Cathode material for lithium-ion power and energy storage battery and preparation method thereof

A technology for energy storage batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., to achieve the effects of reduced production costs, good anisotropy, and high compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

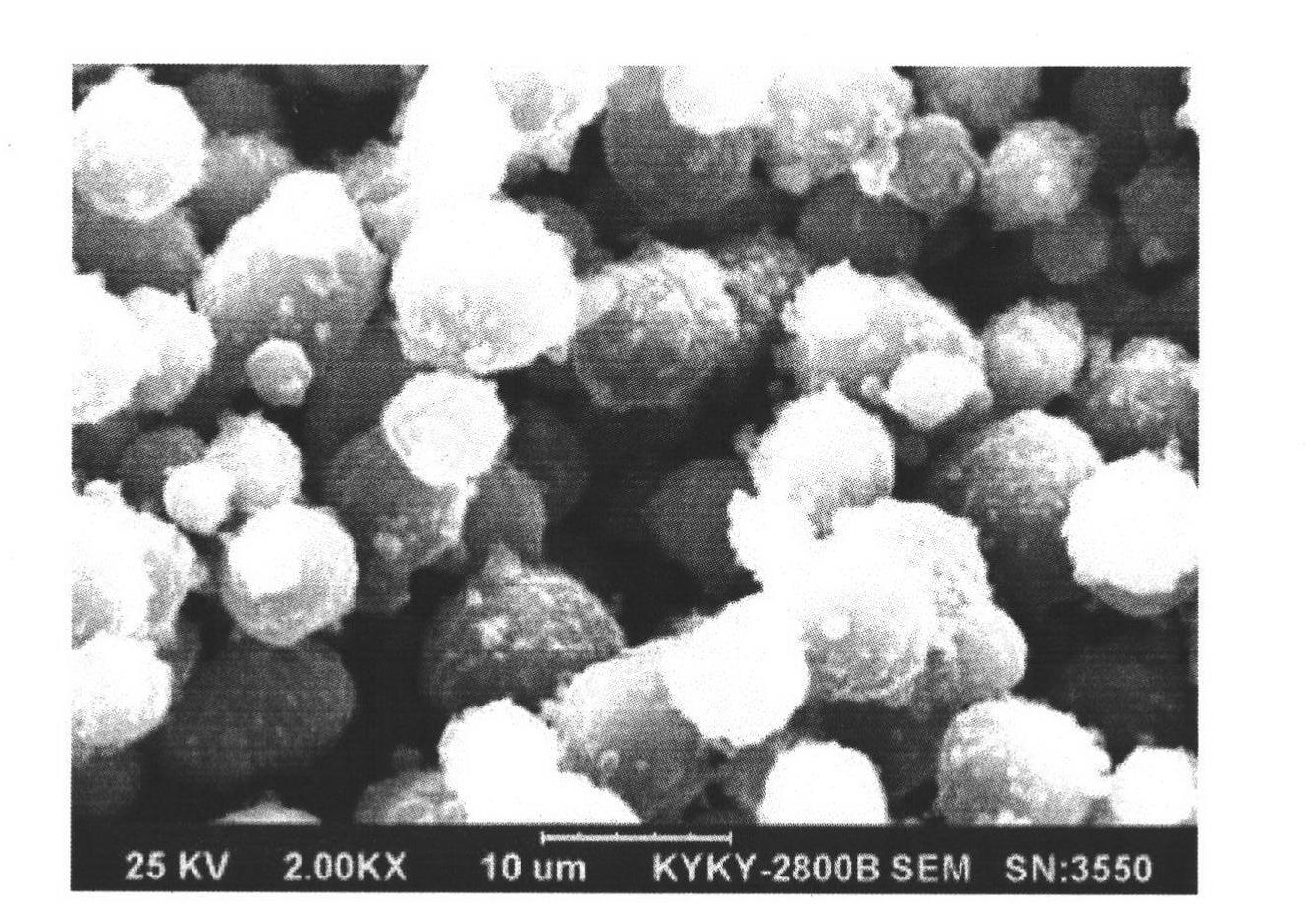

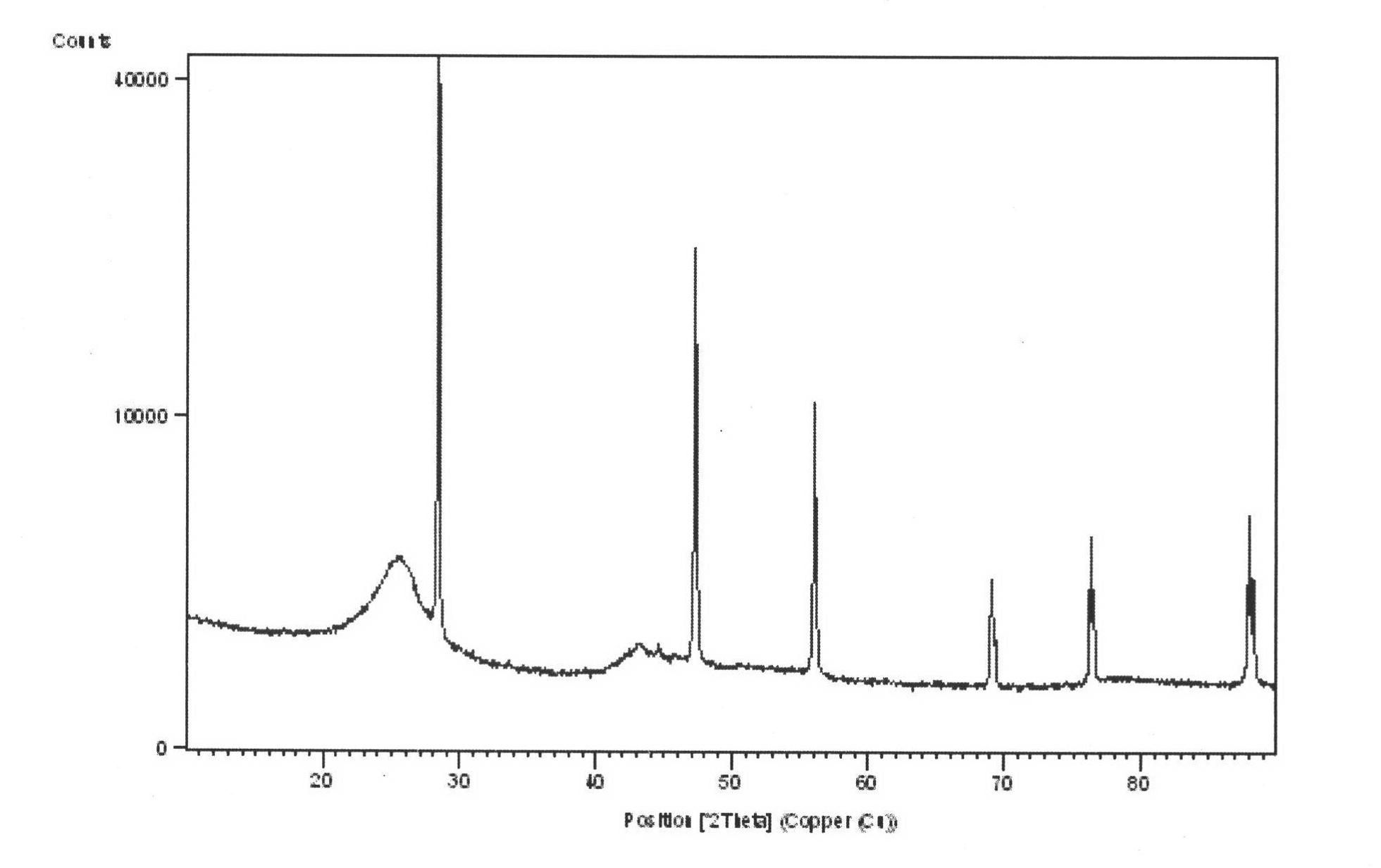

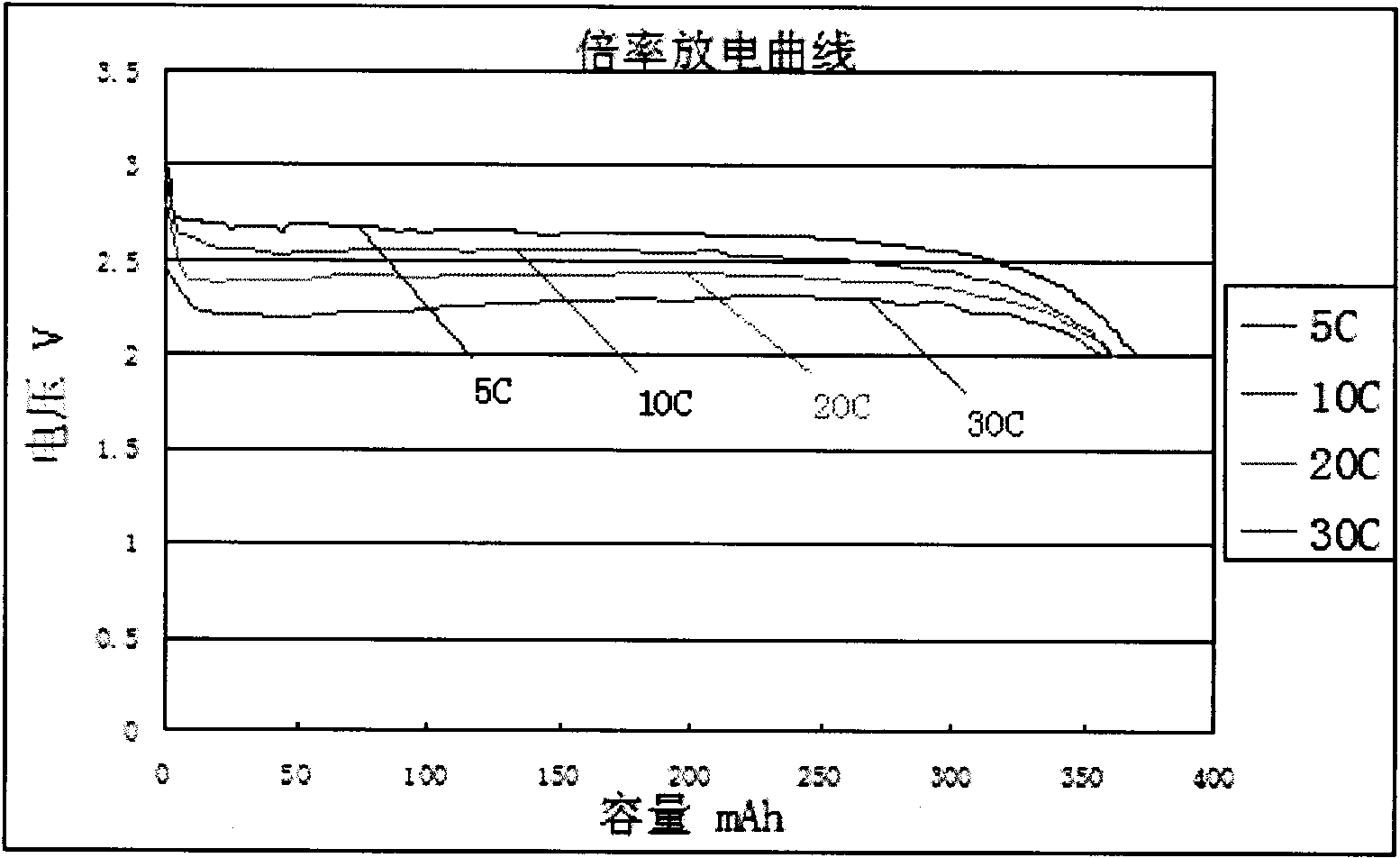

[0048] Example 1, 400 grams of coal tar pitch with a softening point of 60 ° C, 2.3 wt % of quinoline insoluble matter of coal tar pitch were added to a 2 L reactor, and 5.6 grams of ferric nitrate was added; with a heating rate of 3 ° C / min, the temperature was raised to 100 ℃, stirred at a stirring rate of 90 rpm for 4 hours; at a heating rate of 5 °C / min, the temperature was raised to 300 °C, and the temperature was kept constant for 2 hours; Generate a pitch product containing mesophase carbon microspheres; add 400g of quinoline to the pitch product containing mesophase carbon microspheres, heat to 160°C at a heating rate of 3°C / min, and stir at a speed of 100 rpm Suction filter with Buchner funnel for 1 hour; and use toluene to continuously extract the residual filter cake after filtration in a Soxhlet extractor until the extract is colorless or light yellow; The balls were cleaned with acetone, and baked in an oven at 100°C for 8 hours; the yield was 30%, and the avera...

Embodiment 2

[0053]Example 2, 400 grams of petroleum pitch with a softening point of 80°C and 3.5 wt% of quinoline insolubles were added to a 2L reaction kettle, and 20 grams of aluminum chloride was added; at a heating rate of 10°C / min, the temperature was raised to 140°C. Stir at a stirring rate of 95 rpm / min for 10 hours; at a heating rate of 10 °C / min, raise the temperature to 340 °C and keep the temperature constant for 1 hour; Pitch product of mesophase carbon microspheres; 2000 grams of coal tar light components (distillation range 150-200°C) are added to the pitch product containing mesophase carbon microspheres, and heated to 120°C at a heating rate of 10°C / min , and stirred at a speed of 80 rev / min for 0.5 hour, and suction-filtered with a Buchner funnel; and used quinoline to continuously extract the residual filter cake after filtration in a Soxhlet extractor until the extract was colorless or light Yellow; the extracted mesophase carbon microspheres were washed with acetone, a...

Embodiment 3

[0054] Example 3, 350 grams of coal tar pitch with a softening point of 110 ° C, 2.3 wt % of quinoline insolubles and 50 g of anthracene oil are added to a 2L reactor, and 30 grams of nickel acetate and 10 grams of cobalt nitrate are added; at 14 ° C / min The heating rate is raised to 160°C, and stirred at a stirring rate of 85 rpm for 12 hours; at a heating rate of 16°C / min, the temperature is raised to 330°C, and the temperature is kept at a constant temperature for 4 hours; at a heating rate of 10°C / min, the temperature is raised to 460 ℃, constant temperature reaction for 6 hours to generate a pitch product containing mesophase carbon microspheres; 800g of pyridine was added to the pitch product containing mesophase carbon microspheres, heated to 120°C at a heating rate of 8°C / min, and heated at 90°C Stir at a speed of rev / min for 2 hours, suction filter with a Buchner funnel; and use pyridine to continuously extract the filter cake remaining after filtration in a Soxhlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com