Orientation coalescence liquid-liquid separator

A technology of liquid separator and liquid accumulation, applied in the field of orientation and accumulation liquid-liquid separator, can solve the problems of blocking the outlet of the equipment, affecting the separation efficiency, and weak impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

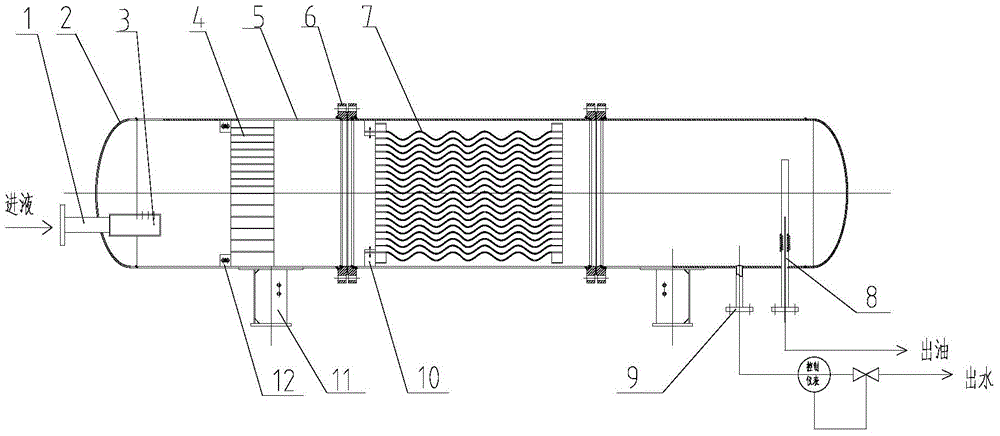

[0036] When two types of liquid mixtures with different specific gravity mixed with each other are separated by an orientation-merging liquid separator, the numerical simulation of the flow of the liquid mixture in the liquid channel and the volume ratio in the liquid mixture is carried out.

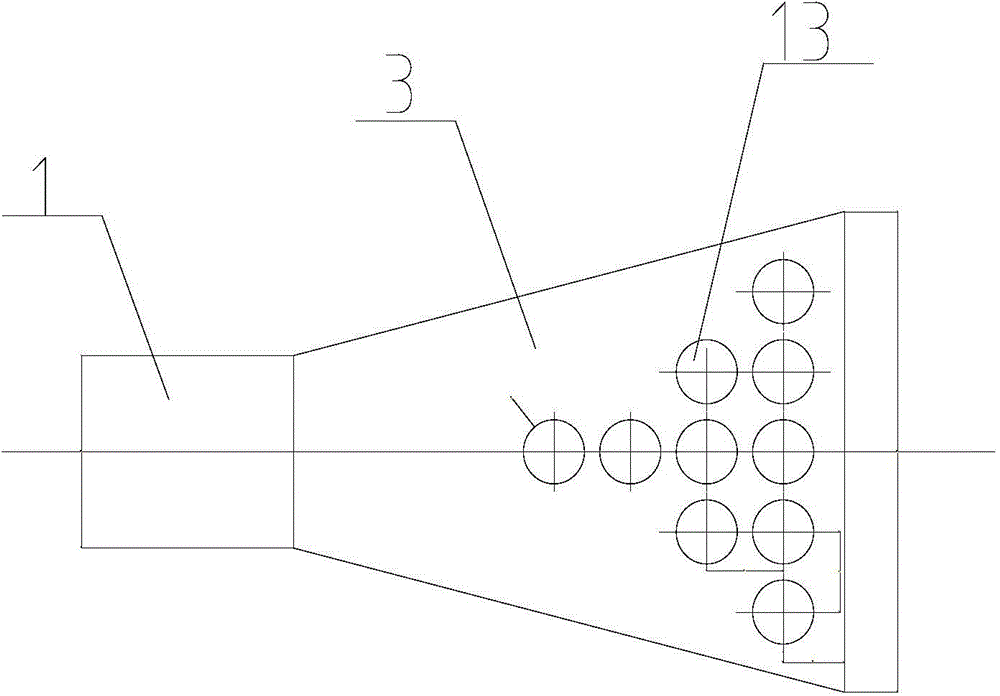

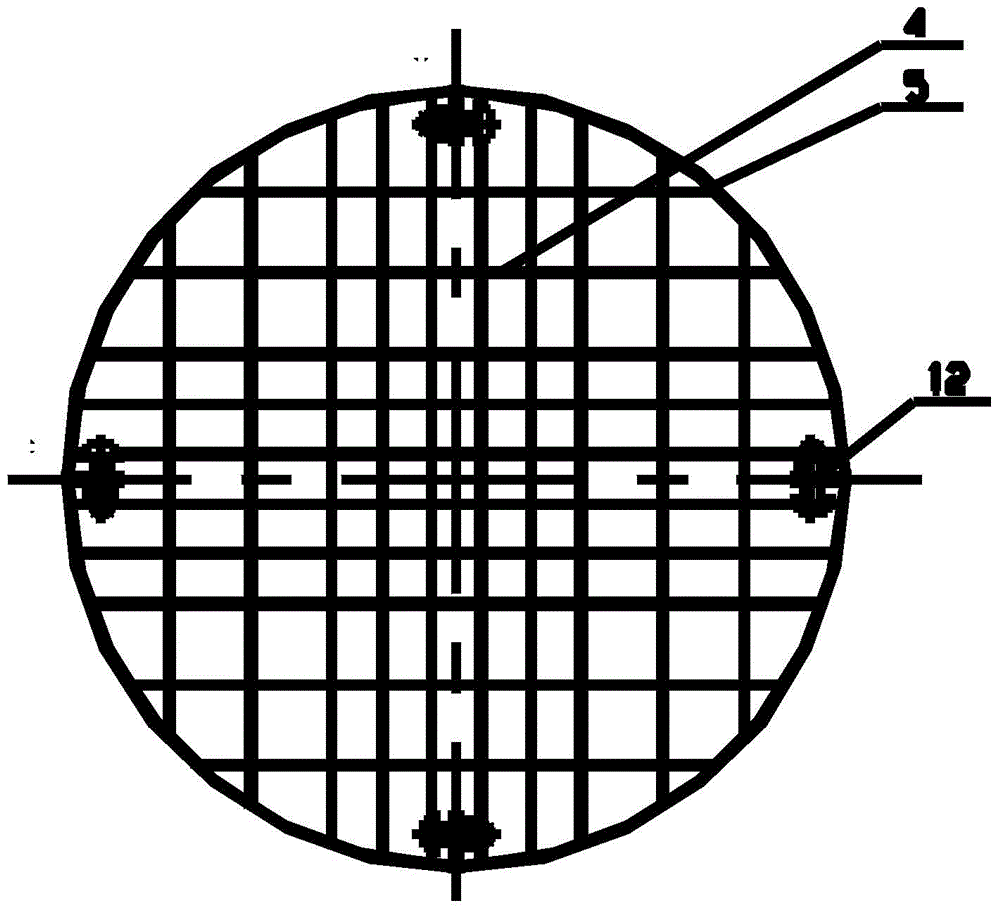

[0037] right figure 1 Numerical simulations were carried out on the orientation and liquid-condensing liquid separator (example) of the present invention with trapezoidal inlet orifice box 3, rectifying plate group 4, and coalescing plate group 7 structures and the liquid-liquid separator without the above structure (comparative example).

[0038] Calculated according to ANSYS Workbenck 14.5, the calculation conditions are as follows:

[0039] (1) Liquid mixture

[0040] Liquid mixture: a liquid mixture comprising white oil (density 870kg / m3 and dynamic viscosity 0.15Pa·s) and water (density 980kg / m3 and dynamic viscosity 0.04Pa·s).

[0041]The inlet condition is set as the velocity bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com