Glazing process for daily ceramic blank

A ceramic body and daily-use technology, which is applied in the field of glazing technology for daily-use ceramic bodies, can solve the problems of serious wear of the crushing blades, limited particle size of the pulverizer, and long time, so as to avoid friction loss of the runner and ensure Wiping effect, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

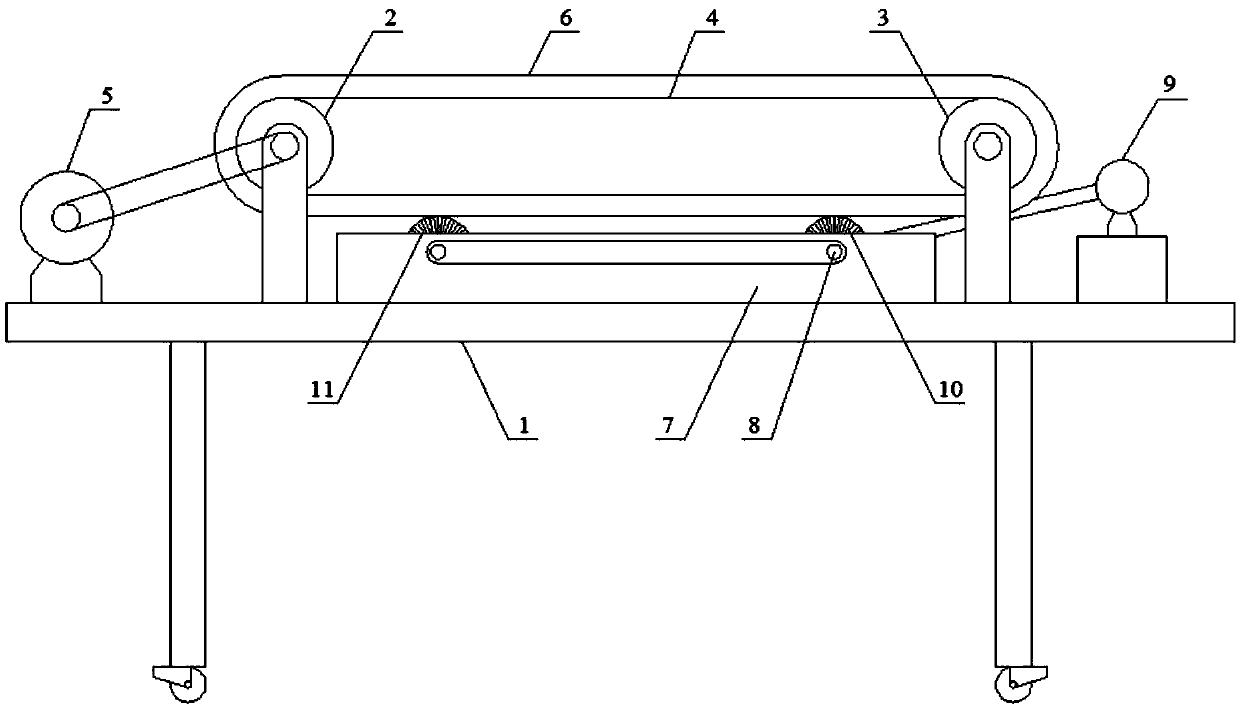

Image

Examples

Embodiment 1

[0028] A kind of glazing process of daily-use ceramic green body, comprises the following steps:

[0029] (1) Glaze preparation: Mix the glaze fully and put it into a vacuum bag. After vacuuming, place it in a -15°C environment and freeze it for 5 hours. Take out the glaze and use a pulverizer to make a 270-mesh micropowder. Heat at a heating rate of -10°C / min to 115-125°C and mix for 15 minutes, then cool naturally to room temperature;

[0030] (2) Preparation of glaze slurry: Heat water to 40-50°C and keep stirring for 10 minutes, then add the glaze after the above treatment, continue to keep warm and stir at 40-50°C for 30 minutes, and let it stand for 1 hour after natural cooling to room temperature. Pass through a 270-mesh sieve, transfer the obtained filtrate into a ball mill, and ball mill until the output particle size is less than 30 μm, and then obtain the glaze slurry; wherein, the mass ratio of the glaze material to water is 1:2;

[0031] (3) Automatic glazing: th...

Embodiment 2

[0035] A kind of glazing process of daily-use ceramic green body, comprises the following steps:

[0036] (1) Glaze preparation: Mix the glaze fully, put it into a vacuum bag, and freeze it at -15°C for 5 hours after vacuuming, take out the glaze, and use a pulverizer to make a 270-mesh micropowder. Heat at a heating rate of -10°C / min to 115-125°C and mix for 15 minutes, then cool naturally to room temperature;

[0037] (2) Preparation of glaze slurry: Heat water to 40-50°C and keep stirring for 10 minutes, then add the glaze after the above treatment, continue to keep warm and stir at 40-50°C for 30 minutes, and let it stand for 1 hour after natural cooling to room temperature. Pass through a 270-mesh sieve, transfer the obtained filtrate into a ball mill, and ball mill until the output particle size is less than 30 μm, and then obtain the glaze slurry; wherein, the mass ratio of the glaze material to water is 1:2;

[0038] (3) Automatic glazing: the above-mentioned prepared...

Embodiment 3

[0042] (1) Glaze preparation: Mix the glaze fully and put it into a vacuum bag. After vacuuming, place it in a -15°C environment and freeze it for 5 hours. Take out the glaze and use a pulverizer to make a 270-mesh micropowder. Heat at a heating rate of -10°C / min to 115-125°C and mix for 15 minutes, then cool naturally to room temperature;

[0043] (2) Preparation of glaze slurry: Heat water to 40-50°C and keep stirring for 10 minutes, then add the glaze after the above treatment, continue to keep warm and stir at 40-50°C for 30 minutes, and let it stand for 1 hour after naturally cooling to room temperature. Pass through a 270-mesh sieve, transfer the obtained filtrate into a ball mill, and ball mill until the output particle size is less than 30 μm, and then obtain the glaze slurry; wherein, the mass ratio of the glaze material to water is 1:2;

[0044] (3) Automatic glazing: the above-mentioned prepared glaze slurry is sent into the automatic glaze spraying machine, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com