Patents

Literature

4115 results about "Ultrapure water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrapure water (also UPW or high-purity water) is water that has been purified to uncommonly stringent specifications. Ultrapure water is a commonly used term in the semiconductor industry to emphasize the fact that the water is treated to the highest levels of purity for all contaminant types, including: organic and inorganic compounds; dissolved and particulate matter; volatile and non-volatile, reactive and inert; hydrophilic and hydrophobic; and dissolved gases. ***

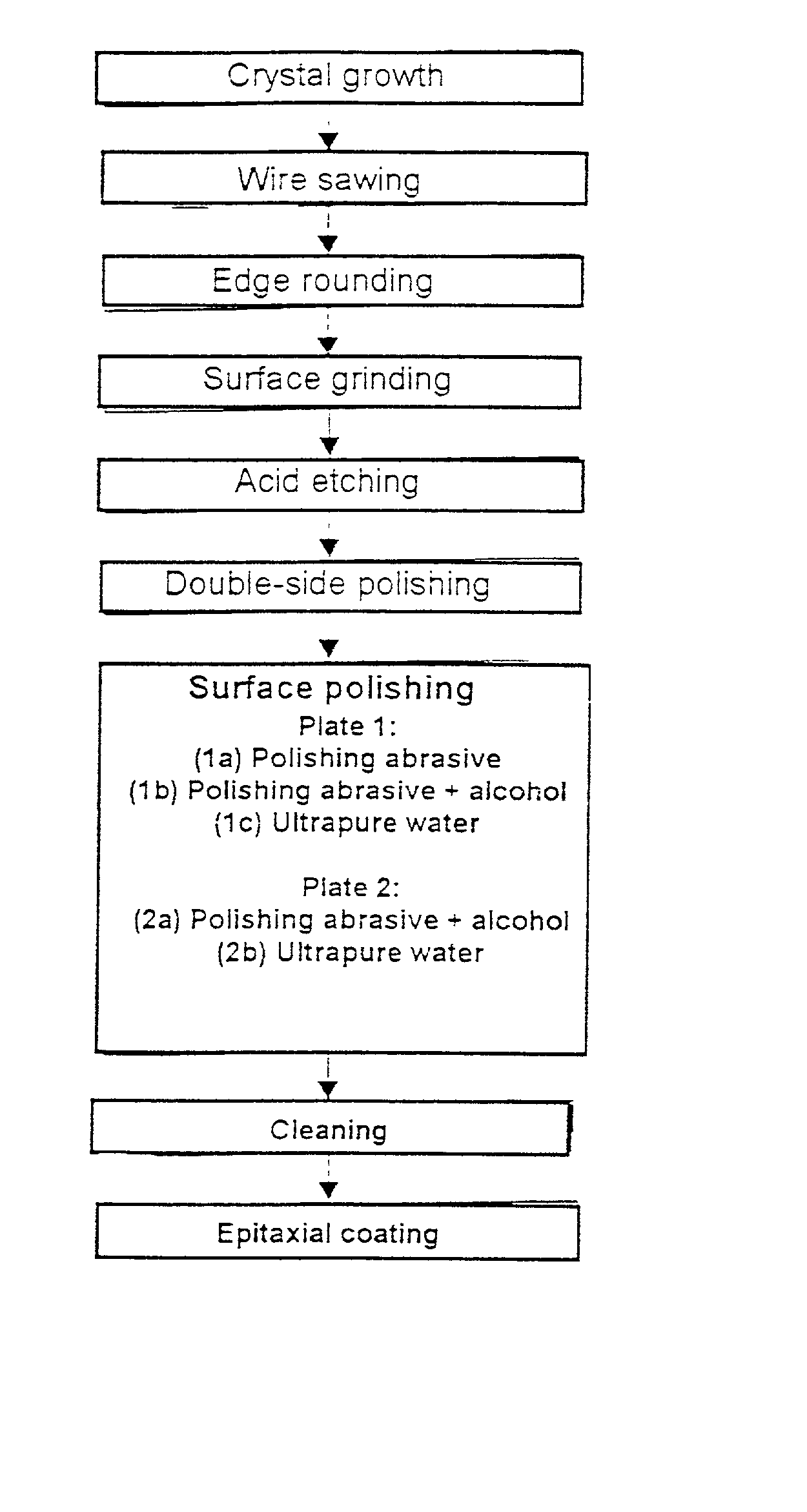

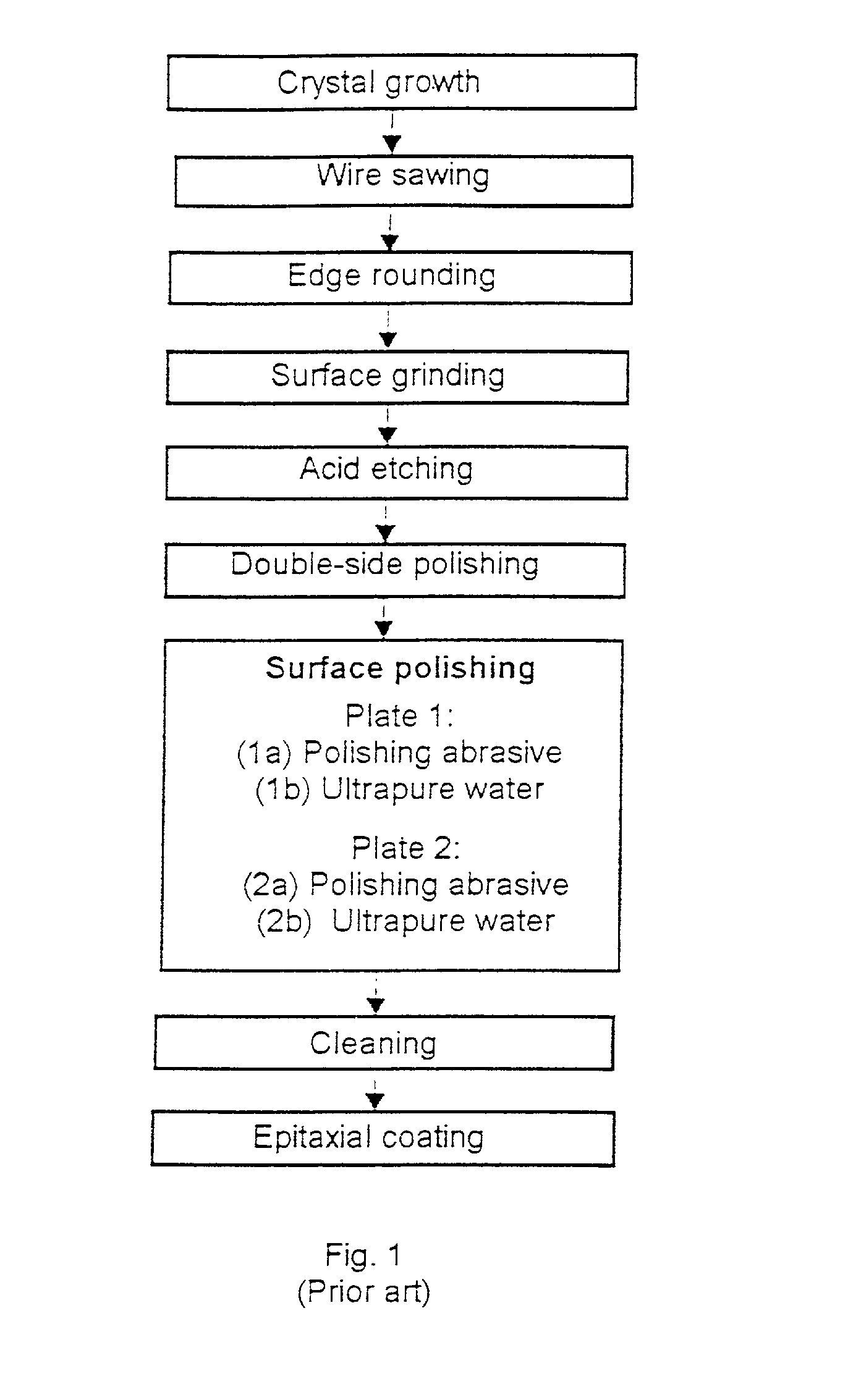

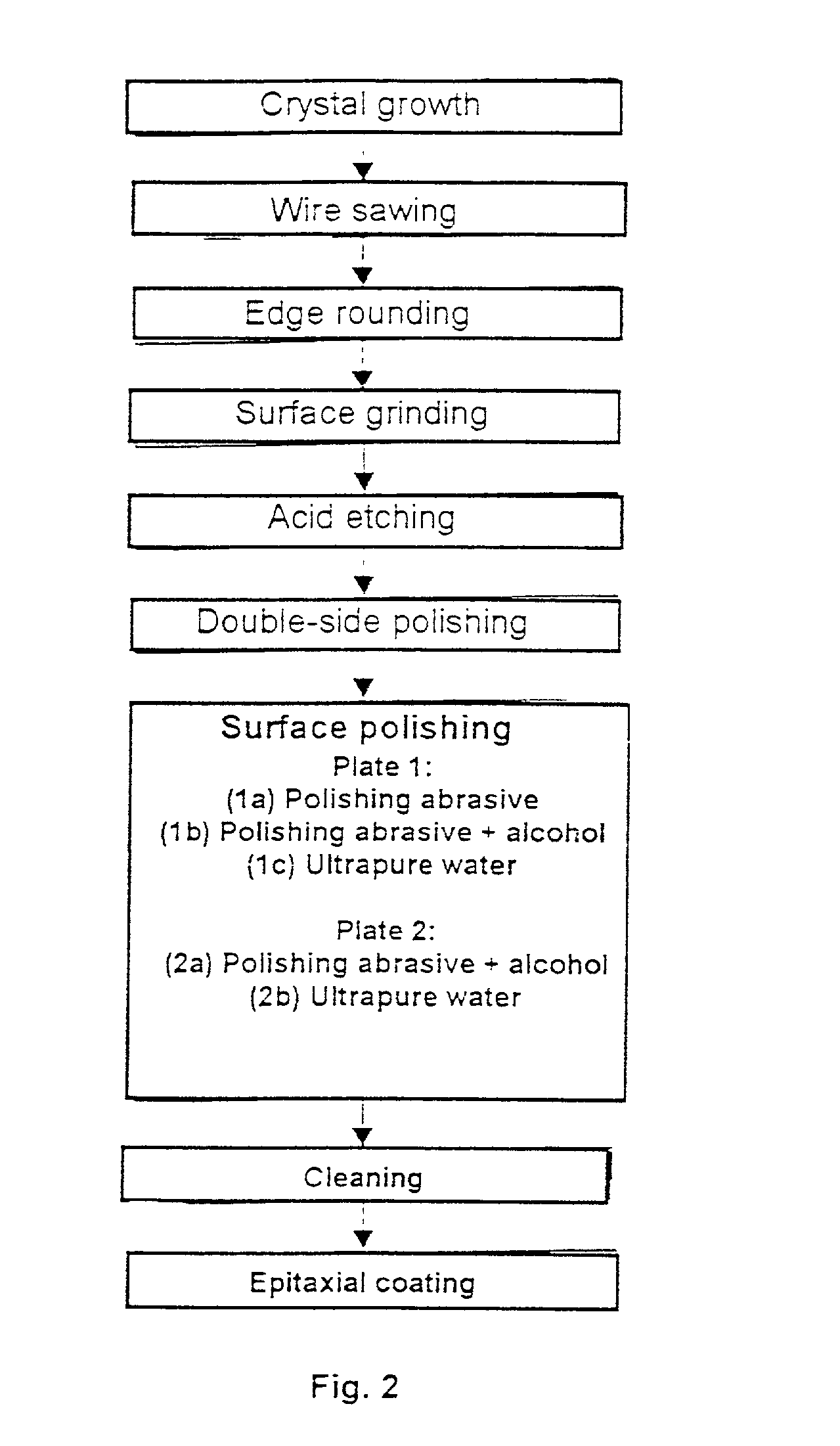

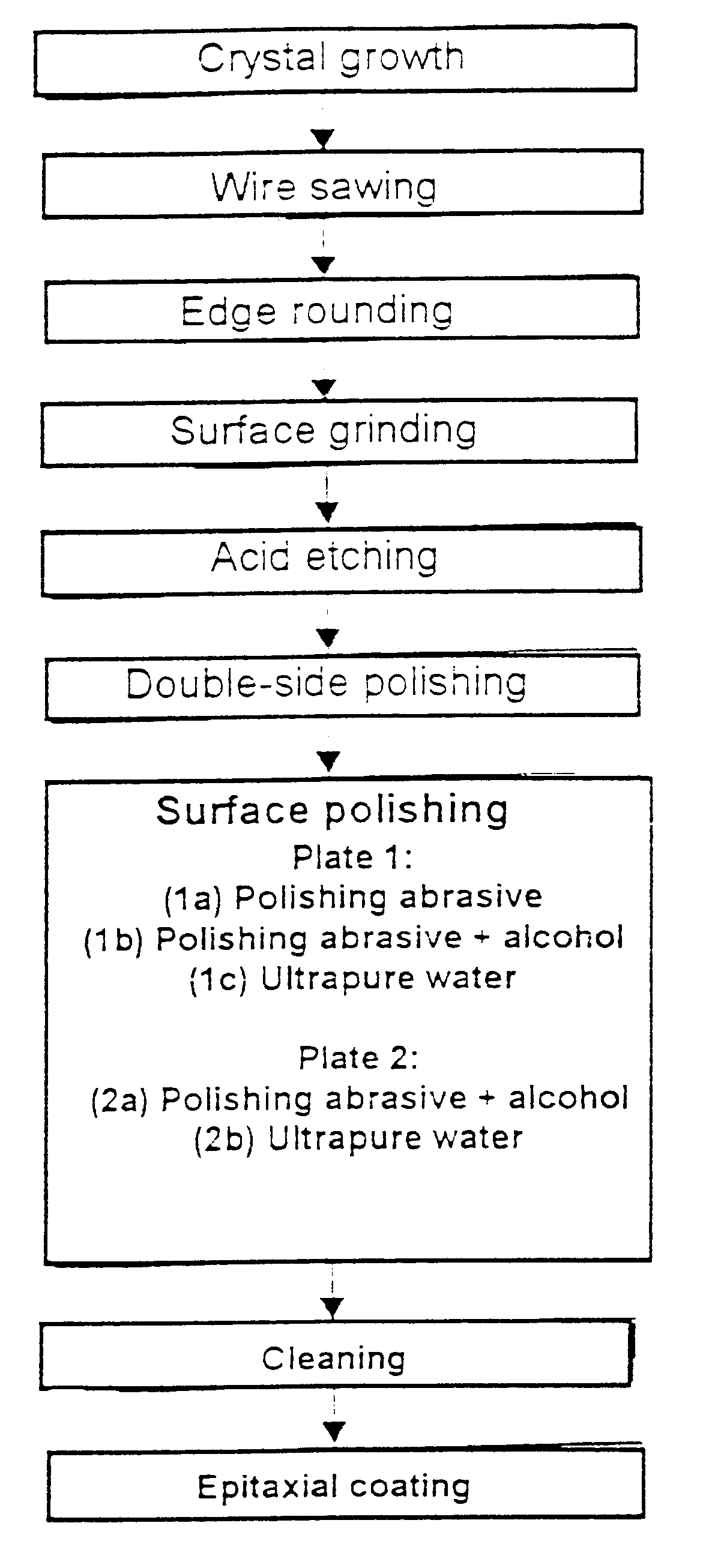

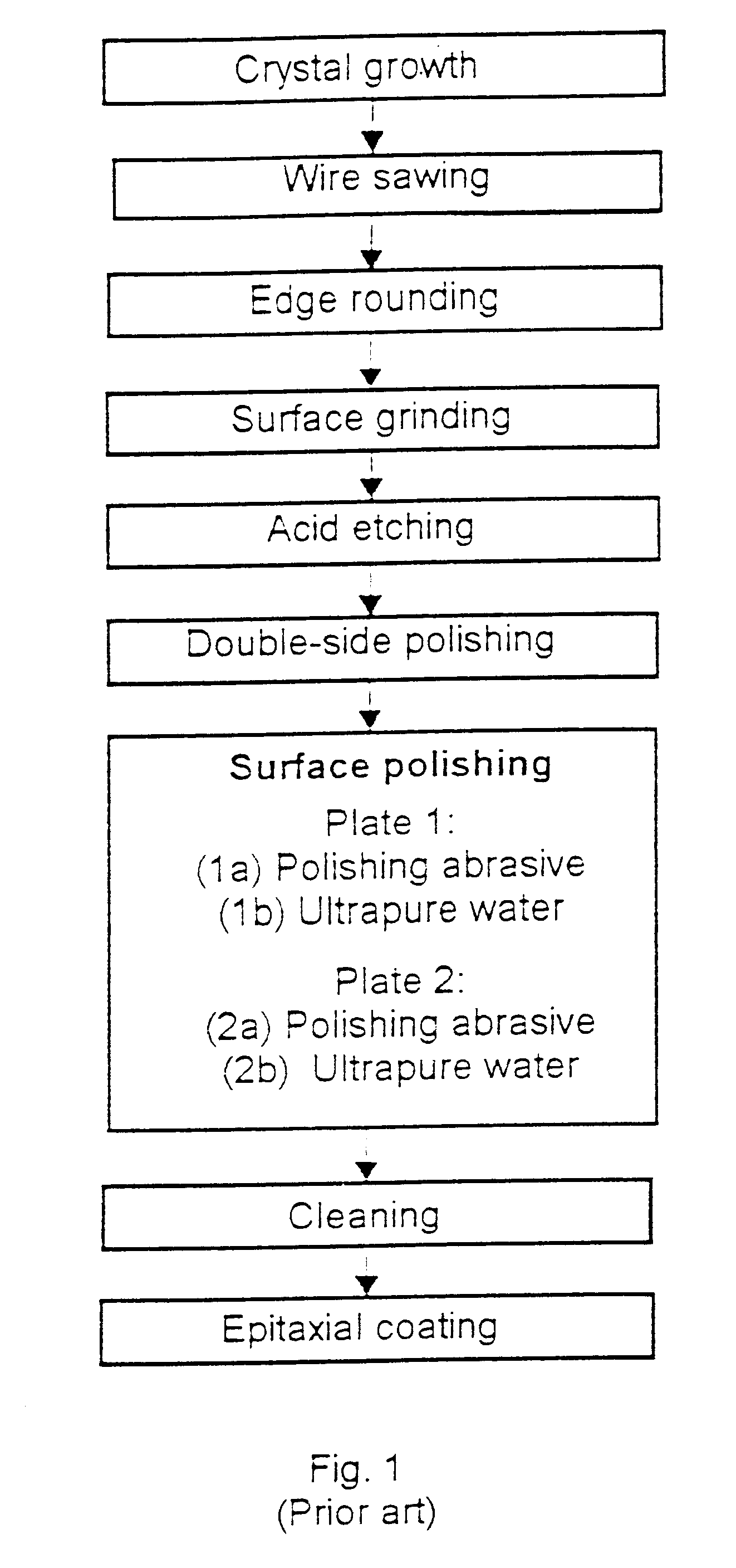

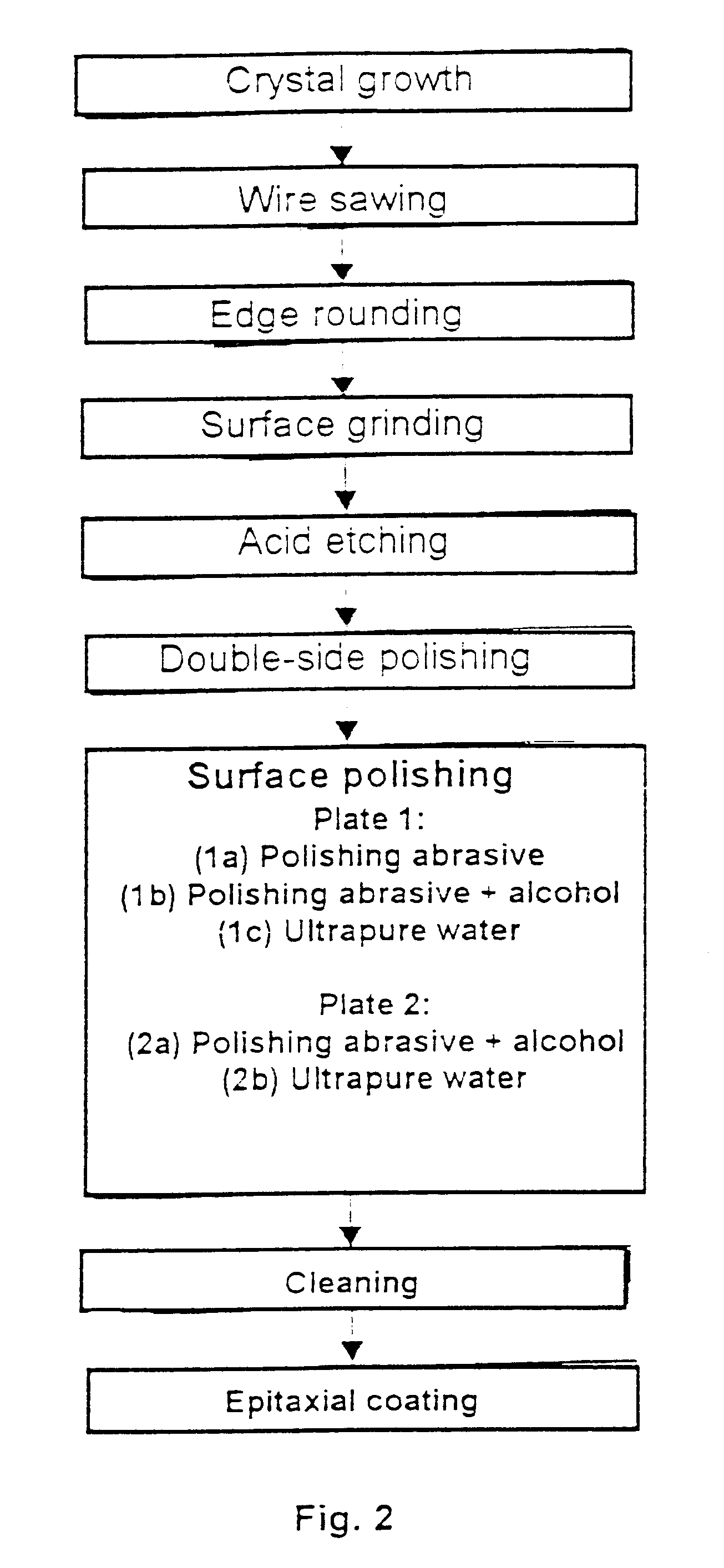

Process for the surface polishing of silicon wafers

InactiveUS20020077039A1High yieldLow costPigmenting treatmentPolishing machinesUltrapure waterAlcohol

A process for the surface polishing of a silicon wafer, includes the successive polishing of the silicon wafer on at least two different polishing plates covered with polishing cloth, with a continuous supply of alkaline polishing abrasive with SiO2 constituents, an amount of silicon removed during the polishing on a first polishing plate being significantly higher than on a second polishing plate, with the overall amount of silicon removed not exceeding 1.5 mum. A polishing abrasive (1a), then a mixture of a polishing abrasive (1b) and at least one alcohol, and finally ultrapure water (1c) are added to the first polishing plate, and a mixture of a polishing abrasive (2a) and at least one alcohol and then ultrapure water (2b) are added to the second plate.

Owner:SILTRONIC AG

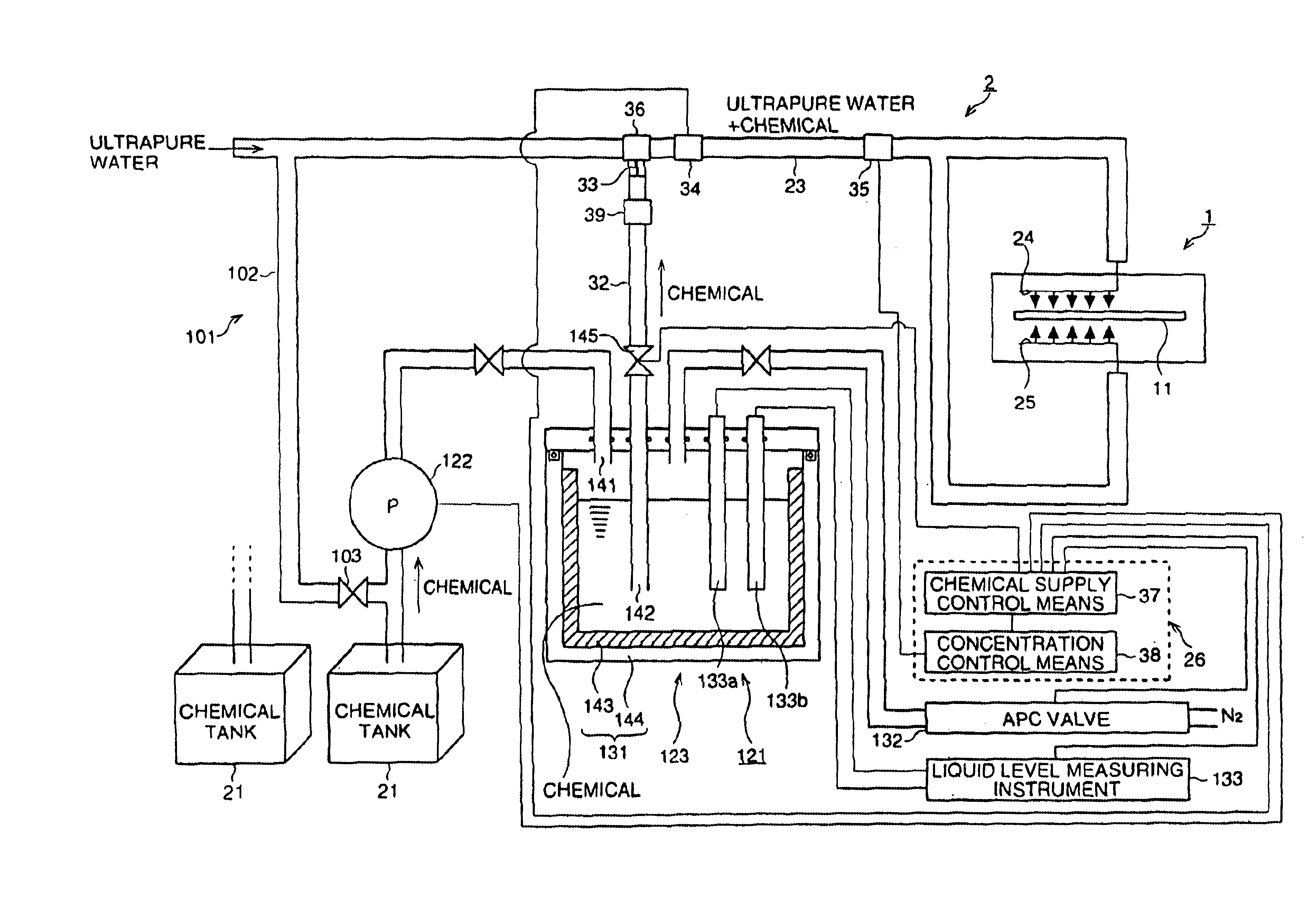

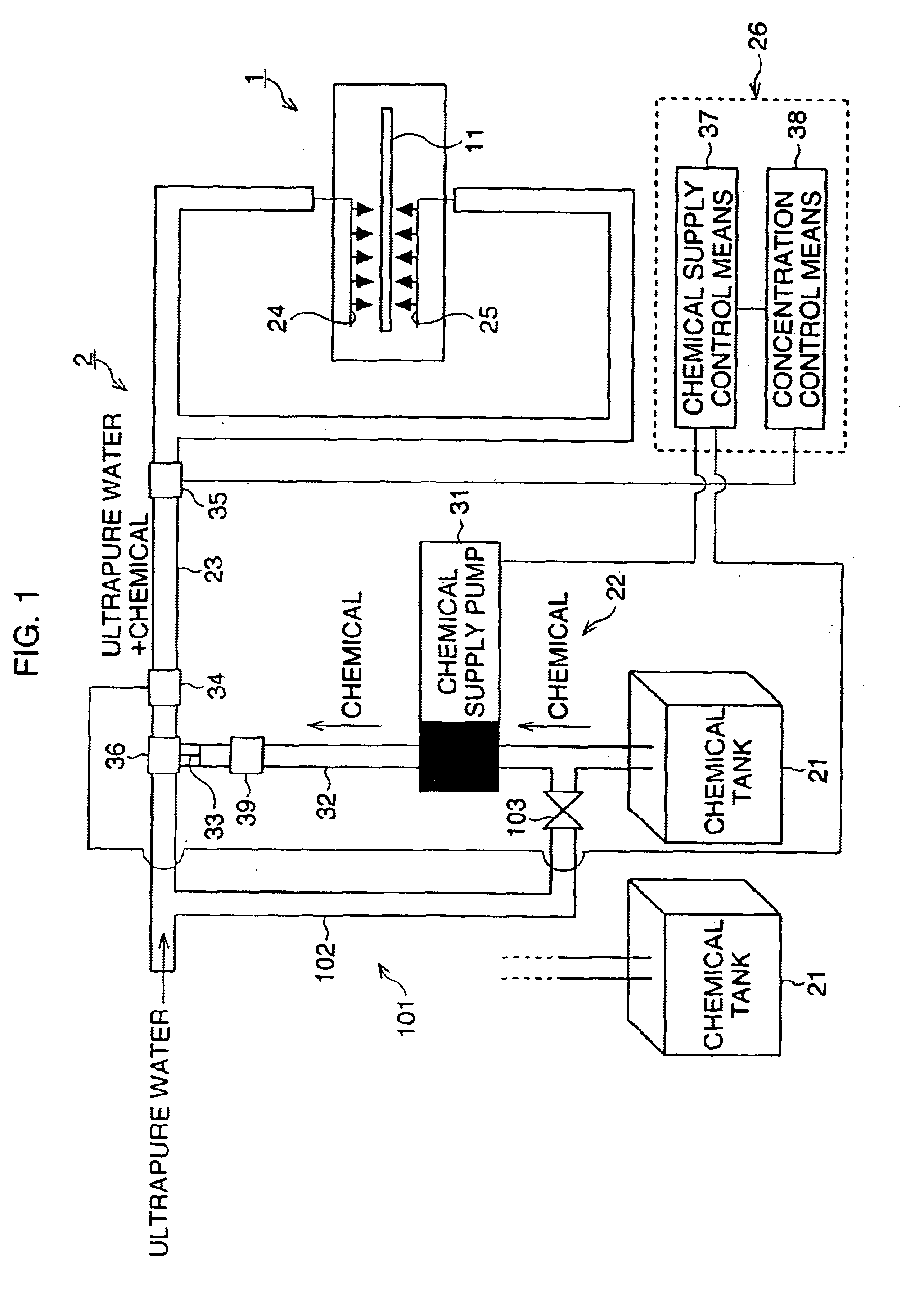

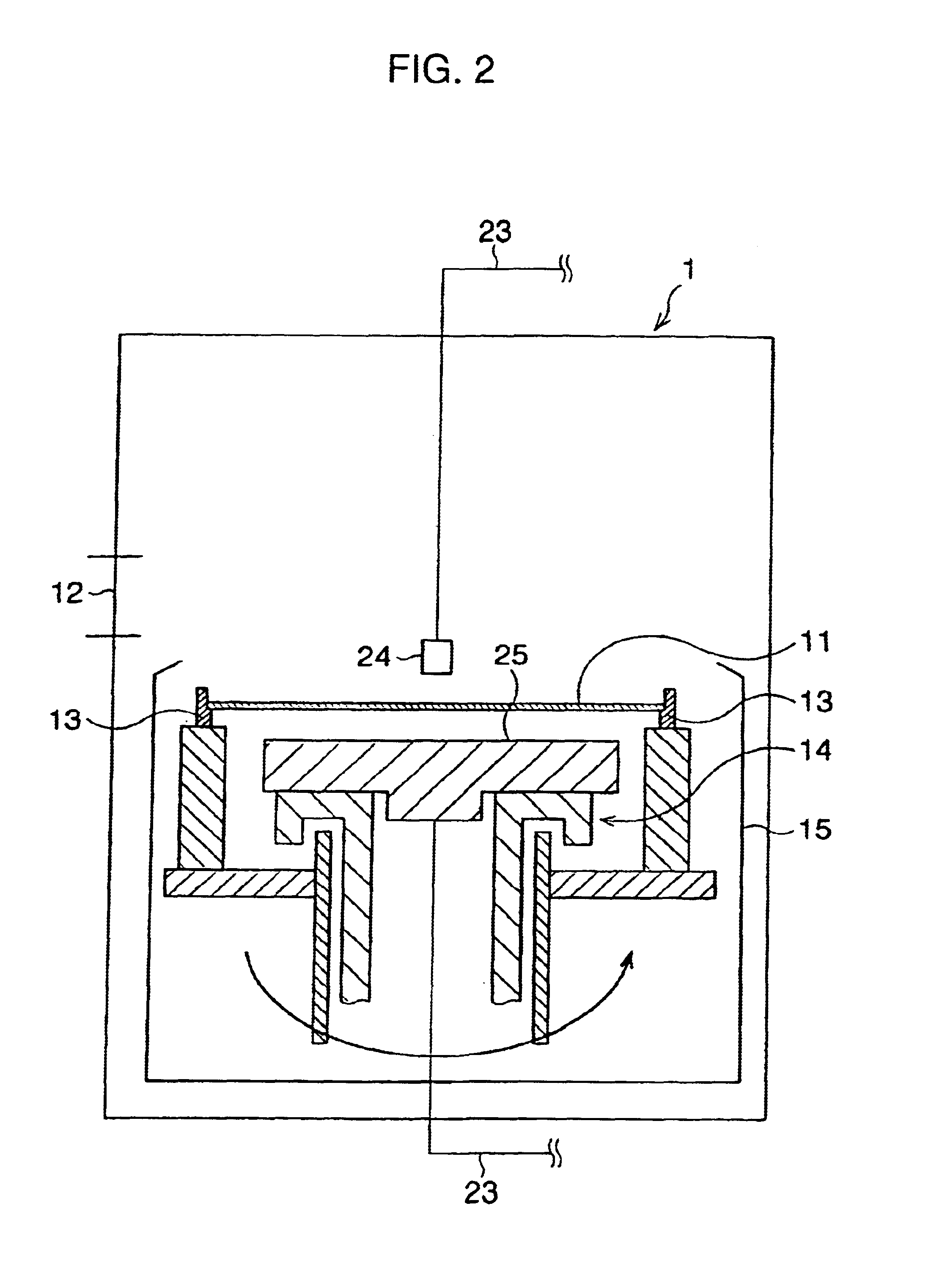

Chemical supply system

InactiveUS6764212B1Improve anti-corrosion performanceEasy to control its porosityDiaphragm valvesShaking/oscillating/vibrating mixersChemical storageMiniaturization

A chemical supply system comprises, as principal elements, a chemical storage tank in which a liquid chemical for cleaning is stored in the state of its formulated concentrate, a chemical supply apparatus connected to the chemical storage tank for positively performing chemical supply, a piping system connected to the chemical supply apparatus to form a supply flow passage that is a passage for ultrapure water which the liquid chemical is to be mixed with, a pair of discharge nozzles disposed at end portions of the piping system so as to oppose surfaces of a wafer set in a cleaning chamber to supply a cleaning liquid onto the surfaces. Thereby, remarkable miniaturization / simplification of a cleaning liquid supply system including chemical tanks is intended, it is made possible easily and rapidly to compound and supply a cleaning liquid at an accurate chemical concentration, and particles or the like being generated and mixing in a cleaning liquid, are suppressed to the extremity.

Owner:ULTRACLEAN TECH RES INST

Cleaning method

InactiveUS6348157B1Strong resistanceSuppress formationSemiconductor/solid-state device manufacturingElectrostatic cleaningCleaning methodsChemical cleaning

A cleaning method capable of processing at room temperatures without conducting heating, uses little chemicals and water, and does not require special devices or materials. The chemical cleaning processes and rinse processes employ pure water or ultrapure water in a semiconductor wet cleaning process, rinse water or chemicals which suppresses formation of surface oxide films, removes particles and prevent their redeposition, and aids in the hydrogen termination of the silicon atoms. The cleaning method of the resent invention includes cleaning which is conducted using pure water containing ozone, cleaning conducted using a cleaning liquid containing HF, H2O, and surfactant, while applying vibration having a frequency of 500 kHz or more, cleaning conducted using pure water containing ozone, cleaning conducted using a cleaning liquid containing HF and H2O in order to remove oxide films, and cleaning which is conducted using pure water. After cleaning a material to be cleaned using chemicals, rinsing is conducted using pure water or ultrapure water containing hydrogen gas in an amount of 0.5 ppm or more and containing oxygen gas in an amount of 100 ppb or less.

Owner:OHMI TADAHIRO +1

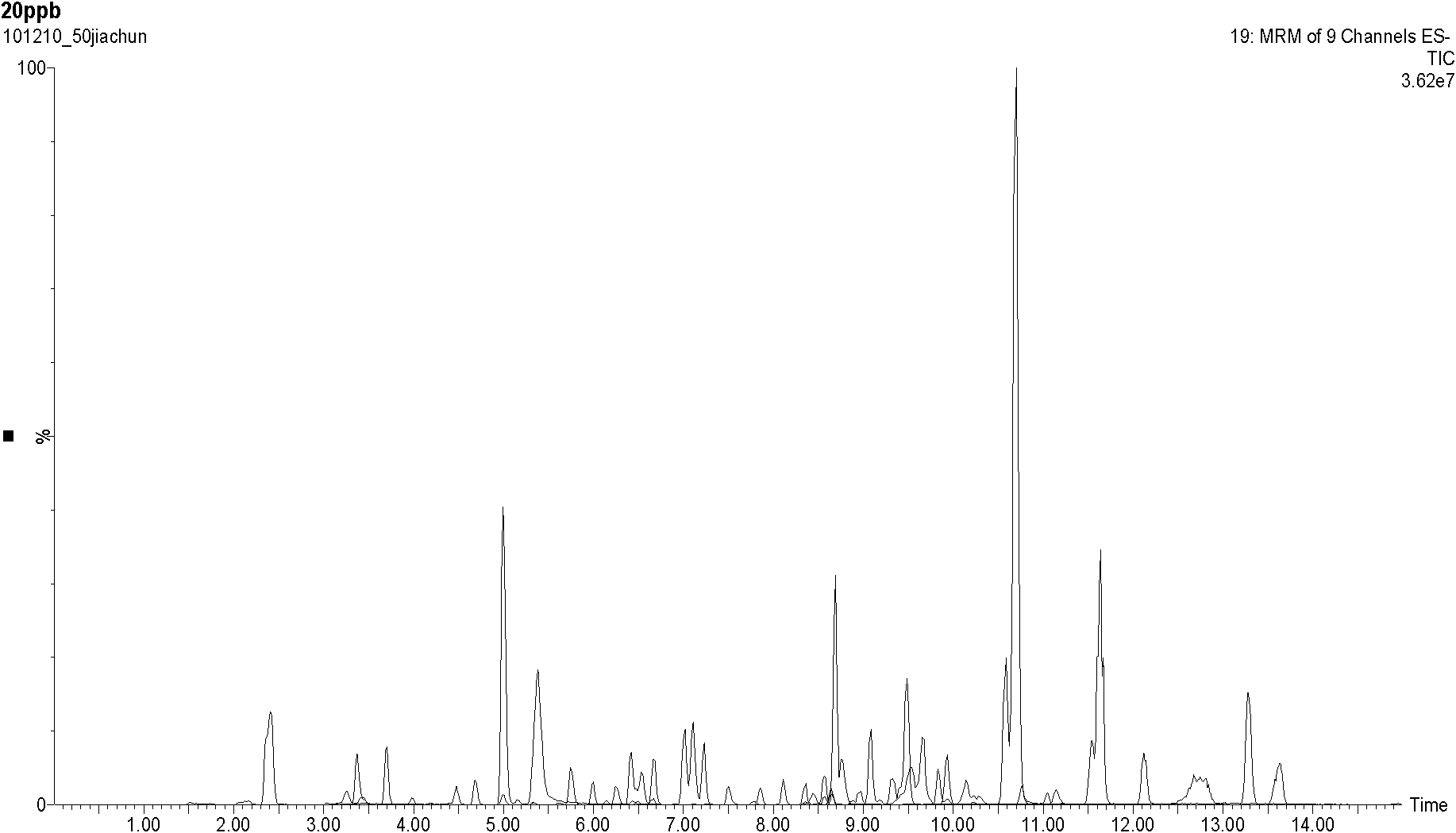

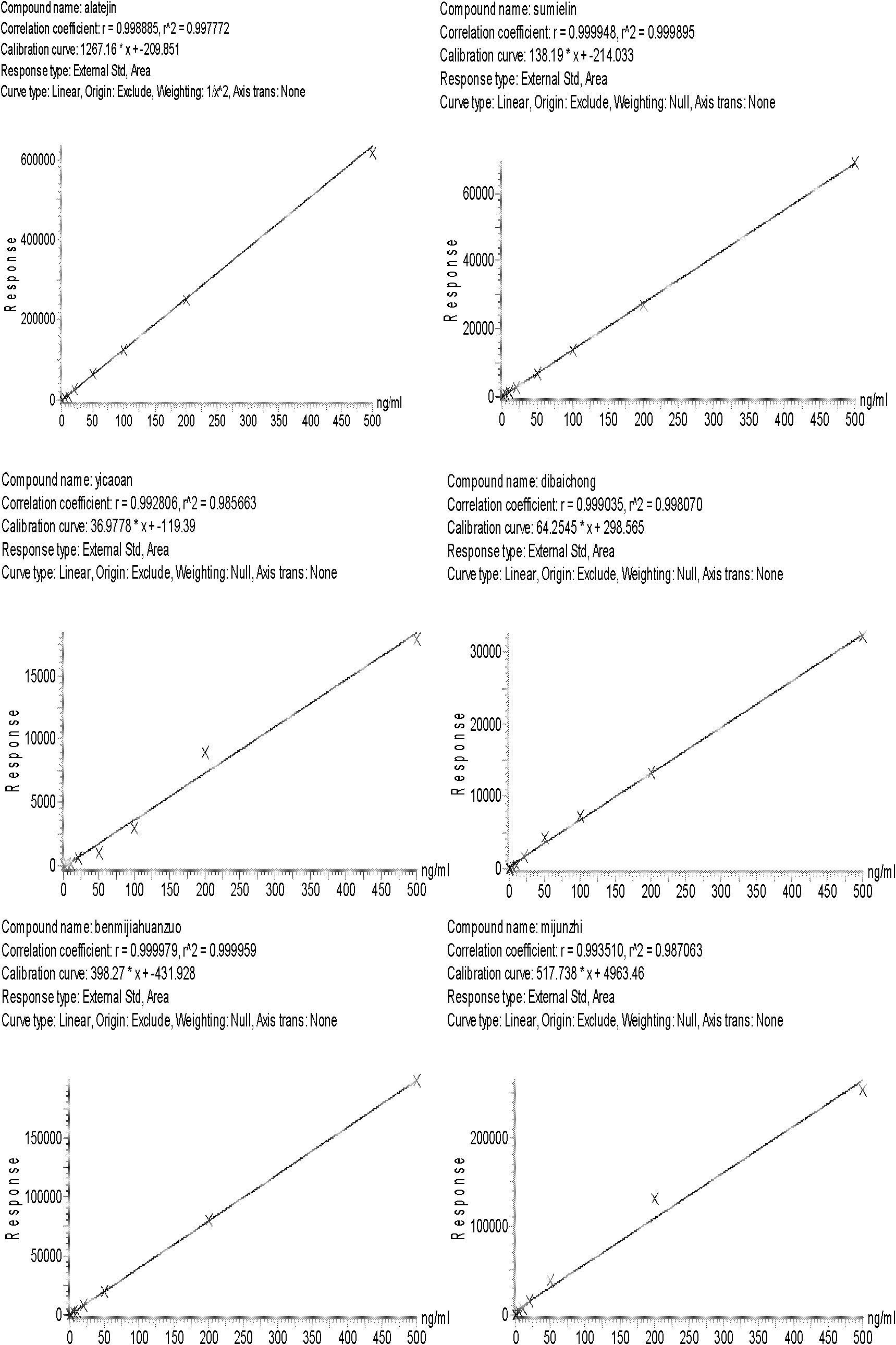

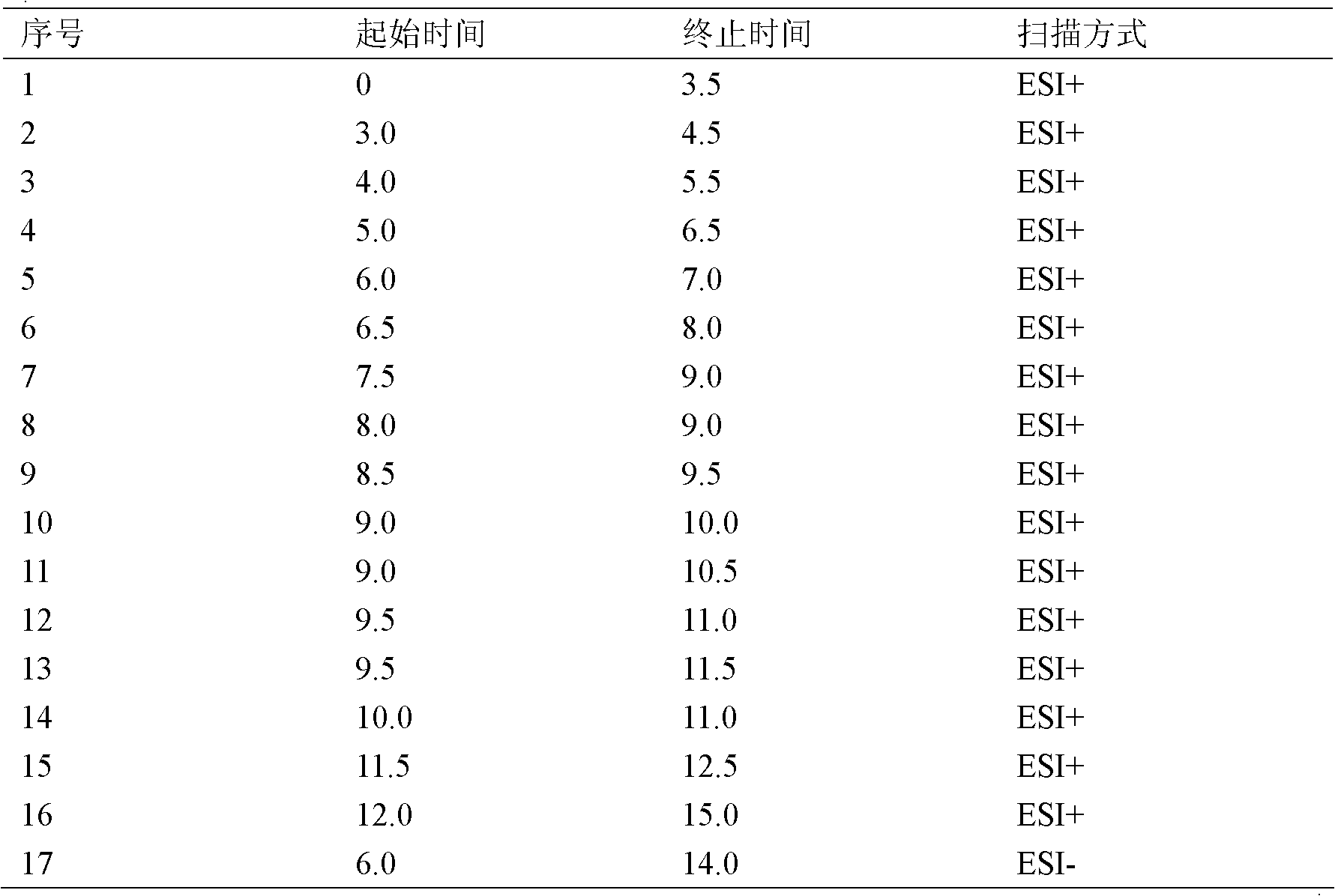

Method for simultaneously determining one hundred pesticide residuals in traditional Chinese medicine through ultrahigh performance liquid chromatography-tandem quadrupole mass spectrum

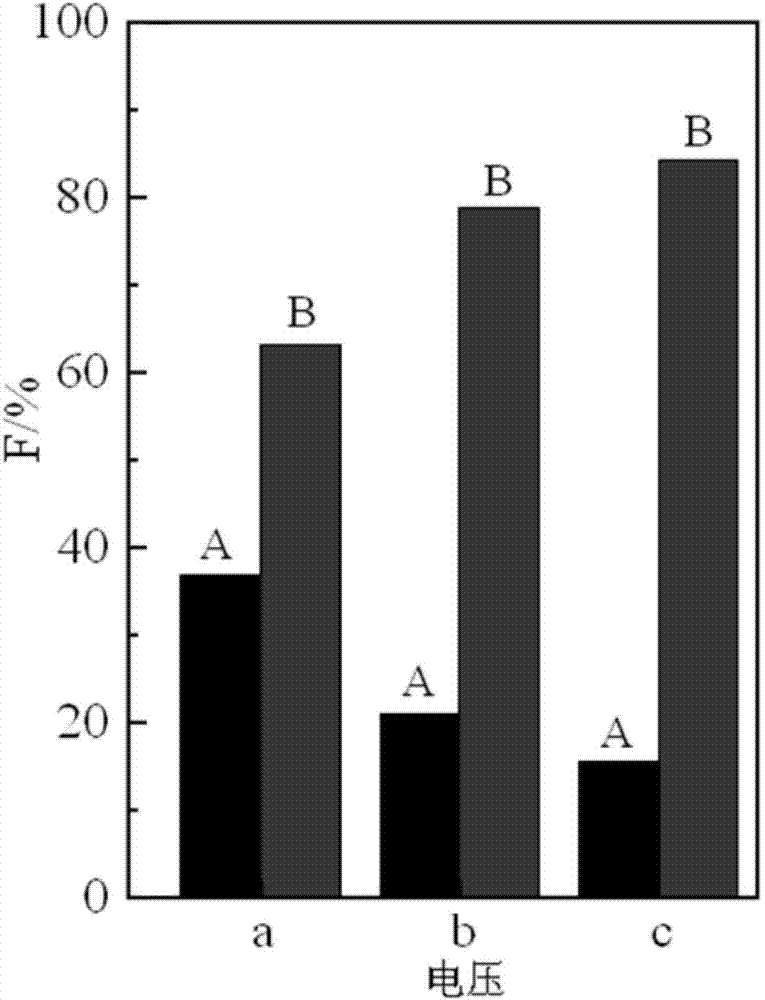

ActiveCN102735784AReduce usageReduce pollutionComponent separationHigh concentrationRelative standard deviation

The invention provides a method for simultaneously determining one hundred pesticide residuals in a traditional Chinese medicine through ultrahigh performance liquid chromatography-tandem quadrupole mass spectrum. The method comprises the following steps: immersing traditional Chinese medicine powder with ultrapure water, extracting with acetonitrile containing 0.1% acetic acid through a homogenate method, carrying out solid phase dispersing purification with N-propylethylenediamine and graphitized carbon, detecting in a timesharing multi-reaction monitoring mode through the ultrahigh performance liquid chromatography-tandem quadrupole mass spectrum, and quantifying with an external standard curve method. 88% of pesticides have good linear relations in a range of 5-500ng / mL, correlation coefficients are above 0.99, and the correlation coefficients of above 98% of the pesticides are above 0.97; the average recovery rate of the pesticides with the low concentration of 10mug / kg, the middle concentration of 50mug / kg and the high concentration of 100mug / kg is 70-130%, and the relative standard deviation is less than 0.15; and the detection limit is equal to or less than 0.01mg / kg, so routine detection requirements can be completely satisfied. The method has the advantages of strong versatility, good selectivity, high sensitivity, and rapidness and simplicity.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

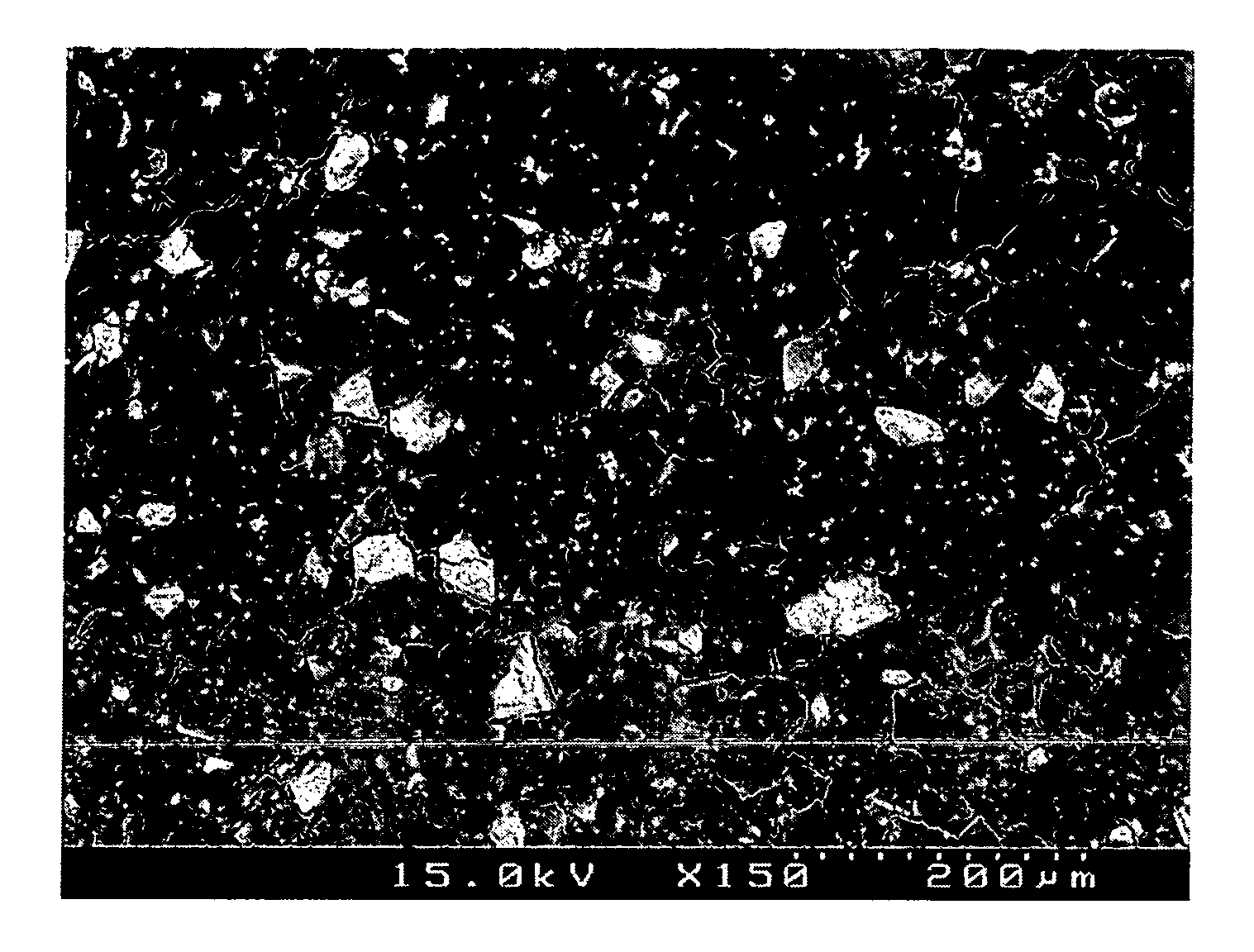

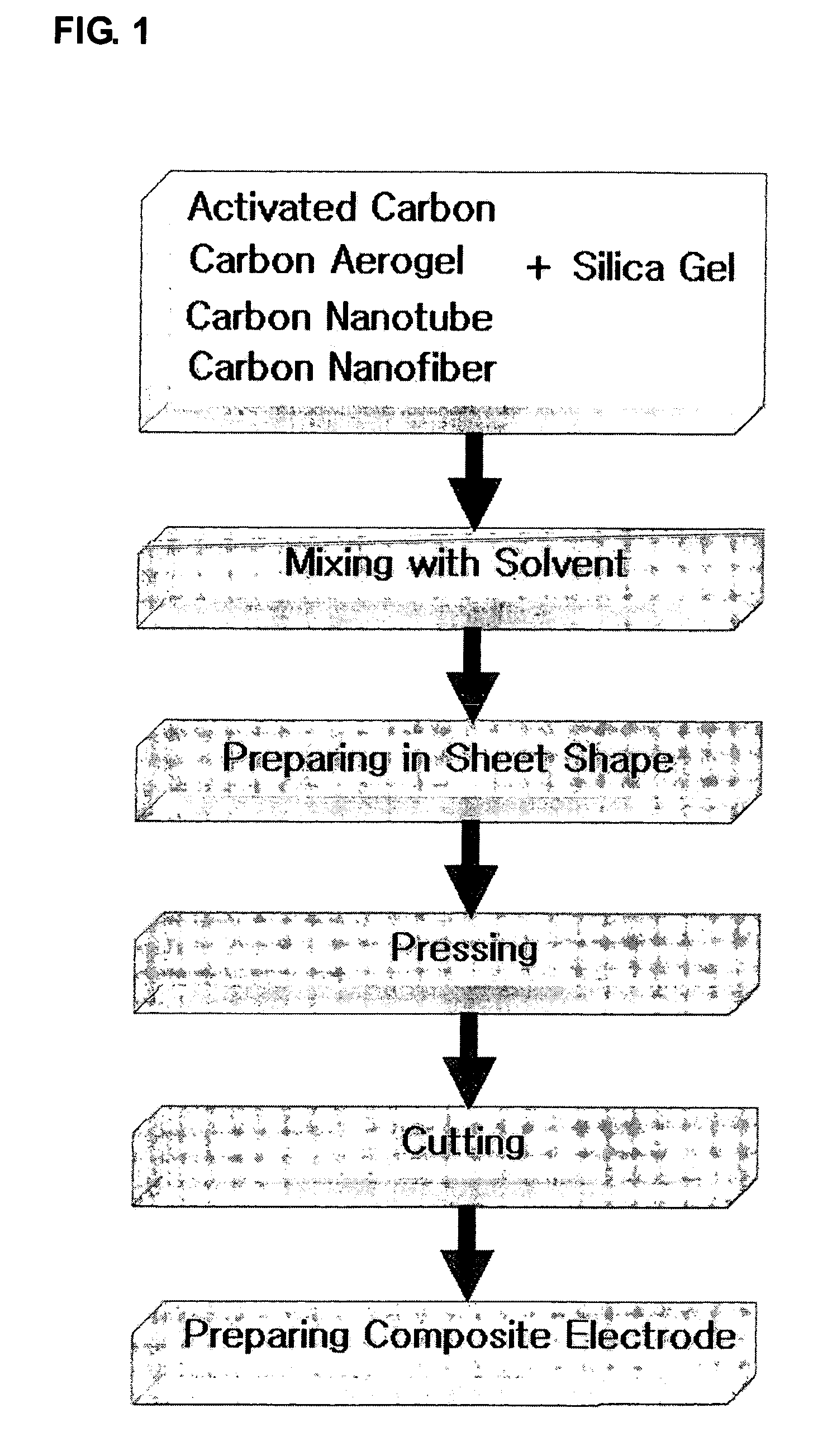

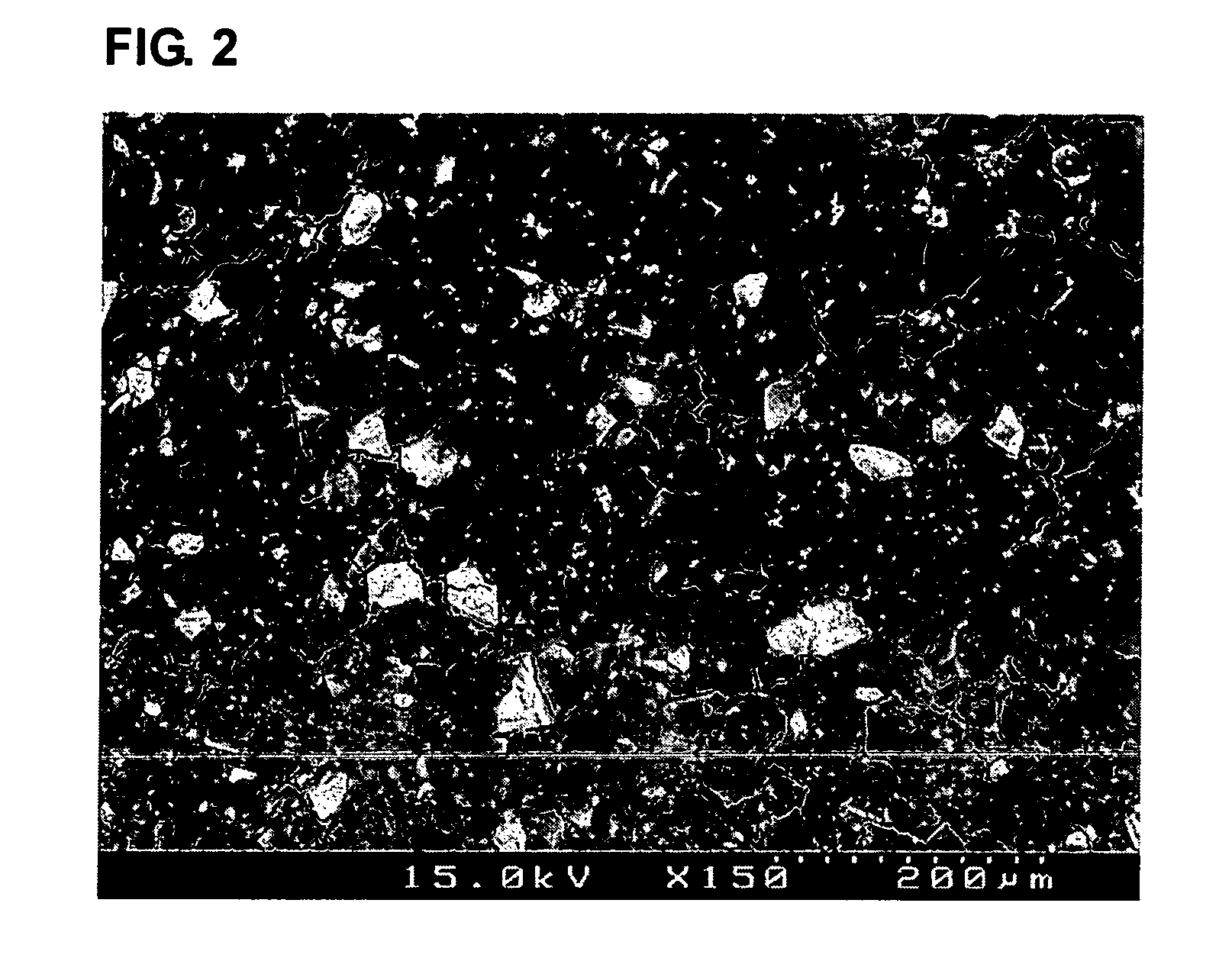

Carbon-porous media composite electrode and preparation method thereof

InactiveUS7505250B2Improve hydrophilicitySimple processMaterial nanotechnologyElectrolytic capacitorsCapacitanceWater use

The present invention discloses a carbon-porous media composite electrode material, a composite electrode using the same and a preparation method thereof. The carbon-porous media composite electrode can be applied for a device such as a secondary battery, a capacitor or the like, or for preparing ultra pure water using a capacitive deionization process, purifying salty water or the like.

Owner:KOREA INST OF SCI & TECH

Method for preparing composite nanofiltration membrane

The invention relates to a method for preparing composite nanofiltration membrane, to the field of film separating technology. The electrolyte multilayer film is assembled on the substrate film as an ultrathin separating film using layers static self-assembly technology, to obtain the composite nanofiltration membrane. The preparation method alternately immerges the substrate film into the polyanion solution and the polycation solution to alternately and repeatedly aggrade on the surface of the substrate film to get the composite nanofiltration membrane ultrathin separating layer after the assemble of a certain layers. The said polyanion solution is sodium polystyrene sulfonate or sodium polyacrylate; the said polycation solution is poly dimethyl diallyl ammonium chloride or polyallyl ammonium chloride, and the said substrate film is polyethersulfone ultrafiltration film or polysulfone ultrafiltration film. The method of the invention has a simple process, and the thickness of ultrathin separating layer is controlled. The compositenanofiltration membrane has a using foreground in the field of sea water and bitter desalination, sewage disposal and callback, ultra pure water preparation and so on.

Owner:SHANGHAI UNIV

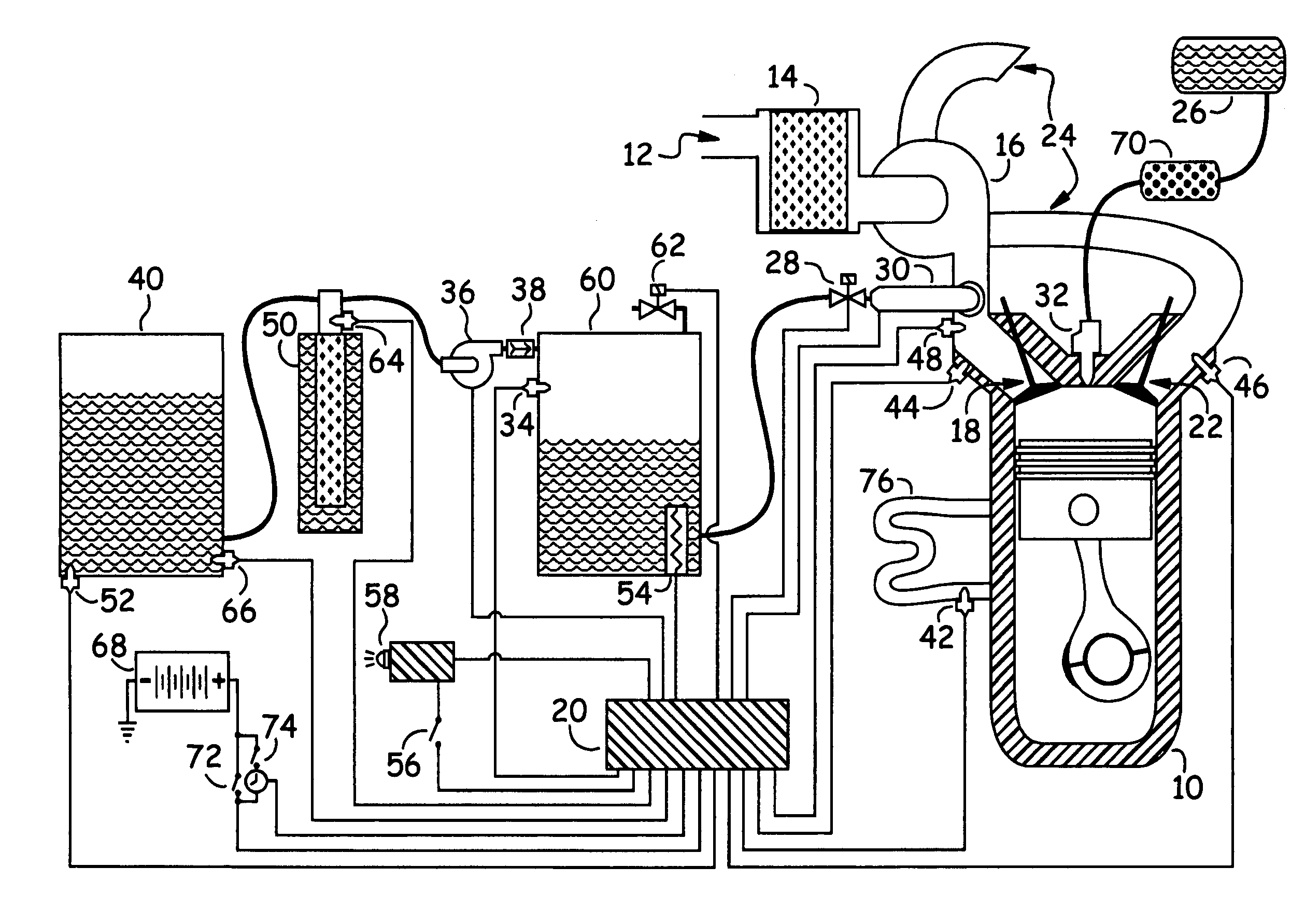

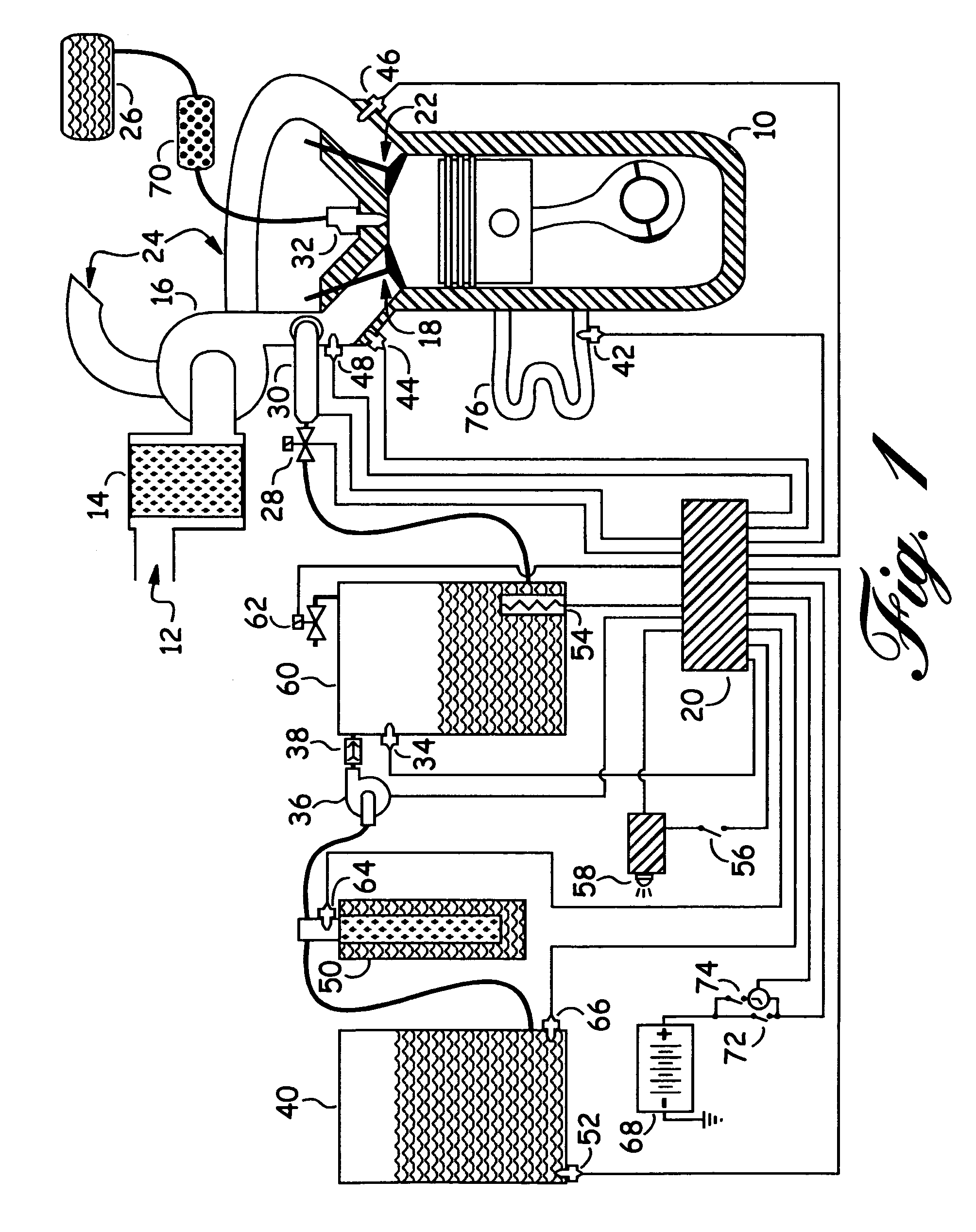

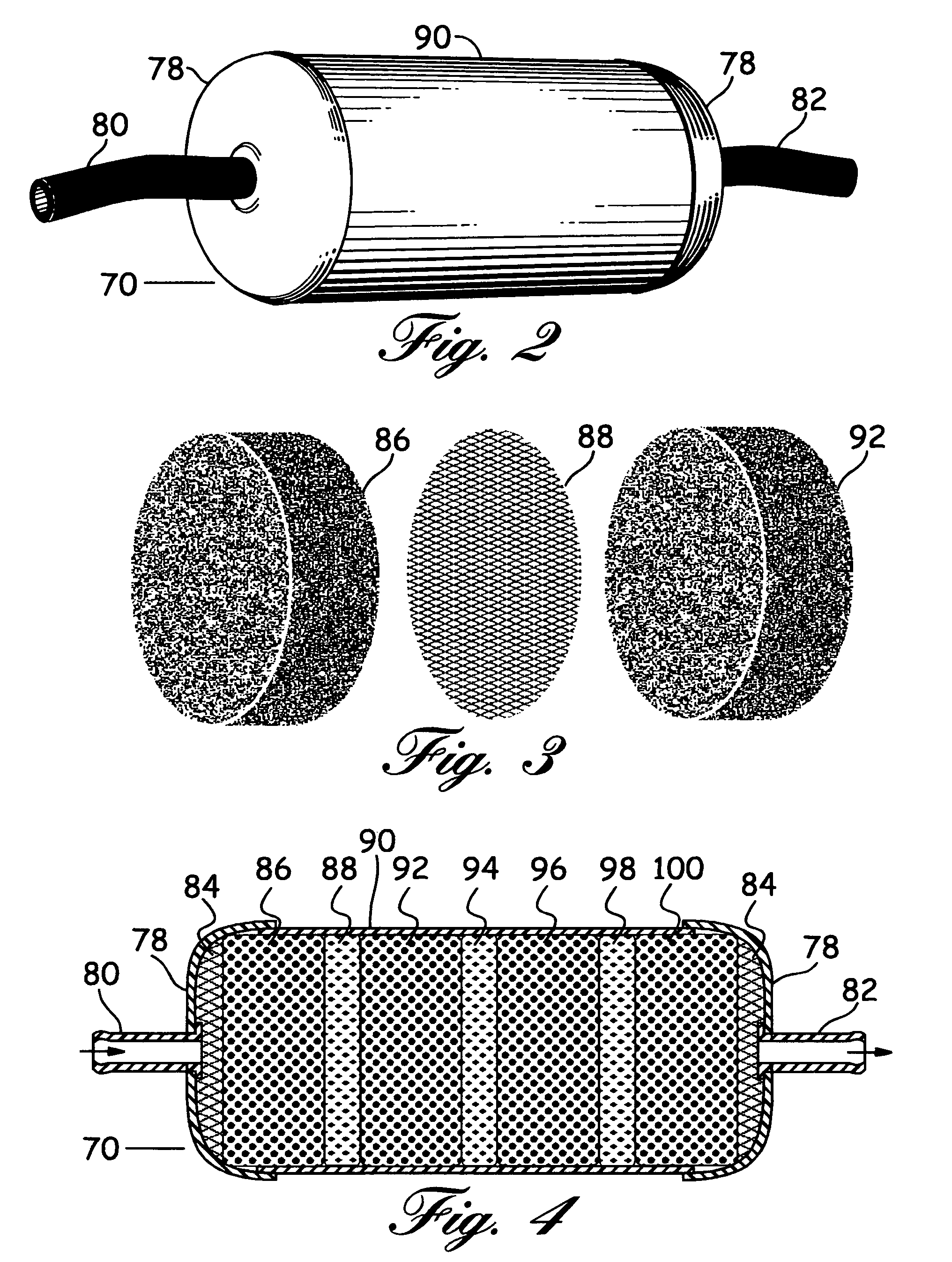

Emissions reduction system for an internal combustion engine

InactiveUS7013845B1Reduce harmful emissionsImprove performanceInternal combustion piston enginesNon-fuel substance addition to fuelPrime moverNitrogen oxides

A dual system for overall engine emissions control, including prevention of excessive formation of nitrogen oxides and carbon compounds 1) by cooling and humidifying intake air and 2) by restructuring and modifying hydrocarbon fuels, resulting in a more complete combustion, a significant reduction of the latent heat of combustion and increased combustion potency. The invention utilizes one or more ultrasonic devices to create an aqueous vapor from an ultra-pure water supply, said vapor varying in quantity according to engine size and load, having electronic sensors and controls for precision switching, metering and delivery. Simultaneously, while humidifying the intake air, the hydrocarbon fuel is passed from a fuel supply through a catalytic reactor to restructure the hydrocarbon molecules into a more homogeneous, more combustible and cleaner-burning fuel. Thus equipped, said internal combustion engine can be run as a fuel conserving, low emissions prime mover.

Owner:CONTEGO MEDICAL INC

Process for the surface polishing of silicon wafers

A process for the surface polishing of a silicon wafer, includes the successive polishing of the silicon wafer on at least two different polishing plates covered with polishing cloth, with a continuous supply of alkaline polishing abrasive with SiO2 constituents, an amount of silicon removed during the polishing on a first polishing plate being significantly higher than on a second polishing plate, with the overall amount of silicon removed not exceeding 1.5 mum. A polishing abrasive (1a), then a mixture of a polishing abrasive (1b) and at least one alcohol, and finally ultrapure water (1c) are added to the first polishing plate, and a mixture of a polishing abrasive (2a) and at least one alcohol and then ultrapure water (2b) are added to the second plate.

Owner:SILTRONIC AG

Method for cleaning surface of ceramic parts

ActiveCN101152651AWon't hurtEfficient removalDrying solid materials without heatCleaning using toolsOrganic solventPolymer thin films

The invention provides a cleaning method for ceramics component surface. In the process of cleaning, organic solvent, alkaline solution, acid solution and super ultrapure water is adopted to clean the component and can effectively remove polymer film attached on the surface of the ceramics component, moreover, the invention has simple and convenient procedure and ideal cleaning effect and cannot lead to damage of the ceramic surface. If the ceramic component used for a certain period in semiconductor process is cleaned with the method, contamination on the surface of the ceramic component can be fully removed without damage of the surface of the ceramic component, and cleaned ceramic component can fully satisfy the requirement of normal process, moreover, cleaning effect can be realized.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Preparation method for uniform gradient-colour zirconium oxide porcelain blocks

ActiveCN104909745AContinuous uniform changeEasy to processImpression capsDentistry preparationsPolyethylene glycolMaterials science

The invention relates to zirconium oxide porcelain blocks for dental prosthesis, and aims at providing a preparation method for uniform gradient-colour zirconium oxide porcelain blocks. The preparation method comprises the following steps: (1) weighing the raw materials of CeO2, Fe2O3, ZrO2, Y2O3, Pr6O11 and Er2O3; (2) adding a polymer binder in the dried mixed powder, and granulating; (3) shaping the granulated material by a die by means of dry pressing to obtain porcelain block blanks; (4) carrying out isostatic cool pressing on the shaped porcelain block blanks; (5) pre-sintering the porcelain block blanks after the isostatic cool pressing; (6) flatly placing the pre-sintered porcelain block blanks in a dyeing container and dyeing, wherein the depth of soaking solution in the dyeing container is 0.1-5mm, the dyeing time is 1-3min, and the used dyeing solution comprises 1-5wt% of polyethylene glycol, 0.1-3wt% of erbium oxide, 0.5-10wt% of praseodymium oxide and the balance of ultrapure water; and (7) sintering the dyed porcelain blocks to obtain the uniform gradient-colour zirconium oxide porcelain blocks for dentistry. The porcelain blocks disclosed by the invention are stable and uniform in colouring, and continuous and uniform in colour changes.

Owner:CHENGDU BESMILE BIOTECH

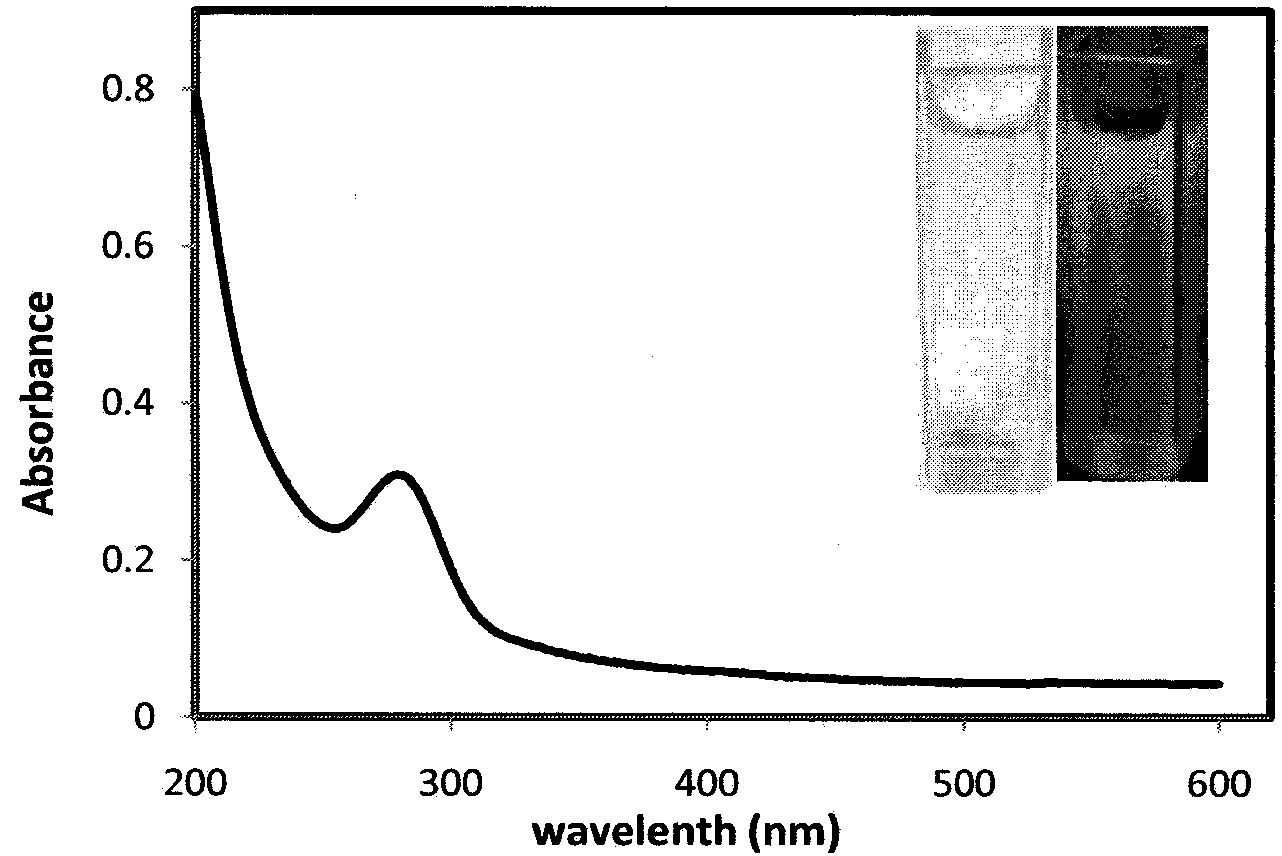

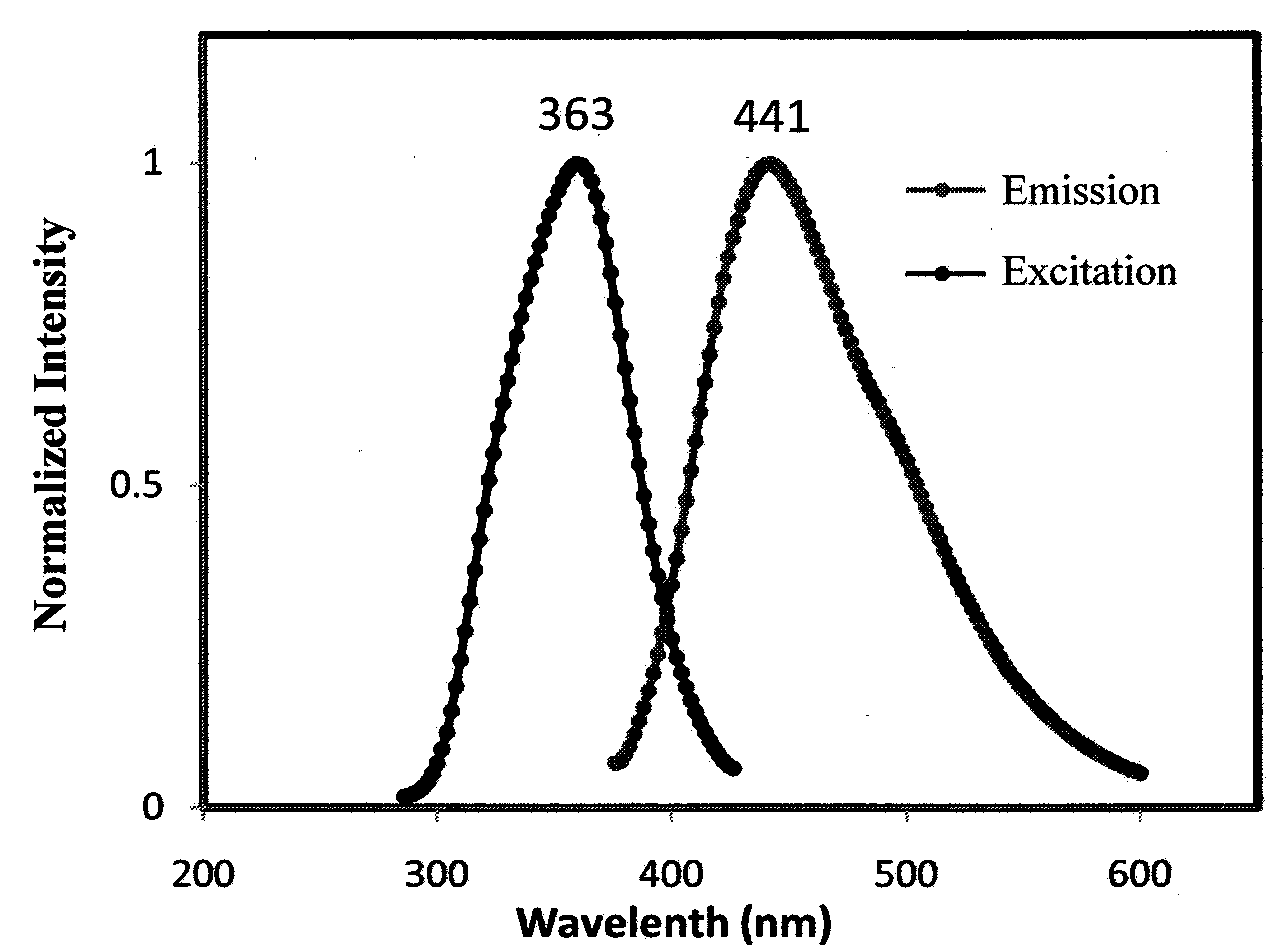

Method for preparing carbon dots with hydrothermal process on basis of plant leaves

InactiveCN104261386ARaw materials are safe and easy to obtainLow costLuminescent compositionsCentrifugationDialysis

The invention discloses a method for preparing carbon dots with a hydrothermal process on the basis of plant leaves. The plant leaves are transferred into a reaction kettle, ultrapure water is added, and the mixture is uniformly mixed and subjected to hydrothermal treatment at the temperature of 130 DEG C-250 DEG C for 2-15 hours; the mixture is cooled and filtered to obtain a brown yellow liquid, the brown yellow liquid is subjected to dialysis for 15-48 hours by a dialysis bag with interception of 3,500, and dialysate is collected; or high-speed centrifugation is performed, and fluorescent carbon dots are obtained. The method is simple and safe to operate, environment-friendly raw materials are used, chemical reagents and surface passivation are not required for assisting synthesis, and the method can be applied to the fields of fluorescence labeling, analysis, sensing, catalyzing and the like.

Owner:中国人民解放军防化学院

Method for cleaning ceramic parts surface in polysilicon etching cavity

ActiveCN101224458AWon't hurtMeet the requirements of normal processDrying solid materials with heatDrying solid materials without heatOrganic solventSemiconductor

The invention relates to a cleaning method of the surface of ceramic component in a polysilicon etching cavity. By adopting organic solvents, alkaline solution, acid solution and ultrapure water to clean the components, the polymers attached on the surface of ceramic component in polysilicon etching cavity can be removed effectively. The invention also has the advantages of simple steps and ideal cleaning effect without damnification of the ceramic component in polysilicon etching cavity. The ceramic component in polysilicon etching cavity used in the semiconductor process is cleaned for a certain period by applying semiconductor technique, so that the pollutants on the surface of ceramic component in a polysilicon etching cavity can be completely removed without damnification of the ceramic component in polysilicon etching cavity. The cleaned ceramic component in polysilicon etching cavity completely meets the normal technique requirements, thus the cleaning method completely achieves good pollutants removal effect.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Method for preparing silicon dioxide magnetic composite microballoon with core-shell structure

ActiveCN101707106AThickness is easy to controlNarrow particle size distributionInorganic material magnetismInductances/transformers/magnets manufactureMicrosphereLayer thickness

The invention belongs to the field of the synthesis of magnetic nano materials, and relates to a method for preparing a silicon dioxide magnetic composite microballoon with a core-shell structure. The method comprises the following steps: adding magnetic iron oxide nano particles monodispersed in water into the mixing solution of alcohol and ultrapure water, and stirring for 0.3-2h; then adding 0.01-1ml of tetraethyl silicate in the mixture, and stirring for 0.3-2h; then adding 0.5-5ml of stronger ammonia water, continuing to stir for 2-24h, and obtaining the solution of the silicon dioxide magnetic composite microballoon with the core-shell structure; and using applied magnetic field for separating the microballon from the solution. In the invention, by proportioning the quantity of the reactant reasonably, and setting the reaction conditions reasonably, one or a plurality of the iron oxide magnetic nano particle(s) are covered in each produced silicon dioxide microballoon, and the microballoon has good balling performance and monodispersity, has controllable shell layer thickness and narrow particle size distribution, and is easy to clean, simple and convenient in operation, low in cost, less in waste, and high in productivity.

Owner:XIAN GOLDMAG NANOBIOTECH

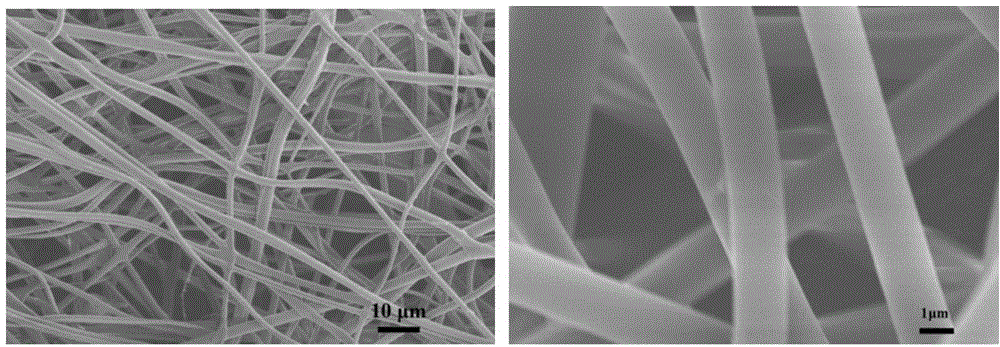

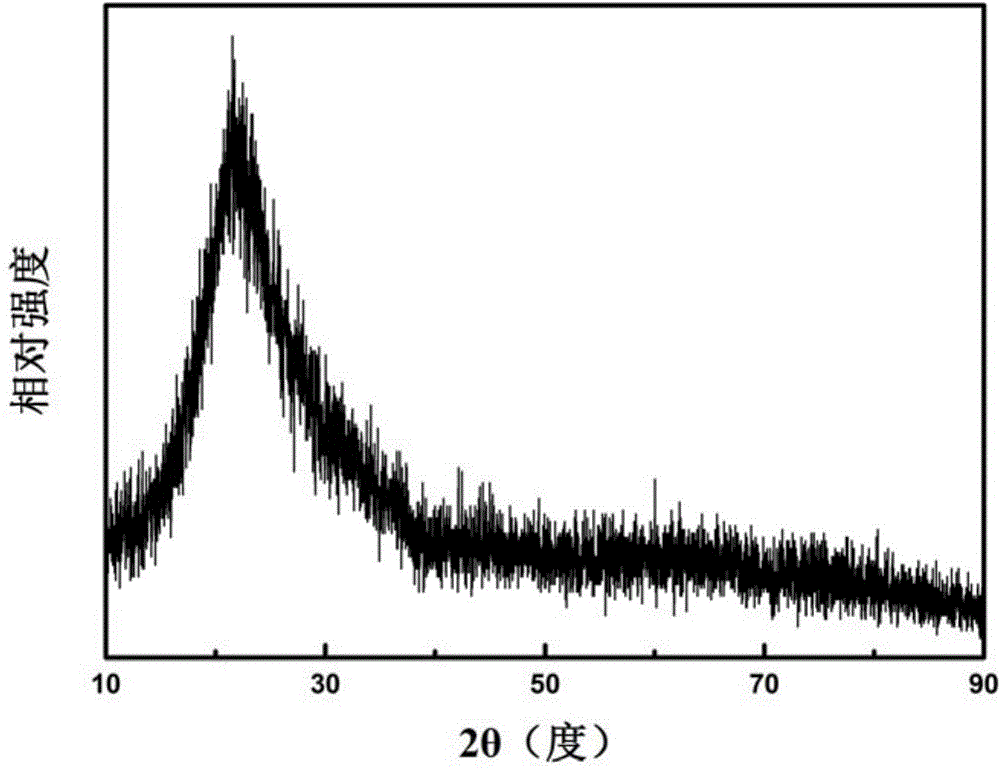

Preparation method of flexible silicon dioxide fiber film

InactiveCN103603136AHigh yieldThe preparation method is simple and feasibleFilament/thread formingFibre chemical featuresFluorescencePhosphoric acid

The invention relates to a preparation method of a flexible silicon dioxide fiber film. The method includes: (1) mixing tetraethyl orthosilicate, ultrapure water and phosphoric acid at room temperature to obtain a transparent and clear silicon source solution; (2) dissolving polyvinyl alcohol in the ultrapure water with stirring at the temperature of 80-90 DEG C for 4-5 hours to obtain a polyvinyl alcohol solution; (3) mixing the silicon source solution with the polyvinyl alcohol solution to obtain a colorless clear spinning solution, standing and ageing prior to electrostatic spinning, and collecting a layer of uniform white fiber film; (4) putting the white fiber film in a muffle furnace, heating to 500 DEG C prior to retaining the temperature for 2-4 hours, then heating to 800 DEG C prior to retaining the temperature for 2-3 hours, and finally naturally cooling to obtain the flexible silicon dioxide fiber film. The preparation method is simple, and the prepared silicon dioxide fiber film is resistant to organic solvents and corrosion, has good flexibility after being subjected to high temperature and has potential application in the fields of catalyst loading and fluorescent films.

Owner:DONGHUA UNIV

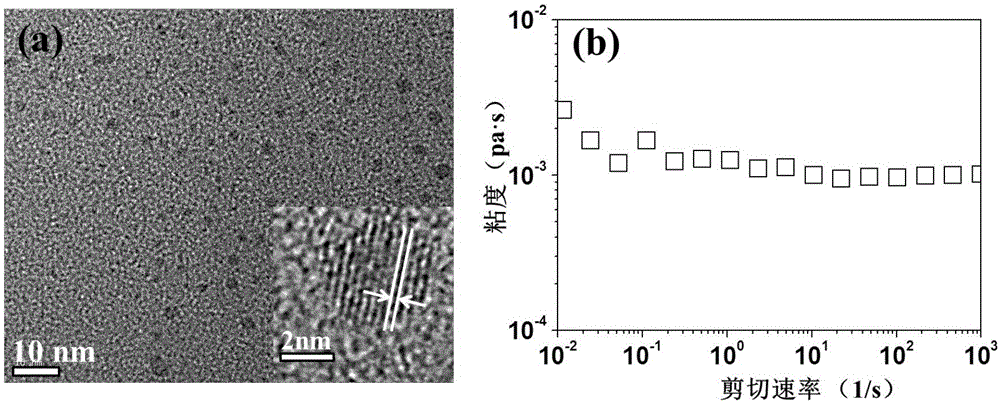

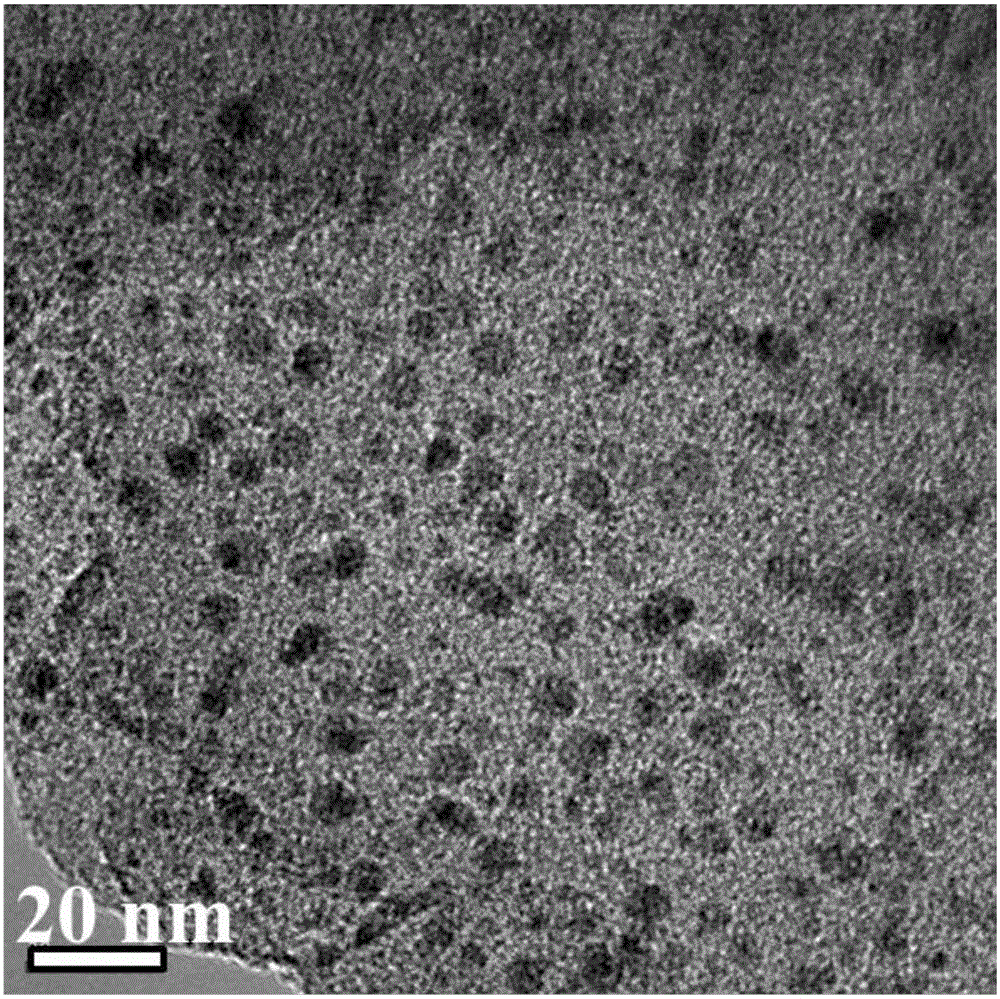

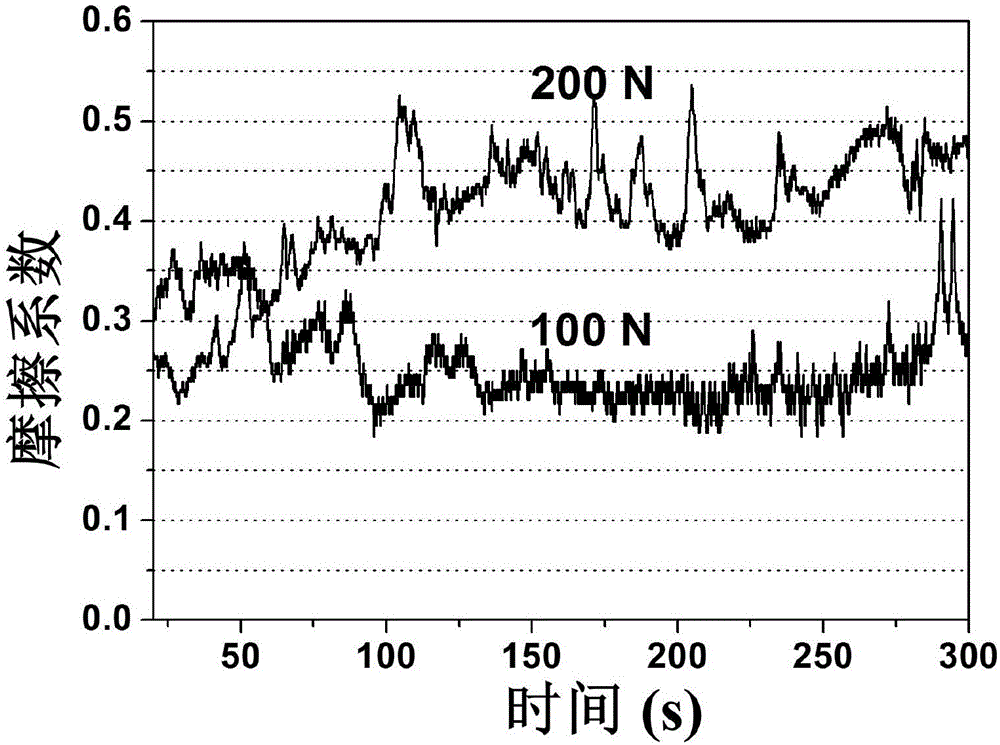

Water-based lubricant based on two-dimensional material nanosheets/carbon quantum dots and preparation method of water-based lubricant

InactiveCN106520354AReduce coefficient of frictionImprove adaptabilityLubricant compositionWater basedMaterials preparation

The invention belongs to the technical field of nano lubricant material preparation and relates to a water-based lubricant based on two-dimensional material nanosheets / carbon quantum dots and a preparation method of the water-based lubricant. Carbon quantum dot powder is first prepared, then the prepared carbon quantum dot powder is added into ultra-pure water, and ultrasonic treatment is conducted for 10 min to obtain a carbon quantum dot aqueous solution; then, two-dimensional material nanosheets are added into the carbon quantum dot aqueous solution for ultrasonic treatment to prepare the water-based lubricant based on the two-dimensional material nanosheets / carbon quantum dots, wherein the water-based lubricant comprises, by mass, 0.01-15% of the carbon quantum dots, 0.001-0.1% of the two-dimensional material nanosheets and the balance ultra-pure water. The lubricant is simple and controllable in preparation process, low in cost, environmentally friendly, clean and free of toxin, large-scale production is easy, and the prepared water-based lubricant is extremely low in friction coefficient and good in adaptability with friction pairs, and does not corrode common carbon steel.

Owner:QINGDAO UNIV +1

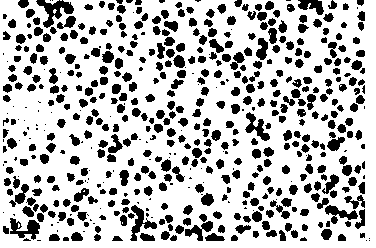

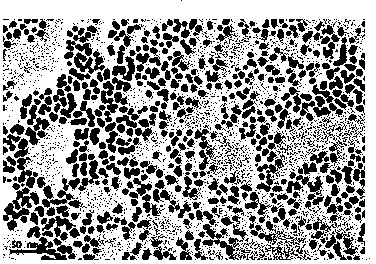

Method for reducing and preparing functionalized nano-silver based on polyphenol

The invention discloses a novel method for reducing and preparing functionalized nano-silver based on polyphenol. The preparation process is as follows: 1), stock solutions of all reaction liquids are prepared, and the stock solutions comprise a silver-bearing predecessor stock solution, a polyphenol compound stock solution and an alkaline stock solution; 2), a polyphenol compound solution is prepared: a certain amount of the polyphenol compound stock solution is taken and added into ultrapure water, and the stock solution and the ultrapure water are mixed uniformly; 3), the pH value and the temperature of the polyphenol compound solution are adjusted: a proper amount of the alkaline stock solution is taken and added into the polyphenol compound solution prepared in the step 2), the pH value of the mixed solution is adjusted, the mixed solution is placed and kept out of the sun, and the temperature of the mixed solution is adjusted; and 4), a nano-silver solution is generated: a certain amount of the silver-bearing predecessor stock solution is added into the mixed solution with adjusted pH value and temperature in the step 3) and is kept out of the sun, and reaction is performed for a certain time. The operation method is simple, the synthesis speed is high, the cost is low, the biocompatibility is high, the method is pollution-free, the sizes of the synthesized nano-silver particles are small, the monodispersity is good, and the nano-silver also has the performance of a polyphenol compound.

Owner:SOUTHEAST UNIV

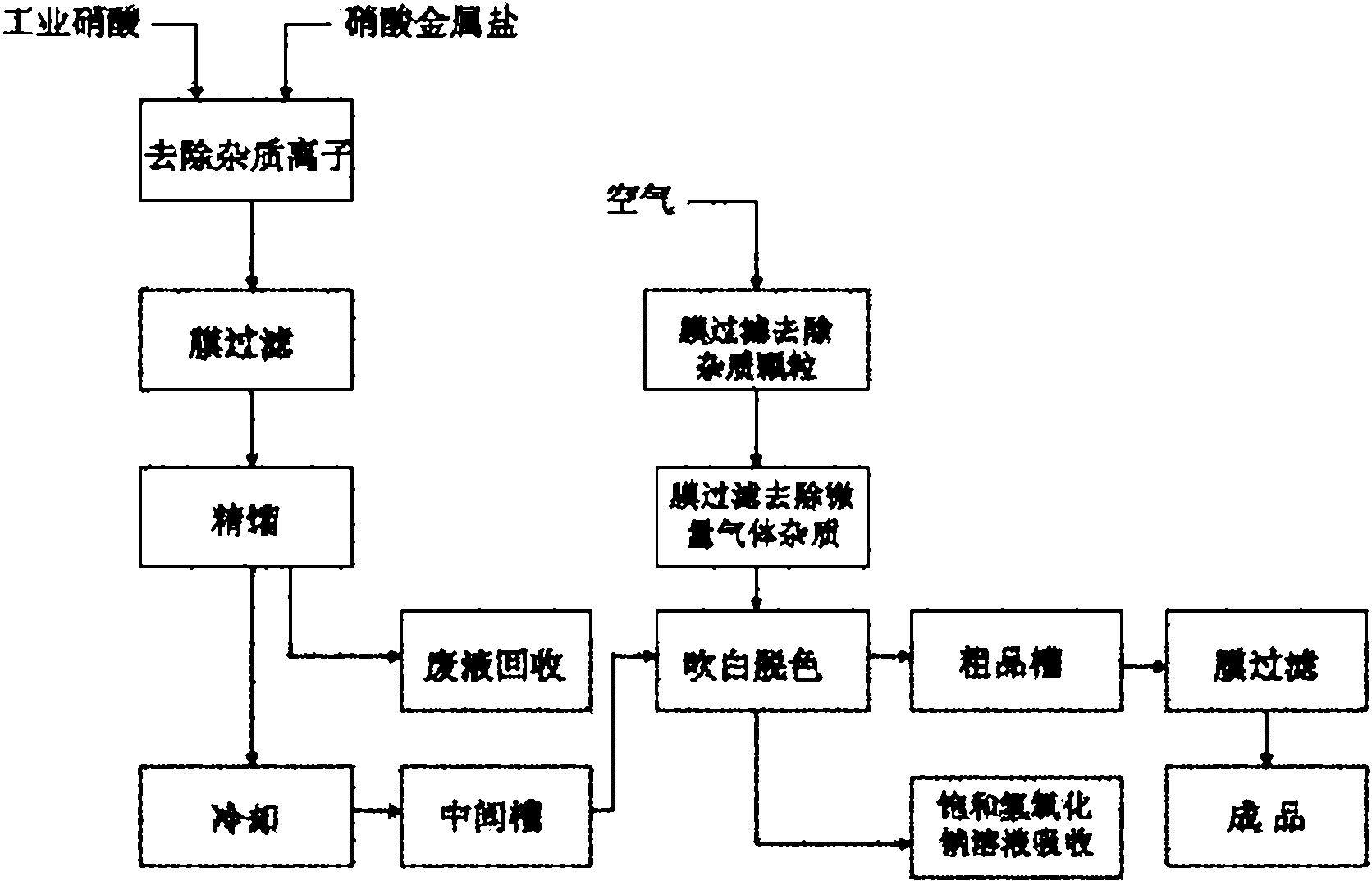

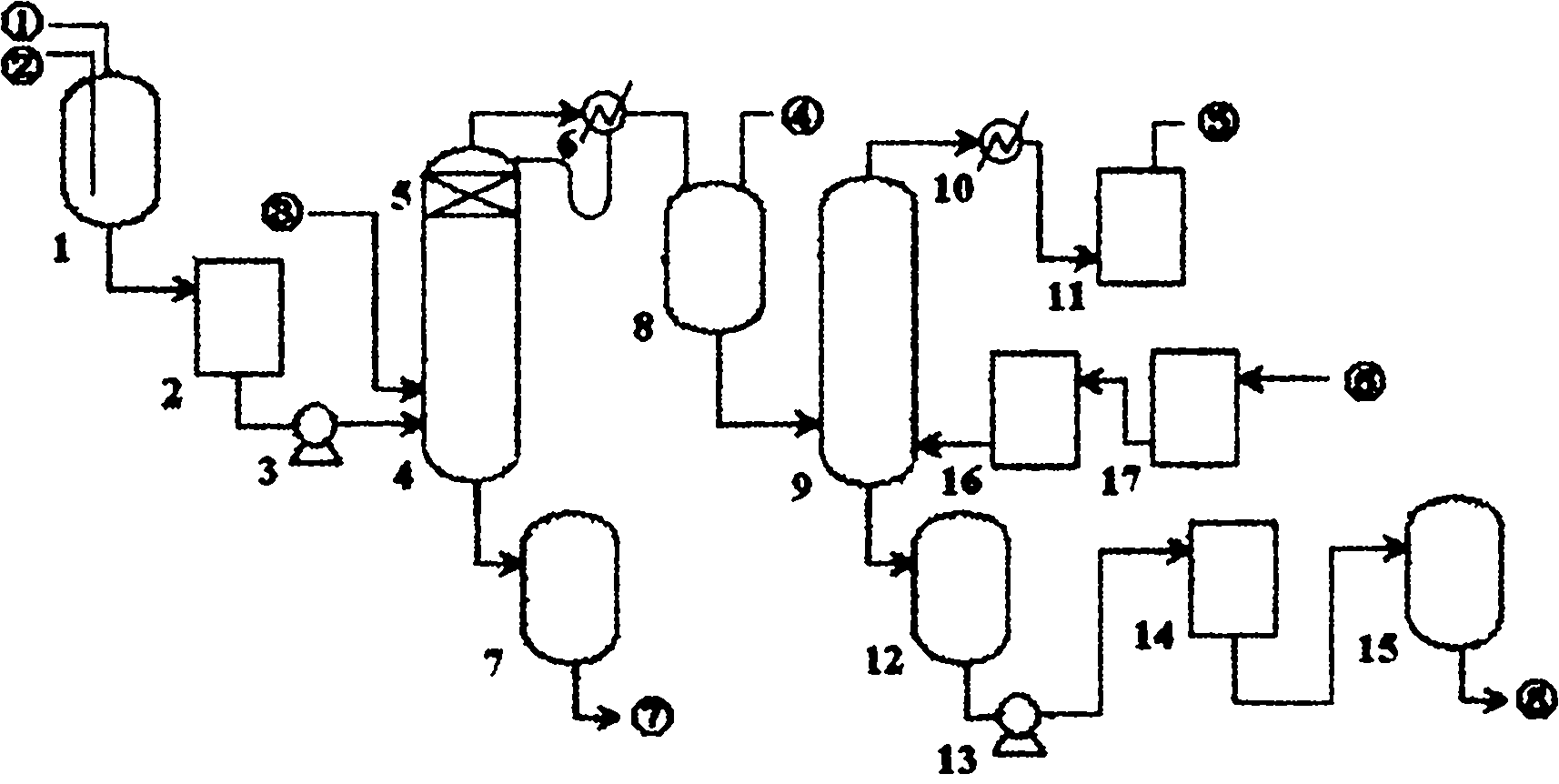

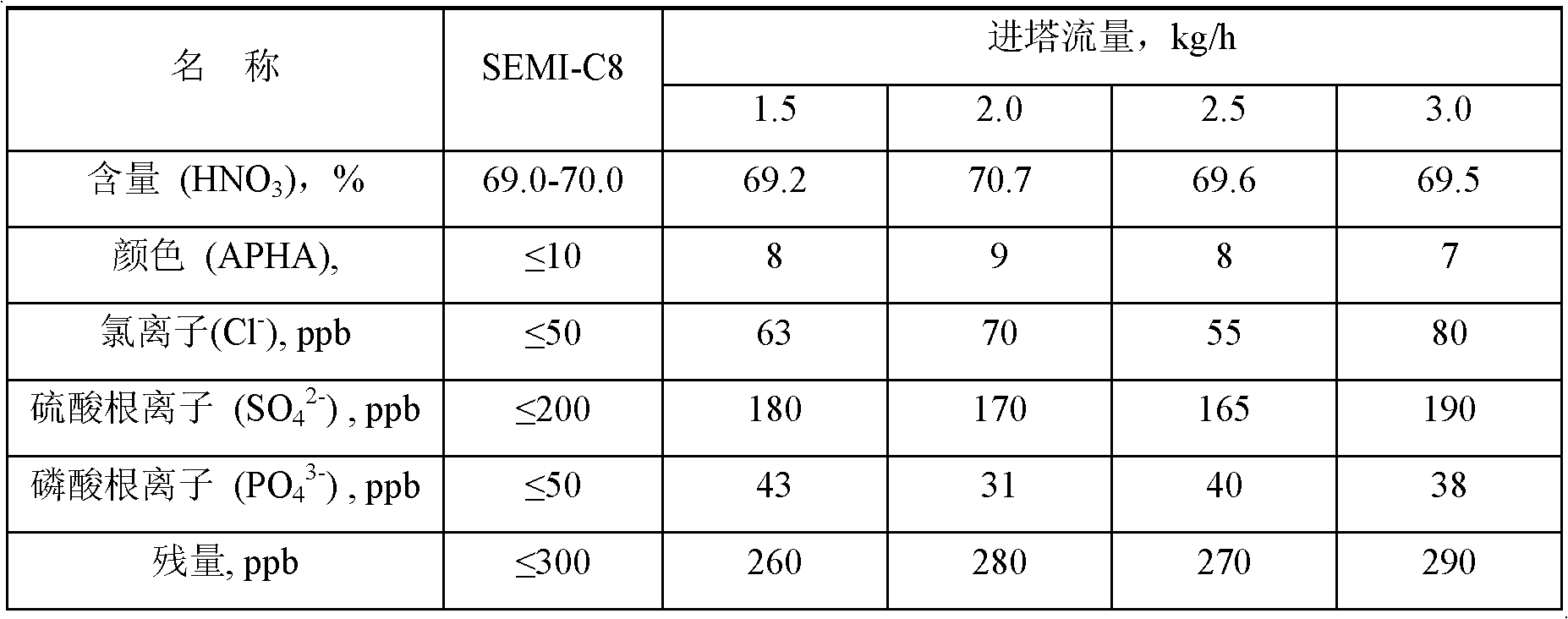

Process for preparing ultrapure nitric acid

InactiveCN102001635AEfficient removalSolve the problem of high content of impurity ionsNitric acidInorganic saltsNitrogen oxides

The invention discloses a process for preparing ultrapure nitric acid. The method comprises the following steps of: adding nitric acid metal salt to react with impurity anions, namely Cl<-> and SO4<2-> in industrial nitric acid serving as a raw material, precipitating, performing membrane filtration purification, rectifying to remove inorganic salt, regulating rectification liquid to form 69 to 70 weight percent nitric acid by using ultrapure water, white-blowing by using purified air in a white-blowing tower, absorbing blown nitrogen oxide by using saturated aqueous solution of sodium hydroxide, adding white-blowing liquid into a crude product groove, and performing membrane filtration to obtain the ultrapure nitric acid. The detection shows that: the content of the ultrapure nitric acidprepared by the process reaches 69 to 70 weight percent and various indexes of the product all meet the semiconductor equipment and material international (SEMI) C8 standard. The rectification is performed and waste acid is collected simultaneously, and the waste acid is treated and recycled, so that the quality and productivity of the product are improved; and the product has stable quality, lowimpurity content and high purity and is suitable for large-scale and continuous production.

Owner:SHANGHAI CHEM REAGENT RES INST

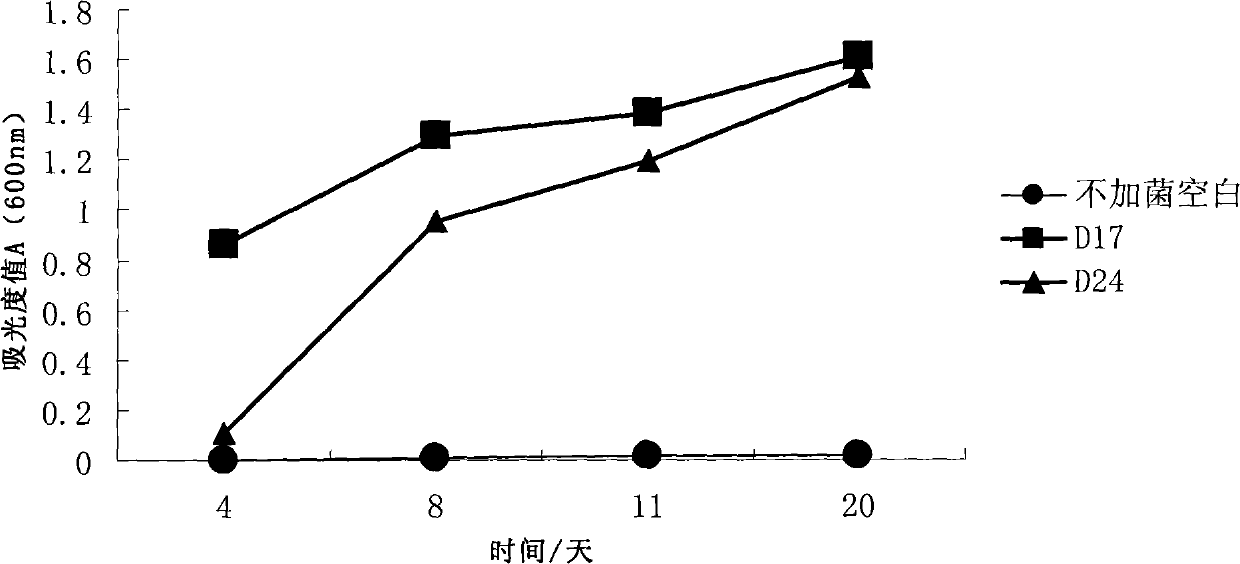

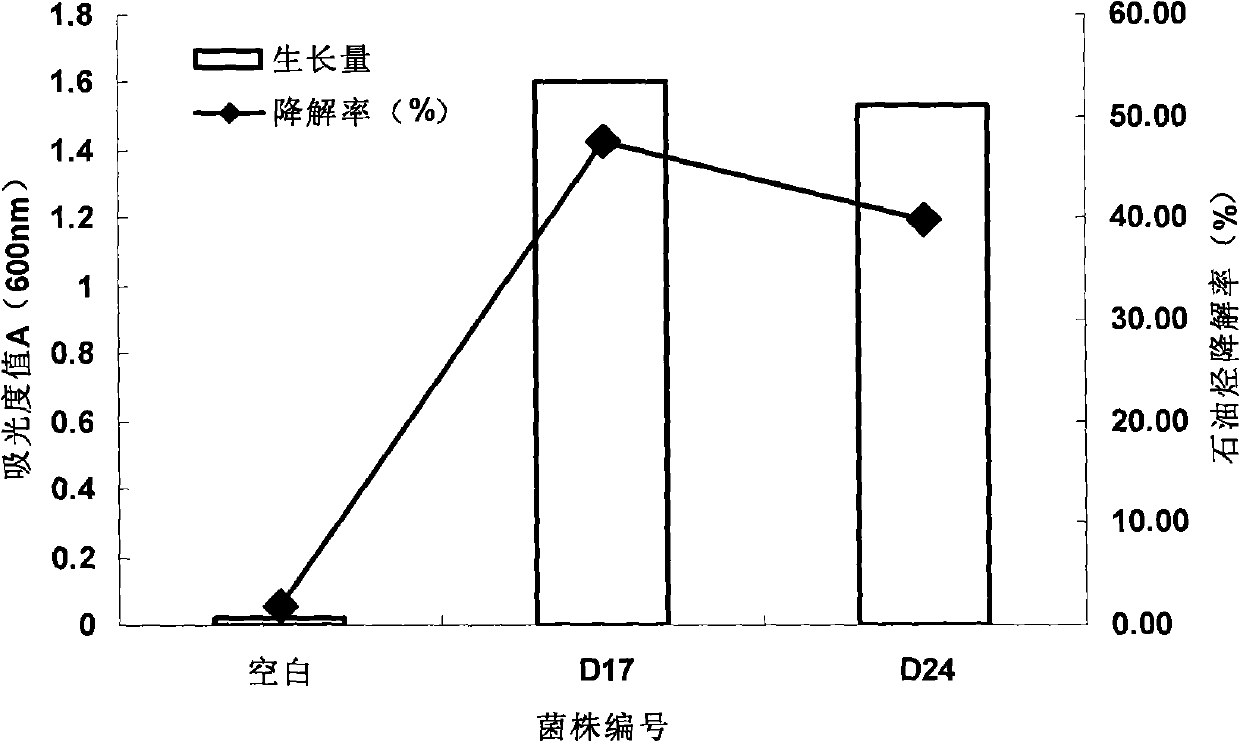

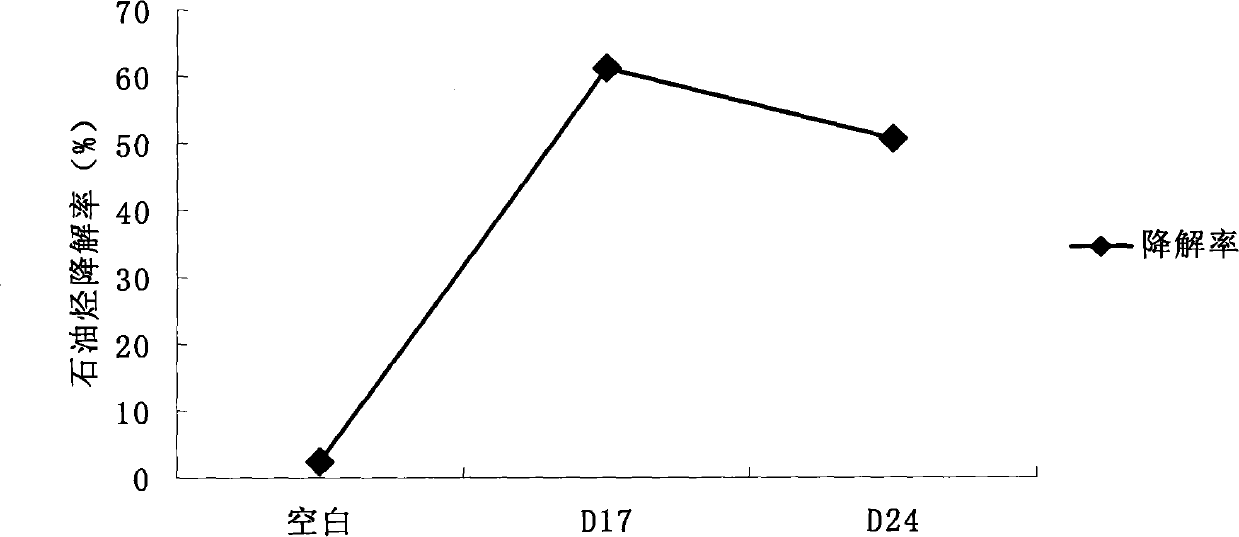

Low-temperature-resistant petroleum degradation strains as well as culture method, culture medium and application thereof

InactiveCN102021128AImprove adaptabilityHigh activityWaste water treatment from quariesBacteriaBioremediationBiology

The invention relates to low-temperature-resistant petroleum degradation strains as well as a culture method, a culture medium and application thereof, wherein the low-temperature-resistant petroleum degradation strains are Paracoccus sp. D17 and Paracoccus sp. D24;a liquid culture medium for the two strains is screened, and per 1000ml of the liquid culture medium comprises 0.5g of NaCl, 0.1g of K2HPO4, 0.1g of NH4H2PO4, 0.1g of (NH4)2SO4, 0.02g of MgSO4.7H2O, 0.3g of KNO3, 700-900ml of oilfield wastewater and the balance of ultrapure water; a solid culture medium for the two strains is screened and is formed by additionally adding 15-20g of agar into each 1000ml of the liquid culture medium and further uniformly coating 20-30 mu l of sterile crude oil on the surface of the culture medium; and the two strains can be applied in degradation of petroleum hydrocarbon and bioremediation of petroleum pollution in soil or a water body. The two low-temperature strains can be applied in a low-temperature environment and have great value for controlling the petroleum pollution in the soil in the low-temperature environment.

Owner:BEIJING NORMAL UNIVERSITY

Preparation method of noble metal-graphene nanometer composite

InactiveCN101797502AGood dispersionEasy to prepareCell electrodesCatalyst activation/preparationHydrazine compoundVolumetric Mass Density

The invention provides a preparation method of a noble metal-graphene nanometer composite, which comprises the steps of: oxidizing powdered graphite to prepare graphene oxide by oxidizing potassium permanganate; dispersing the graphene oxide in water; ultrasonically stripping a dispersed graphene oxide piece which is formed in water solution; reducing the graphene oxide piece with hydrazine hydrate under the existence of surface active agent to obtain graphene water solution which can be stably dispersed in water phase; centrifugally concentrating the graphene water solution; adding noble metal prodromic salt and electrolyte salt into surface active agent-containing water solution; adding water phase-dispersed graphene in proportion; adjusting PH value; reacting by means of ultrasonic electrochemistry under the density of the constant current and the intensity of ultrasound; centrifugally separating with high speed; and washing with ultrapure water to prepare the noble metal-graphene nanometer composite. The method has the advantages of convenience, speediness and controllability, etc. The prepared graphene nanometer composite has good dispersibility in water, can be stably existed for a long term, and has good electro-catalysis redox characteristic to organic matter.

Owner:NANJING UNIV

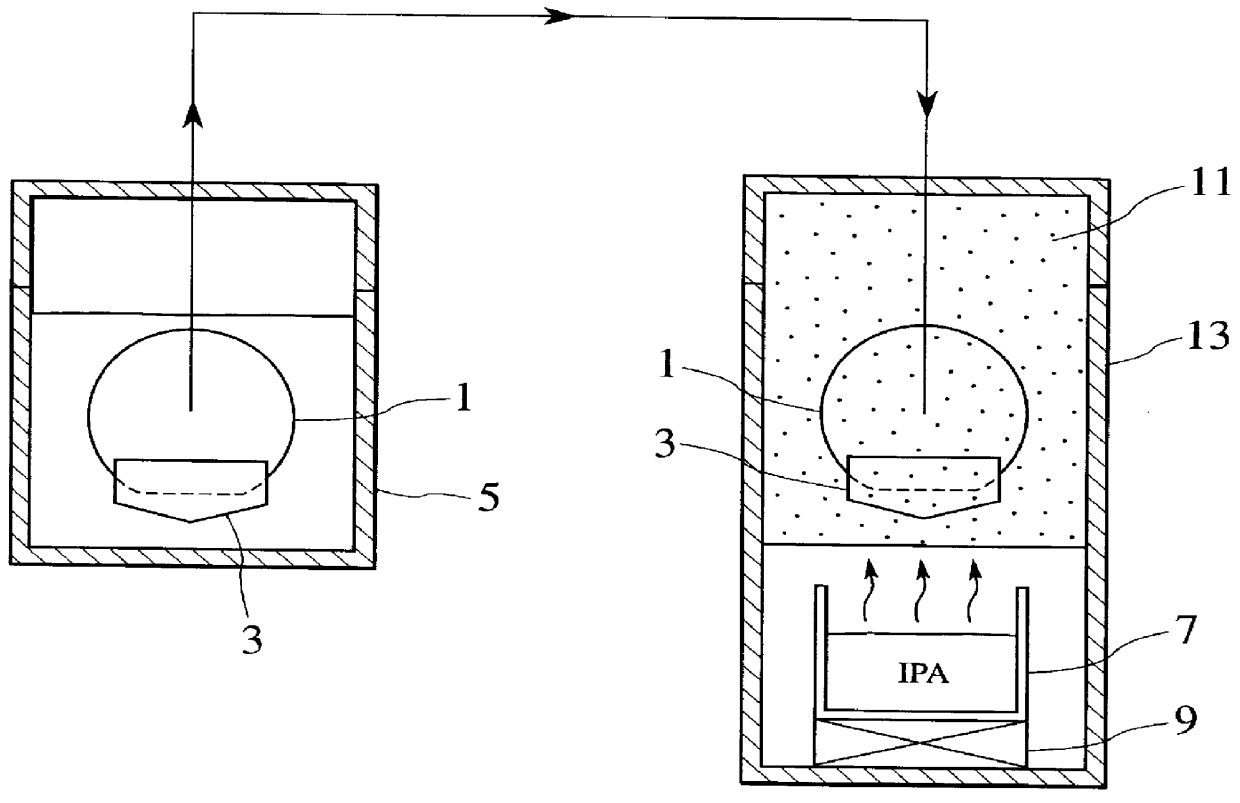

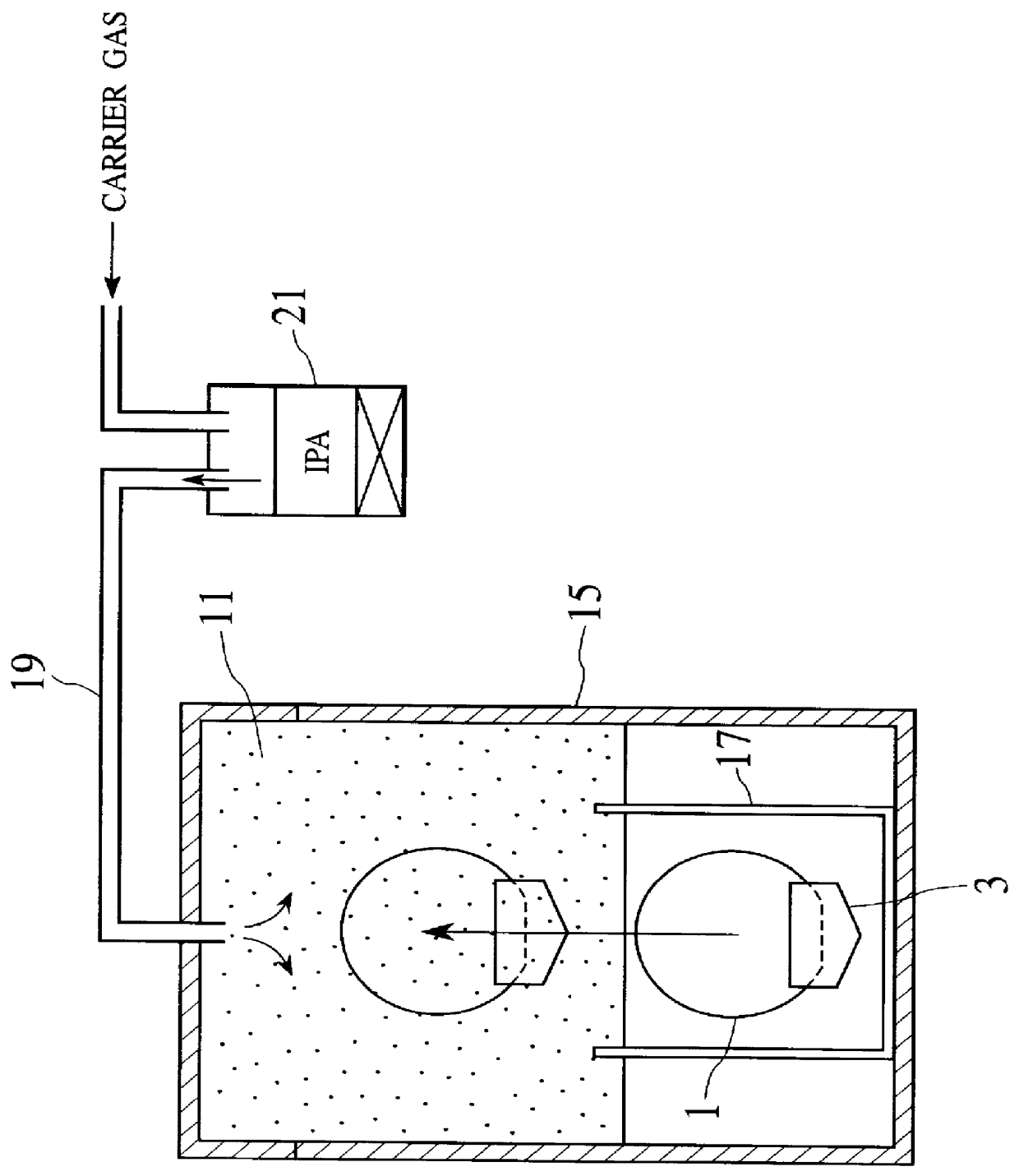

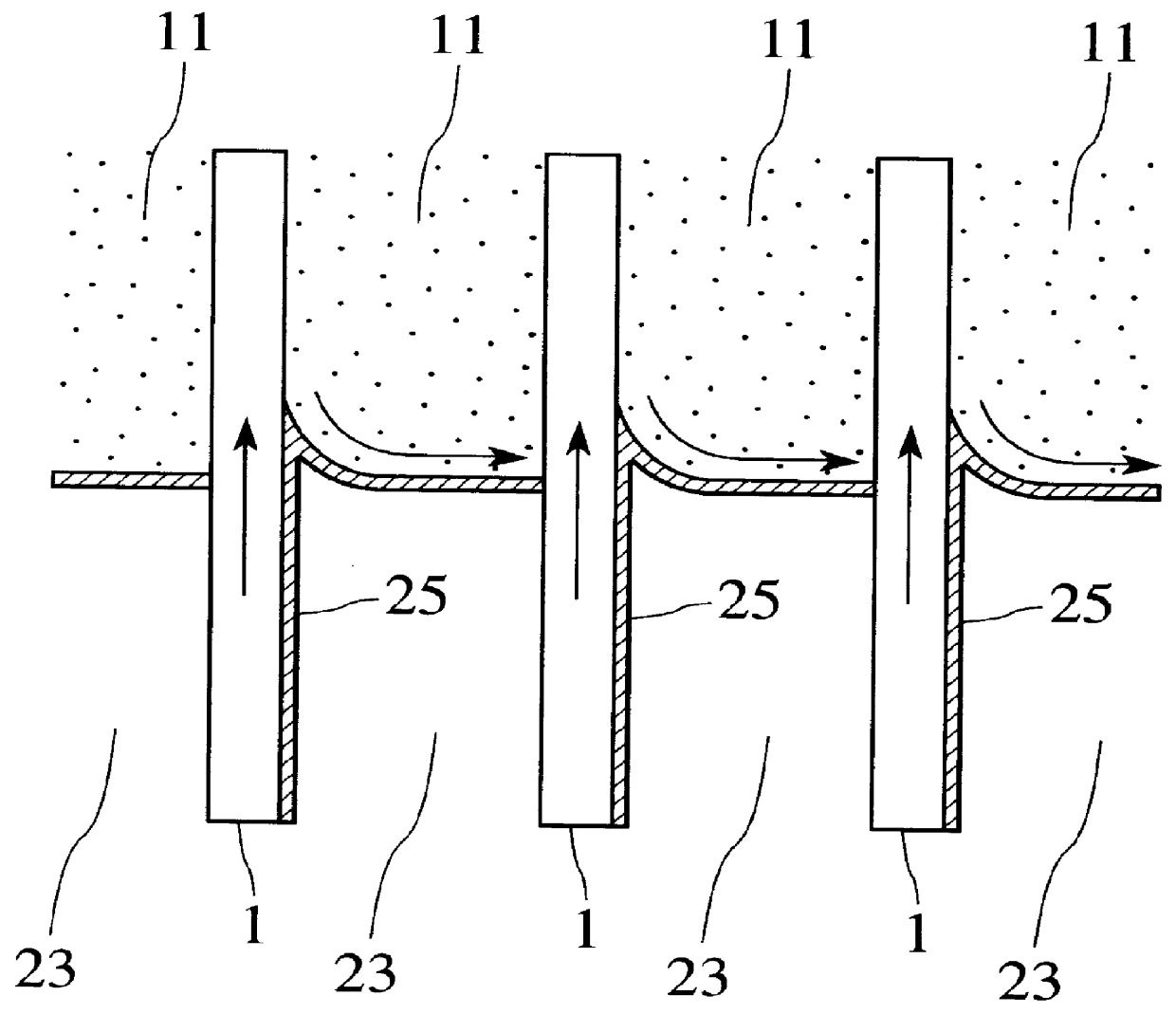

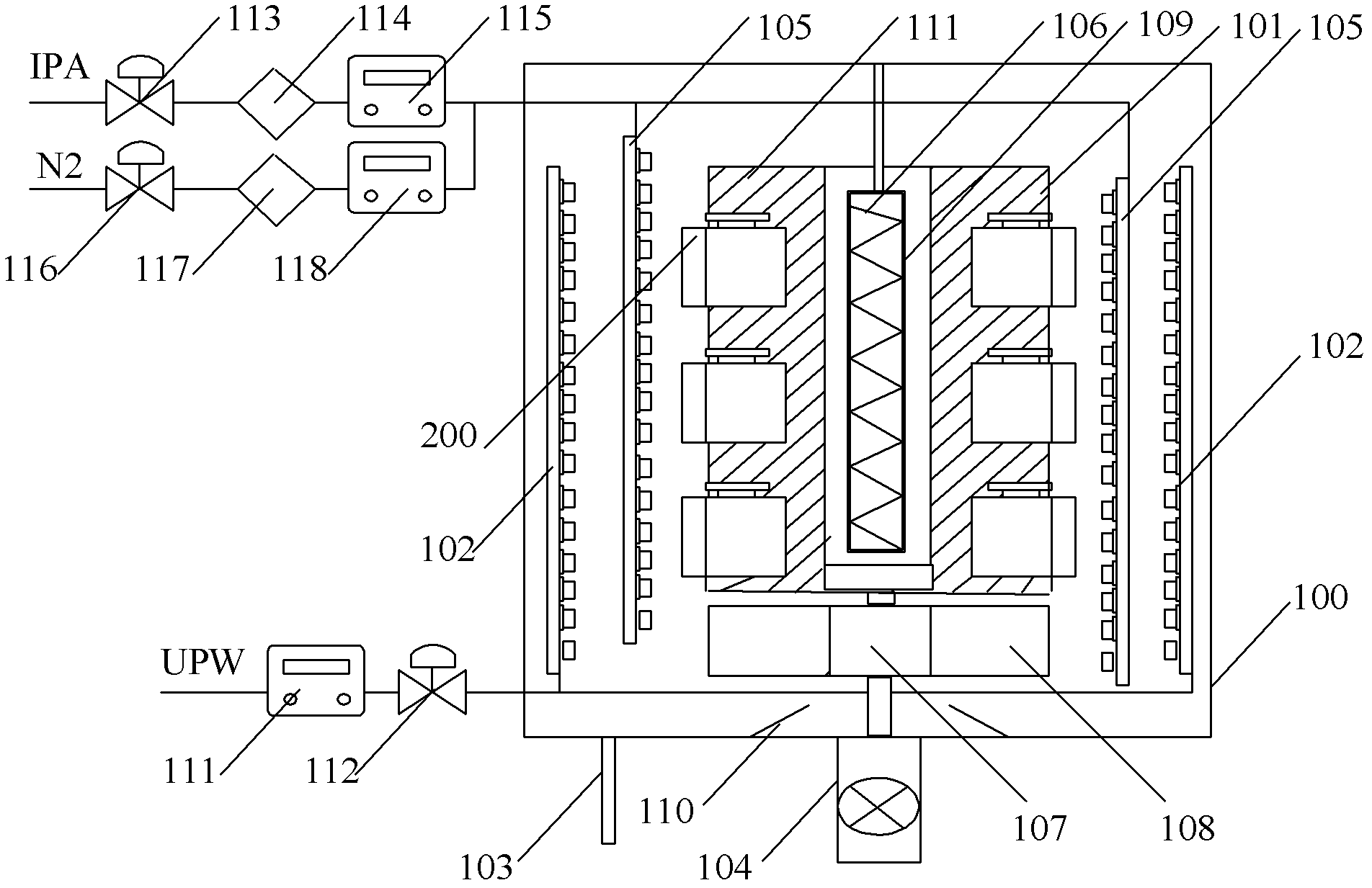

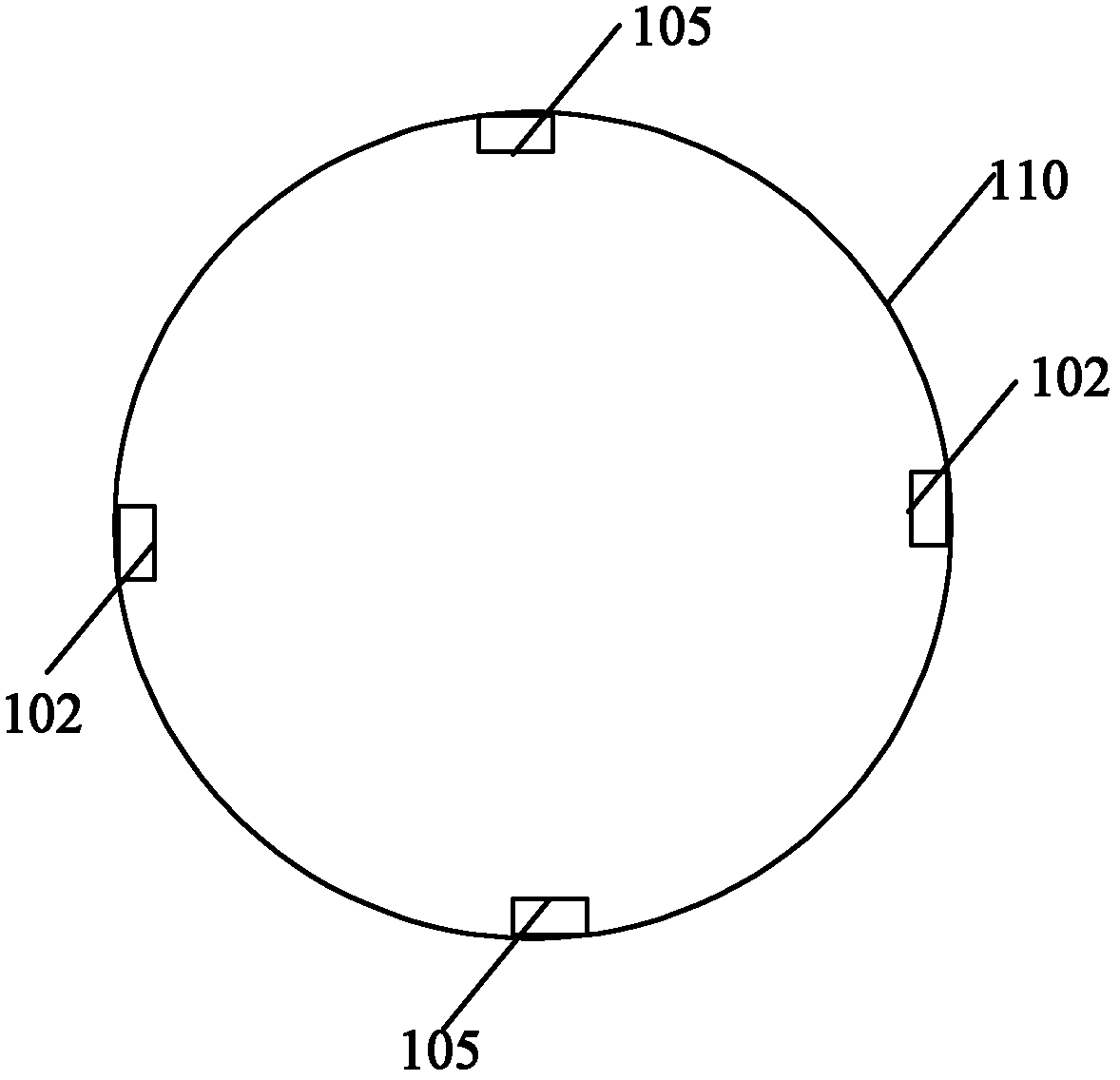

Substrate cleaning/drying equipment and substrate cleaning/drying method

InactiveUS6152153AHollow article cleaningSemiconductor/solid-state device manufacturingEngineeringUltrapure water

There is provided a substrate cleaning / drying equipment for removing residual moisture from a substrate by exposing the substrate to an IPA steam after the substrate has been cleaned by a ultra pure water. The substrate cleaning / drying equipment comprises a cleaning / drying chamber for cleaning / drying the substrate, a cleaning tub which is provided below the cleaning / drying chamber and to which at least a ultra pure water is supplied, an IPA steam supplying pipe for supplying the IPA steam to an upper area of the cleaning / drying chamber such that the upper area of the cleaning / drying chamber is filled with the IPA steam, a steam supplying pipe for supplying a steam between the ultra pure water in the cleaning tub and the IPA steam, and a carrying unit for carrying the substrate, which has been cleaned by the ultra pure water, from the ultra pure water into the IPA steam via the steam. The ultra pure water, the steam, the IPA steam may be supplied onto the substrate by using injection nozzles respectively in order of the ultra pure water, the steam, the IPA steam.

Owner:KK TOSHIBA

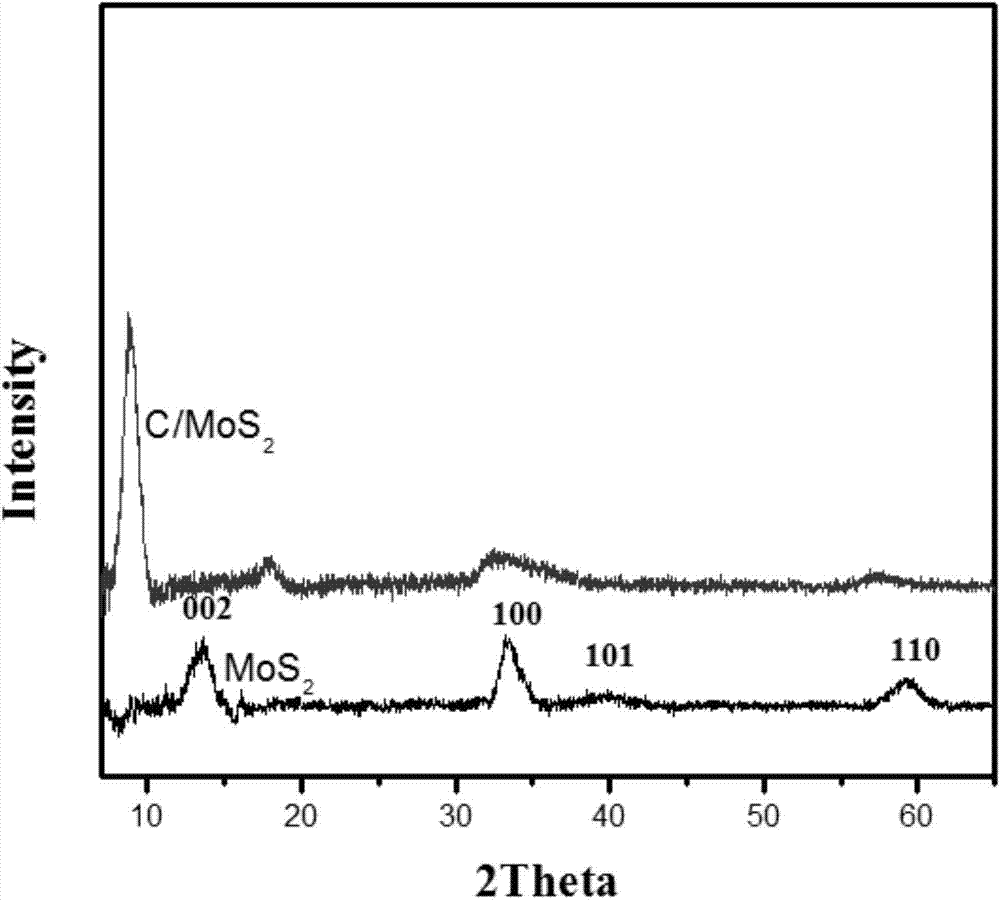

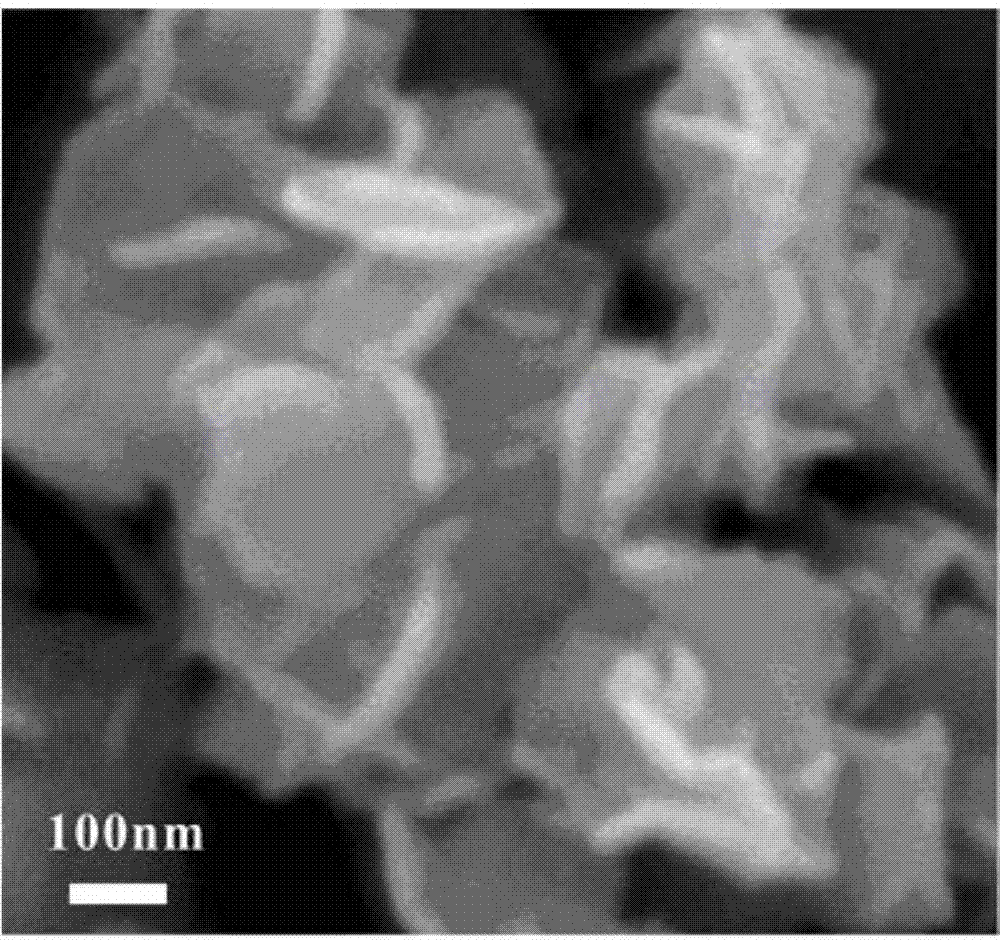

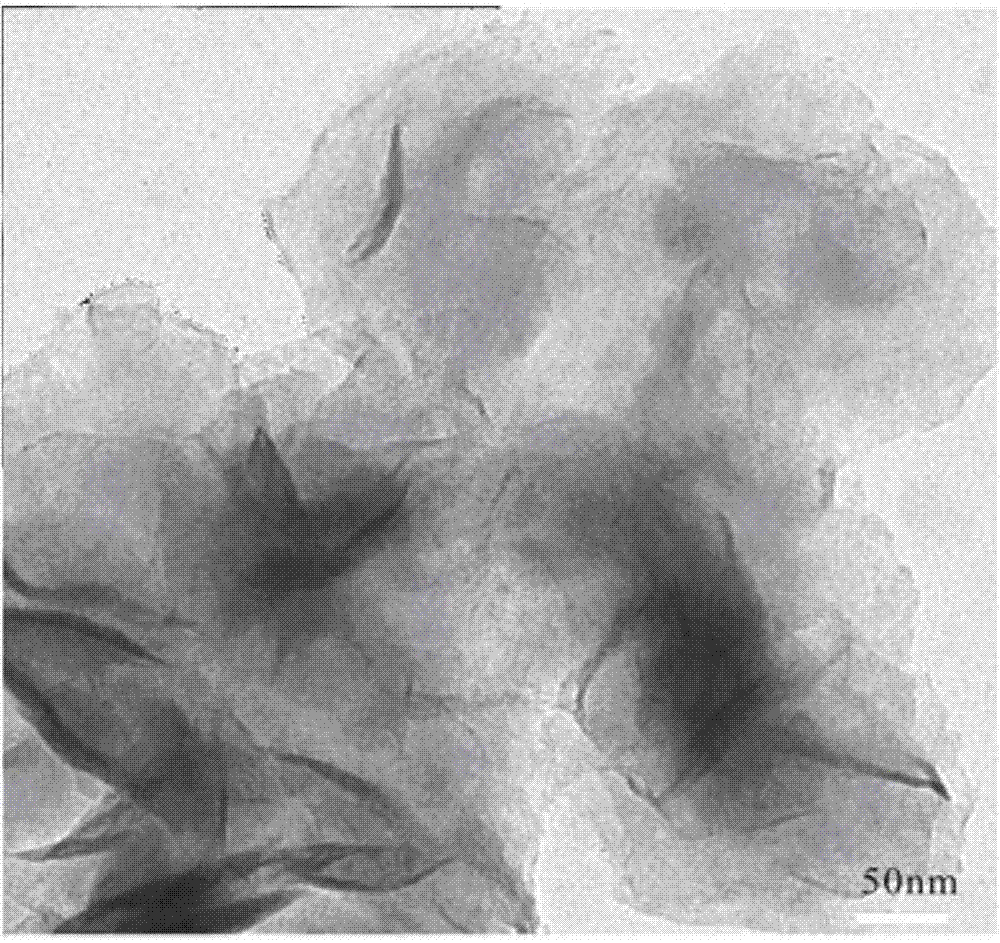

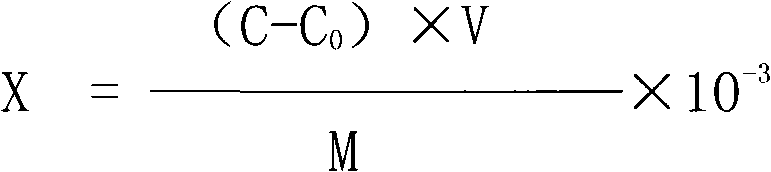

Preparation method of carbon-doped molybdenum disulfide nanometer material

InactiveCN104495937AImprove cycle stabilityLittle change before and afterMaterial nanotechnologyMolybdenum sulfidesSodium acetateDispersity

The invention provides a preparation method of a carbon-doped molybdenum disulfide nanometer material. The method comprises the following steps: weighing sodium molybdate, ammonium molybdate or molybdenum oxide and thiourea, sodium sulphide, potassium rhodanate or dithiocyano sodium acetate to be firstly dissolved into an ethylene glycol solution, then dissolved into ultrapure water, and fully stirring, so as to prepare a mixed solution; adjusting the pH value of a mixed solution with ammonia water and hydrochloric acid; transferring the mixed solution into a reaction kettle, and carrying out solvothermal reaction; taking out the mixed solution after reaction, and naturally cooling to room temperature; sequentially washing with ultrapure water and ethyl alcohol, and collecting a black substance; and drying the black substance in a vacuum drying oven, so as to prepare the carbon-doped molybdenum disulfide nanometer material. According to the carbon-doped MoS2 nanometer material prepared by the method, the sheet is uniform in size, good in dispersity, small in pollution in preparation process, and free of harmful air; and the molybdenum disulfide nanometer material with good dispersity can be greatly prepared.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

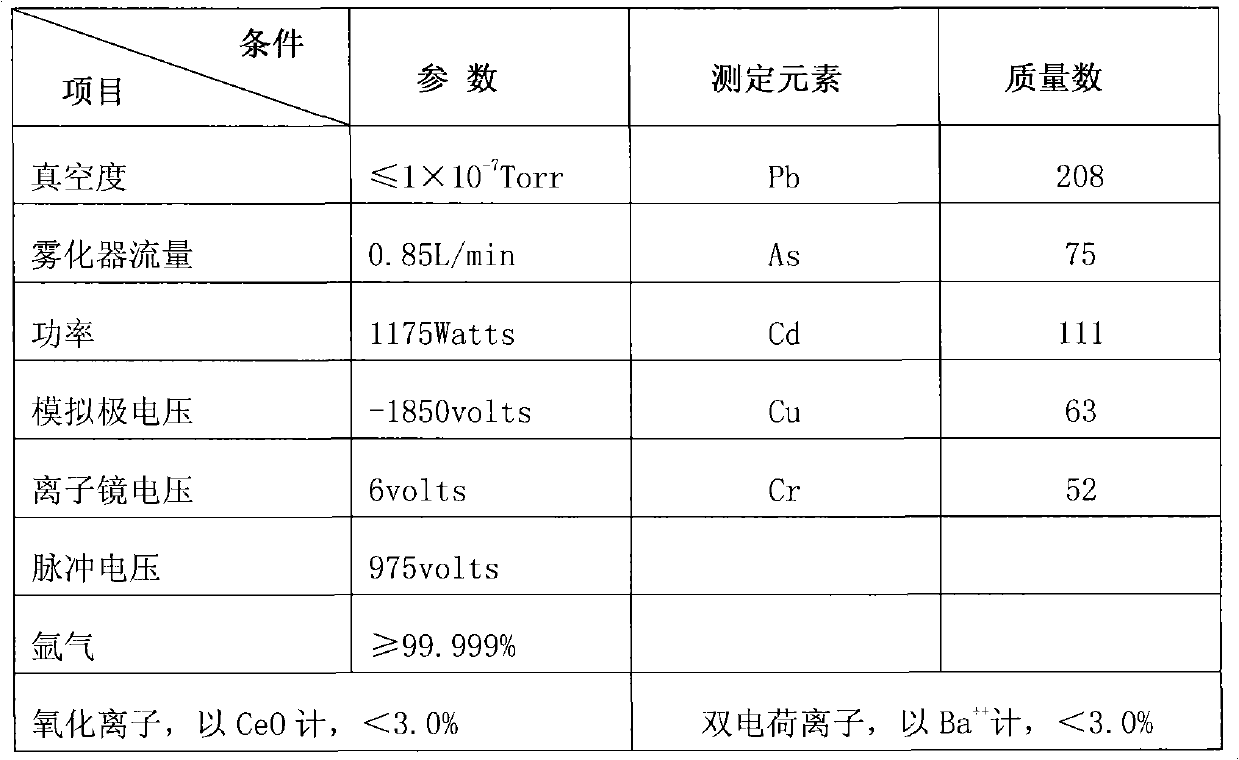

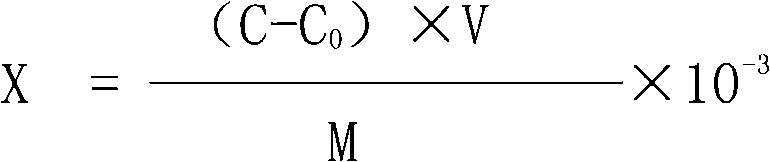

Method for measuring harmful elements of lead, arsenic, cadmium, copper and chromium in eucalyptus oil food additive

InactiveCN102023192AMeet testing needsLow detection limitComponent separationPreparing sample for investigationFood additiveSpectroscopy

The invention belongs to the field of chemistry and is suitable for measuring the harmful elements of lead, arsenic, cadmium, copper and chromium in a eucalyptus oil food additive. The measuring method comprises the following steps of: firstly, quantitatively splitting a sample of the eucalyptus oil food additive and placing the sample into a polytetrafluoroethylene digester of a microwave digestion instrument; secondly, digesting the sample by adding 40-50mL of nitric acid-peroxide into each 10mL of the sample of the eucalyptus oil food additive; thirdly, taking off a sample solution to cool, release pressure and discharge waste gas and adding ultrapure water to 50mL; fourthly, using 4 percent nitric acid to dilute lead, arsenic, cadmium, copper and chromium of a national standard stock solution (GBW) into standard solution mixing liquid with concentrations of 0.00microgram / L, 2.50microgram / L, 5.00microgram / L, 10.00microgram / L, 20.00microgram / L and 30.00microgram / L step by step, measuring ion abundance by using an ICP-MS (Inductively Coupled Plasma-Mass Spectroscopy) instrument, and with the concentrations as traverse coordinate and the ion abundance as longitudinal coordinate, automatically drawing an element calibration curve by a computer; and fifthly, measuring the ion abundance of the lead, the arsenic, the cadmium, the copper and the chromium in the sample solution of the third step and calculating the content of each element.

Owner:CHECKOUT & QUARANTINE TECH CENT YUNNAN ENTRY &EXIT CHECKOUT & QUARANTINE BUR

Multi-coordination-agent cyanide-free electrogilding liquid and electrogilding process

ActiveCN103741181AExcellent bath performanceGood coating performancePotassium hydroxidePotassium carbonate

The invention relates to multi-coordination-agent cyanide-free electrogilding liquid and an electrogilding process, which belong to the technical field of electrogilding. The electrogilding liquid is prepared from a main coordination agent, an auxiliary coordination agent, potassium hydroxide, potassium carbonate, goldpotassium chloride, combined additives and ultrapure water. The electrogilding process comprises the following steps: 1, preprocessing a substrate; 2, electroplating an intermediate nickel plating layer; 3, electrogilding, namely washing the substrate after electroplating the intermediate nickel plating layer with ultrapure water, directly feeding the substrate into a plating cell containing the multi-coordination-agent cyanide-free electrogilding liquid to be electrogilded, taking out a sample from the electrogilding liquid after the electrogilding, washing the surface of the sample by utilizing distilled water, and drying the sample through cold air. Double coordination agents are used as the coordination agents of gold ions in the electrogilding liquid, so that a cyanide-free electrogilding system which has high current efficiency, smoothness and compactness in plating layer crystallization, wide current density range, wide temperature requirement and capability of guaranteeing the golden bright appearance of the plating layer compared with those of a single coordination agent system is obtained.

Owner:HARBIN INST OF TECH

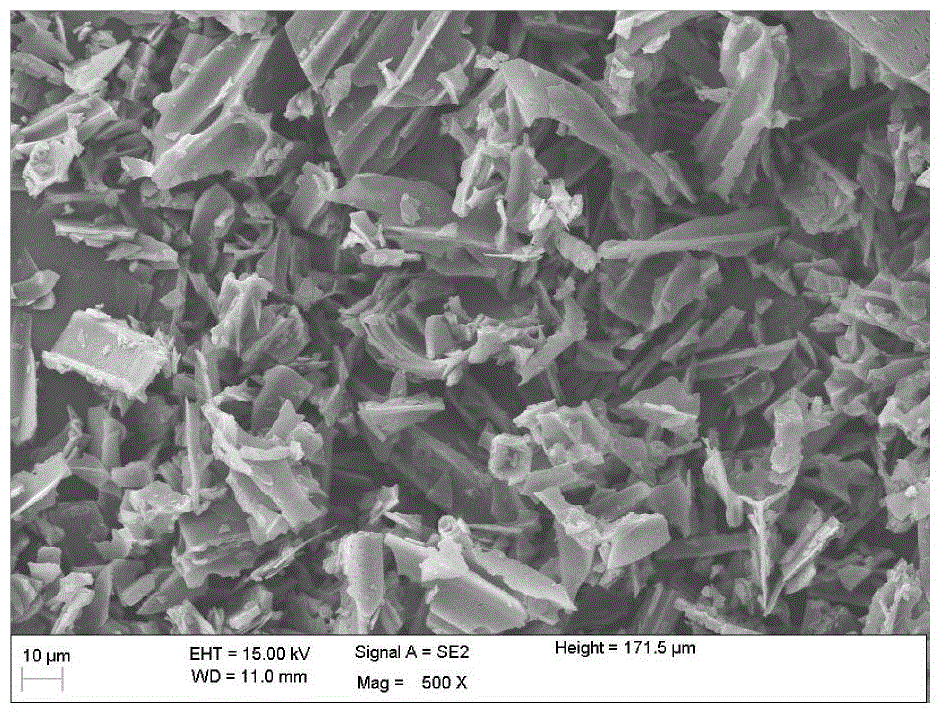

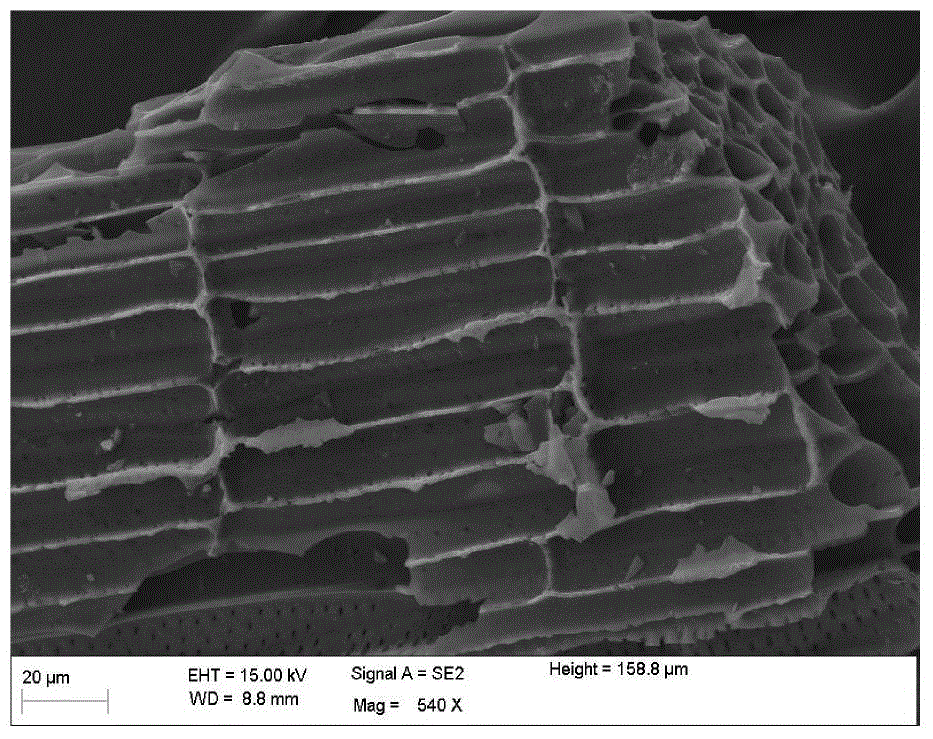

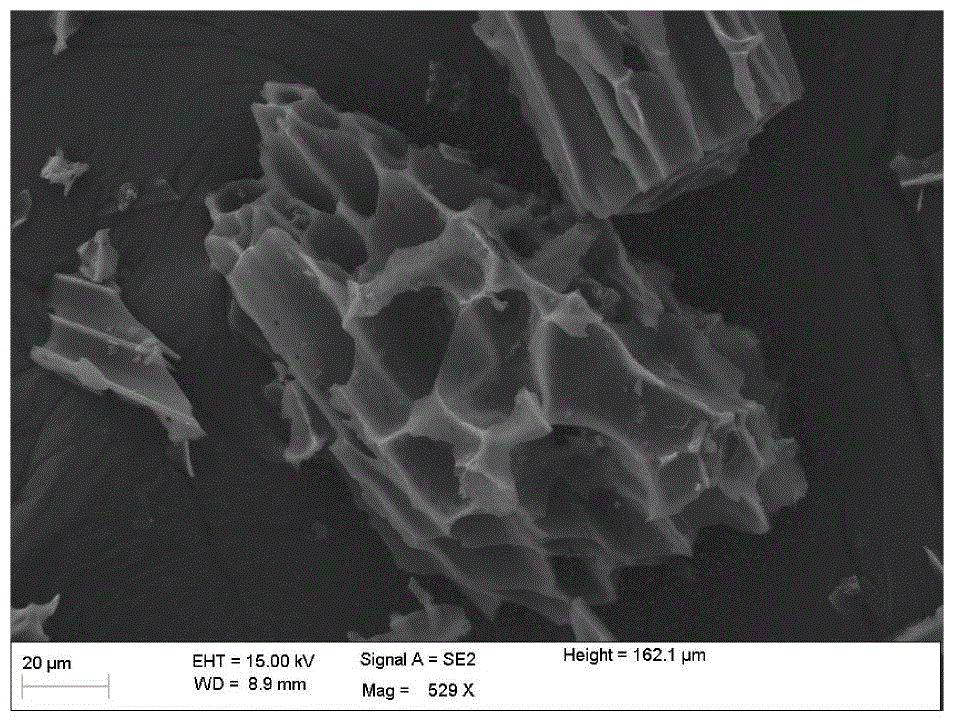

Preparation method of porous biological carbon heavy metal adsorbing material based on cotton straw

ActiveCN104941589AHigh porositySubtle structureOther chemical processesAlkali metal oxides/hydroxidesFiltrationSilanes

The invention discloses a preparation method of a porous biological carbon heavy metal adsorbing material based on cotton straw. The preparation method comprises the following steps: (1) adding the cotton straw into a ZnCl2 solution, carrying out stirring and impregnation for a certain time, and drying; (2) placing the dried cotton straw into an electric tube furnace for high-temperature calcination, grinding the calcined product into powder, adding the powder and ultrapure water into a hydrothermal reaction kettle, stirring till swelling is sufficient, heating for a reaction, and conducting centrifugal drying on the reaction product, so as to obtain a biological carbon material; (3) adjusting the pH of an ethanol aqueous solution with an acetic acid solution, adding 3-mercaptopropyl triethoxy silane into the ethanol aqueous solution, and carrying out oscillation to obtain a modified liquid; adding the biological carbon material into the modified liquid, carrying out oscillation and filtration, drying the obtained solid, washing the dried solid with an ethanol aqueous solution, and drying to obtain the biological carbon heavy metal adsorbing material. The preparation method is simple, and easy to operate; the biological carbon heavy metal adsorbing material prepared according to the method adopts a porous honeycomb-shaped structure, is large in specific surface area, high in heavy metal adsorbing property, and high in economic value and environment-friendly meaning.

Owner:WESTERN MINING CO LTD

Method for cleaning glass substrate for coating

ActiveCN102649625AEfficient removalHighly activated atomic activityVacuum evaporation coatingSputtering coatingCooking & bakingStrong acids

The invention discloses a method for cleaning a glass substrate for coating and belongs to the technical field of preparation methods of materials. According to the cleaning method, the cleaning is realized by hydrogen peroxide ultrasound, ultrapure water ultrasound, acetone ultrasound, ethanol ultrasound, drying, wiping, baking and plasma cleaner; a cleaned glass substrate is obtained; and finally, the surface of the glass substrate can be coated. According to the cleaning method provided by the invention, no strong acid or alkali is used, so that the damage to the surface of the glass can be avoided. The cleaning method is simple in operation and is lower in flow; no great cleaning device or much cleaning liquid is needed; and the space can be effectively saved and the cost, energy sources and the time can be saved.

Owner:北京鼎臣世纪超导科技有限公司

CO2 electrochemical reduction method with Ag-containing electrode as working electrode

The invention provides a CO2 electrochemical reduction method with an Ag-containing electrode as a working electrode and relates to a CO2 electrochemical reduction method. The CO2 electrochemical reduction method with the Ag electrode as the working electrode is used for solving the problem of low product efficiency of the existing CO2 electrochemical reduction method. The method comprises the following steps: 1, mixing an ionic liquid with ultrapure water to obtain an electrolyte; 2, assembling an apparatus; and 3, performing CO2 electrochemical reduction, namely completing the CO2 electrochemical reduction with the Ag-containing electrode as the working electrode. The CO2 electrochemical reduction method has the advantages that 1, the Ag-containing electrode is taken as the working electrode and the reduction performance is stable, 2, the ionic liquid is mixed with the ultrapure water to obtain the electrolyte, and in combination with taking the Ag-containing electrode as the working electrode, the generation of CO is promoted in a cathode region, and therefore, the product efficiency is greatly improved, and 3, a cathode tank is separated from an anode tank by use of an ion exchange membrane, and consequently, oxygen generated in an anode region is prevented from going into the cathode region to produce negative effects on the reduction reaction. The method is mainly applied to CO2 electrochemical reduction.

Owner:HARBIN INST OF TECH

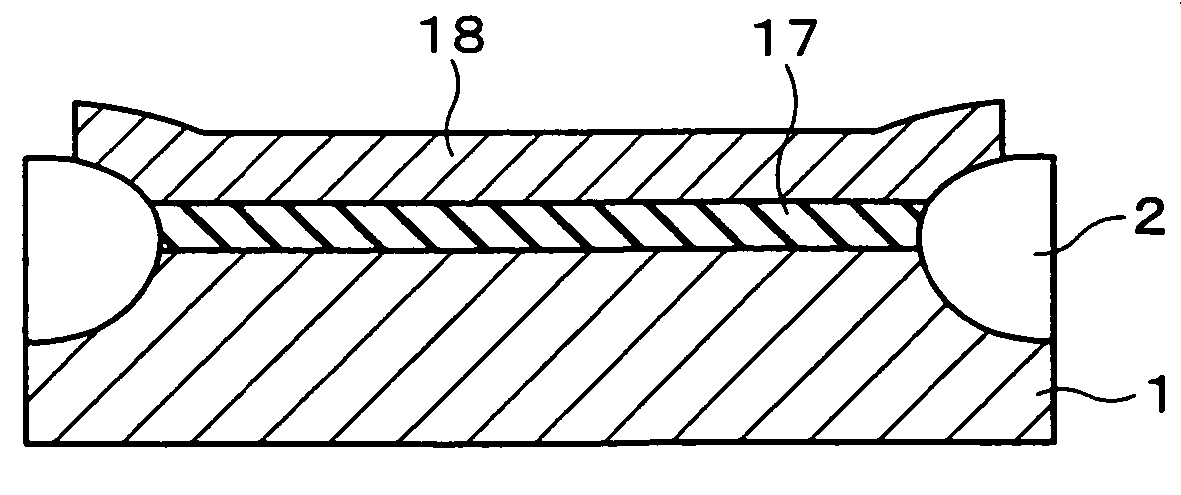

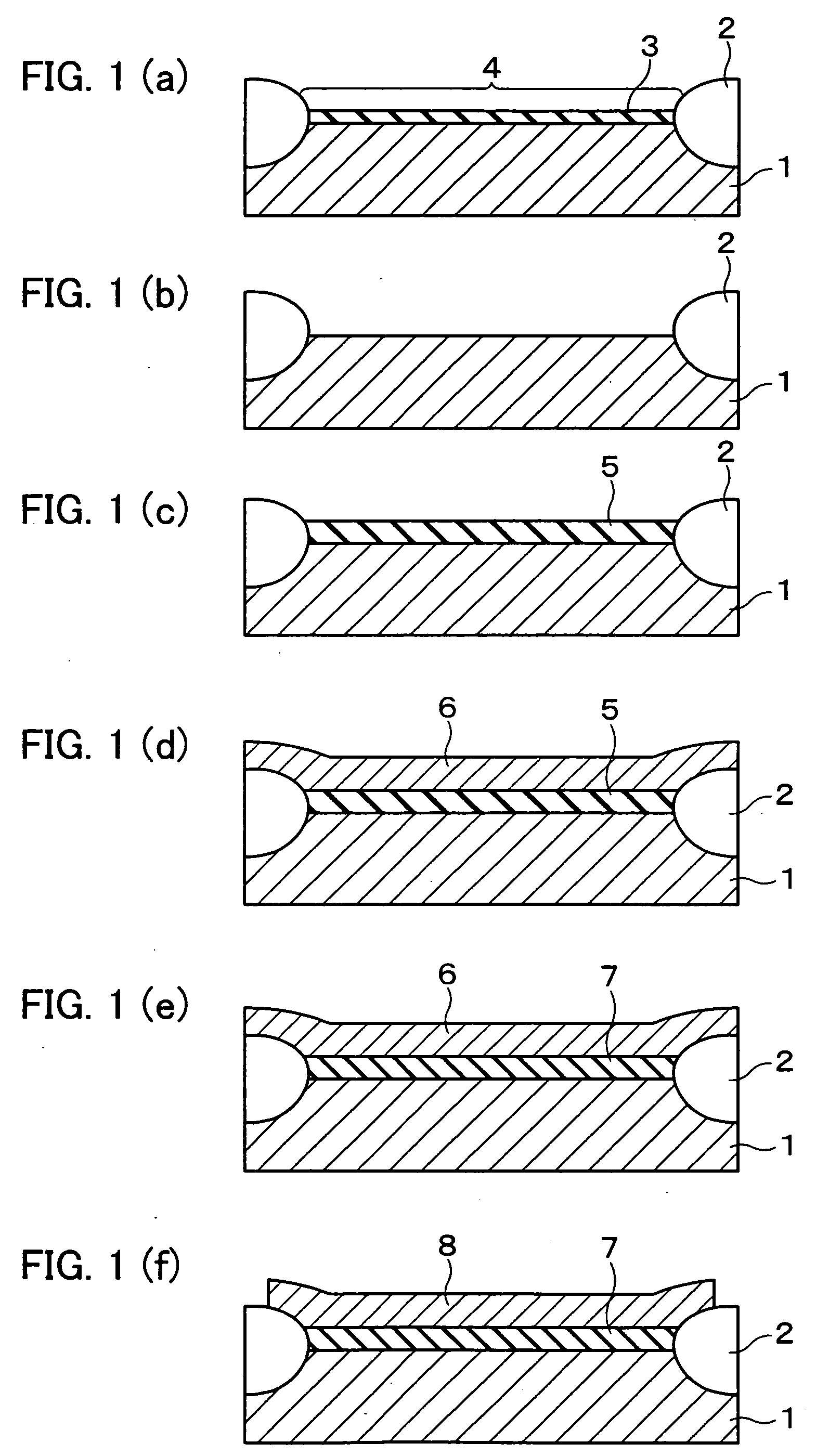

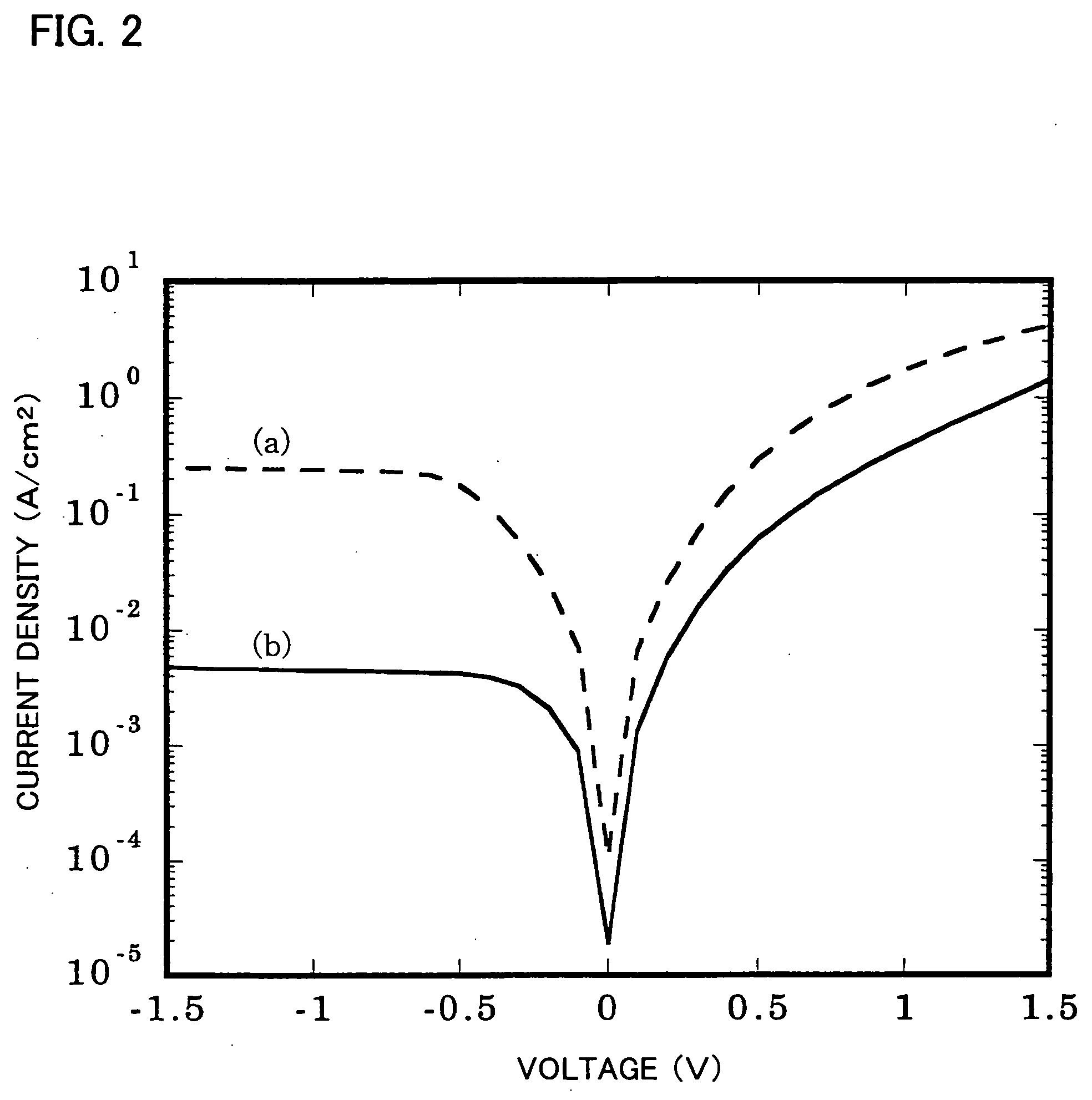

Method for forming silicon dioxide film on silicon substrate, method for forming oxide film on semiconductor substrate, and method for producing semiconductor device

InactiveUS20050215070A1Quality improvementIncrease ratingsTransistorSolid-state devicesDevice materialSilicon alloy

After cleaning a surface of a silicon substrate (1), impurities and natural oxide film existing on the silicon substrate (1) are removed by soaking the silicon substrate (1) in a 0.5%-by-volume HF aqueous solution for 5 minutes. The silicon substrate (1) is rinsed (cleaned) with ultrapure water for five minutes. Then, the silicon substrate (1) is soaked for 30 minutes in azeotropic nitric acid heated to an azeotropic temperature of 120.7° C. In this way, an extremely thin chemical oxide film (5) is formed on the surface of the silicon substrate (1). Subsequently, a metal film (6) (aluminum-silicon alloy film) is deposited, followed by heating in a hydrogen-containing gas at 200° C. for 20 minutes. Through the heat processing in the hydrogen-containing gas, hydrogen reacts with interface states and defect states in the chemical oxide film (5), causing disappearance of the interface states and defect states. As a result, the quality of the film can be improved. Thus, it is possible to form a high quality (with low leak current density), extremely thin silicon dioxide film on the silicon substrate at a low temperature with excellent film-thickness controllability.

Owner:JAPAN SCI & TECH CORP

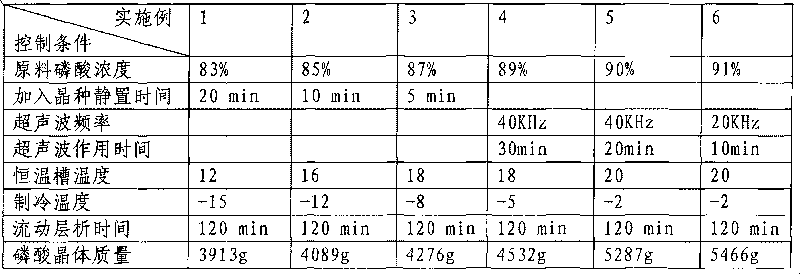

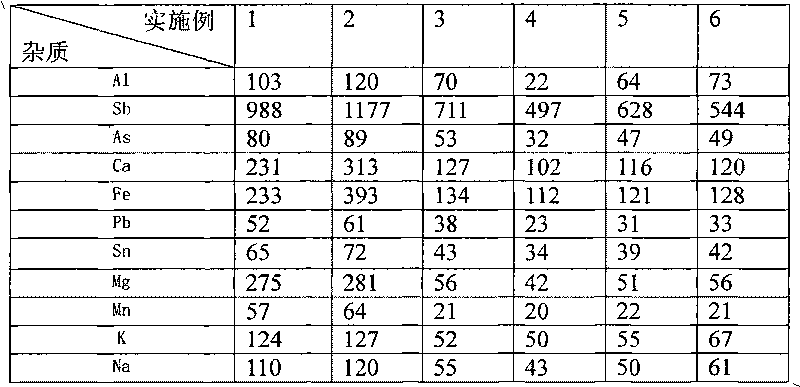

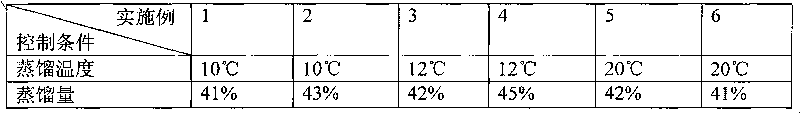

Method for preparing highly-pure phosphoric acid by flow chromatographic crystallization method

ActiveCN101759167AImprove efficiencyShort processPhosphorus compoundsSurface cleaningPhosphoric acid

The invention discloses a method for preparing a highly-pure phosphoric acid by a flow chromatographic crystallization method, in particular a production method for preparing the highly-pure phosphoric acid from an industrial phosphoric acid, which relates to highly-pure phosphoric acid preparation technology. The method comprises the following steps: (1) filtering the raw material phosphoric acid for crystallization with a film of 0.1 to 0.5 mu m for later use; (2) filling the phosphoric acid in a crystallizer, keeping the phosphoric acid at 12 to 20 DEG C and adding phosphoric acid seed crystals into the crystallizer, and standing for 1 to 20 minutes or acting on the stood phosphoric acid for 10 to 30 minutes by using an external sound field of 20 to 40 KHz; (3) keeping the phosphoric acid at 12 to 20 DEG C in a phosphoric acid thermostatic bath, pumping the phosphoric acid into the crystallizer by using a pump for circulation, making a crystal layer grow for 1 to 2 hours at a crystallization temperature of minus 15 to 2 DEG C and discharging the raw material phosphoric acid from the crystallizer; (4) melting and distilling the phosphoric acid crystal layer in the crystallizer at the temperature of 0 to 25 DEG C, wherein discharged distillate accounts for 40 to 50 percent of the mass of the crystal layer; (5) cleaning the surface of the crystal layer with spray highly-pure water; and (6) melting the cleaned phosphoric acid crystal layer at the temperature of 35 to 55 DEG C and diluting the melted phosphoric acid crystal layer with the highly-pure water to produce the highly-pure phosphoric acid product. The highly-pure phosphoric acid product produced by the method of the invention can be applied in the fields of chip wet-process cleaning and wet-process etching, silicon wafer surface cleaning, glass optical fiber production and the like.

Owner:YUNNAN CHEM RES INST

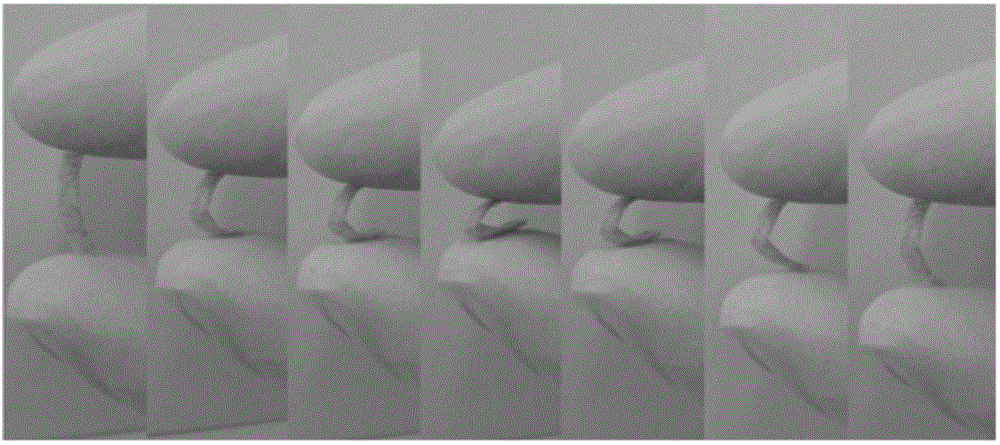

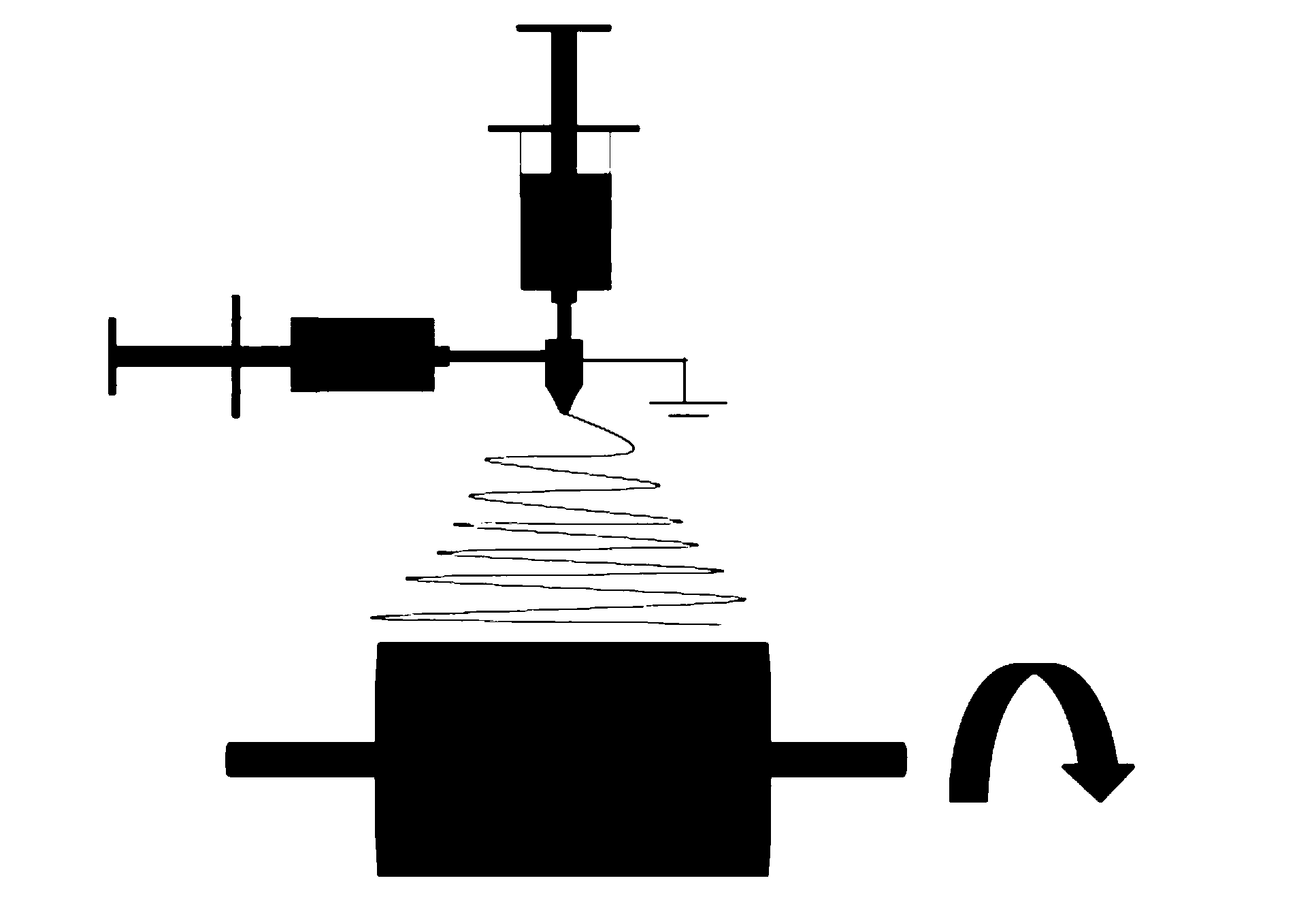

Preparation method for conduction and sustained release type nervous tissue engineering scaffold

ActiveCN104225685AGood cell compatibilityExtended highFilament/thread formingNon-woven fabricsConductive polymerDefect repair

The invention relates to a preparation method for a conduction and sustained release type nervous tissue engineering scaffold. The method comprises the following steps: silk fibroin Silk and lactic acid-caprolactone copolymer are dissolved in a solvent, dissolved and stirred to obtain a solution, then polyaniline and camphorsulfonic acid are added and stirred and mixed uniformly to obtain a cortex electrospinning solution, and NGF (nerve growth factors) are dissolved in ultrapure water completely to obtain a core electrospinning solution; and the cortex electrospinning solution and the core electrospinning solution are accommodated in an injector respectively for coaxial electrospinning, and then fumigation treatment and vacuum drying are performed to obtain the conduction type nervous tissue engineering scaffold. According to the prepared nanofiber scaffold, the nerve repair speed is increased from ways including external electrical stimulation (conductive polymer), biochemistry (NGFs), a topological structure required by nerve regeneration (orientation guide) and the like. The method is simple to operate, good in repeatability and high in economic benefit, and provides novel experimental thought for nerve defect repair in clinical application.

Owner:诺一迈尔(山东)医学科技有限公司

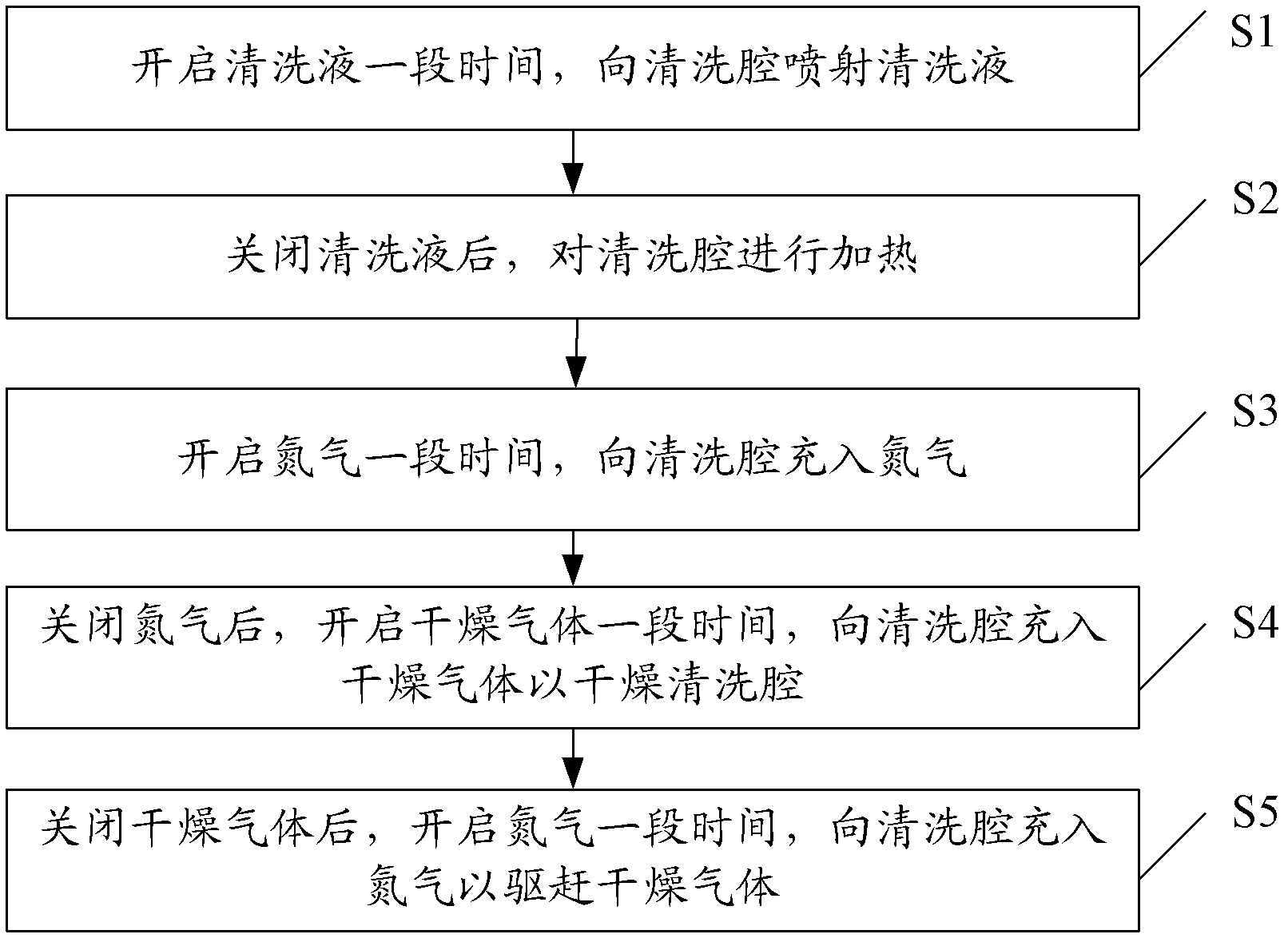

Device and method for cleaning and drying wafer cassettes

ActiveCN103170469ADry comprehensiveFully dryDrying gas arrangementsCleaning using liquidsUltrapure waterWaste management

The invention discloses a device for cleaning and drying wafer cassettes. The device for cleaning and drying the wafer cassettes comprises a cleaning cavity, a support frame used for supporting a plurality of the wafer cassettes, a cleaning liquid spray pipe externally connected with a cleaning liquid source, a liquid discharging pipeline and an air exhausting pipeline, wherein the liquid discharging pipeline and the air exhausting pipeline are respectively connected with the bottom of the cleaning cavity, and the support frame and the cleaning liquid spray pipe are arranged in the cleaning cavity. The device for cleaning and drying the wafer cassettes further comprises a dry air spray pipe externally connected with a dry air source, and the dry air spray pipe is arranged in the cleaning cavity. The invention further discloses a method for cleaning and drying the wafer cassettes. The cleaning liquid spray pipe externally connected with the cleaning liquid source is arranged in the cleaning cavity, the dry air spray pipe externally connected with the dry air source is further provided, dry air can not only drive away ultrapure water vapor in the cleaning cavity, but also suck all condensed water condensed in the wafer cassettes, and comprehensive and sufficient drying of the wafer cassettes is achieved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com