Patents

Literature

440results about How to "Improve crushability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

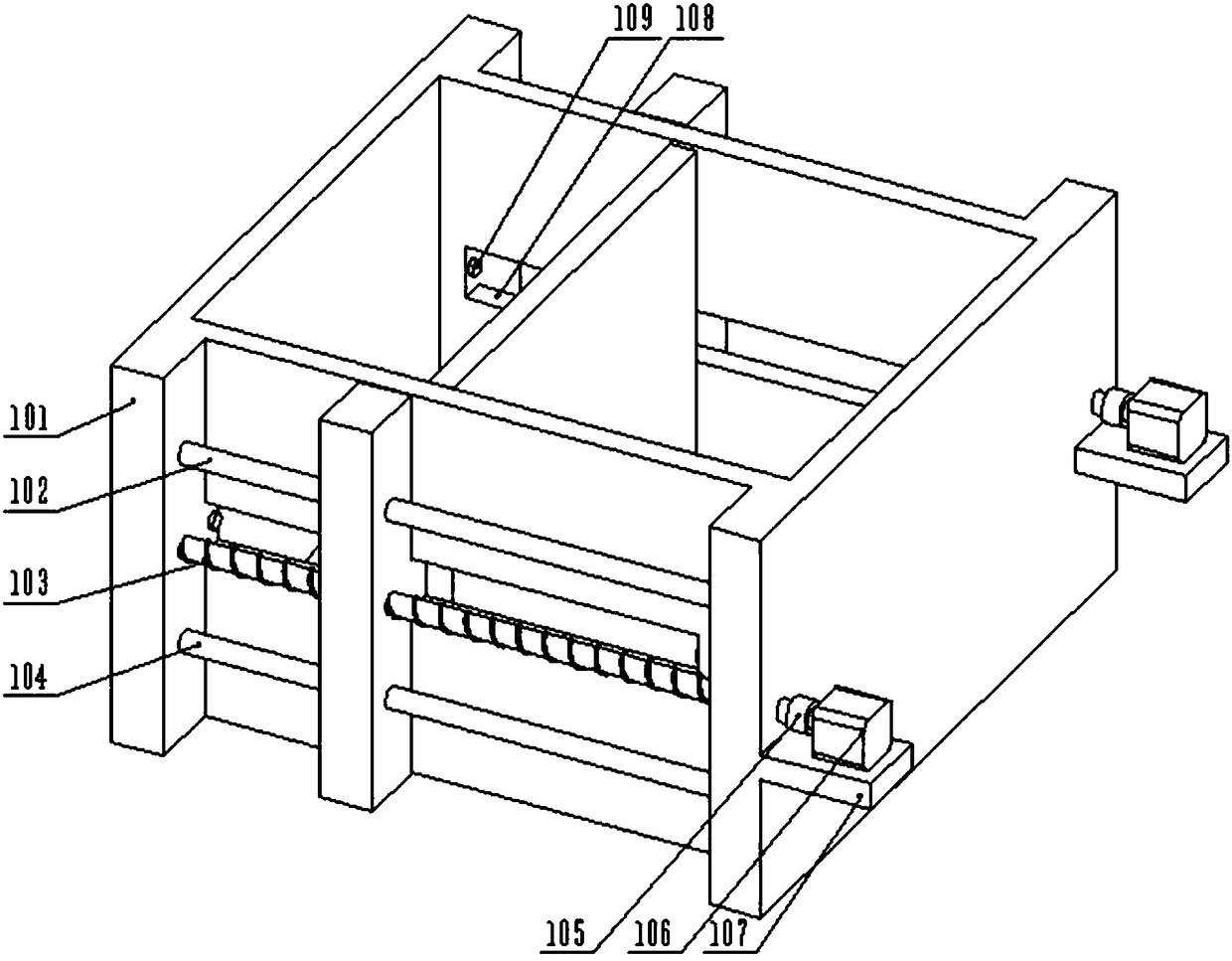

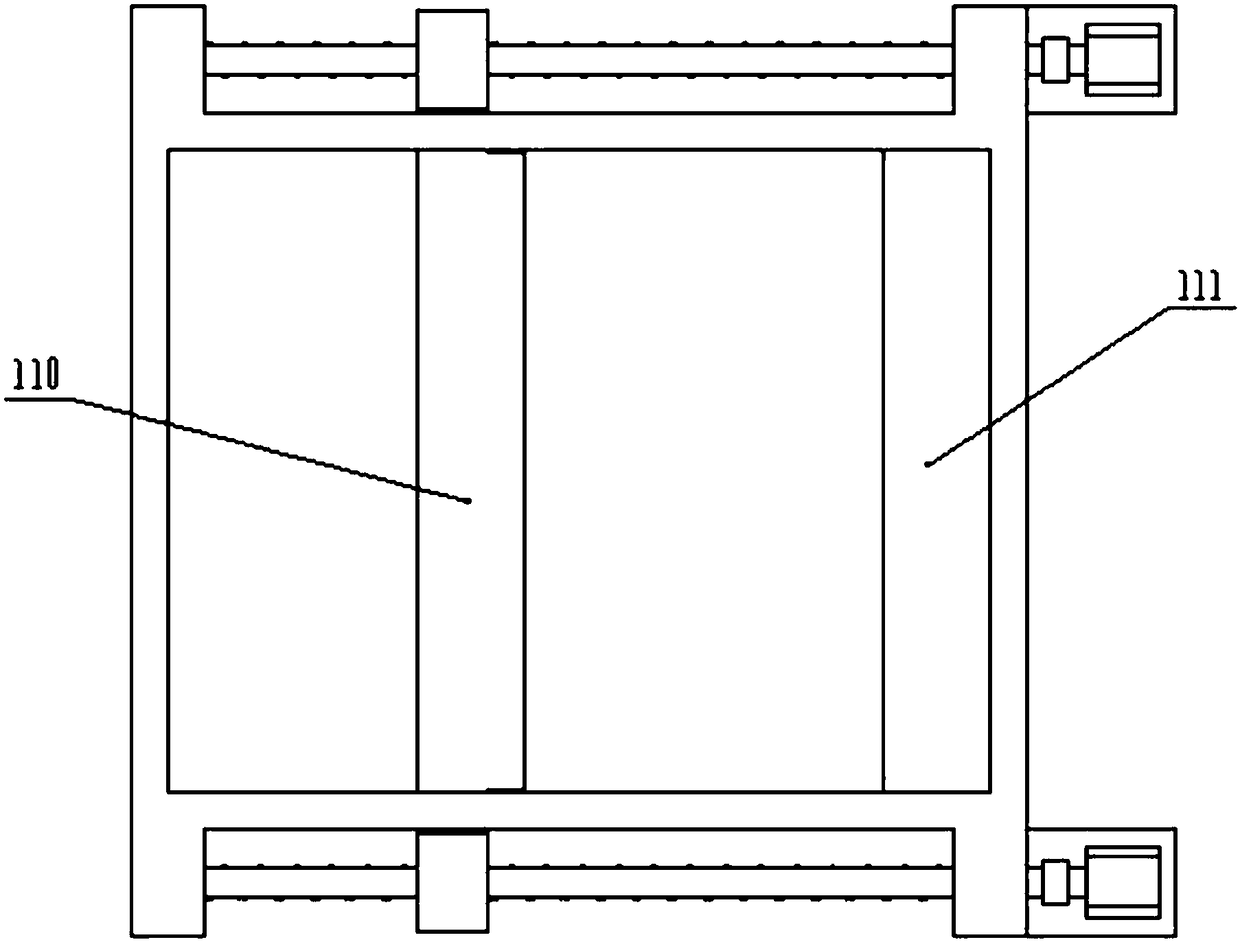

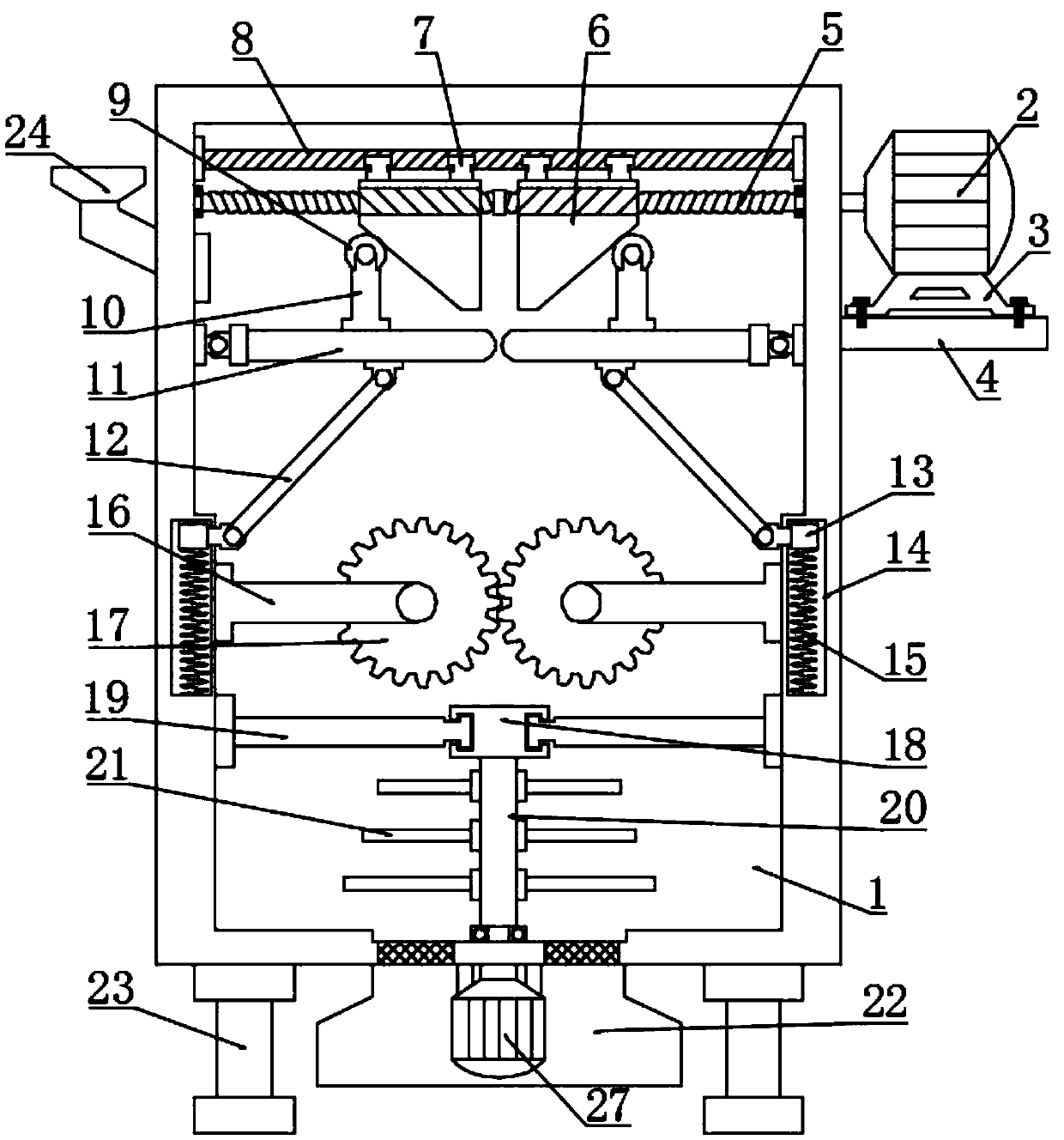

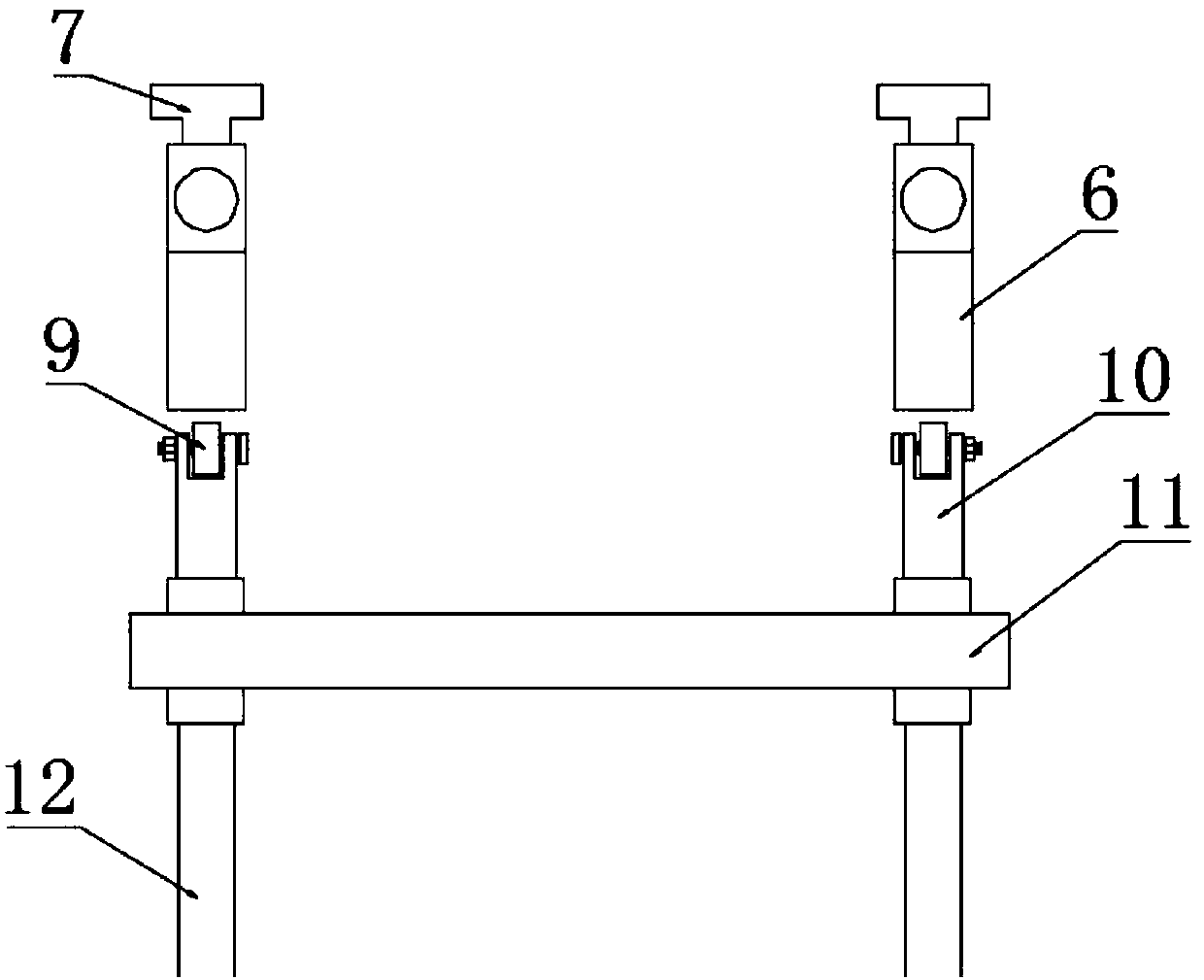

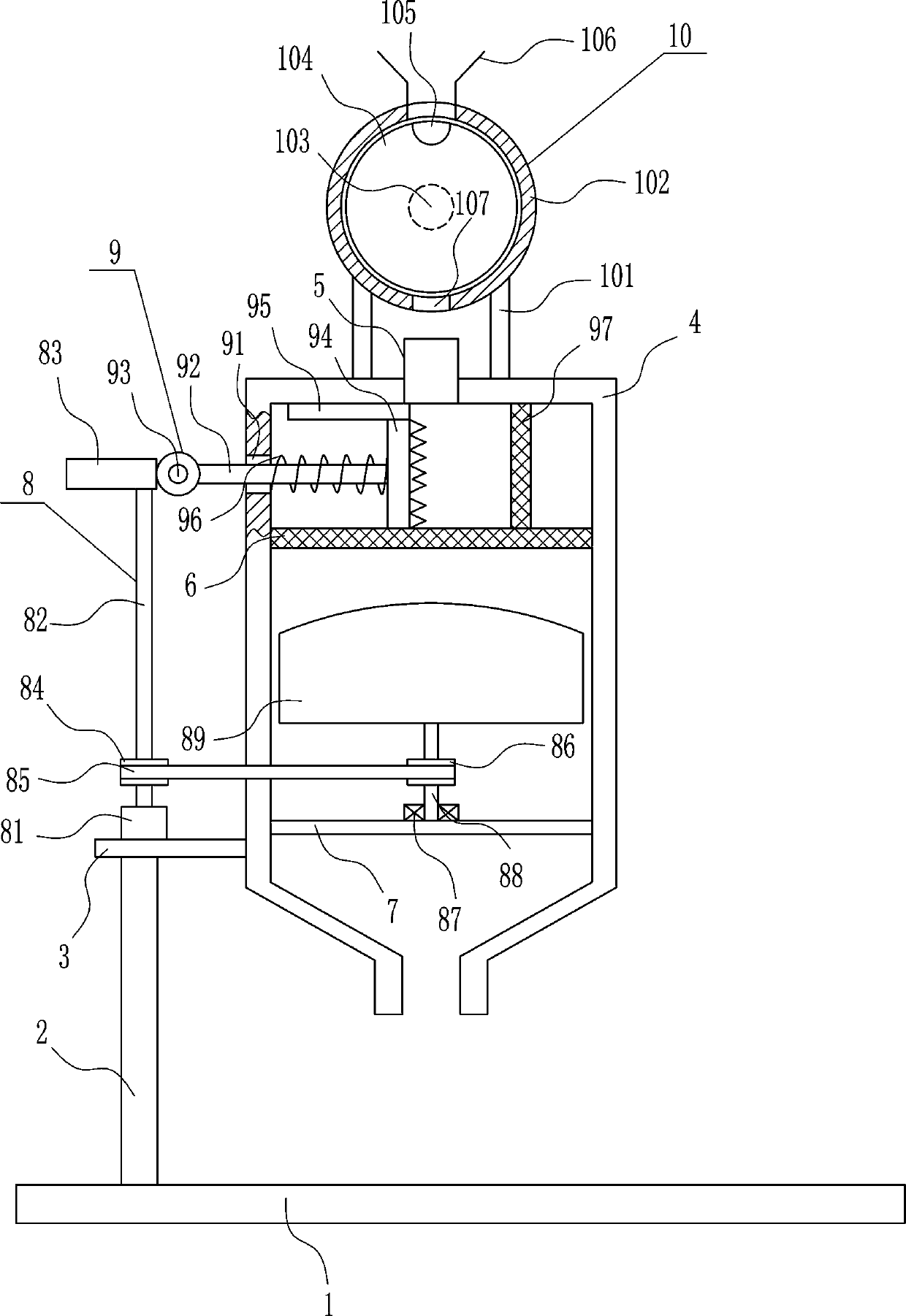

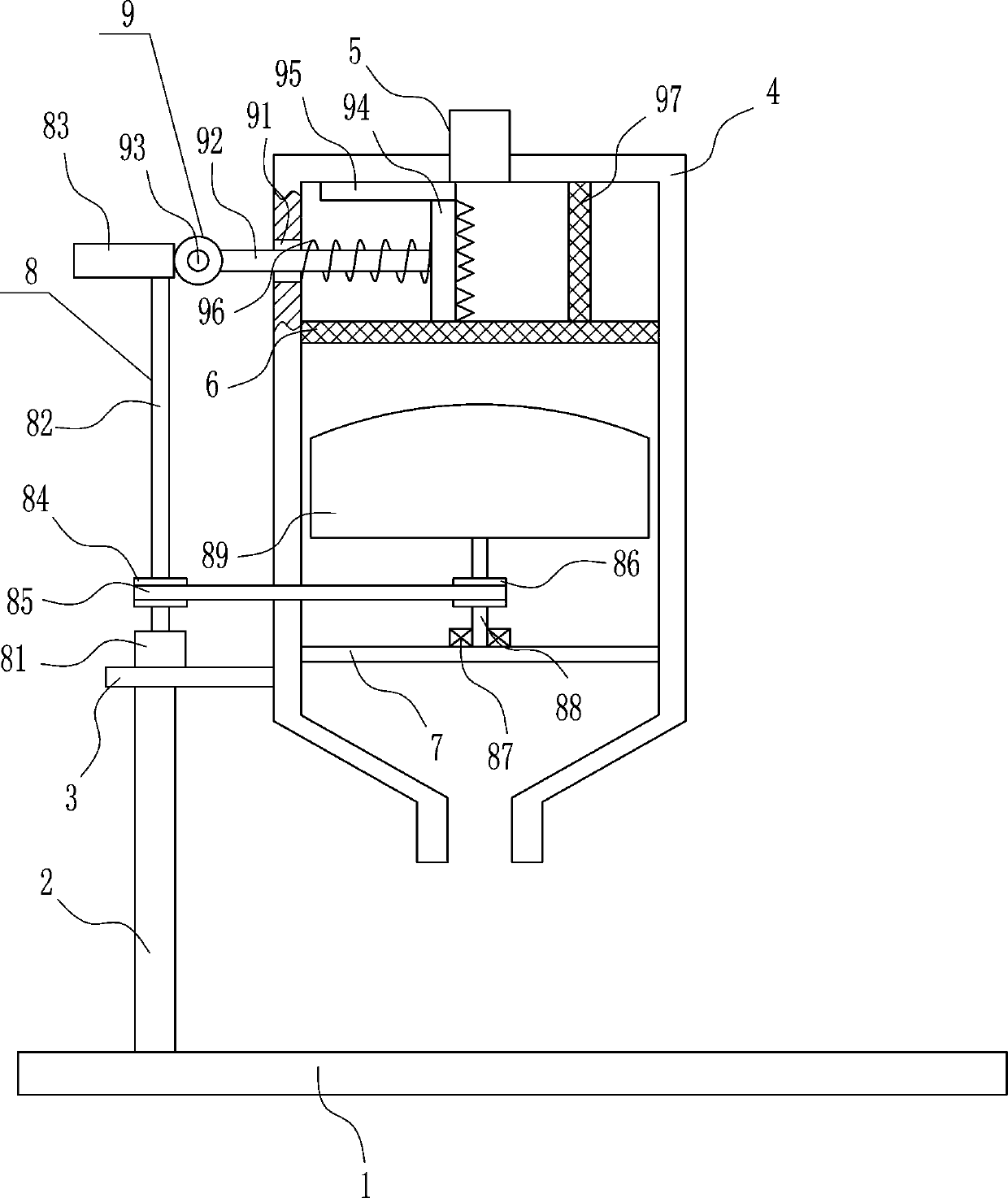

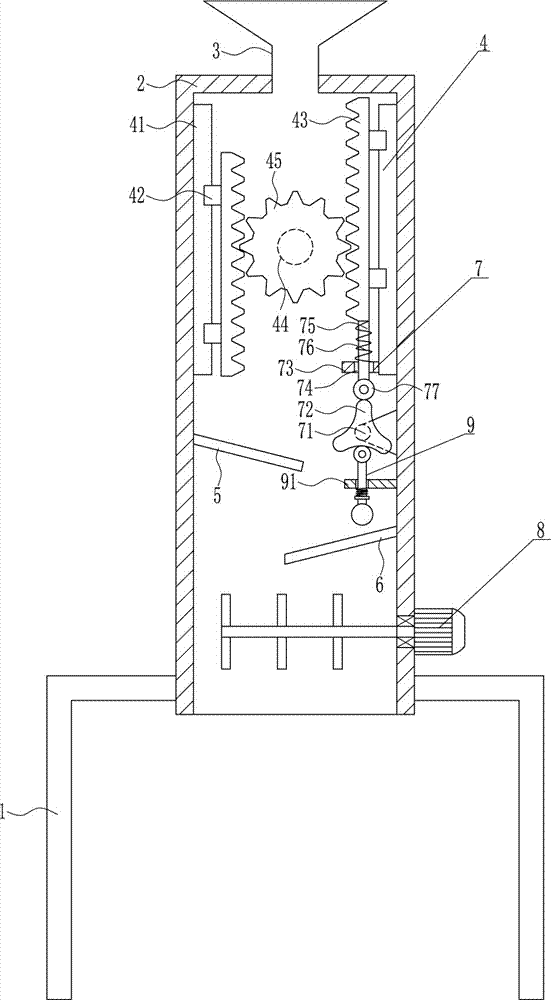

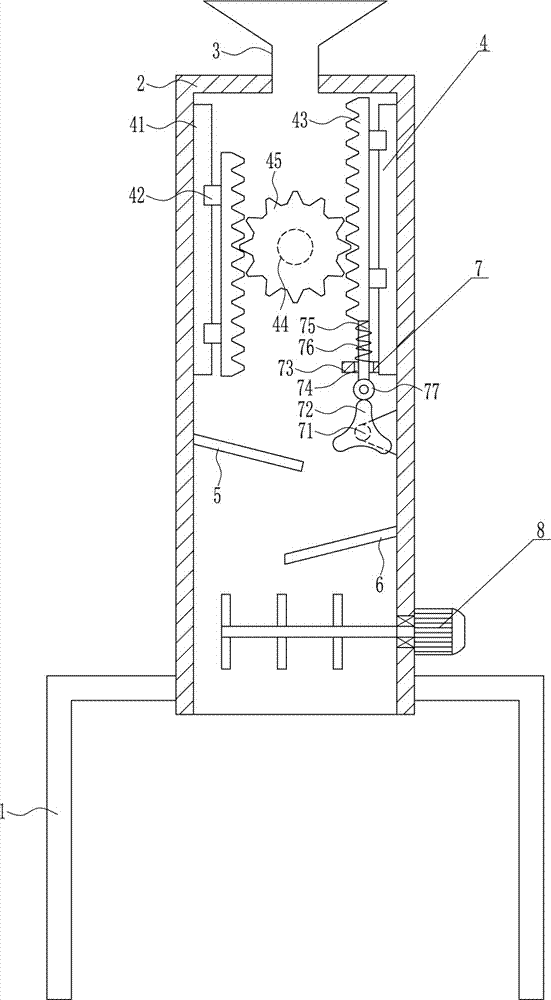

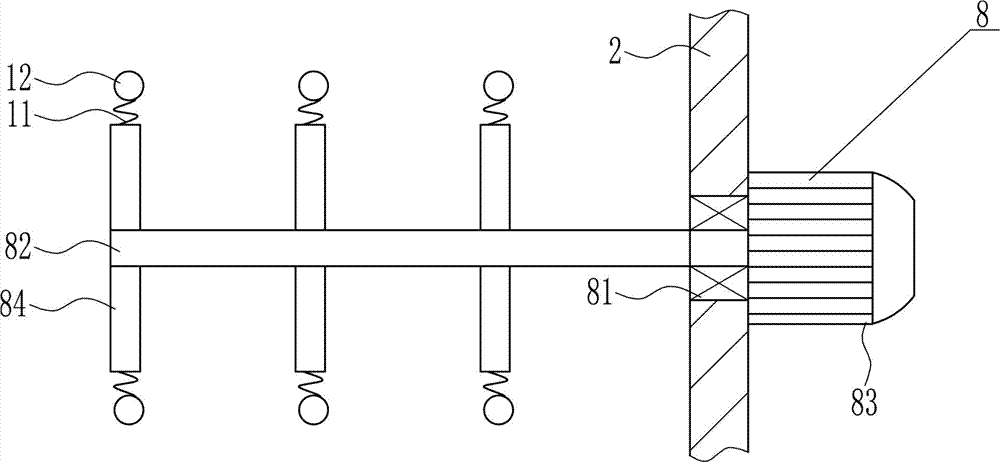

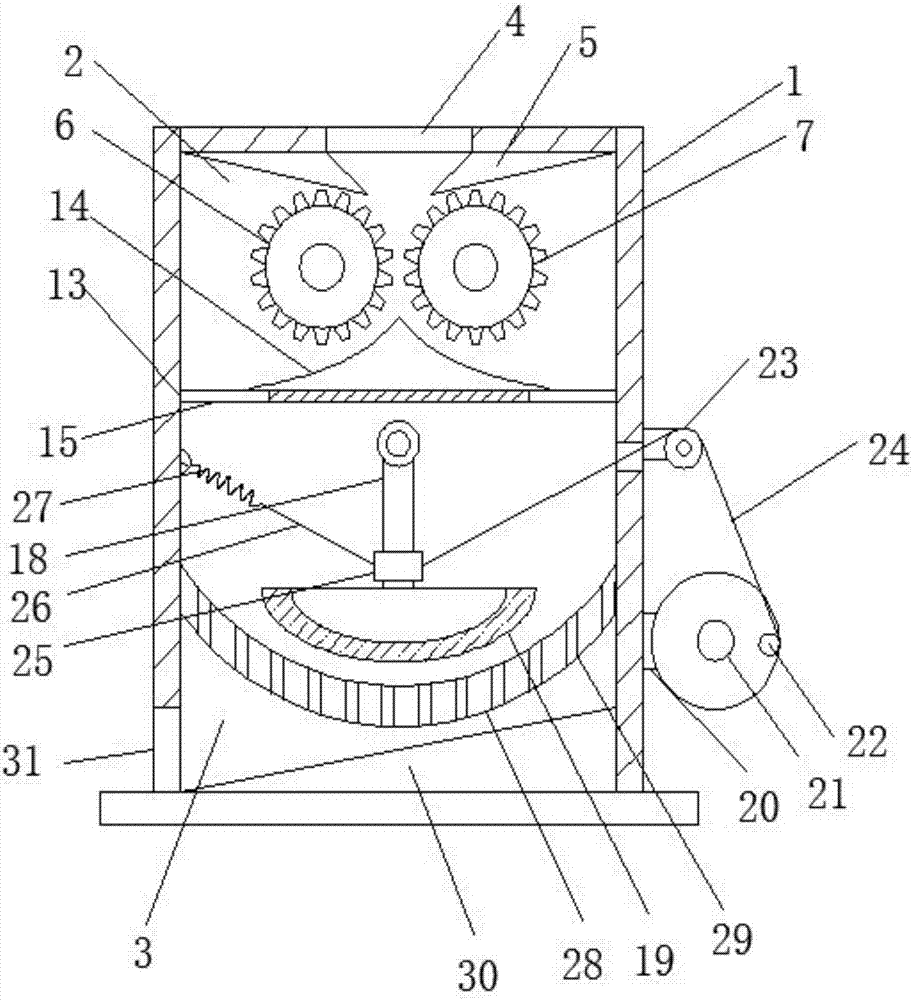

System for squeezing, smashing and winnowing municipal solid waste

ActiveUS20160250648A1Good effect in squeezingGood effect in smashingSievingGas current separationLitterCrusher

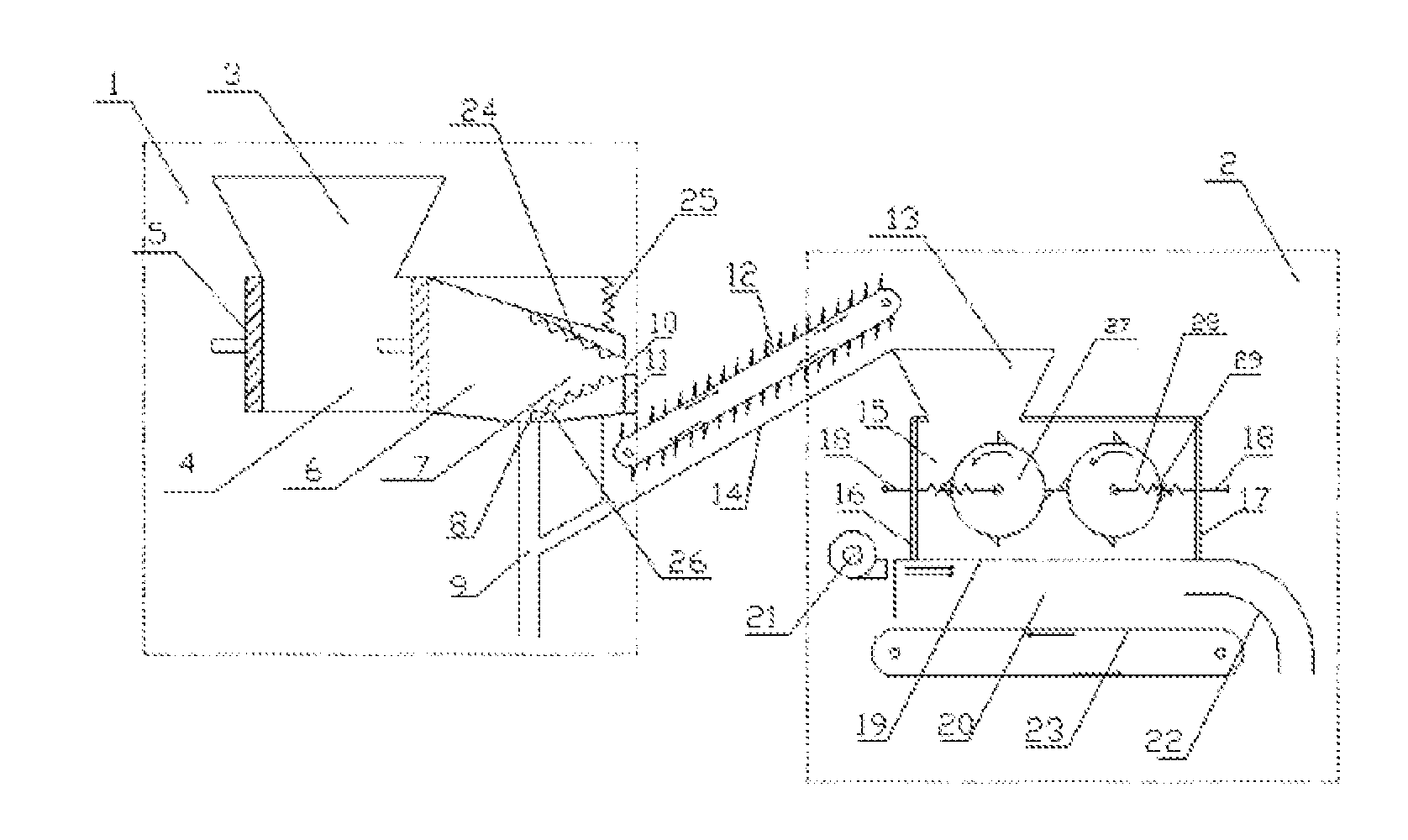

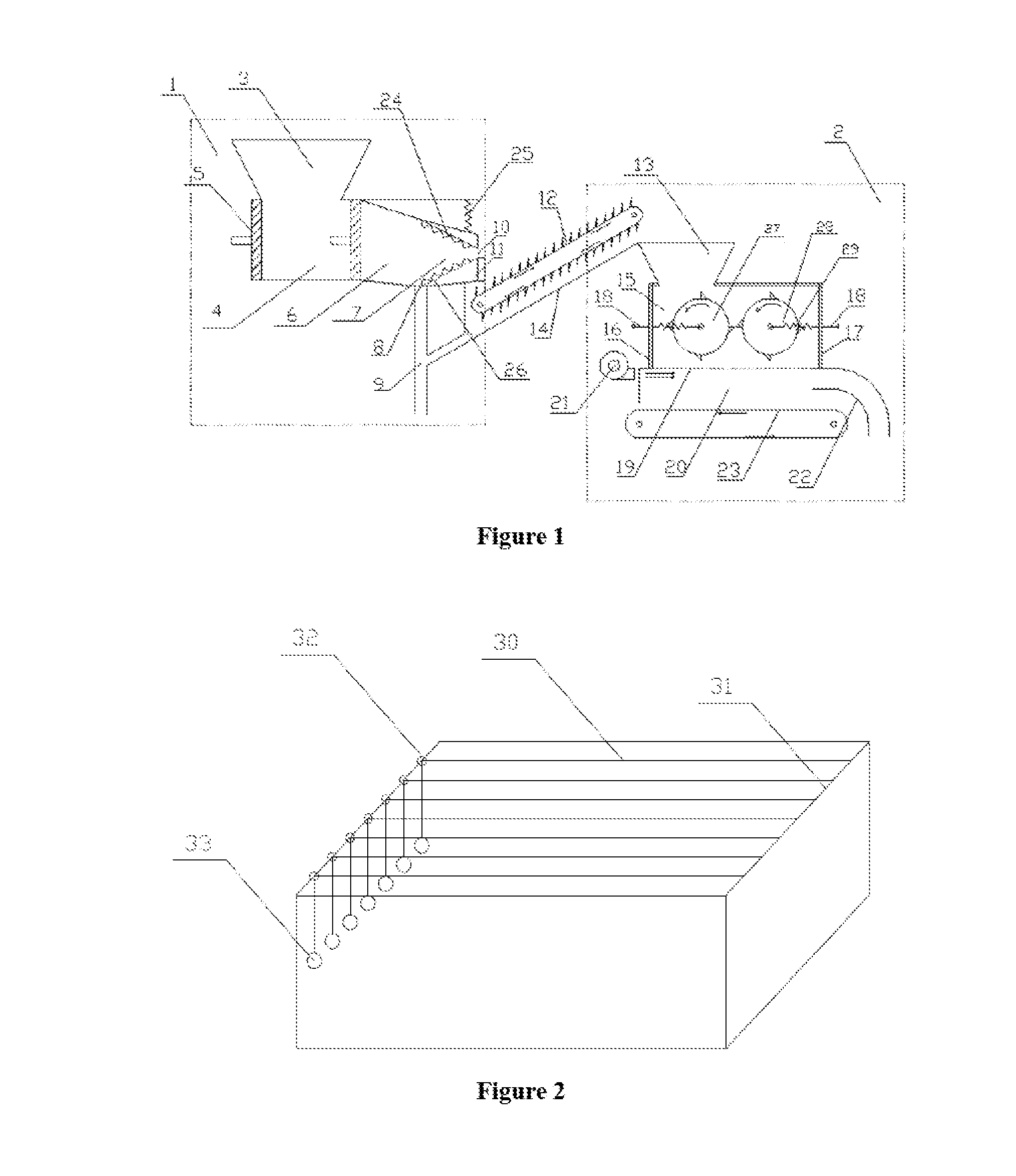

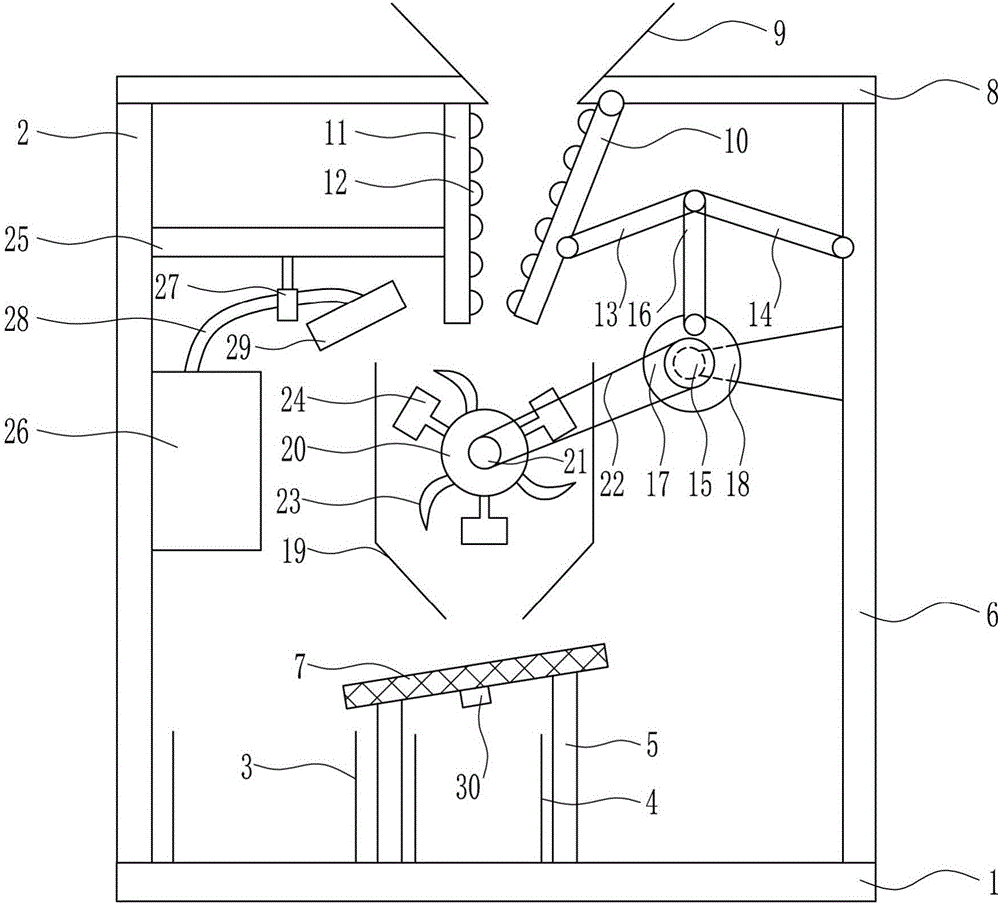

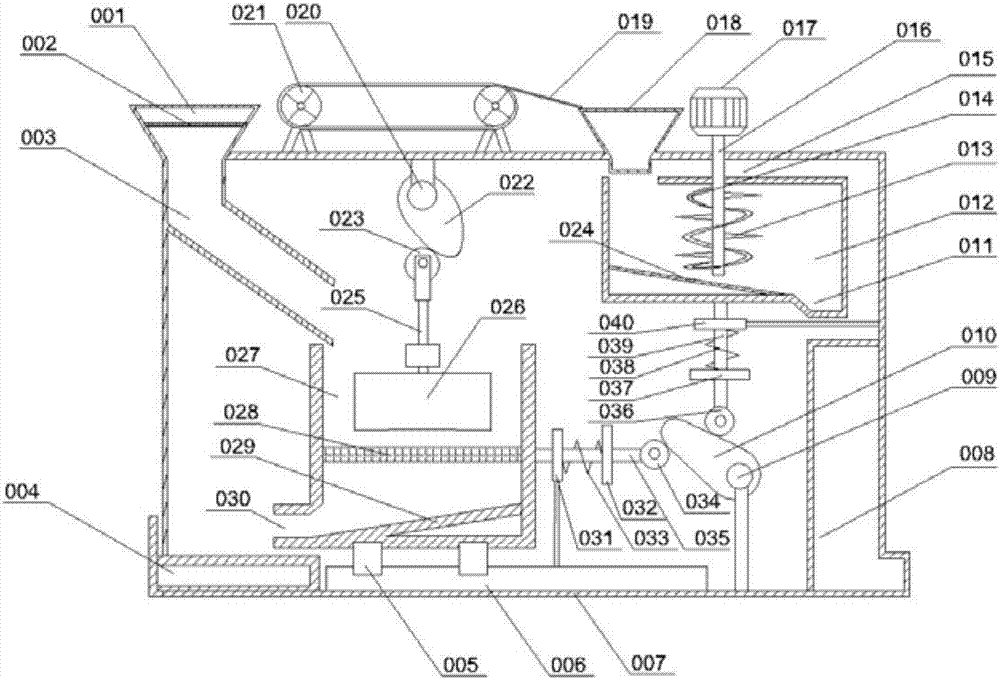

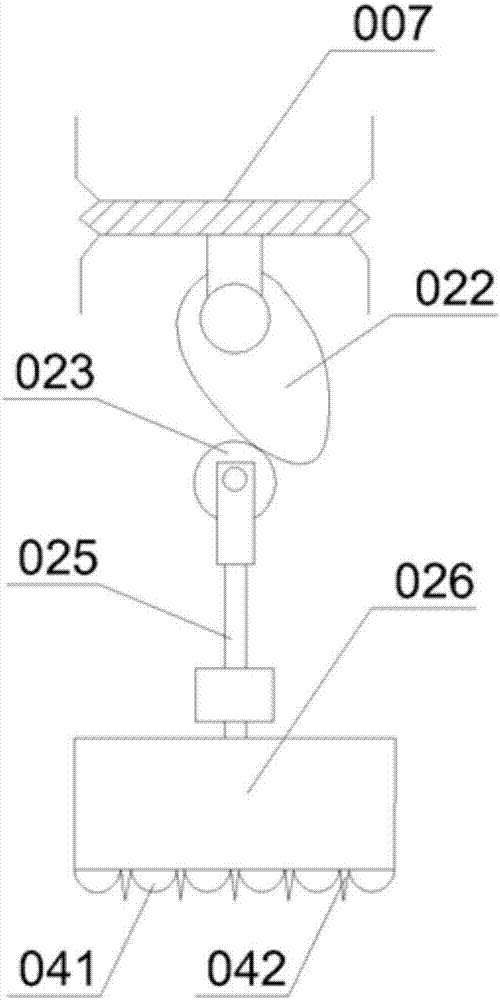

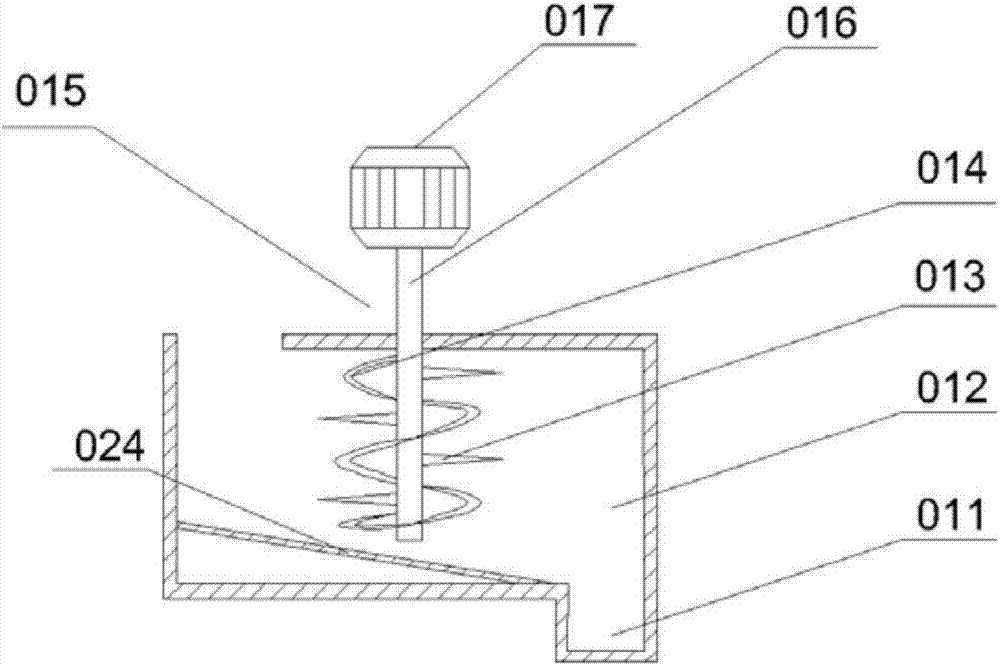

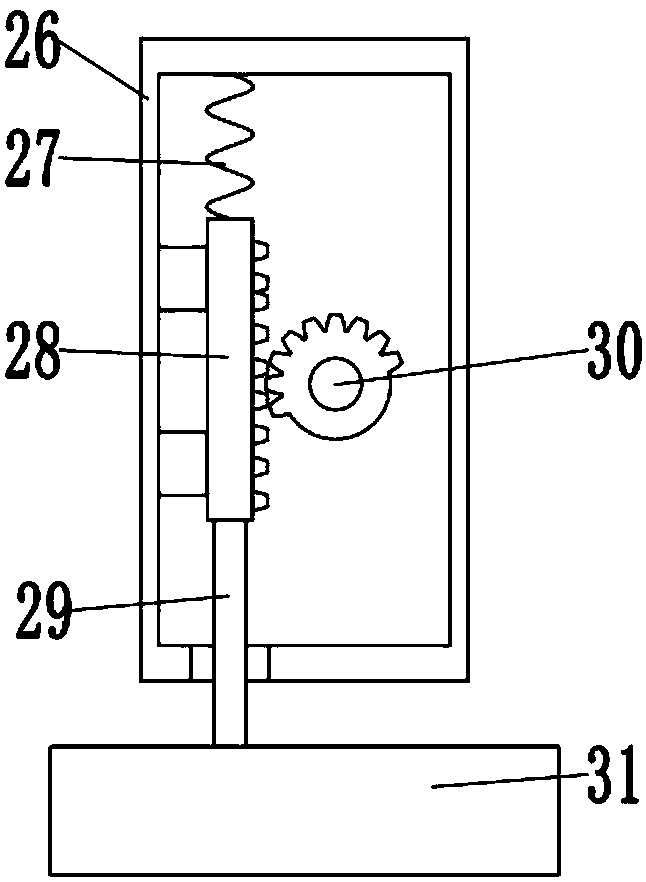

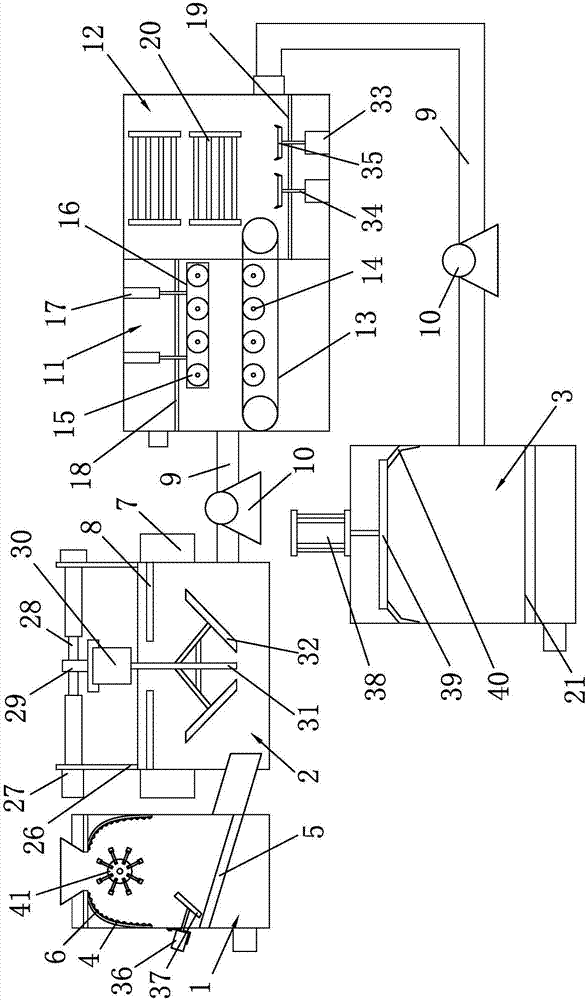

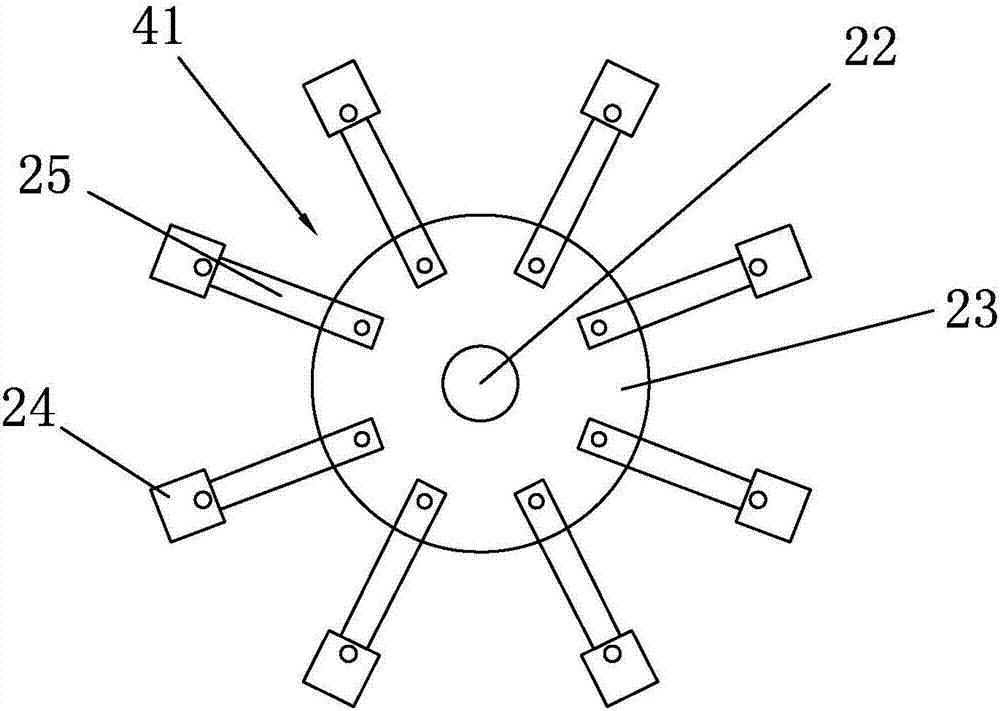

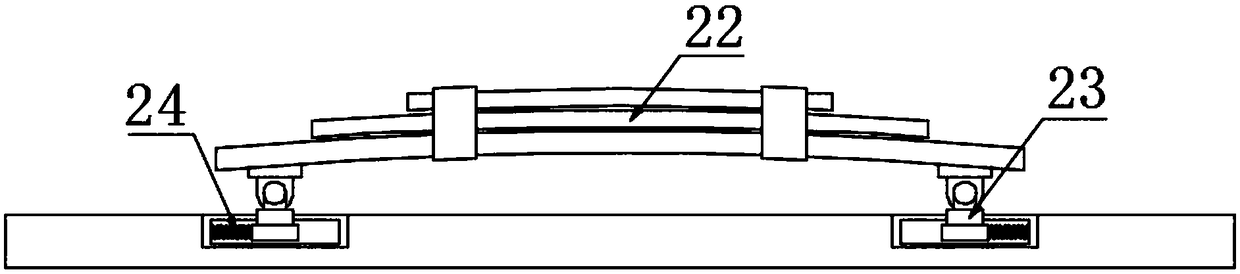

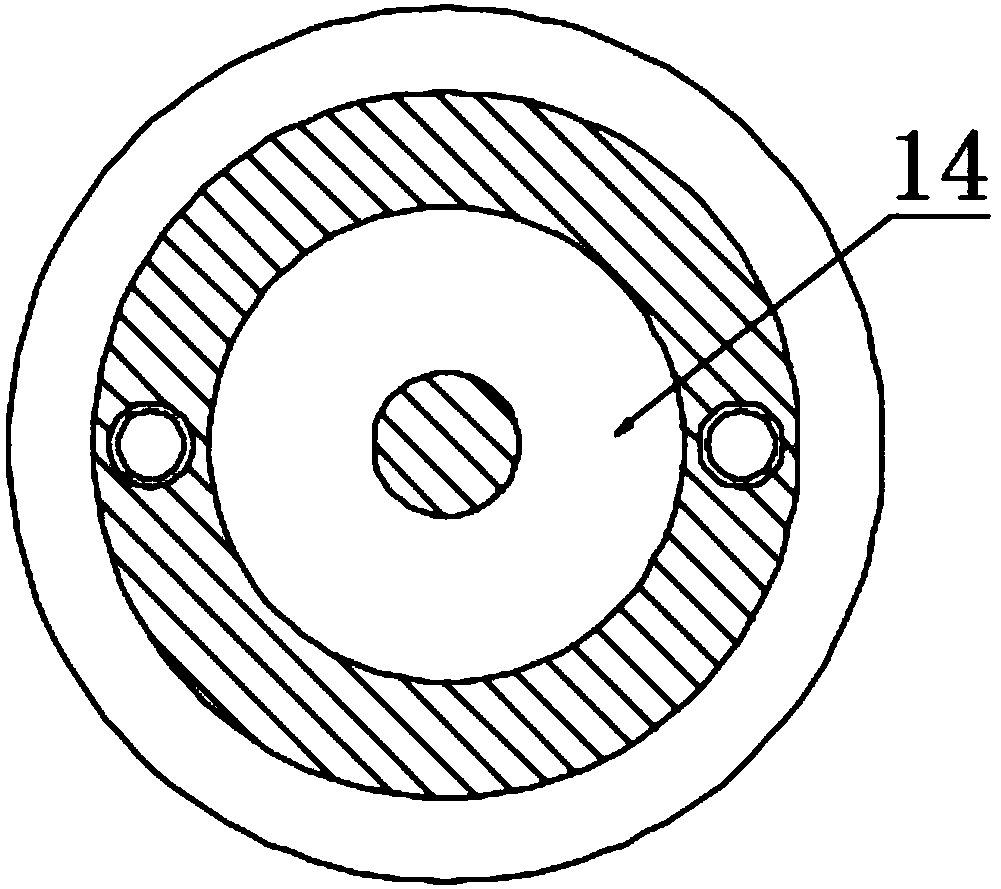

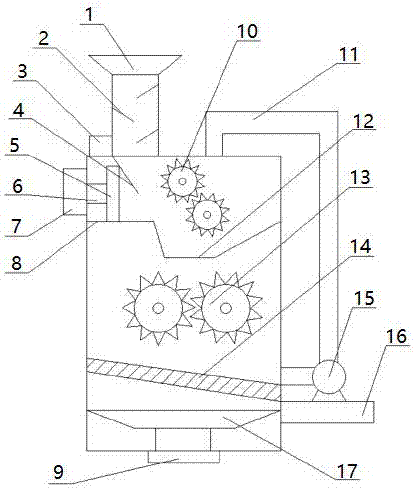

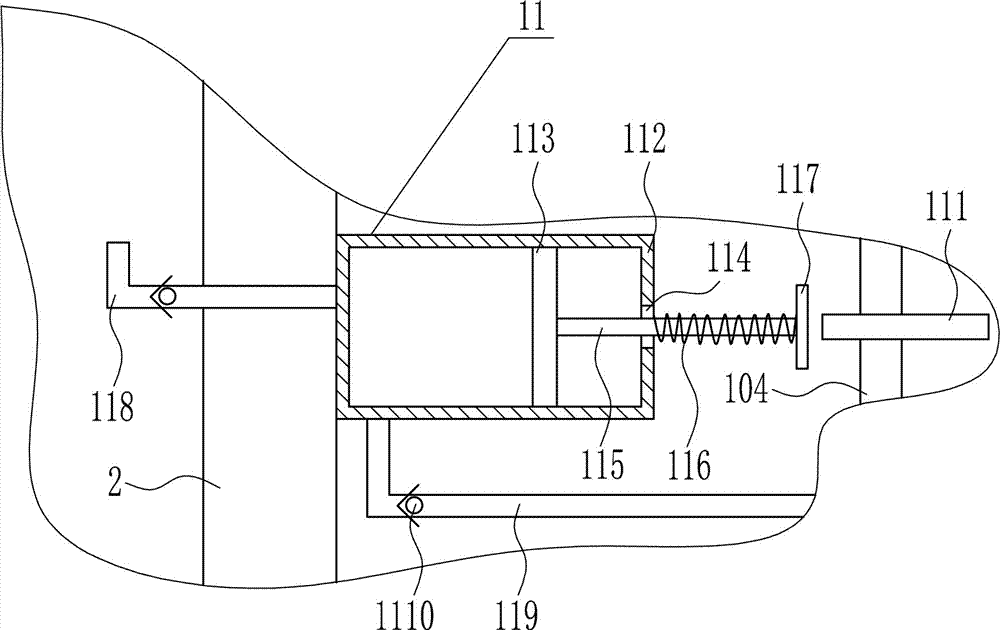

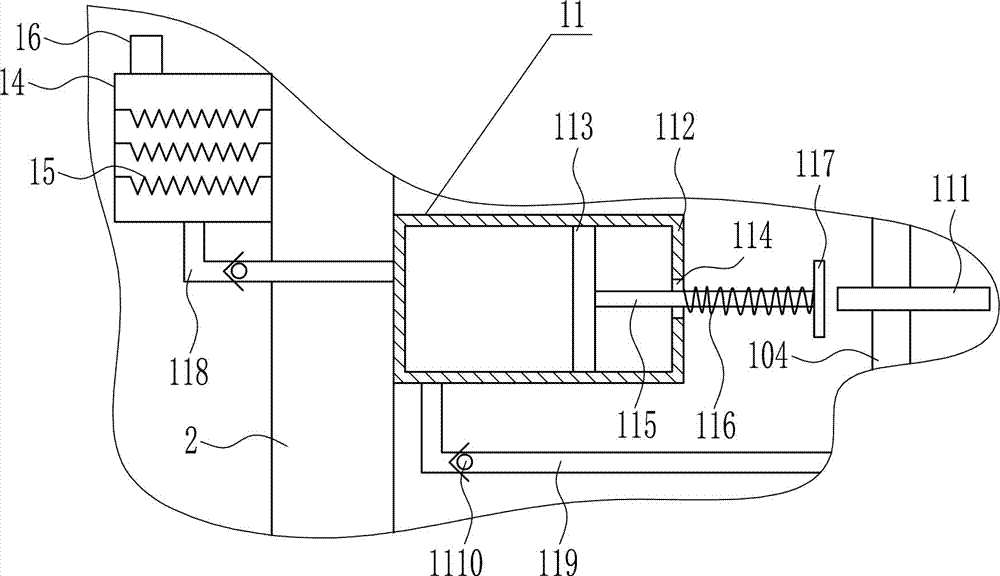

The invention discloses a system for squeezing, smashing and winnowing municipal solid waste (MSW). The system comprises a primary squeezing and smashing, device and a secondary smashing and winnowing device. The system of the invention has good effect m squeezing, smashing and winnowing, can greatly reduce the water content of MSW and efficiently separate the MSW into combustible matters and non-combustible matters, so as to facilitate further subsequent utilization of the municipal waste; moreover, an upper jaw of a jaw crusher is connected with a spring device, so that the squeezing pressure, smashing effect and processing capacity of the jaw crusher can be adjusted according to the amount of the MSW. In addition, the system of the invention is further provided with emergency brake switches, spring protection devices and a sieve, so as to ensure the stability and the reliability of the system.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

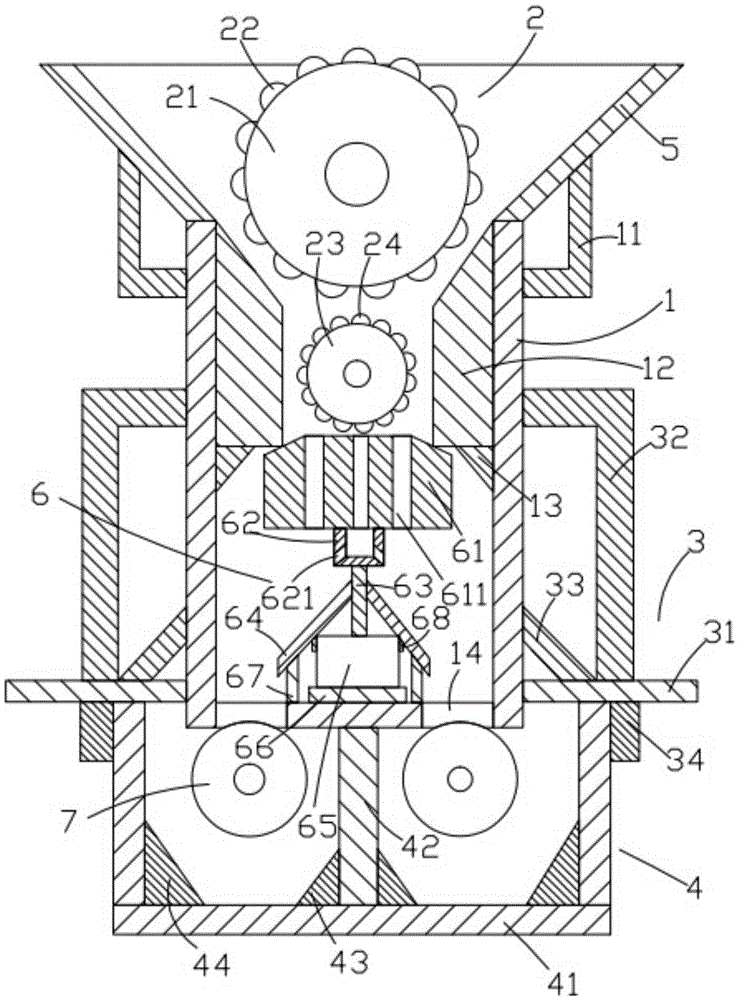

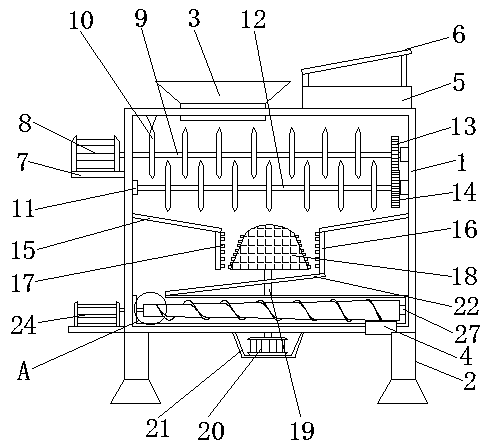

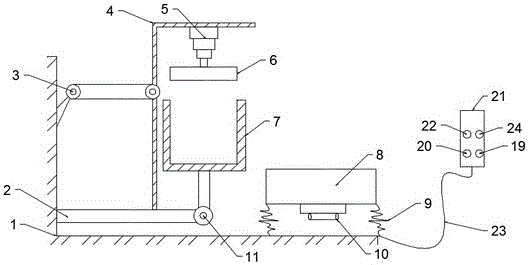

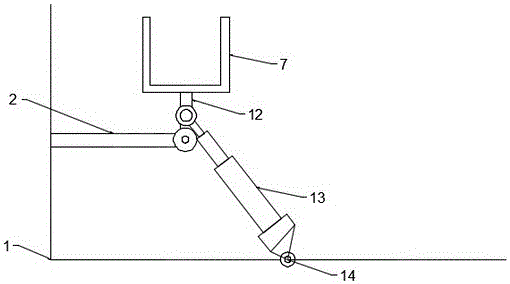

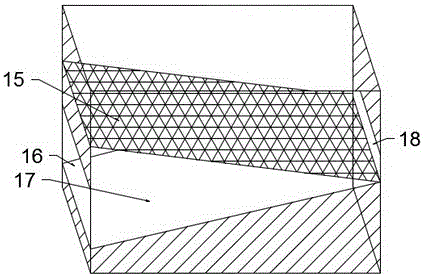

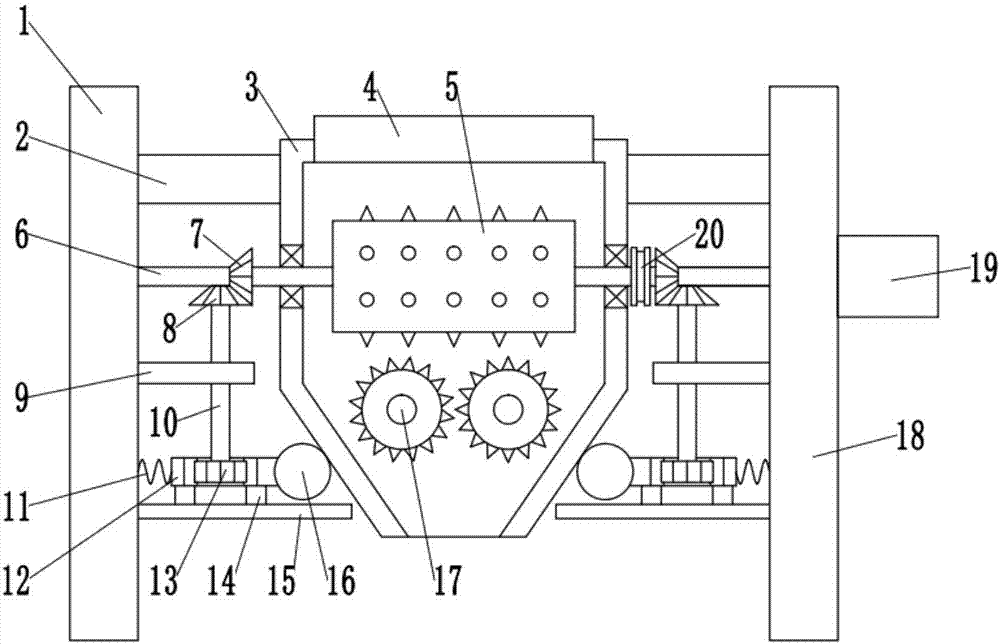

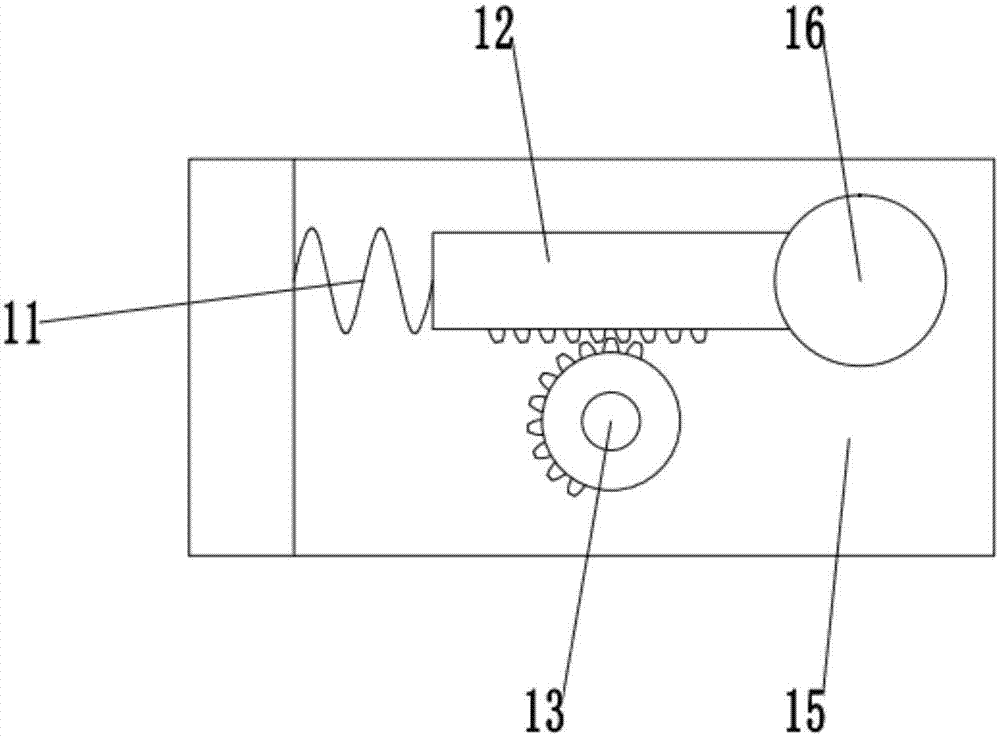

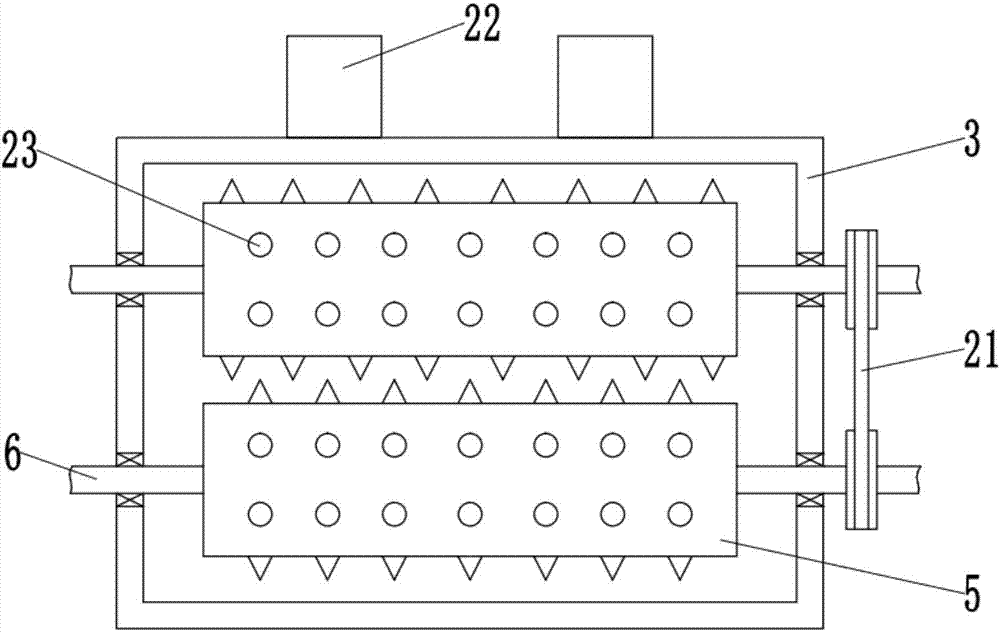

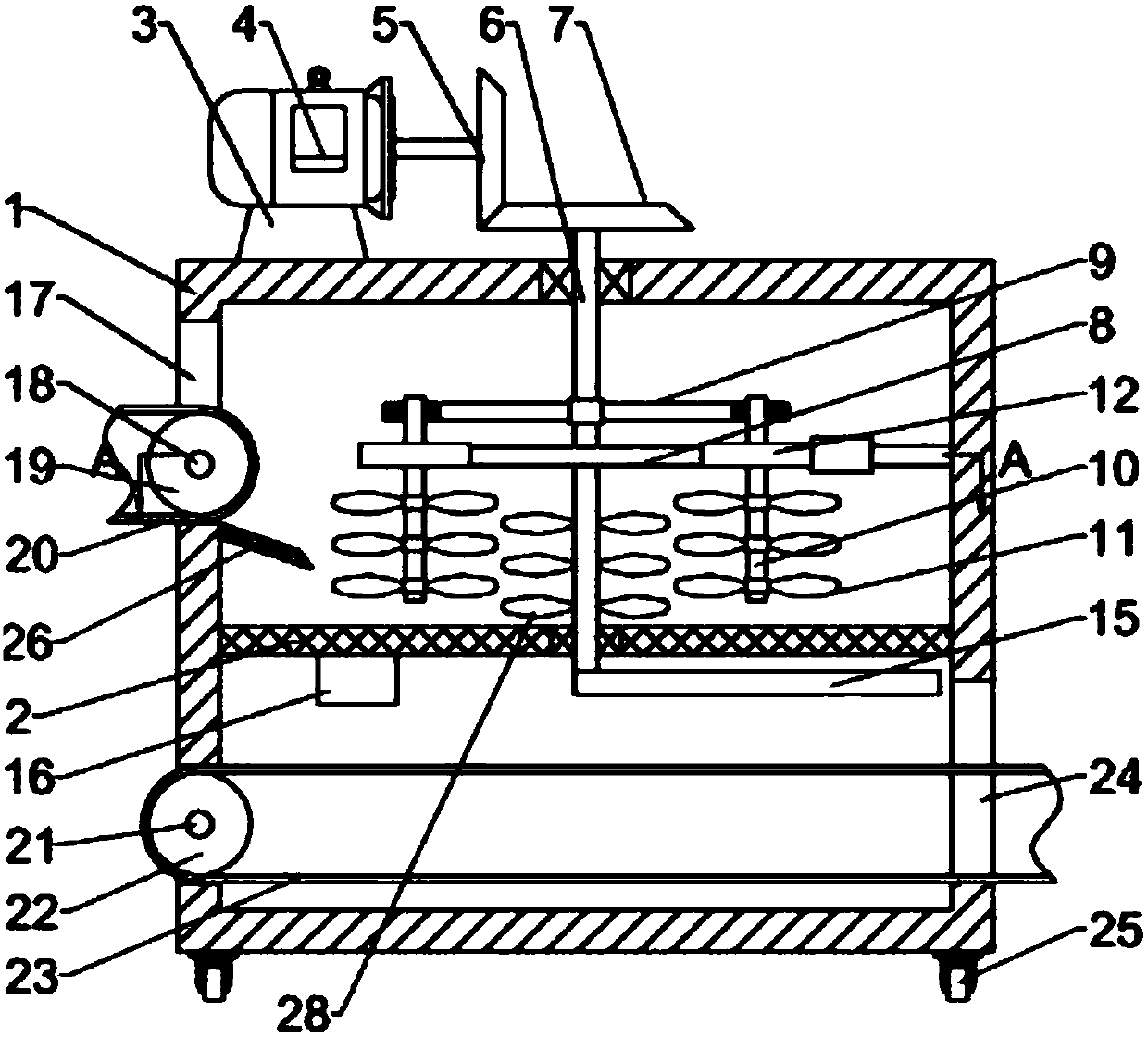

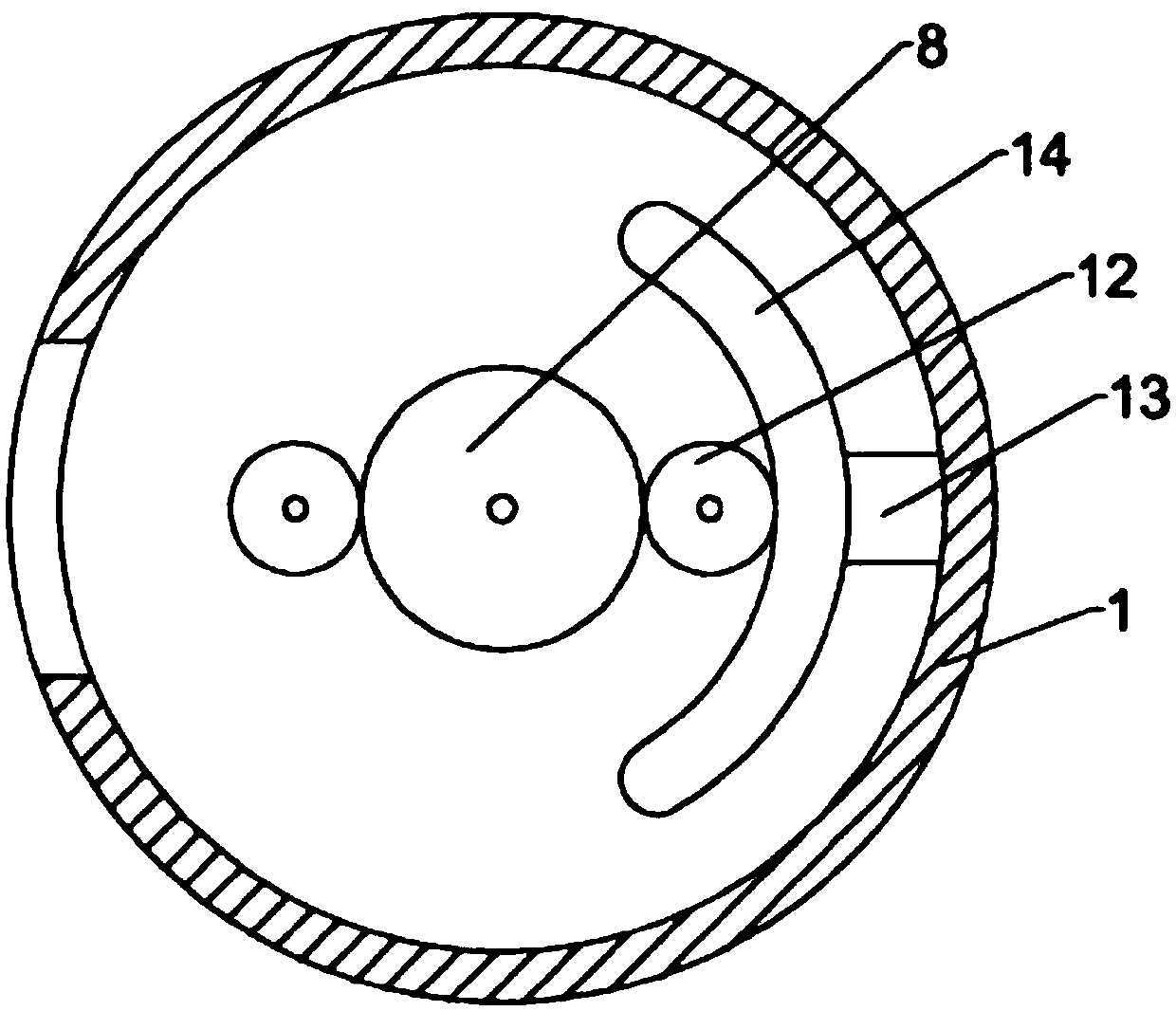

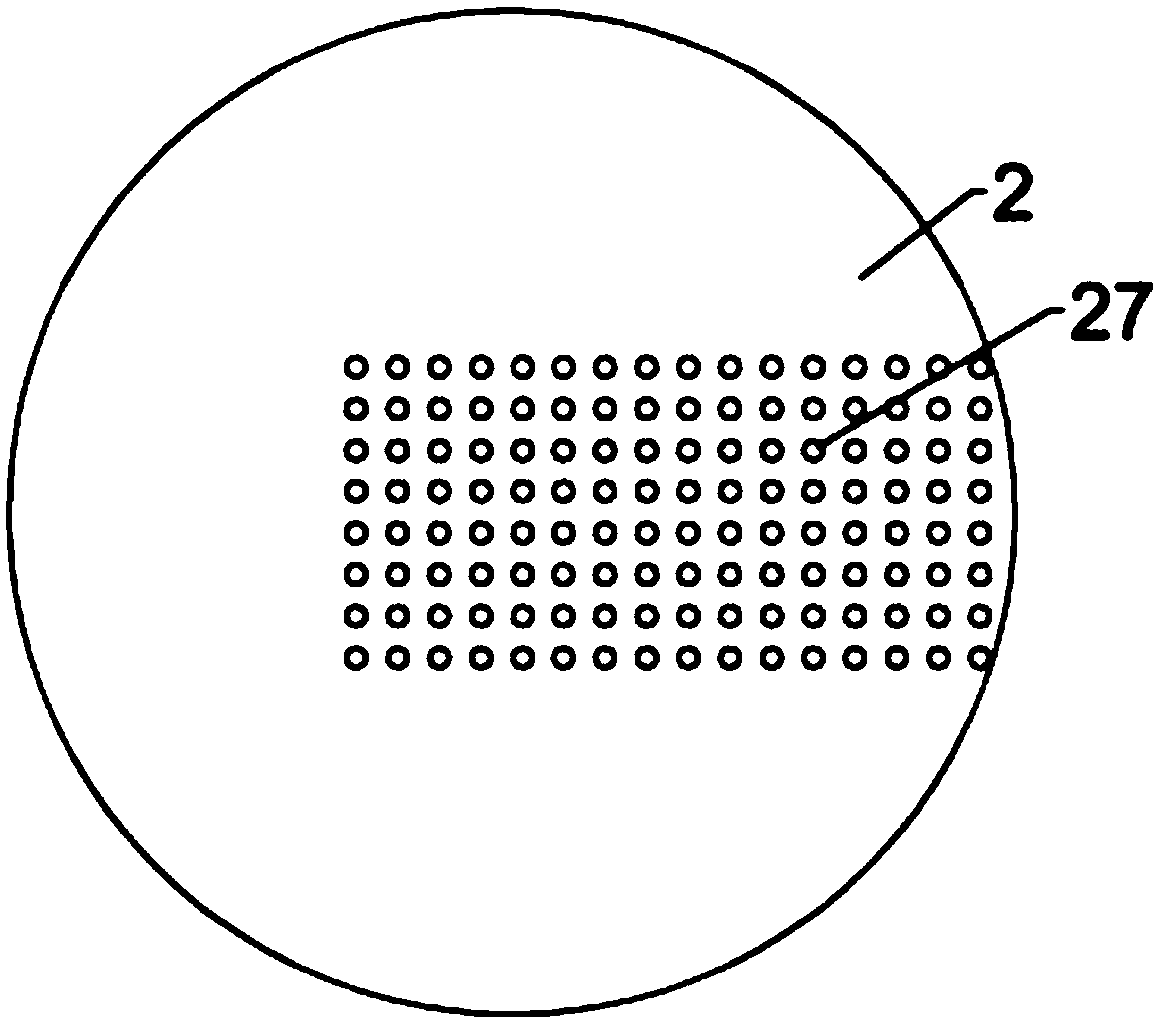

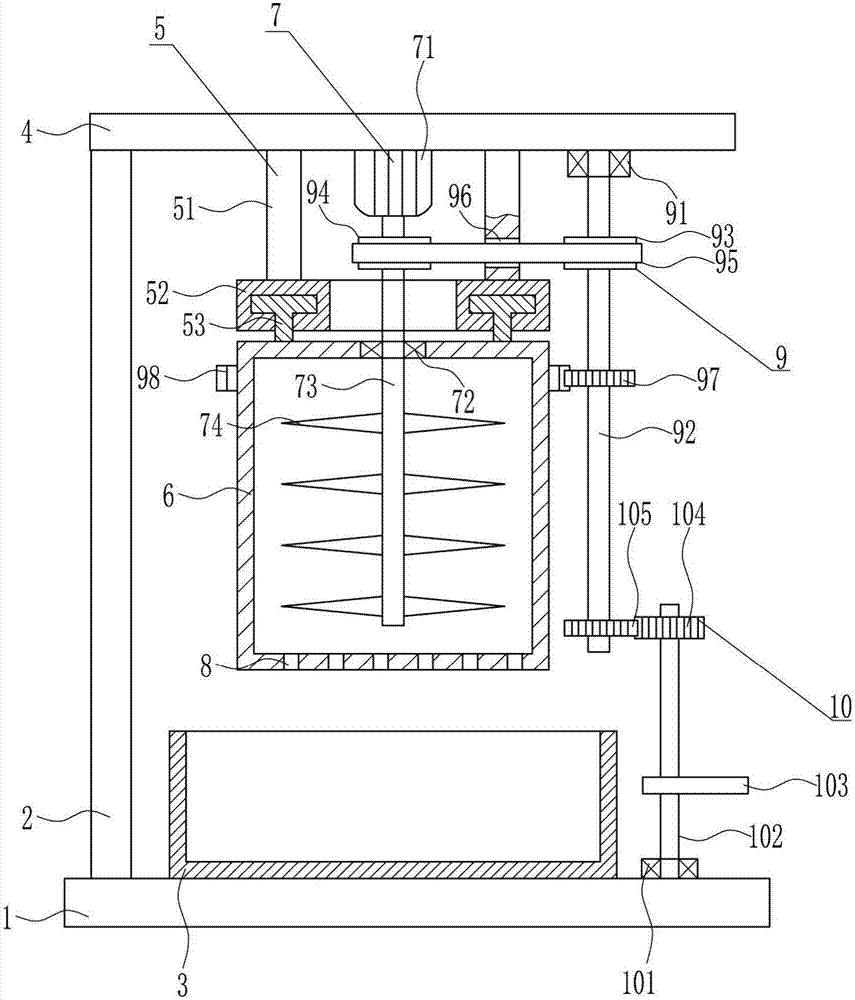

Caking fertilizer crushing device for agriculture big data

ActiveCN106733087AImprove work efficiencyGood effectGrain treatmentsFertilizerAgricultural engineering

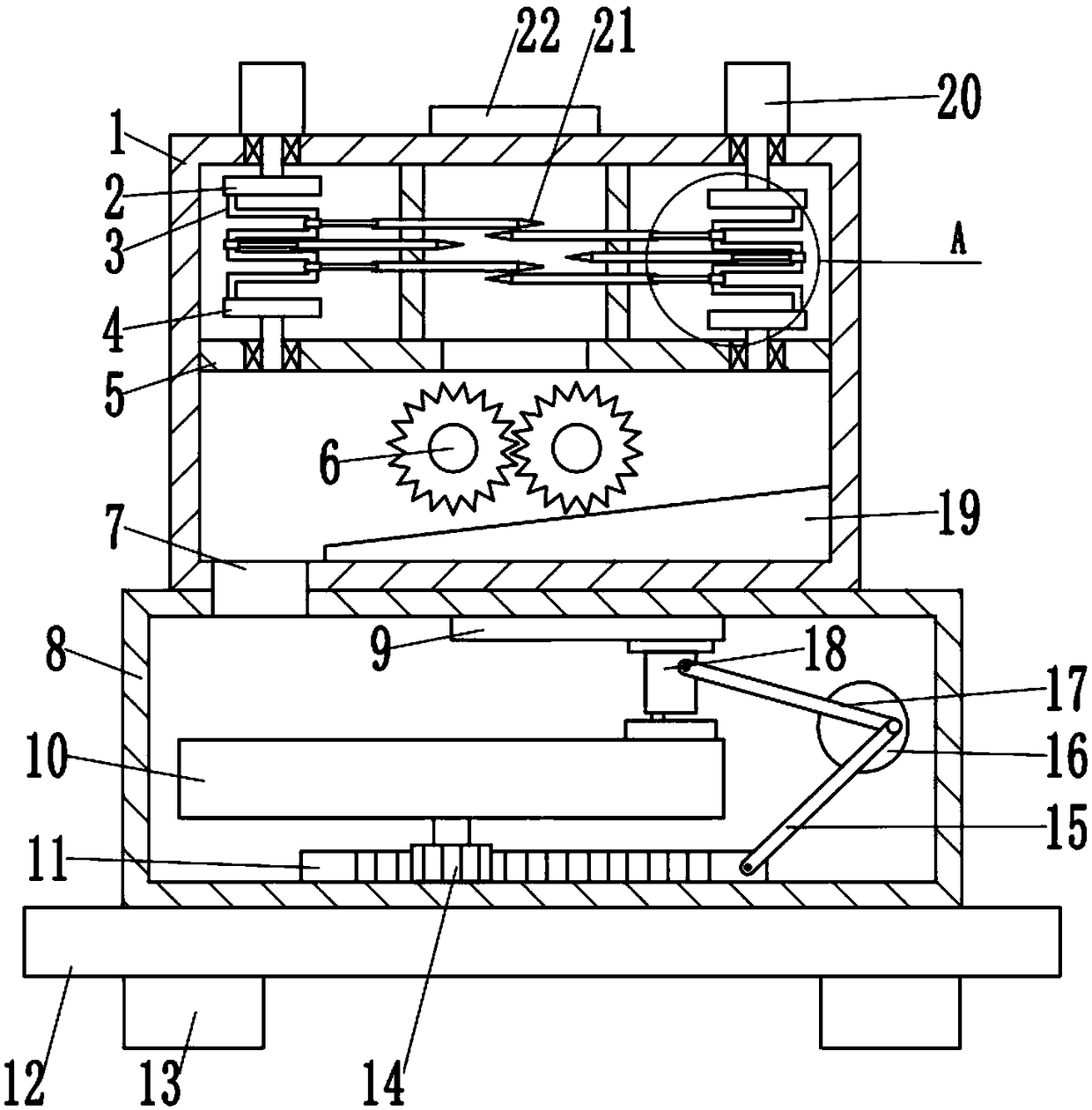

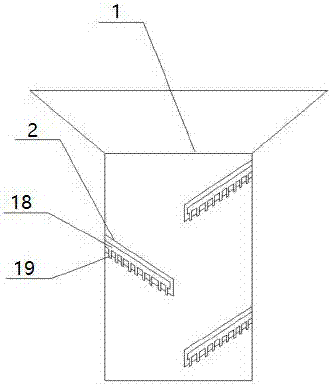

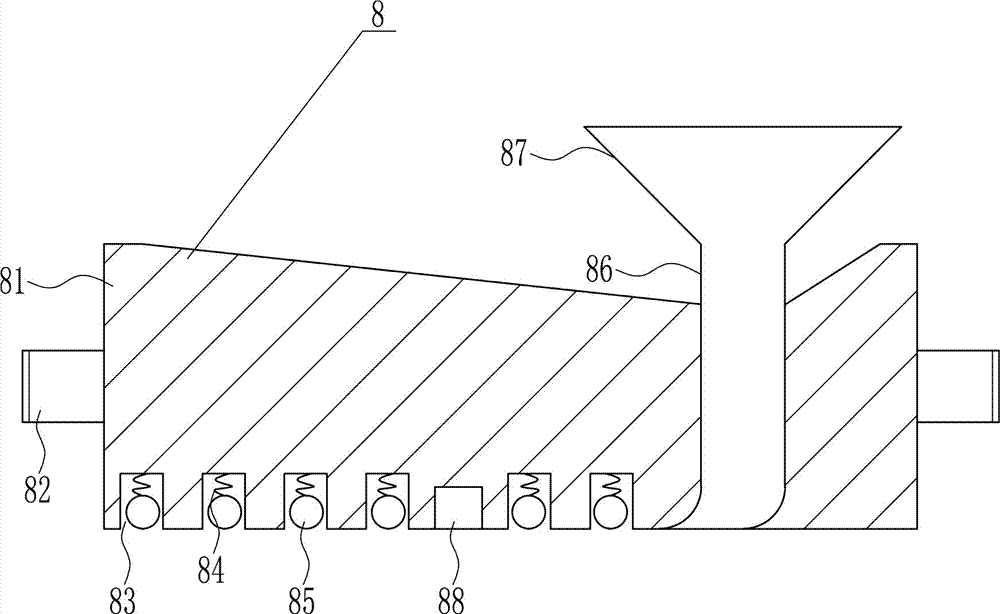

The invention belongs to the technical field of agriculture big data, and particularly relates to a caking fertilizer crushing device for agriculture big data and aims at achieving the technical purpose of providing the caking fertilizer crushing device for the agriculture big data, wherein the caking fertilizer crushing device is good in crushing effect, easy to operate and high in work efficiency. To achieve the above technical purpose, the caking fertilizer crushing device for the agriculture big data is provided and comprises a bottom plate, a left support, a first collecting frame, a second collecting frame, a supporting frame, a right support, a screen, a top plate, a discharging hopper, a right clamping plate, a left clamping plate, grinding teeth and the like. The left support, the first collecting frame, the second collecting frame, the supporting frame and the right support are sequentially welded to the bottom plate from left to right. According to the provided caking fertilizer crushing device for the agriculture big data, caking fertilizer is crushed firstly through the right clamping plate and the left clamping plate, and a crushing cutter and a crushing hammer conduct cutting and hammering on the crushed caking fertilizer at the same time.

Owner:安徽众力农业装备科技有限公司

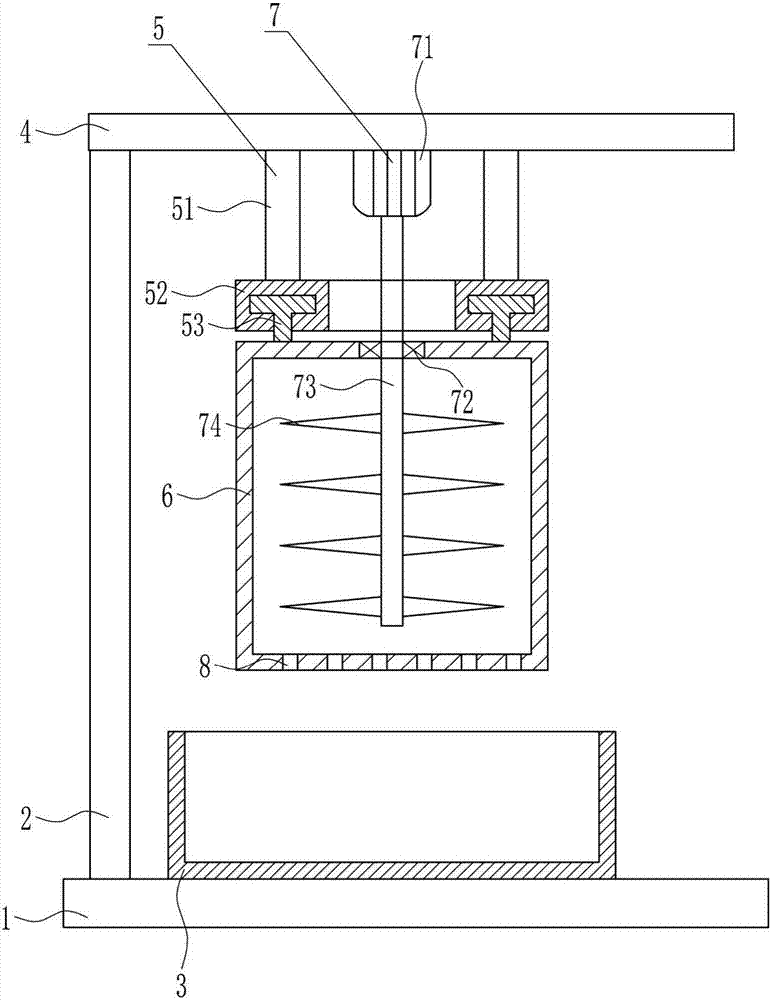

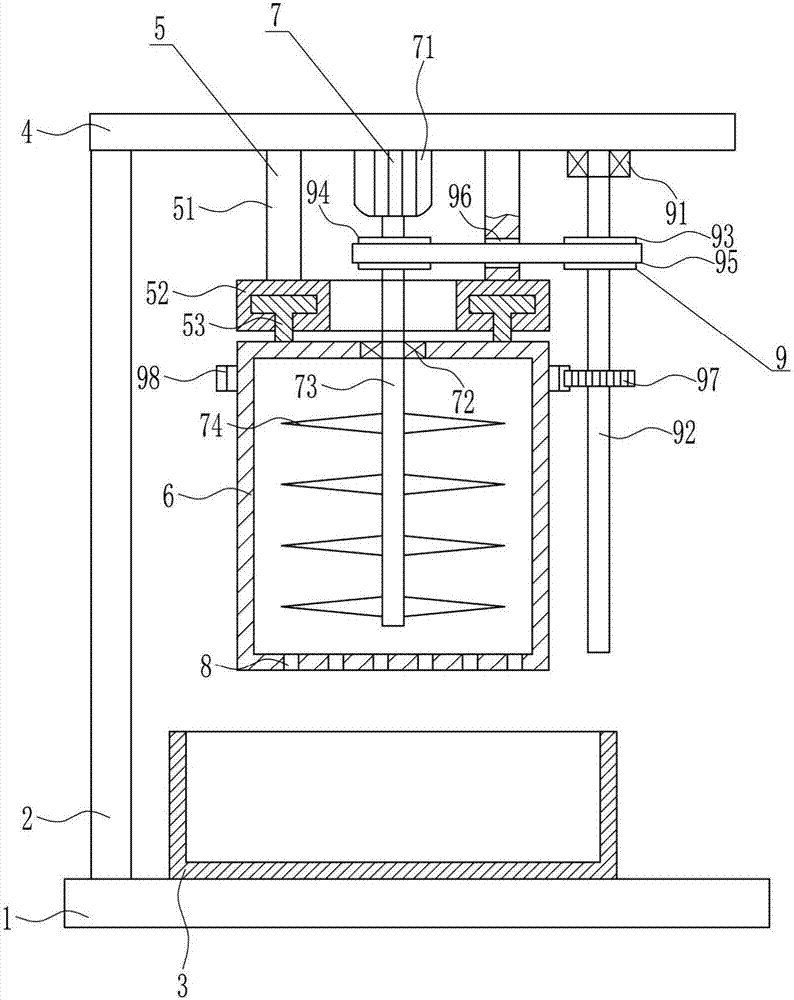

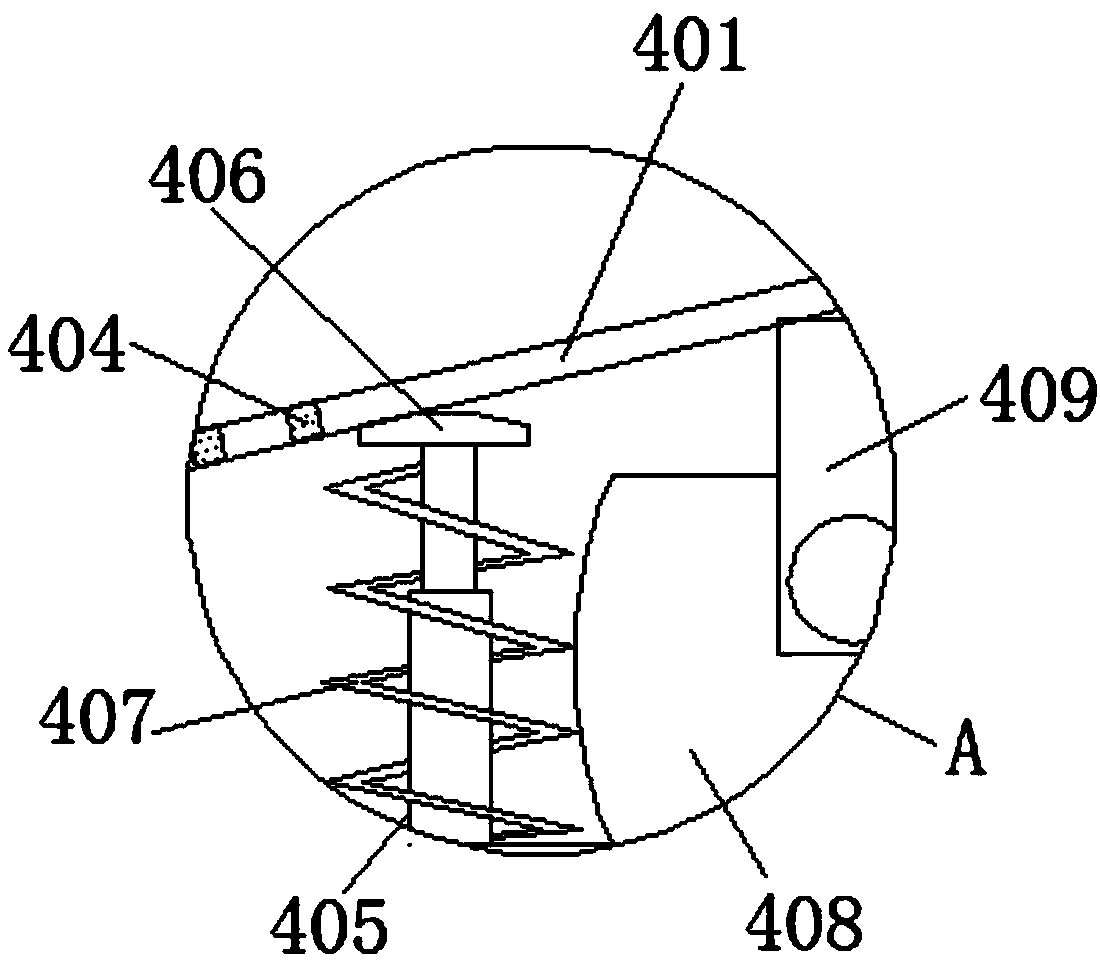

Collision grinding type ultrafine smashing device

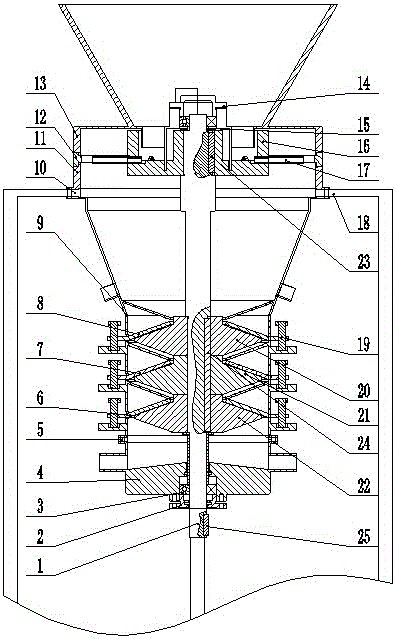

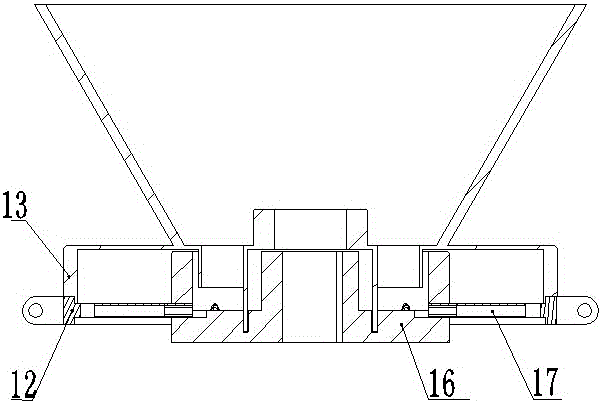

InactiveCN105833979ARealize one-time crushingImprove crushing efficiencyCocoaGrain treatmentsEngineeringCentrifugal force

The invention discloses a collision grinding type ultrafine smashing device. The device mainly comprises a feeding device, a collision device, a grinding device and a discharging device, wherein a feeding barrel body in the feeding device is matched with a material collecting disc; the material collecting disc is mounted on a main shaft through a key; discharge holes are formed in the edge of the material collecting disc; the main shaft rotates to drive the material collecting disc to rotate; material leakage pipes in the collision device are in threaded connection with the discharge holes of the material collecting disc; when materials are accelerated, the materials are thrown through a pipeline under the action of centrifugal force at a high speed to collide with collision pieces to be crushed; the grinding device comprises three levels of grinding mechanisms; the materials are sequentially fed into the first-level, the second-level and the third-level grinding mechanisms under the action of gravity; and grinding mechanisms comprise grinding discs and grinding blocks. According to the collision grinding type ultrafine smashing device, materials of which the particle size difference is relatively large can be smashed at a time, the condition that a pulverizer needs a sieving net is improved, the smashing efficiency and the smashing effect are improved, and the production efficiency for producing ultrafine powder can be improved.

Owner:TAIYUAN UNIV OF TECH

Construction garbage crushing device

Owner:刘汉佑

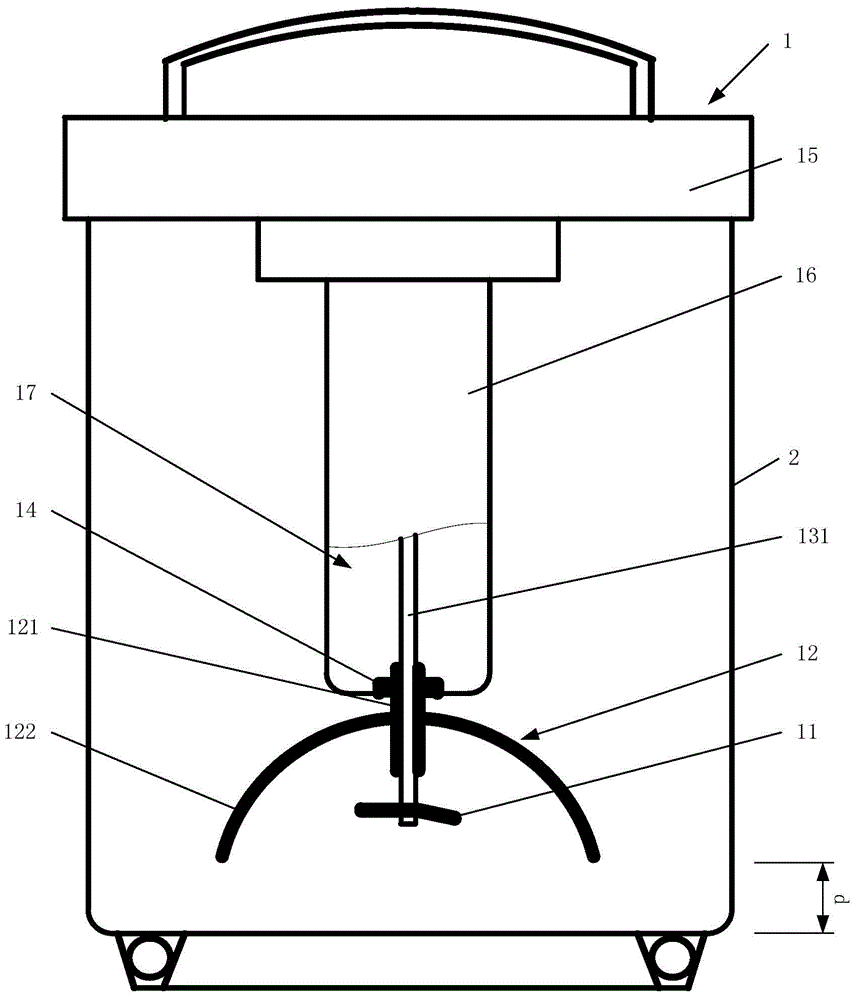

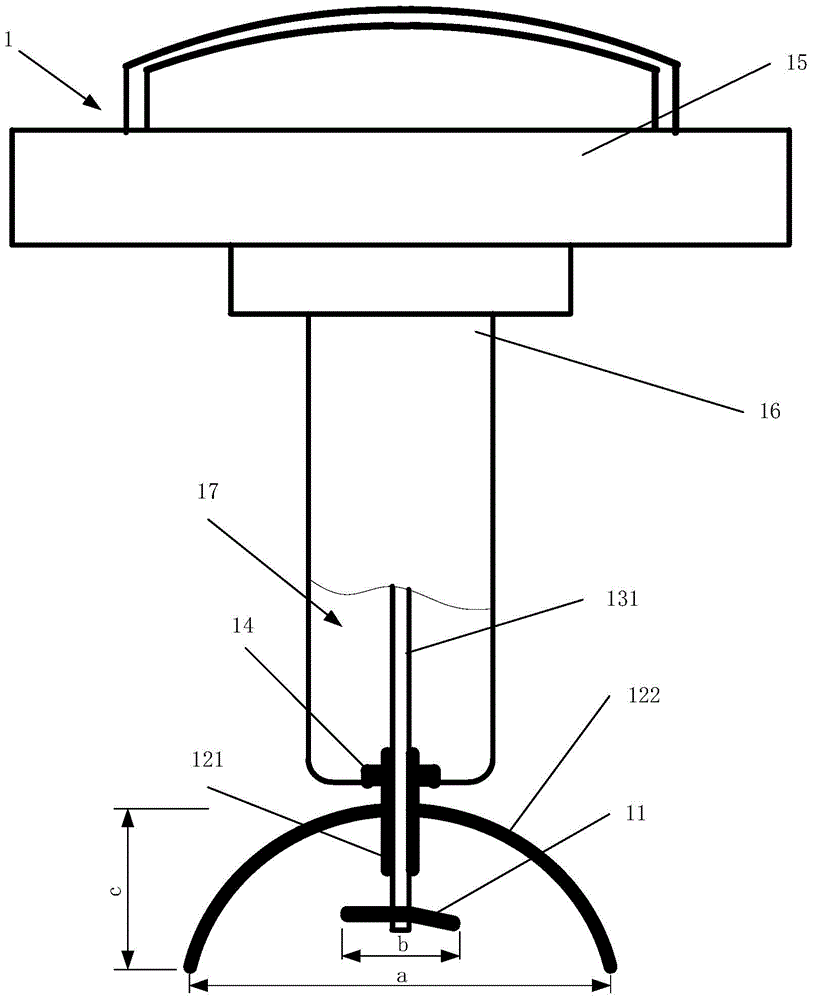

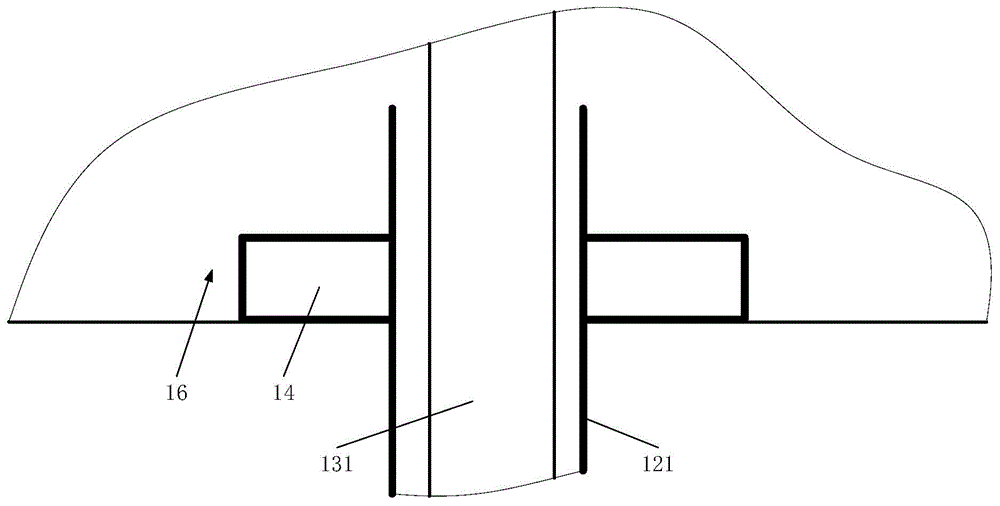

Soymilk machine head

InactiveCN104055423ATo achieve the purpose of noise reductionSmooth rotationBeverage vesselsFood materialEngineering

The invention provides a soymilk machine head, which is arranged on a barrel body of a soymilk machine. A crushing blade and a spoiler are arranged on a rotating shaft of the machine head, wherein the spoiler sleeves on the rotating shaft, and can rotate relative to the rotating shaft, and the crushing blade drives a food material in the barrel body to rotate; the food material drives the spoiler to rotate. According to the soymilk machine head provided by the invention, the rotating shaft drives the crushing blade to rotate at high speed, and the crushing blade which rotates at high speed drives the food material to rotate in the barrel body, accordingly, under the rotation of the food material, the spoiler absorbs the kinetic energy of part of food material to rotate along with the food material in the same direction, and the rotating speed difference between the spoiler and the food material becomes small; meanwhile, by matching of the rotation of the spoiler, the food material can be stably stirred by the spoiler, accordingly, the food material is more uniformly distributed in the barrel body, the rotation of the food material is more stable, and the disturbing effect of the spoiler is more obvious; meanwhile, the noise generated by the larger rotating speed difference between the food material and the spoiler is also reduced to better achieve the purpose of noise reduction in the soymilk machine.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

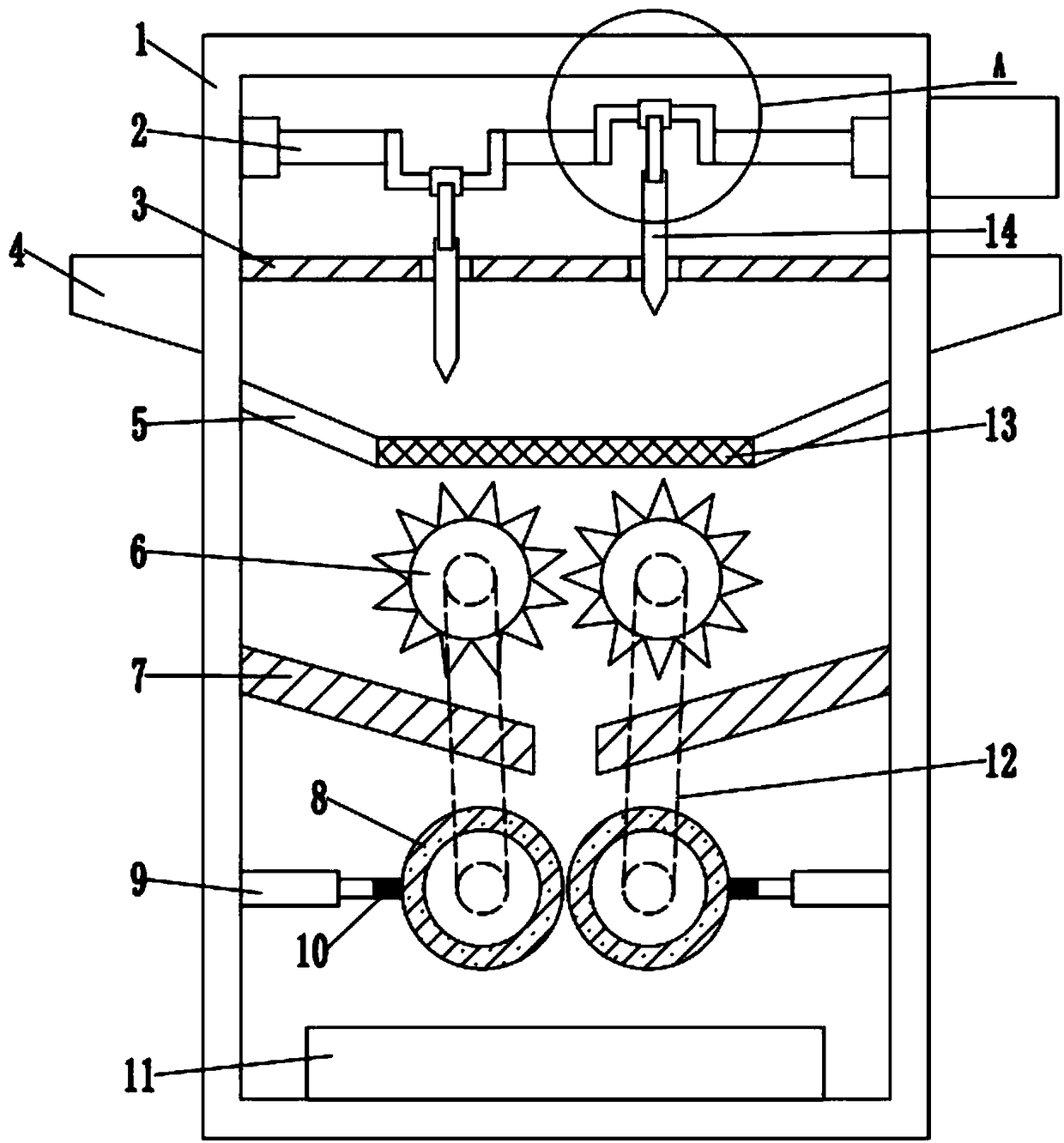

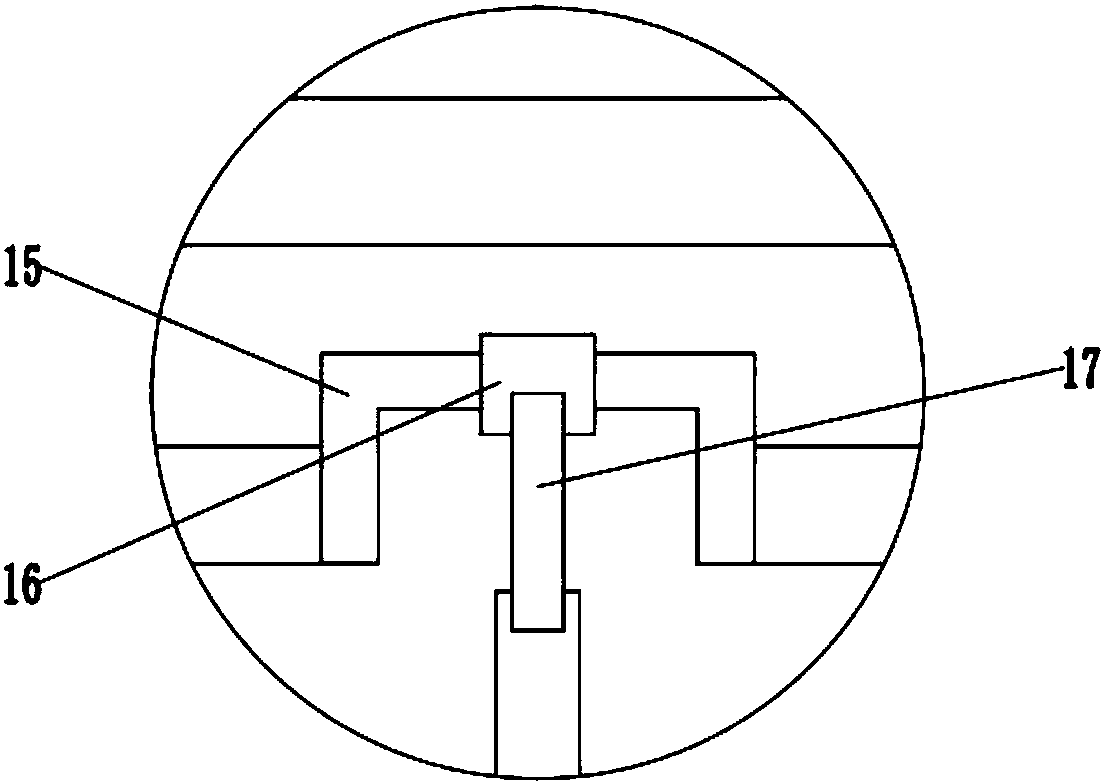

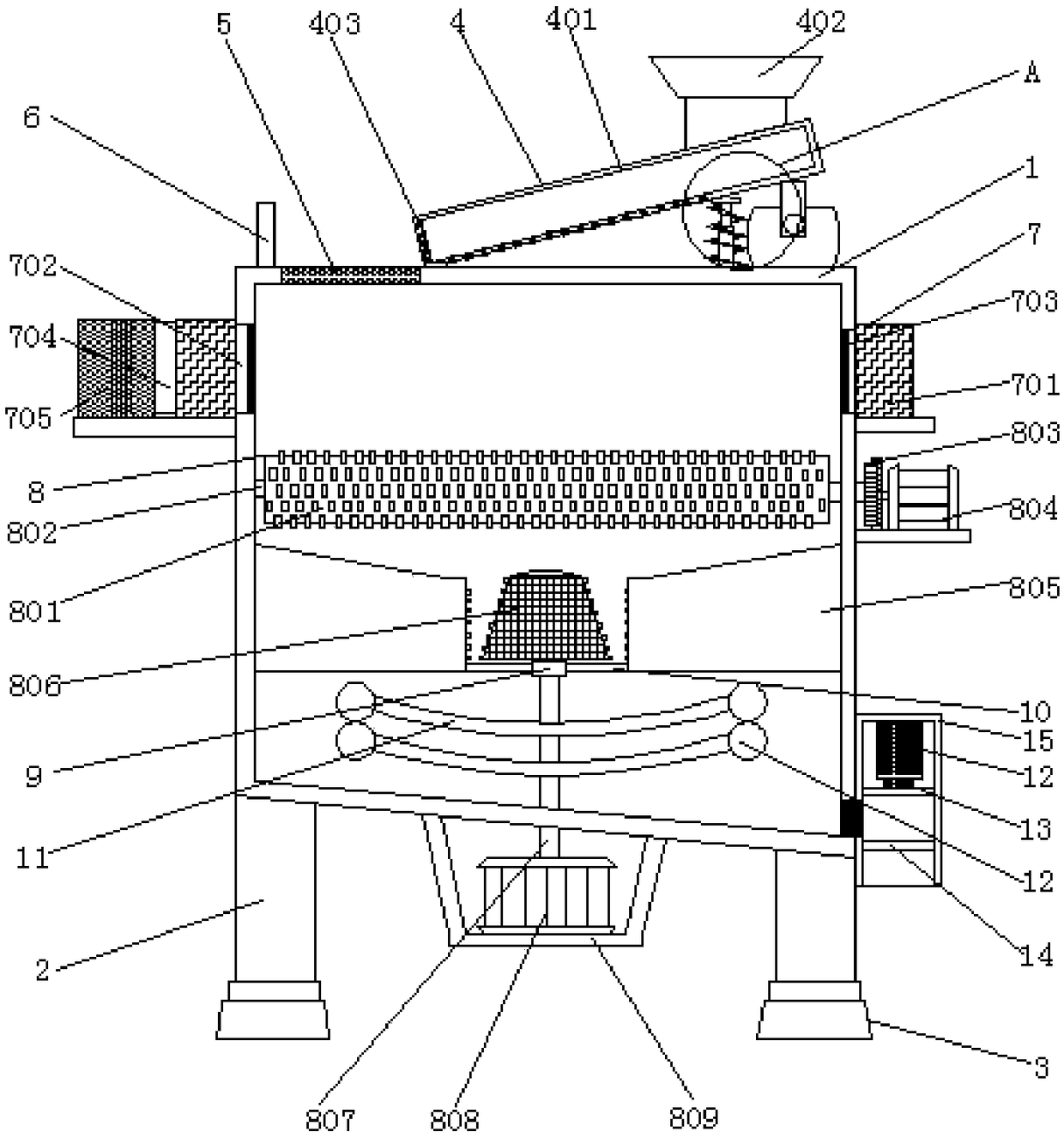

Environment-friendly garbage smashing device

InactiveCN108212455AImprove crushabilityEasy to handleGrain treatmentsShaping pressMotor driveEngineering

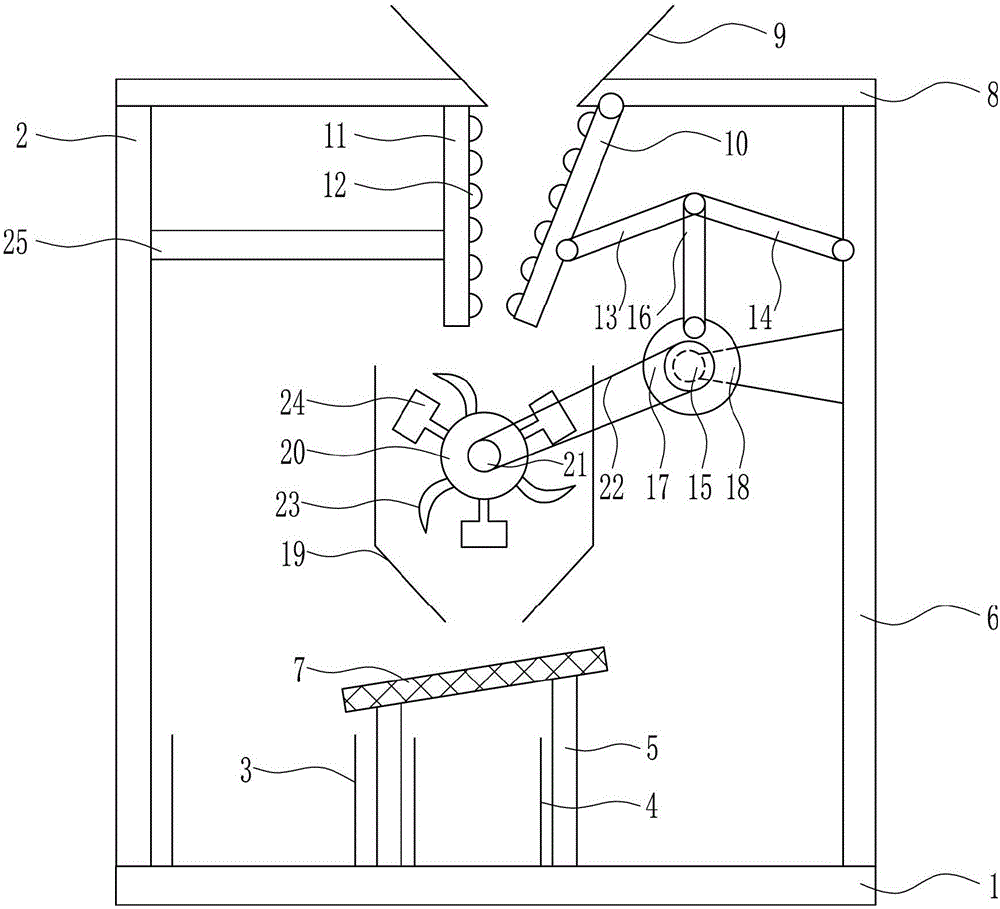

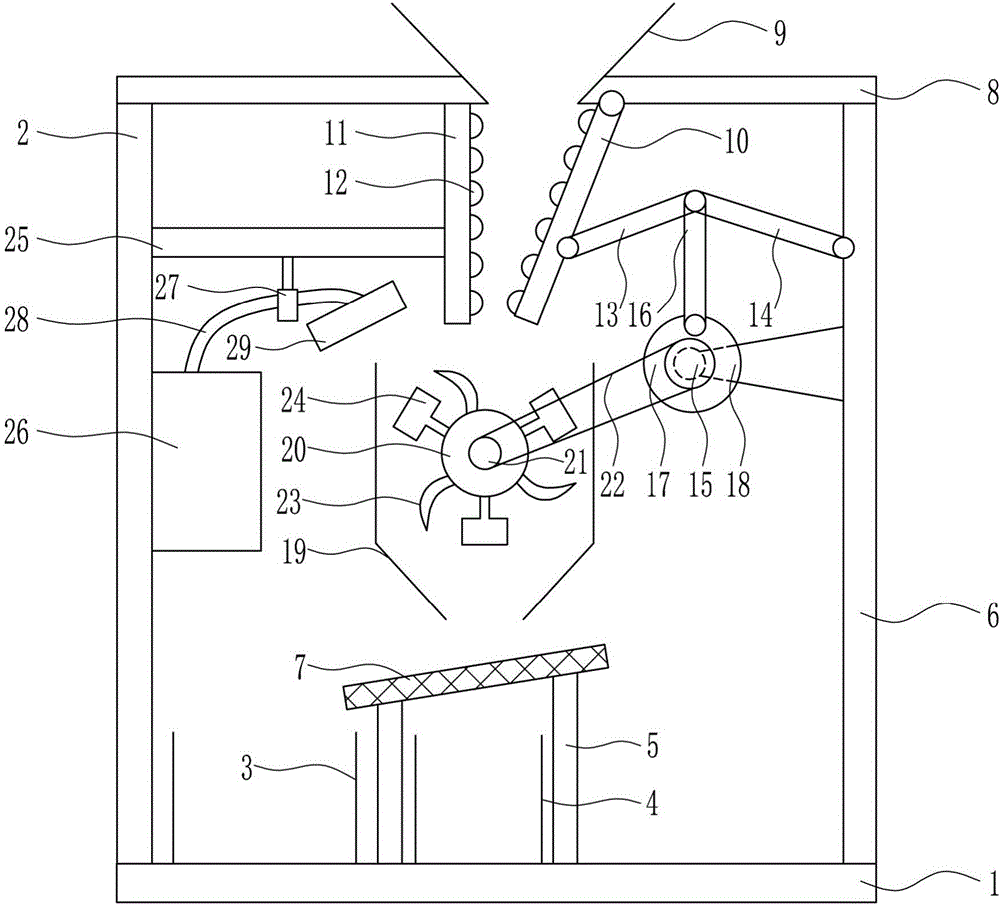

The invention provides an environment-friendly garbage smashing device, and relates to the technical field of environment friendliness. The environment-friendly garbage smashing device comprises a boxbody, bottom feet are arranged on the bottom of the box body fixedly, a discharging opening is formed in the bottom of the box body, the top of the box body communicates with a feeding opening, the top of the box body is fixedly provided with a storage battery, the top of the storage battery is fixedly provided with a solar panel. According to the environment-friendly garbage smashing device, a cutting motor drives a rotating rod to rotate, a drive gear and a transmission gear are used for driving a rotating shaft to rotate, smashing rollers welded to the side walls of the rotating rod and the rotating shaft rotate, garbage falling on the rollers are cut and smashed, primary smashing is achieved, a bottom motor drives a rotating drum to rotate through a rotation rod, the rotating drum which rotates drives grinding blocks welded to the outer wall of the rotating drum to be matched with grinding blocks welded to the inner wall of a smashing cylinder, garbage falling the rotating drum iscut and smashed, the garbage is subject to two-time cutting and smashing, and the smashing effect is better.

Owner:佛山市倍尚利环保科技有限公司

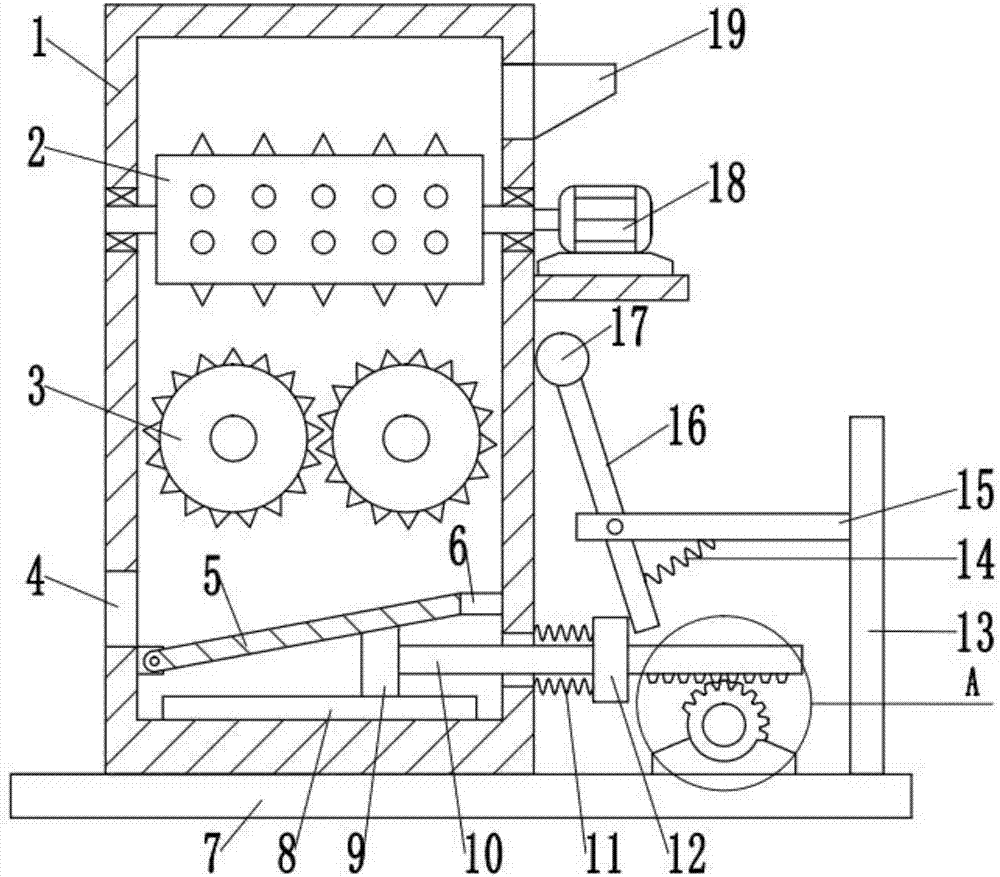

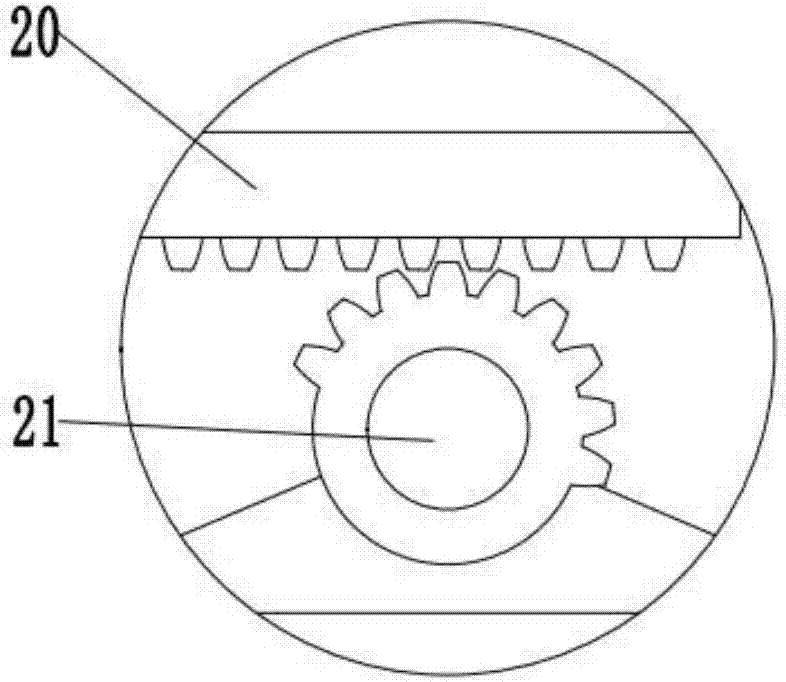

Shaking discharge type frosted glass multi-stage smashing and recycling device

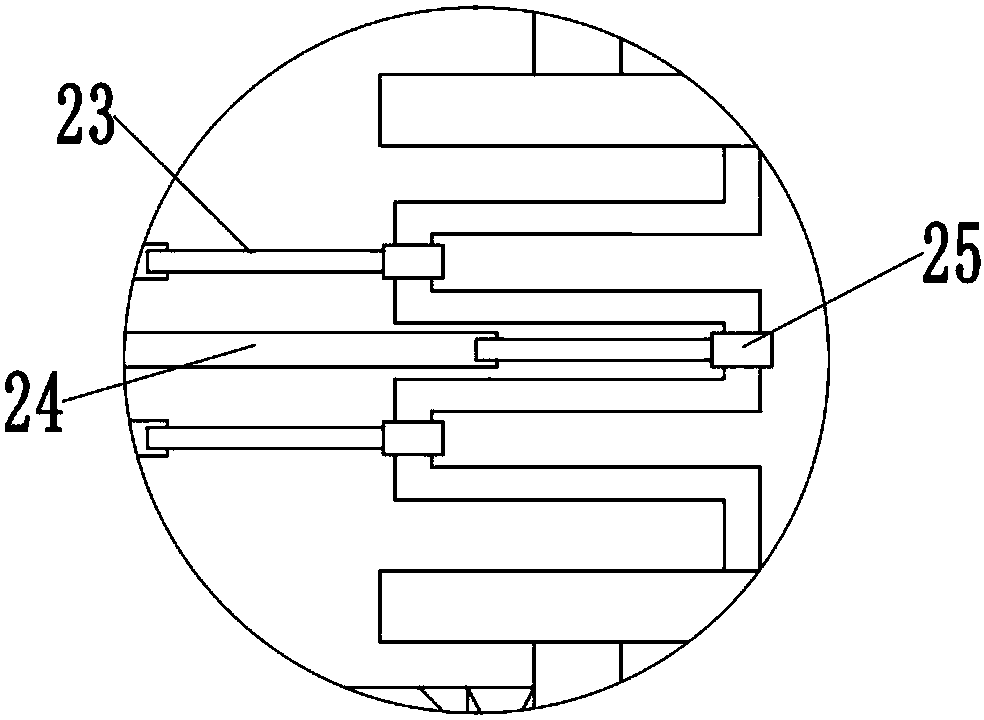

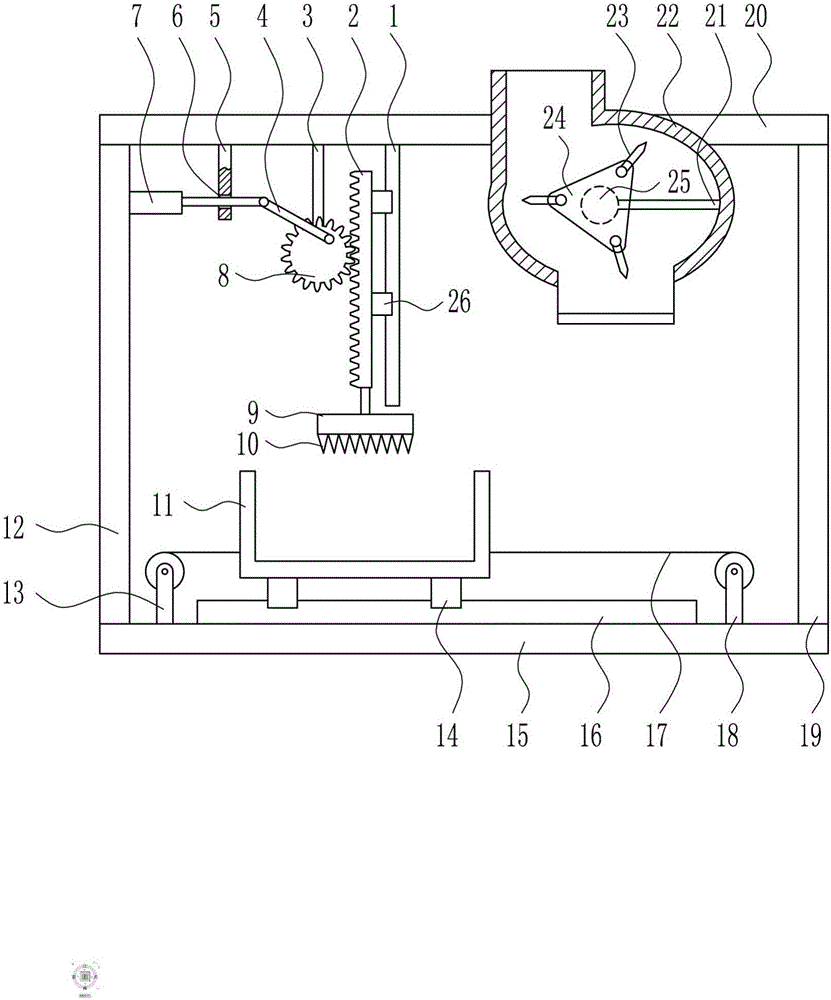

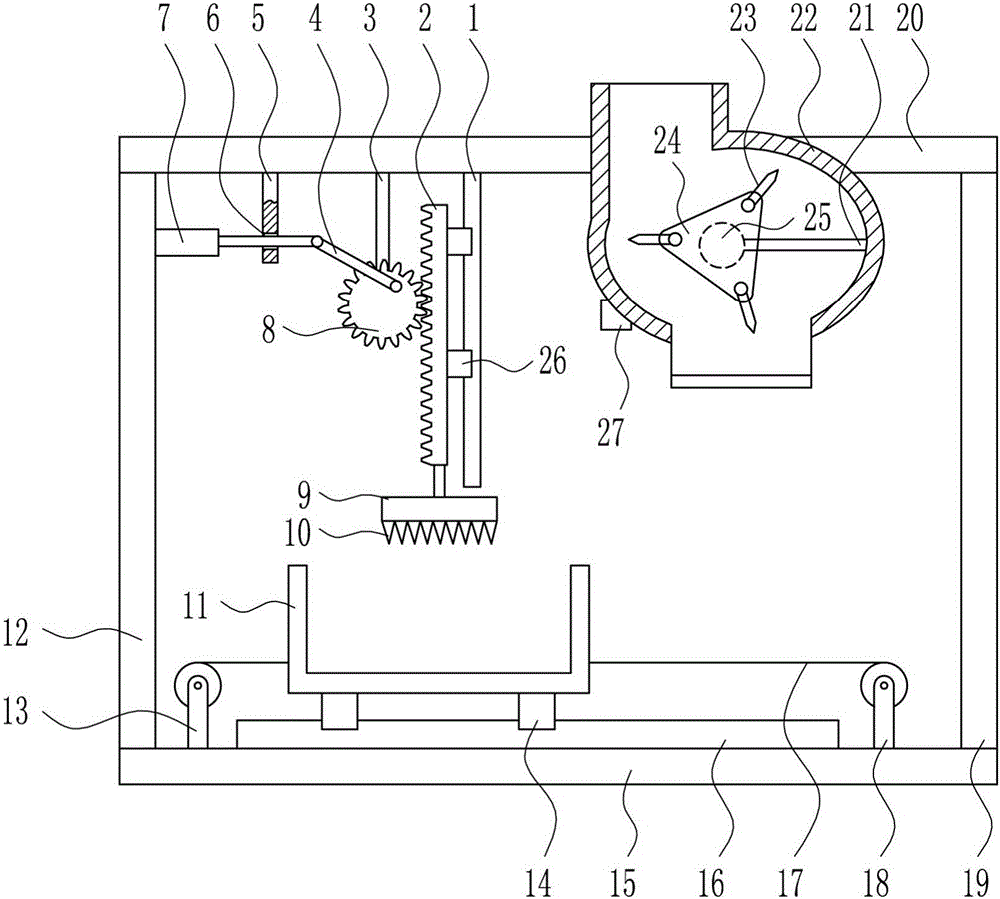

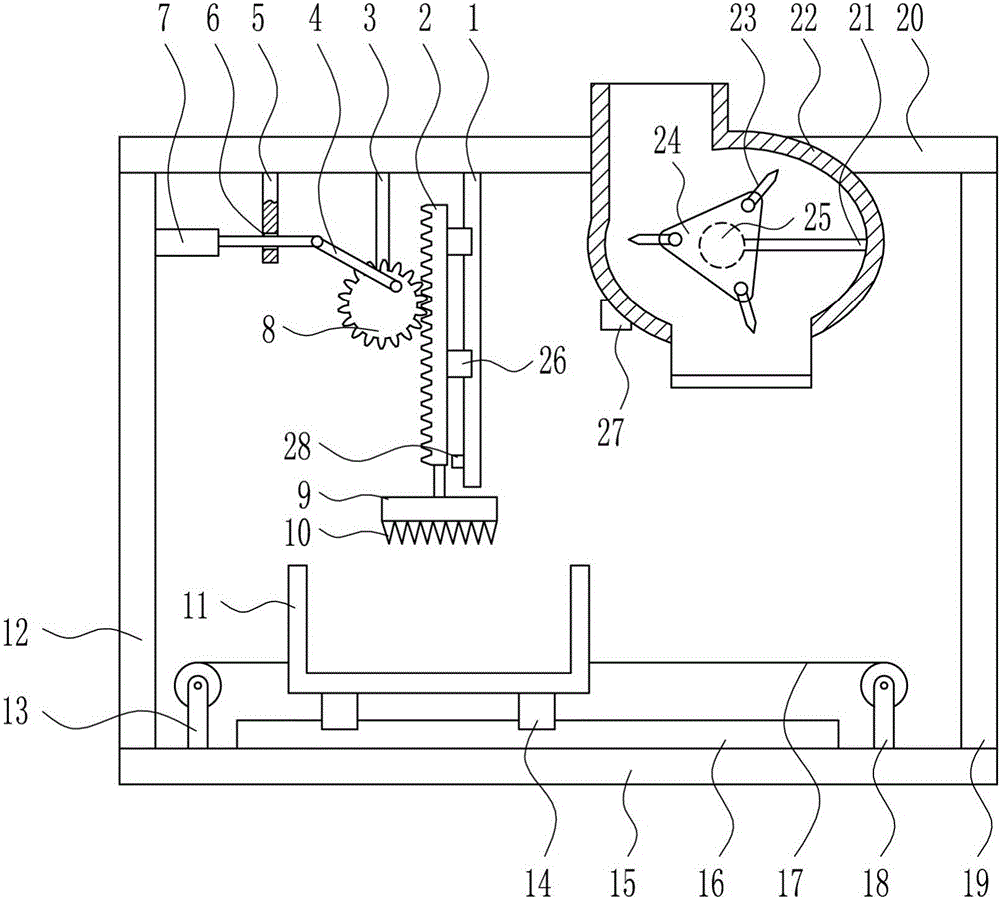

The invention discloses a shaking discharge type frosted glass multi-stage smashing and recycling device. The shaking discharge type frosted glass multi-stage smashing and recycling device comprises abox body, a guide plate, a push rod and a sector gear, wherein the bottom of the box body is fixedly mounted on a base; two crushing rollers are symmetrically and rotatably mounted on the front and back sides of the upper part of the box body; two smashing rollers are further symmetrically and rotatably mounted in the position, below the crushing rollers, in the box body; the guide plate is rotatably mounted on the left lower side in the box body; the guide plate inclines to the right; and the other end of the guide plate is fixedly connected with the inner wall of the right side of the box body through an elastic connecting block. According to the shaking discharge type frosted glass multi-stage smashing and recycling device, the two crushing rollers with crushing teeth and the two smashing rollers with smashing teeth are arranged to perform multi-stage smashing on glass, the smashing effect is excellent, and production efficiency is improved; and discharge is achieved through the inclined plate, a wedge block is pushed through a rack which moves left and right, the guide plate continuously shakes, glass is prevented from splashing during direct discharge, and a discharge openingcan be prevented from being blocked.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Chinese herbal medicine sorting and crushing device

The invention discloses a sorting and crushing device for Chinese herbal medicine, which relates to the technical field of crushing devices for medical Chinese herbal medicine. The invention includes a crushing device shell, a feed port 1 and a feed port 2, and a pounding box is arranged in the middle of the crushing device shell. The upper part of the pounding box is provided with a pounding block, and the bottom of the pounding box is moved on the moving slide rail by setting a slider. A crushing box is arranged in the shell of the smashing device, and a crushing mechanism is set in the crushing box. A motor is arranged on the top wall of the crushing device shell. , motor one connects cam one, contact roller one, first connecting rod and pounding block sequentially from top to bottom, cam two is arranged on the bottom wall of the shell of the pulverizing device, and cam two connects contact roller two and the second one from left to right in sequence The second connecting rod and the side wall of the pounding box, and the right side of the second cam are sequentially connected from bottom to top to contact the third and third connecting rods and the bottom of the crushing box. The present invention adopts the method of first sieving and then classifying and crushing Chinese herbal medicines, and the smashing efficiency is high. The crushing effect is good, saving time and effort, and improving work efficiency.

Owner:弘毅天承知识产权股份有限公司

Agricultural corn straw recycling briquetting device

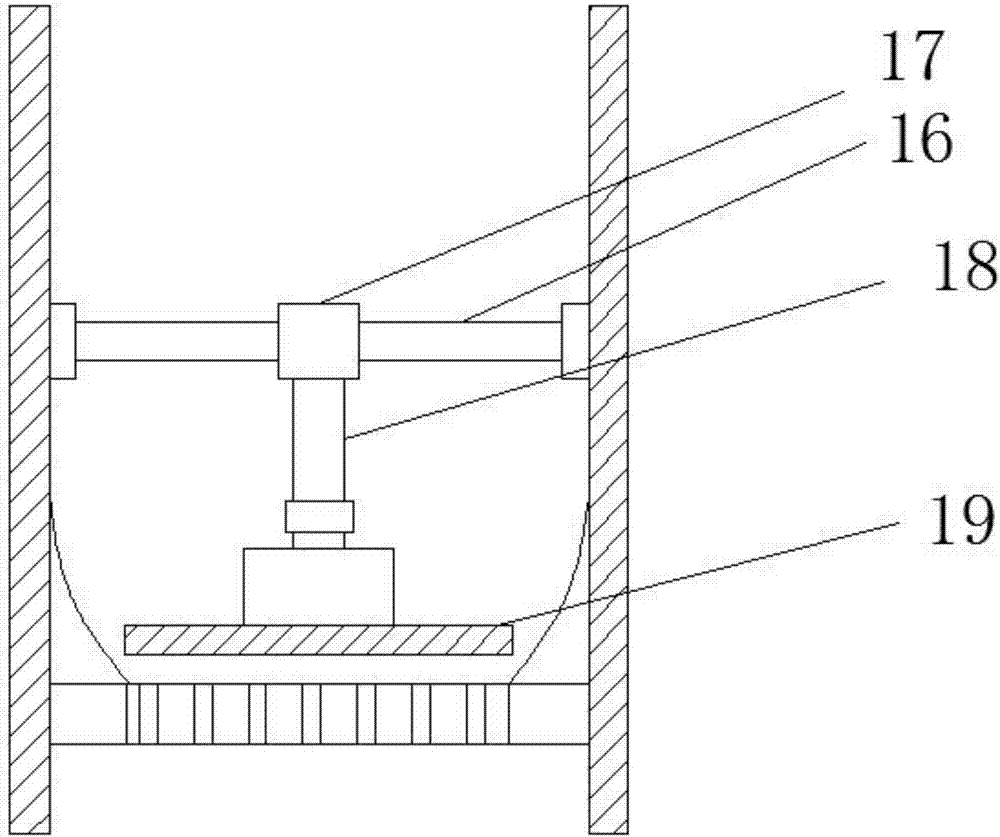

InactiveCN108055929AReduce wasteFully compactedCrop conditionersMowersAgricultural engineeringCorn stover

The invention discloses an agricultural corn straw recycling briquetting device. The device comprises a pulverizing case, a briquetting case, a briquetting box and a base; the pulverizing case is fixedly installed on the upper side of the briquetting case, the briquetting case is fixedly installed on the base, and the left side of the bottom of the pulverizing case is communicated with the interior of the briquetting case through a feeding port; a feeding inlet is formed in the top of the pulverizing case, a separation plate is fixedly installed in the pulverizing case, and the inside of the pulverizing case is separated into a primary pulverizing case and a fine-pulverizing case from top to bottom by the separation plate. According to the device, the pulverizing case and the briquetting case are arranged as an integrated structure, so that the amount of equipment is reduced, not only are operation of people facilitated and economic costs reduced, but also waste of straw is reduced totake the full advantage of straw resources, and meanwhile the straw are pulverized by arranging a plurality of cutter blades in a scattered mode, pulverizing shafts are arranged to perform pulverizingon the straw, so that the pulverizing effect is excellent.

Owner:王泽成

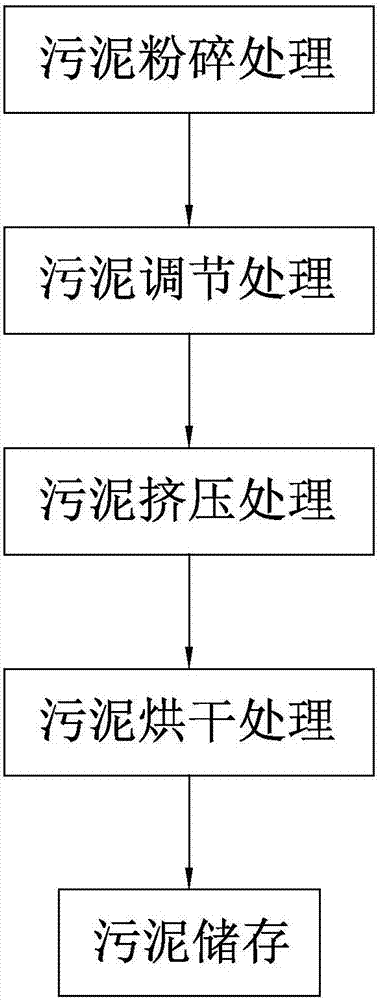

Sludge concentration and dewatering treatment method

ActiveCN107129127AEasy to dehydrateReduce moisture contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMultiple treatmentsCapillary water

The invention discloses a sludge concentration and dewatering treatment method. The method comprises the following steps: (1) sludge pulverizing treatment; (2) sludge conditioning treatment; (3) sludge extrusion treatment; (4) sludge drying treatment; and (5) sludge storage. The method disclosed by the invention is simple in structure, high in practicality, convenient to use and remarkable in the sludge dewatering effect; through the multiple treatments of a pulverizing cavity, a conditioning tank and a dewatering cavity, void water, adsorbed water and capillary water in sludge are all separated out, so that the dewatering rate of the sludge is effectively improved, and the volume of the sludge is reduced, thereby facilitating subsequent recycling of the sludge; and the overall structure design is more reasonable and scientific.

Owner:浙江金华德朗水务有限公司

Construction waste treatment device

The invention discloses a construction waste treatment device comprising a base body and a screening machine; the upper part of the base body is provided with a conveying belt; the right side of the conveying belt is provided with a support frame; the lower bottom face of the support frame is provided with a hydraulic jack I; a cubic groove is arranged under the hydraulic jack I; a rotary arm is arranged at the middle position of the lower surface of the cubic groove; the right side of the rotary arm is provide with a hydraulic jack II; the right side of the hydraulic jack II is provided with the screening machine; the interior of the screening machine is provided with a filter screen and a drainage plate; because the conveying belt is arranged for conveying crushed stone and other construction waste into the cubic groove and cooperates with the hydraulic jack I for squashing the crushed stone in the cubic groove, at the time, the hydraulic jack I works to dump the cubic groove, and then the crushed stone falls into the screening machine and is subjected to fine and coarse filtration, so the construction waste treatment device realizes use diversification of the construction waste, increases the reuse rate of the construction waste, thereby reducing the occupation of land and being worthy of promotion.

Owner:淮南中科盛联环保科技股份有限公司

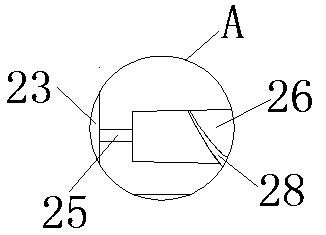

Efficient shredding device for discarded shoe soles for shoe industry

The invention relates to a sole shredding device, in particular to an efficient shredding device for discarded shoe soles for the shoe industry. To solve the technical problem, the efficient shredding device for the discarded shoe soles for the shoe industry is provided, wherein the efficient shredding device is high in shredding speed, uniform in shredding and simple in structure. The efficient shredding device for the discarded shoe soles for the shoe industry comprises a first sliding rail, a rack, a first supporting rod, a first connecting rod, a guide plate, an electric push rod, a gear, a pressing block, shredding teeth, a shredding frame, a left frame, a first electric winding wheel, a first sliding block, a bottom plate, a second sliding rail, a pull wire, a second electric winding wheel, a right frame, a top plate, a second connecting rod, a feeding hopper, cutters, a disc-shaped cam, a motor and a second sliding block. By means of the efficient shredding device, the effects that the shredding speed is high, shredding is uniform, and the structure is simple are achieved, the efficient shredding device plays an important role in achieving the good shredding effect, the working efficiency is improved as well, and the safety is high.

Owner:临沂港控能源有限公司

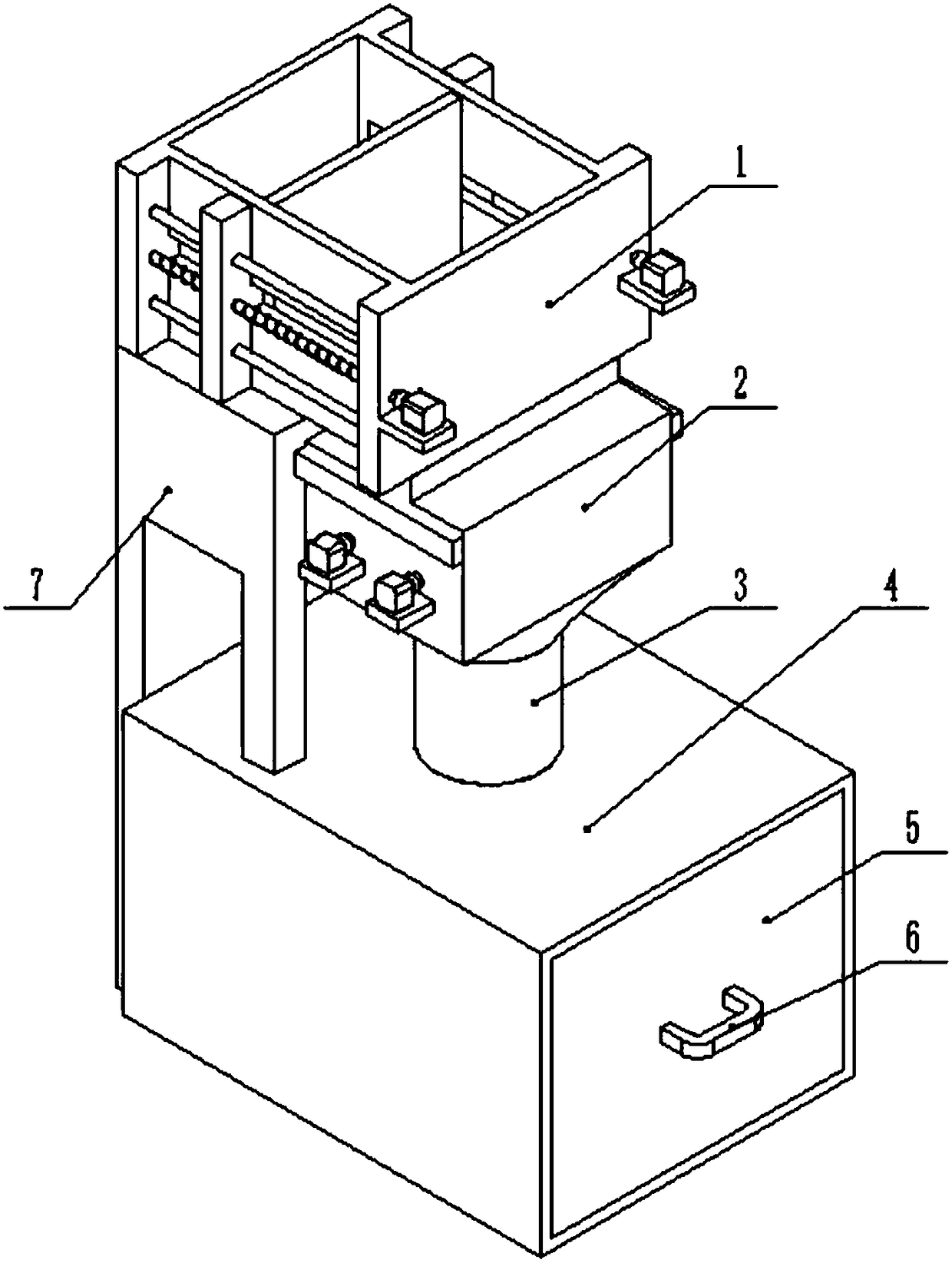

Express delivery paper box processing device

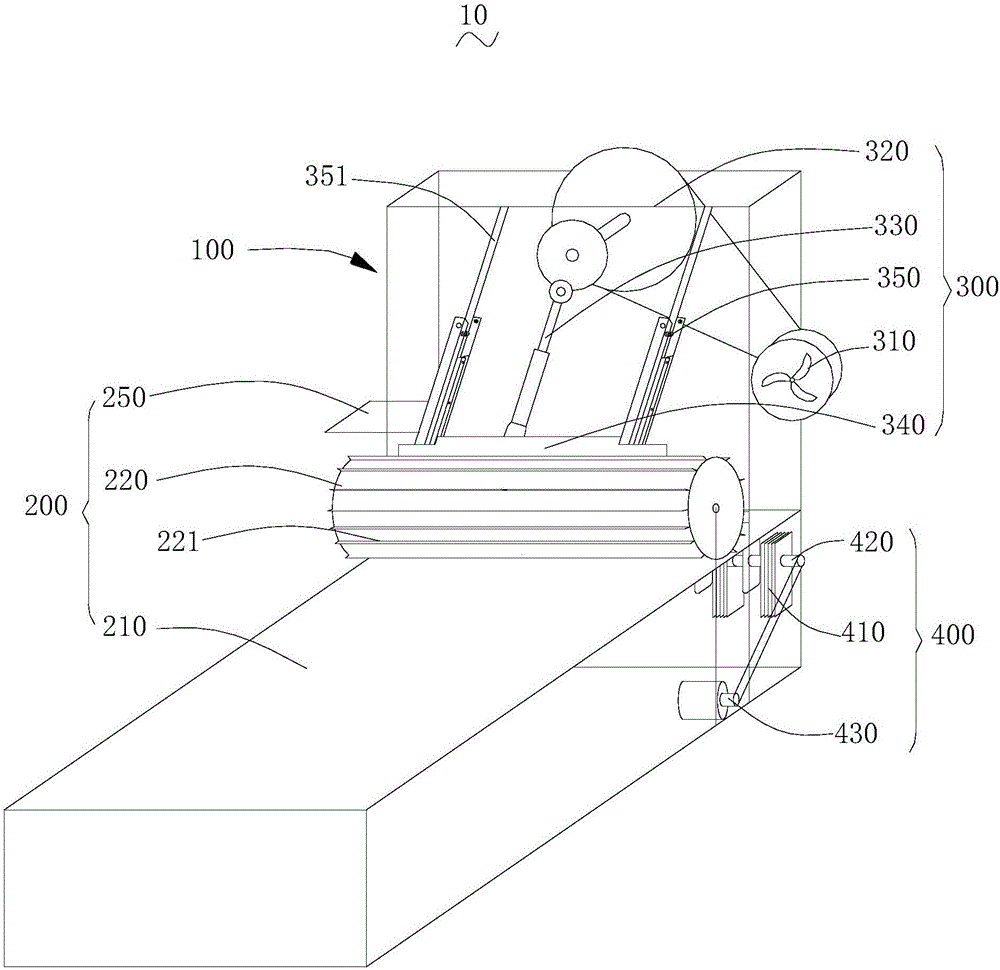

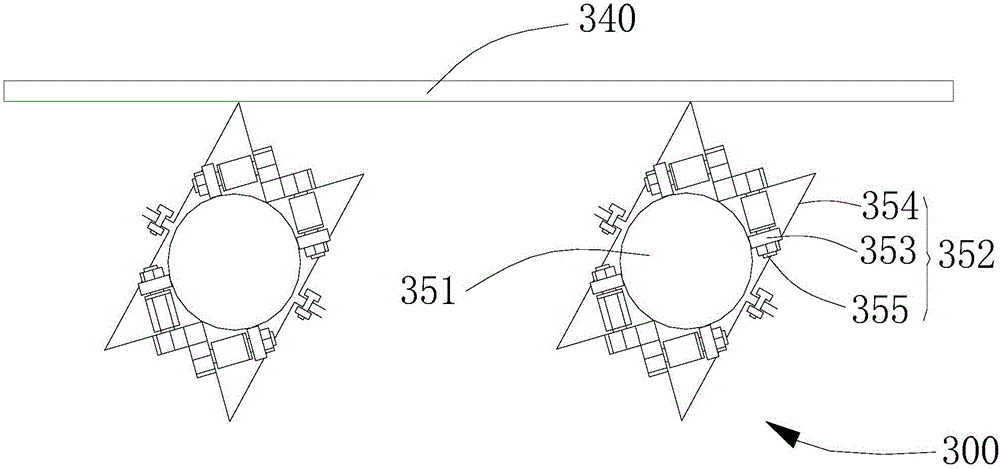

ActiveCN108080395AImprove recycling efficiencyConvenient crushing and handling workSolid waste disposalGrain treatmentsCartonPulp and paper industry

The invention discloses an express delivery paper box processing device and belongs to the field of environment-friendly equipment. The express delivery paper box processing device comprises a paper box compressing device, a primary smashing device, a secondary smashing device, a material storage box casing, an inner box body, a handle and a supporting frame, wherein the paper box compressing device is fixedly arranged at the uppermost end of the supporting frame, the primary smashing device is arranged under the paper box compressing device, the primary smashing device is fixedly arranged onthe supporting frame, the secondary smashing device is arranged under the primary smashing device, the material storage box casing is arranged under the secondary smashing device, the inner box body is arranged in the material storage box casing, and the handle is arranged on the outer end face of the inner box body. Aiming at the express delivery paper box characteristics, the express delivery paper box processing device disclosed by the invention is newly provided the paper box compressing device, so that the paper boxes with large sizes and easiness in being compressed can be compressed tothe maximum extent, and convenience is brought to following smashing treatment work; by means of two-stage smashing, a smashing effect is more obvious, an automation degree is high, and a paper box recycling efficiency is improved.

Owner:江苏富星纸业有限公司

Agricultural fertilizer crushing and stirring device

InactiveCN107649236AAvoid insufficient crushingQuality improvementTransportation and packagingMixersEngineeringScrew thread

The invention discloses an agricultural fertilizer crushing and stirring device. The left end of a first motor is rotataby connected with a two-way threaded rod, the left end and the right end of thetwo-way threaded rod are in threaded connection with wedge-shaped blocks correspondingly, and supporting feet are fixedly connected to the upper ends of the wedge-shaped blocks. Threads of the left end and the right end of the two-way threaded rod are opposite in rotating direction and the same in thread pitch and lead. A sealing plate is arranged at the lower end of each wedge-shaped block, the ends of the sealing plates are hinged to the inner wall of a device body, and the upper ends of the sealing plates are fixedly connected with vertical support rods. Connecting rods are hinged to the lower ends of the sealing plates, and sliding blocks are hinged to the lower ends of the connecting rods and slidably connected with movable cavities. According to the agricultural fertilizer crushing and stirring device, through the first motor, the two-way threaded rod 5 is driven to conduct positive and negative rotation to drive the wedge-shaped blocks to move in the left-right direction to openand close the sealing plates intermittently to achieve intermittent material putting down, the lower ends of the sealing plates are provided with crushing wheels to crush a fertilizer put down intermittently, and the crushing effect is better through the intermittent crushing mode, so that the situation that the fertilizer is excessive and thus insufficiently crushed is avoided. According to theagricultural fertilizer crushing and stirring device, the structural design is reasonable and applicable, the fertilizer crushing quality is greatly improved, the labor force is saved, and the work efficiency is improved.

Owner:南宁商之源科技有限责任公司

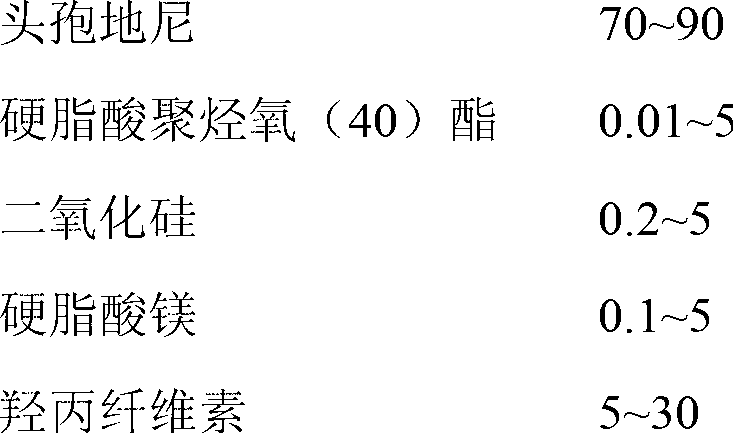

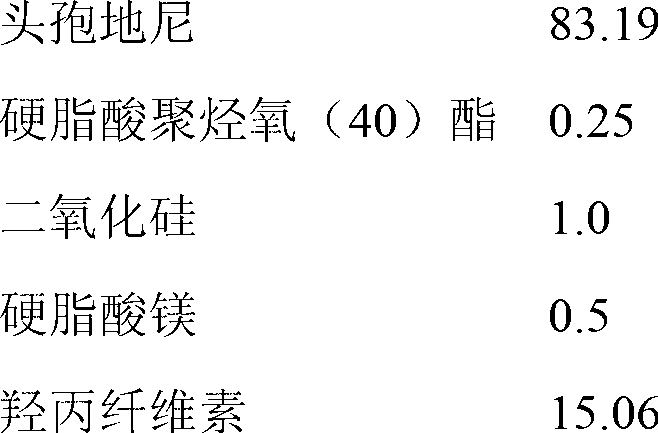

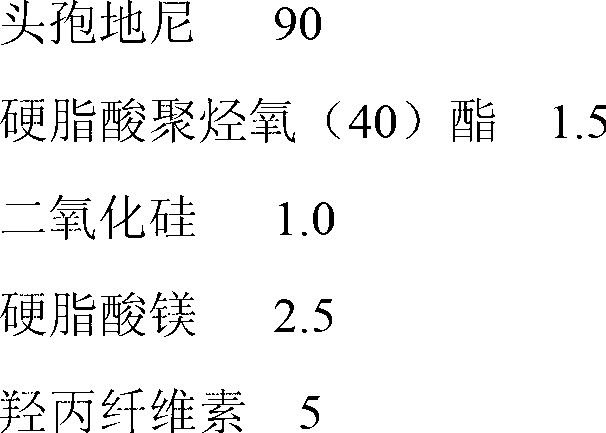

Cefdinir capsule and preparation method thereof

ActiveCN102935075AGood dissolution effectImprove liquidityAntibacterial agentsOrganic active ingredientsMedicineQuality control

The invention provides a cefdinir capsule and a preparation method of the cefdinir capsule. The content of the cefdinir capsule comprises the necessary components based on parts by weight: 70-90 parts of cefdinir, 0.01-5 parts of polyoxyl (40) ester stearate, 0.2-5 parts of silicon dioxide, 0.1-5 parts of magnesium stearate and 5-30 parts of hydroxypropyl cellulose. The medicine prepared by cefdinir capsule prescription is good in dissolution effect and fluidity, and stable in medicine effect; the provided preparation method is simple in technology; the product is less in introduced impurity, easy in quality control and good in reproducibility and uniformity; and the preparation method saves the energy and reduces the consumption, thus easily meeting the demand of mass production.

Owner:海南三叶美好制药有限公司

Rapid garbage smashing device for blanking conveniently

The invention discloses a rapid garbage smashing device for blanking conveniently. The device comprises a smashing box, wherein a left frame and a right frame are symmetrically arranged on the left side and the right side of the smashing box; the left side and the right side of the upper part of the smashing box are fixedly mounted on the inner side of the left frame and the inner side of the right frame by two mounting frames respectively; two coarse smashing rollers are also symmetrically arranged on the front side and the rear side of the upper part of the mashing box; the two coarse smashing rollers are rotatably mounted inside the smashing box by two first rotating shafts respectively; a belt pulley is fixedly mounted at each of the right ends of the two first rotating shafts; the twobelt pulleys are connected with each other by a belt in a transmission manner; two fine smashing rollers are also symmetrically and rotatably mounted at the lower part of the smashing box. In the device, the coarse smashing rollers and the fine smashing rollers are rotatably mounted inside the smashing box, so that garbage can be smashed at multiple levels, the smashing effect is excellent, and the smashing efficiency is high; meanwhile, a knocking ball is arranged for knocking a blanking hole of the smashing box, so that the blocking caused by the garbage can be prevented, and the blanking efficiency is high.

Owner:SUZHOU RUISHUO ENVIRONMENT TECH CO LTD

Agricultural feed crushing and mixing device

InactiveCN108295756AImprove pulverization and mixing effectWell mixedFeeding-stuffRotary stirring mixersThree stageDrive shaft

The invention discloses an agricultural feed crushing and mixing device; an incomplete bevel gear is fixedly connected with the right end of a driving shaft; the upper part and lower part of the incomplete bevel gear are separately provided with a first bevel gear, and the bevel gears are fixedly connected with a screw rod; the toothed part of the incomplete bevel gear is meshed with the first bevel gears, and a bearing at the upper end of the screw rod is rotatably connected with the upper end of a device body; the screw rod is connected with the middle of a rolling plate by means of threads,the lower end of the screw rod is fixedly connected with a driven shaft, the upper part of the driven shaft is fixedly connected with a rotating disc, and the rotating disc is connected with the inner wall of the device body in a clamping way. According to the device, the rolling plate is driven to move up and down in a reciprocating way so as to squeeze a feed material on the rotating disc, andthe screw rod drives the rotating disc to rotate, so that rotary rolling is realized, and the crushing effect is better; a rotating shaft rotates while making revolution so as drive mixing teeth to rotate for fully mixing the crushed feed; a spring telescopic rod and a three-stage plate spring are used for damping, so that noise generated during the work of the device body is reduced. The structural design of the device is reasonable and applicable, so that the crushing and mixing effect of the feed is greatly improved.

Owner:徐琪

Material rapid crushing device

The invention discloses a material rapid crushing device, which includes a crushing shell, a crushing group and a small crushing roller arranged inside the inner body, the small crushing roller is arranged at the upper end of the casing, and a material bearing plate is arranged on the left side of the small crushing roller. A pusher plate is placed above the material plate, the left side of the pusher plate is connected to the push rod, the push rod is connected to the cylinder outside the shell, the upper end of the shell is provided with a feed hopper, and a hot air blower is installed at the connection between the feed hopper and the shell. There is a guide hopper in the middle of the material bearing plate, the crushing group in the shell is located under the guide hopper, the inclined vibrating sieve plate is arranged under the crushing group, the receiving funnel is provided under the vibrating sieve plate, and the receiving funnel is provided under the receiving hopper. At the discharge port, the device of the present invention has an excellent material crushing effect, and is not easy to be blocked during the feeding process. An anti-rust coating is provided on the surface of the crushing parts, which is beneficial to ensure the quality of the crushing materials and the service life of the crushing parts.

Owner:浦江县协盈动物饲料技术开发有限公司

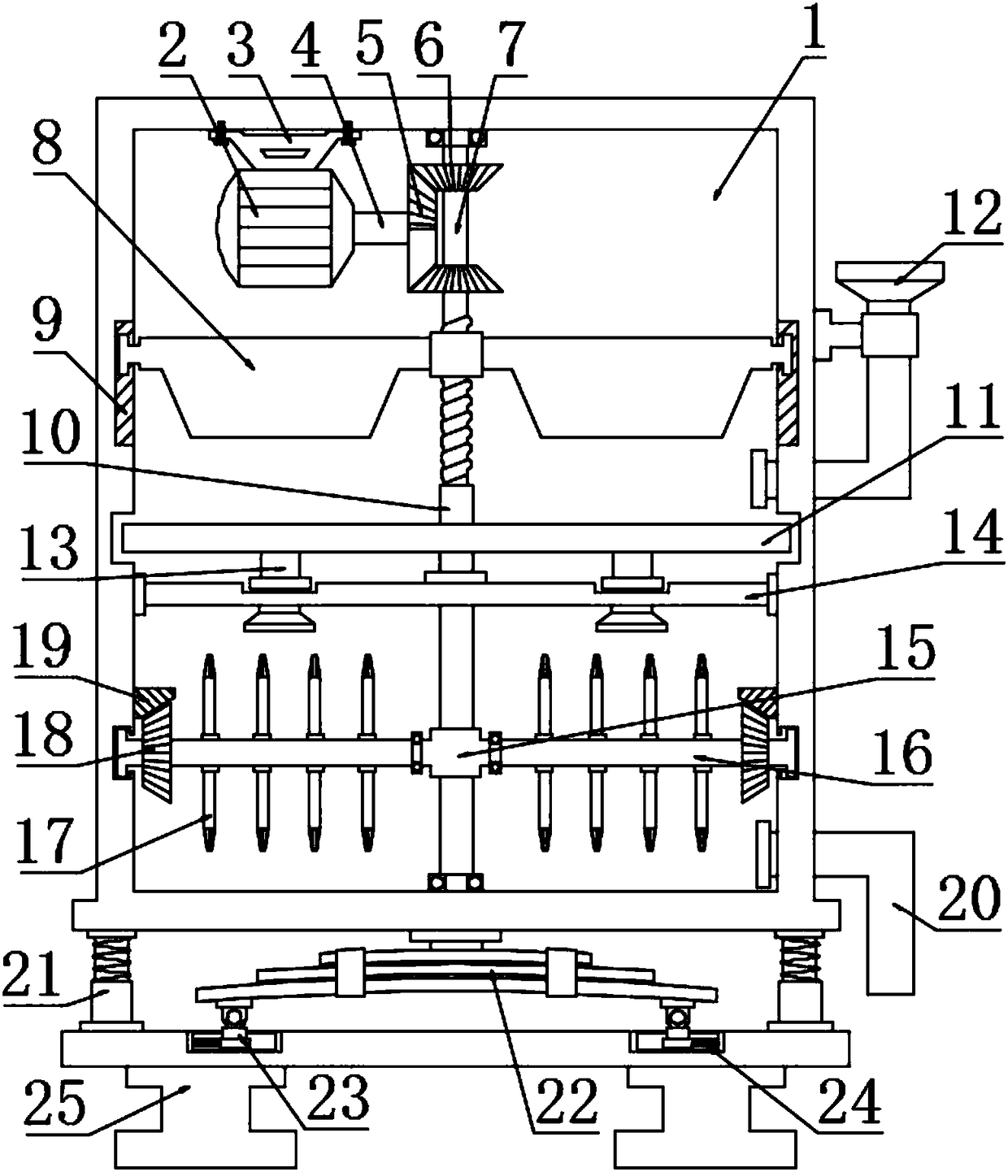

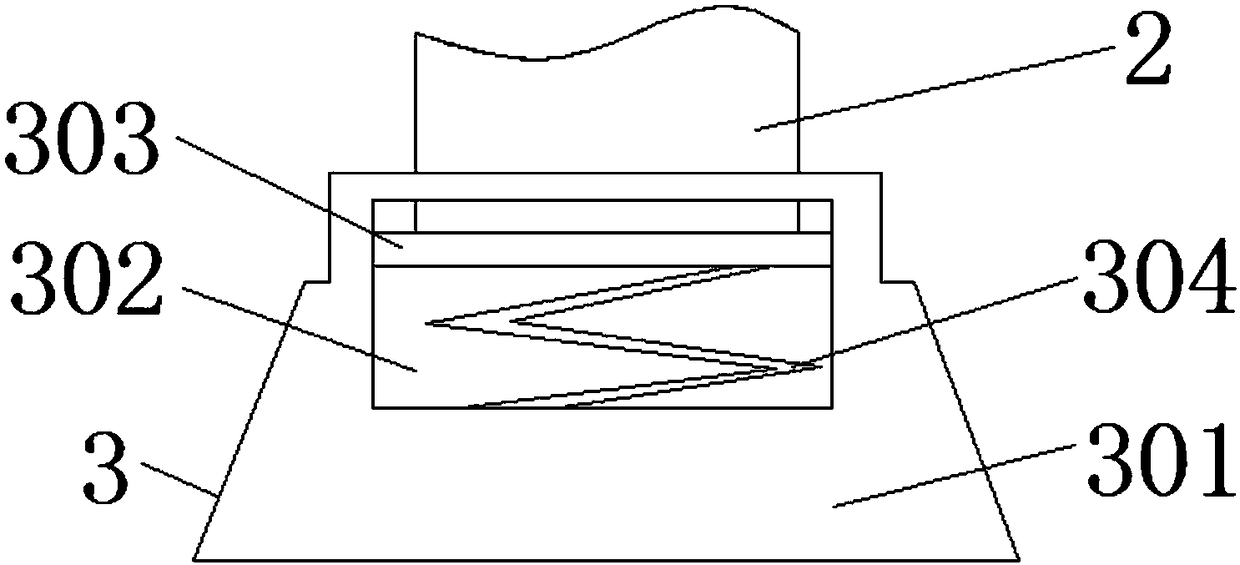

Fodder crushing and drying integrated equipment for raising livestock

ActiveCN107159397ANot easy to shiftImprove crushabilityFeeding-stuffDrying gas arrangementsEngineeringLivestock

The invention relates to fodder crushing equipment, in particular to fodder crushing and drying integrated equipment for raising livestock. According to the fodder crushing and drying integrated equipment for raising livestock, the equipment is good in crushing effect, the crushed fodder can be dried, the fodder is not prone to being damp and getting mildewed, and the financial loss is decreased. The fodder crushing and drying integrated equipment for raising livestock comprises a bottom plate, supports, a collecting frame, fixing columns, a fodder-stopping funnel, a fixing block, a crushing device and the like. The top of the bottom plate is vertically provided with the supports in a left-right symmetrical bolted connection. The tops of the inner side surfaces of the two supports are horizontally provided with the fixing columns in bolted connection. According to the fodder crushing and drying integrated equipment for raising livestock, the effects that the crushing effect is good, the crushed fodder can be dried, the fodder is not prone to being damp and getting mildewed, and the financial loss is decreased are achieved.

Owner:江苏桂柳牧业丰县有限公司

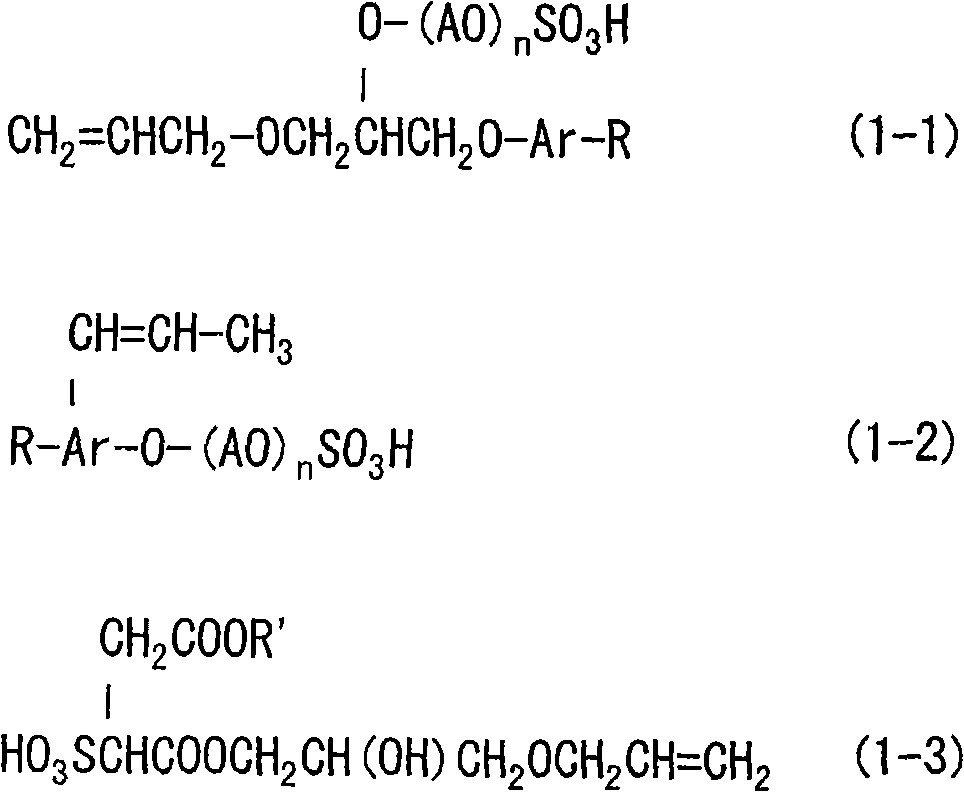

Resin particle

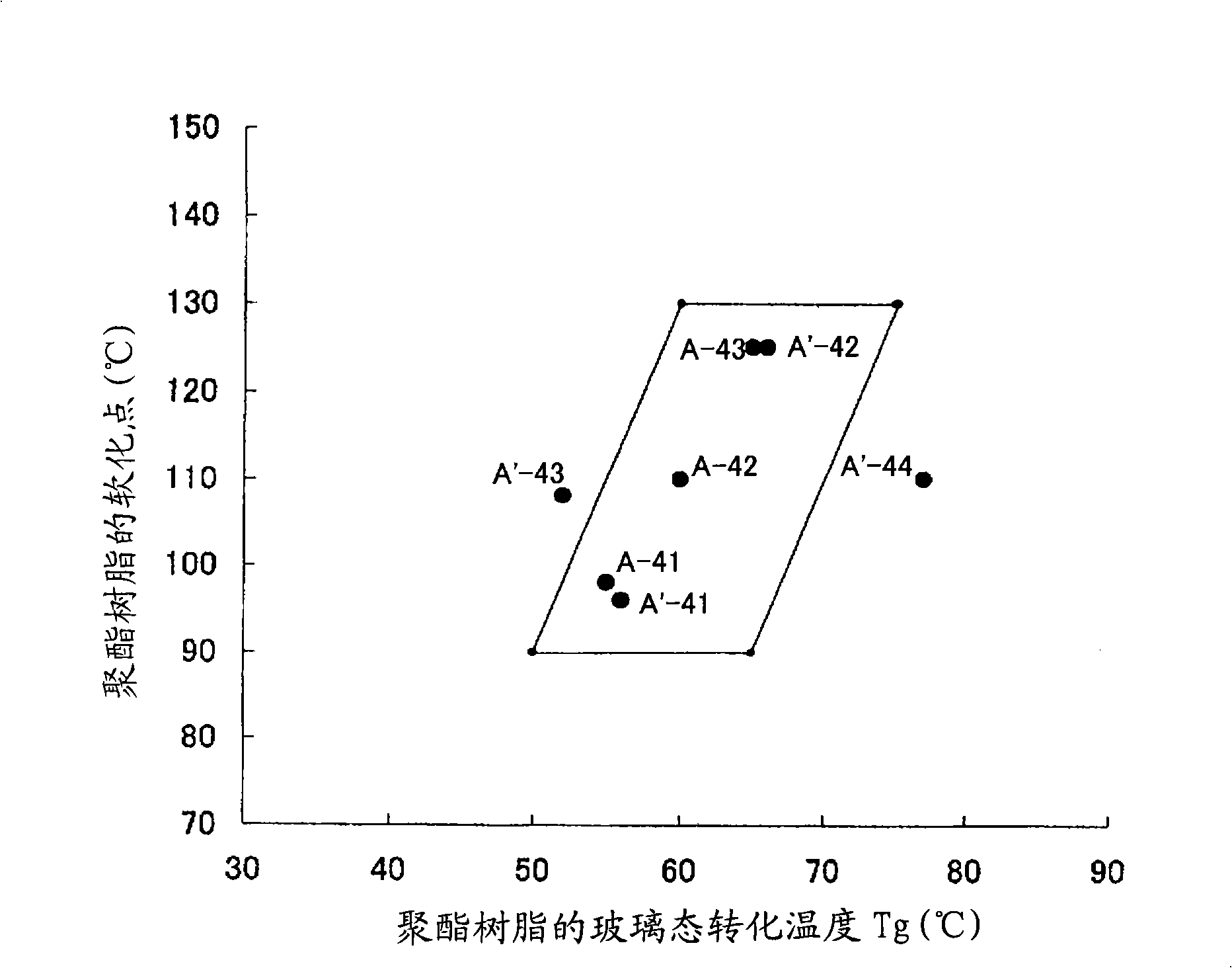

ActiveCN101324763AExcellent low temperature fixing characteristicsExcellent stainingDevelopersPolyester resinCarboxylic acid

The invention discloses a heat-fusible electrostatic image developing toner which has an excellent balance between fixability at low temperatures and grindability and is excellent in glossiness after fixation, also discloses a resin for toners, wherein a polyester resin for toners which is obtained by polycondensing a polyol component and a polycarboxylic acid component. The invention also relates to resin particles used for hollow forming resin, powder coating, electrical photography toner, electrostatic record toner, electrostatic print toner, or heat melt adhesive.

Owner:SANYO CHEM IND LTD

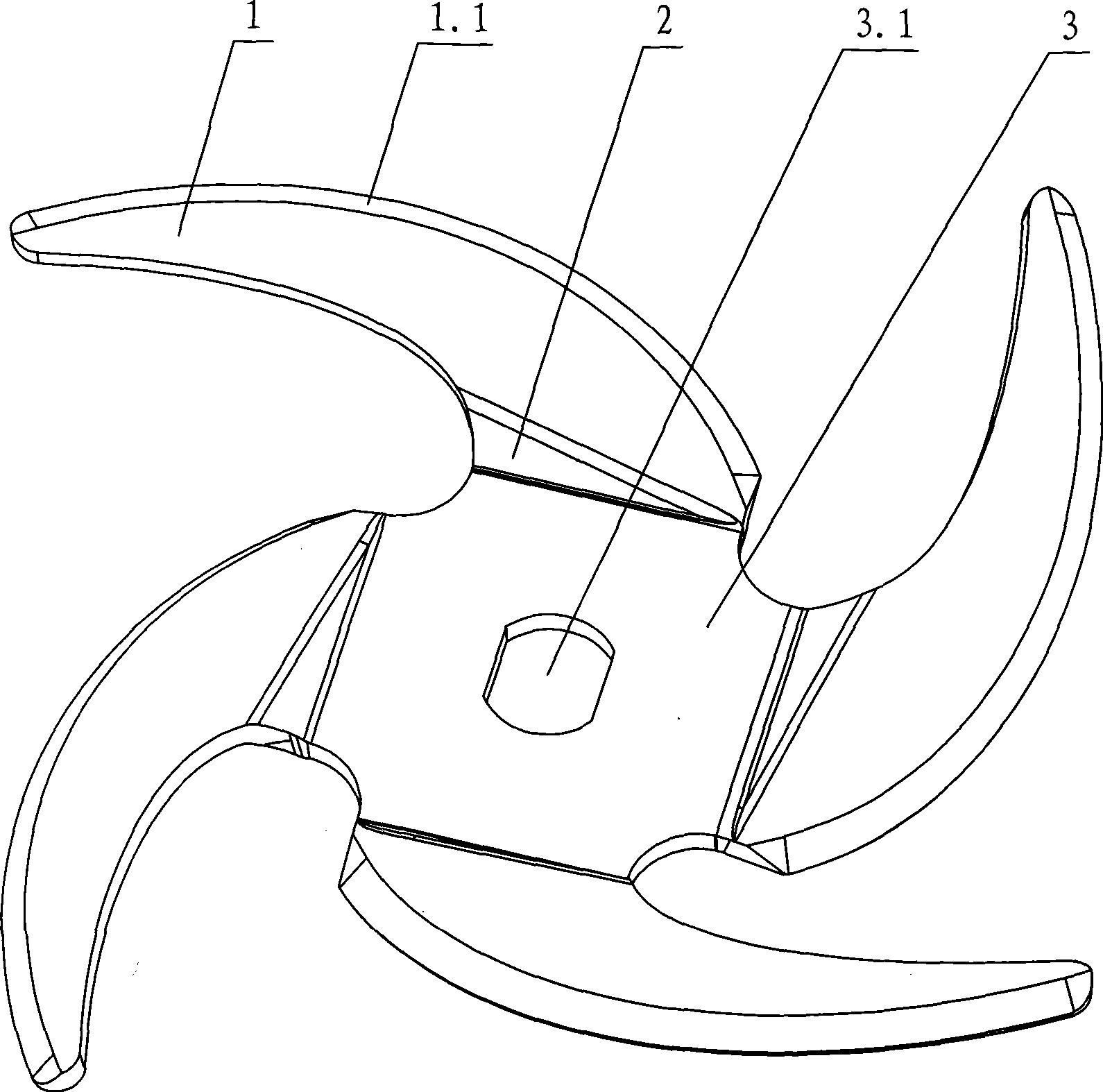

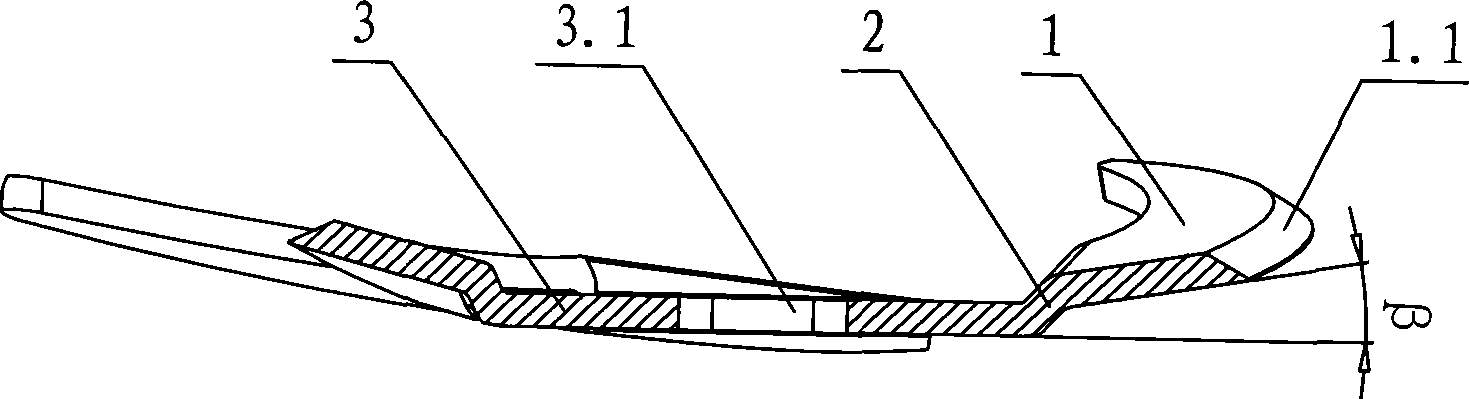

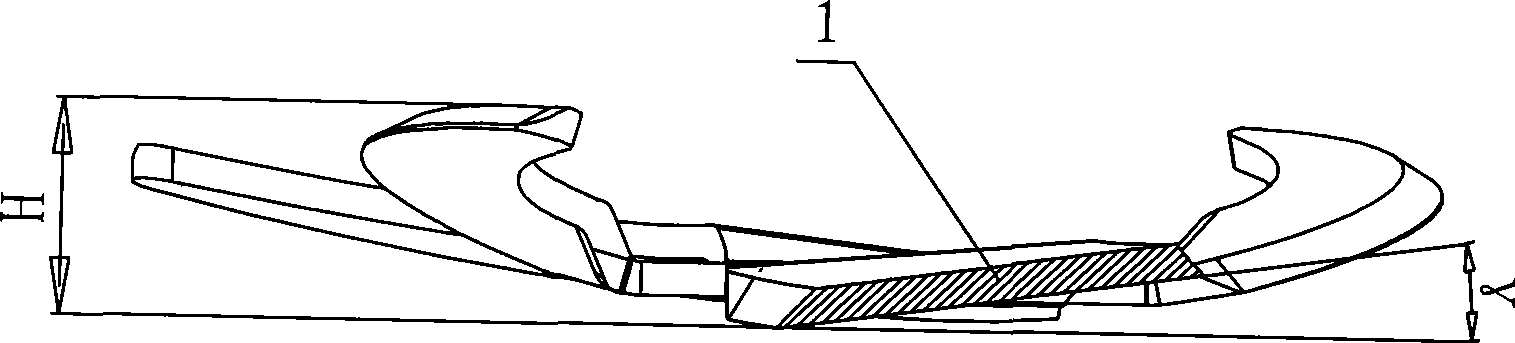

Tool for food processing machine

InactiveCN101361638AThe effect is obviousImprove crushabilityKitchen equipmentGrain treatmentsSuction forceCurve shape

The invention discloses a knife tool used for food processing machines which comprises a knife holder, a knife root and a knife blade that are connected in sequence, an arc-shaped or a curve-shaped knife edge is arranged on a rotating cutting face of the knife blade, a variation range Omega of a cutting angle Alpha from a start point to an end point of the knife edge lies in a closed interval between 0 and 60 degrees, and the cutting angle Alpha lies in a closed interval between 10 and 70 degrees. The knife blade is twisted in a certain twisting angle Gamma from 0 to 10 degrees. The knife root is kinked upward and / or downward with a certain kinking angle Beta from 0 to 25 degrees. Under the action of the cutting angle Alpha and the twisting angle Gamma, the knife blade of the knife tool has greatly improved agitating and smashing effects, greatly extends raw food materials that are used by combined soybean milk and rice paste machines, and can obtain excellent smashing effect of both dry materials and steeped materials from the aspect of material status. Under the condition of equal processing material amount, the knife tool greatly reduces the size of a knife body, remarkably decreases the power that is required by drive motors, and has simple and reasonable structure, good smashing effects, wide application range and large circular suction force to liquid paste.

Owner:漳州万利达光催化科技有限公司

Raw ore smashing equipment used for coal mining

The invention discloses raw ore smashing equipment used for coal mining. The raw ore smashing equipment comprises an equipment box, wherein a sieve plate is fixedly connected to the center inside theequipment box, a mounting seat is fixedly connected to the left side of the top of the equipment box, a motor is fixedly above the mounting seat, a driving bevel gear is fixedly connected to the output end of the right side of the motor, the center of the top of the equipment box is rotationally connected with a longitudinal rotating shaft through a bearing, a driven bevel gear is fixedly connected to the top of the longitudinal rotating shaft, and the driven bevel gear is meshed with the driving bevel gear; the middle of the longitudinal rotating shaft is fixedly connected with a driving gear, and auxiliary blades are fixedly connected below the driving gear. Compared with the prior art, the raw ore smashing equipment has the beneficial effects that the framework is simple, the use is convenient, the smashing states are different when raw ores are smashed by changing different working states when coal ores are smashed, and different smashing effects are realized in different states, and the smashing effects are better through mutual matching, so that the raw ore smashing equipment is worthy of promotion.

Owner:INNER MONGOLIA HUANGTAOLEGAI COAL CO LTD SHI LIN CHEM BRANCH

Solid drug crushing device for department of pediatrics

ActiveCN107714481ADoes not affect crushingNot easy to spillOral administration deviceDrugEngineering

The invention relates to a crushing device, in particular to a solid drug crushing device for a department of pediatrics. The technical problem to be solved by the invention is to provide a solid drugcrushing device for a department of pediatrics, which saves the time and the labor, is optimal in crushing effect and ensures that a solid drug is hard to spill out in the crushing process so as notbe wasted. In order to solve the technical problem, the invention provides the solid drug crushing device for the department of pediatrics, which comprises a bottom plate and the like; a supporting rod is mounted on the left side at the top of the bottom plate, a cross plate is mounted at the top end of the supporting rod, a cylinder is mounted on the right side surface of the cross plate, a firstnet plate is mounted between the upper part on the inner left side of the cylinder and the upper part on the right side, and a cross rod is mounted between the lower part on the inner left side of the cylinder and the lower part on the right side. The solid drug crushing device provided by the invention has the beneficial effects that through a grinding device, the solid drug can be ground; a cleaning device can clean the inside of the cylinder, so that the crushing of the solid drug at the next time is not influenced; the effects that both the time and the labor are saved, a crushing effectis optimal, and in the crushing process, the solid drug is hard to spill out so as not to be wasted are achieved.

Owner:苗艳秋 +1

Efficient smashing equipment for corn for sheep raising

The invention relates to corn smashing equipment, in particular to efficient smashing equipment for corn for sheep raising. The efficient smashing equipment for corn for sheep raising is low in manufacturing cost, easy to operate and capable of achieving fine smashing, and comprises a bottom plate and the like. A support and a collecting frame are installed on the top of the bottom plate in a bolt connection mode. The support is located on the left side of the collecting frame. A top plate is horizontally connected to the top of the support in a bolt connection mode. A guide device is arranged on the bottom of the top plate. A guide component of the guide device is connected with a smashing bin which is provided with a smashing device. Corn particles are smashed through the smashing bin and the smashing blade which are opposite in rotation direction, the smashing effect is quite good, and the effects of low manufacturing cost, easy operation and fine smashing are achieved.

Owner:王成志

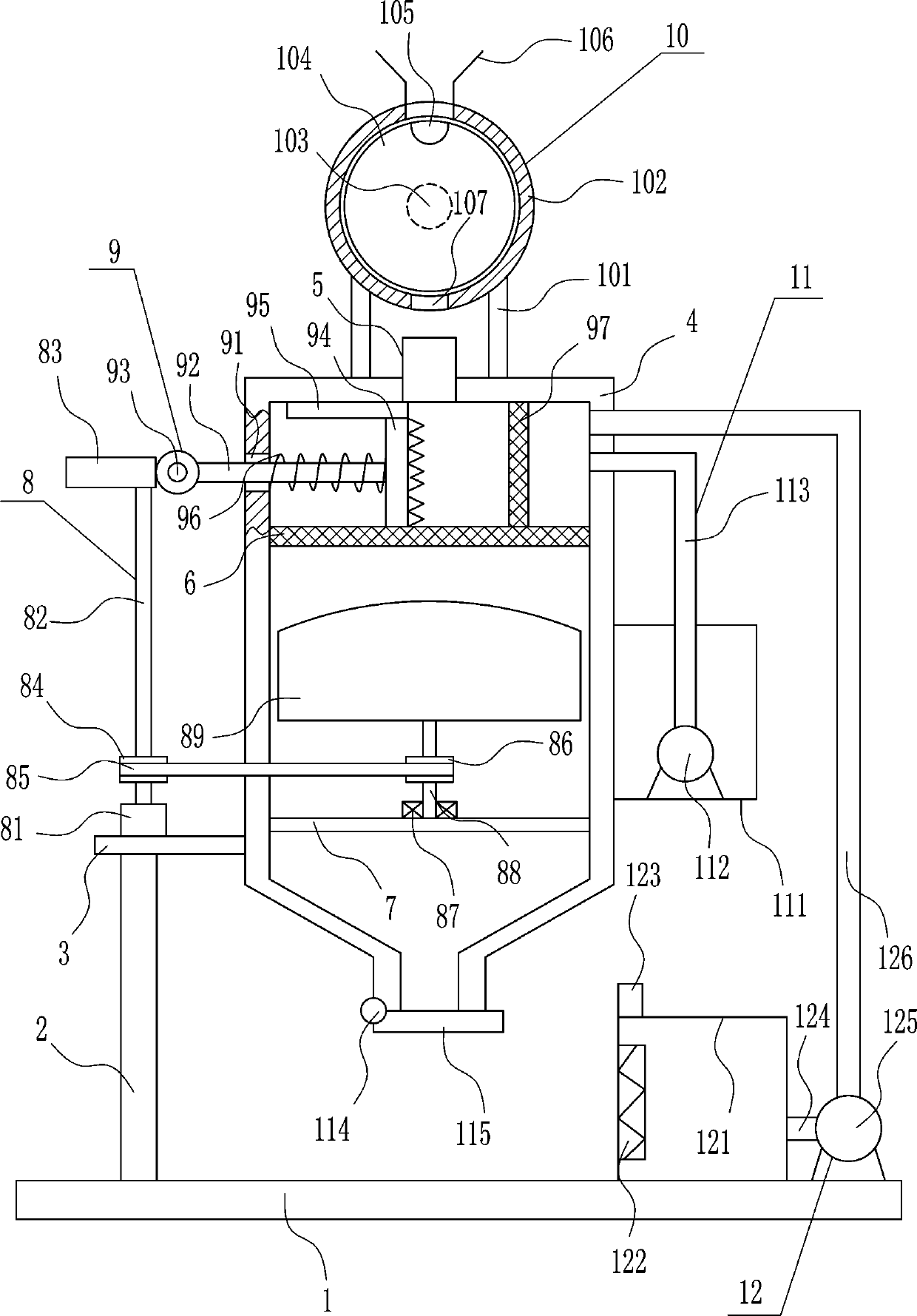

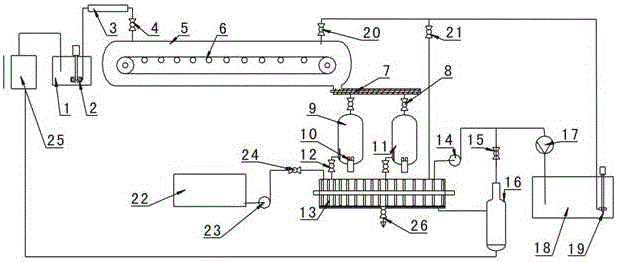

Production method and production apparatus for insoluble sulfur

ActiveCN106082139ANo pollution in the processEasy accessSulfur preparation/purificationDistillationVacuum pump

The invention discloses a production method for insoluble sulfur. The method comprises the steps of: sulfur melting and heating; quenching; conveying and solidification; coarse crushing; curing and fine crushing; and sieving, washing, drying, and oil charging. The invention also discloses a production apparatus of insoluble sulfur. The production apparatus consists of: a sulfur melting groove, a liquid sulfur pump, an electric heater, a reaction pot, a conveyer belt, a screw conveyer, aging pots, colloid mills, screen meshes, a rake dryer, a vacuum pump, a distillation tower, a condenser, a naphthenic oil storage tank, a submerged pump, a carbon disulfide storage tank, a metering pump and a sulfur purifier. Through the components, the process of sulfur melting, heating, quenching, conveying, solidification, coarse crushing, curing, fine crushing, sieving, washing, drying, and oil charging can be finished. The method and apparatus for production of insoluble sulfur provided by the invention can realize whole process closed production, completely eradicate dust, and achieve the purpose of environment-friendly and clean production.

Owner:黄煜

Multistage smashing and granulating device for garbage

The invention discloses a multistage smashing and granulating device for garbage. A first discharging plate and a second discharging plate are arranged in a smashing box. The interior of the smashingbox is sequentially divided into a primary smashing chamber, a fine smashing chamber and a grinding chamber through the first discharging plate and the second discharging plate. The upper side of theinterior of the primary smashing chamber is rotationally provided with a rotating shaft, and two journals are symmetrically arranged on the left side and the right side of the rotating shaft. The journals are rotationally provided with a rotating sleeve. The lower side of the rotating sleeve is fixedly provided with a connecting rod. A smashing blade is hinged to the lower end of the connecting rod. Two smashing rollers are symmetrically and rotationally installed in the fine smashing chamber, and two grinding rollers are symmetrically and rotationally installed in the grinding chamber. By means of the multistage smashing and granulating device for garbage, the smashing blade moving vertically, the rotating smashing rollers and the grinding rollers are arranged for smashing garbage multiple times stage by stage, the smashing efficiency is high, the smashing effect is good, the smashed garbage are in the shape of granules which are uniform in size, and subsequent treatment of garbage isfacilitated.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Animal husbandry efficient pulverizing equipment capable of preventing fodder caking

InactiveCN107362866ANot easy to agglomerateDoes not affect feedingFeeding-stuffGrain treatmentsEngineeringAnimal husbandry

The invention relates to fodder pulverizing equipment, in particular to animal husbandry efficient pulverizing equipment capable of preventing fodder caking. According to the technical purpose, the equipment is easy to operate and good in pulverizing effect, pulverized fodder is not prone to caking, and the livestock feeding work is not affected. For achieving the technical purpose, the animal husbandry efficient pulverizing equipment capable of preventing fodder caking comprises supporting legs, a tank, a discharging hopper, a pulverizer, a first cantboard and the like; and the supporting legs are arranged symmetrically, the tank is mounted at the top of the space between the two supporting legs in a bolt connection mode, the discharging hopper is mounted in the middle of the top of the tank in an embedded mode, the discharging hopper communicates with the interior of the tank, and the bottom of the tank is open. By adopting the animal husbandry efficient pulverizing equipment capable of preventing fodder caking, the effects that operation is easy, the pulverizing effect is good, the pulverized fodder is not prone to caking, and the livestock feeding work is not affected are achieved.

Owner:徐州三维饲料有限公司

Dry-type granulator for feed processing

The invention provides a dry-type granulator for feed processing, and relates to the field of feed processing. The dry-type granulator for feed processing comprises a box body, wherein supporting rodsare welded to the bottom of the box body; vibration-absorbing mechanisms are fixedly mounted at the bottoms of the supporting rods; a screening mechanism is arranged on the top of the box body; a feed port adapted to the screening mechanism is formed in the top of the box body; the bottom side of the box body is downwards inclined; a side box is welded to the side wall of the box body; a discharge port communicated with the inner part of the side box is formed in the side wall of the box body and in the bottommost end. According to the dry-type granulator for feed processing, a material is added into a screening box through a feed hopper, a vibrating motor drives a hitting roller to rotate to continuously hit the screening box so as to vibrate the material inside the screening box, impurities smaller than the material drop out of the screening box through screening holes, and the material slides out of the screening box through material passing holes and enters the box body through the feed port, so that the impurity content of the material is reduced and guarantee of the granulating quality is facilitated.

Owner:YANCHENG INST OF IND TECH

Swing type medicinal material grinding and processing device

The invention discloses a swing type medicinal material grinding and processing device. The device comprises a machine box; the machine box is internally provided with a crushing cavity and a grindingcavity; a first crushing roller and a second crushing roller are arranged in the crushing cavity and are transversely arranged in the crushing cavity through a first roller shaft and a second rollershaft correspondingly; the rear ends of the first roller shaft and the second roller shaft penetrate through the rear side wall of the crushing cavity and are provided with a driving gear and a drivengear correspondingly; a driving motor is arranged on the rear side of the crushing cavity; the driving gear is connected to the driving motor through a rotating shaft; and the grinding cavity is located below the crushing cavity. The device has the advantages that a grinding wheel is driven to regularly grind materials through a crank connecting rod mechanism, and therefore the grinding effect can be more uniform, and the quality of the discharged materials can be improved.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

Pulverizer

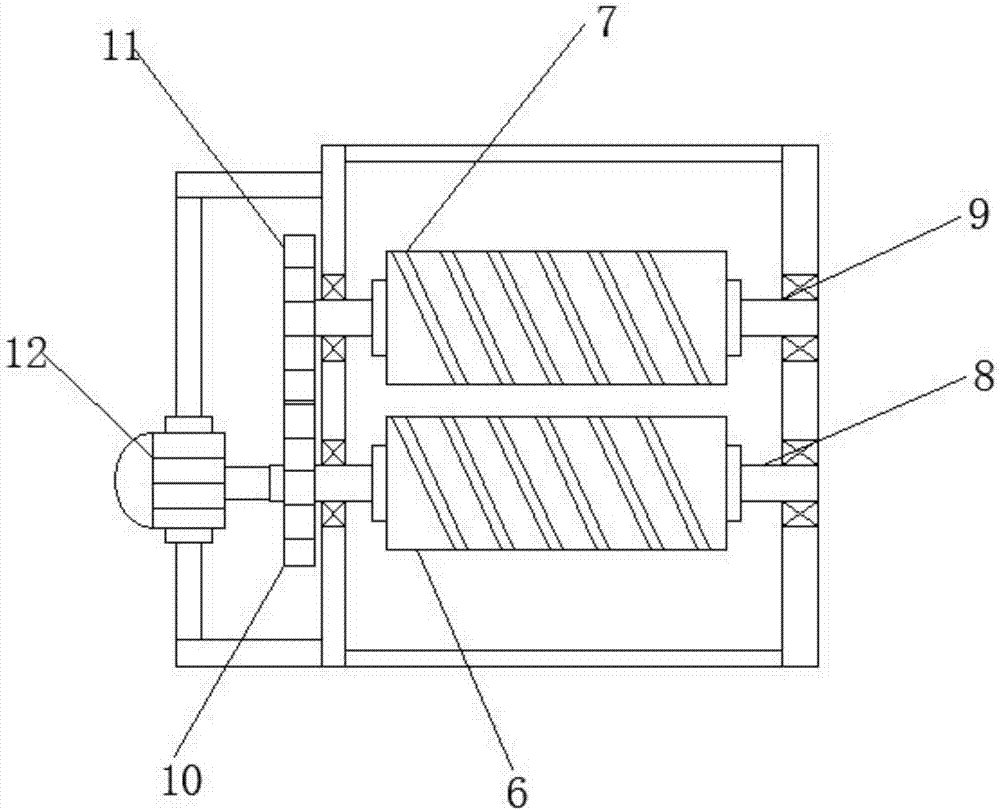

ActiveCN106272640AFully cutImprove crushabilityGrain treatmentsMetal working apparatusFiberEngineering

The invention relates to a pulverizer which comprises a frame, and a feeding device, a cutting device and a pulverizing device are arranged on the frame and sequentially connected. The cutting device comprises a first motor, an eccentric wheel, a connecting rod, a cutter and a guiding mechanism, wherein the first motor is connected with the eccentric wheel in a driving mode, one end of the connecting rod is connected with the eccentric wheel, the other end of the connecting rod is connected with the cutter, and the guiding mechanism is obliquely arranged on the frame and connected with the cutter. After materials enter the cutting device from the feeding device, the cutter moves in the direction of the guiding mechanism under driving of the eccentric wheel and the connecting rod so as to cut the materials obliquely; since the cut-in direction of the cutter is oblique relative to the materials, it is equivalent that vertical cutting force and horizontal cutting force are applied to the materials, and fibers in the materials are fully cut and broken; and afterwards, the materials enter the pulverizing device to be pulverized, and therefore the materials containing the fibers are fully cut, and the pulverizing effect is better.

Owner:赵金

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com