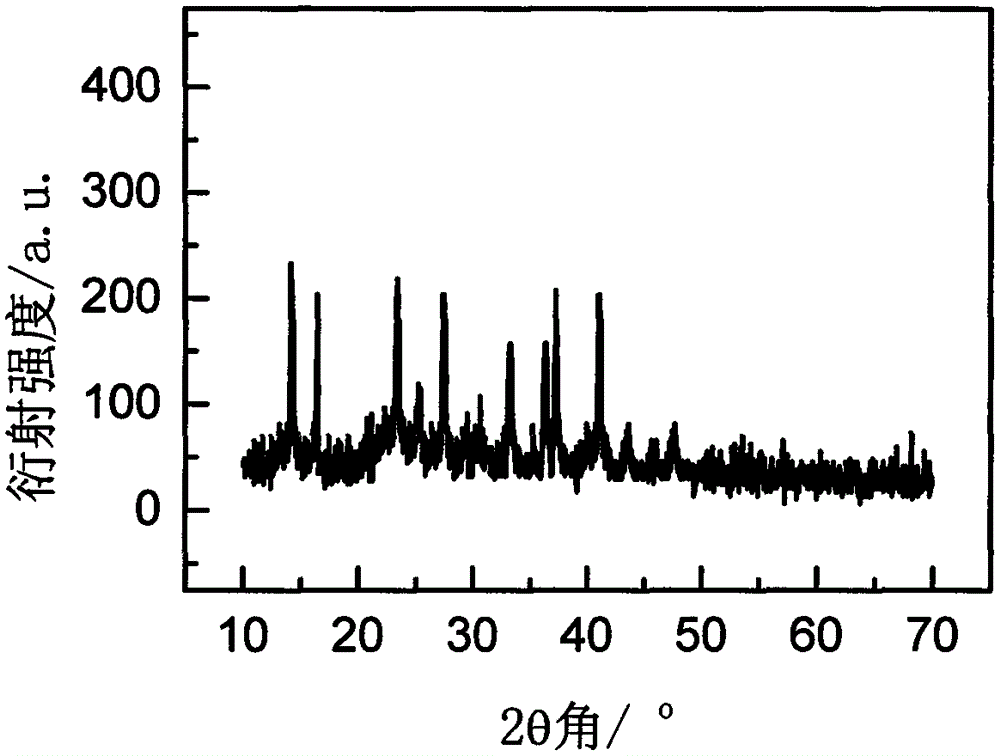

Rare earth ion doped K3LuCl6 glass ceramic and preparation method thereof

A technology of glass-ceramic and rare-earth ions, applied in the field of rare-earth ion-doped glass-ceramic, can solve the problems of poor chemical stability and mechanical strength, easy hygroscopicity of crystals, low phonon energy, etc. The effect of high violet transmittance and low phonon energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

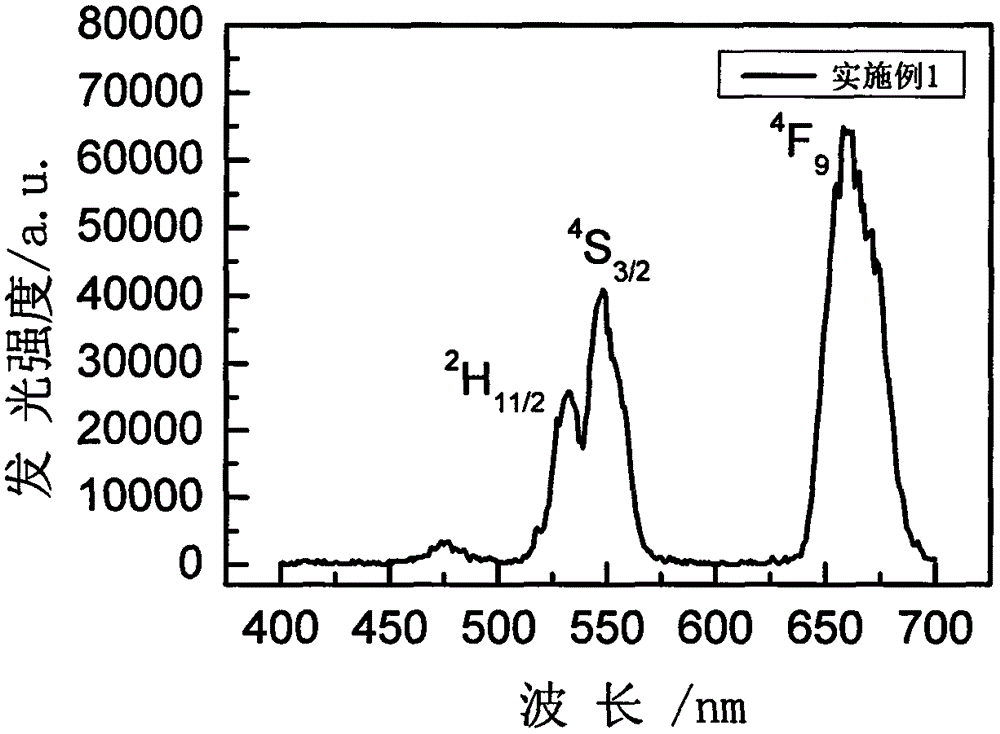

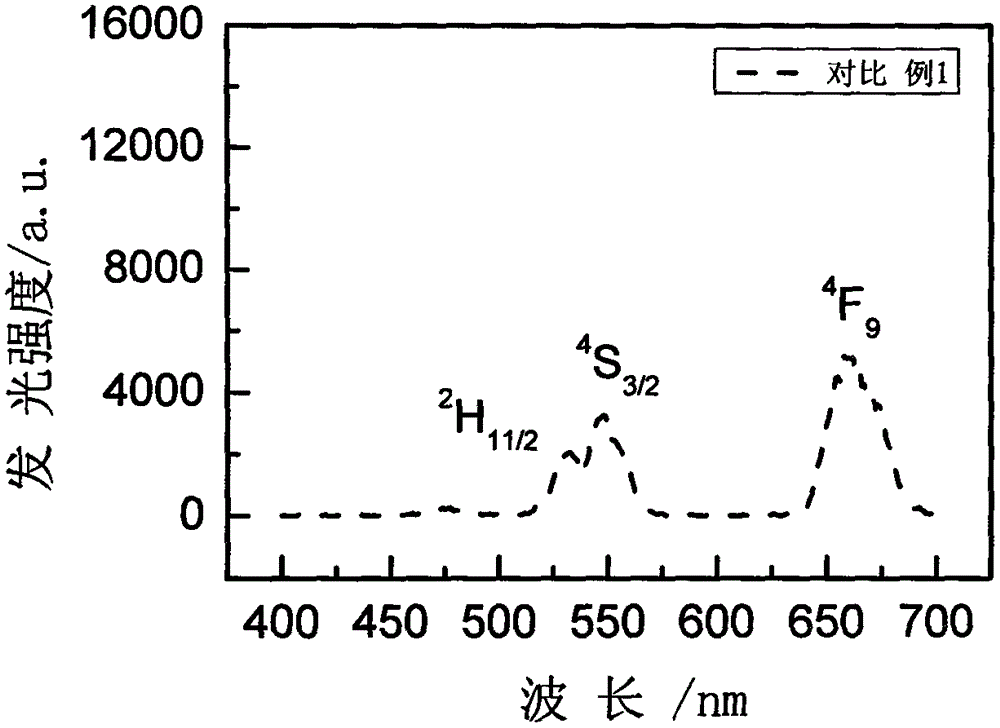

Embodiment 1

[0020] Er 3+ , Yb 3+ Doping K 3 LuCl 6 The molar percentage composition of glass ceramics is: SiO 2 90mol%, K 3 LuCl 6 8mol%, ErCl 3 0.5mol%, YbCl 3 1.5mol%, the process for preparing the up-conversion luminescent glass-ceramic material with the above composition is as follows:

[0021] (1) Weigh lutetium acetate, potassium acetate, ytterbium acetate and erbium acetate, wherein the parts of lutetium acetate and potassium acetate are respectively in molar percentage composition K 3 LuCl 6 The mole percentage content weighs, and the part of ytterbium acetate and erbium acetate is composed of YbCl in the same mole percentage as above. 3 , ErCl 3 Weigh the molar percentage content, dissolve the above-mentioned acetate in deionized water to form an acetate solution, add trichloroacetic acid to the acetate solution to obtain a transparent mixed solution, wherein trichloroacetic acid and acetate solution The molar ratio of the sum of metal ions is 3:1;

[0022] (2) SiO in...

Embodiment 2

[0027] T m 3+ , Yb 3+ Doping K 3 LuCl 6 The molar percentage composition of glass ceramics is: SiO 2 88.5mol%, K 3 LuCl 6 9mol%, TmCl 3 0.5mol%, YbCl 3 2mol%, after the same preparation and heat treatment process as in Example 1, a transparent rare earth ion Tm 3+ , Yb 3+ Doped K 3 LuCl 6 Glass-ceramic. The glass-ceramic was measured with a TRIAX550 fluorescence spectrometer, under the excitation condition of a 970nm laser, a strong blue up-conversion luminescence was observed.

Embodiment 3

[0029] Er 3+ 、Tm 3+ , Yb 3+ Doping K 3 LuCl 6 The molar percentage composition of glass ceramics is: SiO 2 87mol%, K 3 LuCl 6 10mol%, ErCl 3 0.2mol%, TmCl 3 0.1mol%, YbCl 3 2.7mol%, after the preparation and heat treatment process identical with embodiment 1, obtain transparent rare earth ion Er 3+ 、Tm 3+ , Yb 3+ Doped K 3 LuCl 6 Glass-ceramic. The glass-ceramic was measured with a TRIAX550 fluorescence spectrometer, under the excitation condition of a 970nm laser, strong blue, green and red upconversion luminescence were observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com