Patents

Literature

408 results about "Soxhlet extractor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Soxhlet extractor is a piece of laboratory apparatus invented in 1879 by Franz von Soxhlet. It was originally designed for the extraction of a lipid from a solid material. Typically, Soxhlet extraction is used when the desired compound has a limited solubility in a solvent, and the impurity is insoluble in that solvent. It allows for unmonitored and unmanaged operation while efficiently recycling a small amount of solvent to dissolve a larger amount of material.

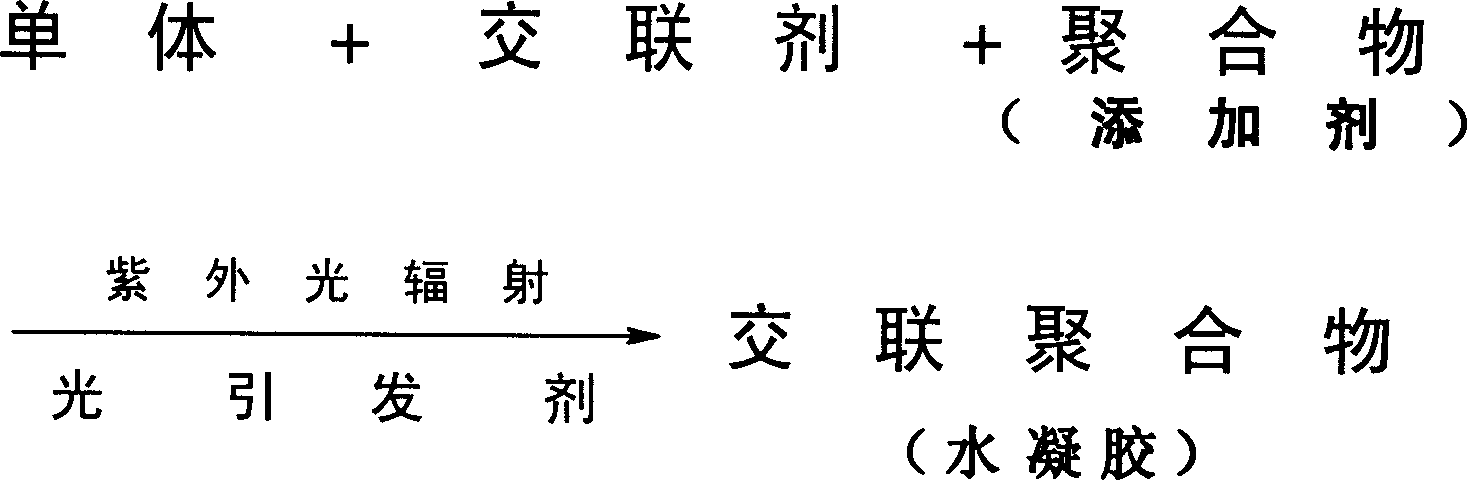

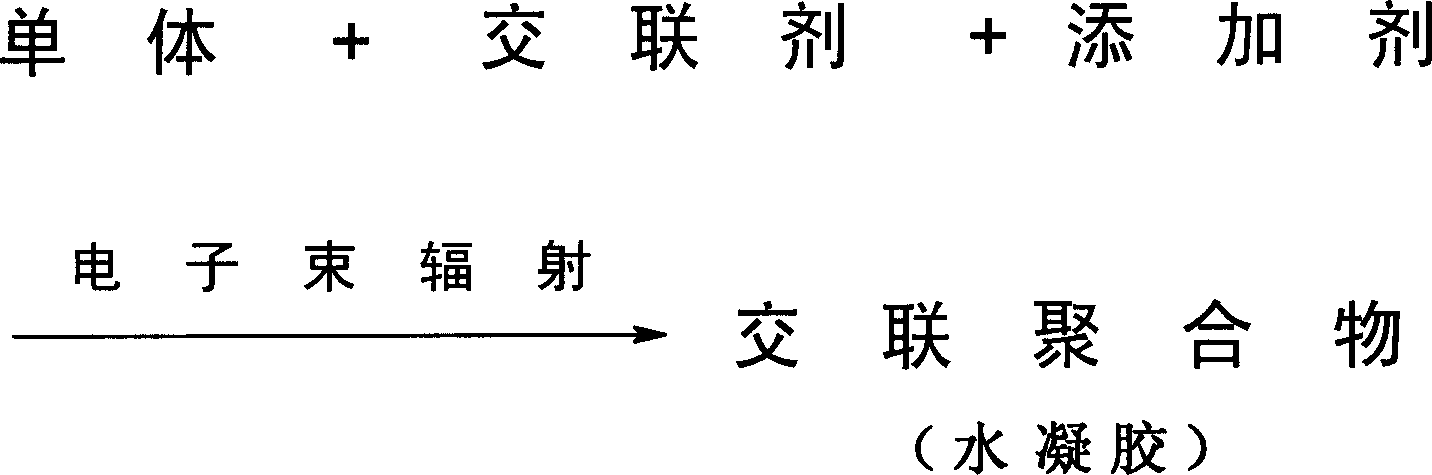

Direct synthesis of temperate sensitive aquogel by ultraviolet radiant polymerization

Synthesis of warm sensitive aquagel from ultraviolet light radiation polymerization is carried out by adding reacting raw materials into deionized water to prepare preformed solution, laying aside under ultraviolet light radiation, exposing, polymerizing directly to prepare cross-linking polymer, putting the polymer into sorbitic extractor, extracting from boiled deionized water for 24hrs, taking it out, and drying in vacuum drier to obtain warm sensitive aquagel. Its low critical temperature varies between 30-40 Deg C. with raw material formula. It can be used for various aquagels, medicine control-releasing system, memory element switch, artificial muscle and chemical industrial separation. It achieves low cost, simple process, high efficiency and normal-temperature operation.

Owner:TSINGHUA UNIV

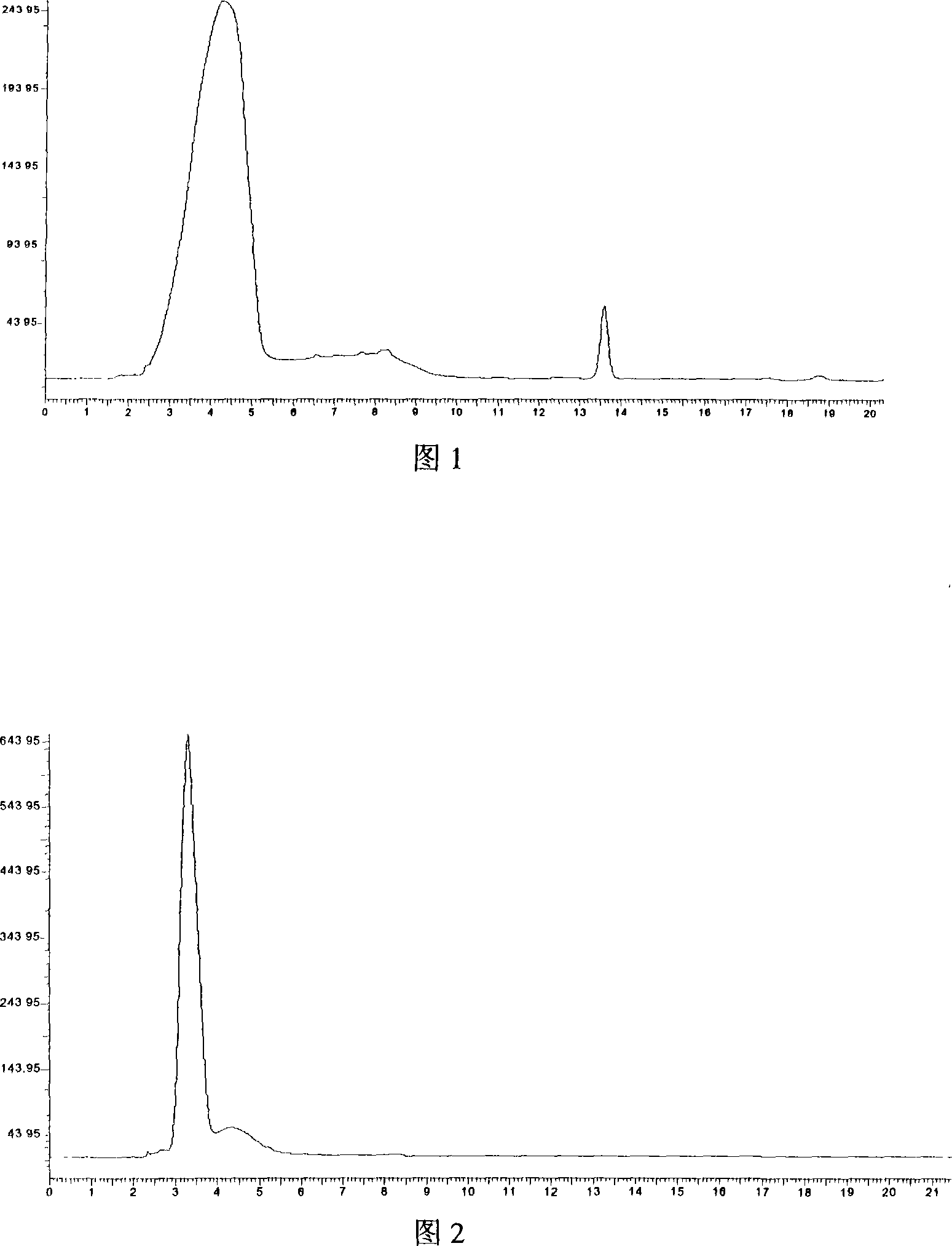

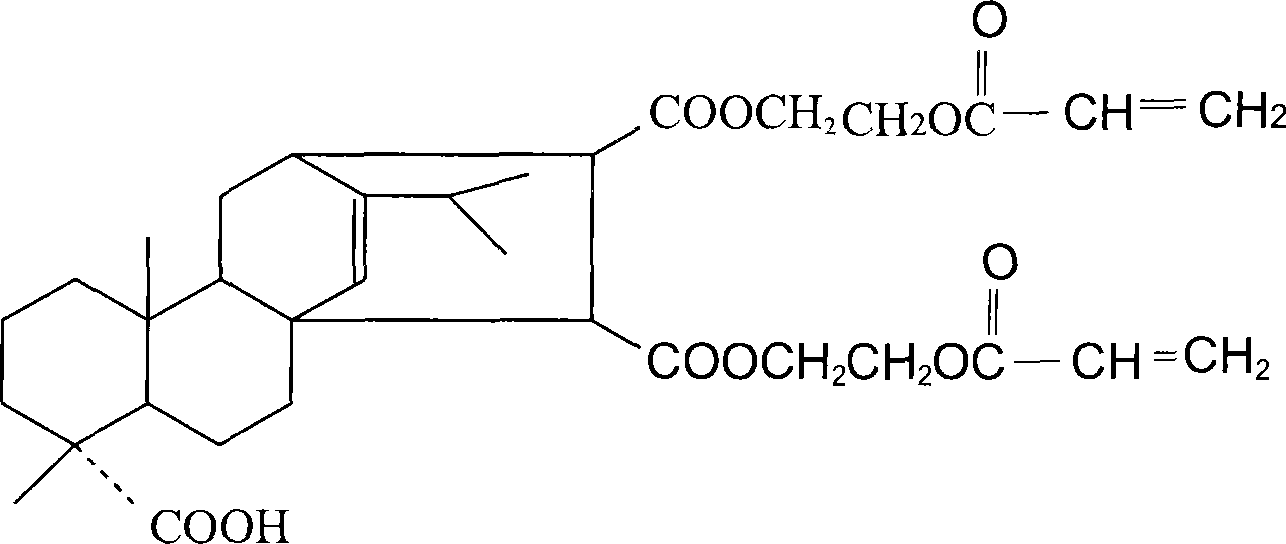

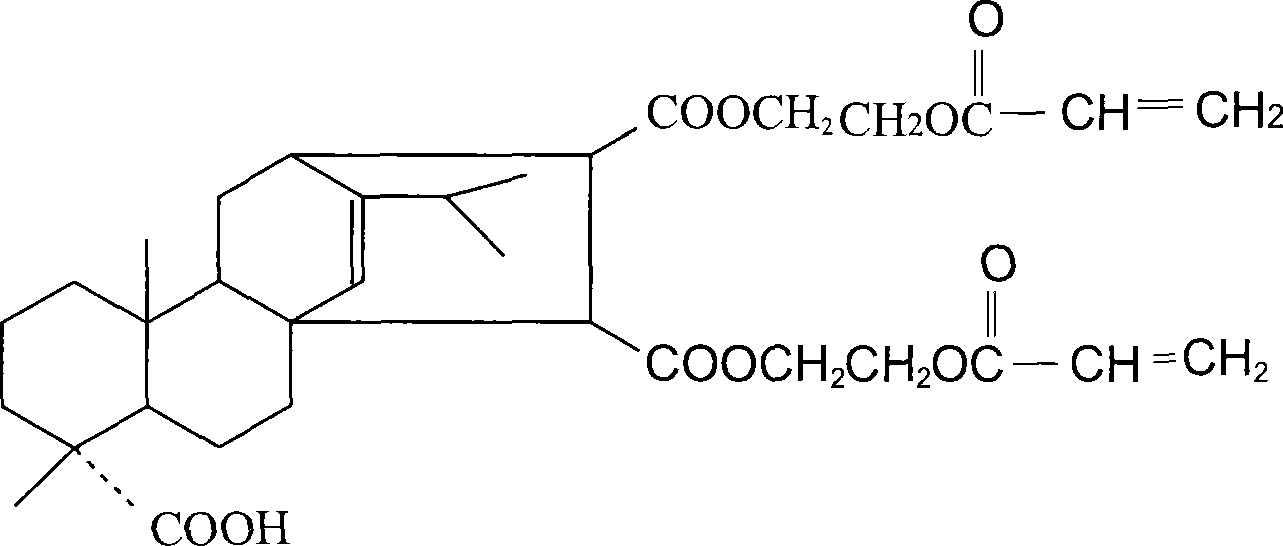

Molecular engram polymer containing ternary phenanthrene ring frame and preparation method thereof

The invention is a molecularly imprinted polymer and a preparation method thereof. The name of the molecularly imprinted polymer is a molecularly imprinted polymer containing a three-membered phenanthrene ring skeleton, and its preparation method is: using maleic rosin ethylene glycol propylene ester as a crosslinking agent, dehydroabietylamine or theophylline as a template molecule, Acrylic acid or derivatives of acrylic acid such as methacrylic acid, methyl methacrylate, acrylamide, etc. are used as monomers, in a 500 ml three-necked flask, gasoline-chloroform-water mixed solvent is used as a solvent, an initiator is added, heated, Stir and carry out free radical suspension polymerization to obtain a polymer product, then use a methanol-acetic acid mixture to elute the polymer in a Soxhlet extractor, remove the template molecule dehydroabietylamine or theophylline, and obtain a Molecularly imprinted polymers, that is, molecularly imprinted polymers containing a three-membered phenanthrene ring skeleton, can be used for the adsorption and separation of organic compounds.

Owner:GUANGXI UNIV FOR NATITIES

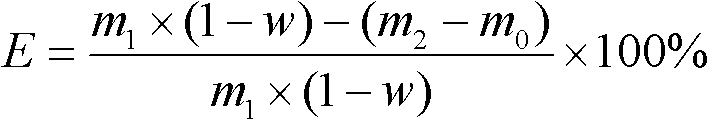

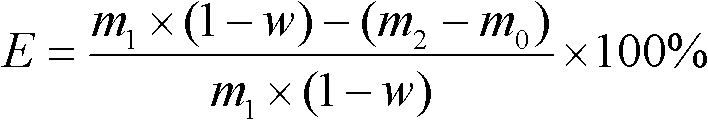

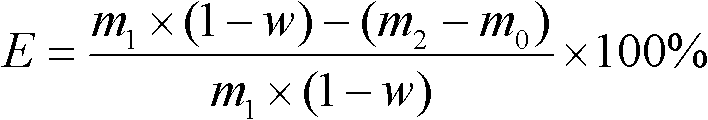

Method for determining spreading rate of paper-process reconstituted tobacco finished products

The invention relates to a method for determining the spreading rate of paper-process reconstituted tobacco finished products, which belongs to the technical field of reconstituted tobacco. The method includes steps: a, taking a certain quantity of paper-process reconstituted tobacco and a sheet base to be shredded, and the placing the tobacco shreds into a constant-temperature and constant-humidity box with the temperature of 22 DEG C and the humidity of 60% to balance for 48 hours; b, weighing a certain quantity of reconstituted tobacco shred samples m1 to be placed in a solvent cup of a Soxhlet extractor, adding distilled water according to feed to liquid ratio of 1:30, and setting the circulation times of the Soxhlet extractor to be 10 times, and the extracting temperature to be 19-level and the temperature of a condensing circulation pump to be 2 DEG C to extract; c, taking out the samples after extraction is finished, transferring the samples into an aluminum box reaching the constant weight of m0, placing the aluminum box into a drying oven, drying the samples at the temperature of 100+ / -1 DEG C so that the constant weight of the aluminum box is m2, realizing the precision of the constant weight to be 0.001g, determining moisture content w of the samples, and extracting the sheet base of the reconstituted tobacco by the same method; and d, calculating the spreading rate according to a formula. The method has the advantages that the method is simple, and is applicable to determining the spreading rate of the paper-process reconstituted tobacco finished products.

Owner:YUNNAN RES INST OF TOBACCO SCI

Fibers capable of heat storage and temperature adjustment

InactiveCN101845683AReduce leakageImprove thermal stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterCore component

Owner:YINGBAO FIBER TECH RENHUA

Process for isolation of hepatoprotective agent silymarin from the seeds of the plant Silybum marianum

The invention relates to a novel process for the isolation of a hepatoprotective agent Silymarin from the seeds of the plant Silybum marianum comprising (i) Precooling the seeds to (-) 20° C. for 24 hours in a deep freezer / cold room. (ii) Powdering the cooled seeds in a hammer mill, fitted with about 40 mesh discharge screen. (iii) Defatting the seeds by extracting with hexane in a soxhlet type extractor to remove the total quantity of fatty oil without using a scrain. (iv) Extracting the defatted seeds with acetonitrile at 20-30° C. to extract silymarin fraction. (v) Concentration of the sensitive silymarin fraction under vacuum in a agitated wiped thin film evaporator (vi) stirring the silymarin such dry powder with cold dichloromethane at 5° C. followed by filtration and drying with a slow purge of nitrogen gas. (vii) Further purification of silymarin by suspending in 5 times its weight of acetonitrile and precipitating by 8-12 times its weight of water at 20° C. (viii) Filtering the precipitated silymarin in a closed vacuum filter and having 1-2 mum screen washing the cake three times with distilled water (ix) Drying of Silymarin cake in vacuum oven to obtain substantially pure silymarin.

Owner:COUNCIL OF SCI & IND RES

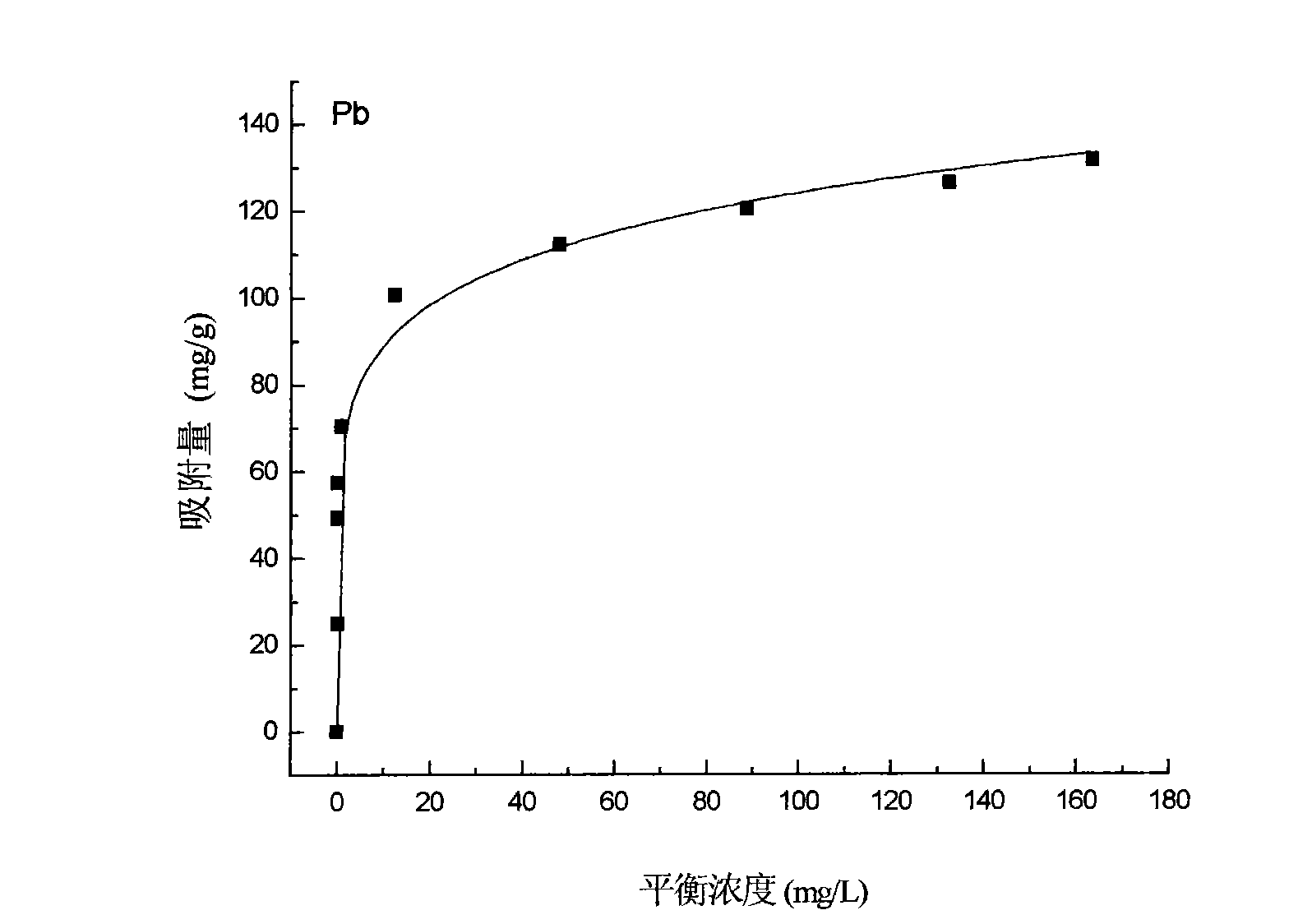

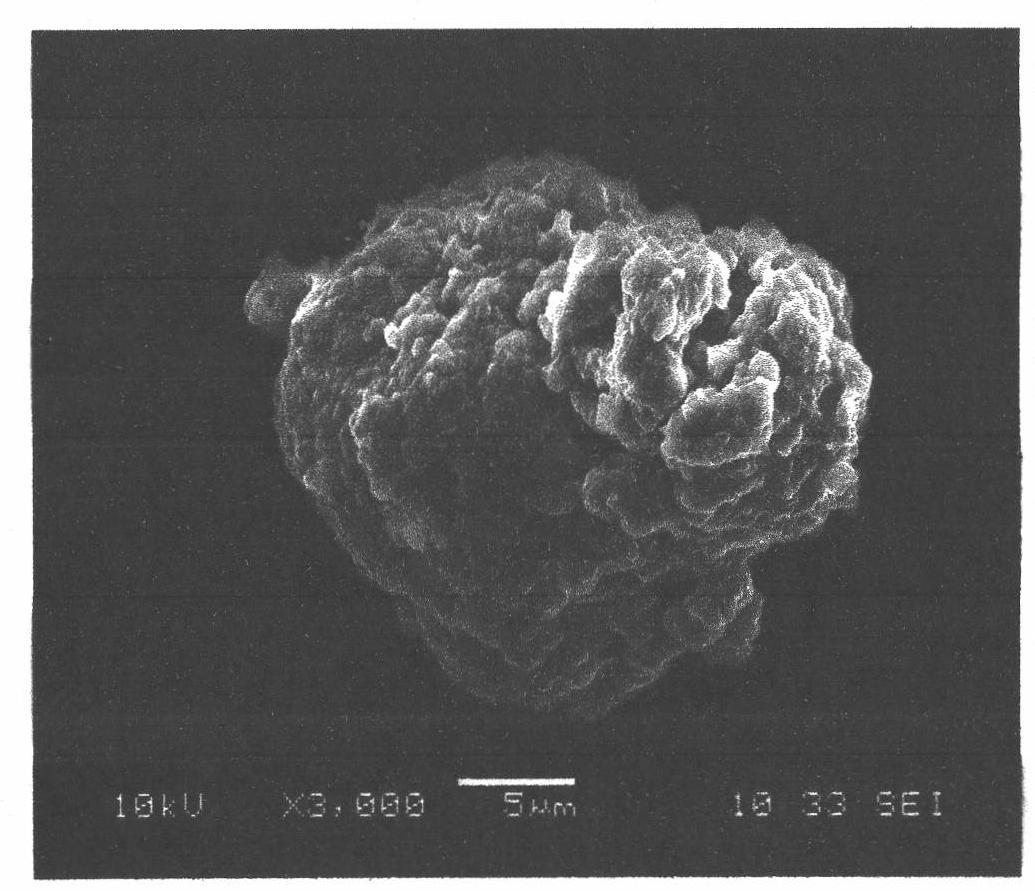

Method for preparing in-situ passivation restoring material of soil heavy metal with copolycondensation method

InactiveCN101664755AImprove repair effectLarge specific surface areaWater contaminantsContaminated soil reclamationWater bathsSoil heavy metals

The invention relates to a method for preparing an in-situ passivation restoring material of soil heavy metal with a copolycondensation method. A cellular material with high specific surface area is prepared by using a mesoporous silicon dioxide SiO2 as the base material and introducing sulfydryl having strong bonding fixation ability with a heavy metal ion via surface modification. The preparation method comprises the following steps: (1) mixing water with methanol; (2) adding templates of hexadecyl trimethyl ammonium bromide and sodium hydroxide; (3) using methyl orthosilicate and mercapto-propyl trimethoxy silane as a silicon source; (4) continuously stirring the mixed solution for 12h; (5) heating the solution in water at a constant temperature of 96 DEG C; (6) obtaining white powder by filtering, collecting and air drying; and (7) transferring the mixture into a soxhlet extractor to be extracted by ethanol, collecting samples for air drying and performing vacuum drying at 80 DEG Cto obtain the finished product. The invention has the advantages of simple process, low cost, high restoring efficiency, no secondary pollution and safe use, and is suitable for large-scale promotionand application.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

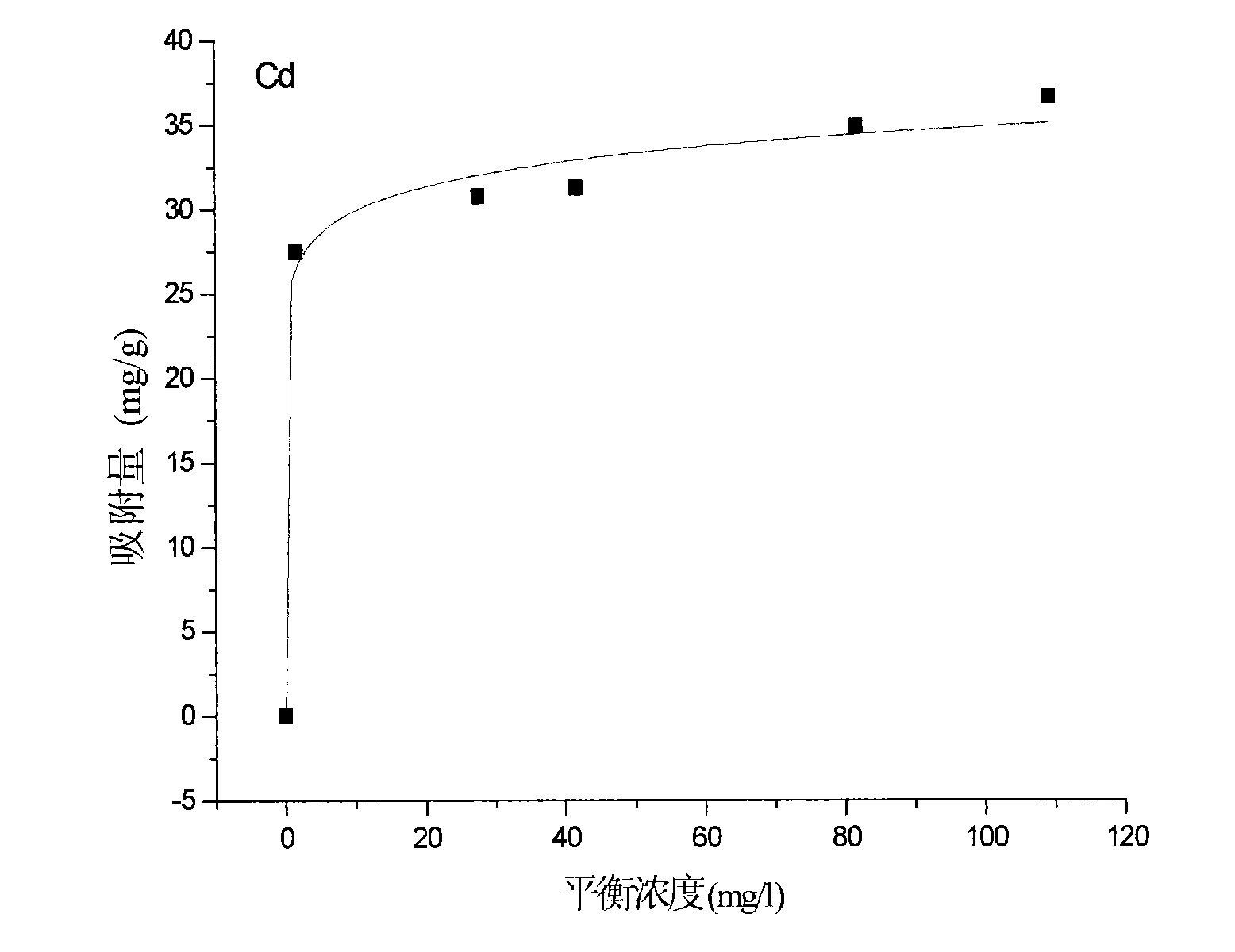

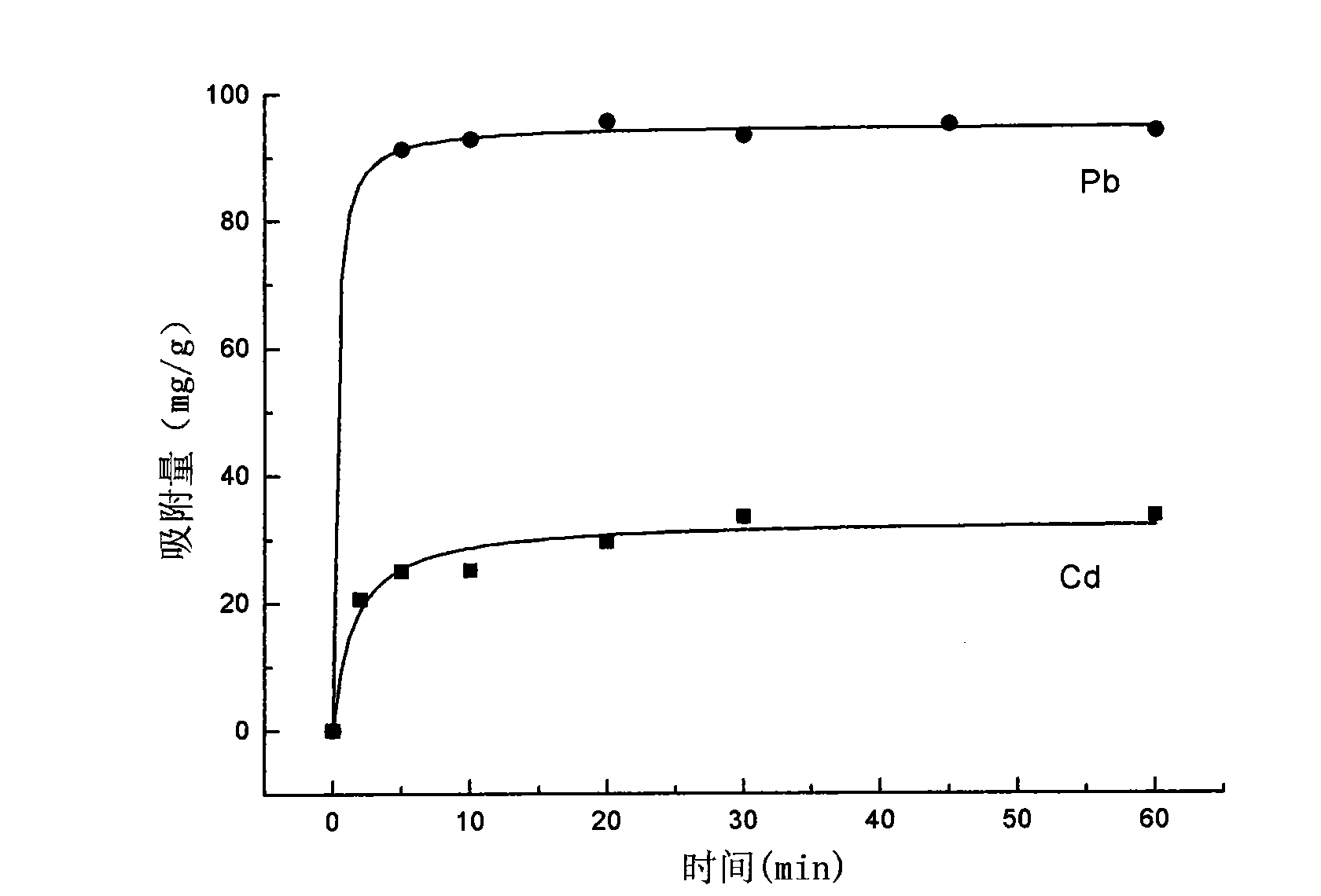

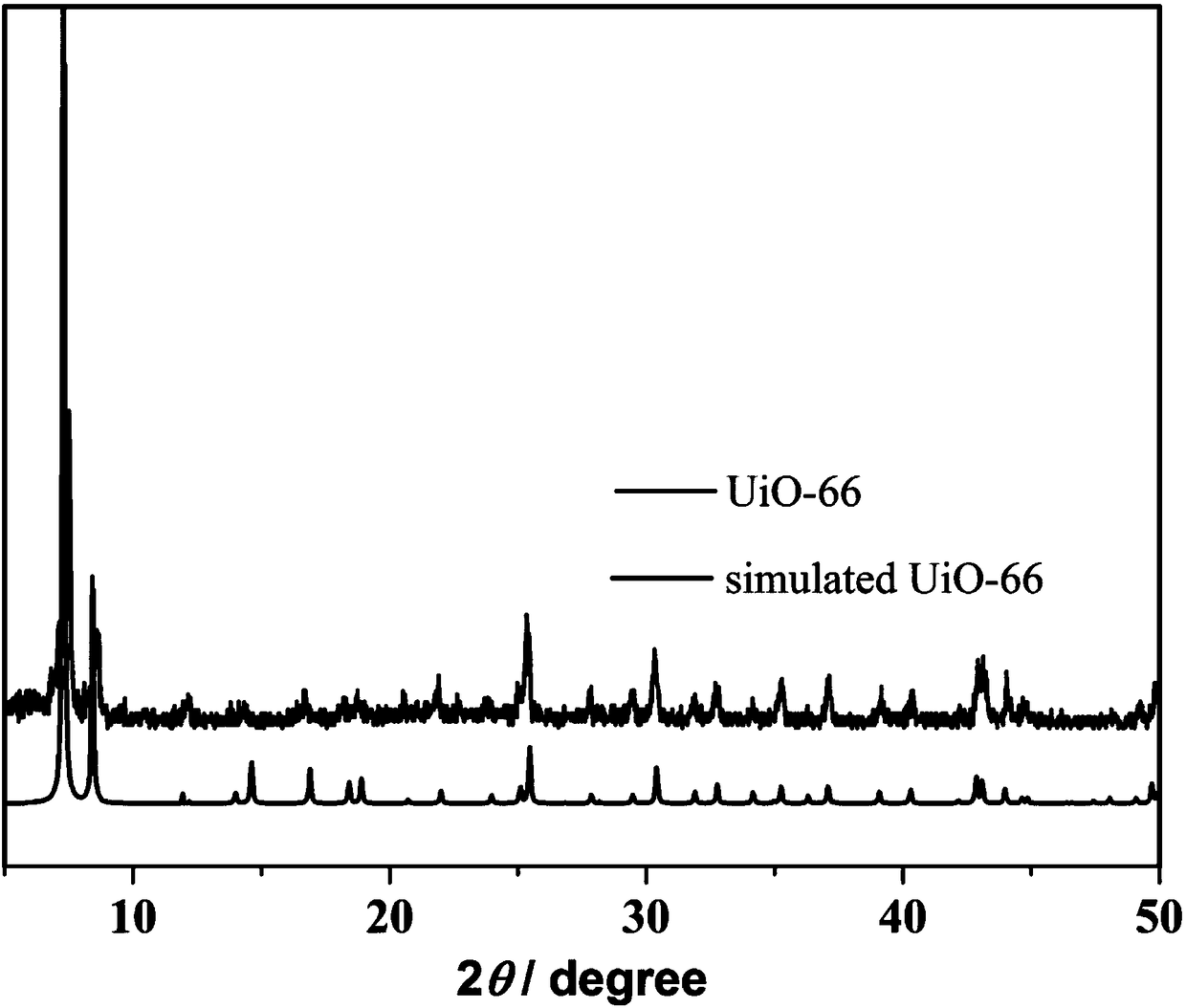

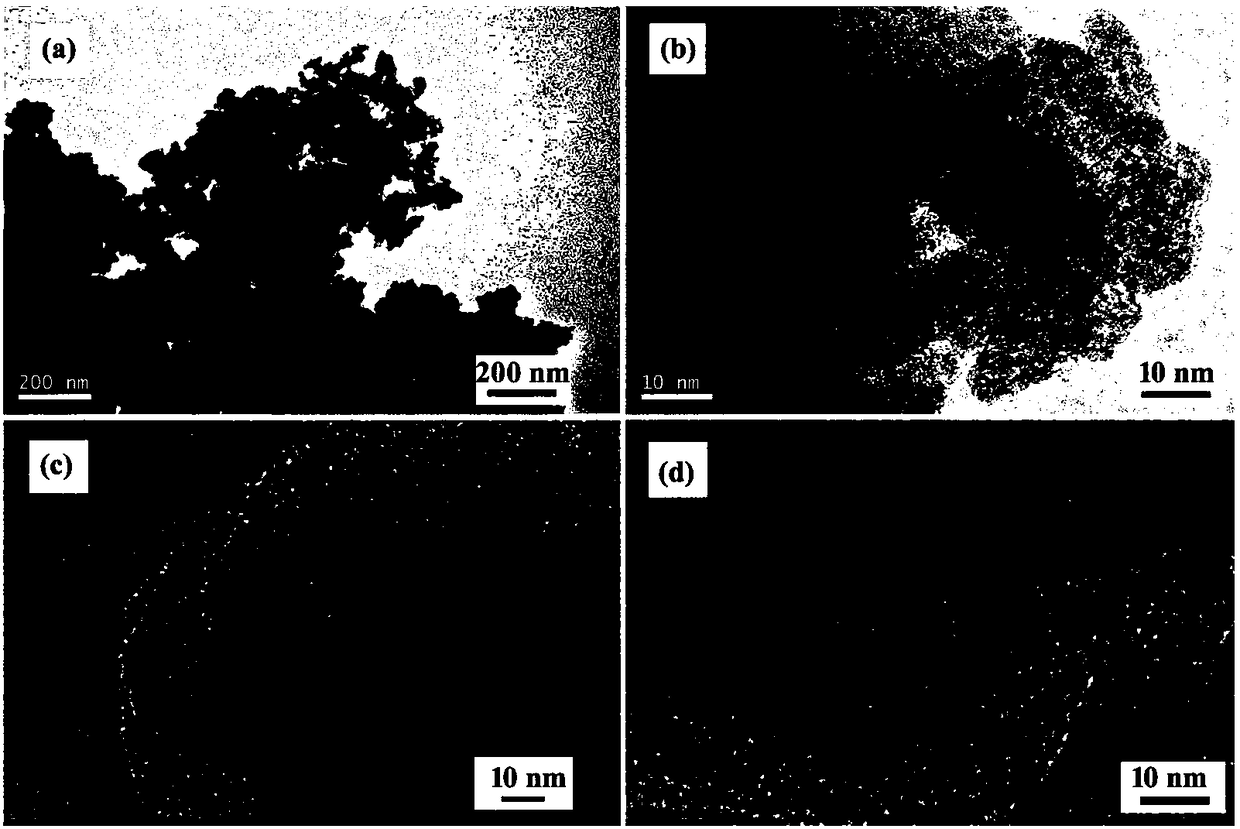

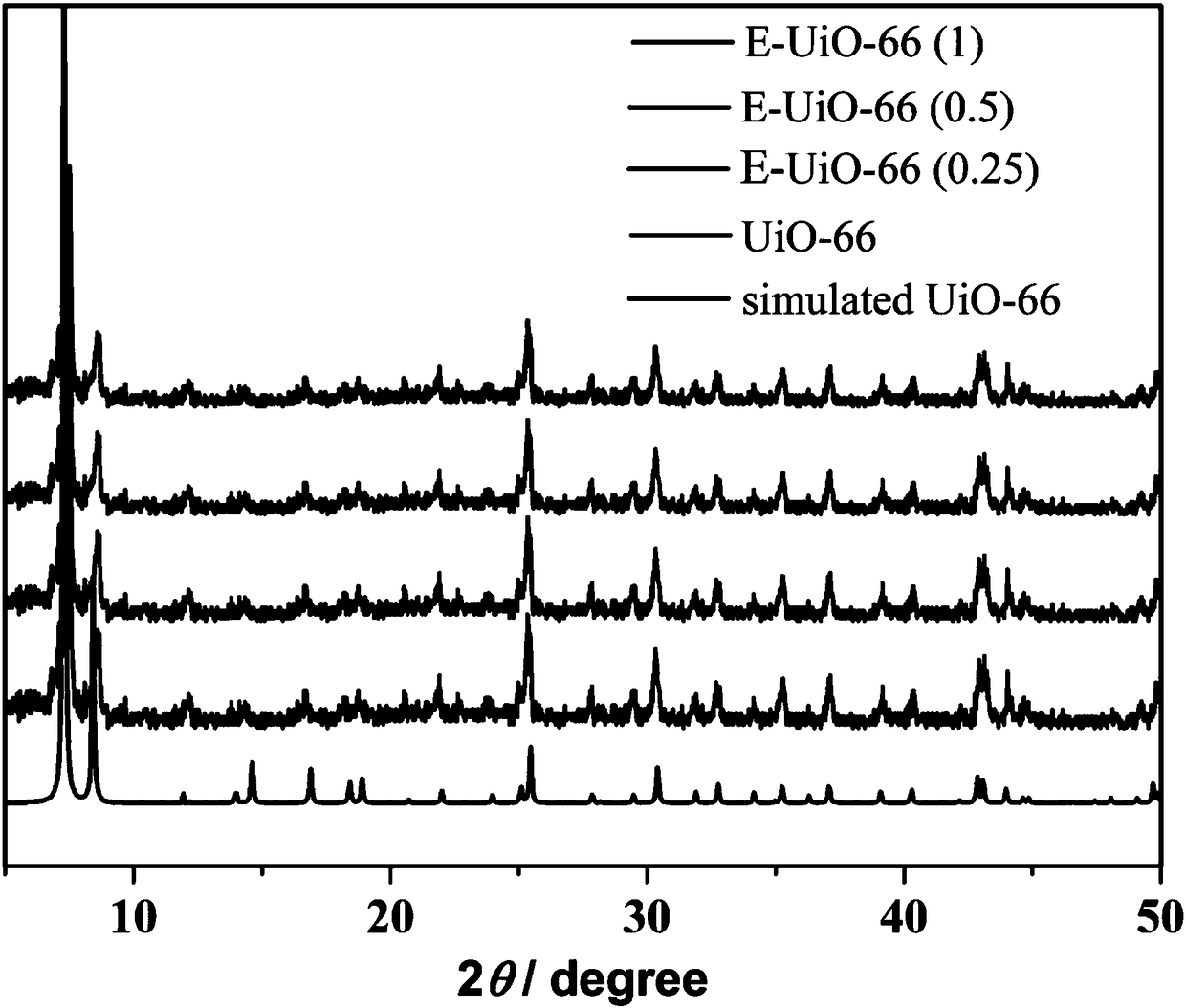

Pore-diameter extension method for UiO-66 metal organic framework material and application

ActiveCN108084453AEasy to makeEasy to operateOther chemical processesWater contaminantsOrganic dyeMetal-organic framework

The invention discloses a pore-diameter expanding method for a UiO-66 metal organic framework material. The pore-diameter expanding method comprises the following steps of: taking and mixing 2.47 parts by weight of zirconium tetrachloride, 1.47 parts by weight of terephthalic acid and 95 parts by weight of N, N-dimethyl formamide in a single-opening flask to carry out ultrasonic dissolving; putting in a microwave oven, condensing and refluxing for 15 minutes, and carrying out centrifugal separation; using alcohol and N, N-dimethyl formamide to wash a solid product, taking 1 part by weight of solid product, adding the solid product into 20 parts by weight N, N-dimethyl formamide solution with the concentration of dilute sulfuric acid being 0.25-1mol / L, stirring for 24 hours, then carrying out centrifugal separation, using N, N-dimethyl formamide and alcohol to wash, then drying in an environment with the temperature of 60-150 DEG C, then putting into a Soxhlet extractor, adopting acetone as a solvent to wash till siphoning for three times, after washing, drying for 6 hours in an environment with the temperature of 80 DEG C, and obtaining a mesoporous UiO-66 metal organic framework material. The UiO-66 metal organic framework material can be used as an absorbent to be applied to treatment of organic dyestuff wastewater.

Owner:BENGBU COLLEGE

Novel technique for preparing tea saponin by solvent extraction and selectively separating integration

InactiveCN101177447AHigh purityReduce consumptionSteroids preparationHigh concentrationOrganic solvent

The invention relates to a novel process for preparing tea saponin, which integrates solvent extraction and selective separation. The steps are as follows: a. extraction and absorption: adding proper amount of the defatted cake of degreased oil-tea into a sorbitic extractor and adding macroporous absorption resin into the round bottom flask with low-concentration organic solvent, which is then heated up and back flowed; b. absorption stripping: addubg the macroporous absorption resin which has absorbed tea saponin into the solution of high-concentration organic solvent, which is heated up and back flowed in the round bottom flask to obtain the solution of tea saponin through filtering; c. obtaining the products of tea saponin by decoloring and spray drying the solution of tea saponin. The invention has the advantages that macroporous absorption resin is used to absorb tea saponin simultaneously while the tea saponin is extracted and solvent extraction and selective separation are integrated so that the manufacturing process is shortened, the energy consumption and production cost are reduced, the pollution during the process is decreased, the extracting solution is recycled and the consumption of organic solvent is reduced substantially, which can make full use of and fully develop the resource of defatted oil-tea cake.

Owner:NANCHANG HANGKONG UNIVERSITY

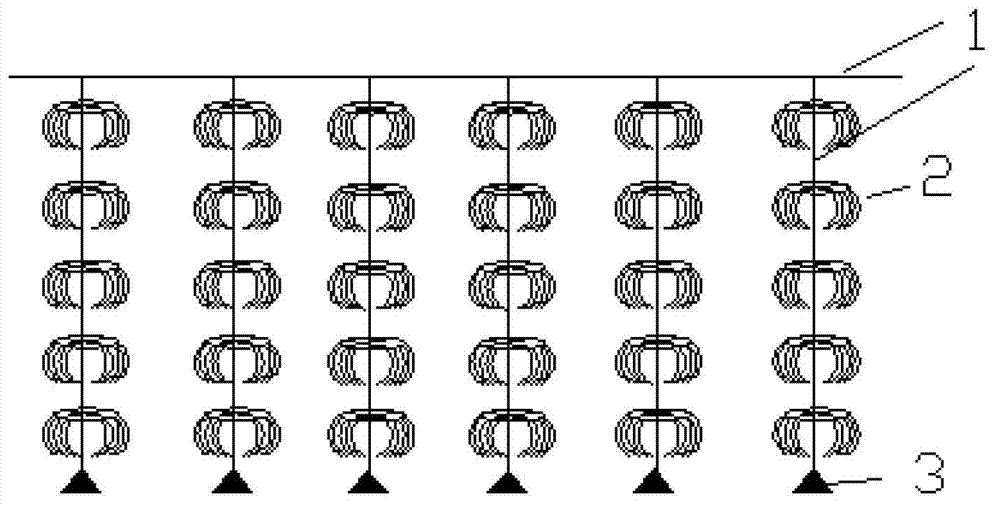

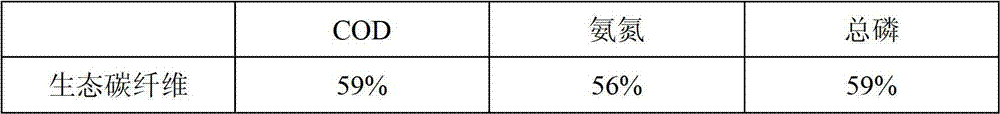

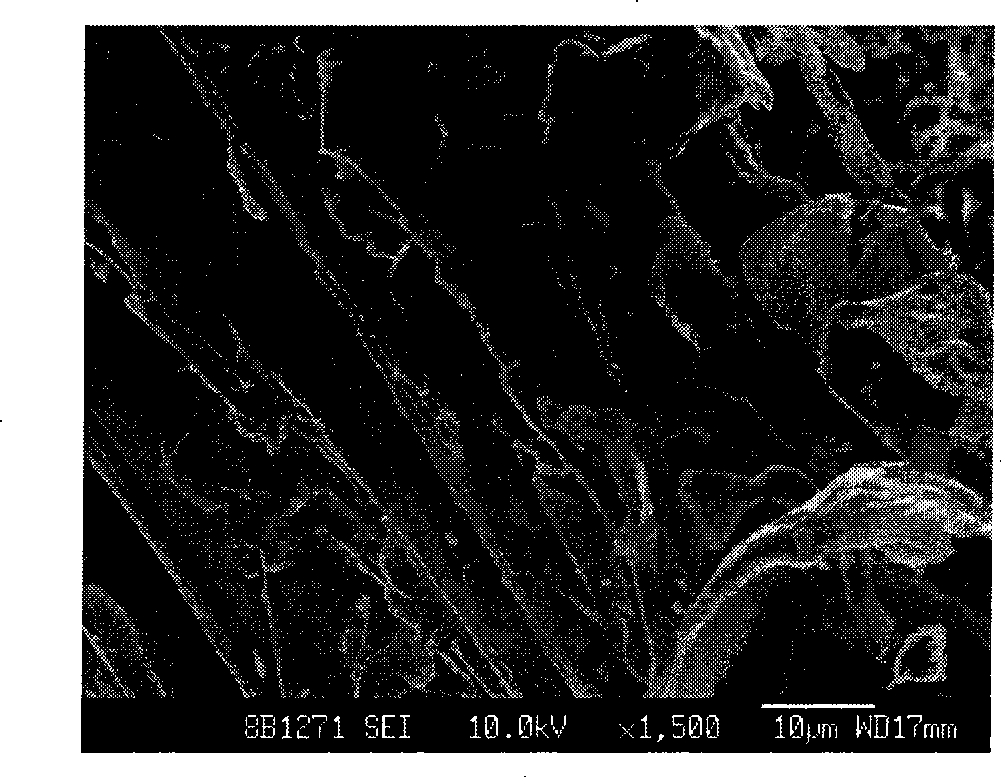

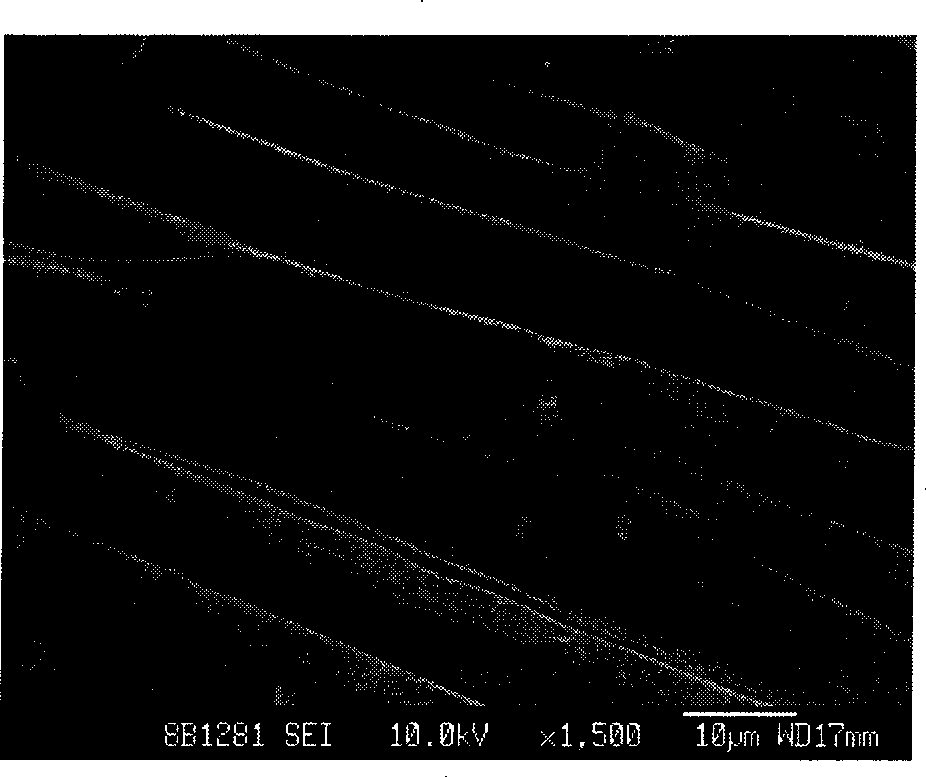

Preparation method and application of biological carbon fiber water treatment filler

InactiveCN102849845AImprove adsorption capacityLarge specific surface areaTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesFiberCarbon fibers

The invention relates to a preparation method and application of a biological carbon fiber water treatment filler, and belongs to the field of water treatment in environmental engineering. High-strength biological carbon fiber is subjected to a surface degumming treatment by acetone by a Soxhlet's extractor to obtain high-strength carbon fiber with good biocompatibility; and the high-strength carbon fiber treated with degumming is prepared into a bundle or disc shape. The biological carbon fiber water treatment filler can be applied to purification treatment of freshwater aquaculture water, printing and dyeing wastewater, oily wastewater, pharmaceutical wastewater and effluent from sewage treatment plant, so as to produce good economic benefits, social benefits and environmental benefits.

Owner:BEIJING UNIV OF CHEM TECH +1

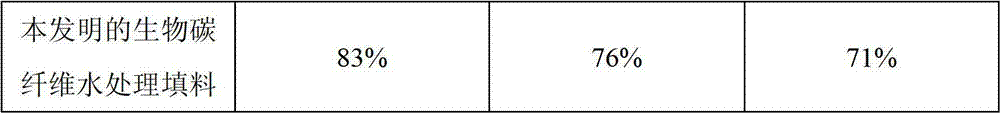

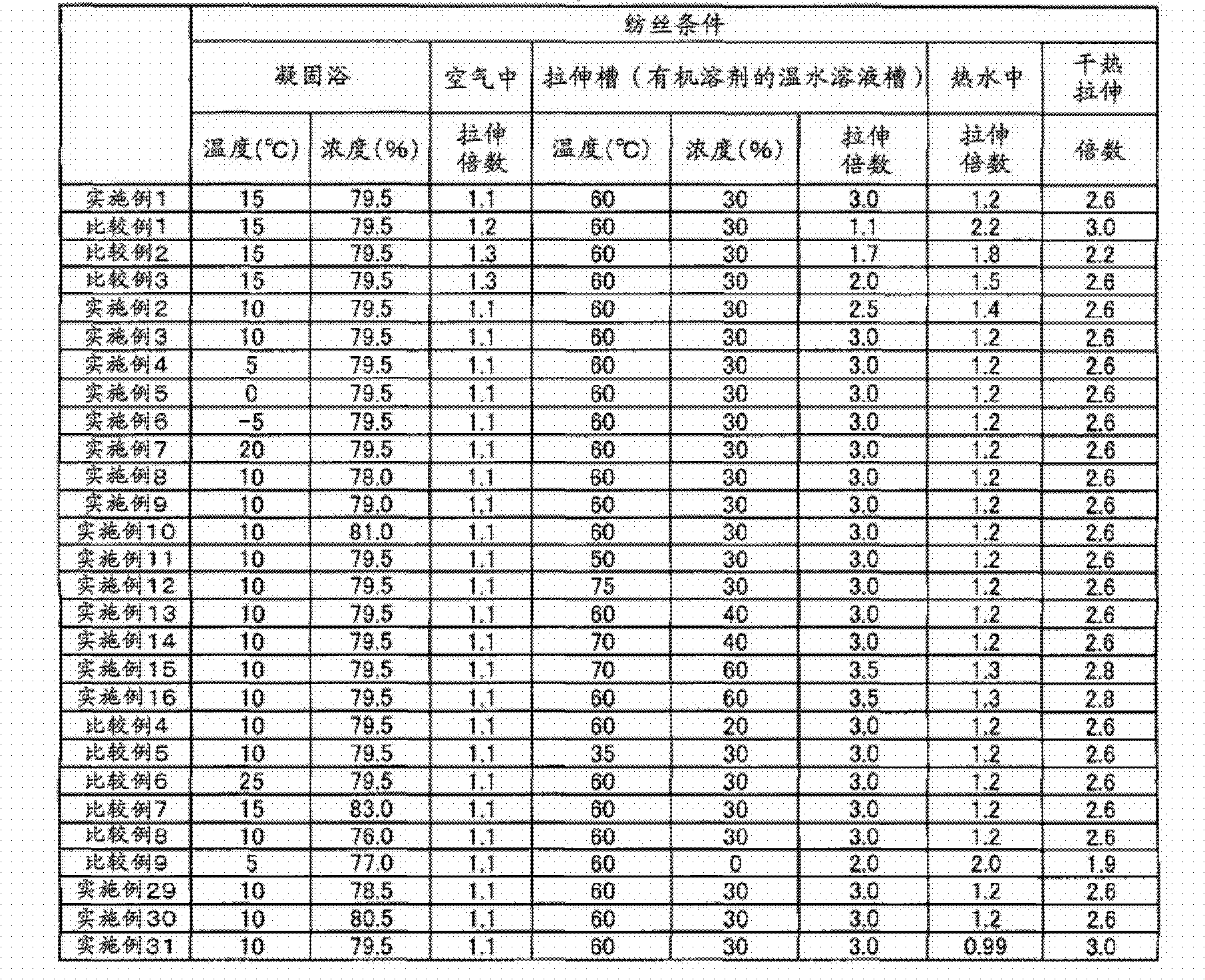

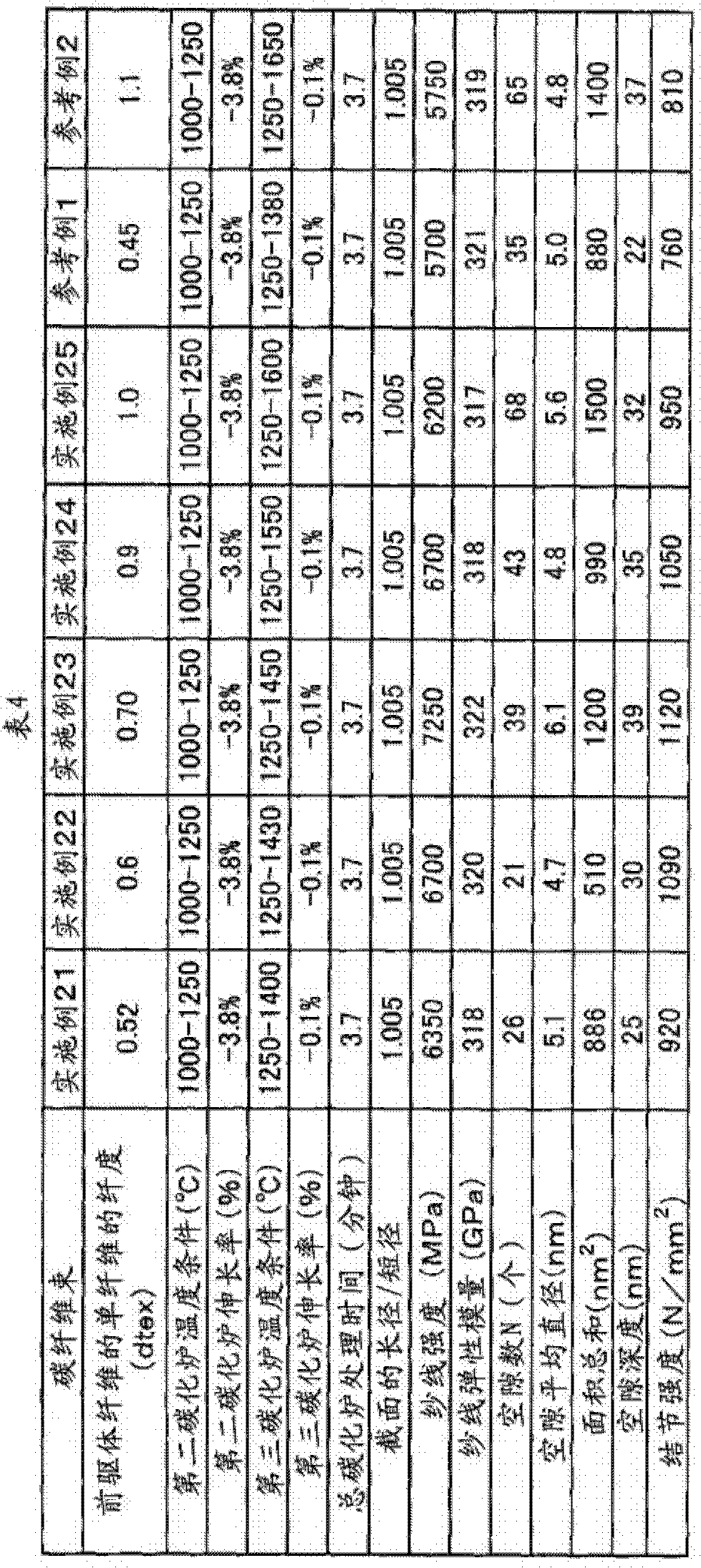

Acrylonitrile swollen yarn for carbon fiber, precursor fiber bundle, flame-proof fiber bundle, carbon fiber bundle, and production methods thereof

ActiveCN102459722ASuppresses the phenomenon of penetrating into the surface layer of the precursor fiberImprove mechanical propertiesWet spinning methodsMonocomponent synthetic polymer artificial filamentYarnCarbon fibers

Owner:MITSUBISHI CHEM CORP

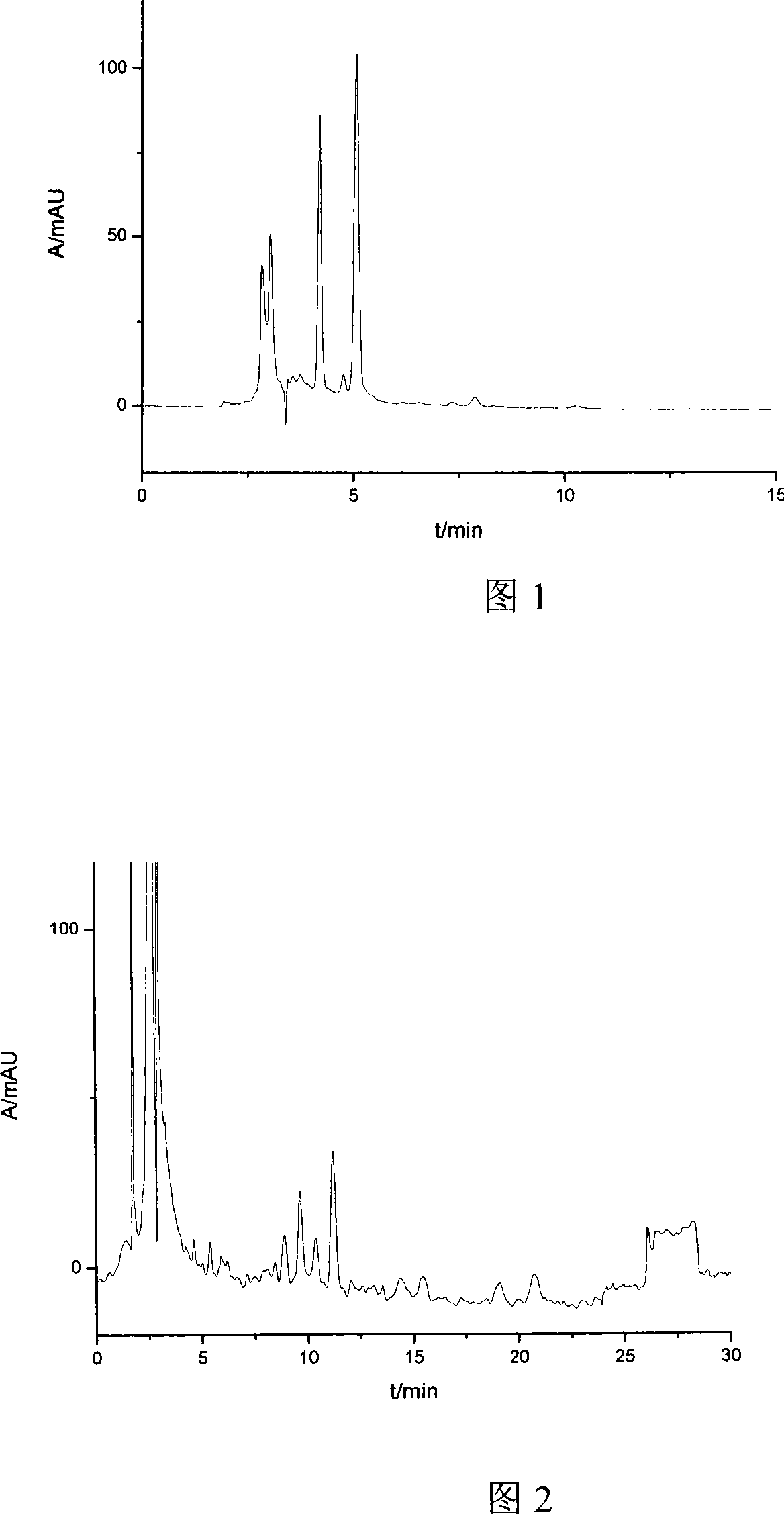

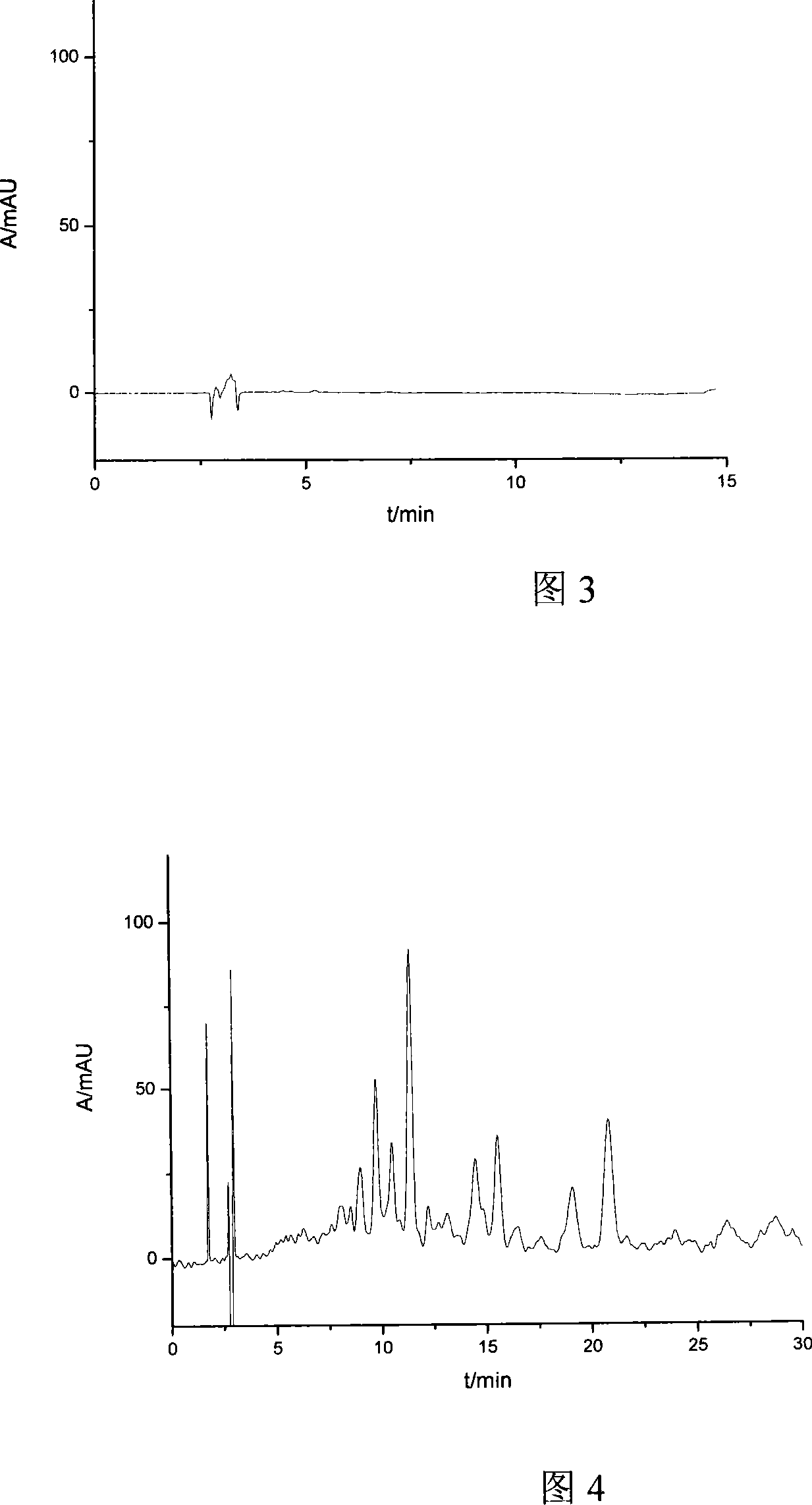

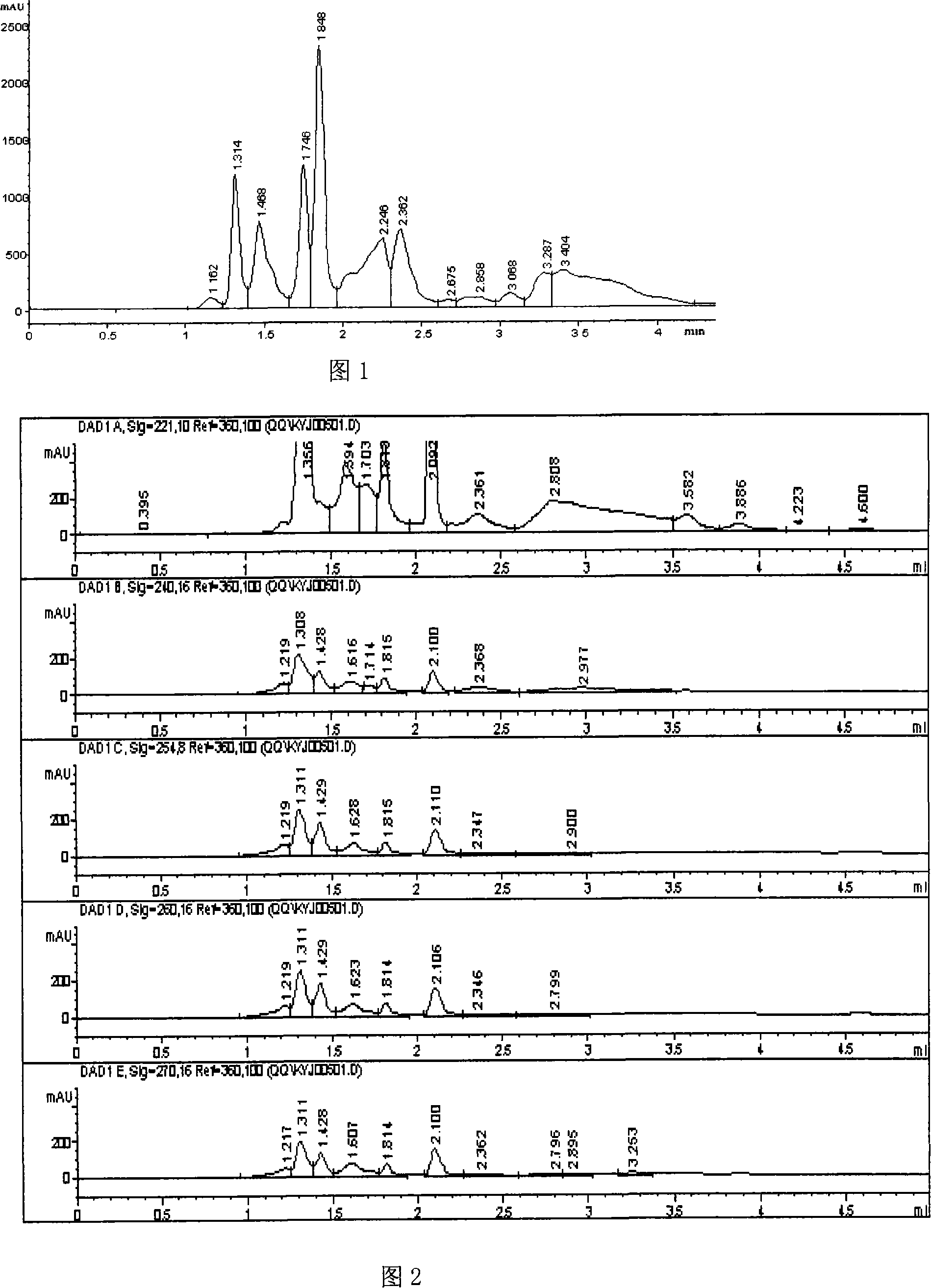

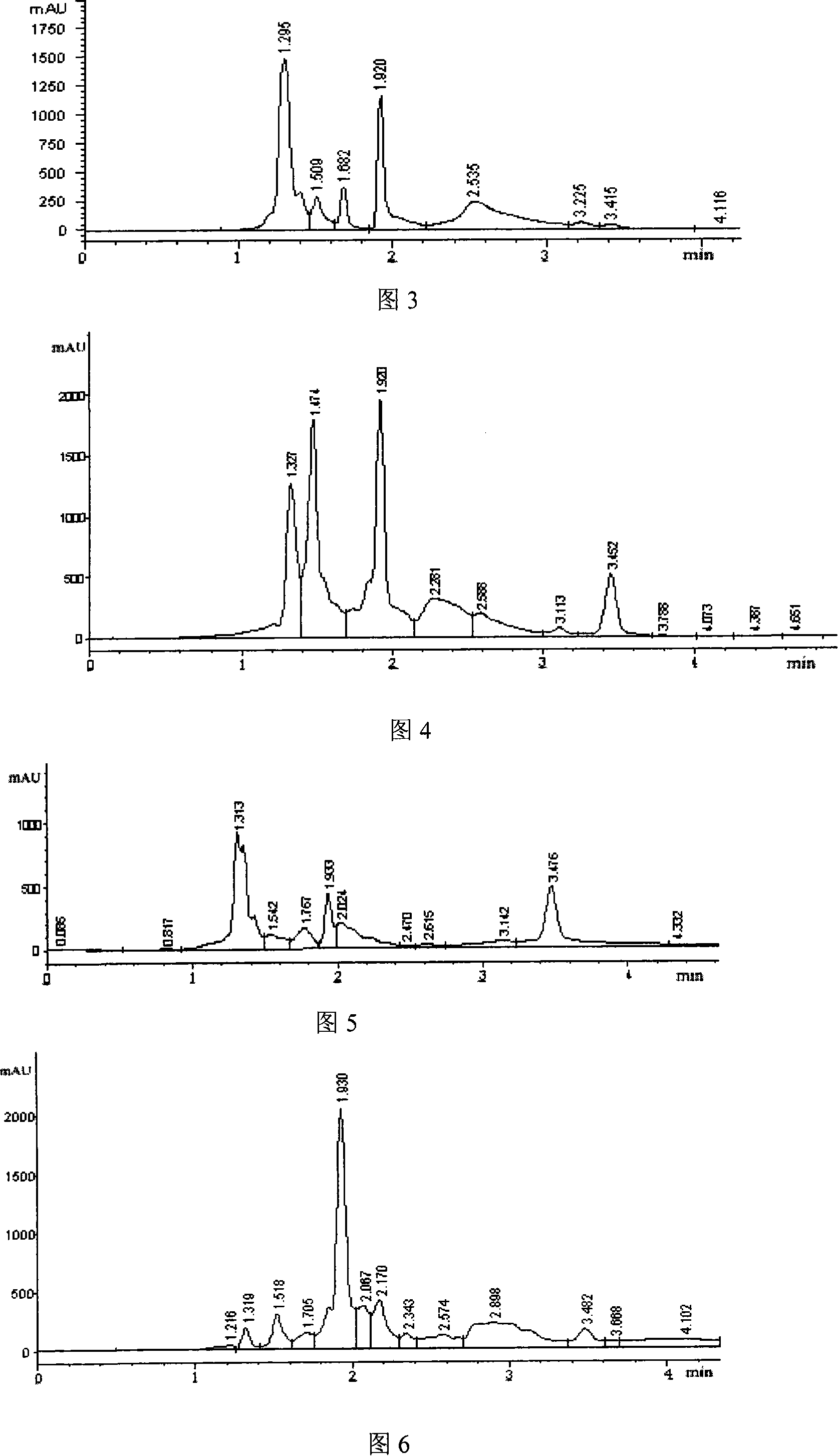

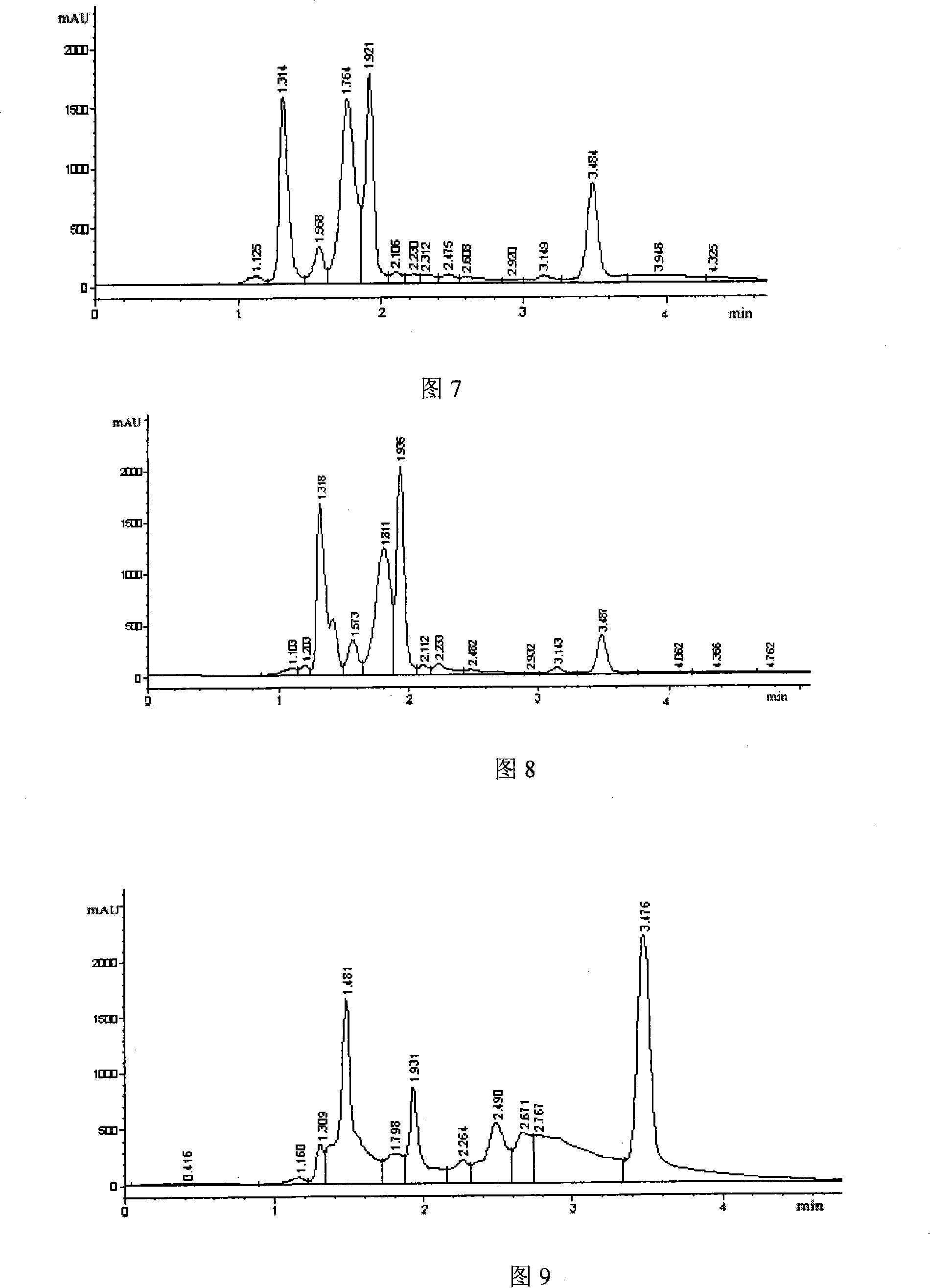

Gastrodia elata medicinal materials discrimination method

An identification method of the rhizome gastrodiae includes the below processes: (1) setting the standard chemical fingerprint atlas of rhizome gastrodiae: a. putting the rhizome gastrodiae standard sample into the sorbitic extractor; b. adding the ethanol and putting in the water bath for hot reflux, treating it by the ultrasonic cell knapper and weight, then to loss weight by the corresponding solvent; repeating it again; after filtration, concentration and drying, it uses the 10% acetonitrile to constant volume; c. using the HPLC, Eclipse, XD13-C8 chromatographic column, the 10% acetonitrile solution is as the mobile phase, the light of 221+-1nm wavelength is as the detection light source to determine the chemical fingerprint atlas of rhizome gastrodiae of rhizome gastrodiae standard sample; which has seven evidence peaks, the peak with 1.920min holding time is the rhizome gastrodiae element peak, the rhizome gastrodiae element peak of the other rhizome gastrodiae has the big warp of 1.9% with the standard sample. (2) Determining the chemical fingerprint of the detected sample and the dummy sample according to the progress (1) and comparing to identify.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ginseng saponin superhigh pressure extraction process

The invention provides a ginseng saponin superhigh pressure extraction process which comprises, drying ginseng, integrating and passing 40 mesh sieve, charging trichloromethane or ethyl ether dissolvent into ginseng powder, carrying out backflow and degreasing for 3h, filtering and drying the filtration slag under normal temperature, charging water or ethanol, methanol, n-butanol organic solvent into the defatted material, mixing and sealing, steeping at normal temperature for 0-24h, loading the mixed material into high-pressure container, applying 100-6000 MPa pressure under normal temperature for leaching, sustaining the pressure for 1-5min, releasing pressure and filtering slag, and gathering filter liquor.

Owner:JILIN UNIV

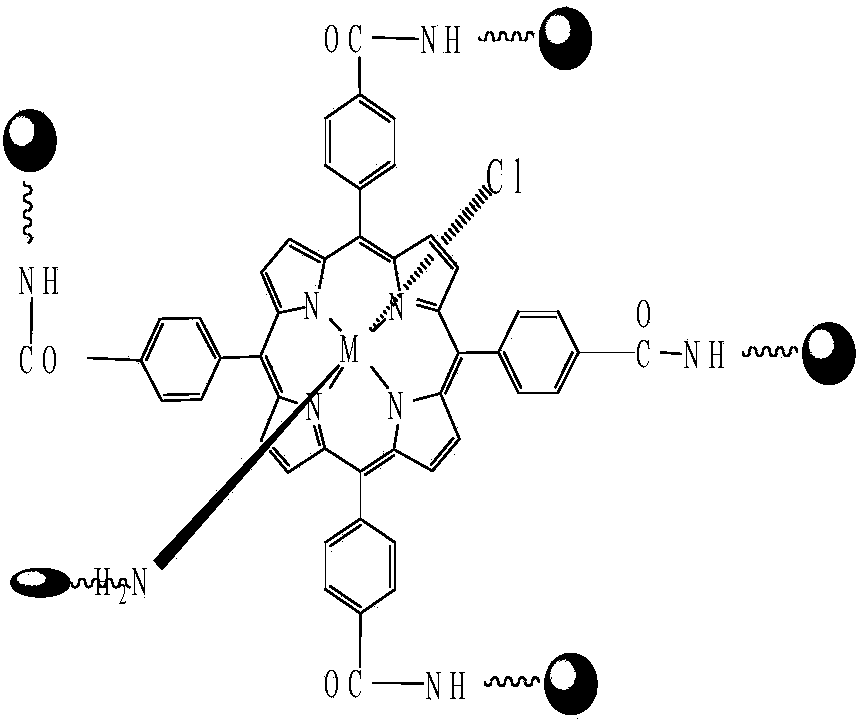

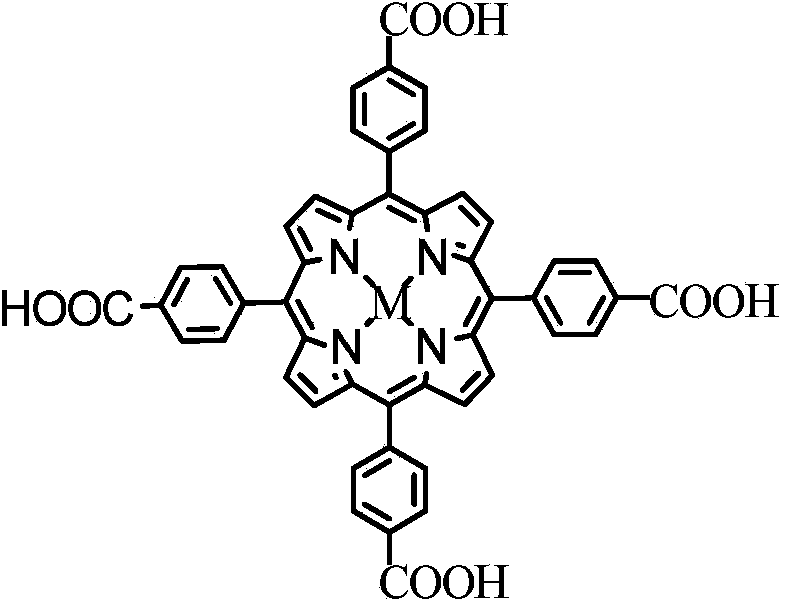

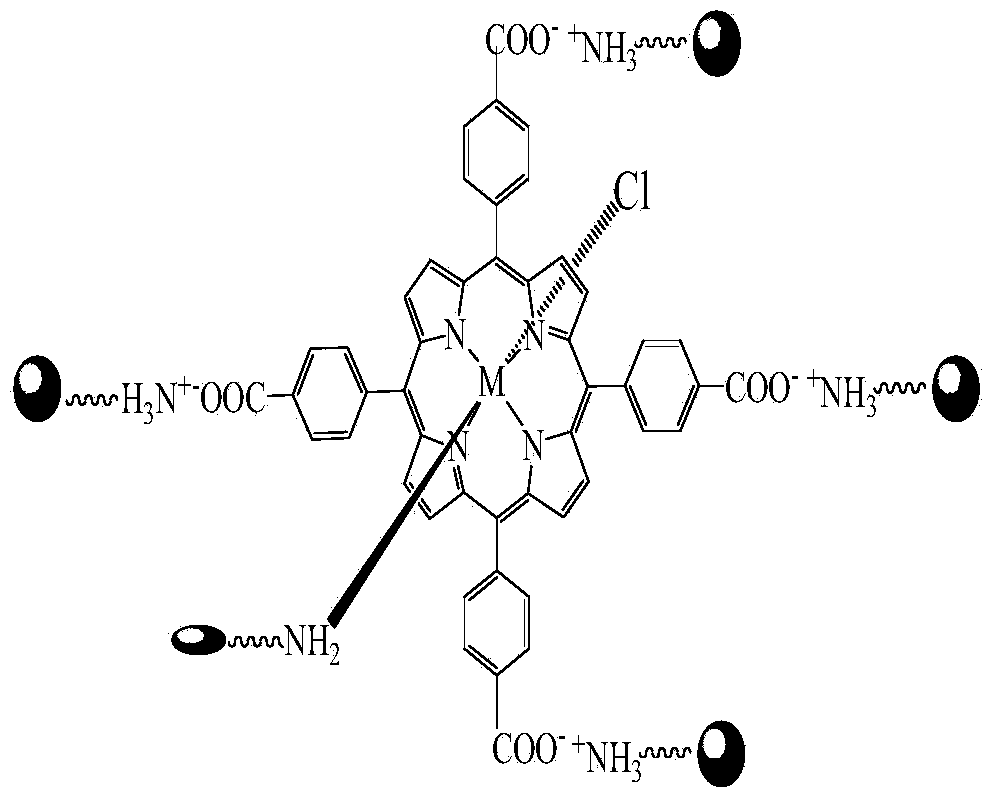

Preparation method and application for chitosan-grafted quadri(p-carboxylphenyl) metalloporphyrin

InactiveCN103554302ASource friendlyLow pricePreparation by oxidation reactionsOrganic compound preparationN dimethylformamidePorphyrin

The invention discloses a preparation method and an application for chitosan-grafted quadri(p-carboxylphenyl) metalloporphyrin. The preparation method comprises the following steps: adding metalloporphyrin in a three-neck flask filled with dichloromethane and N,N-dimethylformamide, charging dry nitrogen, adding thionyl chloride, and heating and stirring; adding chitosan powder and dichloromethane, reacting under heating reflux; performing suction filtration, washing by dichloromethane, then washing off the unamidated metalloporphyrin in a filter cake in a Soxhlet extractor; and performing vacuum drying on the filter cake to obtain the chitosan-grafted quadri(p-carboxylphenyl) metalloporphyrin. The catalytic material, namely the chitosan-grafted quadri(p-carboxylphenyl) metalloporphyrin is simple in preparation method and used for catalyzing ethylbenzene oxidation, easy to separate from a catalytic oxidation product, and capable of being recovered and repeatedly used for catalyzing for at least four times, as well as has an average conversion rate of 13.79-18.42% for ethylbenzene and an average productivity of 10.87-15.51% of ketone alcohol (the sum of acetophenone and 1-phenethyl alcohol).

Owner:GUANGXI UNIV

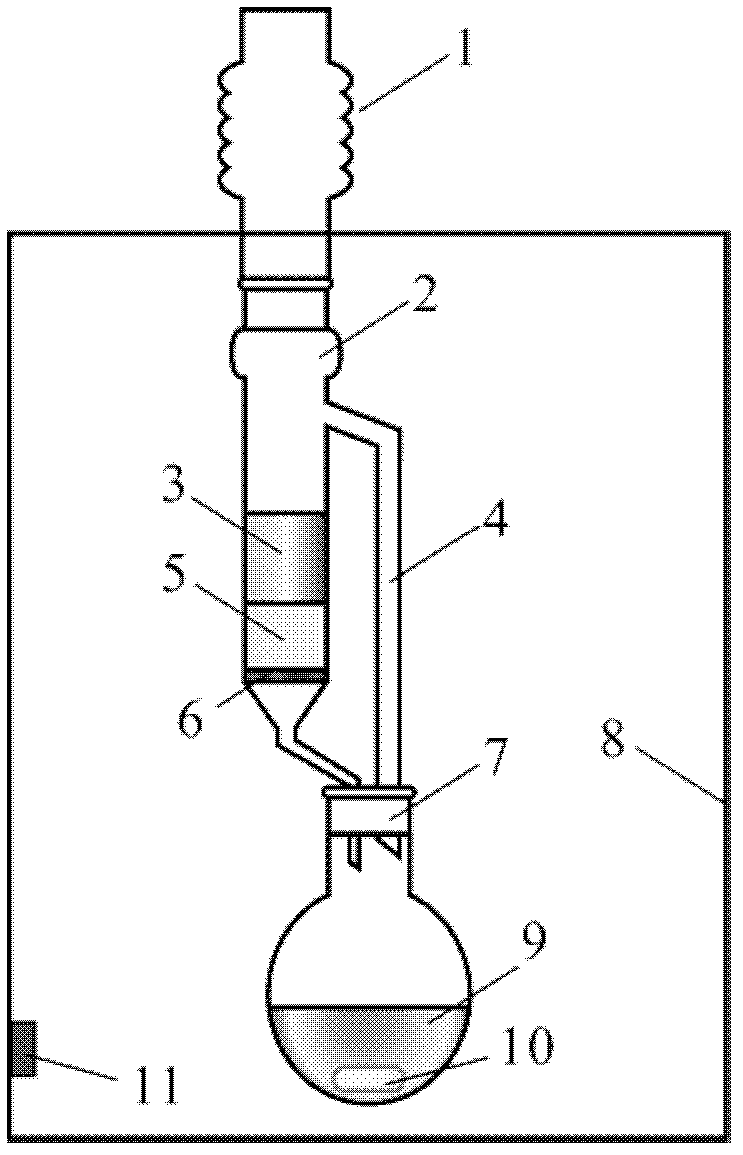

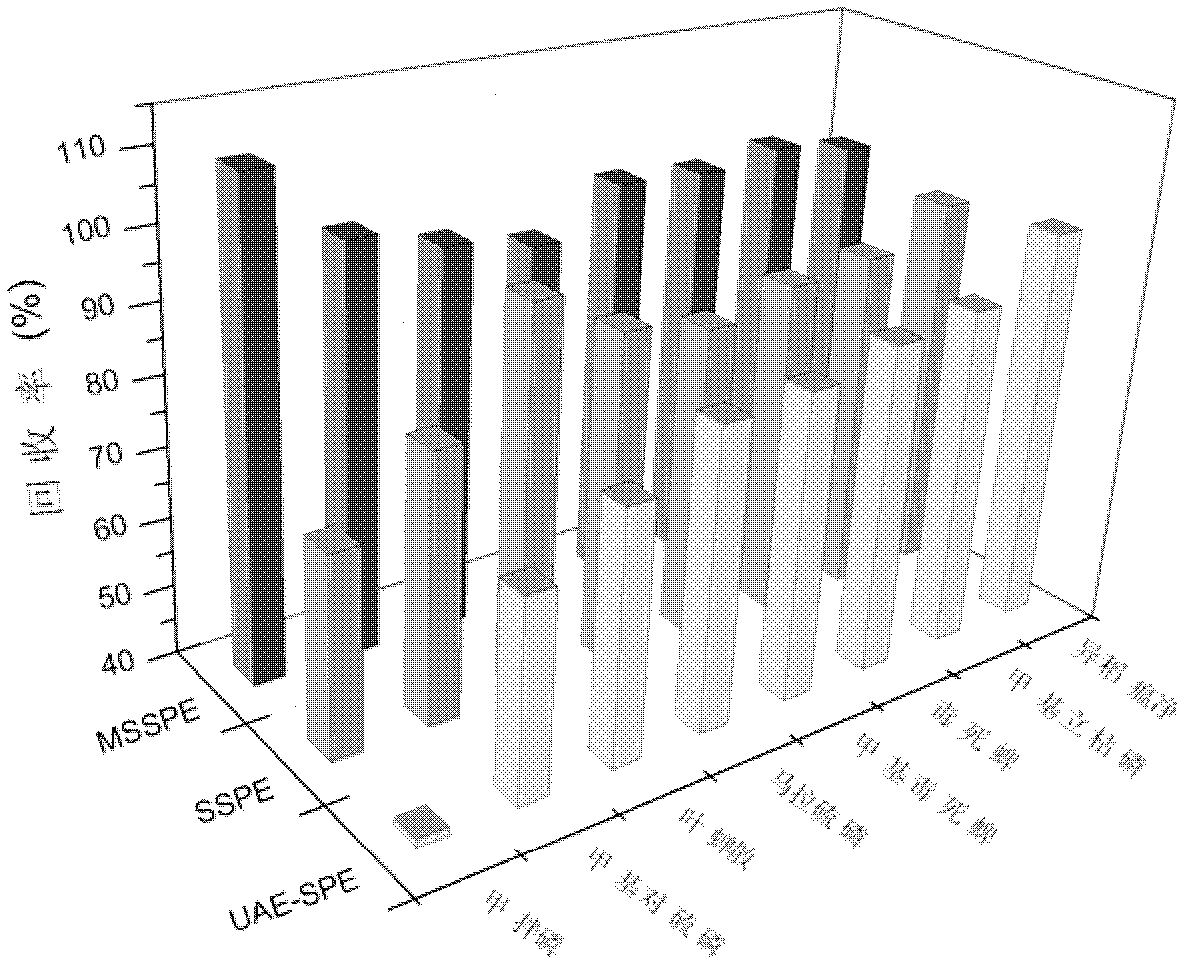

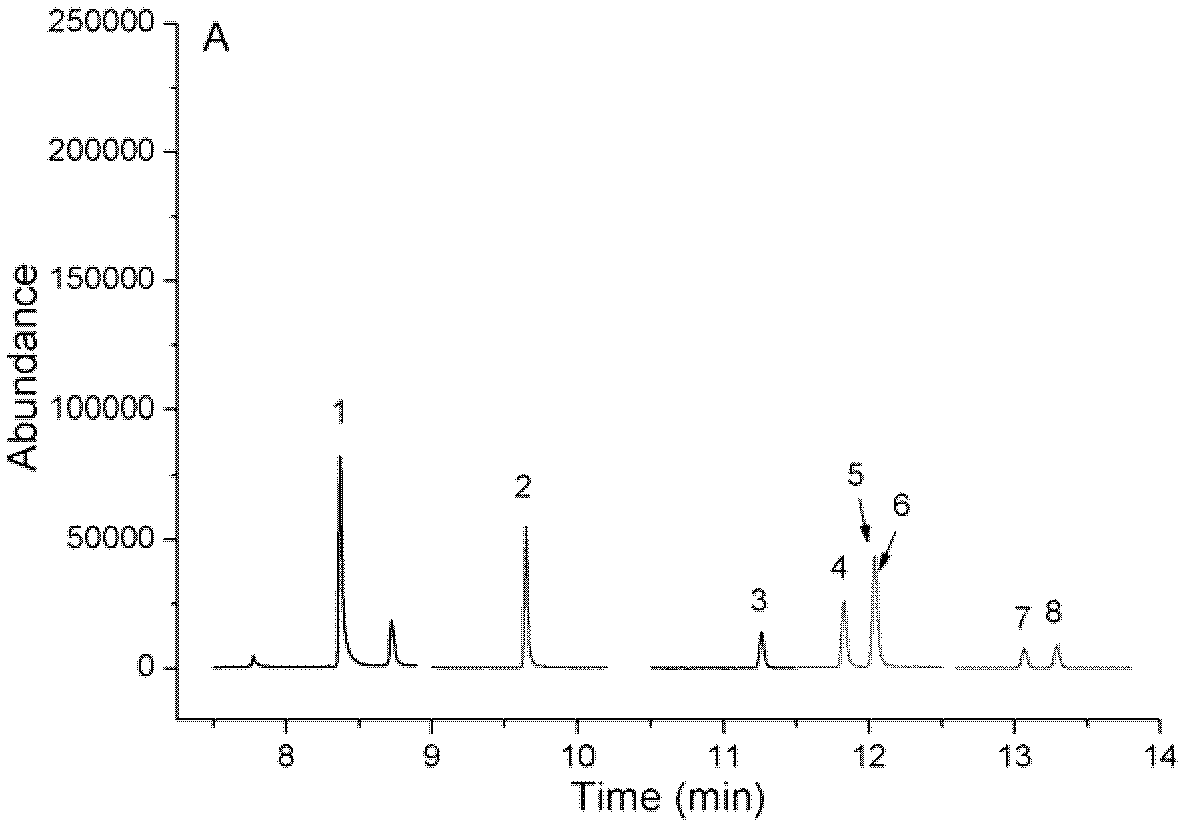

Microwave-assisted Soxhlet and solid-phase extraction coupling device, microwave-assisted Soxhlet and solid-phase extraction coupling method and application of microwave-assisted Soxhlet and solid-phase extraction coupling

The invention discloses a microwave-assisted Soxhlet and solid-phase extraction coupling device, a microwave-assisted Soxhlet and solid-phase extraction coupling method and application of microwave-assisted Soxhlet and solid-phase extraction coupling. The microwave-assisted Soxhlet and solid-phase extraction coupling device comprises a microwave-assisted extractor, a Soxhlet extractor, solid-phase adsorbents, an extraction bottle, a reflux condensing pipe and the like, and extraction and purification are synchronously completed by means of coupling microwave-assisted Soxhlet extraction and solid-phase extraction. When in extraction, the solid-phase adsorbents are filled into a Soxhlet extraction device, the extraction bottle is directly placed in the microwave-assisted extractor for extraction after extraction solvents are added into the extraction bottle, analytes are collected into the extraction solvents, and interfering components in samples are adsorbed by the solid-phase adsorbents. High efficiency of microwave-assisted extraction, universality of Soxhlet extraction and high selectivity of solid-phase extraction are combined, the device is simple and convenient in operation, is conveniently used with an analysis instrument, and is suitable for extraction and purification of trace organics in complicated samples.

Owner:SUN YAT SEN UNIV

Metal ion imprinting solid phase extraction small column, preparation and application thereof

InactiveCN101623564AImprove adsorption capacityHigh adsorption selectivityIon-exchange process apparatusOther chemical processesFunctional monomerSorbent

The invention relates to a metal ion imprinting solid phase extraction small column, which comprises the small column which takes a metal ion imprinting absorbent of 50-200mg as a filling matrix and has a polypropylene outer shell with the diameter of 6-10mm; and the preparation comprises the steps of dissolving metal ions, CTMAB and functional monomers in DDW, adding a mixed sol of alkoxy silane and methanol, further adding a catalyst, stirring, filtering and drying; then placing in a Soxhlet extractor, removing the CTMAB and the metal irons, washing and drying for preparation; and weighing the metal ion imprinting absorbent, filling in the solid phase extraction small column with the polypropylene outer shell and filling the column by homogenization under the vacuum-pumping state. The filler synthesis process of the solid-phase extraction small column is simple, the cost is low, the reaction conditions are mild, the prepared metal ion imprinting solid phase extraction small column can be applied in selective separation and enrichment of trace metal ions in environmental water samples, compared with the ordinary liquid-liquid extraction method, the operation is simple, rapid and highly efficient.

Owner:DONGHUA UNIV

Polluted water body heavy metal adsorption material and preparation method thereof

InactiveCN101497031AGood removal effectGood effectOther chemical processesWater/sewage treatment by sorptionAcrylonitrileCadmium Cation

The invention discloses a method for preparing a heavy metal adsorption material for polluted water. The method comprises that: corn stalk or straw stalk is used as a raw material; under conditions of the temperature of between 40 and 90 DEG C, using 0.0025 to 0.03mol / L potassium permanganate as an initiator, 0.1 to 3.0mol / L acrylonitrile as a monomer and 0.1 to 3.0 percent of nitrogen and nitrogen-methylene-bisacrylamide as crosslinking agents, the raw material is subjected to graft copolymerization, and under the condition of using 1 to 25 mmol / L sulfuric acid as a catalyst, the raw material is subjected to graft copolymerization for 1 to 6 hours; the reaction product is washed by ethanol, suction-filtered, and dried to obtain a coarse product; and the coarse product is placed in a soxhlet extractor to continuously extract the grafting product for 42 to 48 hours, washed by ethanol, washed by deionized water until the pH value is between 6.5 and 7.0 and dried to obtain the heavy metal adsorption material for polluted water. The adsorption material has better adsorption capability on the heavy metal cadmium ions.

Owner:SOUTH CHINA UNIV OF TECH

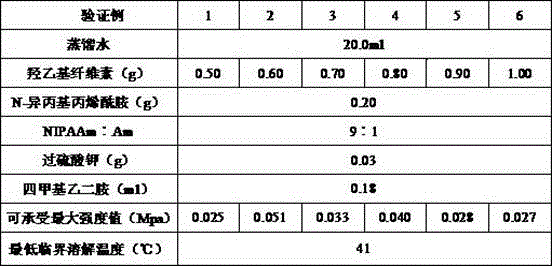

Drug-loading thermosensitive hydrogel

InactiveCN106065048ANo harmEnhanced network structureAerosol deliveryOintment deliveryCross-linkEpoxy

Drug-loading thermosensitive hydrogel. Raw materials for preparation of the drug-loading thermosensitive hydrogel contain N-isopropylacrylamide, acrylamide and hydroxyethyl cellulose. Corresponding steps contain: dissolving hydroxyethyl cellulose in distilled water; adding an intermixture of N-isopropylacrylamide and acrylamide into a hydroxyethyl cellulose solution; adding an initiator potassium peroxodisulfate and an additive tetramethylethylenediamine, and introducing nitrogen for protection so as to obtain a grafting product; drying the grafting product, and extracting in an extractor by using acetone as an extractant; dissolving the purified grafting product in distilled water, adding sodium hydroxide and a cross-linking agent epoxy chloropropane, and carrying out magnetic stirring to obtain a drug-loading thermosensitive hydrogel semi-finished product; and soaking the semi-finished product in deionized water to obtain the drug-loading thermosensitive hydrogel with lower critical solution temperature being 37-41 DEG C. the product has equal level of mechanical strength in comparison with the prior art. In addition, the preparation is more convenient to operate, and time cost is saved.

Owner:CHONGQING UNIV

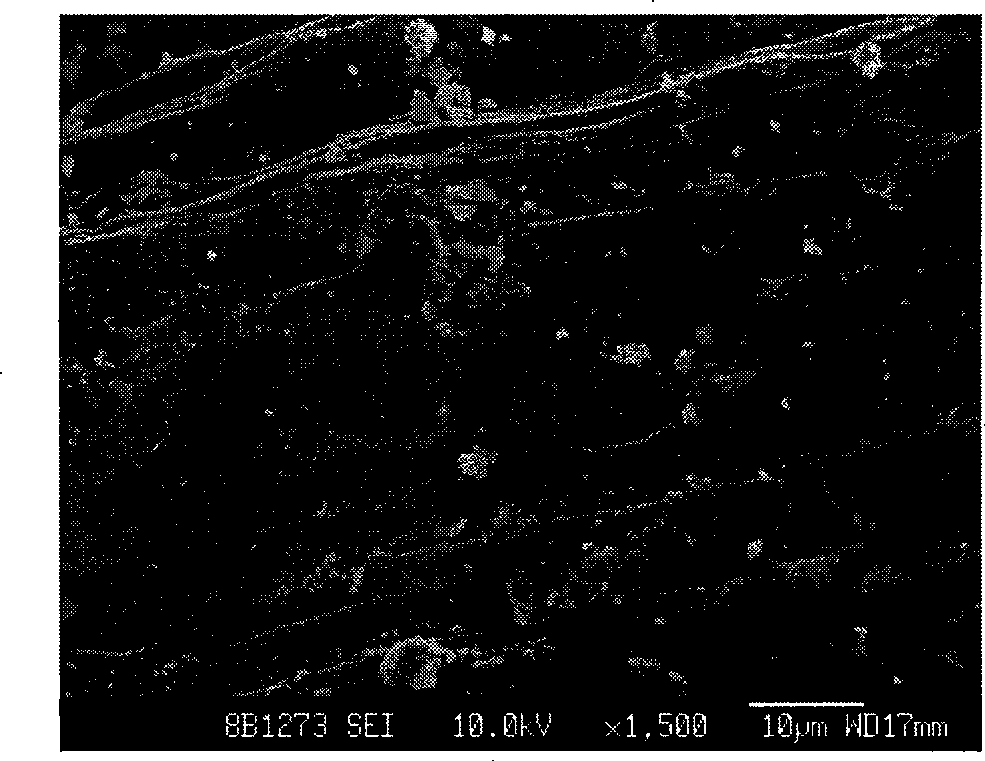

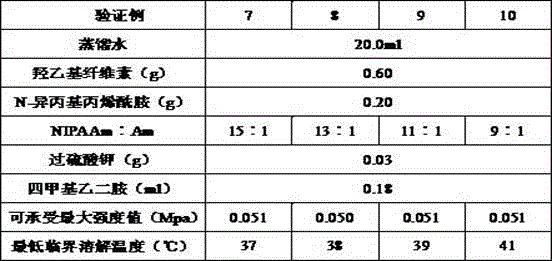

Electronic beam radiopolymerization process of directly synthesizing temperature sensitive hydrogel

The present invention is electronic beam radiopolymerization process of synthesizing temperature sensitive hydrogel directly, and belongs to the field of temperature sensitive hydrogel preparing technology. Material monomer, cross-linking agent and additive in the weight ratio of 75-98.5 to 0.1-1 to 1-10 are dissolved in deionized water and polymerized through electron radiation to form cross-linked polymer. The cross-linked polymer is then extracted in a Soxhlet extractor with boiled deionized water for 24 hr and dried in a vacuum oven to obtain the temperature sensitive hydrogel. The temperature sensitive hydrogel may be used in medicine controlled releasing system, memory element switch, artificial muscle, chemical separation and other field. The present invention has the features of simple technological process, high polymerization efficiency, less pollution, low cost, normal temperature operation, etc.

Owner:TSINGHUA UNIV

Method for preparing high-oil absorption resin

The invention discloses a method for preparing high-oil absorption resin, which is characterized by adding a dispersant of polyvinyl alcohol, a precipitating reagent of cyclohexane, an emulsifying agent of sodium dodecylbenzene sulphonate, a single body of butyl methacrylate and stearyl methylacrylate, an initiator of potassium persulphate into deionized water, introducing nitrogen for deoxygenation, performing suspended emulsion polymerization, after reaction for a certain time, adding a cross-linking agent of diallyl phthalate, continuously reacting for at least two hours, performing cooling, separation, extraction by using an Soxhlet extractor for at least 12 hours and vacuum drying to obtain the products. By the aid of the preparation method of the invention, porous high-oil absorption resin can be obtained, which has oil-absorption capability to toluene reaching up to 24, and can be applied to the field of environmental protection and the like.

Owner:LUDONG UNIVERSITY

Synthetic process of rhodium caprylate dimer

ActiveCN101353301AReduce churnShort reaction timeCarboxylic acid salt preparationOctanoic AcidsChloride

A synthetic process of a rhodium octanoate dimer comprises the following two steps: firstly, a DMF solvent of rhodium chloride is added to acetate solution of acetate dimethylamine to generate (Me2NH2]2[Rh2(CH3COO)4Cl2) which is heated in hot water to prepare (Rh2(CH3COO)4).2H2O; then the (Rh2(CH3COO)4).2H2O is dissolved in hot toluene to obtain the rhodium acetate dimer; secondly, the rhodium octanoate dimer is synthesized by a soxhlet extractor. By adopting the method of exchanging and separating the octanoic acid and the acetate dimmer at the same time, chlorobenzene backflow is utilized to keep the system at constant temperature to obtain a pure product of the rhodium octanoate dimer. The synthetic process is characterized by high reaction yield, high product purity, less loss of precious metals, etc.

Owner:浙江微通催化新材料有限公司

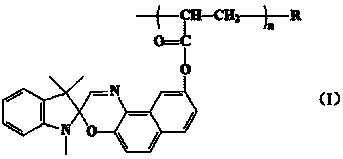

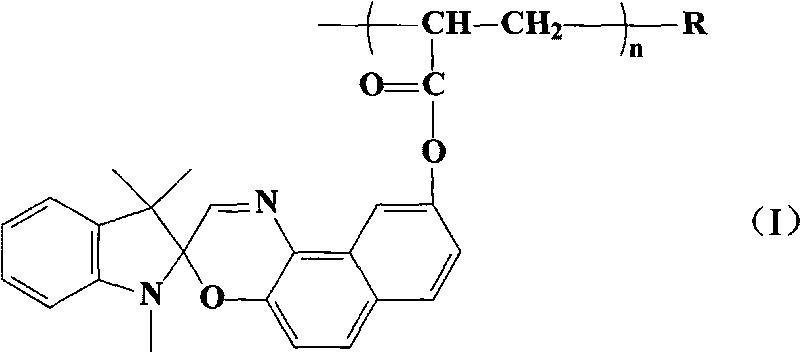

Nitrated cellulose grafted by spirooxazine group and preparation method thereof

The invention discloses a nitrated cellulose grafted by spirooxazine group, which is shown by structural formula (I), wherein R is nitrated cellulose, and n is equal to 1-100; and the invention also discloses a preparation method of the nitrated cellulose, which comprises: dissolving the nitrated cellulose into methylisobutylketone, and obtaining mixture A; adding acrylic ester dye monomer containing the spirooxazine group into the mixture A, filling nitrogen for protection, evenly stirring, heating up to 70 DEG C, adding benzoyl peroxide for initiating polymerization reaction, reacting for 3.0h, cooling in ice water bath, and obtaining mixture B; using petroleum ether to lead impure graft to be precipitated, and using benzene to extract the graft for 48.0h in a Soxhlet extractor; and finally, removing dye homopolymer, carrying out vacuum drying at 60 DEG C, and obtaining high polymer of the nitrated cellulose. The high polymer has good photochromic performance, and can be used for preparing a photochromic film and coating. On the molecular level, the nitrated cellulose is a homogeneous system, and the spirooxazine can not be separated from the nitrated cellulose after a long-term use.

Owner:SHAANXI TECHN INST OF DEFENSE IND

Sterilizing deodorant made of attapulgite and preparation method

InactiveCN106823678AExtended service lifeCause some damagesBiocideGas treatmentAlcoholAcorus calamus

The invention discloses a sterilizing deodorant made of attapulgite and a preparation method and belongs to the technical field of attapulgite. The sterilizing deodorant comprises the following components: attapulgite clay, shale diatom ooze, folium artemisiae argyi, rhizoma atractylodis, pyrethrum, liquorice, cortex cereis, croton, acorus calamus, cortex moutan, fructus cnidii, artemisia apiacea, clove oil, tea tree essential oil and mint essential oil. The preparation method comprises the following steps of: taking and crushing Chinese herbal medicine components, mixing and obtaining a Chinese herbal medicine mixture; putting the Chinese herbal medicine mixture into a Soxhlet extractor, extracting in a mixed solvent of alcohol and water and obtaining extracting liquid; and then preparing thermally-modified attapulgite clay; and then putting the thermally-modified attapulgite clay in the extracting liquid, adding the clove oil, the tea tree essential oil and the mint essential oil, soaking under the stirring condition, then adding the shale diatom ooze, mixing uniformly, drying and grinding. The sterilizing deodorant disclosed by the invention not only has the high-performance sterilization and deodorization, but also has longer service life, is simple and easy in preparation method and has better application value.

Owner:明光市安盛非金属材料厂

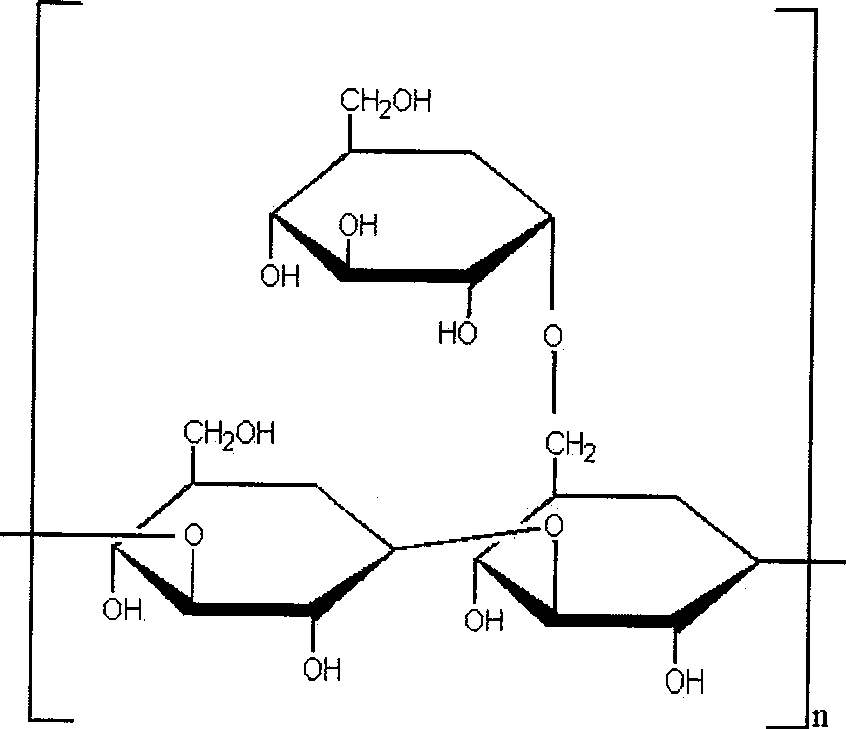

Method for extracting triple helix Dictyophora phalloidea polysaccharide

The invention relates to an extraction method for triple helical edible fungus amylase, the specific steps of which are that firstly, crashed natural bamboo fungus is degreased with an organic solvent in a soxhlet extractor, secondarily, the residue is sequentially extracted with water in the gradient temperature of 20-80 DEG C, filtered to obtain filtrate, and repeated for three times; the supernatant fluid is taken by decentralization to obtain an extraction solution; the proteic extraction is carried out on the extraction solution by a Sevage method, and then the extraction solution is respectively dialyzed with clear water and secondary distilled water after being decolored by H2O2, and after the DEAE pillar removes the acidic polysaccharide, the solution is frozen and dried to obtain the white cotton-shaped triple helical edible fungus amylase. The extraction method is easy to be implemented; and the product has high purity, is discovered for the first time and verifies the triple helical structure of the edible fungus amylase, and has wide application prospect in the aspects of medicine and material.

Owner:WUHAN UNIV OF TECH

Method for preparing grafted bagasse xylan copolymer

The invention discloses a method for preparing a grafted bagasse xylan copolymer. Bagasse xylan, acrylamide and butyl acrylate are fed according to a xylose unit, acrylamide and butyl acrylate molar ratio equaling to 1 : (0.5-2) : (0.5- 2.0), and the method comprises the following steps of: firstly adding the bagasse xylan and a solvent into a reaction kettle for uniformly mixing, controlling a pH value of a reaction at 6-9, and reacting for 0.5-1 hour at a room temperature; adding an initiating agent and a composite cross-linking agent, then adding the acrylamide dissolved by using the solvent and mixing with the butyl acrylate to obtain a mixture, adding the mixture in the reaction system and reacting for 6-10 hours at 40-70 DEG C; regulating the pH value of the reaction system to be neutral, and performing suction filtering while the reaction system is hot; repeatedly washing a product by using a 80-95 percent ethanol water solution for 2-3 times, placing in a vacuum drying oven, and drying for 12 hours at 60 DEG C and then naturally cooling along with the oven to obtain a crude copolymer; and extracting the crude copolymer to obtain a pure grafted copolymer by using an Saxhlet extractor. The invention has the advantages of simple process flow, easiness for controlling reaction condition, high raw material utilization ratio, low energy consumption, high attached value and wide application range.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

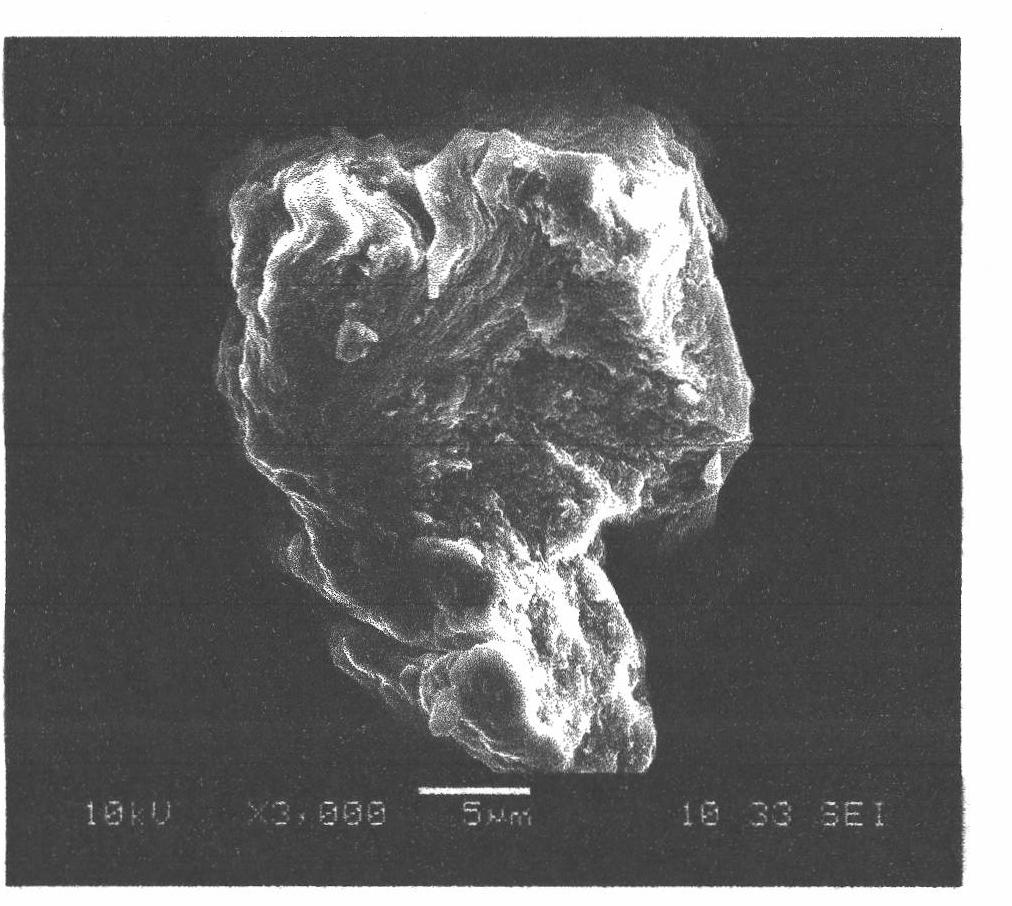

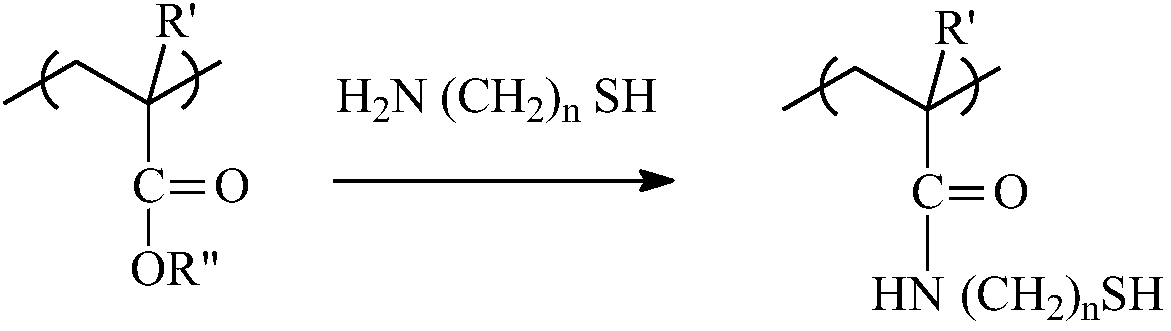

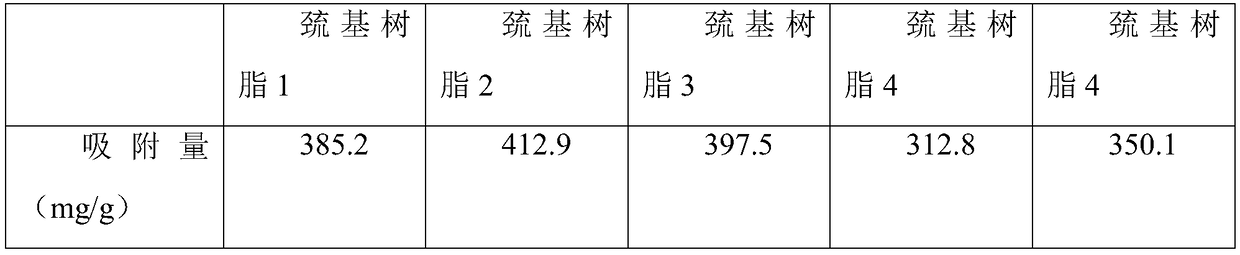

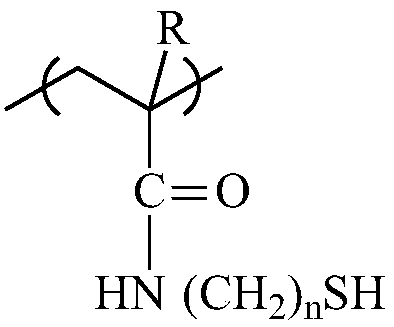

Preparation method of mercury ion adsorption resin

InactiveCN109289807ASimple preparation processLow costOther chemical processesAlkali metal oxides/hydroxidesCross-linkIon exchange

Belonging to the technical field of ion exchange resin, the invention specifically relates to a preparation method of a mercury ion adsorption resin. The steps include: mixing a functional group monomer containing double bonds and ester group, a cross-linking agent, a pore-forming agent and an initiator, and performing dissolution to obtain an oil phase; then dissolving a dispersant and sodium chloride in water to obtain an aqueous phase, finally dispersing an oil phase in the aqueous phase, performing stirring to disperse the oil phase into oil droplets in the aqueous phase, performing stirring, controlling the diameters of the oil droplets, conducting heating for polymerization reaction to get obtain a post-polymerization product, and performing cleaning with hot water; then conducting extraction in a Soxhlet extractor, and performing cooling and drying to obtain white spheres; under the protection of nitrogen, adding cysteamine hydrochloride into a solvent for dissolution, conducting stirring, adding triethylamine or a sodium hydroxide solution, then adding the white spheres, carrying out heating reflux reaction, and performing cooling, filtering and washing to obtain the mercury ion adsorption resin. The mercury ion adsorption resin prepared by the method provided by the invention can achieve a mercury ion adsorption capacity up to 412.9 mg / g, the adsorption effect is outstanding, and the application prospects are broad.

Owner:扬州金珠树脂有限公司

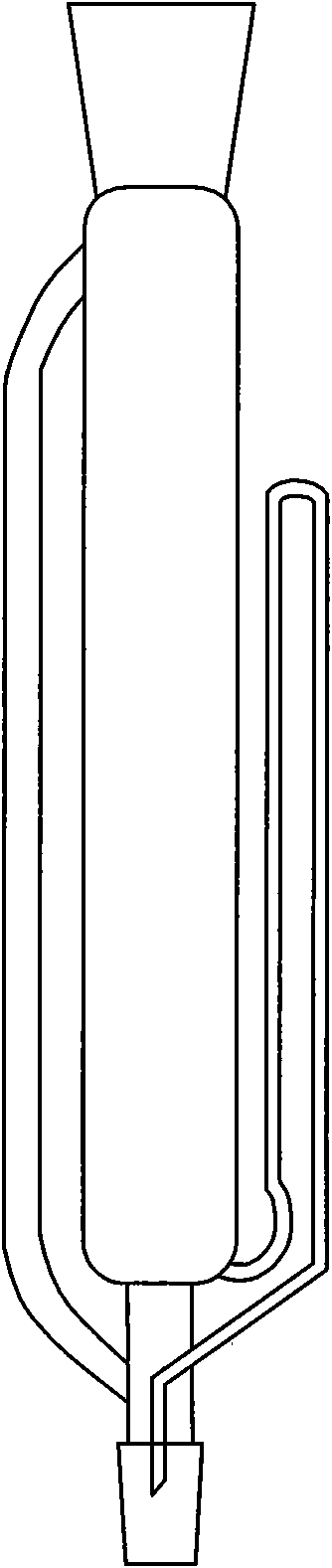

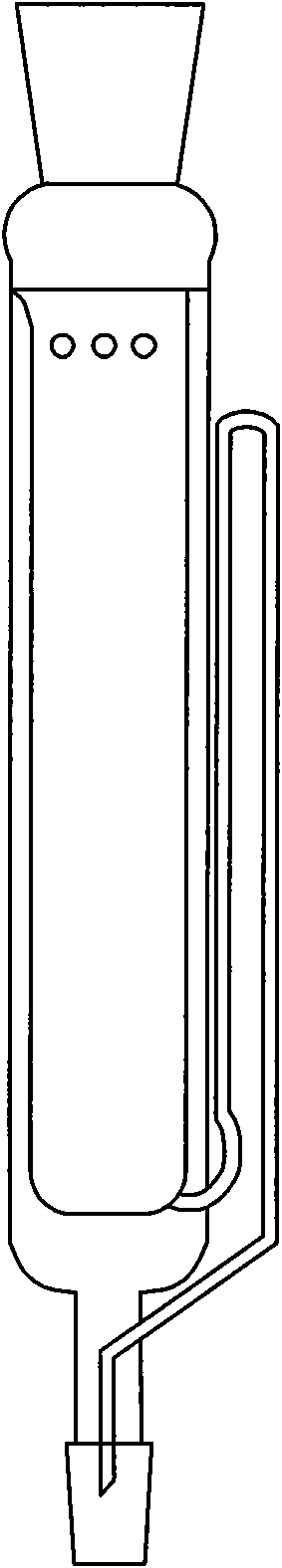

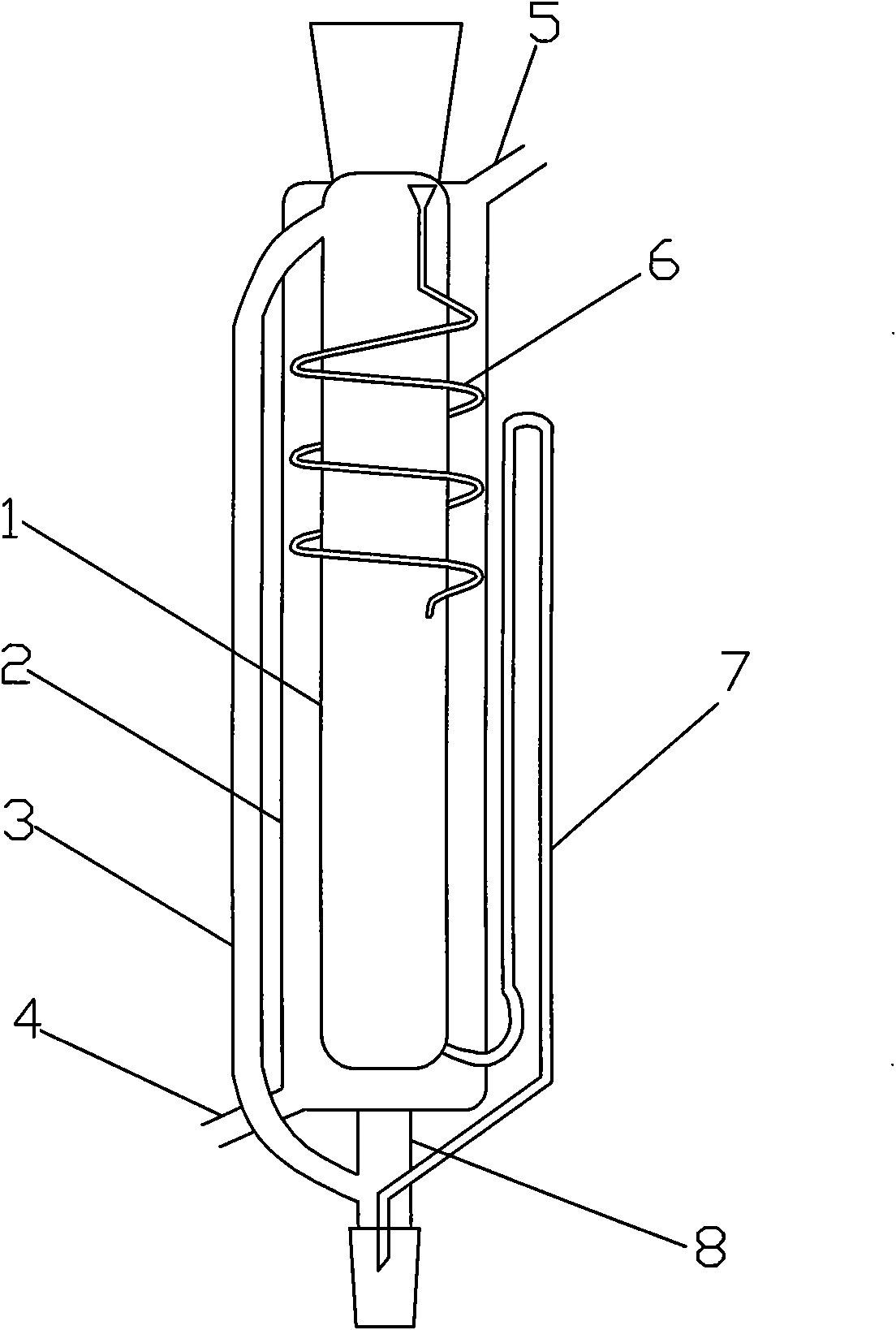

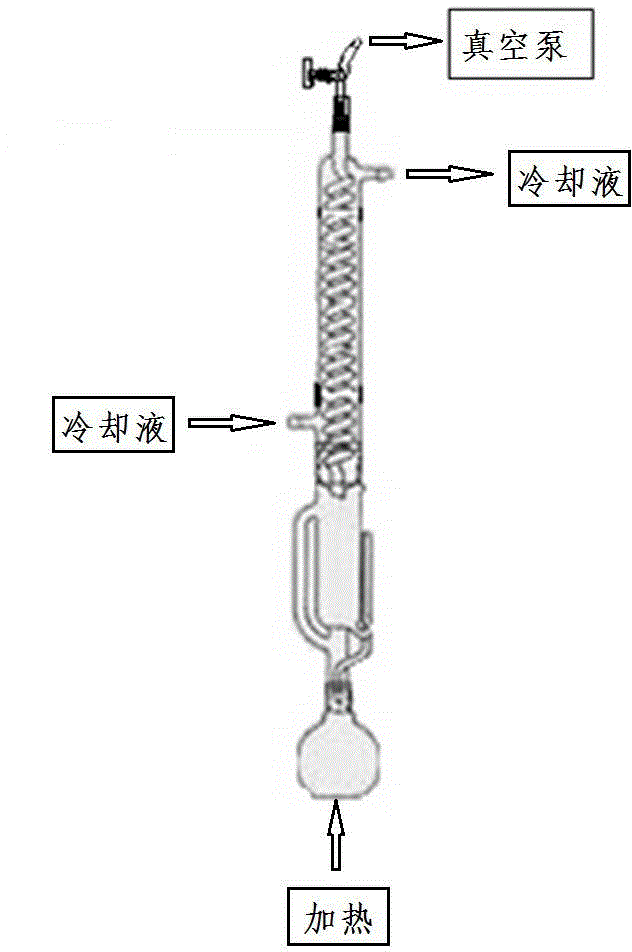

Temperature controlled Soxhlet extractor

ActiveCN101940849ATemperature controlGuaranteed stabilitySolid solvent extractionTemperature controlSoxhlet extractor

The invention relates to a Soxhlet extractor, particularly relating to a temperature controlled Soxhlet extractor. The temperature controlled Soxhlet extractor comprises an external pipe and an internal pipe which are arranged in a sheathing manner; one end of the external pipe is provided with a temperature control liquid inlet; the other end of the external pipe is provided with a temperature control liquid inlet; a ground connecting end is arranged at the lower part of the external pipe; a branch pipe is arranged between the upper part of the internal pipe and the ground connecting end; a syphon pipe is arranged at the bottom of the internal pipe; a coiled pipe is arranged between the external pipe and the internal pipe; and the pipe body of the coiled pipe is positioned in the interlayer between the external pipe and the internal pipe. In the invention, the internal pipe is sheathed in the external pipe; the temperature control liquid circulates in the interlayer between the external pipe and the internal pipe to lead the internal pipe to keep a certain temperature; the coiled pipe is arranged between the external pipe and the internal pipe; the pipe body of the coiled pipe is arranged in the interlayer between the external pipe and the internal pipe; the condensed and refluxed solvent flows into the internal pipe after passing through the coiled pipe, thus the condensed solvent is controlled at a certain temperature through the temperature control liquid, so as to lead the extracting process to be performed at the required temperature.

Owner:CHINA TOBACCO HENAN IND

Method for preparing paprika red pigment by ultrasonic pre-treatment

InactiveCN102807770AReduce usageReduce extraction timeNatural dyesAqueous sodium hydroxidePre treatment

The invention discloses a method for preparing paprika red pigment by ultrasonic pre-treatment. The method comprises the steps of: selecting red chillies from Chengdu, Sichuan, removing pedicles and seeds, drying, crushing, screening by a 40meshes of standard screen, so as to obtain dry chilli powder; adding acetone in the dry chilli powder, carrying out pre-treatment by ultrasonic wave; adding the pre-treated material in a Soxhlet extractor, leaching and extracting for 3h at the temperature being 50 DEG C, conducting filter separation and decompression concentration so as to obtain chilli oil resin; adding ethanol in the chilli oil resin, extracting to obtain paprika red pigment rough product; adding sodium hydroxide aqueous solution in the paprika red pigment rough product, then adding normal hexane, adjusting pH value to be 3 by hydrochloric acid, conducting centrifugal separation, decompressing concentrating and drying so as to obtain the paprika red pigment product. According to the method, the industrial mass production is realized, and the prepared paprika red pigment product has the characteristics of high extracting speed, high purity, and the like.

Owner:JIANGSU UNIV OF SCI & TECH

Method for recovering lac and extracting lac wax

InactiveCN101392147AMeet lacFulfil requirementsFatty substance recovery/refiningNatural resin processWaxOrganic solvent

The invention relates to a method for recovering a lac and extracting a lac-wax, which comprises: water or a dilute sodium carbonate solution is utilized for dissolving red dregs containing the lac and the lac-wax which are generated during the production process of a bleached lac, the dissolving temperature is between 70 DEG C and 100 DEG C and heat filtration is carried out so as to obtain a sodium carbonate solution containing the lac and the lac-wax removed from lots of mechanical substances; the solution is cooled and a dilute sodium hypochlorite solution is added for bleaching; the bleached solution stands to separate into layers and a lac-wax crude product is obtained by taking out the surface coagulum; the solution is filtered with diatomite or active floridin, the filtrate is added with dilute sulphuric acid so as to separate out a white floc and a bleached lac-wax is obtained after washing, solid-liquid separation and drying; the lac-wax crude product is covered with a piece of filter paper or filter cloth and put into a soxhlet extractor, an organic solvent is added to carry out refluxing extraction so as to obtain a mixture of organic substances and the lac-wax; the mixture of the organic substances and the lac-wax is carried out with normal pressure or reduced pressure volatilization and distillation and after the organic solvent is recovered, the rest is cooled and a refined lac-wax product is obtained.

Owner:KUNMING UNIV OF SCI & TECH

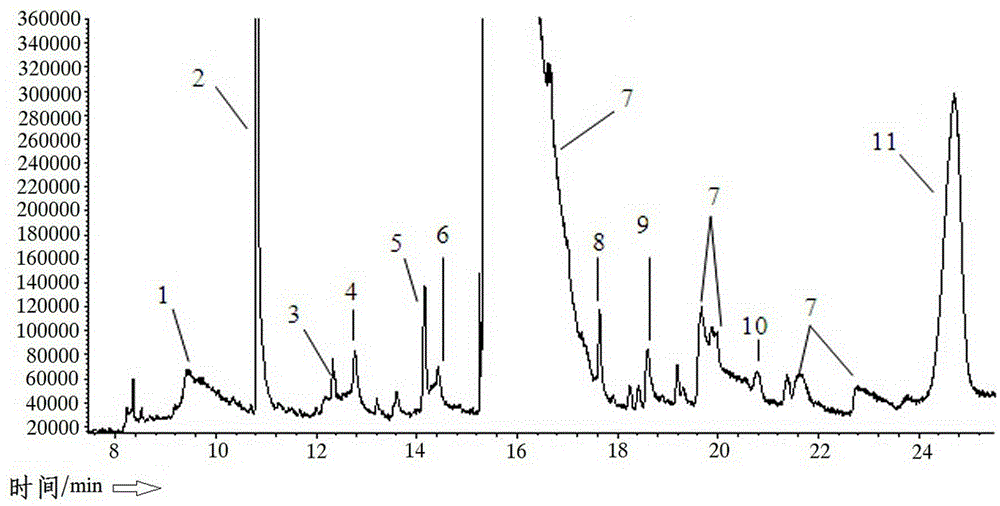

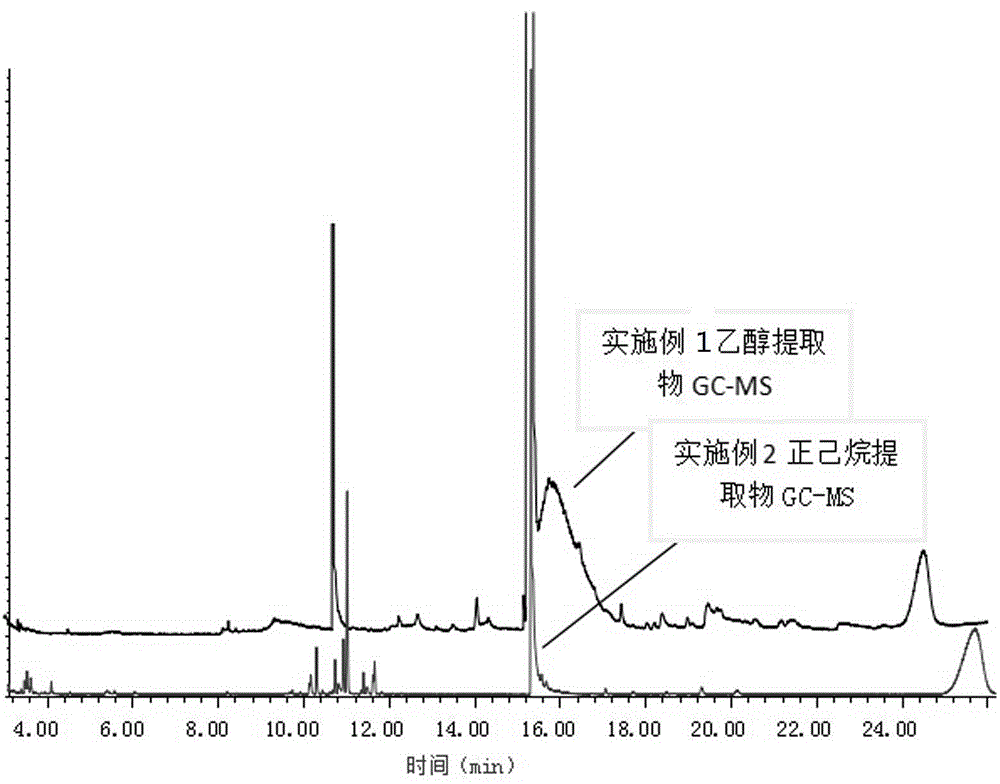

Burley tobacco extractive, electronic tobacco juice and tobacco extraction method

ActiveCN104621708ALower boiling temperatureLow heating temperatureTobacco treatmentEssential-oils/perfumesNicotiana tabacumChemical reaction

The invention relates to burley tobacco extractive, electronic tobacco juice and a tobacco extraction method. The raw materials of the burley tobacco extractive are tobacco leaves, cut tobacco leaves, tobacco powder and / or tobacco ash of burley tobacco, and Soxhlet extraction is carried out on the raw materials by adding an extraction solvent in a Soxhlet extraction device. The tobacco extraction method is characterized in that a condensation pipe of the Soxhlet extraction device is connected with a vacuum pump, and the vacuum degree of the Soxhlet extraction device keeps at 20-80 mmHg; the temperature of condensate in the condensation pipe is below minus 5 DEG C; after Soxhlet extraction, an extraction solution is collected and concentrated to obtain the burley tobacco extractive. The whole Soxhlet extraction system is in a negative pressure state, the boiling point of the extraction solvent is lowered, the extraction temperature is lowered, circulation of the solvent is accelerated in the extraction process, the extraction frequency is improved, and efficiency is higher. As the heating temperature of the solvent is lower, the extraction conditions are milder, extreme chemical reaction among aroma components in the extractive caused by high-temperature heating of the solvent is avoided, and less impurity gas in the extractive is generated.

Owner:CHINA TOBACCO HUNAN INDAL CORP

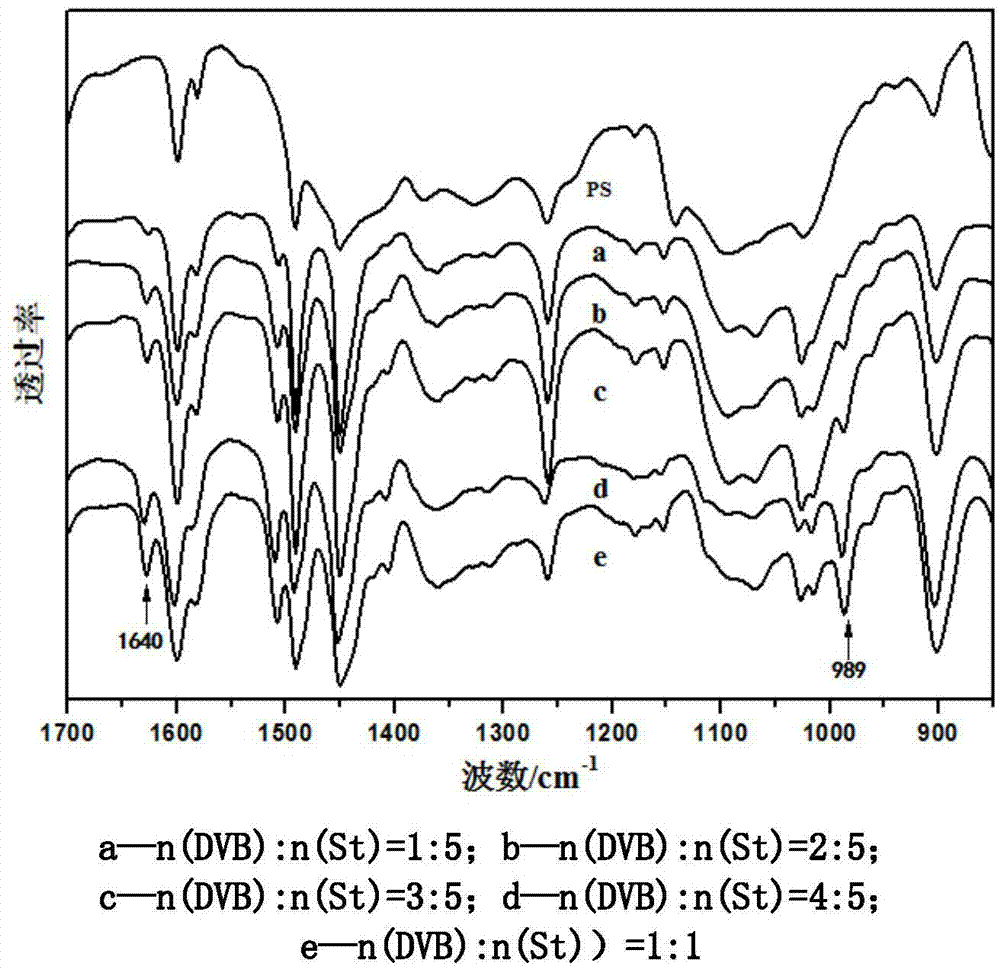

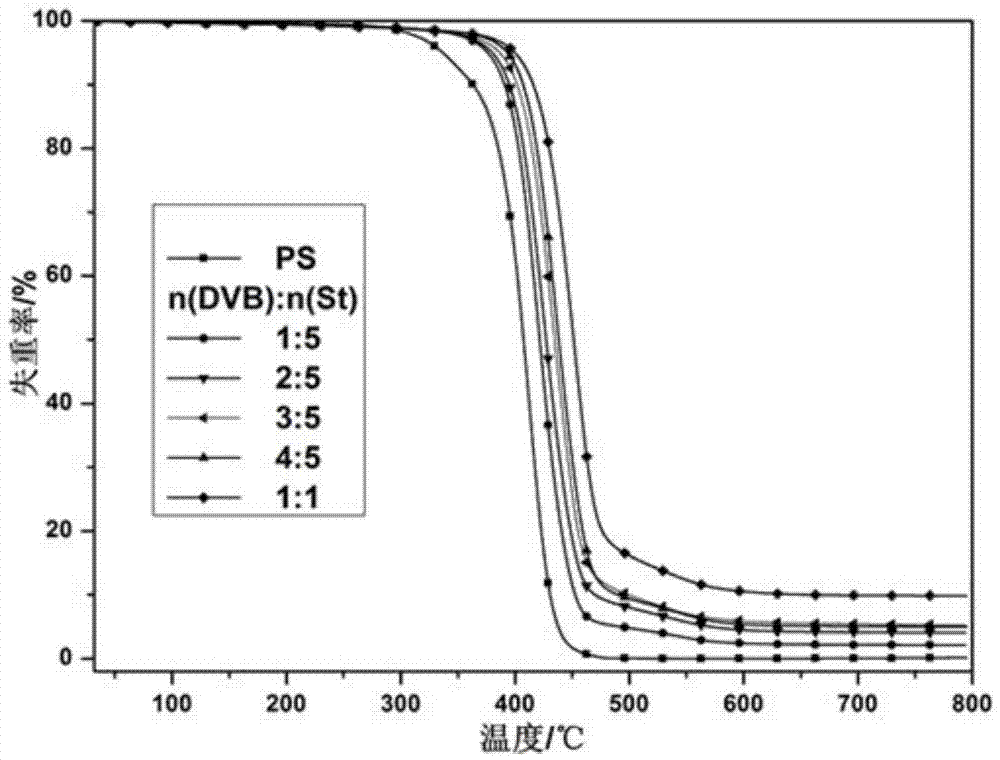

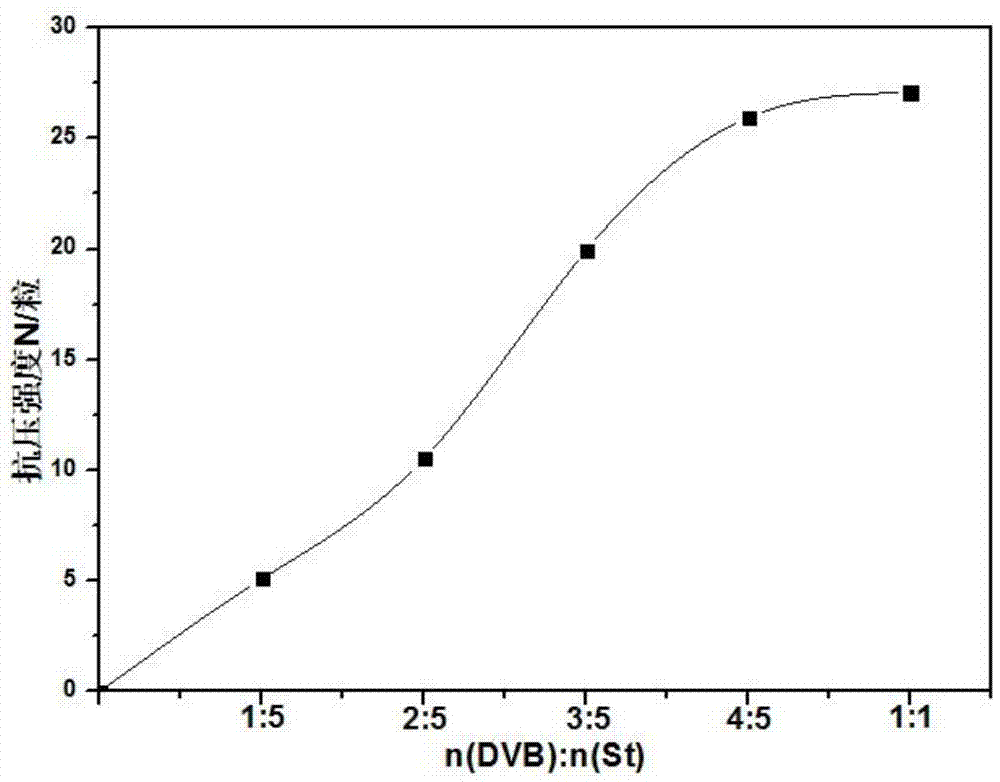

Preparation method of styrene-divinylbenzene copolymer hydrophobic catalyst support

The invention discloses a preparation method of a styrene-divinylbenzene copolymer hydrophobic catalyst support, which is characterized by comprising the following steps: adding deionized water, organic matter polyvinyl alcohol-1799, inorganic salt and sodium dodecyl benzene sulfonate into a reaction vessel, heating to 25-40 DEG C while stirring, adding a mixture of styrene, divinylbenzene, benzoperoxide, toluene, n-heptane and dichloroethane, heating to 70-90 DEG C, carrying out suspension polymerization reaction for 7-9 hours while stirring, and filtering; and washing the reaction solid with deionized water and anhydrous ethanol, extracting with acetone in a Soxhlet extractor for 12-48 hours, washing the solid with methanol and deionized water, drying, and screening to obtain the styrene-divinylbenzene copolymer hydrophobic catalyst support. The Pt / SDB hydrophobic catalyst prepared by using the product as the support has favorable use effect when being used for heavy water tritium extraction and wastewater detritiation.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com