Patents

Literature

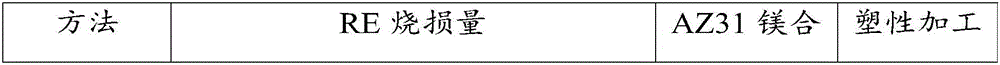

269results about How to "Reduce residual rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Traditional Chinese medicine feed additive for improving disease resistance of grass carp

ActiveCN102940157AImprove the body's immunityImprove survival rateAnimal feeding stuffBiotechnologyDisease

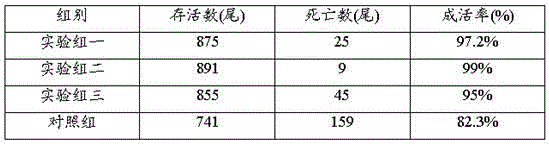

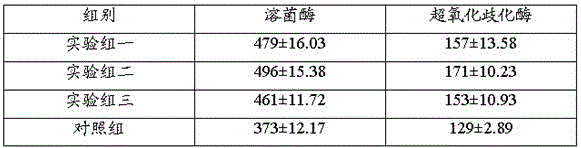

The invention provides a feed for improving the disease resistance of a grass carp. The feed is characterized by comprising soybean cake, wheat meal, shell meal, fish meal, table salt, rice bran, fish oil, betaine, traditional Chinese medicine feed premix additive, zinc-containing polypeptide, zinc-containing microelement additive, vitamin mixture additive at least containing vitamin C, vitamin E and inositol, yeast and amino acid mixture additive at least containing threonine. The feed provided by the invention can improve the immunity of the organism of the grass carp and protect the grass carp from getting sick; the application of antibacterial chemical medicines and anti-virus chemical medicines is reduced to a certain degree, the survival rate of the grass carp is increased, and the activity of lysozyme and superoxide dismutase in the grass carp is improved; and moreover, the feed ensures little drug residue and low toxicity, and does not influence the quality of the grass carp or harm the human health.

Owner:黄冈新希望饲料科技有限公司

Energy and water saving dyeing method for seamless underwear

ActiveCN102561070AReduce residual rateHigh whitenessBiochemical fibre treatmentBleaching apparatusWater savingOxygen

The invention relates to an energy and water saving dyeing method for a seamless underwear. A seamless weft knitting weaving technology is used for achieving one-off weaving forming of the seamless underwear. The dyeing and finishing process of the seamless underwear after being woven includes oxygen bleaching by the liquor ratio of 1: 8-10, dyeing by the liquor ratio of 1: 12-15 and soaping by the liquor ratio of 1: 8-10. By means of the energy-saving dyeing and finishing technology of non-caustic-soda oxygen bleaching process, one-bath one-step dyeing process and biological enzyme soaping process, one-time accurate dyeing is achieved, one-bath one-step completion is achieved, processing time is shortened, and sewage discharge and treatment are reduced.

Owner:GUANGDONG RUIYUAN TECH

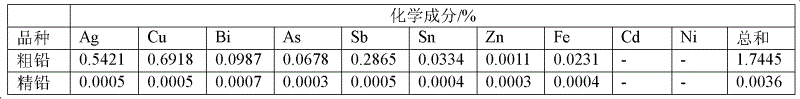

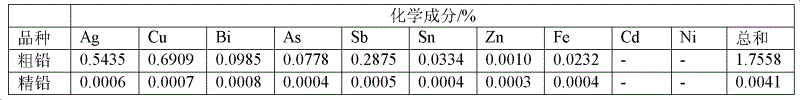

Method for direct electrolytic refining of crude lead

ActiveCN102618883AImprove solubilityImprove conductivityPhotography auxillary processesElectrolysisEconomic benefits

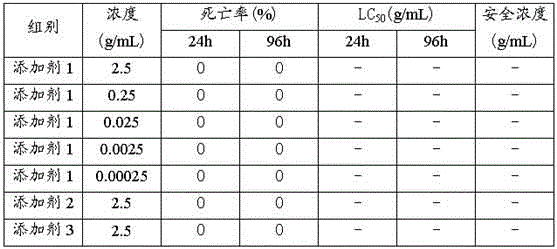

The invention relates to a method for direct electrolytic refining of crude lead, and belongs to the technical field of lead refining. According to the method, the crude lead prepared by pyrometallurgy is casted into a crude lead anode, wherein the crude lead anode is sleeved inside an anode bag; and electrolysis is performed in an additive-containing perchloric acid-lead perchlorate solution electrolyte to electrically deposit the lead in the anode on the cathode, such that the high purity electrolyzed lead and the anode mud are respectively obtained from the cathode and the anode. With the present invention, the lead without a pre-refining treatment can be directly subjected to electrolytic refining to obtain the pure lead with the purity more than 99.99% and the anode mud doped with noble metals, such that the recovery rate of the noble metals can be substantially improved so as to provide greater economic benefits.

Owner:BEIJING UNIV OF CHEM TECH

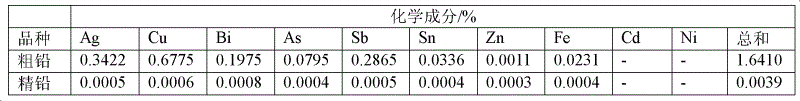

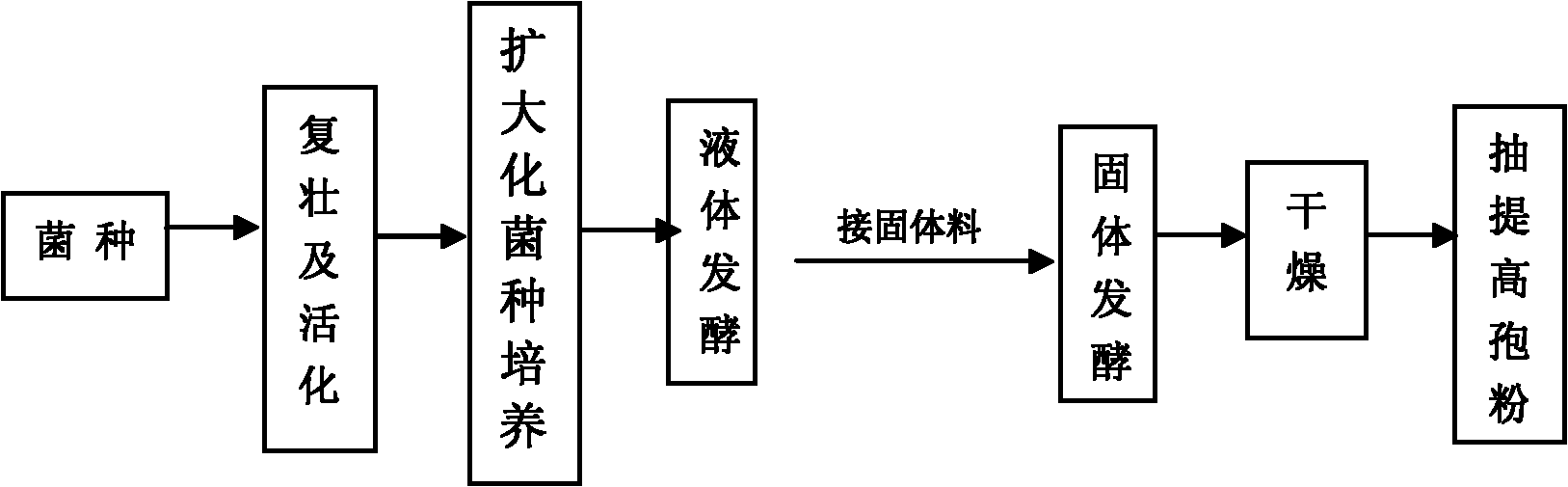

Preparation method and application of eauveria-spinosad suspending agent

InactiveCN102172250AOvercome the disadvantage of slow drug effectObvious synergism of toxicityBiocideAnimal repellantsSpinosadHas active ingredient

The invention relates to a preparation method and application of q beauveria-spinosad suspending agent. Beauveryia bassiana and spinosad are the active ingredients of the suspending agent which is used for preventing and treating agriculture and forestry injurious insects, such as leptinotarsa decemlineata and acridid and the like. The invention is characterized in that (1) the suspending agent comprises active ingredients, namely the beauveryia bassiana and the spinosad; and (2) the mass ratio of the beauveryia bassiana and the spinosad is (30:1)-(30:2), and the mass percent of the effective components in the preparation is 3.1-10%. The preparation method has the advantages that the product can be dissolved with oil or water; the effective duration of the beauveria vuillemin and the relative quick action of spinosad have complementary advantages, and injurious insects of various crops are treated; and the suspending agent prepared by the method has the advantages of good synergism and permeability, strong adhesivity and evaporation resistance and the like.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Glazing process for daily ceramic blank

The invention discloses a glazing process for a daily ceramic blank and relates to the technical field of daily ceramics. The glazing process comprises the following steps: (1) preparing a glaze; (2)preparing glaze pulp; (3) performing automatic glaze application; (4) polishing the bottom of the blank. In the glaze preparation process, the glaze is vacuumed and frozen to reduce the crushing granularity of the glaze, the abrasion degree of the glaze to blades of a crushing machine in the crushing process is reduced, and meanwhile the crushing time is shortened; due to adoption of the glaze application process, the glaze application quality is ensured, a glaze surface which is smooth and fine in hand feeling, clear and bright in gloss and fluent and smooth in line is formed on the surface of a ceramic blank after the glaze is sintered, and thus the market competitiveness of a ceramic product is improved.

Owner:安徽省德邦瓷业有限公司

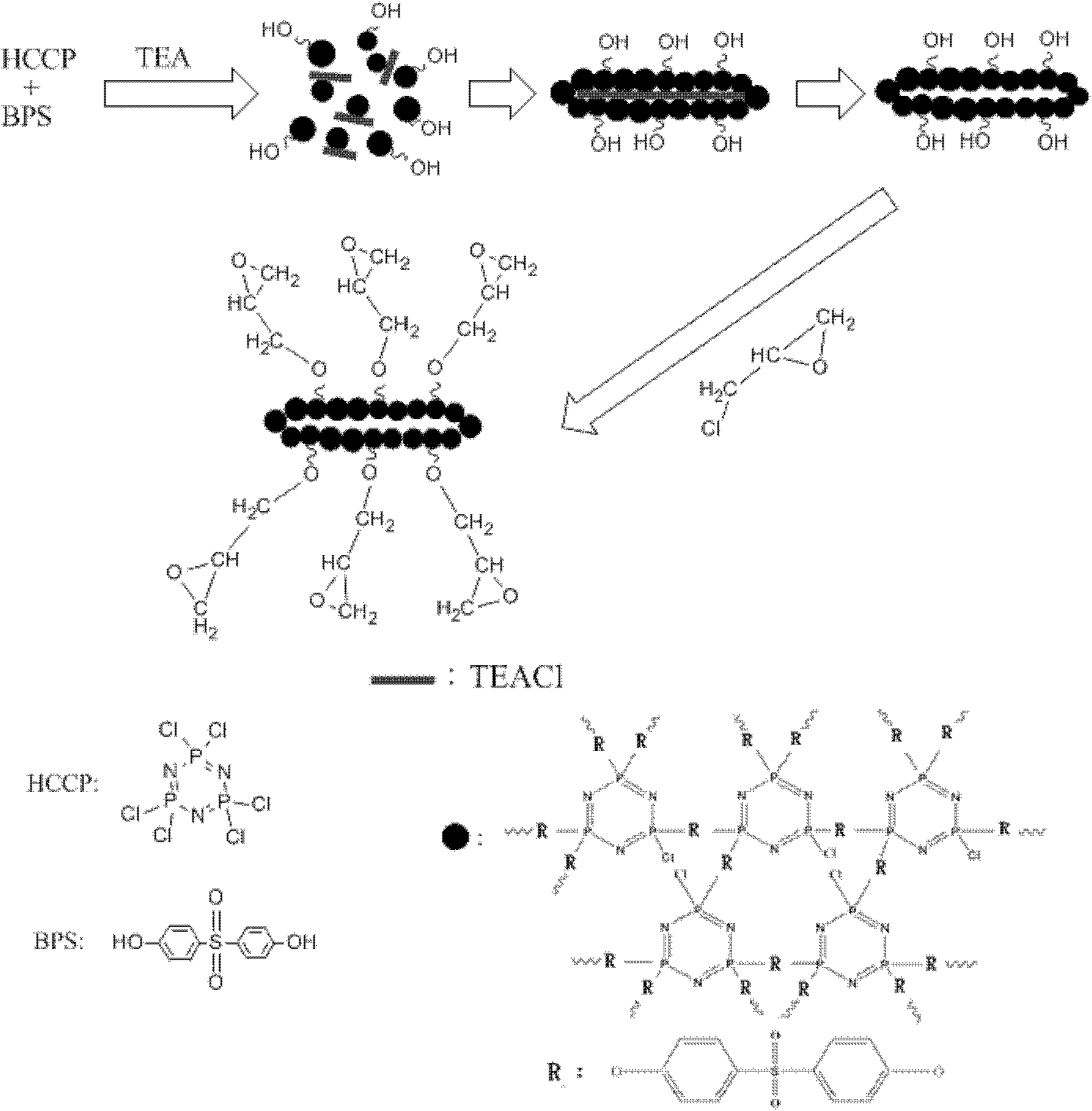

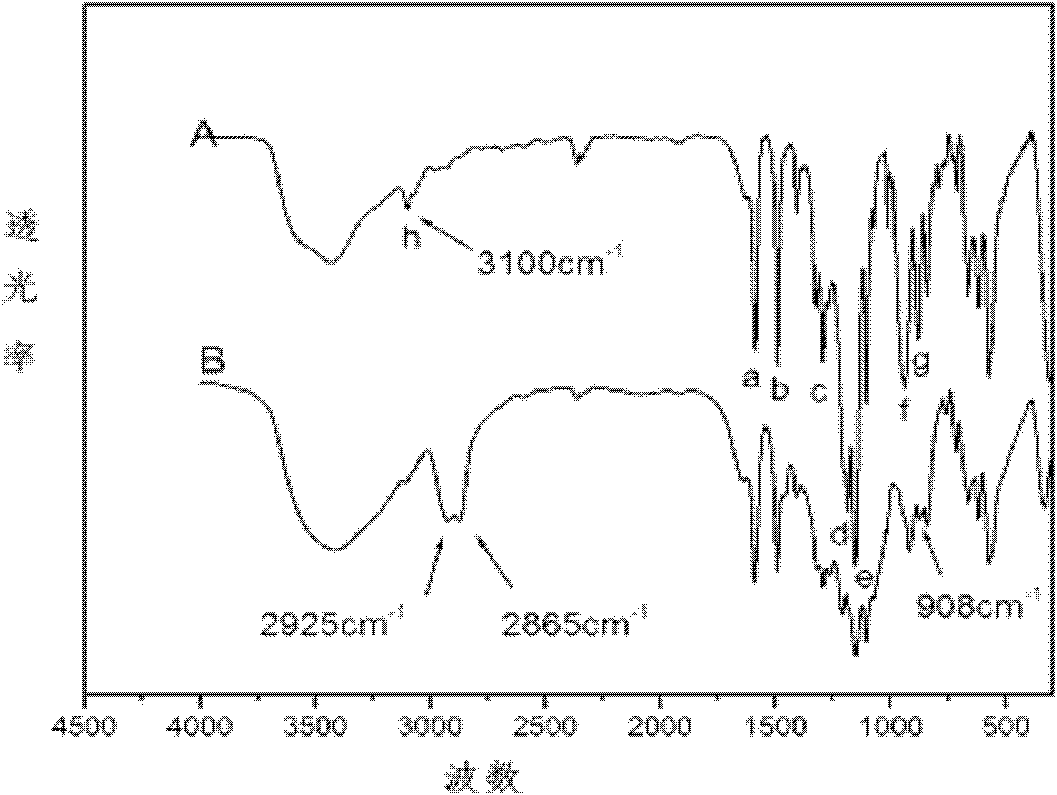

Preparation method of composite material based on epoxy resin and phosphazene nanotubes

The invention relates to a preparation method of a composite material based on epoxy resin and phosphazene nanotubes, which belongs to the technical field of nano materials. The preparation method comprises the following steps: under ultrasonic conditions, adding acid binding agent into tetrahydrofuran; adding 4,4'-dihydroxy-diphenyl sulfone and hexachlorocyclotriphosphazene to carry out condensation reaction; adding epoxy chloropropane; dropwise adding sodium hydroxide water solution; heating to carry out water bath reaction, thereby obtaining epoxide group modified phosphazene nanotubes; adding the epoxide group modified phosphazene nanotubes into the acetone dissolved epoxy resin, adding epoxy resin curing agent, carrying out ultrasonic dispersion, removing acetone in a vacuum drying oven at low temperature, and pouring the mixture into a die; and curing at high temperature to obtain the composite material based on epoxy resin and phosphazene nanotubes. The epoxy resin composite material has the advantages of high shock resistance, tensile property and thermal stability.

Owner:SHANGHAI JIAO TONG UNIV

Post-treatement method for PVA (polyvinyl alcohol) jelly glue fibre

InactiveCN101314871AEasy to stretchReduce residual rateFilament manufactureArtificial filament washing/dryingFiberVacuum extraction

The invention relates to a post-processing method of a polyvinyl alcohol PVA gel fiber, which comprises the following steps: firstly, pre-stretching and fiber washing are carried out; secondly, a solvent is extracted under the negative pressure and the vacuum conditions; and thirdly, multi-step drawing, design finalizing and coiling steps are carried out. The extraction method is replaced by the vacuum extraction method, thereby removing the solvent in the gel-spinning fiber. The post-processing method has the advantages of simple process, high equipment utilization rate, low solvent residual rate, good fiber tensile property, no harmful gas, solvent recycling under complete sealing condition, reutilization after recycling, etc., and reduces the recycling cost.

Owner:DONGHUA UNIV +1

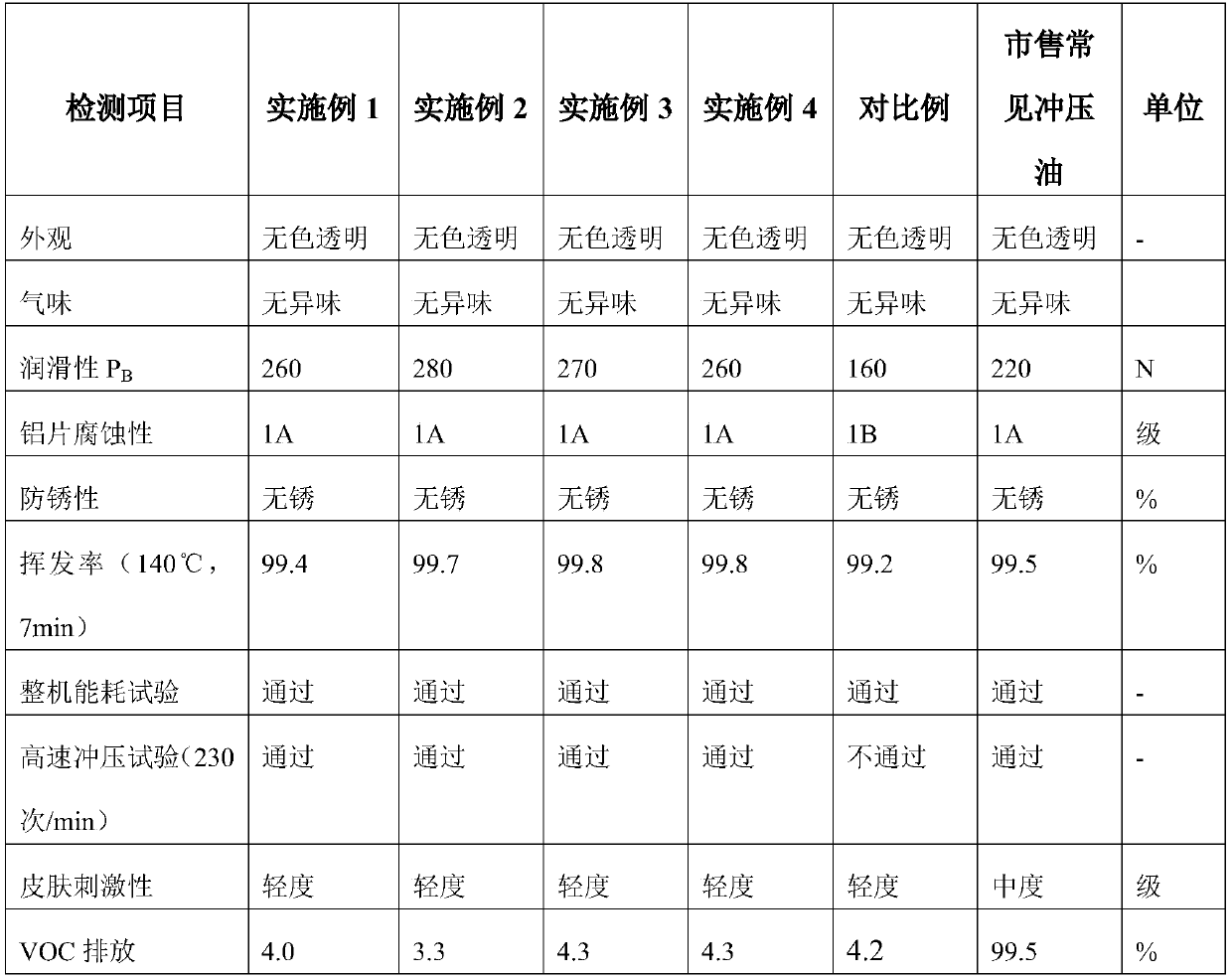

Environment-friendly water-based aluminum foil stamping liquid

ActiveCN109735388AExcellent overall performanceReduce residual rateLubricant compositionStamping processAluminium

The invention relates to the field of lubricating oil, in particular to environment-friendly water-based aluminum foil stamping liquid which comprises, in weight percent, 0.05-0.5% of lubricants, 0.5-5% of wetting agents, 0.001-0.05% of corrosion inhibitors, 0.05-0.1% of antirust agents, 0.2-0.6% of pH (potential of hydrogen) regulators and distilled water supplemented to reach 100%. Optimized additives are optimally combined to obtain the stamping liquid with excellent comprehensive performances, a formula system provides a protective die for the stamping process, the stamping liquid is a lubricant for stamping an aluminum foil, VOC (volatile organic compounds) emission is avoided, drying temperature is greatly reduced, energy is saved, residual rate is low, and residues have slight influence on the heat-conducting property of aluminum fins and can be removed by self-cleaning of an air conditioner, namely, flushing of condensate water.

Owner:广州科卢斯流体科技有限公司

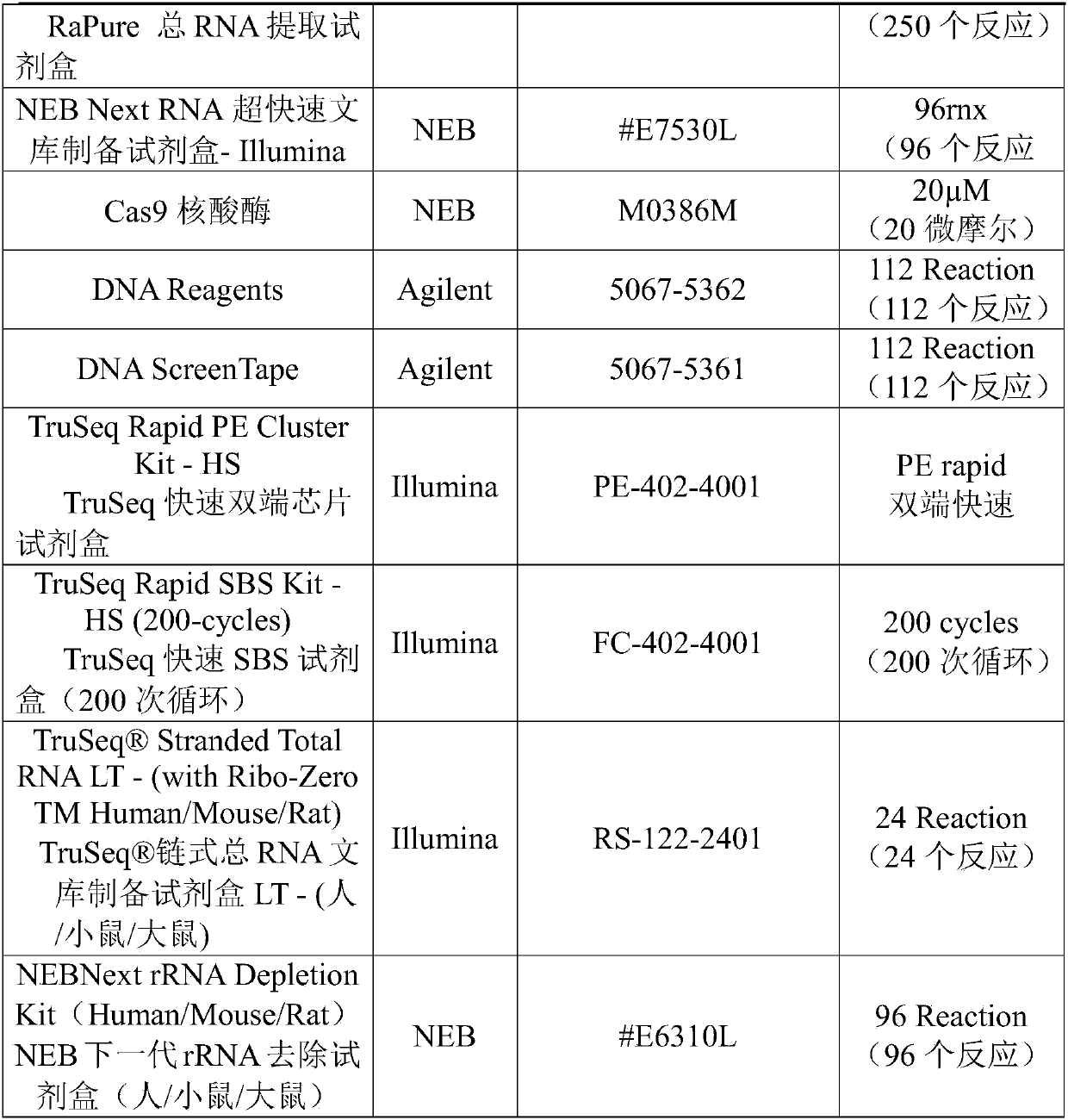

Method for preparing AZ31-RE wrought magnesium alloy

The invention provides a method for preparing an AZ31-RE wrought magnesium alloy, and relates to the technical field of alloys. The method comprises the following steps that a, a first scrap material and a second scrap material are mixed, cold pressing is conducted, and a blank is obtained, wherein the first scrap material is an AZ31 magnesium alloy scrap material, the second scrap material is an Mg-RE intermediate alloy scrap material, and the mass ratio of the first scrap material to the second scrap material is 4-299:1; b, the blank is subjected to heat extrusion, and then cold pressing is conducted, wherein heat extrusion comprises the step that the blank is subjected to heat preservation at the temperature ranging from 350 DEG C to 400 DEG C for 10-20 min; and c, the step b is repeatedly conducted at least one time, and then heat extrusion of the step b is conducted again. According to the method for preparing the AZ31-RE wrought magnesium alloy, oxidization of raw materials can be effectively reduced, the burnout rate of the raw materials is reduced, and pollution to the environment can be effectively reduced.

Owner:HARBIN UNIV OF SCI & TECH

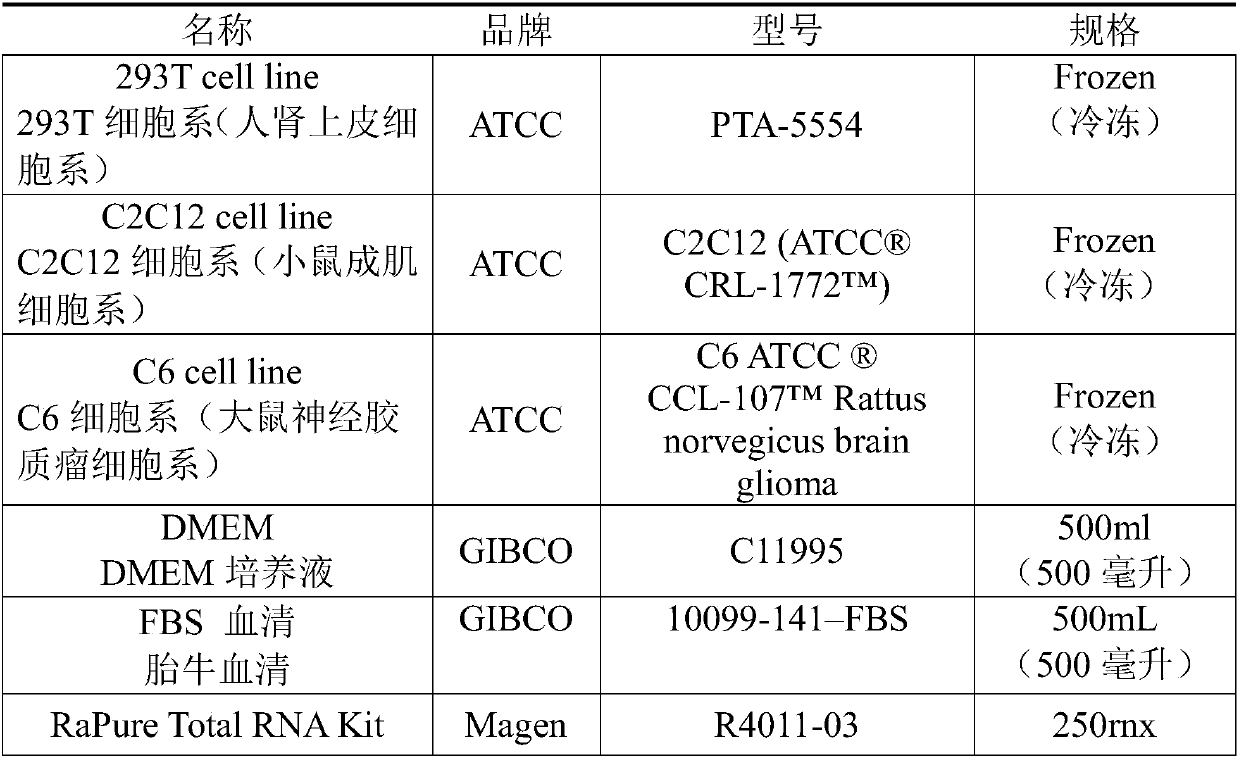

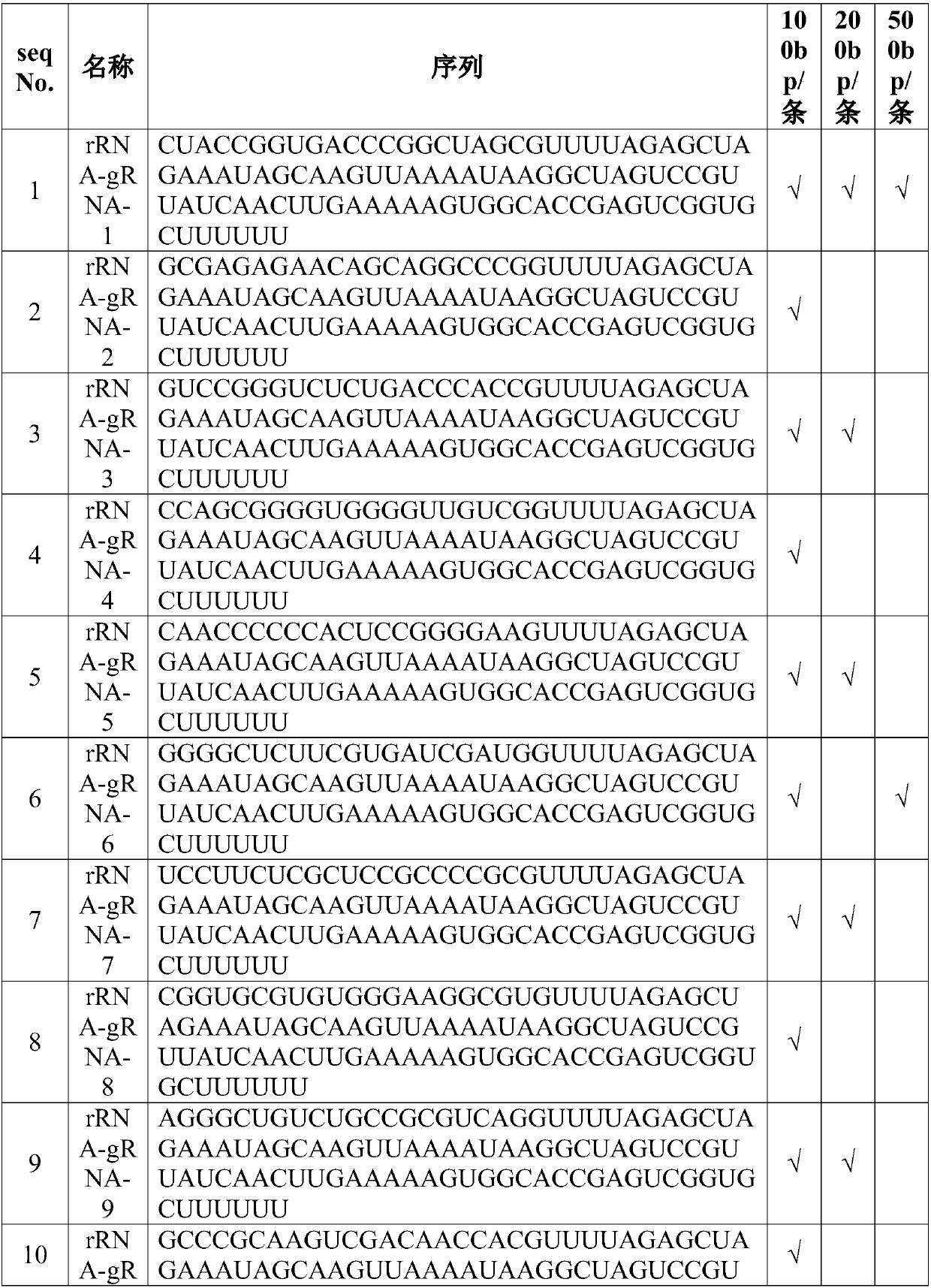

Method and kit capable of removing ribosomal RNA with high efficiency for construction of transcriptome sequencing library

ActiveCN107893260AImprove data qualityImprove effectivenessLibrary creationDNA preparationRibosomal RNAA-DNA

The invention discloses a method for construction of a transcriptome sequencing library. The method comprises the following steps: providing a DNA molecule containing to-be-removed rRNA; carrying outdesigning on account of a DNA sequence of the to-be-removed rRNA so as to obtain a Crispr RNA pool; and allowing a DNA sample to contact with the Crispr RNA pool and Crispr protein so as to obtain a sample compiled by a Crispr system and obtain the transcriptome sequencing library and a kit used for construction of the transcriptome sequencing library. The method and the kit provided by the invention can remove a large number of redundant RNA like rRNA with high efficiency, enrich other molecules in the sample, improve the data quality and the effective data ratio of initial transcriptome sequencing, and reduce the cost of sequencing.

Owner:GUANGZHOU RIBOBIO

Cleaning addition agent for cleaning beef bloodstain before making of beef broth

InactiveCN107439913AGuaranteed food safetyImprove the safety of useFood ingredientsVitamin CSesbania gum

The invention discloses a cleaning addition agent for cleaning beef bloodstain before making of beef broth, and relates to the technical field of food processing. The cleaning addition agent is prepared by mixing the following raw materials in parts by weight: 10-20 parts of hydroxypropyl starch-polyglutamic acid-mannitol, 5-10 parts of microcrystalline cellulose-glycine, 0.5-3 parts of a poloxamer 188, 0.5-3 parts of sodium alginate, 0.05-0.5 part of sesbania gum and 0.05-0.5 part of vitamin C powder. The cleaning addition agent can effectively eliminate beef bloodstain, the elimination rate is 99% or above, and based on the situations that the cleaning time is obviously shortened and the consumption of water for cleaning is reduced, the cleaning effect is guaranteed. The cleaning addition agent is non-toxic and harmless, in the rinsing process through the clean water, the cleaning addition agent can be rapidly removed, and the remaining rate of the cleaning addition agent on the beef is lower than 0.01%, so that the eating safety of the beef is guaranteed.

Owner:安徽芈八子食品科技有限公司

Indoor air disinfecting and killing module for airborne virus epidemic prevention

ActiveCN111912044AImprove inactivation efficiencyReduce the risk of infectionLighting and heating apparatusSpace heating and ventilation detailsAir decontaminationUltraviolet

The invention discloses an indoor air disinfecting and killing module for airborne virus epidemic prevention. The module is characterized in that the lower part of a module shell is provided with a machine body quick-mounting structure for quickly connecting a terminal, and the upper part of the module shell is provided with an air outlet protection structure. A protection net, a plasma generationdevice, a photocatalyst net film, a UVCLED array light source and an ultraviolet ion absorption net film are sequentially arranged between the machine body quick-mounting structure and the air outletprotection structure from bottom to top, and the plasma generation device and the UVCLED array light source are electrically connected with an electrical control box. Air sequentially passes throughthe protection net, the plasma generation device, the photocatalyst net film and the UVCLED array light source, is filtered by the ultraviolet ion absorption net film and then is exhausted. The moduleis high in single cycle efficiency, easy to deploy and controllable in cost, has higher inactivation efficiency on common airborne viruses such as 2019-nCov, can be directly deployed in an existing air purification system, is safe and efficient in sterilization process, does not cause secondary pollution, and effectively meets the urgent requirements of virus epidemic prevention and disinfectionand killing in air of hospitals, classrooms, shopping malls and families.

Owner:XI AN JIAOTONG UNIV

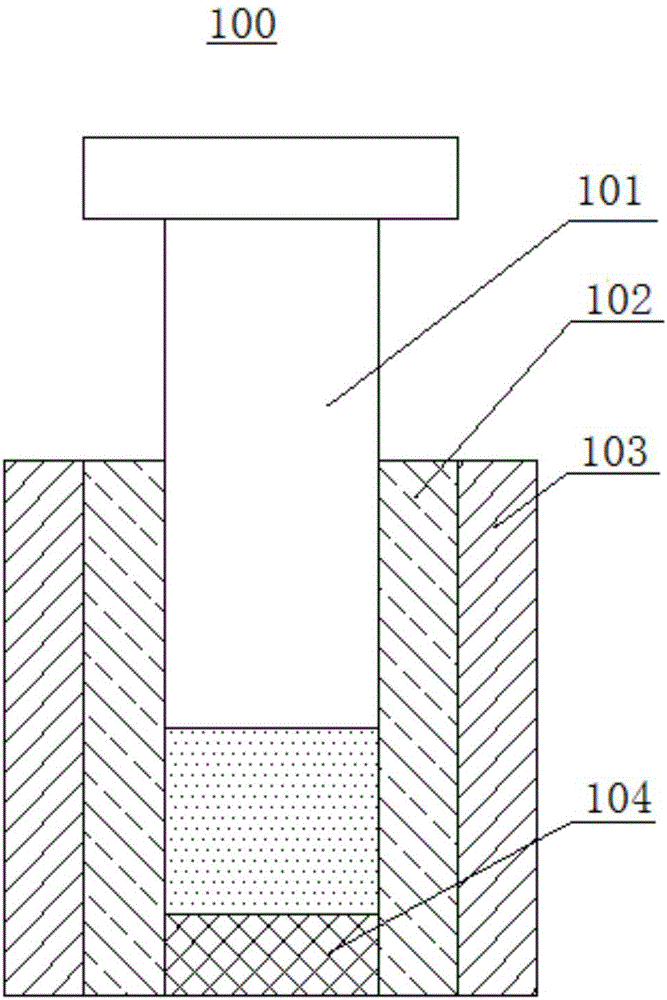

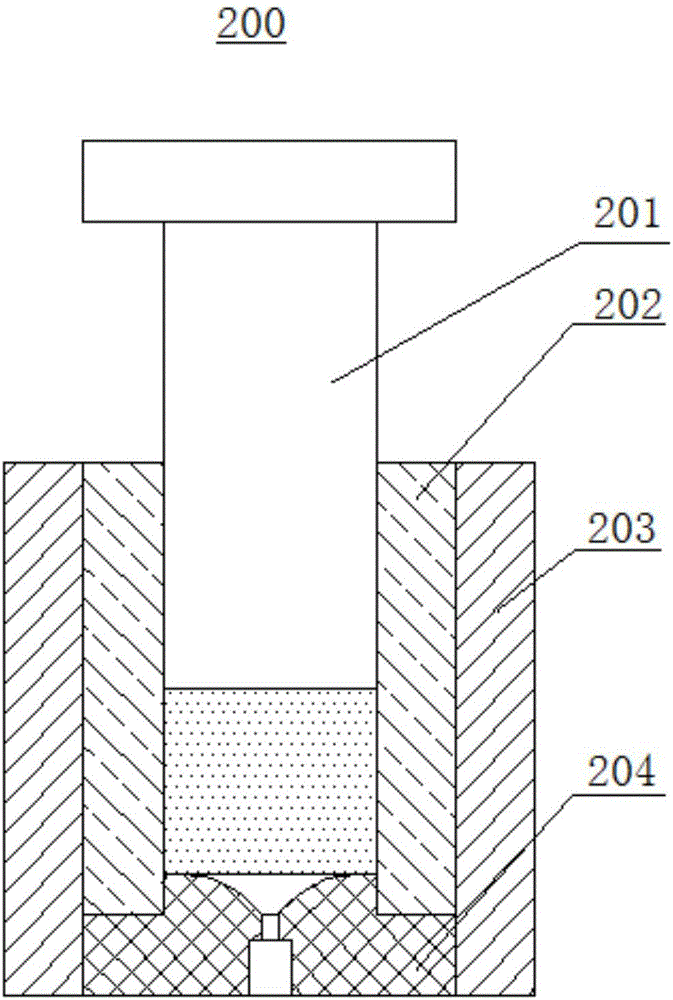

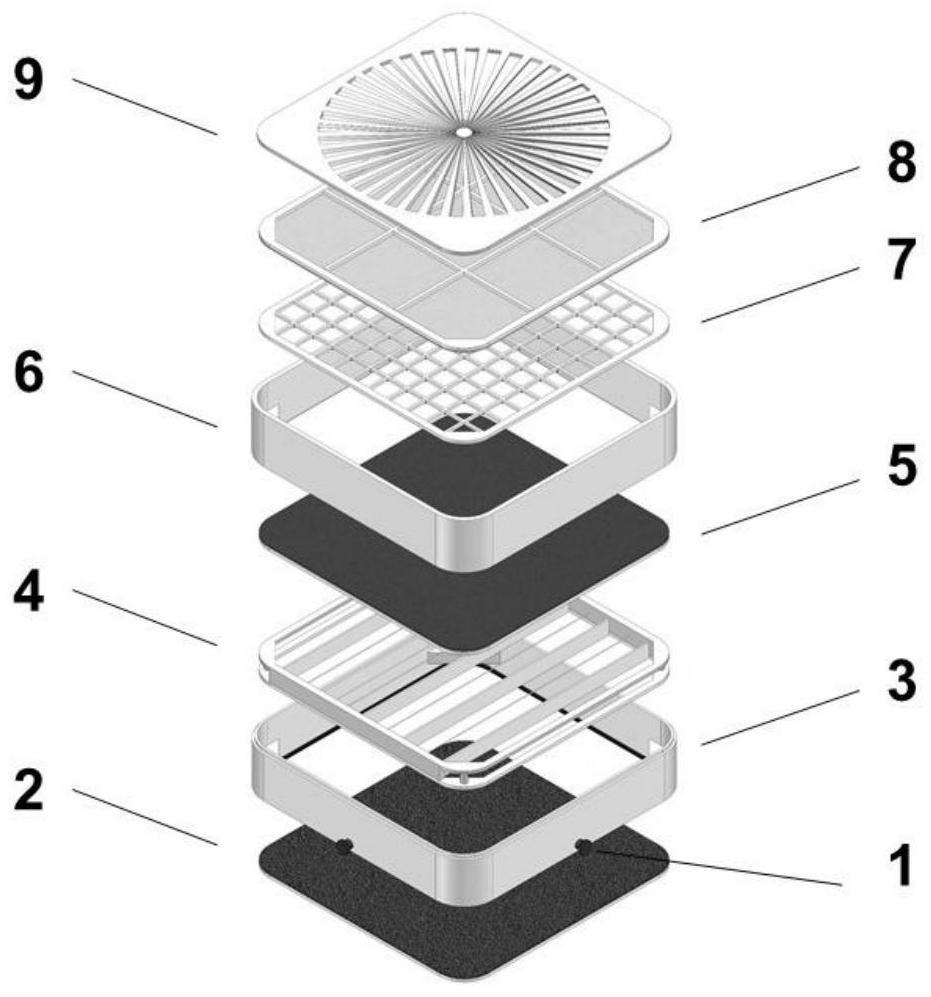

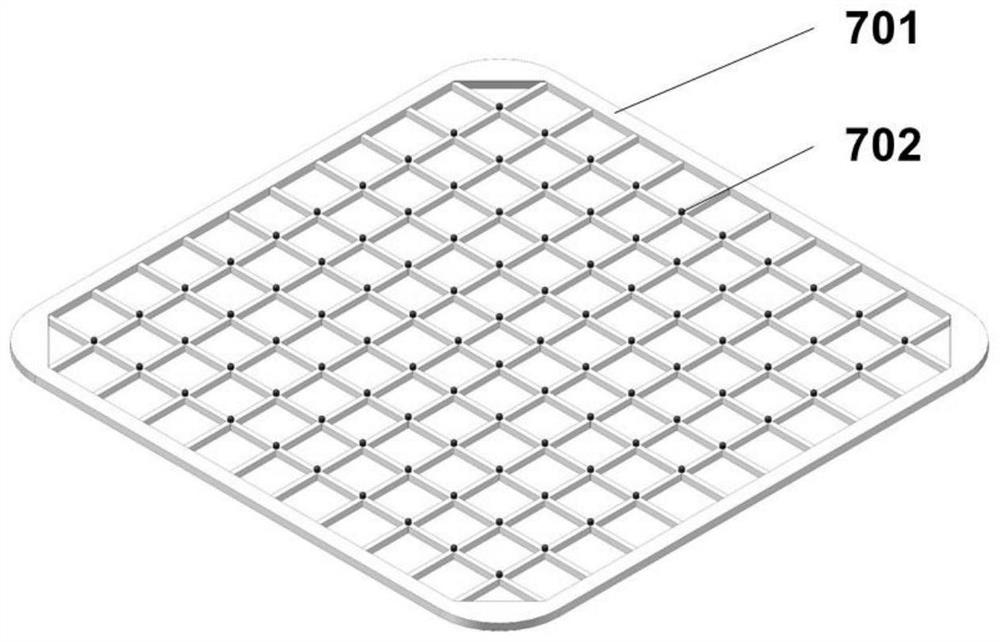

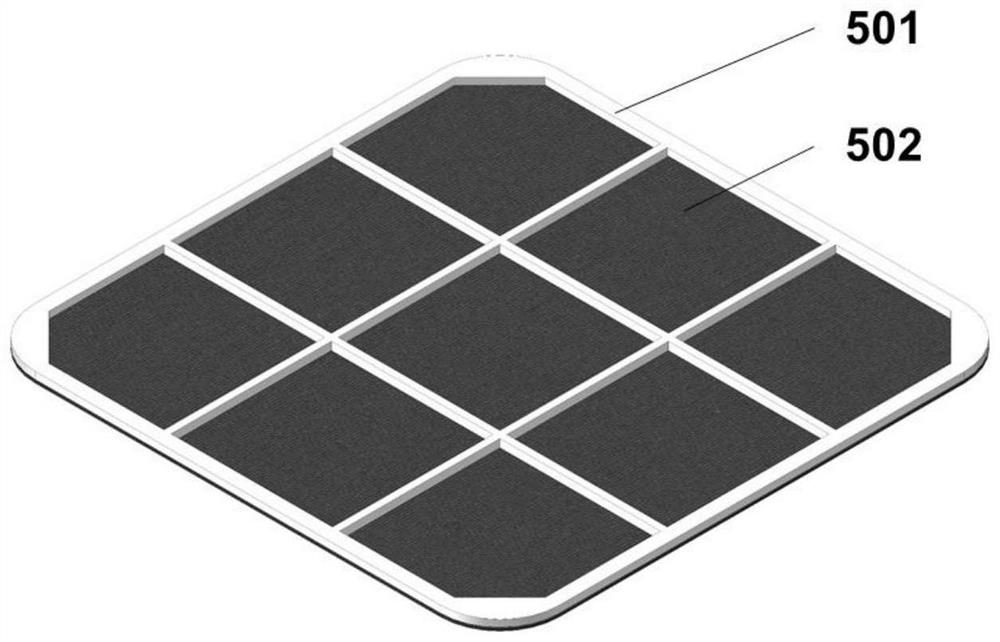

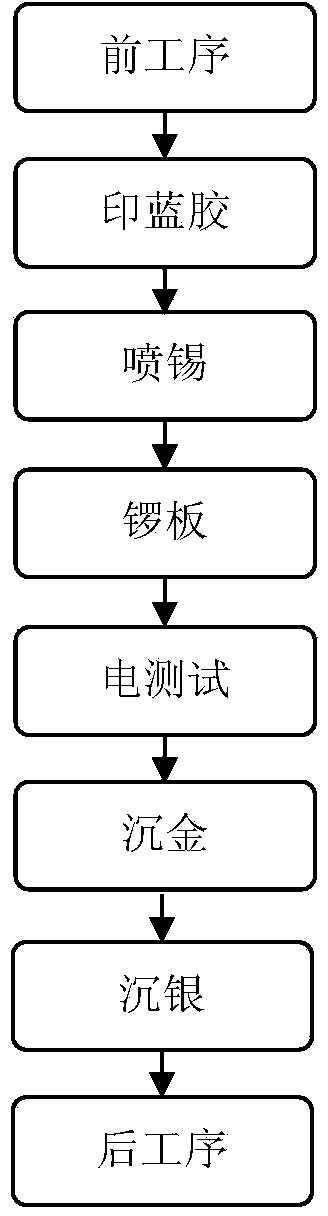

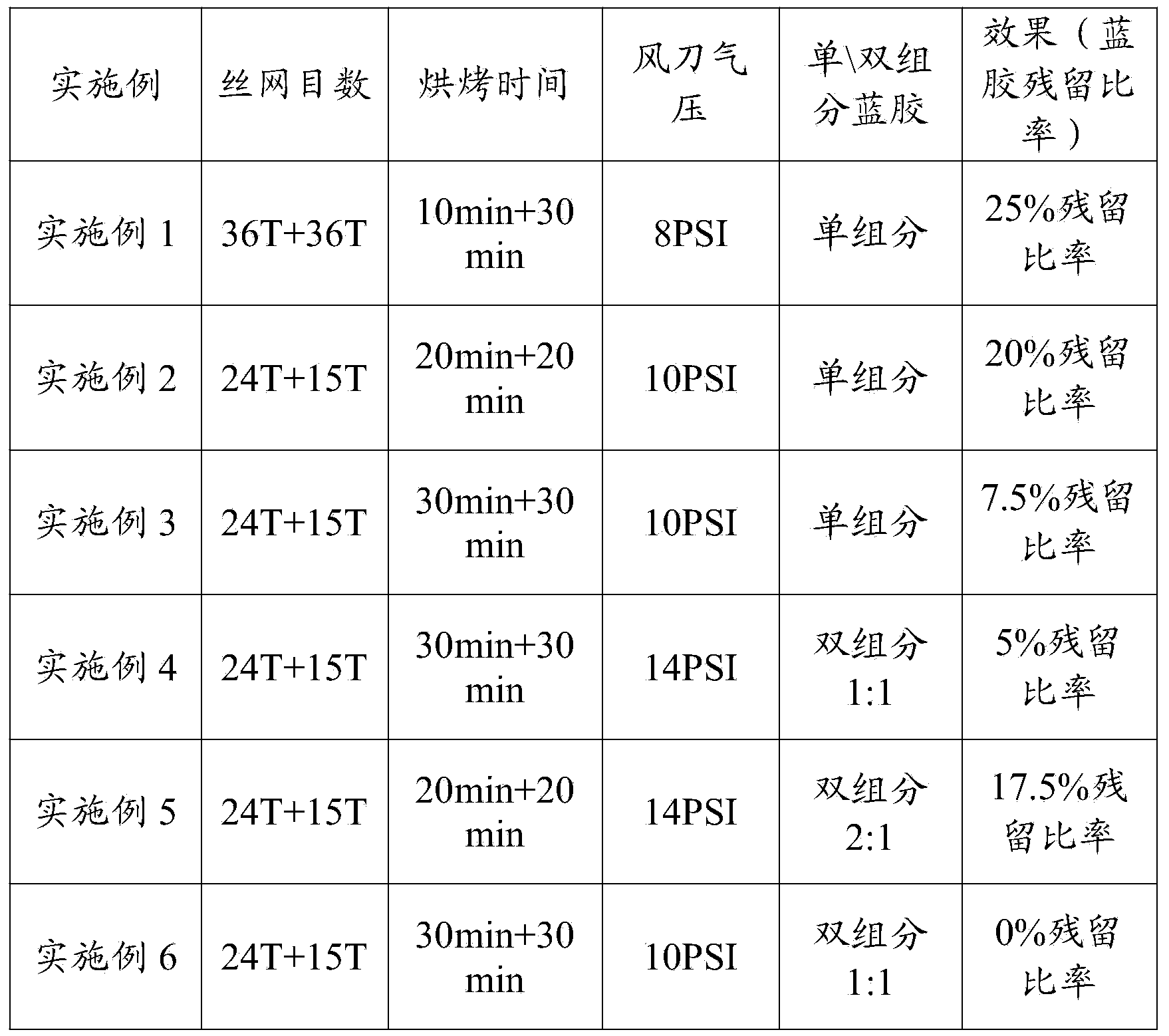

Printed circuit board and mixed surface treatment process thereof

ActiveCN104378925AReduce residual rateMeet various requirementsConductive pattern reinforcementNon-metallic protective coating applicationScreen printingEngineering

The invention discloses a printed circuit board and a mixed surface treatment process of the printed circuit board. The mixed surface treatment process comprises the following procedures of the previous procedure, blue glue printing, the tin spraying procedure, the plate milling procedure, electric tests, gold deposition, silver deposition and the subsequent procedure, wherein the blue glue is printed in a silk-screen printing mode, the silk screen has the specification of 15T or 24T or 36T; an element face is first printed with the blue glue, then, baking is performed for 5 min to15 min at the temperature of 135+ / -5 DEG C; a welded face is printed with the blue glue, then, baking is performed for 25 min to 35 min at the temperature of 150+ / -5 DEG C. According to the printed circuit board and the mixed surface treatment process of the printed circuit board, the blue glue technology is creatively used for forming a selective tin spraying protection layer; particularly blue glue with two different models is used in cooperation, and the blue glue residual rate on the plate faces is reduced; the various surface treatment processes are used for the same circuit board, and therefore various product requirements can be met; cost can also be reduced, and very high economic value is achieved.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

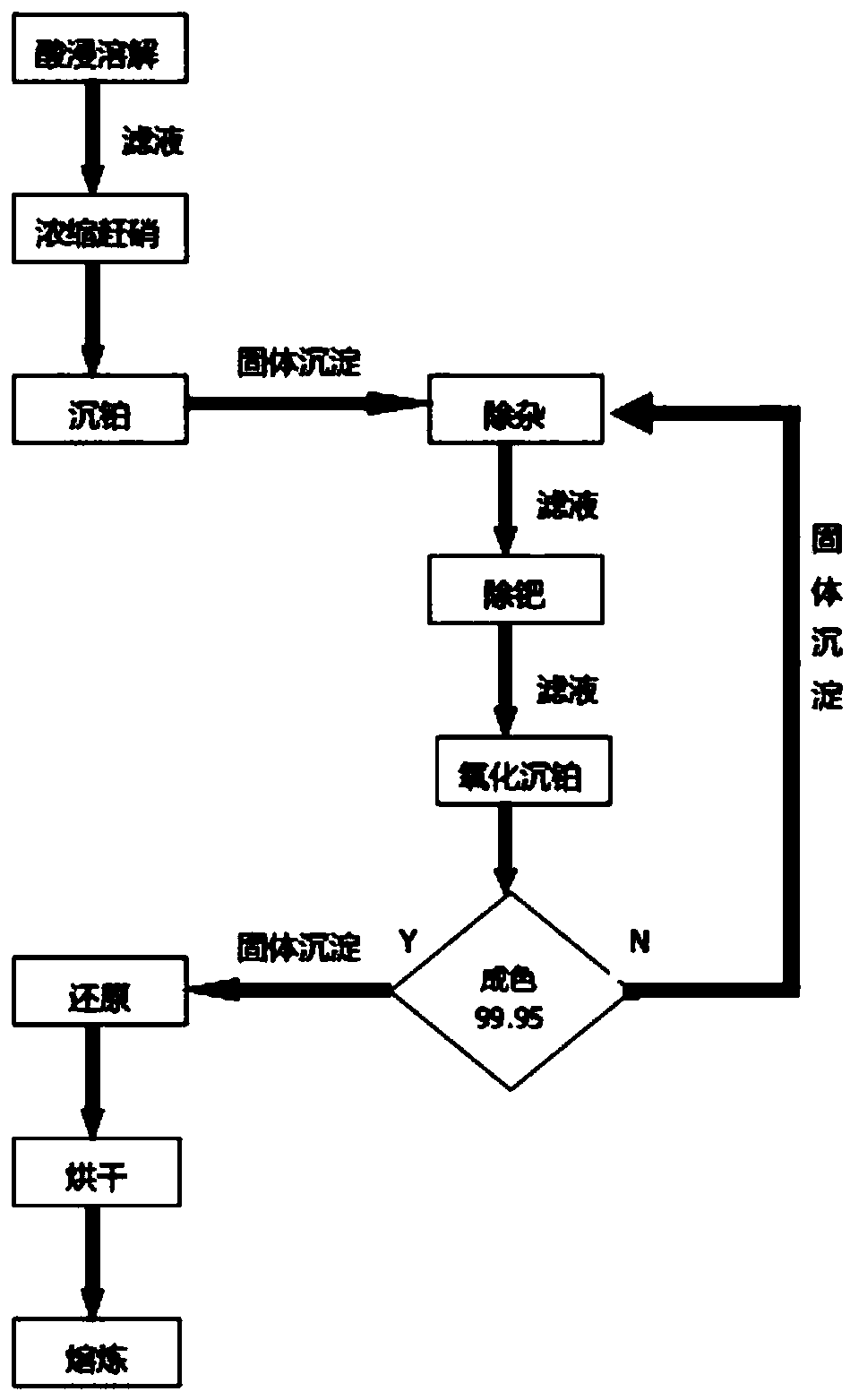

Method for separating and extracting platinum with purity of 99.95% from gold-palladium-platinum-containing alloy

InactiveCN109609784ARemove completelyValence reductionProcess efficiency improvementChemistryPalladium

The invention discloses a method for separating and extracting platinum with purity of 99.95% from a gold-palladium-platinum-containing alloy. The method comprises the steps of acid leaching dissolution, concentration and denitrification, platinum precipitation, impurity removal, palladium removal, oxidation and platinum precipitation, reduction and the like. The method is simple, easy to operateand short in process, and the platinum with the relative purity of 99.95% or above can be obtained after impurity removal and purification are carried out twice; according to the method, the purification effect is good, and the direct yield of the platinum is high; and meanwhile, the method has the advantages of being simple and short in operation process, short in recovery period, low in residualquantity of gold, palladium and platinum in wastewater and the like.

Owner:KANFORT JIANGMEN ENVIRONMENTAL TECH CO LTD

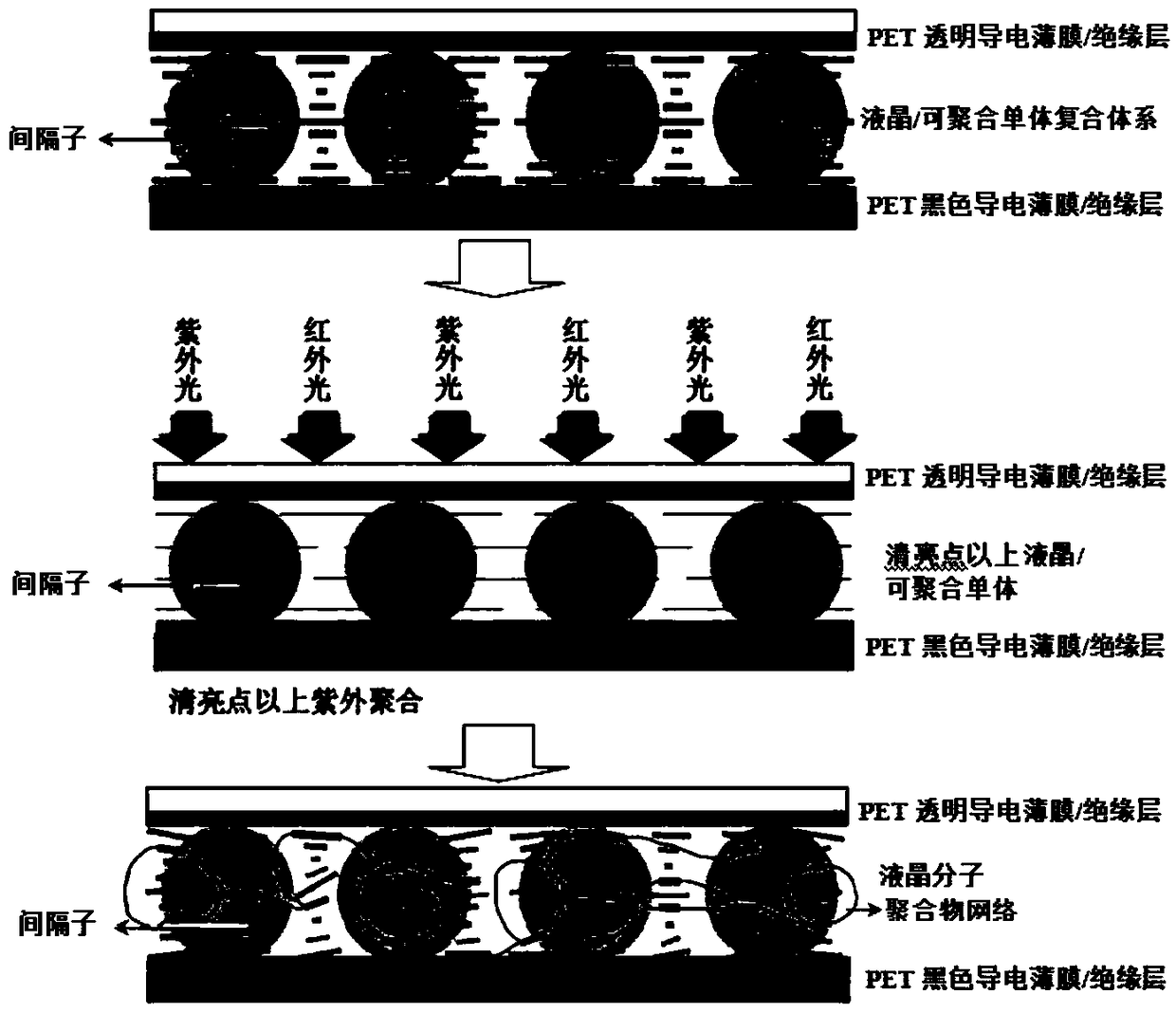

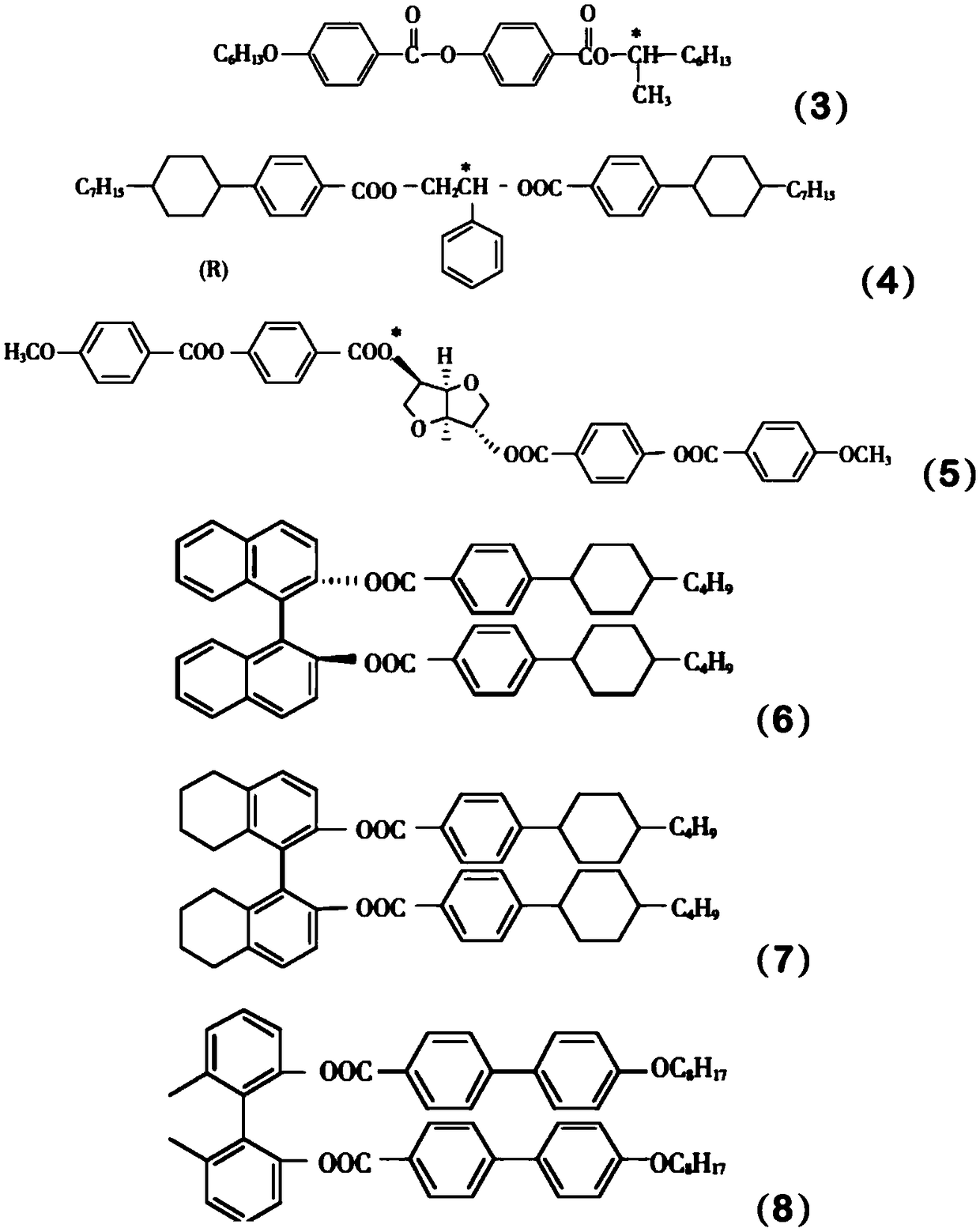

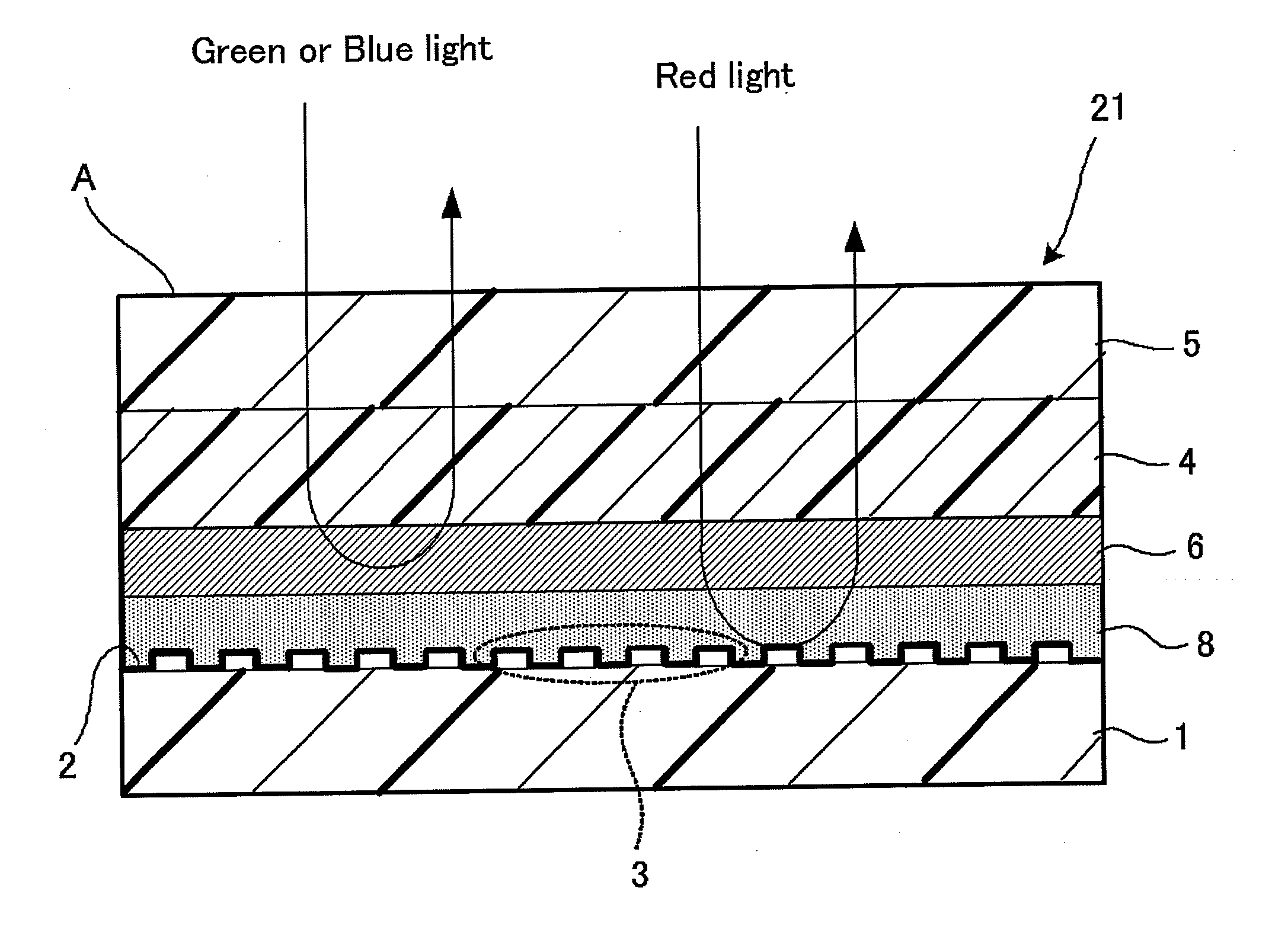

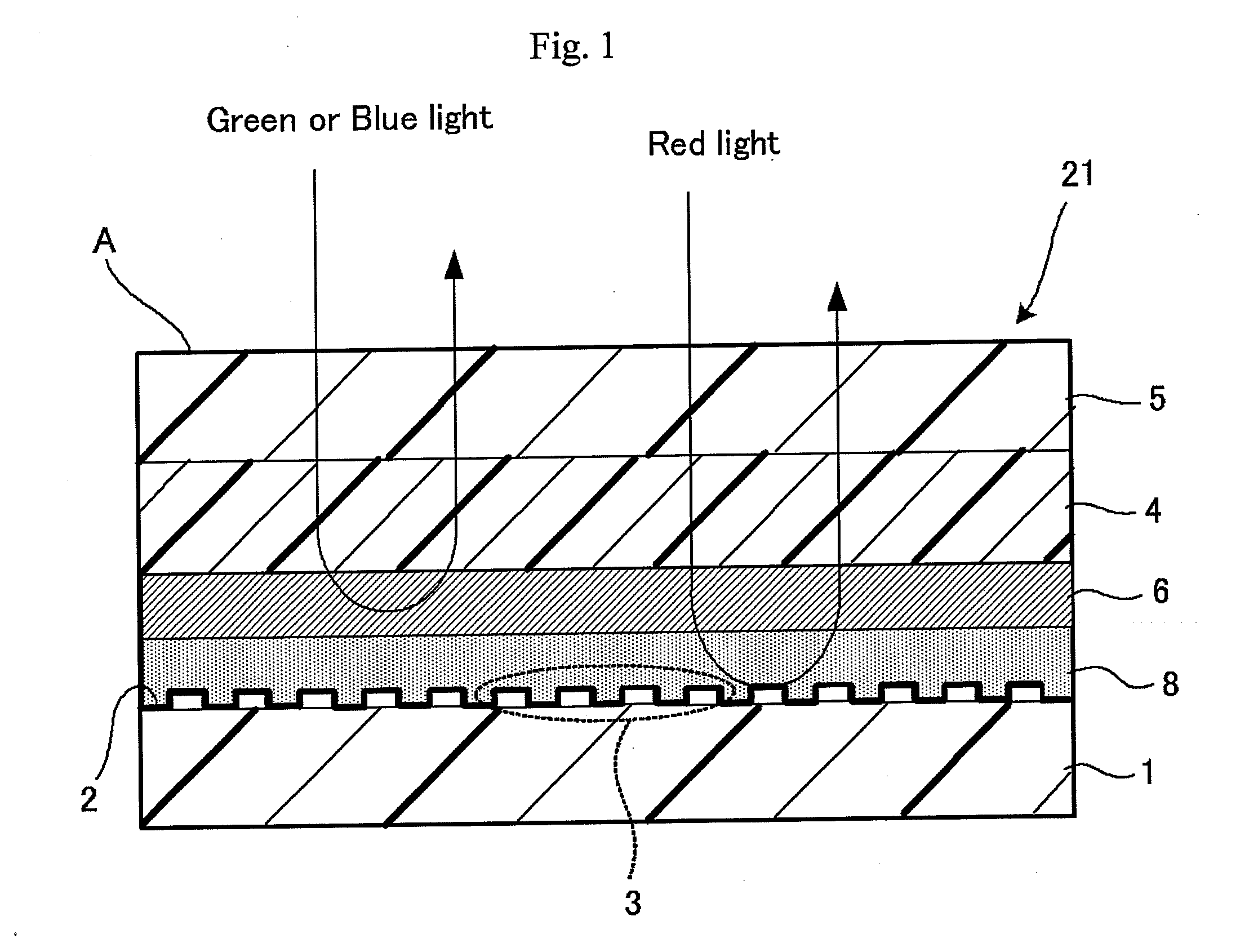

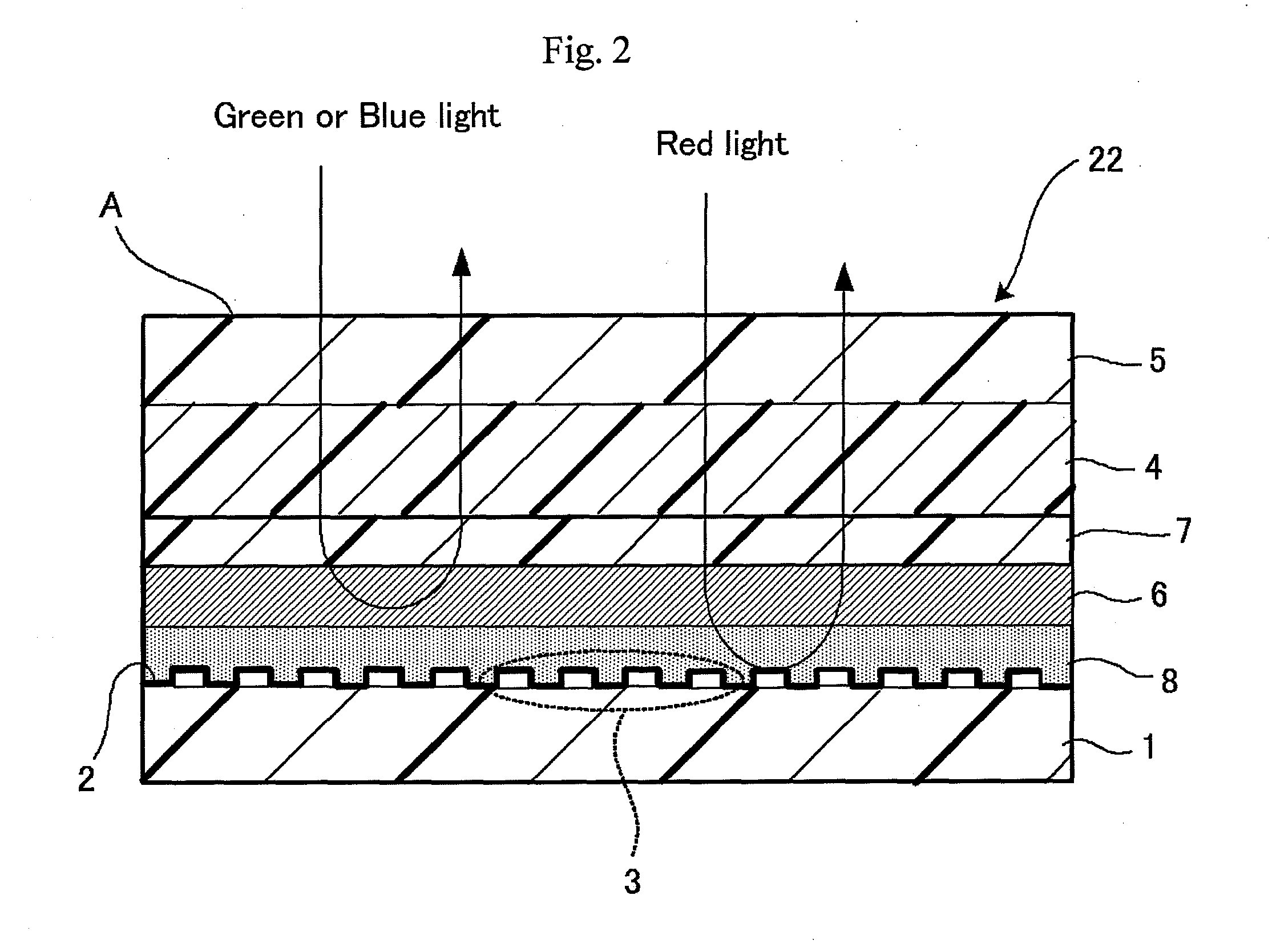

Easy thermal erasing type liquid crystal membrane writing board and preparation method

ActiveCN108717239ABroaden the reflected wave widthLower threshold voltageLiquid crystal compositionsNon-linear opticsLiquid-crystal displayLiquid crystal

The invention relates to the technical field of liquid crystal displaying, in particular to an easy thermal erasing type liquid crystal membrane writing board and a preparation method. The easy thermal erasing type liquid crystal membrane writing board comprises a PET transparent thin membrane with the single side coated with ITO, a liquid crystal thin membrane and a PET non-transparent black thinmembrane with the single side coated with ITO from top to bottom; the sides of conducting layers of the PET transparent thin membrane with the single side coated with the ITO and the PET non-transparent black thin membrane with the single side coated with the ITO are coated with insulating layers. Words written on the easy thermal erasing type liquid crystal membrane writing board can be completely removed under the lower voltage condition; the easy thermal erasing type liquid crystal membrane writing board can be packaged in rolling, and conveniently transported; the erasing and writing temperatures are low, the words can be reserved clearly at 0-4 DEG C, and the words written on the liquid crystal membrane writing board can be completely erased at the temperature between 45-60 DEG C.

Owner:山东蓝贝易书信息科技有限公司

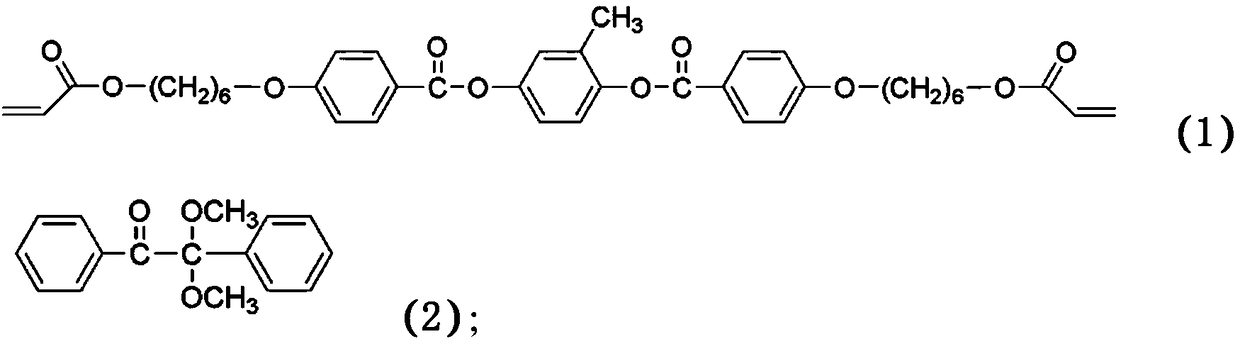

Holographic recording composition and holographic recording medium

InactiveUS20080254374A1High sensitivityReduce residual ratePhotosensitive materialsPhotomechanical apparatusArylAlcohol

The present invention provides a holographic recording composition and a holographic recording medium comprising a recording layer formed with the holographic recording composition. The holographic recording composition comprises a bifunctional or greater isocyanate, a polyfunctional alcohol comprising a bifunctional alcohol and a trifunctional or greater alcohol, a titanocene-based radical polymerization initiator, a bifunctional or greater acrylate monomer, and an amidine salt denoted by General Formula (1).In General Formula (1), R1, R2, and R3 each independently denote an alkyl group, aryl group, amino group, or acyl group, R1 and R2 may be bonded together to form a ring, R2 and R3 may be bonded together to form a ring, and A− denotes an anion.

Owner:FUJIFILM CORP

Environment-friendly refining method of theobromine

The invention discloses an environment-friendly refining method of theobromine, and relates to the technical field of synthetic chemistry. The method comprises the following steps: (1) dissolving a crude product to prepare a sodium salt; (2) carrying out decoloration; and (3) carrying out acidification and crystallization. According to the method provided by the invention, the theobromine in a theobromine crude product is converted into a sodium salt by adding a sodium hydroxide solution and insoluble impurities are filtered out; then, the decoloration effect is ensured by use of a decolorant,and pigment impurities are removed; and then, by controlling the pH value during acidification, the residual rate of theobromine in crystallization mother liquor can be reduced and the purity of theobromine in precipitated crystals can be increased. The prepared finished product of theobromine is white or creamy in appearance, and the residual rate of 3-methylxanthine is less than 0.15% or more,and meets requirements of the quality standard of theobromine; and the refining yield reaches 95% or more, thus reducing the loss amount of theobromine in a refining process.

Owner:安徽省百花香料香精有限公司

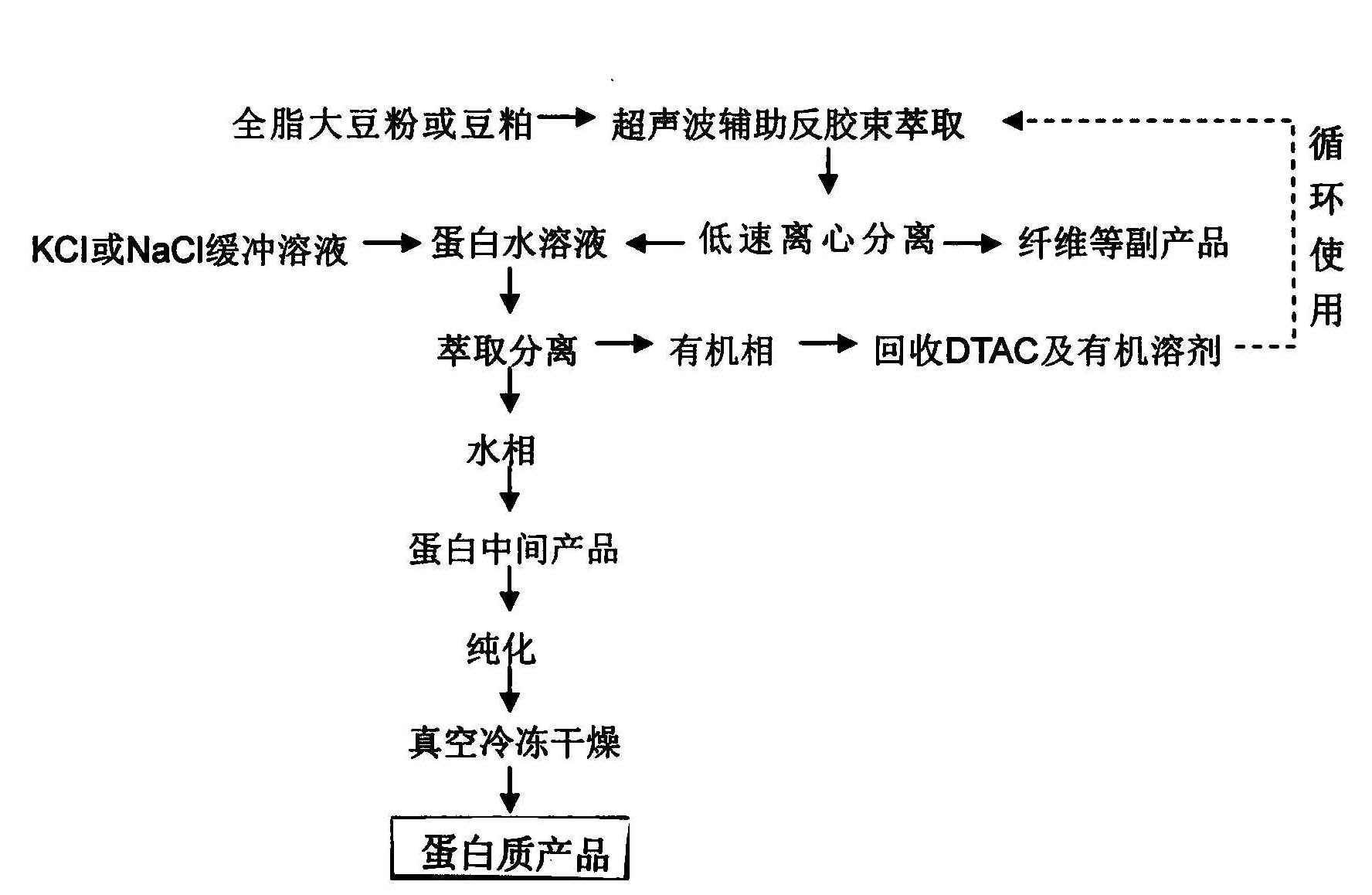

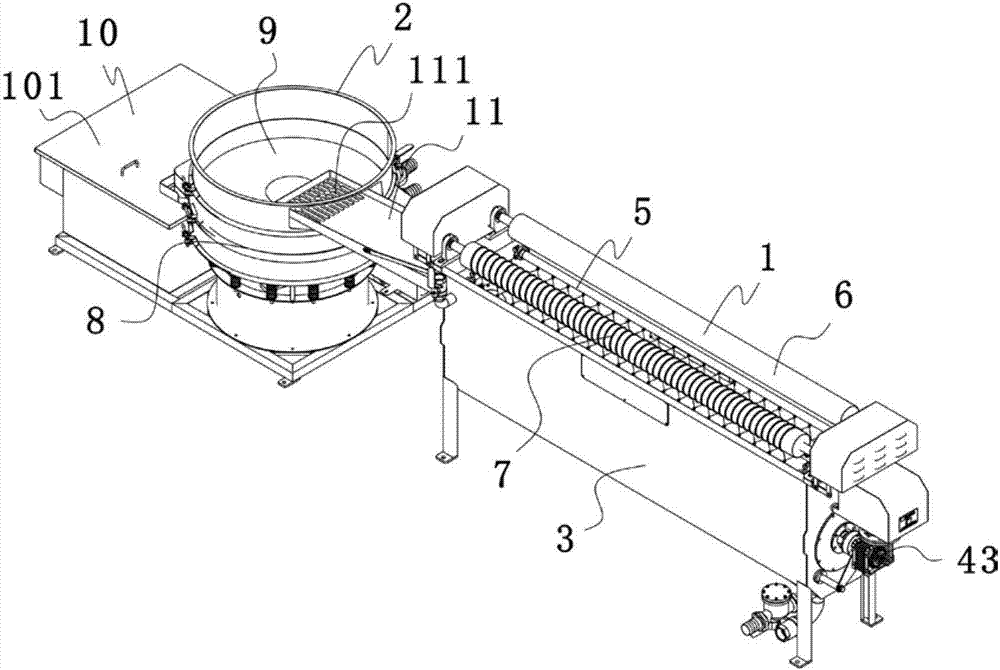

Method for extracting soybean protein by using dodecyltrimethylammonium chloride reverse micellar solution

ActiveCN101912030AHigh extraction rateShortened extraction timeProtein composition from vegetable seedsWastewaterSURFACTANT BLEND

The invention relates to a method for extracting soybean protein by using a dodecyltrimethylammonium chloride reverse micellar solution, which is characterized by comprising the following steps: adding full-fat soybean powder or soybean meal powder to a dodecyltrimethylammonium chloride (DTAC) reverse micellar solution, extracting, and carrying out solid-liquid separation to obtain a soybean protein solution. The invention has the following major advantages: because of the use of the dodecyltrimethylammonium chloride reverse micelle, the formation time of the reverse micellar system is short, and the preparation is more convenient and faster; because the extraction of soybean protein by DTAC / n-heptane-n-hexyl alcohol reverse micellar system is assisted by ultrasound, the preparation is more convenient and faster; the extraction rate is obviously improved, and the extraction time is shortened; in the extraction process, the protein is enclosed by water environment in the reverse micelle, the water environment is similar to the intracellular environment and the conditions are wild, thereby ensuring that the protein can not be denatured easily and the bioactivity thereof can be kept; compared with other surfactants, the residual surfactant in the soybean protein, i.e. the dodecyltrimethylammonium chloride, is easy to separate, thereby achieving high product purity; and the method has the advantages of no acid and alkaline wastewater discharge and no pollution.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

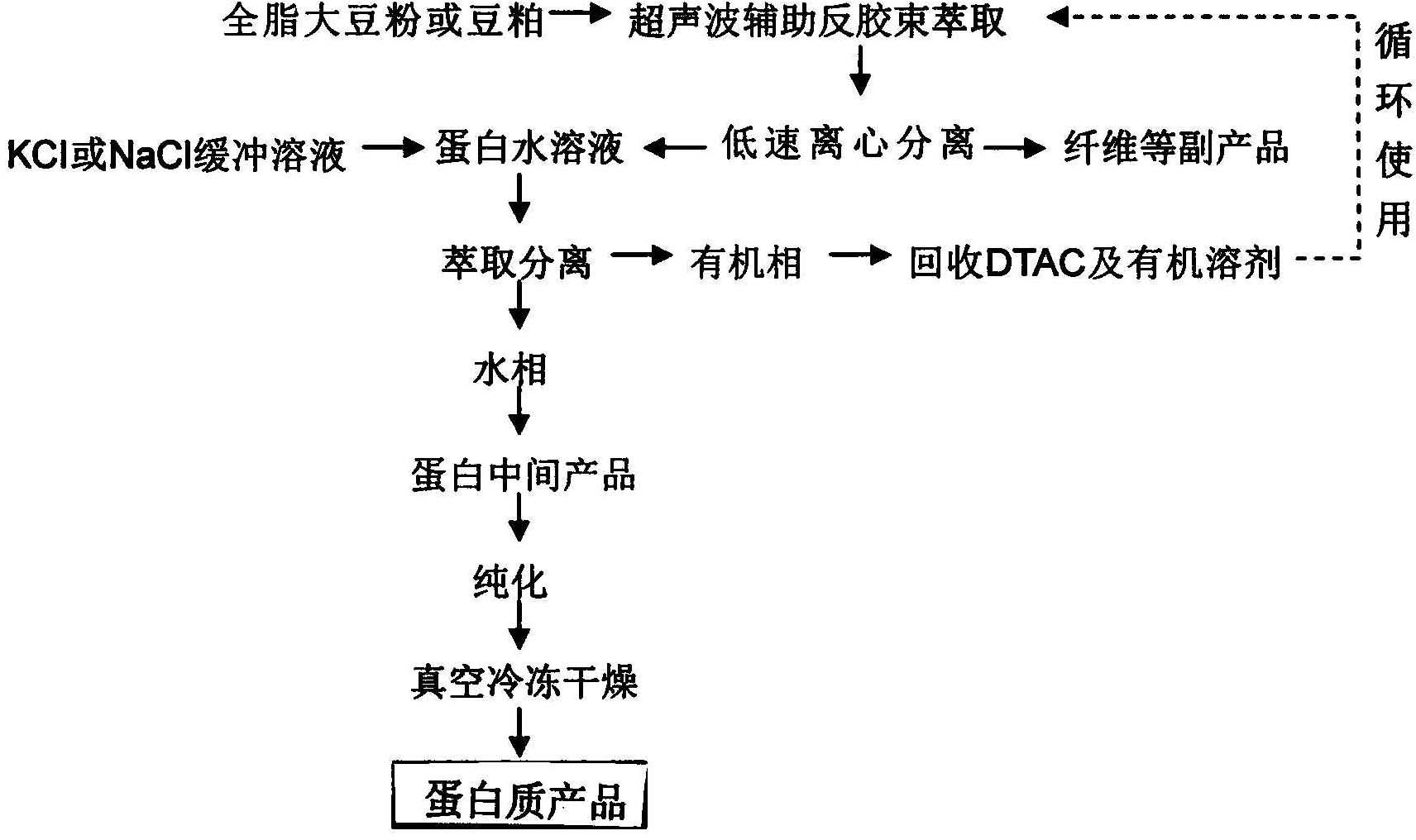

Kit for synchronously separating cord blood PRP, cord blood plasma and cord blood cells

ActiveCN105567630AReduce residual rateNumber of orders of magnitude lessCell dissociation methodsBlood/immune system cellsCord blood stem cellSeparation technology

The invention aims at providing a kit for synchronously separating cord blood PRP, cord blood plasma and cord blood cells and a using method. The kit is adopted for synchronously separating the cord blood PRP, the cord blood plasma and the cord blood cells. By means of cord blood PRP two-part concentration, the concentration of blood platelets is increased by more than one time, and the number of red blood cells is small in order of magnitude; by means of plasma two-time purification, the cord blood plasma obtained through separation is high in purity and almost contains no red blood cell or blood platelet or mononuclear cell or granulocyte under microscopic examination; by means of cord blood cell two-time purification, the purity of the cord blood cells obtained through separation can reach 95% or above, the red cell and blood platelet residue rate is small, and the irritability risk caused by the components is greatly avoided. In the primary separation step of plasma, compared with a conventional separation technology, the using dosage of a separation reagent is reduced by one half in the cord blood cell separation step, and the separation cost is effectively reduced.

Owner:齐湘杰

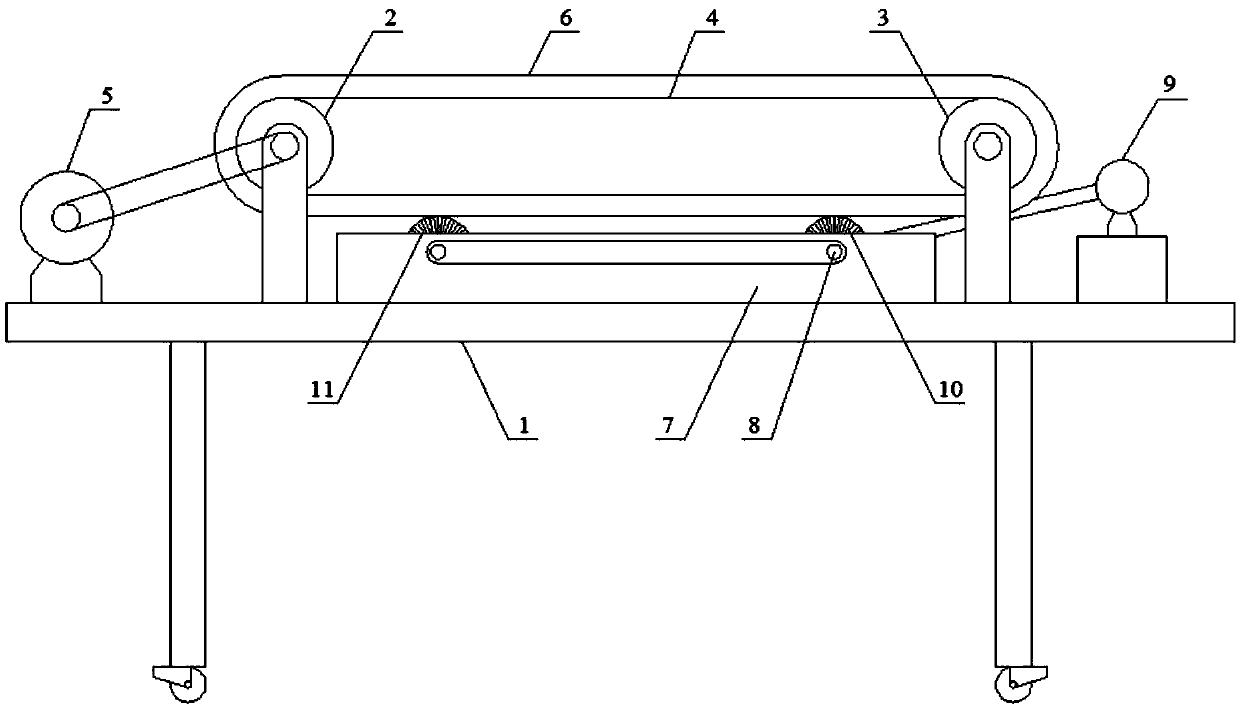

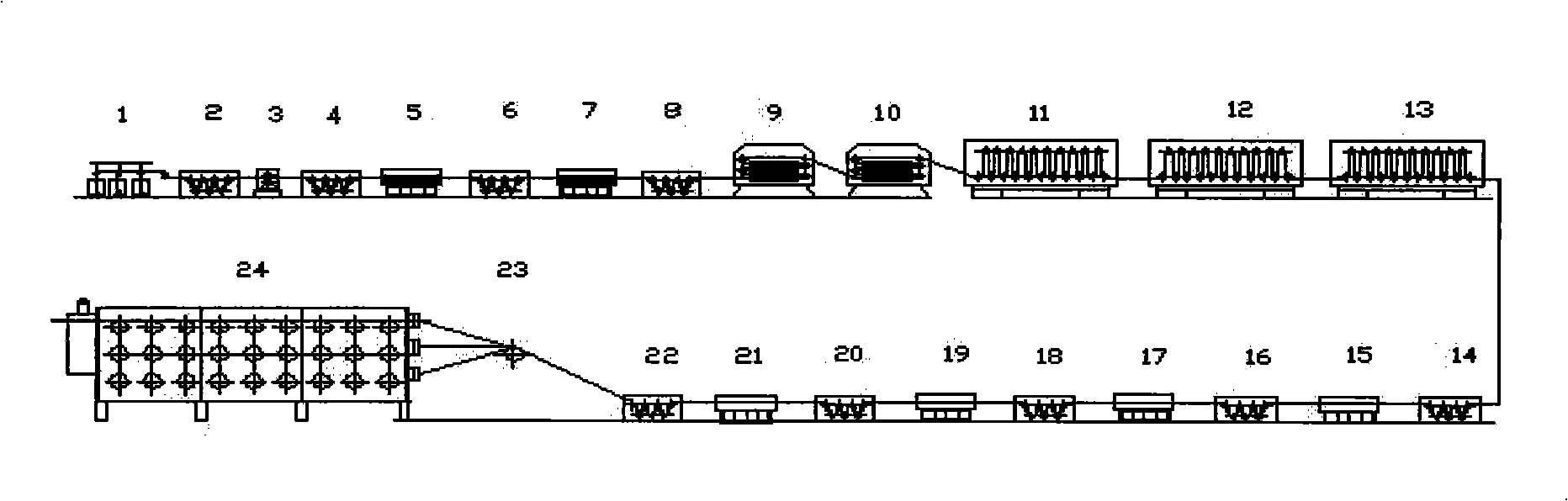

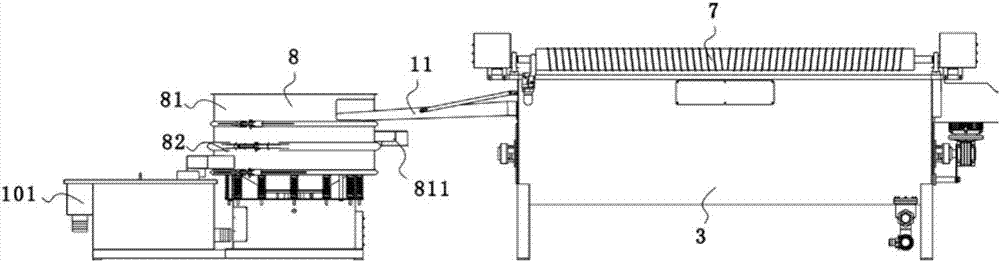

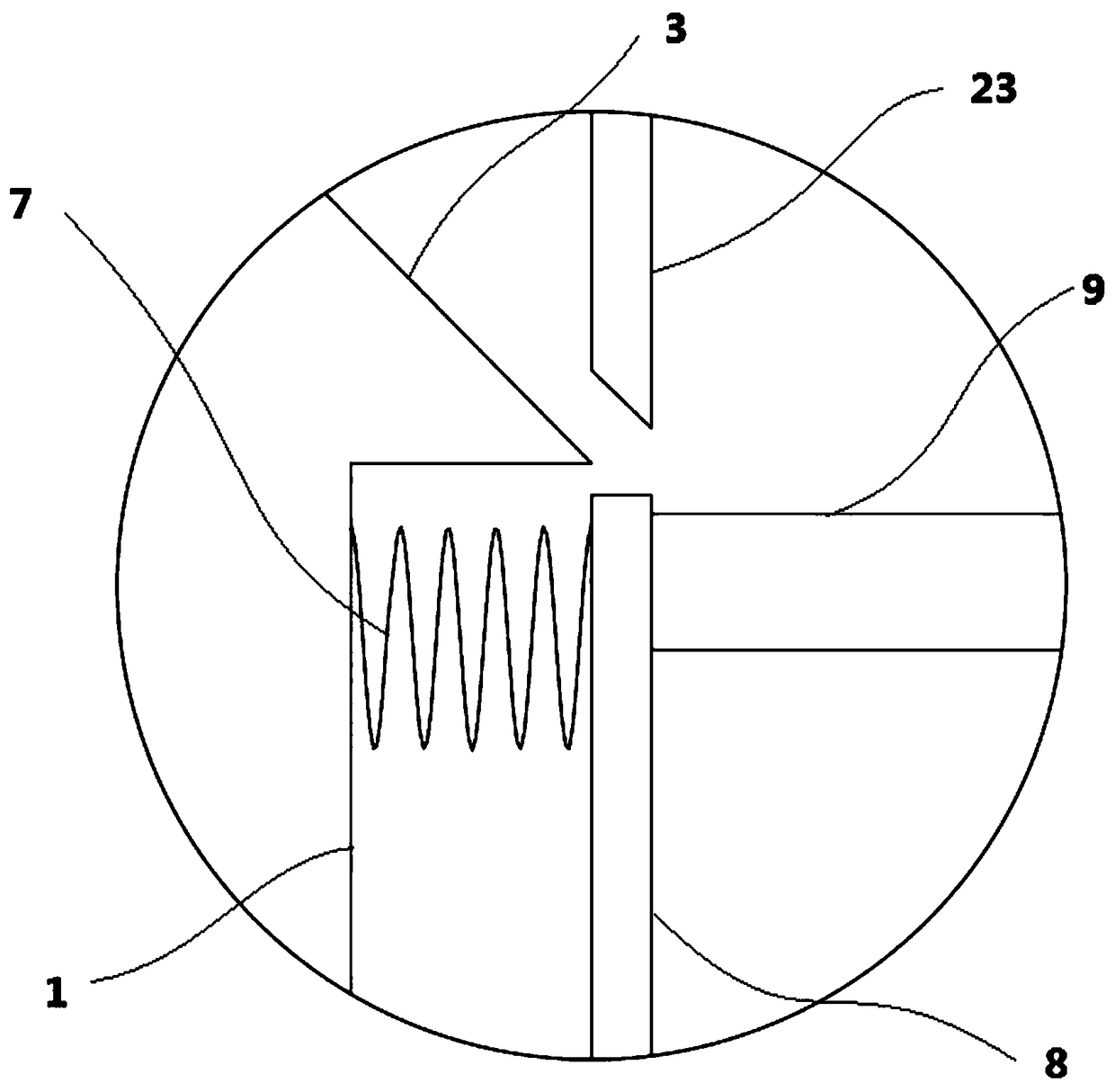

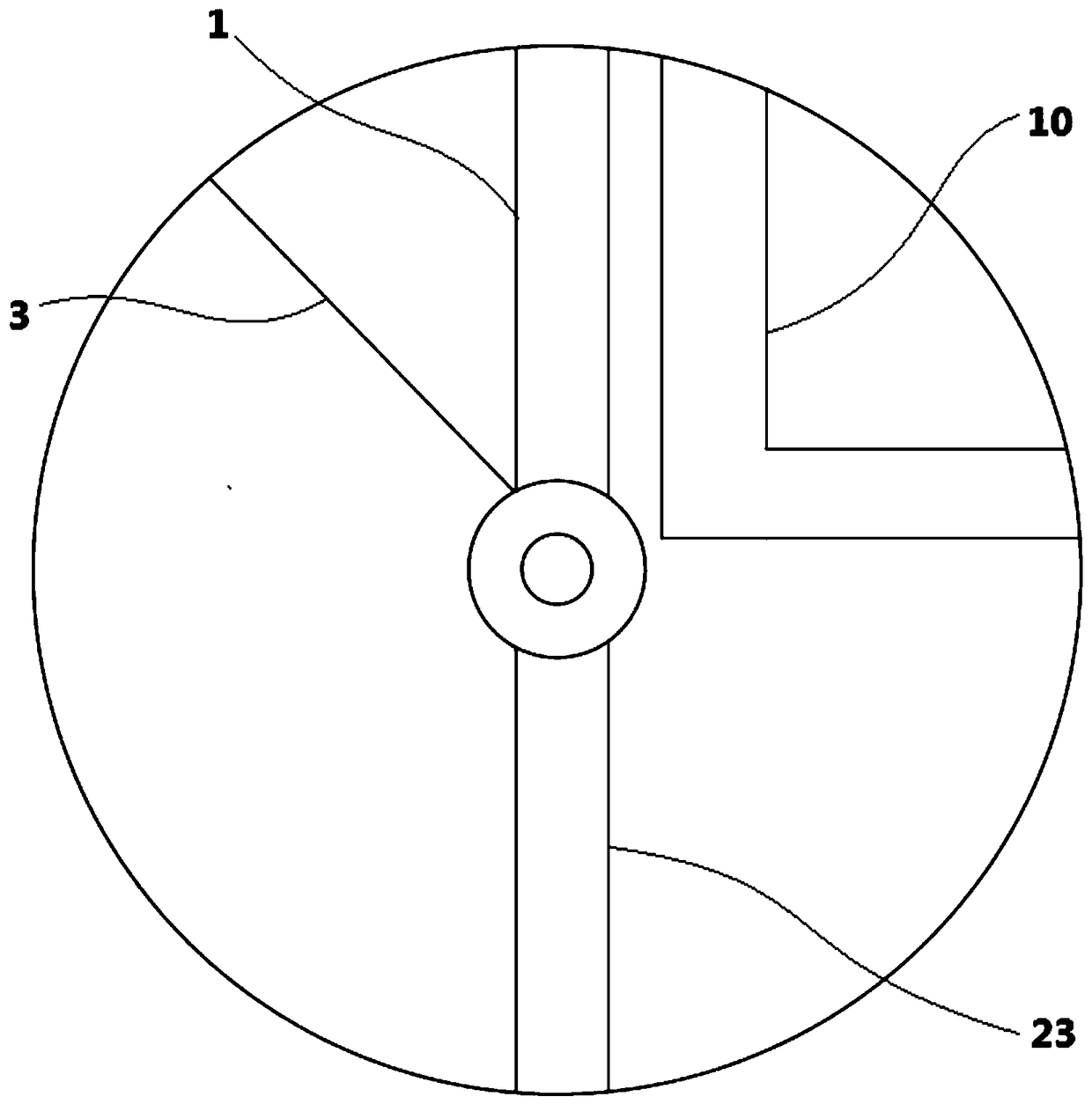

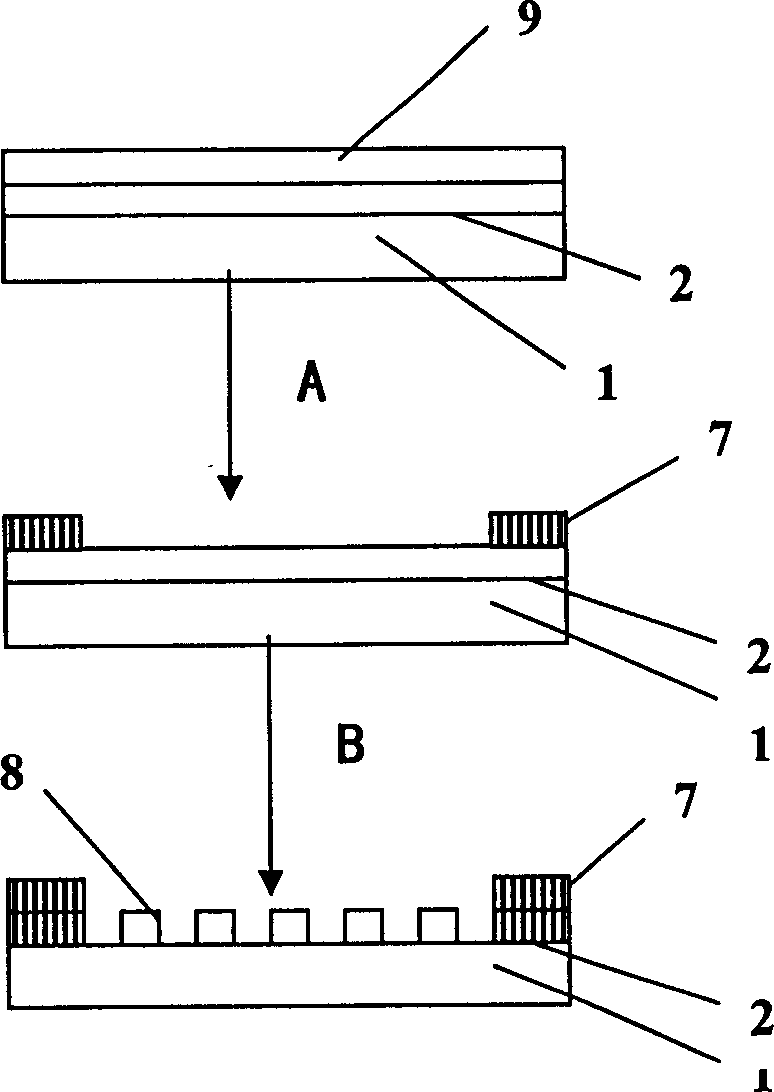

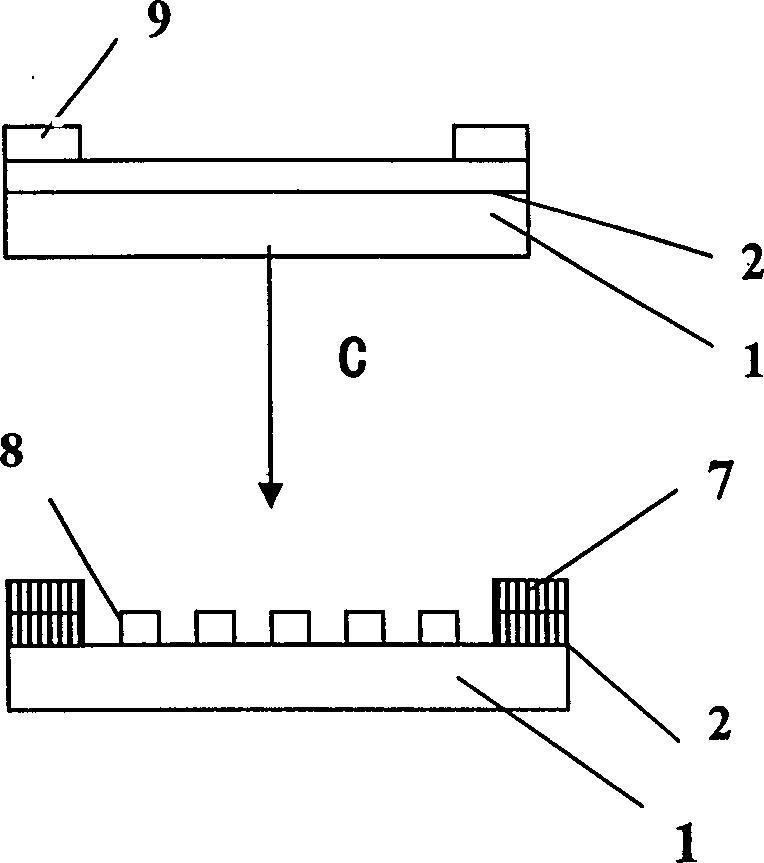

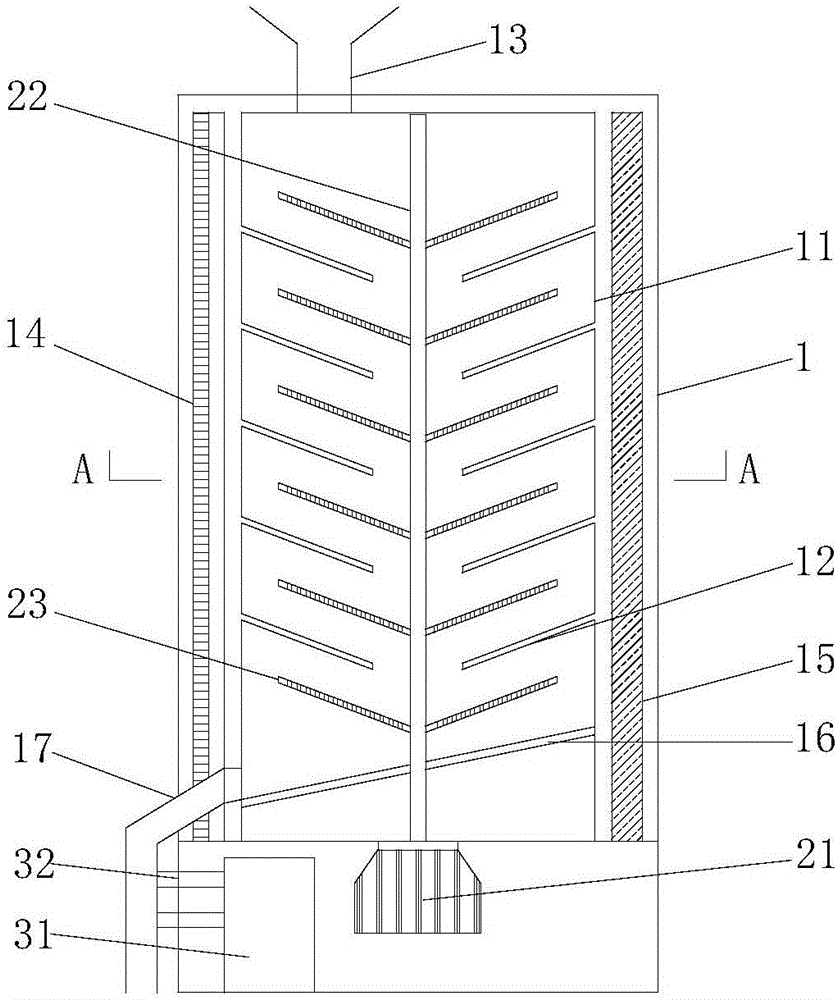

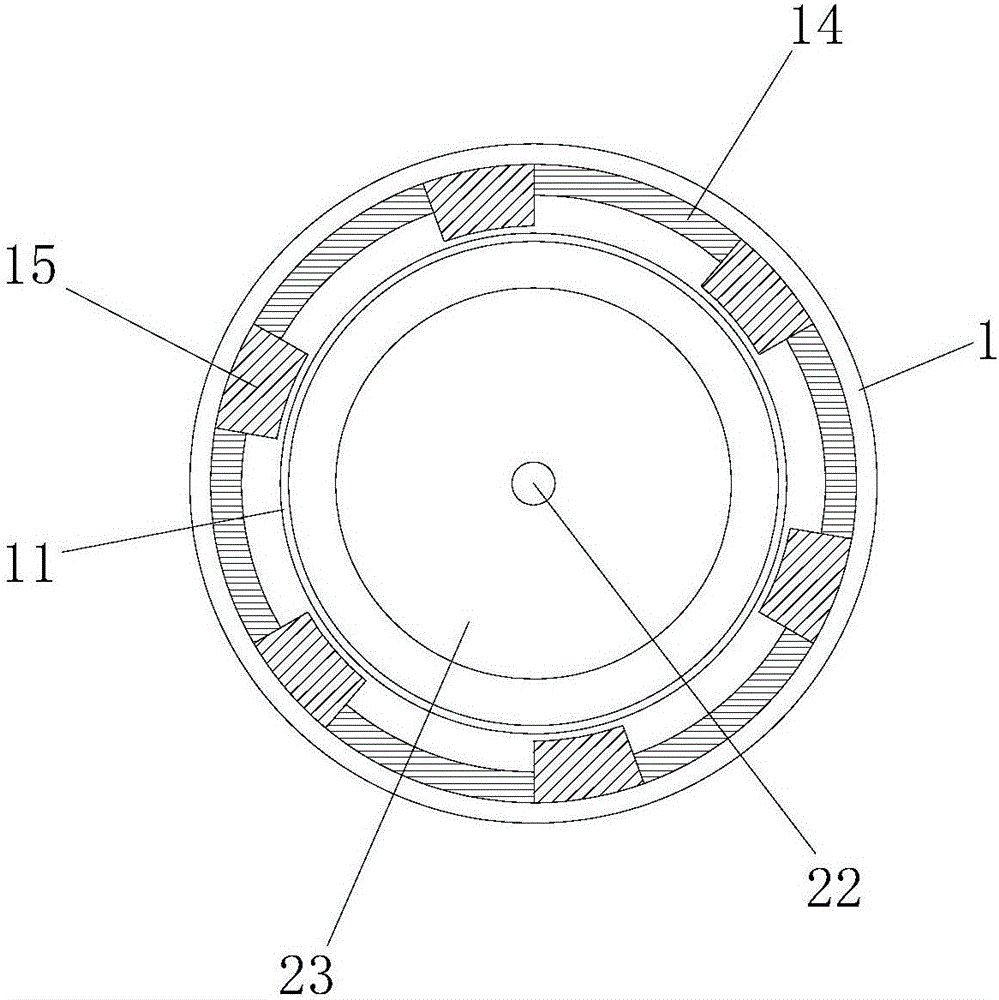

Printing and dyeing fabric cleaning device

ActiveCN107956064AGood cleaning effectLow wool residue rateTextile treatment machine arrangementsTextile treatment by spraying/projectingMechanical engineering

The present invention discloses a printing and dyeing fabric cleaning device comprising a cleaning unit for cleaning and deburring the fabric and a filtering unit for filtering fabric burrs. The cleaning unit comprises a cleaning chamber, a vibration deburring apparatus disposed in the cleaning device, a spraying apparatus disposed over the vibration deburring apparatus, and a fabric guide piece and a dividing piece which are disposed over the spraying apparatus. The vibration deburring apparatus comprises an inner rod piece capable of rolling, an outer cylinder piece sleeving the inner rod piece, and a driving piece for driving the inner rod piece to rotate. The fabric burrs on the fabric can be effectively cleaned, in cooperation with spraying, the cleaning effect is good, and the residual rate of the fabric burrs is low.

Owner:绍兴超超染整有限公司

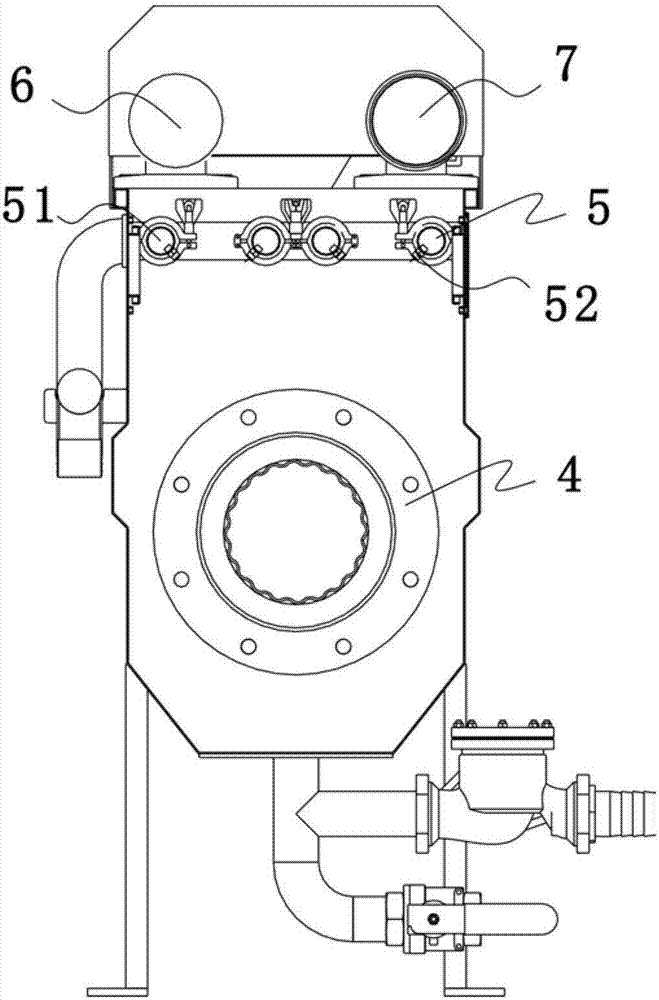

Method of passivating trypsin inhibitor in soybean milk by means of hydrodynamic cavitation technology

ActiveCN103689100AReduce residual rateReduce manufacturing costMilk substitutesFood scienceChemistryCarbon dioxide

The invention relates to a method of passivating a trypsin inhibitor in soybean milk by means of a hydrodynamic cavitation technology. The method comprises the following steps: heating soybean milk grinded by soybeans to 80-95 DEG C; then, treating by an eddy-based hydrodynamic cavitation device and continuously and circularly treating for 1-3 times, wherein the pressure at the outlet of the hydrodynamic cavitation device is controlled within 0.2-0.4MPa; and meanwhile, introducing food-grade carbon dioxide gas or food-grade nitrogen to the hydrodynamic cavitation device, wherein the introduced amount is 0.01-0.1% (v / v) of soybean treatment amount. Soybean milk is treated by the hydrodynamic cavitation technology, so that the residual rate of the trypsin inhibitor can be reduced to below 5%. In addition, the method provided by the invention further has the advantages that treatment cost is low, loss of nutritional ingredients is less, the product has fine and smooth taste, and the like.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

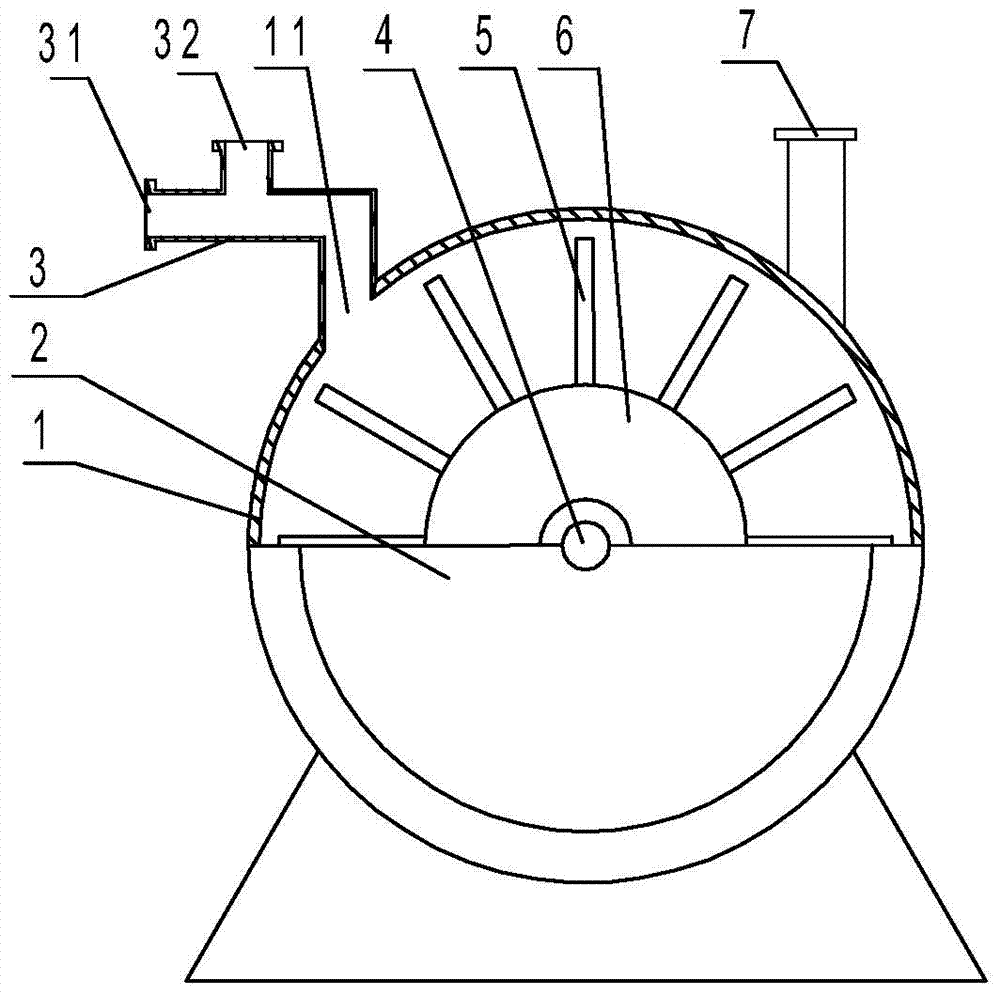

Environment-friendly low-noise construction waste treatment equipment

InactiveCN109046710ASmall sizeAvoid hearing damageUsing liquid separation agentGrain treatmentsLow noiseArchitectural engineering

The invention discloses environment-friendly low-noise construction waste treatment equipment, and relates to the technical field of construction waste treatment. The environment-friendly low-noise construction waste treatment equipment comprises a first machine body; a feeding port is formed in one side face of the first machine body; a feeding pipe communicates to one end of the feeding port; one end surface of the feeding pipe is fixedly connected with the first machine body; the top of the inner wall of the first machine body is fixedly connected with a first motor; a rotating shaft is fixedly connected to one end of an output shaft of the first motor; a plurality of crushing blades are fixedly connected to the circumferential side face of the rotating shaft; a plurality of anti-noisesprings are fixedly connected to the circumferential side face of the first machine body; the circumferential side face of the first machine body is fixedly connected with an anti-noise plate throughthe anti-noise springs; a plurality of crushing bars are fixedly connected to the surface, away from the first machine body, of the anti-noise plate; and a water pipe penetrates through one end face of the first machine body. By means of the environment-friendly low-noise construction waste treatment equipment, through the design of the anti-noise plate and the anti-noise springs, noise generatedby the treatment equipment during the treatment process can be effectively reduced, and hearing damage to construction and surrounding people is avoided.

Owner:芜湖青悠静谧环保科技有限公司

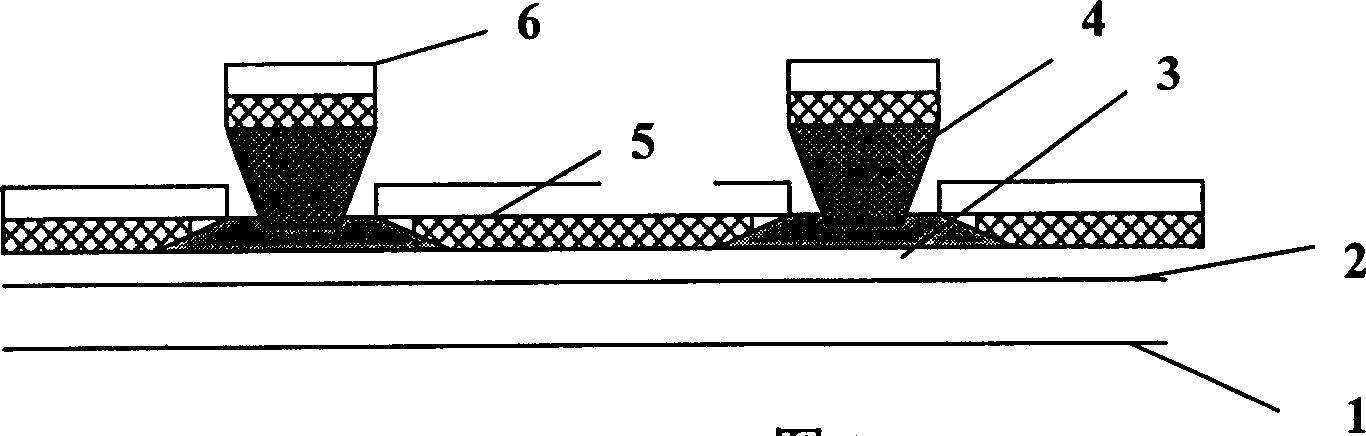

Method for manufacturing transparent anode and electrode lead wire of organic luminescent display unit

InactiveCN1791287AImprove performanceExtend your lifeElectrical apparatusElectroluminescent light sourcesSputteringOrganic electroluminescence

The invention discloses a manufacture method for transparent anode and electrode lead-out wire for organic luminous display unit, which comprises: preparing mask plate; sputtering directly need metal layer of lead-out wire with the mask plate on glass substrate with ITO transparent conductive film; spin coating positive photoresist film; exposing; developing, baking; etching Cr and ITO transparent conductive film; and releasing film. This invention just needs development and releasing-film process for one time, cuts time, and improves yield.

Owner:INESA ELECTRON

Preparation method of polyphenol biomass flocculating agent

ActiveCN105440225AReduce turbidityGood turbidity and decontamination effectWater/sewage treatment by flocculation/precipitationChemical industryFlocculation

The invention relates to a preparation method of a polyphenol biomass flocculating agent, and belongs to the field of fine chemicals. The preparation method comprises following steps: firstly acrylamide is uniformly mixed with water, potassium peroxodisulfate is added, and an obtained mixture is stirred at 80 DEG C for 2h of reaction; an obtained product is filtered and washed, and an obtained filter residue is dried at 85 to 90 DEG C until weight is constant so as to obtain a modified polyphenol biomass; the modified polyphenol biomass particles, potassium peroxodisulfate, and methacryloyloxyethyl trimethyl ammonium chloride are added into acrylamide step by step, reaction is carried out for a certain period of time, and an obtained product is dried and smashed so as to obtain the polyphenol biomass flocculating agent. The polyphenol biomass flocculating agent can be used for treating domestic wastewater, and waste water of the fields such as food, paper and paper pulp, light industry, chemical industry, and oil and gas processing, is nontoxic, is friendly to the environment, possesses no potential safety hazard, and is low in cost. The raw materials of the polyphenol biomass flocculating agent are cheap, and are widely available; flocculation effect is excellent; and the polyphenol biomass flocculating agent is convenient to degrade, and is safe to use.

Owner:FUJIAN NORMAL UNIV

Chinese medicament for treating keratoconjunctivitis sicca and preparation method thereof

InactiveCN102920911AConvenient treatmentEffective in treating keratoconjunctival xerosisSenses disorderPlant ingredientsConjunctival xerosisDisease

The invention provides a Chinese medicinal composition for treating keratoconjunctivitis sicca, which comprises the following raw material drugs: heartleaf houttuynia herb, dendrobe, mulberry leaf, medlar, yerbadetajo herb, cassia seed, multiflower knotweed vine, red bean, mulberry, kamuning, liriope spicata, America ginseng, plantain herb, fragrant solomonseal rhizome, figwort root, raw rehmannia, coral ardisia root, buerger pipewort flower, papermulberry fruit, motherwort and liquorice. Compared with a western medicament, the Chinese medicinal composition has good curative effect, relapse prevention, small toxic and side effects and low residue rate in treating keratoconjunctivitis sicca, can regulate a whole human body to achieve the effect of treating both principal and secondary aspect of disease, and is a safe and reliable Chinese medicament for treating keratoconjunctivitis sicca with remarkable curative effect.

Owner:QINGDAO CENT HOSPITAL +1

Method for using chitin to promote rooting of vegetable seedlings

ActiveCN103718803APromote absorptionAvoid pollutionAgriculture gas emission reductionCultivating equipmentsPesticide residueRecovery period

The invention discloses a method for using chitin to promote rooting of vegetable seedlings. The method is characterized by mainly including the following steps: 1), weighing, by weight, 5-10 parts of chitin powder, and preparing chitin organic water-soluble fertilizer with chitosan content to be 30-40g / l for standby use; 2), taking and diluting 50% of the chitin organic water-soluble fertilizer obtained in the step 1) by 700-800 times, and soaking roots of green vegetable seedlings in a dilution of the chitin organic water-soluble fertilizer for 0.3-1h; 3), subjecting the green vegetable seedlings to organic-ecotype soilless cultivation, and diluting another 50% of the chitin organic water-soluble fertilizer obtained in the step 1) by 500-700 times for sprinkle-applying when a leaf vegetable has 5-6 main leaves or a melon has 2-4 main leaves. By the method, the chitin is used to quickly increase rooting speed of the green vegetable seedlings, so that seedling recovery period is shortened; natural organic fertilizer is used in the whole process of planting, so that harvested vegetables are low in pesticide residue rate, and standards of green vegetables are met.

Owner:GUANGXI NANNING BIWAN GARDAN ENG

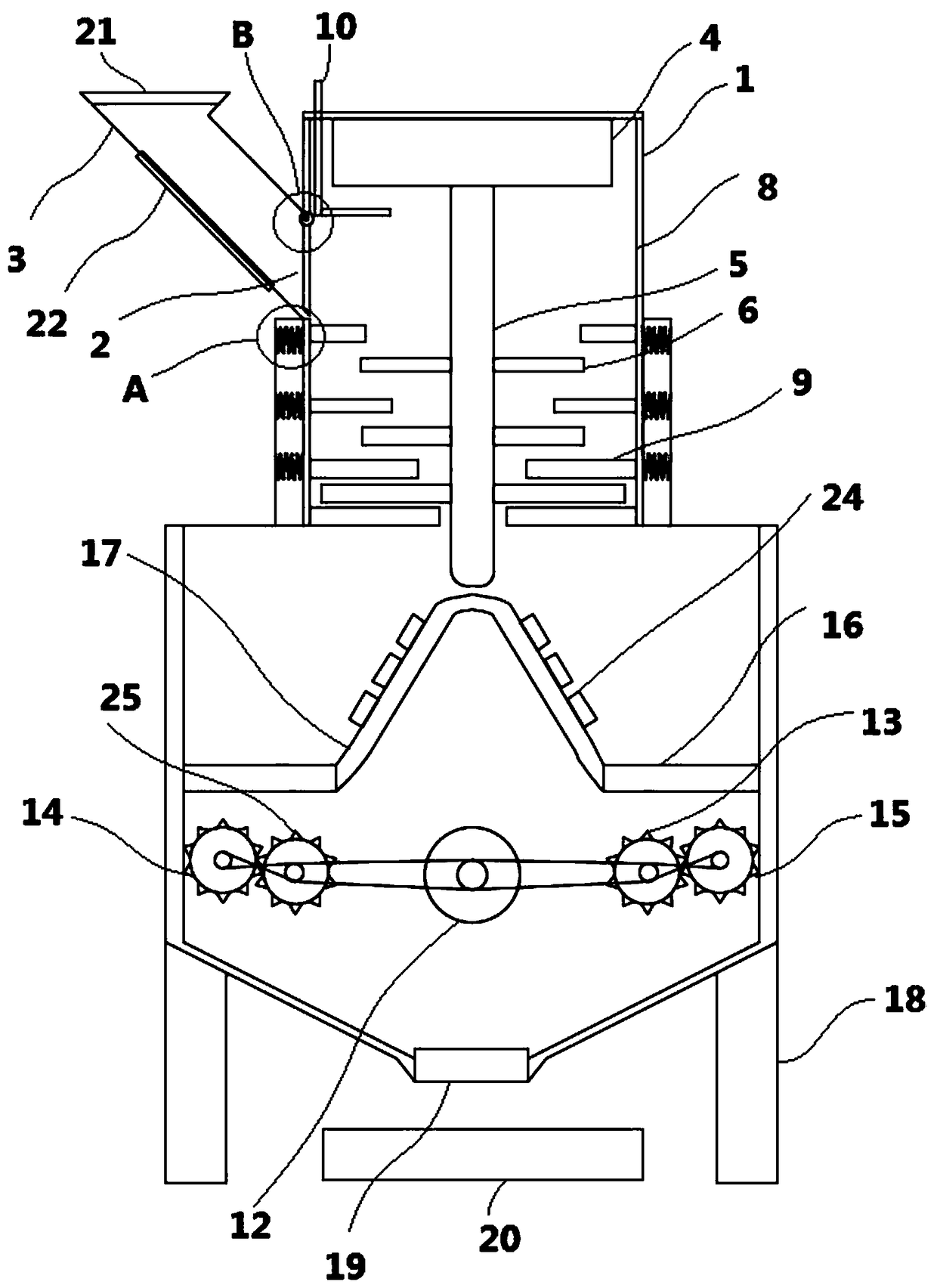

Electrostatic dust removal capsule polishing and drying device and using method

ActiveCN106363514AEasy to dropEasy to shake offGrinding machine componentsPolishing machinesEngineeringElectromagnetic heating

The invention relates to an electrostatic dust removal capsule polishing and drying device and a using method and belongs to the technical field of capsule polishing equipment. An elastic steel wire mesh is arranged in a polishing cylinder. A gap is formed between the elastic steel wire mesh and the inner wall of the polishing cylinder. Baffles which incline downwards are arranged on the inner side of the elastic steel wire mesh from outside to inside at intervals. A polishing device comprises a motor, a rotary shaft and polishing discs. The motor is arranged at the bottom of the polishing cylinder. The rotary shaft penetrates through the bottom of the polishing cylinder and extends into the polishing cylinder. The polishing discs are arranged obliquely from inside to outside. The inner ring of each polishing disc is fixedly connected with the rotary shaft. The polishing discs and the baffles are arranged alternately. A dust removal and drying device comprises an electromagnetic heating device and an electrostatic dust removal device. The electromagnetic heating device and the electrostatic dust removal device are arranged in the gap between the elastic steel wire mesh and the inner wall of the polishing cylinder in a spaced mode. According to the electrostatic dust removal capsule polishing and drying device and the using method, dust falling in the polishing process is adsorbed through the electrostatic dust removal device, and residual quantity of the dust is reduced.

Owner:ZHEJIANG HUAGUANG CAPSULE

Method for reducing concentration of lead ions in lead electrolyte

InactiveCN104264185AIncrease precipitation speedReduce the concentration of lead ionsElectrolysis componentsPhotography auxillary processesElectrolysisEnergy consumption

The invention discloses a method for reducing the concentration of lead ions in a lead electrolyte. The method is applied in an electrolytic refining process of lead and comprises the following steps: (1) casting by virtue of a vertical die to obtain anode plates of which sizes are 1210*810*27mm and preparing cathode starting sheets of which sizes are 1370*840*(0.85+ / -0.05) mm by virtue of a cathode sheet processing machine; (2) arranging pitches between the newly manufactured cathode starting sheets and the anode plates by virtue of an automatic pitch arranging machine, loading into a tank, switching the direct current on and electrolyzing for 3.5-4 days; and (3) taking the cathodes out, reloading the newly manufactured cathode starting sheets, continuously electrolyzing for 3.5-4 days and taking the cathodes and residual anodes out so that an electrolytic period is completed. The method disclosed by the invention has the characteristics that the effect of reducing the concentration of lead ions in a lead electrolyte is obvious and economic and technical indexes such as the current efficiency, the rate of residual anodes and energy consumption are significantly improved, and is economical, environmentally friendly and strong in operability.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Harmless disposal method of waste diatomite containing sodium thiocyanate

InactiveCN101381084ASimple processInvestment and operating cost savingsSilicon compoundsBuilding materialMethanol

The invention discloses a method for harmless treatment of waste diatomite containing sodium thiocyanate. The method comprises the following steps: mixing a raw material of waste diatomite with water to produce slurry with stirring; spreading the slurry on a filter belt fabric for continuous conveying and at the same time spraying water on the slurry to wash the slurry; keeping the space below the filter belt fabric vacuum and collecting the filtrate sectionally. The amount of water used for treatment is no more than four times of that of the diatomite. The content of sodium thiocyanate in the treated waste diatomite is less than 0.1 percent, and the treated waste diatomite can be reused in the system as a filter aid or used as a building material, a road bed material and so on. Compared with the prior process such as a methanol method, the method of the invention has the advantages of avoiding secondary pollution, and saving investment, transportation cost and water, along with simple and easy-to-implement process, a content of residual sodium thiocyanate less than 0.1 percent, low energy consumption, and suitability to mass production.

Owner:ZHEJIANG UNIV

Cleaning fluid

InactiveCN104017665AImprove cleaning effectLow cost of reagentsNon-ionic surface-active compoundsDetergent compounding agentsEnvironmental chemistryAlkali hydroxide

The invention discloses cleaning fluid which comprises an anionic surfactant, a non-ionic surfactant, an alkali metal hydroxide, plantrennet and a buffer agent for stabilizing the pH value to be greater than 12.0. When being used, the cleaning fluid disclosed by the invention has the characteristics of low protein substance residue rate, low fat substance residue rate, good in-batch repeatability of clinical projects, low cross contamination, low reactant deposition and the like, and meanwhile the testing result of a biochemical analyzer is not affected; a liquid path system and a reaction cup of the biochemical analyzer are not corroded in the washing process; meanwhile, all components of the cleaning fluid disclosed by the invention can be biologically degraded, no potential pollution to the environment is caused, and the requirements of environmental protection are met.

Owner:NANTONG YONGKANG DETECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com