Low-shrinkage mortar for aerated bricks

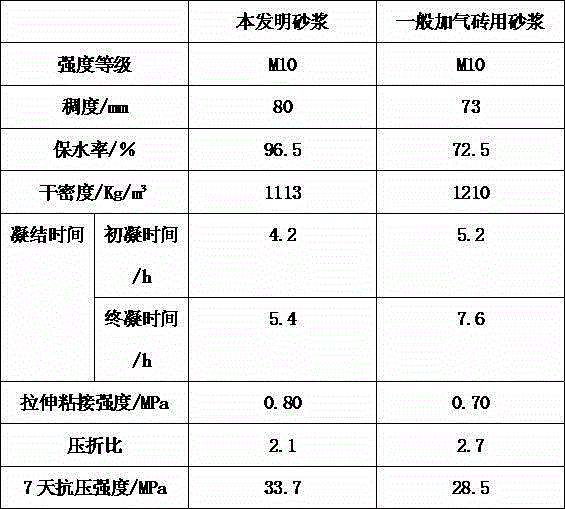

A low-shrinkage, air-entrained brick technology, applied in the field of mortar for air-entrained bricks, can solve the problems of crack resistance, durability, impact resistance, earthquake resistance and fire resistance, building wall leakage, and high water absorption of mortar. and other problems, to achieve the effect of improving construction operability, low thermal conductivity and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A low-shrinkage mortar for aerated bricks, made of the following components by weight percentage: 55% quartz sand, 10% fly ash, 4% magnesia lime, 2% calcium carbonate, 3% bentonite, hard silicon Calcium stone 2.5%, cement 9%, pottery sand 10%, redispersible latex powder 2.5%, water reducing agent 1%, additive 1%.

[0024] Further, the magnesium lime and xonotlite need to be calcined and ground at 250-300° C. for 2-3 hours, and then crushed to 150-200 mesh.

[0025] Further, the redispersible latex powder is acrylate and styrene copolymer powder.

[0026] Further, the water reducer is a melamine-based water reducer.

[0027] Further, the additive is hydroxyethyl cellulose.

[0028] Further, the calcium carbonate is soaked in 3.5-4% methacrylic acid solution for 1.5 hours, filtered, washed with deionized water, then soaked in 1.5-2.5% polybutylacrylic acid solution, heated to 85-90°C , kept for 1-2 hours, cooled to room temperature, filtered, washed with deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com