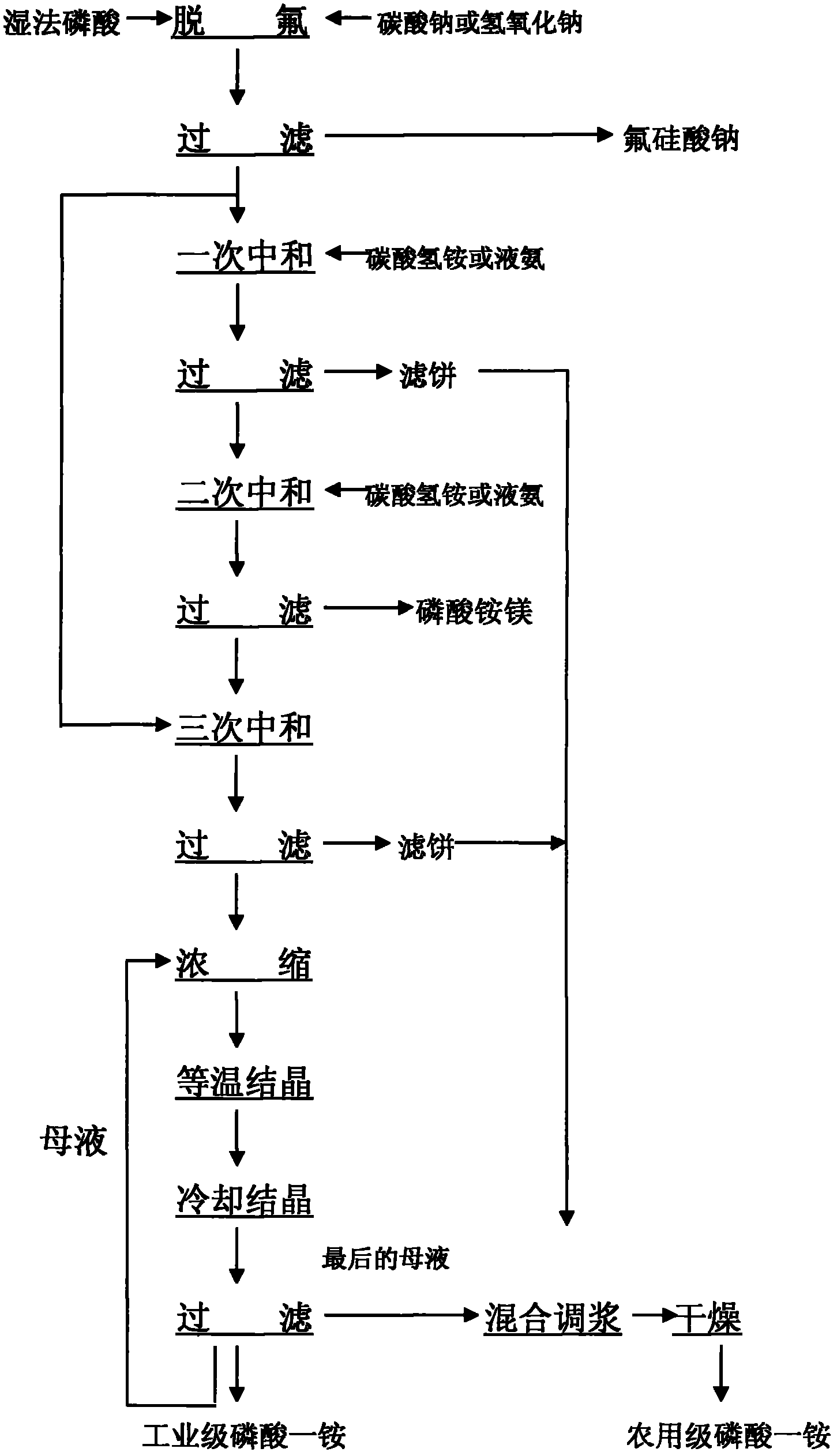

Method for producing industrial and agricultural monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid

A technology of high-grade monoammonium phosphate and wet-process phosphoric acid, which is applied in the chemical industry, can solve the problems of not meeting the requirements of fully water-soluble phosphate fertilizers, poor water solubility of products, and low production costs, so as to save the desulfurization process, solve subsequent processing problems, and avoid The effect of fluorine pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A, get 8000 grams of wet dilute phosphoric acid from a phosphate fertilizer factory (wherein: P 2 o 5 24.11%; F1.67%; SO 3 1.97%; CaO 0.25%; MgO1.06%; Fe 2 o 3 0.87%; AL 2 o 3 0.49%), slowly add 126 grams of industrial-grade sodium carbonate, fully react for 1 hour under normal temperature stirring, filter and separate the filtrate and filter residue, wash the filter residue with 200 grams of water, and then dry it to obtain 150 grams of sodium fluorosilicate product (Na 2 SiF 6 Content 98.10%), wash water and merge in the filtrate, then add 1400 grams of water and dilute to obtain 9460 grams of defluorinated dilute phosphoric acid;

[0032] B, get A step gained defluorinated dilute phosphoric acid 7730 grams, slowly add technical grade ammonium bicarbonate under stirring at normal temperature and carry out neutralization reaction to pH value 4.6 rear filtration separation, filtrate is monoammonium phosphate solution, and filter cake is subsequent use;

[003...

Embodiment 2

[0038] A, get 8000 grams of wet dilute phosphoric acid from a phosphate fertilizer factory (wherein: P 2 o 5 24.11%; F1.67%; SO 3 1.97%; CaO 0.25%; MgO1.06%; Fe 2 o 3 0.87%; AL 2 o 3 0.49%), slowly add 95 grams of industrial-grade sodium hydroxide, fully react for 1 hour under normal temperature stirring, and then filter and separate the filtrate and filter residue; wash the filter residue with 200 grams of water several times until it is acid-free, and dry to obtain 151 grams of sodium fluorosilicate Product (Na 2 SiF 6 Content 98.05%), wash water and merge in the filtrate, then add 1400 grams of water to dilute to obtain 9480 grams of defluorinated dilute phosphoric acid;

[0039] B. Take 7200 grams of defluorinated dilute phosphoric acid obtained in step A, and slowly add industrial grade ammonium bicarbonate under normal temperature stirring to carry out neutralization reaction to pH value 4.9 and then filter and separate. The filtrate is monoammonium phosphate so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com