Patents

Literature

5054results about "Powdery paints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

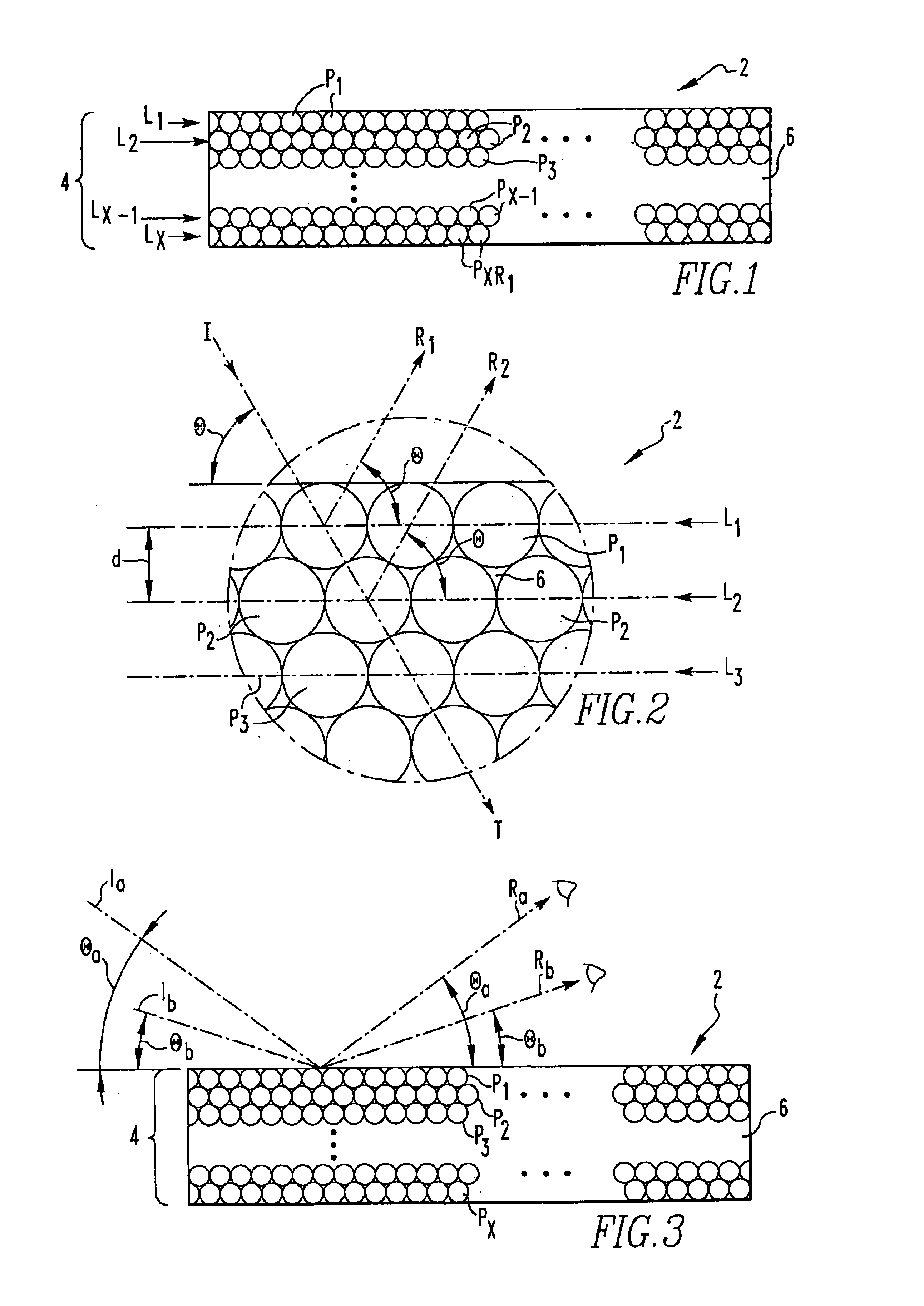

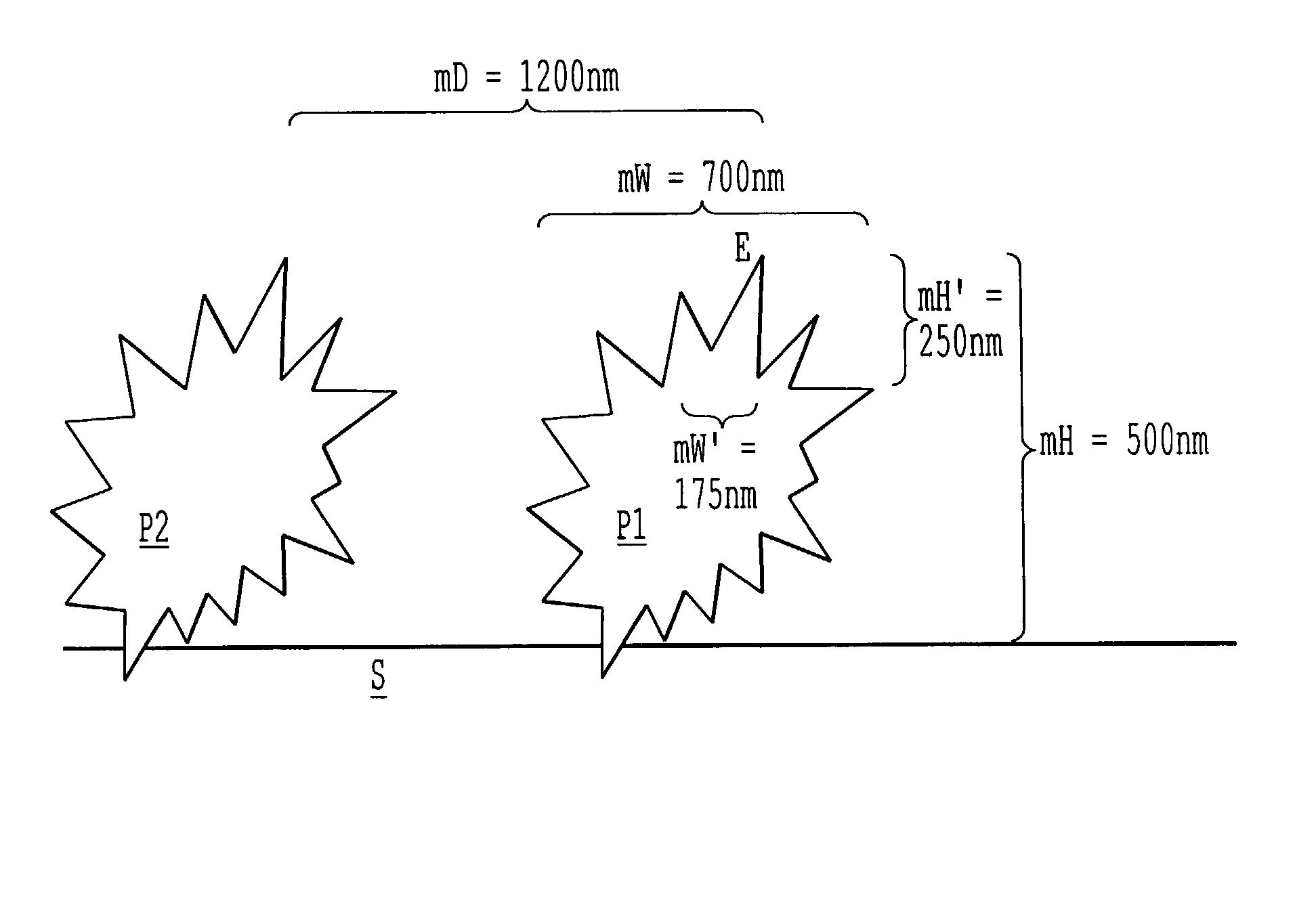

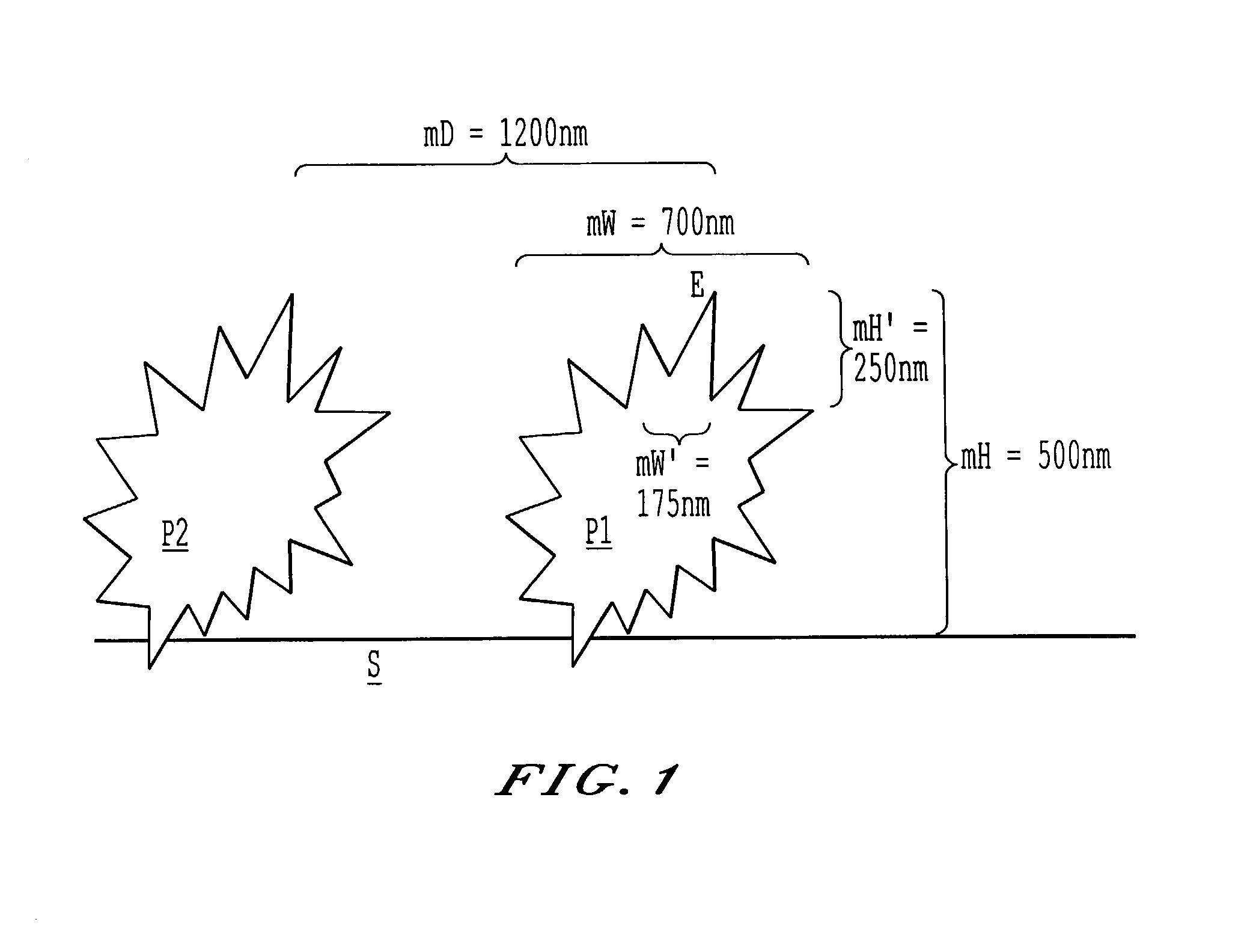

Color effect compositions

A coating composition comprising a resinous binder and a color effect colorant in particulate form. The colorant includes an ordered periodic array of particles held in a polymer wherein a difference in refractive index between the polymer and the particles is at least about 0.01. The colorant reflects visible light according to Bragg's law to yield a goniochromatic effect to the coating composition.

Owner:PPG IND OHIO INC

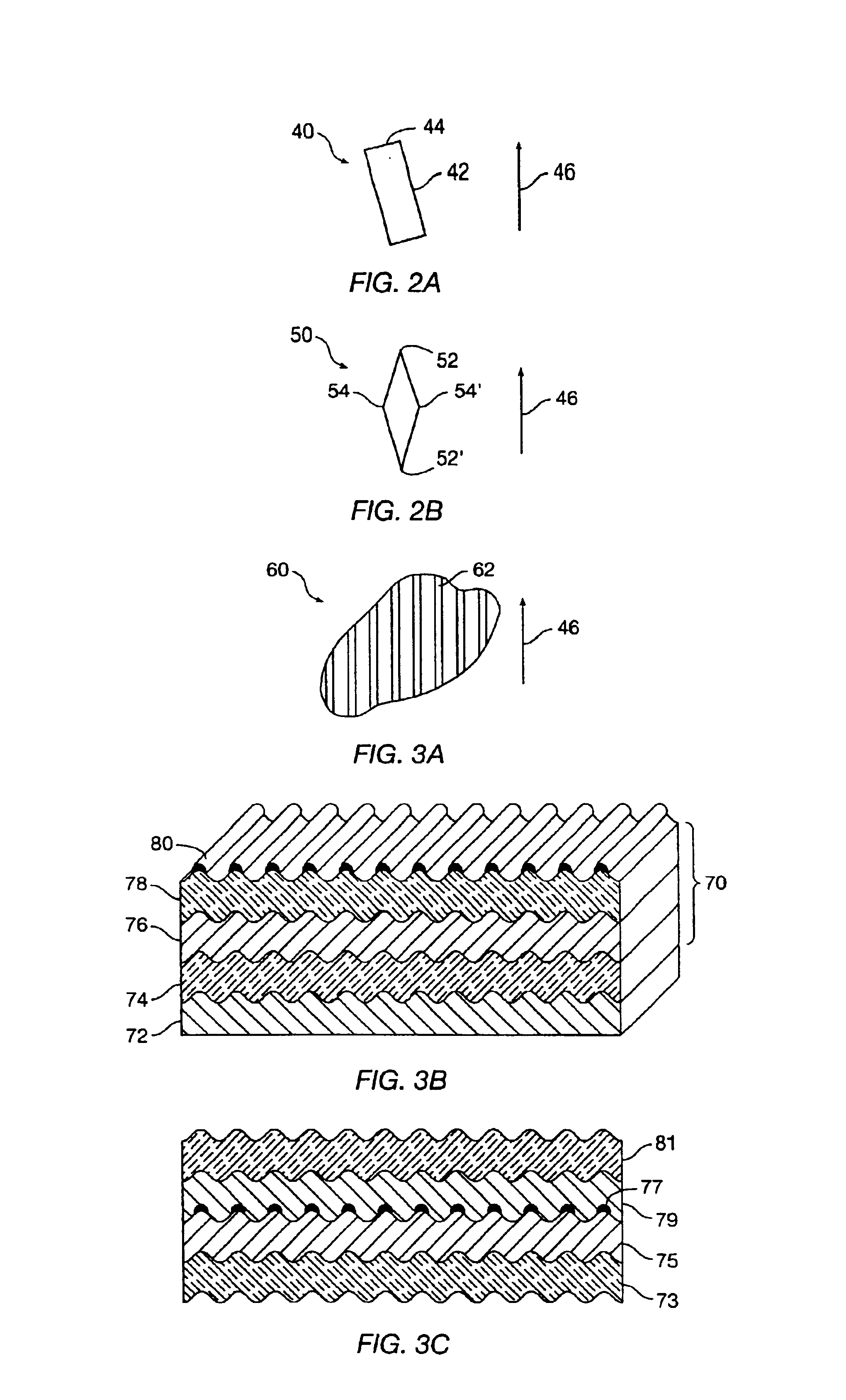

Alignable diffractive pigment flakes

Diffractive pigment flakes are selectively aligned to form an image. In one embodiment, flakes having a magnetic layer are shaped to facilitate alignment in a magnetic field. In another embodiment, the flakes include a magnetically discontinuous layer. In a particular embodiment, deposition of nickel on a diffraction grating pattern produces magnetic needles along the grating pattern that allow magnetic alignment of the resulting diffractive pigment flakes. Color scans of test samples of magnetically aligned flakes show high differentiation between illumination parallel and perpendicular to the direction of alignment of the magnetic diffractive pigment flakes.

Owner:VIAVI SOLUTIONS INC

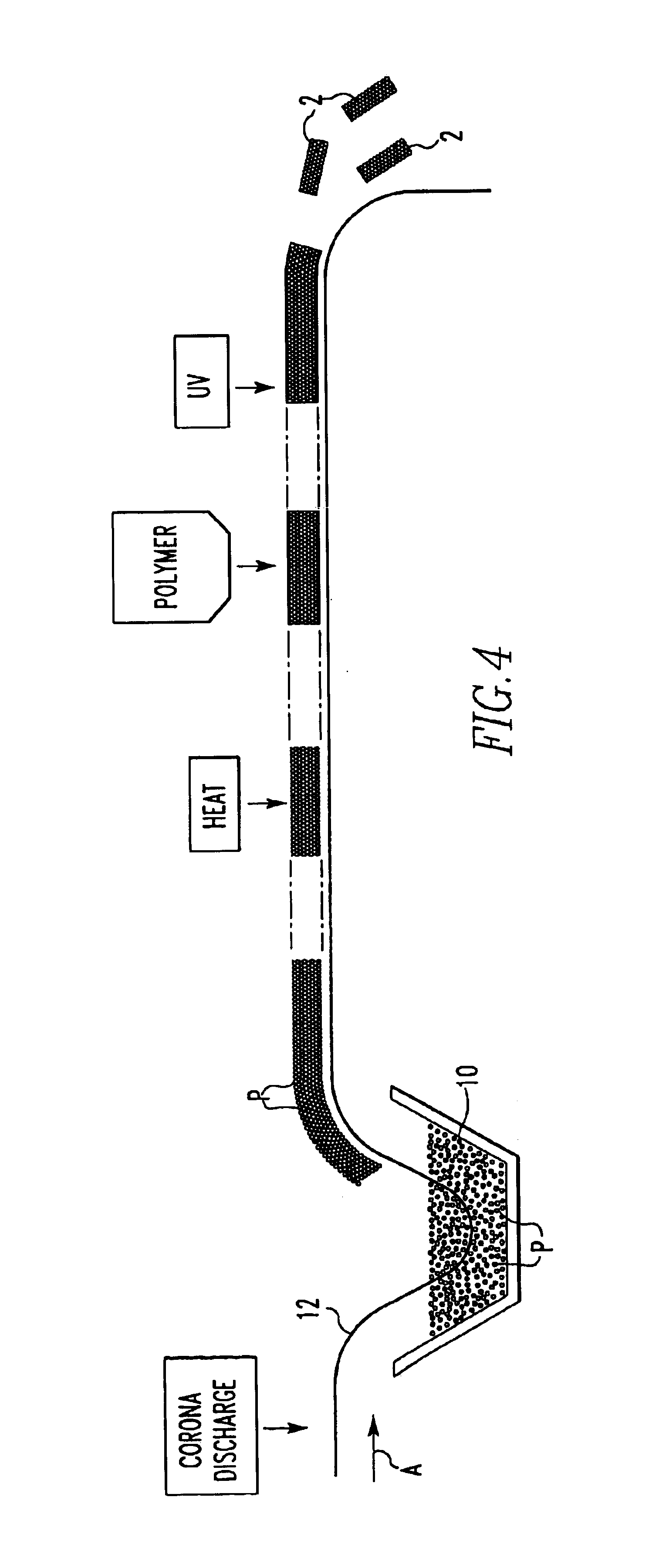

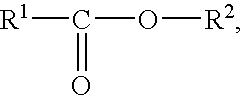

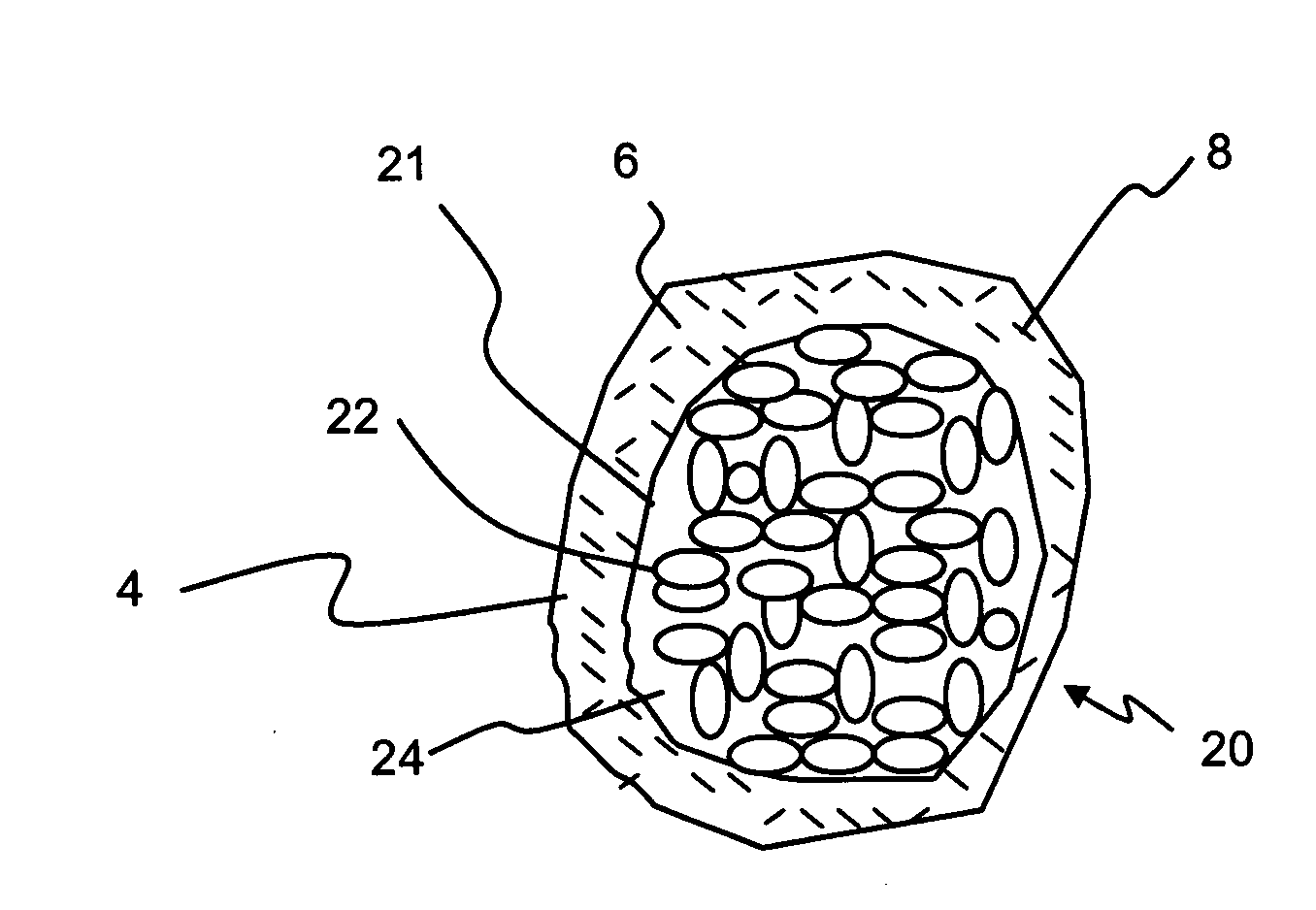

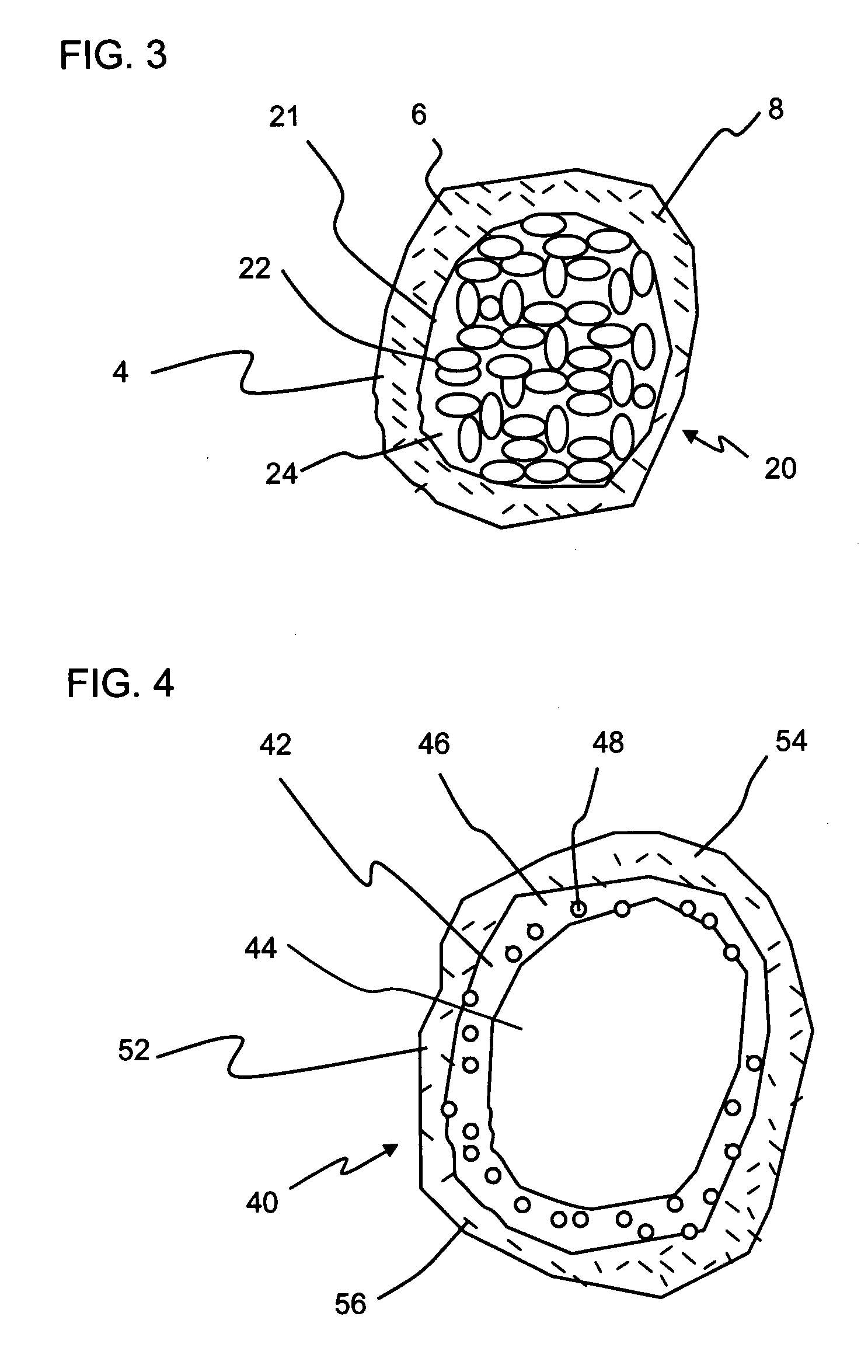

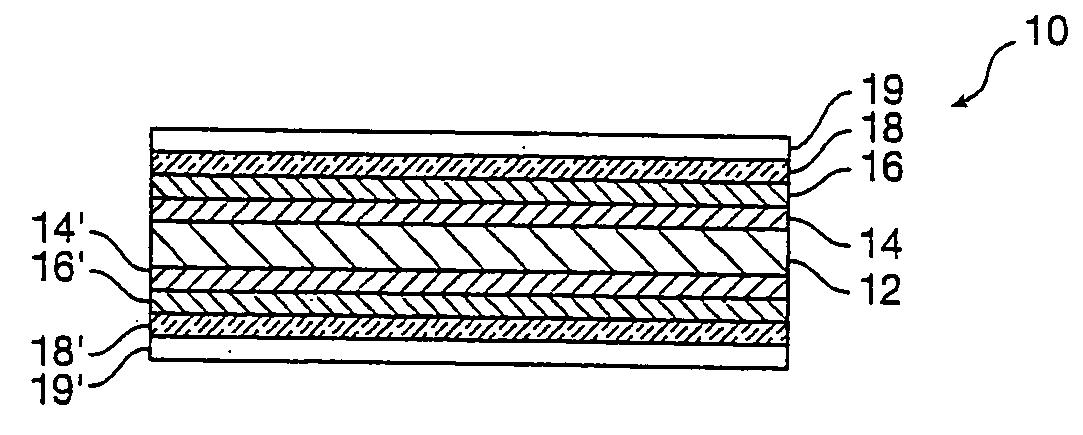

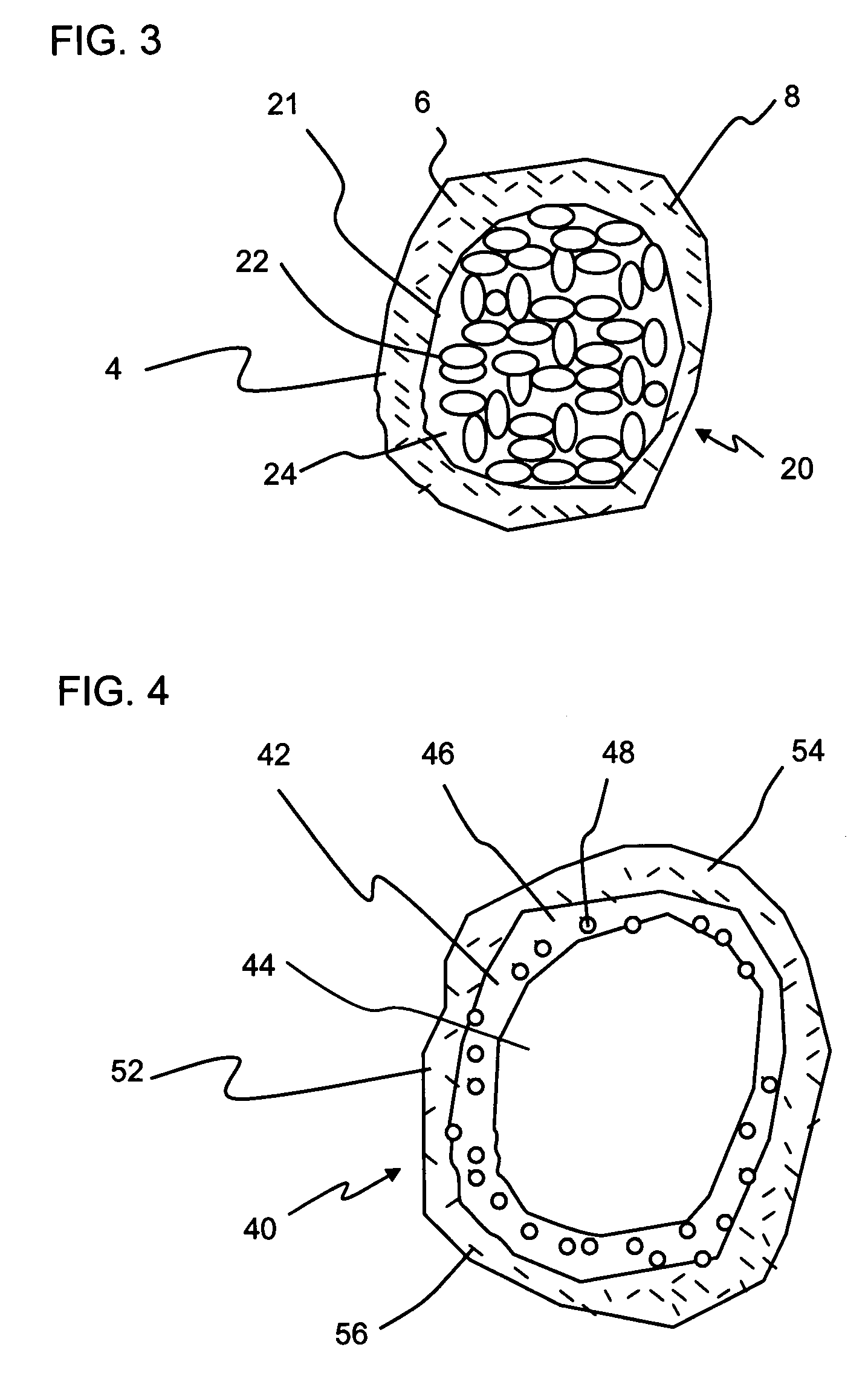

Aqueous dispersions of polymer-enclosed particles, related coating compositions and coated substrates

ActiveUS20060251896A1Nanostructure manufactureSynthetic resin layered productsNanoparticleMaterials science

Disclosed are aqueous dispersions of polymer-enclosed particles, such as nanoparticles. Also disclosed are methods for making an aqueous dispersion of polymer-enclosed particles, polymerizable polymers useful in such a method, powder coating compositions formed from such an aqueous dispersion, substrates at least partially coated with such a composition, and reflective surfaces comprising a non-hiding coating layer deposited from such a composition.

Owner:PPG IND OHIO INC

Reactive hyperbranched polymers for powder coatings

Novel powder coating compositions containing reactive hyperbranched polymers are disclosed and claimed. Preferred embodiments include powder coating compositions formed from hyperbranched polyesters having terminal hydroxy, carboxy, epoxy, and isocyanate groups. Preferred hyperbranched polyesters are formed from alpha , alpha -bis-(hydroxymethyl)-propionic acid, which act either as crosslinkers, adhesion promotors, or flow and leveling agents. A process for the synthesis of powder coating compositions is also disclosed which involves (a) self condensation of one or more of the multifunctional monomers to form the hyperbranched polymer, optionally, in the presence of suitable reactive end-capping moieties which are described herein; (b) melt blending of the hyperbranched polymer with suitable amounts of one or more of polyesters, epoxy resins, blocked urethane resins, or acrylic resins, a crosslinker, and one or more of suitable additional ingredients including degassers or flow and leveling agents, to form a flake; and (c) grinding and sieving of the flake to form the powder coating composition. These compositions exhibit improved flow and curing properties. These compositions can therefore be formed into thin films and can be cured at low temperatures to form smooth surfaces. Additionally, these films are hard and exhibit enhanced impact resistance properties than the conventional polyester resins. Thus, these powder coating compositions find utilities in automotive, packaging, and appliances.

Owner:HERBERTS GMBH

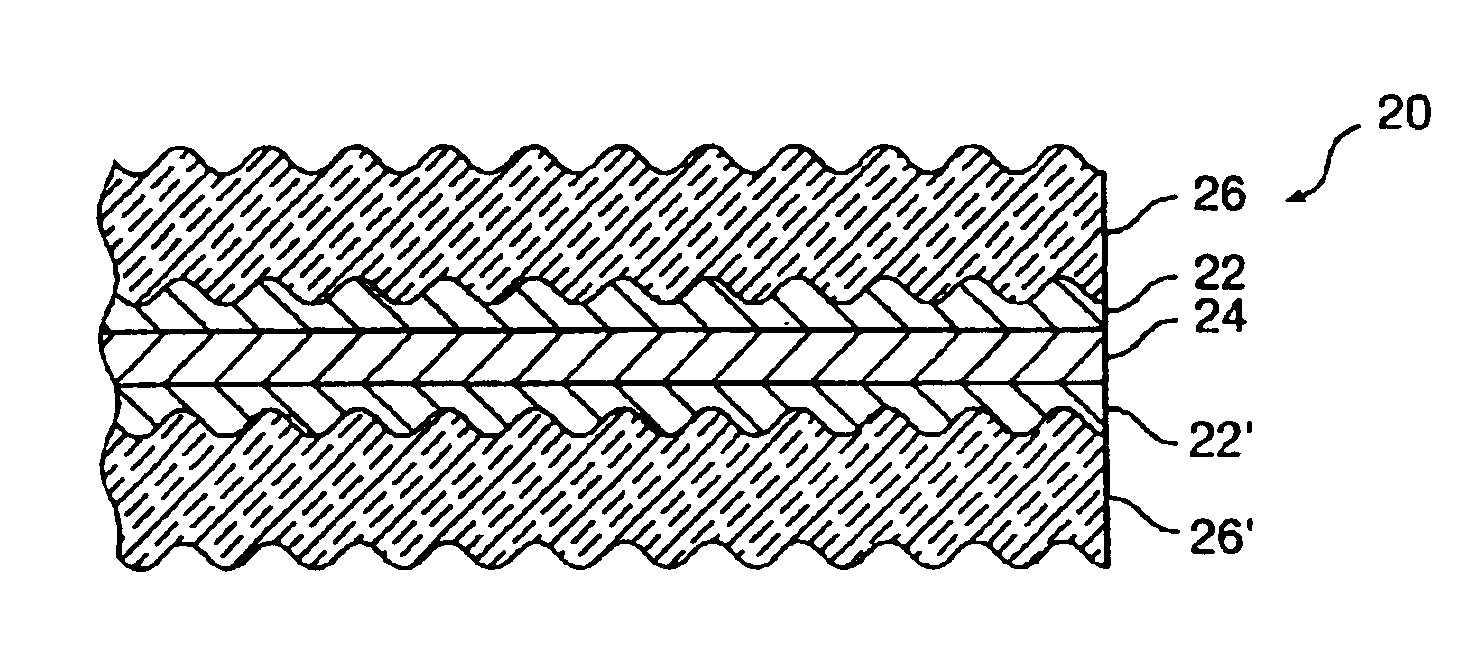

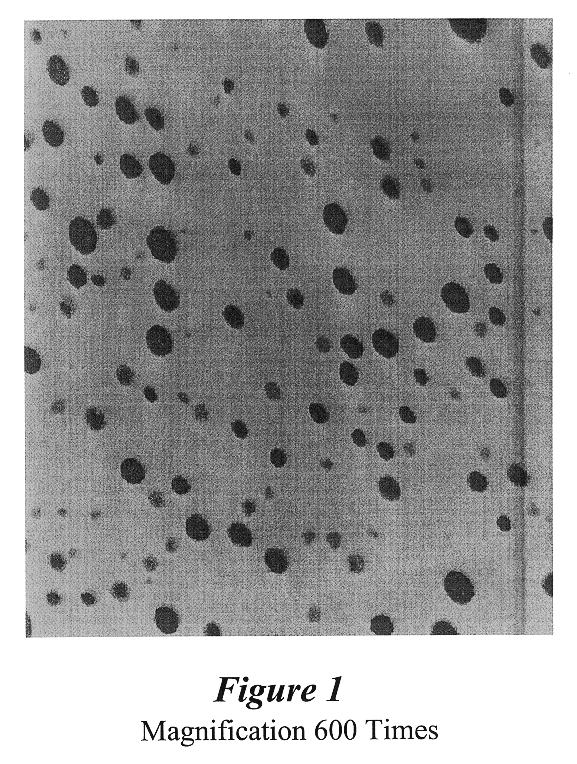

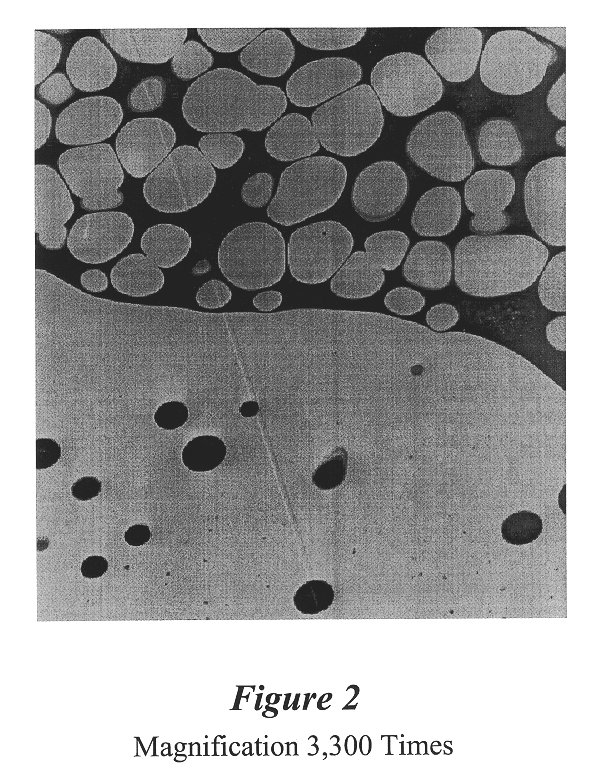

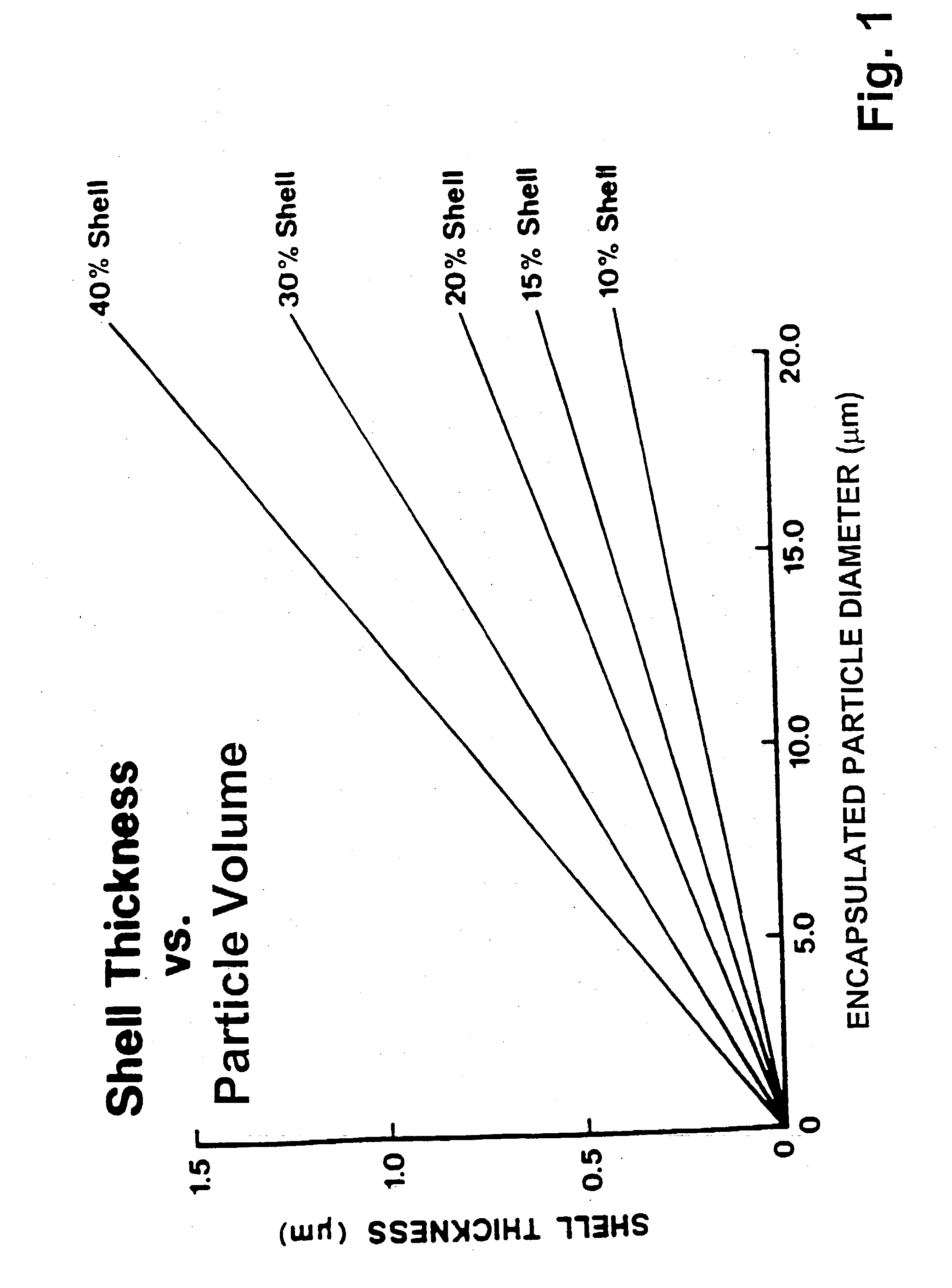

Smooth, flexible powder coatings

The present invention, a powder composition for making powder coatings comprising one or more than one curable polymer or resin and an agglomerate of a core-shell polymer, wherein the agglomerate of a core-shell polymer has an average particle size of from 5 to 190 microns, preferably from 10 to 127 microns. The powders in accordance with the present invention provide a cured powder coating that is flexible, smooth, and which may be applied in a thickness of only from 0.3 to 8 mils. In a preferred embodiment of making a powder in accordance with the present invention, the agglomerate is cryoground to form a reduced agglomerate prior to adding it into a powder as a post-blend or a powder-forming mixture as a preblend. The preferred core-shell polymer for use in accordance with the present invention comprises an acrylic impact modifier having a poly(methyl methacrylate) shell and a poly(butyl acrylate) core. Further, the preferred curable polymer or resin powder is an epoxy resin, wherein the powder composition is a low temperature curing one component powder composition which cures at from 107 to 149 degrees C.

Owner:ROHM & HAAS CO

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

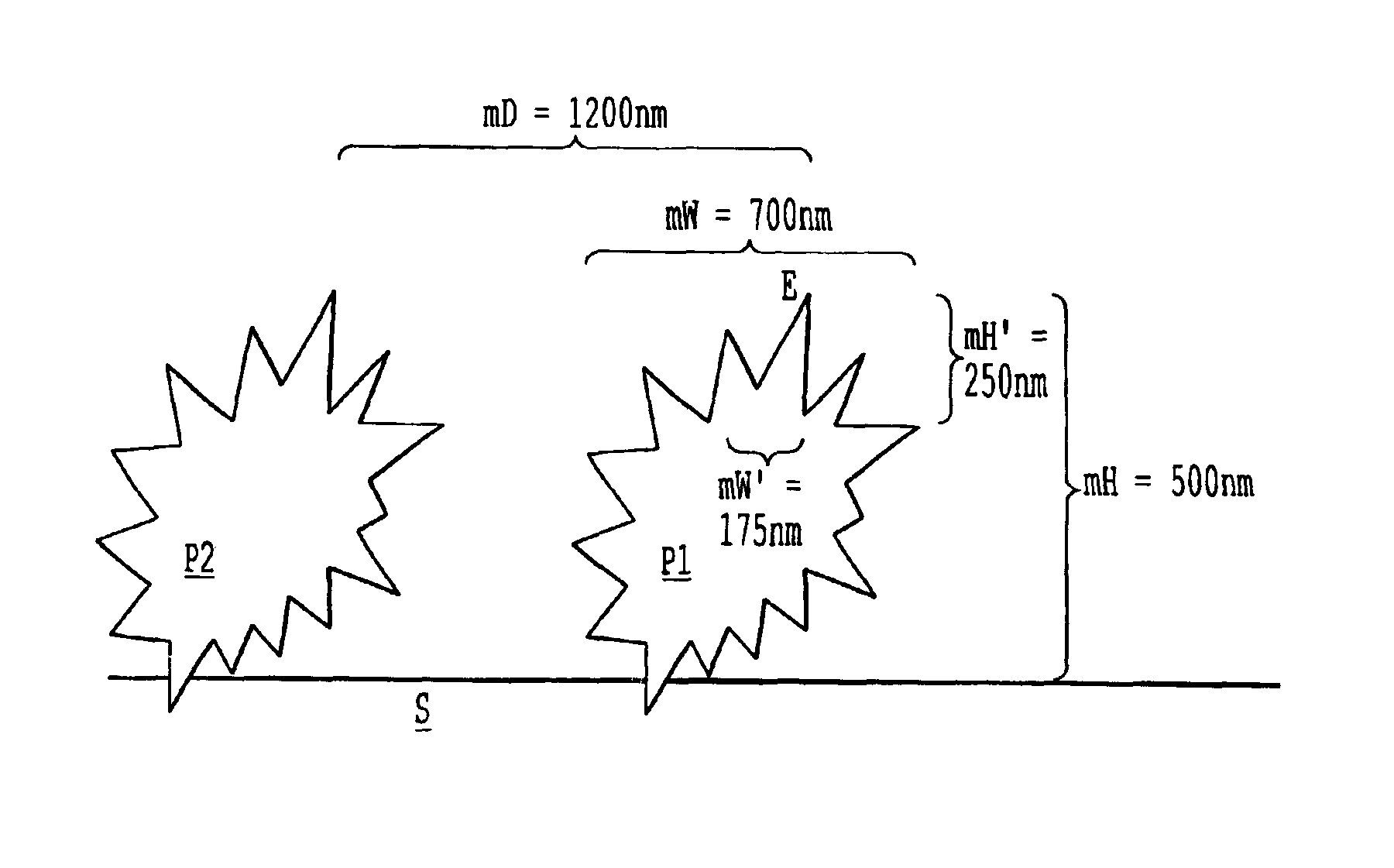

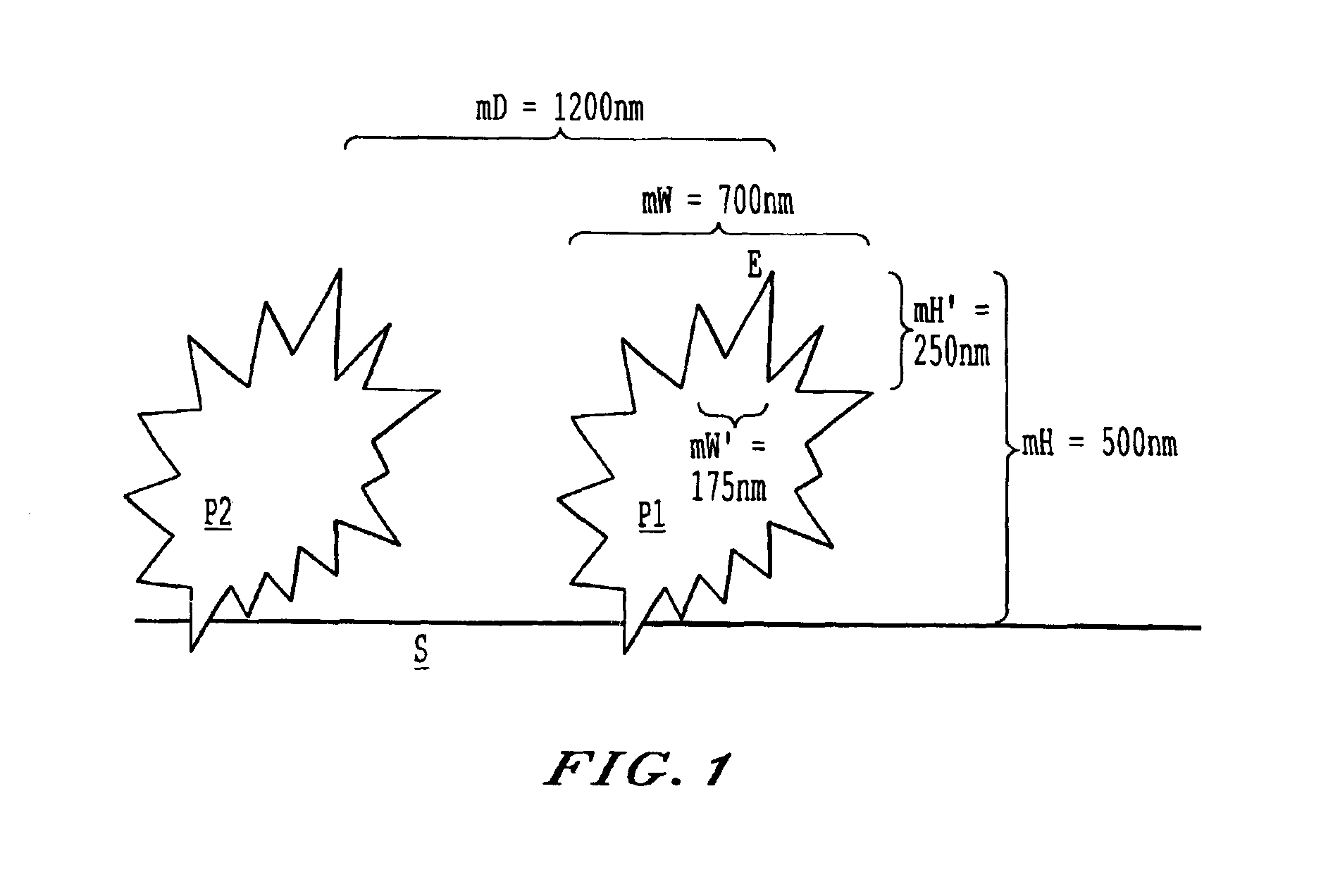

InactiveUS6852389B2Effectively self-cleaningSimple processNanotechSpecial ornamental structuresFissured structureFumed silica

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, which comprises a surface having structure-forming particles, which are formed of hydrophobic, fumed silica, adhered thereto by way of fixative particles applied to the surface, whereby the structure-forming particles and the fixative particles have elevations and depressions ranging in dimensions of 1 to 1000 nm and the particles themselves having an average size of less than 50 μm, the particles providing said surface structure of elevations and depressions, wherein, by incipient melting of the fixative particles, only partial melting of the fixative particles occurs which is sufficient to bond the structure forming particles without substantial wetting of the particles by the fixative particles to said surface while retaining, the fissured structure of the structure-forming particles in the nanometer range.

Owner:DEGUSSA AG

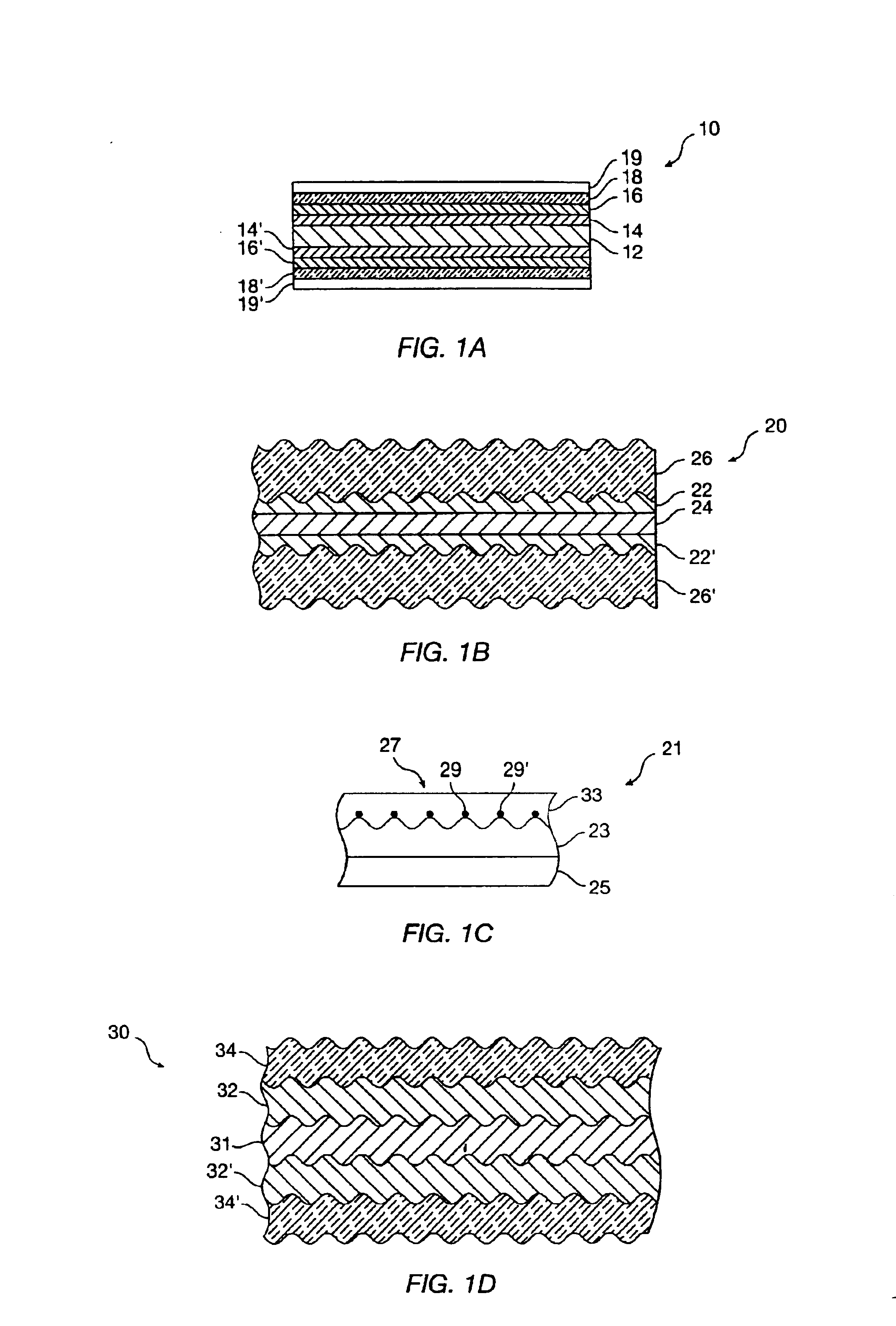

Low temperature coated particles for use as proppants or in gravel packs, methods for making and using the same

ActiveUS20080230223A1Improves unconfined compressive strength propertyImprove performanceLiquid surface applicatorsSynthetic resin layered productsPolyesterParticulates

Disclosed herein are free flowing coated particles and low temperature methods of making same. Each particle has a curable coating disposed upon a substrate. The substrate is a particulate substrate including an inorganic material, a particulate substrate including an organic material, a composite substantially homogeneous formed particle including a first portion of an at least partly cured binder and filler particles, or a hybrid particle having an inorganic particle as a core and a composite coating including at least partially cured resin and filler. The curable coating includes a continuous phase including resole resin and reactive powder particles embedded or adhered to the continuous phase. The reactive powder particles typically include resole resin, novolak resin, polyester, acrylic and / or urethane. A method including applying a coating including the continuous phase including resole resin and reactive or non-reactive powder particles embedded or adhered to the continuous phase.

Owner:HEXION INC

Alignable diffractive pigment flakes

Diffractive pigment flakes are selectively aligned to form an image. In one embodiment, flakes having a magnetic layer are shaped to facilitate alignment in a magnetic field. In another embodiment, the flakes include a magnetically discontinuous layer. In a particular embodiment, deposition of nickel on a diffraction grating pattern produces magnetic needles along the grating pattern that allow magnetic alignment of the resulting diffractive pigment flakes. Color scans of test samples of magnetically aligned flakes show high differentiation between illumination parallel and perpendicular to the direction of alignment of the magnetic diffractive pigment flakes.

Owner:VIAVI SOLUTIONS INC

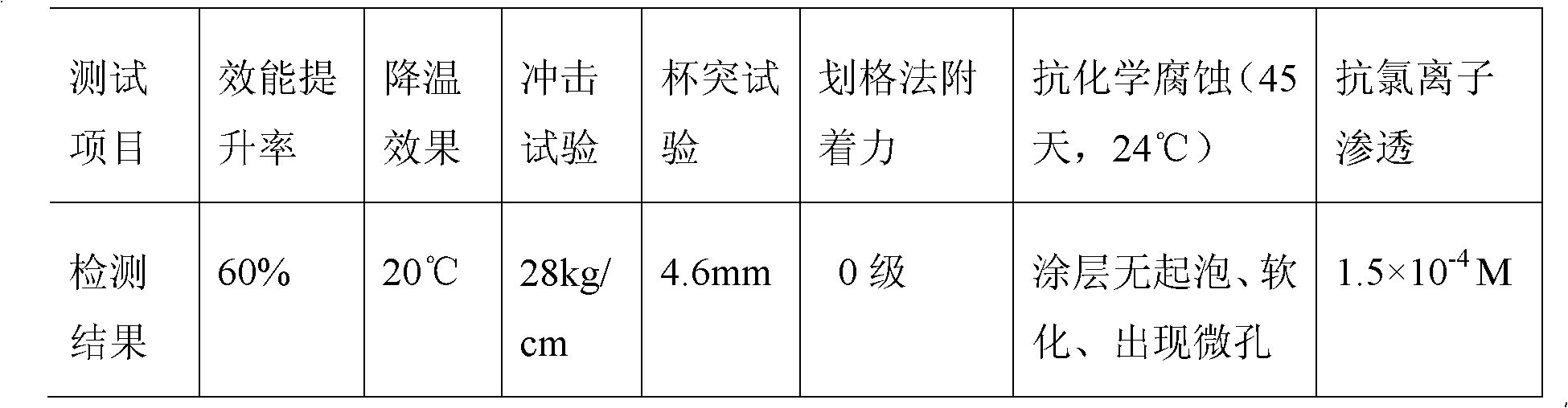

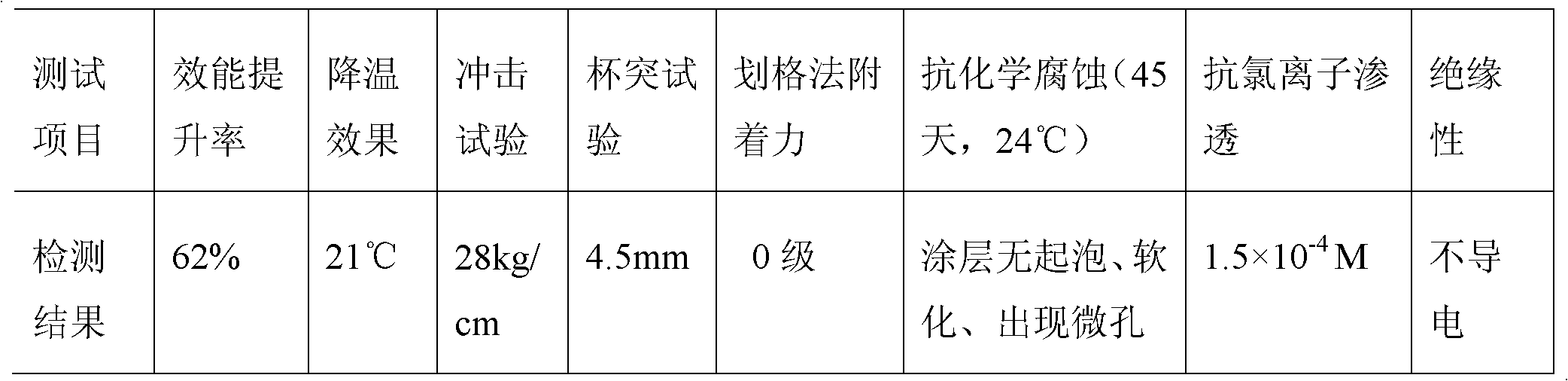

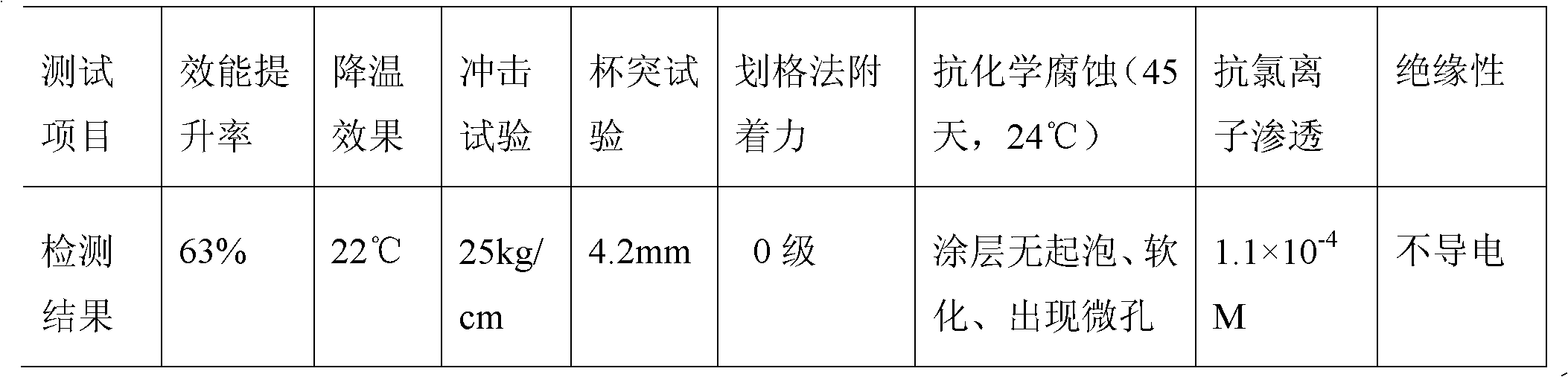

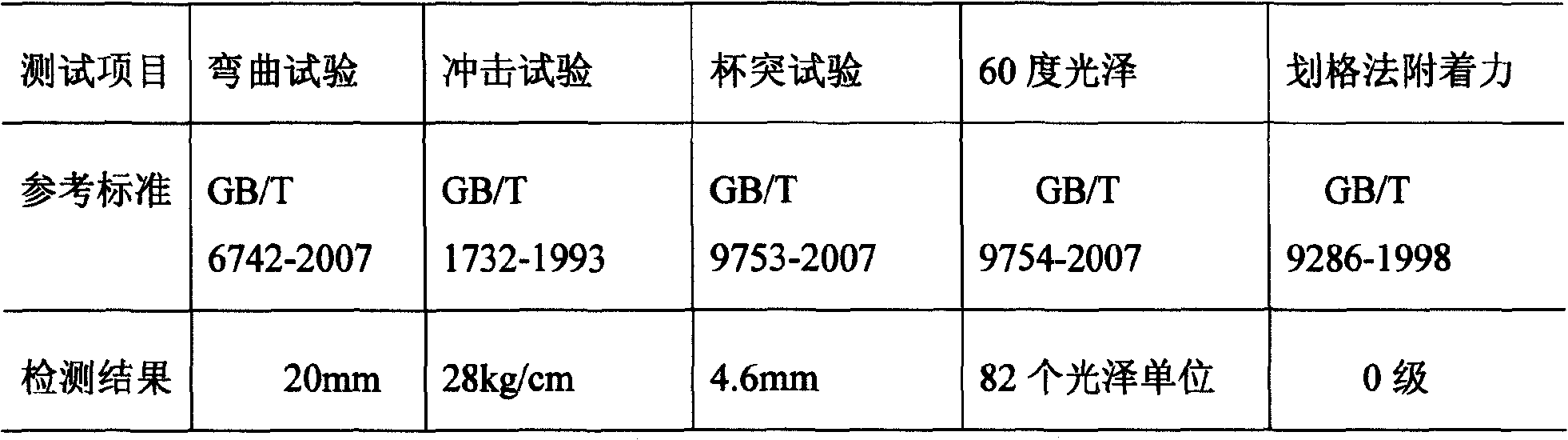

Environmental-protection anti-corrosive heat-dissipation powder paint, and preparation method and application thereof

ActiveCN102061121AFacilitate cross-linkingImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsHexagonal boron nitrideCooling effect

The invention discloses an environmental-protection anti-corrosive heat-dissipation powder paint, and a preparation method and application thereof. The environmental-protection anti-corrosive heat-dissipation powder paint comprises the following raw materials in parts by weight: 40-90 parts of matrix resin, 2-40 parts of curing agent, 0.5-10 parts of carbon nanotube, 0.5-2 parts of additive, 0-4.5 parts of hexagonal boron nitride, 0-15 parts of aluminum nitride, 0-10 parts of magnesium nitride, 0-10 parts of silicon carbide and 5-30 parts of pigment and filler. The composition and proportioning of the raw materials of the powder paint disclosed by the invention are scientific and reasonable. The experimental result indicates that the powder paint has the advantages of favorable heat-dissipation effect, high efficacy enhancement rate (higher than 60%) and favorable cooling effect (more than 20 DEG C), and can effectively solve the problem of poor heat-dissipation effect in the high-power electronic product, thereby prolonging the service life of the electronic product. The powder paint disclosed by the invention is free of organic solvent, and is environment-friendly and safe; the powder paint disclosed by the invention also has favorable comprehensive properties, such as flexibility, hardness, adhesive force and the like, and stable chemical properties; and the coating formed by the powder paint has the advantages of high corrosion resistance and shock resistance, favorable insulation property and wide application range.

Owner:TIGER DRYLAC TAICANG

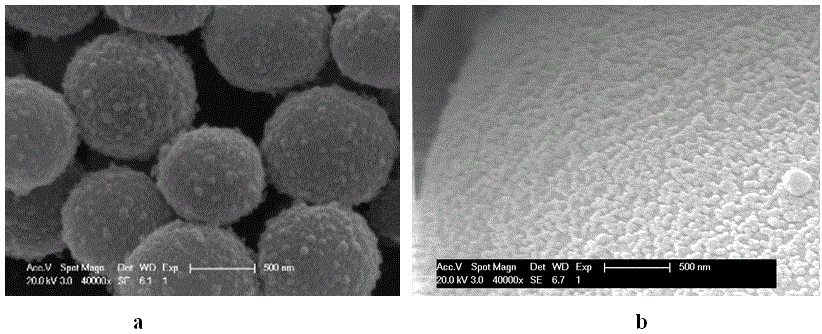

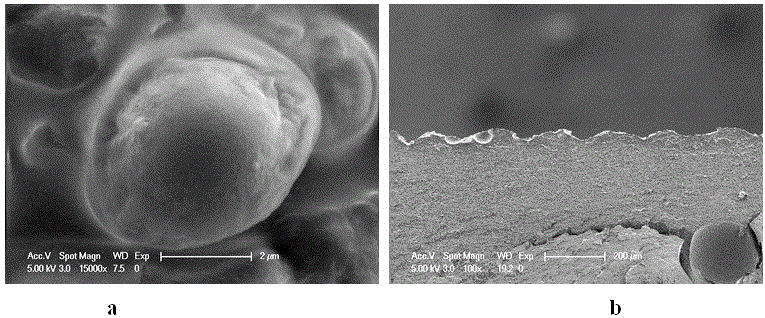

Micro-nano coating material with low surface energy and preparation method thereof

ActiveCN106085070AEasy to control surface topographyEasy to control the size of the surface energyPolyurea/polyurethane coatingsPowdery paintsEtchingMicrosphere

The invention belongs to the technical field of functional materials, and particularly relates to a micro-nano coating material with low surface energy and a preparation method thereof. The preparation method comprises the following steps of mixing composite microspheres with micro sodium structure and hydrophobic nature, matrix resin with contact angle more than 90 degrees with coating film, solvent, powder, and additive, and adopting a co-mixing method, an in-situ emulsion polymerizing method, an in-situ solution polymerizing method, an in-situ concentration and polymerizing method, an in-situ addition and polymerizing method and the like, so as to prepare the coating material with micro-nano structure; performing spraying, brushing, roll coating, photo-etching, 3D (three-dimensional) printing, mechanical processing and the like, drying and curing at the temperature of 0 to 1000 DEG C, and coating the coating material with micro-nano structure onto different matrix surfaces, so as to obtain the micro-nano coating material with low surface energy and groove structure. The micro-nano coating material has the advantages that the preparation technology is simple, the coating hardness is high, the water-resistant property is good, the adhesion force to different matrix surfaces is strong, and the micro-nano coating material can be used for self-cleaning, resistance-reducing, denoising, anti-icing and other functional materials.

Owner:FUDAN UNIV

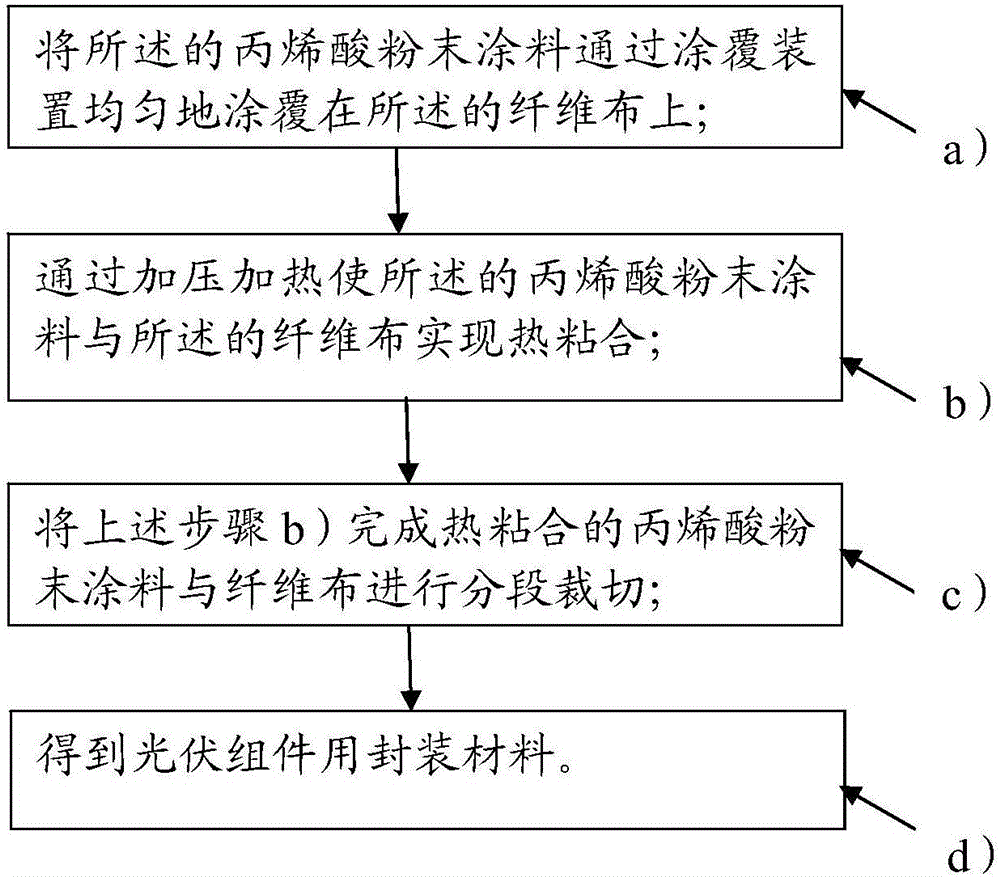

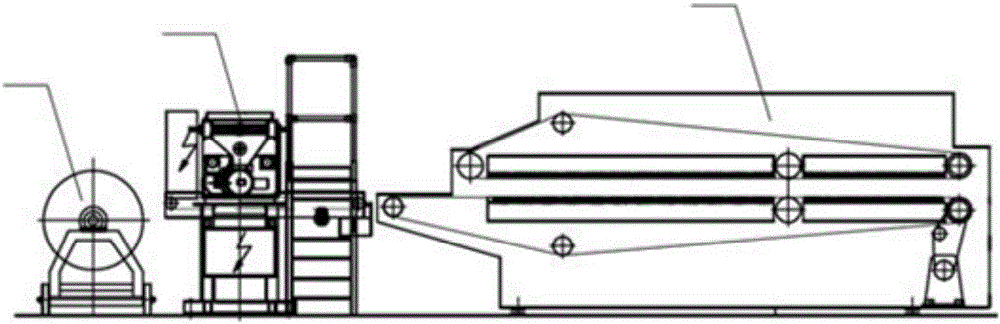

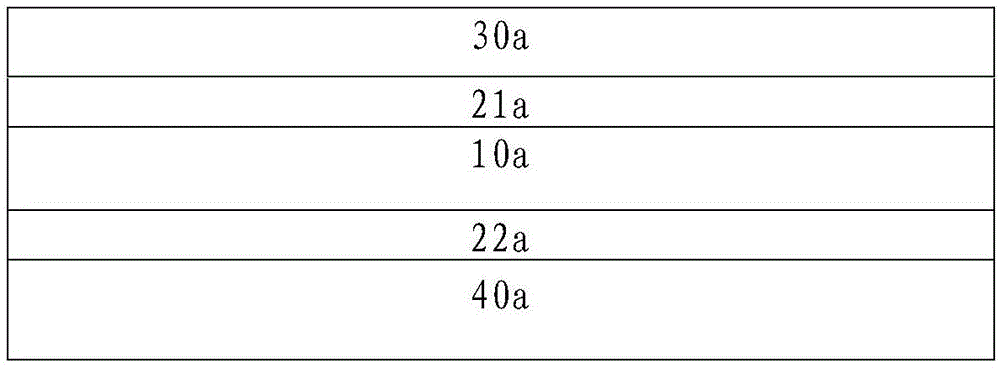

Packaging material for photovoltaic module and preparation method of the packaging material

ActiveCN106299000AReduce weightReduce installation costsFinal product manufactureFibre treatmentFiberPhotovoltaic industry

The invention discloses a packaging material for a photovoltaic module. The packaging material comprises the following raw materials in parts by weight: 30-50 parts of fiber cloth produced from fiber material through weaving; and 50-70 parts of acrylic powder coating including acrylic resins and a curing agent. The acrylic powder coating is evenly spread on the fiber cloth. The packaging material is low in manufacturing cost. While meeting the prerequisites of resistance to ultraviolet, aging, impact and fire which are standard requirements of the photovoltaic industry, the packaging material solves the problem of lightweight photovoltaic module packaging material, makes installation more convenient, reduces the installation cost, and thus is very suitable for large-scale promotion and application in the photovoltaic field. The invention also discloses a preparation method of the packaging material for a photovoltaic module. The method meets installation requirement for changing the packaging size of a photovoltaic module at will to adapt to different buildings and thus further facilitates installation and application of photovoltaic modules.

Owner:TIGER DRYLAC TAICANG +1

Surfaces rendered self-cleaning by hydrophobic structures, and process for their production

InactiveUS20020150725A1Pretreated surfacesRecord information storageSurface structureMaterials science

A self-cleaning surface which has an artificial, at least partially hydrophobic, surface structure containing elevations and depressions, wherein the elevations and depressions are formed by structure-forming particles and fixative particles applied to the surface, wherein the fixative particles act to secure the structure-forming particles to the surface and the fixative particles are also secured to the surface; and a process for making such a surface.

Owner:DEGUSSA AG

Low temperature coated particles for use as proppants or in gravel packs, methods for making and using the same

ActiveUS7624802B2Improves unconfined compressive strength propertyImprove performanceLiquid surface applicatorsSynthetic resin layered productsPolyesterParticulates

Disclosed herein are free flowing coated particles and low temperature methods of making same. Each particle has a curable coating disposed upon a substrate. The substrate is a particulate substrate including an inorganic material, a particulate substrate including an organic material, a composite substantially homogeneous formed particle including a first portion of an at least partly cured binder and filler particles, or a hybrid particle having an inorganic particle as a core and a composite coating including at least partially cured resin and filler. The curable coating includes a continuous phase including resole resin and reactive powder particles embedded or adhered to the continuous phase. The reactive powder particles typically include resole resin, novolak resin, polyester, acrylic and / or urethane. A method including applying a coating including the continuous phase including resole resin and reactive or non-reactive powder particles embedded or adhered to the continuous phase.

Owner:HEXION INC

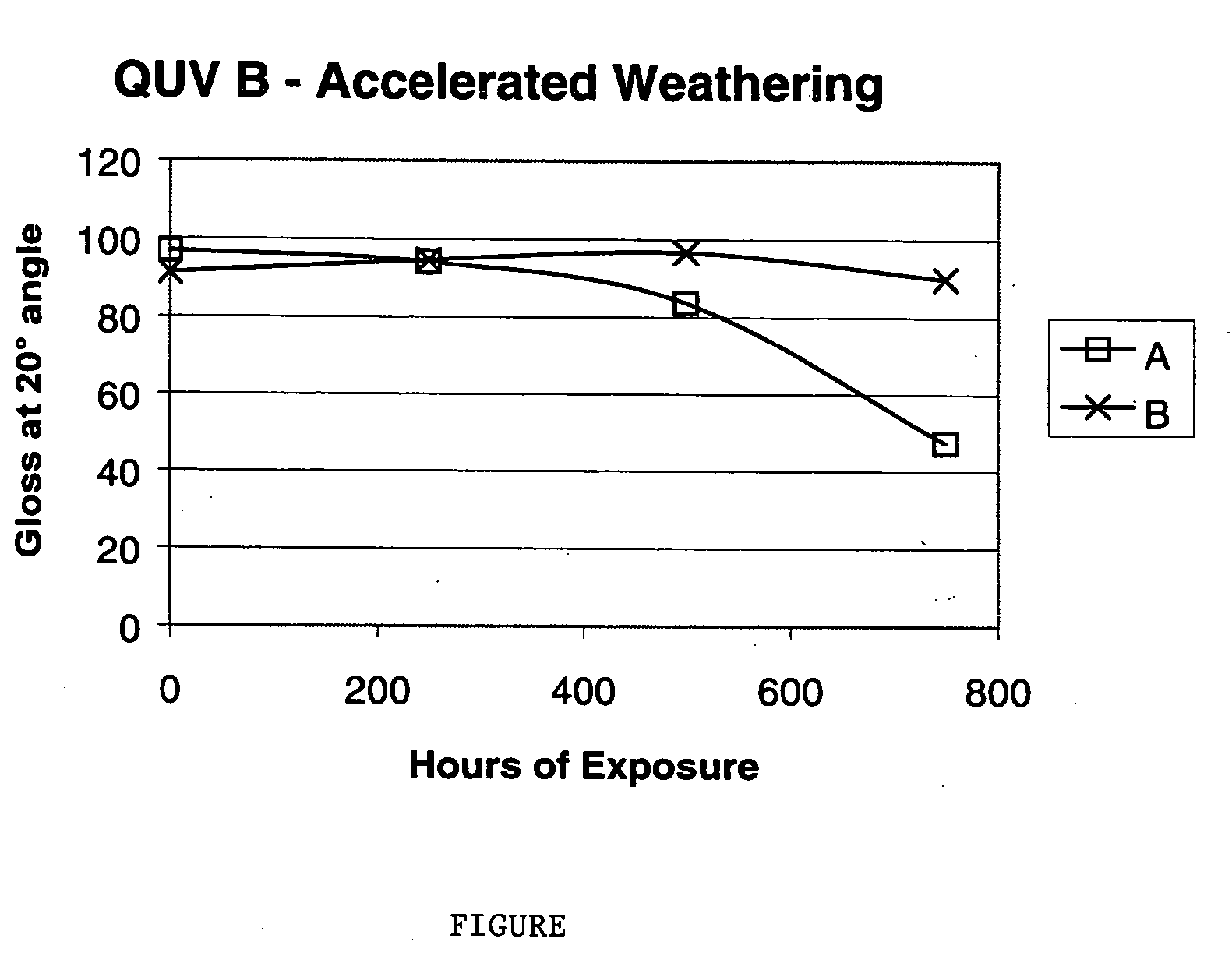

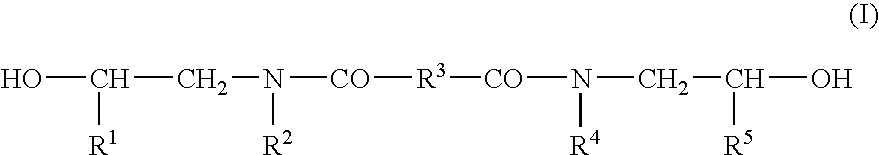

Flexible, super durable powder coating composition

InactiveUS20060079650A1Good weather resistanceImprove mechanical propertiesPolyurea/polyurethane coatingsPowdery paintsPolyesterPolymer science

Powder coatings having good impact resistance and weatherability characteristics are produced with an isophthalic acid-based polyester and an isocyanate-based curing agent.

Owner:BAYER MATERIALSCIENCE AG

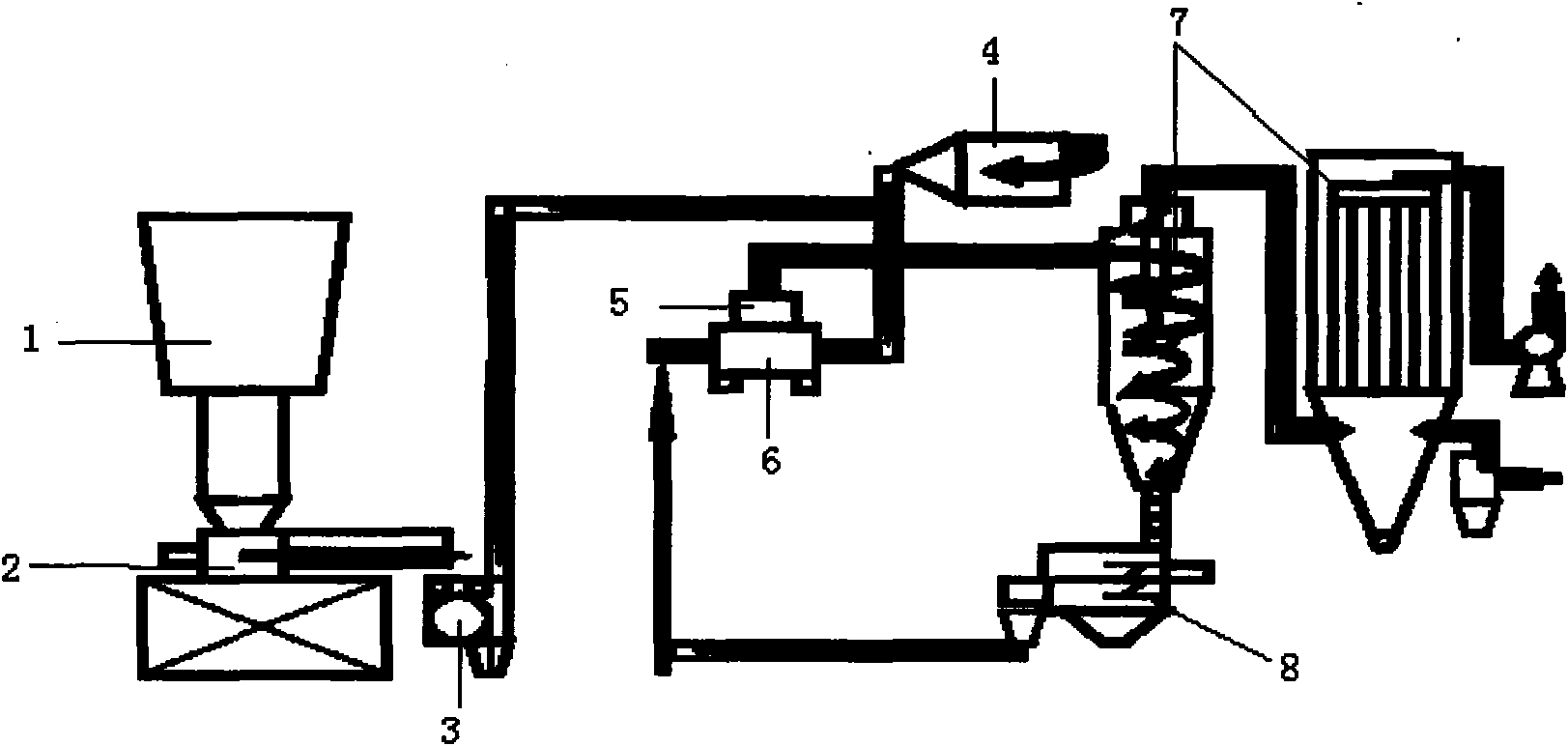

Novel fast-set anticorrosion and wear-resistant epoxy powder coating and preparation process thereof

InactiveCN102492353AImprove anti-corrosion performanceSimple preparation processAnti-corrosive paintsPowdery paintsWear resistantWear resistance

The invention relates to the field of chemical coating, in particular to epoxy powder coating applied to material conveying steel belts in oilfield oil pumping pipelines or coal transportation in the oil industry. In a formula, the coating comprises the following components in percentage by weight: 32-56% of epoxy resin, 8-14% of curing agent, 30-50% of pigments and fillers, 2-10% of resin modifier and 2-6% of assistant, wherein the epoxy resin in the formula is bisphenol A type epoxy resin, a mixture of the bisphenol A type epoxy resin and phenolic aldehyde modified epoxy resin, and phenolic aldehyde modified epoxy resin, and the curing agent is phenolic hydroxyl resin. The epoxy powder coating disclosed by the invention belongs to fast-set anticorrosion and wear-resistant epoxy powder coating, has the granularity being 10-125 mu m, is applied under general curing conditions that the curing temperature is 180-200 DEG C and the curing time is 3-10min, can be regulated according to user needs and is superior to like products in anticorrosion performance, coating film mechanical performance and wear resistance, a preparation process is simple, the labour productivity can be obviously increased, and the epoxy powder coating is suitable for industrialized production.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Powder coating with super-weathering resistance, preparation method and application thereof

InactiveCN101671518AWith super weather resistanceThe ratio is scientific and reasonablePowdery paintsPolyester coatingsPliabilityUltraviolet

The invention discloses powder coating with super-weathering resistance, a preparation method and an application thereof. The powder coating comprises the following raw materials in parts by weight: 40-90 parts of weather-resistant polyester resin, 3-30 parts of thermosetting fluorocarbon resin, 4-50 parts of curing agent, 0.1-1.5 parts of flatting agent, 0.2-0.8 part of degasifying agent, 0-4.5 parts of defoaming agent and 4-45 parts of pigment and filler. The powder coating with super-weathering resistance provided by the invention has scientific and reasonable proportioning in the aspects of raw material composition and raw materials, fine comprehensive properties such as flexibility, hardness, adhesive force and the like, stable chemical property, easy storage, performances of acid rain, ozone, ultraviolet ray and chemical medicine resistance and the like in long-term outdoor use, environment protection and wide application range. The preparation method provided by the invention has reasonable processes, strong operability, high qualified rate of finished products and capability of realizing industrialized production.

Owner:TIGER DRYLAC TAICANG

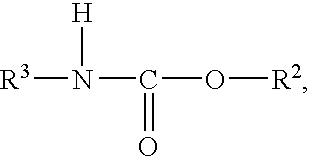

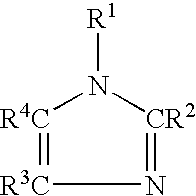

Use of carbamate-modified aminoplast resins to improve the appearance and performance of powder coatings

InactiveUS20050182189A1Low viscosityPowdery paintsPaints for electrolytic applicationsCarbamatePowder coating

A powder coating composition comprising at least about 0.1% by weight of a reaction product of an aminoplast and a compound having one carbamate group has improved smoothness.

Owner:BASF CORP

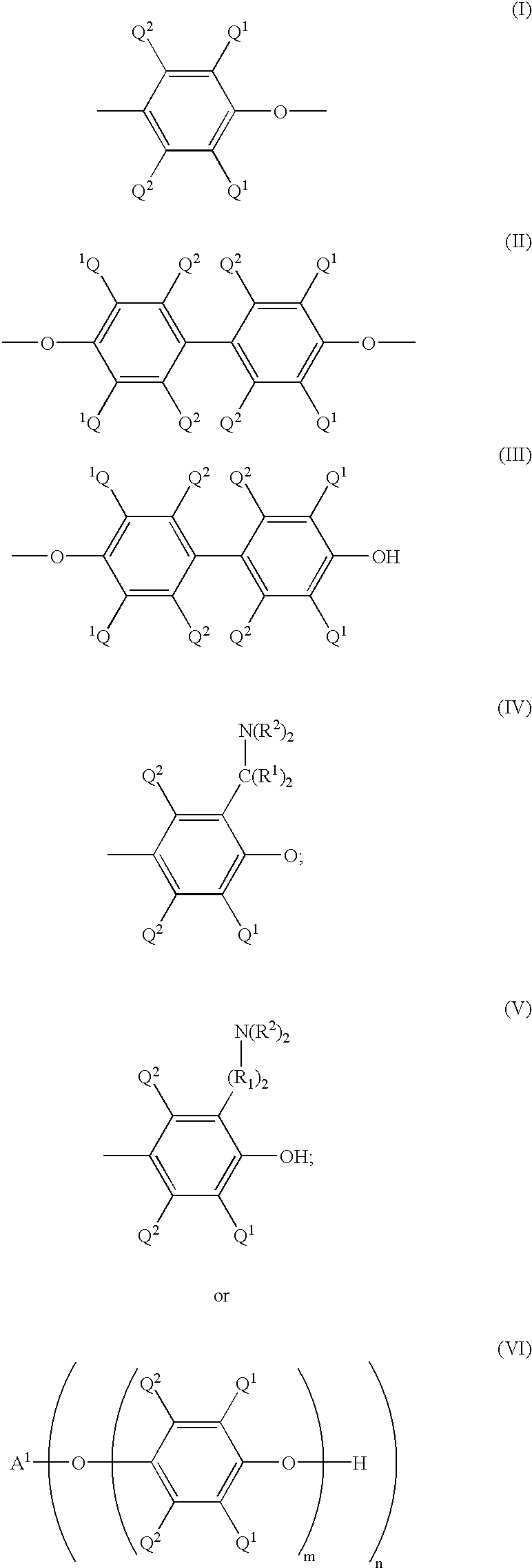

Powder coating of thermosetting resin(s) and poly(phenylene ethers(s))

InactiveUS6576718B1High softening temperatureSignificant positive effectSynthetic resin layered productsPolyether coatingsEtherPowder coating

Owner:SABIC INNOVATIVE PLASTICS IP BV

Graphene anticorrosive powder paint and preparation method thereof

ActiveCN104109450AImprove corrosion resistanceIncrease resistanceAnti-corrosive paintsPowdery paintsEpoxyArray data structure

The invention relates to a graphene anticorrosive powder paint which is composed of the following components in parts by weight: 25-70 parts of epoxy resin, 25-70 parts of polyester resin, 5-40 parts of titanium white, 5-40 parts of barium sulfate, 3-10 parts of assistant, 0.5-10 parts of graphene and the balance of other pigments. The powder paint has excellent anticorrosive property and favorable powdering penetrating power, and the surface scratch resistance is up to 2H above. The preparation technique is simple; the application technique is convenient; and the paint has excellent comprehensive properties.

Owner:宁波派特勒新材料股份有限公司

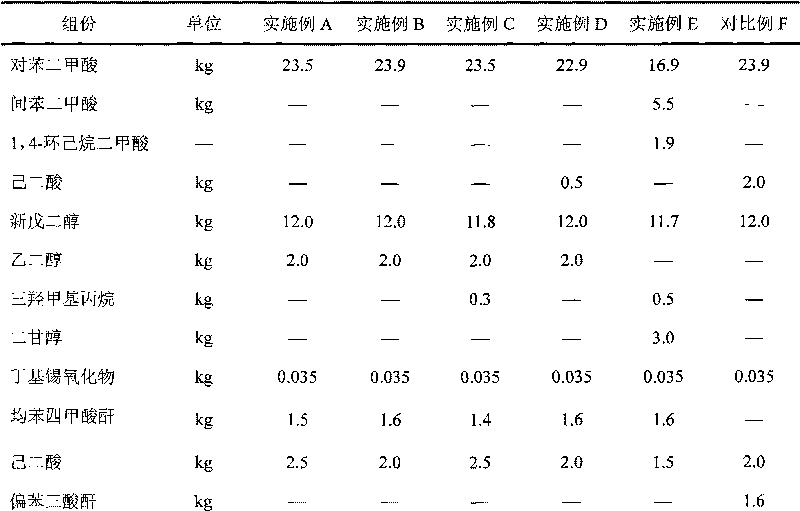

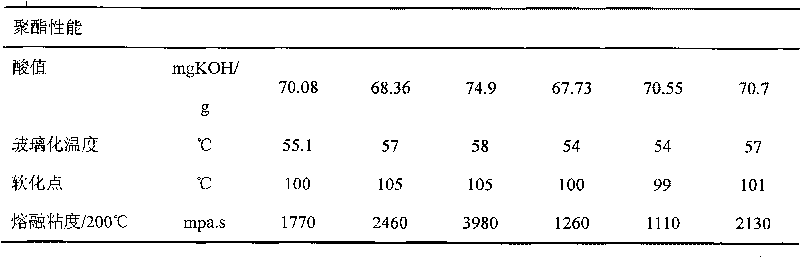

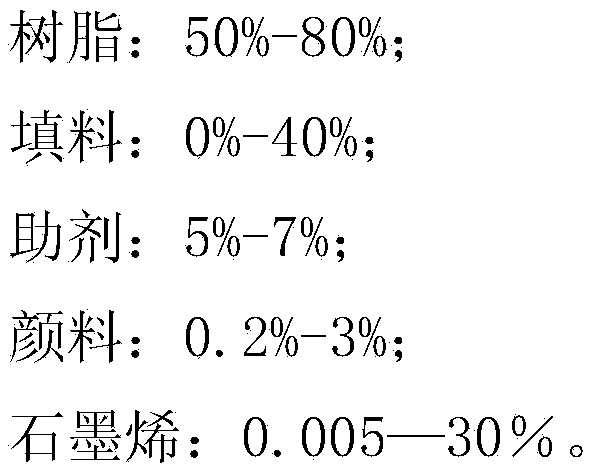

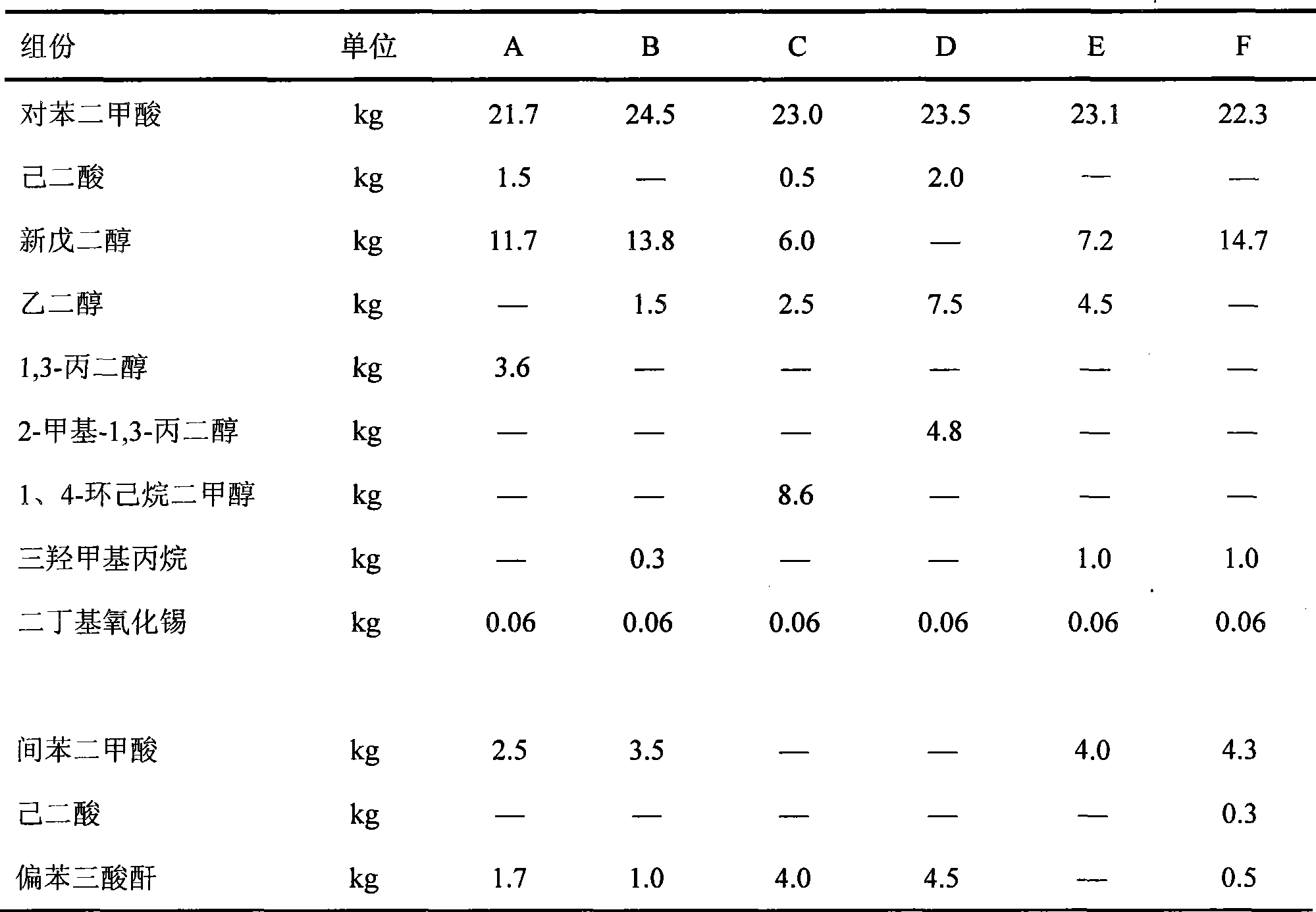

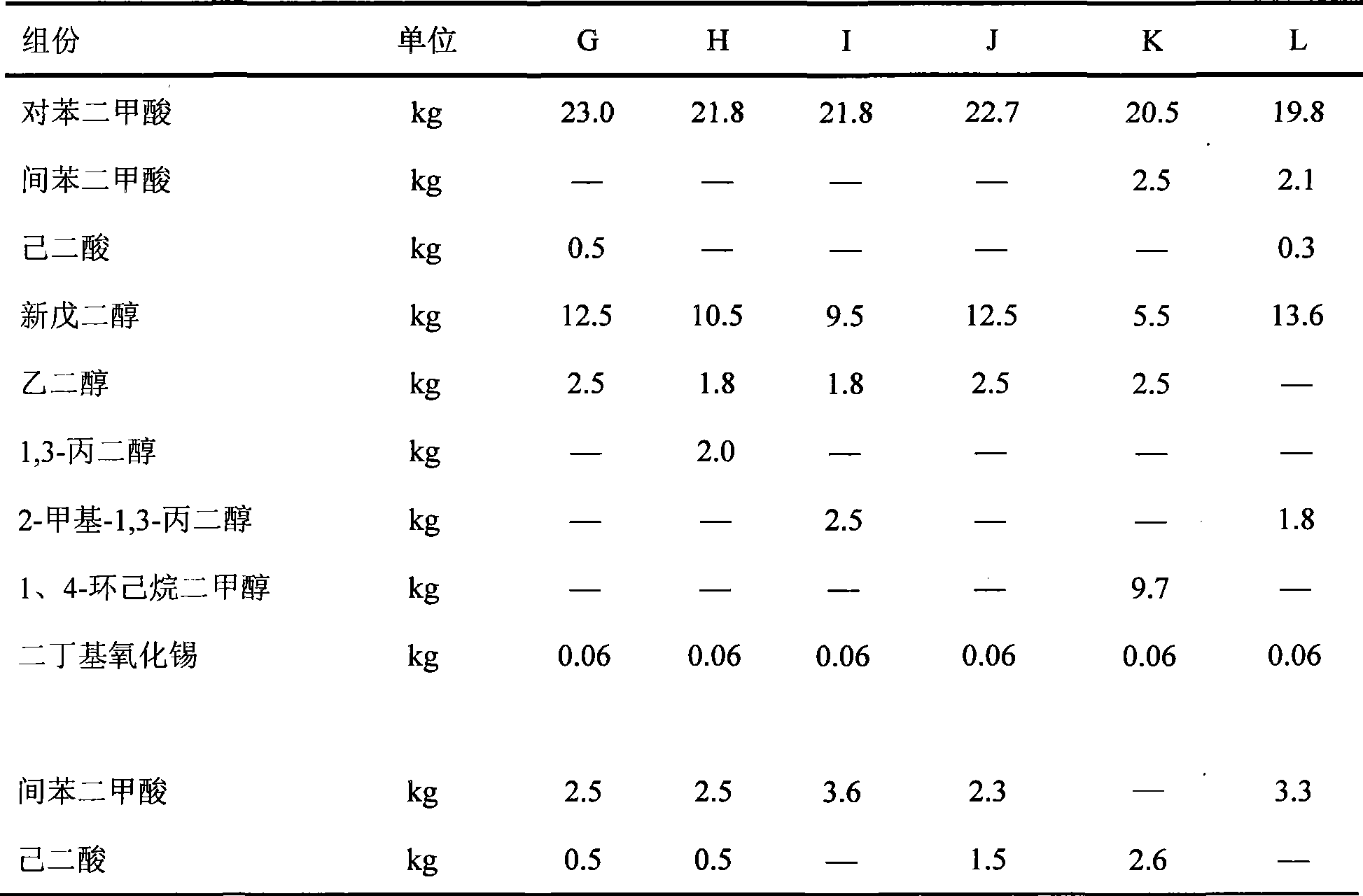

Low-temperature cured terminal carboxyl polyester resin for mixed powder coating and preparation method thereof

ActiveCN101735432ASuitable glass transition temperatureGood storage stabilityPowdery paintsEpoxy resin coatingsHybrid typeEpoxy

The invention discloses a low-temperature cured terminal carboxyl polyester resin for mixed powder coating. The polyester resin is prepared by performing melt polycondensation reaction on the following components in percentage by weight: 25 to 45 percent of polyalcohol, 35 to 65 percent of aromatic polyatomic acid, 0 to 10 percent of fat polyatomic acid, 0 to 2 percent of branching agent, 6 to 15 percent of acid hydrolysis agent, and 0.01 to 0.15 percent of esterification catalyst. The invention also discloses a method for preparing the low-temperature cured terminal carboxyl polyester resin. The prepared polyester resin has the characteristics of proper glass-transition temperature, softening point, good storage stability, and the like; the polyester resin, epoxy resin, filler and assistant in a certain proportion are mixed, and the mixture is prepared into powder through melt extrusion mixing, cooling, crushing and sieving; and the prepared powder can be cured at the temperature of 160 DEG C, and has the advantages of excellent leveling performance, good impact performance, and the like.

Owner:GUANGZHOU KINTE IND

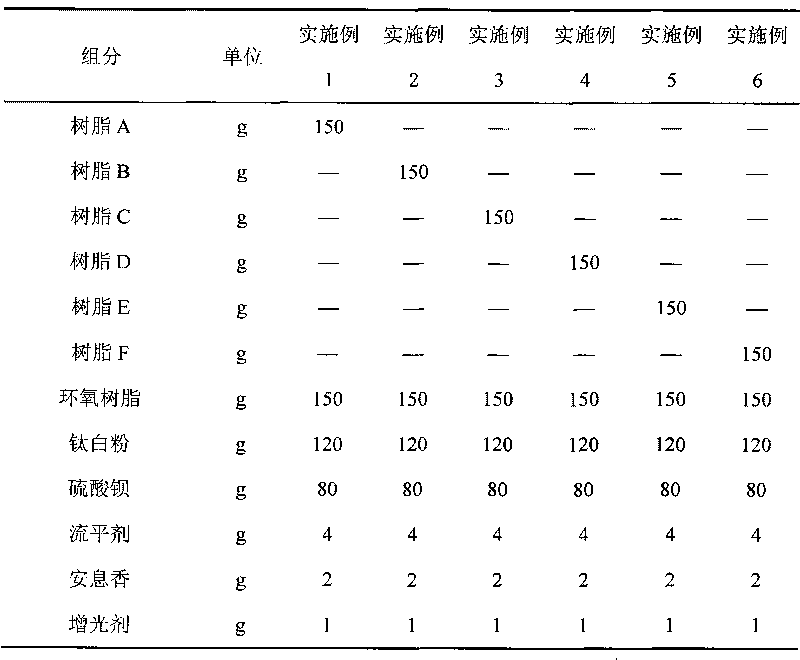

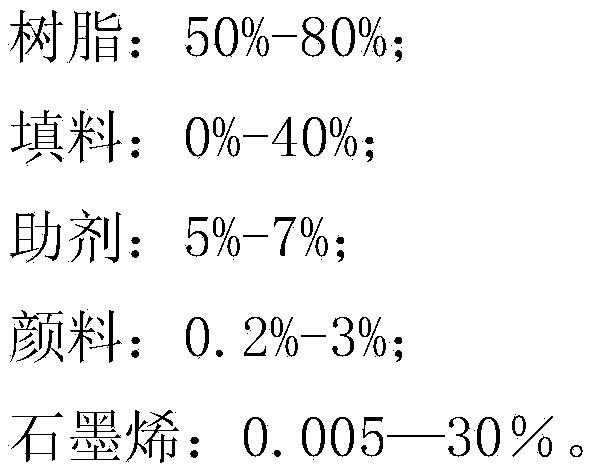

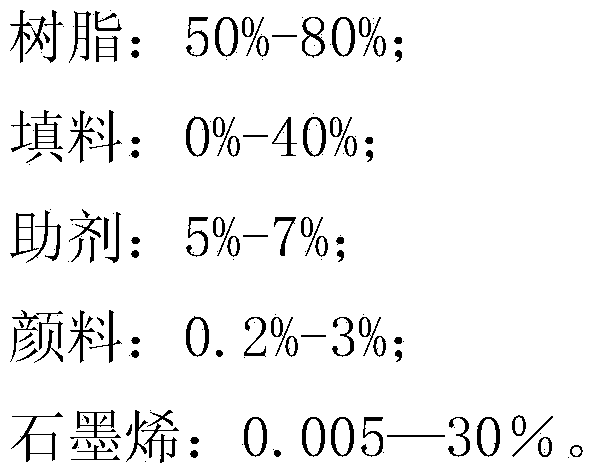

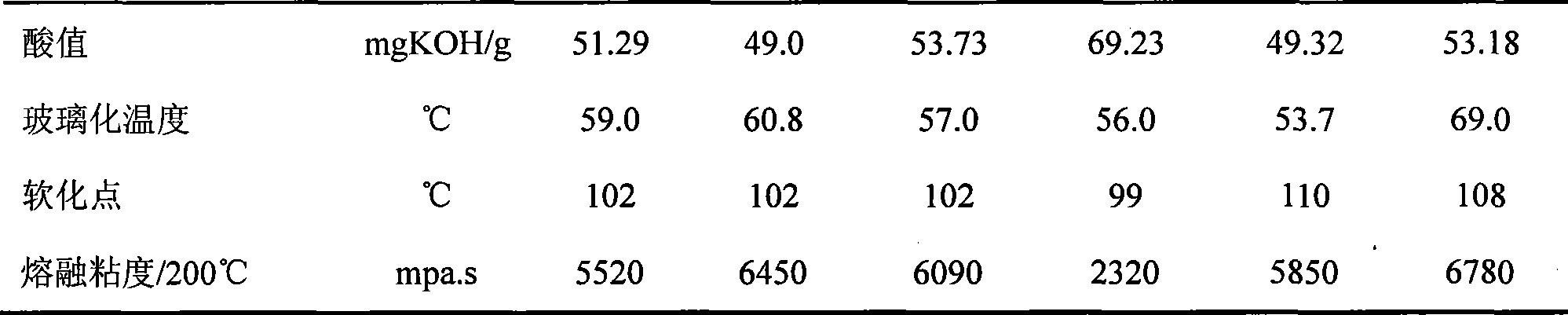

Graphene-modified resin powder coating and production process thereof

InactiveCN104194585AIncrease profitReduce pollutionFireproof paintsPolyurea/polyurethane coatingsWeather resistanceGraphene

The invention relates to graphene-modified resin powder coating and a production process thereof. The graphene-modified resin powder coating comprises the following components in percentage by weight: 50-80 percent of resin, 0-40 percent of filler, 5-7 percent of an auxiliary agent, 0.2-3 percent of pigment and 0.005-30 percent of graphene. According to the graphene-modified resin powder coating provided by the invention, a proper amount of graphene is added in the traditional resin powder coating, so that the mechanical property, the conductivity, thermal conductivity, flame resistance, corrosion resistance and weather resistance of the resin powder coating are greatly improved; the graphene-modified resin powder coating has a broad market prospect.

Owner:周诚

Polyester resin with high acid value and low acid value for environment-friendly dry blended low-gloss powder coating and preparation method thereof

InactiveCN101445591ASuitable glass transition temperatureHigh softening pointPowdery paintsPolyester coatingsPolyolAcid value

The invention discloses a polyester resin with a high acid value and a low acid value for an environment-friendly dry blended low-gloss weather-resistant powder coating. The polyester resin is made from the following raw materials by weight percentages by virtue of esterification and condensation reaction: 15%-60% of polyol, 30%-65% of polyacid, 0%-5% of a branching agent, 5%-15% of an acidolysis agent and 0.01%-0.15% of an esterification catalyst. The invention further discloses a preparation method of the polyester resin with the high acid value and the low acid value for the environment-friendly dry blended low-gloss weather-resistant powder coating. Thepolyester resin with the high acid value and the polyester resin with the low acid value have the characteristics of proper glass transition temperature, proper softening point and good storage stability. A powder coating made by curing beta-hydroxyalkyl amide with the polyester resin has the advantages of excellent deglossing effect and good mechanical properties.

Owner:GUANGZHOU QINGTIAN INDAL

Mixed polyester resin for matte powder coatings and preparation thereof

InactiveCN101205293ALiquefiedSuitable glass transition temperaturePowdery paintsPolyester coatingsEpoxyPolyol

The invention discloses a mixed polyester resin for matte powder coating, which is obtained through the melting polycondensation by using the components with the following weight fraction: 23 percent to 50 percent of polyol, 35 percent to 65 percent of aromatic polybasic acid, 0 percent to 10 percent of fat polybasic acid, 0 percent to 2 percent of branching agent, 10 percent to 20 percent of acidulate agent and 0.01 percent to 0.15 percent of esterification catalyst. The invention also discloses a preparation method for a mixed polyester resin for matte powder coating. The polyester resin prepared through the method of the invention has the advantages of proper glass transition temperature,softening temperature, good storage stability, low cost, etc., and the matte powder coating with a gloss lower than 30 percent can be obtained by mixing the polyester resin with a certain proportion of the epoxy resin,stuffing, paint, flatting agent and matting agent and then melting, extruding, grinding and cribrating the mixtures and the obtained polyester resin has an outstanding mechanical performance and flatting effect.

Owner:GUANGZHOU QINGTIAN INDAL

Dry powder type shell powder interior wall coating material and preparation method thereof

ActiveCN103627261AHave production costsNice decorationAntifouling/underwater paintsCellulose coatingsCobalt-60High energy

The invention relates to a dry powder type shell powder interior wall coating material which has the functions of adsorbing and decomposing harmful gas and peculiar smell, restraining bacteria, sterilizing and resisting static electricity and using shell powder, nanometer inorganic filler and high molecular powder materials as main components. The invention solves the defects of high cost, high energy consumption, pollution and incapability of purifying indoor harmful gas in the existing interior wall coating materials. The coating material uses natural or manually cultivated shell powder as basic materials; meanwhile, a certain quantity of nanometer titanium dioxide and nanometer electric stone powder radiated by cobalt-60 gamma ray and the high molecular powder materials are added; the weight percentages of all components are as follows: 30-60% of shell powder, 10-20% of calcined kaolin, 10-20% of heavy calcium, 10-20% of talcum powder, 1-5% of nanometer titanium dioxide, 1-5% of nanometer electric stone powder, and 5-20% of high molecular powder materials; the particle size of the shell powder is 200-1250 meshes.

Owner:JILIN RIHE TECH DEV

Green powdered paint and its prepn

The present invention discloses one kind of green powdered paint and its preparation process. The green powdered paint consists of re-dispersible polymer latex powder 5-20 wt%, white cement 20-40 wt%, calcium carbonate 20-45 wt%, titanium white powder 5-25 wt%, diatomite 2-8 wt%, bentonite 1-2 wt%, cellulose ether 0.2-0.5 wt%, defoaming agent 0.2-0.5 wt% and coloring pigment 0-4 wt%. It is prepared through mixing all the components in a stirrer, and packing. It is used after mixing with water in construction site. It has the combined decoration functions of both putty and emulsion paint and may be used widely for decorating inner and outer wall.

Owner:SOUTH CHINA UNIV OF TECH

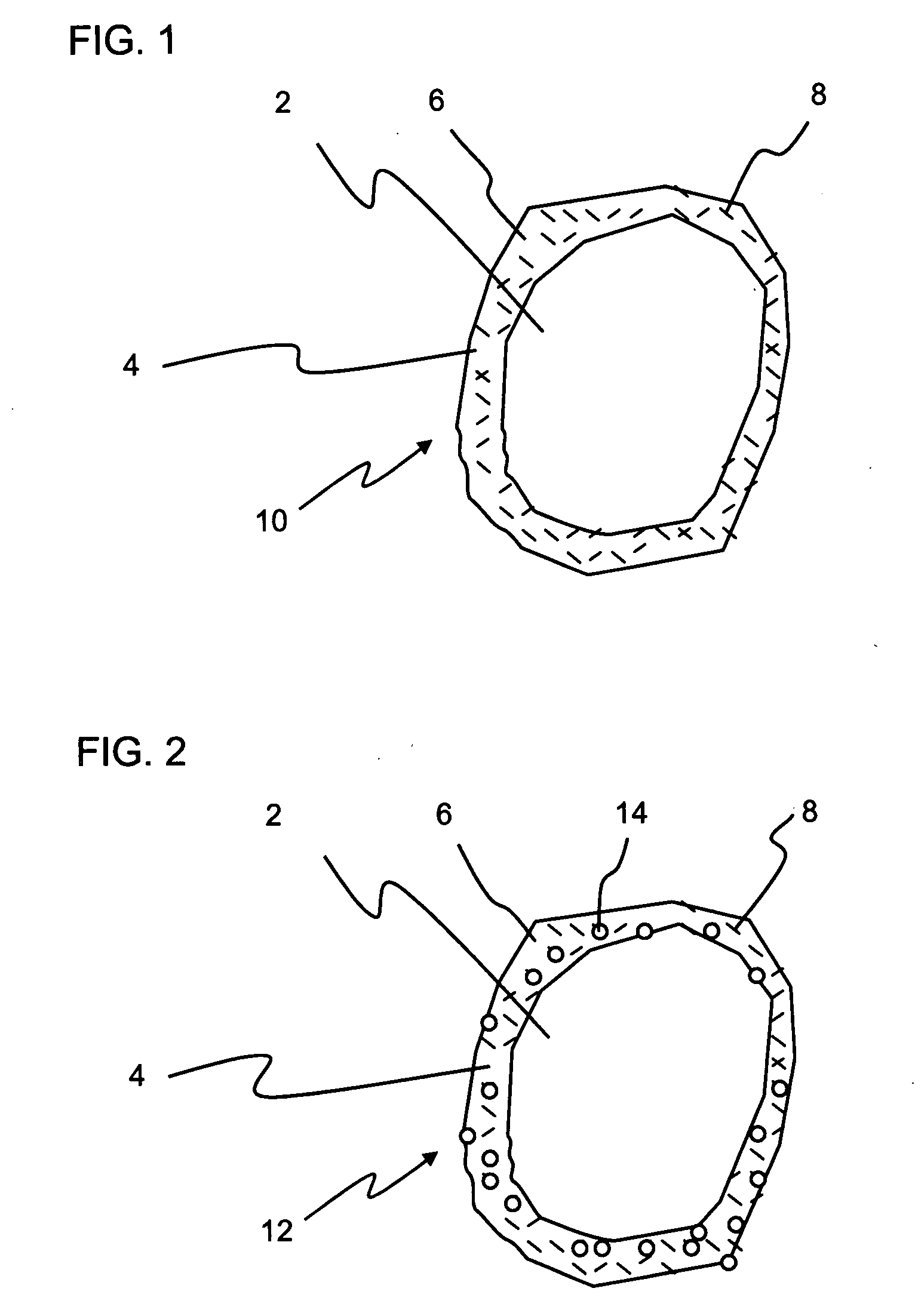

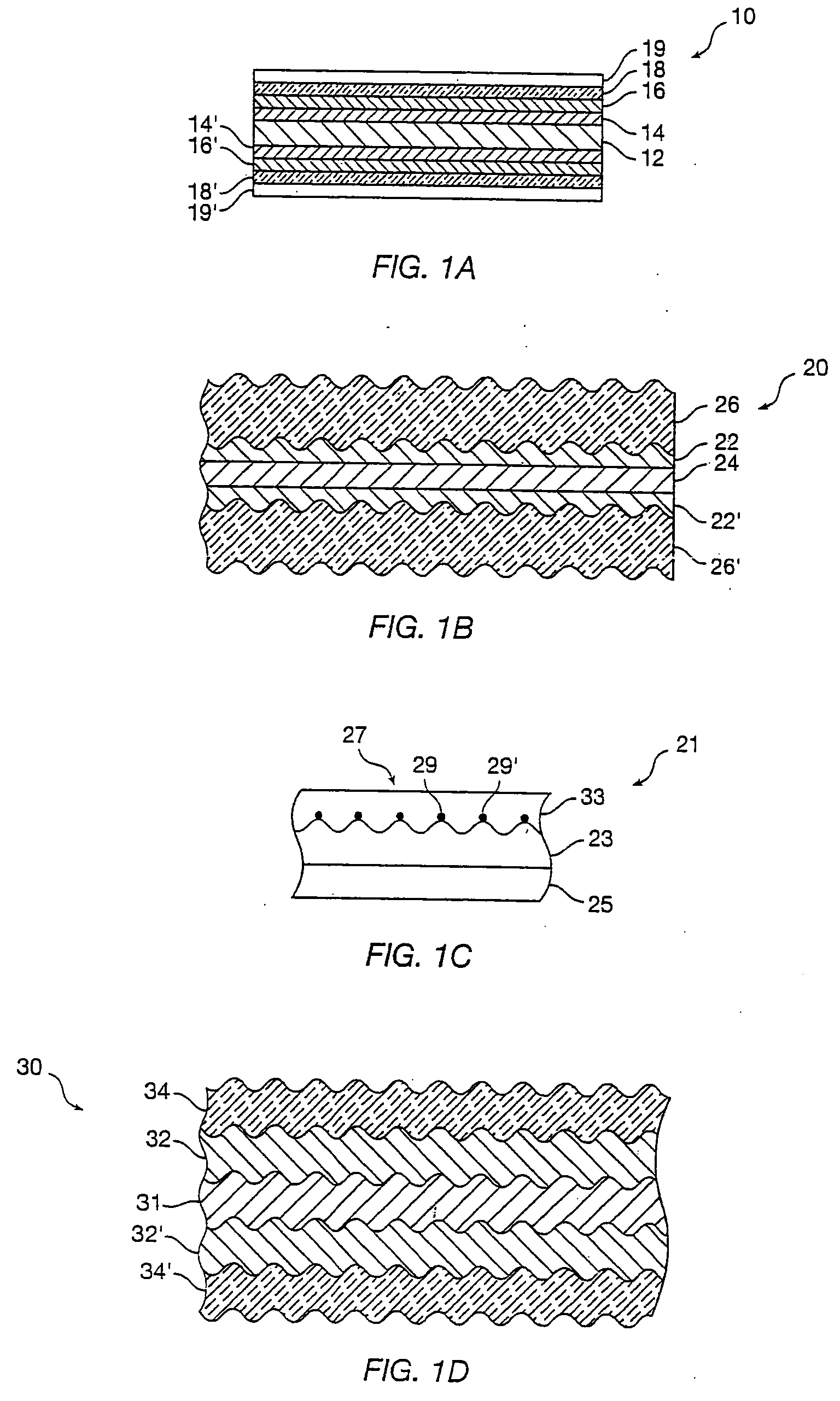

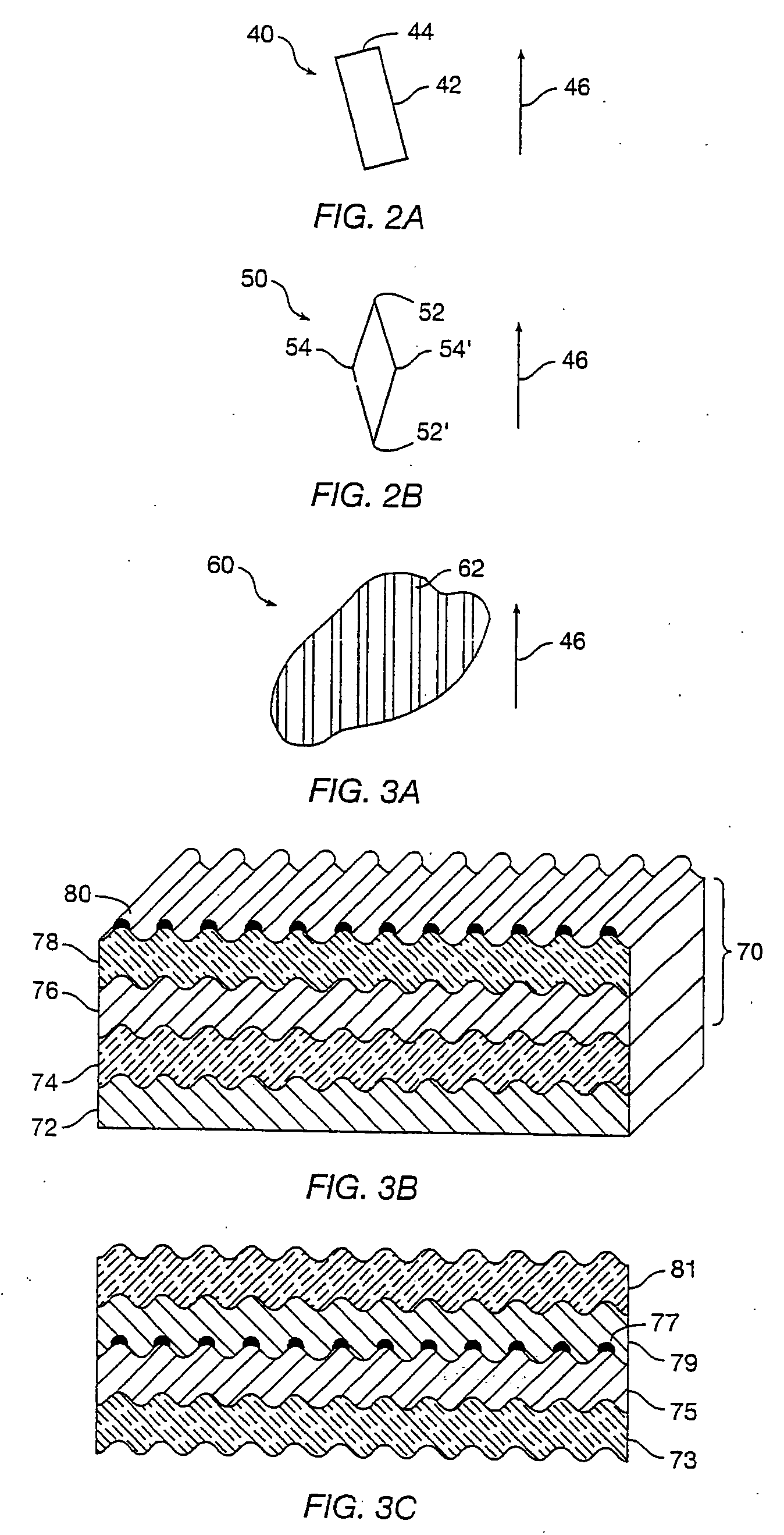

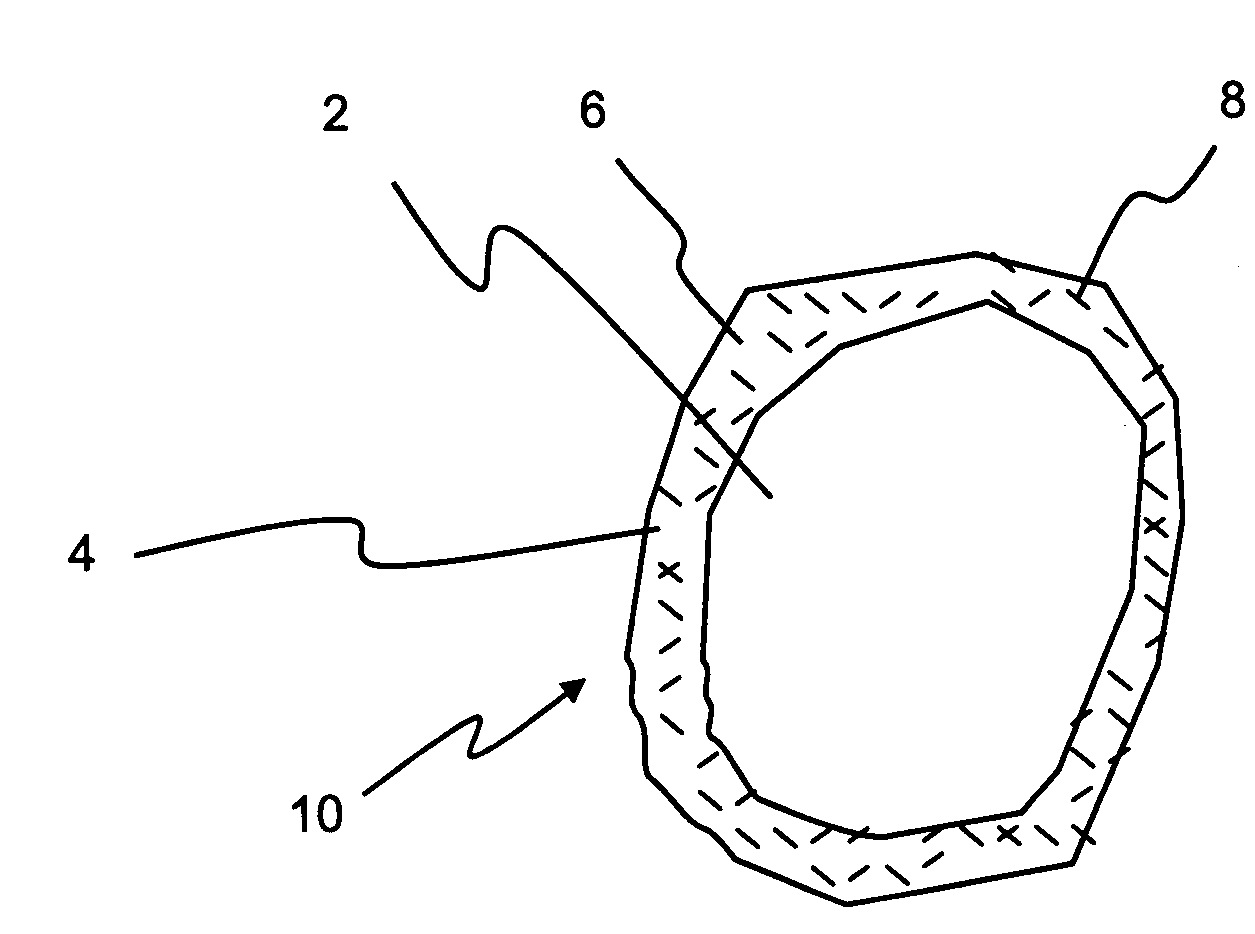

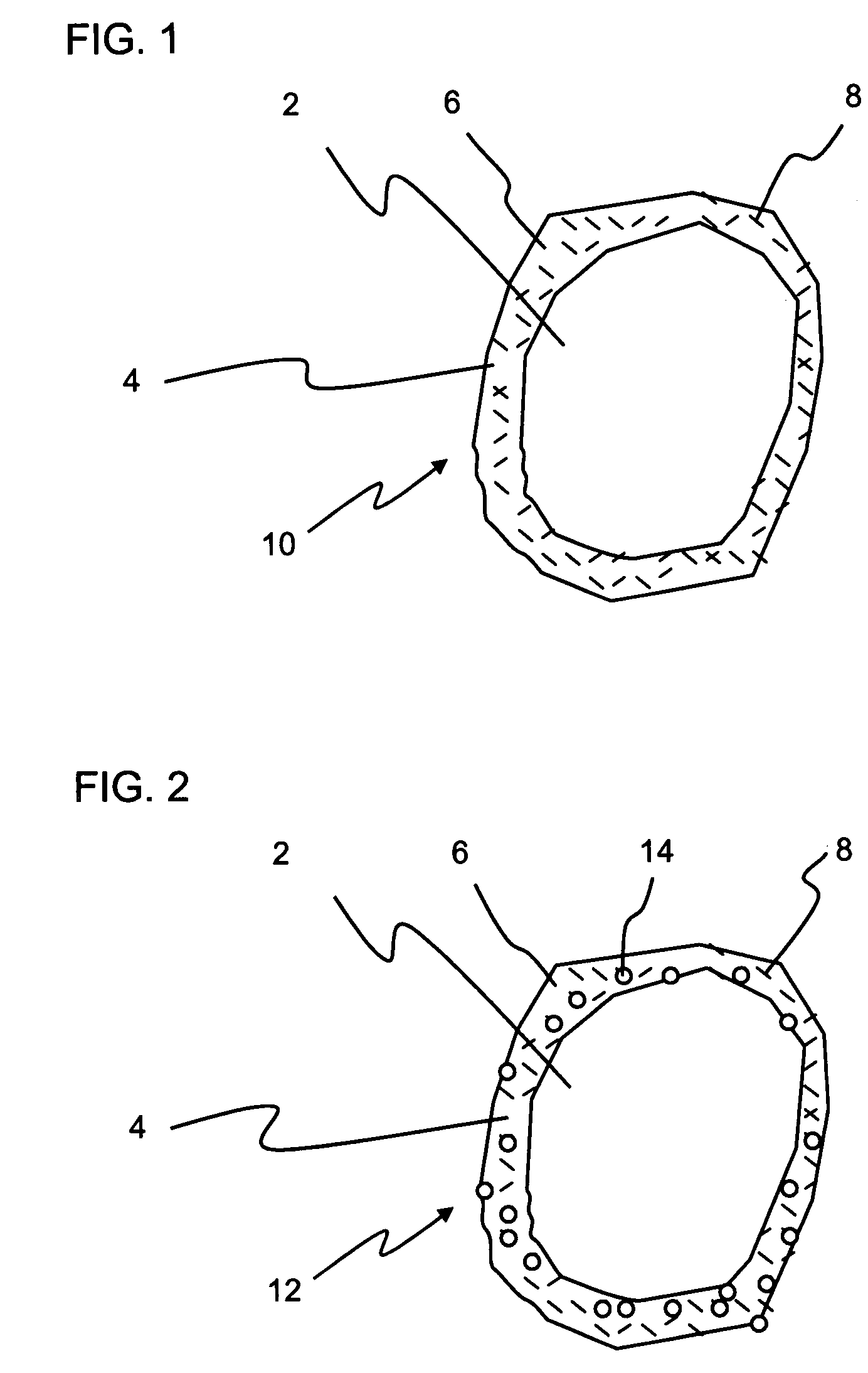

Powder material for electrostatic application to a substrate and electrostatic application of the powder material to a substrate

InactiveUS20030113445A1Electric shock equipmentsInorganic non-active ingredientsPhysical propertyMaterials science

This invention concerns a powder material suitable for electrostatic application to a substrate and a method of electrostatically applying said powder material to a substrate. At least some of the particles which constitute the powder material comprise a core and a shell surrounding the core. The shell and core generally have differing compositions and have different chemical and / or physical properties. Components which are likely to be altered can be placed in the core whilst maintaining the shell composition, thus allowing changes in formulation of the powder material without destroying the performance of the material in electrostatic application. The powder material is especially suitable for electrostatic application to pharmaceutical solid dosage forms.

Owner:GLAXO GROUP LTD +1

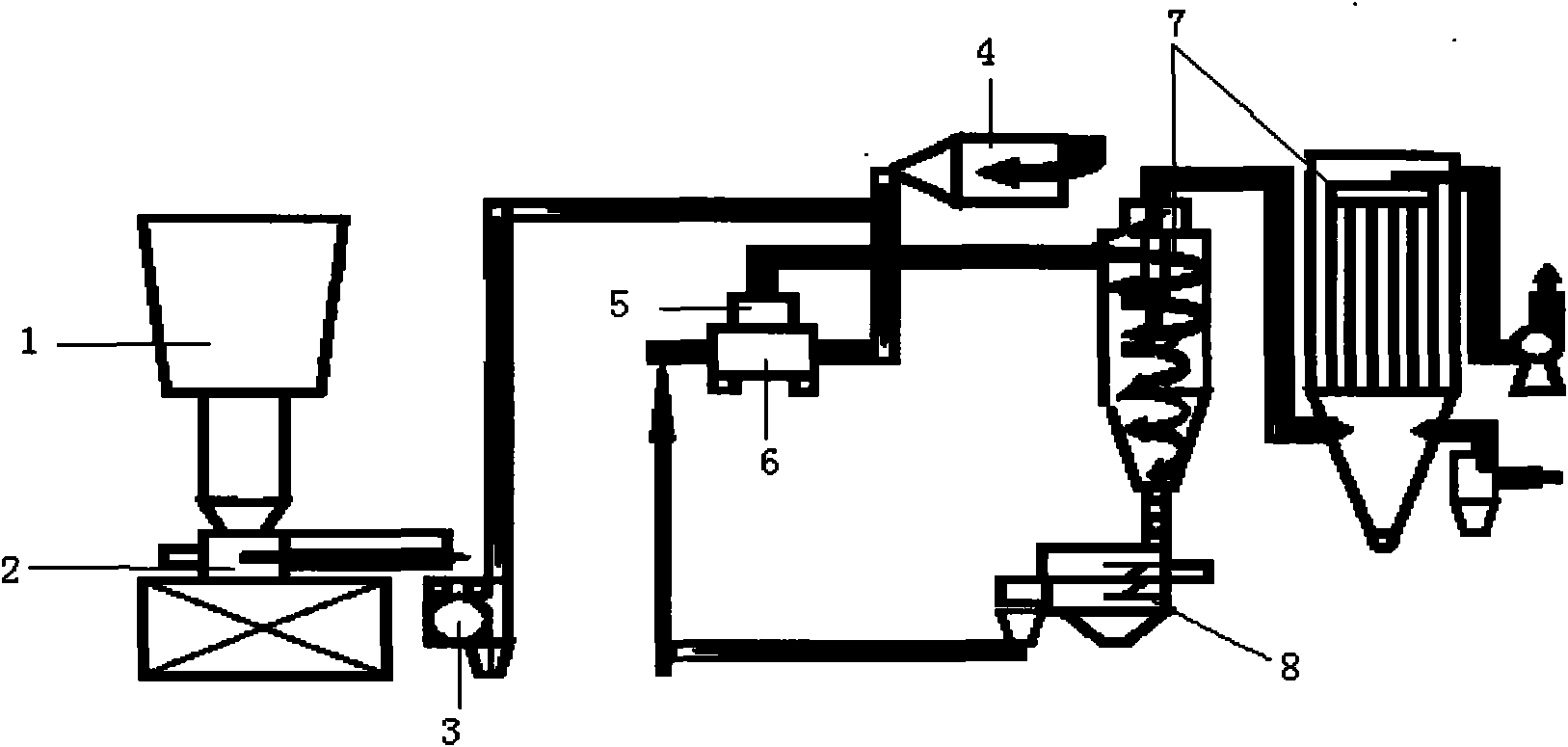

Powder coating containing aerogel particles and preparing method thereof

InactiveCN101143981AImprove insulation performanceImprove sound insulationPolyurea/polyurethane coatingsPowdery paintsInsulation layerMixed materials

A powder coating containing aerogel particles and a method for preparing the same relates to a powder coating and a preparation method, which solves the problem that the existing heat insulating composite material containing aerogel is not suitable for making thinner heat insulation material and spraying insulation layer on the component surface, and the aqueous coating has high water content, long construction period and low heat insulation property. The coating of the invention is prepared by 5-80 percent of aerogel particles and 20-95 percent of powderedd resin by volume percentage, and the method includes the following steps: firstly, aerogel, resin and additive are mixed by volume percentage; secondly, the mixed materials are delivered into a melting-extruder melt and extrude; thirdly, the extrudate is pressed into thin sections; fourthly, the thin sections are ground into small pieces by roller machine; fifthly, the small pieces are conveyed into an air staged milling equipment to grind, so as to obtain the powder coating. The powder coating containing aerogel of the invention has advantages of environmental protection, clearness, economy, high efficiency, and good heat insulation property, sound insulation property and surface hydrophobicity.

Owner:HARBIN INST OF TECH

Powder coating with antibacterial function and preparation method and application thereof

InactiveCN101665652AHas antibacterial functionThe ratio is scientific and reasonableAntifouling/underwater paintsPaints with biocidesThermal stabilityInhibitory effect

The invention discloses a powder coating with an antibacterial function and a preparation method and an application thereof. The powder coating comprises the following raw materials in the parts by weight: 60-90 parts of resin, 2-40 parts of curing agent, 1.5-10 parts of antibacterial agent color concentrate, 0.5-2 parts of flatting agent, 0-4.5 parts of defoaming agent, 4-30 parts of pigments andfillers and 0-15 parts of other auxiliary agents. The powder coating provided by the invention has the functions of bacterium resistance and broad spectrum and has strong functions of sterilizing andinhibiting various bacteria and mould fungi; the heat resistant temperature of the inorganic antibacterial agent can reach 500 DEG C, and the inorganic antibacterial agent has good heat stability; and the inorganic antibacterial agent is a silver ion antibacterial agent using glass as a carrier, has good transparency and can be made into a transparent antibacterial powder coating which has the advantages of safety and wide application range. The preparation method provided by the invention has reasonable processes, strong operability and high qualified rate of the prepared finished products and can realize industrial production in a large batch.

Owner:TIGER DRYLAC TAICANG

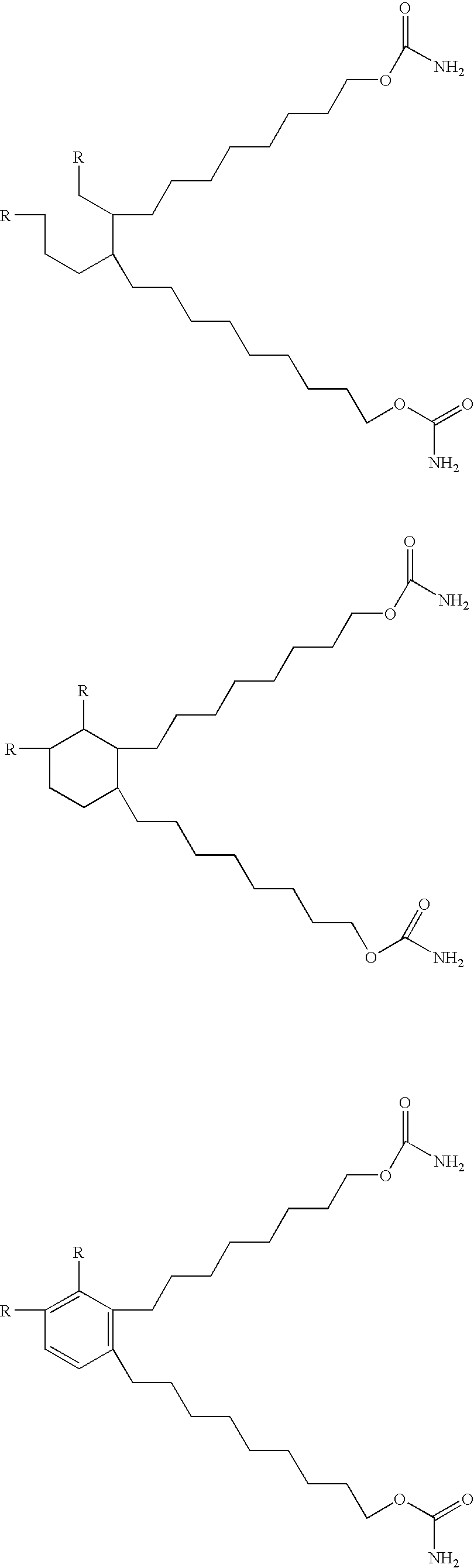

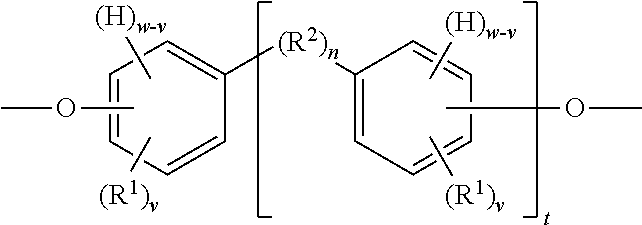

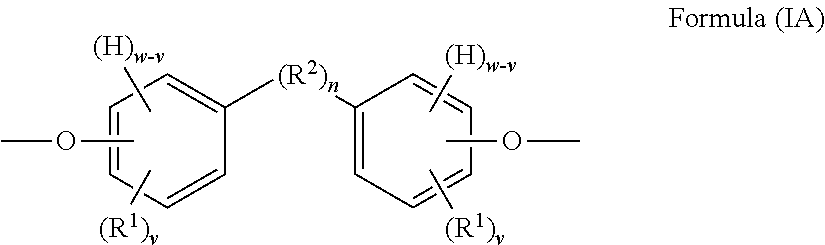

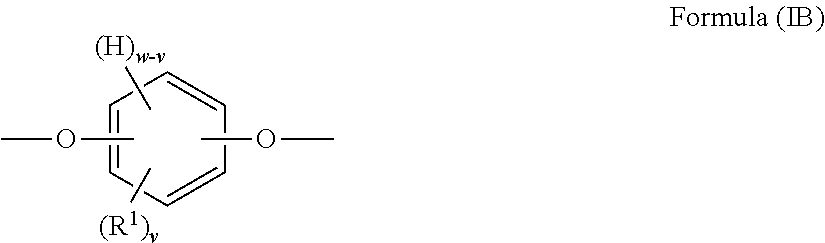

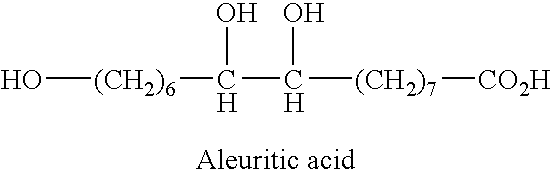

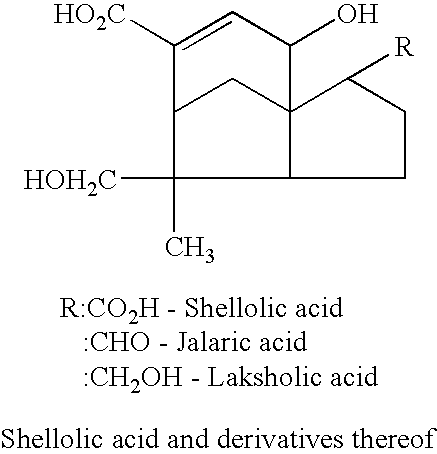

Compositions for containers and other articles and methods of using same

ActiveUS9409219B2Eliminate and reduce any undesirable levelAvoid undesirable estrogenic agonist activityLiquid surface applicatorsAnti-corrosive paintsPolymer chemistryPowder coating

This invention provides a polymer, which is preferably a polyether polymer. The polymer may be used in coating compositions. Containers and other articles comprising the polymer and methods of making such containers and other articles are also provided. The invention further provides compositions including the polymer (e.g., powder coatings), which have utility in a variety of coating end uses, including, for example, valve and pipe coatings.

Owner:SWIMC LLC

Composite Powder Coating Material, Process for Production Thereof and Method for the Color Matching of Powder Coating Material Technical Field

InactiveUS20070299196A1Improve film propertiesHighly uniform hueLiquid surface applicatorsChemical/physical/physico-chemical stationary reactorsSolventMaterials science

The present invention provides a composite powder coating composition obtained by granulating, with a liquid binder, a plurality of starting powder coating materials that are different from each other in hue and / or kind of base resin, and drying the granules, the liquid binder being a solution or dispersion of a binder compound having a softening temperature of 30 to 200° C. and containing a self-crosslinkable functional group or groups and / or a functional group or groups that complementarily react with functional groups of the starting powder coating materials, in a solvent that does not dissolve the starting powder coating materials; production process therefor; and a method for color-matching a composite powder coating composition, the method comprising the steps of dry blending, for color matching, a plurality of starting powder coating materials having different hues, granulating the resulting blend by adding the above-mentioned liquid binder, and drying the granules.

Owner:KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com