Patents

Literature

251results about How to "Reduce speed difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

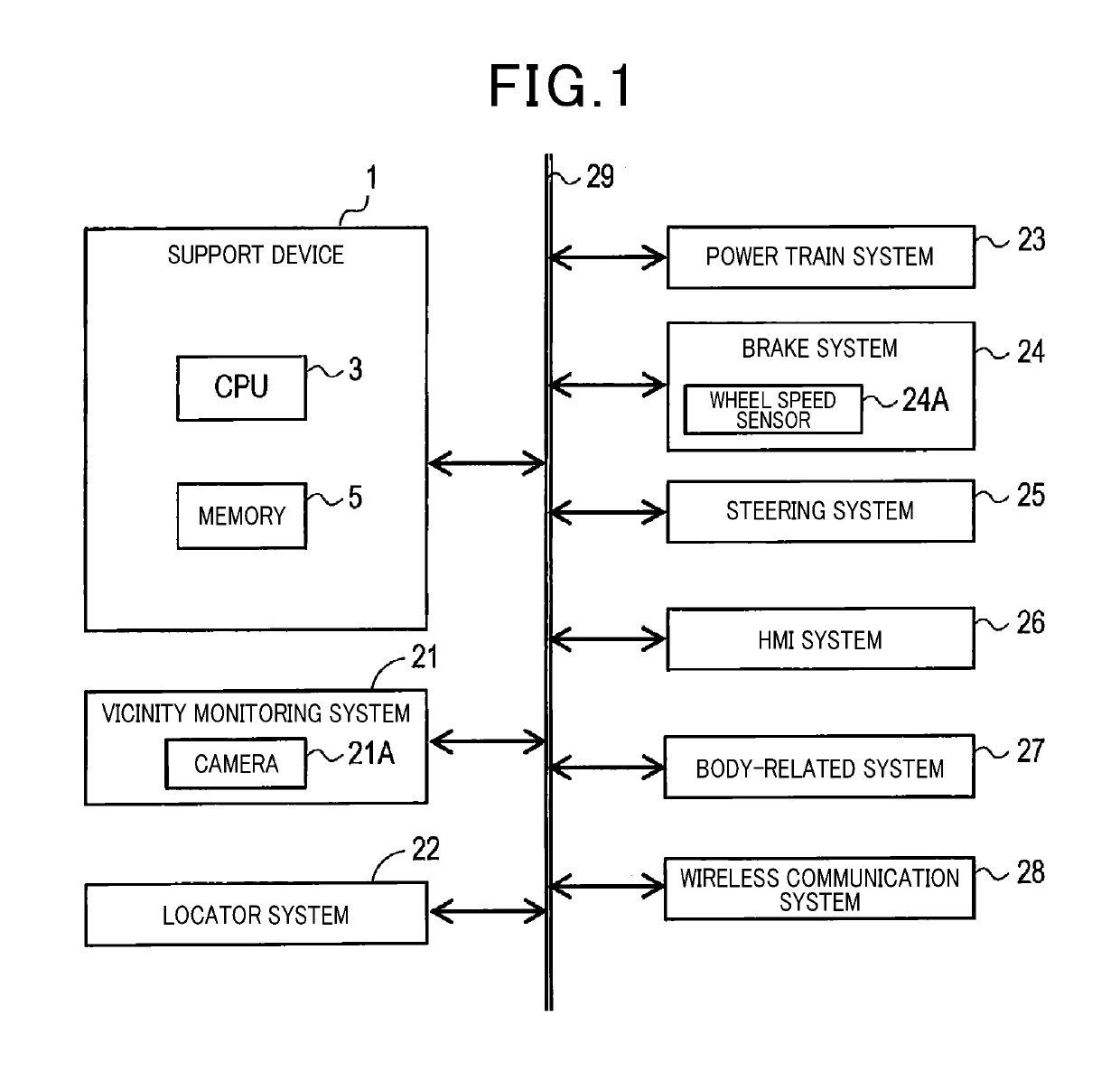

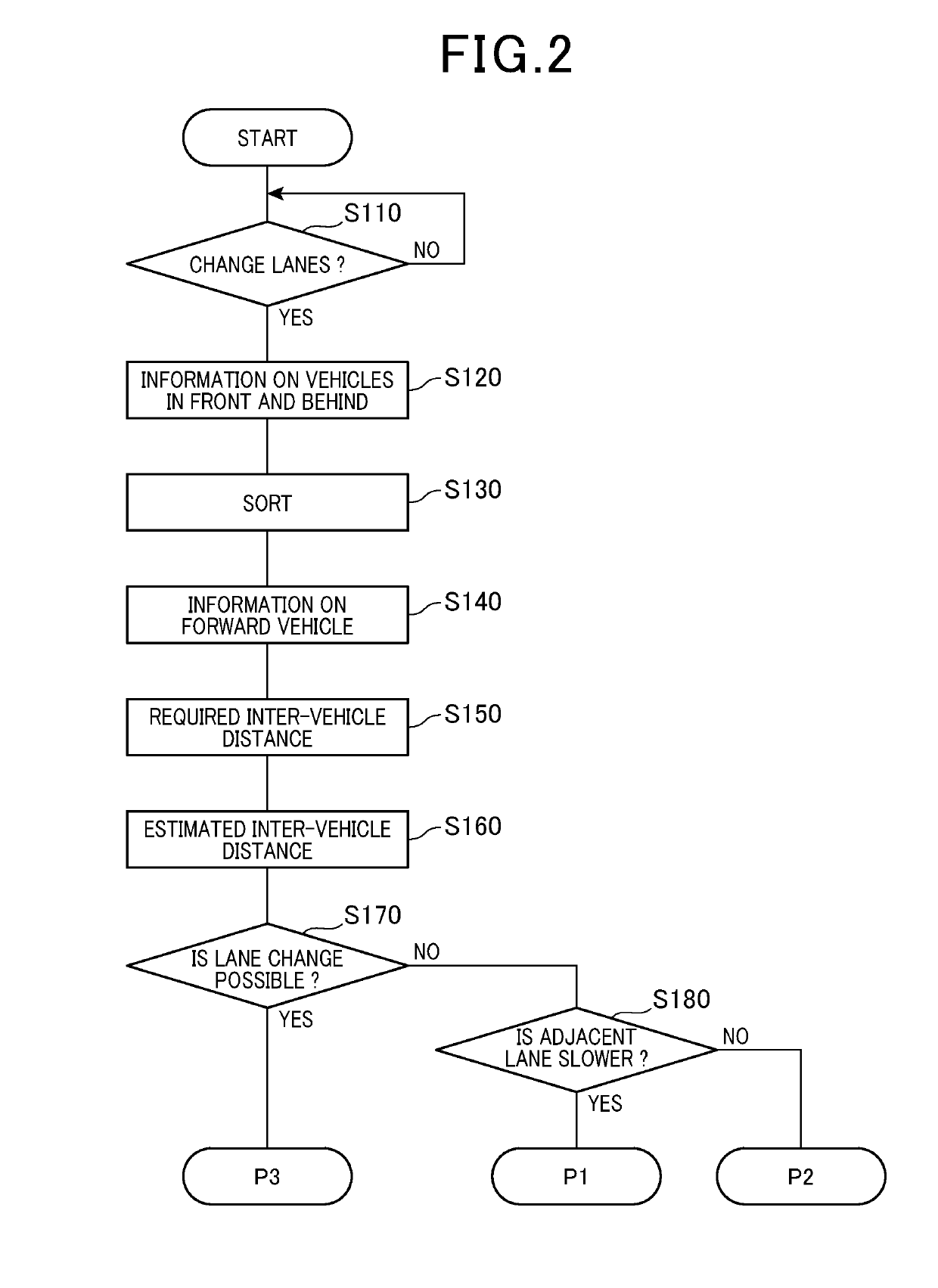

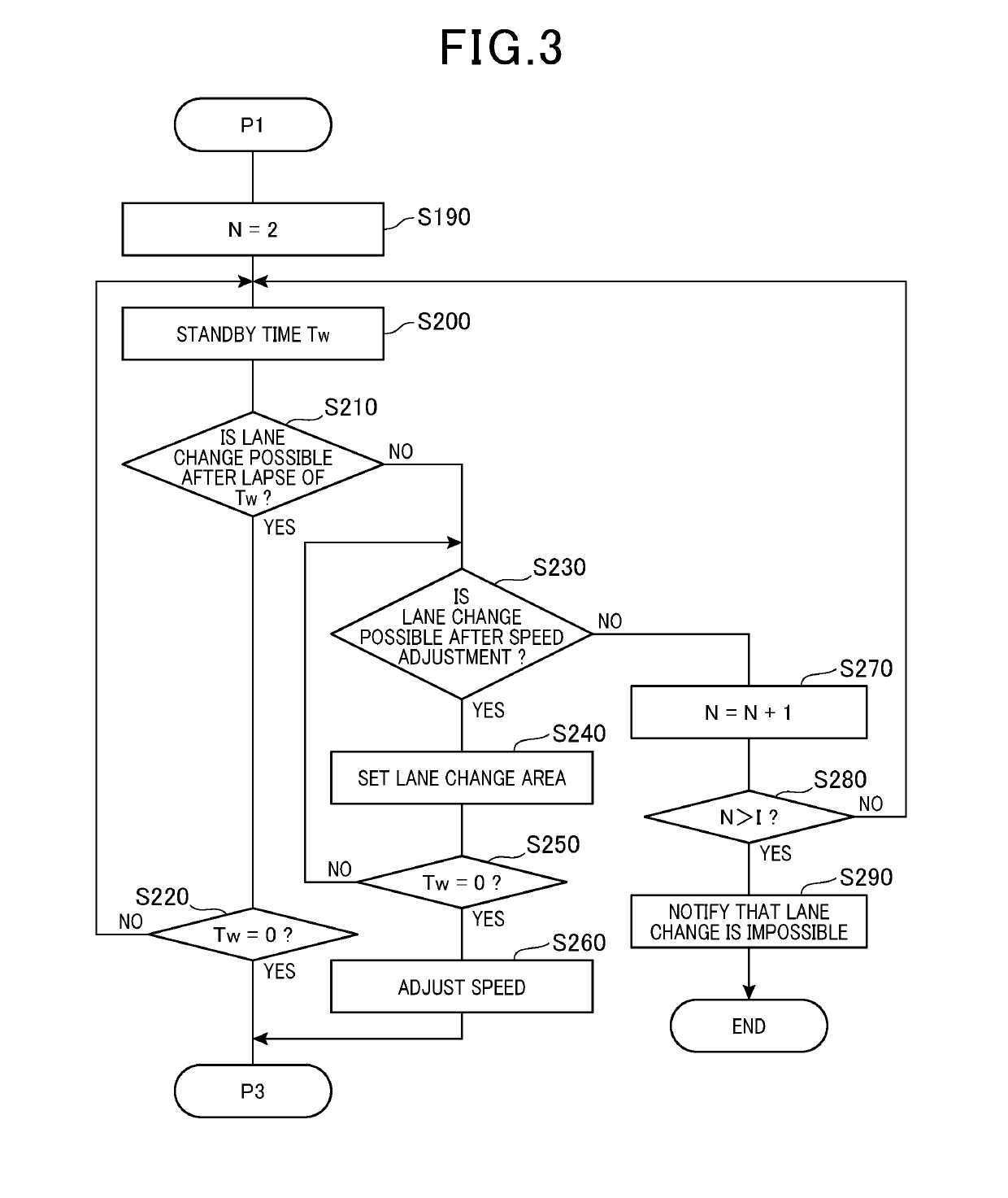

Support device

ActiveUS20190185005A1Reduce speed differencePrevent inter-vehicle distanceAnti-collision systemsExternal condition input parametersEngineering

Owner:DENSO CORP

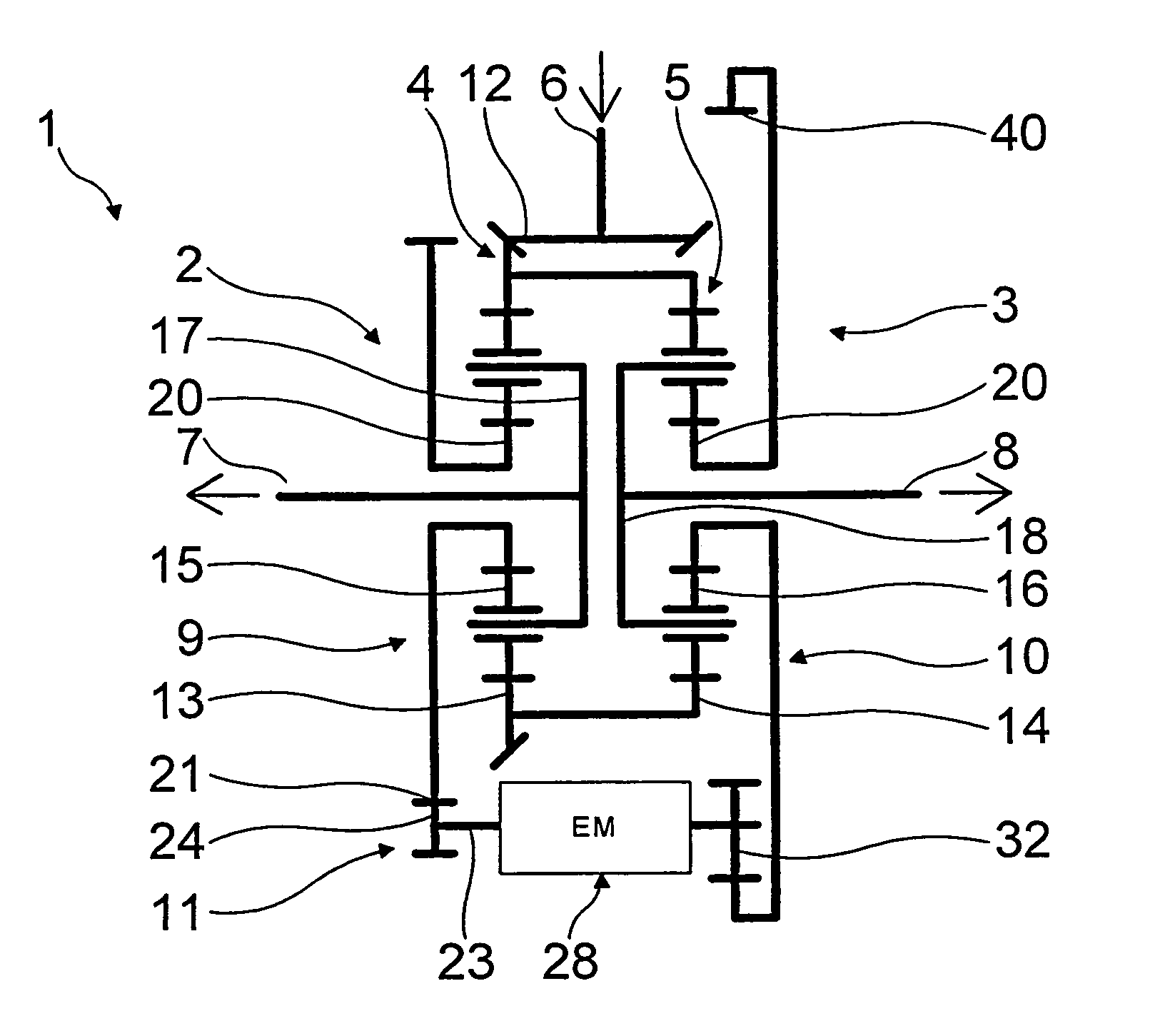

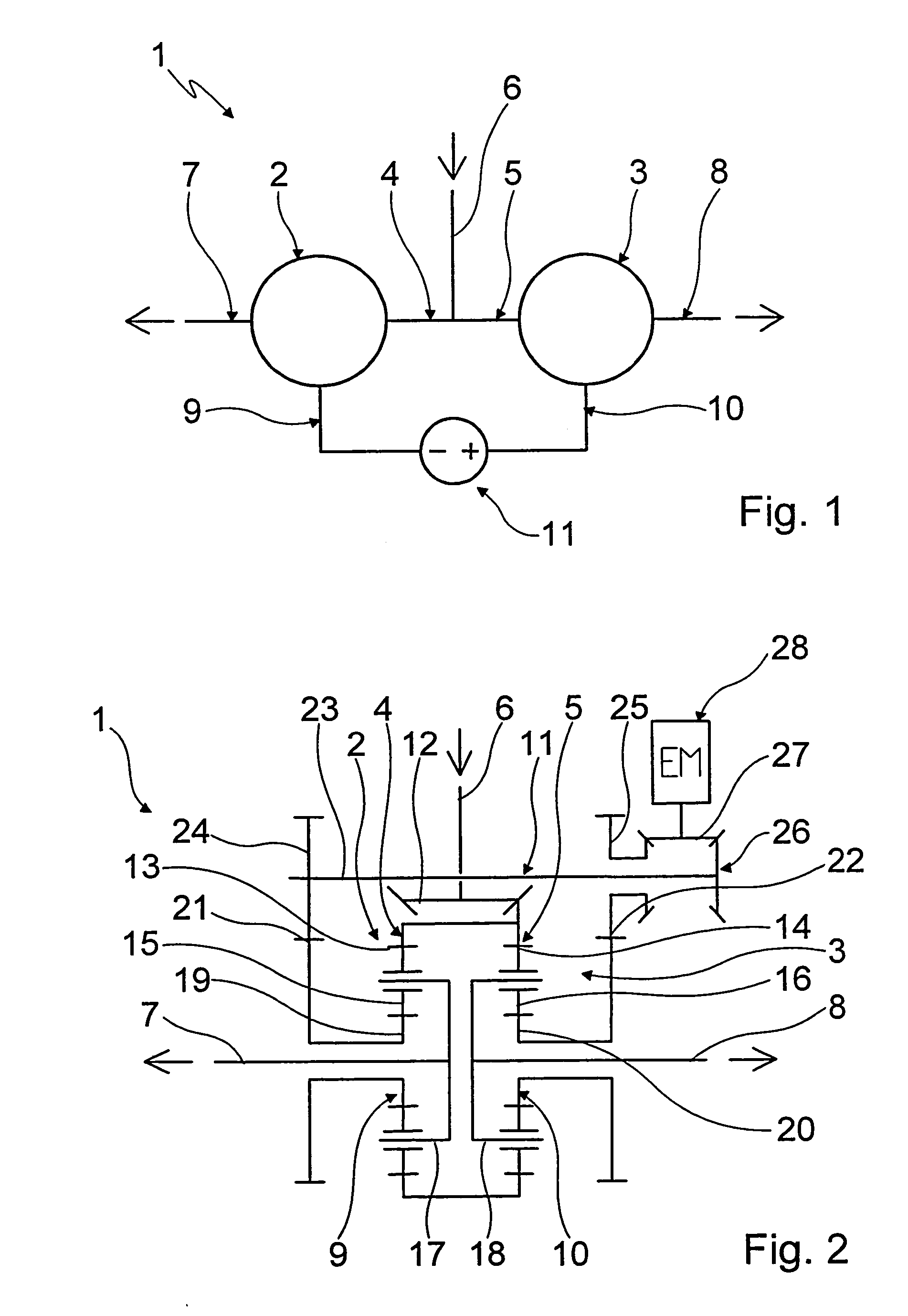

Transmission for distributing a drive torque

InactiveUS7056252B2Simple constructive meanLow technical controlToothed gearingsDifferential gearingsPlanetControl theory

Owner:ZF FRIEDRICHSHAFEN AG

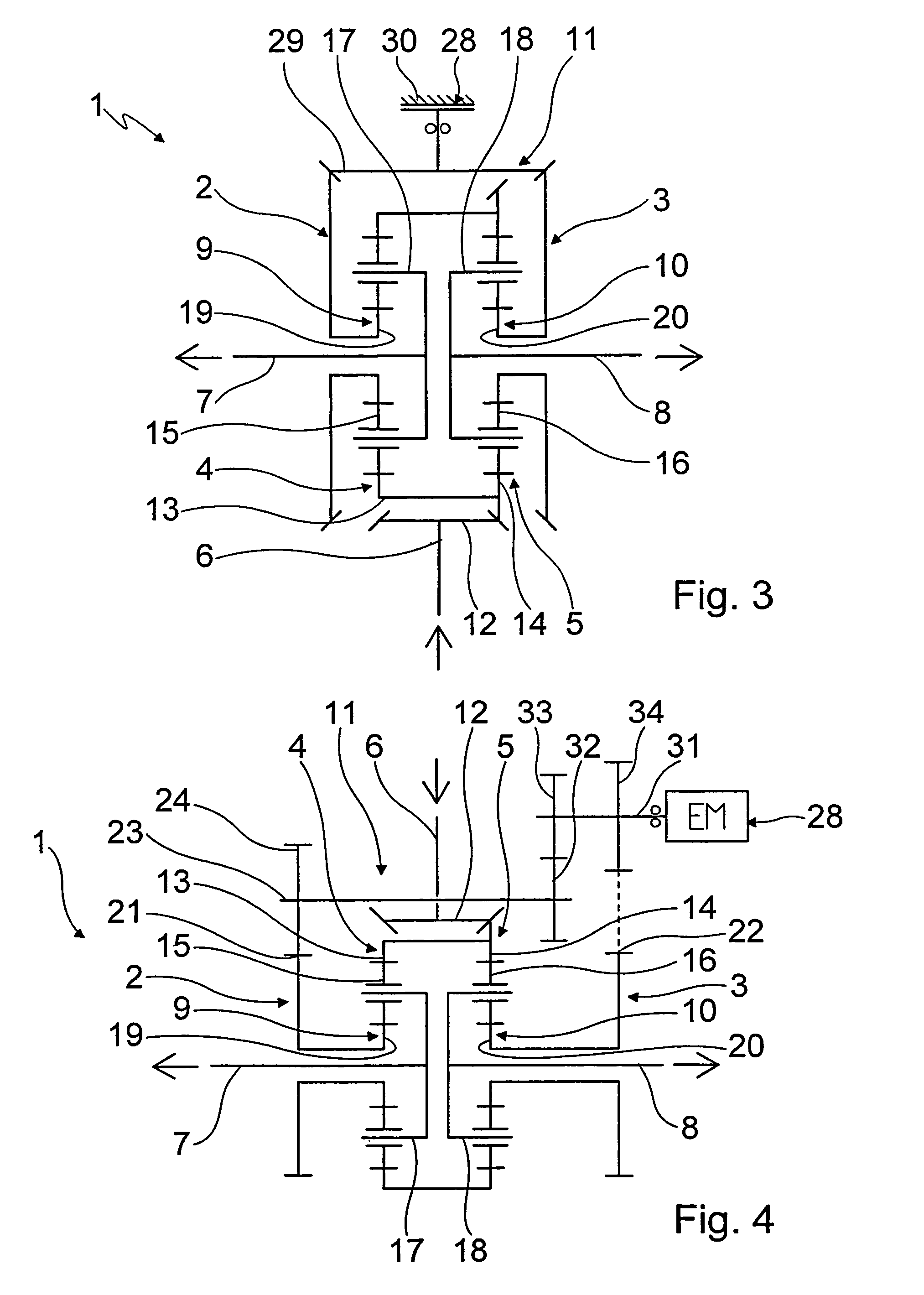

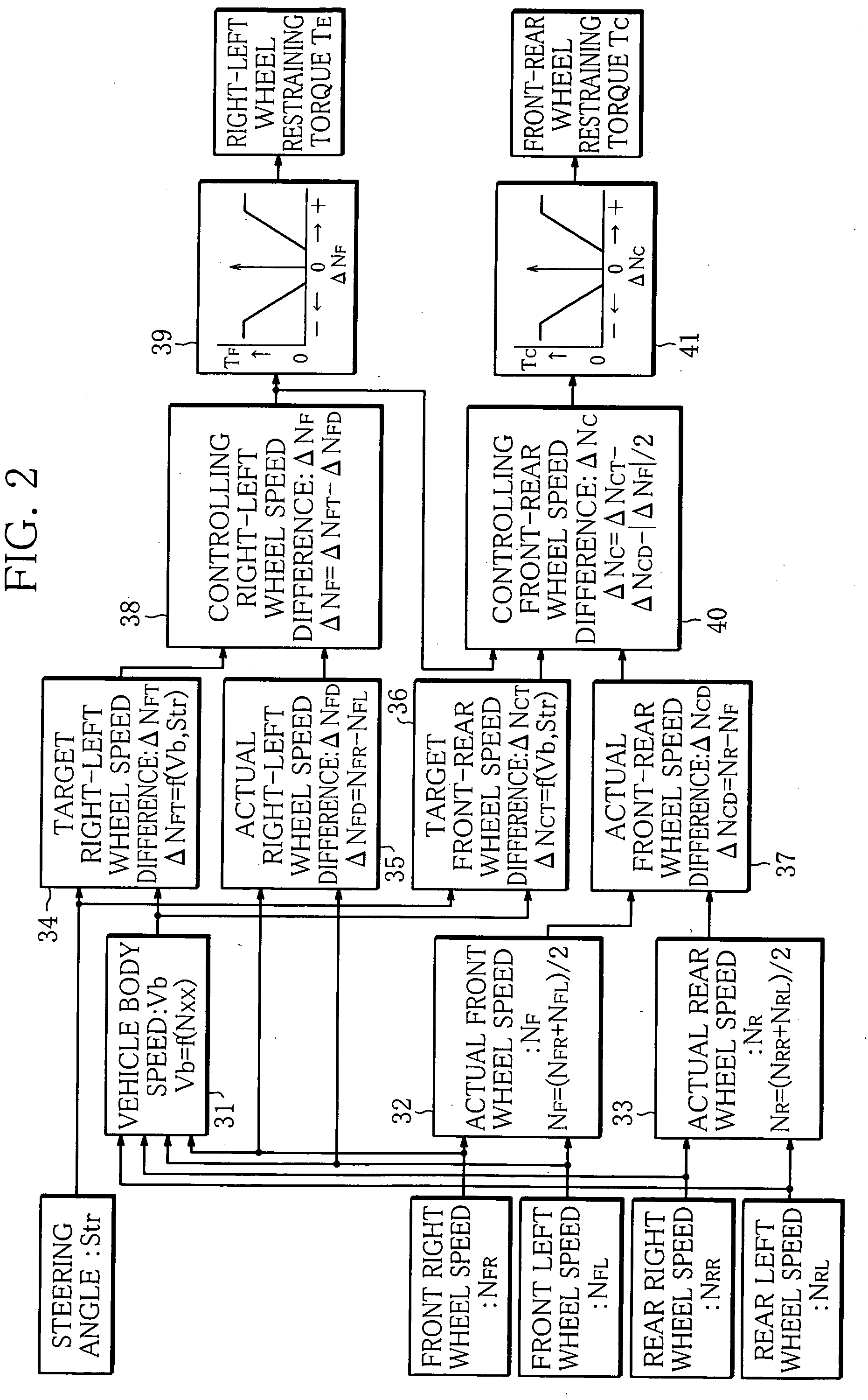

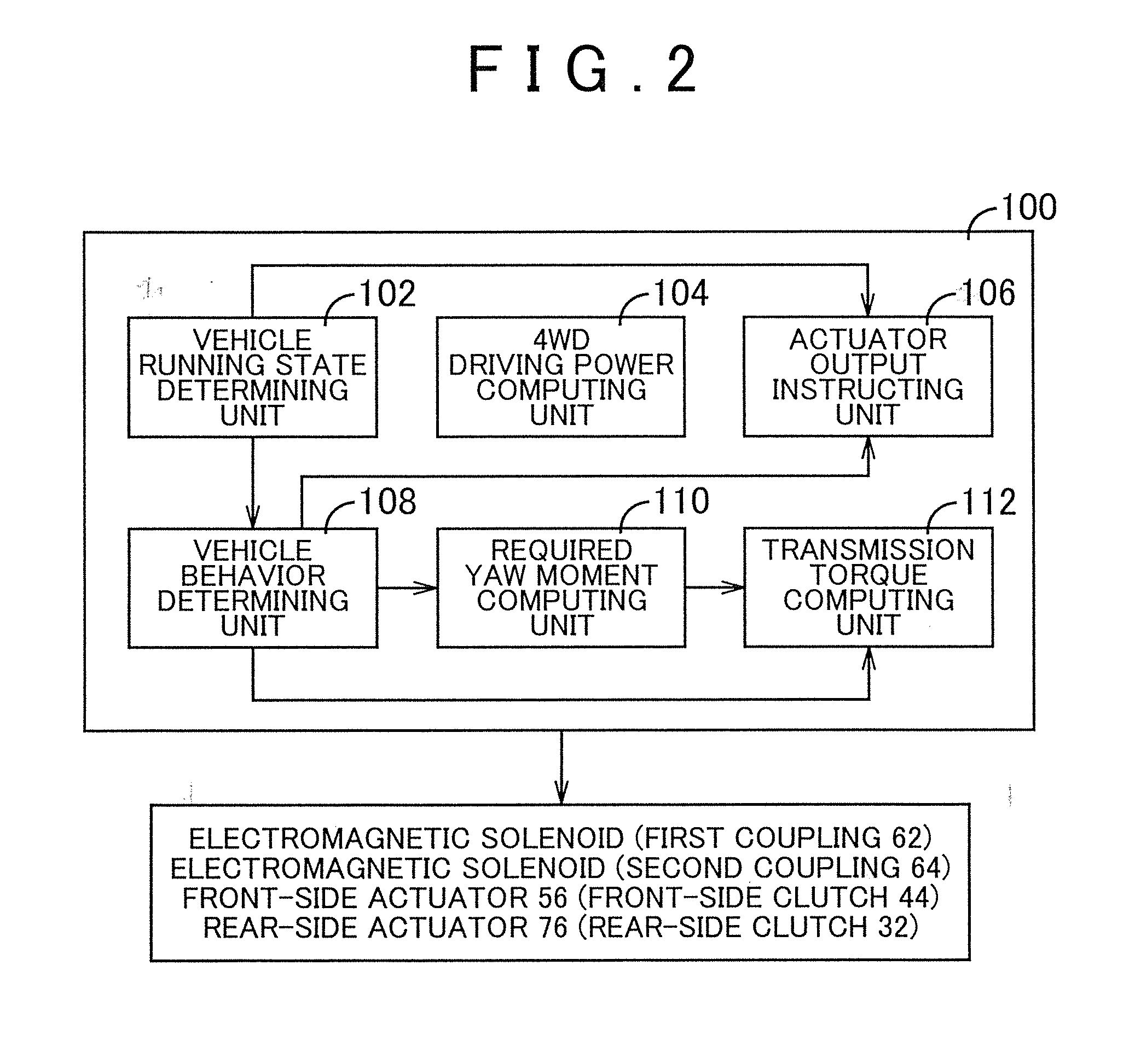

Differential Limiting Control Apparatus For Four-Wheel Drive Vehicle

ActiveUS20090127014A1Improved turning performanceSatisfactory performanceDriver input parametersPropulsion unit safety devicesLimited-slip differentialCoupling

Restraining torque TF of an electronic controlled front limited slip differential (5) arranged between right and left front wheels is controlled in accordance with controlling right-left wheel rotational speed difference ΔNF, which is the rotational speed difference between the right and left front wheels, while restraining torque TC of an electronic controlled coupling (8) arranged between the front and rear wheels is controlled in accordance with controlling front-rear wheel rotational speed difference ΔNC obtained by subtracting ½ of the rotational speed difference between the right and left wheels (|ΔNF| / 2) from the rotational speed difference (ΔNCT−ΔNCD) between the front and rear wheels.

Owner:MITSUBISHI MOTORS CORP

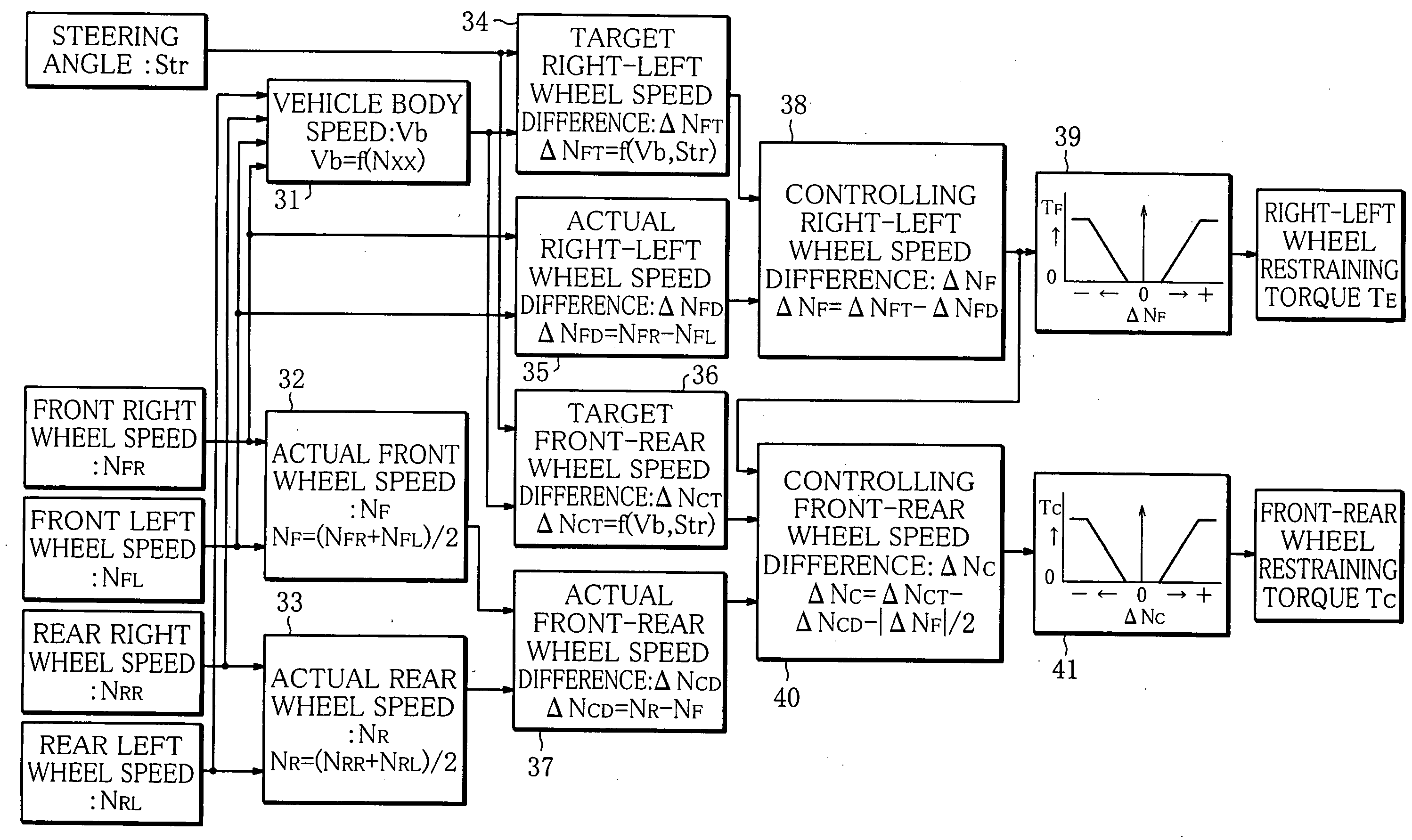

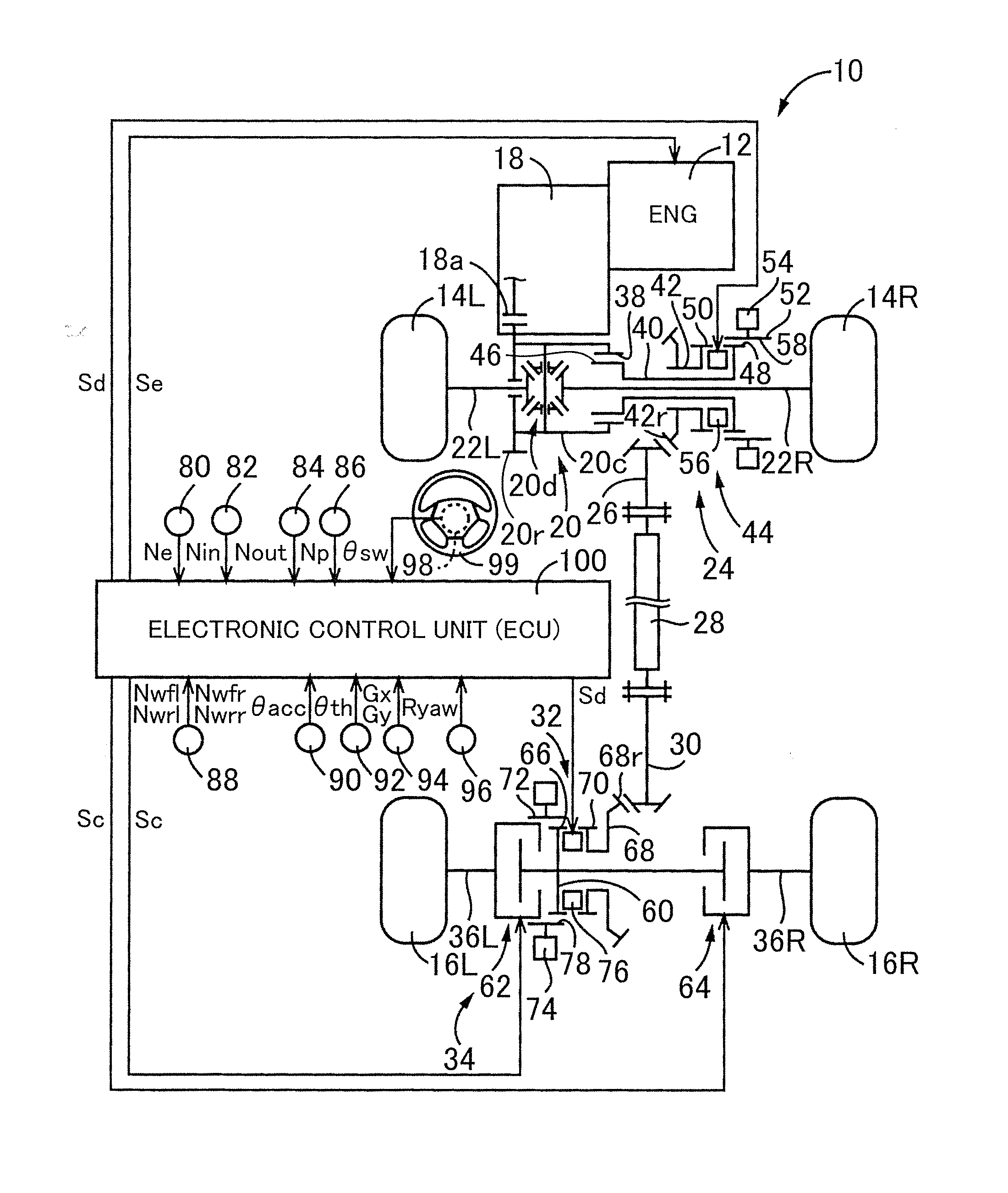

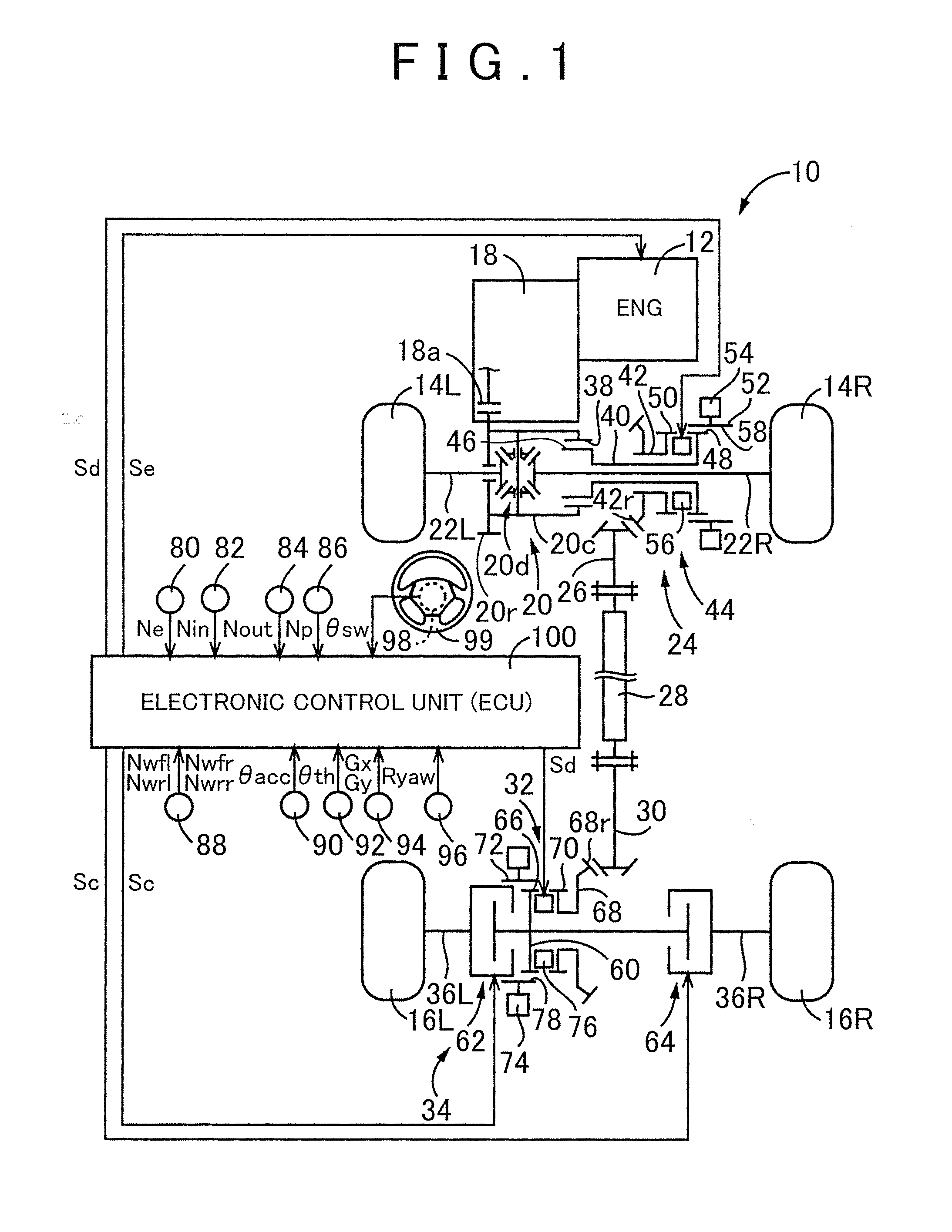

Control system for four-wheel-drive vehicle

ActiveUS20150096814A1Increase rotation speedReduce speed differenceNon-deflectable wheel steeringSteering gearsDrive wheelControl system

A control system includes a transfer. The transfer is disposed in a power transmission path between the driving power source and primary driving wheels and distributes dynamic power of the driving power source to the secondary drive wheels. A driving power transmission shaft transmits the dynamic power of the driving power source distributed by the transfer to the secondary drive wheels. A clutch mechanism is disposed in a power transmission path between the transfer and the driving power transmission shaft. A electronic control unit engages at least one of a first and second clutches and then engages the clutch mechanism on the basis of a steering state at the time of switching from a two-wheel-drive traveling state in which the clutch mechanism and the first and second clutches are disengaged to a four-wheel-drive traveling state in which the clutch mechanism and the first and second clutches are engaged.

Owner:TOYOTA JIDOSHA KK

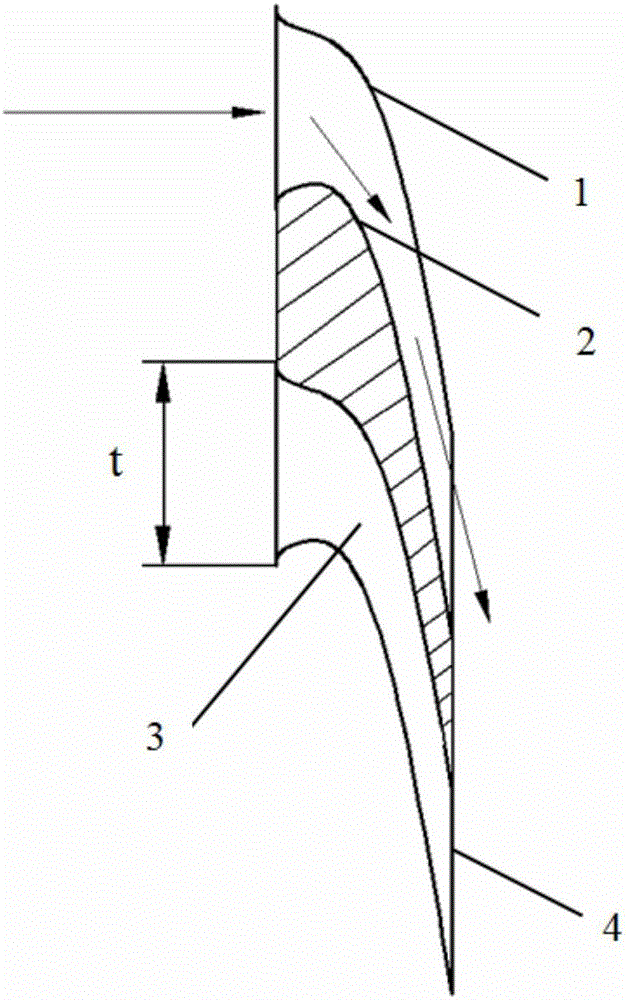

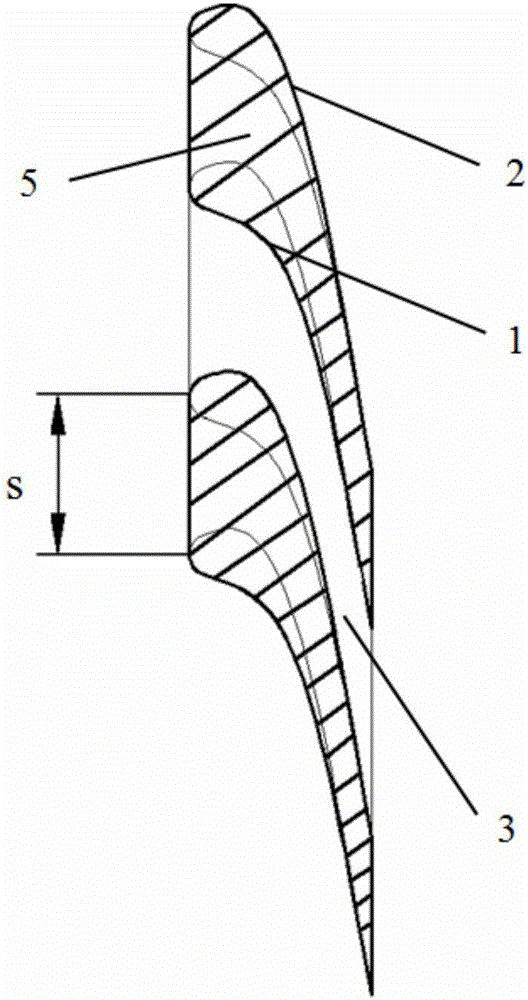

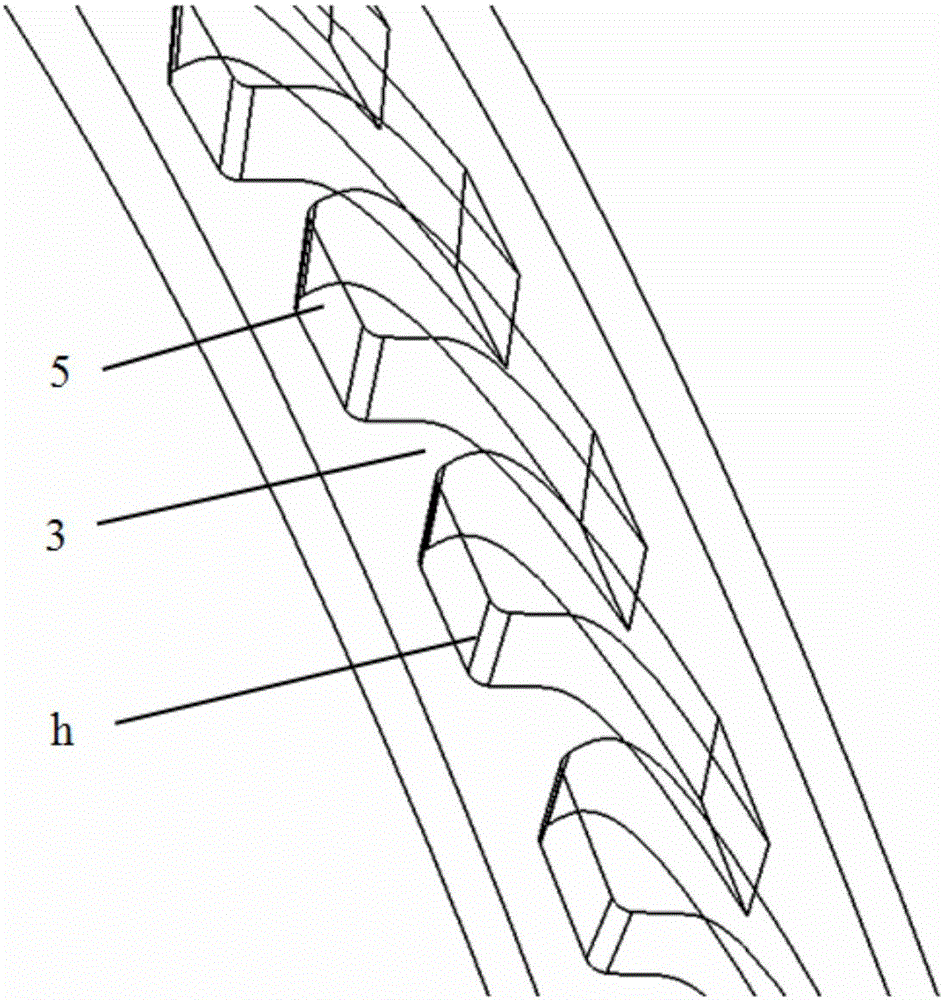

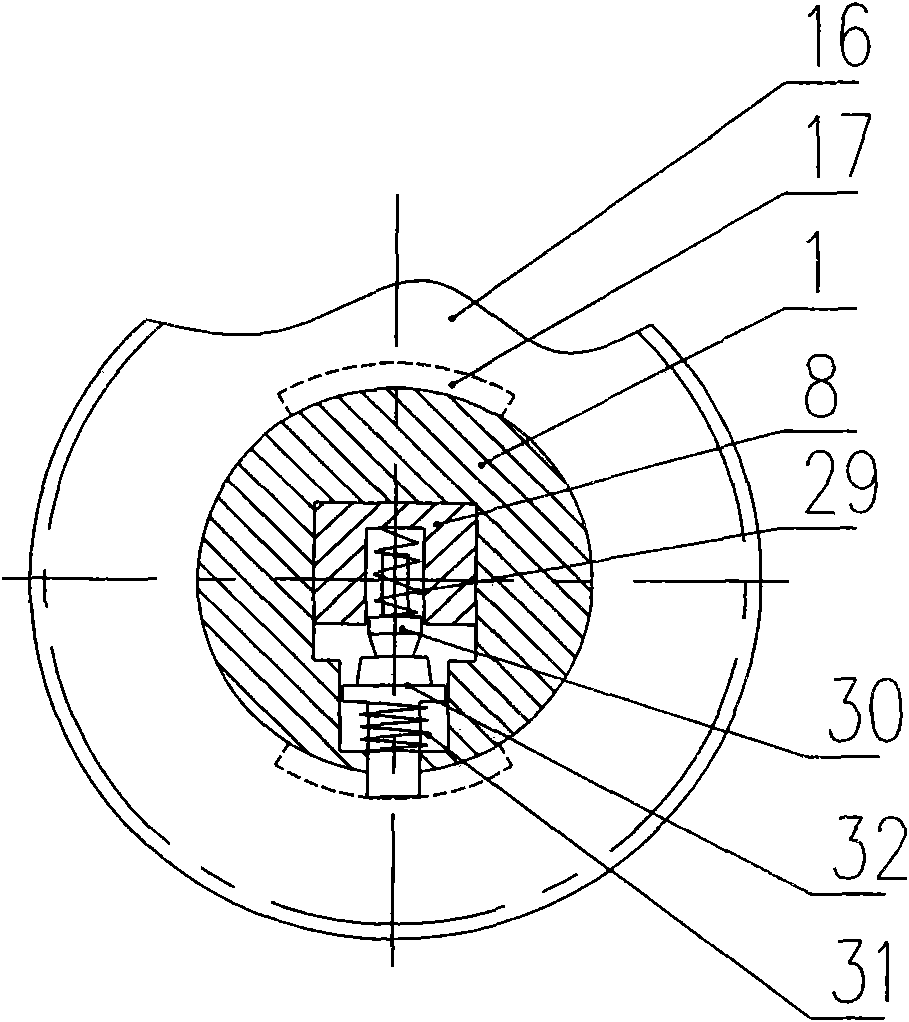

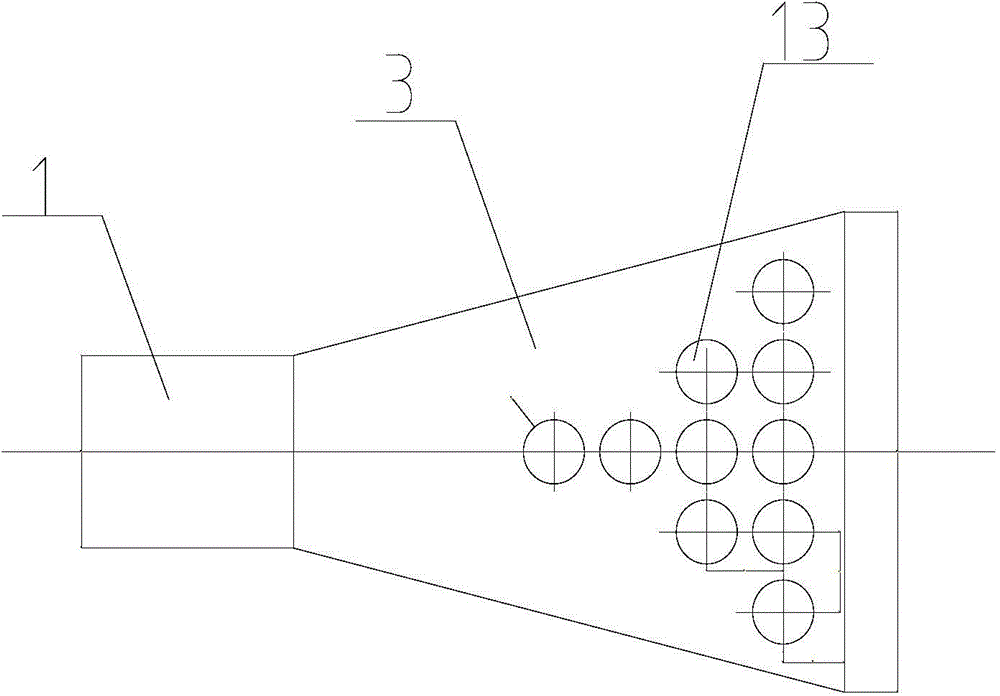

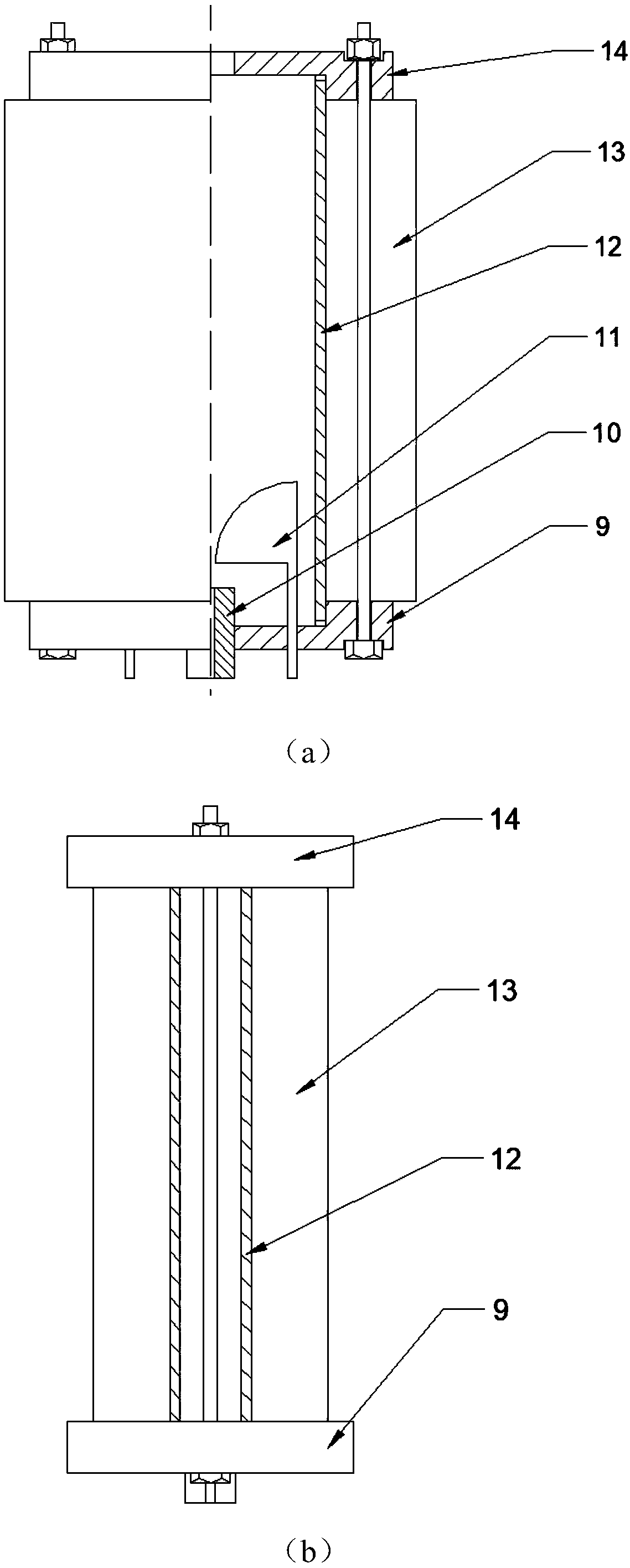

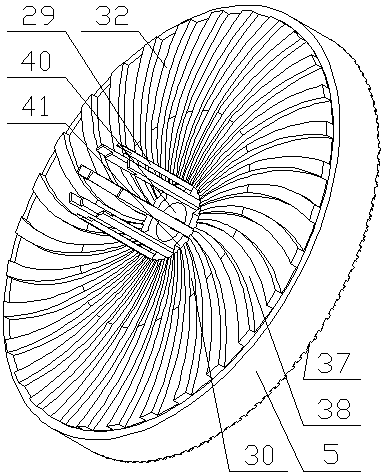

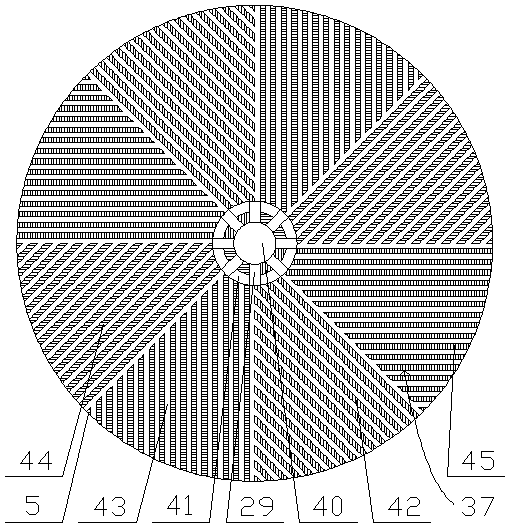

Blade hole type prewhirl nozzle for prewhirl cooling system

InactiveCN105114186AGuaranteed accelerationGuaranteed deflection performanceTurbine/propulsion engine coolingAviationEngineering

The invention discloses a blade hole type prewhirl nozzle for a prewhirl cooling system, and belongs to the field of application of aero-engine prewhirl cooling systems. The blade hole type prewhirl nozzle is characterized in that a blade pressure face and a blade suction face are adopted for forming inclined hole runners deflecting in the circumferential direction of a nozzle ring at equal intervals, deflecting molded faces of the nozzle runners are in a gradually-contracted shape, a minimum laryngeal area is achieved at an outlet of the prewhirl nozzle, the accelerating performance and the deflecting performance of the prewhirl nozzle are effectively guaranteed, and the flowing loss of a main flow is small. Blade type solid blocks are distributed between adjacent runners of the prewhirl nozzle, under the condition that the laryngeal area of the nozzle is definite, the ratio of the blade height to the pitch of the prewhirl nozzle can be flexibly adjusted by additionally arranging the blade type solid blocks, and the long and narrow performance of the sections of the runners is effectively improved, so that the secondary flow loss of the end walls in the runners is reduced, the flow coefficient and the prewhirl efficiency of the prewhirl nozzle are improved, and the system temperature drop effect is further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

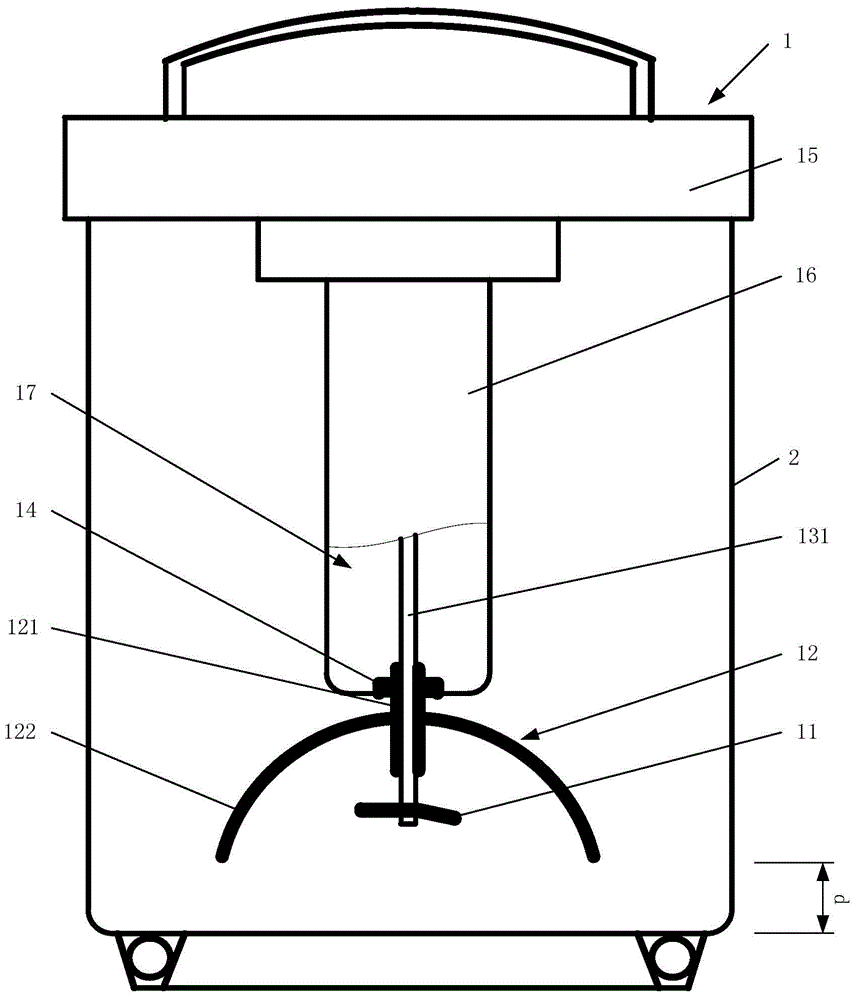

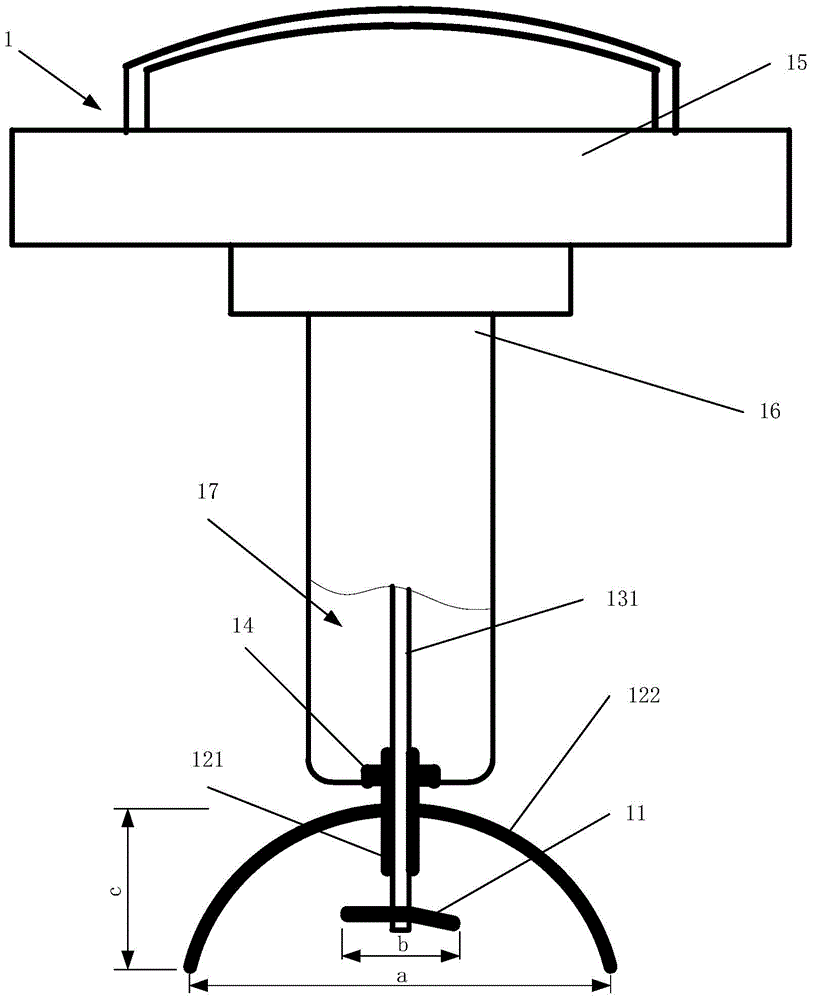

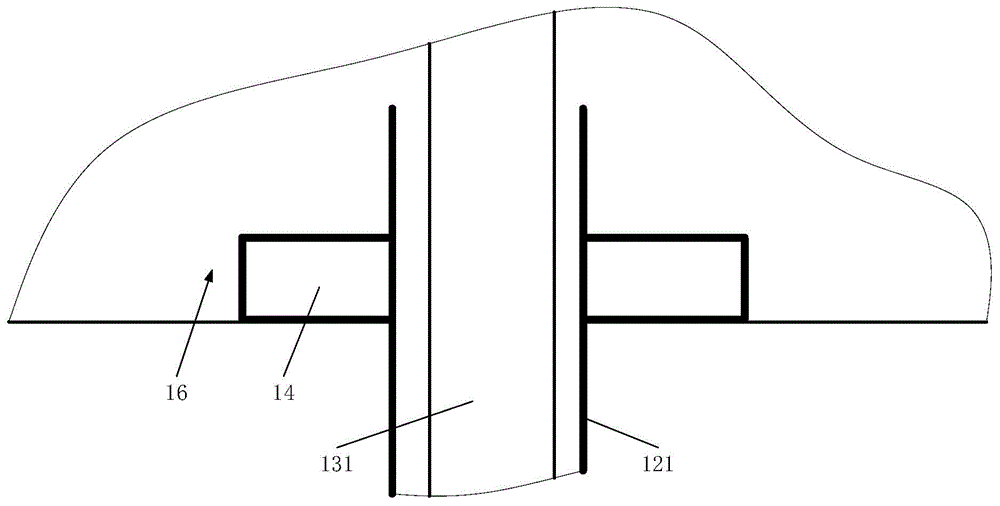

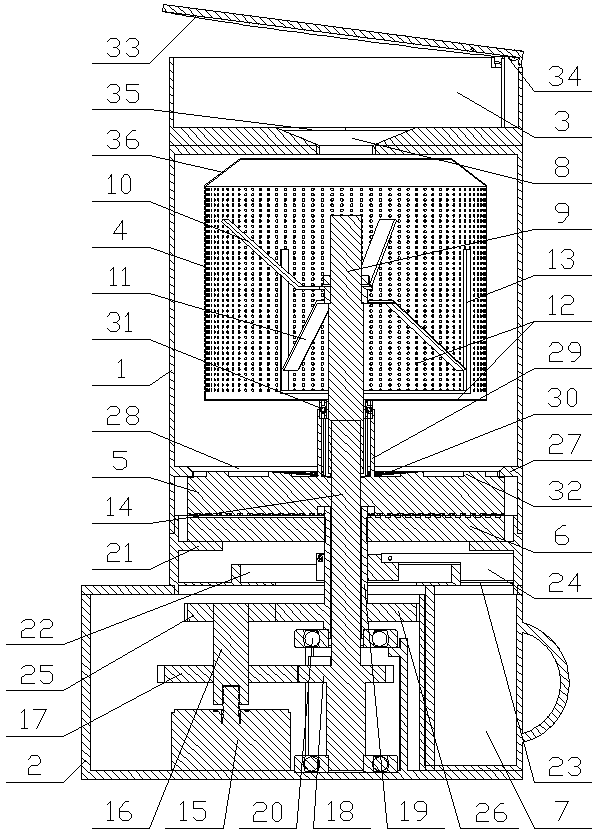

Soymilk machine head

InactiveCN104055423ATo achieve the purpose of noise reductionSmooth rotationBeverage vesselsFood materialEngineering

The invention provides a soymilk machine head, which is arranged on a barrel body of a soymilk machine. A crushing blade and a spoiler are arranged on a rotating shaft of the machine head, wherein the spoiler sleeves on the rotating shaft, and can rotate relative to the rotating shaft, and the crushing blade drives a food material in the barrel body to rotate; the food material drives the spoiler to rotate. According to the soymilk machine head provided by the invention, the rotating shaft drives the crushing blade to rotate at high speed, and the crushing blade which rotates at high speed drives the food material to rotate in the barrel body, accordingly, under the rotation of the food material, the spoiler absorbs the kinetic energy of part of food material to rotate along with the food material in the same direction, and the rotating speed difference between the spoiler and the food material becomes small; meanwhile, by matching of the rotation of the spoiler, the food material can be stably stirred by the spoiler, accordingly, the food material is more uniformly distributed in the barrel body, the rotation of the food material is more stable, and the disturbing effect of the spoiler is more obvious; meanwhile, the noise generated by the larger rotating speed difference between the food material and the spoiler is also reduced to better achieve the purpose of noise reduction in the soymilk machine.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Speed changer

InactiveCN101818804AReduce speed differenceGuaranteed smoothnessToothed gearingsGearing controlPush and pullDrive shaft

The invention discloses a speed changer capable of solving the problems of large size, complex operation, high maintenance cost, and the like of the traditional speed changer. The speed changer has about 97 percent of transmission mechanical efficiency and easy and convenient operation and is characterized in that a power input gear can be fixed with a jacket; a sliding sleeve is matched with thejacket through a helical rack and is matched with a gear shaft through a spur rack; a pin shaft of the sliding sleeve contacts with a push rod of a gear shift shuttle; a crank arm is movably connected with a lug through the pin shaft; a shifting fork forks on a shaft rod of a push-and-pull rod; a hollow cavity or a sliding chute of the gear shaft is internally provided with the gear shift shuttle; the gear shift shuttle is provided with a top bulge; the gear shaft is provided with a sliding key and is assembled with an angle gear matched with a chamfered groove strip and a plurality of gearshift gears; the gearshift gears can be respectively meshed with a driven gear; the driven gear is assembled on a driven shaft; and the driven shaft is fixed with a power output gear. The invention can be used for an epicyclic gear train and realize the full-automatic speed change from two gears to more than ten gears.

Owner:HUNAN JINLONG MOTOR

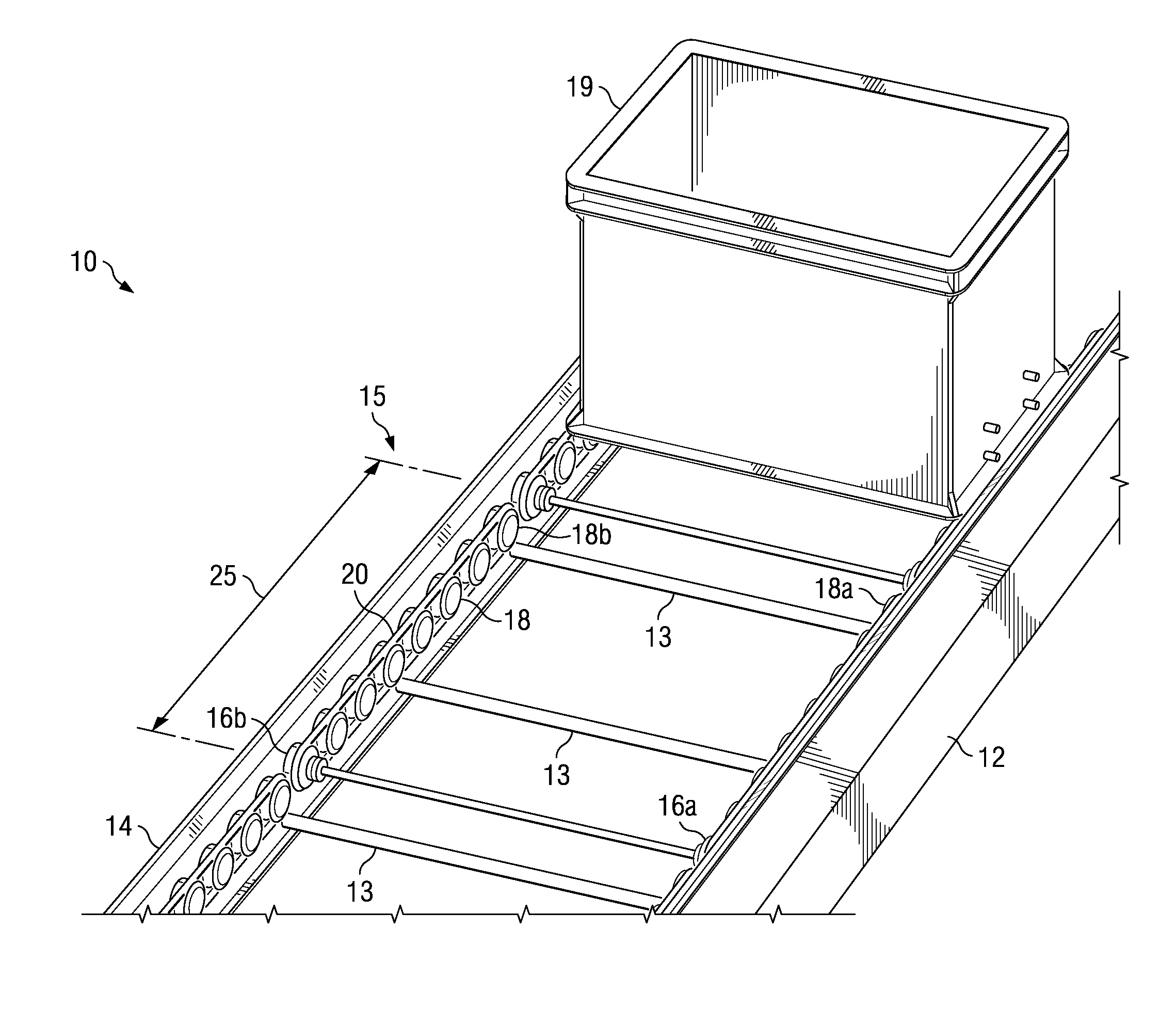

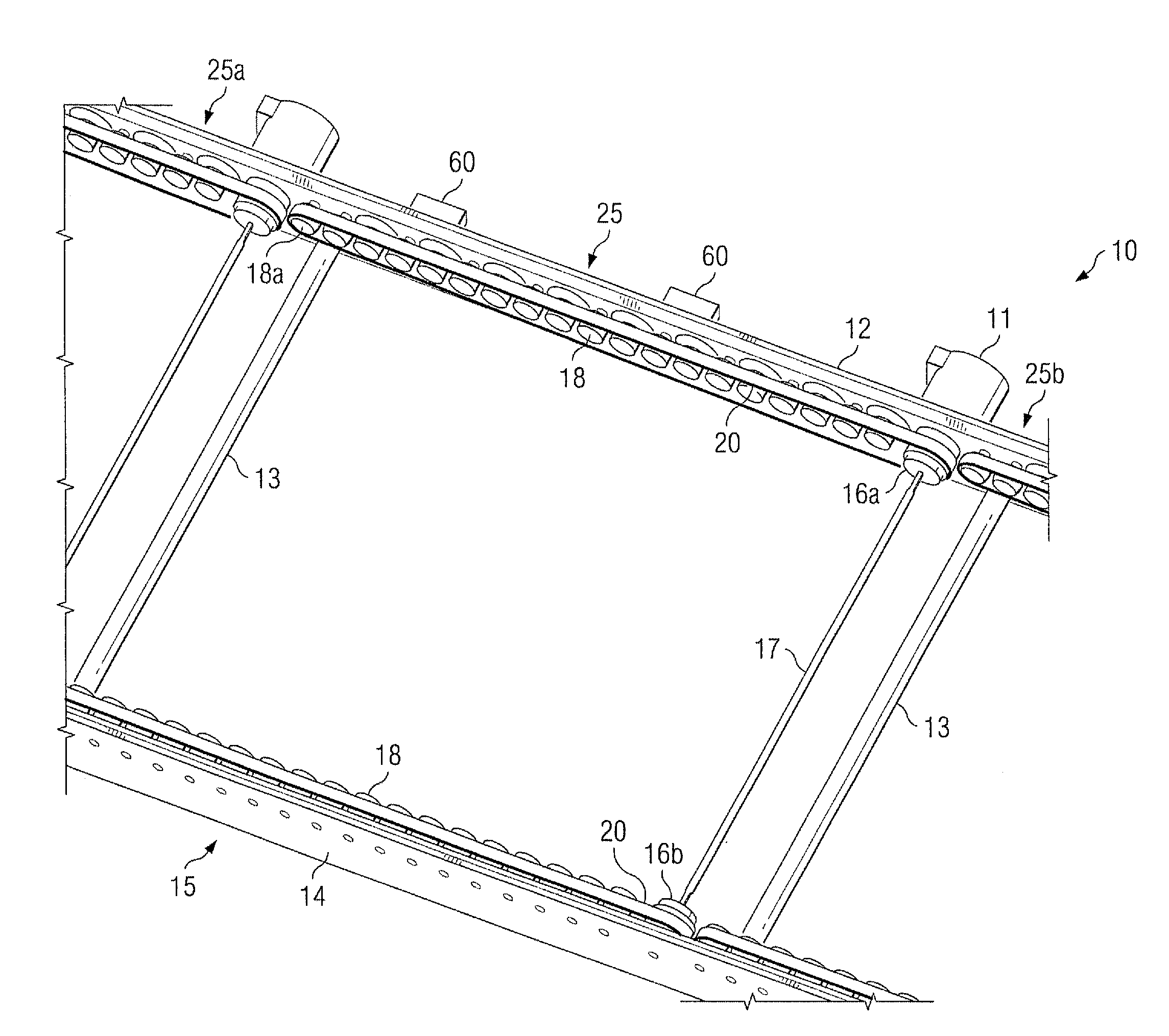

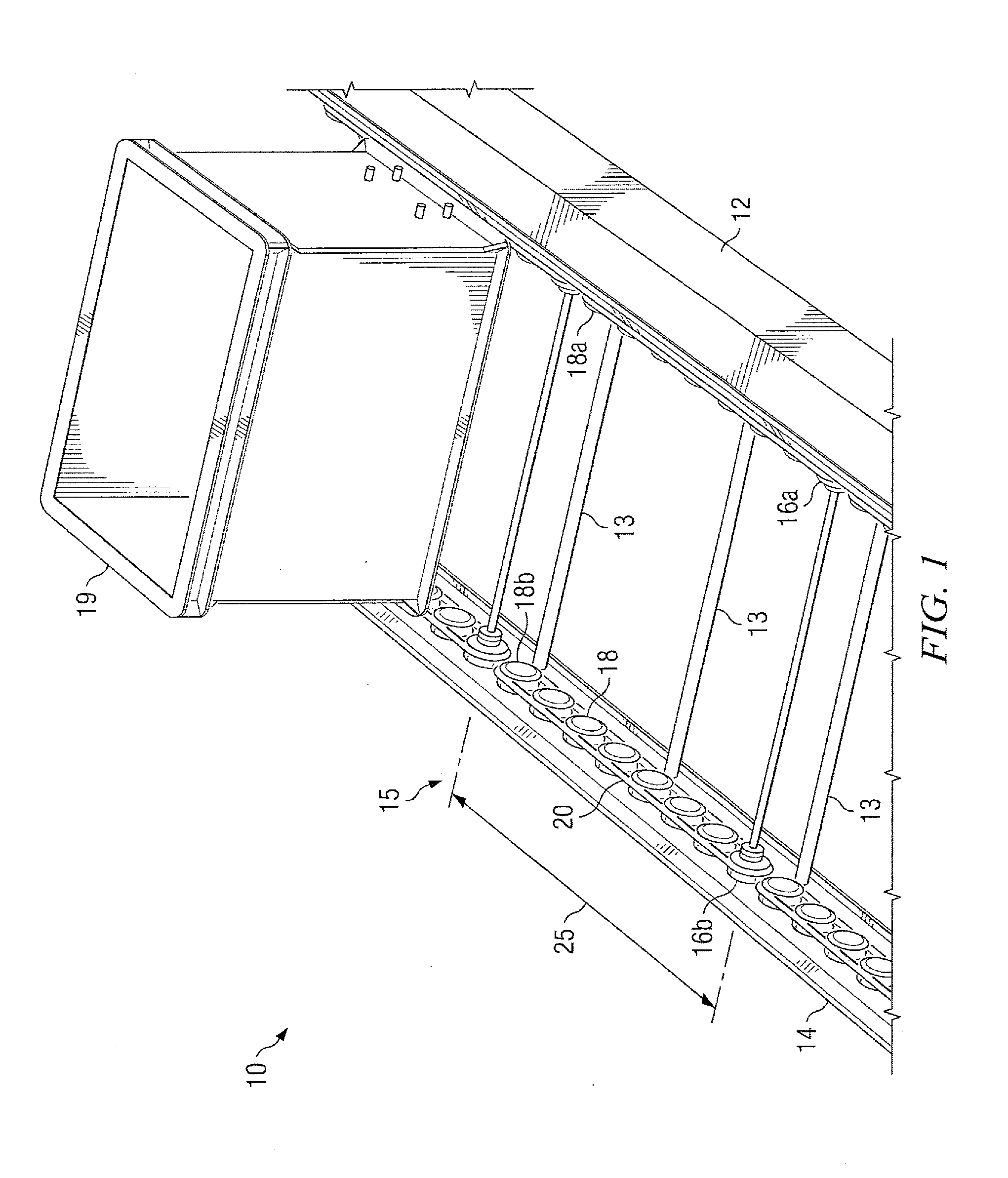

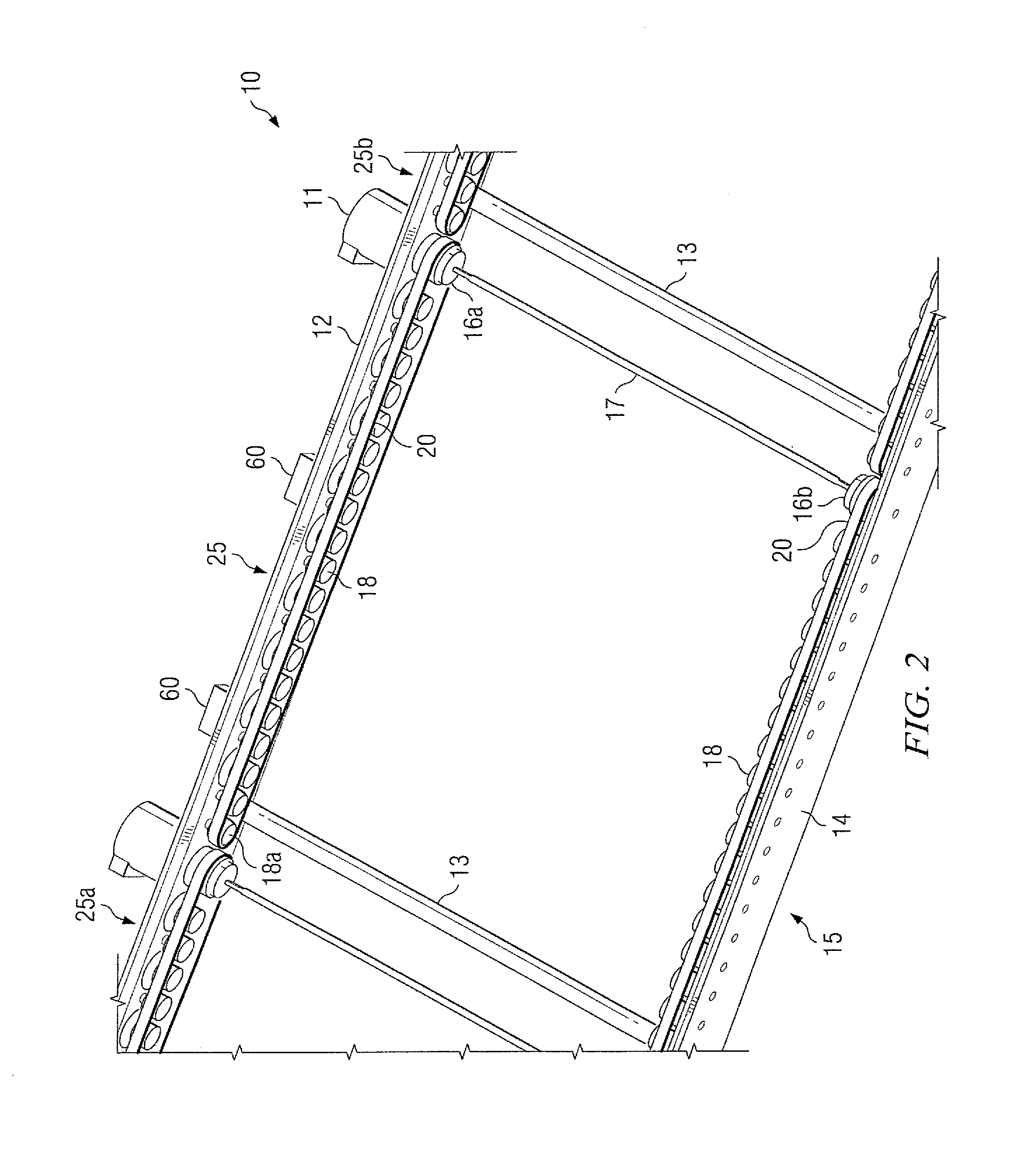

Clean, high density, soft-accumulating conveyor

InactiveUS20090266678A1Reduce speed differenceMaintain levelDigital data processing detailsConveyor partsDrive wheelHigh density

A conveyor for clean manufacturing applications. The conveyor comprises interconnected conveyor modules, each of which includes a conveyor belt segment (s). Each conveyor belt segment includes a pair of side rails that are in parallel or substantially in parallel to each other; a pair of autonomous, belt-drives for transporting work pieces or objects carrying work pieces from a proximal end of the belt segment to a distal end of the belt segment; a pair of driving wheels for turning the belt-drives, and a motor for directly or indirectly driving each of the pair of driving wheels. One of the driving wheels is mechanically or magnetically coupled to a magnetic hysteresis clutch that allows the driving wheels to disengage from the drive shaft of the motor if the inertia of the work piece does not permit synchronization of work piece with the drive speed of the motor during acceleration or deceleration.

Owner:MIDDLESEX GEN INDS MESNE

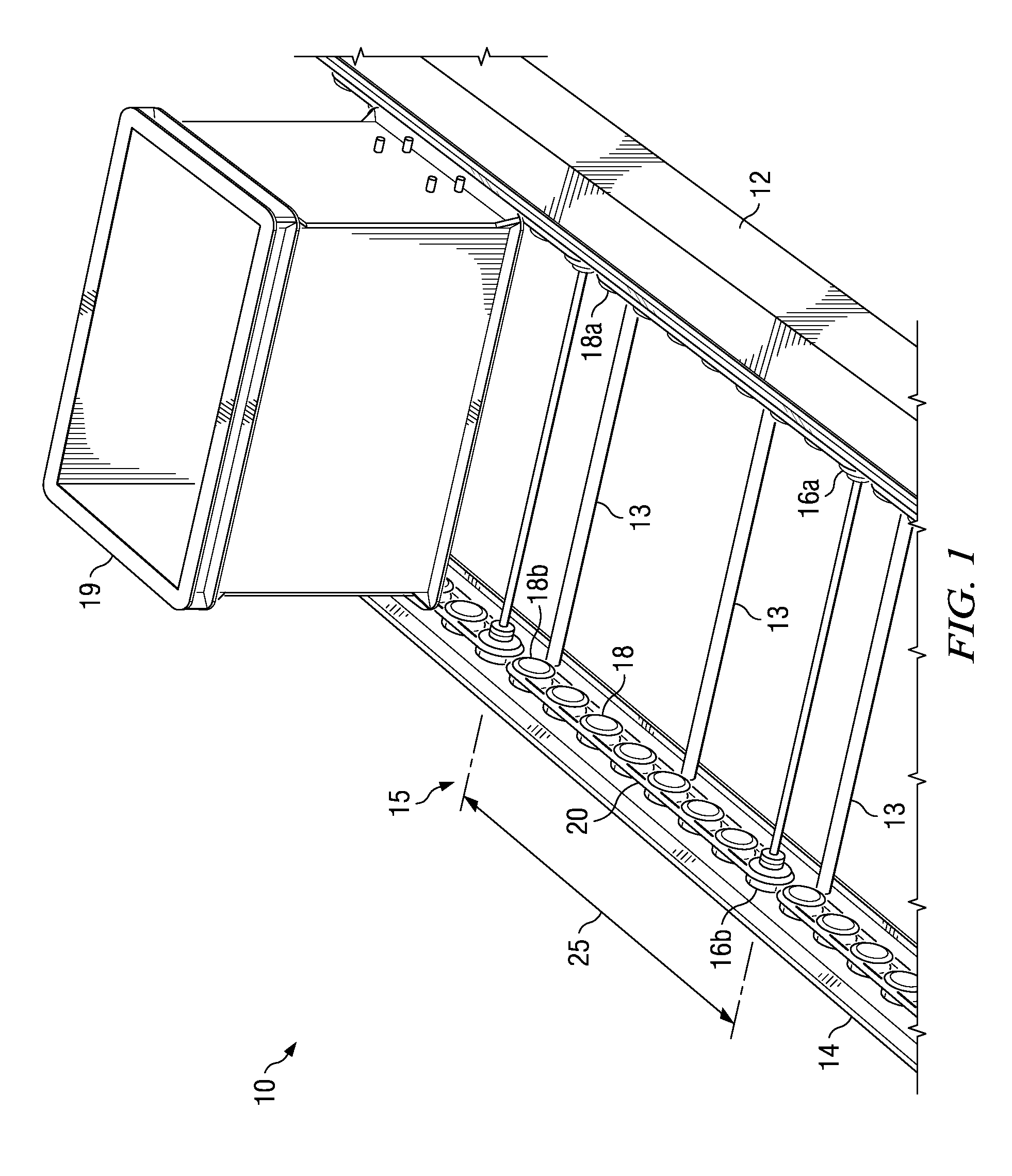

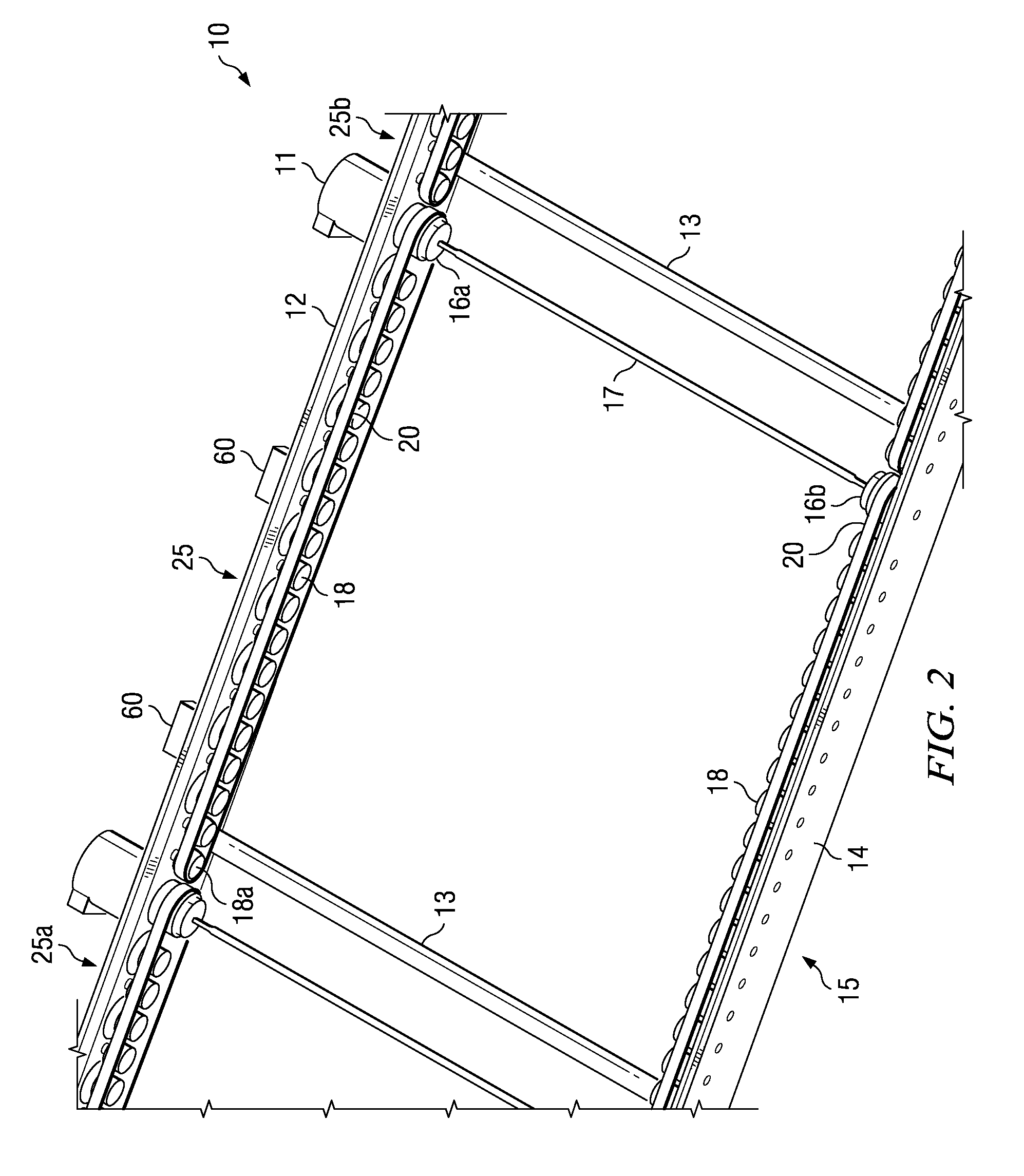

Clean, high density, soft-accumulating conveyor

InactiveUS20110303510A1Reduce speed differenceMaintain levelConveyor partsMechanical conveyorsDrive wheelHigh density

A conveyor segment for clean manufacturing applications. Each conveyor belt segment includes a pair of side rails parallel to each other; a pair of belt-drives for transporting work pieces from a first end to a second end of the belt segment; a pair of driving wheels for turning the belt-drives. The belt of each of the belt-drives is disposed in a serpentine path about plural, load-bearing upper idler wheels, around either a lower loop-back idler wheel or a driving wheel, and back up and around another pair of upper idler wheels. This sequence is repeated a selected number of times about additional pairs of upper idler wheels and lower loop-back idler wheels or a driving wheel before the belt is disposed beneath plural return idler wheels and back up to the starting point. Slipping between the belt and wheels is thus minimized, even in the absence of a work piece on the belt segment.

Owner:MIDDLESEX GEN INDS MESNE

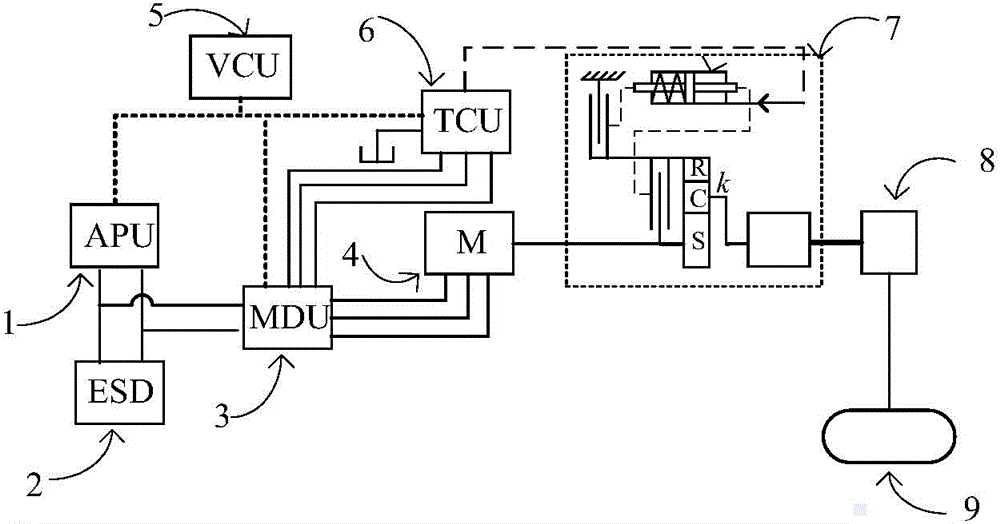

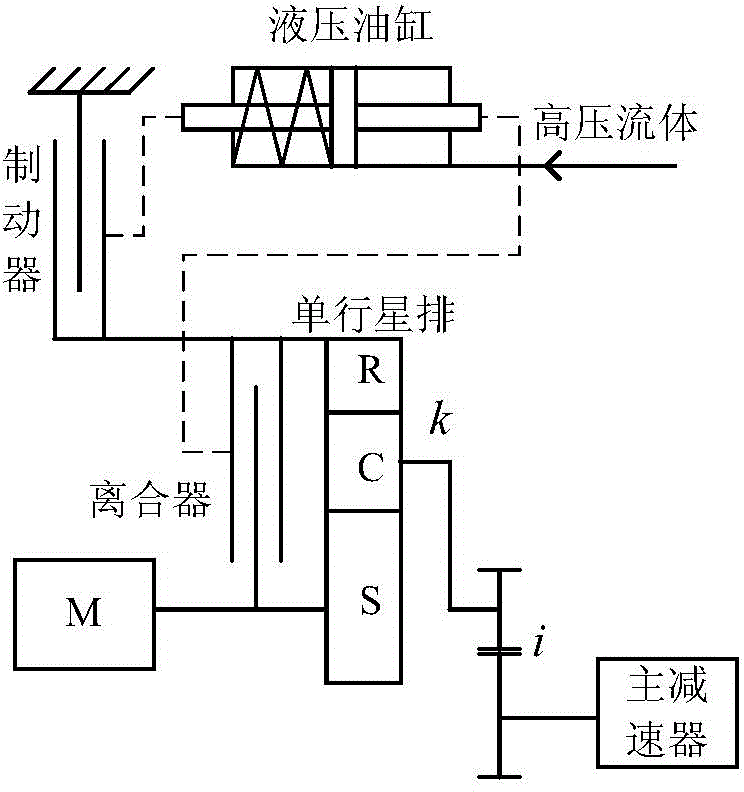

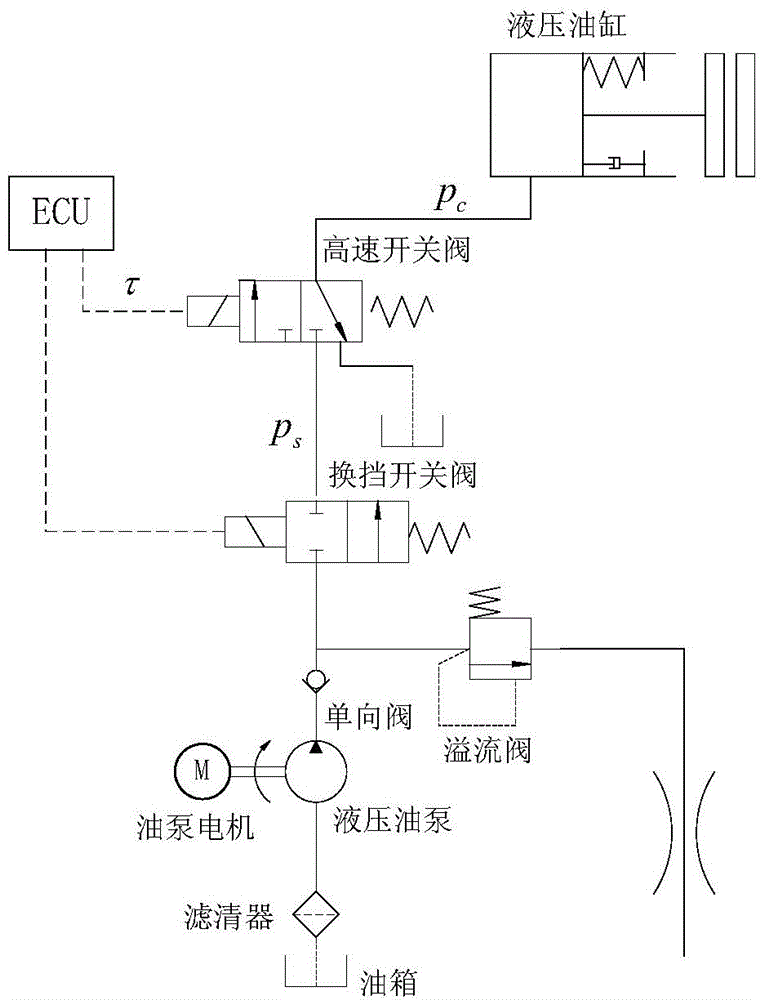

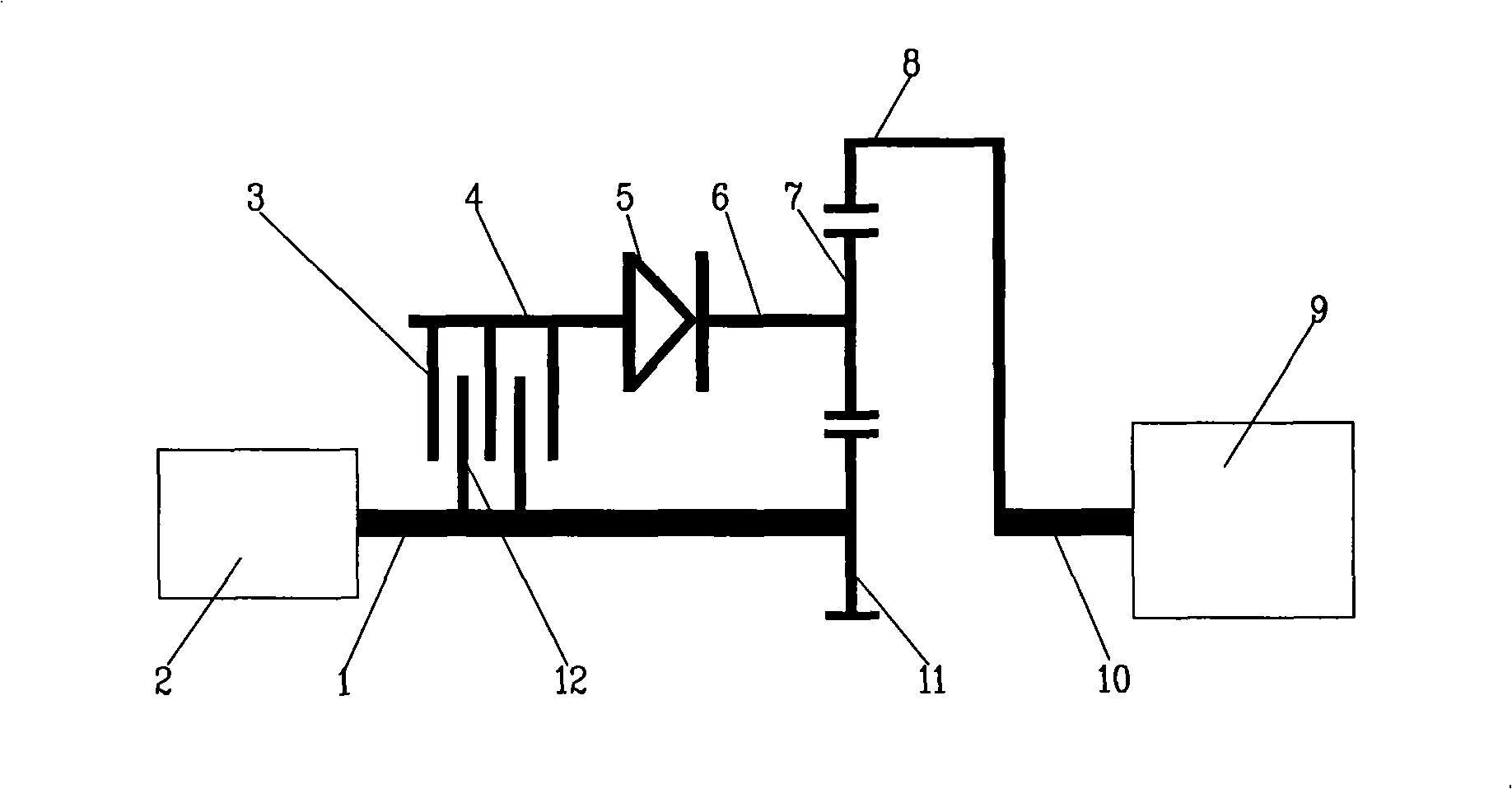

Electric drive system based on two-gear speed changing and coordinated gear shifting control method of electric drive system

ActiveCN104455384ASimple structureReduce volumeGearing controlTransmission elementsClutchElectric drive

The invention provides an electric drive system based on two-gear speed changing and a coordinated gear shifting control method of the electric drive system. The electric drive system comprises a power supplying unit, a motor controller, a motor, a vehicle controller, a gear shifting controller and a two-gear planet speed changer. The two-gear planet speed changer is internally provided with a planet transmission two-gear automatic speed changing box and a wet clutch to shift gears, gear shifting is convenient, and the size and the weight are greatly reduced. In the gear shifting process, the vehicle controller controls the motor controller and the gear shifting controller through a bus in a communication mode, the motor controller controls the motor output torque to track the optimal motor torque track, the gear shifting controller controls gear shifting oil pressure to track the optimal gear shifting oil pressure track, and therefore synchronous adjusting of the motor torque and the gear shifting oil pressure is achieved, the difference of the rotating speed of a main component and the rotating speed of an auxiliary component and the gear shifting impact when a clutch and a brake are combined or separated are reduced, and smooth gear shifting is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

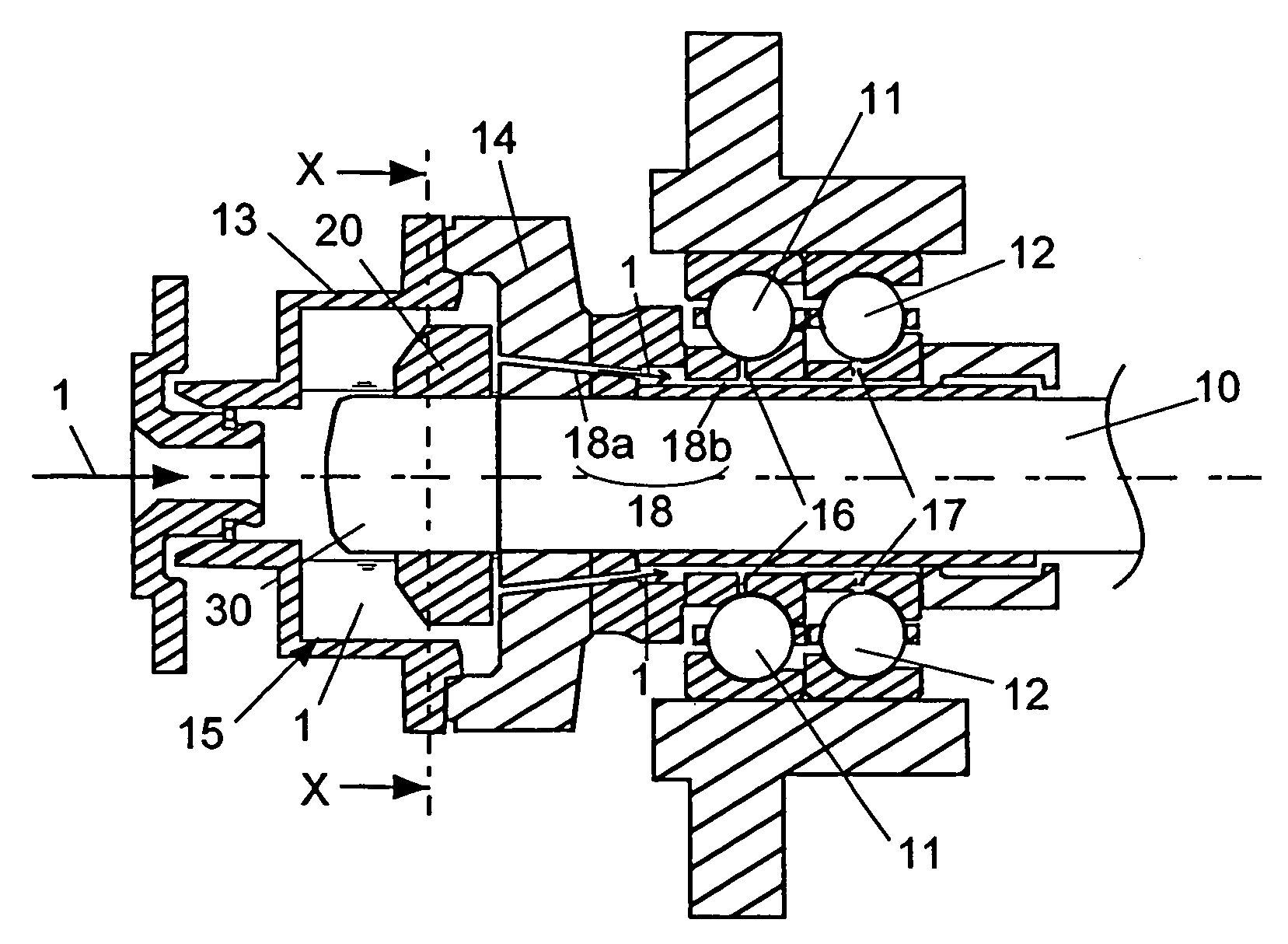

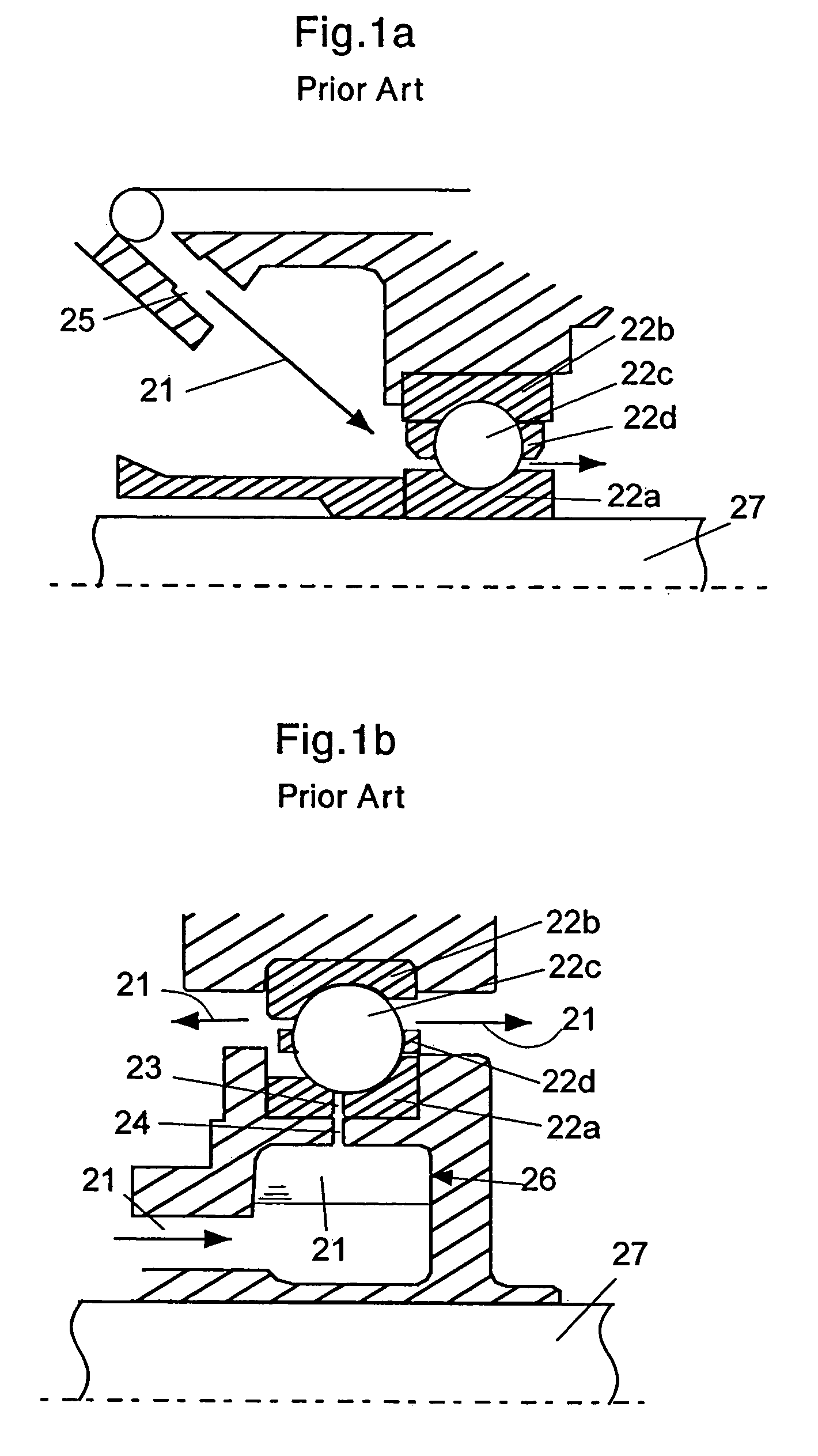

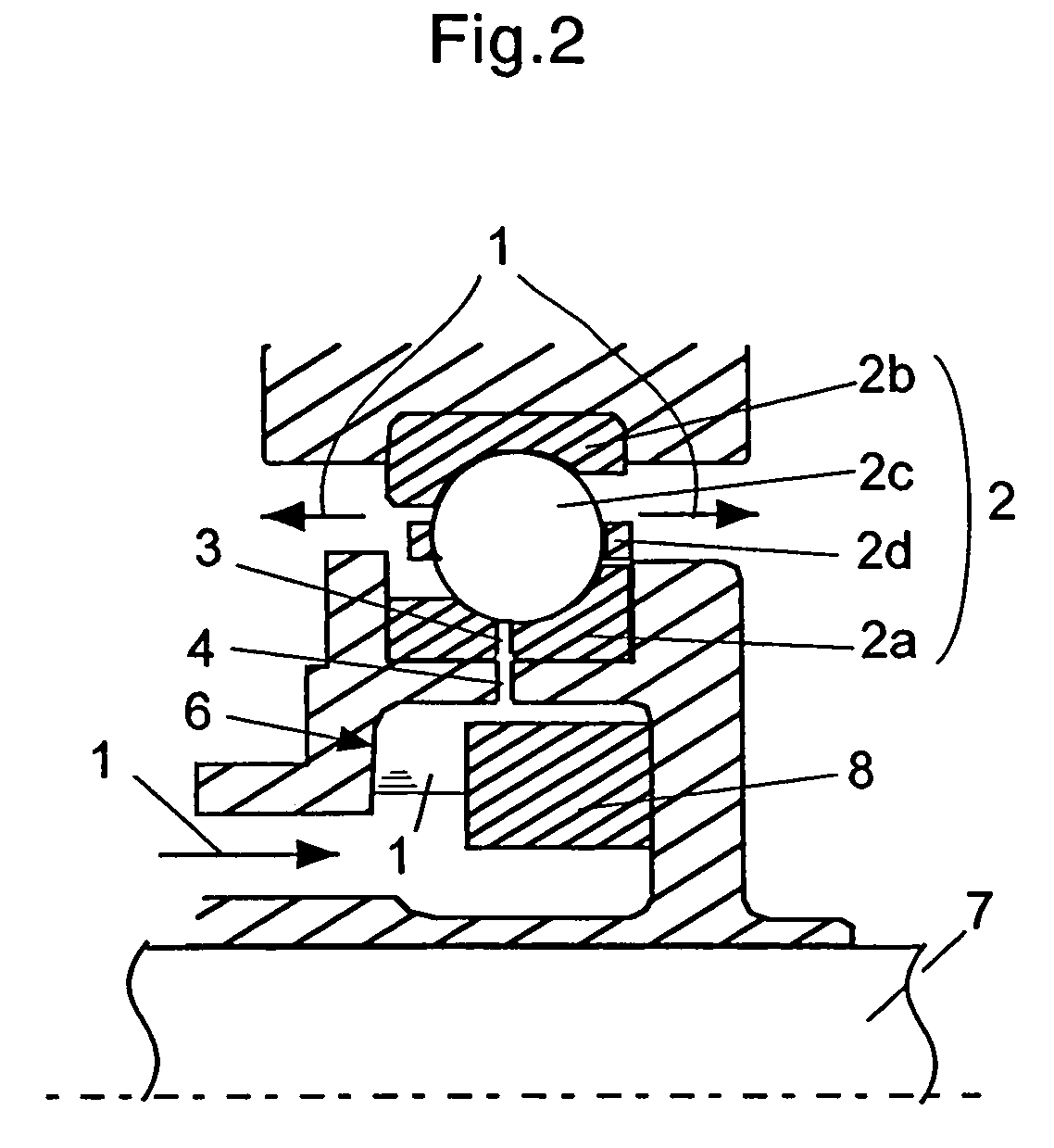

Lubrication structure for rolling bearing

InactiveUS7070333B2Increased load-bearing capacityGood estimateShaftsBall bearingsRolling-element bearingCentrifugal force

A fin member is installed in an oil accumulating room. The fin member causes lubrication oil to follow rotation of the oil accumulating room so that the lubrication oil can be forcibly rotated. In this manner, a rotational speed difference between the oil accumulating room and the lubrication oil is made small, and an adequate oil supplying pressure is generated by the centrifugal force. As a result, a sufficient quantity of the lubrication oil can be supplied. Therefore, estimation of a supplying oil quantity becomes easy, and accuracy in prediction of the lubrication oil quantity actually used for the bearing lubrication can be improved.

Owner:IHI CORP

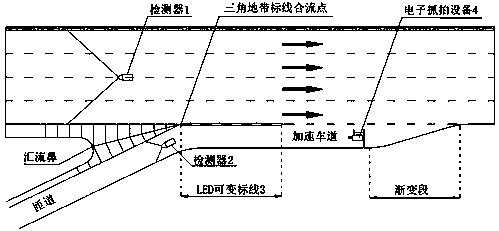

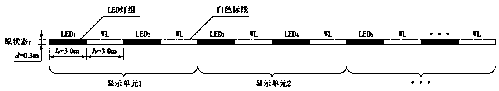

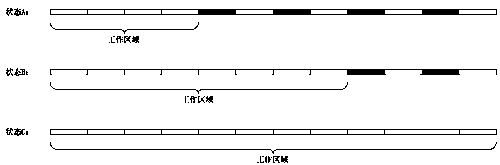

Changeable confluence area marking line of expressway ramp confluence area and setting method thereof

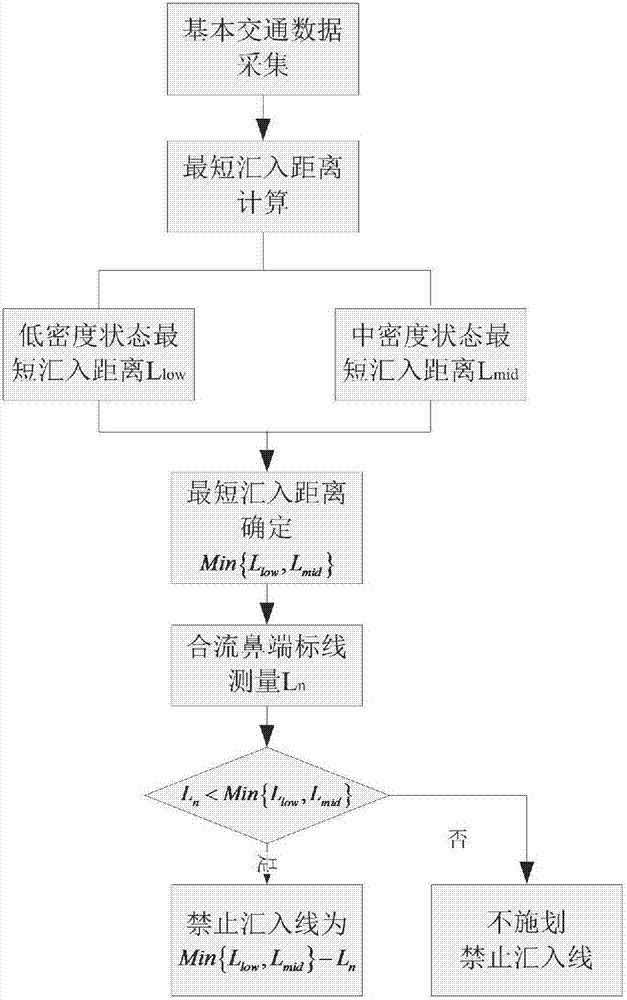

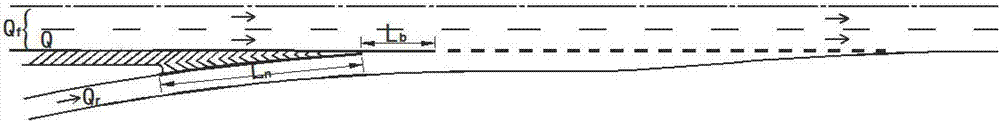

ActiveCN108842652AImprove securityReduce speed differenceTraffic signalsRoad signsEngineeringWhite line

The invention discloses a changeable confluence area marking line of an expressway ramp confluence area and a setting method thereof. An LED changeable marking line arranged on the boundary portion ofan acceleration lane and the outermost side lane of a main line in the confluence area is utilized, according to flow and speed combinations of different traffic flows of the main line and ramp traffic, the length of the lane line which cannot be crossed in the same direction can be dynamically adjusted, therefore it is ensured as far as possible that vehicles in the ramp can avoid the areas which are not suitable for confluence, the speed difference between traffic flow of the main line and the vehicles needing to converge in the ramp is reduced, and the safety of the confluence area is improved; in addition, according to the length required by vehicles in the confluence area speeding up to the lowest converging speed and the length required by the vehicle converging process, the lengthof the solid white line which cannot be crossed theoretically is determined, that is, the total length of the solid line composed of a white line and an LED lamp set is determined, working combinations of LED lamp set displaying units and the white line are flexibly matched, so that the marking line adapts to highway types of different structures, the flexibility is better, and the application range is wider.

Owner:SOUTHEAST UNIV

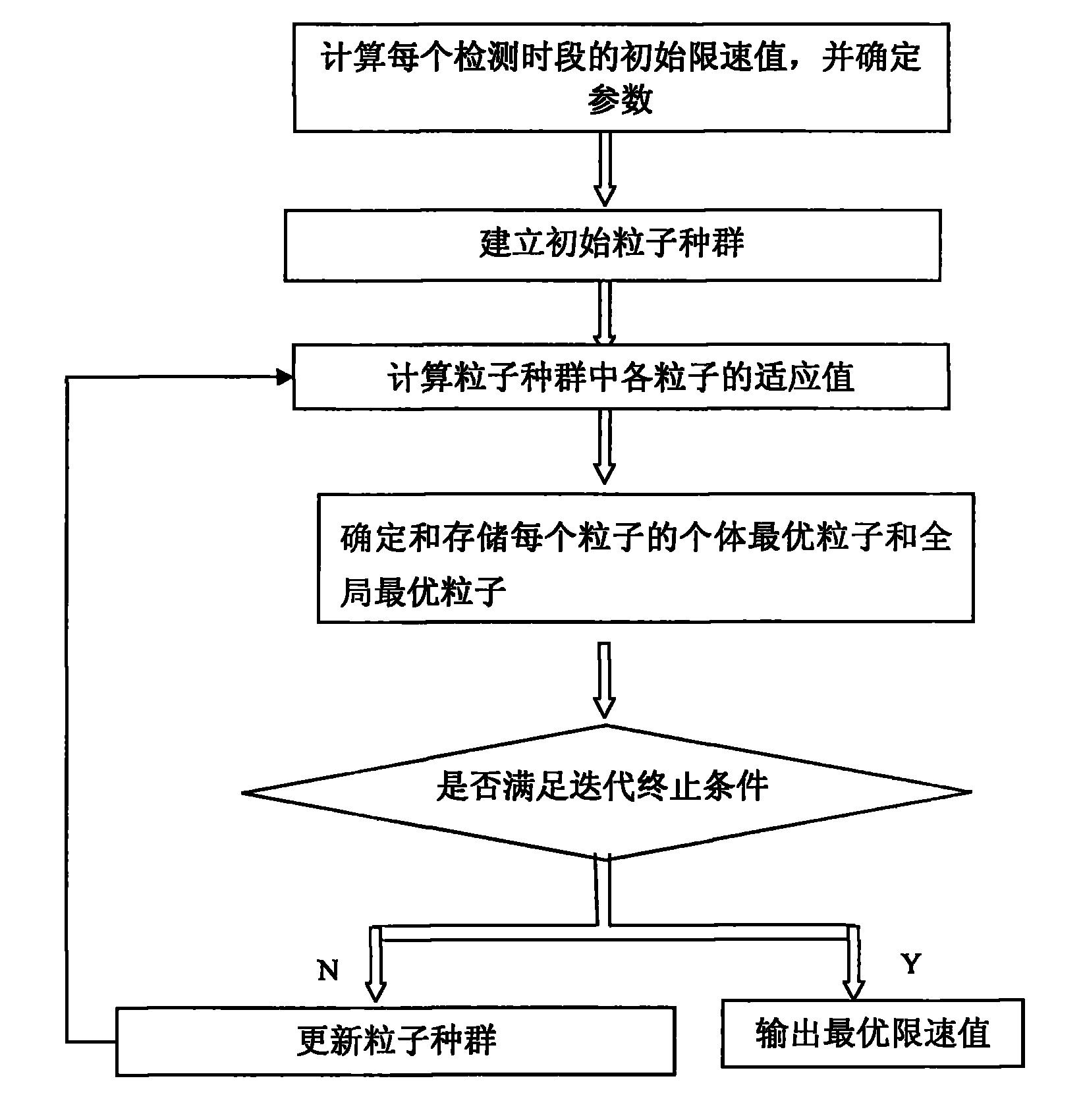

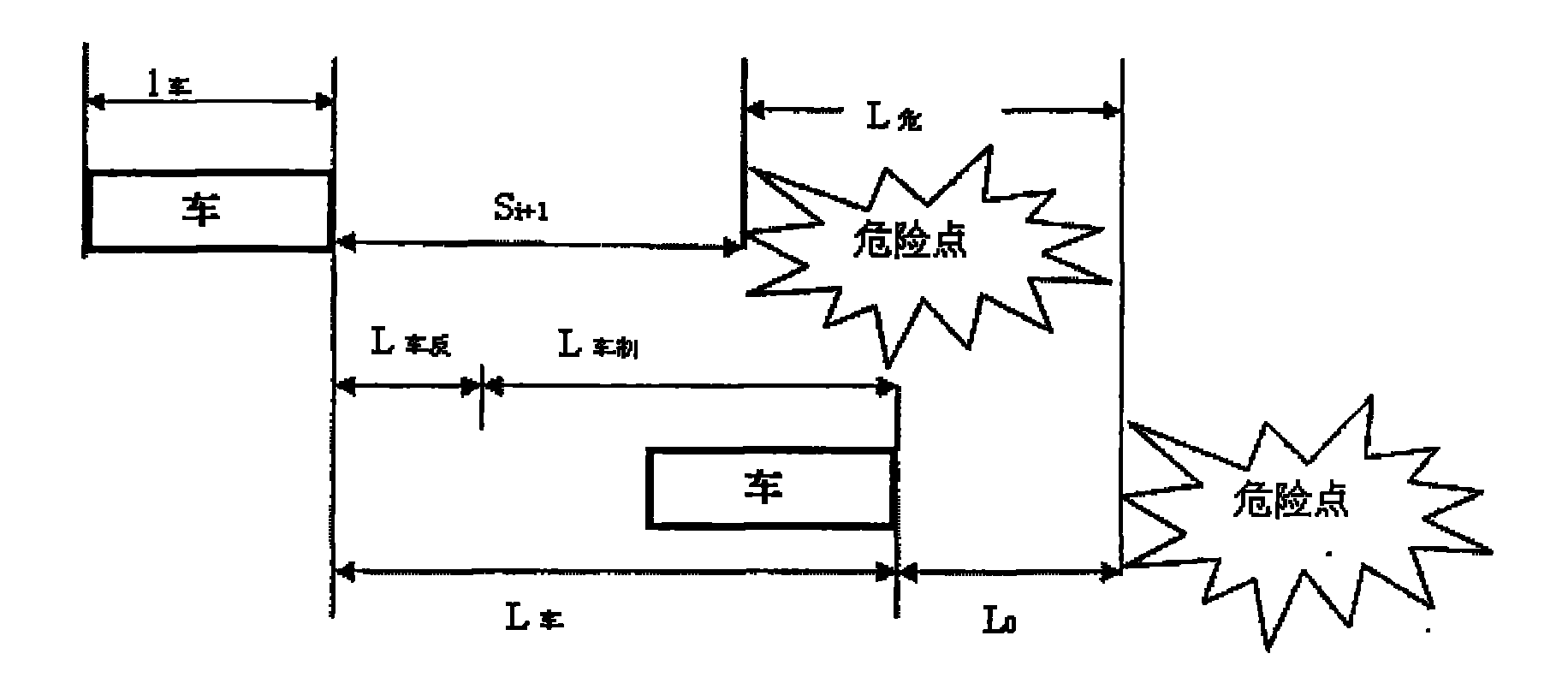

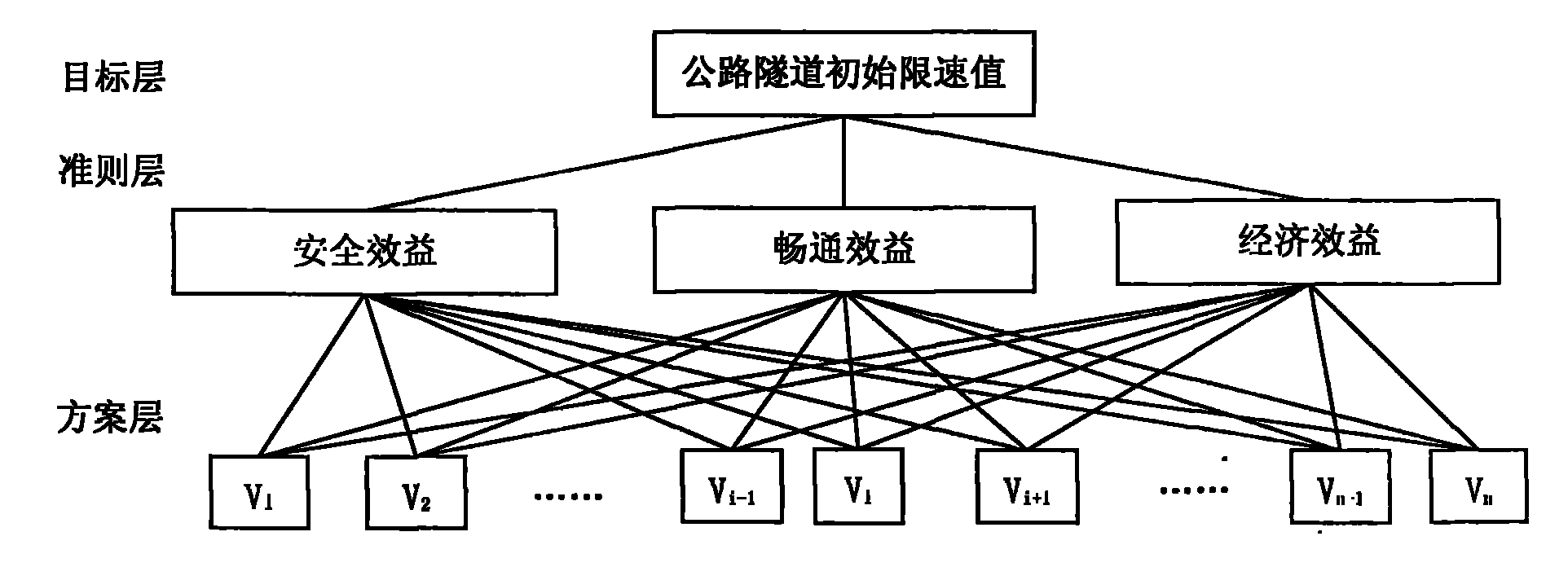

Variable speed-limiting control method based on artificial immune particle swarm algorithm

InactiveCN101840635AImprove global search performanceReduce the proportion of high-speed drivingDetection of traffic movementAnti-collision systemsRear-end collisionAlgorithm

The invention discloses a variable speed-limiting control method based on the artificial immune particle swarm algorithm. The method is characterized by comprising the following steps: 1) calculating the initial speed-limiting values of N-numbered detection intervals, determining parameters; 2) determining N-numbered particles, establishing a initial particle swarm; 3) calculating the fitness value f(xi) of each particle in the particle swarm; 4) determining and storing the personal best particle and the global best particle; 5) judging whether to satisfy the iteration terminal condition, if so, inputting the optimal speed-limiting value, if not, entering the step 6; and 6) updating the particle swarm to generate a new generation of swarm, and returning to the step 2. The invention controls the running speed of vehicles to adjust the running speed and maintain the balanced running speed, thus avoiding the occurrence of rear-end collisions or collision accidents.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

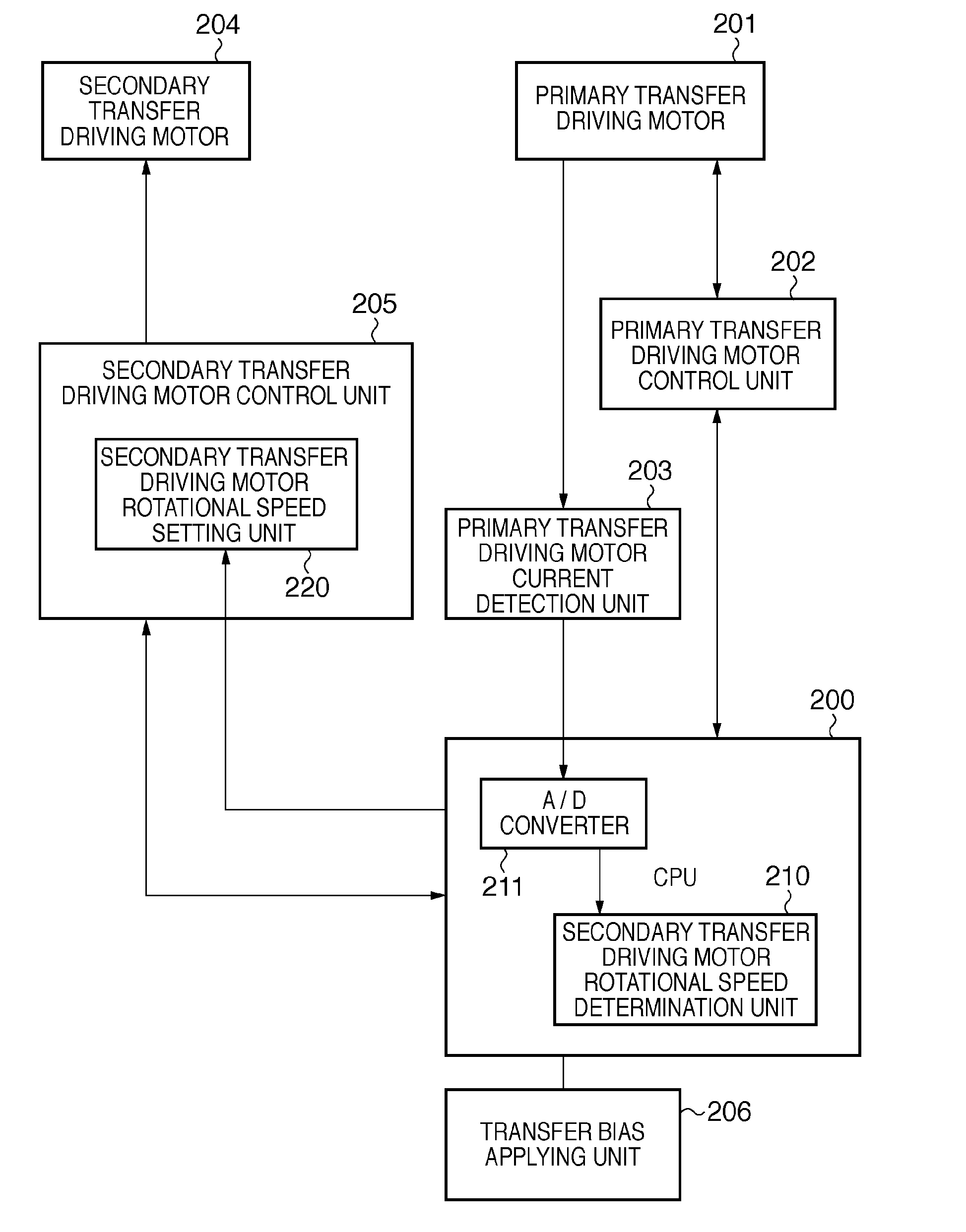

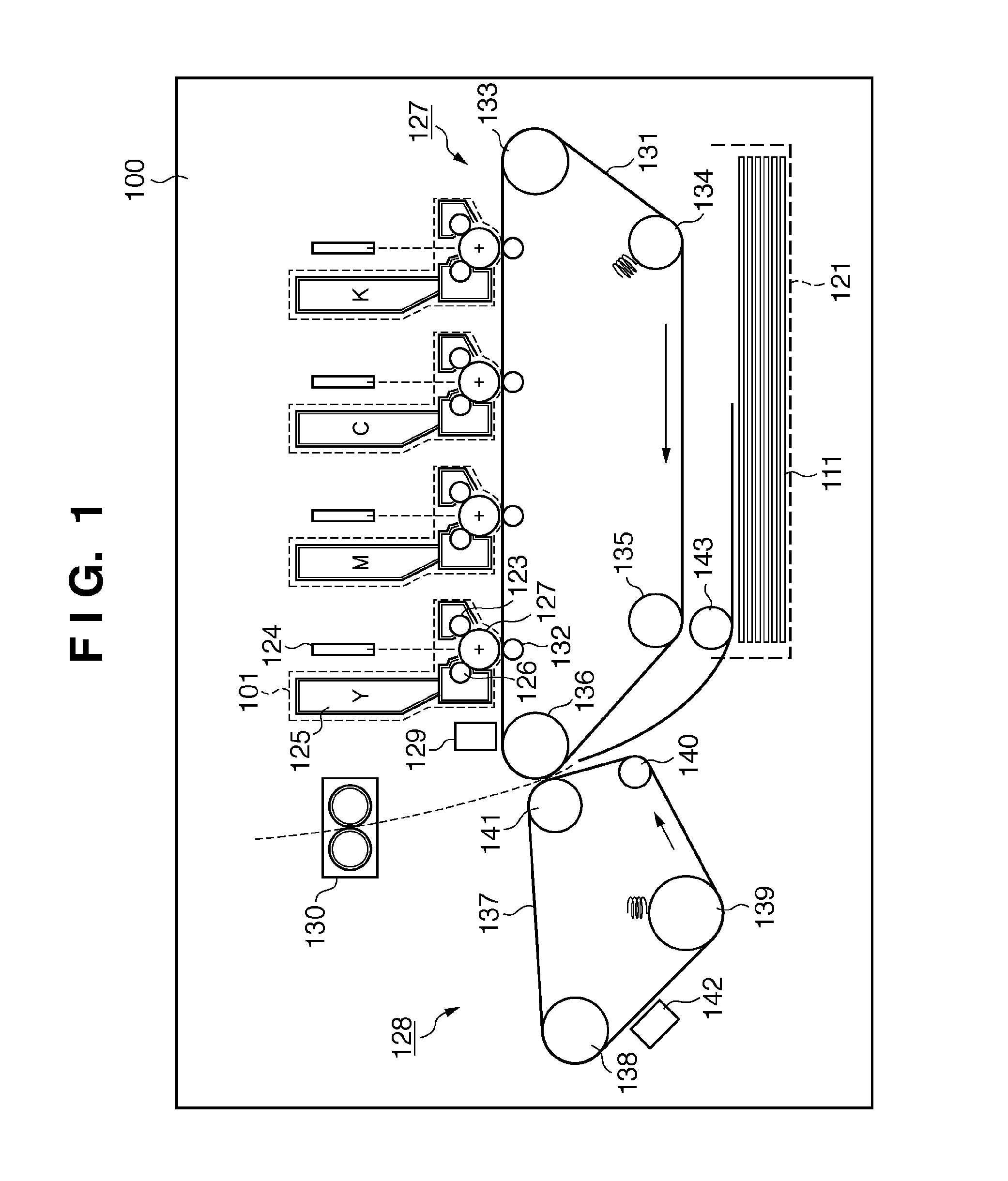

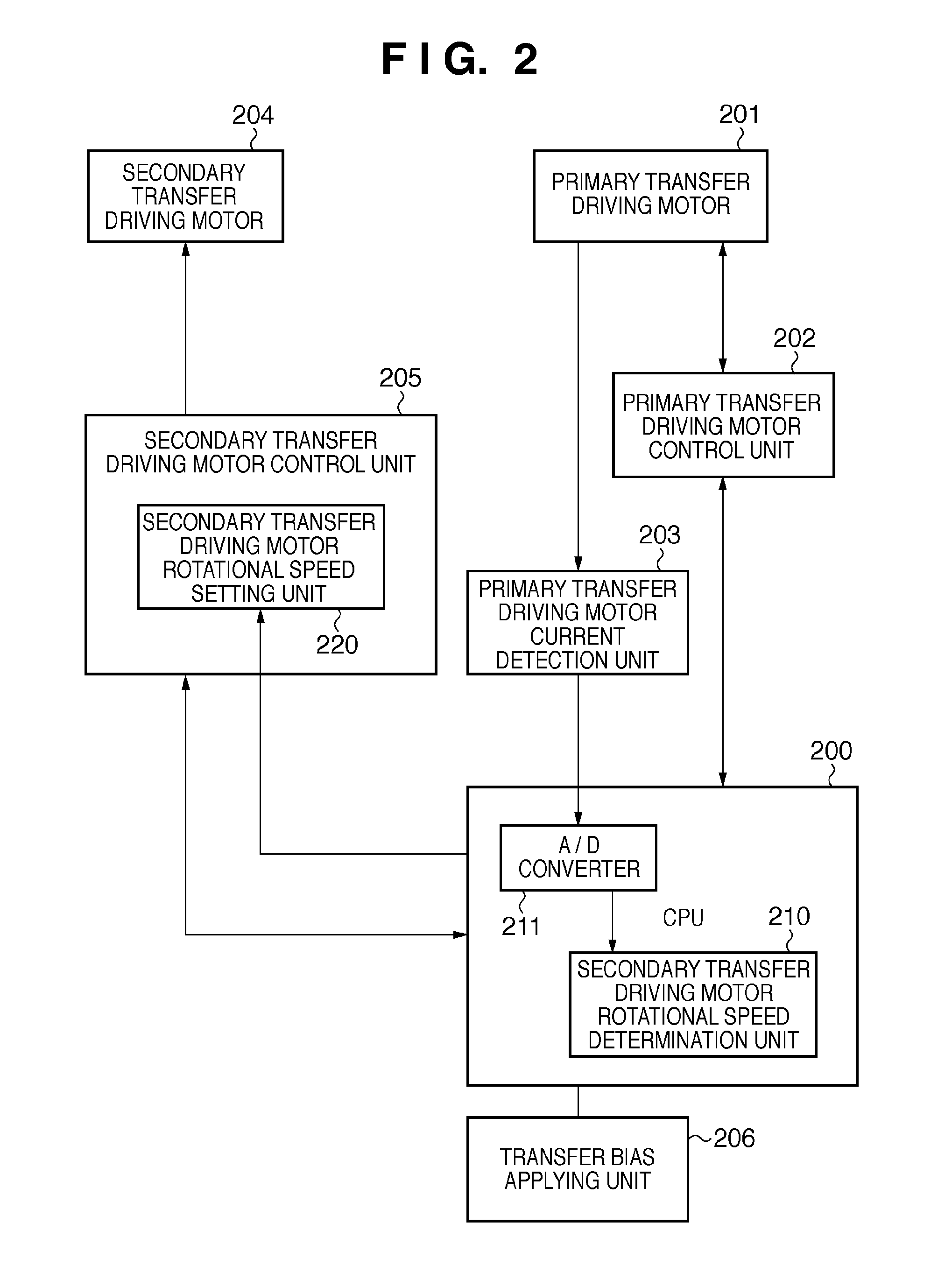

Image forming apparatus using plurality of rotation members, and control method thereof

InactiveUS20110129241A1Reduce speed differenceElectrographic process apparatusMotor driveElectric machine

An image forming apparatus includes first and second rotation members which are a plurality of rotation members for performing image formation and rotate in contact with each other. A first driving motor drives the first rotation member. A second driving motor drives the second rotation member. The obtaining unit obtains pieces of motor driving information about driving states of the first or second driving motor at respective relative driving speeds when the relative driving speed of the second driving motor with respect to the driving speed of the first driving motor is changed to a plurality of relative driving speeds. The control unit controls the driving speed of at least either the first or second driving motor in image formation to reduce the relative speed difference between the circumferential velocities of the first and second rotation members based on the pieces of motor driving information obtained by the obtaining unit.

Owner:CANON KK

Novel multi-blade centrifugal fan

ActiveCN105508265AImprove work efficiencyReduce speed differencePump componentsRadial flow pumpsAir volumeEngineering

The invention discloses a novel multi-blade centrifugal fan. The novel multi-blade centrifugal fan comprises a volute, a volute tongue and a plurality of fan blades fixed in the volute, wherein one lateral side of the volute tongue is fixed on the inner lateral side of the air outlet of the volute, the other lateral side of the volute tongue is a concave face, a plurality of air guide grooves are formed in the concave face, the two end faces of each fan blade are arc-shaped faces, a zigzag structure is arranged on one arc-shaped face of each fan blade, a bionic non-smooth structure is arranged on the other arc-shaped face of each fan blade, and airflow sequentially passes the bionic non-smooth structures and the zigzag structures and then is discharged from the air outlet of the volute. The novel multi-blade centrifugal fan has the advantages that the air quantity and air pressure of the fan are increased effectively, the noise of the fan is lowered effectively, and the efficiency of the fan is increased effectively.

Owner:XI AN JIAOTONG UNIV

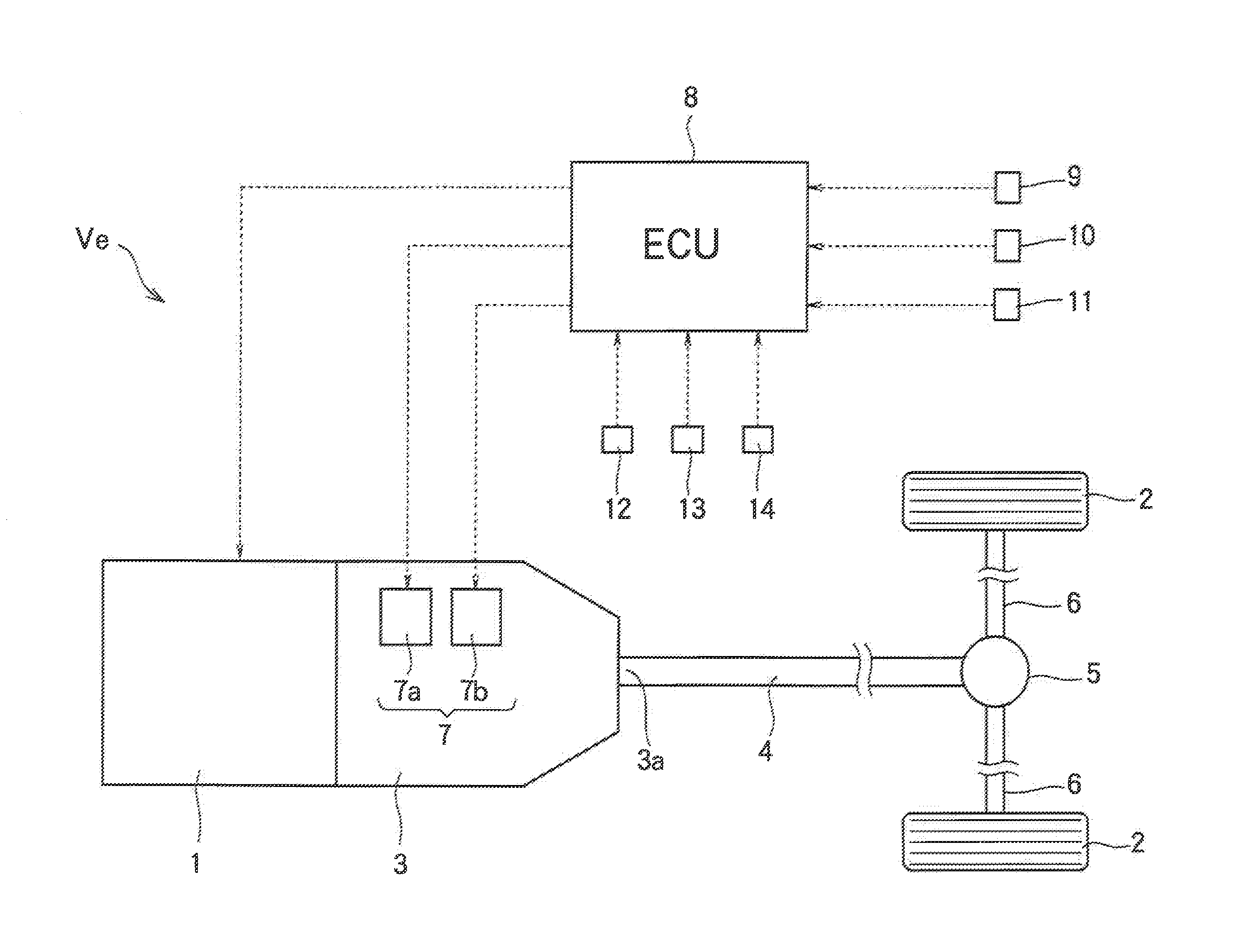

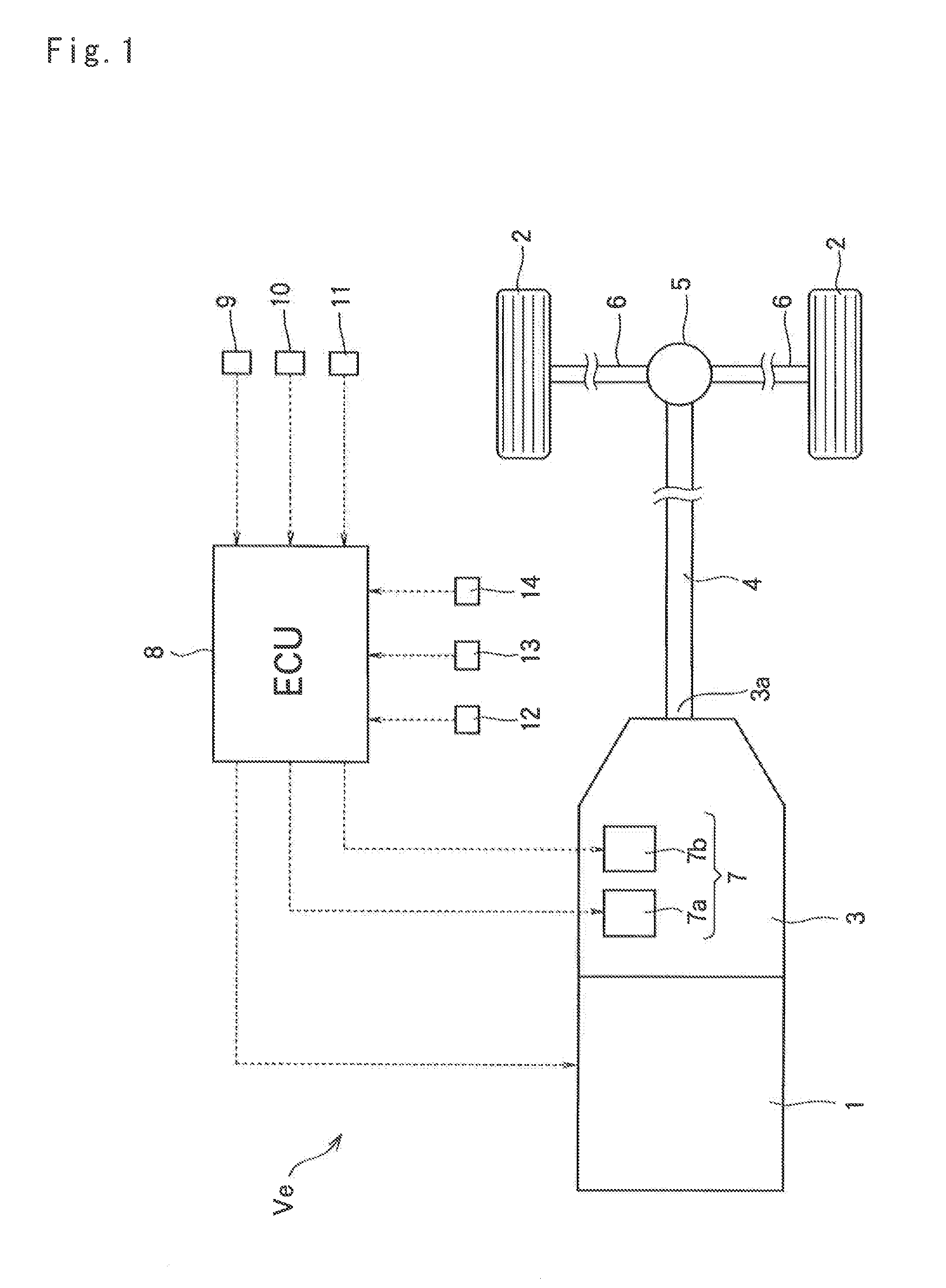

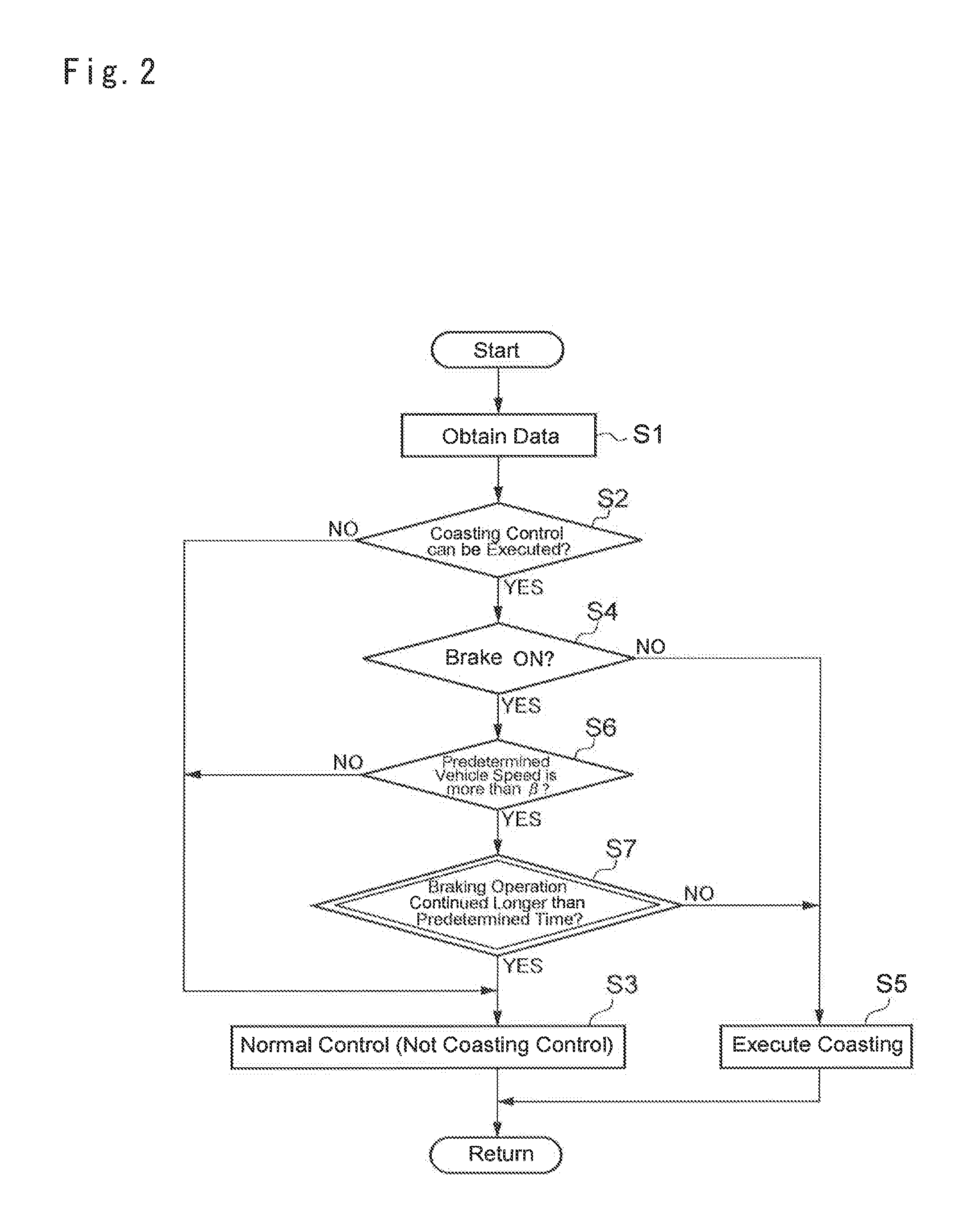

Vehicle control system

ActiveUS20150149058A1Improve energy efficiencyShort durationClutchesDigital data processing detailsDrive wheelControl system

A vehicle control system is provided. The vehicle control system is applied to a vehicle having a clutch device adapted to selectively connect and disconnect a power transmission route between a prime mover and drive wheels. The vehicle control system disconnects the power transmission route during running to allow the vehicle to coast. The vehicle control system is comprised of: a means detecting a vehicle speed; a means detecting an operation of an accelerator by a driver; a means detecting a braking operation of the driver; an execution means executing a coasting control when an operating amount of the accelerator is reduced to be smaller than a predetermined value during running, by bringing the clutch device into disengagement to disconnect the power transmission route so as to allow the vehicle to coast; a determination means determining whether or not a deceleration demand of the driver is larger than a predetermined value during execution of the coasting control based on the vehicle speed and the braking operation; and a termination means determining a fact that the deceleration demand is strong if the deceleration demand is larger than the predetermined value, and that terminates the coasting control by bringing the clutch device into engagement to connect the power transmission route.

Owner:TOYOTA JIDOSHA KK

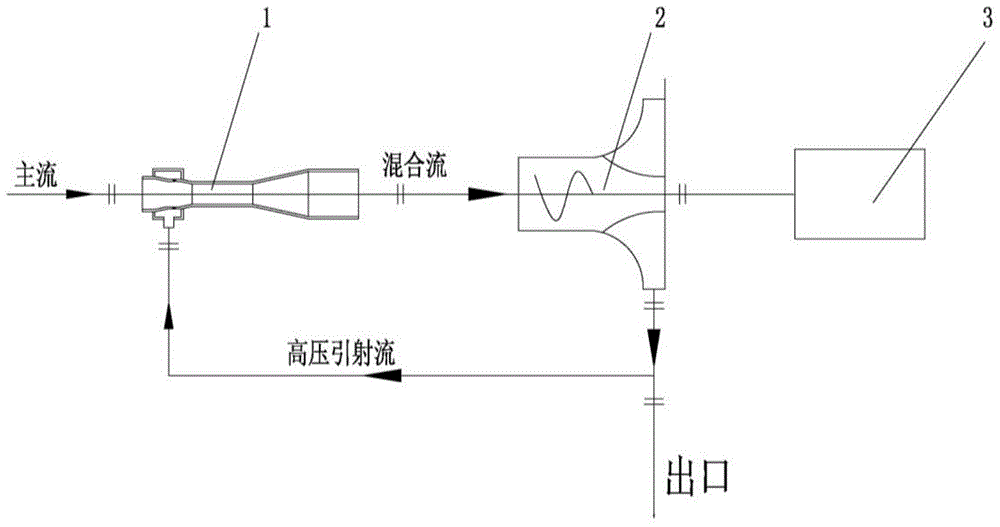

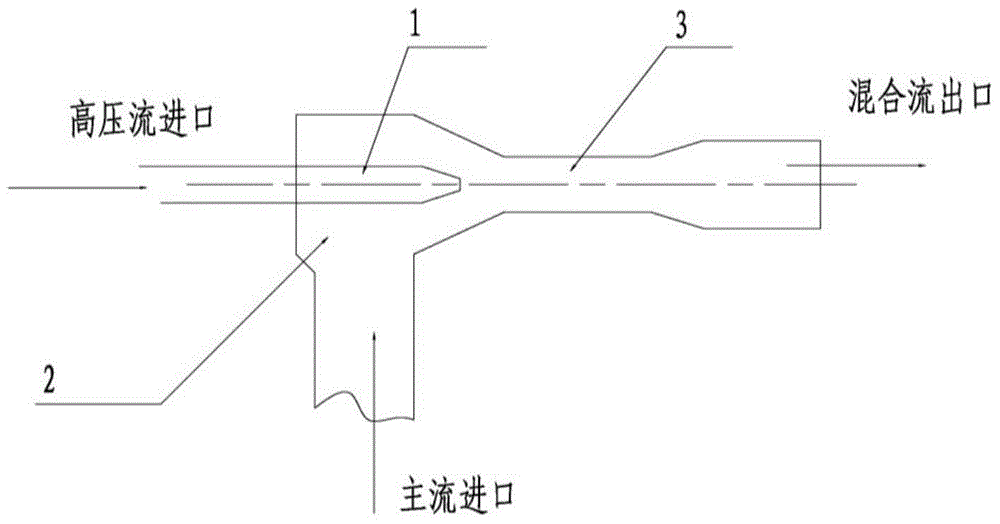

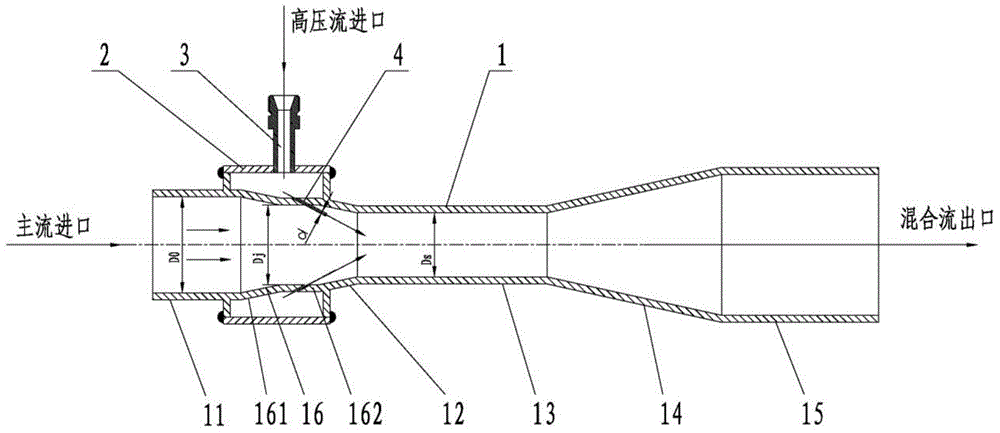

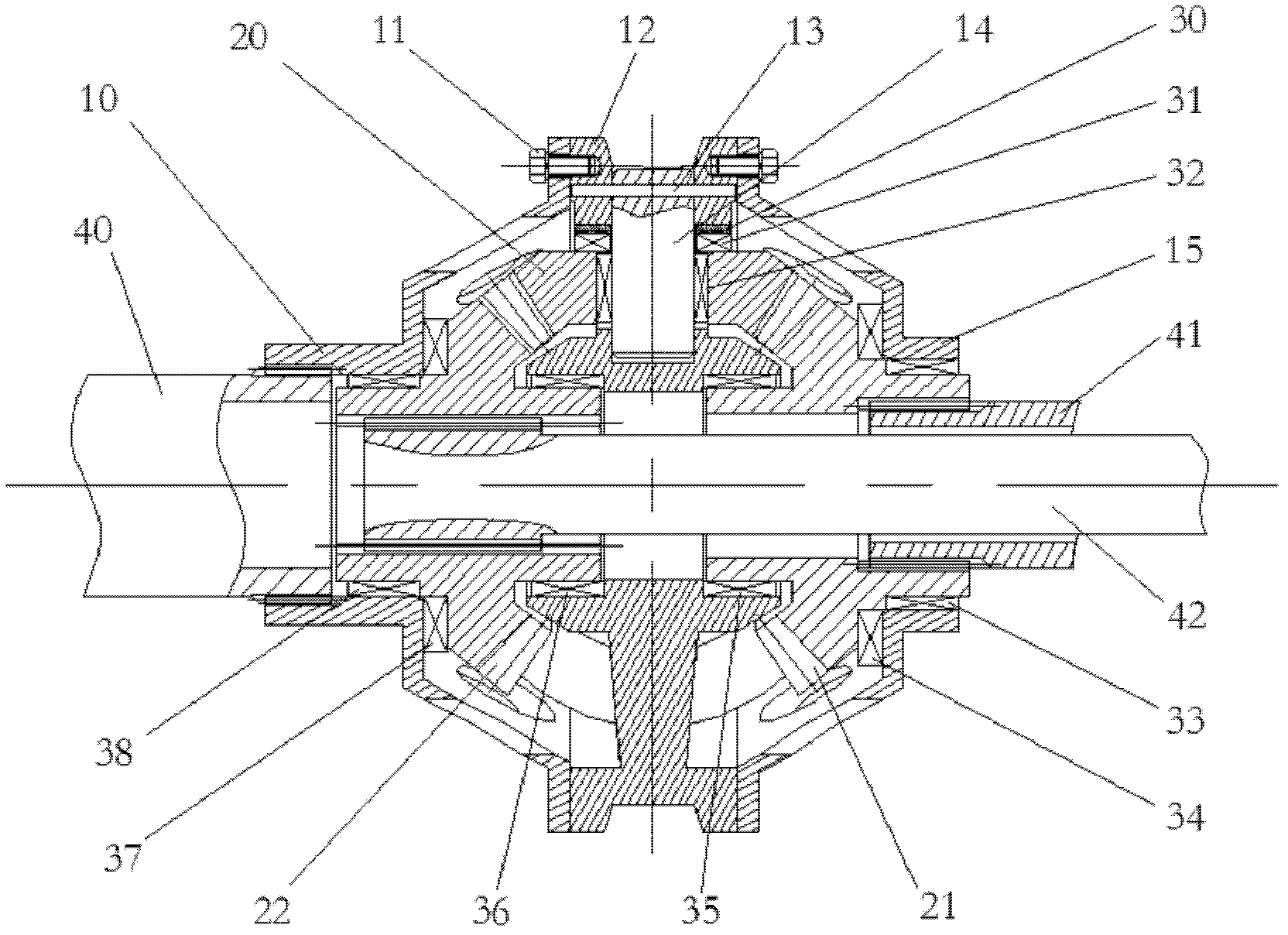

High pressure annular jet pump suitable for pumping pressure type supply system

The invention belongs to the technical field of aviation and space, and particularly relates to a high pressure annular jet pump suitable for a pumping pressure type supply system. The high pressure annular jet pump comprises an inlet section pipe, a mixing section pipe, a throat pipe, a diffusion section pipe and an outlet section pipe which are sequentially arranged in the flowing direction of main fluid. The high pressure annular jet pump is characterized by further comprising step section pipes which are sequentially arranged between the inlet section pipe and the mixing section pipe; each step section pipe comprises a convergence section pipe and a straight section pipe; each straight section pipe is provided with a spraying nozzle for providing high pressure fluid. The high pressure annular jet pump is compact in structure, light in weight, good in anti-cavitation performance and capable of meeting the requirement for normal work under the working conditions of high rotating speed and low inlet pressure.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Multi-group color separation spinning and crocheting wool yarn and manufacturing method thereof

The invention discloses multi-group color separation spinning and crocheting wool yarn and a manufacturing method of the multi-group color separation spinning and crocheting wool yarn. The manufacturing method comprises the steps that elastic nylon or filaments are crocheted to be net-shaped yarn, drafted multi-group color separation spinning short fiber thick yarn wool tops are fed and enter false twisting hooks of hook wood ingots under the traction of the nylon filaments or the elastic filaments, 10-20 false twists are added on strands and the nylon filaments or the elastic filaments to form thick yarn to be attached to the net-shaped yarn of the nylon filaments or the elastic filaments, and the multi-group color separation spinning and crocheting wool yarn is obtained after untwisting. As the tape yarn is of a drafting type, the yarn has the advantages of being soft, fluffy, high in strength and the like, wool does not fall off easily, the yarn is applicable to sweater yarn of autumn and winter clothes, and good moisture absorption performance, the heat retention performance and the air permeability are achieved. The manufacturing method overcomes the defect that a traditional twisting machine is single in fiber mode, enriches the characteristics of multiple components of the yarn, subsequent dyeing is avoided, and the yarn is an environmentally friendly product.

Owner:JIANGSU LUGANG SCI & TECH

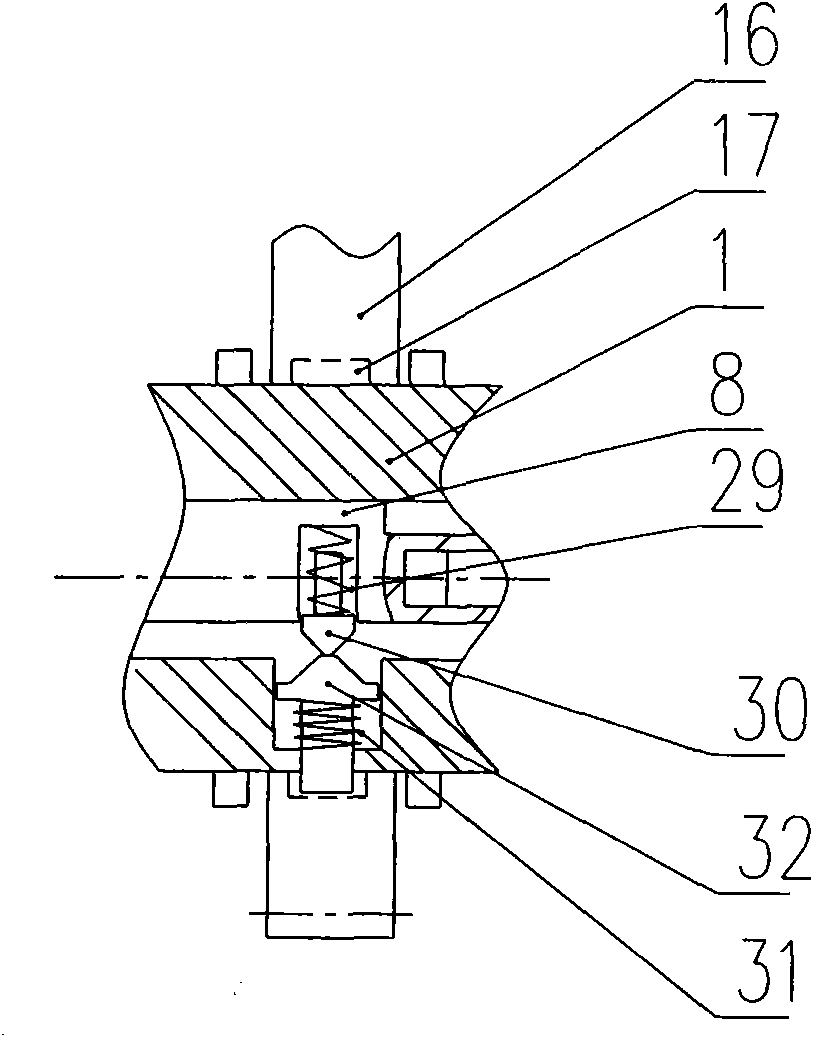

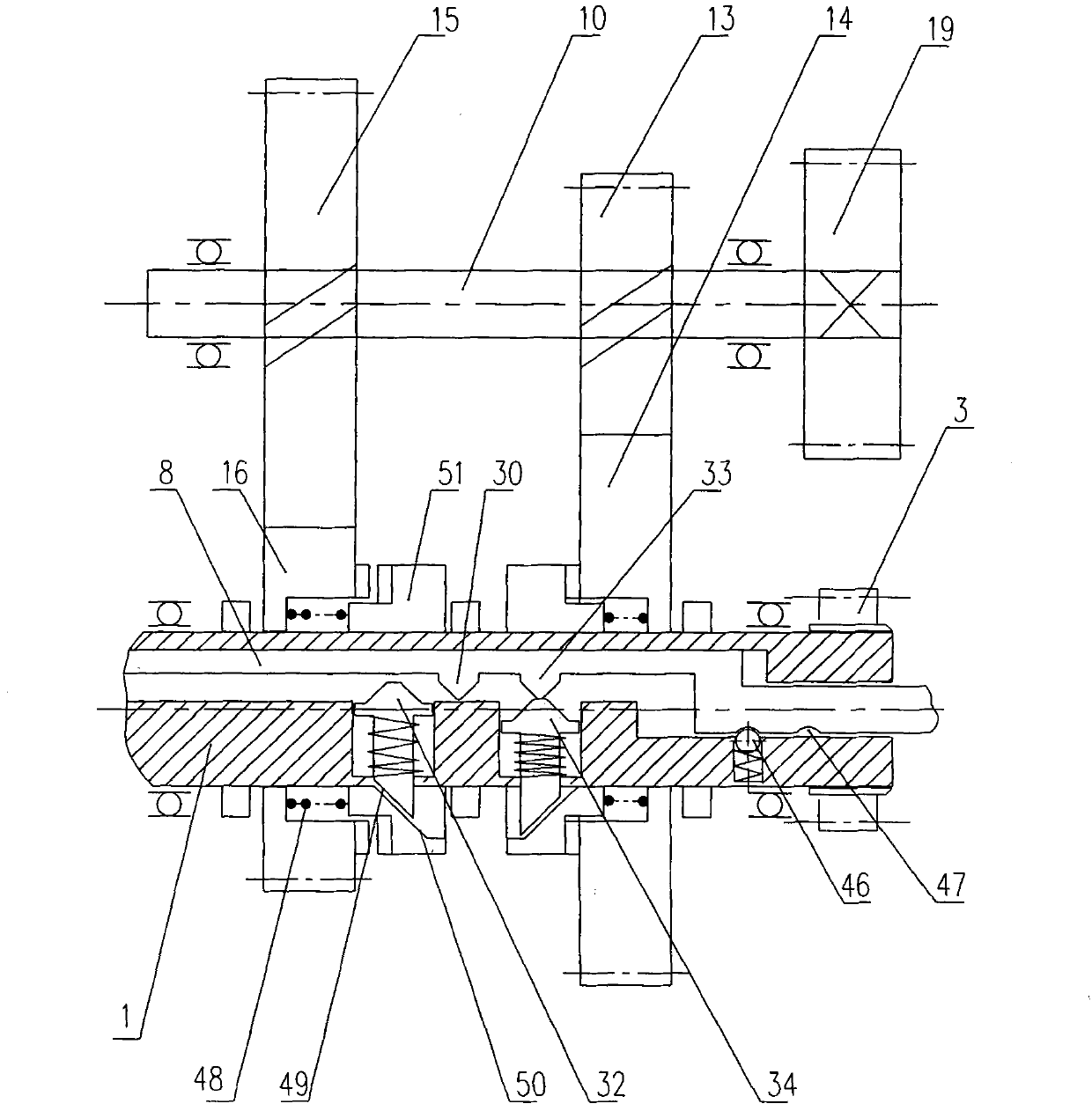

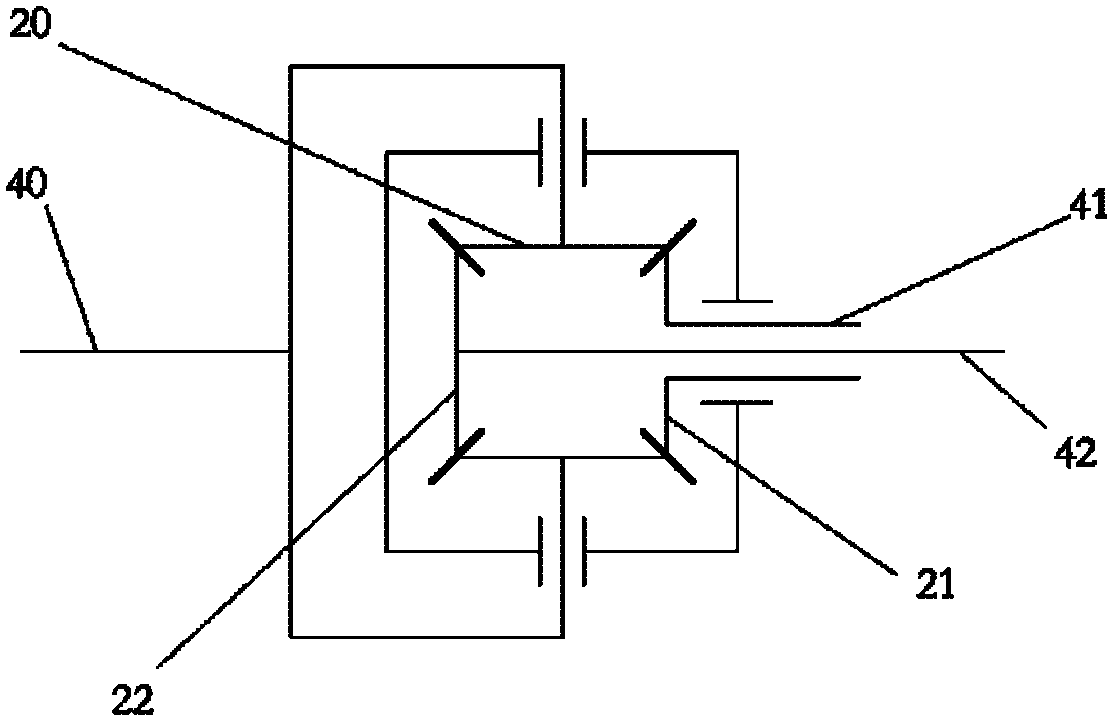

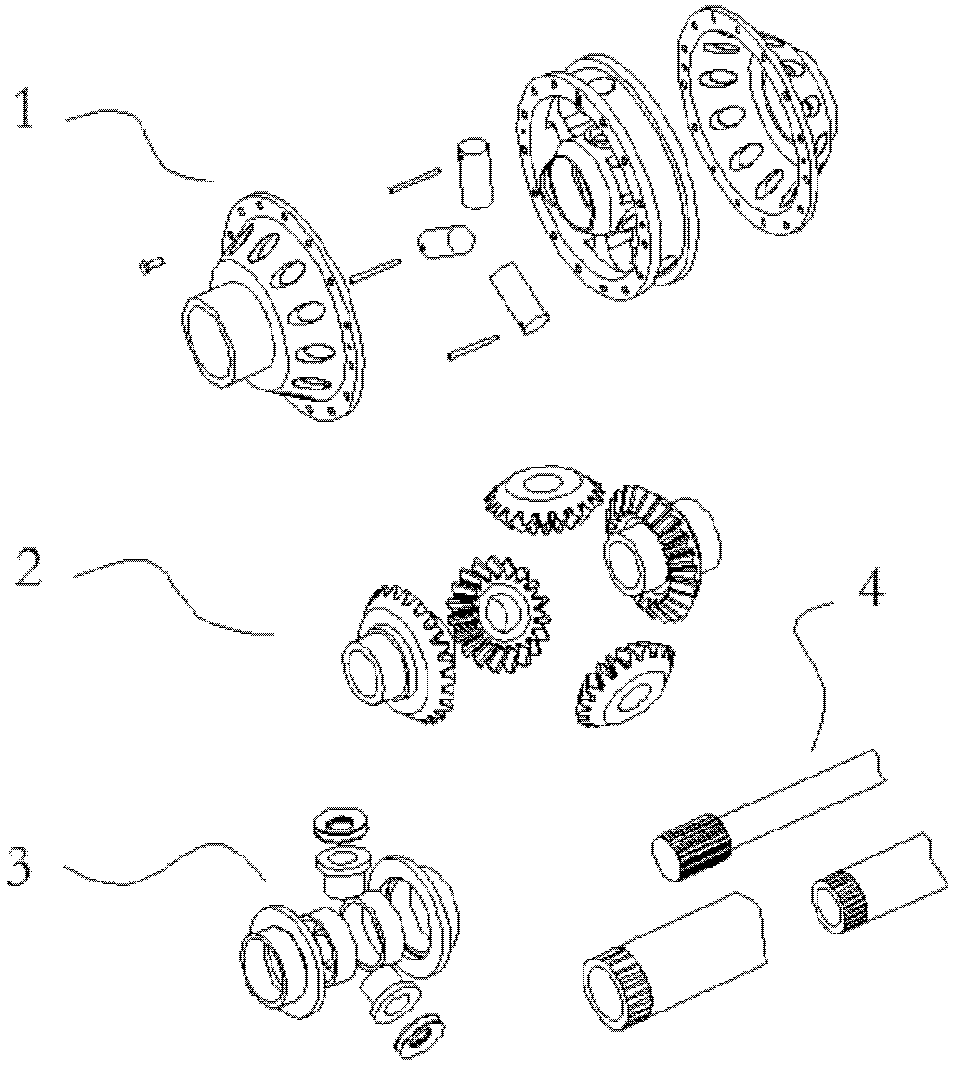

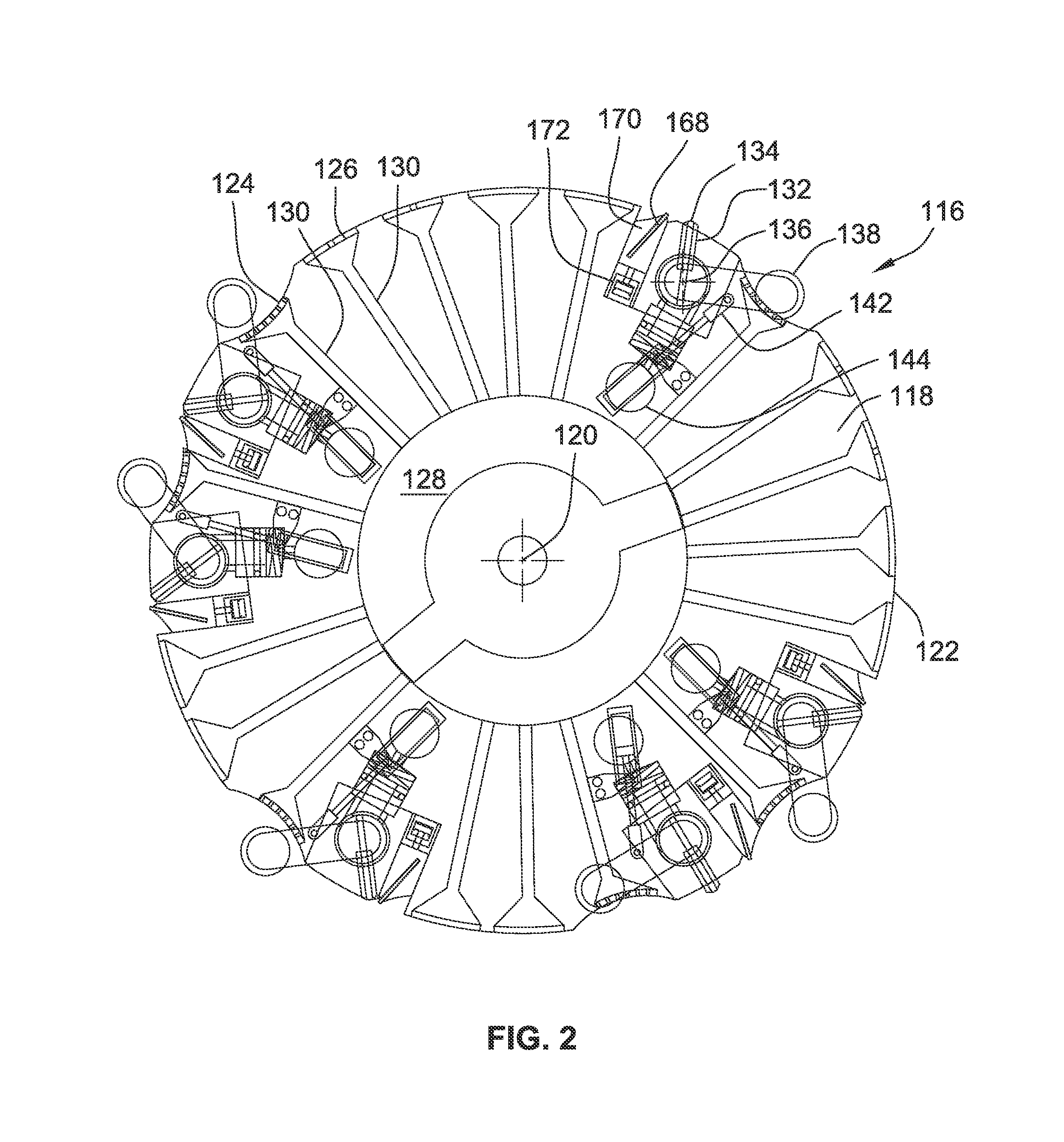

Power distributor and unitary power distribution system of hybrid power automobile

InactiveCN102563003ASmall footprintImprove the support effectHybrid vehiclesGas pressure propulsion mountingLeft halfDistribution system

The invention discloses a power distributor and unitary power distribution system of a hybrid power automobile. The power distributor comprises a housing assembly, a bevel gear planetary gear train, a bearing, disk spring parts and shaft parts, wherein power is supplied from the left side of the power distributor via a spline shaft of a left end cover; at least three planetary gears of the bevel gear planetary gear train are driven by the housing assembly to revolute, thereby distributing the power to a right half shaft gear and a left half shaft gear of the bevel gear planetary gear train; finally the power is output from the right half shaft gear spline shaft and the left half shaft gear spline shaft from the right side of the power distributor through the spline. According to the invention, the unitary power distribution system adopts the power distributor; the input shaft of the power distributor disclosed by the invention is arranged at the left side of a device, two output shafts are led out from the right side of the device, so that a power generator of the unitary power distribution system can be arranged in parallel with a motor coaxially, so that the occupied space of the system is reduced; furthermore, the gear has good bearing effect and high revolution precision.

Owner:JILIN UNIV

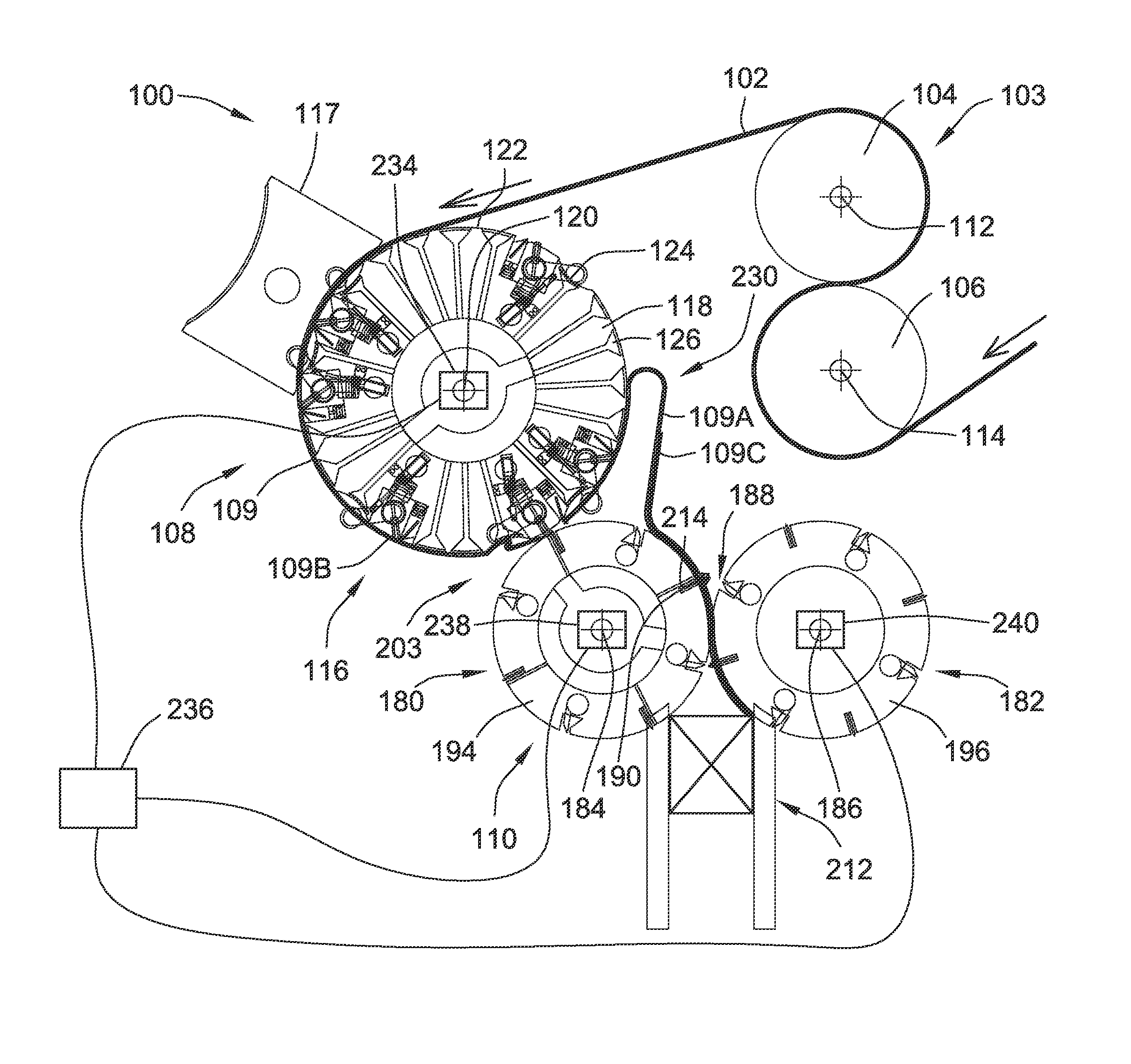

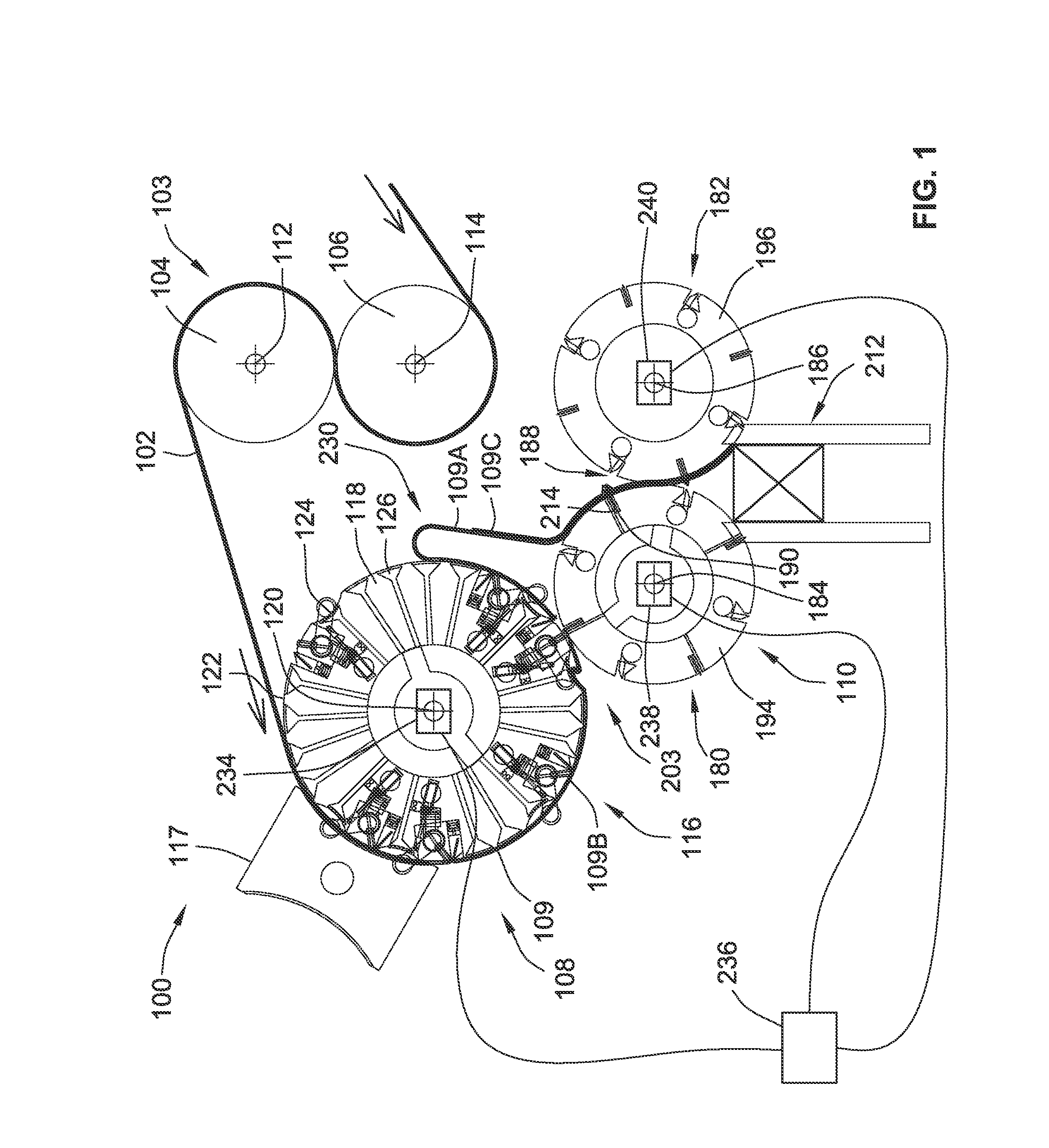

Folding machine and methods

ActiveUS20150360901A1Reduce speed differenceMechanical working/deformationFolding thin materialsEngineeringMechanical engineering

Folding machines and methods are provided. A folding machine that utilizes a direct transfer of sheets from a knife roll to a folding roll is provided. Sheet handling rolls are provided that incorporate movable vacuum ports to assist in transfer of a sheet from one roll to another roll.

Owner:C G BRETTING MFG

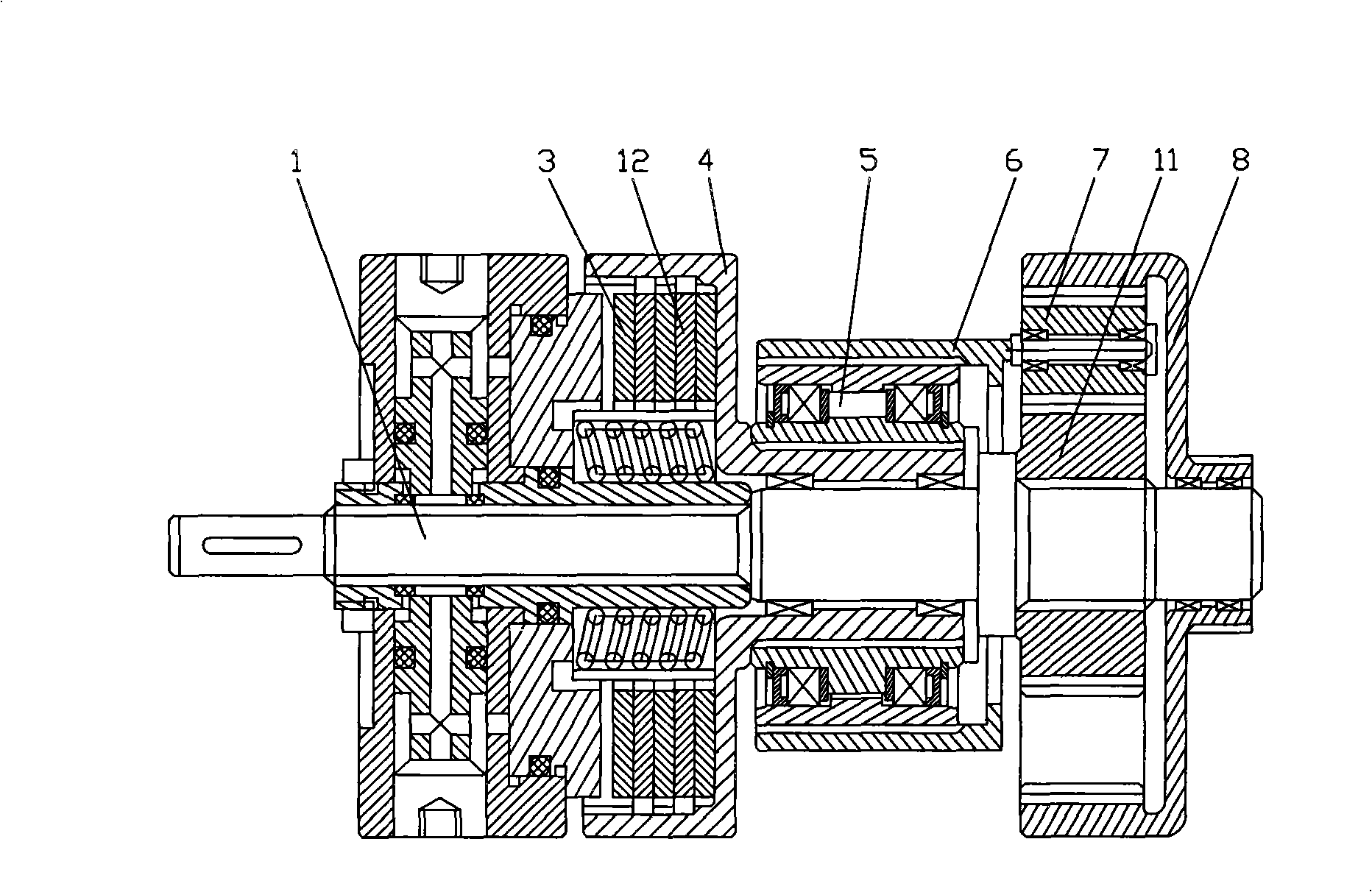

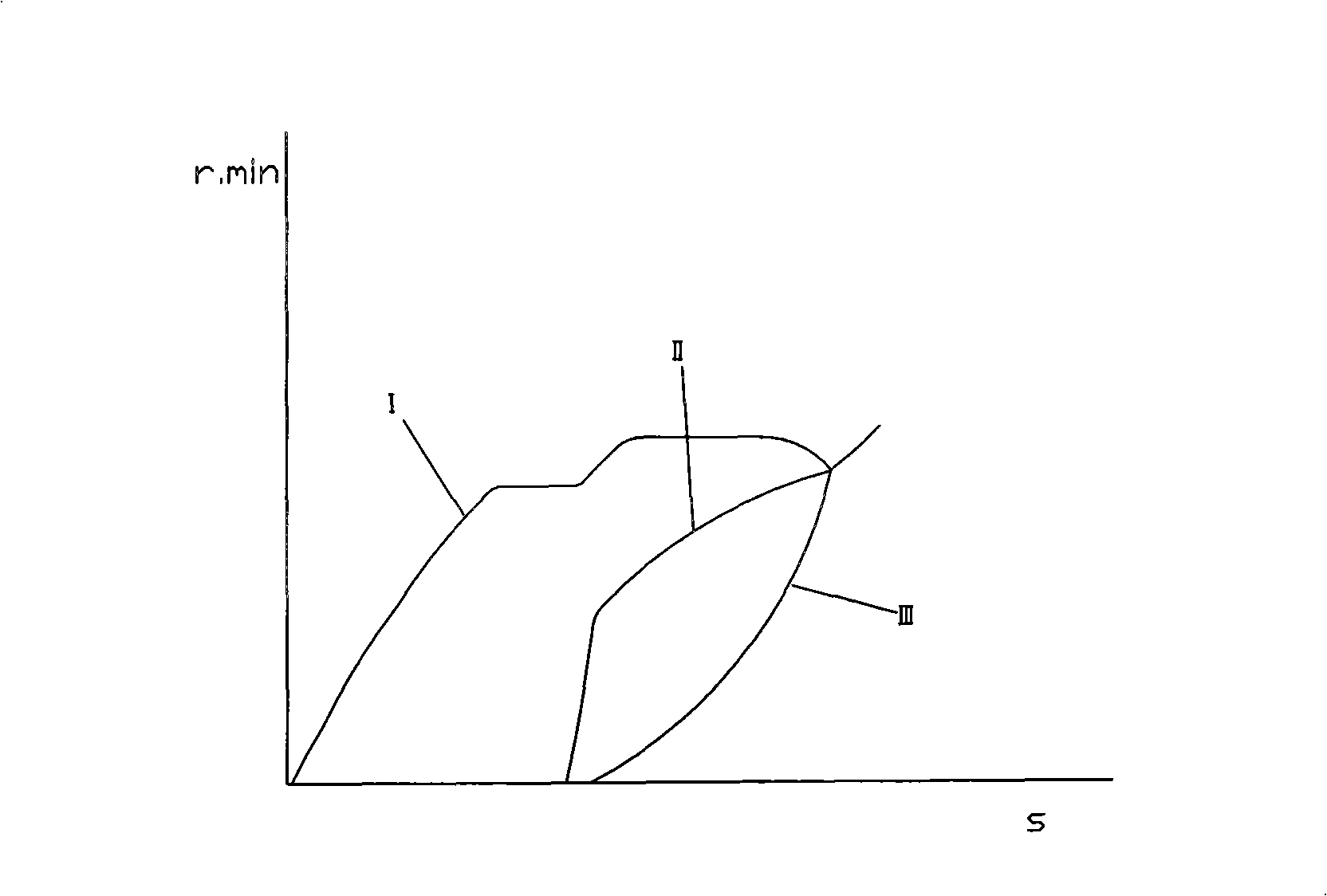

Planetary type main clutch for automobile

InactiveCN101349310AReduce speed differenceExtended service lifeFreewheel clutchesStaringDrive shaft

The invention discloses a vehicular planetary type main clutch device, which comprises a power input shaft, a power output shaft, a driving friction disk and a driven friction disk, the driving friction disk is fixedly arranged on the power input shaft, and the vehicular planetary type main clutch device further comprises a planetary gear train which includes a sun gear, a planet gear and an outer gear ring. The driving friction disk is fixedly arranged on a driven shaft, the sun gear is fixedly arranged on the power input shaft, the outer gear ring is fixedly connected with the power output shaft, and the planet gear is rotationally engaged with a planet carrier. At operating time, power is transmitted to the planet carrier through a one way clutch from the driven shaft. The vehicular planetary type main clutch device reduces the rotational speed difference between the driving friction disk and the driven friction disk of the clutch in starting process, reduces the starting jointing time of the clutch, reducing the slip energy, simultaneously reducing the vehicle impact and enabling the slip energy and the vehicle impact to sufficiently coordinate because the rotational speed difference of the driving friction disk and the driven friction disk is reduced, and the jointing speed requirement is reduced. The vehicular planetary type main clutch device not only increases the vehicle ride comfort in the staring process, but also can prolong the service life of the main clutch.

Owner:CHONGQING UNIV

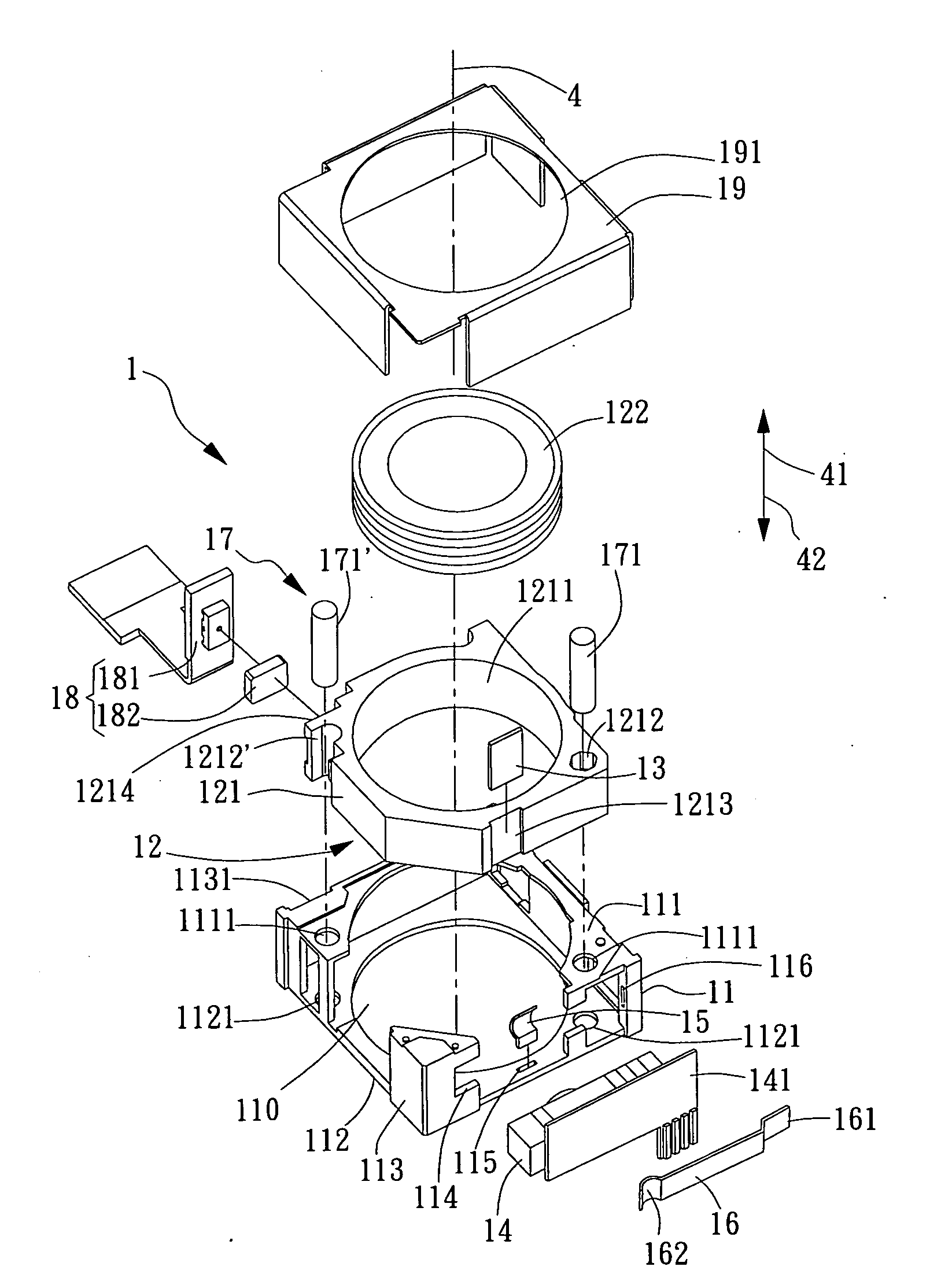

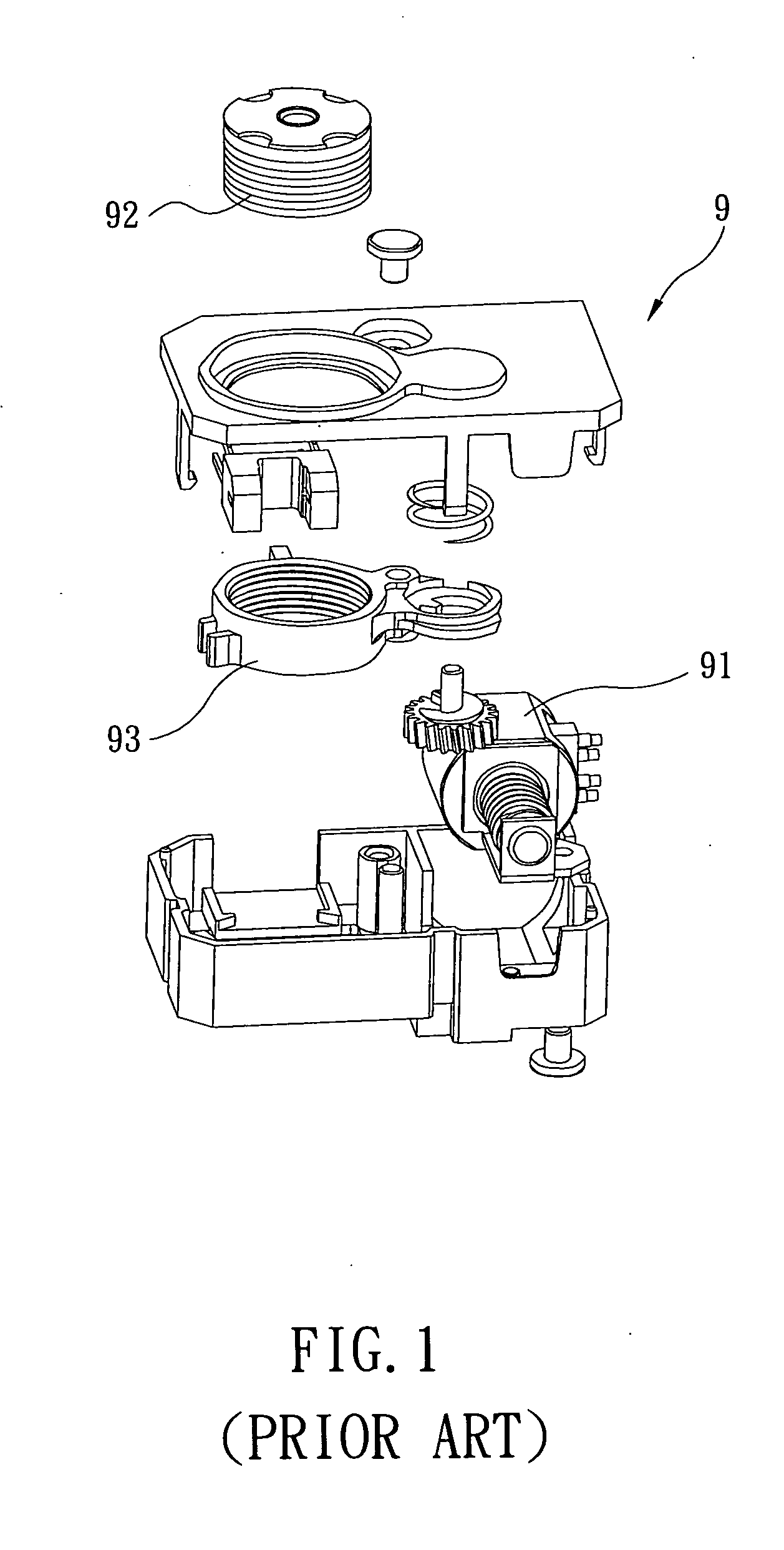

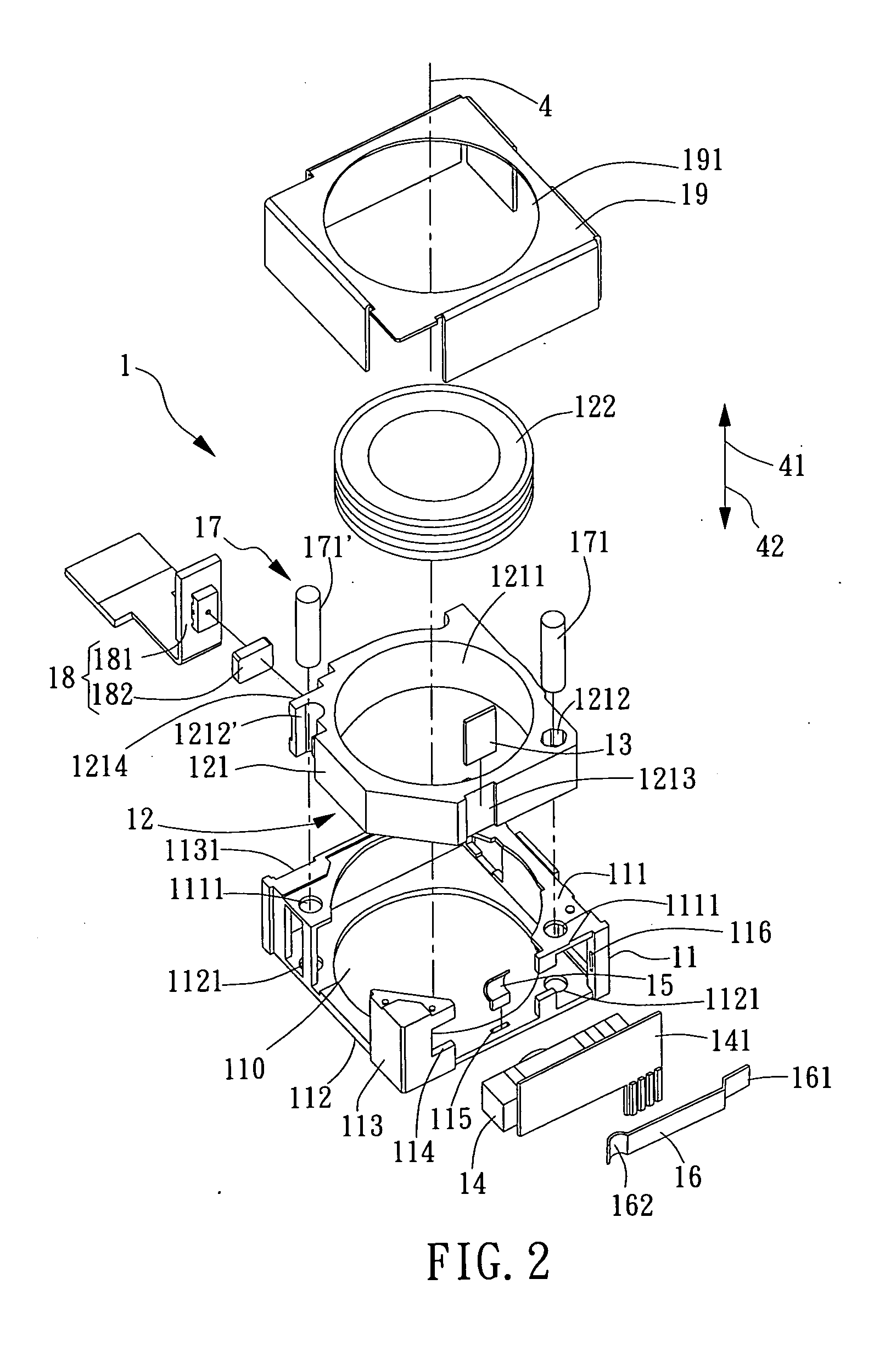

Piezoelectric driving module for lens

ActiveUS20130120855A1Reduce gravity-induced speed differenceReduce speed differenceMountingsElectricityCamera lens

A piezoelectric driving module for lens, which defines a photographic optical axis and includes a housing, a driven object (e.g., a lens module), a piezo member, and a rubbing element. The piezo member and the rubbing element are provided in the housing and located on two lateral sides of the driven object respectively. The piezo member drives the driven object by friction so that the driven object can be moved along the photographic optical axis until focused. Meanwhile, a predetermined frictional force is generated between the rubbing element and the driven object to reduce a gravity-induced speed difference between forward and backward movements of the driven object along the photographic optical axis.

Owner:TDK TAIWAN

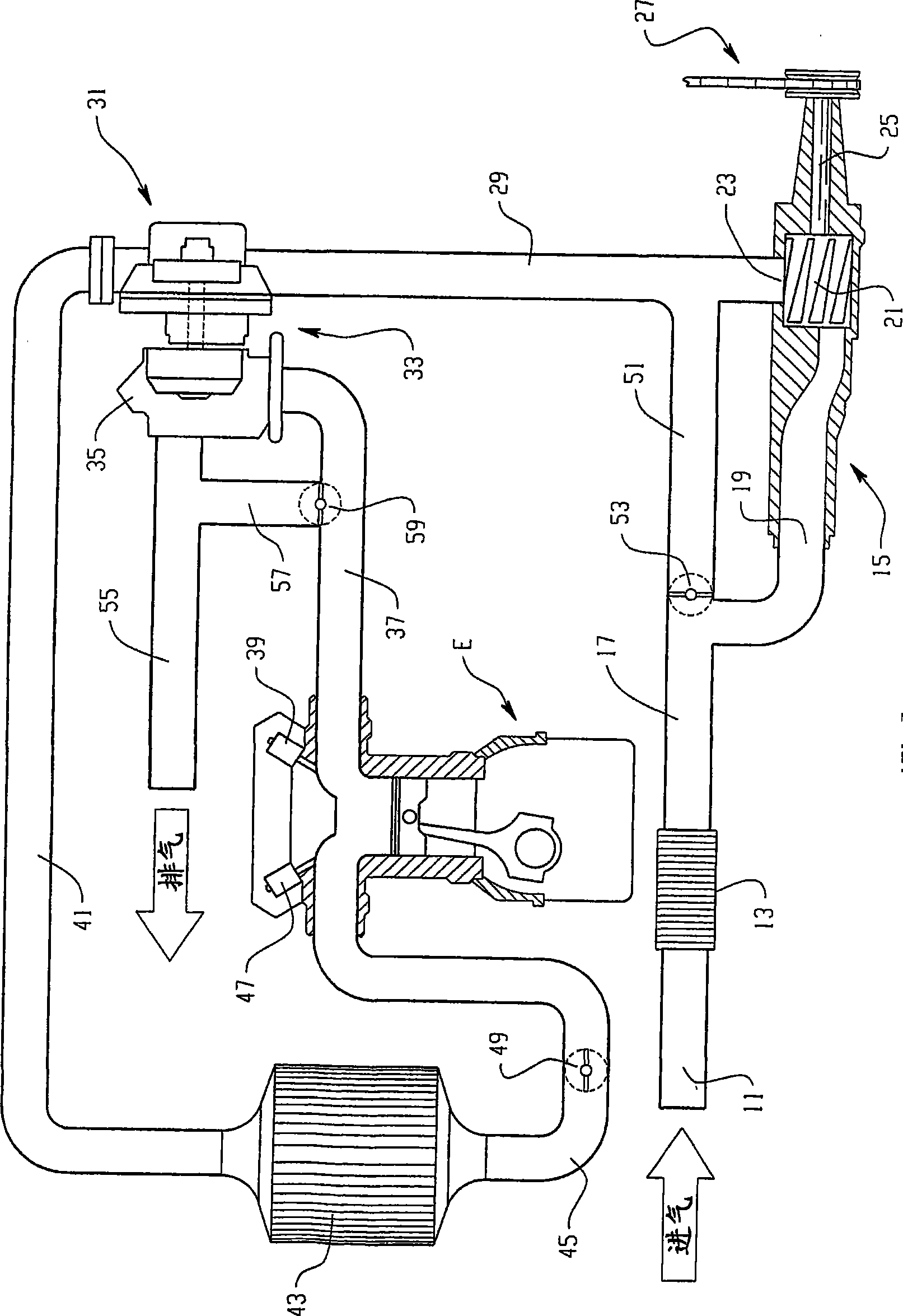

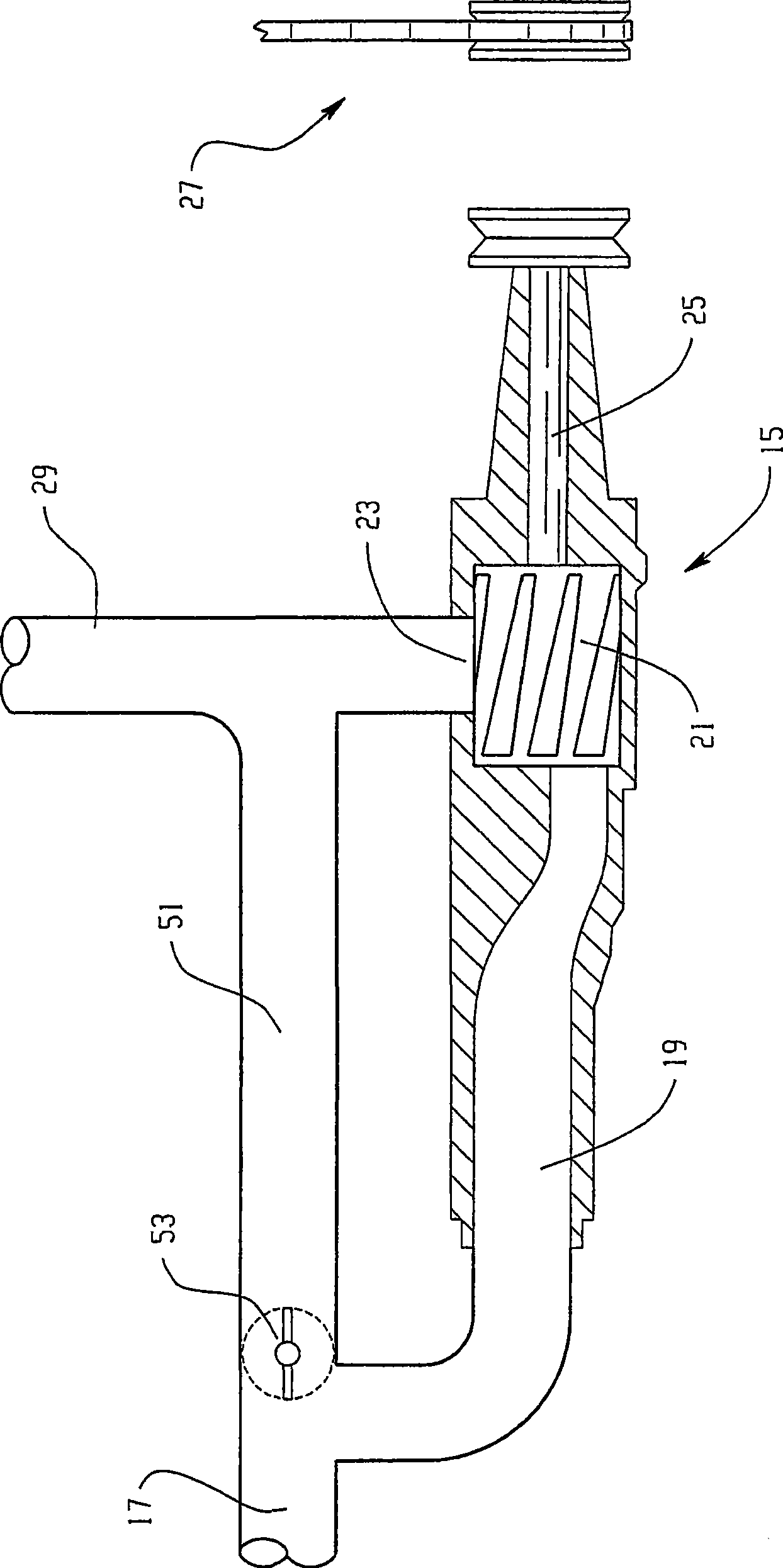

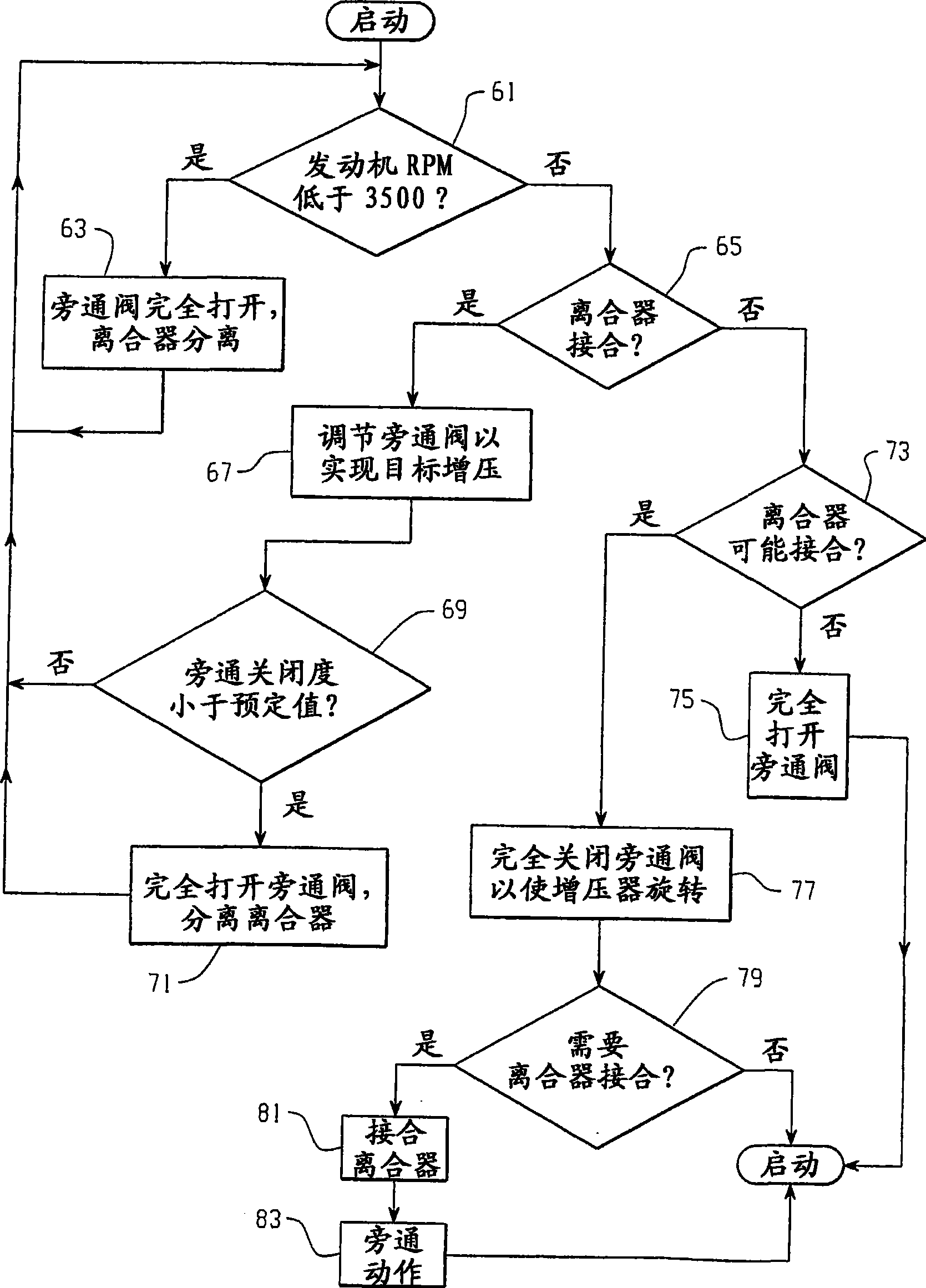

Clutched super turbo control strategy

InactiveCN101501313AReduce speed differenceReduce unwanted outcomesInternal combustion piston enginesEngine controllersTurbochargerForced-air

A method of controlling an internal combustion engine boosting system of the type including an exhaust-driven turbocharger (33) and a mechanically-driven supercharger (15). The supercharger (15) includes rotors (21) and a clutch (27) operable in a first condition to transmit torque from a mechanical drive source (E) to a supercharger input (25) in response to a positive input (75), and operable in a second condition to interrupt the transmission of torque from the source (E) to the input (25). The method is characterized by determining possible operation of the clutch (27) in a first condition; and commanding a bypass valve (53) toward a closed position, forcing air through the supercharger (15). The airflow causes the supercharger rotors (21) to rotate, thus rotating the input (25) of the supercharger prior to the clutch (27) operating in the first condition.

Owner:EATON CORP

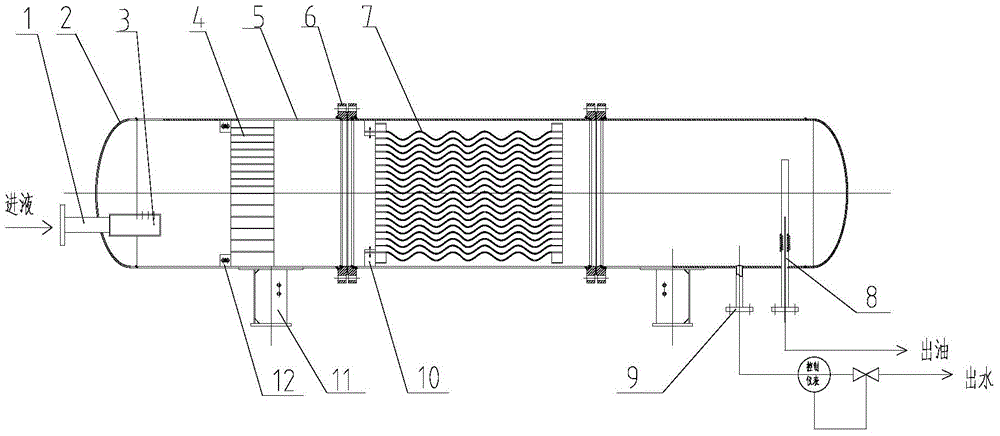

Orientation coalescence liquid-liquid separator

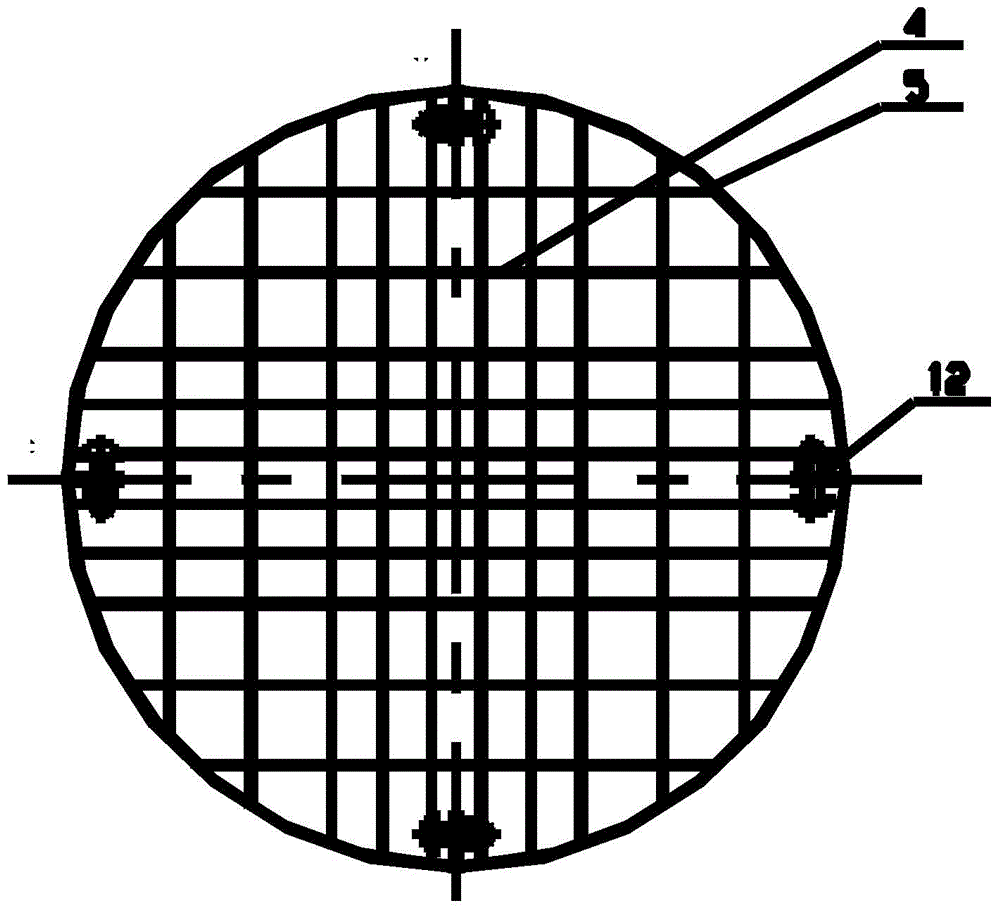

ActiveCN104474741AReduce shockImprove washing effectFatty/oily/floating substances removal devicesNon-miscible liquid separationHarmonicHorizontal axis

The invention discloses an orientation coalescence liquid-liquid separator which comprises a cylinder (5), a trapezoidal inlet hole box (3), a rectification plate group (4) and a coalescence plate group (7). The orientation coalescence liquid-liquid separator is characterized in that the coalescence plate group (7) is corrugated plate packing; a corrugated plate is fixedly supported by a pull rod distance tube (14) and a hoop (15); the corrugated plate is arranged in an angle of 45 degrees with the horizontal axis. Compared with a conventional pore box, the trapezoidal inlet hole box is somehow improved, so that the impact of flow to a separation field of the equipment is reduced, at the same time relatively good functions of gravity energy dissipation and washing are achieved, and pre-separation can be effectively achieved. A periodic harmonic wave is adopted as the waveform curve of the coalescence plate group, so that the fluid flowing state can be switched between laminar flow and periodic harmonic wave pulsating flow, and collision and agglomeration of droplets are facilitated; due to adoption of the multi-layer inclined corrugated type composite coalescence plate, the oil droplet removal efficiency is improved.

Owner:TIANJIN UNIV

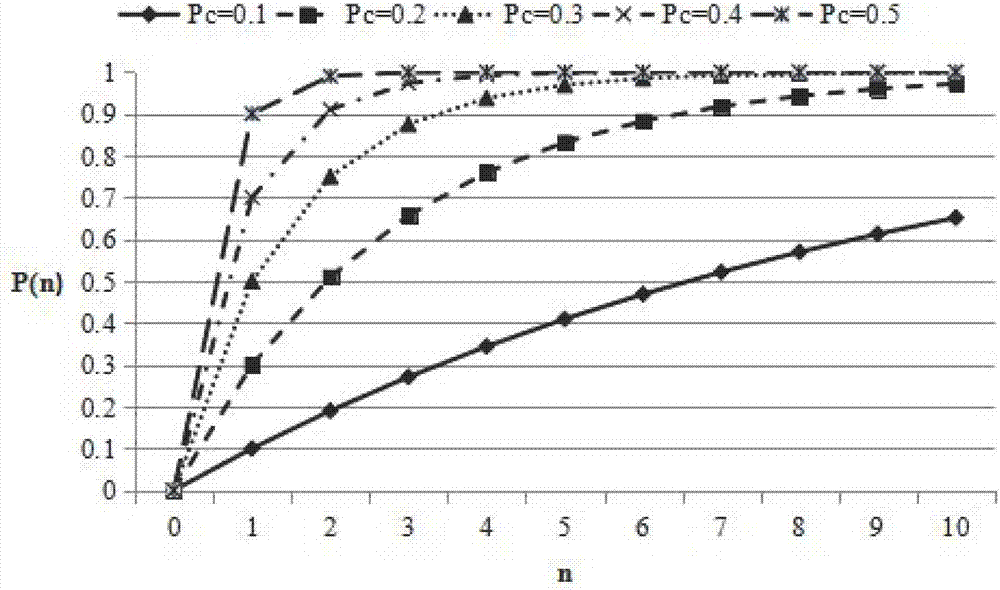

Arrangement method of expressway merging area prohibition afflux line

ActiveCN107146406AImprove securityReduce the phenomenon of entering the main line without accelerating completelyRoadwaysDetection of traffic movementMedium densityTraffic accident

Owner:SOUTHEAST UNIV

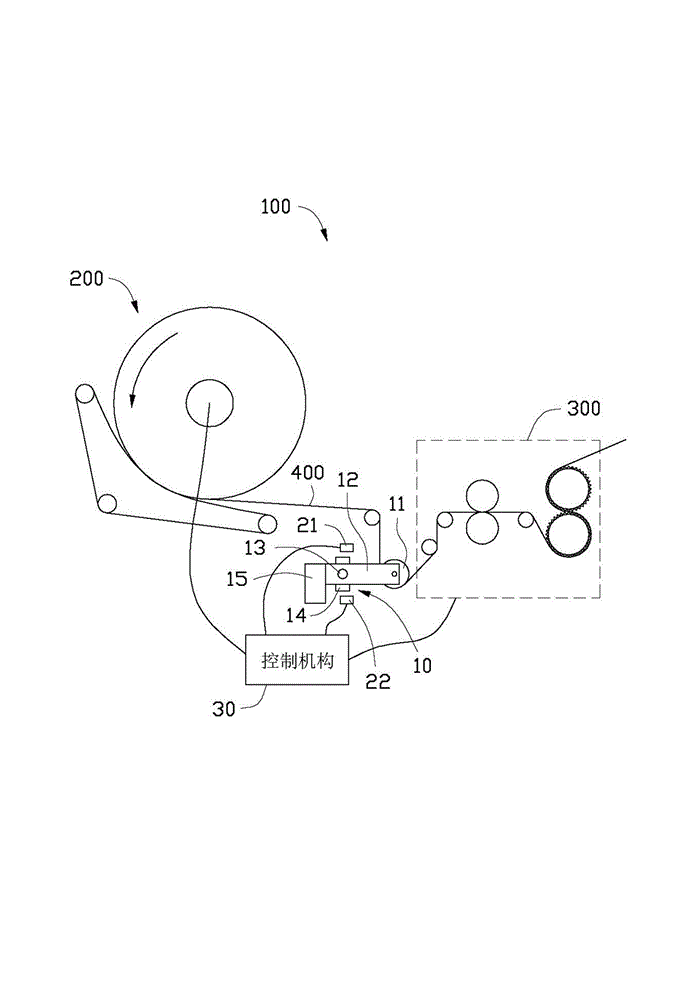

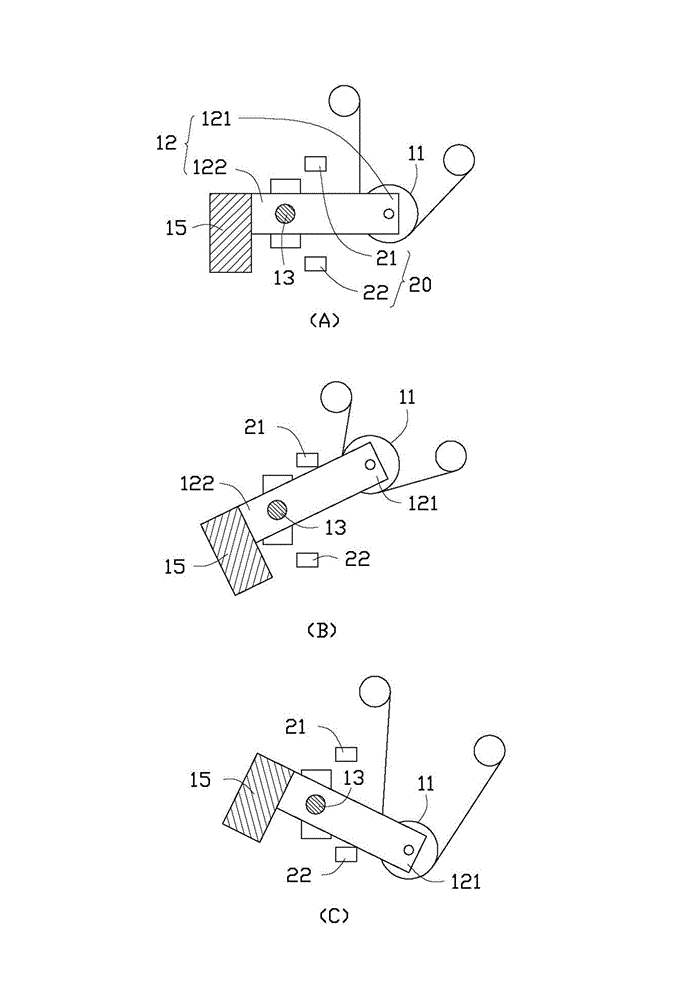

Automatic sheet transmission tension adjustment device and sheet post-processing system

InactiveCN103144989AStable tensionEliminates the effects of transmission tensionWebs handlingTransfer procedurePendulum

The invention relates to an automatic sheet transmission tension adjustment device, which is used for automatically adjusting the transmission tension force of a sheet unreeled from a sheet unreeling device and transmitted to a sheet post-processing device. The automatic sheet transmission tension adjustment device comprises a swing roller mechanism, wherein the swing roller mechanism is provided with a swing roller, a swing rod and a swing shaft; the swing roller is arranged at one end of the swing rod to do the pendulum movement around the swing shaft; the swing roller is positioned between the sheet unreeling device and the sheet post-processing device and pressed on the sheet; and the swing roller is used for swinging up or down with the change of the sheet unreeling speed of the sheet unreeling device and the sheet traction speed of the sheet post-processing device to reduce or increase the transmission stroke of the sheet between the sheet unreeling device and the sheet post-processing device so as to keep stable sheet transmission tension force in the transmission process. The invention further relates to a sheet post-processing system comprising the automatic sheet transmission tension adjustment device.

Owner:GOLD HONG YE PAPER

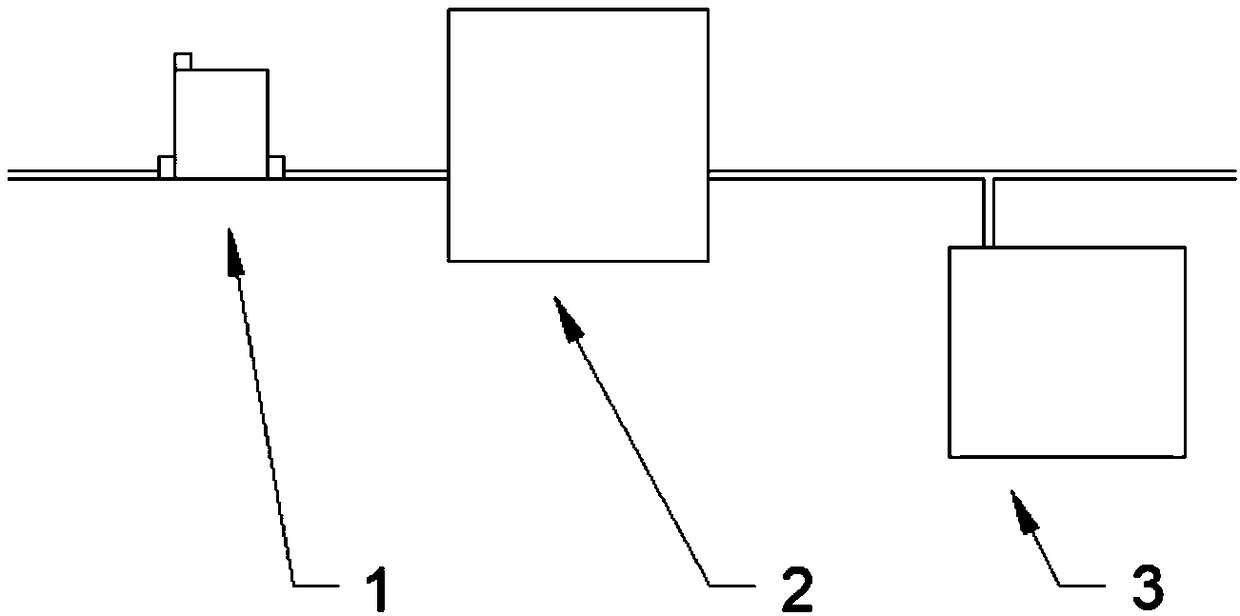

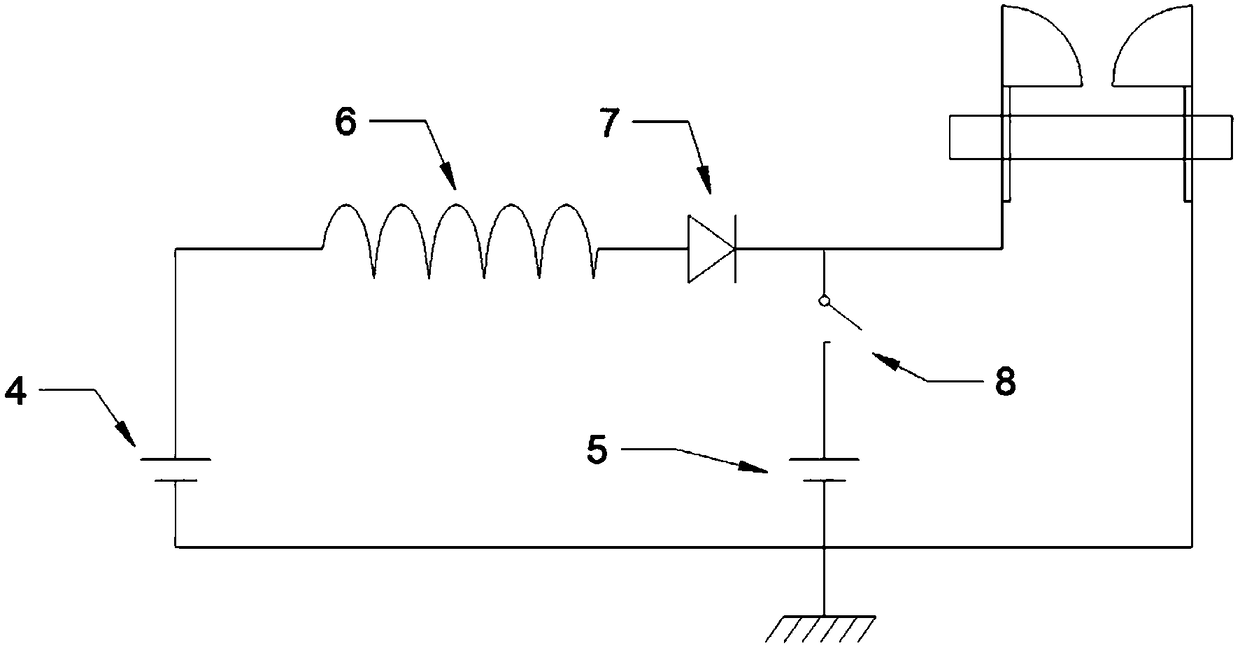

Greenhouse gas conversion device and method utilizing magnetic field to strengthen blade gliding arc

ActiveCN109289457AAchieve breakdownStable currentGas treatmentDispersed particle separationEngineeringPrism

The invention discloses a greenhouse gas conversion device and method utilizing a magnetic field to strengthen a blade gliding arc. The device comprises a blade gliding arc stabilization system and areactor. The blade gliding arc stabilization system comprises a first DC power supply, a second DC power supply, an inductance coil, a diode and an electromagnetic relay switch. The voltage of the second DC power supply is greater than that minimum breakdown voltage between two electrodes of the reactor. The voltage of the first DC power supply is 1 / 8-1 / 2 of the minimum breakdown voltage between the two electrodes of the reactor. The second DC power supply provides breakdown voltage, and the first DC power supply maintains power feeding. The reactor consists of an encloser, two electrodes, twoflat magnets and a nozzle. The encloser is a straight quadrangular prism structure with a rectangular cross section, and the two flat magnets are arranged outside the encloser parallel to each other.The invention improves the traditional blade reactor, utilizes the dual driving of the magnetic field and the airflow field, significantly improves the treatment capacity on greenhouse gas, and greatly prolongs the reactor lifetime.

Owner:ZHEJIANG UNIV

Tea powder grinding machine

ActiveCN109201283AImprove grinding efficiencyImprove grinding effectSievingScreeningEngineeringDrive motor

The invention discloses a tea powder grinding machine. The bottom of a machine case is communicated and provided with a base; a feeding groove is communicated and arranged in the top of the machine case; a material crushing device and a grinding device which are mutually communicated are arranged in the machine case from top to bottom; the crushing device and the grinding device are in coaxial arrangement and are respectively in transmission connection with a driving motor arranged in the base through a transmission shaft A; a feeding opening is formed in the bottom of the feeding groove; thefeeding opening is positioned above the material crushing device; a material containing notch used for placing a material container is arranged at the side wall of one side of the base; a dischargingopening communicated with the machine case is arranged on the top surface, positioned in the material containing notch position, of the base. Through the structure, the tea powder grinding machine hasthe advantages that the tea is fast crushed into crushed materials; then, the crushed materials are directly ground into powder; material discharging is performed; the tea grinding efficiency and grinding effect are improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

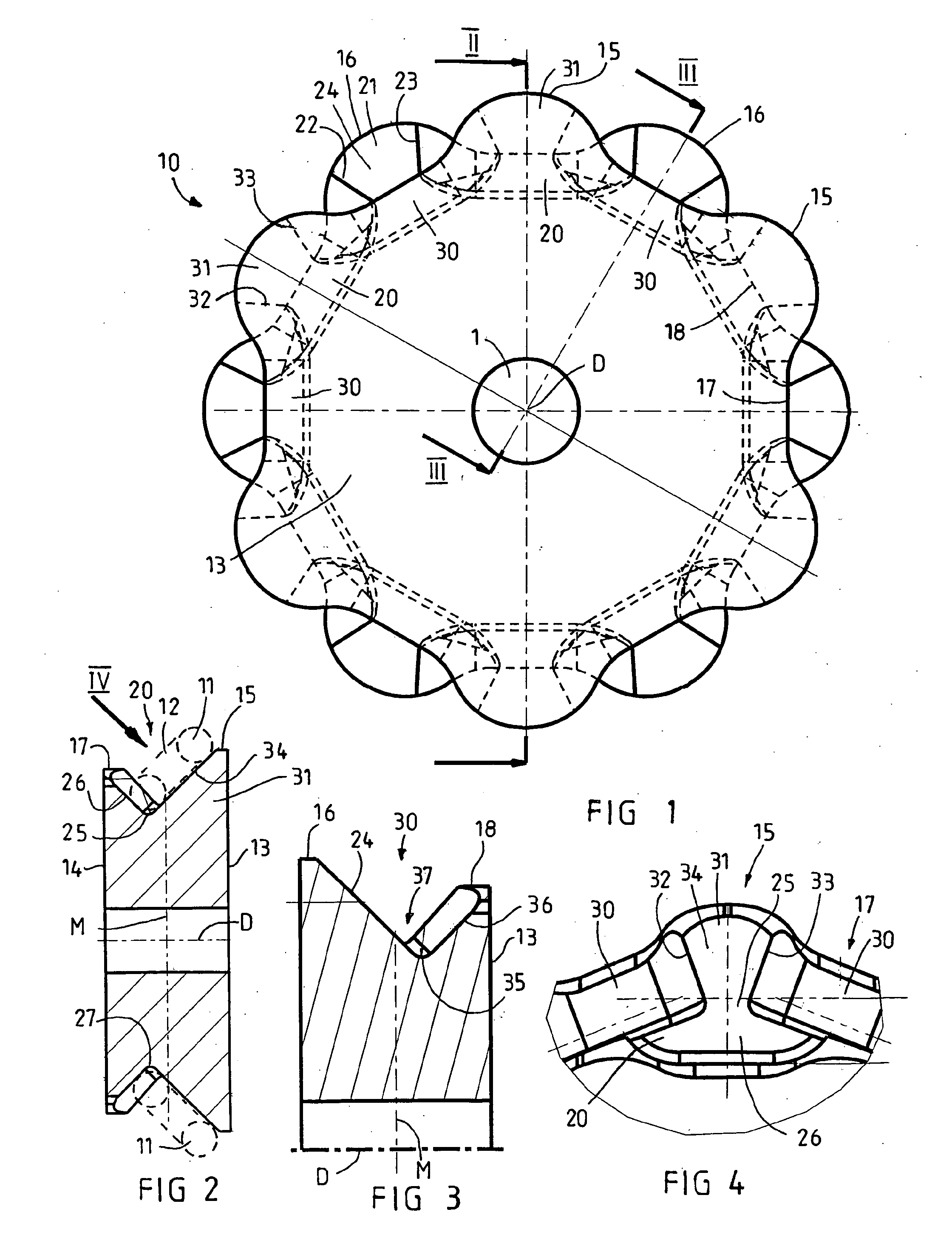

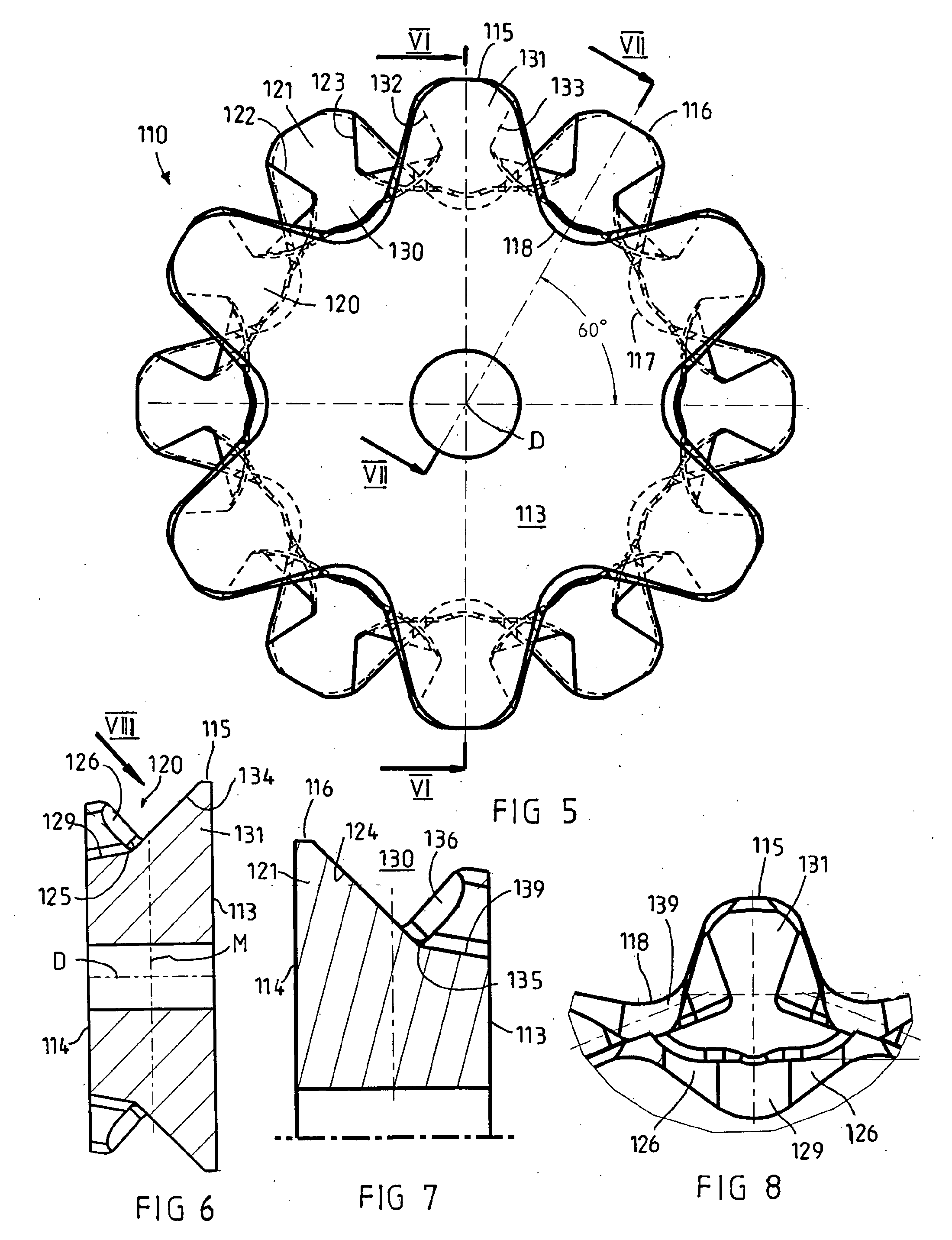

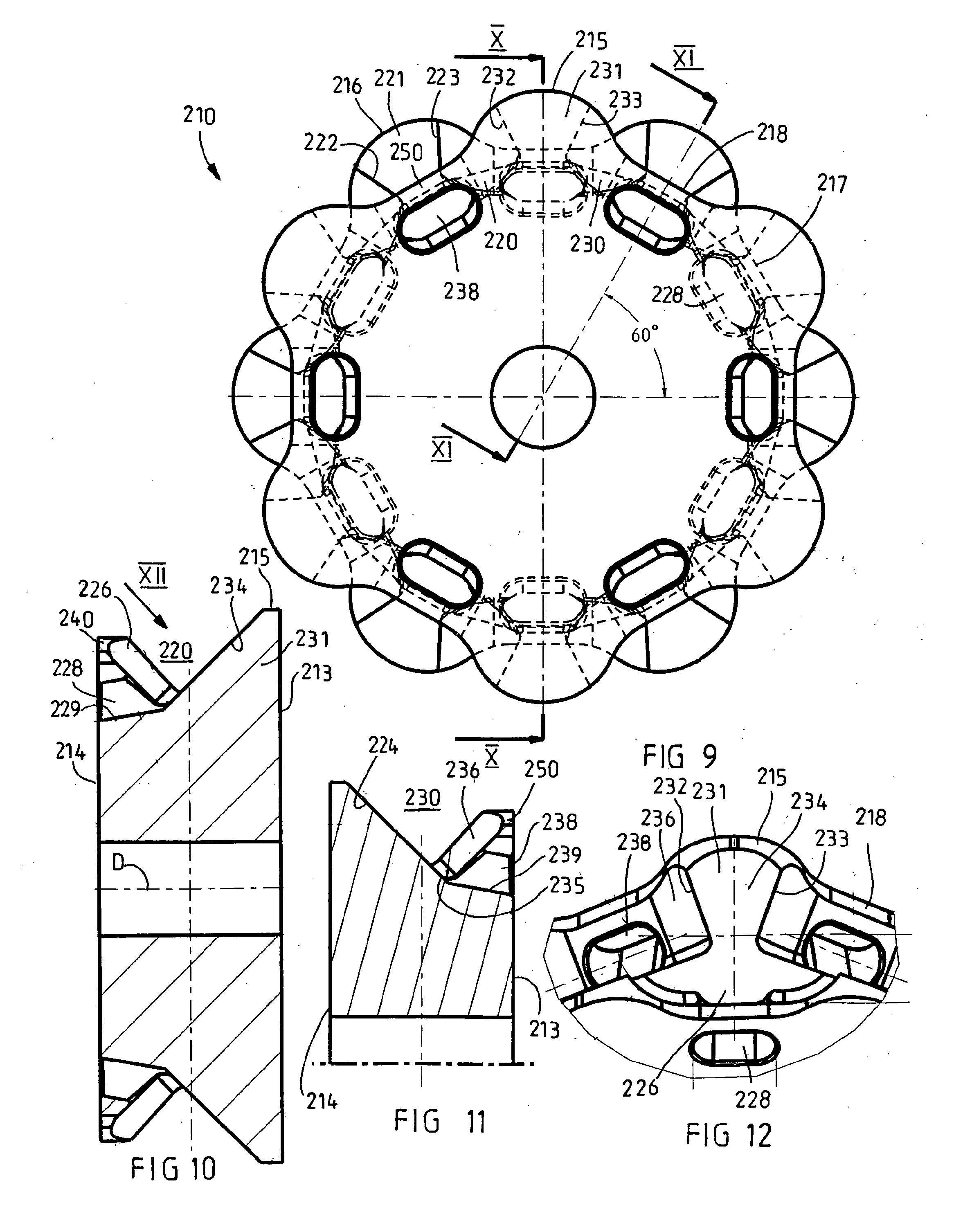

Sprocket for chain drives

The invention relates to a sprocket for chain drives, with an axis of rotation and with two groups, arranged next to and offset with respect to one another on the circumference of the sprocket, of pockets for chain links passing the sprocket in an oblique position. Each pocket is delimited laterally by a side wall and an opposite wall and, in the circumferential direction, by webs. In order that a sprocket for chain links running in obliquely can be produced more simply and to provide a better distribution of forces, according to the invention the side wall and the opposite wall of a pocket form for the chain links bearing surfaces which run obliquely with respect to the axis of rotation and which extend as far as a bottom of the pockets.

Owner:CATERPILLER GLOBAL MINING EURO GMBH

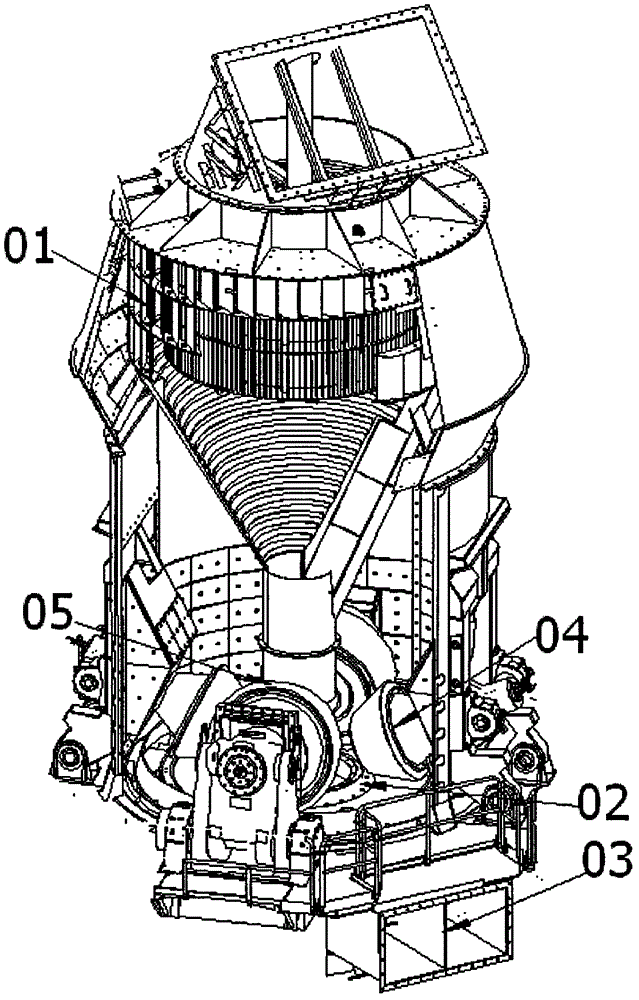

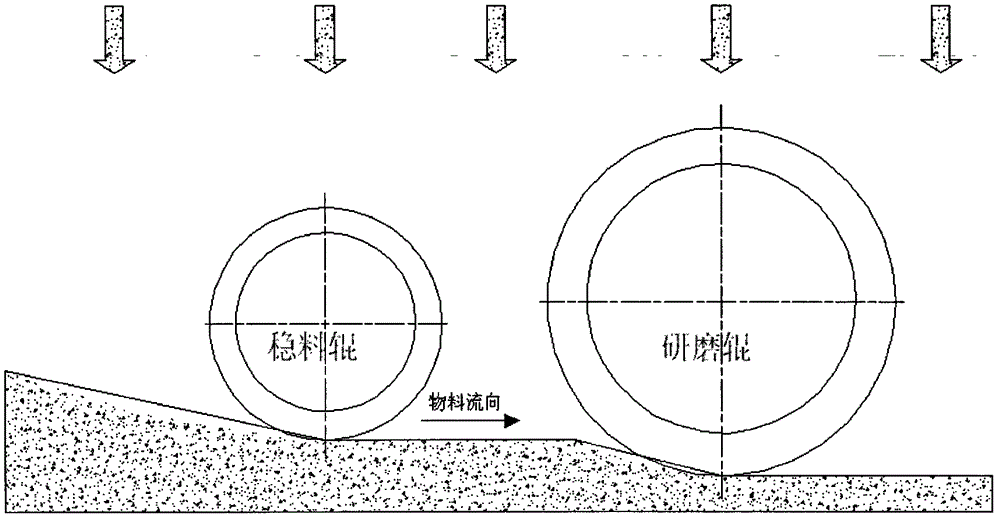

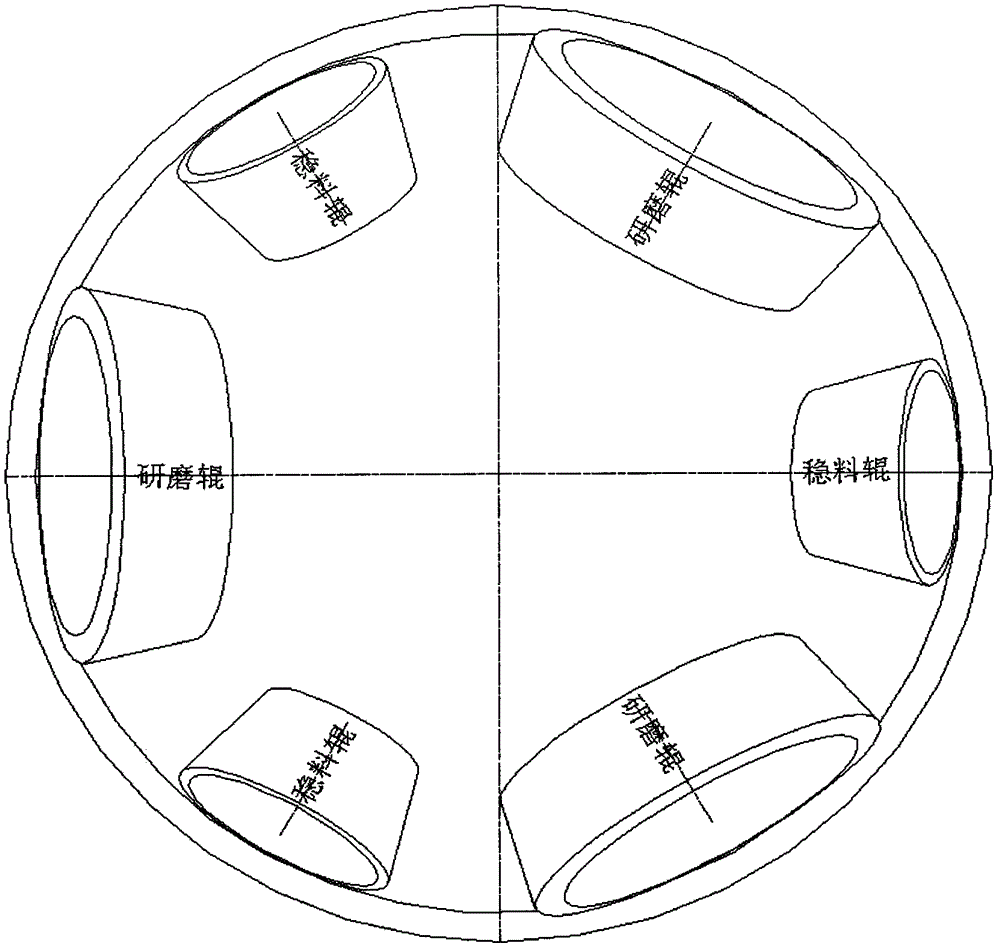

Roller grinding device capable of stabilizing material layer and improving grinding effect of fine particles

InactiveCN102794214AImprove reliabilityReduce speed differenceCement productionGrain treatmentsWedge shapeConcentrator

The invention discloses a roller grinding device capable of stabilizing a material layer and improving a grinding effect of fine particles and relates to a grinding process and a grinding device which are suitable for grinding micro powder substances, cement clinker and other particles. Materials enter a grinding disk 02 through a discharge pipe of the roller grinding device and are dried by hot air of an air chamber 03, and the ground micro powder is carried into a powder concentrator 01 and is sorted so as to obtain finished products of which the specific surface area is 450m<2> / kg; the materials are pre-compacted and distributed by material stabilizing rollers 04 with design of small-inclination angle roller surfaces to ensure that air is discharged, and a firm wedge shape is formed; grinding rollers 05 stably roll and crush the materials to ensure that the materials are thinned; the thinned materials are crushed by the grinding rollers and then staggered, and then are distributed by the material stabilization rollers again so as to form a wedge shape; the materials are distributed and ground by the material stabilizing rollers and the grinding rollers alternately to ensure that the materials can achieve the required fineness; and due to the design of the small-inclination angle roller surfaces, the key function of stabilizing the material layer is exerted, the sliding and blockage effects and vibration can be prevented by the roller arranging scheme with refined functions, the function of the device is enhanced, the vibration in a running process is reduced, the powder fineness can be controlled reliably, and the grinding efficiency can be improved simultaneously.

Owner:成都建筑材料工业设计研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com