Patents

Literature

110 results about "Xonotlite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

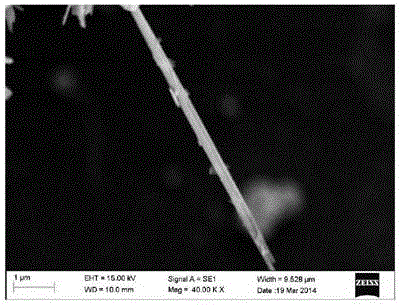

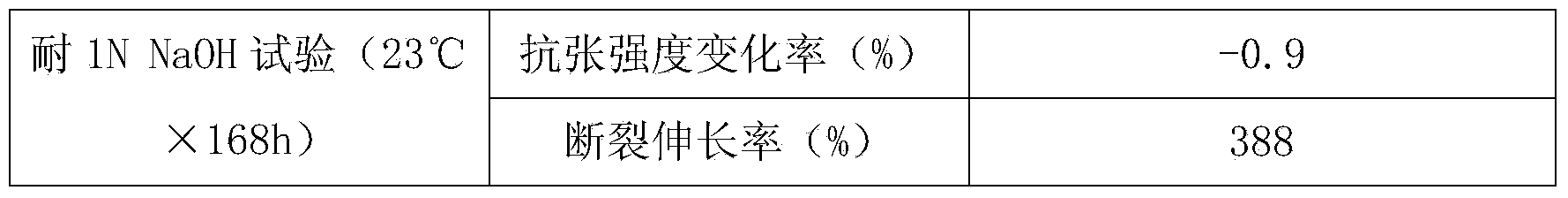

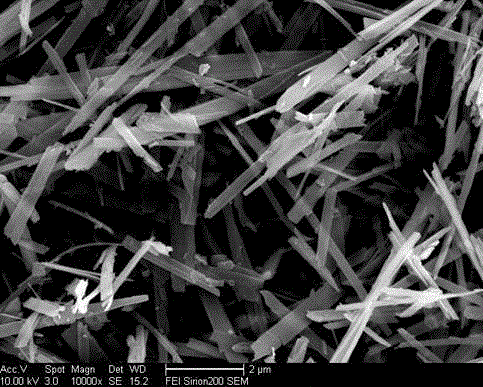

Xonotlite is a mineral with the chemical formula Ca₆Si₆O₁₇(OH)₂. It crystallizes in the monoclinic - prismatic crystal system with typically an acicular crystal form or habit. It can be colorless, gray, light gray, lemon white, or pink. It is transparent with a vitreous to silky luster. It leaves a white streak. Xonotlite is rated 6.5 on the Mohs Scale of hardness. It was first described in 1866 and named for its occurrence in Tetela de Xonotla, Puebla, Mexico. It occurs as veins in serpentinite and contact metamorphism aureoles.

Method for producing xonotlite by taking pulverized fuel ash as raw material

The invention discloses a method for producing xonotlite by taking pulverized fuel ash as a raw material. The method comprises the following steps: with the pulverized fuel ash as a raw material, preparing a refined desilicification solution by adopting an alkali dissolution method, and mixing the refined desilicification solution with a refined lime milk solution to carry out a hydro-thermal synthesis reaction to obtain the xonotlite. According to the method for producing the xonotlite by taking the pulverized fuel ash as the raw material, the pulverized fuel ash is used as the main raw material and is effectively subjected to desilicification by using dilute alkali liquor, so that the dosage of the alkali liquor is reduced, and meanwhile, exploitation and utilization of ores, such as silica sand, kieselguhr and the like are greatly reduced.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Xonotlite compound super insulating material and preparation method thereof

InactiveCN101671156AImprove thermal conductivityLow thermal conductivityThermal insulationPipe protection by thermal insulationFiberXonotlite

The invention relates to an xonotlite compound super insulating material and a preparation method thereof. The xonotlite compound super insulating material comprises the following mixed raw materialsby weight percentage: 40 to 80 percent of SiO2 aerogel, 5 to 40 percent of infrared opacifier and 0 to 25 percent of reinforcing fiber. The preparation method comprises the following steps: adopting secondary particles which are provided with surface loose structures and are formed by mutual winding of xonotlite fiber with ultrafine diameters and SiO2 aerogel precursor prepared by adopting industrial water glass as silicon source to carry out compounding in advance; filling the SiO2 aerogel precursor in loose accumulation body of secondary particles of vacuum-dehydrated xonotlite, and drying after gelatinization and surface modification; filling the aerogel at the inner parts and the shells of the secondary particles of the xonotlite to form xonotlite-aerogel compound powder; and then mixing the xonotlite-aerogel compound powder with the infrared opacifier and the reinforcing fiber evenly, pressing the mixture in forming equipment with a negative pressure device and forming to obtain the xonotlite compound super insulating material. The invention has simple technique and low cost; and the prepared xonotlite compound super insulating material has excellent performance and can be used for insulation of a heating power device and a high-temperature pipeline.

Owner:NAVAL UNIV OF ENG PLA

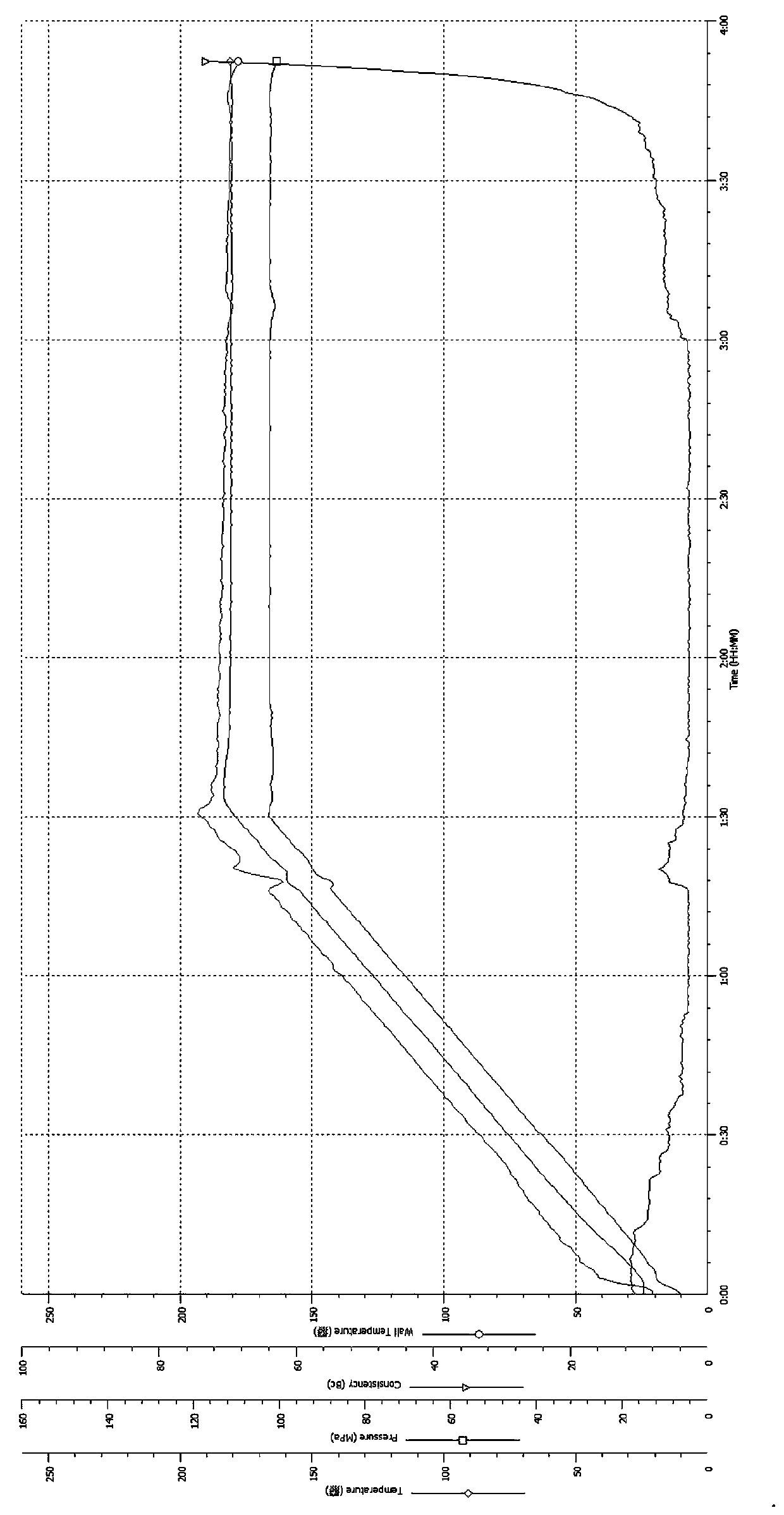

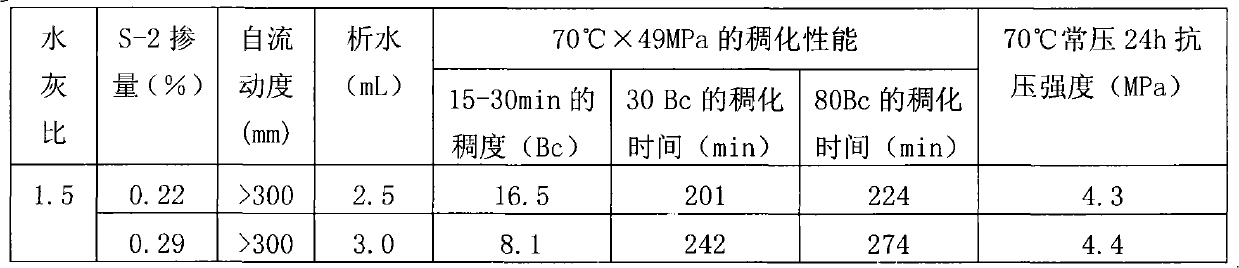

High-temperature-resistant well cementation cement paste system

ActiveCN111072350ALower requirementReduce dosageDrilling compositionHydration reactionPortland cement

The invention discloses a high-temperature-resistant well cementation cement paste system, and relates to the technical field of cement paste systems. The system comprises the following components: 60-75% of Portland cement; 15-25% of a strength recession resisting agent; 2-8% of a crystal form stabilizer; 0.5%-6% of a high-temperature retarder; and 3-8% of a high-temperature fluid loss agent, wherein the Portland cement is one of D-grade oil well cement or low-heat cement, and the specific surface area of the Portland cement is 280-350 m<2> / kg; the SiO2 content in the strength recession resisting agent is greater than 90%, and the mesh number is greater than or equal to 150 meshes; the content of SiO2 in the crystal form stabilizer is greater than 30%, and the mesh number is greater thanor equal to 600 meshes. The crystal form stabilizer is added and participates in hydration reaction when cement is hydrated, metal ions enter the structure of hydrated calcium silicate, so that conversion of tobermorite in a hydration product into xonotlite is prevented, the set cement is kept in a compact structure, and therefore, good high-temperature stability is achieved.

Owner:JIAHUA SPECIAL CEMENT +1

Expansive pearlite-hard cilicon calcium stone composite thermal insulating material and preparing process thereof

InactiveCN1559954AOvercome the disadvantages of using temperatureLow thermal conductivityHeat proofingFiberPolymer science

The invention is an expanded perlite-xonotlite compound heat-preserving material and its preparing method, and its characteristic: selecting expanded perlite with loose bulk weight of 60-100 kg / cu m, mixing in xonotlite active slurry, where the mixing proportion: expanded perlite 74-85 Wt.% and dry xonotlite active slurry 14-25 Wt.%, additionally adding in 1.0 Wt.% alkali resistant glass fiber as reinforcing fiber. After mixed material is stirred uniformly, making pressure filter forming in a water filtering mould; as pressing, the pressure is controlled at 0.10-0.15 MPa, and the wet blank is placed in a drying kiln for drying, and the temperature of the drying kiln is controlled at 50-110 deg.C, and the water content in the product <=1.0%, and the water content after absorbing moisture <=4.0%. The product at 800 deg.C heat conductivity coefficient is reduced by near 30% as compared with that of traditional water glass combined expanded perlite product, the folding strength and pressive strength are increased by twice above, the use temperature increased by near 200 deg.C, and the preparation cost is near that of traditional expanded perlite product.

Owner:UNIV OF SCI & TECH BEIJING

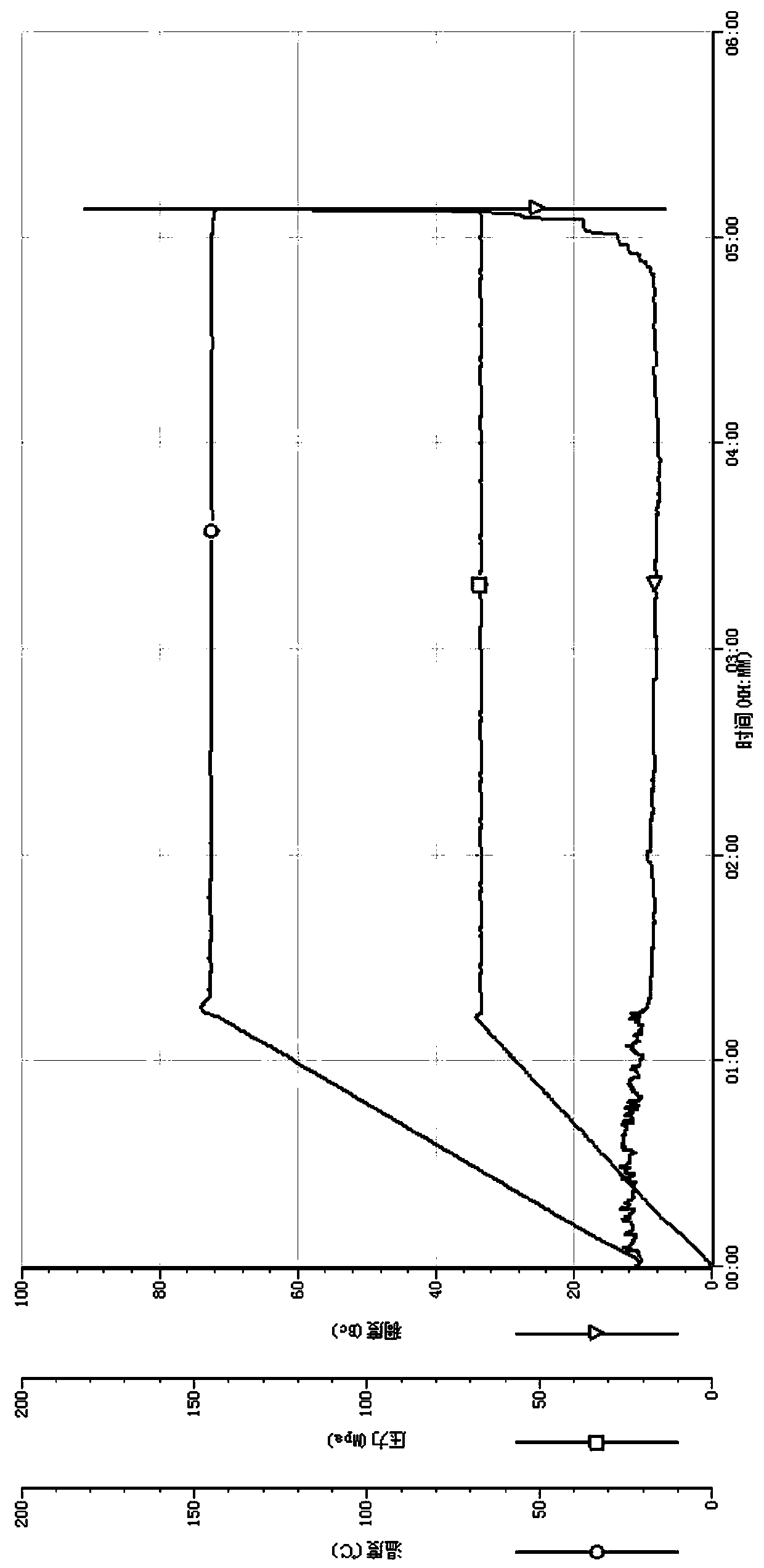

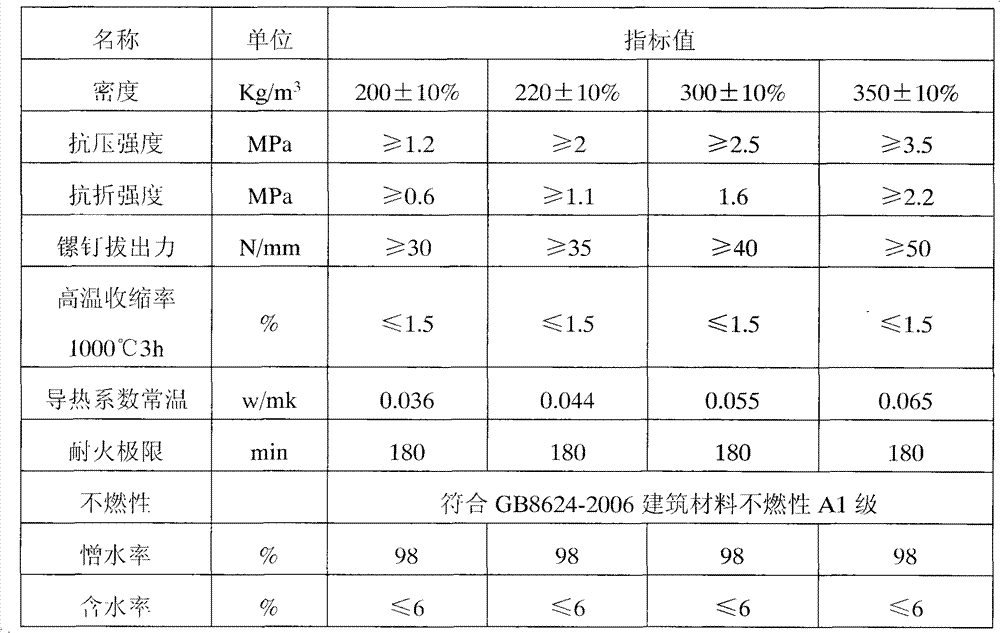

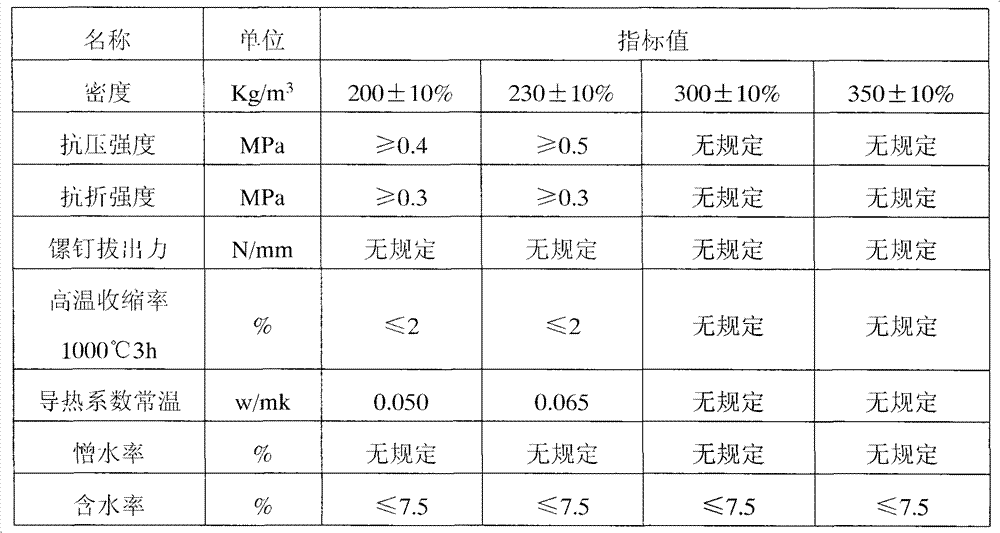

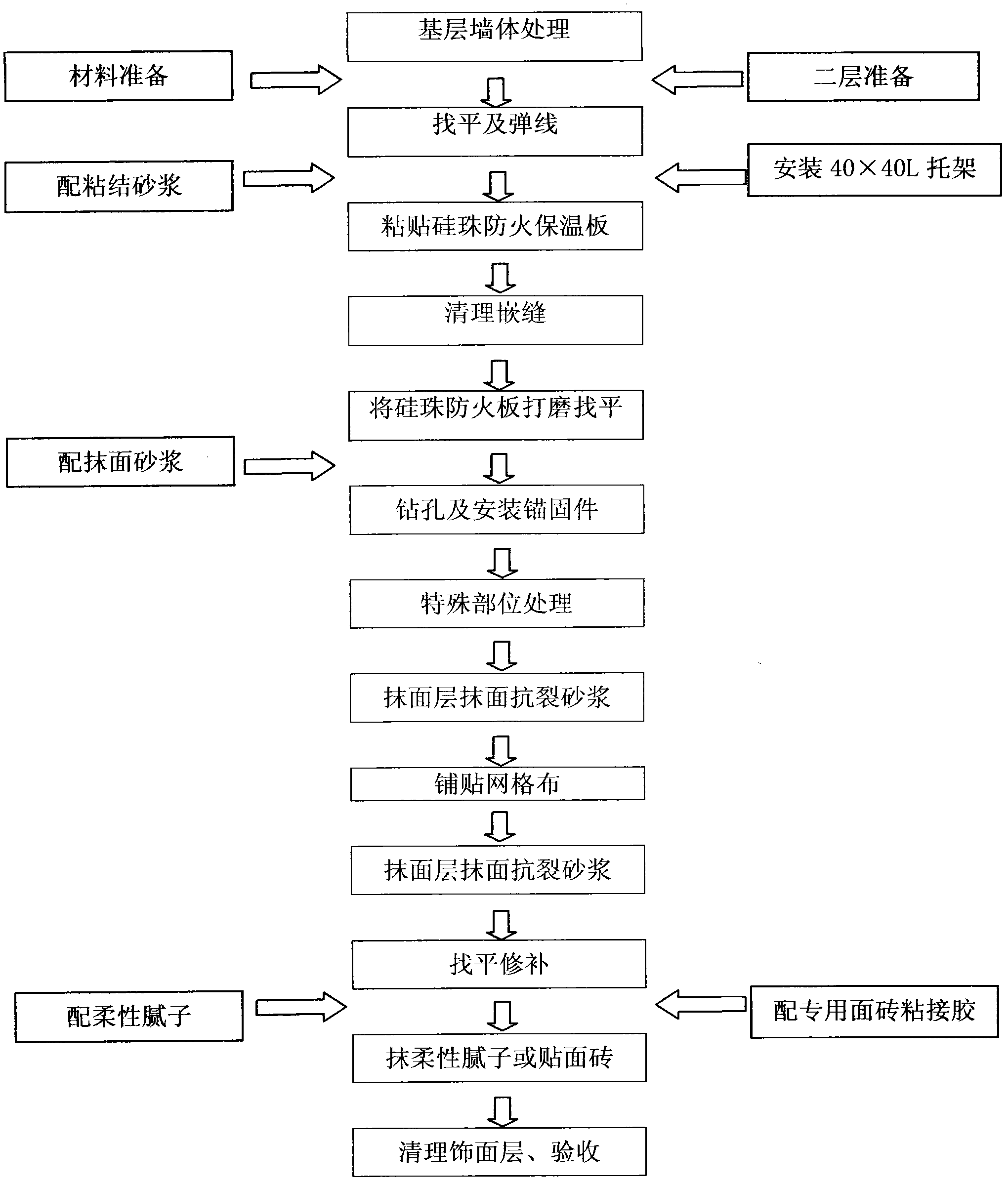

Making method of high-strength light-weight integral-hydrophobic xonotlite fireproof insulation board

ActiveCN102825650AOvercome the effects of poor activityHigh activityCeramic shaping apparatusCalcium in biologyFiber

The invention discloses a making method of a high-strength light-weight integral-hydrophobic xonotlite fireproof insulation board, comprising the following steps of: (1) mixing silicon raw materials and calcium raw materials according to a Ca / Si mole ratio of 0.9-1.1, then, injecting the mixed raw materials into a dynamic reaction kettle, synthesizing by using superheated steam of 250-400 DEG C at the steam pressure of 2.0-2.7MPa for 3-8hours to obtain xonotlite slurry, and adding reinforced fibers; (2) removing redundant water in the xonotlite slurry obtained in the step (1) and adding 0.1-8% of inorganic glue (according to the weight ratio of the slurry to the inorganic glue); (3) adding 0.1-8% of reaction type organic silicon waterproof agent in the xonotlite slurry obtained in the step (2) to enable the reaction type organic silicon waterproof agent and the slurry to form interface combination; and (4) carrying out compression molding on the xonotlite slurry prepared in the step (3), and drying to obtain the material-uniform high-strength light-weight complete-hydrophobic xonotlite board. The fireproof insulation board produced by the invention has the characteristics of high strength, uniform material, no bubble hole, light weight and complete hydrophobicity.

Owner:山东昊海凤栖新材料科技有限公司

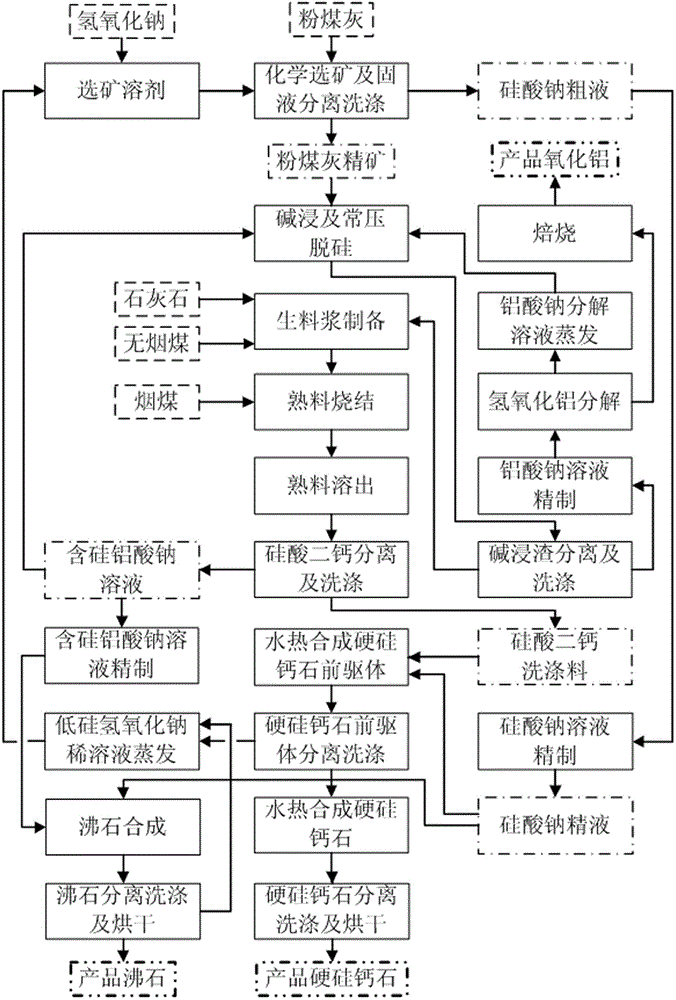

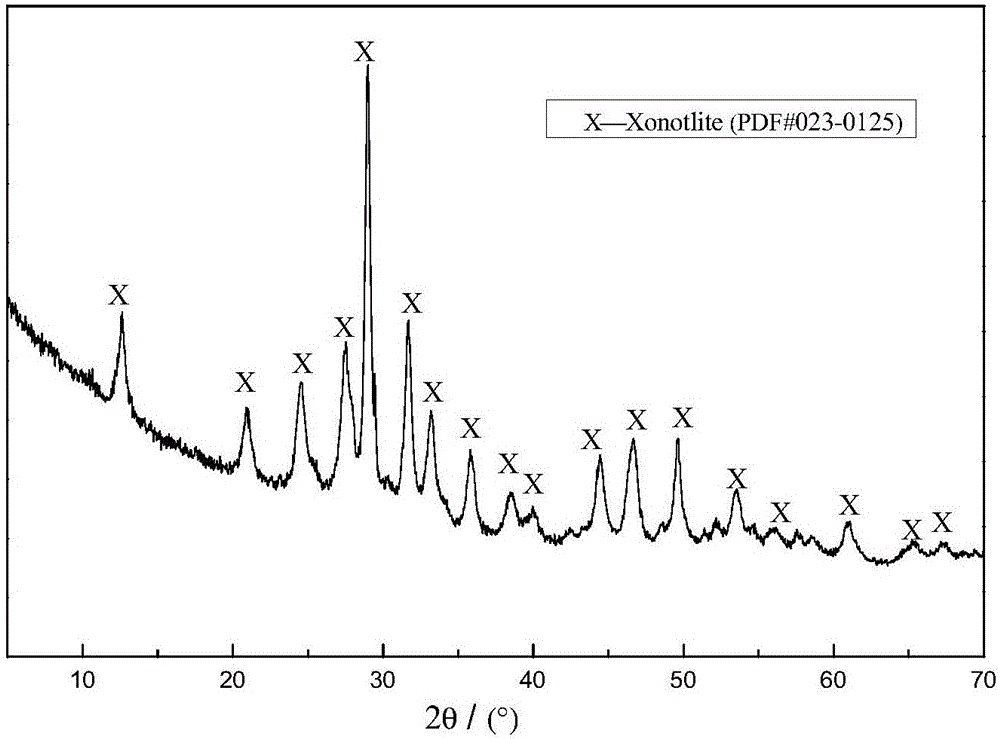

Method for producing xonotlite and aluminum oxide by using coal ash alkaline leaching sintering hydrothermal method

ActiveCN104477926AEngineering stabilityAdvanced EngineeringAlkaline-earth metal silicatesEnergy inputSlagXonotlite

The invention discloses a method for producing xonotlite and aluminum oxide by using a coal ash alkaline leaching sintering hydrothermal method. The method comprises the following steps: (1) performing chemical ore separation; (2) producing aluminum oxide through alkaline leaching; (3) preparing raw material slurry; (4) sintering to prepare clinker; (5) dissolving, separating and washing the clinker; (6) preparing xonotlite precursor raw material slurry; (7) performing hydro-thermal synthesis to prepare a xonotlite precursor; (8) performing hydro-thermal synthesis to prepare xonotlite filter cakes. By adopting the method, the problems and the defects that in the prior art a great deal of limestone is consumed, the energy consumption is large and a great deal of slag is generated, are effectively solved, coal ash is comprehensively utilized, both xonotlite and aluminum oxide can be produced, a silicon mineral resource is saved, a monohydrallite resource is replaced, sources such as soil are also saved, and large-scale economic production is achieved.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD +1

Method for preparing xonotlite by using silicium-calcium slag

The invention provides a method for preparing xonotlite by using silicium-calcium slag. The method comprises the following steps: mixing the silicium-calcium slag, a siliceous raw material and an additive so as to obtain a mixture; and mixing the mixture with water according to the liquid-to-solid ratio of (10 to 40): 1, carrying out a dynamic hydrothermal synthetic reaction on the mixed reaction system, and carrying out filtering, washing and drying after the reaction is completed, thereby obtaining the xonotlite, wherein the mole ratio of CaO to SiO2 in the mixture is 0.95 to 1.25, and the additive accounts for 0% to 2% the total mass of the silicium-calcium slag and the siliceous raw material. The method for preparing the xonotlite by using the raw materials such as the silicium-calcium slag, provided by the invention, has the characteristics of low cost, short reaction time, low energy consumption, and the like, and the prepared xonotlite meets the requirements of standards of GB / T 10699-2015 calcium silicate heat-insulation products and can replace the existing xonotlite products. In addition, the method provided by the invention can be used for consuming a large amount of silicium-calcium slag, thereby having obvious social, economic and environmental benefits.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

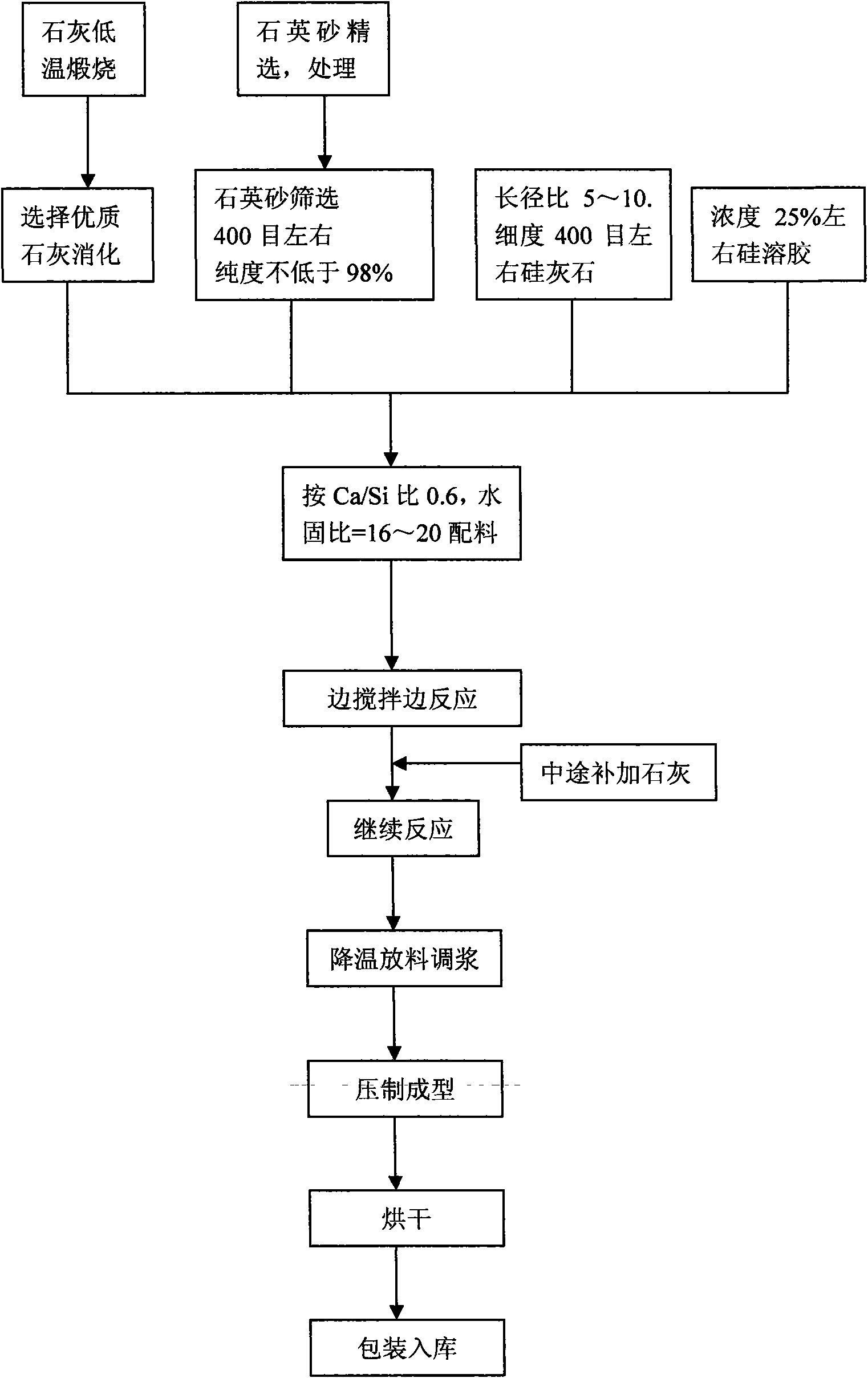

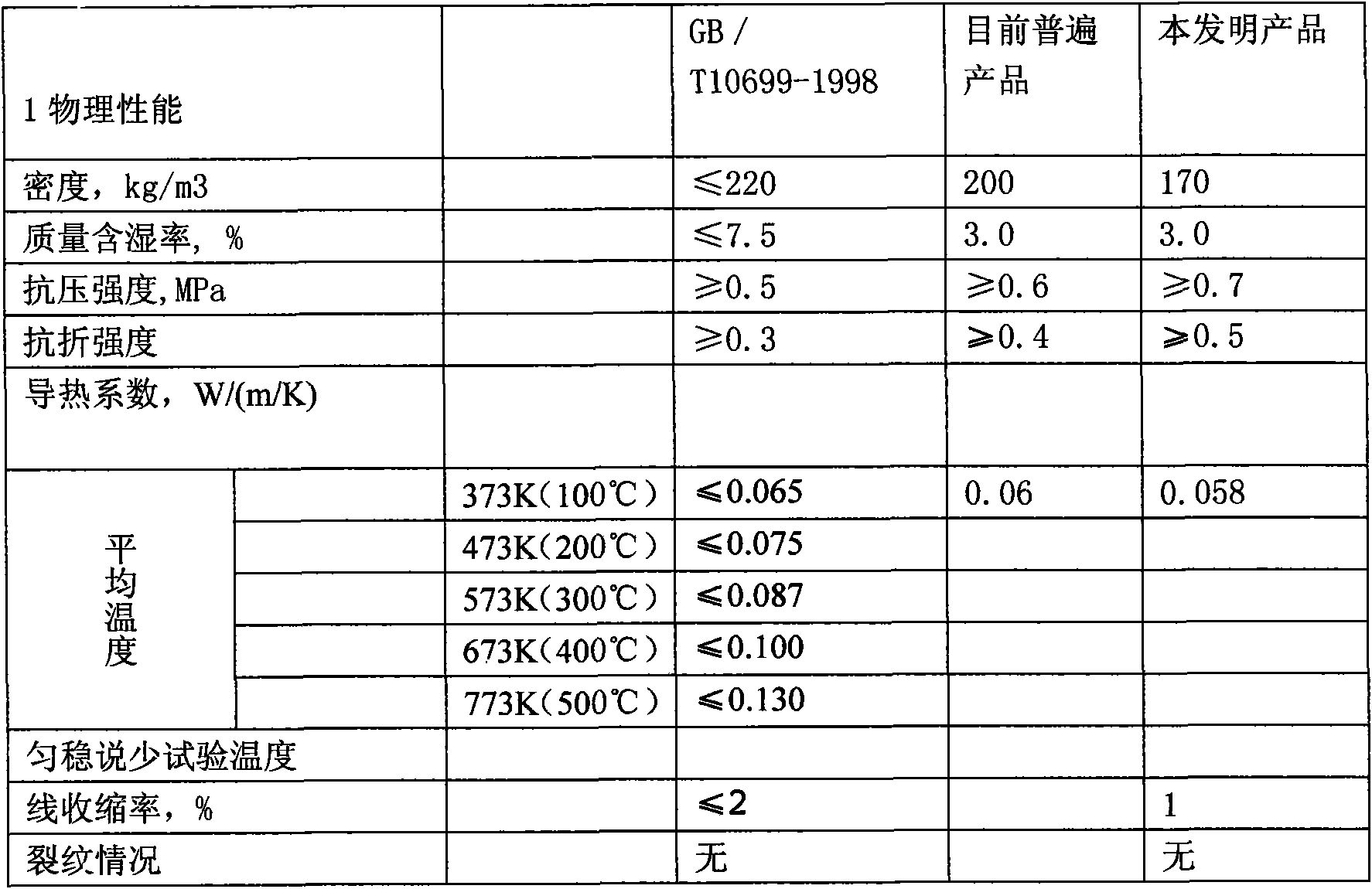

Process for manufacturing xonotlite type calcium silicate heat insulation material

The invention relates to a process for manufacturing a xonotlite type calcium silicate heat insulation material. The heat insulation material comprises the following raw materials in percentage by weight: 2.3 to 2.7 percent of superfine quartz sand, 3 to 3.3 percent of active calcium hydroxide, 0.04 to 0.1 percent of silica sol, 0.3 to 0.5 percent of wollastonite, 0.1 to 0.3 percent of cotton fiber, 0.1 to 0.3 percent of glass fiber and 92 to 94 percent of water. The process comprises the following steps of: 1, raw material selection; 2, burdening; 3, slurry pre-reaction; 4, secondary addition; 5, active slurry synthesis of the xonotlite; 6, compression molding; and 7, drying, packing and warehousing. The heat insulation material has the advantages of light capacity, stable quality, high utilization rate of the raw materials, high finished product rate and the like.

Owner:ZHEJIANG ASKER TECH

Inorganic heat-insulation fireproof plate

InactiveCN102619287ASolve easy pulverizationIncrease diversityHeat proofingBuilding material handlingPolymer scienceAging resistance

Disclosed is an inorganic heat-insulation fireproof plate, namely a silica bead fireproof heat-insulation plate. The fireproof plate is made of vitrified small balls and xonotlite, the weight ratio of the vitrified small balls to the xonotlite ranges from 1:2 to 1:5, in addition, waterproof materials with the weight ranging from 1% to 5% of the total weight of the fireproof plate and gel materials with the weight ranging from 8% to 10% of the total weight of the fireproof plate are added, and the fireproof plate is manufactured via working procedures including preparation, screening, pressure forming and drying. The vitrified small balls replace traditional common expanded perlite and traditional common polyphenyl particles to be used as lightweight aggregates of dry mixed heat-insulation mortar, shortcomings that the expanded perlite is high in water absorption and easy in pulverization and is high in volumetric shrinkage during slurry stirring, accordingly, low long-term strength, hollowing and cracking of a product are caused easily, and the like are overcome, defects of flammability, poor fireproof performance, harmful gas generation at a high temperature, low ageing resistance and weather fastness, high rebounding during construction and the like of the polyphenyl particles are also overcome, and comprehensive performances and construction property of the heat-insulation mortar are improved. In addition, the hydrophobic vitrified small balls cannot be degraded at a high temperature and are not easy to deform, and the flame retardant property of a polymer can be improved when the vitrified small balls are used as filling materials of the polymer.

Owner:QINGDAO FENGXIANG CHEM

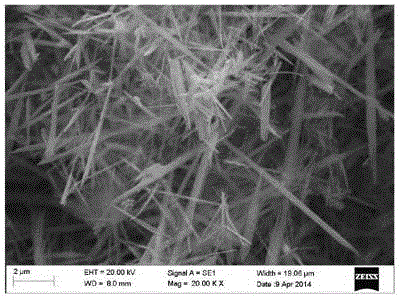

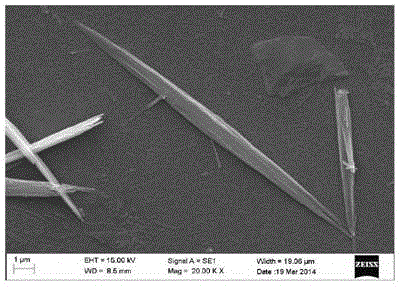

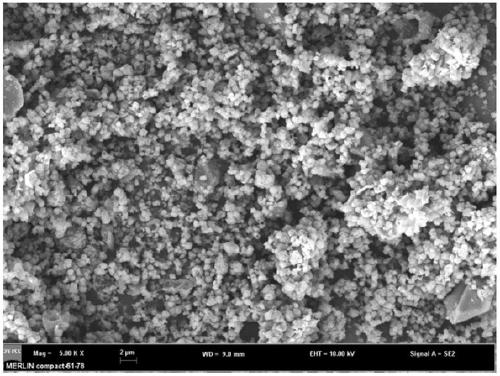

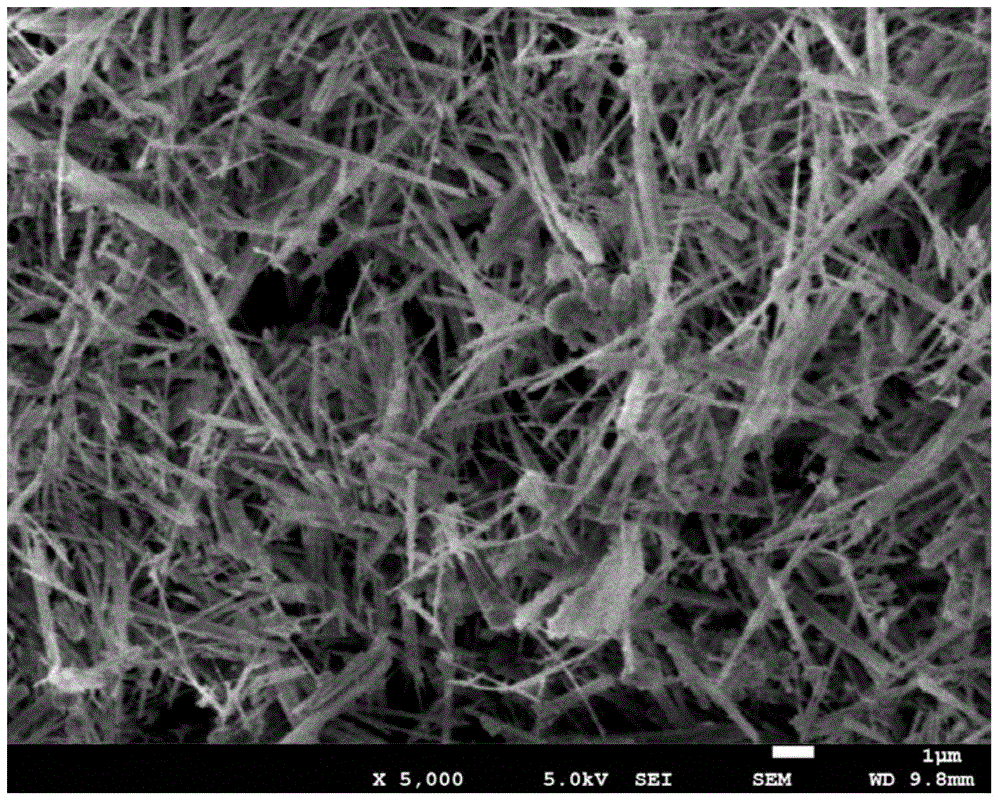

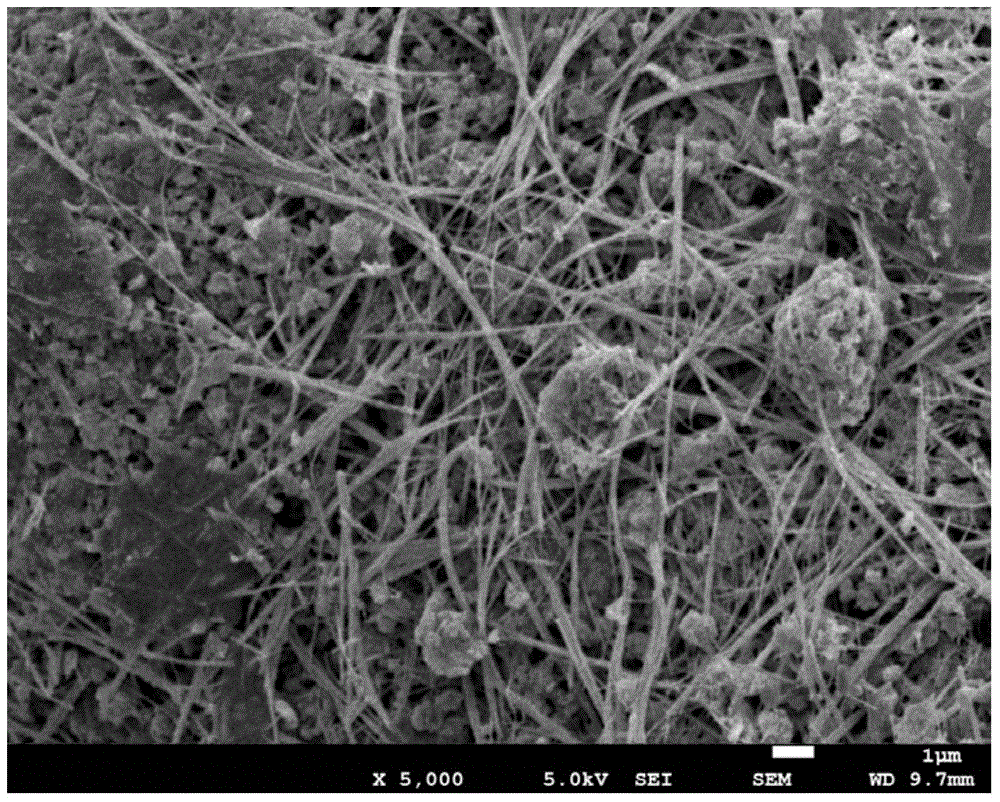

Preparation method of xonotlite crystal whisker

ActiveCN104451883AHigh strengthLow thermal conductivityPolycrystalline material growthFrom normal temperature solutionsReaction temperatureDiameter ratio

The invention discloses a method for preparing a xonotlite crystal whisker by using an active silica raw material and a calcium carbonate raw material. The method comprises the following steps: (1) grinding the active silica raw material and the calcium carbonate raw material to obtain active silica powder and calcium carbonate powder; (2) batching the active silica powder or / and the calcium carbonate powder obtained in the step (1), adding industrial water and directly putting into a closed reaction unit to perform a synthesis reaction by controlling the heating rate, the reaction temperature and the reaction time; and (3) filtering and drying, namely dispersing reaction products obtained in the step (2) to obtain the xonotlite crystal whisker. The xonotlite crystal whisker prepared by the method disclosed by the invention is relatively large in crystal grain, large in length-diameter ratio, high in strength, good in stability, wide in application range and beneficial to promotion and application.

Owner:SOUTHWEAT UNIV OF SCI & TECH

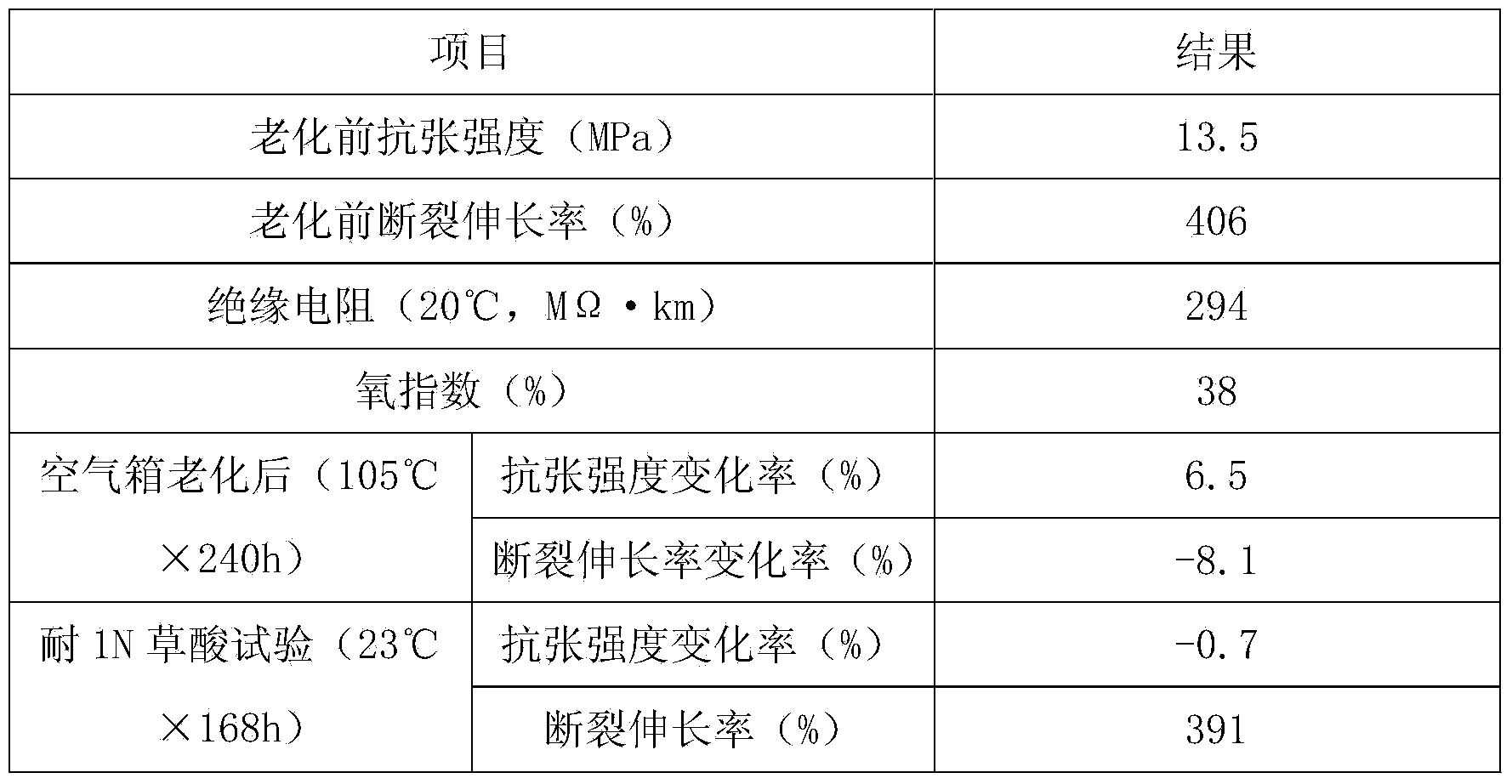

High-weather-resistance cable material for railway passenger trains and preparation method thereof

InactiveCN104017278AGood weather resistanceImprove heat aging resistanceRubber insulatorsCadmium CationStannate

The invention discloses a high-weather-resistance cable material for railway passenger trains and a preparation method thereof. The cable material is prepared form the following raw materials in parts by weight: 40-60 parts of ethylene-propylene-diene monomer, 35-45 parts of epichlorohydrin rubber, 20-30 parts of polypropylene, 5-10 parts of silicone OV-210, 10-15 parts of dicyclopentadiene petroleum resin, 2-4 parts of insoluble sulfur, 1.5-2.5 parts of N,N'-m-phenylenedimaleimide, 2-3 parts of magnesium methacrylate, 1-2 parts of zinc oxide, 4-6 parts of low-molecular-weight polybutadiene, 5-10 parts of titanium dioxide, 9-16 parts of nanometer xonotlite, 5-10 parts of cashew shell oil, 20-30 parts of fast extruding furnace black N550, 4-8 parts of diallyl bisphenol A, 2-3 parts of N,N'-di-2-naphthyl-p-phenylenediamine, 2-3 parts of cadmium diethyldithiocarbamate, 1.5-2.5 parts of zinc stannate, 12-18 parts of ammonium octamolybdate and 15-20 parts of modified stone flour. The cable material has excellent weather resistance, thermal aging resistance, chemical corrosion resistance and fatigue resistance, is usable for a long time in environments of sunlight, moisture, ozone, acid rain and the like, and is long in service life and wide in application prospect.

Owner:ANHUI KANGLIYA CO LTD

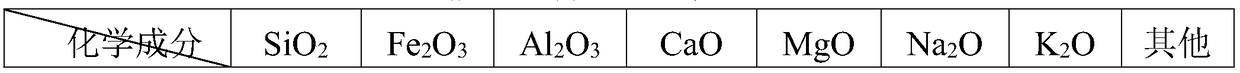

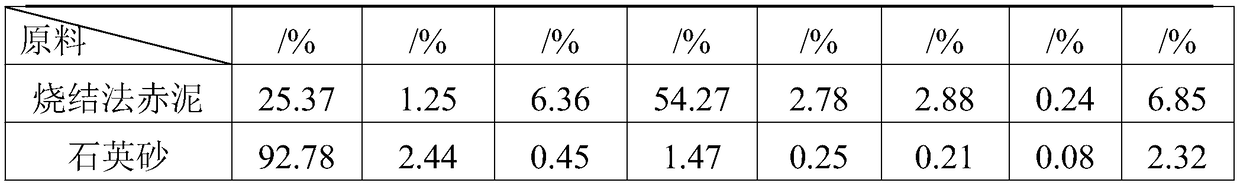

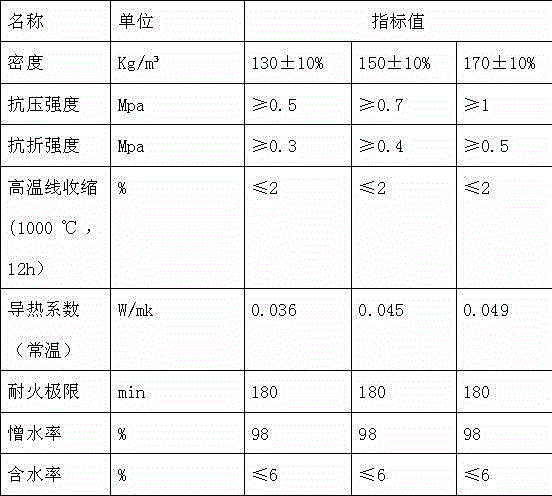

Method for preparing xonotlite type thermal-insulation fireproof material from sintered red mud

The invention relates to a method for preparing a xonotlite type thermal-insulation fireproof material from sintered red mud, and belongs to the field of inorganic thermal insulation materials. Raw materials used in the method include a mixture, a trace additive, a reinforcing fiber, an inorganic glue and a waterproof agent. The method comprises the following steps: mixing the mixture with water,injecting the obtained solution into a dynamic reaction kettle, carrying out a reaction to obtain a xonotlite slurry, and adding the reinforcing fiber; filtering the slurry, and sequentially adding the inorganic glue and the waterproof agent; and carrying out compression molding and drying to obtain the xonotlite type thermal-insulation material. The main raw material sintered red mud is a solid waste formed by extracting alumina from bauxite or high-alumina fly ash through an alkali lime sintering process, so the production cost of xonotlite is greatly reduced, the raw materials have wide sources, the reaction time is short, and the obtained thermal-insulation fireproof material has a high strength, a light unit weight and a good water repellency; and the method for preparing the xonotlite is simple, can consume the solid waste generated in the alumina production process, and suitable for being industrially promoted.

Owner:内蒙古中建亚太建材科技有限公司

Method for manufacturing high-strength low-heat conduction coefficient xonotlite heat-insulating material

The invention discloses a method for manufacturing a high-strength low-heat conduction coefficient xonotlite heat-insulating material. The method comprises the following steps: (1) mixing a siliceous material body and a calcareous material body according to the ca / si ratio (mole ratio) of 0.6-1.2; (2) carrying out pregelatinization reaction on a mixed body obtained from the step (1) to obtain a tobermorite colloid body; (3) adding the colloid body obtained from the step (2) to a thickening and activating material; (4) remixing the colloid body obtained from the step (3) according to the Ca / Si ratio (mole ratio) of 0.7-1; (5) injecting the colloid body obtained from the step (4) into a dynamic reaction kettle for reaction to obtain a porous fine poriform xonotlite extremely-light slurry body; (6) adding 1%-15% of fiber bodies to the slurry body obtained from the step (5), adding 1%-100% of inorganic diffusing colloid bodies, adding a right quantity of foam-stabilizing materials and foaming materials, and sufficiently stirring; and (7) carrying out compression moulding forming on a colloid slurry body obtained from the step (6), and drying. The heat-insulating material produced through the method disclosed by the invention has the characteristics of high strength, low heat conduction coefficient and uniformity in material.

Owner:王民艳

Nano thermal insulation material and preparing method thereof

InactiveCN105503037ALight in massGood heat insulationSolid waste managementMicrosphereThermal insulation

The invention discloses a nano thermal insulation material and a preparing method thereof, belonging to the technical field of thermal insulation material. The nano thermal insulation material is prepared from following components in parts by weight; 60-70 parts of titanium dioxide / silicon dioxide binary aerogel, 2-4 parts of inorganic nano material, 1-2 parts of xonotlite, 2-4 parts of modified polypropylene fiber, 5-7 parts of ceramic powder body opacifying agent, 0.6-0.8 part of anhydrous calcium chloride, 2-4 parts of binder, 20-30 parts of hollow microspheres, 3-5 parts of polyethylene glycol, 6-8 parts of perlite, 2-6 parts of silica fume, 1-3 parts of fire retardant, 0.4-0.6 part of aluminum powder, and 0.1-0.3 part of methyl sodium silicate. By the binary aerogel, the two hollow microspheres and internal-external combination through use of the aluminum powder, comprehensive performances of the nano thermal insulation material are effectively improved and the promotion and application of the thermal insulation material in the thermal insulation material engineering are promoted.

Owner:葛宏盛

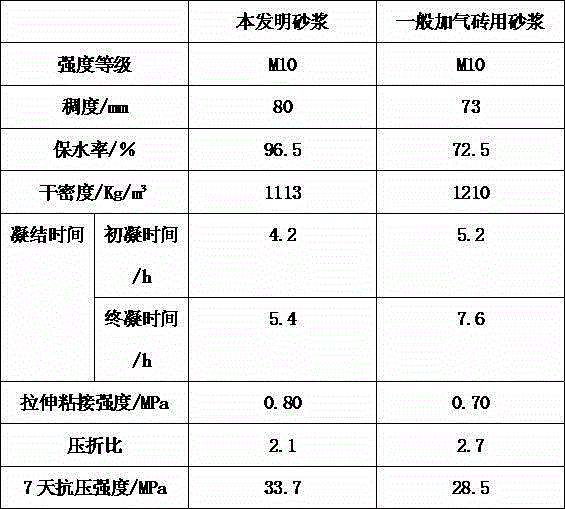

Low-shrinkage mortar for aerated bricks

The invention discloses low-shrinkage mortar for aerated bricks. The low-shrinkage mortar comprises, by weight, 55% of quartz sand, 10% of coal ash, 4% of magnesium lime, 2% of calcium carbonate, 3% of bentonite, 2.5% of xonotlite, 9% of cement, 10% of ceramsite sand, 2.5% of redispersible latex powder, 1% of water reducing agents and 1% of additives. The low-shrinkage mortar has the advantages that the low-shrinkage mortar is simple in production process, low in cost and heat conductivity coefficient and high in strength, is environmental friendly and conforms to environmental protection requirements, excellent anti-cracking effects can be realized, energy can be saved, and requirements of construction engineering can be met; the calcium carbonate is grafted and modified and is dispersed in mortar to form dispersion systems, accordingly, internal stress of the mortar can be absorbed, and shrinkage settlement of the mortar can be reduced; calcined magnesium lime and xonotlite powder is added into the mortar, so that the impermeability performance of the mortar further can be improved, and the problem of phenomena of poor hardening, cracking and the like due to the fact that existing mortar is excessively quickly dried and has insufficient moisture can be effectively solved; the quartz sand is pre-treated, so that the plasticity of the mortar can be enhanced, and the construction operability can be improved.

Owner:ANHUI KUNLONG BUILDING MATERIALS CO LTD

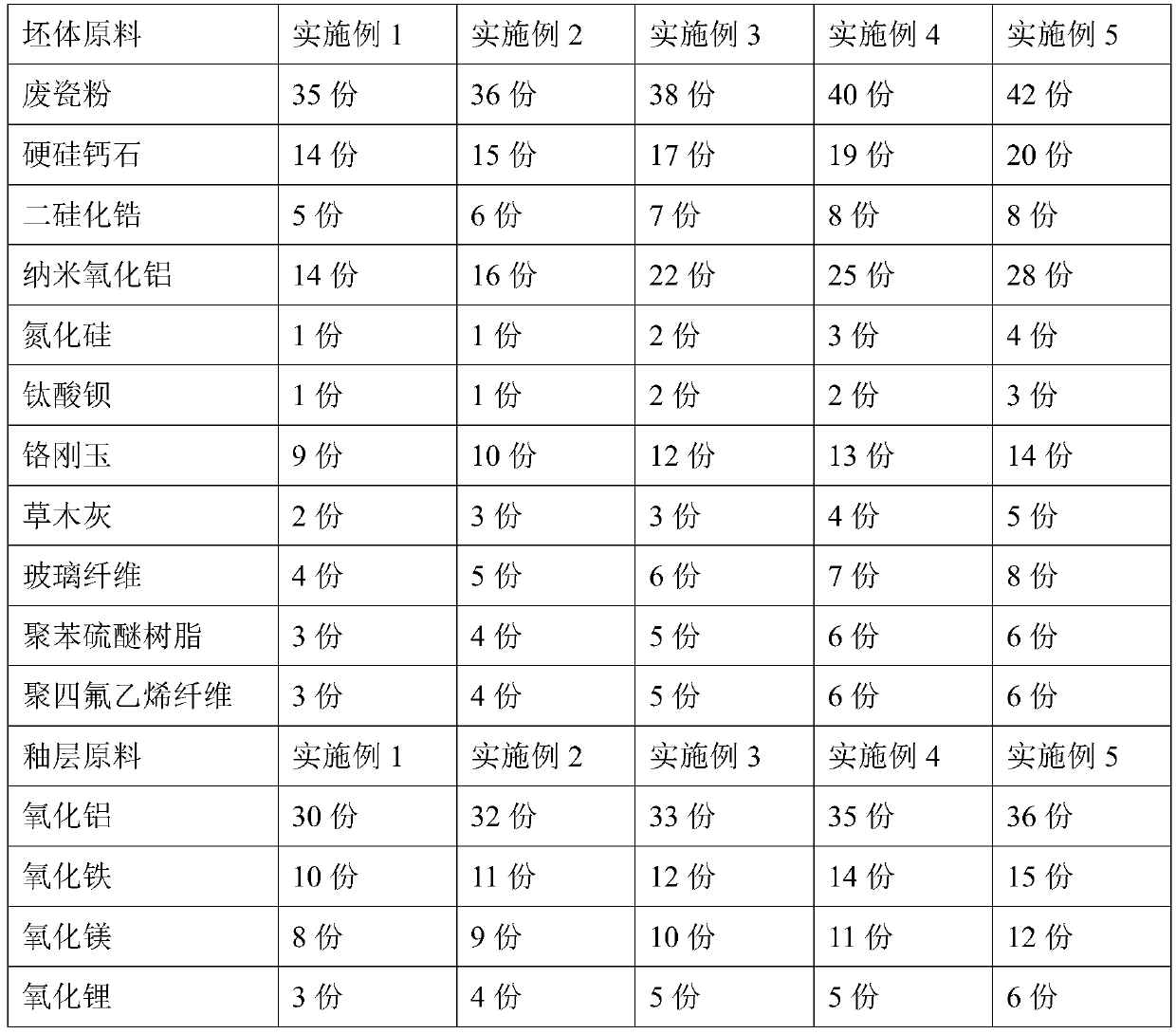

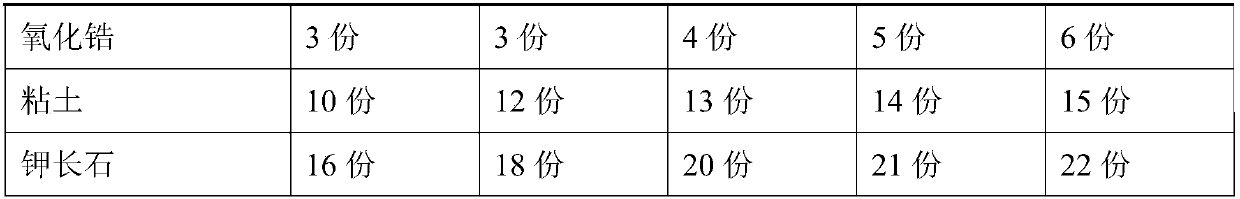

High-buffering and shock-proof environmental-protection ceramic product and preparation method thereof

InactiveCN110194650AAvoid breakingReduce brittlenessCeramic materials productionClaywaresLithium oxideBarium titanate

The invention provides a high-buffering and shock-proof environmental-protection ceramic product and a preparation method thereof. The high-buffering and shock-proof environmental-protection ceramic product comprises a billet material and a glaze material, wherein the billet material comprises waste porcelain powder, xonotlite, zirconium disilicide, nanometer boron fiber, nanometer alumina, silicon nitride, barium titanate, chrome corundum, plant ash, glass fiber, a polyphenylene sulfide resin and polytetrafluoroethylene fiber, and the glaze material comprises alumina, iron oxide, manganese oxide, lithium oxide, zirconium oxide, clay and potassium feldspar. The preparation method comprises: (1) crushing raw materials; (2) mixing the materials; (3) producing a billet; (4) glazing; and (5) firing. According to the present invention, by adding the fiber component, the prepared ceramic has good strength and good toughness, such that the high buffering and shockproof effect is ensured, thedisadvantages of large brittleness and easy cracking of the traditional ceramic product are overcome, and the broad market prospect is achieved.

Owner:德化东华陶瓷有限公司

Preparation method, application and regeneration of xonotlite and natrium-doped xonotlite

ActiveCN109485055AIncrease the areaLarge hole volumeOther chemical processesAlkaline-earth metal silicatesEggshellWastewater

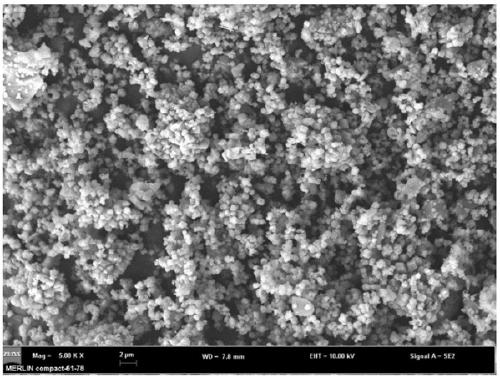

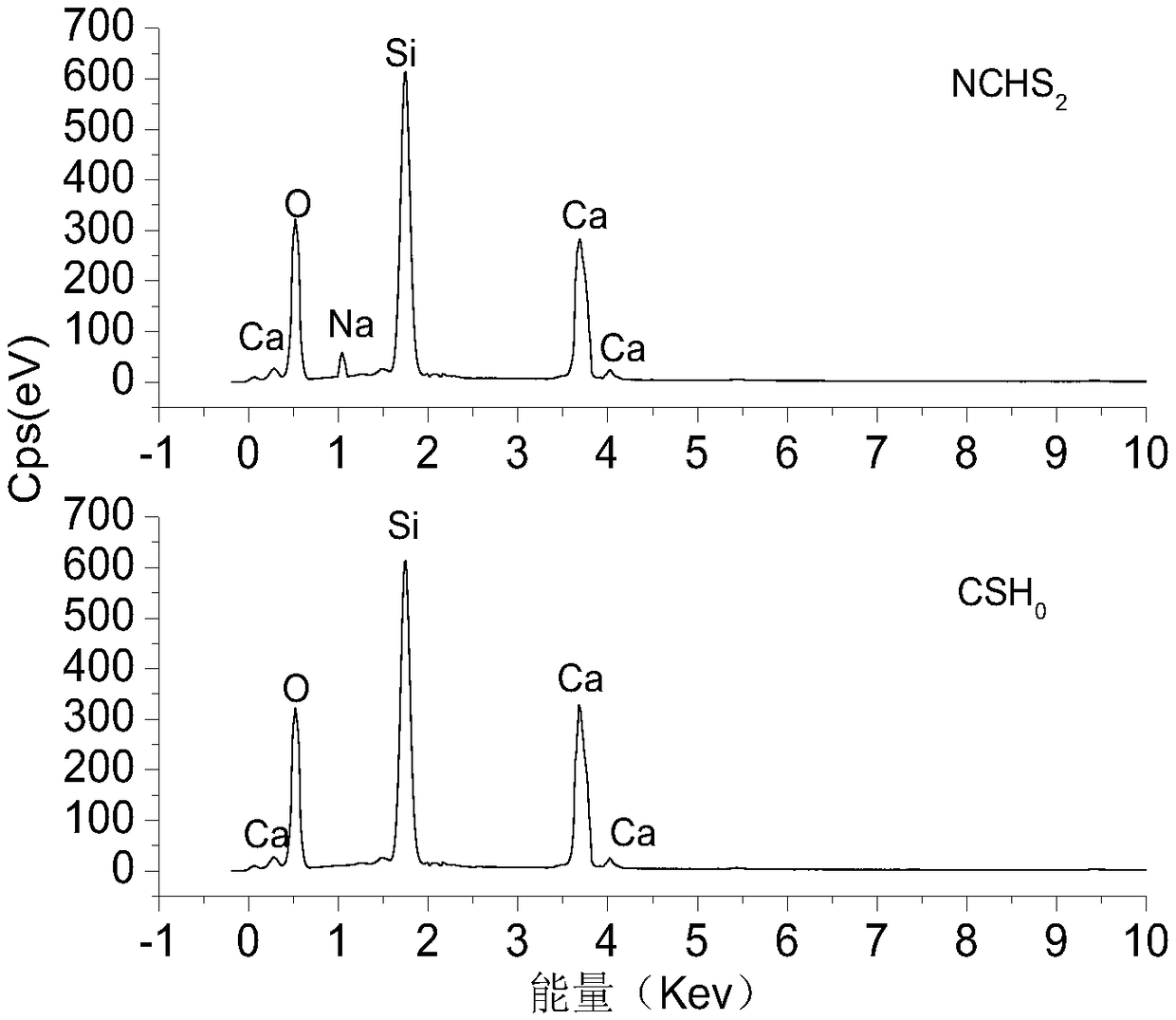

The invention discloses a method for preparing xonotlite and natrium-doped xonotlite serving as porous adsorption function materials by abandoned eggshells. The prepared materials have large specificsurface area and pore volume, meet mesoporous material standards and are adsorption materials with obviously concave-convex surfaces and porous development capacity. 100mL of 120mg / L wastewater containing Cd<2+> is adsorbed by 0.12g of CSH0 and NCSH2, removal rates reach up to 81.68% and 98.01% under the optimization condition of pH=6, T=313K and t=45min, equilibrium adsorption capacity reaches upto 81.68mg / g and 98.01mg / g, the xonotlite and the natrium-doped xonotlite have high adsorption performances, the surface and the porous structure of the xonotlite can be improved by doping natrium, and the adsorption performances can be improved. Adsorption behaviors of the xonotlite and the natrium-doped xonotlite are described by a Langmuir equation, the saturated adsorption capacity of the materials are obviously superior to that of other materials, the used xonotlite and natrium-doped xonotlite can be regenerated, and the repeatedly used and regenerated xonotlite still has excellent adsorption capacity. Natural waste resources are sufficiently used, the preparation process is simple and convenient, and products have good performances and high popularization values.

Owner:HENGYANG NORMAL UNIV

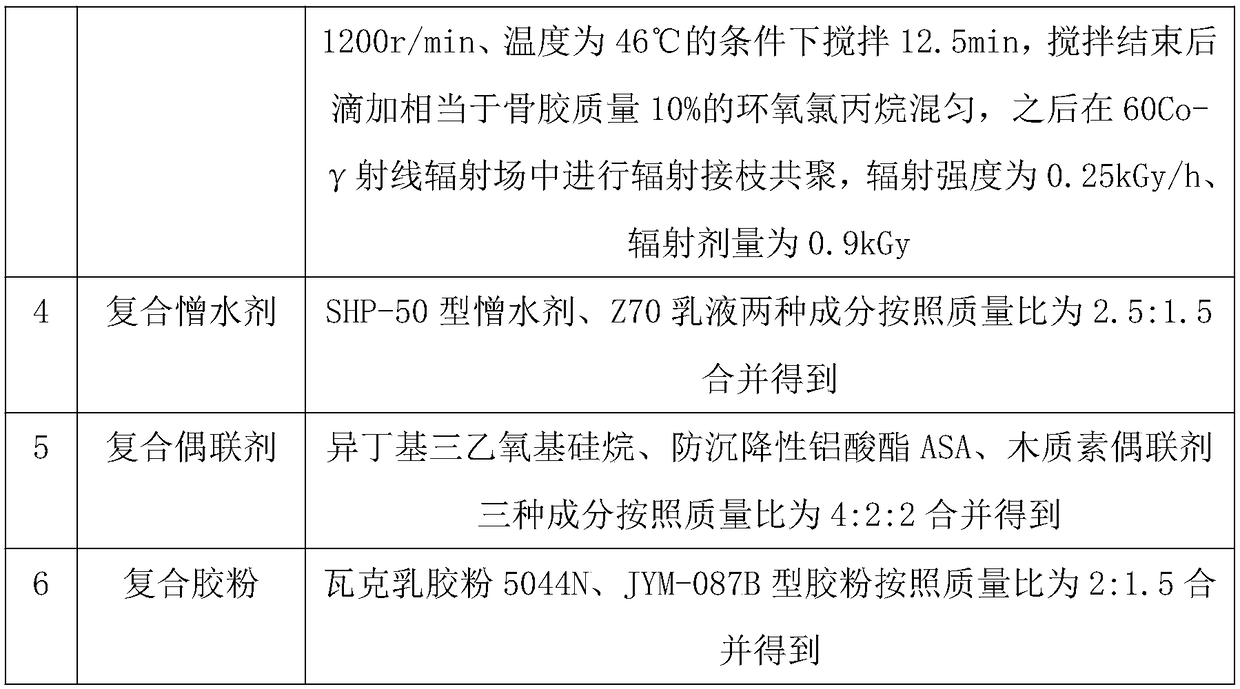

Preparation method for cement-based crack grouting material for road bridges

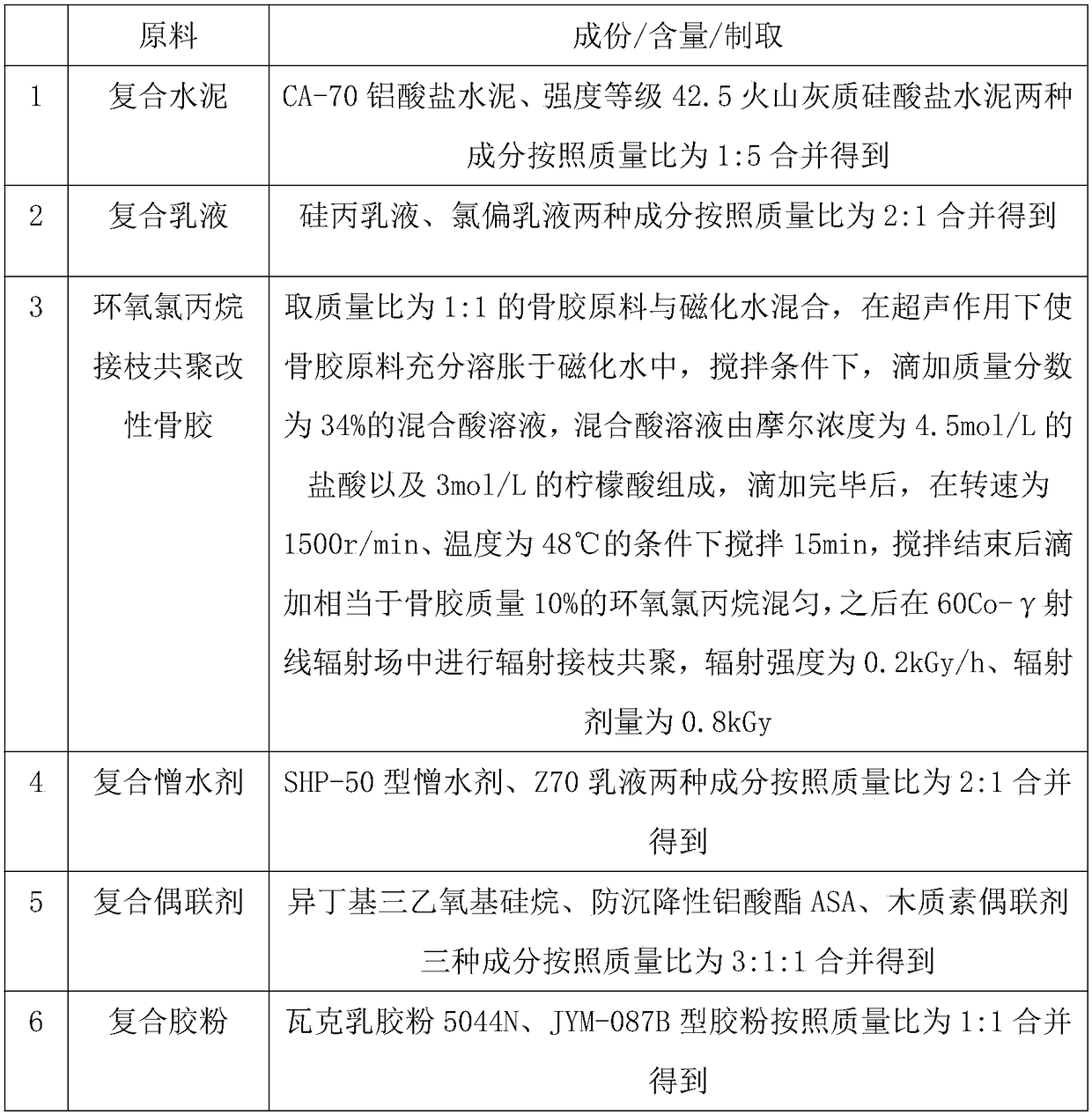

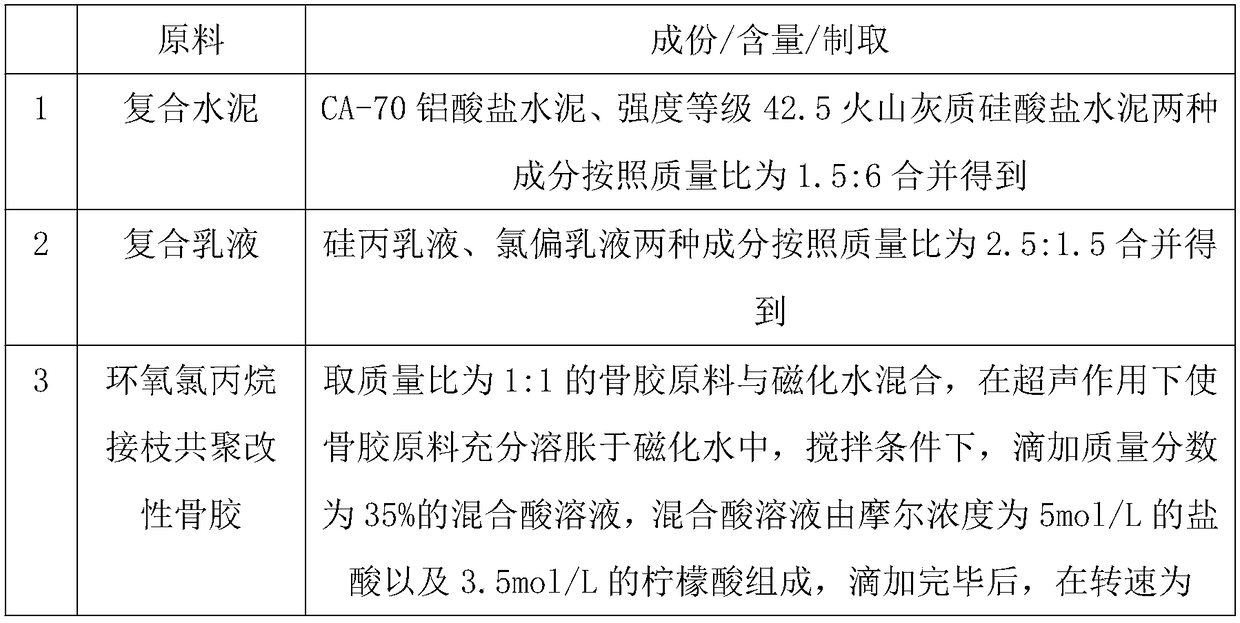

The invention discloses a preparation method for cement-based crack grouting material for road bridges, and relates to the technical field of concrete crack-grouting materials of bridges. The preparation method comprises the following steps: first weighing the following raw materials: composite cement, composite emulsion, pearlite sand, halloysite clay, sepiolite velvet, epichlorohydrin grafted copolymerized modified bone glue, fibrous xonotlite, a composite water repellent, a composite coupling agent and a composite latex powder; conducting graded chopping on the sepiolite velvet; conductingpulverization and activation on the halloysite clay and the xonotlite; and mixing the materials. The crack grouting slurry material of the invention has excellent slurry performance, bonding performance, process performance and resistance to construction negative temperature, has strong environmental adaptability and high stress resistance, and has broad application prospects.

Owner:合肥慧林建材有限公司

Preparation method for xonotlite type heat-preserving material

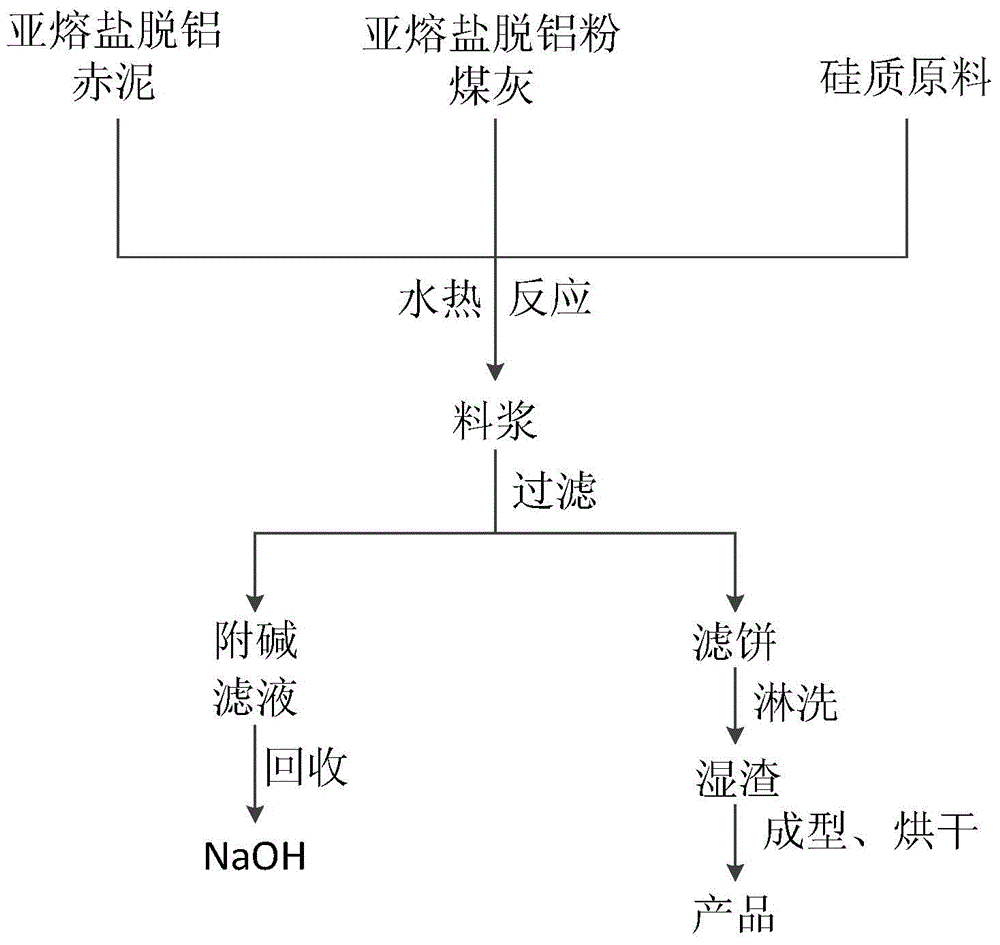

The invention provides a preparation method for a xonotlite type heat-preserving material. According to the invention, the xonotlite type heat-preserving material is prepared by utilizing sub-molten salt dealuminized red mud and sub-molten salt dealuminized fly ash as calcareous and siliceous raw materials through a dynamic hydrothermal reaction. The method in the invention solves problems of high cost and high resource consumption due to synthesis of xonotlite from native silicon sources and calcium sources; a novel solution way is provided for emission problems of large quantities of two solid wastes of fly ash and Bayer process red mud; meanwhile, the sub-molten salt dealuminized red mud and fly ash, after drying and crushing, do not need high energy consumption processes like activation and high-temperature treatment, and can directly undergo a thermal reaction; thus, heat-preserving material cost is greatly reduced, and economic benefits are improved; meanwhile, pollutions of two solid wastes to the environment are indirectly solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Xonotlite reinforced and foamed cement and production method thereof

InactiveCN103011732ASolve the problem of not being waterproofImprove insulation effectCeramicwareCompressive resistanceXonotlite

The invention discloses xonotlite reinforced and foamed cement which comprises 10-20wt% of xonotlite slurry and 80-90wt% of foamed cement and is produced by uniformly mixing the xonotlite slurry and the foamed cement and then foaming the mixture. According to the invention, by using the xonotlite active slurry is used as a reinforcing material and by combining the inherent characteristics of the foamed cement material, and the xonotlite reinforced and foamed cement with high compressive strength and low heat conduction coefficient is produced.

Owner:LAIZHOU MINGGUANG THERMAL INSULATION MATERIALS

Method for preparing calcium silicate heat insulation material by using fly ash desiliconized solution

The invention provides a method for preparing a calcium silicate heat insulation material by using a fly ash desiliconized solution. The method comprises the following steps of (1) performing pre-desiliconizing reaction on fly ash and a sodium hydroxide solution, so as to obtain the desiliconized fly ash and a fly ash desiliconized solution; (2) mixing the fly ash desiliconized solution and lime emulsion, and performing hydrothermal synthesizing reaction on the obtained slurry, so as to obtain the xonotlite slurry; (3) washing the xonotlite slurry, mixing with enhanced fibers, pressing, forming and drying, so as to obtain the calcium silicate heat insulation material. The method provided by the invention has the advantages that by using the fly ash desiliconized solution as the silicon rawmaterial to prepare the xonotlite type calcium silicate heat insulation material, the reaction time is short, the energy consumption is low, and the product property is good; a new high-quality utilization path is provided for the fly ash.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

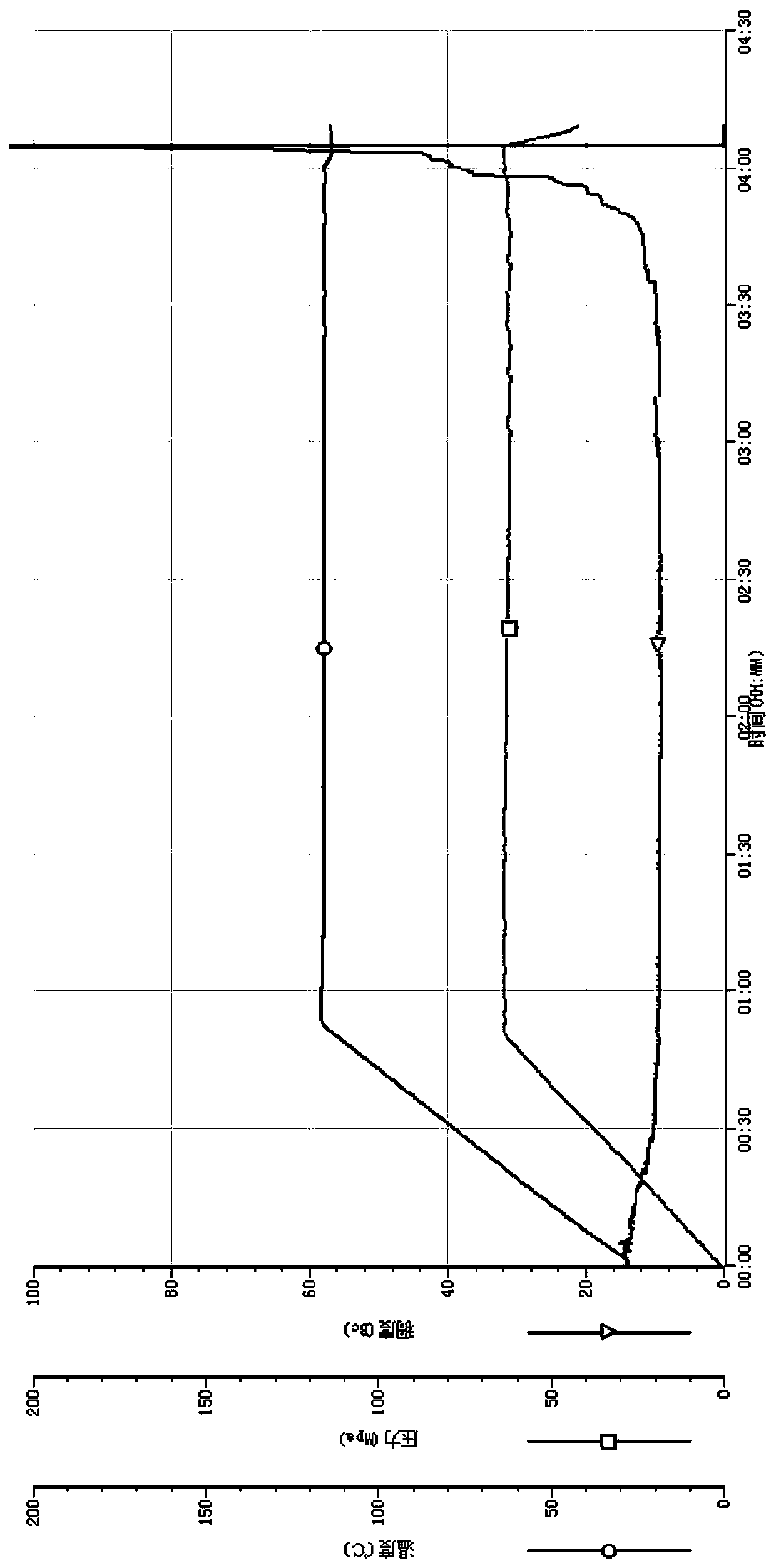

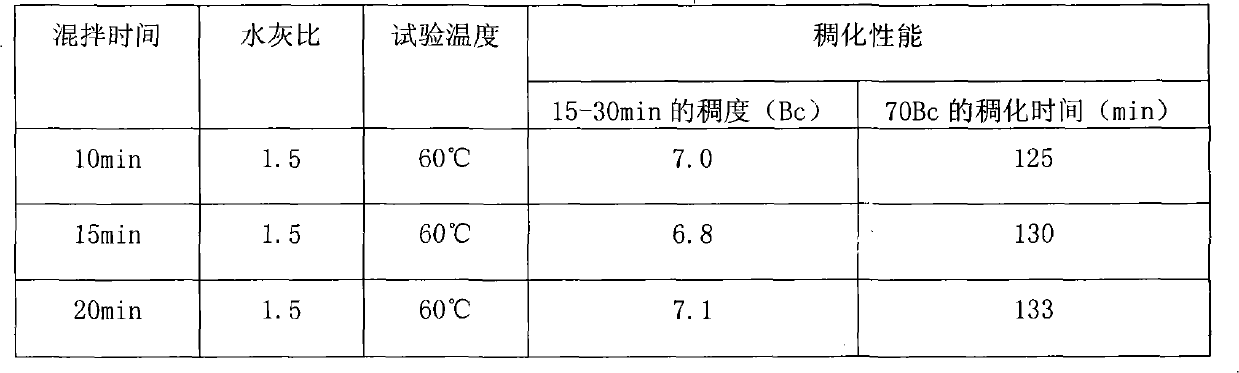

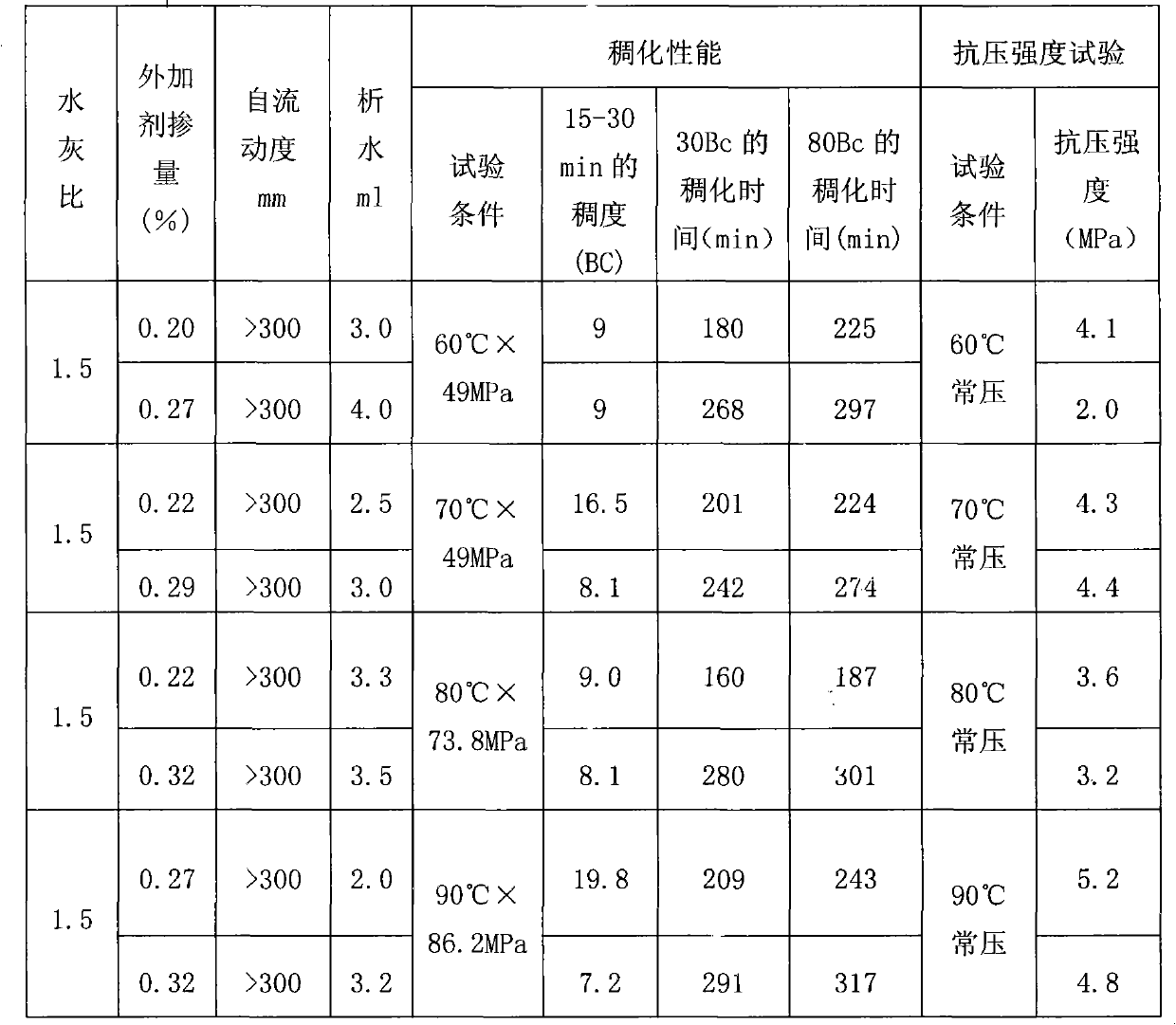

High-temperature special oil well cement material and preparation method thereof

ActiveCN101906291AGood physical propertiesWide adjustable range of specific gravityDrilling compositionCalcium hydroxideXonotlite

The invention discloses a high-temperature special oil well cement material and a preparation method thereof. The cement is a product obtained by doping quartz sand powder and admixture to high belite cement and evenly mixing the substances. The cement product of the invention has the following advantages that: (1) the high-temperature special oil well cement which is prepared by compounding highbelite cement with suitable quartz sand and admixture has favorable thermal stability; (2) hydration products of the high-temperature special oil well cement vary with temperature, i.e. Aft and calcium hydroxide occur at 60 DEG C to 80 DEG C; Aft disappears and xonotlite occurs at 90 DEG C; all the hydration products are converted into xonotlite at 110 DEG C; (3) all the performances of the high-temperature special oil well cement in a water-cement ratio of 1.2 to 1.8 basically satisfy the requirements of technical indexes; and (4) the high-temperature special oil well cement has stably enhanced strength along with the prolongation of a hydration age without causing a retraction phenomenon. The cement product of the invention has the advantages of high thermal stability, low pollution, and the like, the preparation method has the advantages of low requirement for instruments and equipment, low cost, and the like and is suitable for large-area popularization and application.

Owner:CHINA BUILDING MATERIALS ACAD

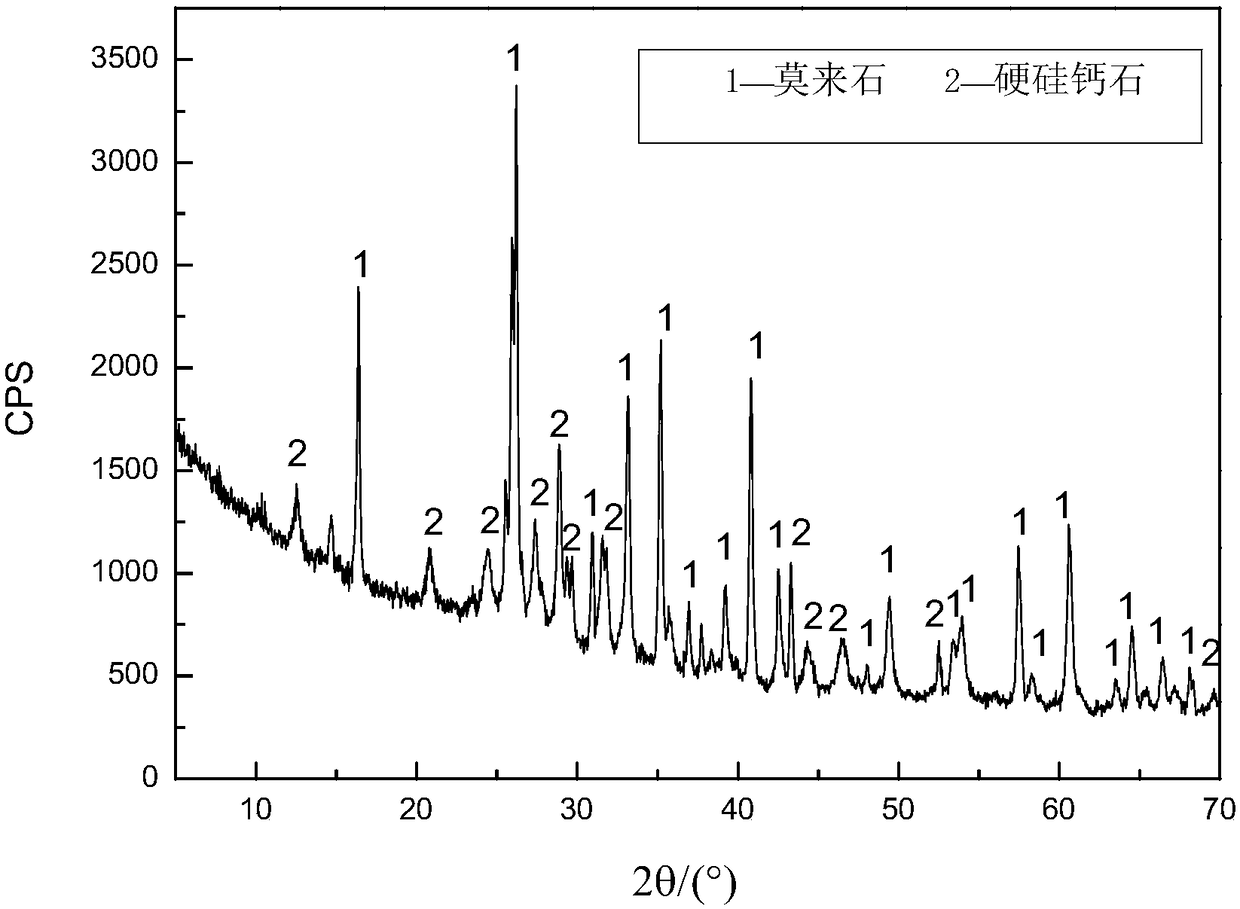

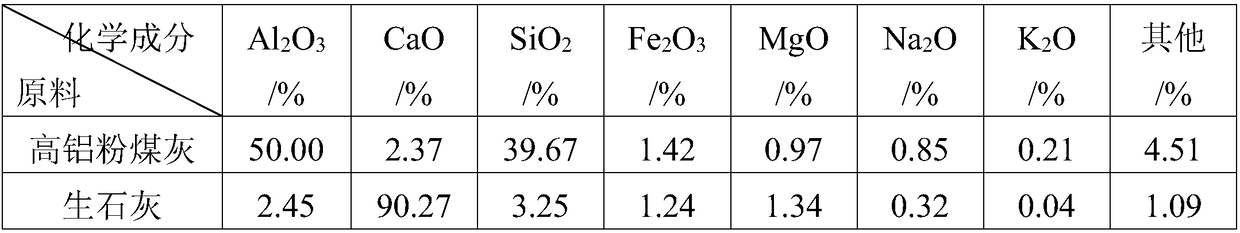

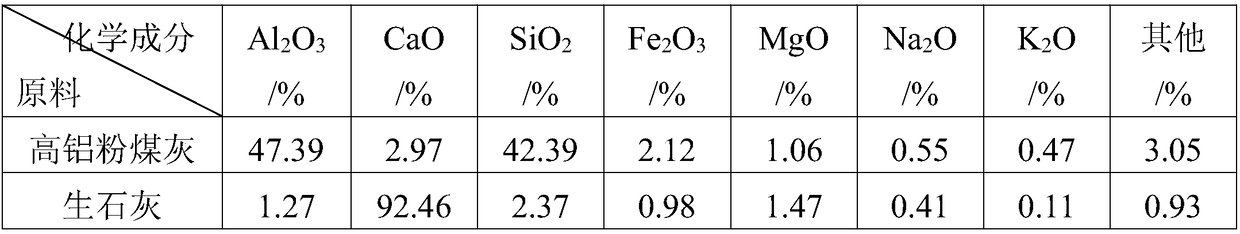

Method for using high-aluminium coal ash to synthesize composite xonotlite insulation material

ActiveCN108946748AWide variety of sourcesLow priceSolid waste managementAluminium silicatesCalcium hydroxideXonotlite

The invention relates to a method for using high-aluminium coal ash to synthesize a composite xonotlite insulation material and belongs to the field of inorganic insulation materials. The method comprises the following steps of: adopting the high-aluminium coal ash as a main material, uniformly mixing with water for pulping after mixing with calcium oxide or calcium hydroxide and grinding, carrying out dynamic hydrothermal-synthesis reaction after adding a trace additive, carrying out filtering and drying treatment in sequence after reaction and obtaining a composite insulation fireproof material of mullite and the xonotlite. The method has the beneficial effects that the main material high-aluminium coal ash is solid waste obtained by burning of high-aluminium coal in a coal-powder furnace of a power plant, so that the production cost of the composite material is greatly reduced; the material source is wide; simultaneously, the method for preparing the composite insulation fireproof material of the mullite and the xonotlite is simple, is short in reaction time, can consume the solid waste generated in a thermal power plant by large scale and is suitable for industrial promotion.

Owner:内蒙古中建亚太建材科技有限公司

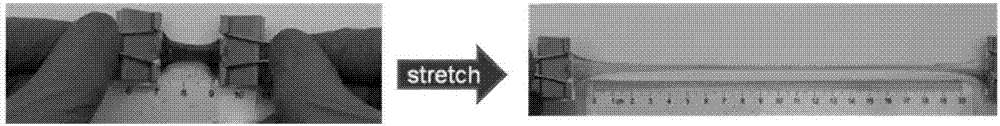

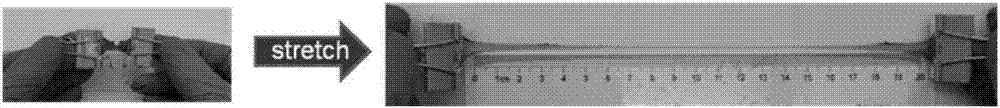

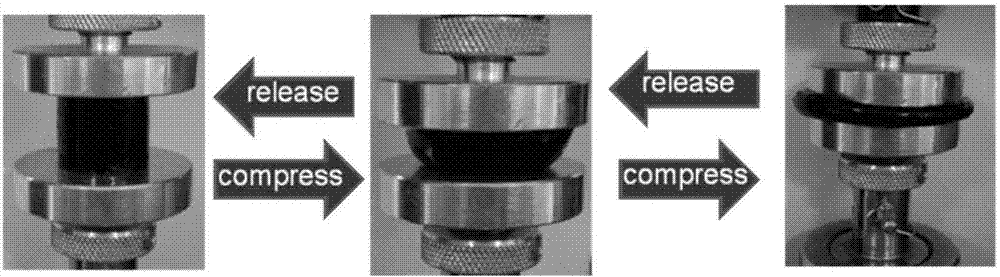

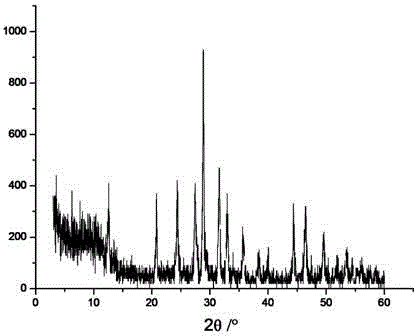

Preparation method of high-tenacity and tear-resistant ternary hydrogel based on synergetic enhancement of one-dimensional and two-dimensional nano-materials

The invention discloses a preparation method of high-tenacity and tear-resistant ternary hydrogel based on synergetic enhancement of one-dimensional and two-dimensional nano-materials. According to the preparation method, a two-dimensional graphene nanosheet and a one-dimensional xonotlite nanowire are taken as crosslinking agents, and monomers can be simultaneously crosslinked with two different nanomaterials so as to form a uniform network structure; and meanwhile, a graphene oxide sheet and the xonotlite nanowire can generate a very strong synergetic enhancement effect, so that the prepared ternary hydrogel has very good tenacity and excellent tear resistance.

Owner:HEFEI UNIV OF TECH

Method for preparing xonotlite powder from fused quartz as raw material

InactiveCN104445232AIncrease productivityHigh purityAlkaline-earth metal silicatesSolid massDistilled water

The invention relates to a method for preparing xonotlite powder from fused quartz as a raw material. The method comprises the following steps: with fused quartz and calcium oxide as raw materials, weighing the fused quartz and calcium oxide at the molar ratio of Ca / Si being 1.01:1 to 1.05:1; adding distilled water according to the water-solid mass ratio of 10:1 to 20:1, and stirring evenly; adding the prepared slurry to a high-pressure reaction kettle, carrying out electric stirring at the speed of 200-400r / min, and reacting at 160-210 DEG C, wherein the pressure of the reaction kettle is 1.5-2.5MPa; carrying out heat preservation for 2-6 hours, turning off a power supply after heat preservation is finished, stopping stirring, and naturally cooling; and taking out reaction slurry, filtering, and baking, so as to obtain the xonotlite powder. The xonotlite powder prepared by the method has the advantages of simple process, low reaction temperature and short heat preservation time; and the synthesized xonotlite powder is high in purity.

Owner:SHANDONG UNIV OF TECH

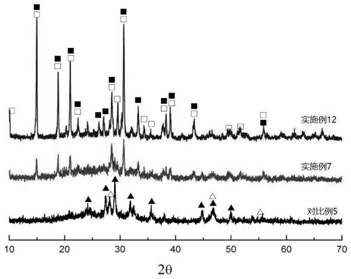

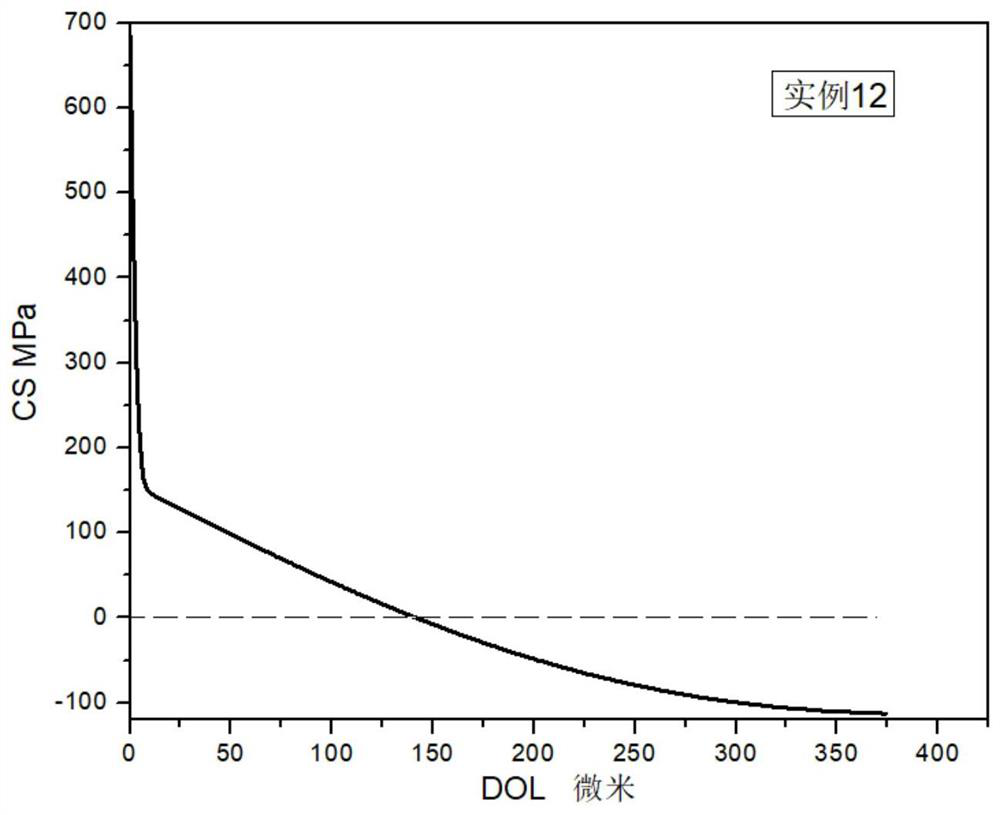

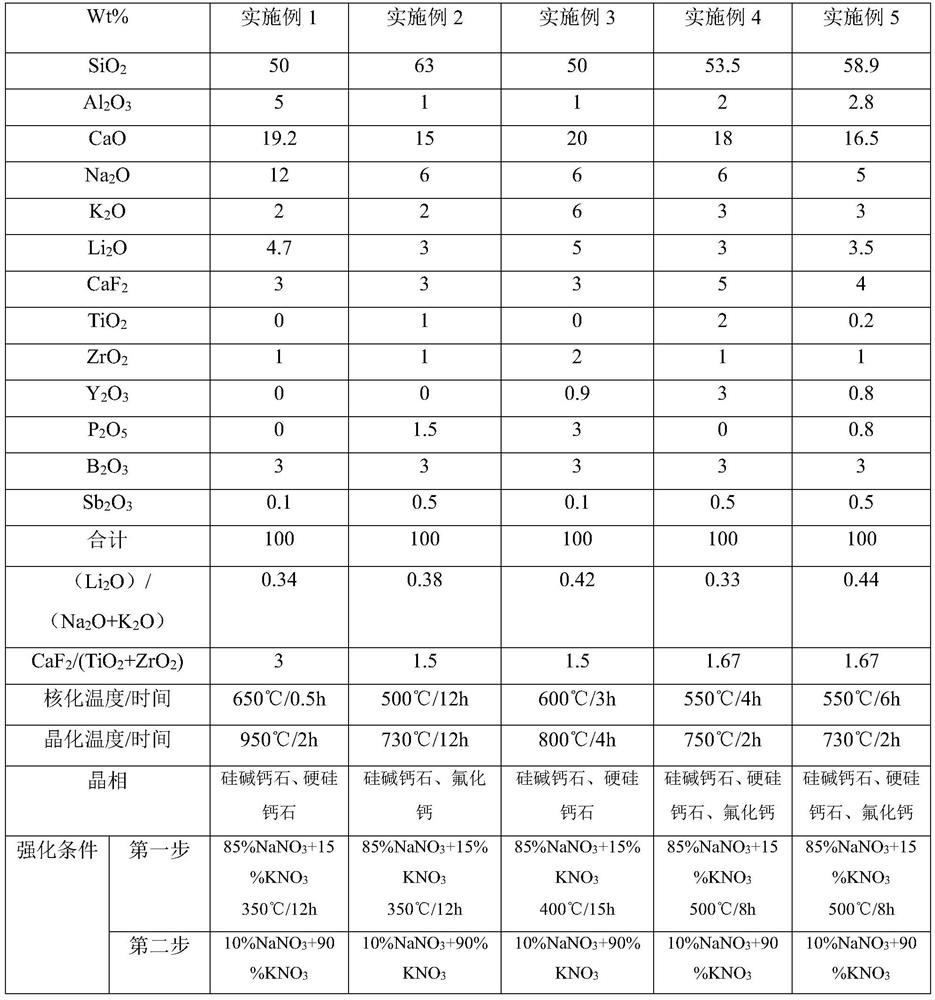

High-fracture-toughness microcrystalline glass for mobile phone backboard and preparation method of high-fracture-toughness microcrystalline glass

The invention relates to the technical field of glass ceramics, and provides high-fracture-toughness microcrystalline glass for a mobile phone backboard. The glass comprises the following components in percentage by mass: 30-60% of primary crystal phase which is silicalite, 5-10% of secondary crystal phase which is one or two of xonotlite and calcium fluoride, and the balance of glass phase. The glass comprises the following components in percentage by mass: 50 to 63 percent of SiO2, 1 to 5 percent of Al2O3, 15 to 20 percent of CaO, 6 to 12 percent of Na2O, 2 to 6 percent of K2O, 3 to 5 percent of Li2O, 3 to 6 percent of CaF2, 0 to 2 percent of TiO2, 1 to 3 percent of ZrO2, 0 to 3 percent of Y2O3, 3 to 7 percent of B2O3, 0 to 3 percent of P2O5 and 0.1 to 0.5 percent of Sb2O3. According to the technical scheme, the problem that microcrystalline glass in the prior art cannot have fracture toughness and chemical strengthening property at the same time is solved.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE +1

Anti-cracking mortar and preparation method thereof

The invention discloses anti-cracking mortar and a preparation method thereof and relates to the technical field of building materials. The anti-cracking mortar is mainly prepared from cement, quartz sand, xonotlite, furnace slag powder, expanded slag beads, EVA re-dispersible latex powder, polysiloxane emulsion, calcium sulphoaluminate expansion agents, polypropylene fiber, polyimide fiber, glass beads, magnesium hydroxide, melamine water reducer, guar gum, citric acid and the like. The polysiloxane emulsion is added into the mortar, so that the hollowing resistance of the mortar is improved; through the calcium sulphoaluminate expansion agents and the polypropylene fiber, the shrinkage performance of the hardened mortar is improved, thus the cracking resistance of the mortar is improved; through the components such as magnesium hydroxide and glass beads and the like, the heat preservation performance and the performance stability of the mortar are improved; the produced mortar is high in overall performance and high in applicability.

Owner:王星烨

Nano-silica modified styrene-acrylic external wall composite thermal insulation coating and preparation method thereof

InactiveCN108504203AImprove insulation effectWith sound insulationAntifouling/underwater paintsPaints with biocidesAluminum CarbonateEmulsion

The invention provides a nano-silica modified styrene-acrylic external wall composite thermal insulation coating and a preparation method thereof. The coating is prepared from the following componentsin parts by weight: 50-70 parts of styrene-acrylic emulsion, 10-20 parts of xonotlite powder, 5-8 parts of hollow glass beads, 8-12 parts of titanium dioxide, 4-5 parts of ultrafine aluminum carbonate powder, 10-20 parts of talcum powder, 2-4 parts of nano-silica, 0.8-1.2 parts of an anti-mildew bactericide, 0.4-0.8 parts of a wetting agent, 0.3-0.5 part of a dispersant, 0.5-0.9 parts of a defoamer, 1.5-2.5 parts of a coalescing agent, 0.8-1.2 parts of a thickener, 4-8 parts of an antifreezing agent, 0.1-0.3 parts of a PH regulator and 30-50 parts of deionized water.

Owner:邹奇峰

Method for synthesizing calcium silicate by utilizing soda-lime sintering process red mud alkaline method

ActiveCN107892307ASolve the large stockSolution covers a wide areaAlkaline-earth metal silicatesThermal insulationRed mud

The invention discloses a method for synthesizing calcium silicate by utilizing a soda-lime sintering process red mud alkaline method, and belongs to the field of thermal insulation materials. The method comprises the following steps: step 1, preparing a raw material slurry: mixing soda-lime sintering process red mud and a sodium silicate solution according to a ratio of the liquid to the solid of(10-25):1 to prepare the raw material slurry, wherein the molar ratio of calcium to silicon in the prepared raw material slurry is (0.83-1):1; step 2, preparing a calcium silicate material slurry bya hydrothermal synthesis method: performing a reaction on the raw material slurry obtained in the step 1 under stirring at the temperature of 150-200 DEG C for 4-20h under a closed condition to obtaina calcium silicate material slurry; and step 3, synthesizing a calcium silicate powder material: cooling the calcium silicate material slurry obtained in the step 2 at room temperature, performing separation to obtain a solid product and a sodium hydroxide solution, washing the separated solid product with water until the product is neutral, and performing drying to remove moisture, so as to obtain tobermorite or / and xonotlite. The method provided by the invention has the advantages of simple operation, less working procedures, low costs, high preparation efficiency, high-value-added utilization of waste resources, energy conservation and environmental protection.

Owner:NORTHEASTERN UNIV

Superfine dry powder extinguishing agent

The invention discloses a superfine dry powder extinguishing agent. Raw materials used for preparing the superfine dry powder extinguishing agent mainly comprise, by mass, 7-10 parts of alkali residues, 30-40 parts of sodium bicarbonate, 0.5-1 part of talcum powder, 5-8 parts of marlstone, 1-3 parts of xonotlite, 30-45 parts of ammonium sulfate, 3-7 parts of ammonium polyphosphate, 10-20 parts of gypsum, 1-4 parts of stannic oxide, 2-5 parts of silicon nitride, 1-2 parts of silicone oil and 0.4-0.6 part of polybutylene. The prepared superfine dry powder extinguishing agent is good in mobility and hydrophobicity, high in anticaking capacity and fire extinguishing performance, and shortened in fire extinguishing time.

Owner:海门市知舟工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com