Patents

Literature

587 results about "Trichloroacetic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trichloroacetic acid (TCA; TCAA; also known as trichloroethanoic acid) is an analogue of acetic acid in which the three hydrogen atoms of the methyl group have all been replaced by chlorine atoms. Salts and esters of trichloroacetic acid are called trichloroacetates.

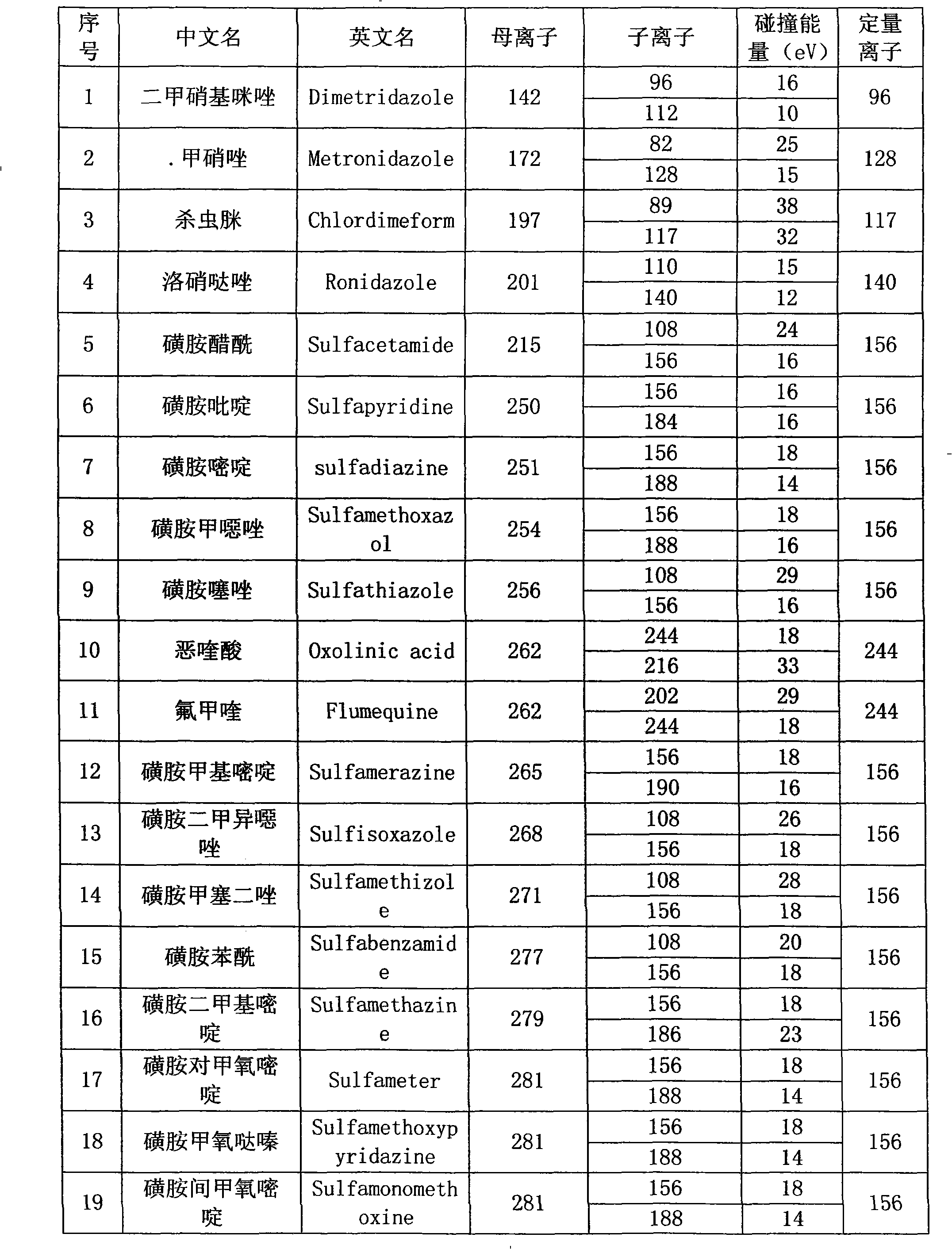

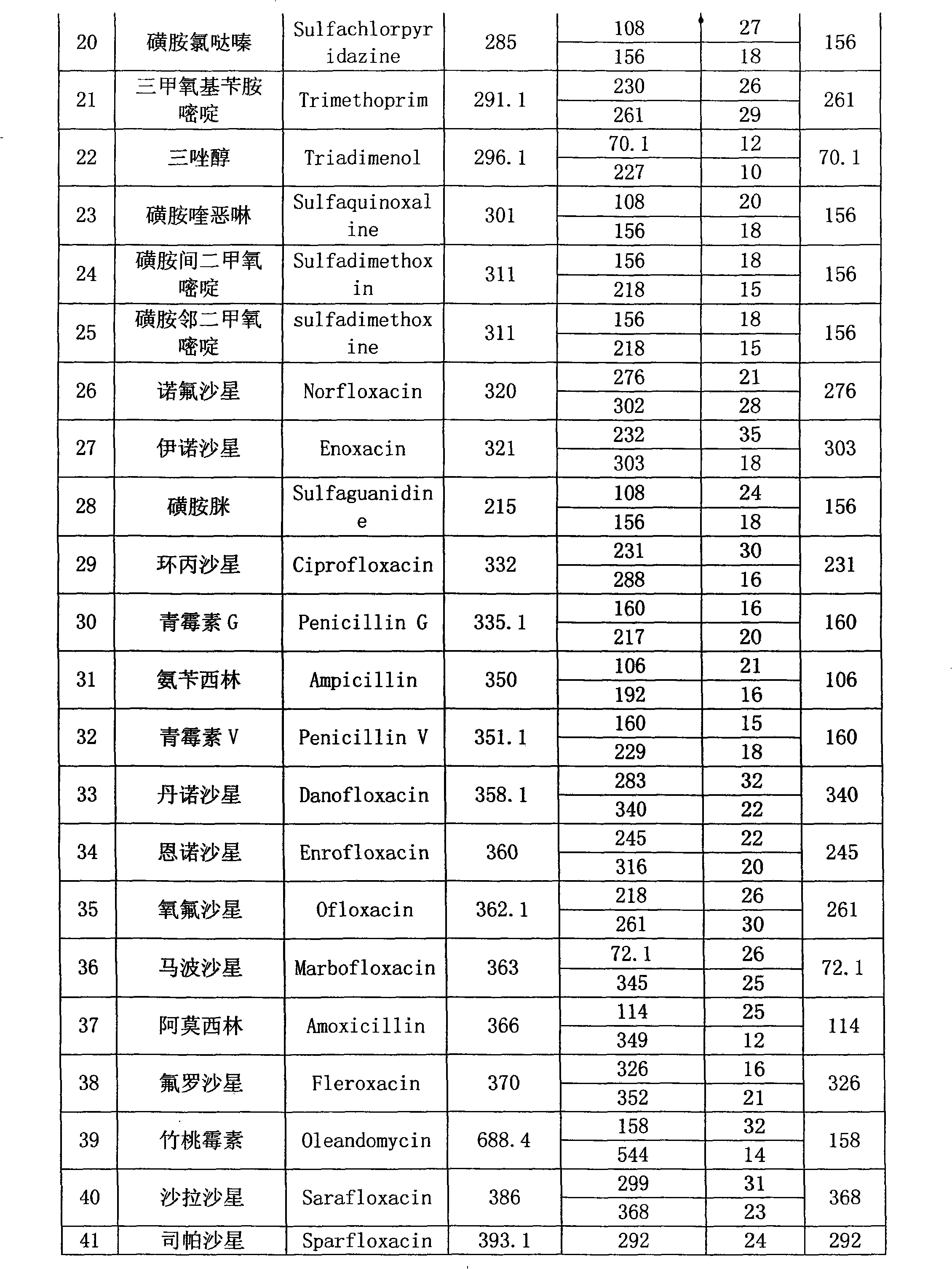

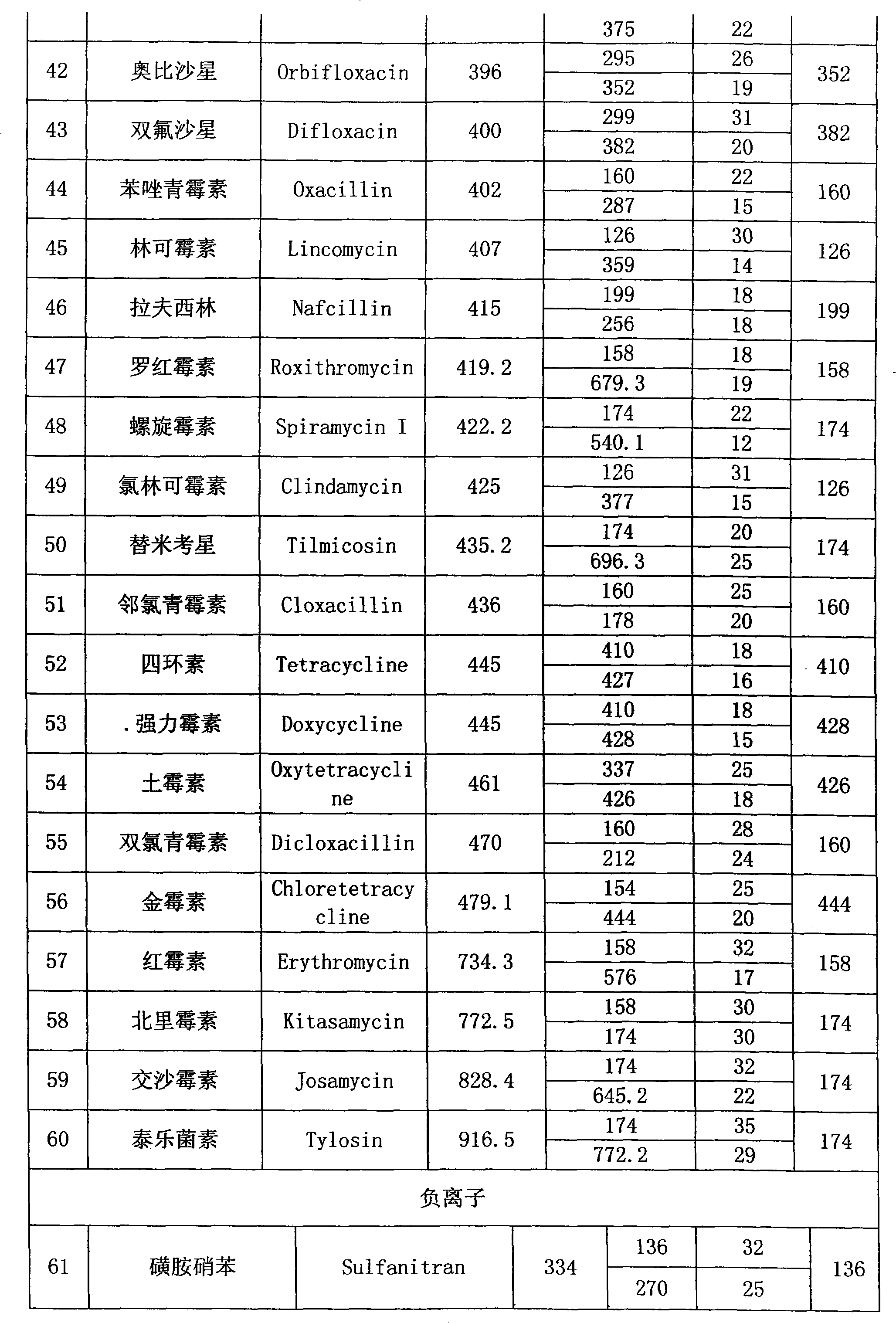

Method for simultaneously detecting multi-kind pesticide residues in bee products

InactiveCN101358953ASolve the problem of matrix effectFast wayComponent separationRetention timePhosphate

The present invention relates to a method of simultaneously detecting a plurality of agro-veterinary drug residues in bee products. The extracted liquid trichloroacetic acid or perchloric acid and the extracted liquid acetate, phosphate or borate solution are added into a sample; the pH value is controlled between 4.5 and 9.0; the mixed solution is centrifuged, the filtrate is added into a solid phase extraction column to be extracted, the extraction column is eluted and dried, the column is washed by oxalic acid-methanol solution, the volume of the eluent is defined by the aqueous solution of methanol, the eluent is added into liquid chromatography-tandem mass spectrometry to be analyzed and tested, the acquired chromatographic peak is contrasted with the known standard chromatographic peak of the drug, and according to the retention time and the abundance of the mass spectrum ions, the specific name of the detected drug is determined. The method only requires one pre-treatment of the sample, and thus can simultaneously extract 11 classes and more than 60 kinds of veterinary drug residues, such as sulfonamides, quinolones, macrolides, lincomycins, nitroimidazoles, beta-lactams, tetracyclines, chloromycetins, trinethoprims, chlordimeform, triadimenol and the like, the efficiency of analysis is high, and the detection cost is greatly reduced.

Owner:中华人民共和国江苏出入境检验检疫局

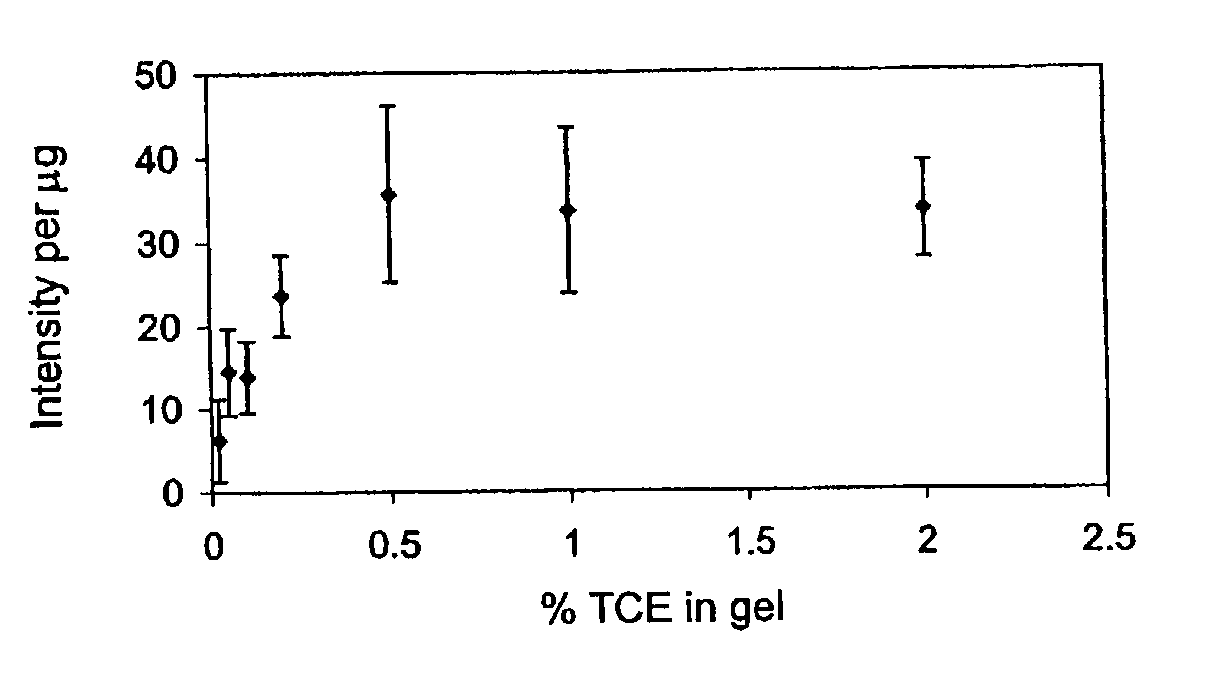

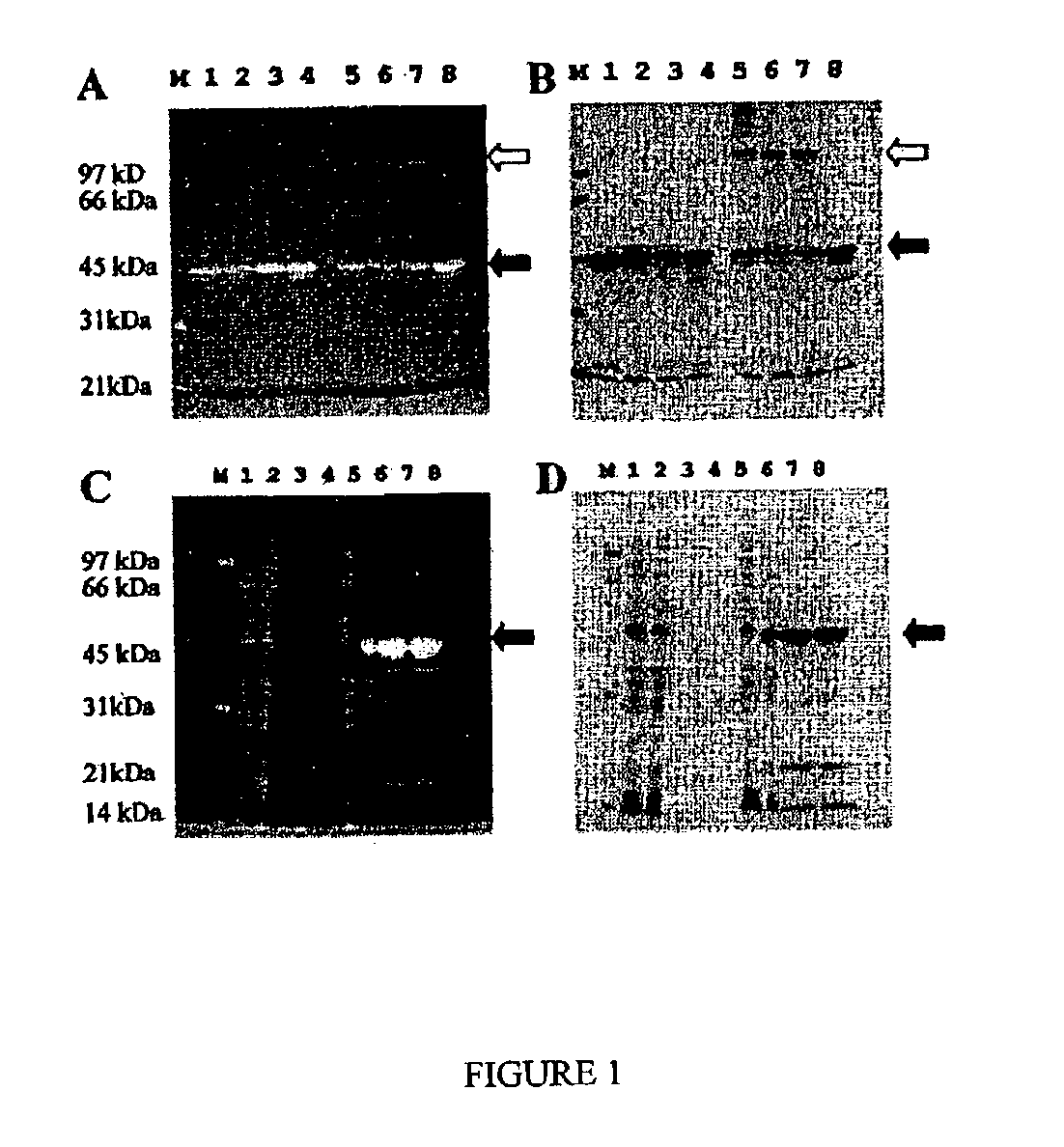

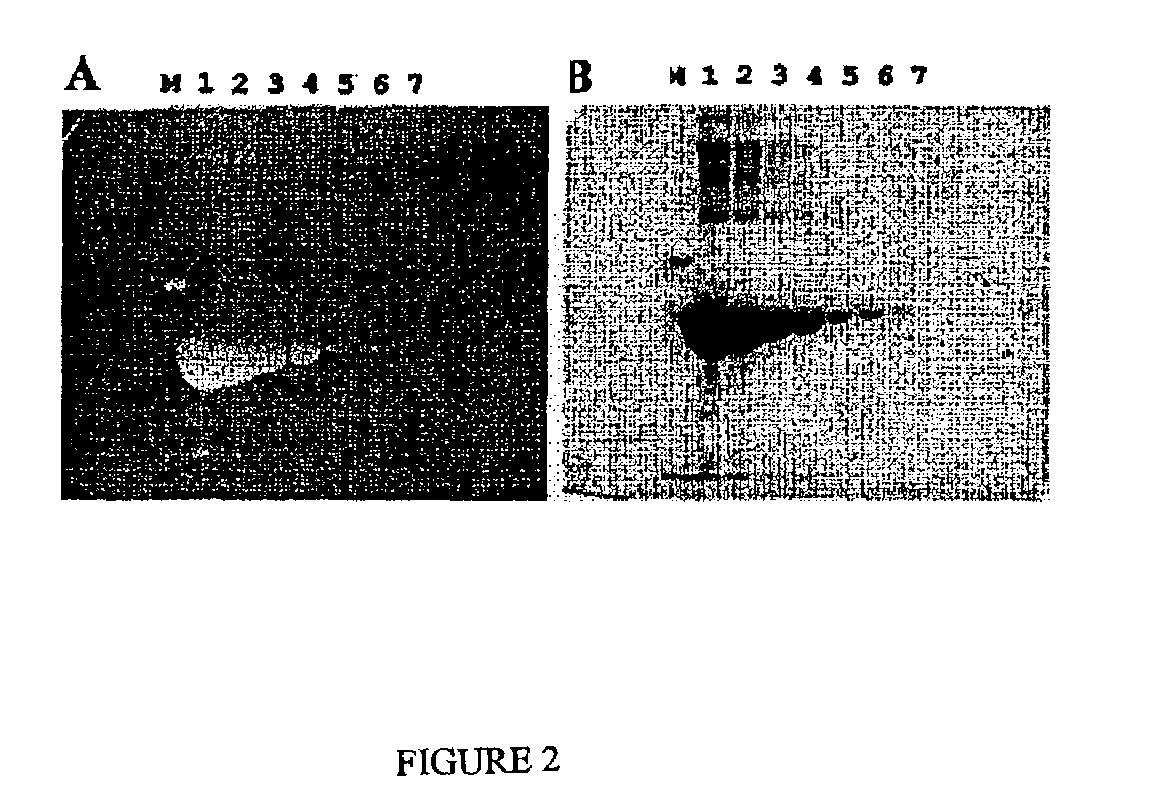

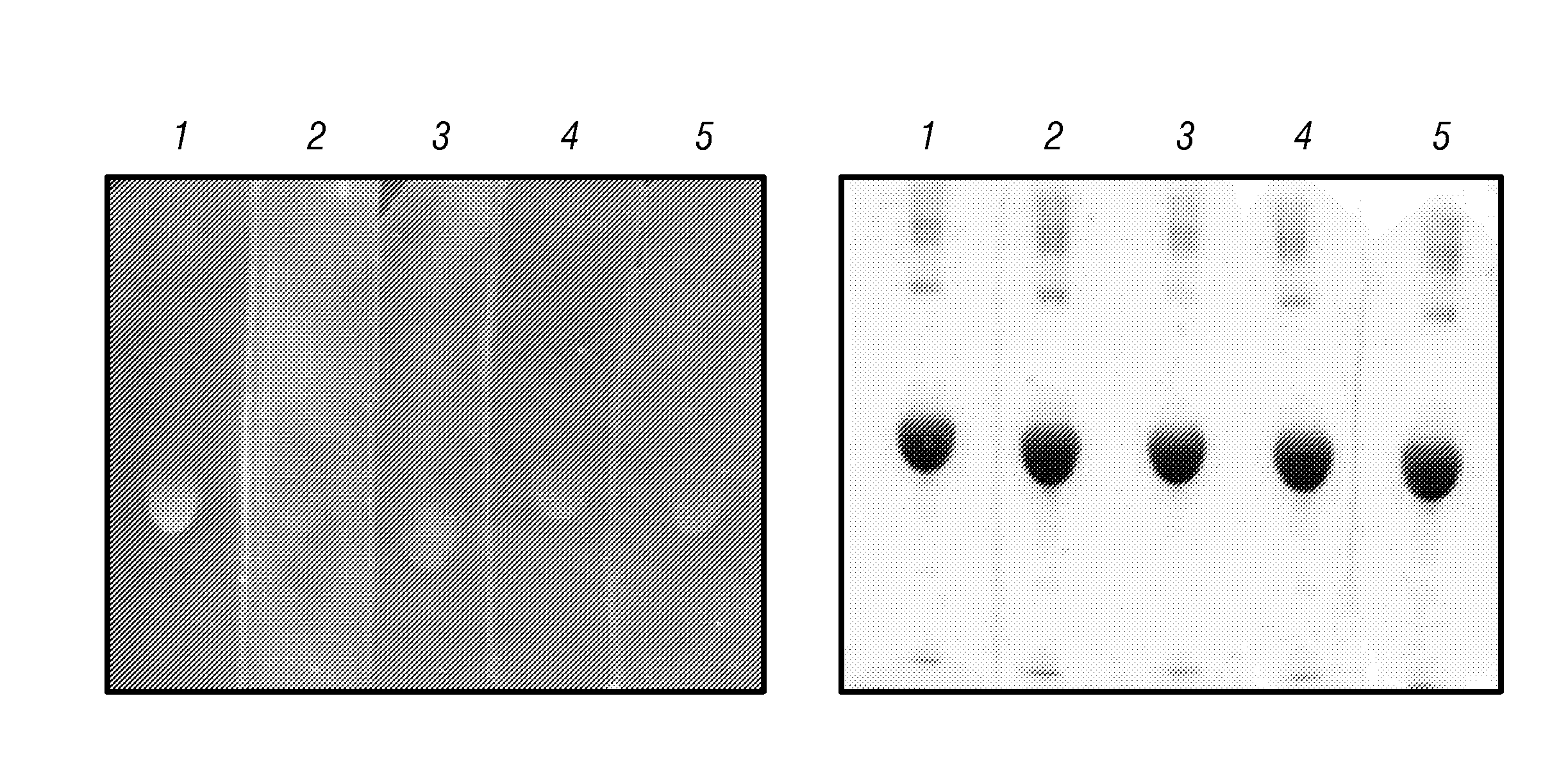

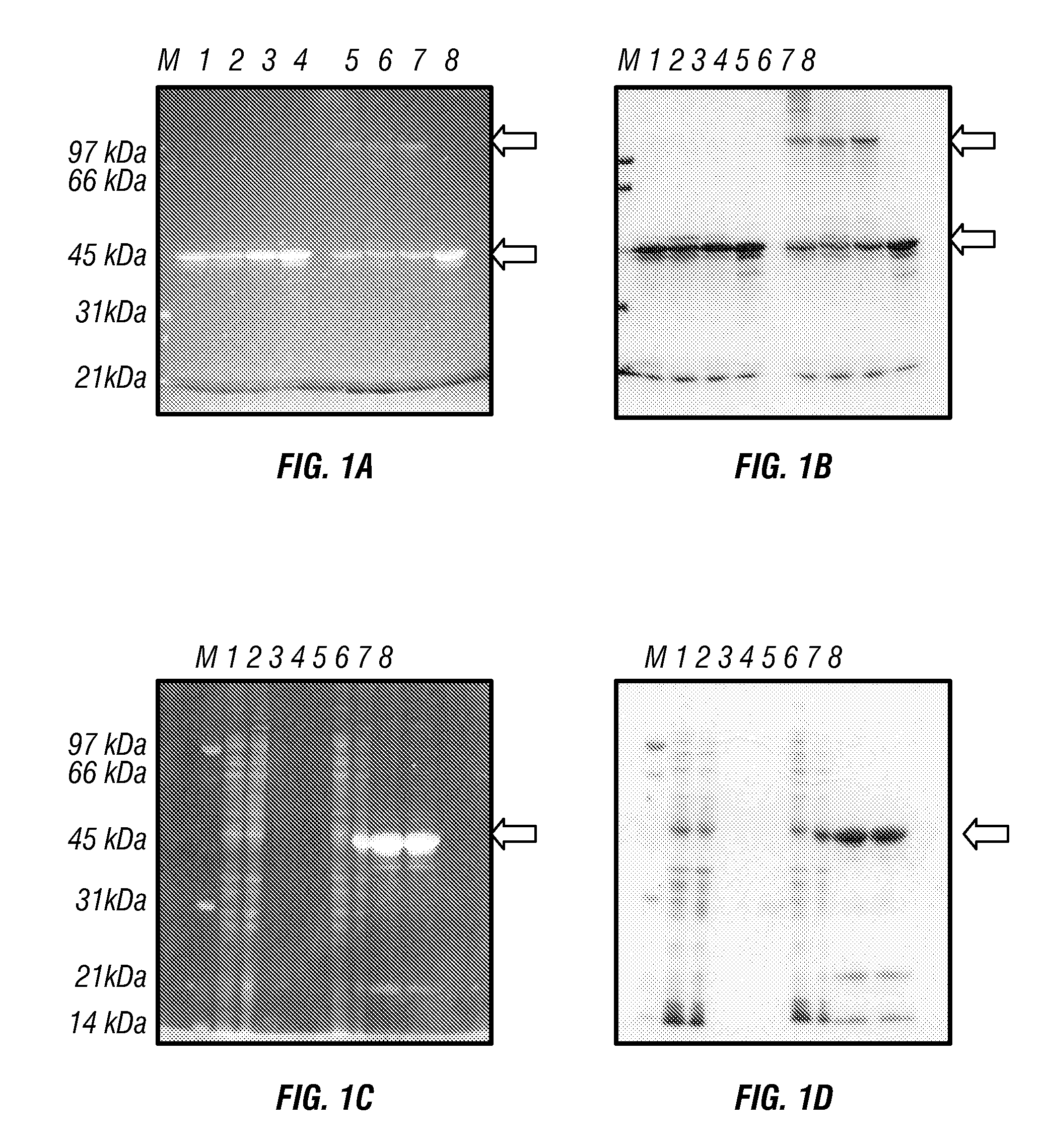

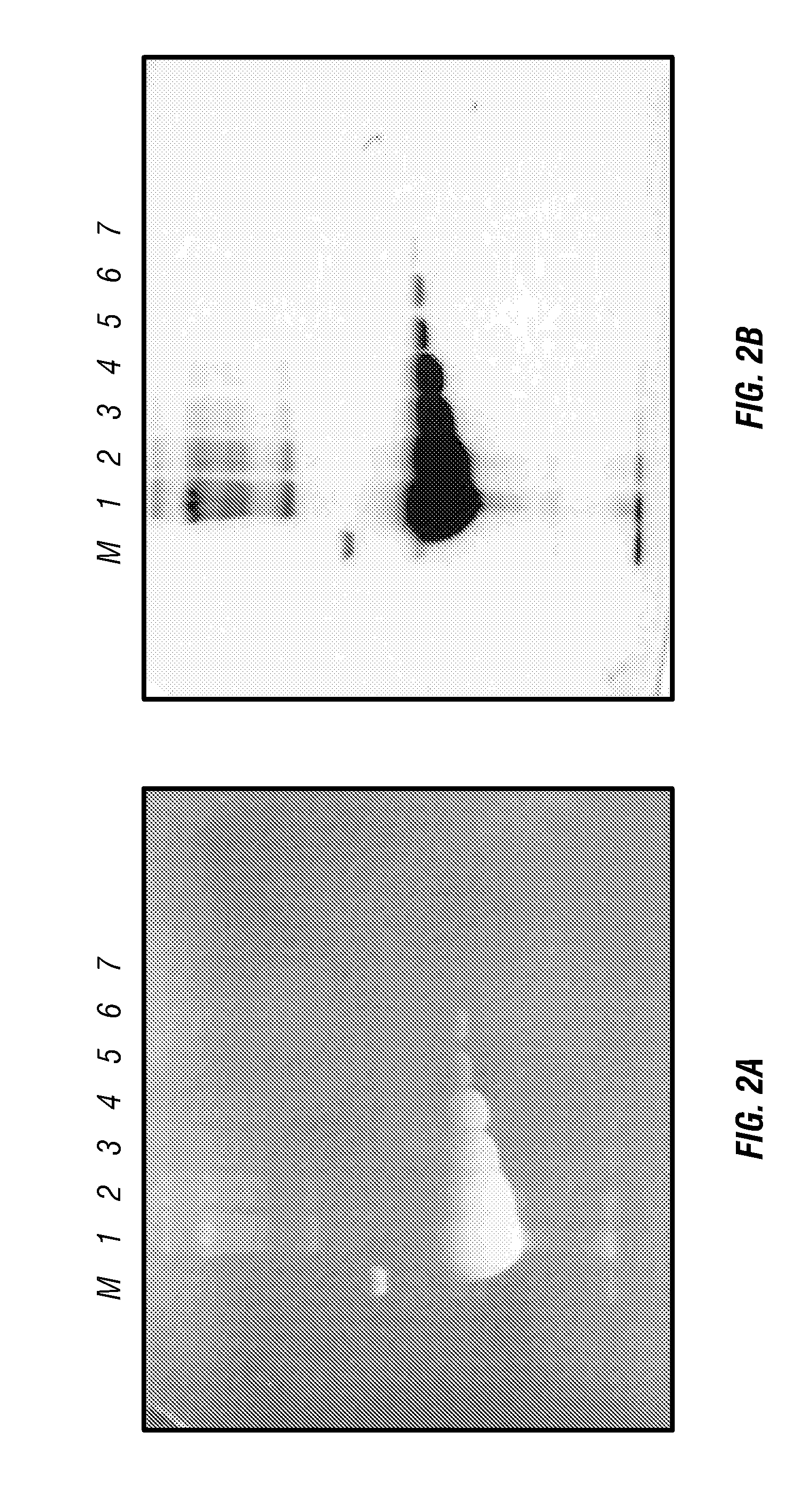

Fluorescent detection of proteins in polyacrylamide gels

ActiveUS7569130B2Laborious labelingLaborious staining stepElectrolysis componentsChemiluminescene/bioluminescenceSpectroscopyTryptophan

The mechanism of the UV light-induced reaction between the indole moiety of tryptophan and chloroform, and the structure of the modified tryptophan and polypeptides including such modified tryptophan residues. The excited indole moiety, which is formed upon UV light irradiation, emits a solvated electron which initiates a series of events that yield fluorescent derivatives that have CHO group covalently bound to the indole moiety. These derivatives are herein referred to as formyltryptophan, and are relatively stable. Similar reactions are observed when 5-hydroxytryptophan, 5-fluorotryptophan, or N-methylindolacetate are used in place of tryptophan, or when other haloalkanes, such as trichloracetic acid, trichlorethanol, trichlorethane, bromoform, and iodoactetate are used in place of chloroform. The derivatives can be used in a variety of applications in fluorescence spectroscopy, and for nuclear magnetic resonance, X-ray crystallography, infra-red spectroscopy, circular dicroism and mass spectroscopy. Additionally, the UV light-induced reaction between the indole moiety of tryptophan and haloalkanes can be used to prepare derivatives of tryptophan for chemical cross-linking studies of proteins and peptides.

Owner:UNIV TECH INT +1

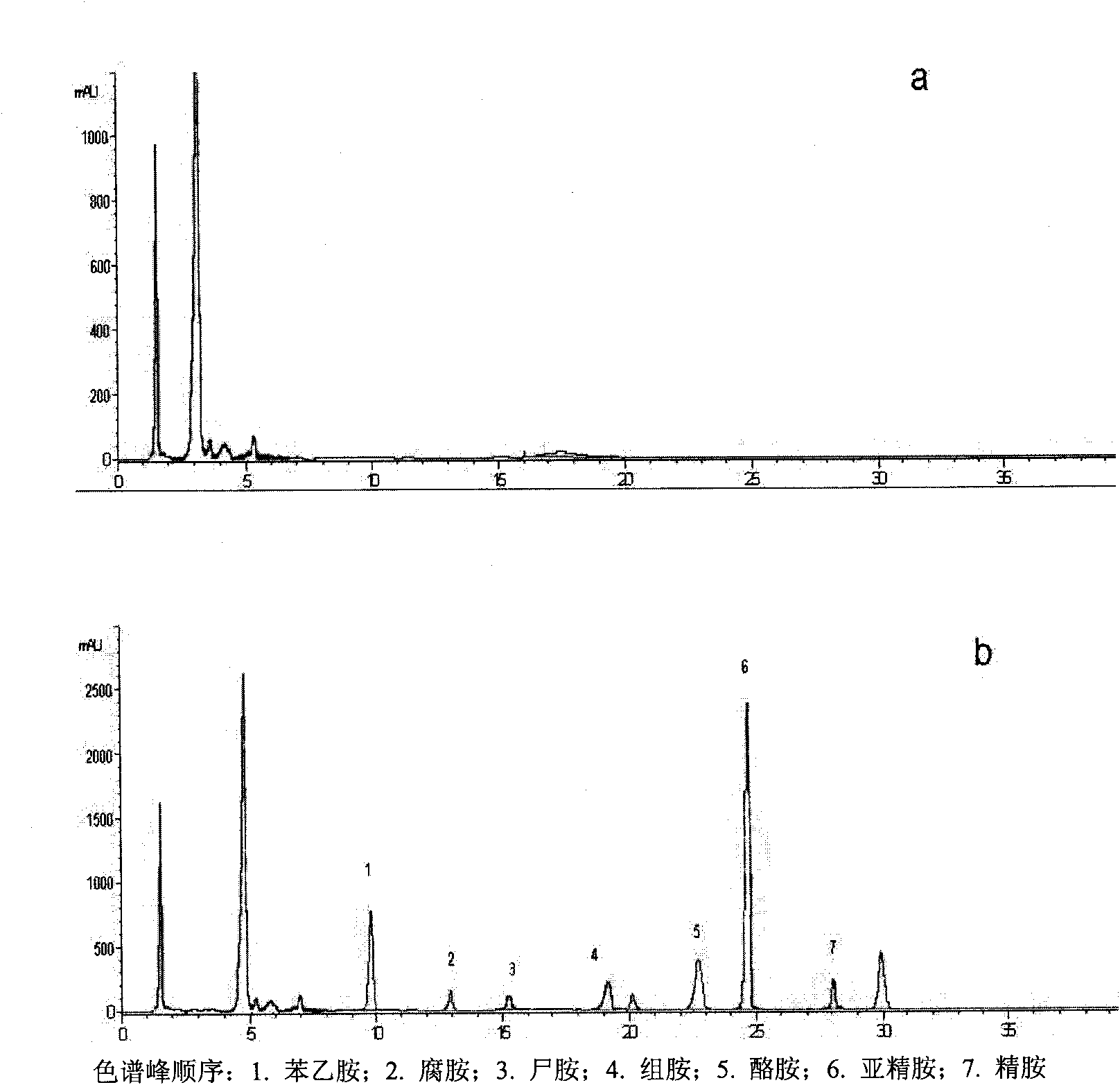

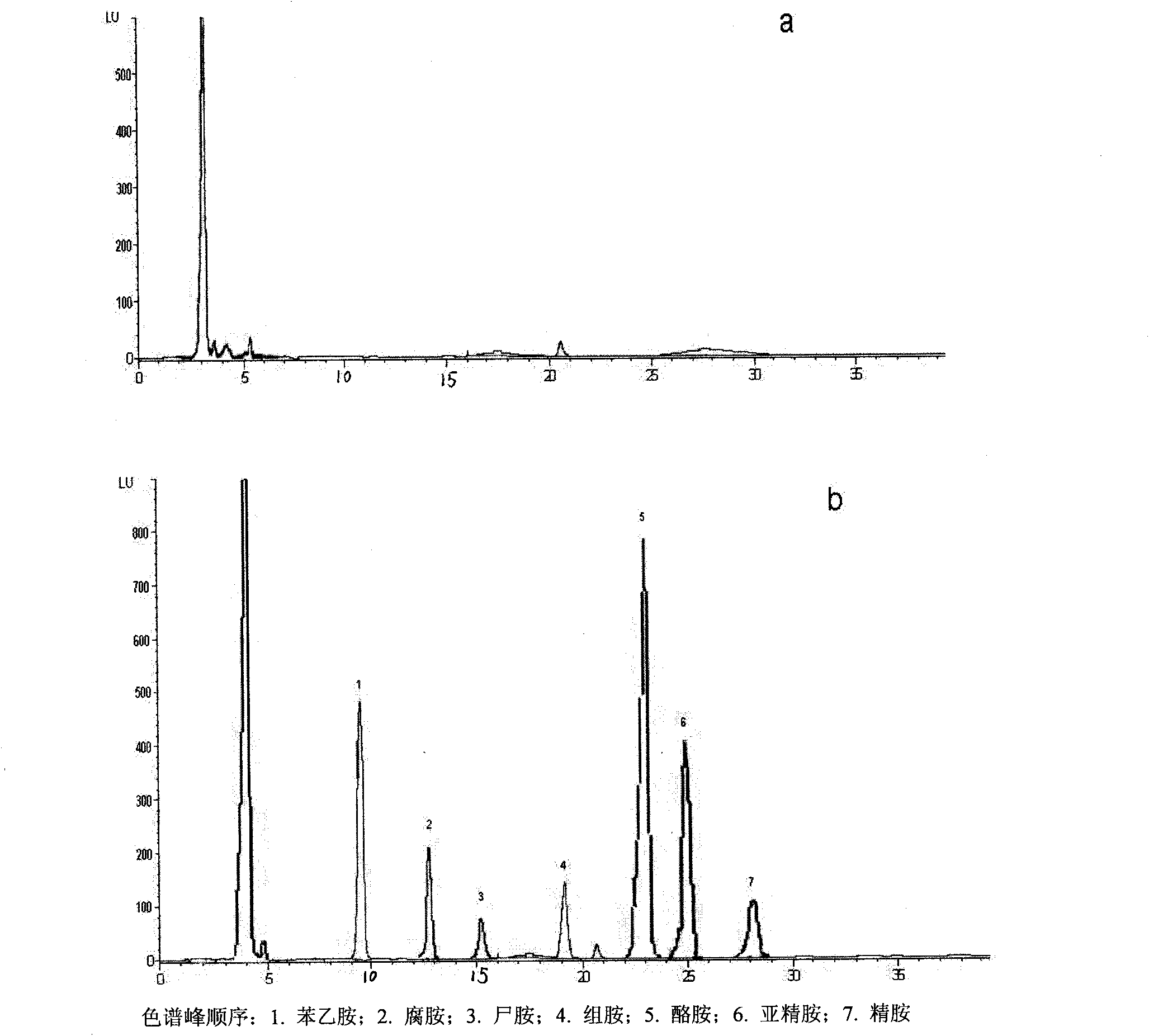

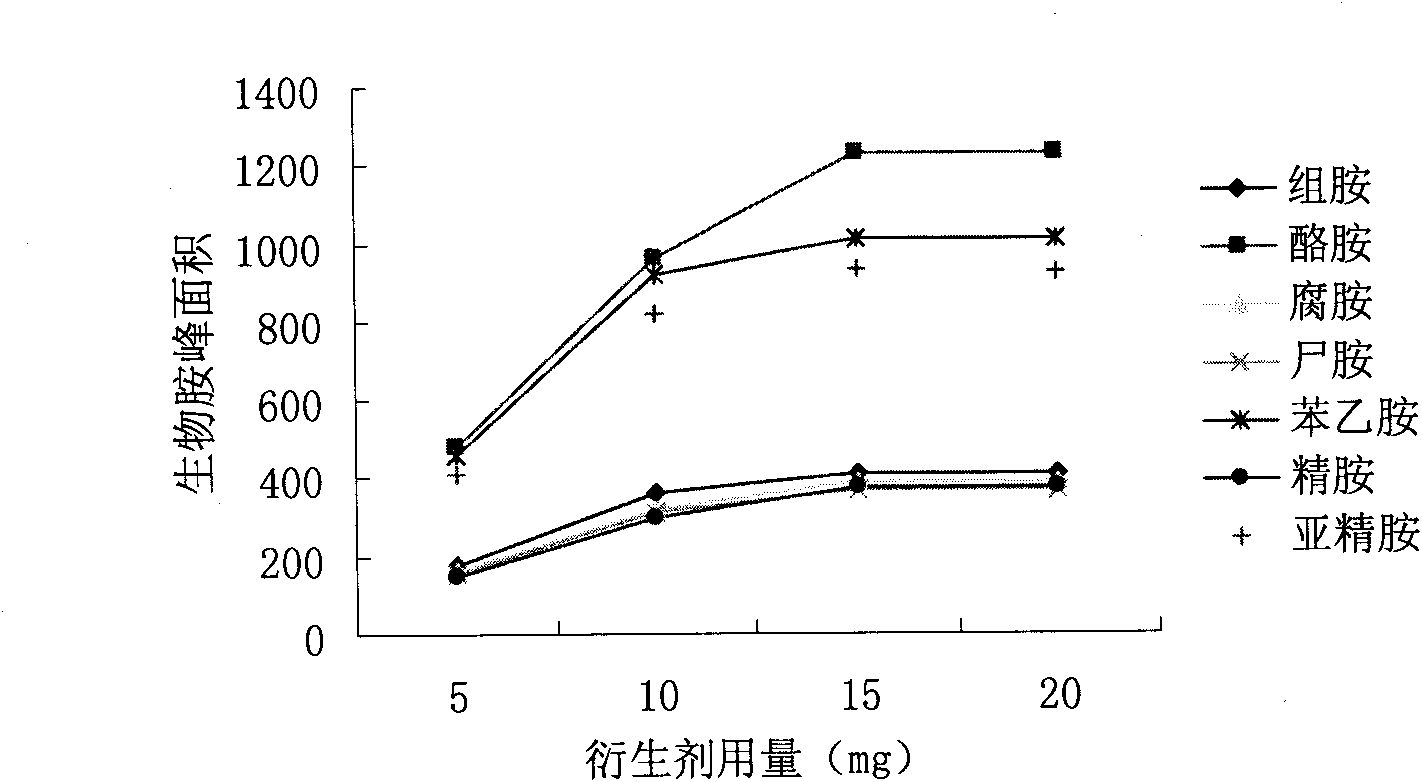

Separation and liquid chromatography column pre-column derivatization method of biogenic amine in soybean paste

InactiveCN101793642AReduce consumptionReduce distractionsComponent separationPreparing sample for investigationChromatography columnChemistry

The invention discloses a separation and liquid chromatography column pre-column derivatization method of biogenic amine in a soybean paste, comprising the following steps of: (1) adding a trichloroacetic acid solution to the soybean paste, homogenizing, centrifuging and collecting a supernate; (2) adding normal hexane to the supernate, vibrating and taking out a lower layer trichloroacetic acid phase for later use after static layering; (3) adding an NaOH solution to the trichloroacetic acid phase, then adding an NaHCO3 solution for buffering, and mixing in a dansyl chloride acetone solution to carry out derivatization; and (4) removing dansyl chloride to terminate the reaction to obtain a derivative solution and filtering. The separation method has simple treatment process and low reagent consumption and avoids analyte loss caused by transfer. The soybean paste can reach detection demands after being separated and purified; undesired peak disturbance of a spectrogram is less and the determinand loss is low, and the recovery rate of the biogenic amine can reach more than 80 percent. The method determines the optimum condition for deriving the biogenic amine; dansyl chloride derivative products are stable and the detection sensitivity is high.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Fluorescent detection of proteins in polyacrylamide gels

InactiveUS20100089753A1Without laborious labeling and staining stepElectrolysis componentsVolume/mass flow measurementSpectroscopyTryptophan

The mechanism of the UV light-induced reaction between the indole moiety of tryptophan and chloroform, and the structure of the modified tryptophan and polypeptides including such modified tryptophan residues. The excited indole moiety, which is formed upon UV light irradiation, emits a solvated electron which initiates a series of events that yield fluorescent derivatives that have CHO group covalently bound to the indole moiety. These derivatives are herein referred to as formyltryptophan, and are relatively stable. Similar reactions are observed when 5-hydroxytryptophan, 5-fluorotryptophan, or N-methylindolacetate are used in place of tryptophan, or when other haloalkanes, such as trichloracetic acid, trichlorethanol, trichlorethane, bromoform, and iodoactetate are used in place of chloroform. The derivatives can be used in a variety of applications in fluorescence spectroscopy, and for nuclear magnetic resonance, X-ray crystallography, infra-red spectroscopy, circular dicroism and mass spectroscopy. Additionally, the UV light-induced reaction between the indole moiety of tryptophan and haloalkanes can be used to prepare derivatives of tryptophan for chemical cross-linking studies of proteins and peptides.

Owner:UNIV TECH INT +1

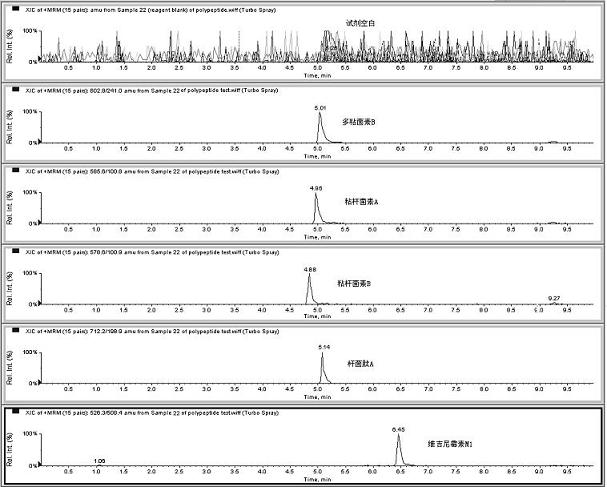

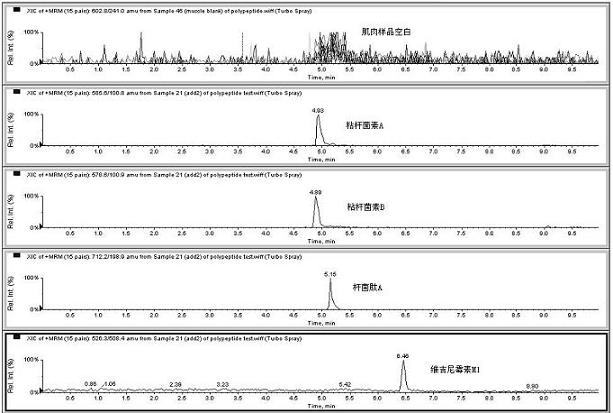

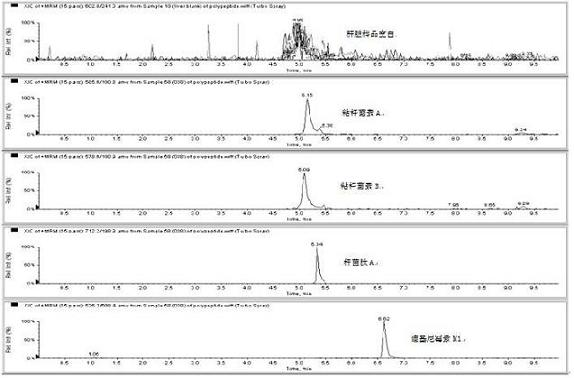

Method for detecting residual quantity of multiple polypeptidepolypeptide veterinary drugs in animal-derived food

InactiveCN102236005AAchieving Simultaneous DetectionReduce dissolutionComponent separationVirginiamycinVeterinary Drugs

The invention relates to the fields of analytical chemistry and food safety, particular to a method for detecting the residual quantity of multiple polypeptide veterinary drugs in animal-derived foods. The method comprises the following steps of: processing a sample with a TCA(trichloroacetic acid) and acetonitrile system for depositing proteins; extracting with a carbinol and 0.1% formic acid aqueous solution system; purifying with a Oasis HLB solid phase extraction column; performing gradient elution with an Eclipse XDB-C18 analytical column in the presence of an acetonitrile and 0.1% formic acid aqueous solution used as a mobile phase; and then performing electrospray and positive ion scanning mode separation for finally detecting four polypeptides. The limits of the four polypeptides, namely colistin, bacitracin A, polymyxin B and virginiamycin M, are 25 micrograms / kilogram, 100 micrograms / kilogram, 250 micrograms / kilogram and 120 micrograms / kilogram respectively; the recovery rates of colistin, bacitracin A, polymyxin B and virginiamycin M are 74.9-88.1%, 76.2-89.0%, 76.6-81.2% and 77.3-86.9% respectively; and the coefficients of variation (CV%) of colistin, bacitracin A, polymyxin B and virginiamycin M are 5.7-15.1%, 7.2-15.7%, 6.0-8.0% and 9.5-18.6% respectively. The detection limit, the recovery rate, the accuracy and other technical indexes all meet related detection requirements at home and aboard.

Owner:林维宣

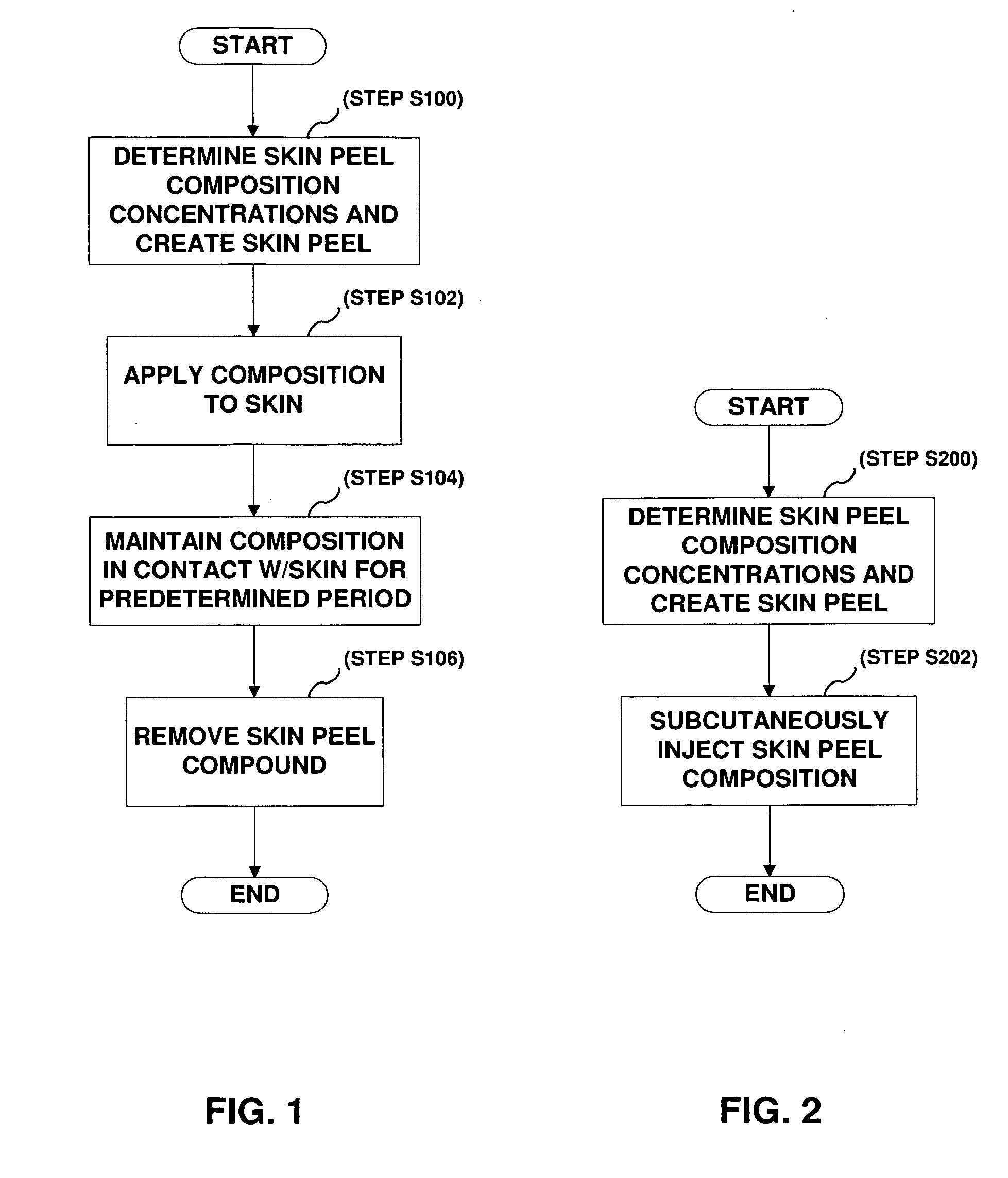

Method and compound for skin chemical peel

The present invention provides a skin peel composition including a plurality of keratolytic substances, such as trichloroacetic acid and salicylic, and a post inflammatory hyper pigmentation reducing substance such as retinoic acid. In addition, the skin peel composition may further include ascorbic acid (vitamin C), as well as vitamins A and E. Application of the skin peel composition may be either topically in the form of a cream or gel, and may further be injected subcutaneously into the skin to achieve deeper penetration of the composition within the skin layers of the area to be treated.

Owner:KALIL ENTERPRISES

Method for extracting laminarin from kelp

The invention discloses a method for extracting laminarin from kelp. The method comprises the following steps: raw material treatment, ultrasonic treatment, enzymolysis, destaining, deproteinization and drying to obtain the product. Compared with the existing trichloroacetic acid precipitation method, savage method and the like, the method has the advantages that laminarin is high in yield and high in content.

Owner:广西还珠海洋生物科技有限公司

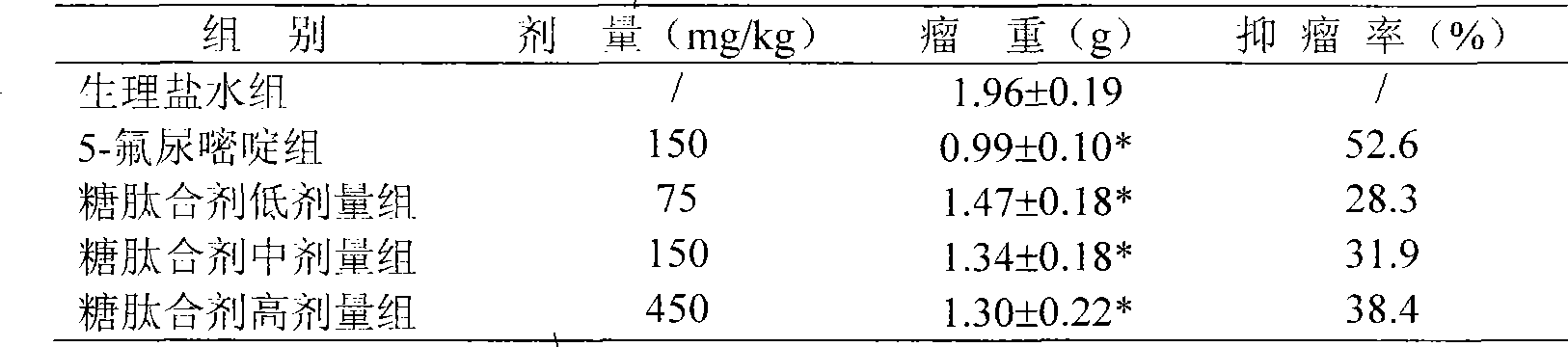

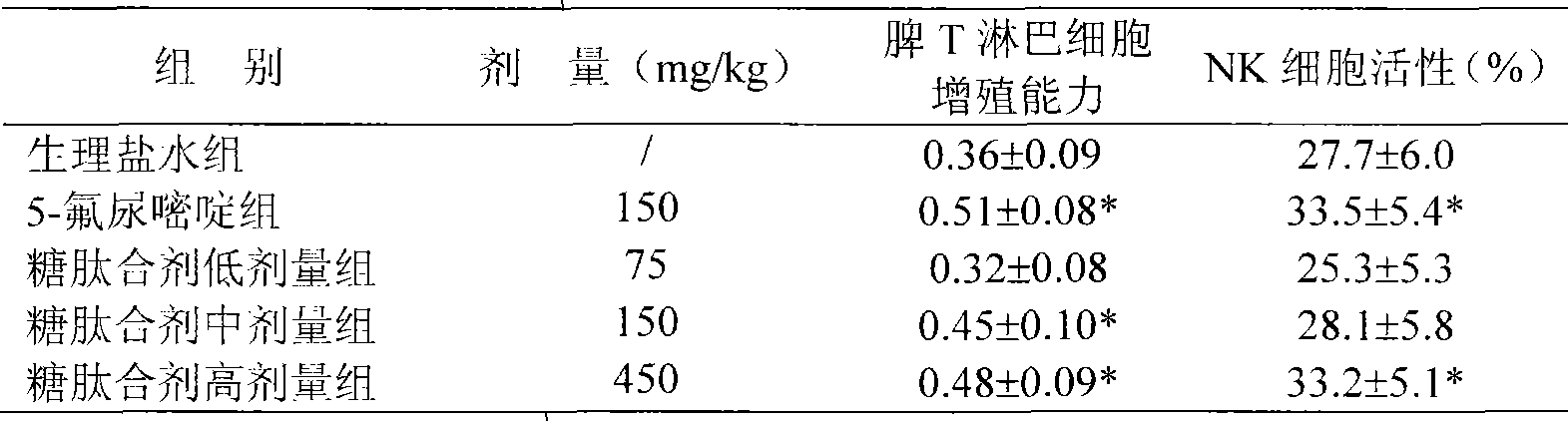

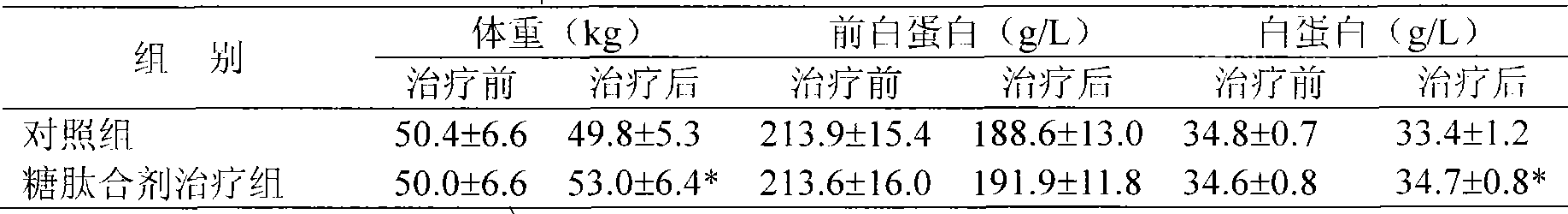

Application of glycopeptide mixture in preparing adjuvant therapy medicaments of tumor and health food

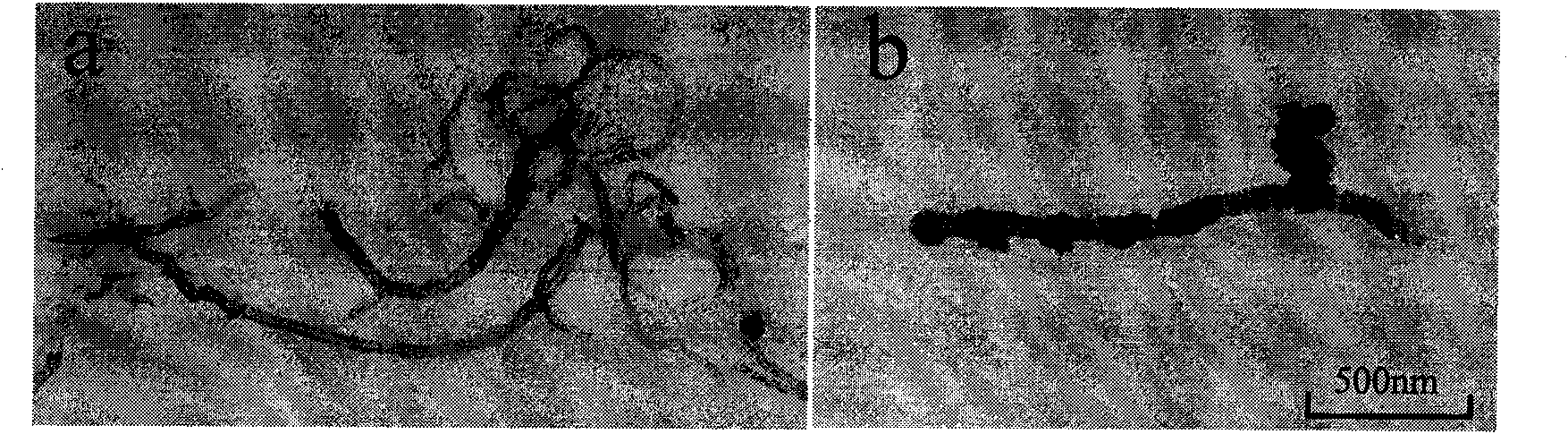

The invention relates to a glycopeptide mixture product and application thereof in preparing a medicament for improving the nutritional status and immunologic function of tumor patients receiving radiotherapy and chemotherapy and health food or food. A glycopeptide mixture is prepared by mixing marine oligopeptide and bioactive polysaccharide according to certain proportion. The marine oligopeptide is a group of oligopeptide mixtures with low molecular weights which are produced by taking fish skin, fish meat or fish bone of marine fishes as main raw materials through enzymatic hydrolysis, can be dissolved by trichloroacetic acid, and have relative molecular mass less than 1,000, and has the characteristics of easy absorption, quick absorption, low viscosity, good water solubility, and the like. The bioactive polysaccharide comprises lentinan, ganoderan, grifola polysaccharide, panaxan, lycium bararum polysaccharide and algal polysaccharide. Animal experiments and clinical observation prove that the glycopeptide mixture prepared by mixing the marine oligopeptide and the bioactive polysaccharide has the effect of improving the immunologic function of tumor-bearing mice and the nutritional status of the tumor patients receiving radiotherapy and chemotherapy.

Owner:李勇 +1

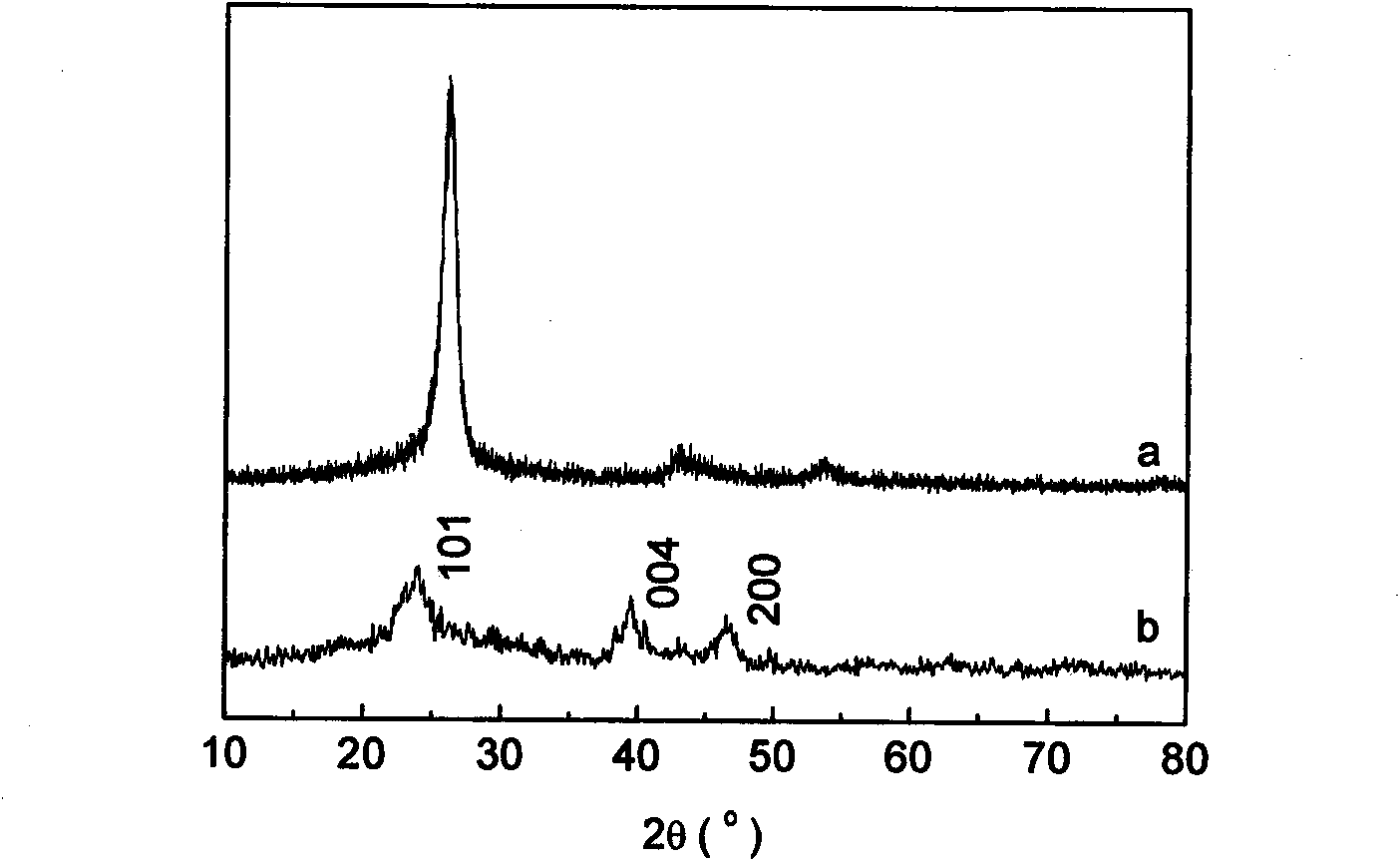

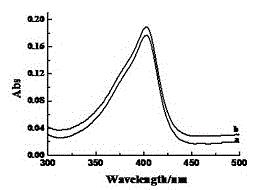

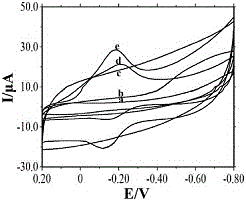

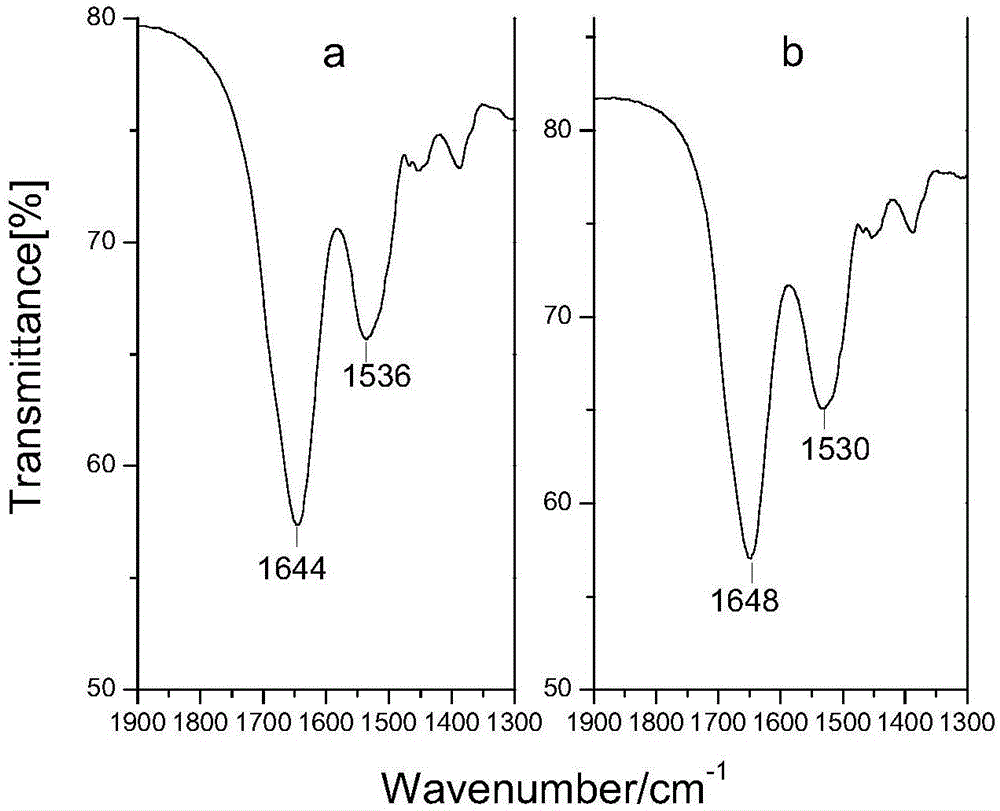

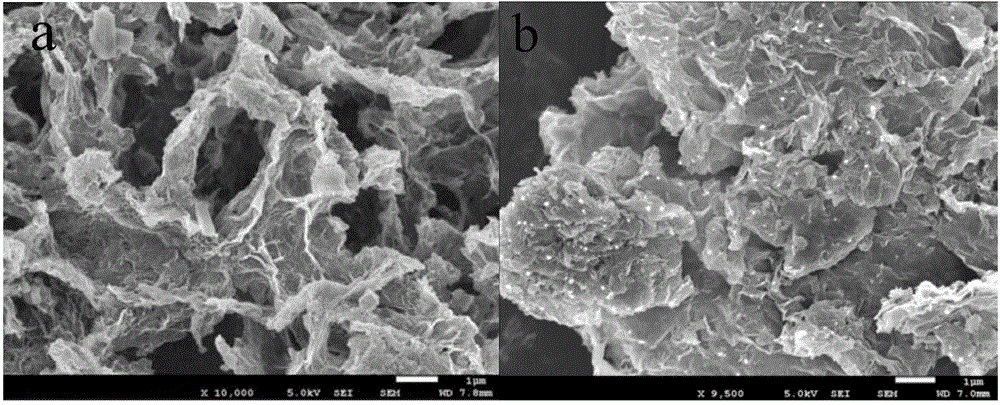

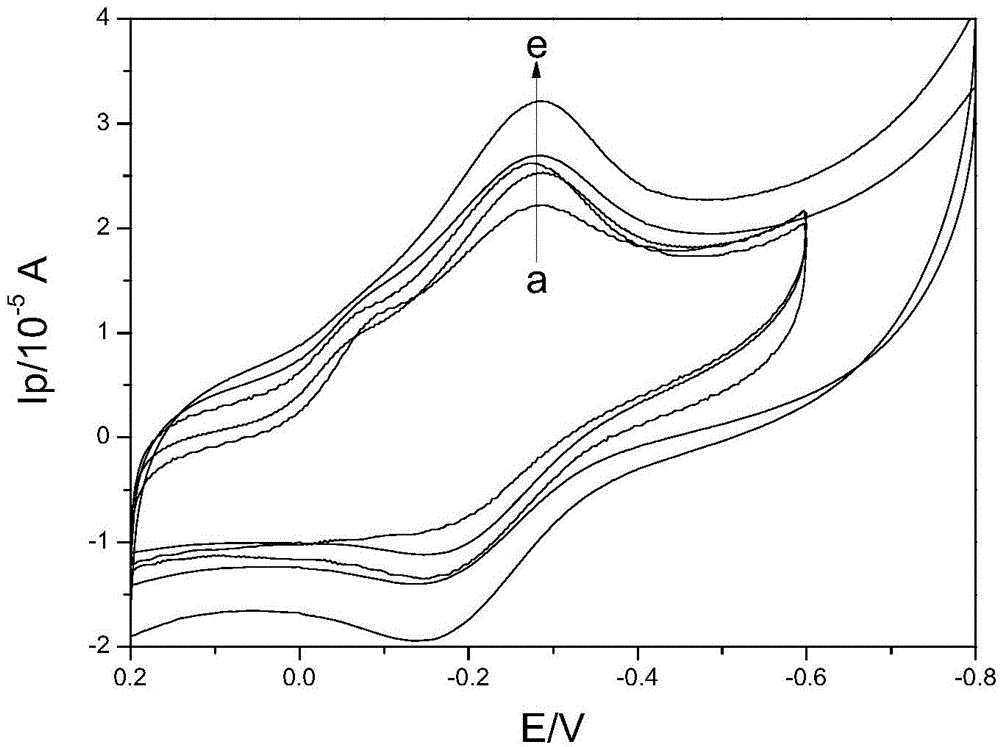

Method for preparing enzyme electrode with MWCNTs-TiO2/Nafion composite medium

InactiveCN101603940AExplanation of validityImprove catalytic abilityMaterial electrochemical variablesBiocompatibility TestingCore shell nanocomposites

The invention discloses a method for preparing an enzyme electrode with an MWCNTs-TiO2 / Nafion composite medium. In the method, MWCNTs-TiO2 core-shell nanocomposite materials are scattered into Nafion to prepare an organic-inorganic composite membrane as a fixed matrix for biological molecules for structuring a hemoglobin electrode, and a hemoglobin biosensor with fast response, high sensitivity and strong catalytic capacity is prepared by using the properties of large specific surface area, high surface reactivity, strong adsorption capacity, large electrical conductivity and the like of the MWCNTs-TiO2 core-shell nanocomposite materials and the properties of membrane forming, high chemical stability, high anti-interference capacity and the like of the Nafion. The biosensor has good biocompatibility, stability and repeatability, and has potential application in structuring biosensors. The sensor can be used for detecting the substances of hydrogen peroxide, trichloroacetic acid and the like, and has the advantages of low sensitivity, low detection limit and the like.

Owner:NANJING UNIV OF TECH

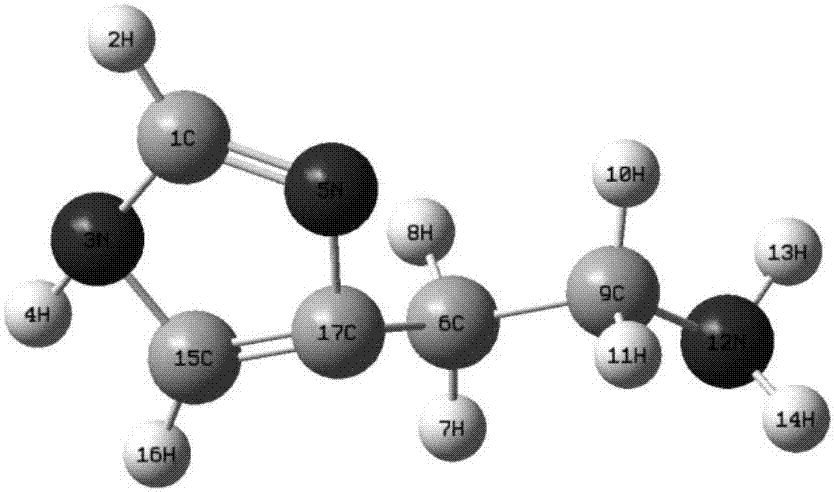

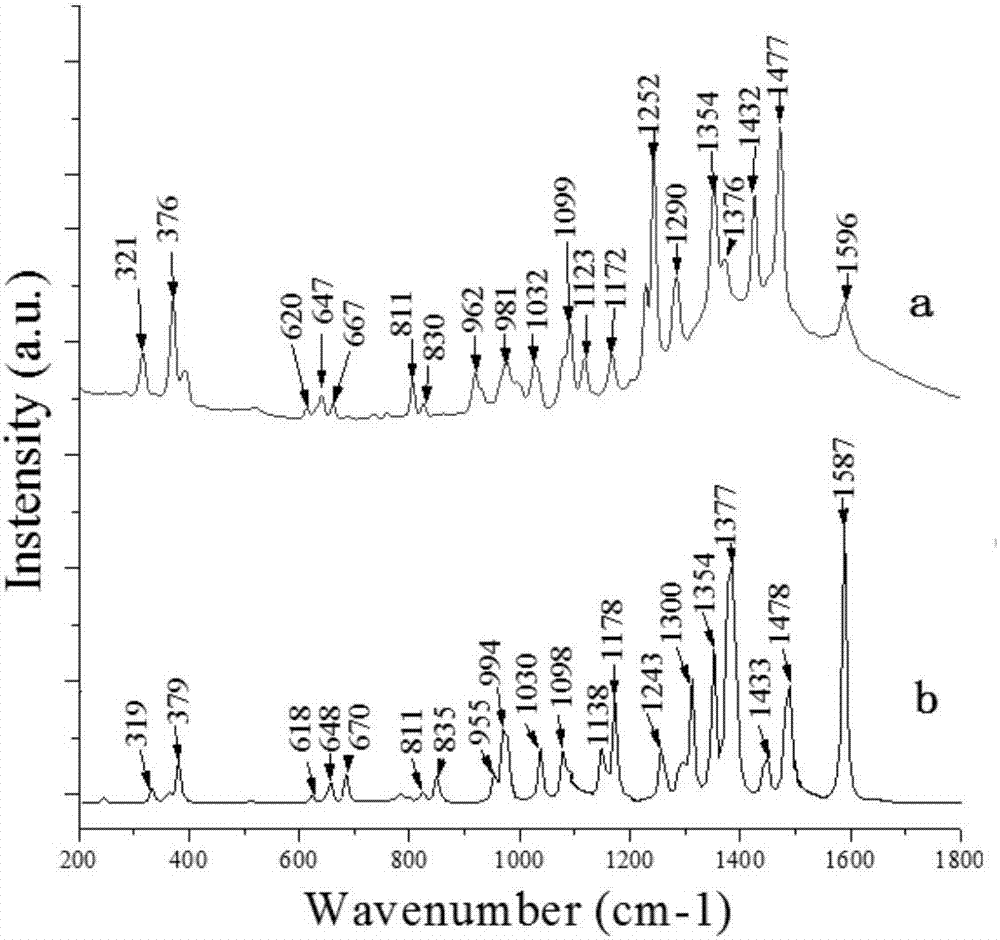

Method for qualitatively and quantitatively analyzing histamine in muscles of miichthys miiuy by surface-enhanced Raman spectroscopy

InactiveCN107345911AGood test resultReliable detectionComponent separationRaman scatteringSurface-enhanced Raman spectroscopyData acquisition

The invention discloses a method for qualitatively and quantitatively analyzing histamine in muscles of miichthys miiuy by surface-enhanced Raman spectroscopy. The method comprises the following steps: mincing the muscles of the miichthys miiuy, making the minced muscles into minced meat, weighing certain parts of equivalent miichthys miiuy muscles to serve as samples, preparing histamine standard solutions of different concentrations, adding the histamine standard solutions into the samples, and using samples at different time points as labeling samples and prediction samples in a storage process; adding the labeling samples and the prediction samples into trichloroacetic acid, and filtering to obtain an extracting solution; measuring the histamine content of the miichthys miiuy meat of the prediction samples through HPLC (High Performance Liquid Chromatography); adding a nanometer enhancer into the extracting solution of the labeling samples, performing Raman spectrum data acquisition, and calculating corresponding Raman characteristic peaks of the histamine by a density functional theory; establishing a quantitative analysis model by using the peak intensity of the Raman characteristic peaks and the histamine content, and measuring the histamine concentration of the muscles of the miichthys miiuy by the quantitative analysis model. By adopting the method, the content of histamine of which the concentration is 1 to 150 mg / L in fresh fish can be detected accurately and quickly.

Owner:ZHEJIANG UNIV

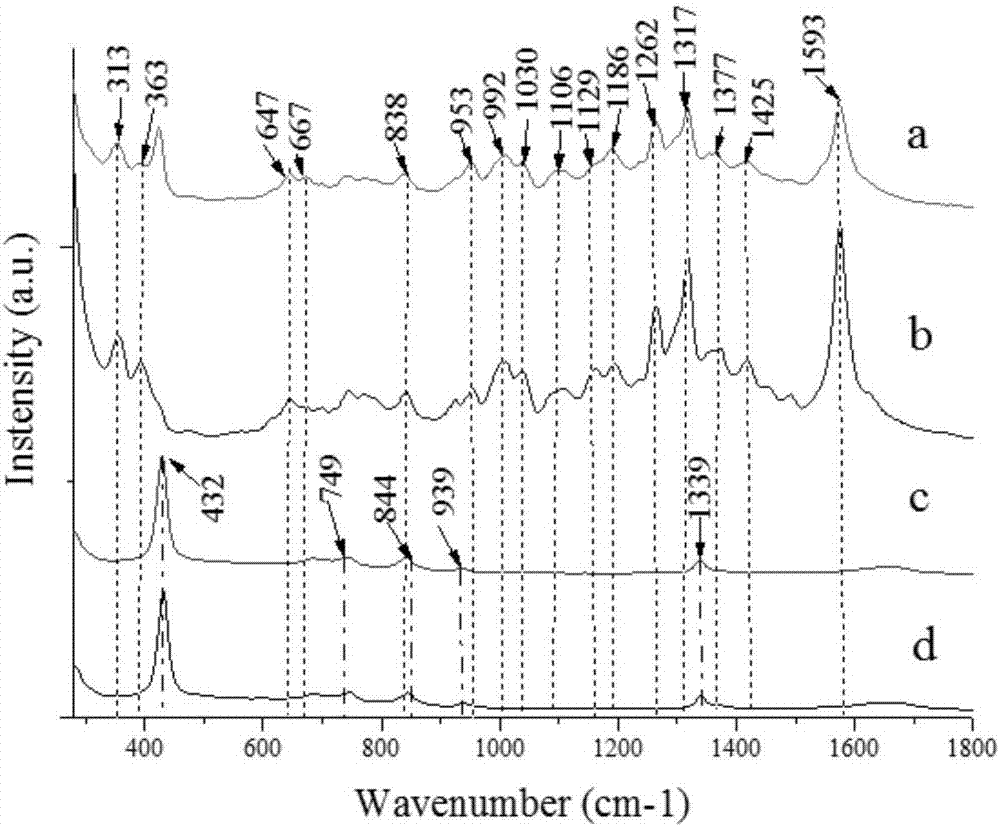

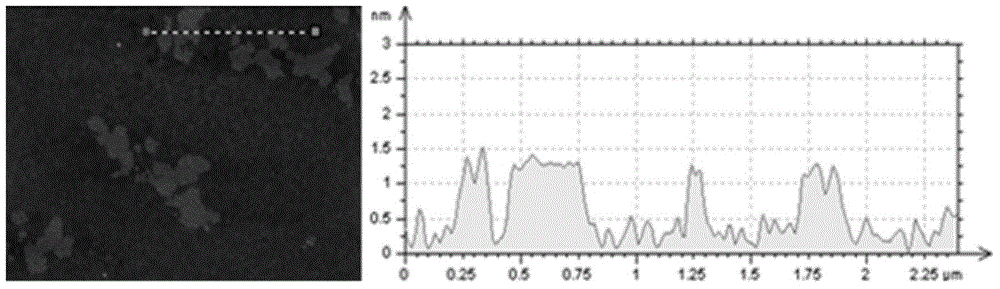

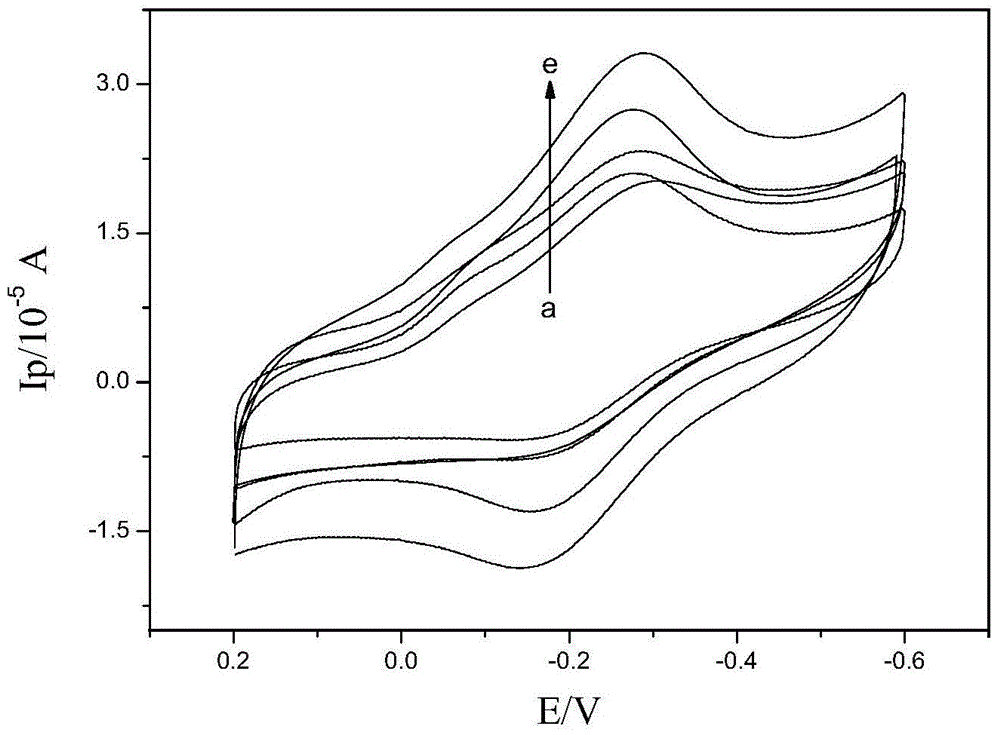

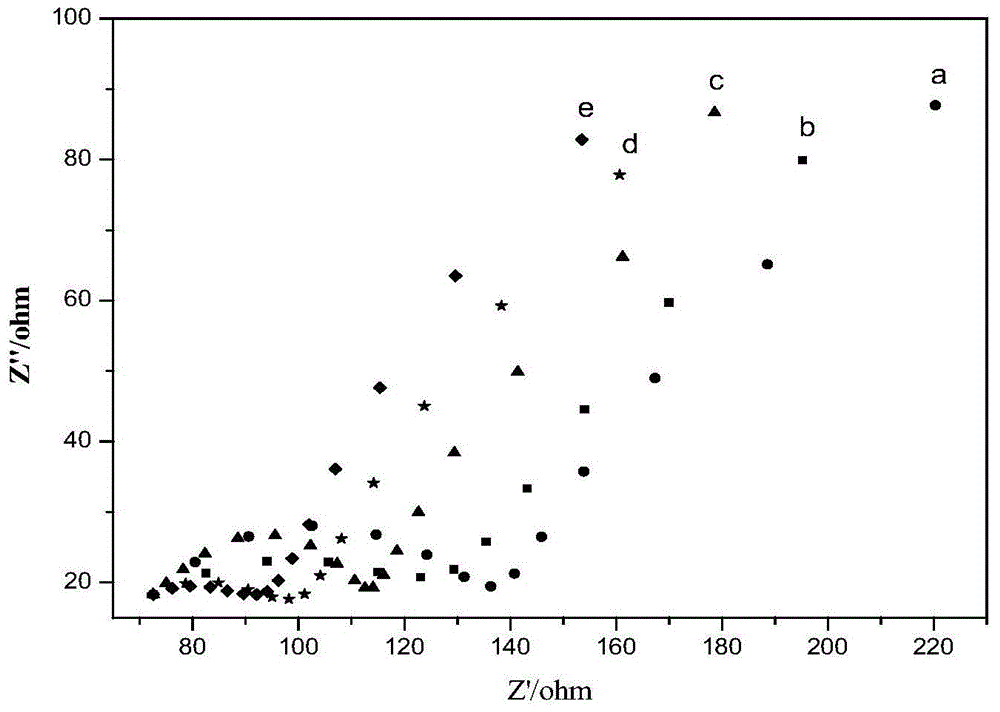

Graphene-exfoliation hydrotalcite-like compound composite material immobilized protein modified electrode, production method and application thereof

ActiveCN104977342AImprove conductivityInhibit aggregationMaterial electrochemical variablesComposite filmModified carbon

The invention discloses a graphene (GR)-exfoliation hydrotalcite-like compound (ELDH) composite material immobilized protein modified electrode, a production method and an application thereof. The method comprises the following steps: compounding ELDH with negatively-charged exfoliation graphene oxide (GO) nanosheets through electrostatic attraction by using the characteristics of positive charges and large specific surface area of the ELDH, and reducing by using hydrazine hydrate to prepare a GR-ELDH hybrid; and sequentially immobilizing the GR-ELDH, ferrohemoglobin and chitosan on an ionic liquid modified carbon paste electrode through adopting a dispensing technology to produce the graphene-exfoliation hydrotalcite-like compound composite material immobilized protein modified electrode. The obtained modified electrode has monolayer GR nanosheet and ELDH synergistic effects, and the GR nanosheets increase the conductivity of the ELDH and inhibits the aggregation and accumulation of the ELDH; and the ELDH effectively inhibits the afresh stacking of the GR nanosheets, reduces the interlamellar contact resistance and improves the electron transfer rate of the above composite material, and a constructed CTS / GR-ELDH-Hb composite film-based third-generation trichloroacetic acid sensor has the advantages of low detection limit, wide detection range and small Michaelis constant.

Owner:徐州圣都金属科技有限公司

Milk and milk product tetracycline antibiotic residual quantity checking method

ActiveCN101290306AShort detection timeHigh sensitivityComponent separationTesting medicinal preparationsTriple quadrupole mass spectrometryGradient elution

The invention relates to a method for detecting the residue amount of terracycline antibiotics in milk and dairy products. The method utilizes an ultra performance liquid chromatography - electrospray tandem triple quadrupole mass spectrometer to determine the residue amount of the terracycline antibiotics. The method is as follows: a sample is extracted from Na2EDTA-McIlvaine buffer solution (pH4.0); proteins are removed by trichloroacetic acids; a columella is extracted through an HLB solid phase and then purified and enriched; the sample is separated by a chromatographic column, with the column temperature of 30 DEG C; gradient elution is performed by utilization of water solution (v / v) which contains 0.1 percent of methanoic acids and acetonitrile as a moving phase; and quantitative detection is performed by adoption of the multi-reaction monitoring means. The detection limit of instruments is between 1.0 and 2.0 mu g / kg; a related coefficient r reaches over 0.999 within the linear range of between 1 and 100 mu g / kg; and the recovery rate is between 81.7 and 100.7 percent (the addition levels are 10 mu g / kg, 50 mu g / kg and 100 mu g / kg). The method has the advantages of quickness, accuracy, high sensitivity and wide application scope.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

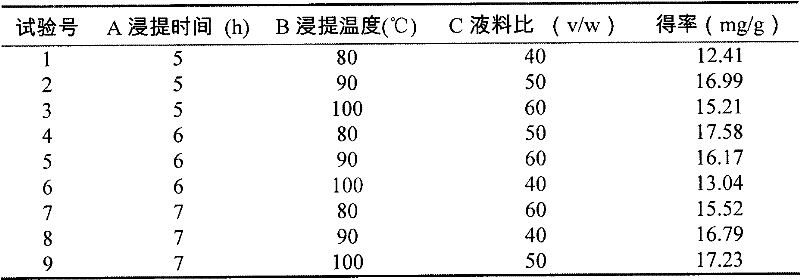

Squash polysaccharide and preparation method thereof

InactiveCN101314621AReduce the number of washesSimple processOrganic active ingredientsMetabolism disorderTrichloroacetic acidPolysaccharide

The invention discloses pumpkin polysaccharide and the preparation method thereof. The preparation method comprises the steps as follows: pre-treating pumpkin, extracting in water for 0.5-3h, filtering to obtain filtrate, centrifuging the filtrated supernatant, purifying the supernatant with a resin column chromatography, and colleting eluent; concentrating the eluent, and precipitating with ethanol; and dissolving the precipitate into water, adding trichloroacetic acid, centrifuging for deproteinization to obtain supernatant, concentrating the supernatant, drying and pulverizing. The washing number of times is reduced, the technological process is simplified, and the extraction condition and technological parameter are optimized to shorten the time of the extraction and purification processes by purifying the pumpkin polysaccharide with advanced resin chromatography technology. Therefore, the preparation method has the advantages of simple technological process, short production period, easily-controlled production, and low production cost. The purity of the obtained pumpkin polysaccharide is as high as more than 80%, and the extraction rate is as high as more than 25%.

Owner:卢照凯 +1

Extraction refining method for aloe-polysaccharide

InactiveCN1418892AThe extraction and refining method is simpleEasy to extract and refineAlcohol contentAloe arborescens

The method for extracting and refining aloe polysaccharide includes the following steps: uctting fresh leaf of aloe into small block, extracting with water at 40-80 deg.C, filtering extract, centrifugation and taking out supernatant fluid, adding 95% ethyl alcohol in the supernatant fluid, making the ethyl alcohol content be up to 50-80%, precipitating crude aloe polysaccharide, dissolving said crude aloe polysaccharide in water, adding 20-50% trichloroacetic acid or trifluoroacetic acid to make end concentration of trichloroacetic acid or trifluoroacetic acid be up to 2-6%, standing still, then centrifugation to remove precipitate to obtain secondary supernatant fluid, feeding it into macroporous resin column bed and using water to make elution, concentrating and adding 95% ethyl alcohol, precipitating polysaccharide, freeze-drying so as to obtain refined aloe polysaccharide.

Owner:NANJING UNIV

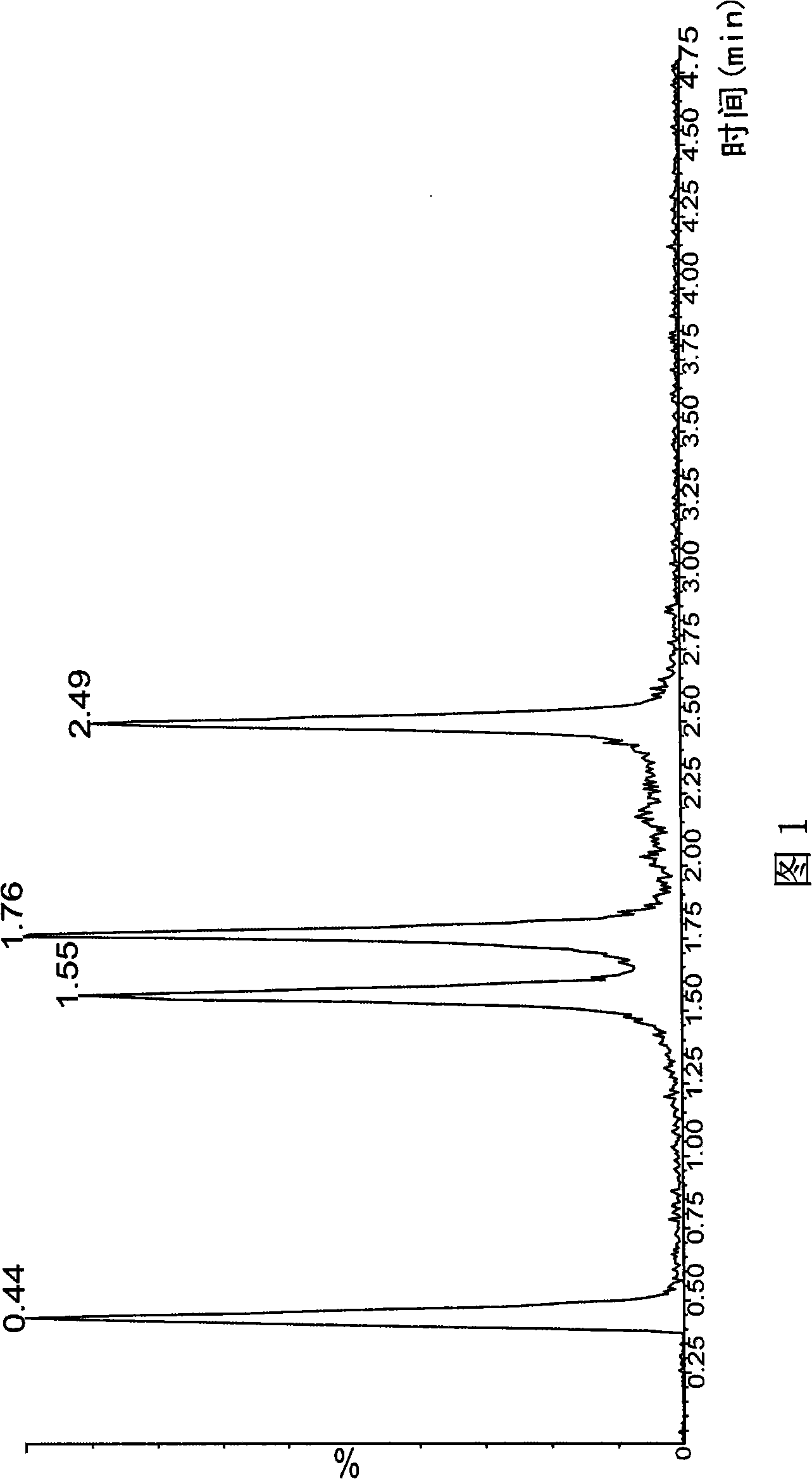

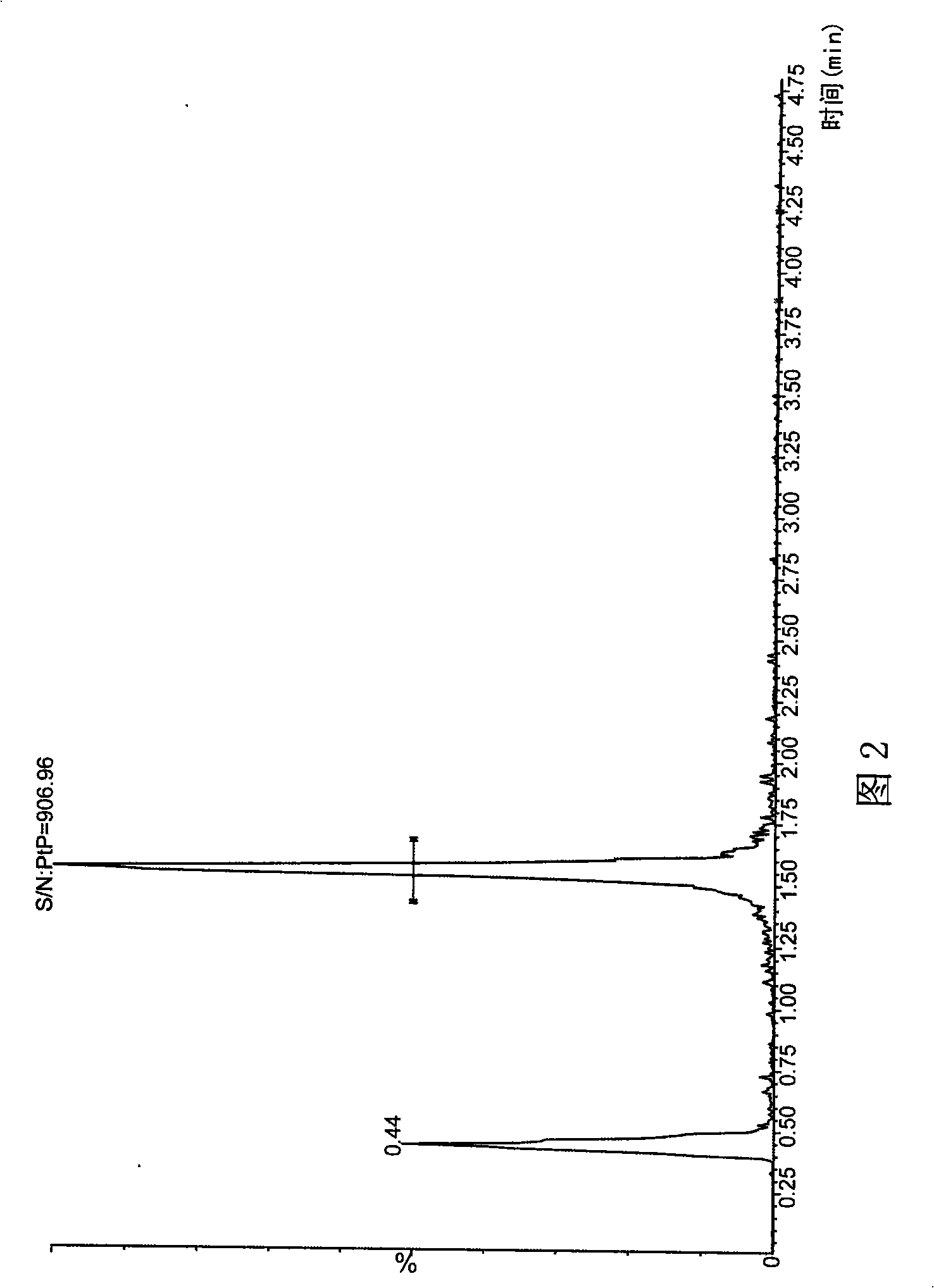

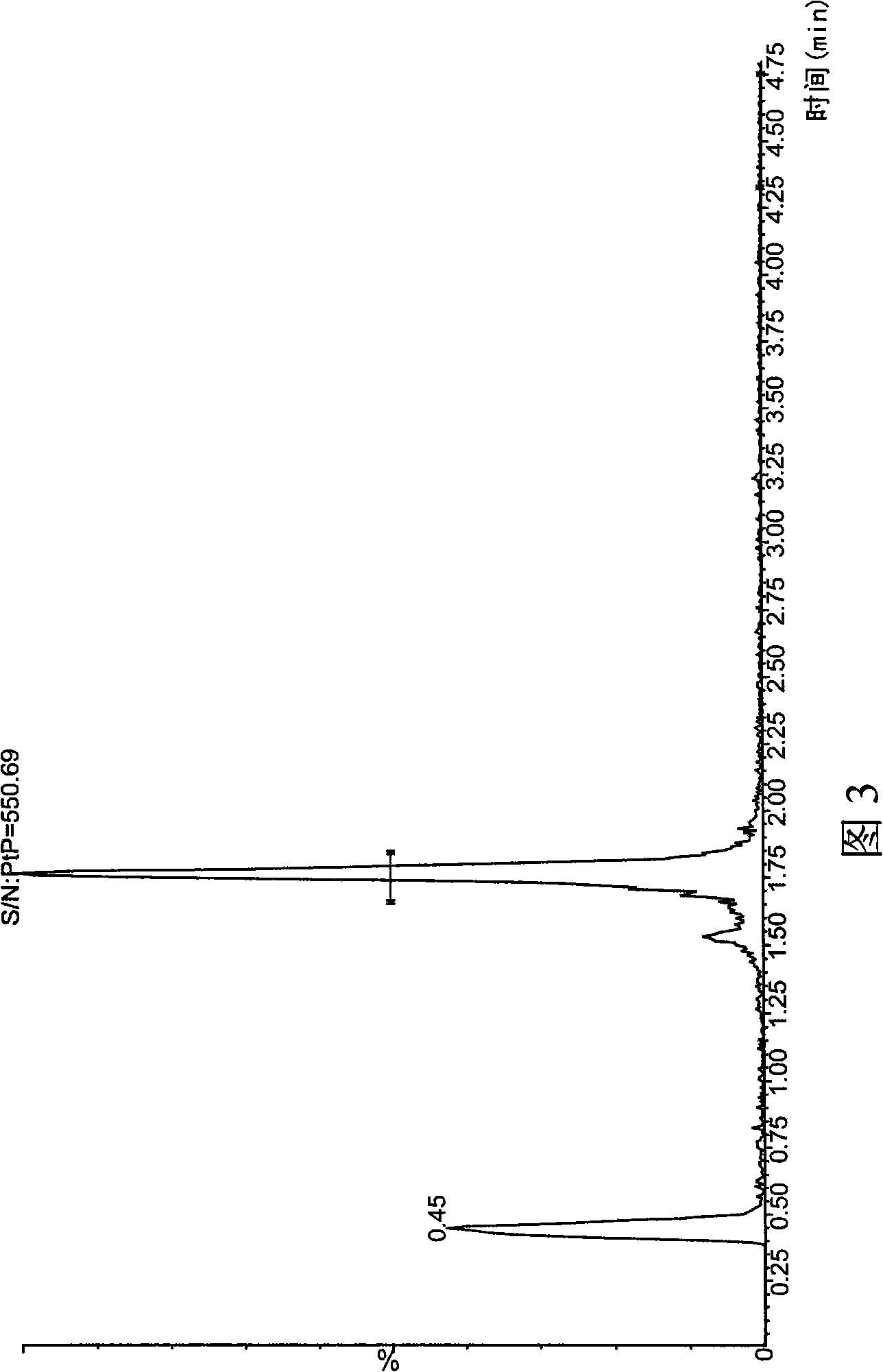

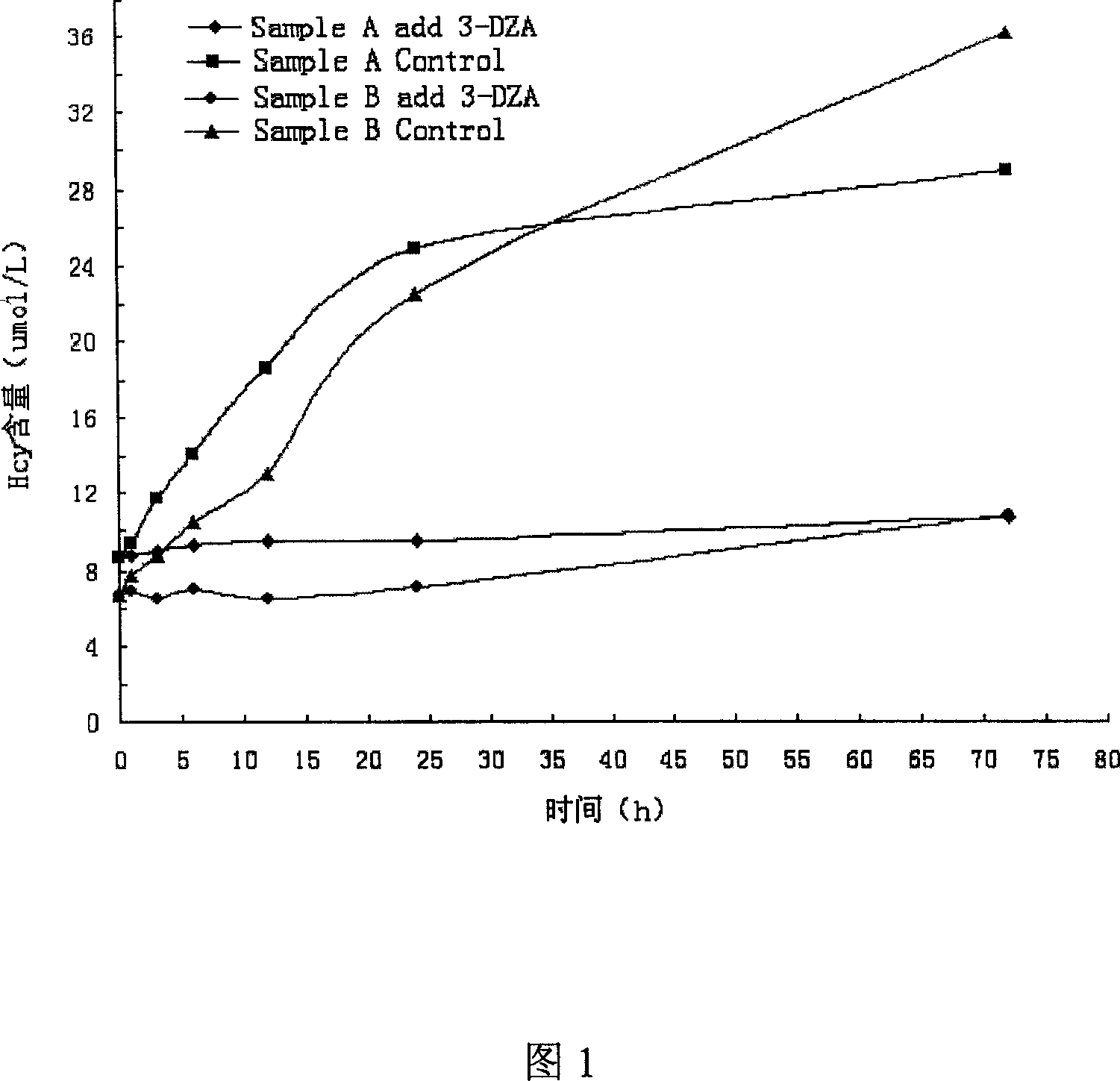

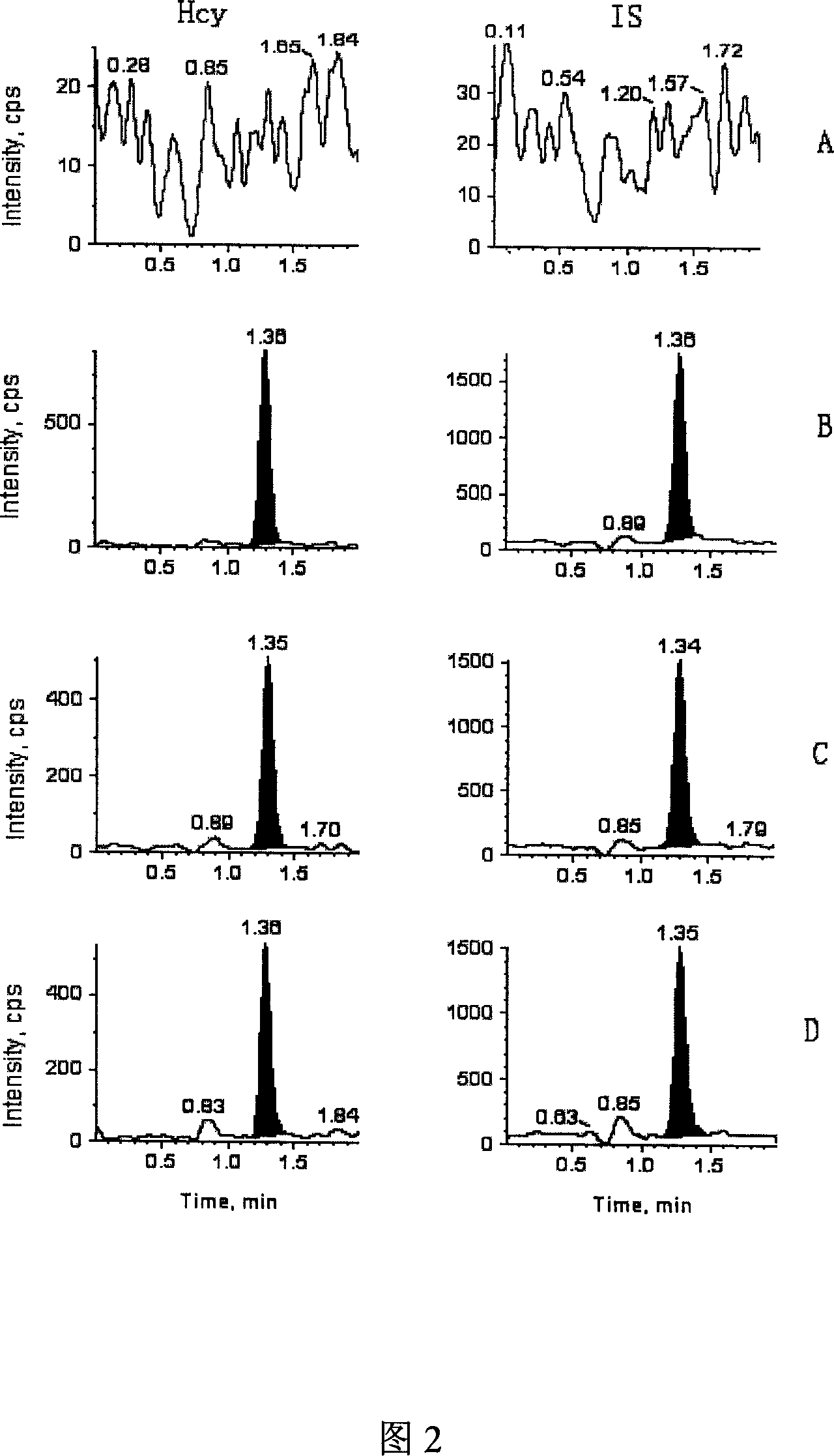

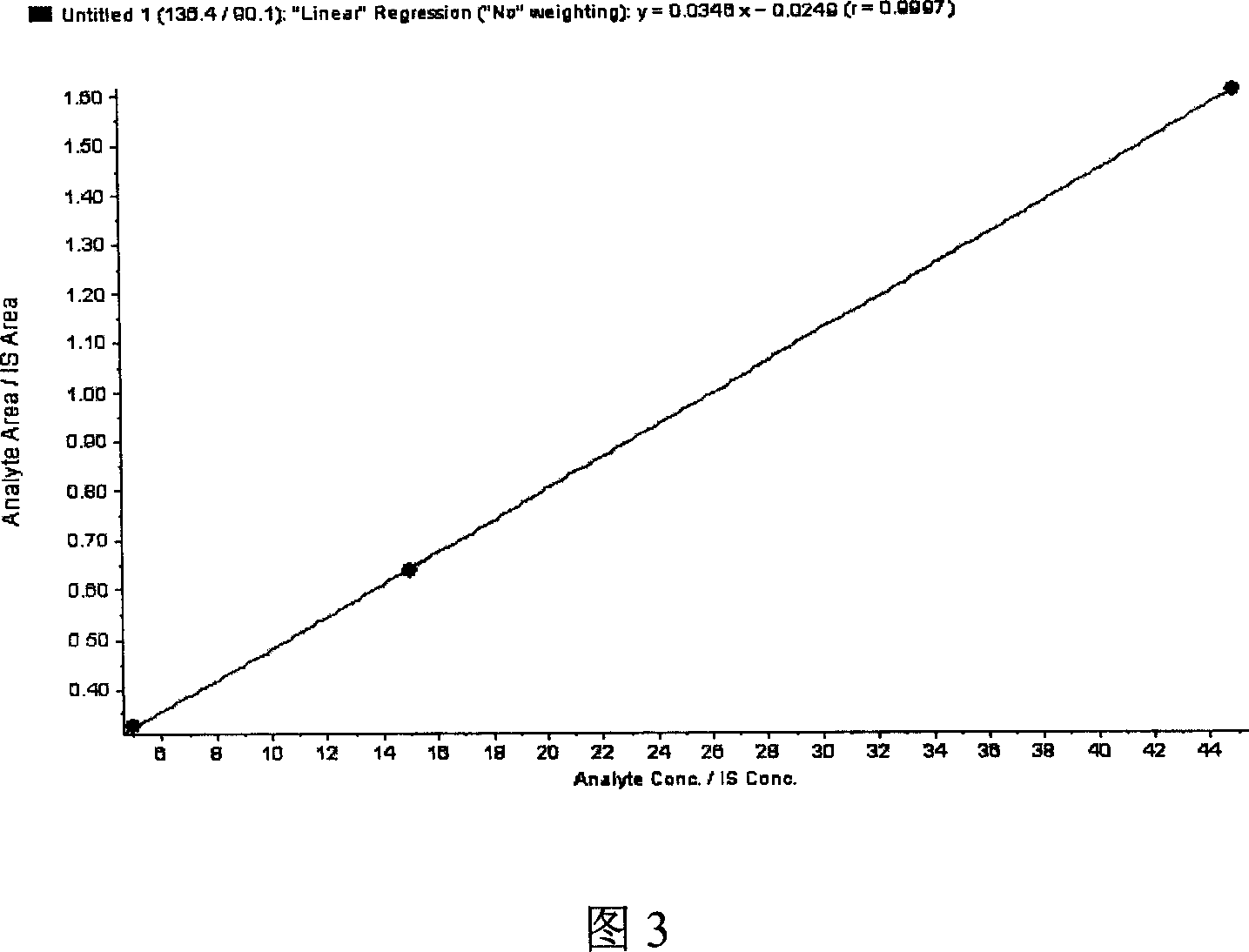

High-sensitive blood-plasma total homocysteine detection reagent box

InactiveCN1979155AStrong detection specificityHigh sensitivityComponent separationOther chemical processesTotal homocysteineHomocysteine testing

The invention relates to a high sensitive blood plasma homocysteine testing kit that includes sample tube with stabilizer, reference substance and quality control serum of different Hcy thickness, DL- homocystine-D8 internal standard solution, reducer and trichloroacetic acid albumen precipitation. The invention has strong specificity for sample testing, and high sensitivity. It could be accurately and rapidly used in Hcy research.

Owner:上海特敏生物医药科技有限公司

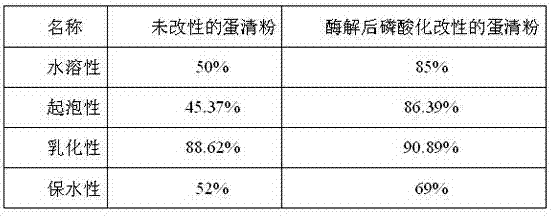

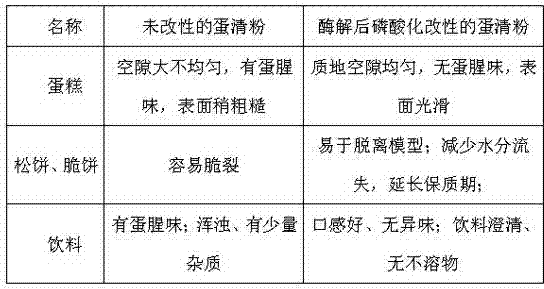

Process method for modified collaborative preparation of egg white powder through enzymolysis and phosphorylation

InactiveCN104839760AImprove qualityImprove solubilityFood preparationPhosphorylationTrichloroacetic acid

The invention discloses a process method for modified collaborative preparation of egg white powder through enzymolysis and phosphorylation. The process method sequentially comprises the steps of egg cleaning, egg white separation, gauze filtration, distilled water dilution, constant temperature enzymolysis, enzyme deactivation treatment, enzymatic hydrolysate centrifugal filtration, phosphorylation, TCA (Trichloroacetic Acid) precipitation and the like. According to the method, the egg white is used as a raw material; the egg white powder which is easy to absorb, has small fishy smell and has good solubility, foaminess and emulsibility is prepared through the combined mode of the enzymolysis and the phosphorylation. The processing characteristic of egg white protein and the utilization rate of the protein are improved.

Owner:HENAN UNIV OF SCI & TECH

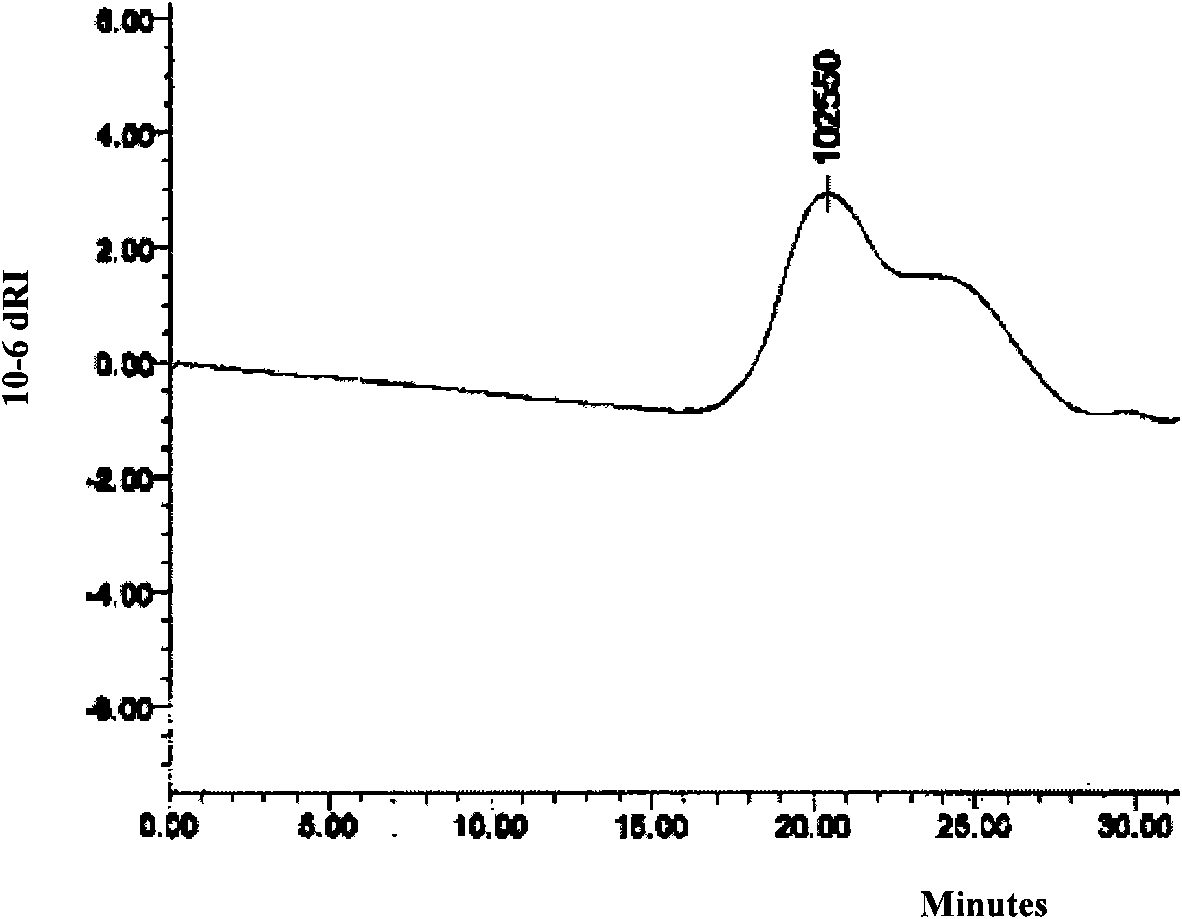

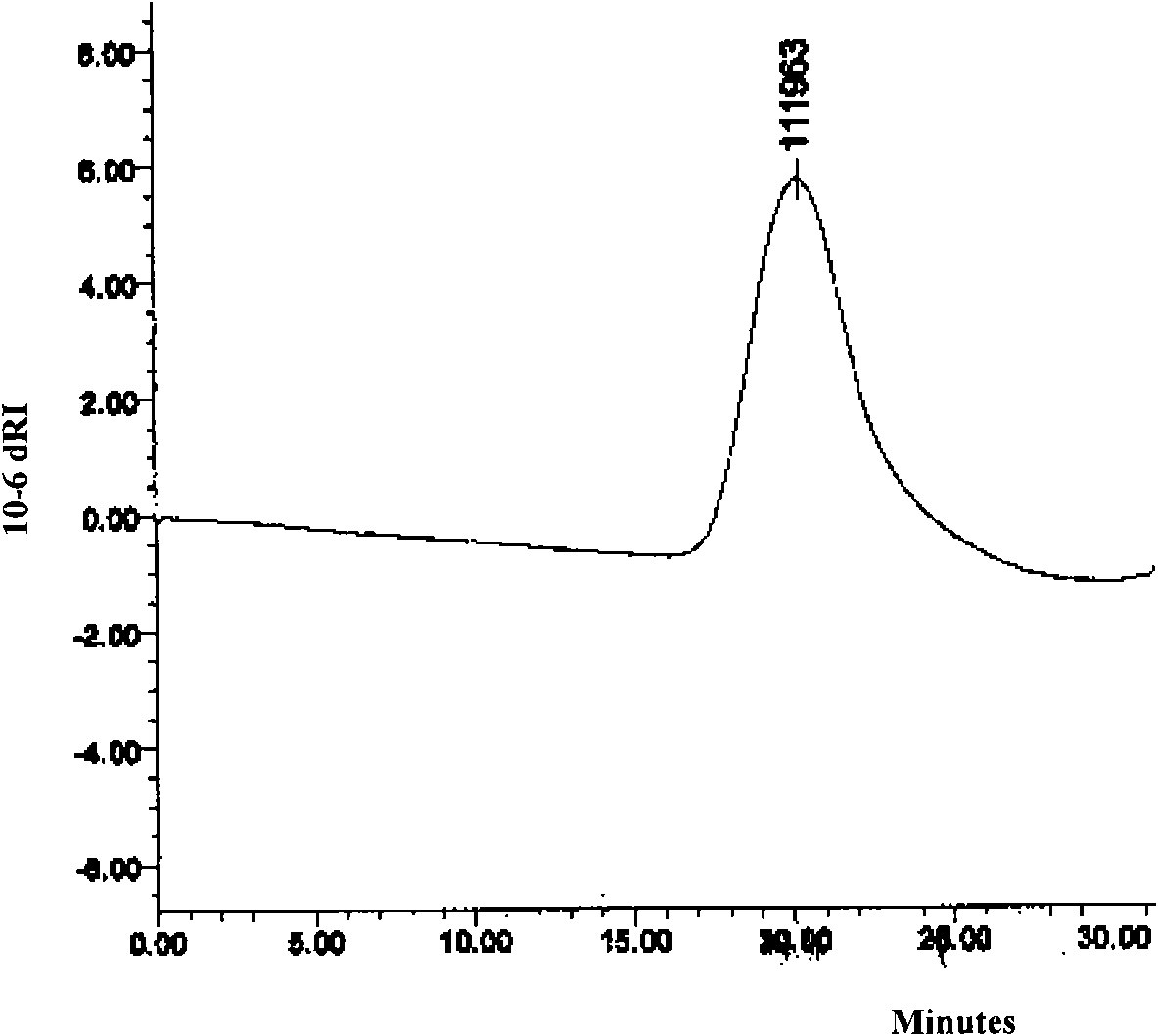

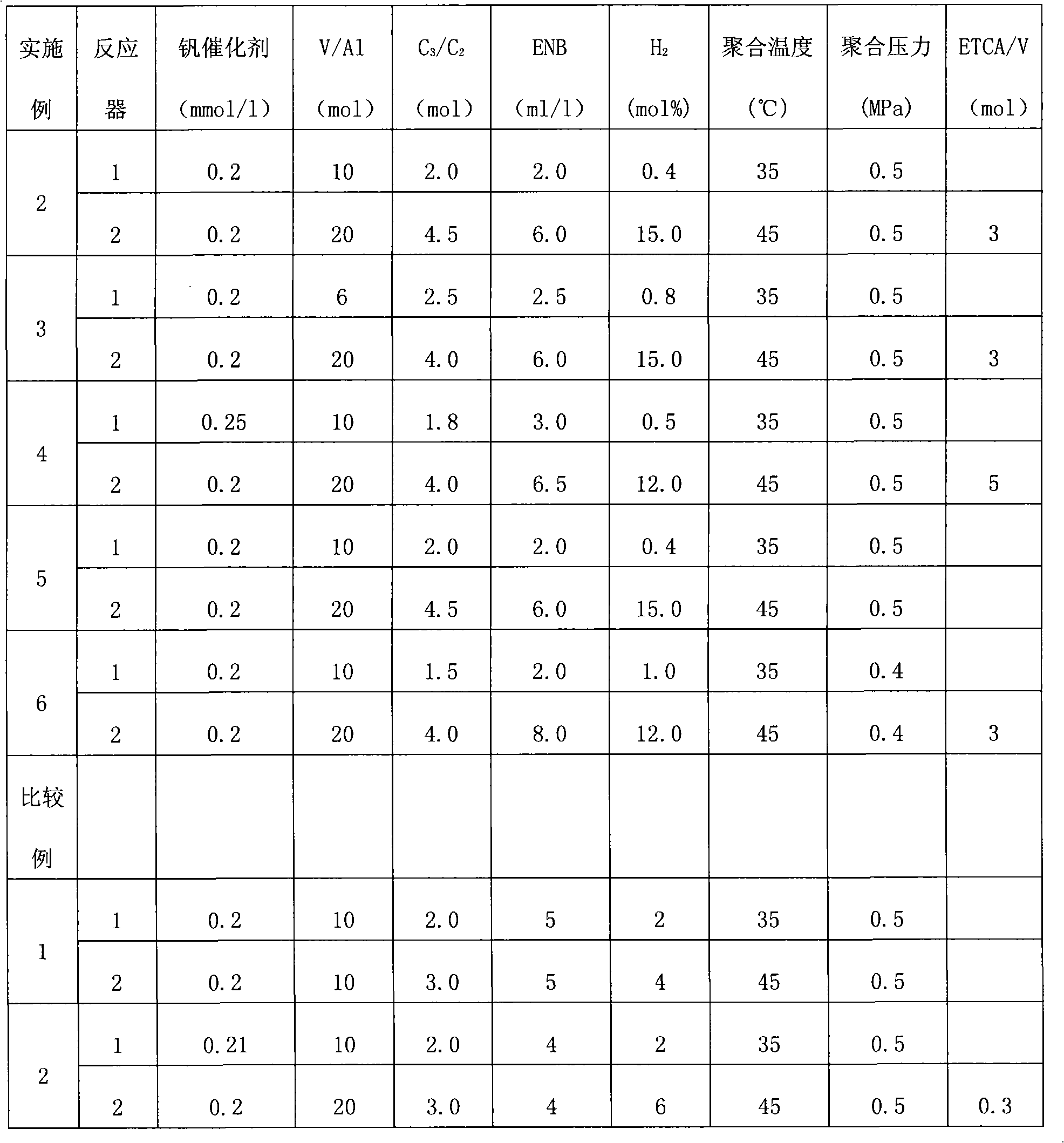

Synthesis method of bimodal-distribution ethylene-alpha-alkene-non-conjugated dialkene random copolymer

ActiveCN101838365AHigh Mooney viscosityModerate molecular weight distributionSynthesis methodsMooney viscosity

The invention relates to a synthesis method of a bimodal-distribution ethylene-alpha-alkene-non-conjugated dialkene random copolymer. The method comprises the following steps: a high-molecular weight part ethylene-propylene copolymer is synthesized from ethylene, propylene and hydrogen (the mol ratio is 1:1.0-3.0:0.15-0.30) and ethidene norbornylene 2-5 mL / L hexane; a low-molecular weight part ethylene-propylene copolymer is synthesized from the ethylene, the propylene and the hydrogen (the mol ratio is 1:3.0-4.5:0.9-2.0) and ethidene norbornylene 8-12 mL / L hexane; the main catalyst is soluble vanadium complex, and the cocatalyst is ethylaluminium sesquichloride; the mol ratio of Al to V is 1-100; the activating agent for the low-molecular weight part is ethyl trichloroacetate; and the mass ratio of the high-molecular weight part ethylene-propylene copolymer to the low-molecular weight part ethylene-propylene copolymer is 80 / 20-40 / 60. The copolymer has the advantages of high Mooney viscosity and moderate molecular weight distribution, and can be used for processing rubber for automobile gland strips.

Owner:PETROCHINA CO LTD

Method for preparing stichopus japonicus selenka glycosaminoglycans

The invention discloses a method for preparing stichopus japonicus selenka glycosaminoglycans, which comprises the following steps: (1) carrying out pretreatment on fresh sea cucumber; (2) carrying out alkaline hydrolysis on body wall of the sea cucumber; (3) carrying out dual-enzyme enzymatic hydrolysis on the body wall of the sea cucumber; (4) using trichloroacetic acid for removing proteins in dual-enzyme enzymatic hydrolysis solution after completing the enzymatic hydrolysis; (5) using ethanol for precipitating the stichopus japonicus selenka glycosaminoglycans; (6) drying for obtaining crude stichopus japonicus selenka glycosaminoglycans; (7) using potassium acetate for precipitating the stichopus japonicus selenka glycosaminoglycans; (8) decoloring the stichopus japonicus selenka glycosaminoglycans; (9) using the potassium acetate for precipitating the stichopus japonicus selenka glycosaminoglycans; and (10) drying for obtaining fine stichopus japonicus selenka glycosaminoglycans. The method can balance the relationship between the yield and the purity of the stichopus japonicus selenka glycosaminoglycans and improve the purity of the stichopus japonicus selenka glycosaminoglycans.

Owner:QINGDAO MUNICIPAL HOSPITAL

Method for extracting hirudin from leech saliva

InactiveCN104926937ANot corrosiveEasy extractionAnimal husbandryLeech-based protease inhibitorsFiltrationLiving body

The invention discloses a method for extracting hirudin form leech saliva. The method includes the following steps of a), placing leeches in a container to allow the leeches to be hungered sufficiently, inputting inductive substances to the leeches to allow the same to absorb fully, adding vomitives to allow the leeches to spit the saliva in bodies, taking out blood-sucking leech living bodies to return to a rearing pond to feed continuously, and meanwhile, collecting hirudin crude product liquid in the container; b), freezing above hirudin crude products, adding into precooled cold acetone, stirring prior to placing in a refrigerator for setting overnight, sucking supernatant acetone the next day prior to centrifuging, adding a trichloroacetic acid solution, and centrifuging to remove residues to obtain concentrated liquid; c), eluting the above concentrated liquid with an anion exchange column chromatography method, and performing gel filtration chromatography to obtain finished products. The method has the advantages of reasonable process, convenience and practicability in operation, good quality stability of the finished hirudin products and high yield, one-time pillage on the leeches with a traditional method can be avoided, wild resources of the leeches are protected, and development of leech farming is driven.

Owner:广西复鑫益生物科技有限公司

Preparation and catalytic application of Nafion/horseradish peroxidase/tricobalt tetraoxide-graphene/ionic liquid carbon paste electrode

ActiveCN105758917AEasy to makeGood choiceMaterial electrochemical variablesBiocompatibility TestingIonic liquid

The invention relates to a biosensor, particularly relates to a preparation method and catalytic application of a Nafion / horseradish peroxidase / tricobalt tetraoxide-graphene / ionic liquid carbon paste electrode (Nafion / HRP / Co3O4-GR / CILE) and belongs to the technical field of electrochemical analysis and detection. According to the preparation method of the Nafion / HRP / Co3O4-GR / CILE, an ionic liquid carbon paste electrode is used as a substrate electrode, and by virtue of the specific advantages of a Co3O4-GR nano composite material of large surface area and good biocompatibility, HRP is adsorbed on the surface of the material; and furthermore, the material is fixed by a Nafion film to prepare the Nafion / HRP / Co3O4-GR / CILE. HRP in the modified electrode keeps a natural structure and biological activity. Research on electrochemical properties of the modified electrode shows that the modified electrode has good electrochemical catalysis capability on trichloroacetic acid (TCA), and can be used for effectively detecting TCA, and the detection limit is 0.33mmol / L. The preparation method and the catalytic application, provided by the invention, do not cause environmental pollution; the modified electrode has good stability, repeatability and sensitivity, and the preparation process is simple, low in cost and easy to operate, so that the modified electrode has wide social benefits.

Owner:HAINAN NORMAL UNIV

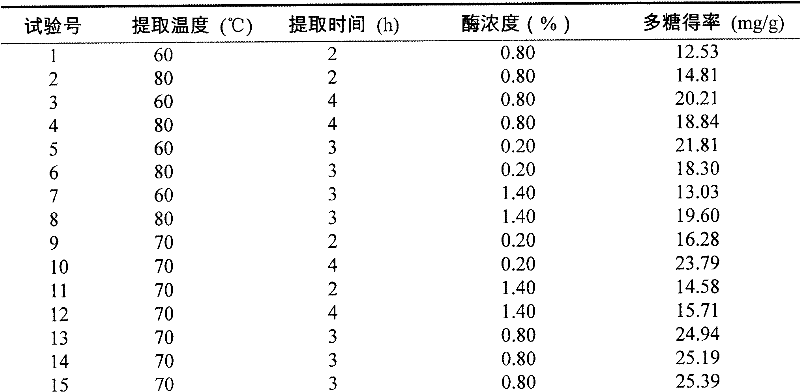

A kind of enzyme-assisted extraction method of high-purity laver polysaccharide

The invention discloses an enzyme-assisted extraction method of high-purity laver polysaccharide, which belongs to the field of biomedicine. The seaweed is dried and ultrafinely pulverized to obtain seaweed powder, and the pulverized seaweed powder is subjected to supercritical CO2 extraction (extraction pressure is 31 MPa, temperature 50 ° C, extraction for 3 hours, separation pressure 5.6 MPa, temperature 55 ° C) degreased, and then The defatted seaweed powder was mixed with 50 times of pure water, 0.5% papain was added to extract at 70°C for 3.5 hours, the filter residue was discarded by centrifugation at 5000 rpm for 15 minutes, the extract was concentrated to 1 / 4 of the original volume by rotary evaporation, and 80% of Trichloroacetic acid (TCA) was mixed to 2% of the total volume of the solution, and then the solution was reacted in a 70°C water bath for 20 minutes to remove protein, centrifuged at 5000 rpm for 30 minutes to remove the precipitate, and dialyzed in deionized water for 48 hours to remove trichloroacetic acid. The dialysate was collected, and then Slowly add 4 times the volume of 95% ethanol, alcohol precipitation at 4°C for 12h, centrifuge at 5000rpm for 10min, discard the supernatant, wash the precipitate with absolute ethanol, acetone, and ether for three times, respectively, and dry it in an oven at 55°C. Seaweed crude polysaccharide. The yield of papain extraction technology was 26.07%, and the purity reached 84.32%. Compared with hot water extraction, the time was shortened by 50% and the yield was increased by 46%. The obtained laver polysaccharide can be widely used as the base material of medicine and health food.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Method for extraction and purification of lipopolysaccharide from corn dipped in water

The invention discloses a method for extraction and purification of lipopolysaccharide from corn dipped in water which comprises the steps of, first isolating the proteins in the immersion water through the combination of isoelectric point method, hyper-filtration method and trichloroacetic acid method, carrying out filter membrane concentration, further isolating proteins through ethanol precipitation method, then extracting the lipopolysaccharides in the immersion water with activated charcoal, finally purifying the lipopolysaccharides through activated charcoal chromatography and ion-exchange chromatography.

Owner:HEBEI AGRICULTURAL UNIV.

Graphene-hydrotalcite-like compound-graphite phase carbon nitride composite material immobilized protein modified electrode, production method and application thereof

InactiveCN104977341ASuppress restackingLarge specific surface areaMaterial analysis by electric/magnetic meansElectrochemical responseCarbon composites

The invention discloses a graphene (GR)-hydrotalcite-like compound (LDH)-graphite phase carbon nitride (g-C3N4) composite material immobilized protein modified electrode, a production method and an application thereof. The method comprises the following steps: compounding an exfoliation hydrotalcite-like compound with negatively charged exfoliation graphene oxide nanosheets, mixing the obtained material with melamine, roasting, and adding water to recover in order to prepare a GR-LDH-g-C3N4 hybrid; and adding a GR-LDH-g-C3N4 and Hb mixed solution to an ionic liquid modified carbon paste electrode in a dropwise manner in order to produce the GR-LDH-g-C3N4 composite material immobilized protein modified electrode. The graphene-hydrotalcite-like compound-graphite phase carbon nitride composite material immobilized protein modified electrode fully displays advantages of a gel method and an integrating, merging and layering method, increases the specific surface area, the conductivity and the biocompatibility of the hybrid material, and inhibits the afresh stacking of GR sheets; and a roasting method allows g-C3N4 to grow on the surface of a GR sheet layer, increases the specific surface area of the hybrid material, and improves the electron transfer rate of an electrochemical reaction process. A constructed CTS / GR-LDH-g-C3N4-Hb composite film-based third-generation trichloroacetic acid sensor has the advantages of low detection limit, wide detection range and small Michaelis constant.

Owner:上海铭煦新材料有限公司

Method for isolating small RNA

InactiveUS20120295328A1Rapidly and efficiently isolateRapid and flexible and also automated high throughput isolationSugar derivativesHydrolasesSilica particleWhole blood product

A method for isolating small RNA from a sample is provided, the method comprising binding the RNA to silica particles by contacting the sample with a) at least one alcohol, b) at least one chaotropic salt comprising a chaotropic anion selected from the group consisting of trichloroacetate, perchlorate and trifluoroacetate and c) silica particles and separating the bound RNA from the rest of the sample. The present invention also provides compositions and kits to efficiently isolate small RNA molecules from samples, in particular biological samples such as blood, blood products tissue and body fluids.

Owner:QIAGEN GMBH

Extraction method of morindea officinalis polysaccharide

The invention provides an extraction method of morindea officinalis polysaccharide, belonging to the technical field of traditional Chinese medicines and solving the problems that in the existing morindea officinalis polysaccharide extraction method, the extraction method has complicated process steps and a poor protein removal effect, and the yield and purity of the obtained morindea officinalispolysaccharide are low. The extraction method of morindea officinalis polysaccharide in the invention comprises the following steps of: drying morindea officinalis rhizome and then smashing to 40-80 meshes; adding a chloroform / methanol mixed solvent in morindea officinalis powder for carrying out reflux extraction; carrying out alcohol extraction on a filter cake obtained by filtration and then adding water for lixiviation; subsequently, filtering and concentrating a filtrate, carrying out alcohol precipitation on a concentrated liquid and then filtering so as to obtain the crude morindea officinalis polysaccharide; adding the crude morindea officinalis polysaccharide into a n-butanol / trichloroacetic acid mixed solvent for processing, and entering a chromatographic column for elution; andcarrying out concentration, alcohol precipitation, filtration and drying on an effluent liquid so as to obtain the morindea officinalis polysaccharide. The extraction method of the morindea officinalis polysaccharide in the invention has a simple process and a good protein removal effect, and the extracted morindea officinalis polysaccharide has less impurities and high yield and purity.

Owner:朱孟勇

Preparation method of traditional Chinese medicine spices for tobaccos

InactiveCN103564647AWeaken energyReduce stimulationTobacco preparationTobacco treatmentSandalwood oilEthyl cinnamate

The invention discloses a preparation method of traditional Chinese medicine spices for tobaccos. The preparation method includes the following steps: 1), taking tangerine peels, scutellaria baicalensis, radix ophiopogonis, rehmannia, jasmine, semen lepidii, perilaseed and liquorice; continuously extracting 2-4 times by using a solvent, combining extracting solutions, concentrating the extracting solutions into a concentrated solution, recycling volatile oil, and combining the concentrated solution with the volatile oil to obtain a main spice agent; 2), taking vanillin, cananga oil, ethyl cinnamate, leaf alcohol, trichloroacetic acid methyl benzene methyl ester, sandalwood oil, ethanol and propylene glycol, and uniformly mixing to obtain a surface spice agent; 3), uniformly mixing the main spice agent with the surface spice agent to obtain the traditional Chinese medicine spices. The traditional Chinese medicine spices prepared by the method have effect of clearing heat and decreasing internal heat and freeing lung and relieving asthma; after the traditional Chinese medicine spices are added into the tobaccos, aroma quantity, aroma quality and harmony of the tobaccos can be richened and improved, and strength, stimulation and offensive odor can be reduced.

Owner:马瑞

Extraction process of black corn silk polysaccharide

InactiveCN102504039AHigh recovery rateHigh purityMetabolism disorderAntineoplastic agentsCelluloseCombined method

The invention discloses an extraction process of black corn silk polysaccharide, which comprises a raw refining process, a protein removing process, a decolorization process and a grading and purifying process, wherein in the raw refining process, protease K water digestion and ultrasound extraction combined method is adopted in the raw refining process, the protein removing process is that sevage method and TDA (trichloroacetic acid) method are alternatively used for deproteinization, an ethanol decolorizing and peroxide decolorizing combined method is adopted in the decolorization process, and DEAE- cellulose (chlorine type) column chromatography method is adopted in the grading and purifying process. Compared with the prior art, the invention has the characteristics of high recovery ratio, excellent decolorization effect, high purity of polysaccharide and the like. The prepared black corn silk polysaccharide has better anticancer and hypolipemic effects.

Owner:ANHUI NORMAL UNIV

Herbicide

InactiveCN104255786AImprove securityEconomical to useBiocideAnimal repellantsSodium chlorateTrichloroacetic acid

The invention discloses a herbicide. The herbicide is composed of the following components in parts by weight: 10 to 20 parts of butralin, 5 to 10 parts of trichloroacetic acid, 5 to 12 parts of sodium chlorate, 5 to 8 parts of propisochlor, 10 to 15 parts of acetochlor, 5 to 15 parts of lactofen, 4 to 9 parts of fomesafen, 3 to 8 parts of quizalofop-p-ethyl, 1 to 5 parts of bispyribac-sodium, 5 to 10 parts of auxiliary agent, and 100 to 200 parts of water. The herbicide has the advantages of high safety, low application cost, long lasting effect, and wide weeding area, and is capable of achieving the goals of weeding and yield increasing by using the lowest dosage and the lowest cost.

Owner:NANTONG SHI ZHUANG CHEM

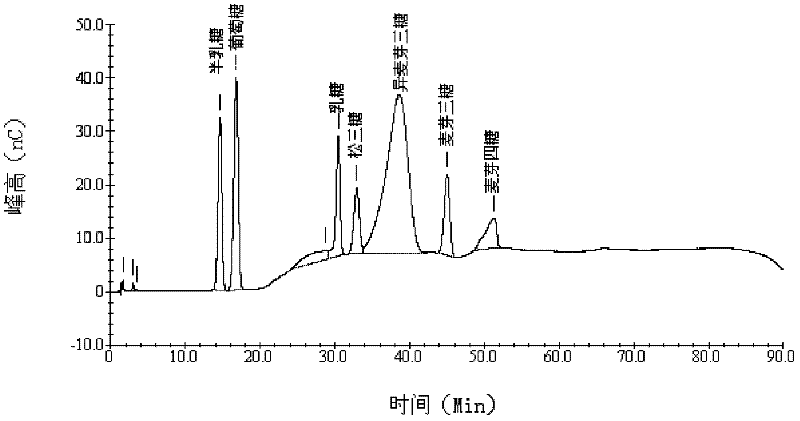

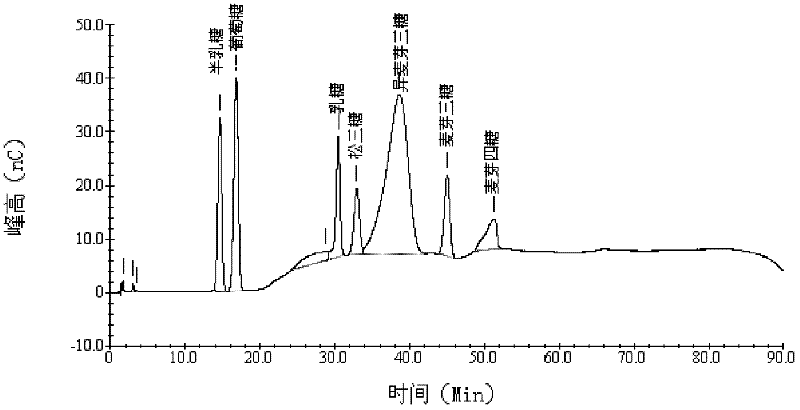

Detection method for galacto-oligosaccharide based on biological enzyme technology

InactiveCN102353730AQuantitatively accurateHigh precisionComponent separationSodium acetateIon chromatography

The invention provides a detection method for galacto-oligosaccharide based on biological enzyme technology, which belongs to the technical field of food engineering. According to the invention, at first, the method of removing proteins by using trichloroacetic acid and lead acetate is employed for pretreatment of an object to be detected, and membrane filtration is utilized to remove impurities so as to obtain a sample to be detected; then, sodium hydroxide and sodium acetate with different concentration are utilized for ion exchange and gradient elution; finally, a four-potential pulsed amperometric detector is used for detection. The invention is applicable to separation and detection of cow's milk containing galacto-oligosaccharide and a variety of galacto-oligosaccharide components in a galacto-oligosaccharide solution system; employment of ion chromatography, utilization of the methods of ion exchange and gradient elution for separation of galacto-oligosaccharide and cooperativedetection with the four-potential pulsed amperometric detector enable contamination and interference to an analytical column, the detector and the like caused by macro-molecular substances such as proteins, fat and emulsifiers which might exist in the sample to be eliminated, thereby allowing accurate and rapid detection to be achieved.

Owner:SHANGHAI JIAO TONG UNIV

Separation and purification method of gamma-polyglutamic acid

InactiveCN102952266AImprove the quality of the final productAchieve separationPurification methodsFiltration

The invention relates to a separation and purification method of polyglutamic acid from fermentation broth. The method comprises the following steps of: regulating the pH value to be between 3.0 and 4.0 by adopting trichloroacetic acid to reduce the viscosity of the fermentation broth; adding activated carbon to decolor and diatomite to adsorb and filter into the fermentation broth; performing super-filtration concentration and alcohol-precipitated purification to the treated fermentation broth sequentially; and drying in vacuum to obtain gamma-polyglutamic acid with purity of more than or equal to 95 percent. The separation and purification method has the advantages of normal temperature performance, no phase change, no secondary pollution, simple process, high yield, high product purity and the like, and is applicable to industrial production.

Owner:SHANDONG LUBEI PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com