Method for preparing layered cobalt base oxide thermoelectric material

A thermoelectric material and oxide technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, cobalt compounds, etc., can solve the problems of high reaction temperature, long process cycle, long reaction time, etc., and achieve chemical High stability, low reaction temperature and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

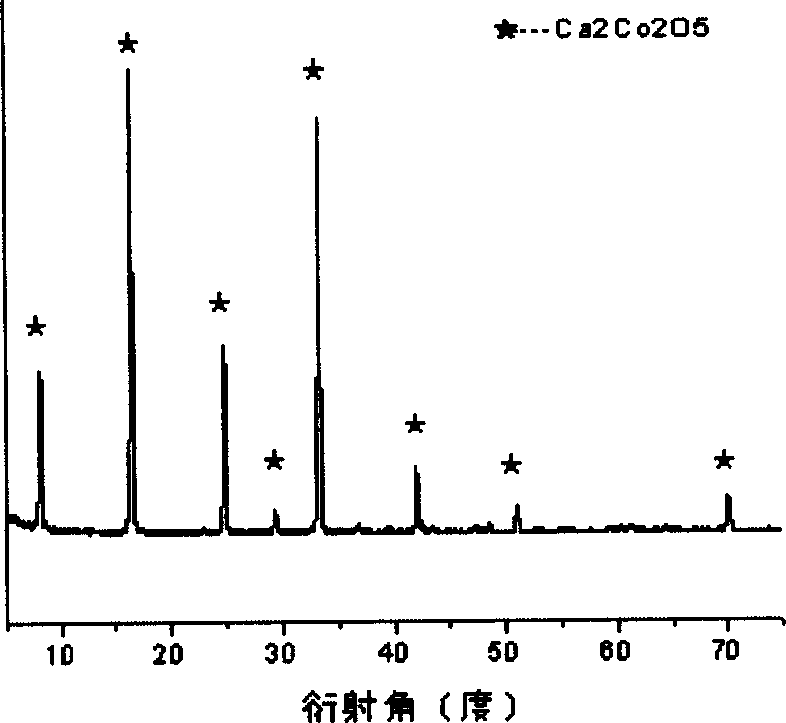

[0030] [Example 1] Ca 2 Co 2 O 5 Preparation

[0031] The reactant Co(NO 3 ) 3 ·6H 2 O and Ca (NO 3 ) 2 ·4H 2 O is configured into Ca at a molar ratio of 1:1 2+ The mixed solution with a concentration of 0.1 mol / L is then added dropwise with NaOH solution under constant stirring to make the pH value of the solution reach 12.50. The resulting precipitate is filtered and washed until the filtrate is neutral to remove the residual NaOH in the product. After drying the washed precipitate, put it in a muffle furnace and heat it to 750°C and heat it for 2 hours. Finally, put the calcined powder product into the mold and put it in the SPS sintering furnace to quickly heat it to 850°C and keep it warm. The bulk thermoelectric material is obtained in 5 minutes. The phase and fracture morphology of the bulk compound can be seen figure 1 with 2 , The product appears as single-phase Ca 2 Co 2 O 5 The phase structure is arranged in sheets. At 700°C, the ZT value of the compound reached 0.21. ...

Embodiment 2

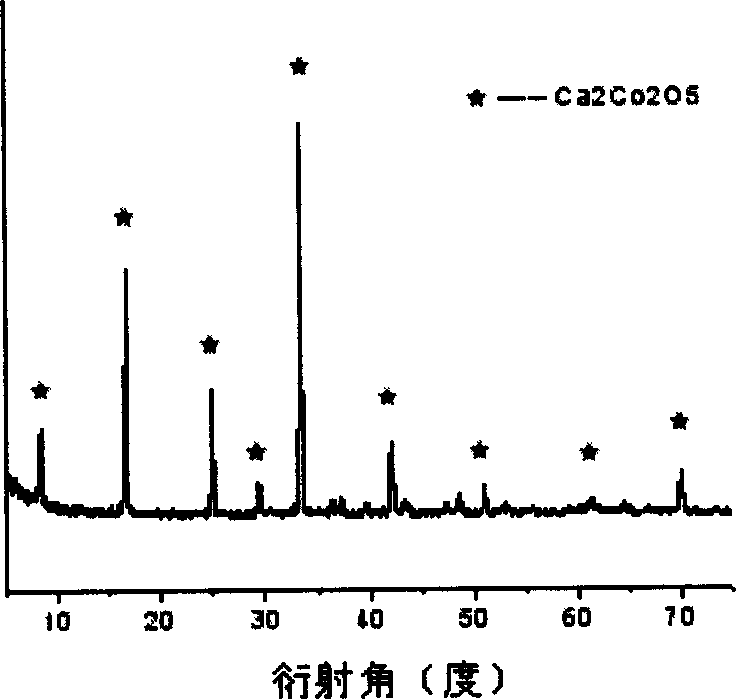

[0032] [Example 2] Ca 2 Co 2 O 5 Preparation

[0033] The reactant Co(NO 3 ) 3 ·6H 2 O and Ca (NO 3 ) 2 ·4H 2 O is configured into Ca at a molar ratio of 1:1 2+ A mixed solution with a concentration of 0.5mol / l, and then Na is added dropwise to it under constant stirring 2 CO 3 Solution, make the pH of the solution reach 13.20. Filter and wash the formed precipitate until the filtrate is neutral to remove residual Na in the product 2 CO 3 . After drying the washed precipitate, put it in a muffle furnace and heat it to 600°C and heat it for 5 hours. Finally, put the calcined powder product into the mold and put it in the SPS sintering furnace to quickly heat it to 900°C and keep it warm. The bulk thermoelectric material is obtained in 3 minutes. The phase and fracture morphology of the product image 3 with 4 , Manifested as single-phase Ca 2 Co 2 O 5 The phase structure is arranged in sheets. At 700°C, the ZT value of the compound reached 0.21.

Embodiment 3

[0034] [Example 3] Ca 2 Co 2 O 5 Preparation

[0035] The reactant Co(NO 3 ) 3 ·6H 2 O and Ca (NO 3 ) 2 ·4H 2 O is configured into Ca at a molar ratio of 1:1 2+ The mixed solution with a concentration of 0.2mol / l, and then add dropwise (NH 4 ) 2 C 2 O 4 Solution, make the pH of the solution reach 13.60. The formed precipitate is filtered and washed until the filtrate is neutral. After drying the washed precipitate, put it in a muffle furnace and heat it to 700°C and heat it for 3 hours. Finally, put the calcined powder product into the mold and put it in the SPS sintering furnace to quickly heat it to 700°C and keep it warm. The bulk thermoelectric material is obtained in 10 minutes. The phase and fracture morphology of the compound can be seen Figure 5 with 6 , Manifested as single-phase Ca 2 Co 2 O 5 The phase structure is arranged in sheets. At 700°C, the ZT value of the compound reached 0.20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com