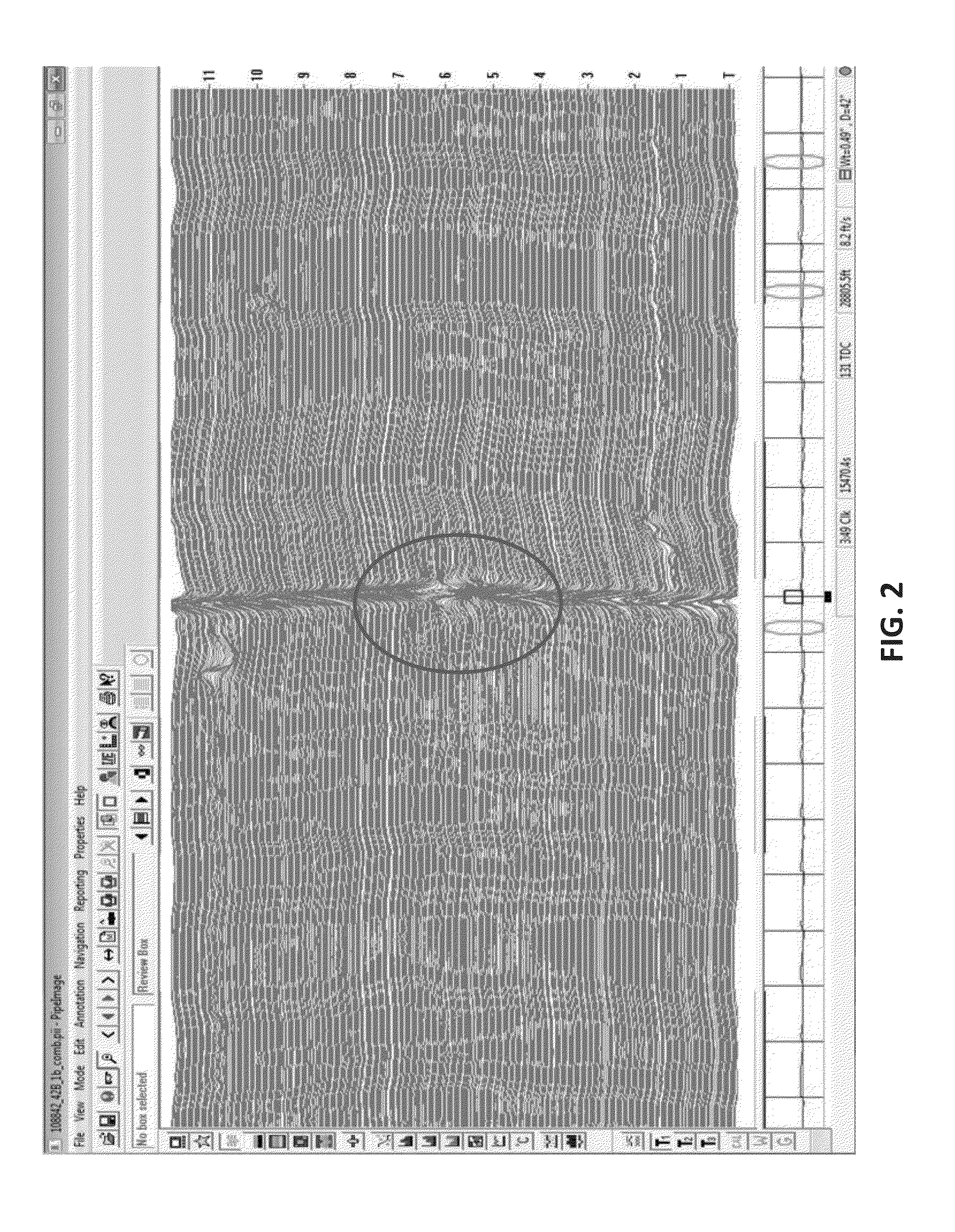

Method, machine, and computer medium having computer program to detect and evaluate structural anomalies in circumferentially welded pipelines

Embodiments of the present invention provide methods, machines, and a computer medium or media having computer programs to determine presence anomalies in circumferential welds of one or more pipelines transporting fluids associated with energy therethrough. Wave form analysis or pattern recognition in pipeline data such as magnetic flux leakage data is employed. A screening process, for example, does not affect or change how survey data is recorded such as in survey tools; only how it is analyzed after the survey data is completed. Embodiments of the machines, methods, and computer medium having computer programs can be used to screen for anomalies potentially threatening the structural integrity of the one or more pipelines so that site excavation can occur for confirmation and validation of the output results.

Owner:KINDER MORGAN

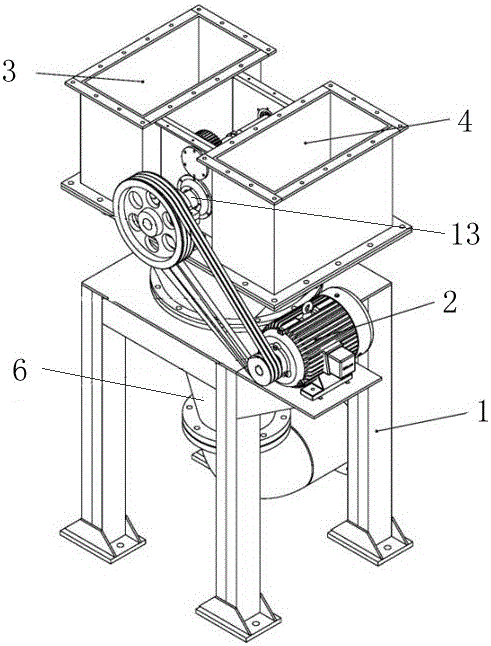

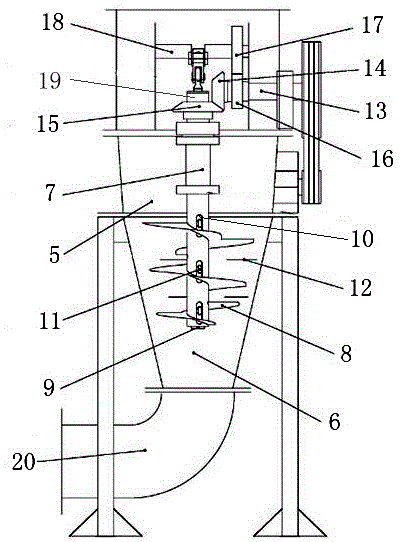

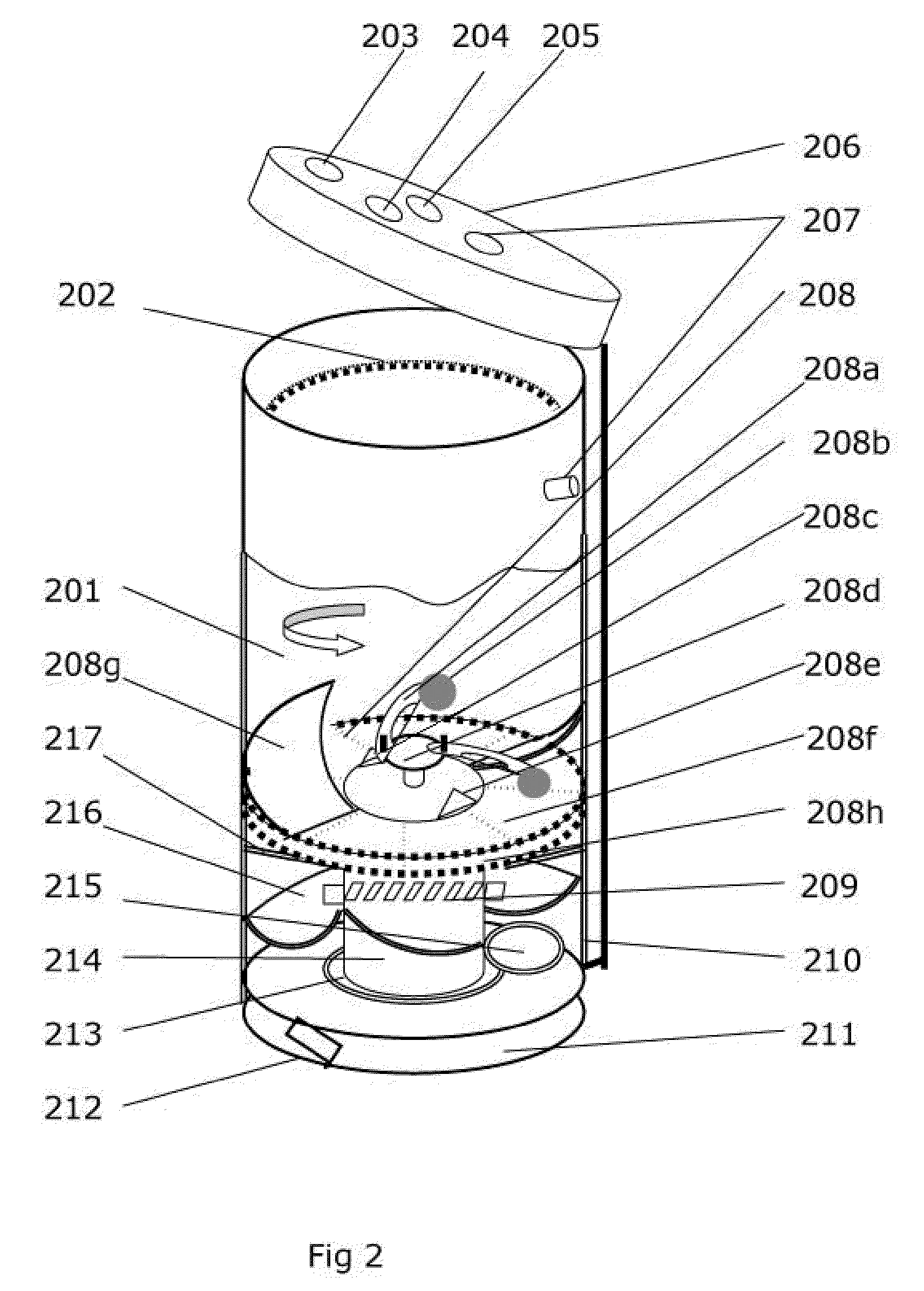

Pipeline transporting spiral crushing device for solid waste and household garbage

The invention belongs to the technical field of garbage disposal equipment and discloses a pipeline transporting spiral crushing device for solid waste and household garbage. The pipeline transporting spiral crushing device for the solid waste and the household garbage is used for solving the problems that because a direct recycling manner is adopted for scenic spots, stations, airports and other sites which are huge in waste amount and require instantaneous recycling in the prior art, a conveying pipeline can be blocked easily, and the gas explosion noise can be caused easily. The pipeline transporting spiral crushing device for the solid waste and the household garbage comprises a machine body which is provided with a feeding bin; the lower end of the feeding bin is communicated with a feeding channel; the lower end of the feeding channel is communicated with a spiral crushing barrel; the lower end of the spiral crushing barrel is communicated with a conveying pipeline of a matched pneumatic waste recycling system; a hollow rotating shaft is arranged in the spiral crushing barrel; spiral blades are arranged on the periphery of the hollow rotating shaft; a plurality of through grooves formed in the axial direction of the hollow rotating shaft are formed in the circumferential wall of the hollow rotating shaft; a core shaft capable of rotating along with the hollow rotating shaft and capable of moving up and down along the hollow rotating shaft is arranged in the hollow rotating shaft in a sleeved manner; and the core shaft is connected with a plurality of longitudinal cutters capable of sliding up and down in the through grooves.

Owner:浙江易顺通科技有限公司

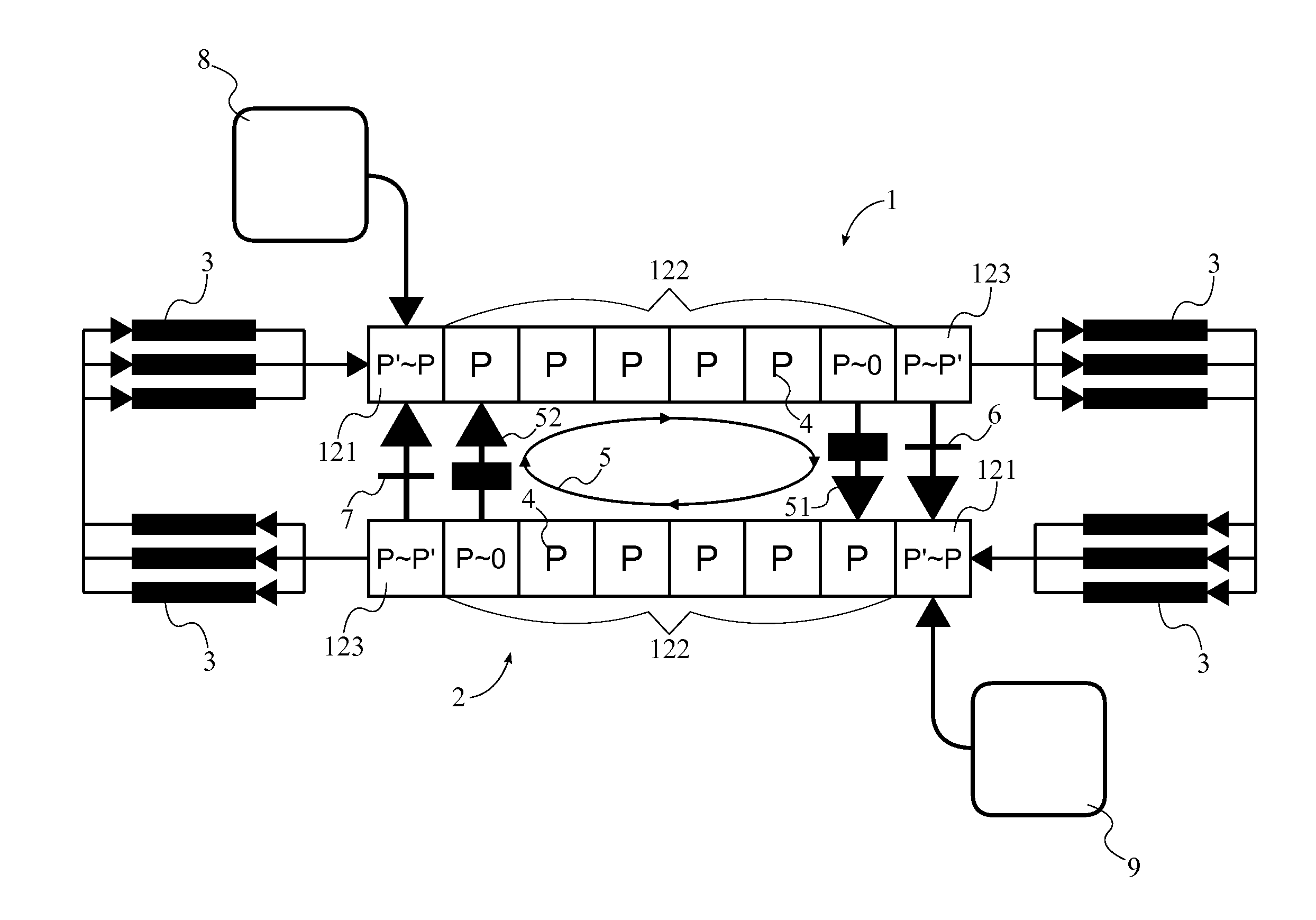

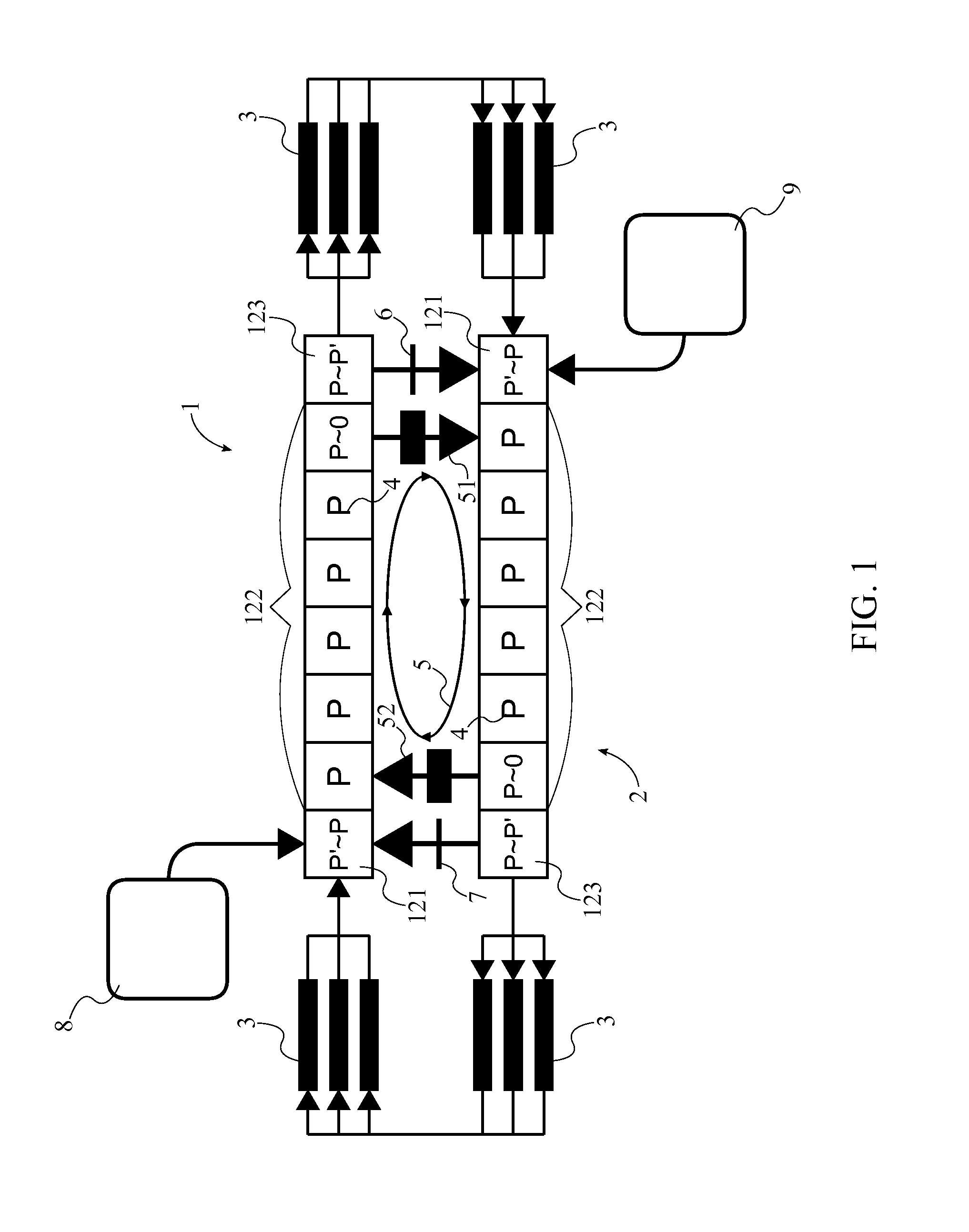

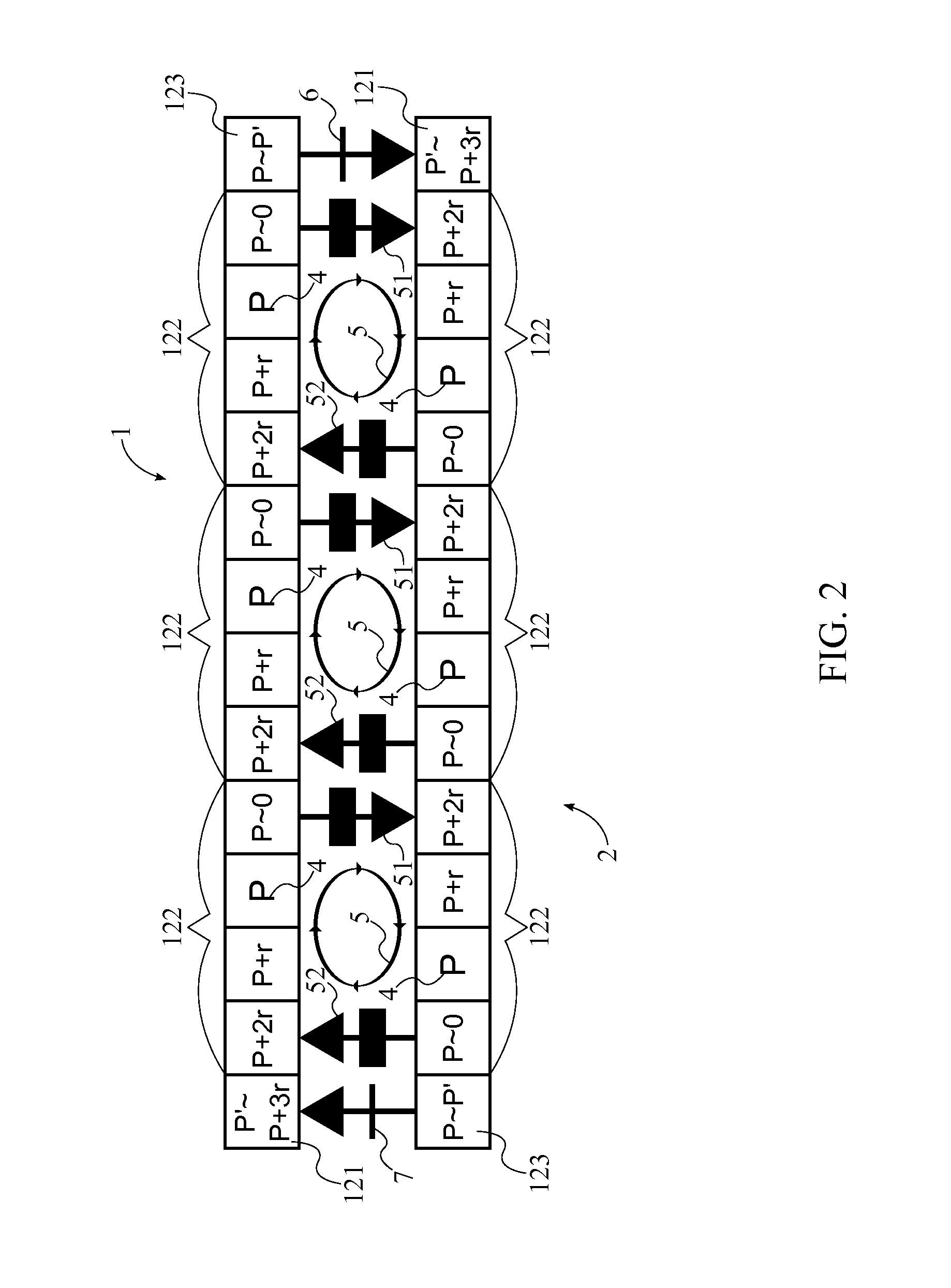

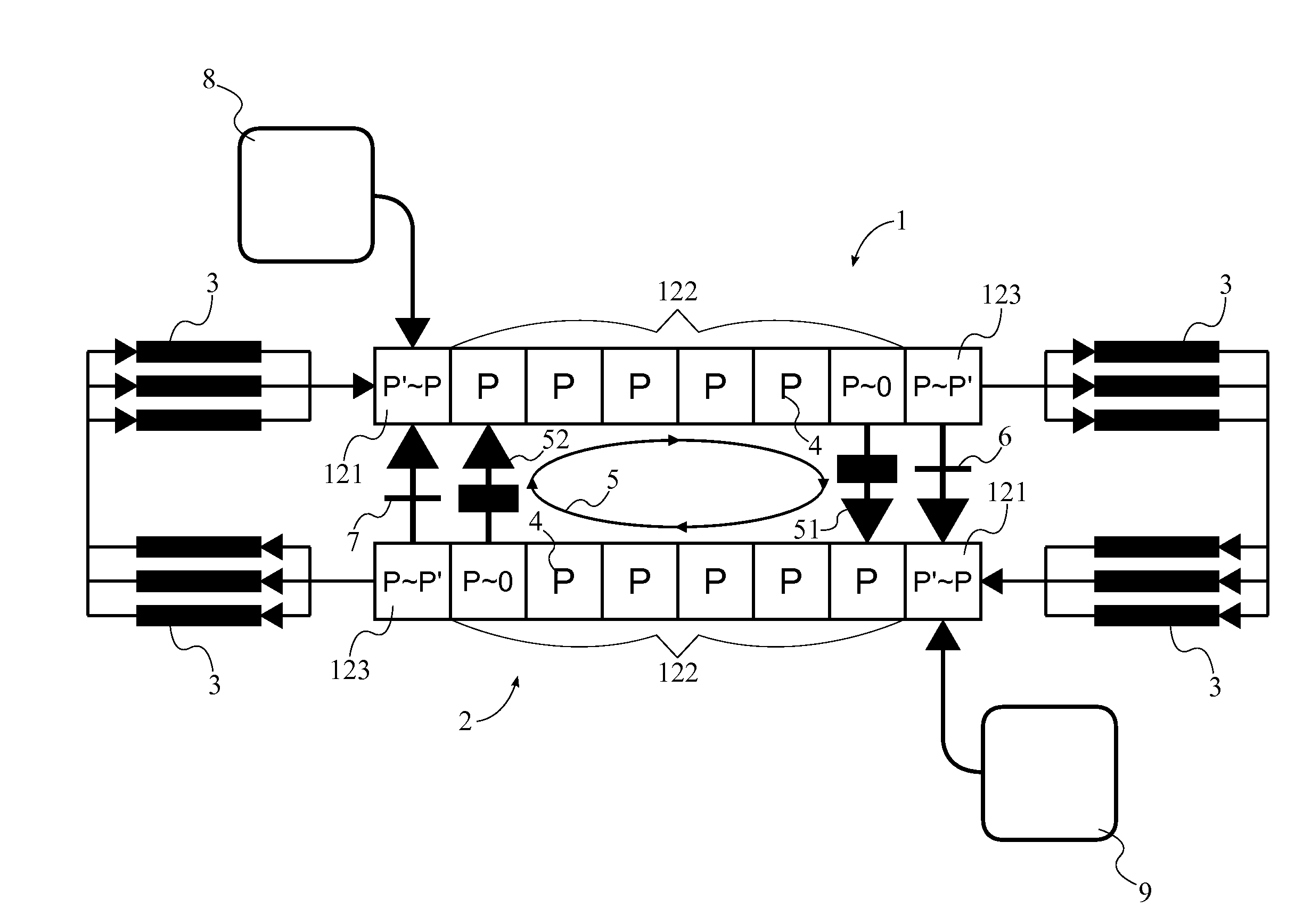

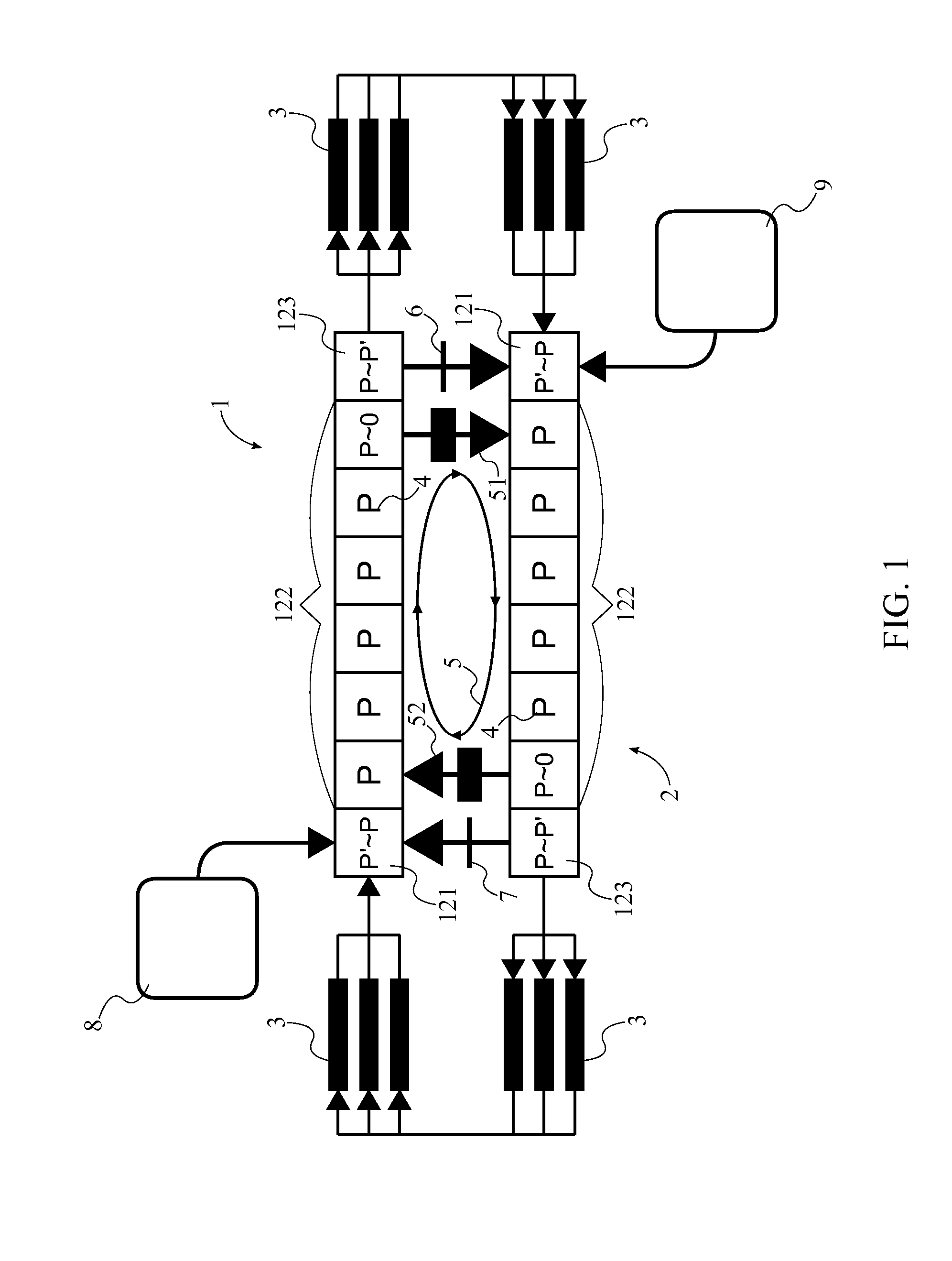

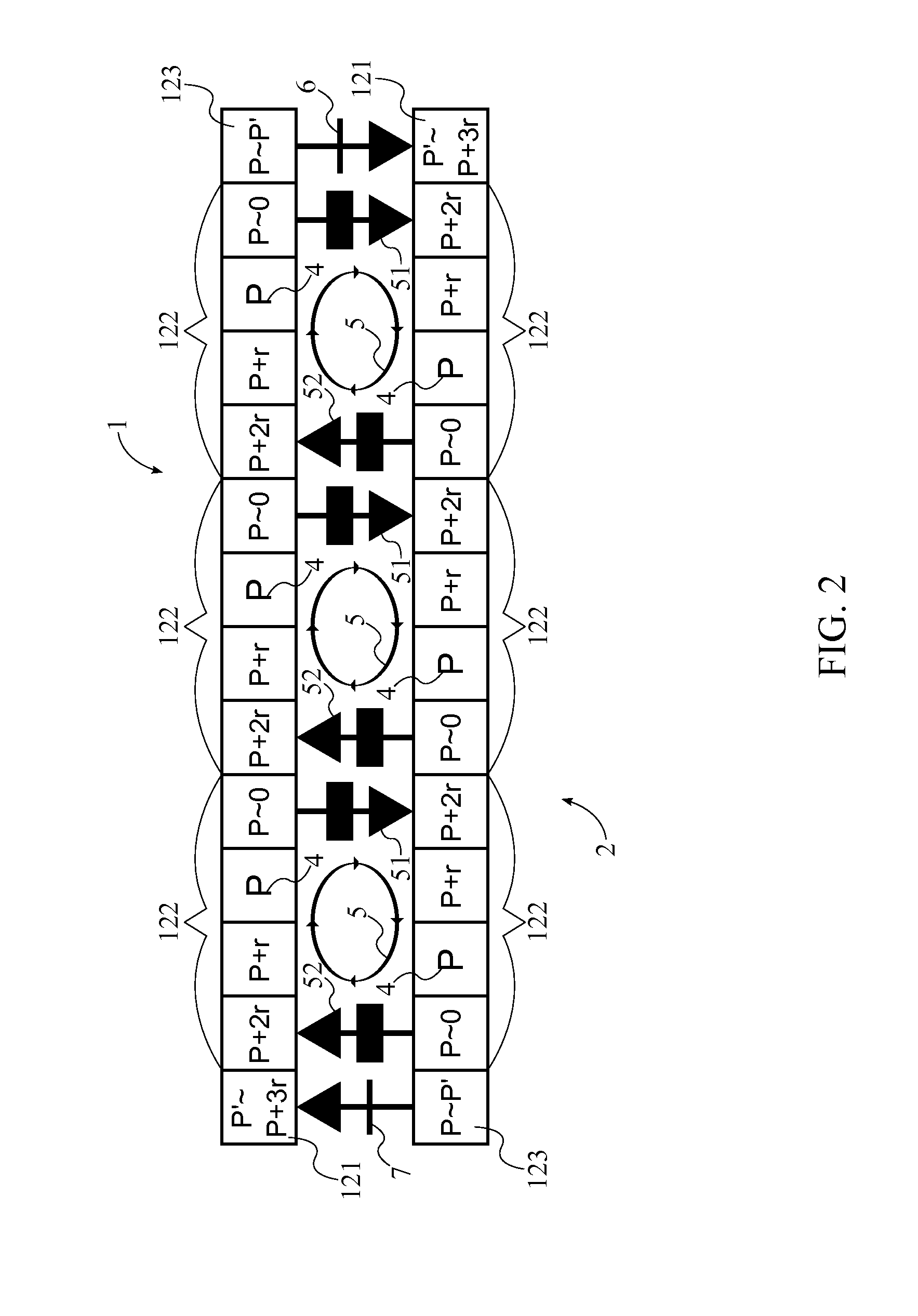

Circulated pneumatic tube transit system

A circulated pneumatic tube transit system is used to transport passengers / cargo along a pair of pneumatic tubes, which are positioned along each other. Capsules are movably suspended within the tubes by either a maglev system or wheels. The capsules travel in opposite directions in each tube so that the system provides back and forth transportation between two destinations. A fluid loop mechanism cycles a volume of air through the tubes as a means to propel the capsules through each tube. A series of fluid loop mechanism can be air multipliers as the volume of air cycles through the tubes. Two one-directional valves are located at opposite ends of the tubes and are used to transfer the kinetic energy for an arriving capsule within one tube into kinetic energy for a departing capsule within the other tube.

Owner:ZHOU BO

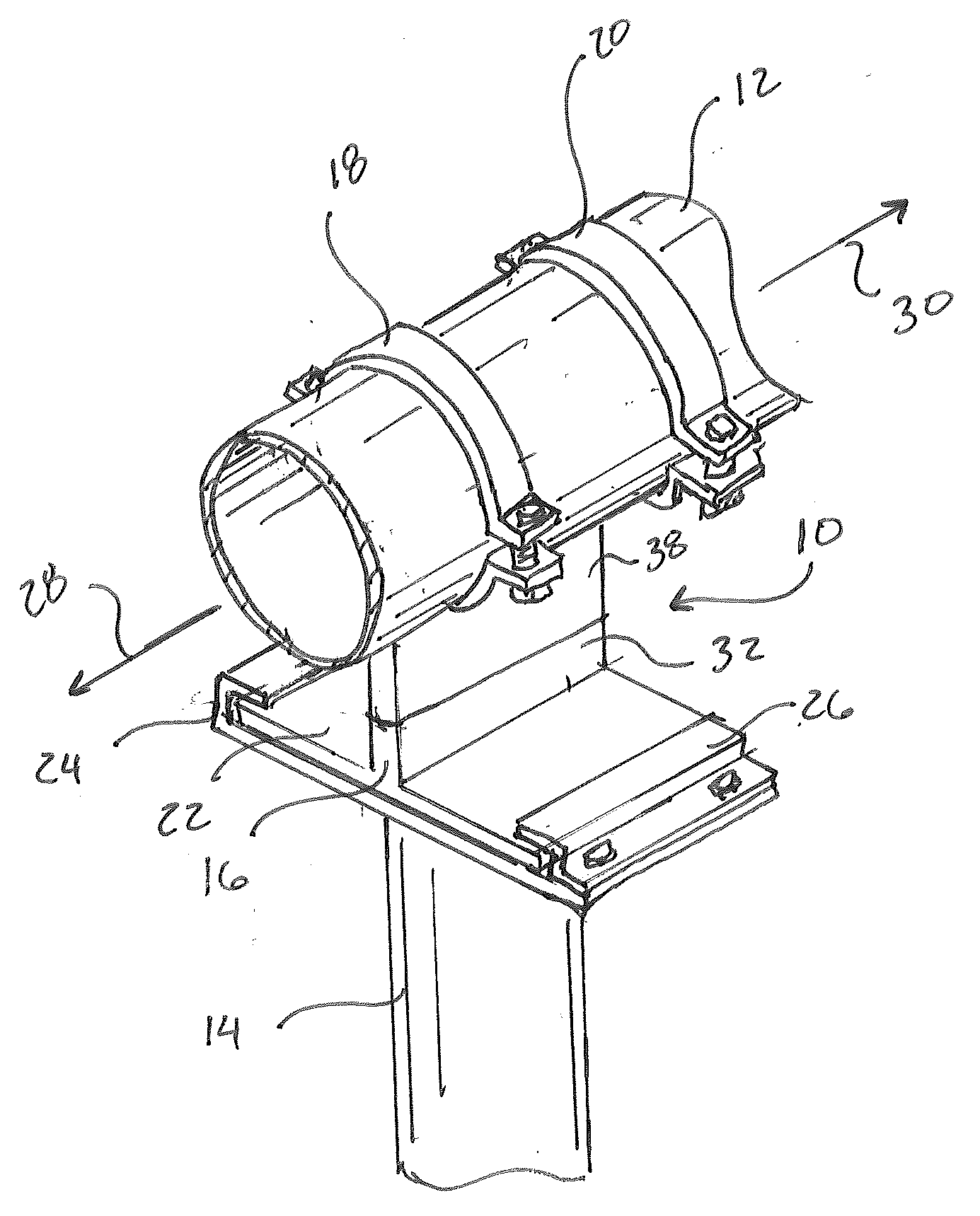

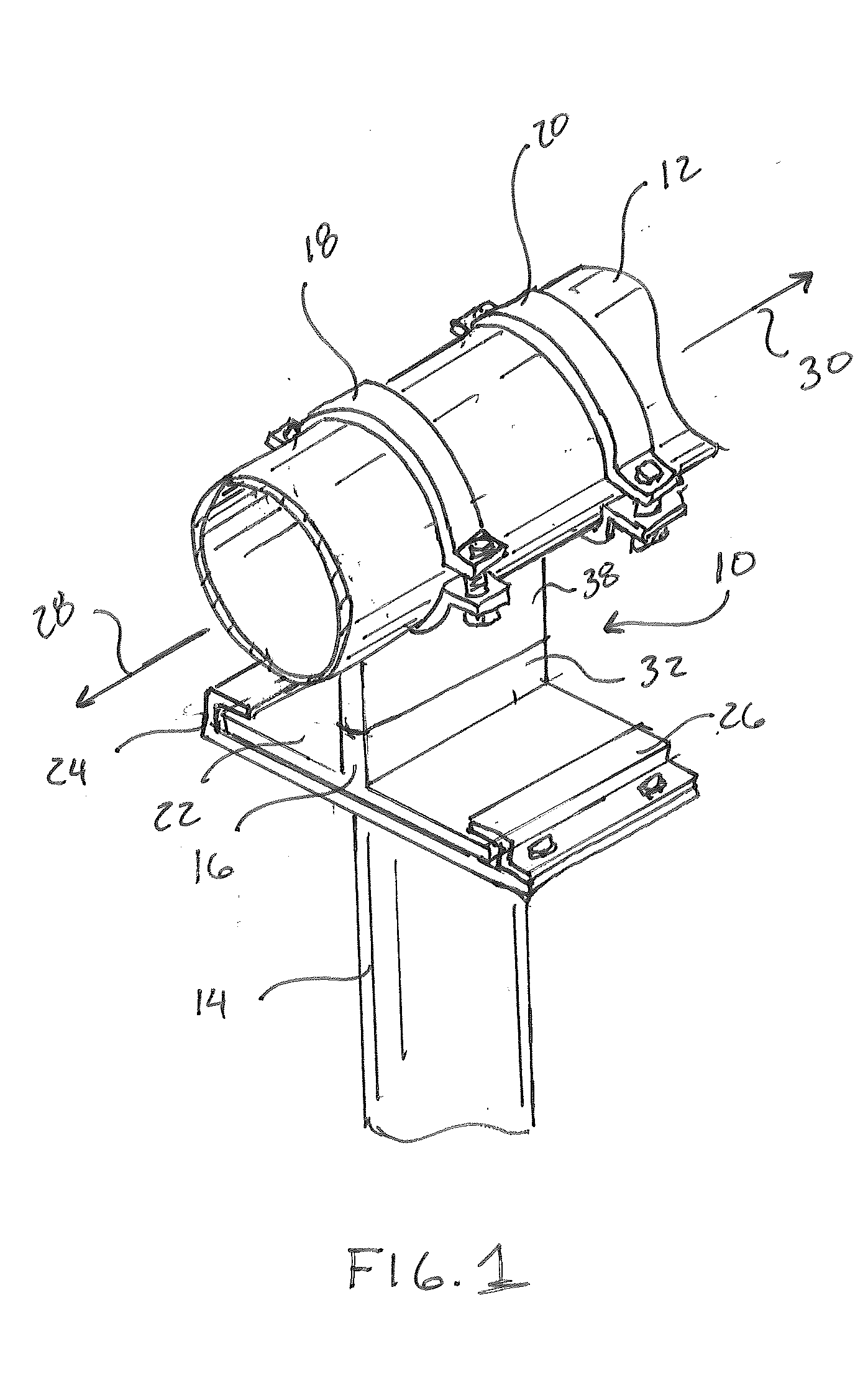

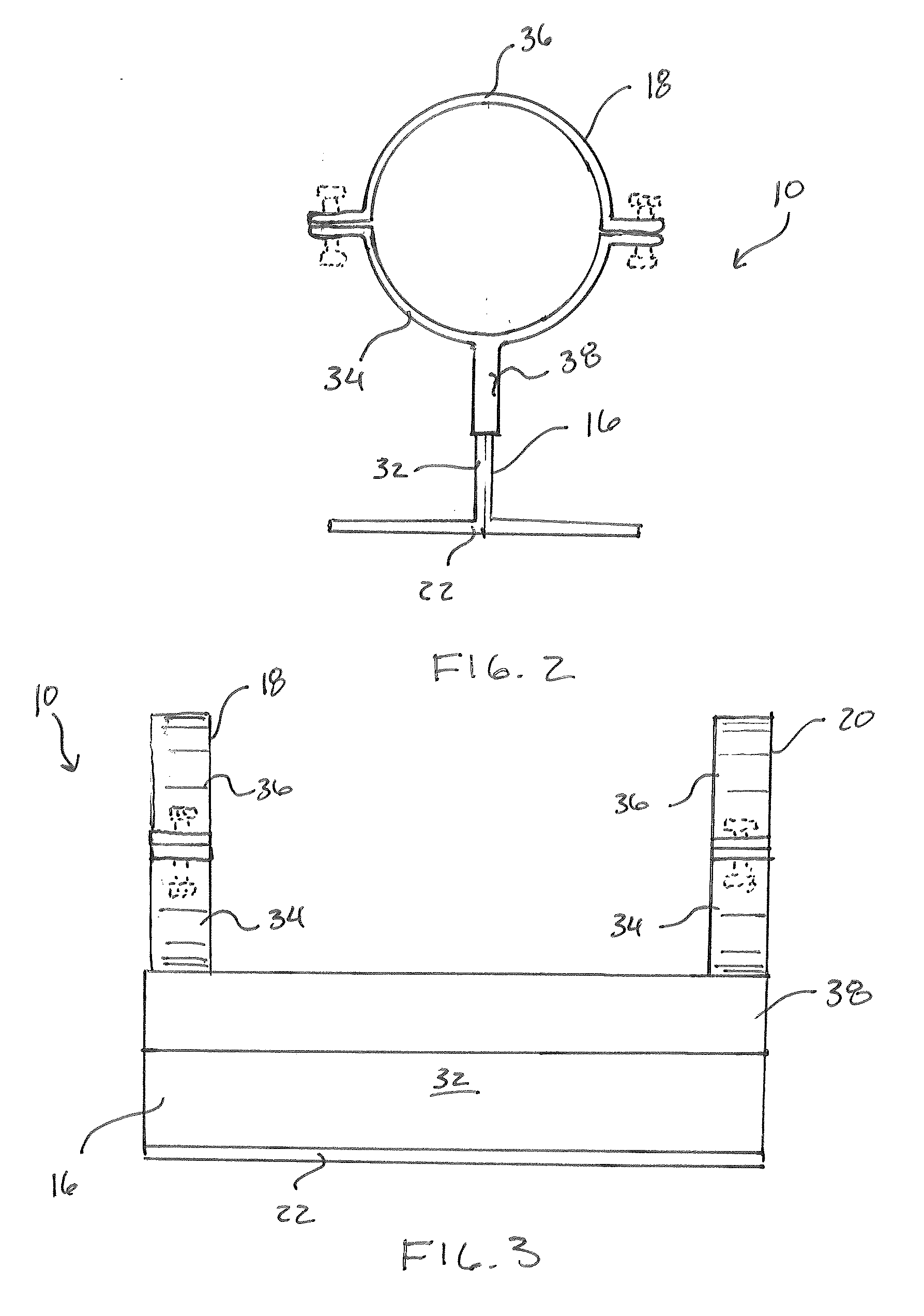

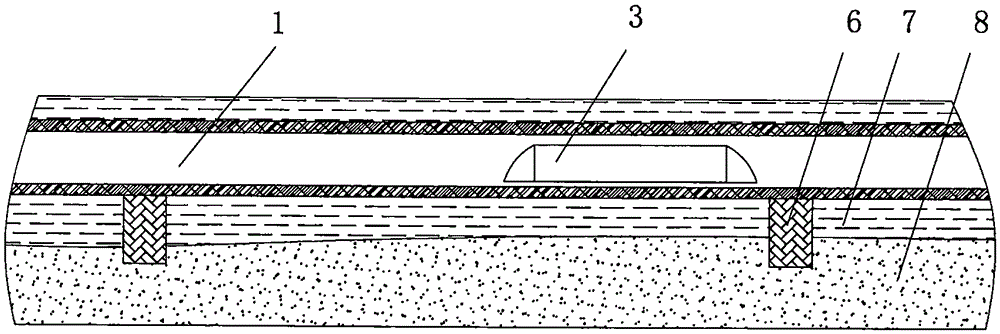

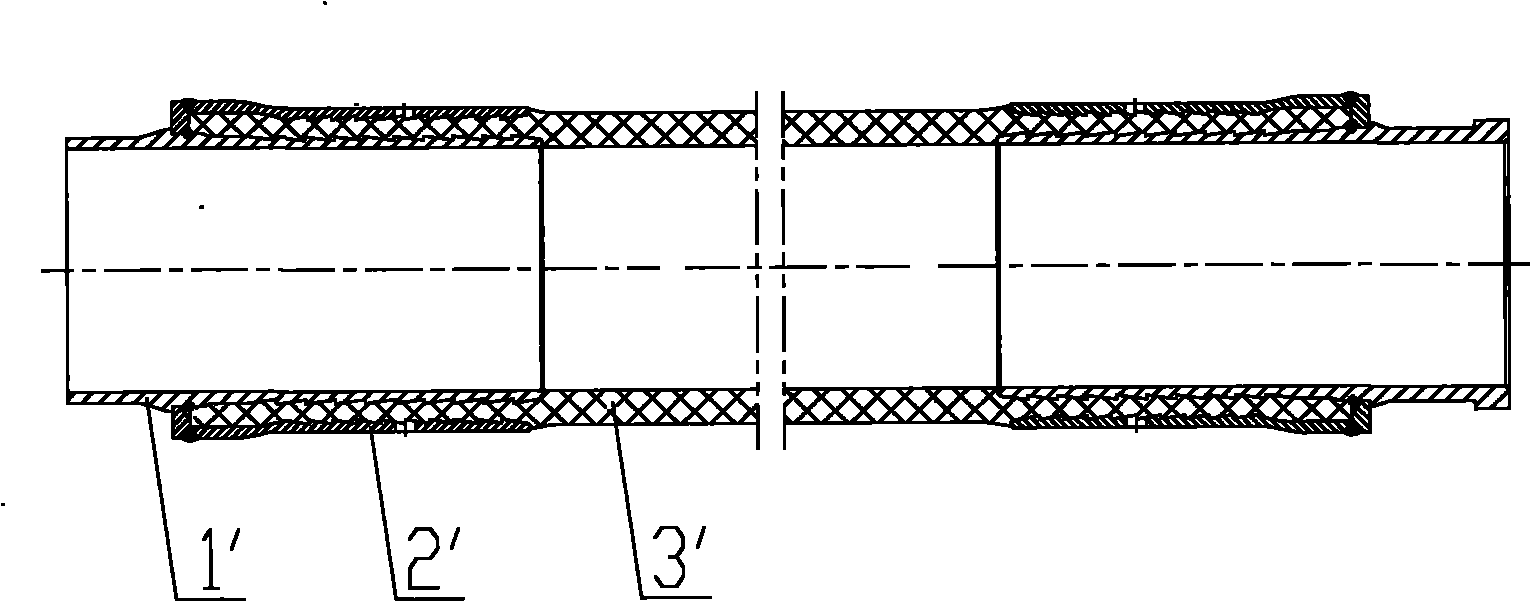

Insulated Pipeline Support

A pipeline support for securing an elevated pipeline to a piling is provided. The pipeline support electrically insulates the pipeline from the piling without using an insulating block disposed between the pipeline support and the piling. The pipeline support is also moveable relative to the piling to move along with the thermal expansion and contraction of the pipeline. The pipeline support includes a pipe shoe and a pipeline clamp attached to the pipe shoe. A coating of an electrical insulator material substantially covers the pipeline clamp and an upper half of the pipe shoe.

Owner:OCONNELL LESLIE

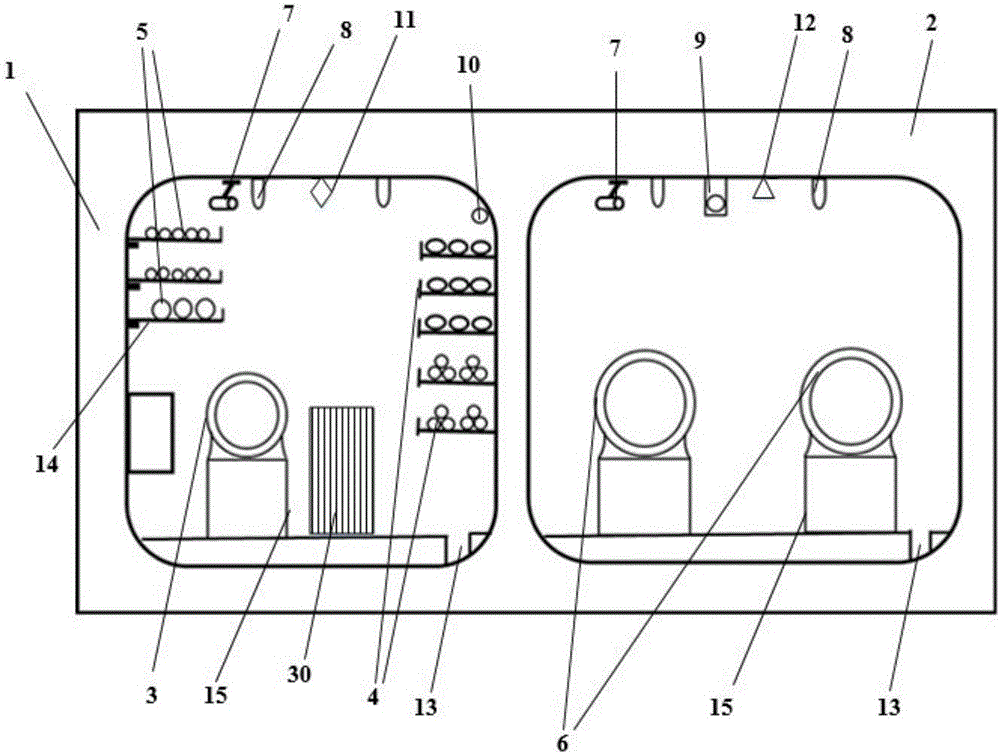

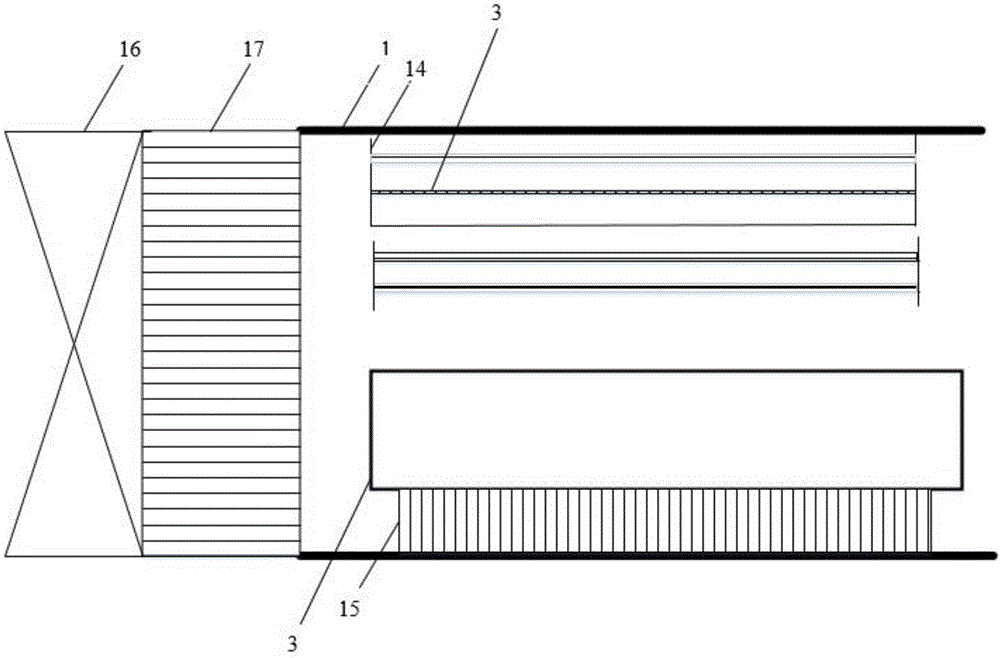

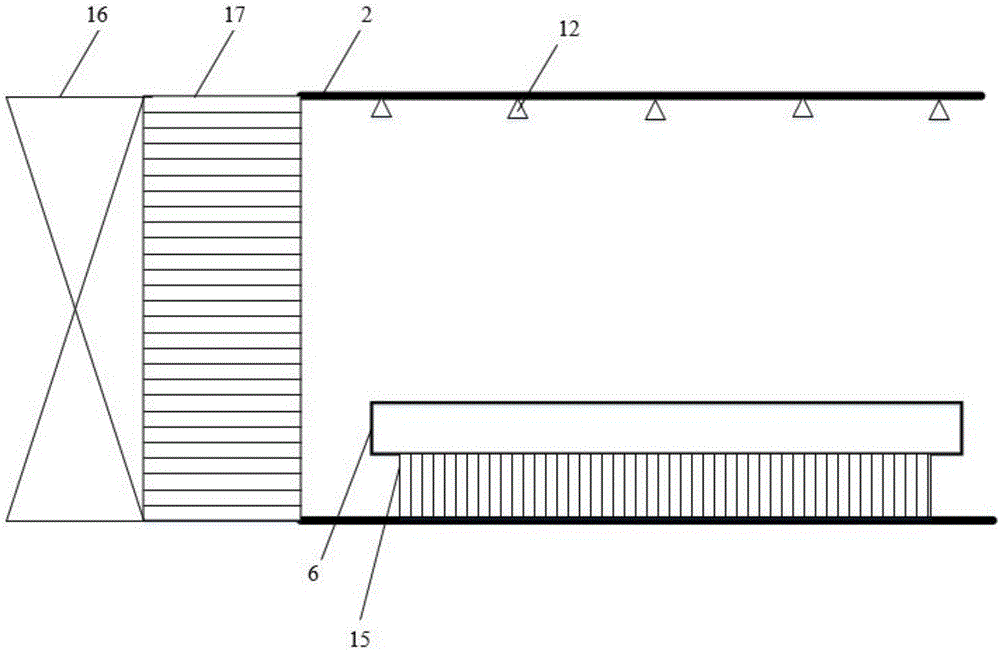

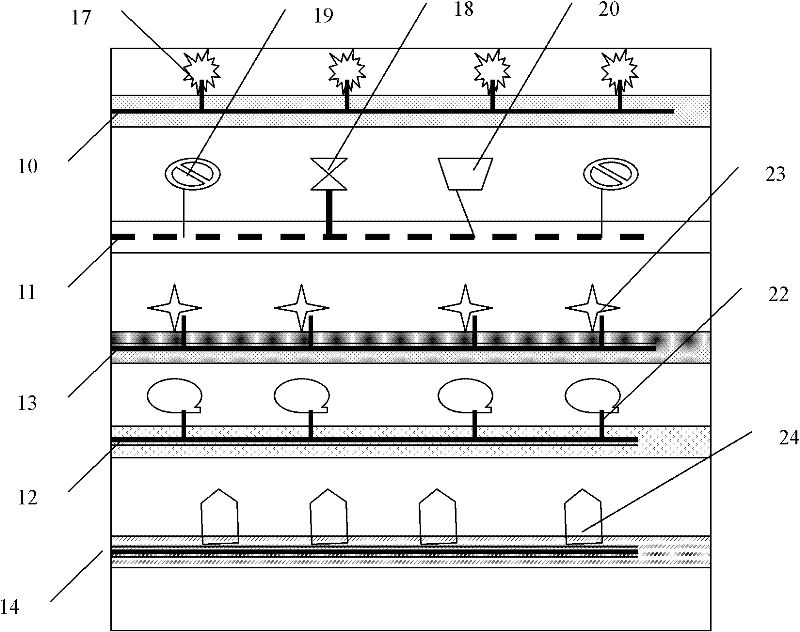

Fire experiment device based on city underground comprehensive pipe rack

The present invention discloses a fire experiment device based on a city underground comprehensive pipe rack. The pipe rack comprises a left side pipe rack and a right side pipe rack; a water supply pipeline is arranged on the ground of the left side pipe rack through a pipeline support; a high electric cable and a weak electric cable are respectively arranged at two sides of the left side pipe rack through an insulation support; a camera and an illumination lamp are installed at the top of the left side pipe rack; a drainage ditch is arranged at the bottom of the left side pipe rack; a gas pipeline is arranged on the ground of the right side pipe rack through the pipeline support; a camera and an illumination lamp are installed at the top of the right side pipe rack; and a drainage ditch is arranged at the bottom of the right side pipe rack. The fire experiment device comprises a transverse ventilation control system, a simulation fire source system, a fire detection system, a water mist fire extinguishing system and a water spray fire extinguishing system. The fire experiment device based on a city underground comprehensive pipe rack can simulate the city underground comprehensive pipe rack fire experiment so as to provide scientific reference for underground comprehensive pipe rack control and optimization, power-on electric wire propagating, fire detection and fire extinguishing.

Owner:HEFEI UNIV OF TECH

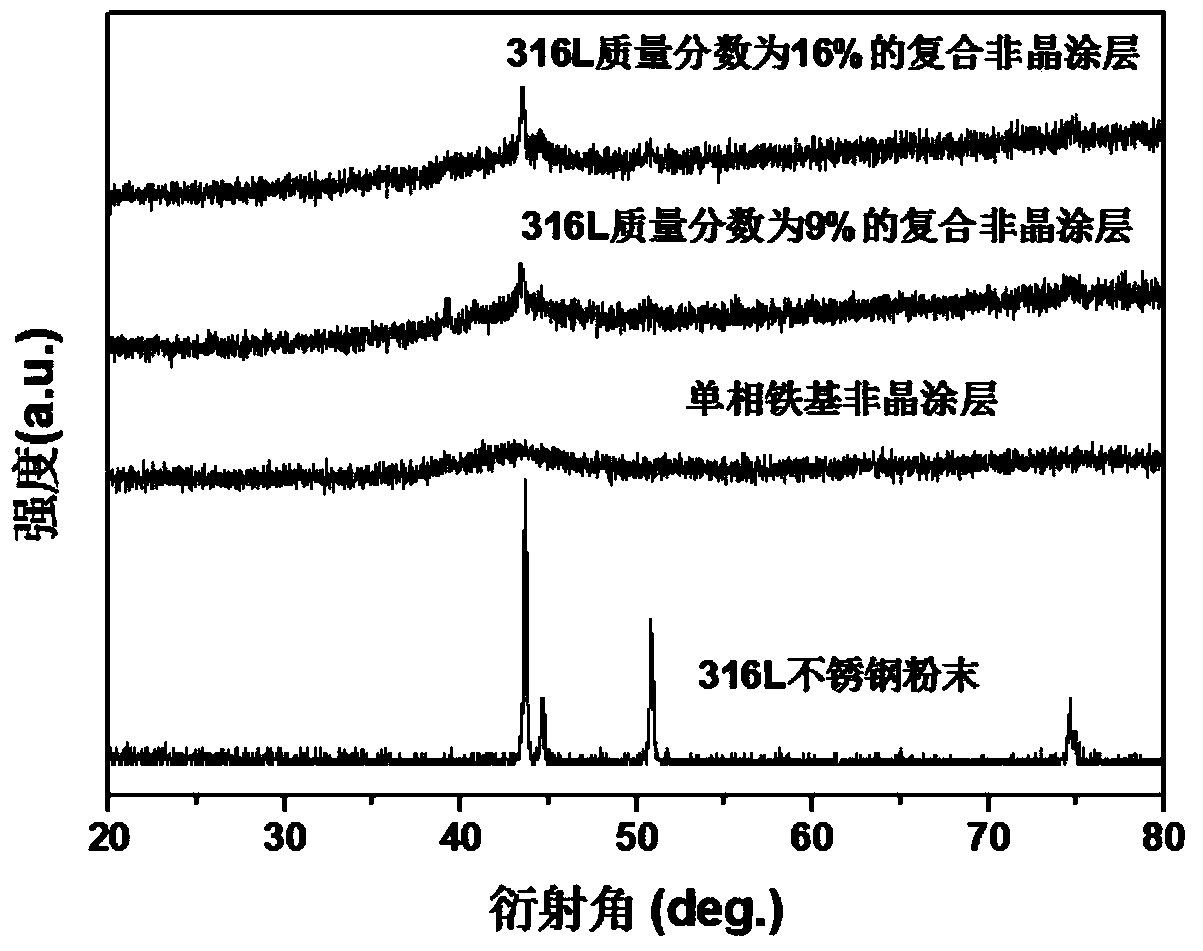

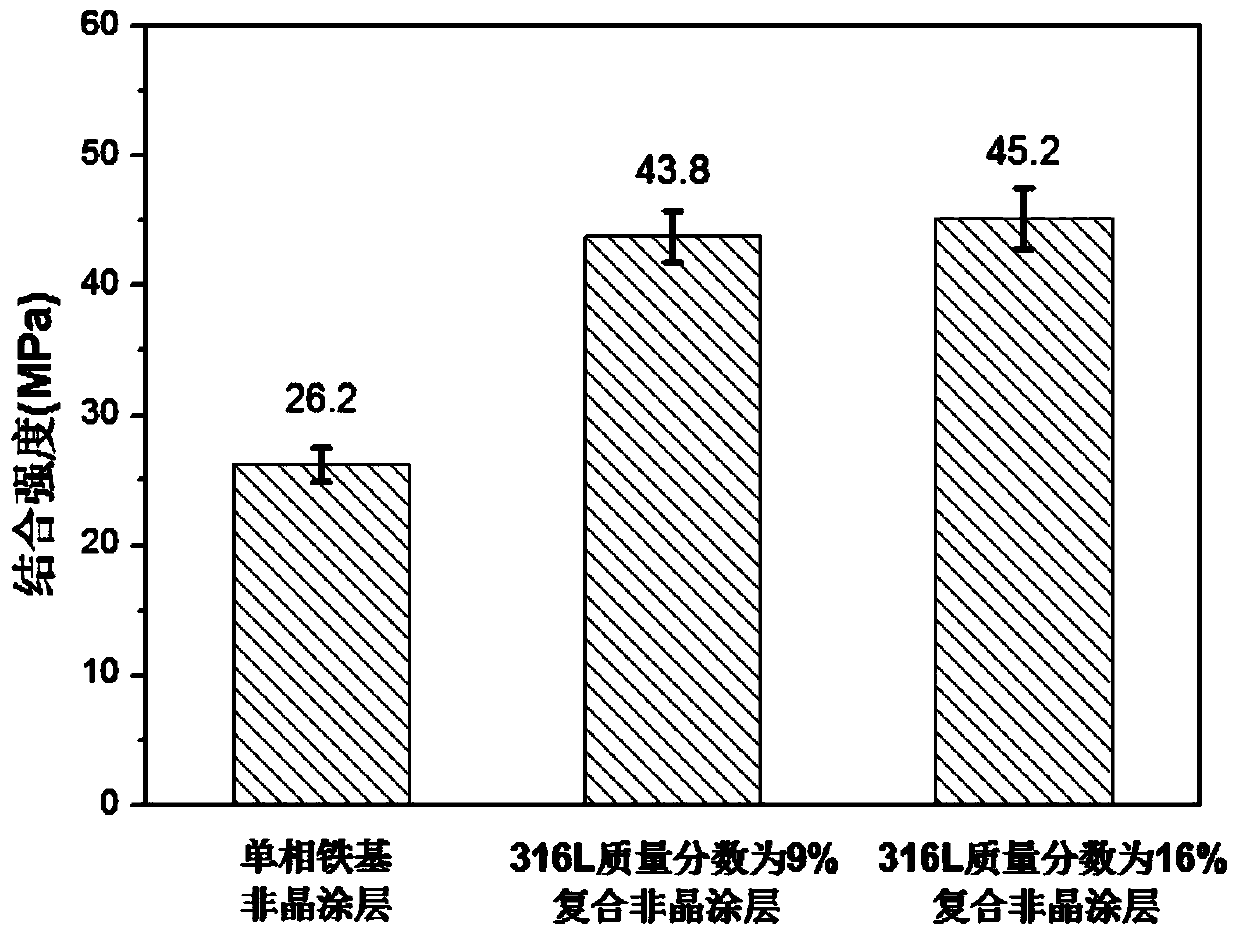

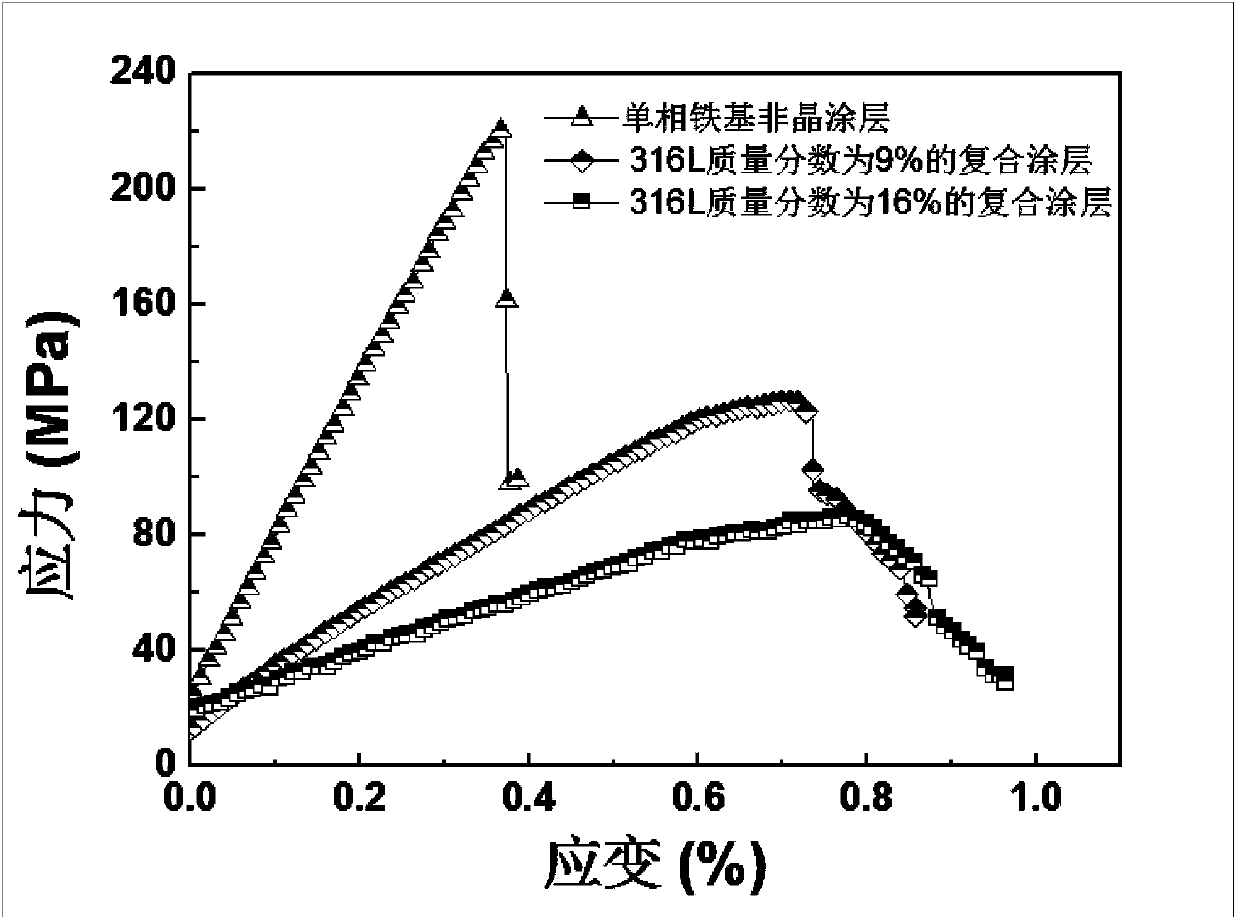

Novel tough particle strengthened iron-based amorphous composite coating

The invention provides a novel tough particle strengthened iron-based amorphous composite coating. The mechanical composite powder of iron-based amorphous alloy powder and tough metal powder is used as a raw material, wherein the iron-based amorphous alloy powder consists of the following elements and unavoidable impurities in percentage by atom: 10.0-17.0% of Cr, 12.0-20.0% of Mo, 4.0-8.0% of B, 10.0-18.0% of C, 0.0-5.0% of Y and the balance of Fe; the tough metal powder can be stainless steel powder, nickel-based metal powder, cobalt-based metal powder, aluminum-based metal powder or copper-based alloy powder; the coating is prepared by the high velocity oxy-fuel technology. The iron-based amorphous composite coating provided by the invention has dense structure, low porosity, relatively high toughness and good bonding strength with the metal substrate. The composite coating has great application prospects in the industrial fields such as waterpower and oil-gas field development facilities, pipeline transportation, ship decks and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

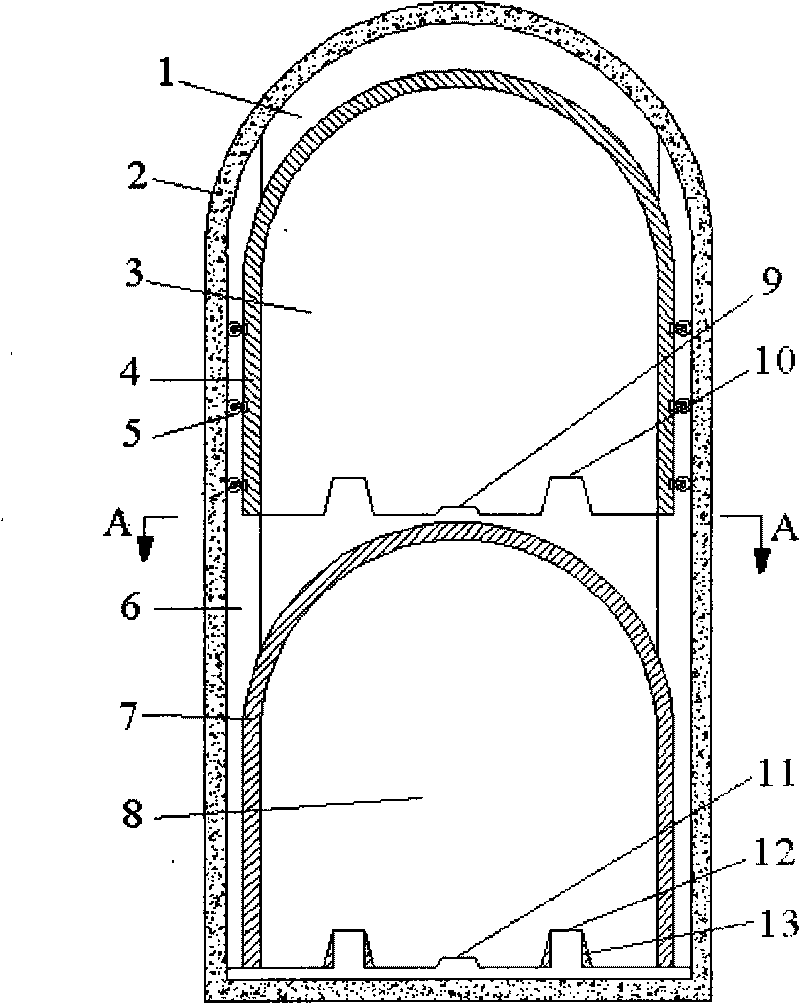

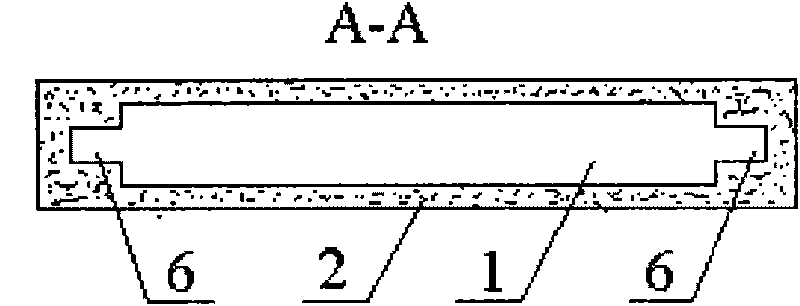

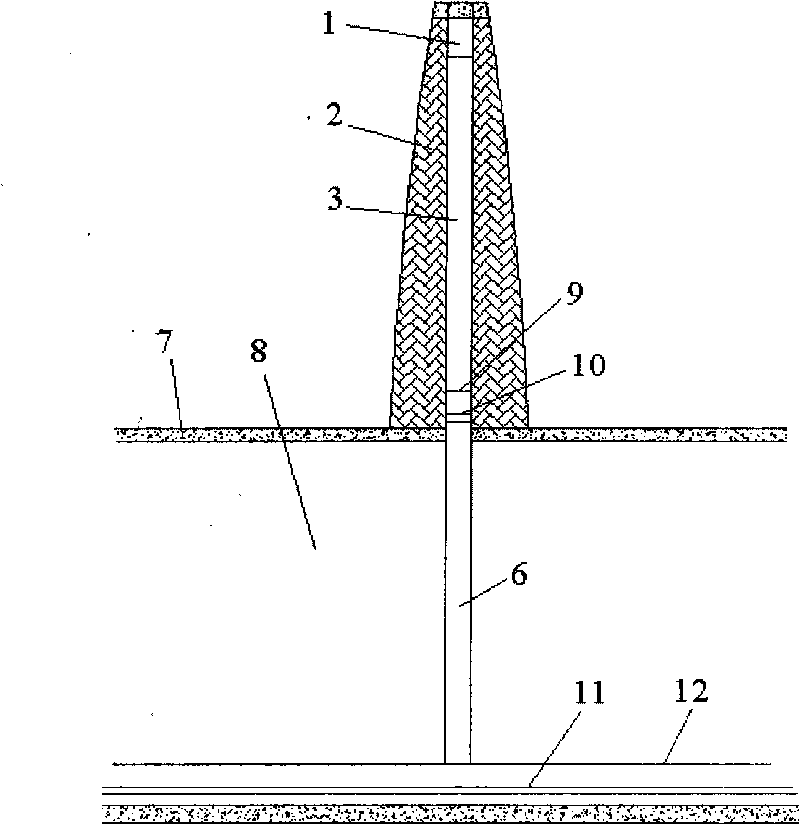

Underwater vacuum pipeline transportation system with emergency channels

InactiveCN105480234AOpen quicklyImprove securityArtificial islandsRailway heating/coolingOcean bottomSocial benefits

The invention provides an underwater vacuum pipeline transportation system with emergency channels. The underwater vacuum pipeline transportation system is characterized in that a floating tunnel is arranged on piers and is fixedly connected with the piers, the piers are fixed in rock at the ocean floor, the floating tunnel adopts a reinforced concrete structure, the resultant force of the gravity and the buoyancy force borne by the whole floating tunnel is upward vertically, a vacuum pipeline and the emergency channels are arranged in the floating tunnel, the emergency channels are symmetrically distributed on two side surfaces of the vacuum pipeline, a supporting separation barrier is arranged between each emergency channel and the vacuum pipeline, re-pressing valves are arranged on each supporting separation barrier at a certain interval, train rails are arranged in the vacuum pipeline, and a vacuum train is arranged on the train rails. The underwater vacuum pipeline transportation system has the benefits of high engineering reliability, good safety, low building cost, very wide commercial prospect, filling of blank of related techniques and generation of greater social benefits and economic benefits.

Owner:BEIJING JIUZHOU ARTERY TUNNEL TECH CO LTD

Products produced from rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS20070170095A1Upgrade and reduce viscosityRapid heat treatmentThermal non-catalytic crackingLiquid organic insulatorsParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The process of the present invention provides for the preparation of a partially upgraded feedstock exhibiting reduced viscosity and increased API gravity. This process selectively removes metals, salts, water and nitrogen from the feedstock, while at the same time maximizes the yield of the liquid product, and minimizes coke and gas production. Furthermore, this process reduces the viscosity of the feedstock in order to permit pipeline transport, if desired, of the upgraded feedstock with little or no addition of diluents. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream. This invention also pertains to the products produced by the method.

Owner:IVANHOE HTL GASOLINEEUM

Circulated Pneumatic Tube Transit System

A circulated pneumatic tube transit system is used to transport passengers / cargo along a pair of pneumatic tubes, which are positioned along each other. Capsules are movably suspended within the tubes by either a maglev system or wheels. The capsules travel in opposite directions in each tube so that the system provides back and forth transportation between two destinations. A fluid loop mechanism cycles a volume of air through the tubes as a means to propel the capsules through each tube. A series of fluid loop mechanism can be air multipliers as the volume of air cycles through the tubes. Two one-directional valves are located at opposite ends of the tubes and are used to transfer the kinetic energy for an arriving capsule within one tube into kinetic energy for a departing capsule within the other tube.

Owner:ZHOU BO

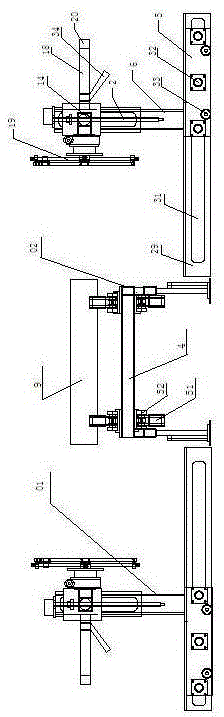

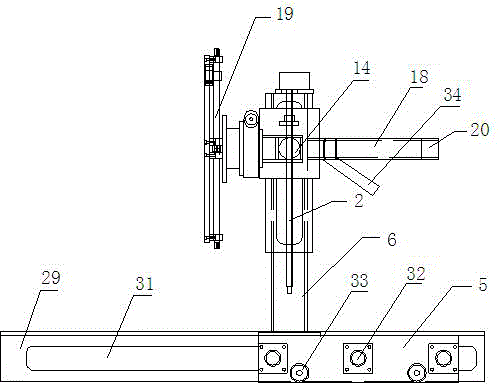

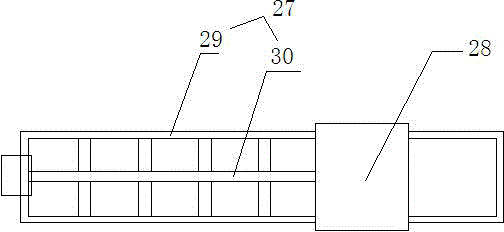

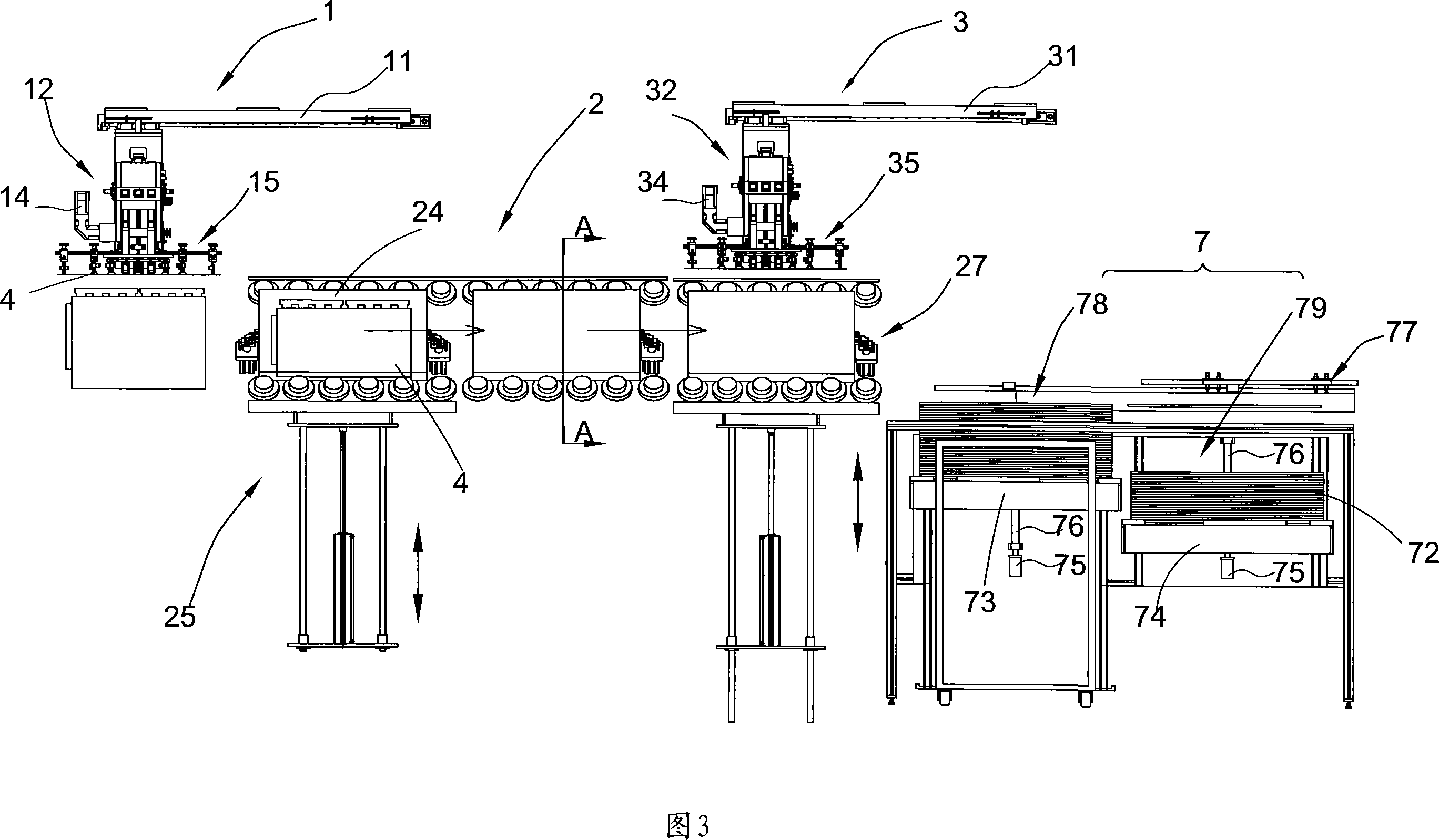

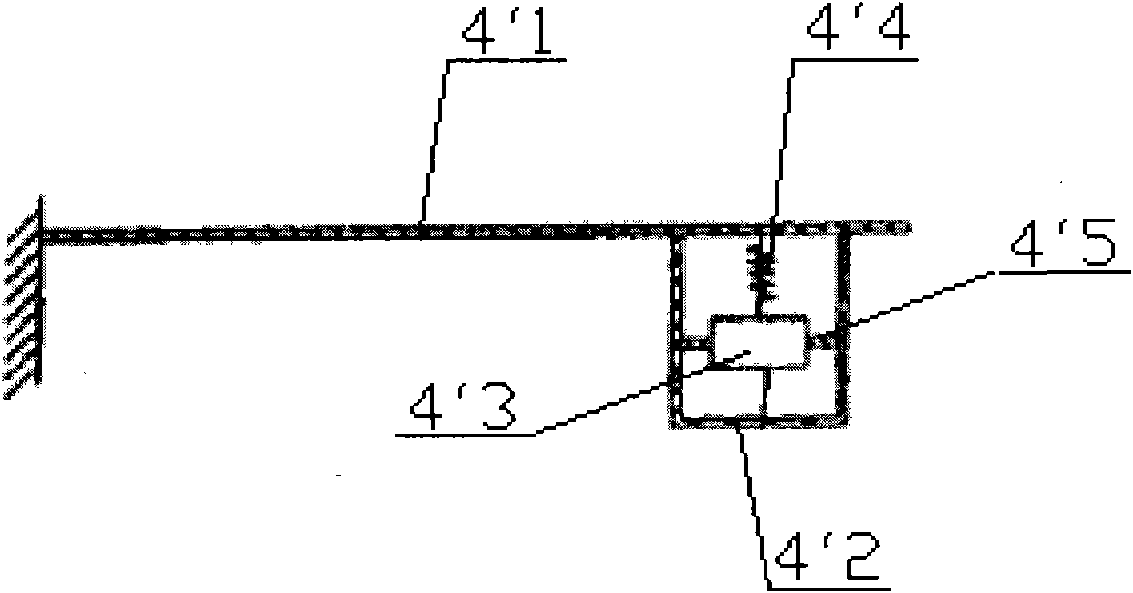

Flange assembly machine

ActiveCN104551496ASave manpower and material resourcesReduce production finished productWelding/cutting auxillary devicesAuxillary welding devicesAxis of symmetryPipeline transport

The invention relates to a flange assembly machine. The flange assembly machine comprises a pipeline transporting mechanism, and regulating mechanisms which are positioned at the two sides of the pipeline transporting mechanism and are symmetrically distributed left and right by taking the pipeline transporting mechanism as an axis of symmetry; when a pipeline transporting device transports a pipeline to an assembly position, the regulating mechanisms grip a flange and transport the flange to the two sides of the pipeline, so that the flange and the pipeline are aligned and fitted with each other and are finally welded into an integer; when the pipeline assembly is ended, the pipeline transporting device operates for transporting away the assembled pipeline. The flange assembly machine is convenient to operate, fully automatic and intelligent in operation in the whole process, and relatively safe and reliable, greatly saves manpower and material resources, and reduces production cost.

Owner:江苏振光电力设备制造有限公司

Rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS8105482B1Upgrade and reduce viscosityRapid heat treatmentThermal non-catalytic crackingRefining by heating/coolingLiquid productThermodynamics

The present invention is directed to the upgrading of heavy hydrocarbon feedstock. The process of the present invention provides for the preparation of a partially upgraded feedstock exhibiting reduced viscosity and increased API gravity. This process reduces the viscosity of the feedstock in order to permit pipeline transport of the upgraded feedstock with little or no addition of diluents. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

Vertical mobile isolating door for vacuum pipeline transport

InactiveCN101705839ASatisfy the operationMeet maintenanceMining devicesPower-operated mechanismPipeline transportEngineering

The invention discloses a vertical mobile isolating door for vacuum pipeline transport, which comprises a door chamber body wall arranged vertically, wherein the inside of the door chamber body wall is provided with a door chamber; the inside of the door chamber is provided with an isolating door body which is connected with a power driving device and a puller device respectively; the two lateral surfaces and the top surface of the isolating door body are provided with first continuous sealing rings; the two lateral surfaces of the isolating door body are provided with at least one moveable pulley respectively; the isolating door body can move up and down through the moveable pulleys; the lower part of the door chamber body wall is provided with a door hole; and the lower end surface of the isolating door body is a sealing surface. Under the condition that the vacuum pipeline transport is operated normally, the vertical mobile isolating door can meet the requirements on operation, maintenance and vacuum preservation of the vacuum pipeline without occupying effective clearance for a vehicle to drive or blocking a magnetic levitation track.

Owner:XIJING UNIV

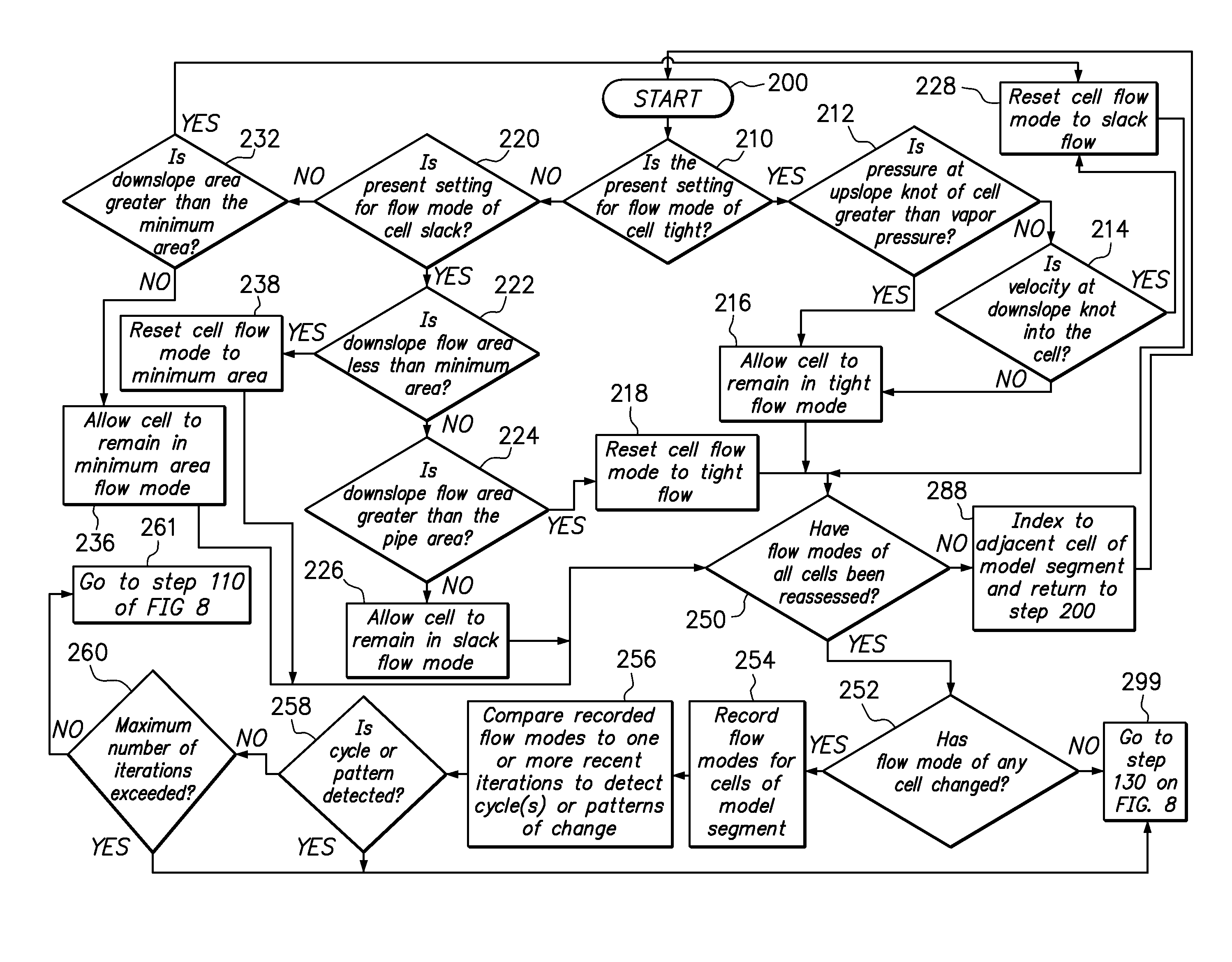

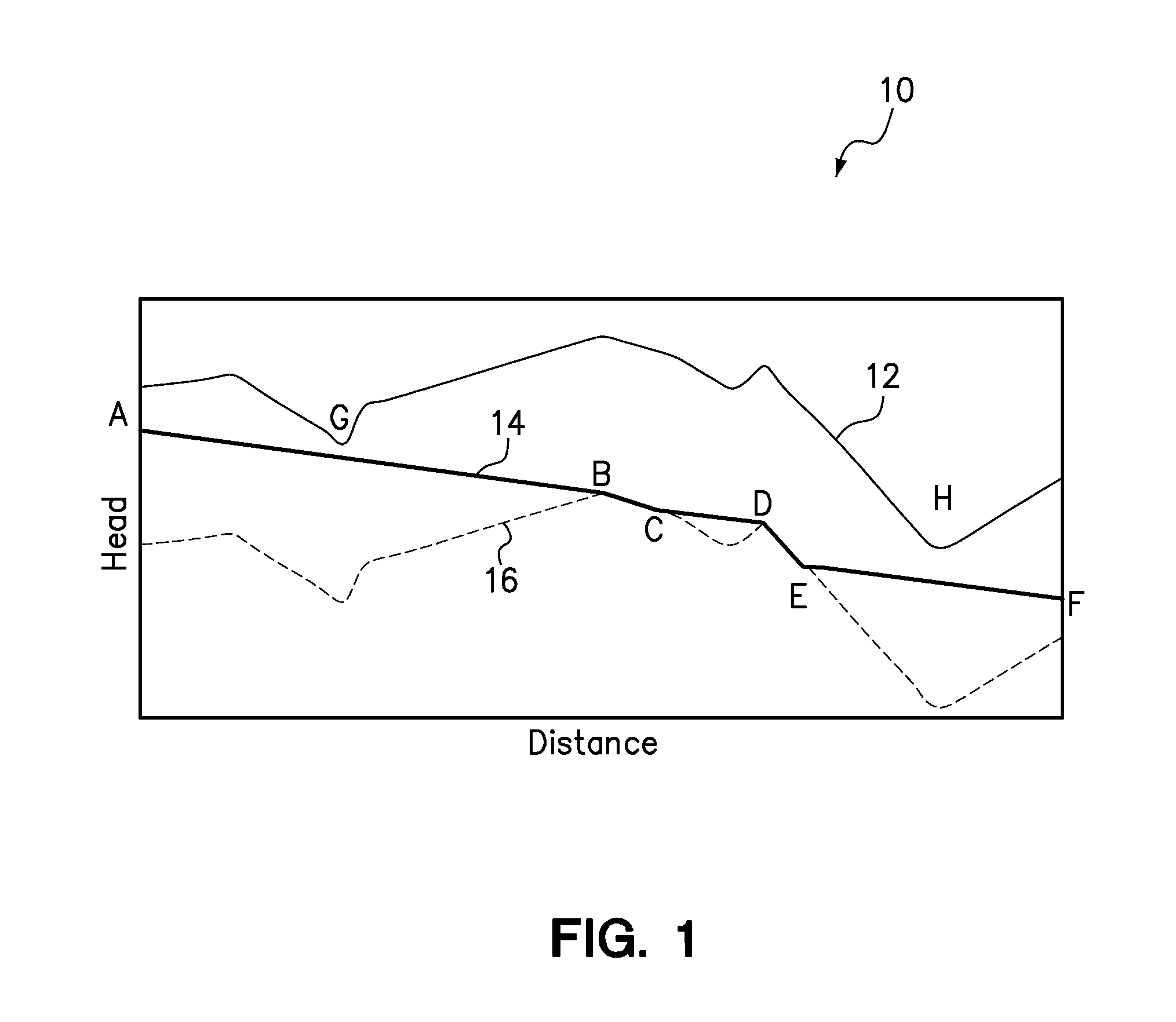

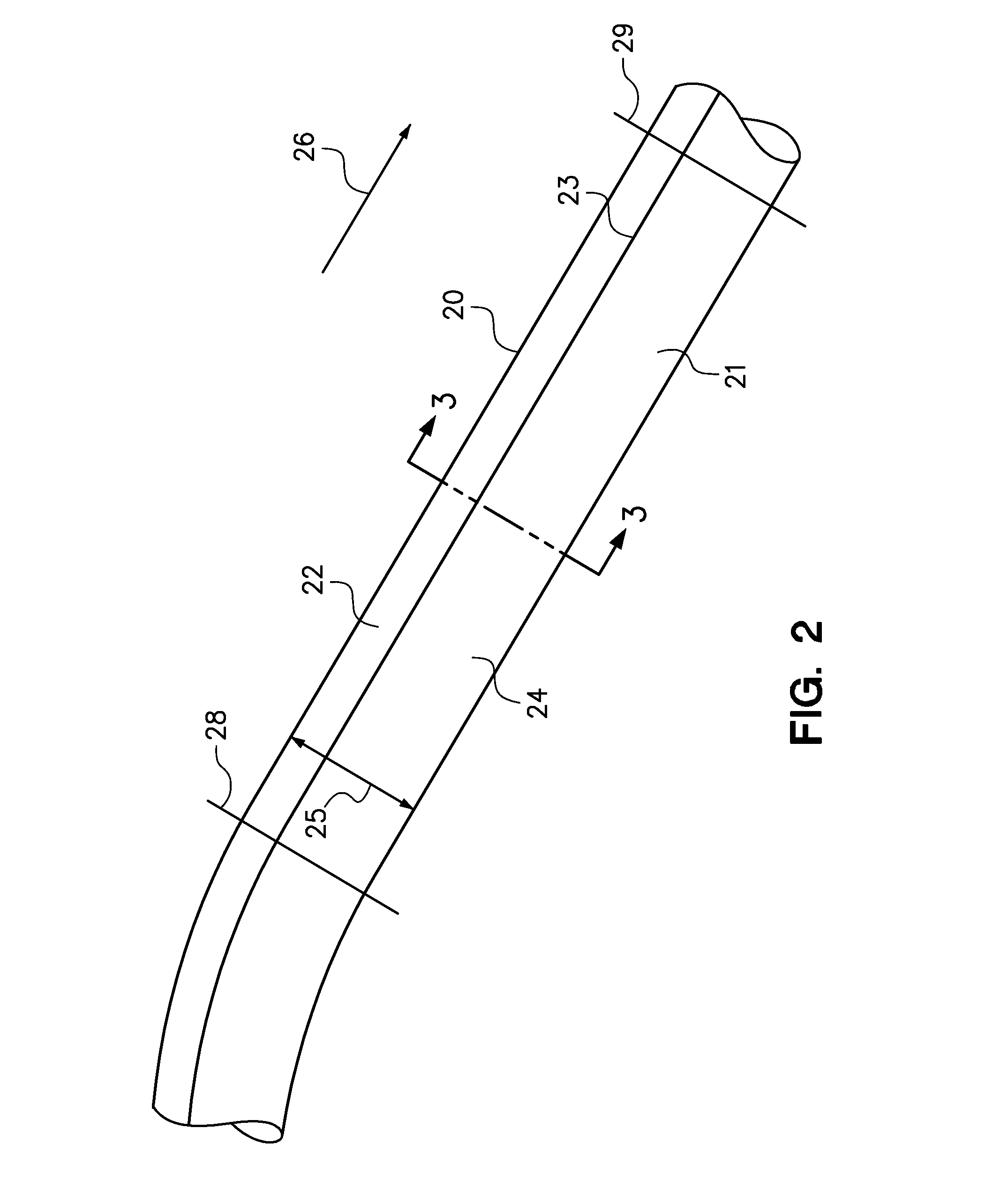

Pipeline flow modeling method

ActiveUS20130103370A1Accurate modelingSequencing is facilitatedComputation using non-denominational number representationDesign optimisation/simulationModel methodMomentum

Owner:ENERGY SOLUTIONS INT

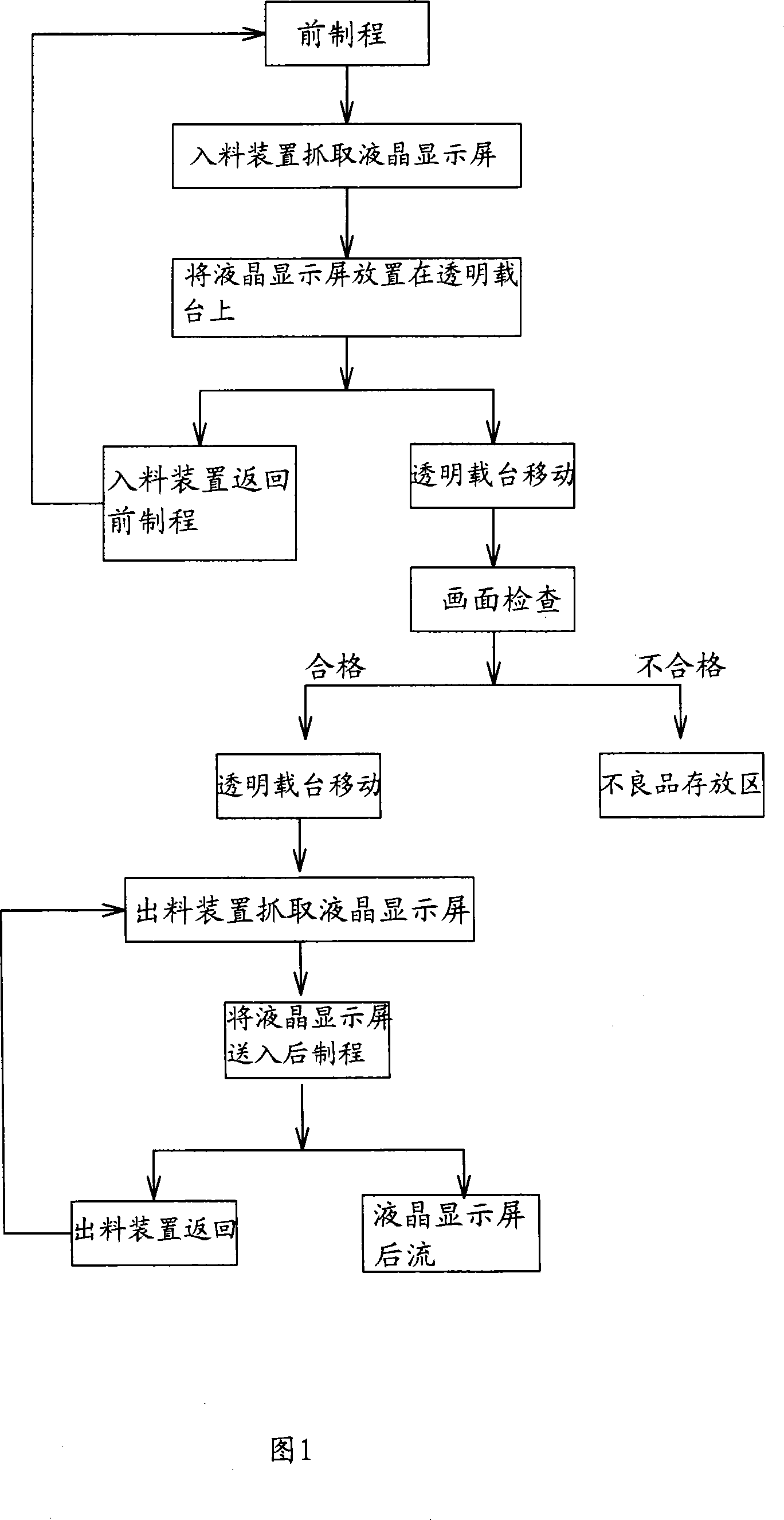

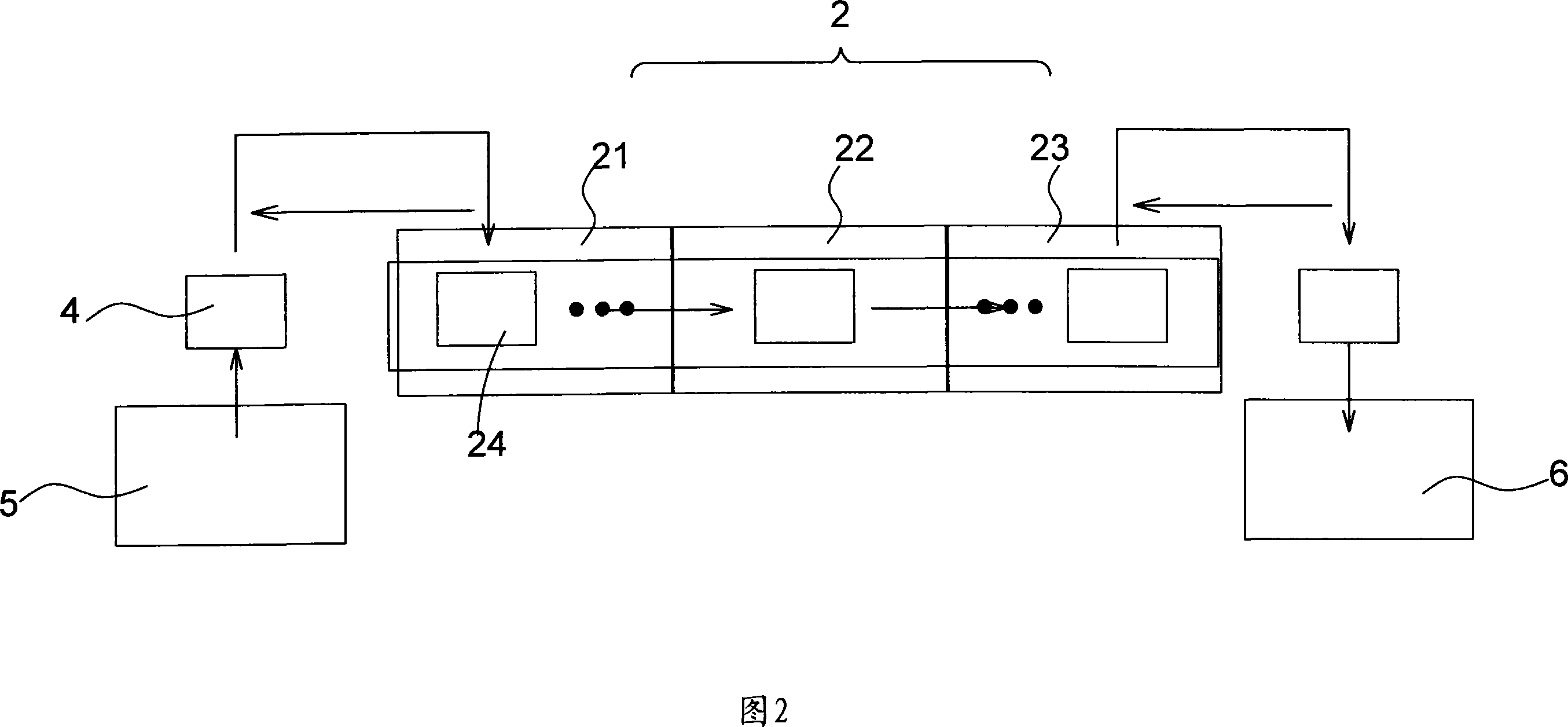

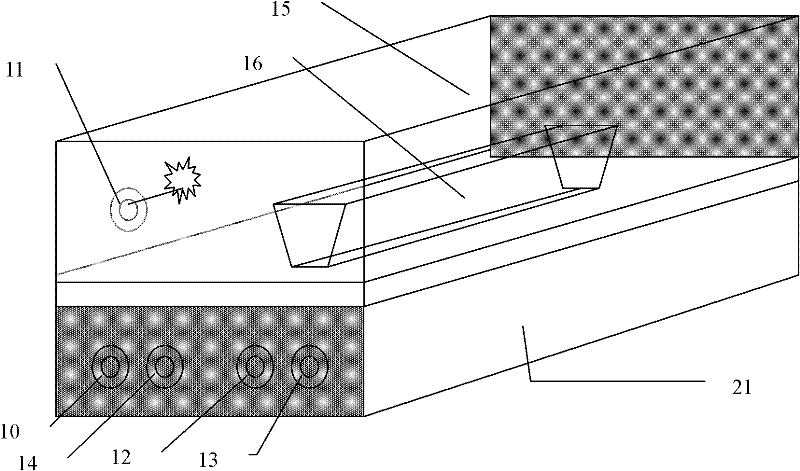

Liquid crystal display screen manufacture process and its apparatus

InactiveCN101169528AAvoid contactShorten working timeNon-linear opticsTransport timeLiquid-crystal display

The invention relates to a liquid crystal display manufacturing process and its manufacturing equipment. The technical proposal mainly includes: using a material feeding device to grab the liquid crystal display produced in the previous process; placing the liquid crystal display on a transparent carrier; Before the device returns to the process, the next LCD screen is grabbed, and the transparent carrier moves to the inspection station, which is located between the LCD screen and the backlight unit; the LCD screen is inspected; and the LCD screen that passes the inspection is sent to the downstream of the assembly line. Through the above technical solution, the processes of taking, placing, detecting and transporting the LCD display are not interfered with each other and can work at the same time. Therefore, the working time can be greatly shortened, and the work efficiency and production capacity can be improved; The transportation time of the display screen on the assembly line not only facilitates the operation, but also shortens the operation time; finally, due to the higher degree of automation of the present invention, it can avoid human contact, thereby reducing the defects caused by it.

Owner:庄添财

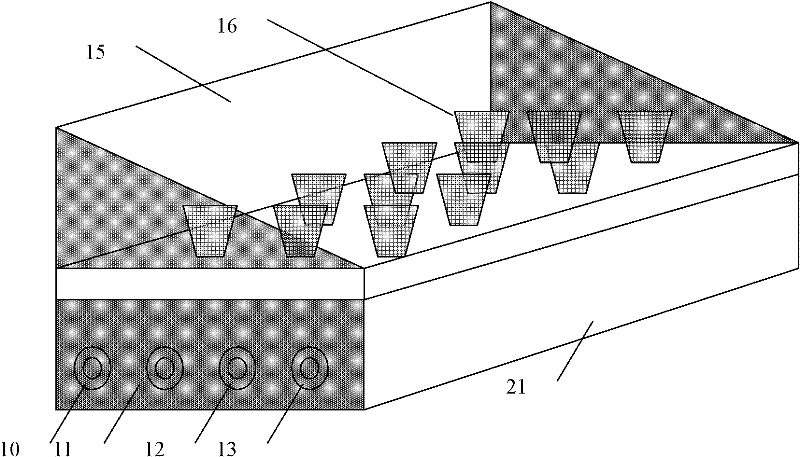

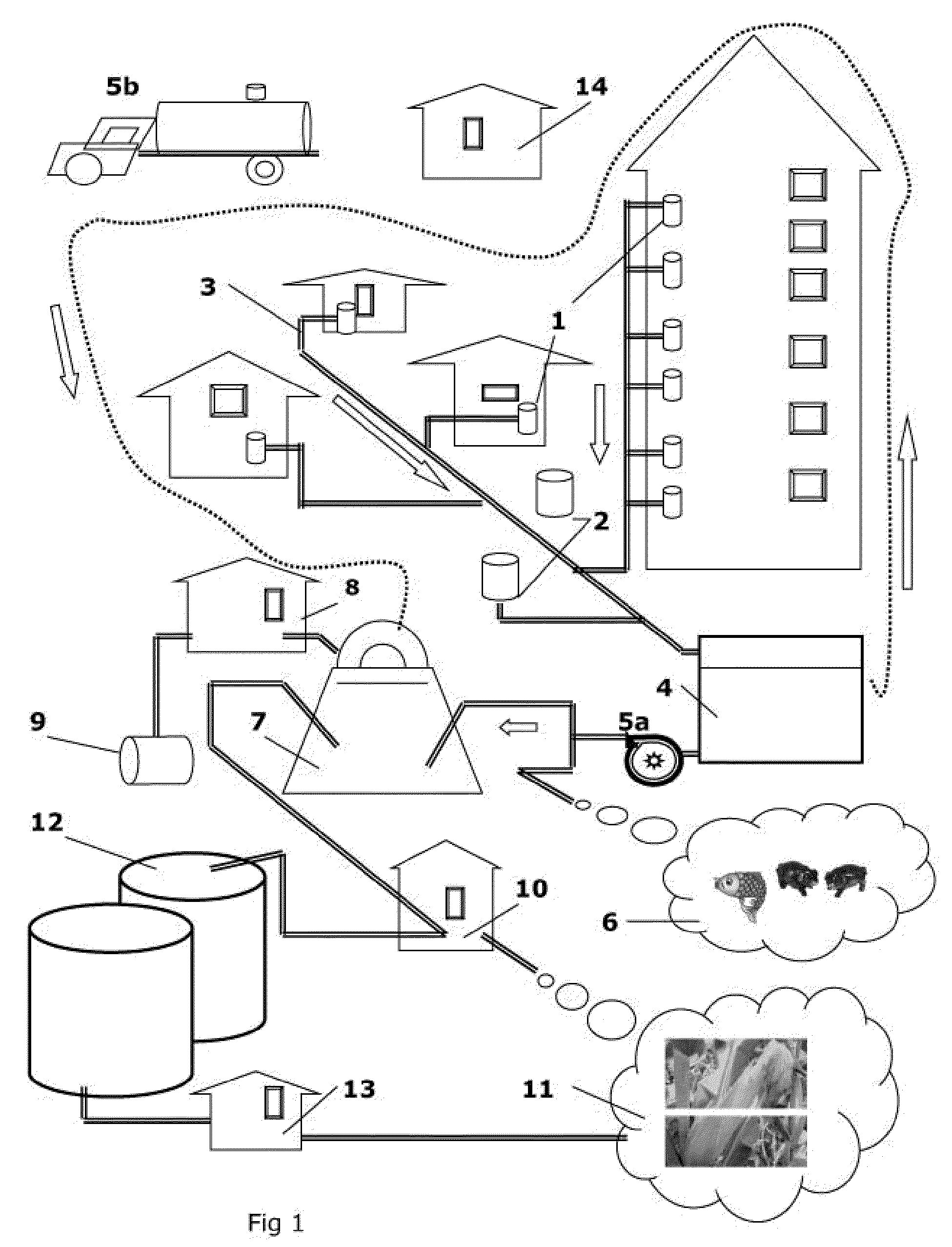

Agricultural planting facility for internal nutrient source

InactiveCN102235102AAchieve productionEasy to controlAgricultural buildingsClimate change adaptationNew energyPipeline transport

The invention aims at providing an industrialized planting facility realized by means of an internal nutrient source, which is a facility for realizing the agricultural planting in scale, intelligentized, modularized, new energy source and industrialized manner. A plurality of agricultural planting box bodies are arranged inside at least one building; one or more layers of planting disks are arranged inside the box bodies; a liquid delivering pipeline, a power transmitting pipeline and an air-conditioning delivering pipeline are respectively connected with water supply equipment, power supply equipment and air-conditioning supply equipment and enter the box bodies; at least one pipeline port is arranged on each agricultural planting box body; the liquid delivering pipeline, the power transmitting pipeline or the air-conditioning delivering pipeline enters the interiors of the box bodies respectively through a corresponding liquid delivering pipeline port, a corresponding power transmitting pipeline port or a corresponding air-conditioning delivering pipeline port; the plurality of box bodies are respectively connected through the corresponding pipeline ports; or the liquid delivering pipeline, the power transmitting pipeline and the air-conditioning delivering pipeline enter the interiors of the box bodies through a shared pipeline port; and the plurality of box bodies are connected through the shared pipeline interface.

Owner:BEIJING WISWORD HI TECH

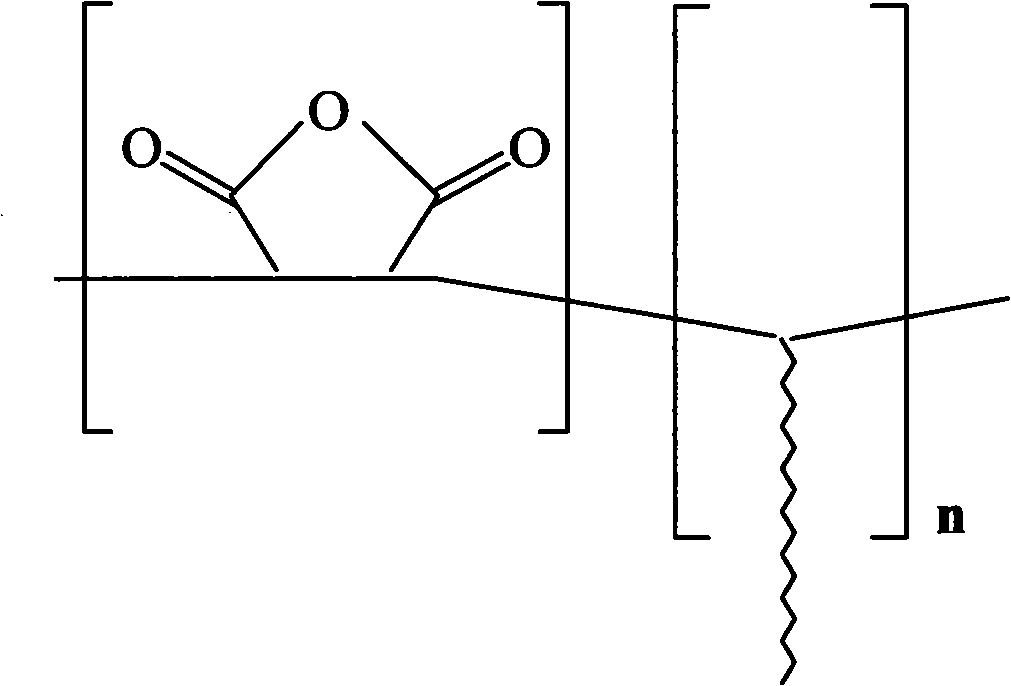

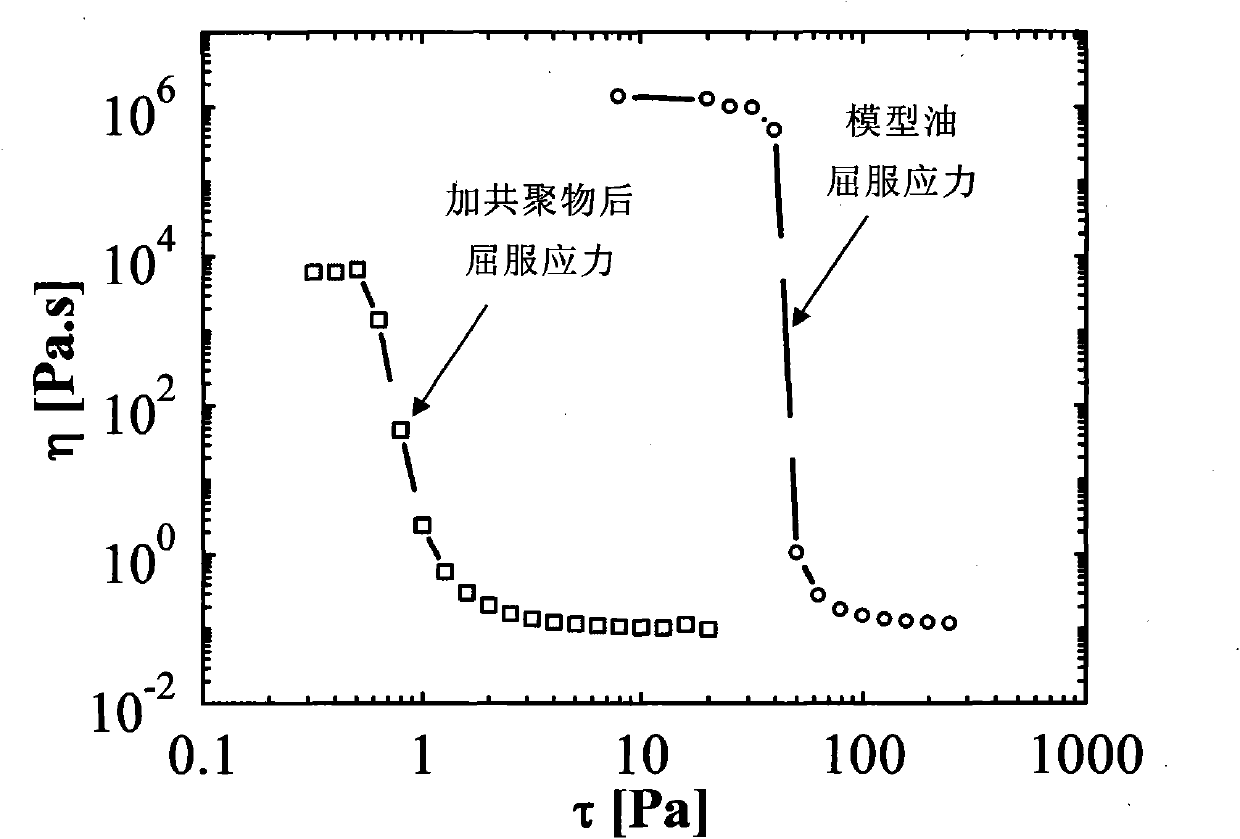

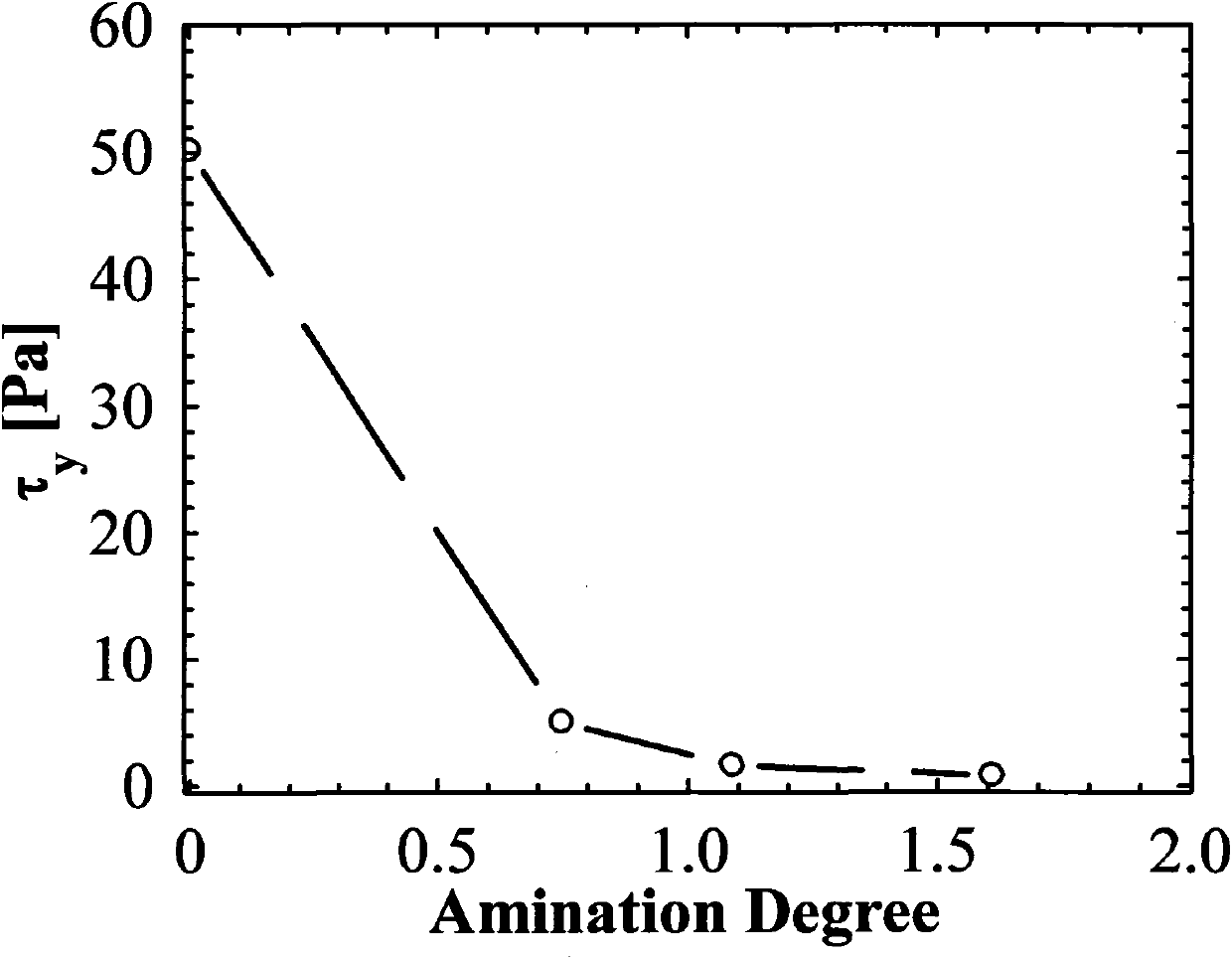

Comb copolymer, preparation method and application thereof

The invention relates to a comb copolymer, a preparation method and application thereof, in particular to the preparation of a functional comb copolymer by a method of free radical solution polymerization and group modification and the application of the comb copolymer in pipeline transportation and offshore production of wax-containing crude. The structural formula of the comb copolymer is shown in the specification, wherein the molecular weight of the comb copolymer is 3,000 to 30,000g / mol; and the degree of esterification or amination is 0.5 to 2.0.

Owner:EAST CHINA UNIV OF SCI & TECH

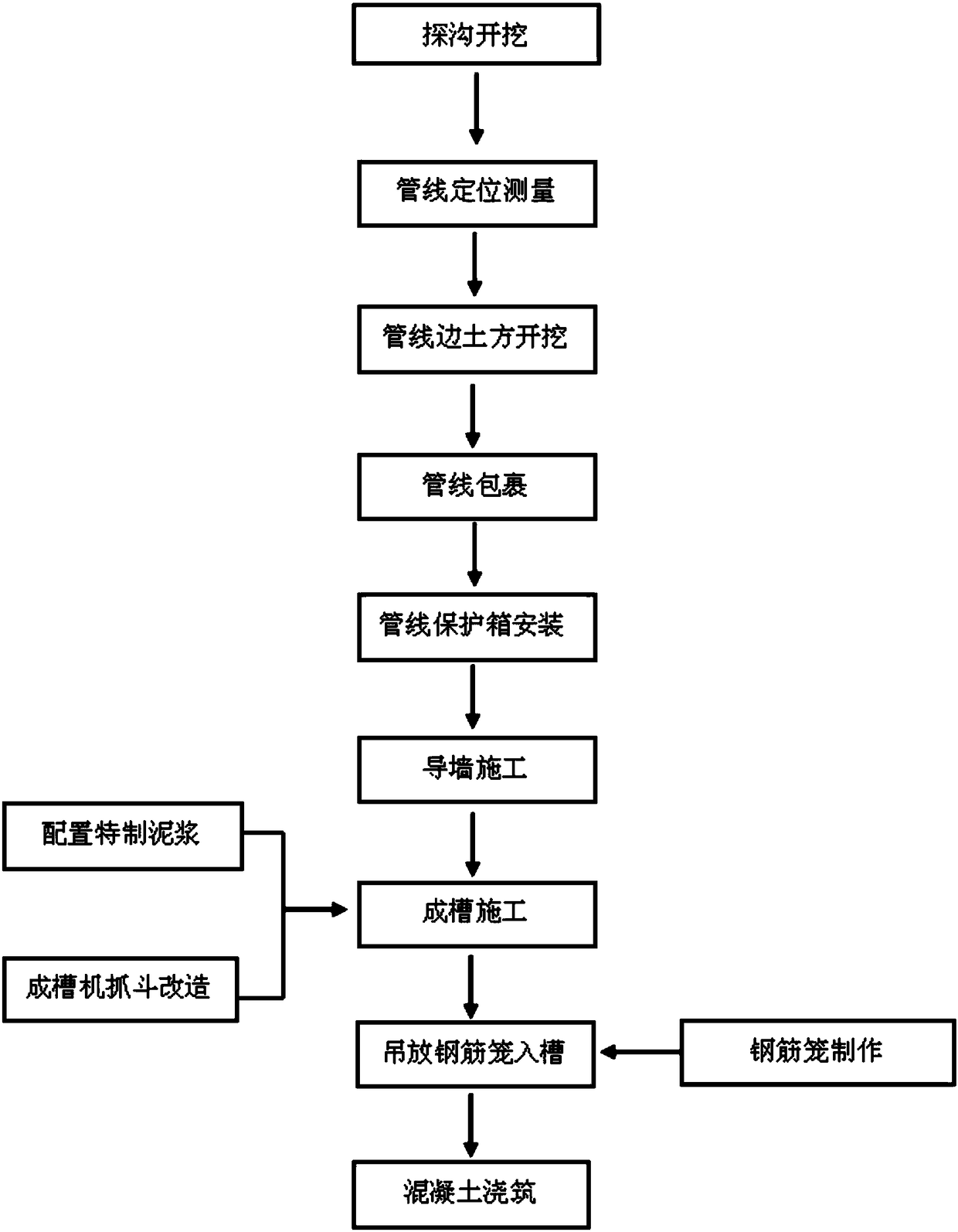

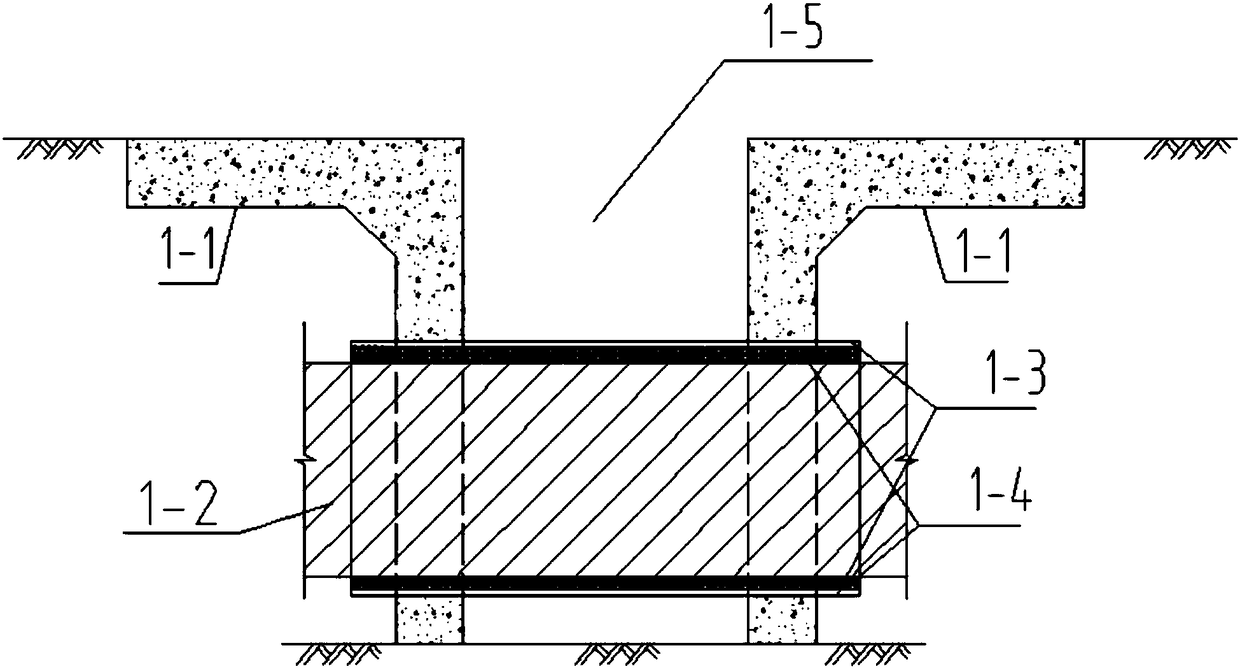

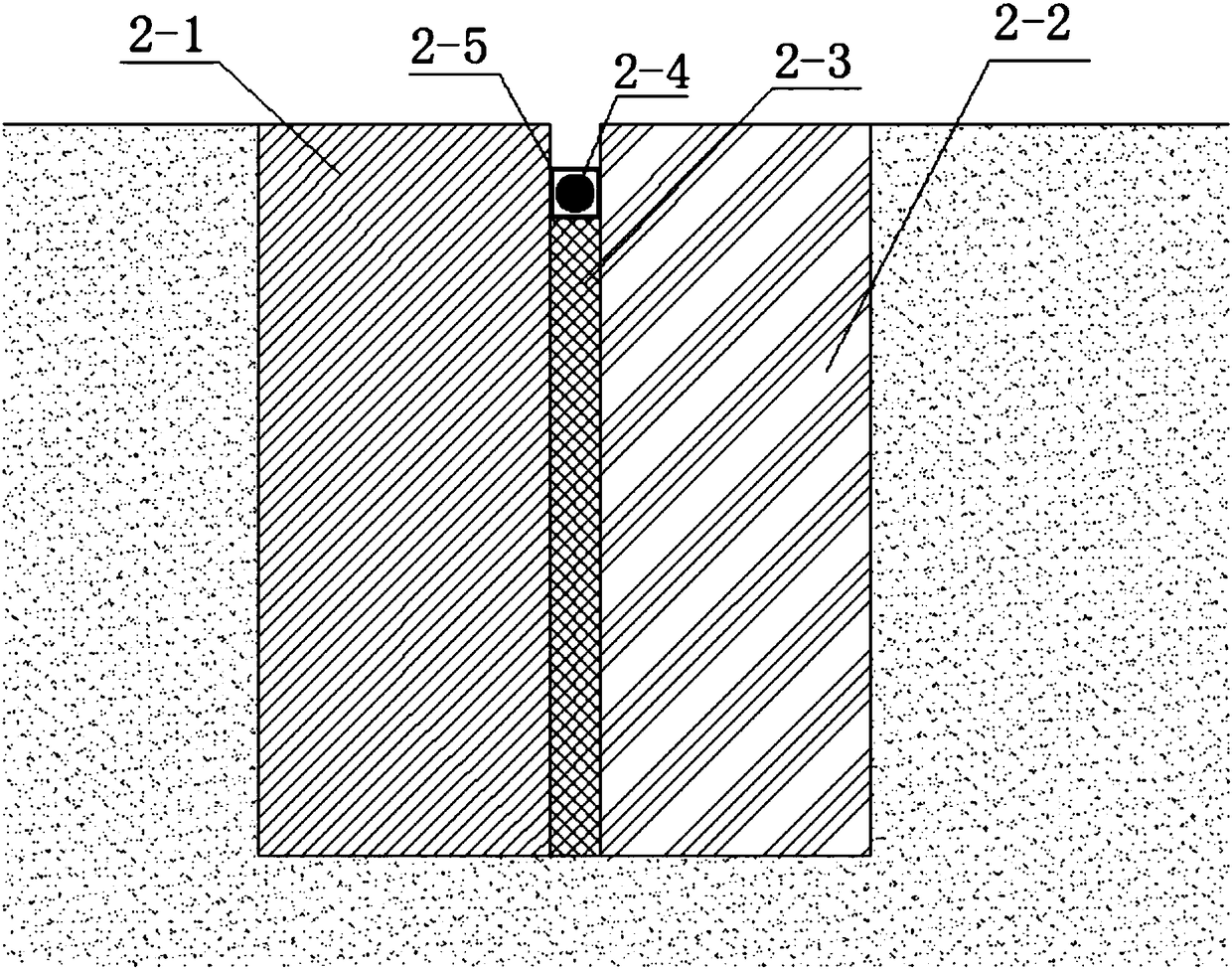

Underground continuous wall pipeline in-situ protection construction method

InactiveCN108252296AAvoid the impact of relocationShorten the construction periodBulkheads/pilesSlurry wallPipeline transport

The invention relates to the engineering technical science, and in particular to an underground continuous wall pipeline in-situ protection construction method. The method comprises the steps of ditchexploration and excavation, pipeline positioning and measuring, pipeline side earth excavation, pipeline wrapping, pipeline protection box installation, guide wall construction, slurry preparation, trenching construction, reinforcing cage manufacturing, reinforcing cage hanging in a groove, and concrete pouring. According to the method, the influence of pipeline transition is avoided, the projectconstruction period is shortened, the construction cost is saved, the underground continuous wall trenching construction of the non-straight-up-straight-down mode is realized, and the technical problem of excavating the soil below the pipeline is solved.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

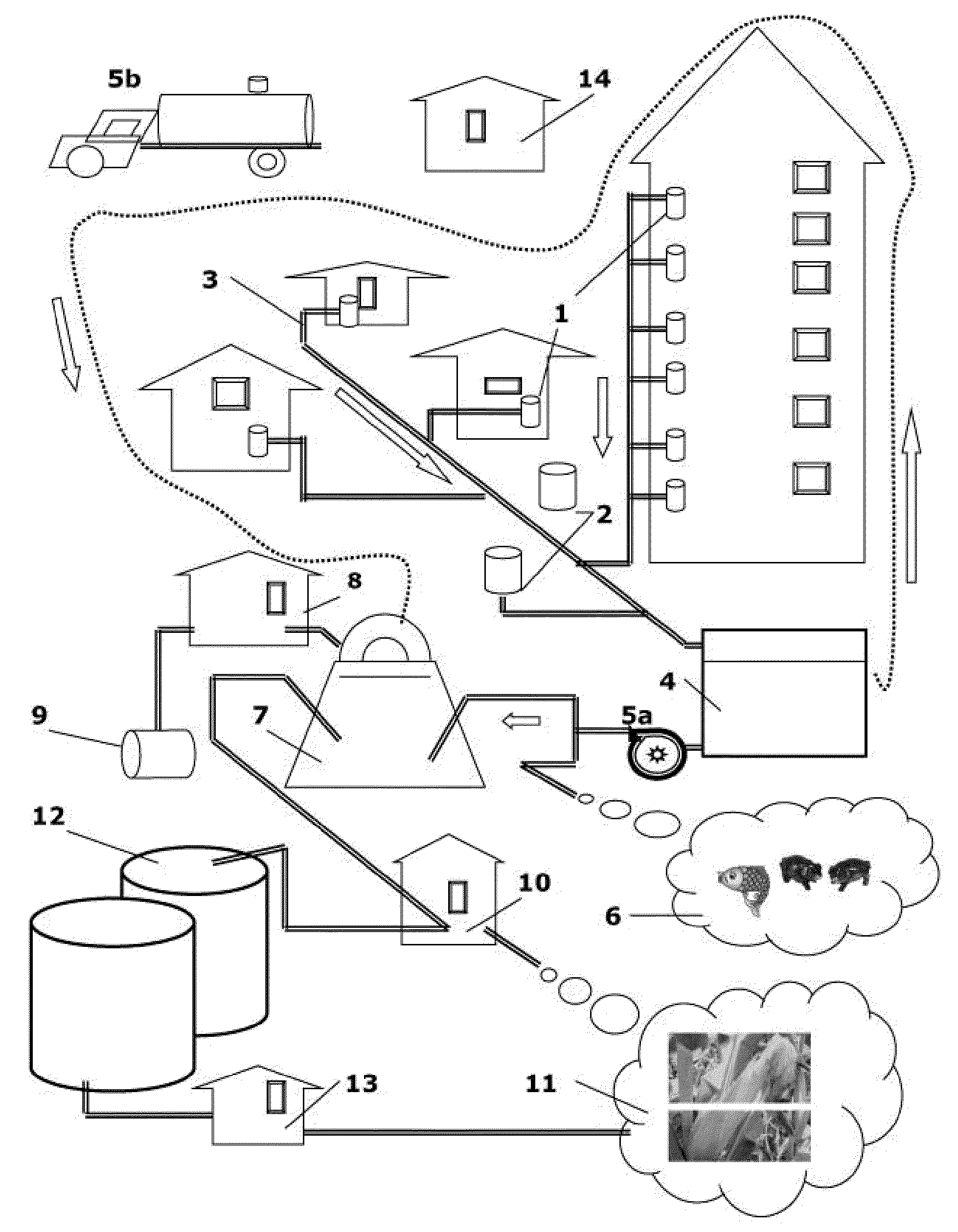

Method and Apparatus of Solid Wastes Automatic Collection Ductwork Evacuation and Comprehensive Utilization

ActiveUS20100243559A1Save wasteIncrease wasteBio-organic fraction processingLiquid degasificationLiquid mediumSystem capacity

The method and apparatus of solid wastes automatic collection ductwork evacuation and comprehensive utilization contemplated to reach a facilitative dropping, quietly, effectively and automatically collecting, evacuating, transporting of all kinds of biodegradable solid waste, getting poly package-less uniform waste particle and jam for recycle that largely reduce the emission of greenhouse gas, pollution of poly package materials, contamination of putrefactive solid waste, generate resource from waste and benefit dwellers, industrials, business units. The disclosed method, procedure and apparatus comprise setting multiple waste grinding collectors indoor and outdoor; cutting, shredding and grinding all kinds of biodegradable solid waste with gaseous and liquid medium into both dry fluidized particle for gaseous medium transportation and wet fluidized jam for liquid medium transportation by the invention multiple waste grinding collectors with multiple functions of automatic information exchange, water proportion, waste cut, shred & grind to satisfy duct pipe evacuation and transportation; Through ductwork pipes, which connect all the waste grinding collectors, pumps with liquid medium, and air pump, suction with gaseous medium, respectively evacuate and transport the fluidized particle and jam into regional collect tanks; By sorting, vehicles, pumps and vacuum aspirators via duct pipeline transport the fluidized particle and jam respectively going to feedstuff plants, bio-purifications, methane generating pools and alcohol generating pools; Methane and alcohol products purified for fuel; Dreg and sludge after disinfecting and sterilization, is respectively transported to farm for irrigation, and transported to dewater chamber to produce organic fertilizer, and further carbonized for fuel; Wastewater purified by filter and activated carbon for recycle and discharged; The regional manage house manages the regional disposal system capacity and to share living regional municipal drainage ductwork and facilities by timer, automatic information exchange assembly and the switch set at the end of the regional municipal drainage pipeline.

Owner:QIU ZEGUO

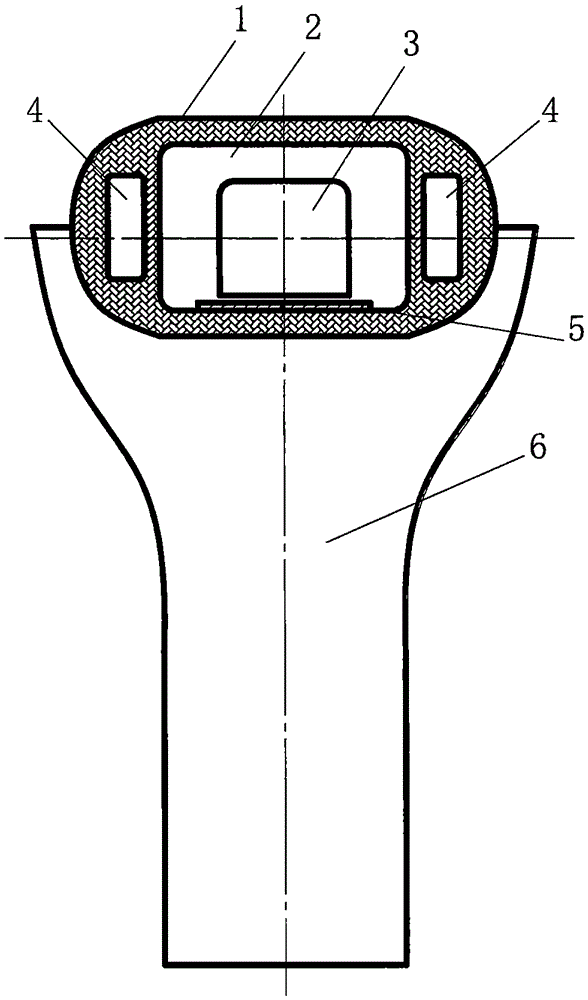

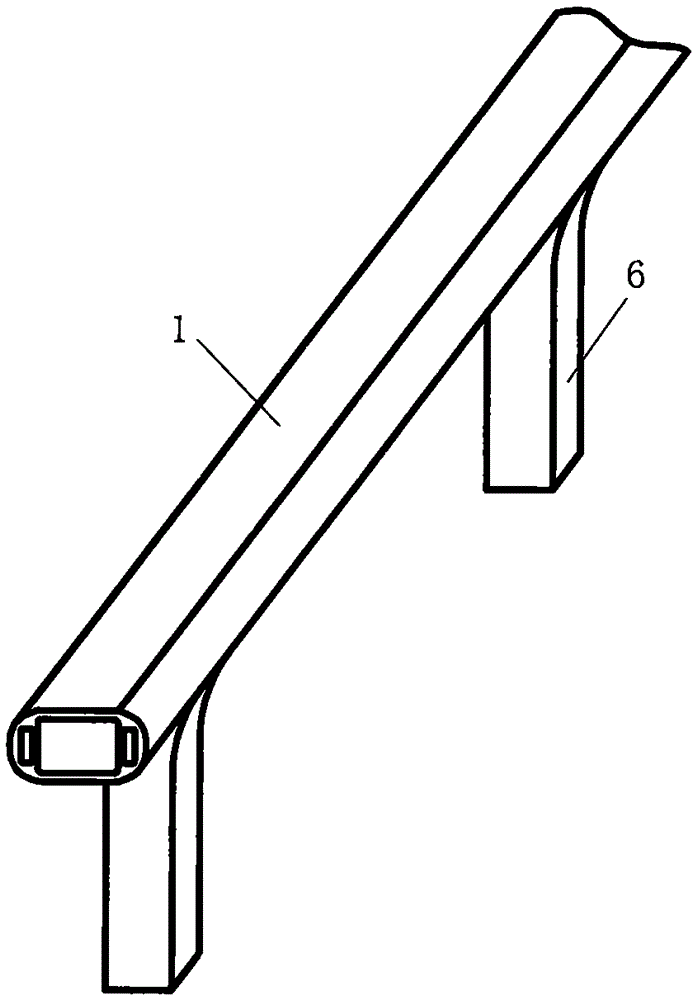

Tail end hose device, concrete pump vehicle and pipeline transporter

ActiveCN101839066AReduce vibrationSimple structureBuilding material handlingShock absorbersPipeline transportEngineering

The invention discloses a tail end hose device used for a concrete pump vehicle, comprising a delivery pipe (1). The lateral wall of the delivery pipe (1) is sleeved with a mass disc (2), and a gap is arranged between the side wall of the inner ring of the mass disc (2) and the lateral wall of the delivery pipe (1); and a support part protruding out of the lateral wall of the delivery pipe (1) is arranged at least one of the upper and down parts of the mass disc (2), and the mass disc (2) is connected the with the support part through a flexible part so as to facilitate the mass disc (2) to reciprocate along the axial direction of the delivery pipe (1). The device can effectively reduce the vibration when the tail end hose device delivers materials, and has high the reliability of reducing vibration and low operation cost. In addition, the invention also discloses a concrete pump car comprising the tail end hose device. Furthermore, the invention discloses a pipeline delivery device.

Owner:SANY AUTOMOBILE MFG CO LTD

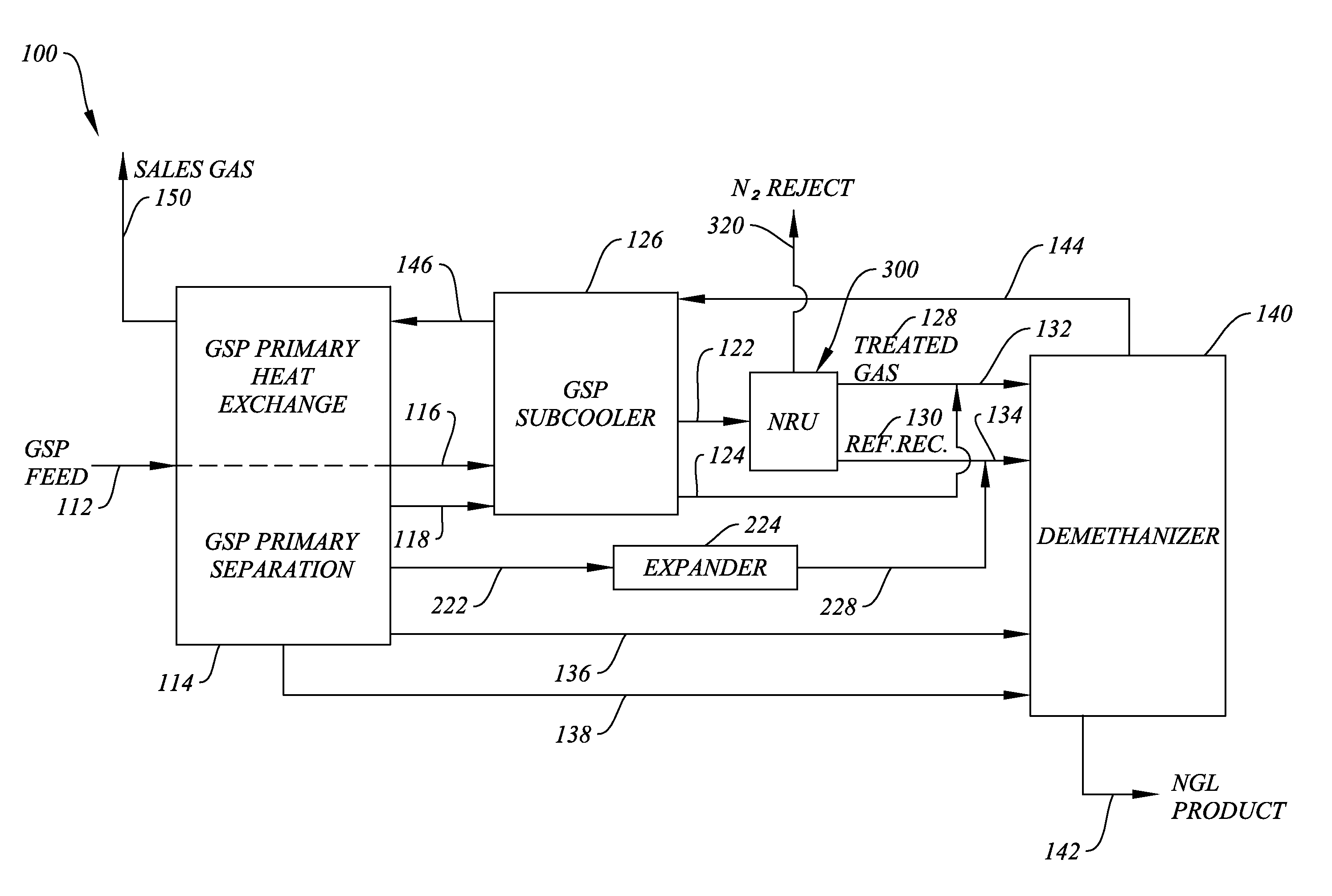

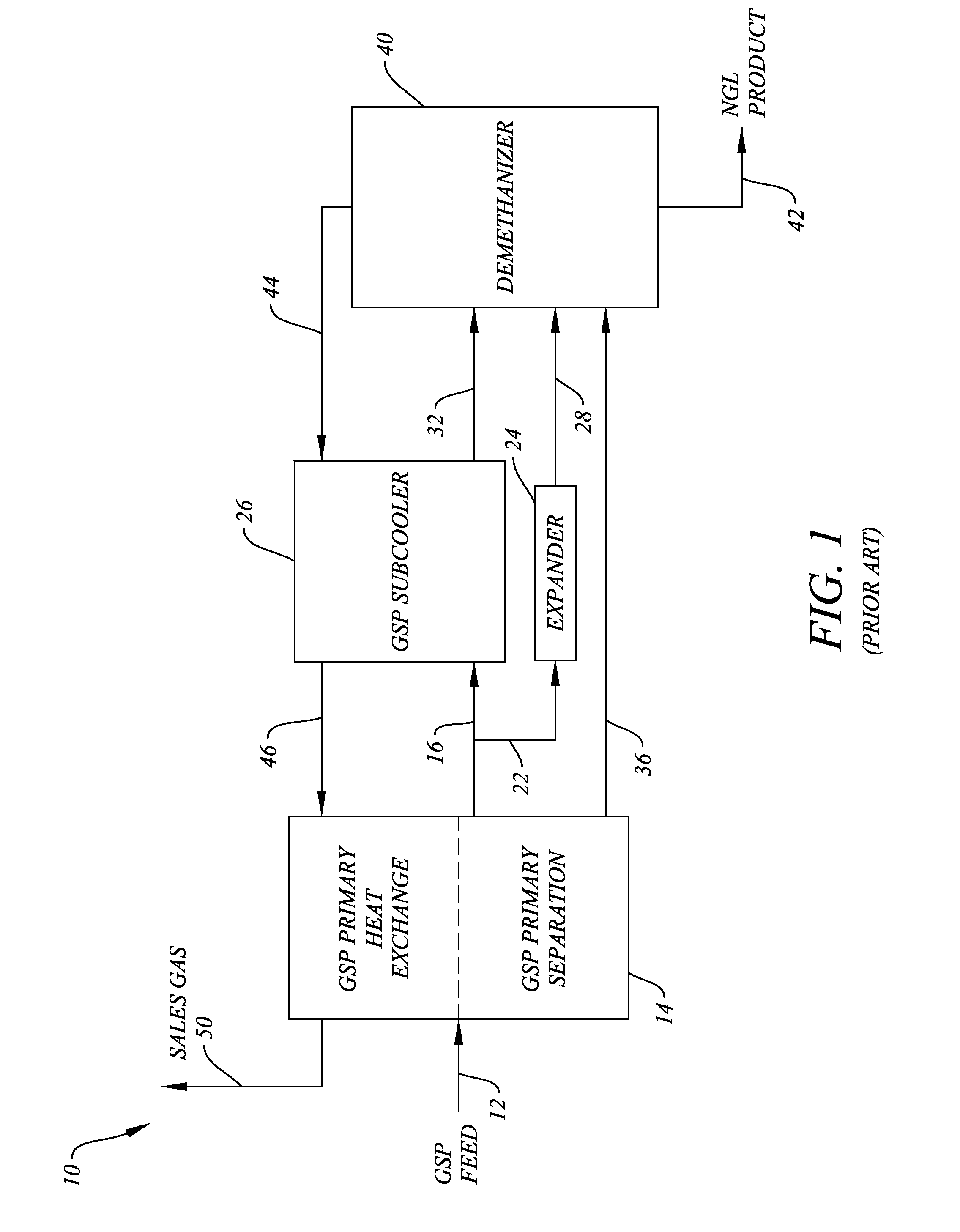

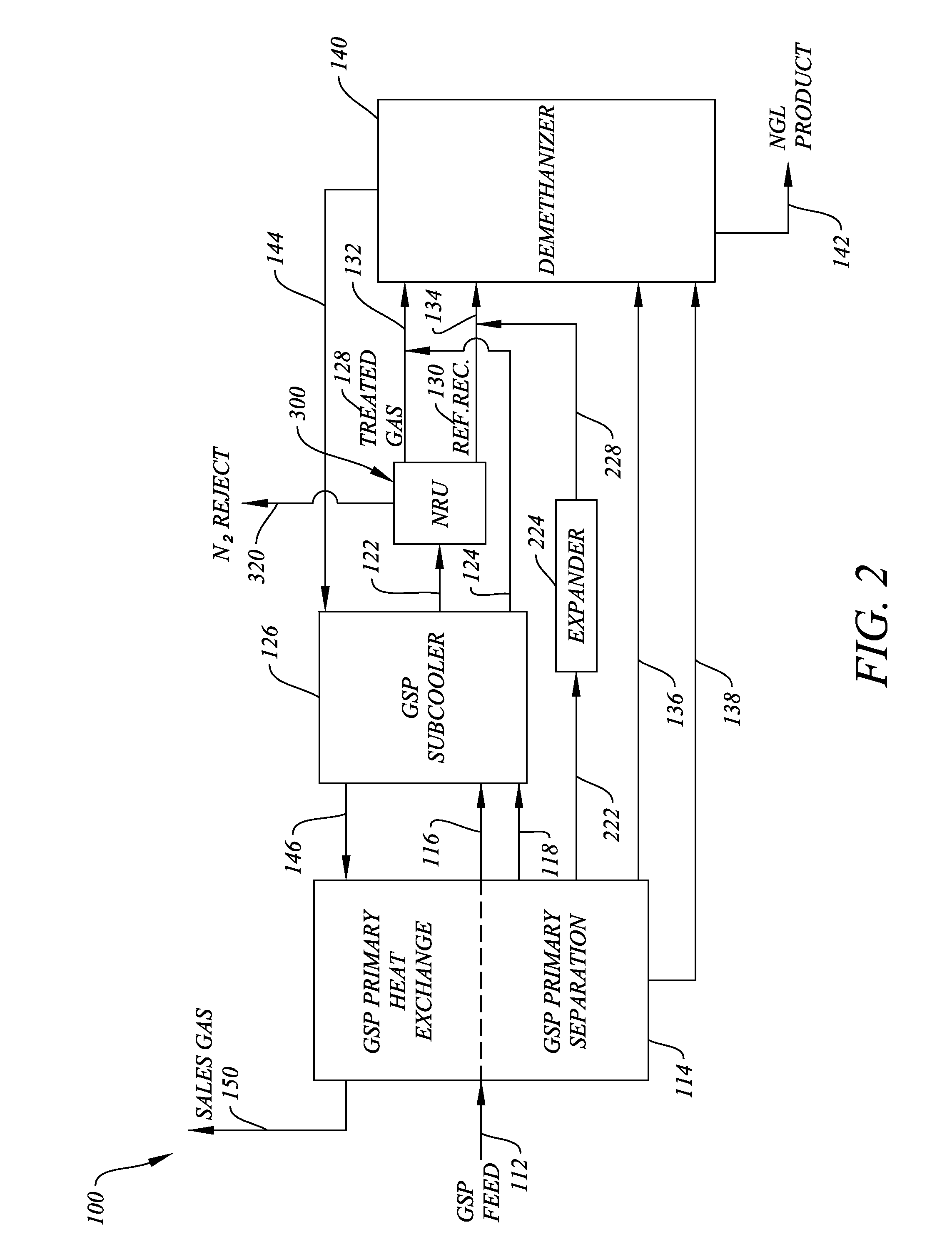

System and Method for Removing Excess Nitrogen from Gas Subcooled Expander Operations

ActiveUS20140013797A1Facilitate economically efficient removalNitrogen contentSolidificationLiquefactionNatural-gas processingPipeline transport

A system and method for removing nitrogen from an intermediate stream in a gas subcooled process operation that processes natural gas into a sales gas stream and a natural gas liquids stream. The system and method of the invention are particularly suitable for use with gas subcooled process operations where the sales gas stream exceeds pipeline nitrogen specifications by up to about 3%, such as for reducing the nitrogen content of sales gas streams to levels permissible for pipeline transport.

Owner:BCCK HLDG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com