Detoxification method of wood fibre hydrolysis sugar liquid

A technology for hydrolyzing sugar liquid and wood fiber, which is applied in the field of detoxification of wood fiber hydrolysis sugar liquid, and can solve the problem of secondary pollution of solvents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The raw material is pre-hydrolyzed sugar solution obtained from corn stalks obtained by dilute sulfuric acid pretreatment process, and concentrated by vacuum evaporation. The main sugar components and fermentation inhibitors before and after concentration were analyzed by high performance liquid chromatography (HPLC), and the absorption value at 280nm (λ 280 ) was determined using a UV spectrophotometer. The changes of main components before and after concentration of the prehydrolyzed sugar solution are shown in Table 1.

[0020] Table 1 Changes in main components of dilute acid pretreatment hydrolyzed sugar solution before and after vacuum concentration

[0021]

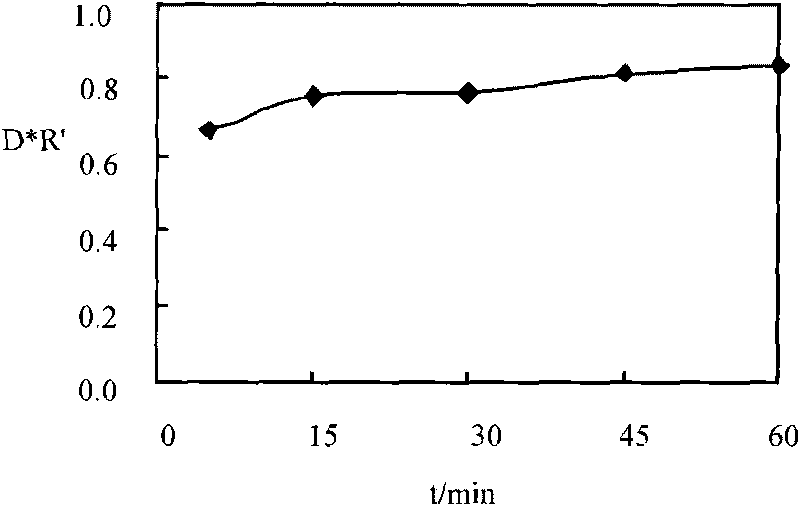

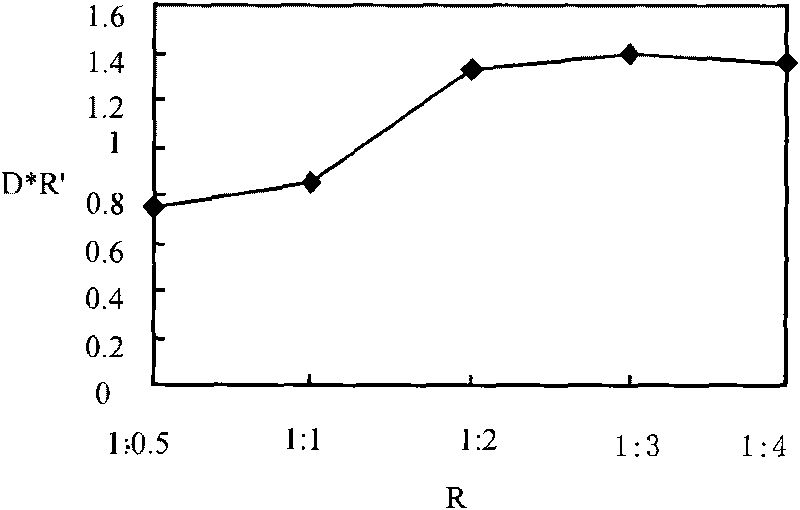

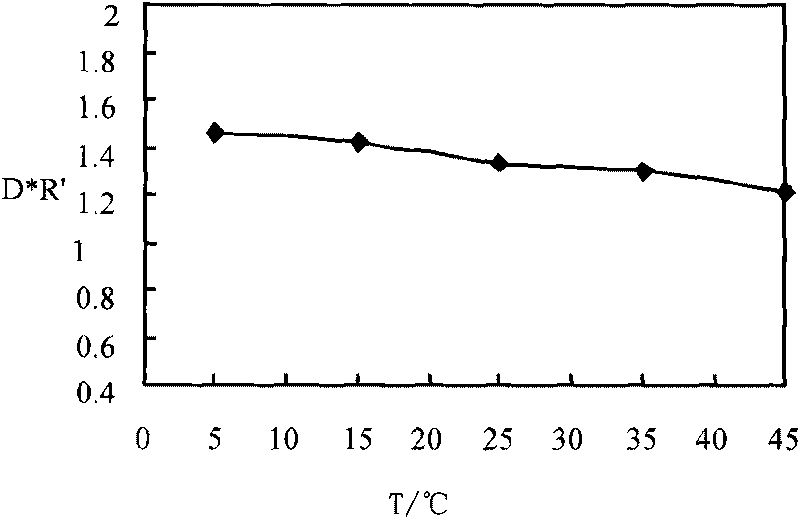

[0022] Using a mixture of trialkylamine, n-octanol and kerosene in a certain proportion as a complex extraction agent, the concentrated prehydrolyzed sugar solution is complex extracted. The following are the effects of extraction equilibrium time, water-oil ratio, extraction temperature and complexing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com