Patents

Literature

1853 results about "Ammonium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium phosphate is the salt of ammonium and phosphate. It is a highly unstable compound with the formula (NH₄)₃PO₄. Because of its instability, it is elusive and of no commercial value. A related "double salt", (NH₄)₃PO₄·(NH₄)₂HPO₄ is also recognized but is too unstable for practical use. Both triammonium salts evolve ammonia. In contrast to the fragile nature of the triammonium salts, diammonium phosphate (NH₄)₂HPO₄ is a valuable material, mainly as a fertilizer. Also of value is monoammonium salt (NH₄)H₂PO4, which is also valued as a fertilizer. These two salts provide plants with fixed nitrogen and phosphorus.

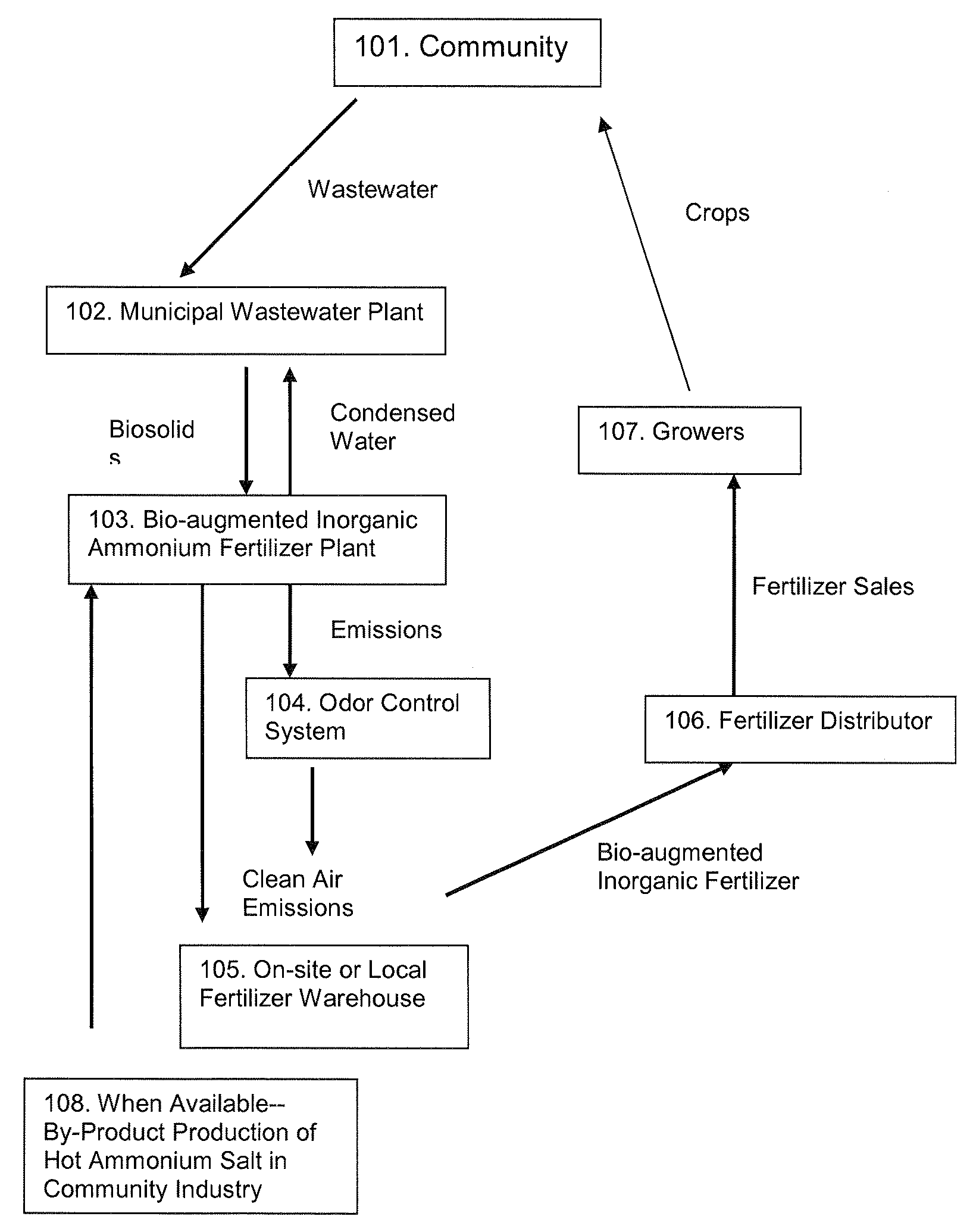

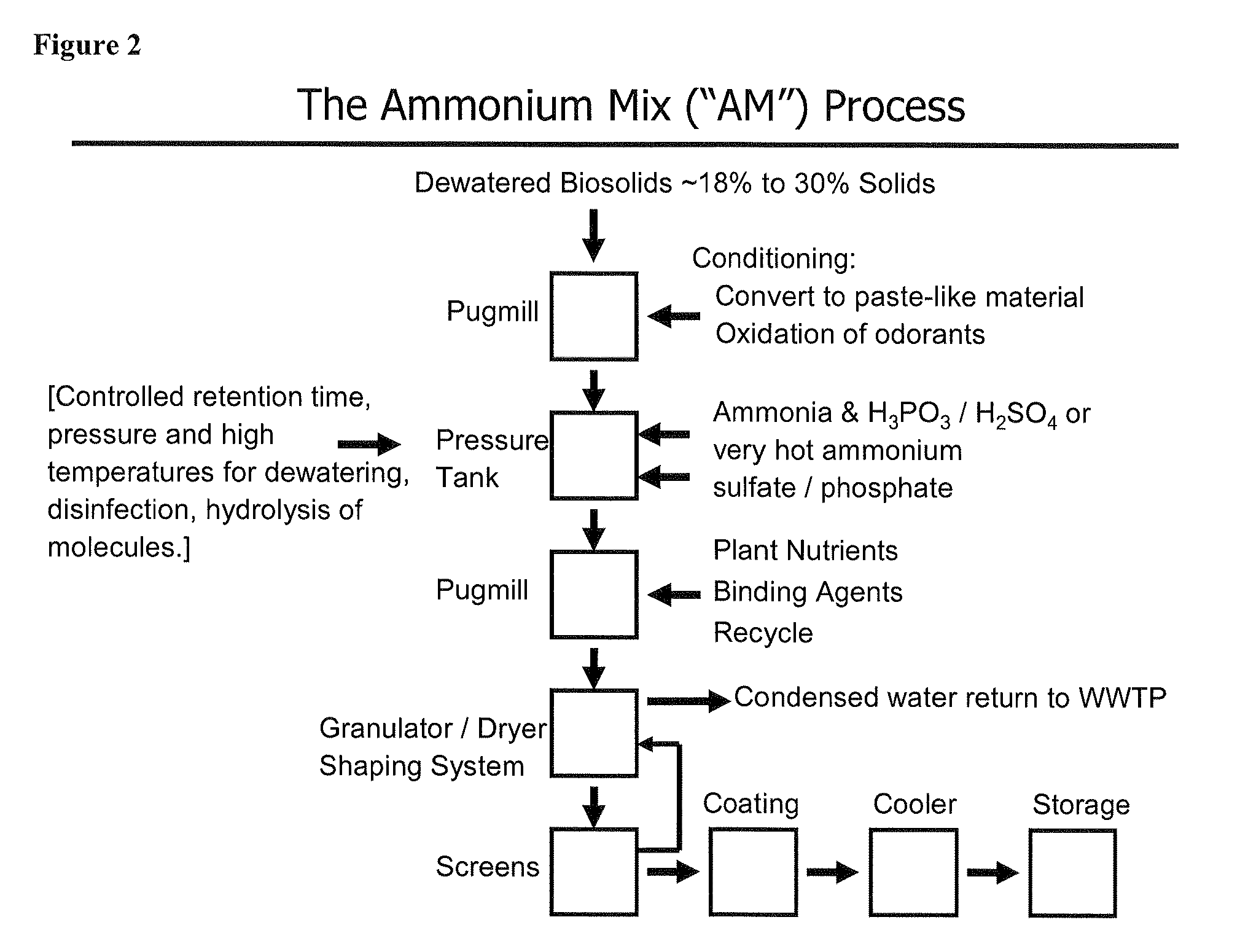

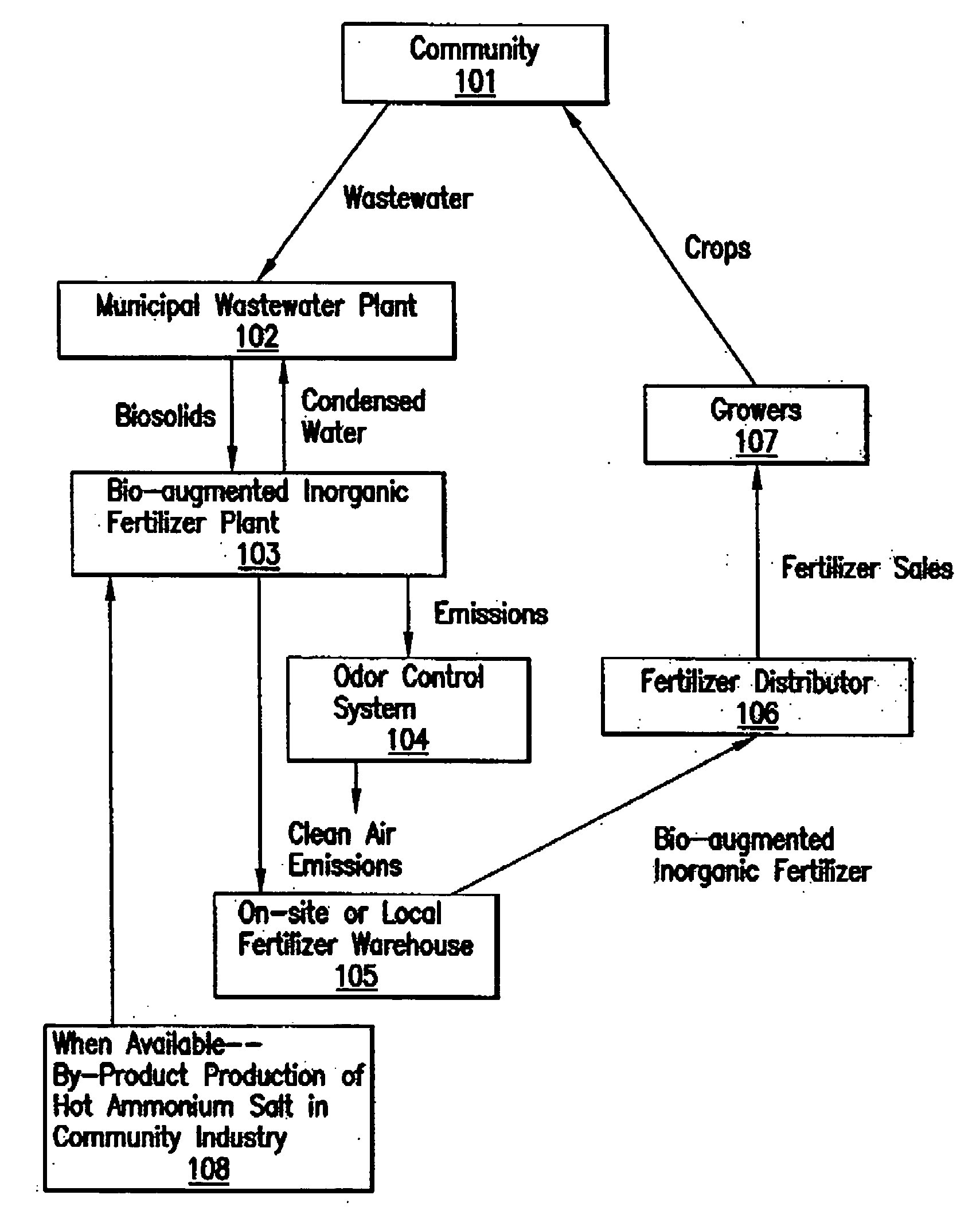

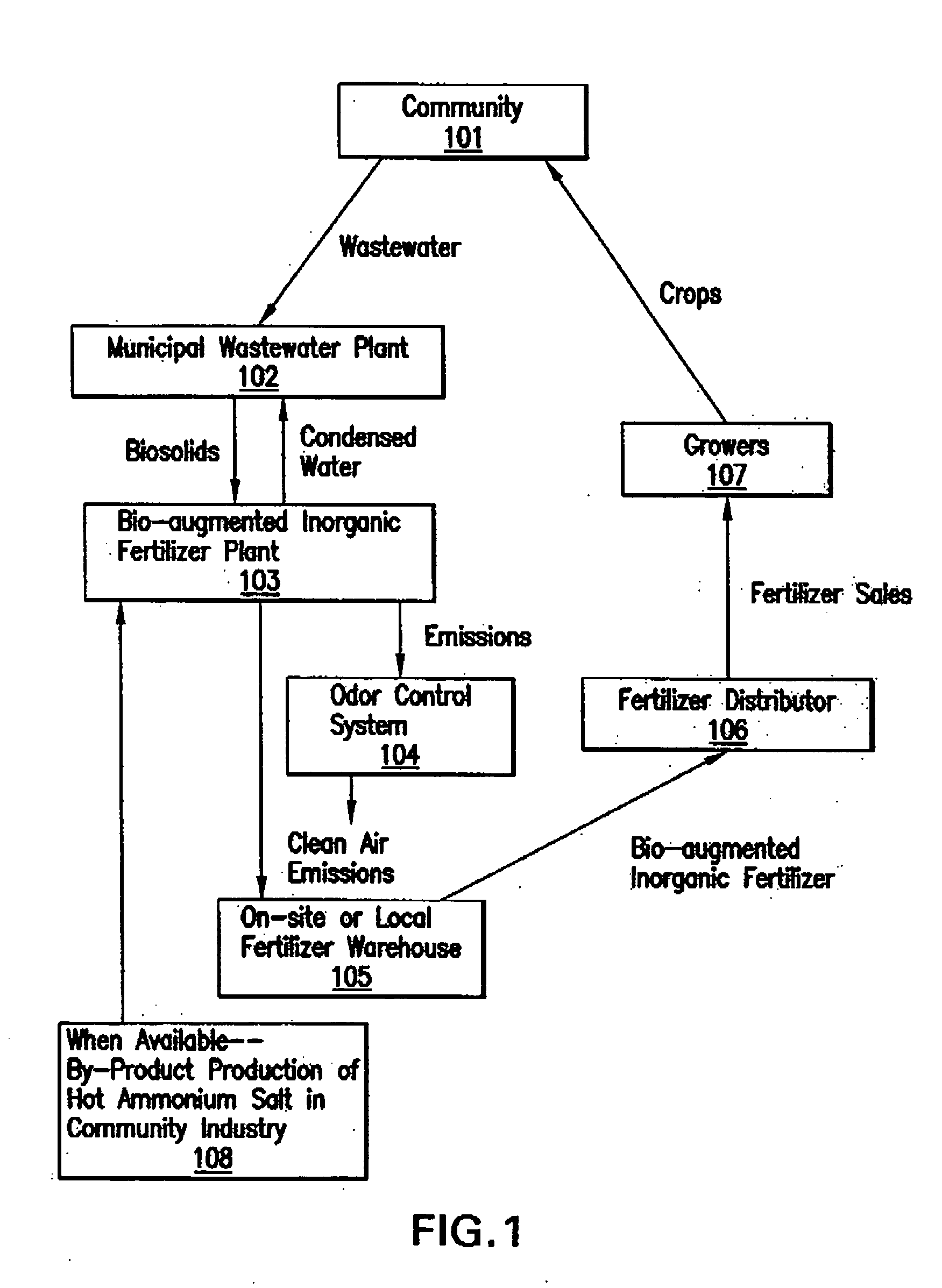

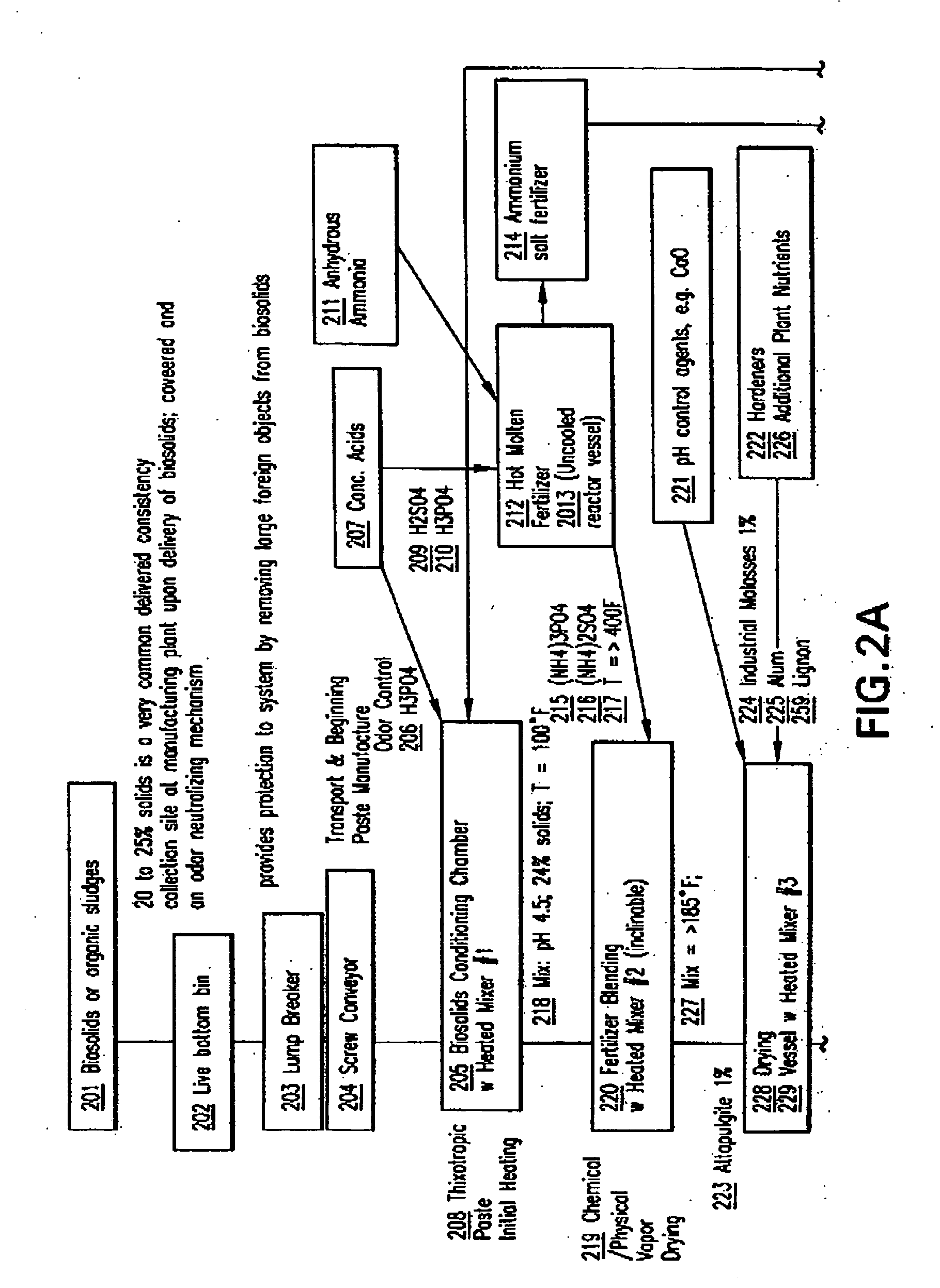

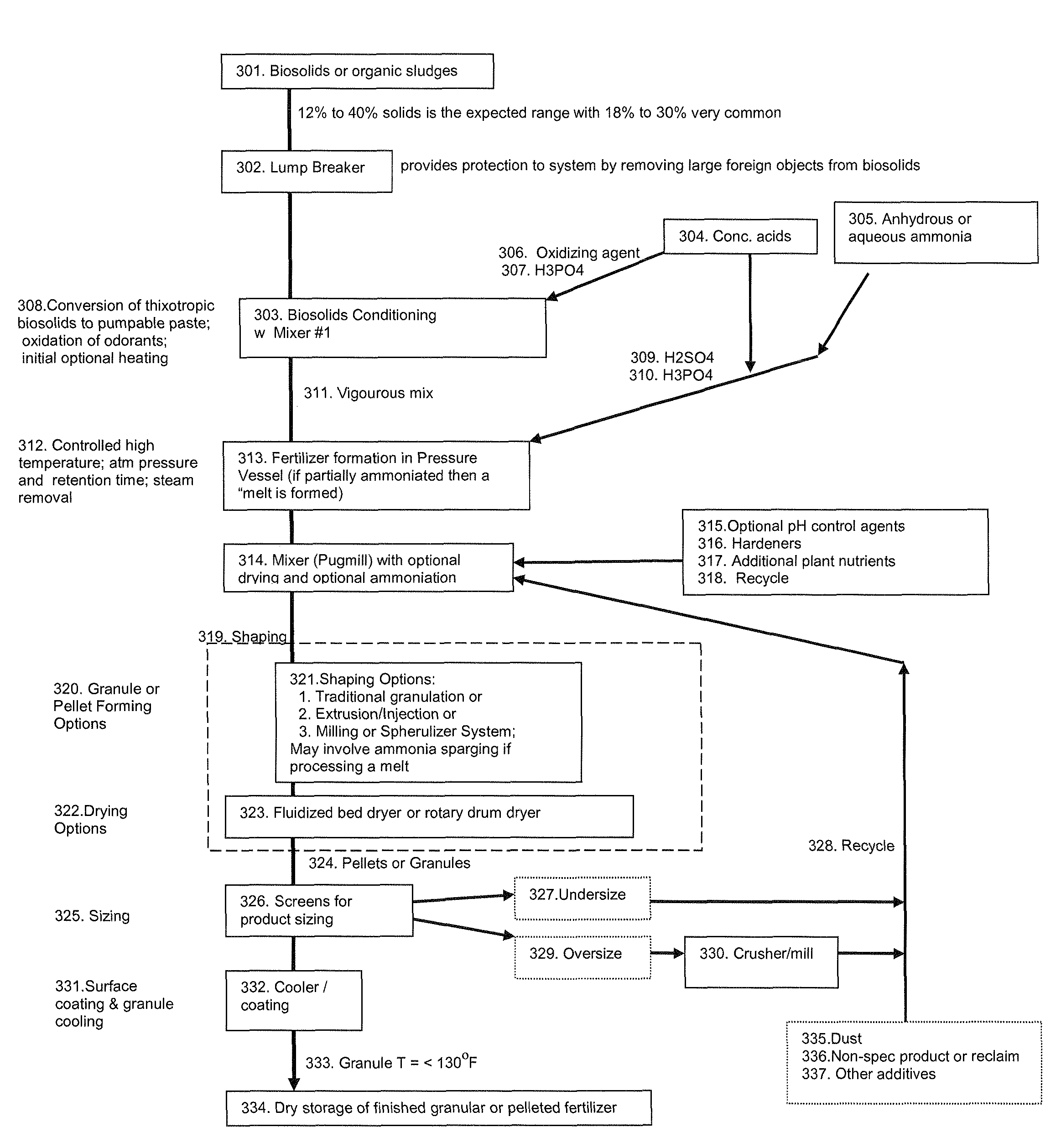

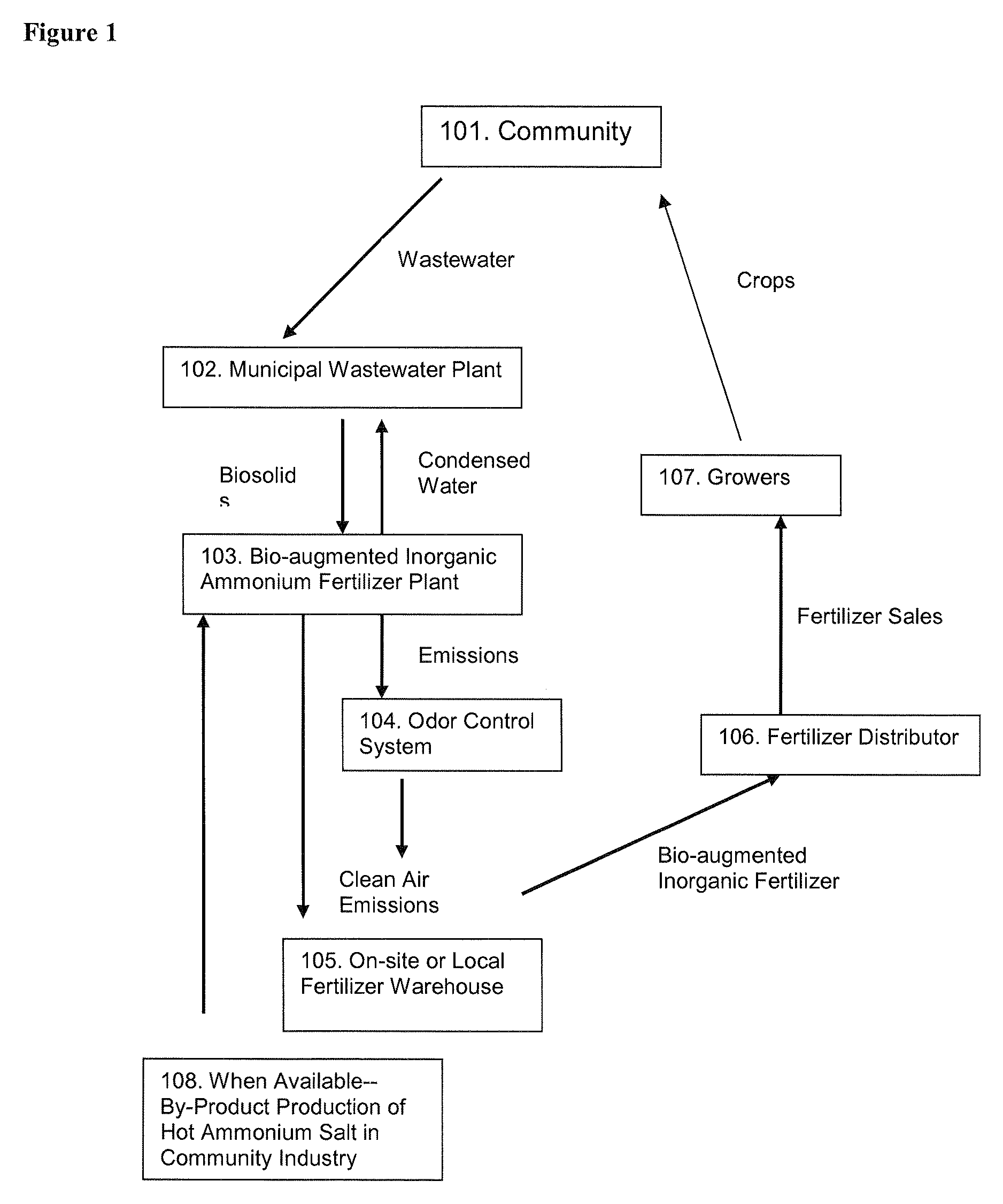

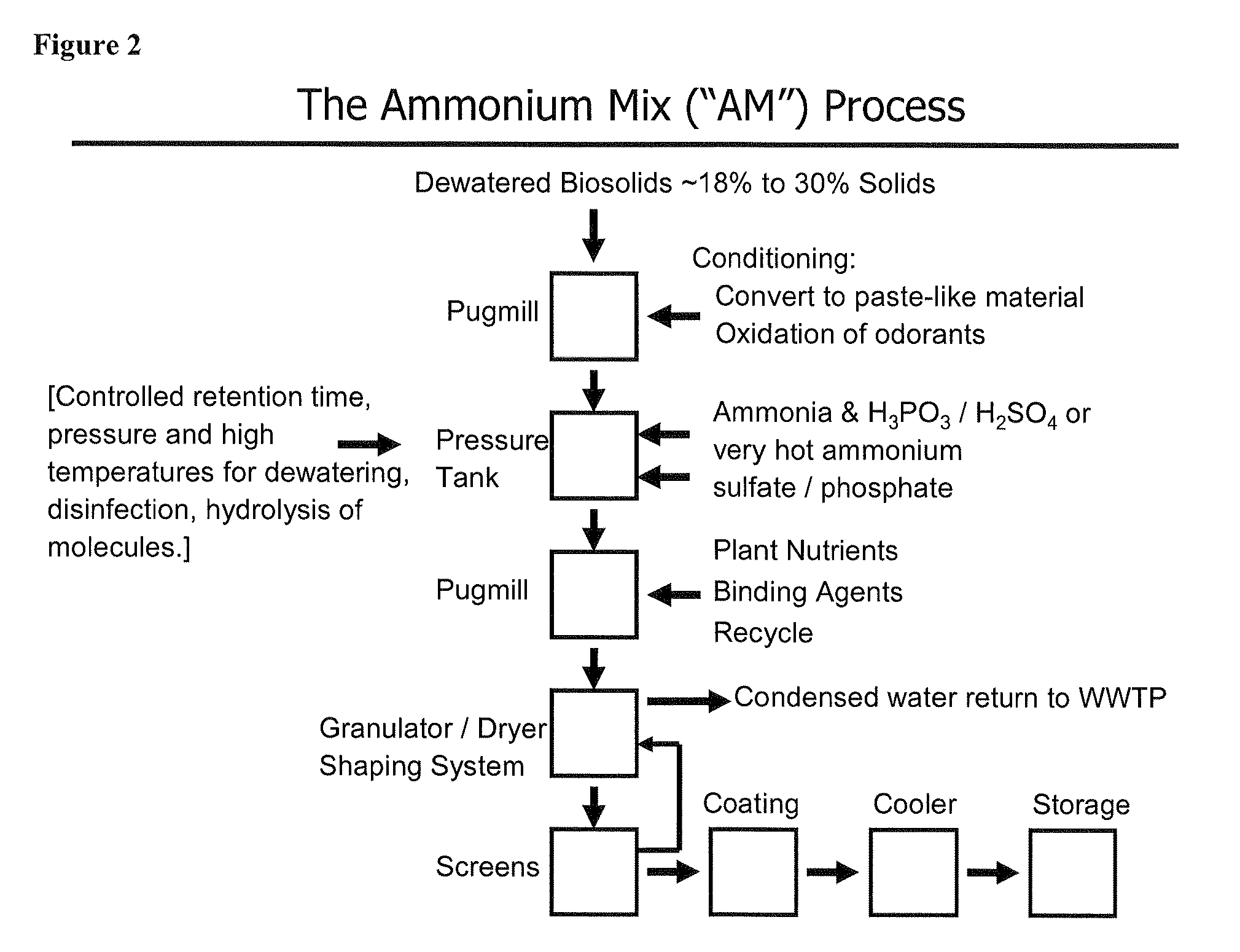

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS20080230484A1Reduce logisticsReduces liabilityByproduct vaporizationExcrement fertilisersPhosphateRetention time

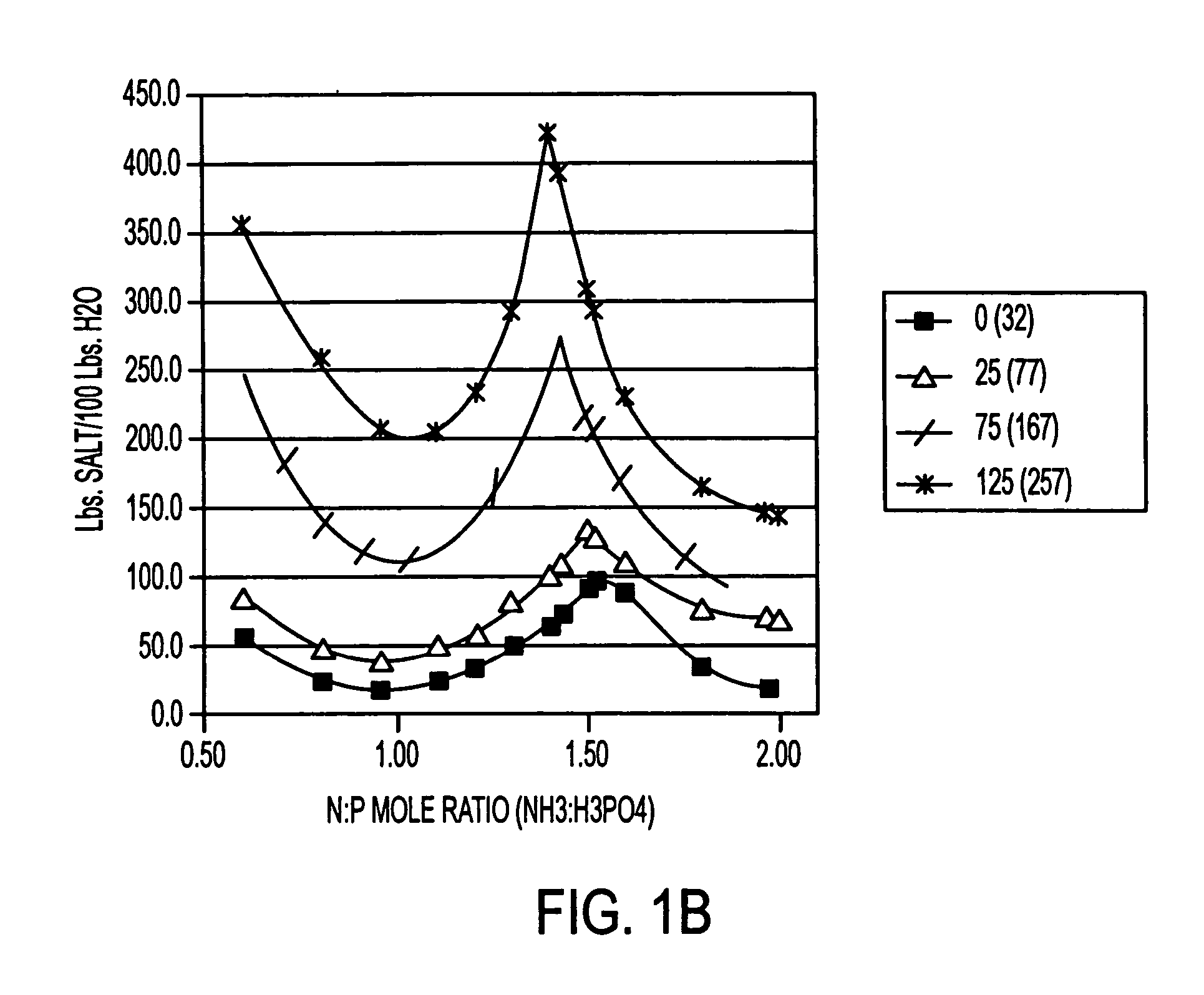

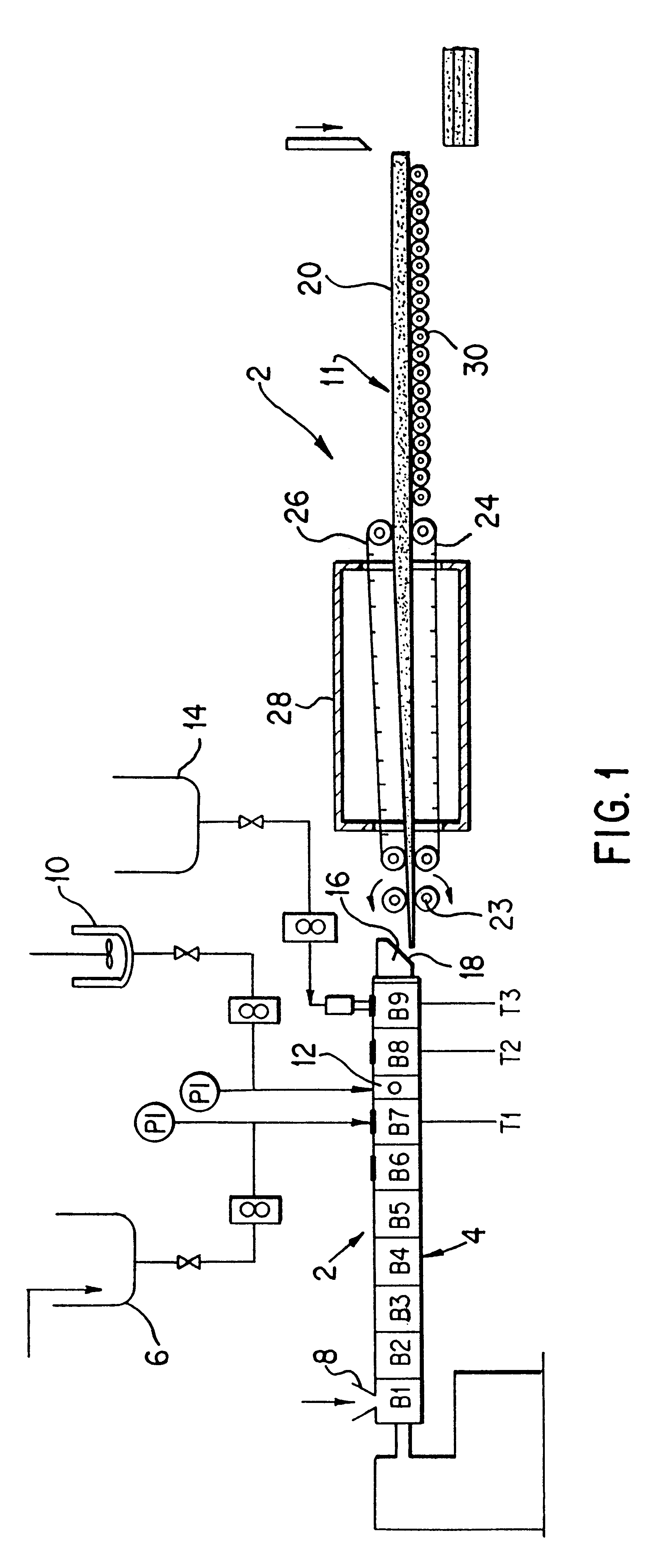

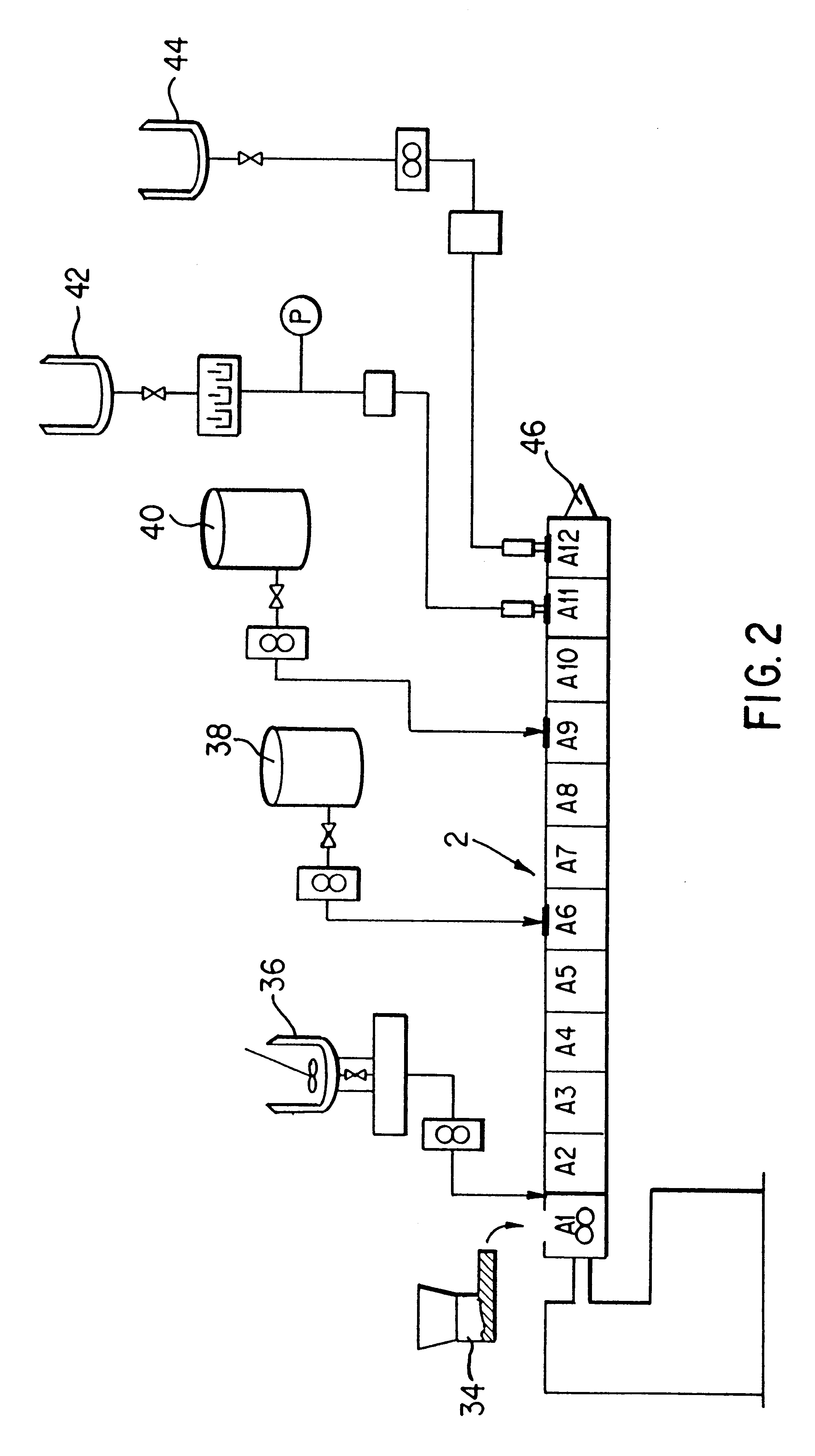

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

Fire retardant with mold inhibitor

Fire retardant composition has a mold inhibitor. The composition can embrace a mixture of a substantially neutral ammonium phosphate salt in combination with an active hydrogen-containing nitrogenous organic compound spumific, e.g., urea, and with a hydroxyl-containing carbonific, e.g., a polyol, and further with the mold inhibitor. Such a composition can be made by contacting a phosphoric acid with ammonia to form the ammonium phosphate, contacting the ammonium phosphate with the spumific, the carbonific, and the mold inhibitor, under conditions sufficient to form the composition; and can be used by contacting it with a flammable substrate under conditions sufficient to be flame retardant or mold inhibitory, or both. Another aspect is an article of manufacture comprising, in combination, the fire retardant composition having the mold inhibitor, and the flammable substrate or a residue of the same.

Owner:NO BURN INVESTMENTS

Manufacturing of bioorganic-augmented high nitrogen-containing inorganic fertilizer

The invention describes a new method for the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method creates a thixotropic paste-like material from the biosolids or organic sludge that is blended with hot or molten ammonium salts, especially a mixture of ammonium phosphate and ammonium sulfate. The invention can be an add-on to commercial production of ammonium salts or it can stand alone by manufacturing ammonium salts prior to their introduction to the conditioned biosolids. The invention is oriented to be tailored to production facilities for individual municipal waste treatment plants in order to keep manufacturing plants small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

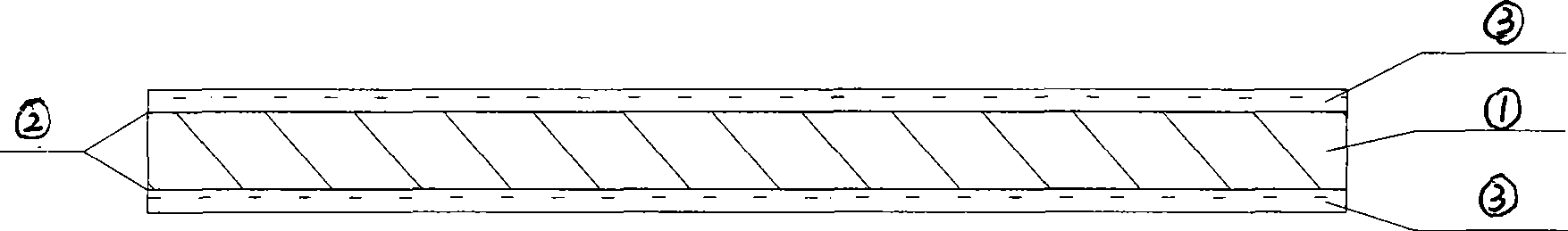

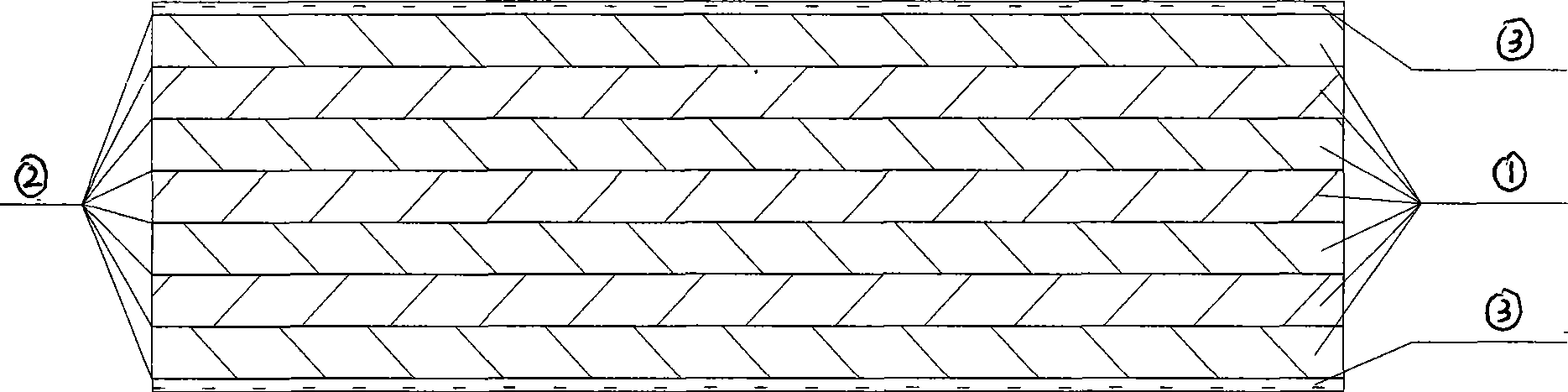

Method for producing flame-retardant glued board

ActiveCN101412231AReduce releaseImprove flame retardant performanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePyrophosphate

The invention discloses a method for producing a flame-retardant veneer plywood, which comprises the following steps: placing wood veneers into a flame retardant aqueous solution to perform dipping treatment, applying the mixed adhesive to the upper surfaces and the lower surfaces of the veneers after the veneers are dried, assembling the veneers into a plate blank according to the principle that odd layers are crossed and symmetrical with even layers, and then performing the processes of cold pressing, hot pressing, cutting edge, sanding, surface treating and the like to obtain the flame-retardant veneer plywood product the thickness of which is between 2.7 and 20 millimeters. The flame retardant in the method is a mixture of low ammonium polyphosphate, ammonium phosphate, ammonium pyrophosphate, urea phosphate, boric acid and pentaerythritol, and the mixed adhesive is a uniform mixture of wood adhesive, filler, and a curing agent. The flame-retardant decorative veneer plywood prepared by the method has the advantages of excellent flame-retardant and fireproof performance, environmental prevention performance, and good mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

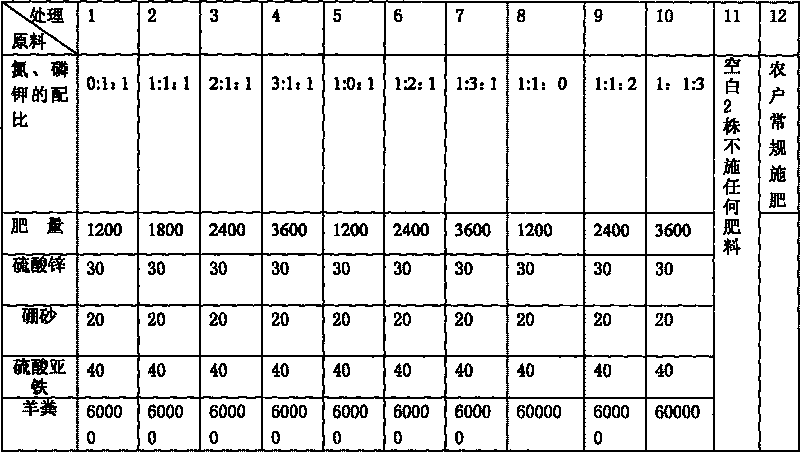

Preparation method and application method of grape special fertilizer

ActiveCN101693639AIncrease productionImprove qualityClimate change adaptationAlkali orthophosphate fertiliserSodium BentoniteAdditive ingredient

The invention relates to preparation method and application method of a grape special fertilizer, wherein the preparation method comprises the following steps: preparing an I-type fertilizer by taking the following ingredients in parts by weight: 30-40 parts of urea, 20-30 parts ammonium phosphate, 15-30 parts of potassium sulphate, 1-3 parts of humic acid, 1-3 parts of excrement, 1-5 parts of synergist, 0.1-1.0 part of ferrous sulphate, 0.1-0.8 part of zinc sulfate, 0.1-0.6 part of manganese sulphate, 0.1-0.6 part of borax, 0.1-0.4 part of copper sulfate, 3-7 parts of plaster and 3-13 parts of bentonite; preparing an II-type fertilizer by taking the following ingredients in parts by weight: 7-15 parts of urea, 25-35 parts ammonium phosphate, 35-45 parts of potassium sulphate, 1-3 parts of humic acid, 1-5 parts of excrement, 2-5 parts of synergist, 0.1-1.0 part of ferrous sulphate, 0.1-0.8 part of zinc sulfate, 0.1-0.6 part of manganese sulphate, 0.1-0.6 part of borax, 0.1-0.4 part of copper sulfate, 3-7 parts of plaster and 3-13 parts of bentonite; and blending, spraying, pelleting and drying at lower temperature to obtain the product. The application method of the fertilizer comprises the following steps: taking an organic fertilizer and the II-type fertilizer as a base fertilizer; applying the I-type fertilizer before blossom, applying the II-type fertilizer in the young fruit development period, and meanwhile, respectively spraying monopotassium phosphate and rare earth mixed liquid once on the leaf surfaces; and spraying calcium nitrate or calcium acetate to enhance the storage resistance property before picking.

Owner:新疆满疆红农资化肥科技有限公司

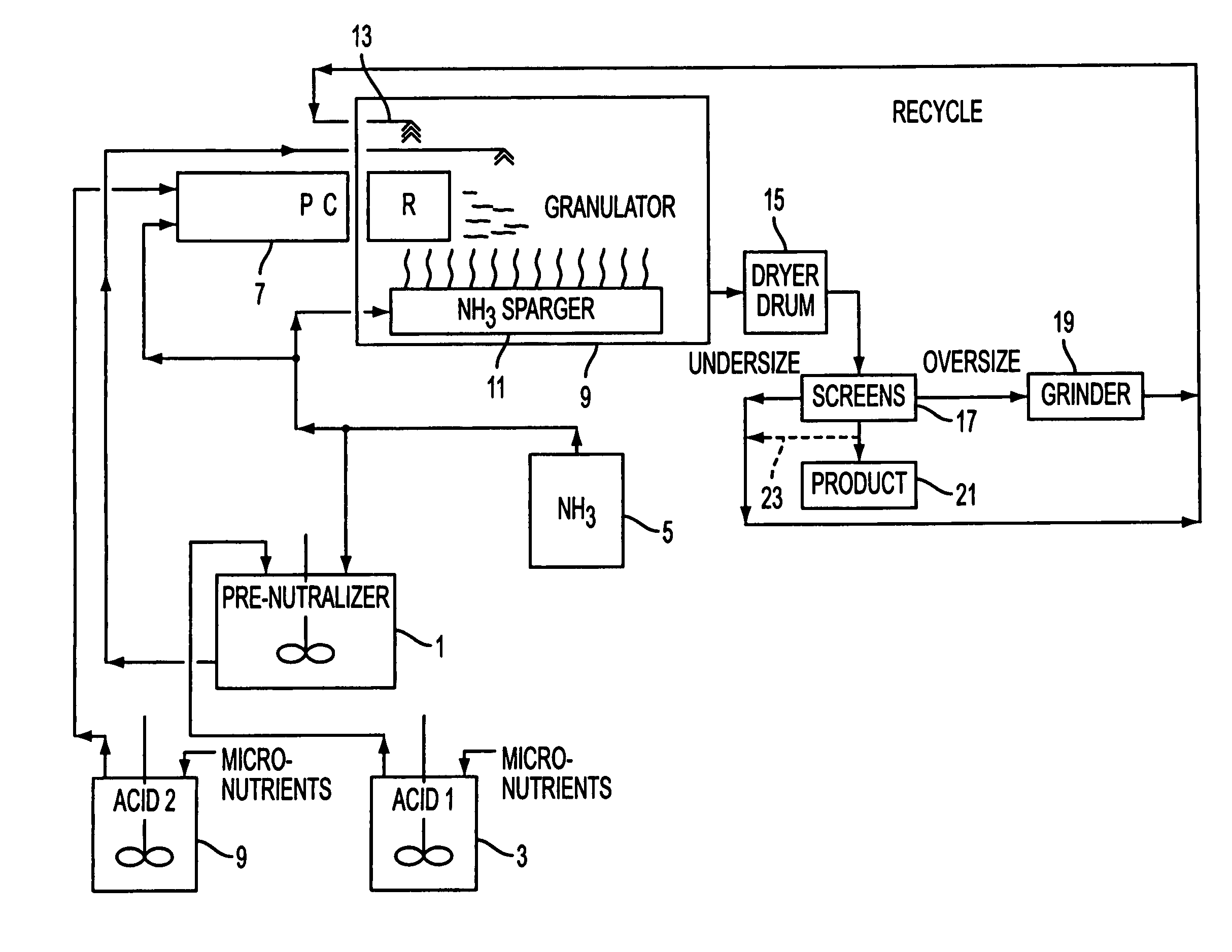

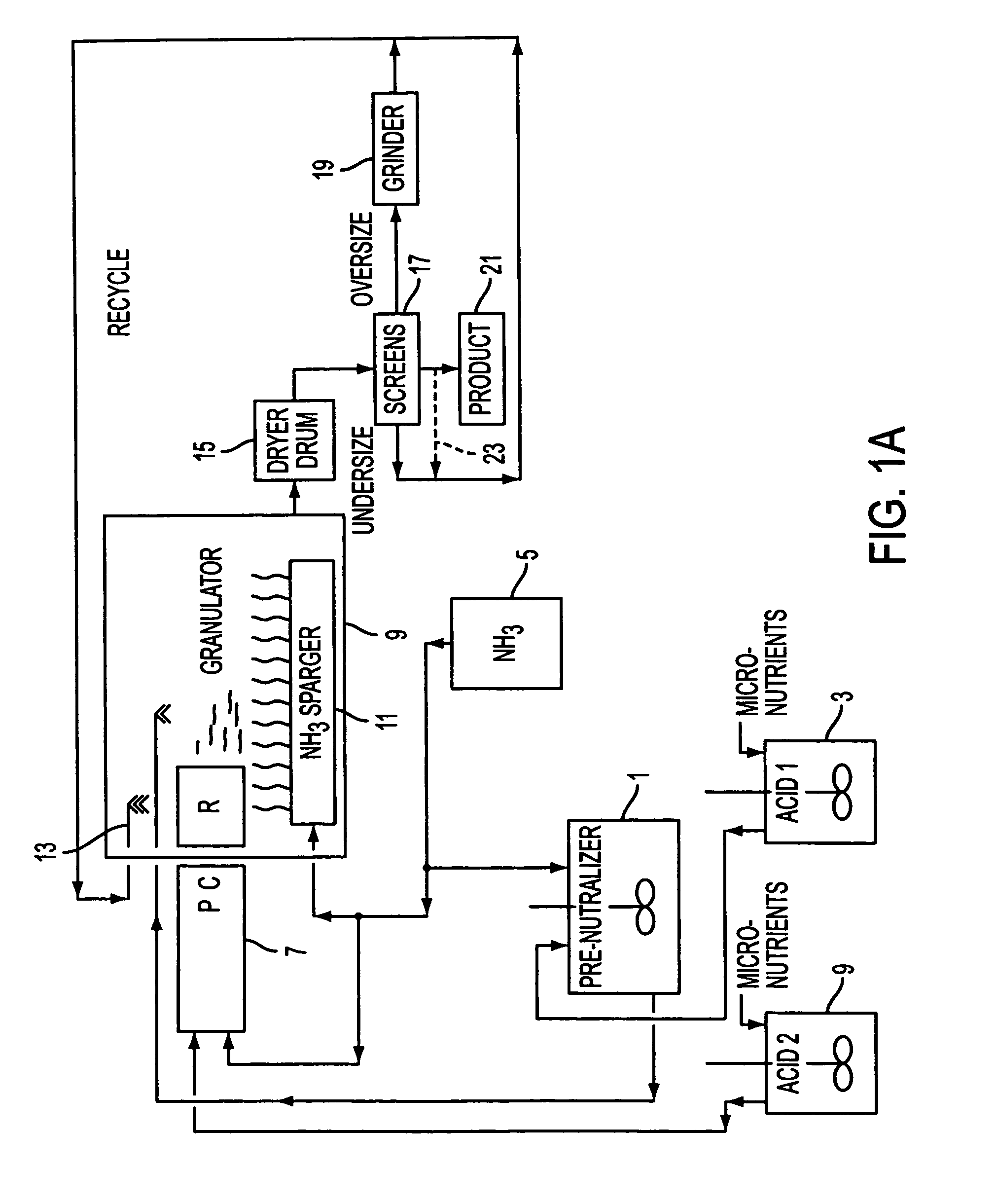

Method for producing a fertilizer with micronutrients

ActiveUS7497891B2Avoid suffocationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphoric acidAmmonia

According to a method of producing a phosphate fertilizer, a first portion of the phosphate is produced in a pipe cross reactor, and a second portion of the phosphate is produced in a pre-neutralizer. Both the first and second portions of the phosphate are supplied to a granulator. Ammonia is added to the granulator to react with the first and second portions of the phosphate. To produce the first portion of the phosphate, a micronutrient is added to phosphoric acid to produce an enriched acid, and the enriched acid and ammonia are added to the pipe cross reactor where they are allowed to react to produce ammonium phosphate.

Owner:THE MOSAIC COMPANY

Method for preparing organic sustained release fertilizer synergist

InactiveCN101591208AHigh calorific valueIncrease temperatureAgriculture gas emission reductionFertilizer mixturesMonosodium glutamateSodium Bentonite

The invention provides a method for preparing an organic sustained release fertilizer synergist. The synergist comprises the following components in portion by weight: 25 to 60 portions of organic component, 3 to 15 portions of synergistic component, 10 to 13 portions (solid) and 3.5 to 9 portions (liquid) of sustained release component, 0.5 to 5 portions of trace elements, 18 to 30 portions of inorganic nutrient, and 2 to 7 portions of additive. The synergist is prepared by the method of weighing, mixing, spray granulation and low-temperature drying, wherein the organic component contains 2 to 5 portions of humic acid, 25 to 45 portions of mature garbage or barnyard manure, and 2 to 5 portions of residue of monosodium glutamate and sugar; the synergistic component contains 1 to 3 portions of zeolite, 1 to 5 portions of fly ash, and 2 to 5 portions of synergistic agent; the sustained release component contains 10 to 13 portions of bentonite, 0.02 to 0.1 portion of nitrification inhibitor, and 4 to 8 portions of urease inhibitor (liquid); the trace elements contain 0.1 to 1 portion of zinc sulfate, 0.1 to 1 portion of manganese sulfate, 0.1 to 1 portion of borax, 0.1 to 1 portion of copper sulfate, and 0.1 to 1 portion of ferrous sulfate; the inorganic nutrient contains 6 to 9 portions of urea, 7 to 9 portions of ammonium phosphate, and 5 to 7 portions of potassium sulfate; and the additive contains 2 to 7 portions of plaster. The synergist is suitable for the planting of field crops and forest fruits.

Owner:新疆满疆红农资化肥科技有限公司

Anti-refiring ultrafine ammonium phosphate dry chemical fire-extinguishing agent and its preparation method

InactiveCN1597024AUltrafine particle sizeLarge specific surface areaFire extinguisherSilicone oilTalc

A superfine ammonium phosphate dry chemical fire-extinguishing agent for preventing refiring is prepared from ammonium phosphate, ammonium sulfate, talc powder, mica powder, white carbon black and calcium carbonate through airflow pulverizing, proportional mixing, coating silicon oil, and coating F-C surfactant.

Owner:SICHUAN UNIV

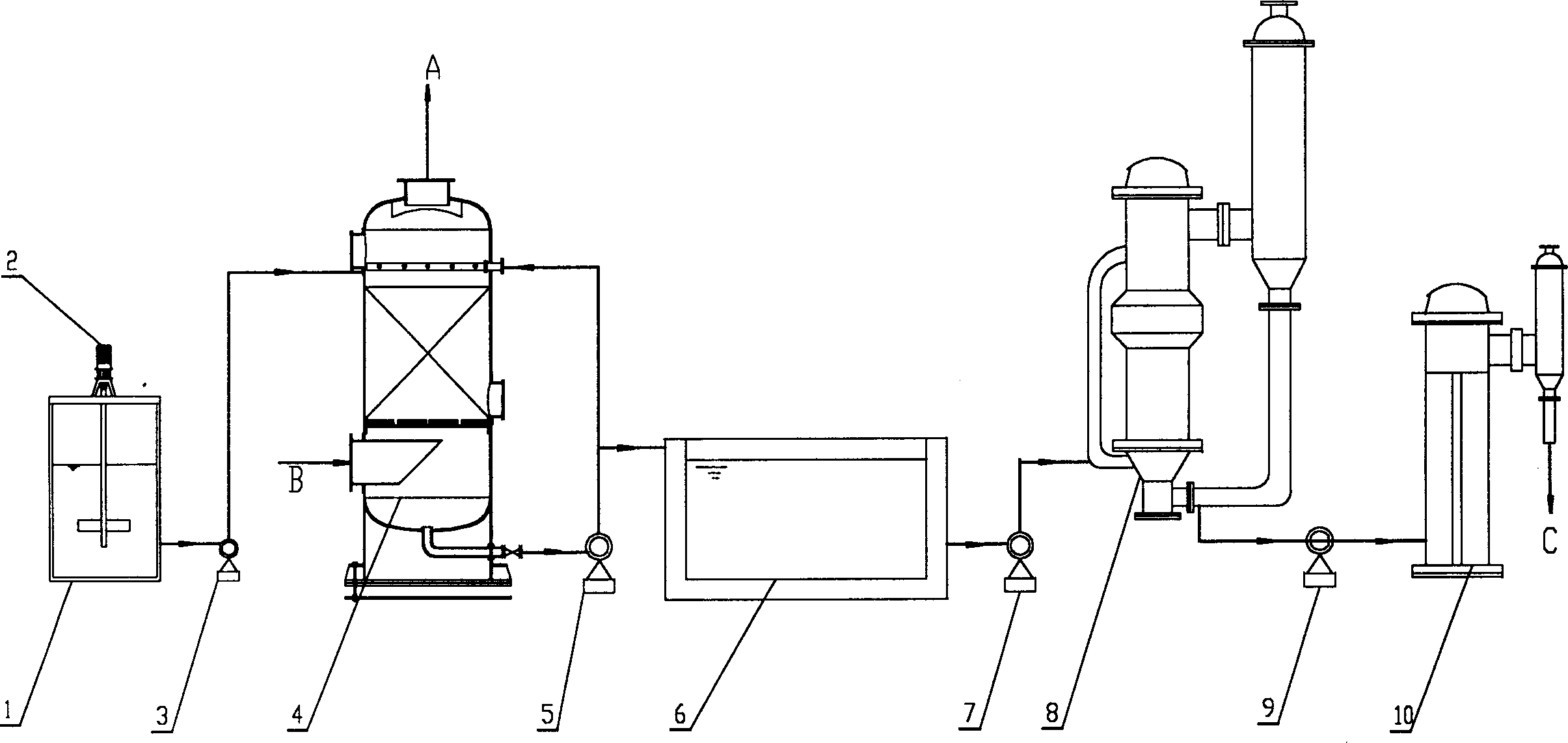

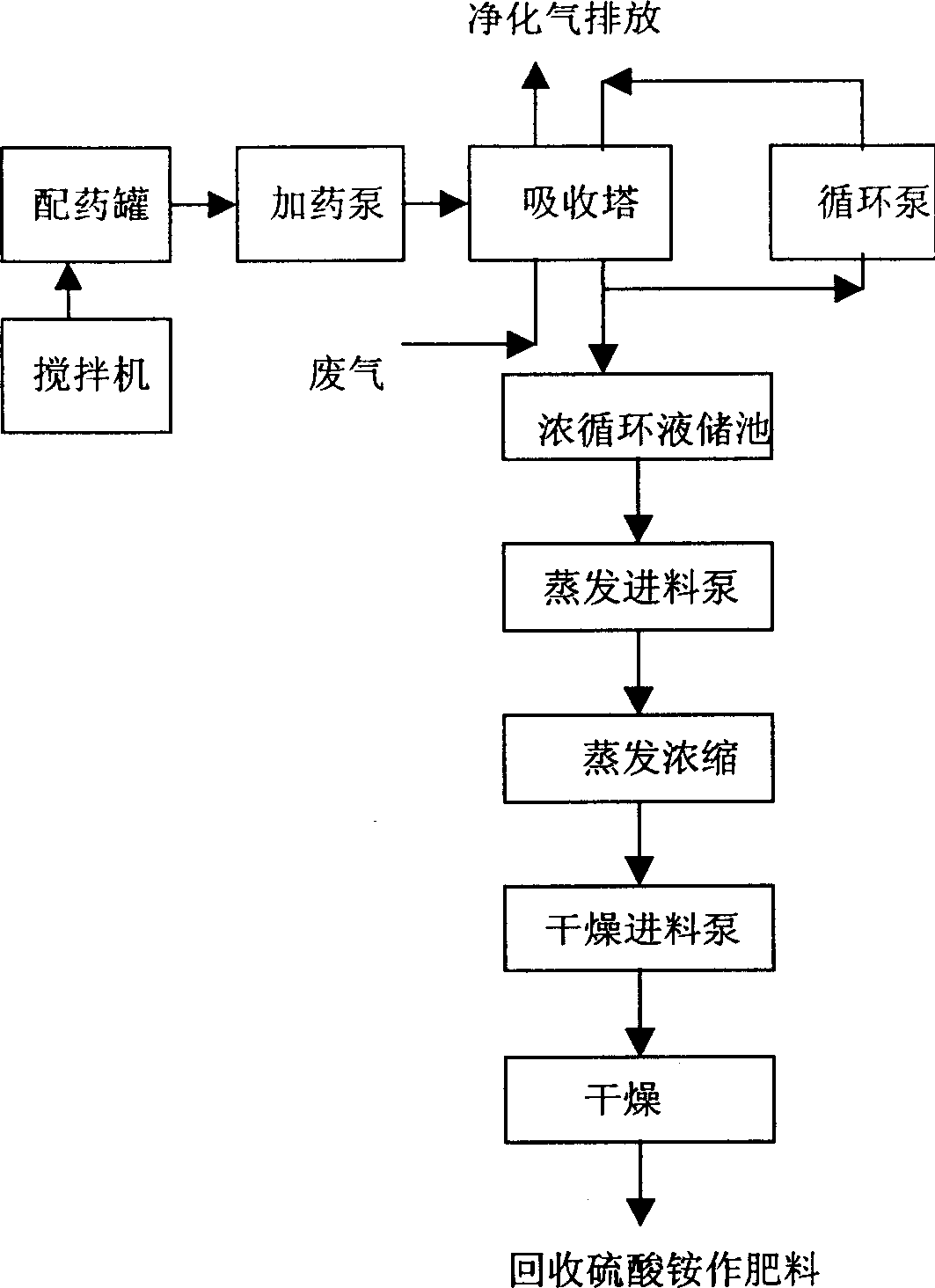

Wet urea additive process for simultanously desulfurizing and denitrification

InactiveCN1377722AReduce volumeGuarantee sustainableDispersed particle separationAir quality improvementEthylenediaminePhosphate

The present invention relates to flue gas purifying treatment technology. The equipment consists of chemical compounding tank with stirrer, chemical adding pump, adsorber tower, circulating pump, storing pond for concentrated absorbent liquid, evaporating inlet pump, evaporator, drying inlet pump and drying machine connected via pipeline. It desulfurizes and denitrificates simultaneously through the mixed reaction of flue gas and absorbent liquid in the absorber tower with urea as absorbent and organic amine or phosphate as additive. It has an SO2 eliminating rate up to 95% and NOx eliminating rate up to 80%, with the recovered ammonium sulfate being used as fertilizer.

Owner:国家环境保护总局华南环境科学研究所

Fire retardant

InactiveUS6989113B1Good fire retarding ratingEffective and cost-efficient and aesthetically pleasingFireproof paintsAntifouling/underwater paintsFoaming agentNitrogen

Fire retardant composition includes an ammonium phosphate substance, which is in contact with a carbonific, for example, glucose, and a nitrogenous spumific, for example, urea. A polysaccharide and / or a nonionic alkylpolyglycoside surfactant may be present. The composition may be in the form of a clear, aqueous liquid.

Owner:NO BURN INVESTMENTS

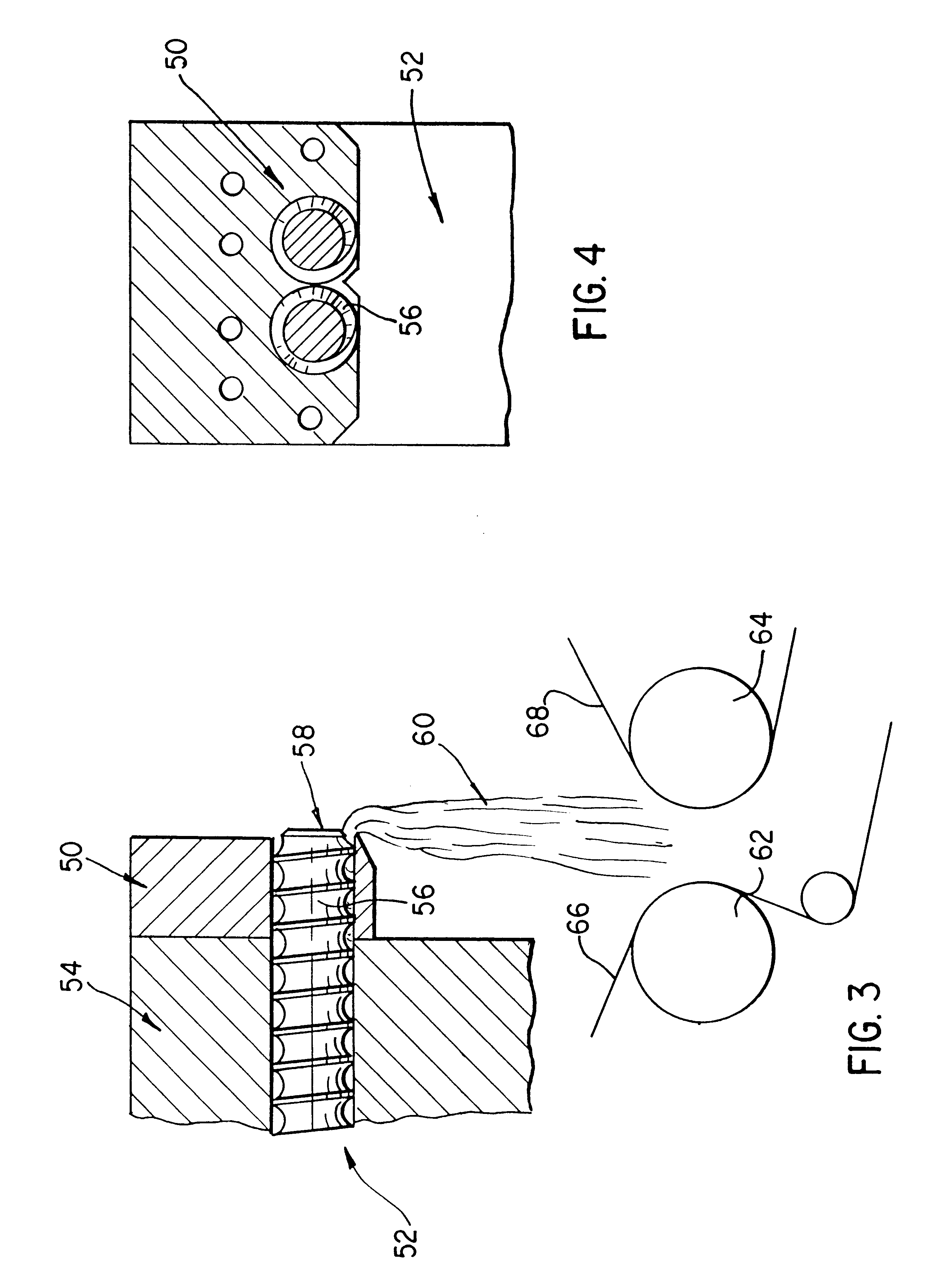

Extruded polymer foam with filler particles and method

InactiveUSRE37095E1High quality dispersionAvoid reactionFlat articlesCalcium silicatePolyisocyanurate

A thermosetting foam, preferably polyisocyanurate or polyurethane foam, is prepared in an extruder which permits the incorporation of high levels of filler particles. The method includes introducing polyol, isocyanate and filler particles to an extruder screw for mixing. In conjunction with extruding, a catalyst is added. The catalyst may be added either in a last extruder barrel or with the extruder head. Foam with filler particle content in excess of 12% made be readily made. Filler particles, such as aluminum trihydrate, perlite, carbon black, diatomaceous earth, polyiso powders, ammonium phosphate, fly ash, barium sulfate, calcium silicate, and calcium carbonate, may be used. The process described is preferably used for making foam boards or bunstock.

Owner:IP RIGHTS

Fruit tree special-purpose fertilizer and preparation method thereof

InactiveCN103524270AAvoid pollutionSolve problems such as pollutionFertilizer mixturesPhosphateAgricultural engineering

The invention discloses a fruit tree special-purpose fertilizer which is prepared from the raw materials of, by weight: 300-340 parts of live stock and poultry manure, 200-230 parts of soybean stalk, 100-120 parts of bagasse, 100-120 parts of air-dried sludge, 50-55 parts of beer grains, 30-35 parts of ox blood powder, 20-24 parts of cooked soybean, 60-65 parts of rock phosphate powder, 14-18 parts of bamboo charcoal, 10-12 parts of maifanite powder, 12-15 parts of zeolite powder, 30-35 parts of urea, 50-55 parts of mono-ammonium phosphate, 20-23 parts of ammonium sulfate, 6-9 parts of an EM inoculant, 10-15 parts of a soil conditioner, and proper amount of water. According to the fruit tree special-purpose fertilizer, wastes such as live stock and poultry manure, soybean stalk, bagasse, air-dried sludge, and the like are adopted as main raw materials, such that resource is saved, and problems such as environment pollution are solved. The raw materials are convenient to obtain, and are cheap, such that good environmental and economic benefits are provided. The fertilizer provided by the invention has the advantages that: with the fertilizer, beneficial microbe number and activity are improved, soil physiochemical traits are improved, soil nutrients are increased and balanced, and pesticide and chemical fertilizer residue and other harmful substances in soil can be degraded.

Owner:ANHUI WANLI ECOLOGICAL LANDSCAPE

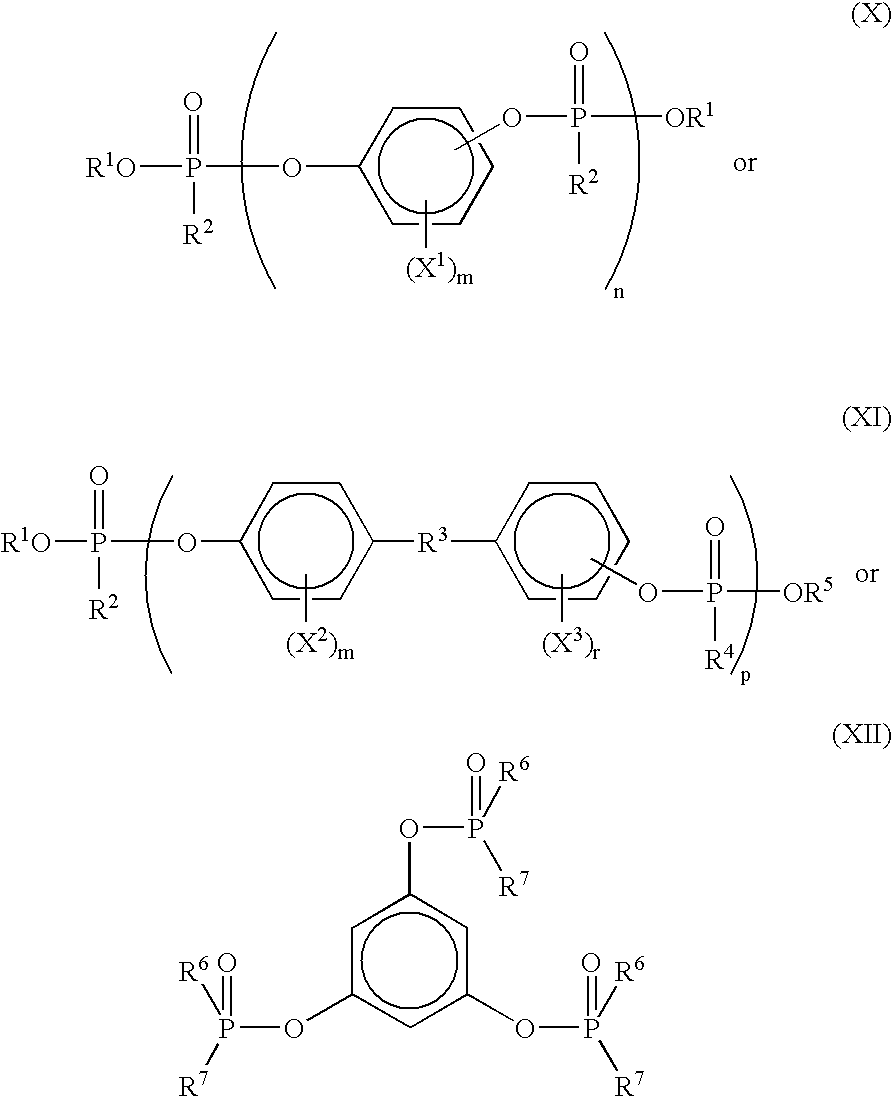

Flame retardant composition

A flame retardant additive composition comprising a phosphoric acid salt selected from the group consisting of melamine phosphate, melamine pyrophosphate, melamine orthophosphate, ammonium phosphate, ammonium phosphate amide, phosphoric acid amide, melamine polyphosphate, ammonium polyphosphate, ammonium polyphosphate amide, polyphosphoric acid amide and combinations of two or more of the foregoing; a metal hydroxide; and an organic phosphate. The flame retardant additive is useful in a wide range of thermoplastic compositions.

Owner:SABIC INNOVATIVE PLASTICS IP BV

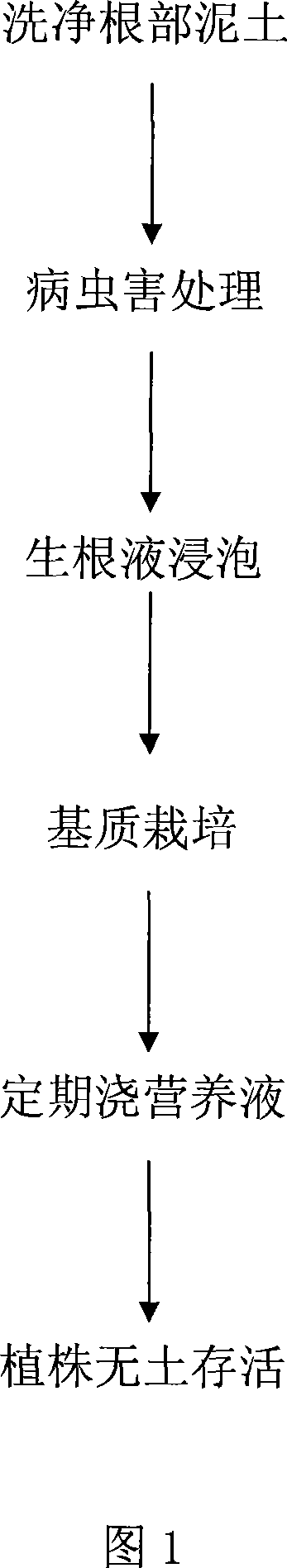

Plant nutrient solution and application in plant cultivation

InactiveCN101062877AImprove survival rateDoes not affect life cycleMagnesium fertilisersAlkali orthophosphate fertiliserManganeseMonopotassium phosphate

The invention discloses a plant nutrition liquid, which is characterized by the following: comprising potassium nitrate, calcium nitrate, magnesium sulfate, ammonium phosphate, potassium sulfate, monopotassium phosphate and so on a good deal of element; comprising edetate disodium, ferrosi sulfas, boric acid, manganese sulfate, zinc sulfate, copper sulfate, ammonium molybdate and so on microelement; comprising azophoska fertilizer and fertilizer booster; including diverse nutritious element of vegetation development; providing nourishing element for large and medium scale bush and small arbor. This invention also discloses a utility scheme in large and medium scale woody plant soilless culture.

Owner:成都市第二农业科学研究所 +1

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS7947104B2Reduce responsibilityEliminate needByproduct vaporizationExcrement fertilisersRetention timePhosphate

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

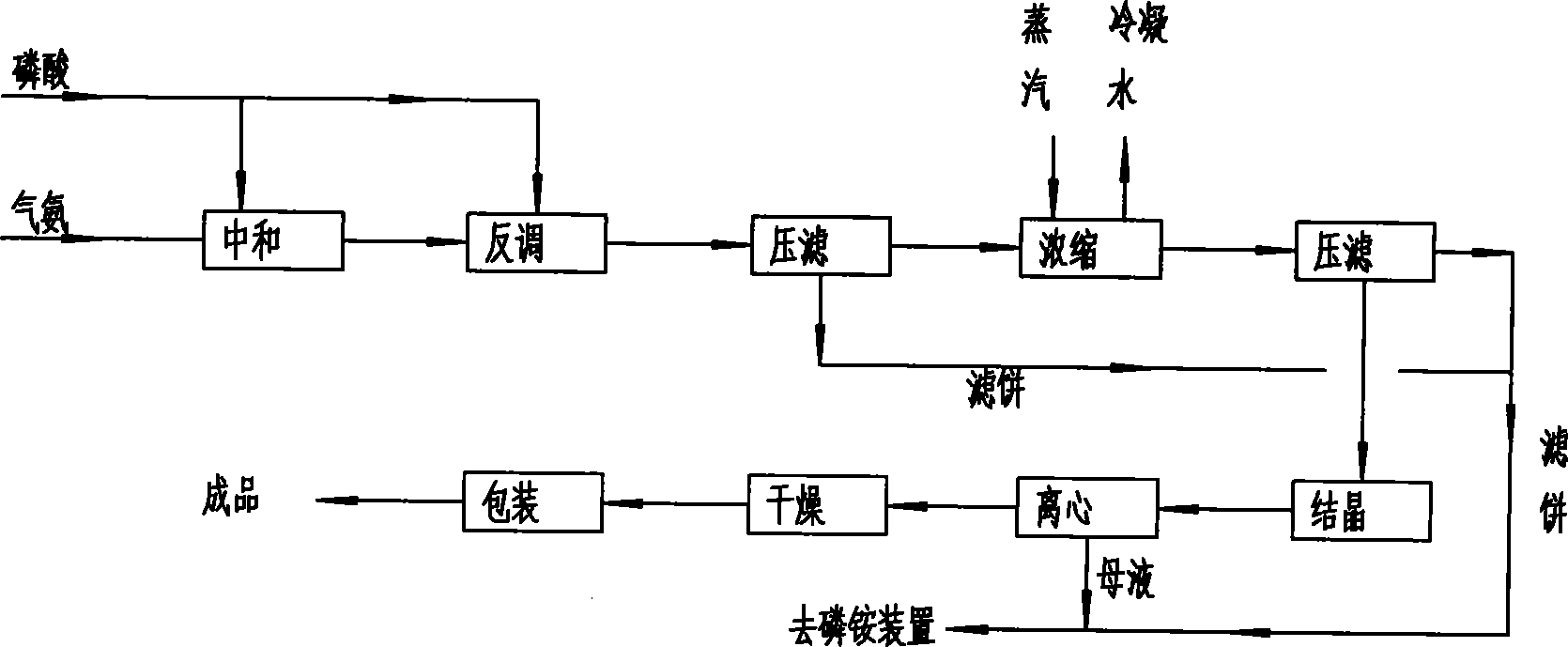

Process for continuous production of technical grade mano-ammonium phosphate with wet-process and phosphoric acid

ActiveCN101367512AReduce labor intensityReduced pressure filter loadPhosphatesPhosphatePhosphoric acid

The invention relates to a craftwork for producing the industrial-level monoammonium phosphate consecutively with the phosphoric acid by wet process, which adopts the following steps: 1) phosphoric acid and phosphorite pulp are desulfurized to get the desulfurized phosphoric acid; 2) the acid is undertaken the first neutralization action to get a neutralized material pulp clarifying solution; 3) after the second neutralization reaction, the solution is reacted with the desulfrized phosphoric acid to get a secondary neutralized material pulp with the pH value being adjusted; 4) the secondary neutralized material pulp with the pH value being adjusted is primarily filtered to get a primary filtering solution and a primary filtering mass; 5) the primary filtering solution is secondarily concentrated and press filtered to get the secondary filtering solution; 6) the obtained secondary filtering solution is dissolved through the grain refining, is cooled down in vacuum, is crystallized, is centrifugally separated and dried to get the finished product of the industrial-level monoammonium phosphate. The invention has the advantages that the operation during the production process is consecutive; the labor intensity of the worker is reduced; the leakage rate of the ammonia is low and the loss is small; the secondary neutralized raw material solution is clear solution, so that the viscosity is low and the loss of the ammonia is small; the neutralization and the press filtering load is reduced; the crystallization production capacity is large; the heat energy is adequately used, thereby reducing the consumption of the vapor.

Owner:HUBEI XIANGYUN GROUP CHEM

Fire retardant composition

InactiveUS20100069488A1Improve flame retardant performanceEfficient and reasonably safe to manufactureFireproof paintsOrganic active ingredientsCross-linkActive agent

A composition can embrace a fire retardant can be combined with a fluoropolymer, which can be a coating, for example, a paint, especially a latex paint, or which can be an organic solvent based coating, for example, a paint. The fire retardant can be an ammonium phosphate containing fire retardant, which can be combined with a fluoropolymer, a penetrating barrier, borate-containing formulation having resistance to water damage with protective properties coming from materials used in food packaging and cosmetics, and / or a medium-to-long chain polar carboxyl substance to make a composition. Also, a composition can embrace a fire retardant formulation having a cross-linked component, which composition may be a coating, for example, a paint or stain, especially a latex paint. The cross-linked component may be a base of the paint or stain, say, a vinyl acetate base of the fire retardant latex paint. At least one other active agent, for example, a mold inhibitor and / or an insecticide, may be included. The composition can be used by contacting it with a substrate, which beneficially is otherwise flammable. The composition or its residue may be found in combination with the substrate.

Owner:NO BURN INVESTMENTS

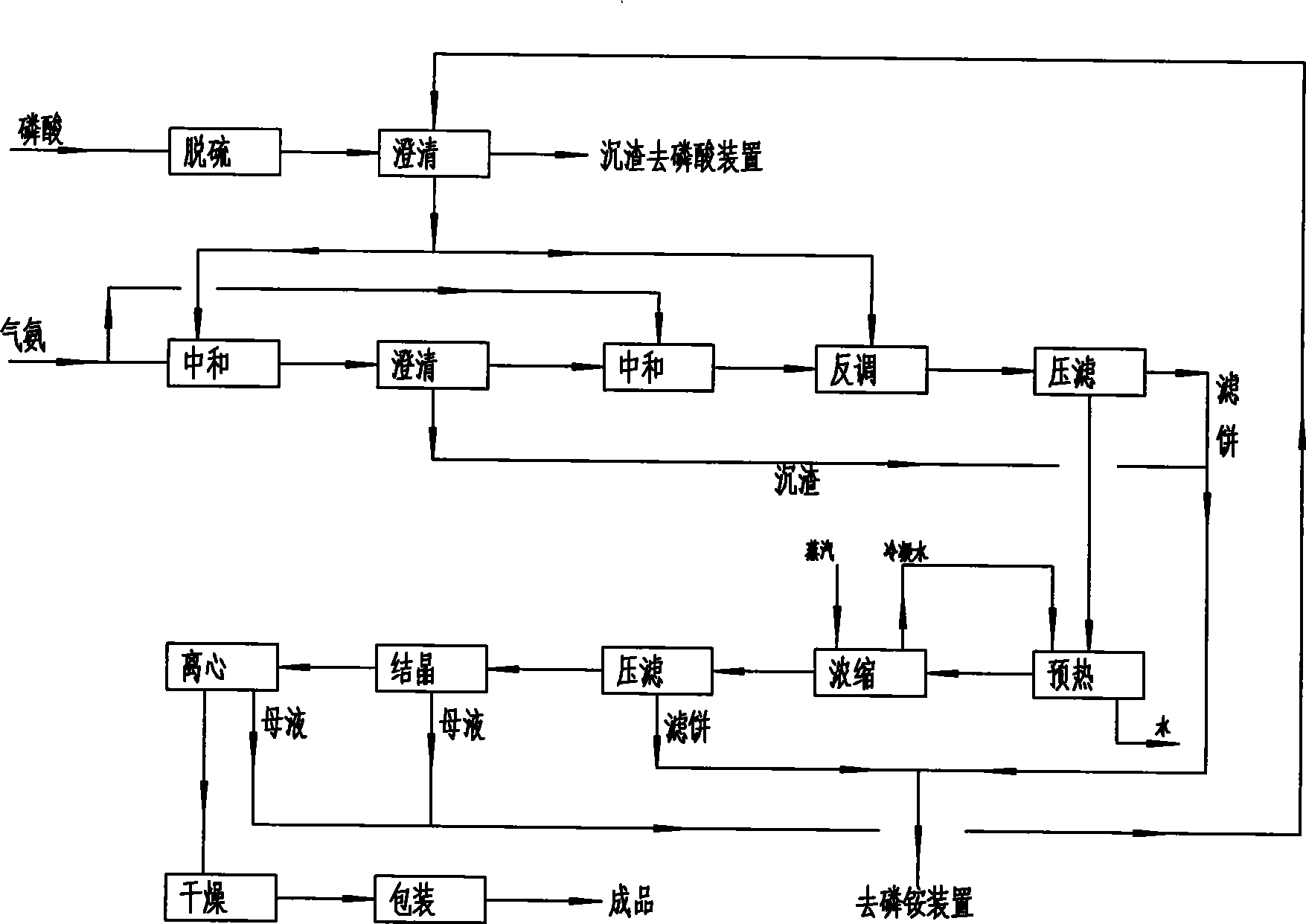

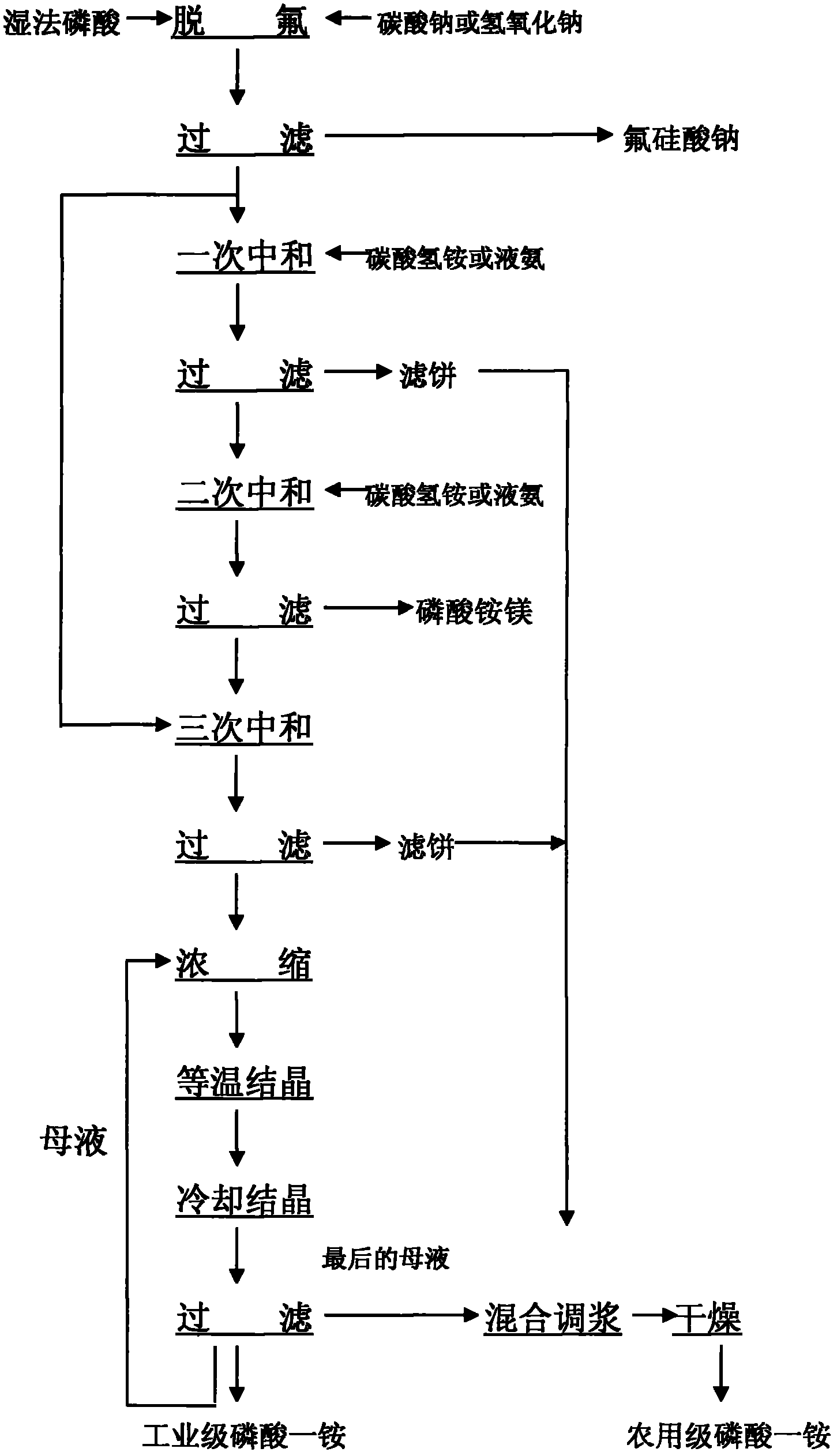

Method for producing industrial and agricultural monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid

ActiveCN102020256AImprove purification effectTroubleshoot follow-up issuesPhosphatesO-Phosphoric AcidAgricultural engineering

The invention provides a method for producing industrial and agricultural grade monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid. The wet-process phosphoric acid is taken as a raw material. Sodium fluosilicate, monoammonium phosphate solution, monoammonium phosphate filter cakes and magnesium ammonium phosphate are respectively obtained through defluorination and a three-section substep neutralization process, wherein the monoammonium phosphate solution is concentrated and crystallized to obtain high-quality water soluble industrial monoammonium phosphate, and the monoammonium phosphate filter cakes and the monoammonium phosphate mother solution subjected to repeated crystallization are subjected to size mixed and dried to obtain qualified agricultural monoammonium phosphate. The magnesium ammonium phosphate is a good slow release nitrogenous fertilizer per se. The process has the advantages of little investment of equipment, good adaptability of raw material, low production cost and good product quality. The water soluble industrial monoammonium phosphate with low cost can provide a cheap and good water soluble phosphatic fertilizer for modern facility agriculture.

Owner:昆明隆祥化工有限公司

Etching liquid composition and etching method

The invention relates to an etchant composition and an etching method, wherein, the etchant composition comprises any two components of oxidants, acid and salt, and the pH value of the etchant composition is between 1 and 7. The oxidant components are selected from hydrogen peroxide, ammonium persulfate, potassium persulfate and ceric ammonium nitrate; the acid components are selected from chloric acid, perchlorate, acetic acid, nitric acid, hydrofluoric acid, sulfuric acid and oxalic acid, and the salt components are selected from ammonium fluoride, ammonium bifluoride, diammonium phosphate, ammonium phosphate, ammonium chloride and perfluorinated octyl sulfanilic acid (C8F17SO3NH4).

Watersoluble coating glue containing multiple coating modified poly-ammonium phosphate and uses on textile finishing

The invention discloses an aqueous coating adhesive containing multiple coating modified ammonium polyphosphate and applications thereof on fabric finishing. The single modified ammonium polyphosphate can not acquire excellent wash-resisting, immersion-resisting and durable fire retardant performance from the fabric, and can not even obtain dry and comfortable hand feeling. The invention is characterized in that the ammonium polyphosphate, which is modified by melamine, single silane or epoxy resin, is subjected to heating and backflow in an organic alcohol-like solvent, a silane coupling agent capable of being bonded with active groups in the modified ammonium polyphosphate is then added so that the surface of the ammonium polyphosphate experiences multilayer coating and has active hydrogen; the coated ammonium polyphosphate is added with a nonionic surfactant, water, a binder and aqueous closed polyurethane, the aqueous coating adhesive containing the multiple coating modified ammonium polyphosphate is obtained by means of dispersed grinding. The invention is coated on terylene or pure cotton fabrics, thus realizing the cross-linked film forming of the ammonium polyphosphate and the aqueous closed polyurethane and the aqueous binder, and obtaining waterproof and durable environmentally-friendly fire retardant coating fabric.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

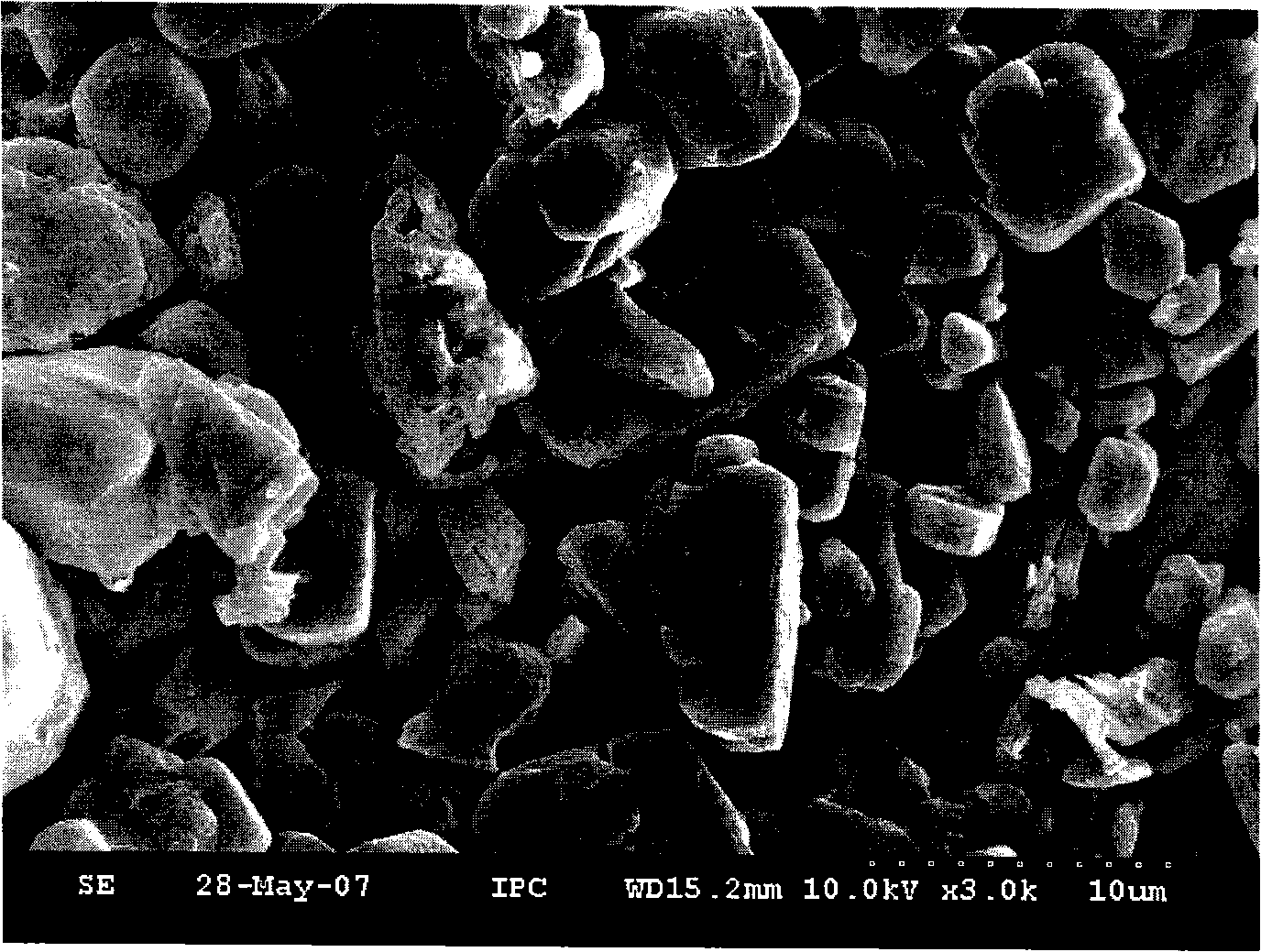

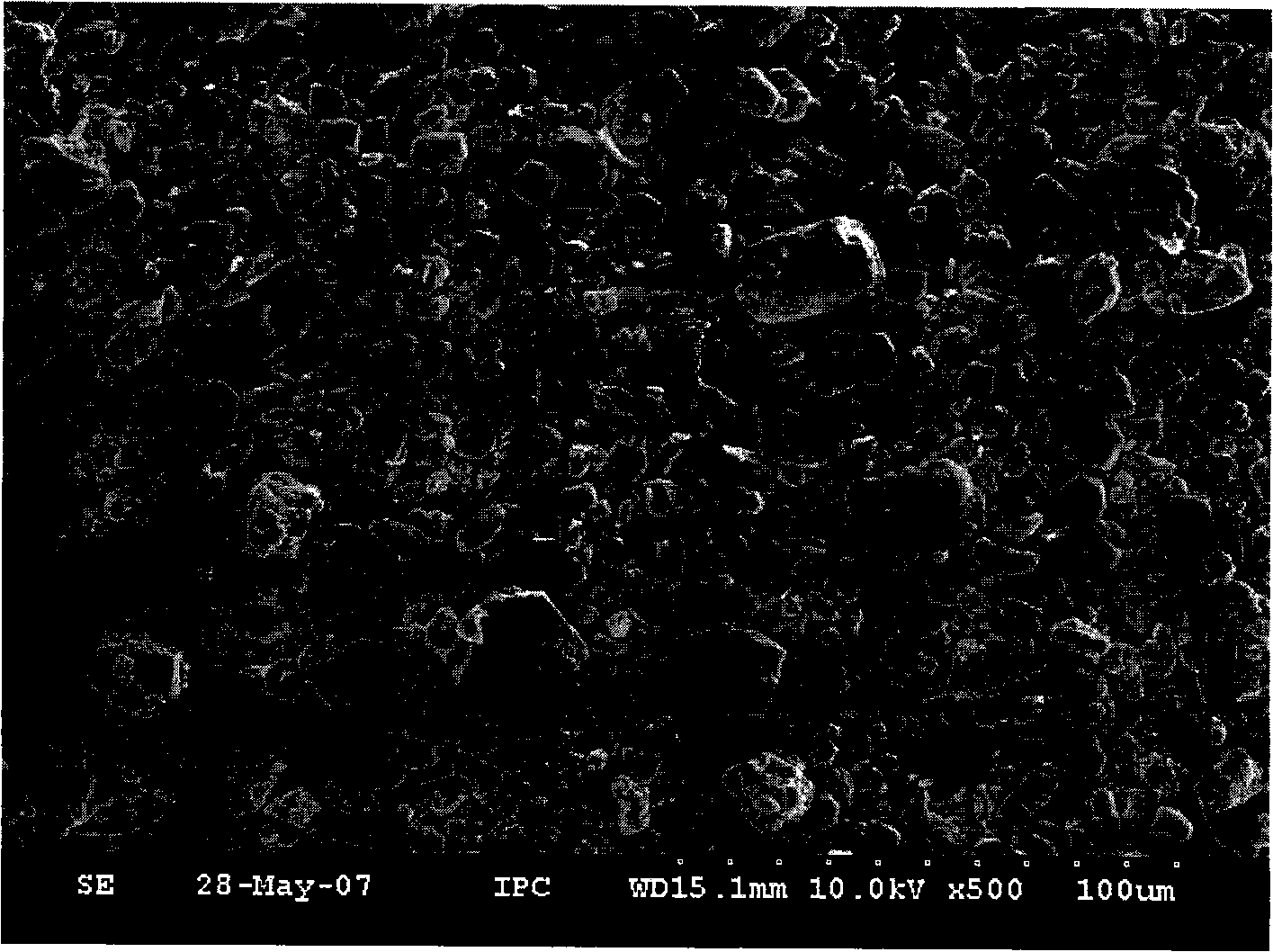

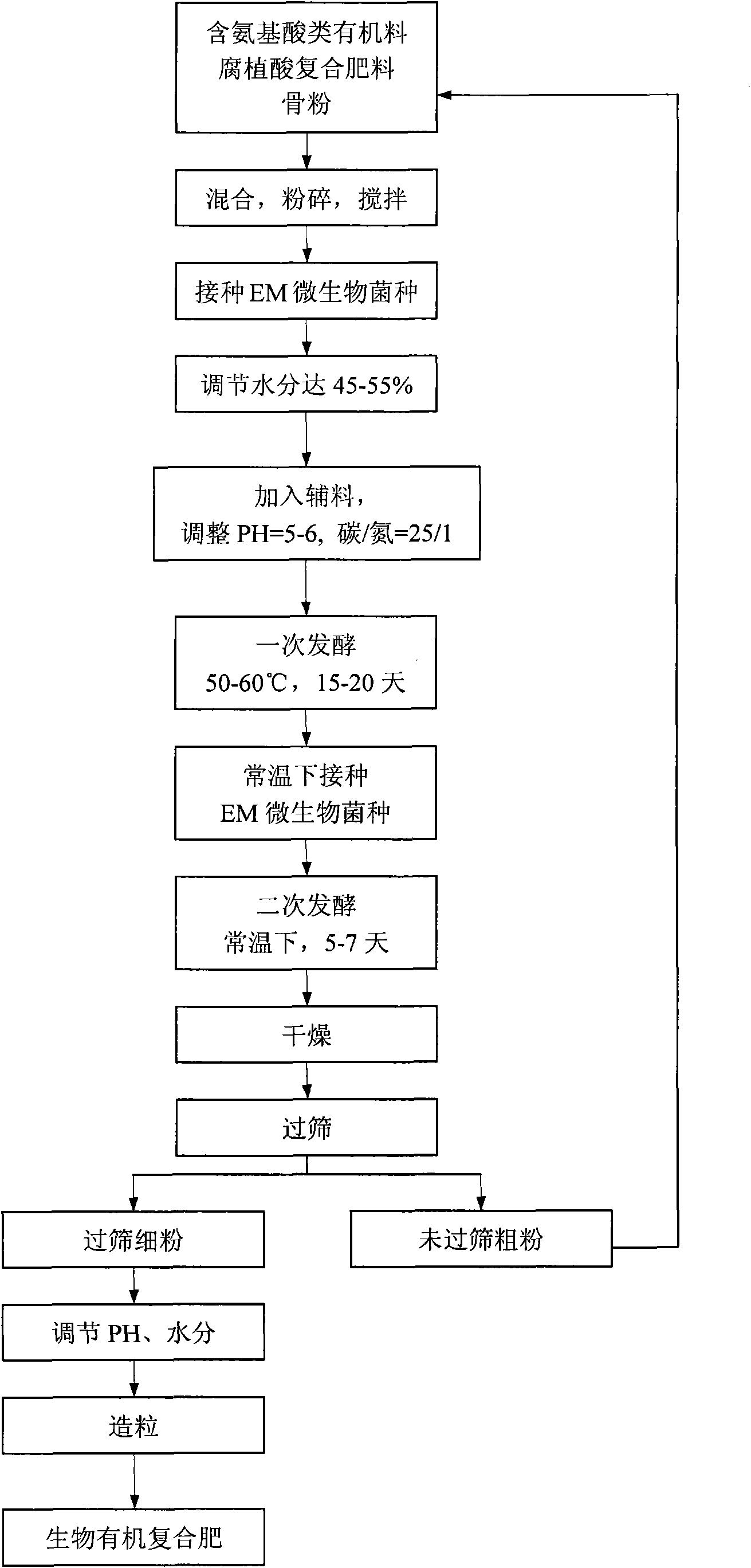

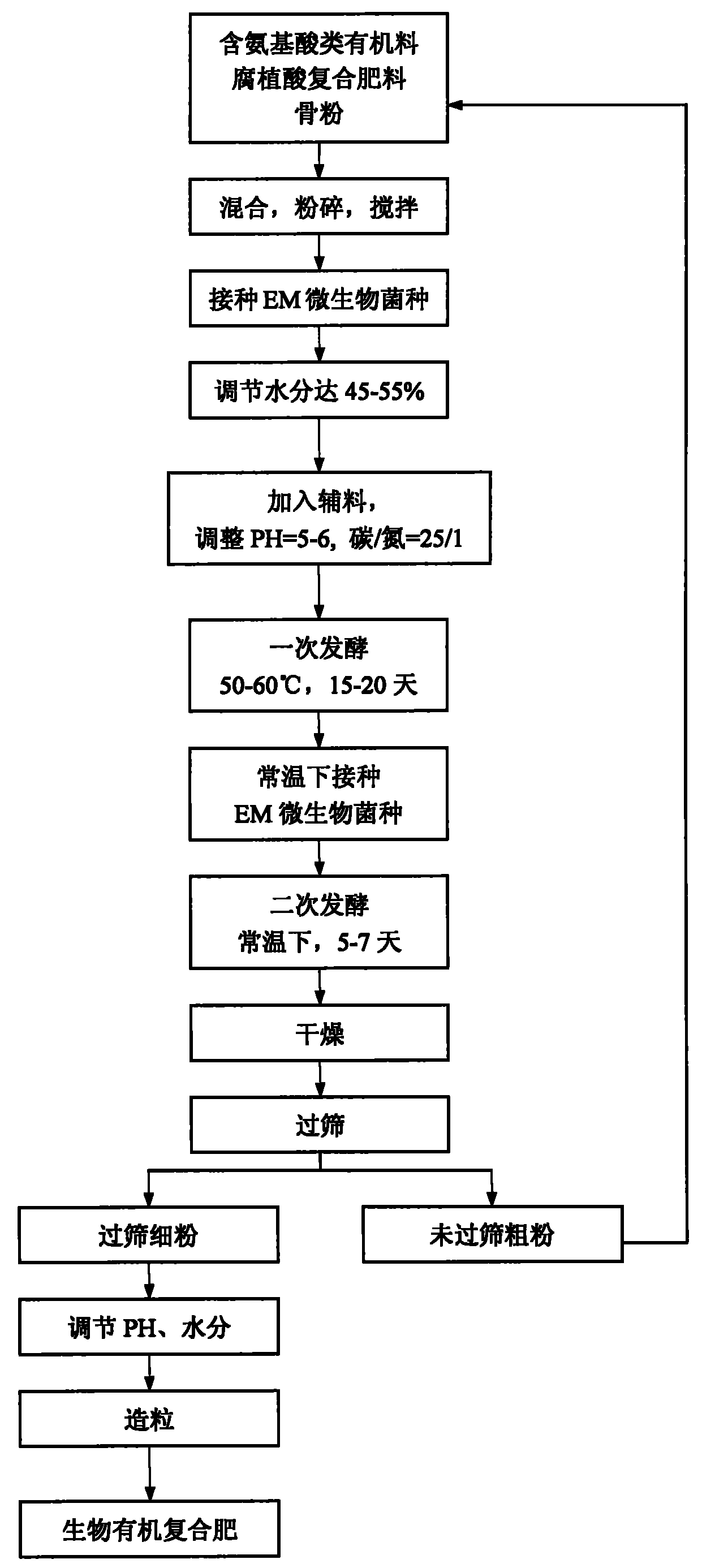

Biological organic compound fertilizer

InactiveCN101774854AMeeting nutritional needsImprove stress resistanceFertilizer mixturesOrganic compoundCrop yield

The invention discloses a biological organic compound fertilizer which comprises the following components in parts by weight: 50-75 parts of organic compound containing amino acids, 15-35 parts of humic acid compound fertilizer, 5-15 parts of bone meal, 0.05-1 part of EM animalcule bacteria and 0.05-1 part of accessory, wherein the organic material containing the amino acid is selected from dry traditional Chinese medicine residue or dry methane residue, the humic acid compound fertilizer comprises humic acidic ammonium, humic acid potassium and humic calcium phosphate, and the accessory comprises humic acid and one or a plurality of components selected from urea, ammonium bicarbonate, calcium superphosphate, ammonium phosphate and triple superphosphate. The effective viable count in the biological organic compound fertilizer is larger than or equal to 200 million / g, the organic matter weight percentage is larger than or equal to 25%, and the weight percentage of NPK total nutrient islarger than or equal to 10%. The invention also discloses a preparation method of the biological organic compound fertilizer. The biological organic compound fertilizer is a green environmentally friendly manure which can increase crop yield and quality.

Owner:袁新华

Method for preparing organic synergistic soil conditioner

ActiveCN101591543AIncrease organic matterSimple structureAgriculture tools and machinesOrganic fertilisersMonosodium glutamateAlkali soil

The invention provides a method for preparing an organic synergistic soil conditioner. The soil conditioner comprises the following components in portion by weight: 30 to 60 portions of organic component, 9 to 23 portions of synergistic component, 10 to 23 portions of conditioning component, and 15 to 30 portions of inorganic nutrient. The soil conditioner is prepared by the method of weighing, mixing, spray granulation and low-temperature drying, wherein the organic component contains 2 to 5 portions of humic acid, 25 to 45 portions of mature garbage or barnyard manure, and 2 to 5 portions of residue of monosodium glutamate and sugar production; the synergistic component contains 1 to 3 portions of zeolite powder, and 8 to 20 portions of synergistic agent; the conditioning component contains 2 to 10 portions of plaster, 9 to 13 portions of bentonite, 4 to 8 portions of polyvinyl alcohol (liquid), and 0.5 to 1.2 portions of starch (liquid); and the inorganic nutrient contains 4 to 7 portions of urea, 7 to 9 portions of ammonium phosphate, 5 to 7 portions of potassium sulfate, and 4 to 6 portions of ammonium sulfate. The preparation method is scientific, reasonable, simple and easy to operate; and the preparation method solves the synergistic effect of soil conditioners, and is suitable for the planting of field crops and forest fruits, in particular suitable for the conditioning of saline-alkali soil. By the determination of the national standard GB18877-2002, various indexes satisfy the national standard, and the content of the humic acid exceeds the standard requirement.

Owner:新疆满疆红农资化肥科技有限公司

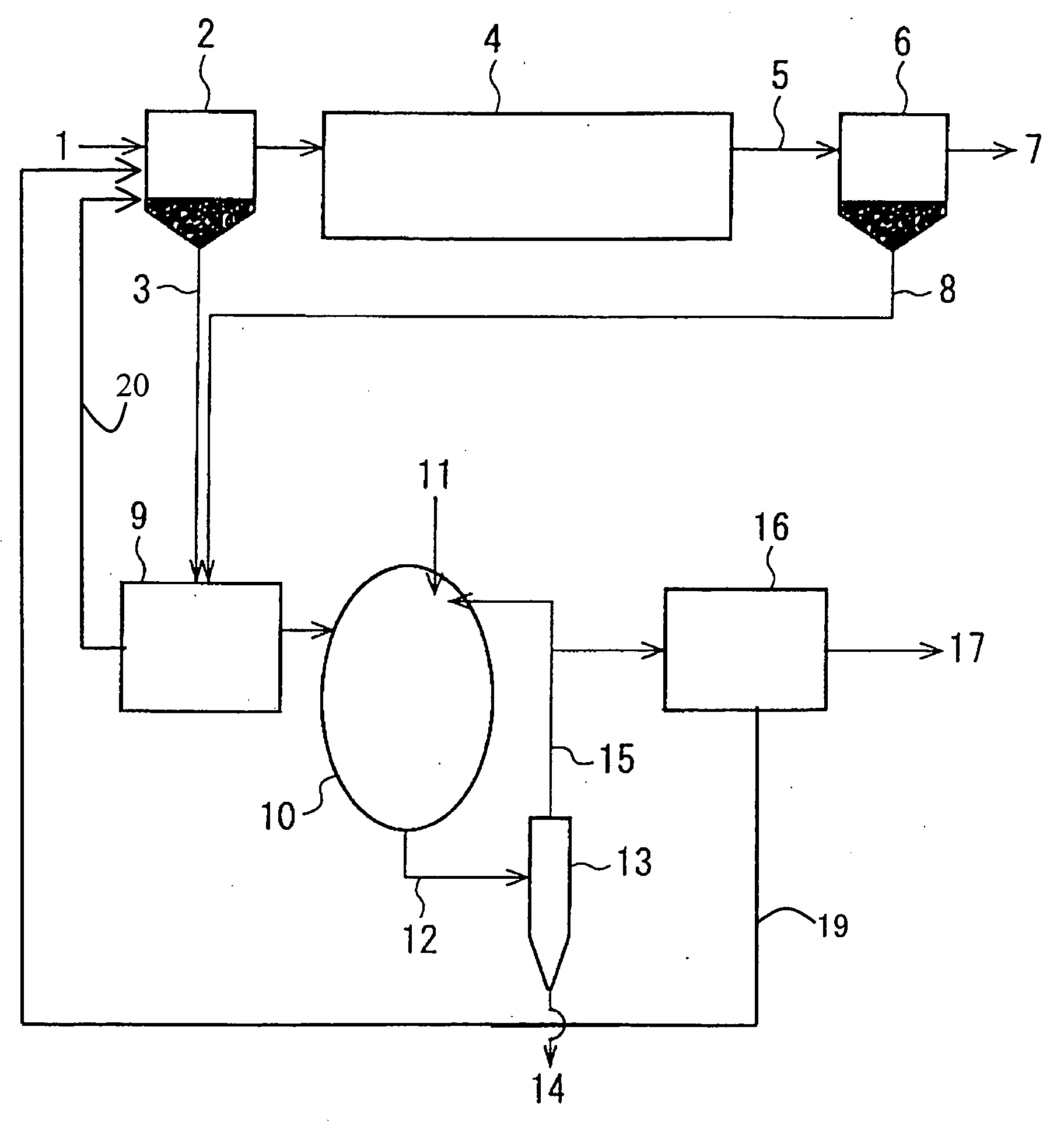

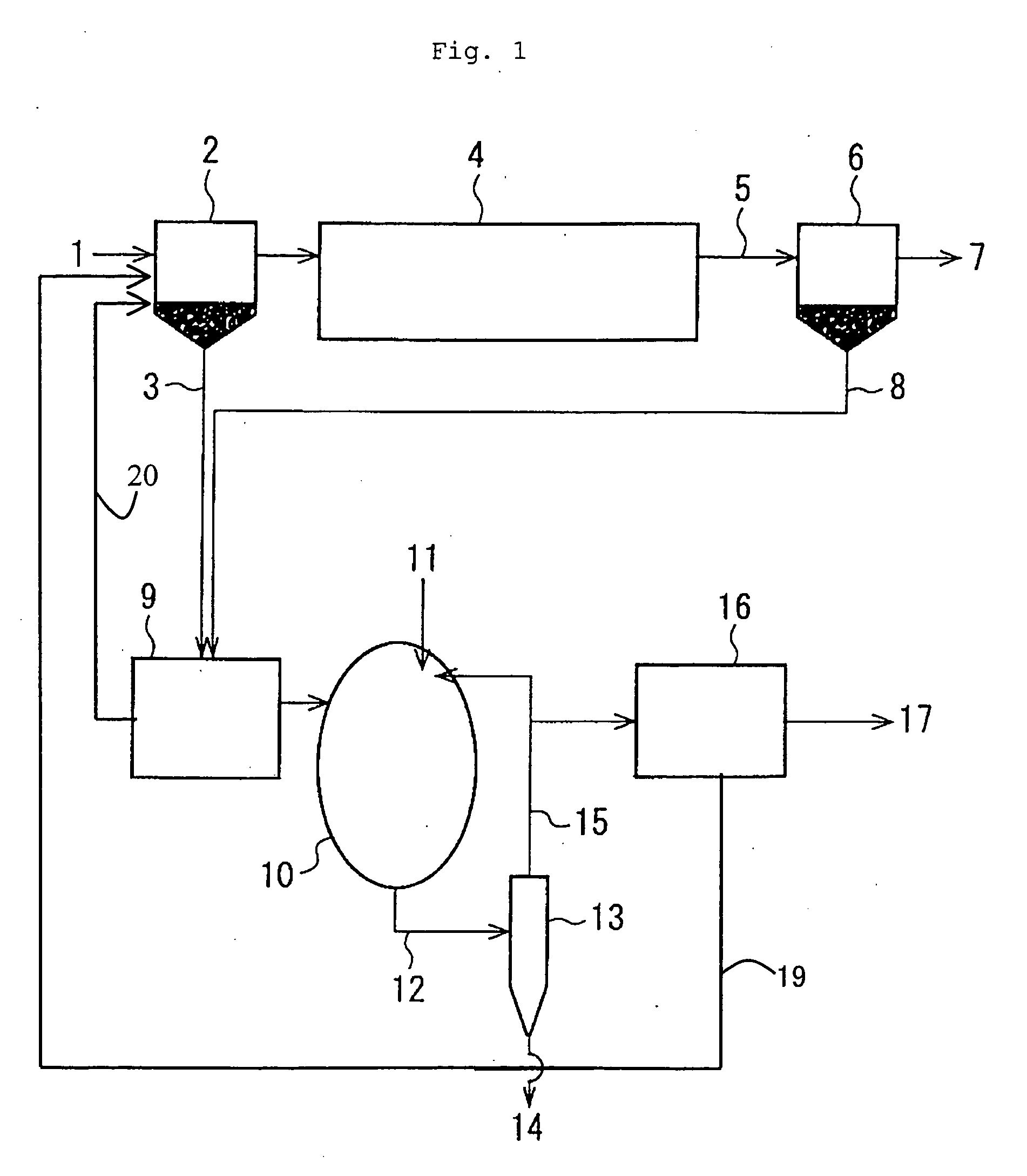

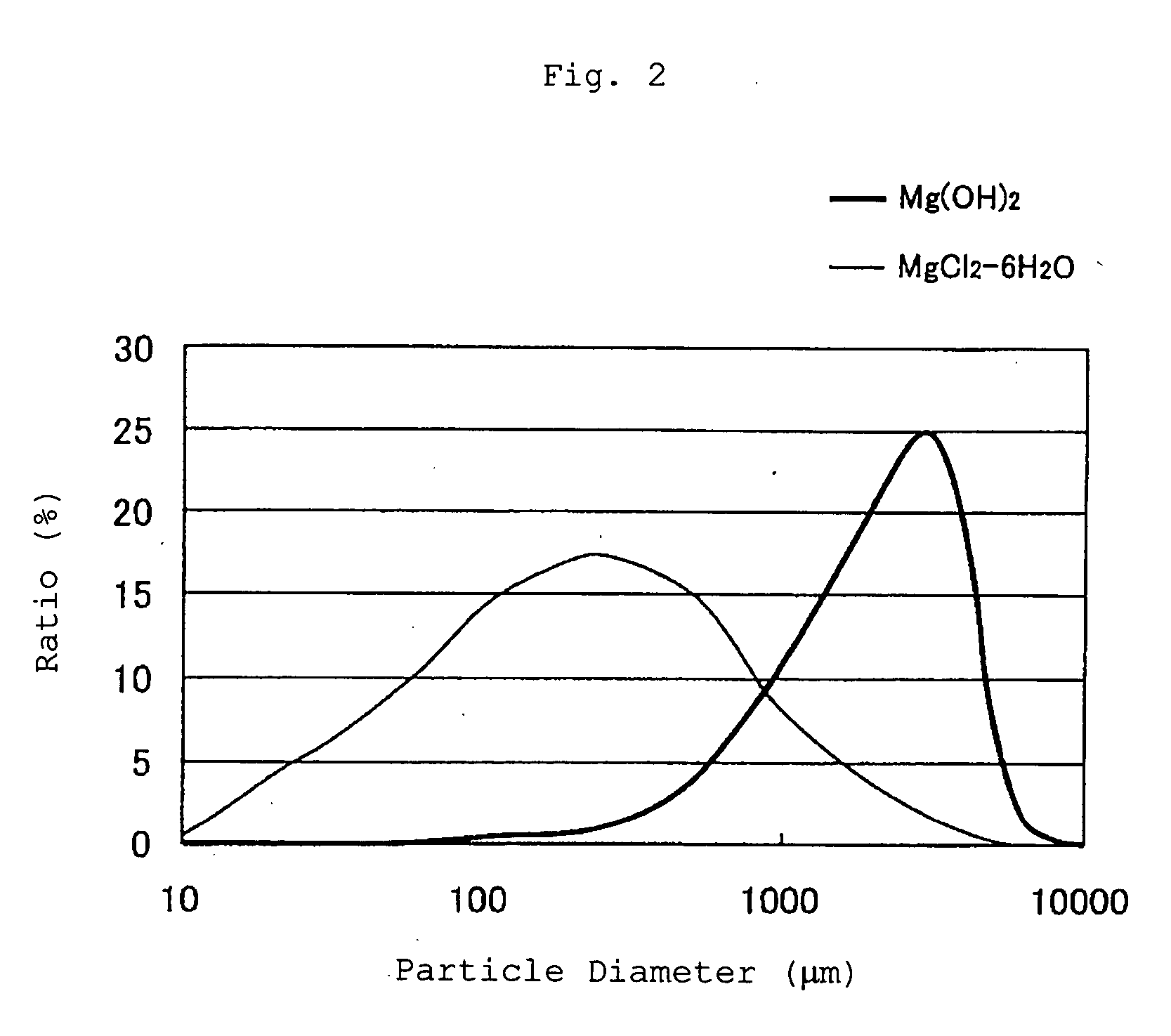

Method of treating organic wastewater and sludge and treatment apparatus therefor

InactiveUS20050016919A1Reduce the amount requiredImprove and stabilize removal ratioWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningHigh concentrationHuman waste

The present invention has an object to provide a process and an apparatus for efficiently recovering magnesium ammonium phosphate (hereinafter referred to as “MAP”) crystals of high purity and good quality in the technique of removing phosphorus and the like as MAP crystals from wastewater containing high concentration organic substance, phosphorus and nitrogen such as a digested supernatant liquor of human waste sewage and septic tank sludge, a digested liquor of sludge, chemical plant wastewater, and simultaneously recovering the MAP crystals. As the means to achieve such an object, the present invention provides a sludge treatment process comprising treating a sludge mixed liquor formed in the biological treatment system for organic wastewater in an anaerobic digestion tank to effect the digestion of sludge, simultaneously adding a magnesium source to the anaerobic digestion tank to allow crystals particles of MAP to form and grow in the anaerobic digestion tank, withdrawing a sludge mixed liquor containing the crystals of MAP from the anaerobic digestion tank, separating and recovering solids containing MAP crystal particles from the withdrawn sludge mixed liquor, and returning part of the sludge mixed liquor after separation and recovery of MAP crystal particles to the anaerobic digestion tank.

Owner:EBARA ENG SERVICE

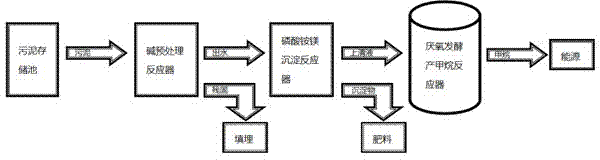

Method for processing residual sludge with integrated process of alkaline hydrolysis preprocessing, nitrogen and phosphorus recovery based on magnesium ammonium phosphate method and methane production based on anaerobic digestion

ActiveCN103693828AReduce consumptionGive full play to the role of alkaline hydrolysis pretreatmentWaste based fuelSludge processingChemical oxygen demandMagnesium salt

The invention discloses a method for processing residual sludge with an integrated process of alkaline hydrolysis preprocessing, nitrogen and phosphorus recovery based on a magnesium ammonium phosphate method and methane production based on anaerobic digestion. The method comprises the steps of: preprocessing residual sludge with a secondary alkaline hydrolysis method to obtain supernate, adding a magnesium salt solution to separate precipitates, subjecting the supernate to anaerobic processing, and drying the precipitates naturally to obtain crude magnesium ammonium phosphate; injecting the supernate into an anaerobic reactor, and inoculating with 10-60% anaerobic granular sludge, wherein the volumetric loading is controlled to be 0.30-0.75kg COD (Chemical Oxygen Demand) / (m<3>.d), and the productivity of methane reaches 200-400mL CH4 / gCOD within 72h. The method disclosed by the invention has the advantages that nutrition elements in the residual sludge are utilized comprehensively, the process is simple and is consistent in flow with low chemical consumption and electricity consumption, methane is recovered while crude magnesium ammonium phosphate is obtained, moreover, residual alkaline solids are beneficial to subsequent processing, and the reduction, stabilization and recycling of the residual sludge are realized comprehensively.

Owner:SOUTH CHINA UNIV OF TECH

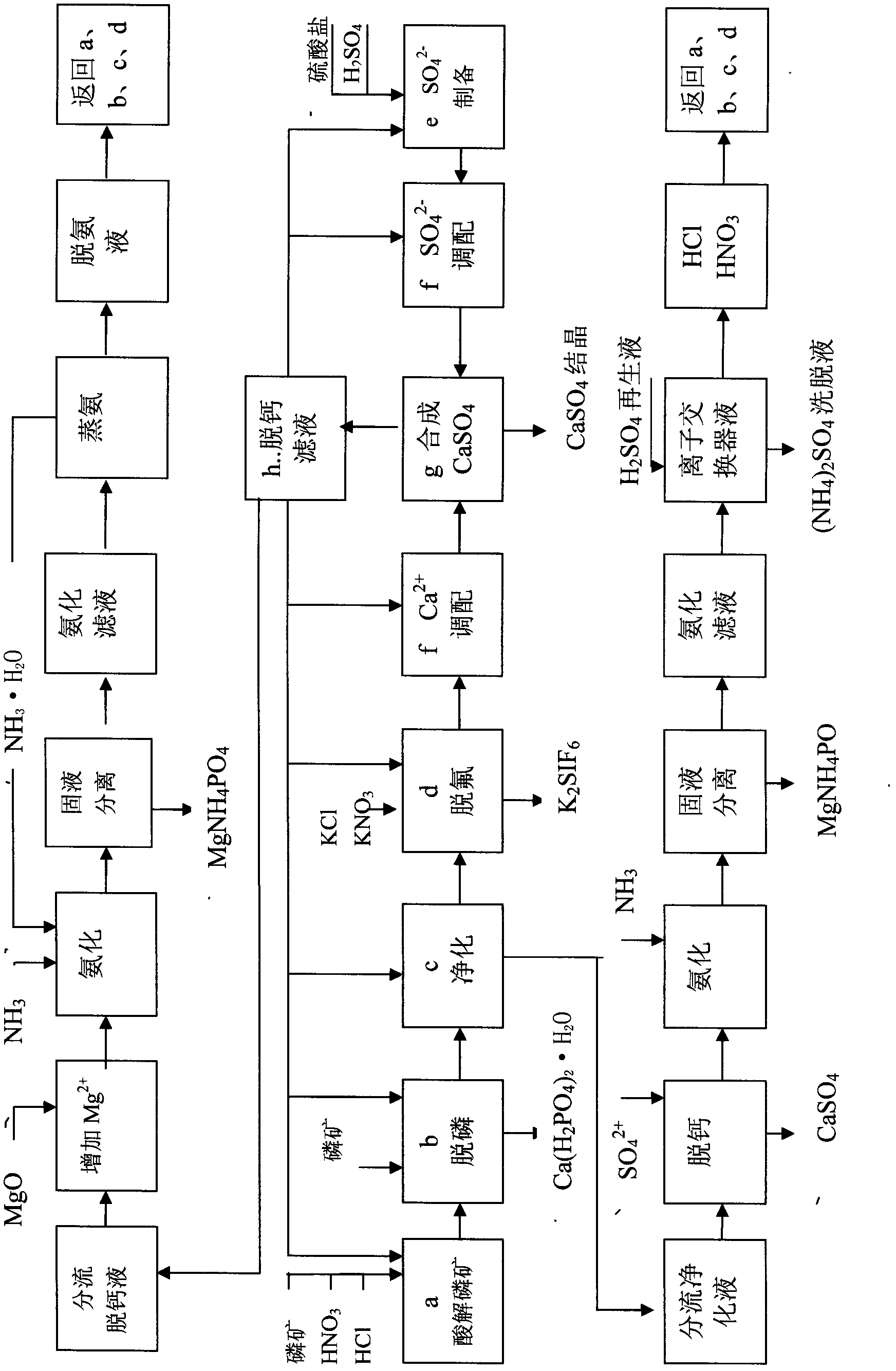

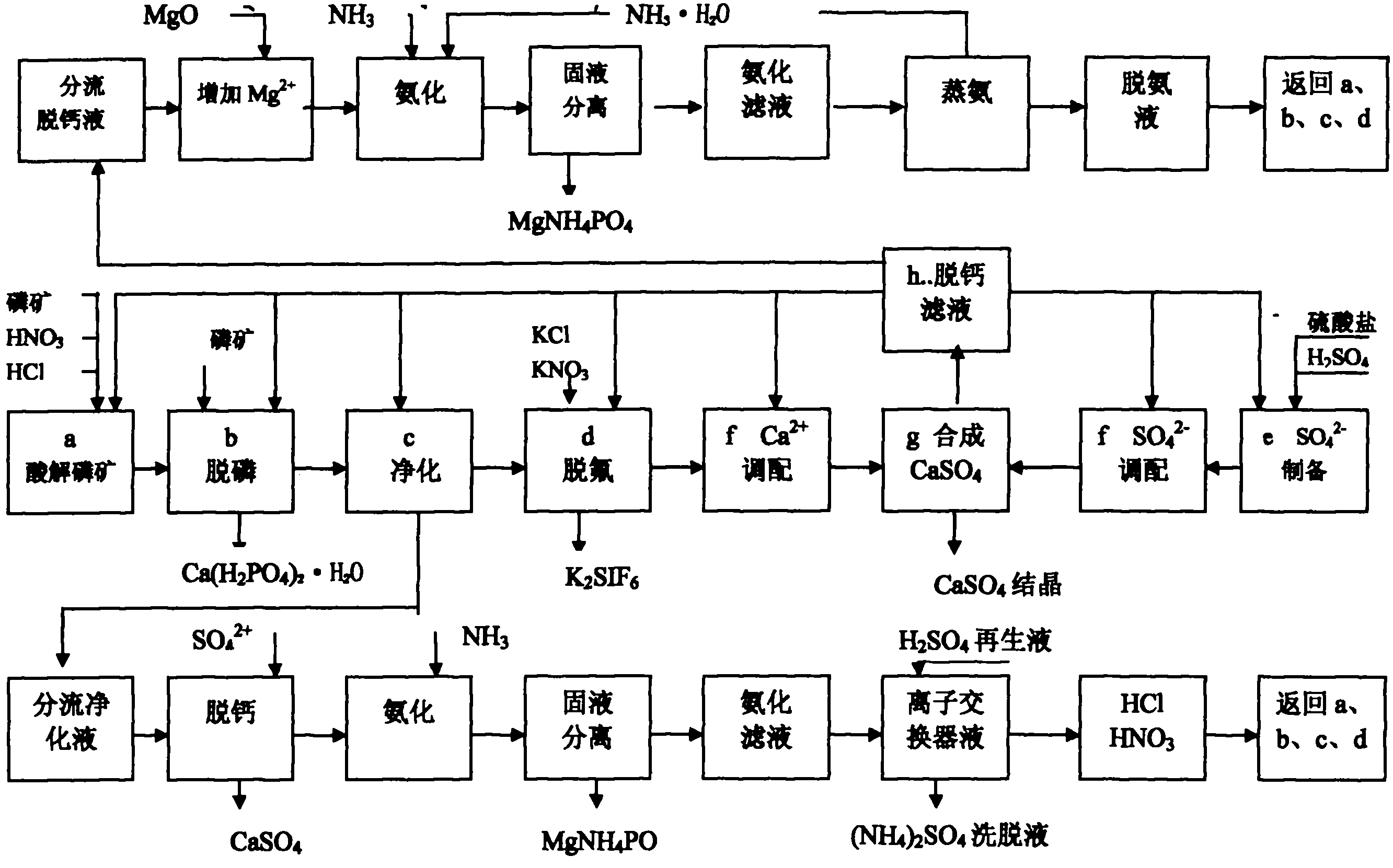

Acidolysis method of magnesium-containing phosphate rock

ActiveCN102417169AAchieving Theoretical UtilizationEasy to processCalcium/strontium/barium sulfatesAmmonium sulfatesHigh magnesiumPhosphor

The invention discloses an acidolysis method of magnesium-containing phosphate rock. The method provided by the invention is characterized by comprising the following steps of: carrying out acidolysis on the magnesium-containing phosphate rock to obtain a water-soluble calcium, magnesium and phosphoric acid containing acidolysis solution, carrying out acidolysis on the phosphate rock by using the generated phosphoric acid to generate Ca(H2PO4)2.H2O solid, performing a reaction between H2SO4 and water-soluble calcium to generate high-pureness calcium sulfate whisker, and performing a reaction between water-soluble magnesium and phosphor in the acidolysis solution and NH3 to generate character separation magnesium ions of a MgNH4PO4 solid so as to realize complete high-efficiency comprehensive utilization of the acidolyzed magnesium-containing phosphate rock. The focus of the invention is to change magnesium ions into controllable parameters which are beneficial to circulation of the acidolysis solution. The magnesium-containing phosphate rock can be efficiently utilized, and also the compound magnesium ammonium phosphate can be used to realize the separation of phosphor magnesium from a circulation medium HCl or HNO3 or CaCL, Ca(NO3)2, thus realizing the combination and combined production with a present ammonium phosphate and phosphor product processing technology. The method provided by the invention has advantages of concise technology, less investment, low energy consumption, low cost, high benefit and no discharge of ''three wastes (waste gas, wastewater and industrial residue)'', and fully presents great business value and great resource value of the high magnesium-containing phosphate rock.

Owner:武善东 +1

Sterilization soil-improvement slow-release composite fertilizer and preparation method thereof

InactiveCN105347916ASolve the problem of insoluble in waterHas a bactericidal effectFertilizer mixturesSlagCopper carbonate

The invention discloses sterilization soil-improvement slow-release composite fertilizer. The sterilization soil-improvement slow-release composite fertilizer comprises, by weight, 20-25 parts of urea, 10-15 parts of ammonium biphosphate, 10-20 parts of potassium phosphate, 5-10 parts of potassium sulfate, 8-12 parts of sodium silicate, 4-6 parts of magnesium phosphate, 7-9 parts of calcium chloride, 0.2-0.4 parts of zinc ammonium phosphate, 0.1-0.3 parts of copper carbonate, 0.1-0.2 parts of manganese ammonium phosphate, 0.4-0.6 parts of potassium borate, 0.3-0.5 parts of ferric sulfate, 0.2-0.4 parts of sodium molybdate, 20-25 parts of sodium alginate, 35-45 parts of a coating material, 5-10 parts of cassava slag, 5-8 parts of furfural slag, 10-20 parts of chicken manure, 5-10 parts of carbonized rice husk, 10-15 parts of humic acid, 10-15 parts of straws, 5-8 parts of plant ash, 0.2-0.5 parts of biological fungi, 4-6 parts of thermopsine and 3-5 parts of Artemisia argyi powder. The invention also discloses a preparation method of the sterilization soil-improvement slow-release composite fertilizer.

Owner:全椒县琪悦家庭农场

Dedicated fertilizer for tobacco and production method of dedicated fertilizer

InactiveCN103772072AReduce contentReduce accumulationFertilising methodsHorticultureChelated zincNitrohumic acid

The invention discloses a dedicated fertilizer for tobacco, and relates to a fertilizer. The dedicated fertilizer comprises the following raw materials: 100 kg of ammonium sulfate, 31 kg of urea, 200 kg of nitric phosphate, 89 kg of di-ammonium phosphate, 100 kg of calcium superphosphate, 10 kg of calcium magnesium phosphate fertilizer, 230 kg of potassium sulfate, 15 kg of borax, 21 kg of amino acid chelated zinc, manganese, copper, iron and tombarthite, 100 kg of nitrohumic acid, 40 kg of magnesium sulfate heptahydrate, 28 kg of a biological agent, 11 kg of a synergistic agent and 28 kg of a soil conditioner. Compared with the prior art, the dedicated fertilizer has the advantages that tobacco yield can be improved by 36 percent; the agronomic character and quality can be improved; the tobacco growing period can be shortened; the environment can be protected; the plant stress resistance can be improved; the prospects in improving economic benefits of tobacco growers and the like are wide; the smoking health of a human body is guaranteed.

Owner:汪庭府

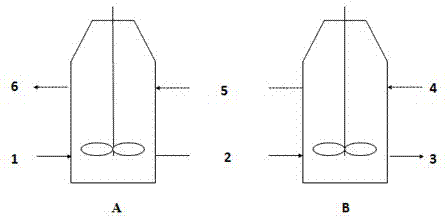

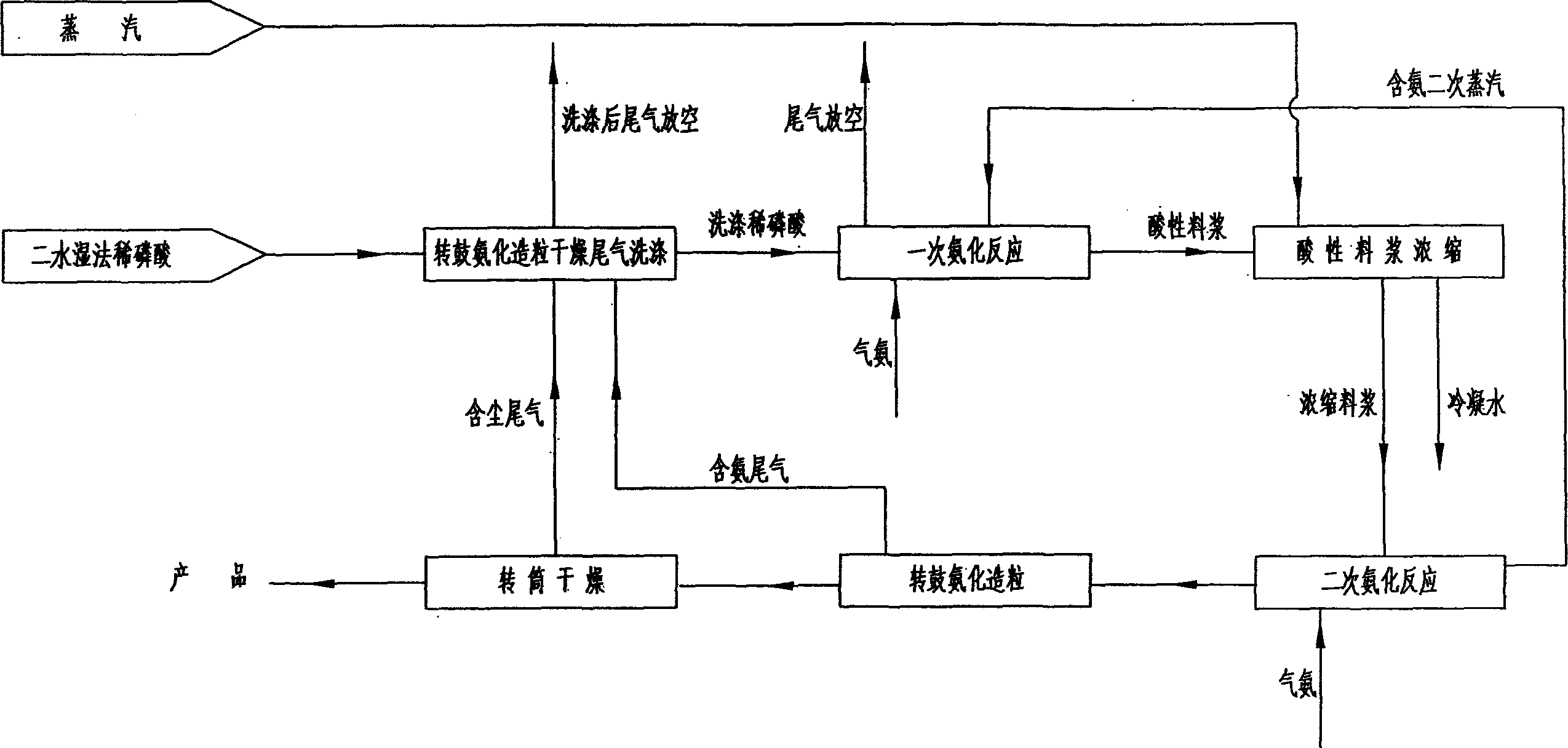

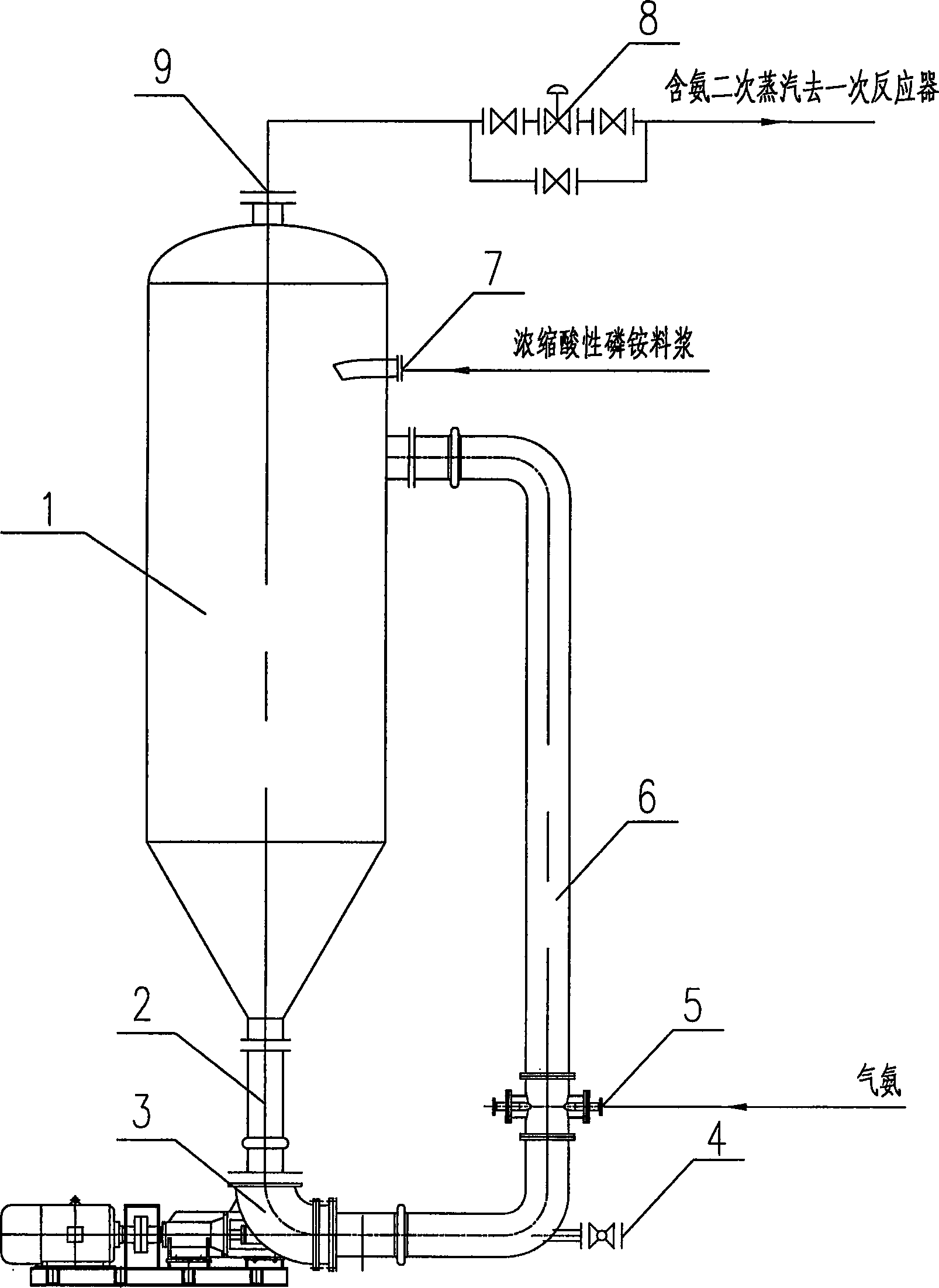

Method for producing diammonium phosphate by concentrating acid slime, and secondary ammoniation reactor

InactiveCN1872669AGood characterIncrease concentrationPhosphatesAlkali orthophosphate fertiliserDiammonium phosphatePhosphoric acid

This invention discloses a method for producing di-ammonium phosphate by concentration of acidic slurry. The method comprises: (1) performing a first ammonification on diluted phosphoric acid to obtain an acidic slurry of ammonium dihydrogen phosphate; (2) concentrating so that the water content is 13-20%; (3) performing a second ammonification so that the neutralization degree is increased to 1.30-1.50; (4) performing further ammonification so that the neutralization degree reaches 1.60-1.90; (5) granulating and controlling the water content at 2-4%. The mol. ratio of P to N in ammonium dihydrogen phosphate is 0.32-0.40.

Owner:四川川大中德环保技术有限公司

Flame-retardant wood-plastic composite material and preparation method thereof

The invention discloses a flame-retardant wood-plastic composite material. The flame-retardant wood-plastic composite material consists of the following components in part by weight: 35 to 60 parts of plant fiber, 10 to 35 parts of ammonium phosphate flame retardant, 20 to 28 parts of plastic and 2 to 10 parts of compatilizer, wherein the total parts of the plant fiber, the ammonium phosphate flame retardant, the plastic and the compatilizer are 100; the plant fiber is powder of 30 to 100 meshes of plant fiber; the ammonium phosphate flame retardant is one or a mixture of ammonium hydrogen phosphate and ammonium dihydrogen phosphate; the plastic is one or a mixture of more than two of the following components: polyethylene, polypropylene, acrylenitrile-butadiene-styrene (ABS) plastic and polystyrene; and the compatilizer is one or a mixture of maleic anhydride grafted polyethylene and maleic anhydride grafted polypropylene. The flame-retardant wood-plastic composite material has the advantages of low flame retardant cost, good flame retardant effect and no harm and toxicity.

Owner:HANGZHOU NORMAL UNIVERSITY

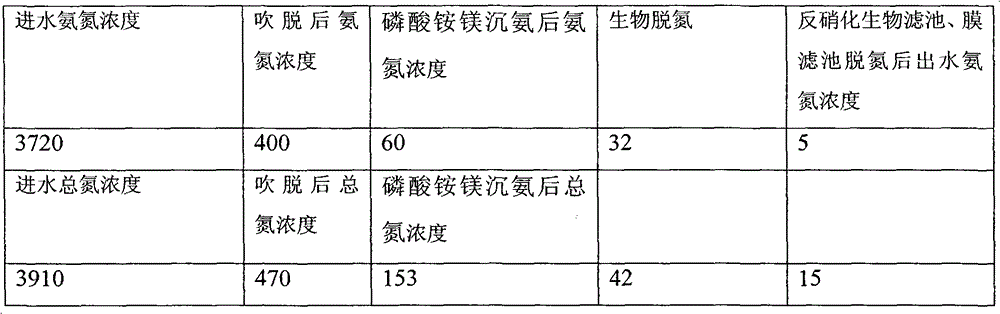

Deep denitrification process for wastewater

InactiveCN102910788AUndisturbedLow costMultistage water/sewage treatmentHigh concentrationMagnesium ammonium phosphate

The invention provides a deep denitrification process for wastewater. The deep denitrification process comprises the following specific steps of: firstly, performing microwave irradiation and coagulating sedimentation on the wastewater, wherein a certain quantity of NaOH is added into the high-concentration ammonia-nitrogen wastewater to adjust the pH value of the wastewater to 11-13, and a flocculant and a coagulant are added into the wastewater at an alkaline condition to perform the coagulating sedimentation, thus obtaining supernatant liquor; secondly, introducing the supernatant liquor obtained in the first step into an air stripping tower, wherein a sprayer is arranged at the top of the air stripping tower, multiple packing layers are arranged in the middle in a tower body, after passing through the sprayer, the wastewater becomes fine flow and flows through the packing layers, an air blower introduces air into the tower through an aeration port at the bottom of the tower, the air is in contact with the fine flow on the surface of packing, and exhaust for air stripping enters an absorption cell containing waste hydrochloric acid or waste sulphuric acid absorption liquid to absorb a part of ammonia nitrogen; thirdly, performing continuous circulating ammonia sedimentation on pyrolysis products of magnesium ammonium phosphate (MAP), and after the sedimentation of the MAP, processing effluent by a biological nitrogen removal process; fourthly, performing anaerobic (A)-anoxia (4)-oxic (O) biological nitrogen removal process on the effluent in the third step; and fifthly, performing denitrification on the left less nitrogen by a denitrification biofilter and a membrane filter. Therefore, ammonia nitrogen and total nitrogen of the effluent of the processed wastewater can reach a first-level A standard in the discharge standard of pollutants for municipal wastewater treatment plants (GB18918-2002).

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com