Shunting guide type inertia cyclone separator

A cyclone separator and split-flow technology, which is applied in the field of two-phase separation treatment technology, can solve the problems of poor separation effect of small particle size dispersed phase, poor separation effect of small particle size droplets, and limitation of cyclone separation efficiency, etc. Achieve considerable promotion and application prospects, reduce turbulent flow, and improve overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

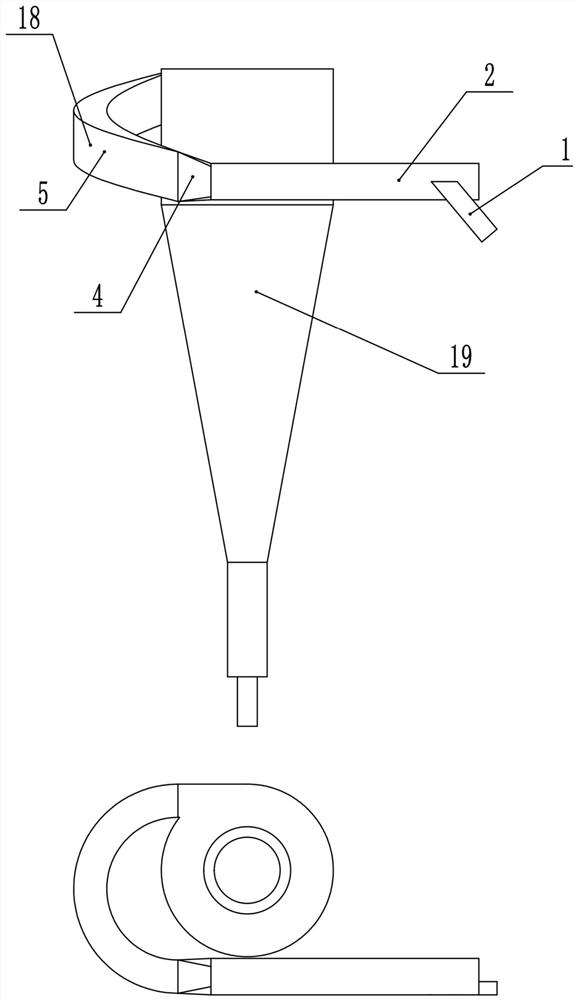

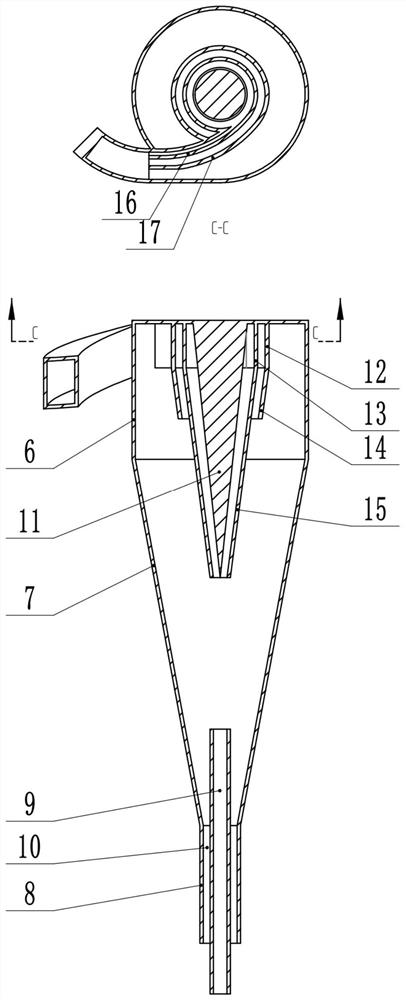

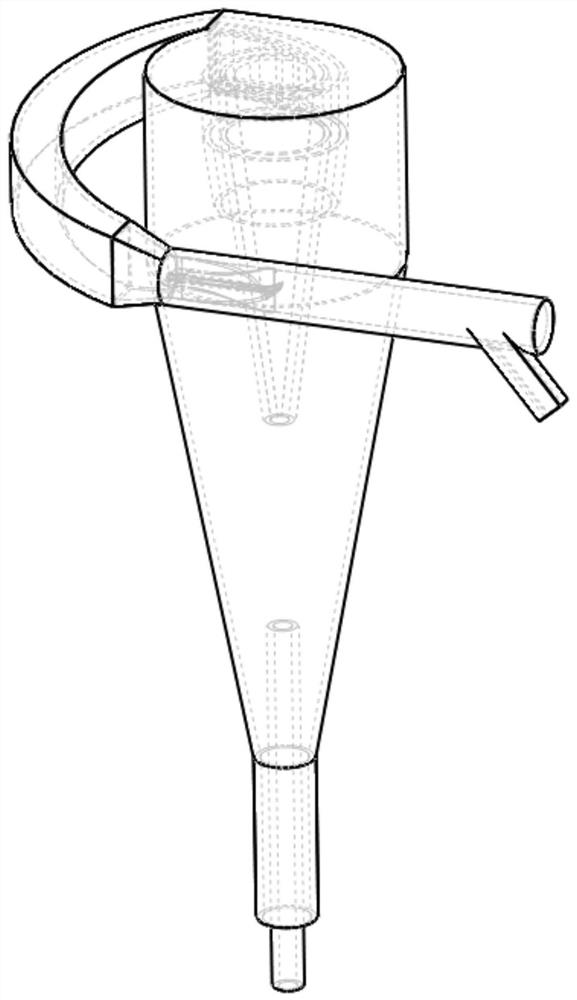

[0025] A split-guided inertial cyclone separator, comprising a coalescing split-type inlet 18 and a cylinder 19, characterized in that:

[0026] The coalescing and splitting inlet 18 is composed of an inclined tangential inlet 1, a coalescing pipe 2, a guide body 3, a conversion pipe 4, and a diverting guide pipe 5. The coalescing pipe 2 is a hollow cylinder, along which the coalescing The outer wall of the coalescing pipe 2 is inclined and tangentially connected to a tangential inlet 1. The tangential inlet 1 connected obliquely can make the fluid generate a tangential velocity in the coalescing pipe 2, so that the oil droplets rotate and coalesce, and the tangential inlet is due to It is inclined, which can share part of the tangential force in the axial direction, and avoid the flow field disorder caused by excessive tangential velocity. The conversion tube 4 is a gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com