Patents

Literature

40results about How to "Achieve pre-separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

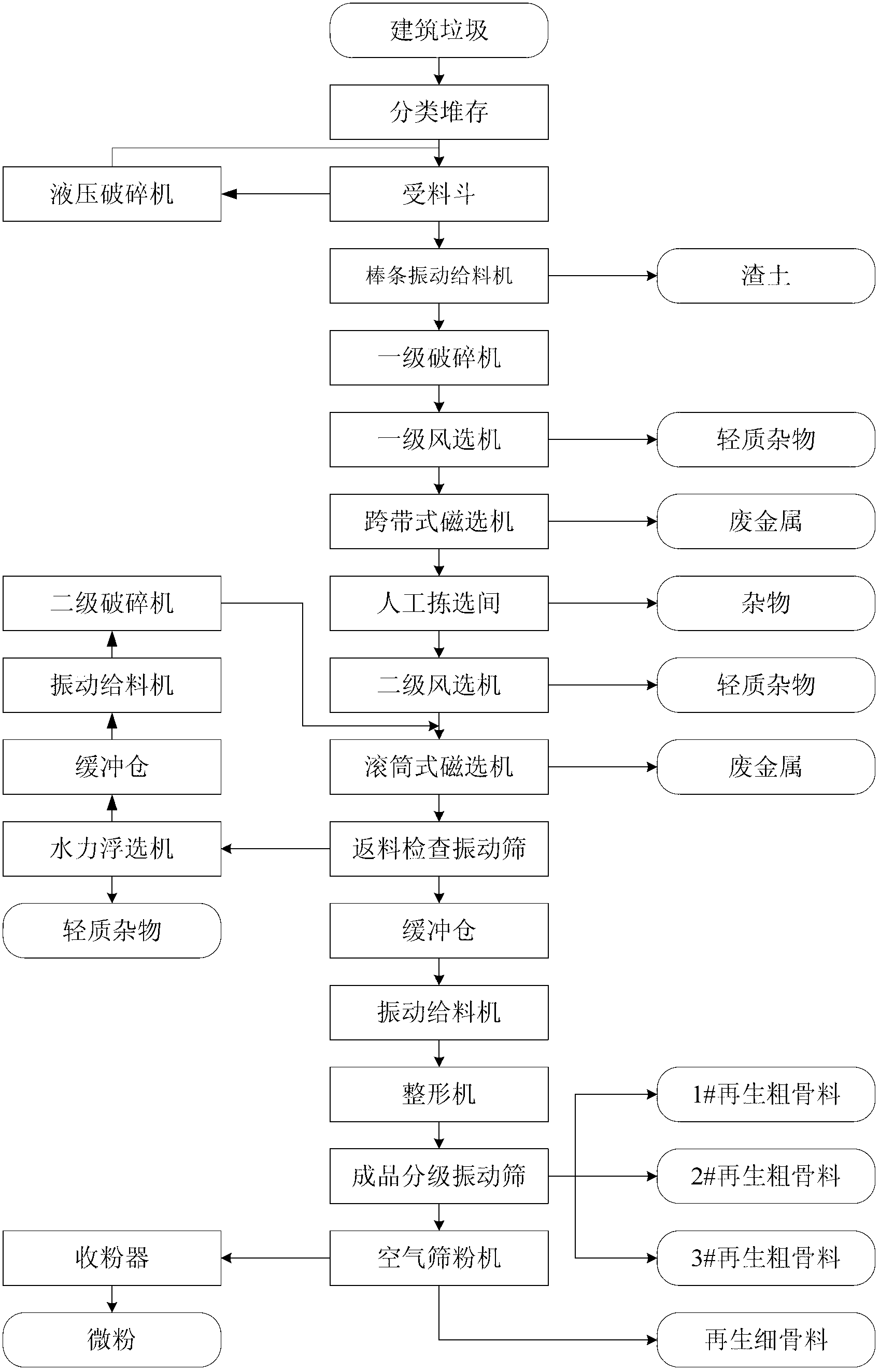

Method and system for treating construction waste

InactiveCN102838307AAchieve pre-separationReduce micronized contentSolid waste managementEngineeringNational standard

The invention discloses a method for treating construction waste, comprising the following steps of: performing feeding and dregs pre-screening, primary crushing, secondary crushing and product screening on a material in sequence; performing sorting and impurity removing treatment on the material subjected to the primary crushing; performing material returning screening on the material subjected to the sorting and impurity removing treatment, performing particle shaping on the material screened down after the material returning screening treatment, and returning the oversize material to the secondary crushing; and combining the material subjected to the secondary crushing with the material in the sorting and impurity removing treatment. The system and method treating construction waste, provided by the invention, have high-efficiency and systemic sorting and impurity-removing functions; the generated construction waste recycled aggregate product meets the requirements of national standard 'recycled coarse aggregate for concrete'(GB / T 25177-2010), 'recycled fine aggregate for concrete and mortar' (GB / T 25176-2010) and other recycled aggregate product raw materials.

Owner:SHOUGANG CORPORATION

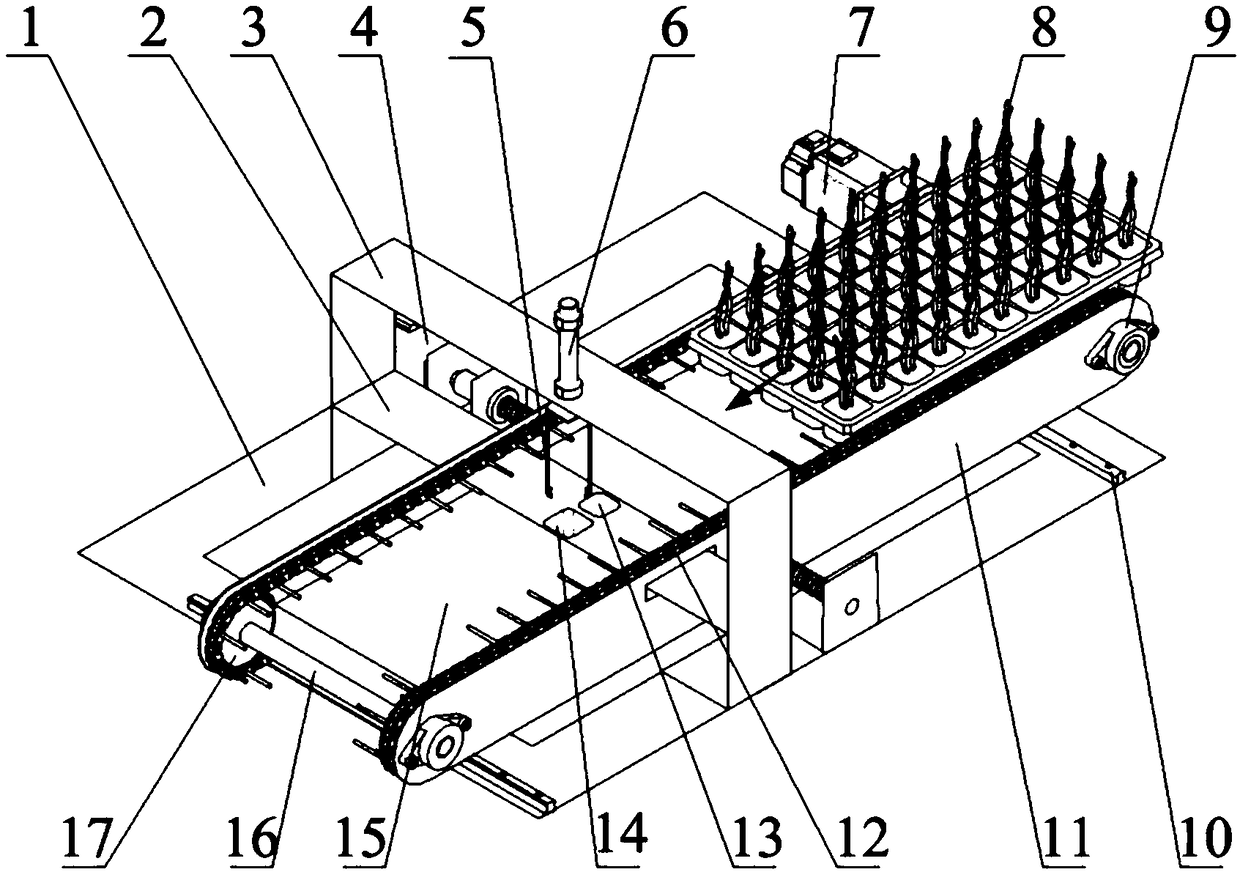

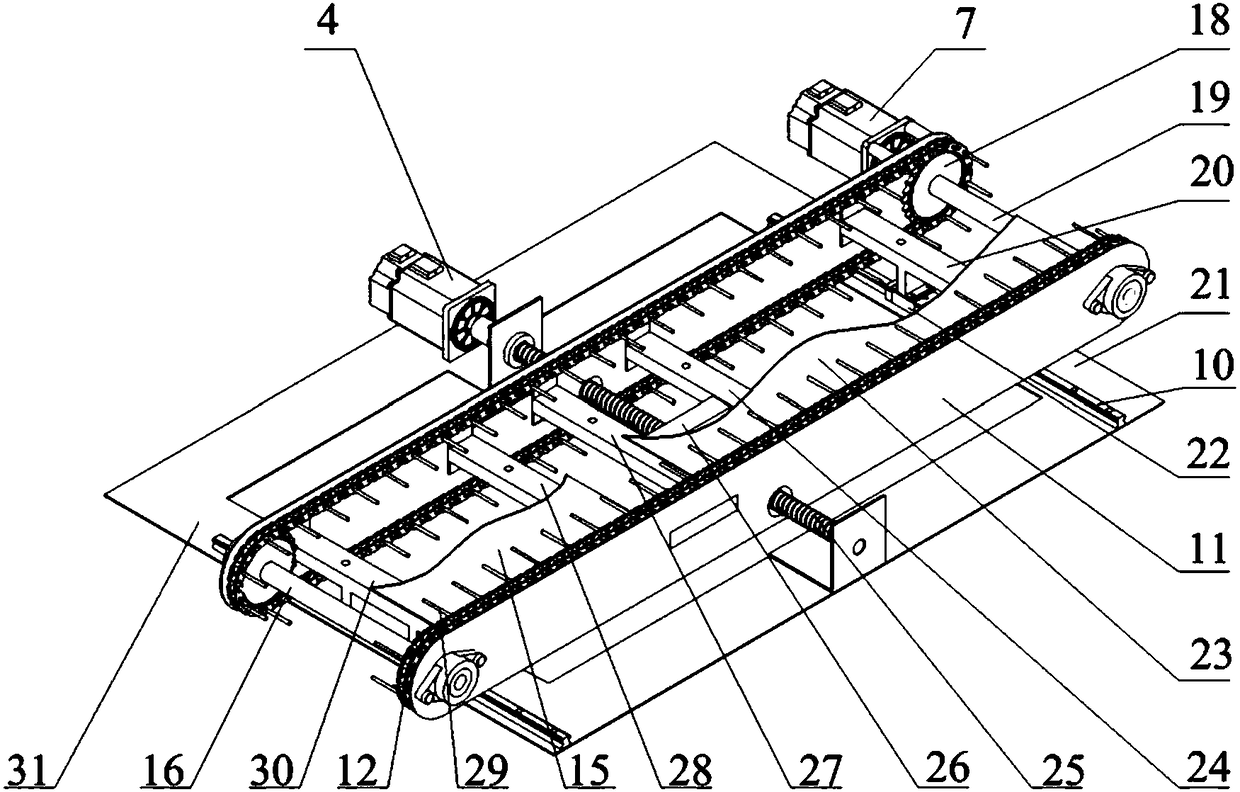

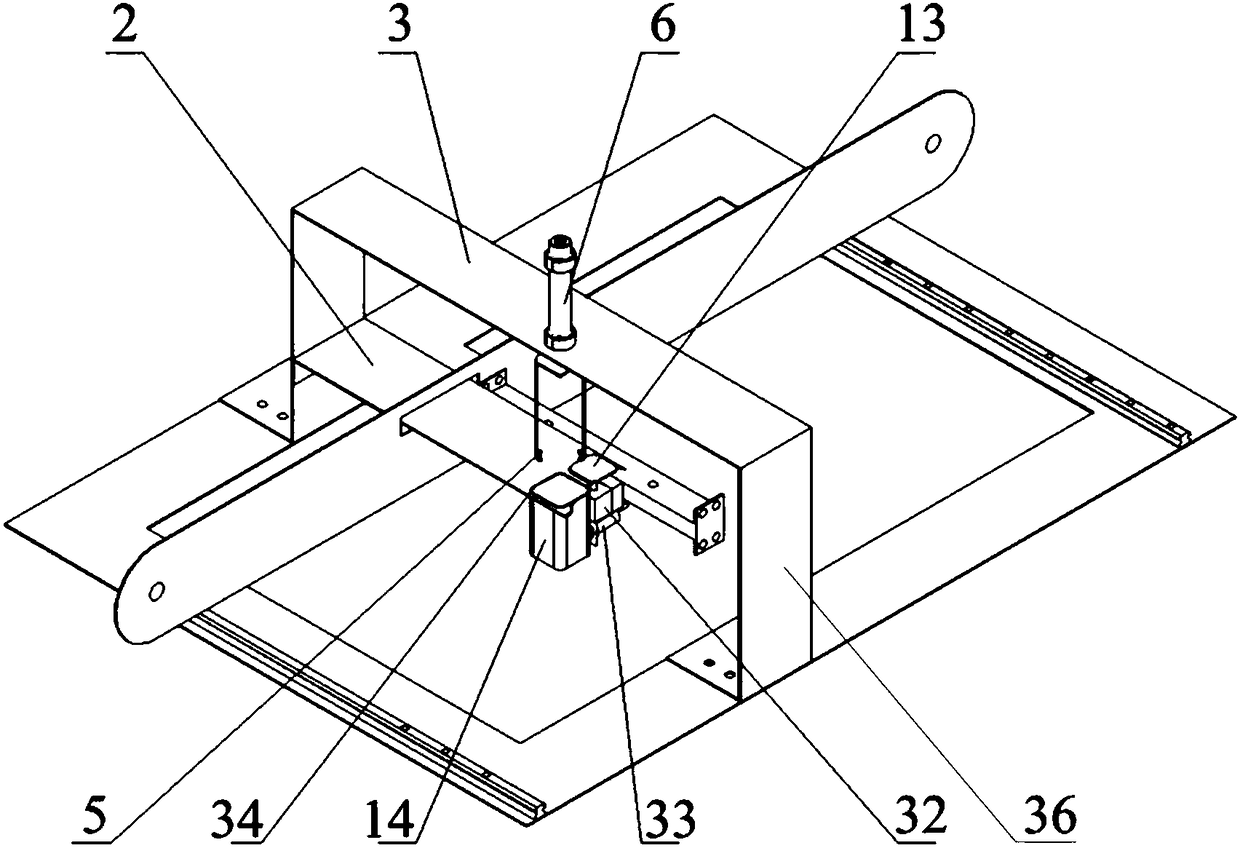

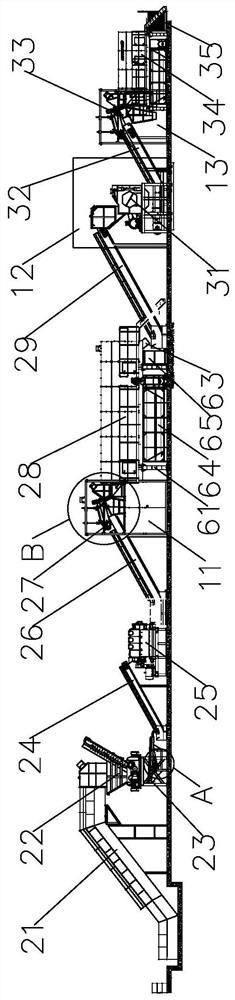

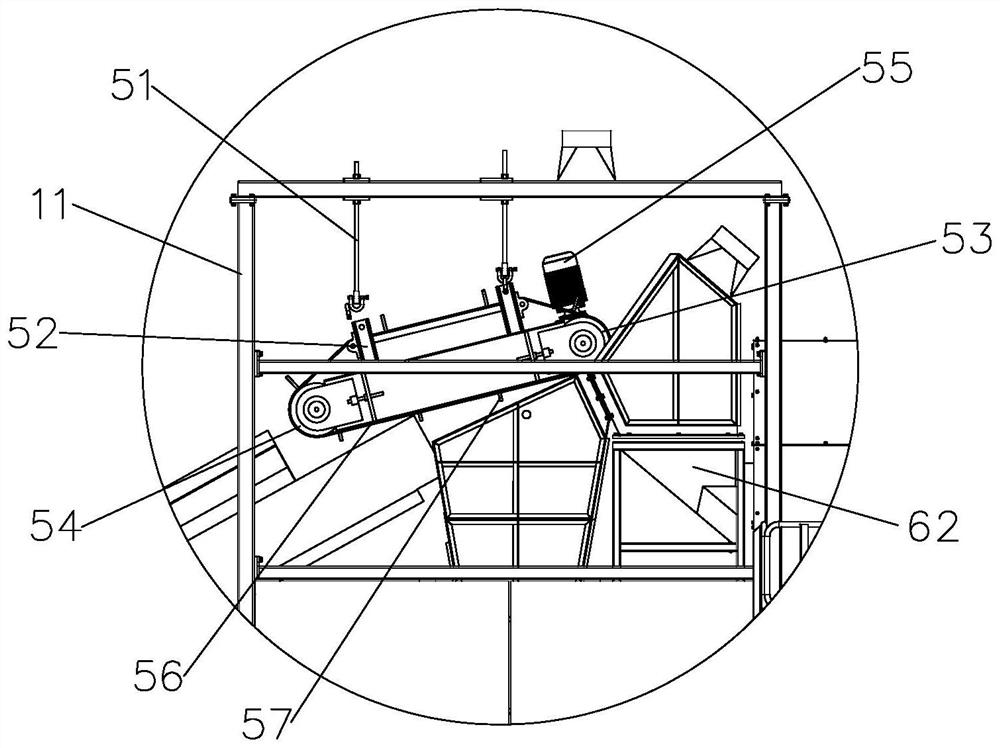

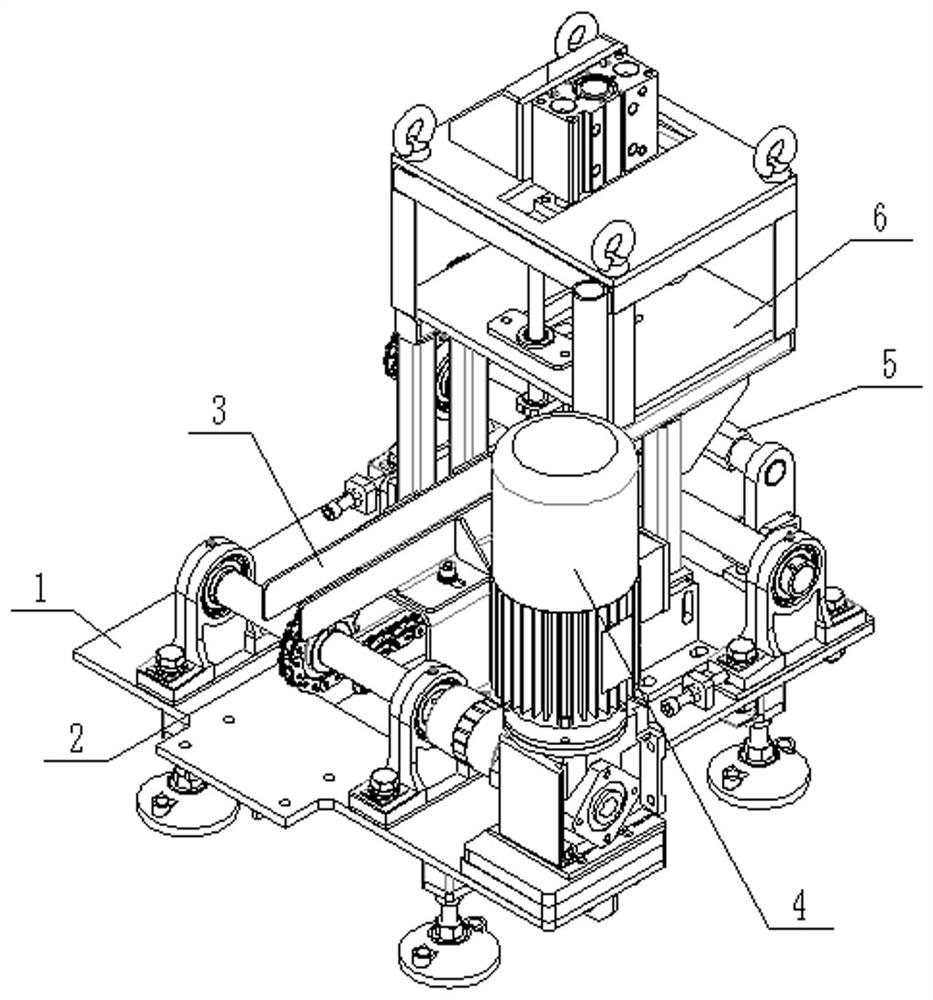

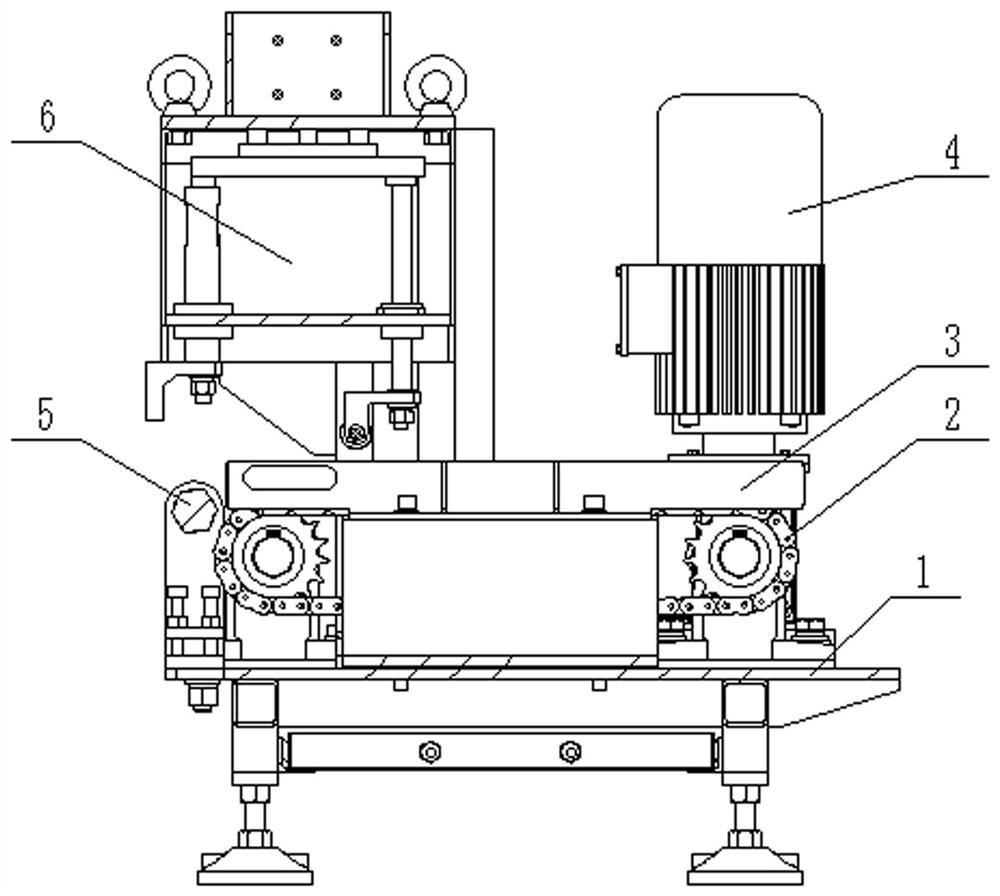

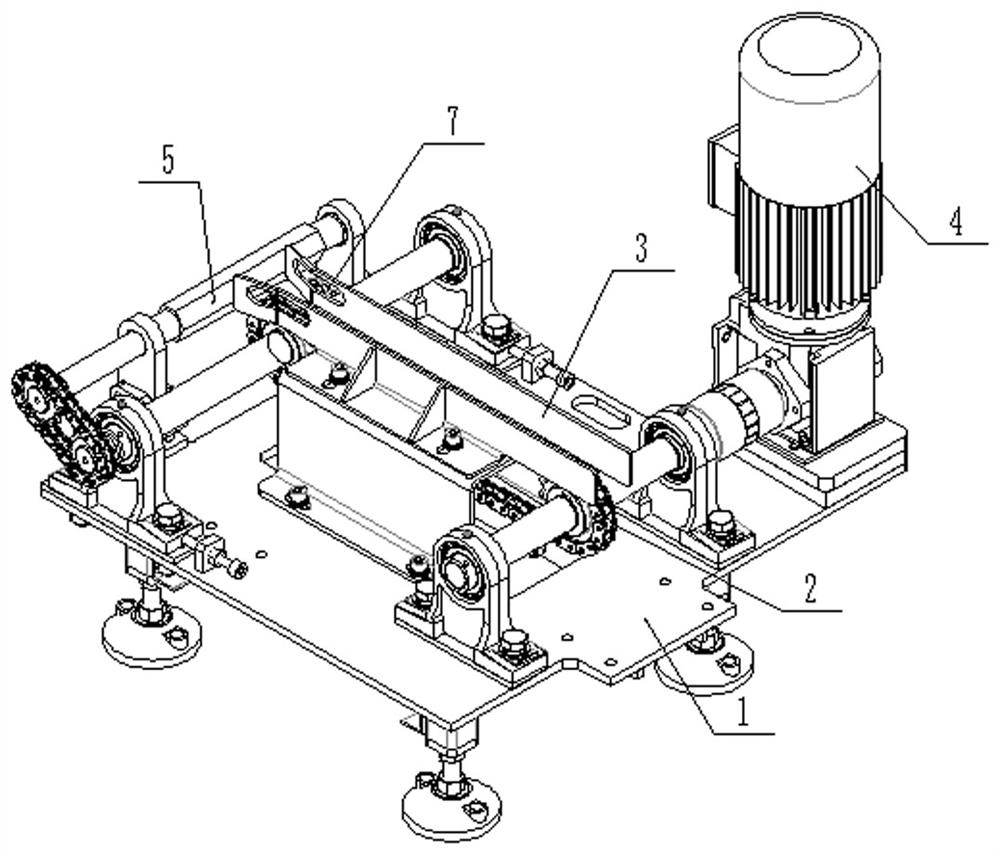

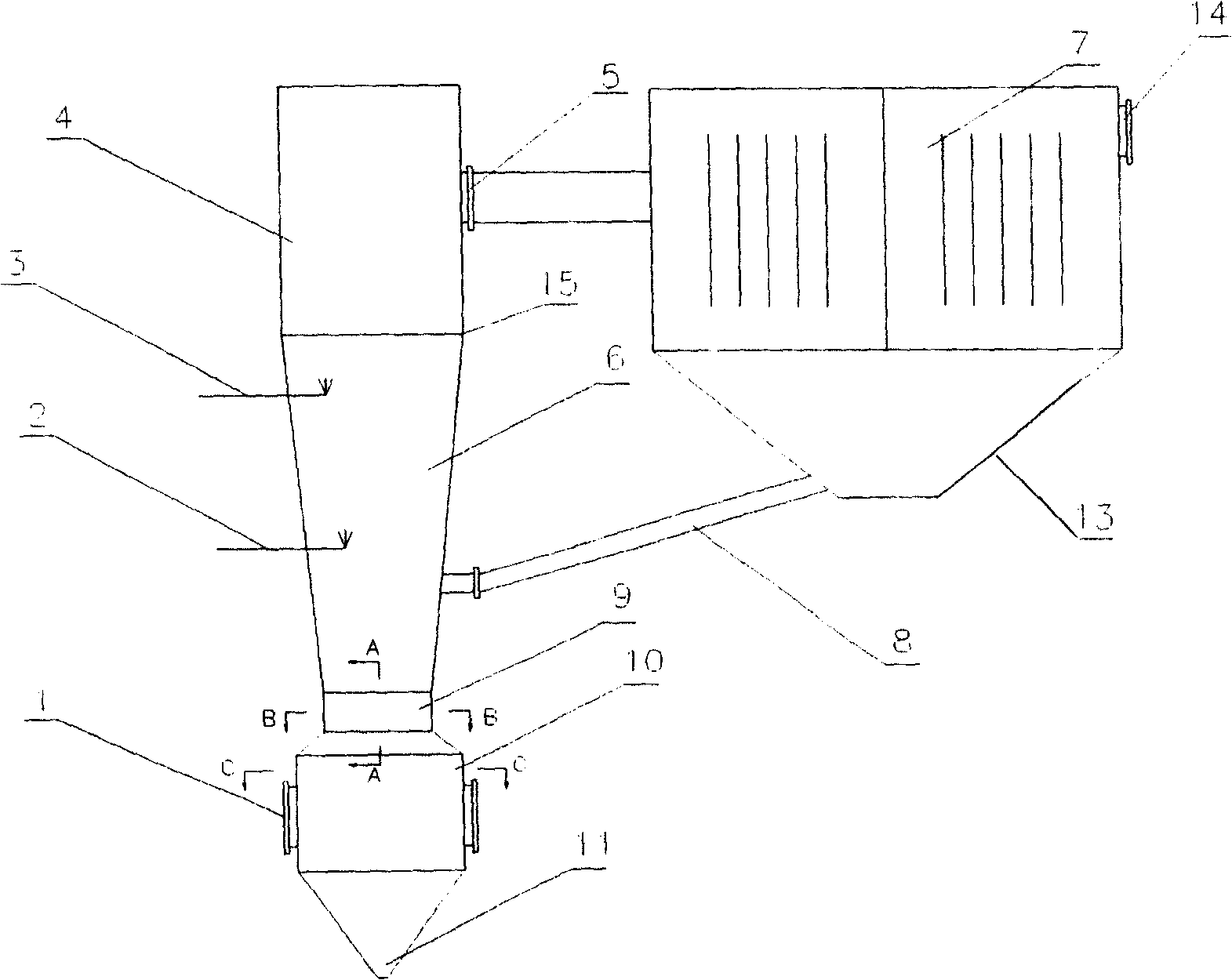

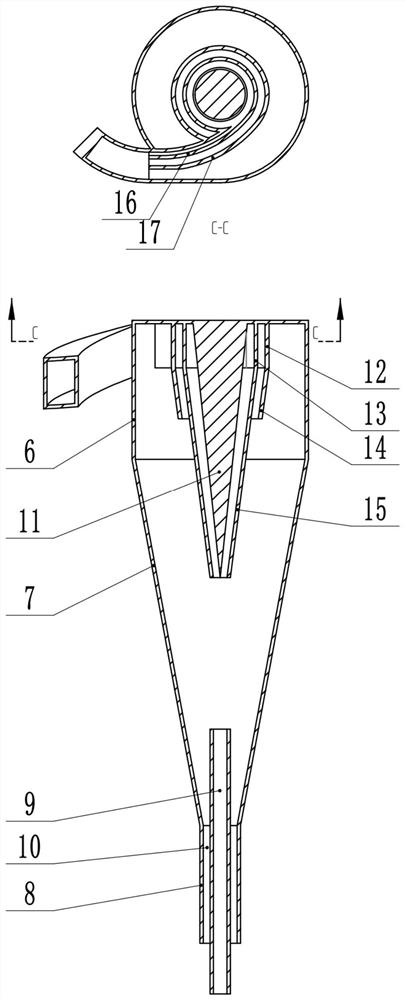

Seedling sending, taking and delivering device for pressing type seedling taking full-automatic seed tray seedling transplanter

InactiveCN108391491AEasy to get seedlingsImprove seedling efficiencyTransplantingEngineeringSeedling

The invention belongs to the technical field of agricultural mechanized transplantation, and particularly relates to a seedling sending, taking and delivering device for a pressing type seedling taking full-automatic seed tray seedling transplanter. The device comprises a rack, a seedling sending mechanism and a seedling taking and delivering mechanism; the seedling sending mechanism comprises a lead screw driving motor, a chain driving motor, a sliding rail, a side plate, a chain, a front bottom plate, a driven shaft, a driving shaft, a rear sliding rail support, a sliding rail sliding block,a rear bottom plate, a first connecting beam, a ball lead screw, a lead screw sliding block, a second connecting beam, a third connecting beam and a front sliding rail support; the seedling taking and delivering mechanism comprises a seedling taking plate, a cylinder mounting plate, a seedling pressing rod, a seedling pressing cylinder and a seedling guide tube. Accordingly, pot seedlings are taken out from the lower portion of a seedling tray, seedling delivering is conducted directly, and the seedling taking process and the seedling delivering process are combined into a whole, and the efficiency is higher.

Owner:CHINA AGRI UNIV

Method for recycling ditrimethylolpropane

ActiveCN101967085AAchieve pre-separationLower requirementEther separation/purificationPlatinumPhysical chemistry

The invention relates to a method for recycling ditrimethylolpropane, which is characterized by comprising the steps of: transferring heavy constituents at the bottom of a rectifying kettle in a refining procedure of trimethylolpropane, then filtering when hot in necessity, removing impurities with high crystallization point, transferring to a dynamic melt crystallizer, carrying out separation of crystallization, sweating and melting at a programmed temperature to ensure that other main impurities of the ditrimethylolpropane and the heavy constituents are separated; and carrying out refining of crystallization, sweating and melting on the collected rough ditrimethylolpropane at a programmed temperature to obtain a ditrimethylolpropane product with content of higher than 95 percent, which accords with the general requirements of industrial products. If higher requirements on platinum-cobalt chroma of not more than 15APHA are required in the color number of the products, the color is removed by combining the melt crystallization method with steps of absorbing and filtering, and the like. The method for recycling the ditrimethylolpropane has the advantages of simple operation, low cost, no need of high vacuum rectification, and low operation temperature.

Owner:JIANGSU BAICHUAN GAOKE NEW MATERIAL CO LTD +1

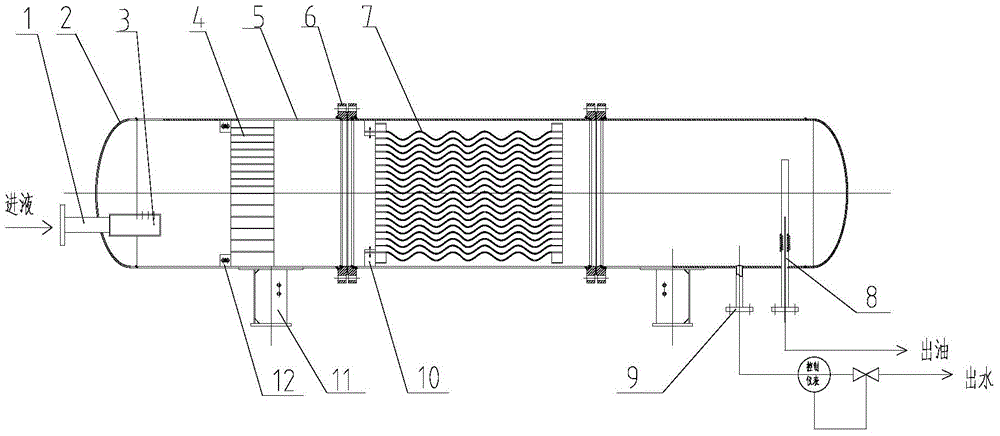

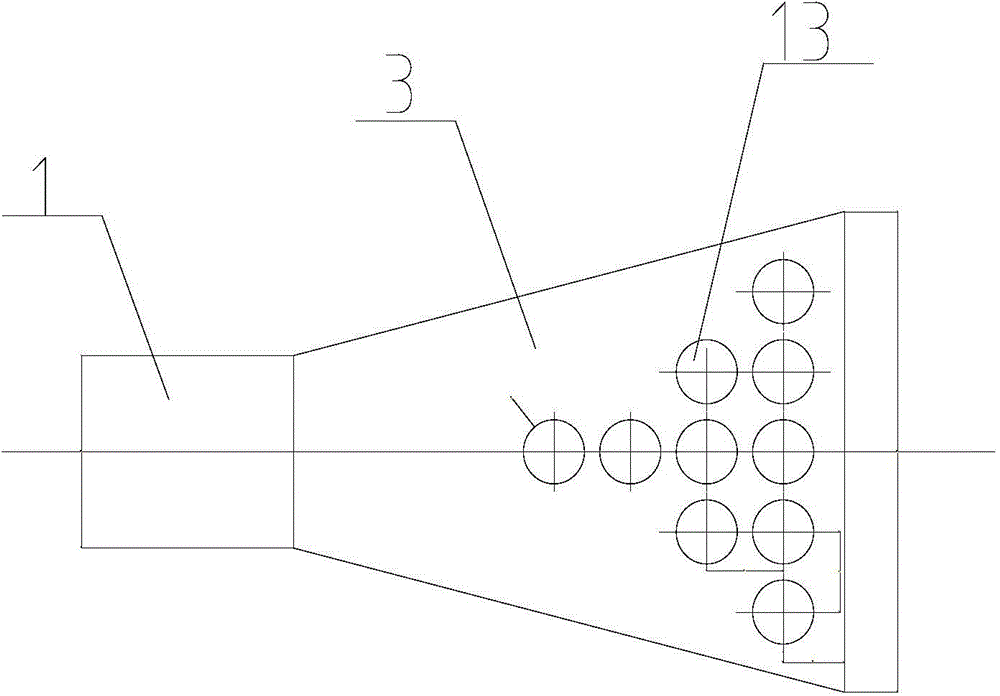

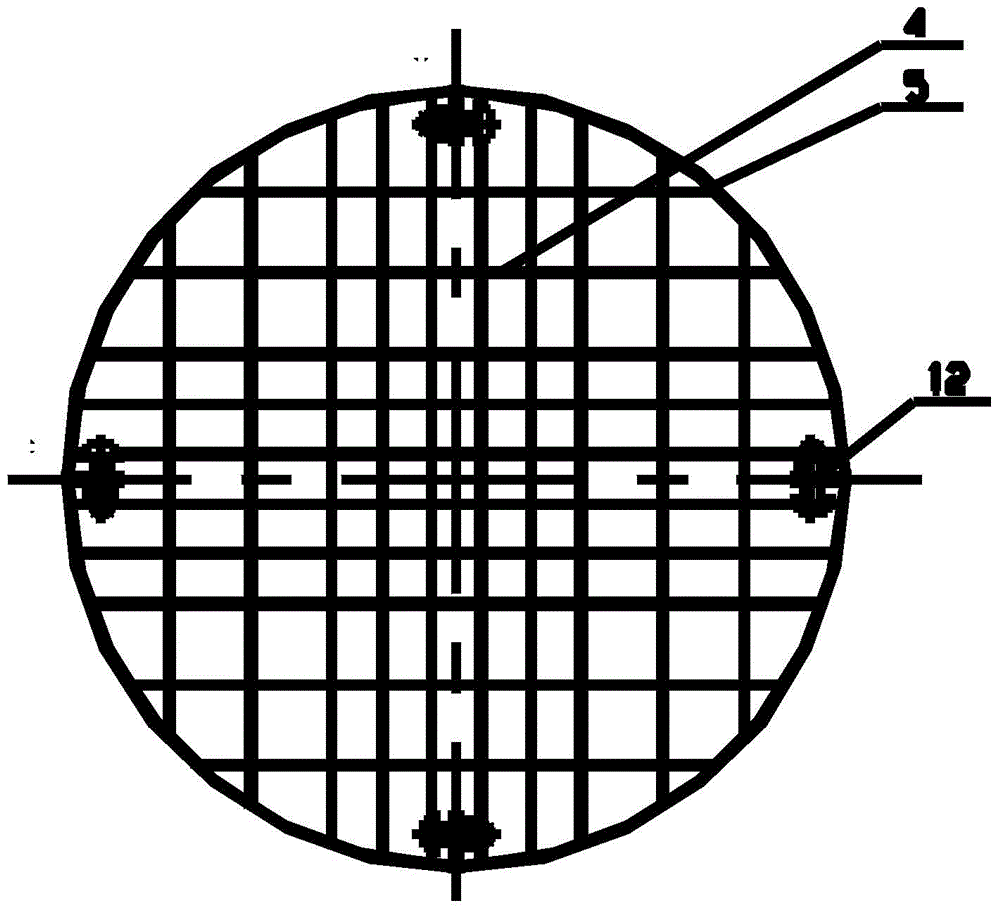

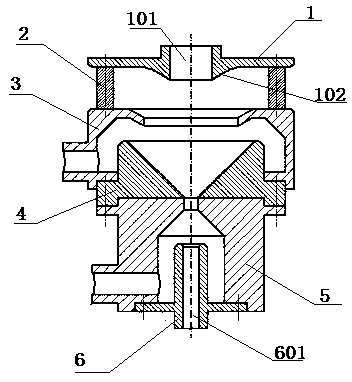

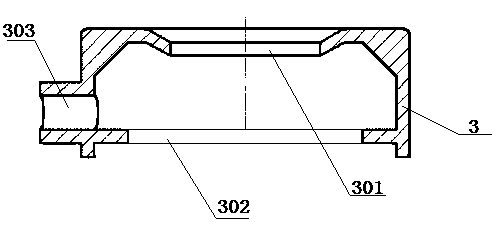

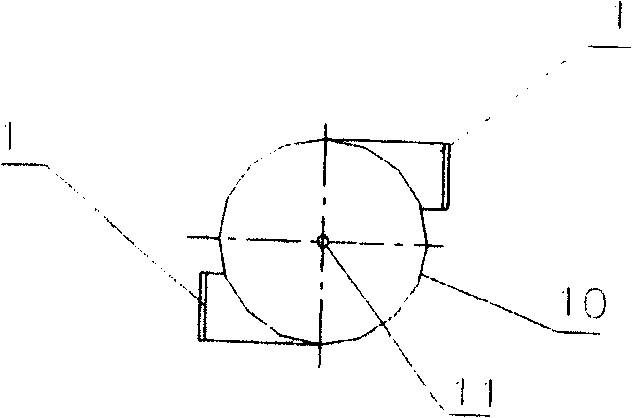

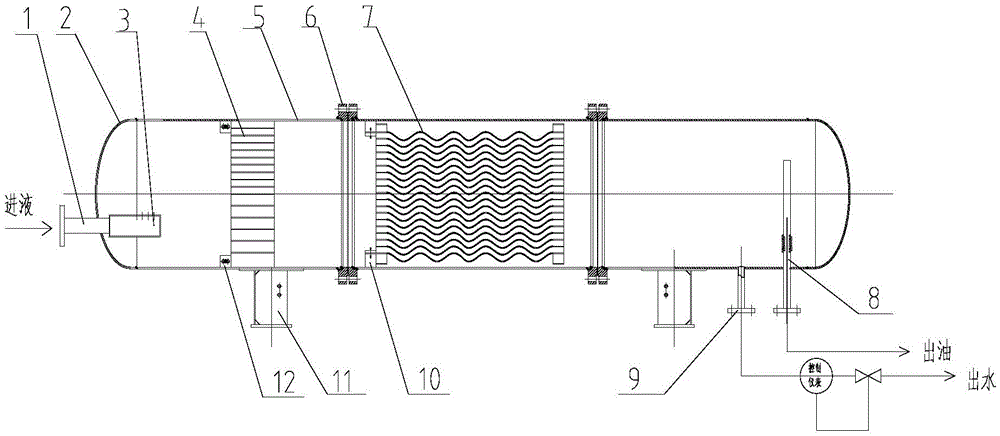

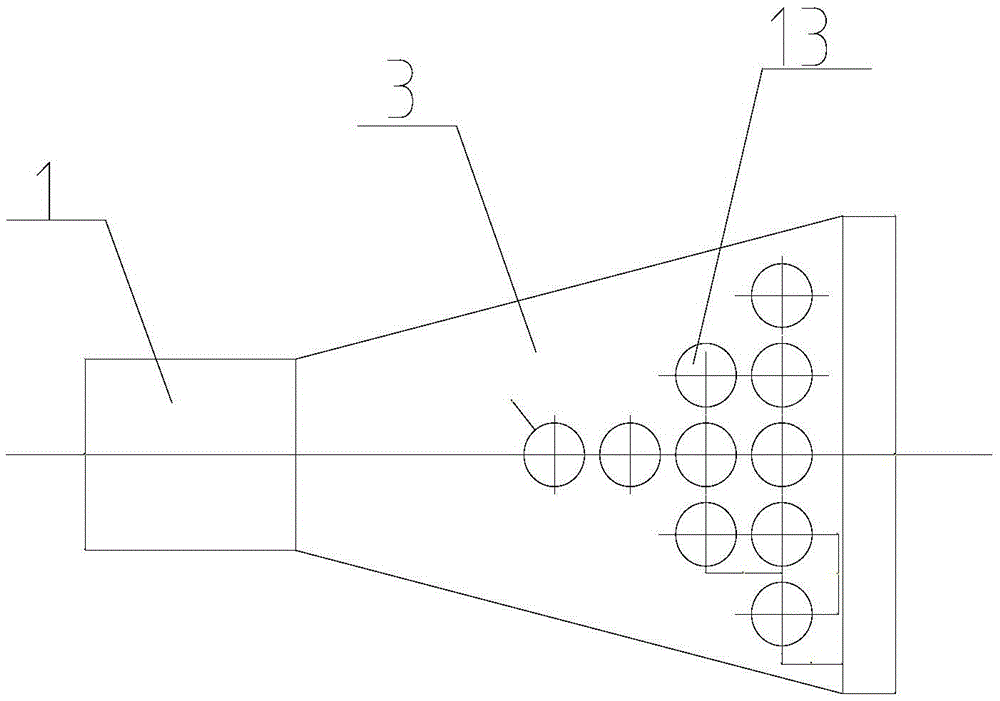

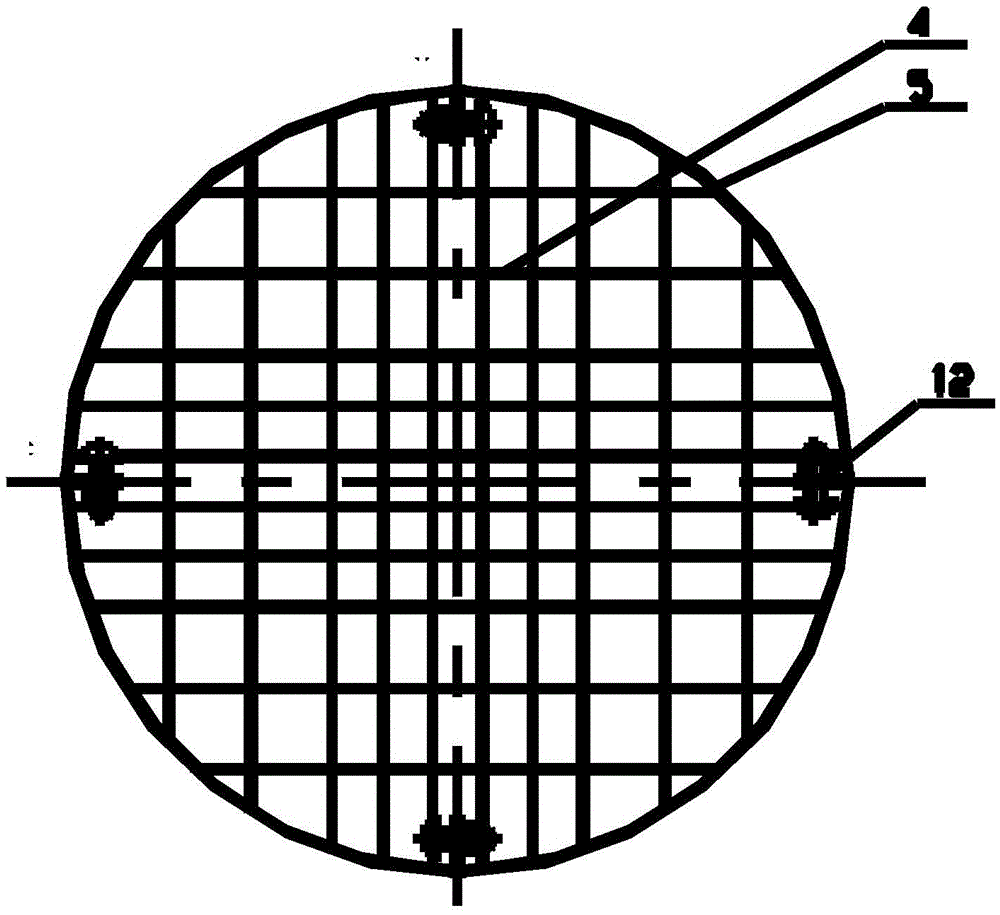

Orientation coalescence liquid-liquid separator

ActiveCN104474741AReduce shockImprove washing effectFatty/oily/floating substances removal devicesNon-miscible liquid separationHarmonicHorizontal axis

The invention discloses an orientation coalescence liquid-liquid separator which comprises a cylinder (5), a trapezoidal inlet hole box (3), a rectification plate group (4) and a coalescence plate group (7). The orientation coalescence liquid-liquid separator is characterized in that the coalescence plate group (7) is corrugated plate packing; a corrugated plate is fixedly supported by a pull rod distance tube (14) and a hoop (15); the corrugated plate is arranged in an angle of 45 degrees with the horizontal axis. Compared with a conventional pore box, the trapezoidal inlet hole box is somehow improved, so that the impact of flow to a separation field of the equipment is reduced, at the same time relatively good functions of gravity energy dissipation and washing are achieved, and pre-separation can be effectively achieved. A periodic harmonic wave is adopted as the waveform curve of the coalescence plate group, so that the fluid flowing state can be switched between laminar flow and periodic harmonic wave pulsating flow, and collision and agglomeration of droplets are facilitated; due to adoption of the multi-layer inclined corrugated type composite coalescence plate, the oil droplet removal efficiency is improved.

Owner:TIANJIN UNIV

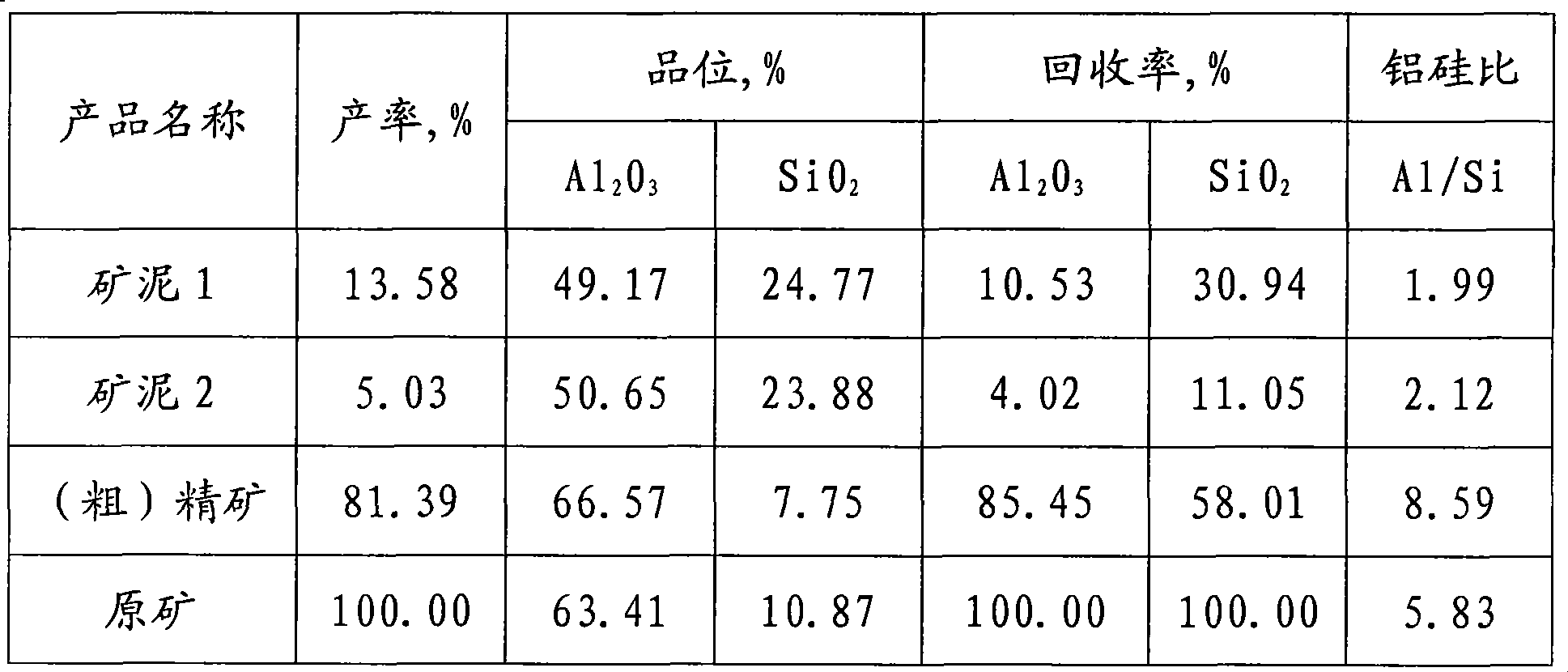

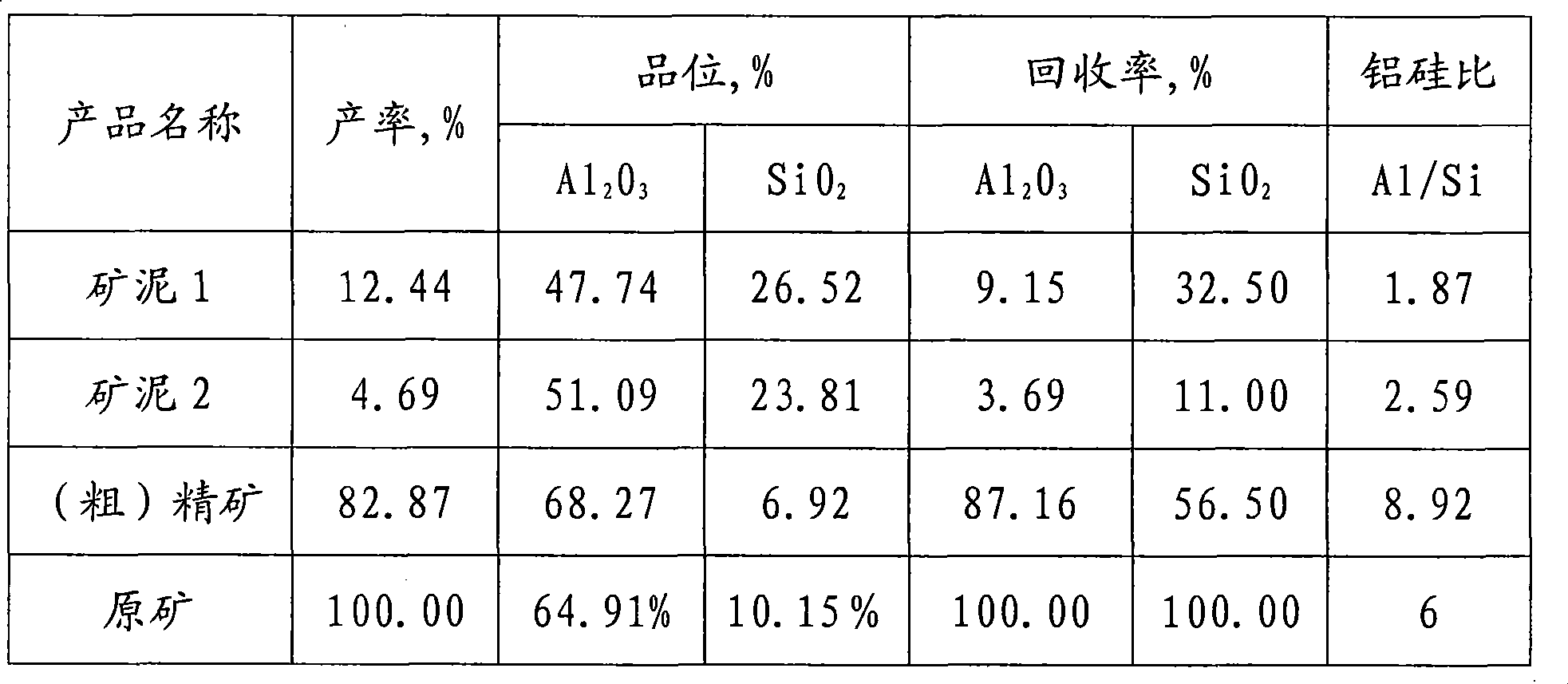

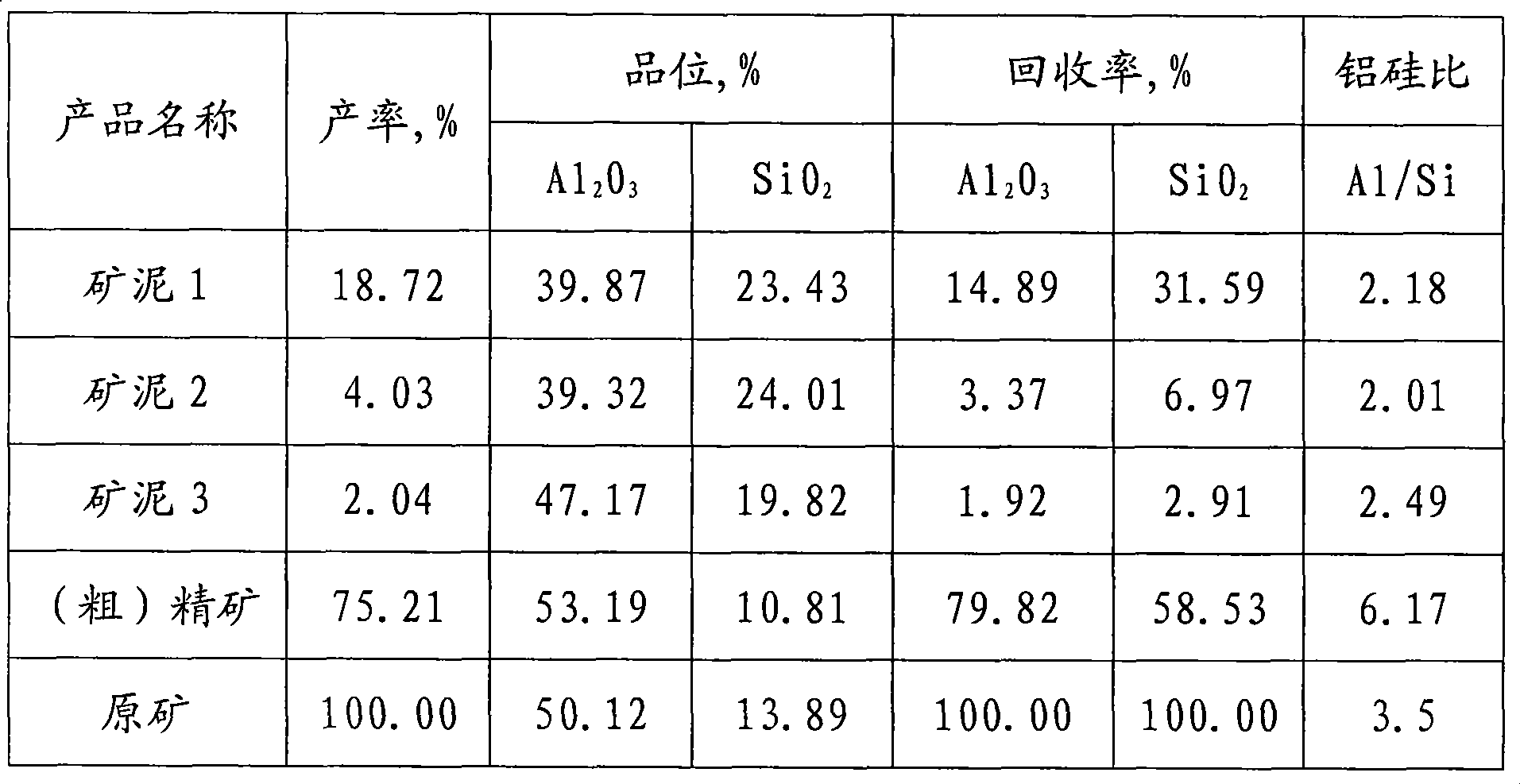

Pre-desiliconisation method for ore concentration of bauxite

InactiveCN101439317APre-desilication achievedImprove separation efficiencyDifferential sedimentationLower gradeLow graded

The invention discloses a method of ore dressing and pre-desilication of alumyte, comprising the following steps: a. the alumyte is treated by milling grinding, and is added with dispersant in the process of milling grinding; b. flocculating agent is added into the ground product of the alumyte obtained in the step a, and then the mixture is settled; c. the dispersant is added into the settlement product obtained in the step b, and settlement product (coarse) concentrated ore is obtained by stirring, scouring and settling separation. The process flow of the method is simple, can improve the separating efficiency of aluminium silicon, and can effectively realize the pre-desilication of alumyte; the obtained products can be directly taken as the raw material of alumina technique, or as the raw material of the next stage of ore dressing and desilication technique, so that the utilization rate of low-grade alumyte resources can be further improved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

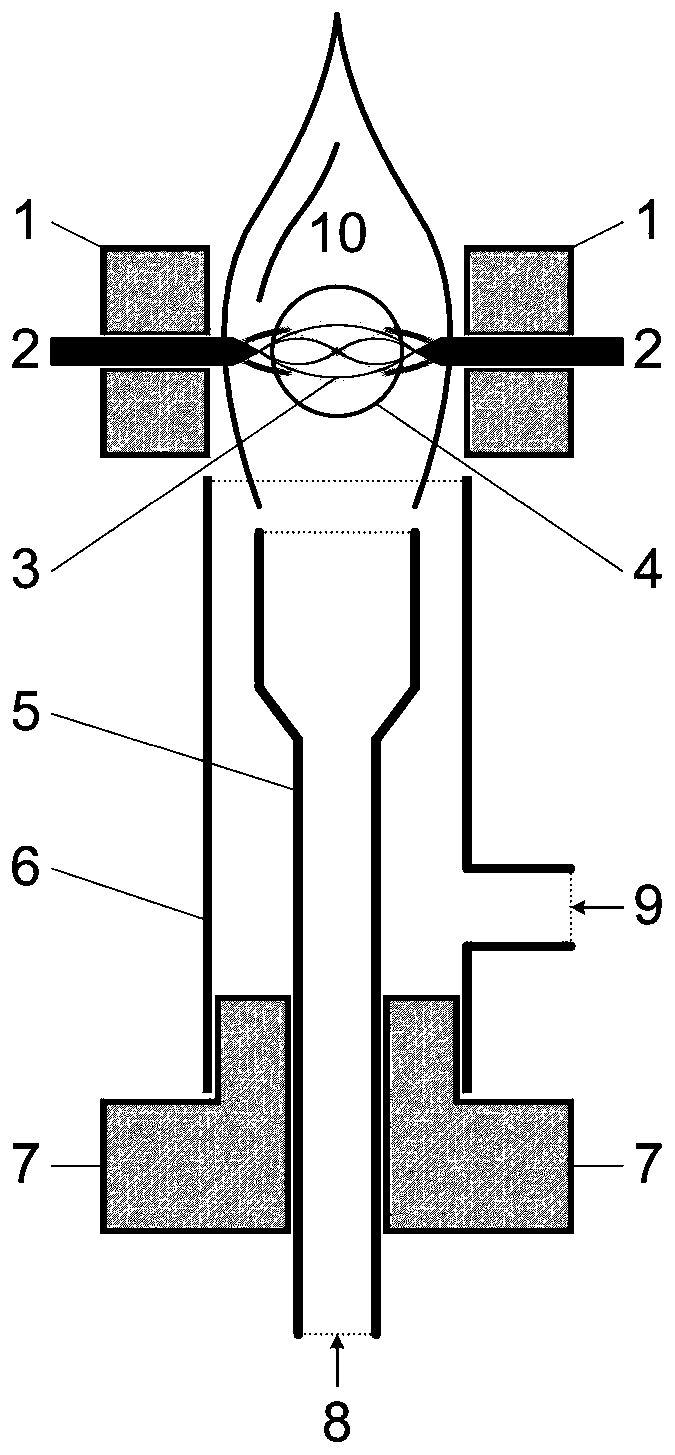

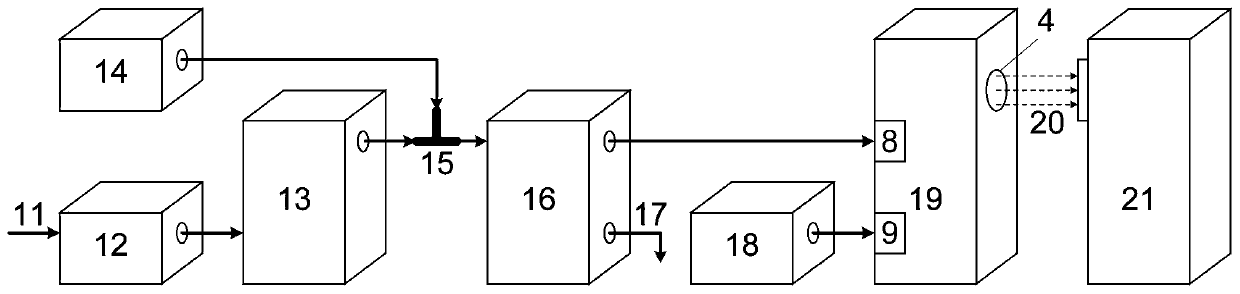

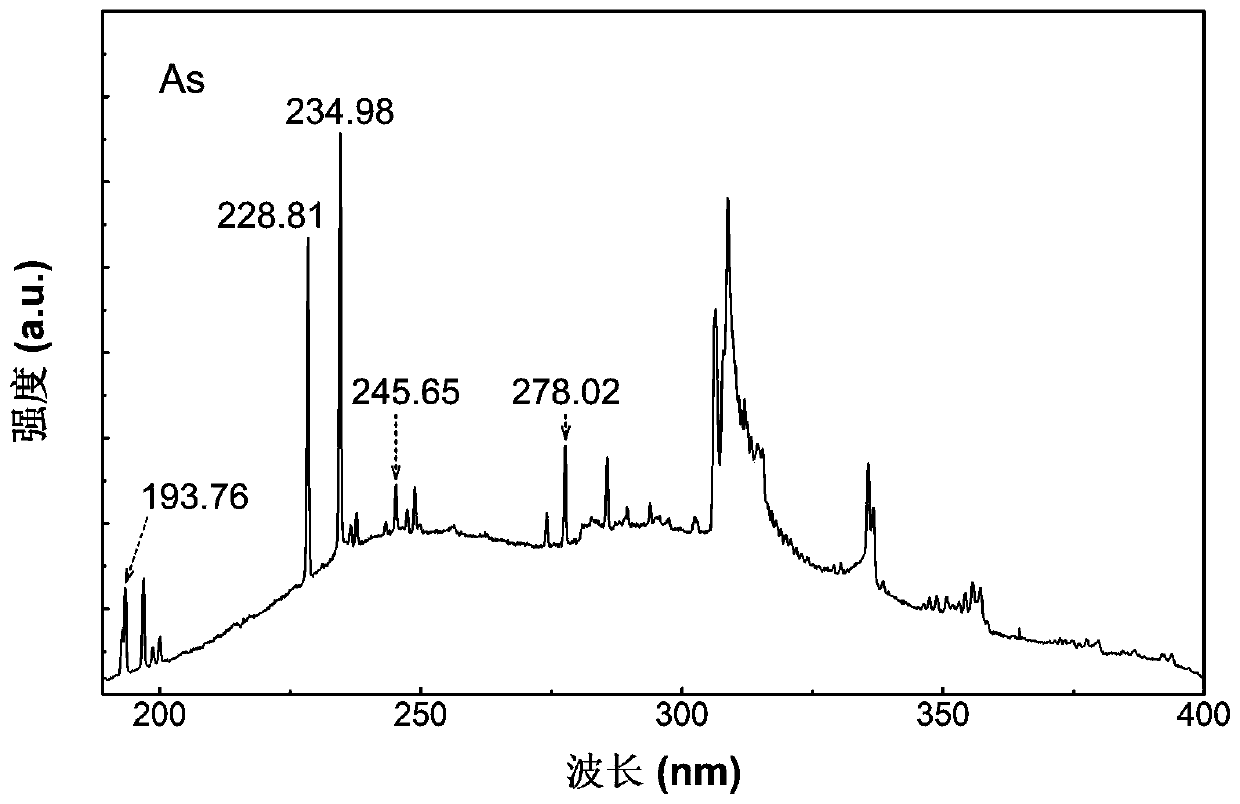

Point discharge micro-plasma atomic emission spectrum analysis device in argon-hydrogen flame

PendingCN111257304AImprove injection efficiencyHigh sensitivityAnalysis by electrical excitationAnalysis by thermal excitationLight spectrumMaterials science

The invention provides a point discharge micro-plasma atomic emission spectrum analysis device in argon-hydrogen flame, sample steam containing elements to be detected and a shielding gas respectivelyenter an atomic emission spectrum excitation source (point discharge micro-plasma in the argon-hydrogen flame), and generated atomic emission spectrum signals are detected by a spectrum detector. Theexcitation source is composed of a point discharge part and an argon-hydrogen flame part which are coaxially arranged in series up and down, the point discharge part is a pair of tip electrodes whichare symmetrically arranged on the two sides of a ceramic fixing base, and a spectrum detection window is formed in the side face of the point discharge part; according to the argon-hydrogen flame part, an outer quartz tube is fixed to a base circle, the outer quartz tube and an inner quartz tube are coaxially arranged, the upper portion of the inner quartz tube is large, the lower portion of theinner quartz tube is small, the lower section of the inner quartz tube is located in a base center hole, a bottom opening serves as an inlet of a working carrier gas and the sample steam, and an inletof the shielding gas is formed in the outer quartz tube. The point discharge micro-plasma atomic emission spectrum analysis device has the characteristics of high atomization / excitation efficiency, high sensitivity, strong anti-interference capability (small interference between sample moisture and a matrix), good stability, low power consumption and the like.

Owner:SICHUAN UNIV

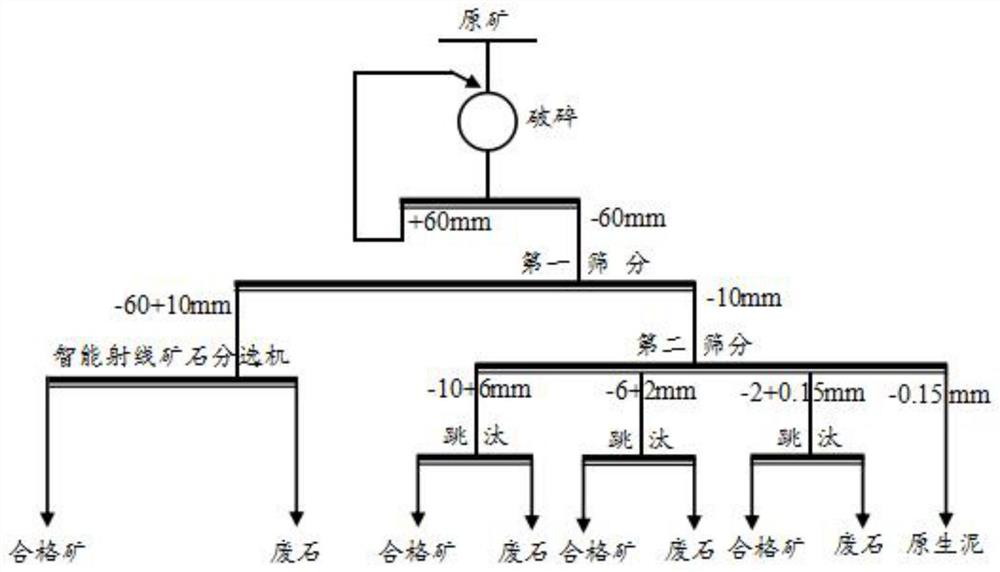

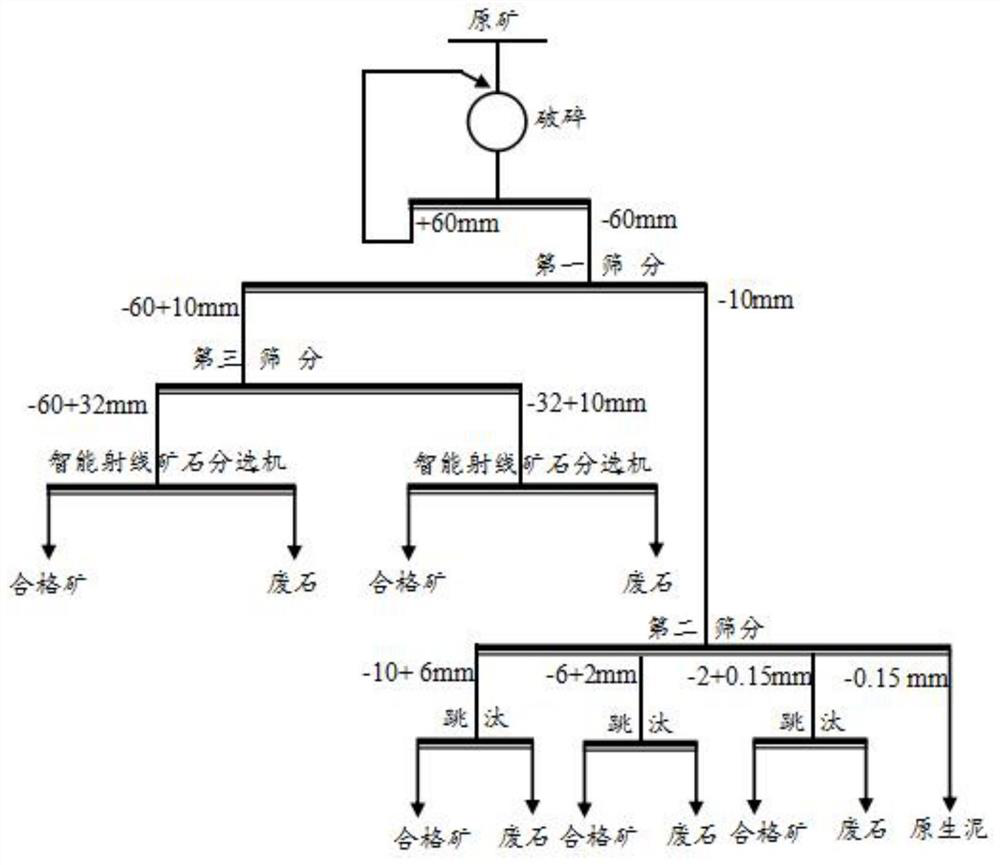

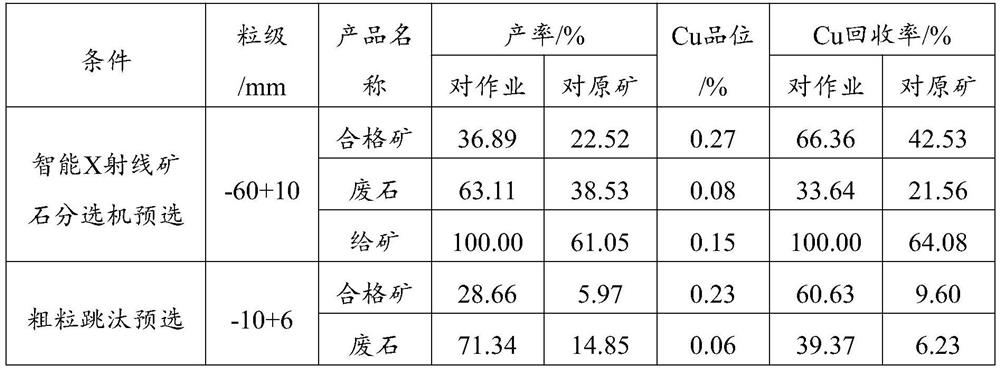

Pre-separation and waste-discarding beneficiation method for low-grade copper sulphide ores

InactiveCN112264181AAchieve pre-separationSave capacityWet separationCopper sulfideMaterials science

The invention relates to the technical field of beneficiation, and provides a pre-separation and waste-discarding beneficiation method for low-grade copper sulphide ores. According to the method, low-grade copper sulfide ores are screened into -60+10 mm, -10+6 mm, -6+2 mm, -2+0.15 mm and -0.15 mm ores through crushing and repeated screening, the -0.15 mm ores are regarded as primary slime and aredirectly used as qualified ores, the -2+0.15 mm, -6+2 mm and -10+6 mm ores are subjected to pre-separation and waste discarding through jigging, and the -60+10 mm ores are subjected to pre-separationand waste discarding through intelligent ray ore separation, and the copper grade of the finally obtained qualified ores is 0.27% or above. According to the provided method, pre-separation of the copper sulphide ore and a large amount of barren rock is realized, the copper grade of the selected ores is improved, the amount of ores entering a concentrating mill for grinding and separation is reduced, operation is stable, the cost is low and industrial production is realized easy.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

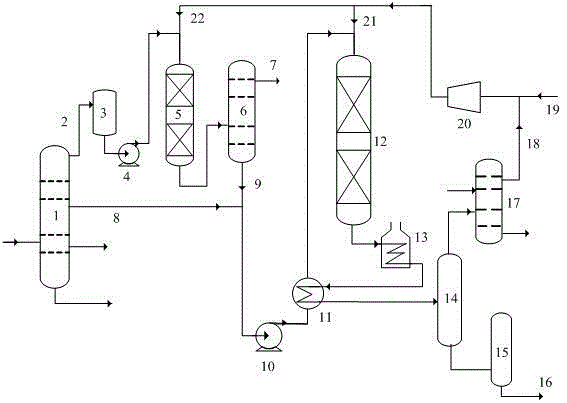

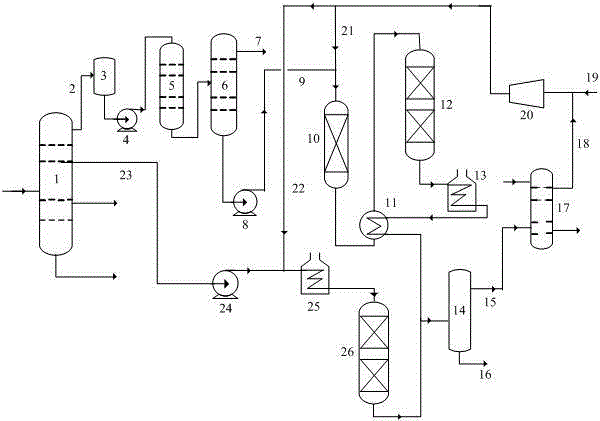

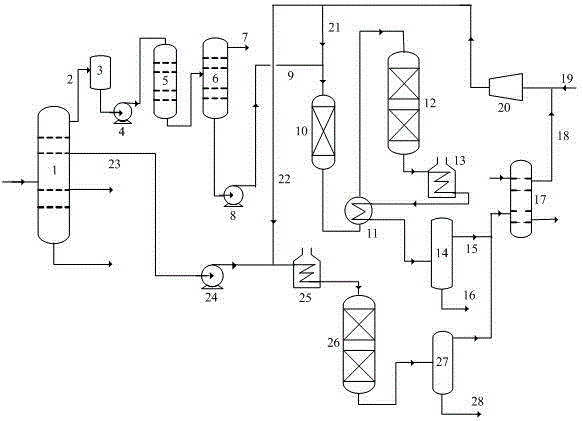

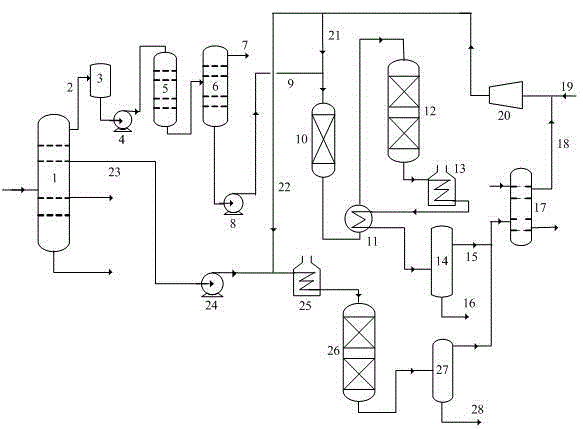

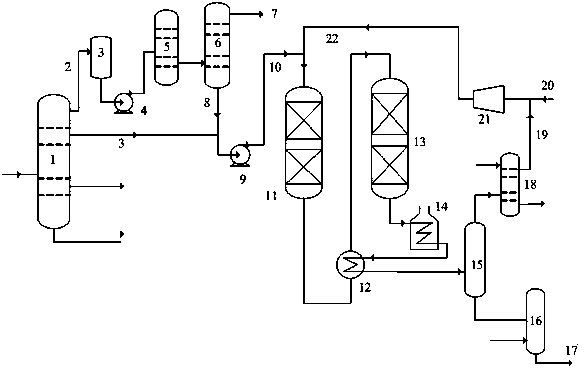

Low-energy consumption catalytic gasoline hydrodesulfurization method

ActiveCN103059957AAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The invention discloses a low-energy consumption catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic cracking device fractionating tower, and adopting an appropriate cutting point to perform pre-separation in an FCC (fluid catalytic cracking) fractionating tower so as to obtain light fractions and heavy fractions; subjecting the mercaptan in the light fractions to hydroconversion to form a heavy sulfide, making the treated light fractions enter a hydrogenation prefractionator to fractionate light gasoline and medium gasoline, mixing the medium gasoline with the heavy fractions generated by the FCC fractionating tower, letting the mixture enter a hydrodesulfurization reactor to undergo deep desulfurization, conducting steam stripping on the obtained refined heavy gasoline, and mixing it with the light gasoline, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention has the advantages that: the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, the gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

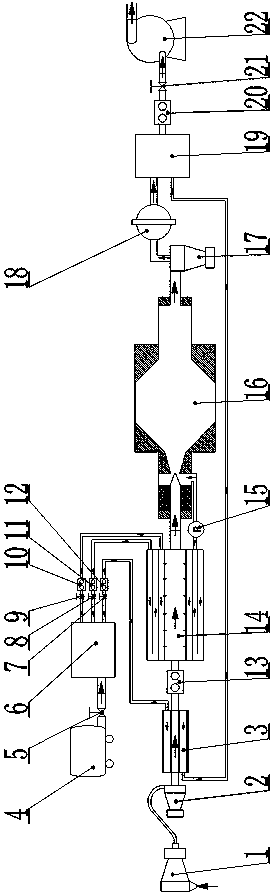

Particulate matter online dilution sampling measurement system and method

PendingCN110068526ARealize online sampling measurementRealize cooling and dilution effectWithdrawing sample devicesPreparing sample for investigationParticulatesCyclone

The invention discloses a particulate matter online dilution sampling measurement system and method. A PM10 cyclone cutter, a PM2.5 cyclone cutter, a sampling gas-flow flowmeter, a primary diluter, asecondary diluter, a charge particle measurement device, a particulate matter filter, a flue gas flowmeter, a flue gas flow control valve and a sampling pump are orderly connected; compressed air provided by an air compressor is divided into three paths after entering a compressed air buffer and processing device: a dry and clean gas-flow path, a primary diluting gas-flow path and a secondary diluting gas-flow path; the drying cleaning gas-flow path leads to an inlet end of the dry and clean gas-flow ionization device, the primary diluting gas-flow path leads to a primary diluting gas-flow inlet of the primary diluter, and the secondary diluting gas-flow path leads to a secondary diluting gas-flow inlet of the primary diluter. The particulate matter online dilution sampling measurement system has obvious advantages that the particulate matter sampling measurement feedback is timely, the cooling and the diluting are enough, the pipeline clogging is avoided, the measurement result is accurate, and the system is long in stable running time.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

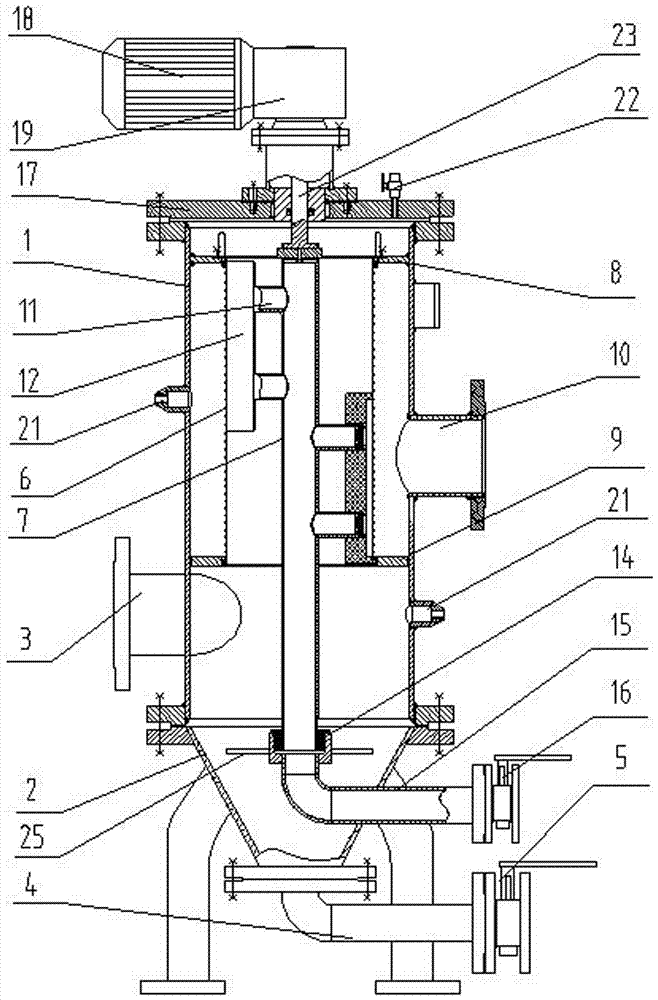

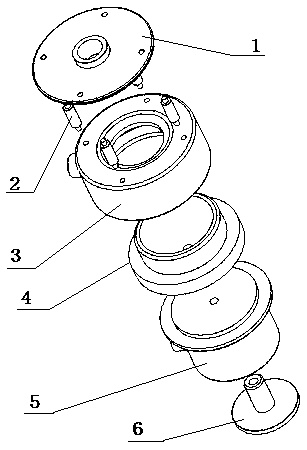

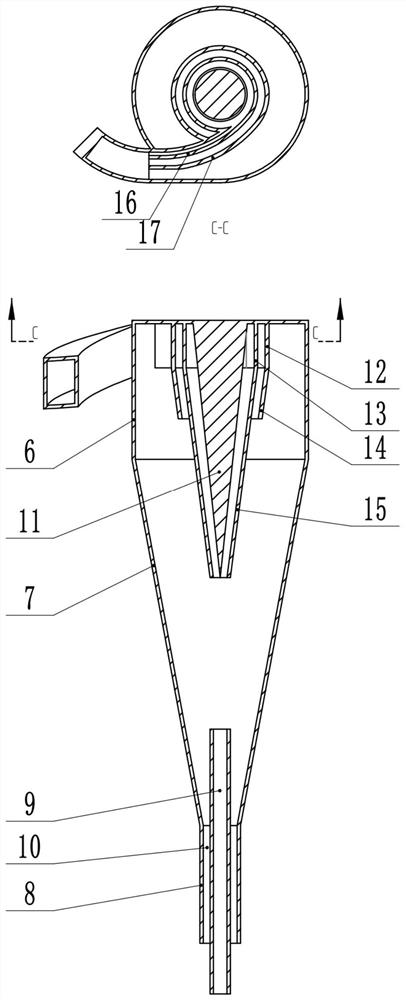

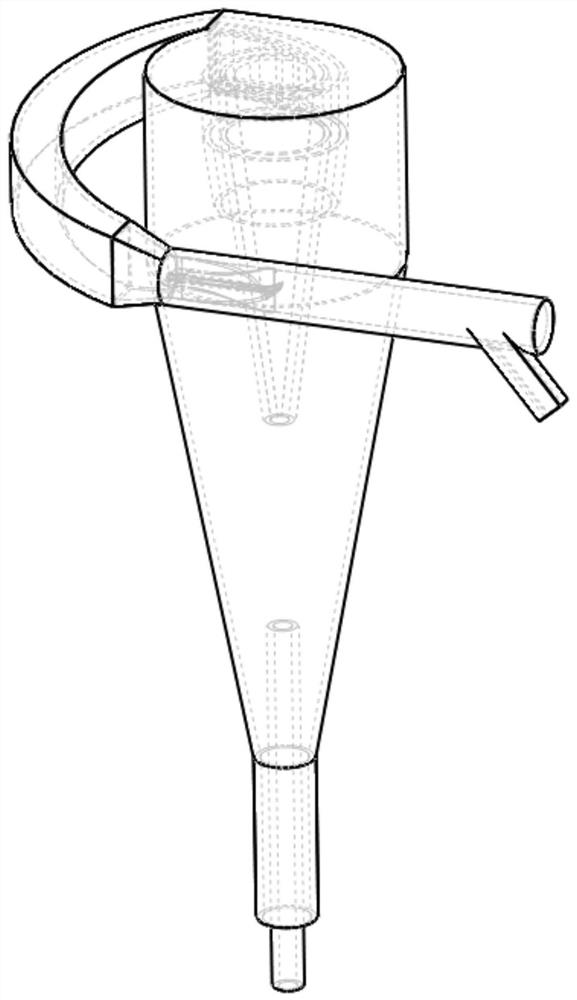

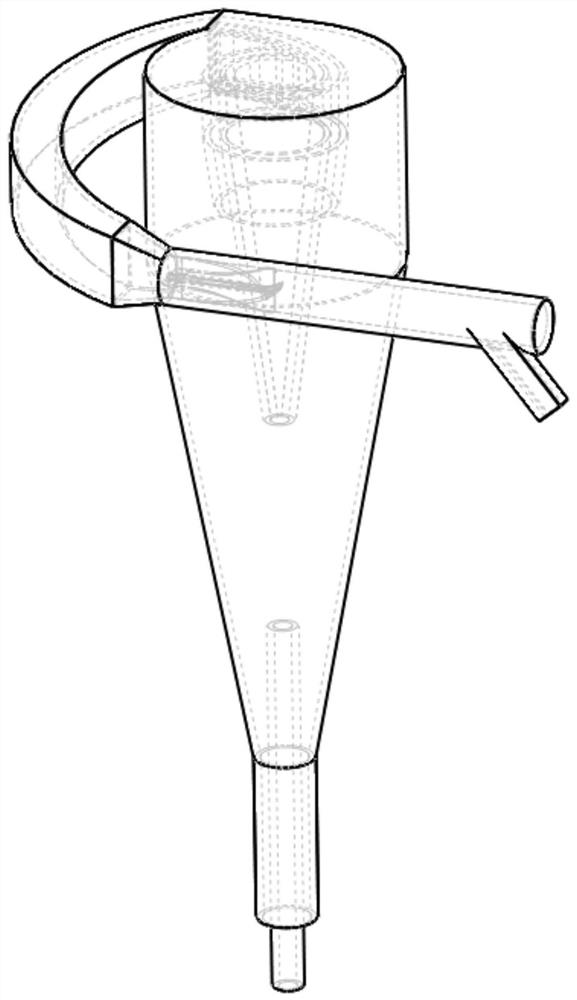

Swirling self-cleaning filter

InactiveCN107398114AAchieve pre-separationReduce filter pressureFiltration circuitsSewage treatmentFilter effect

The invention relates to the field of sewage treatment equipment, in particular to a swirling self-cleaning filter. The filter comprises a straight cylinder and a conical cylinder, wherein a swirling sewage discharge system is formed between the lower part of the straight cylinder and the conical cylinder and comprises a sewage inlet pipe arranged at the lower part of the straight cylinder in the tangential direction and a swirling sewage outlet pipe arranged at the lower end of the conical cylinder; a self-cleaning adsorption drainage system is arranged at the upper part of the straight cylinder and comprises a cylindrical filter element fixed in the straight cylinder and a hollow rotating shaft, a clean water outlet tube is arranged on the wall of the straight cylinder, and a plurality of sewage suction pipes are arranged on the hollow rotating shaft at intervals in the axial direction; a sewage suction head and an elastic element for tightly pressing the sewage suction head on the inner wall of the cylindrical filter element are arranged at one end, away from the hollow rotating shaft, of each sewage suction pipe; an adsorption sewage discharge pipe is connected to the lower end of the hollow rotating shaft through a rotary joint, one end, away from the hollow rotating shaft, of the adsorption sewage discharge pipe extends out of the wall of the conical cylinder, and a pressure control valve is arranged at the end. The filter is good in filtering effect and easy to maintain, and has a self-cleaning function.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

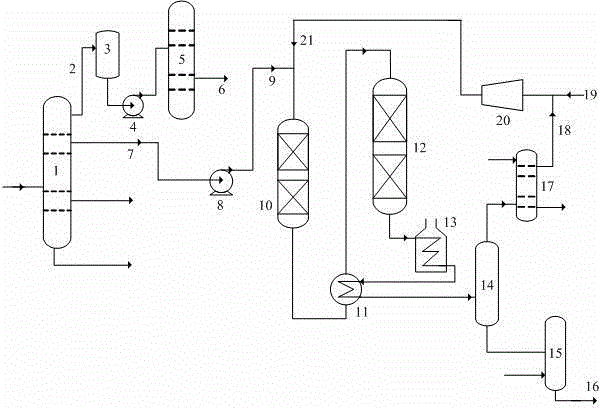

Catalytic gasoline hydrodesulfurization method

ActiveCN103059950AAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrodesulfurizationProcess engineering

The invention discloses a catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, conducting cutting at an appropriate cutting temperature so as to obtain light fractions at the tower top and heavy fractions at the lateral line; subjecting the light fractions to an alkali extraction treatment, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrodesulfurization on the medium gasoline, and carrying out deep selective hydrodesulfurization on the heavy gasoline, subjecting the obtained two refined products to gas stripping, and then mixing them with alkali extracted light gasoline, thus obtaining a clean gasoline product. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are substantially improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

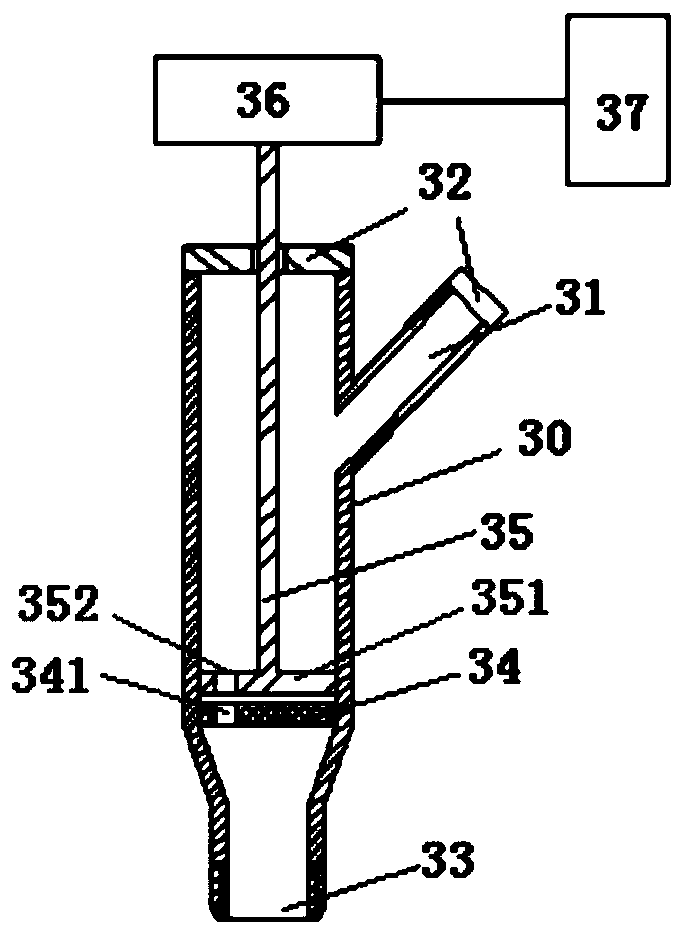

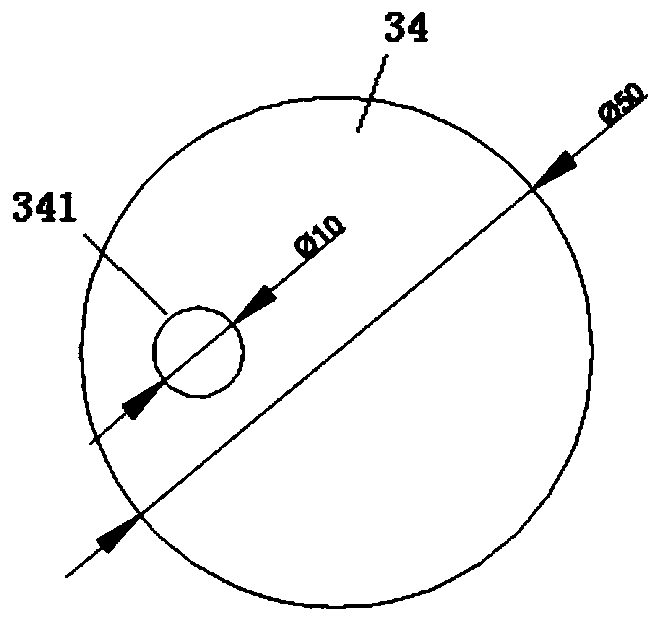

Ultra-low wall loss submicron terminal virtual impactor

ActiveCN109916694AIsolated from direct collisionAvoid collisionPreparing sample for investigationParticle size analysisSurface lossTerminal equipment

The invention relates to an ultra-low wall loss submicron terminal virtual impactor. The impactor comprises an inflow inlet, positioning double-screw bolts, a lateral flow cavity, an accelerating nozzle, a small-particle-size particle collecting cavity and a large-particle-size particle collecting cavity; the inner flow inlet is fixedly connected with the top wall of the lateral flow cavity through the positioning double-screw bolts; the bottom wall of the lateral flow cavity is fixedly connected with the acceleration nozzle; the upper end of the acceleration nozzle is located inside the lateral flow cavity; the lower end of the acceleration nozzle is fixedly connected with the upper end of the small-particle-size particle collecting cavity; the lower end of the small-particle-size particle collecting cavity is fixedly connected with the large-particle-size particle collecting cavity; and the upper part of the large-particle-size particle collecting cavity is located in the small-particle-size particle collecting cavity. The ultra-low wall loss submicron terminal virtual impactor of the invention can be adopted as a terminal device so as to be directly exposed to a sample environment, and can separate aerosol particles at the beginning of collection; a transverse-ring-shaped sample collection inlet design for submicron particles is realized, so that the pre-separation of the particles is realized, and separation precision can be improved; and pure gas flow is added, so that direct contact of the aerosol particles with an inner wall surface can be avoided, so that the wall surface loss of the particles is extremely low.

Owner:CHONGQING JIAOTONG UNIVERSITY

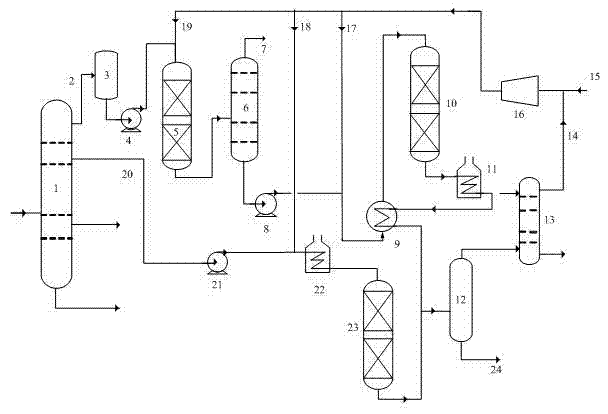

Catalytic gasoline deep hydrodesulfurization method

ActiveCN103059965AAchieve pre-separationLow investment costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a catalytic gasoline deep hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, adopting an appropriate cutting point to conduct cutting so as to obtain FCC (fluid catalytic cracking) gasoline light fractions at the tower top and FCC heavy fractions at the lateral line; subjecting FCC gasoline light fractions to alkali-free deodorization, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrogenation on the medium gasoline, performing deep selective hydrogenation on the heavy gasoline, and mixing the obtained two parts of refined distillate oil with the light gasoline subjected to alkali-free deodorization, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

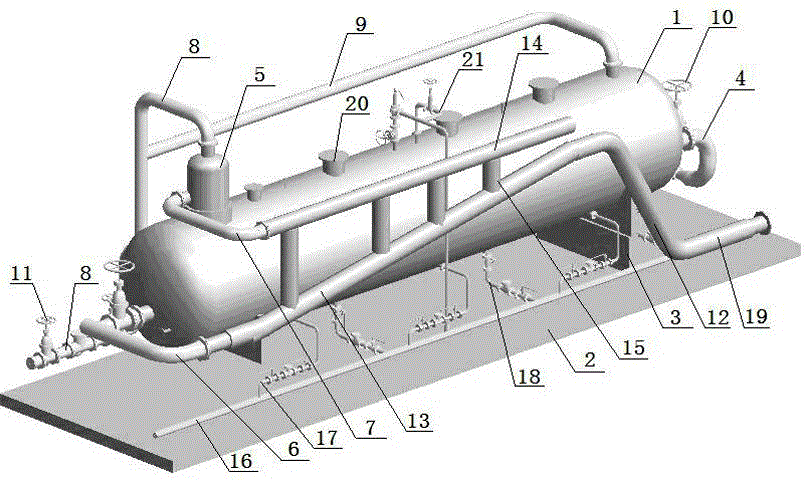

High-temperature gas-carrying super-heavy oil slug flow trapping and treating integrated device

InactiveCN104893753AEasy to separateSmall footprintRefining by heating/coolingThermodynamicsExhaust valve

The invention relates to the technical field of slug flow trapping devices and particularly relates to a high-temperature gas-carrying super-heavy oil slug flow trapping and treating integrated device. The high-temperature gas-carrying super-heavy oil slug flow trapping and treating integrated device comprises a steam treater, a prying seat and a slug flow trap, wherein the steam treater is fixedly arranged on the prying seat through a supporting seat; the lower part of the left end of the steam treater is provided with a liquid inlet end; and the middle part of the right end of the steam treater is provided with a liquid outlet end on which a liquid outlet pipe is fixedly arranged. The high-temperature gas-carrying super-heavy oil slug flow trapping and treating integrated device is reasonable and compact in structure and convenient to use; due to the coordinated application of the steam treater, a gas and liquid mixed conveying pipe, a liquid collecting pipe, a horizontal steam collecting pipe and a vertical branch pipe, the two-phase pre-separation of gas and liquid is realized, and a liquid slug generated by oil and gas mixing is effectively trapped; the apertures of an exhaust valve and a drain valve are regulated through a pressure sensor and a liquid level sensor, so that impact to the next-grade treating equipment is avoided; and the high-temperature gas-carrying super-heavy oil slug flow trapping and treating integrated device has the characteristics of good steam-liquid separation effect, operation stability and small floor area and is convenient to operate and capable of increasing the steam-liquid separation efficiency.

Owner:XINJIANG PETROLEUM ENG DESIGN CO LTD

Dilution sampling device for flue gas under high-humidity condition and sampling method of dilution sampling device

PendingCN109406229AAvoid coagulationAvoid water vapor interactionWithdrawing sample devicesAir quality improvementProcess engineeringFlue gas

The invention relates to a dilution sampling device for flue gas under the high-humidity condition and a sampling method of the dilution sampling device. A PM10 whirlwind cutter, a first-level PM2.5 whirlwind cutter, a flue gas insulation and dehumidification device, a sampling airflow flowmeter, a first-level diluter, a second-level diluter, a second-level PM2.5 whirlwind cutter, a particulate filter, a flue gas mixing device, a flue gas flowmeter, a flue gas flow control valve and a sampling pump are connected in sequence, compressed air produced by an air compressor is divided into three paths through a compressed air buffering and processing device, one path is connected with the flue gas mixing device through a drying air flow control valve, a drying airflow flowmeter and the flue gasinsulation and dehumidification device, one path is connected with the first-level diluter through a first-level dilution airflow control valve and a first-level dilution airflow flowmeter, and one path is connected with the second-level diluter through a second-level dilution airflow control valve, a second-level dilution airflow flowmeter, the first-level diluter, and a second-level dilution airflow pressure gage. According to the dilution sampling device for the flue gas under the high-humidity condition, flue gas capturable particulate matters and condensable particulate matters under thehigh-humidity condition are sampled.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

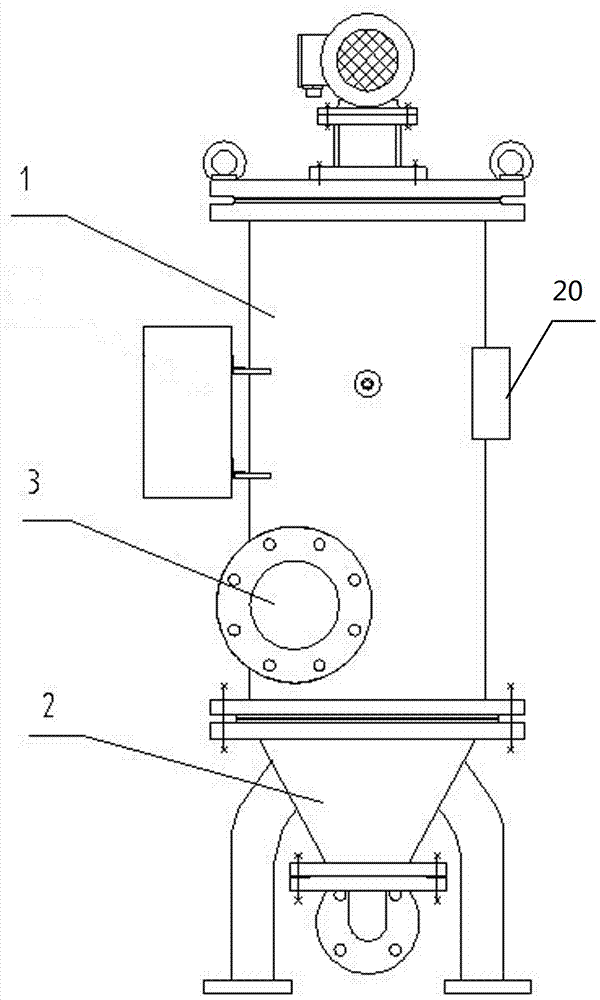

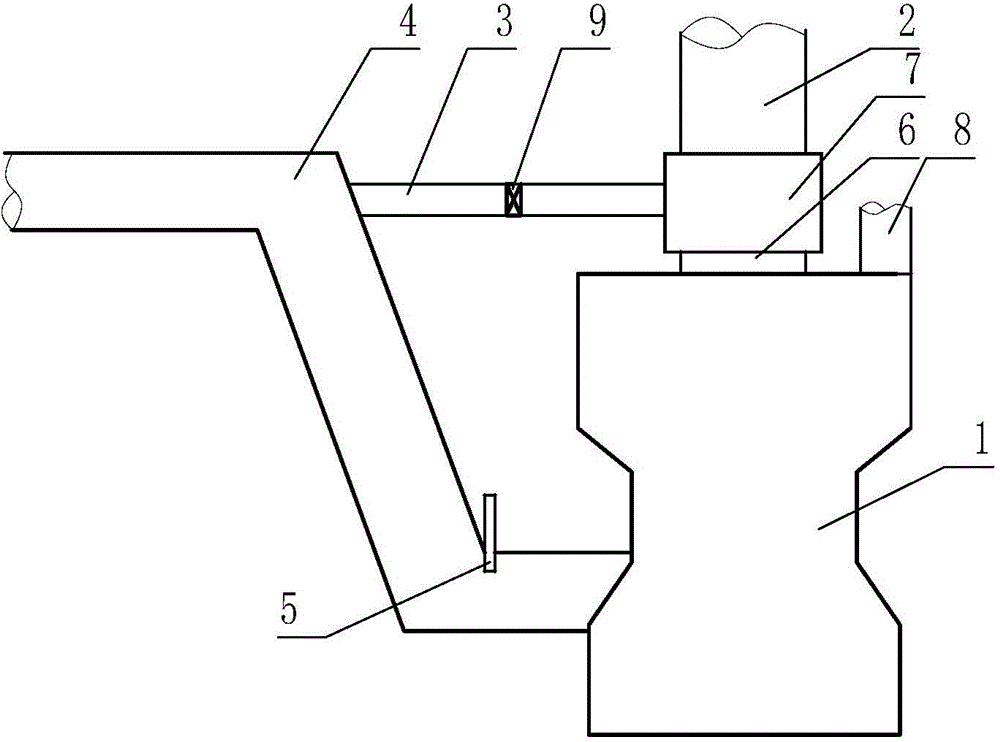

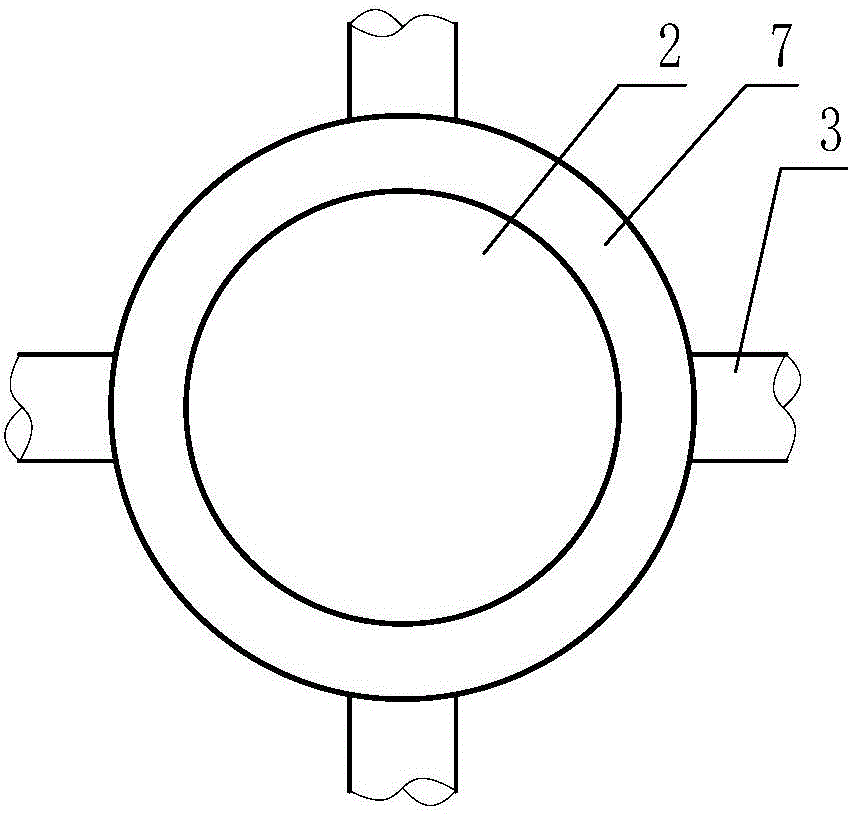

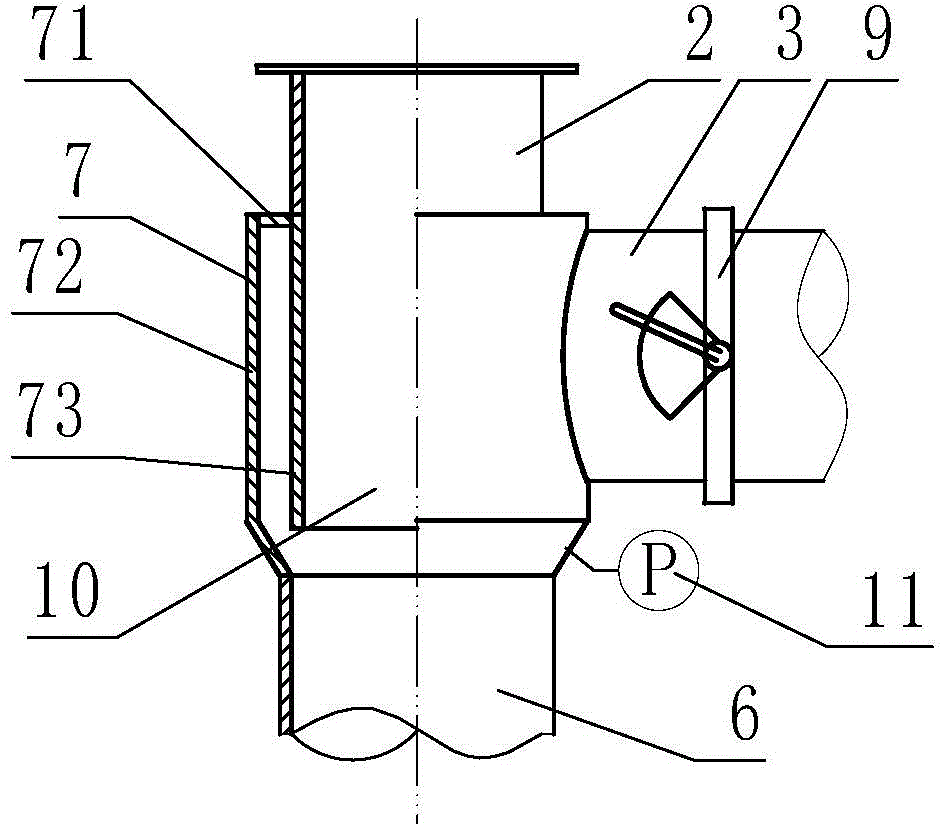

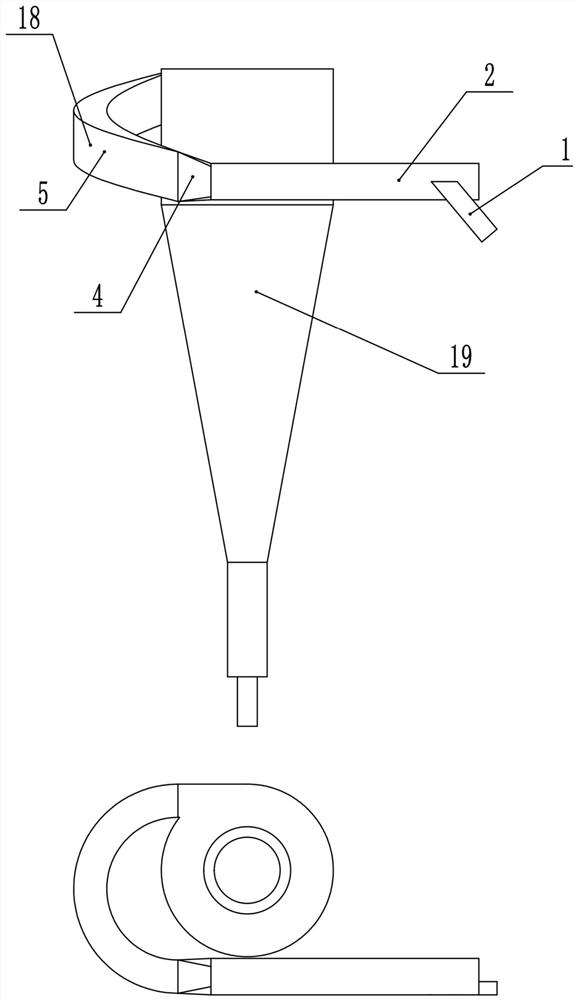

Coal milling method adopting medium speed coal mill as well as used coal mill

InactiveCN104668043AHigh outputReduce unit consumptionDrying gas arrangementsGrain treatmentsThermodynamicsProcess engineering

The invention discloses a coal milling method adopting a medium speed coal mill as well as the coal mill. The coal mill comprises a coal falling pipe (2) and a mill body (1), wherein the mill body (1) is provided with a coal falling port (6), a coal outlet (8) and an air inlet channel (4), a pre-drying device is added to the coal falling port (6) in the front end of the mill body (1) for pre-drying coal entering the coal mill, so that the drying capacity and the working condition of the mill body (1) are improved, further, the drying capacity of the coal mill is improved, the unit consumption of the coal mill is reduced, and wear of a mill roller is reduced.

Owner:邹铭

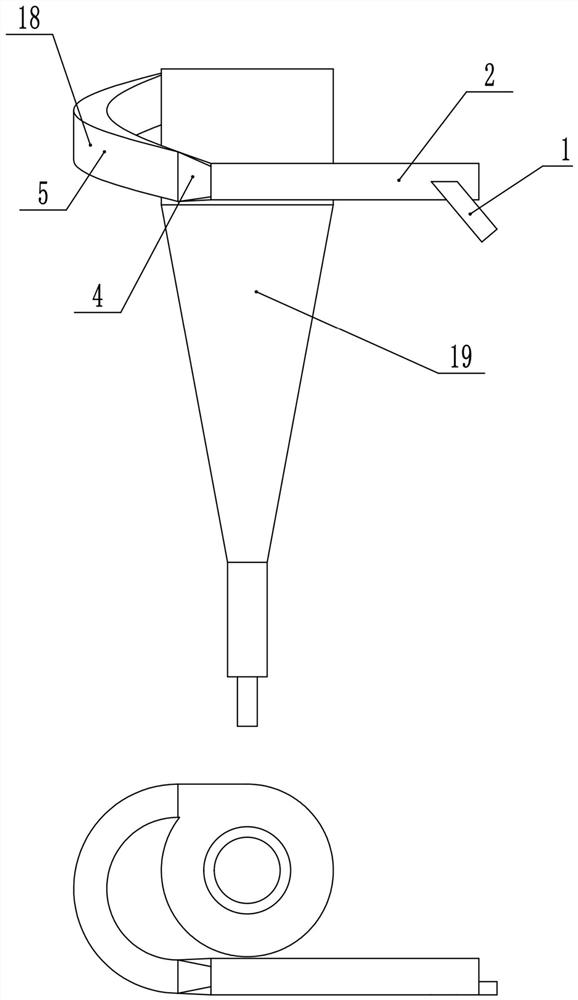

Shunting guide type inertia cyclone separator

ActiveCN112844880AImprove separation efficiencyReduce turbulenceSingle direction vortexShunt typesMechanical engineering

The invention relates to a shunting guide type inertia cyclone separator which comprises a coalescence shunting type inlet and a barrel body; the coalescence shunting type inlet comprises a tangential inlet, a coalescence pipe, a flow guide body, a conversion pipe and a shunting guide pipe; and the barrel body is formed by sequentially connecting a rotational flow section, a conical section and an underflow section which have the same central axis from top to bottom, an inner cone is connected to the axis of the top of the barrel body, and an overflow pipe is arranged at the center of the underflow section. A continuous phase, a large-particle-size dispersed phase and a small-particle-size dispersed phase can be shunted and layered under the action of inertia through the shunting guide type inlet, three different fluids are guided to different positions in the cyclone through an inner-layer guide plate and an outer-layer guide plate, and the dispersed phases with different particle sizes are finely separated. The cyclone can realize higher separation efficiency on dispersed phases with large and small particle sizes, and has the outstanding advantages of small equipment volume, realization of targeted shunting and guiding effects on liquid drops with different sizes so as to finish efficient separation and the like.

Owner:NORTHEAST GASOLINEEUM UNIV

Crushing and cleaning equipment for metal packaging container

PendingCN114602941ANot easy to driftNot easy to polluteDrying solid materials without heatTransportation and packagingMagnetic separatorStructural engineering

The invention provides metal packaging container crushing and cleaning equipment which comprises a first sealing room, a second sealing room and a third sealing room. The feeding chain scraper conveyor, the double-shaft shredding machine, the vibration feeder, the separation chain scraper conveyor, the roller dehydrator, the cleaning chain scraper conveyor, the first magnetic separator, the first roller cleaning machine, the crushing chain scraper conveyor, the hammer crusher, the belt conveyor, the second magnetic separator, the second roller cleaning machine and the collecting frame are connected in sequence. By arranging the machine tables which are connected in sequence, automatic production can be achieved, and the production efficiency is relatively high; a plurality of cover bodies and sealing rooms are arranged and are connected with a negative pressure fan, so that dust is not easy to drift into the air, and the air is not easy to pollute; meanwhile, the vibration feeder and the roller dehydrator are arranged, and the roller cleaning machines are arranged in front of and behind the hammer crusher respectively, so that the impurity rate of the materials is effectively reduced, fire is not prone to occurring in the crushing process, the safety is relatively good, and the quality of the recycled metal aggregate is relatively good.

Owner:HUANCHUANG XIAMEN TECH

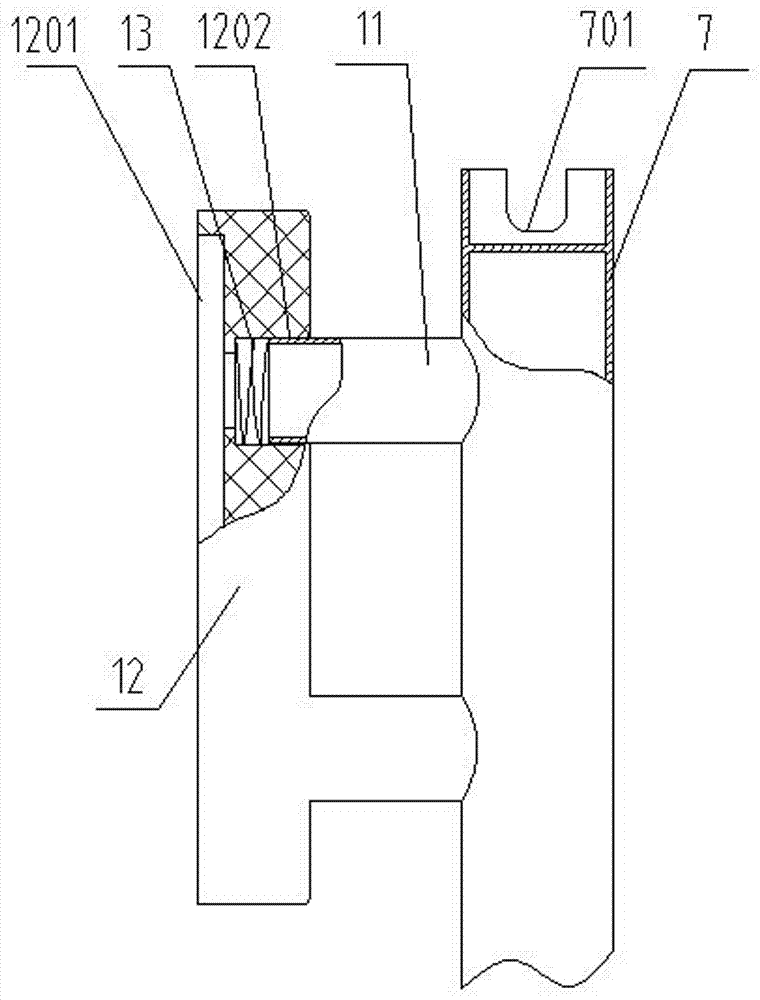

A heating furnace heating bar material anti-adhesion conveying device

ActiveCN113120595BAchieve pre-separationAchieve separationConveyorsControl devices for conveyorsHeater RodEngineering

The invention discloses an anti-adhesion conveying device for heating rods in a heating furnace, which belongs to the field of conveying equipment and includes a base, a conveying chain is arranged above the base, conveying baffles are arranged on both sides above the conveying chain, and conveying baffles are arranged on both sides of the conveying chain. One end of the input direction of the chain is longitudinally provided with polygonal rollers, the center line of the polygonal rollers is perpendicular to the conveying chain, and the height of the uppermost edge of the polygonal rollers is higher than the upper top surface of the conveying chain; An auxiliary separation device is provided above the chain and the polygonal roller, and the auxiliary separation device includes a bracket, and a down-pressing cylinder is arranged on the bracket, and a connecting plate is provided at the end of the down-pressing cylinder, and a separating plate is provided on the connecting plate. Pressing bar and elastic positioning pressing bar, the separation pressing bar is arranged above the conveying chain, the elastic positioning pressing bar is arranged above the polygonal roller, and the elastic positioning pressing bar can be elastically stretched.

Owner:SHANDONG RONGTAI ELECTRIC FURNACE ENGINEER

Catalytic gasoline deep hydrodesulfurization method

ActiveCN103059965BAchieve pre-separationLow investment costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a catalytic gasoline deep hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, adopting an appropriate cutting point to conduct cutting so as to obtain FCC (fluid catalytic cracking) gasoline light fractions at the tower top and FCC heavy fractions at the lateral line; subjecting FCC gasoline light fractions to alkali-free deodorization, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrogenation on the medium gasoline, performing deep selective hydrogenation on the heavy gasoline, and mixing the obtained two parts of refined distillate oil with the light gasoline subjected to alkali-free deodorization, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

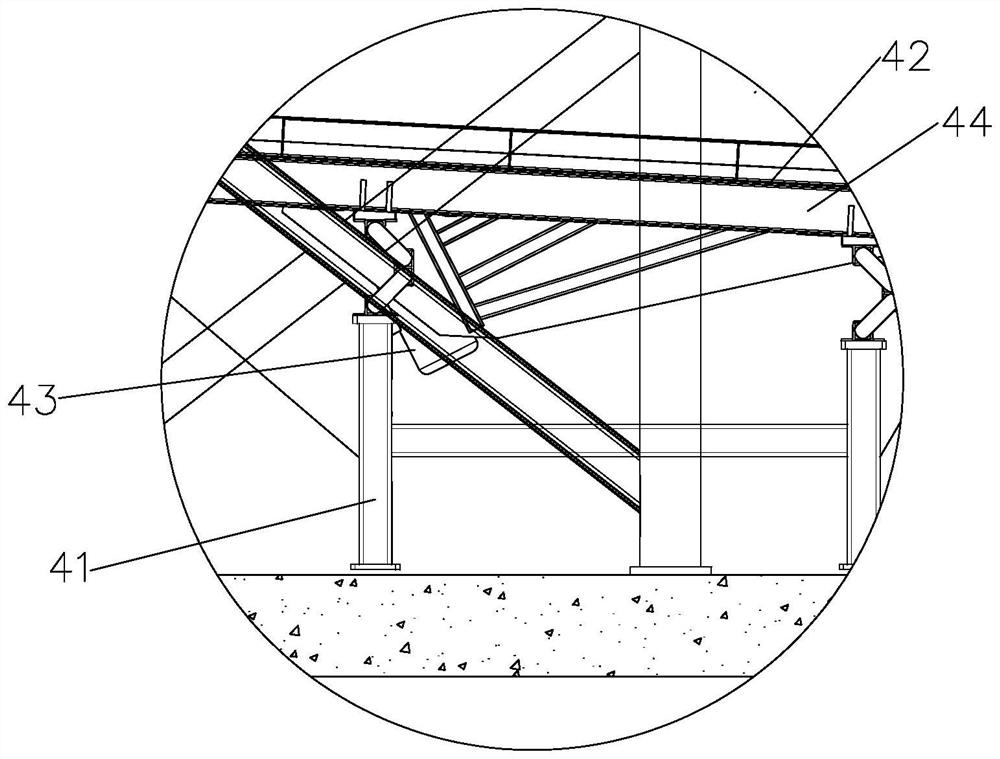

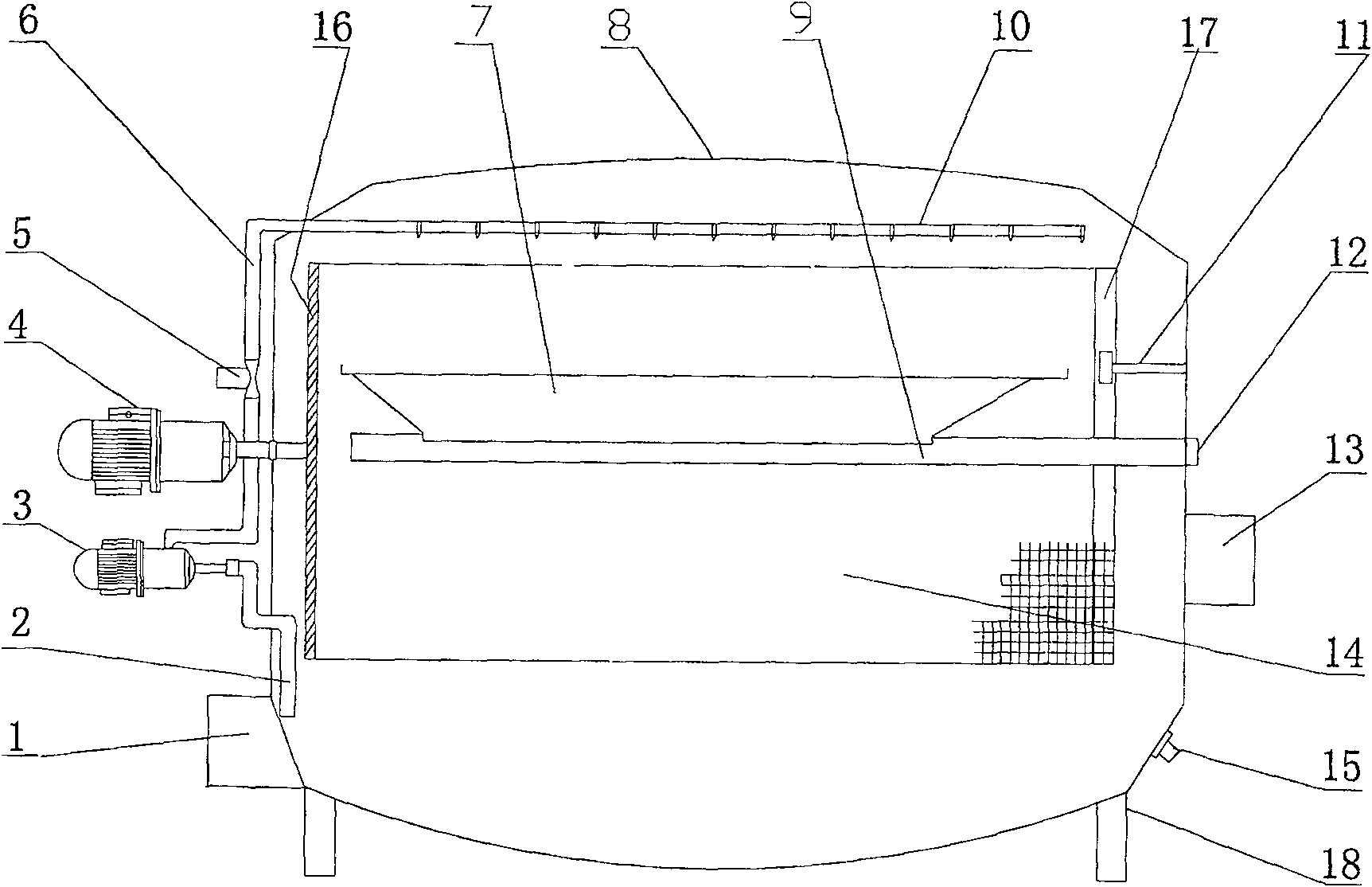

Method and equipment for integrated stack gas desulfurization and dust removal of circulating fluid bed in damp dry type

ActiveCN100441271CRaise the ratioAchieve pre-separationDispersed particle separationBaghouseFluidized bed

The invention relates to a semi-dry circulating fluidized bed flue gas desulfurization and dust-collection integrated method and its equipment, belonging to the field of flue gas purification technology. Said equipment includes a desulfurization tower; said desulfurization tower is composed of mutually-connected straight barrel section and conical column body section. The bottom portion of said conical column body section is connected with a preseparation chamber by meansof a transition section, the bottom portion of the preseparation chamber is equipped with a conical bottom with ash-falling mouth, and the bilateral sides of said preseparation chamber are equipped with flue gas inlets with tangential rotary gas-feeding mode. In the interior of conical column body section a multilayer slurry-spraying mechanism is set, a first flue gas outlet is set in the upper portion of the straight barrel section and connected with a bag dust collector, on the oblique surface of conical bottom of said bag dust collector a material-returning oblique groove is set, and the connection of bottom end of material-returning oblique groove is connected with desulfurization tower, and is placed under the lower-layer slurry-spraying mechanism. The upper portion of side surface of the bag dust collector is equipped with a second flue gas outlet.

Owner:TSINGHUA UNIV +1

Deep hydrodesulfurization method for catalytic gasoline

ActiveCN103059956BAchieve pre-separationLow investment costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a deep hydrodesulfurization method for catalytic gasoline. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, and adopting an appropriate cutting point to perform cutting so as to obtain light fractions at the tower top and heavy fractions at the lateral line; subjecting the light fractions to alkali-free deodorization, then passing the deodorized light fractions through a hydrogenation prefractionator to separate light gasoline and medium gasoline; and subjecting the separated medium gasoline and the heavy fractions to selective hydrogenation, and mixing the refined product with the light gasoline subjected to alkali-free deodorization, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention has the advantages that: the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, the gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for recycling ditrimethylolpropane

ActiveCN101967085BAchieve pre-separationLower requirementEther separation/purificationPlatinumCobalt

The invention relates to a method for recycling ditrimethylolpropane, which is characterized by comprising the steps of: transferring heavy constituents at the bottom of a rectifying kettle in a refining procedure of trimethylolpropane, then filtering when hot in necessity, removing impurities with high crystallization point, transferring to a dynamic melt crystallizer, carrying out separation of crystallization, sweating and melting at a programmed temperature to ensure that other main impurities of the ditrimethylolpropane and the heavy constituents are separated; and carrying out refining of crystallization, sweating and melting on the collected rough ditrimethylolpropane at a programmed temperature to obtain a ditrimethylolpropane product with content of higher than 95 percent, which accords with the general requirements of industrial products. If higher requirements on platinum-cobalt chroma of not more than 15APHA are required in the color number of the products, the color is removed by combining the melt crystallization method with steps of absorbing and filtering, and the like. The method for recycling the ditrimethylolpropane has the advantages of simple operation, low cost, no need of high vacuum rectification, and low operation temperature.

Owner:JIANGSU BAICHUAN GAOKE NEW MATERIAL CO LTD +1

A kind of catalytic gasoline hydrodesulfurization method

ActiveCN103059945BAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention discloses a catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, and adopting an appropriate cutting point to perform cutting so as to obtain gasoline light fractions at the tower top and gasoline heavy fractions at the lateral line; subjecting the light fractions to alkali extraction, carrying out selective hydrodesulfurization on the heavy fractions, and mixing the obtained refined oil with the light gasoline generated by alkali extraction, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention has the advantages that: the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, the gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low energy consumption catalytic gasoline hydrodesulfurization method

ActiveCN103059946BAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrodesulfurizationProcess engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

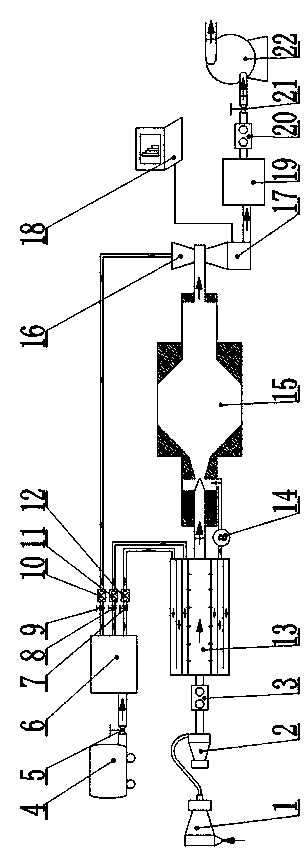

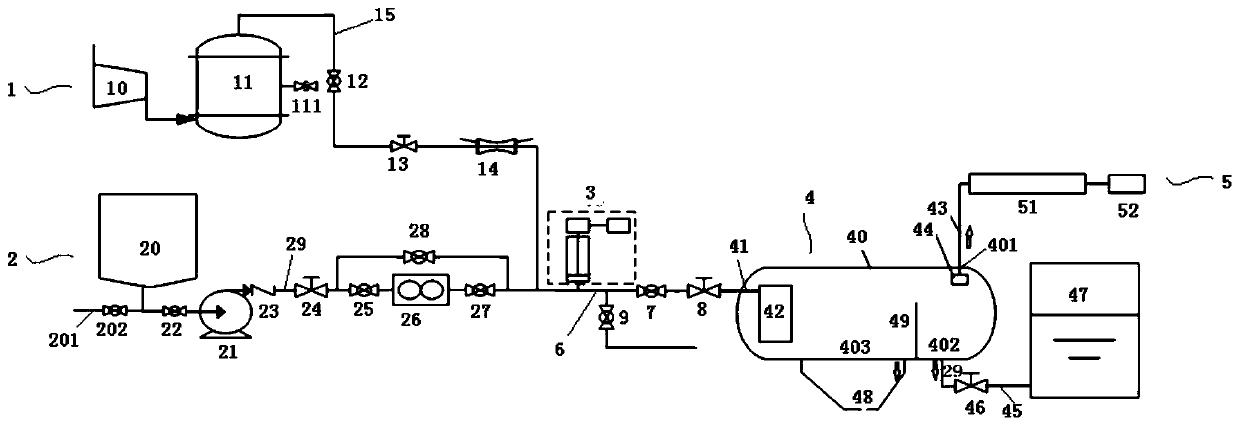

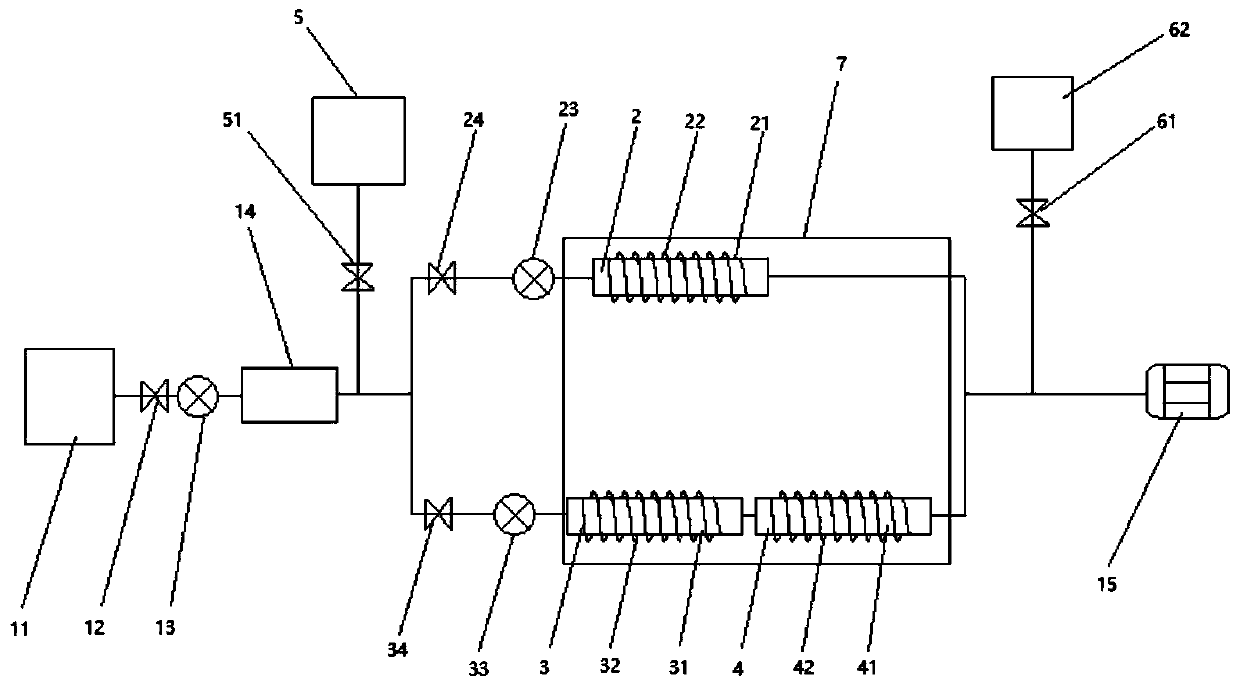

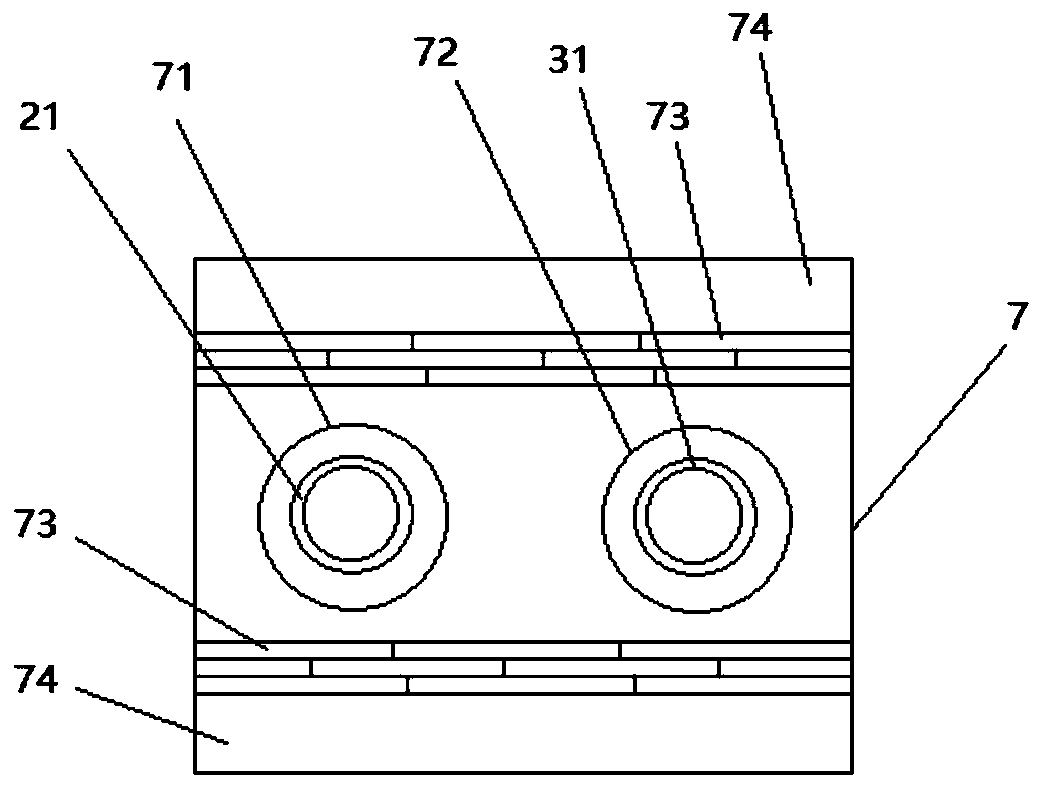

A system and method for testing sand deposition and separation performance of a slug catcher

ActiveCN106932185BImprove sand removal effectEasy to separateMachine part testingFluid removalForming gasGas phase

The invention relates to a slug catcher sand deposition and separation performance testing system and method. The system comprises a gas phase supply system, a liquid phase supply system, an online quantitative sand adding system, a slug catcher testing system, and a data acquisition system. The online quantitative sand adding system is arranged on a main pipeline. The front end of the main pipeline is connected to the gas phase supply system and the liquid phase supply system, and the back end of the main pipeline is connected to the slug catcher testing system. Gas, liquid and solid mediums in the gas phase supply system, the liquid phase supply system and the online quantitative sand adding system are collected at the back end of the main pipeline to form gas, liquid and solid flows, the gas, liquid and solid flows enter into the slug catcher testing system to be separated, the data acquisition system collects and processes related parameters in the separation process, and the comprehensive evaluation and optimization of the separation effect of the slug catcher are realized. The system and the method can be widely applied to performance testing of a slug catcher sand separation effect and optimization design of the slug catcher.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Enrichment and pre-separation system for VOCs in atmosphere

PendingCN111521454ACaptureImprove adsorption efficiencyWithdrawing sample devicesPreparing sample for investigationAdsorption separationSeparation system

The invention discloses an enrichment and pre-separation system for VOCs in atmosphere. The system comprises a sampling device, a water removal device, an enrichment and pre-separation device and a sampling device. The enrichment and pre-separation device comprises a second cold trap, a third cold trap, a fourth cold trap, a second gas flow controller and a third gas flow controller. According tothe enrichment and pre-separation system for VOCs in the atmosphere, VOCs in sample gas can be synchronously adsorbed, concentrated and preliminarily separated, and the adsorption efficiency is high.VOCs subjected to preliminary adsorption and separation are respectively classified and captured through different desorption and capture channels, so that pre-separation of various VOCs is realized.Self-cleaning of the equipment can be achieved, operation is easy, and no extra auxiliary device is needed.

Owner:苏州冷杉精密仪器有限公司

An Oriented Coalescing Liquid Separator

ActiveCN104474741BReduce shockImprove washing effectFatty/oily/floating substances removal devicesNon-miscible liquid separationHorizontal axisEngineering

Owner:TIANJIN UNIV

A split-guided inertial cyclone separator

ActiveCN112844880BCoalescing achievedEasy to separateSingle direction vortexEngineeringMechanical engineering

A split-guided inertial cyclone separator, comprising a coalescing split-flow inlet and a barrel; the coalescing split-flow inlet includes a tangential inlet, a coalescing pipe, a guide body, a conversion pipe, and a split-flow guiding pipe; the barrel The body is composed of a swirl section, a cone section, and an underflow section with the same central axis from top to bottom. The present invention can separate and stratify the continuous phase, the discrete phase with a large particle size and the discrete phase with a small particle size under the action of inertia through the split-guided inlet, and guide three different fluids to the cyclone through the inner layer and the outer layer guide plate At different positions inside, the discrete phases with different particle sizes are finely separated. The cyclone can achieve high separation efficiency for dispersed phases with large and small particle sizes, and it has outstanding advantages such as small equipment volume and targeted diversion and guidance for droplets of different sizes to complete efficient separation.

Owner:NORTHEAST GASOLINEEUM UNIV

Circulating water multifunctional solid dirt separator for fishpond

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com