Patents

Literature

250results about How to "Reduce crushing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

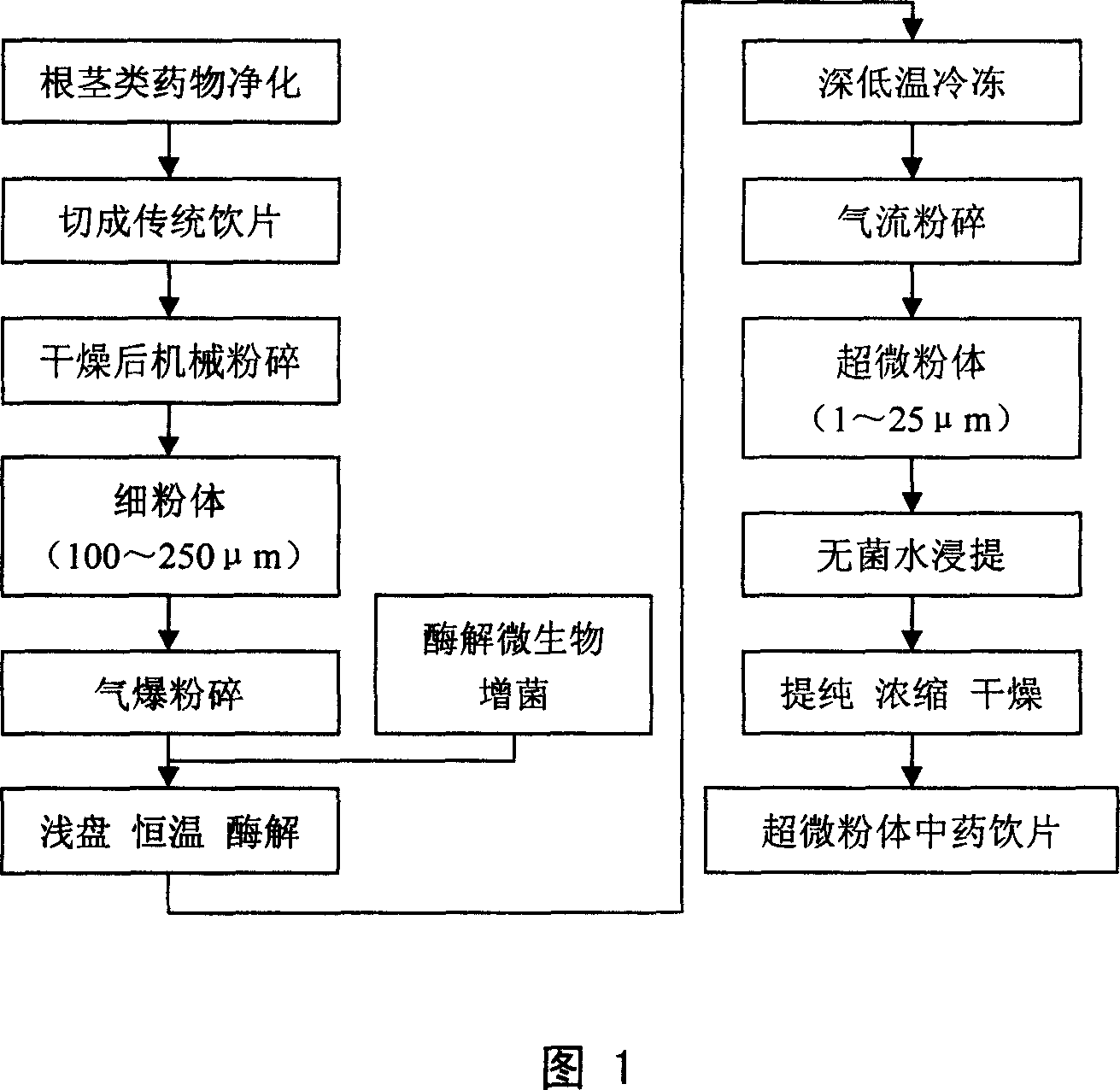

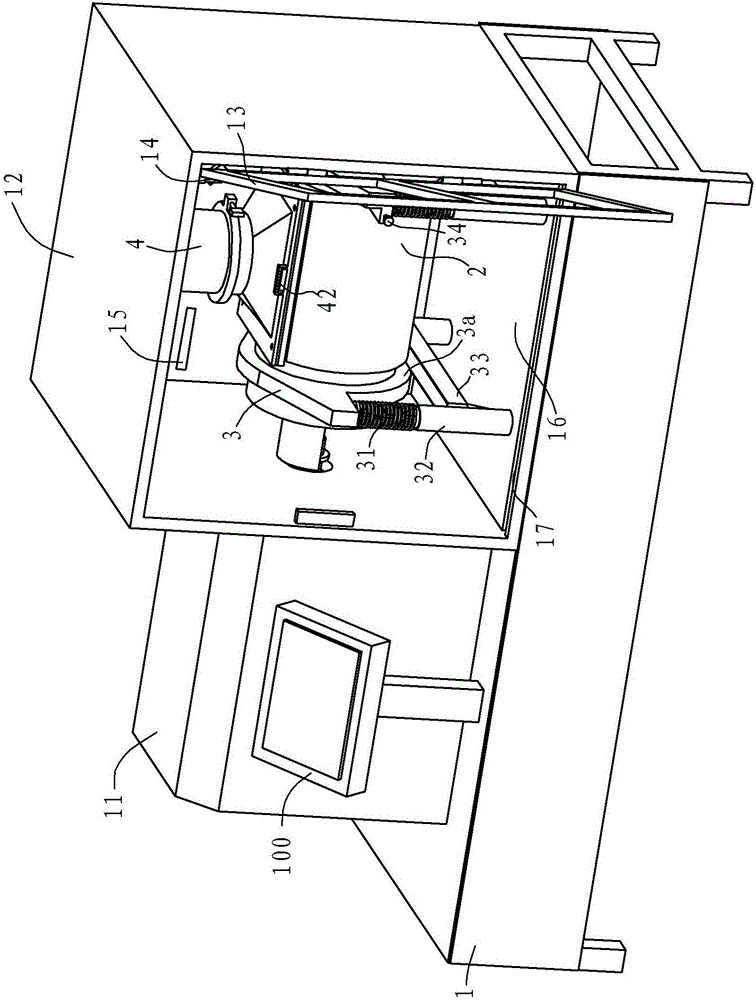

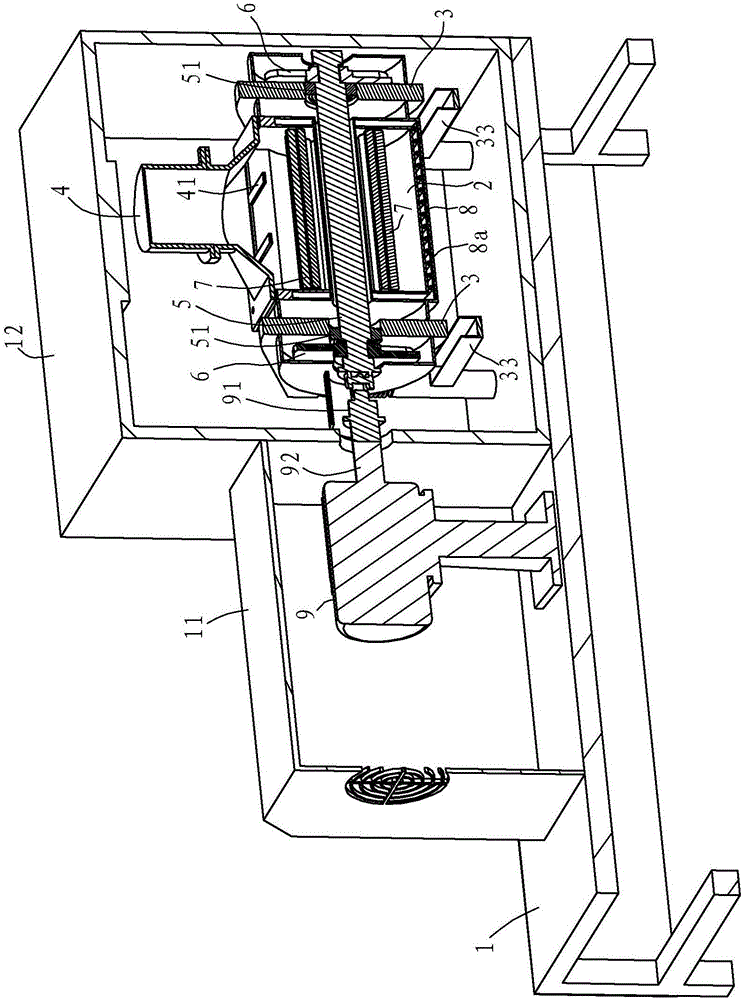

Crushing and grinding device for production and processing of traditional Chinese medicinal materials

InactiveCN108940503AAvoid enteringImprove subsequent grinding efficiencyGrain treatmentsEngineeringMaterials processing

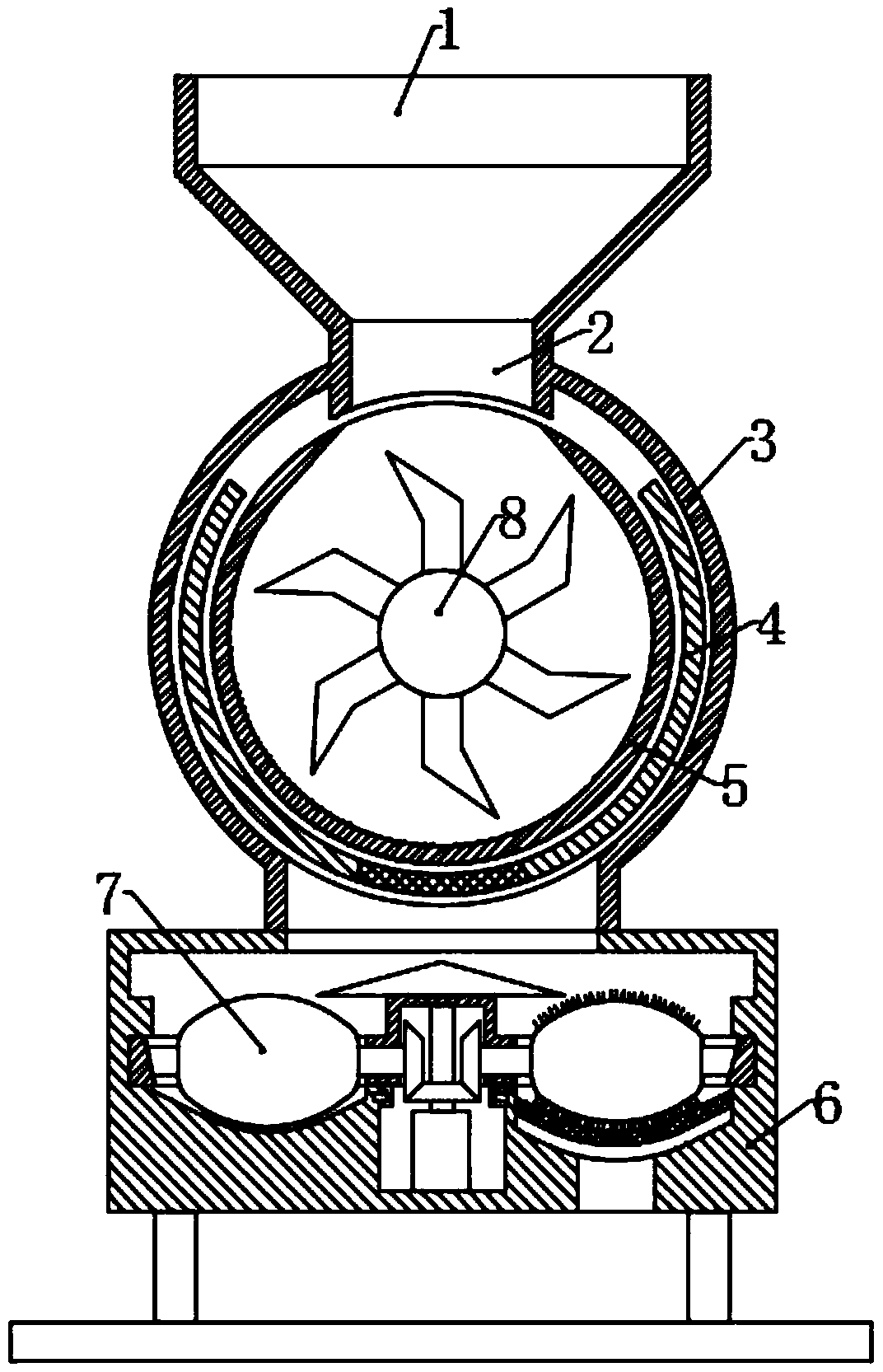

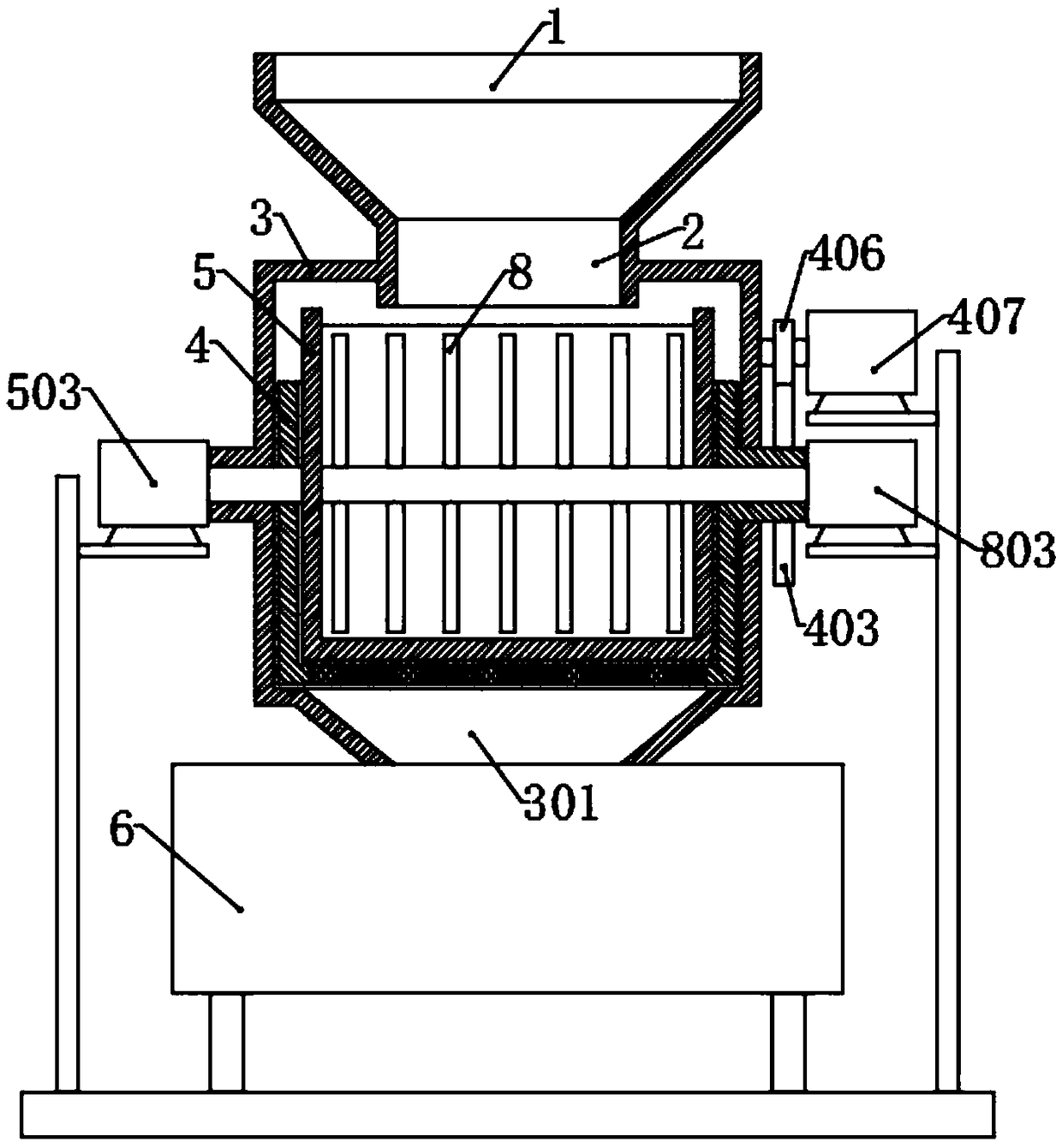

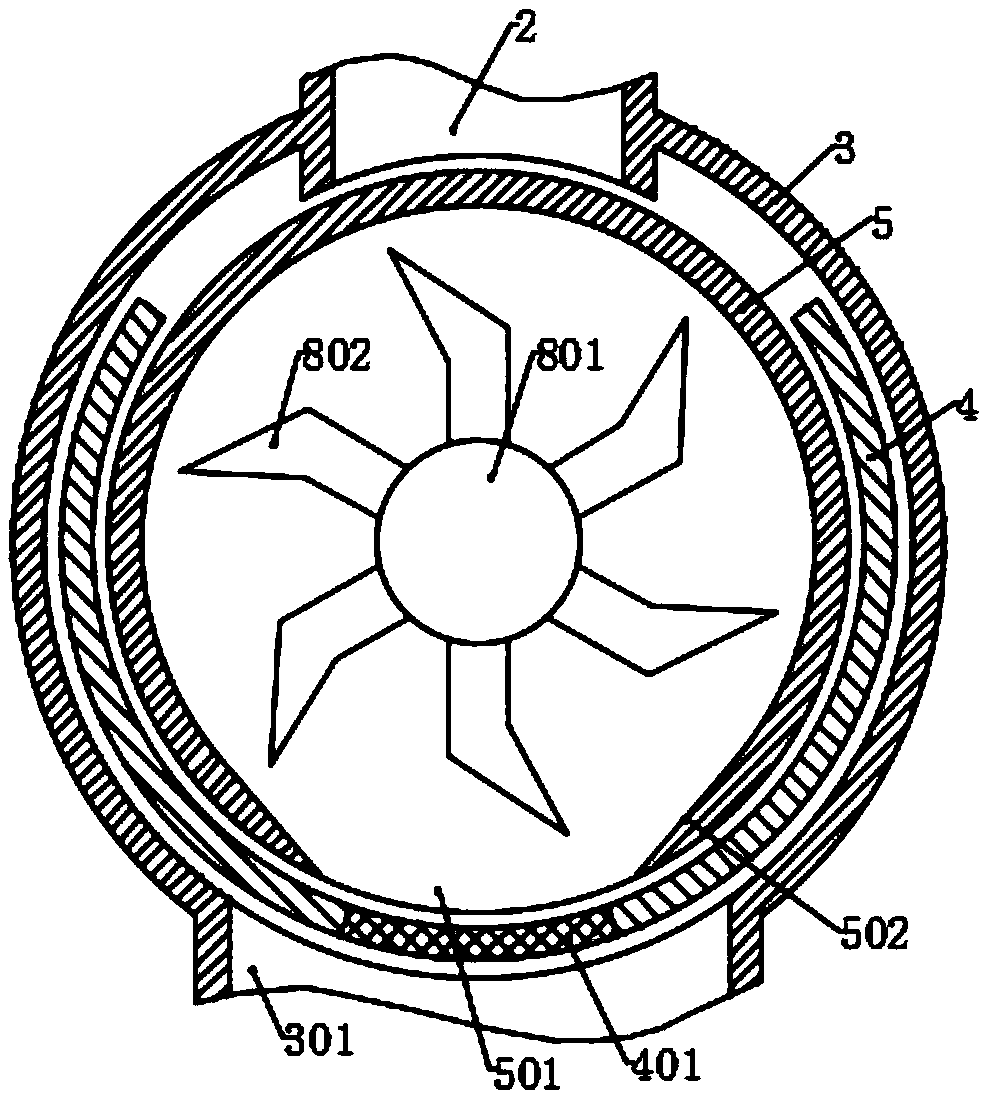

The invention discloses a crushing and grinding device for production and processing of traditional Chinese medicinal materials in the technical field of traditional Chinese medicinal material processing. The crushing and grinding device comprises a feeding hopper, a feeding pipe, a fixing case, a screening case, a crushing case and a grinding case. According to the crushing and grinding device, the traditional Chinese medicinal materials are put into the feeding hopper and then enter the crushing case along the feeding pipe, a crushing mechanism is used for crushing the traditional Chinese medicinal materials, and a feeding inlet of the crushing case conducting crushing rotates to face downwards; the traditional Chinese medicinal materials are screened through the screening case, and thenthe feeding inlet of the crushing case is rotated to face upwards; the traditional Chinese medicinal materials which do not penetrate through a first screening mesh return to the crushing case through the shovel face at the feeding inlet and are subjected to secondary crushing along with next batch of to-be-crushed medicinal materials, and the traditional Chinese medicinal materials enter the grinding case and are ground through a grinding mechanism; and meanwhile, completely ground medicine powder is fed into a powder outlet through a rotating brush, so that the situation that powder particles are too fine due to the fact that ground medicine powder is left in a grinding groove and ground repeatedly is avoided, and the grinding effect is good.

Owner:周意

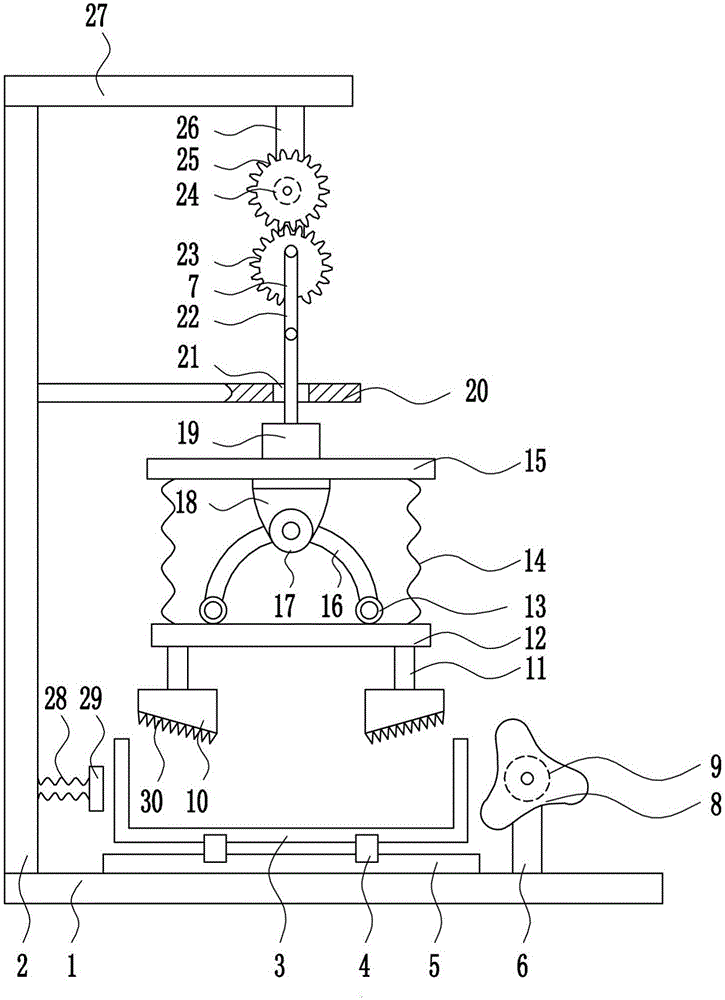

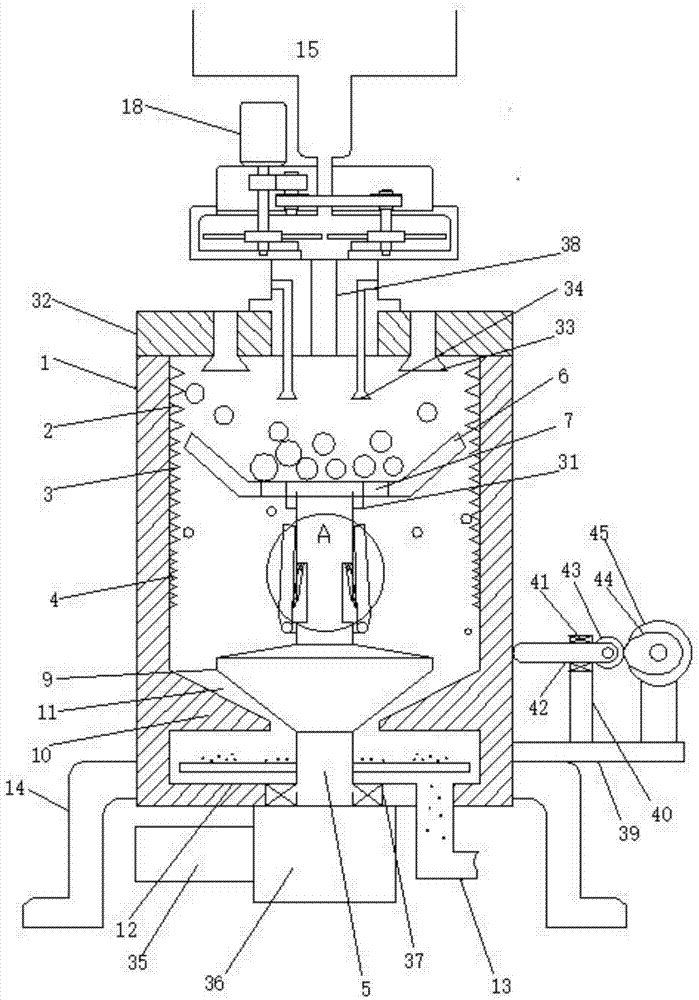

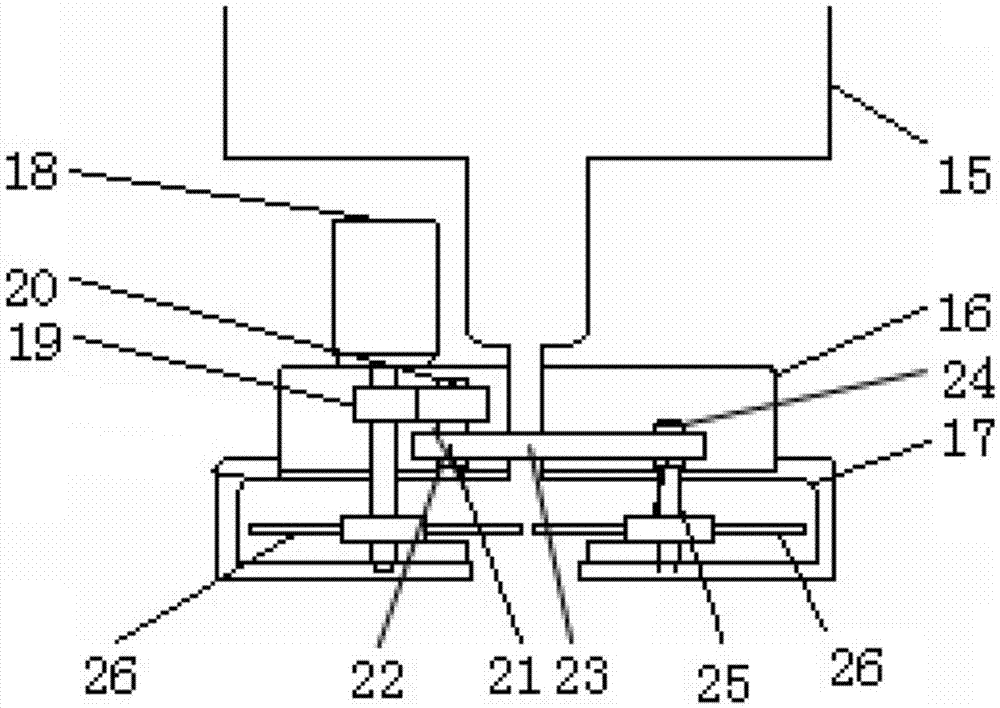

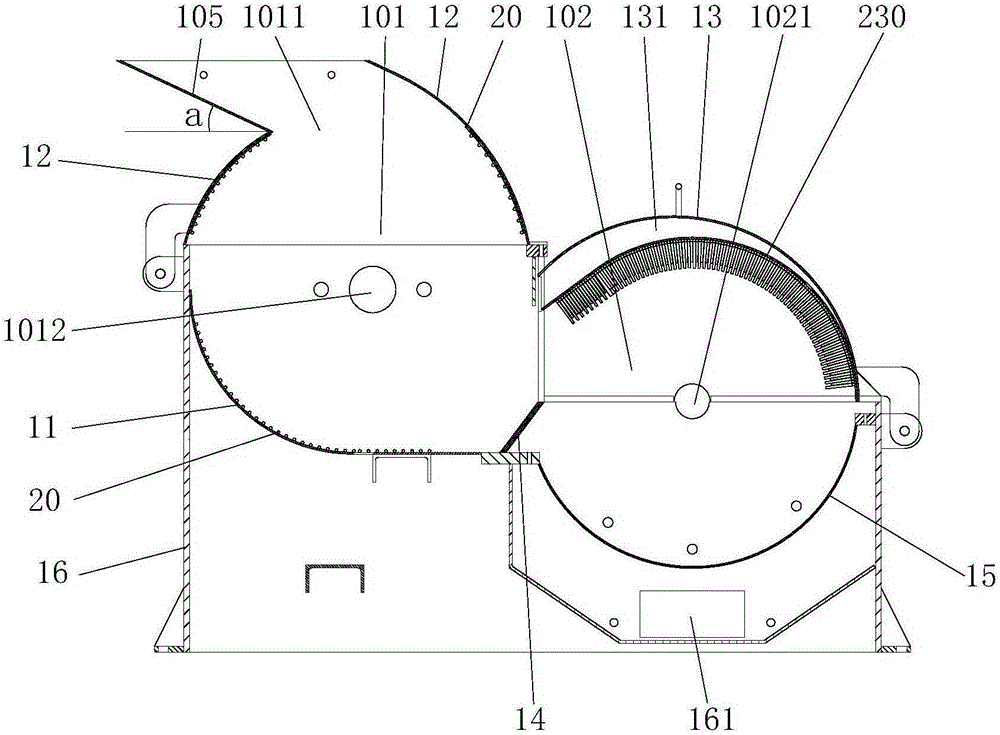

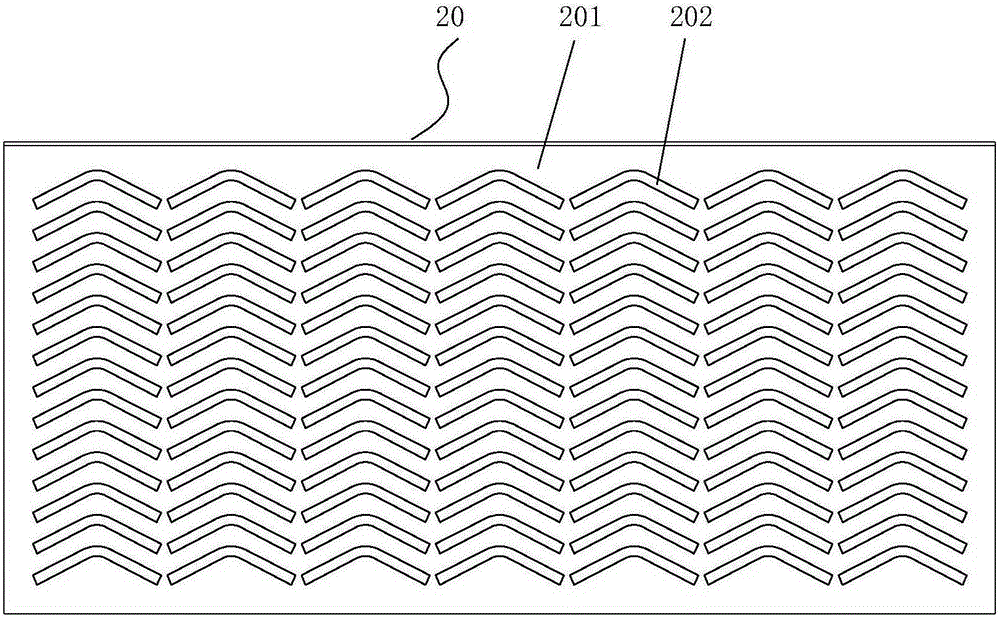

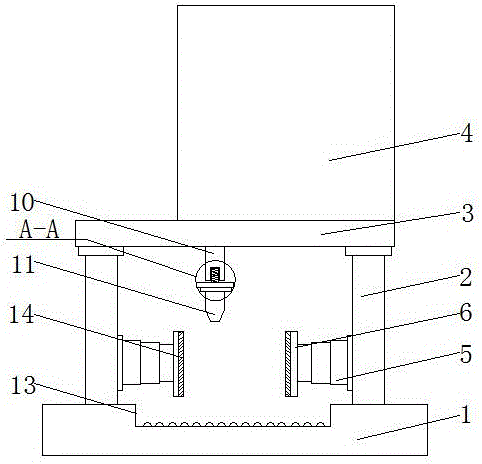

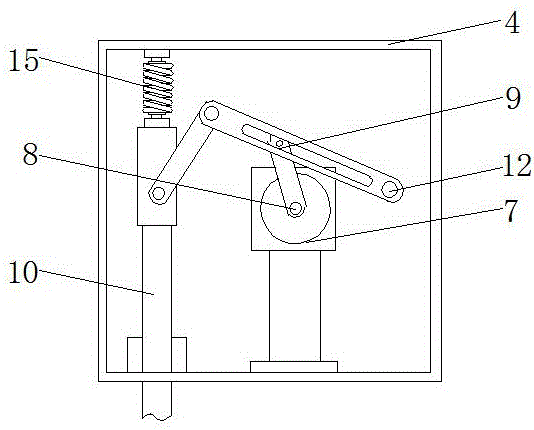

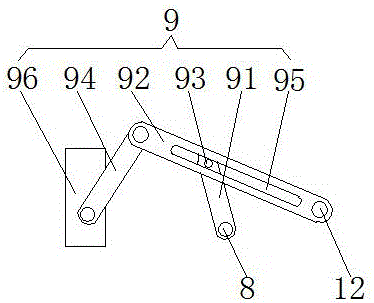

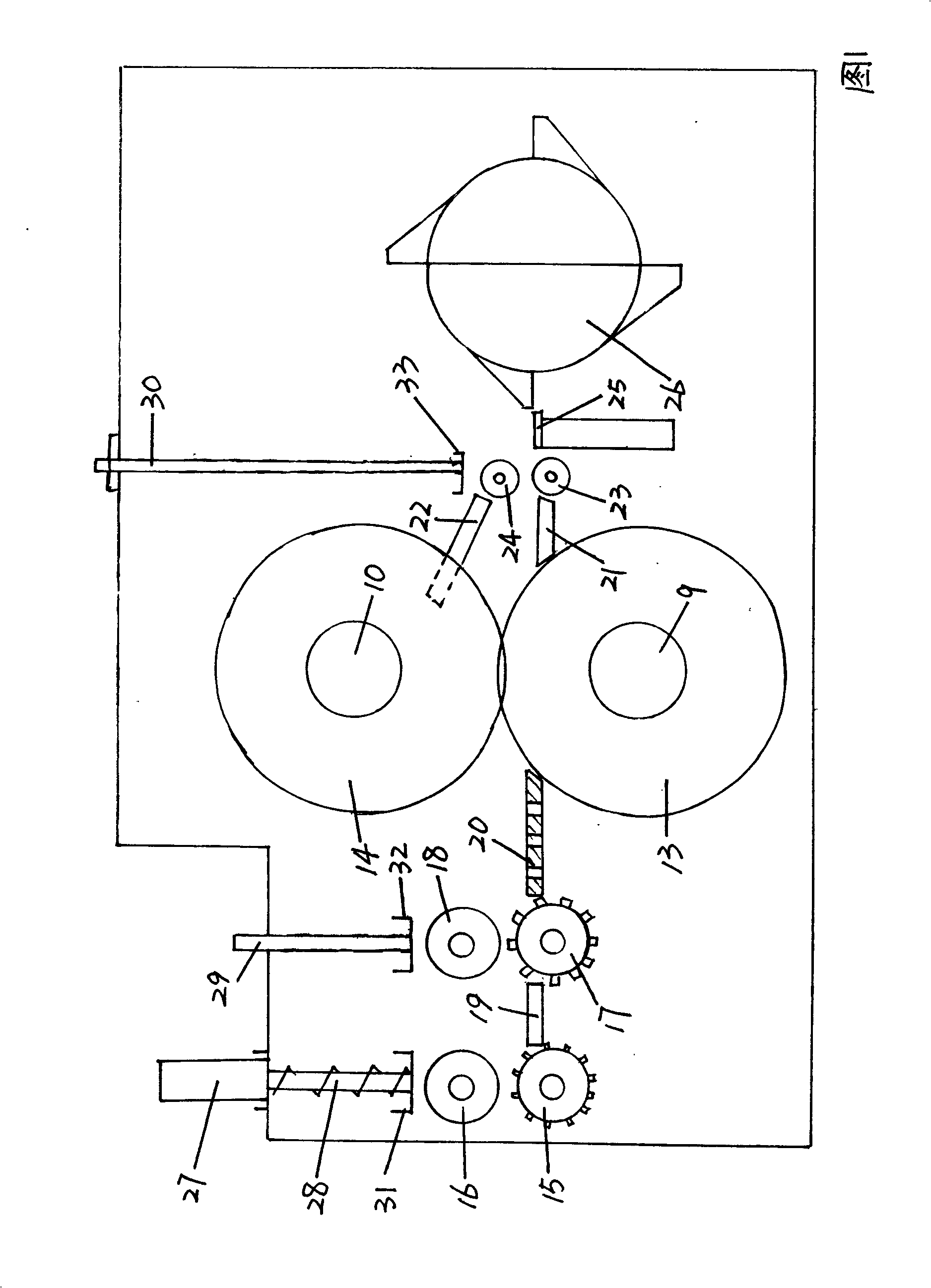

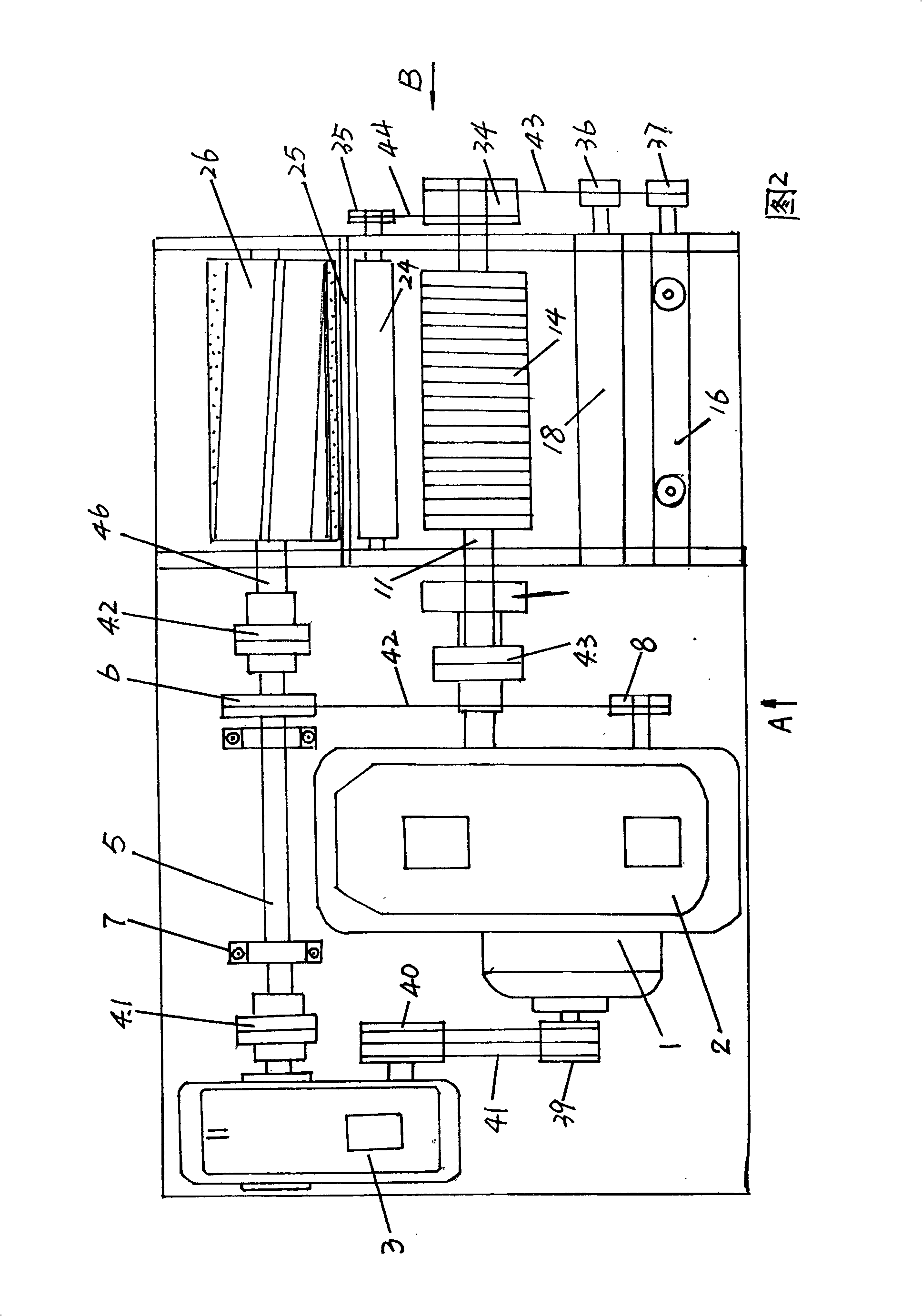

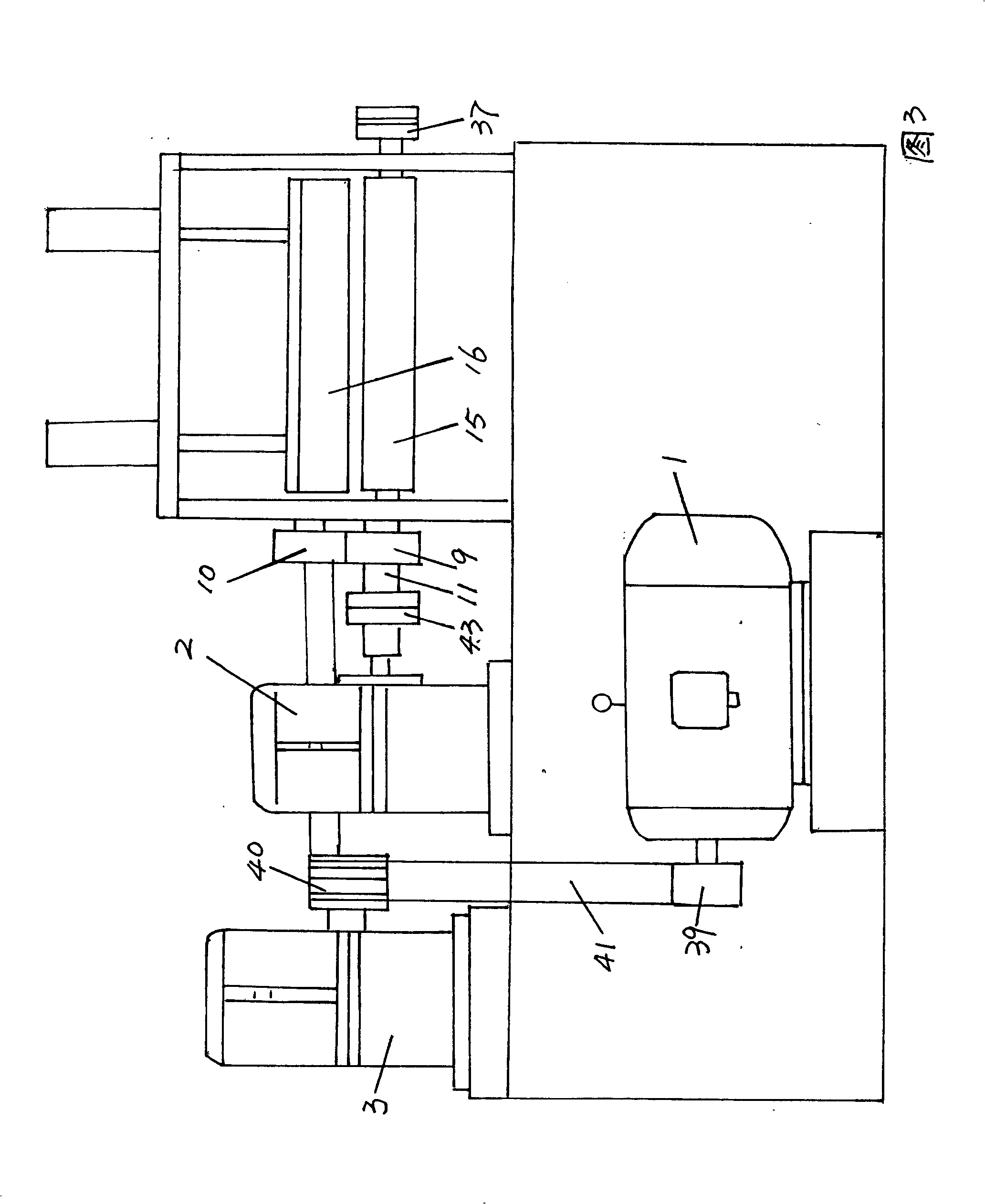

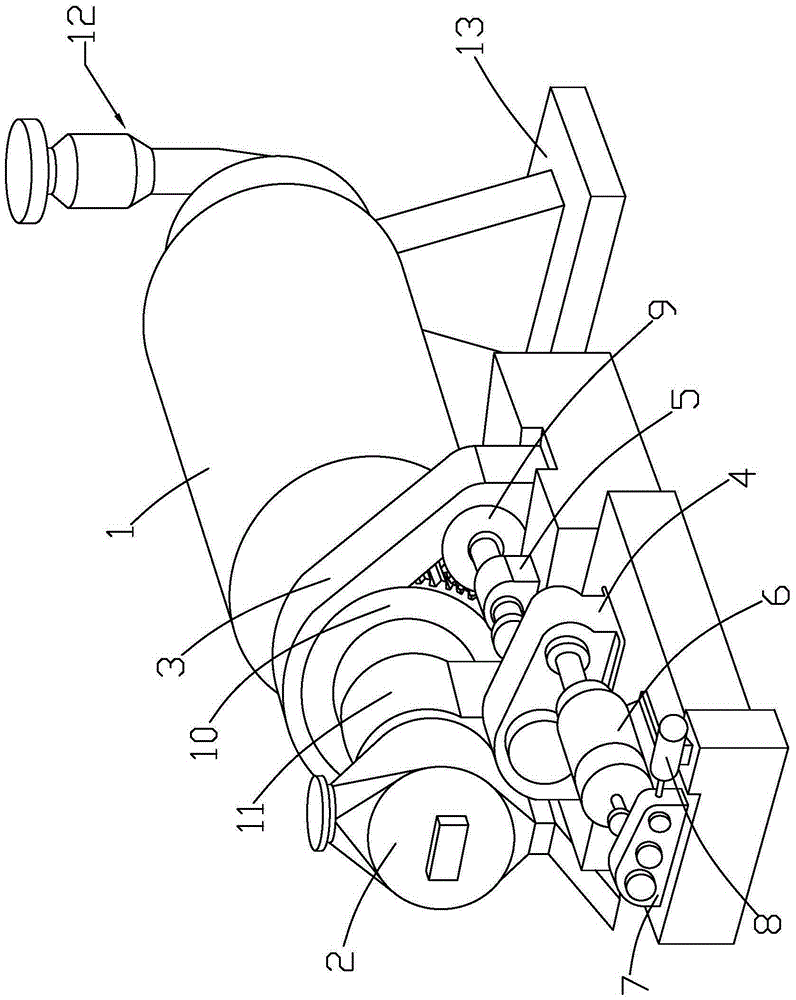

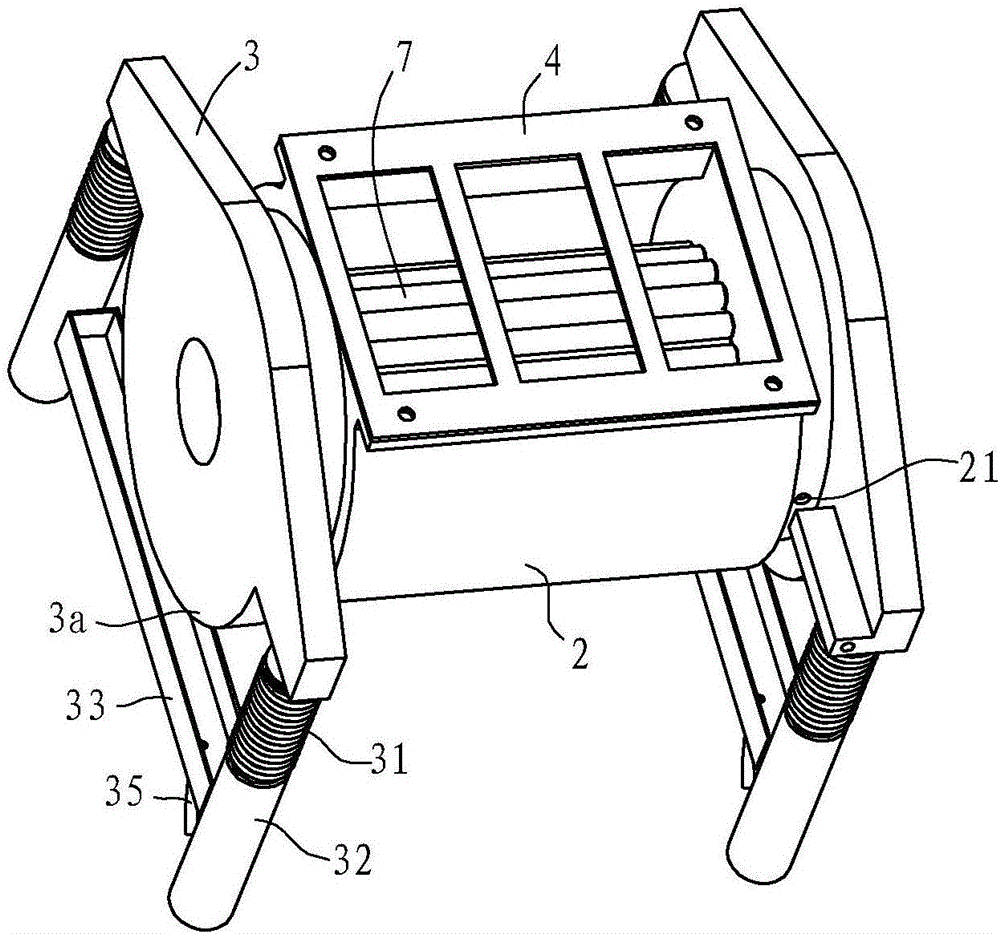

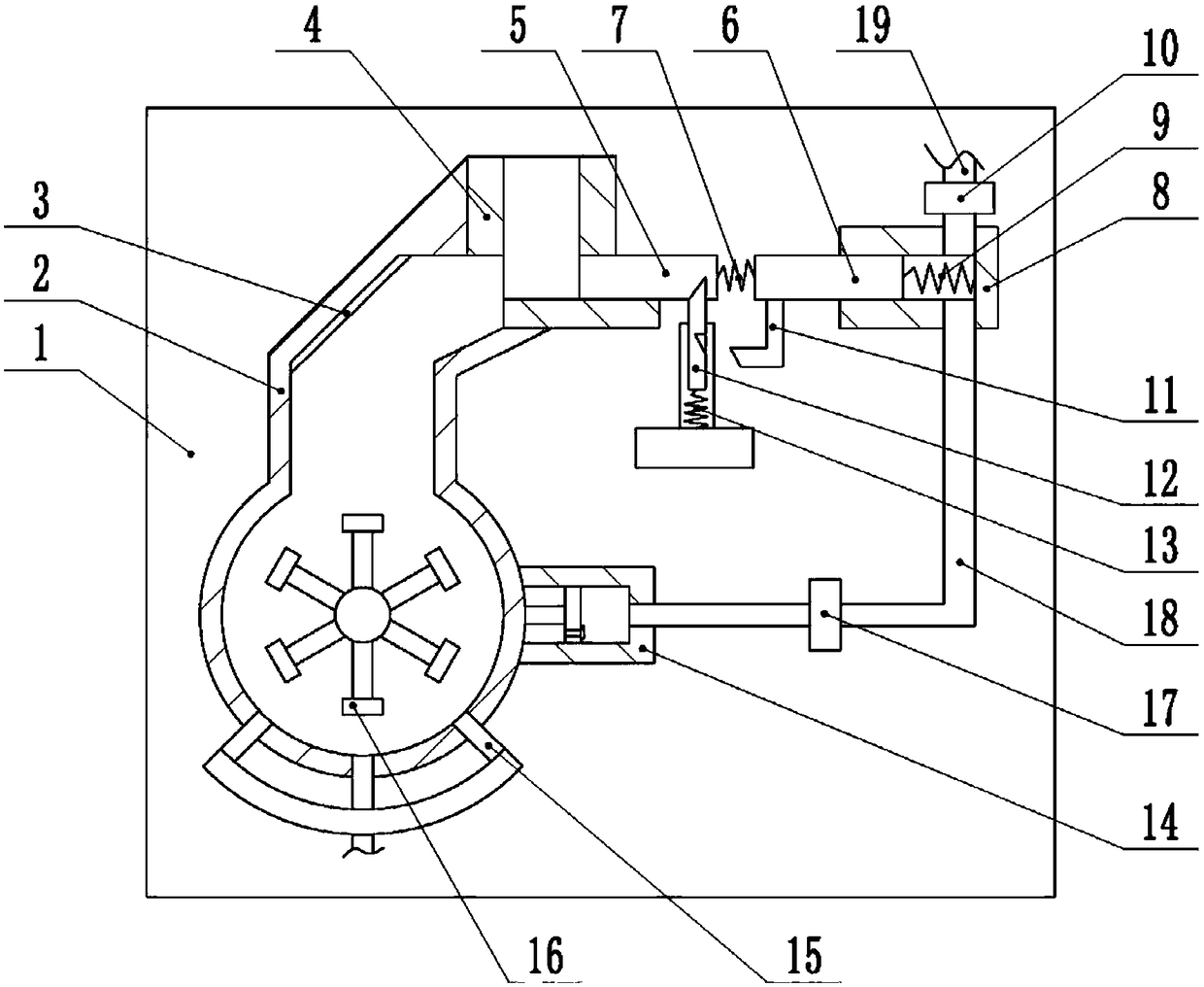

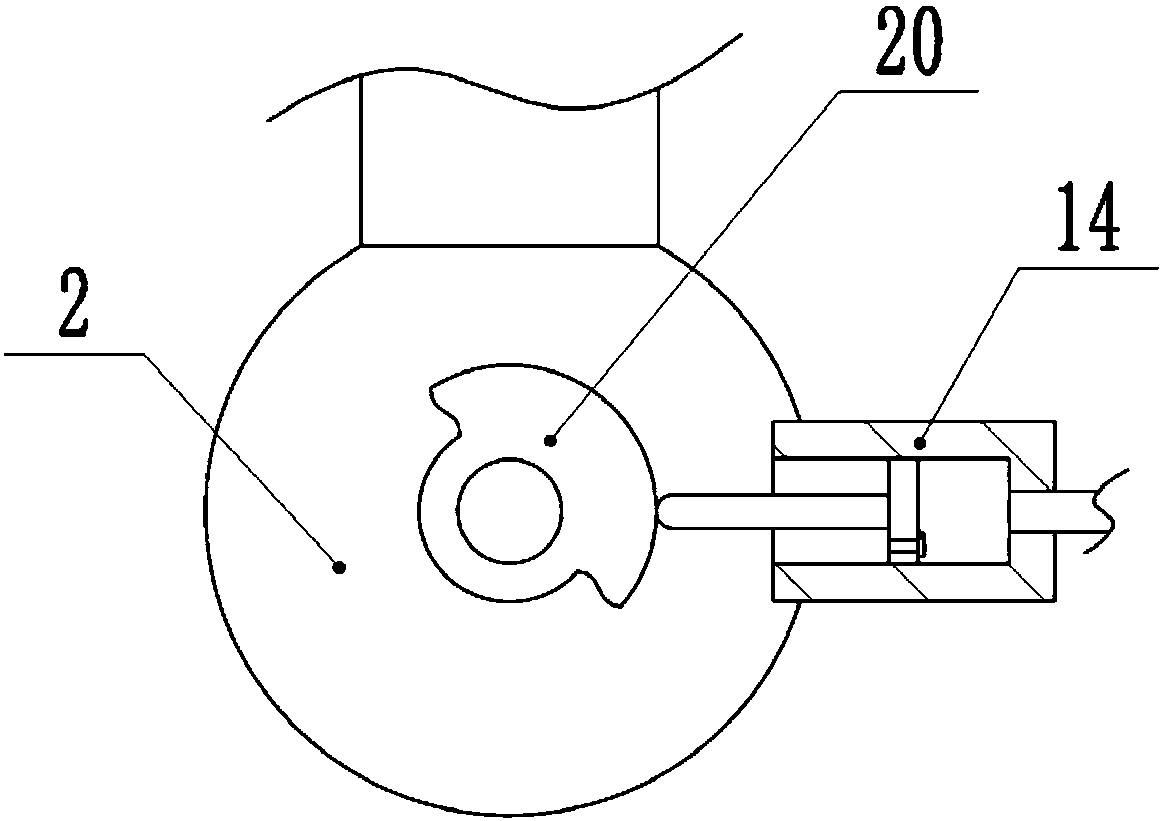

Rotation swinging type wasted shoe sole crushing device for footwear industry

ActiveCN106076463AIncrease the crushing strengthReduce crushing timeGrain treatmentsCamCivil engineering

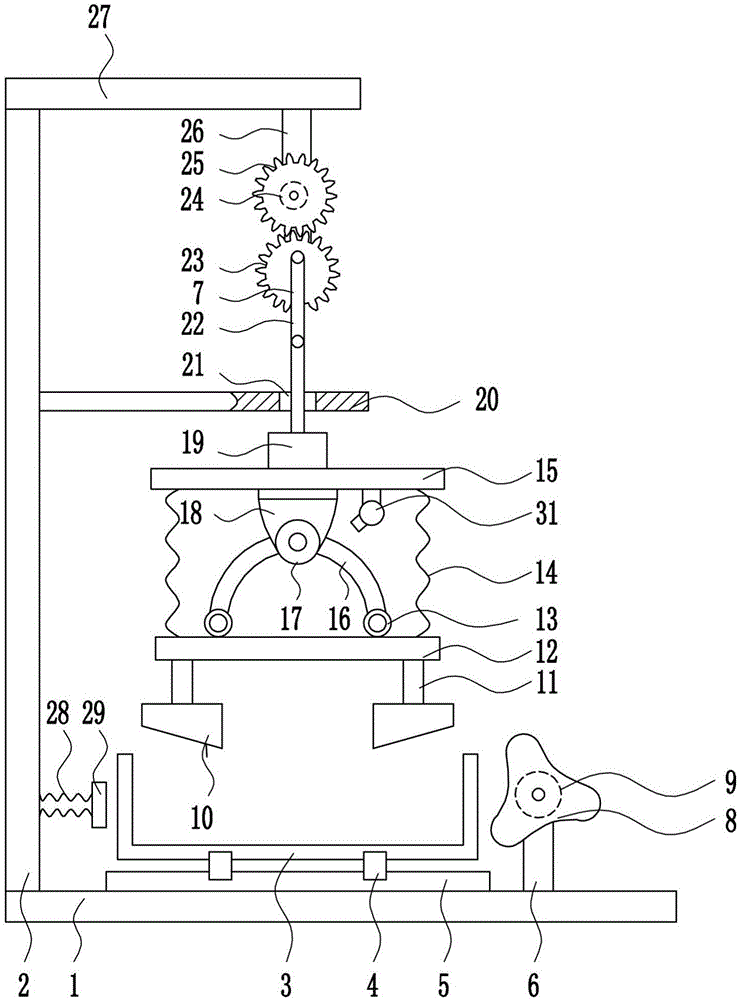

The invention relates to a wasted shoe sole crushing device, in particular to a rotation swinging type wasted shoe sole crushing device for the footwear industry and aims at achieving the technical purpose of providing the rotation swinging type wasted shoe sole crushing device for the footwear industry, wherein the rotation swinging type wasted shoe sole crushing device is simple in structure and high in practicability and work efficiency. To achieve the above technical purpose, the rotation swinging type wasted shoe sole crushing device for the footwear industry is provided and comprises a bottom plate, a support, a crushing frame, sliding blocks, a sliding rail, a first supporting rod, a first connecting rod, a disc cam, a first motor, crushing hammers, second supporting rods, a swing rod, rollers, first springs, a supporting plate, an arc connecting rod, a second motor, an installing base, a rotation motor, a guiding plate and the like, and the top of the bottom plate is sequentially provided with the support, the sliding rail and the first supporting rod from left to right. The effects of the simple structure and high practicability and work efficiency are achieved, the strength for crushing wasted shoe soles through the crushing hammers is increased, and the time for crushing the wasted shoe soles through the crushing hammers is shortened.

Owner:德州纺兴纤维有限公司

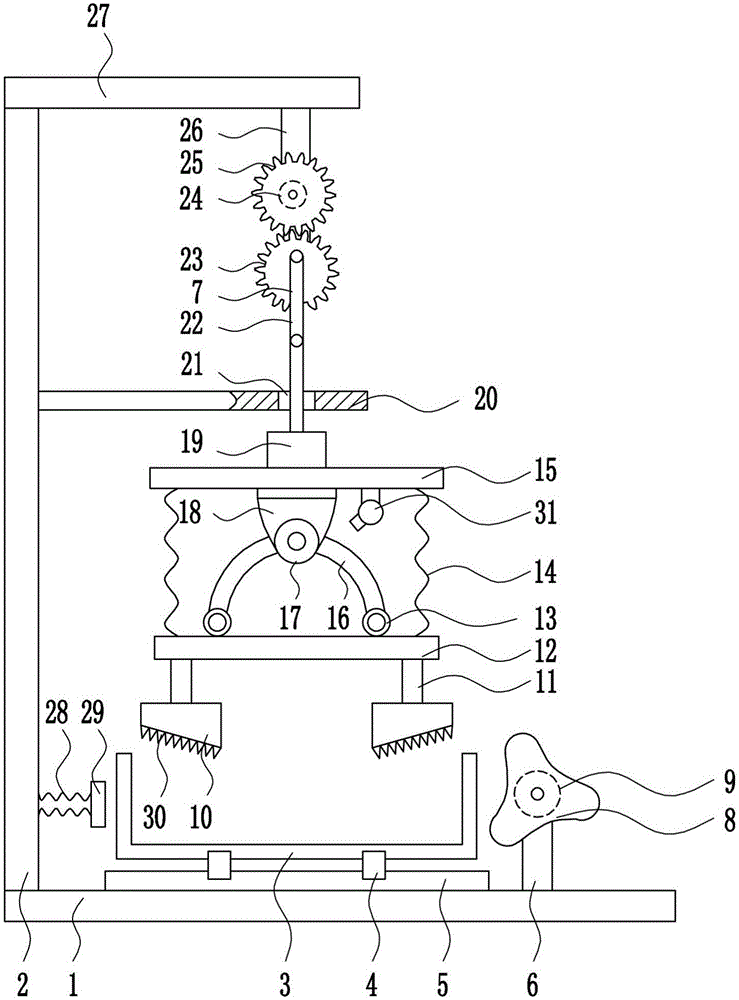

Super micronization method for botanical medicinal, product obtained thereby and use thereof

InactiveCN1994331AAvoid damageIncreased enzymolysis ratePowder deliveryPlant ingredientsEnzymeMicronization

The invention relates to a method for making stem drug containing xylon and cellulose into ultra micro powder, wherein said method comprises that: mechanically breaking; exploding via steam, treating at low temperature, breaking via airflow, enzyme hydrolyzing via microbe enzyme and extracting and separating. The invention also provides relative product and its application for preparing drug, transferring drug element, etc.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

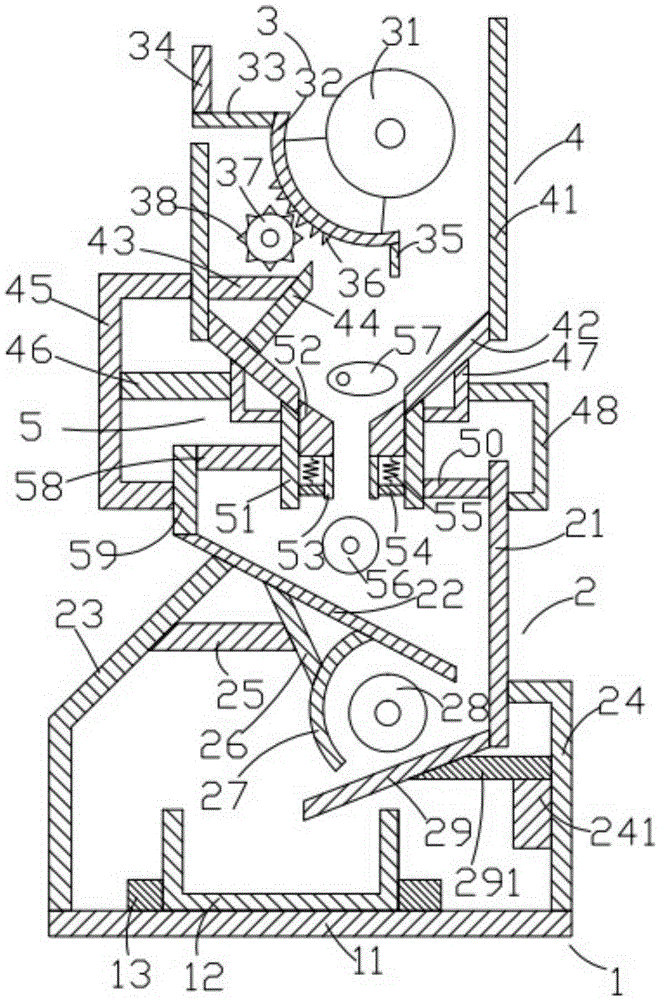

Food pulverizing device

A food pulverizing device comprises a bottom plate device, a first pulverizing device, a second pulverizing device, a frame device and a third pulverizing device, wherein the bottom plate device comprises a bottom plate, a material storage box and a first fixed block; the first pulverizing device comprises a first vertical plate, a first oblique plate, a first bracket, a second bracket, a first cross rod, a first oblique rod, a bend plate, a first roller and a second oblique plate; the second pulverizing device comprises a pulverizing frame, a moving block, a first positioning rod, a first fixed rod, a first spring, a second roller, a cam, a third cross rod, a first vertical rod and a fourth cross rod; the frame device comprises a frame body, a material collecting hopper, a fifth cross rod, a second oblique rod, a third bracket, a sixth cross rod, a fourth bracket, a fifth bracket and a sixth bracket; and the third pulverizing device comprises a third roller, a pulverizing plate, a connecting rod, a grip rod, a second positioning rod, first saw teeth, a fourth roller and second saw teeth. The food pulverizing device can thoroughly pulverize food during food processing and is great in pulverizing effect.

Owner:ZHONGSHAN ZHAISHI HEALTH PRESERVATION CO LTD

Three-level centrifugal corn grinder preventing feed from being bridged and grinding method

The invention provides a three-level centrifugal corn grinder preventing feed from being bridged and a grinding method. The corn grinder comprises a conveying mechanism, and is characterized in that the conveying mechanism is communicated with a grinding barrel, and first-level grinding teeth, second-level grinding teeth and third-level grinding teeth are sequentially arranged on the inner wall of the grinding barrel from top to bottom; a main shaft is arranged in the grinding barrel, first-level rotating supporting plates are arranged on the top of the main shaft and provided with first-level powder falling ports, air cylinder installing grooves are formed in the middle of the main shaft, and second-level grinding mechanisms are arranged in the air cylinder installing grooves; an upper cone grinder is arranged on the lower side of the main shaft, a lower cone grinder used in cooperation with the upper cone grinder is arranged on the side wall of the grinding barrel, and a conical grinding cavity is formed between the upper cone grinder and the lower cone grinder; and powder scraping pulp is arranged on the lower side of the lower cone grinder, a powder discharging pipeline is arranged at the bottom of the grinding barrel, and ground feet are arranged on the outer wall of the grinding barrel.

Owner:WEIFANG UNIV OF SCI & TECH

Method for preparing ceramic tiles from calcium silicate slag

InactiveCN103641446ARealize mass utilizationReduce consumptionCeramic materials productionClaywaresCalcium silicatePyrophyllite

The invention relates to a method for preparing ceramic tiles from calcium silicate slag, belonging to the field of comprehensive utilization of resources and novel technologies for ceramic preparation. The ceramic tiles contain the following raw materials in percentage by weight: 30-60% of calcium silicate slag, 10-30% of clay, 2-25% of quartz, 0-20% of feldspar, 0-10% of pyrophyllite, 0-10% of green coke and 0-10% of talc. According to the method, ceramics are produced from calcium silicate slag, so that the stacked discharge of calcium silicate slag is reduced, the aim of resource recycling is achieved, and a new way for the high-added-value utilization of calcium silicate slag is added; the utilization ratio of calcium silicate slag in calcium silicate slag ceramics can reach 60%; by using the characteristic that a great deal of alkali metal ions are contained, a feldspar raw material can be replaced partially or totally, and the ceramic tiles are produced under the low-temperature condition of 1,130-1,180 DEG C; all properties of the ceramic tiles prepared by the method disclosed by the invention are better than the national ceramic standards.

Owner:UNIV OF SCI & TECH BEIJING

Process of extracting effective component from plant

InactiveCN101019894AChange microscopic propertiesEasy extractionAnimal feeding stuffFood preparationMechanical crushingOrganic solvent

The process of extracting effective component from plant material includes crushing solid plant material mechanically, mixing with proper amount of chemical assistant, and extracting the effective component with water or ethanol. In the process, mechanical crushing of solid plant material produces micro shearing in the material interface and breaks cell wall to expose fresh cut surface, and the chemical assistant produces mutual adsorption with effective component, so that the process can alter the microscopic performance of the effective component and raise the leaching rate to 80-400 %. The present invention has shortened extraction period, high extraction efficiency, high extraction specificity, high selectivity, minimized organic solvent consumption and environment friendship.

Owner:周婕

Chinese medicinals pulverization method

InactiveCN1994332AAddressing Adaptive IssuesTo break through the technical difficulties of the continuous reduction in the efficiency of conventional ultrafine grindingPowder deliveryPill deliveryMedicineDrug

Owner:北京凯瑞创新医药科技有限公司

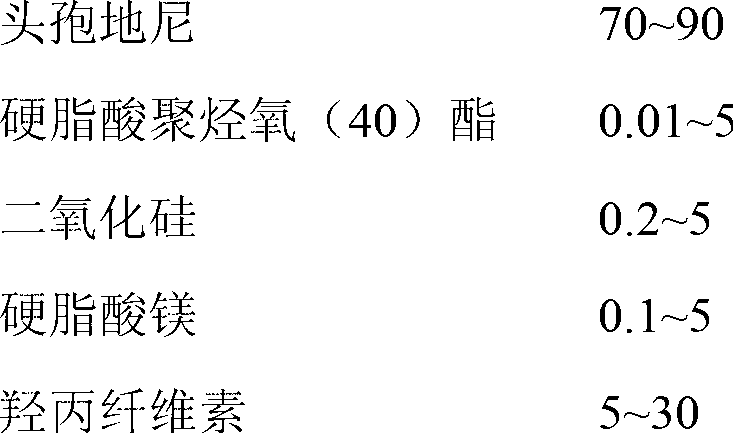

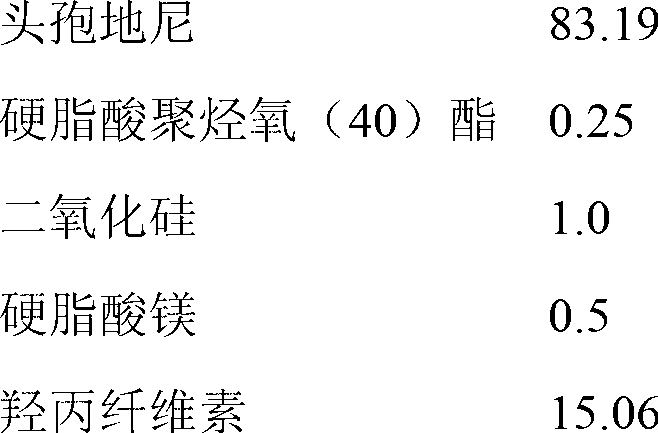

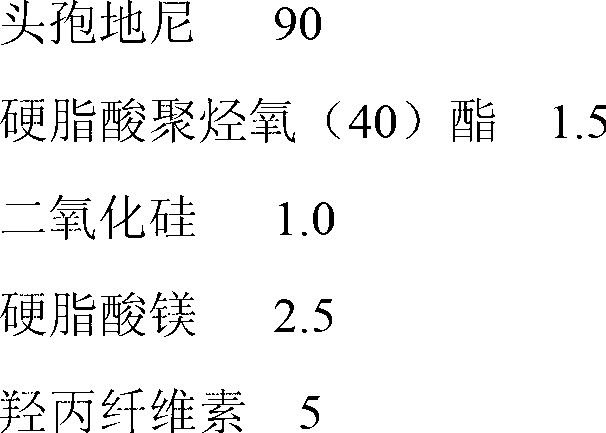

Cefdinir capsule and preparation method thereof

ActiveCN102935075AGood dissolution effectImprove liquidityAntibacterial agentsOrganic active ingredientsMedicineQuality control

The invention provides a cefdinir capsule and a preparation method of the cefdinir capsule. The content of the cefdinir capsule comprises the necessary components based on parts by weight: 70-90 parts of cefdinir, 0.01-5 parts of polyoxyl (40) ester stearate, 0.2-5 parts of silicon dioxide, 0.1-5 parts of magnesium stearate and 5-30 parts of hydroxypropyl cellulose. The medicine prepared by cefdinir capsule prescription is good in dissolution effect and fluidity, and stable in medicine effect; the provided preparation method is simple in technology; the product is less in introduced impurity, easy in quality control and good in reproducibility and uniformity; and the preparation method saves the energy and reduces the consumption, thus easily meeting the demand of mass production.

Owner:海南三叶美好制药有限公司

Ore extraction and transfer device

ActiveCN107670768AAvoid the problem of impact and easy damage to the boxAvoid the problem of fragile cabinetsGrain treatmentsEngineering

Owner:湖北省华建石材股份有限公司

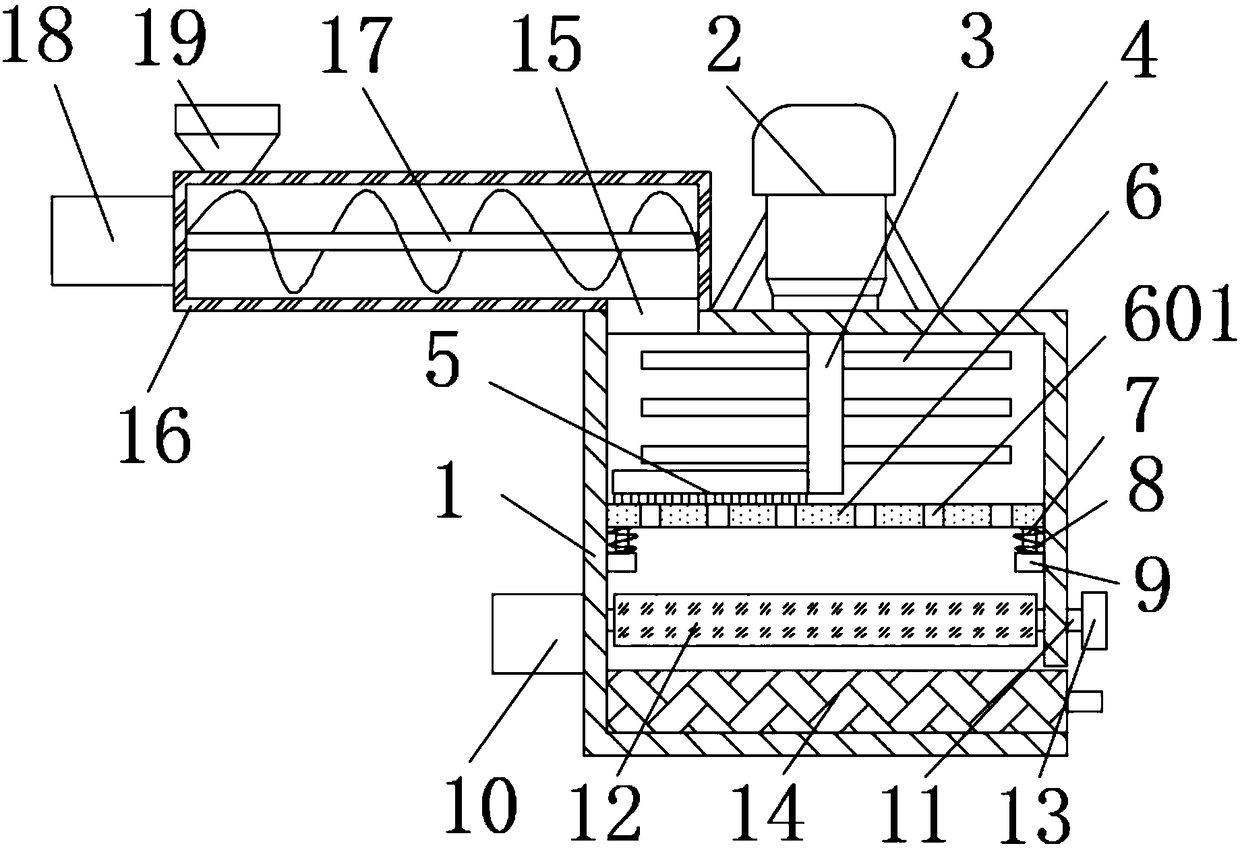

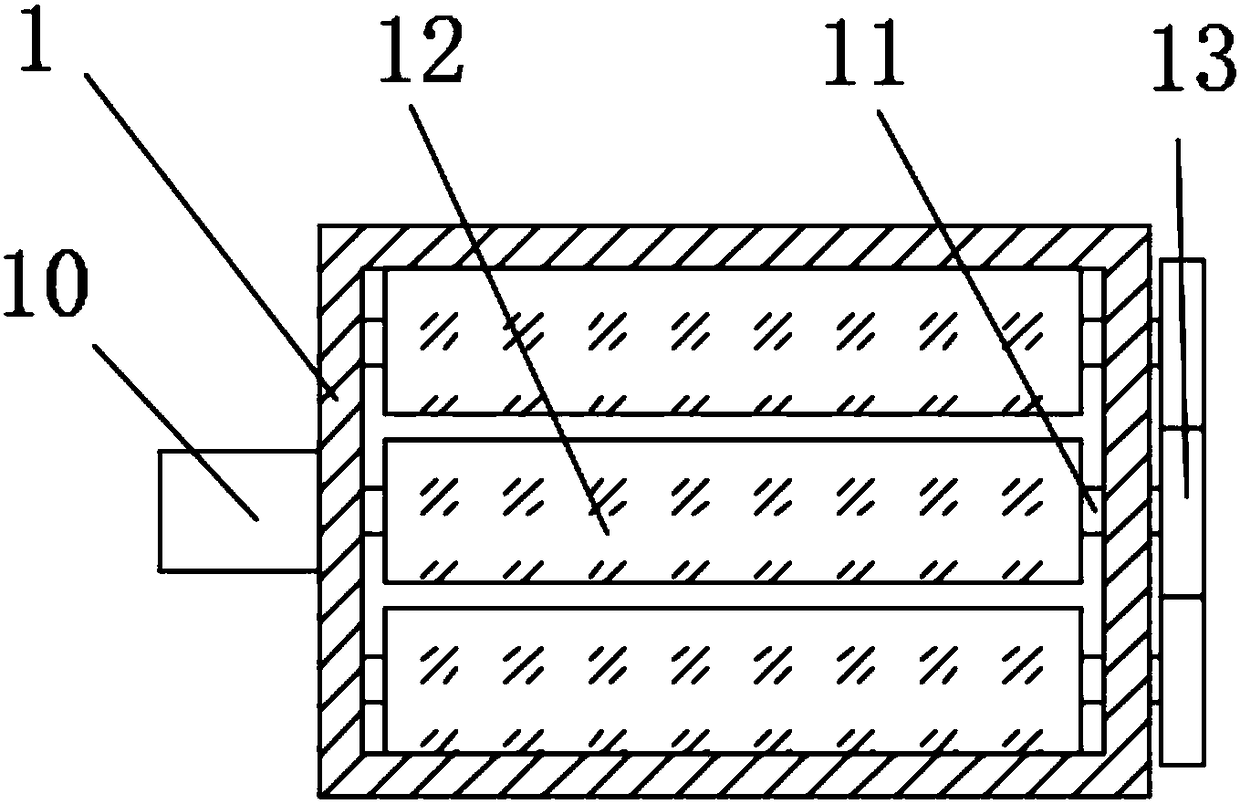

Graphite smashing device in lithium battery

InactiveCN108554595ARealize automatic feedingSimple structureSievingScreeningWorking environmentEngineering

The invention discloses a graphite smashing device in a lithium battery. The smashing device comprises a smashing shell body, a first electromotor, a rotary shaft, smashing blades, a hairbrush, a sieve plate, sieve holes, a rubber column, a spring, a vibration motor, a second electromotor, a rotary shaft, a pulverizing cylinder, a gear, a storing shell body, a feeding pipe, a feeding shell body, ascrew rod, a third electromotor and a discharging shell body. The graphite smashing device in the lithium battery is simple in structure and novel in design, achieves automatic feeding of graphite, can conveniently break bigger graphite blocks, avoids that graphite particles splash during the breaking process, ensures the surrounding working environment quality, screens the broken graphite through the sieve holes in the surface of the sieve plate to conveniently break the graphite, during the use process, further smashes the collected graphite after screening, ensures uniform smashing for thegraphite, reduces the smashing time of the graphite, improves the smashing efficiency of the graphite, and stores the graphite smashed uniformly, the smashed graphite can be conveniently taken out, and the device is applicable to use and popularization.

Owner:JIANGSU OLITER ENERGY TECH

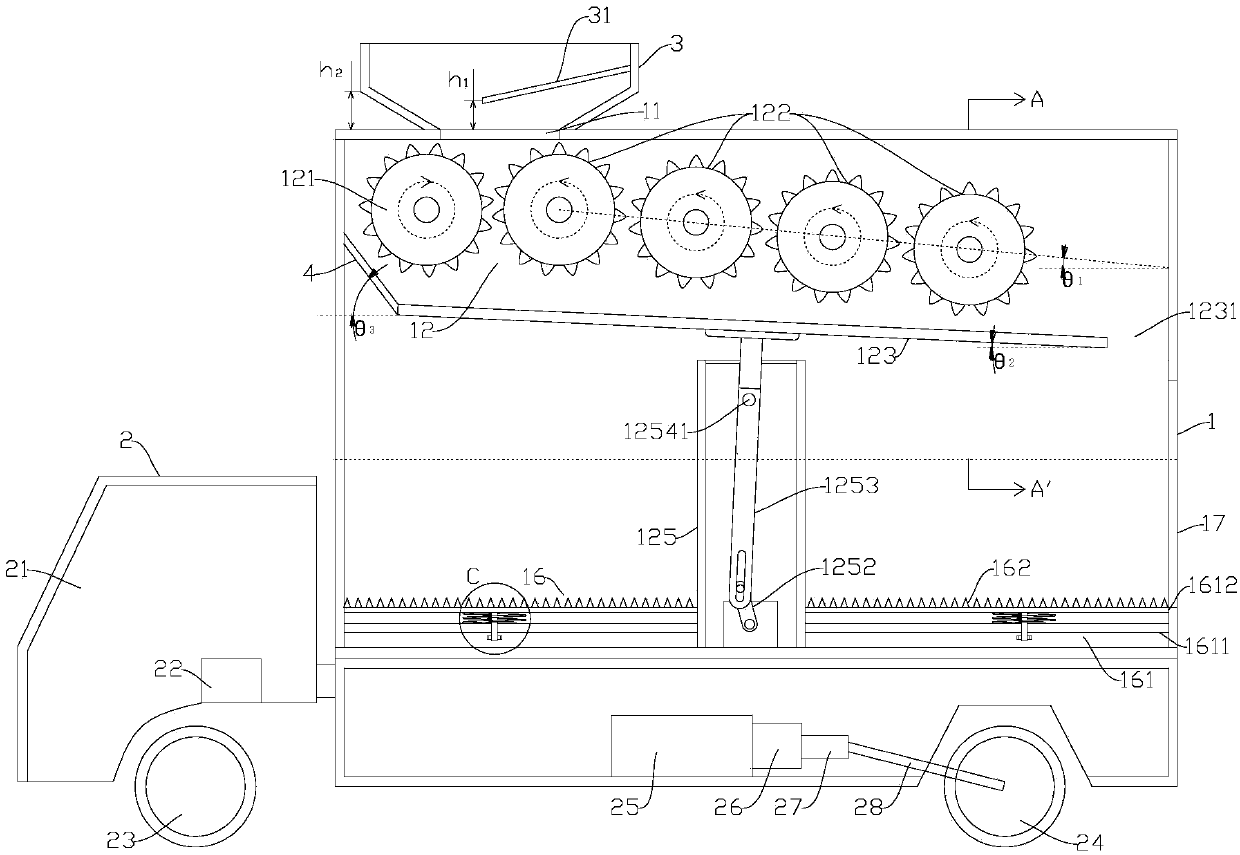

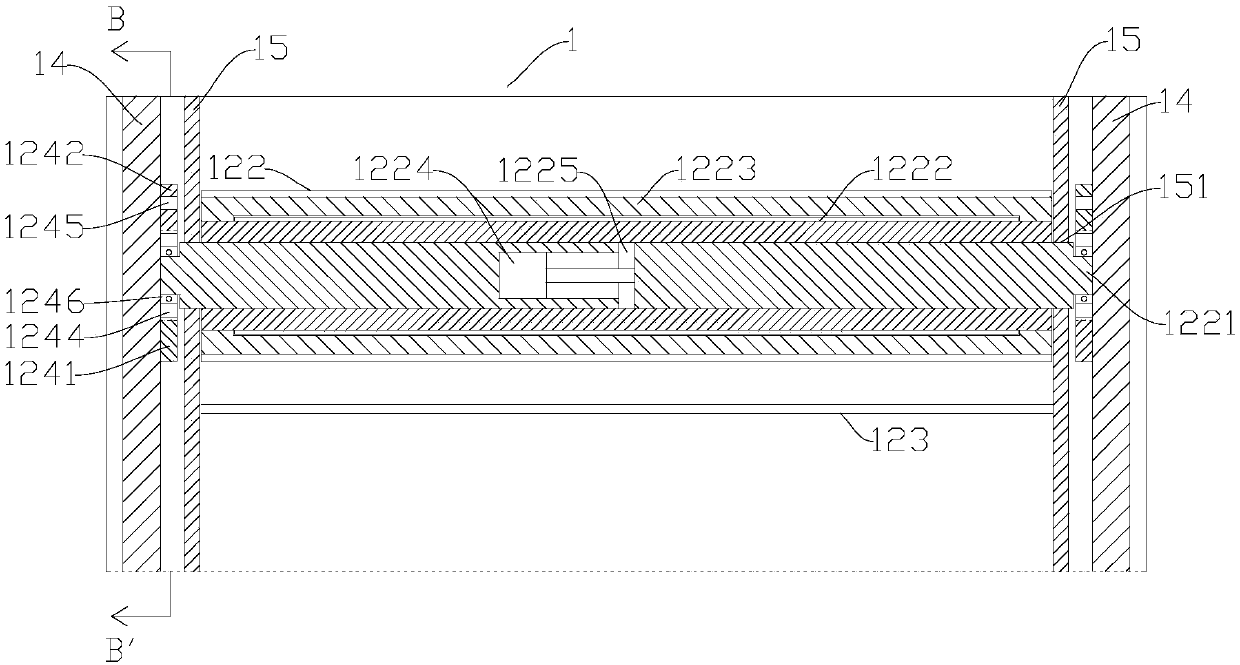

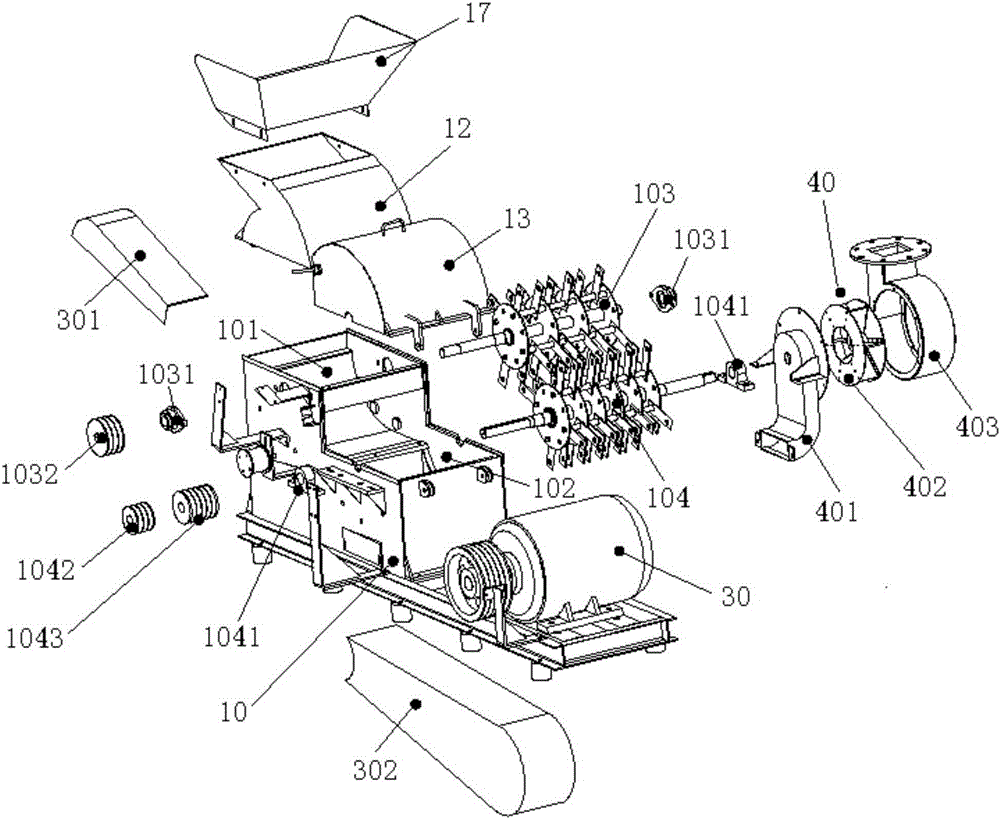

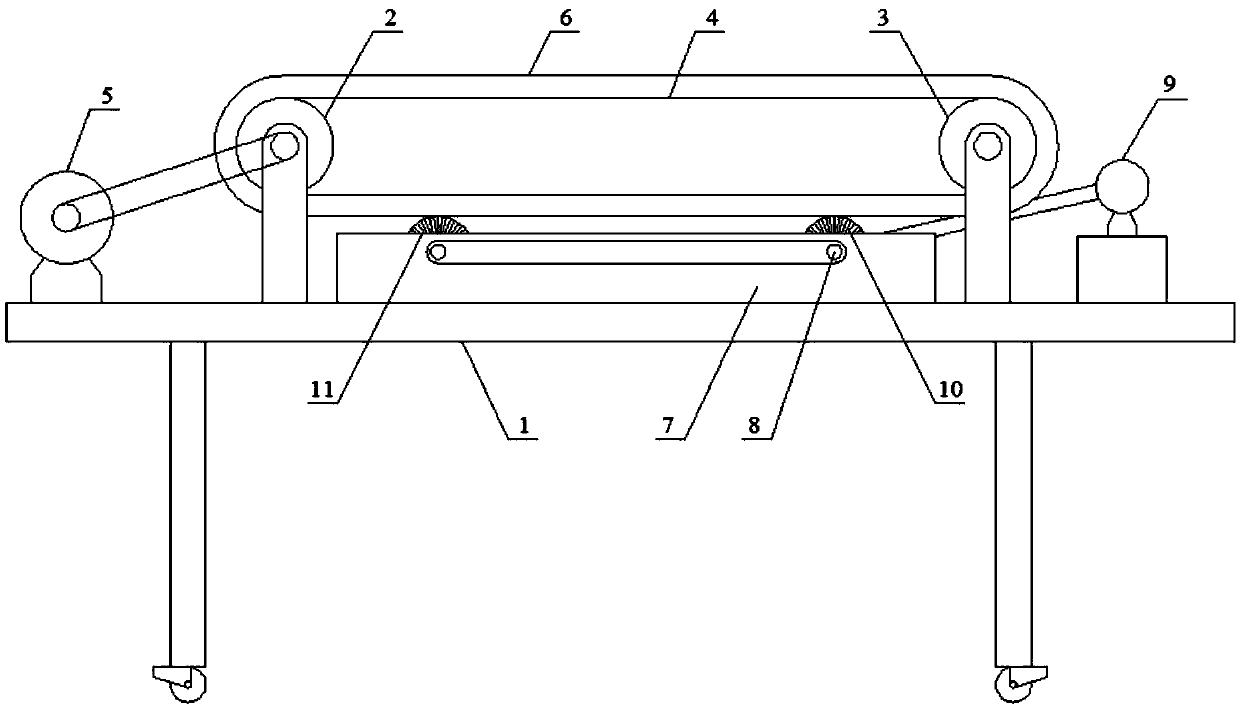

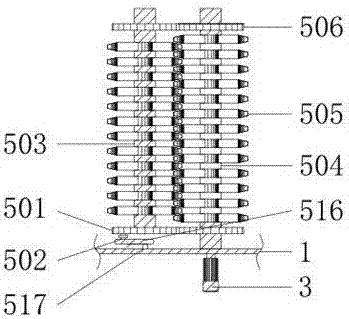

Pulverizer and powder production line comprising same

ActiveCN105170238AEfficient crawlingReduce crushing timeSievingReversed direction vortexProduction lineLower half

The invention provides a pulverizer and a powder production line comprising the same. The pulverizer comprises a second-level pulverizing unit. The second-level pulverizing unit comprises two communicated pulverizing cavities, a first-level pulverizing cutter set, a second-level pulverizing cutter set and a feeding sloping plate, wherein the first-level pulverizing cutter set and the second-level pulverizing cutter set are arranged in the pulverizing cavities respectively. A feeding inlet is formed in the top wall of the pulverizing cavity containing the first-level pulverizing cutter set. The feeding sloping plate is connected to the side edge of the feeding inlet. A second-level screen is arranged on the side wall of the lower half portion of the pulverizing cavity containing the second-level pulverizing cutter set. The powder production line comprises a conveying mechanism, the pulverizer, a cyclone separator, an air seal machine, a screening machine and a cartridge filter which are connected in sequence. When the pulverizer enters the pulverizing cavities, a downward resultant velocity is generated through the speed of the pulverizer and the linear speed of the tail end of a blade, and it is guaranteed that the cutter sets can be used for effectively grabbing materials. Furthermore, through the design of the distance between the tail end of the blade and the inner wall of each pulverizing cavity and a friction arc plate, the materials are effectively collided, rubbed and pulverized in the pulverizing cavities, and pulverizing time is shortened. The powder production line is smooth in production, free of dust, good in pulverizing effect, and short in time consumption.

Owner:陕西金禾农业科技有限公司

Glazing process for daily ceramic blank

The invention discloses a glazing process for a daily ceramic blank and relates to the technical field of daily ceramics. The glazing process comprises the following steps: (1) preparing a glaze; (2)preparing glaze pulp; (3) performing automatic glaze application; (4) polishing the bottom of the blank. In the glaze preparation process, the glaze is vacuumed and frozen to reduce the crushing granularity of the glaze, the abrasion degree of the glaze to blades of a crushing machine in the crushing process is reduced, and meanwhile the crushing time is shortened; due to adoption of the glaze application process, the glaze application quality is ensured, a glaze surface which is smooth and fine in hand feeling, clear and bright in gloss and fluent and smooth in line is formed on the surface of a ceramic blank after the glaze is sintered, and thus the market competitiveness of a ceramic product is improved.

Owner:安徽省德邦瓷业有限公司

Method for separating and extracting composite amino acid from hibiscus syriacus leaf

ActiveCN103642862AMild conditions for enzymatic actionPlay a role in breaking the wallOrganic compounds purification/separation/stabilisationFermentationBiotechnologyActivated carbon

The invention relates to a separation and purification method of composite amino acid, and particularly relates to a method for separating and extracting the composite amino acid from hibiscus syriacus leaves. The method comprises the following steps of: (1) pretreating; (2) ultrasonically treating; (3) decoloring; (4) removing impurities; (5) purifying; (6) dissolving a crystal, adding active carbon, stirring, filtering, placing into a refrigerator for filtration, precipitating an amino acid, and drying to obtain a composite amino acid crystal. The method disclosed by the invention can be used for extracting the composite amino acid from the hibiscus syriacus leaves by jointly acting on the hibiscus syriacus leaves through a complex enzyme and an ultrasonic wave, is moderate in enzyme acting condition and plays a wall-breaking role, namely a role of enabling the amino acid contained in the hibiscus syriacus leaves to be thoroughly dissolved. According to the invention, an ultrasonic wave extracting process is a physical process, no chemical change is generated in the extracting process, and a leached biological active substance is kept unchanged within a short time, so that the crushing time is shortened.

Owner:BEIJING EURO & AMERICAN INST OF SCI & TECH

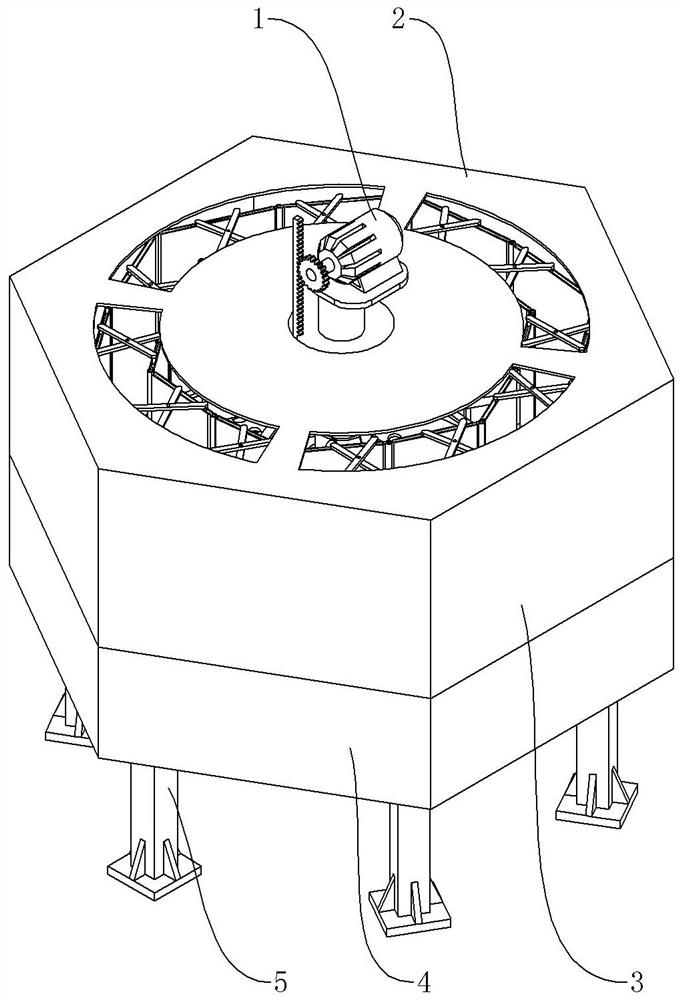

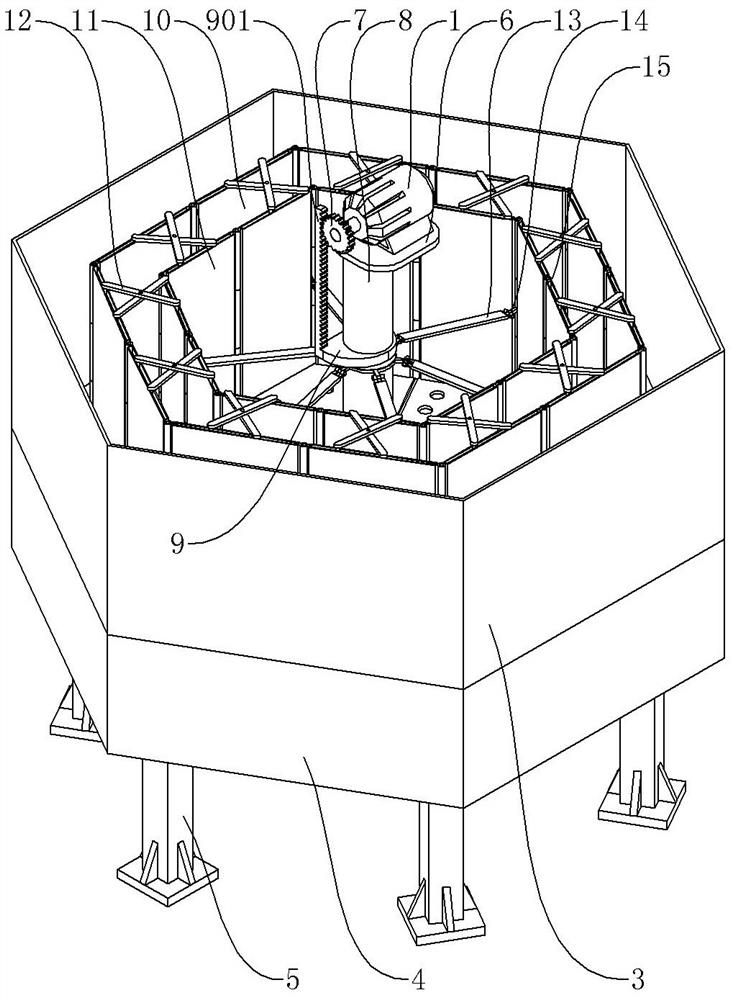

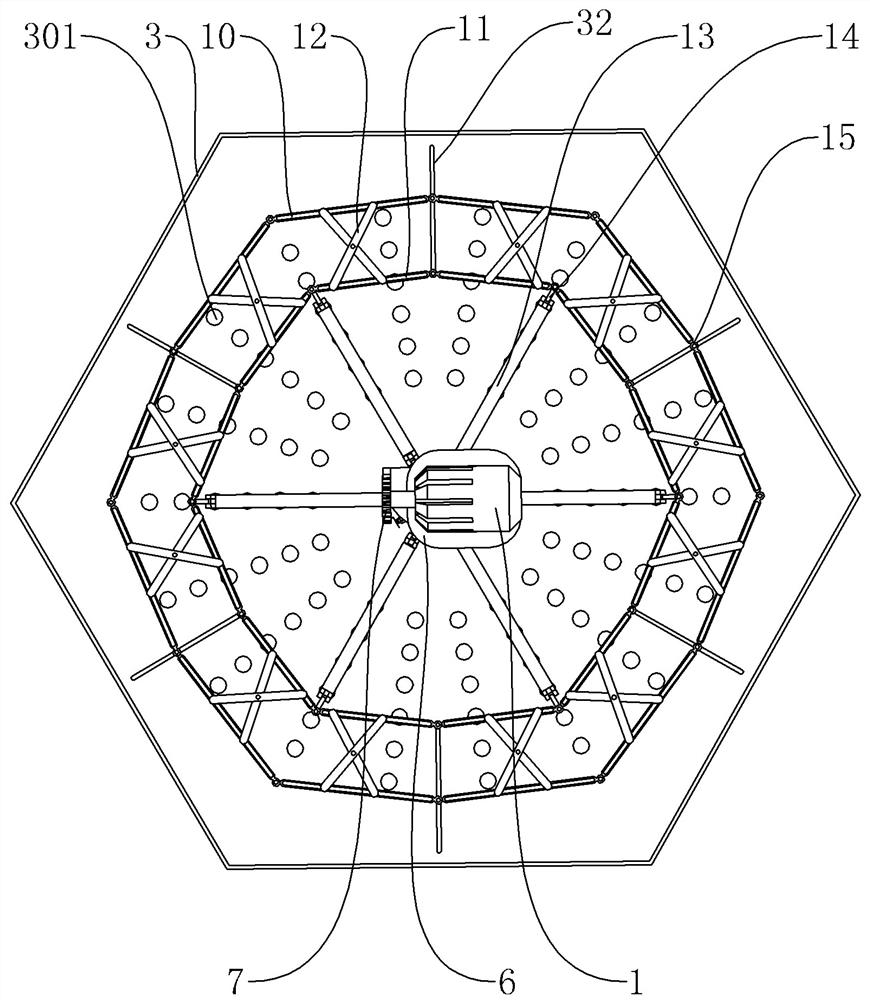

Polygonal hydraulic crushing device

InactiveCN113499840AImprove the crushing effectEvenly brokenGrain treatmentsGrindingStructural engineering

The invention relates to the technical field of grinding and crushing, in particular to a polygonal hydraulic crushing device. The polygonal hydraulic crushing device comprises a shell, a fixed shaft, a double-layer crushing ring, a mounting shaft, a movable shaft, a movable ring, a plurality of pull rods and a driving mechanism. A containing cavity with an upward opening is formed in the shell. According to the polygonal hydraulic crushing device, the polygonal inner crushing ring and the polygonal outer crushing ring are used for crushing materials in a crushing cavity, the shapes of the inner crushing ring and the outer crushing ring slide relatively in the changing process, so that the materials in the crushing cavity are rubbed, the crushing effect on the materials is enhanced, meanwhile, the materials move along with sliding of a crushing plate, thus the materials are crushed more uniformly, the crushing time is saved, and the crushing efficiency is improved.

Owner:JIANGSU OSCEN HYDRAULIC TECH

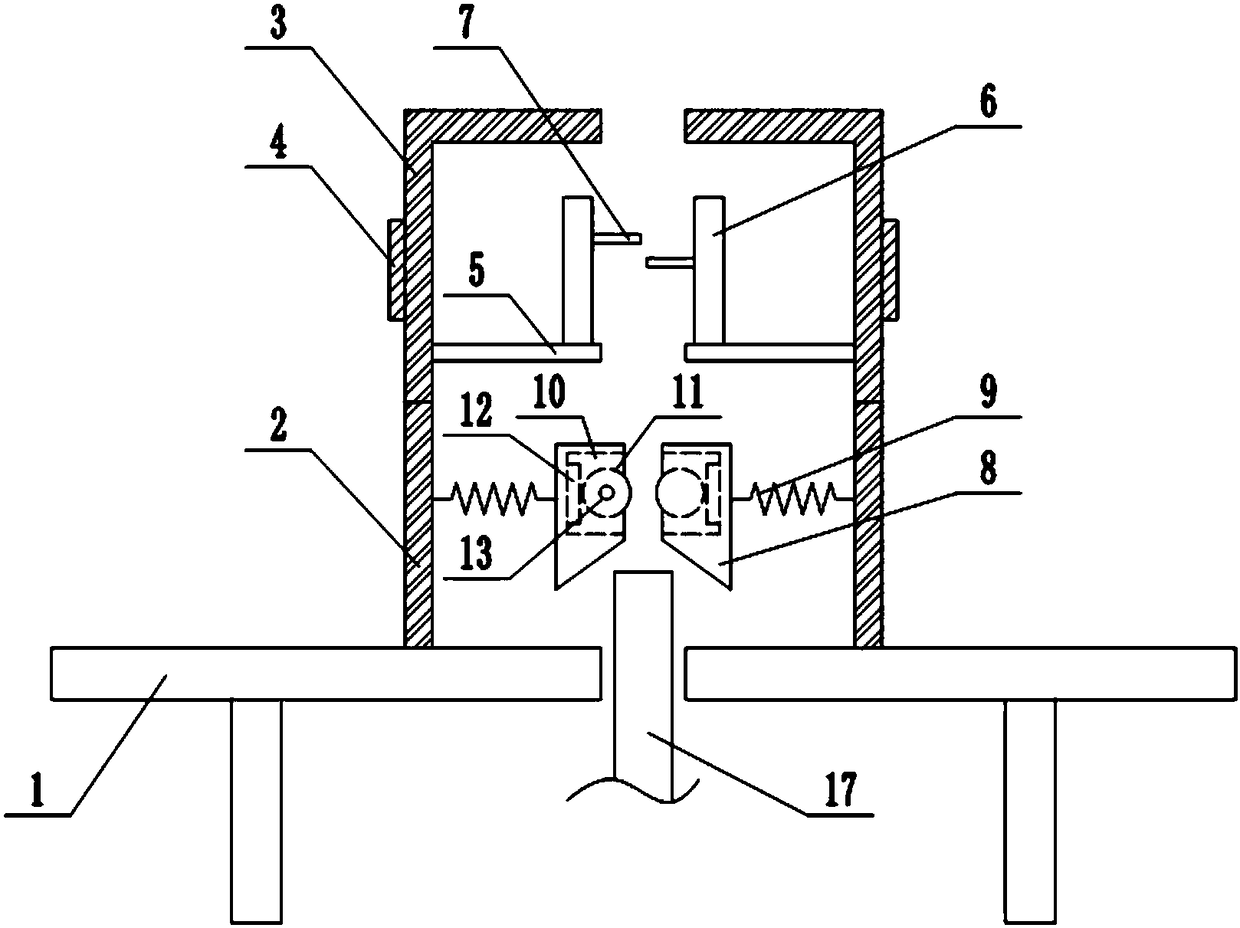

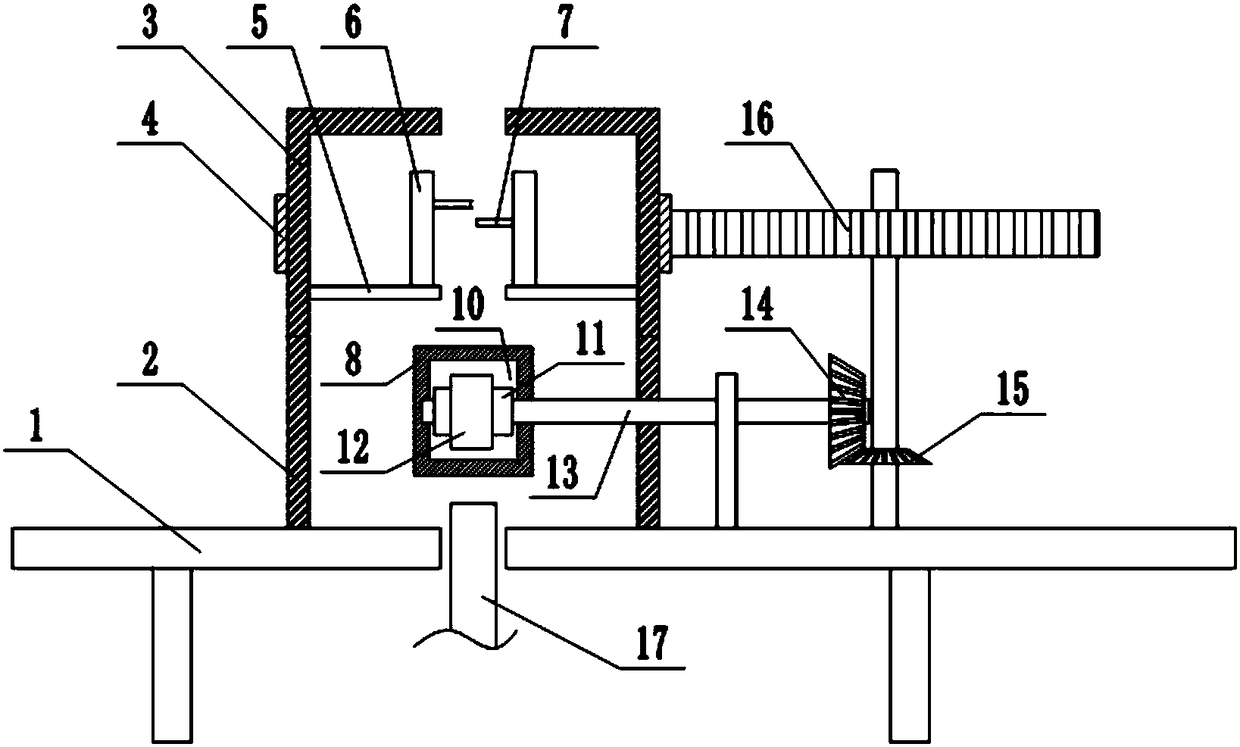

Ore crushing device efficient to use

ActiveCN106076468AReduce crushing timeAddressing Structural ComplexityGrain treatmentsOperations management

The invention discloses an ore crushing device efficient to use. The ore crushing device comprises a bottom plate. Stand columns are fixedly connected with the two sides of the top of the bottom plate. A top plate is fixedly connected with the top ends of the stand column. A shell is fixedly connected to the top of the top plate. A telescopic rod is fixedly connected with one side, between the two stand columns, of each stand column. The end, away from the corresponding stand column, of each telescopic rod is fixedly connected with a fixing plate. A motor is fixedly connected to the interior of the shell through a supporting pillar, and a rotating shaft of the motor is fixedly connected with a connecting rod through a coupler. The surface of the end, away from the motor, of the connecting rod is fixedly connected with a driving device. By the adoption of the ore crushing device efficient to use, the problems that crushing devices on the current market are generally complex in structure and not convenient to operate are solved, use of a user is better facilitated, the higher difficulty is avoided for the user, the expenditure of economic cost is reduced, the crushing time of ore is shortened, and the crushing efficiency and economic benefits are improved.

Owner:阳山温榜山矿业有限公司

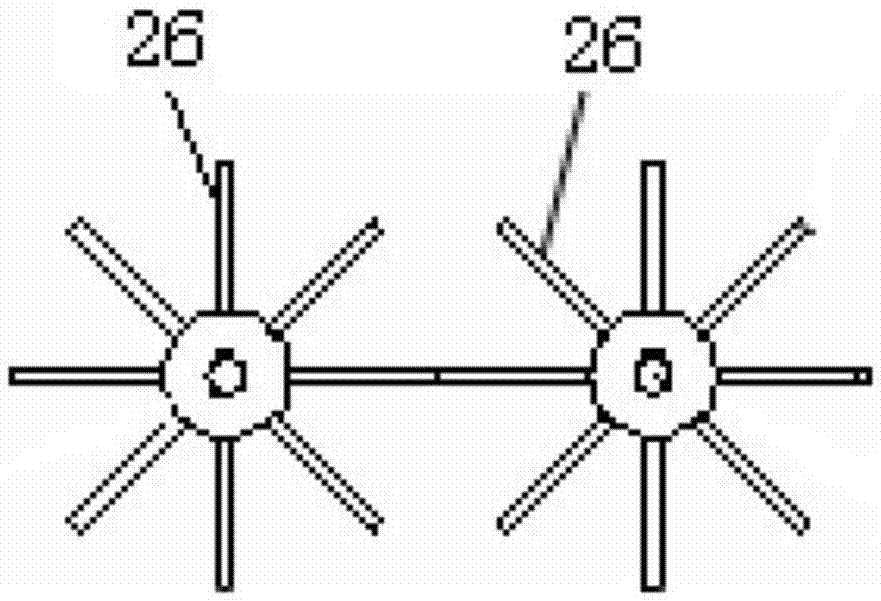

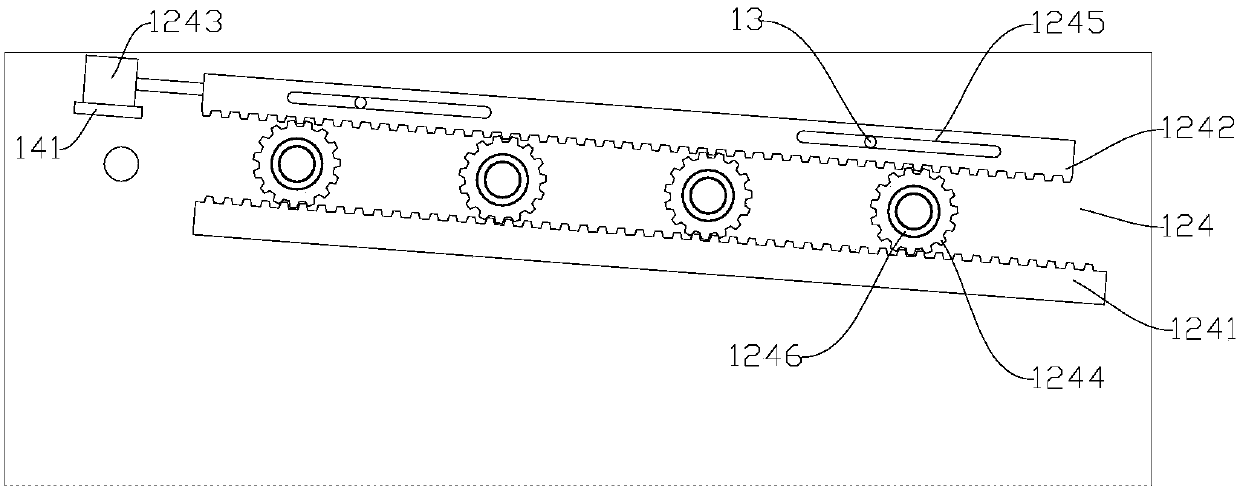

Eight-axle in-phase composite rubber dicer

InactiveCN101337405ALabor savingReduce workflowPlastic recyclingMechanical material recoveryFeed driveWaste rubber

The invention relates to an eight-shaft synchronous compounded rubber cutter, which belongs to the technical field of the waste tire recovery device, and solves the problems of low output of recovery and crushing, large power and labor consumption and long technological flow of waste rubber radial tires in the prior art. The eight-shaft synchronous compounded rubber cutter comprises a feeding mechanism, a crushing mechanism, a power and driving mechanism and a rack, wherein the feeding mechanism comprises a feeding drive roll and a feeding driven roll; a primary cutting knife roll and a primary cutting press roll are arranged on one side of the feeding drive roll along the material conveying direction; a combined drive knife roll and a combined driven knife roll are arranged on one side of the primary cutting knife roll along the material conveying direction; a material conveying drive roll and a material conveying driven roll are arranged on one side of the combined drive knife roll along the material conveying direction; a knife fixing bar and a circular movable knife roll are arranged on one side of the material conveying drive roll along the material conveying direction. The eight-shaft synchronous compounded rubber cutter has the advantages that the manpower is saved, the work flow is shortened, good crushing condition is provided for the subsequent work flow, the heating of the radial tires can not be caused, and odor, dust and pollution can not be generated.

Owner:吕梁升凯胶粉设备制造有限公司

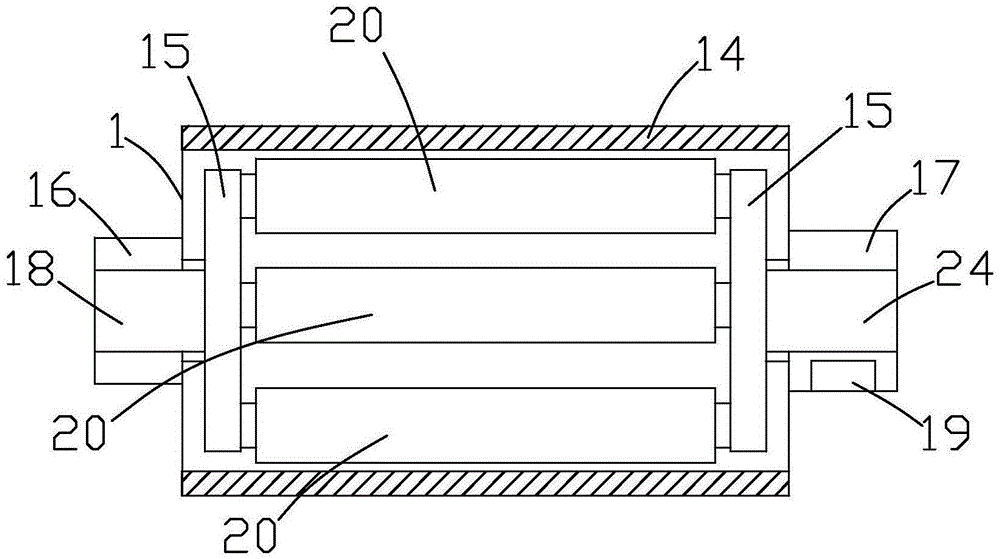

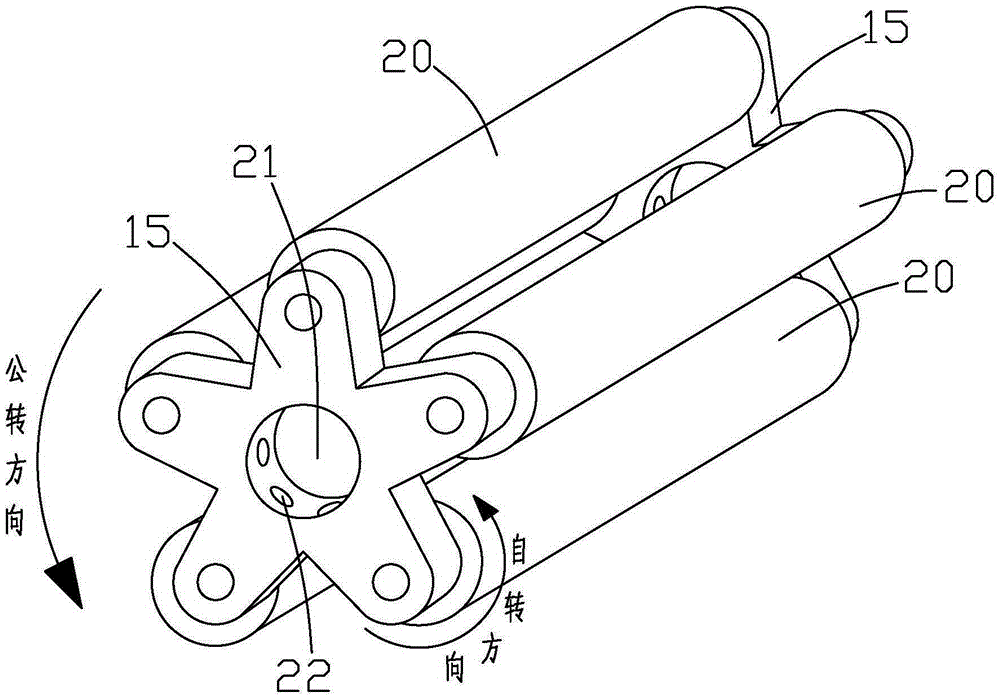

Ball mill used for producing graphite powder

InactiveCN105413813AExcellent crushing speedReduce crushing timeGrain treatmentsSynchronous motorGraphite

The invention discloses a ball mill used for producing graphite powder. The ball mill comprises a roller, a power drive device, a feeder and a dumping device, wherein two star brackets which are parallel to each other are arranged on the inner part of the roller; material distributing tubes are uniformly arranged on the inner parts of the star brackets; five cylindrical ball-milling tanks which are parallel to each other are uniformly distributed between the two star brackets; the two ends of each cylindrical ball-milling tank are provided with supporting tube racks; a synchronous motor is arranged on the inner parts of the star brackets; the cylindrical ball-milling tanks realize autoroatation around the star brackets; the two ends of the roller are respectively provided with a front positioning bearing and a rear positioning bearing; and the cylindrical ball-milling tanks realize rotation around the front positioning bearing and the rear positioning bearing. The ball mill is simple in structure, high in practicability, not only can realize autoroatation and rotation of the cylindrical ball-milling tanks and improve material crushing efficiency and material crushing quality, but also can pre-heat and crush materials, so that the materials are guaranteed to have certain temperature while being output, and therefore, crushing requirements of different materials are met.

Owner:SHENGZHOU SIGMA TECH

Soybean milk making method of soybean milk maker, and soybean milk maker

ActiveCN102823656AReduce the amount of waterIncrease chance of contactBeverage vesselsMilk substitutesSoybean mealSoybean oil

The invention discloses a soybean milk making method of a soybean milk maker. The method comprises a step of soybean milk material obtaining, and a step of water addition for soybean milk making, wherein soybean milk is simultaneously discharged in the soybean milk making process in the step of the water addition for the soybean milk making. Crushing and soybean milk discharge are simultaneously carried out in the invention, so the amount of water in a crushing space (chamber) during crushing is less, thereby the contact probability of blades with the material is increased, the crushing efficiency is improved, and the crushing time is shortened. The invention also discloses the soybean milk maker.

Owner:JOYOUNG CO LTD

Method for extracting polyhydroxyalkanoates from active sludge

InactiveCN1803883AImprove solubilityShorten the timeBiological sludge treatmentWater bathsSupersonic waves

The related extraction method for polyhydroxy fatty acid ester from active sludge comprises: centrifuging the sludge to dry the solid and obtain dried active sludge with 5-15% water content; grinding the product into fine grain of 40-10item; adding chloroform by weight ratio with the sludge as 1:25-50; treating with supersonic wave, water-bath oscillating, centrifuging, condensing, and adding methanol of 20-40 times; and centrifuging to separate solid and put into petri dish for drying. This invention benefits to residual sludge treatment and comprehensive utilization, and cuts the extraction time for higher efficiency.

Owner:NANKAI UNIV

Method for extracting pectin from shaddock peel through enzymolysis and ultrasonic waves

InactiveCN106349405AThe role of complete dissolutionMild conditions for enzymatic actionAdditive ingredientChemical change

The invention discloses a method for extracting pectin from shaddock peel through enzymolysis and ultrasonic waves. The method includes the specific steps of (1) pretreatment of the shaddock peel serving as a raw material, (2), enzymolysis and ultrasonic treatment, (3), decoloration and (4), drying so as to obtain the pectin. The method for extracting the pectin from the shaddock peel through the enzymolysis and the ultrasonic waves has the advantages that a compound enzyme and the ultrasonic waves act on the shaddock peel jointly to extract the pectin from the shaddock peel; the enzyme is mild in action condition and plays a role in wall breaking, so that the pectin in the shaddock peel dissolves out thoroughly; an ultrasonic wave extraction process is a physical process without chemical change and is high in extraction rate and capable of protecting functional ingredients of extract effectively, breaking time is shortened, and the pectin yield of the shaddock peel is higher than 25% which is increased by more than 30% than that of a traditional acid extraction method; with the shaddock peel as the raw material, the method is simple, high in yield and high in extracted pectin quality and achieves the purpose of turning waste into wealth.

Owner:安徽旺润生物科技有限公司

Chitin crushing method

InactiveCN104117418AReduce crushing timeShort crushing timeGrain treatmentsPhysical chemistryCrystal structure

The invention belongs to the technical field of crushing, in particular discloses a chitin crushing method. The overspeed refrigeration is performed for selected chitin packaged in vacuum; the temperature of the overspeed refrigeration is in a range of -35 DEG C to -30 DEG C, and the time of the overspeed refrigeration is 5-10 min; and the chitin after the overspeed refrigeration can be crushed after being stored at the low temperature below -18 DEG C, or can be directly taken out from the package to be crushed in a frozen state. The method shortens the crushing time, enables crushed particles to achieve a powder state, cancels a procedure that in the prior art, crushed raw materials need to be dried before storage, optimizes the process flow, saves the energy consumption, and achieves high efficiency and speediness. Through the analysis and the test, the morphology, molecular structure, crystal structure and thermal property of the chitin are not obviously changed due to the low-temperature condition and mechanical effect of the crushing after and before the overspeed crushing; the dissolving property is prominently improved; and the application range is widened.

Owner:SOUTH CHINA AGRI UNIV

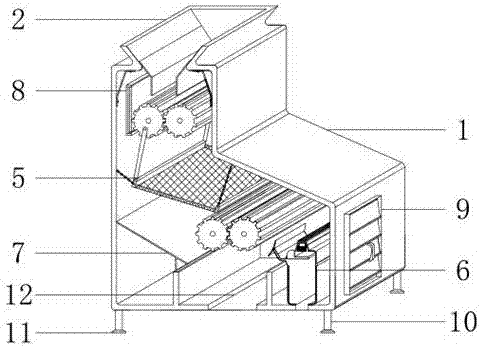

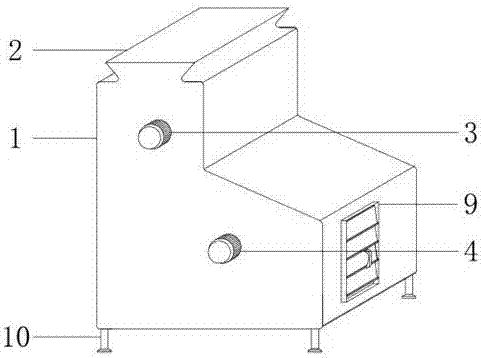

Staggered cutter shaft type rubber product crusher

The invention discloses a dislocation knife shaft type rubber product crusher. The top of the box body is provided with a material inlet through which raw materials are put into the box body. The left side of the outer wall of the box body is provided with an observation window for easy observation at any time. The working conditions inside the box body, there is an inspection port on the right side of the outer wall of the box body, when the machine breaks down, the fault can be eliminated in time, and the bottom of the box body is equipped with a discharge port. Take it out from the mouth. In the crusher for rubber products, when the raw material enters the box, the first gear and the second gear start to work under the drive of the first motor to crush the raw material. When the raw material passes through the first cutter head, it falls into the filter screen and is not completely The broken raw materials continue to move downward through the filter screen and fall onto the second cutter head for further crushing, which saves crushing time, improves work efficiency, and reduces the work intensity of the operator.

Owner:柴红霞

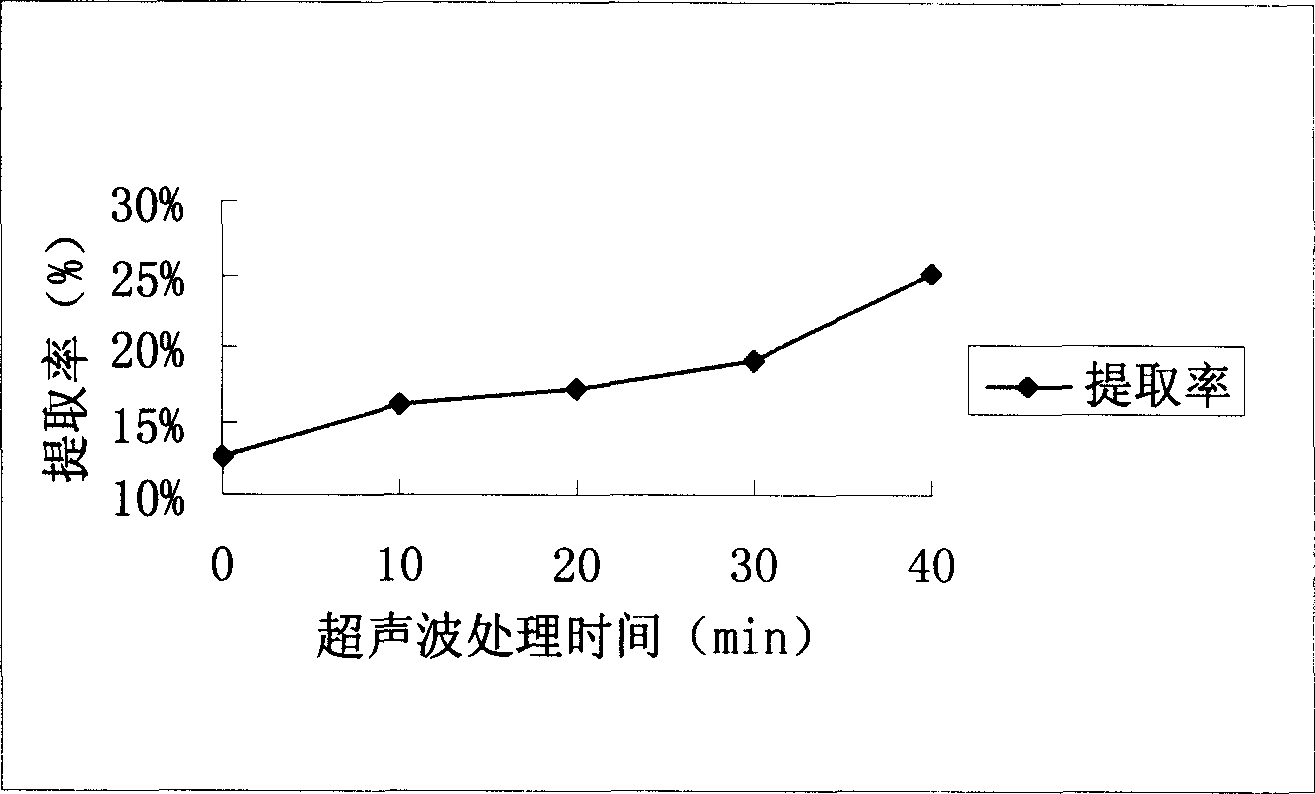

Portulace polysaccharide ultrasonic-auxiliary extraction method

InactiveCN103864943AWith "cavitation phenomenon"Improve solubilityAntibacterial agentsAntipyreticCavitationThermal effect

The invention discloses a purslane polysaccharide ultrasonic-auxiliary extraction method, and purslane polysaccharide is extracted by the following steps: drying, crushing, screening, degreasing, ethanol reflux extraction, drying in air, ultrasonic extraction, concentration, alcohol precipitation, centrifugation, washing, drying and the like. Ultrasonic ''cavitation phenomenon'' can produce an instant thousands of PA pressure, tiny bubbles in an extraction medium are compressed, burst and broken, and a target extract is acceleratedly dissolved; diffusion of dissolved components can be intensified by ''mechanical vibration'' and ''thermal effect'', and the whole process is completed in a moment, so that the broken speed is increased, the broken time is shortened, the extraction efficiency is greatly improved, the extraction cost is saved, and the product quality is improved.

Owner:QINGDAO ZHONGREN PHARMA

Method for extracting amino acids from mulberry leaf

InactiveCN105154511AMild conditions for enzymatic actionPlay a role in breaking the wallFermentationActivated carbonRefrigerated temperature

The invention discloses a method for extracting amino acids from mulberry leaf, which uses mulberry leaf as the raw material and specifically comprises the following steps: (1) carrying out pretreatment; (2) carrying out enzymolysis and ultrasonic treatment; (3) carrying out decolorization; (4) carrying out impurity removal; (5) carrying out purification; and (6) dissolving the crystal, adding activated carbon, stirring, filtering, putting in a refrigerator, filtering, precipitating the amino acid crystal, and drying to obtain the composite amino acid crystal. Under the combined actions of the composite enzyme and ultrasonic on the mulberry leaf, the composite amino acids are extracted from the mulberry leaf; and the enzyme requires mild action conditions and has the wall breaking action, so that the amino acids in the mulberry leaf are thoroughly dissolved out. The ultrasonic extraction process is a physical process and does not have any chemical change; and in the extraction process, the extracted biological active substances are kept unchanged in a short time, thereby shortening the crushing time.

Owner:CHONGQING DOUHAO BIOTECH

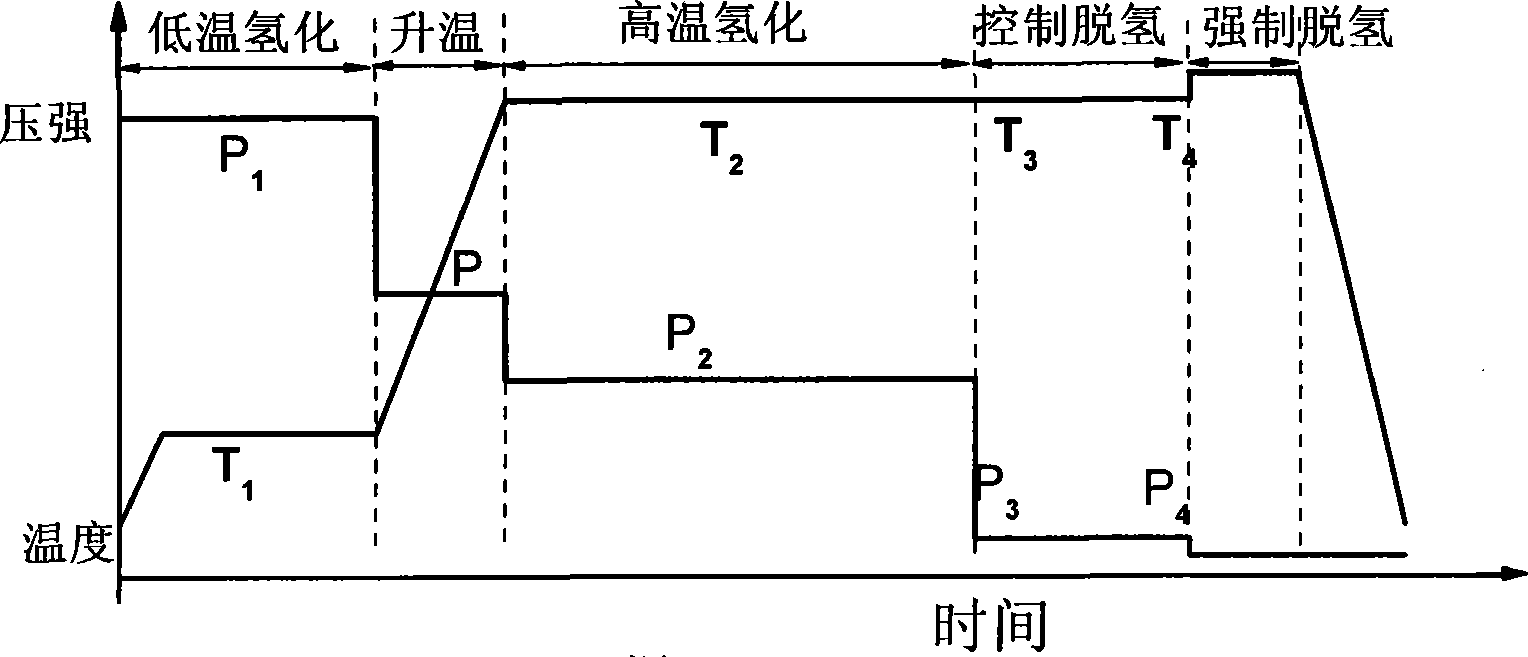

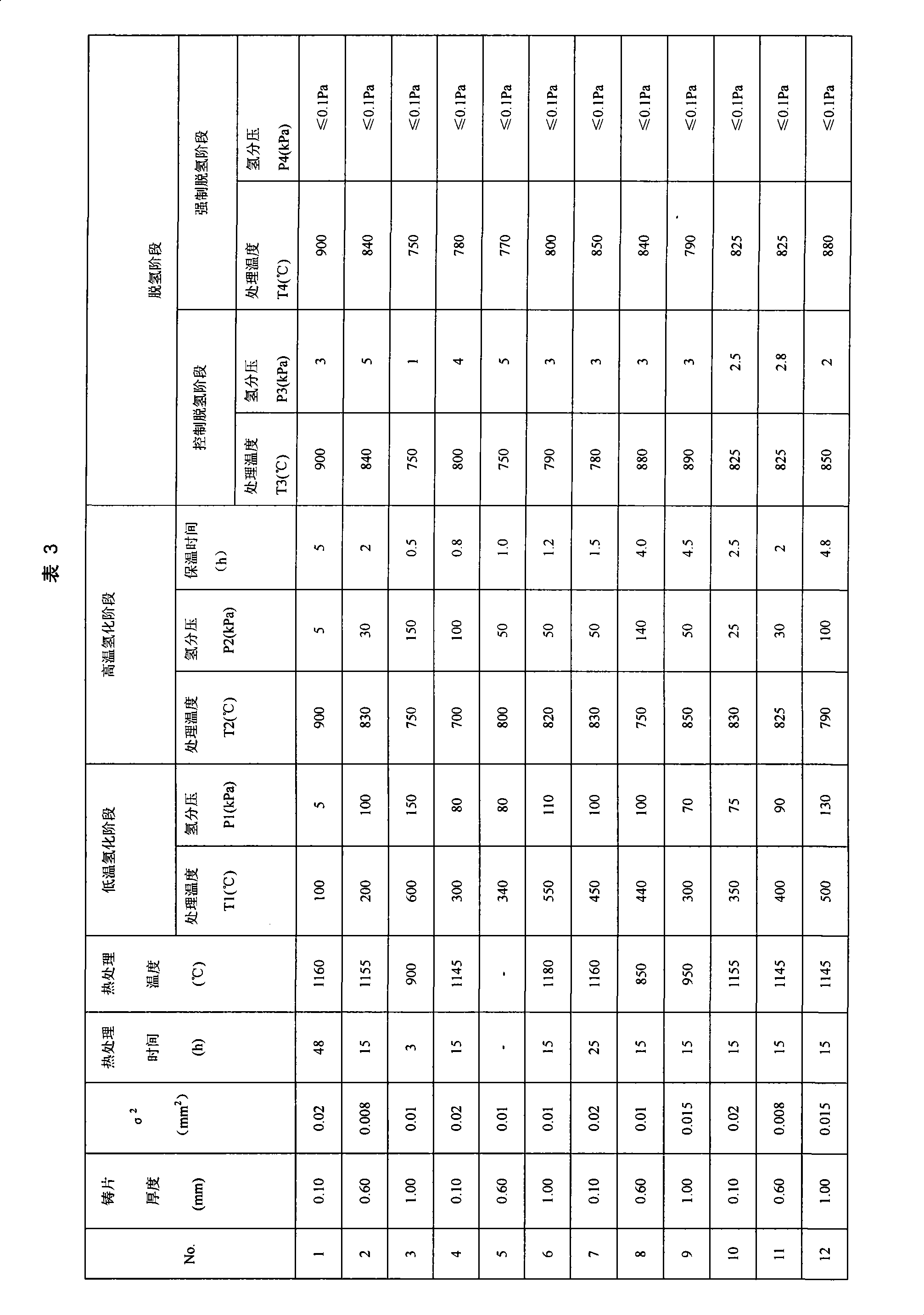

Anisotropic magnetic powder and manufacturing method thereof

ActiveCN101393791ALow costAchieve mass productionInorganic material magnetismOxidation resistantMagnetic powder

The invention provides a high-performance bonded rare earth permanent magnet powder and a preparation method thereof. Raw material compositions and the preparation method of the rare earth permanent magnet powder are as follows: an alloyed casting strip, the composition ratio of which is R1-xNdx8 to 20MyFebalB4 to 12(atm%), is prepared to be high-performance bonded anisotropic magnet powder through a heat treatment (or untreated process), a hydrogenation and dehydrogenation process and fragmentation. The preparation method comprises the following steps: a rare-iron-boron alloyed casting strip is prepared through a strip casting process, the thickness of the rare-iron-boron alloyed casting strip is 0.1 mm to 1.0 mm; and finally the bonding rare earth permanent magnet powder with high coercive force and high oxidation resistance are prepared through the processes of hydrogenation and dehydrogenation. Compared with the magnet powder taking the traditional cast ingot as the raw material, the bonded magnet powder has higher magnetism property and higher oxidation resistance property.

Owner:GRIREM ADVANCED MATERIALS CO LTD

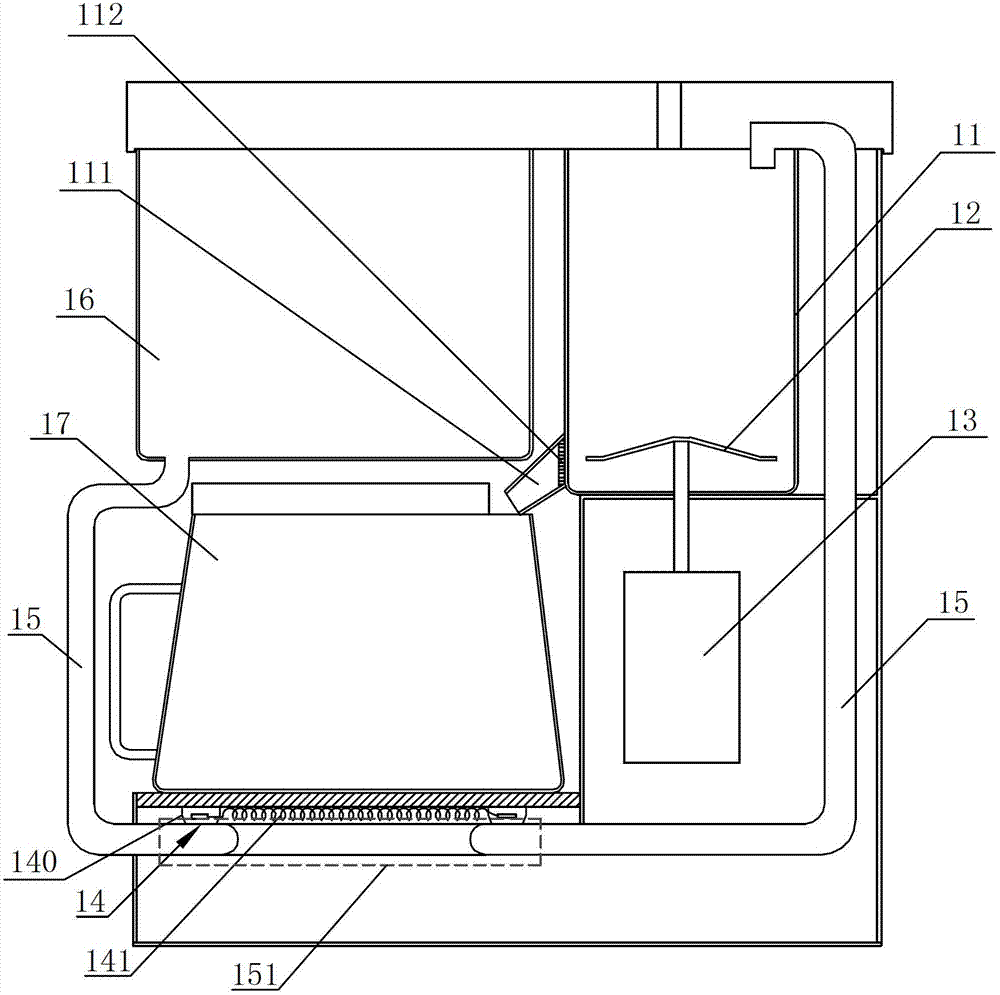

Wall-breaking and pulverizing machine for Chinese herbal medicines

The invention discloses a wall-breaking and pulverizing machine for Chinese herbal medicines. The wall-breaking and pulverizing machine is characterized by comprising a machine base, a motor, a grinding barrel, grinding rods, a refrigerating device, a shock excitation part, a vibration spring, a rotary shaft and an eccentric block; the grinding barrel is positioned in a soundproof box; a cooling coil pipe is wound at the periphery of the grinding barrel, and the inner wall of the grinding barrel is smooth; an axial hollow channel is arranged on the middle part of the grinding barrel; the two ends of the hollow channel are equipped with bearings; the grinding barrel is provided with an end opening; a material collecting barrel capable of being opened and closed is arranged in the end opening; the plurality of the grinding rods are arranged in the grinding barrel; and the surface of each grinding rod is smooth. Compared with the prior art, the wall-breaking and pulverizing machine has the advantages that: the smooth grinding rods and the smooth inner surface of the grinding barrel are adopted, so that materials bear greater planar impact in a grinding process, and a stressed area is great; and meanwhile, abrasion on parts is relatively small, smaller particles can be obtained after being grinded, a material cell wall-breaking rate is higher and wall-breaking is more complete.

Owner:NINGBO SHENGWANG BIOTECH CO LTD

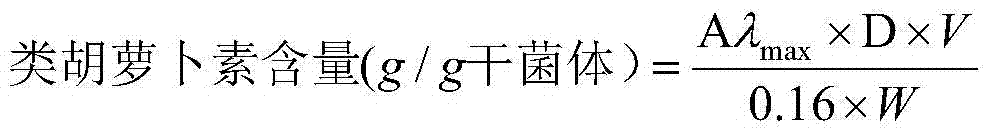

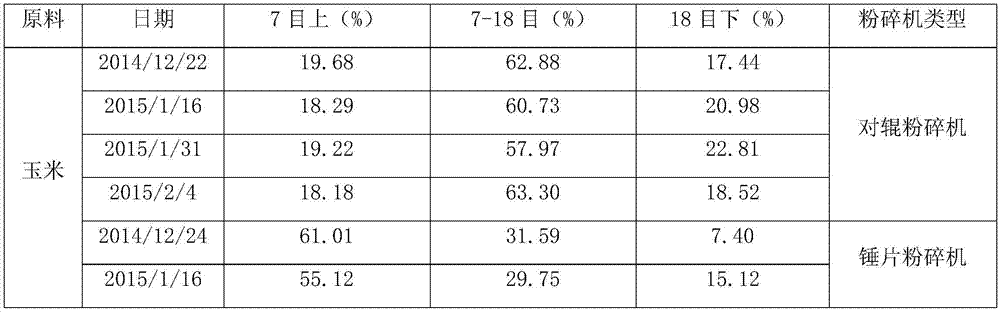

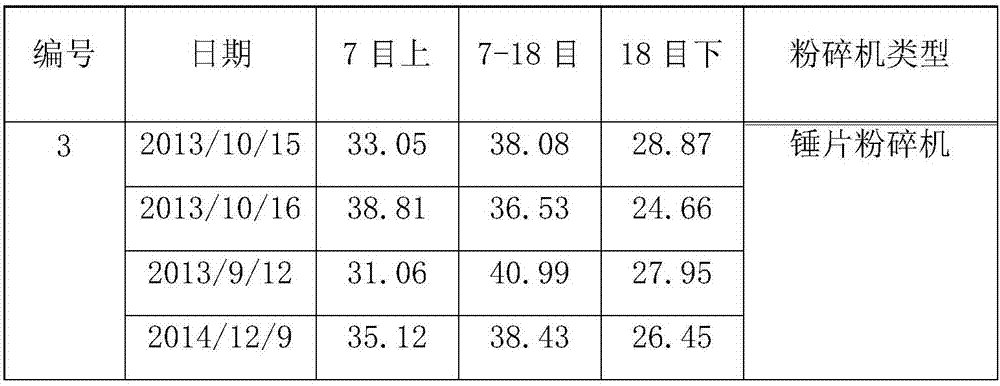

Granularity-adjustable laying hen feed and preparation method thereof

ActiveCN105432954AHigh nutritional valueIncrease contentFood processingAnimal feeding stuffMonosodium glutamateAnimal science

The invention discloses a granularity-adjustable laying hen feed and a preparation method thereof and belongs to the technical field of feed processing. The preparation method of the laying hen feed mainly comprises the following steps: taking corns as the main raw materials of the laying hen feed; grinding the corns by a double-roller grinder; screening the grinded corns by a vibration sieve; further grinding the screen residues by a hammer grinder; uniformly mixing the further grinded screen residues with the screened grinded corns; grinding soybean meal, DDGS, corn bran, double-low vegetable meal, monosodium glutamate protein and palm meal by a hammer grinder; then preparing the laying hen feed according to the conventional method. Preferably, the ratio of the digestible amino acids in the laying hen feed is DLys: (DM plus C): DThr: DVal: DArg equals 100: 84: 67: 87: 94; moreover, the yeast powder fermented from the preserved bacteria Rhodotorula benthica WYN1 whose preservation code is CCTC No: M 2014592 is specially added in the laying hen feed; thus, the grinding time is shortened, the dust is reduced, the production efficiency is improved, the breeding effect is raised and the egg quality is improved.

Owner:LIAONING WELLHOPE AGRI TECH

Crusher for waste plastics

InactiveCN108214999AReduce the difficulty of breakingReduce crushing timePlastic recyclingGrain treatmentsPulp and paper industryCrusher

The invention relates to a crusher for waste plastics. The crusher comprises a rack and a crushing barrel, wherein the crushing barrel is fixed on the rack and is communicated with a feeding channel;the crushing barrel is internally and rotatably connected with a crushing mechanism; the feeding channel is connected with a pushing plate in a sliding way; a first piston cylinder is fixed on the rack; a first piston is connected in the first piston cylinder in a sliding way; a first wedge groove is formed in the pushing plate; a first wedge rod, inserted into the first wedge groove, is fixed onthe rack; a third spring is connected between the first wedge rod and the rack; a second wedge groove is formed in the first wedge rod; a second wedge rod, inserted into the second wedge groove, is fixed on the first piston; the first piston cylinder is communicated with an air inlet pipe; the rack is provided with an air inflating mechanism, and the air inflating mechanism is communicated with the air inlet pipe; the piston cylinder is also communicated with an air outlet pipe; an inclined plate, opposite to the pushing plate is fixed in the crushing barrel. Compared with the prior art, the crusher can be used for preliminarily crushing the waste plastics by means of the pushing plate and the inclined plate which are cooperatively used, so that the production efficiency is improved.

Owner:宁波得晴电器科技有限公司

Equipment for recycling outer-layer plastic of cable

ActiveCN108173172ASave plasticReduce crushing timeBasic electric elementsApparatus for removing/armouring cablesBevel gearPlastic recycling

The invention relates to the technical field of plastic recycling equipment, in particular to equipment for recycling outer-layer plastic of a cable. The equipment comprises a workbench, wherein a cylinder is arranged on the workbench and is rotatably connected with a rotation cylinder, a tooth ring is arranged on an outer wall of the rotation cylinder, a baffle plate is fixedly connected with therotation cylinder, two sliding blocks are fixedly connected with the baffle plate, cutter blades are fixedly connected with the sliding blocks and are used for cutting the outer-layer plastic of thecable, two wedge-shaped blocks are arranged in the cylinder, springs are connected between the wedge-shaped blocks and an inner wall of the cylinder, grooves are formed in the wedge-shaped blocks, rollers are rotatably connected with the grooves, heaters are arranged in the grooves, one of the rollers is fixedly connected with a rotation shaft, the rotation shaft penetrates through the cylinder, afirst bevel gear is coaxially connected with the rotation shaft and is engaged with a second bevel gear, and the second bevel gear is coaxially connected with a gear engaged with the tooth ring on the outer wall of the cylinder. By the equipment, rotation cutting of the outer-layer plastic of the cable can be achieved, so that a metal wire and the plastic are separated, and the plastic is recycled.

Owner:宁波高新区新柯保汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com