Patents

Literature

126results about How to "Short energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cermet composition and method for preparing cermet coat on metal surface

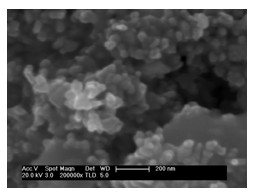

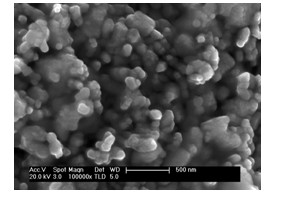

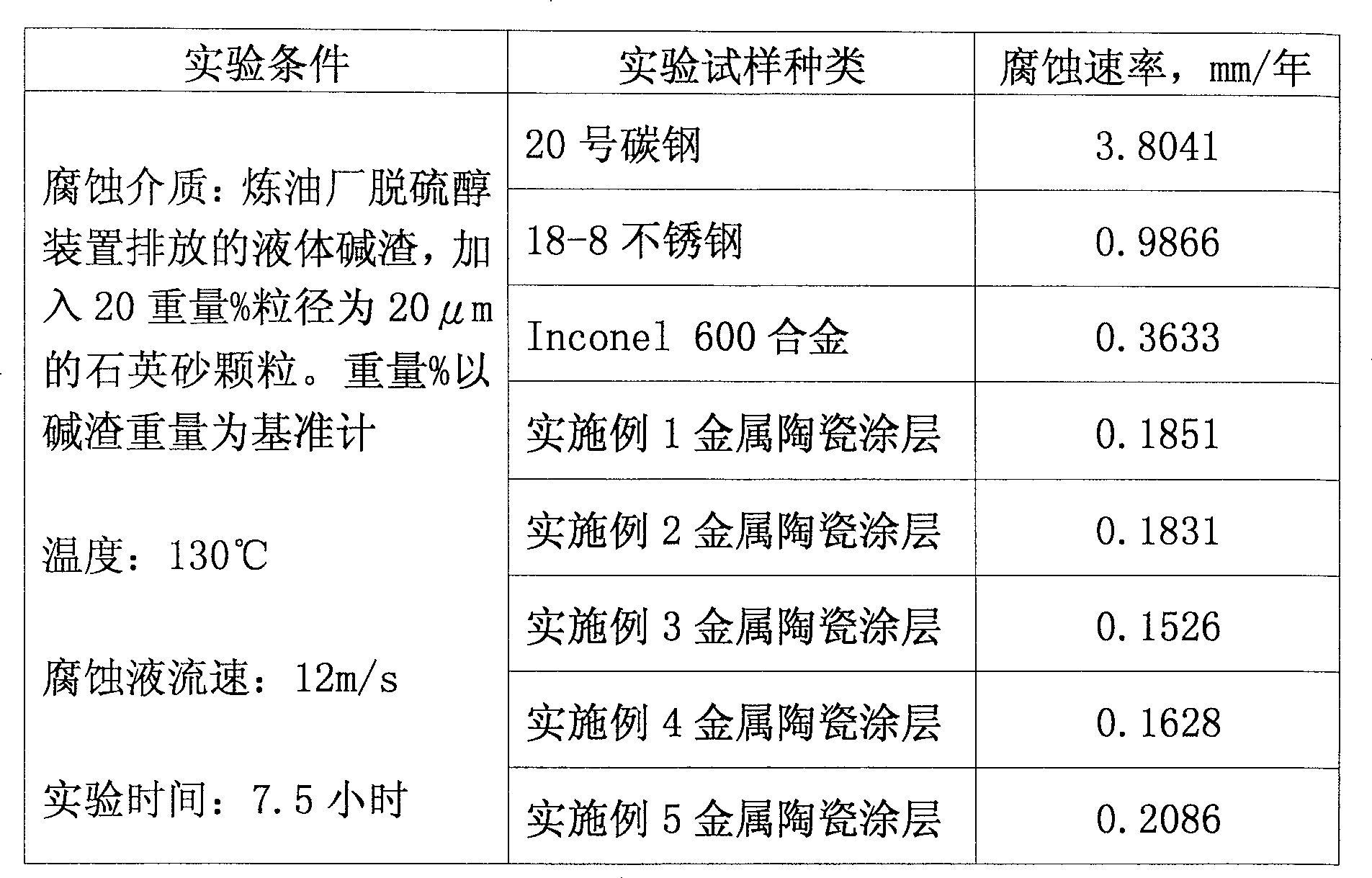

A metal-ceramic composition and coating it on metal surface are both disclosed herewith. It consists both parts of mixed powders containing Cr, B, Si, Fe, Al, La rare-earth oxides and Ni, and carbide materials, TiC or WC. It is coated as following: mixing metal-ceramic composition with polyvinyl alcohol or ethyl estate as binding agent to be slurry, coating it onto metal surface, drying, and firing in gas protecting furnace or vacuum furnace to obtain metal-ceramic coated metal parts. It is available to various shaped parts with different materials, and reduces energy consumption.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

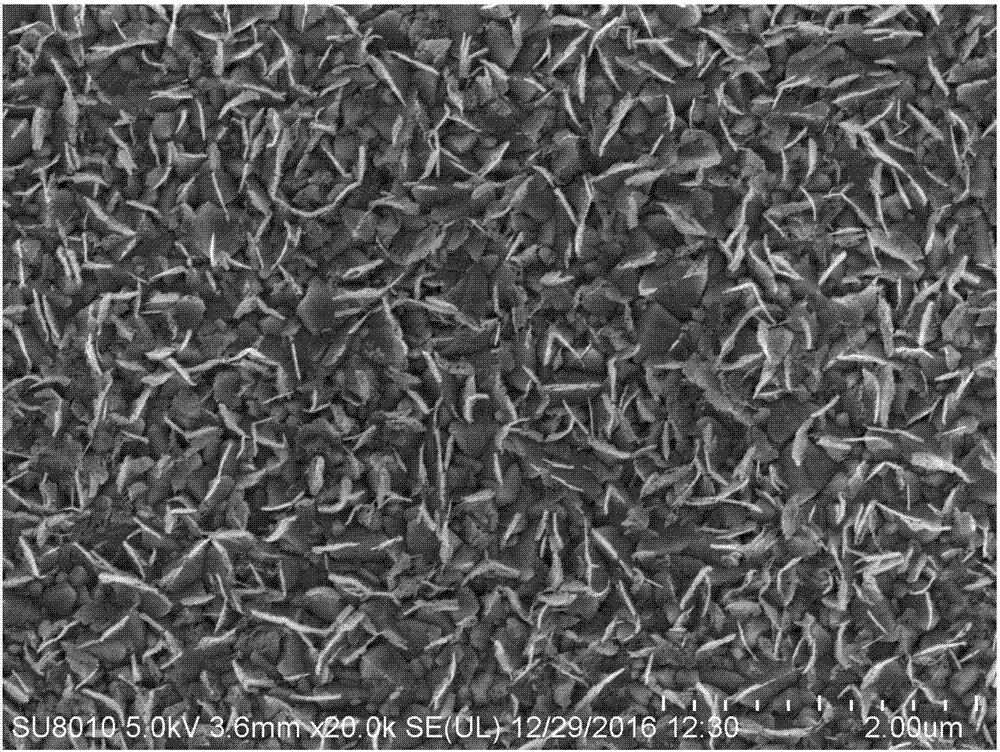

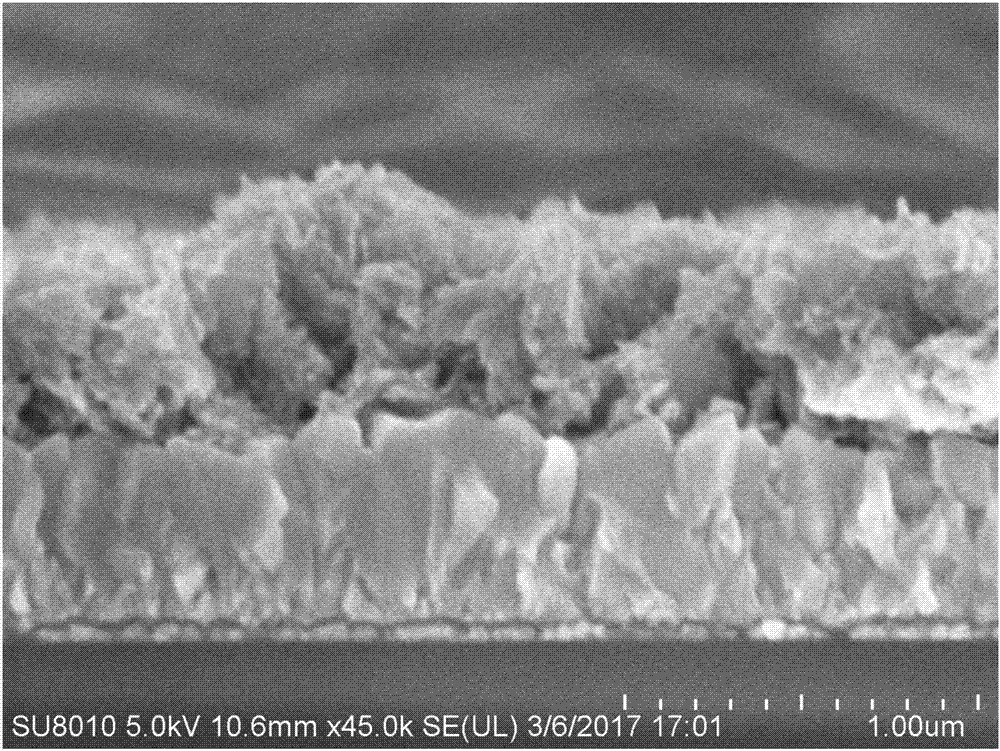

NiCo2S4 nano-material and preparation method thereof

InactiveCN107098403ADiffusion fastGuaranteed normal transmissionLight-sensitive devicesNanotechnologyNano structuringSolvent

The invention provides a preparation method of a NiCo2S4 nano-material. The preparation method comprises the following steps: firstly, mixing a soluble cobalt source, a soluble nickle source, urine and a solvent to obtain a reaction precursor solution; then placing a conductive substrate in the obtained reaction precursor solution, performing reaction under the microwave action, and then performing heat treatment to obtain a NiCo2O4 nanosheet; and enabling reaction between the obtained NiCo2O4 nanosheet and a sulfide to obtain the NiCo2S4 nano-material. The preparation method is simple in process, low in cost and energy consumption, short in reaction time, and favorable for large-scale industrial expansion; the NiCo2S4 semiconductor nanosheet is uniform in shape and large in specific area; controllable growth of a nano-structure thin film can be realized, so that full contact with an electrolyte is realized; quick ion diffusion and effective charge transmission are guaranteed; the NiCo2S4 nano-materia can be directly used as a counter electrode of a dye-sensitized solar cell and has a huge application prospect.

Owner:GUANGDONG UNIV OF TECH

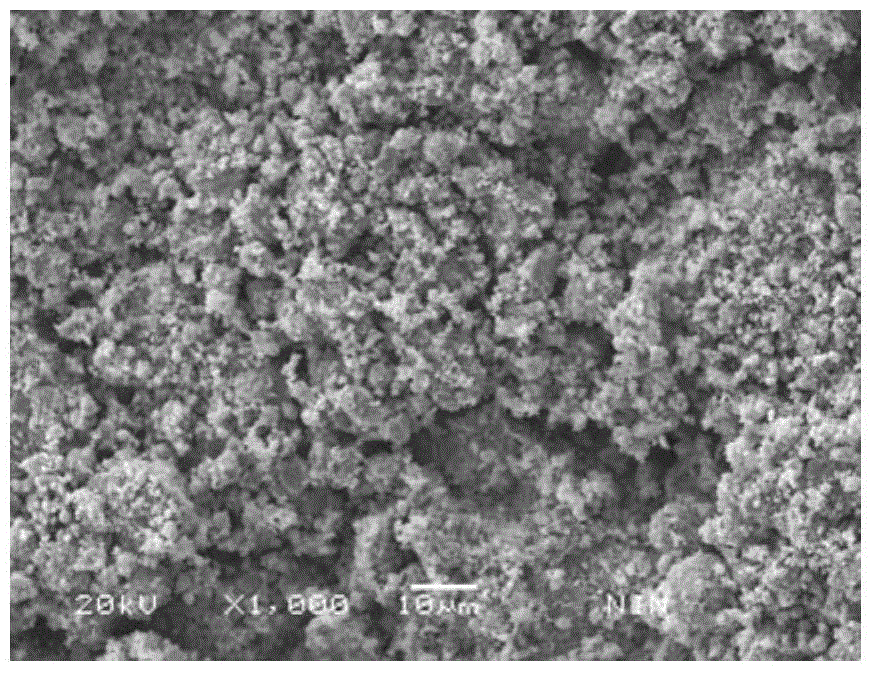

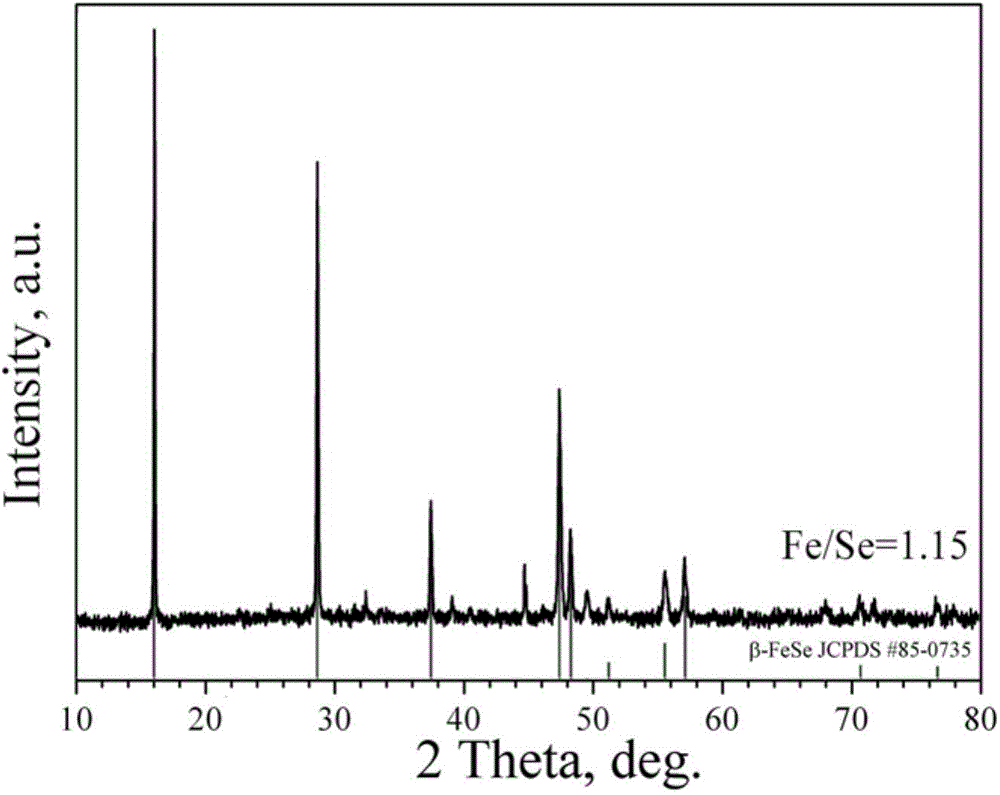

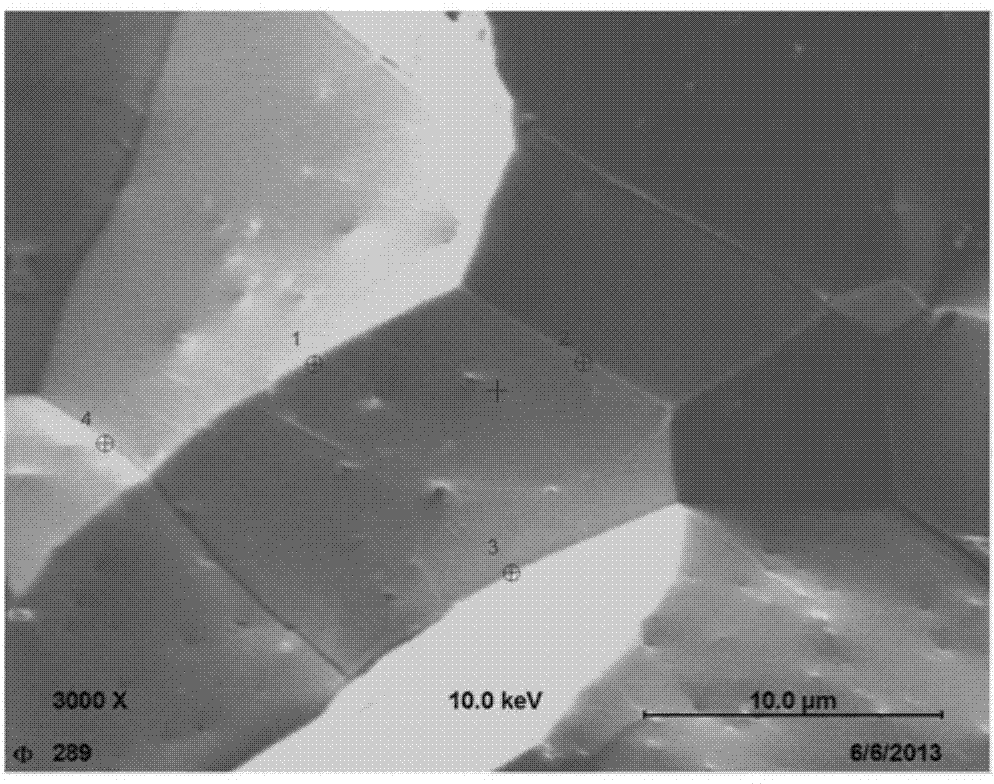

Method for preparing FeSe-based superconducting material

The invention discloses a method for preparing a FeSe-based superconducting material. The method comprises the following steps: 1, putting mixed powder of iron powder and selenium powder into a vacuum ball-milling tank; 2, performing high energy ball-milling treatment on the mixed powder; 3, pressing the mixed powder to obtain a FeSe-base blank; and 4, sintering the FeSe-base blank, thereby obtaining the FeSe-based superconducting material. According to the method disclosed by the invention, a high energy ball-milling machine is adopted to perform high energy ball-milling treatment on the mixed powder within a relatively short time firstly, after the sizes of original grains of the mixed powder are reduced, a Fe-Se solid solution is obtained, Fe and Se in the mixed powder reach atom-grade mixing, the limit on reaction rate in the dispersion process in the sintering treatment is eliminated, the mixed powder is laminated and is subsequently sintered, thereby obtaining the FeSe-based superconducting material with high superconducting phase content and advantages of small energy consumption, short process, high repeatability and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

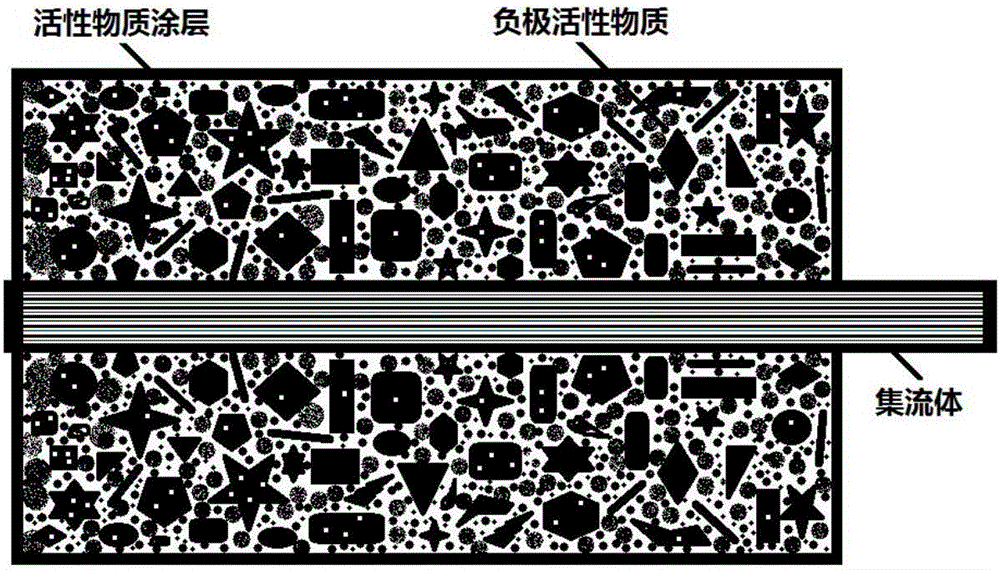

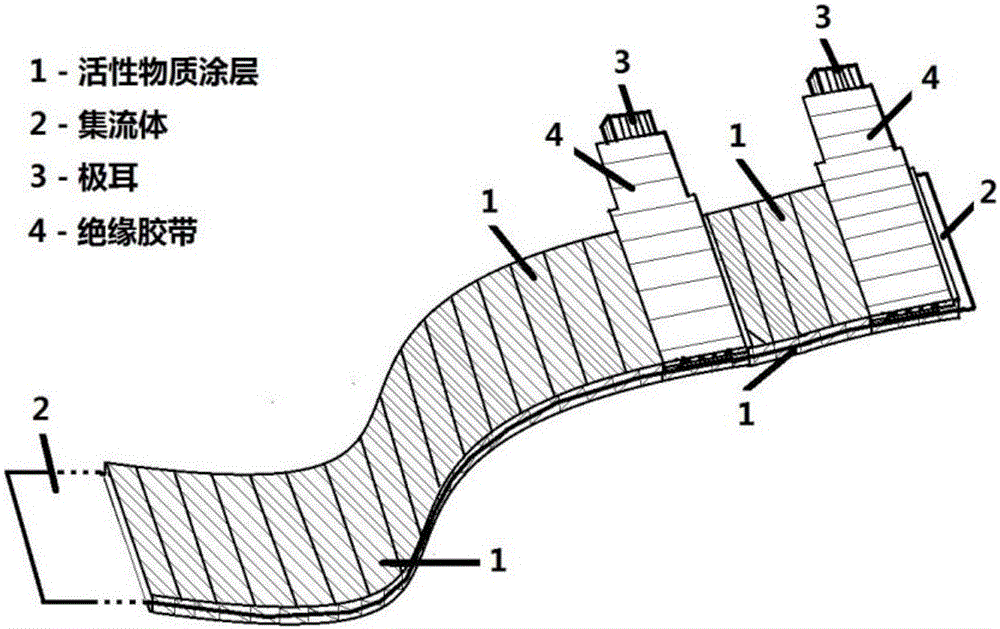

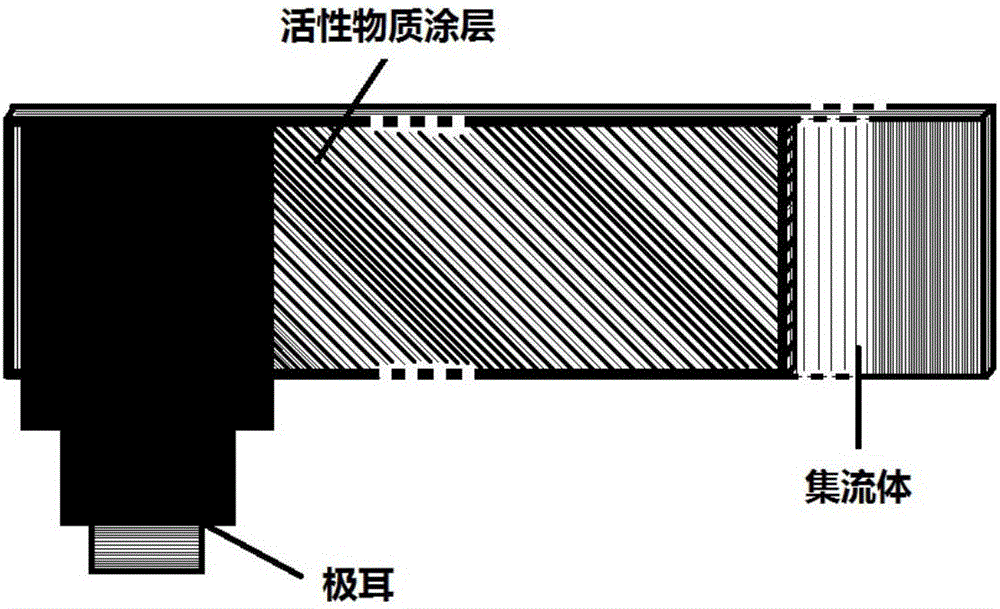

Manufacturing method of negative plate of safety lithium-ion battery

InactiveCN106450169AGood thermal stabilityStable performance during charge and discharge cyclesSecondary cellsElectrode collector coatingCopper foilCurrent collector

The invention discloses a manufacturing method of a negative plate of a safety lithium-ion battery. The method comprises the steps of mixing a negative active material with a conductive agent at a certain mass ratio to obtain a mixture A; carrying out ball-milling and mixing on an additive B and the mixture A at a certain mass ratio to form a mixture C; preparing a certain mass percent of water solution from CMC which accounts for a certain mass ratio of the mixture C, carrying out constant-temperature stirring, adding an SBR which accounts for a certain mass ratio of the mixture C in batches, simultaneously adding an NMP which accounts for a certain ratio of the mixture C and carrying out constant-temperature stirring to form a sizing material D; adding the mixture C to the sizing material D in batches, controlling the solid content of the mixture C and stirring to obtain slurry; adding a proper amount of water, adjusting, controlling the viscosity and stirring to obtain negative slurry E; employing copper foil as a current collector F, intermittently coating a single side or double sides of the current collector F with the negative slurry E, reserving a certain current collector, carrying out drying, controlling the surface density, carrying out rolling and controlling the compactness and the thickness of the negative plate; and dividing, cutting, welding and pasting a tab adhesive tape to obtain the negative plate of the safety lithium-ion battery. The lithium-ion battery assembled by the negative plate has good electric cycle performance and safety performance.

Owner:HUBEI UEE ENERGY TECH CO LTD

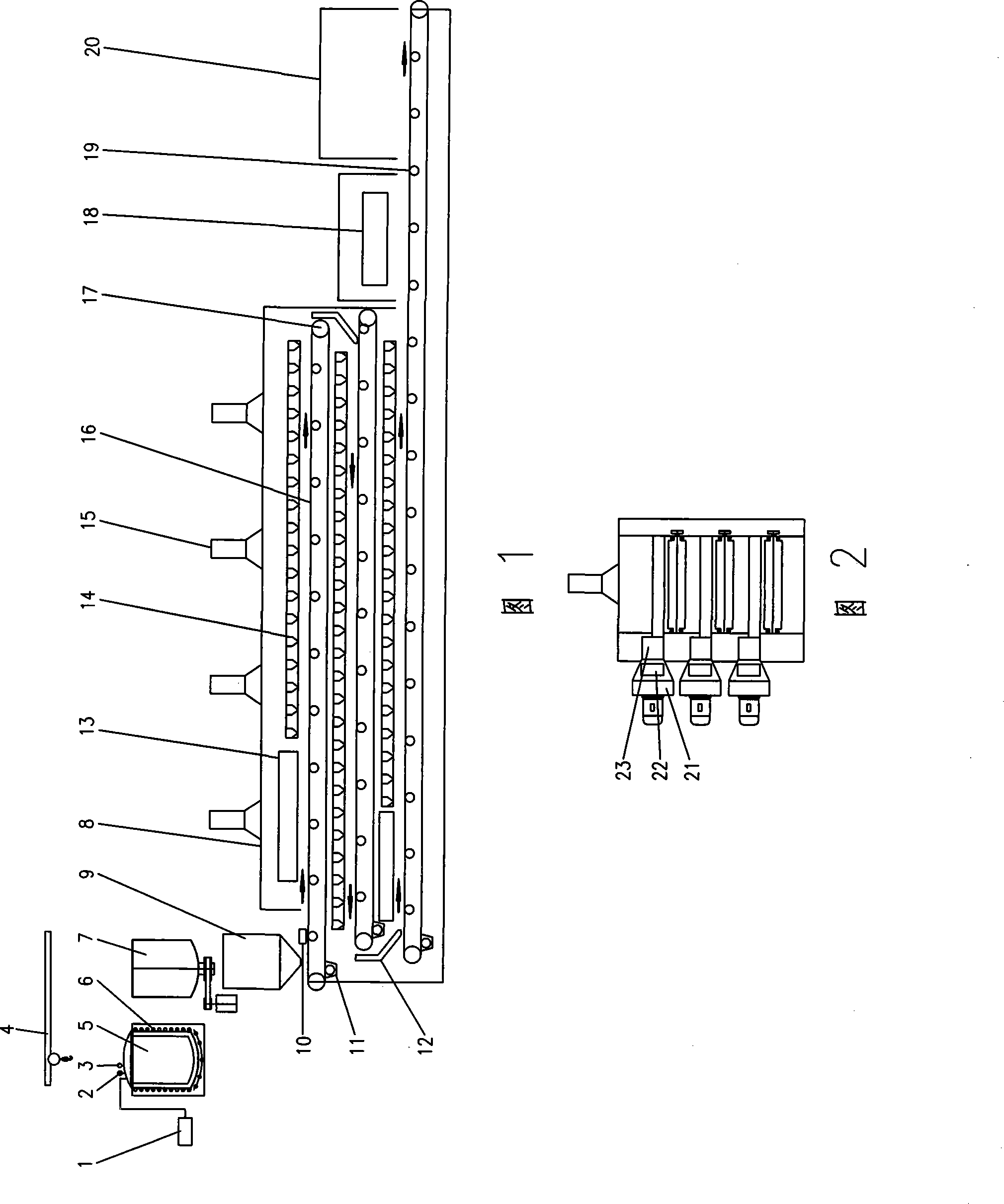

High-efficiency energy-saving automatic roasted seeds and nuts producing system

InactiveCN101238864AReduce energy consumptionShort energy consumptionFood preparationFood treatmentMaterial consumptionProcess engineering

The invention involves a high efficiency energy saving automatic system for producing roasted seeds and nuts, which includes cooking device, after being cooked by cooking device the product is lifted into dehydrator by lifting device, after dehydration the product is transferred into dryer through conveyor belt, entrance region of first layer conveyor belt in the dryer and last layer conveyor belt are equipped with infrared heater respectively, the top part of the dryer is equipped with humidity-discharging port, at least one layer of conveyor belt is installed in the dryer, the conveyor belt is driven by conveying roller and carrier roller belt, the upper part of the conveyor belt is installed with hot air injector, after being dried the product is cooled in cooler, after being cooled the product is separated in separator, at last the finished product is packed. The invention has merits of low energy consumption, low material consumption, high work efficiency, low producing cost and small occupation area.

Owner:邓元恺

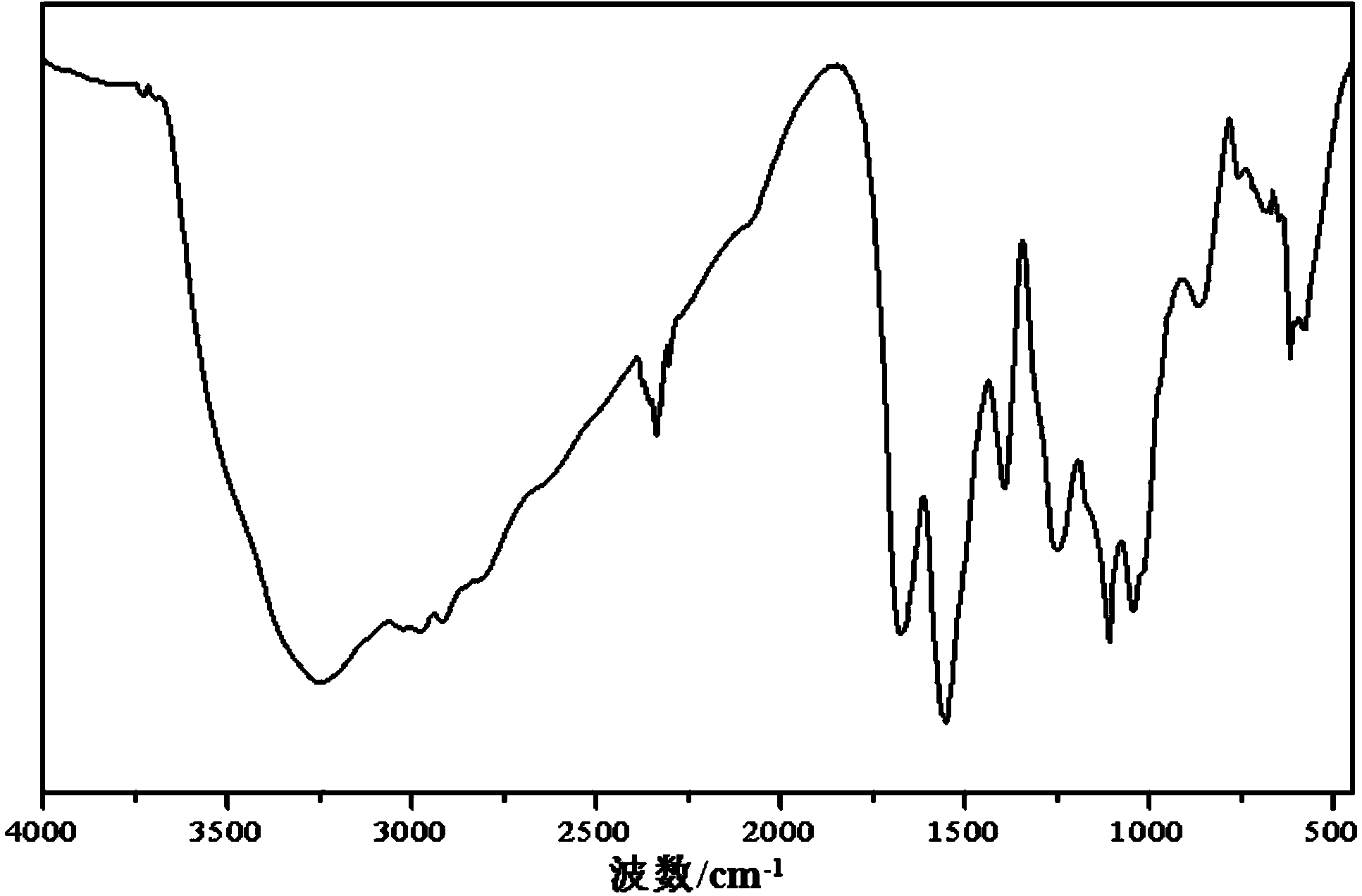

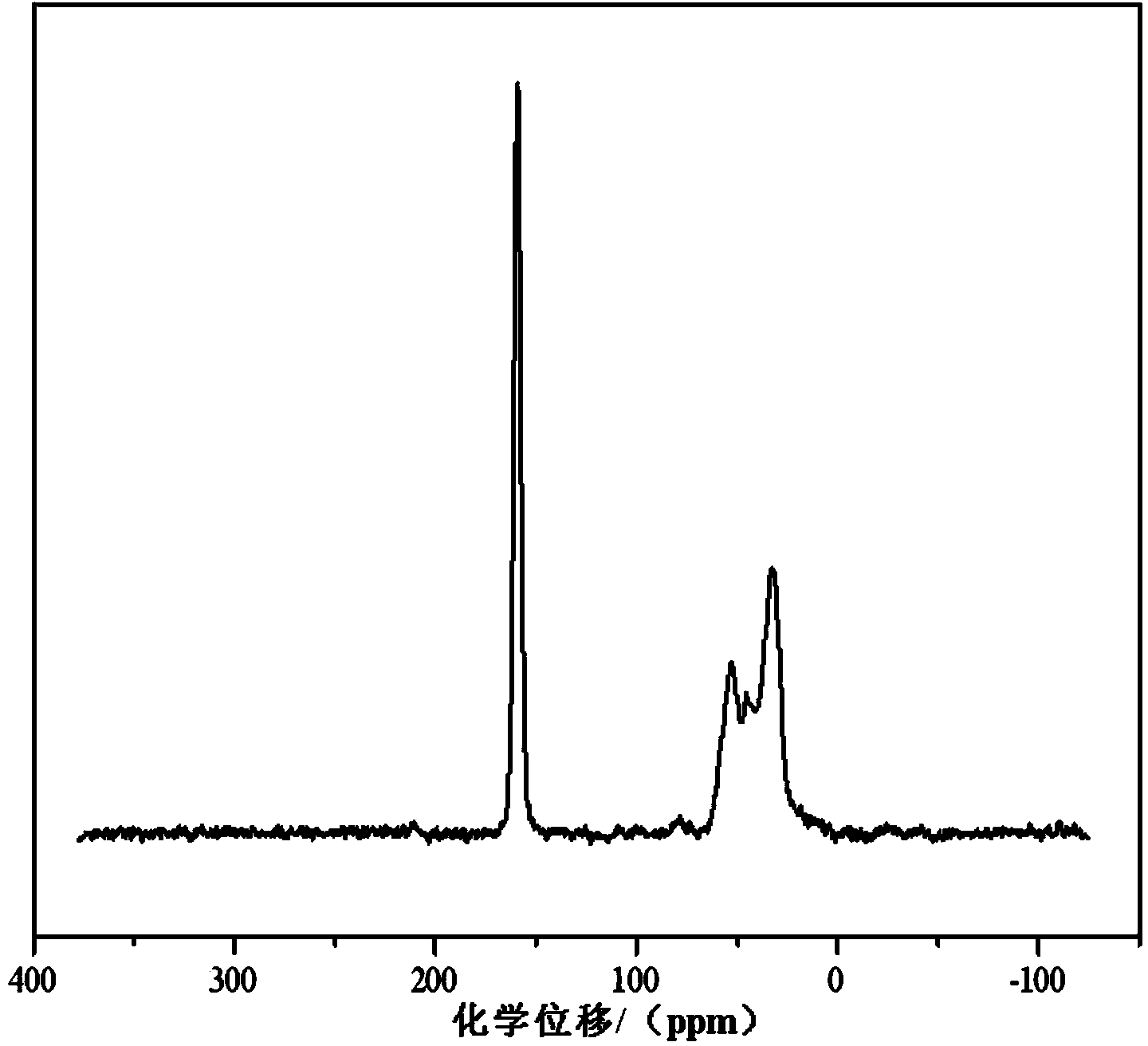

Polymerization type phosphorus-containing flame retardant as well as preparation method and application thereof as epoxy resin flame retardant

InactiveCN104311876AImprove thermal stabilityImprove hydrolysis resistanceGroup 5/15 element organic compoundsEpoxyO-Phosphoric Acid

The invention discloses a polymerization type phosphorus-containing flame retardant as well as a preparation method and application thereof as an epoxy resin flame retardant, relates to a hydrolysis-resisting phosphorus-containing flame retardant and a preparation method thereof, and solves the problems that a conventional phosphorus-containing flame retardant is low in thermal stability, easy to hydrolyte and hard to process. The structural formula of the phosphorus-containing flame retardant is as shown in the specification. The preparation method comprises the following steps: by taking phosphoric acid or sulfuric acid as a catalyst, adding a trisphosphine oxide solution or a tertphosphine oxide solution, a reaction solvent and an additive into a reaction container, adding a melamine or amine compound at the room temperature, adjusting the pH value, heating at a certain stirring speed, reacting at certain temperature, performing backflow reaction, cooling to be the room temperature, sequentially performing suction filtration, washing in water and drying, thereby obtaining white powder solid, that is, the polymerization type phosphorus-containing flame retardant. The polymerized type phosphorus-containing flame retardant can be used as the epoxy resin flame retardant which is added into epoxy resin.

Owner:NORTHEAST FORESTRY UNIVERSITY

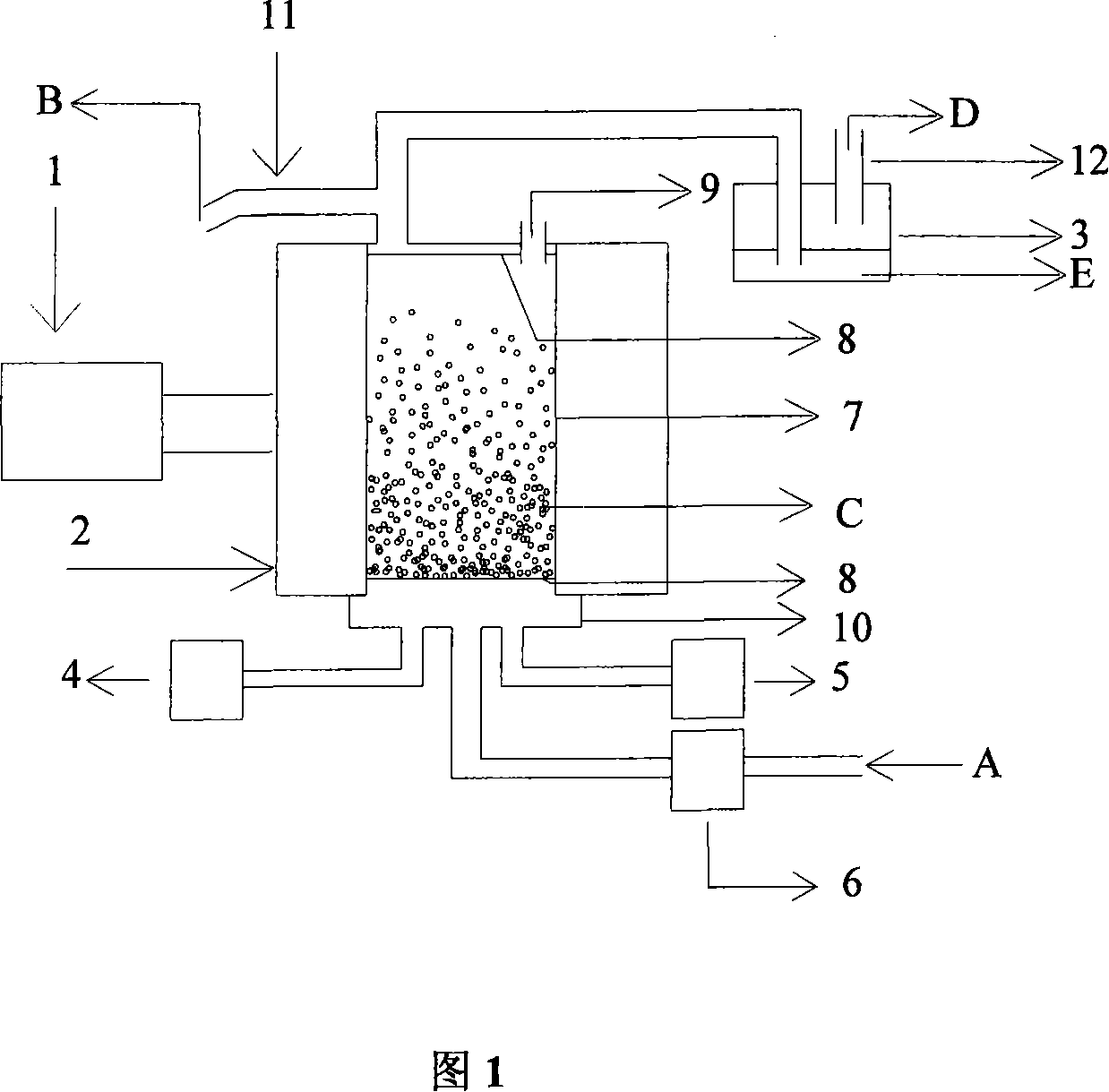

Oxidation strengthening technique and device for processing organic poison waste water

ActiveCN101148287ALow costLess investmentWater/sewage treatment by oxidationCatalytic oxidationWastewater

The present invention relates to reinforced oxidizing process of treating waste water containing toxic organic matter. By means of the excitation of externally applied energy, catalyst, oxidant and oxygen generate synergistic effect to produce strongly oxidizing ozone and free hydroxyl group degrading toxic organic matter, the catalyst being in fluidized or semi-fluidized state during the reaction. The present invention also provides the technological apparatus, which consists of one energy generator, one reactor, one tail gas collector, one water distributor and one water inflow pump. The present invention has short treating period, high treating efficiency and great treating capacity.

Owner:NJTECH ENVIRONMENT TECH CO LTD

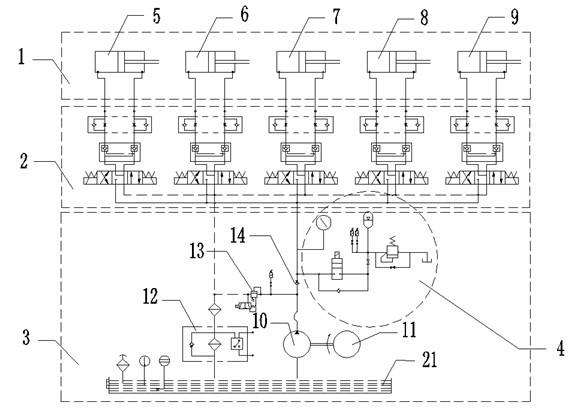

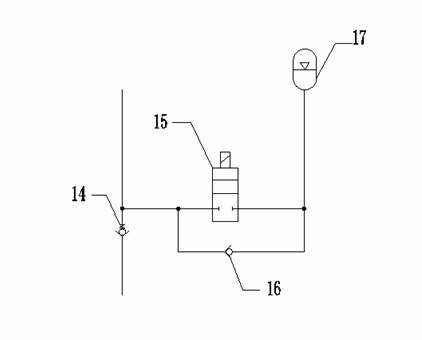

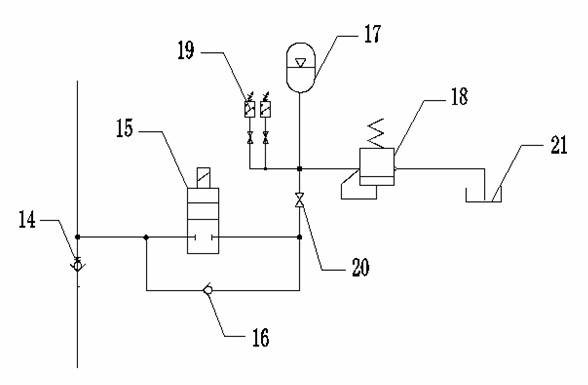

Shark pincers with emergent release function

InactiveCN102050202ARealize emergency releaseSafe and reliableWaterborne vesselsControl systemEconomic benefits

The invention relates to shark pincers with an emergent release function, belonging to the field of towing equipment for a ship. The shark pincers provided by the invention comprise a shark pincers executing system, a hydraulic master control system, a dynamical system and an emergent release device, wherein an oil outlet pipe of the power system is provided with a master oil-way check valve; and the emergent release device is connected in parallel to the oil outlet pipe between the master oil-way check valve and the hydraulic master control system. When the shark pincers normally work, the power system supplies oil to an energy accumulator of the emergent release device, so that a sufficient amount of high-pressure oil is accumulated in the energy accumulator. When the power source of the shark pincers fails, the high-pressure oil in the energy accumulator flows back to the hydraulic master control system to supply a power source to the hydraulic master control system, thereby finishing the emergent release of the shark pincers. The shark pincers provided by the invention have the advantages of simple structure and obvious economic benefit and are convenient to operate and control.

Owner:WUHAN MARINE MACHINERY PLANT

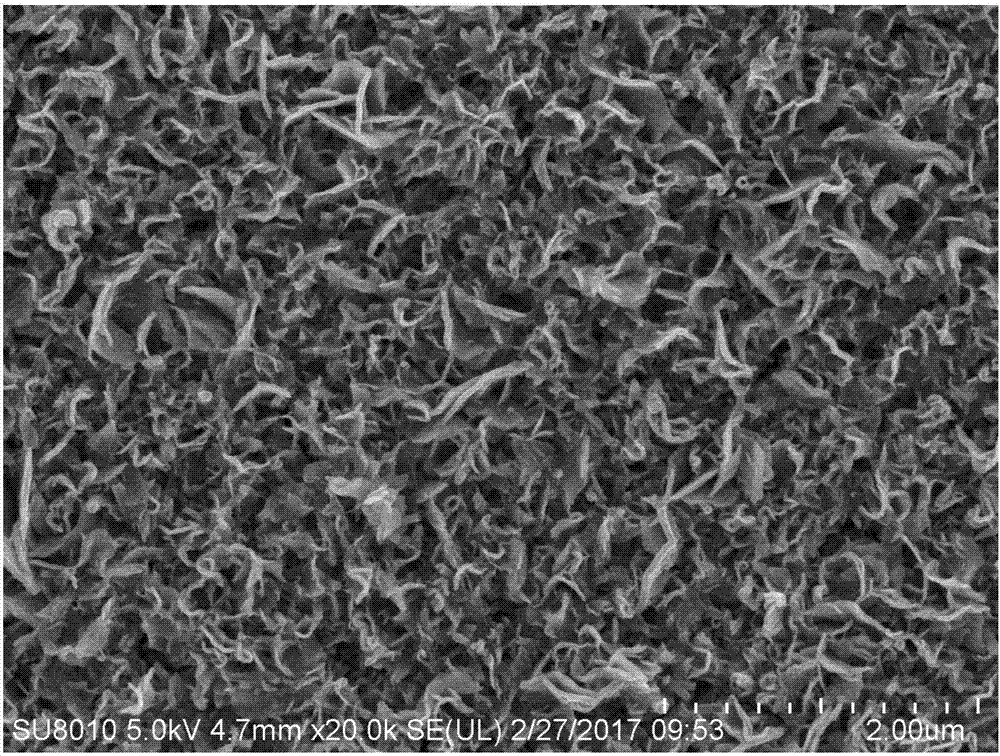

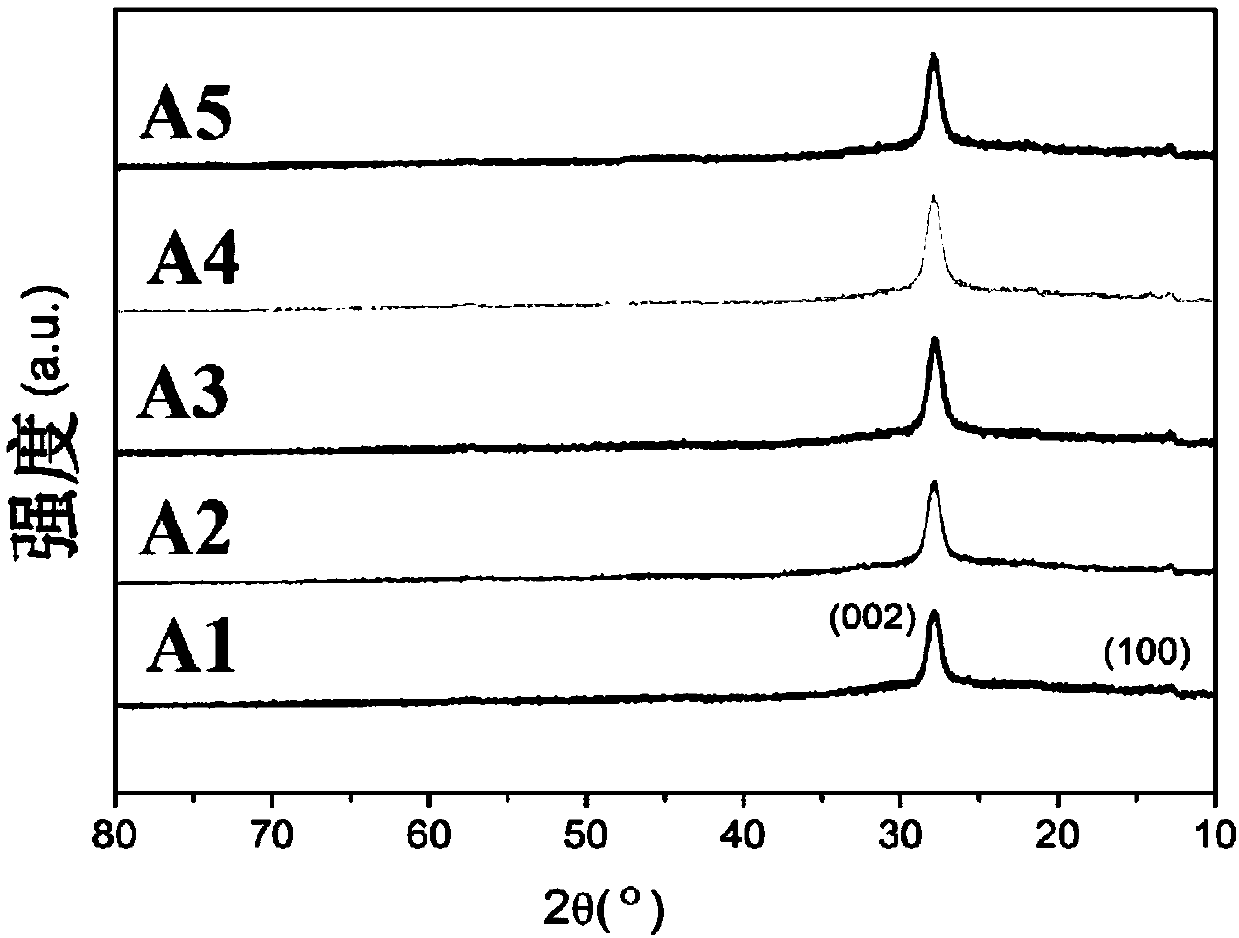

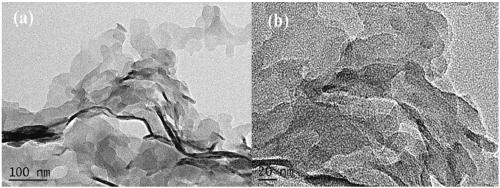

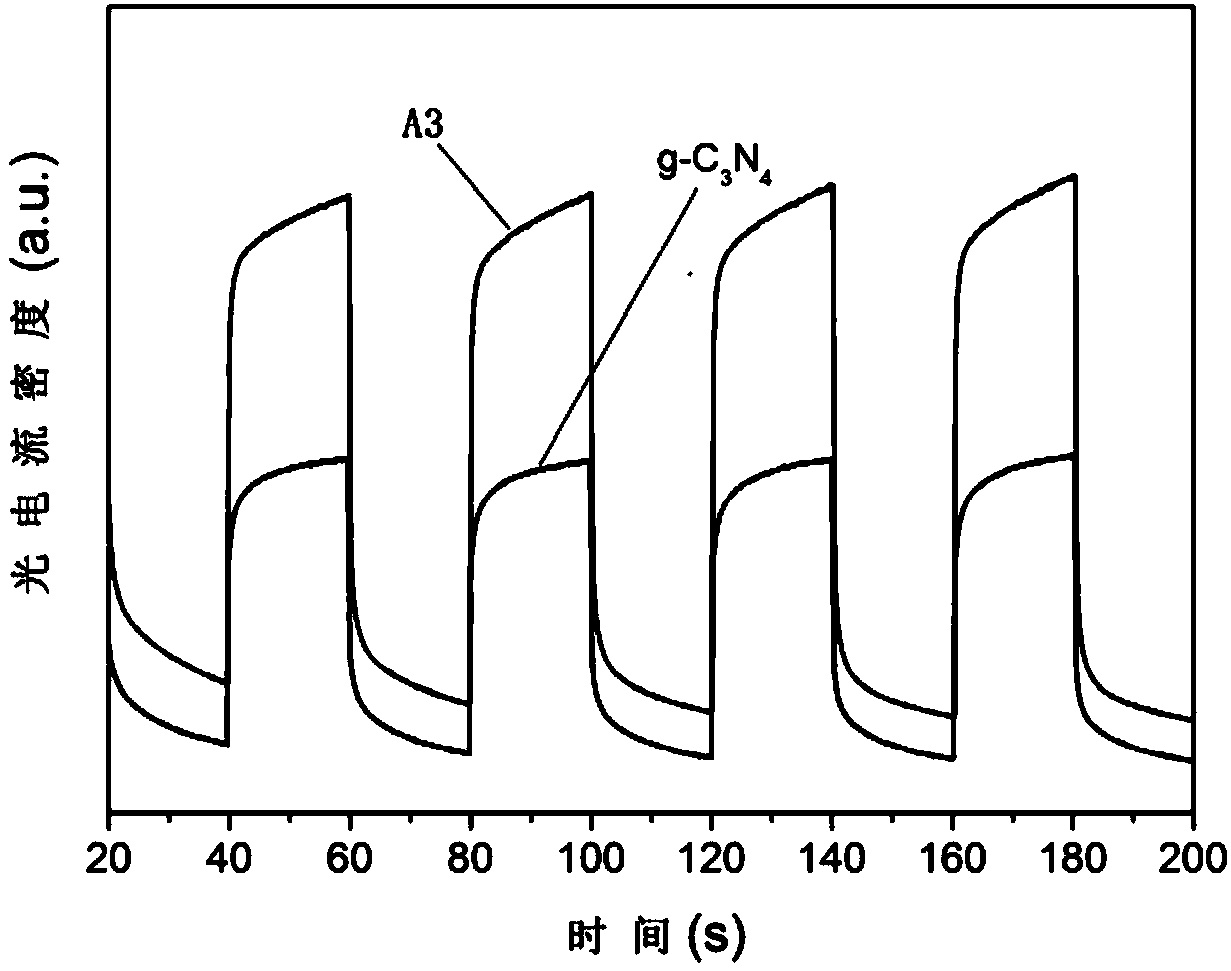

Supramolecular polymerized carbon nitride photocatalyst and preparation method and application thereof

ActiveCN110465315AHigh specific surface areaImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationUreaChemistry

The invention discloses a supramolecular polymerized carbon nitride photocatalyst and a preparation method and an application thereof. The supramolecular polymerized carbon nitride photocatalyst is prepared from melamine, cyanuric acid, urea and dimethyl sulfoxide through a molecular polymerization reaction and calcination. The supramolecular polymerized carbon nitride photocatalyst has the advantages of high specific surface area, high photocatalytic activity and the like, can efficiently degrade organic wastewater and is a novel visible light catalyst. The preparation method has the advantages of simple synthetic method, low raw material cost, less energy consumption, short time consumption, easy control of conditions and the like, is suitable for continuous large-scale batch productionand facilitates the industrial use. the supramolecular polymerized carbon nitride photocatalyst of the invention can be used for degrading the organic wastewater, has the advantages of good degradation effect and good stability, and has good practical application prospects.

Owner:HUNAN UNIV

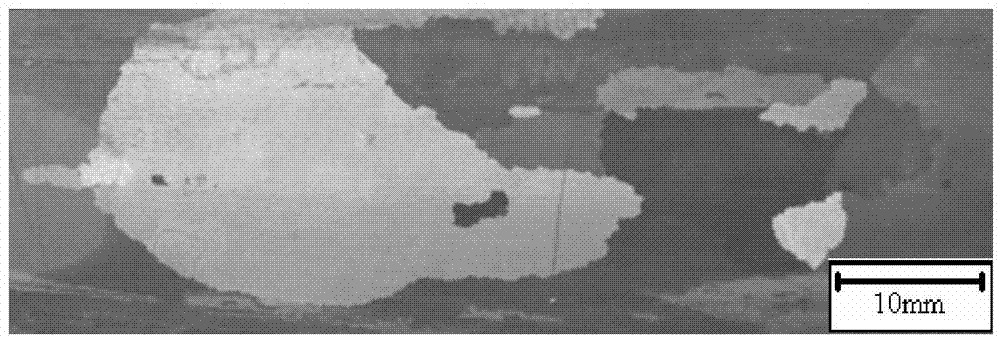

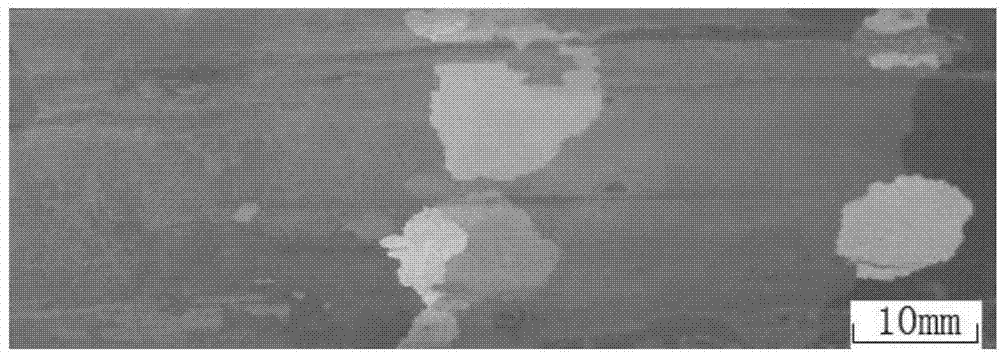

High-magnetic-induction oriented silicon steel prepared through thin slab continuous casting and rolling and preparation method thereof

ActiveCN103774042ALow heating temperatureAvoiding Insufficient Inhibition ProblemsChemical compositionThin slab

The invention provides high-magnetic-induction oriented silicon steel prepared through thin slab continuous casting and rolling and a preparation method thereof. The oriented silicon steel comprises the following chemical components by mass percent: 0.035-0.055% of C, 2.9-3.3% of Si, 0.09-0.15% of Mn, 0.1-0.2% of Cu, not more than 0.005% of S, 0.02-0.04% of AlS, 0.009-0.013% of N and 0.1-0.2% of Sn. The oriented silicon steel is prepared by the following steps: thin slab continuous casting, heating in a soaking pit, hot continuous rolling, normalizing, primary cold rolling, decarburizing annealing and high temperature annealing, wherein the heating temperature of the soaking pit is 1150-1180 DEG C and the soaking time is 30-60 minutes. The oriented silicon steel uses AlN as a main inhibitor and Cu2S as an auxiliary inhibitor, and meanwhile, the trace element Sn is added to the chemical components to avoid the problem of inadequate inhibiting capacities of the inhibitors caused by low temperature heating and serves as an auxiliary inhibitor thanks to the segregation capacity of Sn on the grain boundary. Therefore, the high-magnetic-induction oriented silicon steel can be produced by adopting the thin slab low temperature short-time soaking process, so that the casting blank heating temperature is effectively reduced and the soaking time is reduced. The preparation method has the advantages of short flow, low cost, low energy consumption, high production efficiency and the like.

Owner:CENT IRON & STEEL RES INST +1

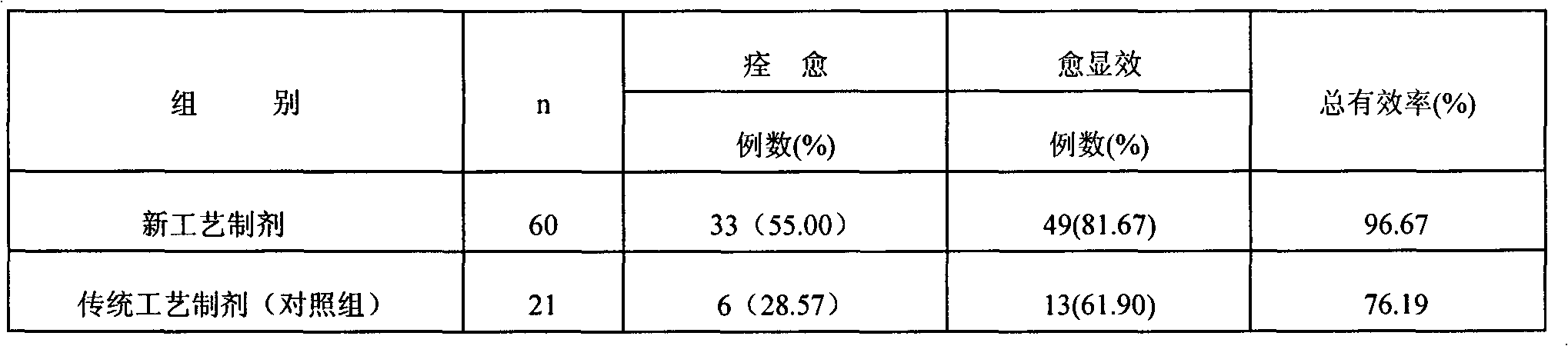

Method for preparing Chinese medicinal granules for treating cold

ActiveCN101954003AReduce energy consumptionLow impurity contentAntiviralsGranular deliveryAdditive ingredientAngelica dahurica

The invention discloses a method for preparing Chinese medicinal granules for treating a cold, which belongs to the field of medicine and overcomes the defects of low extraction rate of the conventional preparation method and high effective ingredient loss of medicaments. The preparation method comprises the following steps of: crushing schizonepeta spike, mint and perilla leaf into coarse powderaccording to a formula of cold heat clearing granules (No.1-644, version 2005), and extracting the medicaments with volatile oil by adopting supercritical CO2 and ultrahigh pressure; crushing bupleurum, parsnip, kudzuvine root, platycodon root, bitter almond kernel, angelica dahurica, bunge's corydalis and reed rhizome into coarse powder, mixing the coarse powder and the rest medicament residue of the extracted medicaments, performing ultrahigh pressure extraction by adding water, filtering the extract, and concentrating the extract with reduced pressure to form clear paste; and adding auxiliary materials into the clear paste to prepare granules, and adding volatile oil into the granules to obtain the Chinese medicinal granules. The method has the advantages of preventing oxidation, dissipation and reaction of thermo-sensitive components, completely keeping the bioactivity of biomass and reducing loss of effective ingredients along with quicker medicament response and stronger function.

Owner:XIUZHENG PHARMA GROUP HOIDING +1

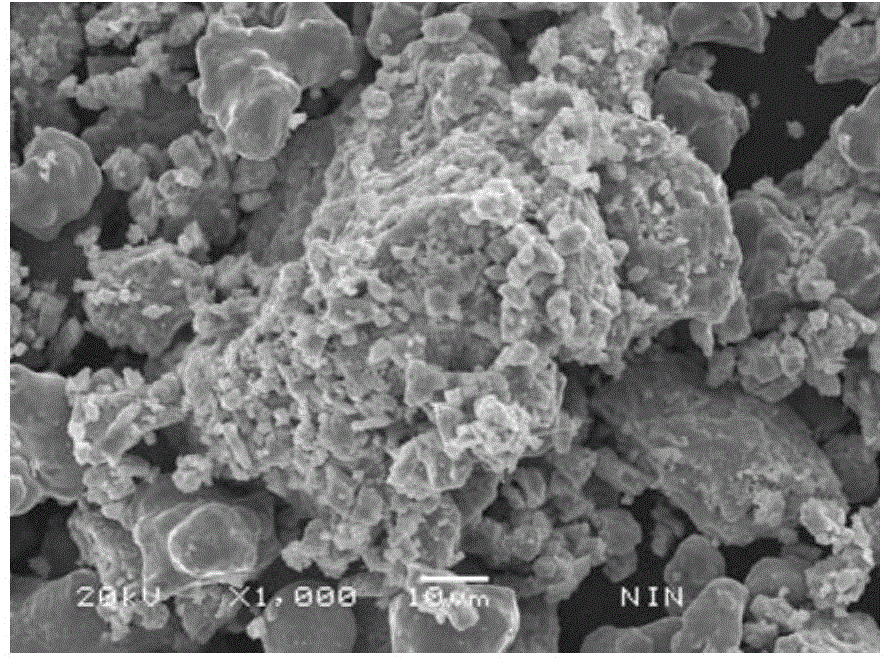

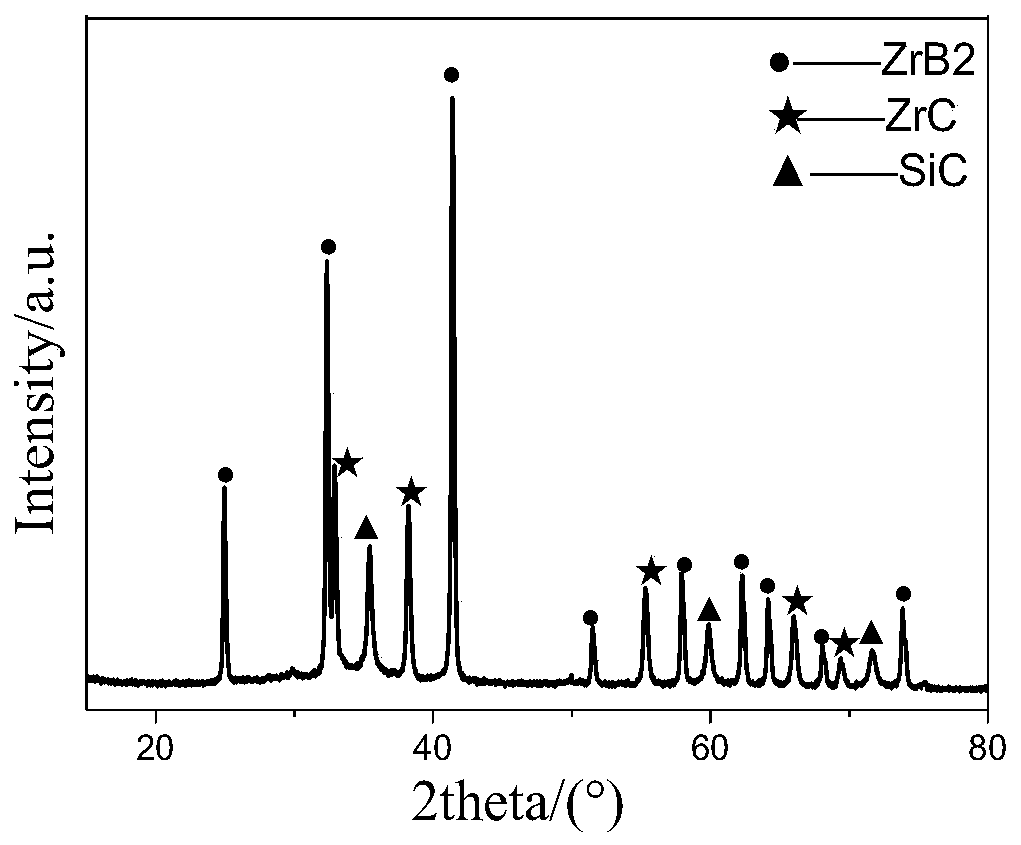

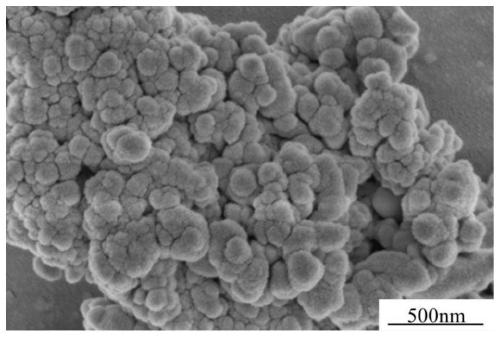

Preparation process of ZrC-ZrB2-SiC ceramic composite powder by precursor conversion method

The invention discloses a preparation process of ZrC-ZrB2-SiC ceramic composite powder by a precursor conversion method. Zirconium oxychloride octahydrate, boric acid, ethyl orthosilicate and glucoseare used as starting raw materials, and absolute ethyl alcohol and deionized water are used as solvents, wherein the molar ratio of the boric acid to the zirconium oxychloride octahydrate to the ethylorthosilicate is (1-5):1:(0.5-5), and the mass ratio of the glucose to the ethyl orthosilicate is (1-4):1. A zirconium precursor solution, a boric acid solution, an ethyl orthosilicate solution and aglucose solution are prepared separately, the solutions are uniformly mixed to obtain a boron-silicon-zirconium precursor solution, the boron-silicon-zirconium precursor solution is dried, and heat treatment is carried out at 1450-1600 DEG C for 1-2 hours under the protection of an argon atmosphere to obtain the ZrC-ZrB2-SiC ceramic powder. The prepared ceramic powder is uniform in particle sizeand the average particle size is about 150 nm. The preparation process has the characteristics of simple process, short period, low energy consumption and low cost, and the obtained ceramic phase is uniform and fine in particle size and high in purity.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

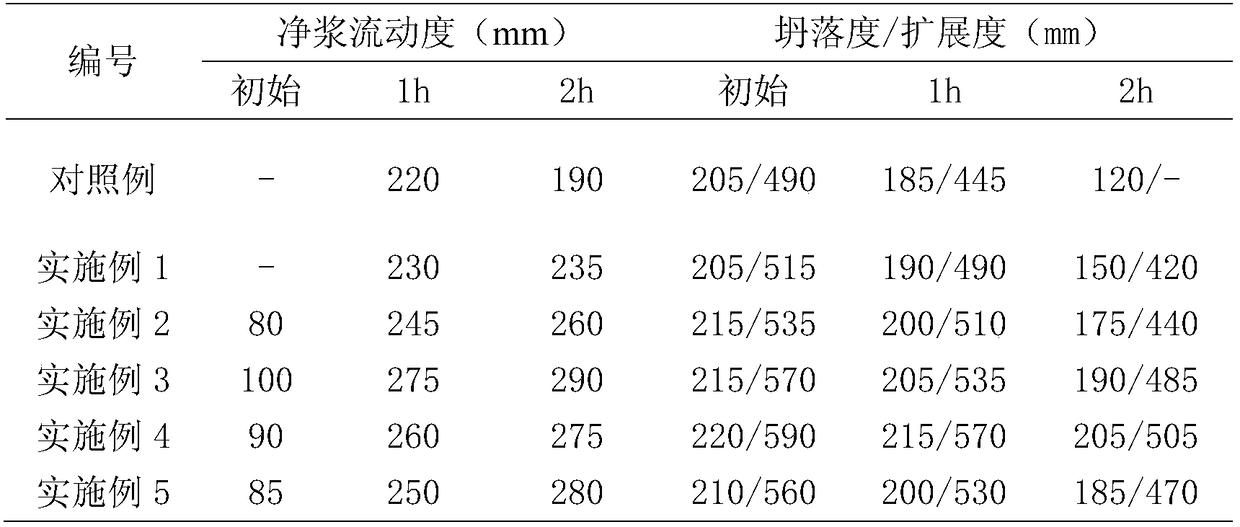

Slump retention type solid poly carboxylic acid water reducing agent and preparation method thereof

Owner:SHANXI SUNWAY INTION TRADE CO LTD

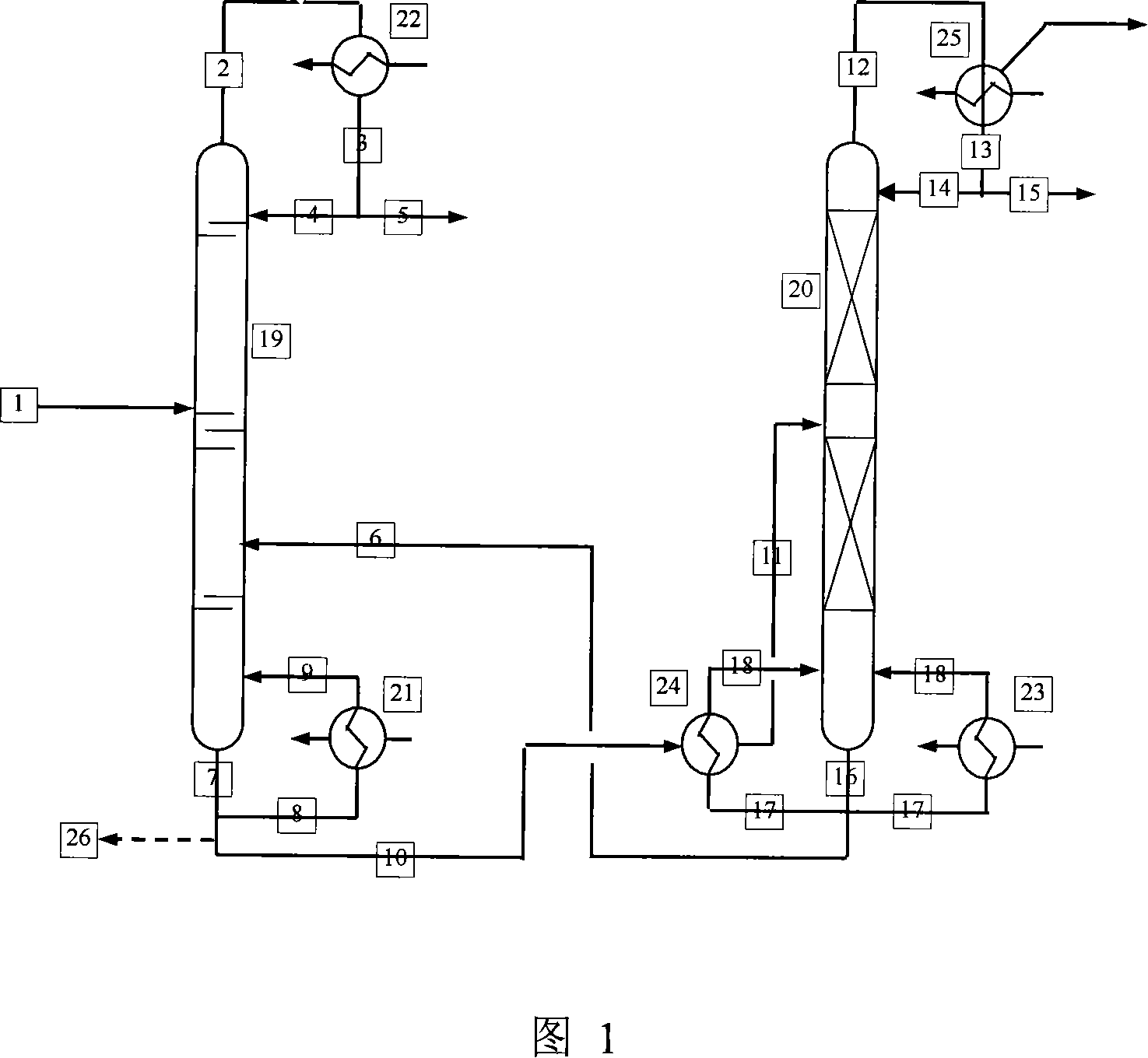

Method for preparing formic acid

ActiveCN101125795AControl incidenceFull recoveryOxygen-containing compound preparationOrganic compound preparationDecreased energyFormate Esters

The invention discloses a preparation method of methanoic acid, main steps of which are that: (1) compound containing water, methanoic acid, methanol and methyl formate is produced by hydrolyzing methyl formate; (2) methanol, water and methyl formate are separated from the compound containing water, methanoic acid, methanol and methyl formate by pressurizing and distilling, and then methanoic acid containing water is taken out of tower bottom. The method for preparing methanoic acid can effectively prevent reversing esterification, increase hydrolyzing reaction, reduce recycle ratio of materiel, improve manufacturing ability of hydrolyzing system equipment and greatly decrease energy consumption.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for preparing tungsten molybdenum copper composite material by microwave sintering

The invention discloses a method for preparing a tungsten molybdenum copper composite material by microwave sintering. The method comprises the steps: firstly, ball milling tungsten powder, molybdenumpowder and copper powder, fully and evenly mixing, putting the evenly-mixed powder into a mold and pressing the evenly-mixed powder into a green body of a cylindrical structure; then putting the green body into a microwave sintering furnace and utilizing a specific thermal treatment technology to prepare the tungsten molybdenum copper composite material under a lower temperature. Directed to theproblems of a traditional method for preparing tungsten molybdenum copper alloy in the prior art, the invention provides the method for preparing the tungsten molybdenum copper composite material by microwave sintering. Compared with the existing traditional method, the method can reduce a preparation temperature to 700 to 1,000 DEG C from 1,100 to 1,600 DEG C and further can shorten the preparation time to 20 to 50 min from 100 to 760 min; furthermore, the method disclosed by the invention can finish a densification process only through three steps of powder mixing, pressing and sintering, sothat a technology is simplified, easiness in implementation is achieved, and a product with finer and evener grains and an excellent mechanical property can be obtained. The defects of high sinteringtemperature, long sintering time, complex technology and the like of the existing traditional sintering method are solved.

Owner:SICHUAN UNIV

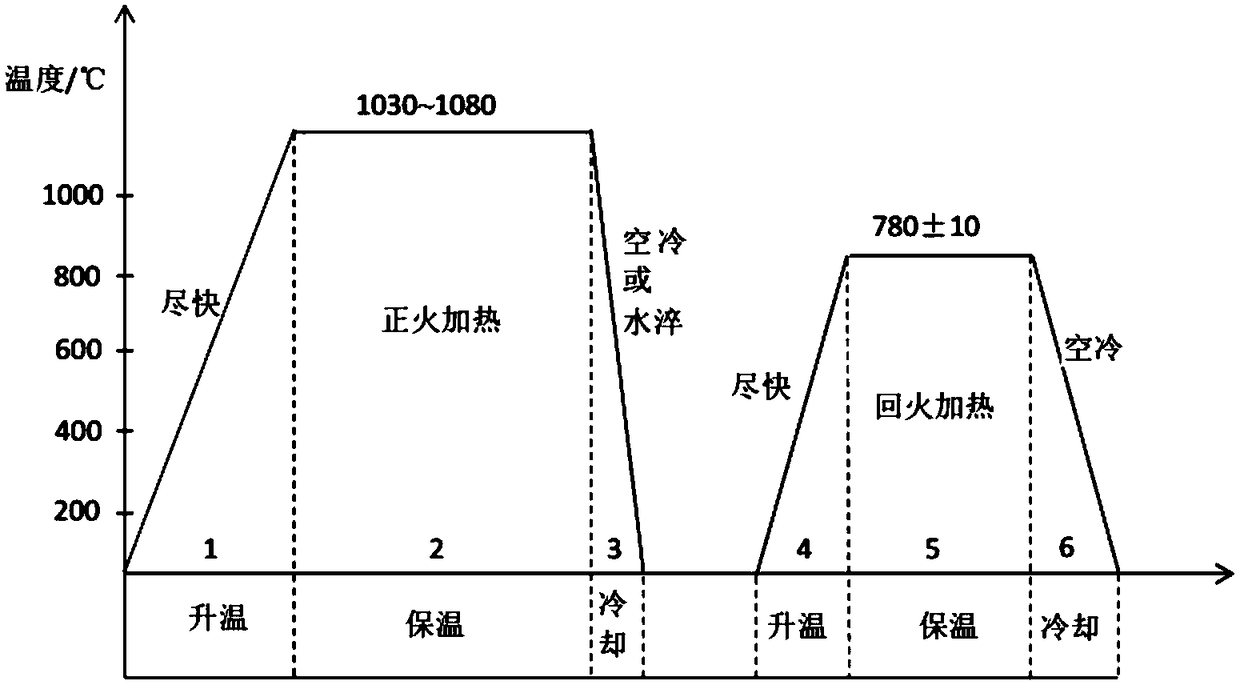

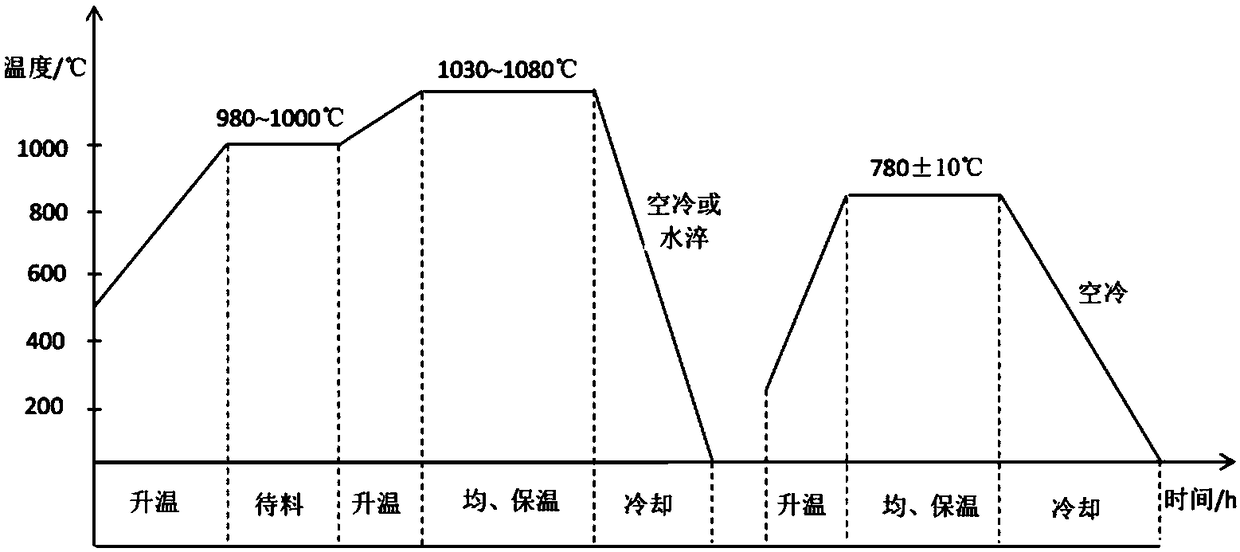

Method for improving radial structure and performance uniformity of G115 steel large-caliber thick-wall pipe

ActiveCN108950148AImprove radial temperature fieldImprove uniformityFurnace typesHeat treatment furnacesQuenchingCaliber

The invention discloses a method for improving radial structure and performance uniformity of a G115 steel large-caliber thick-wall pipe, and belongs to the technical field of steel materials. The process comprises the following steps of a normalizing system and a tempering system, wherein the normalizing system is characterized in that a tube blank subjected to hot-extrusion is adopted, chargingis carried out by using the temperature of 400-600 DEG C, warming is carried out with the heating speed of 100-120 DEG C / h until the temperature reaches 980-1000 DEG C, the hardening time is 0.5-1 min / mm, then warming is carried out with the heating speed of 130-150 DEG C until the temperature reaches 1030-1080 DEG C, then hardening is carried out, the hardening time is 0.5-0.8 min / mm, heat preservation is carried out for 1-3 hours after hardening, and air cooling or water quenching is carried out to the room temperature; and the tempering system is characterized in that charging is carried out by using the temperature less than or equal to 600 DEG C, warming is carried out with the heating speed of 120-150 DEG C / h until the tempering temperature reaches 780 + / - 10 DEG C, the time of heatpreservation is 3-5 hours, and air cooling is carried out to the room temperature. The method has the advantages that the radial temperature field of the thick-wall pipe is improved, moreover, the grain of the thick-wall pipe is not prone to coarsening, so that the radial structure and performance uniformity of the thick-wall pipe is greatly improved.

Owner:CENT IRON & STEEL RES INST

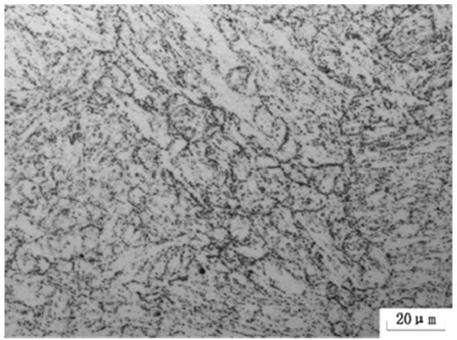

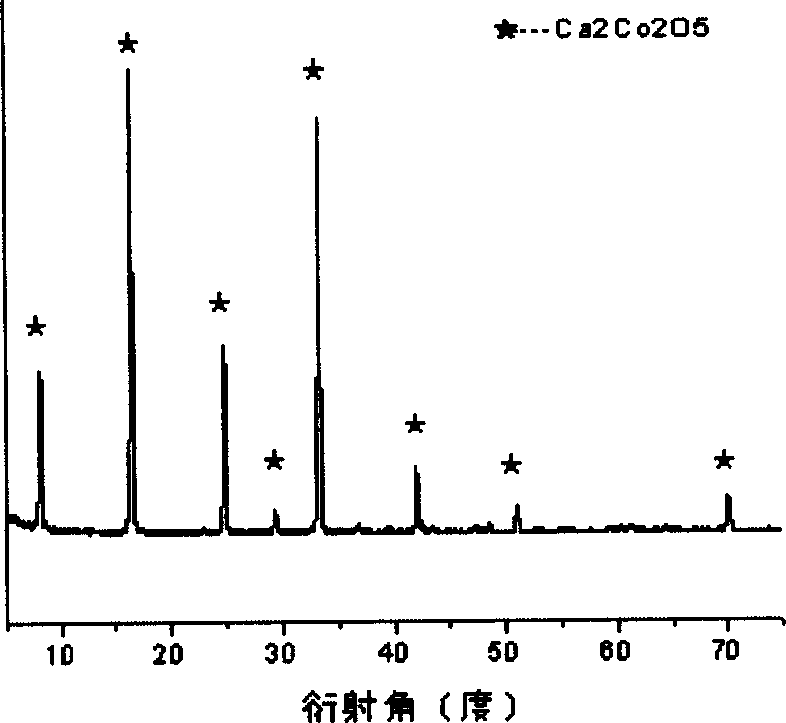

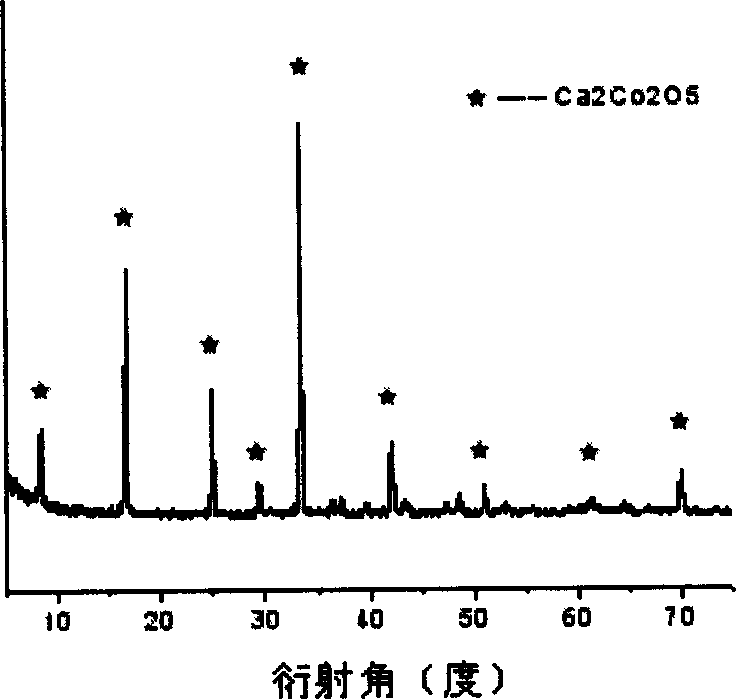

Method for preparing layered cobalt base oxide thermoelectric material

InactiveCN1632961AShort reaction timeReduce energy consumptionCalcium/strontium/barium compoundsThermoelectric device manufacture/treatmentThermoelectric materialsCobalt

It is a layer cobalt oxidation thermoelectricity material process method, which comprises the following steps: to process the solution with concentration of 0.1 to 0.5mol / l by adding Ca#-[2]Co#-[2]O#-[5]íóCa#-[3]Co#-[4]O#-[9]íó M#-[x]Ca#-[2-x]Co#-[2]O#-[5]íóM#-[x]Ca#-[3-x]Co#-[4]O#-[9] as their positive ion countered; to mix the solution and drop with co-deposit agent of sodium hydroxide, sodium carbonate, oxalic acid ammonium or their mixture; to control the pH value between 12.5 to 13.6 to process drive powder after depositing, filtering and washing and drying; to burn it under 600 to 800 degrees for two to six hours and put it into the mode.

Owner:BEIJING UNIV OF TECH

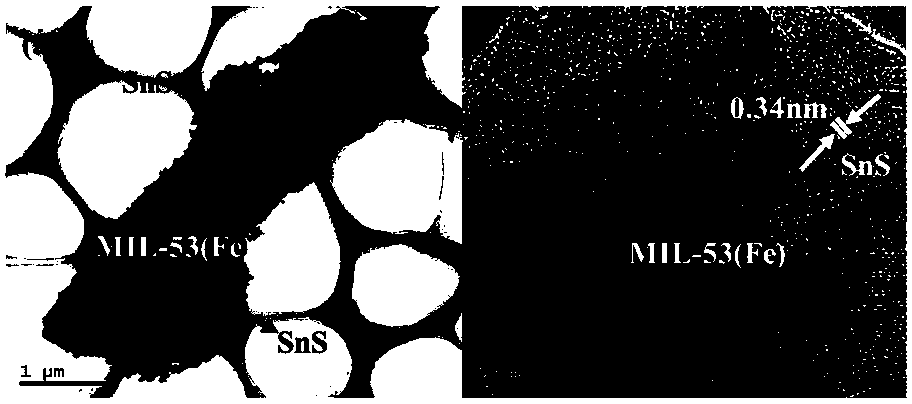

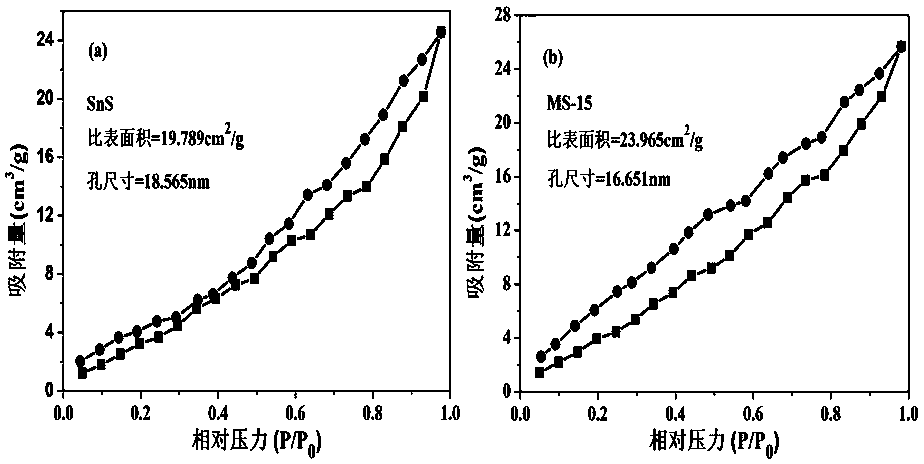

Metal organic framework modified stannous sulfide composite photocatalyst as well as preparation method and application thereof

ActiveCN107913675ALarge specific surface areaIncreased toxicityWater/sewage treatment by irradiationOther chemical processesMetal-organic frameworkWastewater

The invention discloses a metal organic framework modified stannous sulfide composite photocatalyst as well as a preparation method and application thereof. The composite photocatalyst takes a metal organic framework MIL-53(Fe) as a carrier and is loaded with stannous sulfide. The preparation method of the composite photocatalyst comprises the following steps: mixing MIL-53(Fe) with stannous sulfide, adding solution containing S<2->, and carrying out precipitation reaction, so that the metal organic framework modified stannous sulfide composite photocatalyst is obtained. The composite photocatalyst disclosed by the invention has the advantages of environment friendliness, large specific surface area, many reaction sites, high photogenerated electron-hole utilization rate, high photocatalytic activity, good stability and corrosion resistance, and the preparation method has the advantages of simplicity in operation, low raw material cost, low energy consumption, short consumed time and easy-to-control conditions. The composite photocatalyst disclosed by the invention can be used for degrading hexavalent chromium wastewater, has the advantages of high degradation efficiency, simple application method, low cost and no secondary pollution and has a good practical application prospect.

Owner:HUNAN UNIV

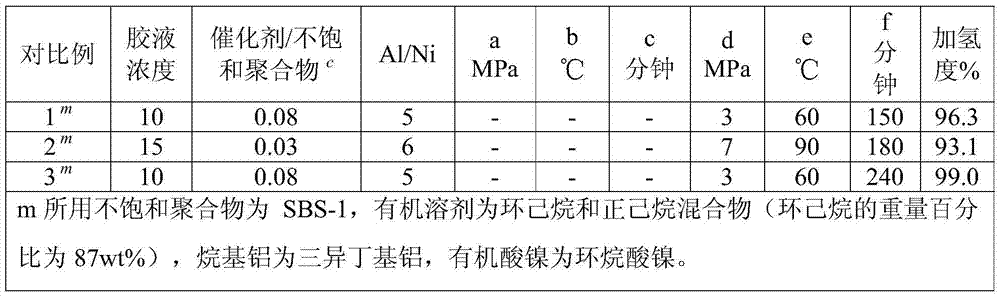

Method for preparing polymers

ActiveCN107200797AImprove hydrogenation reactivityIncrease the degree of hydrogenationHydrogenation reactionReaction temperature

The invention relates to the field of copolymers, and discloses a method for preparing polymers. The method includes steps of (1), mixing glue solution of unsaturated polymers and hydrogenation catalysts with one another; (2), sequentially carrying out first hydrogenation reaction and second hydrogenation reaction on mixtures obtained at the step (1) in the presence of hydrogen; (3), removing solvents in reaction products obtained at the step (2). The hydrogenation catalysts contain organic compounds of organic aluminum and metal of VIIIB groups. The reaction temperatures of the first hydrogenation reaction range from -10 DEG C to 15 DEG C, and the reaction temperatures of the second hydrogenation reaction range from 40 DEG C to 120 DEG C. The method for preparing the polymers has the advantages that the hydrogenation reaction activity of the hydrogenation catalysts and the hydrogenation degrees of hydrogenation products can be improved, and the method is easy to operate and implement, short in reaction time and low in preparation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

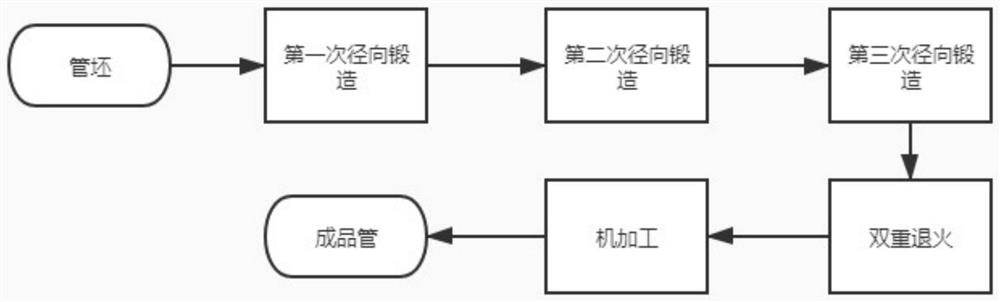

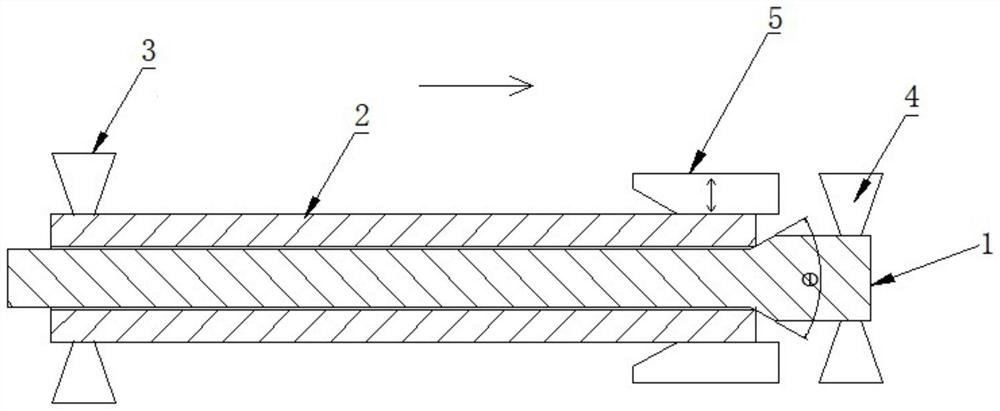

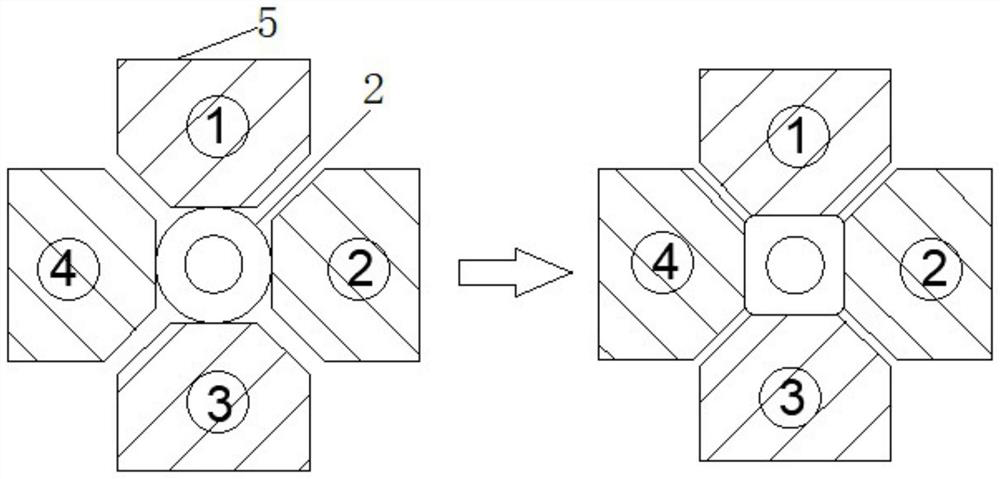

Short-process manufacturing method for titanium and titanium alloy pipes

ActiveCN112775370AIncrease the amount of deformationImprove densification performanceForging hammersFurnace typesProcess manufacturingTitanium

The invention discloses a short-process manufacturing method for titanium and titanium alloy pipes. The method comprises the processes of pipe blank heating, multiple-time radial forging, double annealing and machining, so that the titanium alloy pipes are obtained. The pipe blank heating temperature is 80 DEG C-100 DEG C higher than the titanium alloy beta phase transformation point, and the heat preservation time is larger than or equal to 2h. The multiple-time radial forging process comprises three times of radial forging, wherein the hammering speed of the first time of radial forging is 1000-2000 times per minute, and the pipe blank deformation is controlled to be 40% to 80%; the hammering speed of the second time of radial forging is 2000-3000 times per minute, and the pipe blank deformation is controlled to be 30% to 60%; and the hammering speed of the third time of radial forging is 50-100 times per minute, and the pipe blank deformation is controlled to be 30% to 40%. The manufacturing method is short in processing period and low in cost, the titanium alloy pipes with equiaxial or binary structures and excellent mechanical properties can be directly obtained, and the material utilization rate is high.

Owner:江苏宇钛新材料有限公司

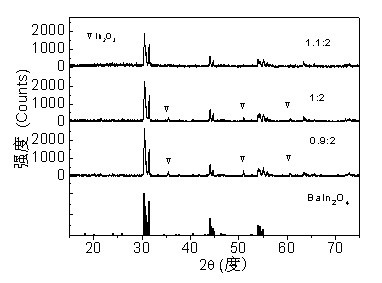

Preparation method of visible light catalyst barium-indium-oxygen

InactiveCN102068977AHigh purityWell mixedCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystBarium nitrate

The invention discloses a preparation method of visible light catalyst barium-indium-oxygen. The method comprises the following steps of: preparing mixed aqueous solution of barium nitrate and indium nitrate in a certain molar ratio; performing a coprecipitation reaction by taking aqueous solution of sodium carbonate and sodium hydroxide as a precipitator so as to prepare a uniformly-mixed precursor; drying the precursor at the temperature of 100 DEG C; and performing high-temperature sintering in a high-temperature furnace at the thermal treatment temperature of between 1,100 DEG C and 1,300 DEG C so as to obtain barium-indium-oxygen with a monoclinic structure. The preparation method of the visible light catalyst barium-indium-oxygen has the advantages of low preparation cost, short period, high product purity, adjustable product particle size, easy operation, and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Preparation method of edible packaging film based on diatom polysaccharide

The invention discloses a preparation method of an edible packaging film based on diatom polysaccharide. The preparation method specifically comprises the following steps: degreasing diatom powder, concretely adding a chloroform methanol mixed solution into the diatom powder, carrying out degreasing, suction filtration, and drying to obtain degreased diatom powder; preparing the diatom polysaccharide, concretely uniformly mixing the degreased diatom powder with water, then adding 8-chlorotheophylline, and carrying out ultrahigh-pressure extraction and suction filtration, wherein the obtained filtrate is the water extracted crude polysaccharide; and preparing the edible packaging film, concretely taking the following components in parts by weight: the diatom polysaccharide, glycerol, gelatin, tea polyphenol and water, dissolving the components to prepare a film liquid, carrying out degassing, then uniformly pouring the degassed film liquid into a mold, and carrying out drying for forming a film, so as to obtain the edible packaging film. The preparation method disclosed by the invention has the beneficial effects that the preparation method is simple and feasible, the time consumption is low, the energy consumption is low, the utilization rate of the raw materials can be improved, and the degradable pollution-free packaging film with good performance can be formed. The surface of the packaging film is smooth and compact, the film is easy to uncover, and the packaging film is edible, is easy for industrial scale production and has good application value and market potential.

Owner:金华市铁骑士生物科技有限公司

Cermet composition and method for preparing cermet coat on metal surface

A metal-ceramic composition and coating it on metal surface are both disclosed herewith. It consists both parts of mixed powders containing Cr, B, Si, Fe, Al, La rare-earth oxides and Ni, and carbide materials, TiC or WC. It is coated as following: mixing metal-ceramic composition with polyvinyl alcohol or ethyl estate as binding agent to be slurry, coating it onto metal surface, drying, and firing in gas protecting furnace or vacuum furnace to obtain metal-ceramic coated metal parts. It is available to various shaped parts with different materials, and reduces energy consumption.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

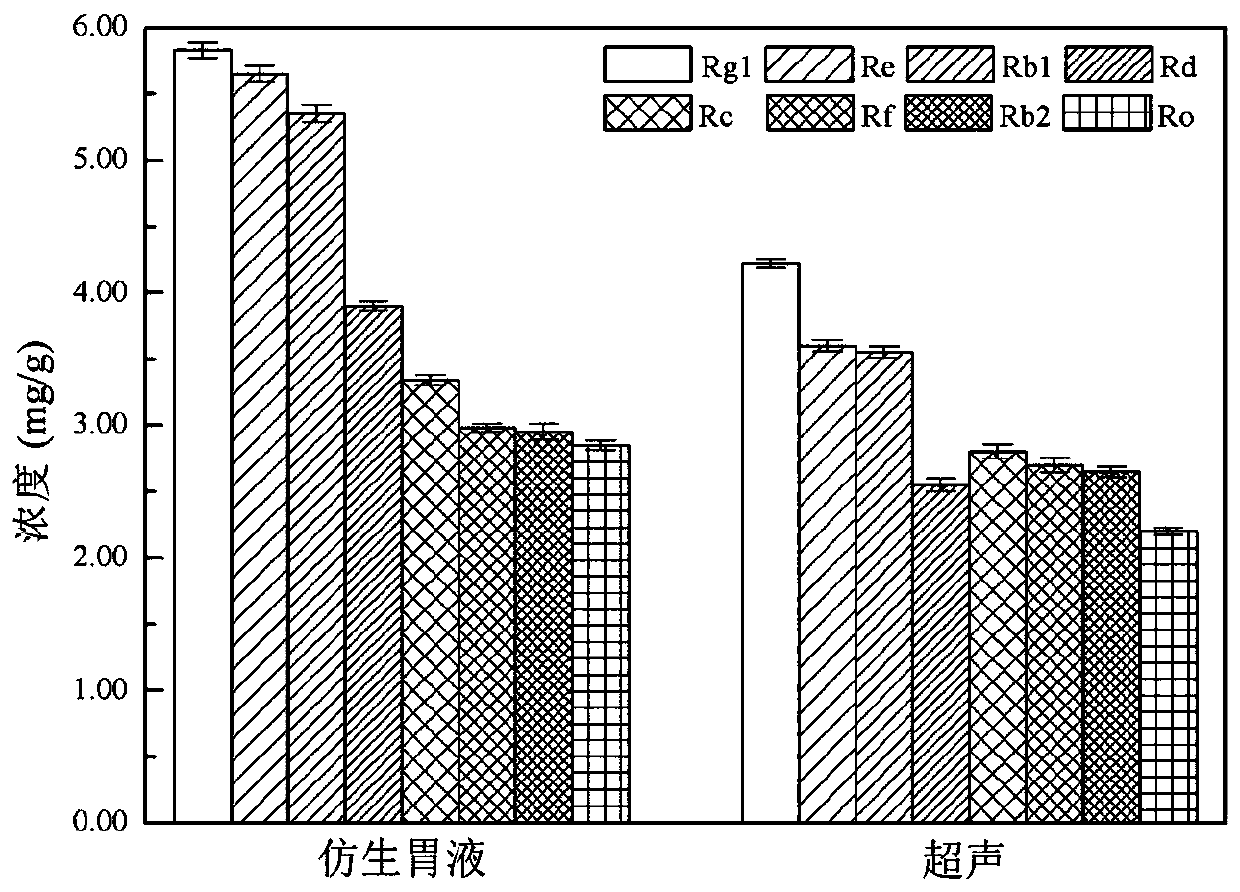

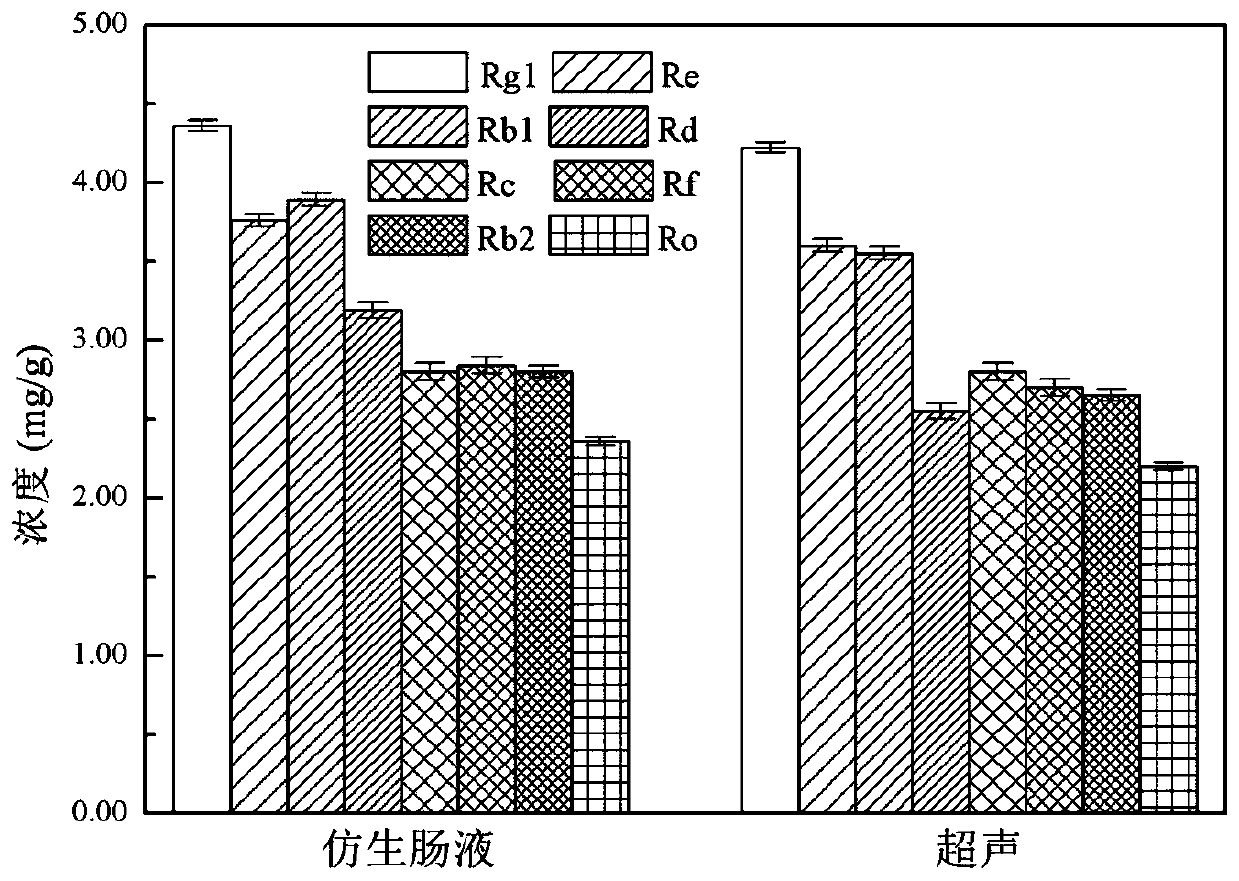

Method for extracting ginsenoside by biomimetic method and ginsenoside extract by using method

InactiveCN111450132AHigh content of active ingredientsImprove extraction efficiencyPlant ingredientsMolecular biologyGinsenoside

The invention discloses a method for extracting ginsenoside by a biomimetic method and a ginsenoside extract by using the method. The extraction method comprises the steps of preparation of a biomimetic extraction solvent, biomimetic extraction of ginsenoside and extraction of an extracting liquid, wherein the biomimetic extraction solvent is biotic gastric juice or biotic intestinal juice; in thestep of biomimetic extraction of ginsenoside, ginseng is extracted by utilizing the prepared biomimetic extraction solvent after being dried and ground, the extracting liquid is centrifuged and filtered, and the extraction solvent is utilized to extract; in the step of extraction of the extracting liquid, the extracting liquid and the extraction solvent are mixed and separated, and the ginsenoside extract is obtained after the extracting liquid volatized and dried. by utilizing the biomimetic extraction method, the ginsenoside extract has high content of effective ingredients. Compared with atraditional organic solvent extraction method, the method has the characteristics of environmental friendliness, no toxicity or harm and high extraction efficiency. The method is low in energy consumption, short in time consumption, small in solvent consumption and simple and convenient to operate, has good accuracy, repeatability and precision, and is applicable to industrial production.

Owner:CHANGCHUN UNIV OF CHINESE MEDICINE

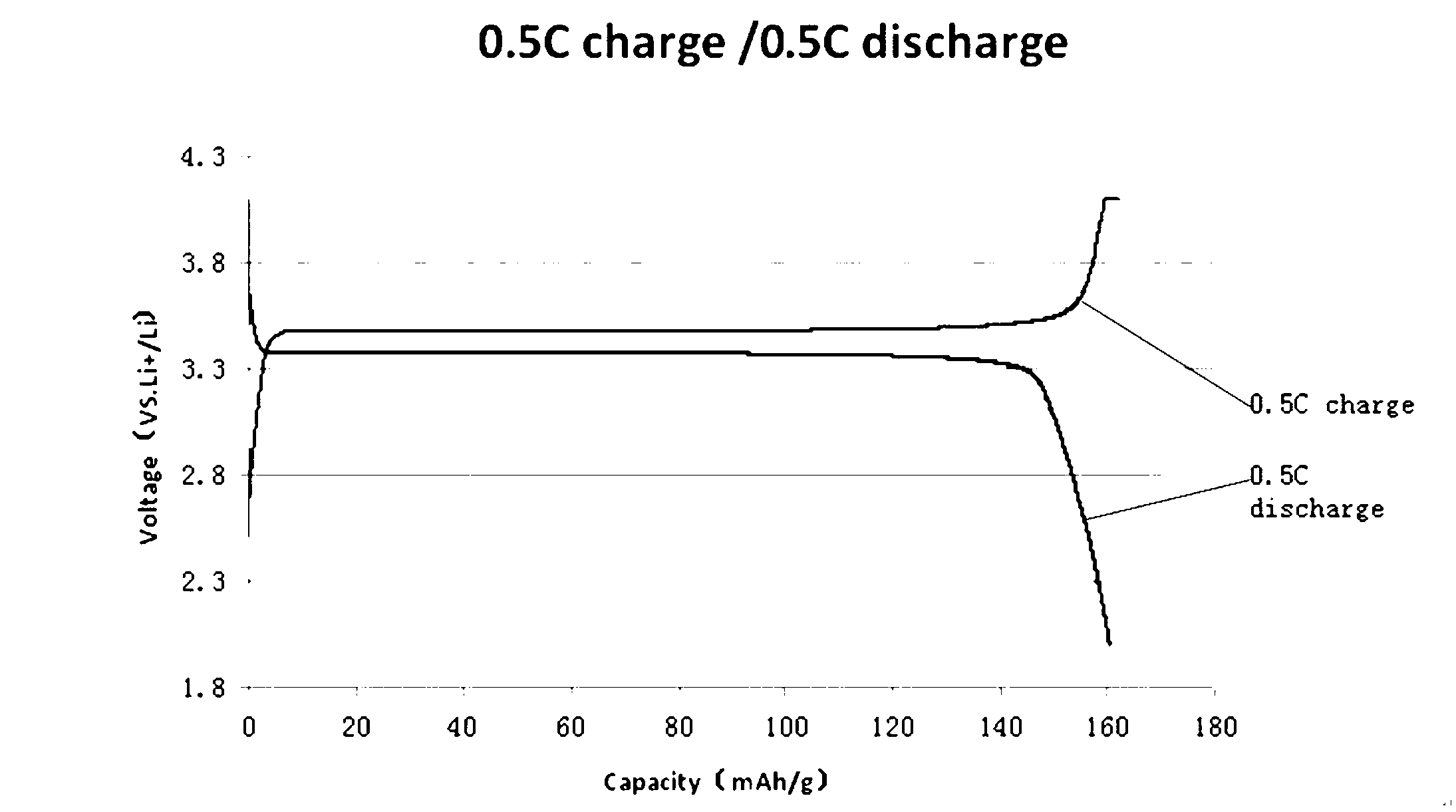

Method for producing amorphous precursor serving as anode material of lithium ion battery

ActiveCN103011116AImprove electrochemical performanceImprove performanceCell electrodesSecondary cellsAluminium-ion batteryPhosphate

The invention discloses a method for producing an amorphous precursor serving as an anode material of a lithium ion battery. The amorphous precursor serving as the anode material of the lithium ion battery has a basic structural formula of MyPO4. The method comprises the following steps of: 1, under the condition that water, a water solution or solvent with a lower temperature or a temperature lower than a room temperature exists, extracting at least one solvend of an M metal sulfate, an M metal nitrate and an M metal halide with a soluble phosphate under the alkaline condition to generate a precipitate, collecting, washing, and drying to obtain the amorphous precursor. The node material of the lithium ion battery, which is produced from the precursor, is LixMyPO4, Li<+> in charge and discharge processes are more favorably inserted and separated, material impedance is reduced, the milling time of the material can be shortened, and the processing energy consumption can be reduced, and the reaction is mild and controllable; and the method is especially suitable for large-scale industrial production.

Owner:LONG POWER SYST SUZHOU

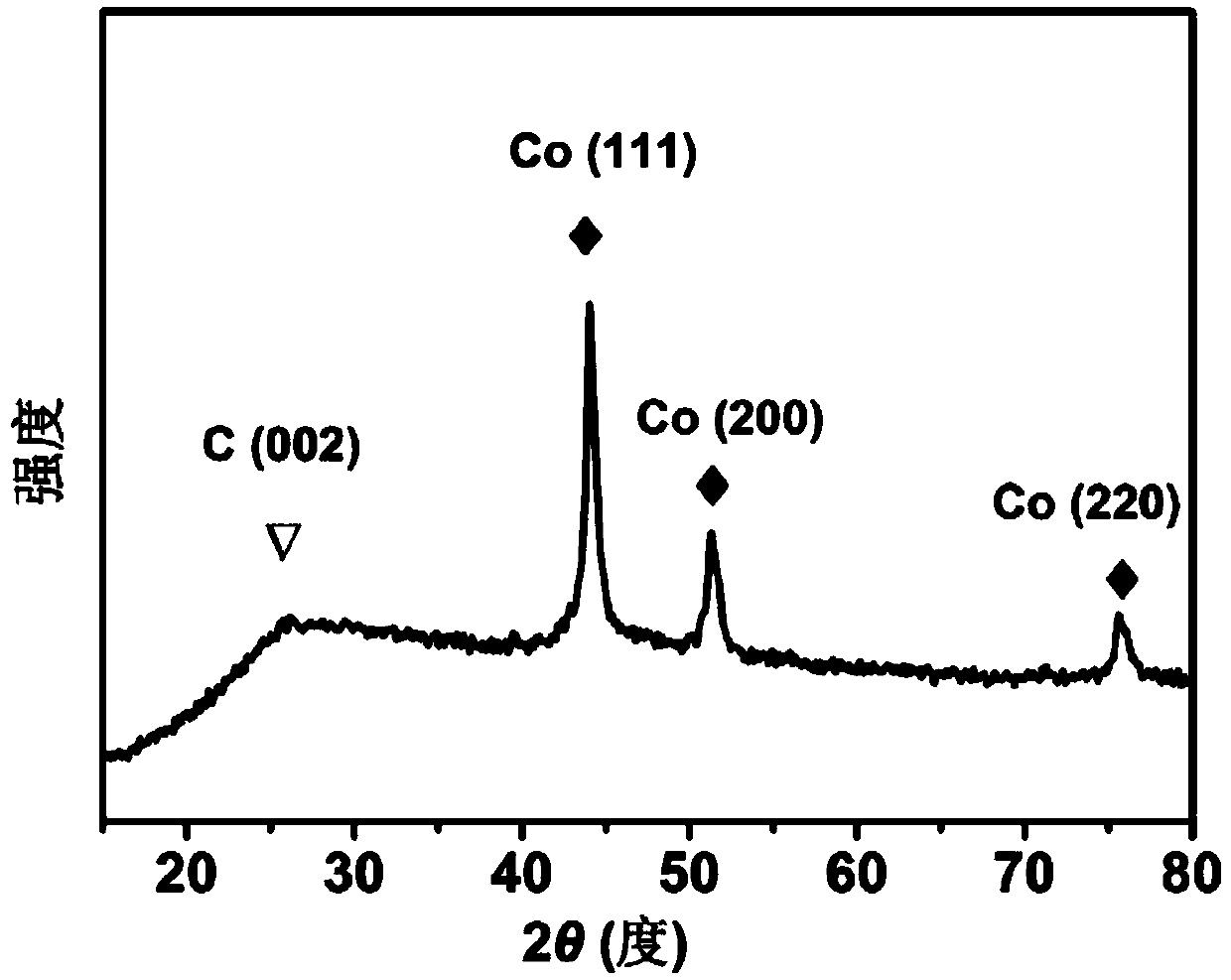

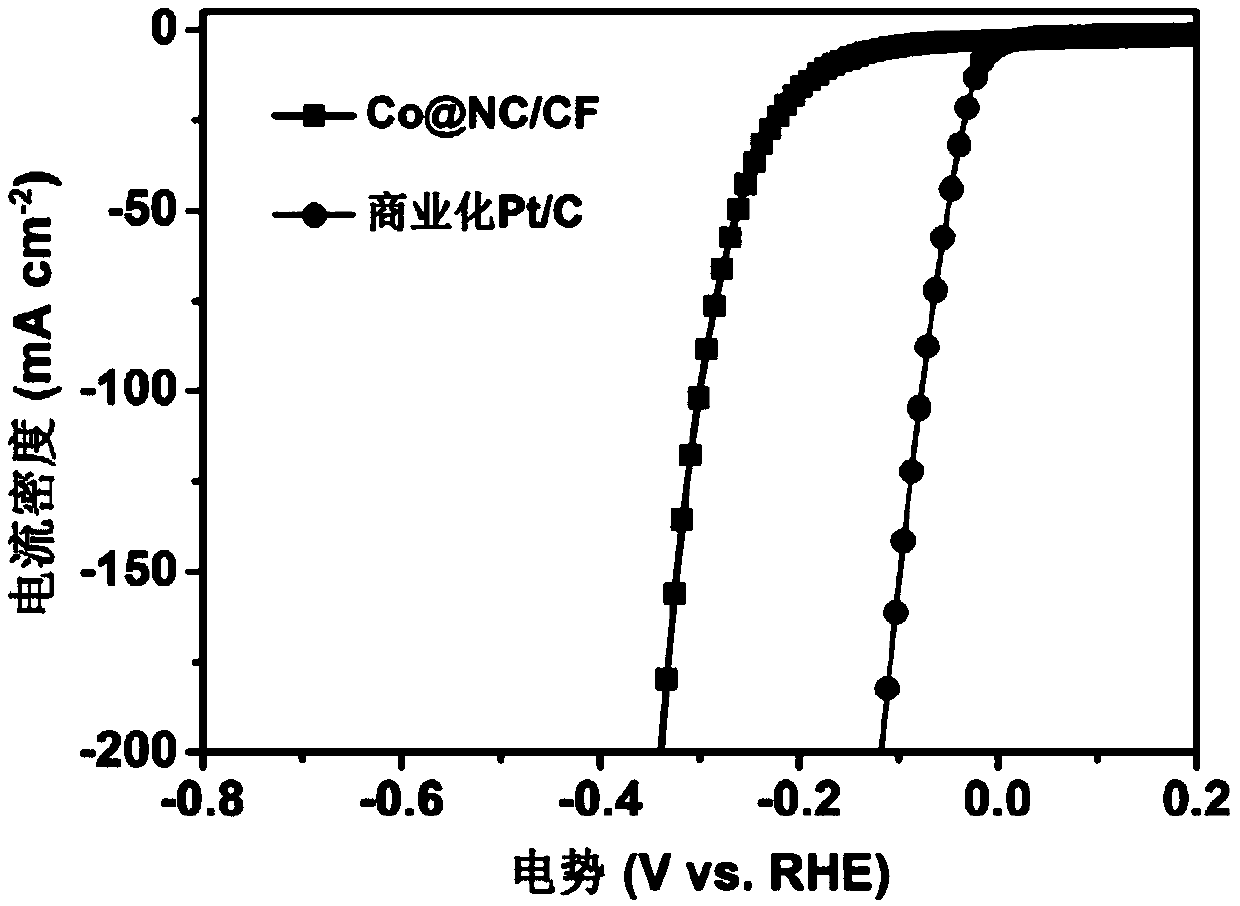

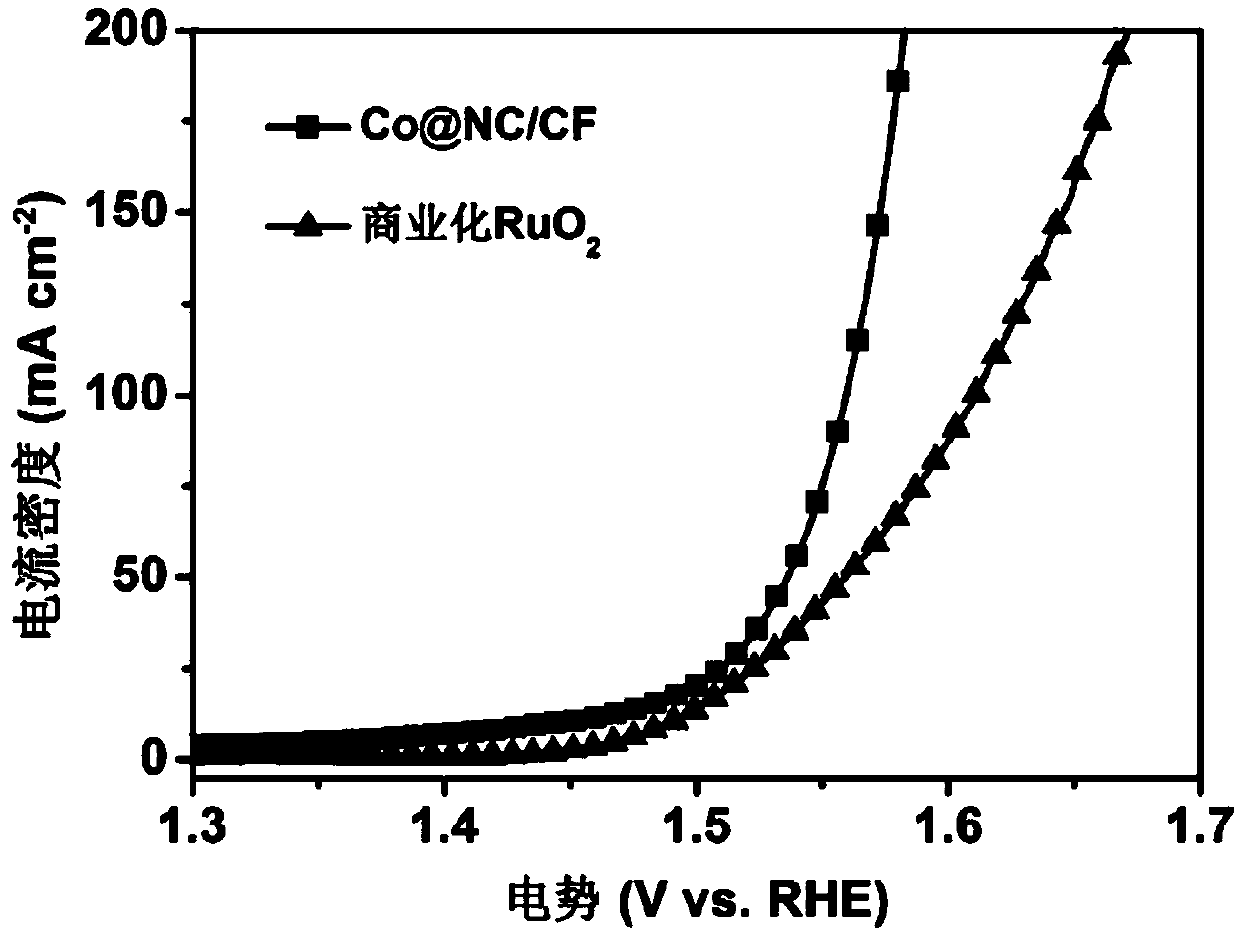

Rapid preparation method and application of high-yield MOF-derived catalyst

ActiveCN109647477AHigh carbon contentRegular structurePhysical/chemical process catalystsElectrodesEnvironmental resistanceElectrolysis

The invention belongs to the technical field of catalytic material preparation, and relates to a rapid preparation method and an application of a high-yield MOF-derived catalyst. The preparation method comprises the following steps: (1) preparation of a precursor Co-MOF; and (2) microwave radiation carbonization treatment. The MOF-derived catalyst prepared by the method has a regular structure anda high carbon content. The MOF-derived catalyst prepared by the method has excellent catalytic activity on electrolytic water cathode hydrogen evolution and anodic oxygen evolution in the electrocatalytic water decomposition process, and is expected to replace noble metal catalysts. The method of the invention has the advantages of rapidity, wide universality, greenness, environmental protection,short time, low energy consumption, simple and safe process, and easiness in large-scale production.

Owner:DALIAN UNIV OF TECH

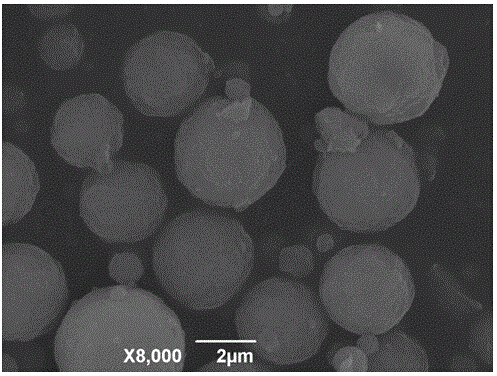

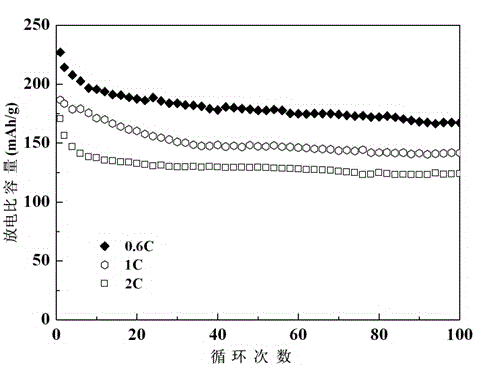

Micron-scale spheroidal ferric fluoride positive electrode material and preparation method thereof

The invention specifically relates to a micron-scale spheroidal ferric fluoride positive electrode material and a preparation method thereof. The micron-scale spheroidal ferric fluoride positive electrode material is prepared from a water / alcohol mixed solution of a ferric salt and a fluorine-containing aqueous solution. The preparation method is performed at a normal temperature and under a normal pressure, the preparation process is simple, the consuming time is short, the energy consumption is low, the cost is low, the environment-friendly effect is achieved, and the industrial production can be realized easily; the prepared FeF3(H2O)0.33 particles are spheroidal at the micron scale; the tap density of the material is improved; the material has excellent mobility, dispersibility and machinability, and is applicable to producing a positive electrode material slurry and coating an electrode plate; meanwhile, the material has a one-dimensional tunnel structure and is beneficial to the migration of lithium ions, so that the electrical conductivity of the material can be improved; in addition, the stability of the FeF3 structure is maintained in the charging / discharging process by use of little crystal water, and therefore, good electrochemical properties can be realized.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

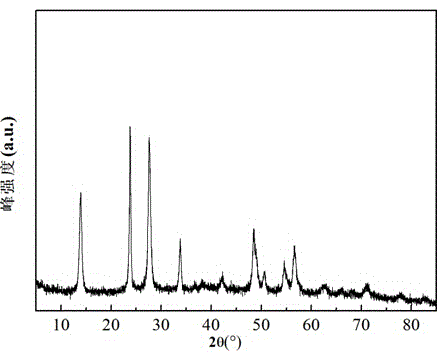

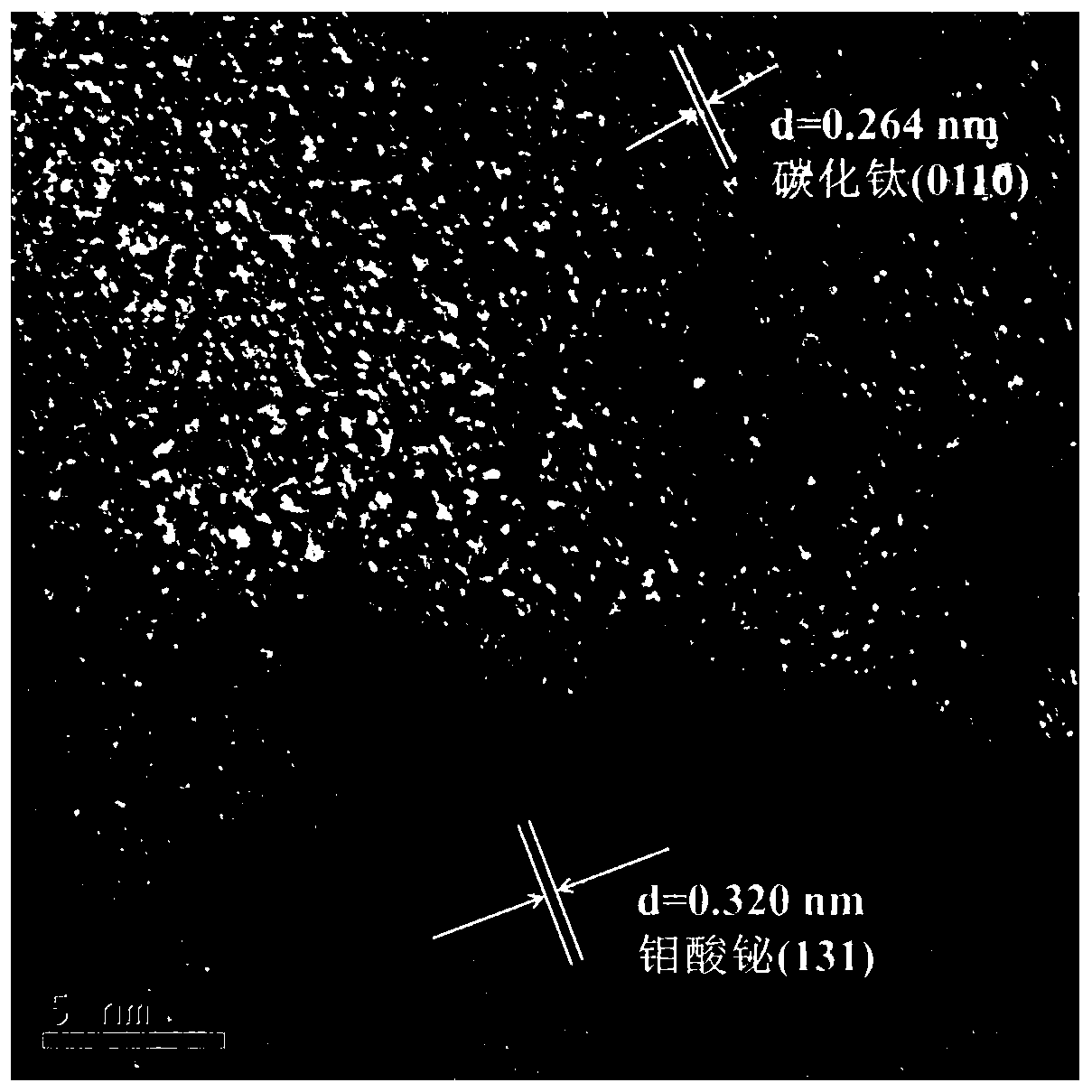

Bismuth molybdate/titanium carbide heterojunction two-dimensional photocatalytic material as well as preparation method and application thereof

ActiveCN110586149AEasy to separateImprove catalytic performanceWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionEnvironmental resistance

The invention discloses a bismuth molybdate / titanium carbide heterojunction two-dimensional photocatalytic material as well as a preparation method and application thereof. The two-dimensional photocatalytic material includes titanium carbide nanosheets and layered bismuth molybdate supported on the titanium carbide nanosheets. The preparation method includes the following steps: preparing bulk titanium carbide; preparing the titanium carbide nanosheets by using dimethyl sulfoxide; and preparing the above two-dimensional photocatalytic material through a hydrothermal reaction. The two-dimensional photocatalytic material has the advantages of low costs, easy availability, low recombination efficiency of photoelectrons and holes, strong catalytic performance, good redox activity, and less harm to the environment, is a green and economic photocatalytic material, can be widely used to treat pollutants in the environment, and has higher use value and better application prospects; and the preparation method provided by the invention has the advantages of a simple process, convenient operation, low raw material costs, low energy consumption, short consumed time, mild easily controlled reaction conditions, greenness and environmental protection, and shows good application prospects in synthesis of functional nanomaterials.

Owner:HUNAN UNIV

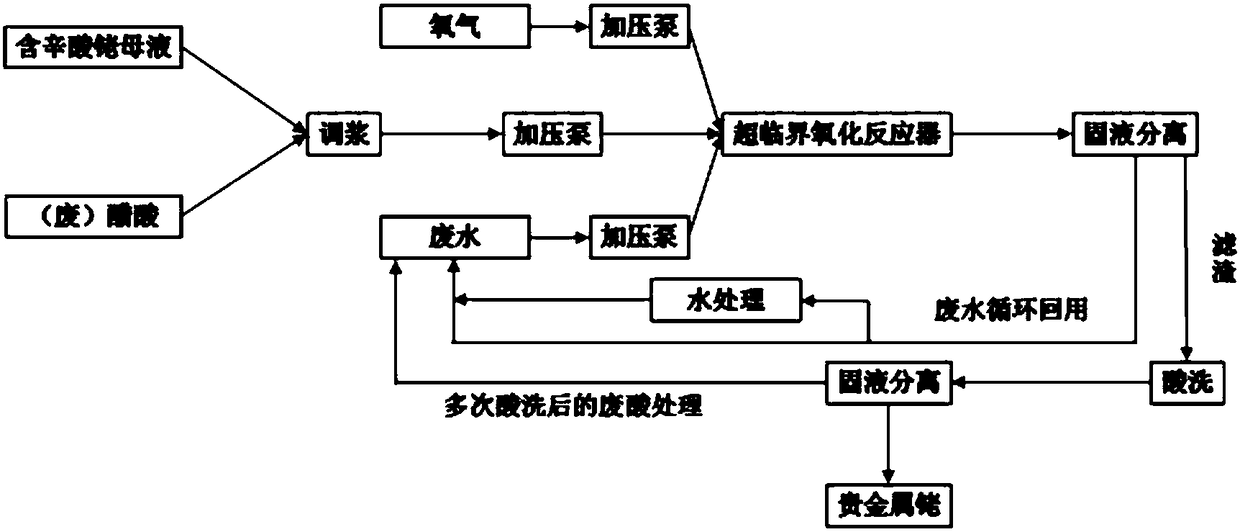

Method for recycling rhodium from rhodium octanoate mother liquor

The invention relates to the technical field of precious metal recycling, and particularly discloses a method for recycling rhodium from rhodium octanoate mother liquor. The method includes the following steps that the rhodium octanoate mother liquor is subjected to slurry-mixing with acetic acid to obtain slurry; after the slurry, an oxidizing agent, and water are mixed, supercritical oxidation treatment is carried out, a gas-phase system and a non-gas-phase system are obtained through gas-liquid separation, the non-gas-phase system is subjected to solid-liquid separation treatment, and a first solid phase is obtained; the first solid phase is subjected to acid pickling treatment to obtain a second solid phase, a mixed system after acid pickling is collected to perform solid-liquid separation to obtain a third solid phase, and the second solid phase and the third solid phase are combined to obtain a rhodium crude product; and the rhodium crude product is washed to obtain the preciousmetal rhodium. The method is simple in technological process, low in pollution since organic matter is rapidly oxidized into innoxious substances such as carbon dioxide and nitrogen, short in processing time, low in energy consumption, and high in recovery rate, the loss of the precious metal rhodium is reduced, and the industrialization is easy.

Owner:南京新奥环保技术有限公司

Method for preparing enzyme by using honeysuckle and curcuma longa as main raw materials

InactiveCN106235318AIncrease profitReduce the risk of slow salesMicroorganism based processesVinegar preparationRoom temperatureMusa basjoo

The invention relates to a method for preparing an enzyme by using honeysuckle and curcuma longa as main raw materials. The method specifically comprises: (1) selecting 35-45 parts by weight of honeysuckle, 10-15 parts by weight of musa basjoo siebold, 10-15 parts by weight of pineapple, and 10-15 parts by weight of clausena lansium, and washing with clear water so as to be spare; (2) peeling the clausena lansium to expose the flesh, cutting the pineapple with the peel and the musa basjoo siebold with the peel into pineapple slices with the thickness of 1-2 cm and musa basjoo siebold slices with the thickness of 1-2 cm, and uniformly mixing the slices to obtain a mixture; (3) placing the mixture into a sealed container, adding honey and water, uniformly mixing, placing into a room, carrying out sealed fermentation at a room temperature, and maintain for 1 month, wherein stirring is performed everyday at the starting 5-7 days and stirring is performed every 7 days at the later days; and (4) washing fresh curcuma longa picked before and after winter solstice, cutting into curcuma longa slices with the thickness of 0.3-2 cm, taking 15-25 parts by weight of the curcuma longa slices, adding to the sealed container, and carrying out sealed fermentation for more than 3 months so as to obtain the product. According to the present invention, the enzyme prepared through the method has advantages of original food function maintaining, rich probiotics, rich nutrition, good taste, and long shelf life.

Owner:唐妙红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com