Patents

Literature

40results about How to "Have production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry powder type shell powder interior wall coating material and preparation method thereof

ActiveCN103627261AHave production costsNice decorationAntifouling/underwater paintsCellulose coatingsCobalt-60High energy

The invention relates to a dry powder type shell powder interior wall coating material which has the functions of adsorbing and decomposing harmful gas and peculiar smell, restraining bacteria, sterilizing and resisting static electricity and using shell powder, nanometer inorganic filler and high molecular powder materials as main components. The invention solves the defects of high cost, high energy consumption, pollution and incapability of purifying indoor harmful gas in the existing interior wall coating materials. The coating material uses natural or manually cultivated shell powder as basic materials; meanwhile, a certain quantity of nanometer titanium dioxide and nanometer electric stone powder radiated by cobalt-60 gamma ray and the high molecular powder materials are added; the weight percentages of all components are as follows: 30-60% of shell powder, 10-20% of calcined kaolin, 10-20% of heavy calcium, 10-20% of talcum powder, 1-5% of nanometer titanium dioxide, 1-5% of nanometer electric stone powder, and 5-20% of high molecular powder materials; the particle size of the shell powder is 200-1250 meshes.

Owner:JILIN RIHE TECH DEV

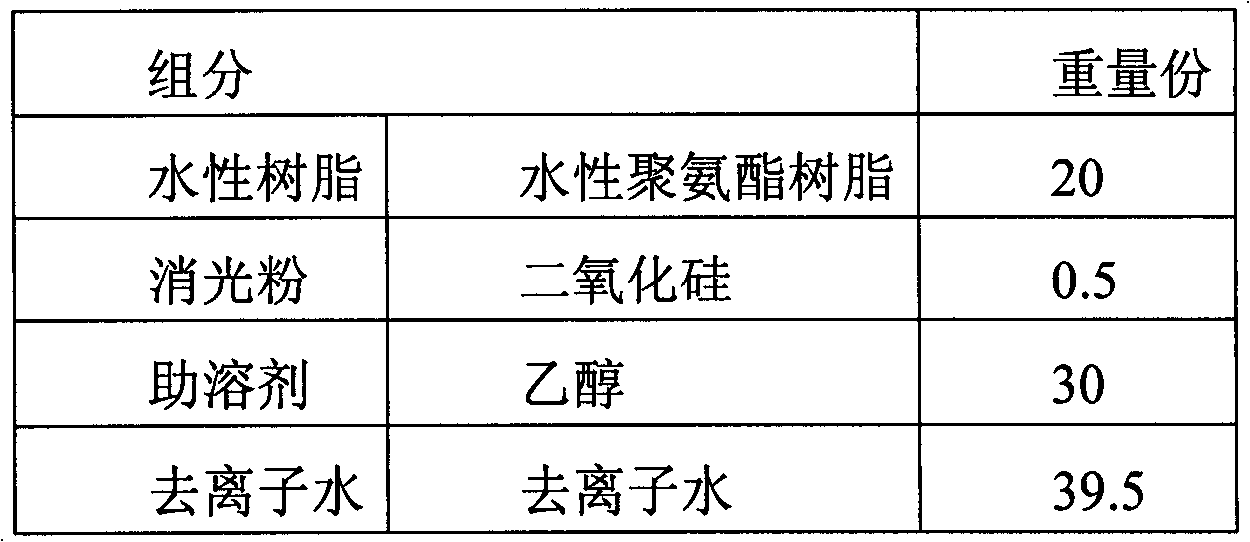

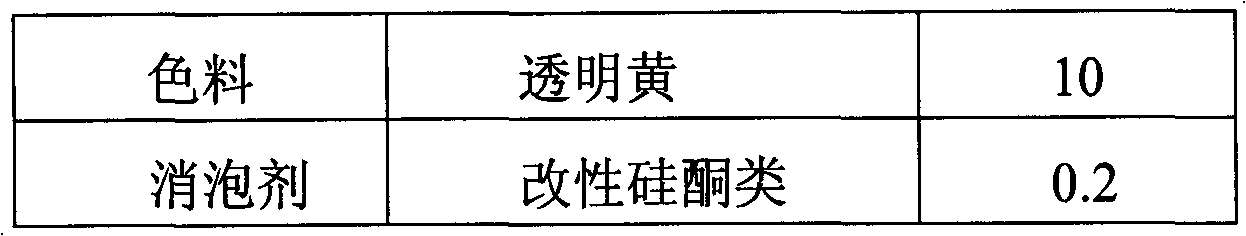

Aqueous single-coating matt transferring aluminum-plating paint and preparation method thereof

InactiveCN102367348AReduce contentEnvironmental costPolyurea/polyurethane coatingsSolventDefoaming Agents

The invention relates to an aqueous single-coating matt transferring aluminum-plating paint and a preparation method thereof. The paint comprises the following components in parts by weight: 20-70 parts of aqueous resin, 10-70 parts of deionized water, 0.5-2 parts of delustering powder, 5-30 parts of cosolvent, 0-10 parts of pigment, 0-2 parts of pH value regulating agent, 0-0.5 part of wetting agent, 0-0.2 part of flatting agent and 0.05-0.2 part of defoaming agent. Compared with the prior art, the aqueous single-coating matt transferring aluminum-plating paint has the advantages of excellent delustering property, simple production process and the like, and is environmentally-friendly.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Polyvinyl chloride function modifier and its prepn process

The present invention discloses one kind of polyvinyl chloride function modifier and its preparation process. The modifier is prepared with polyhydric alcohol borate ester, polyhydric alcohol salicylate ester and acrylate as processing assistant, and oxide homopolymer or oxidized polyethylene wax. The modifier has the functions of coupling agent, dispersant, internal and external lubricant, processing assistant, etc. and has unique PVC / CaCO3 stuffing system modifying effects, including promoting plasticization, raising dispersivity, improving antiageing and machining performance, realizing high stuffing, etc.

Owner:NANJING CONCORD FERTILIZER CHEM

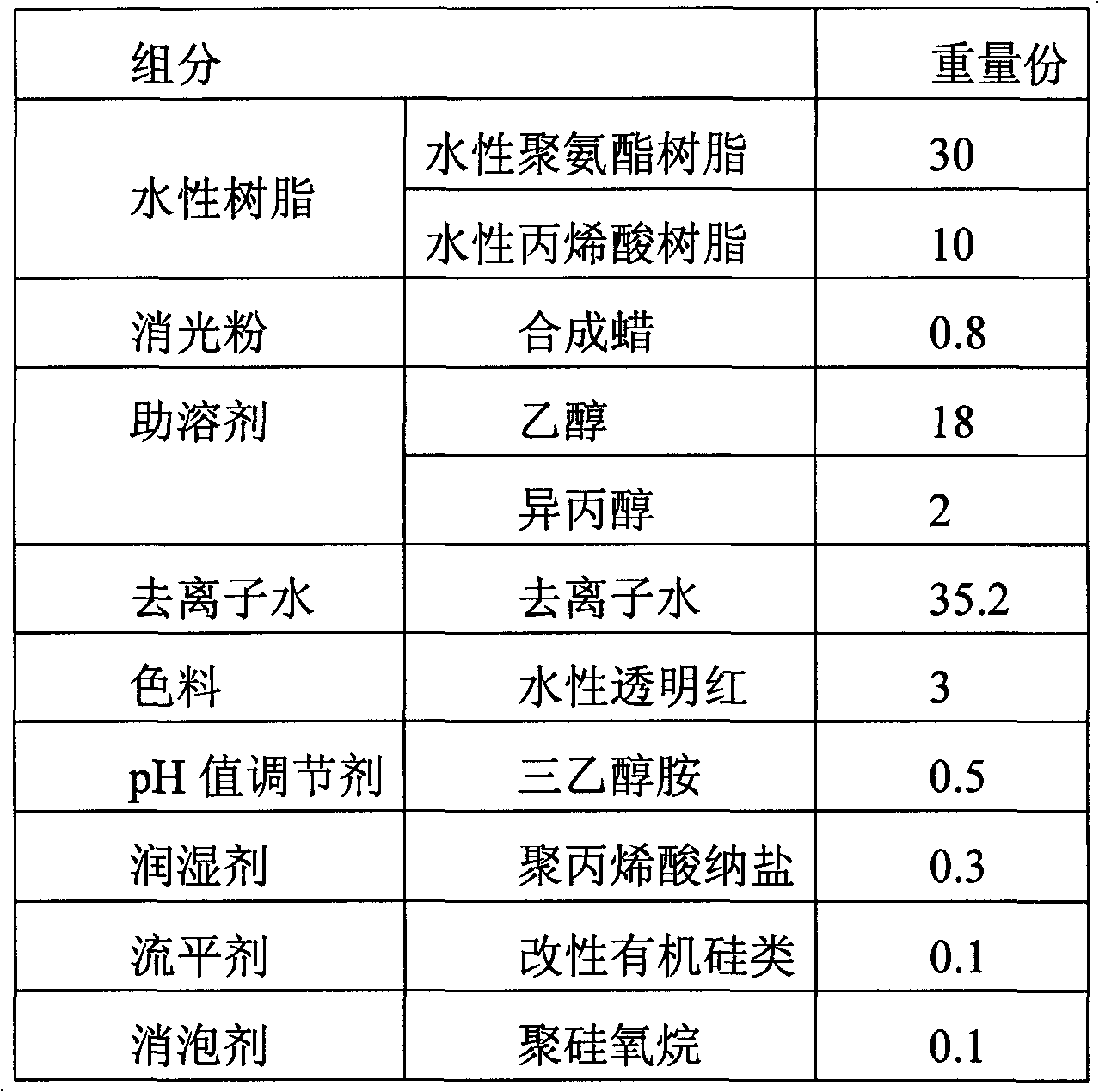

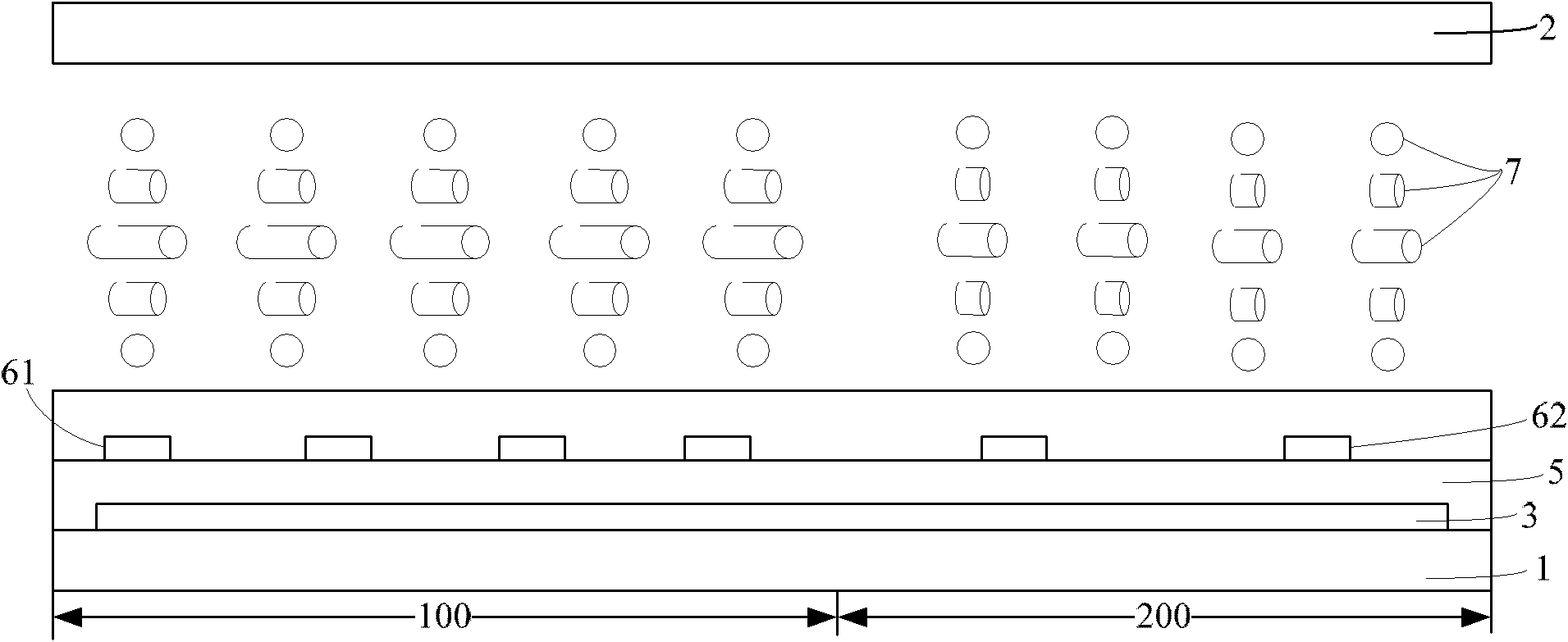

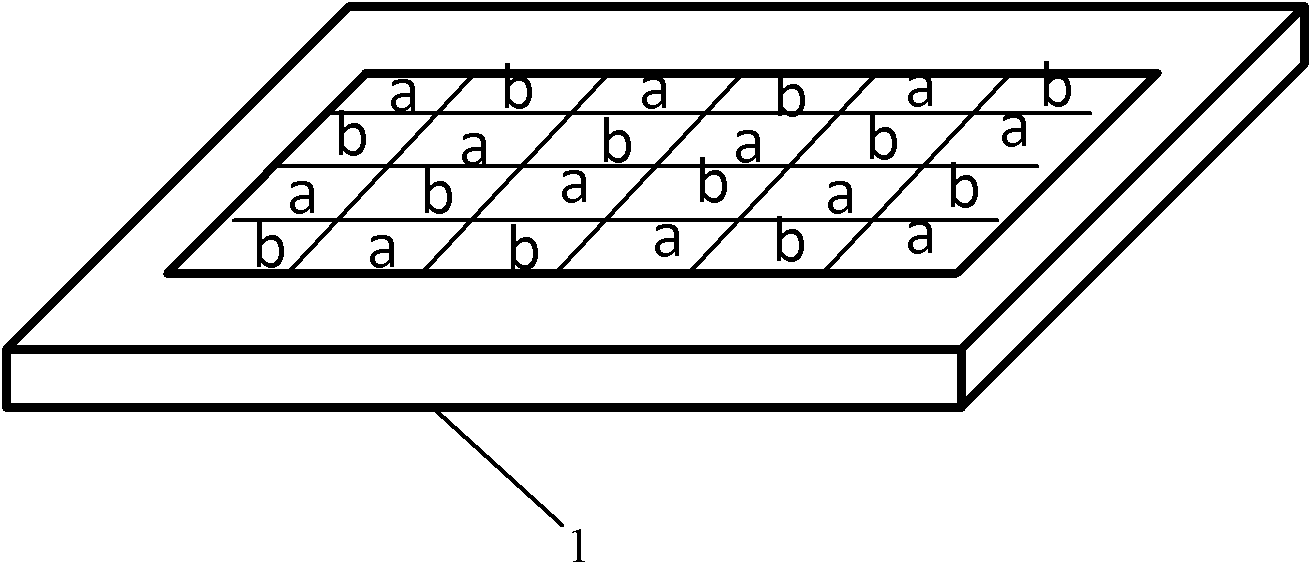

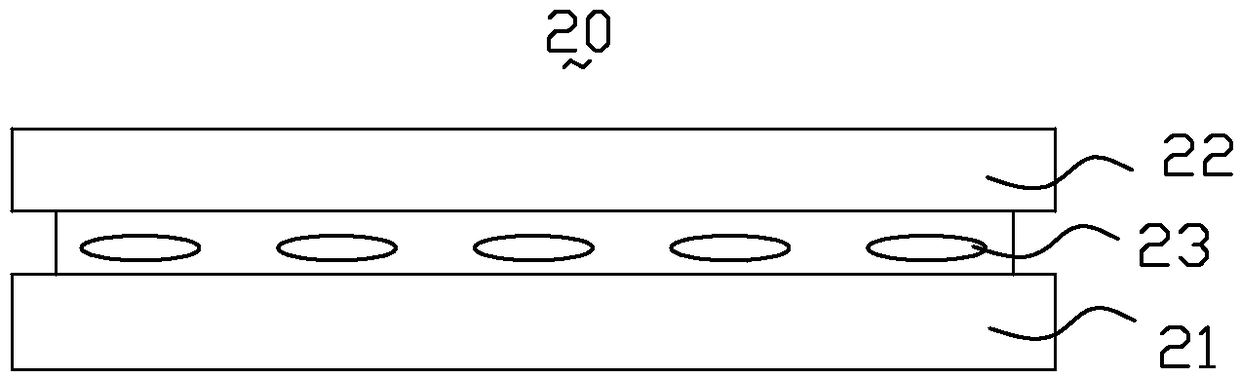

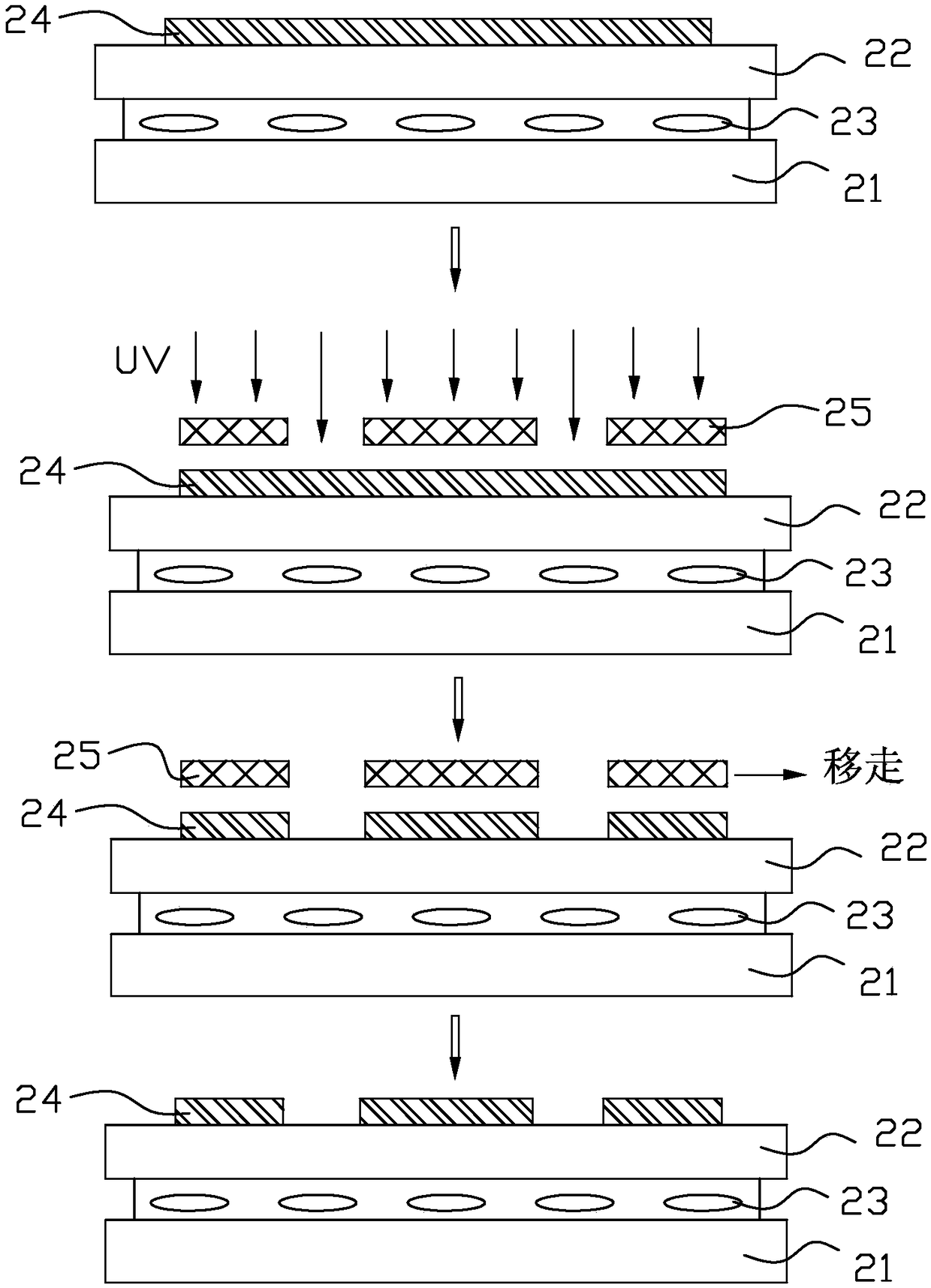

Liquid crystal display and method for manufacturing same

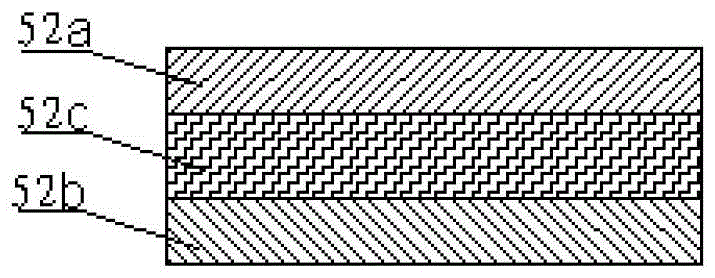

ActiveCN102636919ASimple processHave production costsNon-linear opticsLiquid-crystal displayLiquid crystal

The invention provides a liquid crystal display and a method for manufacturing the same. The liquid crystal display comprises an upper substrate, a lower substrate and a liquid crystal layer, wherein the liquid crystal layer is clamped between the upper substrate and the lower substrate. A plurality of pixel structures are formed on the lower substrate, and each pixel structure comprises a common electrode, a primary pixel electrode, a secondary pixel electrode, a first switching device and a second switching device, wherein the common electrode is formed on the lower substrate and comprises a primary pixel common electrode and a secondary pixel common electrode, the primary pixel electrode corresponds to the primary pixel common electrode, the secondary pixel electrode corresponds to the secondary pixel common electrode, the first switching device is connected with the primary pixel electrode and a data line, and the second switching device is connected with the secondary pixel electrode and a data line. The production technology of the liquid crystal display with a controllable view angle can be simplified, and production cost can be reduced.

Owner:BOE TECH GRP CO LTD

Non-nutrition leak non-fried sweet potato chip processing method

InactiveCN101313740AOvercoming excessive content of color-protecting agent and loss of nutrientsAvoid the production of carcinogen acrylamideFood preparationEnzymeMouthfeel

The invention discloses a method for processing non-fried sweet potato chips without nutrition loss, belonging to the food processing technical field and aiming to provide a green healthy novel chip product which has no nutrition loss and does not contain acrylamide and color-protecting agents. The method for processing the sweet potato chips comprises the following steps of: refined selection of red fleshed sweet potatoes; cleaning; peeling and finishing; slicing to chips, jet impact steam blanching; oil injection; roasting and slaking; drying and cooling package. The sweet potato chips produced by the method have the advantages that: firstly, the jet impact steam blanching enzyme killing and color-protecting technology is adopted and the problems of excessive content of the color-protecting agents, nutrition loss and so on caused by adoption of the color-protecting agents and hot water blanching color protection during the procedure for processing the prior sweet potato chips are solved; secondly, the method adopts the non-fried production technology to avoid generation of carcinogen-acrylamide during the process of producing the prior fried chips; and thirdly, the method adopts the oil injection processing technology to make the product not only have the color and the flavor of the fried chips but also greatly reduce the oil content compared with the prior fried chips, and not only guarantees the mouthfeel and the quality of the chips but also reduces the production cost.

Owner:CHINA AGRI UNIV

Dry powder type shell powder interior wall coating and preparation method thereof

ActiveCN103627261BHave production costsNice decorationAntifouling/underwater paintsCellulose coatingsCobalt-60High energy

The invention relates to a dry powder type shell powder interior wall coating material which has the functions of adsorbing and decomposing harmful gas and peculiar smell, restraining bacteria, sterilizing and resisting static electricity and using shell powder, nanometer inorganic filler and high molecular powder materials as main components. The invention solves the defects of high cost, high energy consumption, pollution and incapability of purifying indoor harmful gas in the existing interior wall coating materials. The coating material uses natural or manually cultivated shell powder as basic materials; meanwhile, a certain quantity of nanometer titanium dioxide and nanometer electric stone powder radiated by cobalt-60 gamma ray and the high molecular powder materials are added; the weight percentages of all components are as follows: 30-60% of shell powder, 10-20% of calcined kaolin, 10-20% of heavy calcium, 10-20% of talcum powder, 1-5% of nanometer titanium dioxide, 1-5% of nanometer electric stone powder, and 5-20% of high molecular powder materials; the particle size of the shell powder is 200-1250 meshes.

Owner:JILIN RIHE TECH DEV

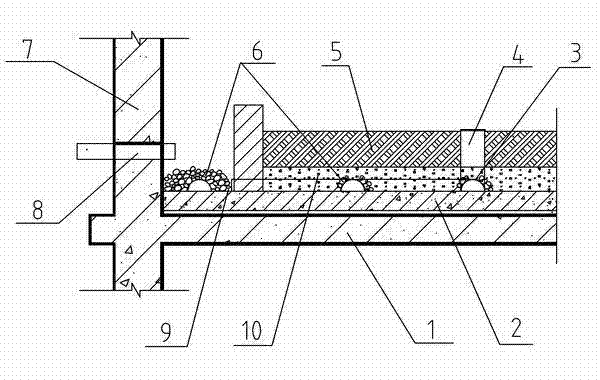

Manufacturing method of environment-friendly ecological waterproof roof

InactiveCN102787722AAvoid puncturePromote growthRoof improvementClimate change adaptationThermal insulationEngineering

The invention provides a manufacturing method of an environment-friendly ecological waterproof roof. The manufacturing method of the environment-friendly ecological waterproof roof includes that basic layer repair is performed on a cast-in-situ roof, a rigid waterproof layer is built, a water and steam discharging layer is established, a water filtering layer is paved on the rigid waterproof layer, the water filtering layer is divided into zones according to intervals, water discharging grooves are arranged between the zones, semicircular blind pipes which are communicated vertically and horizontally are arranged in the water discharging grooves, the semicircular blind pipes in the water discharging grooves and roof water discharging grooves are communicated, earth for growing is paved, and earth for growing is paved on the water filtering layer. The manufacturing method of the environment-friendly ecological waterproof roof breaks a conventional thought of waterproofing work, combines prevention and drainage, gives first place to the drainage, discharges steam to reduce negative pressure by adopting two-stage water and steam discharging systems and stores water and maintains concrete under a natural state. Steam is discharged through ventilation pipes so as to reduce possibility of rotted roots of plants, a whole system is more favorable for growth of the plants, and the manufacturing method integrates functions of water storage, water discharging, steam discharging and thermal insulation and has the advantages of being low in production cost and environment-friendly in materials. Turfs, fruits and vegetables planted on the earth for growing can enhance effects of thermal insulation, sediment fixing, antifreezing, sun blocking and greening.

Owner:邹尚云 +2

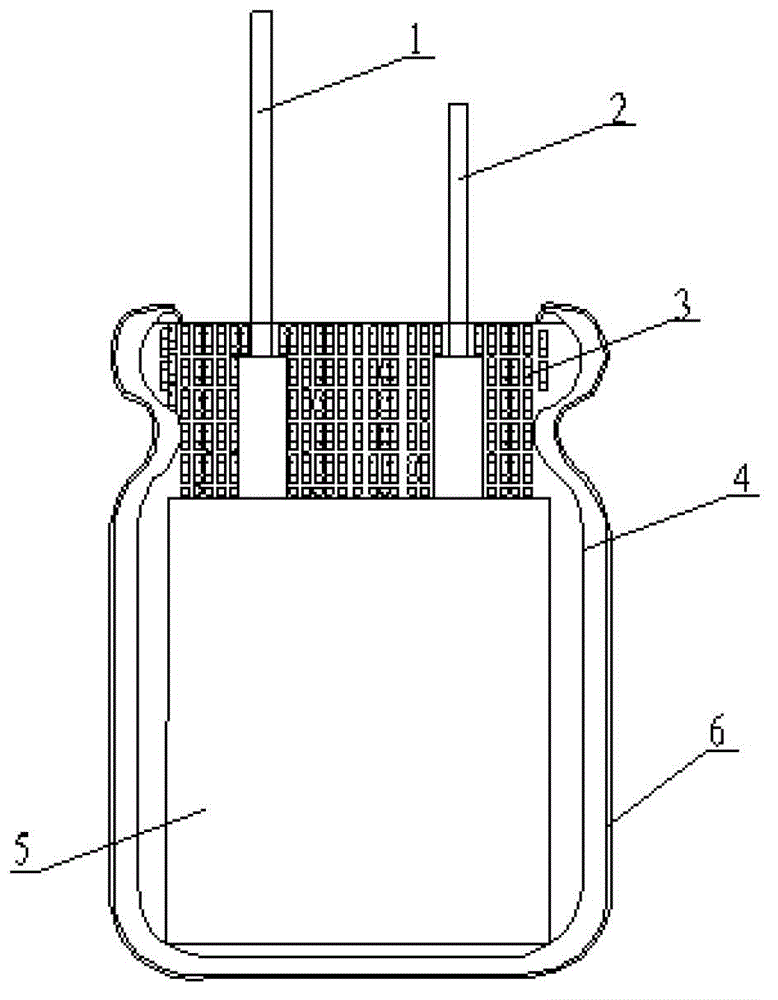

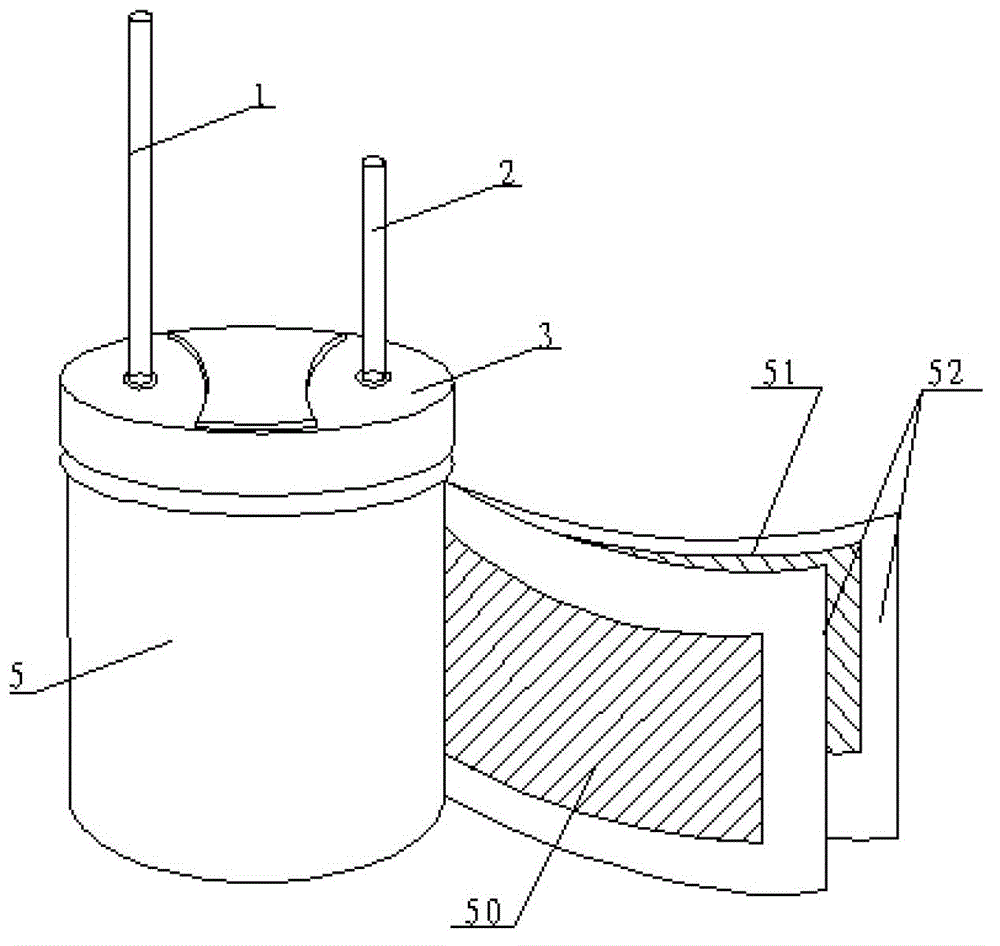

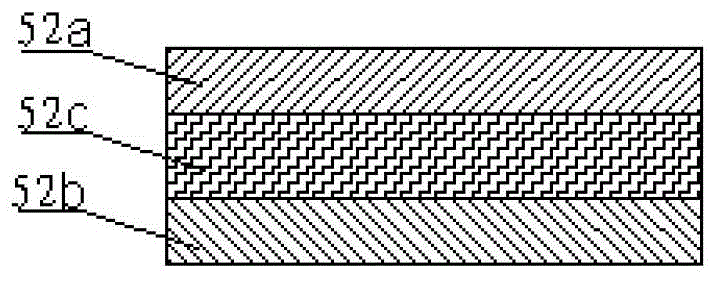

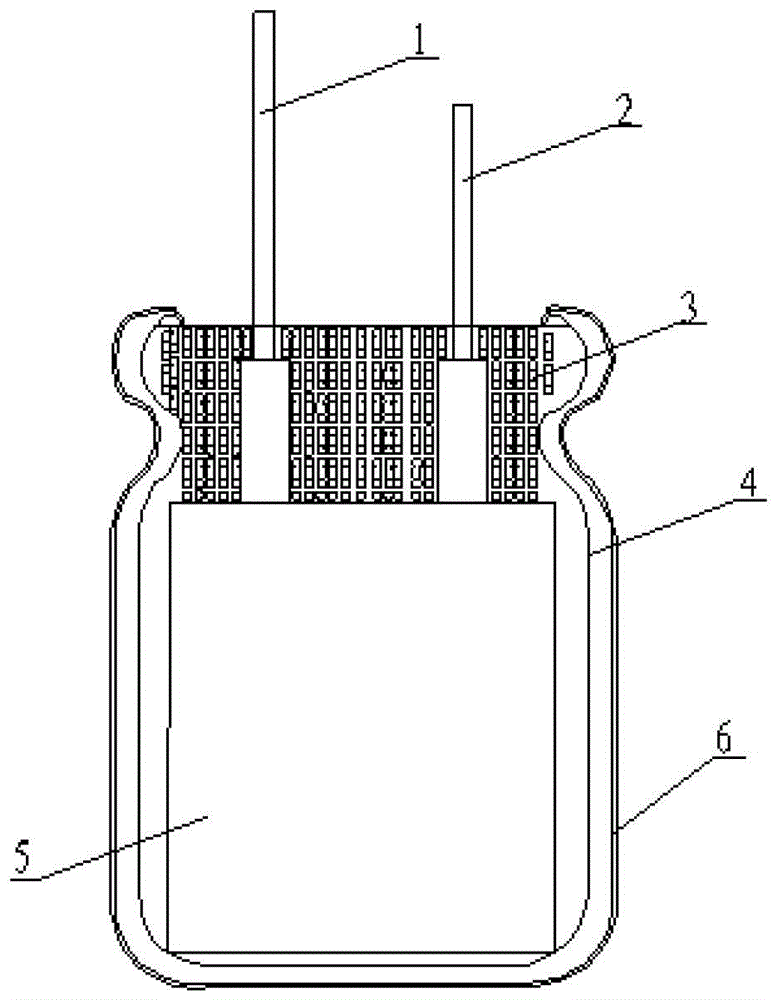

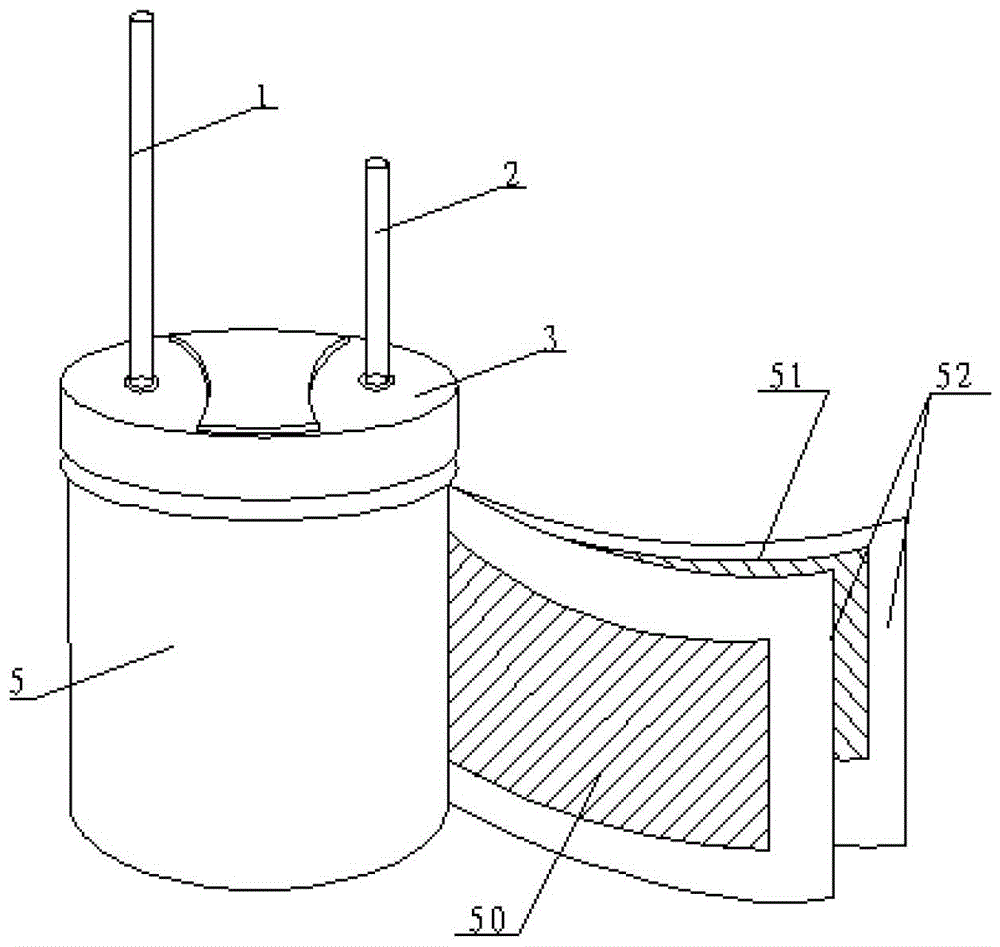

Polymer solid aluminum electrolytic capacitor manufacturing method applicable for alternating current circuit

ActiveCN103337373AReduce consistencyExtended service lifeSolid electrolytic capacitorsCapacitor electrodesPolymer dielectricsAlternating current

The invention relates to a polymer solid aluminum electrolytic capacitor manufacturing method applicable for an alternating current circuit. The polymer solid aluminum electrolytic capacitor manufacturing method applicable for the alternating current circuit comprises steps that: (1), anodized aluminum foils are riveted with guide needles; (2), electrolytic paper is placed between two anodized aluminum foils riveted by the guide needles, the three parts are coiled together to form a core bag, the electrolytic paper is prepared from three layers of non-woven fabric, an upper layer and a lower layer are respectively a coated fiber spun-bonded non-woven fabric, a middle layer is a PET non-woven fabric; (3), the core bag is dipped into a formation liquid, and restoration processing for the two anodized aluminum foils is simultaneously carried out; (4), the core bag is placed in a baking oven with temperature of 85-200 DEG C for dehydration; and (5), the processed core bag is respectively placed in a monomer and an oxidizing agent for impregnation and is heated for polymerization to form a polymer dielectric which is packaged in an aluminum casing and sealed, so a capacitor is obtained. The polymer solid aluminum electrolytic capacitor manufacturing method has properties of simple technology, high production efficiency and low production efficiency, realizes application of products in the alternating circuit and has advantages of low series equivalent resistance, high temperature resistance and long service life.

Owner:FOSHAN SANSHUI RIMING ELECTRONCS

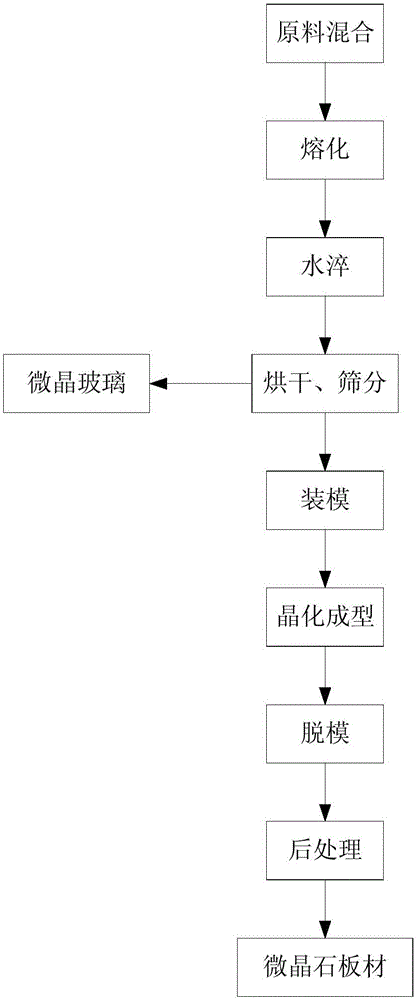

Process for processing microlite slabs

The invention discloses a process for processing microlite slabs, and relates to the technical field of microlite slabs. The finished microlite slabs are obtained by raw material mixing, melting, water quenching, drying, screening, mold filling, crystallization molding, de-molding and post treatment. The process for processing microlite slabs is simple in operation; the finished microlite slabs obtained by raw material mixing, melting, water quenching, drying, screening, mold filling, crystallization molding, de-molding and post treatment have the characteristics of high mechanical strength, strong toughness, good impact resistance and high chemical corrosion resistance, and also have the advantages of stable color, bright color, long service life and low production cost.

Owner:ANHUI JIANSHENG JIYUAN NEW MATERIAL TECH CO LTD

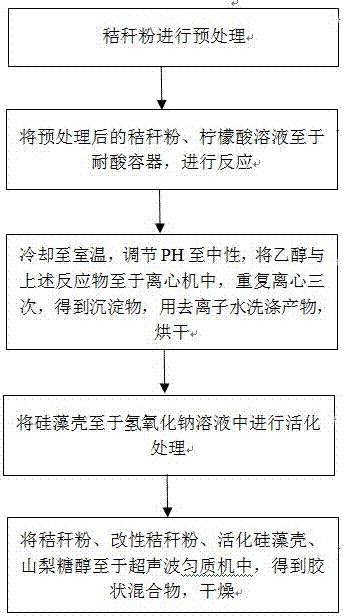

Environment-friendly toxic-free 3D printing consumable and preparation method thereof

InactiveCN107129699AGreen, non-toxic and environmentally friendlyAnti-agingAdditive manufacturing apparatusLiquid wasteToxic material

The invention relates to an environment-friendly toxic-free 3D printing consumable and a preparation method thereof, belonging to the technical field of new materials. A new material is prepared from waste crop straws (main raw material) and diatom shells (auxiliary raw material) and can be applied to 3D printing. The preparation method specifically comprises the steps of carrying out ball-milling pretreatment on straw powder, soaking with acetic acid to activate the straw powder, heating the activated straw powder to react with citric acid, after the reaction is finished, cooling to the room temperature, adjusting the pH value to be neutral, adding ethanol, carrying out centrifugation, washing with deionized water, and drying to obtain modified straw powder, adding the straw powder, activated diatom shells and sorbitol, homogenizing and mixing so as to obtain a colloidal mixture, and drying, so as to obtain the environment-friendly toxic-free 3D printing consumable. By utilizing the preparation method, the environment-friendly toxic-free 3D printing consumable can be obtained; the consumable is high in strength and good in forming performance and has the characteristics of environmental friendliness, no toxin and the like; the waste straws and diatom shells are turned into wealth, so that the timber resource is saved, the utilization ratio of the timber is increased, the cost is greatly lowered, and meanwhile, the preparation method is of great significance to the environmental protection; and the manufacturing process is simplified, the production cost is lowered, and toxic waste liquid which is difficultly treated is not generated.

Owner:TONGJI UNIV

Water gel and ammonium nitrate fuel oil explosive and production method thereof

ActiveCN103242115AProduction cost economyEnsure safetyExplosive working-up apparatusTechnical supportFuel oil

The invention relates to the technical field of industrial explosive production, and in particular relates to a water gel and ammonium nitrate fuel oil explosive and a production method thereof. The water gel and ammonium nitrate fuel oil explosive with adjustable density, initiation sensitivity, explosive property, free-running property or viscosity is produced from different special ammonium nitrate fuel oil explosives and water gel explosives according to different proportioning requirements, has the characteristics of economical production cost and the like, meets the actual demands of different blasting works, and especially solves the problem of difficult explosive filling in an upward blast hole. The research proves that the water gel and ammonium nitrate fuel oil explosive with the adjustable initiation sensitivity can ensure the safety of explosive filling in the on-site blast hole, provides a material basis and technical support for smooth national economy construction, generates good economic and social benefits, and has very good application and popularization prospects.

Owner:山东圣世达化工有限责任公司

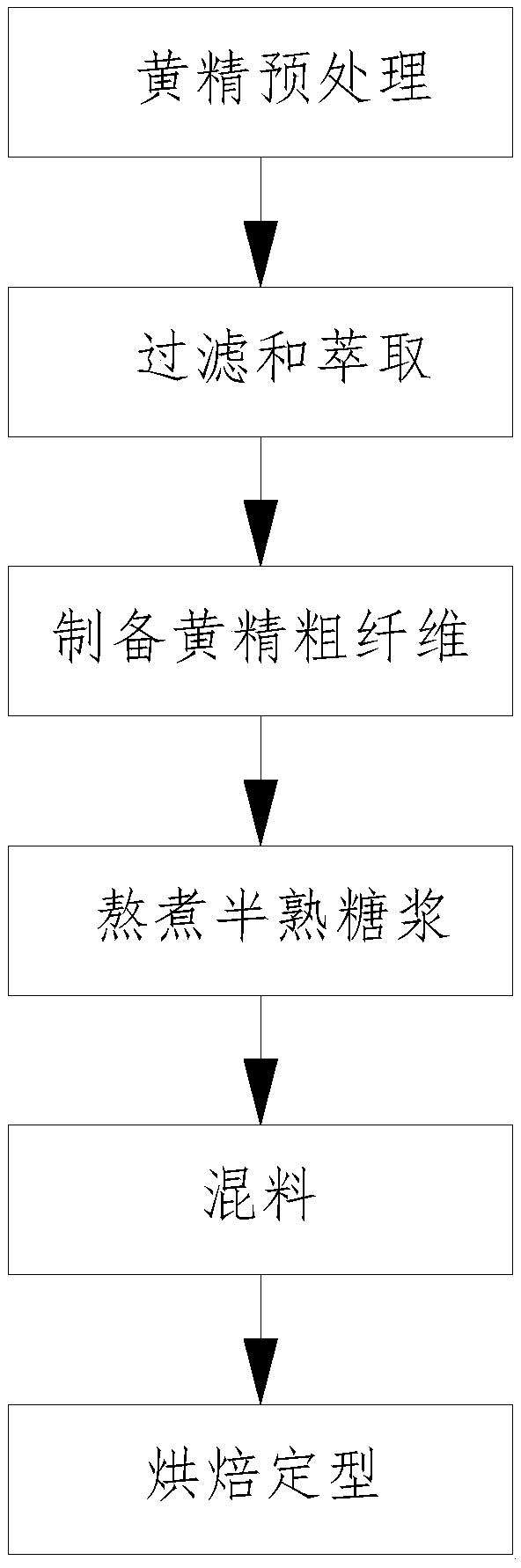

Rhizoma polygonati sugar production formula and production process thereof

The invention discloses a rhizoma polygonati sugar production formula and a production process thereof. The formula comprises 150 to 200 parts of rhizoma polygonati blocks, 10 to 20 parts of maltose,30 to 50 parts of stevioside, 25 to 30 parts of pine needle extract, 100 to 125 parts of whey protein powder, 160 to 180 parts of dried skim milk, 180 to 200 parts of milk, 10 to 20 parts of modifiedaloe gel, 40 to 50 parts of starch, 55 to 70 parts of radix puerariae arrow root powder, 20 to 30 parts of taurine, 30 to 40 parts of purple perilla seed oil, 2 to 5 parts of amylase, 10 to 30 parts of lycium barbarum and 2 to 3 parts of high methoxyl pectin. The rhizoma polygonati sugar production formula and the production process thereof, which are disclosed by the invention, have the beneficial effects that rhizoma polygonati sugar prepared by the rhizoma polygonati sugar production formula has the functions of boosting qi and nourishing yin, tonifying the spleen, moistening lungs and tonifying the kidney and can be used for relieving symptoms of weakness of the spleen and the stomach, body tireness and debilitation, asthenia of essence and blood, endogenous heat consumptive thirst andthe like; the rhizoma polygonati sugar is added with the lycium barbarum and the stevioside, so that when effects of the rhizoma polygonati sugar are increased, carbohydrate in the rhizoma polygonatisugar, which can be directly absorbed by human bodies, is also reduced, and the rhizoma polygonati sugar has the effects of clearing away heat and relieving a cough; and in the process of producing the rhizoma polygonati sugar, residues left after rhizoma polygonati is boiled with water are subjected to puffing fermentation and used as a raw material for producing the rhizoma polygonati sugar, sothat fresh rhizoma polygonati is sufficiently utilized.

Owner:湖南华夏湘众药业饮片有限公司

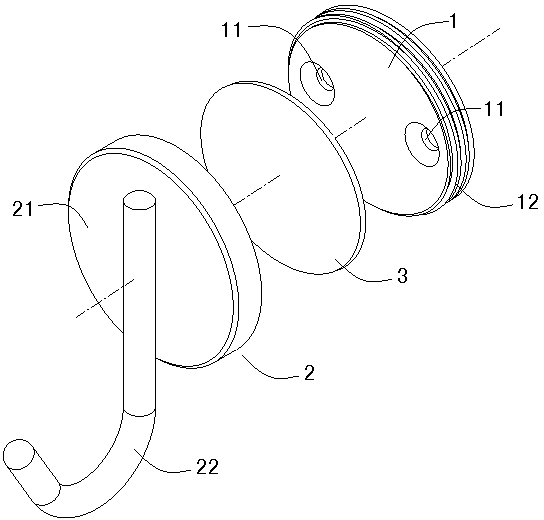

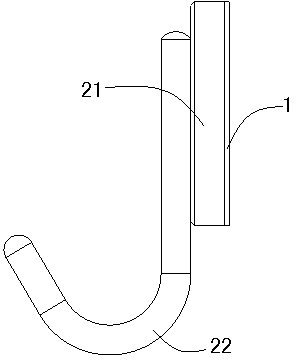

Wardrobe hook with screw concealing function

The invention discloses a wardrobe hook with a screw concealing function, which is characterized by comprising a base (1) and a hook component (2), wherein two mounting fixing holes (11) are formed in the base (1); external threads (12) are formed on the outer side of the base (1); the hook component (2) consists of a hook seat (21) and a hook head (22); the base (1) is sleeved with the hook seat (21) which is in threaded connection and fit with the external threads (12); and the upper part of the hook head (22) is in welded connection with the hook seat (21) into a whole. The hook has the advantages of good protection effect on clothing, fastness, reliability, low production cost, convenience in processing, and simple structure.

Owner:何敬丽

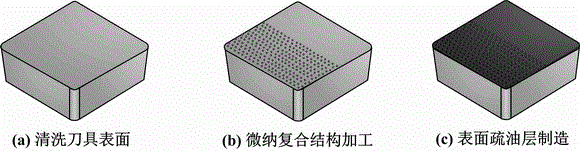

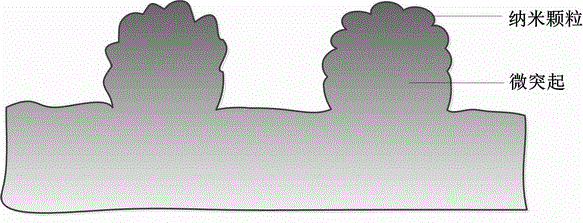

Preparation method of oleophobic cutter with micro-nano composite structure surface

ActiveCN105619041AImprove lubrication statusReduce frictionAustenitic stainless steelSurface finishing

The invention discloses a preparation method of an oleophobic cutter with a micro-nano composite structure surface, and belongs to the technical field of manufacturing of mechanical cutting tools. A micro-nano composite structure can be machined on the surface of a cutter by using a laser processing technology, and is micron projections formed on the surface of the laser-processed cutter and nano particles on the micron projections; and a certain surface treatment is performed for the composite structure to form an oleophobic cutter surface with the micro-nano composite structure. Under the lubricating condition, because of lipophobicity of the cutter surface, cutting liquid can be supplied to a cutter-chip interface more quickly, the lubricating state of a cutting area can be improved, the friction force of the cutter-chip interface is reduced, the guarantee is provided for friction reduction and wear reduction of the cutter, the cutting temperature can be lowered, and the bonding phenomenon of the cutter surface is relieved; and the oleophobic cutter can be widely applied to cutting and high-speed cutting of difficult cutting materials (such as titanium alloys, ultrahigh-strength steel, austenitic stainless steel), so that the cutter durability and the workpiece surface quality can be greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Non-nutrition loss non-fried sweet potato chip processing method

The invention discloses a method for processing non-fried sweet potato chips without nutrition loss, belonging to the food processing technical field and aiming to provide a green healthy novel chip product which has no nutrition loss and does not contain acrylamide and color-protecting agents. The method for processing the sweet potato chips comprises the following steps of: refined selection ofred fleshed sweet potatoes; cleaning; peeling and finishing; slicing to chips, jet impact steam blanching; oil injection; roasting and slaking; drying and cooling package. The sweet potato chips produced by the method have the advantages that: firstly, the jet impact steam blanching enzyme killing and color-protecting technology is adopted and the problems of excessive content of the color-protecting agents, nutrition loss and so on caused by adoption of the color-protecting agents and hot water blanching color protection during the procedure for processing the prior sweet potato chips are solved; secondly, the method adopts the non-fried production technology to avoid generation of carcinogen-acrylamide during the process of producing the prior fried chips; and thirdly, the method adoptsthe oil injection processing technology to make the product not only have the color and the flavor of the fried chips but also greatly reduce the oil content compared with the prior fried chips, and not only guarantees the mouthfeel and the quality of the chips but also reduces the production cost.

Owner:CHINA AGRI UNIV

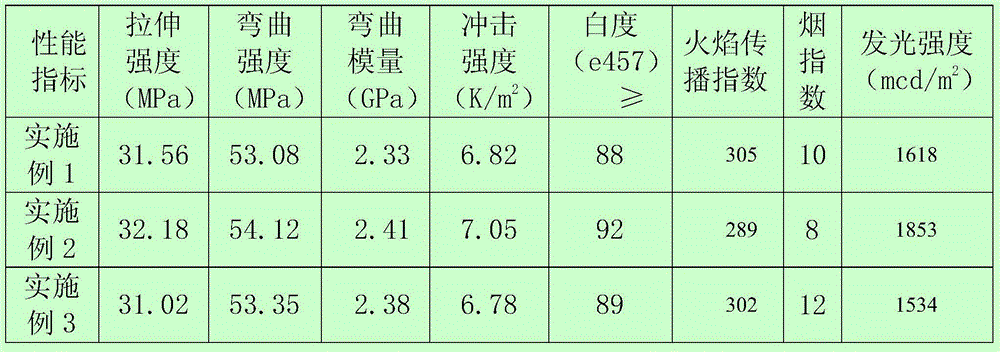

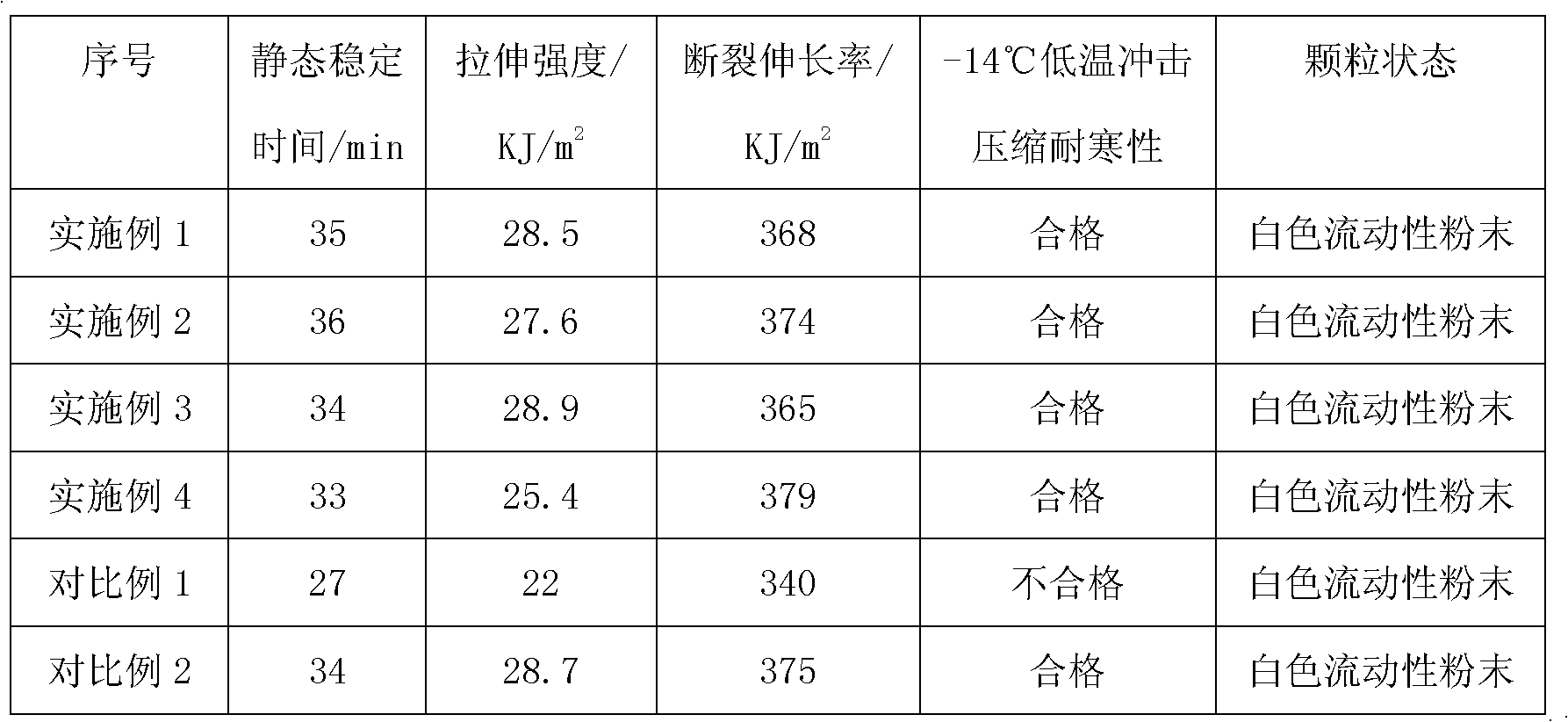

High-impact strength PVC pinch plate and making method thereof

The invention discloses a high-impact strength PVC pinch plate and a making method thereof. The PVC pinch plate is made from, by weight, 45-50 parts of PVC resin, 110-120 parts of heavy calcium carbonate, 3-4 parts of a liquid zinc and tin stabilizer, 1-2 parts of PE wax, 1-2 parts of stearic acid, 3.5-4 parts of titanium dioxide, 0.1-0.15 parts of a whitener, 10-20 parts of recovered PVC wastes, 2-3 parts of an ACM impact modifier, 0.05-0.1 parts of light storing powder, 1-2 parts of nano-silica, 0.3-0.8 parts of a foaming agent, 0.03-0.08 parts of a micro-pore regulator and 3-4 parts of a halogen-free fire retardant. The PVC pinch plate made through the steps of mixing above raw materials, cooling the obtained mixture, drawing the cooled mixture and carrying out curing molding has the advantages of high impact strength, excellent flame retardation performance, environmental protection, low production cost and light storing performance.

Owner:脱德明

A method of manufacturing a polymer solid aluminum electrolytic capacitor suitable for AC circuits

ActiveCN103337373BReduce consistencyExtended service lifeSolid electrolytic capacitorsCapacitor electrodesPolymer dielectricsTemperature resistance

The invention relates to a polymer solid aluminum electrolytic capacitor manufacturing method applicable for an alternating current circuit. The polymer solid aluminum electrolytic capacitor manufacturing method applicable for the alternating current circuit comprises steps that: (1), anodized aluminum foils are riveted with guide needles; (2), electrolytic paper is placed between two anodized aluminum foils riveted by the guide needles, the three parts are coiled together to form a core bag, the electrolytic paper is prepared from three layers of non-woven fabric, an upper layer and a lower layer are respectively a coated fiber spun-bonded non-woven fabric, a middle layer is a PET non-woven fabric; (3), the core bag is dipped into a formation liquid, and restoration processing for the two anodized aluminum foils is simultaneously carried out; (4), the core bag is placed in a baking oven with temperature of 85-200 DEG C for dehydration; and (5), the processed core bag is respectively placed in a monomer and an oxidizing agent for impregnation and is heated for polymerization to form a polymer dielectric which is packaged in an aluminum casing and sealed, so a capacitor is obtained. The polymer solid aluminum electrolytic capacitor manufacturing method has properties of simple technology, high production efficiency and low production efficiency, realizes application of products in the alternating circuit and has advantages of low series equivalent resistance, high temperature resistance and long service life.

Owner:FOSHAN SANSHUI RIMING ELECTRONCS

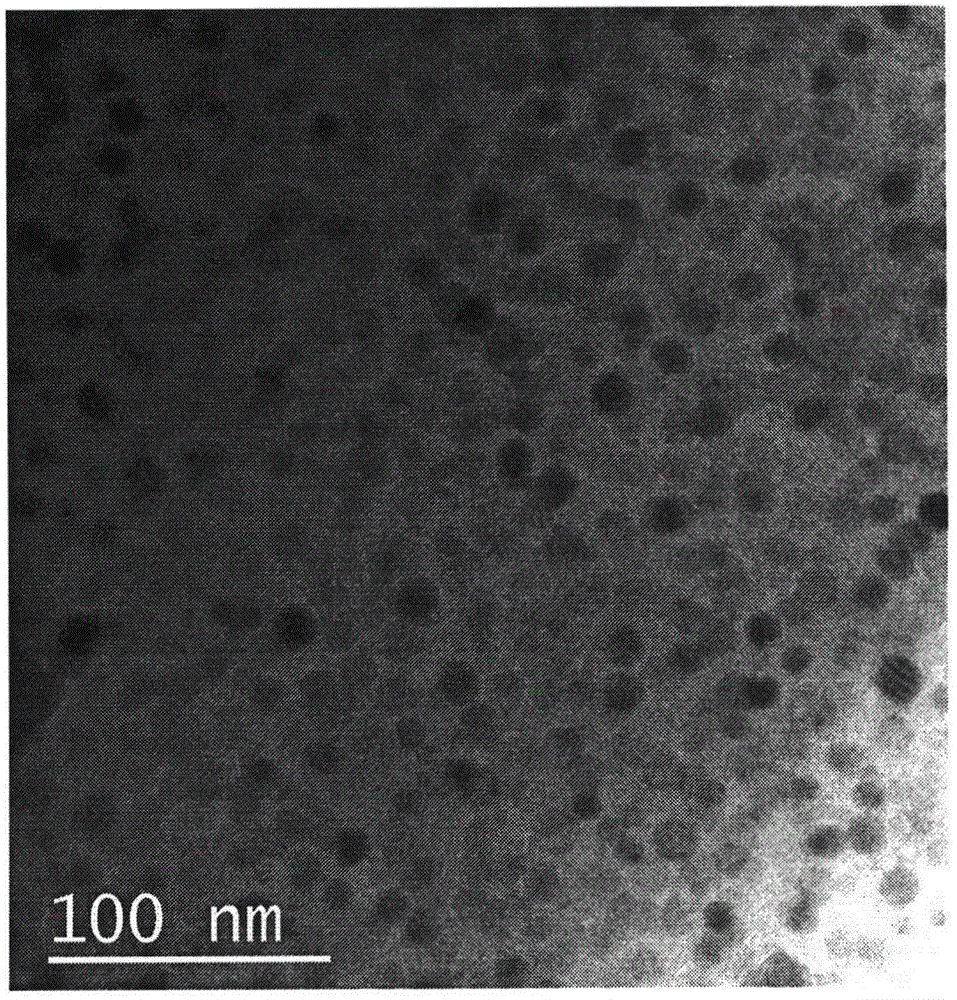

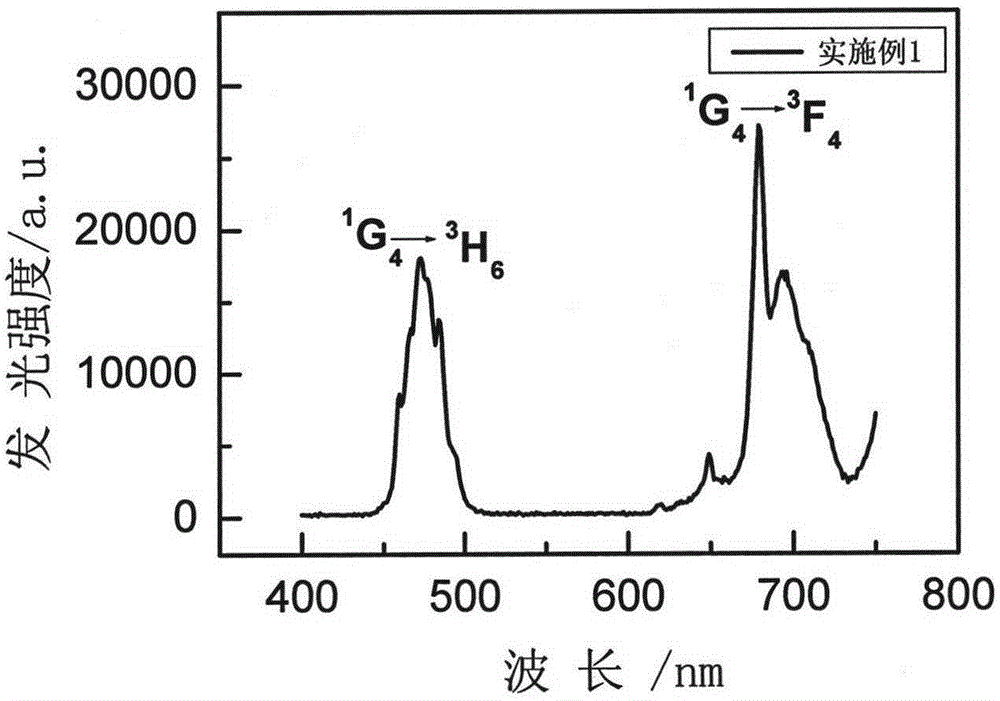

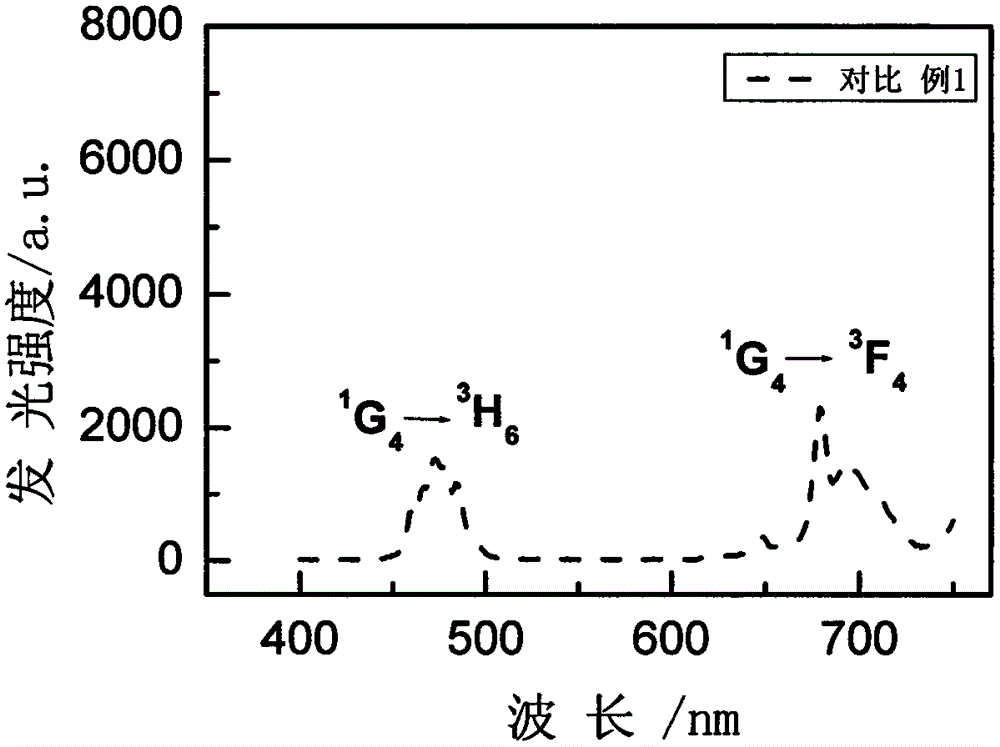

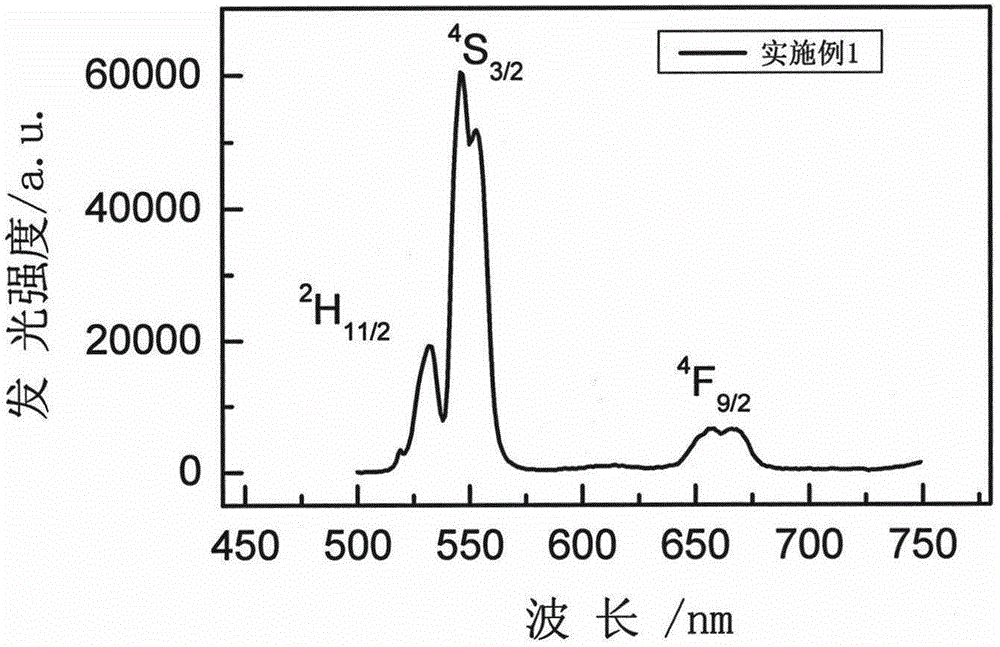

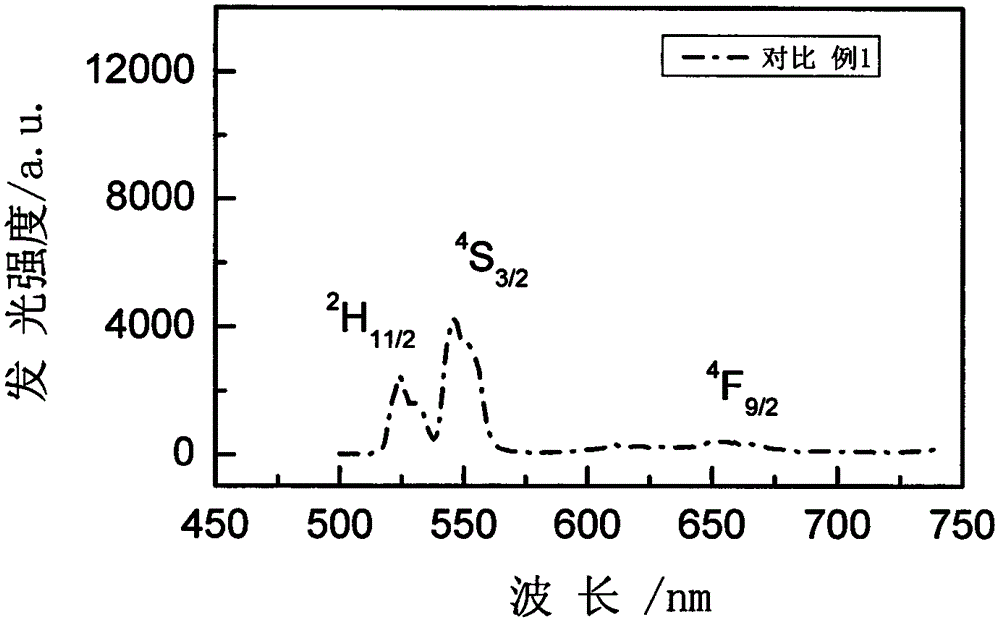

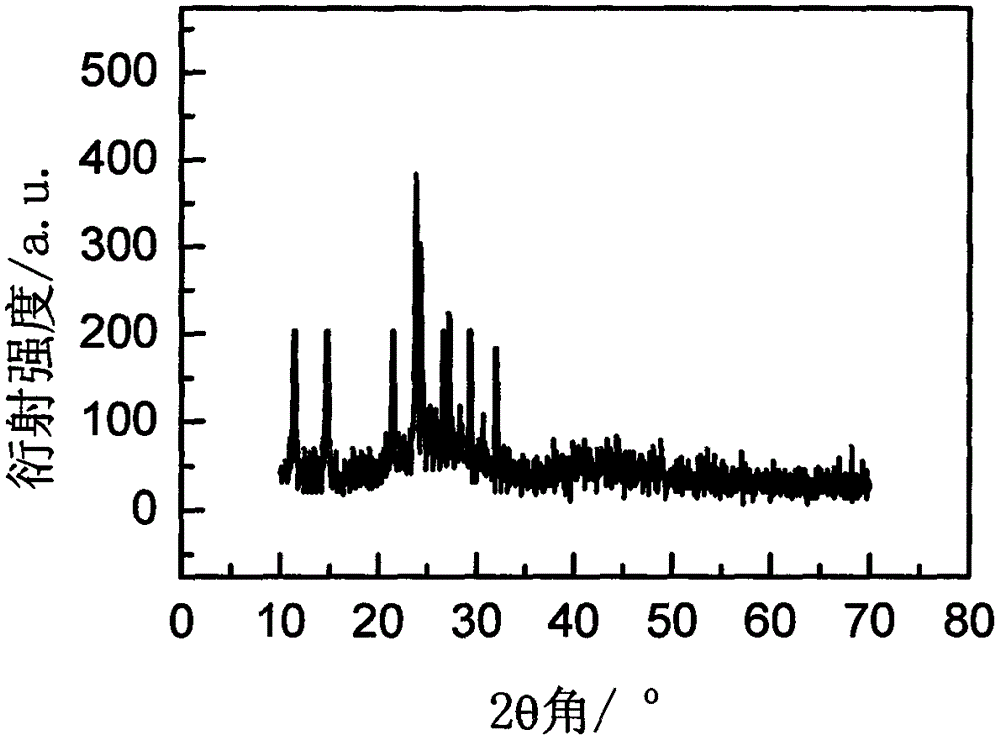

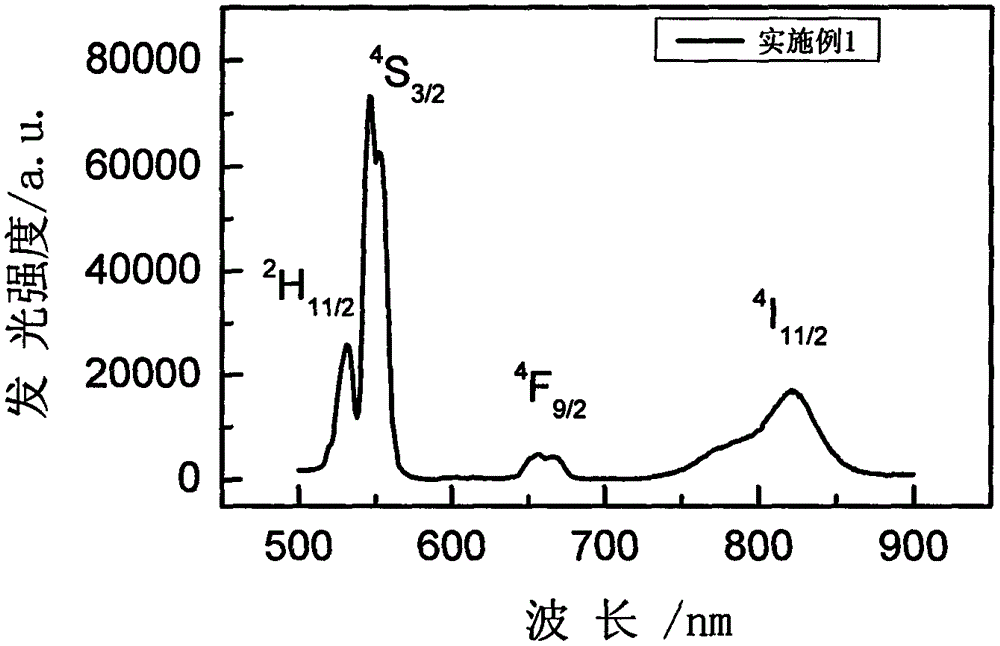

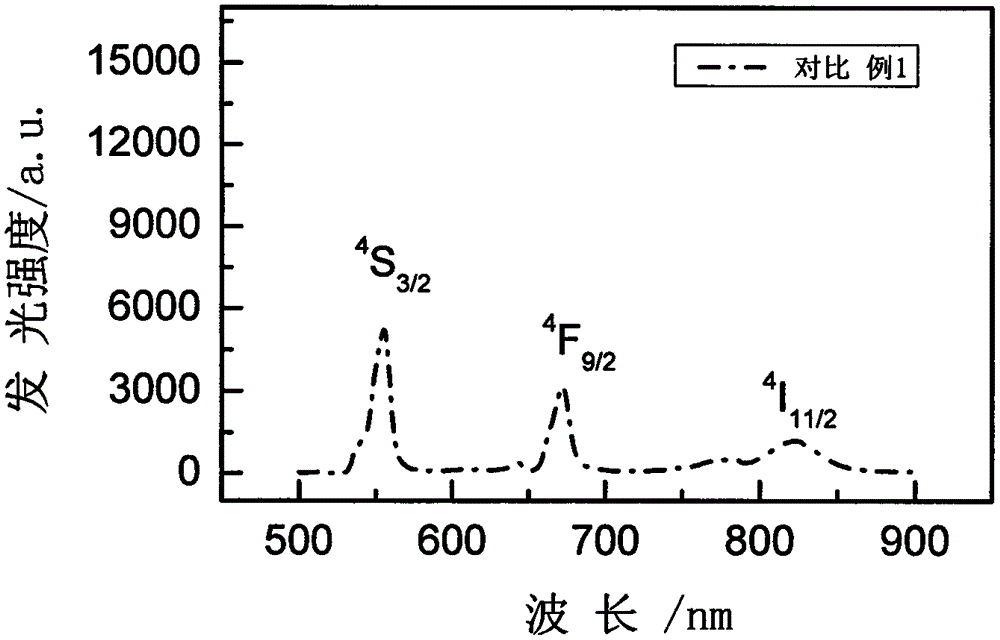

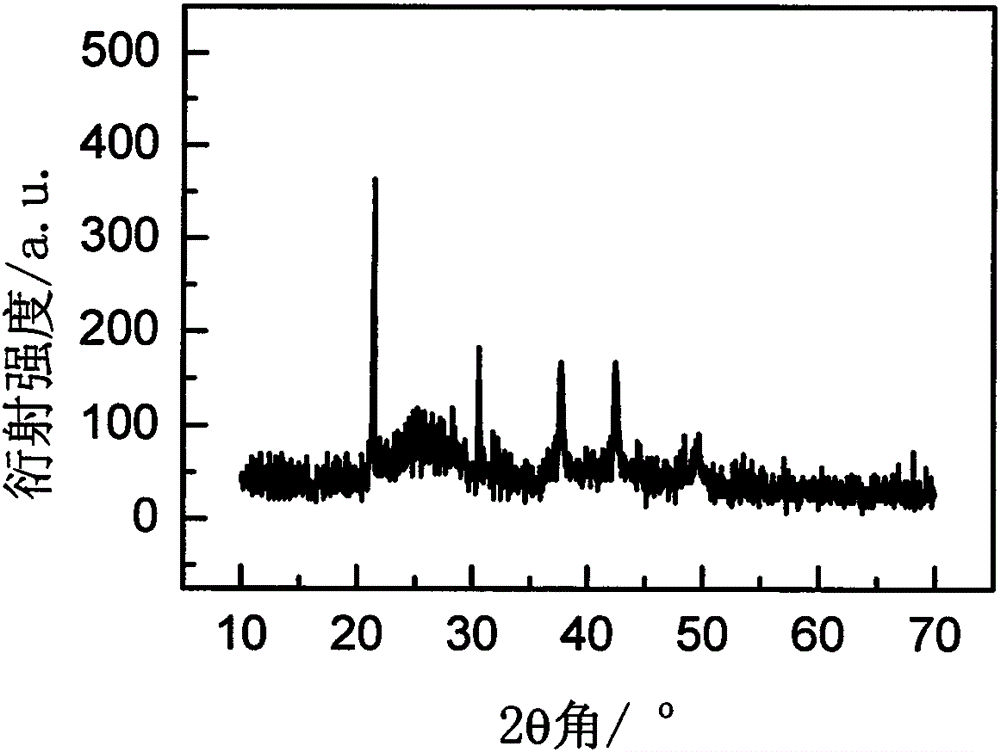

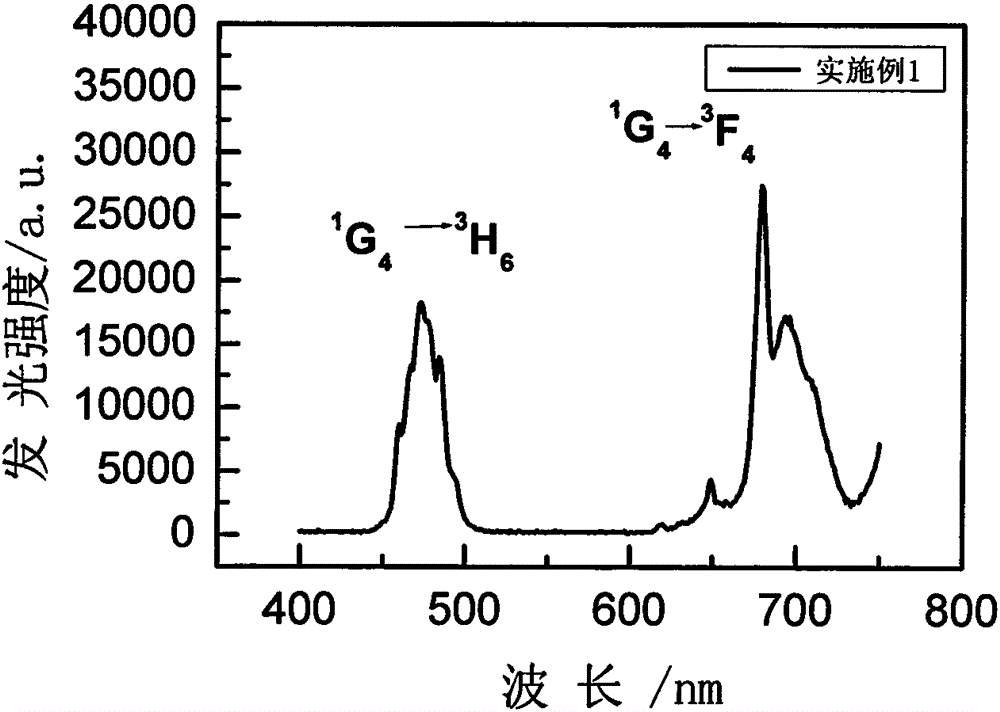

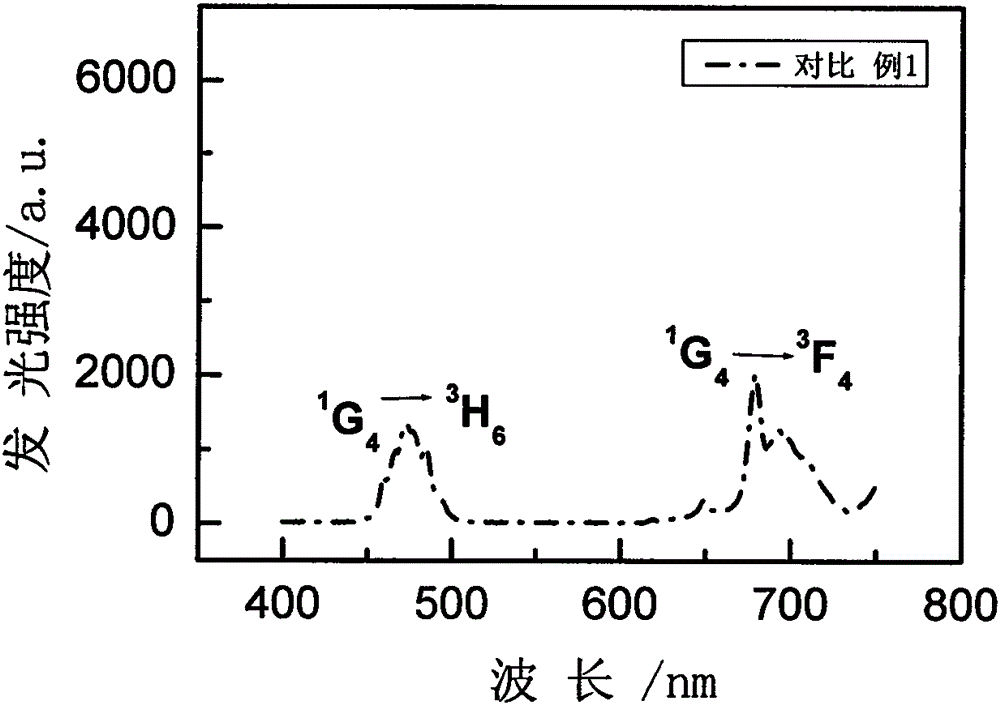

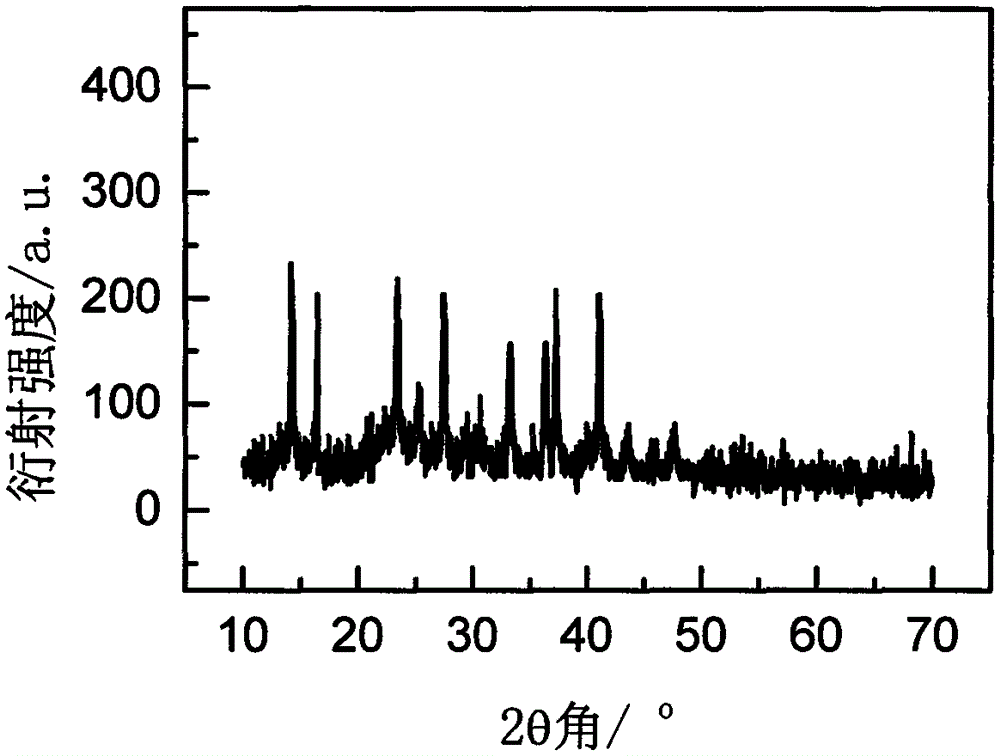

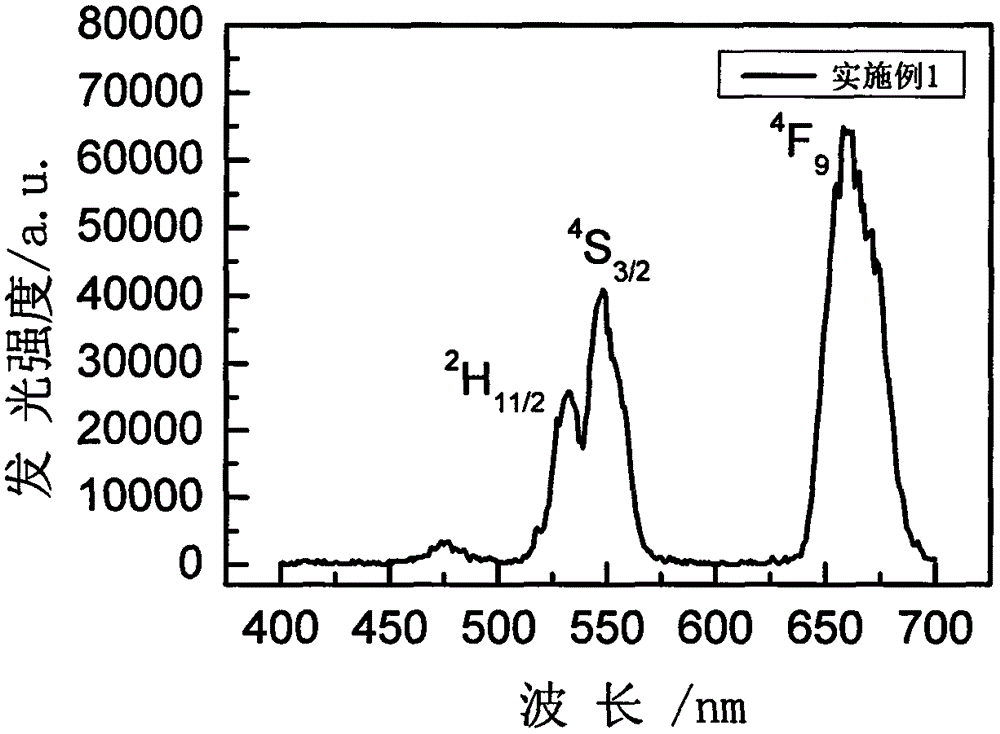

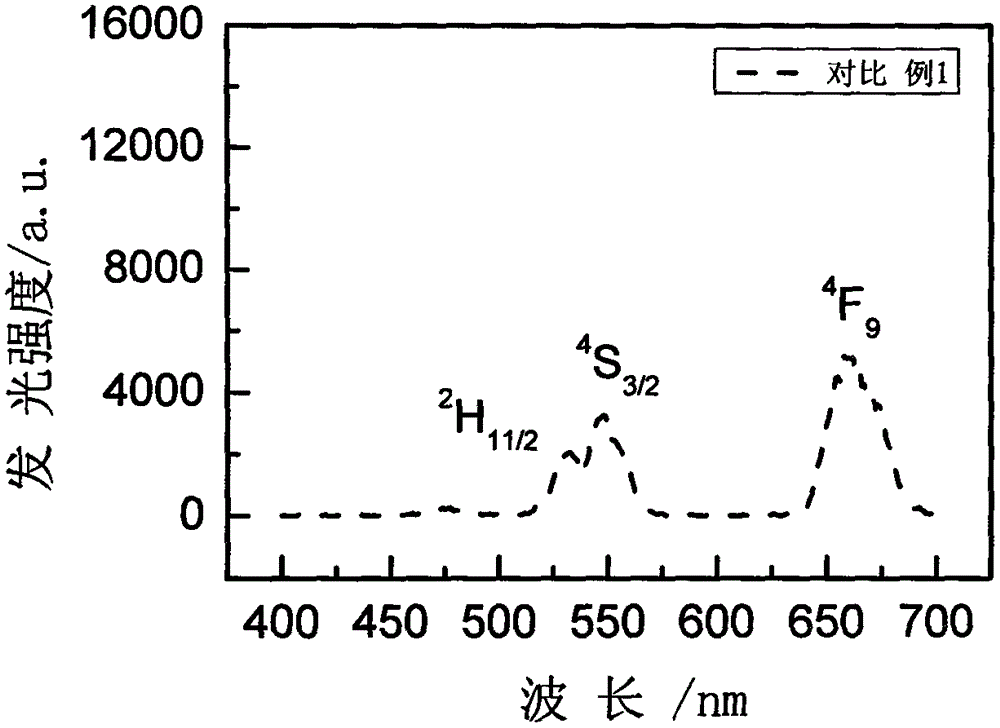

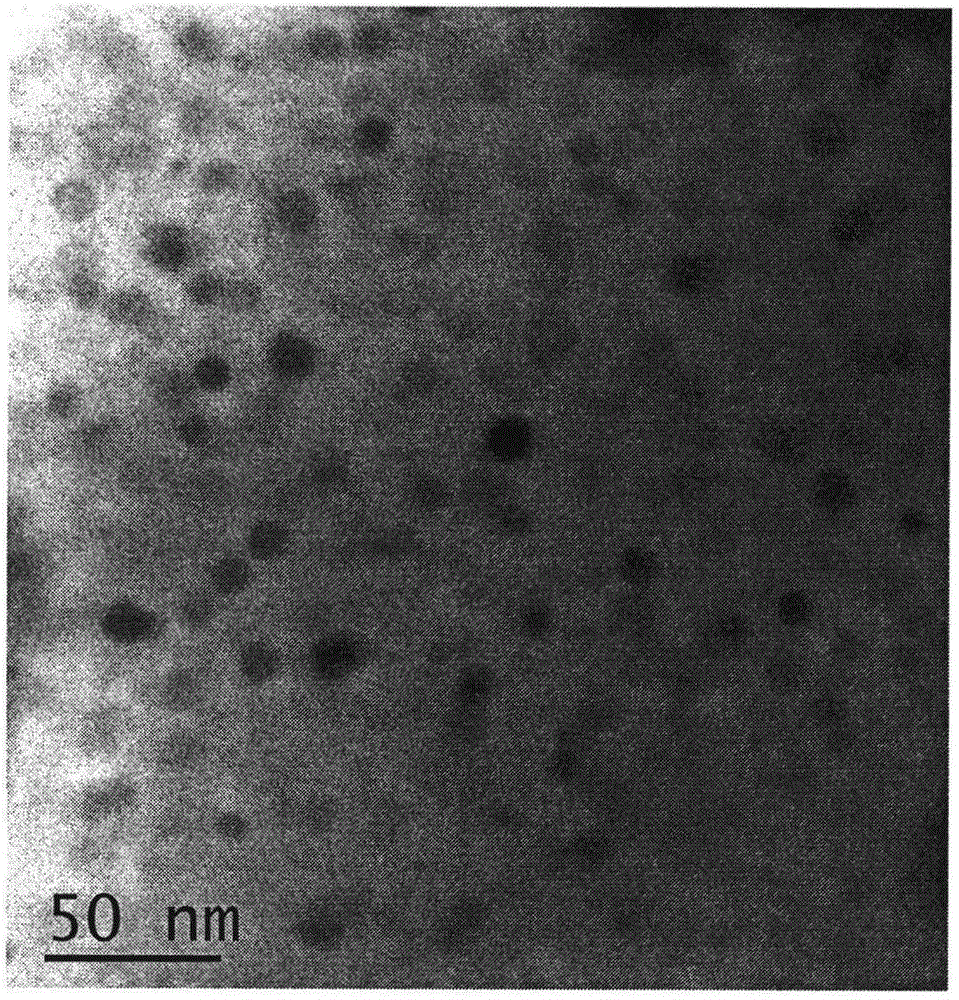

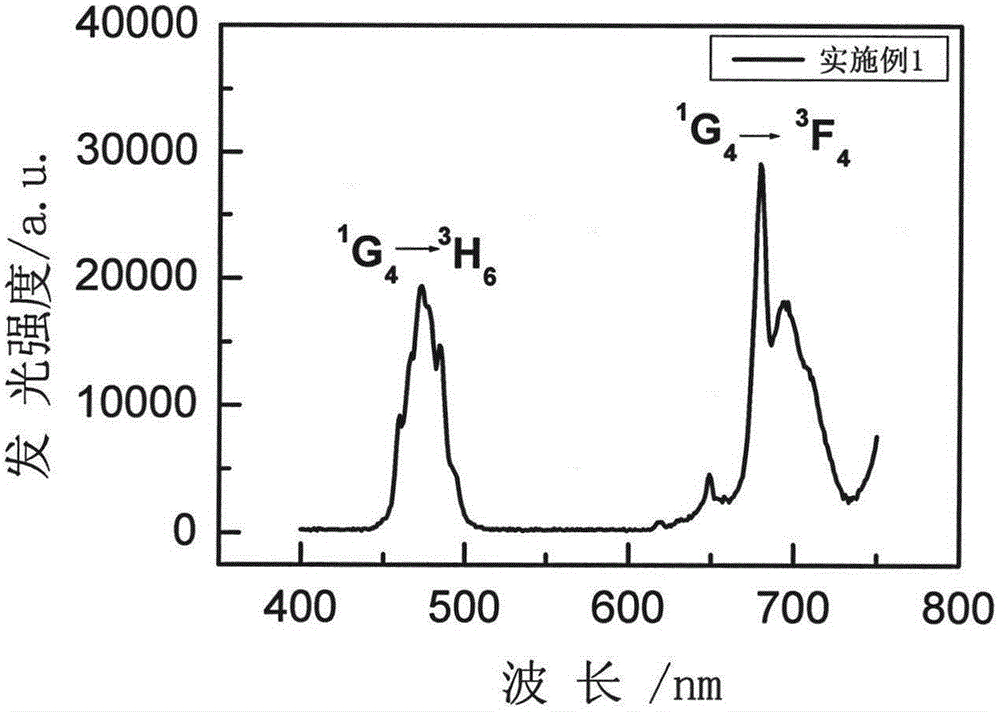

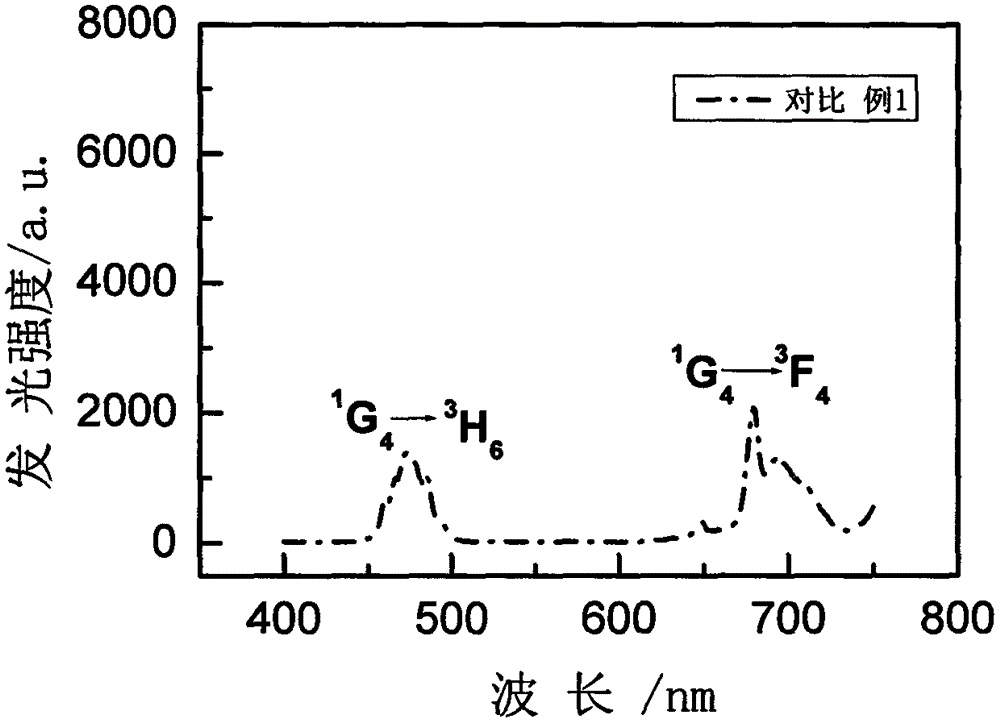

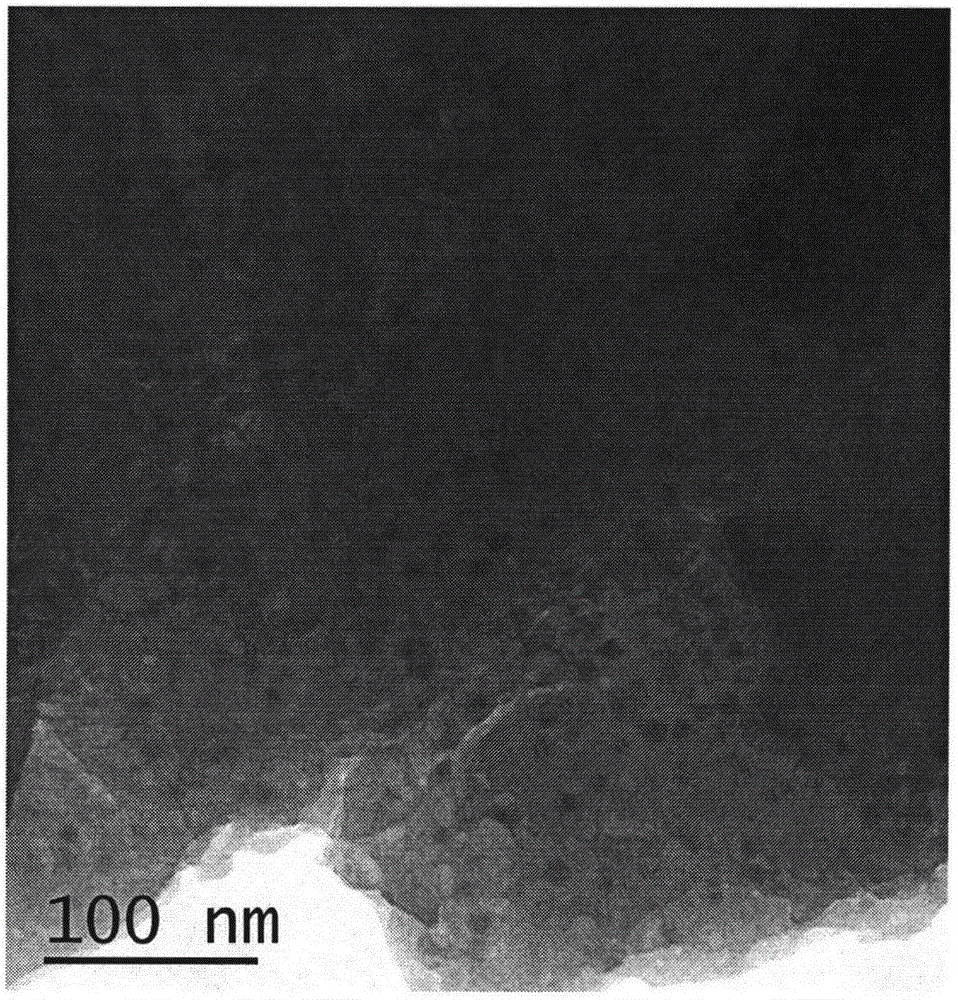

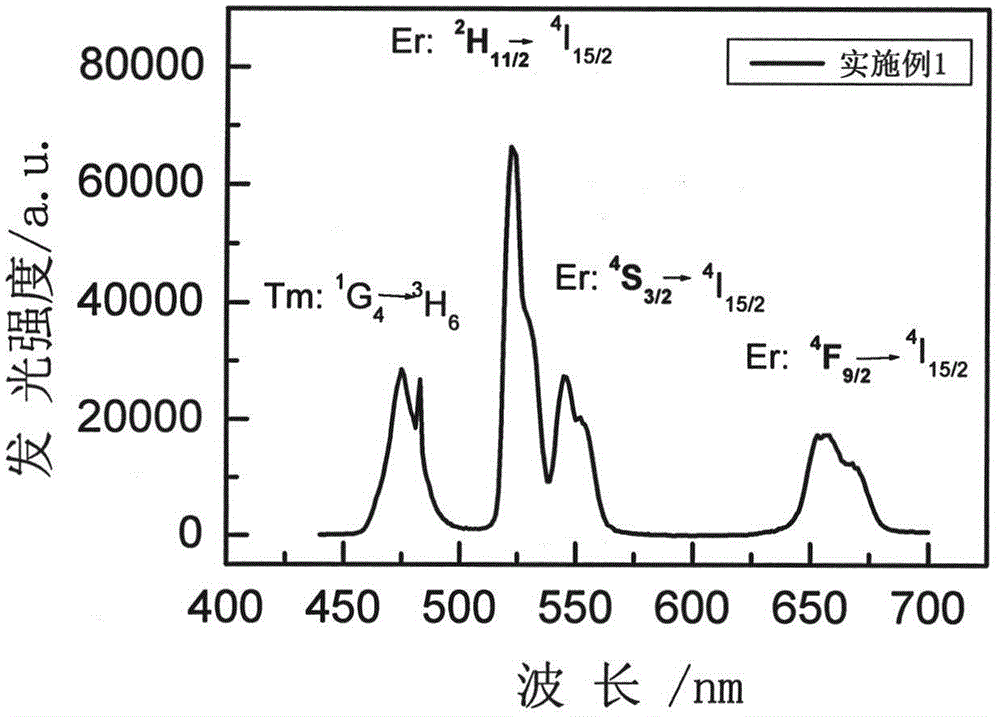

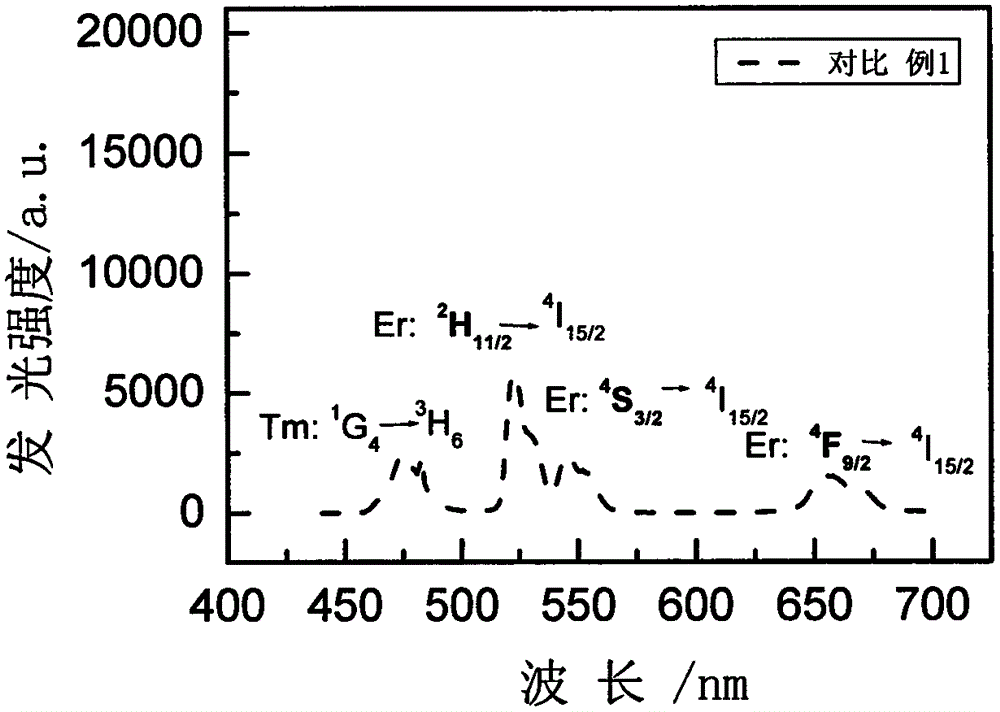

Rare earth ion doped K2CeCl5 glass ceramic and preparation method thereof

The invention discloses a rare earth ion doped K2CeCl5 glass ceramic which comprises the following components by mole percent: 87.8-94mol% of SiO2, 5.5-10mol% of K2CeCl5 and 0.5-3mol% of LnCl3, wherein the LnCl3 is selected from at least one of YbCl3, ErCl3, TmCl3 and HoCl3. The rare earth ion doped K2CeCl5 glass ceramic prepared by the invention has the advantages of transparence, deliquesce resistance, excellent mechanical property, higher blue violet light transmittance, low phonon energy and high up-conversion efficiency; the efficiency of the up-conversion laser device is greatly increased; the preparation method for the glass ceramic is simple; the production cost is lower.

Owner:NINGBO UNIV

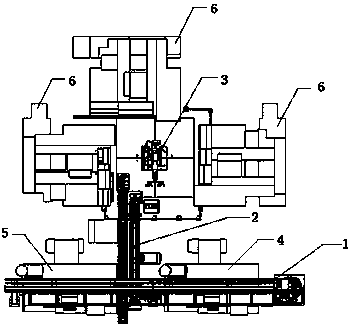

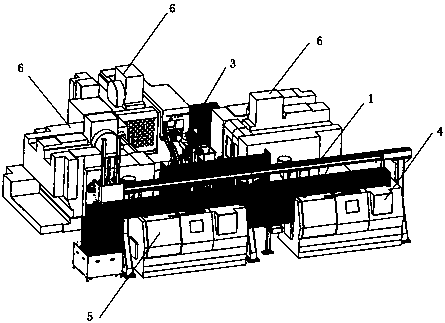

Full-automatic machining process of air conditioner compressor scroll plate

InactiveCN108714823AReduce labor intensityOptimize layoutMetal working apparatusEngineeringMachining process

The invention discloses a full-automatic machining process of an air conditioner compressor scroll plate. The full-automatic machining process comprises the following steps that workpieces are conveyed from a stock bin to an OP1 machining center and an OP2 machining center through a first mechanical arm, the OP1 machining center and the OP2 machining center are used for machining the workpieces one by one according to the workpiece feeding sequence, the machined workpieces are conveyed into a working area of a third mechanical arm through a third mechanical arm, then the workpieces are distributed to OP3 machining centers through a third mechanical arm, the OP3 machining centers are used for milling scroll grooves in the workpieces, and the machined workpieces are transferred to a storagebox through the third mechanical arm. According to the full-automatic machining process of the air conditioner compressor scroll plate, manual work is replaced by an automatic production line, the production efficiency is improved, and production cost is saved.

Owner:苏州勤美达精密机械有限公司

Rare-earth ion doped Rb2LaBr5 microcrystalline glass and preparation method thereof

The invention discloses rare-earth ion doped Rb2LaBr5 microcrystalline glass comprising the following components in mole percentage: 88-93mol% of SiO2, 6.5-9mol% of Rb2LaBr5 and 0.5-3mol% of LnBr3, wherein the LnBr3 is at least one of YbBr3, ErBr3, TmBr3 and HoBr3. The rare-earth ion doped Rb2LaBr5 microcrystalline glass disclosed by the invention has the advantages of being transparent and deliquescence-resistant, good in mechanical property and relatively high in blue-violet light transmission, having the performances of low phonon energy, high up-conversion efficiency and the like, and being capable of greatly improving the efficiency of an up-conversion laser; moreover, the preparation method of the microcrystalline glass is simple, and is relatively low in production cost.

Owner:NINGBO UNIV

Rare earth ion doped K3GdI6 microcrystal glass and preparation method thereof

InactiveCN105271769AEasy to prepareHigh transmittance of blue-violet lightRare earth ionsTransmittance

The invention discloses rare earth ion doped K3GdI6 microcrystal glass and a preparation method thereof. The rare earth ion doped K3GdI6 microcrystal glass comprises the following components in percentage by mole: 87-94mol% of SiO2, 5.7-10mol% of K3GdI6 and 0.3-3mol% of LnI3, wherein LnC13 is at least one of YbI3, ErI3, TmI3 and HoI3. The rare earth ion doped K3GdI6 microcrystal glass has the advantages of transparency, good air-slake resistance, good mechanical property and high blue-violet emission transmittance and has properties such as low phonon energy and high upconversion efficiency, the efficiency of an upconversion laser can be greatly improved, and moreover, the microcrystal glass is simple in preparation method and relatively low in production cost.

Owner:NINGBO UNIV

Rare earth ion doped Cs3CeC16 glass ceramic and preparation method thereof

InactiveCN105271773AExcellent up-conversion performancePromote conversionRare earth ionsTransmittance

The invention discloses a rare earth ion doped Cs3CeC16 glass ceramic which comprises the following components by mole percent: 87-93.5mol% of SiO2, 66-10mol% of Cs3CeC16 and 0.5-3mol% of LnCl3, wherein the LnCl3 is selected from at least one of YbCl3, ErCl3, TmCl3 and HoCl3. The rare earth ion doped Cs3CeC16 glass ceramic prepared by the invention has the advantages of transparence, deliquesce resistance, excellent mechanical property, higher blue violet light transmittance, low phonon energy and high up-conversion efficiency; the efficiency of the up-conversion laser device is greatly increased; the preparation method for the glass ceramic is simple; the production cost is lower.

Owner:NINGBO UNIV

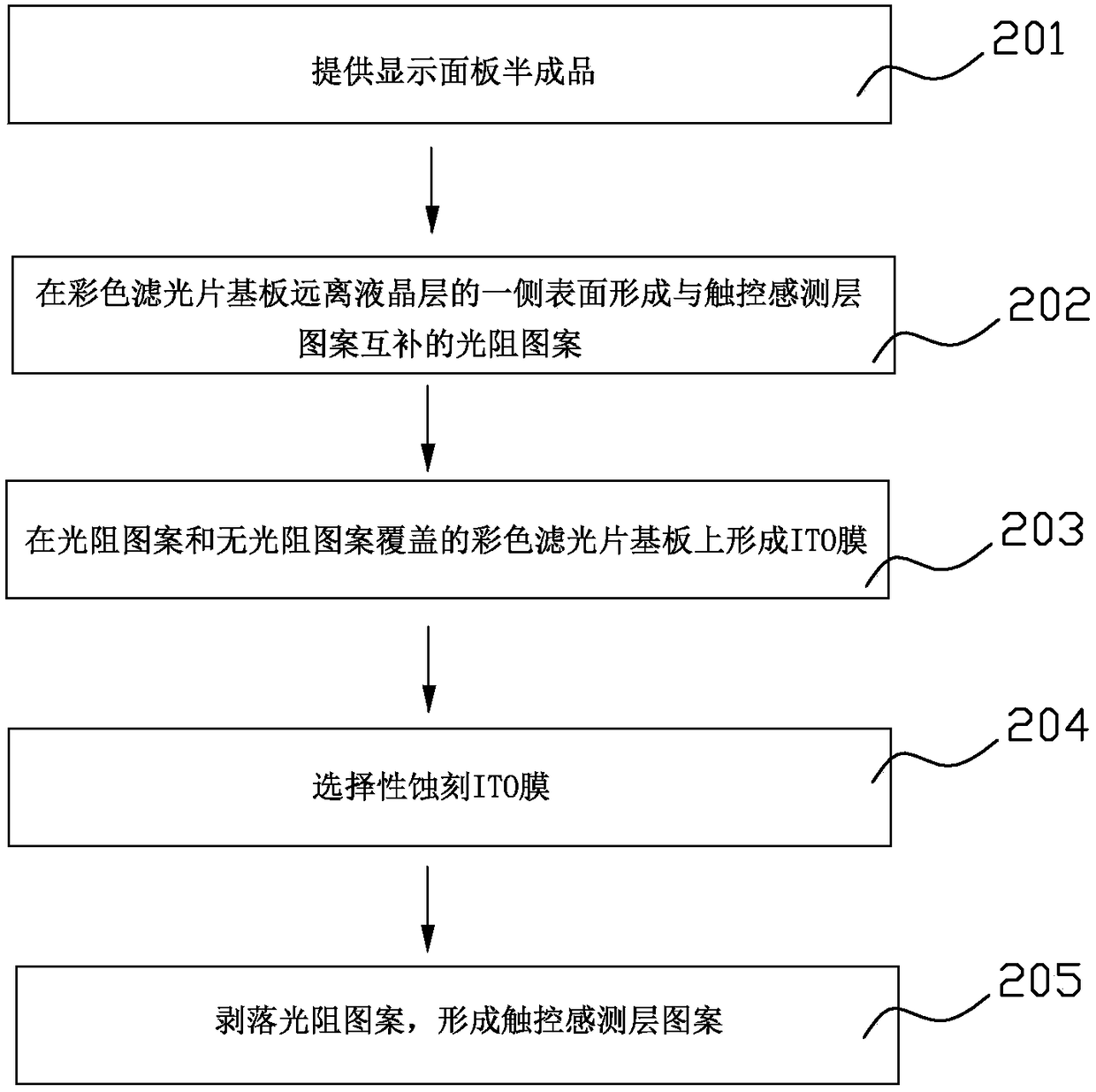

Manufacturing method of touch display panel

ActiveCN105487279BProcess compatibleHave production costsNon-linear opticsInput/output processes for data processingColor gelWork in process

The invention provides a manufacturing method of a touch control display panel. The method includes the steps that a display panel semi-finished product is provided, the display panel semi-finished product comprises an array substrate, a color filter substrate and a liquid crystal layer, the liquid crystal layer is located between the array substrate and the color filter substrate, and according to the display panel semi-finished product, assembling of the array substrate, the color filter substrate and the liquid crystal layer is completed; a photoresistance pattern complementary to a touch control sensing layer pattern is formed on the surface of the side, away from the liquid crystal layer, of the color filter substrate; an ITO membrane is formed on the photoresistance pattern and the color filter substrate which is not covered with the photoresistance pattern; the ITO membrane is etched selectively, the ITO membrane above the photoresistance pattern is etched and removed, the photoresistance pattern is exposed, and the ITO membrane above the color filter substrate which is not covered with the photoresistance pattern is maintained; the photoresistance pattern is stripped off, and the touch control sensing layer pattern is formed.

Owner:KUSN INFOVISION OPTOELECTRONICS

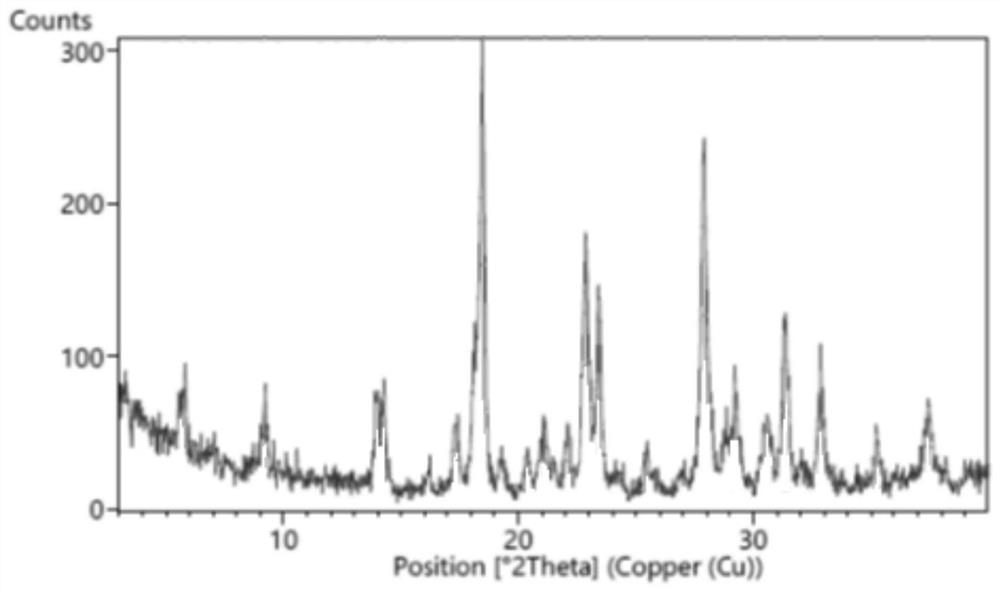

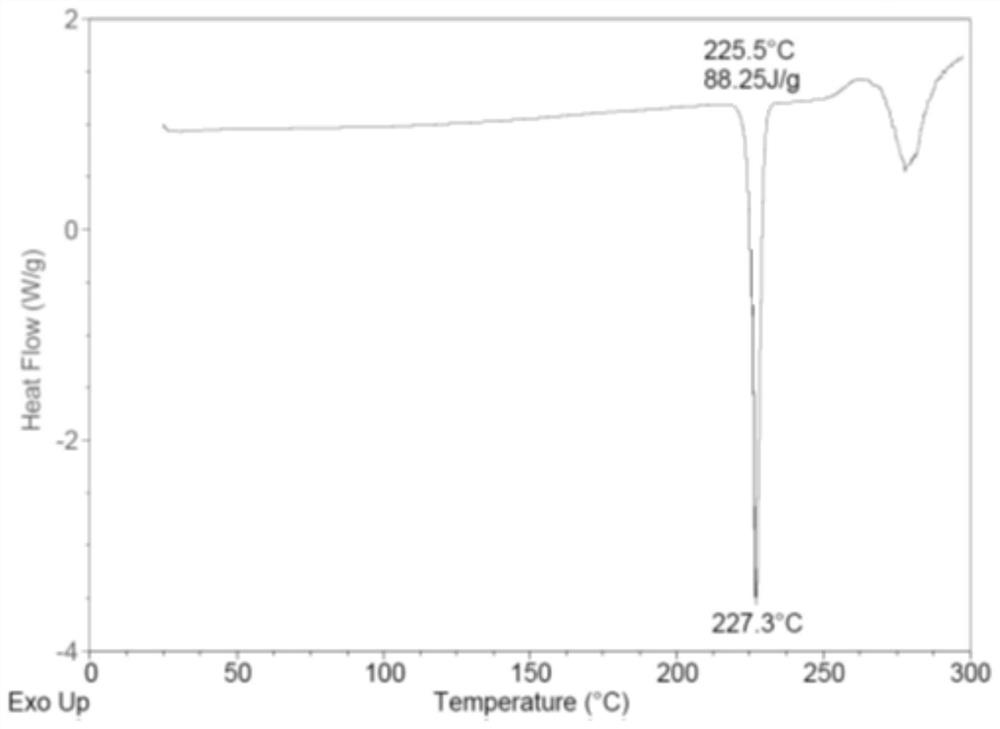

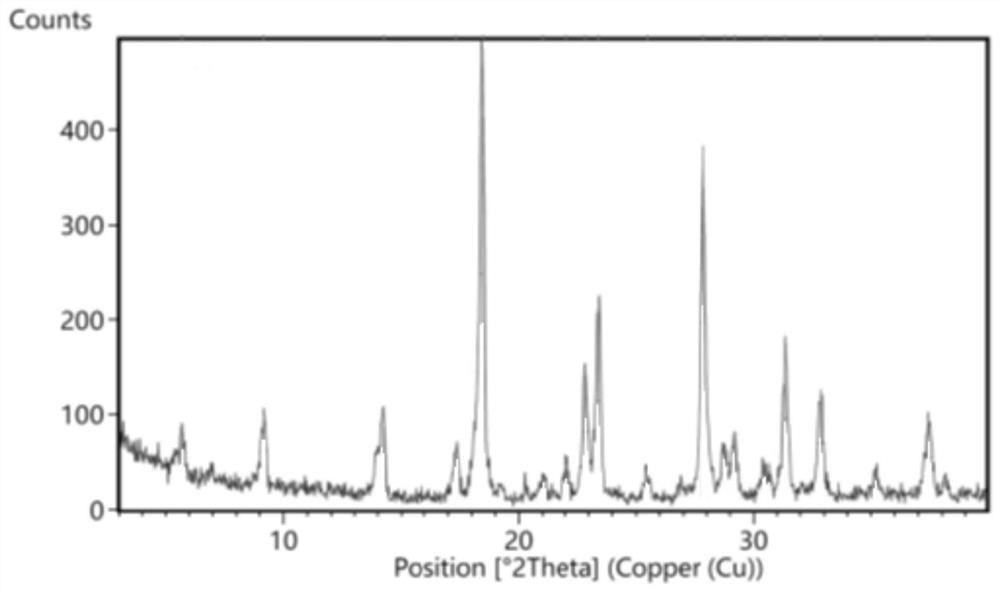

A kind of preparation method of vortioxetine hydrobromide α crystal form

ActiveCN112830906BSimple and fast operationHigh purityOrganic chemistry methodsHydrobromideOrganosolv

The invention relates to the technical field of medicine preparation, in particular to a preparation method of vortioxetine hydrobromide alpha crystal form. It comprises the following steps: (1) heating and dissolving crude vortioxetine hydrobromide in organic solvent A to obtain solution A; (2) filtering the solution A, cooling the filtrate to crystallize, and filtering the precipitated solid A; (3) Using solvent B to beat the solid A, filter and dry to obtain the α crystal form of vortioxetine hydrobromide. The method provided in the present invention prepares the alpha crystal form of vortioxetine hydrobromide with low desolvation temperature, low drying temperature and simple operation, and the obtained crystal form has higher purity, better crystallinity, good stability and uniform particles. The method of the invention has good reproducibility, high yield, low production cost and is suitable for industrialized production.

Owner:微研优仿医药科技(江苏)有限公司

Polyvinyl chloride function modifier and its prepn process

The present invention discloses one kind of polyvinyl chloride function modifier and its preparation process. The modifier is prepared with polyhydric alcohol borate ester, polyhydric alcohol salicylate ester and acrylate as processing assistant, and oxide homopolymer or oxidized polyethylene wax. The modifier has the functions of coupling agent, dispersant, internal and external lubricant, processing assistant, etc. and has unique PVC / CaCO3 stuffing system modifying effects, including promoting plasticization, raising dispersivity, improving antiageing and machining performance, realizing high stuffing, etc.

Owner:NANJING CONCORD FERTILIZER CHEM

Rare earth ion doped K3LuCl6 glass ceramic and preparation method thereof

The invention discloses rare earth ion doped K3LuCl6 glass ceramic which comprises the following elements by mole percent: 87-94mol% of SiO2, 5.6-10mol% of K3LuCl6 and 0.4-3mol% of LnCl3, wherein LnCl3 is at least one of YbCl3, ErCl3, TmCl3 and HoCl3. The rare earth ion doped K3LuCl6 glass ceramic has the advantages as follows: the prepared rare earth ion doped K3LuCl6 glass ceramic is transparent, deliquescence-proof, good in mechanical property and relatively high in blue-violet light transmittance, has the properties of low phonon energy, high up-conversion efficiency, and the like, and enables the efficiency of an up-conversion laser to be improved greatly, in addition, a preparation method for the glass ceramic is simple and the production cost is relatively low.

Owner:NINGBO UNIV

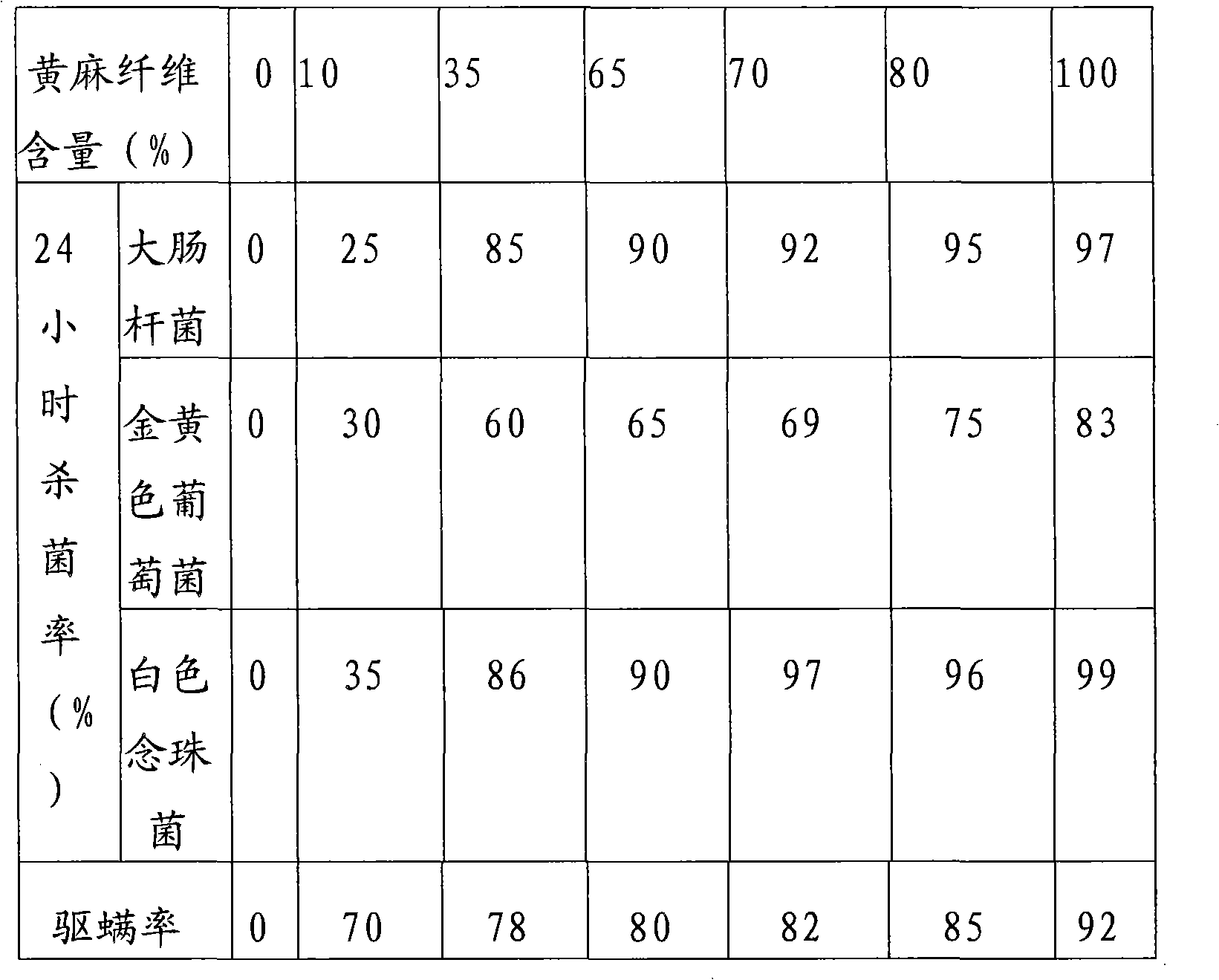

Fibrilia down filler and manufacturing method thereof

The invention provides a fibrilia down feather filling material consisting of fibrilia and down fibers, wherein the mass percentage of the fibrilia is between 10 and 80 percent, and the mass percentage of the down fiber is between 20 and 90 percent; because proper amount of fibrilia is used to replace the down fibers, thereby greatly lowering manufacturing cost of an enterprise; meanwhile, because the fibrilia with natural mould proof and bacteriostatic effects is added, the filling material has the mould proof and bacteriostatic effects which are achieved without adding any chemical matter and undergoing any chemical mould proof and bacteriostatic treatment, so that the filling material of the invention is natural and environment friendly, saves chemical matters, saves the mould proof and bacteriostatic treatment process, and further lowers the manufacturing costs of the enterprise. Due to the addition of fibrilia, the fibrilia down feather filling material of the invention has desirable characteristics of ventilation, bacteriostasis and mite resistance, etc., which are naturally possessed by fibrilia.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Rare-earth-ion-doped NaBaLaBr6 microcrystalline glass and preparation method thereof

The invention discloses rare-earth-ion-doped NaBaLaBr6 microcrystalline glass. The rare-earth-ion-doped NaBaLaBr6 microcrystalline glass comprises the following components in mole percentage: 87-94mol% of SiO2, 5.5-10mol% of NaBaLaBr6 and 0.5-3mol% of LnBr3, wherein LnBr3 is at least one of YbBr3, ErBr3 and TmBr3. The obtained rare-earth-ion-doped NaBaLaBr6 microcrystalline glass has the advantages of transparency, deliquescence resistance, good mechanical properties and high blue and violet light transmittance and has performances of low phonon energy and high upconversion efficiency, efficiency of an upconversion laser can be greatly improved, and the preparation method of the rare-earth-ion-doped NaBaLaBr6 microcrystalline glass is simple and low in production cost.

Owner:NINGBO UNIV

K2CeI5 glass ceramics doped with rare earth ions and preparation method of K2CeI5 glass ceramics

InactiveCN105254183AExcellent up-conversion performanceGood stabilityTransmittanceEnergy conversion efficiency

The invention discloses K2CeI5 glass ceramics doped with rare earth ions. The K2CeI5 glass ceramics is prepared from 87-92 mol% of SiO2, 7.5-10 mol% of K2CeI5 and 0.5-3 mol% of LnI3, wherein LnI3 is at least one of YbI3, ErI3 and TmI3. The K2CeI5 glass ceramics has the advantages of being transparent, resistant to air slake, good in mechanical performance, high in blue and purple light transmittance, low in phonon energy, high in up-conversion efficiency, capable of greatly improving efficiency of an up-conversion laser device, simple in preparation method and low in production cost.

Owner:NINGBO UNIV

Composite heat stabilizer for polyvinyl chloride (PVC), and preparation method for composite heat stabilizer

ActiveCN102432961BImprove thermal stabilityGet rid of dependenceSulfide preparationChemical industryPolyvinyl chloride

The invention belongs to the field of chemical industry and particularly relates to a composite stabilizer for polyvinyl chloride (PVC) processing. The composite stabilizer consists of the following components in part by weight: 55 to 105 parts of main stabilizer, 0.255 to 11 parts of auxiliary stabilizer, and 10 to 35 parts of inorganic filler. The main stabilizer is a 3-dodecylthiopropionic acid metal soap stabilizer, and the chemical formula of the metal soap stabilizer is [CH3(CH2)11S(CH2)2COO]mXn, wherein X is one or more of calcium ion, zinc ion, barium ion or magnesium ion; and the metal soap stabilizer consists of 5 to 20 weight parts of metal ion and 50 to 85 parts of sulfur-containing carboxylate group. The composite stabilizer has the advantages of high thermal stability, safety and no toxicity, certain processability and lubricity and low cost.

Owner:SHANDONG RUIFENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com