Patents

Literature

4307 results about "Ammonium bicarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium bicarbonate is an inorganic compound with formula (NH₄)HCO₃, simplified to NH₅CO₃. The compound has many names, reflecting its long history. Chemically speaking, it is the bicarbonate salt of the ammonium ion. It is a colourless solid that degrades readily to carbon dioxide, water and ammonia.

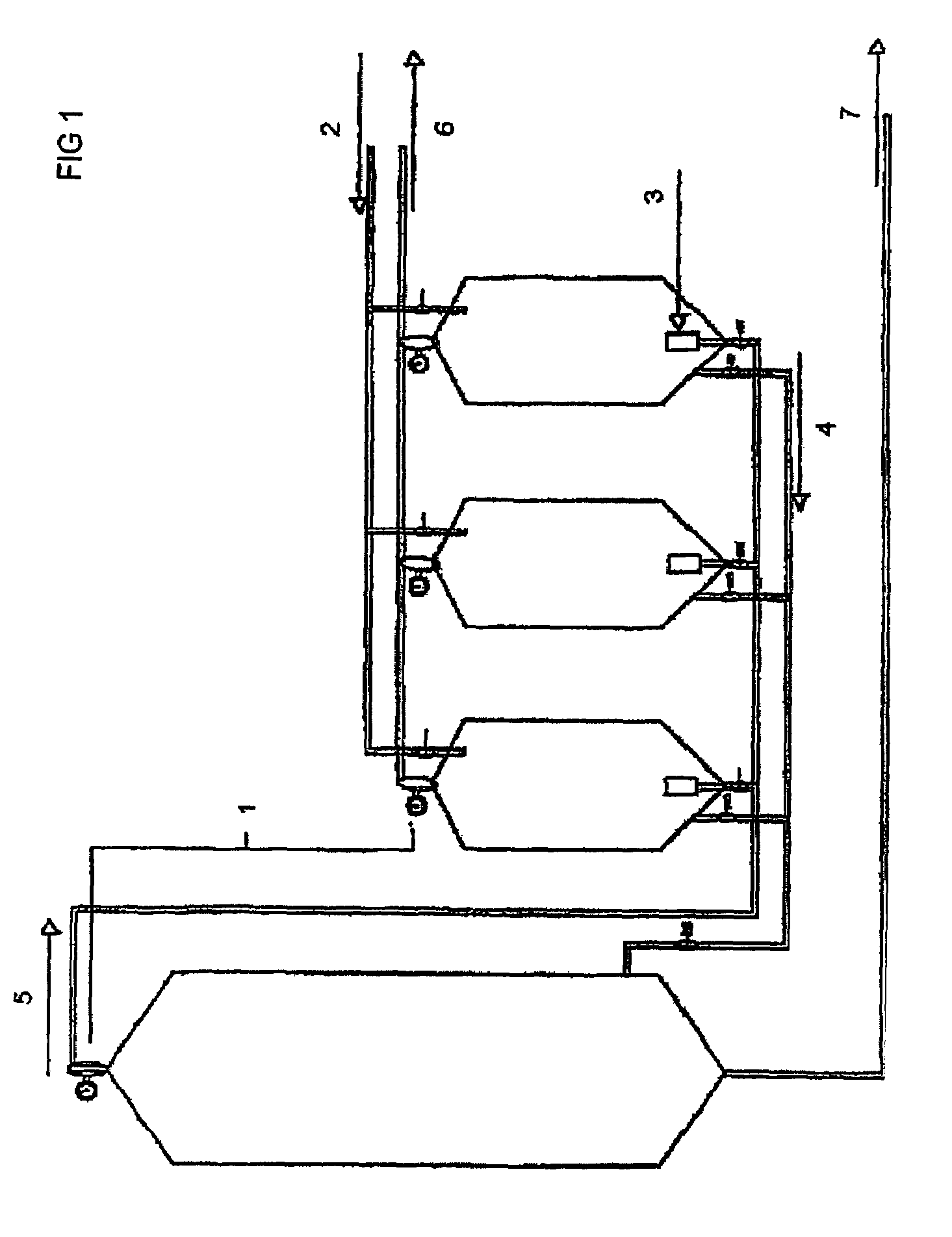

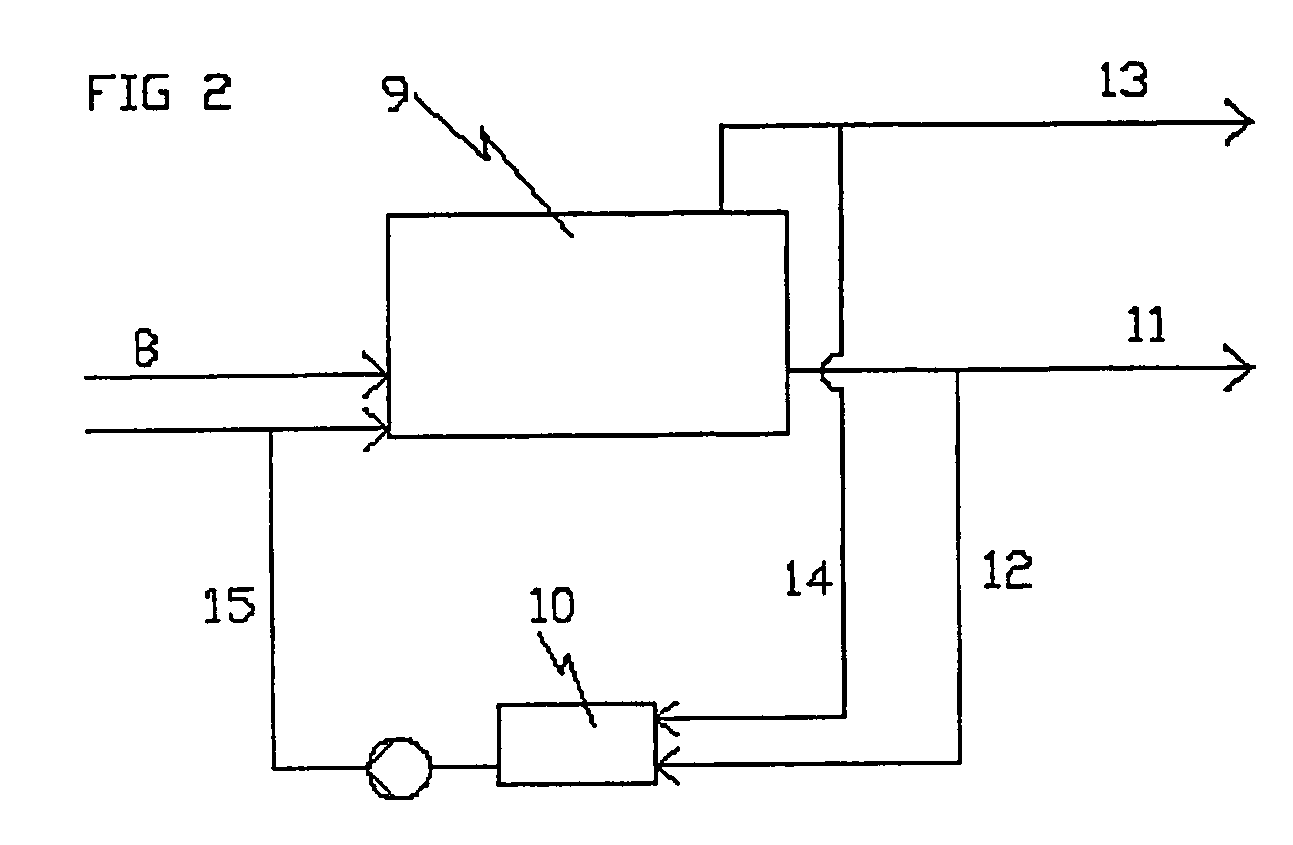

Multi-component removal in flue gas by aqua ammonia

InactiveUS7255842B1Regeneration process is less-costlyIncrease load capacityGas treatmentNitrogen compoundsNitric oxideSlurry

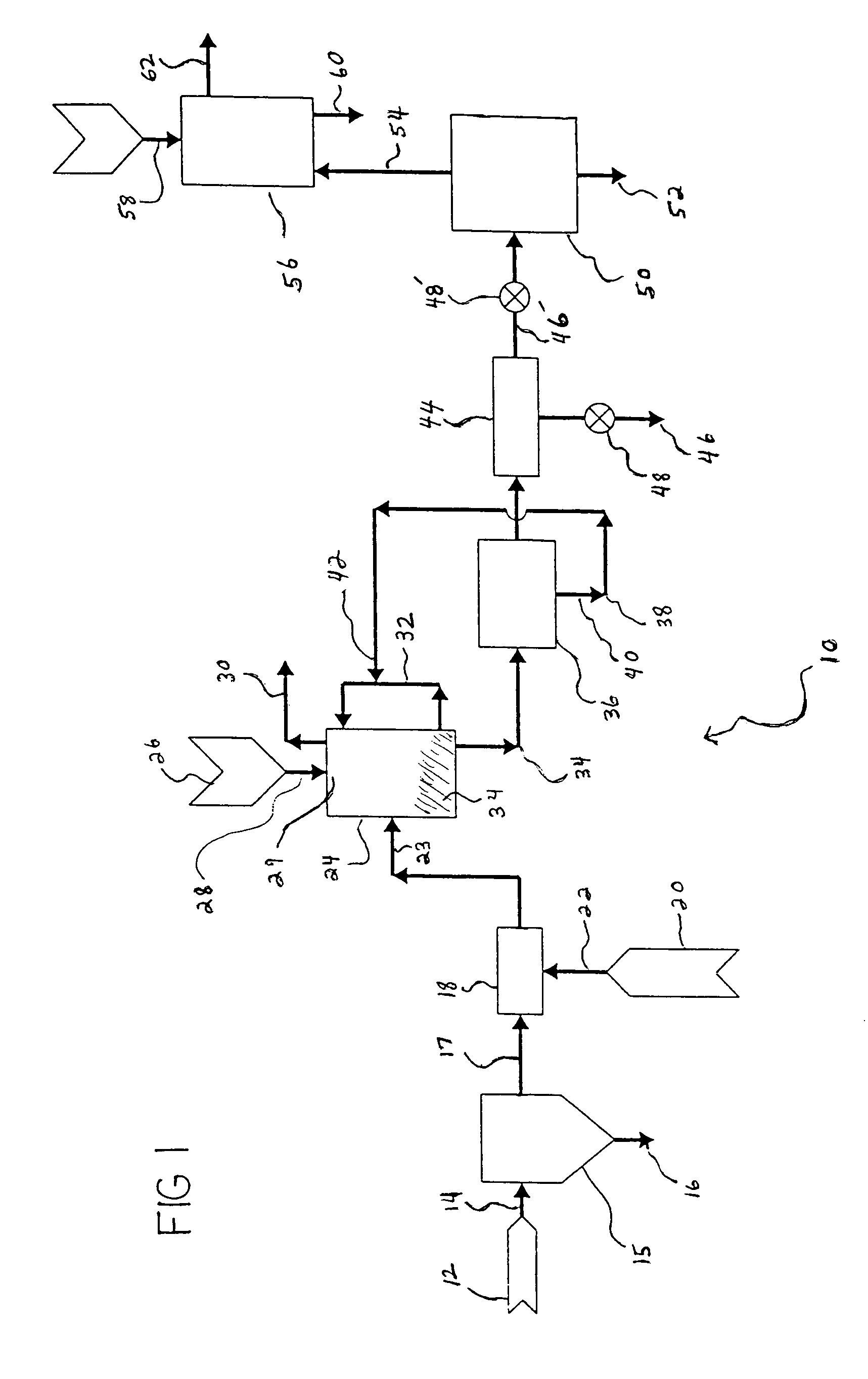

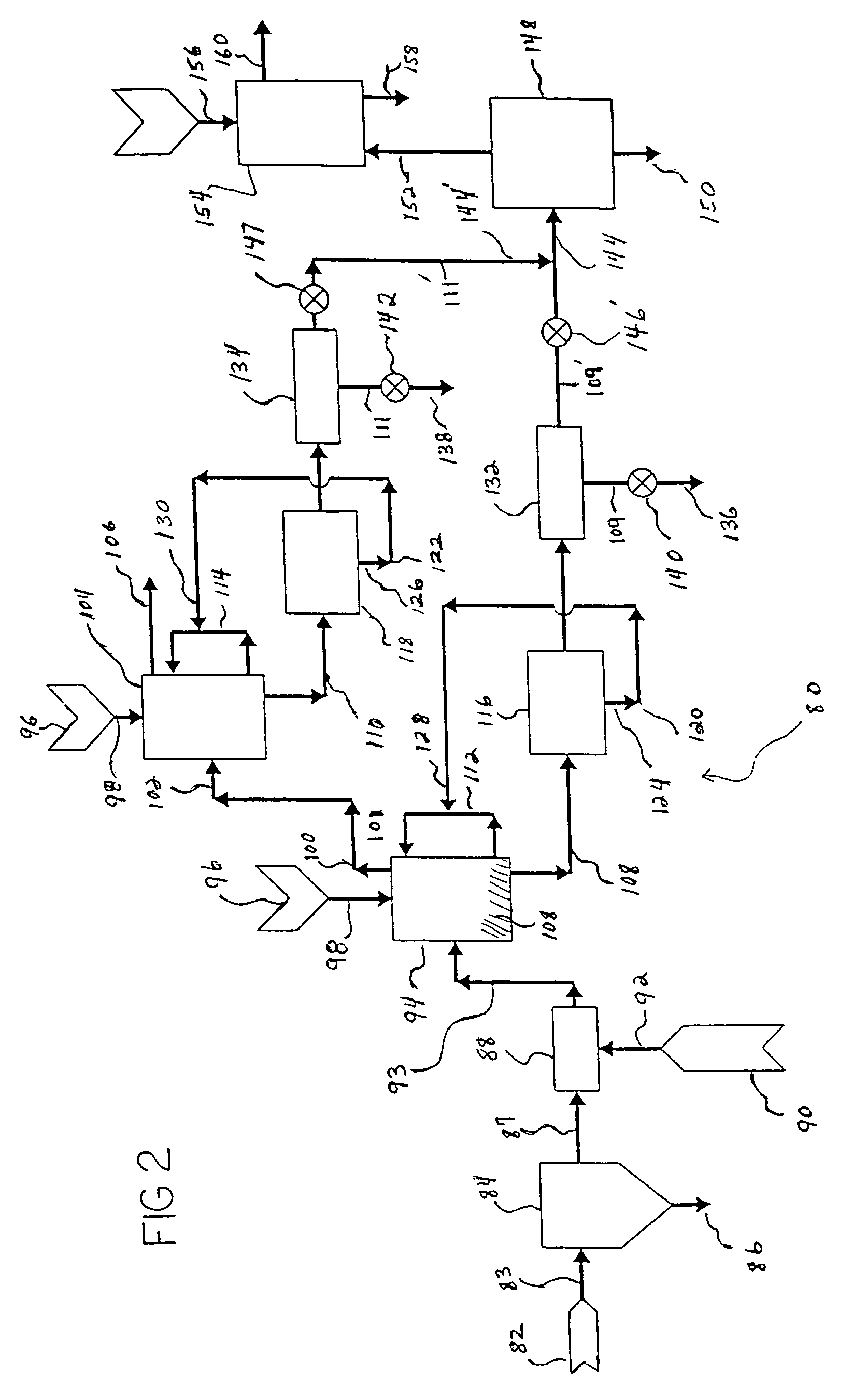

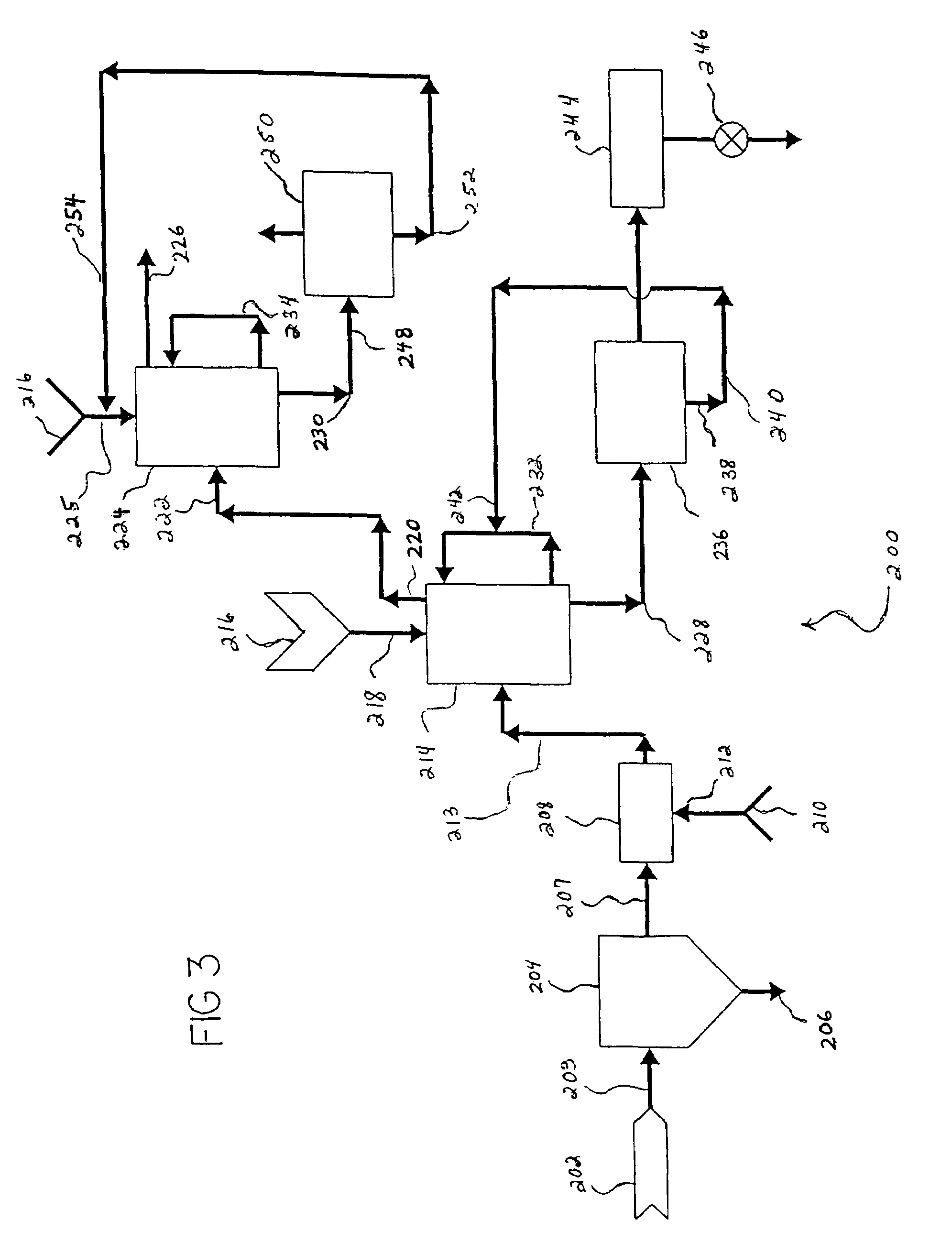

A new method for the removal of environmental compounds from gaseous streams, in particular, flue gas streams. The new method involves first oxidizing some or all of the acid anhydrides contained in the gas stream such as sulfur dioxide (SO2) and nitric oxide (NO) and nitrous oxide (N2O) to sulfur trioxide (SO3) and nitrogen dioxide (NO2). The gas stream is subsequently treated with aqua ammonia or ammonium hydroxide which captures the compounds via chemical absorption through acid-base or neutralization reactions. The products of the reactions can be collected as slurries, dewatered, and dried for use as fertilizers, or once the slurries have been dewatered, used directly as fertilizers. The ammonium hydroxide can be regenerated and recycled for use via thermal decomposition of ammonium bicarbonate, one of the products formed. There are alternative embodiments which entail stoichiometric scrubbing of nitrogen oxides and sulfur oxides with subsequent separate scrubbing of carbon dioxide.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Complex foam extinguishing agent for coal mine

InactiveCN102614615AHigh bonding strengthReduce the drainage rateFire extinguisherSodium bicarbonateMass ratio

The invention discloses a complex foam extinguishing agent for a coal mine and belongs to the technical field of fire prevention and extinguishing. The extinguishing agent is prepared from the following raw materials: main materials are 40 to 60 percent aqueous solution of ammonium bicarbonate or sodium bicarbonate and concentrated sulfuric acid in a solute mass ratio of 2:1-3:1, and auxiliary materials are a stabilizer and a foamer, wherein the auxiliary materials are 0.1 to 2 percent of the total weight of the main materials. Through a test, the extinguishing agent has the foaming coefficient of 20-200 and the foam stabilizing time of more than or equal to 2.5 hours. According to the foam extinguishing agent, the foam of inert gas carbon dioxide is applied to fire prevention and extinguishing of the coal mine, and the foam is diffused in a fire area and fills a fire space, so that the oxygen concentration in the fire area is rapidly reduced, fire is extinguished due to oxygen deficiency in the fire area, temperature is reduced and a fire extinguishing effect is good. The technology also can be applied to coal bed transformation, CO2 foam is easily absorbed by coal to displace partial methane, the recovery ratio of coal seam gas is improved, and CO2 is acid to reduce the generation of secondary precipitates, so that a gas drainage effect is improved. The complex foam extinguishing agent is simple and feasible, and low in cost.

Owner:抚顺正工矿业科技发展有限公司

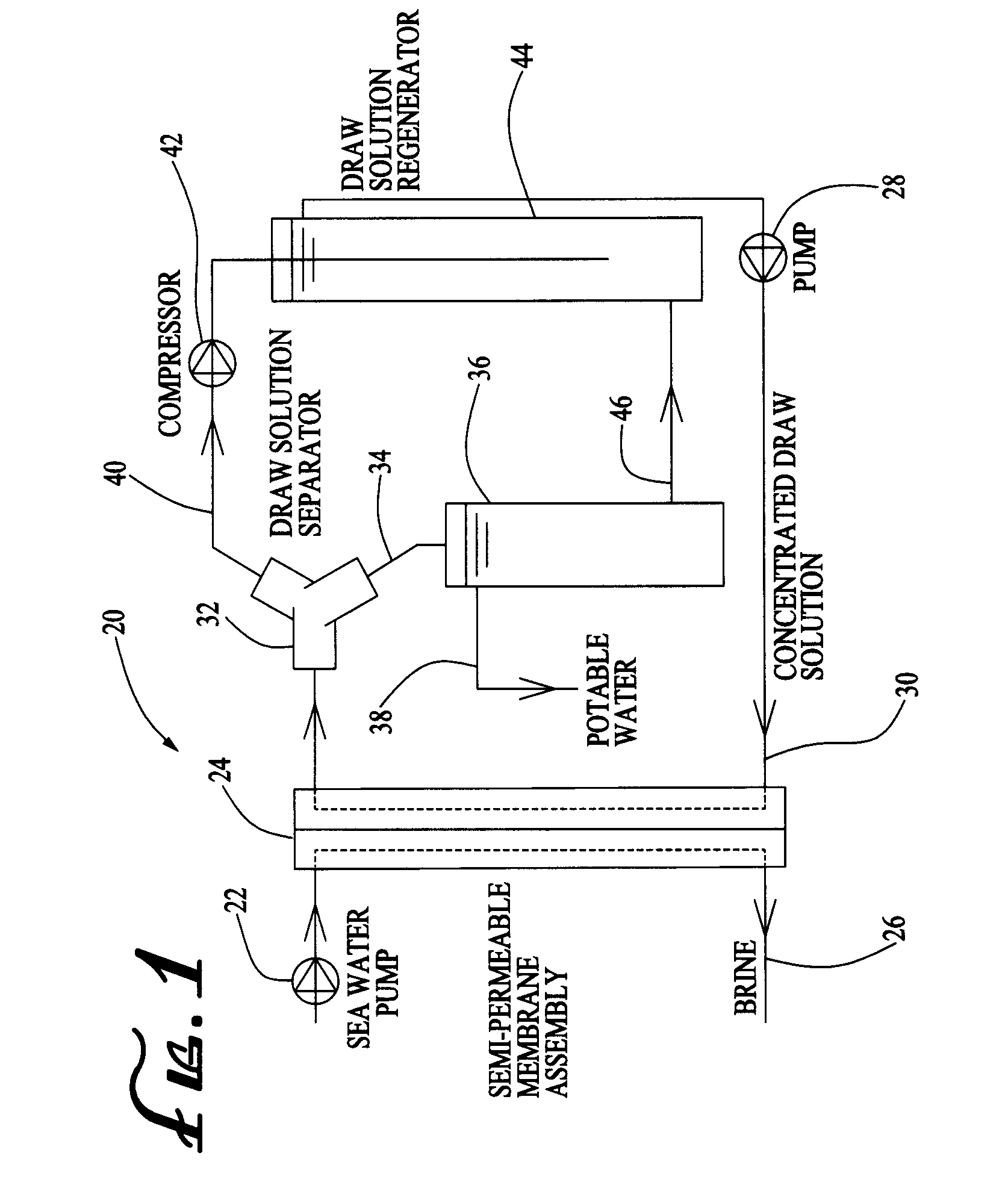

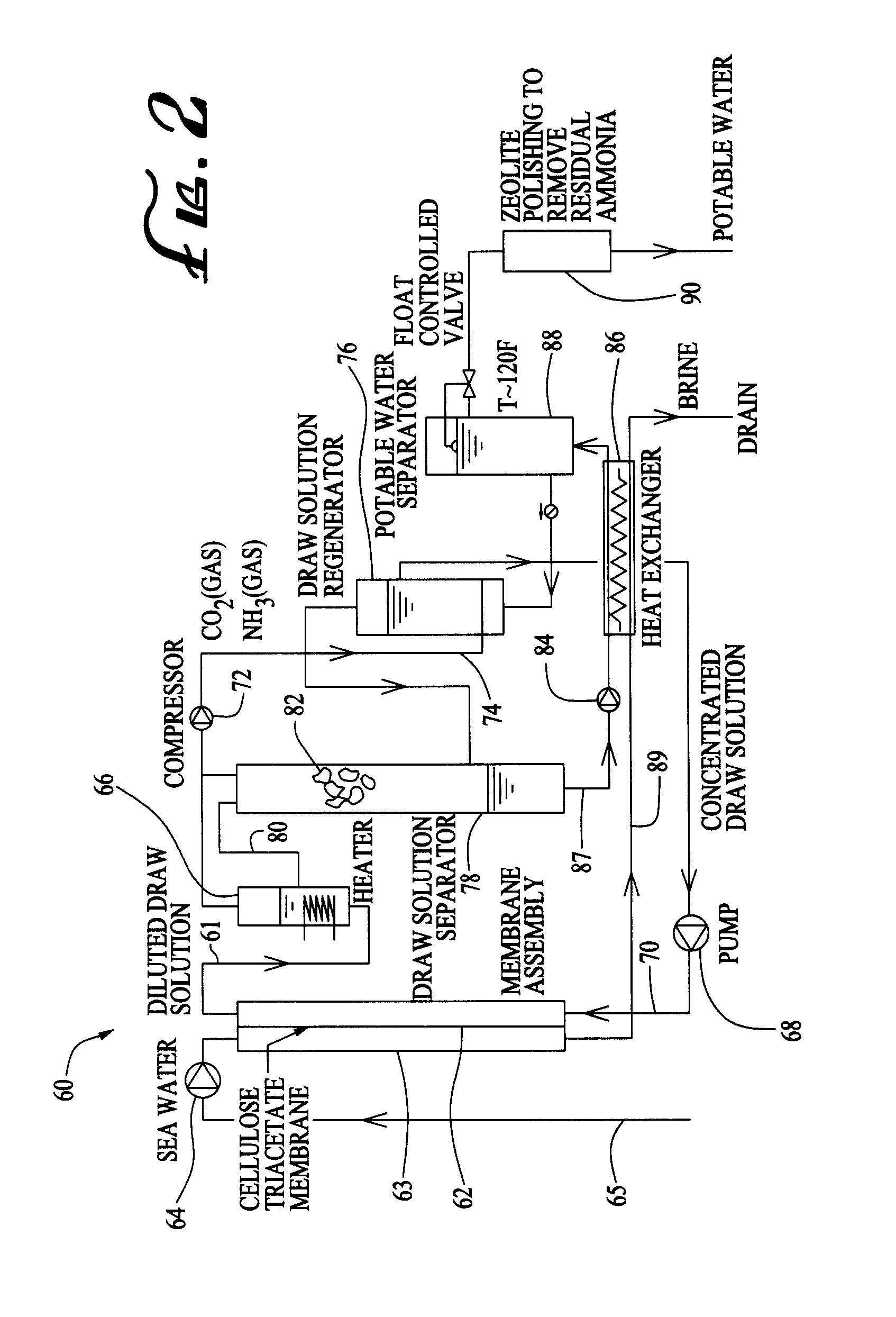

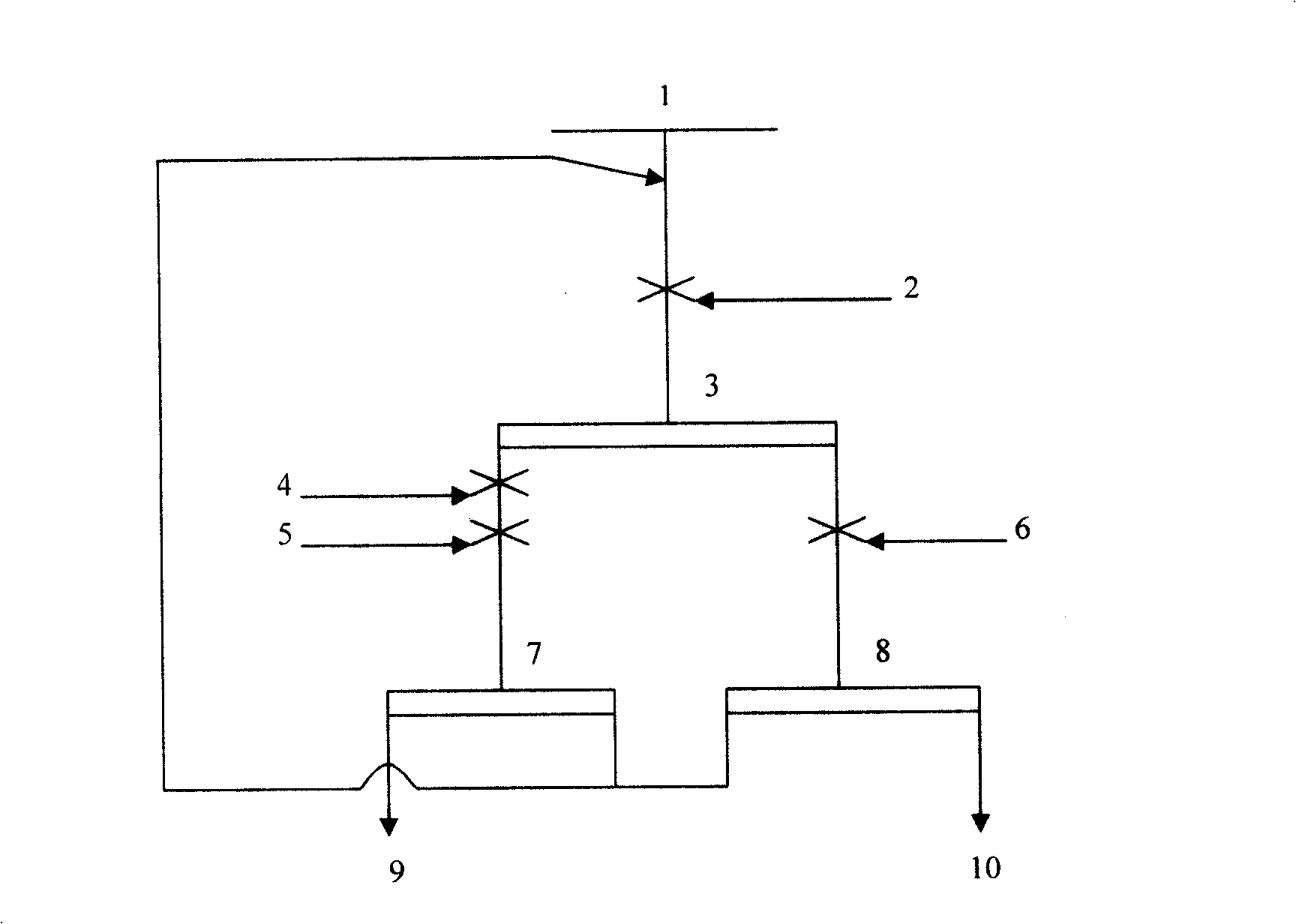

Method and Apparatus for Producing Potable Water from Seawater Using Forward Osmosis

ActiveUS20090308727A1Efficient and effectiveAuxillariesGeneral water supply conservationDesalinationPotable water

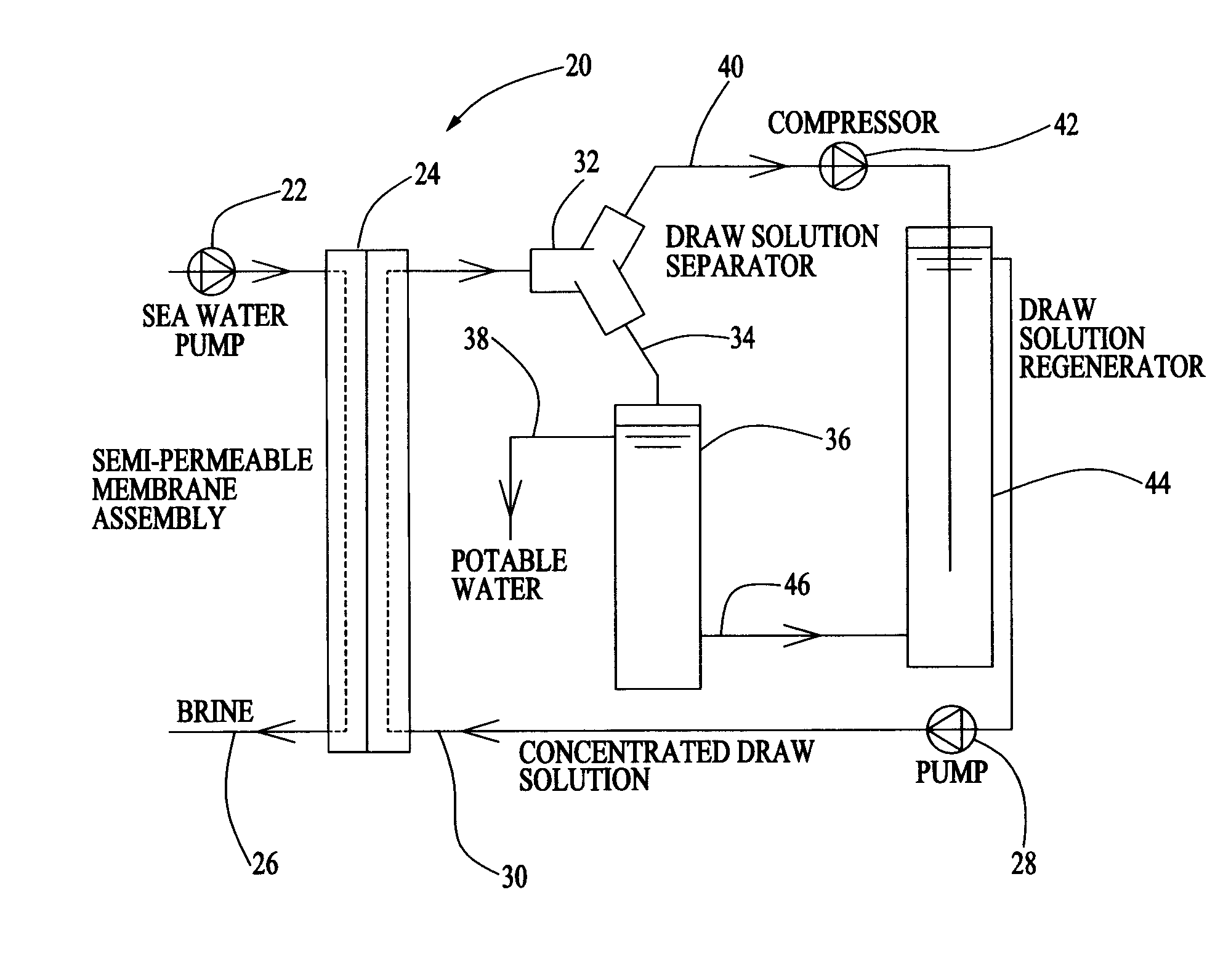

A method and apparatus for desalinating seawater which uses an ammonia bicarbonate forward osmosis desalination process. Seawater is pumped through one side of a membrane assembly. A draw solution is pumped through the other side of the membrane assembly. The draw solution withdraws water molecules from the seawater through the membrane into the draw solution. A draw solution separator receives a heated draw solution which then decomposes into ammonia, carbon dioxide and water. Potable water is separated from ammonia has and carbon dioxide gas. The ammonia gas and carbon dioxide gas are recombined with a portion of the potable water stream to reform the ammonium bicarbonate draw solution.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

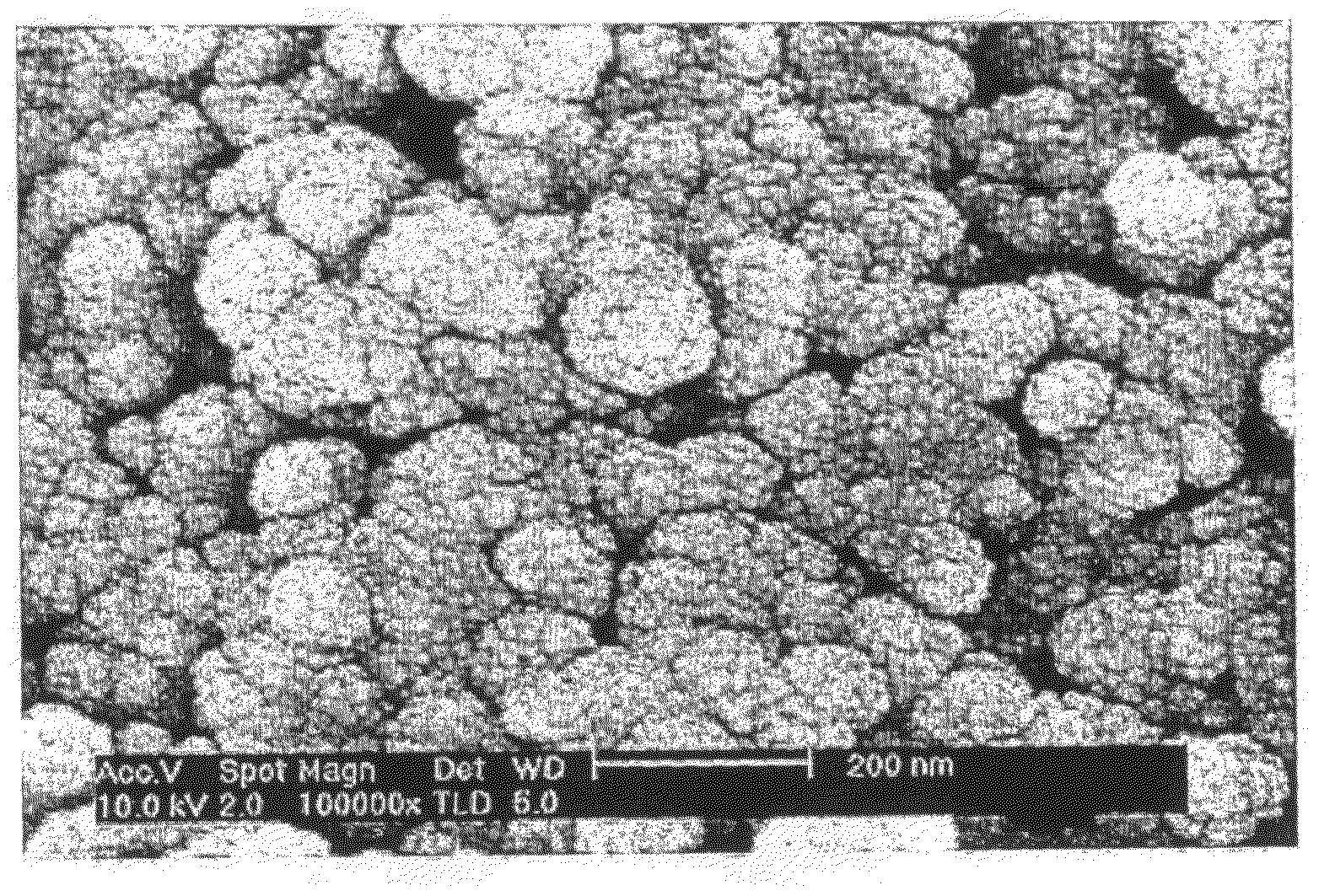

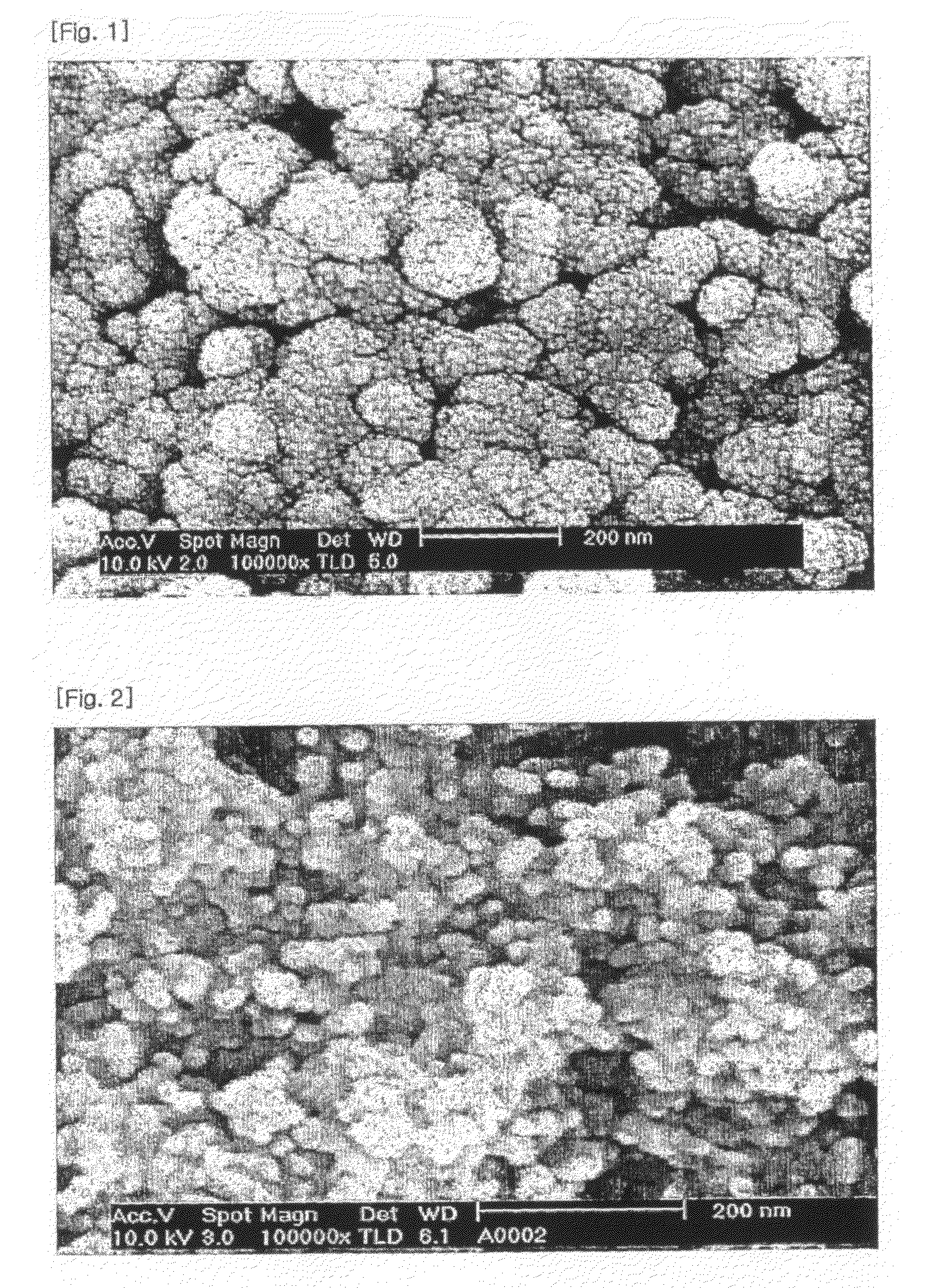

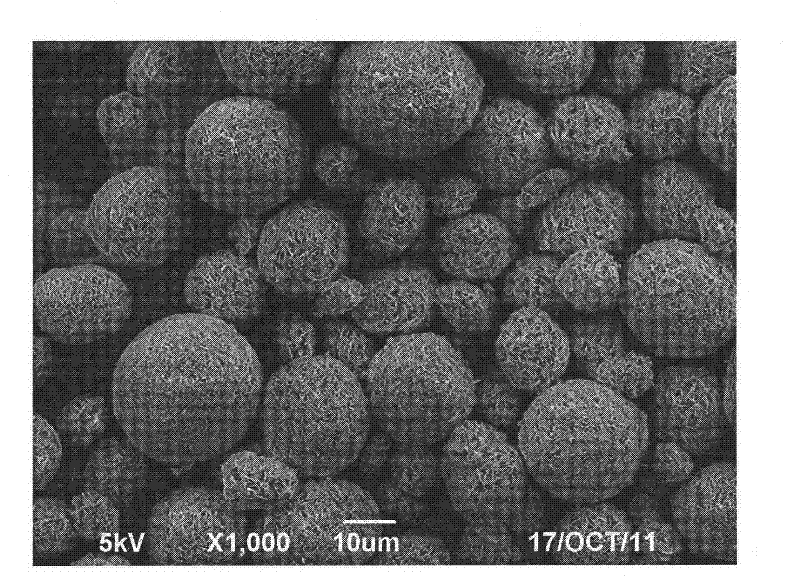

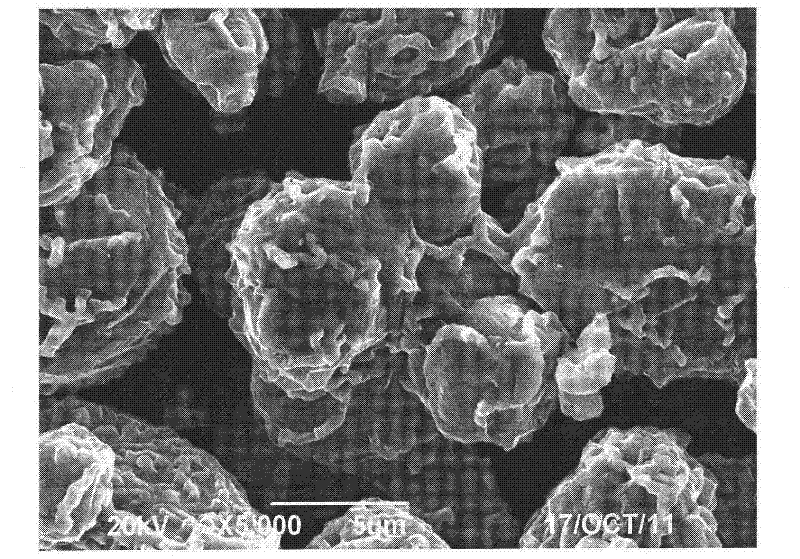

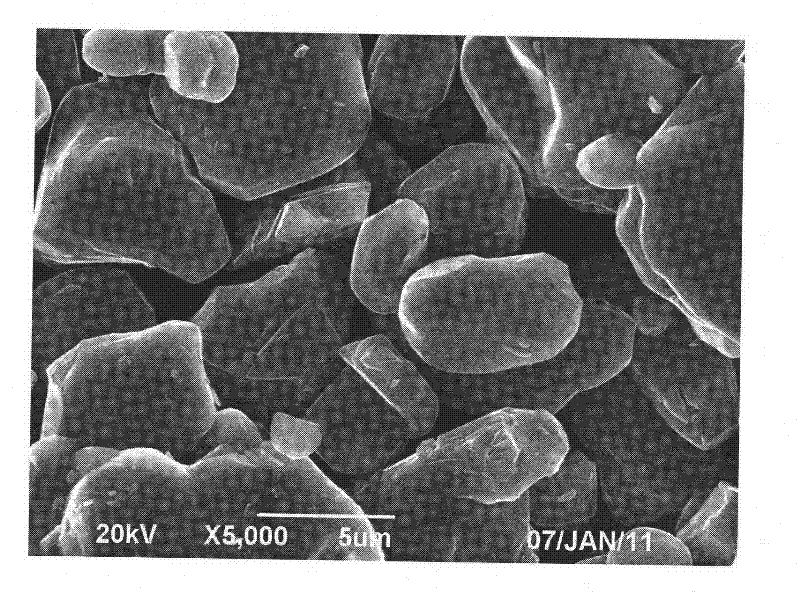

Process for preparation of silver nanoparticles, and the compositions of silver ink containing the same

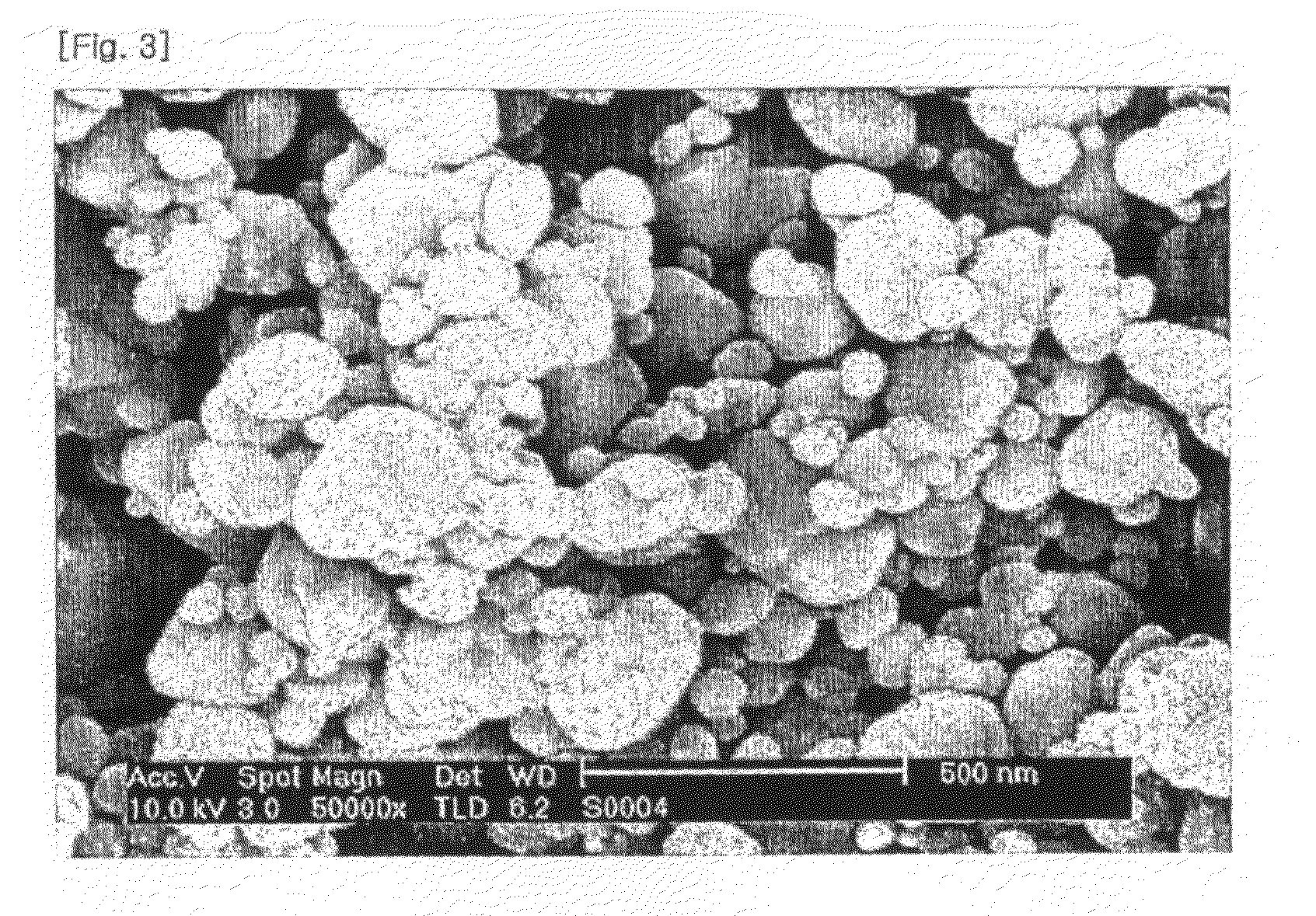

ActiveUS20100189901A1Small sizeGood physical propertiesMaterial nanotechnologyNanostructure manufactureSilver inkAmmonium carbamate

The present invention relates to a process for preparation of silver complex compound and the compositions of silver ink containing the same. The present invention includes a) preparing silver complex compound with special structure by reacting silver compound with at least one or two mixtures selected from ammonium carbamate compound, ammonium carbonate compound or ammonium bicarbonate compound and b) preparing silver nano particles by reacting the silver complex compound with reducer or reducing or pyrolyzing the silver complex compound by applying heat thereto. The preparing method according to the present invention can prepare the silver nano practical with various shapes through a simple preparation process, improve the selectivity of the size of the silver complex compound, fire the silver complex compound even when it is fired at a low temperature of 150° C. or less during a short time, provide the ink compositions capable of forming the coating or the fine pattern showing the high conductivity while facilitating the thickness control of the coating, and provide the ink compositions capable of being applied to the reflective film material, the electromagnetic wave shield, and the antimicrobial agent, etc.

Owner:INKTEC CO LTD

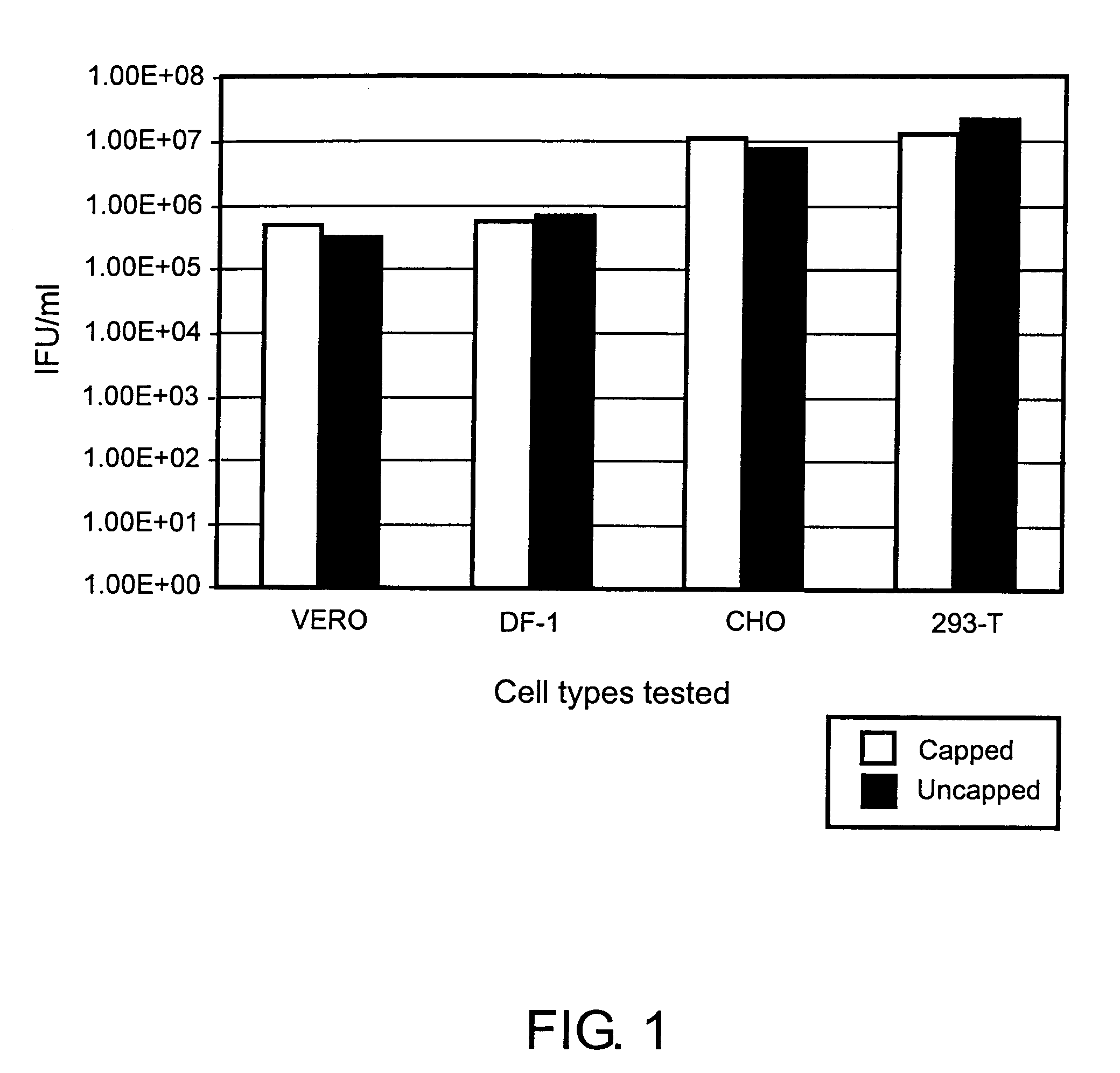

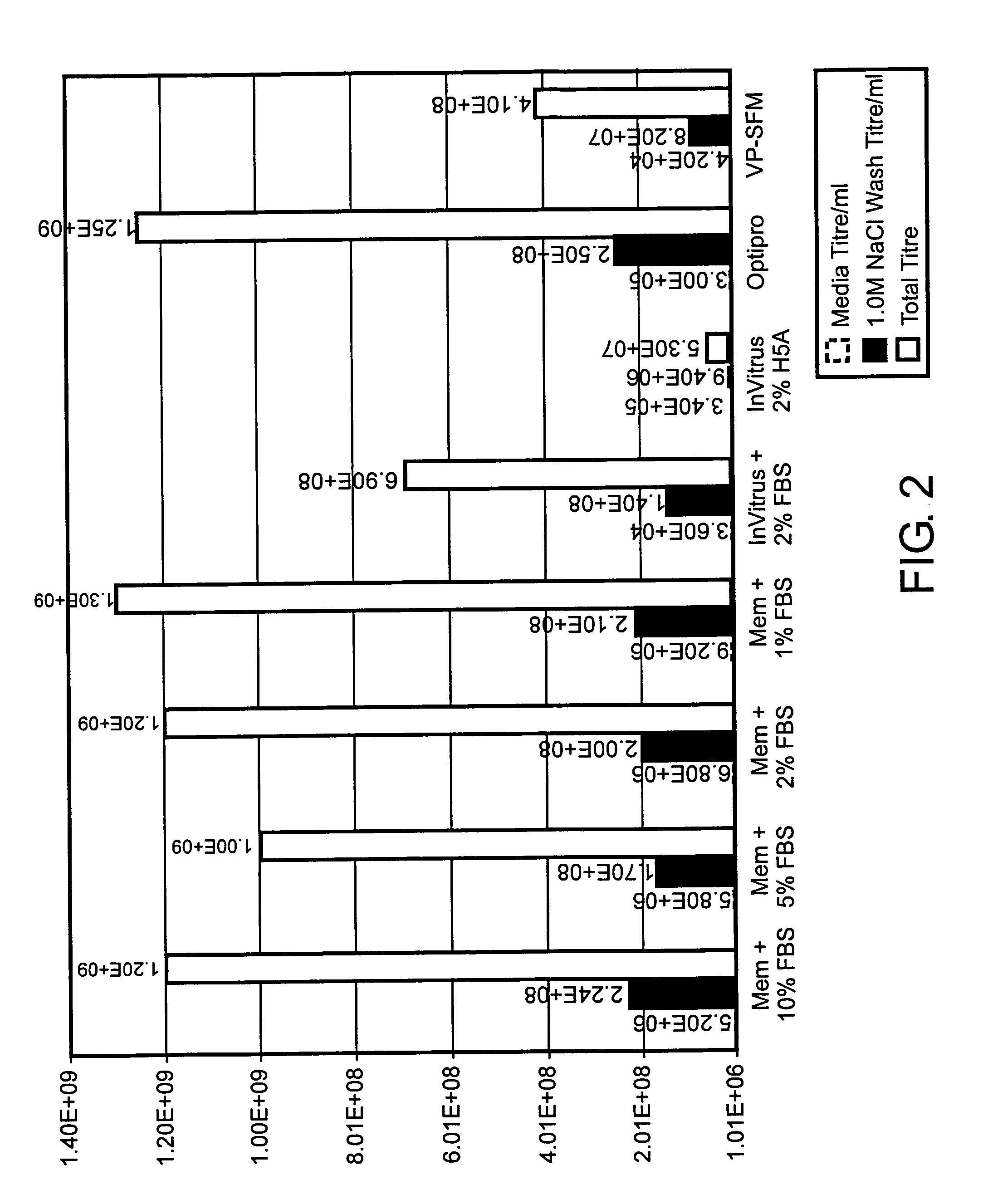

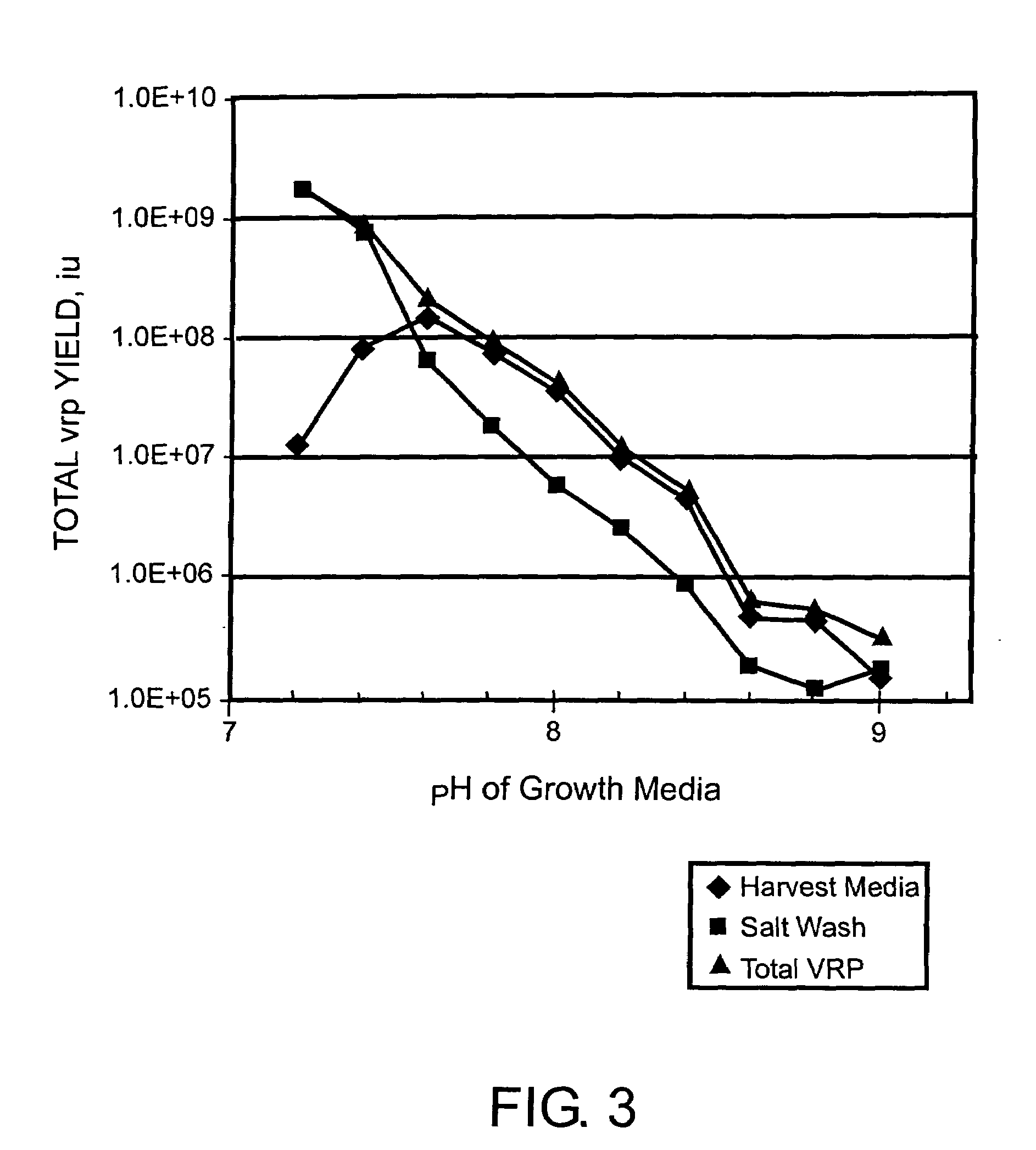

Alphavirus particles and methods for preparation

ActiveUS7078218B2Improve salt wash recoveryIncrease ionic strengthSsRNA viruses positive-senseGenetic material ingredientsHigh densityPotassium

Provided herein are methods for producing alphavirus replicon particles in high yield; replicon RNAs are electroporated into permissive cells, where the cells are at a relatively high density, together with at least one helper nucleic acid providing the necessary functions for packaging. After a growth period in appropriate medium, alphavirus replicon particles are harvested from the surfaces of the cells in which they were produced using a salt wash in which the salt concentration is from about 0.2 to about 5 M sodium chloride, calcium chloride, magnesium chloride, potassium chloride, ammonium acetate, ammonium bicarbonate, among others. After dilution, if necessary, the particles can be purified by a suitable chromatographic technique.

Owner:ALPHAVAX INC

Industrial cultivation method of selenium-enriched agaricus bisporus

InactiveCN101637101AIncrease productionFull of nutritionHorticultureFertilizer mixturesCaladiumAgaricus

The invention provides an industrial cultivation method of selenium-enriched agaricus bisporus, The cultivation materials comprises the materials based on the following part by weight: 100-300 parts of straw, 100-300 parts of cow dung, 0.5-1 part of urea, 0.5-1 part of ammonium bicarbonate, 0.5-1 part of superphosphate, 1-2 parts of lime, 1-2 parts of cake fertilizer, 0.1-0.3 parts of sodium selenite, etc. The invention also provides a series of industrial cultivation methods such as the preparation of mushroom seeds, the preparation of paved soil, the cultivation of the selenium-enriched agaricus bisporus, etc. The cultivation method has low cost, simple and convenient operation and easy realization, and can cultivate the agaricus bisporus with high yield and abundant nutrition, wherein the content of organic selenium generally can reach more than 0.5-1%. The selenium-enriched agaricus bisporus is dried in a drying oven till that moisture content is less than 5%, is crashed and screened to obtain the organic selenium powder; and the organic selenium powder is taken as raw materials to be matched with spirulina, lucid ganoderma, and the like, to prepare various selenium-enriched nutritious foods such as granules, troche, oral liquid, and the like, thereby having wide application range.

Owner:蛟河市黑土白云食用菌有限公司

Method for recovering tungsten trioxide and ammonium metavanadate from selective catalytic reduction (SCR) denitration catalyst

ActiveCN102557142AEmission reductionTungsten oxides/hydroxidesDispersed particle separationWarm waterAmmonium paratungstate

The invention relates to a method for recovering tungsten trioxide and ammonium metavanadate from a selective catalytic reduction (SCR) denitration catalyst. The method comprises the following steps of: crushing the SCR denitration catalyst, sieving to obtain catalyst powder, mixing with sodium carbonate, and stirring fully and uniformly; putting the mixed powder into a sintering furnace, and sintering to obtain a sintered material; keeping temperature for 1 hour, and sieving to obtain sintered material powder; pouring warm water, so that Na2WO4 and NaVO3 in the sintered material powder are dissolved fully, filtering, and removing precipitates to obtain a mixed solution of Na2WO4 and NaVO3; regulating the pH value to be 6.5-7.5, adding an ammonium bicarbonate solution or an ammonium chloride solution, and precipitating ammonium metavanadate precipitate; filtering, washing by using a diluted ammonium bicarbonate solution for 2 to 3 times, washing by using 30 percent ethanol for 1 to 2 times, and drying to obtain an ammonium metavanadate finished product; and converting the Na2WO4 in the residual solution into ammonium paratungstate, evaporating the residual solution to obtain ammonium paratungstate crystals, and calcining to obtain the tungsten trioxide. By the method, the ammonium metavanadate and the tungsten trioxide can be recovered, and the discharge of pollutants is reduced.

Owner:江苏万德环保科技有限公司

Preparation method of double-hole-structure alumina supporter

ActiveCN102861617ALarge hole volumeNo overheating phenomenonCatalyst carriersMaterials scienceAmmonium bicarbonate

The invention discloses a preparation method of a double-hole-structure alumina supporter. The preparation method comprises the steps of weighing a certain quantity of pseudo-boehmite dry glue powders, evenly mixing the pseudo-boehmite dry glue powder with a certain quantity of peptizing agent and extrusion-auxiliary agent, then adding a certain quantity of ammonium bicarbonate aqueous solution in materials, mixing and nipping obtained materials into a plasticizer, squeezing into stripes and molding, placing molded materials in a sealing container, and roasting to prepare the alumina supporter after hydro-thermal treatment. The temperature of the hydro-thermal treatment is 70-120 DEG C, and the treatment time is 5-10 hours. Roasting is carried out at the temperature of 600-750 DEG C for 2-4 hours. The mass concentration of an ammonium bicarbonate solution is 40%-80%, the adding quantity of the ammonium bicarbonate solution is calculated according to NH<4+> and Al<3+>, and a molar ratio of the NH<4+> to Al<3+> is (0.5-1):1. According to the preparation method, the preparation procedure is simple, the prepared alumina supporter is in double-hole distribution and has good mechanical strength, and the preparation method is suitable to the field of preparation of heavy oil and residual oil hydrodemetallization catalysts and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

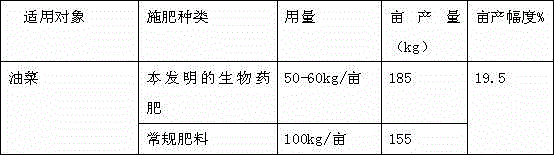

Specialized organic/inorganic composite biological medicine fertilizer for rape, and preparation method thereof

InactiveCN102942406AImprove fertilizer efficiencyLow costFertilizer mixturesBiotechnologyCelastrus orbiculatus

The invention provides a specialized organic / inorganic composite biological medicine fertilizer for rape, and a preparation method thereof. The weight parts of composition raw materials are as follows: 60-80 parts of greenhouse garbage, 6-7 parts of pericarp, 6-8 parts of cotton straws, 8-10 parts of pig manure, 10-12 parts of plant ash, 10-12 parts of sugar residue, 20-25 parts of sodium humate, 10-11 parts of diammonium phosphate, 12-14 parts of potassium sulfate, 12-14 parts of urea, 12-14 parts of ammonium bicarbonate, 14-16 parts of medical stone, 12-14 parts of animal hair, 1-2 parts of EM strains, 20-22 parts of modified bentonite, 8-10 parts of celastrus orbiculatus, 3-4 parts of neem, 4-6 parts of monkshood, 3-5 parts of fiveleaf akebia fruit, 0.7-1.2 parts of boric acid, 1-1.2 parts of manganese sulfate, 2-4 parts of copper sulfate, 4-6 parts of eucalyptus oil and a proper amount of paraffin. A green organic fertilizer is obtained by mixing a plurality of organic wastes and fermenting the mixture, thereby reducing environment pollutions. The specialized organic / inorganic composite biological medicine fertilizer for the rape has the advantages of comprehensive nutrition and enhanced sterilizing effects by mixing the fermented organic materials and inorganic fertilizer and adding medicine juice of the Chinese herbal medicine having insectidical functions. With the application of the fertilizer, rape quality can be effectively increased; and the rape has green leaves, bright flower, prolonged flowering period, full seeds and increased output.

Owner:合肥科友生物科技有限公司

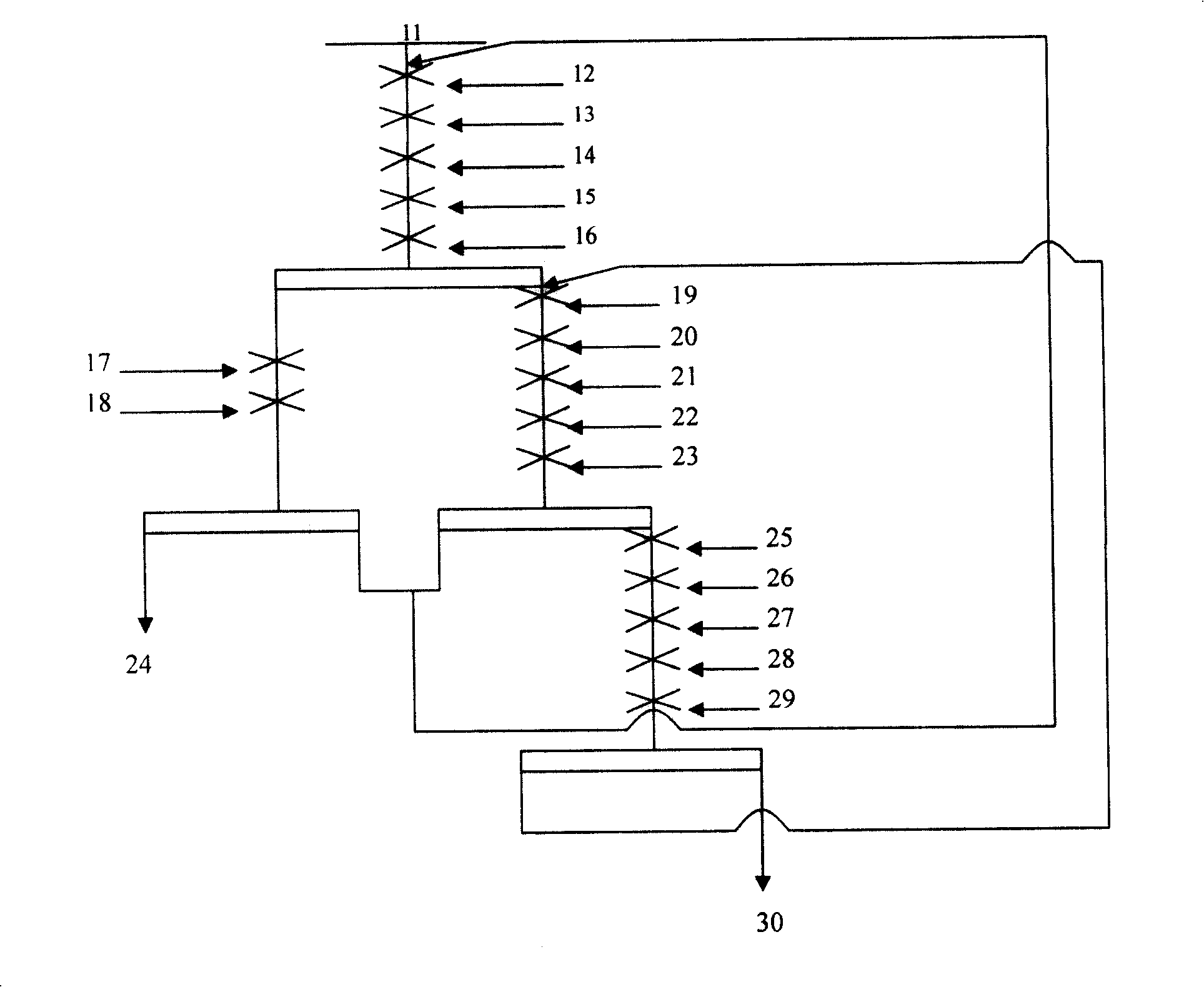

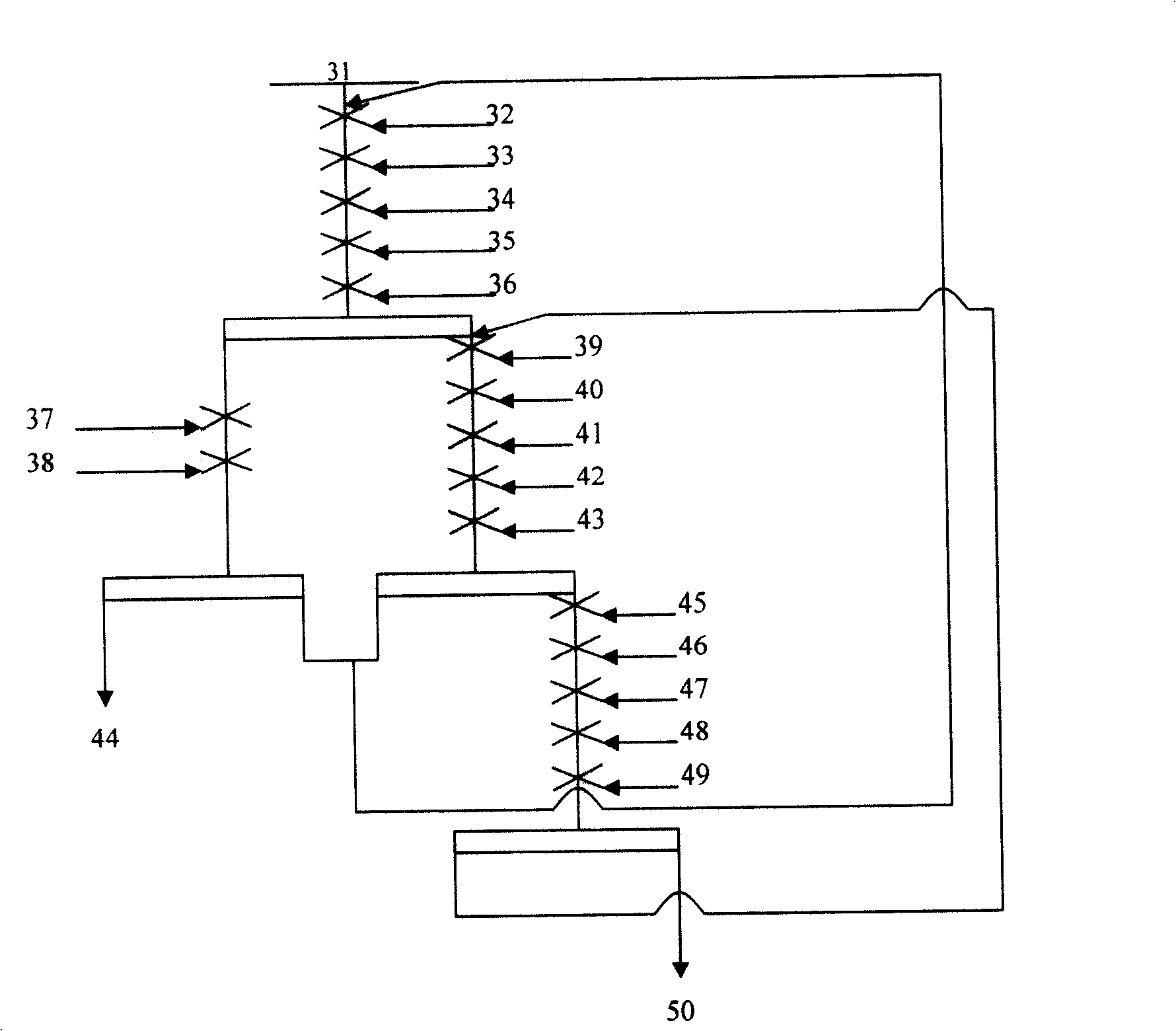

Method for totally extracting vanadium, gallium and scandium by using titanium dioxide hydrolysis waste acid to leach steel slag containing vanadium

InactiveCN102011010AReduce processing costsSave the cost of sulfuric acidProcess efficiency improvementSlagHydrolysis

The invention relates to a method for extracting, separating and recovering vanadium, gallium and scandium in pickle liquor by adopting a total extracting method and using titanium dioxide hydrolysis waste acid to leach steel slag containing vanadium, comprising the following steps of: mixing and stirring titanium dioxide hydrolysis waste acid and steel slag containing vanadium to obtain leaching pulp; performing solid-liquid separation for the leaching pulp, totally extracting vanadium, gallium and scandium in filtered liquor with five-category return flow, then back-extracting vanadium and gallium with five-category return flow, neutralizing with ammonium bicarbonate or ammonia water, warning up, precipitating vanadium to obtain ammonium polyvanadate, repeatedly back-extracting and precipitating vanadium for precipitating-vanadium mother liquor, and then recovering gallium; and when a back-extracting vanadium and gallium organic phase is repeatedly totally extracted and back-extracted till the content of scandium in the back-extracting vanadium and gallium organic phase is 50-1000mg, recovering scandium. The invention has the beneficial effects that waste is treated with waste, namely vanadium, gallium and scandium are recovered by using titanium dioxide hydrolysis waste acid to leach steel slag containing vanadium, and the sulfuric acid cost is saved; the method has great social and economic benefits and low production cost for producing gallium and scandium; without roasting, no waste gas is produced, and three wastes can be discharged with corresponding standards.

Owner:杨秋良 +1

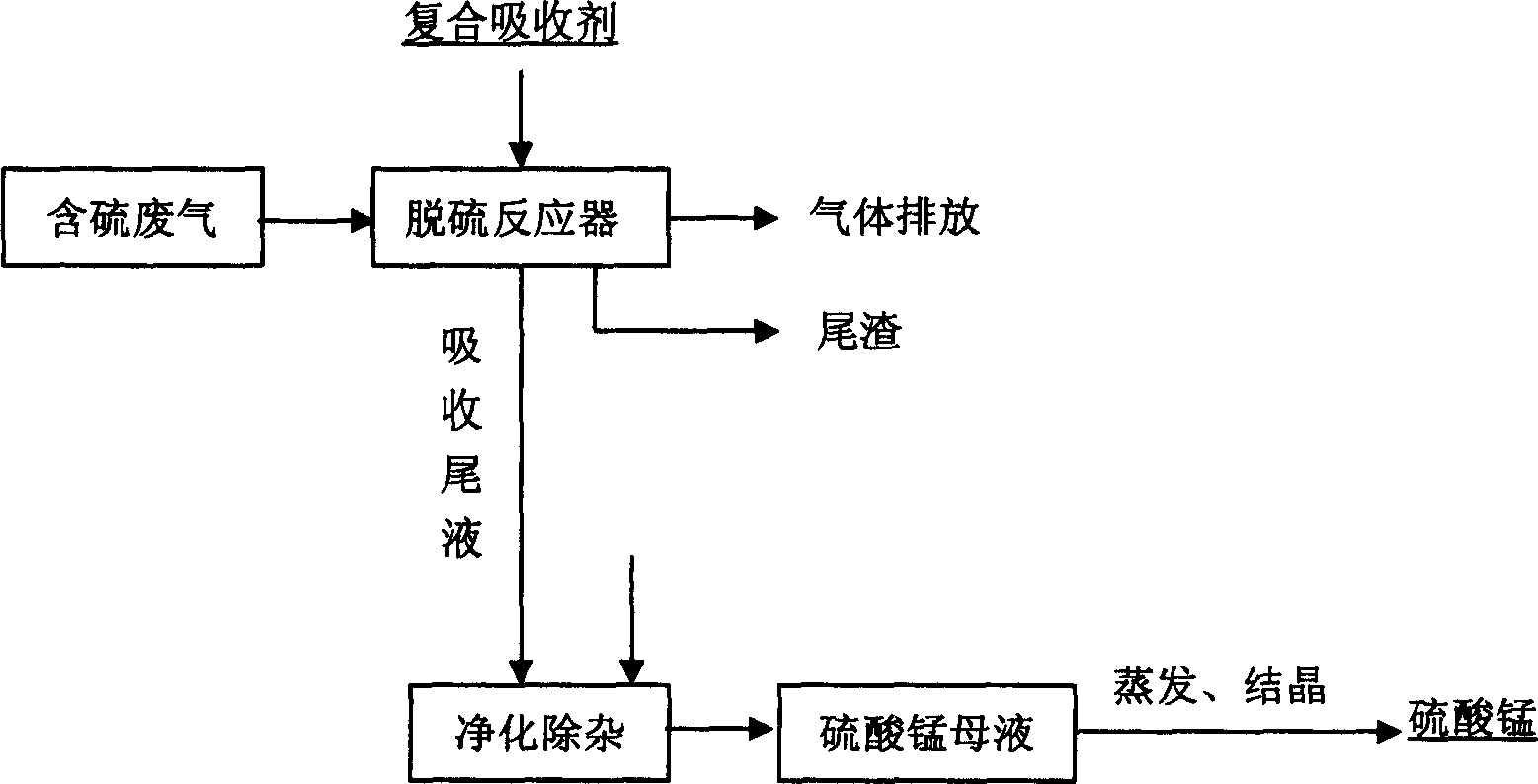

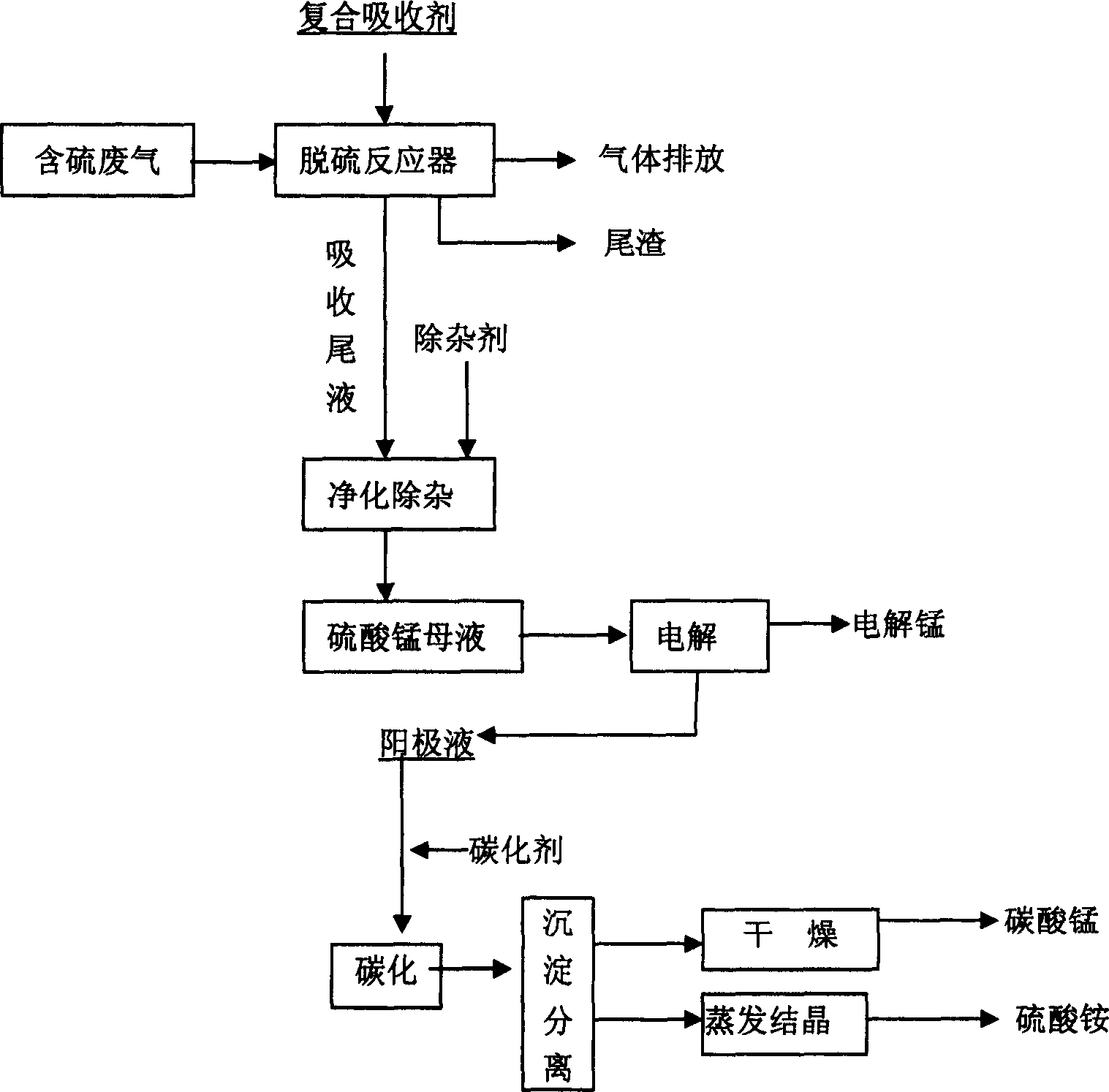

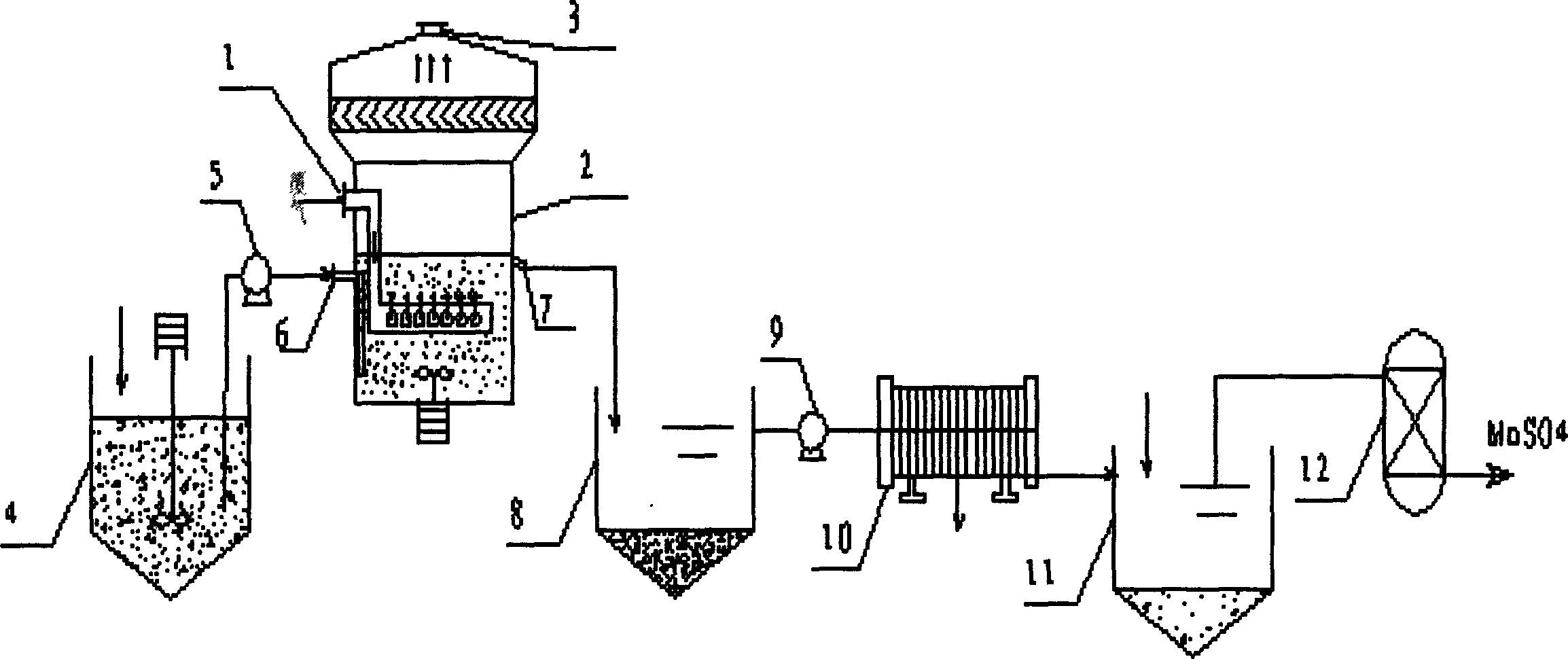

Waste gas desulfurizing method with composite absorbant comprising pyrolusite and pH buffering agent

ActiveCN1772345ARich reservesLow pricePhotography auxillary processesDispersed particle separationPyrolusiteElectrolysis

The present invention is method of comprehensively utilizing waste SO2 gas resource and pyrolusite, and the method includes utilizing the composite absorbent comprising pyrolusite slurry and pH buffering agent to produce oxidation-reduction and neutralizing reaction with waste SO2 gas to eliminate SO2 from the waste gas, purifying the absorbed tail liquid to obtain manganese sulfate product through direct evaporating crystallization or metal manganese product through DC electrolysis, and treating the anode liquid to obtain high purity manganese carbonate product and ammonium sulfate product. The present invention realizes treatment of waste with waste to recover sulfur resource and comprehensively utilize pyrolusite. The method of the present invention is reasonable and has no secondary pollution.

Owner:SICHUAN UNIV

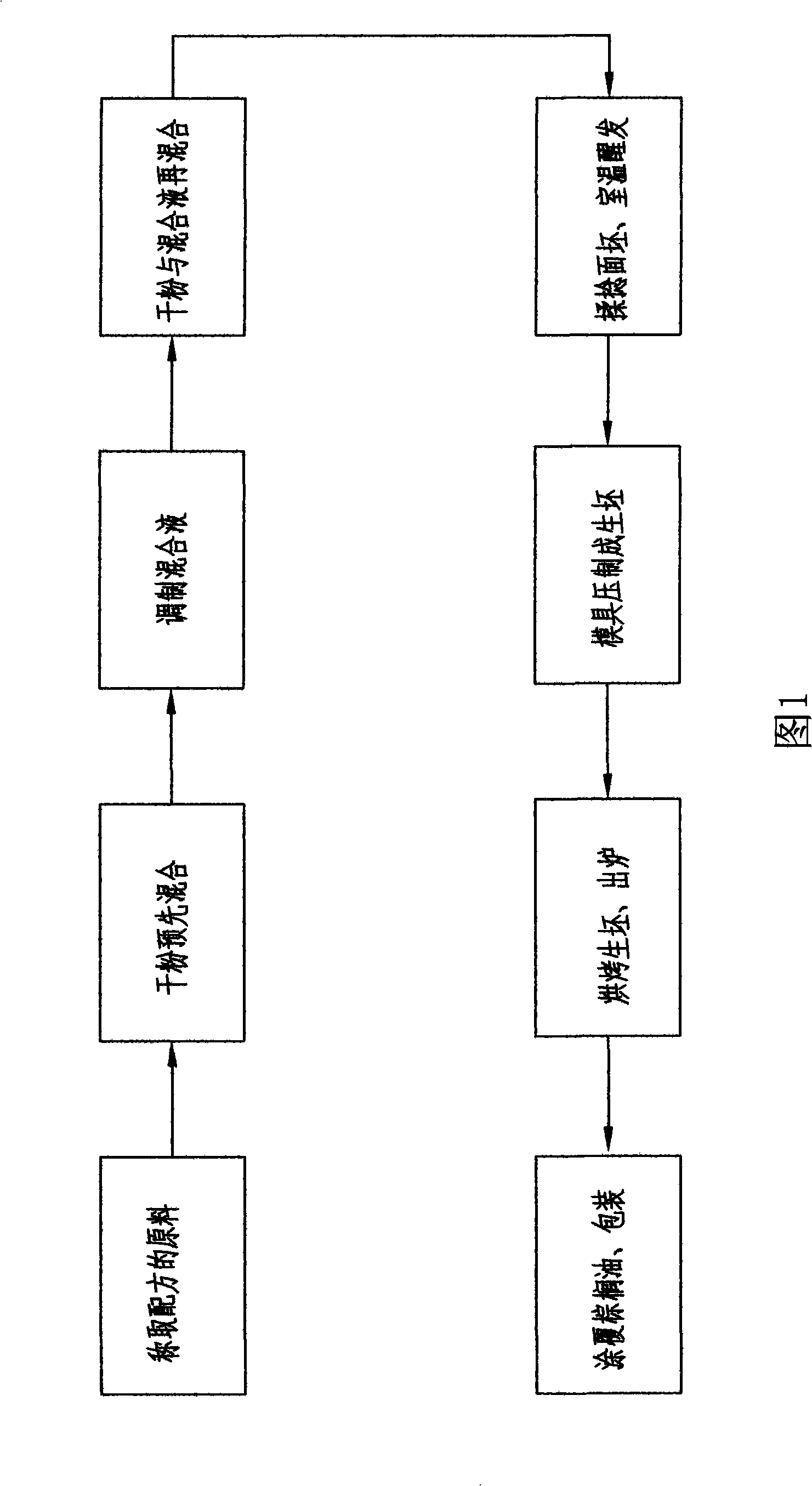

Coarse grain biscuit and preparation method thereof

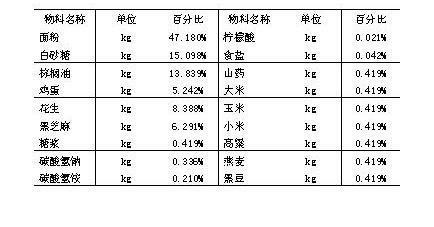

The invention relates to a coarse grain biscuit and a preparation method thereof. The formula of the coarse grain biscuit comprises 15 to 18 percent of coarse grain special flour, 30 to 38 percent of gluten flour, 8 to 15 percent of edible vegetable oil, 12 to 20 percent of white granulated sugar, 2 to 3 percent of dried whole milk, 0.2 to 0.25 percent of sodium bicarbonate, 0.2 to 0.35 percent of ammonium bicarbonate, 0.1 to 0.25 percent of edible salt, 0.1 to 0.25 percent of coarse grain essence, 2 to 3.5 percent of egg and the balance being water. The preparation method comprises the following steps that: needed raw materials are taken and mixed in advance by means of dry powder; a mixed liquid is prepared and then is added in the premixed dry powder so as to be mixed; water is added in the mixture so as to knead the mixture into a dough; the dough is kneaded, fermented and pressed into a dough which is fed into an oven to be roasted; and the roasted dough is coated with palm oil after and is packaged after airing. The coarse grain biscuit adopts coarse grain special flour made of coarse grain of natural corns, beans and tubers, and has easily controlled mixture ratio of raw materials, low cost and stable quality; moreover, the coarse grain biscuit is suitable for large-scale production, and has a nice chewy texture and the efficacies of heal care and weight reducing.

Owner:田丰

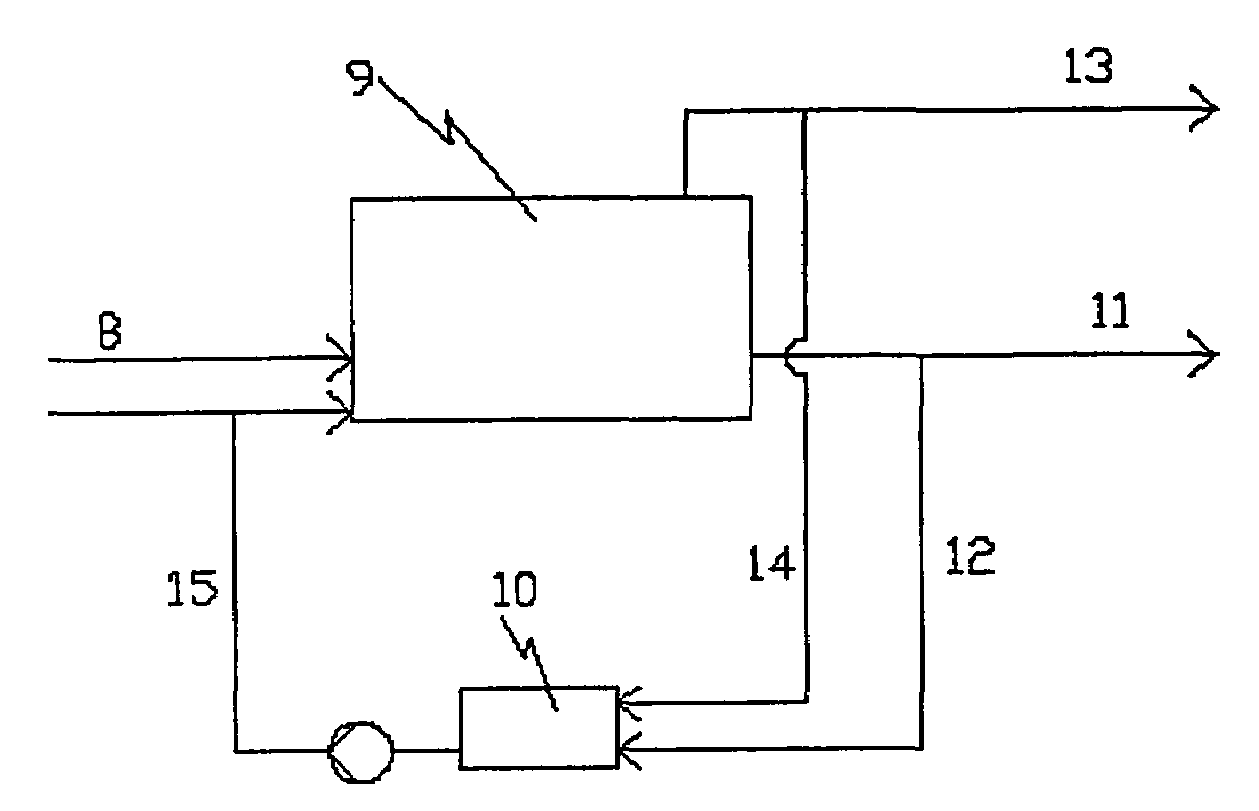

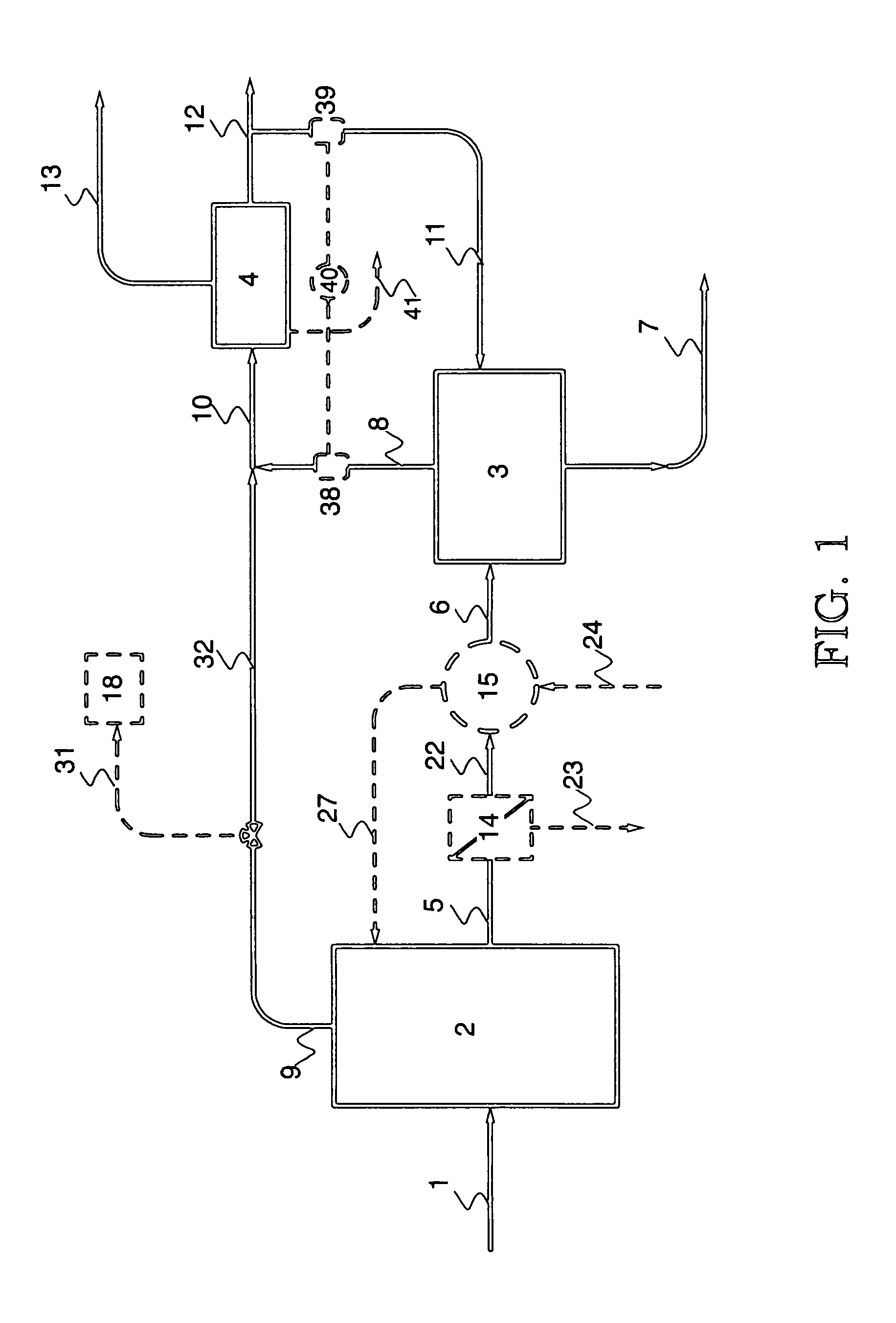

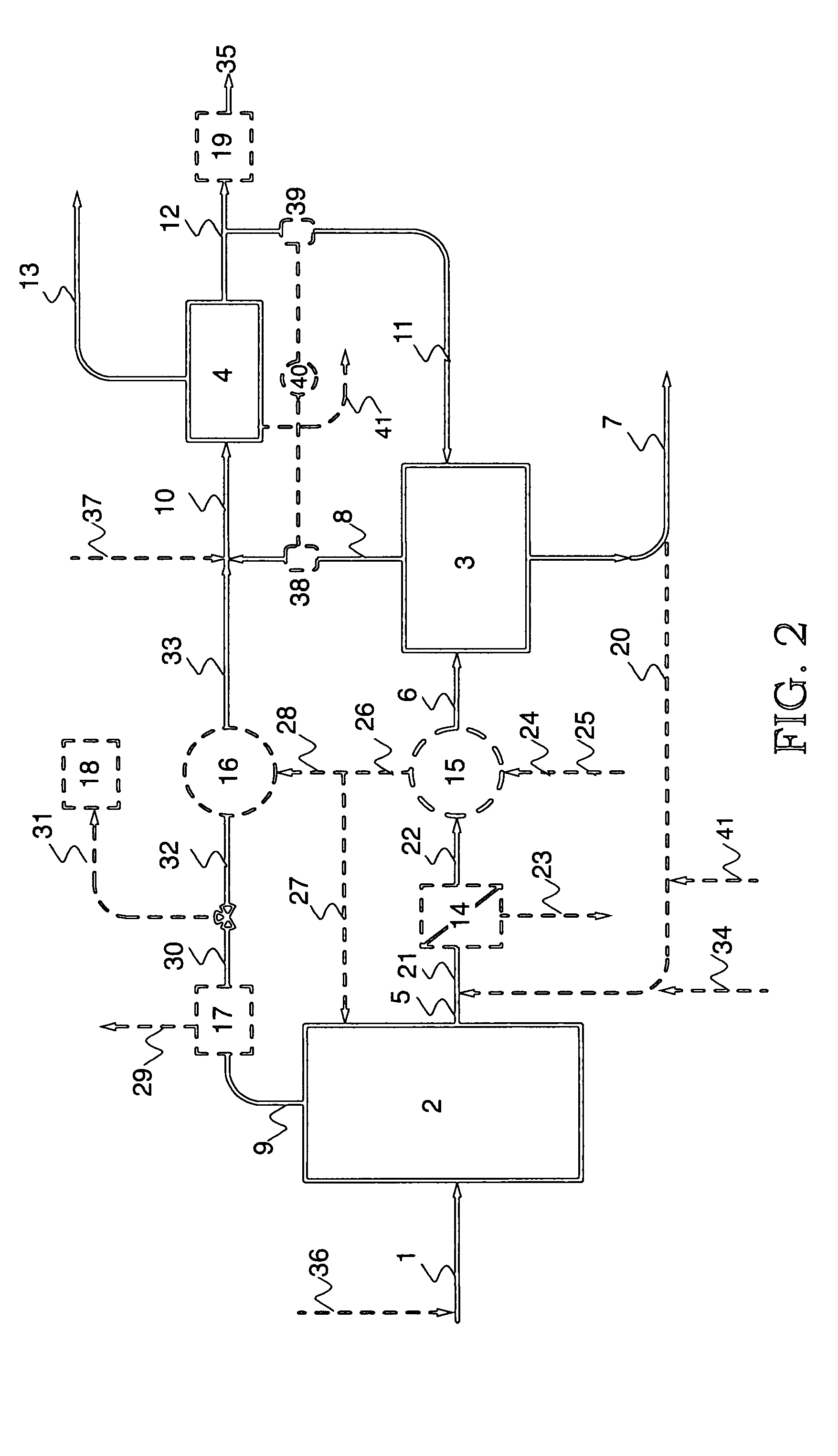

Method and equipment for processing organic material

InactiveUS7160456B2Organic material longerEasy to storeBio-organic fraction processingAnimal corpse fertilisersBuffer solutionAmmonia

A method for processing organic material, in which method bioconversion is performed on the organic material in at least one first reactor, the biogas formed in the bioconversion is treated with ammonia in at least one second reactor and buffer solution produced in the second reactor is recycled to the bioconversion in the first reactor. Thus, the carbon dioxide of the mixed methane / carbon dioxide gas reacts with the ammonia and forms a buffer compound, such as ammonium bicarbonate and / or ammonium carbonate.

Owner:PRESECO

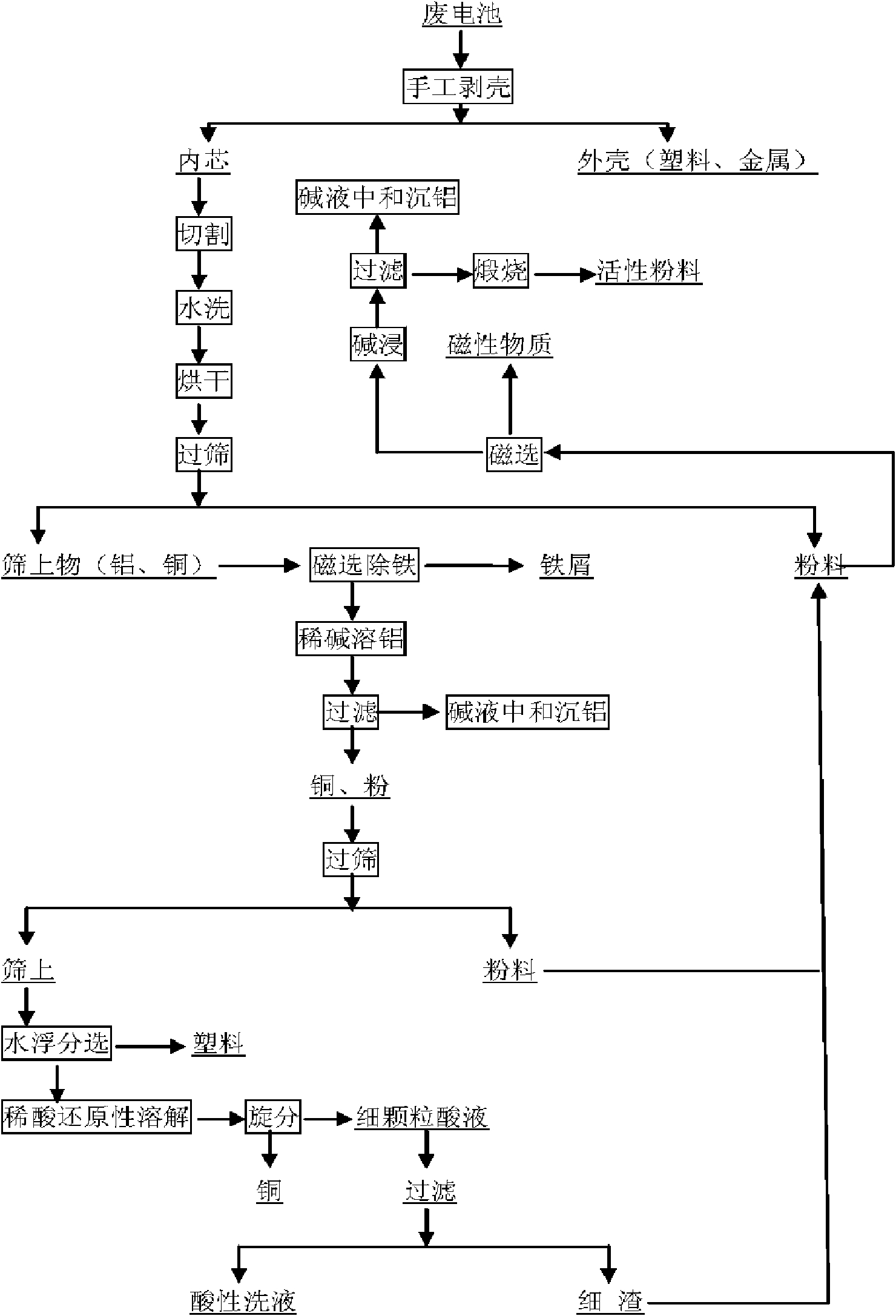

Method for efficiently recovering active materials of positive poles in waste lithium batteries

InactiveCN101599563AWaste accumulators reclaimingProcess efficiency improvementCycloneElectrical battery

The invention discloses a method for efficiently recovering active materials of positive poles in waste lithium batteries, which is mainly characterized by adding crushed electrical core fragments into hot water, stirring the mixture, and performing first vibration screening after the filtration and drying to separate most of an active material; dissolving aluminum foil through alkaline leaching after an oversize part is magnetically separated, adjusting the pH value of an alkaline leaching filtrate by dilute acid and ammonium bicarbonate solution, and recovering aluminum; performing second vibration screening after the filtration and drying to separate a residual powder material; and placing the oversize part into water for water cyclone separation, dumping to remove an upper-layer plastic diaphragm, then using dilute sulfuric acid and sodium thiosulfate solution to wash a copper sheet to ensure that carbon powder and active powder which are adhered to the copper sheet are loosened and fall off, making the powder float on an upper layer through cyclone separation after the washing, mixing the powder and the active powders obtained by two screenings, using NaOH solution to soak the mixture after the magnetic separation, calcining the alkali-leached active powder material after the filtration and drying, and taking the active powder material as active powder for subsequent treatment. The use of the method can ensure that the recovery rates of copper and aluminum in waste lithium ion batteries reach 98.5 percent and 97 percent respectively, and the recovery rate of the active materials is about 99 percent.

Owner:CENT SOUTH UNIV

Method for extracting ultrahigh-purity lithium carbonate from salt lake brine with high magnesium-lithium ratio

The invention discloses a method for extracting ultrahigh-purity lithium carbonate from chloride brine with a high magnesium-lithium ratio. The method comprises the following steps of: preparing a lithium chloride concentrated solution by an adsorption, desorption and evaporation concentration process; purifying, and precipitating lithium carbonate by using ammonium bicarbonate pulp; and converting into a lithium bicarbonate solution, filtering, and decarburizing. By improving steps and parameters of the conventional process, the purity of a product is more than 99.99 weight percent and the total amount of major impurities is not more than 0.002 weight percent without the introduction of additional high-cost purification steps such as ion exchange resin / membranes; and additional sodium ions are not introduced in the production process, byproducts at all stages can be recycled, and only an extremely small amount of waste solution is generated.

Owner:JIANGSU HAILONG LITHIUM IND TECH

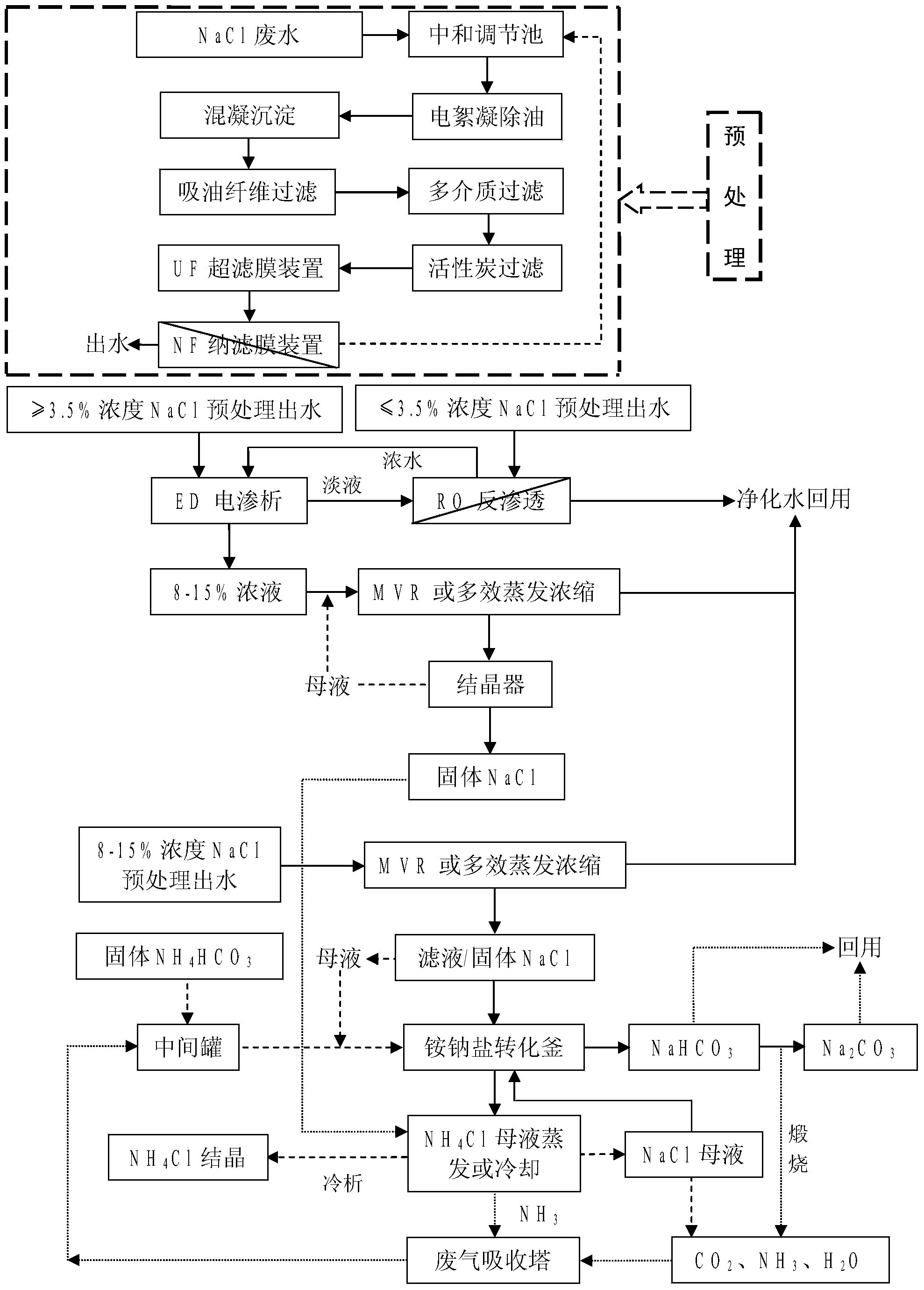

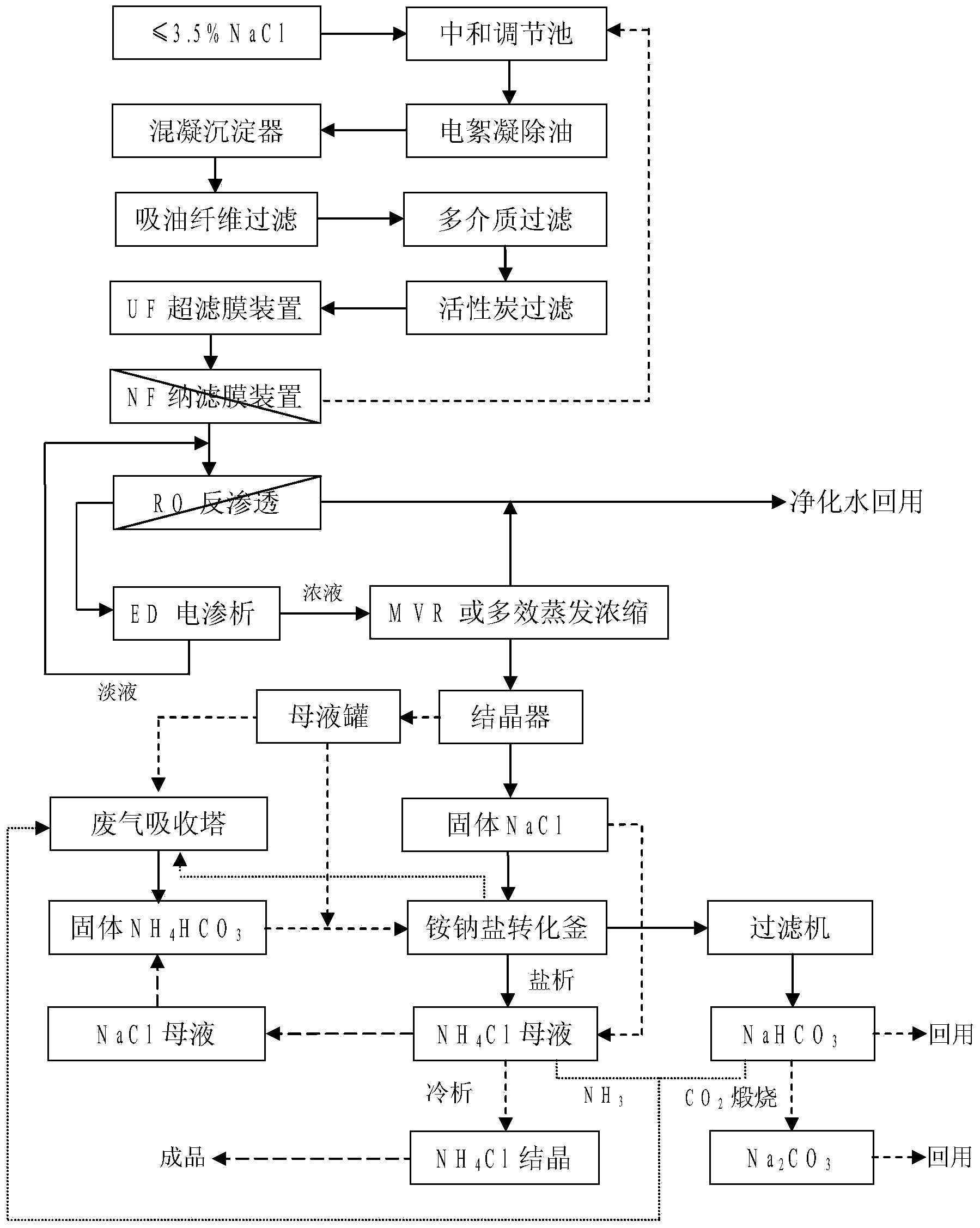

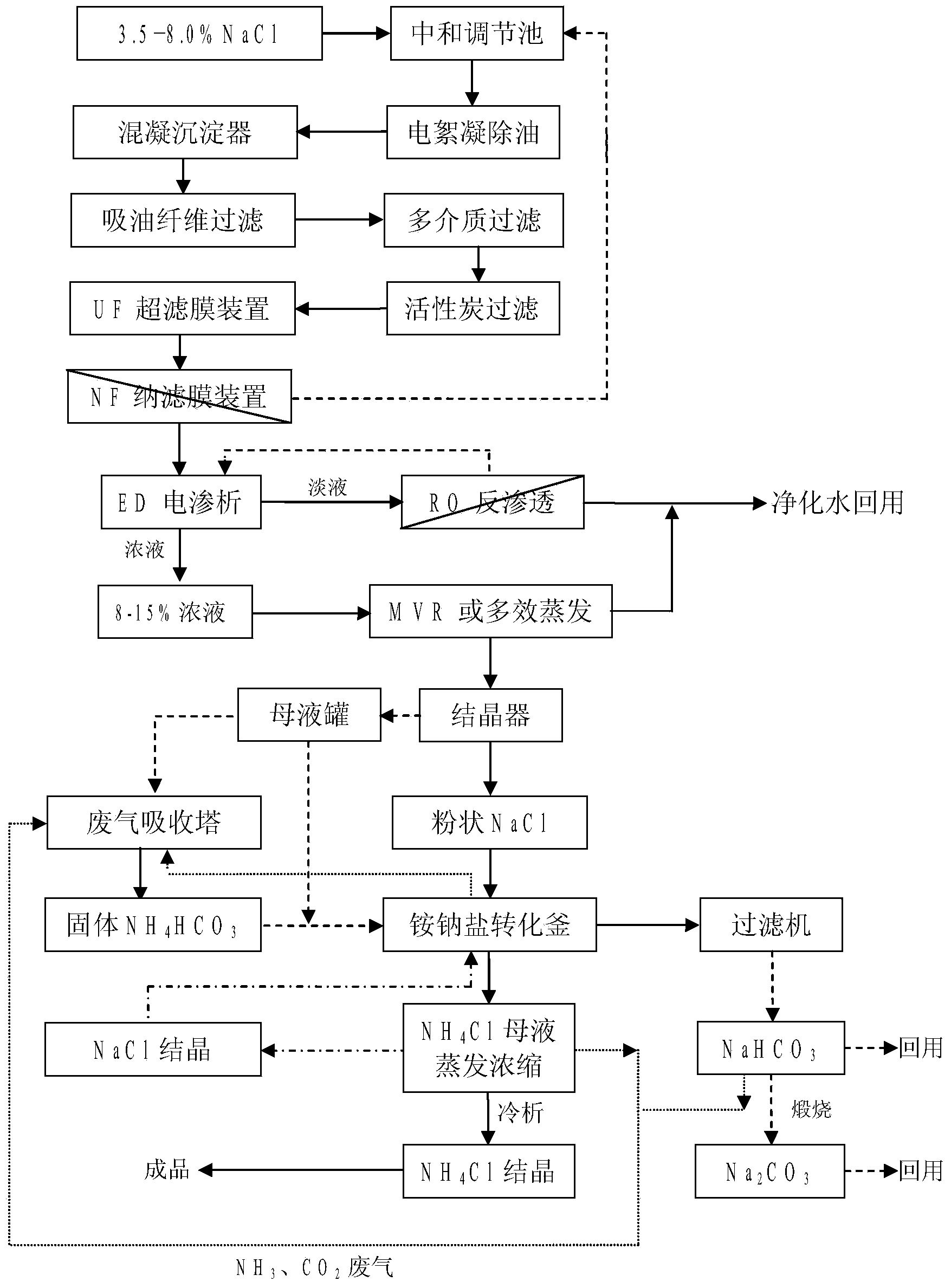

Combined treatment method for sodium chloride-containing wastewater generated in dressing and smelting of rare earth

InactiveCN103449653AImprove environmental protection measuresAvoid volatile lossGeneral water supply conservationMultistage water/sewage treatmentSodium bicarbonateUltrafiltration

The invention relates to a combined treatment method for sodium chloride-containing wastewater generated in dressing and smelting of rare earth. According to the method, a series of desalination and concentration treatments such as deoiling, neutralizing, homogenizing, aeration, flocculation, ultrafiltration, nanofiltration, reverse osmosis, electroosmosis and MVR (mitral valve replacement) concentration are carried out on the wastewater, so that recyclable purified water is obtained; ammonium bicarbonate is added into the sodium chloride extracted from the wastewater, so that the sodium salt can be converted and regenerated into sodium bicarbonate, sodium carbonate and ammonium chloride products for dressing and smelting of the rare earth. According to the method, the recovery rate of the wastewater is high, the effluent quality is stable, the conversion rate of the sodium salt is high, and no three wastes are discharged; production equipment is compact, simple to operate, and easy to realize automation control; the problem that the sodium chloride-containing wastewater and other similar industrial wastewater generated in dressing and smelting of rare earth are difficult to recycle is solved.

Owner:YANSHAN UNIV

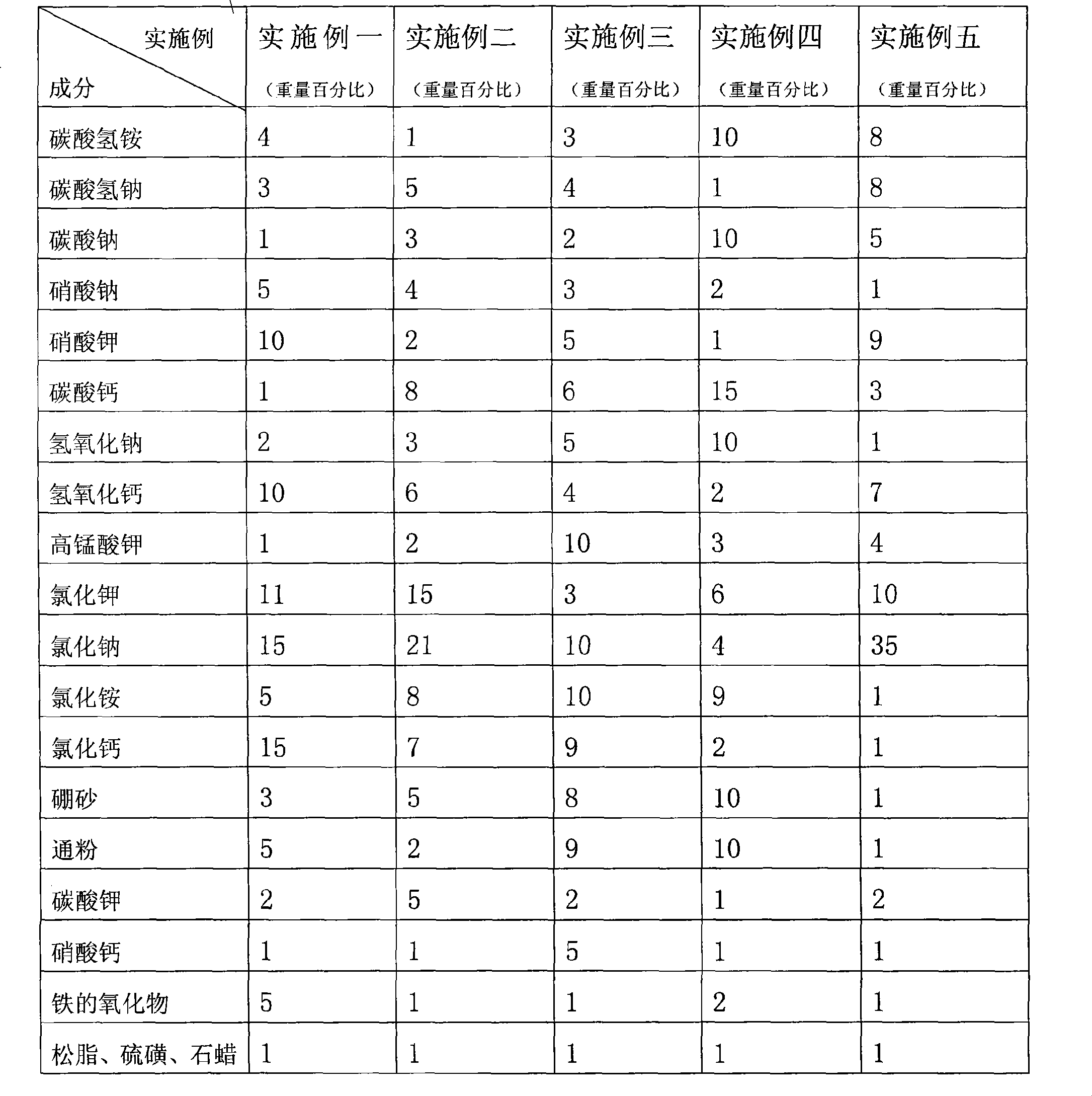

Environment-protecting synergistic agent for fuel coal

InactiveCN101440328AIncreased flammable contentIncreased space gapSolid fuelsFuel additivesSodium bicarbonateFurnace temperature

The invention discloses a bunker coal environment-friendly synergist, which comprises the following components by weight percent: 1 to 10 percent of ammonium bicarbonate, 1 to 8 percent of sodium bicarbonate, 1 to 10 percent of sodium carbonate, 1 to 5 percent of sodium nitrate, 1 to 10 percent of potassium nitrate, 1 to 15 percent of calcium carbonate, 1 to 10 percent of sodium hydroxide, 2 to 10 percent of calcium hydroxide, 1 to 10 percent of potassium permanganate, 3 to 15 percent of potassium chloride, 10 to 35 percent of sodium chloride, 1 to 10 percent of ammonium chloride, 1 to 15 percent of calcium chloride, 1 to 10 percent of borax, 1 to 10 percent of macaroni, 1 to 5 percent of potassium carbonate, 1 to 5 percent of calcium nitrate, 1 to 5 percent of iron oxide, and the balance being micro turpentine, sulfur and paraffin wax. The bunker coal environment-friendly synergist makes flame of combustion be more rampant and denser, the furnace temperature rise to a higher level, the hearth be brighter and cleaner and tail gas be cleaner.

Owner:李政 +1

Preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al

InactiveCN102583585ASimple processReaction is easy to controlCell electrodesCobalt carbonatesSlurryCarbonate

The invention relates to the field of lithium ion battery materials and particularly relates to a preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al. According to the preparation technology, pure water serves as base solution under the conditions that temperature ranges from 40 DEG C to 80 DEG C and a stirring speed is controlled to 60-180 r / min, ammonium bicarbonate is added into the base solution to adjust the alkalinity of the base solution to range from 5 to 30, cobalt-salt mixed solution and ammonium bicarbonate solution are continuously pumped into the base solution in parallel flow and are subjected to sedimentation reaction under the temperature of 40-80 DEG C, the solid content and the alkalinity of slurry in a reaction system are controlled, reaction feed liquid flows out continuously from an overflow gate at the upper part of a reaction kettle to enter into an ageing kettle and then is washed by a washing press and dried by a vacuum drier, spherical cobalt carbonate is subjected to primary calcination to obtain cobaltosic oxide, and the cobaltosic oxide and a lithium source are subjected to secondary calcination to obtain the spherical lithium cobalt oxide doped with Ti, Mg and Al. According to the invention, the process is simple, the reaction is easy to control, the production cost is low, the product application range is wide, and thus, the method is relatively large in production value; and the spherical lithium cobalt oxide is stable in performance and better in overcharging prevention performance.

Owner:ANHUI ALAND NEW ENERGY MATERIALS

Potato chips and processing method thereof

The invention relates to potato chips and a processing method thereof. The potato chips are made from the raw material of fresh potatoes and ingredients by the processing steps of: pretreating, stirring, rolling, forming by roller cutting, baking, cooling and packaging, wherein the ingredients include the following components in parts by weight: 10-20 parts of potato starch, 10-14 parts of white granulated sugar, 6-8 parts of plant oil, 2-3 parts of table salt, 1.5-2.5 parts of aginomoto, 0.6-1 part of sodium bicarbonate, 0.6-1 part of ammonium bicarbonate and a proper amount of water. In theinvention, fresh potatoes are used as the raw material, and equipment of automatic impurity removing, washing, peeling, stirring, rolling, forming by roller cutting, baking, cooling and packaging is adopted, a proper amount of sodium bicarbonate and ammonium bicarbonate is added to be used as leavening agents in the processing so that processed non-fried healthy potato chips have excellent crispness and good taste. The invention not only has reasonable and practical processing method, but also is simple to operate, has good effect and is beneficial to the wide generalization.

Owner:CHACHA FOOD CO LTD

High-efficiency cleaning mineral separation process of complicated sulfuration mine

The invention discloses an efficient and clean beneficiation method of complex sulfide ore. The method includes the following steps: utilizing an activator selected from one of or some of oxalic acid, ammonium carbonate, ammonium bicarbonate, ammonium sulfate, ammonium bisulfate and ferrous sulfate as a combination; utilizing collectors including xanthate collectors, black collectors, white collectors and thionocarbamate collectors; mixing the activator, the collectors and BC; stirring; and performing flotation separation of the sulfide ore to obtain the sulfur concentrate. The inventive beneficiation method has the advantages of high discrimination property, cleanness and non-toxicity; and is suitable for the flotation separation of the complex sulfide ore, particularly the flotation separation of complex sulfide ore containing pyrrhotites and pyrites with fine dissemination size.

Owner:CENT SOUTH UNIV

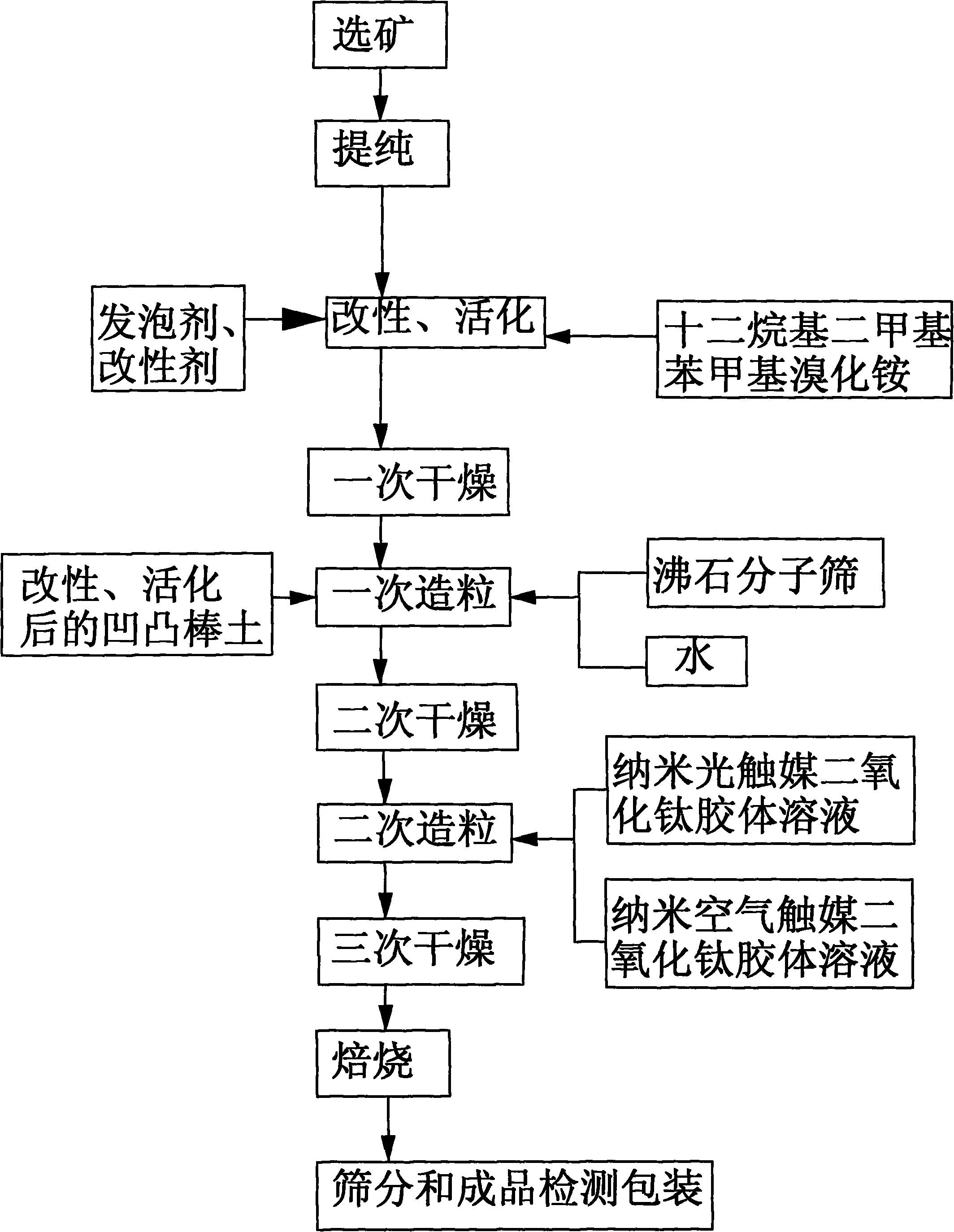

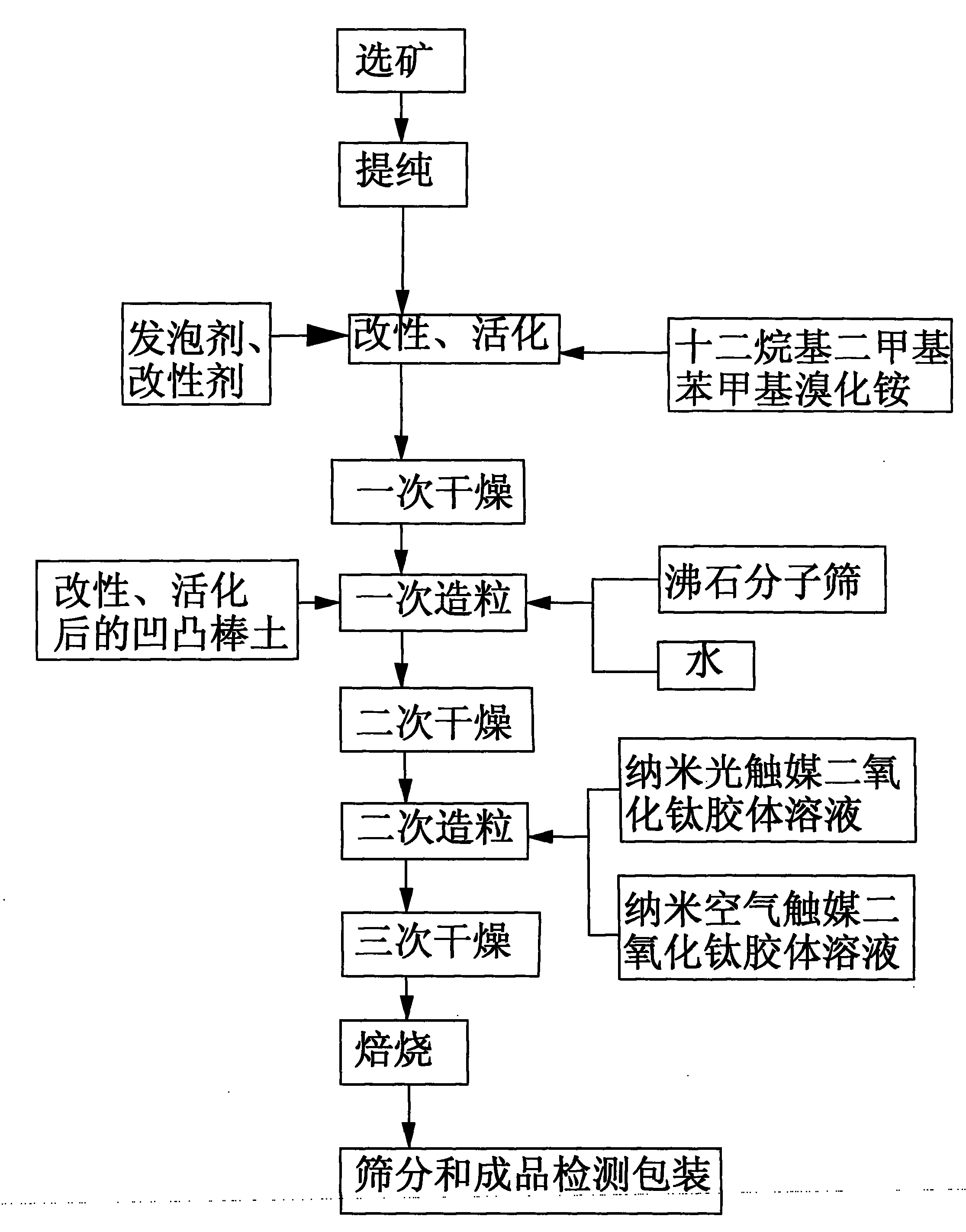

Composite air purificant containing nanometer mineral matters and preparation method thereof

ActiveCN101780288AWill not polluteProcess environmental protectionPhysical/chemical process catalystsDispersed particle separationSodium bicarbonateDecomposition

The invention provides a composite air purificant containing nanometer mineral matters, which contains 47wt% to 78wt% of attapulgite as a natural mineral, 20wt% to 50wt% of synthetic zeolite molecular sieve as a molecular sieve, 0.5wt% to 5wt% of sodium carbonate or sodium chloride or sodium fluoride or sodium hydrogensulfite as a modifier, 0.5wt% to 5wt% of ammonium bicarbonate or sodium bicarbonate or aluminum sulfate as a foaming agent, 0.5wt% to 2wt% of dodecyldimethylbenzylammonium chloride as a surface active agent, 0.2wt% to 2wt% of nanometer photocatalyst titanium dioxide colloidal solution as a photocatalyst and 0.1wt% to 1wt% of nanometer aircatalyst titanium dioxide colloidal solution as photochemical catalysts. The composite air purificant is prepared by first drying, first pelleting, second drying, second pelleting, third drying, baking and finish product detection and package. The invention has high alternative adsorbability and high decomposition efficiency for organic pollutants in the air.

Owner:宁波市沧海新材料开发有限公司

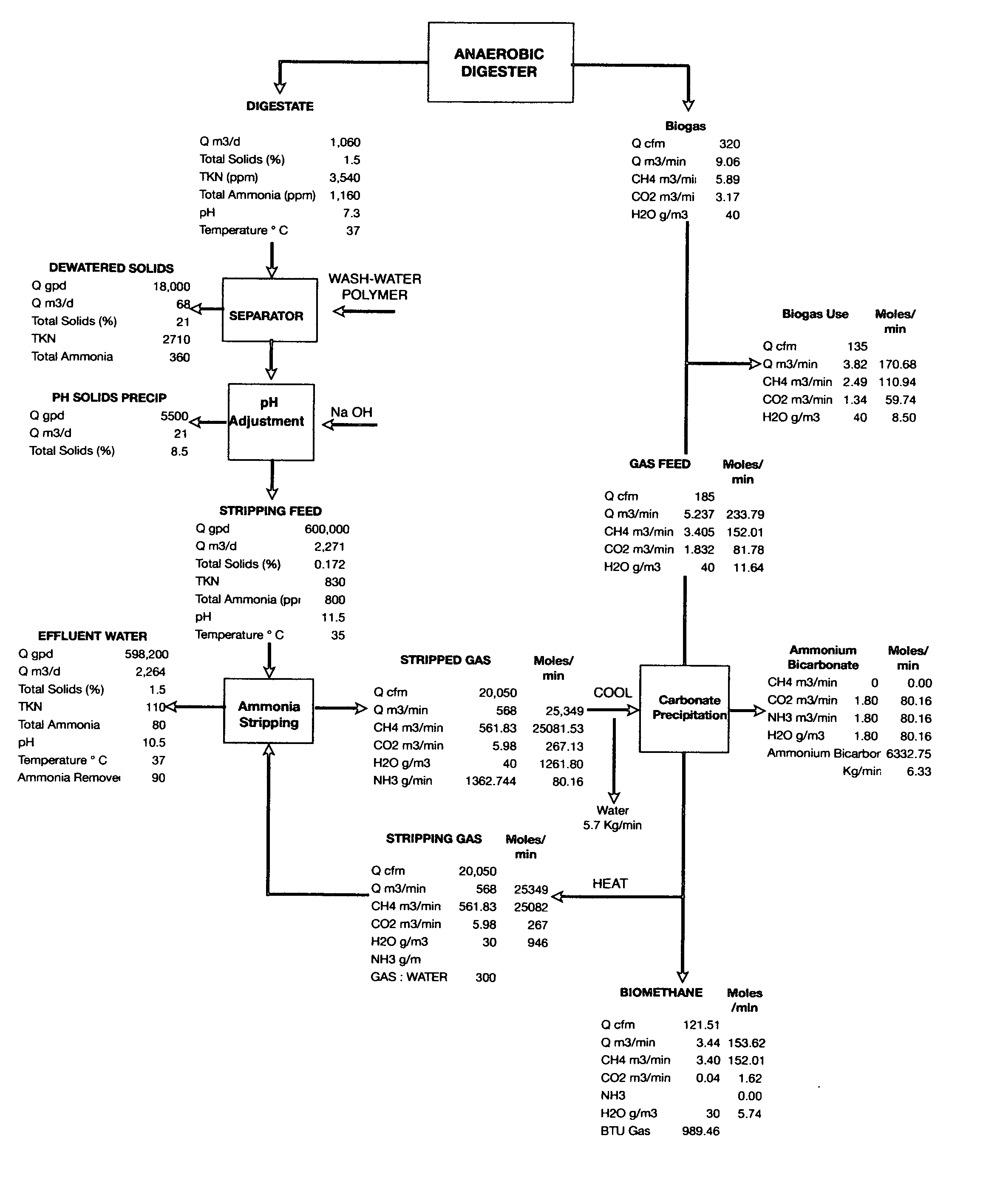

Removal of ammonia from fermentation effluent and sequestration as ammonium bicarbonate and/or carbonate

InactiveUS20080302722A1High economic valueGood economic valueGas treatmentCyanogen compoundsSodium bicarbonateSlurry

A method for the removal and sequestration of ammonia nitrogen from anaerobic fermentation effluent while producing a higher BTU biogas. The method includes the steps of removing the slurry from the digester, stripping the ammonia from the slurry or portion thereof with a high BTU biogas, blending the stripped ammonia with the digesters biogas to remove the carbon dioxide and precipitate ammonium bicarbonate / carbonate as a solid while producing a high Btu biogas, a portion of which is used to strip the ammonia and CO2 from the slurry. The process removes ammonia nitrogen from the digester effluent while producing a high Btu biogas and a solid ammonium bicarbonate / carbonate product. Ammonia stripping is accomplished with a recycled stripping gas deficient in CO2 and ammonia that is capable of removing the CO2 and ammonia from solution by virtue of the lower partial pressures of CO2 and ammonia in the stripping unit.

Owner:COYNE BRIAN J

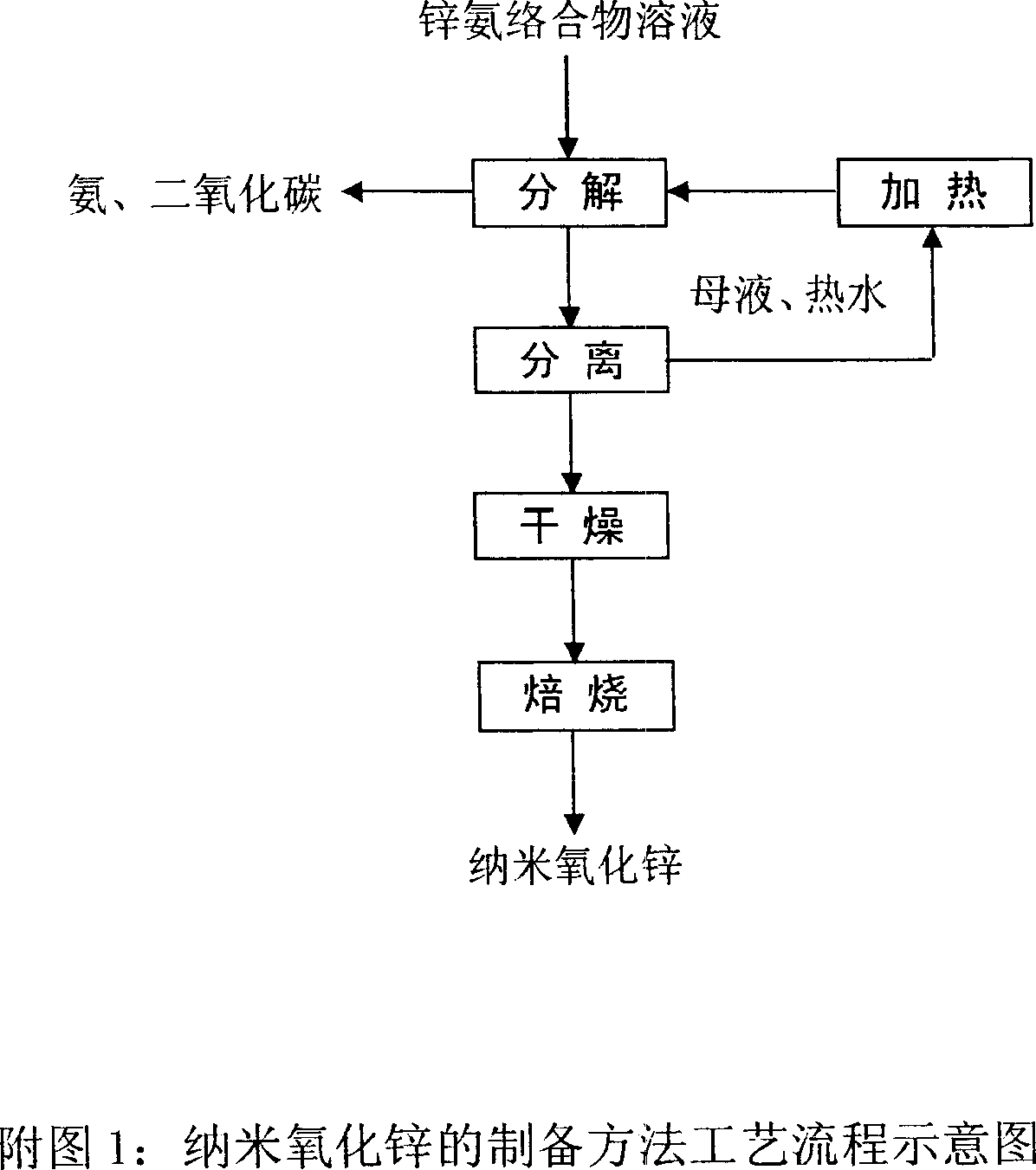

Preparing process of nano zinc oxide

InactiveCN1986421AUniform particle sizeUniform sizeNanostructure manufactureZinc oxides/hydroxidesDecompositionManganese

The process of preparing nanometer zinc oxide with low grade zinc oxide containing material includes the following steps: leaching the material with the mixed solution of ammonium bicarbonate and ammonia, separating to eliminate insoluble impurity, redox to eliminate Fe, Mn, Pb and other metal impurity to obtain zinc-ammonia complex solution; heating the zinc-ammonia complex solution to 90-100 deg.c through continuous mixing with hot circular mother liquid or hot water for fast continuous decomposition of zinc-ammonia complex; controlling the flow rate ratio between the circular mother liquid and the zinc-ammonia complex solution in 2-20, separating the basic zinc carbonate crystal continuously from the decomposed solution; drying and roasting at 400-600 deg.c for 1-4 hr to obtain the nanometer zinc oxide product of homogeneous size 10-50 nm.

Owner:CHINA NAT OFFSHORE OIL CORP +1

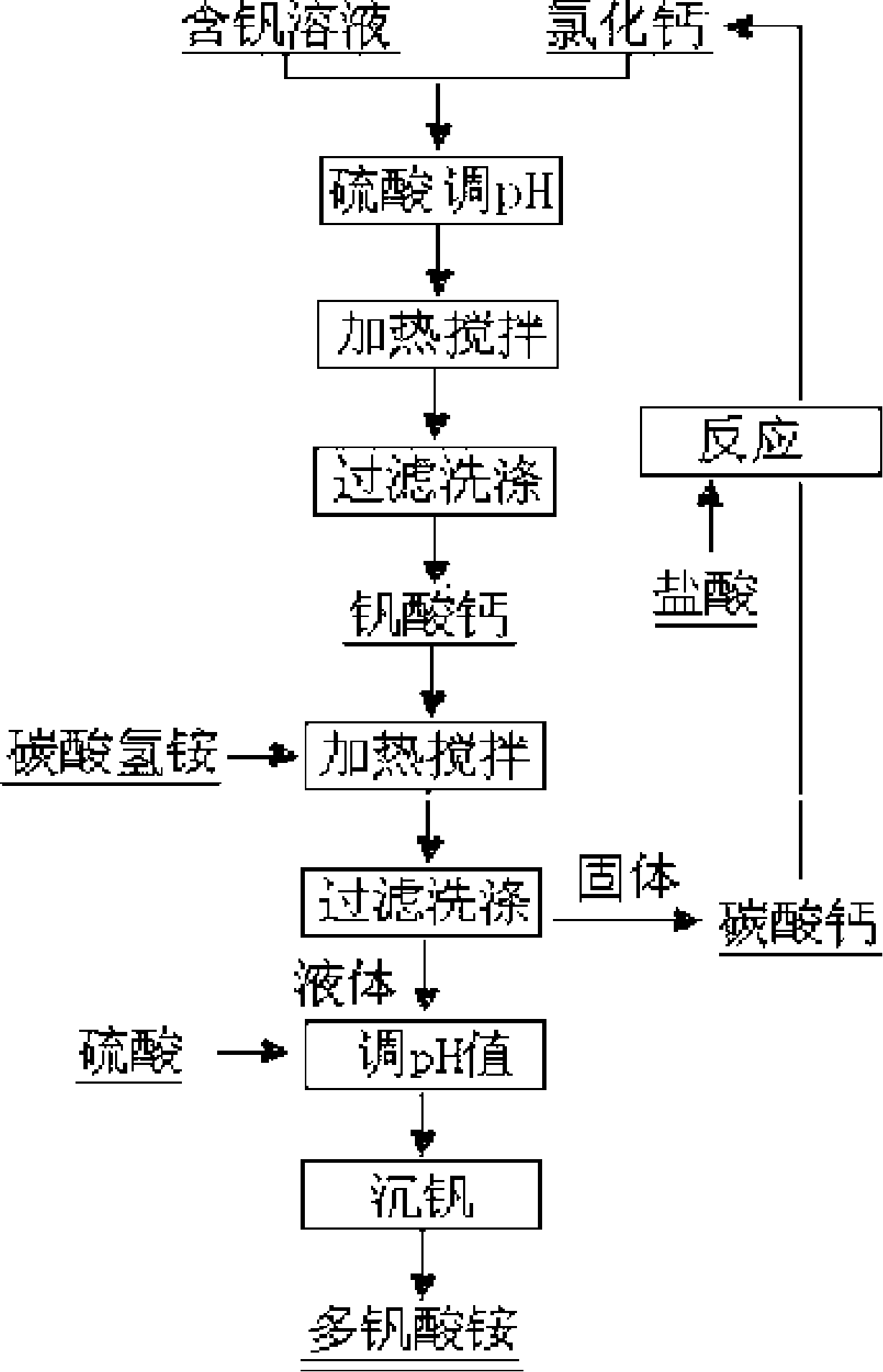

Preparation method of ammonium poly-vanadate

The invention belongs to the chemical engineering field, in particular relates to a method for preparing ammonium polyvandata with vanadium-containing solution. The method uses the vanadium-containing solution produced with the traditional sodium roasting-water immersing technology as the raw material. First, vanadium combines with added calcium compounds and produces calcium vanadate, which reacts with ammonium bicarbonate and transfers vanadium into the solution but transforms calcium into more insoluble calcium carbonate; the ammonium polyvandata is produced with the separated solution under appropriate pH and heating conditions. After redissolution of calcium vandata, the ammonium bicarbonate containing less than 0.1percent of SUM (Na2O+K2 O) can be obtained. The ammonium bicarbonate can be used for production of vanadium trioxide and vanadium pentoxide with exceedingly low contents of potassium and sodium; and the ammonia content of vanadium-precipitation waste water is only 60percent to 75 percent of vanadium-extraction waste water in traditional technologies. The invention has very promising application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

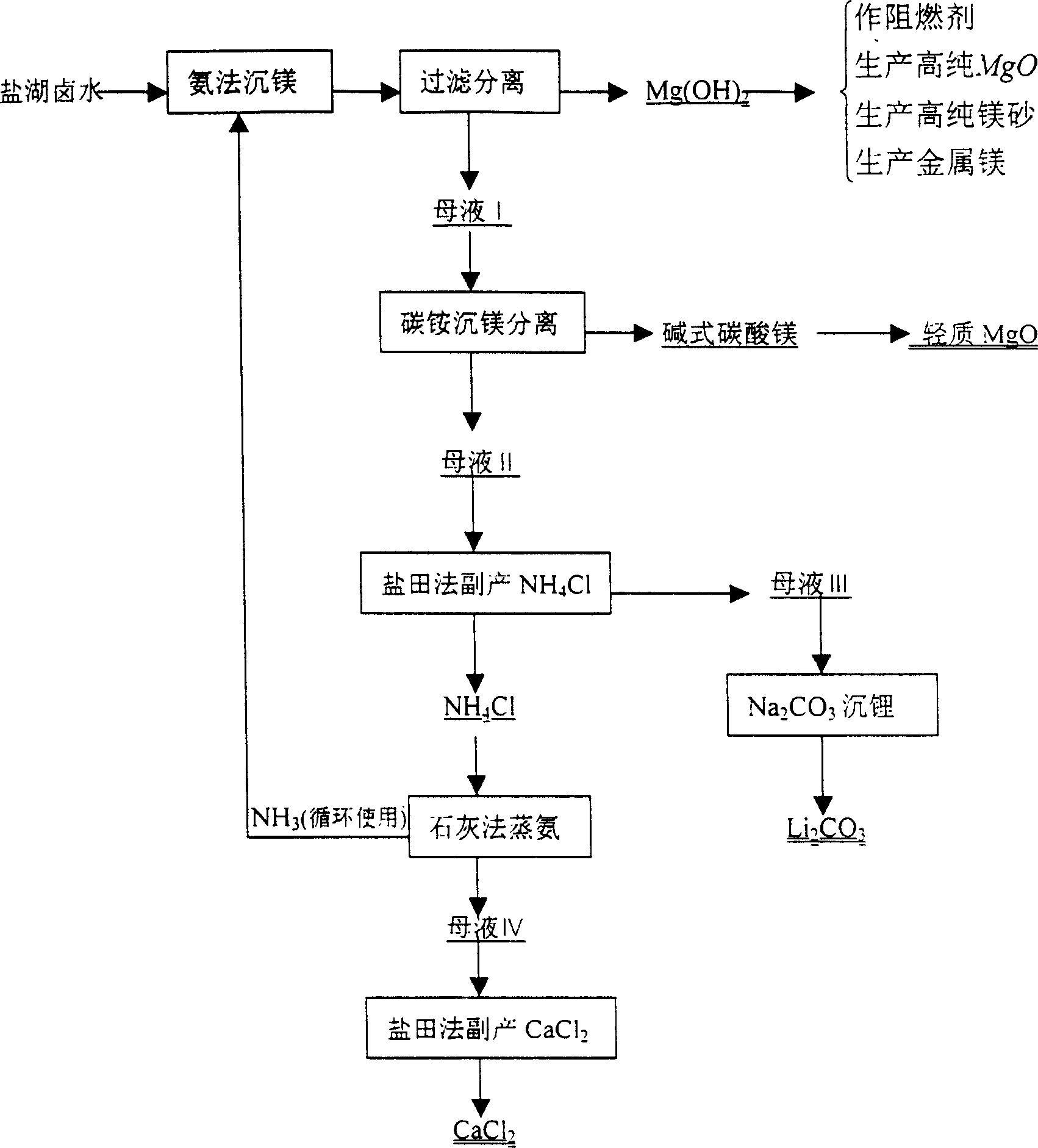

Method of combined extraction of magnesium and lithium in salt lake bittern

A process for extracting Mg and Li from the brine of salt lake features that the ammonia and ammonium dicarbonate are used to implement two stages of magnesium deposition. For the first stage, the crystal seeds (5-10%) are added and the efficiency of magnesium deposition is controlled to 80-85%. For the second stage, the solid ammonium dicarbonate is added for reaction to obtain more than 98% of Mg extraction rate. The ammonium chloride in the mother liquid can be converted to ammonia for reuse. The lithium chloride solution enriched from the mother liquid can be used to prepare lithium carbonate. The extraction rate of Li is more than 95%.

Owner:CENT SOUTH UNIV

Method for extracting rhenium from eluate of flue ash generated by baking enriched ore of molybdenum

This invention relates to a method for extracting Re from flue dust and tail gas rinsing solution of Mo concentrate calcination. The method comprises: (1) adding water to flue dust, leaching out Re in the flue dust to obtain Re-containing leaching solution; (2) adjusting the pH value of the Re-containing leaching solution and tail gas rinsing solution to 5 with ammonium bicarbonate so that Mo, Fe, Cu and Zn ions are converted into hydroxides, separated from Re and precipitated, and filtering to obtain Re-containing solution for extraction; (3) extracting with extractant so that Re enters into the extractant, which is named enriched oil; (4) back-extracting the enriched oil with 3 N ammonia solution so that Re enters into the back extraction solution; (5) adding the back extraction solution into an ion exchange system so that Re is adsorbed onto the resin; (6) preparing 5-10% ammonium thiocyanate solution, adding ammonia solution to adjust the pH value to 8-9, and desorbing Re adsorbed onto the resin to obtain Re-containing desorption solution; (7) evaporating the desorption solution, concentrating, and crystallizing to obtain ammonium perrhenate product.

Owner:锦州沈宏实业集团有限公司

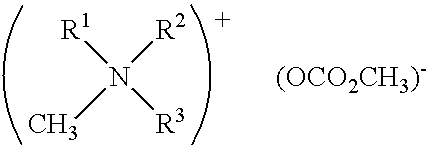

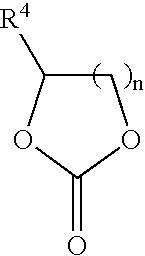

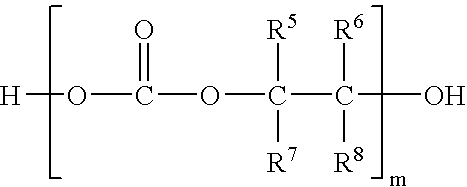

In situ process for preparing quaternary ammonium bicarbonates and quaternary ammonium carbonates

Applicant has discovered an in situ method of preparing quaternary ammonium methocarbonate salts and quaternary ammonium alkylcarbonate salts in high yield from tertiary amines, methanol, and at least one of a cyclic carbonate, an aliphatic polyester (such as a polycarbonate), or an ester (such as a carbonate ester), and their subsequent conversion to quaternary ammonium bicarbonates, quaternary ammonium carbonates or both in a one-pot reaction. According to one embodiment of the invention, the method includes reacting an amine and methanol with at least one of a cyclic carbonate and an aliphatic polyester to yield a quaternary ammonium methocarbonate. This method does not produce or require the handling of corrosive quaternary ammonium hydroxides. Another embodiment is a method of preparing quaternary ammonium alkylcarbonate salts by reacting tertiary amines, methanol, and an ester. The quaternary ammonium methocarbonate or alkylcarbonate can be converted to the corresponding bicarbonate, carbonate, or mixture thereof by methods known in the art.

Owner:ARXADA LLC

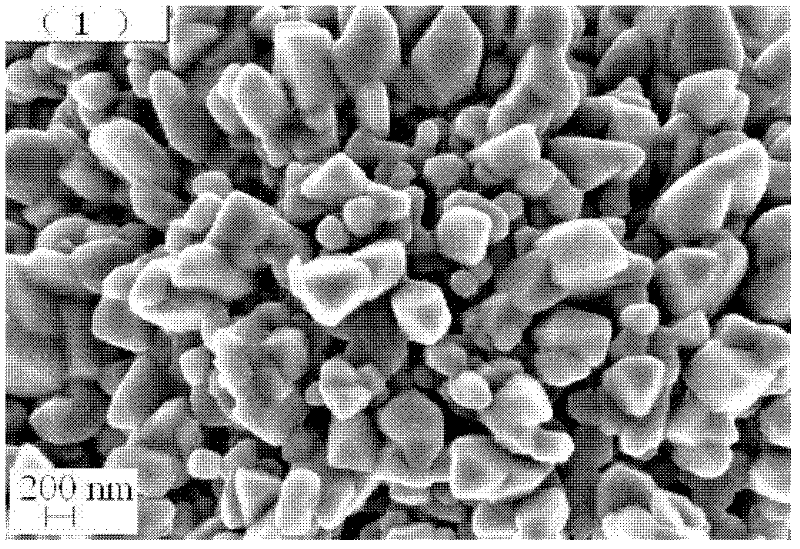

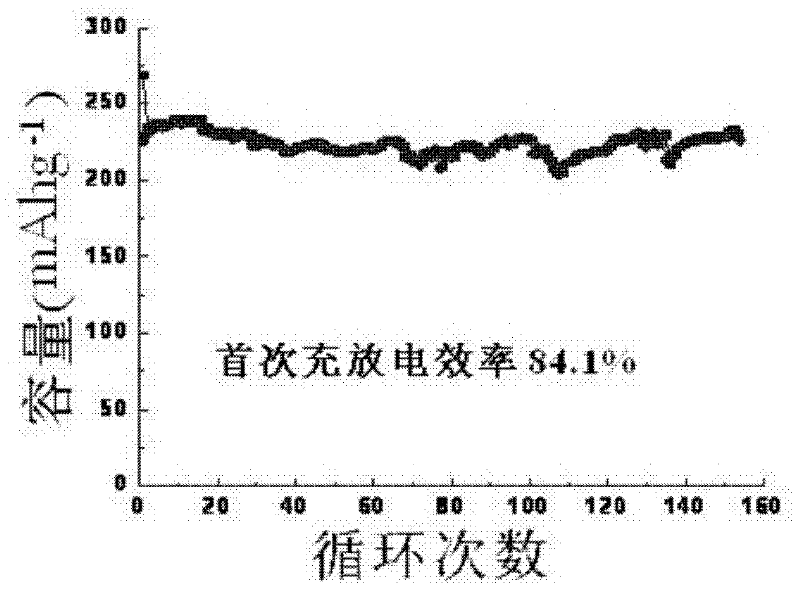

Preparation method of layered manganese-based cathode material for raising initial charge/discharge efficiency

InactiveCN102447103APrecise Control of Chemical CompositionReduced electrochemical performanceCell electrodesDischarge efficiencyManganese

A preparation method of a layered manganese-based cathode material for raising initial charge / discharge efficiency comprises the following steps of: using ammonium bicarbonate as a precipitating agent, simultaneously adding ammoniacal liquor in a dropwise manner so as to control coprecipitation reaction pH value to 8-9, continuing for 8-12 hours, precipitating a coprecipitation product, adding deionized water to prepare a slurry with the concentration of 150-200g / l, carrying out spray drying on the slurry at the temperature of 100-120 DEG C to prepare a Ni-Mn carbonate powder, insulating at the temperature of 300-350 DEG C for 4-6 hours, heating up to 450-500 DEG C and insulating for 2-4 hours to obtain a precursor powder, weighing lithium hydroxide monohydrate with its mole number being K[1+x / (2+x)], grinding the prepared xLi2MnO3.(1-x)LiNi1 / 2Mn1 / 2O2 powder, roasting at the temperature of 600-650 DEG C for 1-6 hours, and annealing. According to the invention, the initial charge / discharge efficiency of the layered manganese-based cathode material is substantially raised, and the cycle stability is obviously improved.

Owner:UNIV OF SCI & TECH BEIJING

Process for preparing Ce-Zr based composite oxide

InactiveCN1369460APromote absorptionGood release effectDispersed particle separationRare earth metal compoundsChemical reactionNitrate

A composite Ce-Zr based oxide is preparedf rom nitrate through precipitation by using ammonium bicarbonate as precipitant, chemical reaction, drying and calcine. It can be used as co-catalyst with high power to absorb and release oxygen. Its advantages are high specific surface are and high oxygen bearing power.

Owner:INNER MONGOLIA UNIV OF TECH

Cereal nutrient biscuit and preparation method thereof

InactiveCN101779690AAnti agingReasonable nutritionDough treatmentBakery productsBiotechnologySodium bicarbonate

The invention relates to a leisure food, namely a cereal nutrient biscuit and a preparation method thereof, belonging to the technical filed of food processing, which is composed of flour, white sugar, edible vegetable oil, black sesame seed, broken peanut, black soy milk powder, yam flour, rice powder, millet powder, corn powder, sorghum powder, oatmeal, fresh hen eggs, salt, sodium bicarbonate, ammonium bicarbonate and citric acid. The preparation method is as follows: evenly mixing the raw materials and stirring into paste; rolling the paste into the shape of biscuit and then baking; spraying palm oil on the surface of biscuits; cooling at room temperature; detecting the biscuits by a metal detector, removing biscuits containing metal chips or metal particles; picking out damaged biscuits; and packaging and warehousing the biscuits. In the invention, multiple grains such as sesame, peanuts and black beans are added to ensure more reasonable nutrition, no fumet is added to let the biscuits keep natural fragrance of rice; and the biscuit has the advantages of rich nutrition, multiple disease prevention, beautifying and body building, prolonging life, thin and crisp mouth feeling and the like, thus is a convenient leisure food suitable for people at all ages.

Owner:WEIHAI DONGWANG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com