Spherical silicon carbon composite anode material of lithium ion battery and preparation method for spherical silicon carbon composite anode material

A technology for lithium-ion batteries and negative electrode materials, applied to battery electrodes, circuits, electrical components, etc., can solve the problems that cannot completely solve the problem of silicon powder exposure, and it is difficult to fully utilize the buffer mechanism of graphite, so as to reduce the probability of dispersion and exposure. The effect of good cycle performance and complete configuration rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

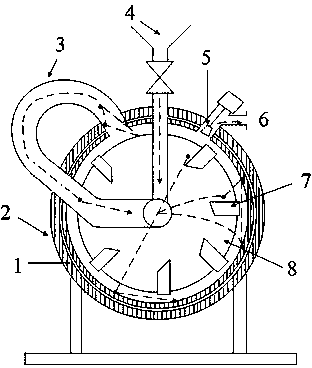

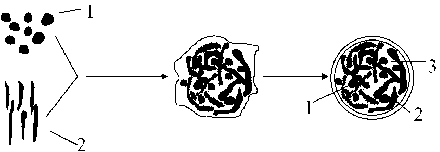

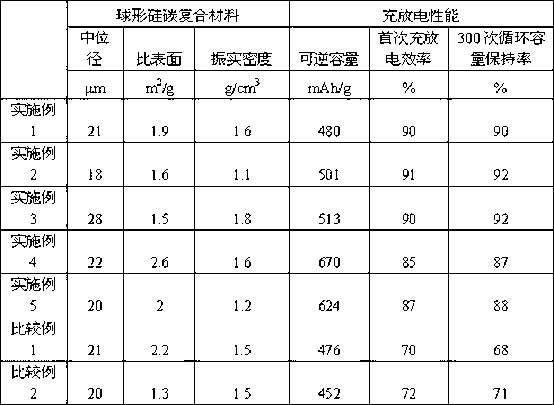

[0031] Example 1. Natural flake graphite with a median diameter of 5μm and an aspect ratio of 10, metallic silicon with a median diameter of 0.5μm and pitch (carbonized) were mixed with tetrahydrofuran with a mass ratio of 88:6:6 and 100% by mass. In a twin-shaft mixer, mix at 160°C for 1 hour, remove the tetrahydrofuran solvent under reduced pressure, calcined at 400°C for 5 hours, pulverize appropriately, and sieve to obtain precursor particles with a median diameter of 30μm. The precursor particles are observed by SEM. The particles are not completely spherical, the graphite is exposed, and the surface is relatively rough. Put the precursor into a fine particle pelletizing system, and shape it at a rotation speed of 1200 rpm for 45 minutes. The processed material is heated at 6°C / min to 1000°C in a nitrogen atmosphere and calcined for 5 hours to obtain a spherical silicon-carbon composite anode material. SEM observation of the composite material showed a spherical structure,...

Embodiment 2

[0034] Example 2. Deionization of artificial flake graphite with a median diameter of 3μm and an aspect ratio of 15, metal silicon and PVA with a median diameter of 0.3μm in a mass ratio of 88:5:7 (carbonized) and 100% by mass Mix with water, mix at 200°C for 1 hour, remove the deionized water solvent under reduced pressure, calcinate at 400°C for 4 hours, and pulverize appropriately to prepare precursor particles with a median diameter of 22μm. The precursor particles are not completely spherical according to SEM observation. , Graphite is exposed and the surface is rough. Put the body into the fine particle pelletizing system, and shape it at a rotation speed of 1500 rpm for 30 minutes. The processed material is heated at 5°C / min to 900°C in a nitrogen atmosphere and calcined for 6 hours to obtain a spherical silicon-carbon composite anode. Material, the composite material has a spherical structure observed by SEM, and its physical properties are shown in Table 2.

[0035] The...

Embodiment 3

[0036] Example 3. The artificial flake graphite with a median diameter of 10μm and an aspect ratio of 10, metallic silicon with a median diameter of 0.3μm and pitch (carbonized) were mixed with a mass ratio of 86:6:8 with 100% tetrahydrofuran. In a twin-shaft mixer, mix at 150°C for 2 hours, remove the tetrahydrofuran solvent under reduced pressure, calcined at 300°C for 8 hours, pulverize appropriately, and sieve to obtain precursor particles with a median diameter of 35μm. The precursor particles are observed by SEM. The particles are not completely spherical, the graphite is exposed, and the surface is relatively rough. In the fine particle pelletizing system, the solvent is removed and the spheroidization treatment is carried out at a constant temperature of 120°C, and the treatment is performed at a rotation speed of 1200 rpm for 120 minutes. The obtained spherical particle precursor is heated at 5°C / min in a nitrogen atmosphere. Calcined at 1000°C for 8 hours, spherical s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com