Nano solid-core iron phosphate-carbon source-graphene composite material and preparation method thereof

A technology of solid iron phosphate and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that sulfate radicals damage the cycle performance of lithium iron phosphate, iron phosphate cannot reach the nanometer level, Increase the ferrous iron oxidation process and other issues to achieve the effect of facilitating large-scale industrialization, improving electronic conductivity, and shortening the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

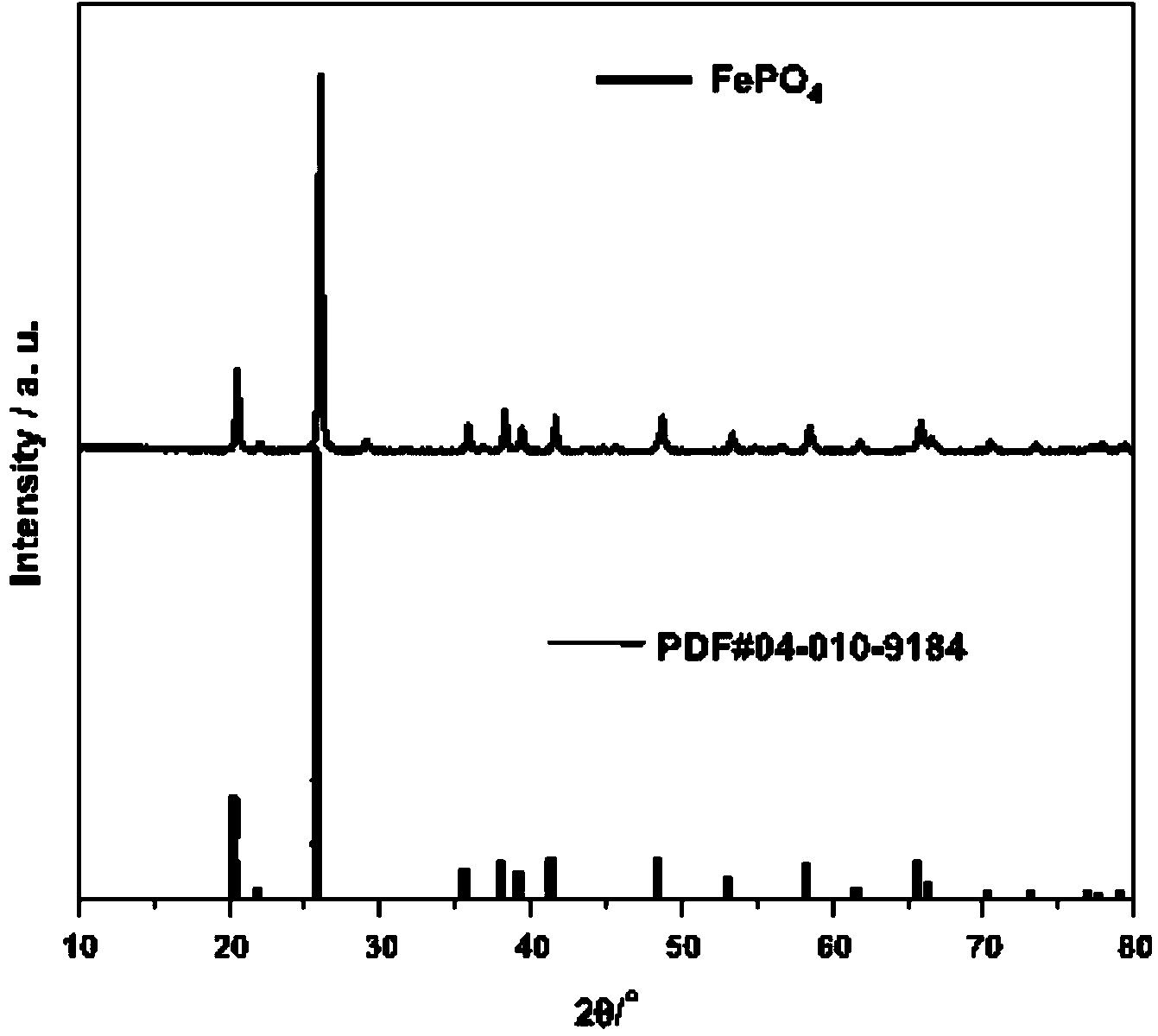

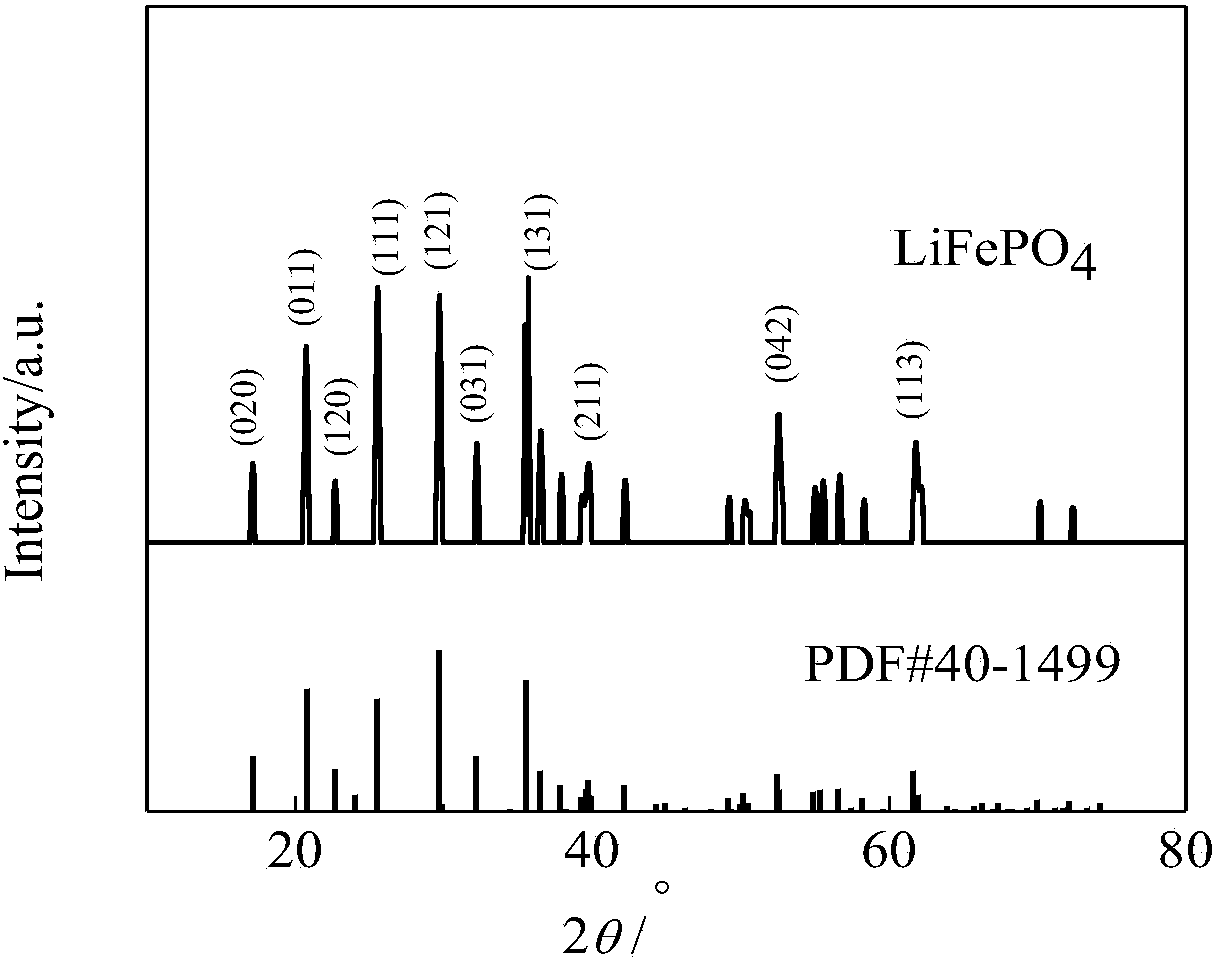

Embodiment 1

[0030] Graphene oxide was ultrasonically dispersed with deionized water for 60 min to obtain a 1.5 mg / mL suspension. In 100mL deionized water, add 0.1mol Fe(NO 3 ) 3 , 0.1mol (NH 4 ) 2 HPO 4 , 5 g of PVA and 1 mL of graphene oxide suspension. The mixture was sonicated in a sonicator for 8 minutes and then placed in a reaction kettle. The constant stirring speed in the reactor was 50 rad / min. Concentrated ammonia solution was added dropwise to the solution, and the pH value of the mixed solution was adjusted to 3. The reaction temperature was kept at 60° C., and the reaction was carried out for 36 minutes to form a light yellow precipitate. The precipitate was stirred in the mother liquor for 30 minutes. Then, it was filtered and washed 6 times with deionized water. Dry in vacuum at 120°C for 4h. That is to obtain nano solid iron phosphate / PVA / graphene composite material.

[0031] The nanometer solid ferric phosphate / PVA / graphene composite material that present embod...

Embodiment 2

[0035] Graphene oxide was ultrasonically dispersed with deionized water for 30 min to obtain a 1.8 mg / mL suspension. In 100mL deionized water, add 0.1mol Fe(NO 3 ) 3 , 0.1mol (NH 4 ) 2 HPO 4 , 1 g of carbon nanotubes and 1 mL of graphene oxide suspension. The mixture was sonicated in a sonicator for 15 minutes and then placed in a reaction kettle. The continuous stirring speed in the reactor was 100 rad / min. Concentrated ammonia solution was added dropwise to the solution, and the pH value of the mixed solution was adjusted to 3.8. The reaction temperature was kept at 80° C., and the reaction time was 10 h, and a light yellow precipitate was formed. The precipitate was stirred in the mother liquor for 10 hours. Then, filter and wash 3 times with deionized water. Dry in vacuum at 60°C for 20h. That is, the nano solid iron phosphate / carbon nanotube / graphene composite material is obtained.

Embodiment 3

[0037] Graphene oxide was ultrasonically dispersed with deionized water for 60 min to obtain a 3 mg / mL suspension. In 100mL deionized water, add 0.1mol Fe(NO 3 ) 3 , 0.3molH 3 PO 4 , 7 g glucose and 0.3 mL graphene oxide suspension. The mixture was sonicated for 3 minutes in a sonicator and then placed in a reaction kettle. The continuous stirring speed in the reactor was 30rad / min. Concentrated ammonia solution was added dropwise to the solution, and the pH value of the mixed solution was adjusted to 4. The reaction temperature was kept at 120° C., and the reaction time was 5 h, and a light yellow precipitate was formed. The precipitate was stirred in the mother liquor for 5 hours. Then, filter and wash 6 times with absolute ethanol. Dry in vacuum at 85°C for 15h. That is to obtain the nano solid iron phosphate / glucose / graphene composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com