Patents

Literature

238results about How to "Reduce the number of washes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

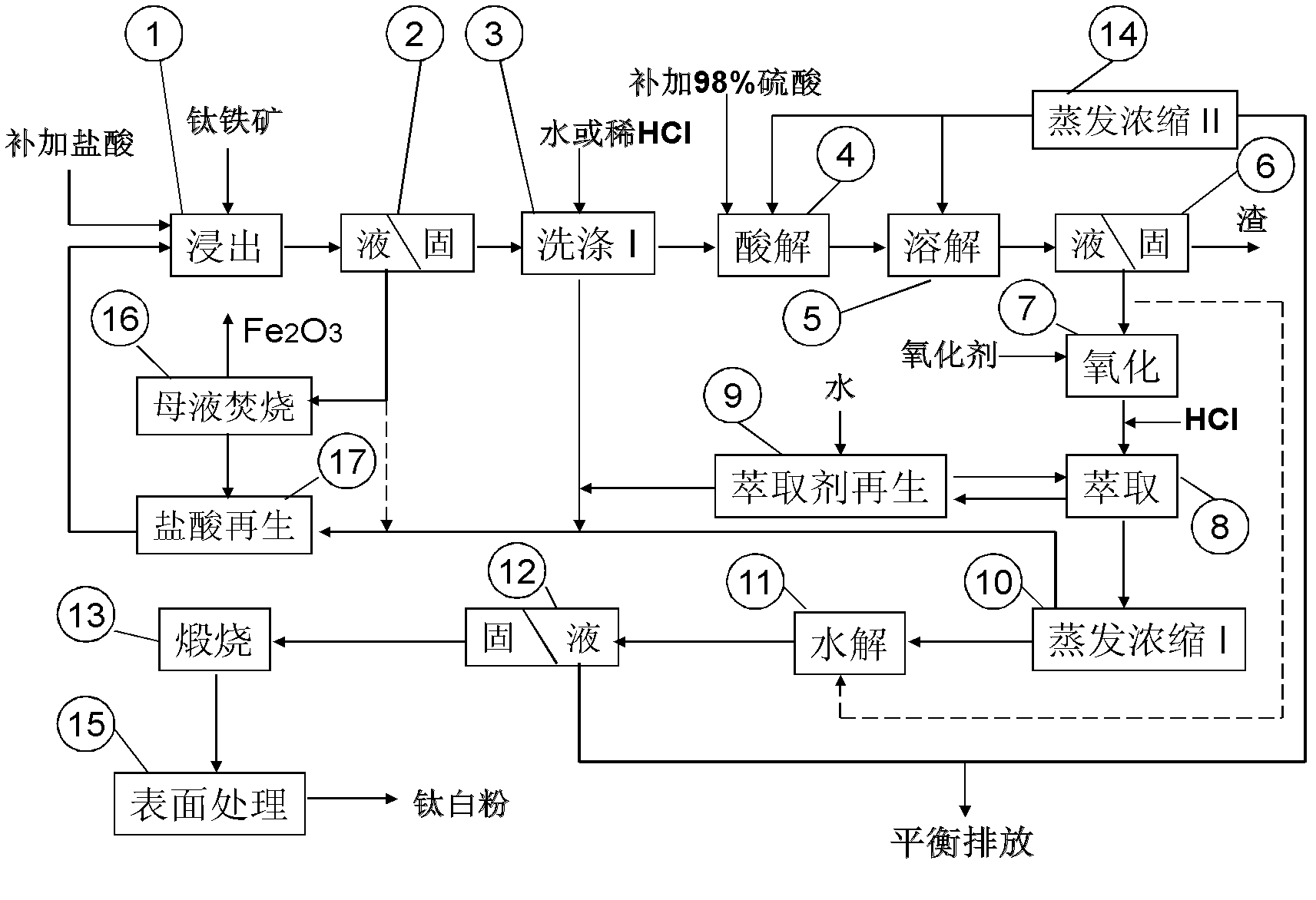

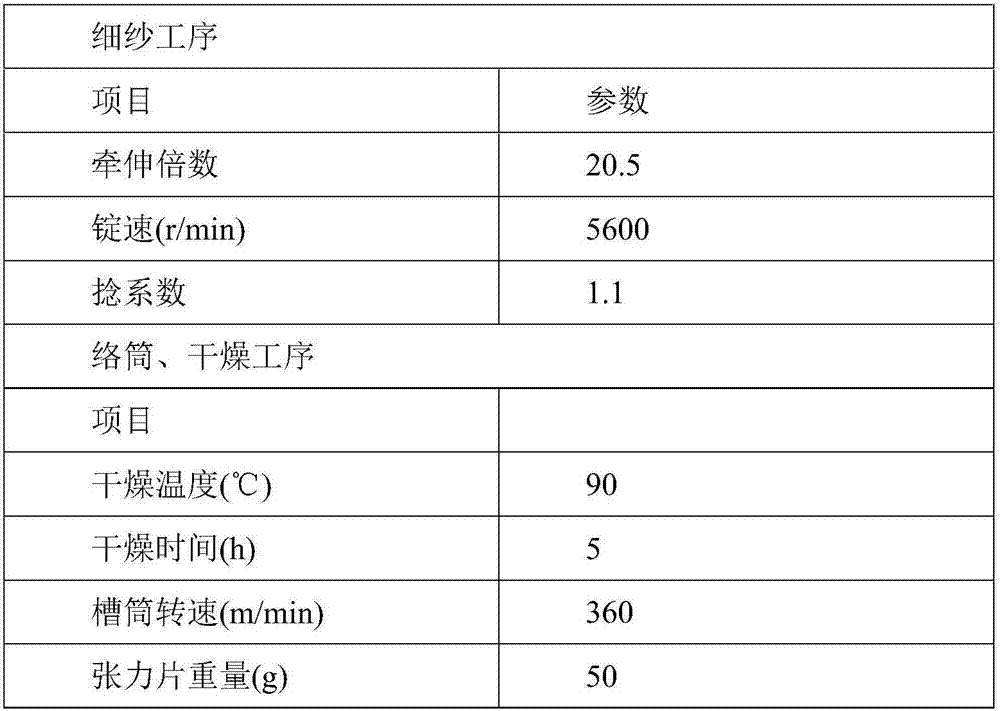

Method for preparing titanium white

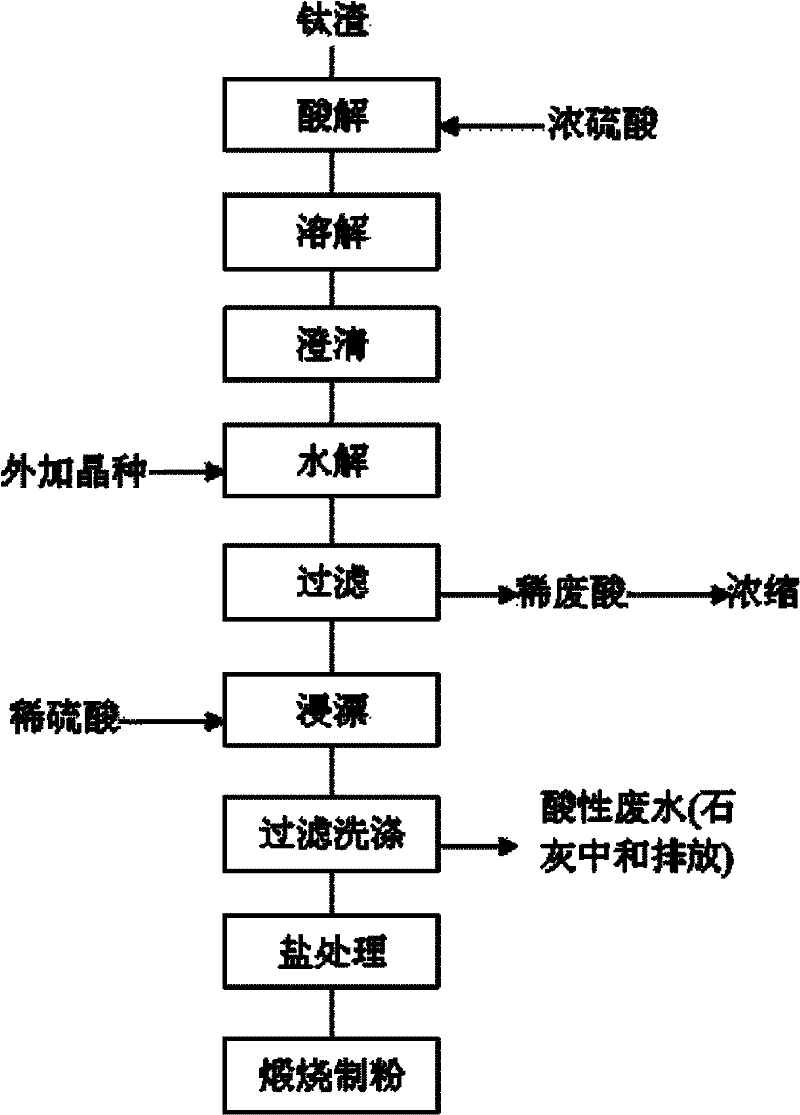

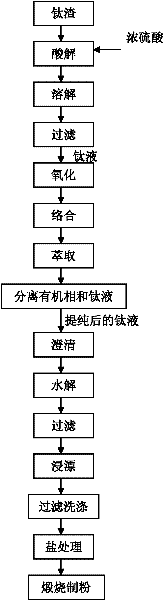

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

Preparation method of potassium sodium dehydroandroan drographolide succinate, potassium sodium dehydroandroan drographolide succinate preparation and preparation method thereof

ActiveCN1927854ADifficult to purifyImprove responsePowder deliveryOrganic active ingredientsNitrogen gasAndrographolide

The present invention relates to the preparation process and preparation of Yanuning. Yanuning is prepared through an esterification reaction and a salt-forming reaction. During the esterification reaction, andrographolide and succinic anhydride react in pyridine solution and the resultant is post-treated to obtain dehydroandrographolide semi-succinate. During the salt-forming reaction, dehydroandrographolide semi-succinate and KOH, KHCO3 or K2CO3 react in water to form monopotassium salt of dehydroandrographolide semi-succinate, and through post-treatment, Yanuning is prepared. The present invention has mild reaction condition and nitrogen protection to avoid oxidation and degradation, excessive pyridine added into the reaction for dewatering without need of vacuumizing, and heating reflux in the later reaction stage for complete reaction.

Owner:珠海晨安医药有限公司

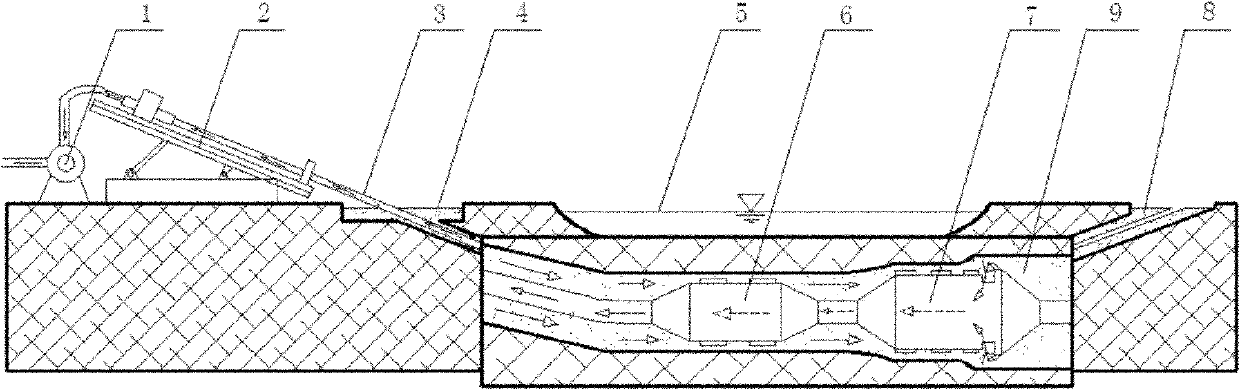

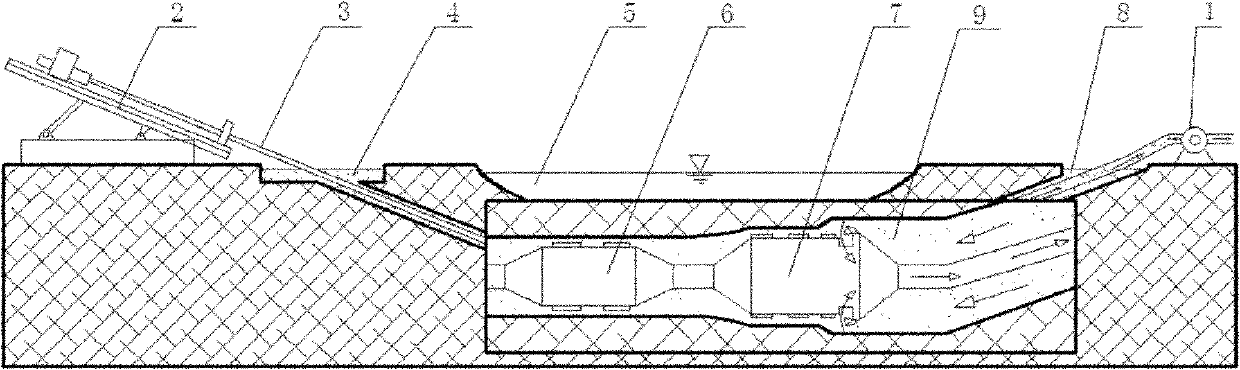

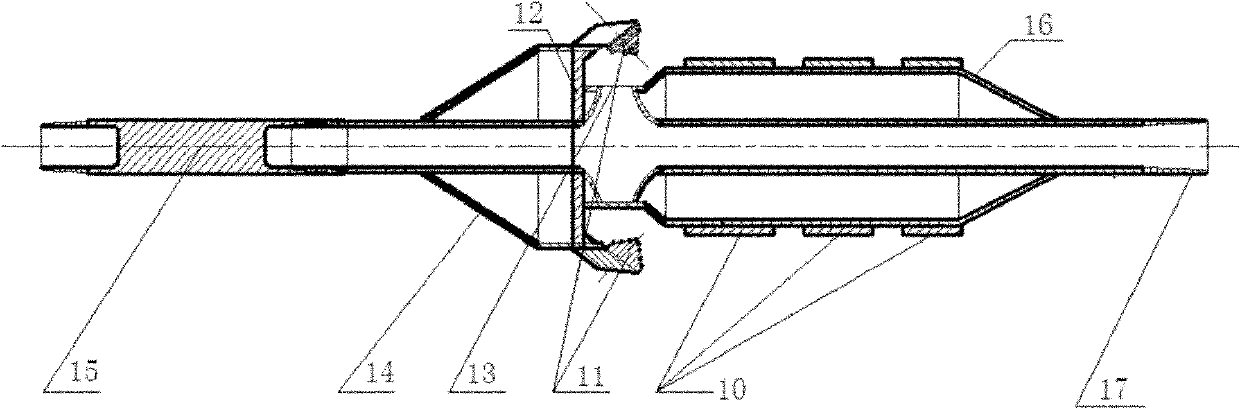

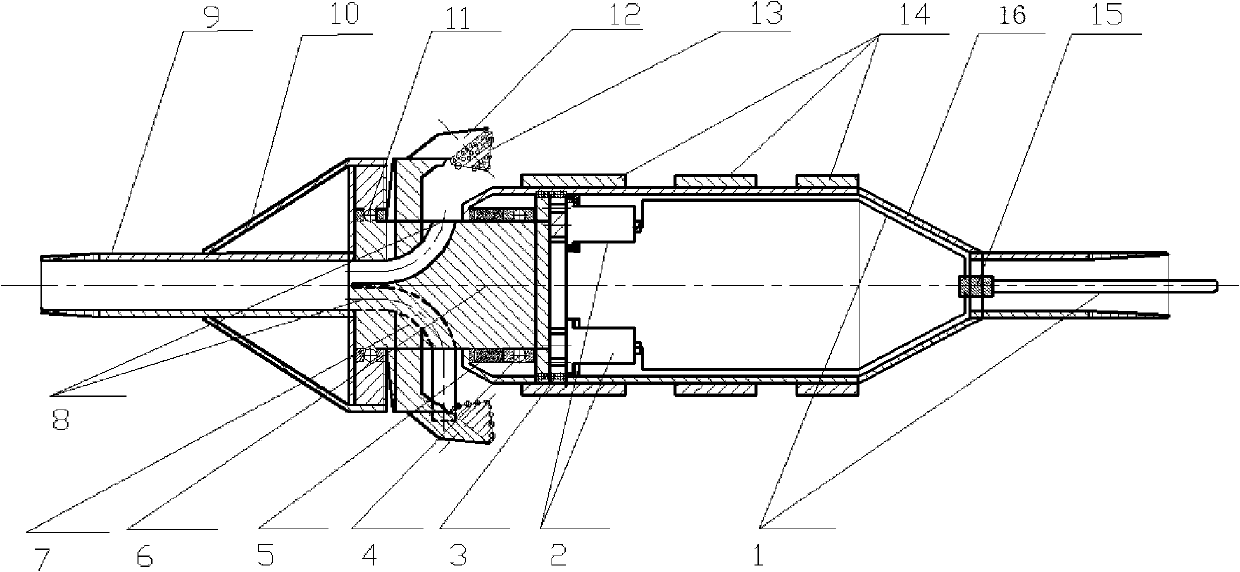

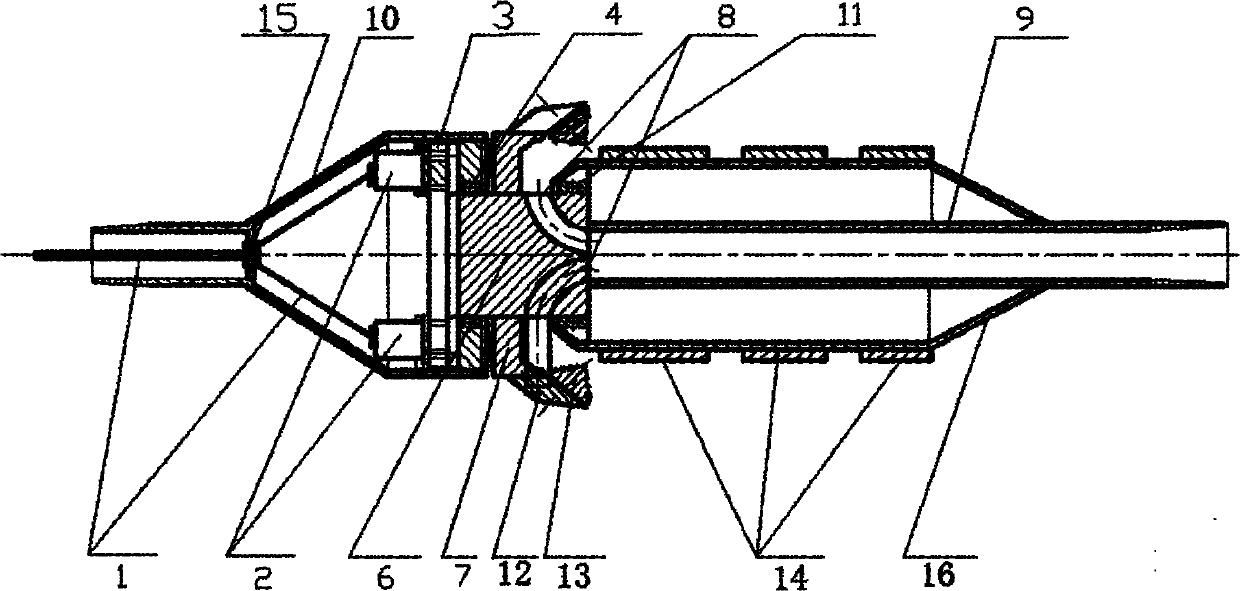

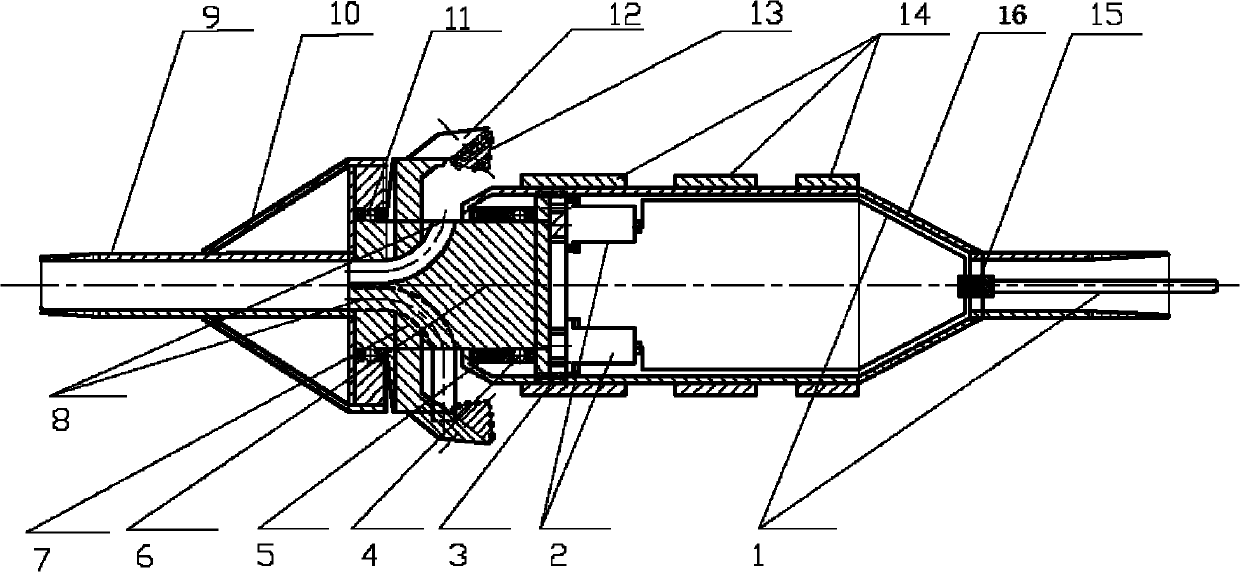

Traversing reverse circulating drilling method of horizontal directional drilling pipeline and special drilling bit

InactiveCN102003140AReduce consumptionImprove drilling efficiencyPipe laying and repairDrill bitsSlurryDirectional drilling

The invention provides a traversing reverse circulating drilling method of a horizontal directional drilling pipeline and a special drilling bit, which are suitable for laying oil-gas pipelines and municipal pipelines. The drilling method comprises the following steps of: mounting a gravel pump at the outer end of a drilling machine or a pit, wherein hollow cavities are formed in the drilling bit and the drilling stem in use; arranging a slag suction port communicated with a borehole circular space on a reaming drilling bit; sleeving a roller cone seat with a roller cone outside the body of the reaming drilling bit, wherein the position of the roller cone corresponds to that of the slag suction port; arranging a plug for blockage at one end of the reaming drilling bit; and circularly flowing slurry according to a flowing direction from a slurry pond to the borehole circular space, the reaming drilling bit, the drilling stem, the gravel pump and the slurry pond during drilling so as to reach the aim of deslagging. The method and the drilling bit of the invention can be adopted to effectively remove drilling slag and gravel in the horizontal borehole and solve various problems in the traversing construction of the large-diameter horizontal directional drilling pipeline.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method of preparing gamma-butyrolactone and/or 1,4-butanediol using chromium less catalyst

InactiveCN1493569AHigh activityEnsure safetyOrganic compound preparationHydroxy compound preparationCis-Butenedioic AcidButanediol

A process for preparing gamma-butyrolactone and / or 1,4-butanediol by use of Cr-free catalyst includes making the the dialkyl maleate and / or dialkyl succinate in contact with hydrocatalyst, reacting at 170-300 deg.c and 0.1-15 hr under 0.1-7 Mpa, and collecting products. Said hydrocatalyst is CuMnaAlbOc, where a=0.01-1.5, b=0.1-2 and c is number of necessary oxygen atoms. Its advantage is controllable ratio between both products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Finishing process for nano three-protective dacron fabrics

InactiveCN1424456AImprove the performance of three defensesGood synergyFibre treatmentPolyesterAdhesive

A technology for finishing the water-, oil-and dirt repellent polyester fabric includes such steps as preparing the finishing liquid from organofluorine composite nano material dispersed liquid and flexible-type self-crosslinking adhesive, dipping it in the finishing liquid for 0.5-1 min, squeezing, prebaking at 100-110 deg.C for 1-2 min, and baking at 130-180 deg.C for 3-5 min. Its advantages are excellent "three repelling" function, better durability and high washing resistance.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

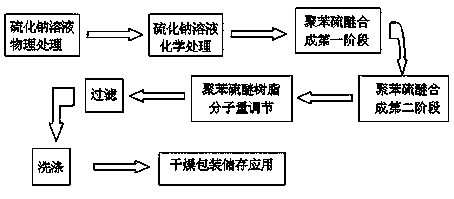

Auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process

The invention discloses auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process. The formula of raw materials required in the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is as follows: the mole ratio of sodium sulfide to sodium hydroxide to santochlor to N-methyl-2-pyrrolidinone is 0.93-1.15 to 1.00-1.28 to 1.98-2.98 to 1.18 to 1.48. The industrial synthetic process mainly comprises the following steps: firstly, in a sodium hydrosulfide dehydration treatment stage, a pipeline filter is adopted to filtrate a sodium hydrosulfide solution to treat mechanical impurities in the solution, then a sodium hydroxide solution with the concentration 84 mol percent is added in the formula for chemical treatment on the sodium hydrosulfide; secondly, in the condensation polymerization stage, anaerobic deionized water is added to further appropriately adjust the molecular weight and molecular weight distribution coefficient of synthesized polyphenylene sulfide resin; thirdly, deionized water is adopted for repeatedly scrubbing for 3 to 6 times, and finally, the target product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process provided by the invention is obtained. The resin in the obtained product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is low in polydispersity index and high in oxygen index, and has an excellent electrical insulation property.

Owner:周洪

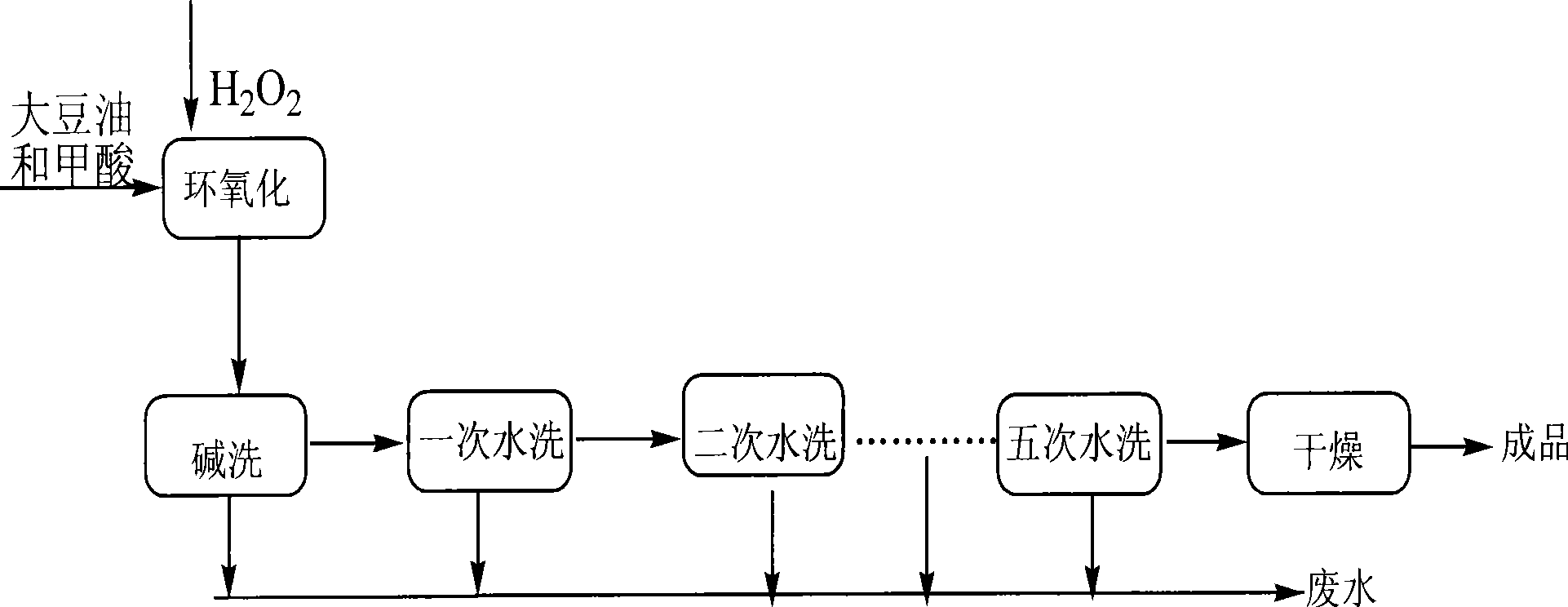

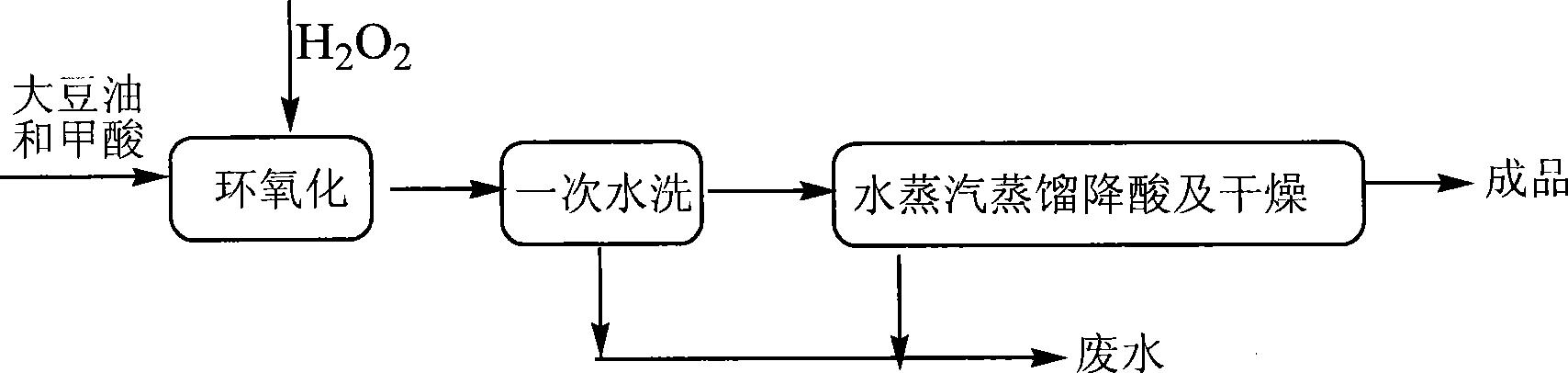

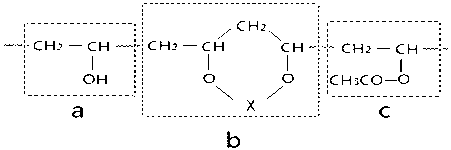

High-quality epoxy ester production method with low energy consumption and little wastewater

InactiveCN101445495AReduce the number of washesReduce material consumptionOrganic chemistrySOYBEAN SEED OILFormic acid

A high-quality epoxy oil and ester production method with low energy consumption and little wastewater belongs to the technical field of fine chemical industry, energy conservation and emission reduction. The method comprises the following steps: selecting soybean oil or unsaturated fatty acid methyl (ethyl) esters as raw materials; adding hydrogen peroxide as oxygen source and formic acid as oxygen carrier; epoxidizing; washing with water for one time; distilling with steam to reduce acid and dry the product; and refining to obtain epoxy soybean oil or epoxy fatty acid methyl (ethyl) esters. The method has the advantages of low energy consumption, reduced wastewater emission, greatly shortened entire production cycle, high quality of the epoxy product and low acid value.

Owner:JIANGNAN UNIV

Acid scouring agent and preparation method thereof

ActiveCN101736618AStrong neutralization abilityHigh chelation valueDyeing processAlkylphenolCellulose fiber

The invention discloses an acid scouring agent and a preparation method thereof. The acid scouring agent comprises a multivariate acidic copolymer, polyvinyl pyrrolidone PVP and sodium gluconate. The scouring agent does not contain phosphorus, alkylphenol ethoxylates and harmful solvents and is degradable; and at the same time, the scouring agent has the characteristics of a little foam, high chelation value and high alkali neutralizing capacity. The scouring agent can be used for scouring cellulose fibers after dyeing, can simplify the traditional process and contributes to energy conservation and emission reduction.

Owner:苏州联胜化学有限公司

Squash polysaccharide and preparation method thereof

InactiveCN101314621AReduce the number of washesSimple processOrganic active ingredientsMetabolism disorderTrichloroacetic acidPolysaccharide

The invention discloses pumpkin polysaccharide and the preparation method thereof. The preparation method comprises the steps as follows: pre-treating pumpkin, extracting in water for 0.5-3h, filtering to obtain filtrate, centrifuging the filtrated supernatant, purifying the supernatant with a resin column chromatography, and colleting eluent; concentrating the eluent, and precipitating with ethanol; and dissolving the precipitate into water, adding trichloroacetic acid, centrifuging for deproteinization to obtain supernatant, concentrating the supernatant, drying and pulverizing. The washing number of times is reduced, the technological process is simplified, and the extraction condition and technological parameter are optimized to shorten the time of the extraction and purification processes by purifying the pumpkin polysaccharide with advanced resin chromatography technology. Therefore, the preparation method has the advantages of simple technological process, short production period, easily-controlled production, and low production cost. The purity of the obtained pumpkin polysaccharide is as high as more than 80%, and the extraction rate is as high as more than 25%.

Owner:卢照凯 +1

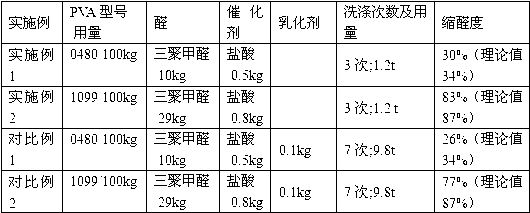

Preparation method of polyvinyl acetal resin

The invention discloses a preparation method of polyvinyl acetal resin, which is characterized by comprising the following steps of: taking the following raw materials in parts by weight: 100 parts of polyvinyl alcohol, 400-1,900 parts of water, 10-220 parts of aldehyde, 0.5-30 parts of catalyst, 400-9,500 parts of organic solvent and 0.01-3 parts of antioxidant; mixing the polyvinyl alcohol and water at 80-97 DEG C to form a solution; cooling to 10-40 DEG C; adding 10-100% of aldehyde and 10-100% of catalyst, adding the antioxidant, and performing an acetalation reaction at 10-40 DEG C; when a powdery or flocculent product is separated out, continuing reaction for 0.1-5 hours; adding the organic solvent and the remaining aldehyde and catalyst, and reacting at 30-80 DEG C till the end; and treating to obtain the polyvinyl acetal resin. The product prepared by the method disclosed by the invention has high acetalization degree and low haze and can be applied to the fields of paint, adhesives, ink, resin modifiers, safety glass and photovoltaic encapsulation materials.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

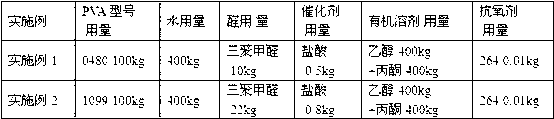

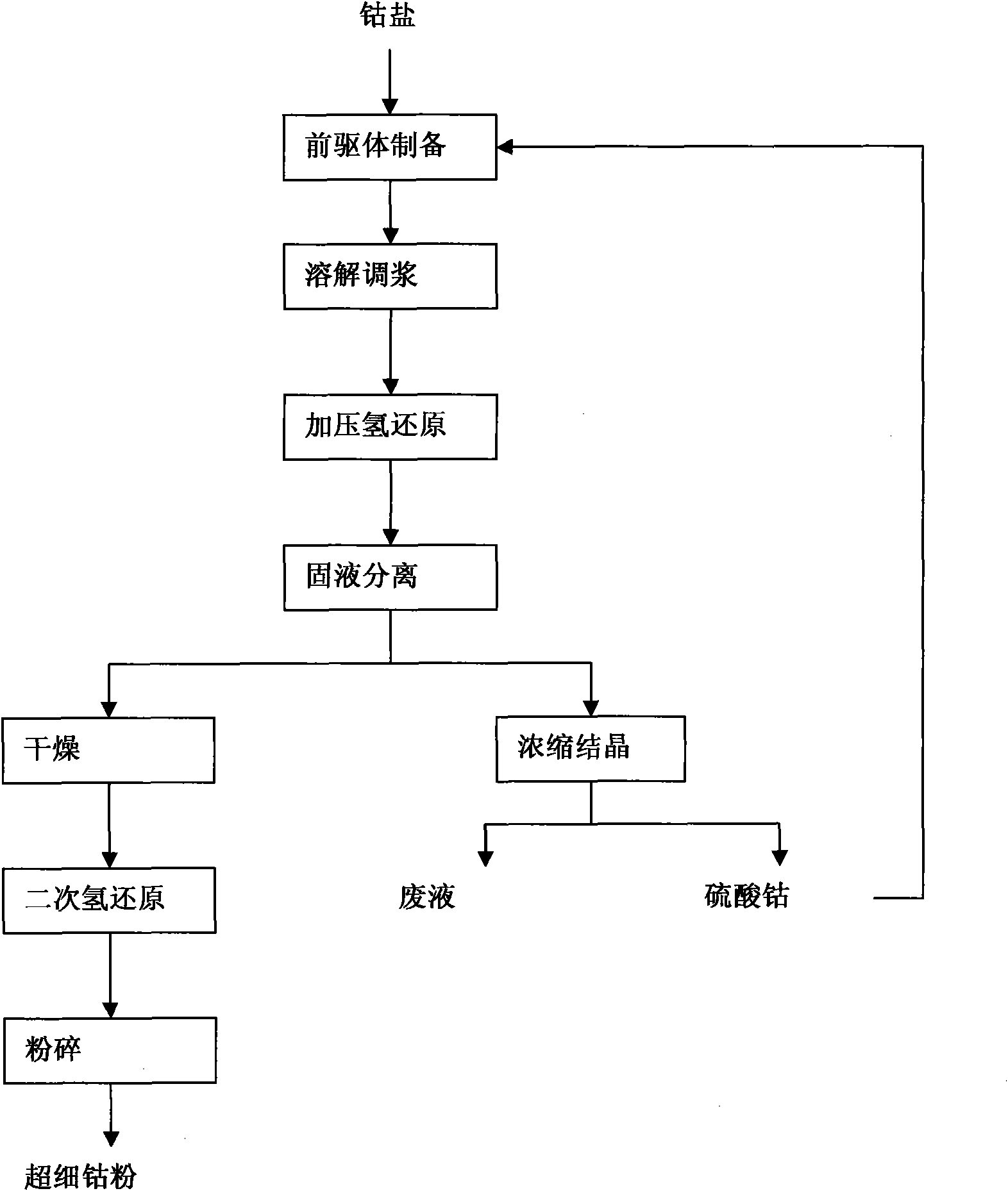

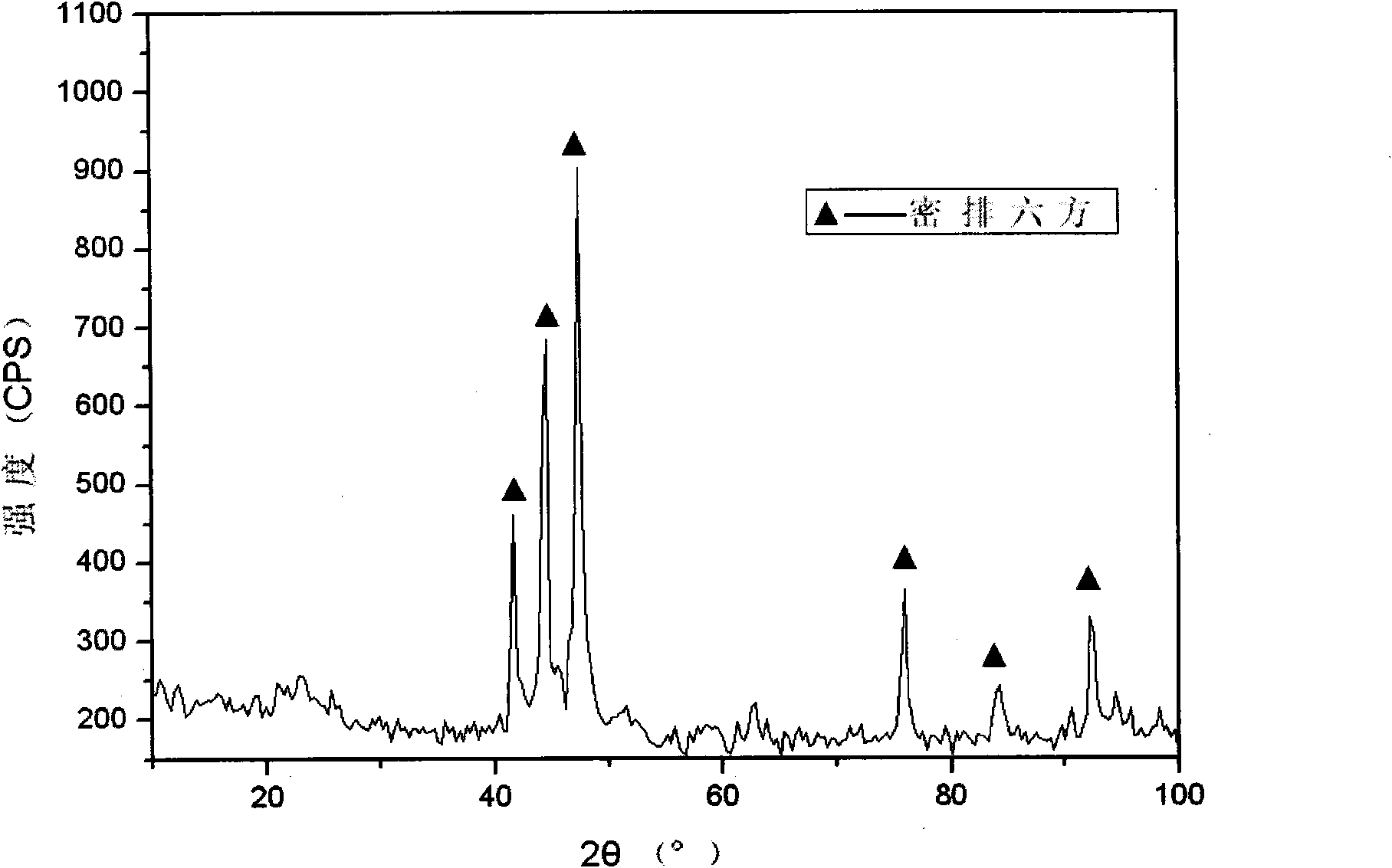

Method for preparing superfine cobalt powder in close-packed hexagonal structure or face-centered cubic structure by hydrogen reduction

The invention discloses a technical method for preparing superfine cobalt powder in a close-packed hexagonal structure or a face-centered cubic structure by hydrogen reduction, and belongs to the technical field of the preparation of metal powdered material. The invention comprises the following steps: excessive alkali is added into the water soluble salt of cobalt which is used as a raw material,obtained precipitation of hydroxide of the cobalt is directly transferred into a high-pressure autoclave without filtration and reduced under the catalysis of a small quantity of palladium chloride below 180 DEG C in poor hydrogen (<1MPa), the reduzate is reduced by secondary consolidation hydrogen in a hydrogen reducing furnace after being filtered, washed and dried and then crashed under the protection of inert gas, and finally, the superfine cobalt powder which has the granularity of less than 0.5um, big specific surface, even distribution and single close-packed hexagonal structure or face-centered cubic structure is produced.

Owner:KUNMING INST OF PRECIOUS METALS

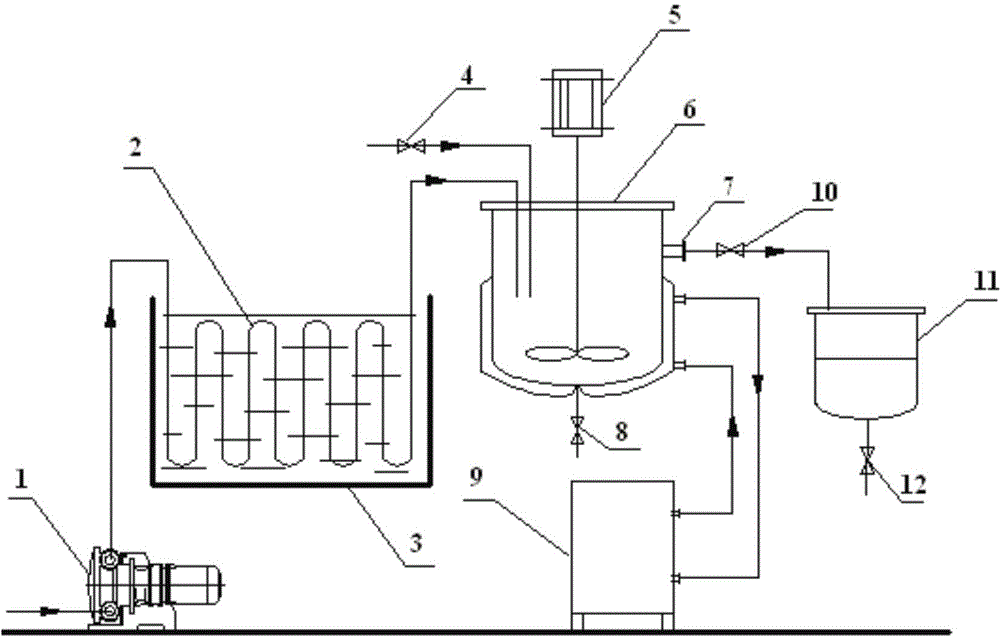

Energy and water saving dyeing method for seamless underwear

ActiveCN102561070AReduce residual rateHigh whitenessBiochemical fibre treatmentBleaching apparatusWater savingOxygen

The invention relates to an energy and water saving dyeing method for a seamless underwear. A seamless weft knitting weaving technology is used for achieving one-off weaving forming of the seamless underwear. The dyeing and finishing process of the seamless underwear after being woven includes oxygen bleaching by the liquor ratio of 1: 8-10, dyeing by the liquor ratio of 1: 12-15 and soaping by the liquor ratio of 1: 8-10. By means of the energy-saving dyeing and finishing technology of non-caustic-soda oxygen bleaching process, one-bath one-step dyeing process and biological enzyme soaping process, one-time accurate dyeing is achieved, one-bath one-step completion is achieved, processing time is shortened, and sewage discharge and treatment are reduced.

Owner:GUANGDONG RUIYUAN TECH

Synthesis-auxiliary-free polyphenylene sulfide resin industrial synthetic process

ActiveCN103819676ASmall polydispersity coefficientHigh crystallinityChemical treatmentMaterials science

The invention discloses a synthesis-auxiliary-free polyphenylene sulfide resin industrial synthetic process. The formula of raw materials required in the synthesis-auxiliary-free polyphenylene sulfide resin industrial synthetic process is as follows: the mole ratio of sodium sulfide to sodium hydroxide to santochlor to N-methylpyrrolidinone is 0.98-1.18 to 0.01-0.30 to 1.00-1.28 to 2.30 to 3.80. The industrial synthetic process comprises the following steps: firstly, a pipeline filter is adopted to filtrate a sodium sulfide solution and a sodium hydroxide solution to treat the mechanical impurities in the solutions; secondly, a sodium hydroxide solution with the concentration of 60 mol percent is added in the formula for chemical treatment on the sodium sulfide solution; thirdly, in a condensation polymerization stage, 0.01-0.03 mol of sodium sulfide and 0.01-0.03 mol of dichlorobenzene are added to adjust the molecular weight and molecular weight distribution coefficient and adjust the content of covalent chlorine below 120 ppm, and finally the target product of the synthesis-auxiliary-free polyphenylene sulfide resin industrial synthetic process is obtained. According to the synthesis-auxiliary-free polyphenylene sulfide resin industrial synthetic process provided by the invention, the halogen in the obtained product is low in total content and polydispersity index, molecular weight distribution is narrow and oxygen index is high, the electrical insulation property is excellent, and the product adopted through the process can be used as packaging materials of electronic devices as well as industrial and civilian products, and particularly clad materials for wires and cables.

Owner:德阳科吉高新材料有限责任公司

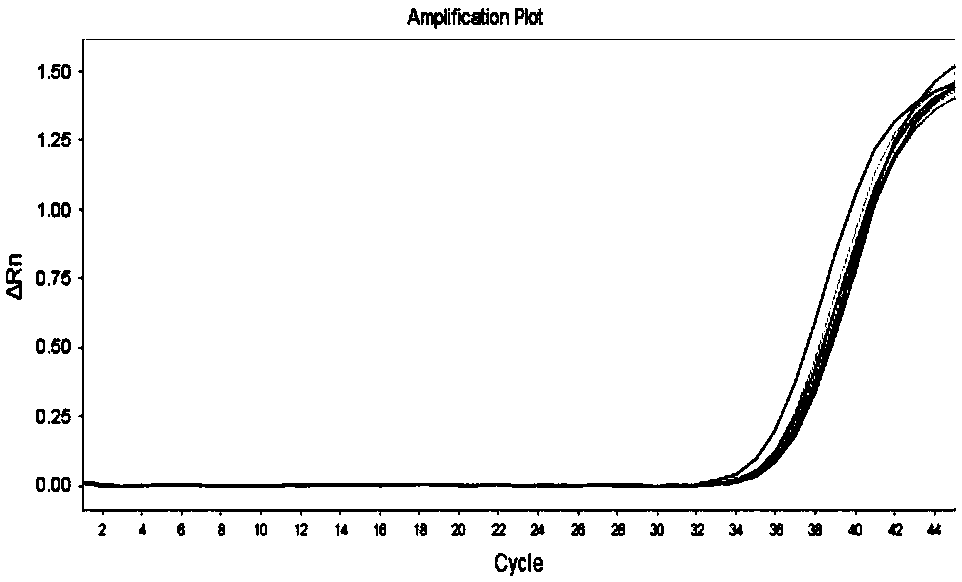

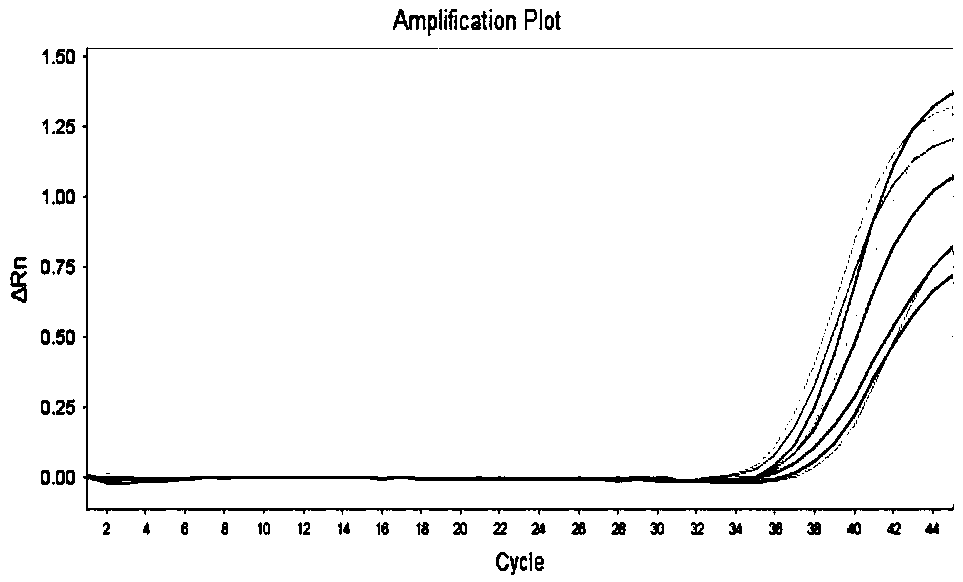

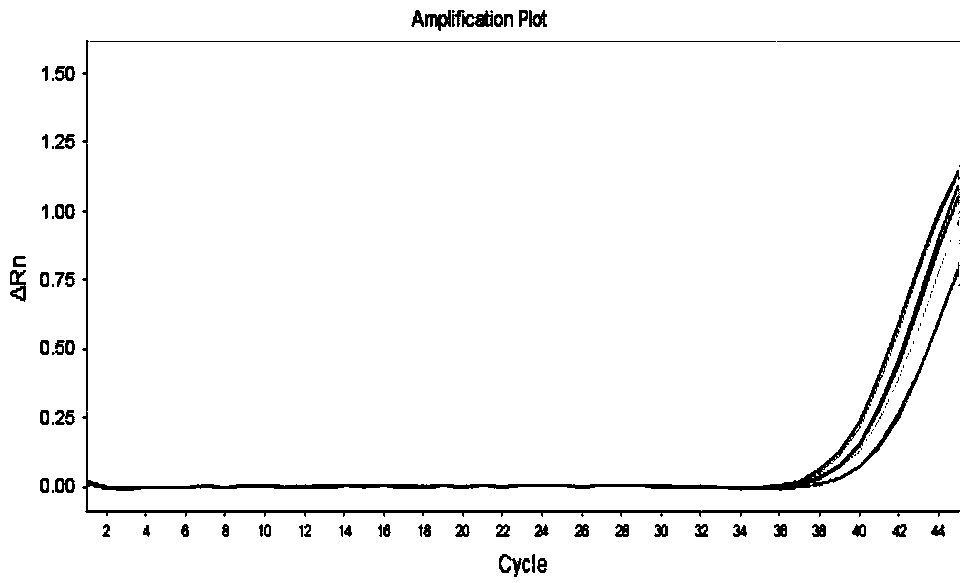

Nucleic acid extraction kit and application method thereof

The invention provides a nucleic acid extraction kit, which comprises pyrolysis combining liquid, washing buffer liquid and elution buffer liquid, wherein the pyrolysis combining liquid is prepared from 0.5 to 2 percent of FAME (fatty acid methyl ester) ethoxylate sodium sulfonate and 3 to 5 percent of magnetic beads; less silicone oil is added into the washing buffer liquid; the whole nucleic acid extraction time is reduced; the waste liquid residue is reduced; nucleic acid extraction purification effect is improved; meanwhile, the precision and the sensitivity of nucleic acid detection are also improved.

Owner:ZYBIO INC

Hole driven type horizontal directional drilling reverse circulation hole dilating drill

InactiveCN102003145AReduce expansion coefficientEfficient removalPipe laying and repairDrill bitsDrive shaftEngineering

The invention provides a hole driven type horizontal directional drilling reverse circulation hole dilating drill. The inner parts of a drill cone and a pen-shaped conehead of a drill body are both hollow cavities, a turnplate is arranged at the middle part of a transmission shaft in a power drive device, a cone seat provided with a cone is arranged on the turnplate, the tail end of the drill cone is arranged on the rear end part of the transmission shaft, the tail end of the pen-shaped conehead is arranged on the front end part of the transmission shaft, and an electric motor drives the turnplate and the cone to do rotation motion through the transmission shaft. The electric motor is positioned in the cavity of the drill cone and a drill rod joint is inserted in the cavity of the pen-shaped conehead, or the electric motor is positioned in the cavity of the pen-shaped conehead and the drill rod joint is inserted in the cavity of the drill cone. The inner part of the drill rod joint is a hollow cavity, the cavity is communicated with the external part through the cavity of the pen-shaped conehead or the cavity of the drill cone and a plurality of slag suction ports, and the slag suction ports are positioned at the side below the cone. By adopting the drill, various disadvantages of surface drive in the prior art can be overcome, and the difficult problem of difficult slagging in the traditional positive circulation major diameter horizontal directional drilling method can be overcome.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Preparation method of linen flat-strip fabric

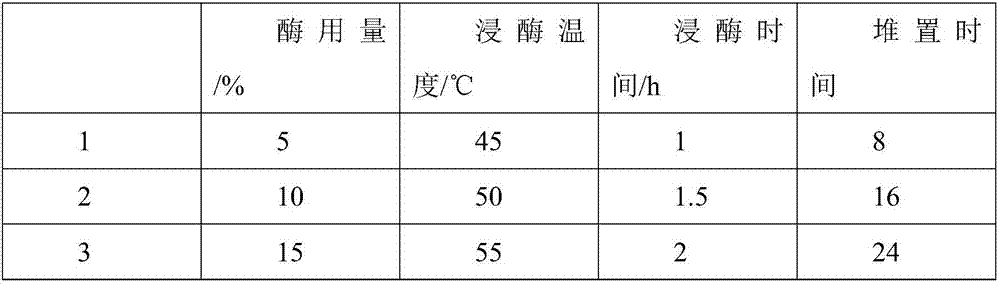

ActiveCN107419403AAchieve productionBig cost energy advantageBiochemical treatment with enzymes/microorganismsDyeing processEngineeringWeft yarn

The invention discloses a preparation method of linen flat-strip fabric. The preparation method comprises the following steps that raw flax with a disintegration degree larger than or equal to 250 count is selected and made into linen roving; bio-enzymatic treatment is conducted, and degumming treatment is conducted on the linen roving; the linen roving treated with bio-enzymes is made into linen S twist yarn and linen Z twist yarn, and the count of both the linen S twist yarn and the linen Z twist yarn is 36 metric count; the linen S twist yarn is put into a humidification storehouse for humidification curing; warping and drawing-in treatment is conducted on the linen Z twist yarn in sequence; the linen Z twist yarn is regarded as warp yarn, the linen S twist yarn is regarded as weft yarn, a loom is used for weaving, and fabric dyeing is conducted on woven gray cloth to obtain the linen flat-strip fabric. According to the preparation method, the prepared linen fabric has the advantages that dyeing is even, colors are beautiful, and the design and color and the cloth type are novel and fashionable.

Owner:JIANGSU HUAXIN LINEN TEXTILE

Method for purifying titanium solution

InactiveCN102191387AAchieve recyclingLess impuritiesProcess efficiency improvementFiltrationWastewater

The invention belongs to the technical field of the production of titanium dioxide. The invention specifically relates to a method which is utilized for purifying a titanium solution, which is treated through acidolysis, dissolution and filtration, in titanium dioxide production by sulfuric acid method. Through the method, wastwater discharge and waste acid discharge are reduced greatly. The method comprises the following steps: A, ferrous ions in a titanium solution is oxidized into ferric irons; B, hydrochloric acid or hydrogen chloride gas is fed into the titanium solution to promote complexation of the ferric irons; C, complexed ferric iron produced by the step B is extracted to enter an organic phase; and D, the organic phase is separated from the titanium solution and thus purified titanium solution is obtained. Through the method for purifying titanium solution, wastwater discharge and waste acid discharge are reduced greatly and the product quality of titanium dioxide is improved.

Owner:沙立林 +1

Reactive dye salt-free pad dyeing method

InactiveCN102199886AReduce the number of washesReduce water consumptionDyeing processLiquid/gas/vapor textile treatmentSocial benefitsSalt free

The invention relates to a reactive dye salt-free pad dyeing method. The method comprises the following steps: (1) mercerizing cotton fabrics, padding caustic soda, then expanding the fabrics, spraying diluted alkali and sucking; then washing with water 2-3 times; and then directly soaking the fabrics in the aqueous solution of caustic soda to carry out alkali wash 2-4 times, drying and cropping for later dyeing so as to obtain the mercerized fabrics with alkali; and (2) dyeing the mercerized fabrics with alkali, wherein dye padding is in an alternately soaking and rolling mode and the machine speed is 20-80m / min; and then pre-drying with infrared for 0-1min, then drying t with hot air and finally washing with cold and hot water and drying. The method has the following beneficial effects: the method is simple to operate and the cost is lowered; and salt-free dyeing is realized under the condition that the performances and color fastness of the dyed fabrics are ensured, the dyeing rate is improved, the washing frequency and water consumption in the mercerizing process are reduced, steam and energy are saved and the method has good economic and social benefits.

Owner:DONGHUA UNIV +1

High titanium hydrochloric acid leaching slag, new application thereof and preparation method of titanium pigment

InactiveCN101935063AEmission reductionReduce generationPigmenting treatmentSolid waste disposalSlagFerrotitanium

The invention belongs to the field of titanium pigment production, particularly relates to a high titanium hydrochloric acid leaching slag obtained by processing ilmenites by a hydrochloric acid leaching method, new application thereof and a preparation method of a titanium pigment. The invention provides the high titanium hydrochloric acid leaching slag suitable for preparing the titanium pigment by using a sulfuric acid method, and the leaching slag can be used as a raw material for preparing the titanium pigment by using the sulfuric acid method. When the titanium pigment is prepared from the high titanium hydrochloric acid leaching slag, granule ilmenites in the west area of Panzhihua can be effectively utilized with utilization rate of almost 100 percent, a titanium liquid with an ultralow ferrotitanium rate can be obtained, the production capacity of acidolysis equipment can be doubled, meanwhile two stages of freezing deferrization and titanium liquid concentration with large amount of energy consumption can be saved, the washing frequency of metatitanic acid is greatly reduced, the discharge of acidic waste water is reduced and the generation of ferrous sulfate can be decreased. The method provides novel and better material selections for preparing the titanium pigment by using the sulfuric acid method.

Owner:攀枝花坤泽投资有限公司

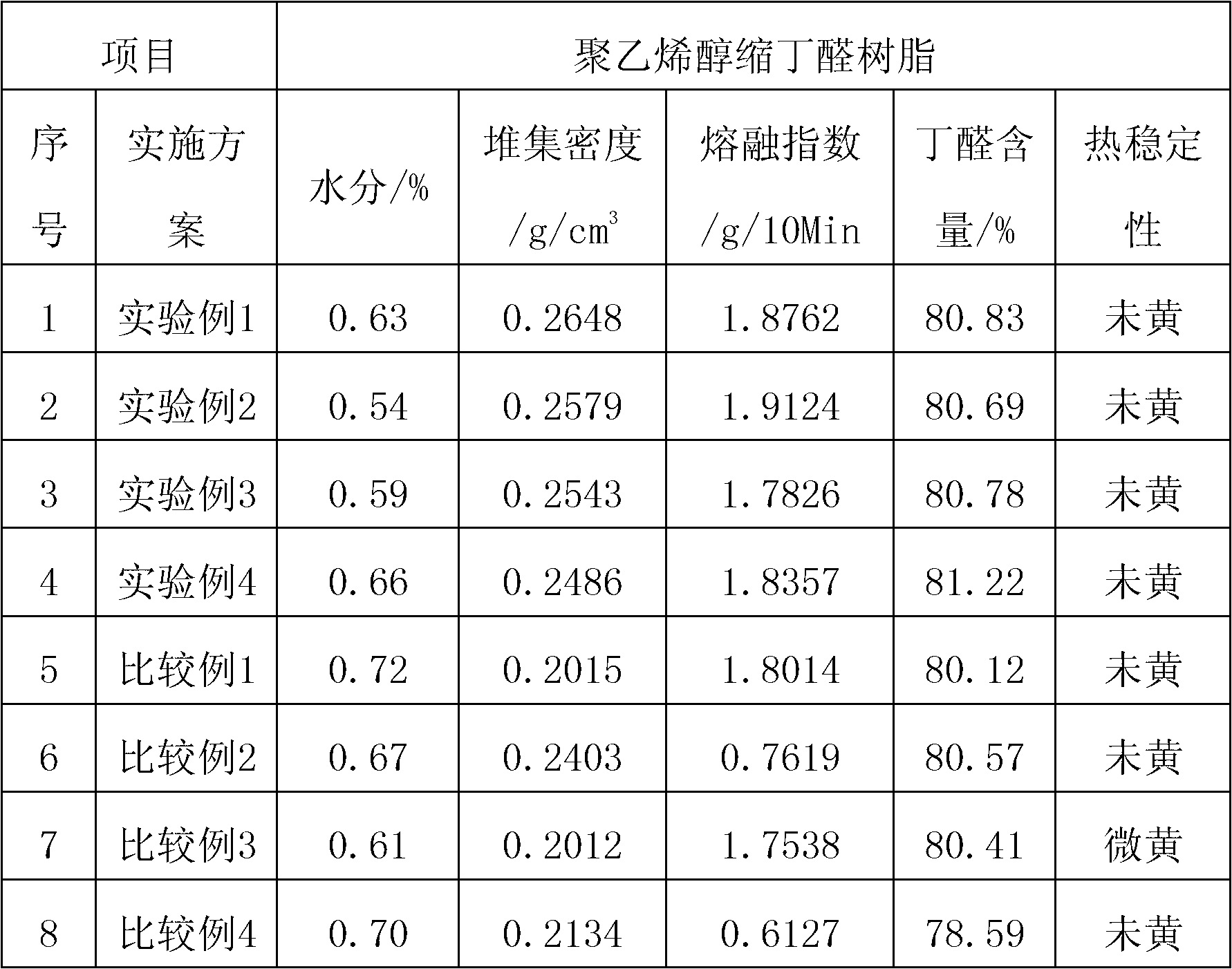

Preparation method of high-acetalization-degree high-flowability polyvinyl butyral resin

The invention provides a preparation method of a high-acetalization-degree high-flowability polyvinyl butyral resin, which comprises the following steps: a. condensation reaction: heating polyvinyl alcohol to 95 DEG C, dissolving in water to prepare a 10% solution, cooling the solution to 40-60 DEG C, adding n-butyl aldehyde to carry out reaction, cooling to 20-25 DEG C, adding a catalyst hydrochloric acid to react for 1 hour, sending the mixed reaction solution to a condensation kettle, gradually heating to 35-40 DEG C within 1 hour, keeping the temperature to react for 1 hour, gradually heating to 50-55 DEG C within 1 hour, keeping the temperature to react for 1 hour, and cooling; b. neutralizing treatment: sending the cooled reaction solution to a water washing kettle to carry out water washing 5-6 times, heating to 40-50 DEG C, adding a right amount of caustic soda solution to regulate the pH value to 8-10, and keeping the temperature for 2-3 hours for sufficient neutralization and acid removal; and c. dehydration and drying: washing the reaction solution subjected to neutralization and acid removal with water 6-8 times, and dehydrating and drying with a centrifugal machine to obtain the polyvinyl butyral resin finished product. The polyvinyl butyral resin prepared by the method provided by the invention has the advantages of high acetalization degree and favorable flowability.

Owner:ZHEJIANG DECENT PLASTIC

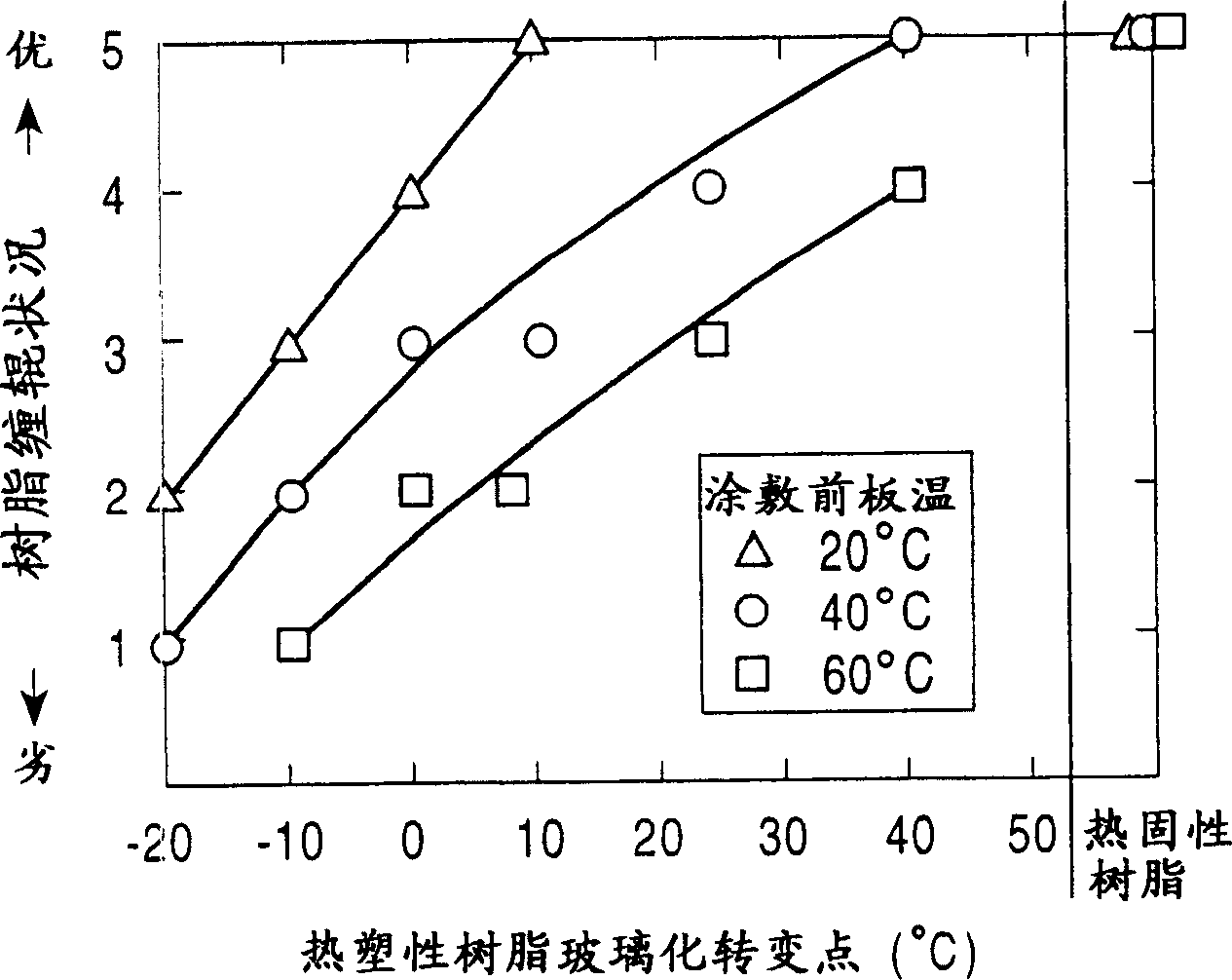

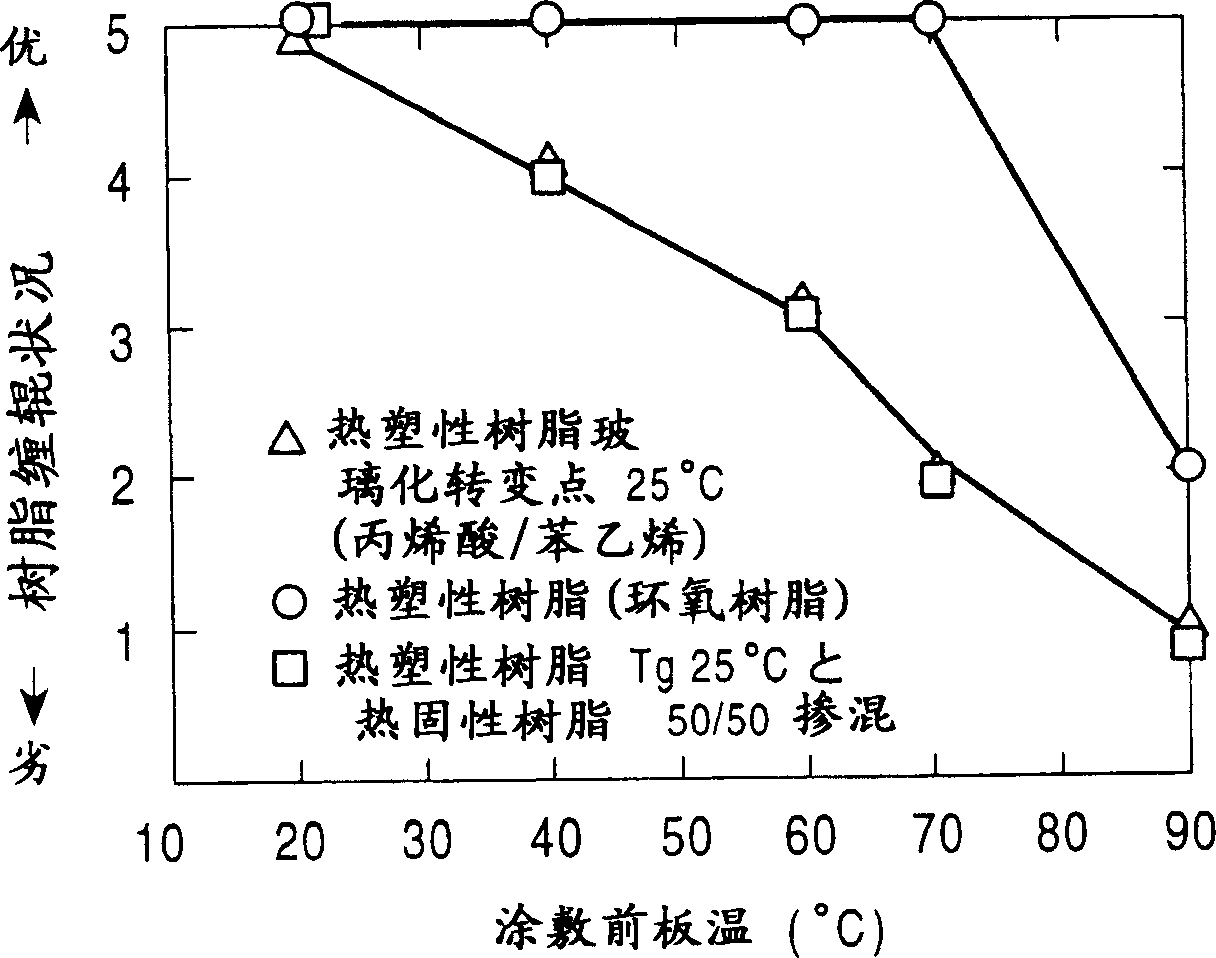

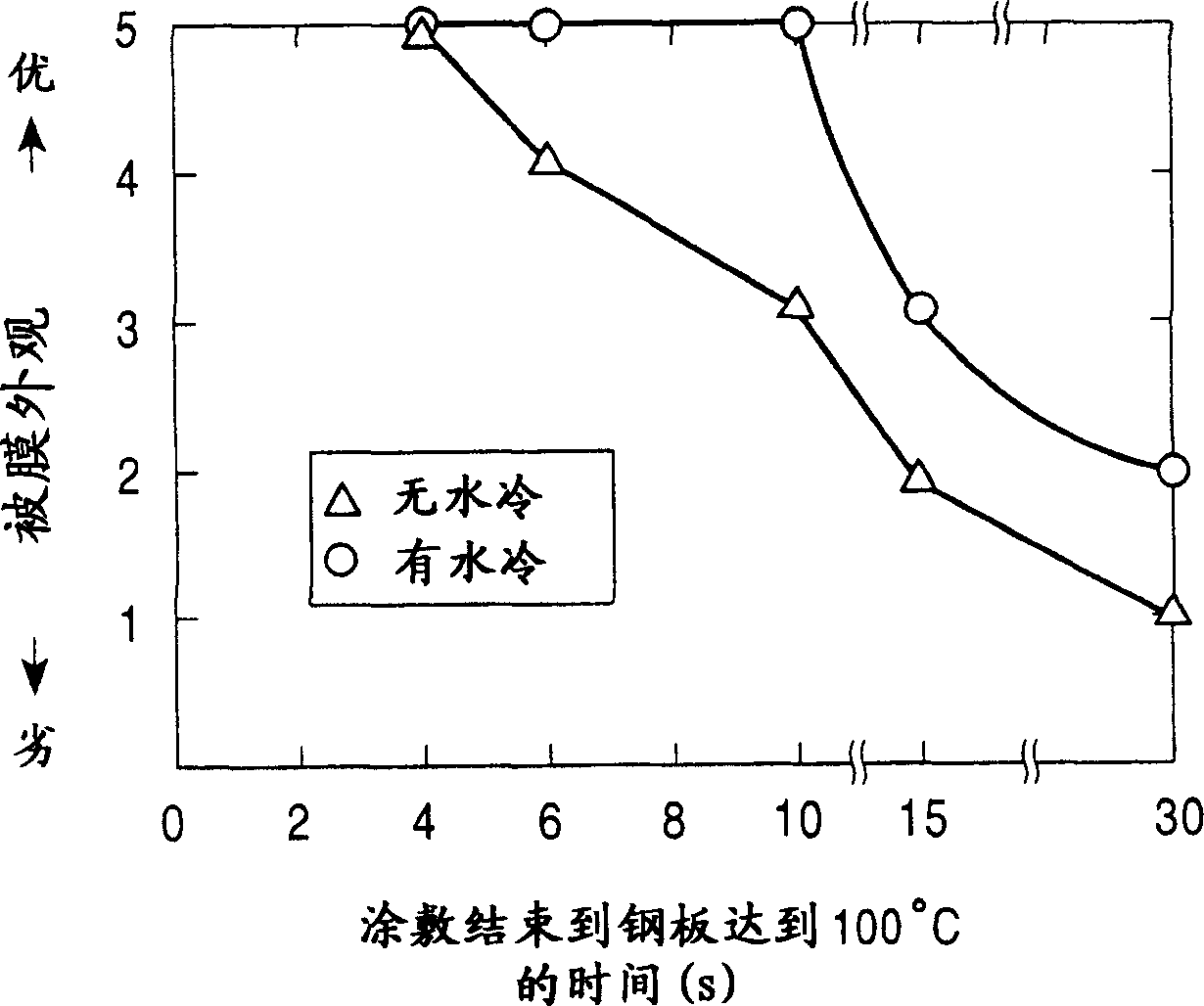

Method for producing coated steel sheet

InactiveCN1642662AGood lookingAvoid entanglementPretreated surfacesInorganic material magnetismWater basedSheet steel

In a process for manufacturing a coated steel sheet such as a coated electromagnetic steel sheet using a water-based coating liquid containing an organic resin, to perform steps subsequent to an annealing step continuously at high speed without causing appearance defects such as coating unevenness; to provide an electromagnetic steel sheet having an insulating film thereon, in which properties of the film are satisfactory, superior weldability and punchability can be obtained without deteriorating the space factor, and the satisfactory film properties can be maintained even if the electromagnetic steel sheet having the insulating film thereon is temper-rolled. A coating liquid is applied onto an untreated steel sheet as settle means of the invention. The applied liquid is heated on the side close to the steel sheet in such a manner that the time elapsed until the steel sheet temperature is increased to 100 DEG C. after the application is completed is 10 seconds or less, thereby drying the coating liquid. The steel sheet temperature is further increased to a predetermined temperature, thereby forming a coating film. When insulating films for electromagnetic steel sheets are formed, the coating liquid preferably further contains a water based inorganic component.

Owner:JFE STEEL CORP

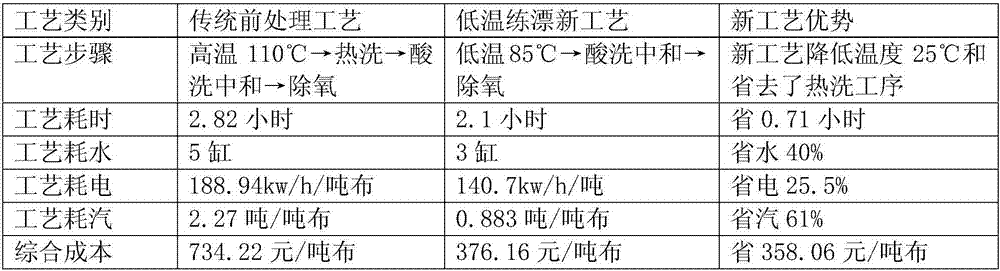

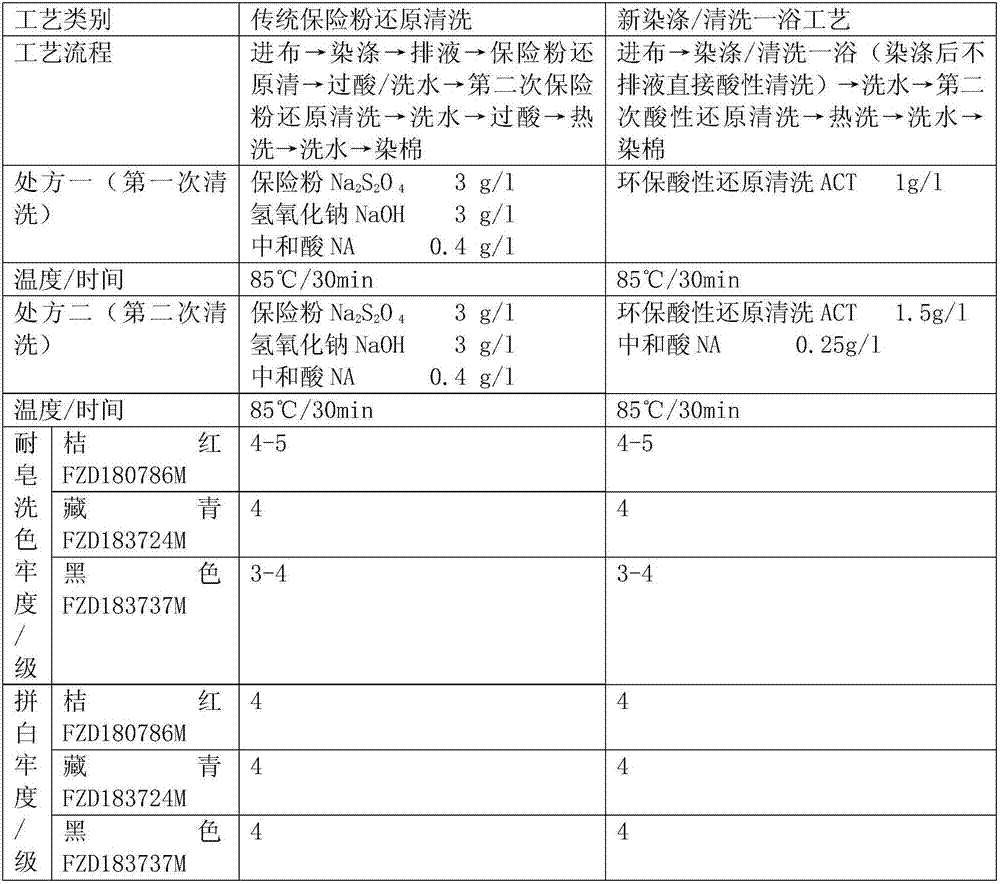

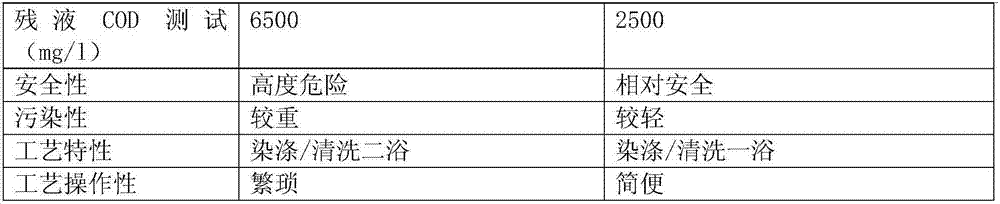

School uniform fabric production technology

InactiveCN106868894AReduce consumptionReduce pollutionDry-cleaning apparatus for textilesGrip property fibresWoolPolyester

The invention discloses a school uniform fabric production technology. The technology comprises pretreatment, polyester dyeing, first reduction cleaning, drainage, hot washing, water washing, second reduction cleaning, hot washing, cotton dyeing, fixation, softening, scutching wool washing machine-based water washing, drying, setting, detection, final inspection, and packaging / warehousing. A low temperature scouring and bleaching agent TF-189 is used, a treatment temperature is reduced by 25 DEG C from a high temperature 110 DEG C to a low temperature of 85 DEG C, a hot washing process is avoided, after treatment, whiteness, hair effects and dyeing effects are similar to those of the traditional oxygen bleaching process, energy consumption is reduced, polyester dying and reduction cleaning processes are combined because of the complementarity, the traditional sodium hydrosulfite alkaline reduction cleaning method is replaced by the technology provided by the invention, sodium hydrosulfite-caused pollution and damage are reduced, environmental friendliness is realized and energy saving and emission reduction effects are obtained.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

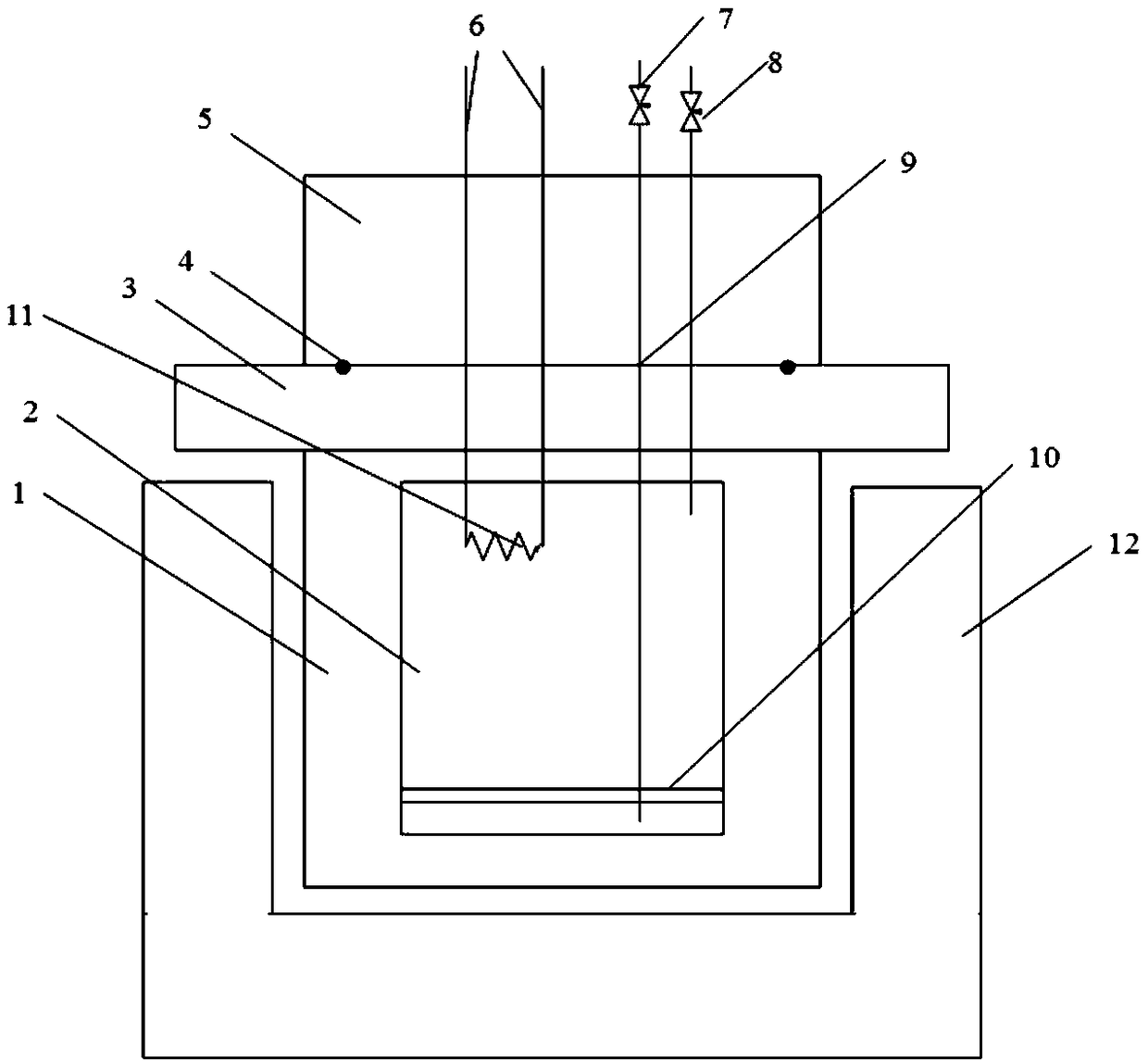

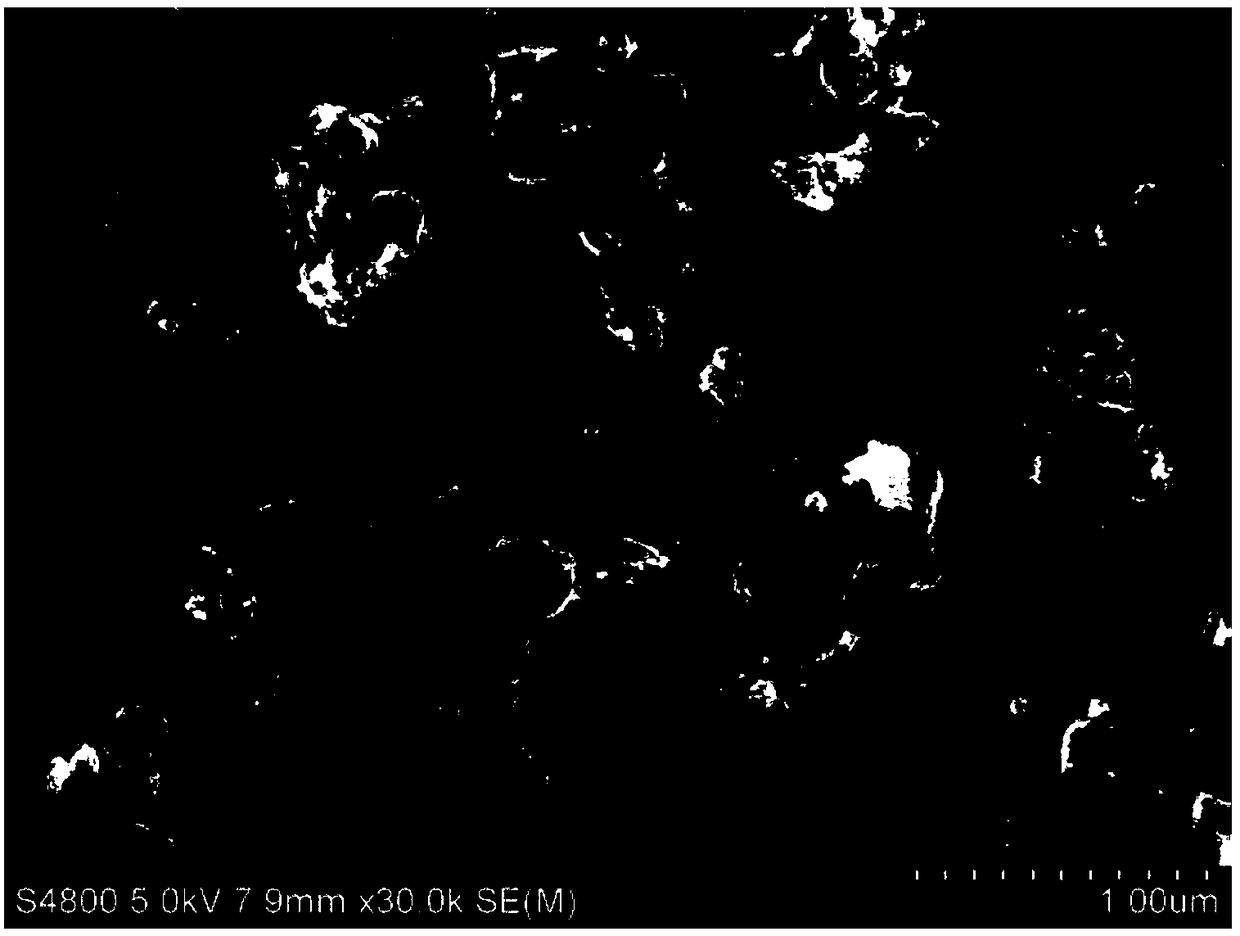

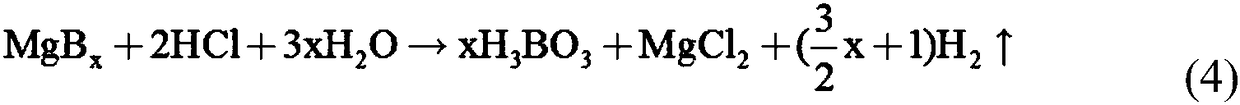

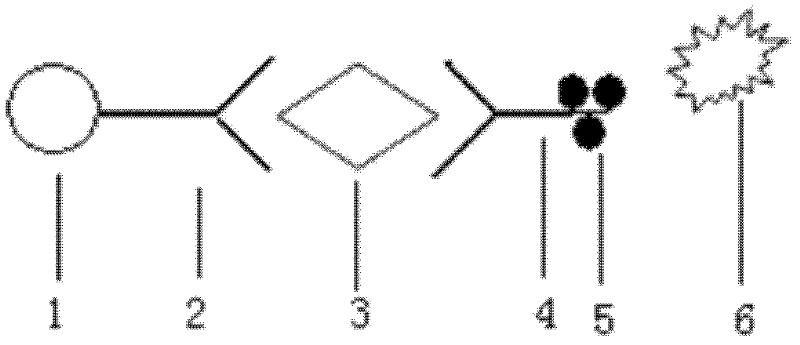

Amorphous boron powder preparation device and method of device for preparing amorphous boron powder

The invention relates to an amorphous boron powder preparation device. The device comprises a sealing body, a reactor (2), a self-propagating reaction initiation assembly, an air inflation valve (7),an air release valve (8), an air guide pipe (9) and a heating body (12); the reactor (2) is used for containing reaction raw materials; the sealing body is used for placing the reactor (2), and the reaction raw materials in the reactor are subjected to heat insulation from the exterior and located in a sealing space in a reaction process; the self-propagating reaction initiation assembly is used for initiating a self-propagating reaction of the reaction raw materials; two air through holes are formed in the sealing body, the air guide pipe (9) penetrates through the air through holes and is connected with the interior and the exterior of the sealing body, and the air inflation valve (7) and the air release valve (8) are arranged on the air guide pipe (9) of the exterior of the sealing body; the heating body (12) is used for heating the sealing body, and accordingly the reaction raw materials in the reactor (2) are pre-heated.

Owner:NAT UNIV OF DEFENSE TECH

Low-temperature hydrogen peroxide catalyst as well as preparation method and application thereof

ActiveCN105597826ARaw materials are easy to getEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsVegetal fibresChemical oxygen demandQuality level

The invention discloses a low-temperature hydrogen peroxide catalyst as well as a preparation method and application thereof. The low-temperature hydrogen peroxide catalyst has a structure as follows: L1ML2n, wherein L1 is water-soluble chitosan having the molecular weight of 800-2000, M is transition metal, L2 is an auxiliary ligand selected from compounds containing complexing groups, and n is an integer in 0-3; the low-temperature hydrogen peroxide catalyst is applied to the pretreatment process of cotton fabrics; the products treated by the low-temperature hydrogen peroxide catalyst have higher quality level and excellent environmental protection property; the low-temperature hydrogen peroxide catalyst can be used for replacing the pretreatment ways of caustic soda desizing and a great deal of additives adding which are generally used at present, so that the additive dosage and washing times are reduced, and the chemical oxygen demand (COD) value and discharge of wastewater can be reduced.

Owner:中国纺织科学研究院江南分院 +1

Ultra-rapid silver dye detecting method of sugarcane molecular marker PAGE gel

InactiveCN101354348AReduce usageLow costPreparing sample for investigationColor/spectral properties measurementsBiologyPolyacrylamide

The invention discloses an ultra-fast silver staining test method of cane molecule tagged PAGE gel, which comprises the following steps: a modified polyacrylamide gel with the concentration of 5 percent is used for the electrophoresis detection of SSR and AFLP tagged PCR amplified primer; the gel after the electrophoresis is placed into a dyeing liquid to be dyed; the gel is taken out from the dyeing liquid, quickly rinsed, and placed into a developing solution to be developed; the developed gel is cleaned by distilled water for two times and dried, and tape reading is implemented; the ultra-fast silver staining test method combines four traditional steps of fixing, dyeing, developing and image fixing into two simplest steps, thus simultaneously reducing rinsing frequency and time, reducing the use of a fixing liquid, an image fixing liquid, acetic acid, absolute ethyl alcohol, sodium carbonate and sodium hyposulfite, not only greatly decreasing silver staining time and reagent cost, but also ensuring high-quality silver staining effect, and compared with other traditional or improved isotopic silver staining methods, the ultra-fast silver staining test method has larger time and cost advantages.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI

Kit for quantitatively detecting GFAP concentration in human serum by polystyrene microsphere

The invention discloses a kit for quantitatively detecting GFAP concentration in human serum by polystyrene microsphere, comprising a 96-hole filter plate, a standard product, a sample diluent, a polystyrene microsphere coupled with an anti-GFAP antibody on the surface, a microsphere storage solution, an enzyme compound, a substrate A, a substrate B, a 20*cleaning solution, an adhesive sticker strip and an operating manual. The kit provided by the invention changes the solid phase carrier made of traditional microporous plate into the polystyrene microsphere, generates the antigen antibody reaction in the liquid phase to keep a good bioactivity and a correct spatial configuration, and eliminates the effect on the antigen antibody reaction by the surface tension and the steric hindrance ofthe traditional reaction mode, and effectively shortens the reaction time and the rinsing times, besides, the invention has the characteristics of simple operation, high sensitivity, good specificityand low cost and has important clinical significance for the diagnosis of the acute cerebral hemorrhage early disease degree.

Owner:山东莱博生物科技有限公司

Continuous crystallization process for preparing nitroguanidine through nitric acid method

InactiveCN104860849AEmission reductionNo importOrganic chemistryOrganic compound preparationNitroguanidineFiltration

The invention relates to a continuous crystallization process for preparing nitroguanidine through a nitric acid method. The process is applied to continuous crystallization for preparing single-compound explosive nitroguanidine and belongs to the technical field of preparation processes of explosives and powder. According to the process disclosed by the invention, the nitroguanidine is dissolved in a nitric acid solution, the synthetic process is optimized by virtue of a micro-tube reactor, the requirement of the reaction system on the nitric acid concentration is reduced, and the product yield is improved. A continuous crystallizer and a filter are arranged behind the micro-tube reactor, the continuous crystallization and filtration process is established, the manual operation is reduced, and the production efficiency of the product is improved; and moreover, with the adoption of ultrasonic oscillating and washing, the washing frequency is reduced, and wastewater emission is reduced. The process disclosed by the invention has the advantages of simplicity, high continuity, high product yield, small wastewater emission amount and the like and is particularly suitable for continuous crystallization for preparing single-compound explosive nitroguanidine.

Owner:XIAN MODERN CHEM RES INST

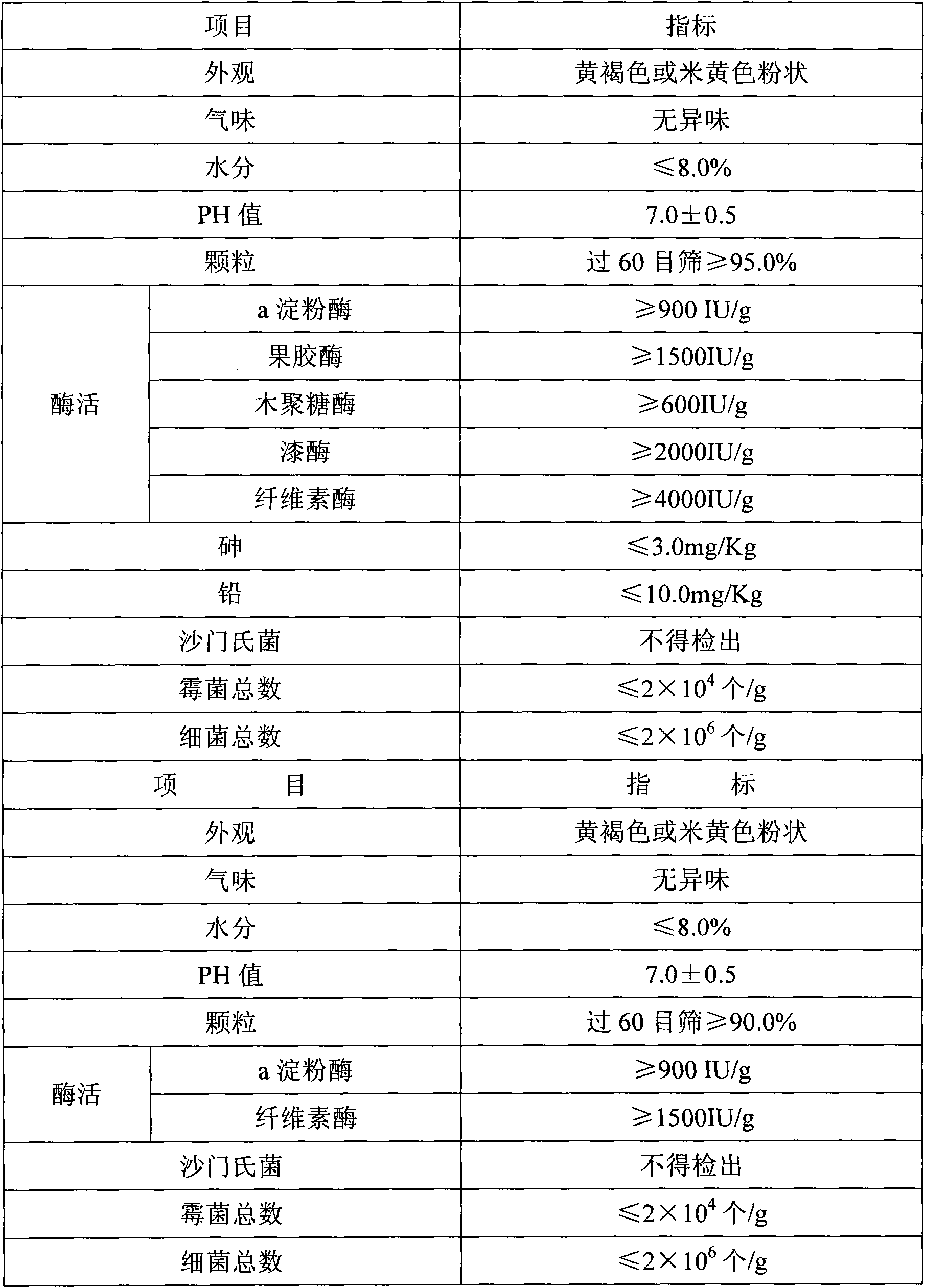

Process for manufacturing energy-saving and environment-friendly cooking and bleaching compound enzyme preparation for weaving

ActiveCN101624583AEasy to cleanReduce the number of washesBiochemical fibre treatmentOxidoreductasesChemistryAlpha-amylase

The invention provides a process for manufacturing an energy-saving and environment-friendly cooking and bleaching compound enzyme preparation for weaving and belongs to the field of bio-enzyme products. The compound enzyme mainly comprises an alpha amylase, a pectinase, a xylanase, a laccase and a cellulase. The process of the invention uses the enzyme preparation capable of degrading hemicelluloses and lignins for pretreating natural fibers and textiles, can effectively degrade fiber containing impurities such as pectins, hemicelluloses and lignins, is easy to clean, and can reduce washing times, sewage discharge and COD value (chemical oxygen demand), effectively assist a bleaching process and decrease the dosage of a hydrogen peroxide solution.

Owner:FIBER CHEM BIOLOGICAL CHEM

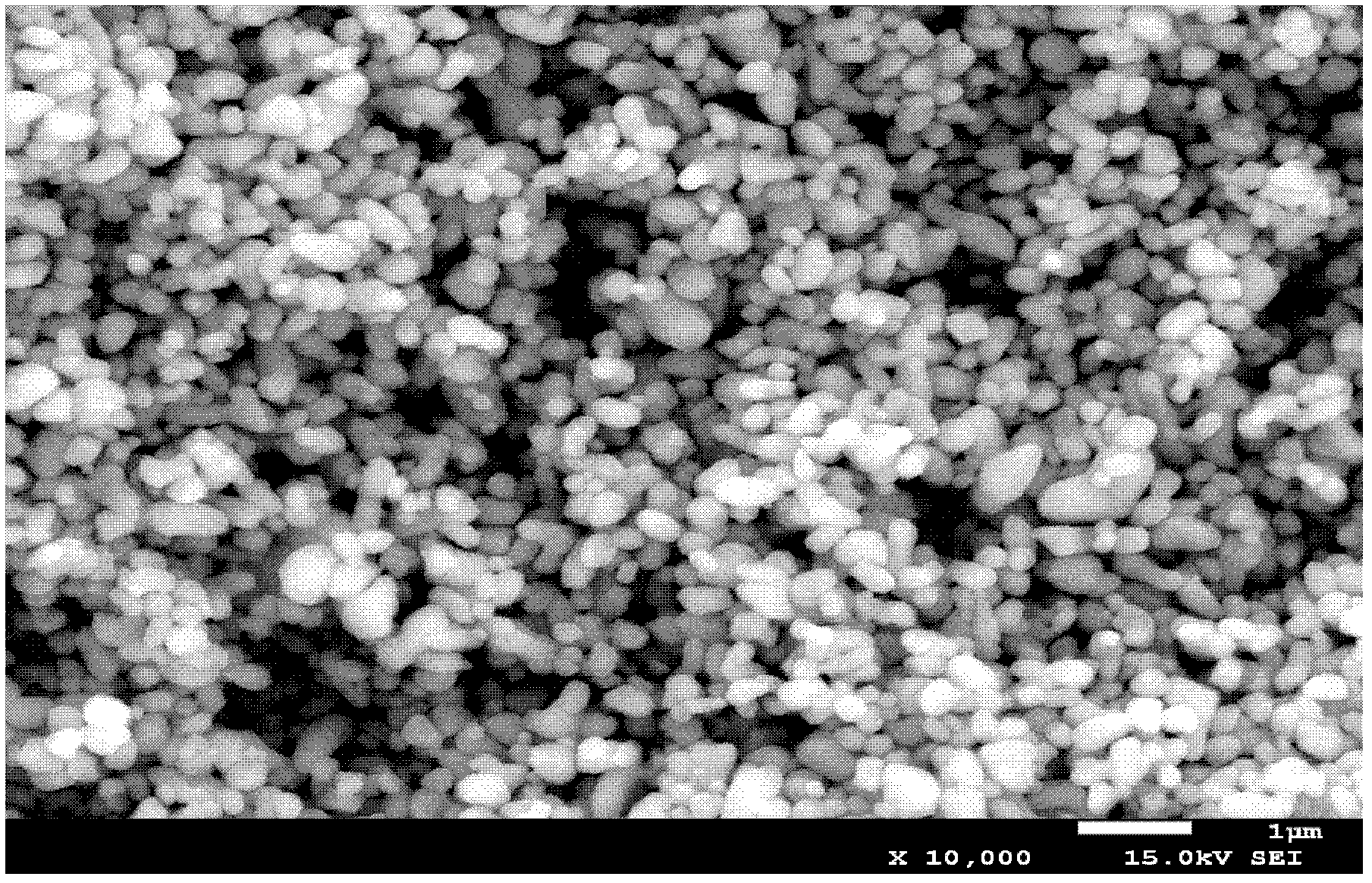

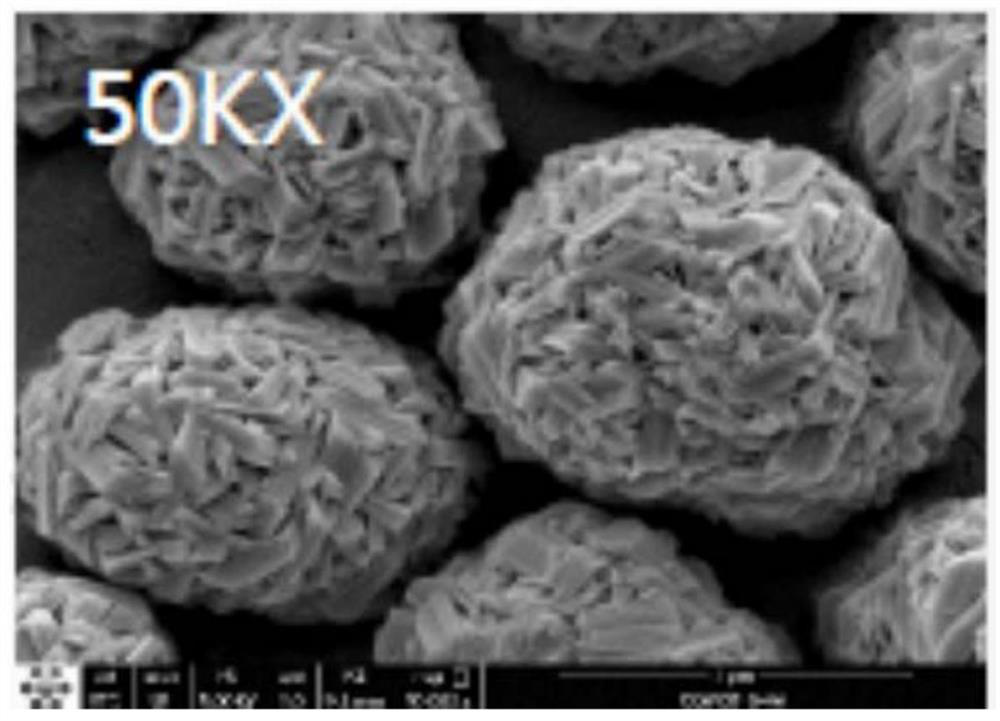

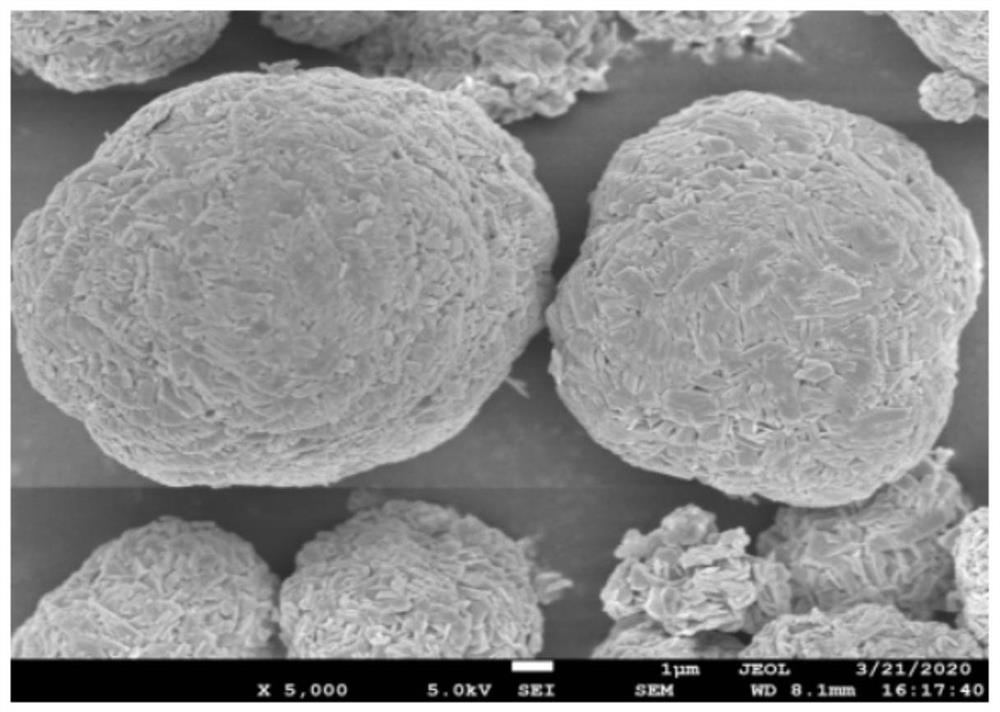

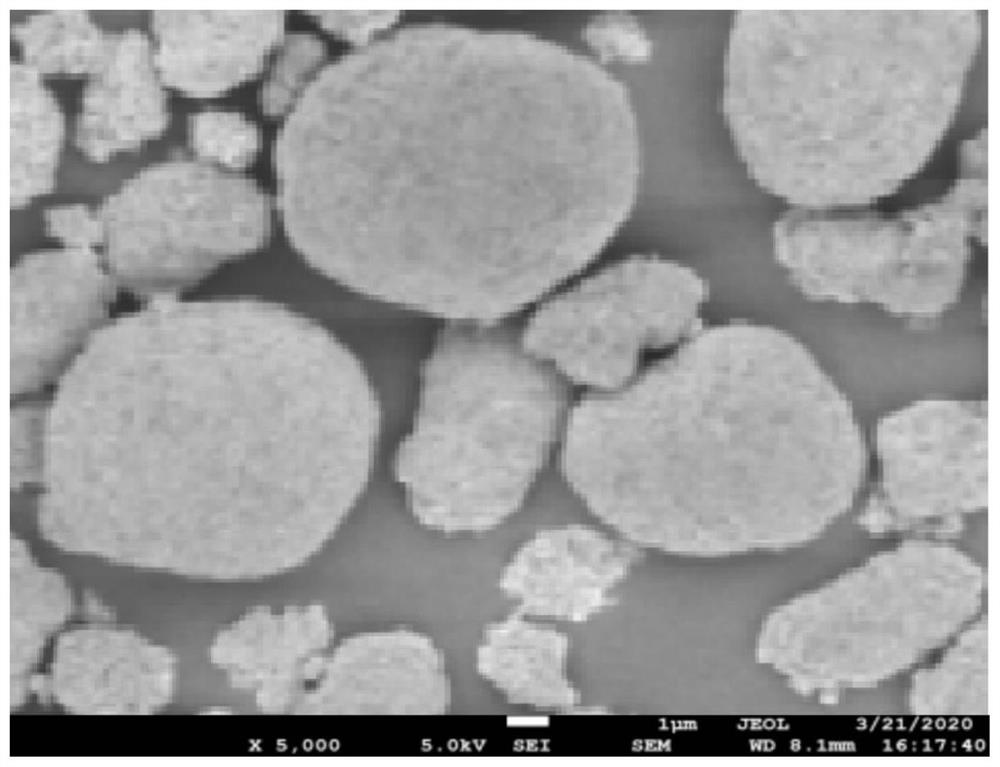

Ternary positive electrode material precursor with specific morphology and preparation method thereof

ActiveCN111725497APerfect shapeUniform sizeCell electrodesSecondary cellsLarge particleMaterials science

The invention relates to the technical field of lithium battery cathode materials and particularly relates to a preparation method of a ternary positive electrode material precursor with a specific morphology. A molecular formula of a precursor is Ni<x>Co<y>Mn<1-x-y>(OH)2, wherein x is larger than or equal to 0.5 and smaller than or equal to 0.9, y is larger than or equal to 0.05 and smaller thanor equal to 0.2, z is larger than or equal to 0 and smaller than or equal to 0.15, tap density is larger than or equal to 1.95 g / cm<3>, the specific surface area is 8-15 m<2> / g, apparent density is 1.4-2.0 g / cm<3>, the Na content is smaller than or equal to 100 ppm. According to the positive electrode material precursor, primary particles are 200-300nm in size, the size is uniform, and the sphericity degree of a small-particle precursor and a large-particle precursor is perfect; compared with the prior art, the lath-shaped ternary positive electrode material precursor provided by the inventionprovides good processability for subsequent washing, sintering and the like.

Owner:福建常青新能源科技有限公司 +1

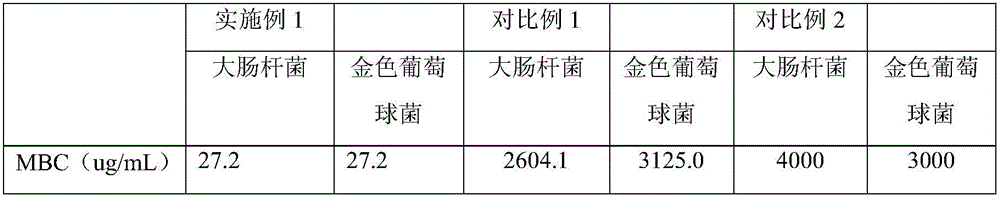

Antibacterial metal ion/titanium-supporting hydroxyapatite nanometer photocatalyst and preparation method thereof

ActiveCN106560243AWith quick-acting sterilization functionLong-acting antibacterialBiocideDead animal preservationTitaniumMetal

The present invention discloses an antibacterial metal ion / titanium-supporting hydroxyapatite nanometer photocatalyst, which is a hydroxyapatite nanometer material, wherein partial Ca<2+> is substituted with antibacterial metal ions and Ti<4+>, the antibacterial metal ions comprise Cu<2+>, Zn<2+> and Ag<+>, and during the preparation, the original feeding molar ratio of various metal ions is that n(Ti+metal) / n(Ca+Ti+metal) is 0.1-0.5, and the "metal" refers to the antibacterial metal ions. According to the present invention, the nanometer material has functions of rapid sterilization, long-term sterilization function and high mildew ability, and can instantly play super-strong sterilization effect in the absence of illumination, wherein the sterilization rate within 1 min can achieve more than 96%, and the sterilization rate within 3-4 min can achieve more than 99%; and after visible light irradiation for 30 min, more than 80% of formaldehyde gas can be removed.

Owner:姚 燕燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com