Patents

Literature

122results about How to "Avoid disposition problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

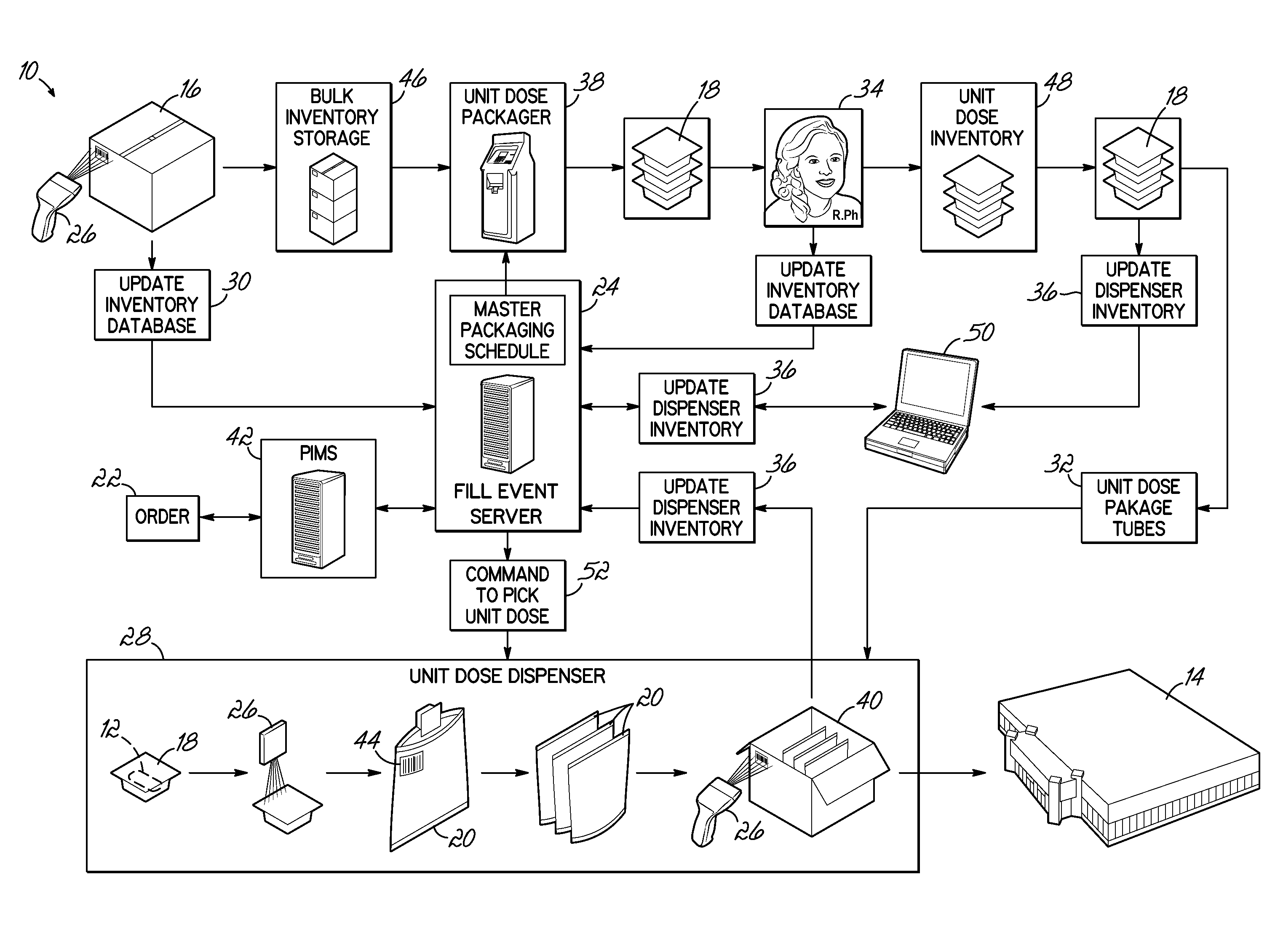

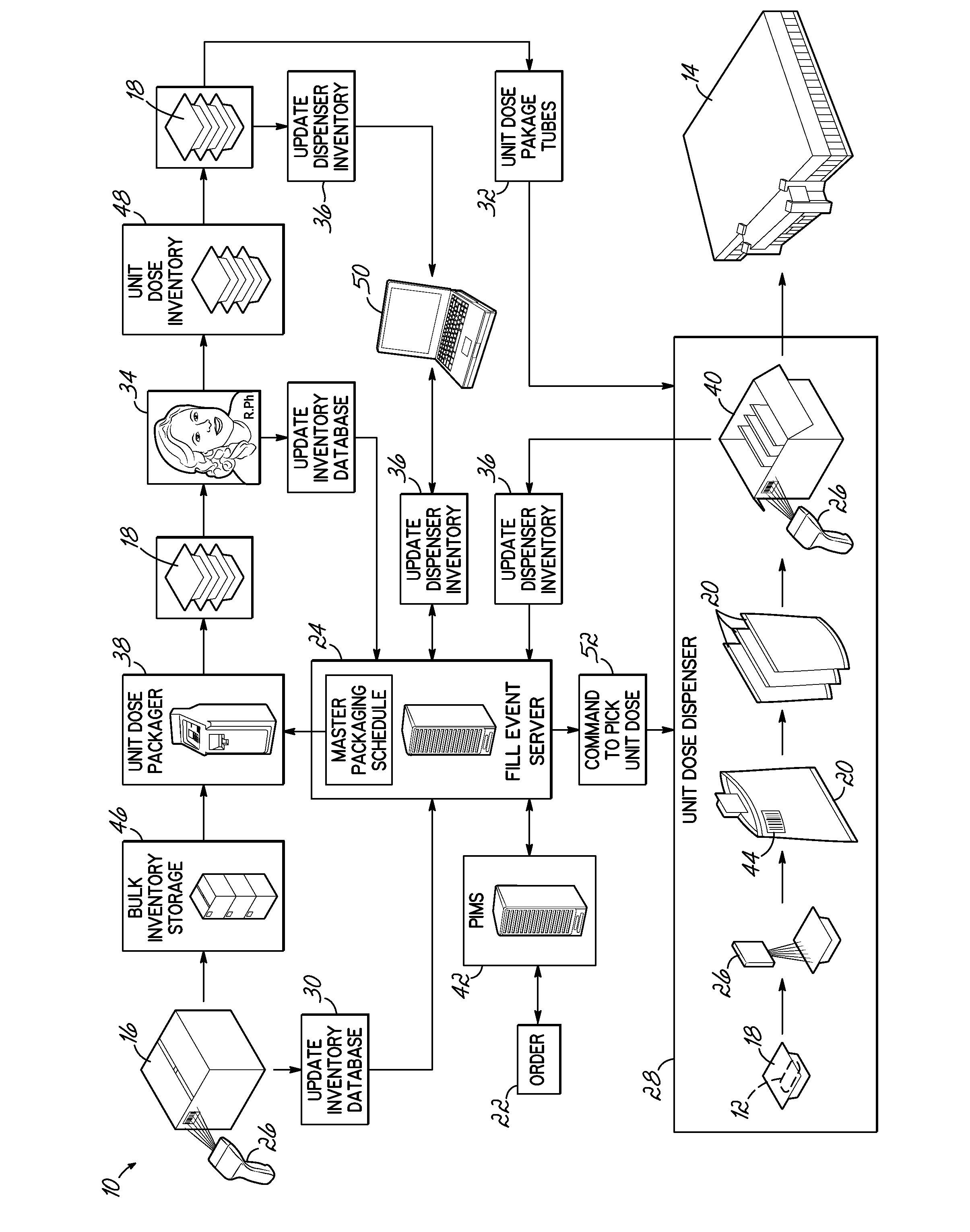

System and methodology for filling prescriptions

ActiveUS20100174552A1Automate processingSolve the real problemData processing applicationsDigital data processing detailsPhysical controlWork flow

An overall pharmacy system and methodology begins with bulk medications and supplements introduced into the work flow, individually packaged and assembled into med pass orders per patient and delivered to the long-term care (LTC) facility or other institution for patient consumption. The process according to one embodiment of this invention begins by converting bulk medications and supplements to packaged unit doses and ultimately individually packaged med pass bags for each patient on a 24-hour schedule. The various safeguards and measures built into this system increase patient safety eliminate waste and increase labor efficiency by reducing and / or minimizing the disposal of unused medications and supplements. The design of the overall system and its individual components allows for physical control of each unit dose package from start to finish without any unit dose package “free fall” in the system. This process is automated and does not rely upon manual sorting. The med pass bags are consolidated into the final shipping container and do not require manual sorting and packing.

Owner:REMEDI TECH HLDG

Pharmaceutical dispensing system and associated method

InactiveUS20100176145A1Improve securityEliminate wasteSmall article dispensingDrug and medicationsLong-term careDrug dispensing

A dispensing system and associated method provides a turnkey solution for dispensing pharmaceutical products such as solid medications and nutritional supplements to be taken orally in health care settings, including but not limited to long term care (LTC) and assisted living settings.

Owner:REMEDI TECH HLDG

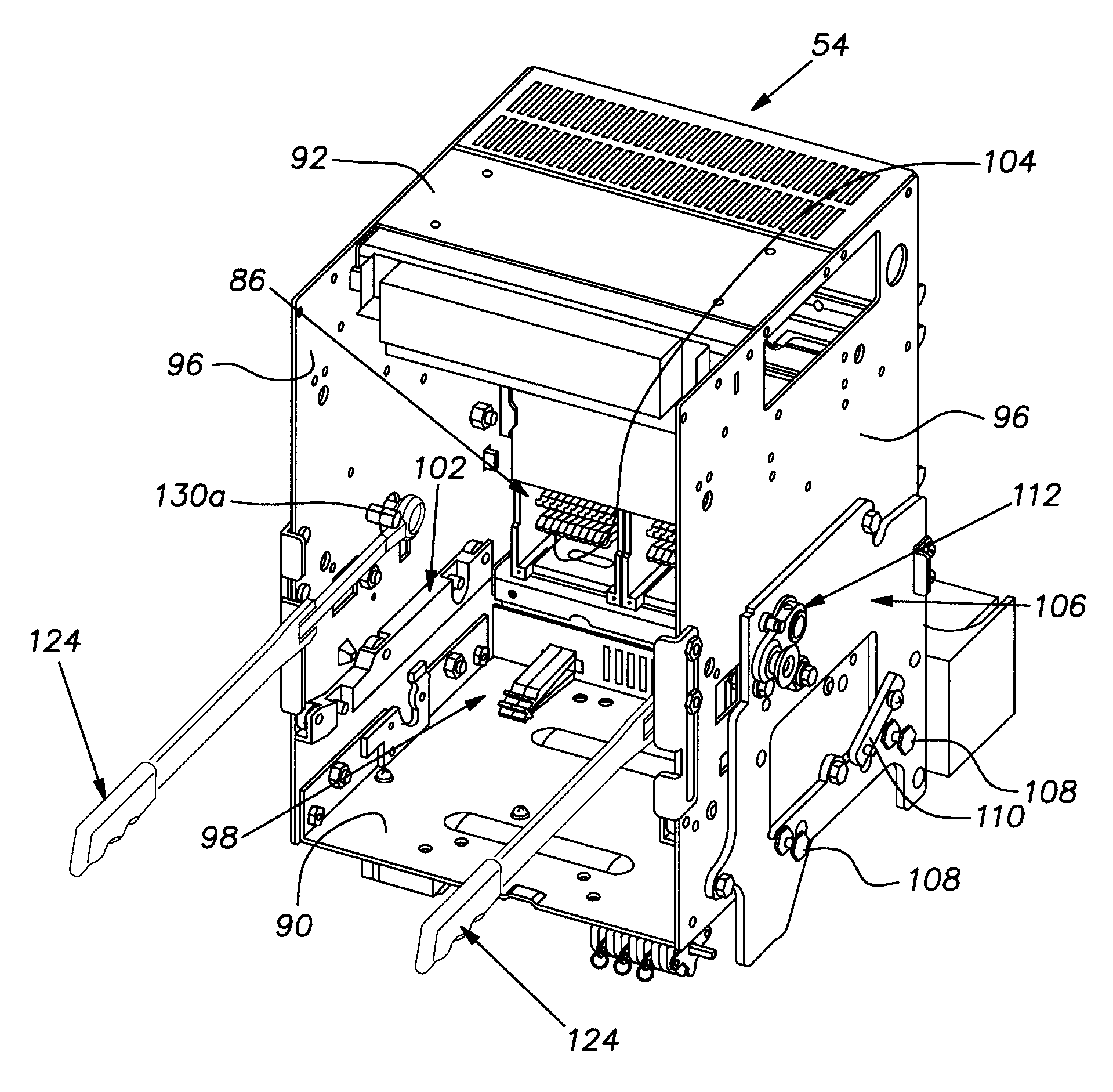

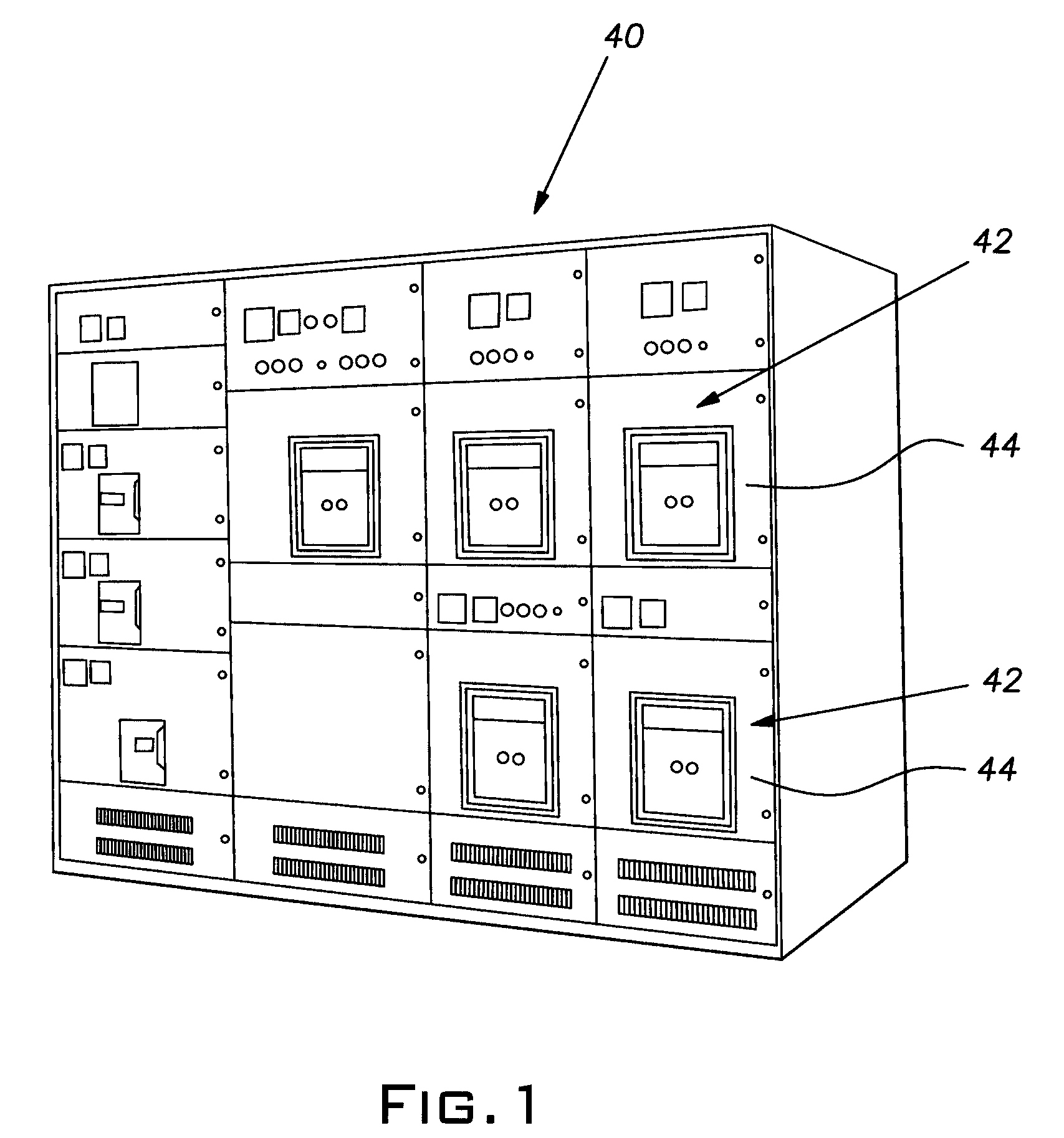

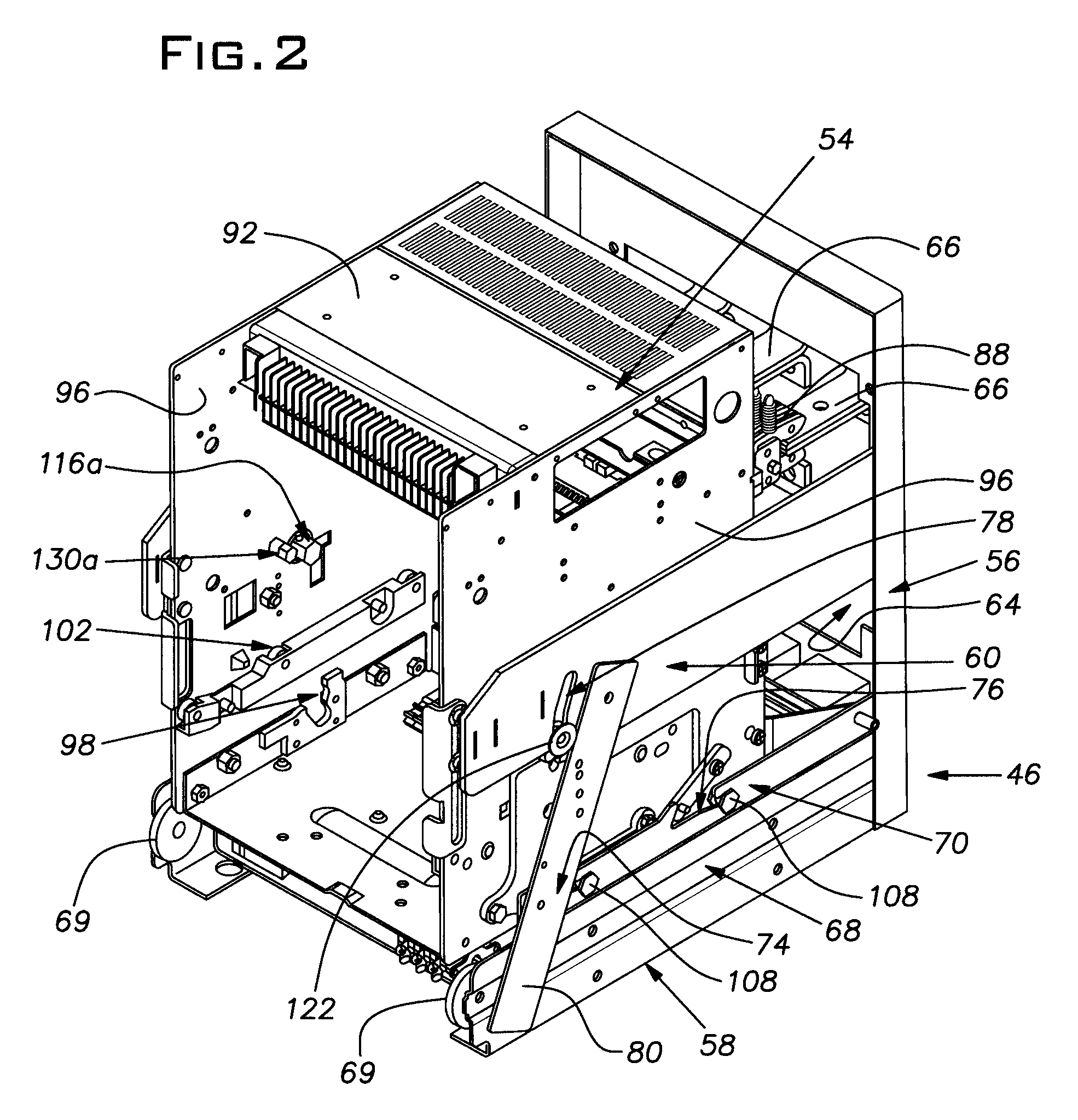

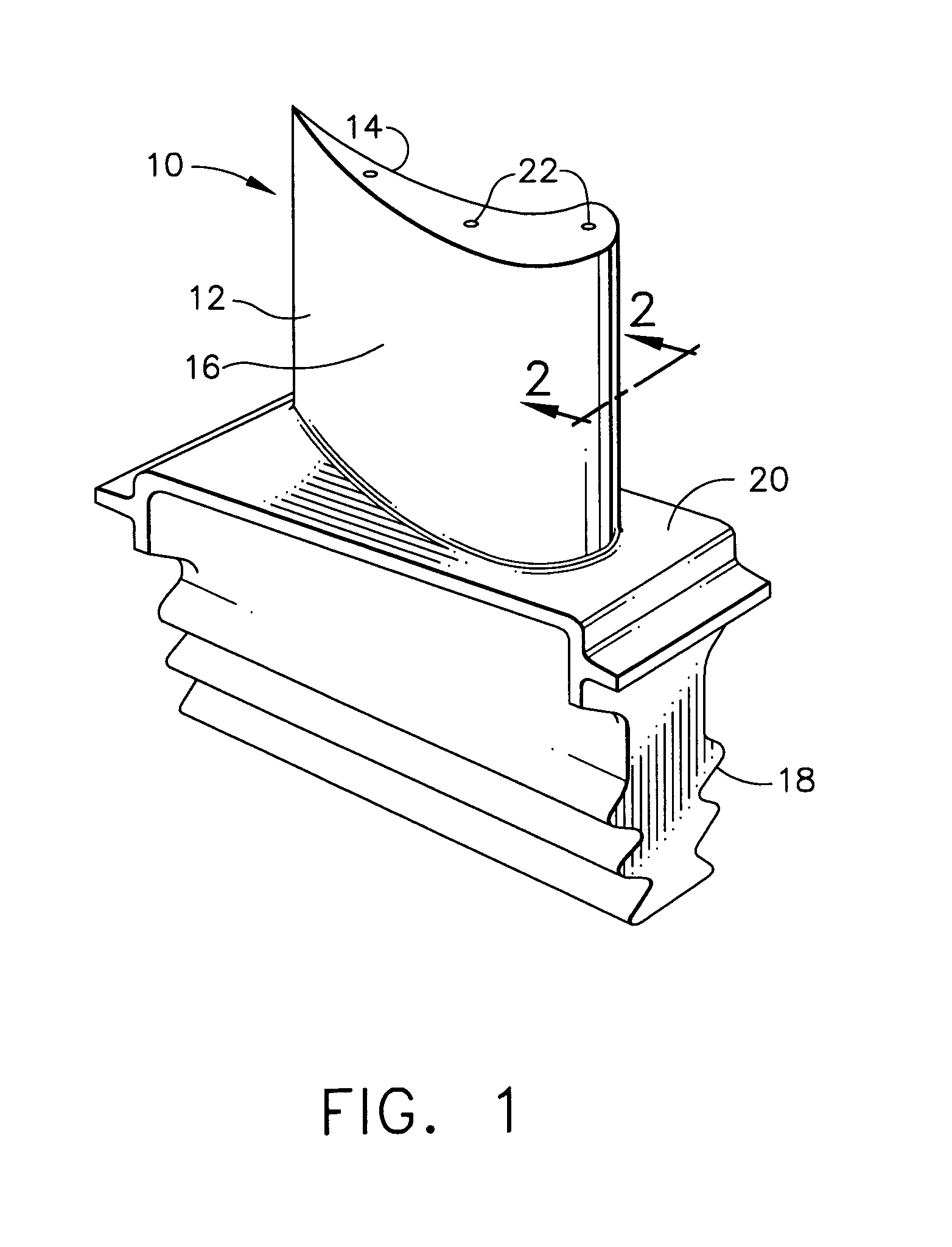

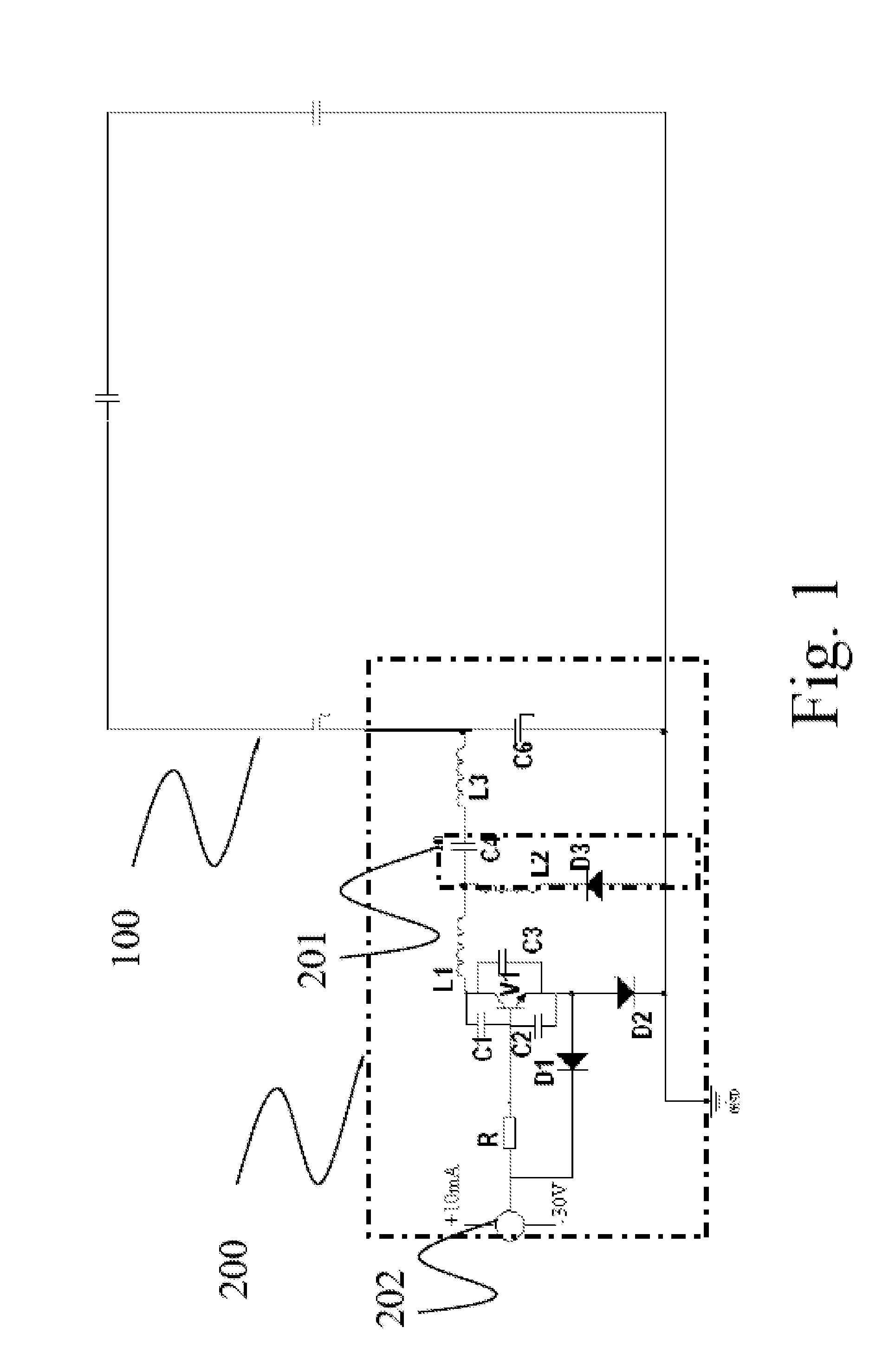

Circuit breaker cradle with an interlock system and a method of using the same

ActiveUS7544908B2Avoid disposition problemsSwitchgear with horizontal withdrawalHigh-tension/heavy-dress switchesElectrical connectionEngineering

A cradle and a method for adapting a circuit breaker for mounting in a switchgear cabinet having a bus bar system. The cradle includes a frame to which a racking apparatus and a locking apparatus are mounted. The racking apparatus is operable to move the cradle into and out of electrical connection with the bus bar system. The locking apparatus has a first operating state, wherein the locking apparatus prevents the circuit breaker from being disposed in the frame and allows the racking apparatus to operate, and a second operating state, wherein the locking apparatus allows the circuit breaker to be disposed in the frame and prevents the racking apparatus from operating.

Owner:ABB (SCHWEIZ) AG

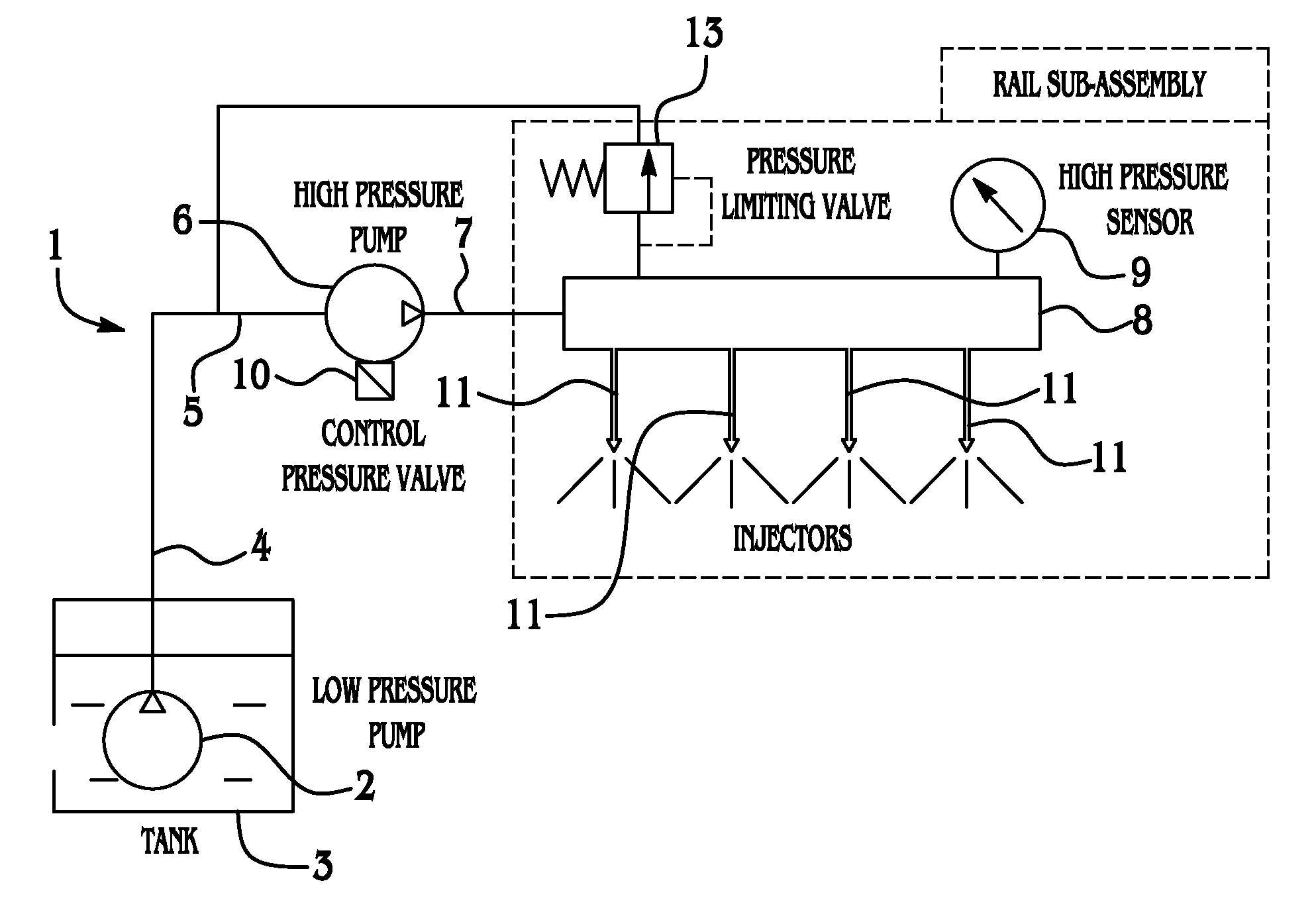

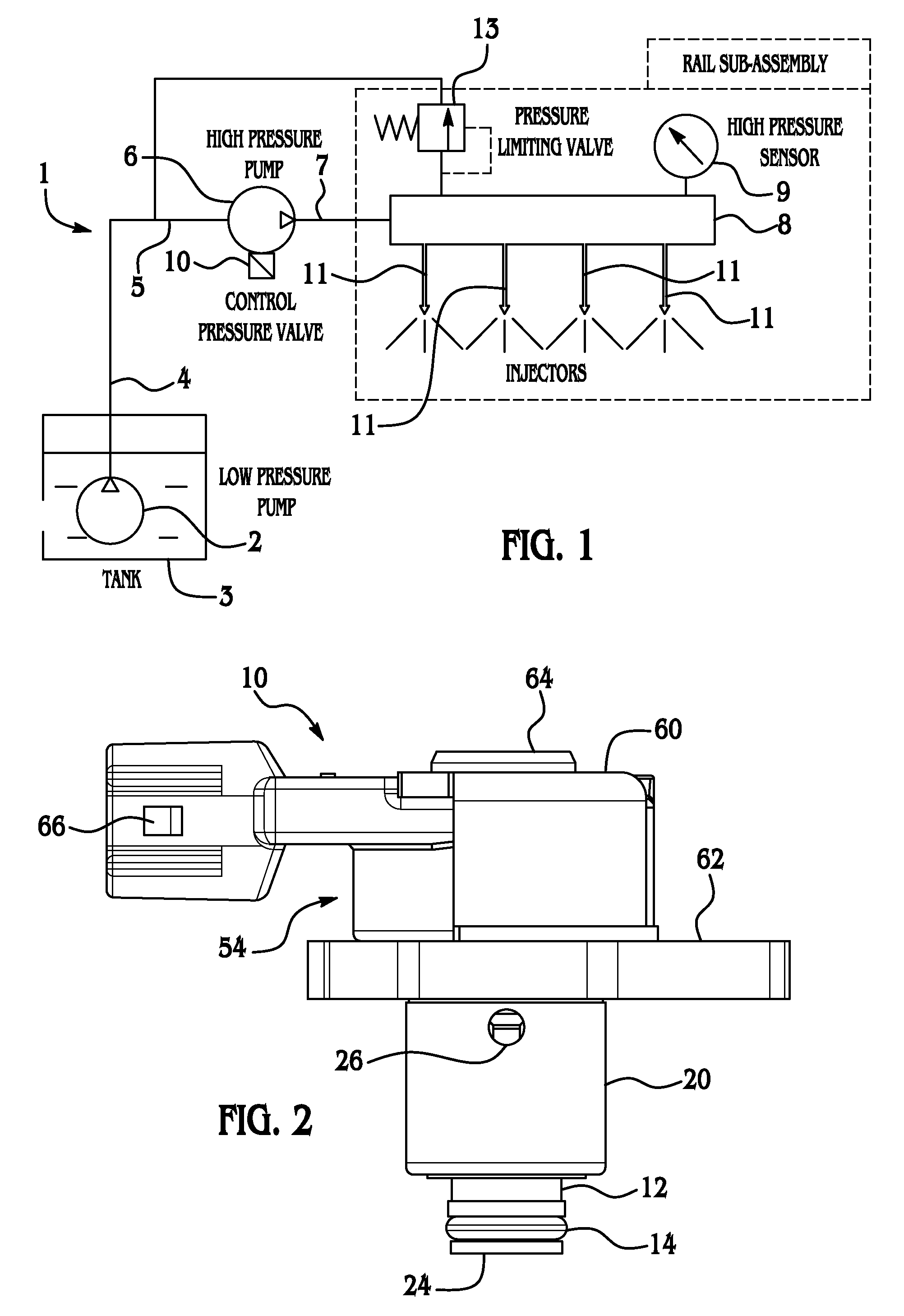

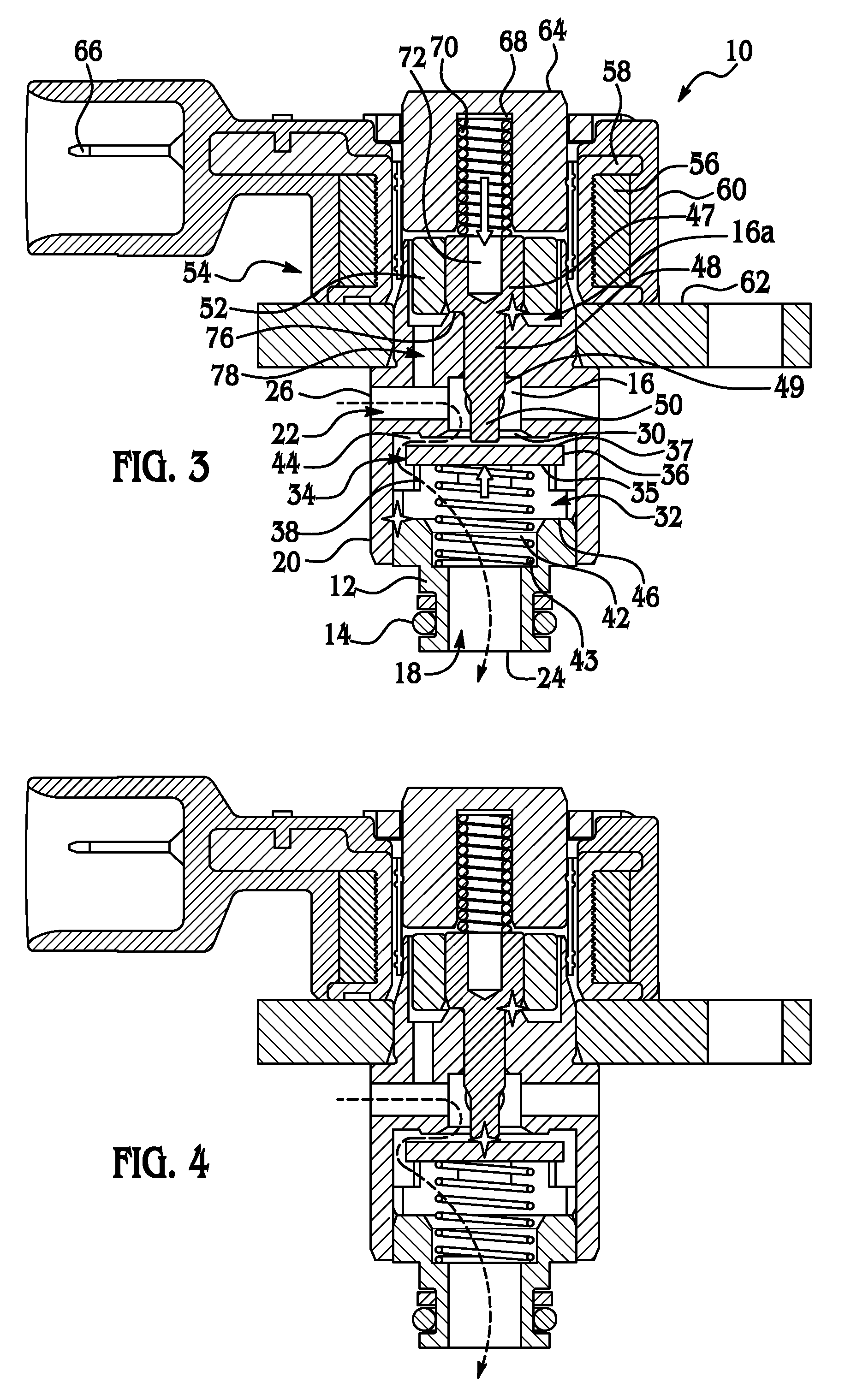

Control valve for a gas direct injection fuel system

InactiveUS20080203347A1Avoid communicationAvoid disposition problemsValve arrangementsMachines/enginesEngineeringActuator

A control valve for a gas direct injection fuel delivery system is provided. The control valve comprises a valve body, a poppet movably received within the valve body, and an actuator disposed within the valve body. The valve body has a first fluid path, a second fluid path, and a valve seat providing fluid communication therebetween. The poppet is capable of movement between a first position and a second position. When disposed in the first position, the poppet seals the valve seat to block fluid communication between the first fluid path and the second fluid path. The poppet permits fluid communication between the first fluid path and the second fluid path as the poppet moves from the first position to the second position. The poppet is configured so that a pressure in the first fluid path produces a force that tends to move the poppet toward the second position and a pressure in the second fluid path produces a force that tends to move the poppet toward the first position. The actuator is configured to transition between an activated and a de-activated state. The actuator prevents the poppet from being disposed in the first position when in the de-activated state and the pressure in the second fluid path does not exceed the pressure in the first fluid path by at least a first pressure differential. The actuator permits the poppet to be disposed in the first position when in the activated state.

Owner:DELPHI TECH INC

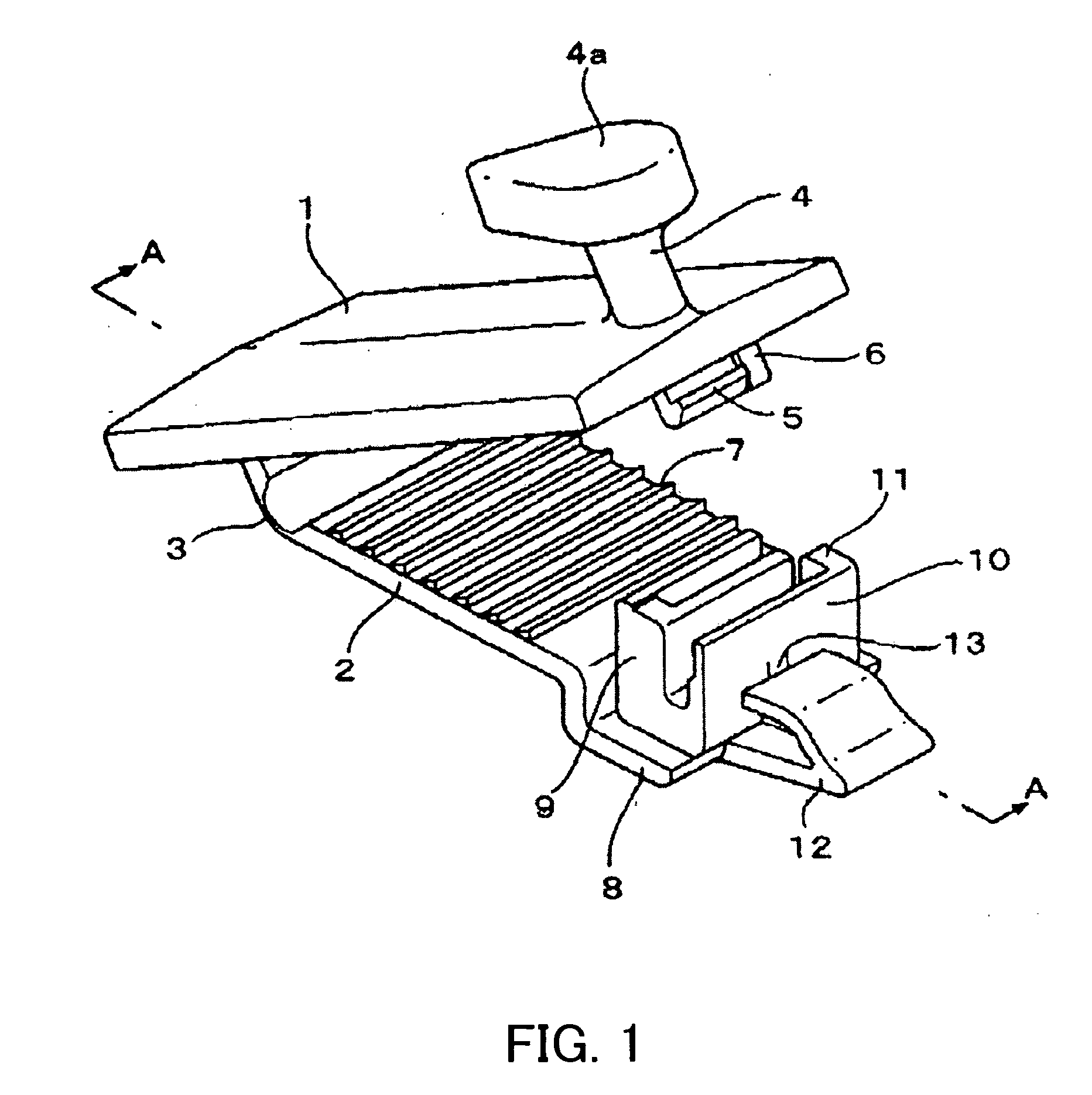

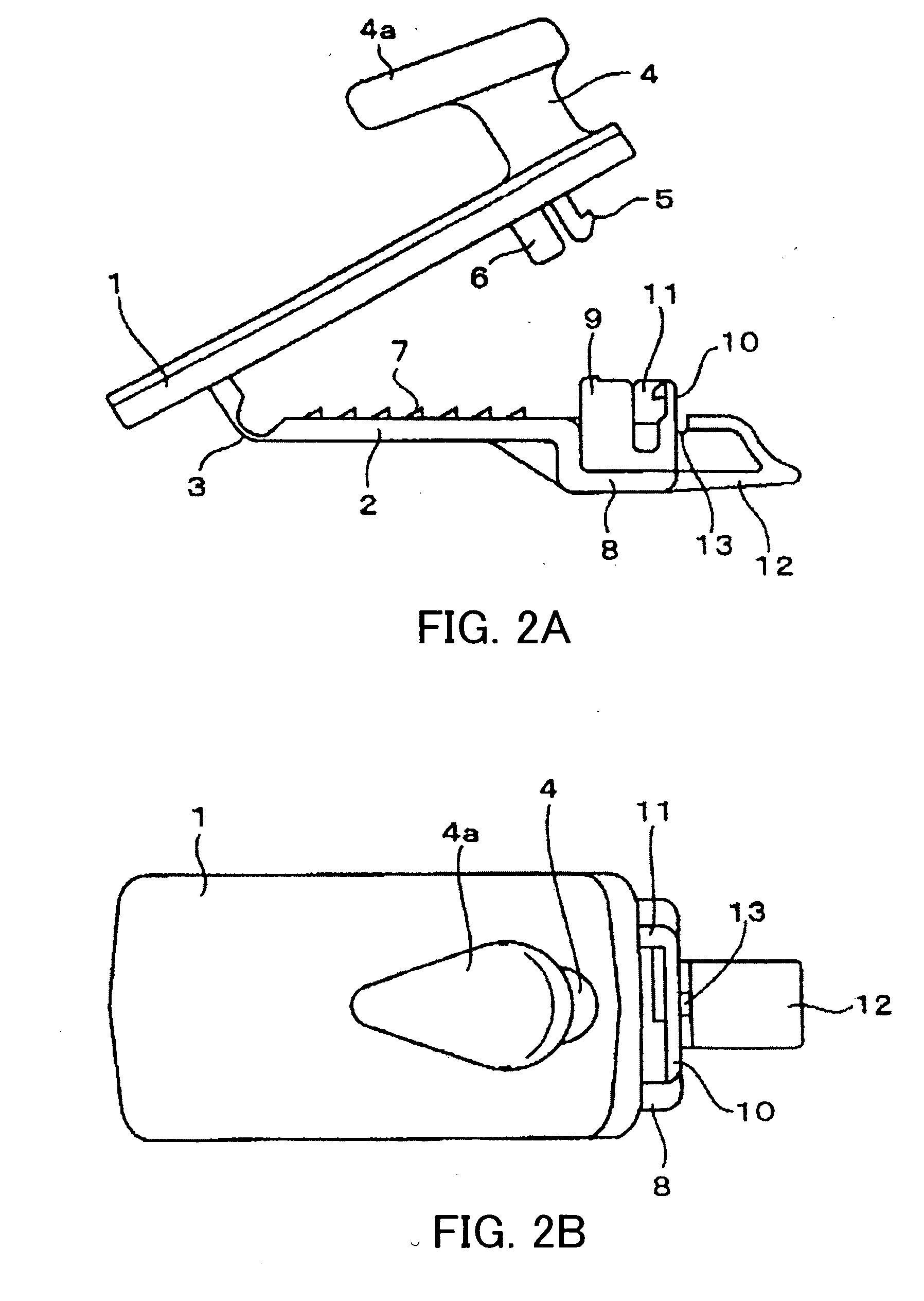

Fastener for floor mat

ActiveUS20070011844A1Avoid disposition problemsEasy to operateVehicle arrangementsMulti-purpose toolsEngineeringFastener

A fastener for securing an automobile floor mat to a carpet laid on a floor within an automobile includes a lower clamping member, an upper clamping member, a hinge portion connecting the upper clamping member and the lower clamping member in a pivotable manner, a supporting portion forwardly protruded from a tip end portion of the lower clamping member, and a guide protrusion forwardly protruded from a tip end portion of the supporting portion and configured to so as to facilitate an insertion of the supporting portion and the lower clamping member to a backside of the carpet via a slit formed in the carpet. The upper clamping member has an engaging projection formed at an outer surface of a tip end portion thereof and configured to be inserted in an attaching hole formed in the floor mat and a locking portion formed at an inner surface of the tip end portion. The supporting portion has an engaging portion for engaging the engaging portion of the upper clamping member. An upper surface of the guide protrusion is tapered.

Owner:PIOLAX CO LTD

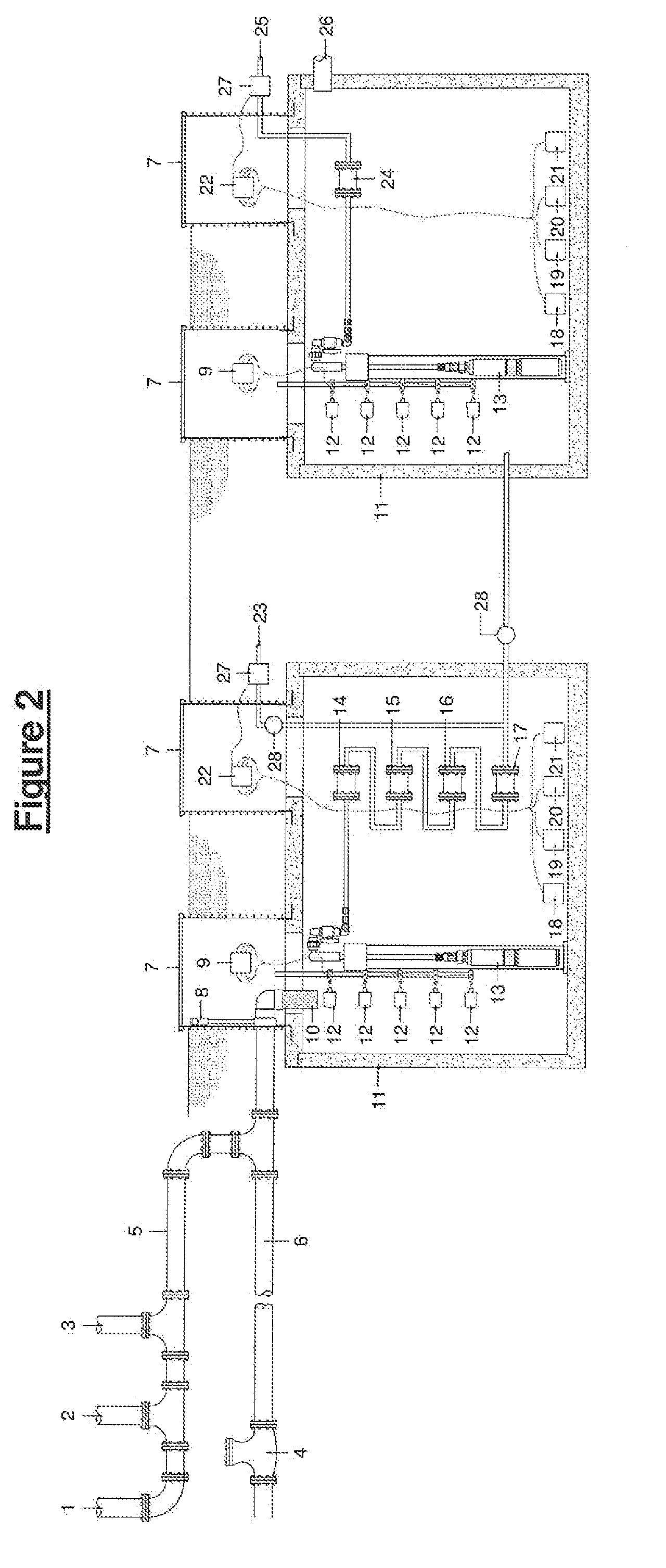

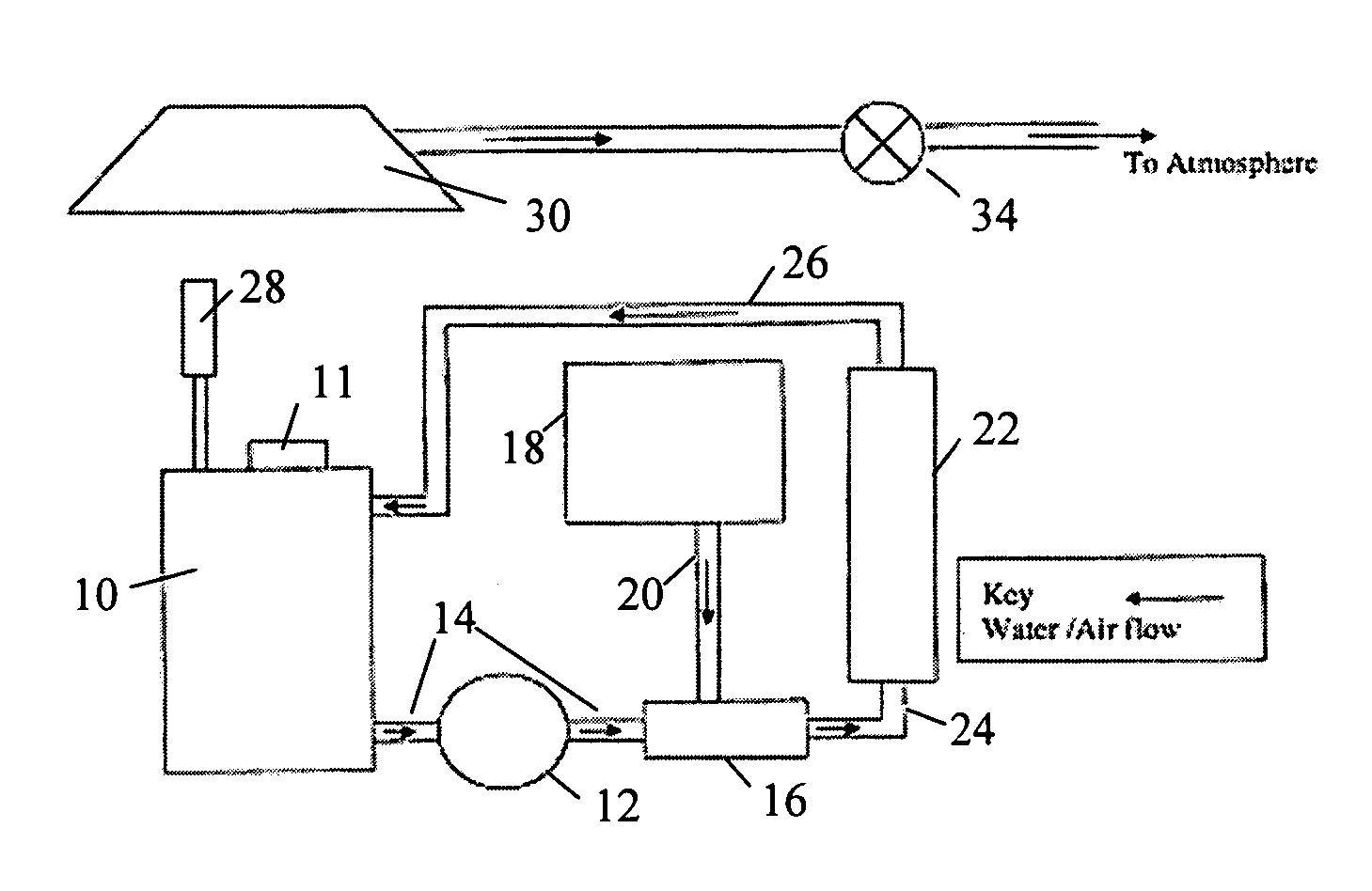

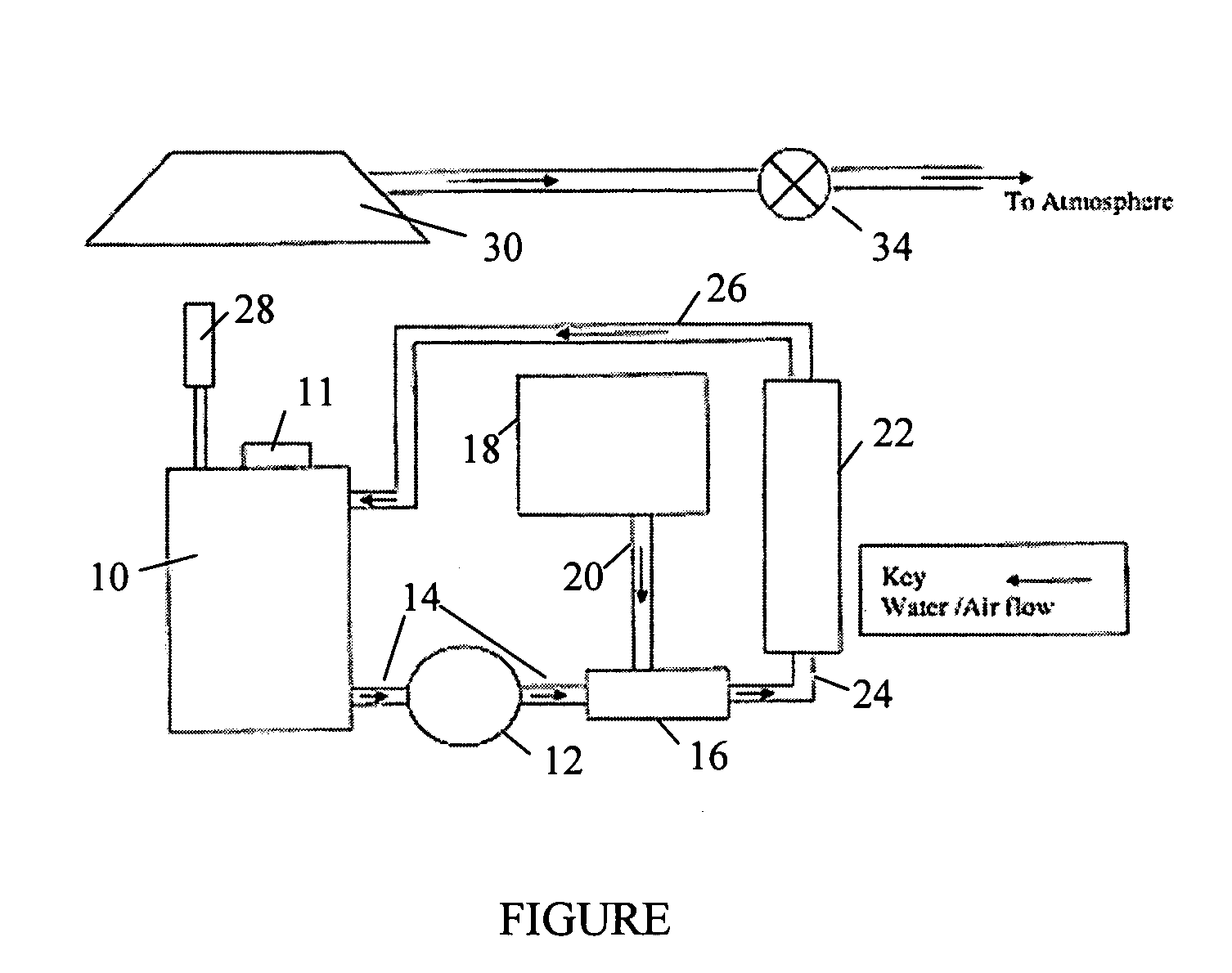

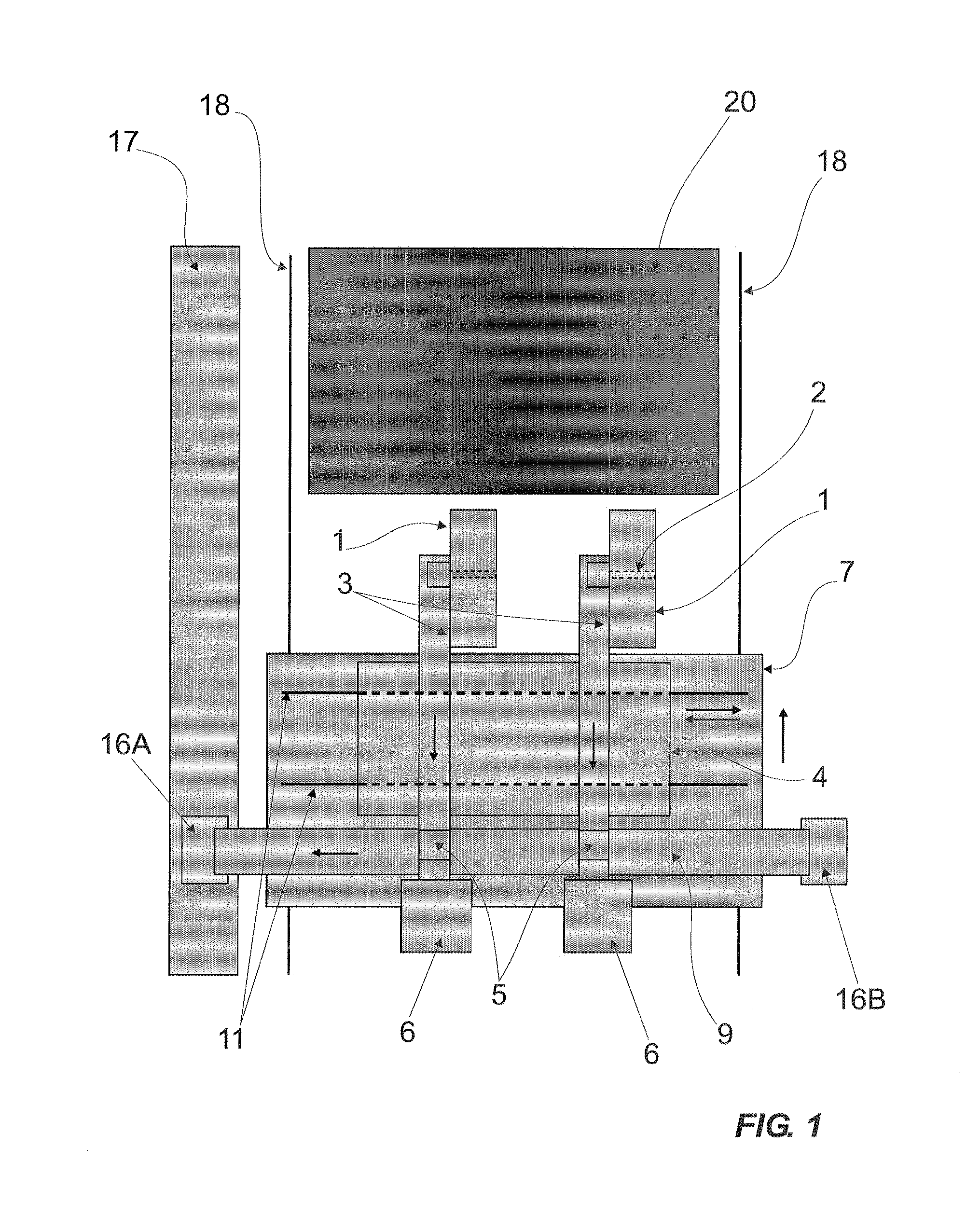

Process for Rain Water, HVAC Condensate and Refrigeration Blowdown/Bleed Blowdown/Bleed Water Recovery, Water Quality Monitoring, Real Time Water Treatment and Utilization of Recovered Water

InactiveUS20110017678A1Easy to useEfficient use of waterProgramme controlSemi-permeable membranesFiltrationWater quality

The present invention includes capturing water from rain, HVAC condensate and refrigeration blowdown / bleed blowdown that is recycled and reutilized in integrated mechanical processes. Water is monitored for volume, flow rate, and contaminants; and automatically cleaned through filtration and / or chemical and / or biological treatment techniques to meet acceptable health and safety standards for engineered end uses. The process components are integrated into an engineered system that includes: 1) water collection from air conditioning and refrigeration units and rain water; 2) custom design, engineering and implementation of a real time and / or scheduled water monitoring for water volume and water quality; 3) custom design, engineering and implementation of a real time and / or scheduled water treatment system to ensure water quality standards are met with respect to the end use of the recovered water; and 4) utilization of the recovered water by an engineered water distribution system.

Owner:ANDERSON DENNIS M +1

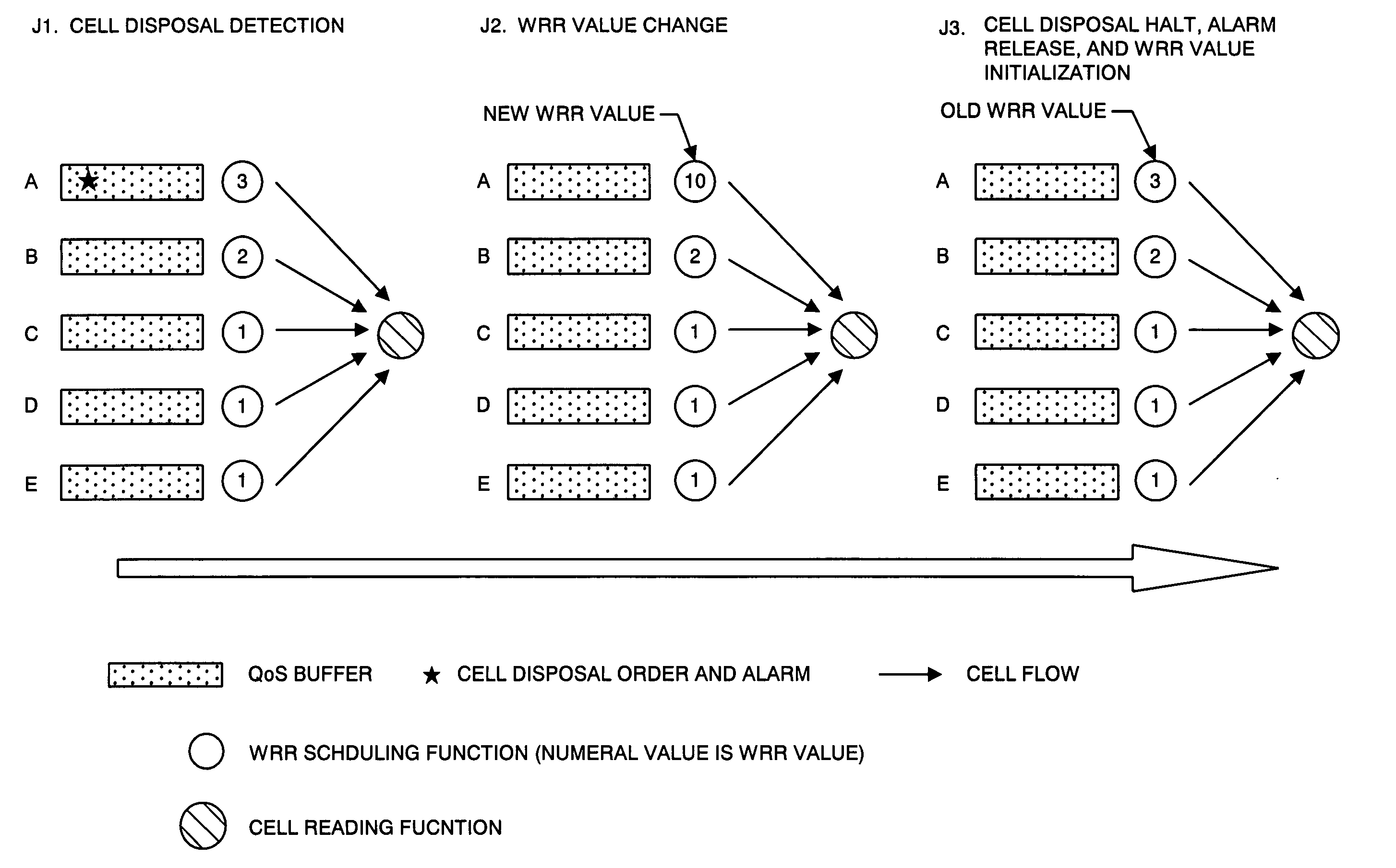

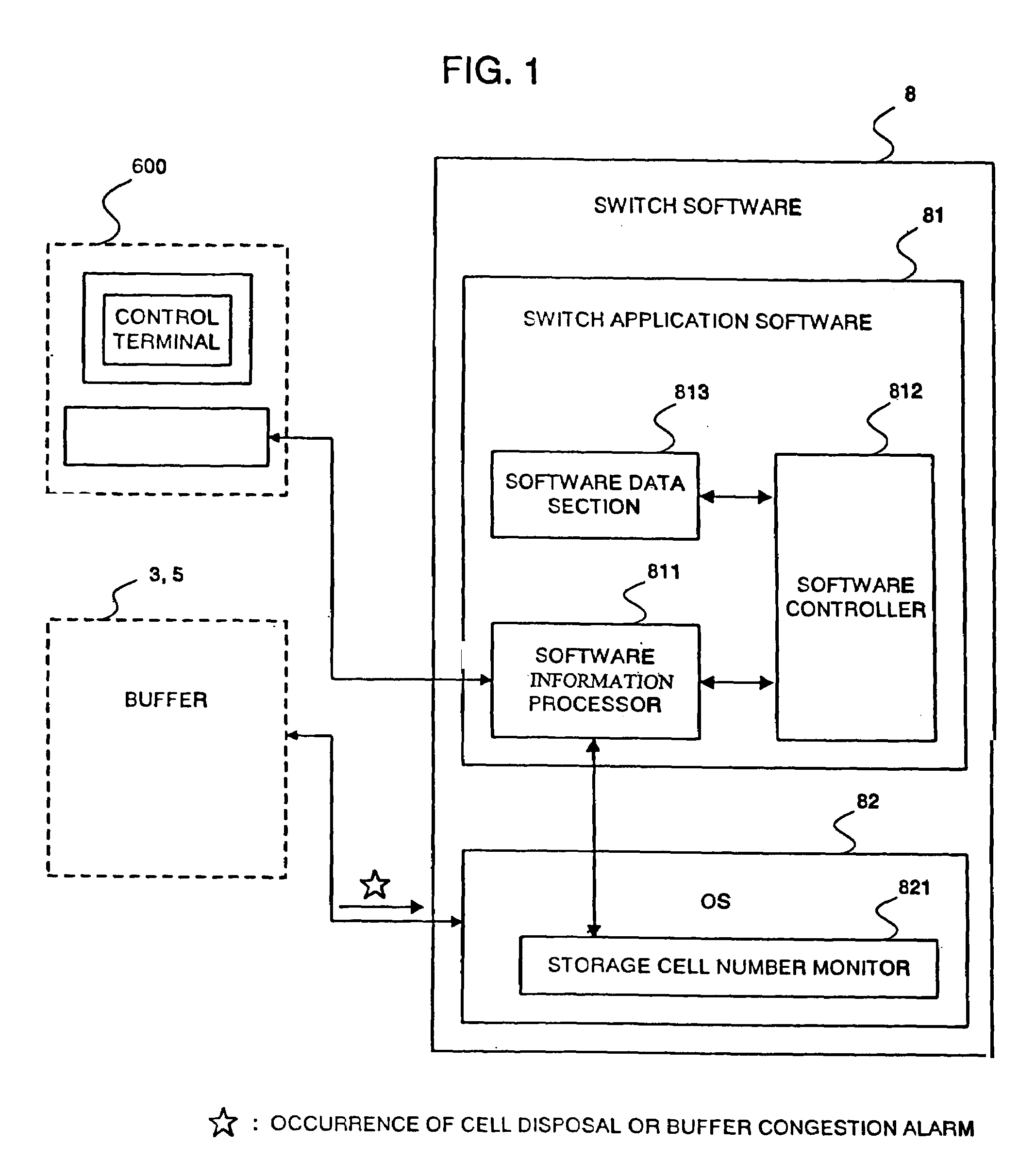

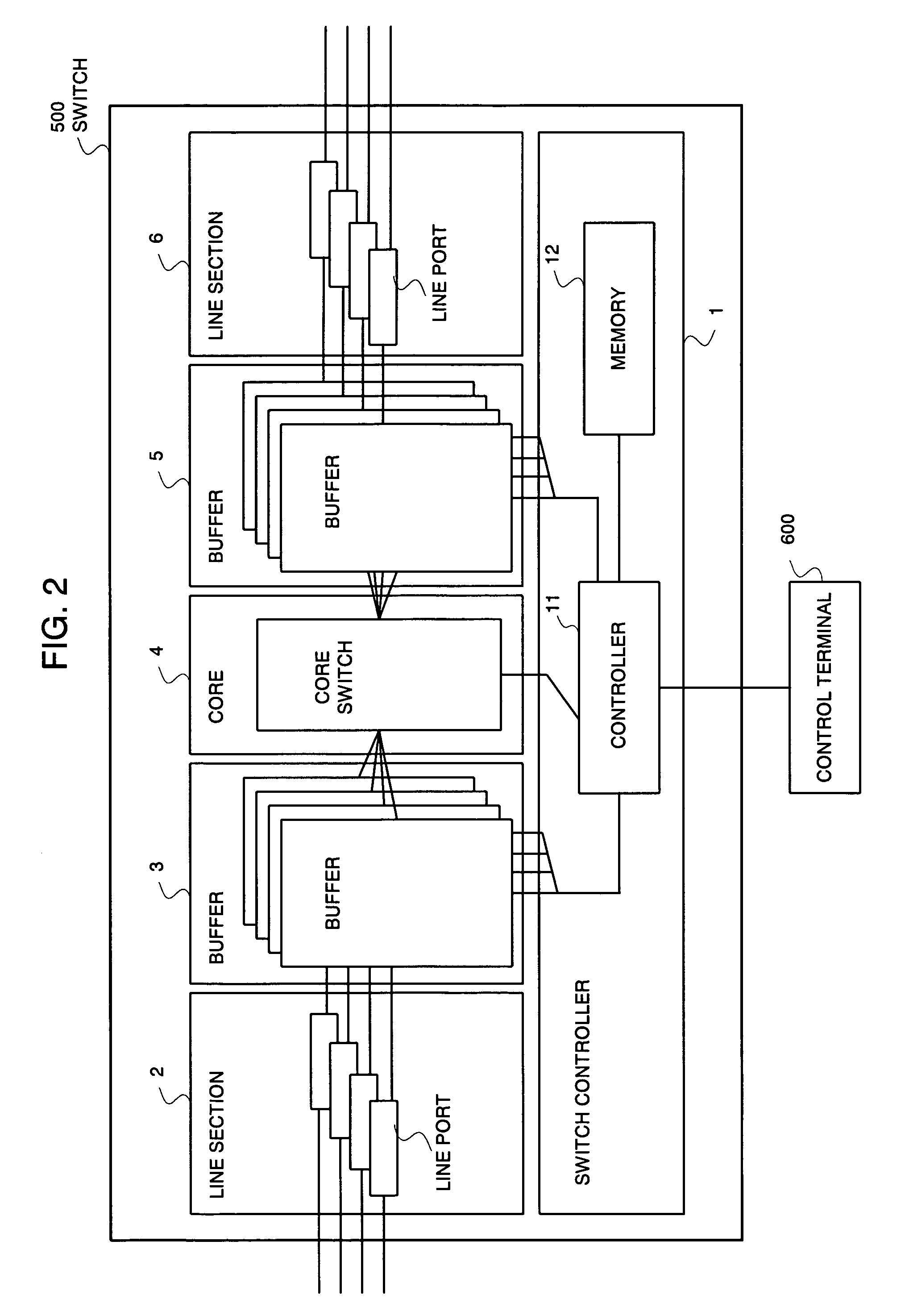

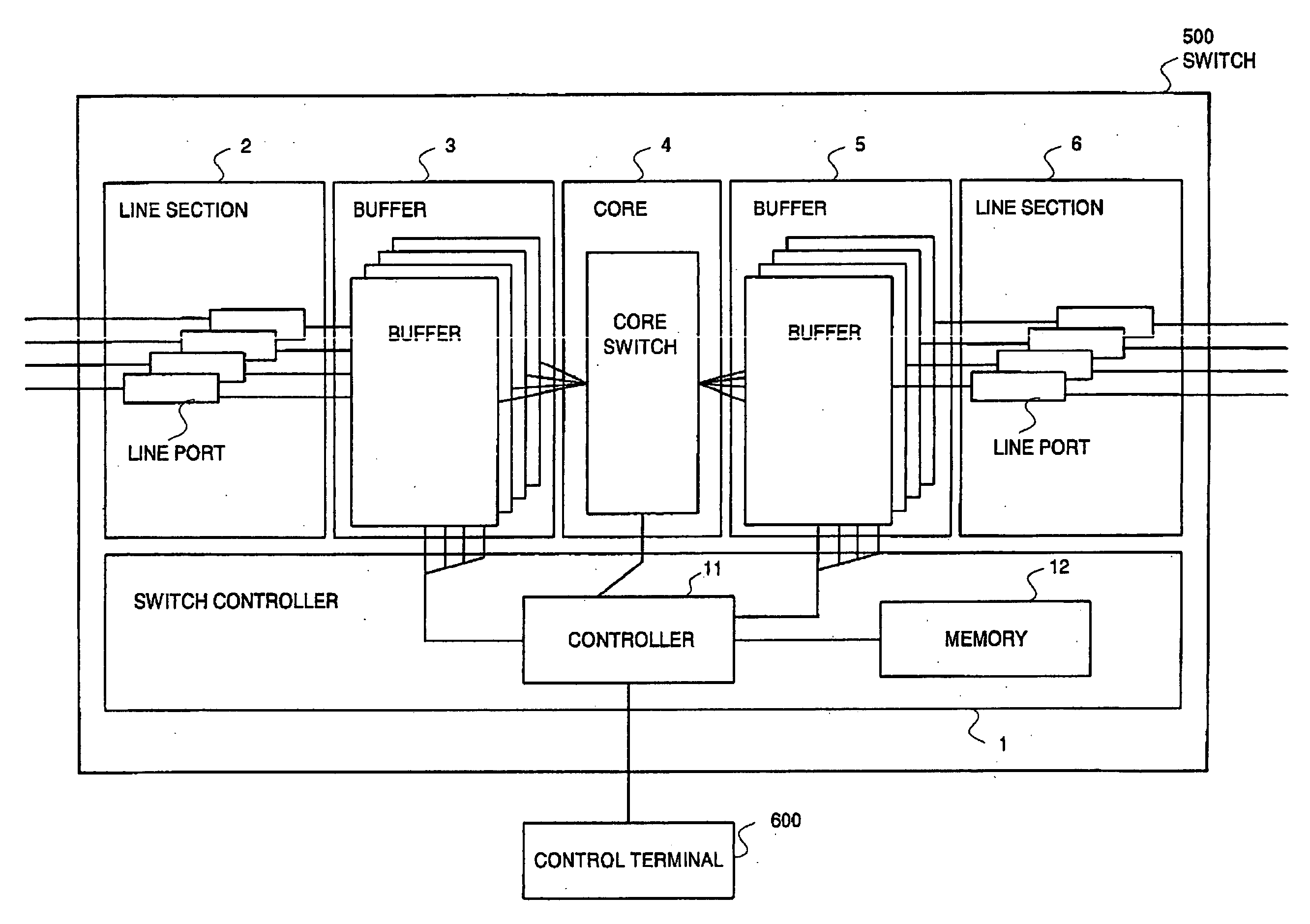

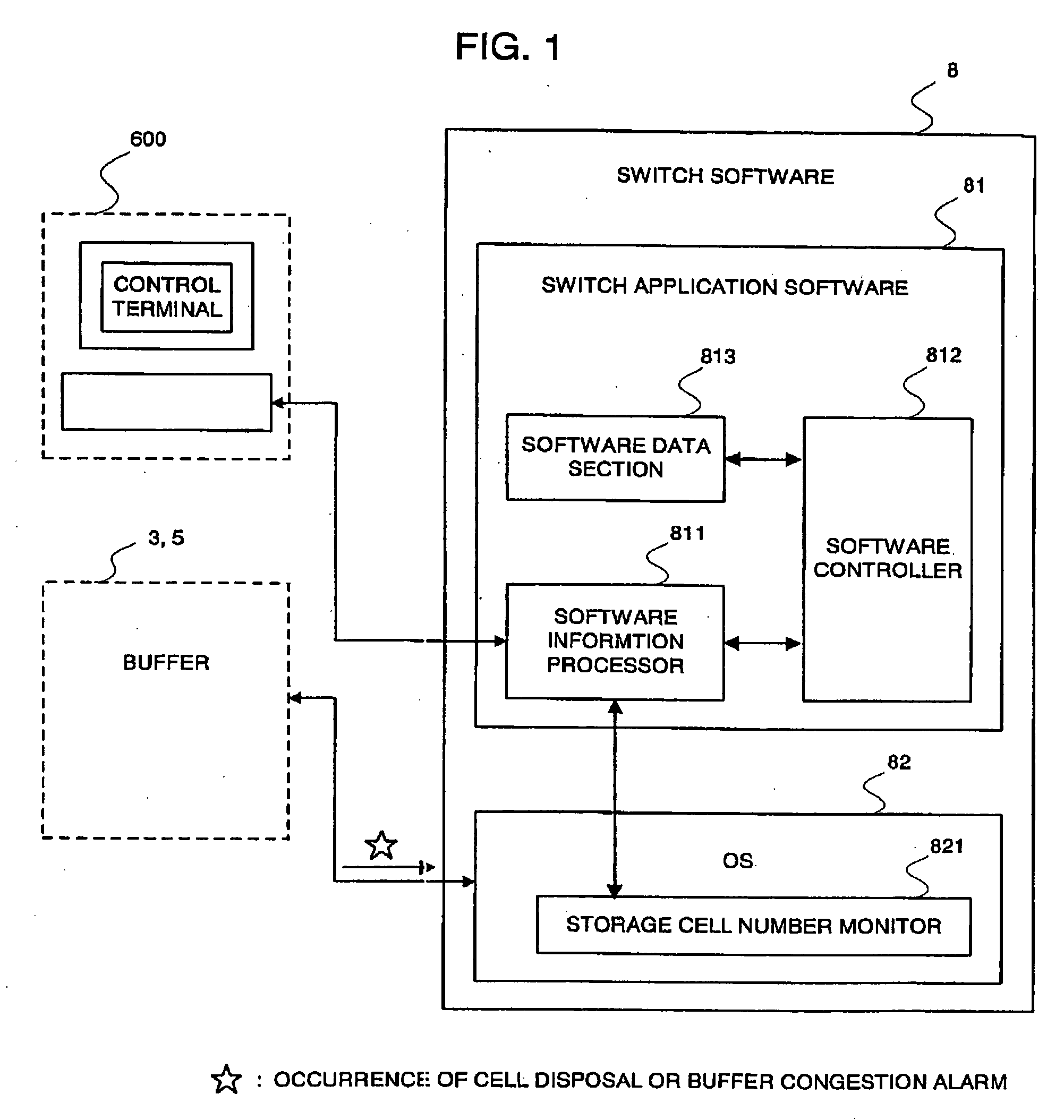

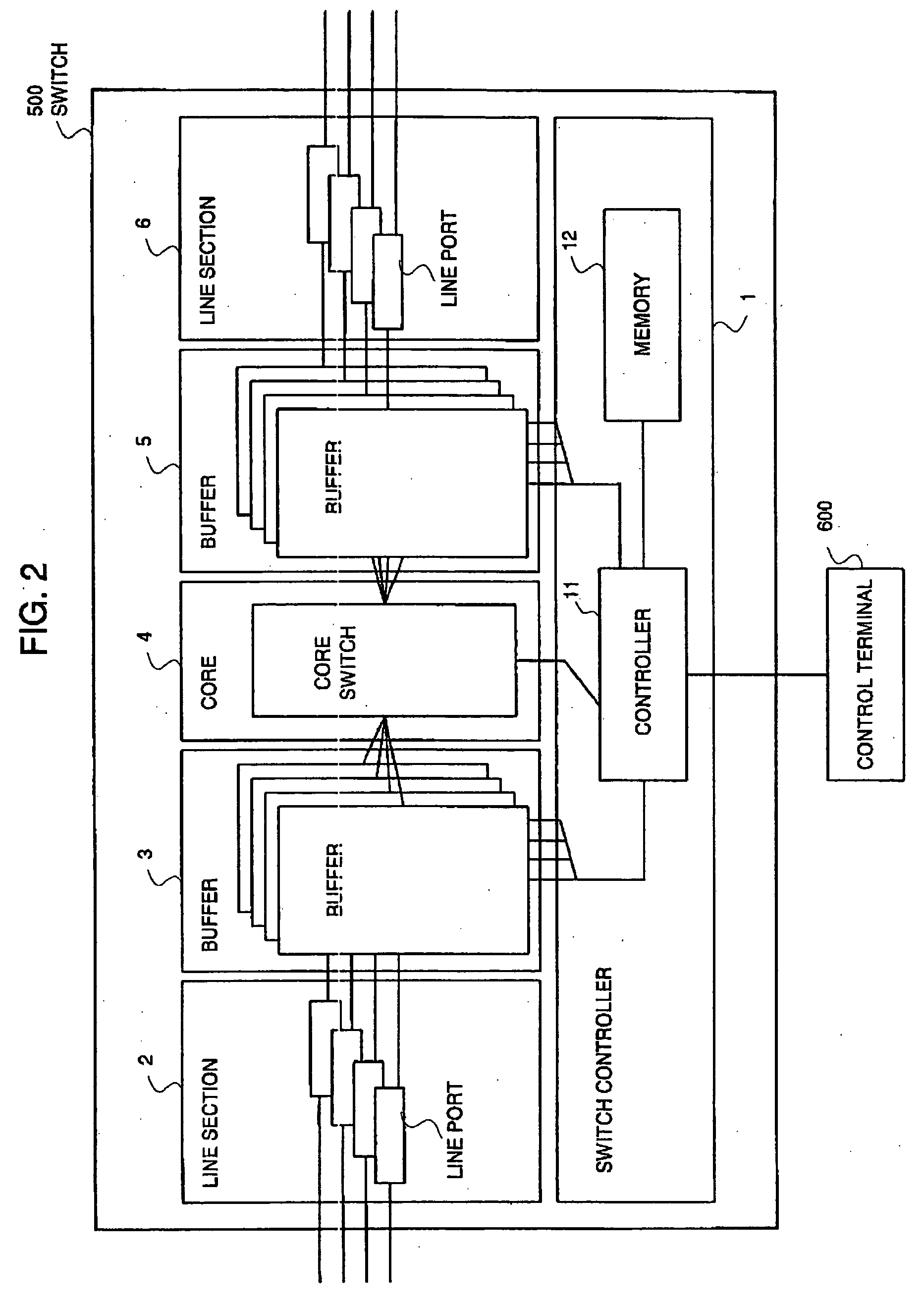

System and method of avoiding cell disposal in buffer

InactiveUS6975630B1Avoid disposition problemsData switching by path configurationFault locationData bufferStorage cell

A cell disposal avoidance system is provided that can avoid disposal of cells resided in the QoS buffer when a traffic of a specified QoS class in an ATM switch increases. The ATM switch includes a storage cell number monitor, a software data section 813, and a software controller 812. The storage cell number monitor monitors congestion of plural QoS buffers in the buffer 3, 5. The software data section 813 stores a cell reading priority (WRR value) attached for each QoS buffer. The software controller 812 dynamically changes the WRR value when congestion of a QoS buffer is in a congestion state (at generation of cell disposal or buffer congestion alarm) and increases the WRR value of the QoS buffer in a cell disposal state. Cells are divided in a time division mode according to the weight of the WRR value and read in a round format from the QoS buffer. The ATM switch resets the WRR value to an initial value when the congestion of the QoS buffer ceases.

Owner:JUMIPER NETWORKS INC

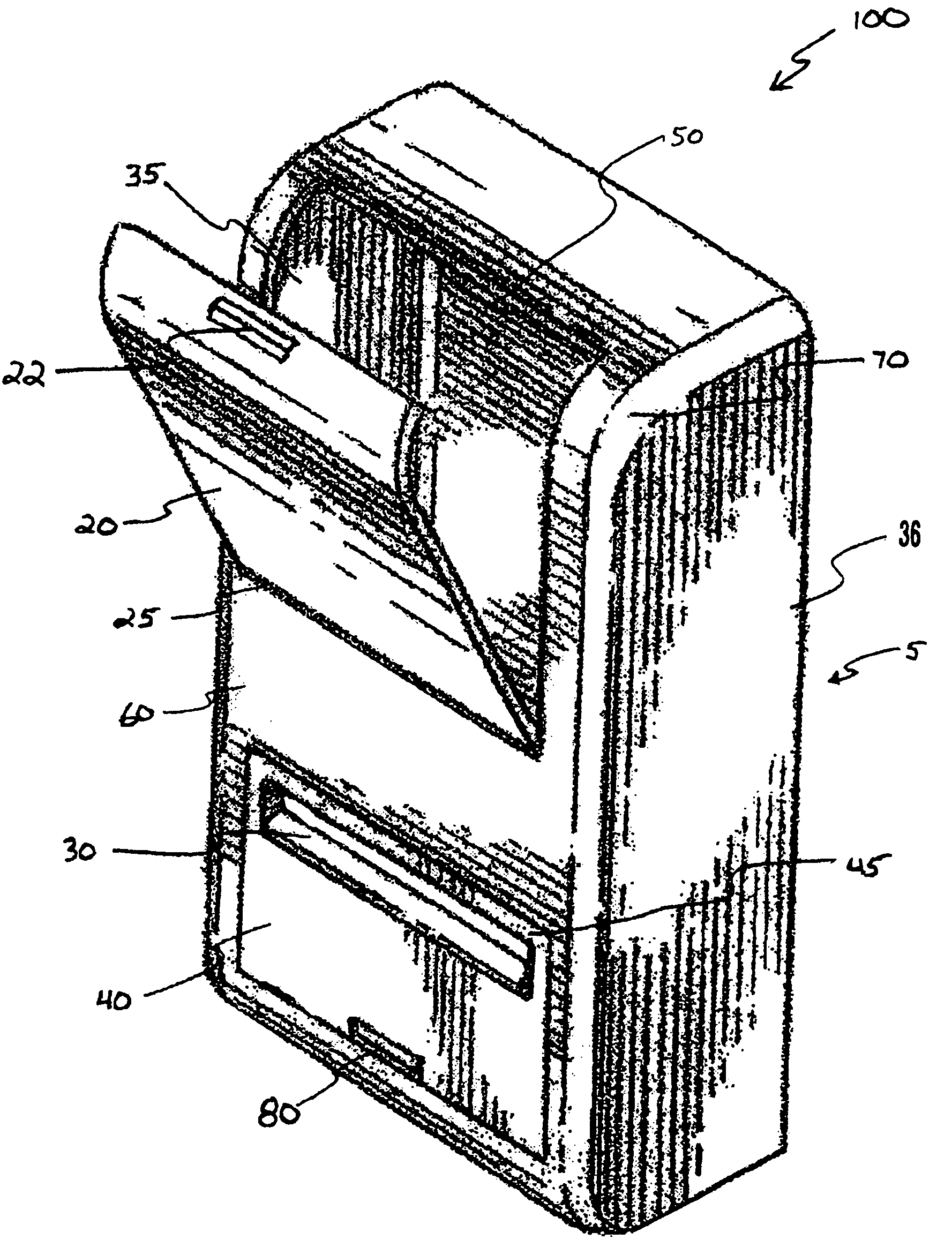

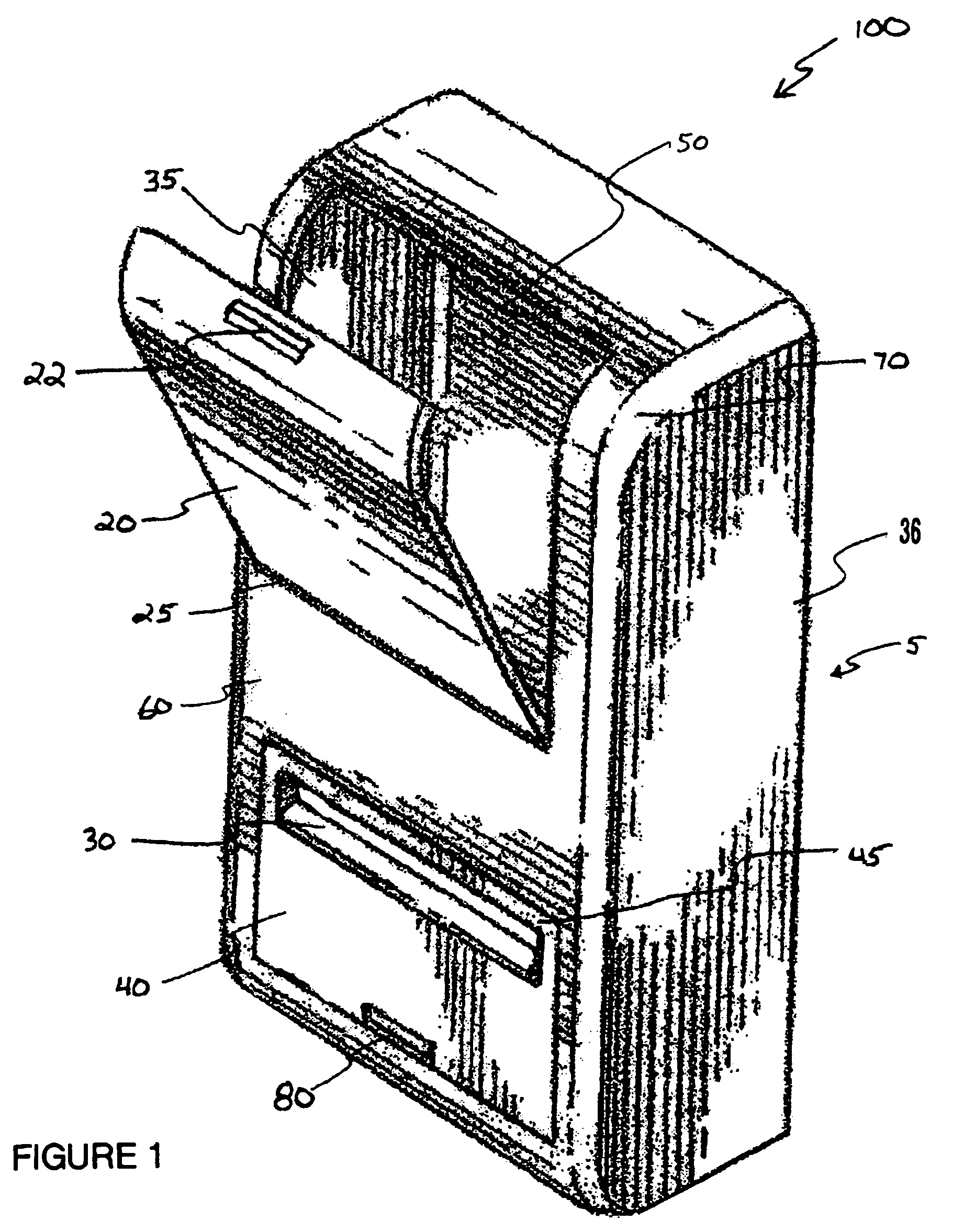

Multiple toilet paper holder and dispenser

InactiveUS7374128B2Avoid disposition problemsFilament handlingDomestic applicationsEngineeringToilet paper

A toilet paper dispenser that is configured to retain and subsequently dispense a plurality of toilet paper rolls. The toilet paper dispenser further includes a front wall, a rear wall and two side walls that are configured to create a container that is generally rectangular in shape having an interior volume. Contiguously mounted to the front wall proximate the upper portion of the container is a door hingedly mounted to allow access to the interior volume for loading of toilet paper rolls. An access flap is mounted generally beneath the door contiguous with the front wall and is hingedly mounted to provide access to the interior volume for retrieval of depleted toilet paper rolls. The access flap further includes a slot that is configured to dispense sheets of toilet paper from the adjacent toilet paper roll substantially disposed within the interior volume of the container.

Owner:HENDRIX ROY D +1

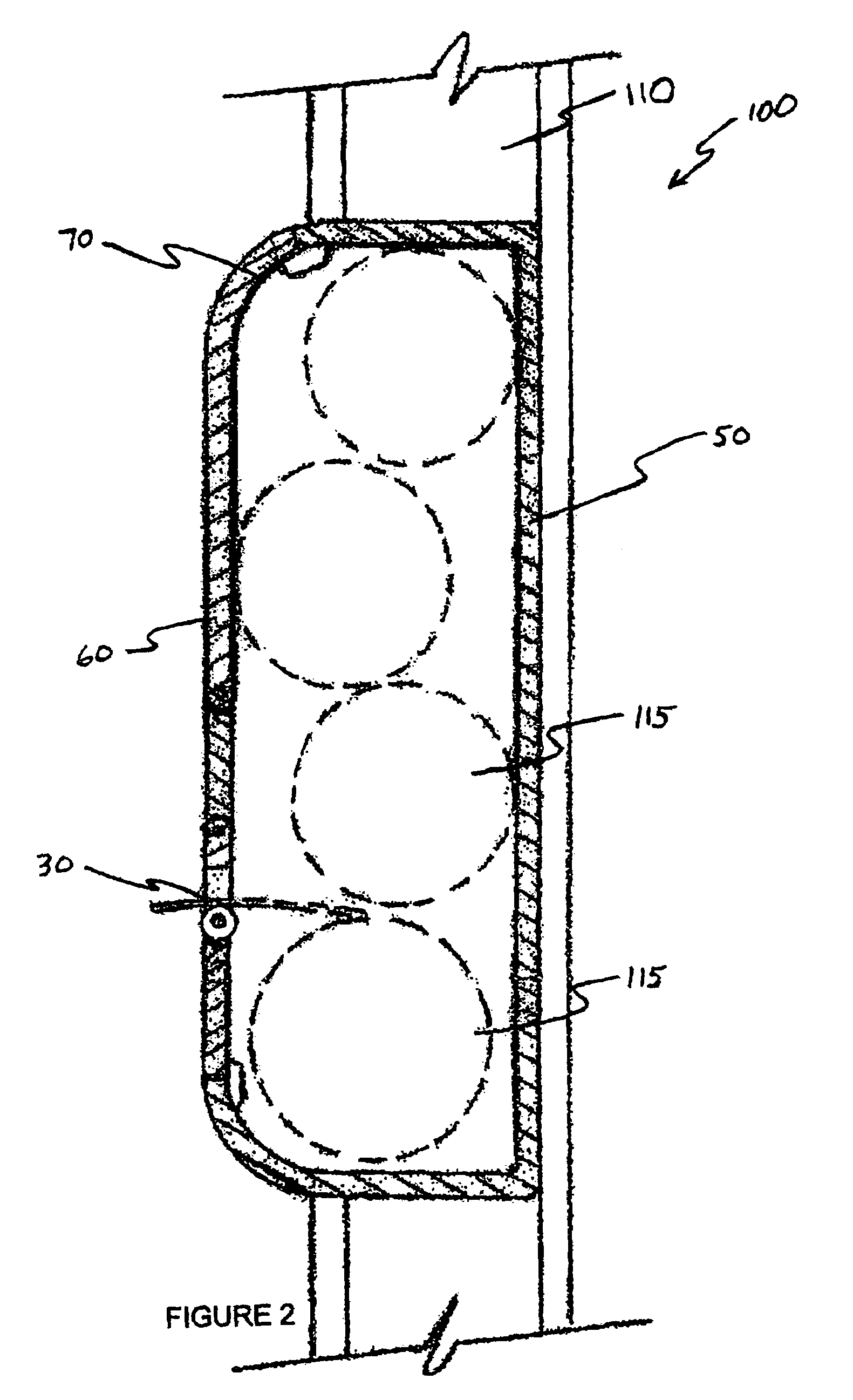

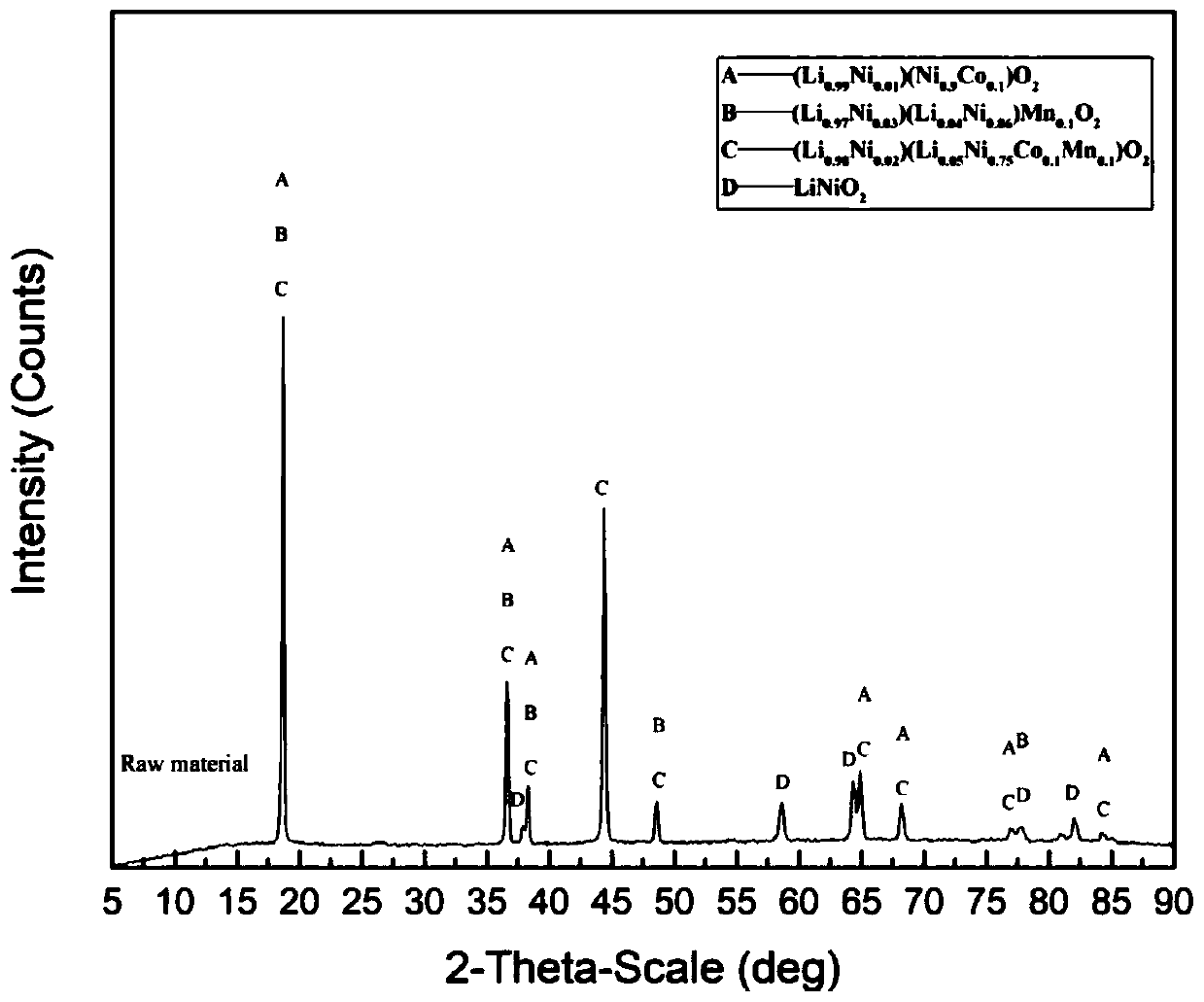

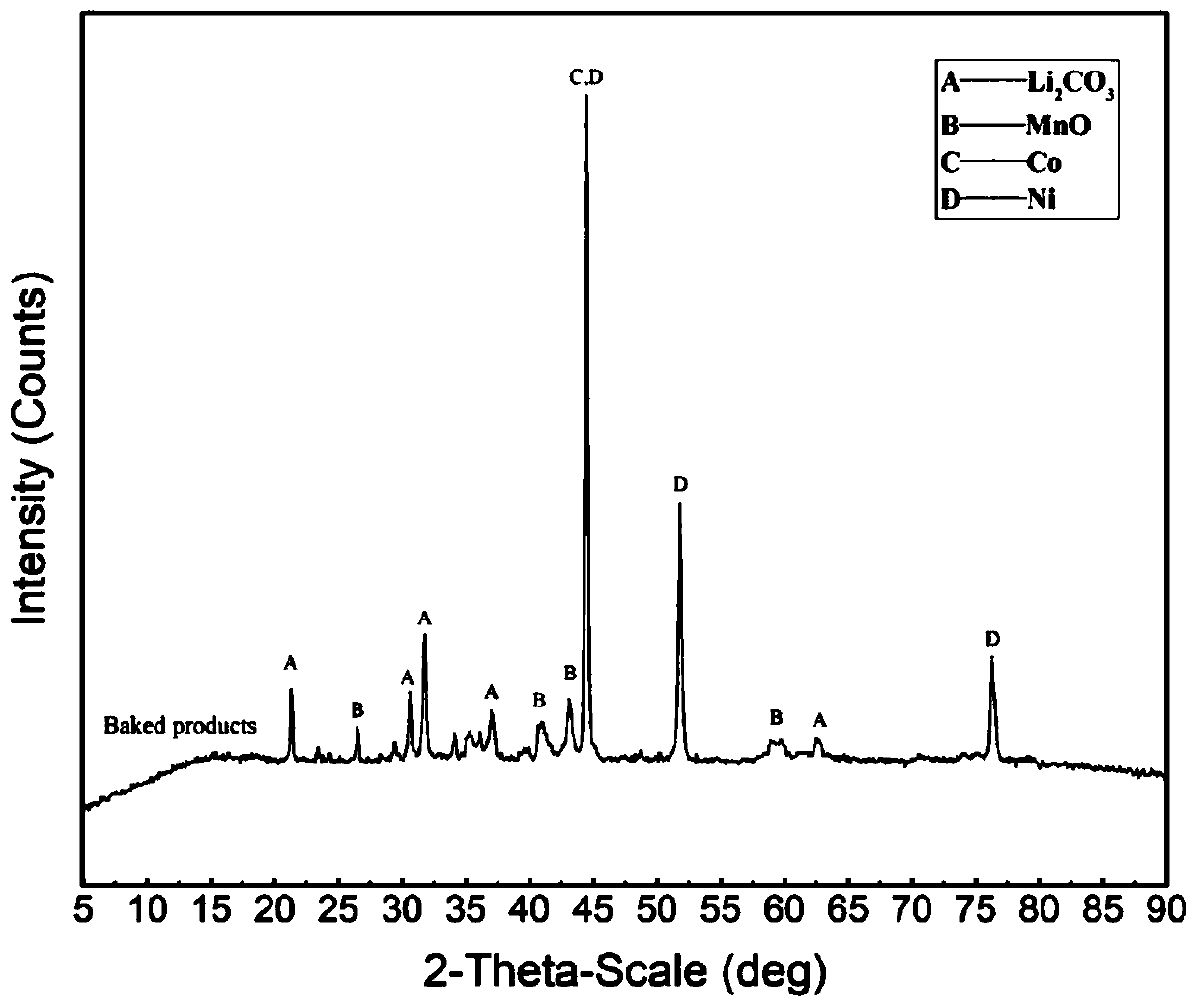

Method for extracting lithium and nickel cobalt from waste lithium ion battery step by step

ActiveCN110938743ASimplify the recycling processHigh selectivityProcess efficiency improvementBattery recyclingLithium carbonateLithium electrode

The invention discloses a method for extracting lithium and nickel cobalt from a waste lithium ion battery step by step, and belongs to the technical field of comprehensive recovery of lithium ion battery materials. The method comprises the following steps of splitting, crushing and screening a waste lithium ion battery to obtain a positive electrode material powder, carrying out reduction roasting on the positive electrode material powder with a carbon-containing reducing agent, size mixing the obtained calcine with water, adding a proper amount of calcium chloride or lime milk solution for reaction transformation, selecting lithium carbonate in the calcine to be extracted into the solution, thereby realizing separation with nickel, cobalt, manganese, iron, aluminum and phosphorus. The method can realize the preferential selective extraction of lithium, the obtained lithium solution is high in purity and lithium concentration, the extraction and impurity removal, evaporation and concentration processes are not needed, the recovery of lithium and the product preparation process are simple, the recovery rate is high, the energy consumption is low, and the environmental problem of high-concentration sodium salt wastewater is not present```.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

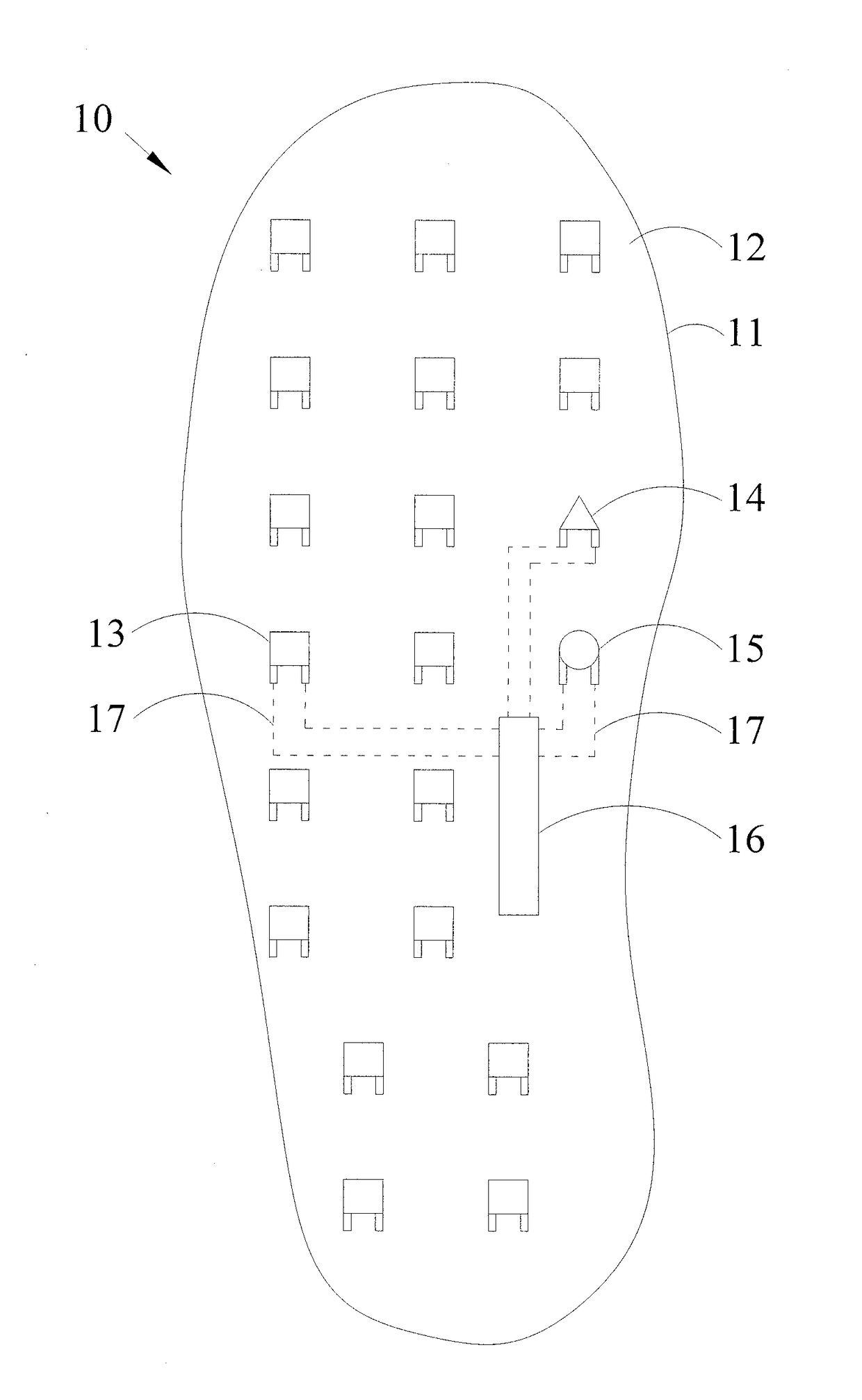

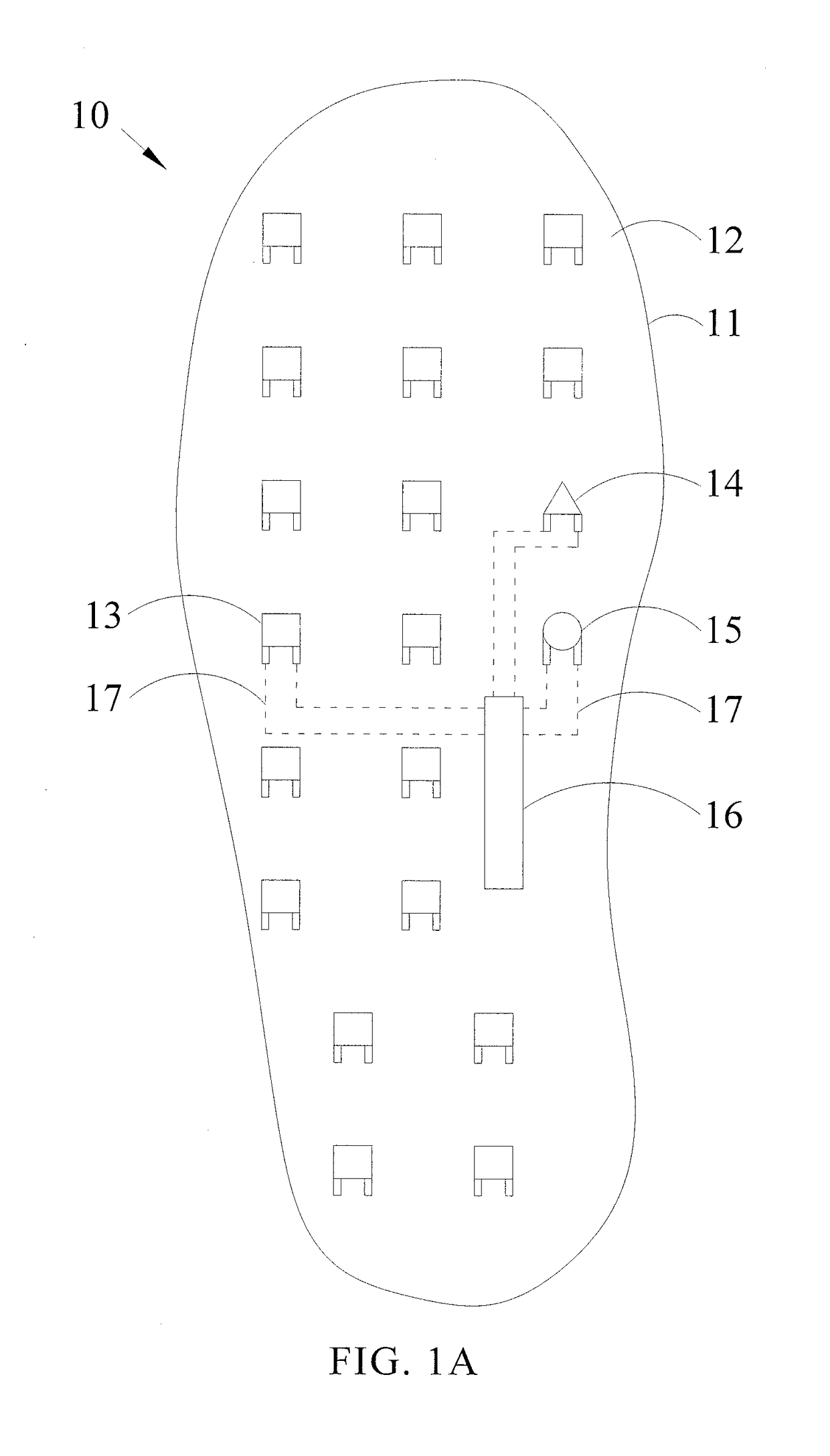

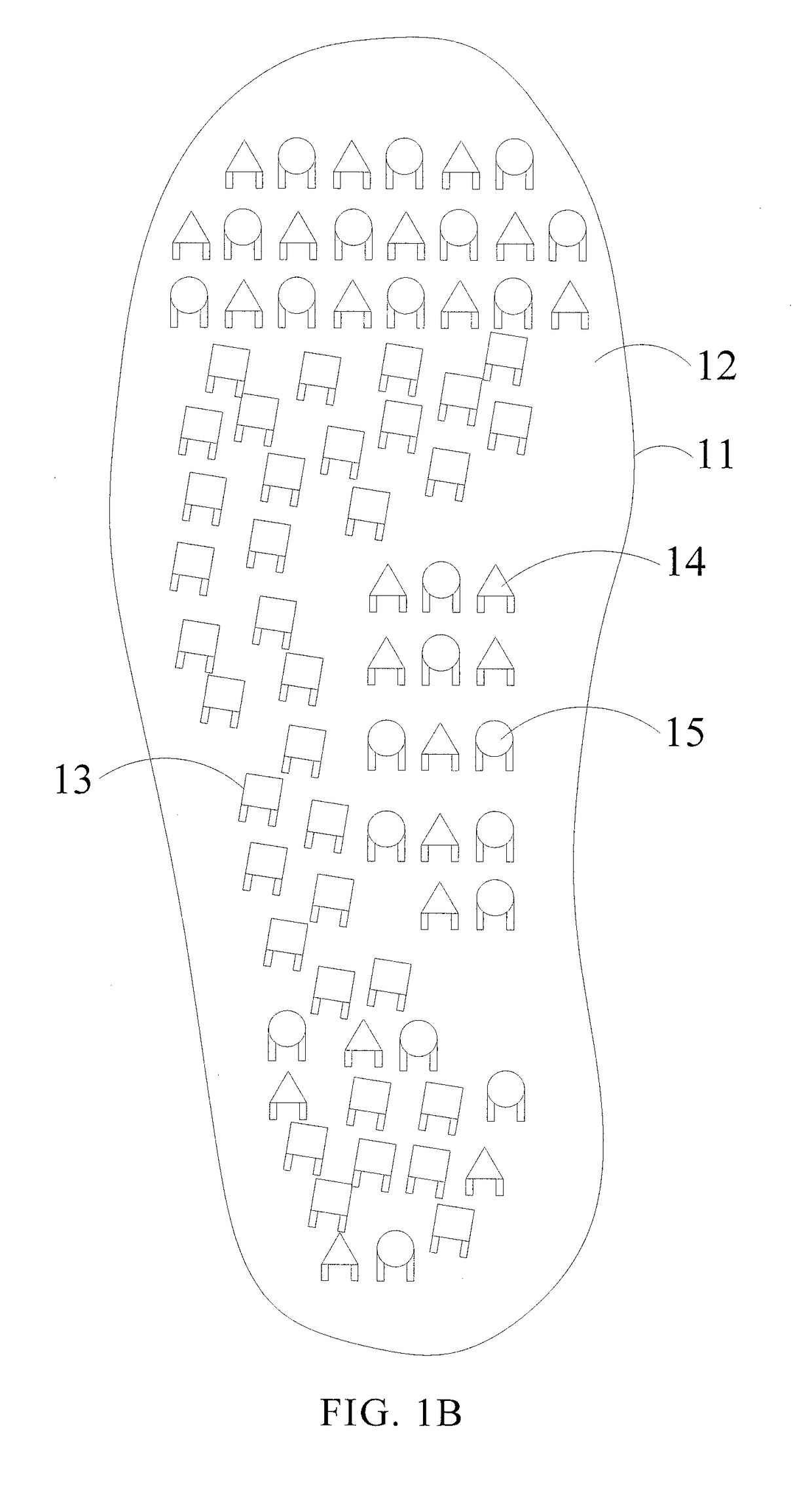

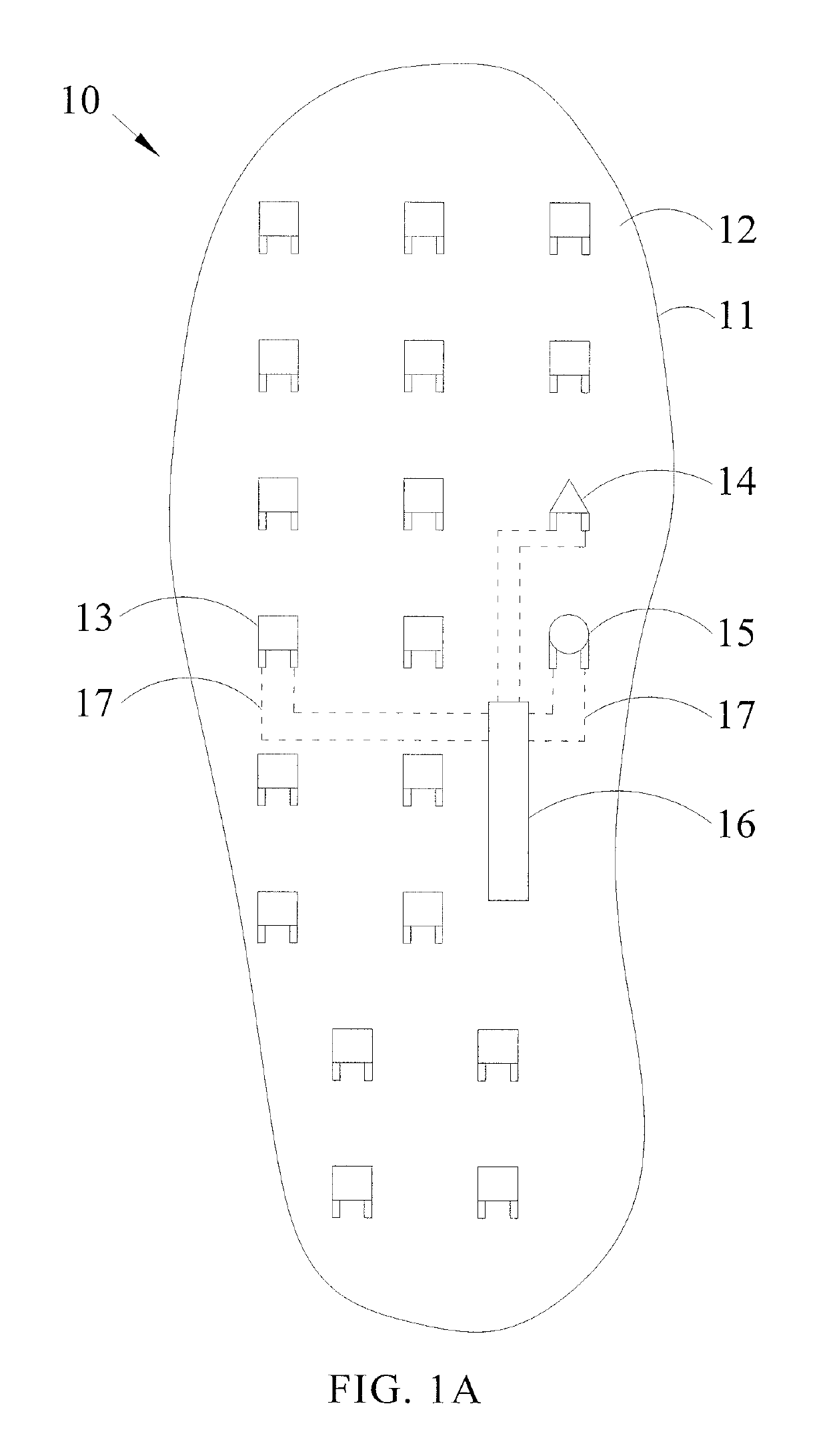

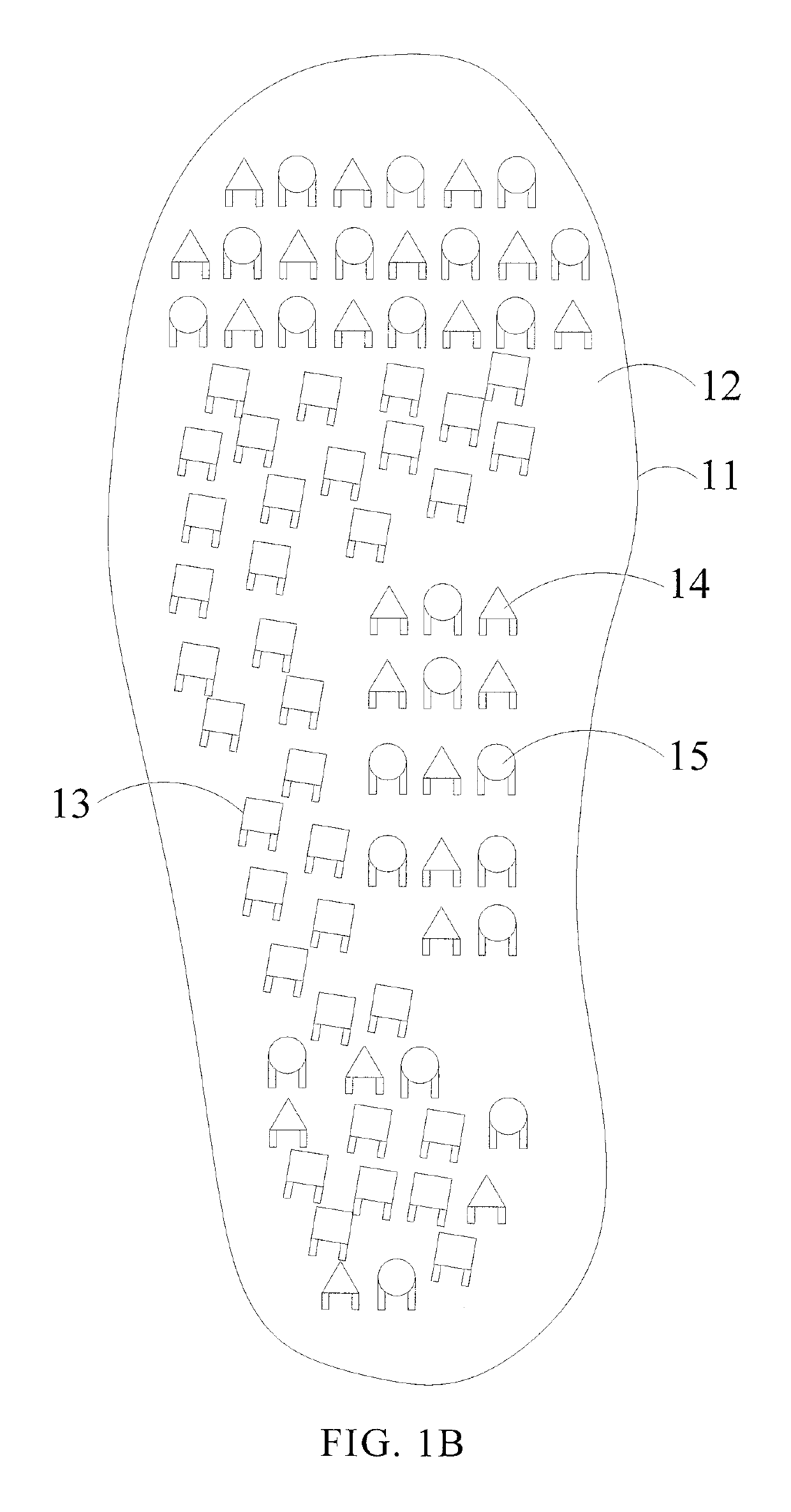

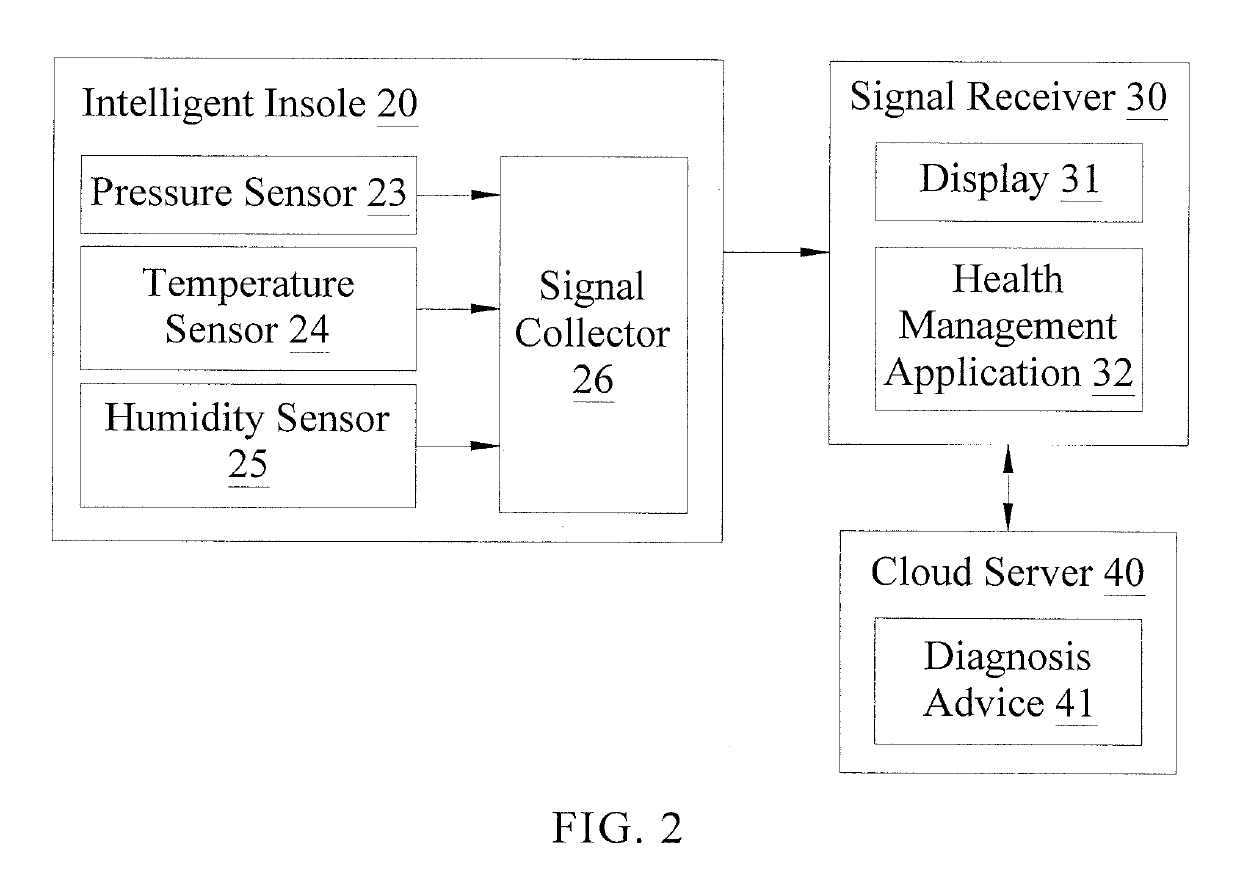

Intelligent insole

ActiveUS20170238870A1Reduce number of stepImprove qualityAdditive manufacturing apparatusHumidity sensorsBiomedical engineeringPressure sensor

An intelligent insole is provided. The intelligent insole includes an insole body, a pressure sensor, a temperature sensor, a humidity sensor and a signal collector. The pressure sensor, the temperature sensor and the humidity sensor are formed on the surface of the insole body, and the above sensors and the insole body are manufactured via the same 3D printing process. The pressure sensor senses the pressure signal from the insole body in contact with the foot. The temperature sensor and the humidity sensor respectively sense the temperature signal and the humidity signal of the insole body. The signal collector is respectively electrically connected to the pressure sensor, the temperature sensor and the humidity sensor to receive the pressure signal, the temperature signal and the humidity signal and then transmit the signals to a signal receiver via wireless transmission.

Owner:NATIONAL TSING HUA UNIVERSITY

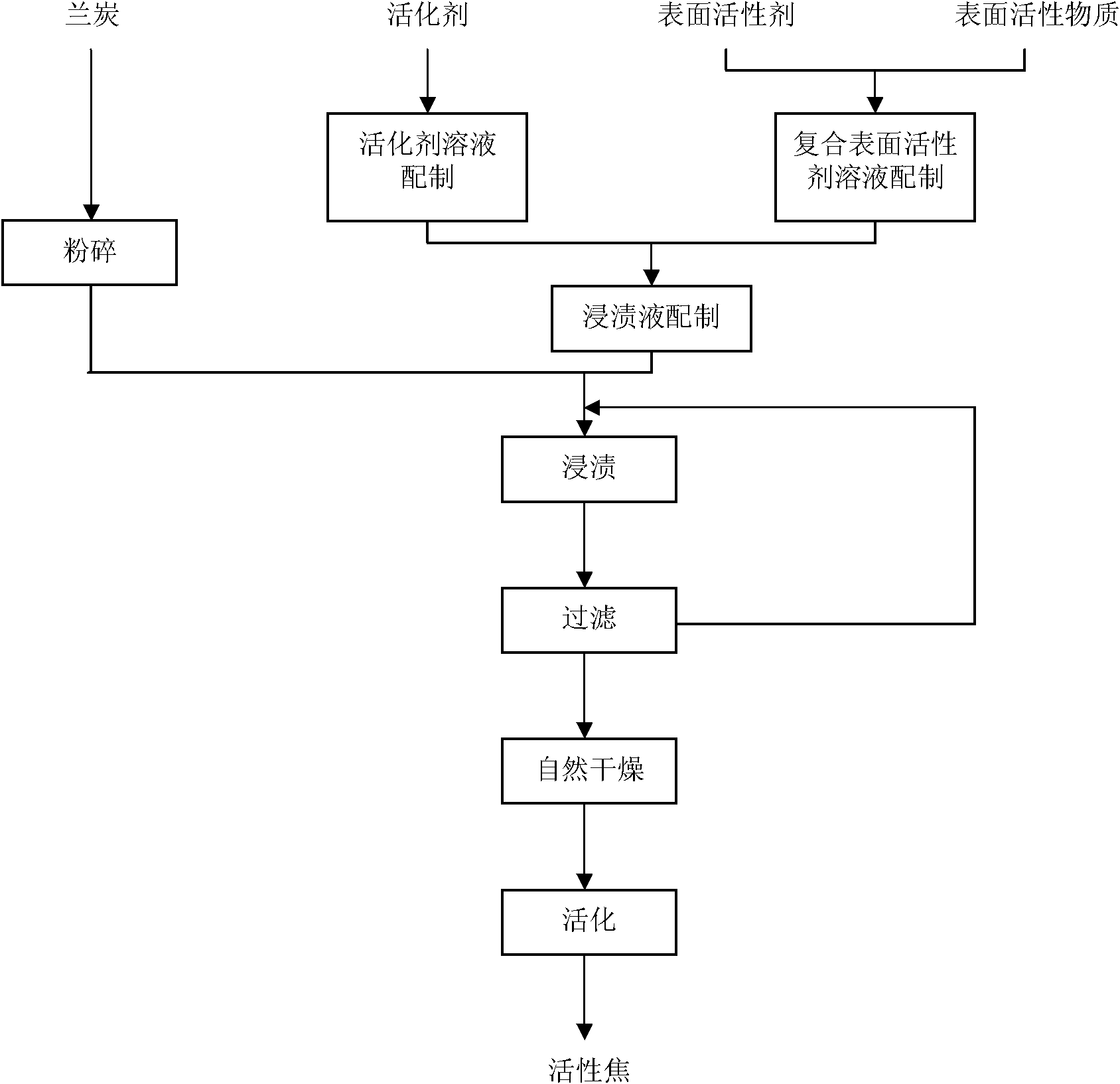

Activated coke for absorbing dioxin in flue gas and preparation method thereof

ActiveCN102728322ASolve spontaneous combustionAvoid disposition problemsOther chemical processesDispersed particle separationSorbentFlue gas

The present invention relates to an activated coke for absorbing persistent organic pollutant like dioxin in flue gas and a preparation method thereof by using coal quality semi coke as a raw material. The preparation method is as follows: crushing the coal quality semi coke; impregnating the coal quality semi coke with an impregnating solution containing metal hydroxide or alkali metal carbonate activator and compound surfactant, and naturally drying; and finally activating the impregnated and dried semi coke at 800-950 DEG C to prepare the activated coke for absorbing dioxin in flue gas. The activated coke has characteristics of developed porous structure, low manufacturing cost and good adsorption effect, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

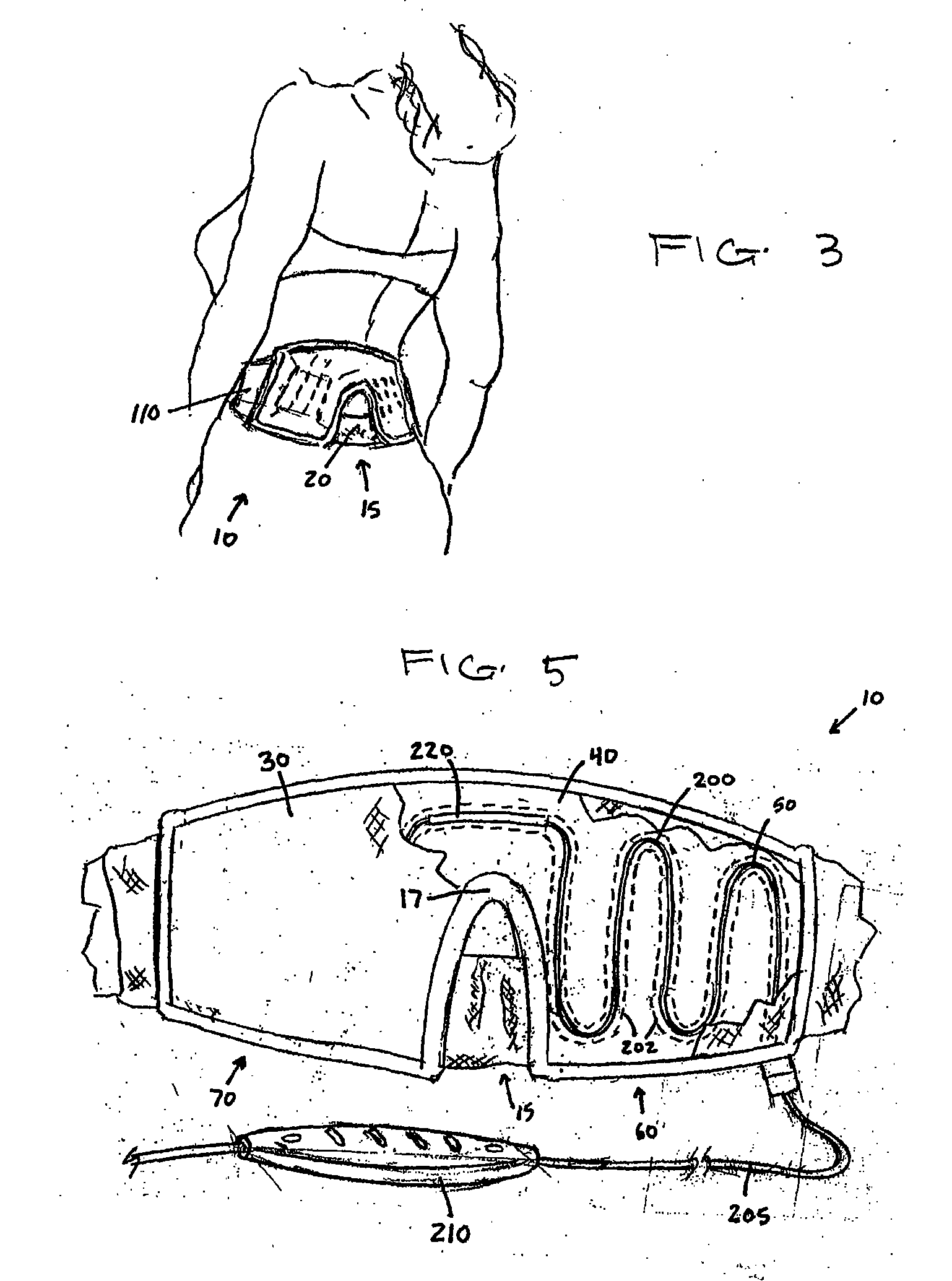

Site-specific pad with notch

InactiveUS20080009926A1Increase flexibilityImprove fitTherapeutic coolingTherapeutic heatingAdhesiveEngineering

A temperature therapy pad for use with a person including a thermal unit for making the pad either hot or cold and a therapeutic slot extending from one side of the pad which substantially divides the pad into sections. An elastic member may extend across the slot. The therapy pad can include a strap or an adhesive for attaching the therapy pad to a user's body. The thermal unit can be an electric heating coil and include a controller. The thermal unit may also be a material which has a high specific heat capacity or a material which heats when exposed to oxygen. The thermal unit may also be in the form of two separate chemical substances which change temperature when mixed. Another embodiment is for a temperature therapy pad including a substance which presents a heating or cooling sensation to a user's skin.

Owner:HELEN OF TROY LIMITED

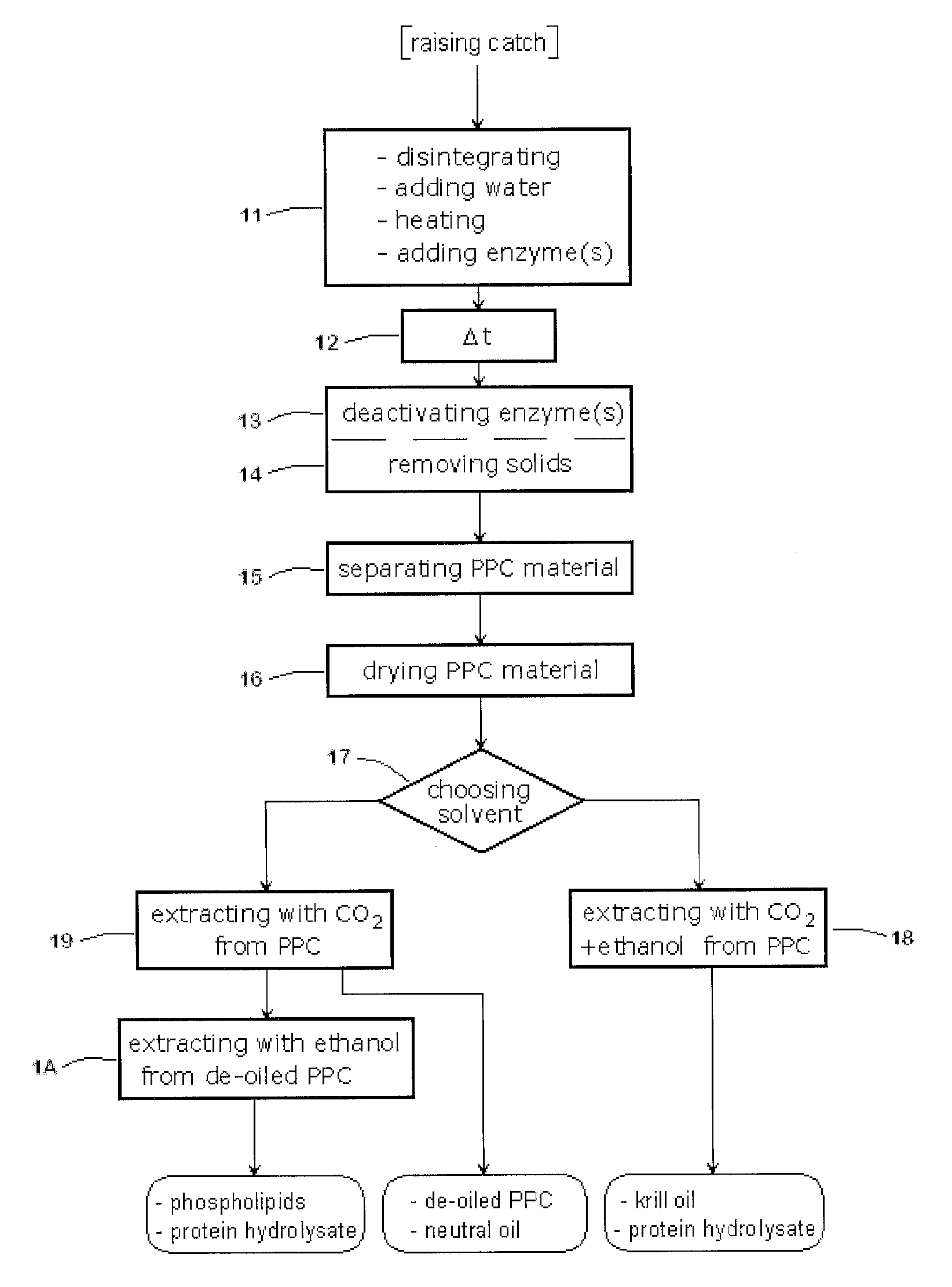

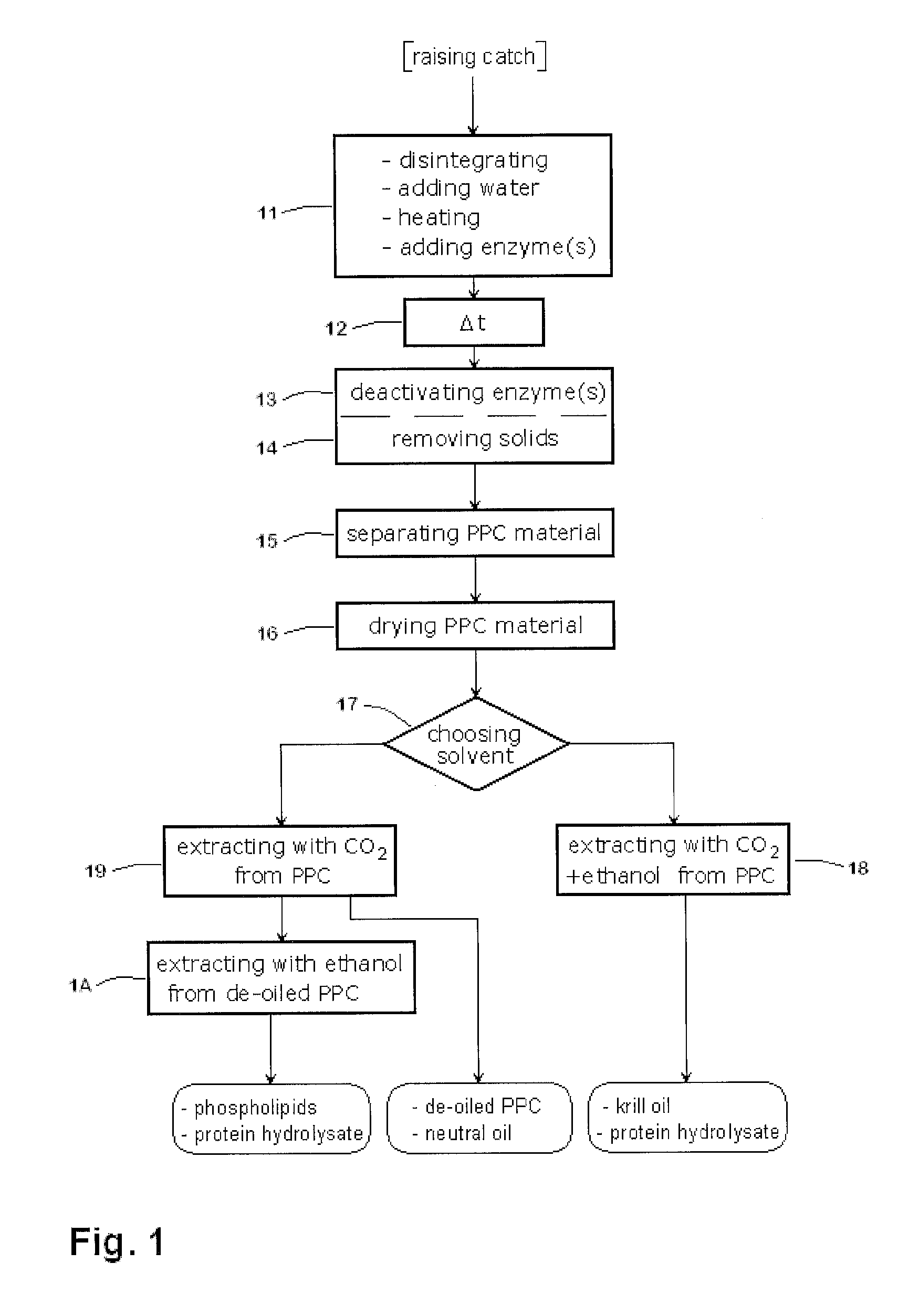

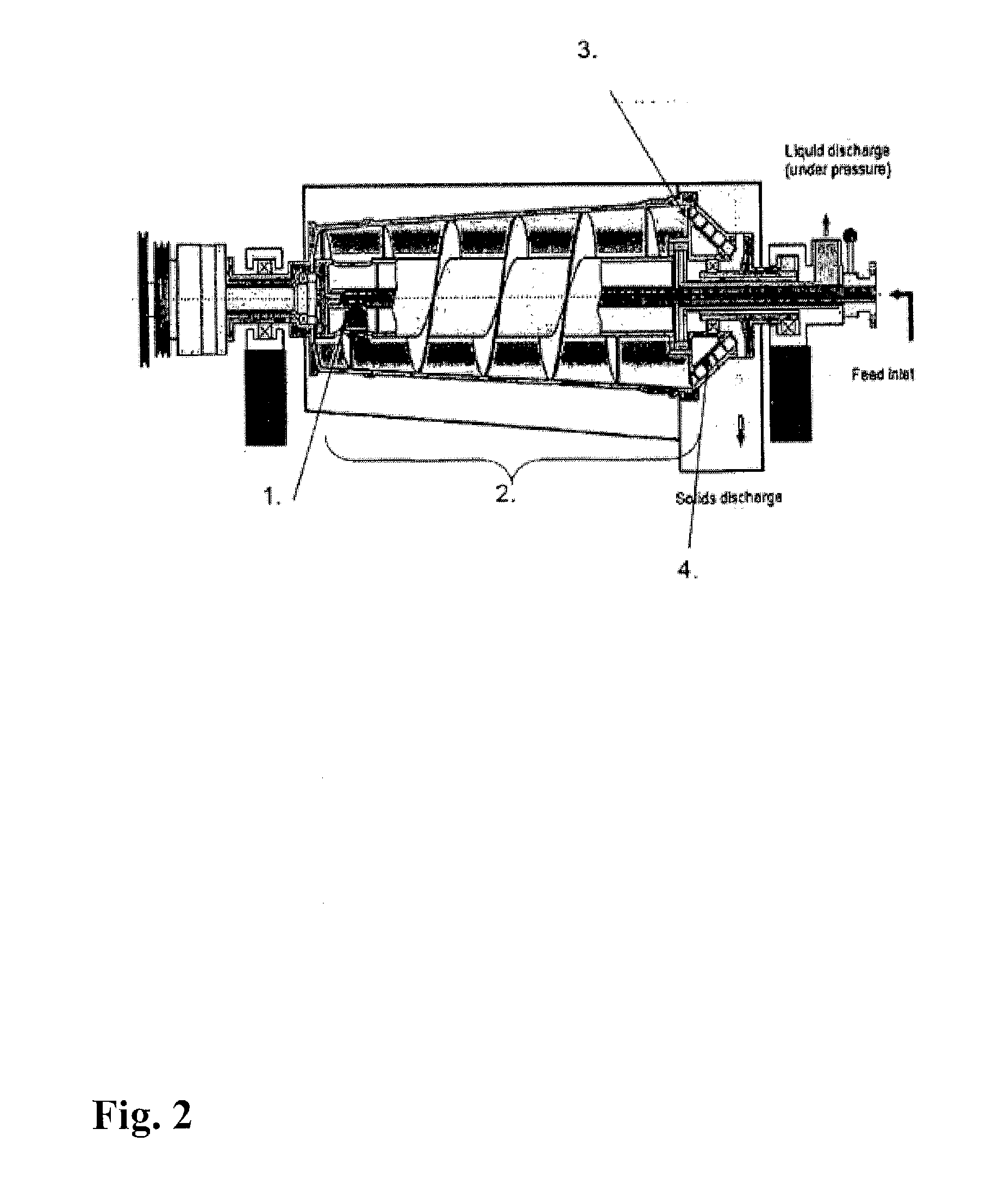

Method For Processing Crustaceans And Products Thereof

ActiveUS20120149867A1Easy extractionEfficient separationPeptide/protein ingredientsFatty-oils/fats refiningCrustaceanProtein-protein complex

The present invention contemplates the creation of a low fluoride oil processed from a phospholipid-protein complex (PPC) formed immediately upon a crustacean (i.e., for example, krill) catch. The process comprises disintegrating the crustaceans into smaller particles, adding water, heating the result, adding enzyme(s) to hydrolyze the disintegrated material, deactivating the enzyme(s), removing solids from the enzymatically processed material to reduce fluoride content of the material, separating and drying the PPC material. Then, using extraction with supercritical CO2 and ethanol as solvents, inter alia krill oil is separated from the PPC. In the extraction the krill oil can be separated almost wholly from the feed material. The products have low fluoride content. The manufacturing costs in the extraction process are relatively low.

Owner:RIMFROST TECH AS

Intelligent insole

ActiveUS10327700B2Reduce in quantityImprove product qualityAdditive manufacturing apparatusHumidity sensorsWireless transmissionMoisture sensor

An intelligent insole is provided. The intelligent insole includes an insole body, a pressure sensor, a temperature sensor, a humidity sensor and a signal collector. The pressure sensor, the temperature sensor and the humidity sensor are formed on the surface of the insole body, and the above sensors and the insole body are manufactured via the same 3D printing process. The pressure sensor senses the pressure signal from the insole body in contact with the foot. The temperature sensor and the humidity sensor respectively sense the temperature signal and the humidity signal of the insole body. The signal collector is respectively electrically connected to the pressure sensor, the temperature sensor and the humidity sensor to receive the pressure signal, the temperature signal and the humidity signal and then transmit the signals to a signal receiver via wireless transmission.

Owner:NATIONAL TSING HUA UNIVERSITY

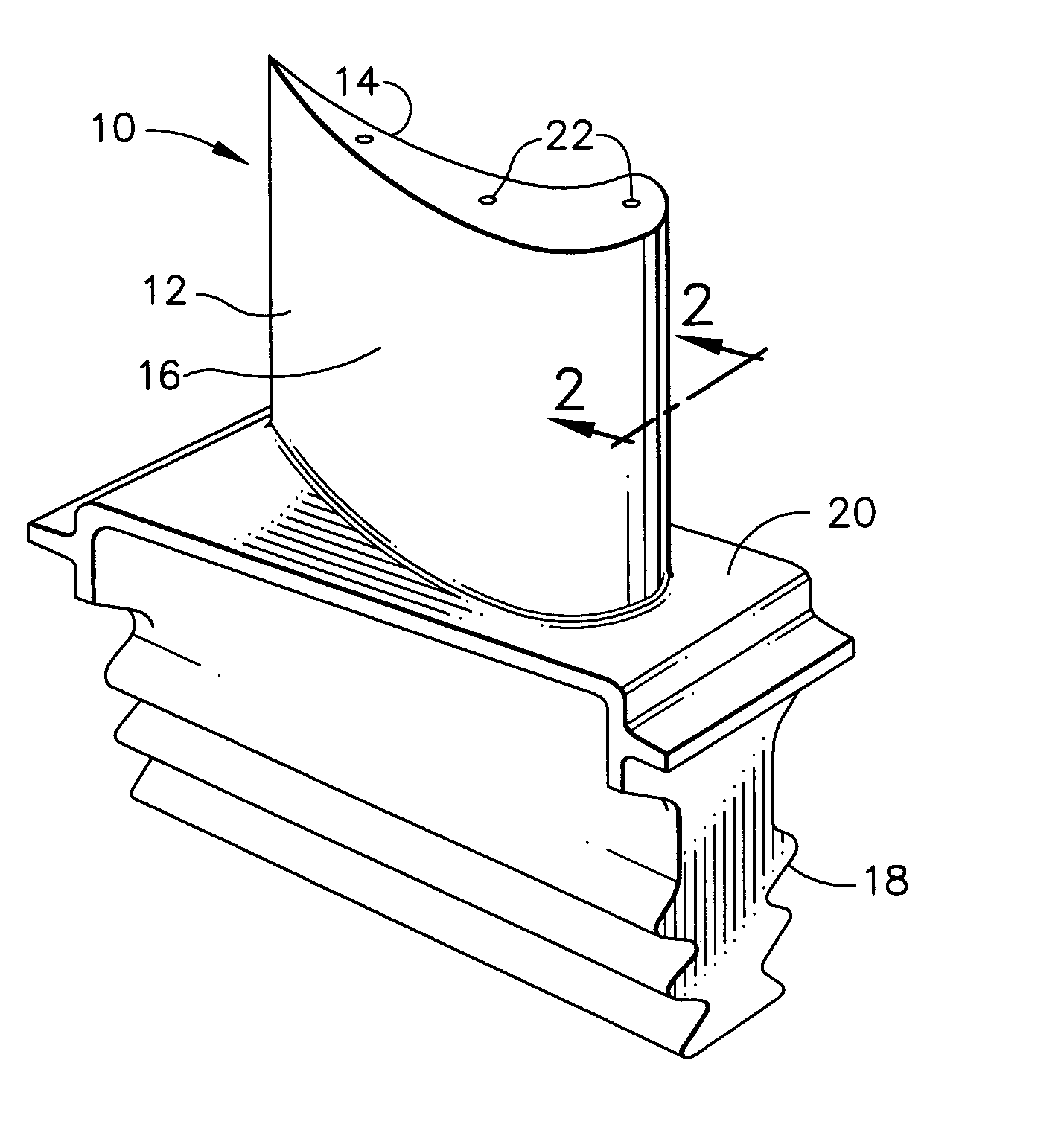

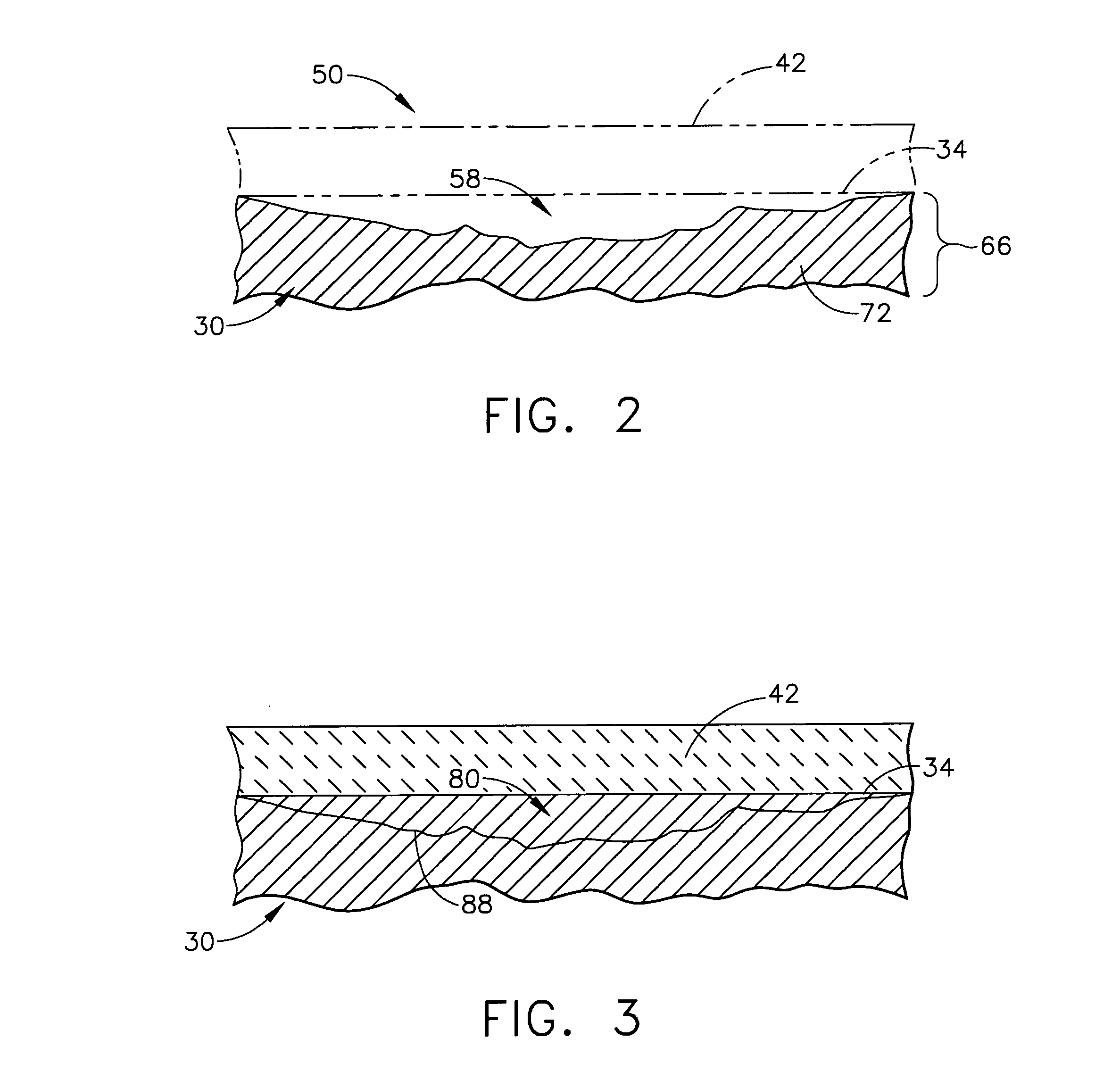

Method for restoring portion of turbine component

InactiveUS20070039176A1Eliminate ThicknessEffectively restore the removed wall thickness of the repaired airfoilBlade accessoriesMachines/enginesTurbineMaterials science

A method for restoring a removed portion of the airfoil wall of a turbine component. This method comprises the following steps: (a) providing a turbine component comprising an airfoil having a metal substrate with a wall thickness, wherein a portion of the wall thickness has been removed so as to provide a residual wall thickness; (b) providing a metal composition that at least substantially matches that of the residual wall thickness; and (c) applying the metal composition to the residual wall thickness such that the metal composition: (1) is adhered to the residual wall thickness; and (2) at least substantially restores the removed wall thickness. Also provided is a method for restoring a removed portion of the airfoil wall of a previously repaired turbine component.

Owner:GENERAL ELECTRIC CO

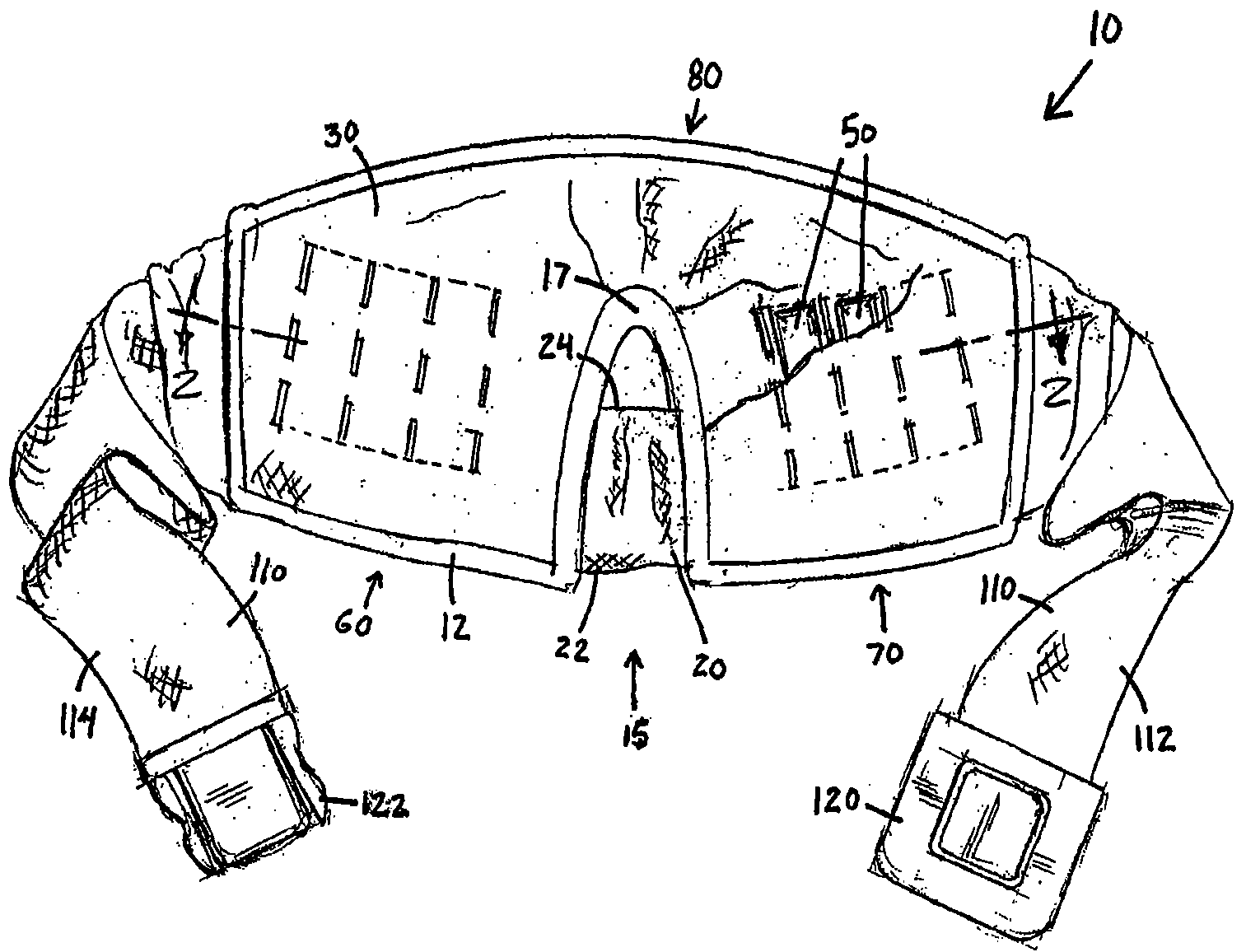

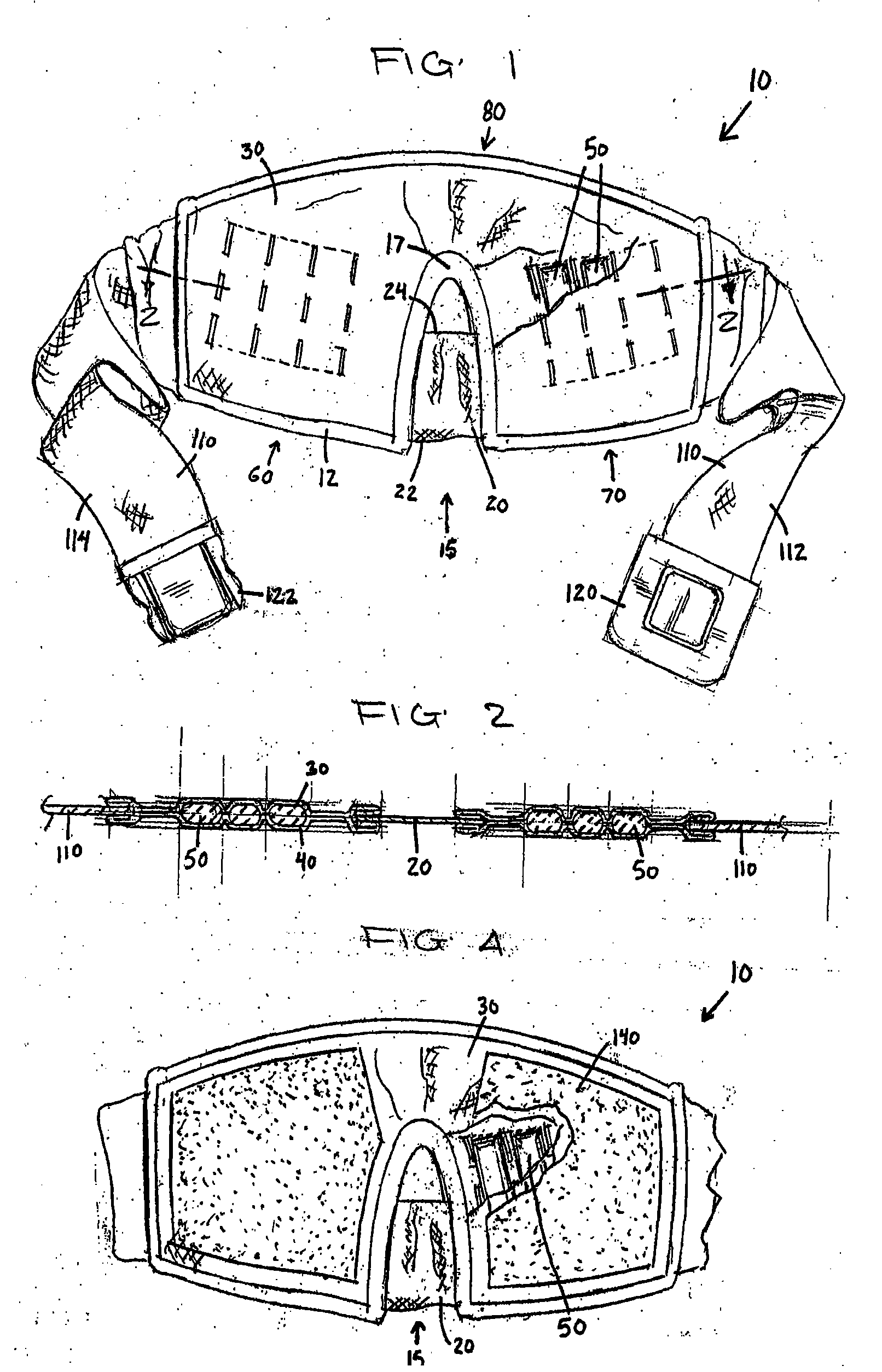

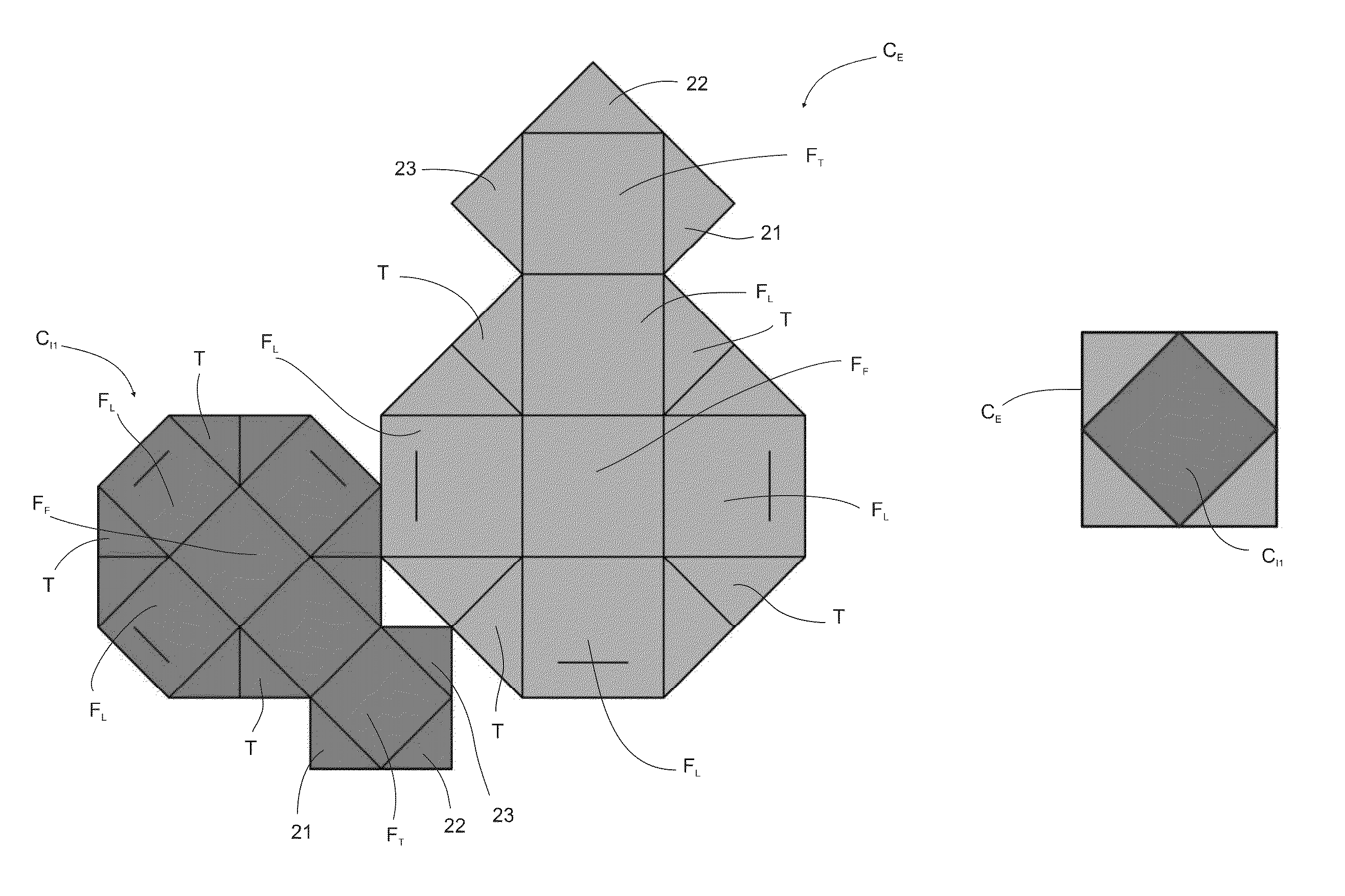

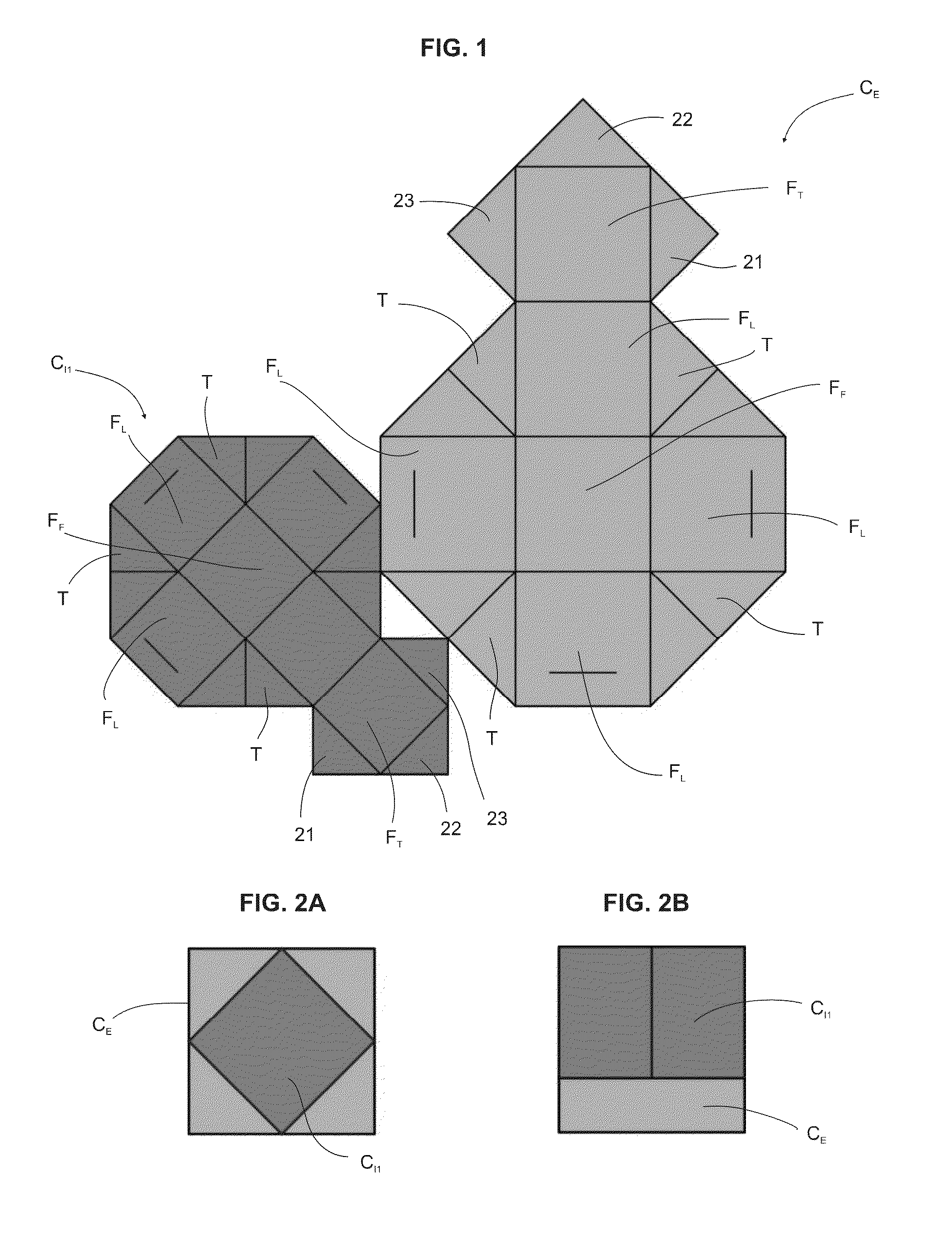

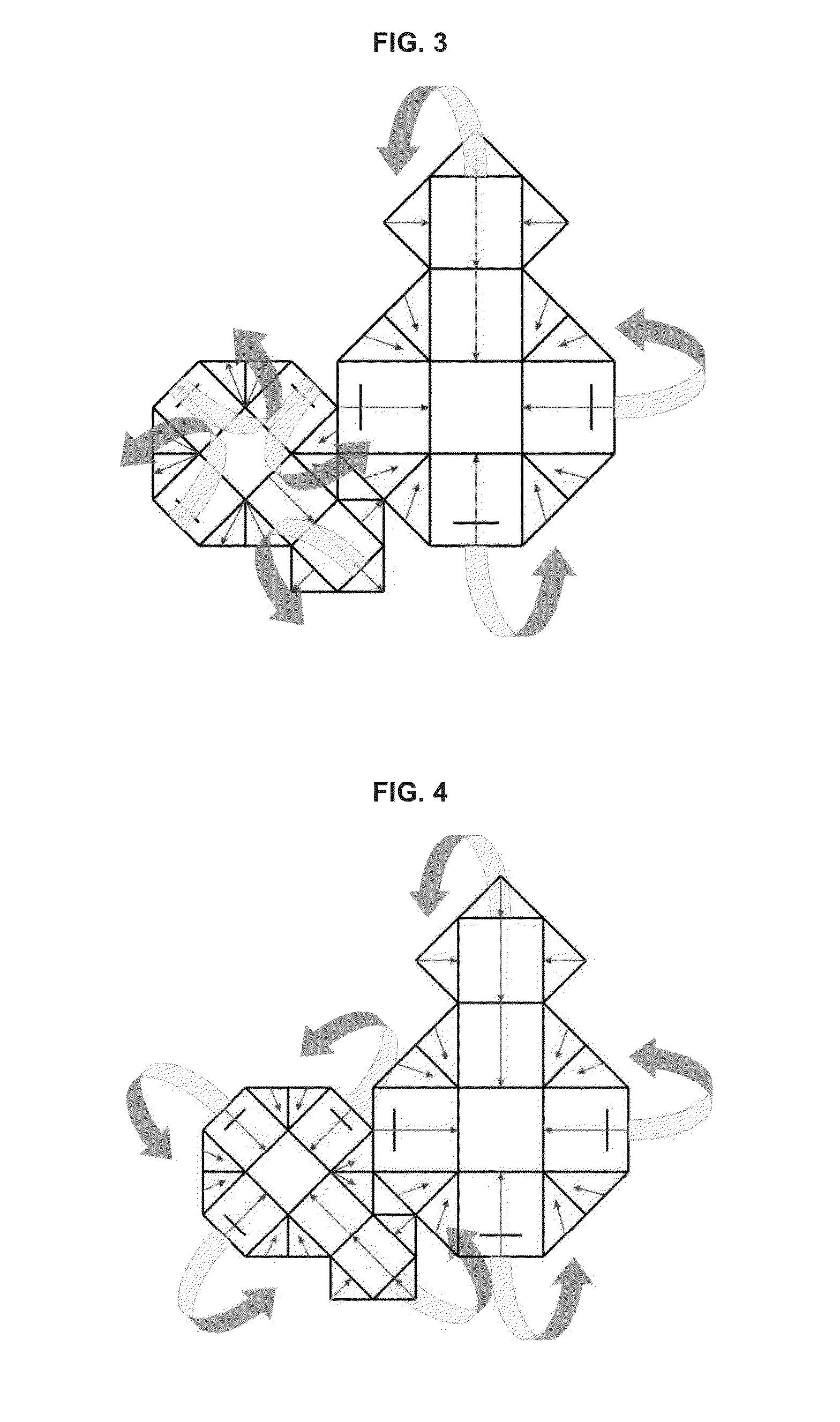

Articulable structure in the form of a fractal

ActiveUS8807417B2Avoid disposition problemsEfficient use ofCoverings/external coatingsContainers to prevent mechanical damageEngineeringSacroiliac joint

The present invention relates to an articulable structure in fractal form, comprising at least one external compartment (CE) and at least a first internal compartment (Cu) that are linked together in an articulated manner via at least one of the edges thereof, the at least two compartments (CE and Cu) essentially having the same format in the erected and flat states and the first internal compartment has smaller dimensions than the external compartment, the first internal compartment, in the erected state, being accommodated inside the external compartment, and each compartment has a polygonal format, comprising at least four lateral faces (FL) and a bottom face (FF); each compartment of the articulable structure comprises at least five quadrangular faces corresponding to the four lateral faces (FL) and to the bottom face (FF), each edge of the bottom face (FF) being linked in an articulated manner to a lower edge of the same size of one of the lateral faces (FL), and at least four identical triangular faces (T) in the form of a right-angled isosceles triangle, each triangular face (T) connecting adjacent lateral faces, with each edge corresponding to a vertical height of the triangle, being linked in an articulated manner to a lateral edge of one of the adjacent lateral faces (FL) and the edge corresponding to the hypotenuse linking the vertices of the two adjacent lateral faces, wherein the length of the hypotenuse edge of the triangular faces (T) of the first internal compartment (Cu) is equal to or less than the length of the upper edge of the lateral faces (FL) of the external compartment (CE). This structure allows the use of countless compartments arranged one inside another in succession and that may be articulated together in different ways, achieving one and the same final format.

Owner:ARAK IDEA SERVICOS DE DESIGN E PATENTES LTDA

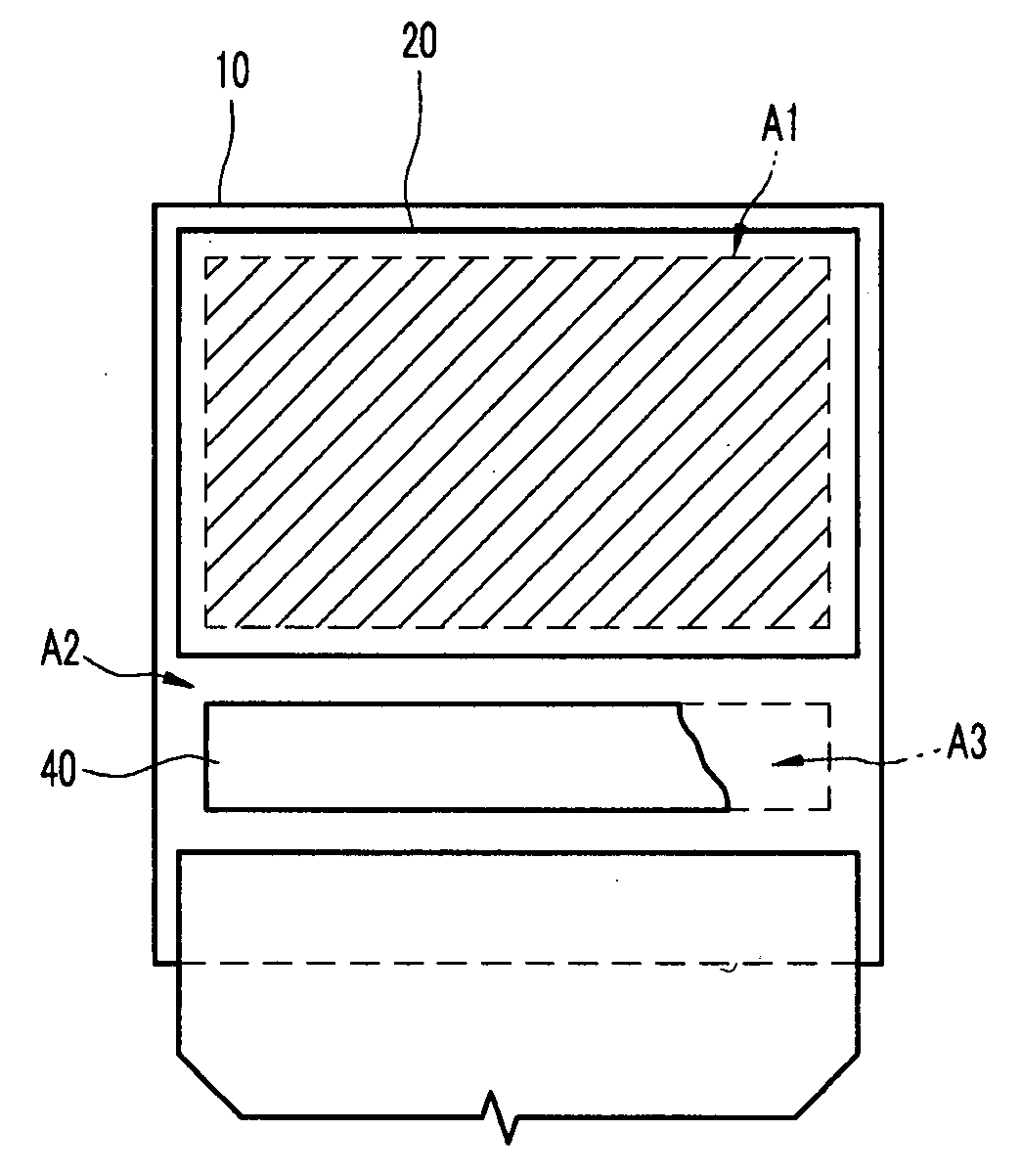

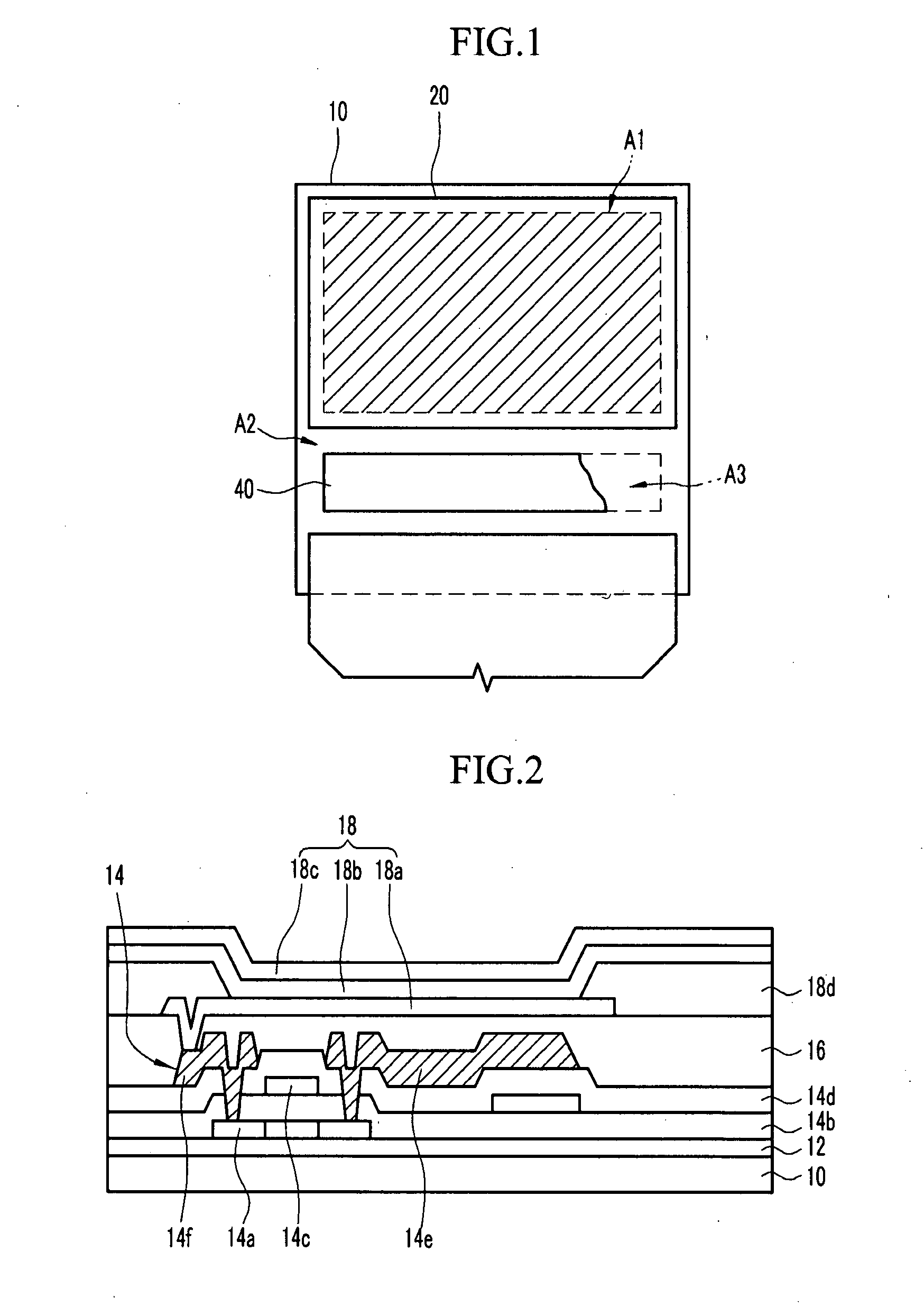

Organic light emitting display

ActiveUS20080055212A1Serious errorAvoid disposition problemsStatic indicating devicesElectroluminescent light sourcesOrganic light emitting deviceOptoelectronics

An organic light emitting display is provided. In the organic light emitting display, when a wiring section including a plurality of signal lines for transmitting signals to a driving circuit unit or an organic light emitting device is formed under a non-display region, more specifically, a COG region where a driving IC is mounted, the signal lines of the wiring section are disposed on two or more different layers to maintain a height difference between neighboring signal lines for transmitting different signals from each other.

Owner:SAMSUNG DISPLAY CO LTD

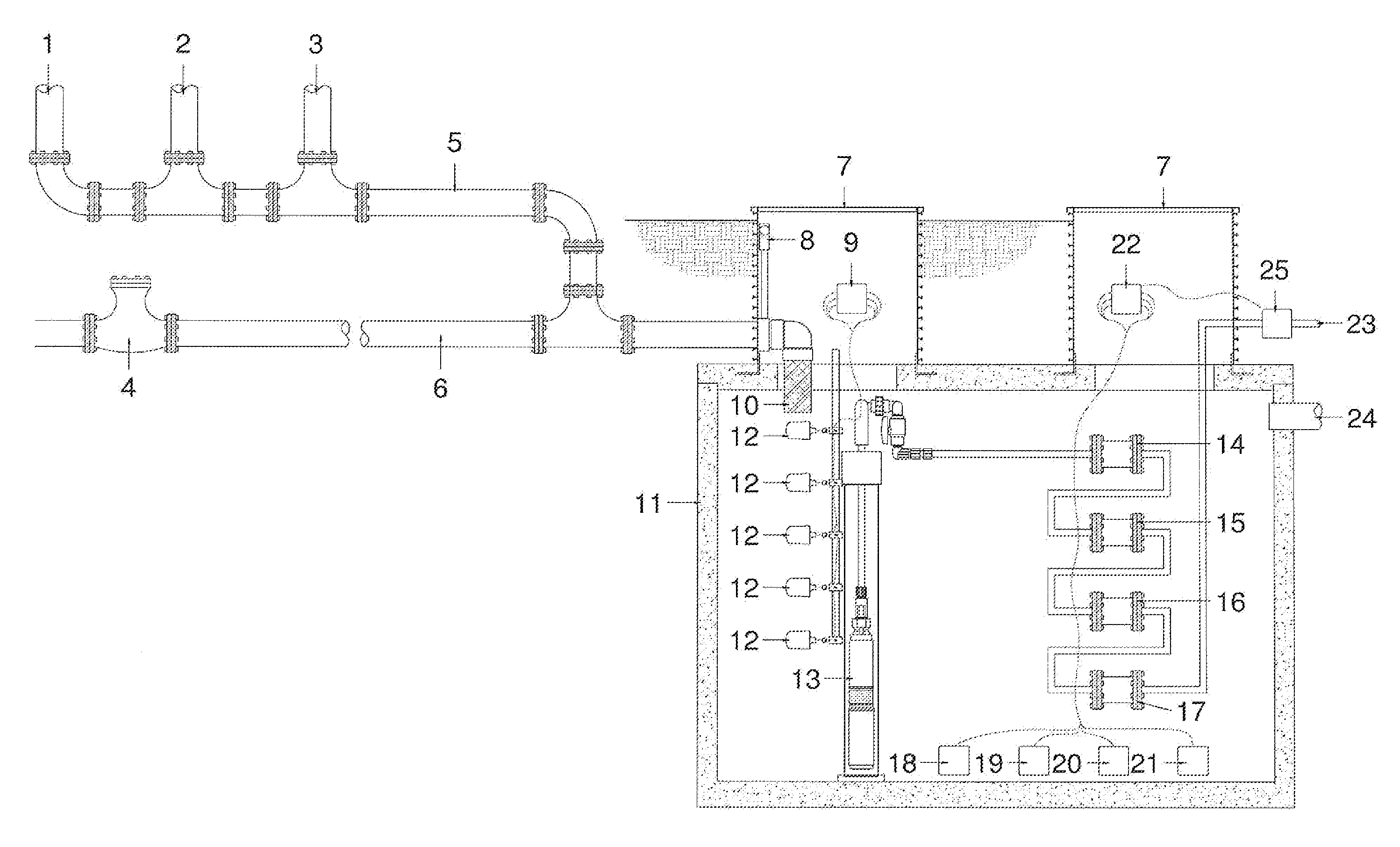

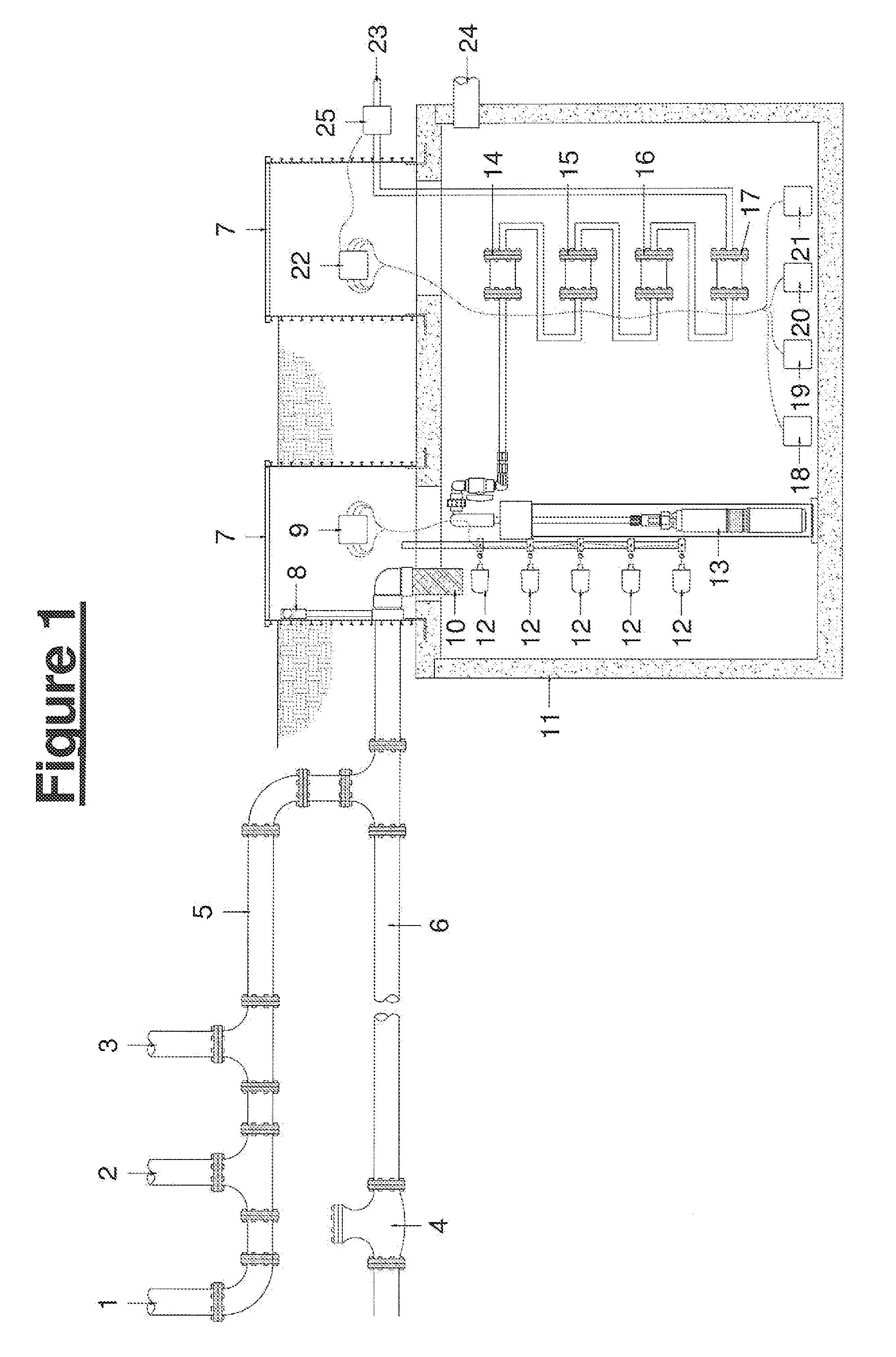

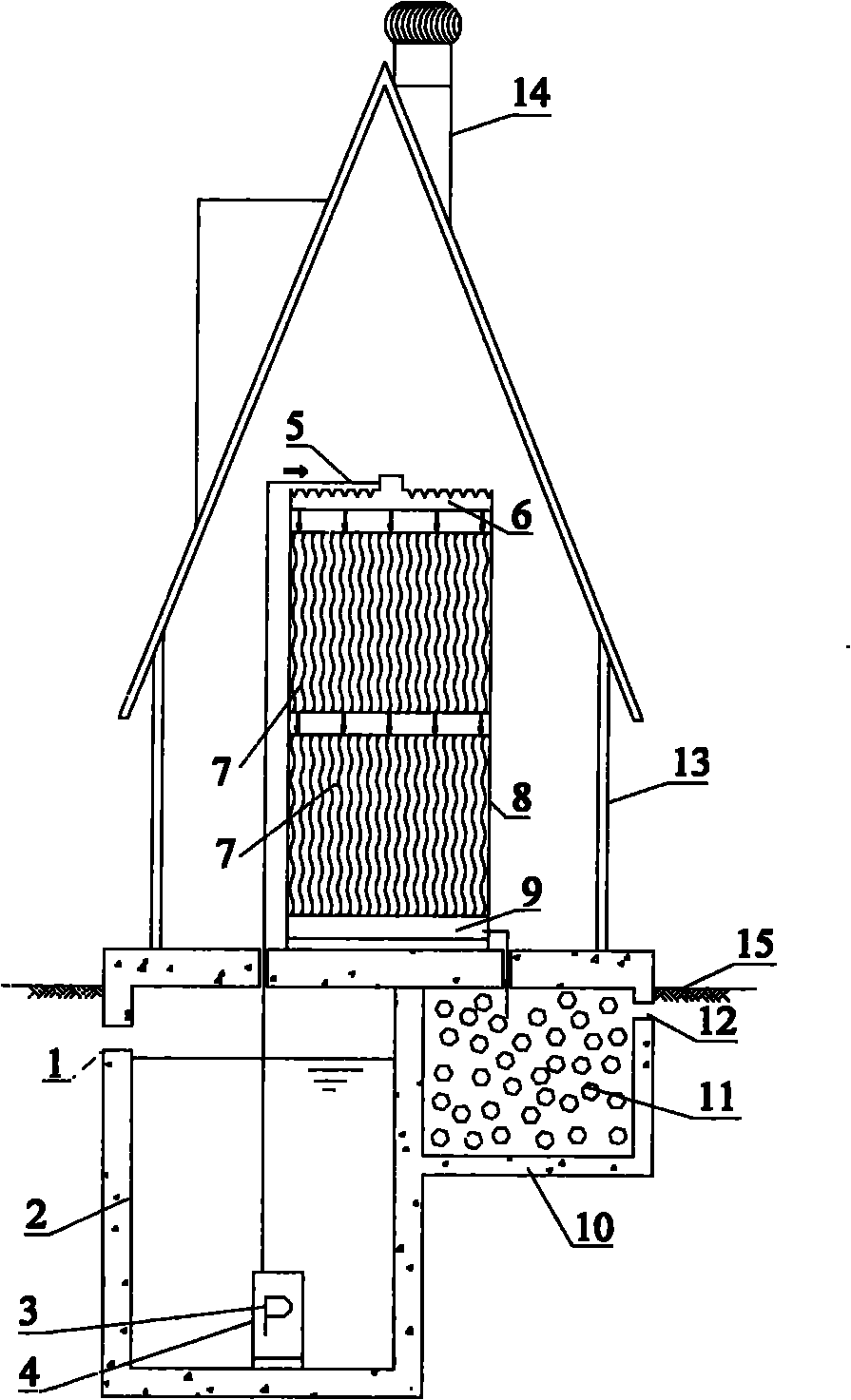

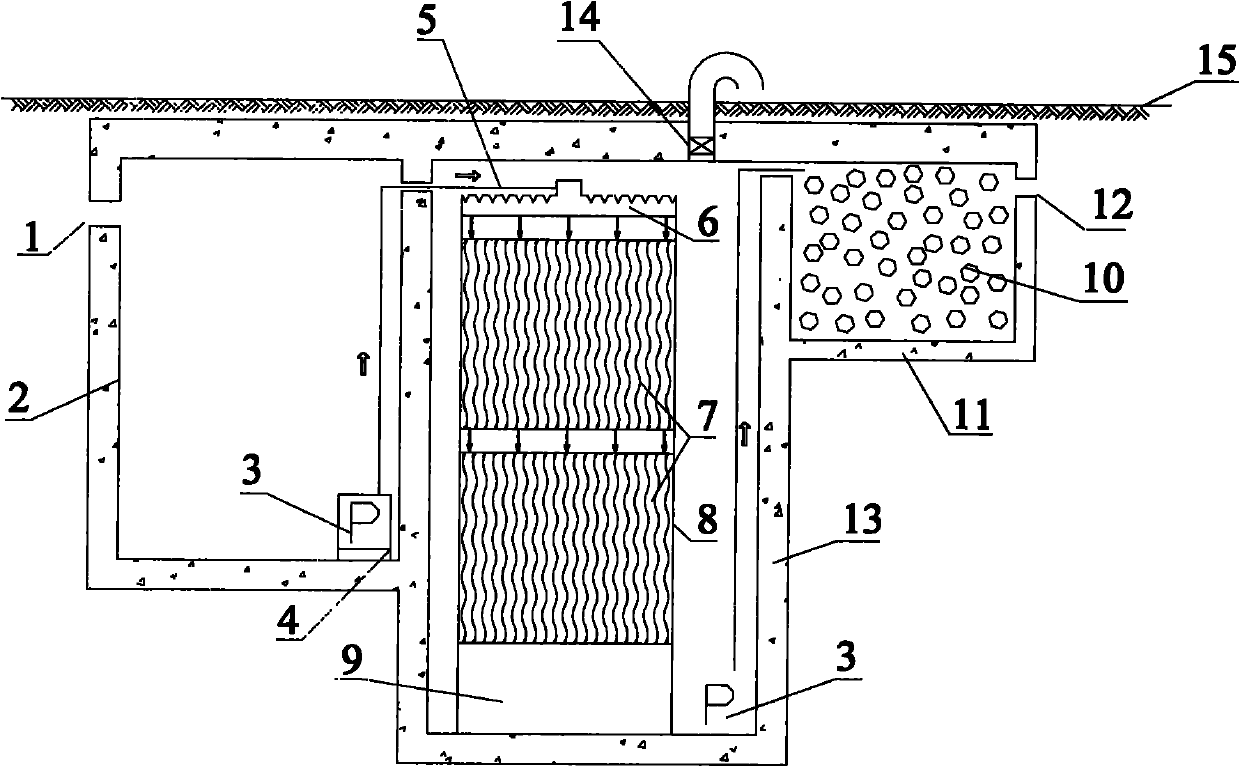

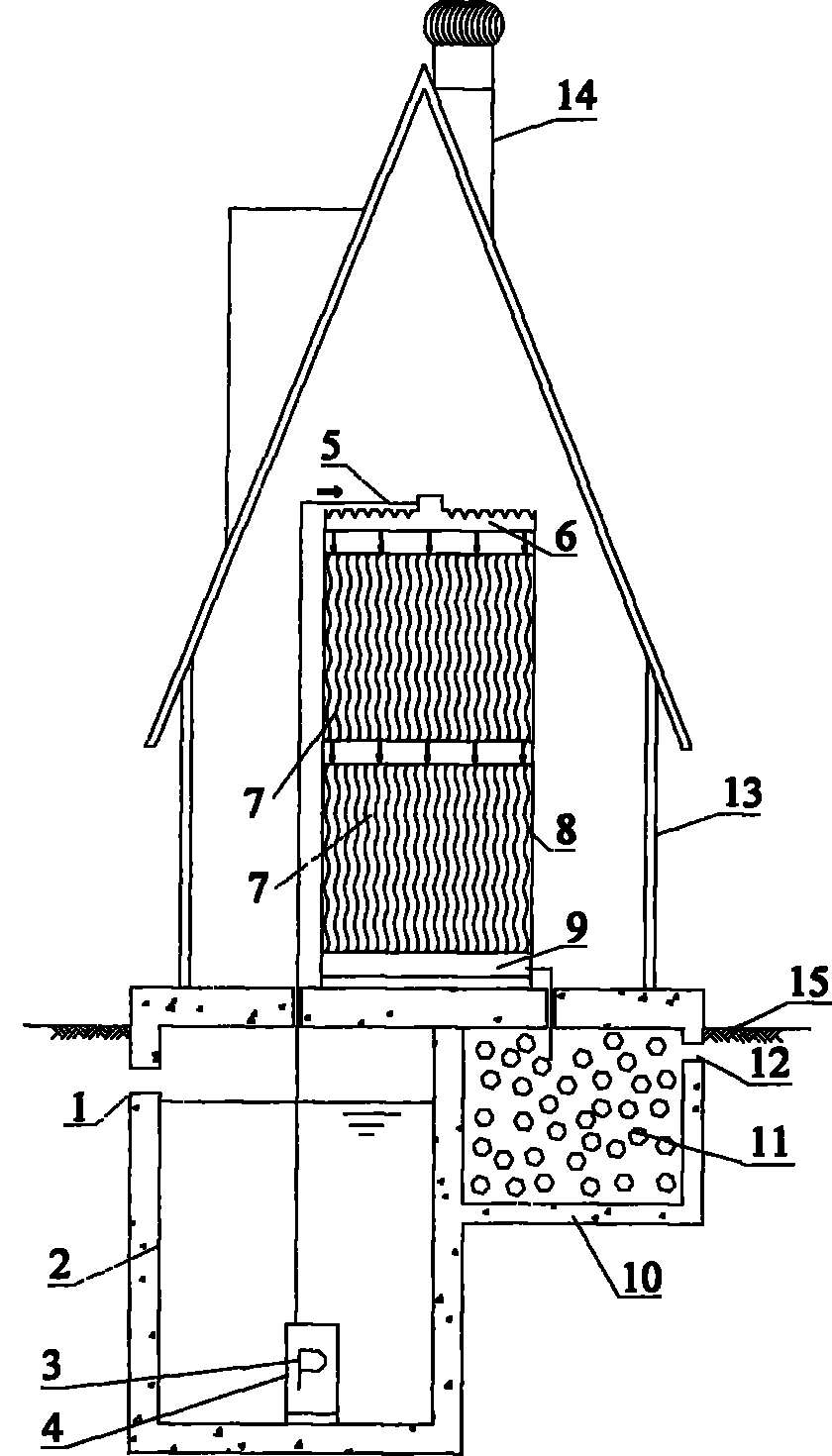

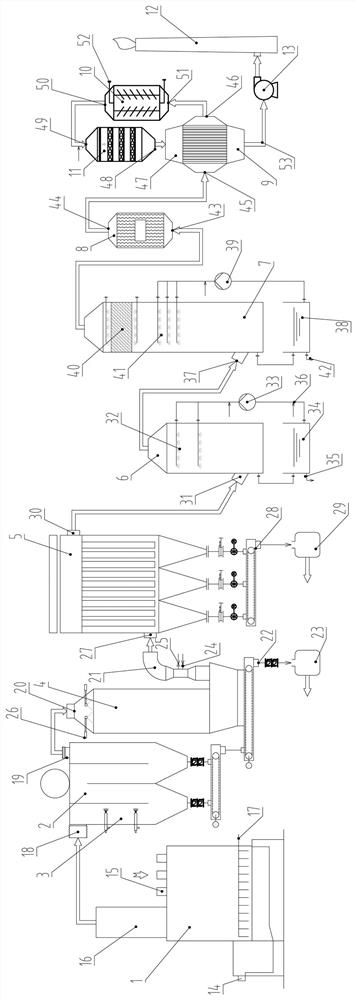

Decentralized sewage treatment method

InactiveCN102020395AEasy to handleSatisfy the need for oxygenTreatment using aerobic processesMultistage water/sewage treatmentMicroorganismNatural ventilation

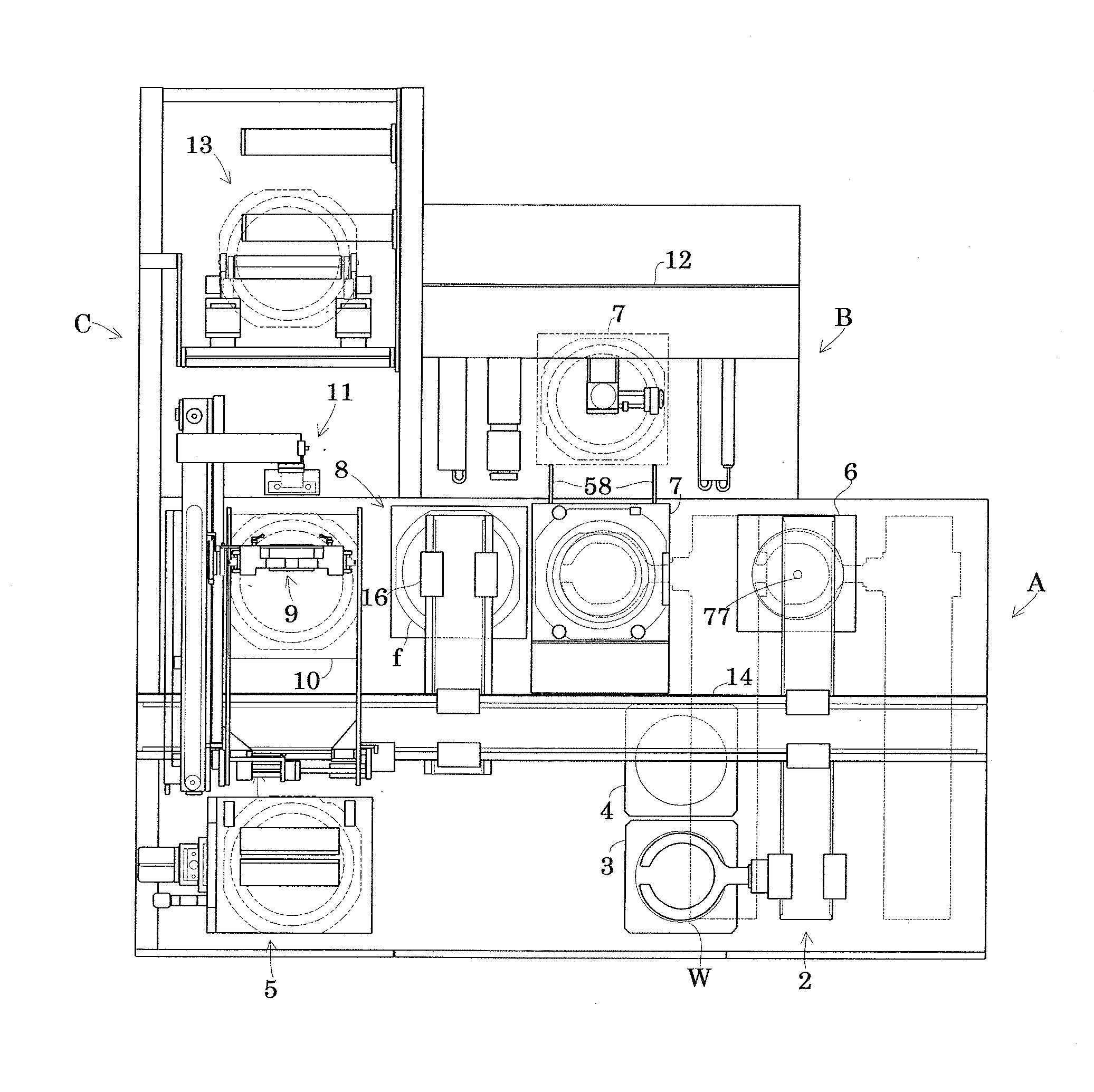

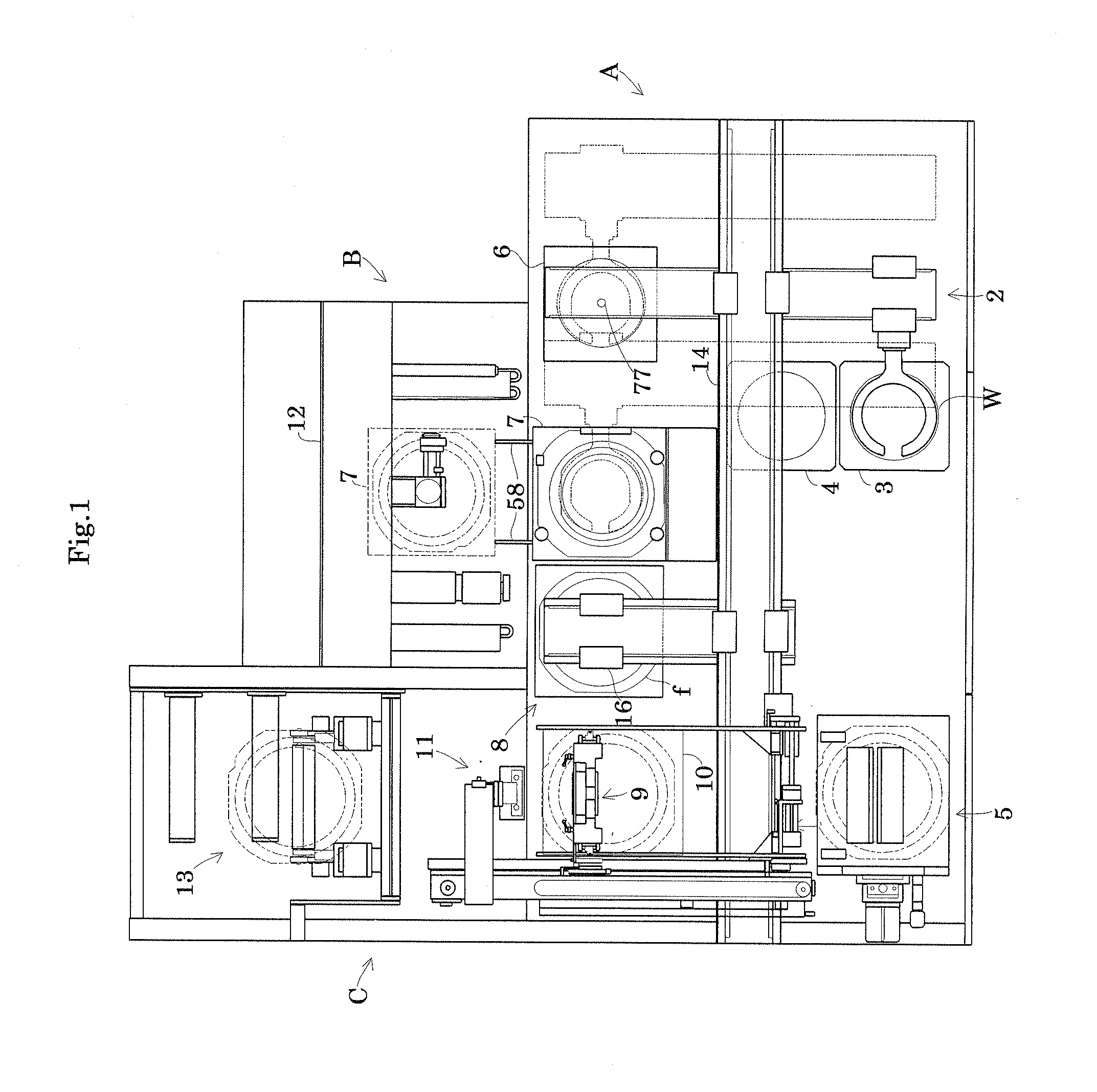

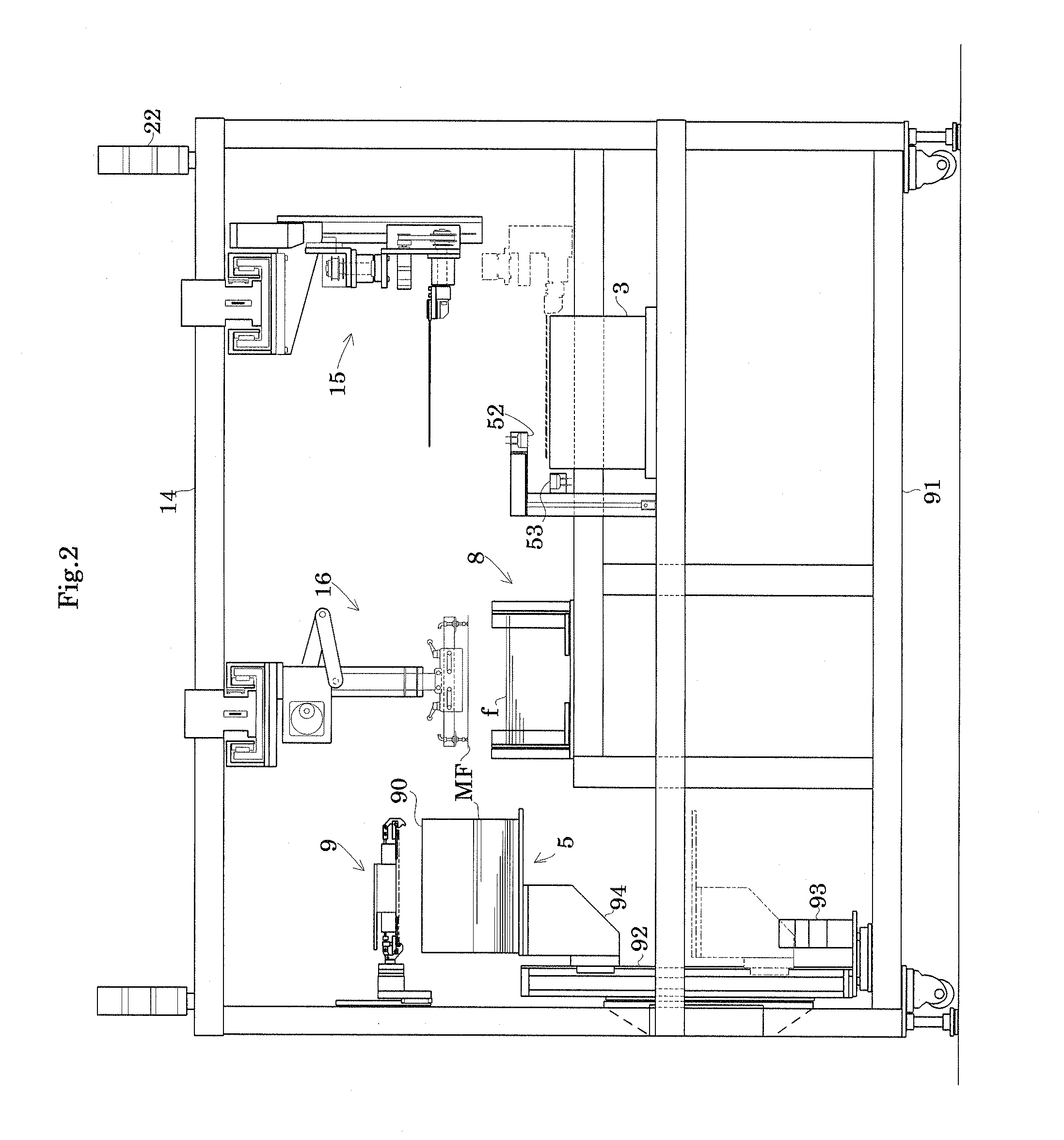

The invention relates to a decentralized sewage treatment method, which comprises that: a sewage inlet pipe (1) is connected with a sewage collection pipe; sewage is carried to an adjusting tank (2); large impurities are separated by a pump gate cover (4); the sewage is lifted into a non-clogging biotrickling filter (5) by a sewage pump (3) and uniformly distributed on a filler module (7) arranged on a filler support frame (8), and fully contacts with biomembranes attached to and grown on the surfaces of fillers to be purified; trickled water drained from the non-clogging biotrickling filter (5) is collected by a biotrickling filter water outlet groove (9), enters a dephosphorization groove (10) and contacts with a dephosphorization medium (11) for dephosphorization; and the dephosphorized water is drained from a water outlet pipe (12). The decentralized sewage treatment method saves the links of a secondary sedimentation tank, sludge concentration, sludge treatment and the like in a conventional sewage treatment process, simplifies a treatment flow and satisfies the needs of microorganisms in oxygen by natural ventilation oxygen supply; and the main unit equipment is modularly designed and simple in control.

Owner:上海浩为环境工程有限公司

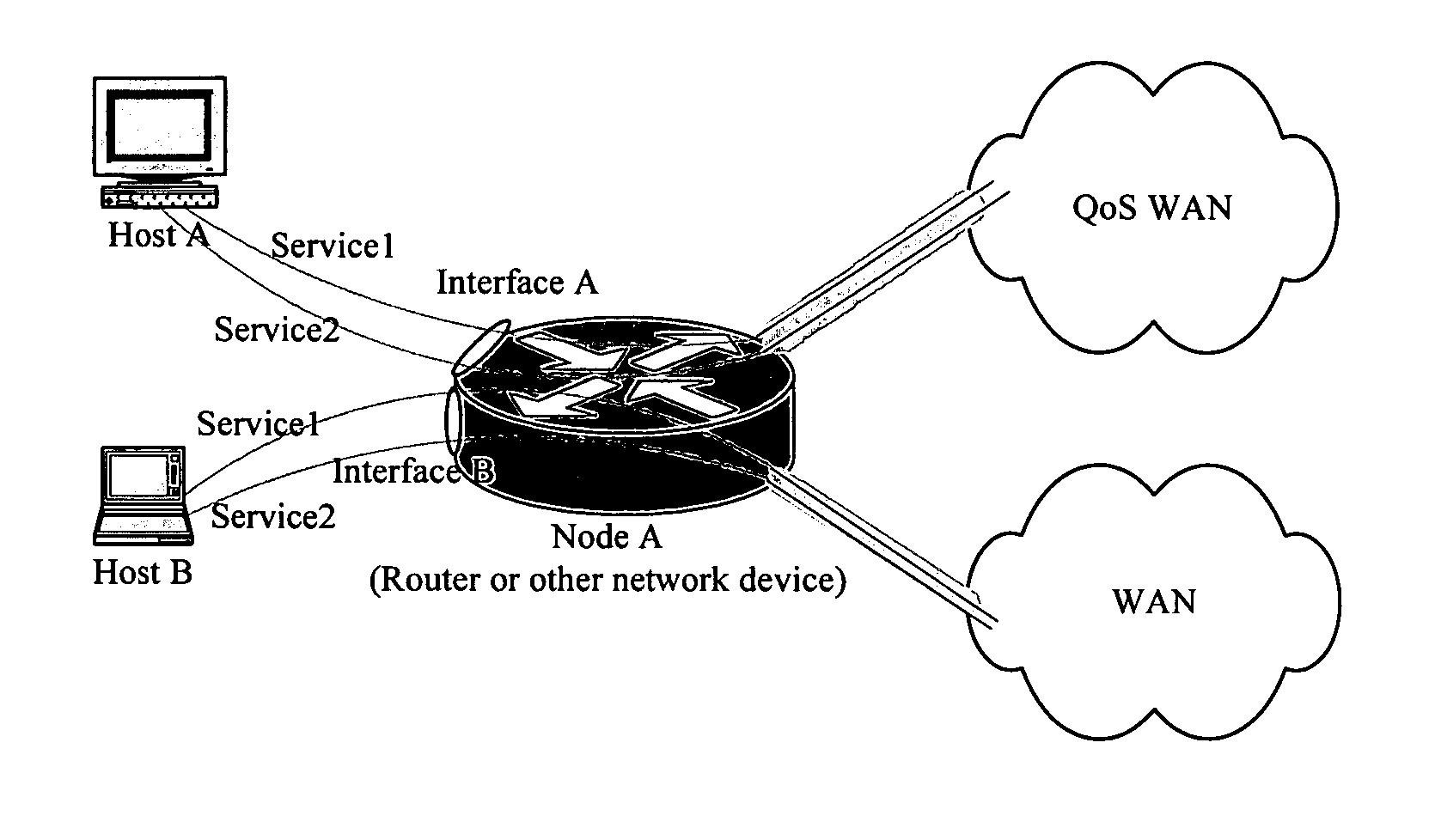

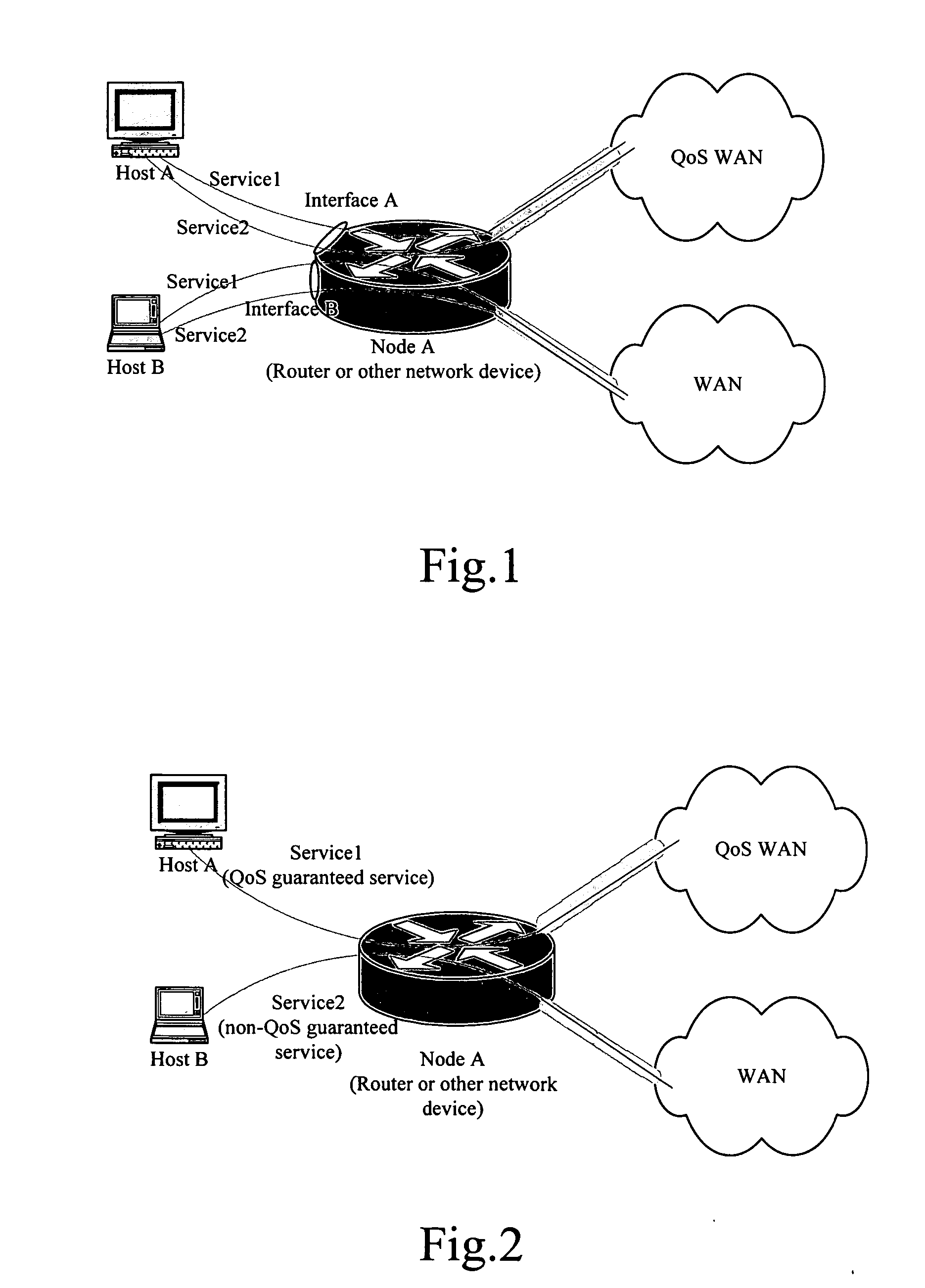

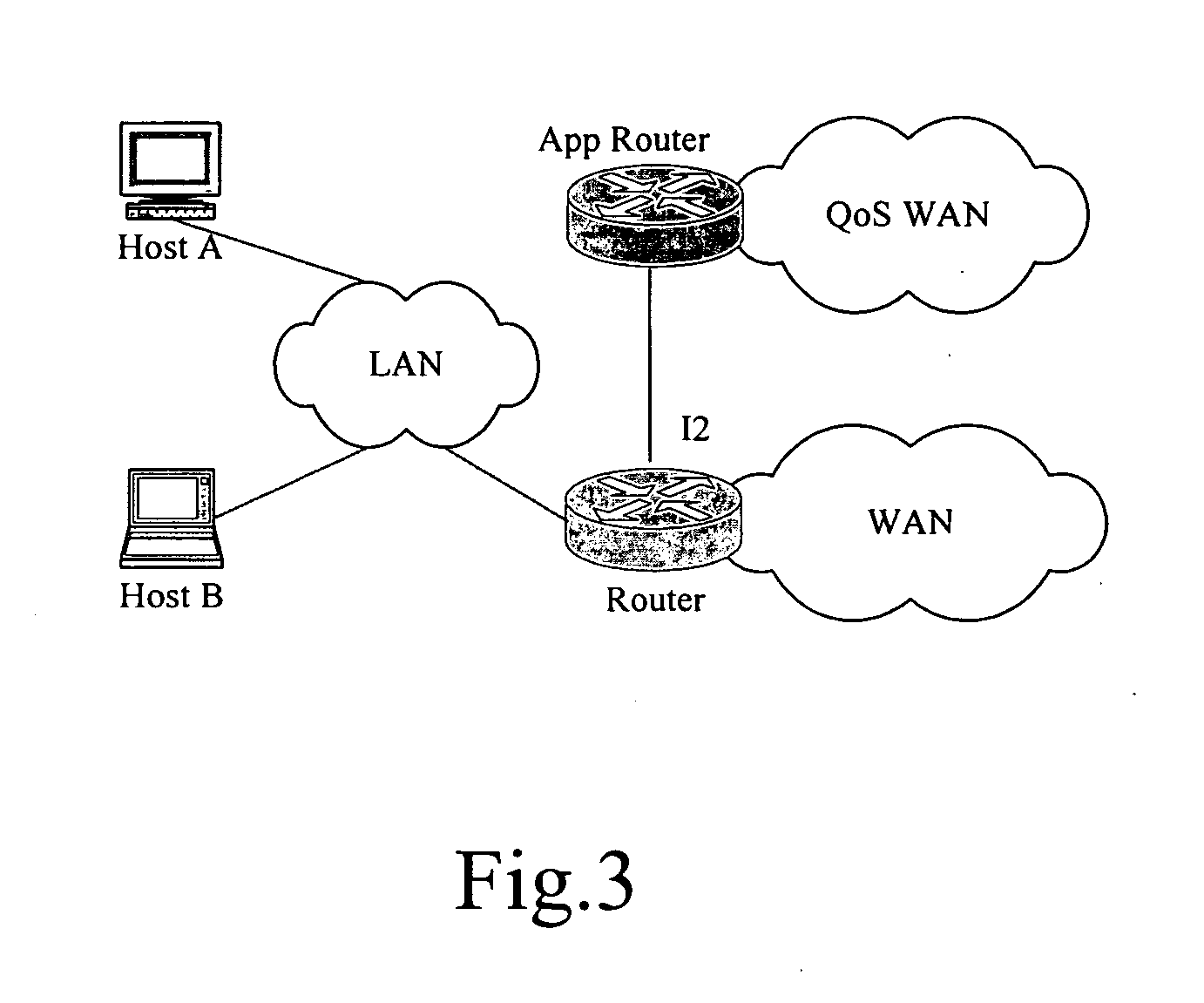

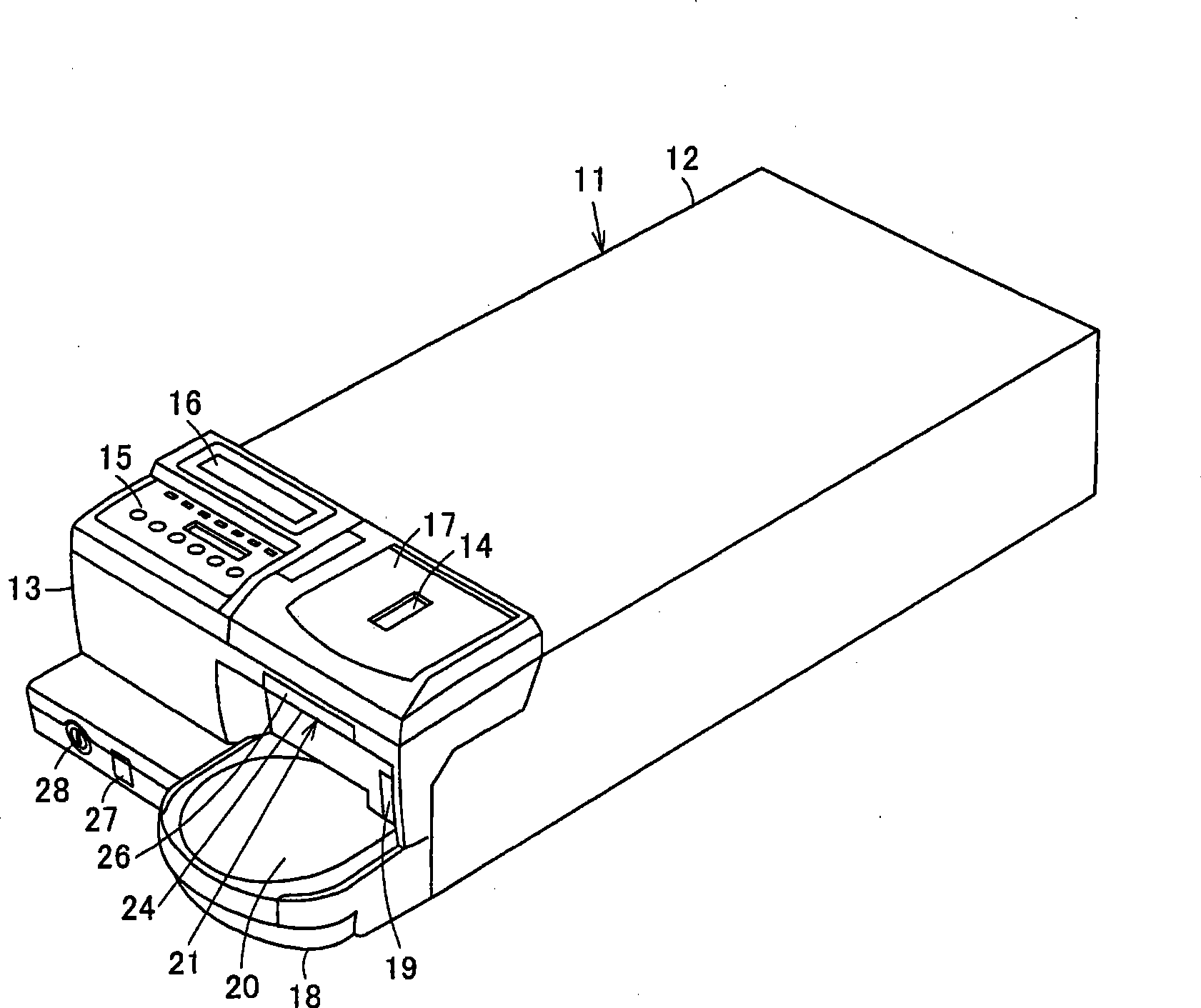

Method for controlling QoS and QoS policy converter

InactiveUS20060268905A1Improve network securityImprove securityTime-division multiplexData switching by path configurationType of service

The present invention discloses a method for controlling QoS, including setting a QPC for each kind of QoS guaranted services in a bearer network; transmitting a QoS guaranteed service to a corresponding QPC by the bearer network, transferring the service and carrying QoS related information in the service by the QPC, and transmitting the service to a QoS WAN according to the QoS related information by the bearer network. The present invention also discloses a kind of QPC. Through the scheme of the present invention, the services can be differentiated according to service type, so that the QoS guaranteed services can be accessed into a QoS WAN. Moreover, the existing network does not need much modification, and only a QPC loosely coupling with a bearer network needs to be added in the existing network. In addition, the scheme of the present invention further realizes service differentiation according to service type and user.

Owner:HUAWEI TECH CO LTD

Soil heavy metal chromium pollution repairing material and making method and application of soil heavy metal chromium pollution repairing material

InactiveCN107722991AImprove adsorption capacityAchieve separationContaminated soil reclamationOrganic fertilisersAdhesiveRepair material

The invention discloses a soil heavy metal chromium pollution repairing material. The soil heavy metal chromium pollution repairing material comprises the following materials by weight percent: 10%-30% of stabilizing and solidifying adhesive, 30%-50% of a composite adsorbent, and the balance of water. The invention also discloses a preparation method of the repairing material. The repairing material adsorbs the Cr material in the soil, is favorable for recycling of the material, realizes the efficient repairing, can be recycled for multiple times, and reduces the repairing cost.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

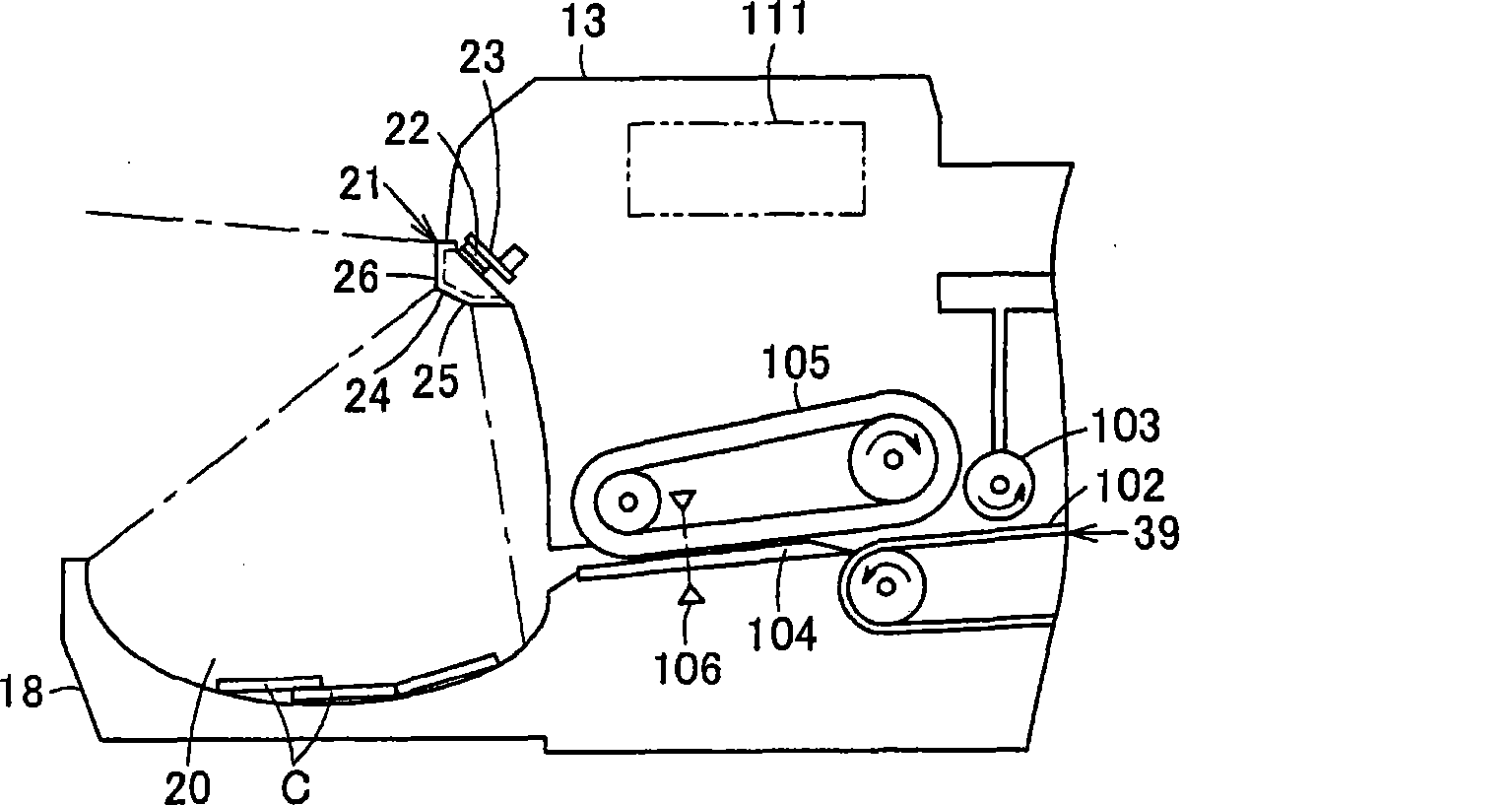

Cash processing machine

InactiveCN101383069AThe type of disposal is clearly identifiedDetermination of the type of disposalLighting applicationsLighting elementsEngineeringGreen-light

This invention provides a coin depositing and dispensing machine capable of clearly specifying whether each coin dispensed into the same coin dispensing port is a coin to be paid or rejected coin, and preventing the coins from being mistakenly mishandled. Light emitting unit (21) capable of emitting light of different colors is disposed in the vicinity of the coin dispensing port (20). The light emitting unit emits a green light if the coin dispensed into the coin dispensing port (20) is a coin to be paid, and emits a red light if the dispensed coin is a rejected coin. The light emitting unit (21) irradiates light to the whole coin dispensing port and the coins themselves in the coin dispensing port (20). When the coins are taken out from the coin dispensing port (20), it can be recognized whether the coin is a coin to be paid or rejected coin.

Owner:GLORY KOGYO KK

Resourceful treatment method for incinerator slag and flying ash

ActiveCN112808746AAvoid disposition problemsReduce disposal costsWaste processingSolid waste disposalBrickSlag

The invention provides a resourceful treatment method for incinerator slag and flying ash. The incinerator slag and the flying ash can be treated with low cost; and meanwhile, the income can be increased, and sustainable development of environment-friendly treatment enterprises can be facilitated. According to the technical scheme, after the incinerator slag and flying ash to be treated are matched with mixed raw materials, the mixture is fed into a high-temperature smelting device, after the incinerator slag, the flying ash and the mixed raw materials are subjected to high-temperature smelting, glass slag is formed and discharged, and the glass slag is common solid waste and can be used for brick making, road building, sand blasting, rust removal and the like. On the basis of a high-temperature smelting device, chlorine and heavy metal in flue gas are promoted to be combined to enter into a gas phase in a high-temperature smelting mode and then enter into a subsequent treatment procedure along with the smelted flue gas. Smelting flue gas is cooled and solidified into a metal chloride product through a waste heat recovery process, a quenching cooling process and a dust removal process, and the metal chloride product serves as a raw material product in the metal recovery industry for resource utilization.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

Methods for recovering metals

InactiveUS20050077250A1Promote recoveryAvoid disposition problemsPhotography auxillary processesWater/sewage treatment by irradiationMetal alloyNitrogen

Metals and metal alloys are recovered from waste fluids, which contain metal ions and heterocyclic nitrogen compounds. Such waste fluids are exposed to short wavelength UV irradiation and ozone to oxidize the heterocyclic nitrogen compounds and the metals or metal alloys are recovered electrolytically.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

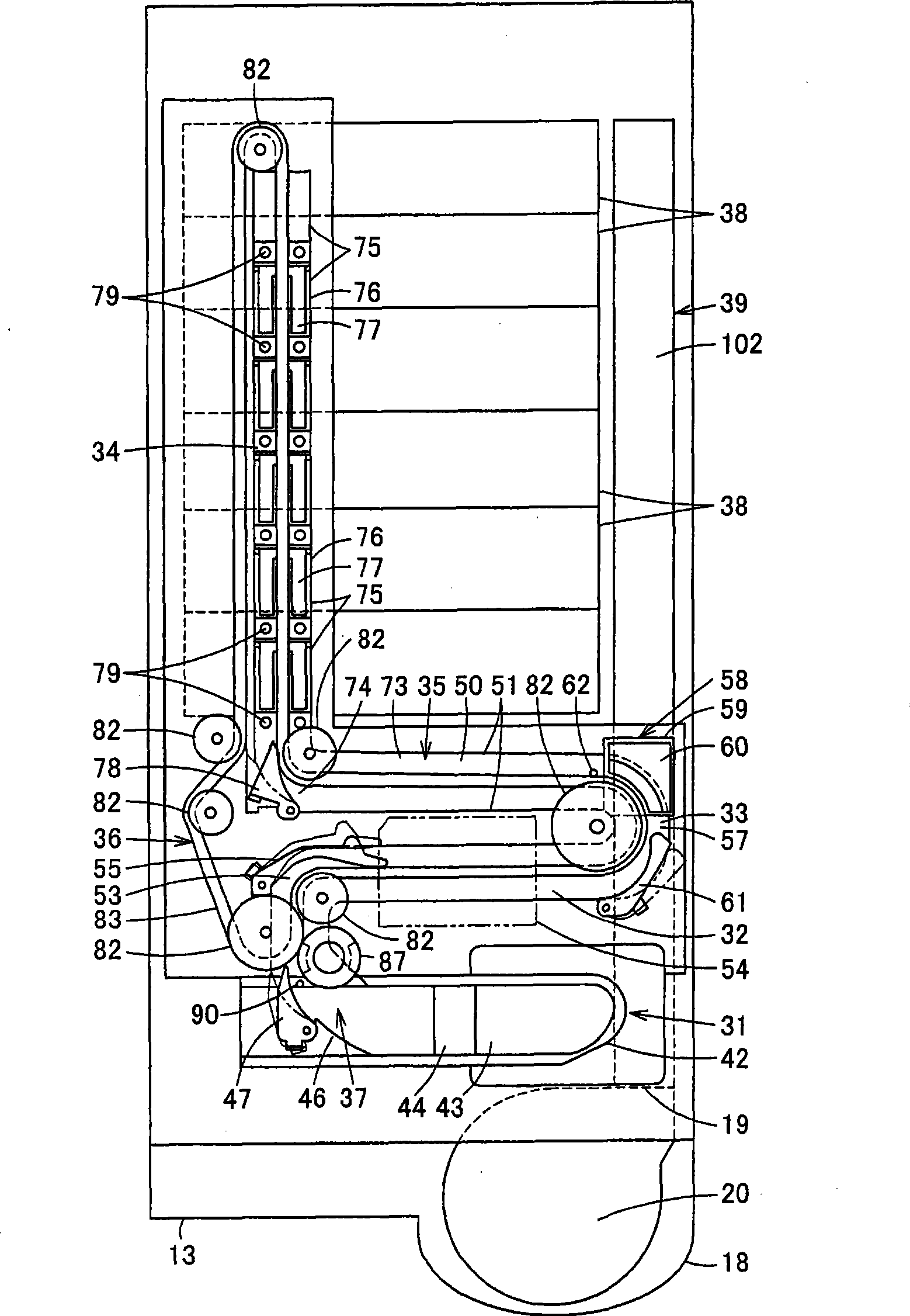

Semiconductor wafer mounting method and semiconductor wafer mounting apparatus

InactiveUS20120298283A1Accurate measurementAccidental mounting of the spacer can be avoidedLamination ancillary operationsControlling laminationEngineeringSemiconductor

A workpiece is unloaded from a wafer-receiving container. A first discriminating sensor detects a front surface of the workpiece, and determines either a semiconductor wafer or a spacer is the workpiece. Where the workpiece is a wafer, the first discriminating sensor also determines whether or not a protective tape is on the front surface of the workpiece. Where it is determined that a protective tape is not on the front surface, a second discriminating sensor detects a back surface of the wafer for discriminating the presence or absence of the protective tape.

Owner:NITTO DENKO CORP

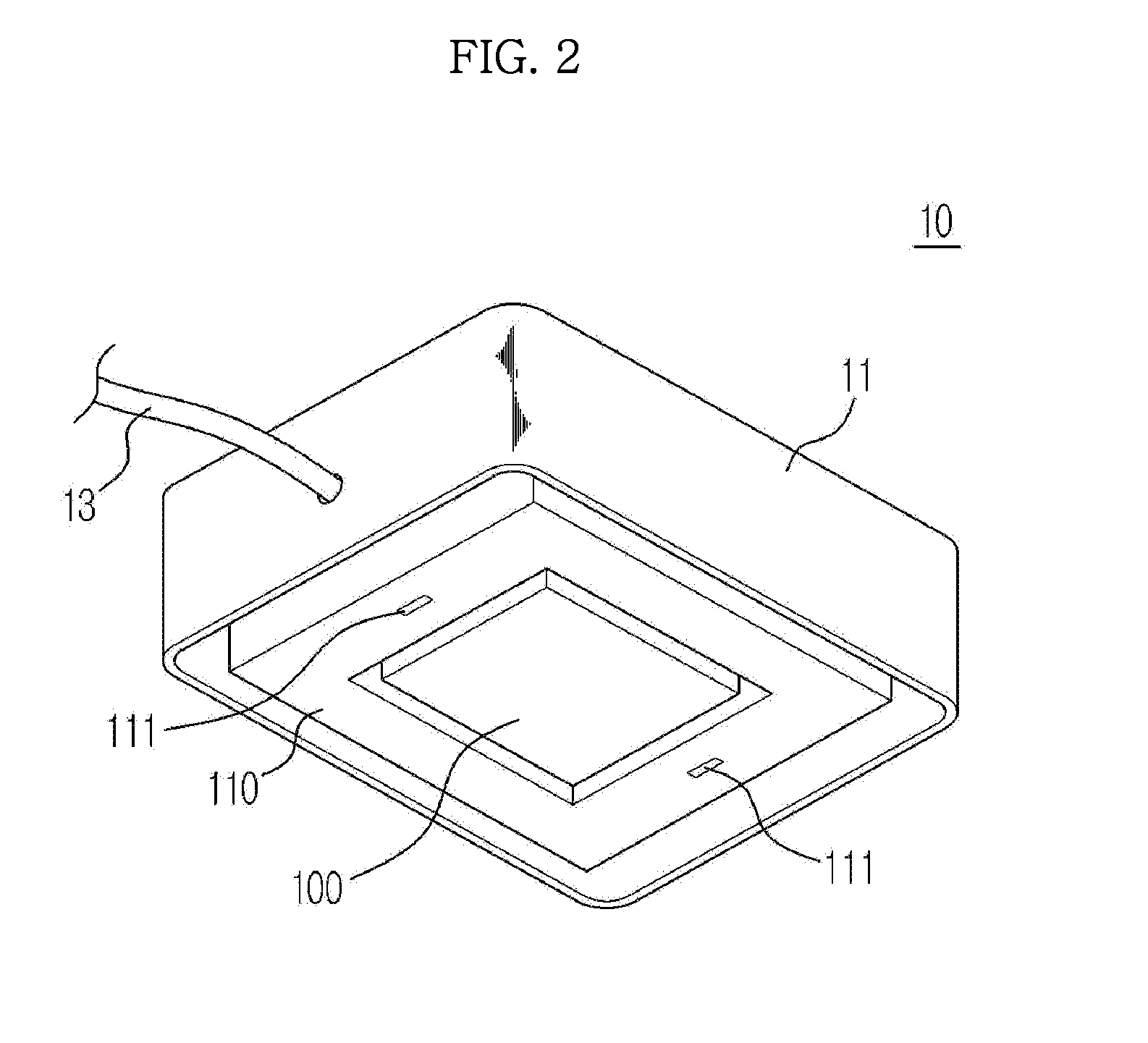

Local Coil

ActiveUS20140312902A1System design be convenientEnergy saveElectric/magnetic detectionMeasurements using magnetic resonanceResonance signalControl circuit

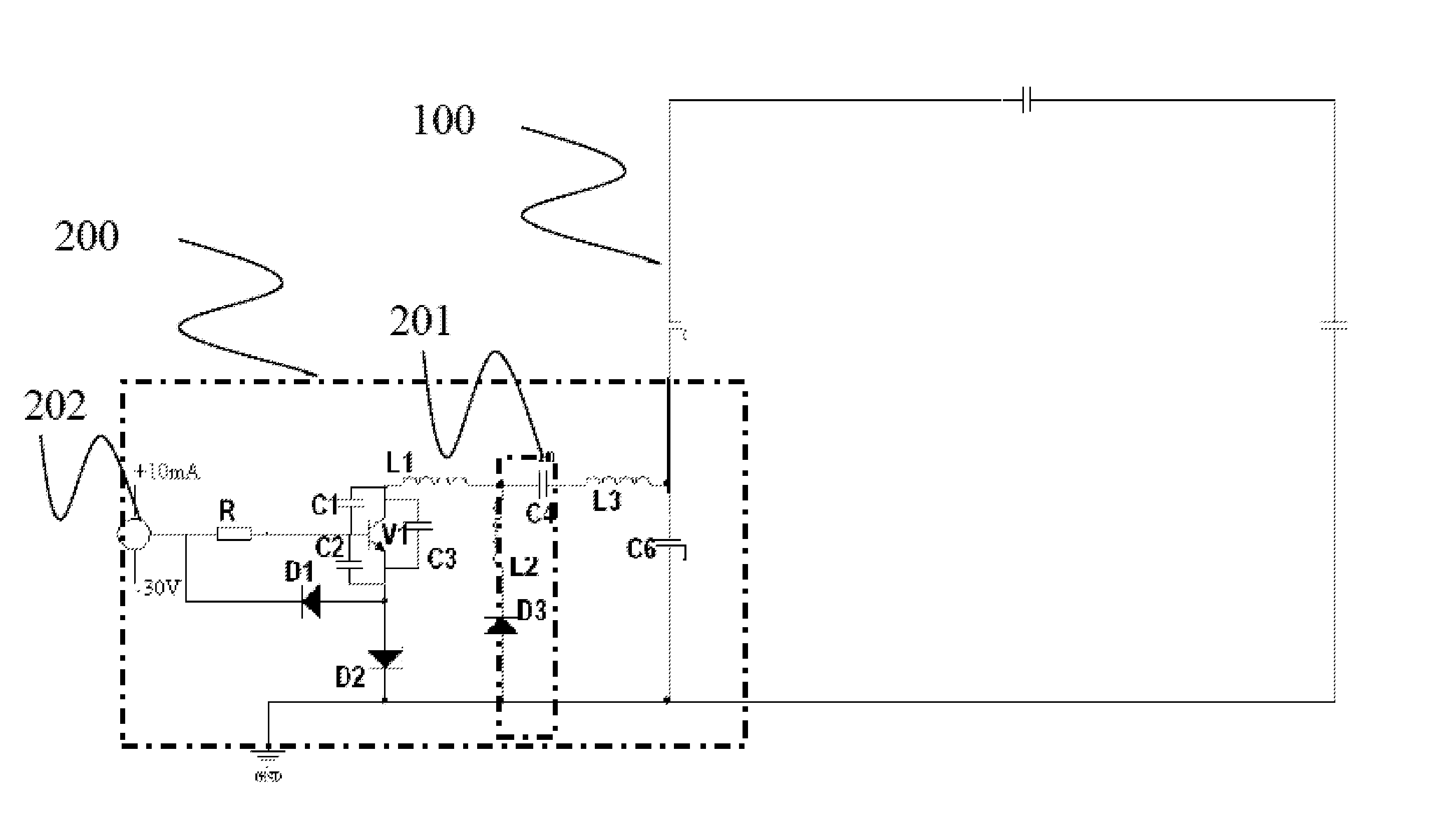

A local coil for an MRI system includes a signal antenna to receive a magnetic resonance signal and a tuning / detuning circuit to subject the signal antenna part to switch control according to a control signal. The tuning / detuning circuit is connected to the signal antenna part. The tuning / detuning circuit includes a control signal interface, a resonant circuit and an AC / DC conversion circuit. The control signal interface receives the control signal. The resonant circuit includes a diode. The AC / DC conversion circuit converts an alternating current generated by an electromagnetic wave to a direct current. The AC / DC conversion circuit is connected in series with the diode. A small detuning control current may be used, and detuning control circuitry may be reduced.

Owner:SIEMENS HEALTHCARE GMBH

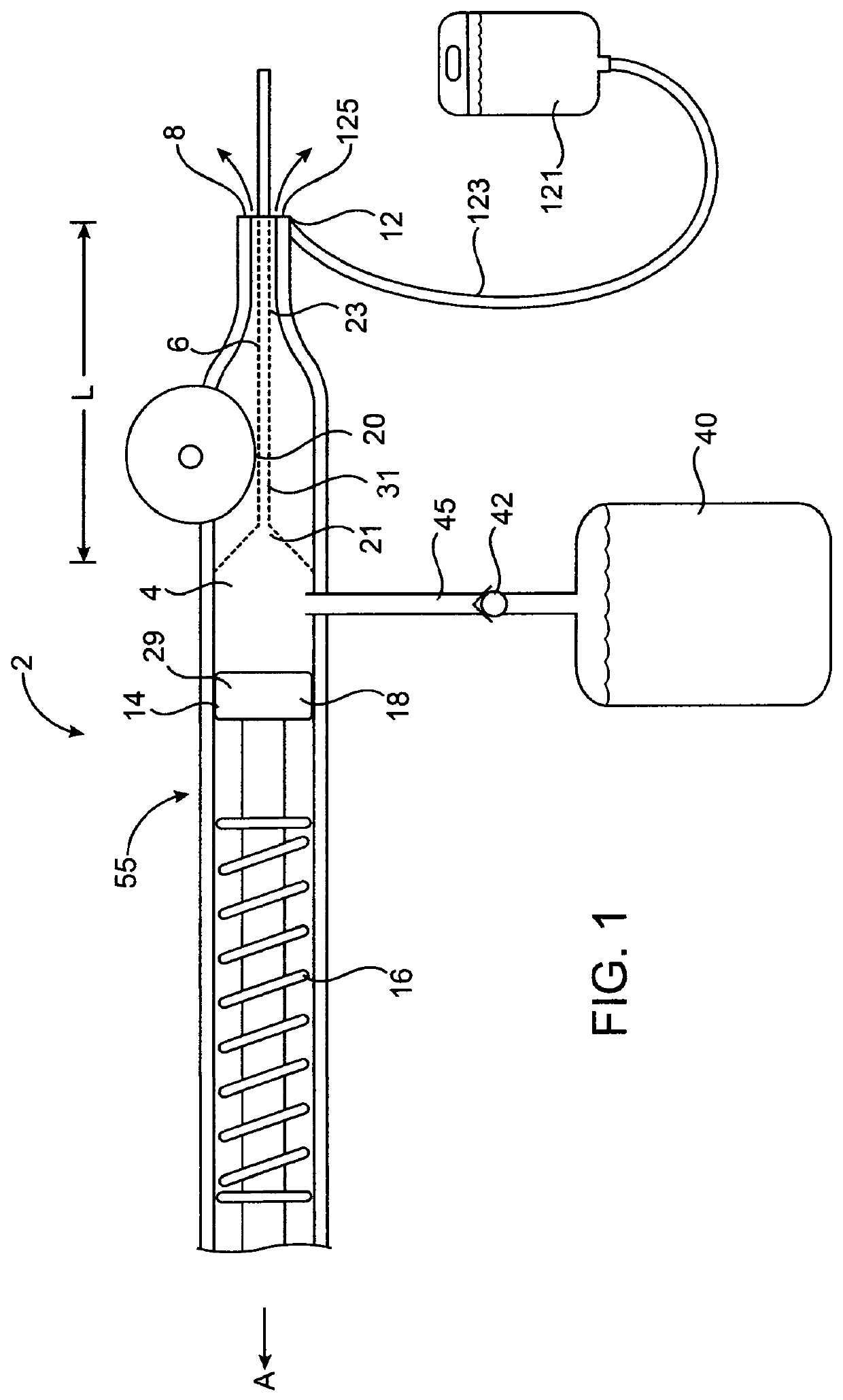

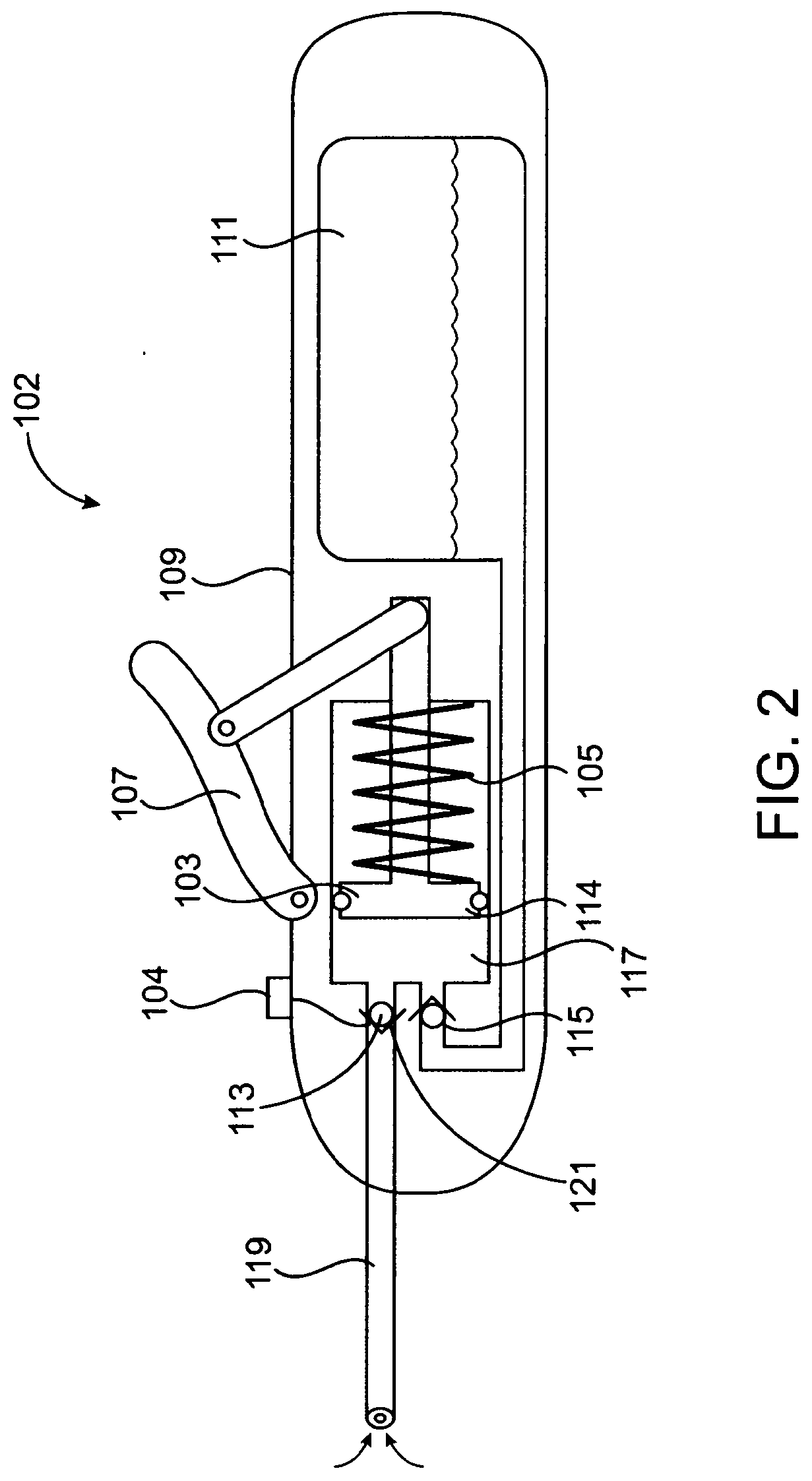

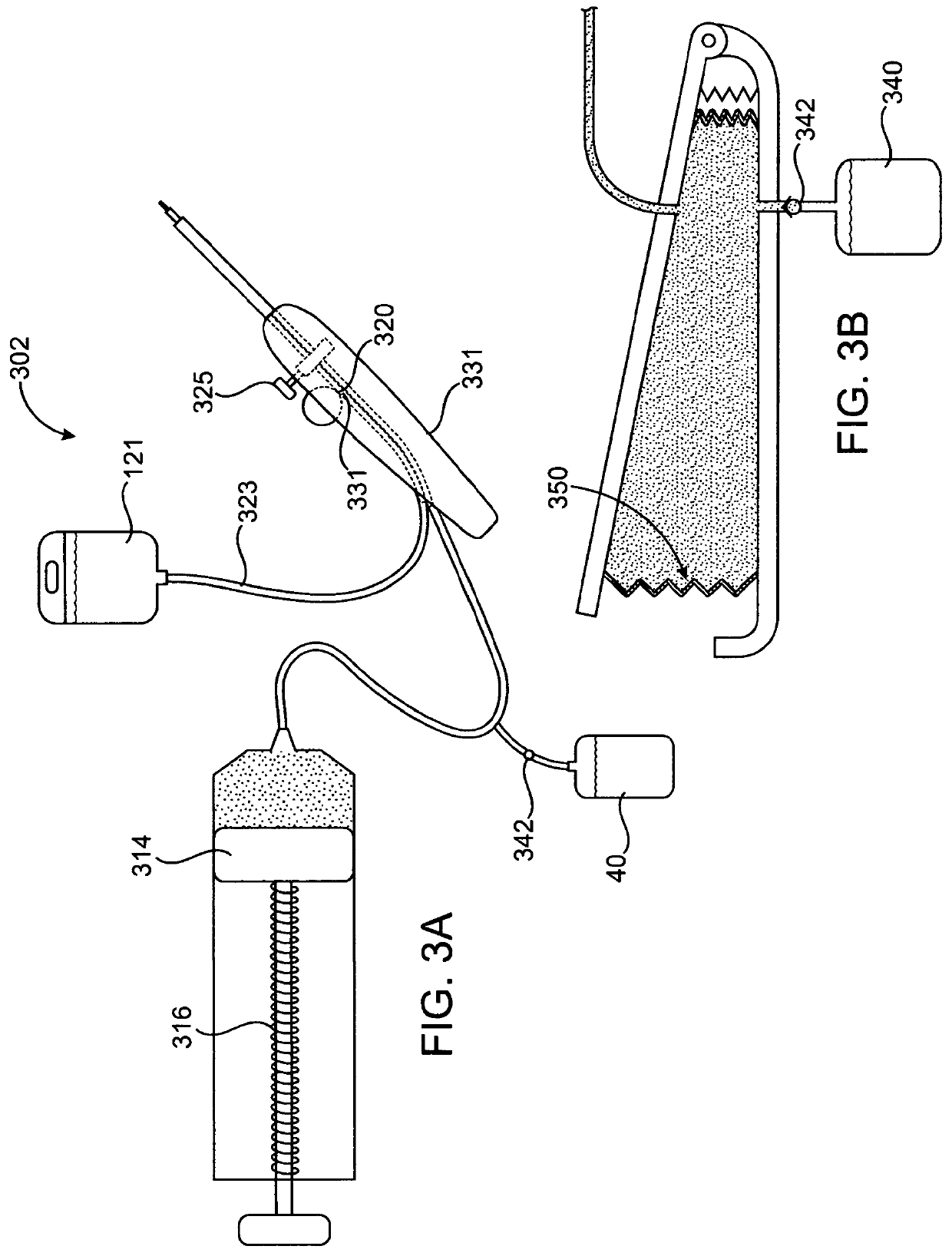

Devices and methods for ocular surgery

ActiveUS20200306083A1Improve responsivenessSmall volumeLaser surgeryExcision instrumentsOcular operationHand held

A hand-held aspiration device is provided which has a relatively small suction volume along a suction path to improve responsiveness of the aspiration device when the device is activated. The device may be manually powered and may be provided without electronic controls. The device has a suction path which may be purged into a disposal enclosure to reduce the volume of material under the influence of the suction pressure during the procedure. The suction source may also be part of the hand-held unit to further reduce the suction path and suction volume.

Owner:CARL ZEISS MEDITEC CATARACT TECH INC

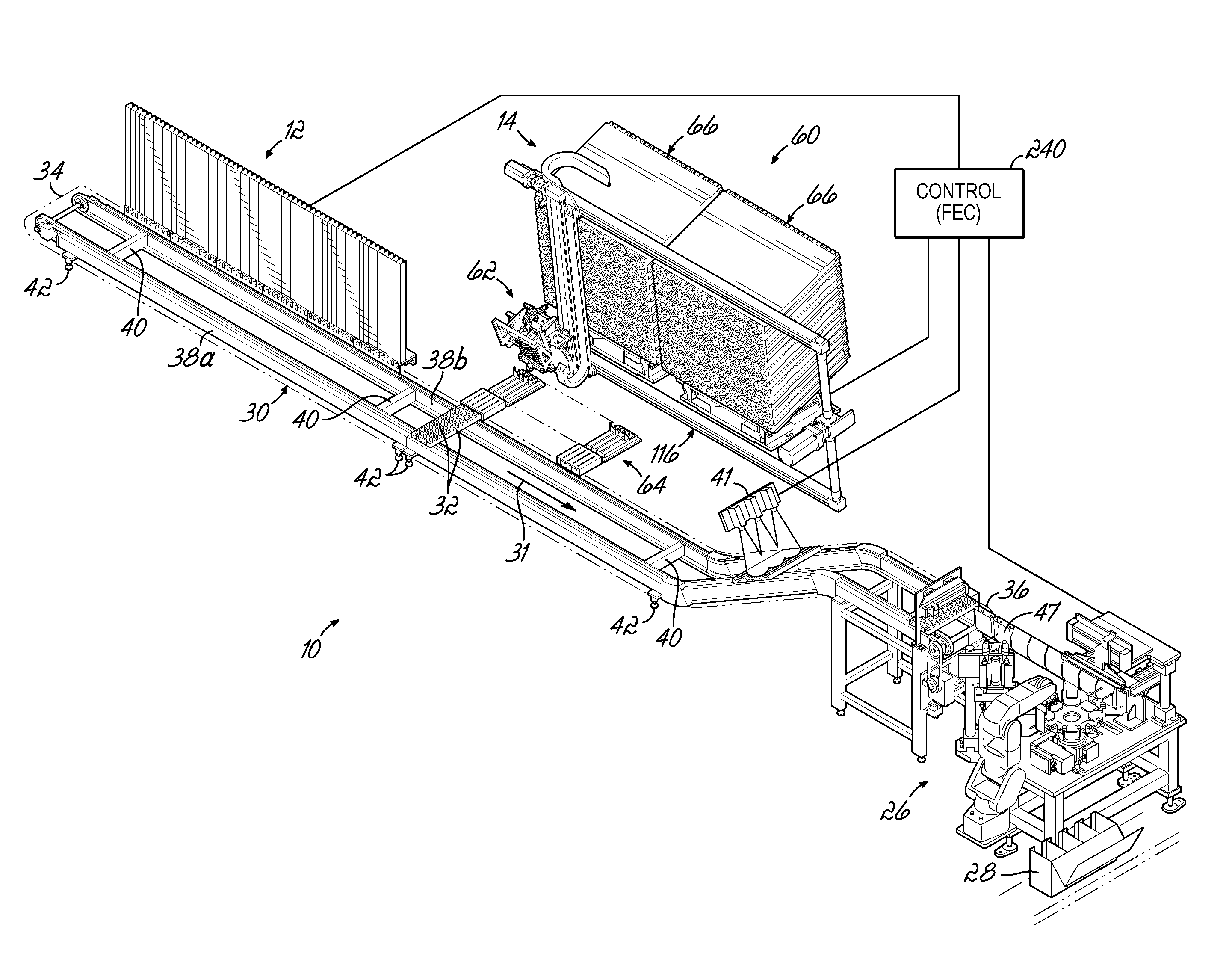

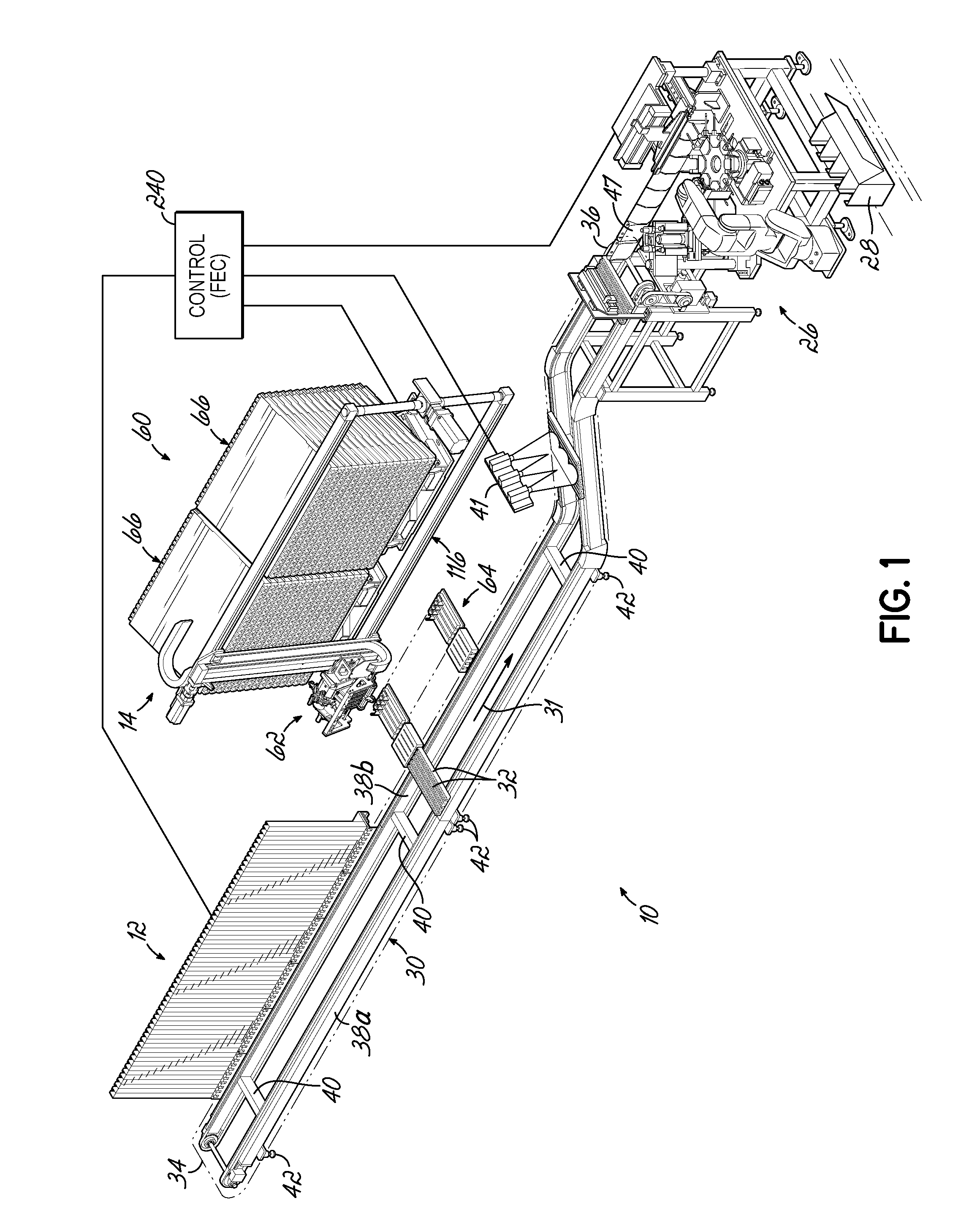

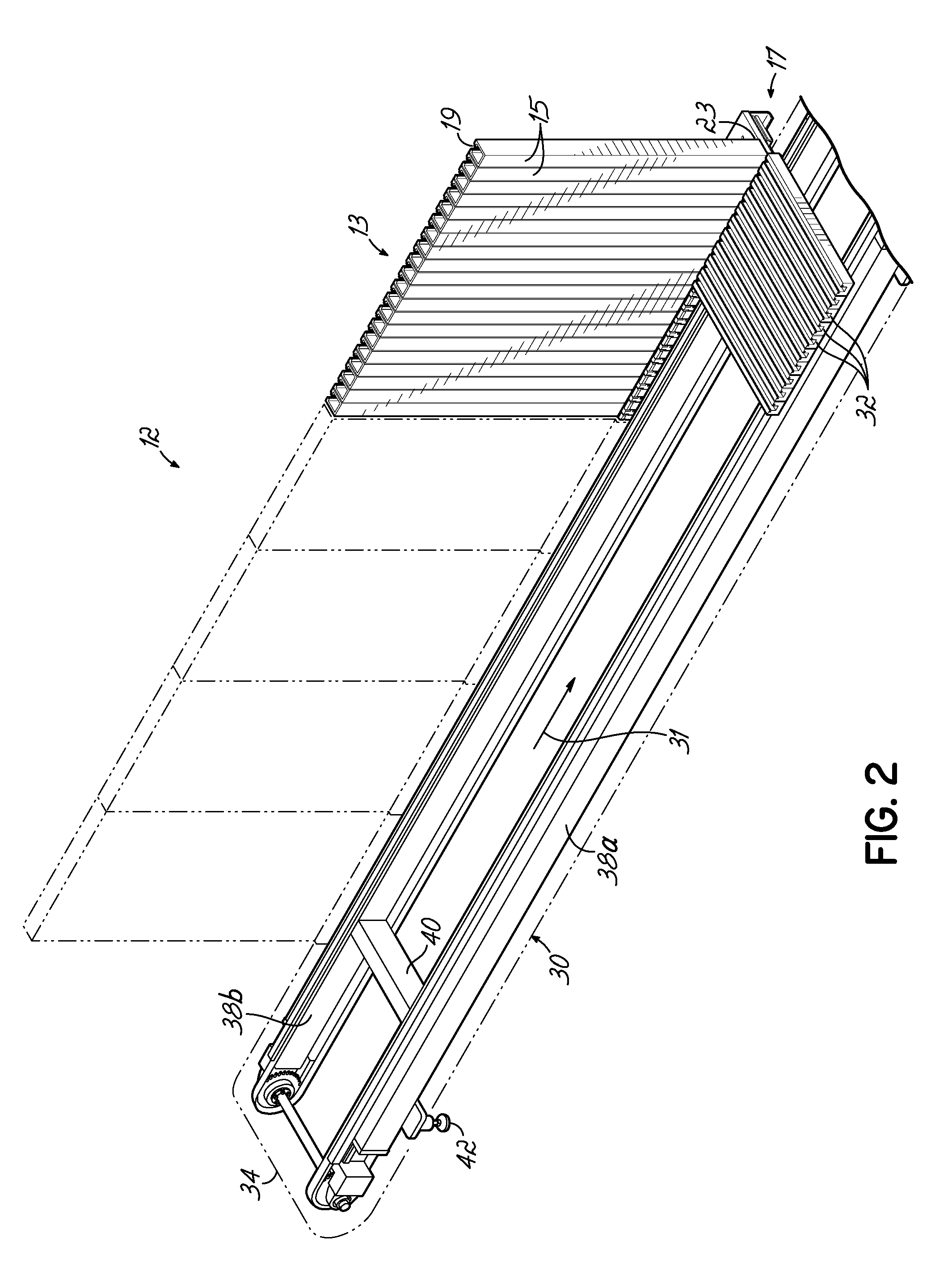

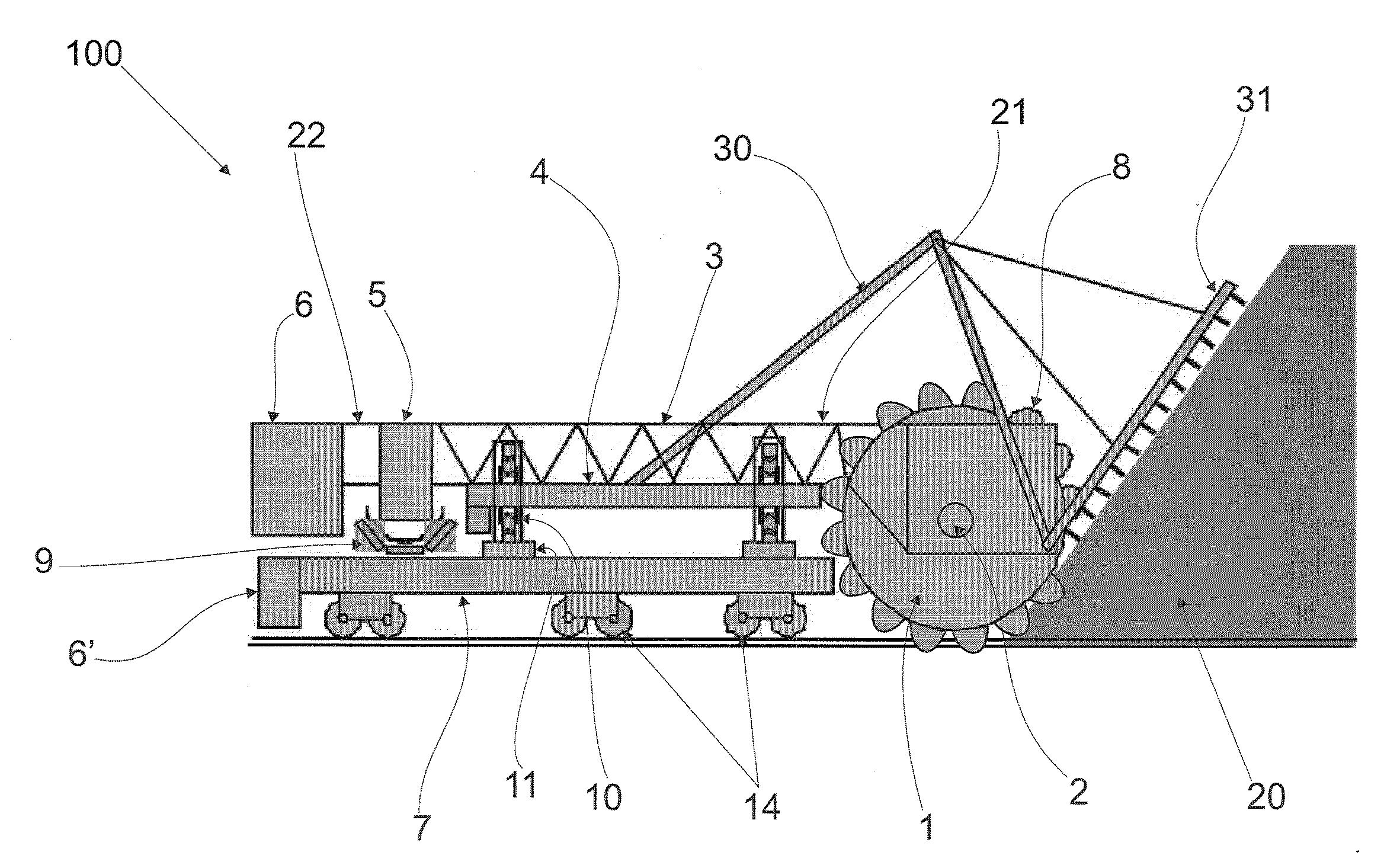

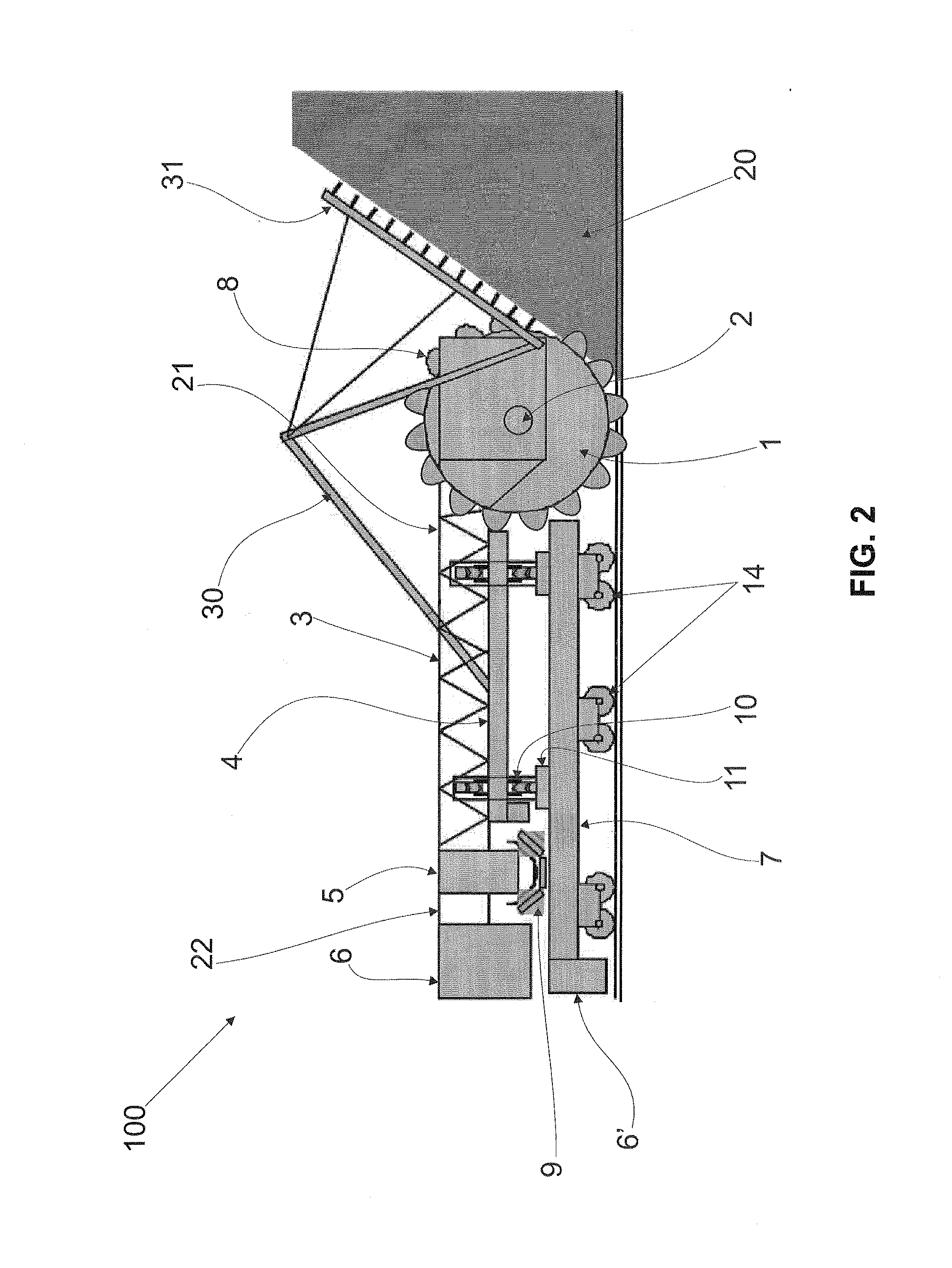

Reclaimer machine

InactiveUS20120138426A1Cost-effective in constructionCost-effective in manufactureConveyorsSoil-shifting machines/dredgersReclaimerConveyor belt

Aspects of this invention include a reclaimer machine for reclaiming and homogenizing materials such as ore, coal and others, stock-piled in yards. The reclaimer machine may include a bucket wheel having a series of buckets rotating around a shaft, a conveyor belt connected to the bucket wheel and to a transfer chute, the conveyor belt being supported by a mobile upper platform that moves laterally to a pile on tracks attached to a mobile lower platform, wherein a first end of the conveyor belt structure may be connected to the bucket wheel and another end of the conveyor belt structure may be connected to a counterweight which maintains the balance of the reclaimer machine and supports the bucket wheel, upper platform and lower platform movements.

Owner:VALE LIMITED

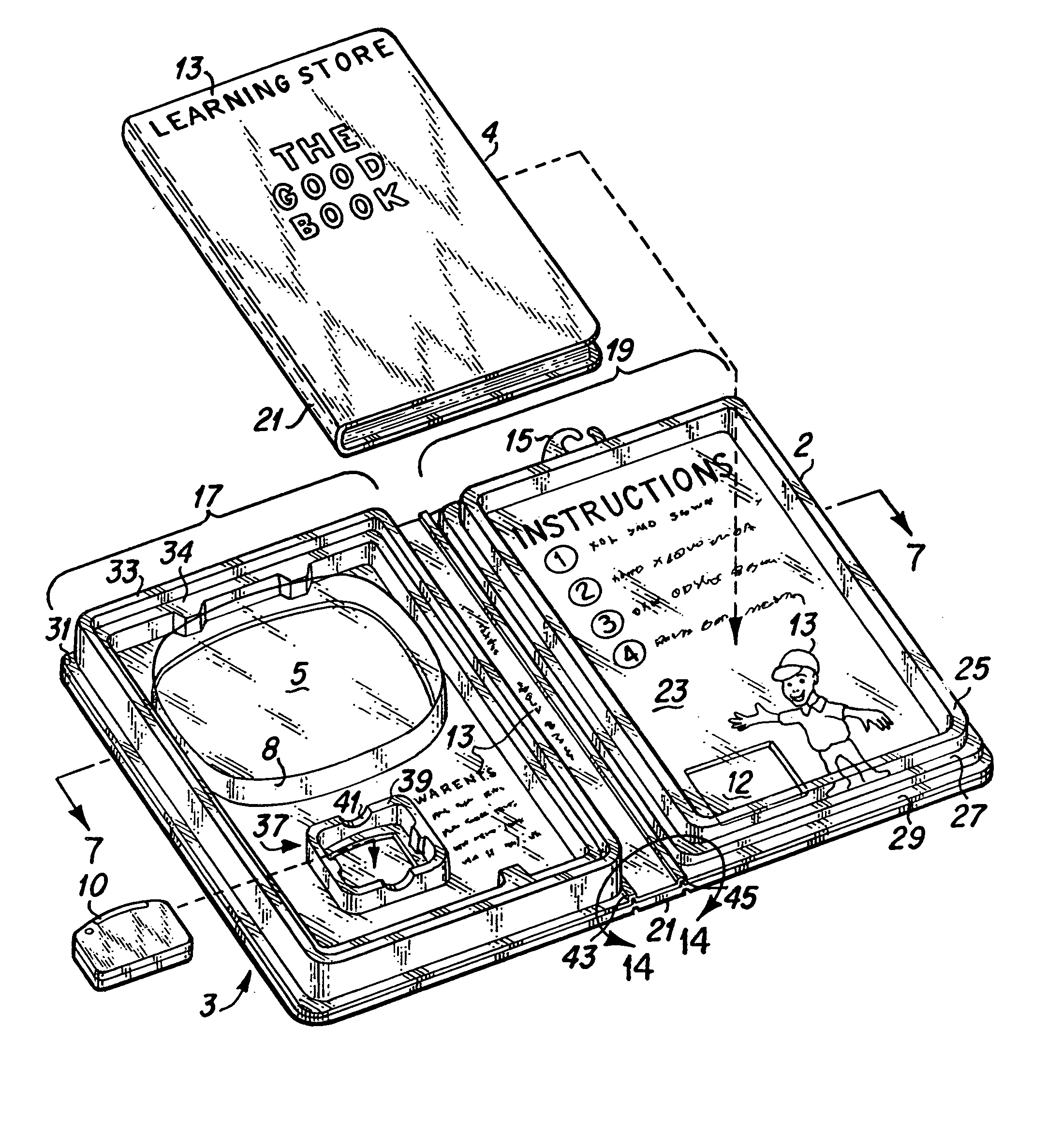

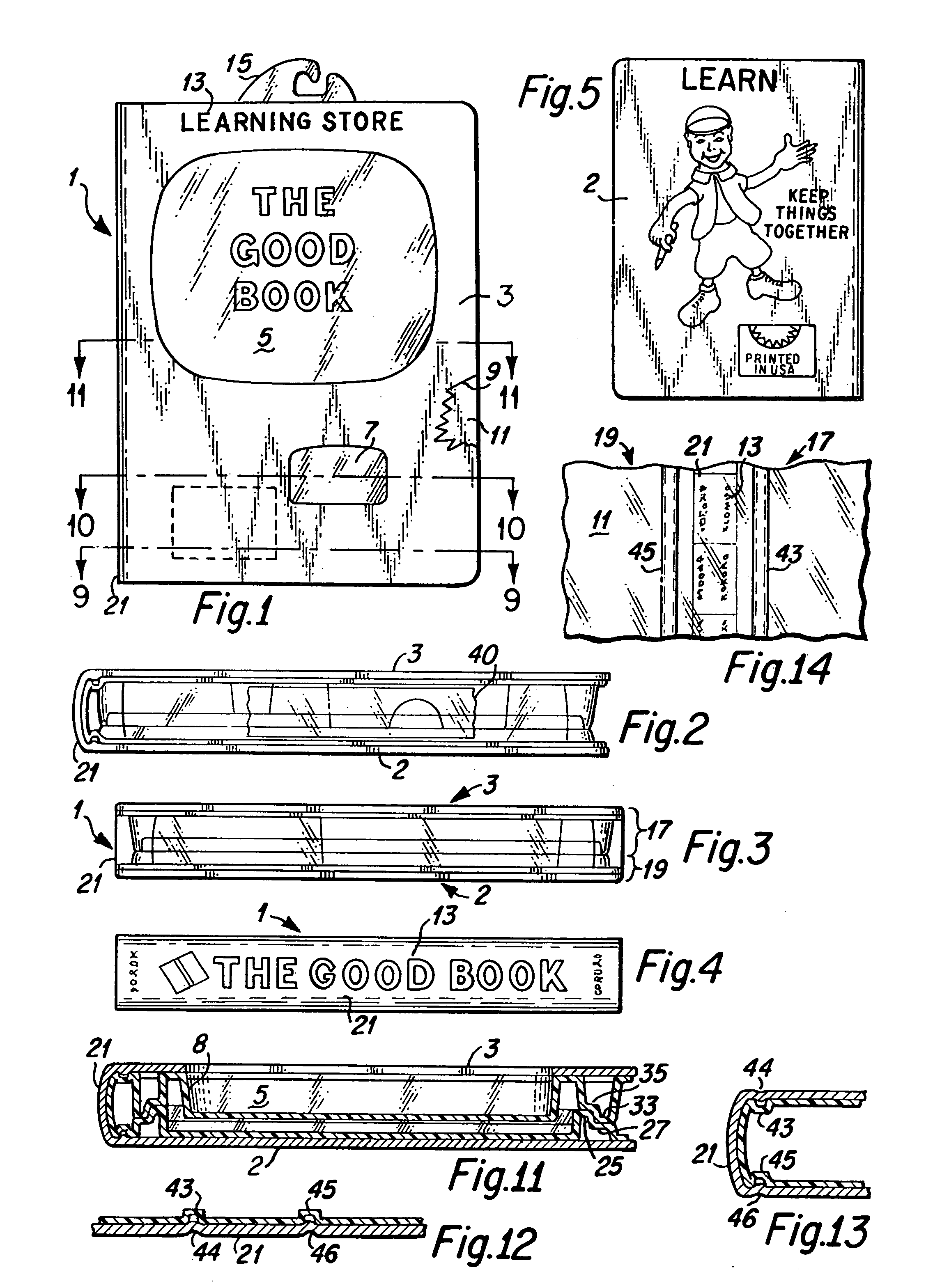

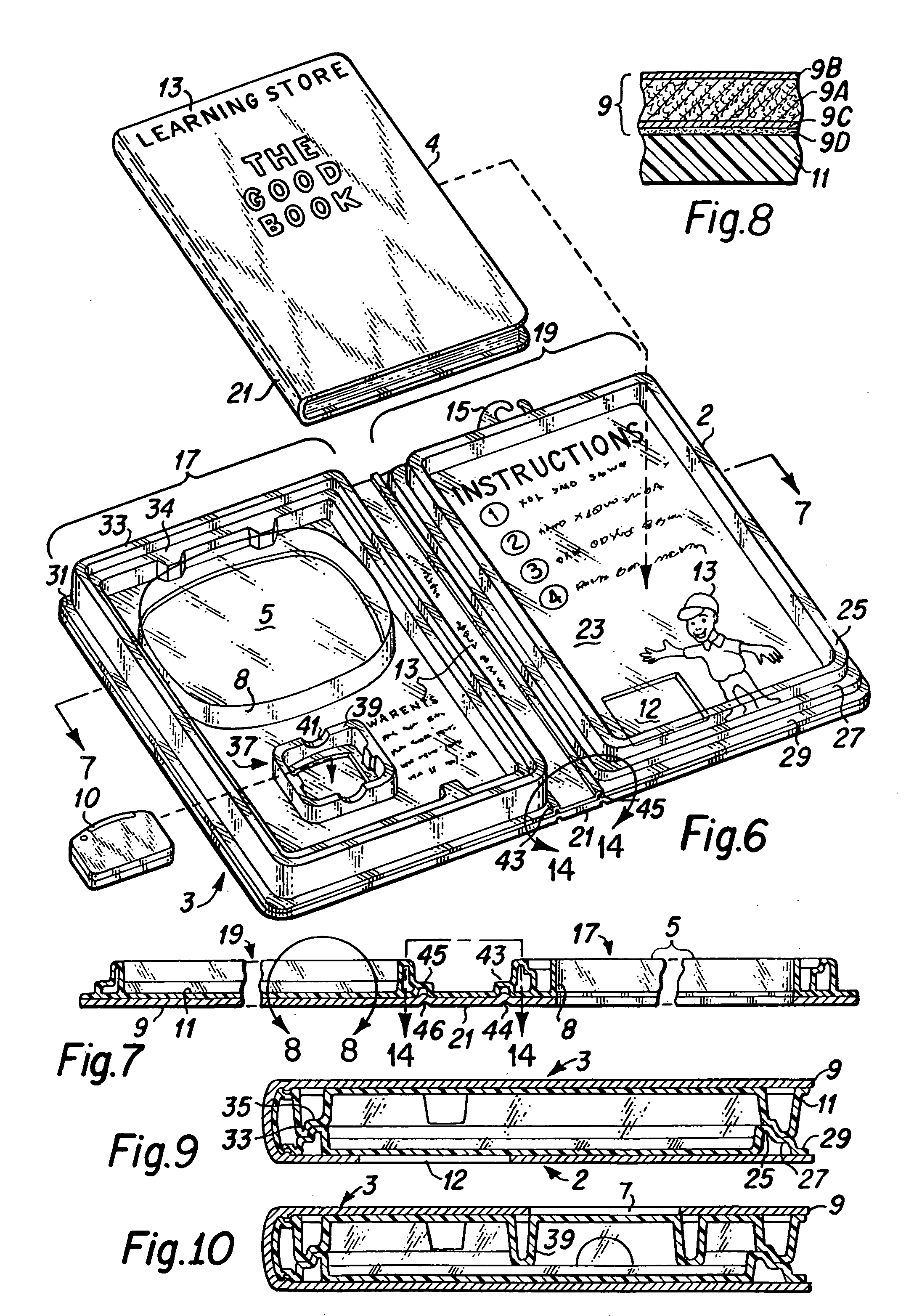

Reusable environmentally friendly package and storage album

InactiveUS20050247581A1Avoid disposition problemsConvenient re-usePackage recyclingOther accessoriesEnvironmental resistancePaperboard

Owner:AVC CORP

Thermal insulation performance measurement apparatus and measurement method using the same

ActiveUS20130193820A1Rapidly and accurately test thermal insulation performanceAvoid it happening againShow cabinetsDomestic cooling apparatusThermal insulationMaterials science

A thermal insulation performance measurement apparatus which measures thermal insulation performance of a thermal insulator by heat flux to the thermal insulator, measured by a heat flux sensor, and a measurement method using the same includes a heat flux sensor provided with one surface adapted to contact an object to be measured, a first heat source arranged on the upper surface of the heat flux sensor to supply heat to the heat flux sensor, a thermal insulator arranged on the upper surface of the first heat source, a third heat source arranged on the upper surface of the thermal insulator, and a second heat source arranged around the heat flux sensor.

Owner:SAMSUNG ELECTRONICS CO LTD

System and method of avoiding cell disposal in buffer

InactiveUS20050286420A1Avoid disposition problemsError preventionFrequency-division multiplex detailsCell processingComputer science

A cell disposal avoidance system is provided that can avoid disposal of the cells resided in the QoS buffer when a traffic of a specific QoS class in an ATM switch increases. The ATM switch includes a storage cell number monitor, a software data section 813, and a software controller 812. The storage cell number monitor monitors congestion of plural QoS buffers in the buffer 3, 5. The software data section 813 stores a cell reading priority (WRR value) attached for each QoS buffer. The software controller 812 dynamically changes the WRR value when congestion of a QoS buffer is in a congestion state (at generation of cell disposal or buffer congestion alarm) and increases the WRR value of the QoS buffer in a cell disposal state. Cells are divided in a time division mode according to the weight of the WRR value and read in a round format from the QoS buffer. The ATM switch resets the WRR value to an initial value when the congestion of the QoS buffer ceases.

Owner:JUMIPER NETWORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com