Patents

Literature

47results about How to "Reduced electrochemical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

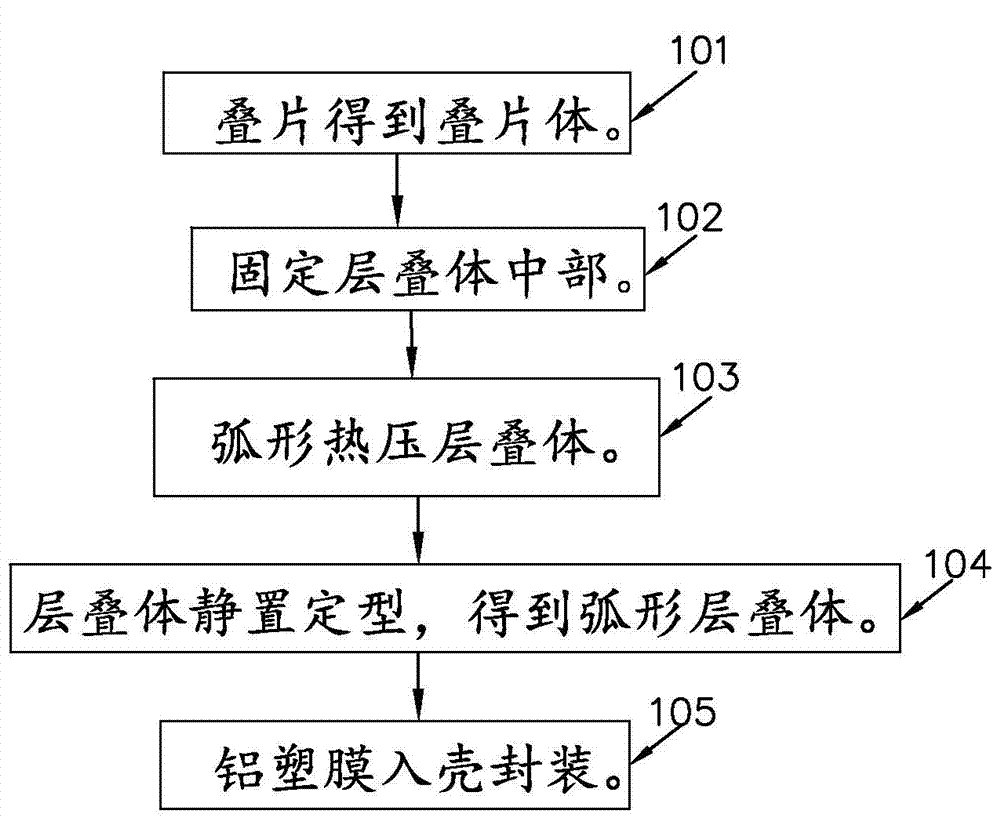

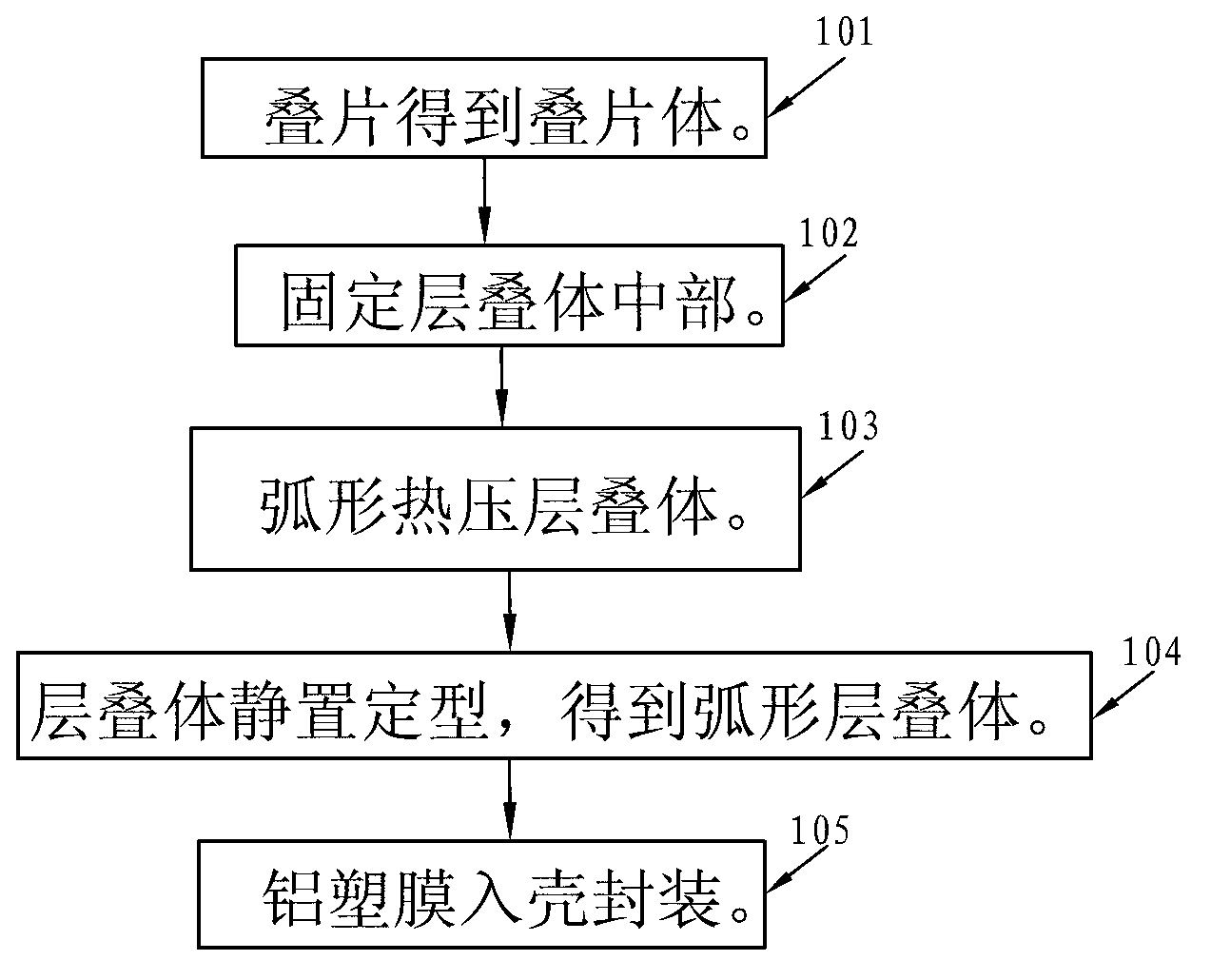

Laminated lithium ion battery preparation method and prepared battery

ActiveCN103247825AGuarantee stabilityEnsure safetyFinal product manufactureSecondary cellsElectrical batteryEngineering

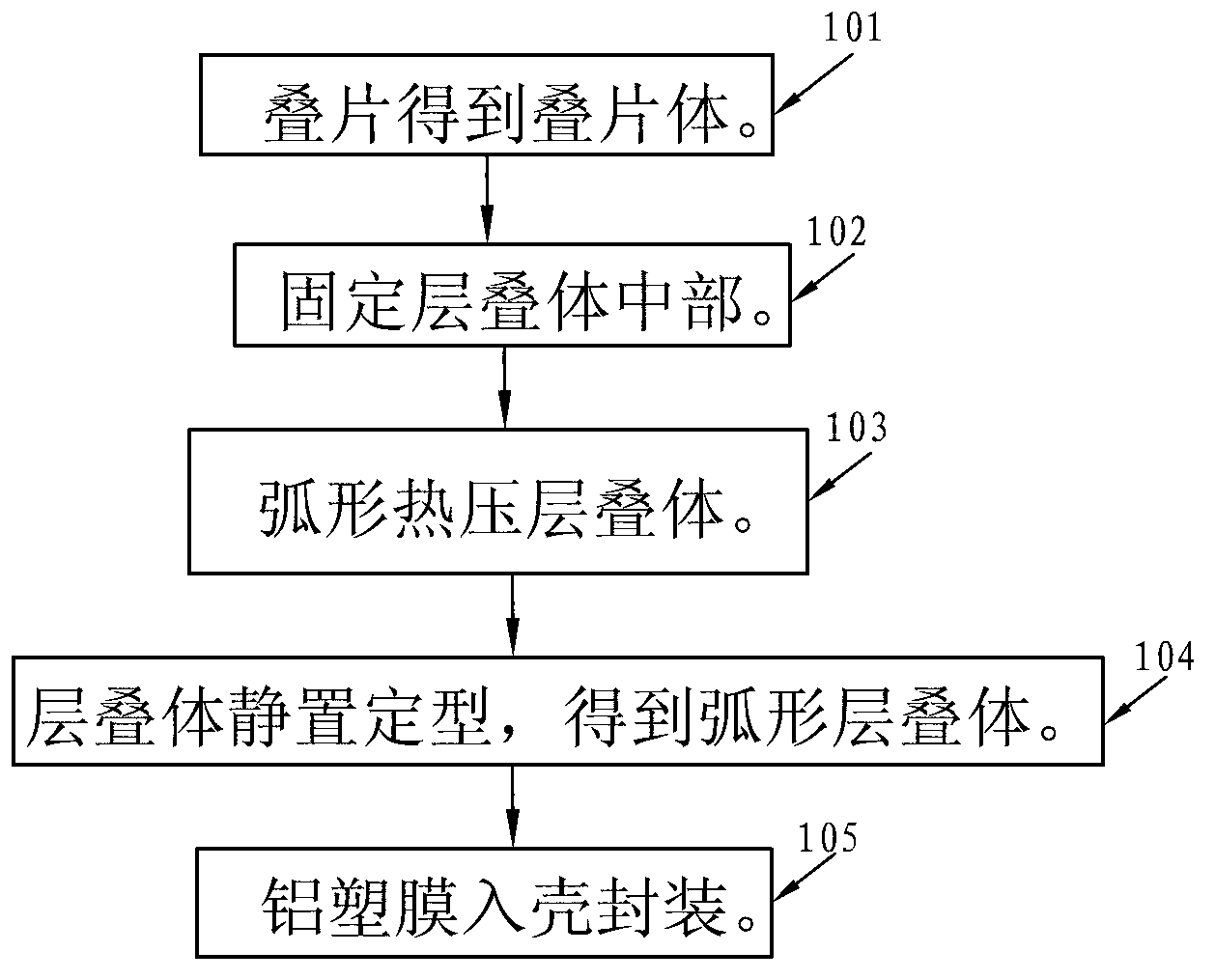

The invention relates to the field of lithium ion batteries and discloses a laminated lithium ion battery preparation method and a prepared battery. The method comprises the following steps of: laminating negative pieces and positive pieces to obtain a laminated cell body; arranging a diaphragm layer between any one of the positive pieces and any one of the negative pieces in the laminated cell body; fixing the middle of the laminated cell body; naturally arranging the laminated cell body on the top of an arc-shaped bracket; carrying out hot-pressing on the laminated cell body so as to adhere each diaphragm layer in the laminated cell body to the corresponding positive piece and the corresponding negative piece; standing the laminated cell body until the laminated cell body is arc-shaped; arranging the arc-shaped laminated cell body into a cell body pit in an aluminum plastic film shell; covering a top aluminum plastic film layer of the aluminum plastic film shell on the top surface of the arc-shaped laminated cell body; and performing heat-sealing on an aluminum plastic film so as to package the arc-shaped laminated cell body in the aluminum plastic film shell, and thus a laminated lithium ion battery is obtained.

Owner:SHENZHEN GREPOW BATTERY CO LTD

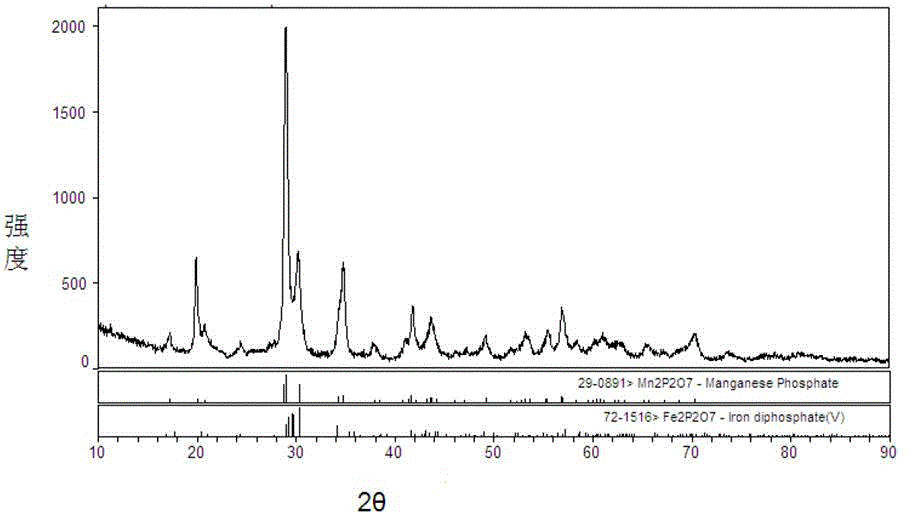

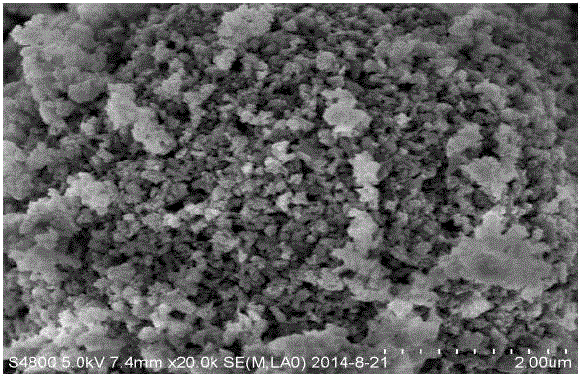

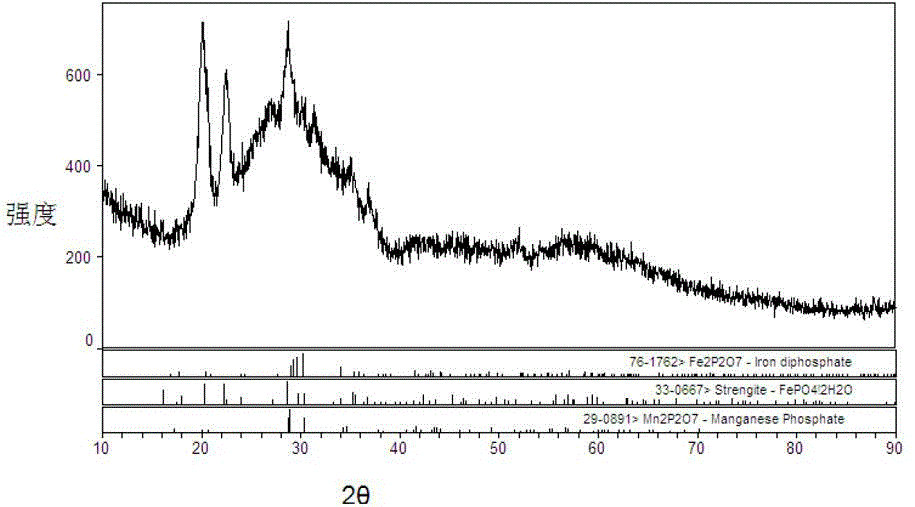

Positive electrode material LiMn1-xFexPO4 / C and preparation method thereof

InactiveCN105702954AReduce distractionsIncreased Consistency RequirementsCell electrodesPhosphorus compoundsPower batteryManganese

The present invention provides a preparation method of a positive electrode material LiMn1-xFexPO4 / C, the method comprises mixing of an A source with a lithium source and a carbon source for reaction to obtain the positive electrode material LiMn1-xFexPO4 / C, and the molar stoichiometric ratio of manganese, iron, phosphorus contained in the A source is Mn: Fe: P = 0.45-0.85: 0.55-0.15: 1. The preparation method is simple, safe in operation, low in cost, and easy in implementation of large-scale production; and a lithium battery positive electrode material prepared by the method has high charge and discharge capacity and stable performance, and is a preferred material for a power battery.

Owner:BYD CO LTD

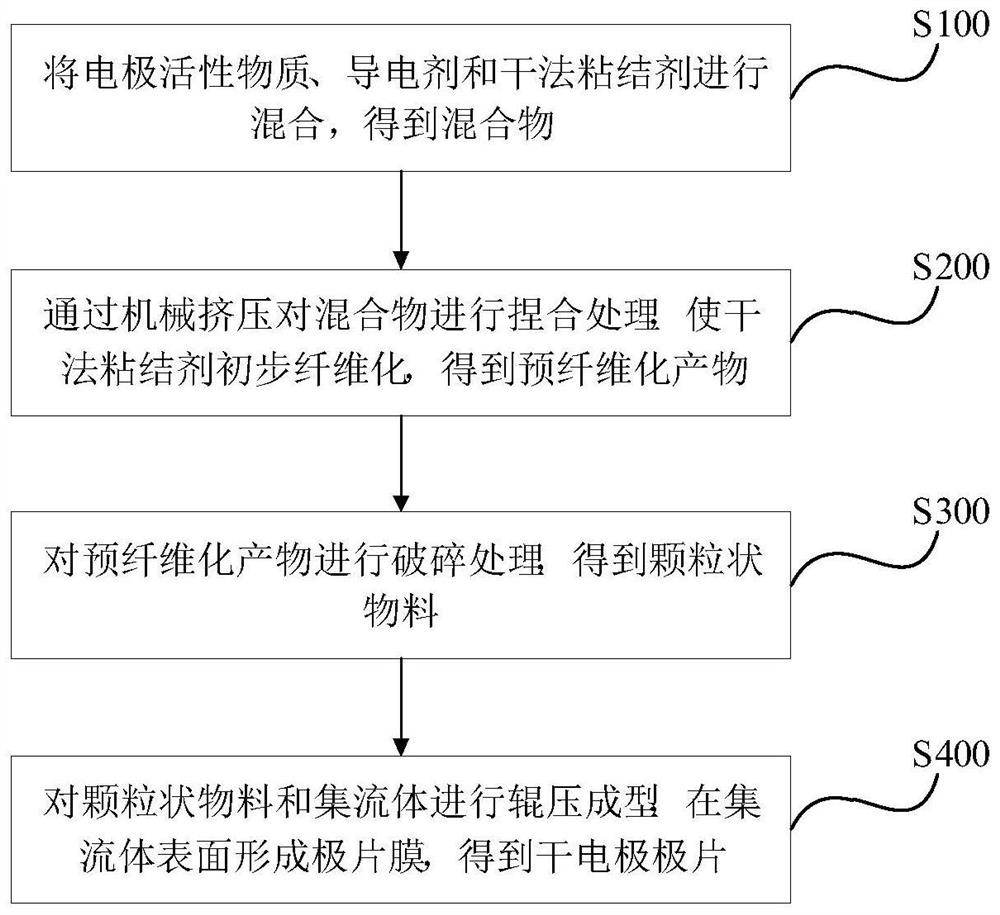

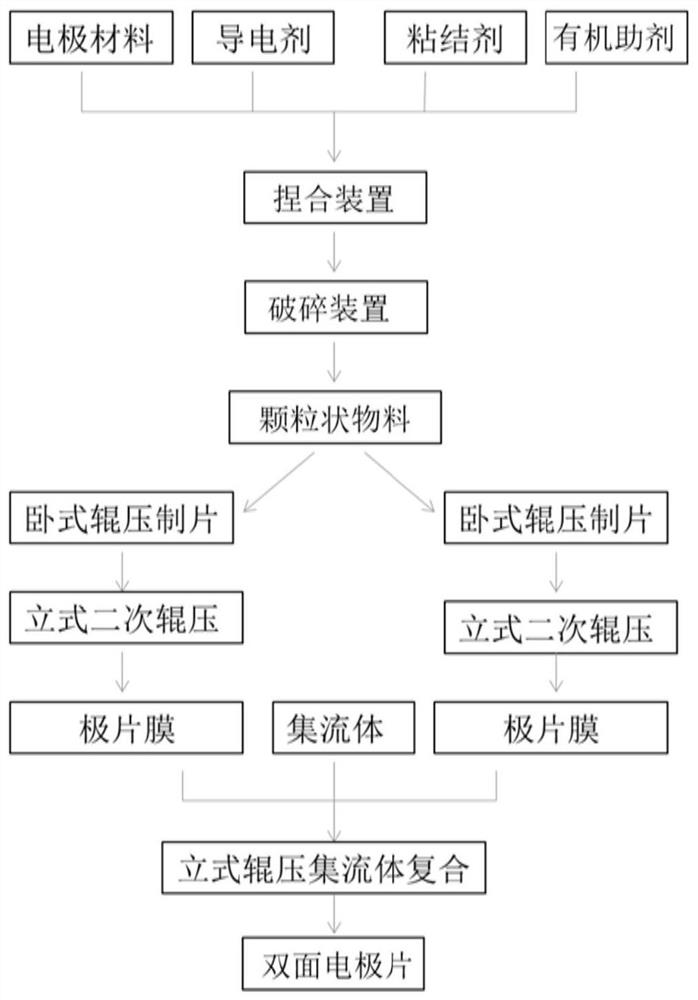

Method and system for preparing electrode plate by dry process, and application

PendingCN113675362AIncrease productivityAffect the electrochemical performanceElectrode rolling/calenderingHybrid/EDL manufactureNew energyProcess engineering

The invention discloses a method and a system for preparing an electrode plate by a dry process, and application. The method comprises the following steps: mixing an electrode active material, a conductive agent and a dry binder to obtain a mixture; carrying out kneading treatment on the mixture through mechanical extrusion so as to carry out preliminary fibration on the dry-method binder to obtain a blocky and / or flocculent pre-fibration product; carrying out crushing treatment on the pre-fibration product so as to obtain a granular material; and carrying out roll forming on the granular material and the current collector so as to form a pole piece film on the surface of the current collector, thereby obtaining the dry electrode plate. The method is simple and feasible, required equipment is simple, the problem that the electrode active material structure is damaged in the material crushing treatment process can be effectively solved, the production efficiency is higher, amplification is easy, the method is more suitable for large-scale mass production of the dry electrode technology, development of the new energy industry is promoted, and the method has wide application prospects.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

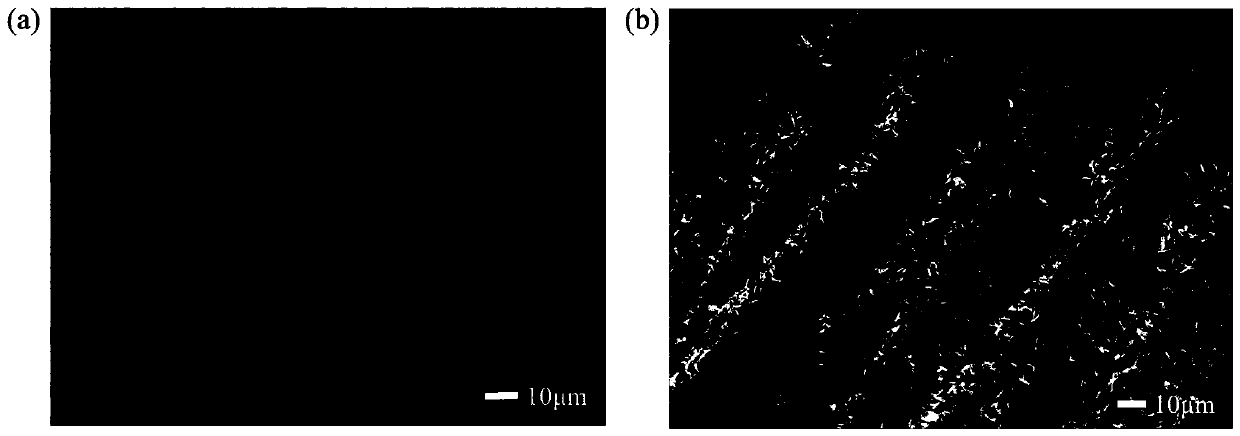

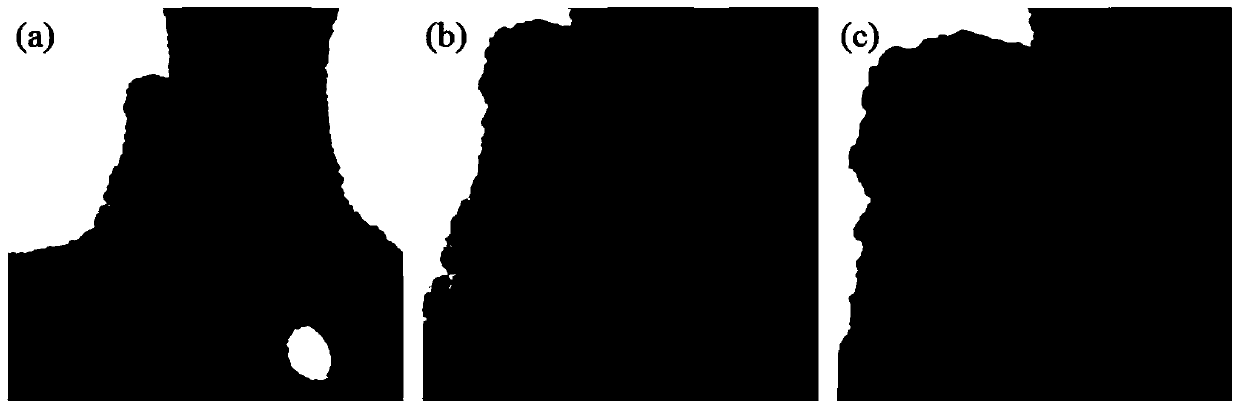

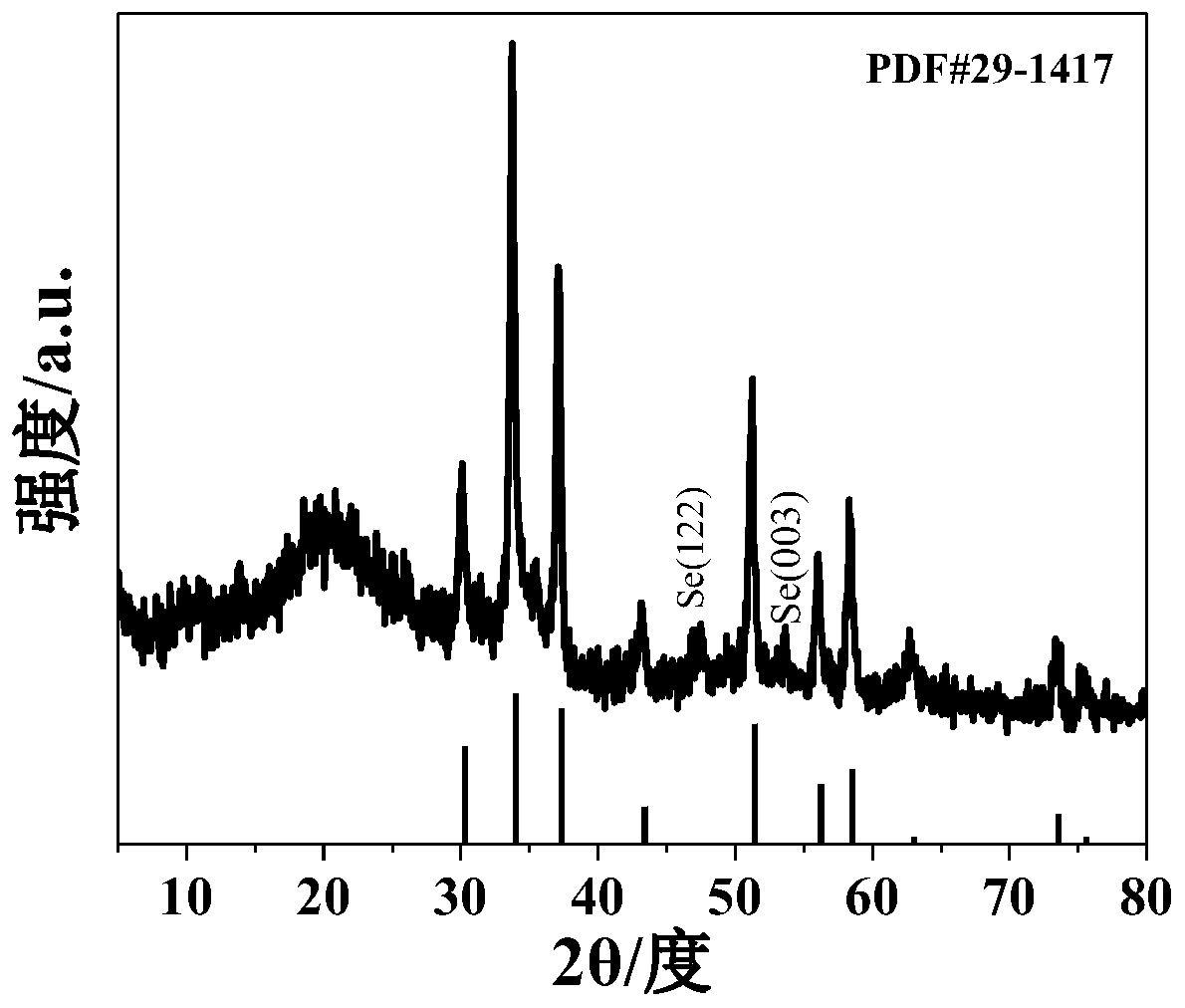

Preparation method of carbon cloth-based nickel-cobalt bimetal selenide nano square sheet electrode material

InactiveCN110610816AHigh specific surface areaMany active sitesMaterial nanotechnologyHybrid capacitor electrodesTube furnaceElectrochemical energy storage

The invention belongs to the technical field of energy materials, and relates to a preparation method and an application of a carbon cloth-based nickel-cobalt bimetal selenide nano square sheet electrode material. The preparation method comprises the following steps: adding a soluble cobalt salt, a soluble nickel salt, medium-tetra(4-carboxyphenyl)porphin and 4, 4 '-dipyridyl into an N, N-dimethylformamide and ethanol solution, carrying out ultrasonic uniform dispersion, carrying out a hydrothermal reaction with controllable temperature programming together with a carbon cloth substrate, and carrying out cleaning and drying to obtain a carbon cloth-based nickel-cobalt bimetal organic framework nano square sheet precursor; and putting selenium powder and the carbon cloth-based nickel-cobaltmetal organic framework nano square sheet precursor into a tubular furnace, and carrying out selenylation reaction to obtain a carbon cloth-based nickel-cobalt bimetal selenide nano square sheet electrode material. The metal selenide electrode material prepared by the invention has stable morphology, high specific surface area, more active sites, good mechanical stability, high conductivity, excellent electrochemical energy storage performance and electrochemical cycling stability.

Owner:JIANGSU UNIV

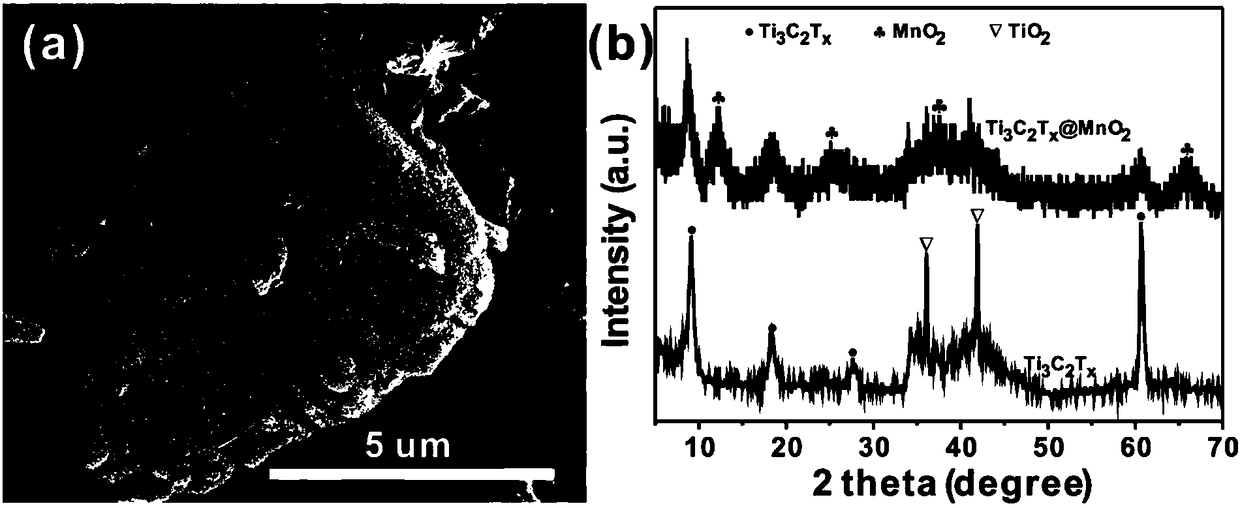

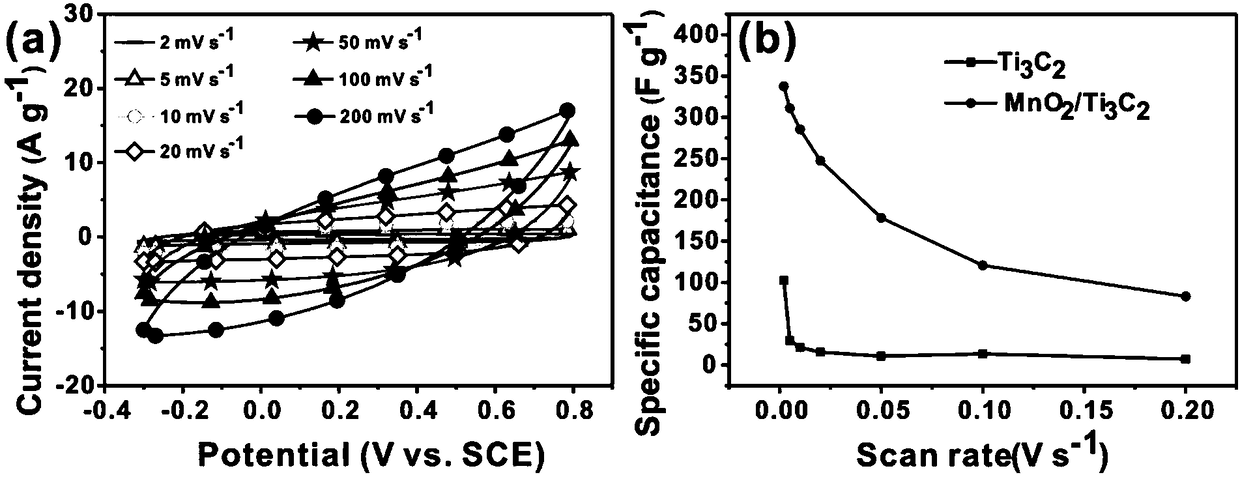

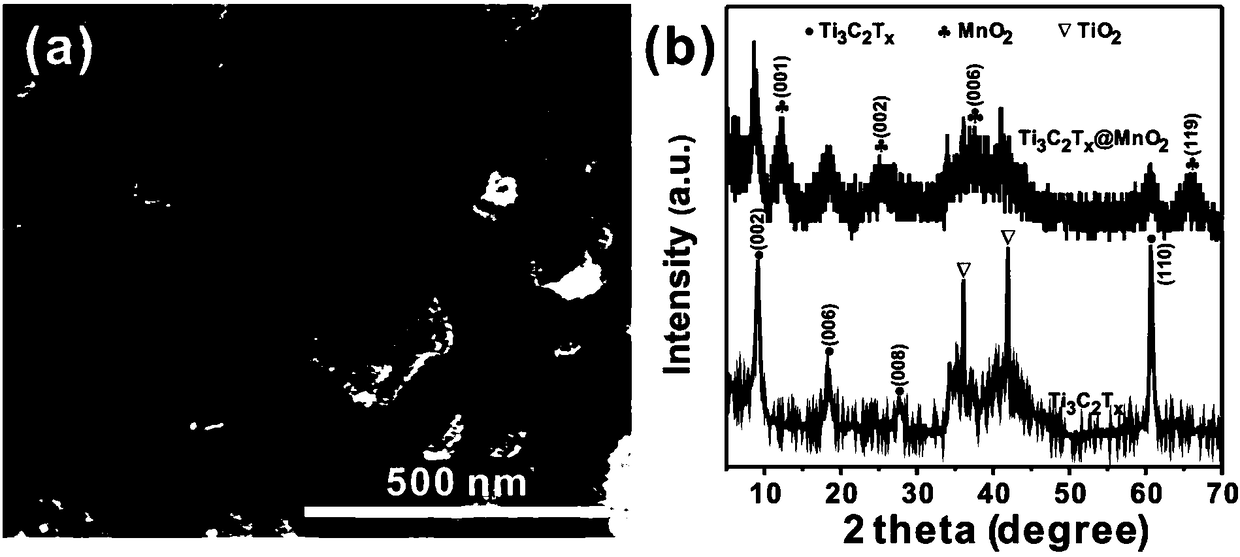

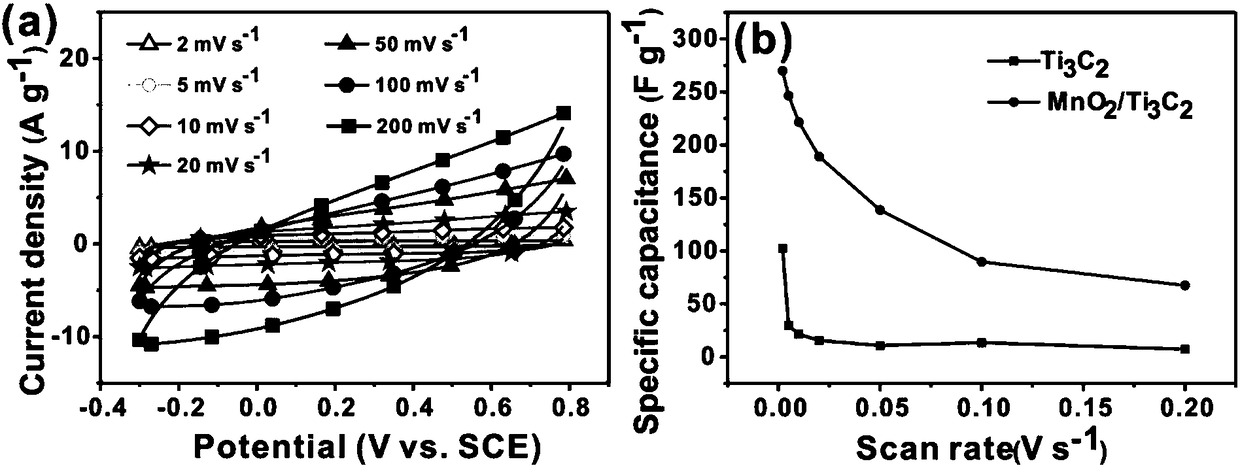

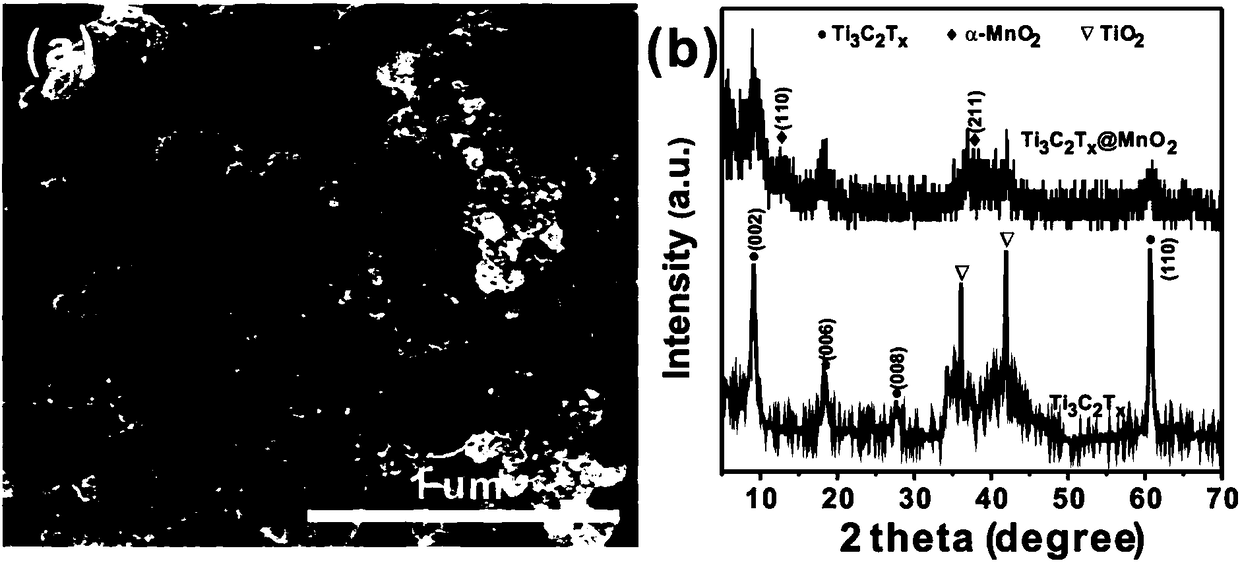

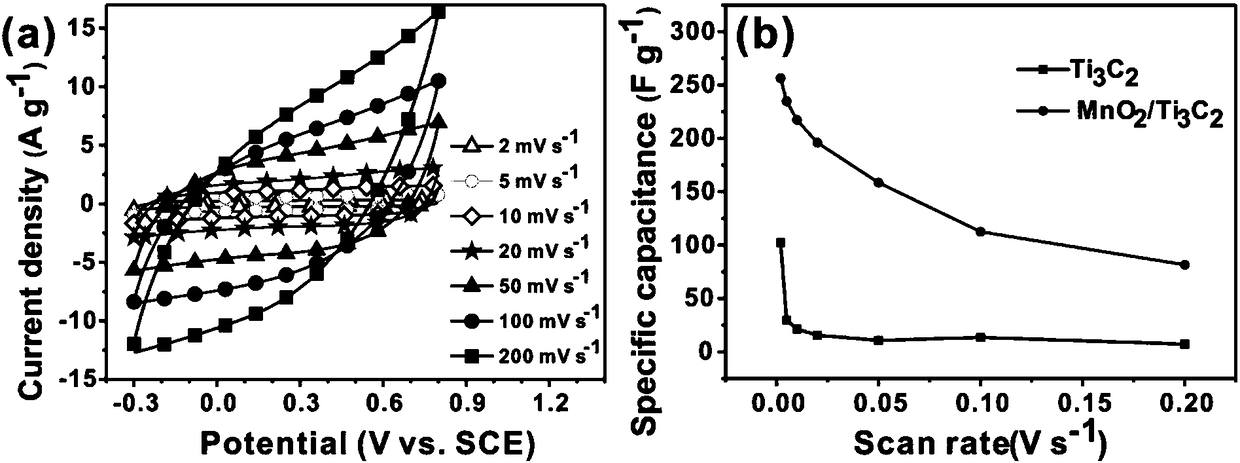

Method for preparing manganese dioxide-titanium carbide composite material through hydrothermal method and composite material prepared through method

InactiveCN108389732AImprove bindingReduced electrochemical performanceHybrid capacitor electrodesCell electrodesFree coolingTitanium carbide

The invention provides a method for preparing a manganese dioxide-titanium carbide composite material through a hydrothermal method and the composite material prepared through the method. The method comprises the steps that Ti3C2 nanopowder and dopamine hydrochloride are dispersed in ultrapure water separately, mixed to be uniform and then stirred under the shading condition; a Tris-buffer solution is added, and stirring continues under the shading condition; the obtained mixed solution is separated, washed and dried to obtain Ti3C2@PDA nanopowder; the Ti3C2@PDA nanopowder is added into ultrapure water and dispersed to be uniform, and then KMnO4 is added for a hydrothermal reaction; and after the reaction ends, natural cooling is conducted, and then the manganese dioxide-titanium carbide composite material can be obtained. According to the method, uniformly-distributed manganese dioxide can be formed on the surface of titanium carbide, the obtained composite material is good in electrochemical performance, and the preparation method is low in requirement on equipment, easy and convenient to operate, low in cost and beneficial to achievement of industrialized mass production.

Owner:SHAANXI UNIV OF SCI & TECH

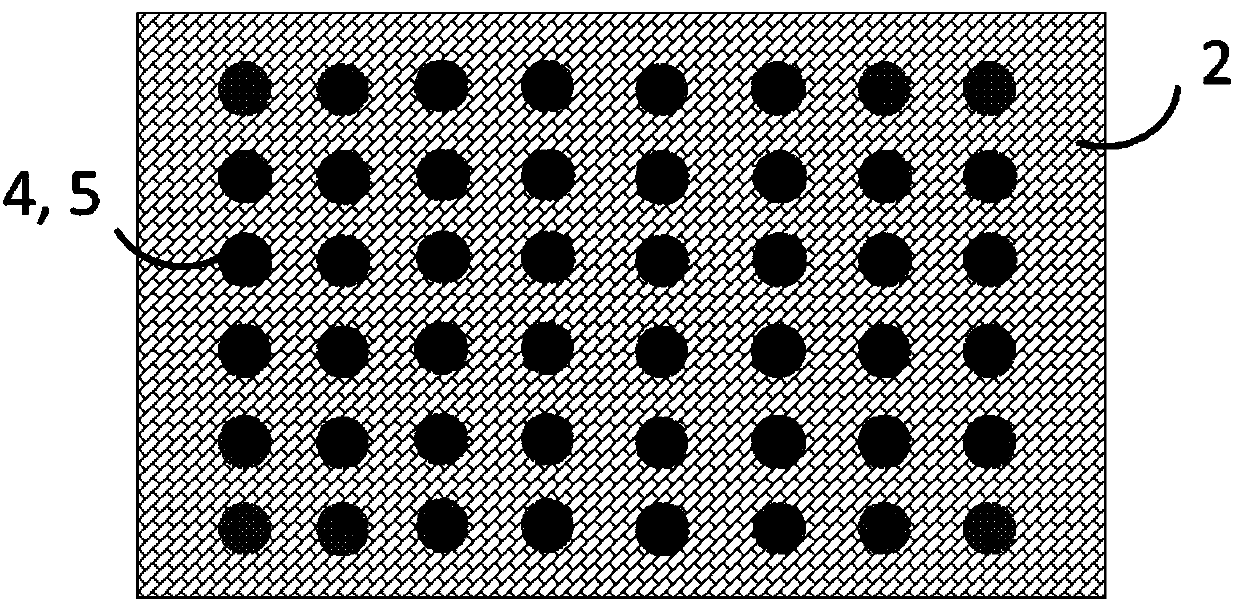

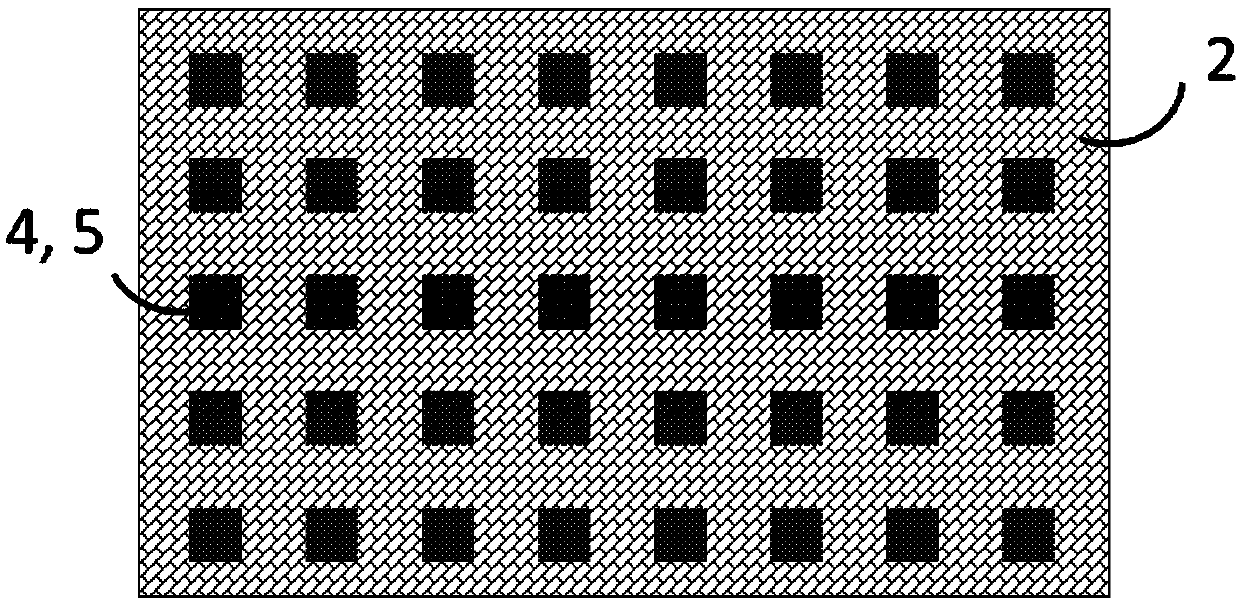

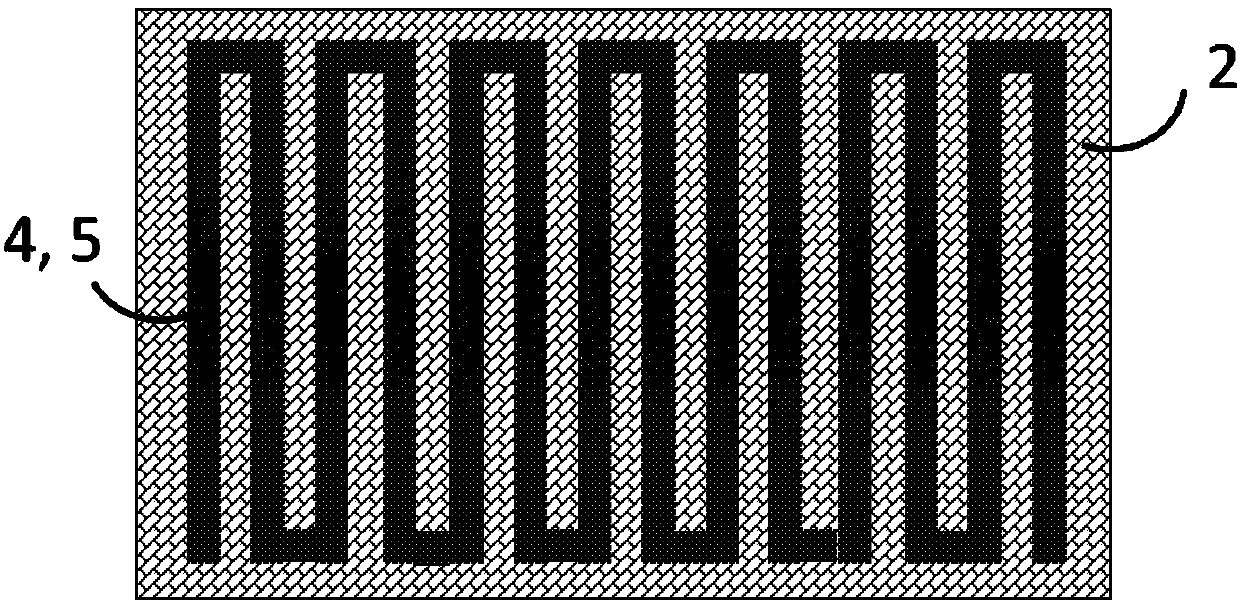

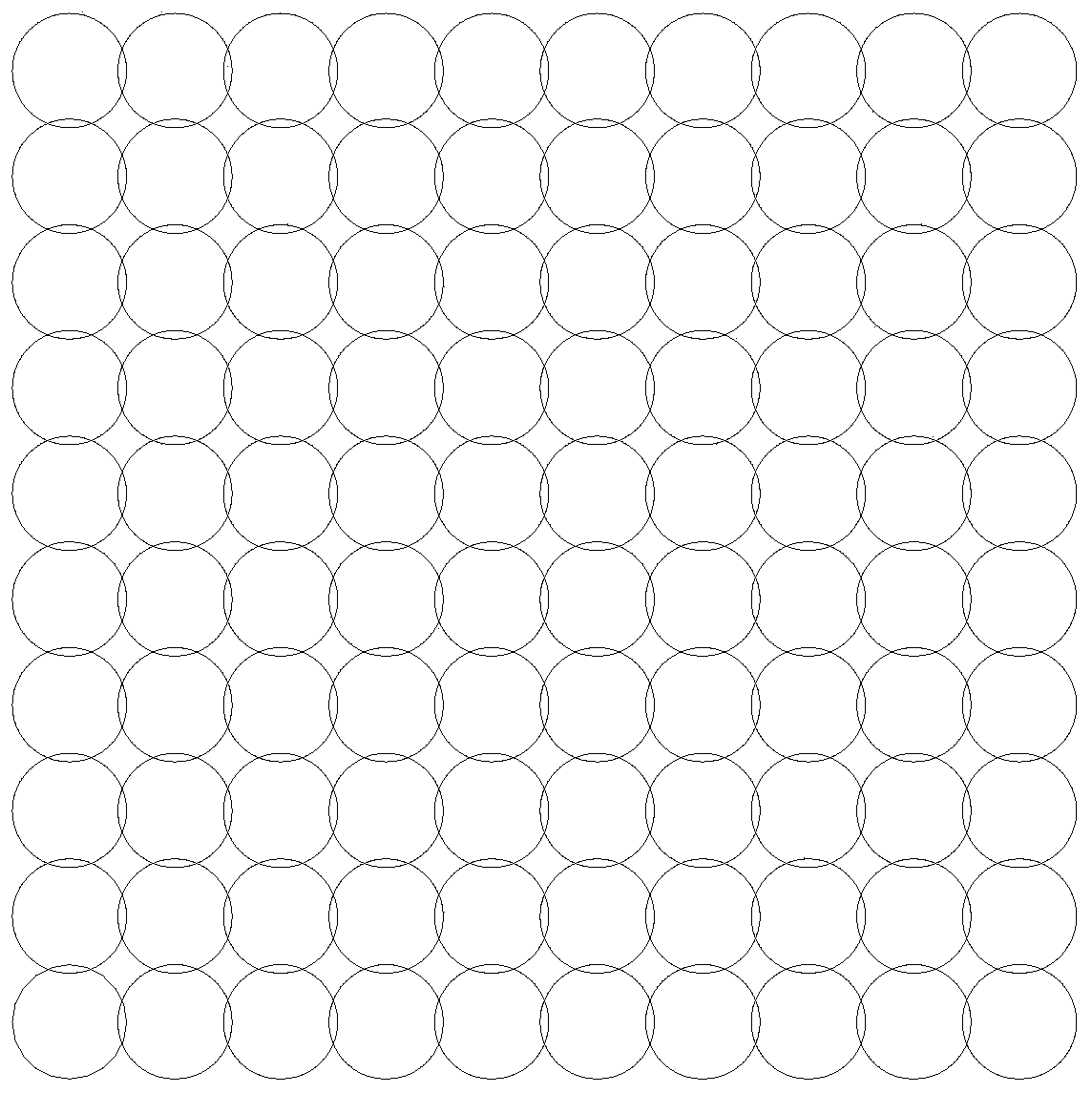

Preparation method of diaphragm, electrode and current collector integrated structure as well as preparation method of battery

InactiveCN107946519AReduce thicknessImprove cycle performanceCell seperators/membranes/diaphragms/spacersEngineeringSlurry

The invention discloses a preparation method of a diaphragm, electrode and current collector integrated structure as well as a preparation method of a battery. The preparation method of the integratedstructure comprises the following steps of S1.taking a diaphragm as a matrix and printing electrode slurry on the surface of the diaphragm through a printing technology or a printing technology in order to distribute the electrode slurry on the surface of the diaphragm in a patterned mode; S2.carrying out vacuum drying on the diaphragm obtained in the step S1 in order to solidify the electrode slurry on the surface of the diaphragm to form an electrode material distributed in the patterned mode; and S3.plating or depositing a conductive thin film on the whole surface of the electrode materialdistributed in the patterned mode as a current collector through a vacuum coating technology or a spraying deposition technology in order to obtain the integrated structure. The integrated structureprepared by the invention is applied to the battery, so that the cycling performance of the battery can be improved, and the energy density of the battery can be improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for improving formation interface of lithium ion battery

ActiveCN110661050AImprove bad "dark spots"Reduced electrochemical performanceSecondary cells charging/dischargingElectrolytic agentElectrical battery

The invention provides a method for improving a formation interface of a lithium ion battery. The method comprises steps that 1) after the lithium ion battery is baked, liquid injection is performed totally twice, the vacuumizing position of a battery core is increased during primary liquid injection, that the air in the battery core is removed is guaranteed, a negative pressure state is kept between the battery core and the electrolyte, nitrogen pressure is utilized for multiple times of liquid injection circulation, after the liquid injection is finished, the battery core is subjected to standing, after standing is finished, secondary liquid injection is performed, pumping negative pressure is performed, the electrolyte is injected into the battery core by utilizing the nitrogen, high-temperature aging of the battery core is performed after secondary liquid injection, clamps are arranged on the aged battery core, two gaskets are placed on a screw, the screw is tightened, lithium ionbattery formation is performed by adopting constant current charging, a vacuum valve is opened in the formation process, the battery is subjected to standing for 5 minutes, and the battery is then subjected to 0.2C constant-current charging to 3.34-3.35 V. The method is advantaged in that bad black spots of the formation interface are ameliorated by adjusting the vacuum degree during liquid injection and negative pressure formation, moreover, electrochemical performance of the battery core is improved, and use cost of the battery core is reduced.

Owner:安徽益佳通电池有限公司

MnO2 nanosheet/TiC composite and preparation method thereof

InactiveCN108190962AImprove bindingReduced electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesFree coolingBuffer solution

The invention provides a MnO2 nanosheet / TiC composite and a preparation method thereof. The method comprises the following steps: dispersing Ti3C2 nanopowder and dopamine hydrochloride in ultrapure water respectively, performing mixing evenly, and performing stirring under the shading condition; adding a Tris-buffer solution, and performing stirring continuously under the shading condition; performing separating, water washing and drying on the obtained mixed solution to obtain Ti3C2@PDA nano-powder; adding the Ti3C2@PDA nano-powder to ultrapure water, and adding a KMnO4 solution after uniformdispersing for liquid phase reaction; performing cooling naturally after the reaction is finished to obtain the MnO2 nanosheet / TiC composite. With the method, uniformly distributed MnO2 nanosheets can be formed on the surface of TiC, and the preparation method has low equipment requirement, is simple to operate and low in cost, and facilitates industrial large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

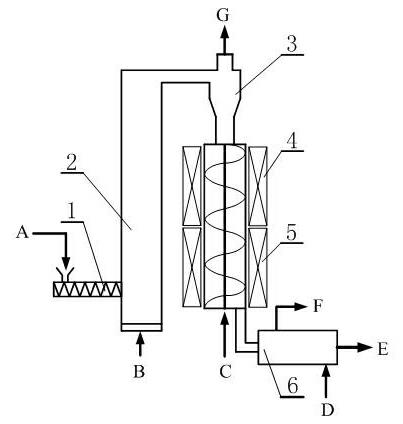

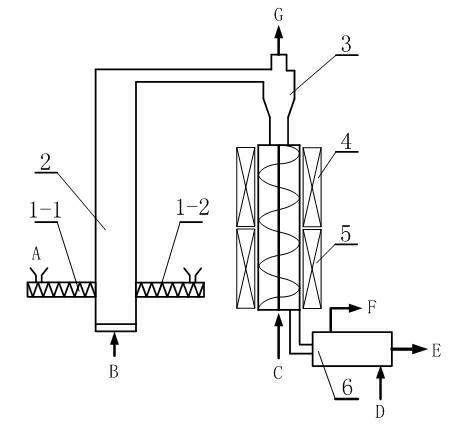

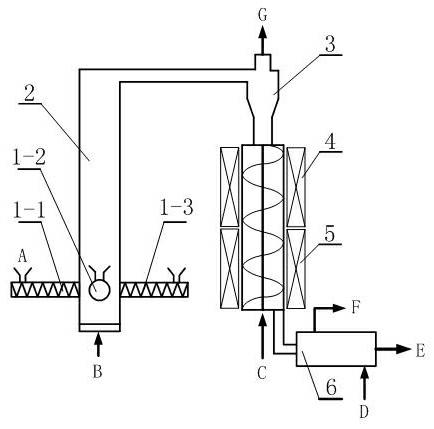

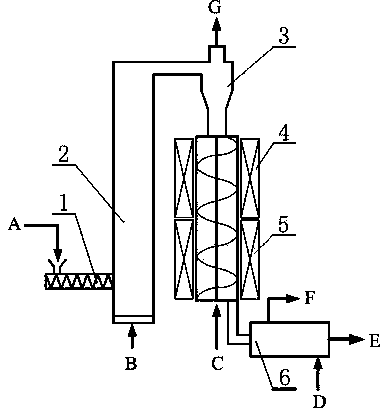

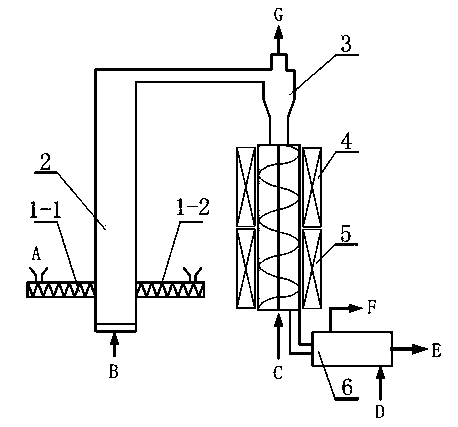

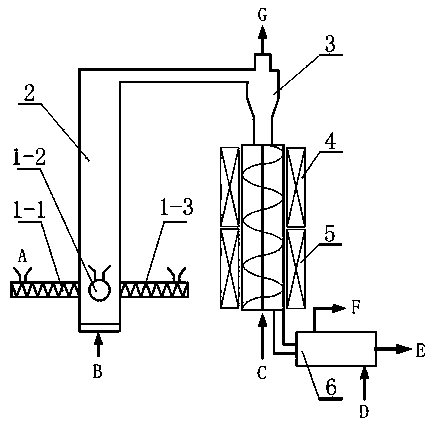

Device and process for manufacturing positive/negative electrode material of lithium battery

ActiveCN102427128AAddress the degree of automationSolve productivityCell electrodesFluidized bedEngineering

The invention relates to a device and process for manufacturing a positive / negative electrode material of a lithium battery. The device consists of a feeder, a fluidized bed mixer, a gas-solid separator, a spiral continuous feeding reaction device preheating section, a spiral continuous feeding reaction device reacting section, and a cooling device. The process for manufacturing the positive / negative electrode material of the lithium battery comprises the following steps of: firstly feeding raw materials for manufacturing the positive / negative electrode material of the lithium battery into the fluidized bed mixer through the feeder, fully mixing and then separating by the gas-solid separator, sequentially entering the spiral continuous feeding reaction device preheating section and the spiral continuous feeding reaction device reacting section, heating and reacting to generate the positive / negative electrode material of the lithium battery, and then entering the cooling device to be cooled, finally discharging the positive / negative electrode material of the lithium battery from a product outlet. The device and process provided by the invention can be used for continuously manufacturing the positive / negative electrode material of the lithium battery efficiently with low energy consumption.

Owner:济宁市无界科技有限公司

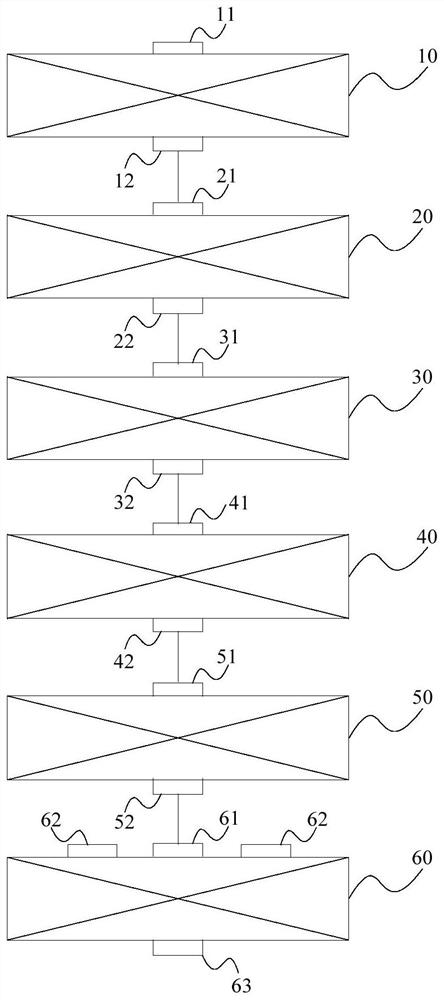

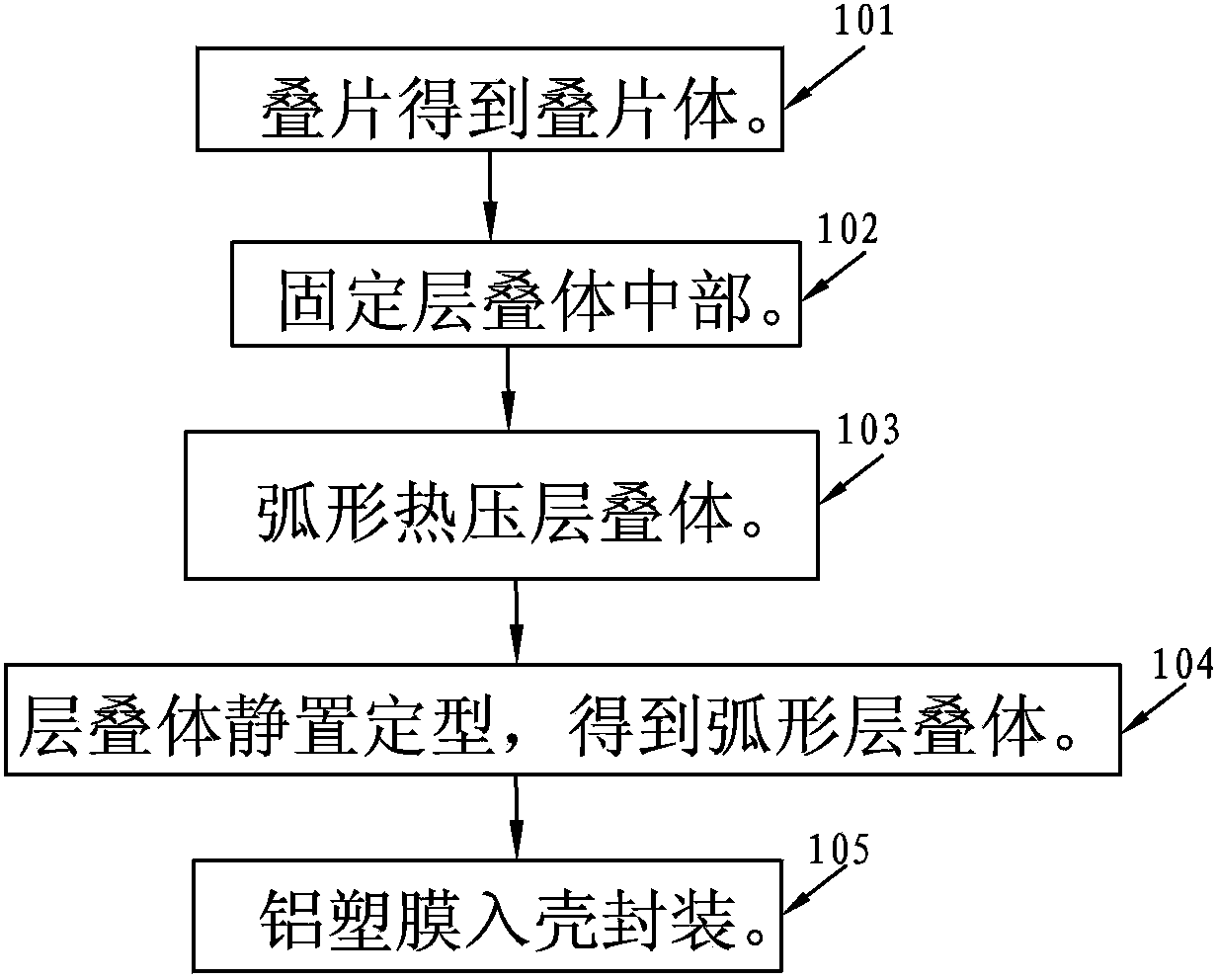

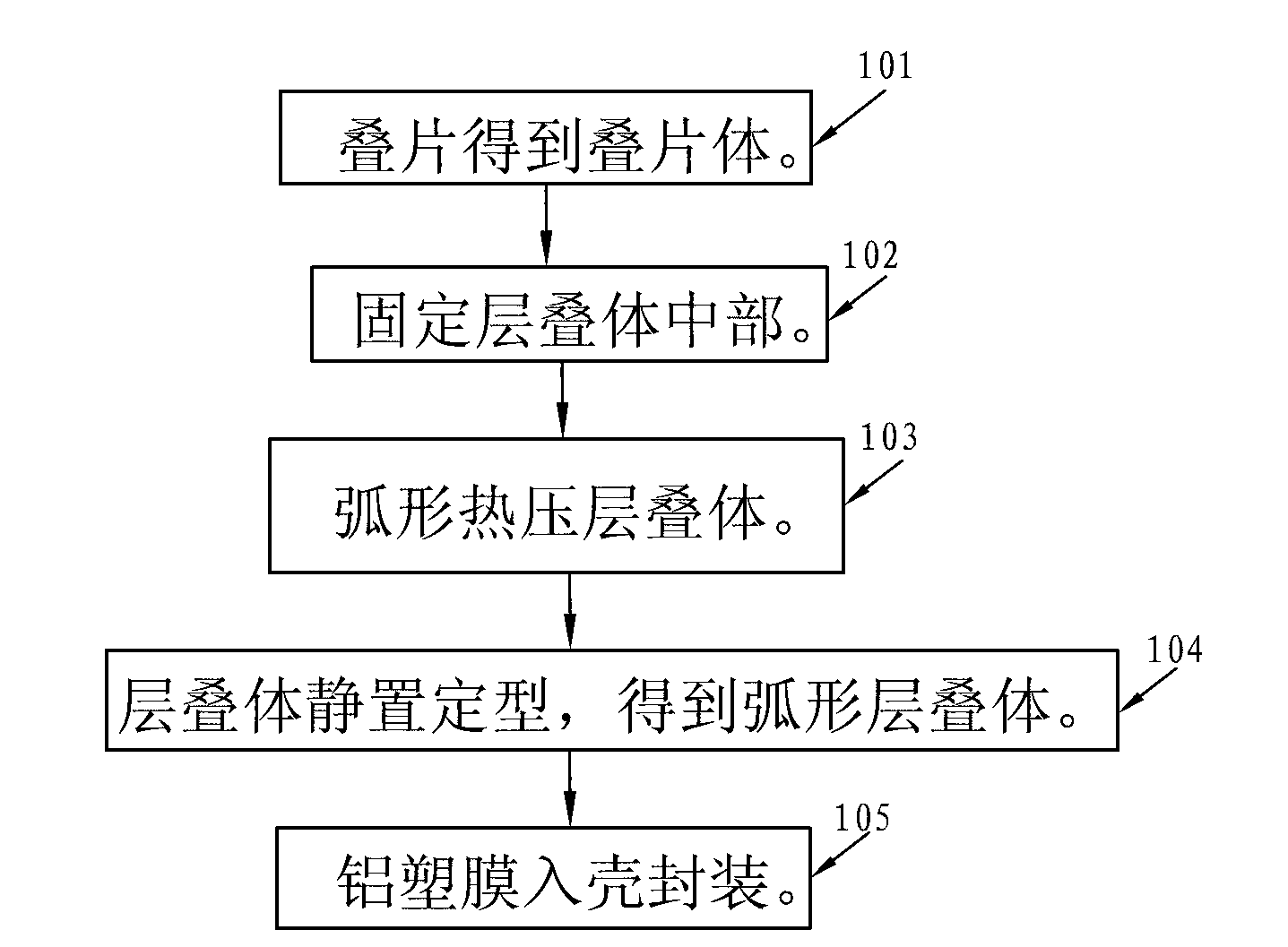

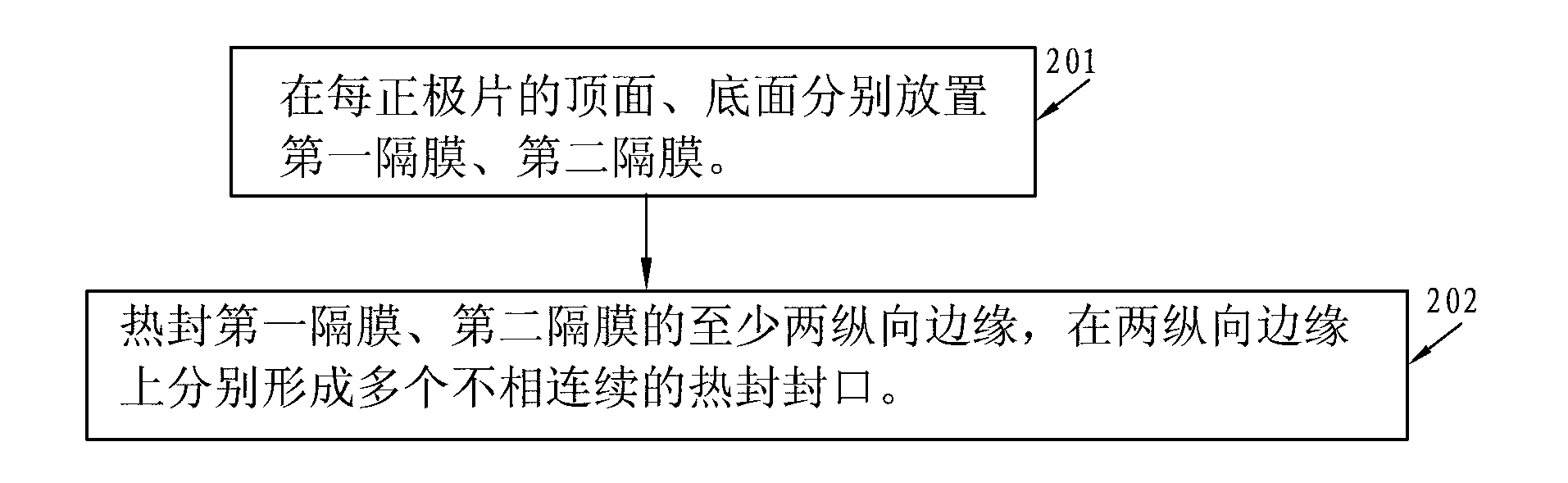

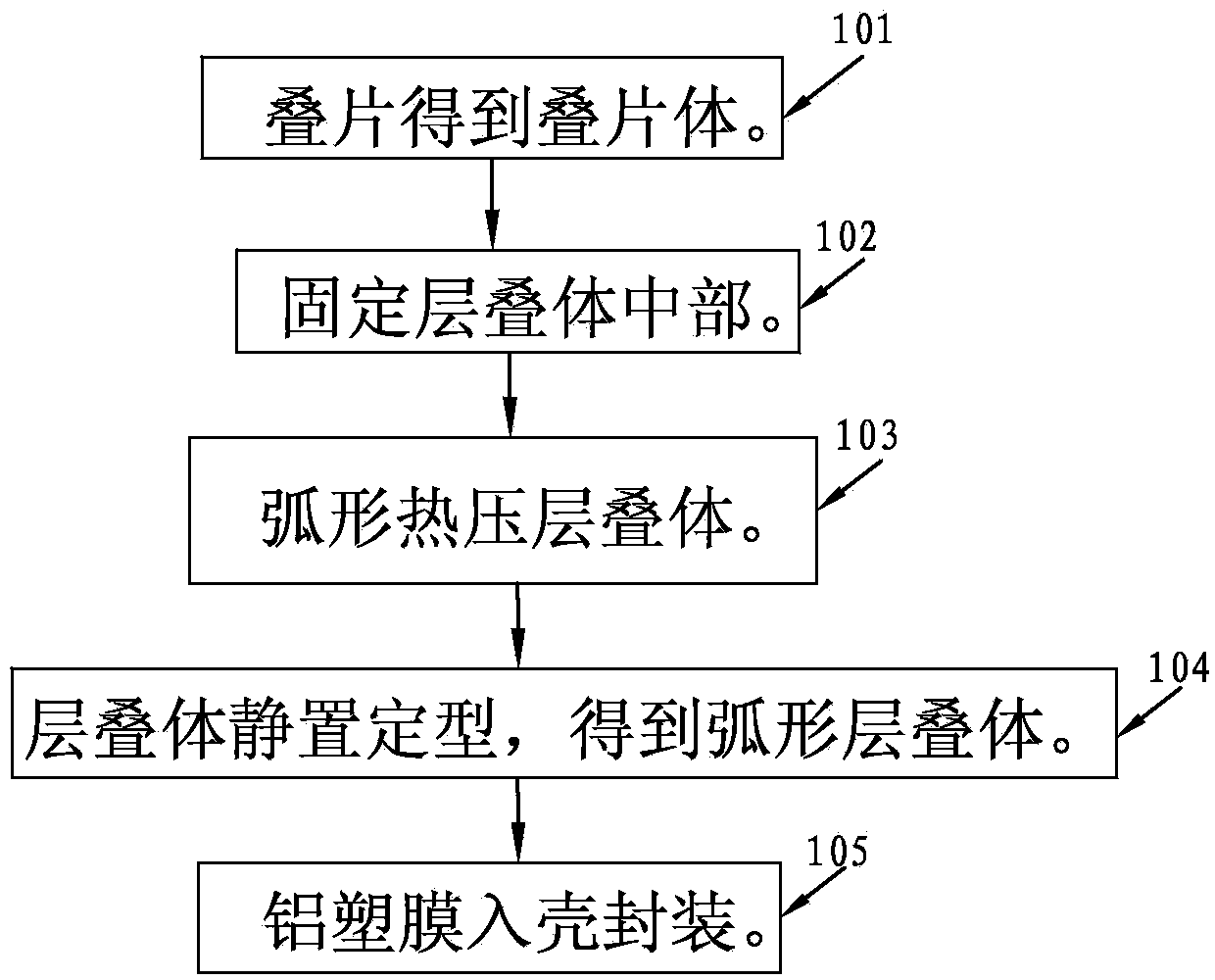

Preparation method of laminated lithium ion battery and laminated lithium ion battery

InactiveCN103441307AReduced electrochemical performanceGuarantee stabilityFinal product manufactureSecondary cellsElectrical performanceEngineering

The invention relates to the field of lithium ion batteries and discloses a preparation method of a laminated lithium ion battery and the laminated lithium ion battery. The method comprises the following steps: laminating a negative plate and a positive plate to obtain a laminated cell body; fixing the middle of the laminated cell body; naturally placing the laminated cell body on the top of an arc-shaped bracket; hot-pressing the laminated cell body; standing the laminated cell body to obtain an arc-shaped laminated cell body, wherein the natural lengths of the positive plate and the negative plate are gradually lengthened from inside to outside along the arc of the arc-shaped laminated cell body in the arc-shaped laminated cell body; placing the arc-shaped laminated cell body into a cell body recess of an aluminum plastic film shell, and thermally sealing an aluminum plastic film to encapsulate the arc-shaped laminated cell body into the aluminum plastic film shell to obtain the laminated lithium ion battery. By the adoption of the technical scheme, the appearance of the battery can be improved, and the electrical performance of the battery is improved.

Owner:SHENZHEN GREPOW BATTERY CO LTD

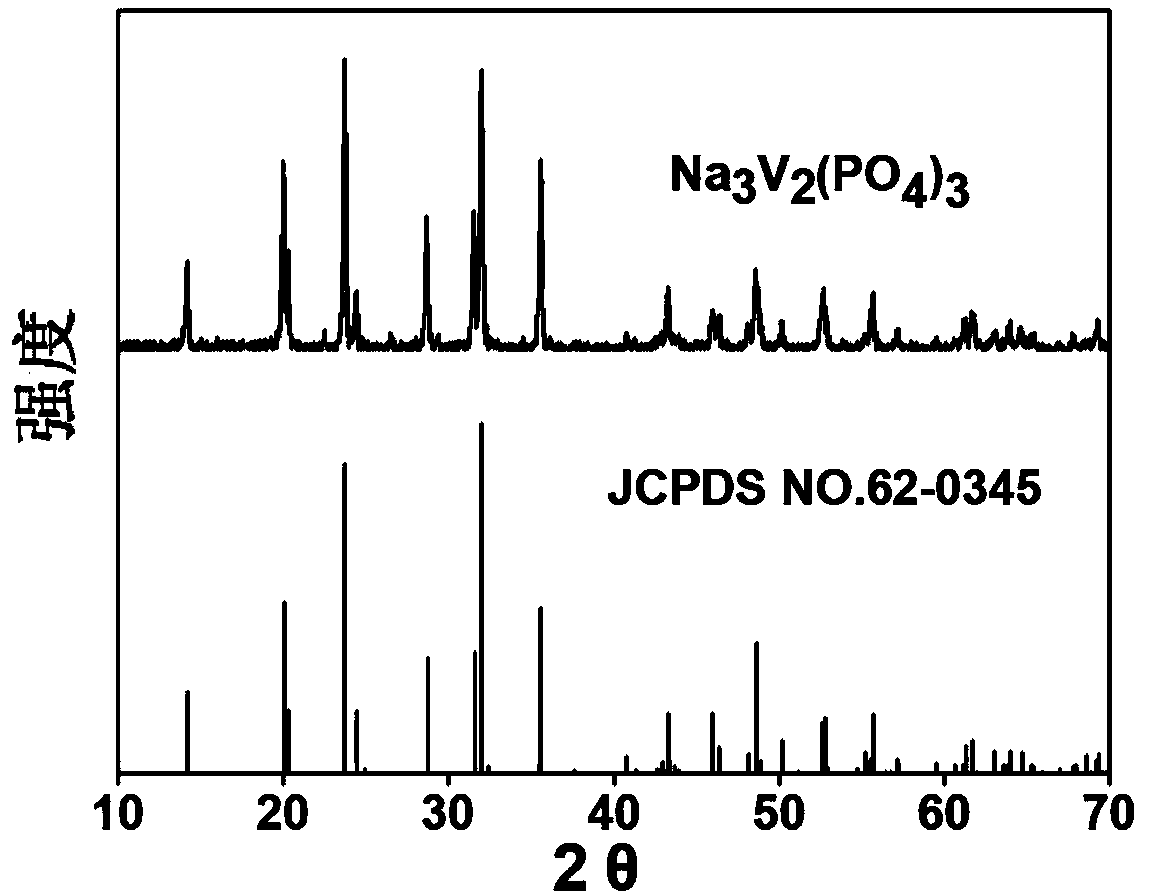

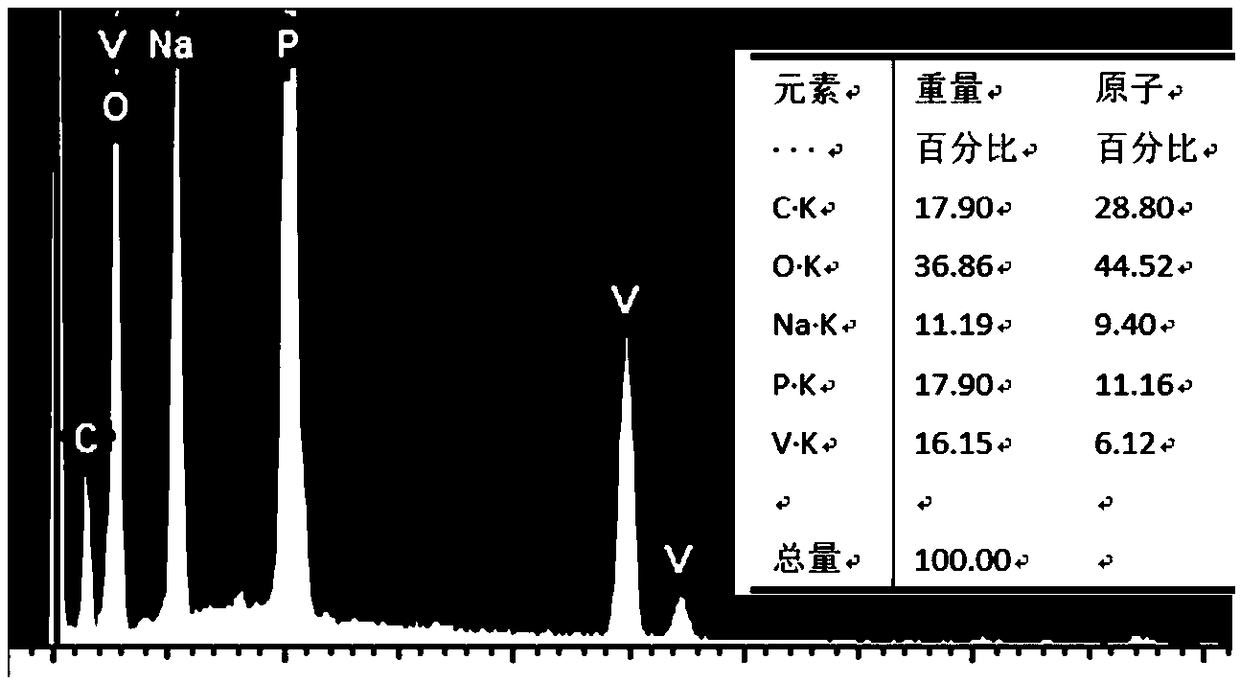

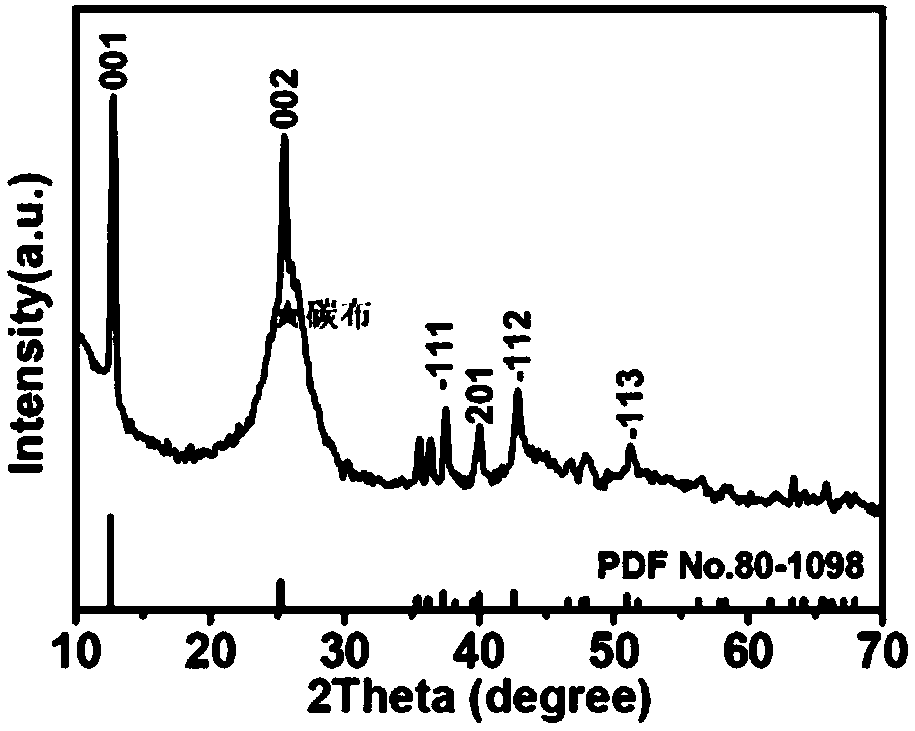

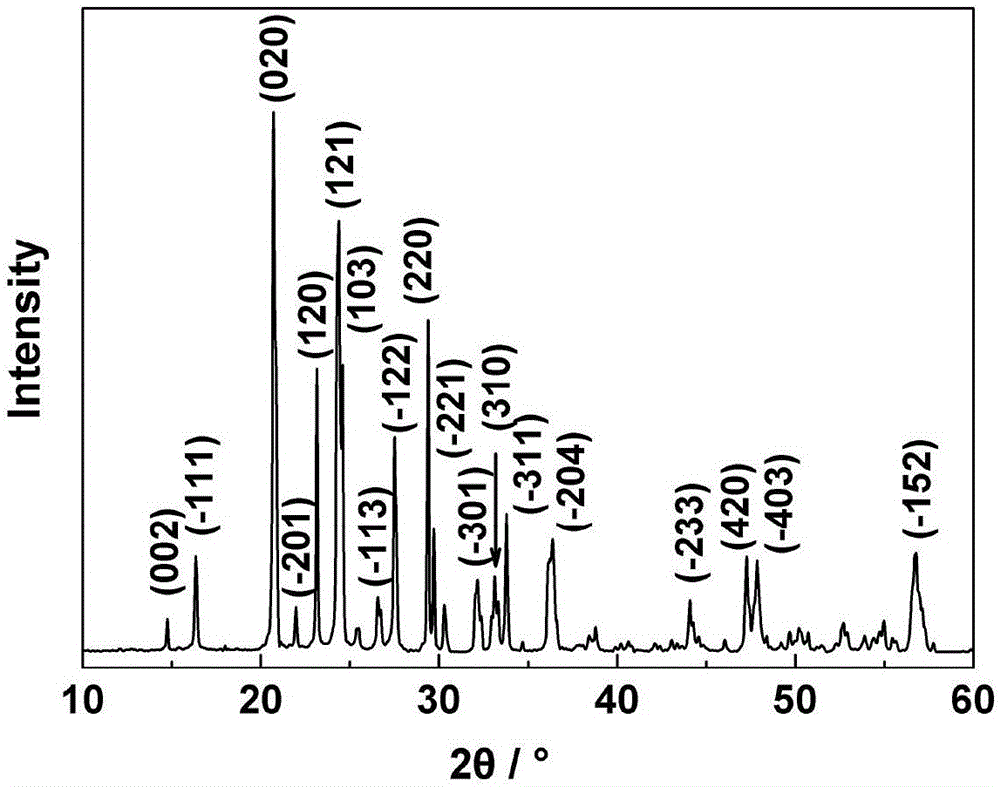

Na3V2(PO4)3/C composite material with quantum dot structure and preparation method thereof

ActiveCN108807895AEasy transferFacilitates volume expansion adjustmentCell electrodesSecondary cellsCarbon compositesSocial benefits

The invention relates to a Na3V2(PO4)3 / C composite material with a quantum dot structure and a preparation method thereof. The Na3V2(PO4)3 / C composite material with the quantum dot structure is obtained by taking paper pulp, a sodium source, a vanadium source and a phosphorus source as raw materials and carrying out hydrothermal and carbothermal reduction thermal treatment; the Na3V2(PO4)3 / C composite material not only has the characteristics of low cost and simple preparation technology, but also is beneficial for transmission of sodium ions and volume expansion regulation caused during an embedding / uplugging process of the sodium ions, the electrochemical performance of the Na3V2(PO4)3 / C composite material can be improved, a good application prospect is obtained, and remarkable economicand social benefit can be obtained.

Owner:山东济清科技服务有限公司

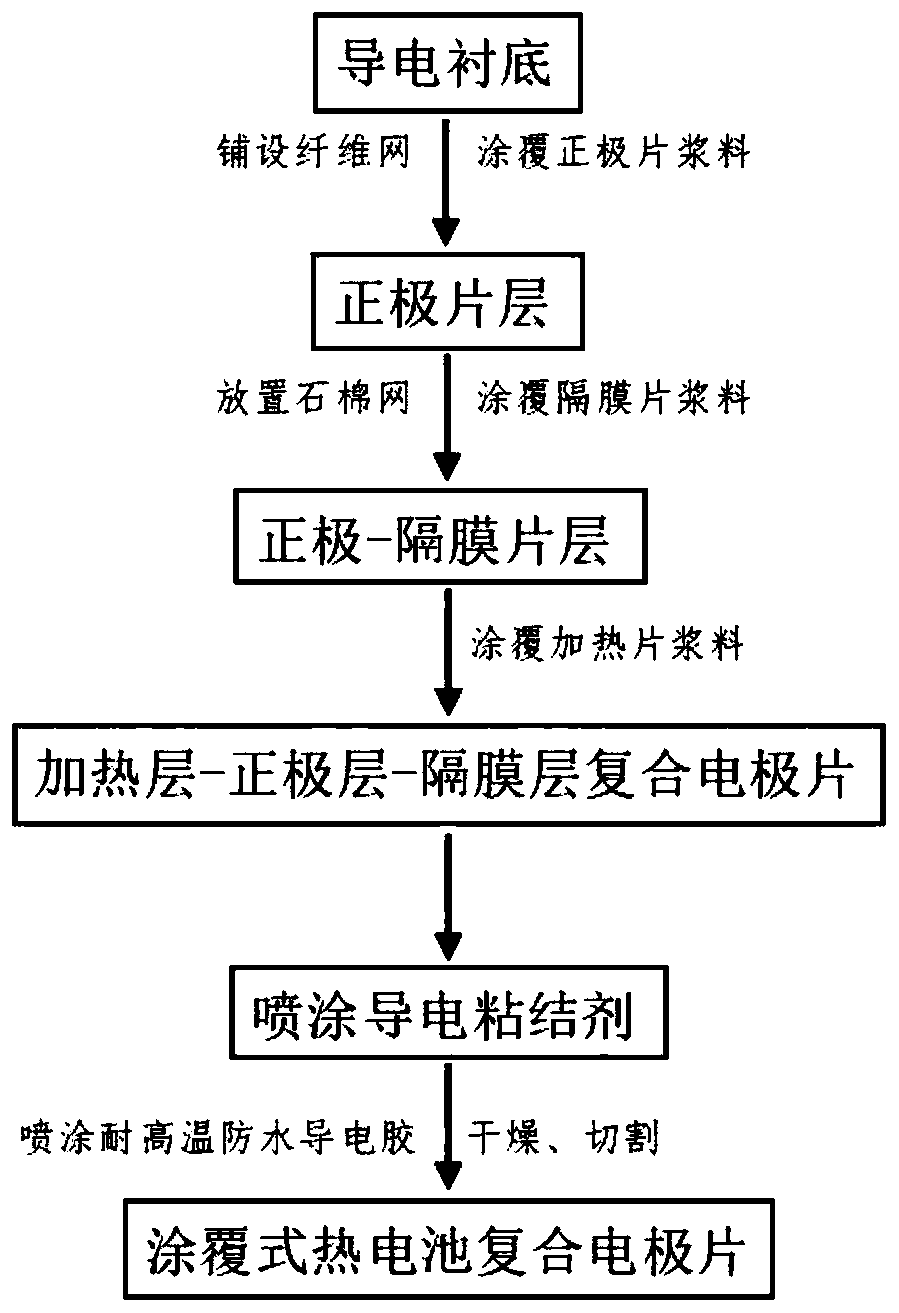

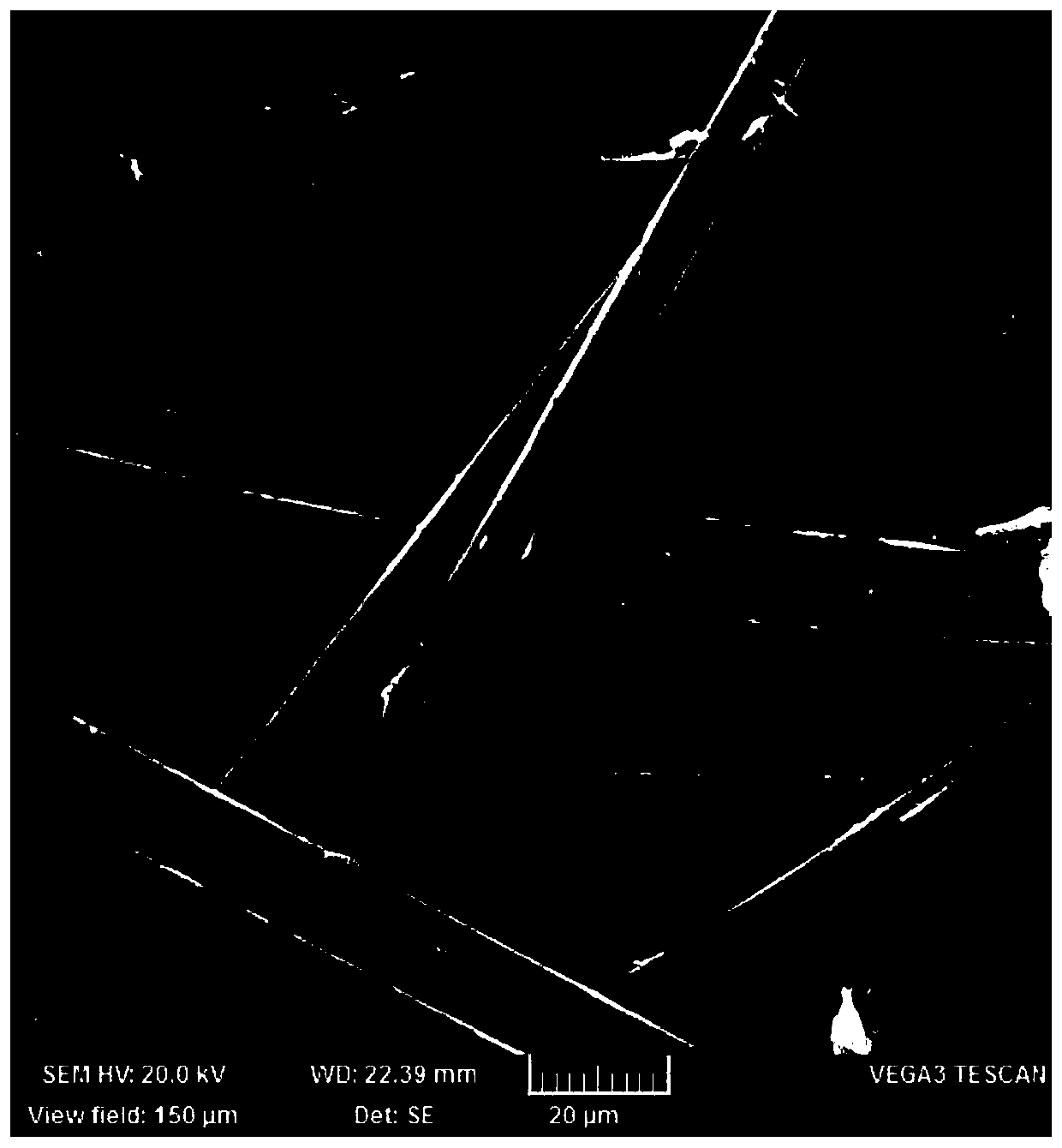

Preparation method of coated thermal battery composite electrode sheet

ActiveCN110112431APrecise and controllable thicknessSuitable for development needsPrimary cell manufactureElectrode manufacturing processesFiberComposite electrode

The invention discloses a preparation method of a coated thermal battery composite electrode sheet. The composite electrode sheet is composed of a heating layer, a positive electrode layer and a separator layer. For the preparation method, firstly, a layer of fiber mesh is laid on a conductive substrate, a positive electrode layer is then coated, after drying, an asbestos mesh is placed on a surface of the positive electrode layer; secondly, the separator layer is then coated on the positive electrode layer on which the asbestos mesh is placed, after the separator layer is dried, the heating layer is coated on the other side of the conductive substrate to obtain a composite sheet; and thirdly, high temperature resistant waterproof conductive adhesive is coated on both sides of the composite sheet, after drying, the composite positive electrode layer is obtained. The composite electrode sheet is advantaged in that thickness of the composite electrode sheet can be adjusted according to height of a scraper in the preparation process, so the thickness of the composite electrode sheet is precisely controlled, the composite electrode sheet is combined with a thermal battery negative electrode LiB sheet with controllable thickness to form an ultra-thin thermal battery cell, the obtained composite electrode sheet has a function of preventing moisture absorption and preventing a diaphragm from being melted and overflowing, and the preparation method has advantages of high chip rate and simple process and meets requirements of engineering use.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

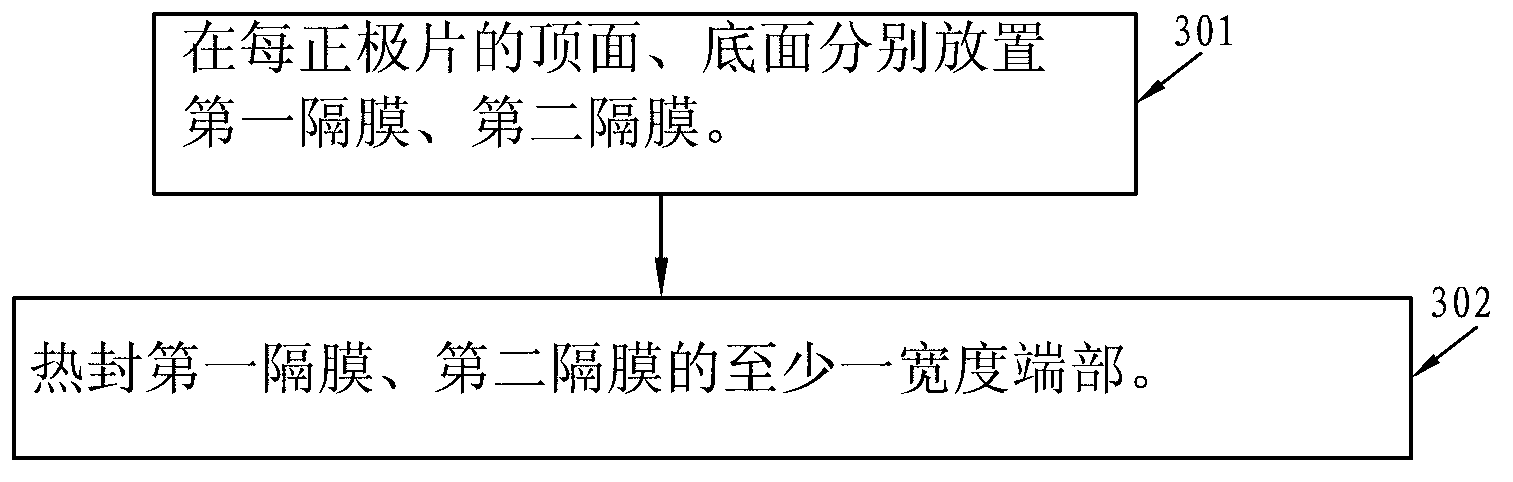

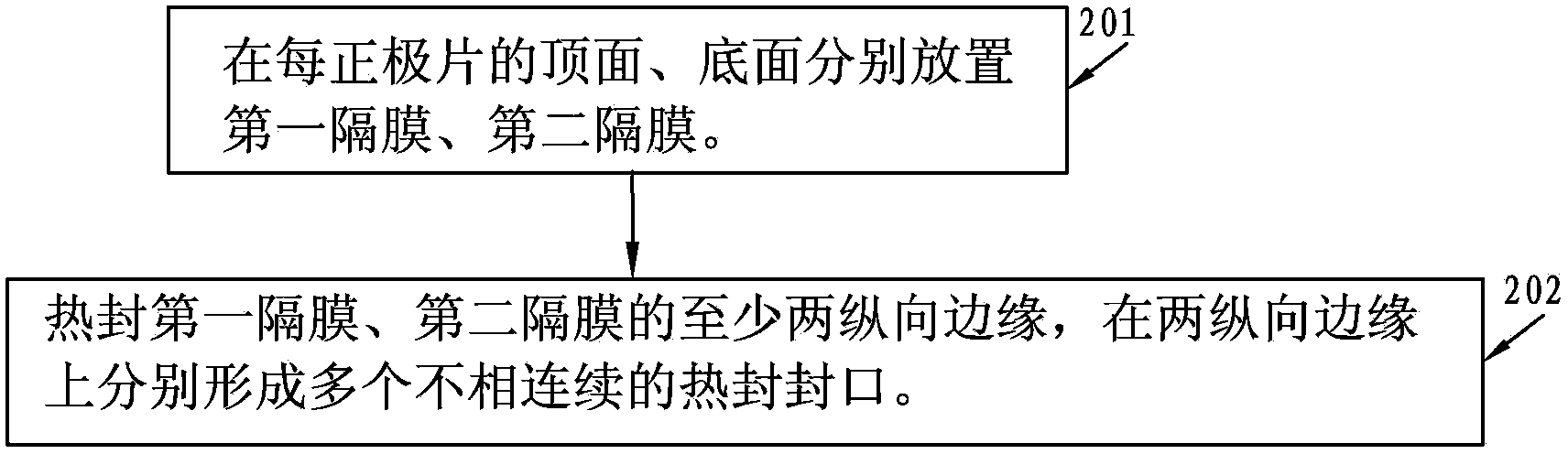

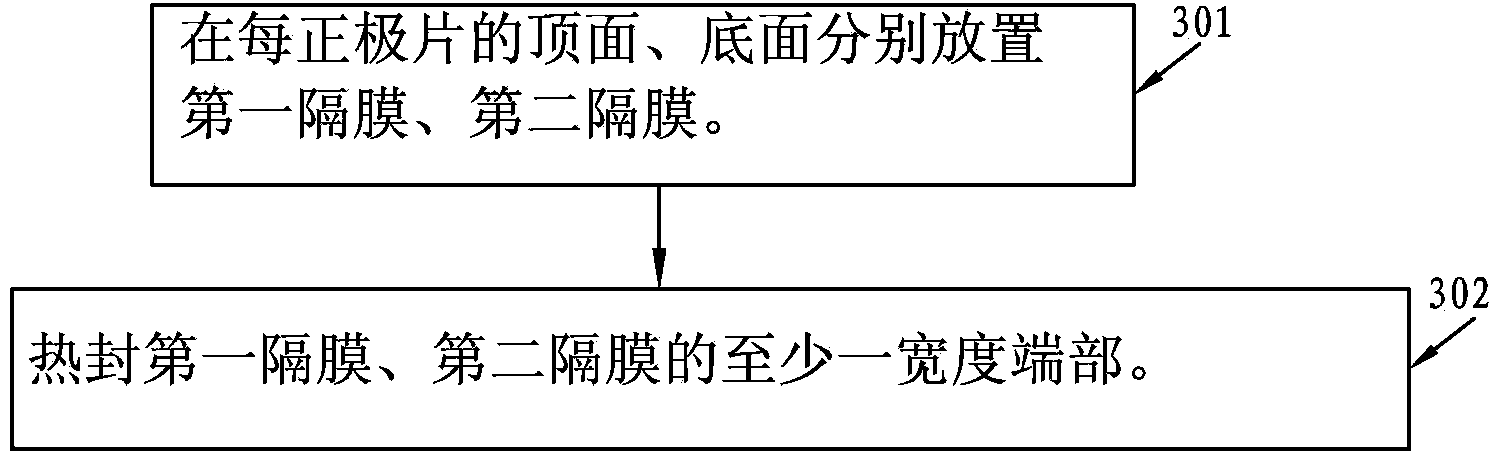

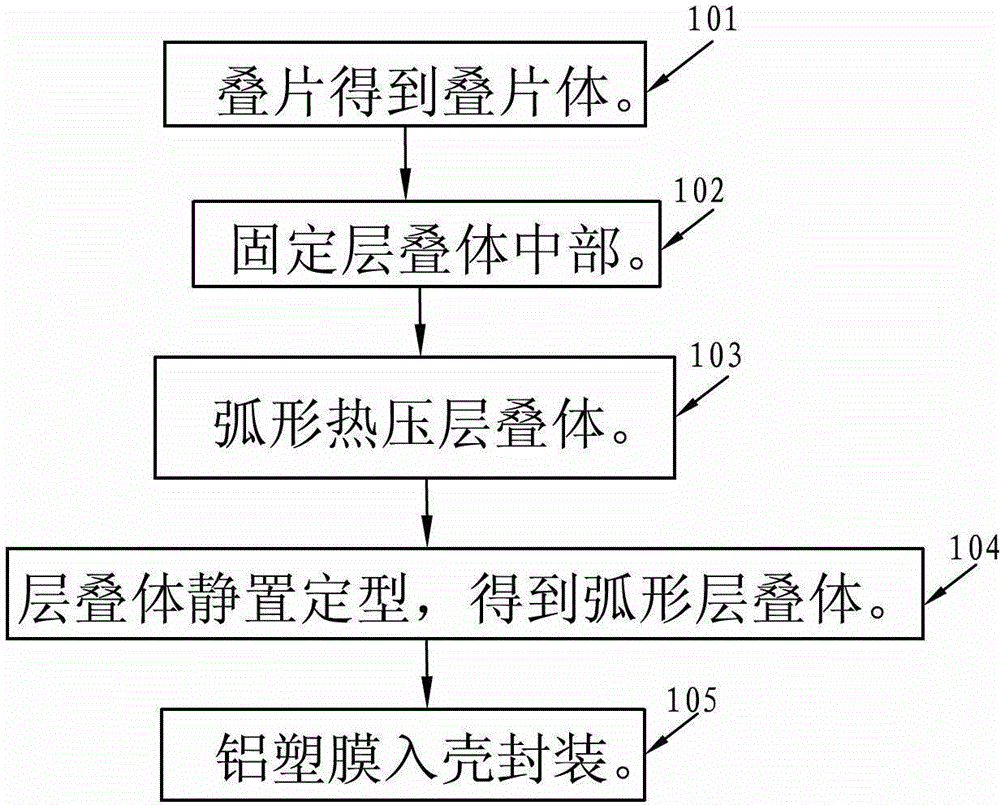

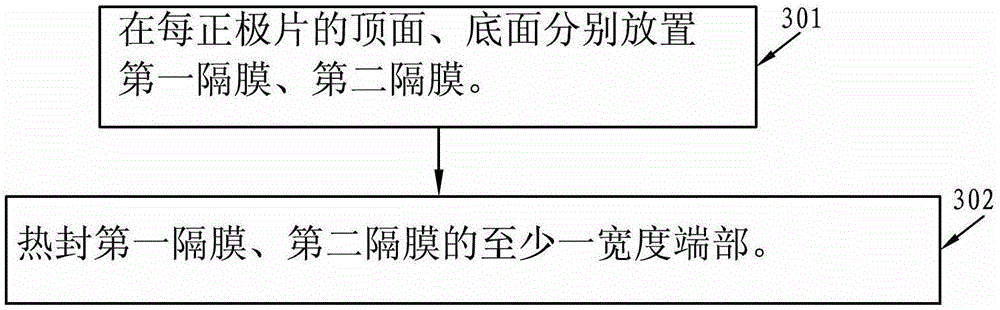

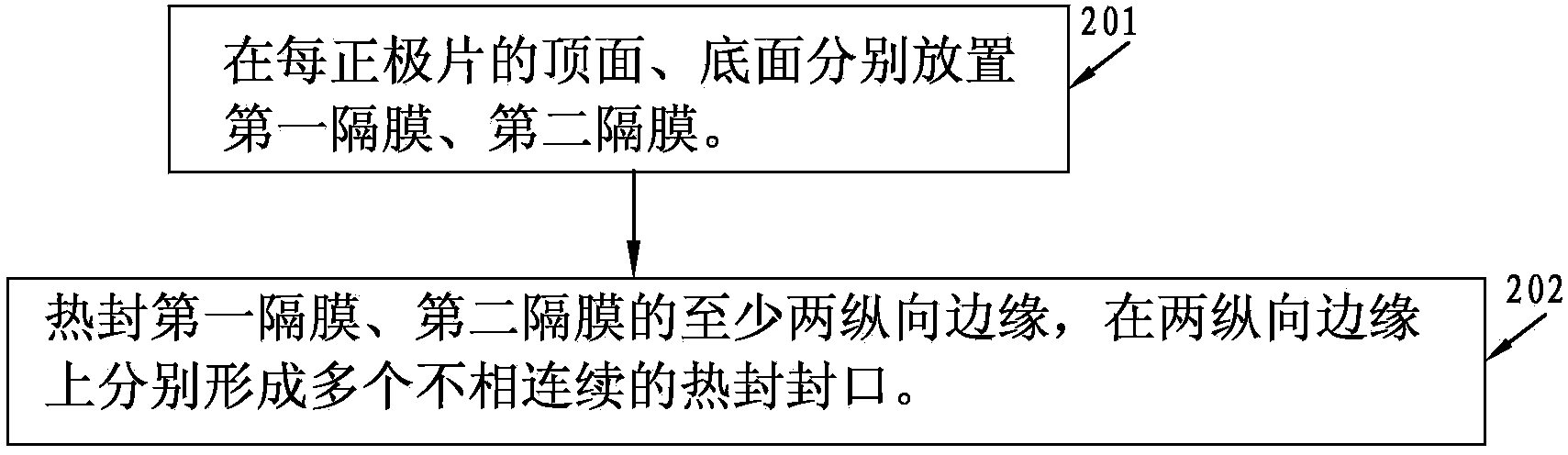

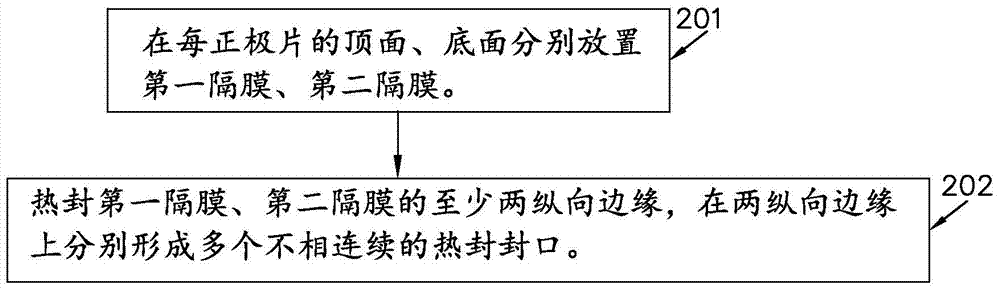

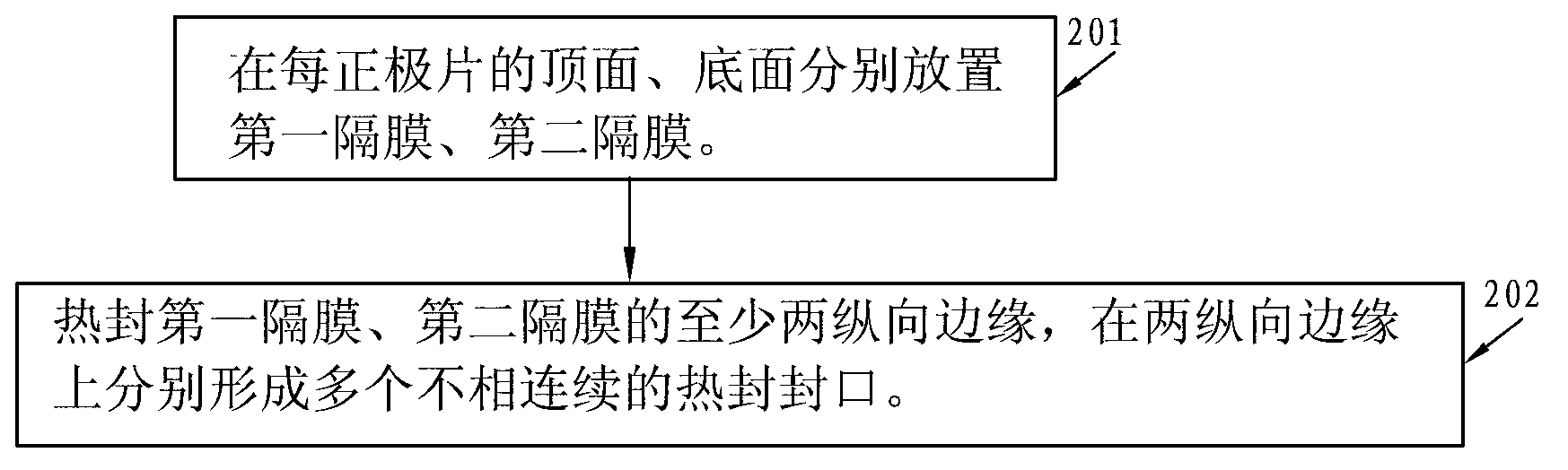

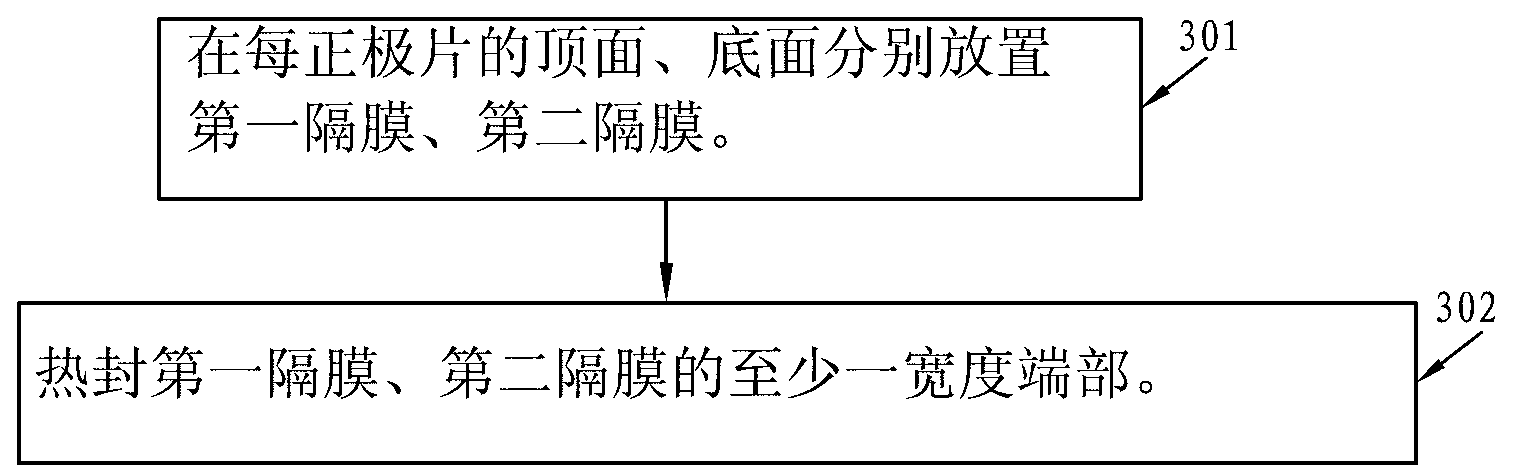

Preparation method of laminated lithium-ion battery and battery

InactiveCN103296314AReduced electrochemical performanceGuarantee stabilityFinal product manufactureSecondary cellsElectrical batteryEngineering

The invention relates to the field of a lithium-ion battery, and discloses a preparation method of a laminated lithium-ion battery and the battery. The preparation method comprises the following steps of: loading each positive plate into a diaphragm bag according to the following bag loading process to obtain a positive plate diaphragm bag, wherein the bag loading process is as follows: a first diaphragm and a second diaphragm are respectively arranged on the top surface and the bottom surface of each positive plate, and at least one wide end of each of the first diaphragm and the second diaphragm is thermally sealed; laminating a negative plate diaphragm bag and the positive plate diaphragm bag to obtain a laminated cell body, fixing the middle part of the laminated cell body, naturally placing the laminated cell body to ensure that each diaphragm layer inside the laminated cell body is bonded with adjacent positive plate and negative plate of the diaphragm layers; standing the laminated cell body to obtain an arc laminated cell body; placing the arc laminated cell body into a cell body concave position of an aluminum-plastic film shell to be thermally sealed with an aluminum-plastic film, and packaging the arc laminated cell body into the aluminum-plastic film shell to obtain the laminated lithium-ion battery.

Owner:SHENZHEN GREPOW BATTERY CO LTD

Packaging mold and packaging method used for aluminum/plastic film

InactiveCN103337661AAvoid damageReduced electrochemical performanceFinal product manufactureElectrolyte accumulators manufacturePlastic filmLithium-ion battery

The invention relates to the technical field of lithium ion battery, and discloses a packaging mold and a packaging method used for an aluminum / plastic film. The mold comprises an upper packaging part and a lower packaging part, the bottom of the upper packaging part is a curved surface; the top of the lower packaging part is a second curved surface; the first curved surface and the second curved surface can be tightly matched with each other face to face. With the technical solution, the appearance of the battery can be improved; and electrochemical performance can be increased.

Owner:SHENZHEN GREPOW BATTERY CO LTD

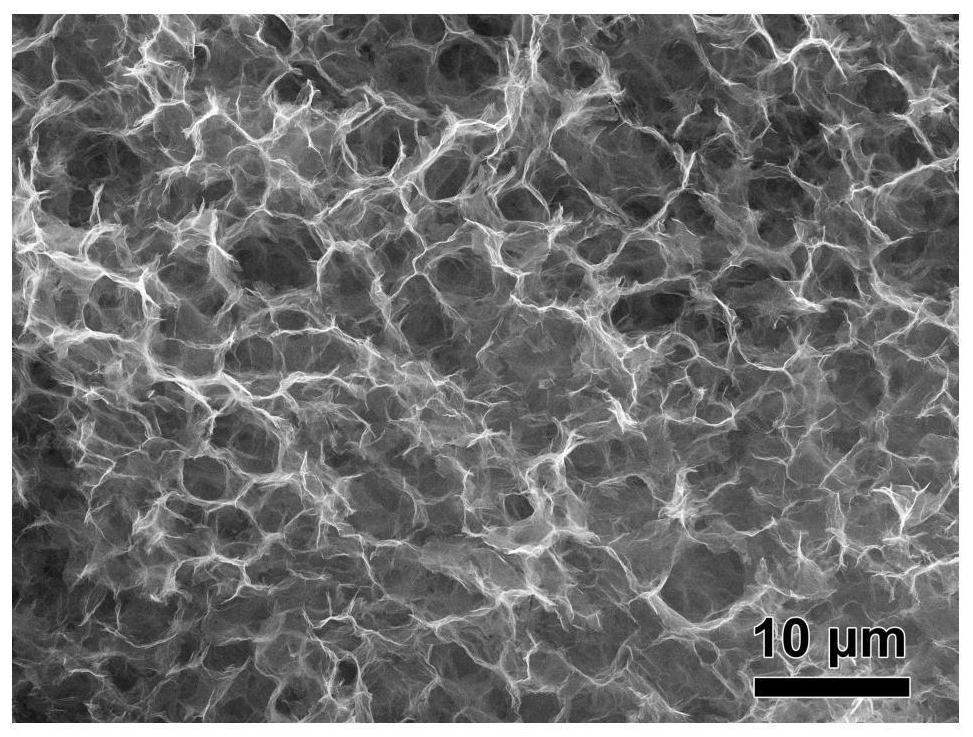

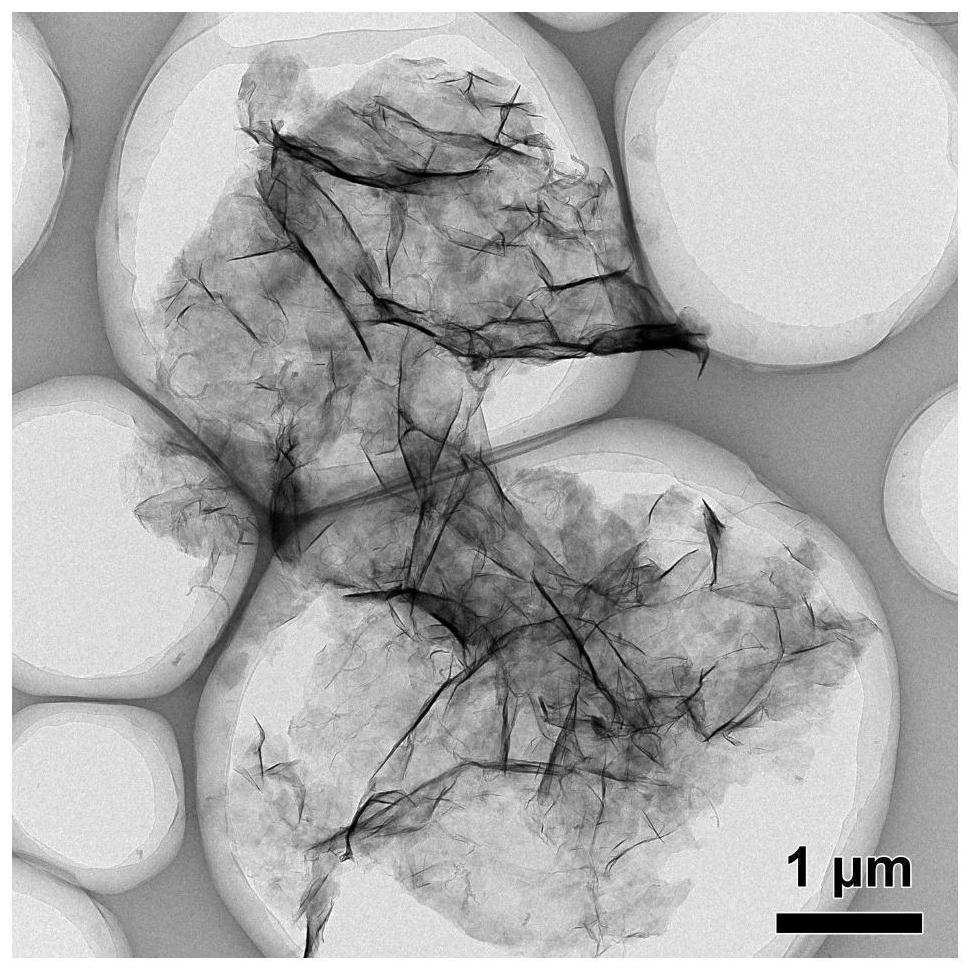

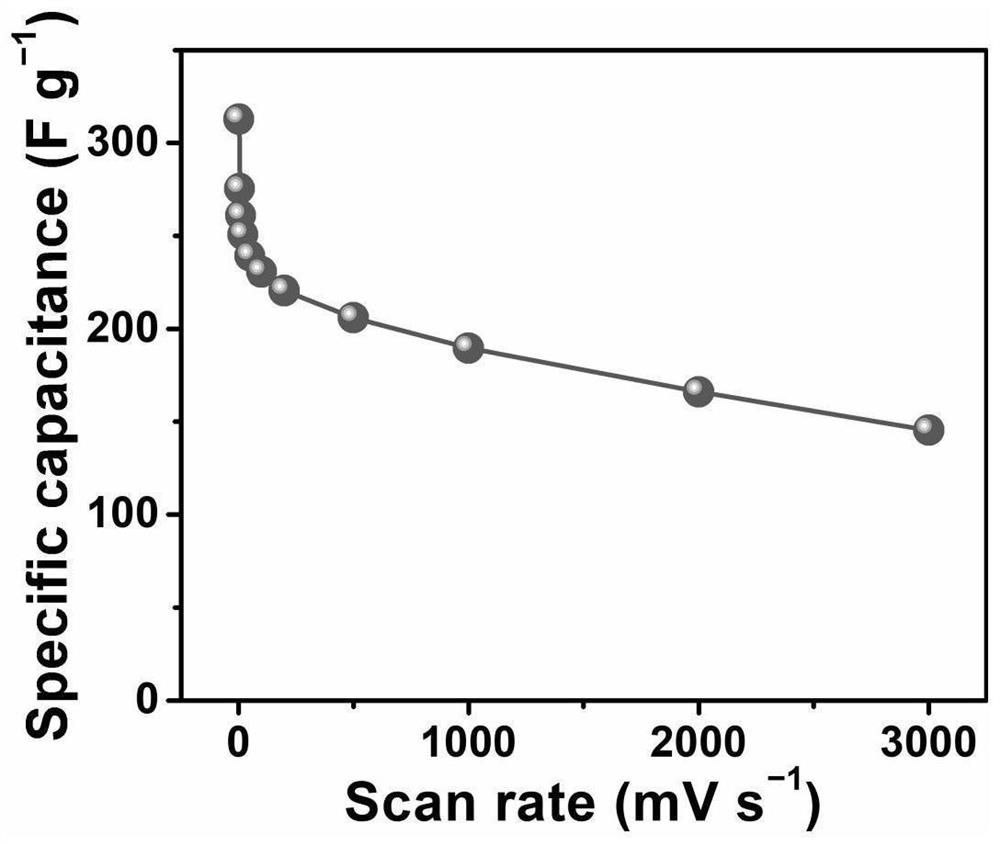

MXene/graphene/carbon nanotube gel with high magnification and long service life as well as preparation method and application of MXene/graphene/carbon nanotube gel

ActiveCN113628893ASolve easy oxidationPrevent oxidationHybrid capacitor electrodesHybrid/EDL manufactureElectrolytic agentVitamin C

The invention discloses MXene / graphene / carbon nanotube gel with high magnification and long service life as well as a preparation method and application of the MXene / graphene / carbon nanotube gel. The invention belongs to the field of supercapacitor electrode materials and preparation thereof. The invention aims to solve the technical problem that the existing supercapacitor electrode material MXene is easy to oxidize, stack and agglomerate. The MXene / graphene / carbon nanotube gel provided by the invention is formed by mutual crosslinking of a two-dimensional MXene sheet layer, a graphene nanosheet and a carbon nanotube, and the MXene / graphene / carbon nanotube gel has a three-dimensional hierarchical porous structure. The three-dimensional porous open structure effectively inhibits serious stacking and agglomeration of two-dimensional MXene sheet layers, improves the surface utilization rate of the MXene material, increases the number of active sites, and increases the specific capacity of the material; meanwhile, due to the addition of graphene and vitamin C, the oxidation of MXene can be inhibited, so that the gel has relatively good oxidation resistance; in addition, the porous structure can be used as a reservoir to shorten the diffusion path of electrolyte ions and improve the rate characteristic of the electrode.

Owner:HARBIN ENG UNIV

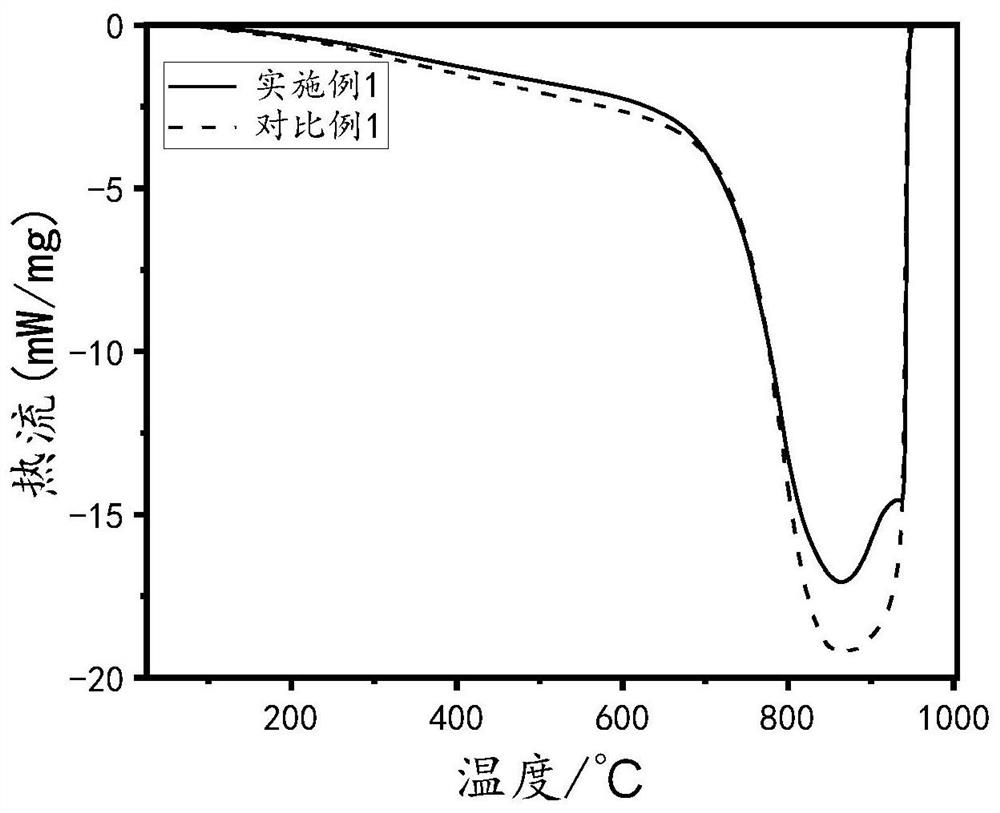

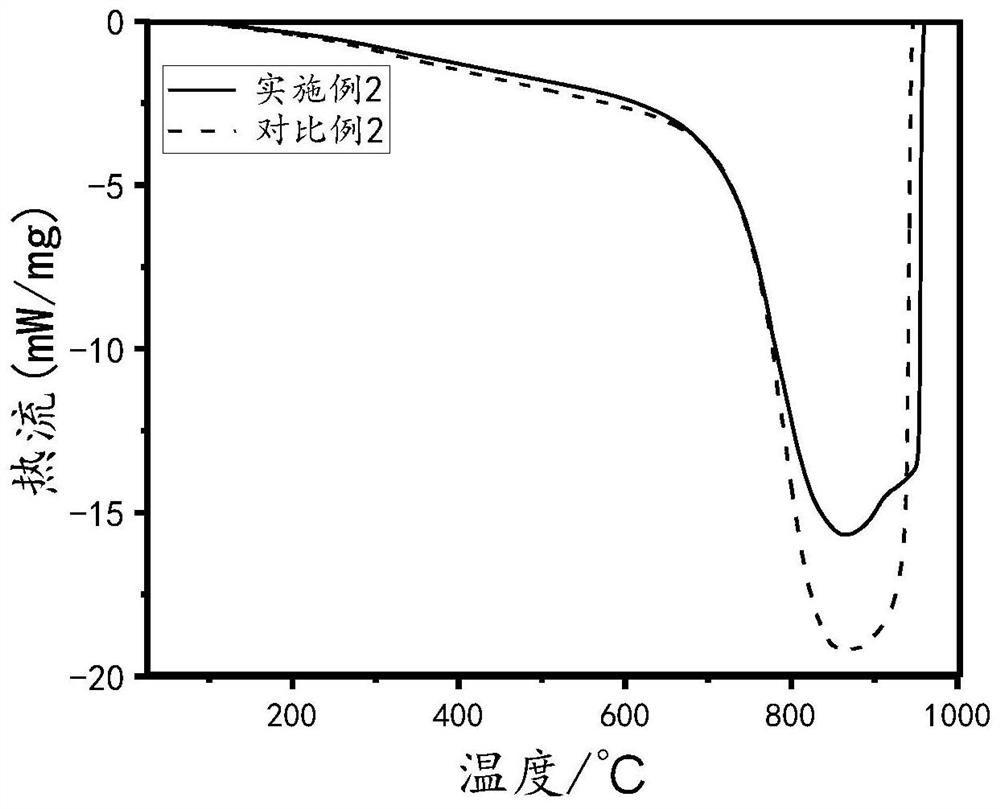

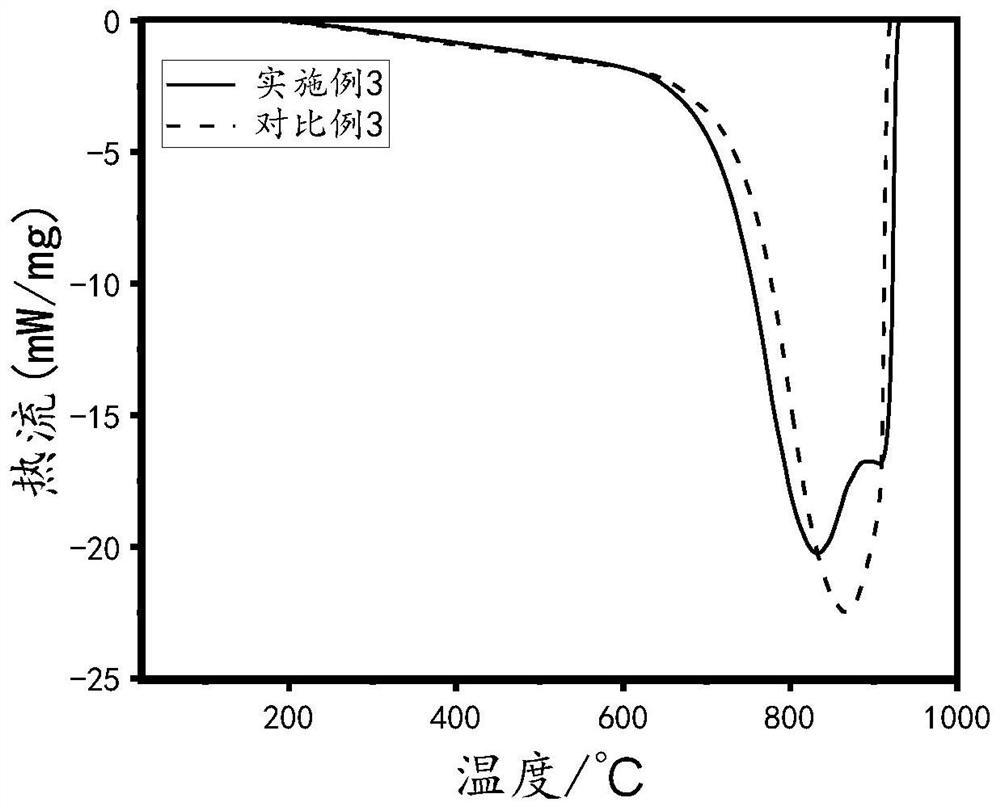

Graphite negative electrode material and preparation method and application thereof

PendingCN113437278ASmall specific surface areaIncrease charging rateSecondary cellsNegative electrodesEpoxyCarbon layer

The invention provides a graphite negative electrode material and a preparation method and application thereof. The graphite negative electrode material is a carbon layer coated graphite negative electrode material, and the carbon layer is a hard carbon coating layer; the graphite negative electrode material has two exothermic peaks when being burnt at the temperature of 600 to 1000 DEG C, and the exothermic peaks are respectively positioned in the range of 800 to 900 DEG C and the range of 900 to 1000 DEG C. The preparation method comprises the following steps: (1) mixing epoxy resin with a curing agent to obtain a mixed solution, and compounding the mixed solution with graphite by using mechanical force to obtain a composite material; and (2) carbonizing the composite material to obtain the graphite negative electrode material. The epoxy resin is wetted and coated on the surface of the graphite under the action of mechanical force and reacts with the curing agent to directly obtain the thermosetting resin on the surface of the graphite, and the graphite negative electrode material uniformly coated with hard carbon is obtained after carbonization, so that the specific surface area of the graphite negative electrode material can be effectively reduced, the charging rate is improved, and rapid charging is realized.

Owner:江西紫宸科技有限公司

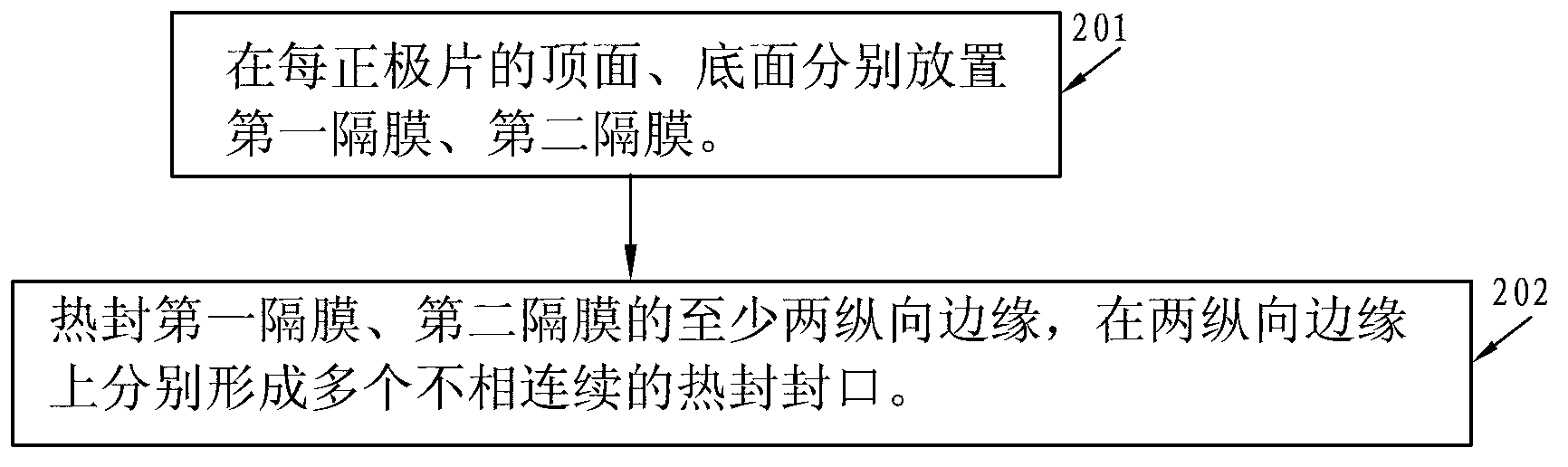

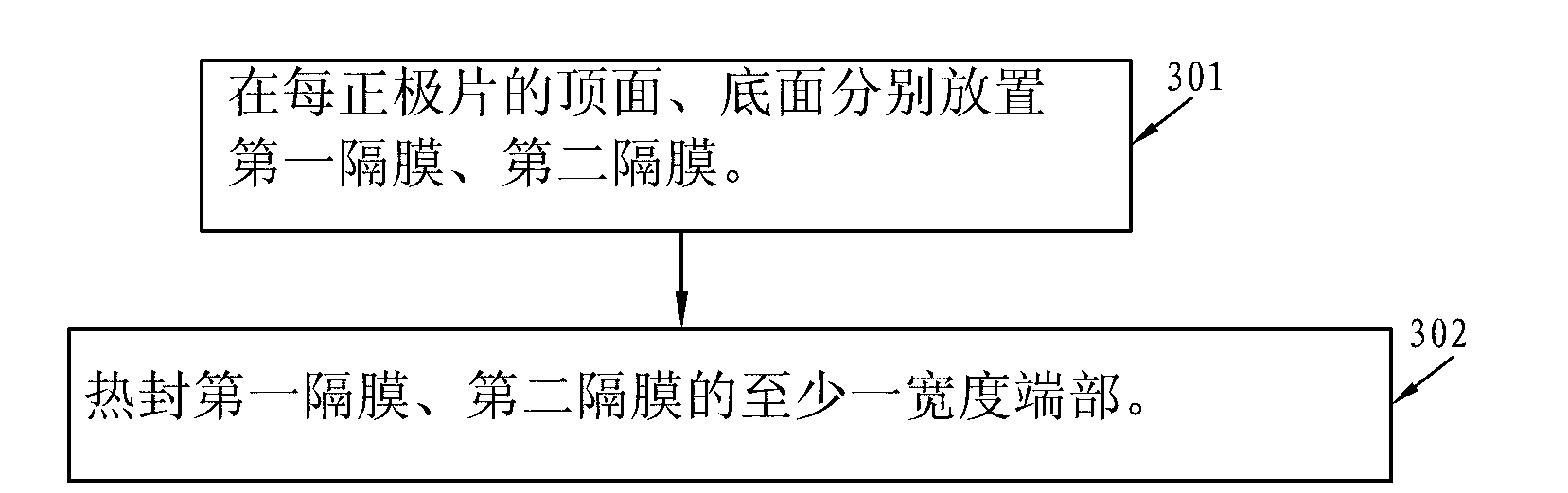

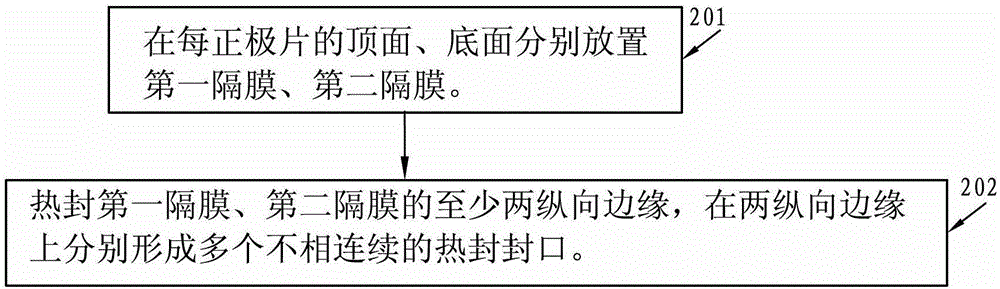

Lamination lithium ion battery and preparation method thereof

InactiveCN103456997AReduced electrochemical performanceGuarantee stabilityFinal product manufactureSecondary cellsPlastic filmLithium-ion battery

The invention relates to the field of a lithium ion battery, and discloses a lamination lithium ion battery and a preparation method thereof. The preparation method comprises the following steps: various positive plates are loaded into various membrane barrier bags according to a loading process, thus obtaining various positive plate membrane barrier bags, wherein in the loading process, a first membrane barrier and a second membrane barrier are respectively placed at the top surface and the bottom surface of each positive plate, and at least two lengthwise edges of each first membrane barrier and each second membrane barrier are heat-sealed to form at least two discontinuous seals of heat sealing; a lamination cell body is acquired by laminating negative plates and the positive plates, the middle part of the lamination cell body is fixed, the lamination cell body is placed naturally at the top of an arc-shaped bracket, the various membrane barrier layers in the lamination cell body are respectively cohered with the positive plates and the negative plates on the membrane barrier layers by virtue of heat pressing of the lamination cell body; the arc-shaped lamination cell body is acquired by virtue of standing of the lamination cell body, and then is placed inside the hollow position of a cell body of an aluminium and plastic film shell body, the aluminium and plastic film shell body is heat-sealed, and the arc-shaped lamination cell body is encapsulated in the aluminium and plastic film shell body, so that the lamination lithium ion battery is acquired.

Owner:SHENZHEN GREPOW BATTERY CO LTD

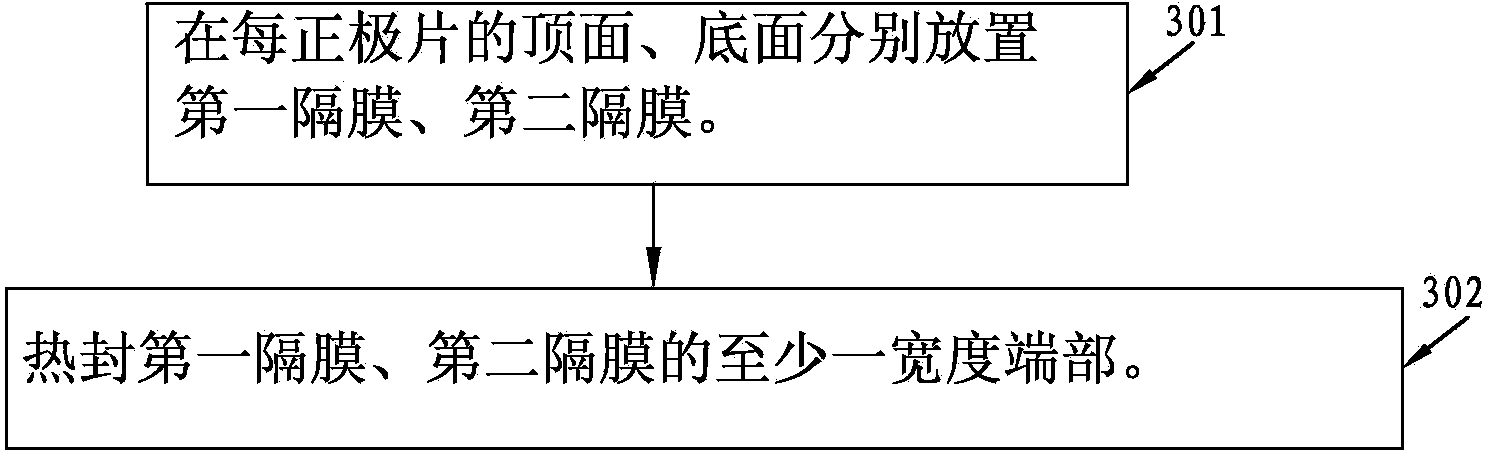

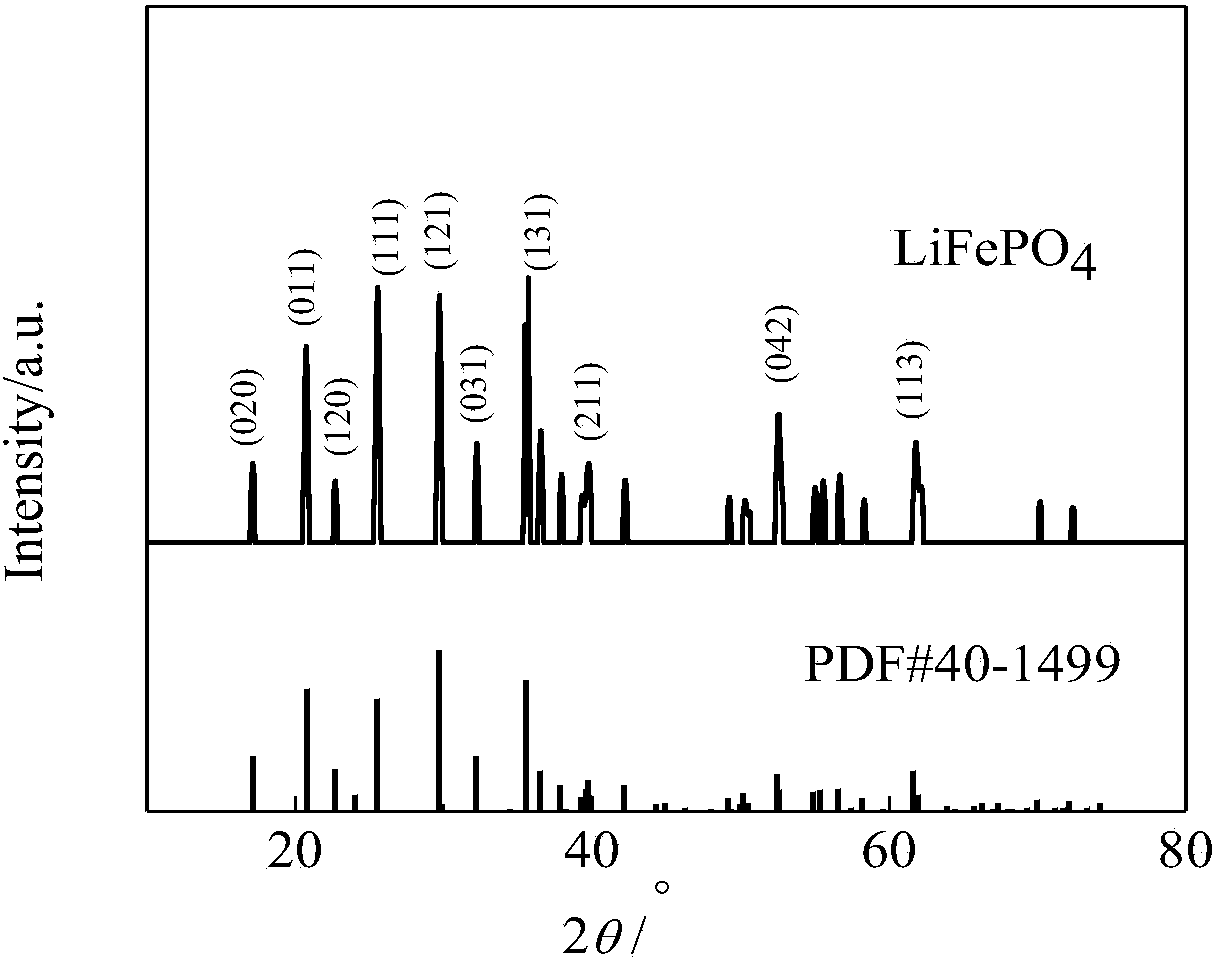

Nano solid-core iron phosphate-carbon source-graphene composite material and preparation method thereof

ActiveCN104167550AImprove the synthesis processShort synthesis processMaterial nanotechnologyCell electrodesSulfate radicalsPhosphoric acid

The invention discloses a nano solid-core iron phosphate-carbon source-graphene composite material; the surfaces of nano solid-core iron phosphate particles are coated with a carbon source, the particles are connected through graphene, and the nano solid-core iron phosphate-carbon source-graphene composite material is formed. The invention also discloses a preparation method of the material. The process flow is simple, the cost is low, at the same time, nitrate radicals are adopted, and the disadvantages in a traditional process that sulfate radicals in an FeSO4 raw material are difficult to wash cleanly and chloride ions in an FeCl3 raw material have a corrosion effect on equipment are overcome. The prepared lithium iron phosphate positive electrode material has the tap density reaching up to 1.68 g / cm<3>, has large volume specific capacity, is beneficial for preparation of a positive electrode material slurry and coating of an electrode slice, and improves the quality of the electrode slice.

Owner:吴位跃

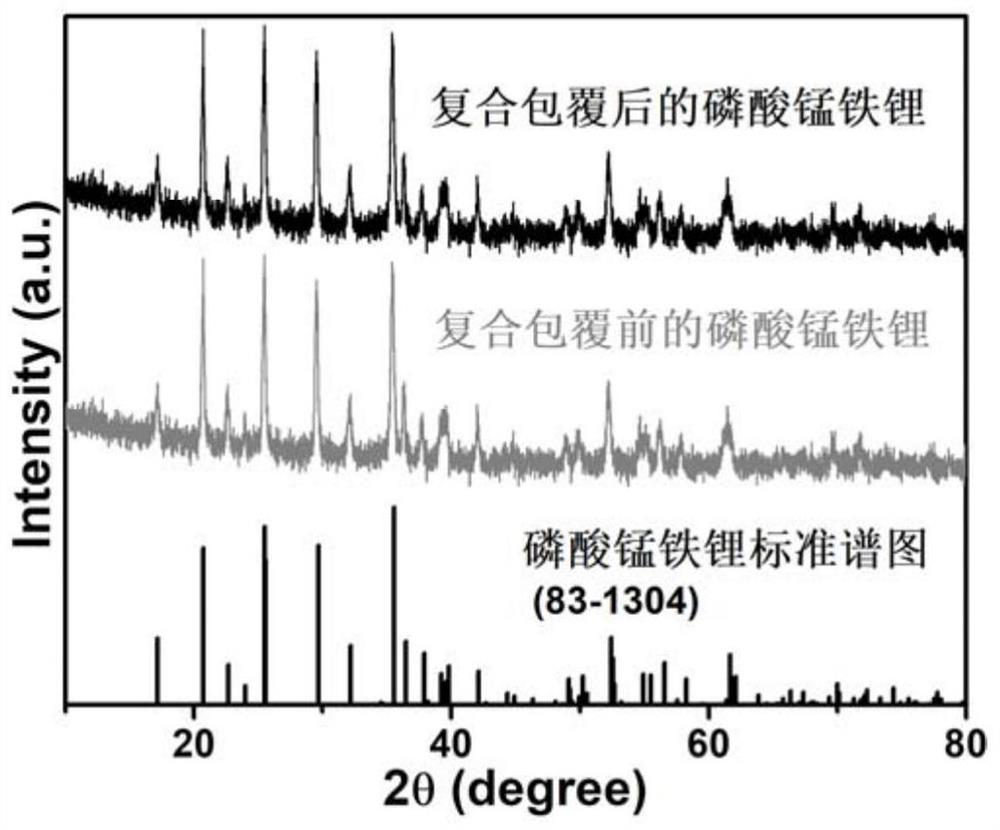

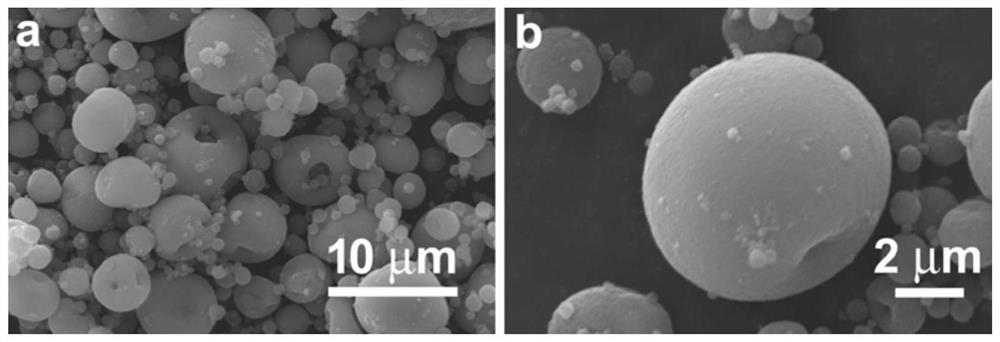

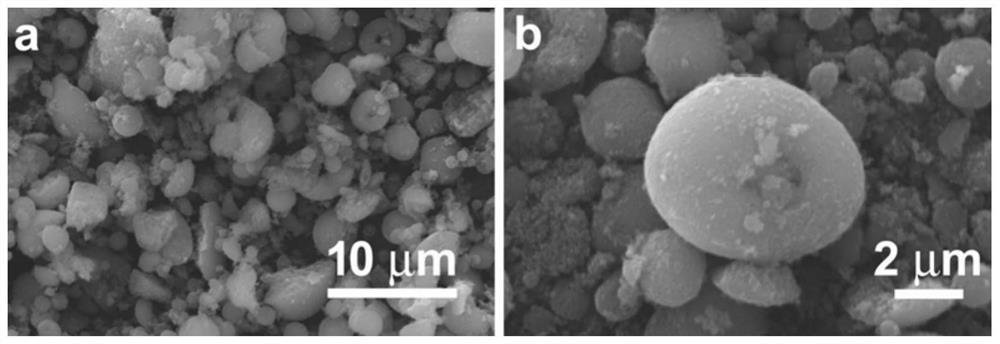

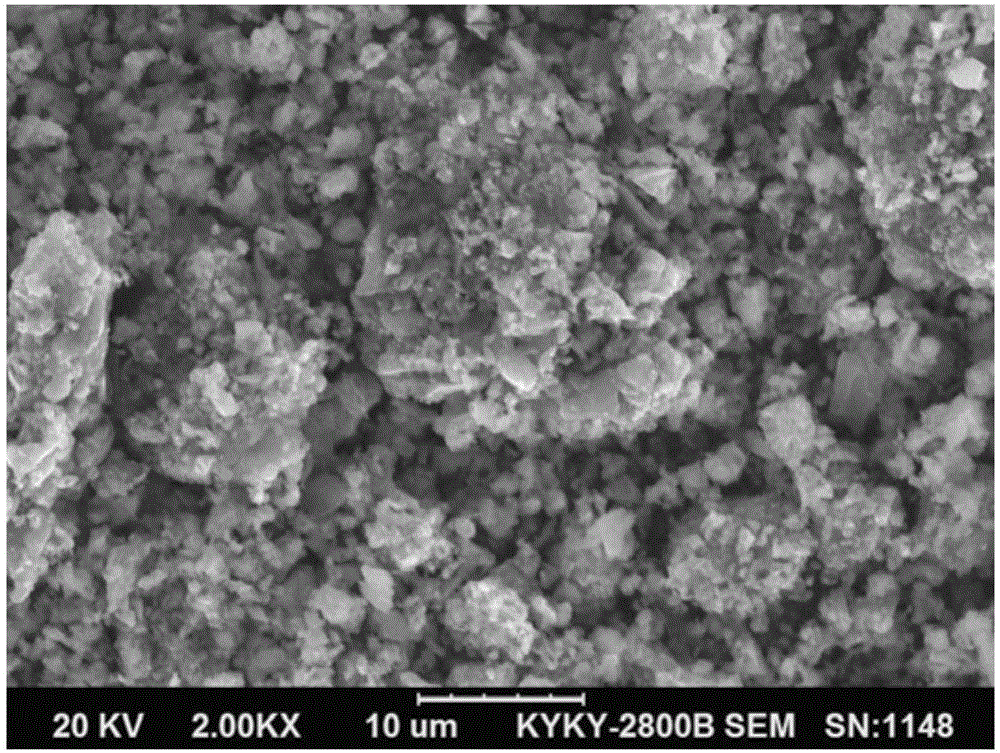

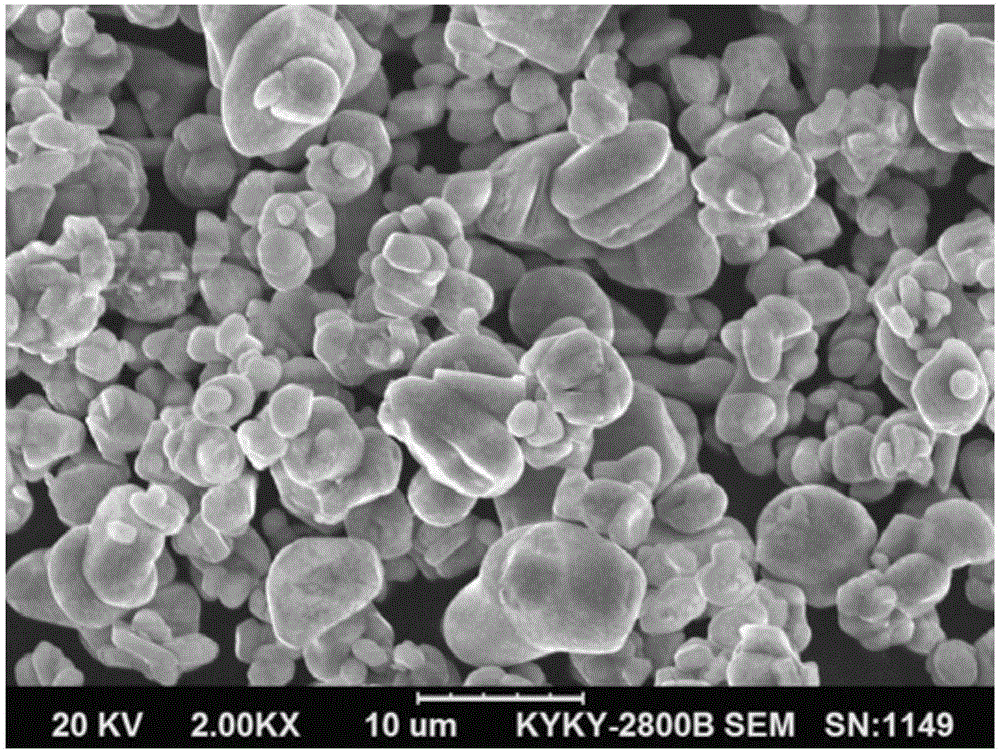

Preparation method of composite coated modified lithium iron manganese phosphate positive electrode material

InactiveCN112864368AComposite wrappingPromote hydrolysisSecondary cellsPositive electrodesCarbon coatingElectrolytic agent

The invention discloses a preparation method of a composite coated modified lithium iron manganese phosphate positive electrode material in the technical field of lithium ion battery positive electrode materials. The preparation method comprises the steps of carrying out composite coating modification on lithium iron manganese phosphate at room temperature by utilizing a mutual promotion effect between silicon source hydrolysis and dopamine polymerization processes; and calcining to obtain the SiO2 and nitrogen-doped carbon co-coated lithium iron manganese phosphate positive electrode material of the lithium battery. By means of composite coating modification of SiO2 and carbon coating, direct contact between the positive electrode material and electrolyte is avoided, harmful side reactions are reduced, the thermal stability of the positive electrode material can be improved, and the conductivity of the positive electrode material can be effectively improved, so that the rate performance and the cycle performance of the positive electrode material can be improved.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

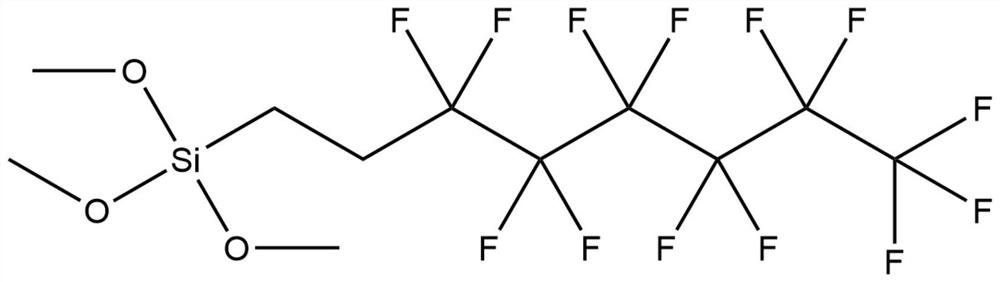

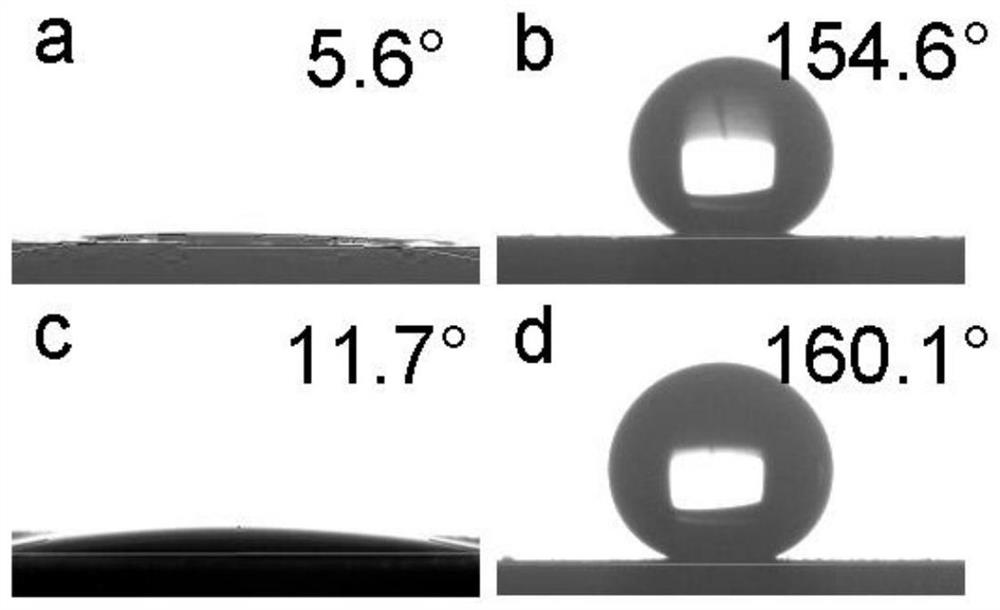

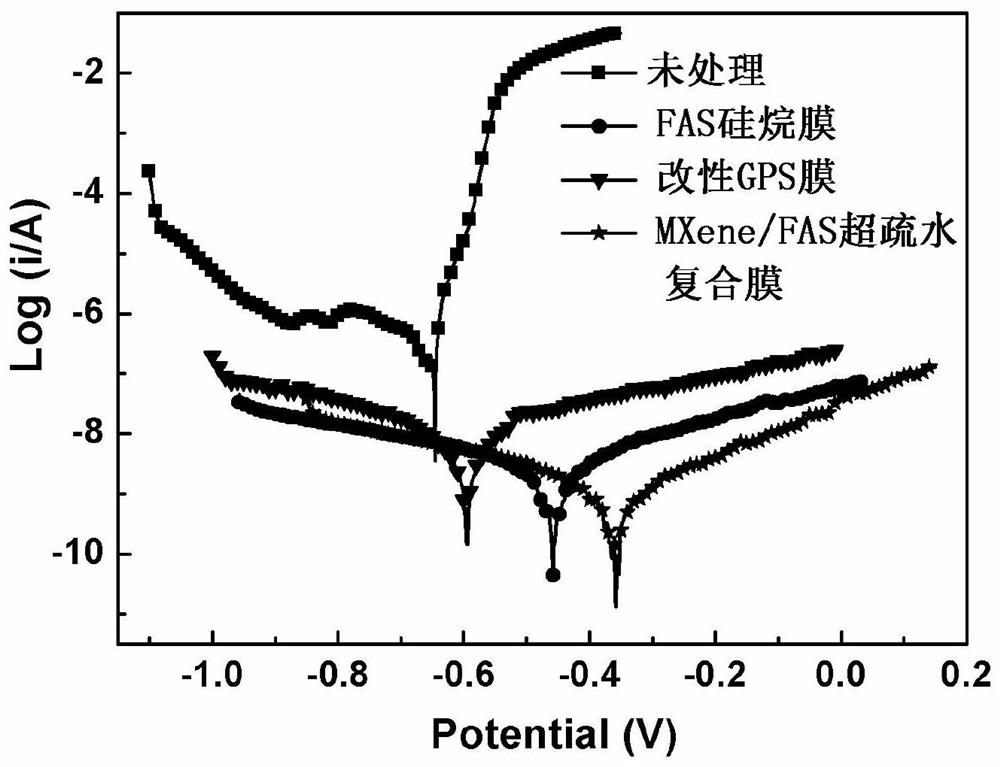

Preparation of super-hydrophobic surface composite film and application of super-hydrophobic surface composite film in metal corrosion protection

PendingCN112111188AImprove corrosion resistanceOvercoming the disadvantages of insufficient wear resistancePretreated surfacesAnti-corrosive paintsSio2 nanoparticleMetallic materials

The invention belongs to the field of metal corrosion protection, and particularly relates to preparation of an MXene / fluorosilane (FAS) super-hydrophobic surface composite film and application of theMXene / FAS super-hydrophobic surface composite film in metal corrosion protection. The application method comprises the following steps: pretreating the surface of a metal sample, modifying SiO2 nanoparticles with gamma-GPS silane, preparing dispersion liquid, preparing an MXene / FAS mixed solution, sequentially spin-coating the surface of the pretreated metal sample with the two dispersion liquidsto form a film, drying the spin-coated metal sample at room temperature, and then conducting curing in a drying oven to form the film. The MXene / FAS super-hydrophobic composite film surface protection technology is adopted, so that the composite film has excellent super-hydrophobic self-cleaning performance and corrosion resistance, and the durable cleaning and corrosion resistance of the surfaceof the metal material can be remarkably improved. In addition, the protective film prepared by the invention is simple to operate and meets the requirement of environmental protection. Doping of MXene can effectively hinder diffusion of a corrosive medium, and the corrosion resistance of the composite film is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Positive plate diaphragm bag as well as a laminated lithium ion battery and manufacturing method thereof

InactiveCN103500808AIncrease in sizeIncrease capacityCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringSpot welding

The invention relates to the field of lithium ion batteries and discloses a positive plate diaphragm bag as well as a laminated lithium ion battery and a manufacturing method thereof. A positive plate diaphragm bag comprises a first diaphragm layer, a second diaphragm layer and positive plates, the first diaphragm layer and the second diaphragm layer directly face the top surface and the undersurface of each positive plate respectively, and edges, exceeding the positive plates, of the first diaphragm layer and the second diaphragm layer are connected together by laser spot welding. By applying the technical scheme, improving of product appearance and electrochemical performance is facilitated.

Owner:SHENZHEN GREPOW BATTERY CO LTD

Electrode material ink, preparation method and method for preparing micro supercapacitor by using electrode material ink

InactiveCN110895998AEvenly dispersedGood film formingHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorUltrasonic dispersion

The invention discloses electrode material ink, a preparation method and a method for preparing a miniature supercapacitor by using the same, and belongs to the technical field of miniature supercapacitors. The preparation method of the electrode material ink comprises the following steps: 1) adding a dispersing agent and an electrode material into an alcohol solution, and carrying out ultrasonictreatment to prepare a primary ultrasonic dispersion solution; 2) adding a target solvent into the primary ultrasonic dispersion liquid of the electrode material, and performing secondary ultrasonic treatment to obtain secondary ultrasonic dispersion liquid; and 3) removing the alcohol liquid in the secondary ultrasonic dispersion liquid to obtain the electrode material ink. By utilizing the preparation method disclosed by the invention, ink with different viscosities and different fluidity can be prepared by adjusting the amounts of the electrode material and the solvent, capacitors with different shapes and different sizes can be printed, and the preparation method does not contain toxic solvents and is suitable for large-scale production. The electrode material ink provided by the invention is uniform in dispersion of the electrode material, has good film-forming property, and can be printed on different substrates.

Owner:XI AN JIAOTONG UNIV

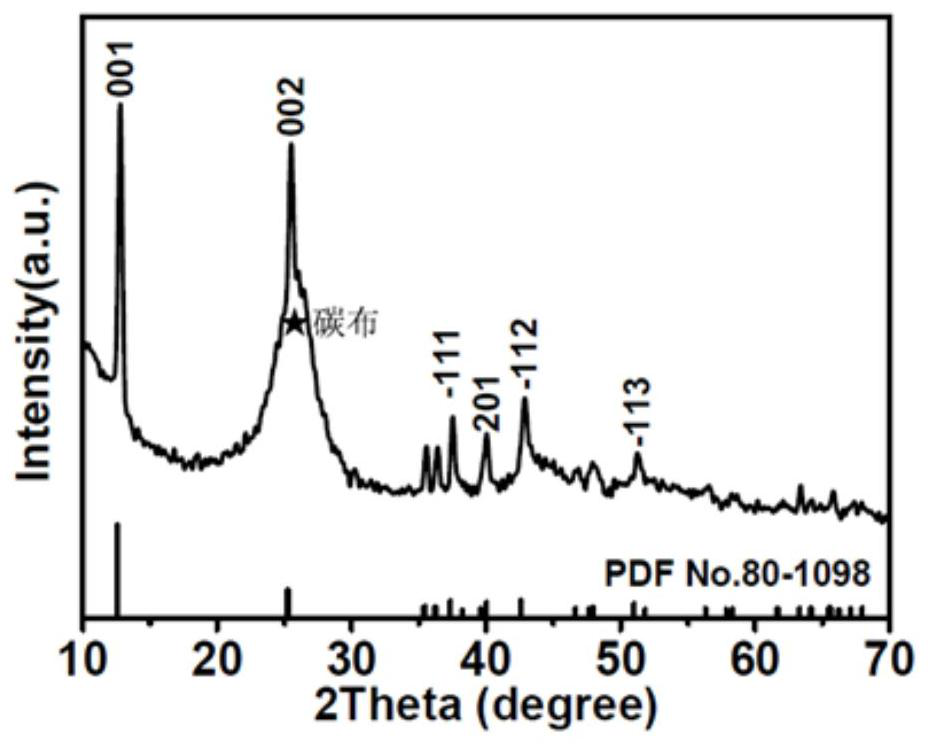

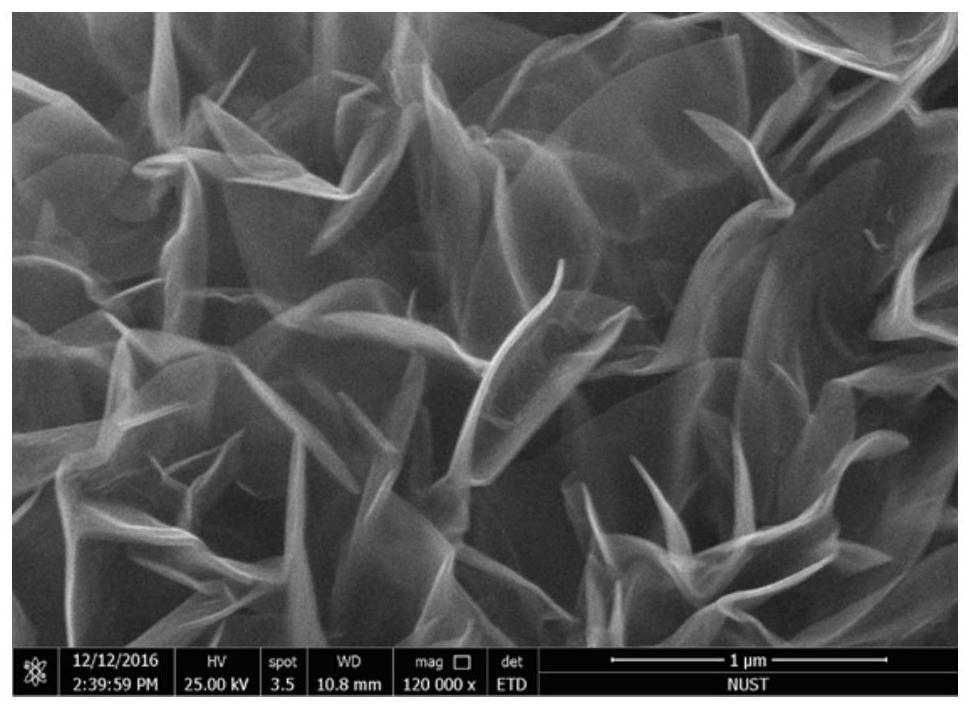

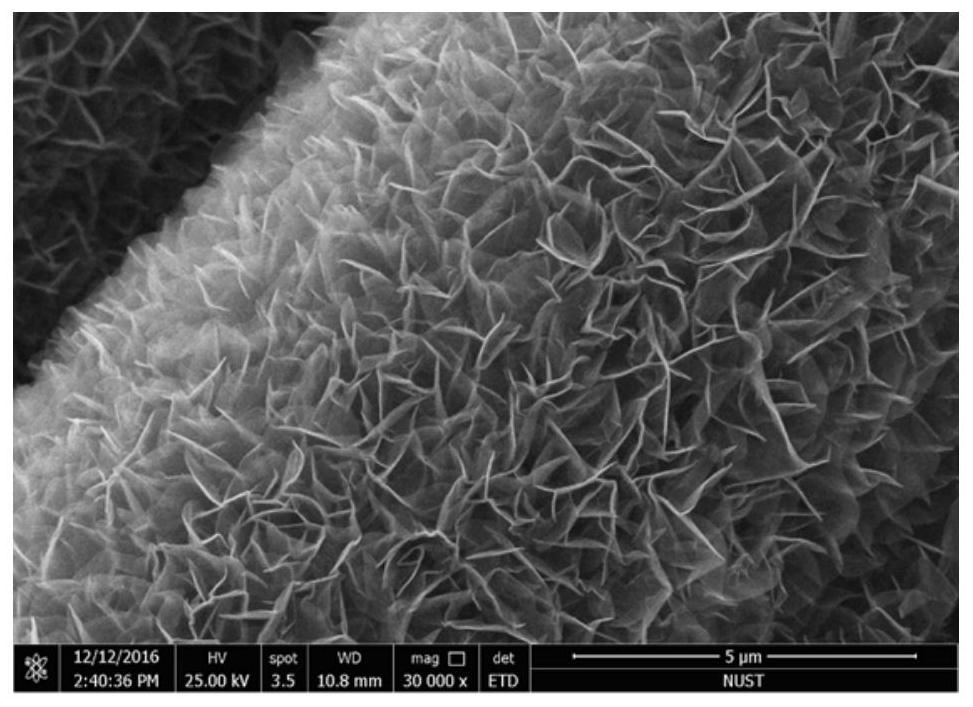

method for synthesizing delta-MnO2 nanosheet array

ActiveCN110551994AIncrease contact surfaceIncrease profitNanotechnologyLiquid/solution decomposition chemical coatingAdhesiveElectrochemistry

The invention discloses a method for synthesizing a delta-MnO2 nanosheet array. The method comprises the steps that a KMnO4 solution and a KF solution are mixed firstly according to the molar ratio ofKMnO4 to KF being 1:(2-6), and the pH is adjusted to range from 1 to 3 with dilute H2SO4; a substrate material is added, and a hydrothermal reaction is carried out at the temperature of 100 DEG C to140 DEG C; after the reaction is finished, flushing is carried out, and drying is carried out to obtain the delta-MnO2 nanosheet array. According to the method, a one-step hydrothermal method is adopted, and the array material which is ultrathin, free of agglomeration, undamaged in crystal, high in purity and controllable in morphology is prepared; and the process is simple, and energy consumptionis low. The prepared delta-MnO2 material with the nanosheet array morphology evenly grows on a substrate, the morphology is even, agglomeration is avoided, the delta-MnO2 material can be directly adopted as an electrode of various electronic devices, and reduction of the specific surface area of a nano material and reduction of the electrochemical performance due to use of an adhesive, a conductive agent and the like are avoided; and meanwhile the contact surface of the material can be effectively increased through the nanosheet array structure, and the utilization rate of the material is increased.

Owner:NANJING UNIV OF SCI & TECH

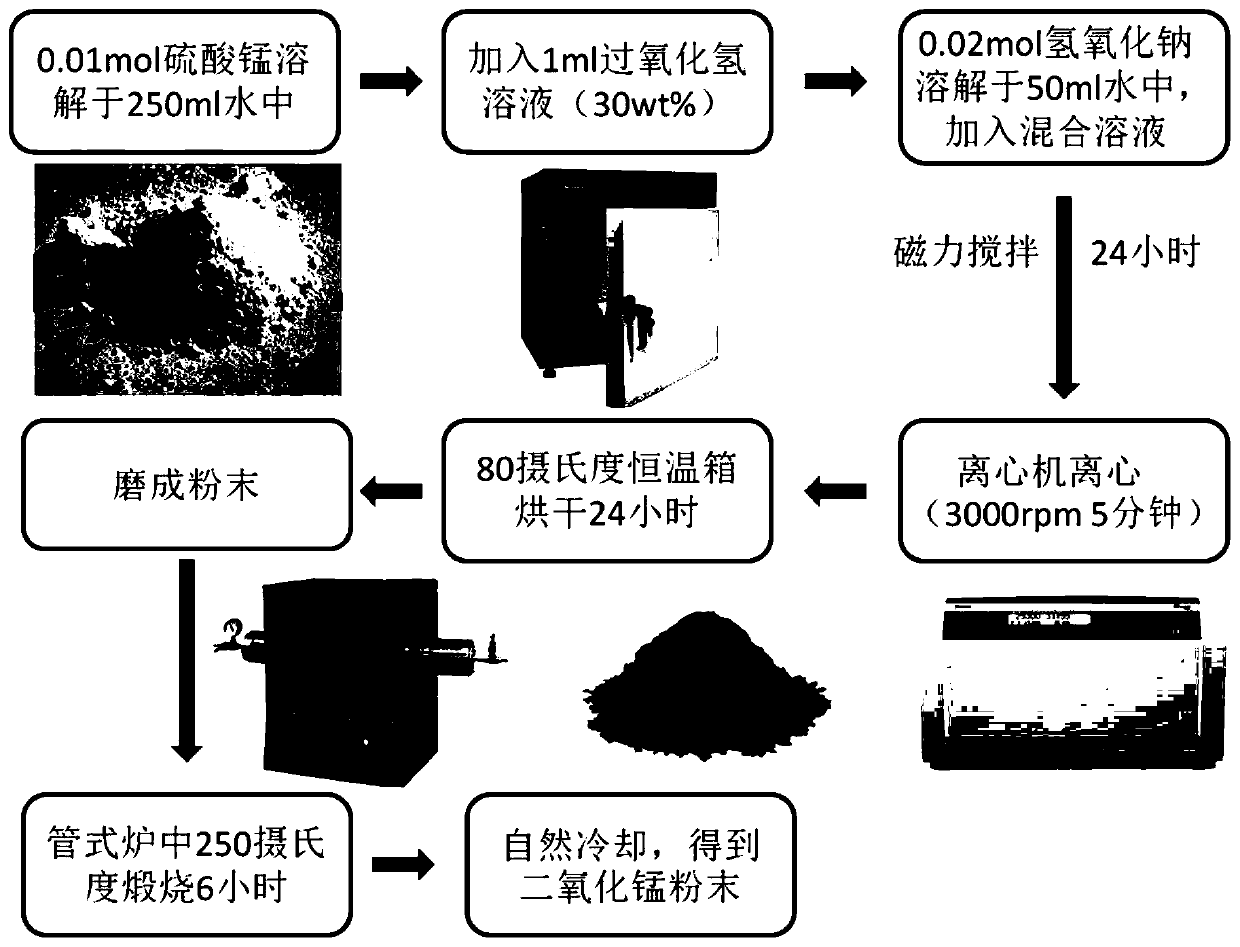

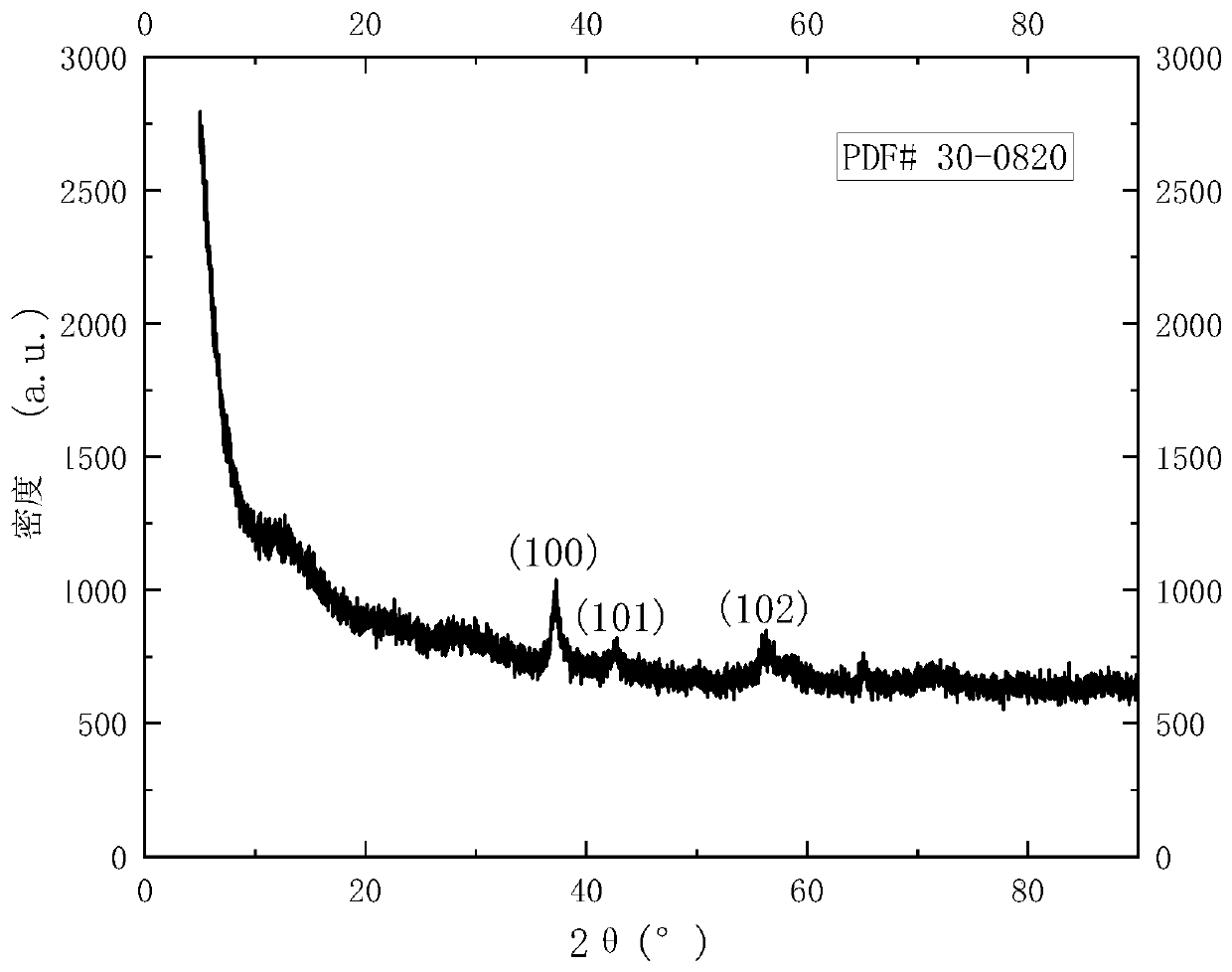

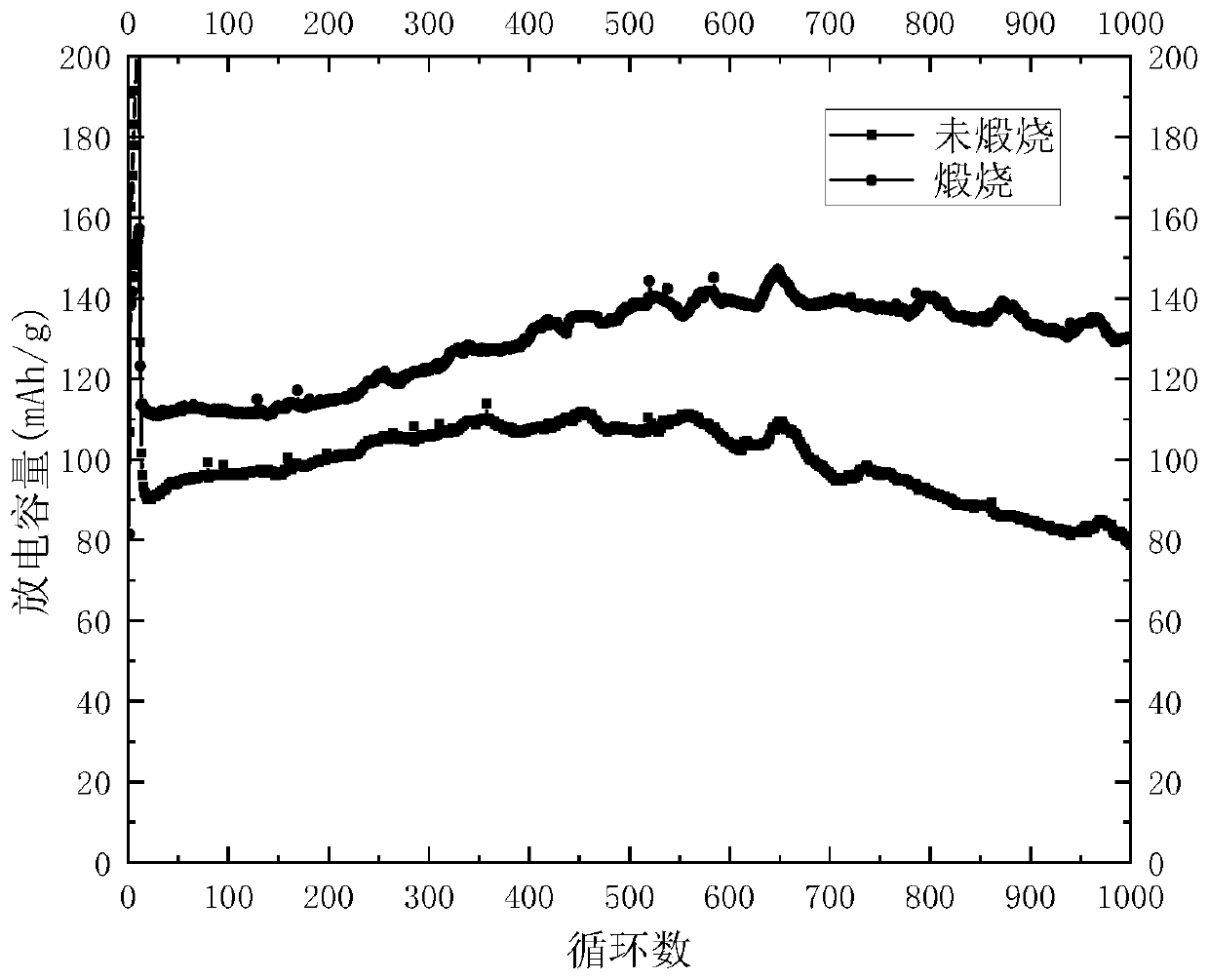

Preparation method and application of manganese dioxide electrode

ActiveCN110563045ALow costLow electrochemical performanceSecondary cellsPositive electrodesManganeseGreek letter epsilon

The invention provides a preparation method of a manganese dioxide electrode (epsilon-MnO2). The method comprises the following steps: mixing a divalent manganese salt, hydrogen peroxide, an alkali metal hydroxide and water; carrying out centrifugal treatment on the mixed treatment product to obtain a centrifugal precipitate; and calcining the centrifugal precipitate to obtain the manganese dioxide electrode. The method is low in production cost, simple in process, convenient to operate, easy to control and environmentally friendly, and the prepared manganese dioxide electrode material has excellent electrochemical performance and is suitable for large-scale industrial production.

Owner:REHAB QINGDAO ENERGY TECH CO LTD

Manganese dioxide nanowire/titanium carbide composite material and preparation method thereof

InactiveCN108364802AImprove bindingReduced electrochemical performanceHybrid capacitor electrodesHybrid/EDL manufactureTitanium carbideElectrochemistry

The invention provides a manganese dioxide nanowire / titanium carbide composite material and a preparation method thereof. The preparation method comprises the steps of respectively dispersing Ti3C2 nanometer powder and dopamine hydrochloride in ultrapure water, performing uniform mixing, and performing stirring under a shading condition; adding a Tris-buffer liquid, and continuing to stir under the shading condition; separating, washing and drying the obtained mixed solution to obtain Ti3C2@PDA nanometer powder; adding the Ti3C2@PDA nanometer powder into a PEG solution, adding KMNO4 solution after uniform dispersion, and performing liquid-phase reaction; and naturally cooling after reaction is ended, thereby obtaining the manganese dioxide nanowire / titanium carbide composite material. By the method, uniformly-distributed manganese dioxide nanowires can be formed on a surface of carbon titanium, the obtained composite material has good electrochemical performance, the preparation methodis low in equipment requirement and low in cost and is simple and convenient to operate, and industrial production on a large scale is favorably achieved.

Owner:SHAANXI UNIV OF SCI & TECH

Laminated lithium ion battery preparation method and battery

InactiveCN103268961AReduced electrochemical performanceGuarantee stabilityFinal product manufactureSecondary cellsPhysical chemistryLithium-ion battery

The invention relates to the field of lithium ion batteries, and discloses a laminated lithium ion battery preparation method and a battery. The laminated lithium ion battery preparation method comprises the following step of: respectively putting positive electrode pieces into membrane bags according to a bagging technology to obtain positive electrode piece membrane bags, wherein the bagging technology comprises the following steps of: respectively arranging a first membrane and a second membrane on the top and at the bottom of each positive electrode piece, performing heat sealing on at least two of four top corners of each of the first membrane and the second membrane to form heat-sealed openings, laminating negative electrode pieces and the positive electrode piece membrane bags to obtain a laminated electric core body, fixing the middle of the laminated electric core body, naturally placing the laminated electric core body on the top of a cambered bracket, performing heat-pressing on the laminated electric core body, standing the laminated electric core body to obtain a cambered laminated electric core body, putting the cambered laminated electric core body into an electric core body sunken position of an aluminum plastic membrane shell, performing heat sealing on an aluminum plastic membrane to package the cambered laminated electric core body into the aluminum plastic membrane shell to obtain a laminated lithium ion battery.

Owner:SHENZHEN GREPOW BATTERY CO LTD

Preparation method for lithium vanadium phosphate slurry-based positive electrode of lithium ion battery

InactiveCN106684337AImprove conductivityImproved magnification performanceElectrode collector coatingDispersitySlurry

The invention provides a preparation method for a lithium vanadium phosphate slurry-based positive electrode of a lithium ion battery. The preparation method comprises the steps of dispersing Li<3>V<2>(PO<4>)<3> / C, a conductive agent, a binder and a slurry additive into N-methyl-2-pyrrolidone in a way of ball grinding or stirring to obtain uniformly-mixed and high-dispersity monoclinic Li<3>V<2>(PO<4>)<3> / C slurry, wherein the ratio of an active material to the conductive agent to the binder to the slurry additive to the N-methyl-2-pyrrolidone is (81-84wt%) to (9-11wt%) to (4-6wt%) to (1-6wt%) to 10wt%, and the total weight percentage is 110%; uniformly coating a current collector with the monoclinic Li<3>V<2>(PO<4>)<3> / C slurry in a spin-coating manner, and performing vacuum drying at a temperature of 100-120 DEG C to obtain a primary electrode plate; and cutting the primary electrode plate into a finished electrode plate with an area of 0.8-1.5cm<2> and performing electrical performance test on the finished electrode plate. The preparation method has the beneficial effects that the rate and cycling performance of the Li<3>V<2>(PO<4>)<3> / C can be simply and effectively improved due to the design.

Owner:中科天达(天津)新能源科技有限公司

High-performance carbon-based substrate for supercapacitor and preparation method thereof

ActiveCN110284319AEasy to prepareImprove electrochemical performancePhysical treatmentHybrid capacitor electrodesIonSpecific volume

The invention discloses a high-performance carbon-based substrate for a supercapacitor and a preparation method thereof. The preparation method comprises the following steps that (1), a carbon cloth is soaked with absolute ethyl alcohol, then washed with deionized water, and then drying is conducted at a constant temperature; (2), the carbon cloth is subjected to high temperature heating treatment, and the heating process is performed under oxygen protection; (3), the carbon cloth obtained after oxidation is placed in aqua regia for soaking, washed with deionized water and then subjected to constant temperature drying treatment; (4), then the cloth is soaked in an aluminum chloride-containing sodium borohydride solution, washed with deionized water under ultrasonication and then dried; (5), then the cloth is soaked in a potassium permanganate solution, washed under the acidic condition of hydrogen peroxide, washed with deionized water and then dried at a constant temperature to obtain a high-performance carbon-based substrate for the supercapacitor. Accordingly, the performance optimization of the carbon-based substrate can be achieved, and the optimized carbon-based substrate has the certain size of oxidized pore morphology, good electrochemical performance and high specific capacitance, and the specific volume is increased by 477.7% compared with non-oxidized blank sample.

Owner:SOUTH CHINA UNIV OF TECH

Device and process for manufacturing positive/negative electrode material of lithium battery

The invention relates to a device and process for manufacturing a positive / negative electrode material of a lithium battery. The device consists of a feeder, a fluidized bed mixer, a gas-solid separator, a spiral continuous feeding reaction device preheating section, a spiral continuous feeding reaction device reacting section, and a cooling device. The process for manufacturing the positive / negative electrode material of the lithium battery comprises the following steps of: firstly feeding raw materials for manufacturing the positive / negative electrode material of the lithium battery into the fluidized bed mixer through the feeder, fully mixing and then separating by the gas-solid separator, sequentially entering the spiral continuous feeding reaction device preheating section and the spiral continuous feeding reaction device reacting section, heating and reacting to generate the positive / negative electrode material of the lithium battery, and then entering the cooling device to be cooled, finally discharging the positive / negative electrode material of the lithium battery from a product outlet. The device and process provided by the invention can be used for continuously manufacturing the positive / negative electrode material of the lithium battery efficiently with low energy consumption.

Owner:济宁市无界科技有限公司

delta-mno 2 Synthesis of Nanosheet Arrays

ActiveCN110551994BIncrease contact surfaceIncrease profitNanotechnologyLiquid/solution decomposition chemical coatingElectrochemistryEnergy consumption

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com