Patents

Literature

66results about How to "Reduce ionic strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

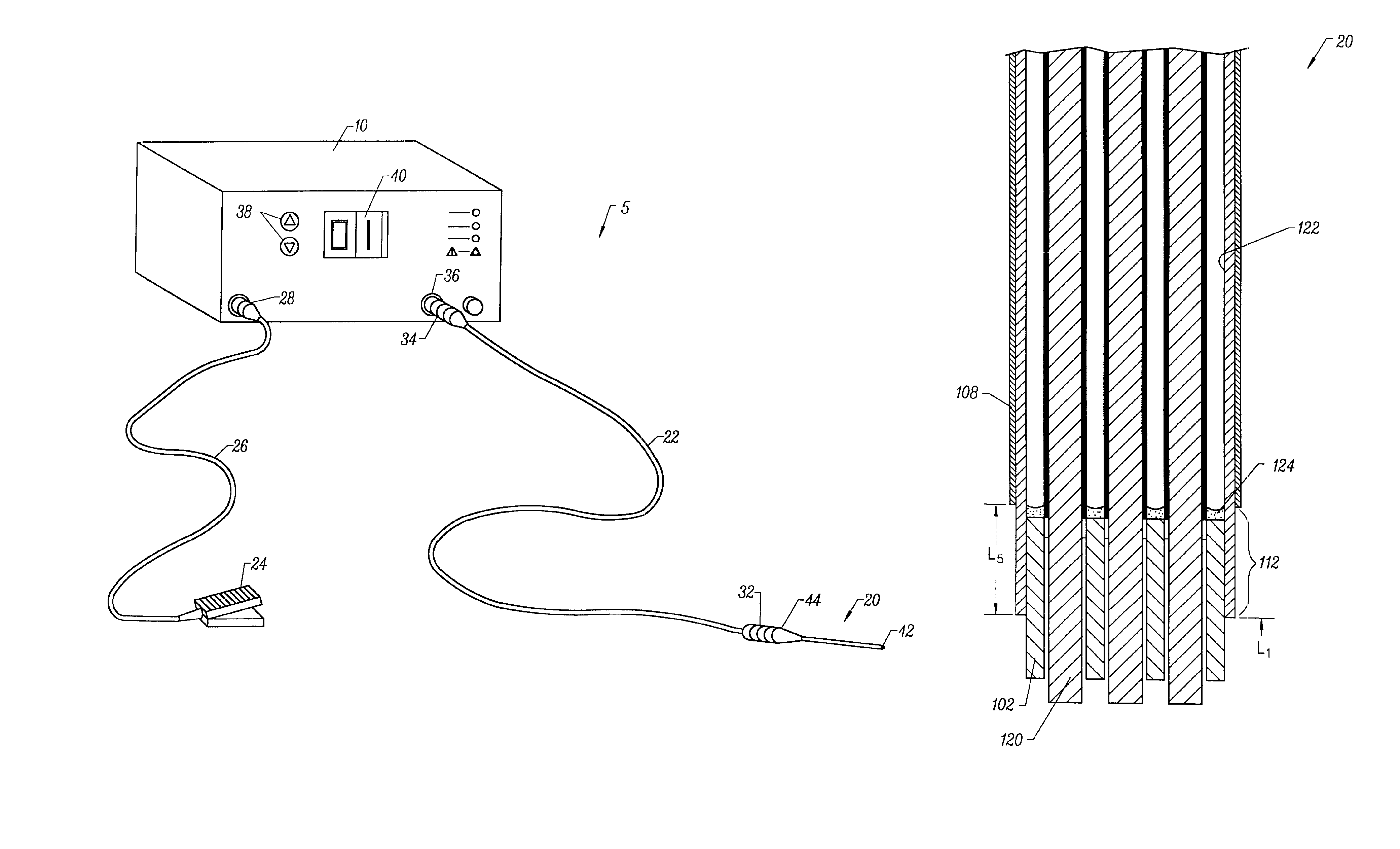

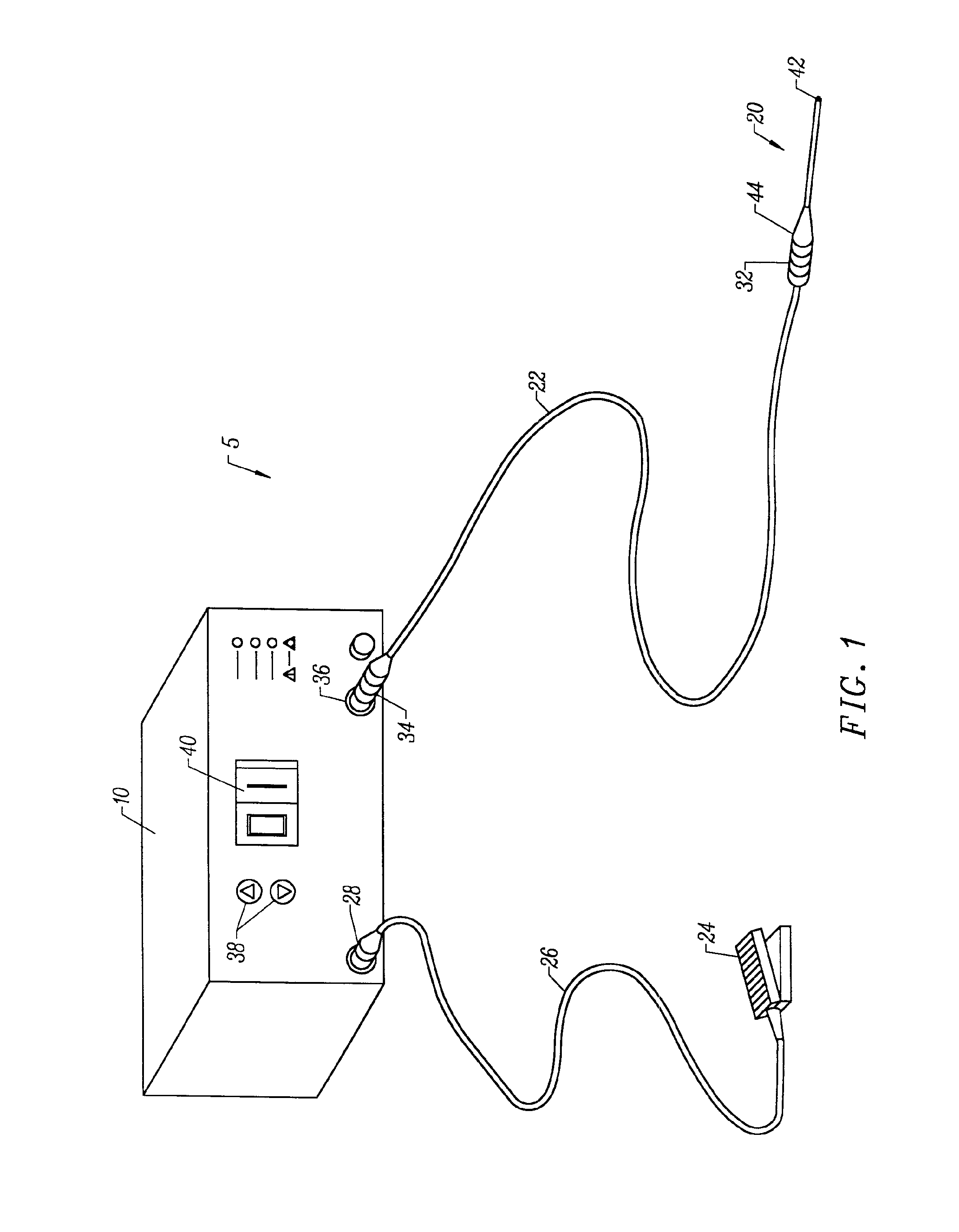

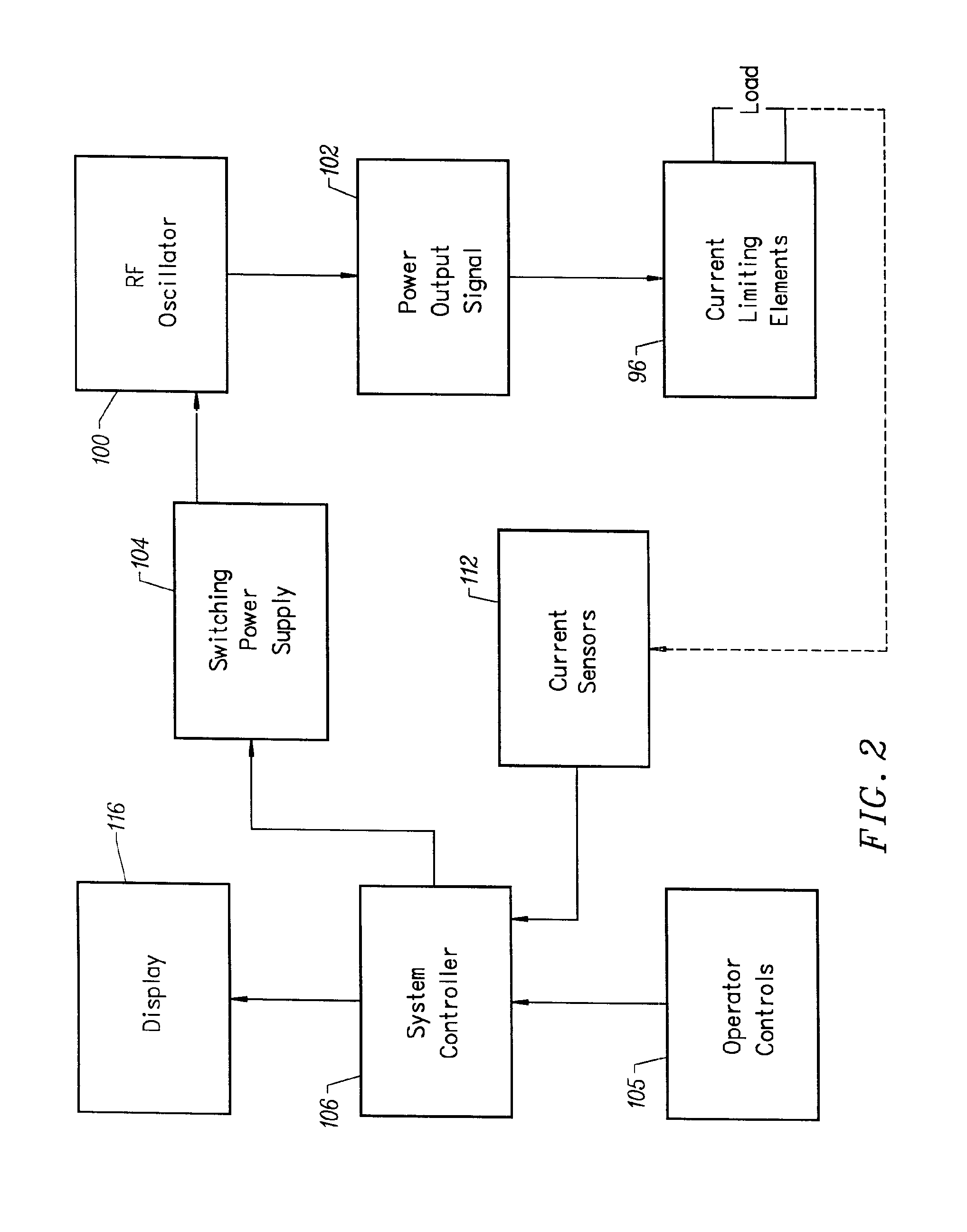

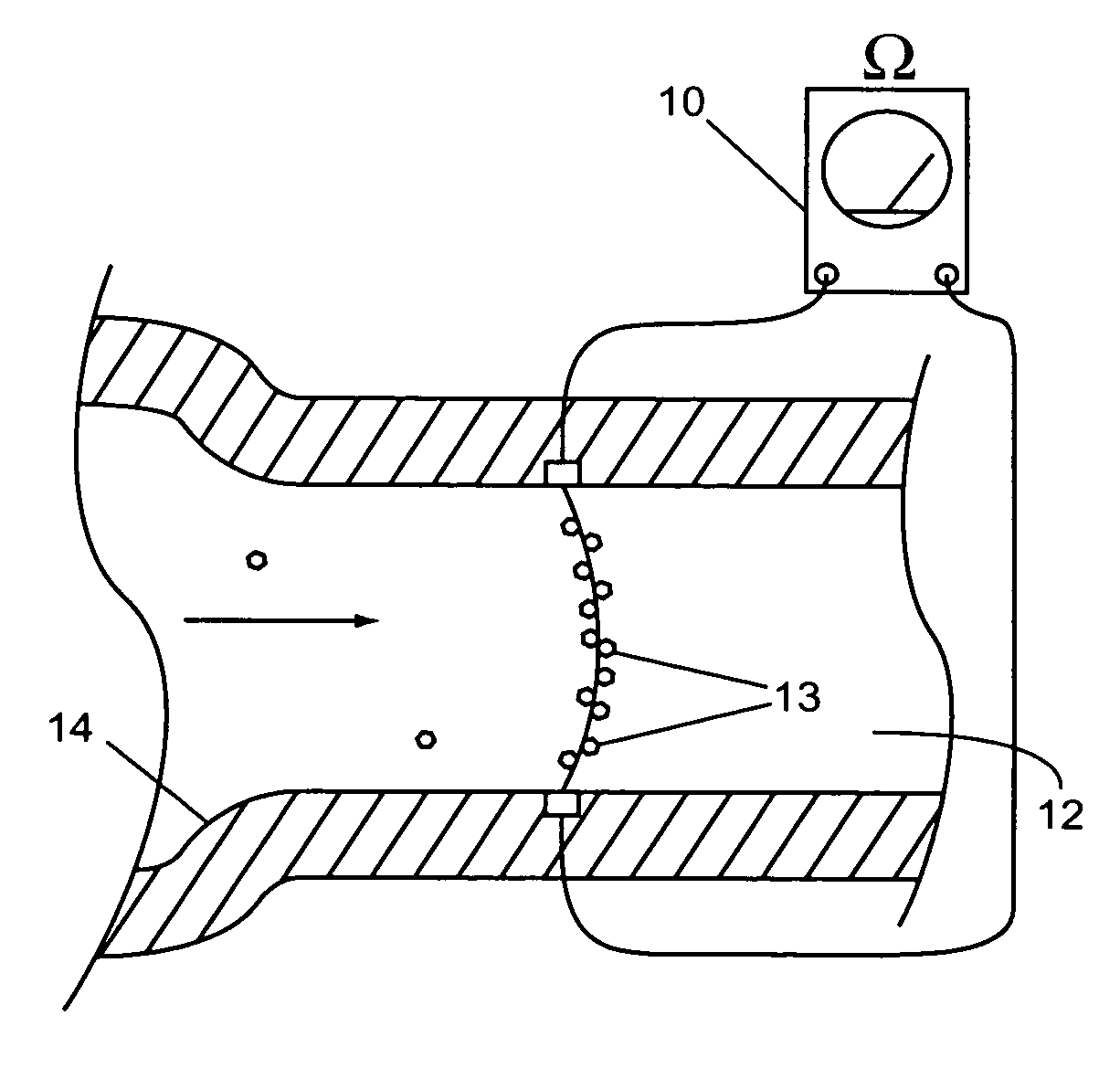

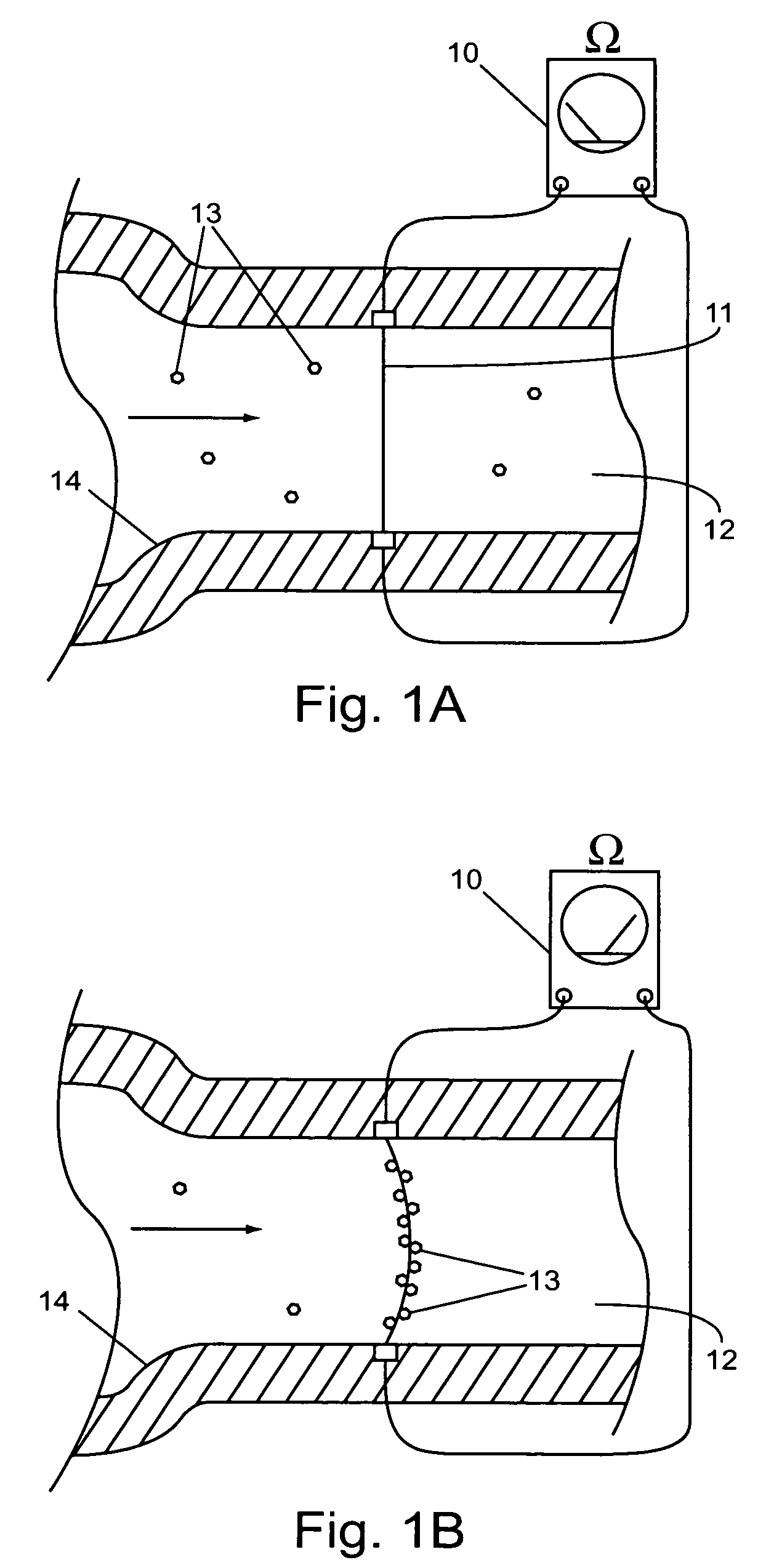

Systems and methods for electrosurgical tissue treatment

InactiveUS7572251B1Reduce ionic strengthFacilitate initiationCannulasEnemata/irrigatorsEngineeringLow temperature plasma

Systems and methods are provided for applying a high frequency voltage in the presence of an electrically conductive fluid to create a relatively low-temperature plasma for ablation of tissue adjacent to, or in contact with, the plasma. In one embodiment, an electrosurgical probe or catheter is positioned adjacent the target site so that one or more active electrode(s) are brought into contact with, or close proximity to, a target tissue in the presence of electrically conductive fluid. High frequency voltage is then applied between the active electrode(s) and one or more return electrode(s) to non-thermally generate a plasma adjacent to the active electrode(s), and to volumetrically remove or ablate at least a portion of the target tissue. The high frequency voltage generates electric fields around the active electrode(s) with sufficient energy to ionize the conductive fluid adjacent to the active electrode(s). Within the ionized gas or plasma, free electrons are accelerated, and electron-atoms collisions liberate more electrons, and the process cascades until the plasma contains sufficient energy to break apart the tissue molecules, causing molecular dissociation and ablation of the target tissue.

Owner:ARTHROCARE

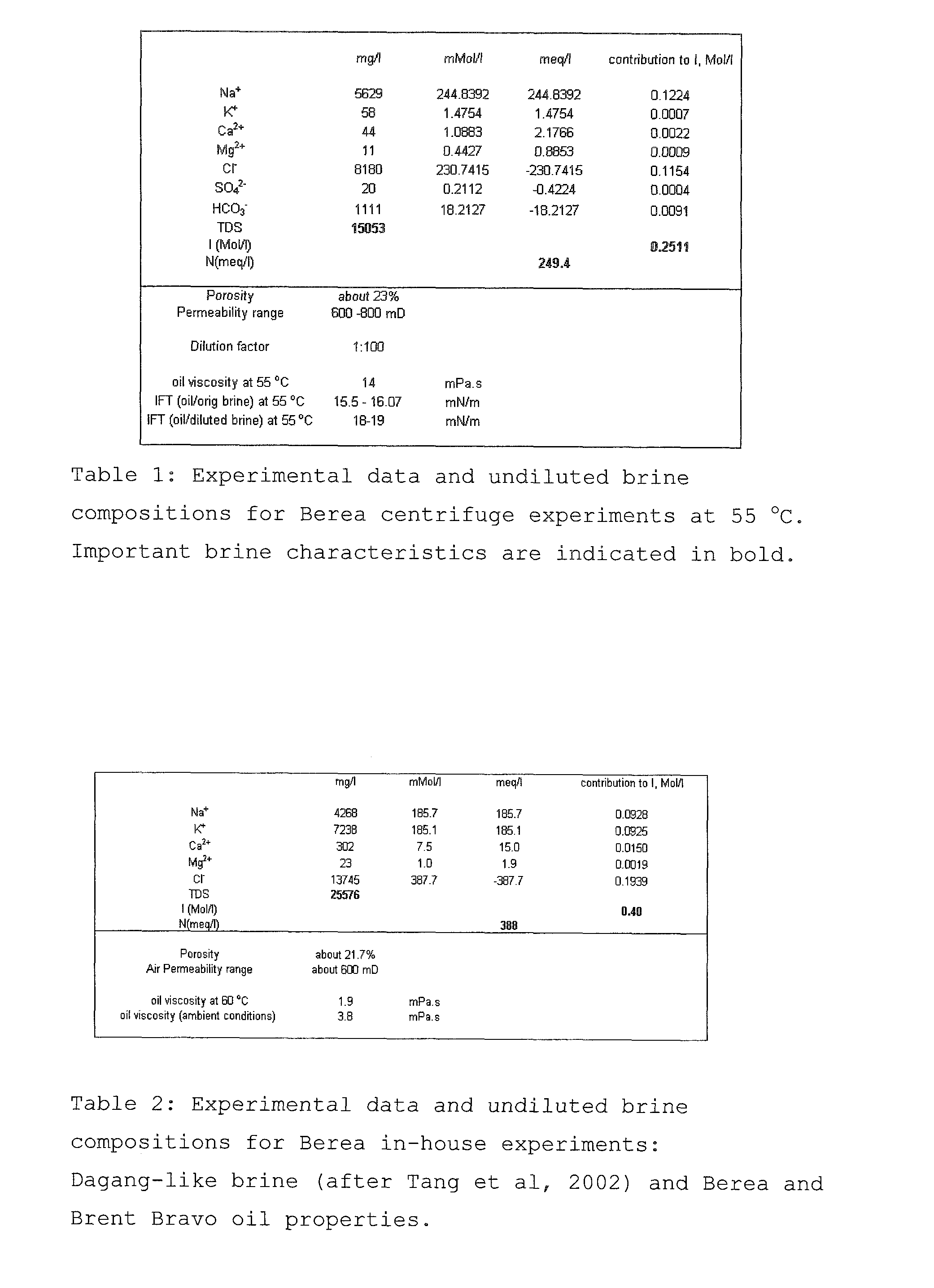

Aqueous displacement fluid injection for enhancing oil recovery from an oil bearing formation

InactiveUS20110306525A1Reduce ionic strengthIncrease oil productionFlushingDrilling compositionLow ionic strengthUltimate tensile strength

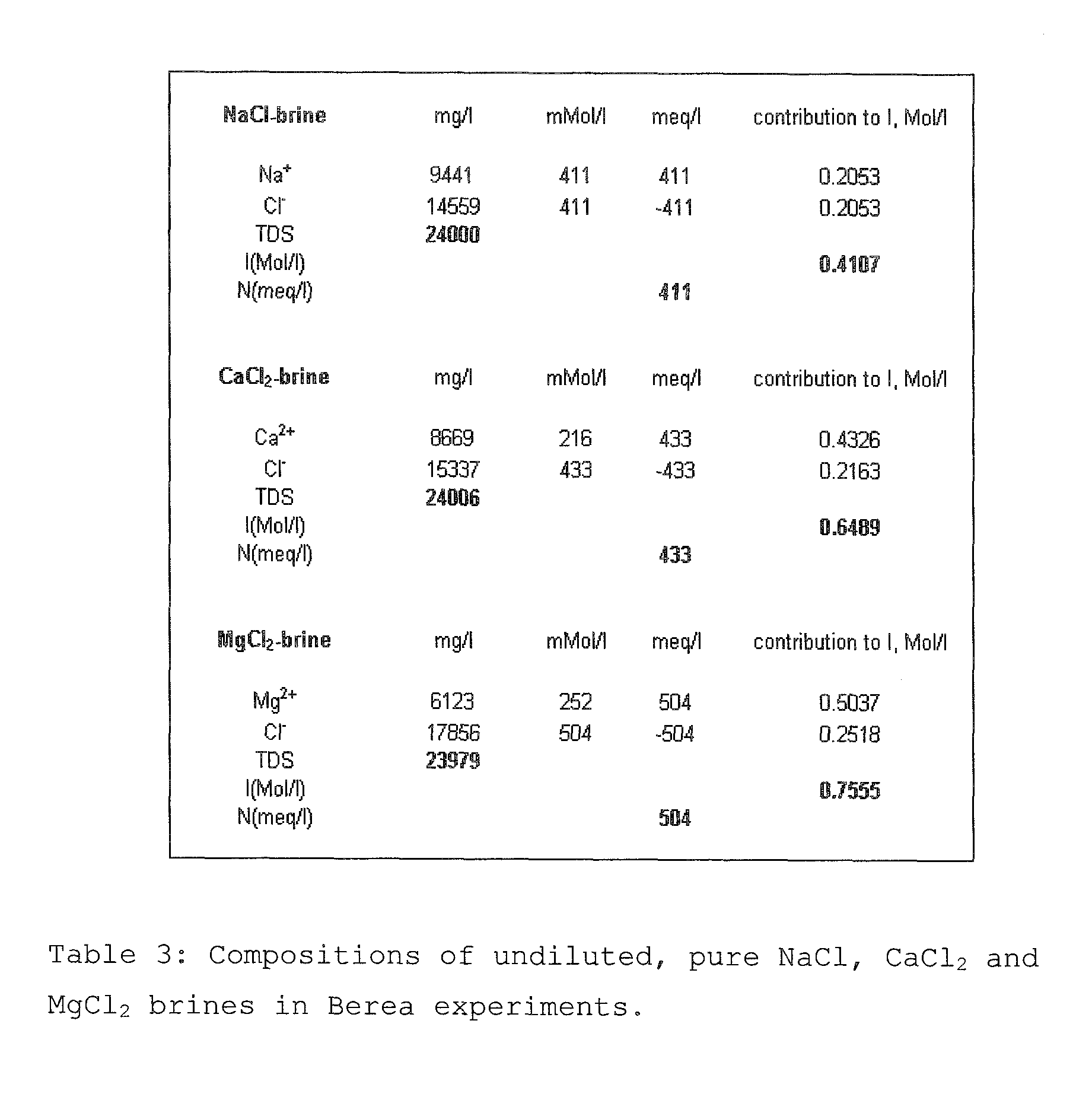

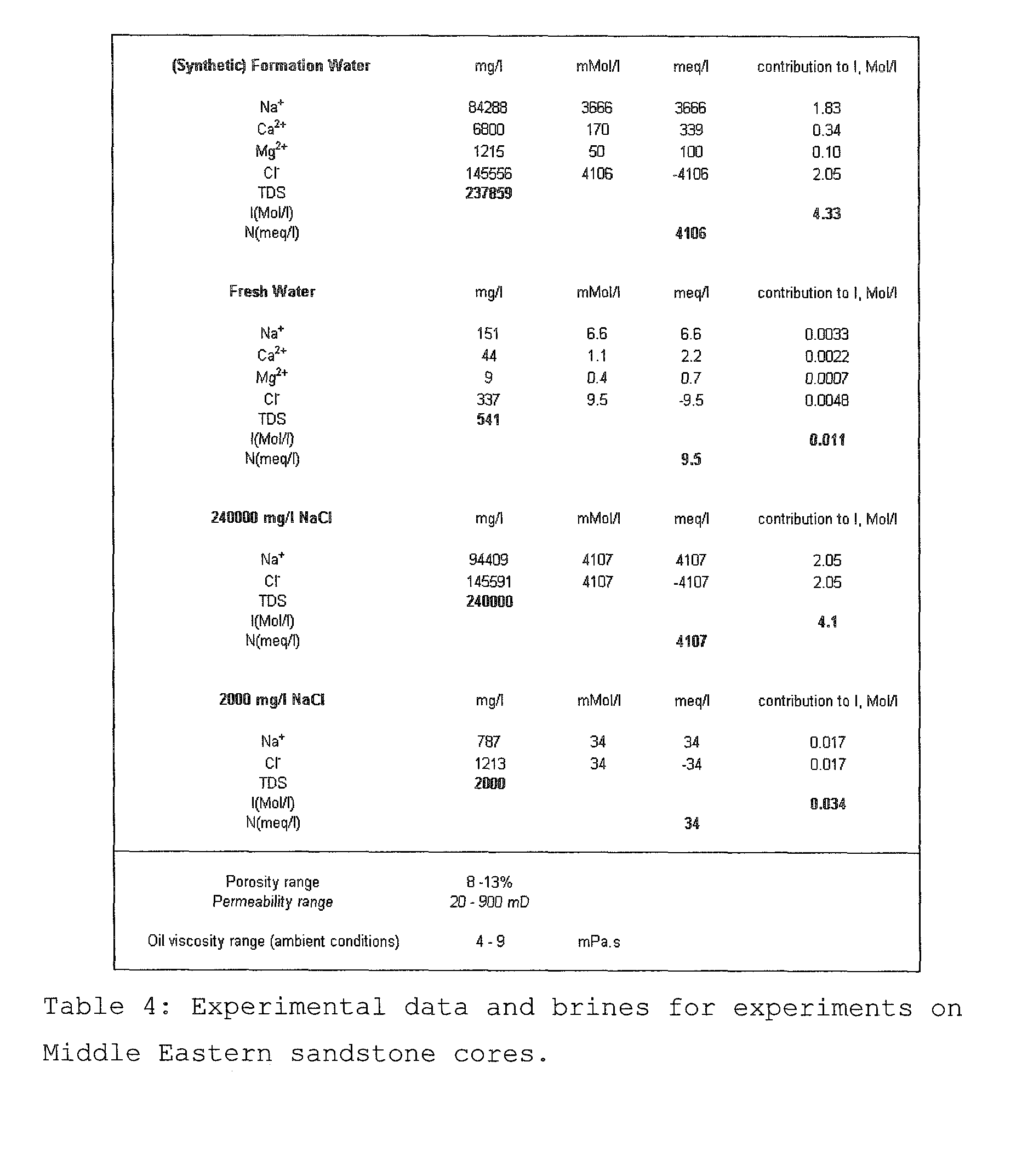

A method for enhancing recovery of crude oil from a porous subterranean formation of which the pore spaces contain crude oil and connate water comprises:—determining the Ionic Strength (Mol / l) of the connate water; and—injecting an aqueous displacement fluid having a lower Ionic Strength (Mol / l) than the connate water into the formation, which aqueous displacement fluid furthermore has an Ionic Strength below 0.15 Mol / l. FIGS. 13 and 16 and Table 4 demonstrate that injection of an aqueous displacement fluid with lower Ionic Strength than the connate water improves oil recovery (IOR).

Owner:SHELL OIL CO

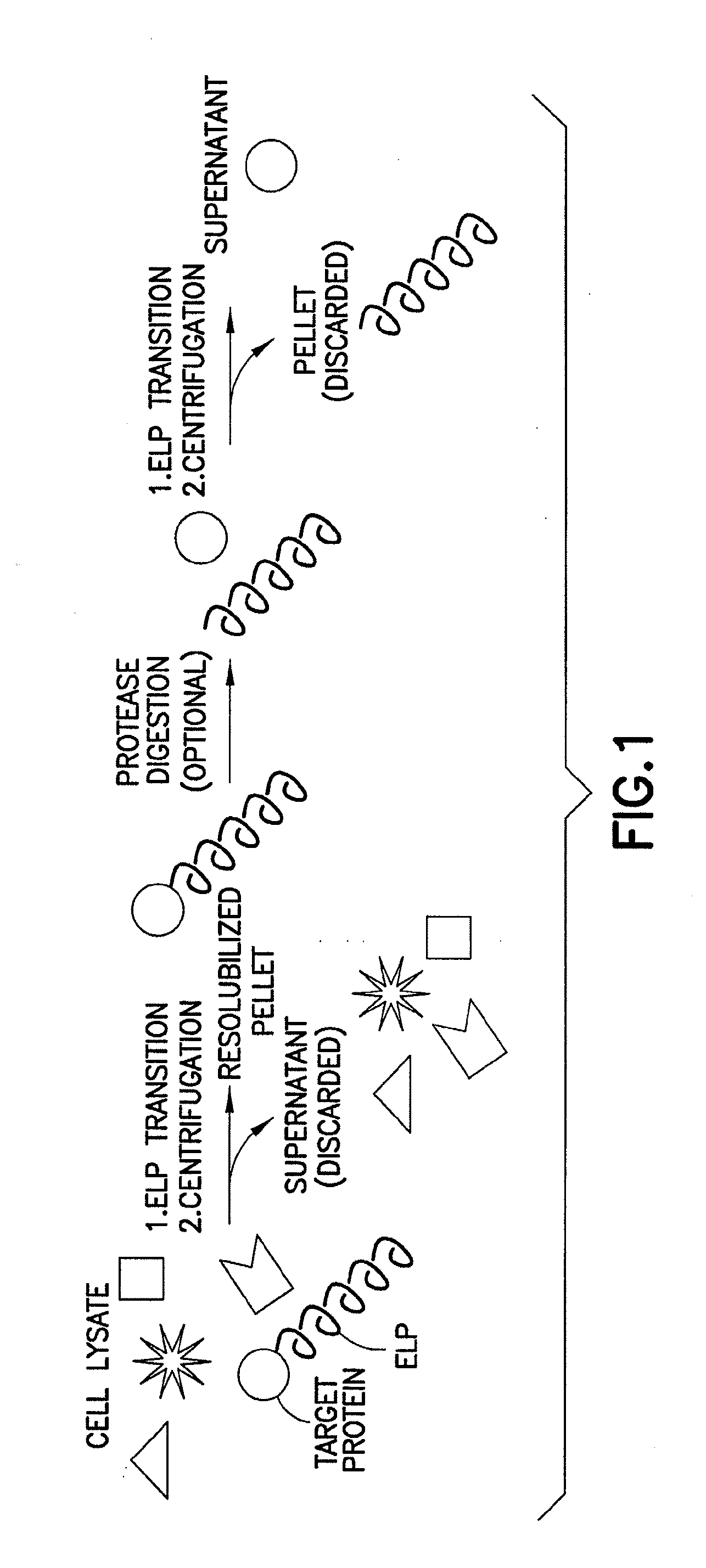

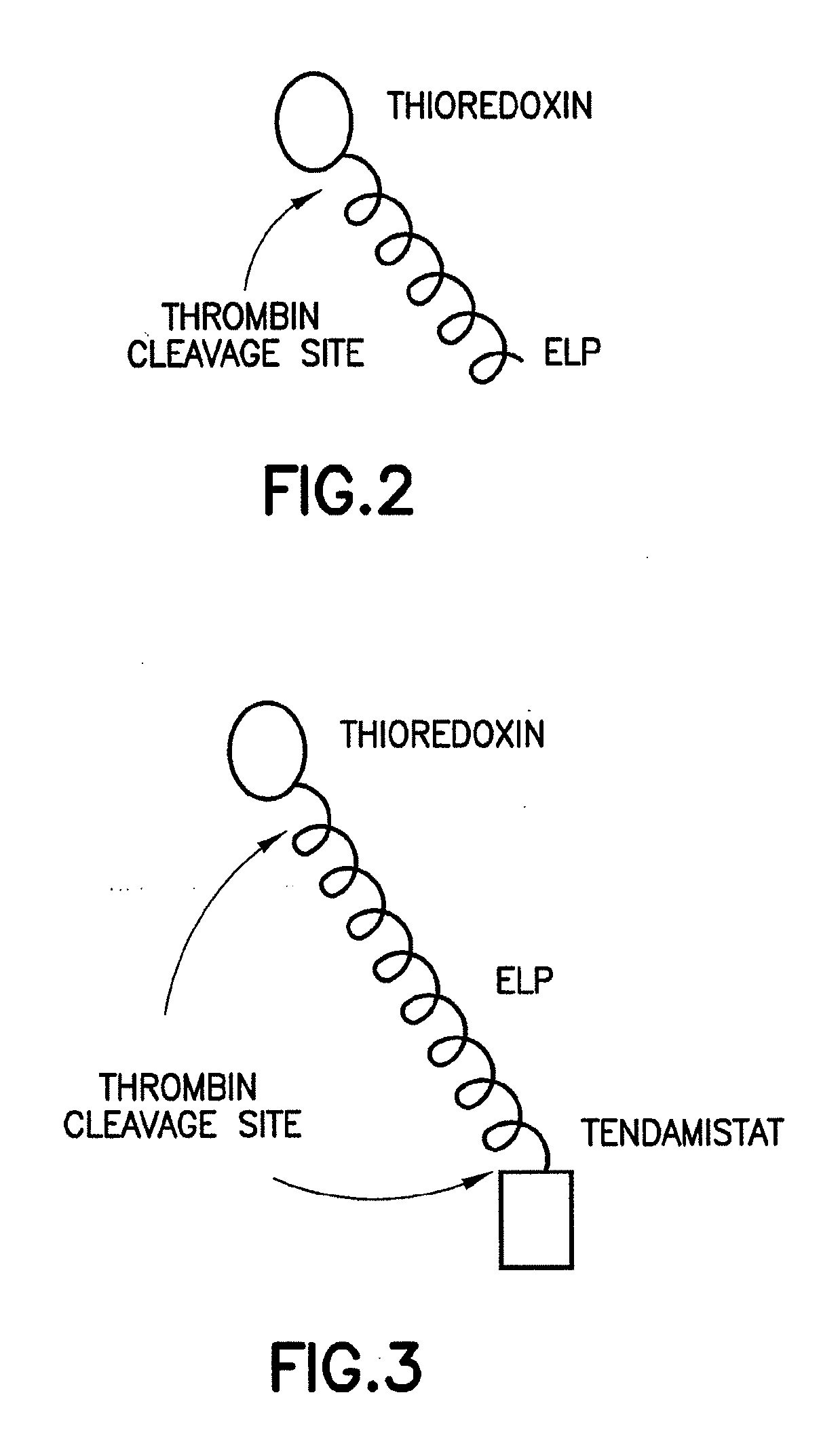

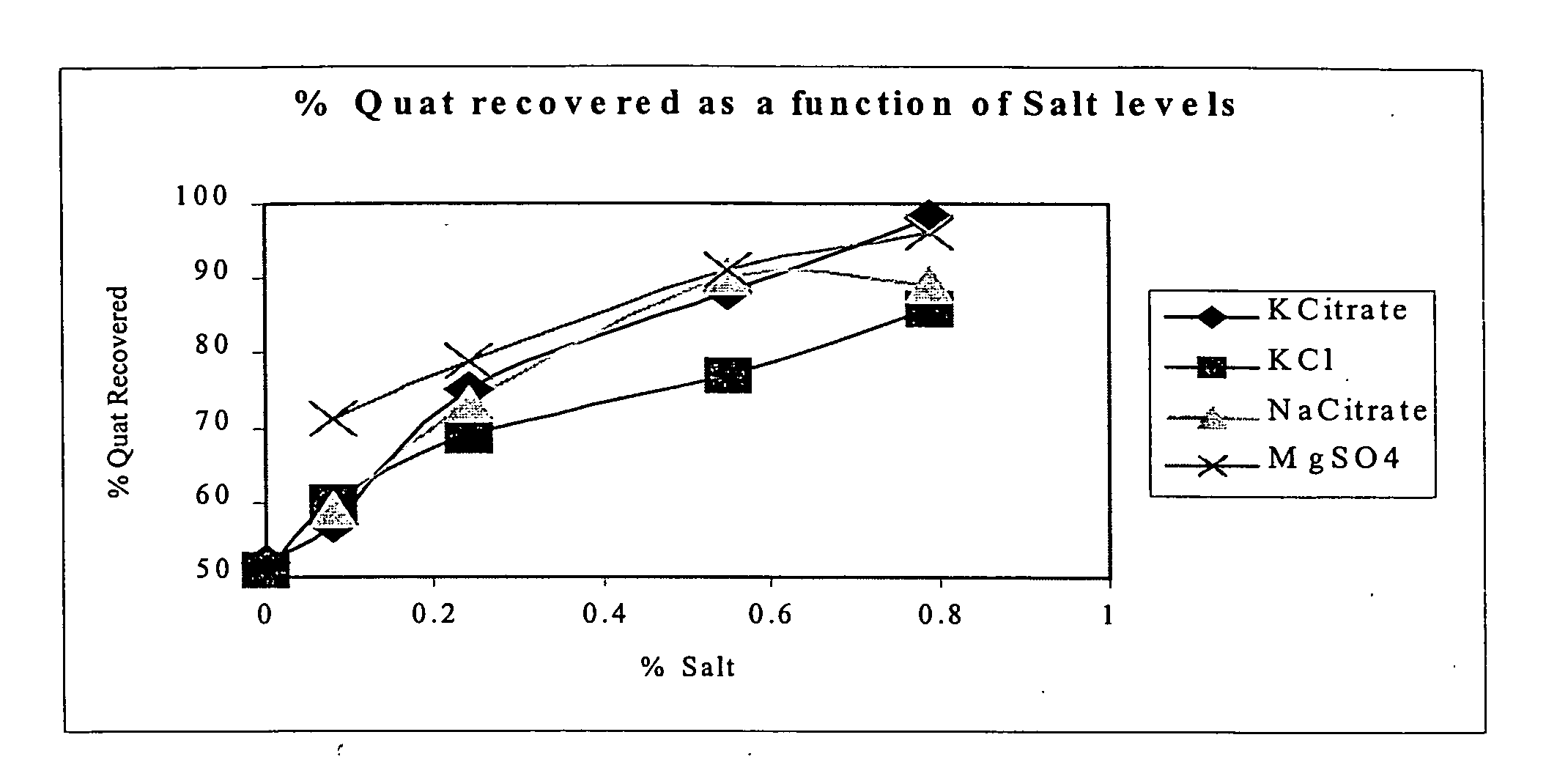

Fusion peptides isolatable by phase transition

InactiveUS20050255554A1Improve scalabilityRecovery conditionPeptide/protein ingredientsAntibody mimetics/scaffoldsBiotechnologyMolecular biology

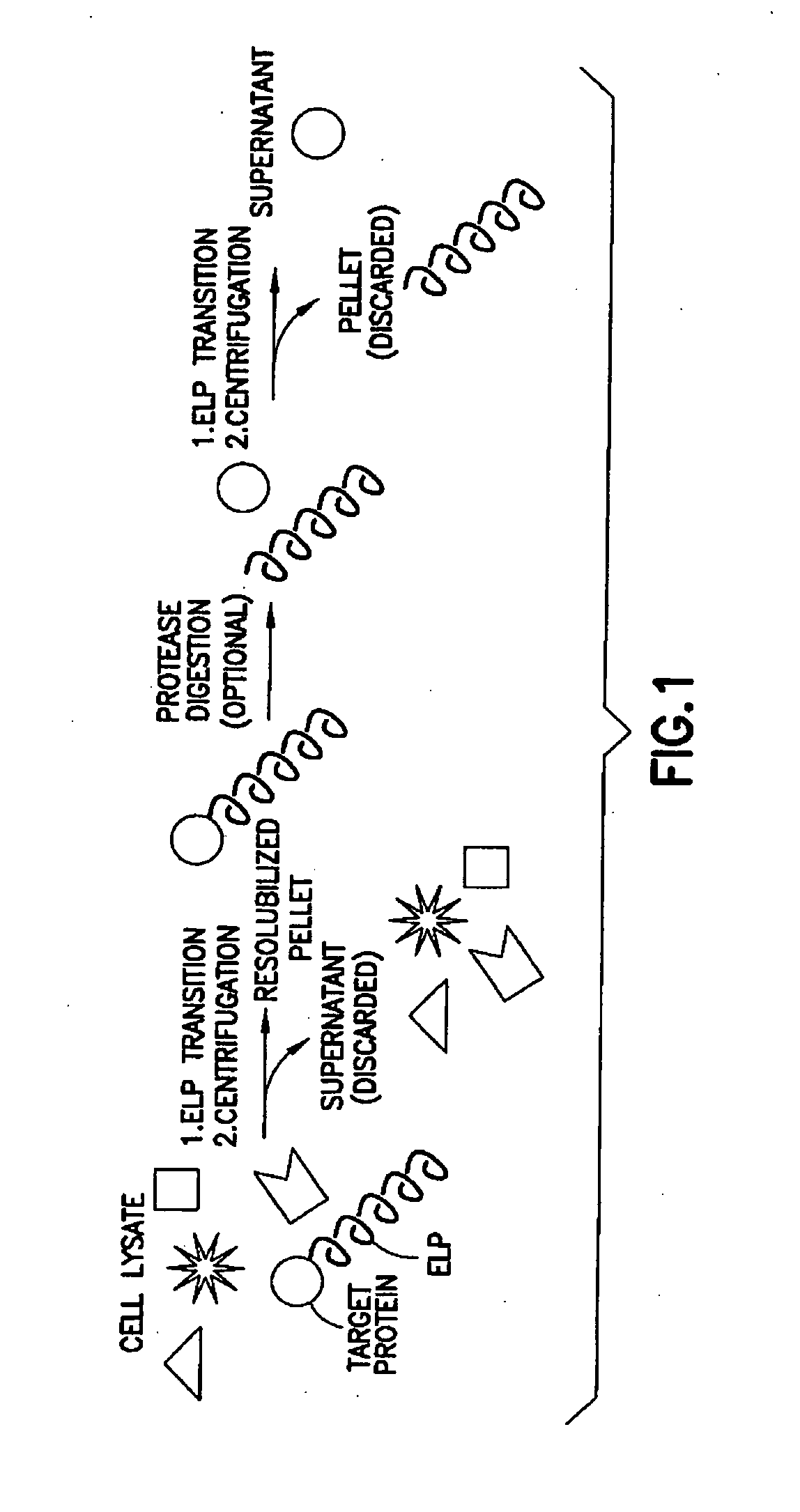

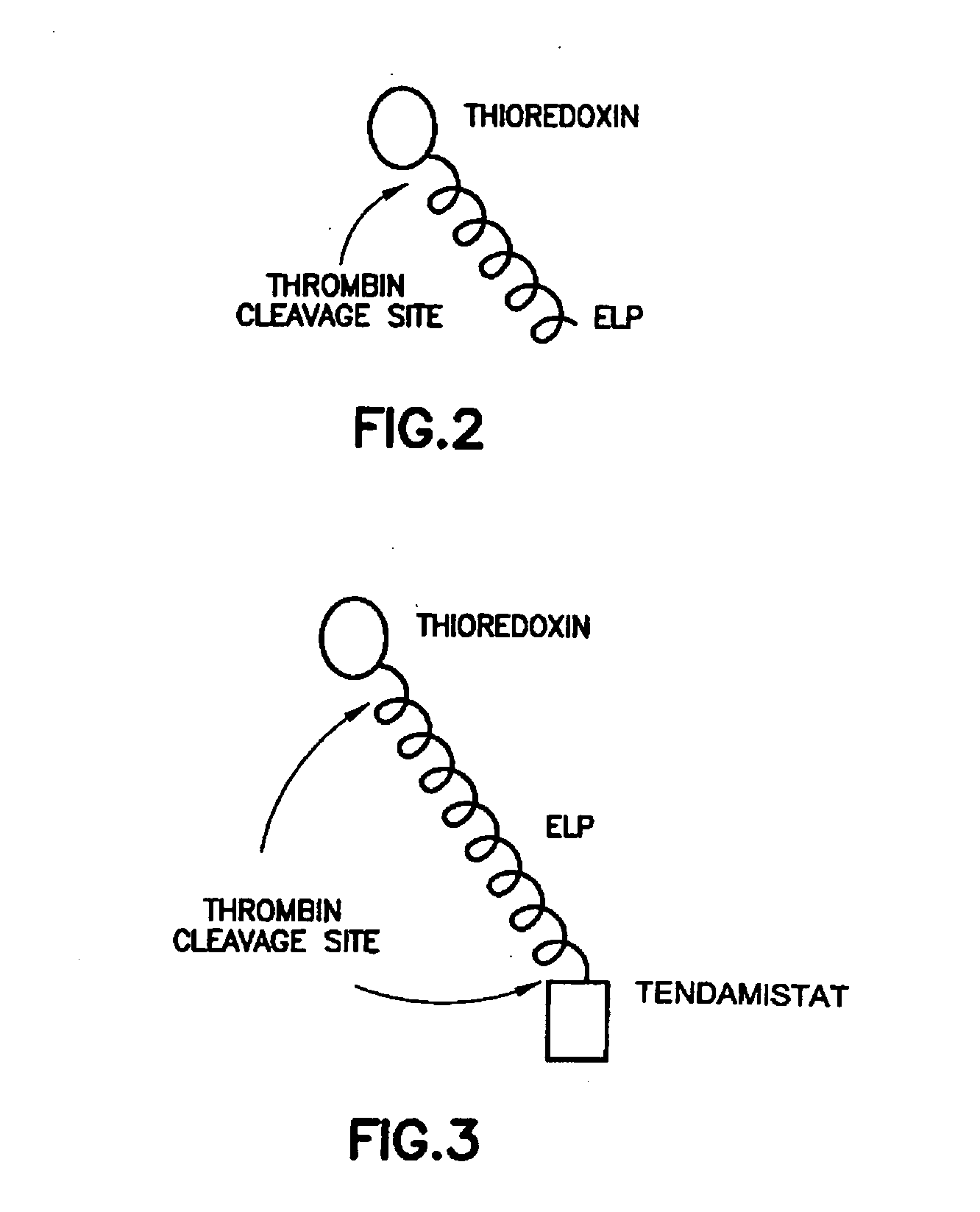

Genetically-encodable, environmentally-responsive fusion proteins comprising ELP peptides. Such fusion proteins exhibit unique physico-chemical and functional properties that can be modulated as a function of solution environment. The invention also provides methods for purifying the FPs, which take advantage of these unique properties, including high-throughput purification methods.

Owner:PHASE BIOSCIENCE INC

Stabilized interleukin 2

InactiveUS6689353B1Reduce ionic strengthFast rebuildPowder deliveryPeptide/protein ingredientsGlycineSucrose

A stable pharmaceutical preparation comprising Human interleukin-2 or a variant thereof and a stabilizing amount of histidine. A preferred formulation includes glycine and sucrose and a variant of IL-2 having a single mutation, N88R. The preferred formulation is in lyophilized form which, on reconstitution with an aqueous diluent, results in a solution having a pH ranging from about 5.0 to 6.5.

Owner:AICURIS GMBH & CO KG

Pharmaceutical compositions comprising elp fusion proteins

InactiveUS20090220455A1Improve scalabilityEquipment eliminatedPeptide/protein ingredientsAntibody mimetics/scaffoldsPurification methodsPeptide

Genetically-encodable, environmentally-responsive fusion proteins comprising ELP peptides. Such fusion proteins exhibit unique physico-chemical and functional properties that can be modulated as a function of solution environment. The invention also provides methods for purifying the FPs, which take advantage of these unique properties, including high-throughput purification methods.

Owner:PHASEBIO PHARMA INC

Cleaning composition

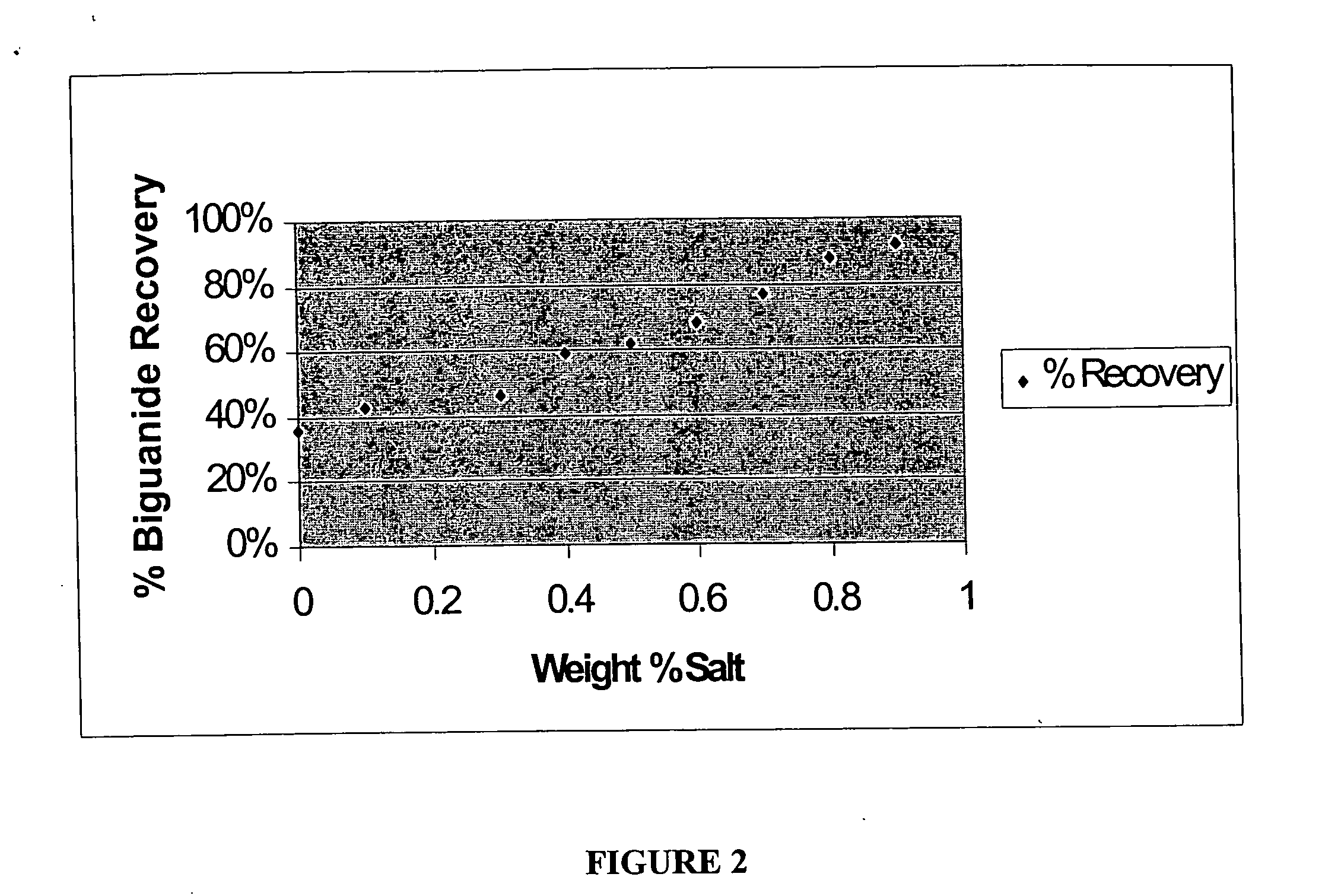

InactiveUS20060009369A1Improve efficiencySimple compositionInorganic/elemental detergent compounding agentsBiocideBiocideBiguanide

Owner:THE CLOROX CO

Dishwashing method

InactiveUS20090082242A1High pHReduce ionic strengthInorganic/elemental detergent compounding agentsOrganic/inorganic per-compounds compounding agentsIonic strengthPhosphate

A method of cleaning a soiled load in an automatic dishwasher comprising the step of contacting the load with a phosphate free wash liquor comprising exfoliated nanoclay, the liquor having a pH of from about 9 to about 12 and an ionic strength of from about 0.001 to about 0.02 moles / l.

Owner:THE PROCTER & GAMBLE COMPANY

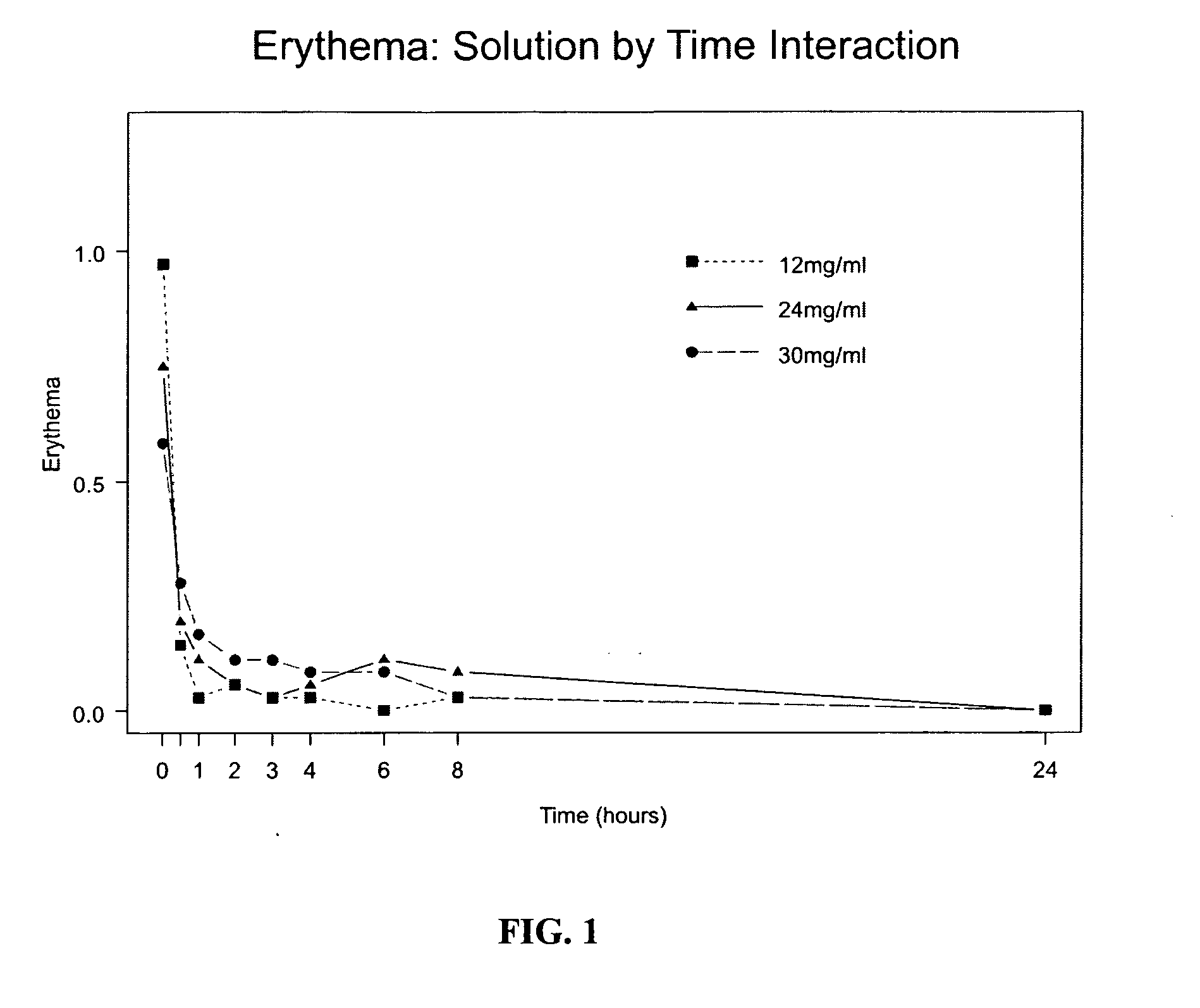

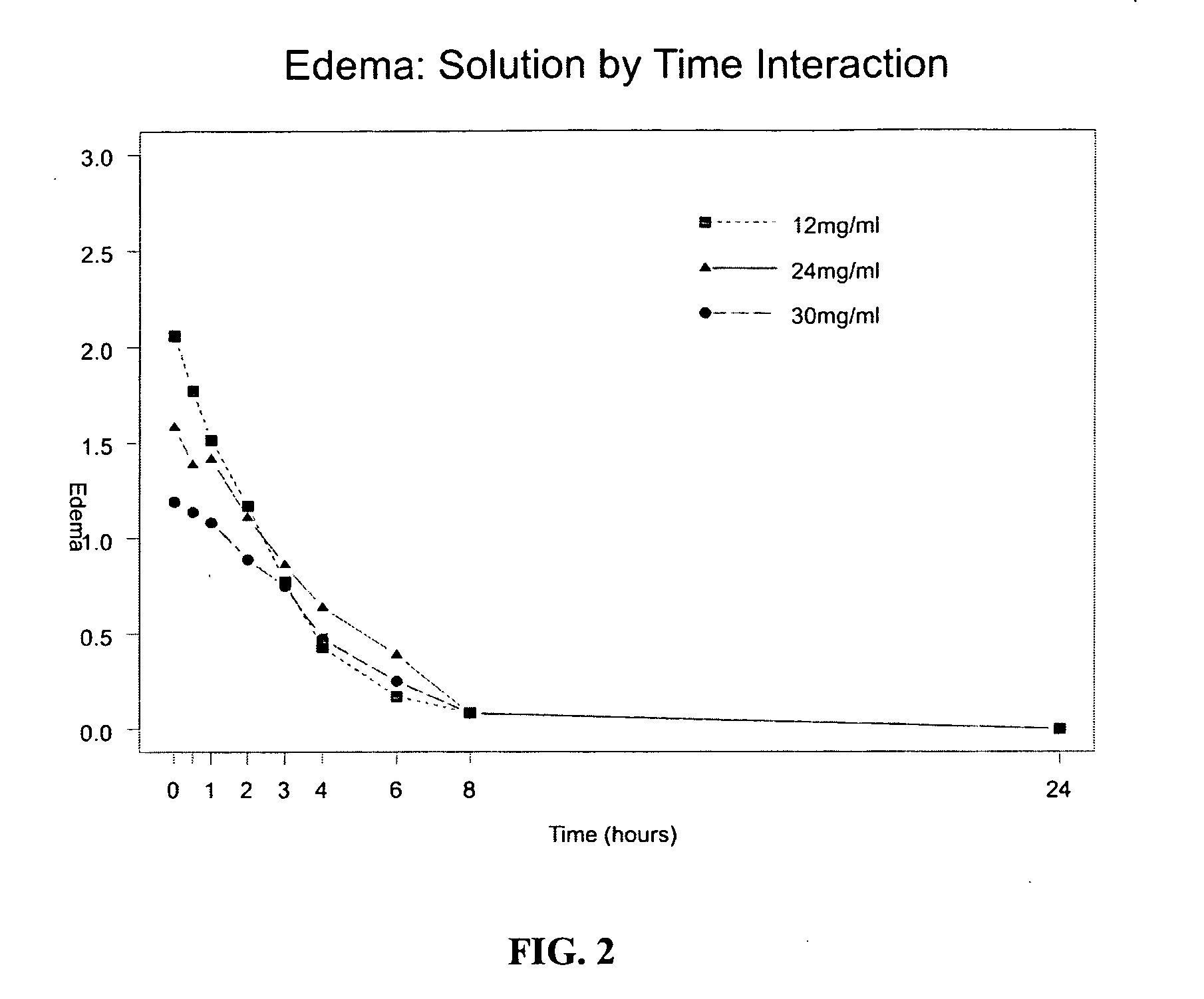

Formulations of anti-pain agents and methods of using the same

InactiveUS20050256182A1Reduce skin irritationRelieve painBiocidePharmaceutical delivery mechanismSide effectDose sparing

The present invention relates to novel anti-pain formulations and methods of their delivery. Anti-pain agents delivered in accordance with the methods of the invention have an improved clinical utility and therapeutic efficacy relative to other drug delivery methods, including oral, intramuscular and subcutaneous delivery. The methods of the present invention provide benefits and improvements over conventional drug delivery methods including dose sparing, increased drug efficacy, reduced side effects.

Owner:BECTON DICKINSON & CO

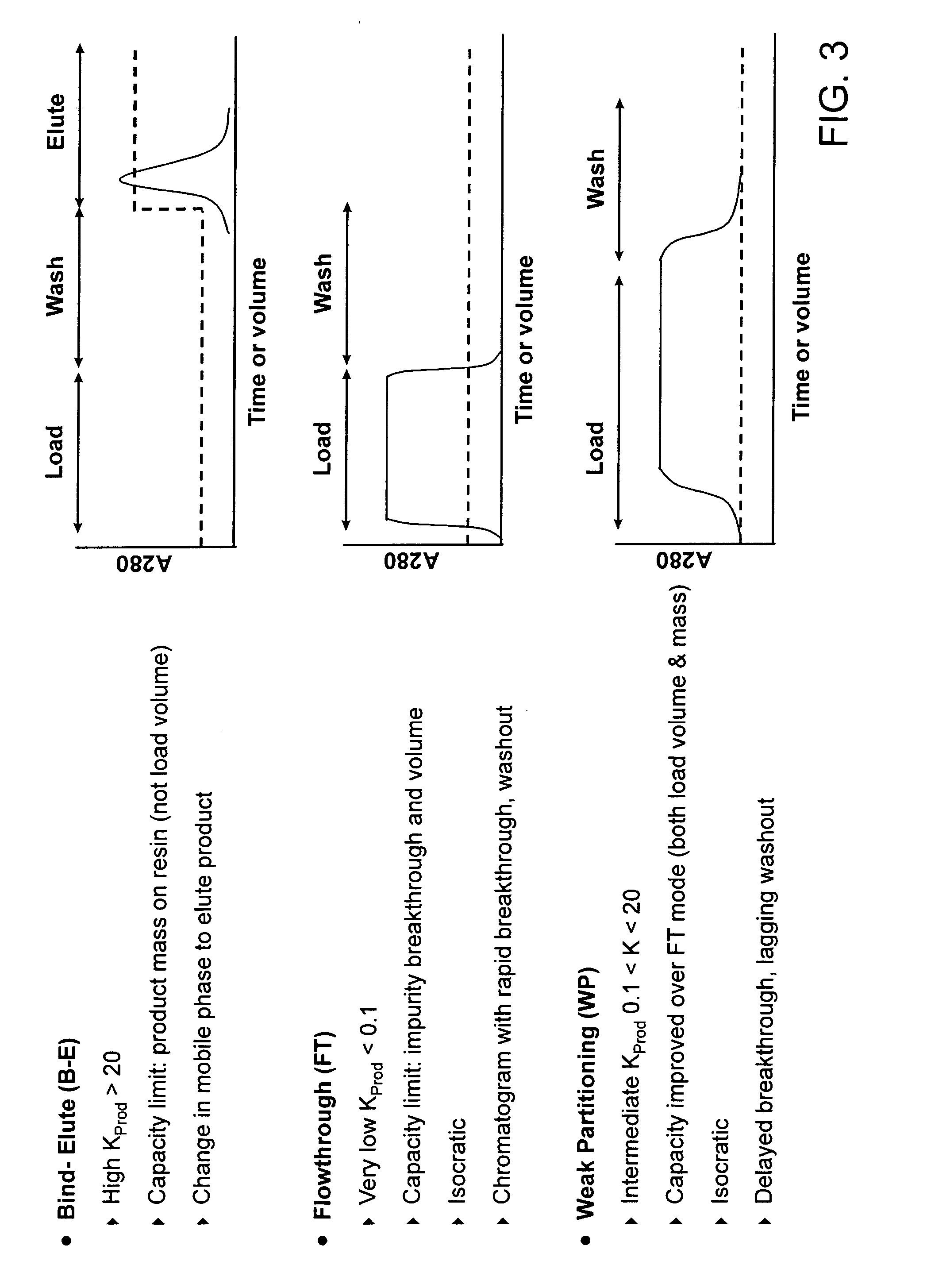

Method of weak partitioning chromatography

InactiveUS20070054390A1Reduce ionic strengthHormone peptidesPeptide/protein ingredientsOperant conditioningPartition coefficient

This invention relates to methods of using weak partitioning chromatography for the purification of a product from a load fluid. Further, the invention relates to methods of weak partitioning chromatography defined by operating conditions which cause a medium to bind least 1 mg of product per mL of medium, or alternatively, defined by a partition coefficient of at least 0.1.

Owner:WYETH LLC

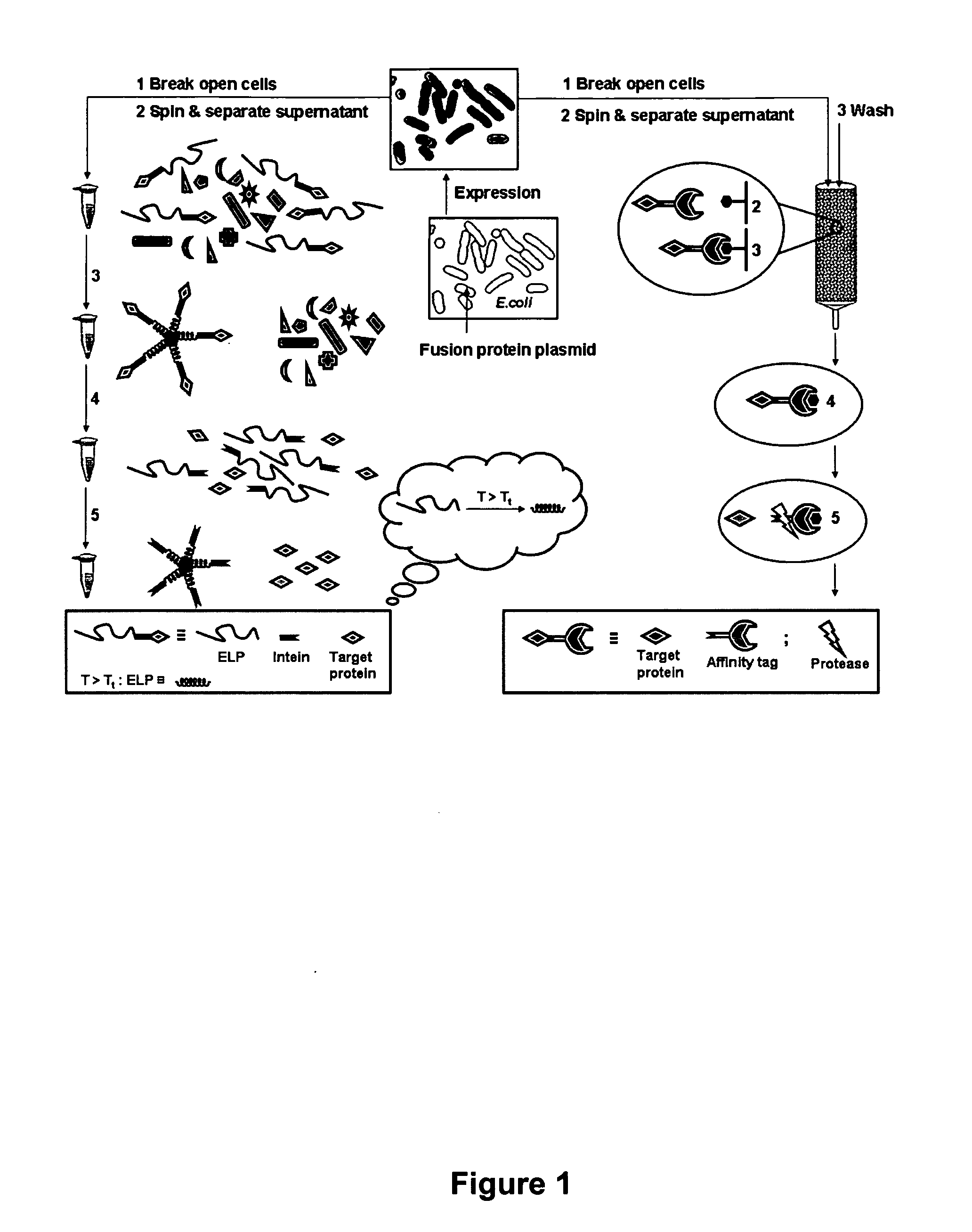

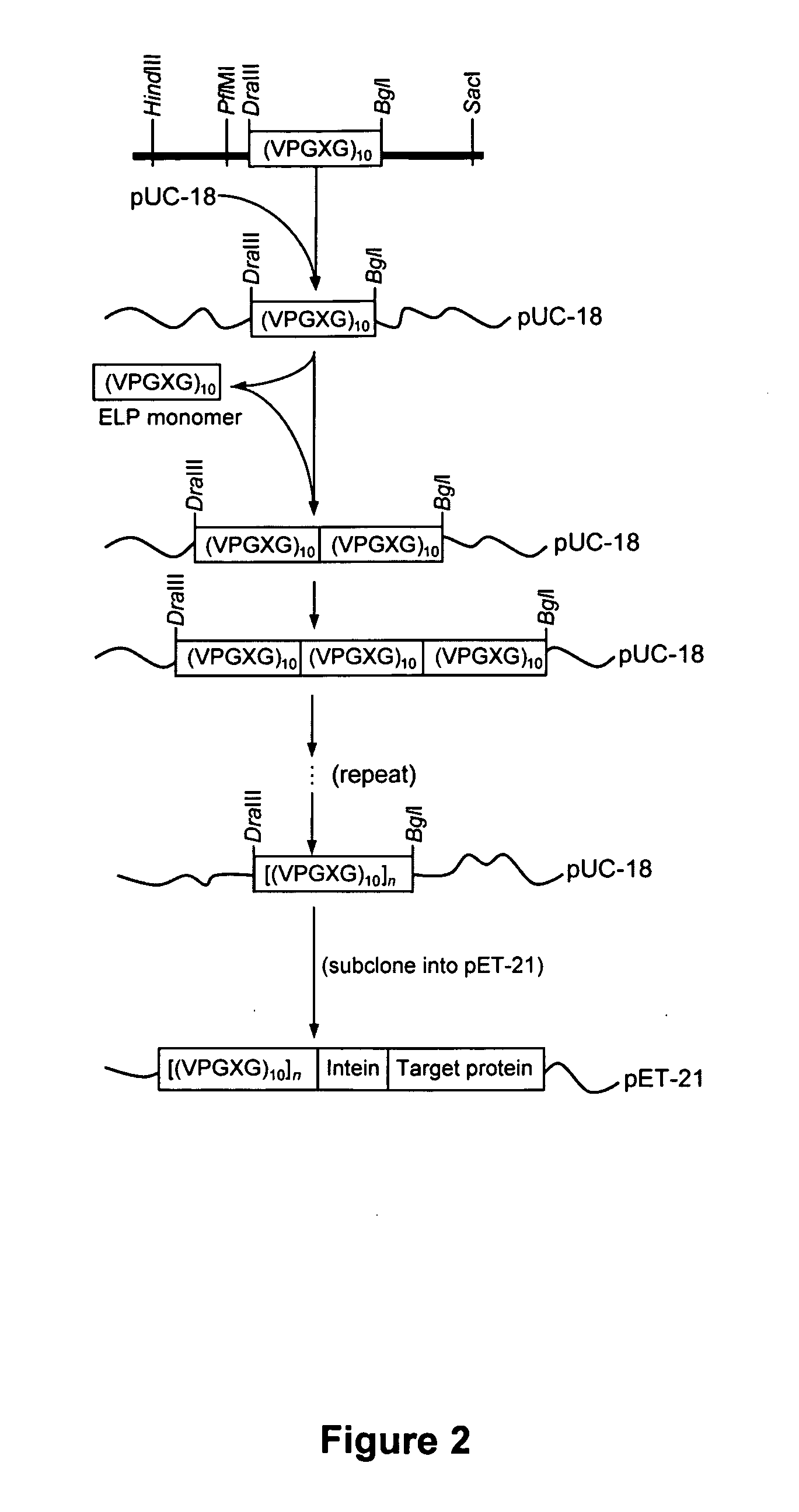

Intein-mediated protein purification using in vivo expression of an elastin-like protein

InactiveUS20060263855A1Successful useFunction increaseConnective tissue peptidesBacteriaInteinIn vivo

Purification of recombinant proteins is performed by expressing in a host cell a fusion protein comprising: (a) a product protein domain, (b) an intein, and (c) at least one aggregator protein domain, wherein the aggregator protein domain comprises a self-aggregating protein such as elastin-like proteins (ELPs).

Owner:PRINCETON UNIV

Method for preparing layer-layer assembled microcapsule based on host-guest interactions

InactiveCN101053813AEasy to achieve controllable changesWide potential application valueMicroballoon preparationMicrocapsule preparationIonic strengthColloidal particle

The invention discloses a method for preparing a layer-layer assembling microcapsule based on interaction of subject and object. The method obtains a microcapsule having multilayer structure, which capsule wall has interaction of subject and object by the steps of: forming a multilayer film on a surface of a colloidal particle in a manner of self-assembling layer upon layer, by the interaction of subject and object of beta-cyclodextrin and dicyclopentadienyl iron in polyallylamine grafting beta--cyclodextrin and polyallylamine grafting dicyclopentadienyl iron, based on the colloidal particle as a template; and removing the colloidal particle. Attractive force of the interaction of subject and object and electrostatic repulsive force of identical electrical charges exist in the capsule wall, so that relative size of the two forces can be controlled by changing chemical environment condition of the microcapsule such as PH value, ionic strength, molecular concentration of free subject and the like, thus controllable variation of the microcapsule size can be easily achieved. The method for preparing the microcapsule of the invention has extremely abroad latent applied cost in nanometer materials, drug releasing, biosensor, etc.

Owner:ZHEJIANG UNIV

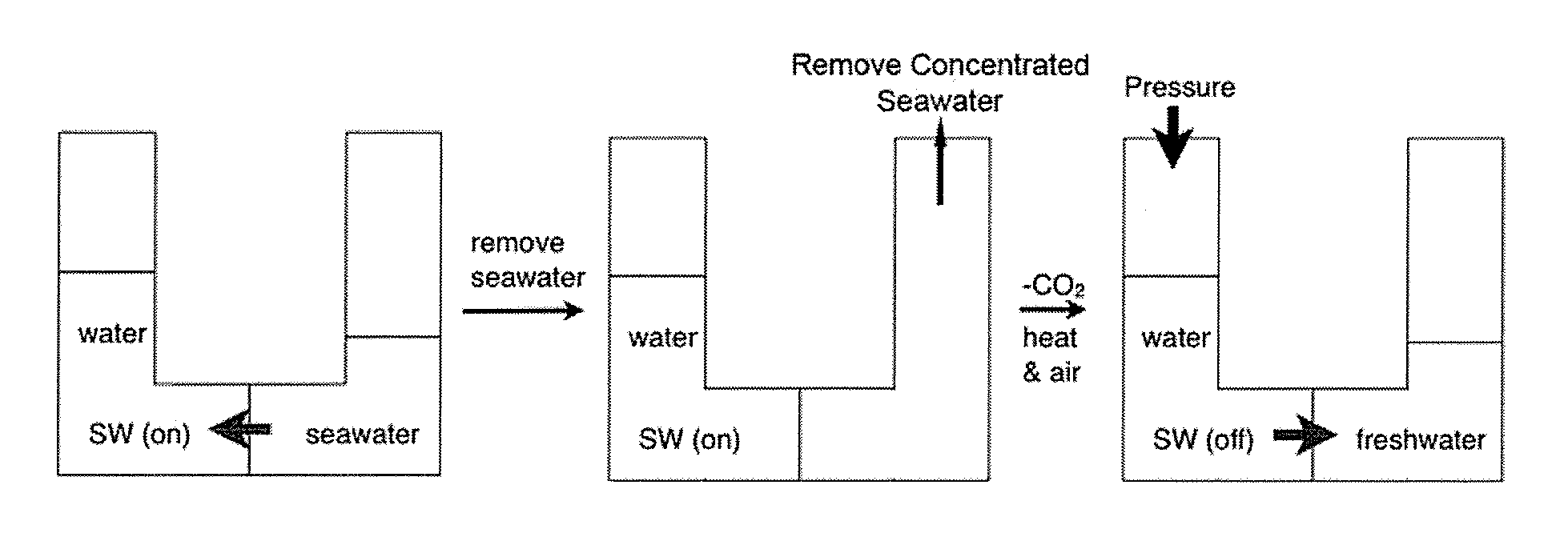

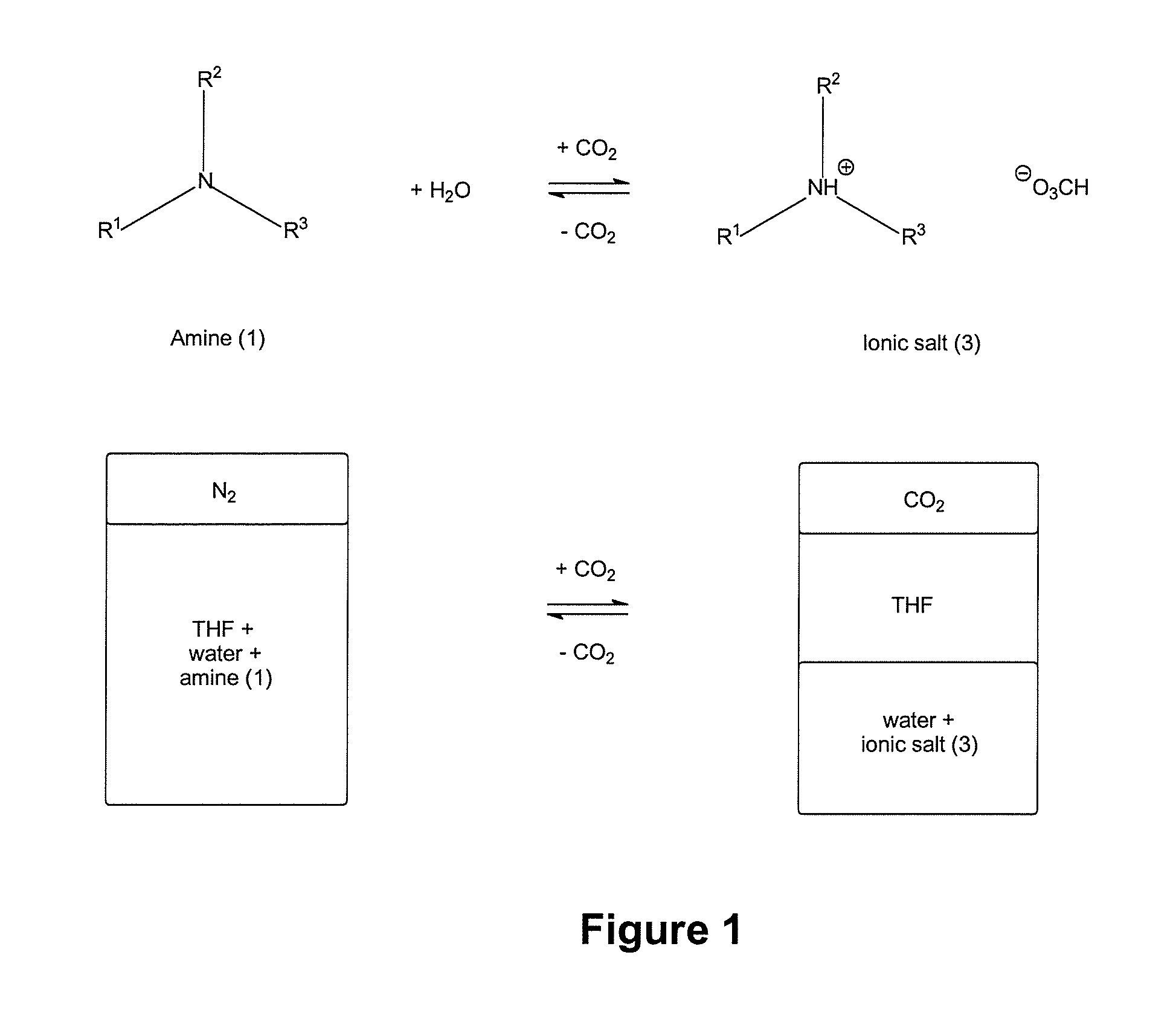

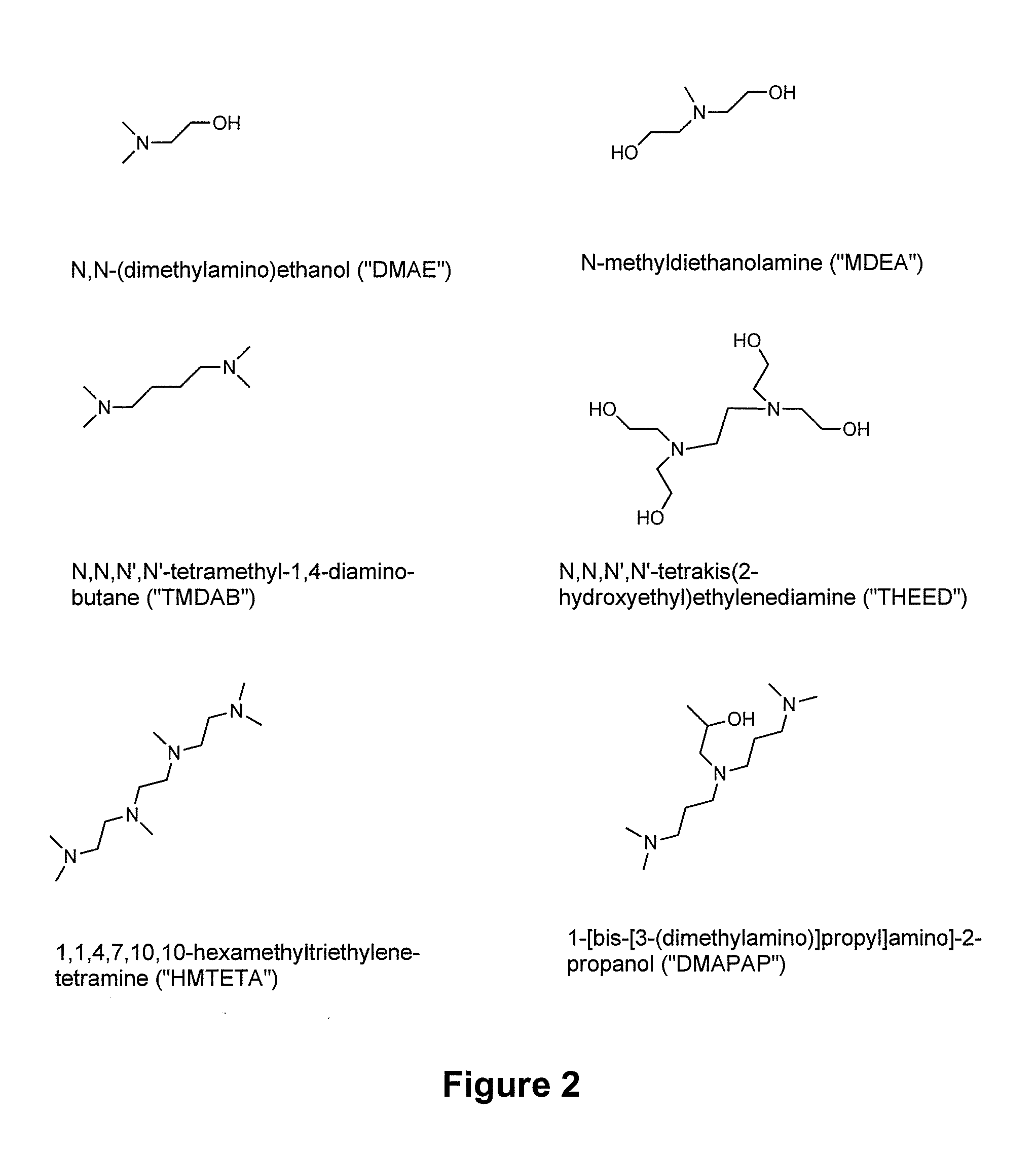

Water with Switchable Ionic Strength

InactiveUS20130105377A1Ionic strengthReduce ionic strengthWaste water treatment from quariesGeneral water supply conservationSalting outDistillation

A method and system for reversibly converting water between an initial ionic strength and an increased ionic strength, using a switchable additive, is described. The disclosed method and system can be used, for example, in distillation-free removal of water from solvents, solutes, or solutions. Following extraction of a solute from a medium by dissolving it in water, the solute can then be isolated from the aqueous solution or “salted-out” by converting the water to a solution having an increased ionic strength. The solute then separates from the increased ionic strength solution as a separate phase. Once the solute is, for example, decanted off, the increased ionic strength aqueous solution can be converted back to water having its original ionic strength and reused. Switching from lower to higher ionic strength is readily achieved using low energy methods such as bubbling with CO2, CS2 or COS. Switching from higher to lower ionic strength is readily achieved using low energy methods such as bubbling with air, heating, agitating, introducing a vacuum or partial vacuum, or any combination or thereof.

Owner:QUEENS UNIV OF KINGSTON

Nanowire-based sensor configurations

ActiveUS7910064B2Solve the lack of rigidityHigh strengthBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityAnalyte

This invention provides nanowire based molecular sensors and methods for detecting analytes in a microfluidic system. Methods for sensing analytes include detecting changed electrical parameters associated with contact of a nanowire with the analyte in a microfluidic system. Sensors of the invention include nanowires mounted in microchambers of a microfluidic system in electrical contact with the detector, whereby electrical parameter changes induced in the nanowire by the analyte can be monitored by the detector.

Owner:GLO TECH LLC

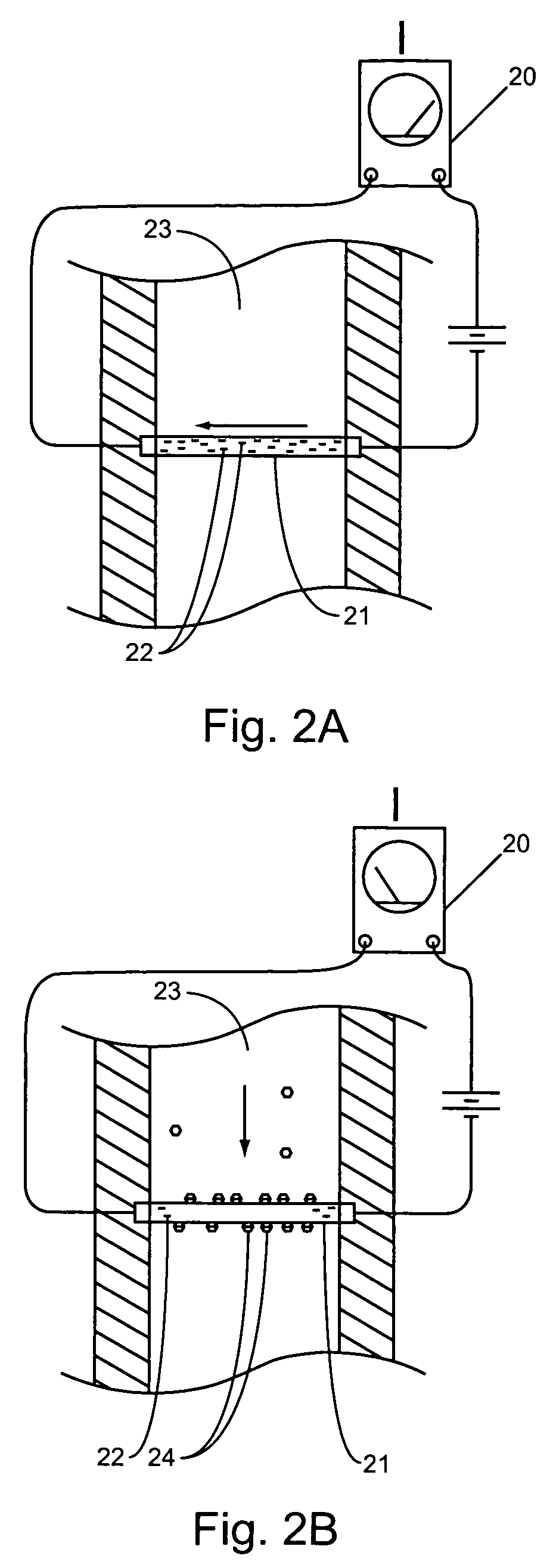

Method for the crystallization of human serum albumin

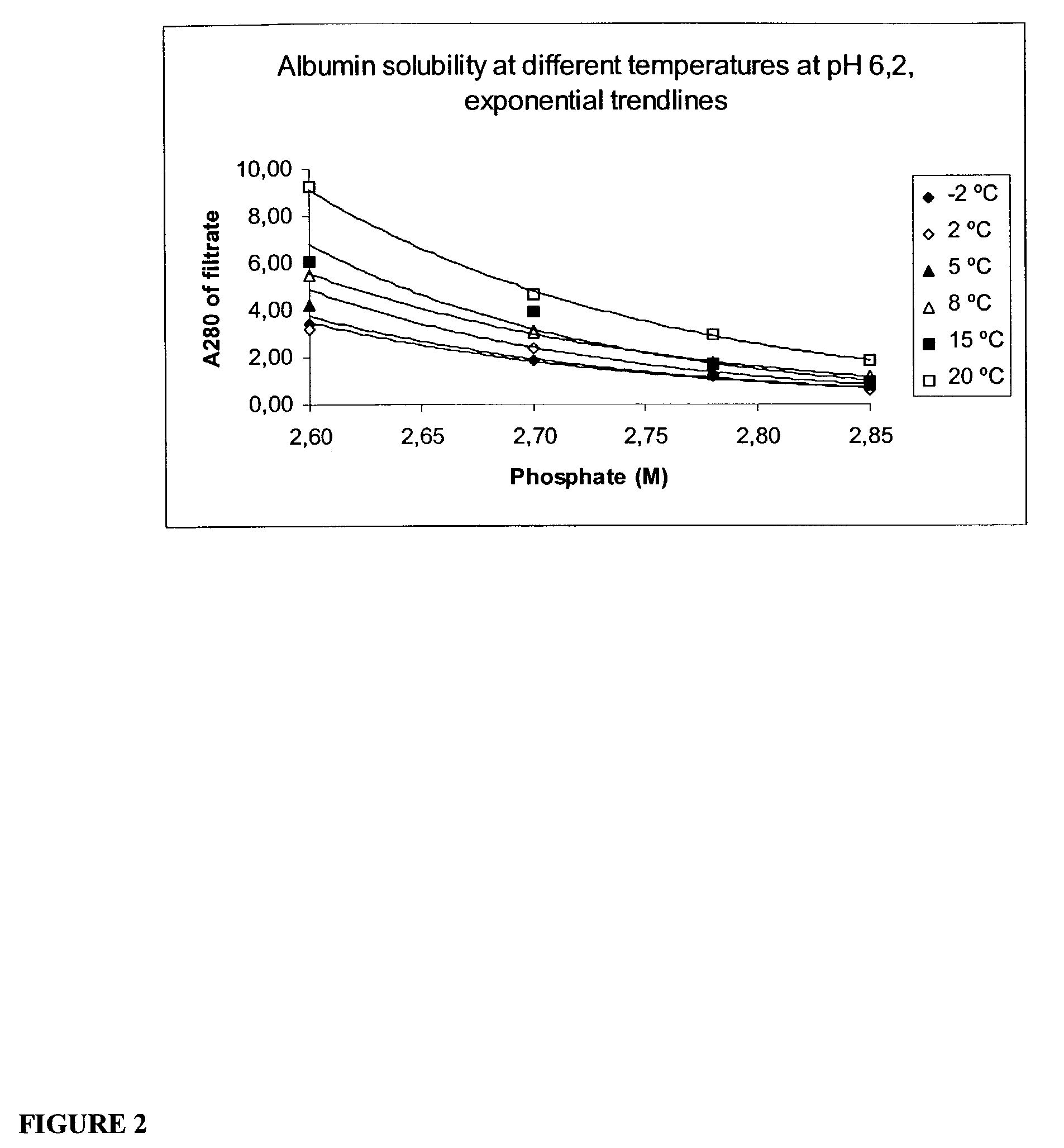

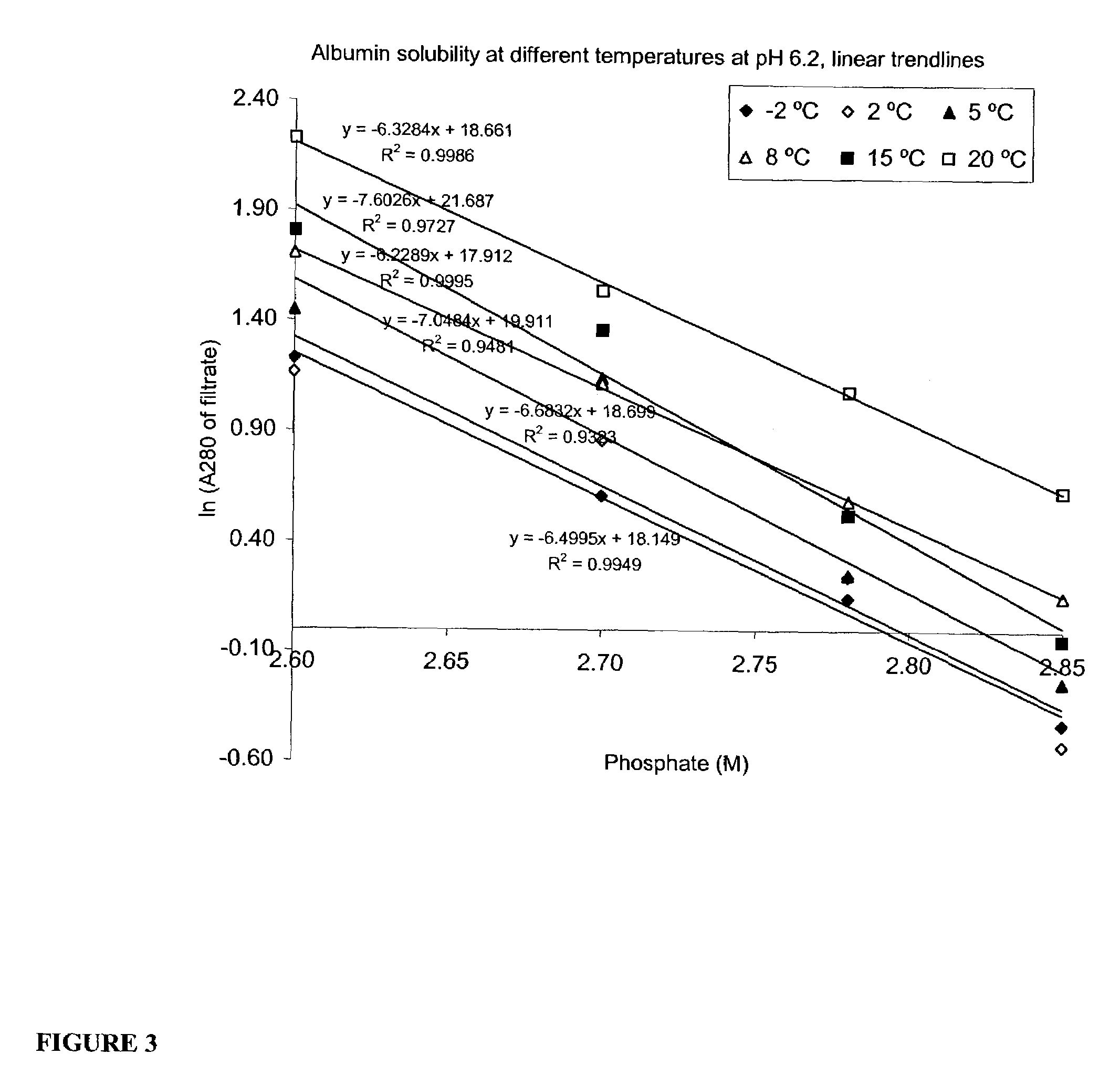

InactiveUS7087719B2Reduce ionic strengthIncrease ionic strengthPeptide/protein ingredientsSerum albuminPhosphateCrystallization kinetics

The present invention relates to the purification and production of human albumin from various sources through crystallization and repeated crystallization. Basic features of the invented process include providing specific reaction conditions and precipitating reagents to maximize albumin crystallization. Solubility diagrams are utilized as the basis for process control of the invented method. The current invention specifically controls phosphate concentration, pH and temperature to precisely guide crystallization kinetics and crystal yield.

Owner:TAURUS HSA

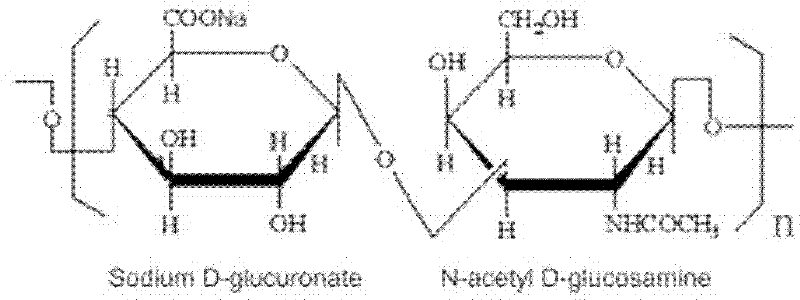

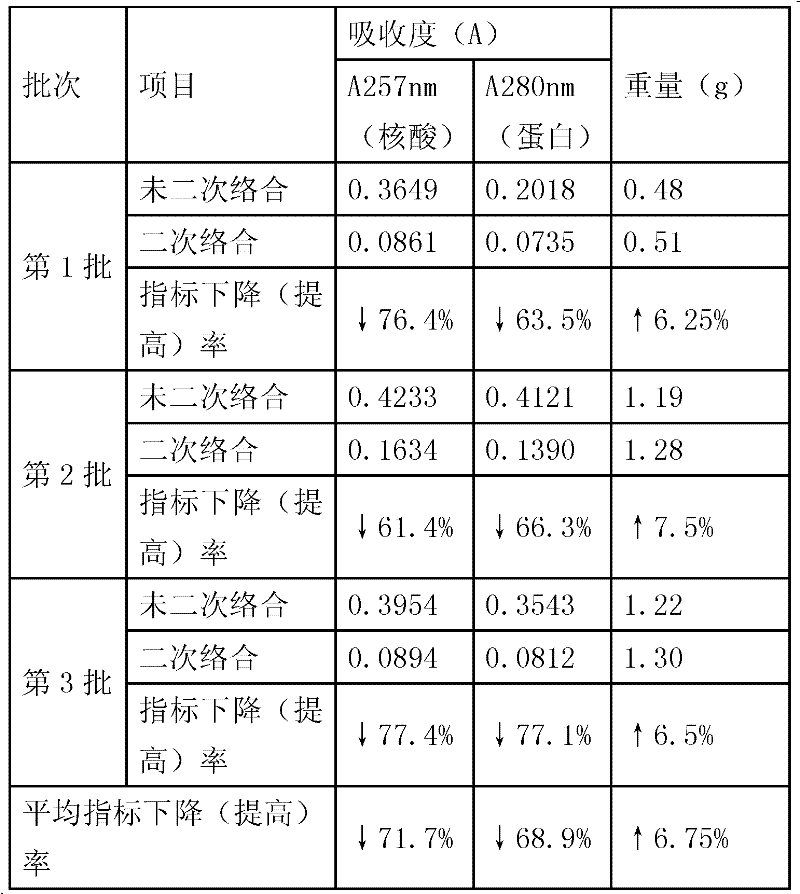

Purification method for sodium hyaluronate

The invention relates to a purification method for sodium hyaluronate, comprising the following steps of: performing adsorption and filtration on comb enzymolysis solution once by active carbon, uniformly stirring and mixing the obtained filtrate with CPC (cetylpyridinium chloride) aqueous solution, performing complex-precipitation thoroughly, standing the precipitate, removing the supernatant, and stirring and dissociating the complex precipitate by dissociating solution; diluting the dissociated liquid to 2-8 folds of the volume thereof, performing complex-precipitation for the second time, removing the supernatant after the complex-precipitation is finished, washing the precipitate for 1-3 times, and stirring and dissociating the complex precipitate by the dissociating solution; and adsorbing the liquid dissociated for the second time by the active carbon, and then removing carbon and filtering, precipitating the filtrate by alcohol, dehydrating the obtained sodium hyaluronate, and vacuumizing. The sodium hyaluronate finished product prepared by the method is low in absorbance, few in impurities, high in yield, good in the physicochemical property of intermediate, and few in adverse reactions.

Owner:SHANGHAI JINGFENG PHARMA

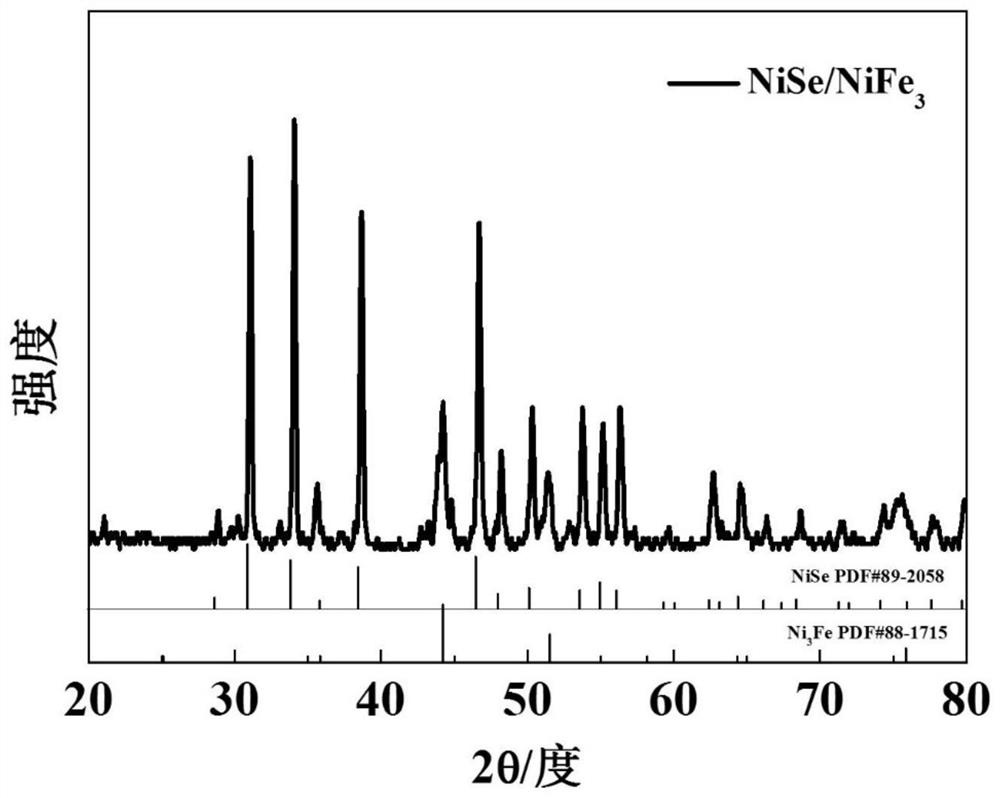

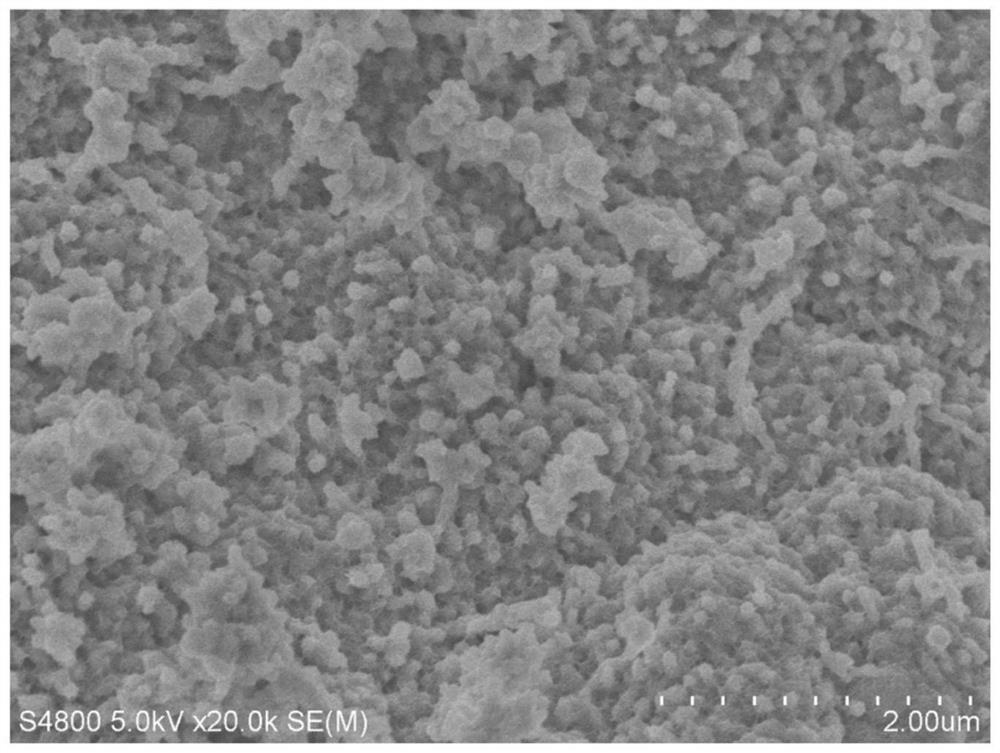

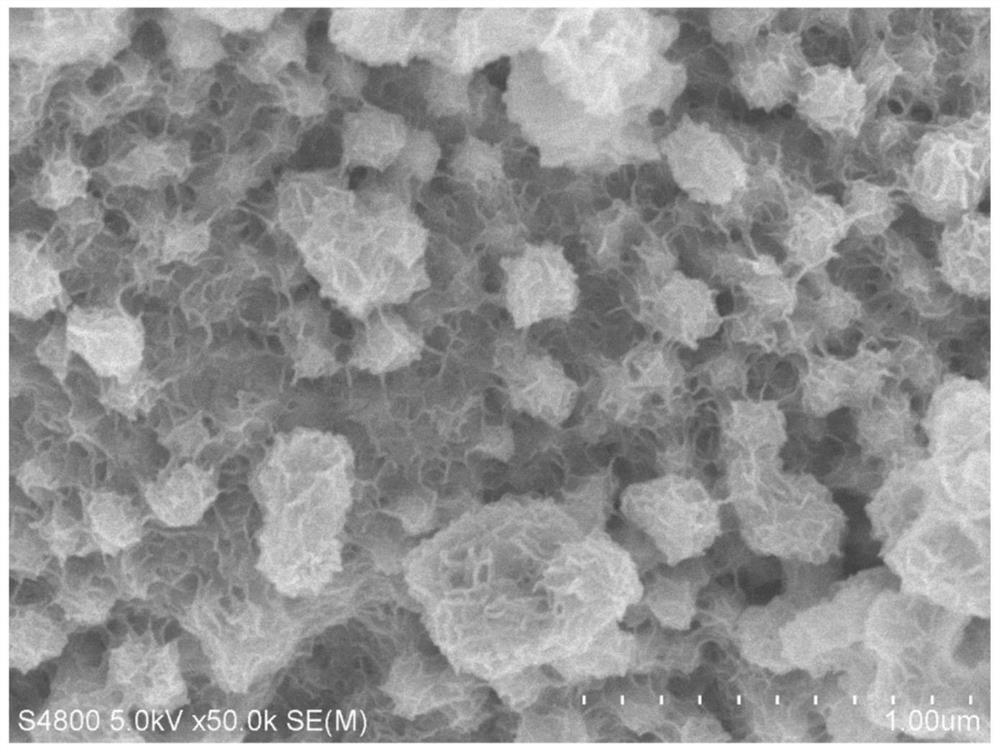

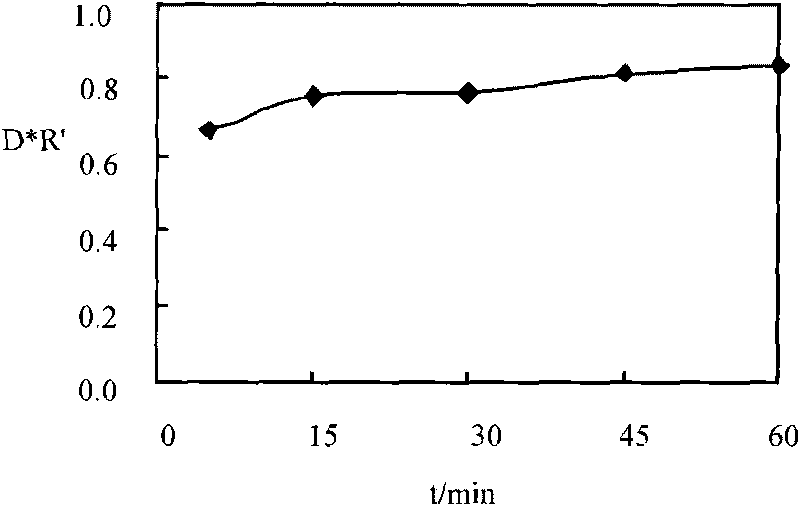

Nickel selenide/ferronickel substrate material as well as preparation method and application thereof

ActiveCN112064060ALow reaction temperatureSimple synthesis pathPhysical/chemical process catalystsElectrode shape/formsVanadium(III) chlorideSolvothermal reaction

The invention discloses a nickel selenide / ferronickel substrate material as well as a preparation method and application thereof, which are applied to the field of electrocatalysis. In the preparationmethod, selenium powder is used as a selenium source, lauryl sodium sulfate is used as a morphology regulating agent, vanadium trichloride is used as a vanadium source, foamed ferronickel is used asa nickel source, vanadium-doped nickel selenide grows on the foamed ferronickel in situ by adopting a solvothermal reaction method, and the foamed ferronickel has high conductivity, so that in-situ vanadium, nickel selenide and the conductive substrate foamed ferronickel are compounded, the contact resistance can be effectively reduced, the distribution of the catalyst is improved, electrons can be quickly transmitted to the surface of the catalyst and participate in the reaction, and the electrocatalytic activity and stability of the catalyst are improved. The prepared nickel selenide / ferronickel substrate material is applied to the field of electrocatalysis, and has excellent HER and OER performances under alkaline and neutral conditions.

Owner:SHAANXI UNIV OF SCI & TECH

Detoxification method of wood fibre hydrolysis sugar liquid

InactiveCN101691587AReduce ionic strengthPromote fermentationBiofuelsMicroorganism based processesAcetic acidAlcohol

The invention provides a detoxification method of wood fibre hydrolysis sugar liquid, which takes prehydrolysis sugar liquid concentration solution of the dilute sulphuric acid pretreatment cornstalks as raw materials. The invention is characterized in that the mixture which is prepared by trialkylamine, n-caprylic alcohol and kerosene is taken as complexing extracting agent; and carrying out complexing extraction and detoxification on the concentrated prehydrolysis sugar liquid under the condition of room temperature. In the concentrated prehydrolysis sugar liquid after complexing extraction, the removal rate of the main inhibitor acetic acid exceeds 70%; the removal rate of hydromethyl furfural exceeds 40%; the removal rate of furfural reaches 100%; and simultaneously, part of the lignin degradation products are removed.

Owner:NANJING FORESTRY UNIV

Mineral slurry make-up base and preparation method for same

InactiveCN102935056AImprove permeabilitySimple processCosmetic preparationsToilet preparationsBetaineAdditive ingredient

The invention discloses mineral slurry make-up base and a preparation method for the same, and relates to make-up base and a preparation method for the same. The invention aims at solving the problem that emulsification systems of make-ups are broken by directly adding mineral substance ingredients in the existing make-up bases. The mineral slurry make-up base disclosed by the invention is formed by emulsifying and homogenizing Wudalianchi volcano mineral slurry extract, squalane, butanediol, titanium dioxide, isononyl isononanoate, polydimethylsiloxane, cyclopentasiloxane, glycine betaine, cetyl PEG / PPG-10 / 1 (polyethylene glycol / polypropylene glycol-10 / 1) dimethicone, silica dimethyl silylate, ginkgo biloba extract, anthemis nobilis flower extract, bisabolol, allantoin, methyl hydroxybenzoate, propyl hydroxybenzoate, phenoxyethanol, sodium chloride, essence CI77288 and treated Wudalianchi mineral water. The method comprises the following steps of: 1, preparing materials; 2, preparing an oil-phase mixture; 3, preparing a water-phase mixture; 4, emulsifying; and 5, mixing and stirring. The method disclosed by the invention is used for preparing the mineral slurry make-up base.

Owner:黑龙江省科学院火山与矿泉研究所

Method for adsorbing and removing phosphates from water body by using zirconium oxide modified carbon nano tubes

InactiveCN102941063AFacilitate adsorption removalHigh removal rateOther chemical processesWater/sewage treatment by sorptionModified carbonPhosphate

The invention discloses a method for adsorbing and removing phosphates from a water body by using zirconium oxide modified carbon nano tubes. The method comprises the following steps of: ultrasonically dispersing the pretreated carbon nano tubes into a zirconium oxide solution; modifying the carbon nano tubes with zirconium oxide by using a hydrothermal synthesis method to prepare the zirconium oxide modified carbon nano tubes; adding the zirconium oxide modified carbon nano tubes into a phosphorus water body, so as to adsorb and remove the phosphates from the water body. According to the method, the zirconium oxide modified carbon nano tube is used as an adsorbers for the first time and is applied to treatment of the phosphorus water body. The adsorber has a good effect of removing phosphates and is acid and alkali resistant; the adsorption time is short; the treatment condition is mild; and the treatment efficiency is high. The method creates good economical and environmental benefits when used for removing phosphates from a water body.

Owner:NANJING UNIV

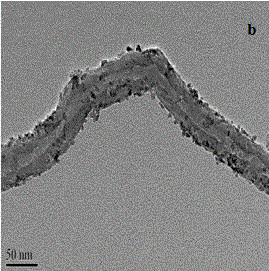

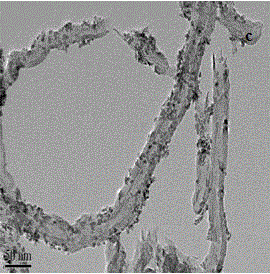

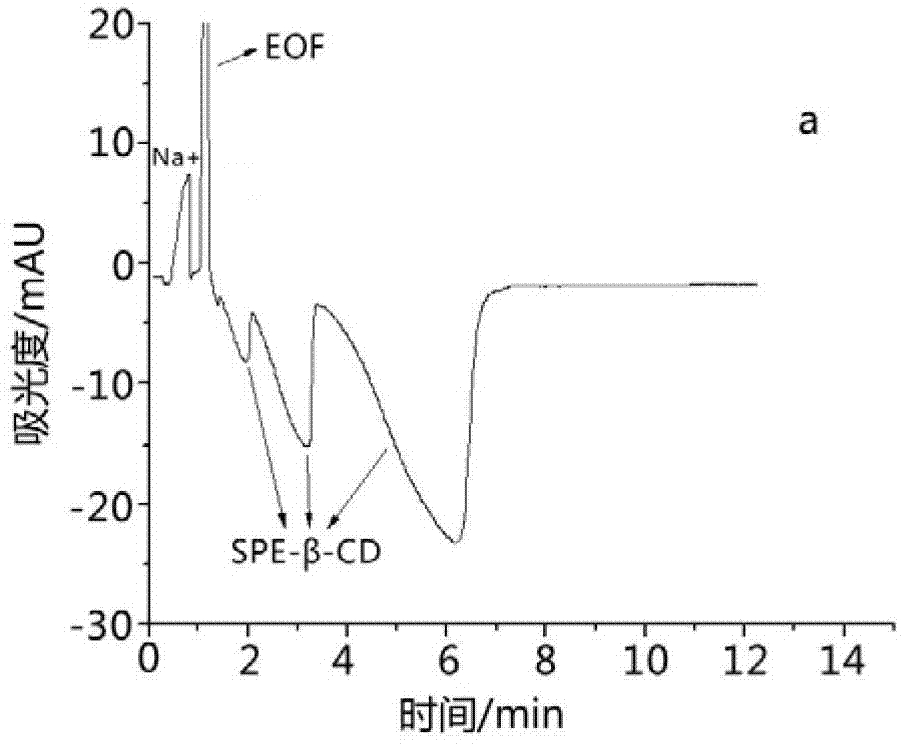

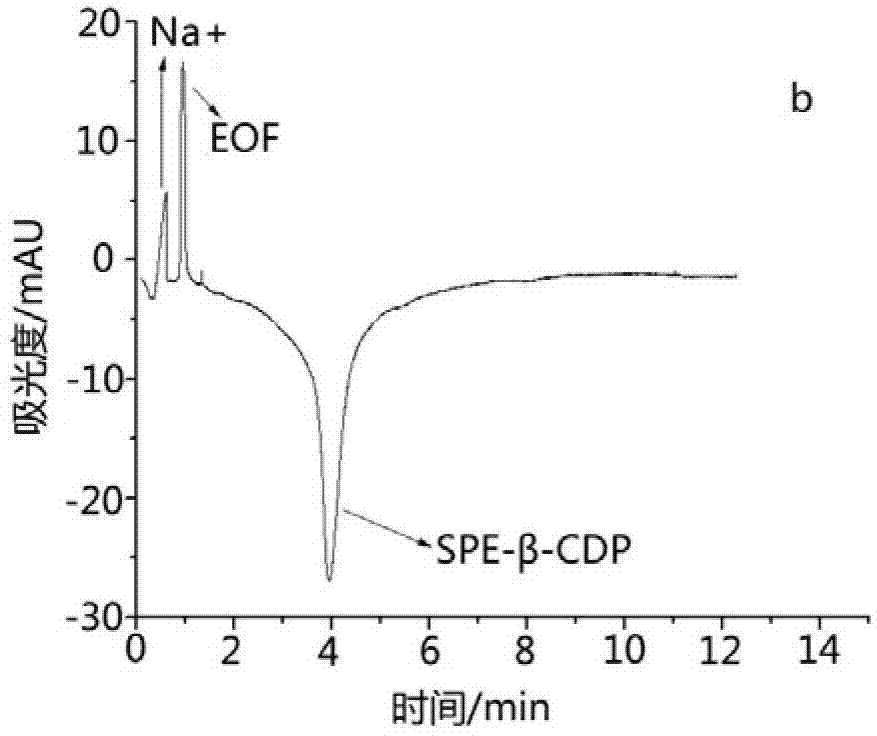

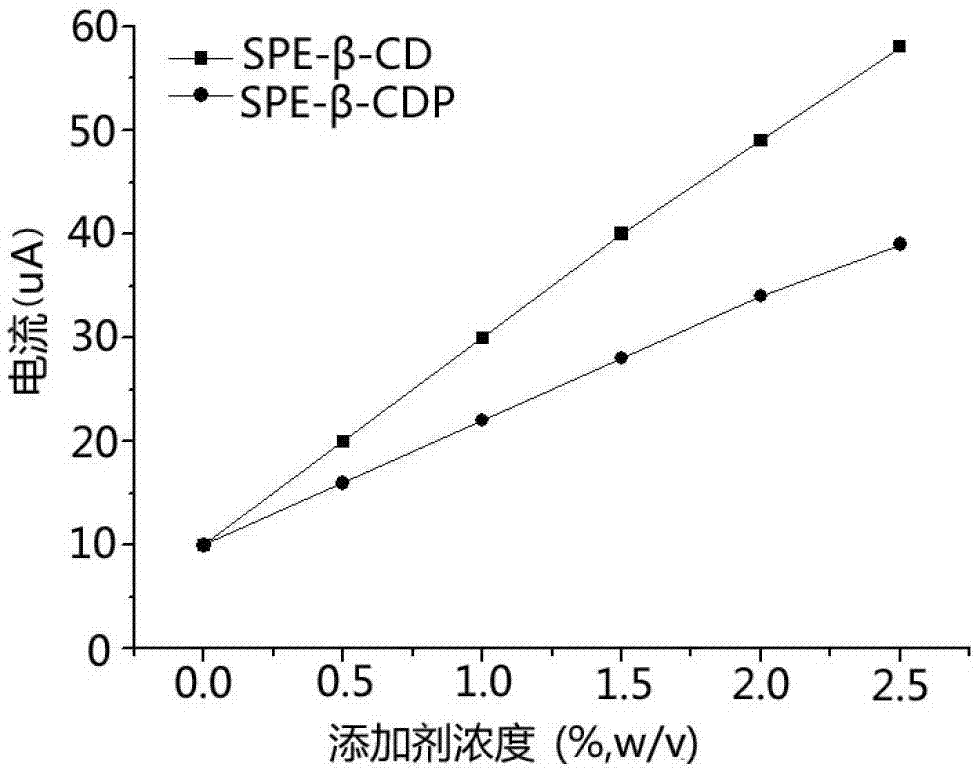

Synthesis and application of novel cyclodextrin polymer chiral resolving agents

InactiveCN102924708AGood water solubilityImprove uniformityElectrophoretic processesSolubilityCapillary electrophoresis

The invention discloses novel sulfopropyl ether ring dextrin polymers and a synthesis method thereof. Derived cyclodextrins with nonuniform substitution degree are connected into a polymer, and the cyclodextrins are sulfonated and polymerized to obtain the derived cyclodextrin chiral resolving agents with uniform substitution position and substitution degree. The characterization on the three novel sulfopropyl ether ring dextrin polymers (sulfopropyl ether alpha-CD (cyclodextrin) polymer, sulfopropyl ether beta-CD polymer and sulfopropyl ether gamma-CD polymer) proves the advantages of the design concept; and the polymers can be respectively used as a buffer additive for separating capillary electrophoresis chiral compounds. The invention can solve the problems of low water solubility, high ionic strength of charged cyclodextrin derivatives, poor batch repetitiveness of synthesized products, wide peak range and the like, and has the advantages of simple synthesis method, fewer steps, low synthesis cost and the like.

Owner:TIANJIN AOSHUNDA TECH CO LTD

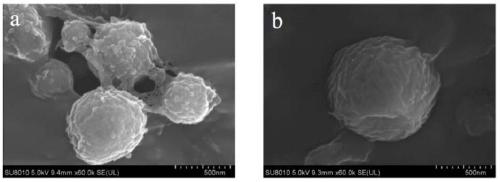

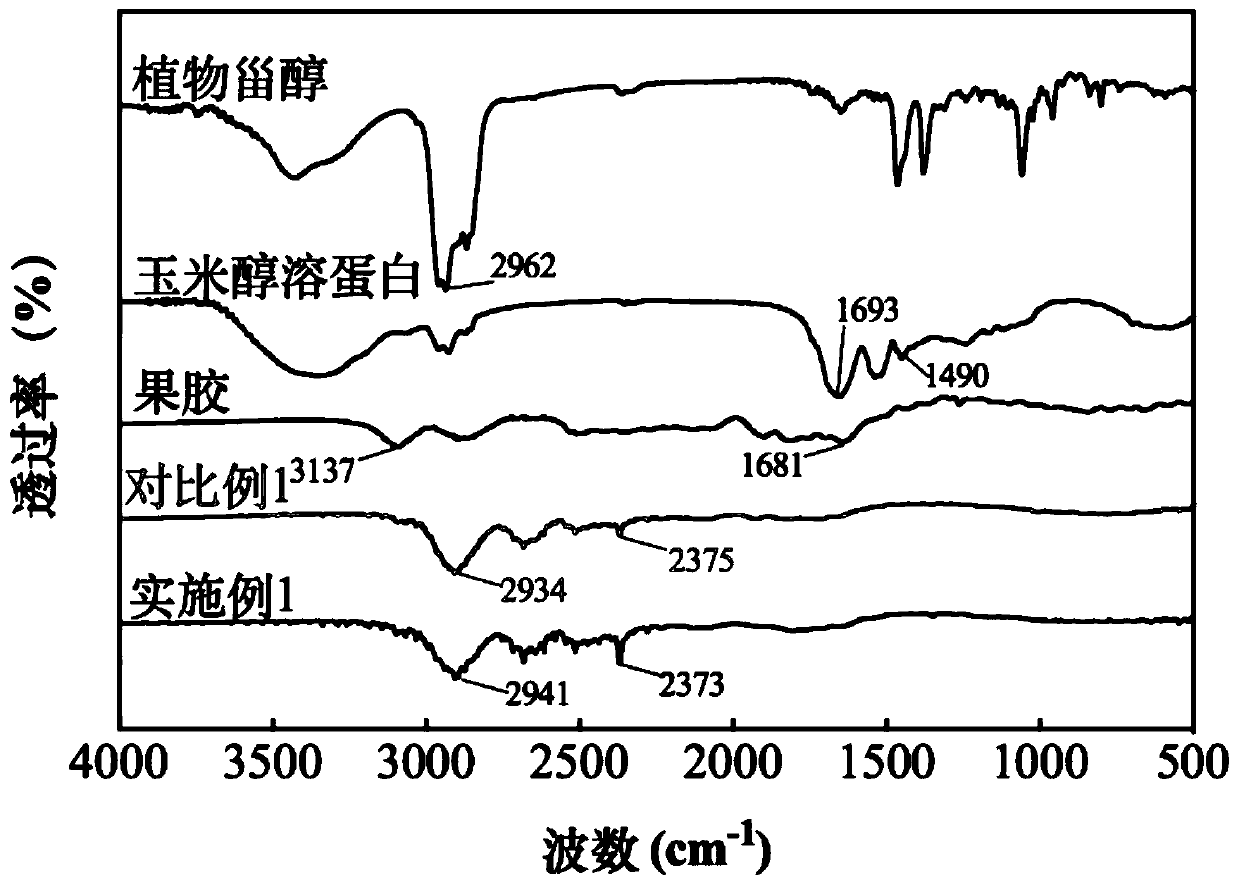

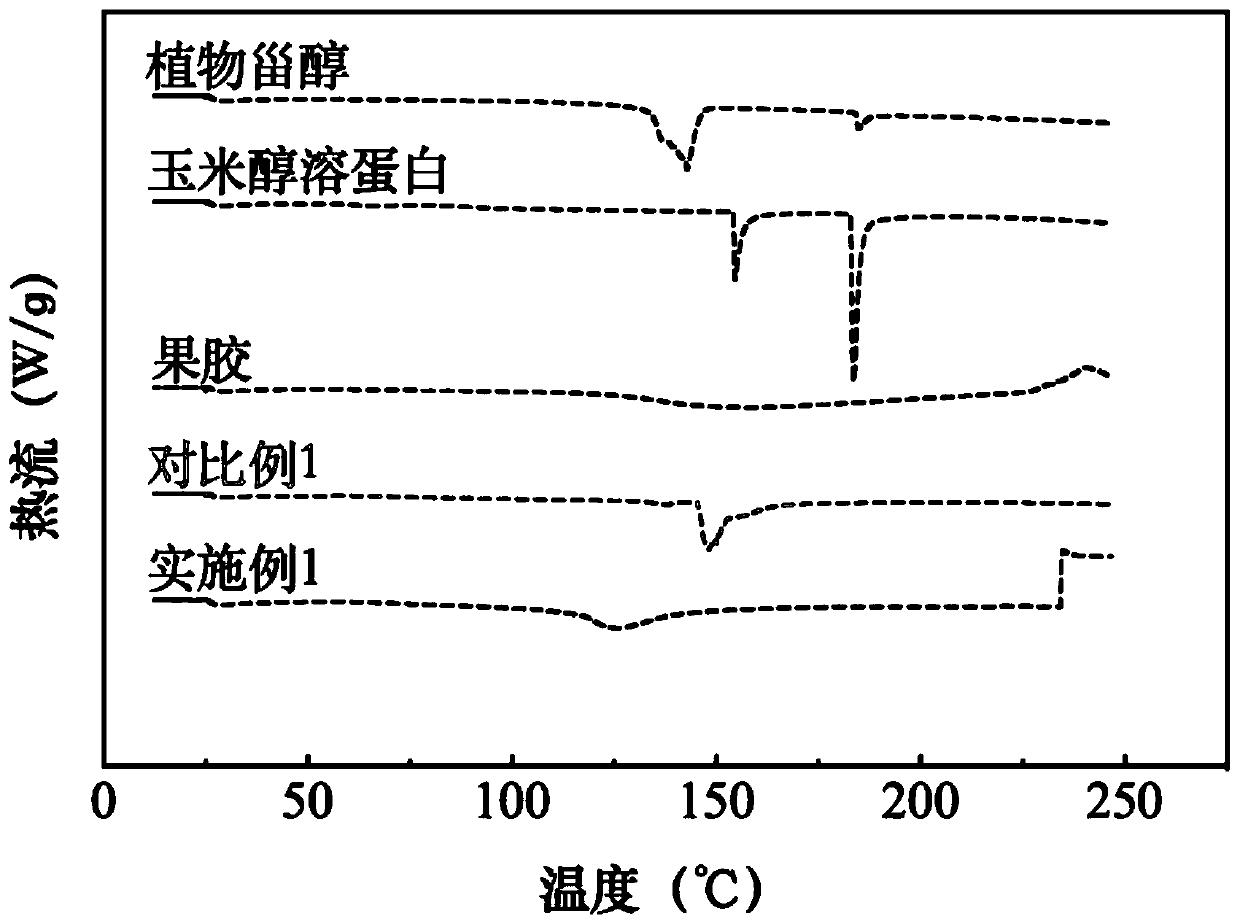

Method for preparing water-soluble phytosterol nano-dispersion system with intestinal targeting release function

InactiveCN111297831AReduce ionic strengthReduce sensitivityOrganic active ingredientsSolution deliveryNanoparticleOrganosolv

Owner:ZHEJIANG UNIV OF TECH

Peptide nucleic acid probes for analysis of microorganisms

InactiveUS20090246758A1Sure easyImprove discriminationSugar derivativesMicrobiological testing/measurementMicroorganismK pneumoniae

The instant invention provides PNA probes for detection, identification and / or quantitation of microorganisms, e.g., Escherichia coli, Klebsiella pneumoniae, Klebsiella oxytoca, Streptococcus agalactiae, fungi, and Acinetobacter species. The invention further provides methods of using the PNA probes of the invention and kits containing the PNA probes of the invention.

Owner:ADVANDX

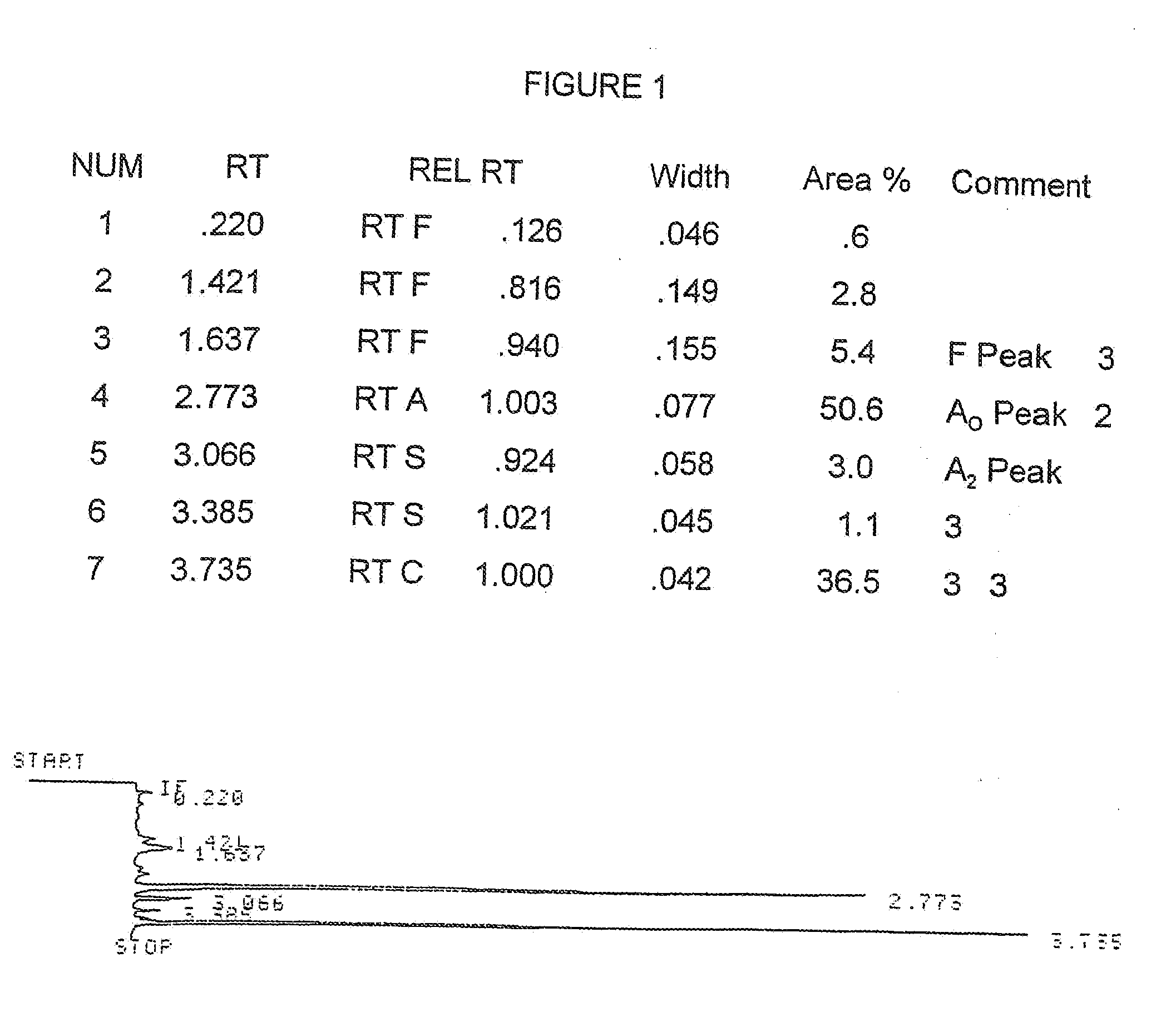

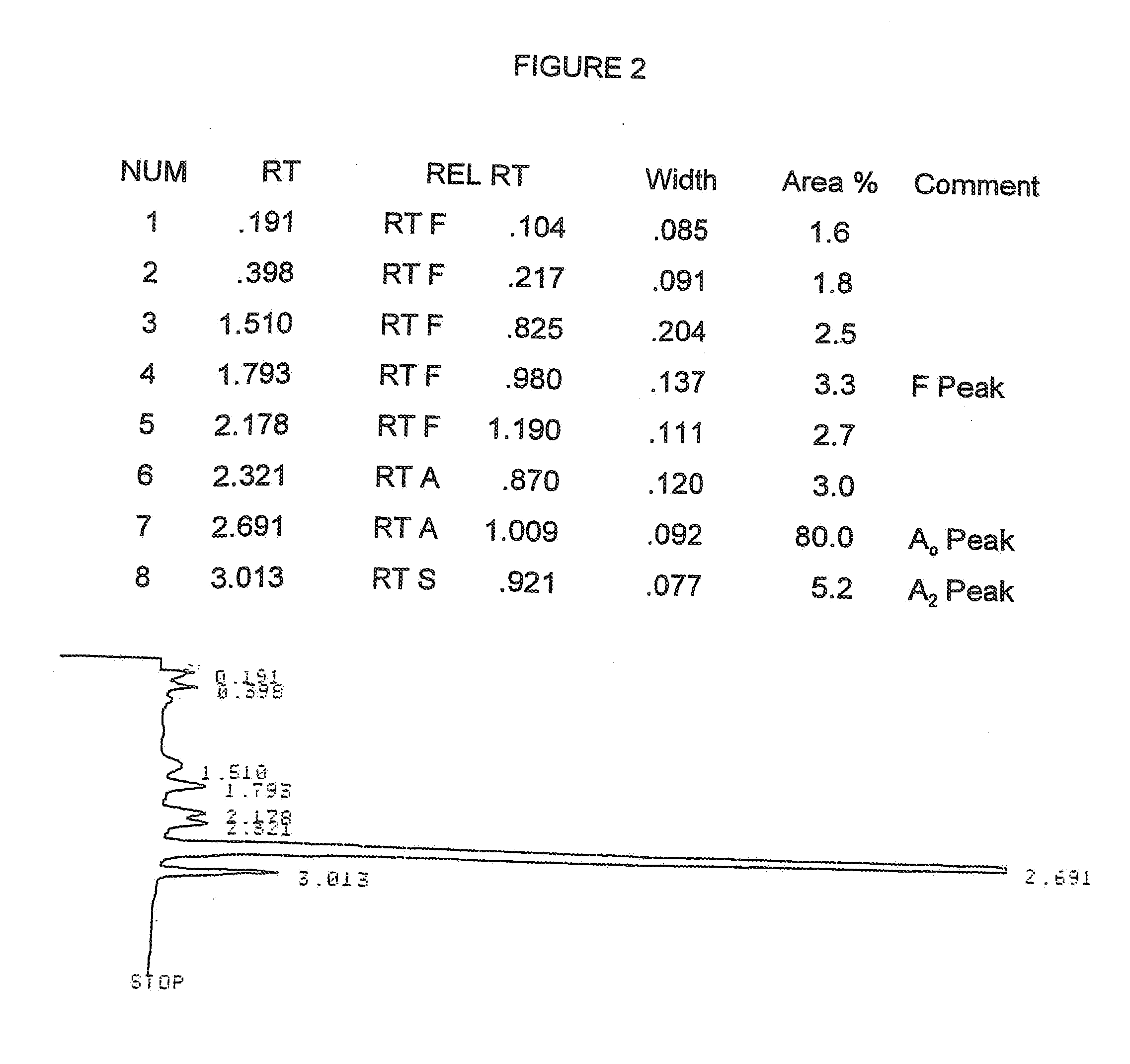

High speed chromatographic method for hemoglobin variants screening and quantification of hemoglobins a2 and f

InactiveUS20060292696A1Reduce ionic strengthIncrease ionic strengthChromatographic cation exchangersComponent separationPolyaspartic acidF hemoglobin

A high speed method is described for analyzing a plurality of individual blood samples to determine characteristics therein indicative of hemoglobin variant(s), while also quantifying the amounts of important A2 and F hemoglobins therein. The method involves analysis of a respective blood sample by passing it through an HPLC column (preferably a polyaspartic acid cation exchange column), eluting hemoglobin species using an eluant stream passing through the column, and characterizing eluted species as a function of their respective adsorbance values and retention times; the characterizing step further includes quantification of the amounts of A2 and F hemoglobins in the sample. The foregoing analysis is repeated for each of the plurality of blood samples, wherein the total time between successive analyses is up to about 7 minutes, and more preferably up to about 5.5 minutes.

Owner:NOFFSINGER JIMMIE K

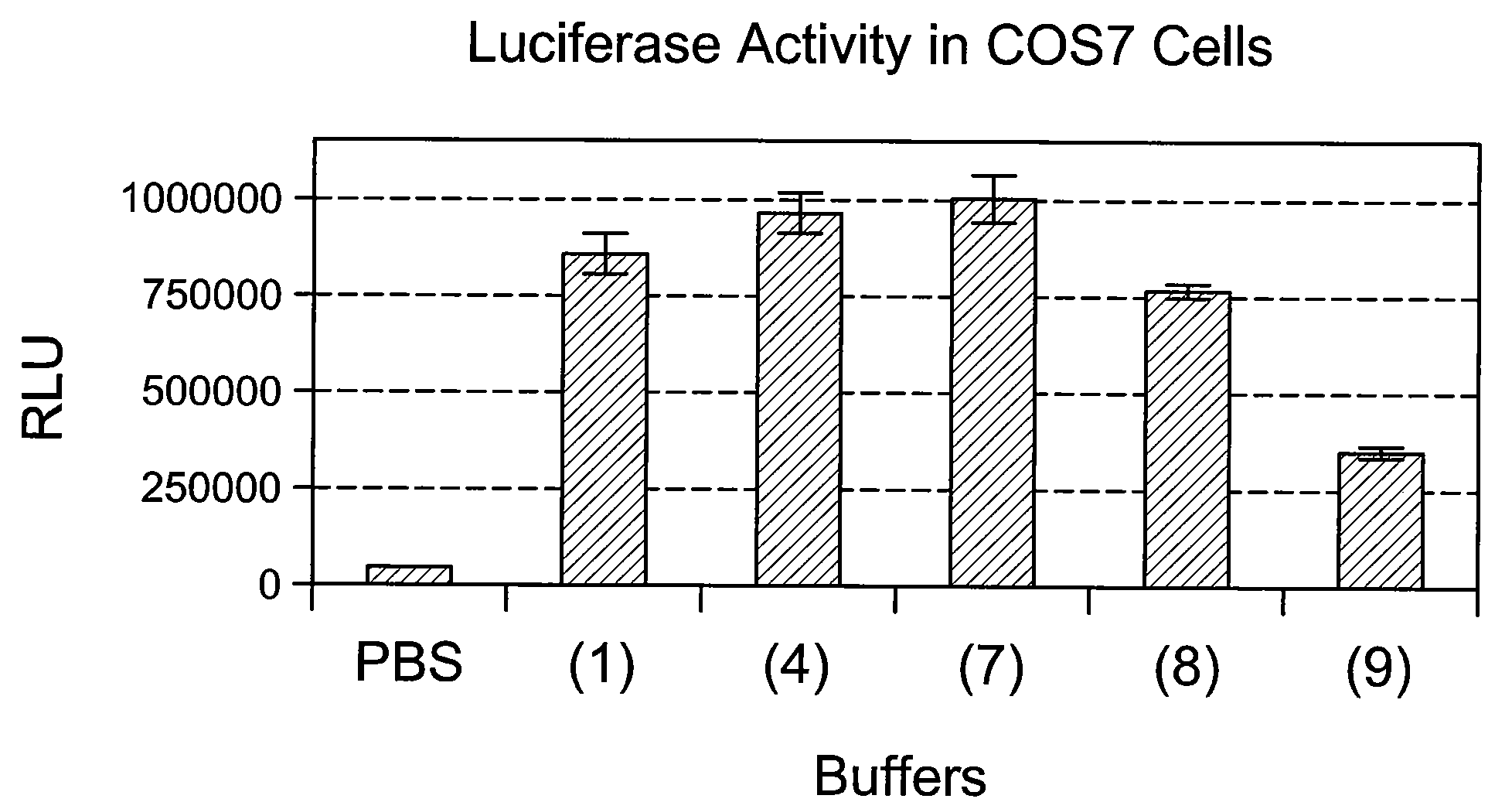

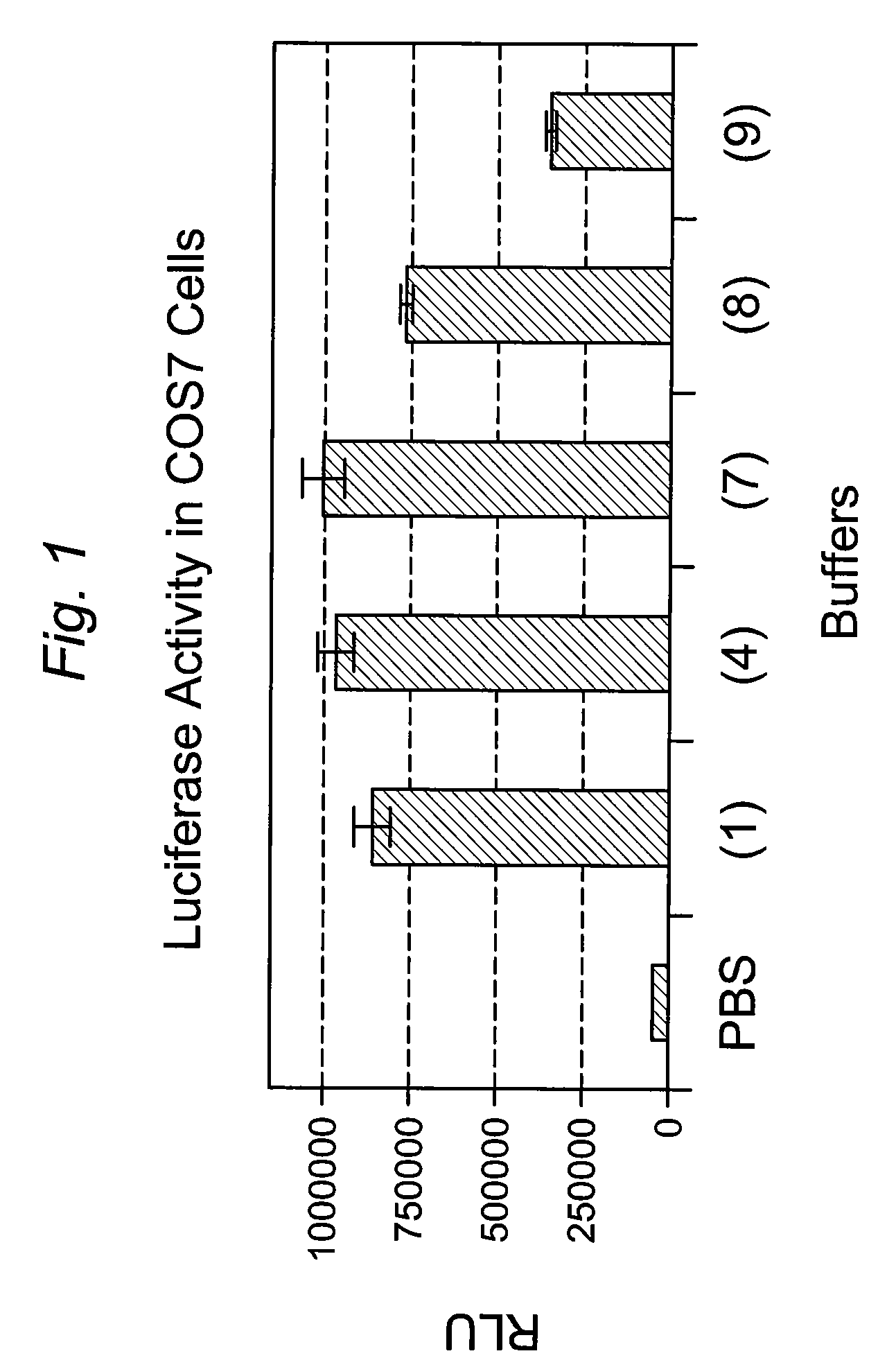

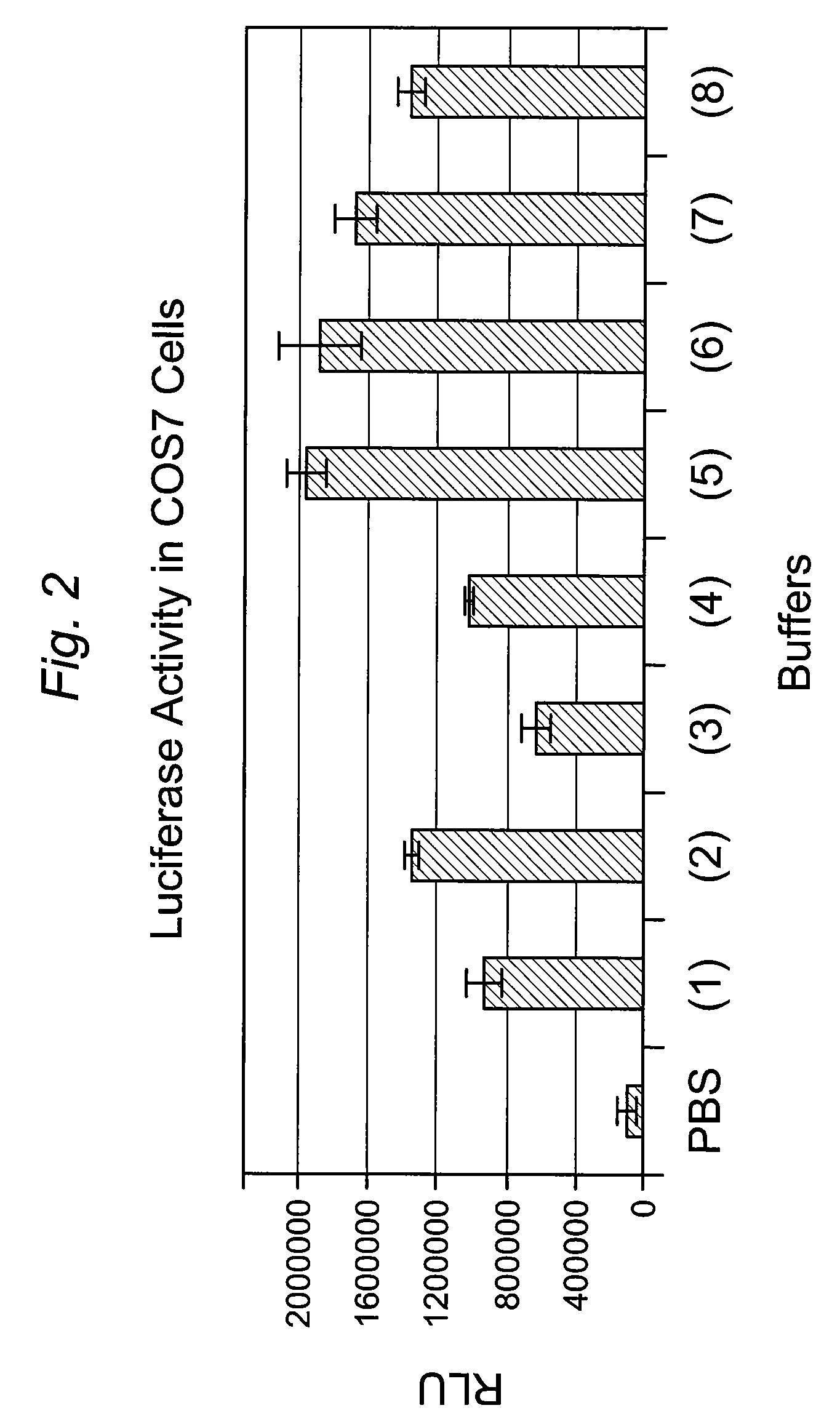

High Efficiency Electroporation Buffer

InactiveUS20080268542A1Preserving cell integrityPreserving viabilitySugar derivativesOther foreign material introduction processesInorganic phosphateOrganic sulfonic acid

Electroporation of mammalian cells is performed to high efficiency by use of a buffer solution containing trehalose, sucrose, or both, in addition to an inorganic phosphate buffer, an organic sulfonic acid buffer, a halide salt of an alkali or alkaline earth metal, a chelating agent, an alkyl methyl sulfoxide, and a nucleotide triphosphate, with substantially no sodium. This buffer solution is effective both in the electroporation of cells that are suspended in the buffer solution and in the electroporation of cells that are fixed on a surface.

Owner:BIO RAD LAB INC

Cell permeabilization and stabilization reagent and method of use

InactiveCN101115388AReduce ionic strengthReduce conductivityBiocideOrganic active ingredientsLow ionic strengthGlycerol

A cell permeabilization and stabilization reagent and method of use are disclosed. The reagent contains a N-acyl sarcosine or a salt thereof, a pH adjusting agent to adjust pH of the reagent in a range from about 4 to about 6; and an aqueous medium; the reagent having a low ionic strength defined by a conductivity of less than 9.0 mS / cm. The reagent further contains bovine serum albumin and glycerol. The reagent may further include an alkyl sulfate surfactant. Upon incubating the cells with the reagent, the reagent permeates the cellular membrane to allow penetration of an intracellular marker, causes intracellular protein aggregation within the cellular membrane, while preserves a cellular constituent for binding with a cellular marker for subsequent analysis by flow cytometry.

Owner:BECKMAN COULTER INC

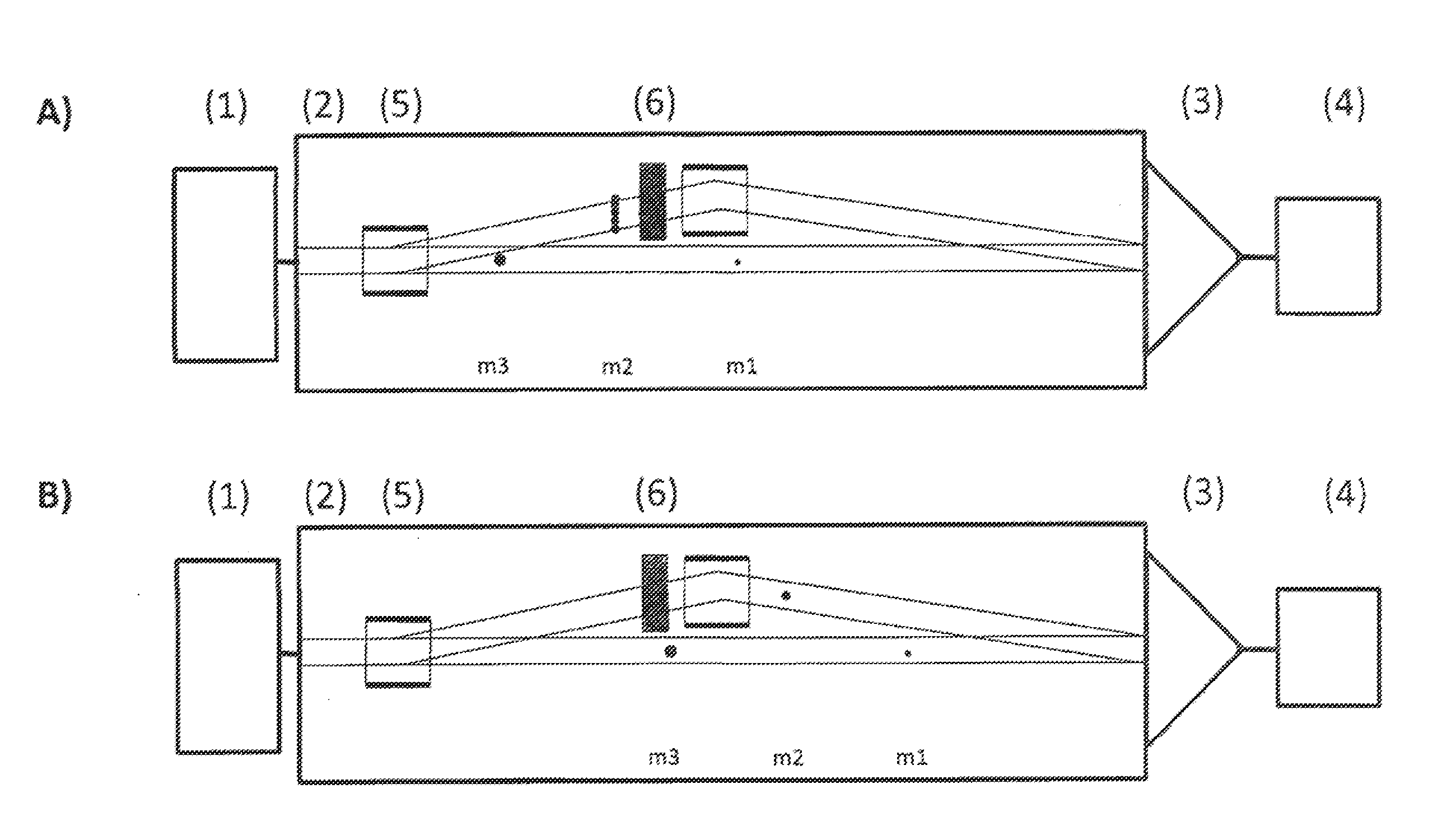

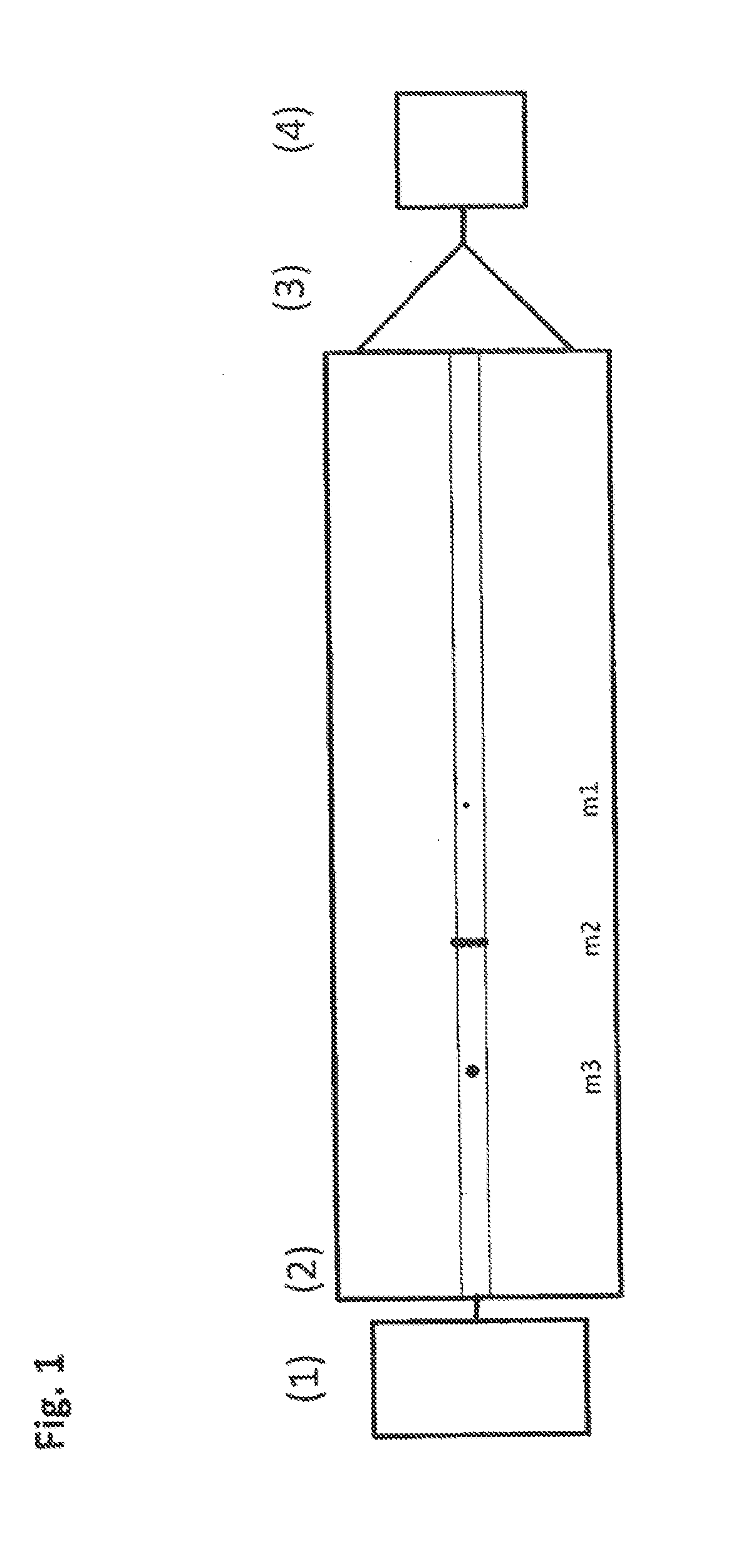

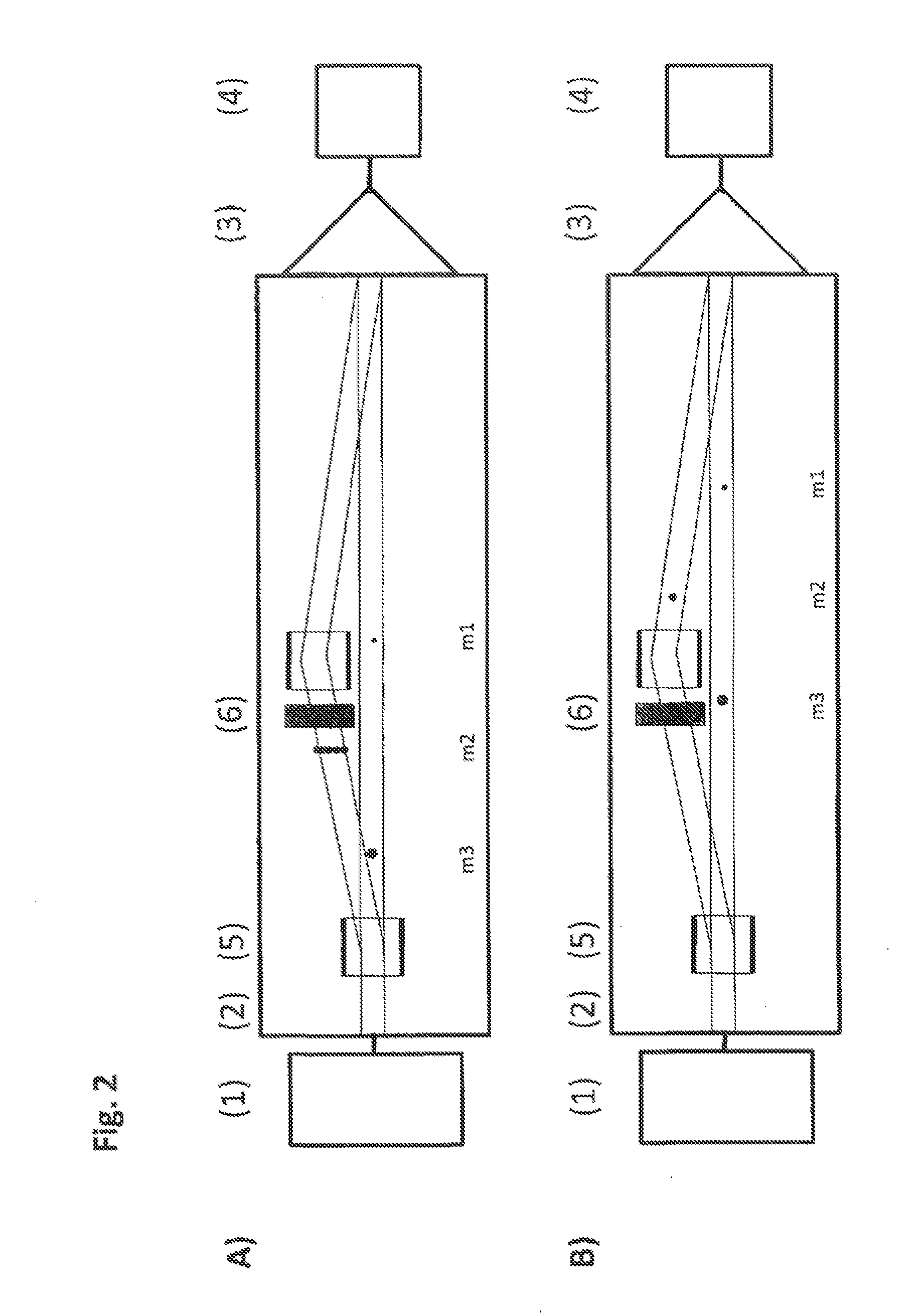

Method and a mass spectrometer and uses thereof for detecting ions or subsequently-ionised neutral particles from samples

InactiveUS20140346340A1Improve dynamic rangeConvenient timeTime-of-flight spectrometersElectron/ion optical arrangementsIon beamTime of flight

Owner:ION TOF TECH

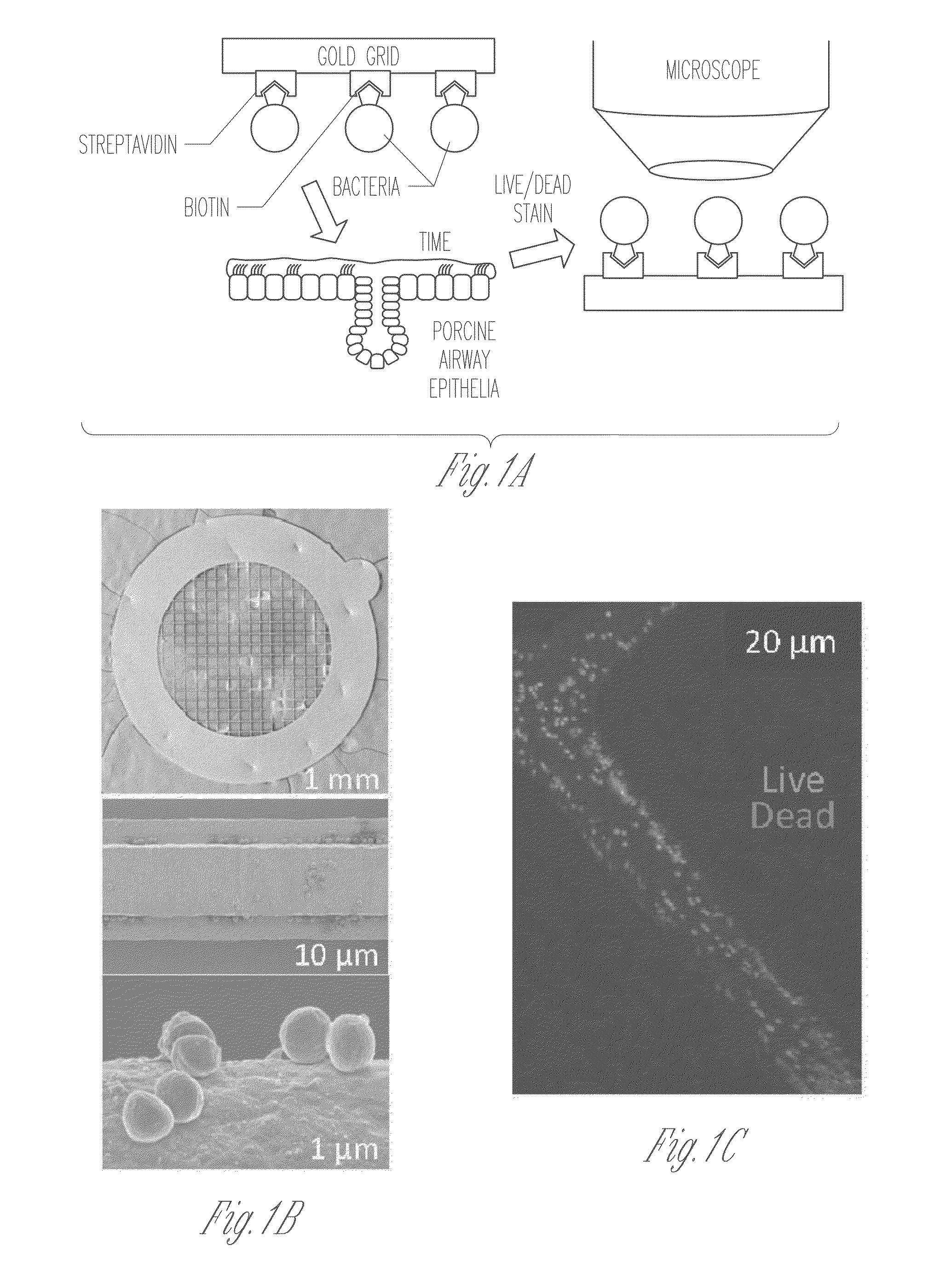

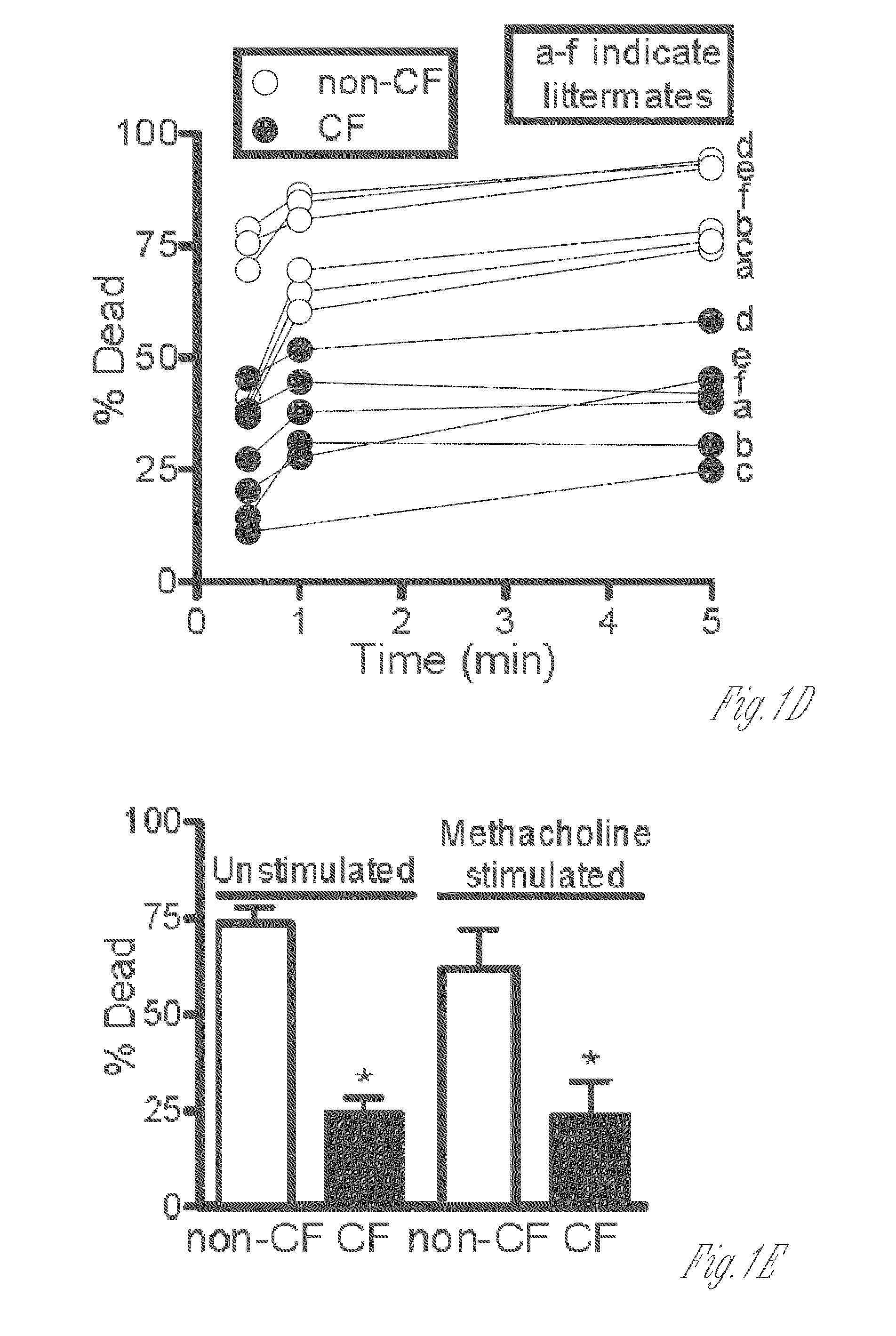

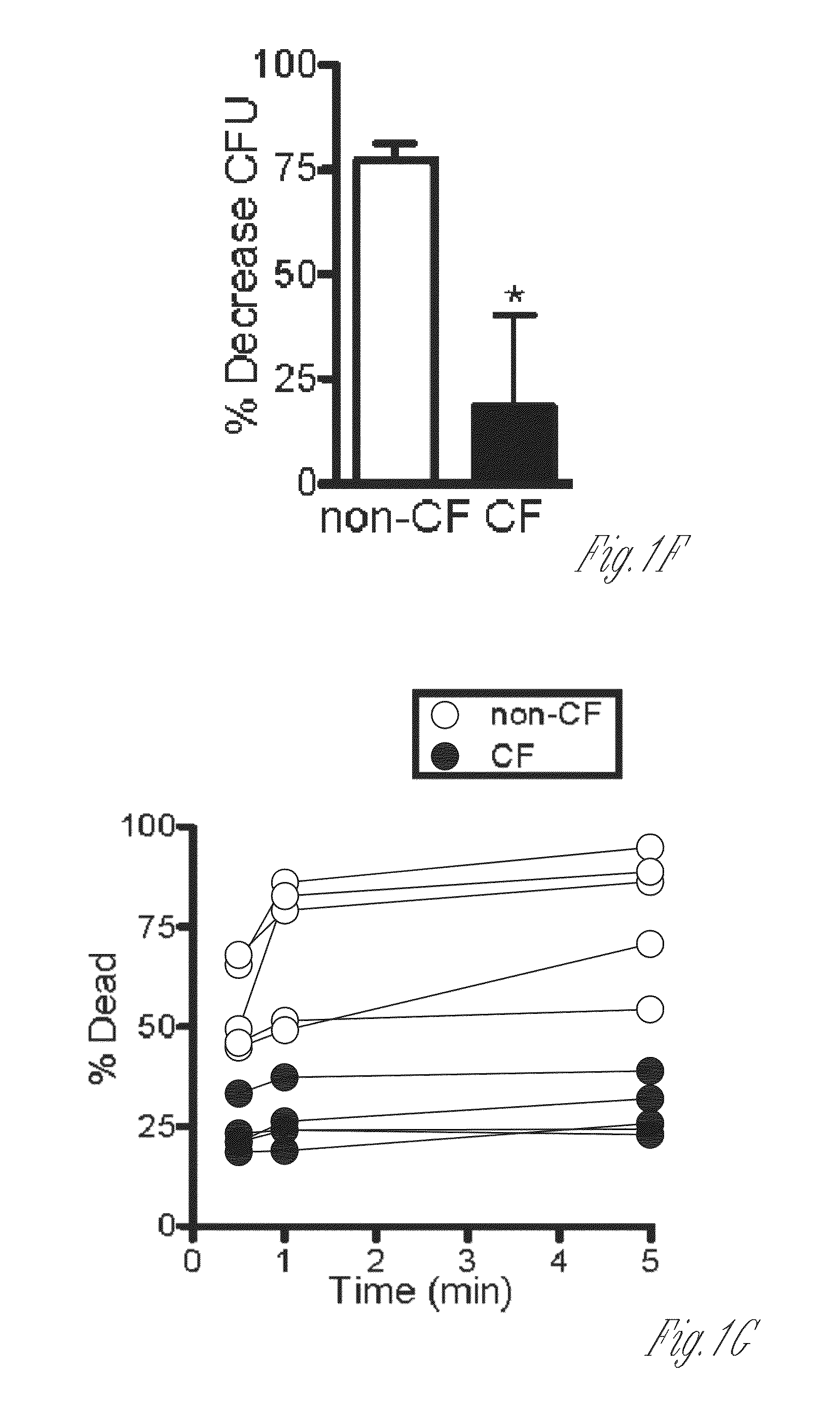

METHOD TO ENHANCE ANTIMICROBIAL ACTIVITY BY INCREASING pH

InactiveUS20130316022A1High activityReduced bacterial killingBiocideInorganic active ingredientsBiologyIncrease ph

Owner:UNIV OF IOWA RES FOUND

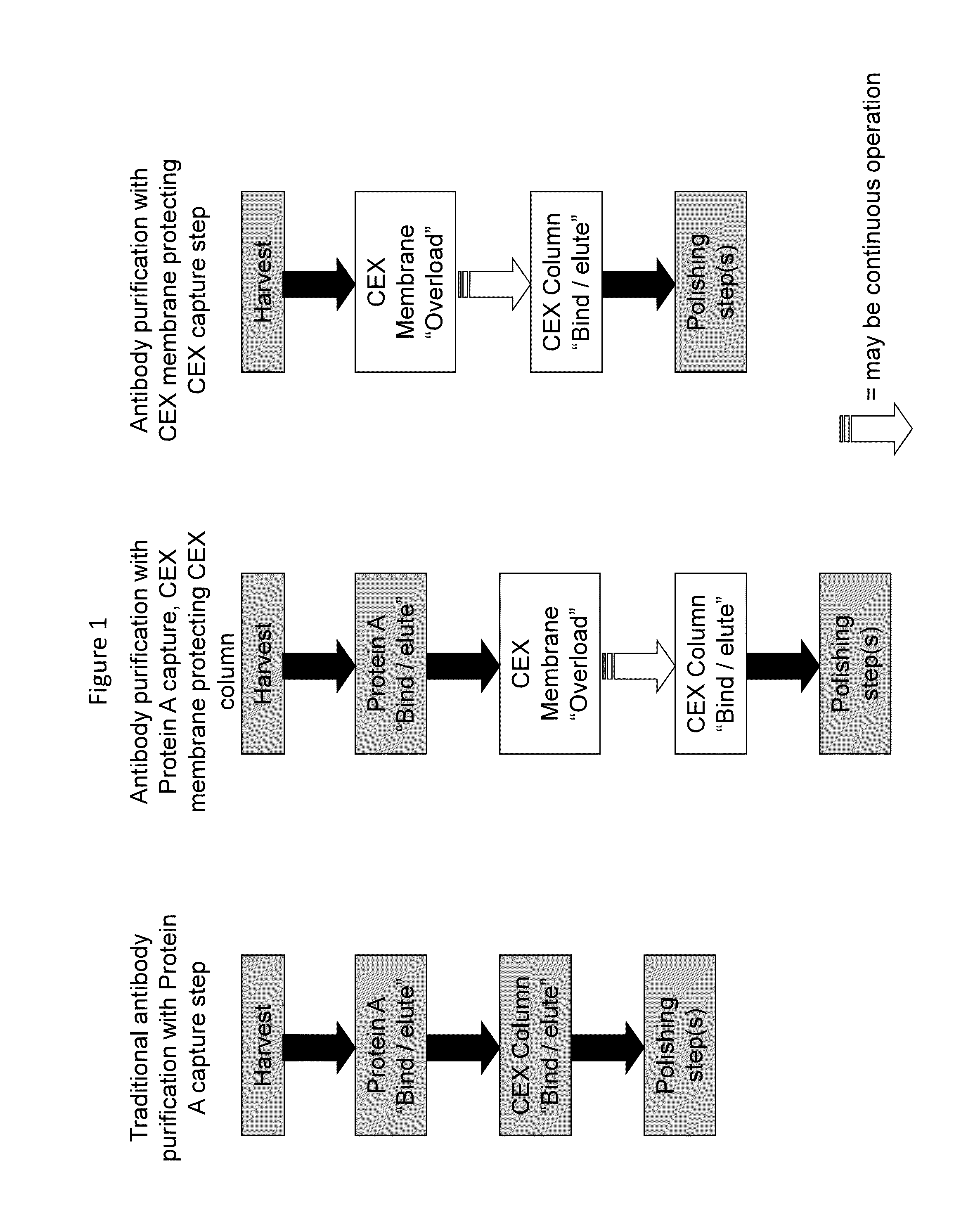

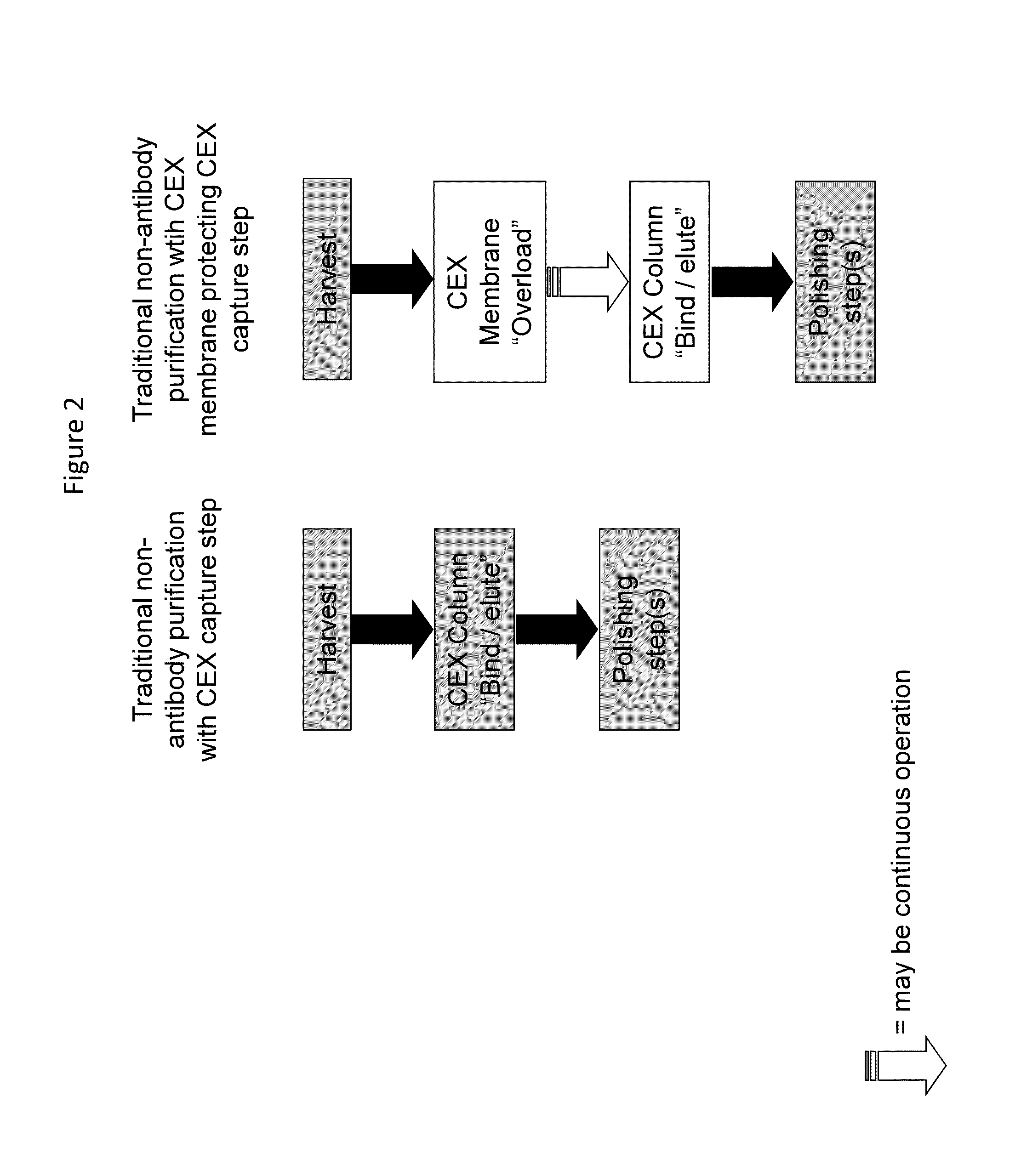

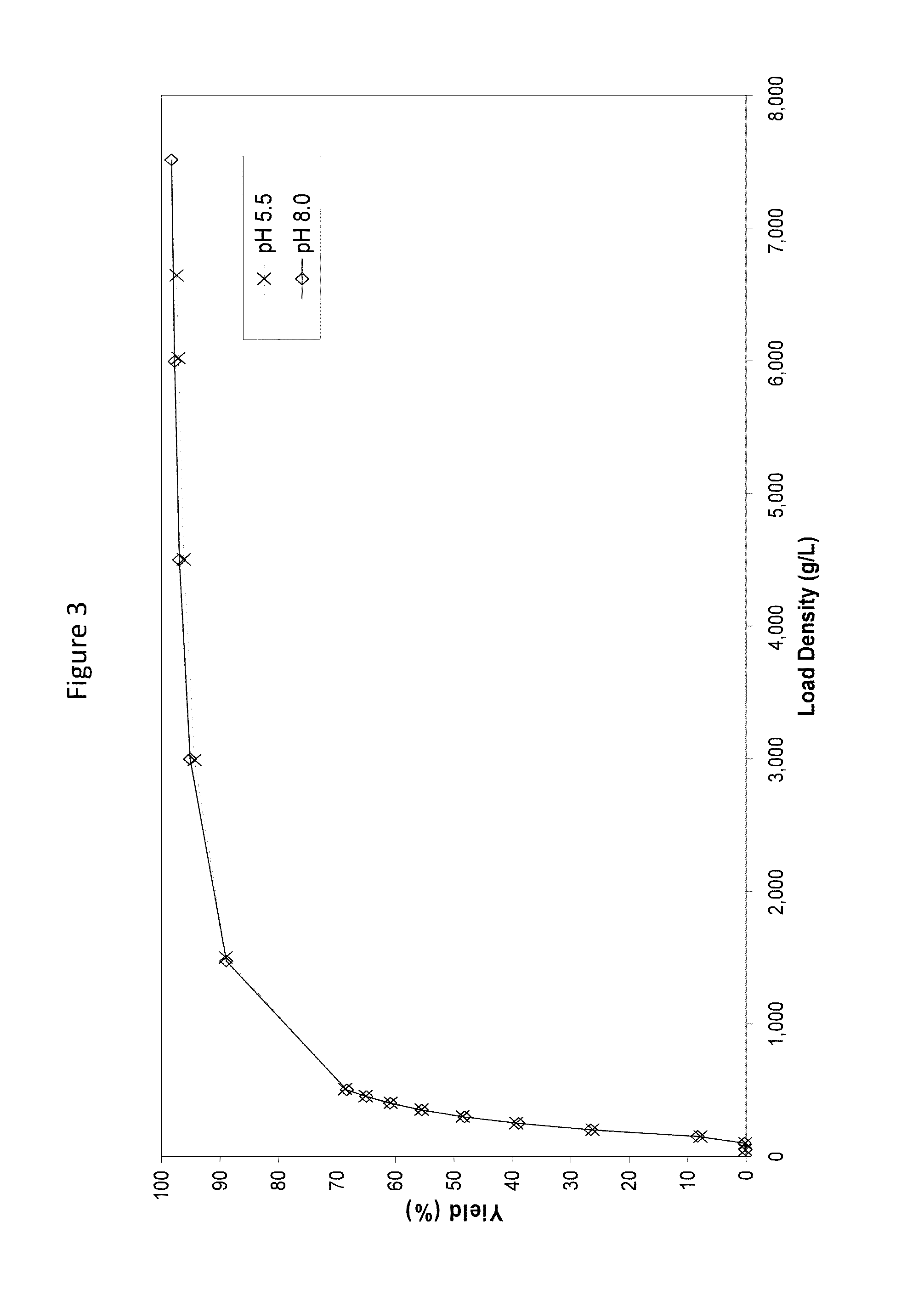

Ion exchange membrane chromatography

ActiveUS20140348845A1Increase costEnhancing efficiency of downstream chromatography stepsPeptide/protein ingredientsSerum immunoglobulinsLow ionic strengthIon-exchange membranes

Methods of enhancing efficiency of downstream chromatography steps for purification of proteins comprising: (a) passing a composition comprising a polypeptide of interest and various contaminants through an ion exchange membrane, wherein the polypeptide and the membrane have opposite charge, at operating conditions comprised of a buffer having a pH sufficiently distinct from the pi of the polypeptide to enhance the charge of the polypeptide and a low ionic strength effective to prevent the shielding of charges by buffer ions, which cause the membrane to bind the polypeptide and at least one contaminant, (b) overloading the ion exchange membrane such that at least one contaminant remains bound to the membrane while the polypeptide of interest is primarily in the effluent; (c) collecting the effluent from the ion exchange membrane comprising the polypeptide of interest; (d) subjecting the membrane effluent comprising the polypeptide of interest to a purification step of similar charge as the previous membrane, and (e) recovering the purified polypeptide from the effluent of the charged ion exchange chromatography purification step.

Owner:GENENTECH INC

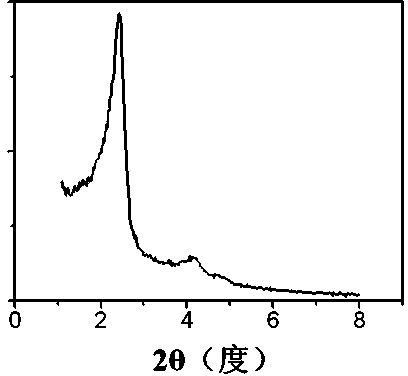

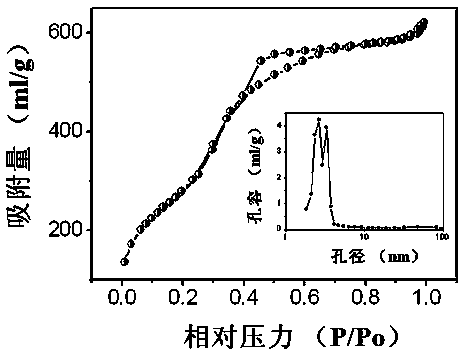

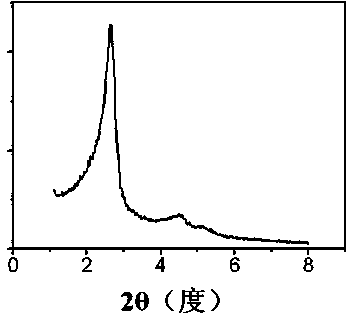

Synthesis method of bimodal mesoporous silicon dioxide

InactiveCN104261414AShort manufacturing cycleImprove production efficiencySilicaO-Phosphoric AcidPtru catalyst

The invention relates to a synthesis method of bimodal mesoporous silicon dioxide, belonging to the technical field of inorganic porous materials. The method is characterized in that by using a cationic quaternary ammonium salt surfactant as a template, a silicon source is subjected to prehydrolysis treatment in a phosphoric acid system incapable of easily forming ordered mesoporous phase, and a phosphate solid which is weakly alkaline after being dissolved is directly added to induce the synthesis of the bimodal mesoporous silicon dioxide, of which the specific area is 949.7-1181.8 m<2> / g, the pore volume is 0.68-1.05 cm<3> / g and the framework pore sizes are respectively 2.1-2.6nm and 3.3-3.9nm. The synthesis system and preparation conditions used by the method are beneficial to in-situ packaging of various metal ions in different mesoporous pore canals and also beneficial to in-situ coating and immobilization of bioactive guest molecules in different pore canals, so that the method has important application prospects in the field of development of novel commercial catalysts, biocatalysts, multistage porous complex function materials and the like.

Owner:TAIYUAN UNIV OF TECH

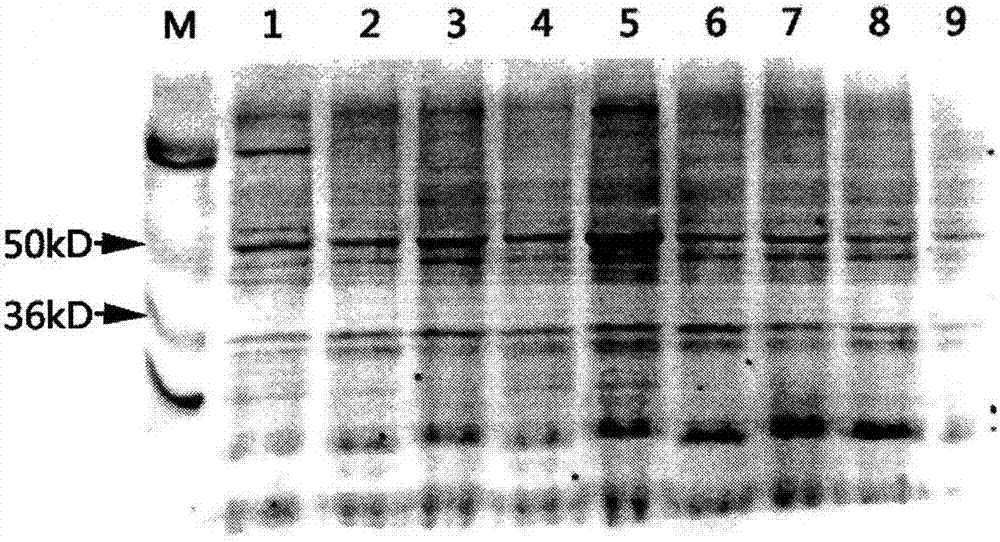

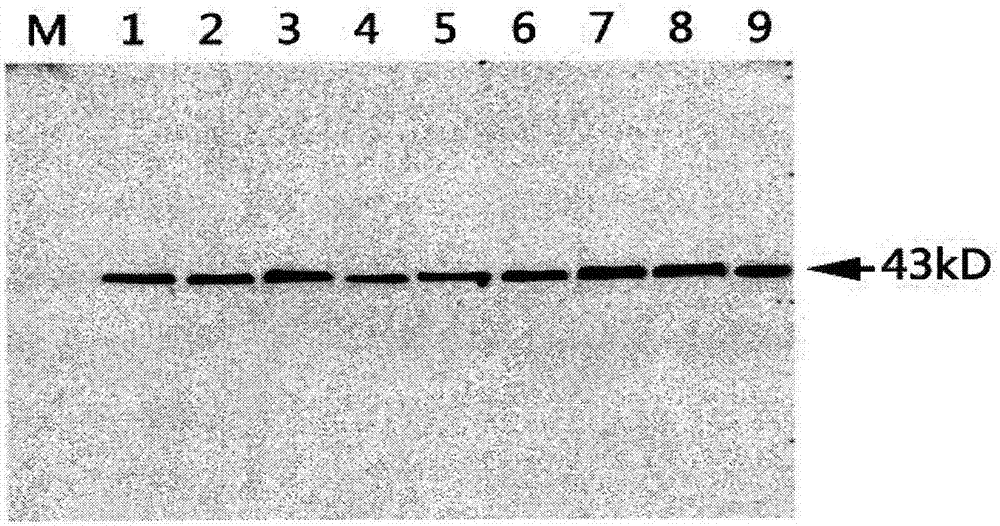

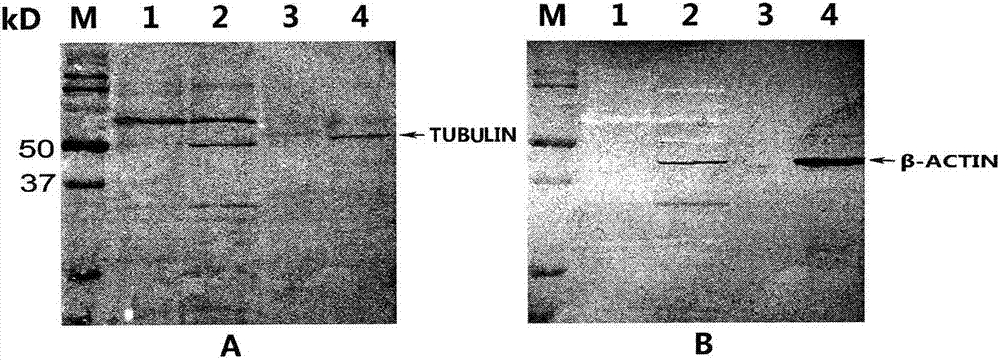

Regeneration solution for Western blot membrane

The invention belongs to the field of molecular biology and mainly relates to a regeneration solution for a Western blot membrane. With the adoption of the regeneration solution for the Western blot membrane, primary antibodies and secondary antibodies on the Western blot membrane can be effectively removed, so that repeated efficient utilization of the blotting membrane with transferred protein during Western blot detection is facilitated, the used blotting membrane can be quite conveniently reused for detecting other target proteins, time and labor are saved, furthermore, errors caused by re-sampling of the proteins can be eliminated, and comparability is enhanced. Detection experiments of multiple antibodies prove that by the aid of the regeneration solution for the Western blot membrane, the western blot membrane can be reused at least three times, so that correlative charges consumed by Western blot detection of conventional molecular biology experiments are greatly saved, and reuse of the Western blot membrane can be realized in about 30 min with the reagent. The regeneration solution is compatible with a substrate color-developing method, a chemiluminiscence color-developing method and a direct inspection method of fluorescence labeled secondary antibodies.

Owner:北京爱普拜生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com