Preparation method of porous biological carbon heavy metal adsorbing material based on cotton straw

A bio-carbon material and cotton straw technology, applied in the fields of phytochemistry and adsorption science, can solve the problems of poor adsorption effect of heavy metals, and achieve the effects of favorable adsorption, low price, and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

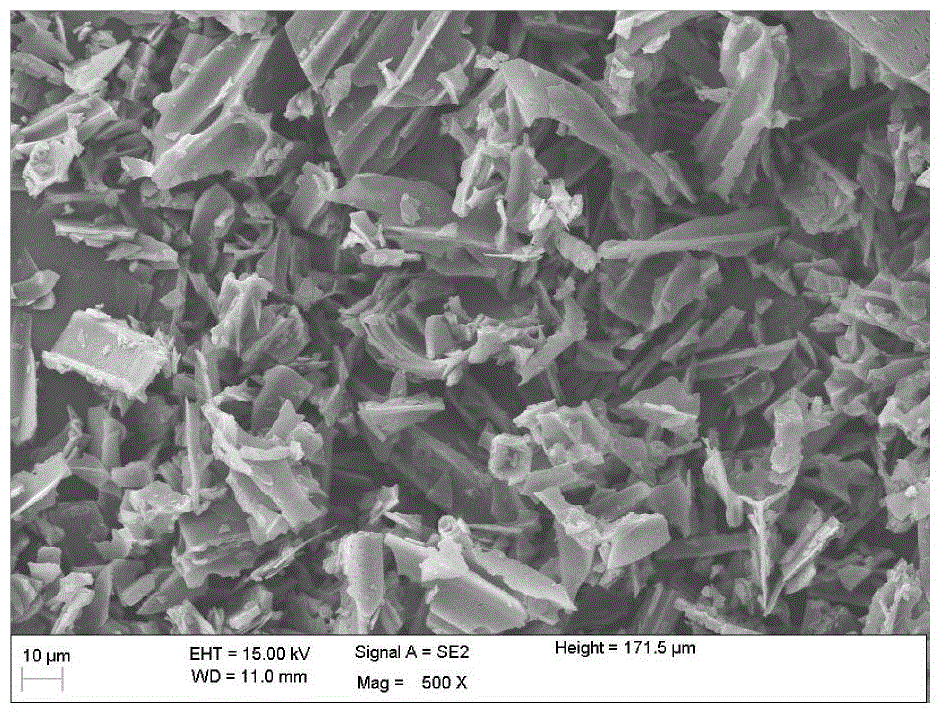

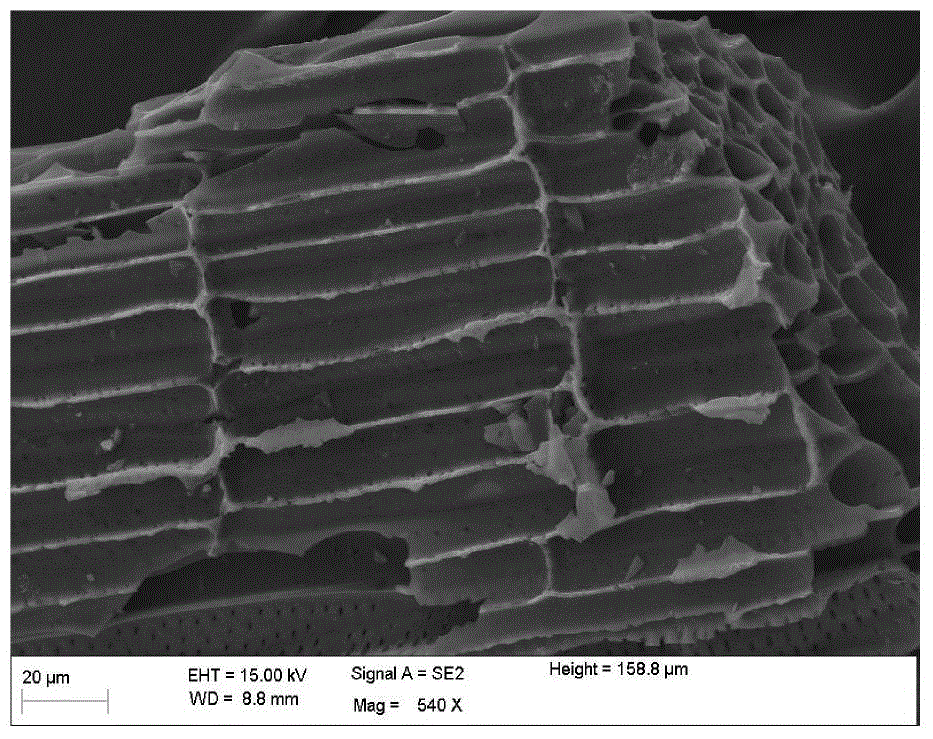

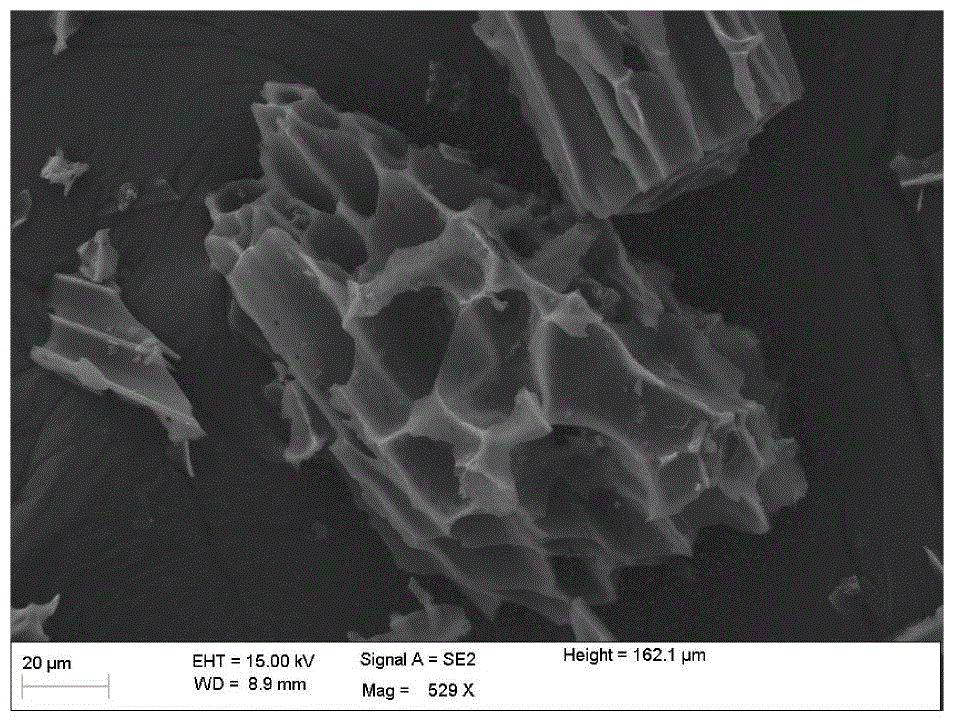

Image

Examples

Embodiment 1

[0033] Step 1, take the cotton stalks and wash them with ultrapure water for 5 times, then soak the cotton stalks in 20% ZnCl 2 solution, stirred and impregnated at room temperature for 10 hours, and then dried the impregnated cotton stalks at 50°C;

[0034] Step 2: Take the dried cotton stalks in step 1 and put them into a tubular electric furnace, protect them with nitrogen, raise the temperature to 600°C at a rate of 10°C / min, then heat-preserve and calcinate for 1 hour, and grind the calcined products into powder. Add 0.5 parts by weight of powder and 30 parts by weight of ultrapure water into the hydrothermal reaction kettle, stir for 8 hours until it swells completely, then heat to 150°C, react for 10 hours, and centrifuge and dry the reaction product to obtain a biochar material;

[0035] Step 3, adjust the pH of the aqueous ethanol solution to 3 with an acetic acid solution with a volume fraction of 6%, add 3-mercaptopropyltriethoxysilane into the pH-adjusted aqueous e...

Embodiment 2

[0037] Step 1, take the cotton stalks and wash them 10 times with ultrapure water, then soak the cotton stalks in 50% ZnCl 2 solution, stirred and impregnated at room temperature for 15 hours, and then dried the impregnated cotton stalks at 70°C;

[0038] Step 2: Take the dried cotton stalks in step 1 and put them into a tubular electric furnace, protect them with nitrogen, raise the temperature to 850°C at a rate of 10°C / min, then heat-preserve and calcinate for 3 hours, and grind the calcined products into powder. Add 1 part by weight of powder and 50 parts by weight of ultrapure water into the hydrothermal reaction kettle, stir for 12 hours until it swells completely, then heat to 200°C, react for 15 hours, and centrifuge and dry the reaction product to obtain a biochar material;

[0039] Step 3, adjust the pH of the aqueous ethanol solution to 4 with an acetic acid solution with a volume fraction of 10%, add 3-mercaptopropyltriethoxysilane into the pH-adjusted aqueous etha...

Embodiment 3

[0041] Step 1, take the cotton stalks and wash them 8 times with ultrapure water, then soak the cotton stalks in 30% ZnCl 2 solution, stirred and impregnated at room temperature for 12 hours, and then dried the impregnated cotton stalks at 60°C;

[0042] Step 2: Take the dried cotton stalks in Step 1 and put them into a tubular electric furnace, protect them with nitrogen gas, raise the temperature to 800°C at a rate of 10°C / min, then heat-preserve and calcinate for 2 hours, and grind the calcined products into powder. Add 0.5 parts by weight of powder and 40 parts by weight of ultrapure water into the hydrothermal reaction kettle, stir for 10 hours until it swells completely, then heat to 180°C, react for 12 hours, and centrifuge and dry the reaction product to obtain a biochar material;

[0043] Step 3, adjust the pH of the aqueous ethanol solution to 3.5 with an acetic acid solution with a volume fraction of 7%, add 3-mercaptopropyltriethoxysilane into the pH-adjusted aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com