Soymilk machine head

Technology of a soymilk machine and machine head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

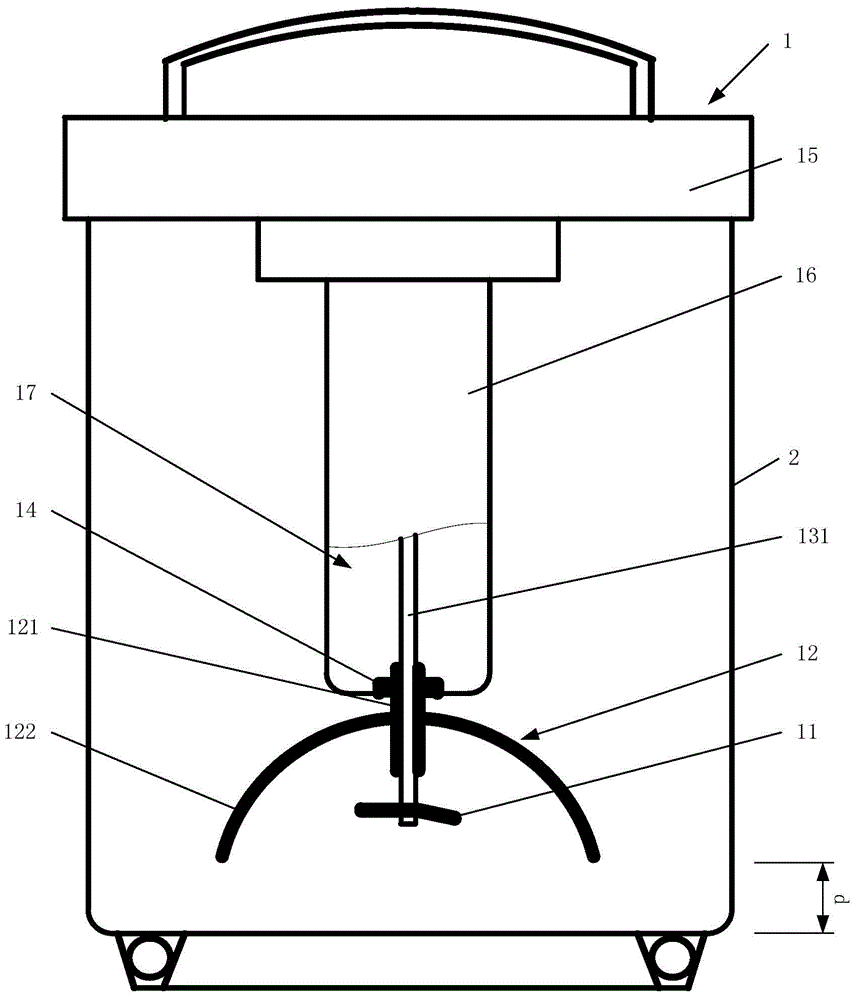

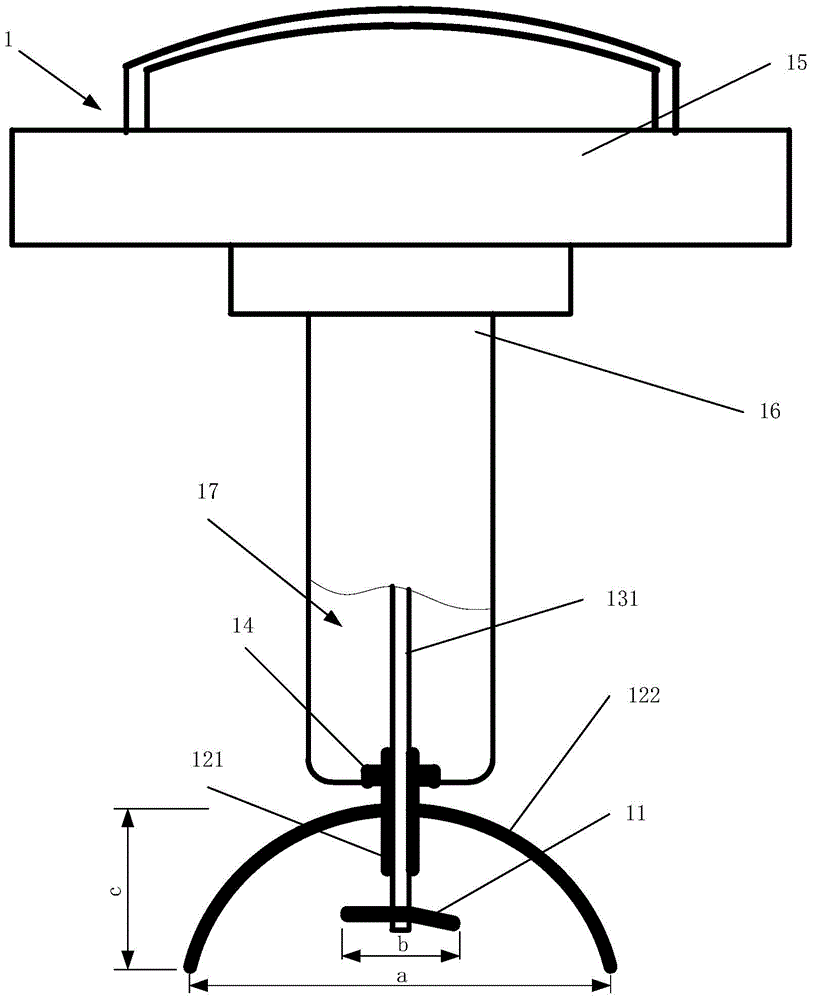

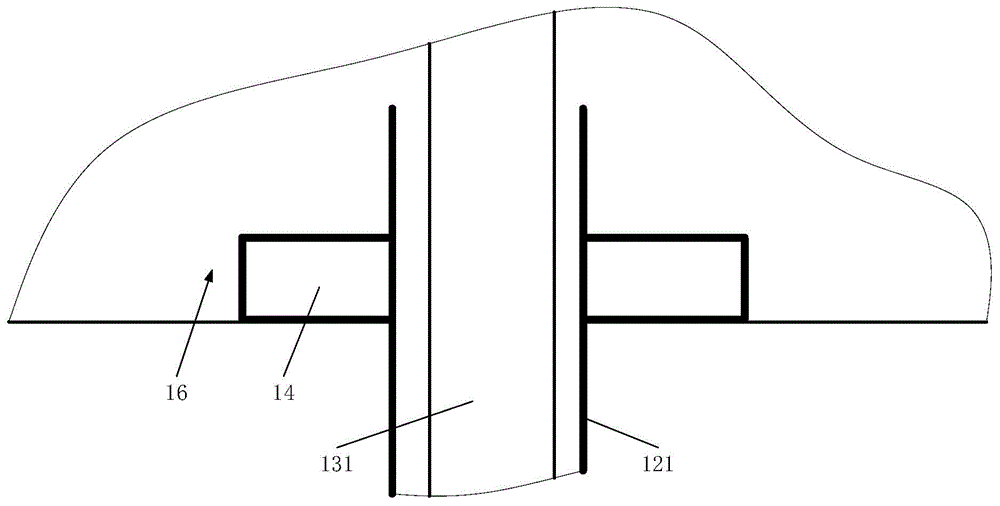

[0048] The invention provides a specific embodiment of a soybean milk machine, as follows:

[0049] The ratio W of the caliber of the turbulent body 122 to the diameter of the crushing knife 11 is 0.3125, the ratio X of the caliber of the turbulent body 122 to its height is 0.139, and the caliber of the turbulent body 122 is the same as the inner bottom of the barrel body 2 The ratio Y of the distance between the walls is 0.416, the distance between the crushing knife 11 and the inner bottom wall of the barrel body 2 of the soybean milk machine is 10 mm, and the crushing knife 11 is 50 mm lower than the lower end of the spoiler body 122, and the spoiler body The caliber (diameter) of 122 is 25mm, and the diameter of crushing knife 11 is 80mm, and the height of spoiler body 122 is 180mm, and the rotating speed of spoiler body 122 is 10r / min, and motor speed (that is: smashing knife 11 rotating speeds) is 500r / min. min, the distance between the spoiler body 122 and the inner bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com