Preparation method of high softening point asphalt

A technology for high softening point bitumen and bitumen raw materials, which is applied in the chemical processing of tar pitch/petroleum pitch/natural pitch, etc., can solve the problems of low reaction efficiency, long reaction time and high temperature sensitivity of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

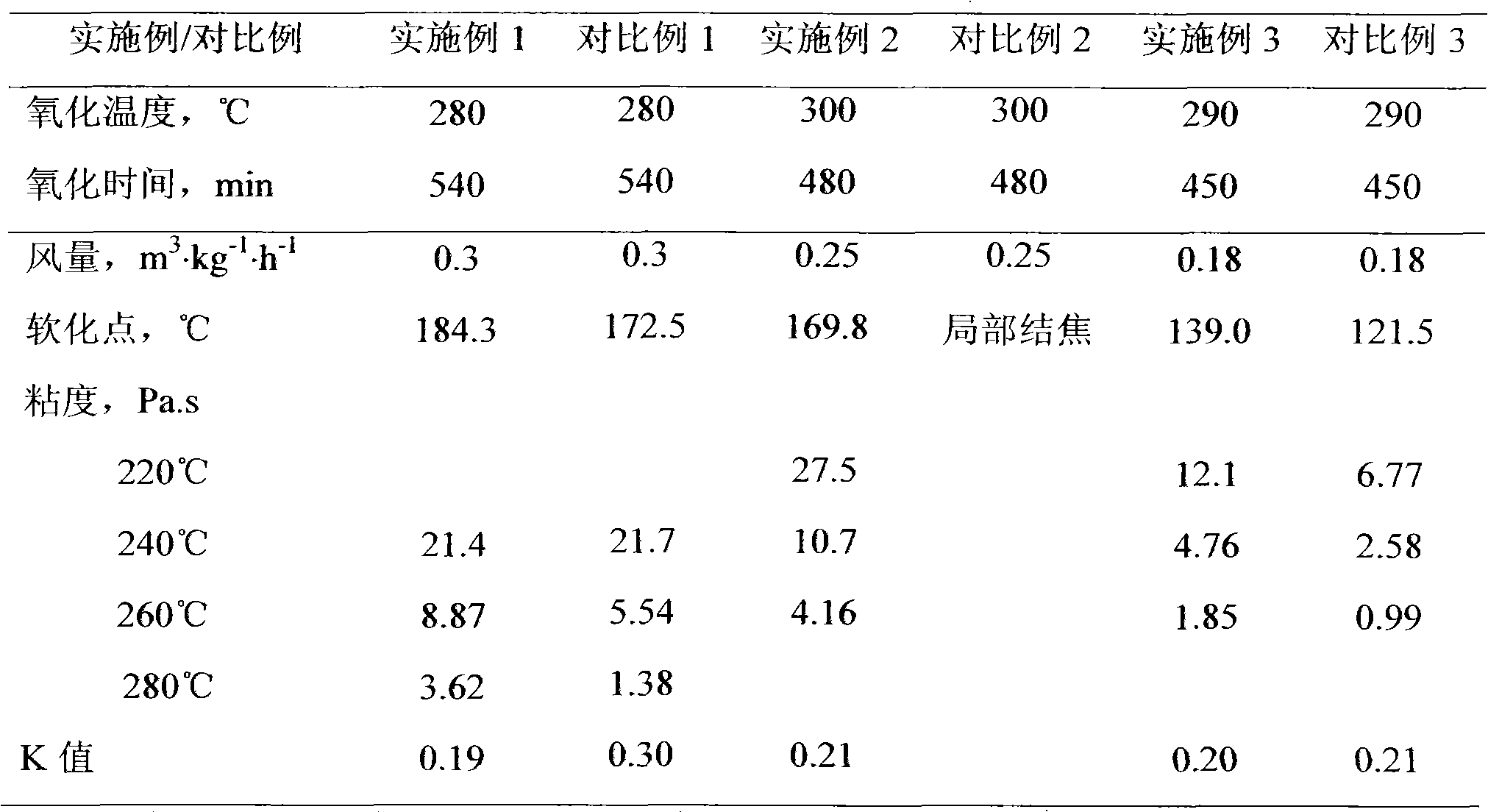

Embodiment 1

[0019] Heat the vacuum residue with a penetration of 121 1 / 10mm at 25°C and a softening point of 41.8°C, accounting for 96.4% (m) of the total amount, to a molten state of 140°C, and add 1.0% (m) of ferric chloride And 2.6% (m) of polyphosphoric acid and pass into the air, the air flow is 0.1m 3 kg -1 h -1 , cut for 30 minutes with a high-shear mixing emulsifier, and then enter the oxidation tower for blowing oxidation. The oxidation conditions and product properties are shown in Table 1.

Embodiment 2

[0023] Heat the vacuum residue with a penetration of 1651 / 10mm at 25°C and a softening point of 37.3°C, accounting for 96.5% (m) of the total amount, to a molten state at 120°C, and add 1.0% (m) of zinc oxide, 0.5 % (m) of copper sulfide and 2.0% (m) of polyphosphoric acid and pass into the air, the flow rate is 0.12m 3 kg -1 h -1 , sheared with a high-shear mixing emulsifier for 35 minutes, and then entered the oxidation tower for blowing oxidation. The oxidation conditions and product properties are shown in Table 1.

Embodiment 3

[0027] Heat the dissolved asphalt with a penetration of 411 / 10mm at 25°C and a softening point of 54.6°C, accounting for 95.5% (m) of the total amount, to a molten state at 150°C, and add 1.2% (m) of ferric chloride and 3.3% (m) of polyphosphoric acid and into the air, the flow rate is 0.1m 3 kg -1 h -1 , cut for 25 minutes with a high-shear mixing emulsifier, and then enter the oxidation tower for blowing oxidation. The oxidation conditions and product properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com