Fiber and silicon dioxide aerogel composite heat insulation material and preparation method thereof

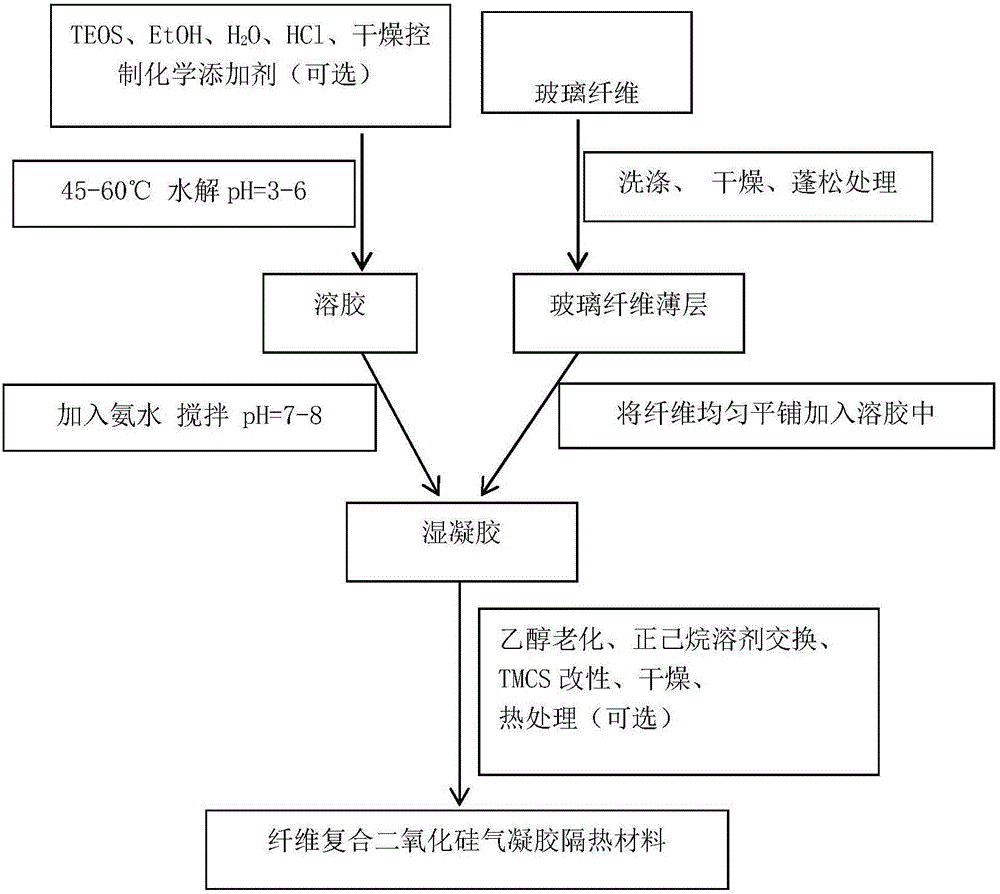

A technology of silicon dioxide and heat insulating material, applied in the field of heat insulating material, can solve the problems of complex preparation process, poor fire safety performance, etc., and achieve the effects of simple preparation process, low equipment cost and low fiber content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh a certain quality of glass fiber, wash it with ethanol and distilled water in sequence, put it into a fiber carding machine for fluffy treatment after drying, and stack the fluffy fiber thin layers in layers for use. Measure tetraethyl orthosilicate (TEOS): 4ml, ethanol (EtOH): 35ml, H 2 O: 12ml, formamide: 2ml, add to a glass container, stir and mix evenly, adjust the pH between 4-5 with 0.1Mol / L hydrochloric acid, put it in a water bath at 45°C for 6 hours for hydrolysis. After the hydrolysis is completed, cool the sol to 15°C, control the ambient temperature to 18°C, adjust the pH to 7-8 with 0.5Mol / L ammonia water, stir for 2-3 minutes, pour it into a plastic mold with a length of 8cm, a width of 6cm, and a thickness of 2cm, and weigh 0.5g fluffy Thin fiber layers are added in layers, sealed, and gelled at 45°C for 8-10 minutes. After gelling, take out the sample and put it in a container slightly larger than the sample, add ethanol for aging at 45°C for 8h, ...

Embodiment 2

[0044] Weigh a certain mass of glass fiber, wash it with ethanol and distilled water in sequence, put it into a fiber carding machine for fluffy treatment after drying, and stack the treated fiber thin layers in layers for use. Measure TEOS: 6ml, EtOH: 60ml, H 2 O: 12ml, formamide: 3ml, put into a glass container, stir and mix evenly, adjust the pH between 4-5 with 0.1Mol / L hydrochloric acid, put it in a 50°C water bath for 6h for hydrolysis. After the hydrolysis is completed, cool the sol to 15°C, control the ambient temperature to 18°C, adjust the pH to 7-8 with 0.5Mol / L ammonia water, stir for 2-3min, pour it into a plastic mold with a length of 8cm, a width of 6cm, and a thickness of 1.5cm, and weigh 0.6g The fluffy fibers are added in layers, sealed, and gelled at 45°C for 2-10min. After gelling, take out the sample and put it into a container slightly larger than the sample, add ethanol for aging at 50°C for 6h, exchange with n-hexane at 45°C twice for 6h each time, add...

Embodiment 3

[0047] Weigh a certain mass of glass fiber, wash it with ethanol and distilled water in sequence, put it into a fiber carding machine for fluffy treatment after drying, and stack the treated fiber thin layers in layers for use. Measure TEOS: 6ml, EtOH: 60ml, H 2 O: 16ml, formamide: 3ml, put into a glass container, stir and mix evenly, adjust the pH between 3-4 with 0.1Mol / L hydrochloric acid, put it in a 60°C water bath for 4h for hydrolysis. After the hydrolysis is completed, cool the sol to 15°C, control the ambient temperature to 18°C, adjust the pH to 7-8 with 0.5Mol / L ammonia water, stir for 2-3min, pour it into a plastic mold with a length of 8cm, a width of 6cm, and a thickness of 1.5cm, and weigh 0.8g The fluffy fibers are added in layers, sealed, and gelled at 45°C for 2-10min. After gelling, take out the sample and put it into a container slightly larger than the sample, add ethanol for aging at 50°C for 6h, exchange with n-hexane at 45°C twice for 6h each time, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com