Synthesis method of bimodal mesoporous silicon dioxide

A technology of mesoporous silica and silica, applied in the direction of silica, silica, etc., can solve the problems such as the decline of the order of the mesoporous structure of the material, shorten the preparation cycle, improve the preparation efficiency, and reduce the ionic strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

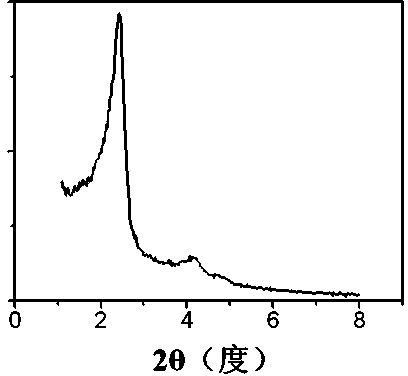

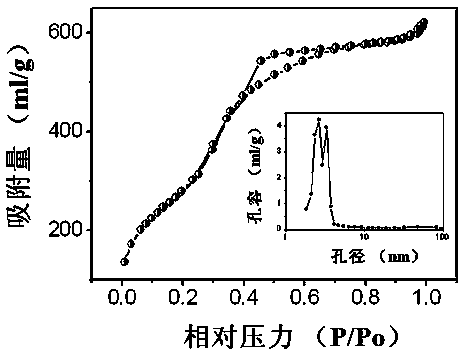

[0026] Mix 0.404 g STAB, 0.25 ml 85% phosphoric acid solution, 1.25 ml TEOS and 10 ml H 2 O Stir and mix successively at 25°C, and continue stirring at 25°C for 6 hours after the system is completely homogeneous, then directly add 1.22 grams of ammonium phosphate solid into the above reaction system under stirring, and continue stirring at 25°C for 24 Hours later, the separated precipitate was centrifuged, washed with deionized water, dried at 60°C, and then baked at 550°C for 6 hours at a heating rate of 2.5°C / min to remove the templating agent. Obtain double mesoporous silica, its XRD figure is shown in figure 1 , its N 2 Adsorption isotherms and corresponding pore size distribution curves are shown in figure 2 , its specific surface area is 1038.3m 2 / g, the pore volume is 0.96cm 3 / g, the skeleton mesopore diameters are 2.6nm and 3.3nm respectively.

Embodiment approach 2

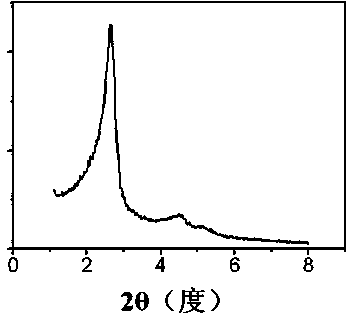

[0028] Mix 0.375 g of CTAB, 0.25 ml of 85% phosphoric acid solution, 1.25 ml of TEOS and 10 ml of H 2 O Stir and mix successively at 25°C, and continue stirring at 25°C for 6 hours after the system is completely homogeneous, then directly add 1.22 grams of ammonium phosphate solid into the above reaction system under stirring, and continue stirring at 25°C for 24 Hours later, the separated precipitate was centrifuged, washed with deionized water, dried at 60°C, and then baked at 550°C for 6 hours at a heating rate of 2.5°C / min to remove the templating agent. Obtain double mesoporous silica, its XRD figure is shown in image 3 , its N2 Adsorption isotherms and corresponding pore size distribution curves are shown in Figure 4 , its specific surface area is 1131.6m 2 / g, the pore volume is 0.82cm 3 / g, the skeleton mesopore diameters are 2.3nm and 3.4nm respectively.

Embodiment approach 3

[0030] Mix 0.404 g STAB, 0.25 ml 85% phosphoric acid solution, 1.25 ml TEOS and 10 ml H 2 O Stir and mix at 25°C in turn, and continue stirring at 25°C for 6 hours after the system is completely homogeneous, then directly add 1.83 grams of ammonium phosphate solid into the above reaction system under stirring, and continue stirring at 25°C for 10 Minutes later, the precipitated precipitate was centrifuged, washed with deionized water, dried at 60°C, and then baked at 550°C for 6 hours at a heating rate of 2.5°C / min to remove the template agent. Obtain double mesoporous silica, its XRD figure is shown in Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com