Patents

Literature

4065 results about "Softening point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The softening point is the temperature at which a material softens beyond some arbitrary softness. It can be determined, for example, by the Vicat method (ASTM-D1525 or ISO 306), Heat Deflection Test (ASTM-D648) or a ring and ball method (ISO 4625 or ASTM E28-67/E28-99 or ASTM D36 or ASTM D6493 - 11). A ring and ball apparatus can also be used for the determination of softening point of bituminous materials.

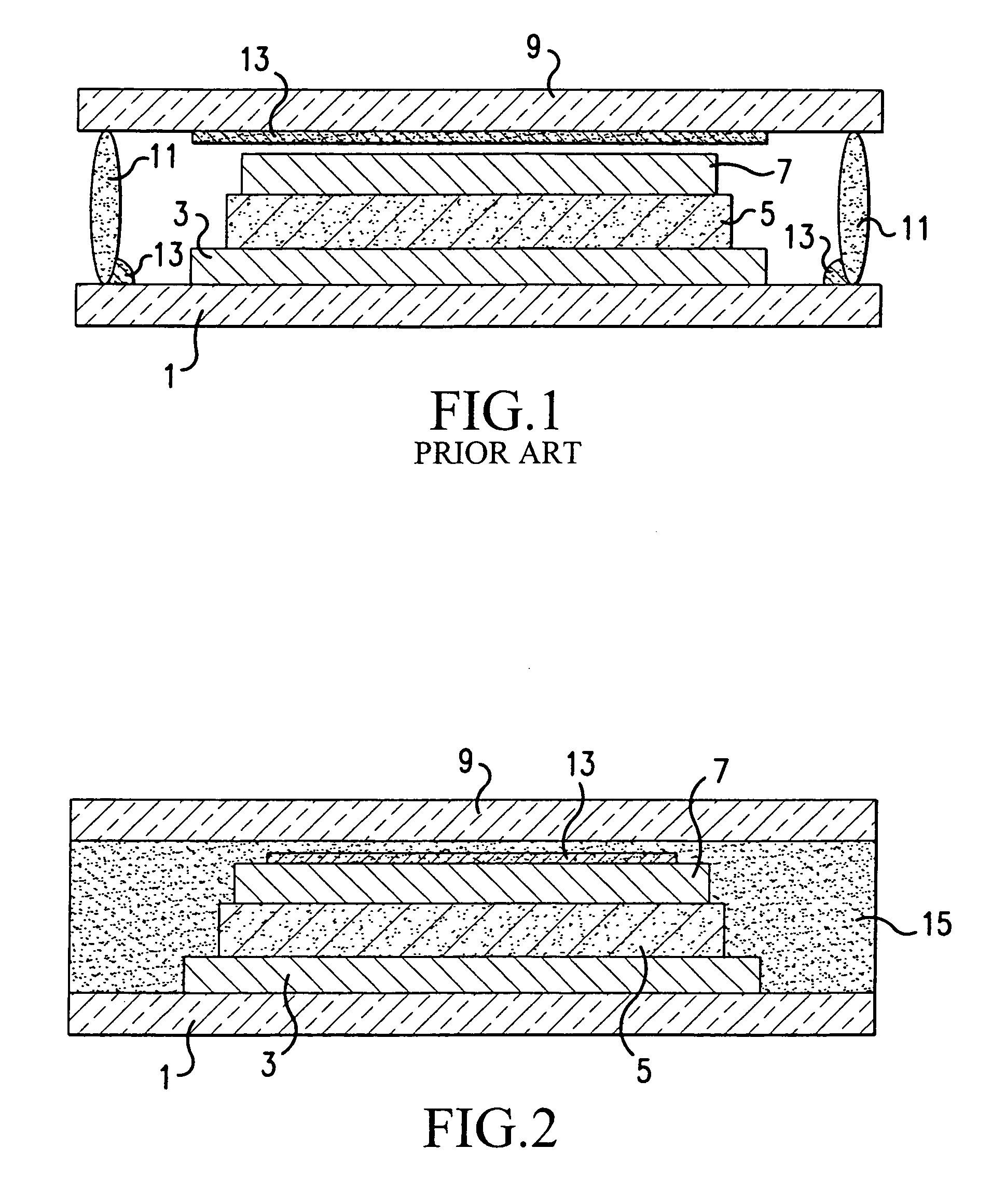

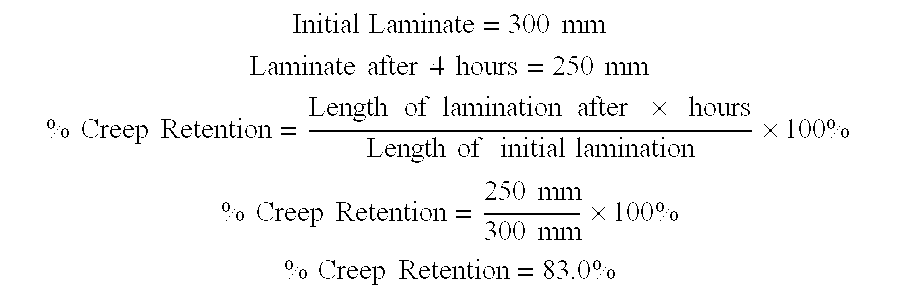

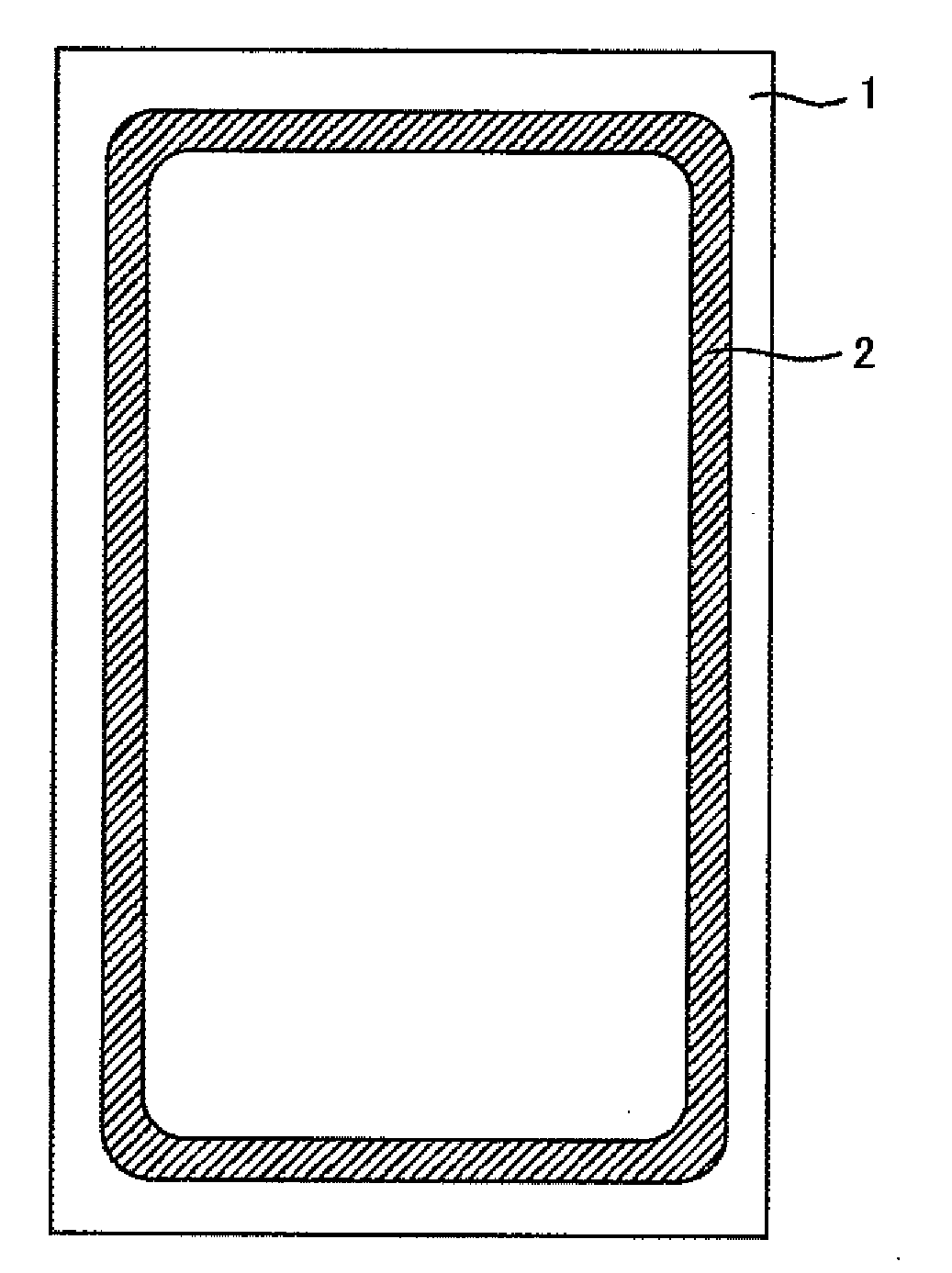

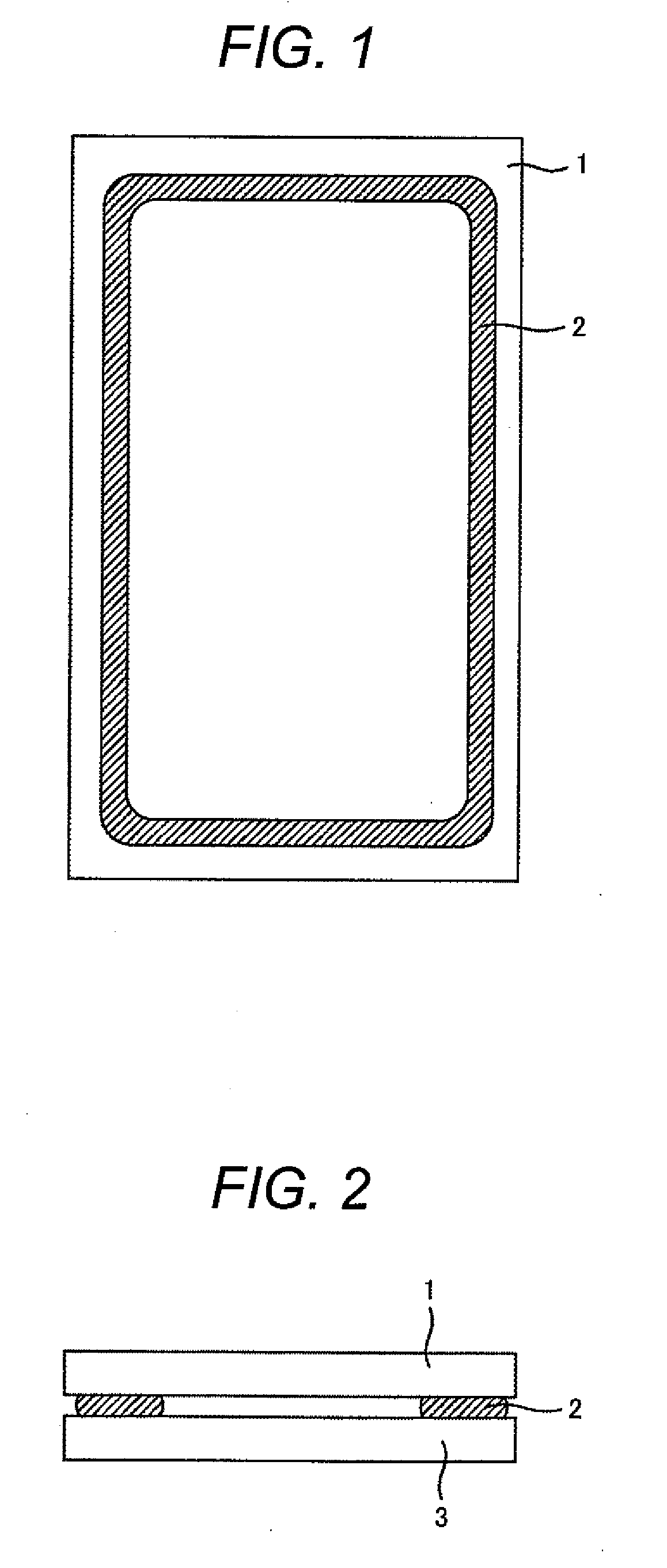

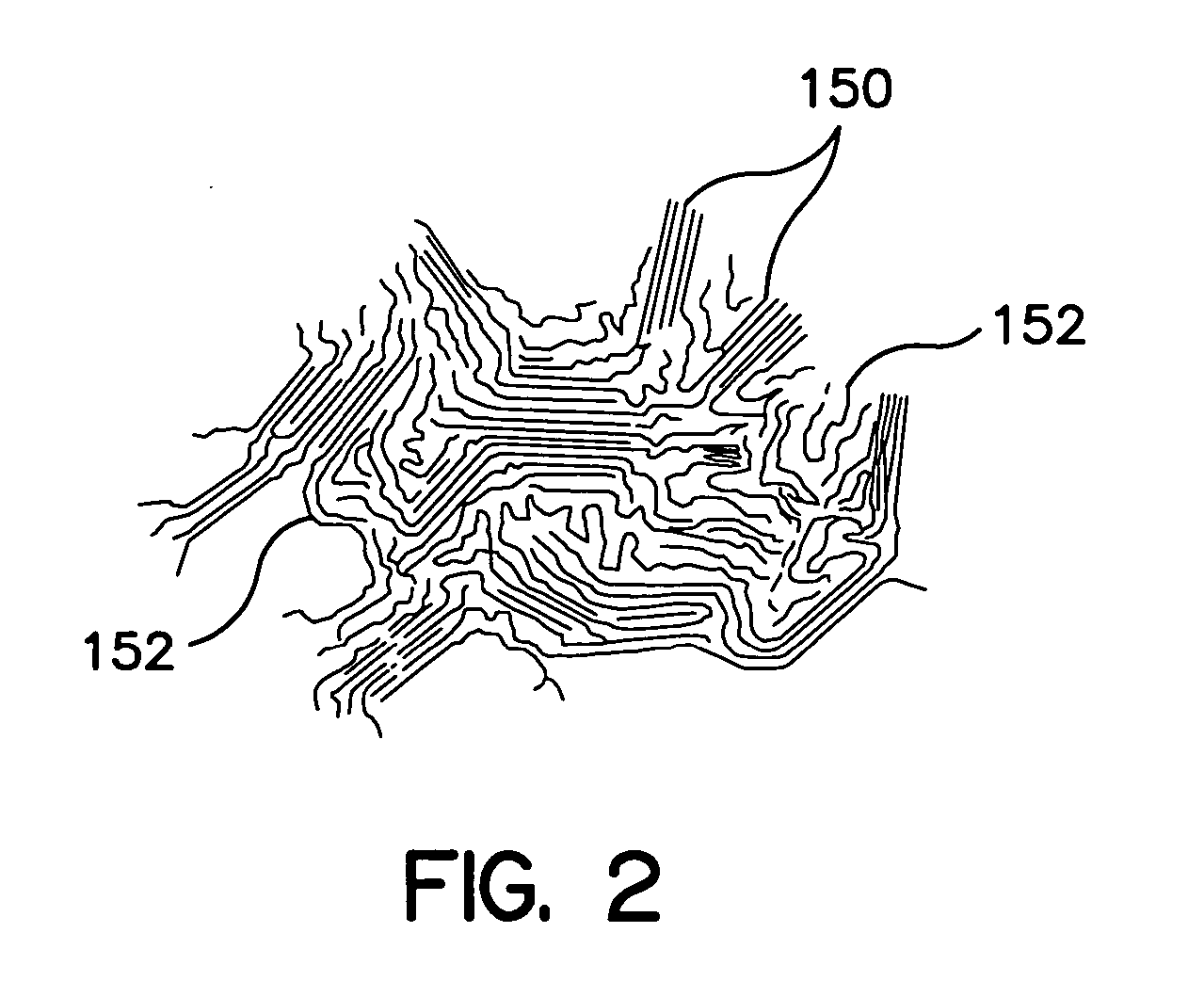

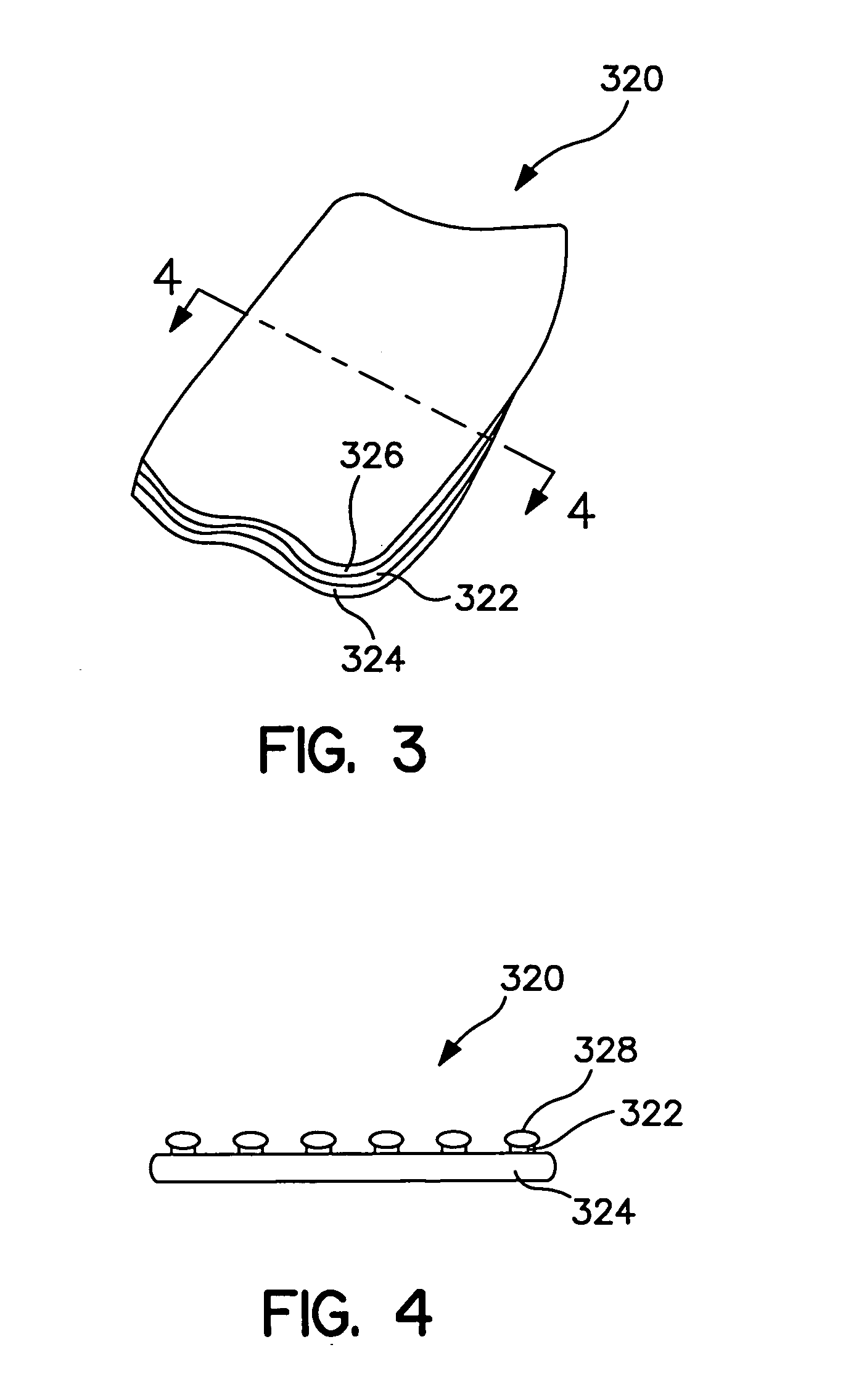

Transformable pressure sensitive adhesive tape and use thereof in display screens

InactiveUS20060100299A1Easy and safe applicationLow level of VOC 'sNanostructure manufactureGas-filled discharge tubesDisplay deviceLight-emitting diode

A transformable pressure sensitive adhesive composition comprised of from about 15 to about 80% by weight of a polymer having a softening point greater than 60° C.; from about 20 to about 85% by weight of a polymerizable resin having a softening point less than 30° C.; a latent initiator in an amount sufficient to cause a reaction between said polymer and said resin; and optionally, a crosslinking agent. The transformable pressure sensitive adhesive has particular applicability in connection with organic light emitting diode display devices, light emitting diode display devices, medical diagnostic testing devices, flexible or rigid LCD display devices, plasma display devices, and electrochromic devices.

Owner:ADHESIVES RES

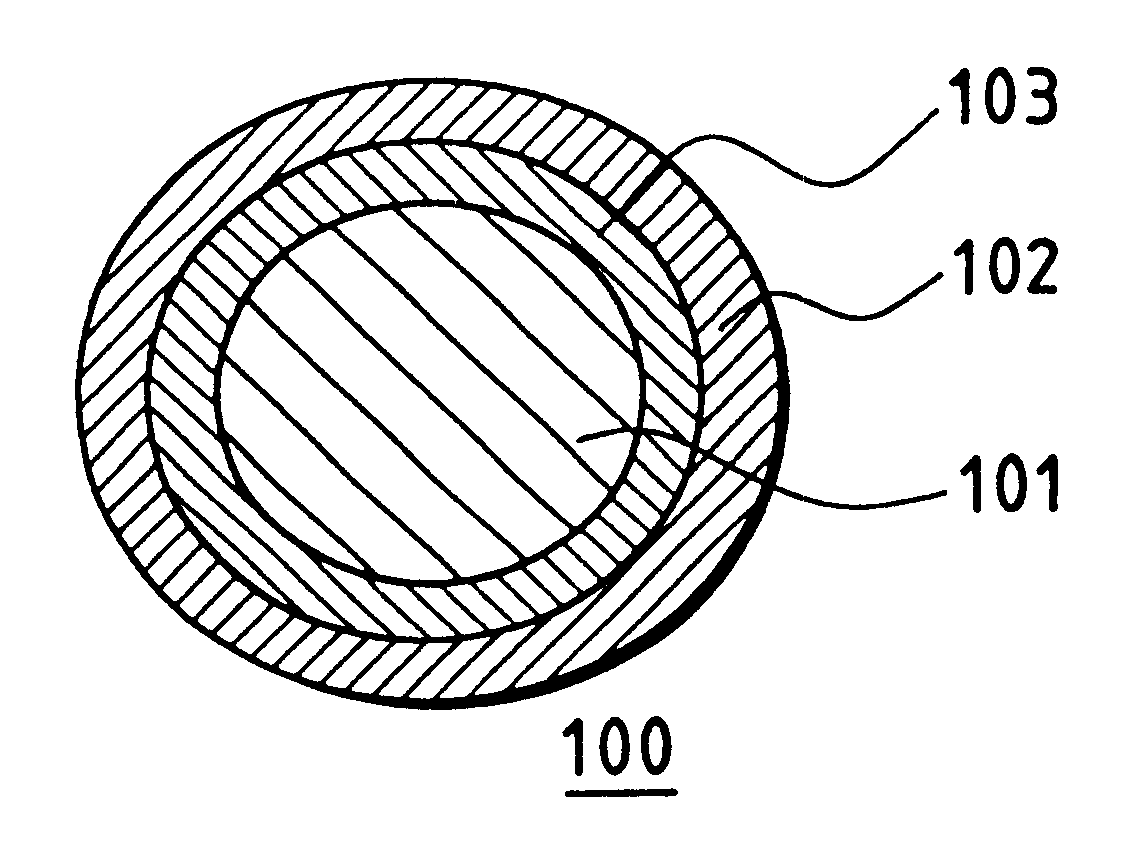

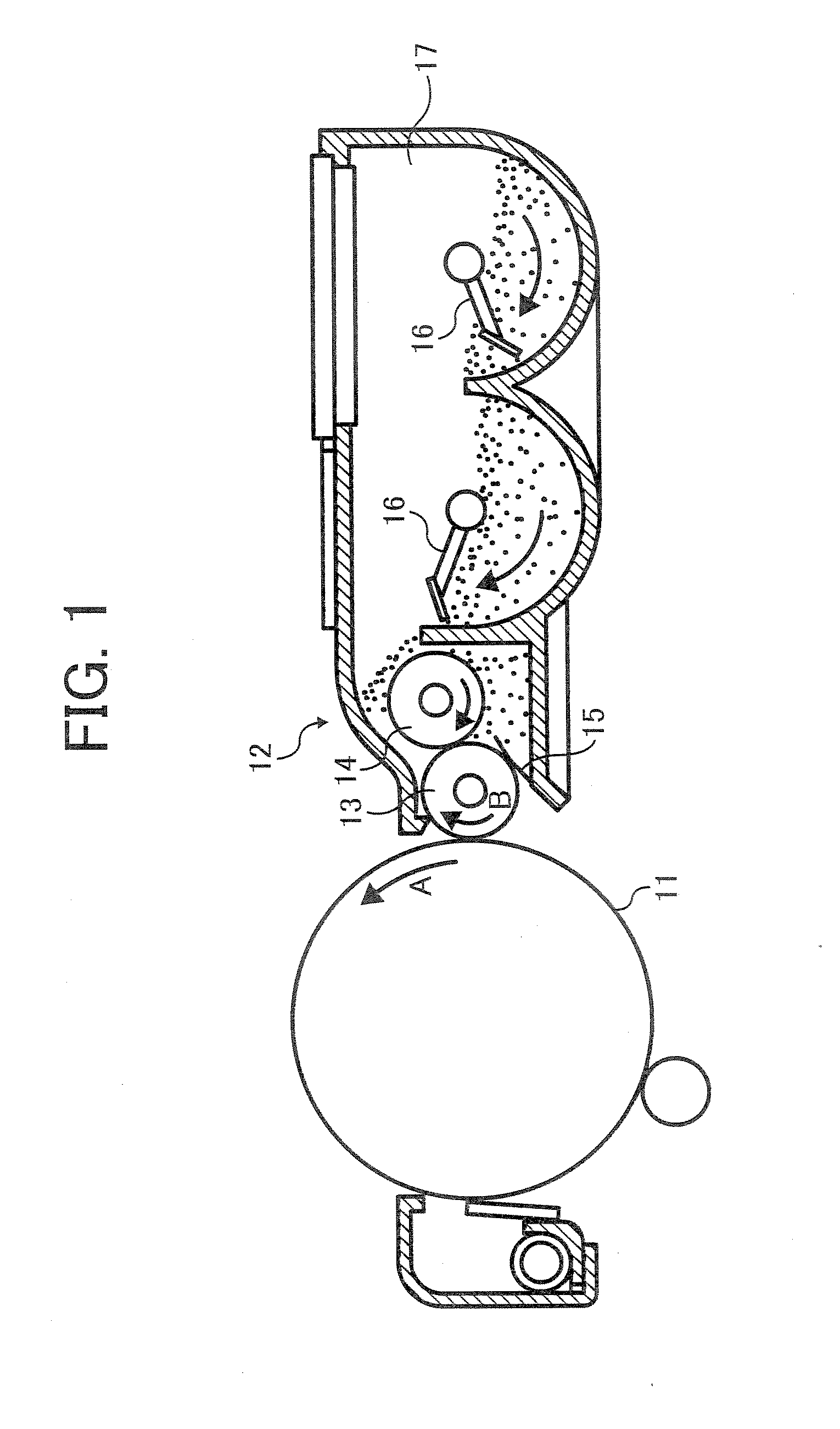

Heat-expandable microcapsules, process for producing the same, and method of utilizing the same

InactiveUS6235394B1High TgHigh heat-resistanceSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceHeat resistance

A heat-expandable microcapsule comprising a polymer shell formed by polymerizing (I) acrylonitrile, a main monomer component, (II) a monomer having carboxyl and (III) a monomer having groups reactive with the carboxyl of the monomer (II) and of a liquid having a boiling point lower than the softening point of the polymer and being encapsulated in the polymer shell. The heat-expandable microcapsules expand within high temperature range, 240° C. or above, and have heat-resistance.

Owner:MATSUMOTO YUSHI SEIYAKU

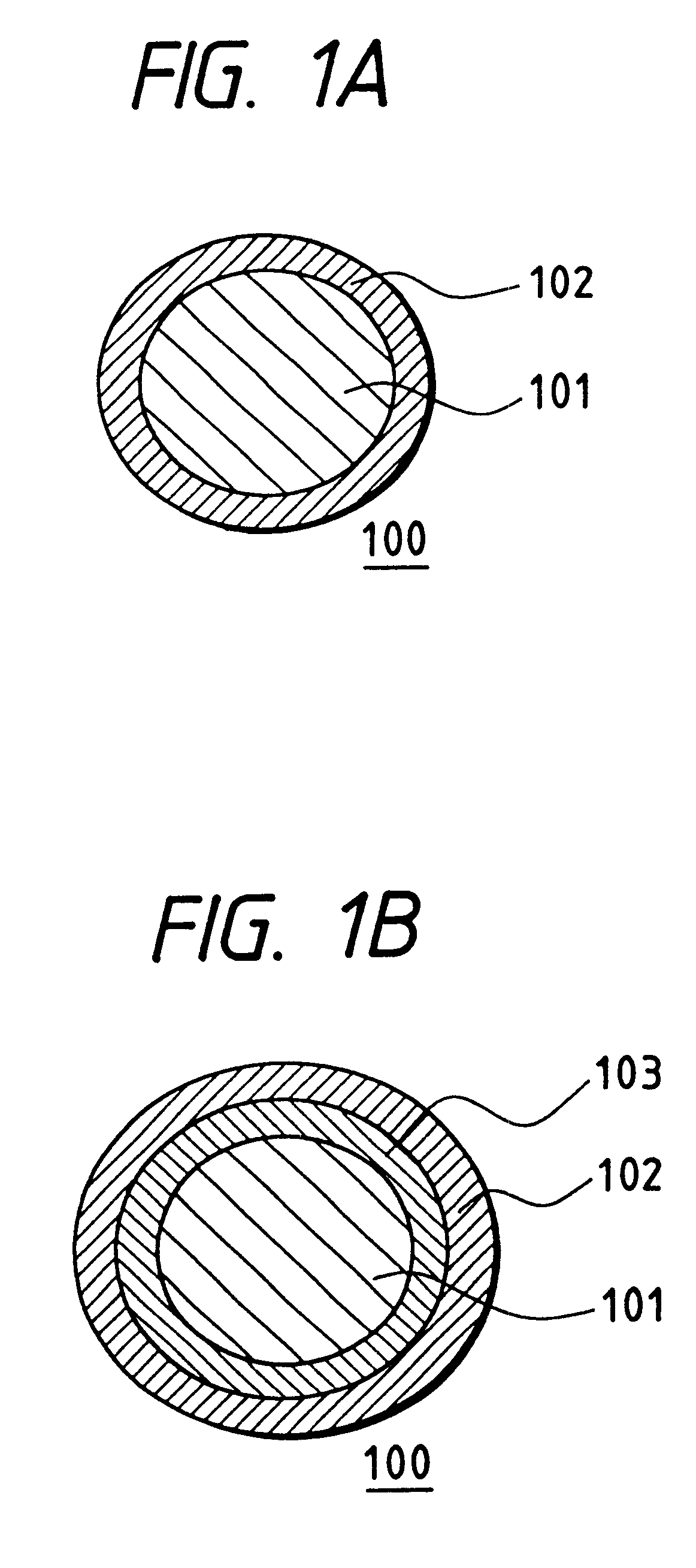

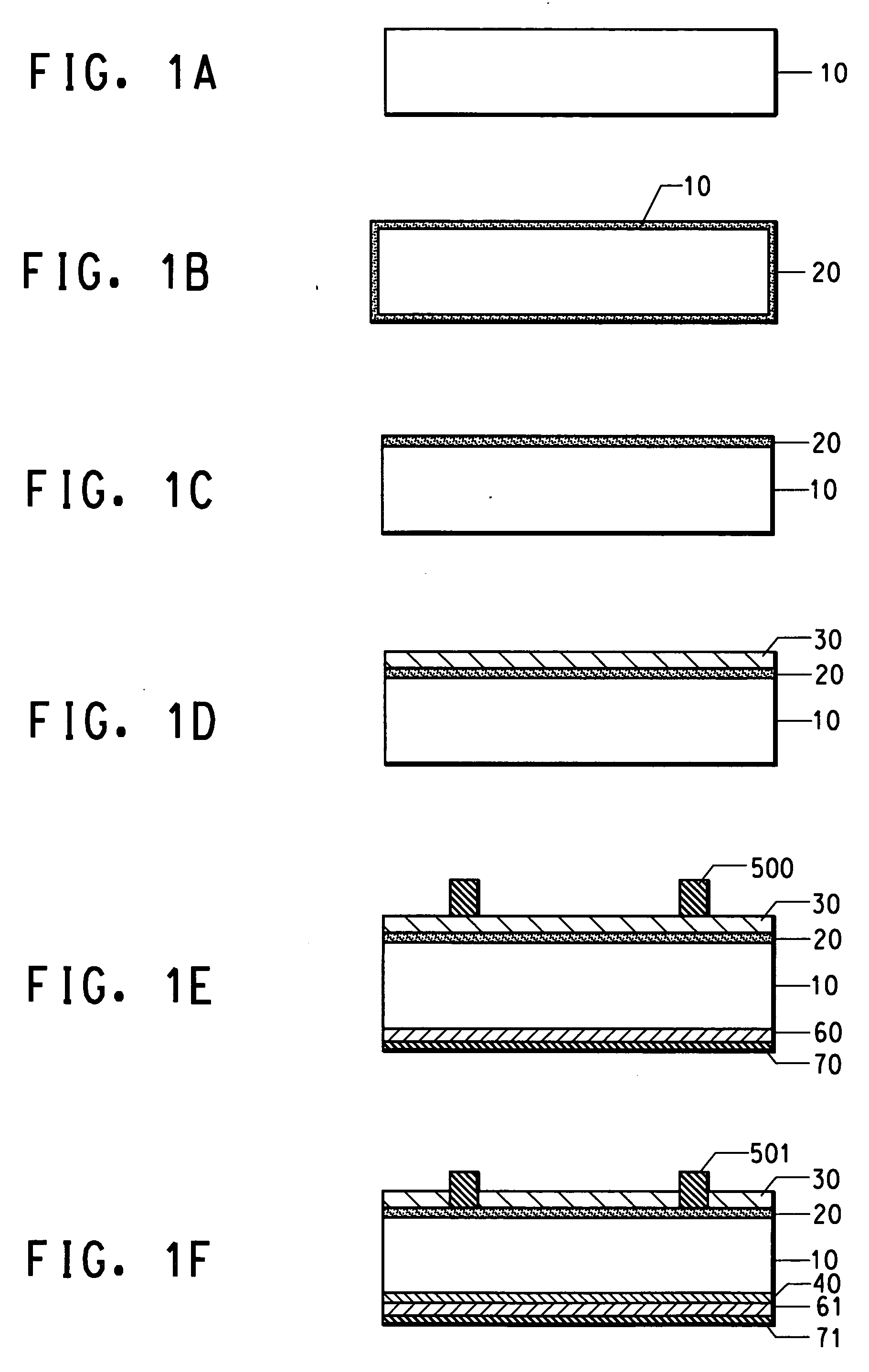

Photovoltaic element and method for producing the same

InactiveUS6472594B1Improve adhesionHigh initial characteristicPhotovoltaic energy generationSemiconductor devicesAdhesiveEngineering

A photovoltaic element comprising an electrode comprising an electrically conductive core member which is coated with a conductive adhesive fixed on the light incident surface of a photoactive semiconductor layer, via the conductive adhesive, is disclosed.The conductive adhesive is composed of at least two layers. The softening point of the conductive adhesive layer nearer to the core member is higher than the highest temperature encountered in the manufacture of the photovoltaic element.

Owner:CANON KK

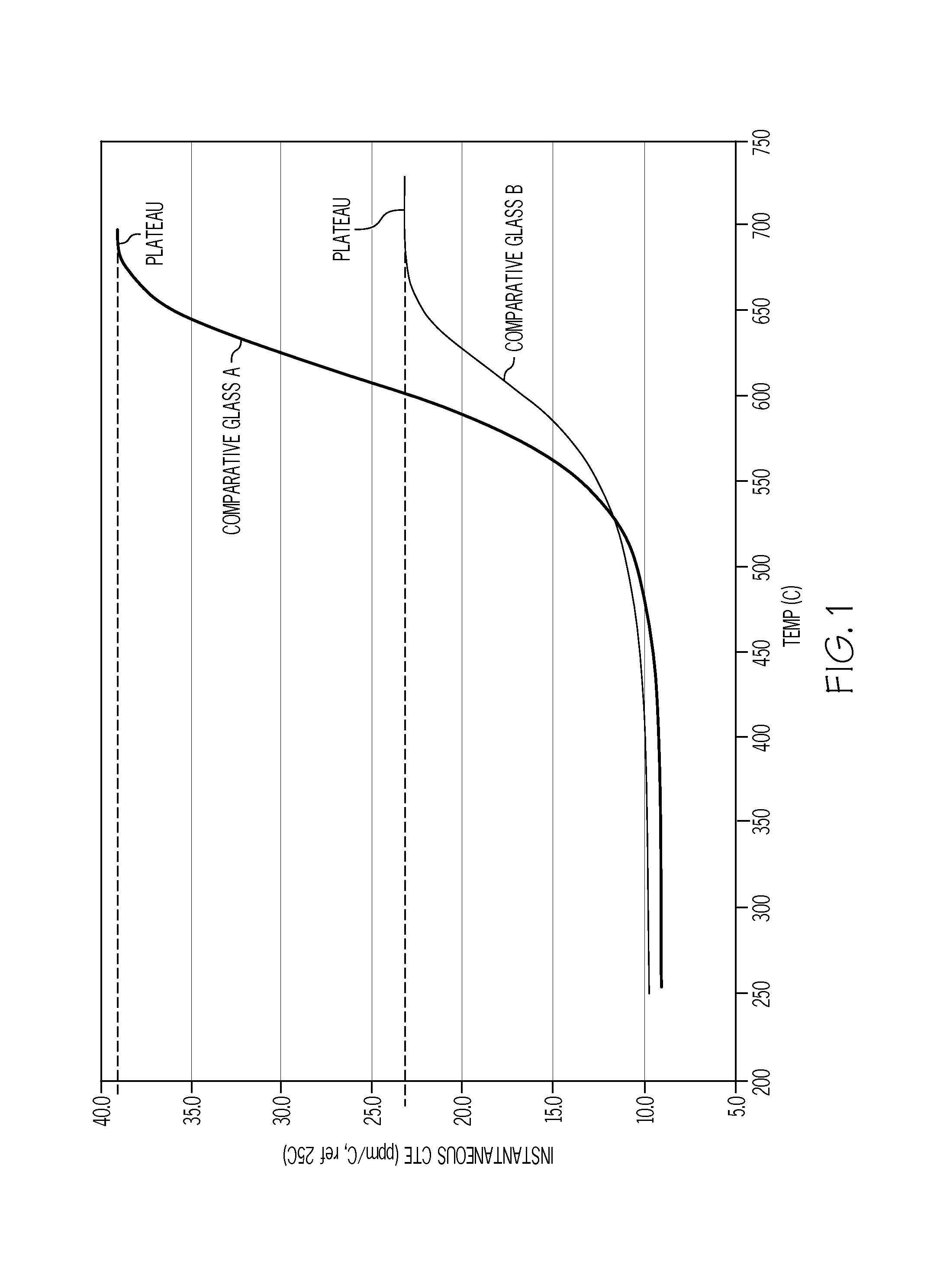

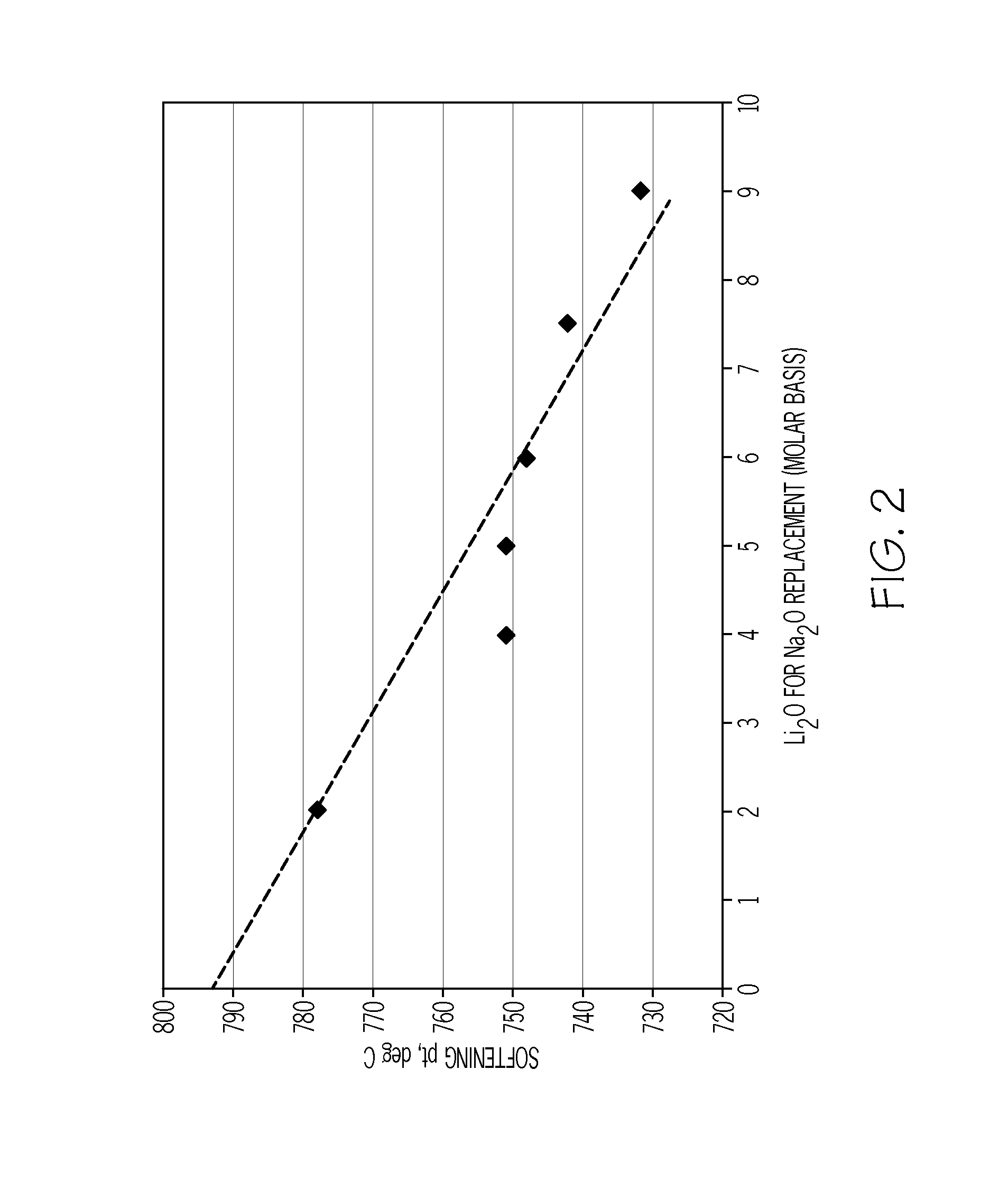

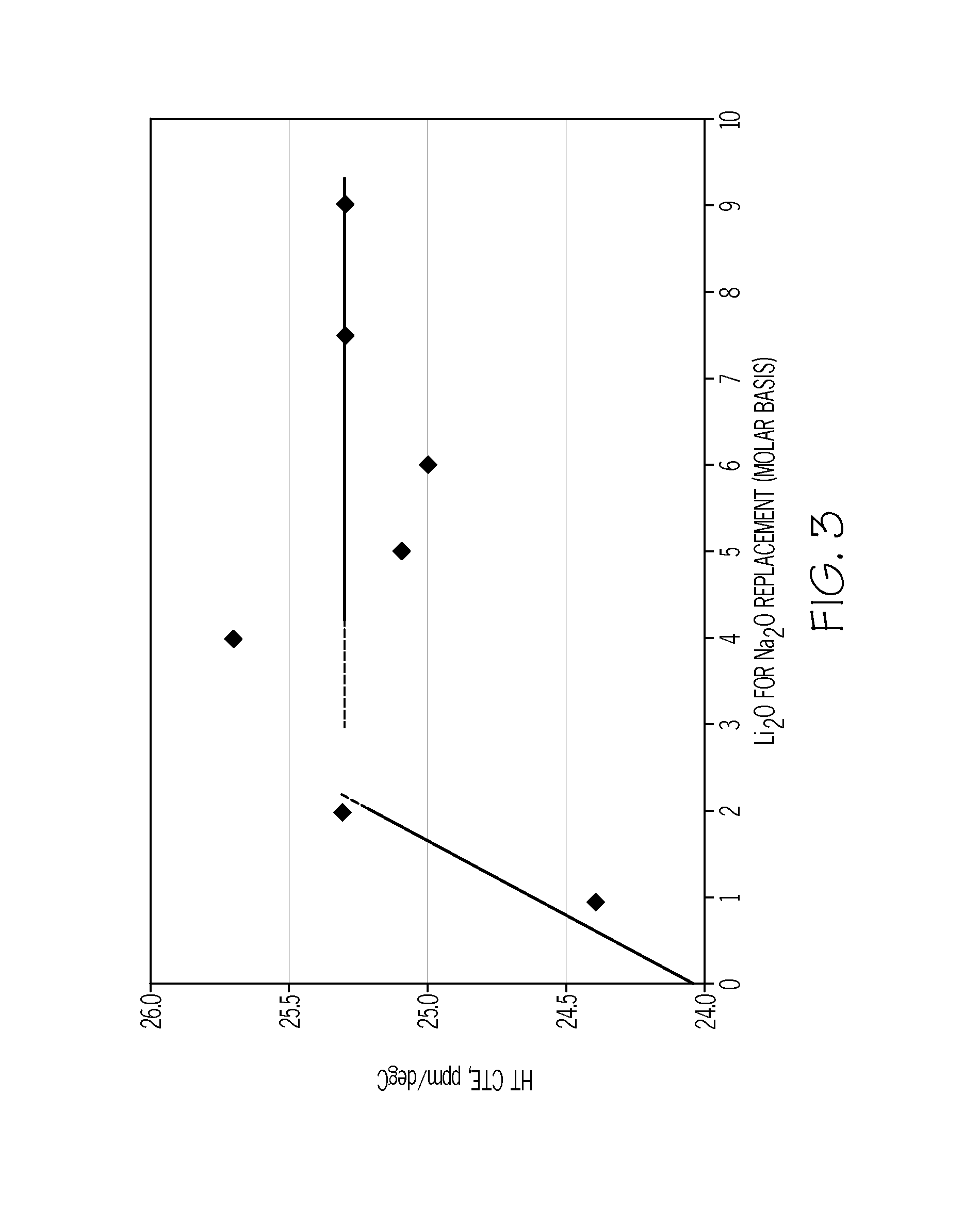

Ion exchangeable li-containing glass compositions for 3-d forming

According to one embodiment, a glass article may include SiO2, Al2O3, Li2O and Na2O. The glass article may have a softening point less than or equal to about 810° C. The glass article may also have a high temperature CTE less than or equal to about 27×10−6 / ° C. The glass article may also be ion exchangeable such that the glass has a compressive stress greater than or equal to about 600 MPa and a depth of layer greater than or equal to about 25 μm after ion exchange in a salt bath comprising KNO3 at a temperature in a range from about 390° C. to about 450° C. for less than or equal to approximately 15 hours.

Owner:CORNING INC

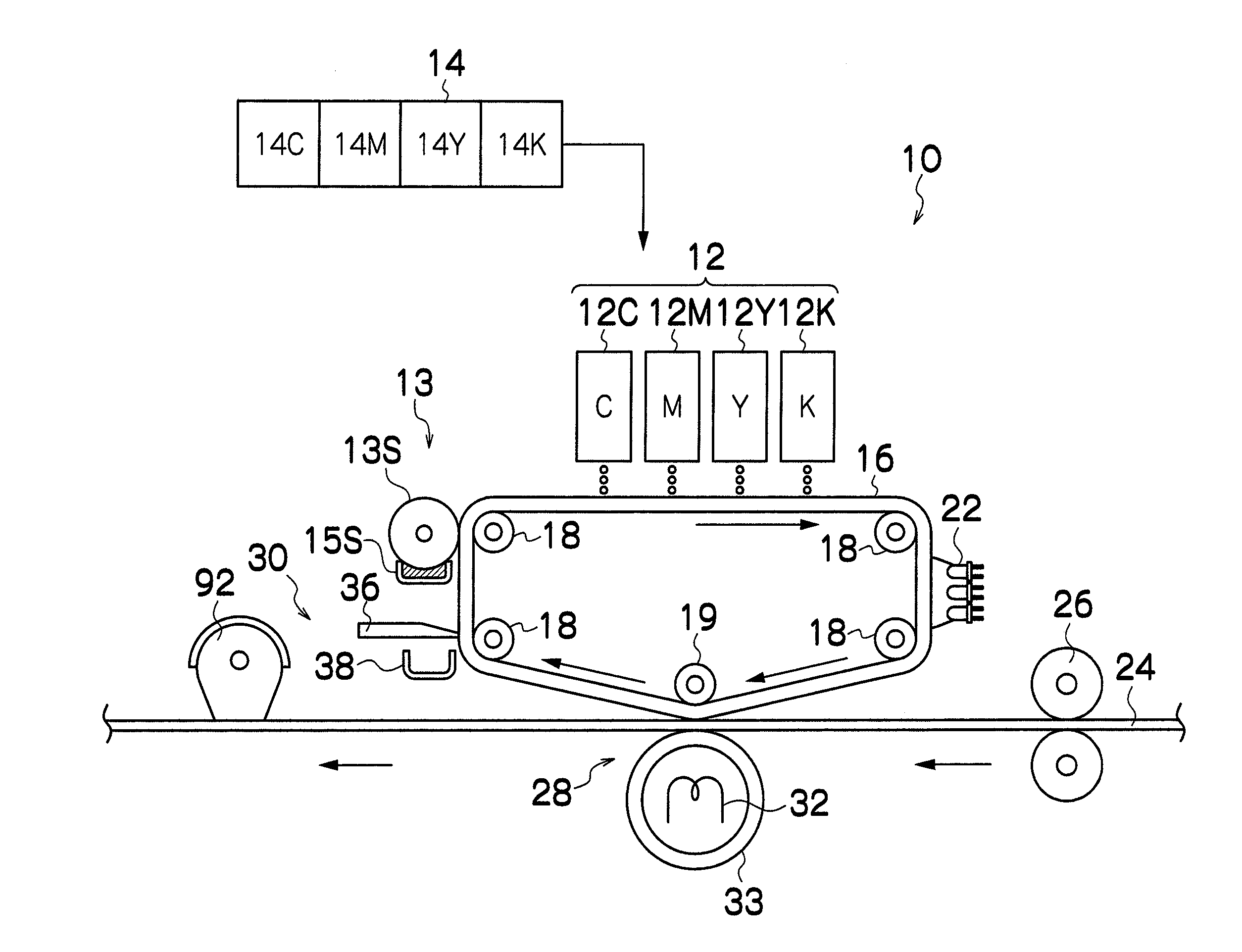

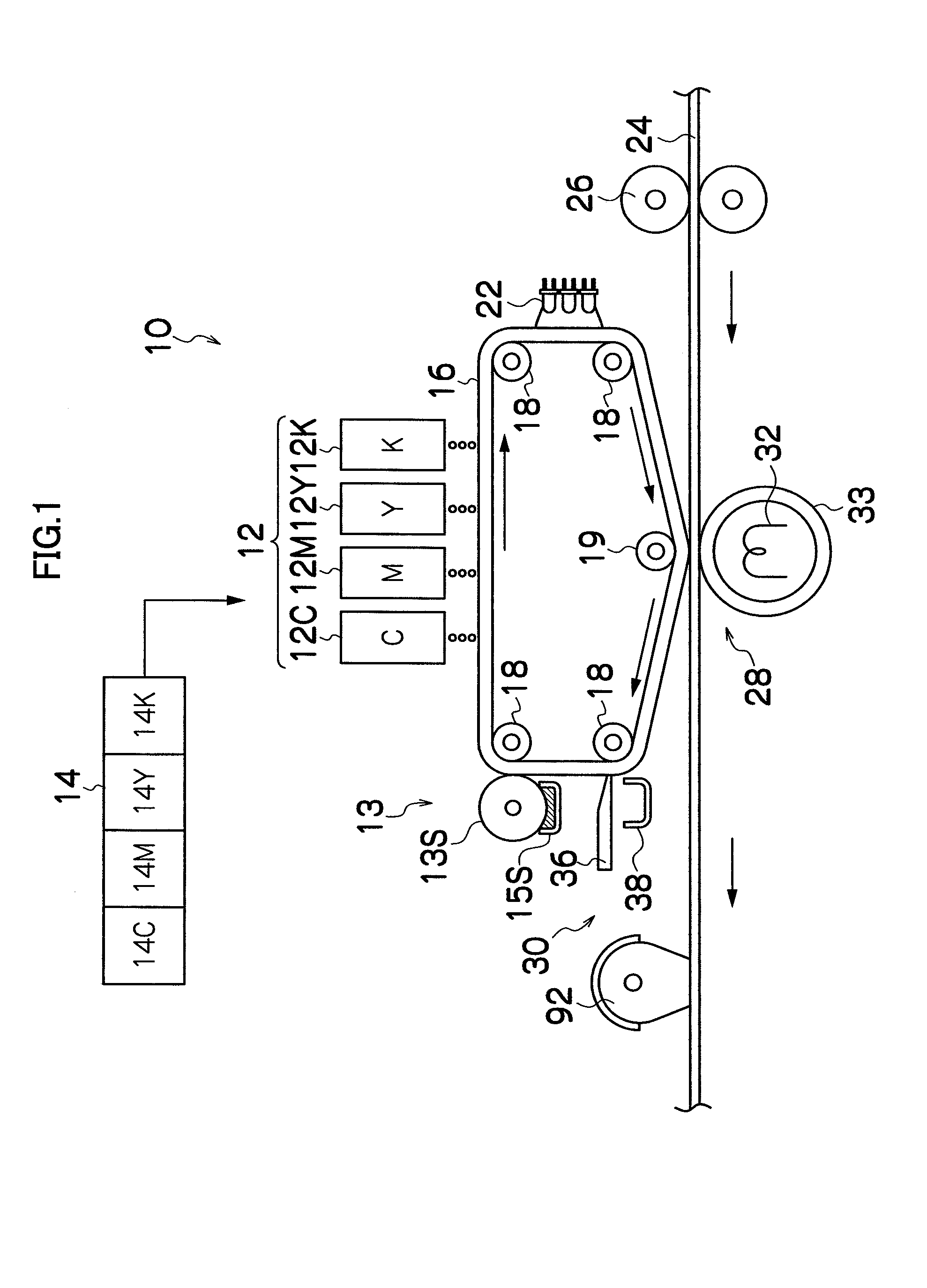

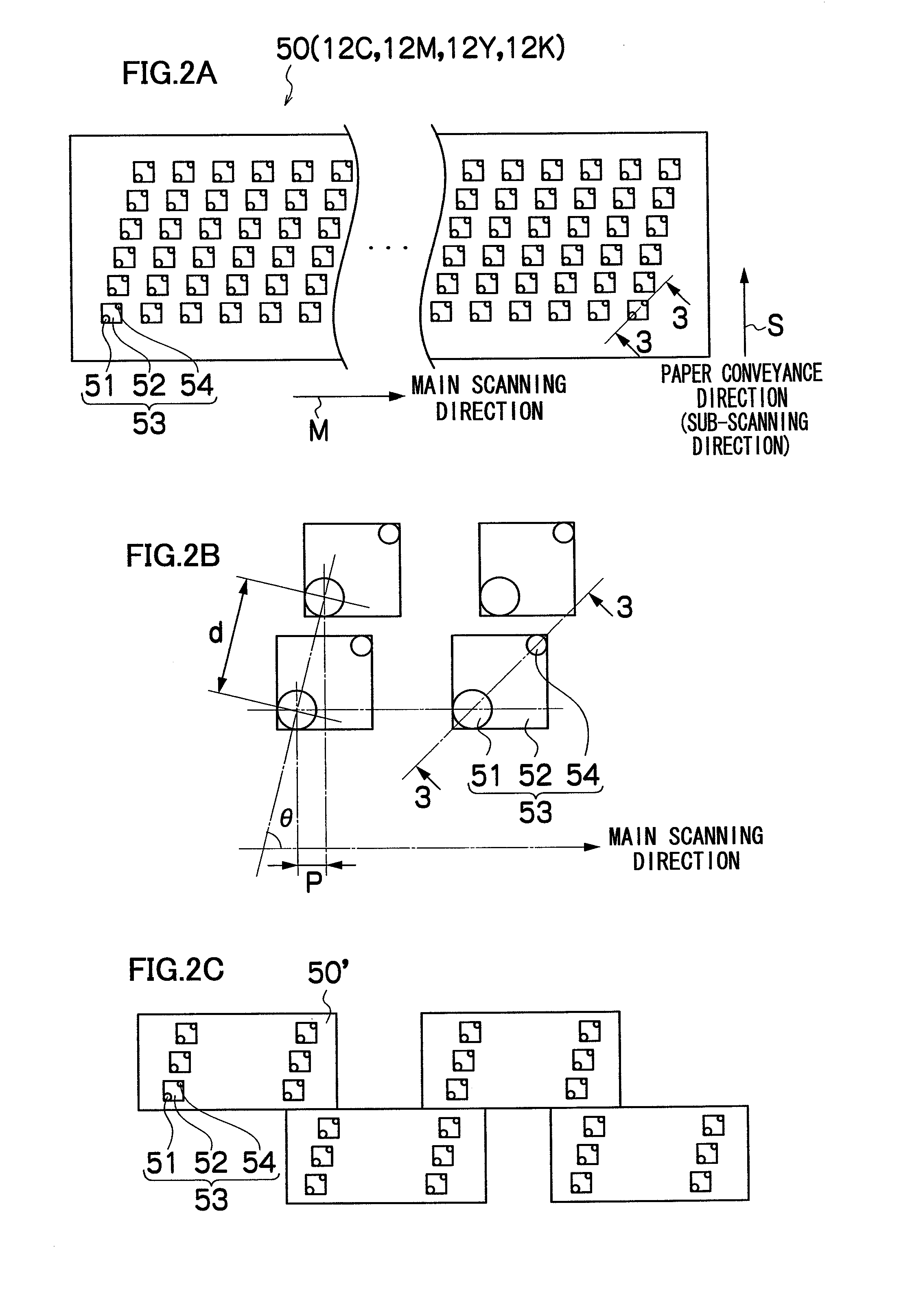

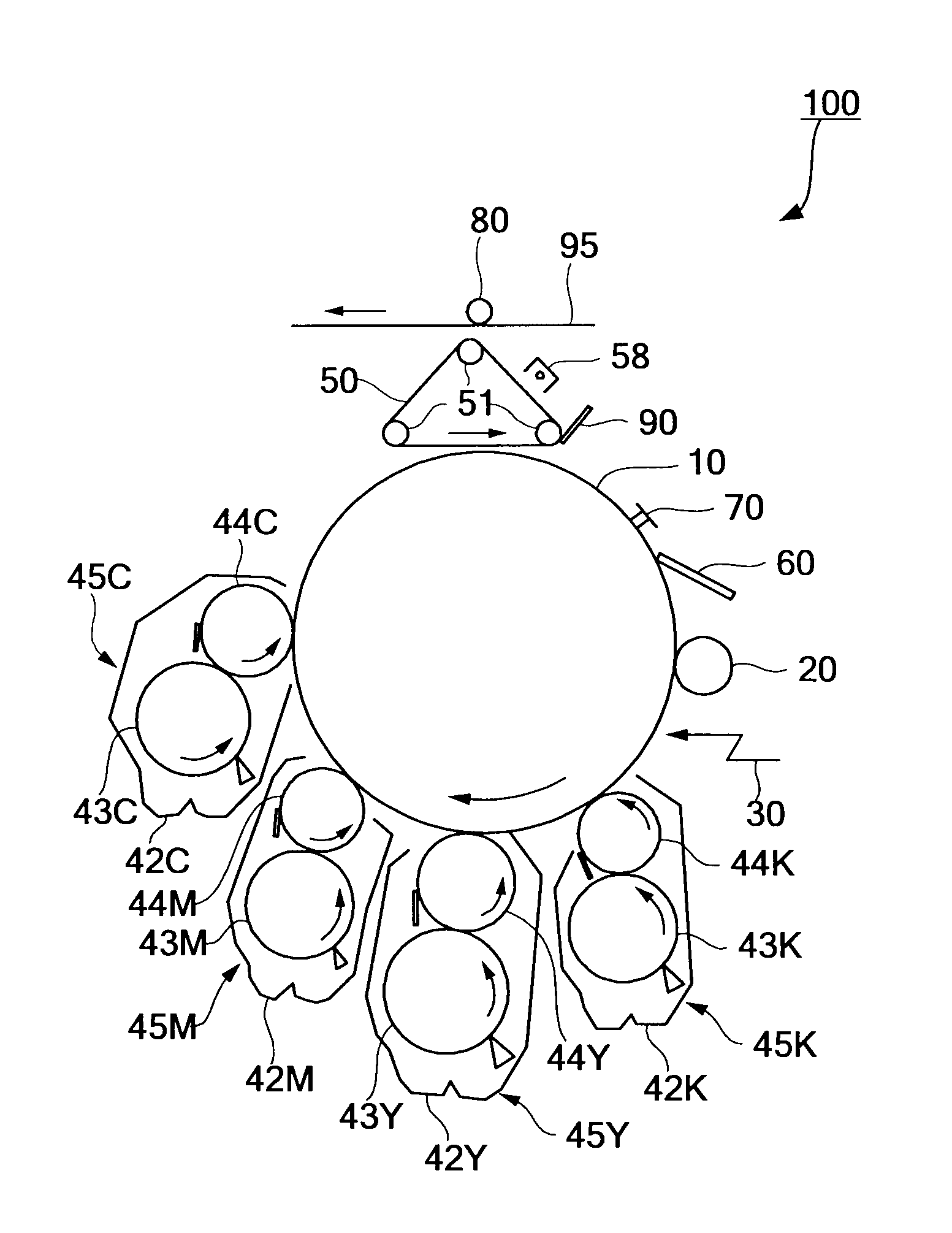

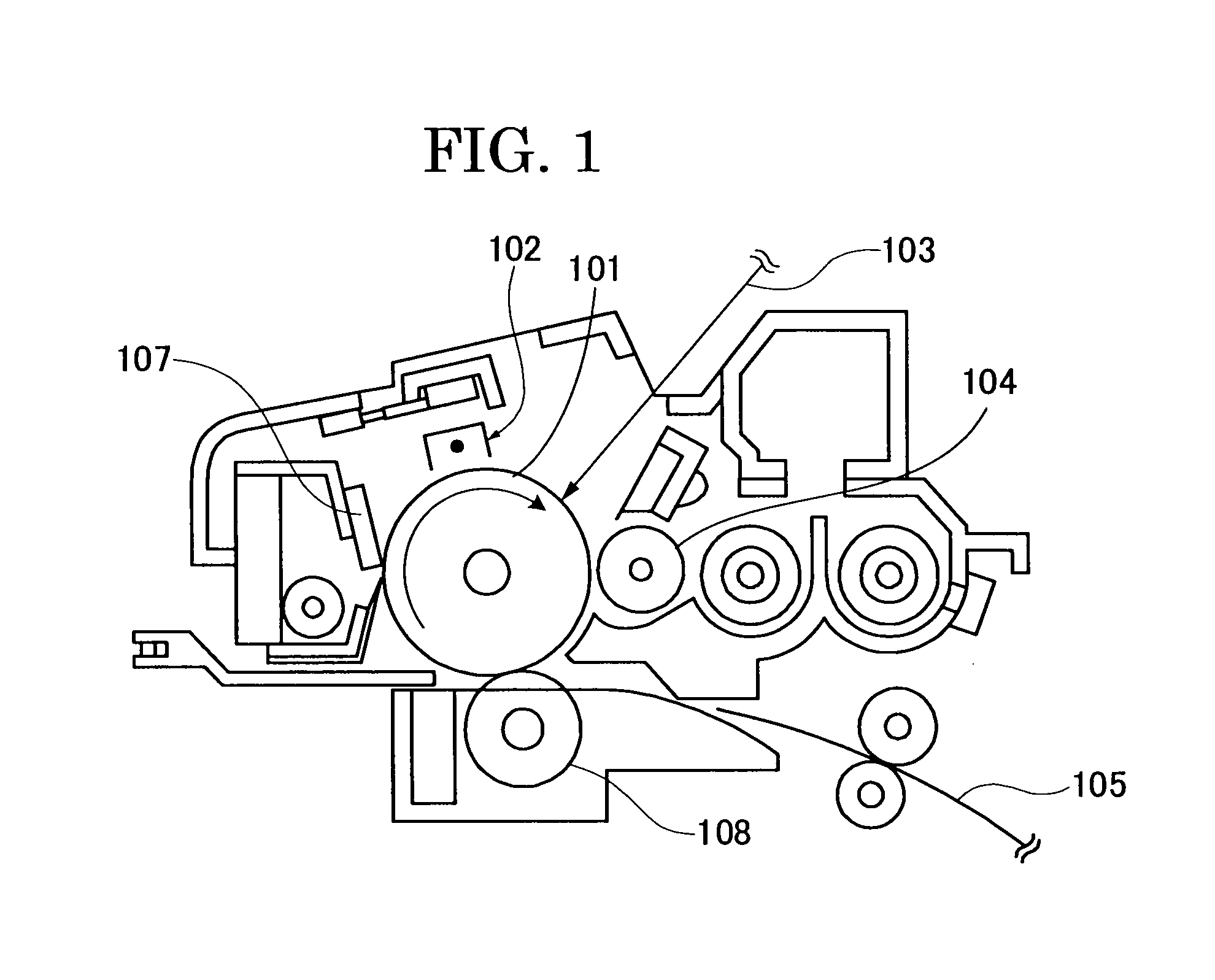

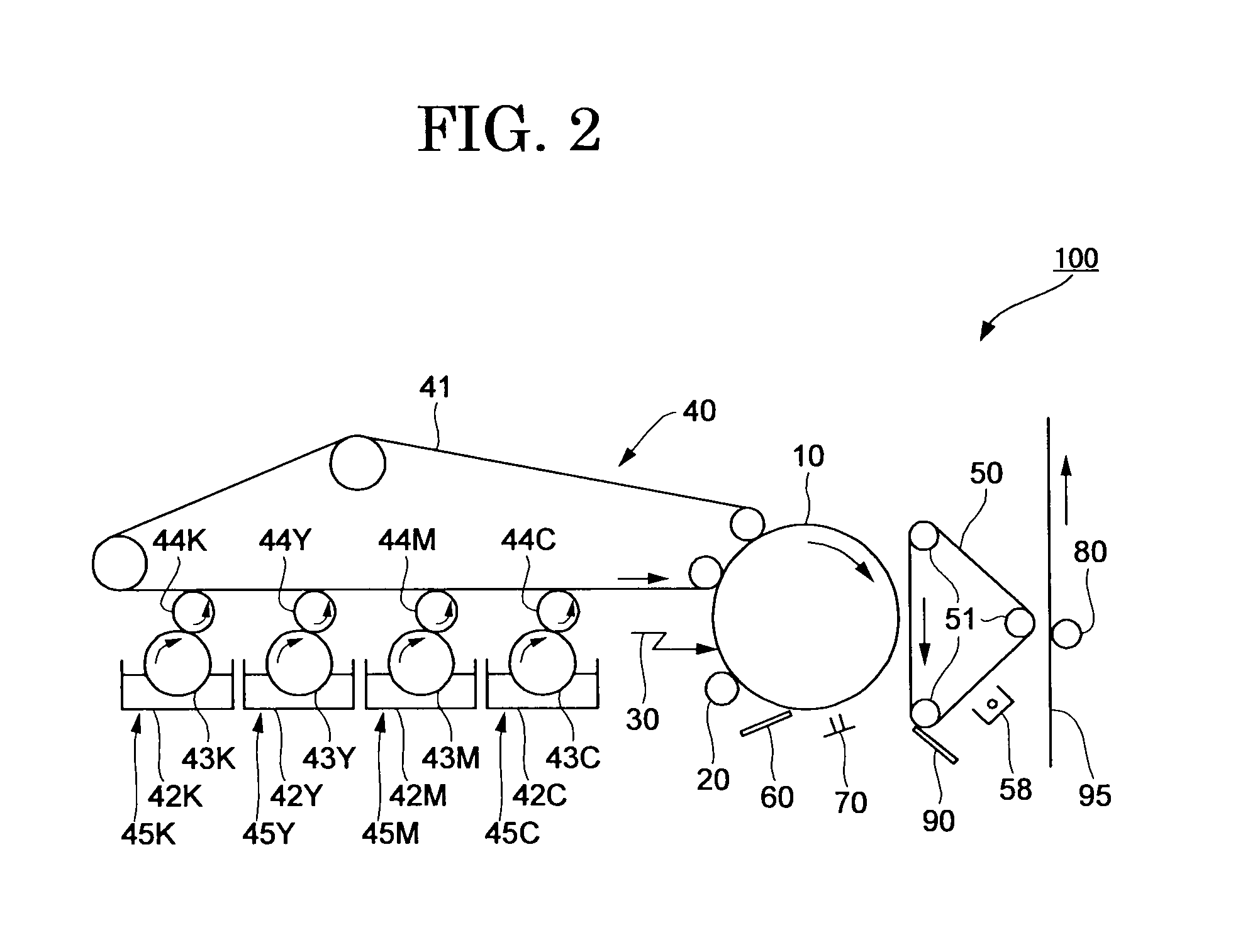

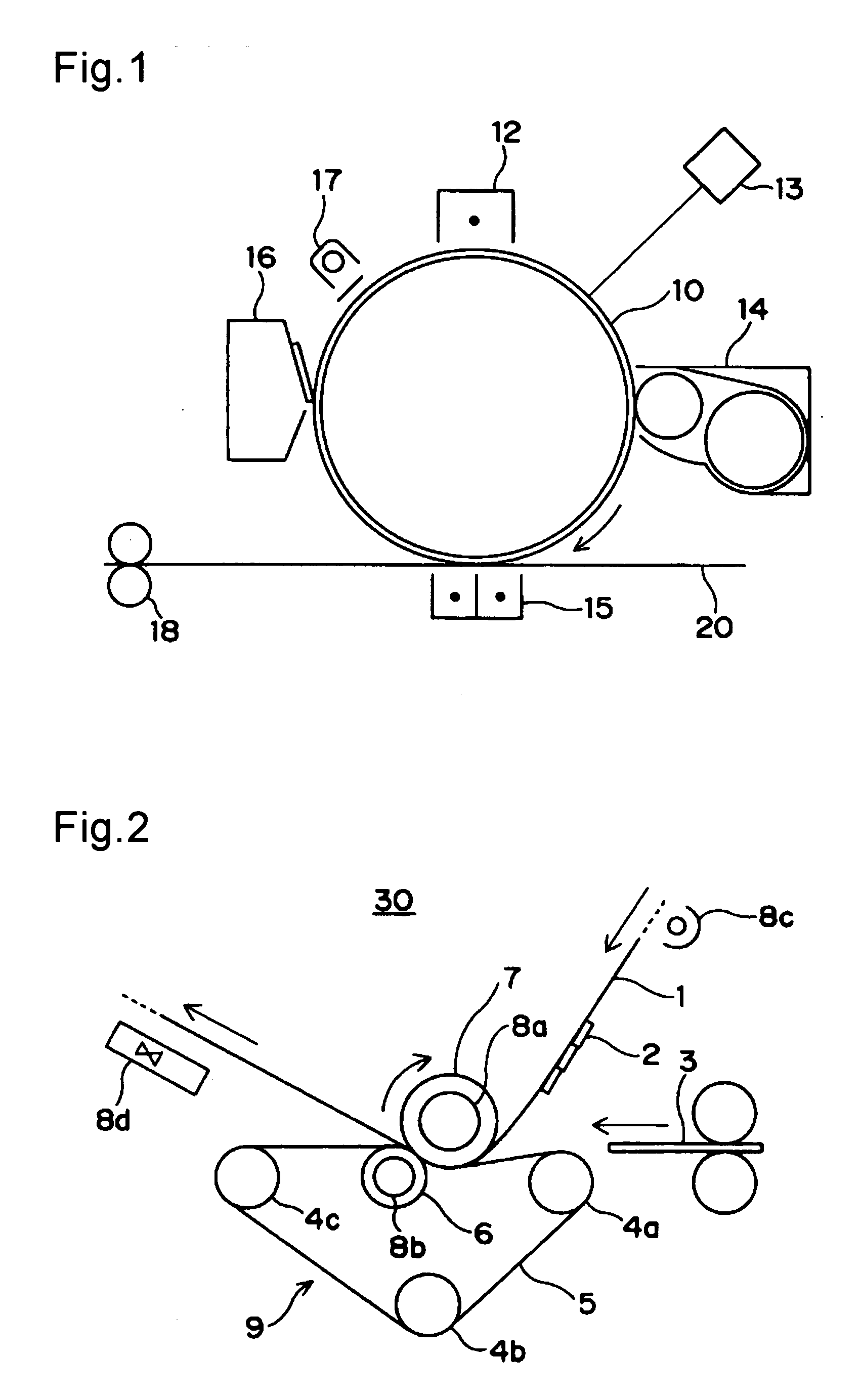

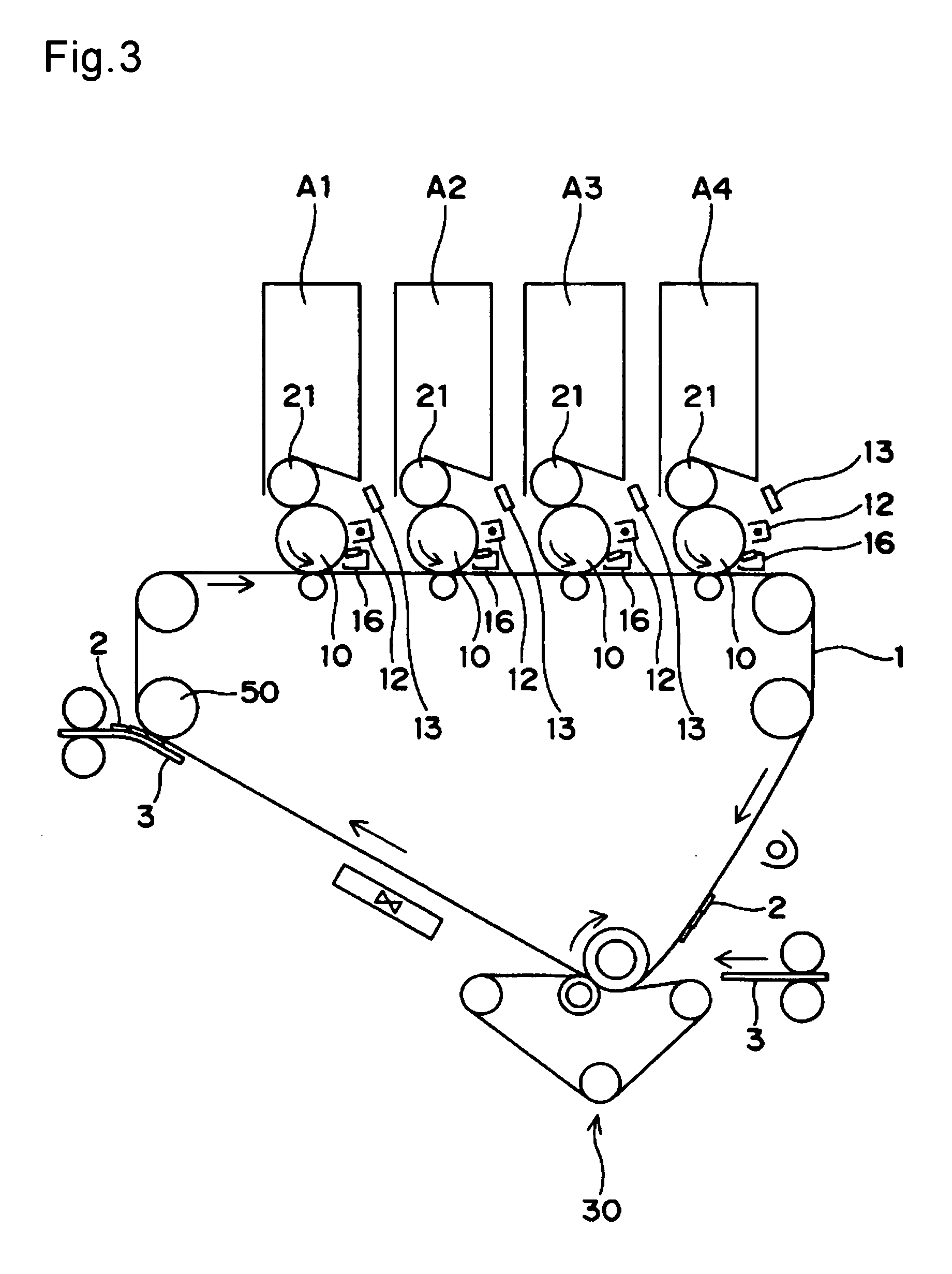

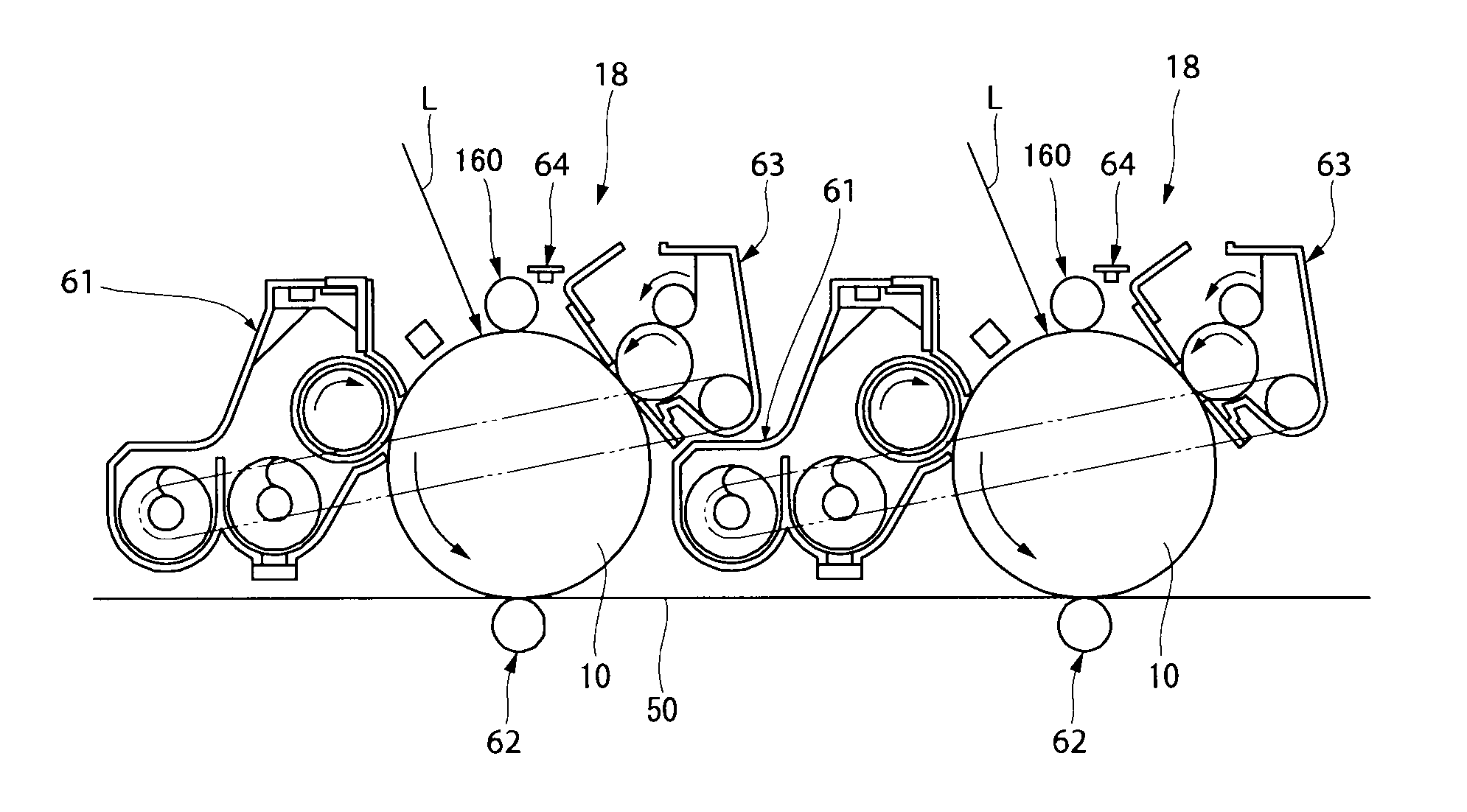

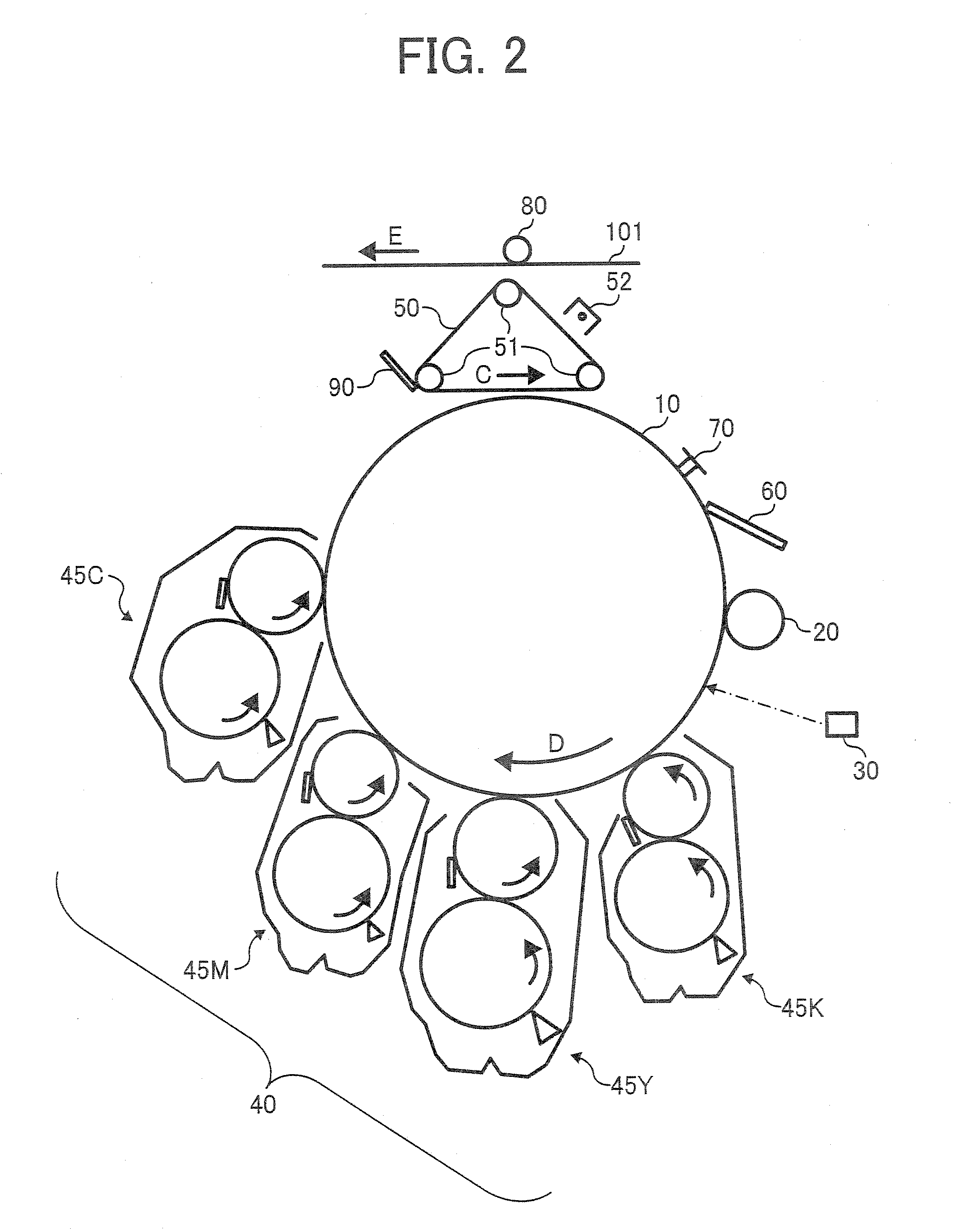

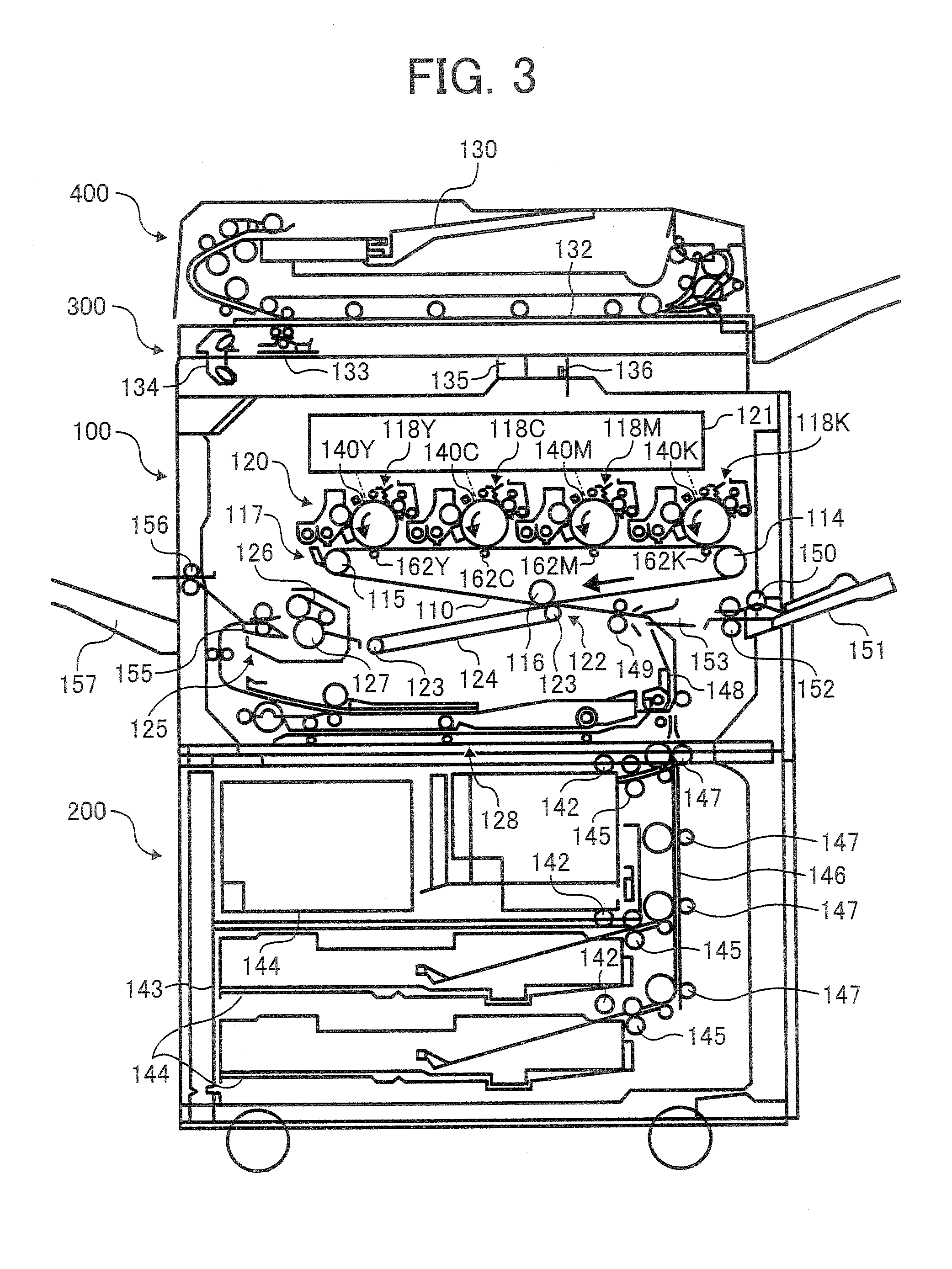

Image forming method and apparatus

InactiveUS20080166495A1Improve ink adhesionHigh strengthInking apparatusDuplicating/marking methodsImage formationPhotochemistry

The image forming method includes the steps of: ejecting and depositing an ink containing a coloring material and a radiation polymerizable compound on an intermediate transfer body, the radiation polymerizable compound having a molecular structure including a radical polymerizable group and a cationically polymerizable group; then irradiating the ink on the intermediate transfer body with a first radiation so that one of the radical polymerizable group and the cationically polymerizable group is selectively polymerized and cured; then heating the selectively polymerized and cured ink to a temperature not lower than a softening point of the selectively polymerized and cured ink and not higher than a temperature above the softening point by 10° C., while transferring the selectively polymerized and cured ink from the intermediate transfer body to a recording medium; and then irradiating the ink on the recording medium with a second radiation so that the other of the radical polymerizable group and the cationically polymerizable group is polymerized and cured.

Owner:FUJIFILM CORP

Hot Melt Adhesive Based on Olefin Block Copolymers

ActiveUS20110021103A1Improve spray characteristicsGood viscosity stabilityPersonal careLayered product treatmentCardboardCrystallinity

A hot melt adhesive composition, comprising a blend of components including about 5% to about 50% by weight of an olefin block copolymer; about 10% to about 70% by weight of a first tackifying resin having a softening point of at least about 95° C.; about 0 to 65% of a second tackifying resin that is different than the first tackifying resin; about 0% to about 60% by weight of a plasticizer; about 0% to about 20% by weight of an aromatic reinforcing resin having a softening point equal to or higher than 115° C.; about 0.1% to about 5% by weight of a stabilizer; and about 1% to about 40% by weight of a secondary polymer that is different from the olefin block copolymer, the first and second tackifying resins and the reinforcing resin, having relatively low crystallinity, which low crystallinity is equal to or less than 250 Joules / gram, wherein the components total 100% by weight of the composition, and the viscosity of the composition is equal to or less than about 20,000 mPa·s at 163° C. Laminates, especially those used in disposable soft goods, and methods of making such laminates using the hot melt adhesive composition are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

Fire-resistant gypsum

InactiveUS20050263925A1Point becomes highImprove fire resistanceConstruction materialWood working apparatusGlass fiberFiber

An improved, fire-resistant, set gypsum composition contains set calcium sulfate dihydrate as the major ingredient and a reinforcing ingredient of resilient, flexible, boron-free glass fibers. Continuous filament forming glass compositions with a softening point preferably greater than about 1580° F. (about 860° C.) and more preferably greater than about 1681° F. (about 916° C.) may be used. The fibers typically are distributed as their separate constituent individual glass filaments uniformly throughout the set calcium sulfate dihydrate.

Owner:OWENS CORNING FIBERGLAS TECH INC

Method of manufacture of semiconductor device and conductive compositions used therein

InactiveUS20060231804A1Semiconductor/solid-state device detailsConductive materialDevice materialFrit

The present invention is directed to a thick film conductive composition comprising: (a) electrically conductive silver powder; (b) Zn-containing additive wherein the particle size of said zinc-containing additive is in the range of 7 nanometers to less than 100 nanometers; (c) glass frit wherein said glass frit has a softening point in the range of 300 to 600° C.; dispersed in (d) organic medium. The present invention is further directed to a semiconductor device and a method of manufacturing a semiconductor device from a structural element composed of a semiconductor having a p-n junction and an insulating film formed on a main surface of the semiconductor comprising the steps of (a) applying onto said insulating film the thick film composition as describe above; and (b) firing said semiconductor, insulating film and thick film composition to form an electrode.

Owner:EI DU PONT DE NEMOURS & CO

Low softening point glass composition, bonding material using same and electronic parts

ActiveUS20100180934A1Flow on effectReduce softeningAddress electrodesConductive layers on insulating-supportsTe elementAntimony

Owner:RESONAC CORP

Nonformaldehyde, nonfuming resorcinolic resins and methods of making and using the same

Methods for preparing formaldehyde-free resorcinol resins are disclosed. The methods generally comprise reacting resorcinol first with dicyclopentadiene and then reacting that mixture with an olefinic compound. The resins produced by this method are also disclosed, as are rubber compositions utilizing the present resins. The resins are characterized as having a free resorcinol content of about 1 wt. % or less, and yielding a suitable softening point when used in rubber applications.

Owner:SUMIKA ELECTRONICS MATERIALS INC USA D B A SUMITOMO CHEM ADVANCED TECH INC

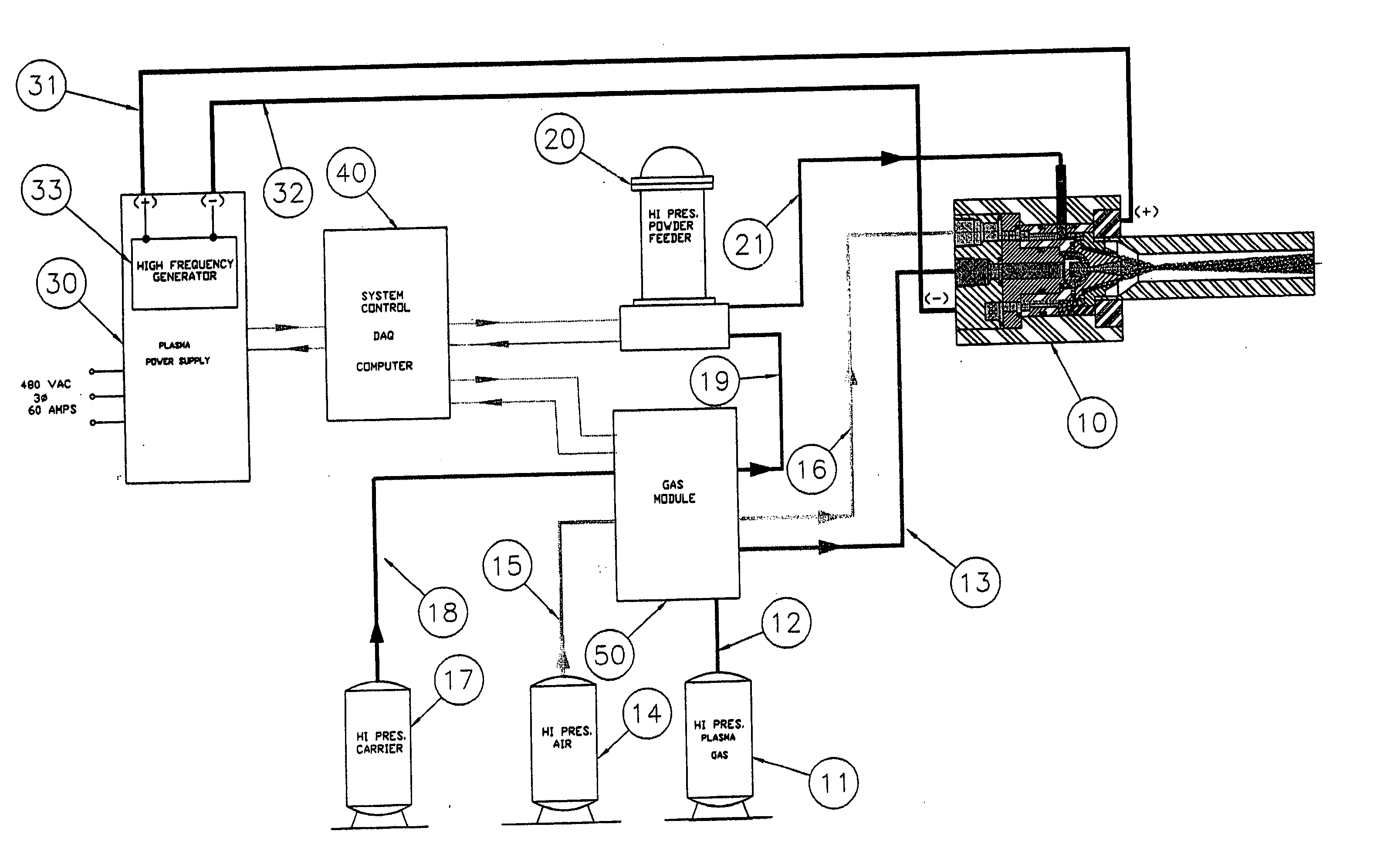

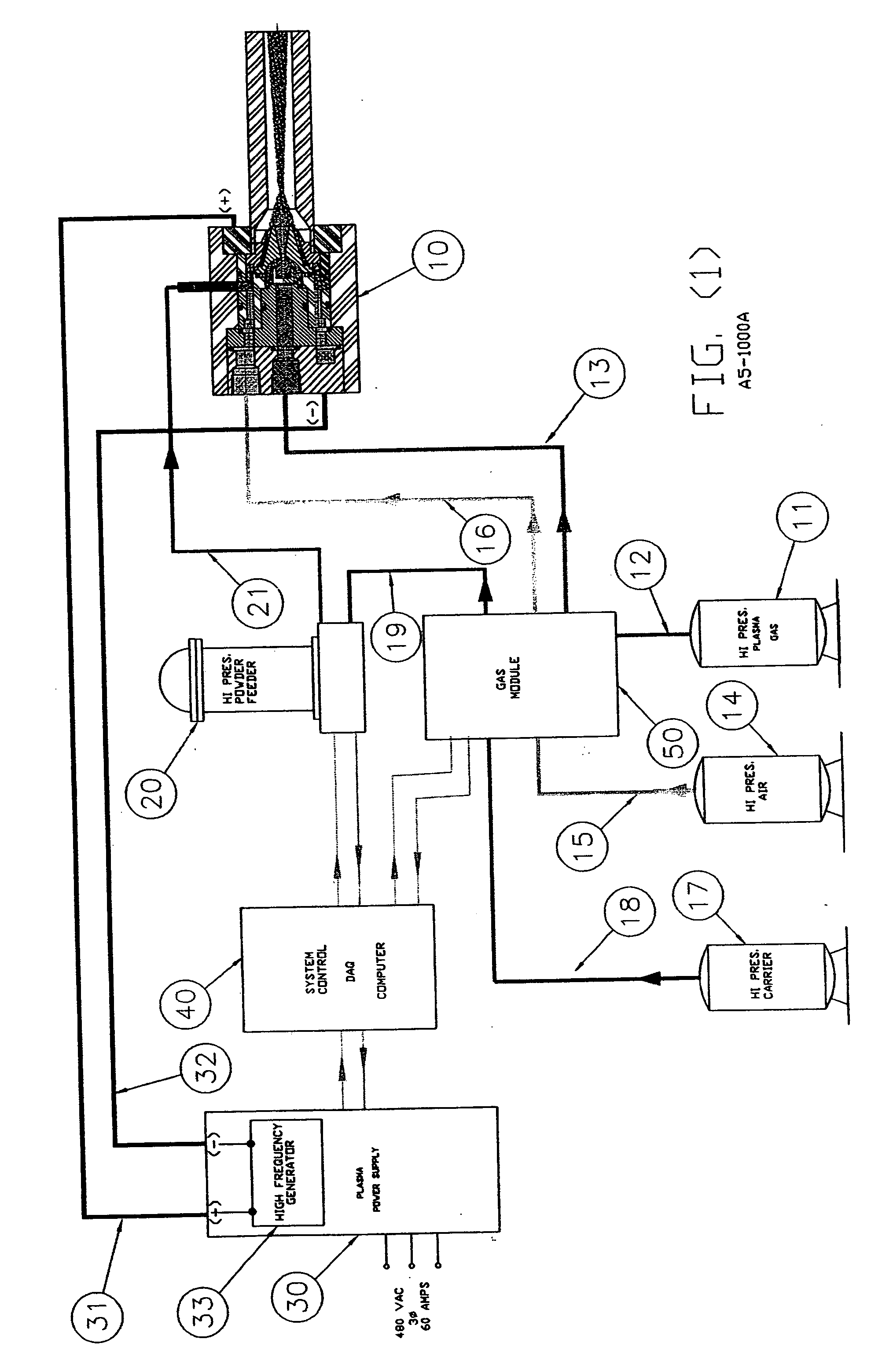

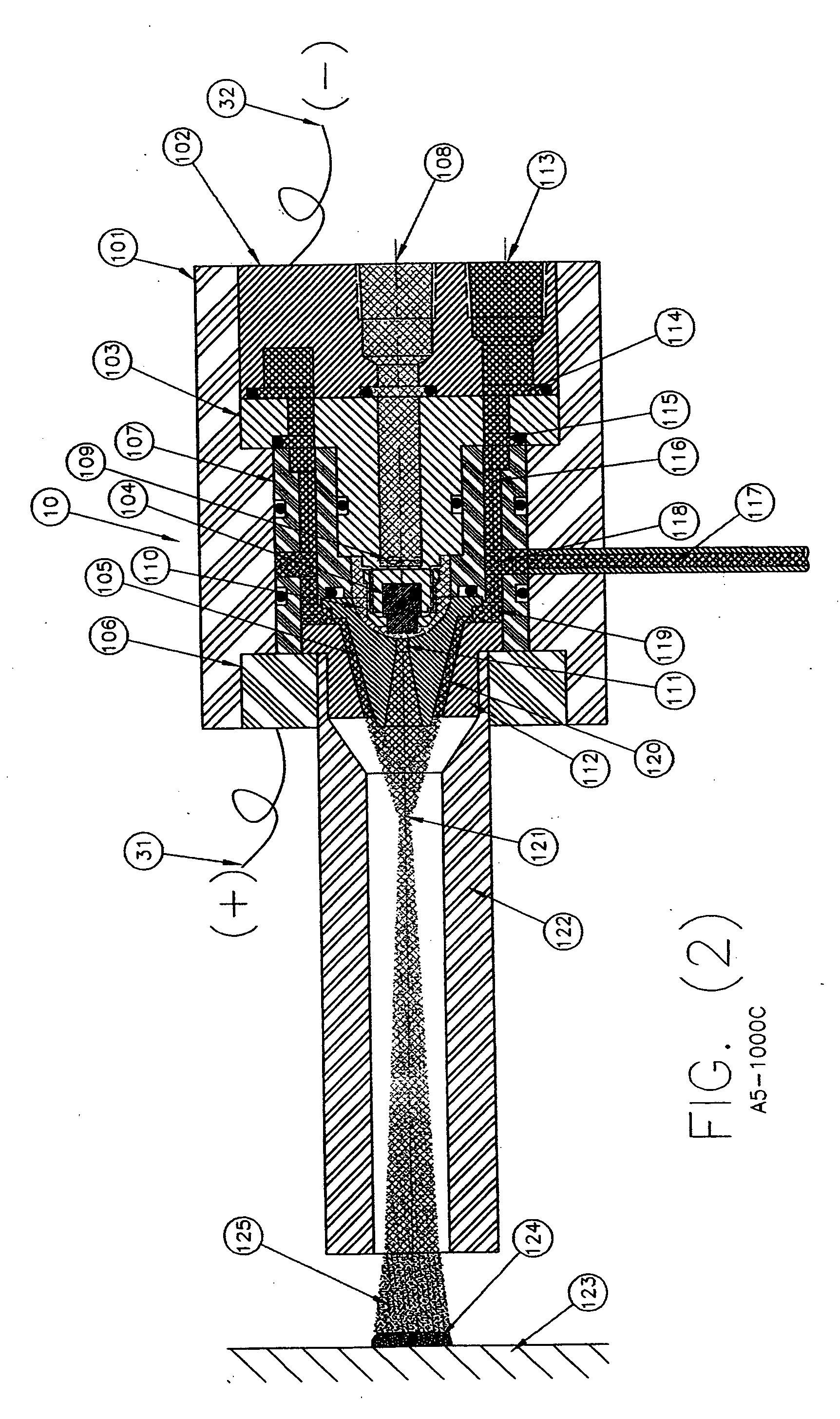

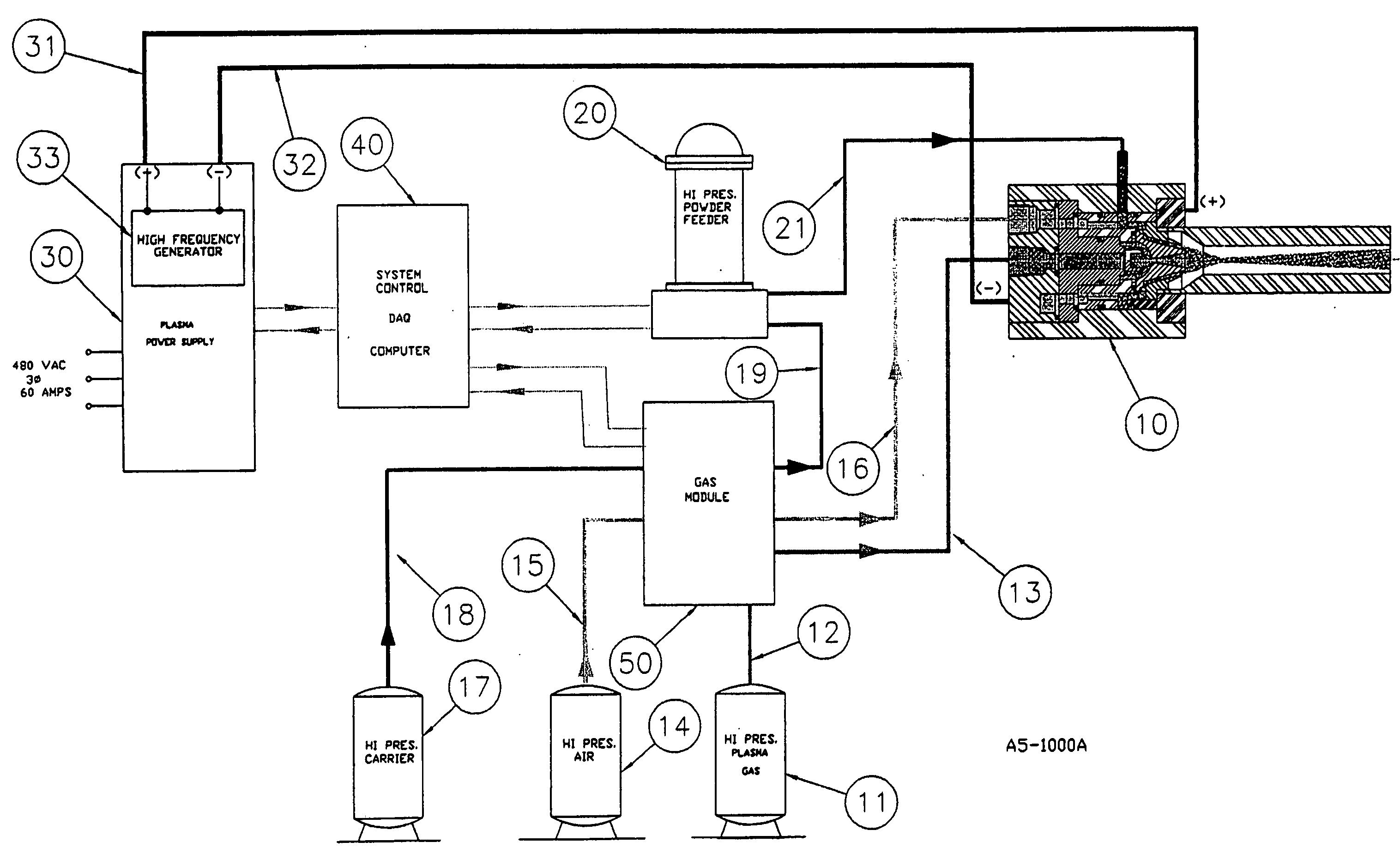

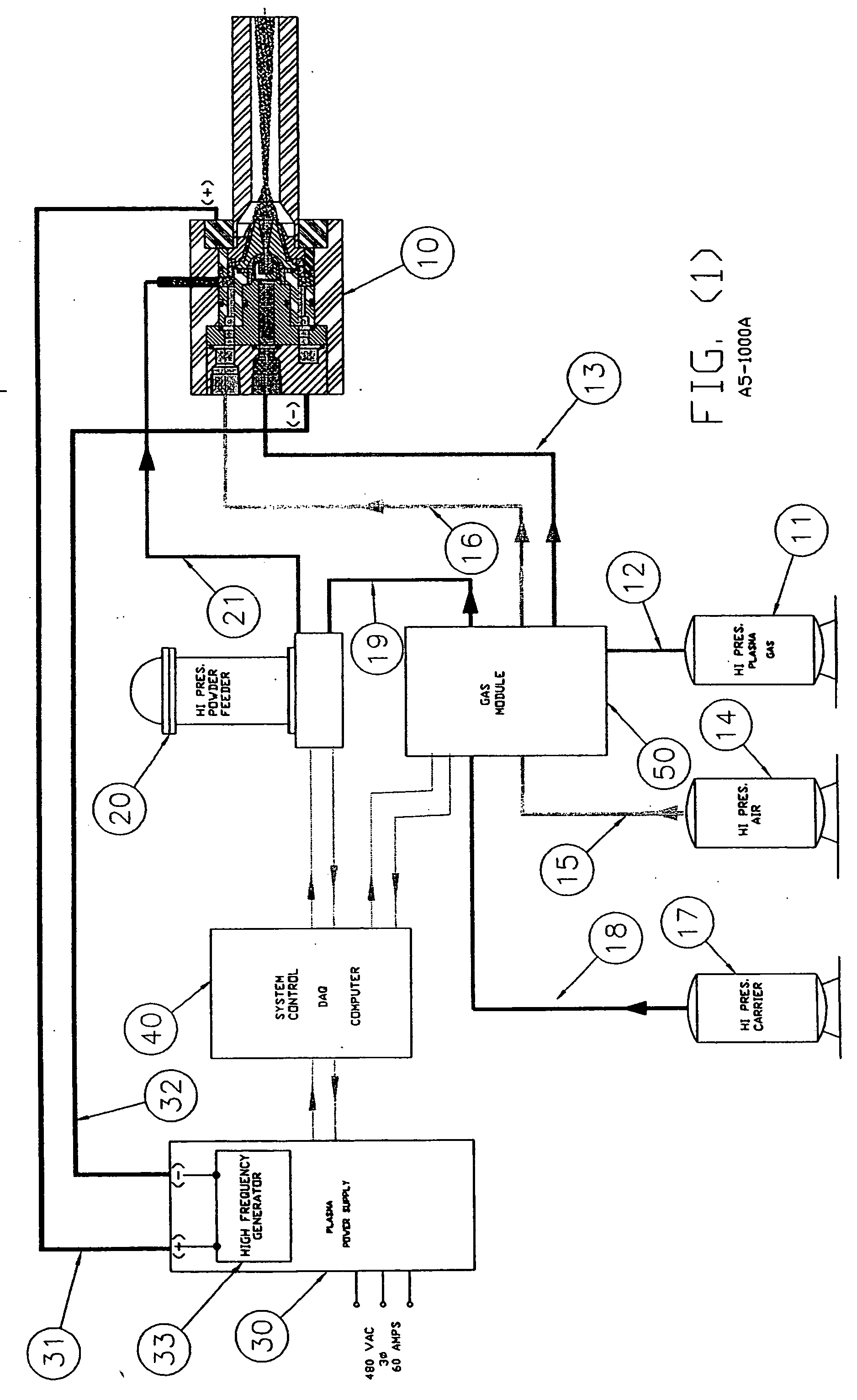

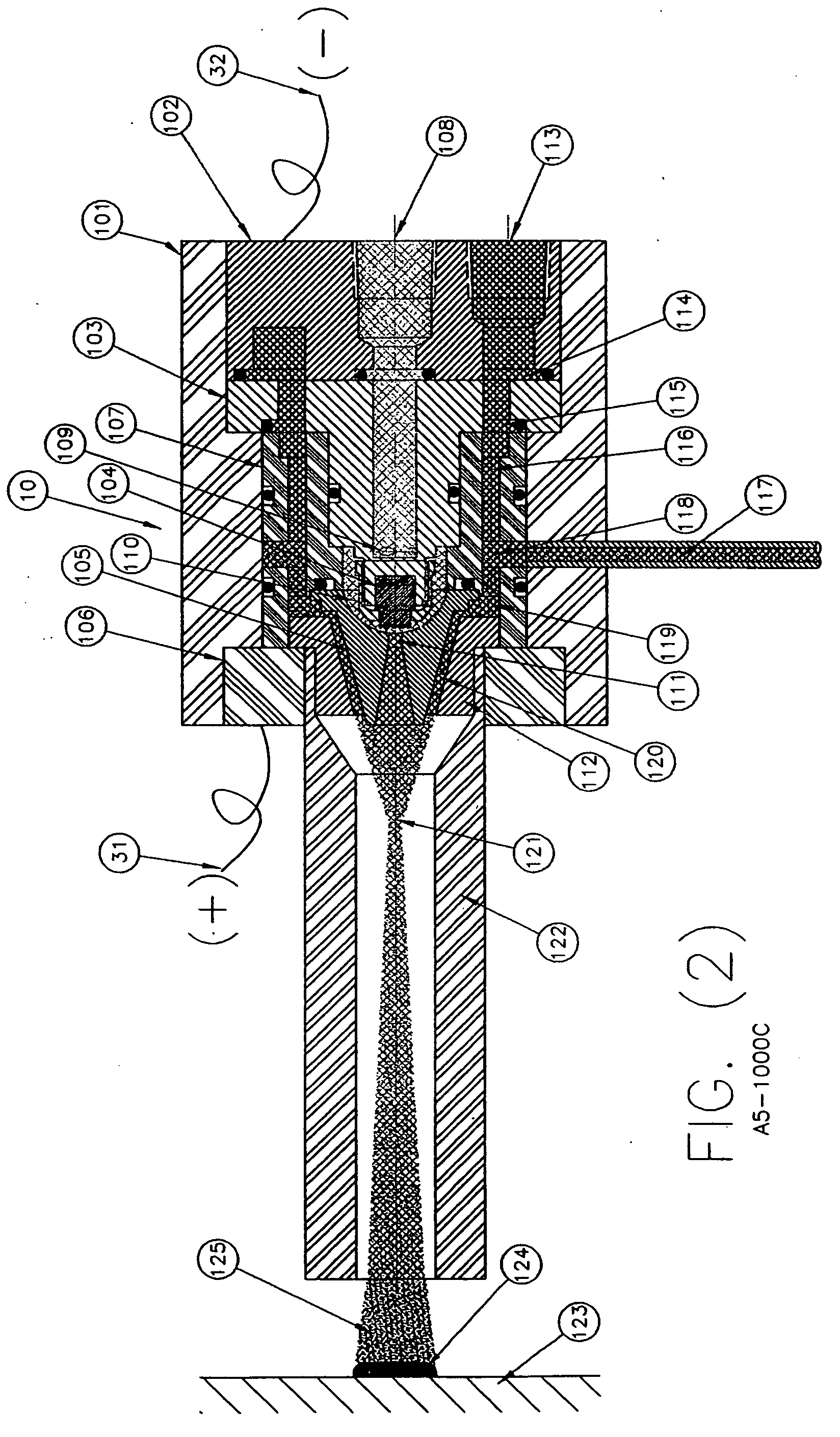

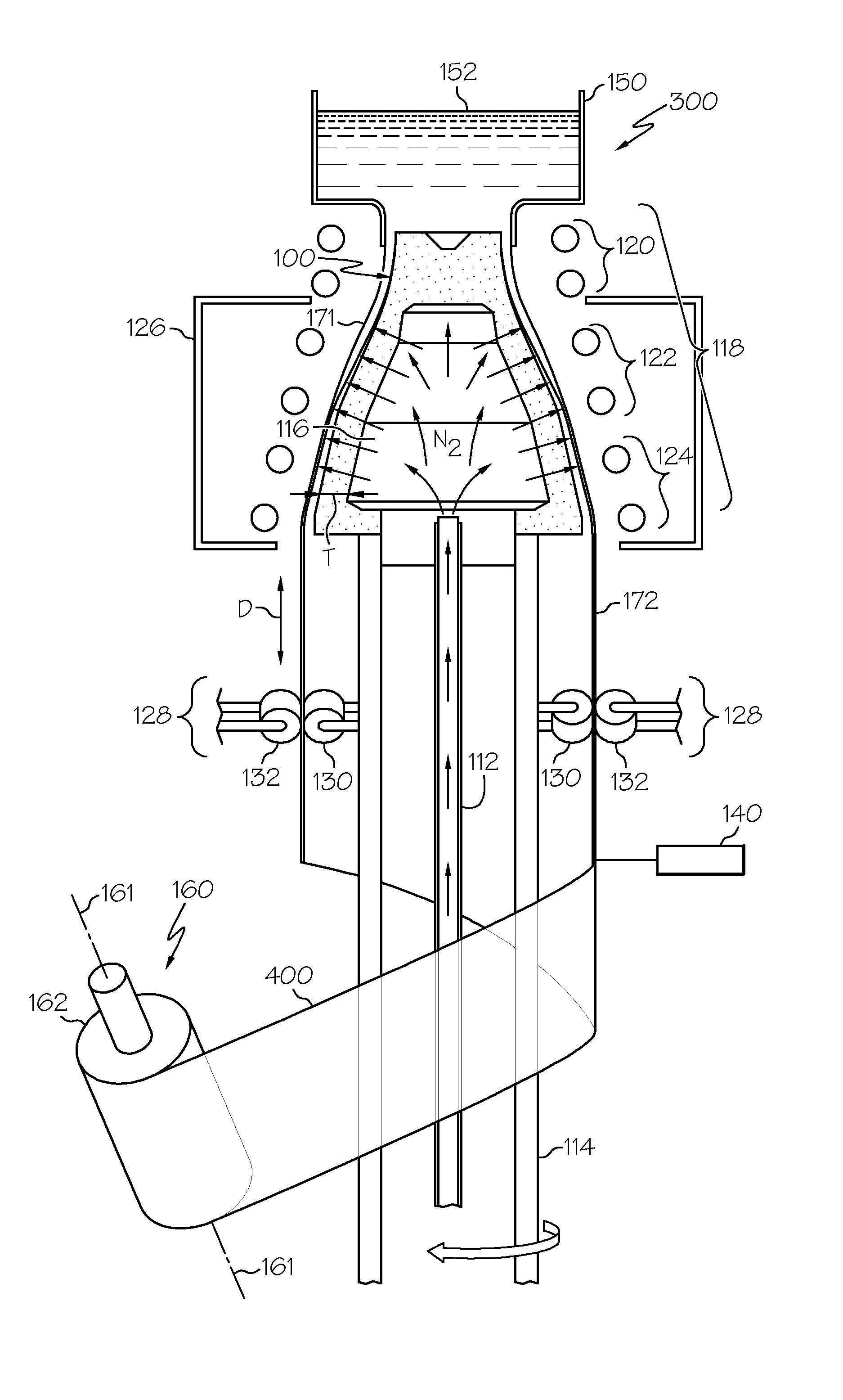

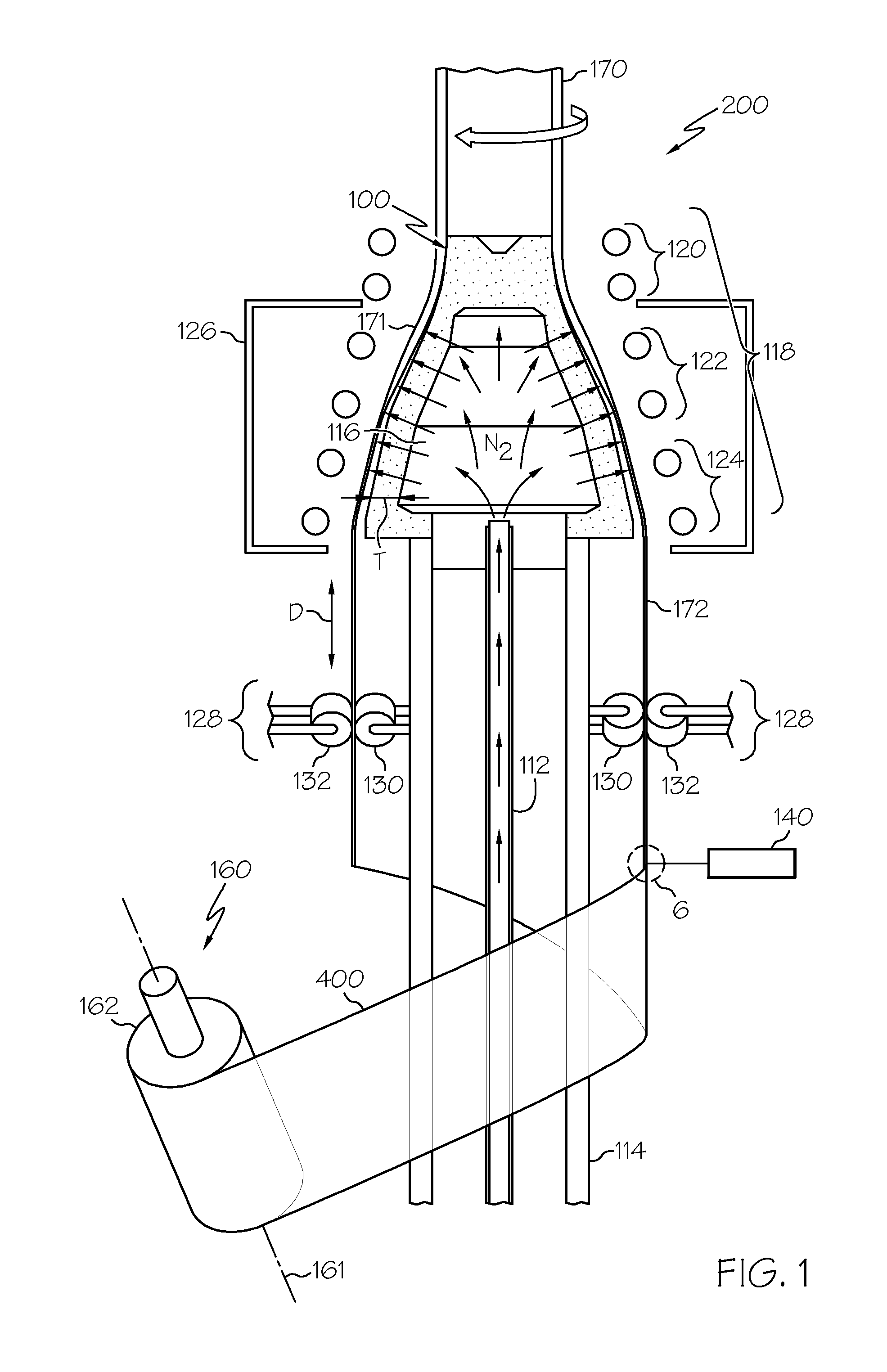

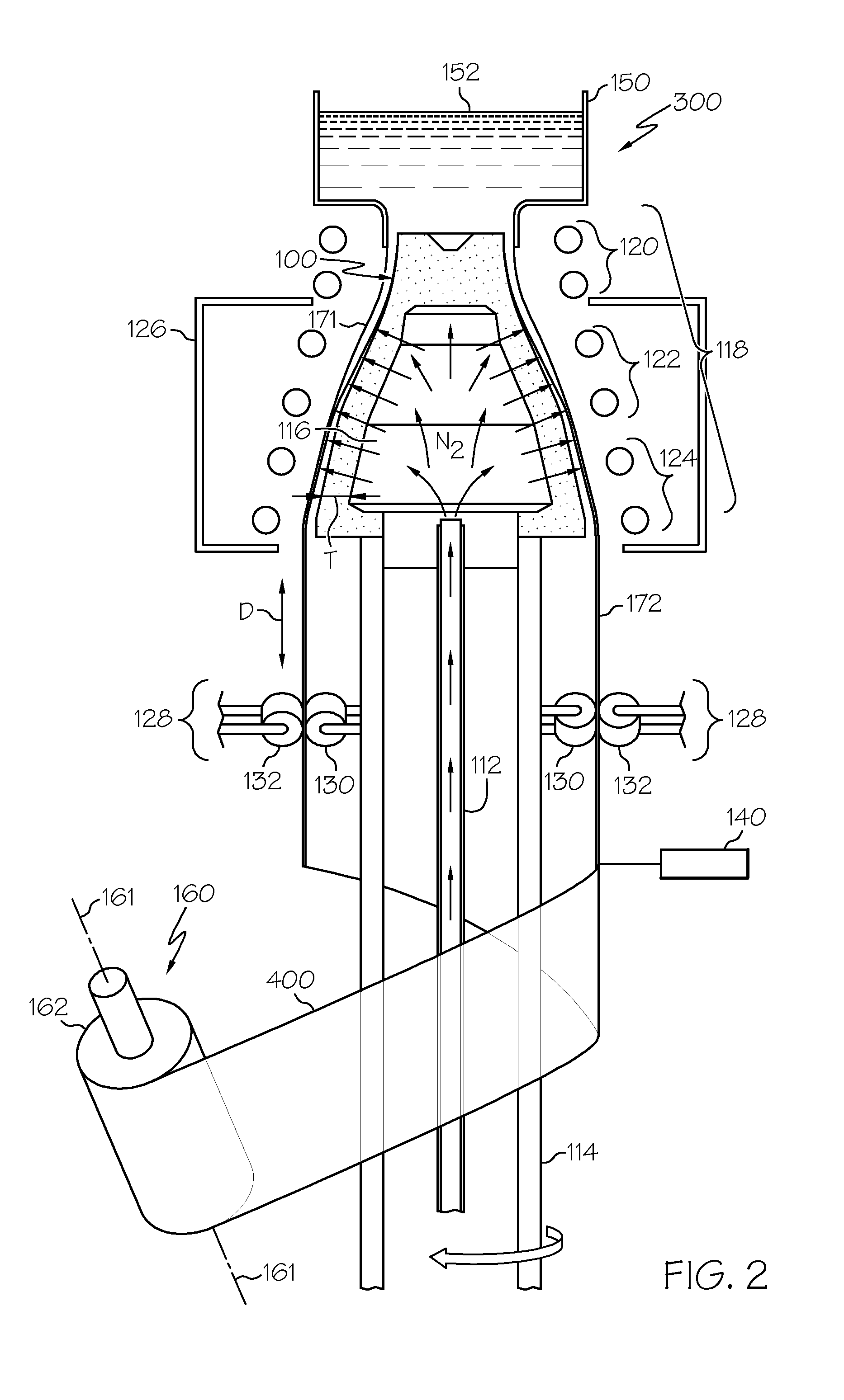

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050252450A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

High chemical resistance borosilicate glass and purpose thereof

InactiveCN101717189AComply with packaging requirementsReduce manufacturing costPharmaceutical containersMedical packagingWorking temperaturePack material

The invention discloses high chemical resistance borosilicate glass, comprising the following components based on oxides in percentage by weight: 71-75 SiO2, 3-6 Al2O3, 8-10 B2O3, 4-10 Na2O and 0-2.5 K2O, 0-1.2 CaO, 0-1 MgO, 1-3 BaO and 0-0.3 CeO2, wherein Na2O+K2O ranges from 7 to 10, and CaO+MgO ranges from 0 to 1.2. The invention has the following advantages: 1. As2O3, Sb2O3, BaSO4 and other harmful substances are not used in constituents, and the borosilicate glass can be used as a material for packing medicines; and 2. tested by experiments, the high chemical resistance borosilicate glass prepared from the constituents by the traditional production equipment has the coefficient of heat expansion ranging from 5.0*10<-6> K<-1> to 6.0*10<-6> K<-1>, the inversion temperature Tg ranging from 520 DEGC to 572 DEGC, the softening point ranging from 765 DEGC to 782 DEGC, the working temperature ranging from 920 DEGC to 1200 DEGC and the density ranging from, 2.32 g / cm<3> to 2.5g / cm<3>, which meet the requirement on medicinal packing and reduces the production cost.

Owner:SHANDONG LINUO NEW MATERIAL

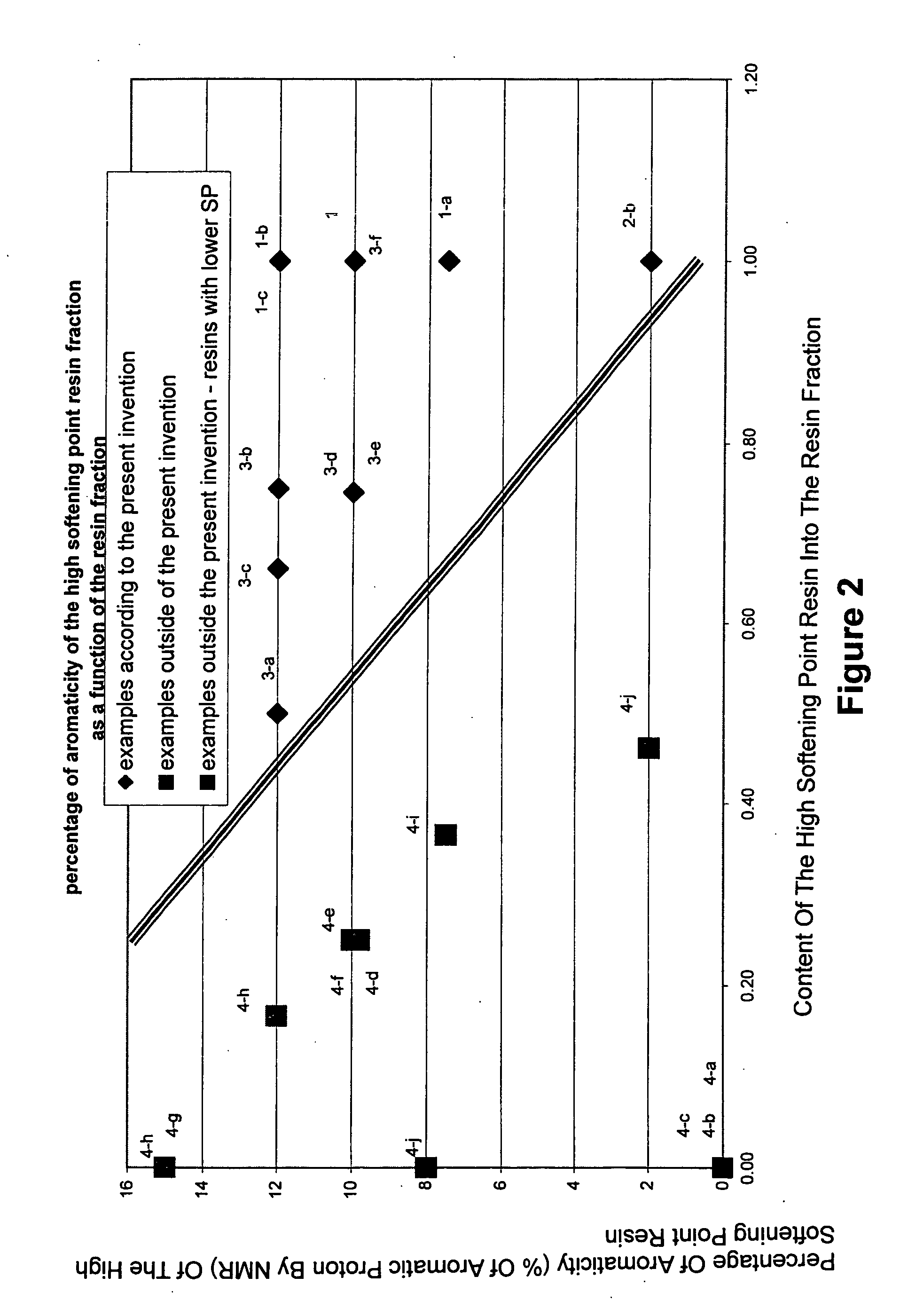

Low application temperature hot melt adhesive

InactiveUS20070088116A1High bond strength levelSame level of performanceAbsorbent padsAdhesivesElastomerCardboard

A hot melt adhesive composition, comprising a blend of components including about 10% to about 40% by weight of an elastomeric block copolymer, preferably styrene-isoprene-styrene (SIS) or styrene-butadiene-styrene (SBS), about 15% to about 70% by weight of a first midblock tackifying resin having a softening point of at least about 110° C. and having an aromatic content of at least about 1.5% by weight; about 0 to 55% of second midblock tackifying resin, about 5% to about 35% by weight of a plasticizer; and about 0% to about 20% by weight of an end block resin having a softening point lower than 125° C.; wherein the components total 100% by weight of the composition, the viscosity of the composition is equal to or less than about 20,000 mPa.s at 120° C., and is applied at a temperature lower that 150° C. and initial bond retention of the composition on elastic strands is at least about 60%. Also, the elastic modulus G′ of the composition is higher than about 5000 Pa, the vicous modules G″ is higher than about 50 Pa, and the tan delta value is between about 0.5 and about 60. Laminates, especially those used in disposable soft goods, and methods of making such laminates are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

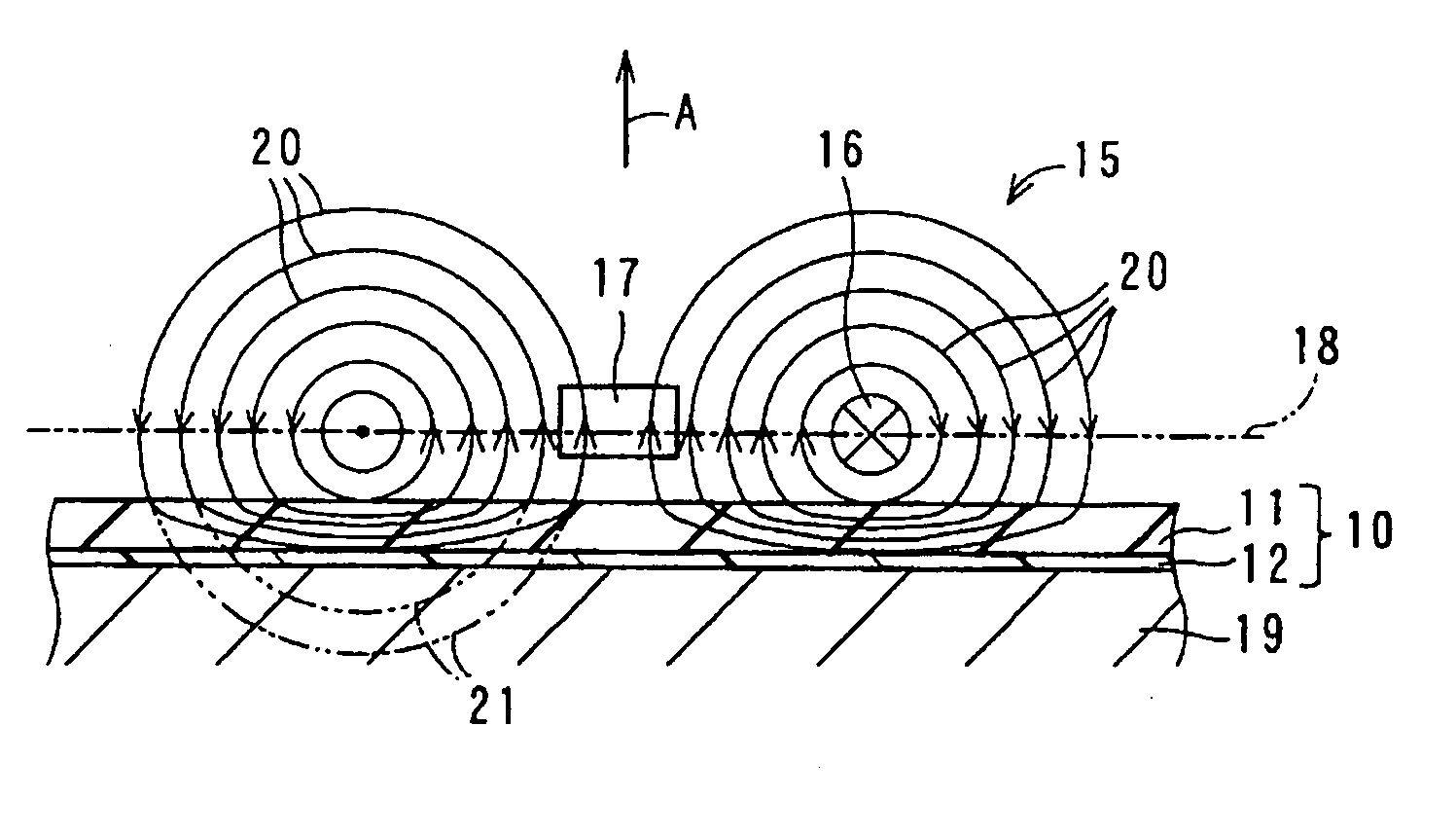

Electromagnetic Interference Suppressor, Antenna Device and Electronic Information Transmitting Apparatus

InactiveUS20070252771A1High densitySuperior electromagnetic interference suppressing effectMagnetic/electric field screeningLayered productsElastomerVitrification

An electromagnetic interference suppressor of substantially unpressurized sheet form is obtained by applying and drying a magnetic paint, and comprises 30 to 80% by volume of soft magnetic powder and 20 to 70% by volume of a binder. The binder is an elastomer or a resin that a glass transition point and / or a softening point is 50° C. or more and a storage modulus (E′) is 107 Pa (JIS K 7244-1) or more in a state containing neither solvent nor filler at room temperature. This electromagnetic interference suppressor exerts a superior electromagnetic interference suppressing effect.

Owner:NITTA CORP

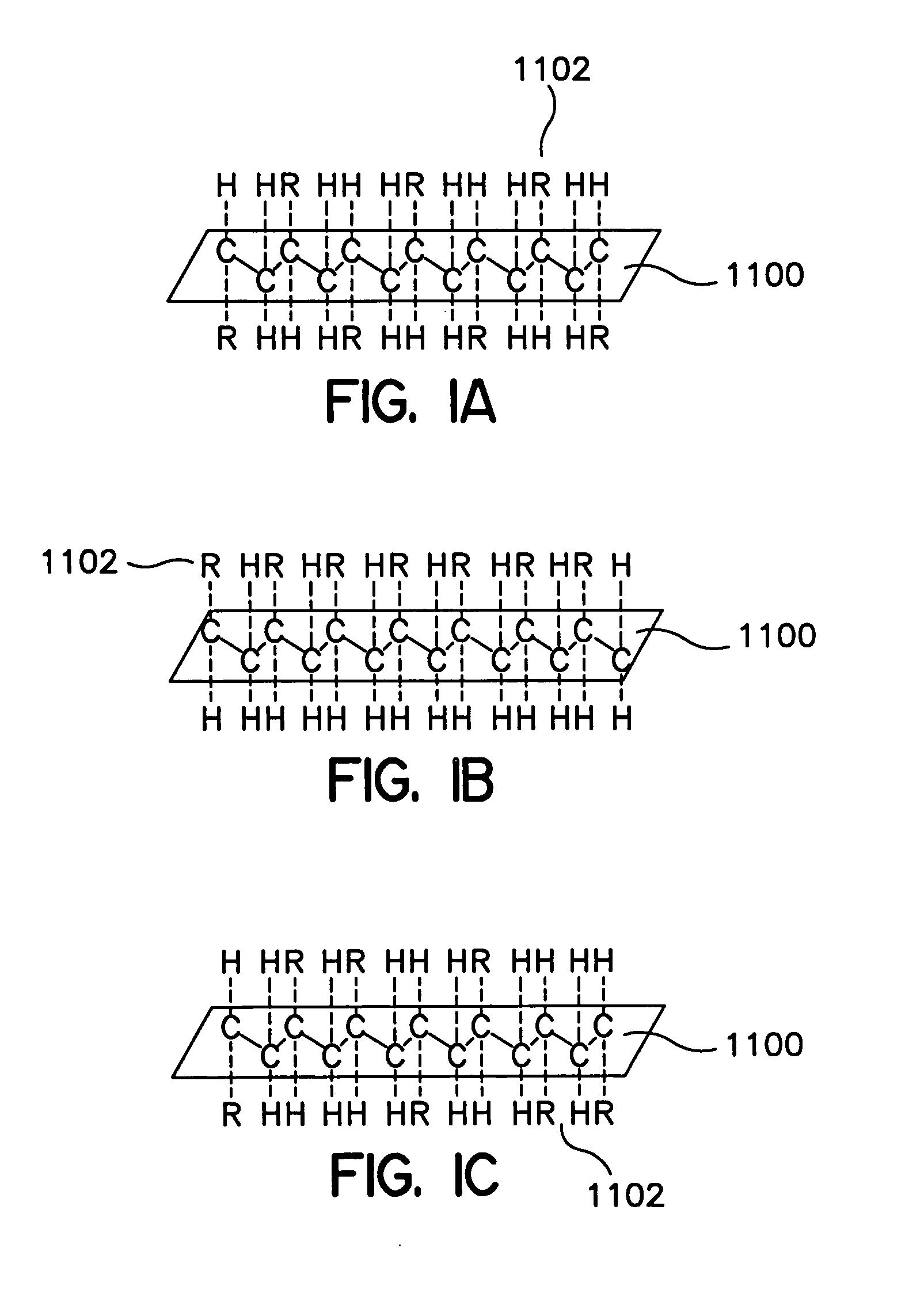

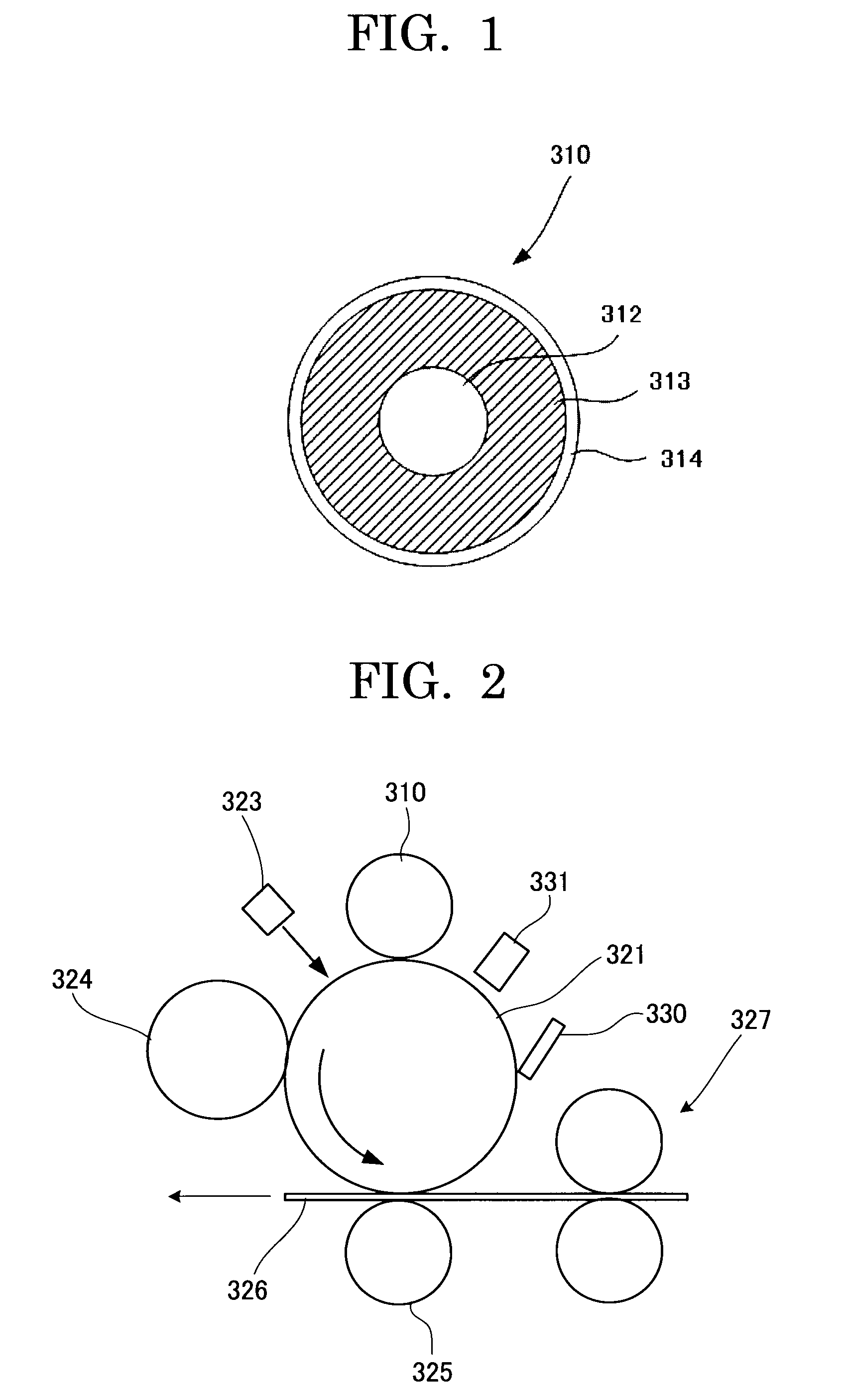

Toner, as well as image forming apparatus and image forming method using the same

ActiveUS20080280218A1Good storage stabilityLow temperature-fixing propertyDevelopersElectrographic process apparatusCarboxylic acidPropanediol

To provide a toner produced by emulsifying or dispersing in an aqueous medium particles containing at least polyester resin particles and by aggregating the polyester resin particles, wherein the polyester resin particles contain a polyester resin, the polyester resin is produced by condensation polymerization of an alcohol component containing 65 mol % or more 1,2-propanediol in a dihydroxy alcohol component and a carboxylic acid component containing purified rosin, and the softening point of the polyester resin is 80° C. or more and less than 120° C., and wherein the toner comprises a colorant and a releasing agent.

Owner:RICOH KK

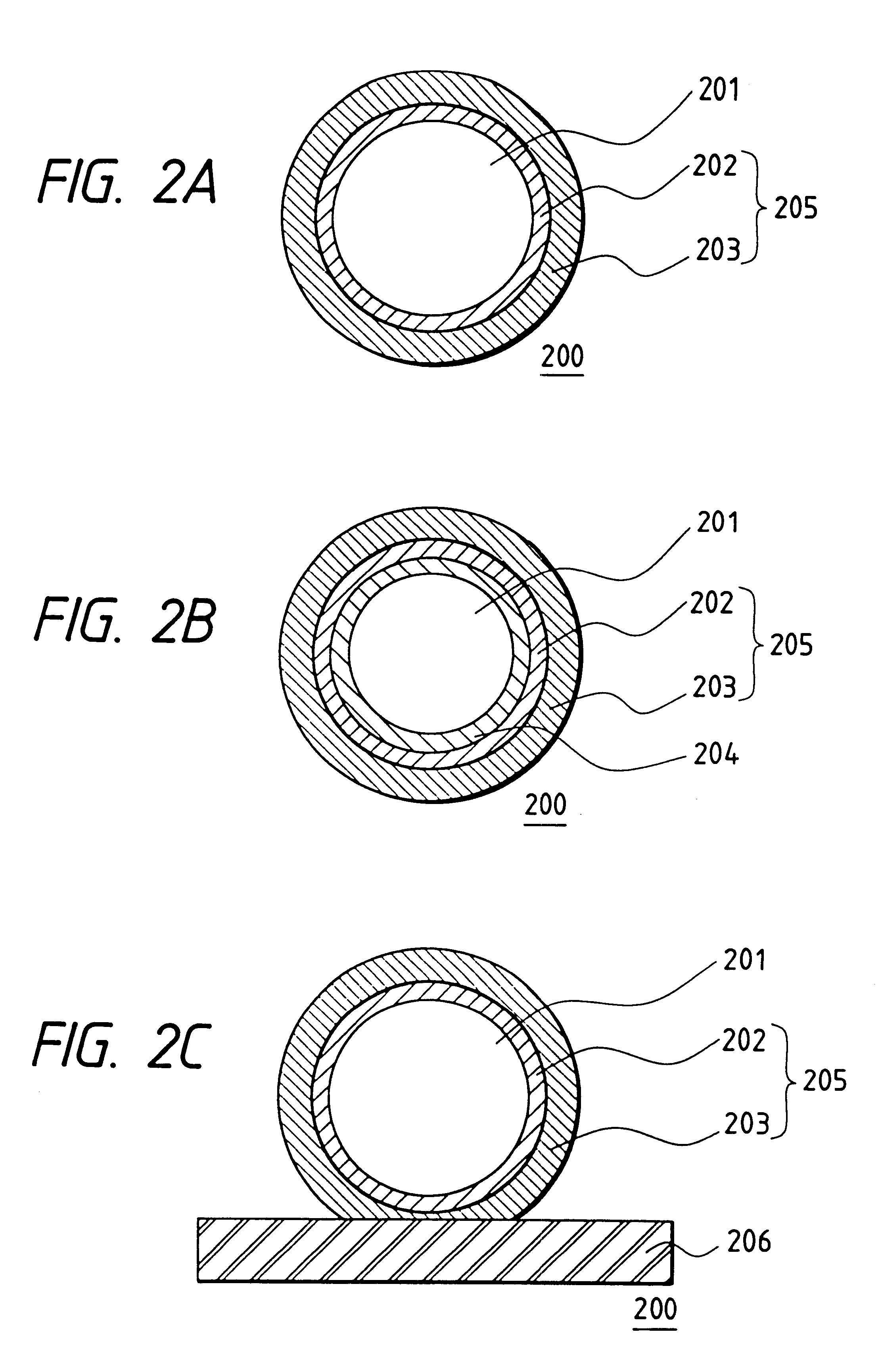

Crosslinked, heat shrinkable polypropylene compositions

InactiveUS6569915B1Reduced effectivenessReduce the degree of crosslinkingElastomerEthylene Homopolymers

A heat-shrinkable article suitable for use as an insulating or coating material comprises a crosslinked composition of a polypropylene homopolymer or copolymer and an ethylene-propylene elastomer. The article is formed by a process comprising: i) creating a blend of the polypropylene homopolymer or copolymer and the ethylene-propylene elastomer by melt mixing; ii) melt processing the blend produced in i) to produce a melt processed material; iii) crosslinking the melt processed material produced in ii) by exposing it to radiation to produce a crosslinked material; iv) stretching the crosslinked material at a first temperature close to or above its softening or melting point and subsequently cooling it to a second temperature below its softening or melting point, to thereby freeze the crosslinked material in its stretched form. Subsequent heating of the article close to or above its softening point or crystalline melting point results in recovery of the pre-stretched dimensions of the article. Due to its relatively high content of polypropylene, the heat-shrinkable article thus produced has greater toughness and rigidity than polyethylene-based systems, making it suitable for use as insulation for wires and cables a heat-shrinkable corrosion resistant sleeves for high-temperature transmission pipeline joints, and for heat-shrinkable tubing or shapes for electrical insulation and mechanical protection.

Owner:SHAWCOR LTD

Stretchable hot-melt adhesive composition with temperature resistance

InactiveUS20050054779A1Improve tensile propertiesHigh bonding strengthPersonal careSynthetic resin layered productsPolymer sciencePlasticizer

An adhesive composition including an atactic polymer, an isotactic polymer, and an elastomeric base polymer. The composition may also include a high softening point tackifier resin, a low softening point additive and / or other additives, such as an antioxidizing agent, a plasticizer, mineral oil, color pigment, filler, polymer compatibilizer, or a combination of any of these additives. Facing layers, particularly stretchable and / or elastomeric substrates, can be bonded with the adhesive composition. The adhesive composition maintains high bond strength, even at body temperature and after initial stretching. Such adhesive compositions and laminates can be made according to a method of the invention.

Owner:KIMBERLY-CLARK WORLDWIDE INC

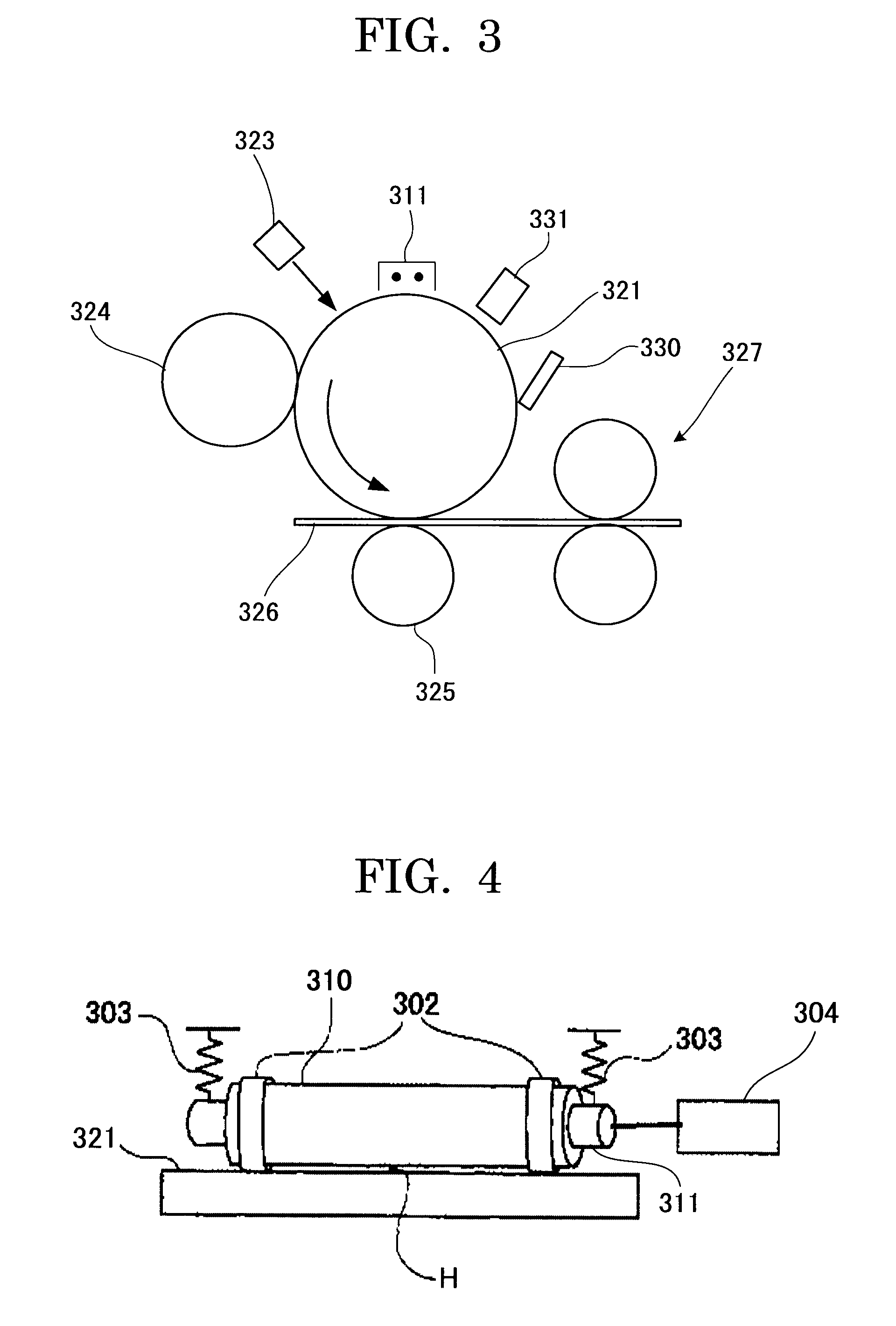

Electrostatic latent-image developing toner

An electrostatic latent-image developing toner comprising: a core particle and a shell layer formed on an outer portion thereof, wherein the shell layer comprises a crystalline polyester resin having a softening point from 60 to 120° C. at 70 to 100% by weight of the entire shell-layer constituent resin, and an image-forming method using the toner.

Owner:KONICA MINOLTA BUSINESS TECH INC

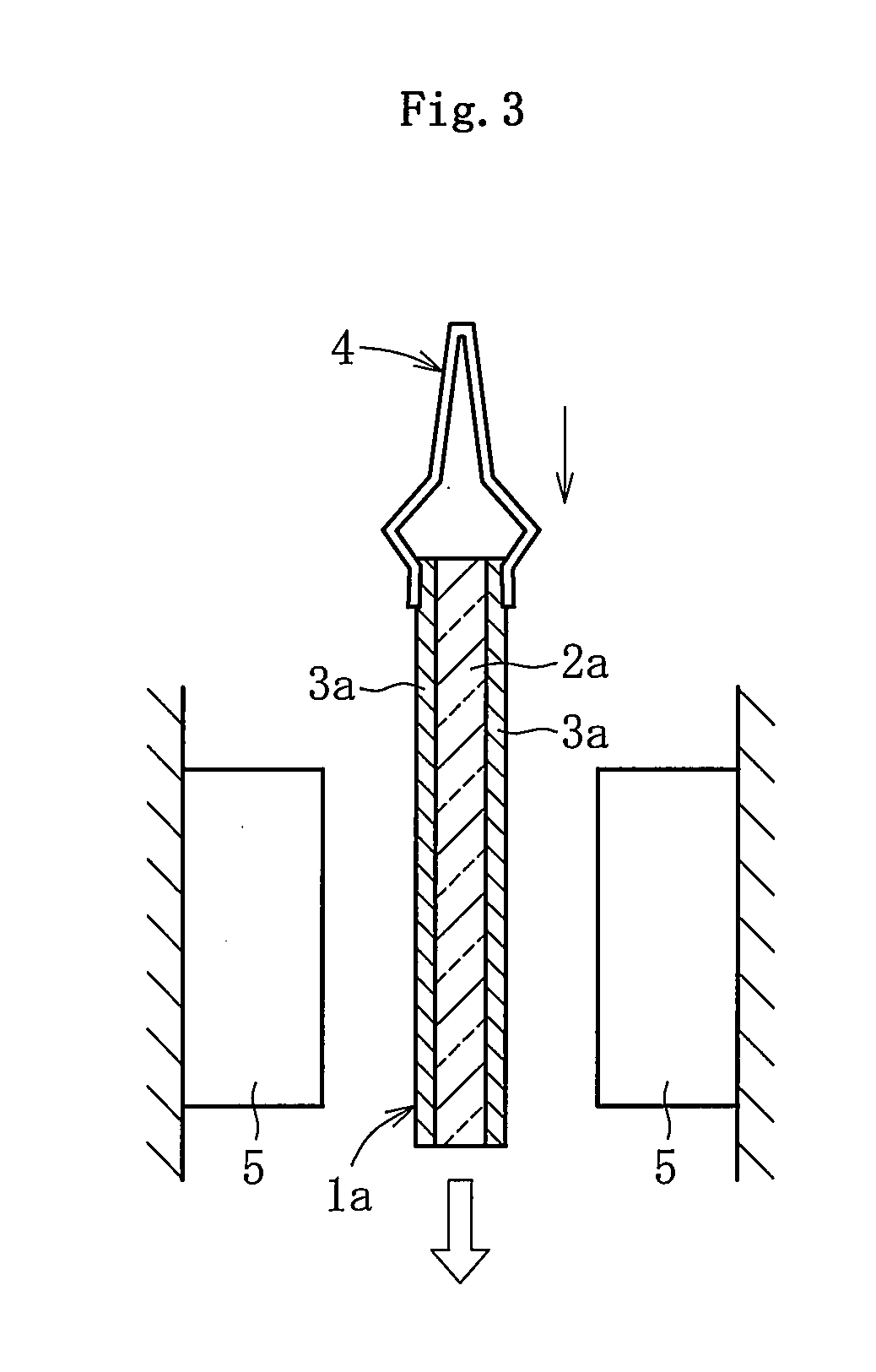

Methods and systems for forming continuous glass sheets

ActiveUS20120047951A1Increase the diameterGlass transportation apparatusGlass forming apparatusSusceptorEngineering

Owner:CORNING INC

Lead-free silver conductive paste used for positive electrode of solar battery and preparation technique thereof

InactiveCN101609850AStrong adhesionLower resistanceFinal product manufactureConductive materialConductive pasteSilver electrode

The invention provides a lead-free silver conductive paste used for positive electrode of solar battery and a preparation technique thereof. The paste comprises the following materials by weight percentage: 65 to 85 percent of silver powder, 2 to 8 percent of lead-free glass powder, 10 to 25 percent of organic carrier and 0.1 to 3 percent of additive. The paste adopts the lead-free glass powder of Si-B-Bi-Al-Ti-Zn-O series to replace the traditional lead-bearing glass powder; and the series glass powder has lower softening point, can lead the silver electrode to have good adhesive force after sintering, and ensures the silver electrode to be well contacted with a silicon substrate. In addition, zinc resinate is used as the additive in the invention, not only can well improve the printing performance of the paste, but also can improve the electrical property of the electrode.

Owner:CENT SOUTH UNIV

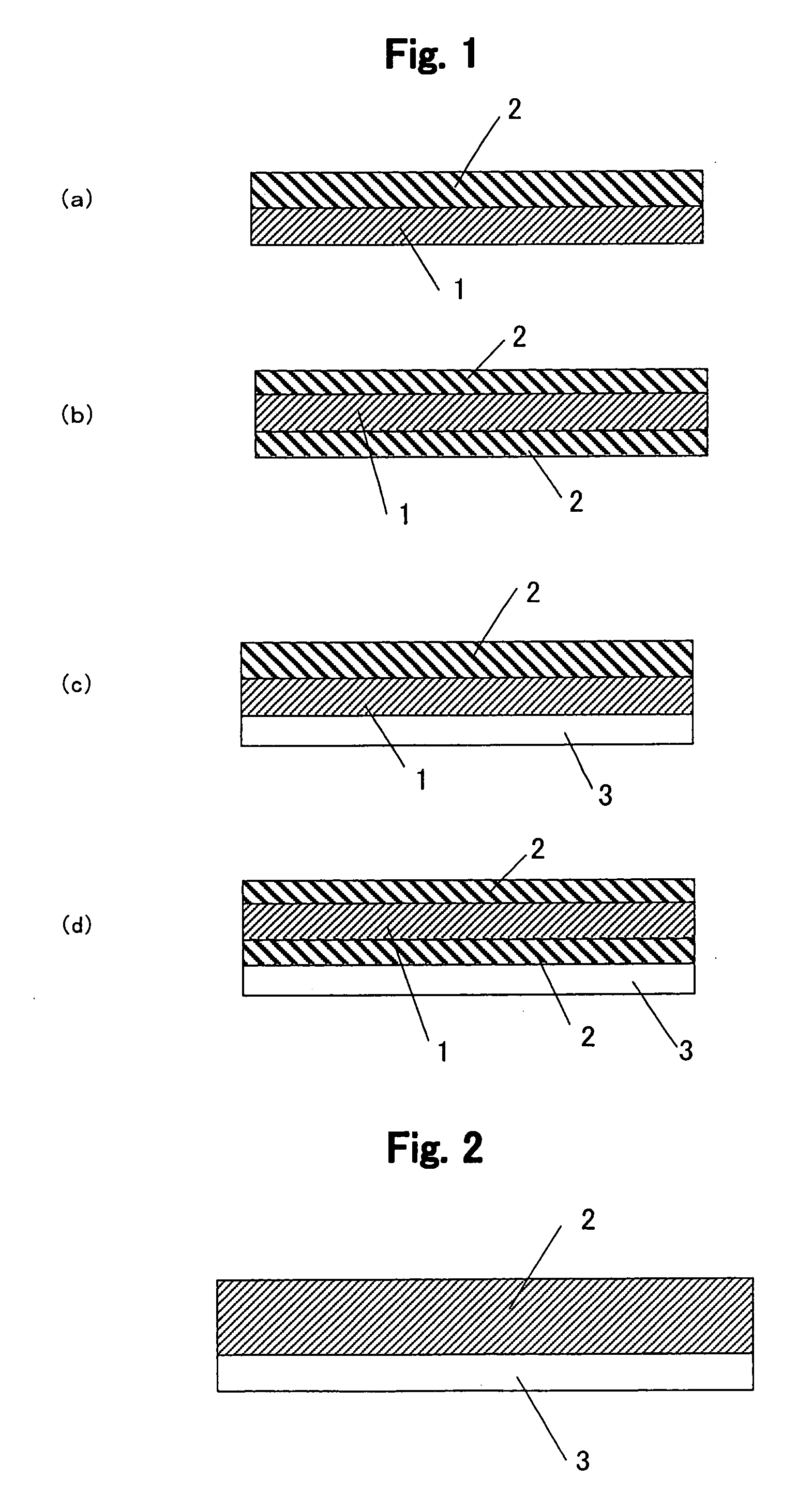

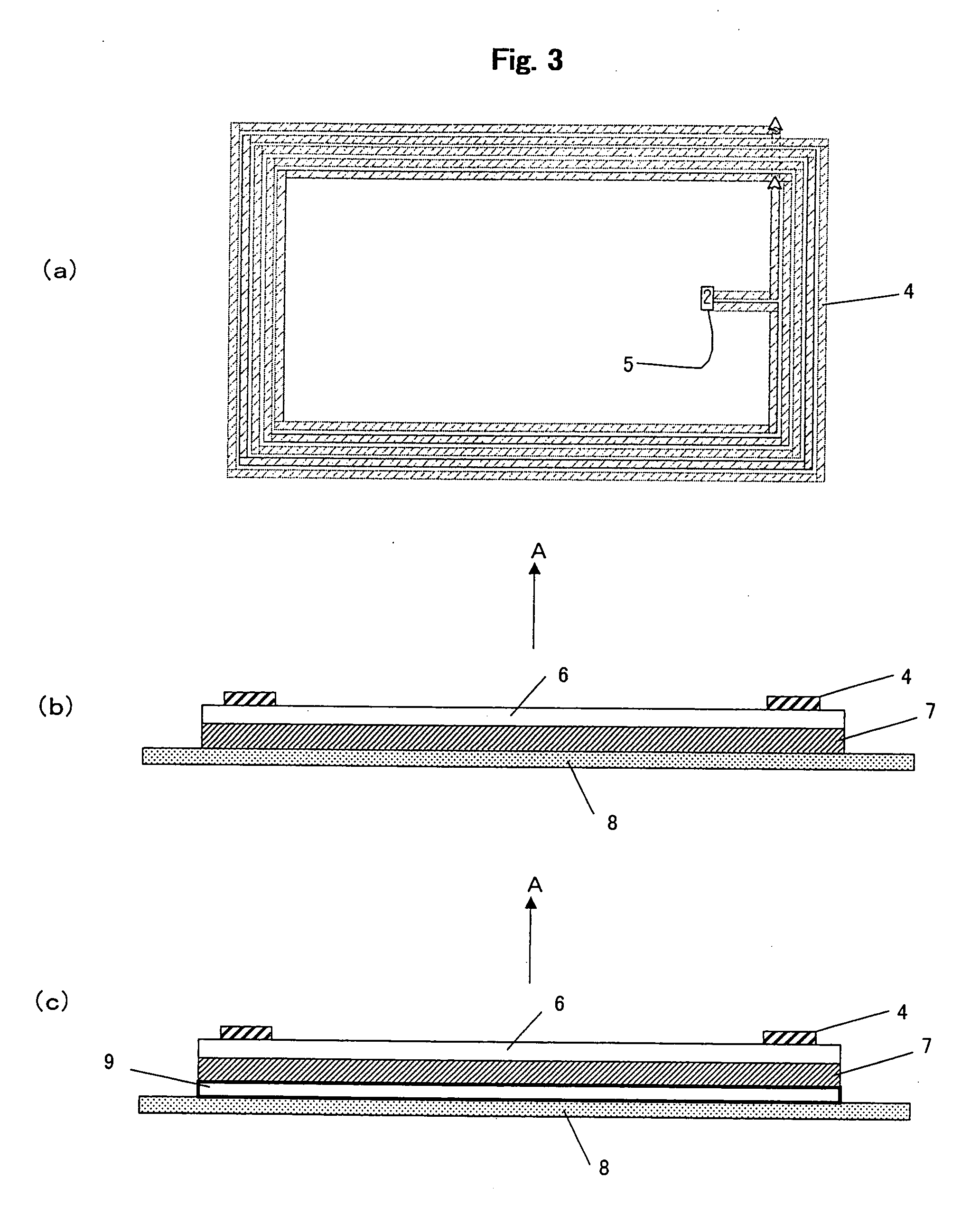

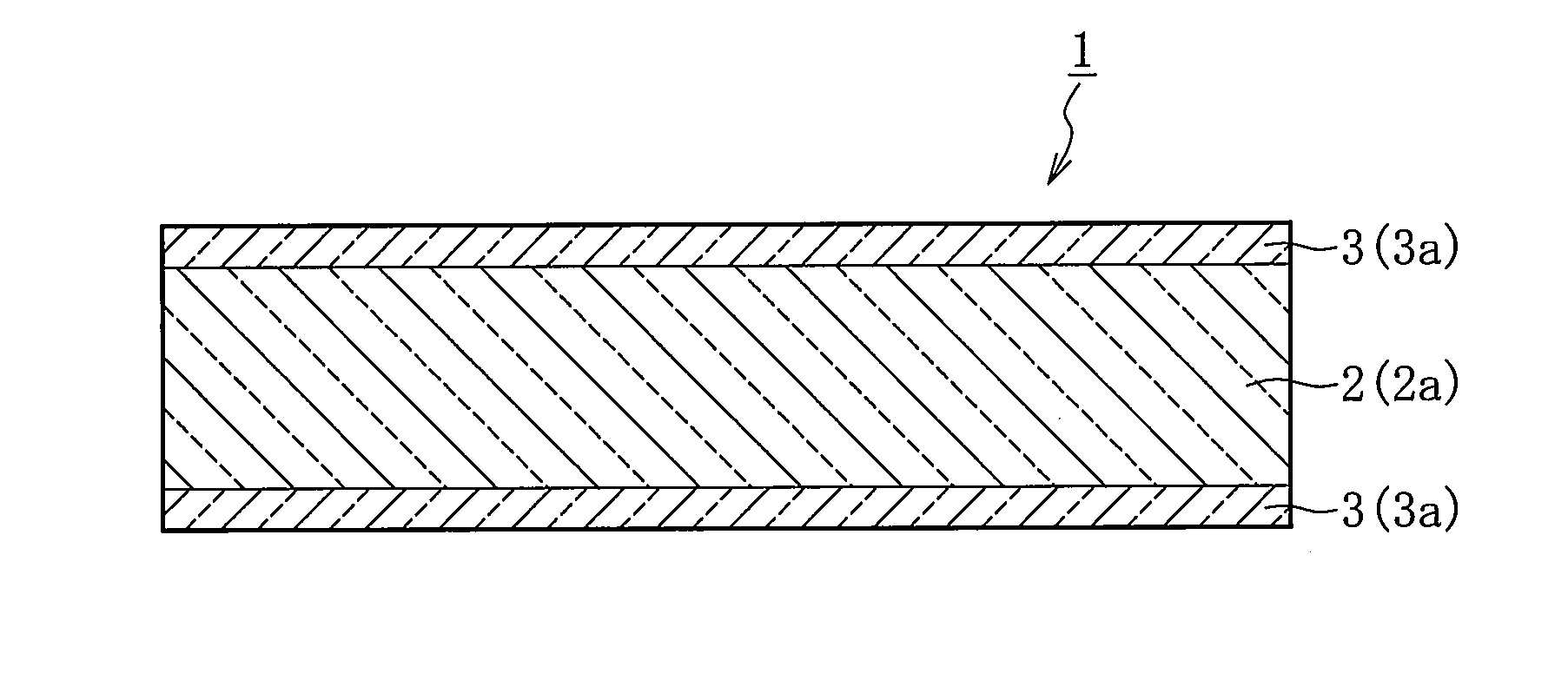

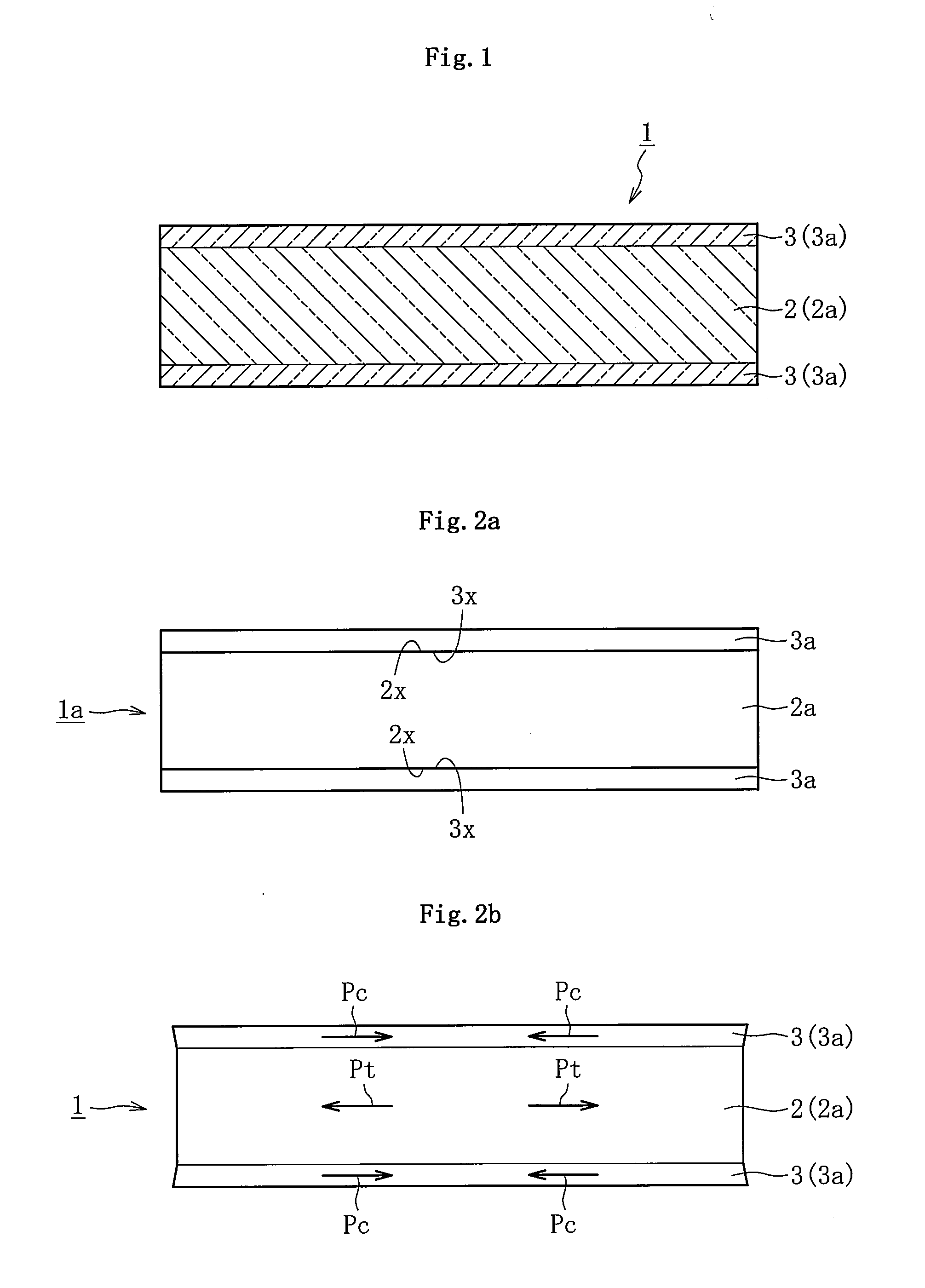

Reinforced plate glass and method for manufacturing the same

InactiveUS20110200805A1Simple processReduce work costsGlass/slag layered productsGlass reforming apparatusFlat glassSurface layer

Provided is a method, including: performing heat treatment, under a state in which a thick core plate glass (2a) having a higher thermal expansion coefficient and a thin surface-layer plate glass (3a) having a lower thermal expansion coefficient are laminated together, so that the laminated portion has a temperature equal to or higher than the lower softening point out of the softening points of the core plate glass (2a) and the surface-layer plate glass (3a), thereby melt-bonding the core plate glass (2a) and the surface-layer plate glass (3a); and then performing cooling so as to attain a temperature less than the lower strain point out of strain points of the core plate glass (2a) and the surface-layer plate glass (3a), to thereby form a compression stress in a surface layer portion (3) corresponding to the surface-layer plate glass (3a) and form a tensile stress in a core portion (2) corresponding to the core plate glass (2a).

Owner:NIPPON ELECTRIC GLASS CO LTD

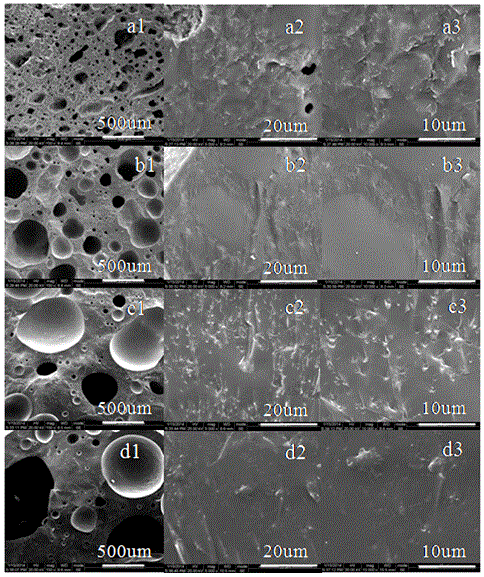

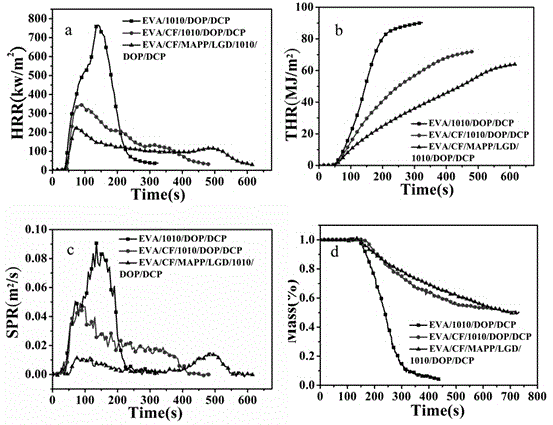

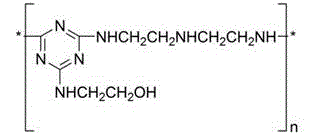

Ceramic bovine flame retardant polymer composite material and application thereof

InactiveCN104650441AImprove high temperature strengthImprove flame retardant performanceInsulatorsPolyolefinPlasticizer

The invention provides a ceramic bovine flame retardant polymer composite material based on polyolefin or a thermoplastic polyurethane elastomer. The ceramic bovine flame retardant polymer composite material is prepared from the following components in parts by weight: 30-40 parts of polyolefin resin or the thermoplastic polyurethane elastomer, 25-45 parts of a ceramic forming filler, 20-30 parts of a halogen-free flame retardant, 1-5 parts of a flame-retardant synergist, 1-3 parts of a plasticizer, 0.5-2 parts of an antioxidant and 0.02-0.15 part of a crosslinking agent, wherein the ceramic forming filler is prepared from the following components including low softening point glass powder and a silicate mineral filler. The invention also provides application of the ceramic bovine flame retardant polymer composite material in the field of cables. According to the ceramic bovine flame retardant polymer composite material disclosed by the invention, a dense ceramic bovine product can be formed within a range from 600 DEG C to 1000 DEG C, and the formed ceramic bovine product is good in high-temperature strength and flame retardancy and is also good in mechanical properties under room temperature.

Owner:SICHUAN UNIV

Toner, image forming apparatus, image forming method, and process cartridge using the toner

ActiveUS20080280219A1High quality imagingDecrease in image densityDevelopersElectrographic processes using charge patternImage formationCarboxylic acid

The present invention provides a toner containing at least a binder resin, a releasing agent, and a colorant, wherein the binder resin contains at least a polyester resin (A) having a softening point Tm(A) of 120° C. to 160° C., a polyester resin (B) having a softening point Tm(B) of 80° C. or more and less than 120° C. and a composite resin (C) containing a condensation polymerization monomer and an addition polymerization monomer, at least any one of the polyester resins (A) and (B) is a polyester resin prepared by condensation-polymerizing an alcohol component substantially composed of only aliphatic alcohol with a carboxylic acid component, and 65% or more of the alcohol component is 1,2-propanediol.

Owner:RICOH KK

Process for producing polar polyolefines and modified polyolefines thereof

InactiveUS20050218551A1Increase polarityReduce volatilityCeramic shaping apparatusFlat articlesPolyolefinCompound (substance)

A novel process for modification of polyolefines and their copolymers thereof, enables the production of modified PP with minimal deterioration of molecular weight and low gel content PE and their copolymers and with minimal yellowness. The novel compound is comprised of polyolefin resin or a mixture of resins, unsaturated acidic monomer and organic peroxide, together with low volatility polar acrylic co-monomer and low softening point resin, in a continuous reactive reactor The novel process minimizes sublimation of maleic anhydride and improves distribution of monomers and initiator prior to the melting of the polyolefin.

Owner:POLYRAM RAM ON INDS LP

Toner, and image forming method, image forming apparatus, and process cartridge using the toner

InactiveUS20070122729A1Good fixabilityHigh quality imagingDevelopersElectrographic process apparatusWaxImage formation

A toner is provided including a colorant; a resin composition (A) comprising at least one binder resin and a hydrocarbon wax having a melting point of 70-90° C. in an amount of from 6 to 30% by weight based on total weight of resin composition (A), and having a softening point (T1 / 2(A)) of from 120 to 150° C.; and a resin composition (B) having a softening point (T1 / 2 (B)) of from 100 to 130° C., wherein a weight ratio of the resin composition (A) to the resin composition (B) is from 10 / 90 to 45 / 55, and the following relationship is satisfied: T1 / 2(A)≧T1 / 2(B)+3; and the use of the toner in an image forming method, an image forming apparatus, and a process cartridge.

Owner:RICOH KK

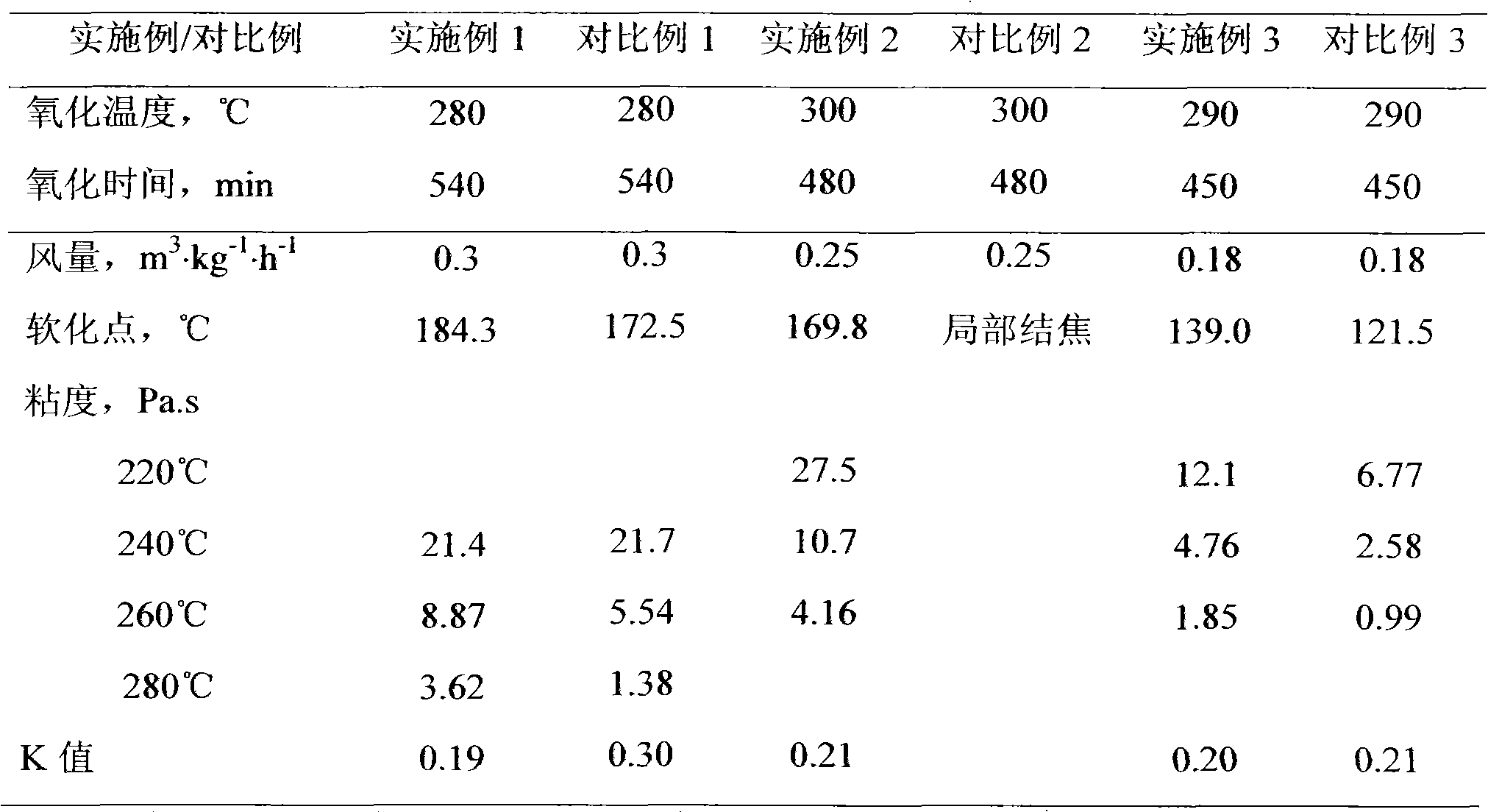

Preparation method of high softening point asphalt

ActiveCN102464989AIncrease profitQuality improvementWorking-up pitch/asphalt/bitumen by chemical meansMolten stateTemperature control

The invention provides a preparation method of high softening point asphalt, and the method comprises: heating an asphalt raw material to a molten state, subjecting the asphalt raw material, reaction additives accounting for 0.01%-5% of the total mass of the asphalt raw material, as well as air to full premixing reaction, with the mixing temperature controlled at 80-180DEG C and the mixing time controlled at 1min-40min; then introducing the mixture to an oxidation reactor for air blowing oxidation at a temperature of 200-340DEG C for 3-10h, with the air blowing rate of an oxidation tower maintained at 0.05-0.5m<3>.kg<-1>.h<-1>, thus obtaining a high softening point asphalt product with excellent high temperature performance and temperature susceptibility resistance. The method of the invention solves the problems of overlong reaction time, nonuniform air distribution, easy coking, short oxidation tower operation cycle, and poor product performance, etc. existing in current high softening point asphalt production processes by oxidation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

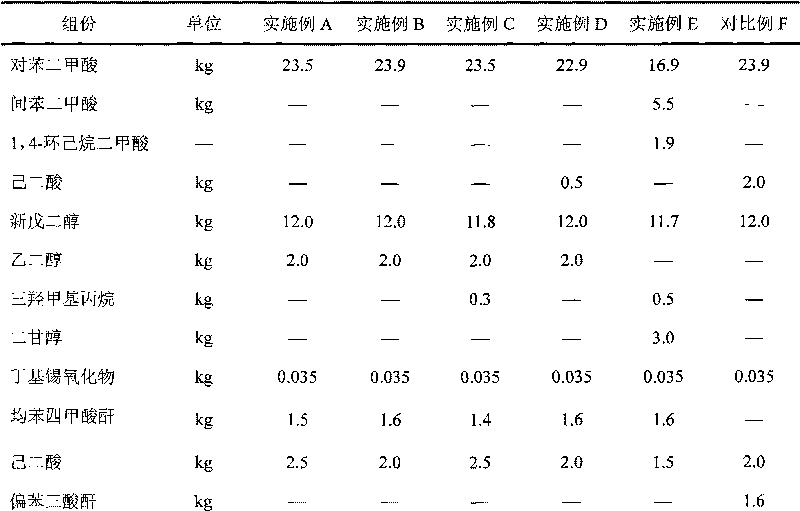

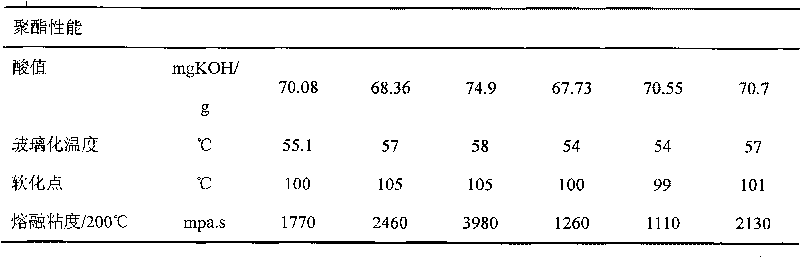

Low-temperature cured terminal carboxyl polyester resin for mixed powder coating and preparation method thereof

ActiveCN101735432ASuitable glass transition temperatureGood storage stabilityPowdery paintsEpoxy resin coatingsHybrid typeEpoxy

The invention discloses a low-temperature cured terminal carboxyl polyester resin for mixed powder coating. The polyester resin is prepared by performing melt polycondensation reaction on the following components in percentage by weight: 25 to 45 percent of polyalcohol, 35 to 65 percent of aromatic polyatomic acid, 0 to 10 percent of fat polyatomic acid, 0 to 2 percent of branching agent, 6 to 15 percent of acid hydrolysis agent, and 0.01 to 0.15 percent of esterification catalyst. The invention also discloses a method for preparing the low-temperature cured terminal carboxyl polyester resin. The prepared polyester resin has the characteristics of proper glass-transition temperature, softening point, good storage stability, and the like; the polyester resin, epoxy resin, filler and assistant in a certain proportion are mixed, and the mixture is prepared into powder through melt extrusion mixing, cooling, crushing and sieving; and the prepared powder can be cured at the temperature of 160 DEG C, and has the advantages of excellent leveling performance, good impact performance, and the like.

Owner:GUANGZHOU KINTE IND

Asphalt compositions and products comprising tall oil derived materials, and methods for making and using same

InactiveUS8034172B2Working-up pitch/asphalt/bitumen by chemical meansCoatingsSolubilityNeedle penetration

Asphalt compositions and products in which the binder comprises tall oil materials possibly previously subjected to distillation, and / or oxidation, and / or combined with a polymer, the tall oil materials having a softening point in the range of 75 F to 400 F, a Needle Penetration value (0.1 mm) at 25 C of at least 1, a Rotational Viscosity at 275 F in the range of 650 cps to 8,000 cps, and a water solubility of less than 10 percent.

Owner:PVS MERIDIAN CHEM

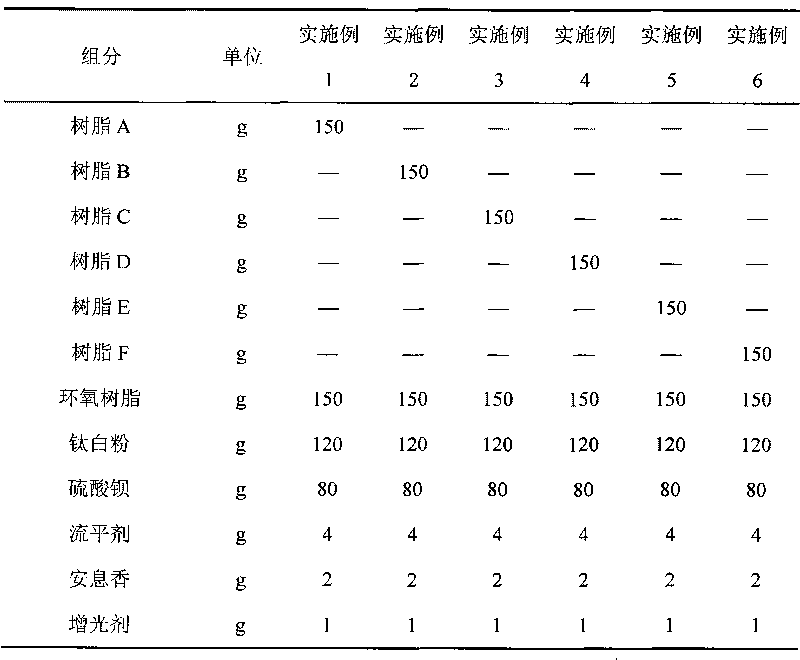

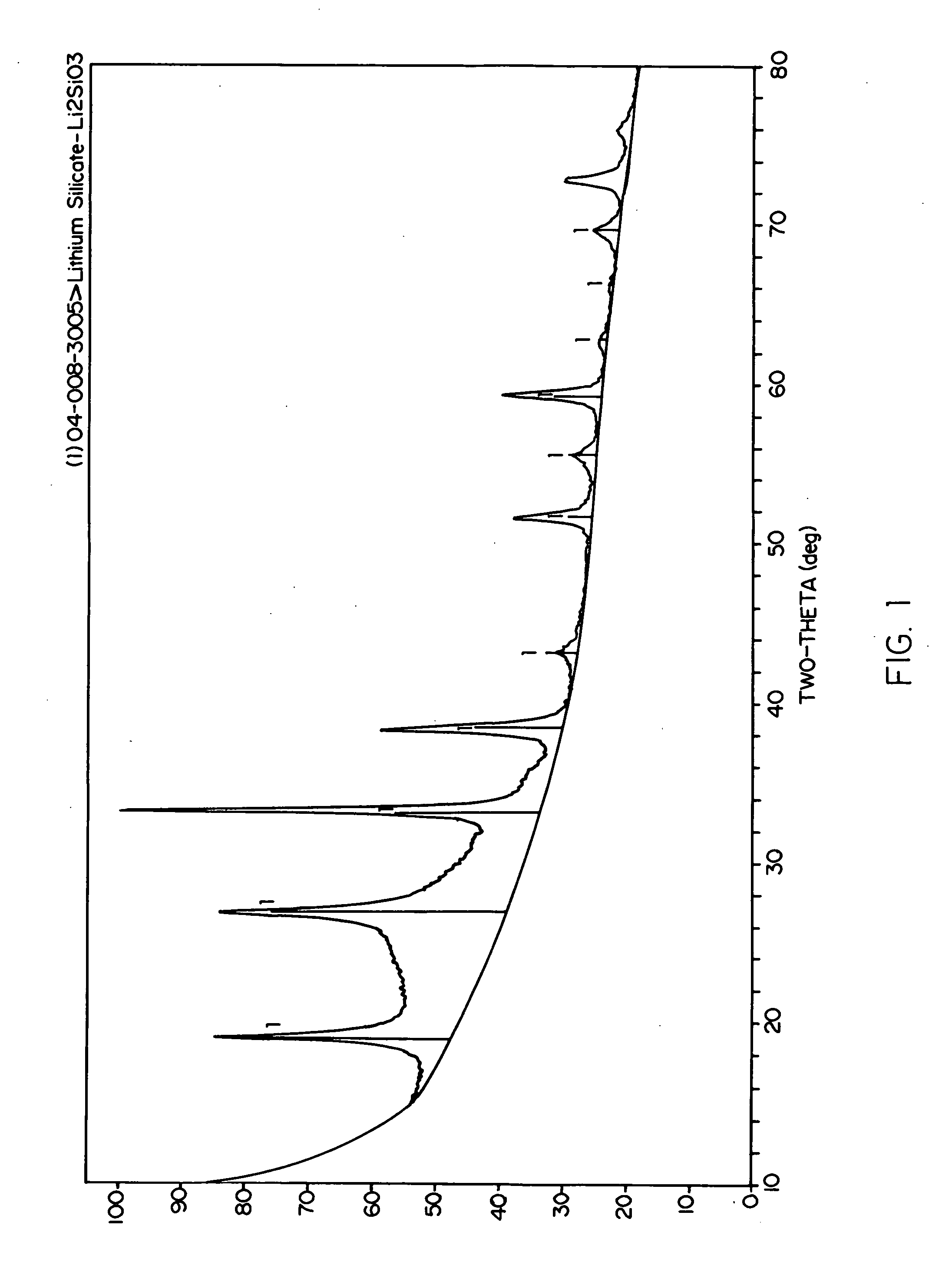

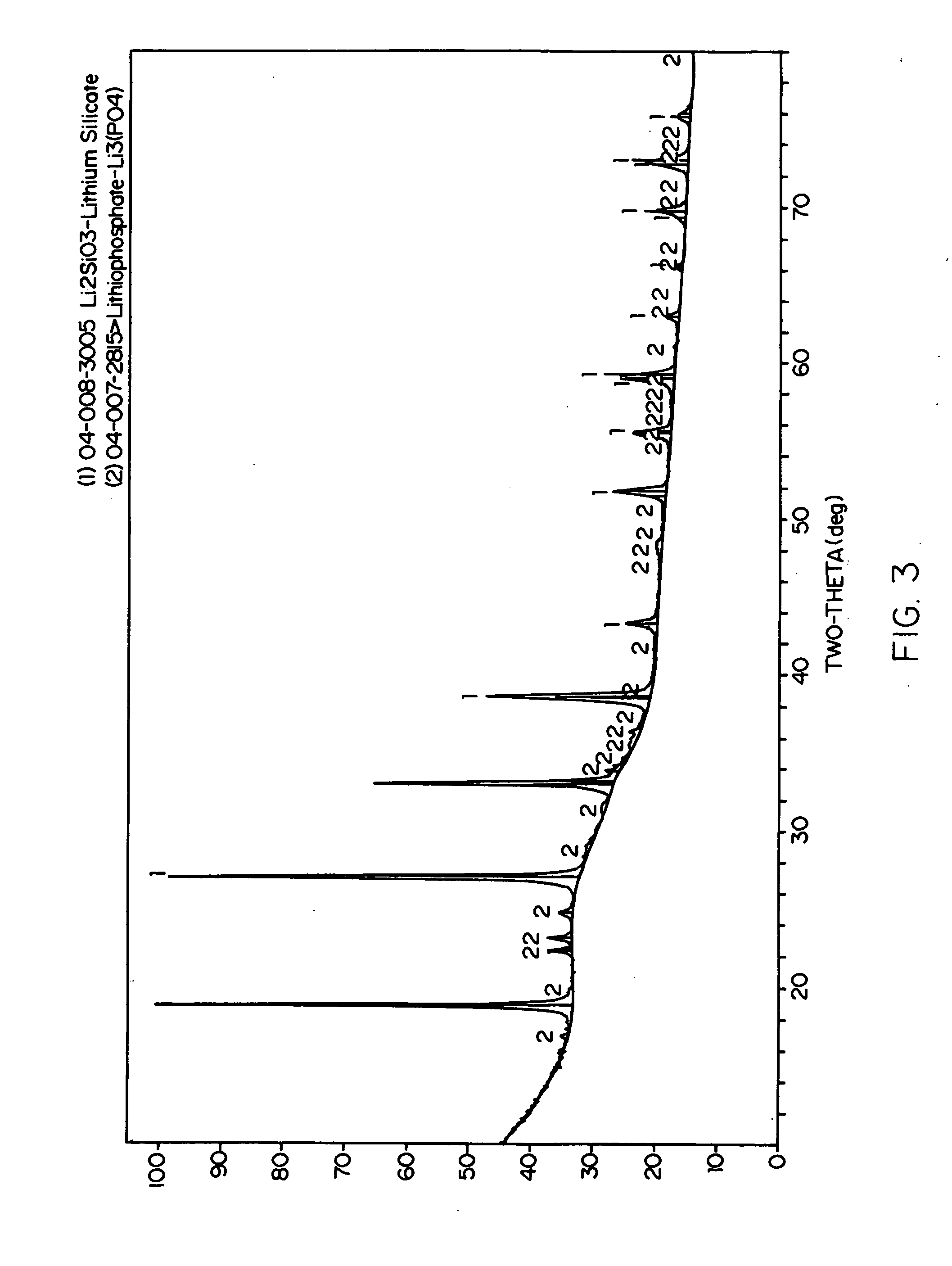

Lithium silicate glass ceramic for fabrication of dental appliances

ActiveUS20120094822A1Easy to controlGood physical propertiesGlass drawing apparatusGlass forming apparatusLithiumChemical composition

The present invention relates to a method of fabricating an improved lithium silicate glass ceramic and to that material for the manufacture of blocks for dental appliances using a CAD / CAM process and hot pressing system. The lithium silicate material has a chemical composition that is different from those reported in the prior art with 1 to 10% of germanium dioxide in final composition. The softening points are close to the crystallization final temperature of 800° C. indicating that the samples will support the temperature process without shape deformation.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com