Preparation method and application of manganese dioxide electrode

A manganese dioxide electrode, divalent manganese technology, applied in manganese oxide/manganese hydroxide, positive electrode, battery electrode and other directions, can solve the problems of high cost of raw materials, serious environmental pollution, difficult to obtain biomass sources, etc. Excellent chemical properties, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

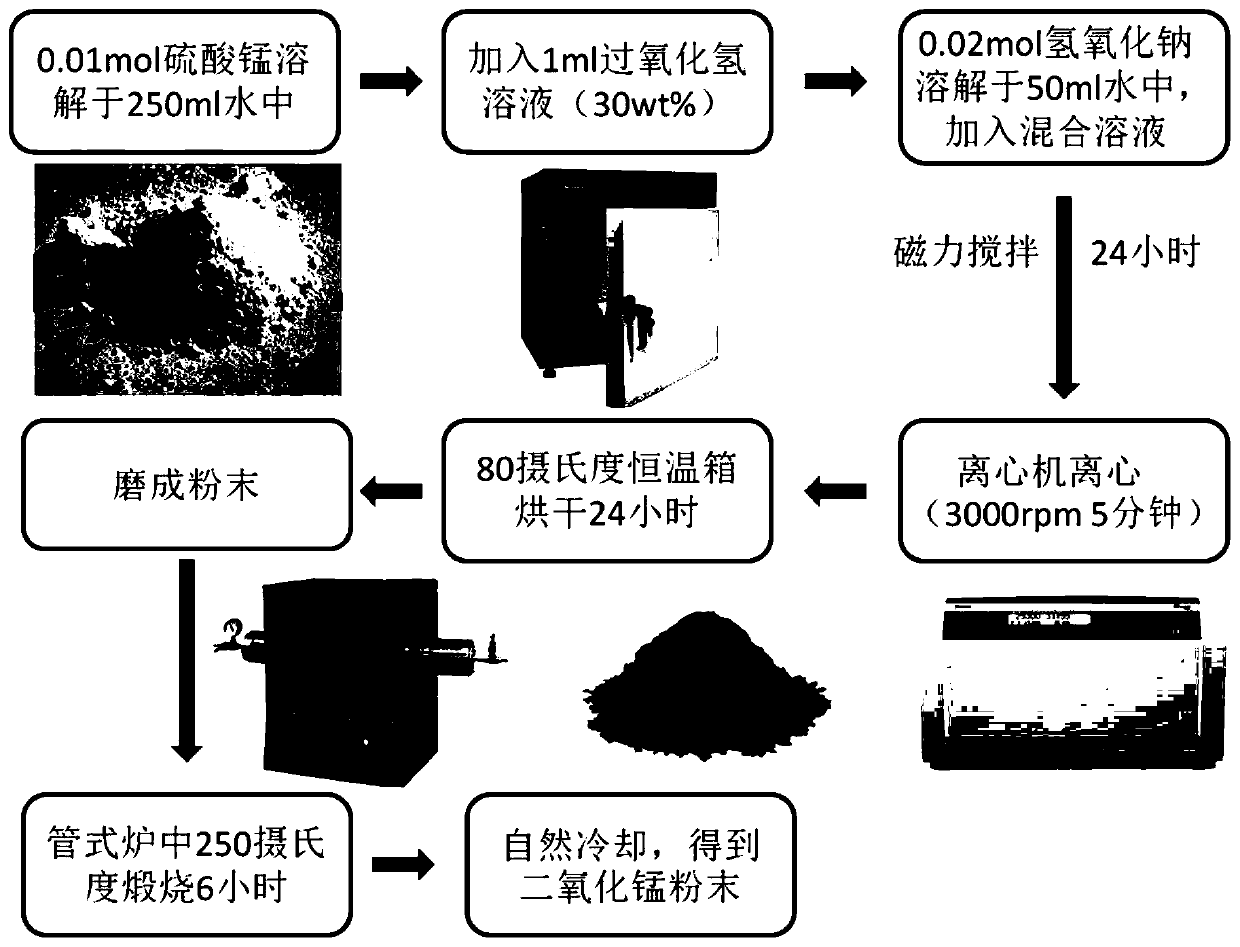

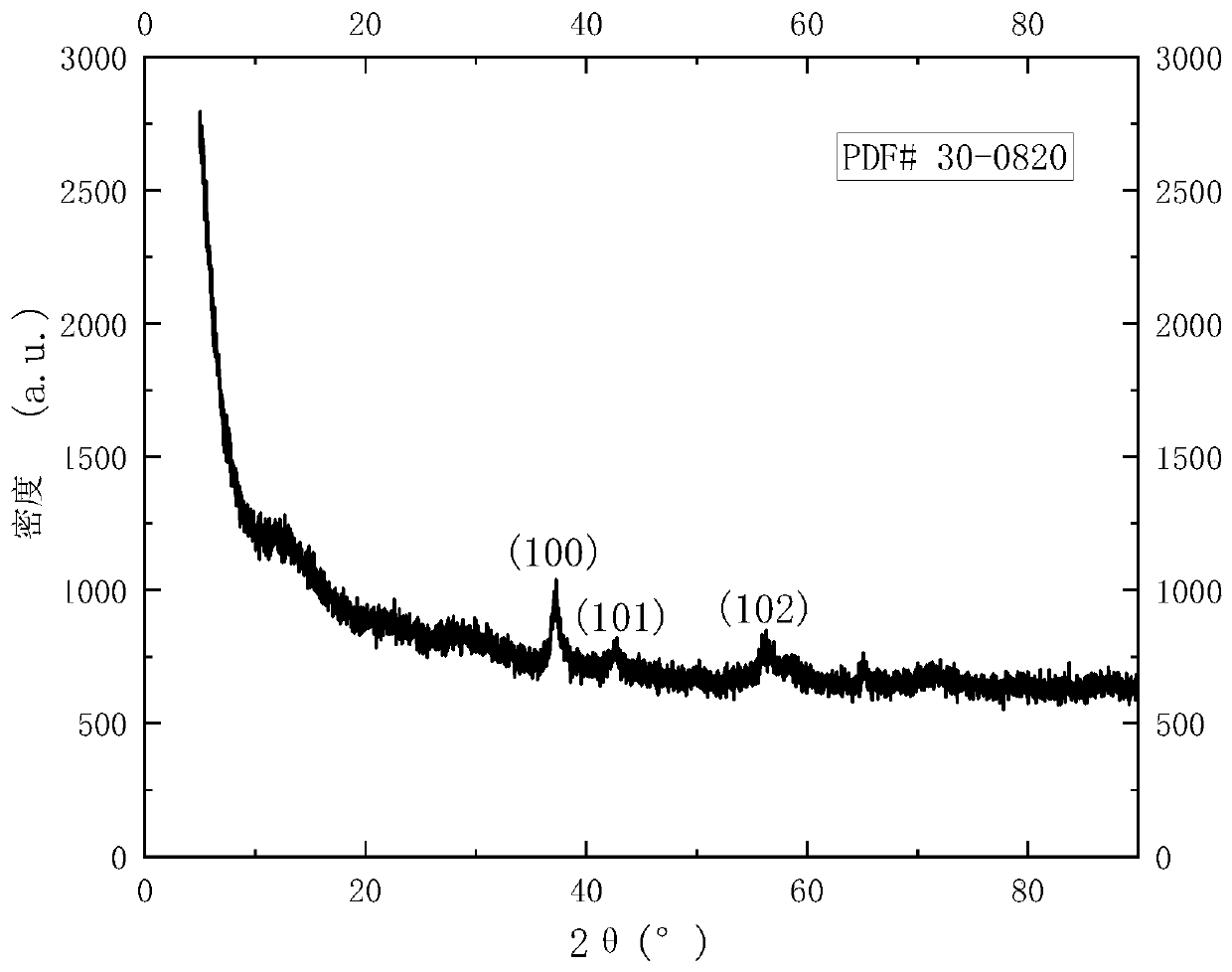

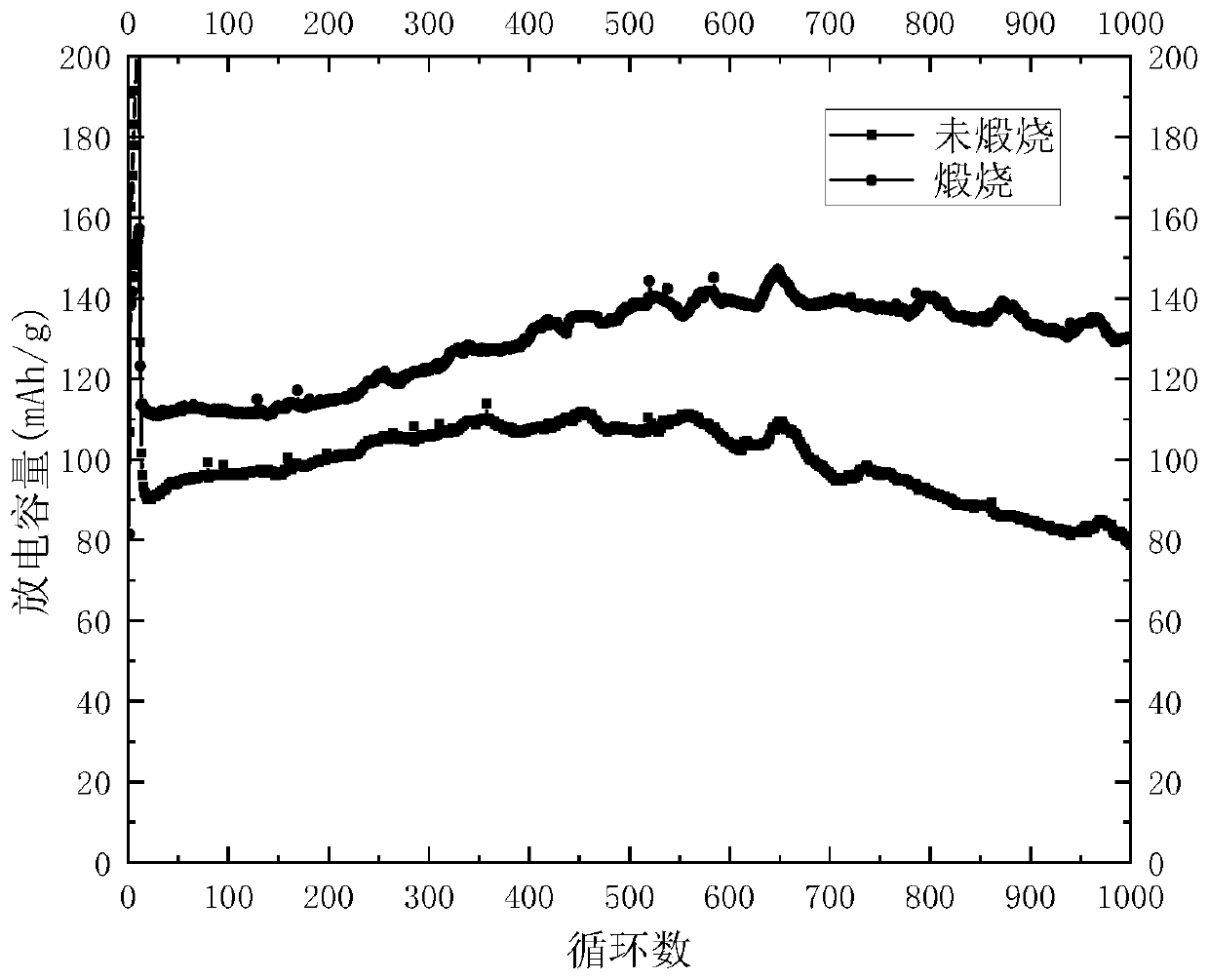

[0031] Dissolve 0.01mol of manganese sulfate in 250mL of deionized water, then add 1mL of hydrogen peroxide solution with a mass fraction of 30%, dissolve 0.02mol of sodium hydroxide solid in 50mL of deionized water, and after it is completely dissolved, add it to sulfuric acid In the mixed solution of manganese and hydrogen peroxide, the pH is 7.19, and it is magnetically stirred at room temperature for 24 hours (350 rpm). After 24 hours, the centrifuge centrifuged the material (3000rpm, 5 minutes), rinsed it three times with deionized water, and then put it into a constant temperature oven at 80 degrees Celsius to dry it under vacuum for 24 hours. After being dried, the obtained solid matter is ground into powder, put into a tube furnace and calcined at 250 degrees centigrade for 6 hours, and after natural cooling, manganese dioxide powder ( figure 1 ). XRD test results such as figure 2 As shown, through further XRD image verification, the manganese dioxide prepared by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com