Polluted water body heavy metal adsorption material and preparation method thereof

A technology for adsorbing materials and heavy metals, applied in the fields of phytochemistry and adsorption science, can solve problems such as destroying ecological balance, existing fire hazards, and polluting the environment, and achieves good adsorption capacity, significant removal effect, and good adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

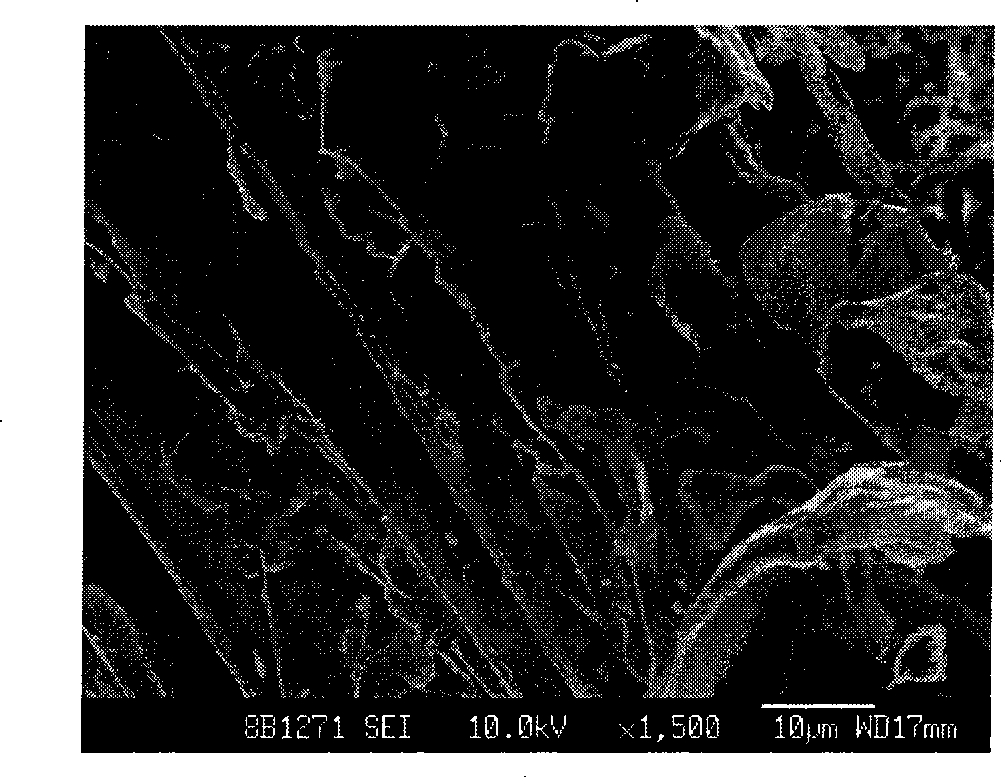

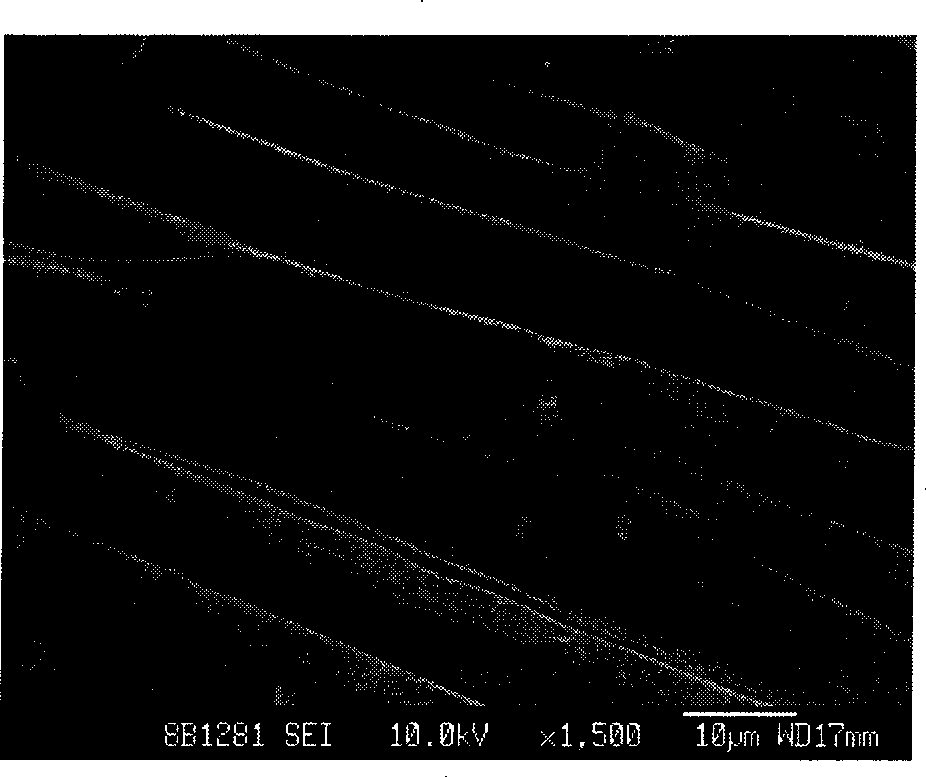

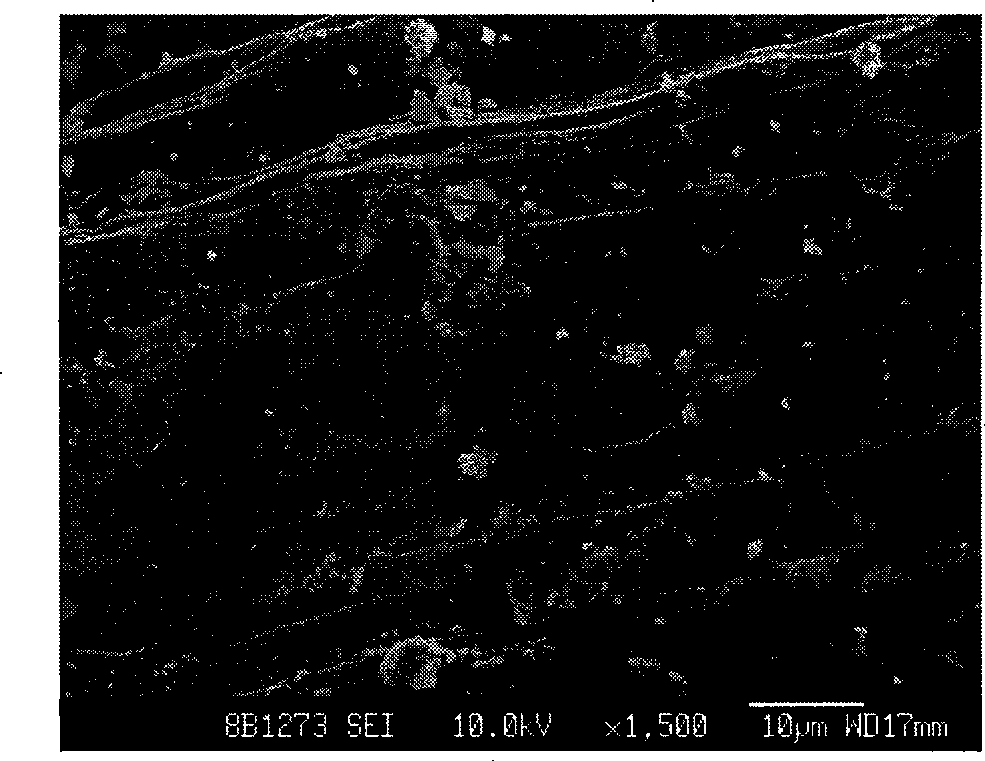

Image

Examples

Embodiment 1

[0041]Wash the corn stalks, dry them, and pass through a 10-mesh sieve after crushing; add corn stalks and ultrapure water into a four-necked flask equipped with a nitrogen inlet tube, an electric stirrer and a condenser tube, and the weight of the corn stalks and ultrapure water The ratio is 1:100; nitrogen gas is introduced and the temperature is raised to 90°C, then potassium permanganate is added as an initiator to make its concentration 0.0025mol / L, and the time for stirring and pre-oxidation is 5 minutes; acrylonitrile is added successively as a monomer , nitrogen, nitrogen-methylenebisacrylamide as a crosslinking agent and concentrated sulfuric acid as a catalyst for graft copolymerization, nitrogen, nitrogen-methylenebisacrylamide consumption is 0.1% of the corn stalk quality, and the acrylonitrile concentration is 1.5 mol / L, sulfuric acid concentration is 15mmol / L, the time of graft copolymerization reaction is 5 hours; Add polymerization inhibitor hydroquinone solutio...

Embodiment 2~13

[0045] According to the preparation conditions shown in Table 1, the operation steps of Example 1 were repeated for preparation.

[0046] The adsorption materials prepared in Examples 1-13 were respectively added to the solution of 100 mg / L heavy metal cadmium ions. The amount that adds is 1% of solution weight, is 120r / min, water temperature 25 ℃, and the pH value is 6.8 under the condition of shaker rotating speed, adsorption 12 hours, the removal rate of cadmium ion is as follows: Figure 8 shown. Depend on Figure 8 It can be seen that the adsorption material prepared in Example 12 has the highest removal rate of cadmium ions, which is 98%; while the adsorption material prepared in Example 8 has the lowest removal rate of cadmium ions, only 11%.

Embodiment 14

[0048] Clean the straw straw, dry it, and pass it through a 10-mesh sieve after crushing; add the straw straw and ultrapure water into a four-necked flask equipped with a nitrogen inlet tube, an electric stirrer and a condenser tube, and the weight of the straw straw and ultrapure water The ratio is 1:100; nitrogen gas is introduced and the temperature is raised to 90°C, then potassium permanganate is added as an initiator to make its concentration 0.0025mol / L, and the time for stirring and pre-oxidation is 5 minutes; acrylonitrile is added successively as a monomer , nitrogen, nitrogen-methylenebisacrylamide as a crosslinking agent and concentrated sulfuric acid as a catalyst for graft copolymerization, nitrogen, nitrogen-methylenebisacrylamide consumption is 0.1% of the quality of rice straw, and the concentration of acrylonitrile is 1.5 mol / L, sulfuric acid concentration is 15mmol / L, the time of graft copolymerization reaction is 5 hours; Add polymerization inhibitor hydroqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com