Patents

Literature

89results about How to "Avoid horizontal displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

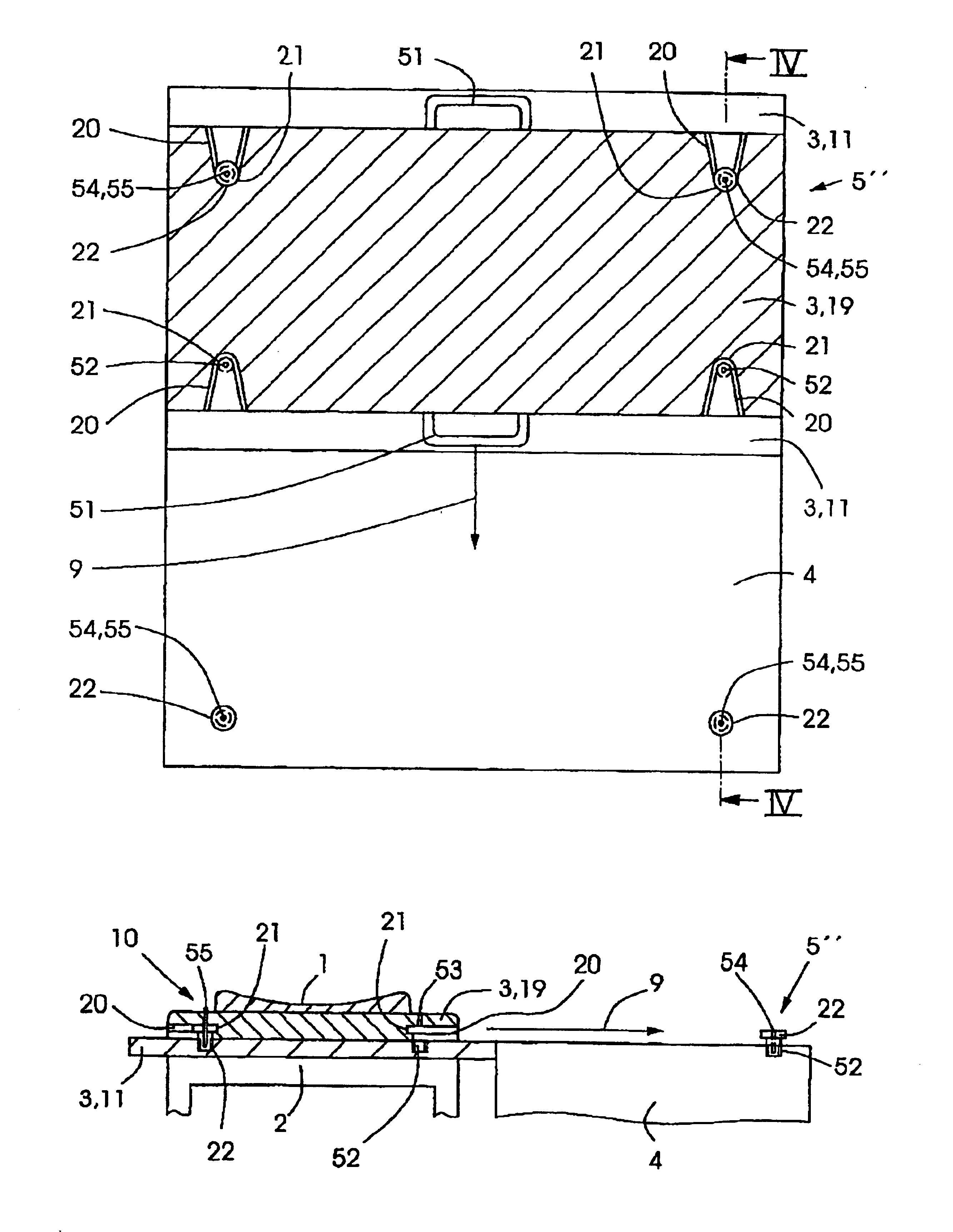

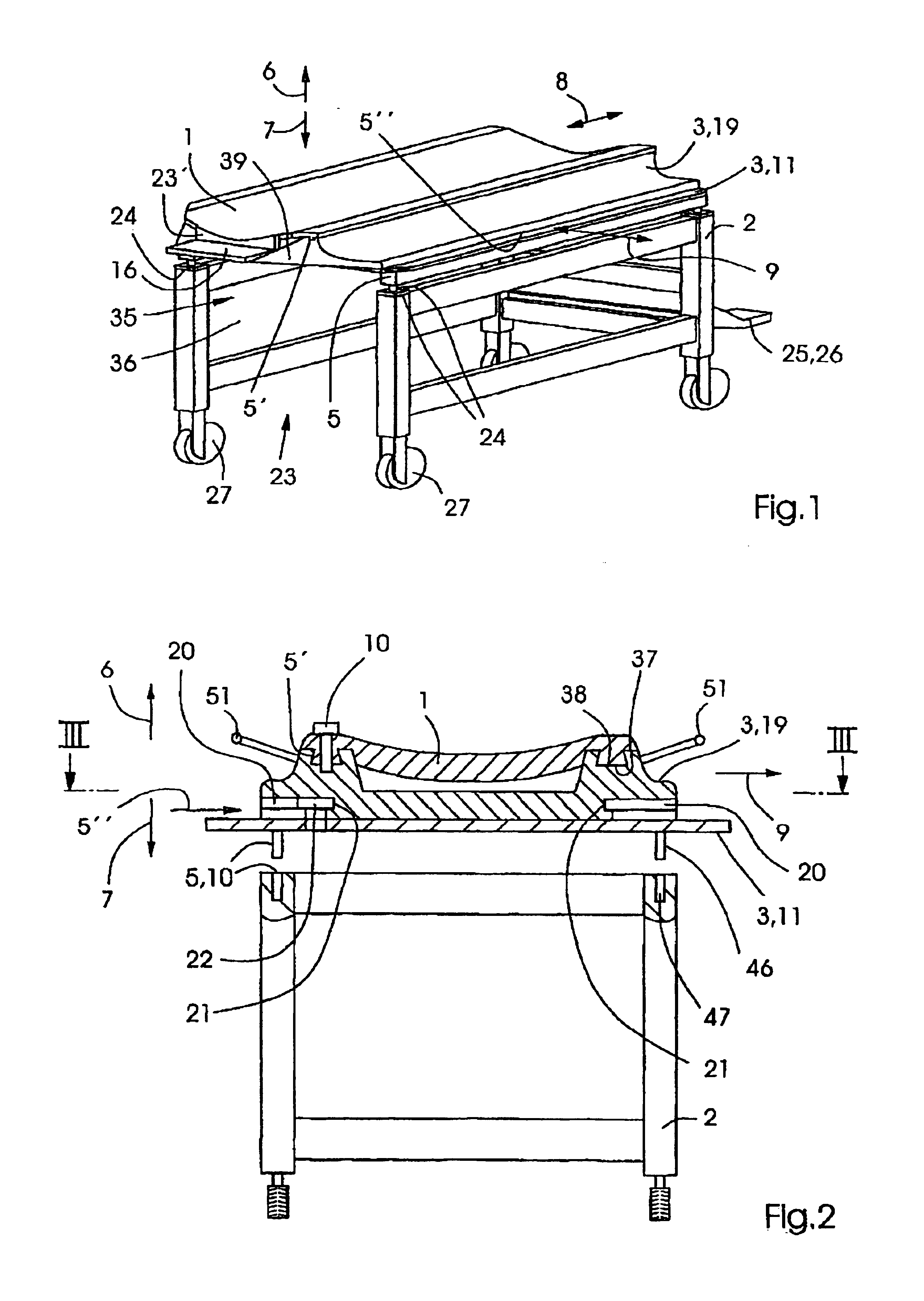

Patient positioning and transport system

InactiveUS6928672B2Easy to adjustSufficiently secureStretcherPatient positioning for diagnosticsCartEngineering

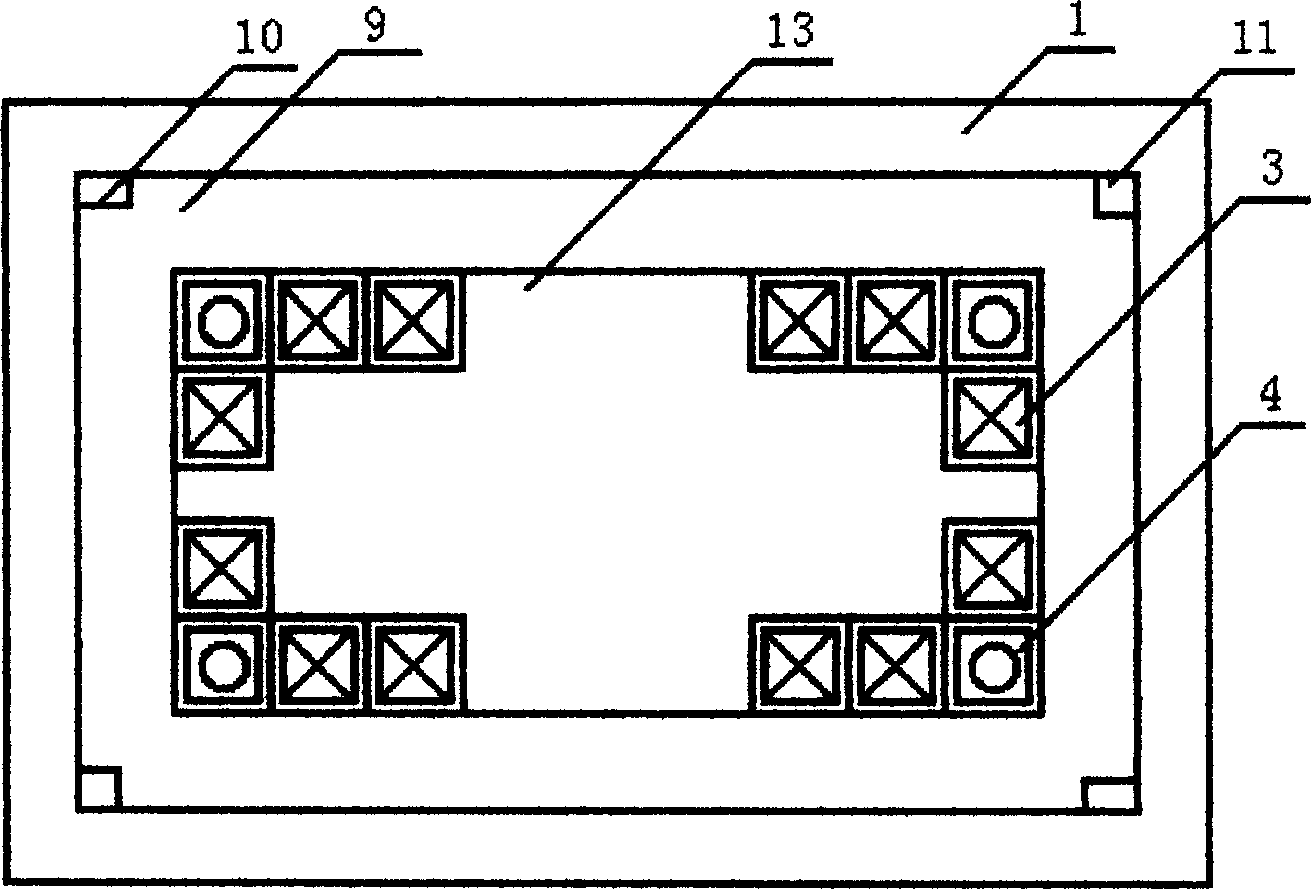

The invention relates to a patient positioning and transport system comprising a transportable stretcher (1) and a cart (2) for transporting the stretcher (1) with the patient. The stretcher (1) can be removed from the cart (2) to be placed on a diagnosis or treatment station (4). A patient positioning and transport system of the aforementioned type should be designed as to avoid, to the greatest possible extent, repositionings of the patient between separate diagnosis or treatment stations (4). Towards this end, at least one adapter plate (3) that can be assigned to the stretcher (1) is provided, whereby the stretcher (1), the adapter plate (3) and the cart (2) can be joined to another and are configured in such a manner that the stretcher (1) with the patient can be transferred from the cart (2) to various, differently designed diagnosis or treatment stations (4) and back.

Owner:DEUTES KREBSFORSCHUNGSZENT STIFTUNG DES OFFENTLICHEN RECHTS

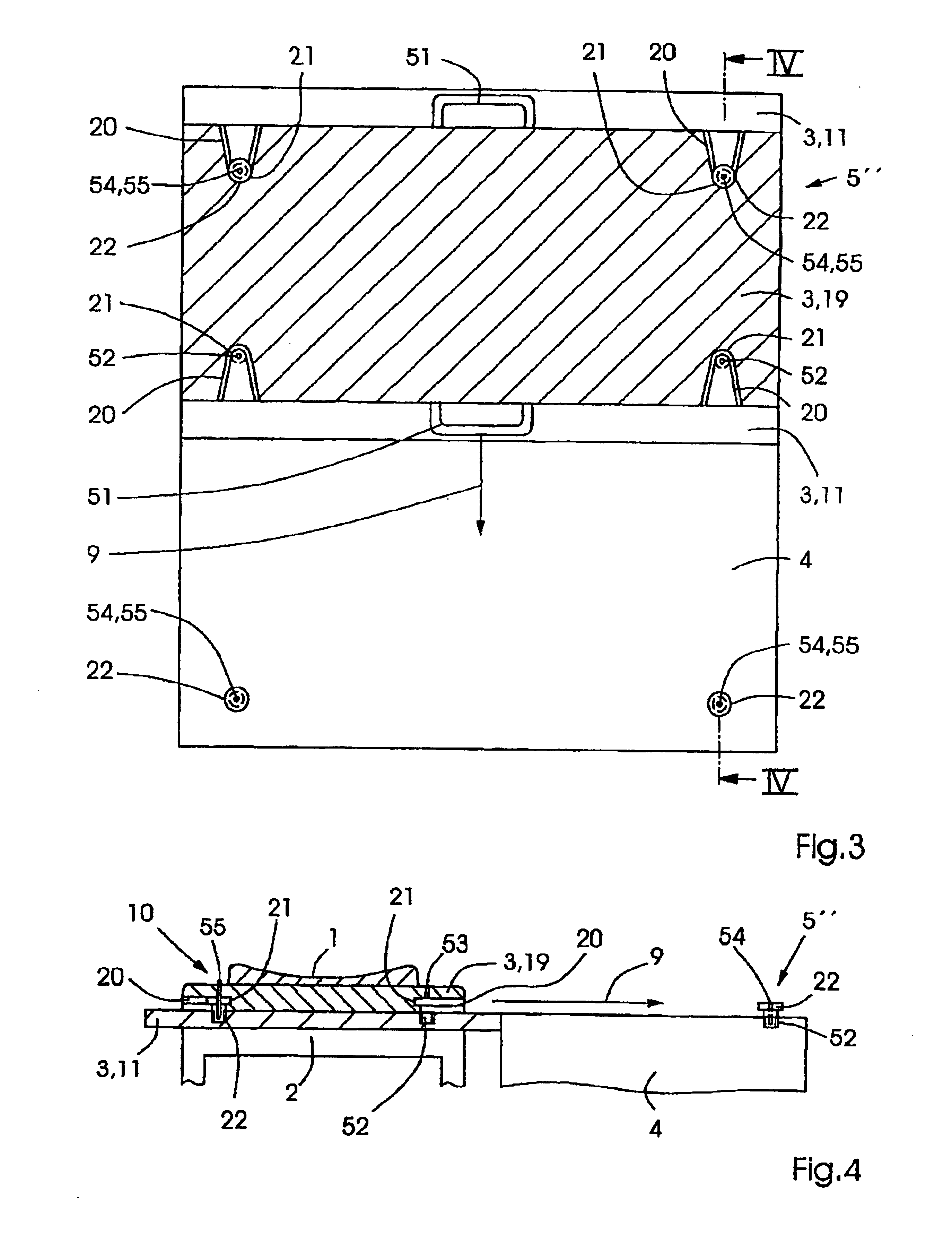

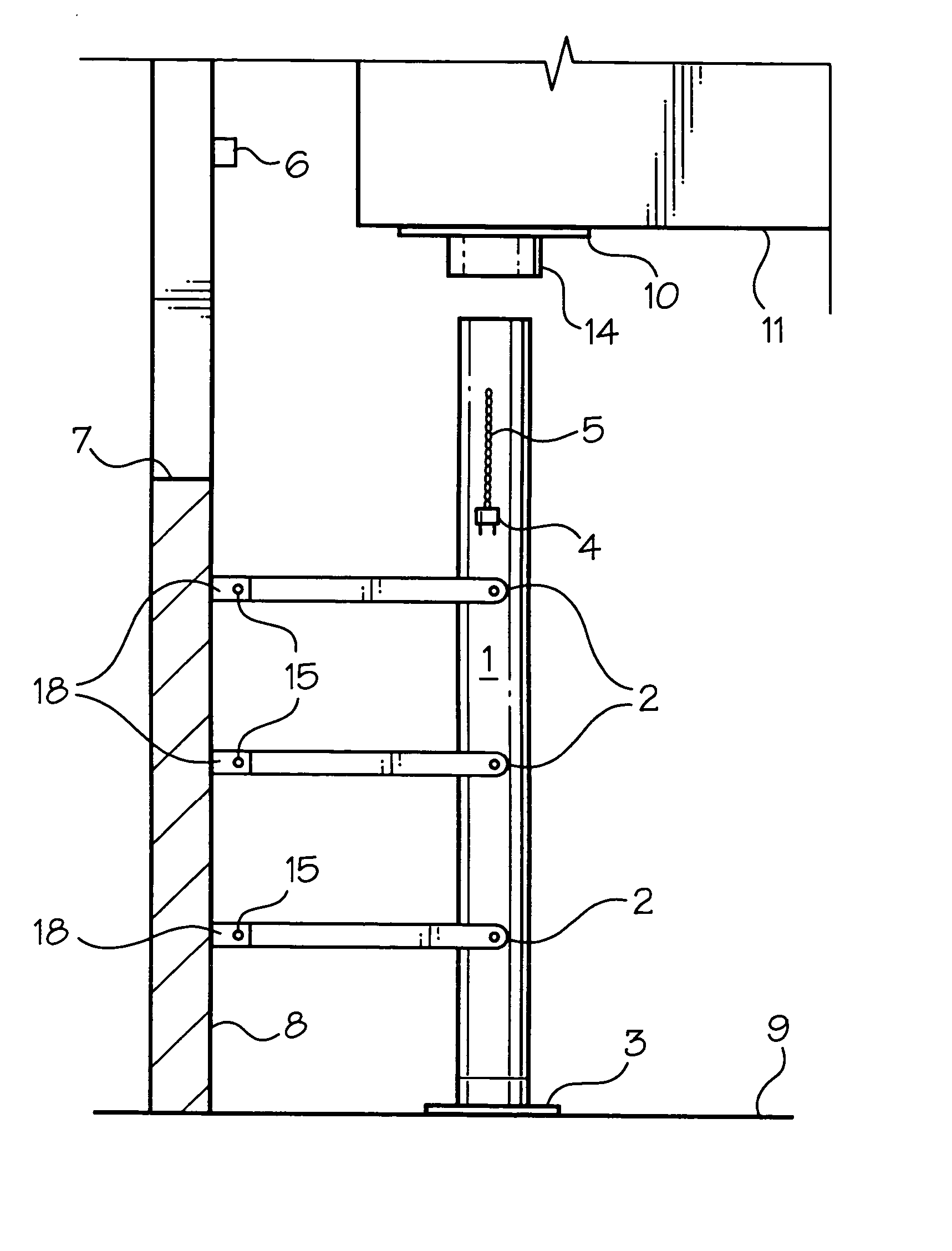

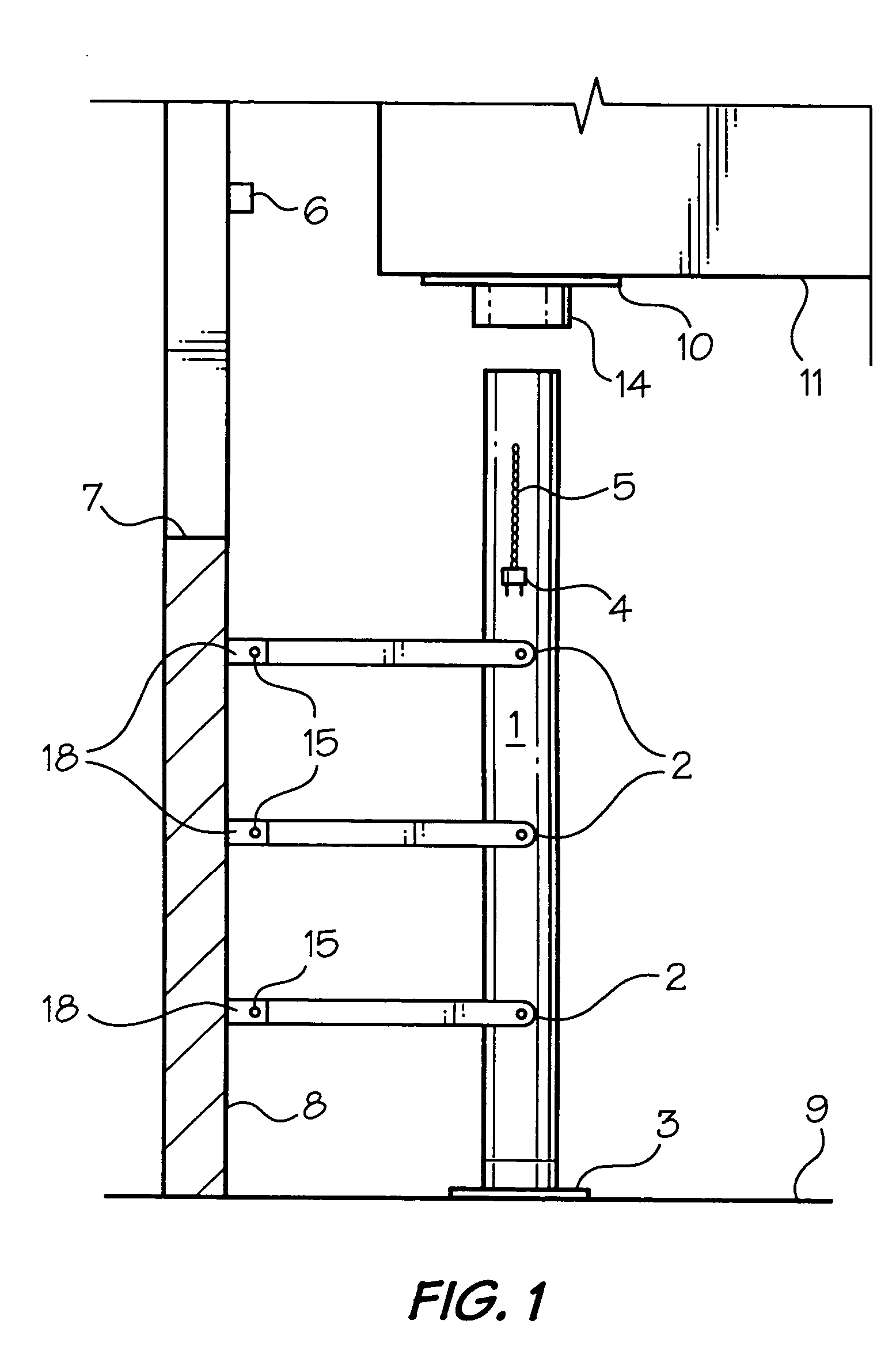

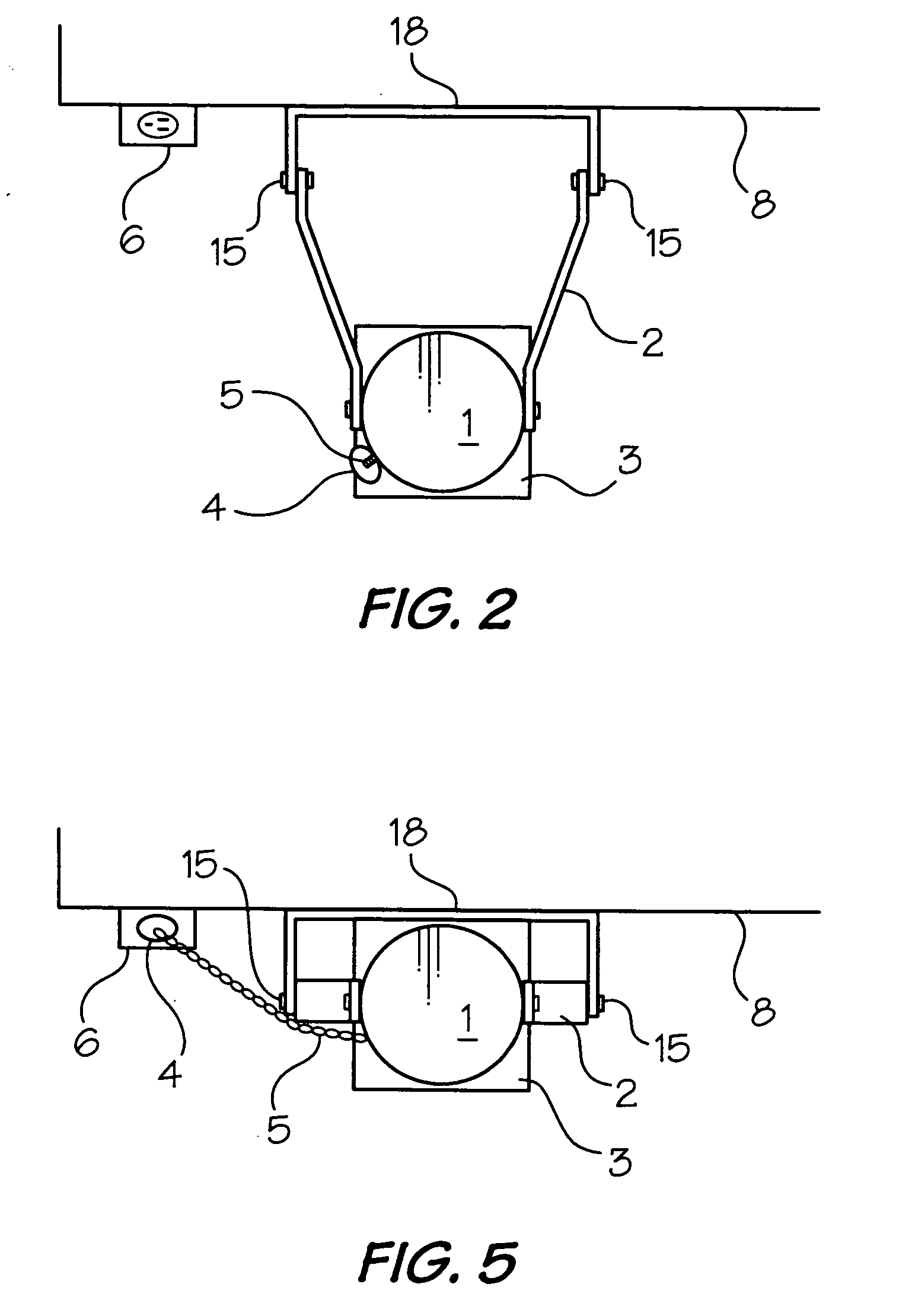

Elevator pit safety device

The present invention relates to an improved safety device for elevator or lift maintenance and service. The safety device of the present invention can be used in any vertical transportation shaft to provide protection to individuals in the pit of an elevator. The safety device consists of a shoring means which is connected to the vertical side surface of the vertical transportation shaft via mounting means, which allow the shoring means to be moved from a retracted position, wherein the shoring means is disposed in the vicinity of the vertical side surface, to a deployed position, wherein the shoring means is disposed vertically and spaced from the side vertical surface. In the deployed position, the shoring means provides a physical barrier between the elevator car and the floor of the vertical transportation shaft, thus preventing potential injury to the serviceperson working in the pit.

Owner:SCOTT GARY

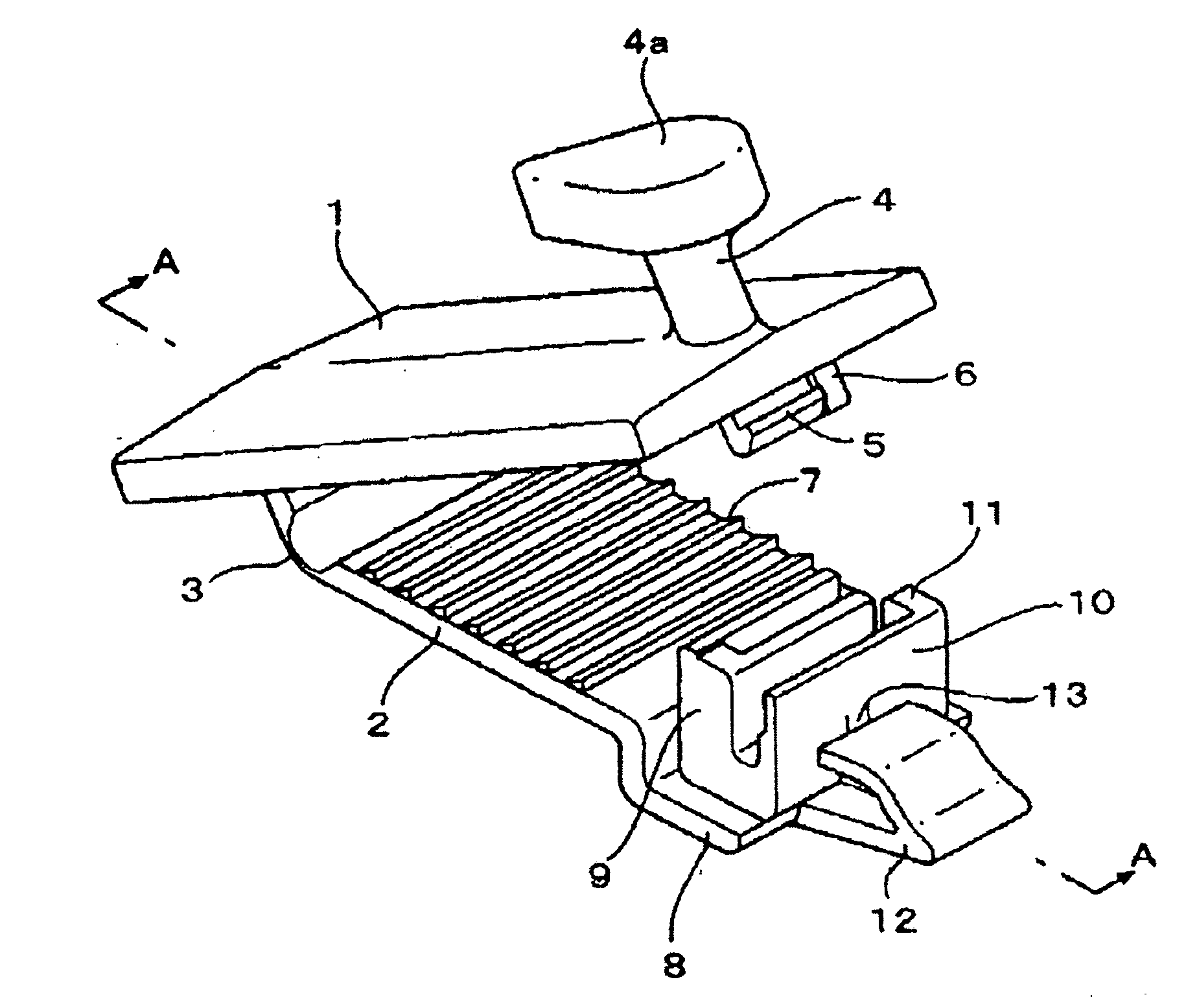

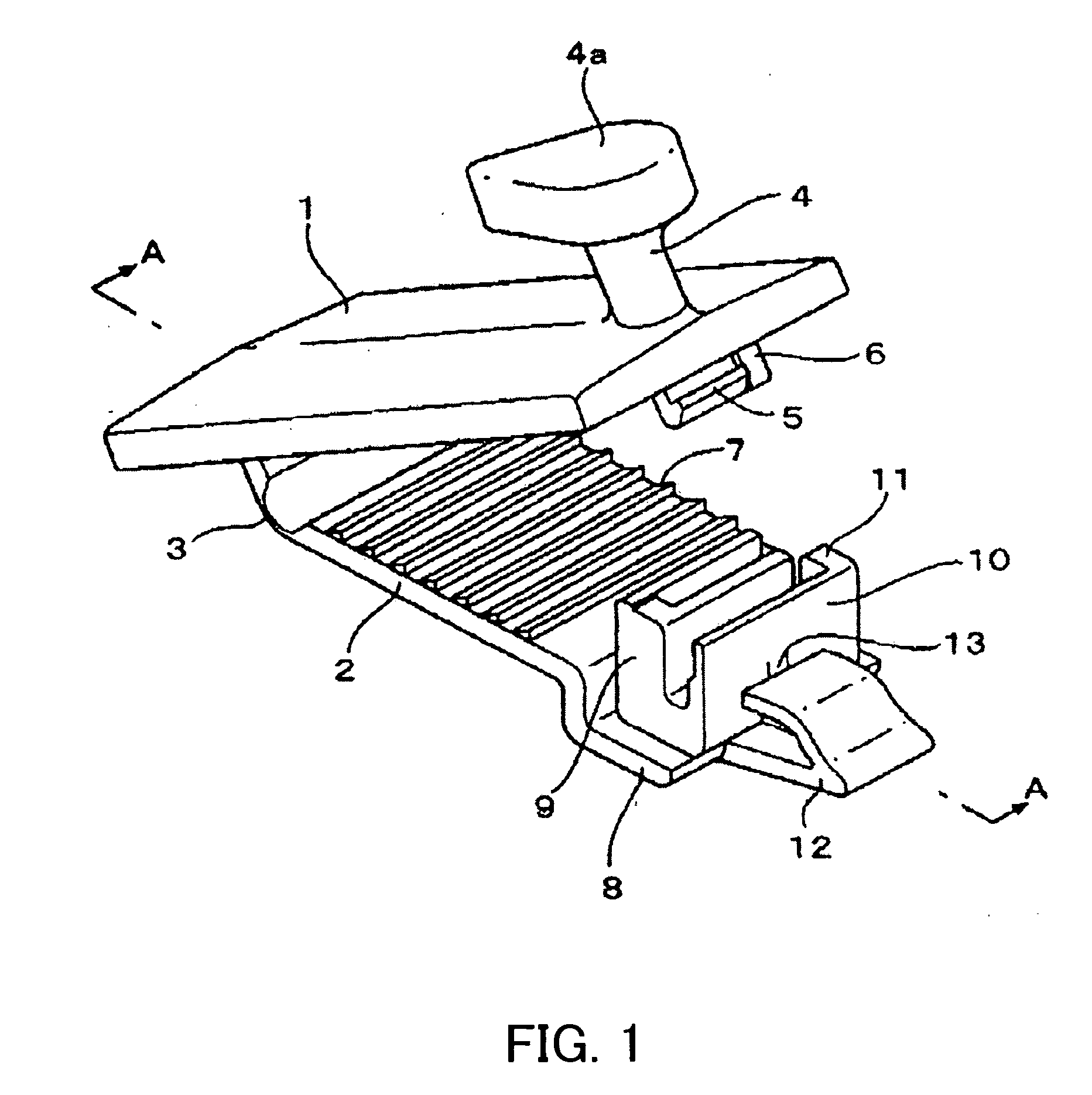

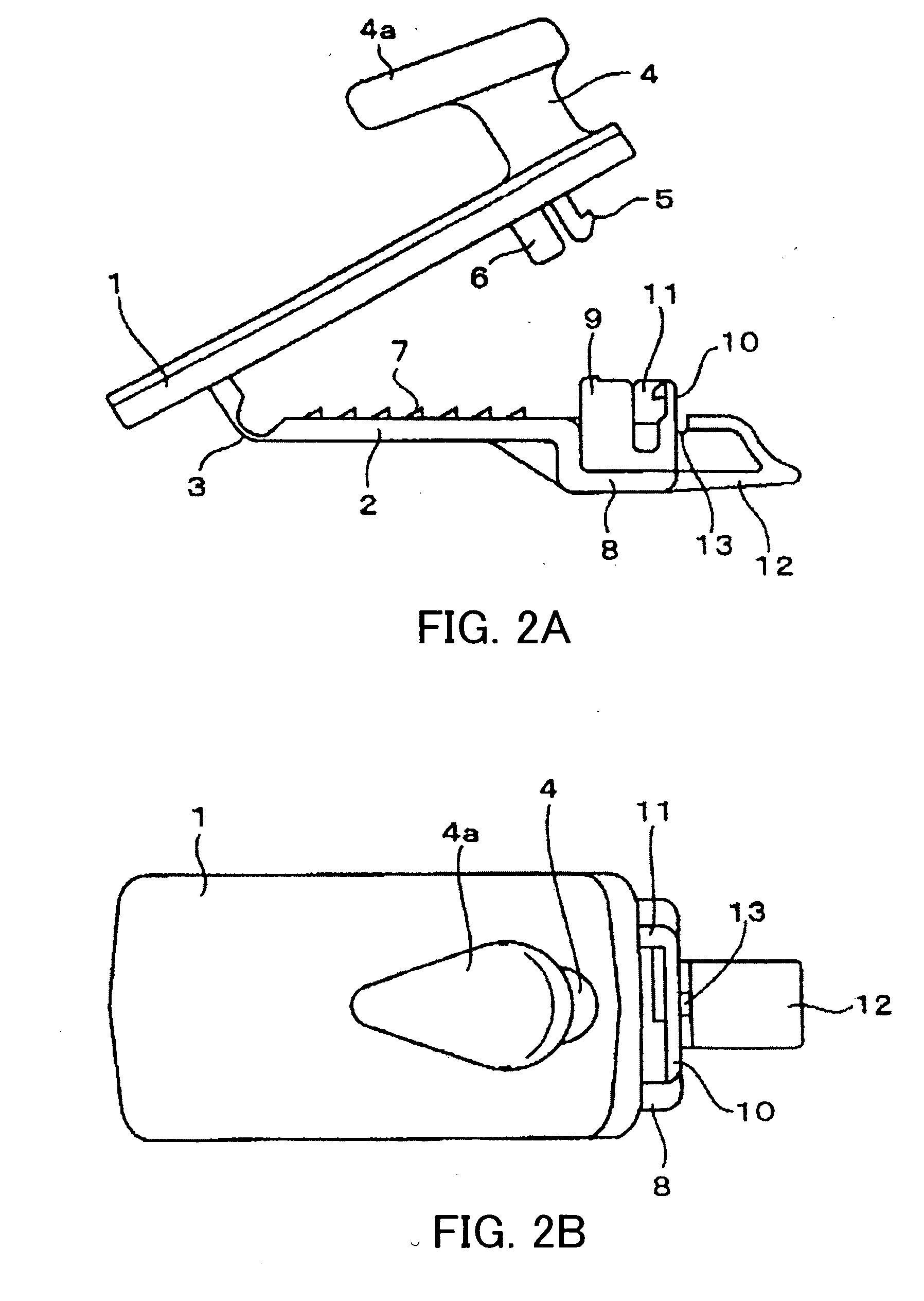

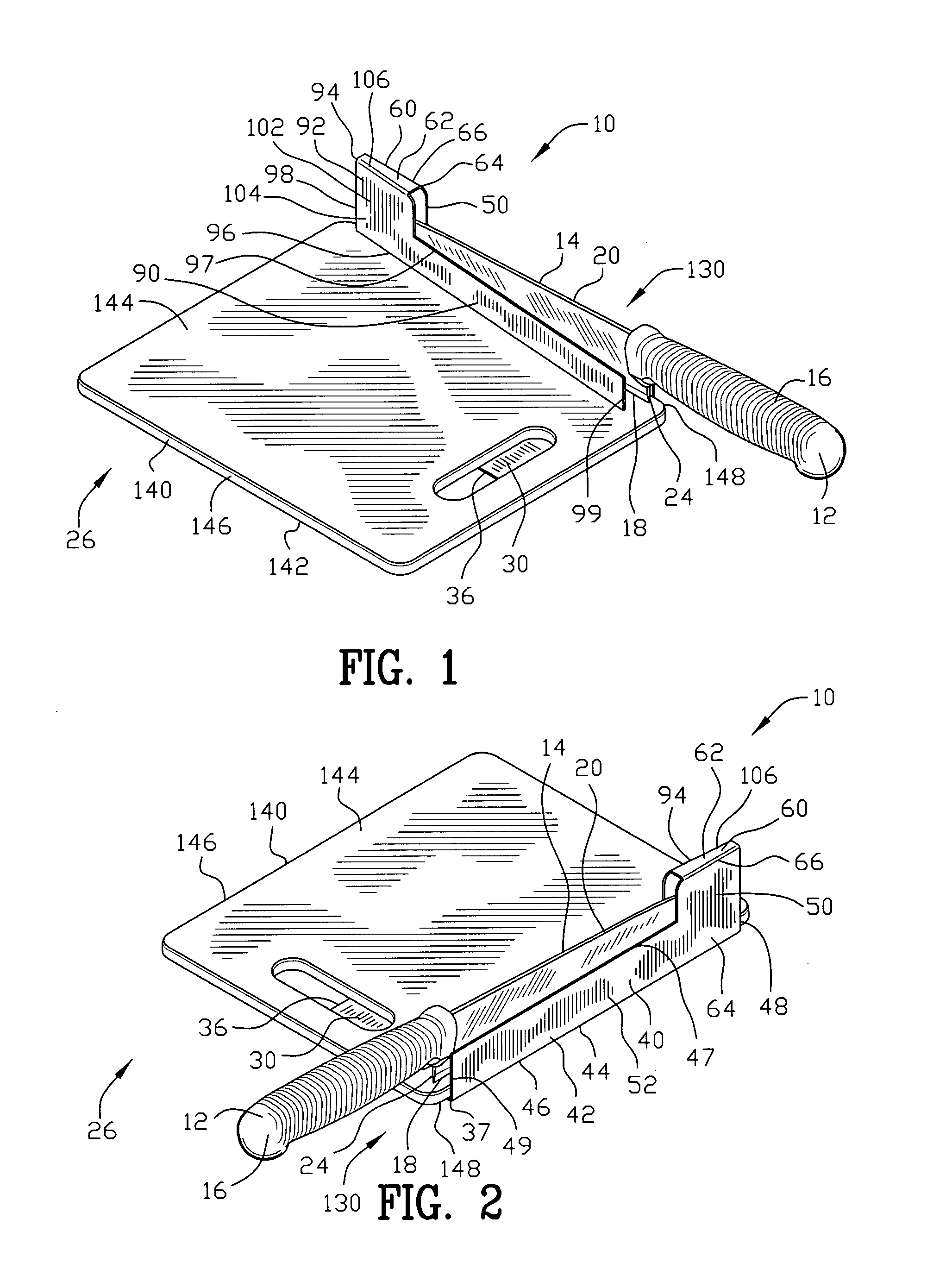

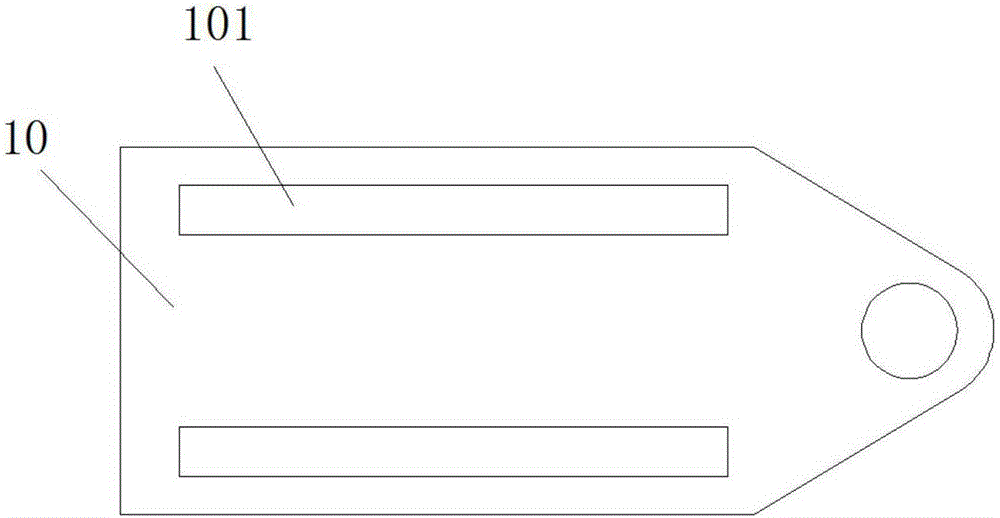

Fastener for floor mat

ActiveUS20070011844A1Avoid disposition problemsEasy to operateVehicle arrangementsMulti-purpose toolsEngineeringFastener

A fastener for securing an automobile floor mat to a carpet laid on a floor within an automobile includes a lower clamping member, an upper clamping member, a hinge portion connecting the upper clamping member and the lower clamping member in a pivotable manner, a supporting portion forwardly protruded from a tip end portion of the lower clamping member, and a guide protrusion forwardly protruded from a tip end portion of the supporting portion and configured to so as to facilitate an insertion of the supporting portion and the lower clamping member to a backside of the carpet via a slit formed in the carpet. The upper clamping member has an engaging projection formed at an outer surface of a tip end portion thereof and configured to be inserted in an attaching hole formed in the floor mat and a locking portion formed at an inner surface of the tip end portion. The supporting portion has an engaging portion for engaging the engaging portion of the upper clamping member. An upper surface of the guide protrusion is tapered.

Owner:PIOLAX CO LTD

Travelling carrier delivery equipment

InactiveUS20070289845A1Easy to carryLow costRailway componentsControl devices for conveyorsDrive wheelReciprocating motion

Travelling carrier delivery equipment includes a delivery unit for transferring a travelling carrier that has no self-running means between a movable rail and a main rail by means of external friction-driven, and the travelling carrier is provided with a friction driving surface across its entire length, the delivery unit has a friction drive wheel and friction drive wheel moving means, the friction drive wheel is provided on the movable rail and is switchable between a driving state, in that it propels the travelling carrier via the friction driving surface and a driving release state, and the friction drive wheel moving means reciprocates the friction drive wheel between a retreating position (R), at which the friction drive wheel can be made to contact with the friction driving surface of the travelling carrier supported on the movable rail and a forwarding position (F), at which the friction drive wheel can be made to contact with the friction driving surface of the travelling carrier supported on the main rail.

Owner:DAIFUKU CO LTD

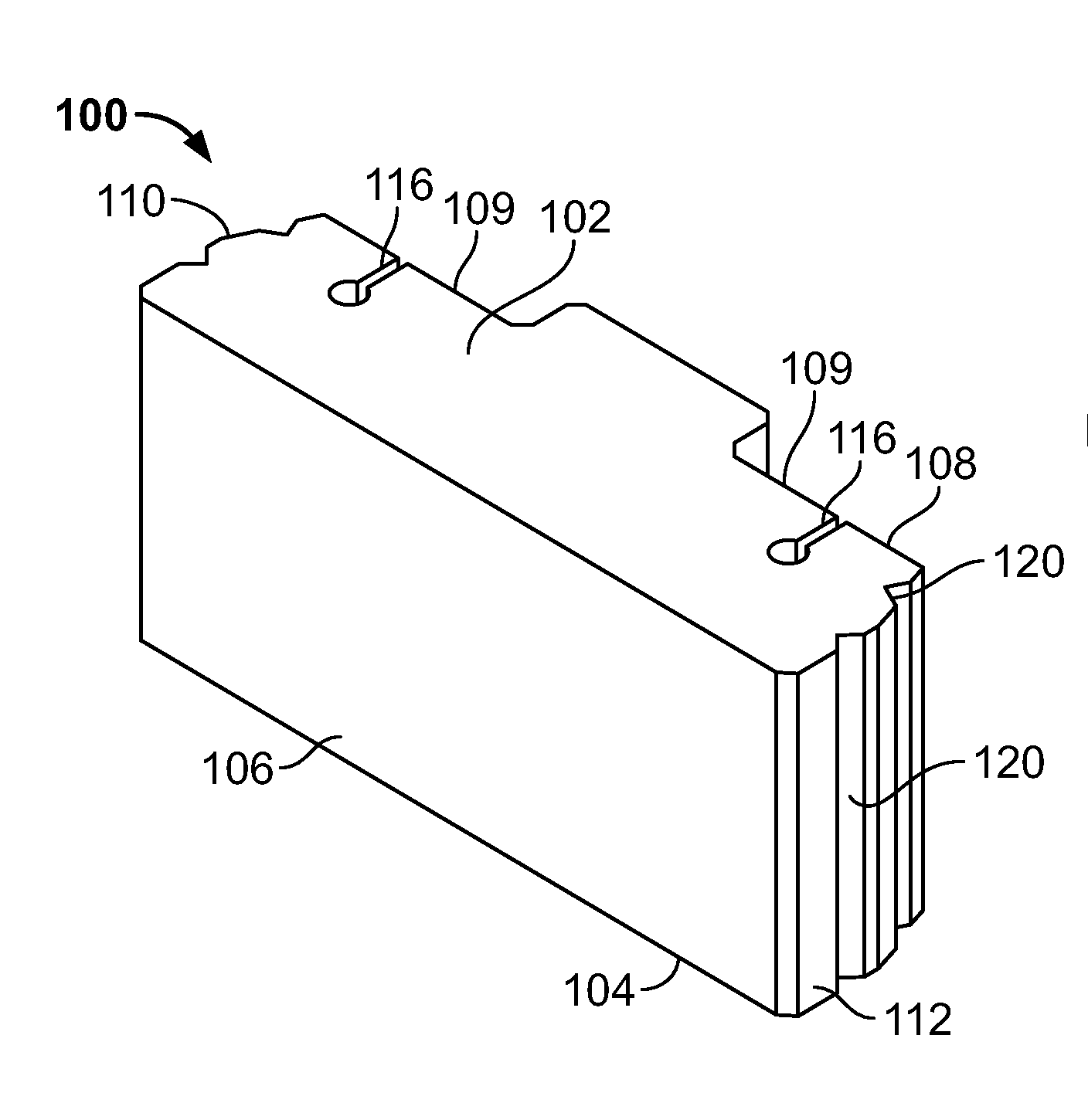

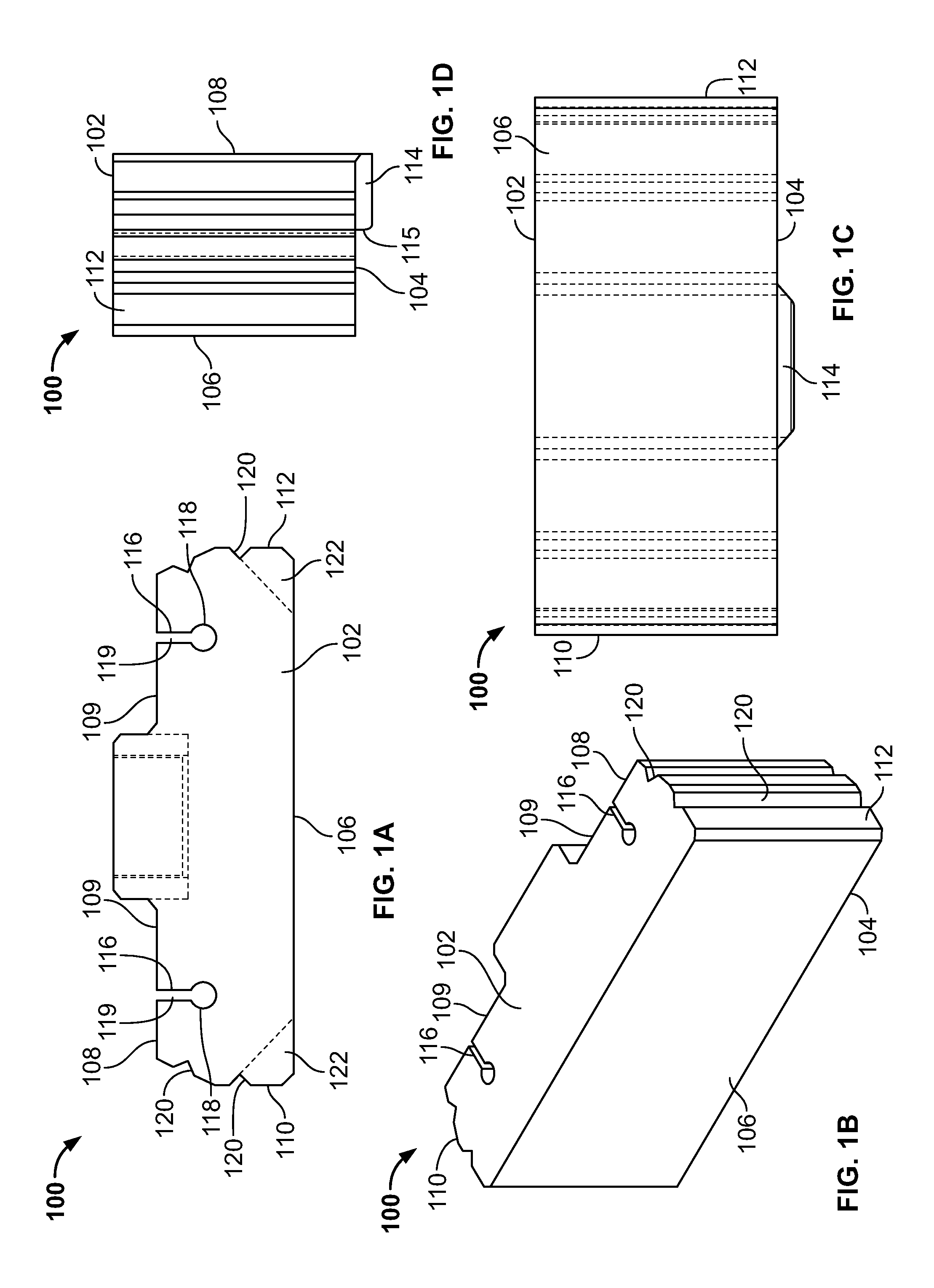

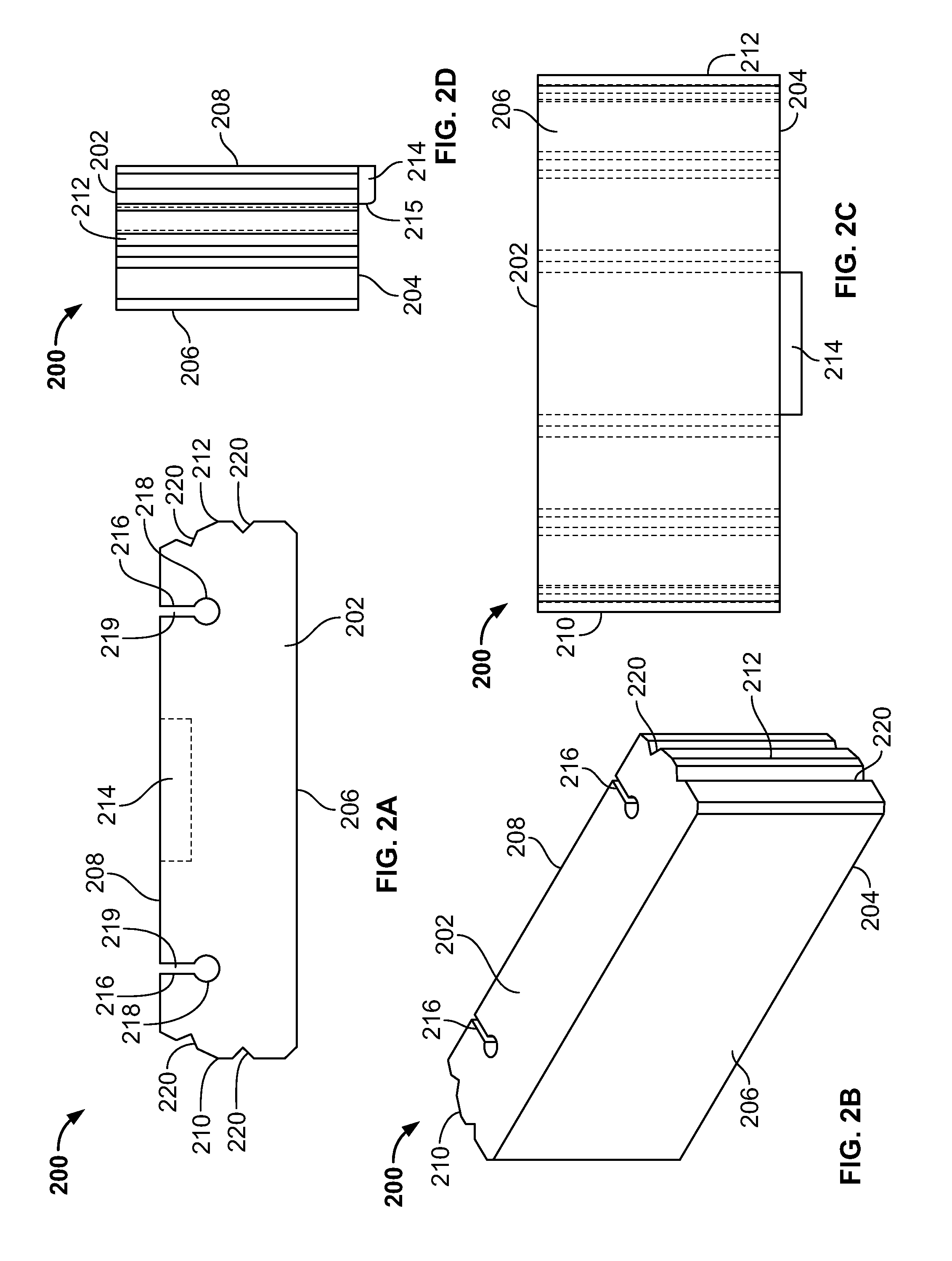

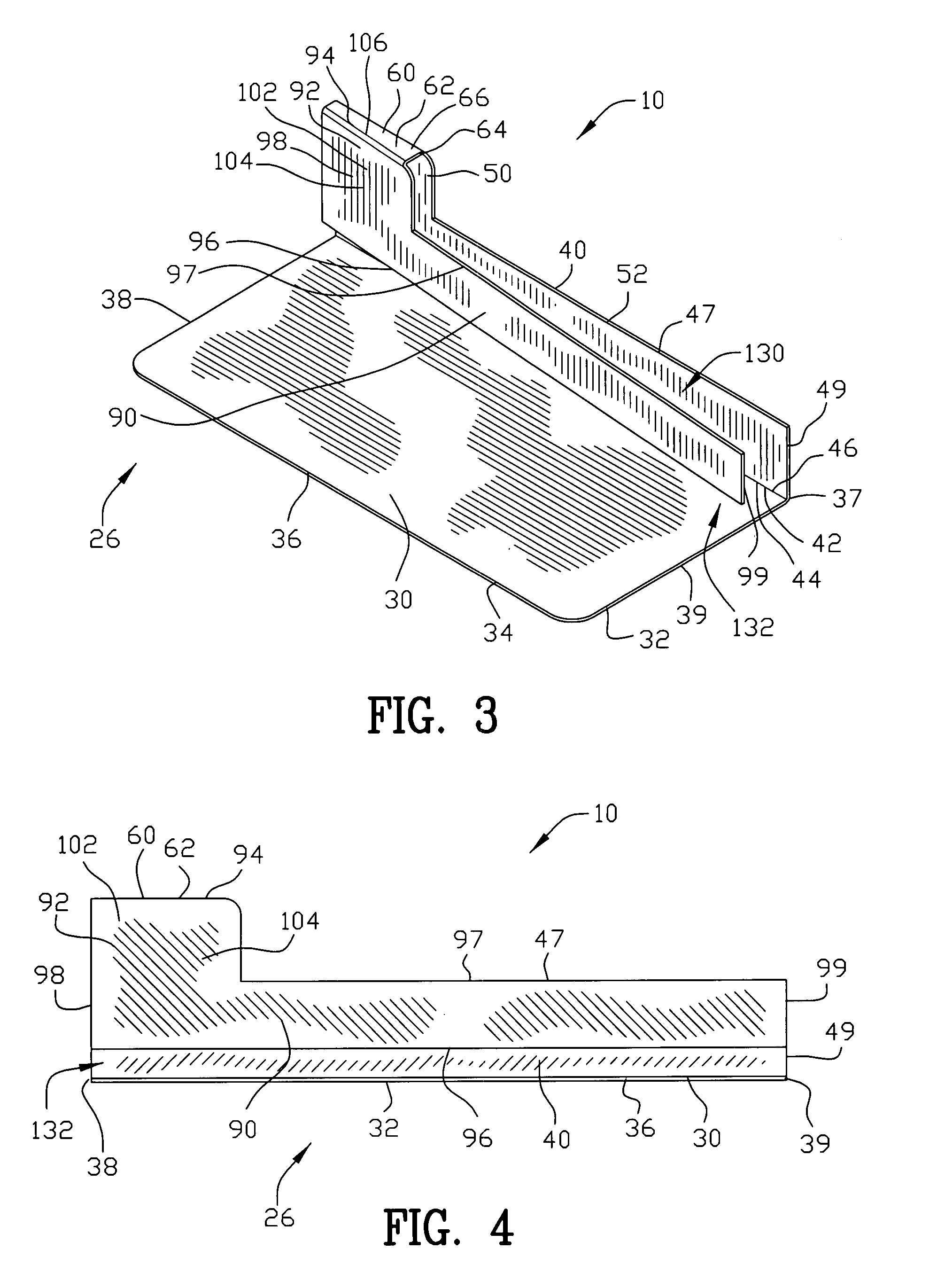

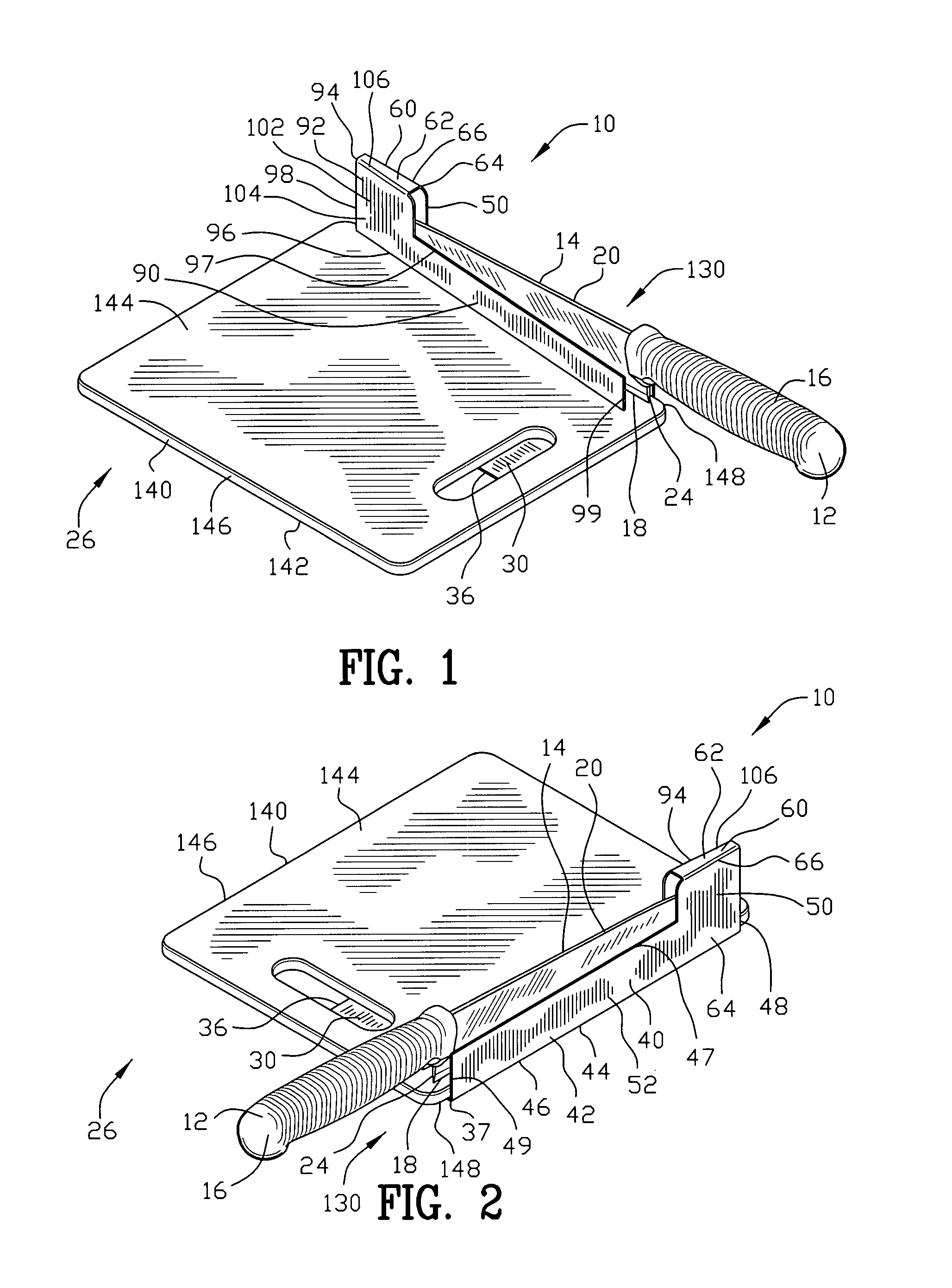

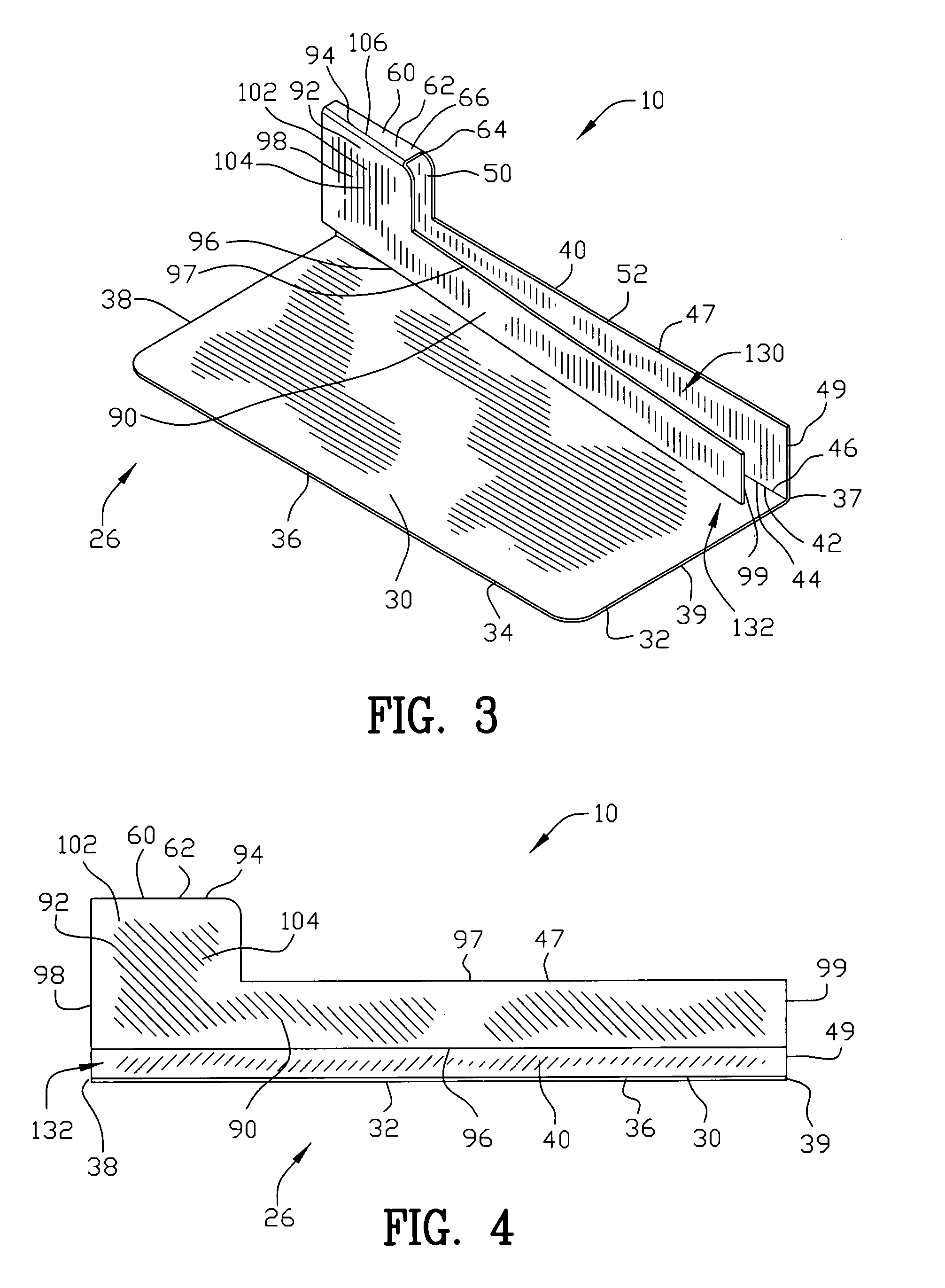

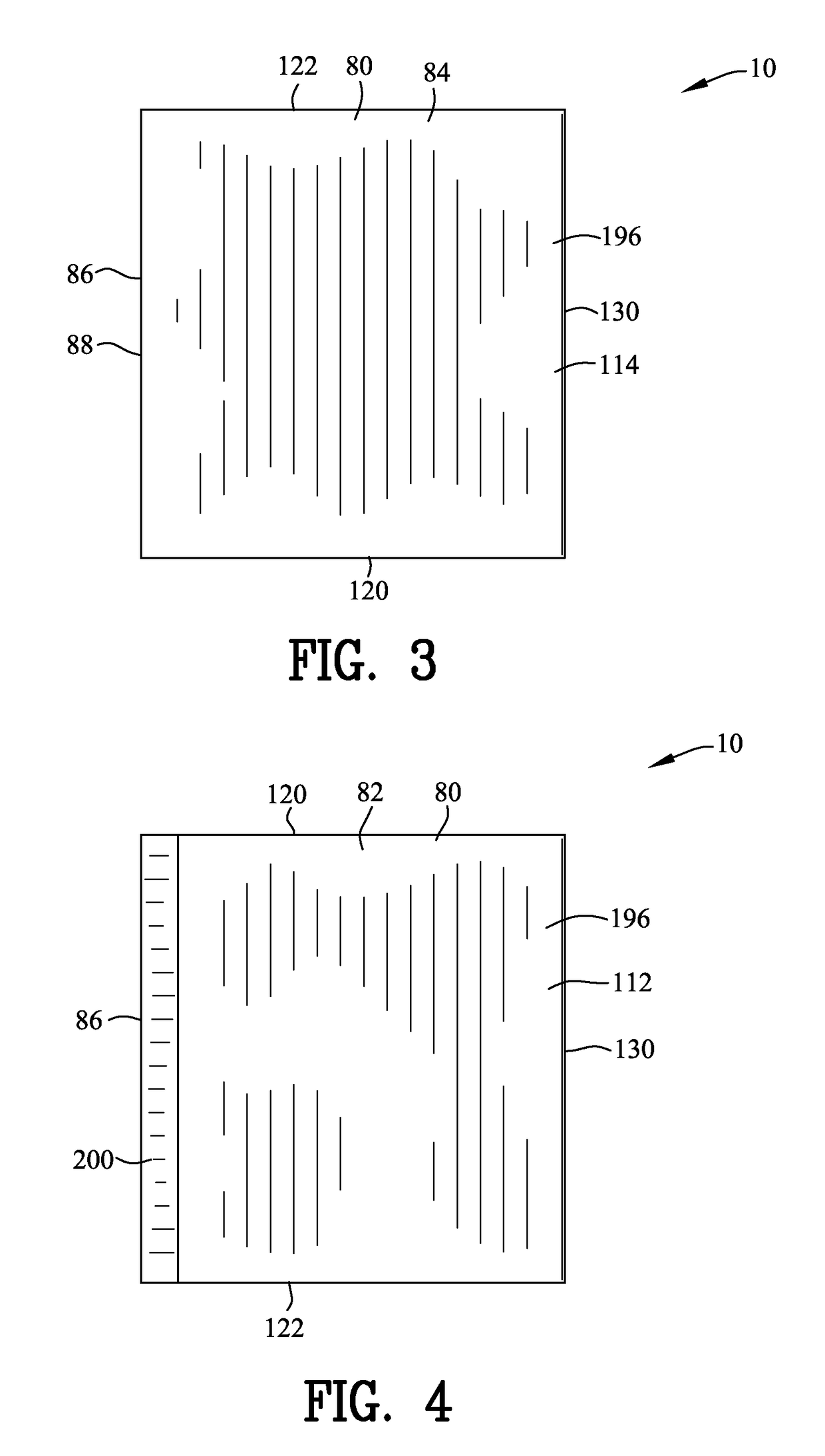

Wall Block With Barrier Member

ActiveUS20100284751A1Avoid horizontal displacementArtificial islandsConstruction materialFilling materialsEngineering

A retaining wall block can include a top surface and opposing bottom surface, a front surface and opposing rear surface, and first and second opposing side surfaces. A projection can extend downwardly from the bottom surface and can include a forwardly facing indexing surface oriented generally parallel with the front surface of the block. The indexing surface can be configured to engage a rearwardly facing surface of a block in a lower course of blocks. The block can also include a pair of spaced apart key slots defined in the rear surface. Each key slot can include an enlarged interlocking portion and a throat portion extending from the interlocking portion to the rear surface. An assembly can be created whereby a pair of correspondingly shaped keys of an elongate barrier member are engaged with key slots of block so as to inhibit rearward horizontal displacement of the keys within the key slots. Elongate barrier member can include a body presenting an inner surface and an outer surface and a pair of opposing ends, each opposing end defined one of the keys. The inner surface of the barrier member and the rear surface of the block can together define a core region for receiving fill material.

Owner:MORTARLESS TECH

Explosion mitigating cover

ActiveUS8784000B2Increase pressureRestrict movementArtificial islandsUnderwater structuresEngineeringSafety valve

A manhole cover assembly configured to behave as a relief valve in an explosion event, opening so that fluid, such as air or explosive gas, may vent from an underground area. The manhole cover assembly may include a manhole cover and a frame, and may be configured to limit movement of the manhole cover with respect to the frame in response to increased pressure on the manhole cover. In one embodiment, the manhole cover may include legs having angled surfaces adapted to substantially center or guide the manhole cover in the frame while the manhole cover displaces to release pressure. In another embodiment, one or more legs slidable within the manhole cover to enable configuring the manhole cover between a restraint mode and a removal mode.

Owner:EAST JORDAN IRON WORKS

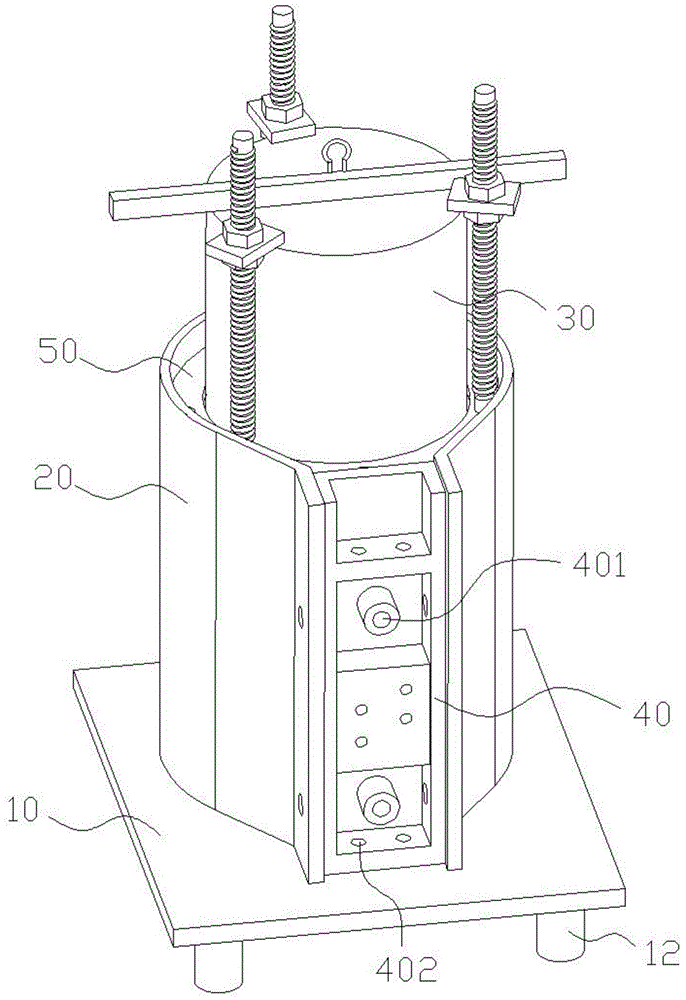

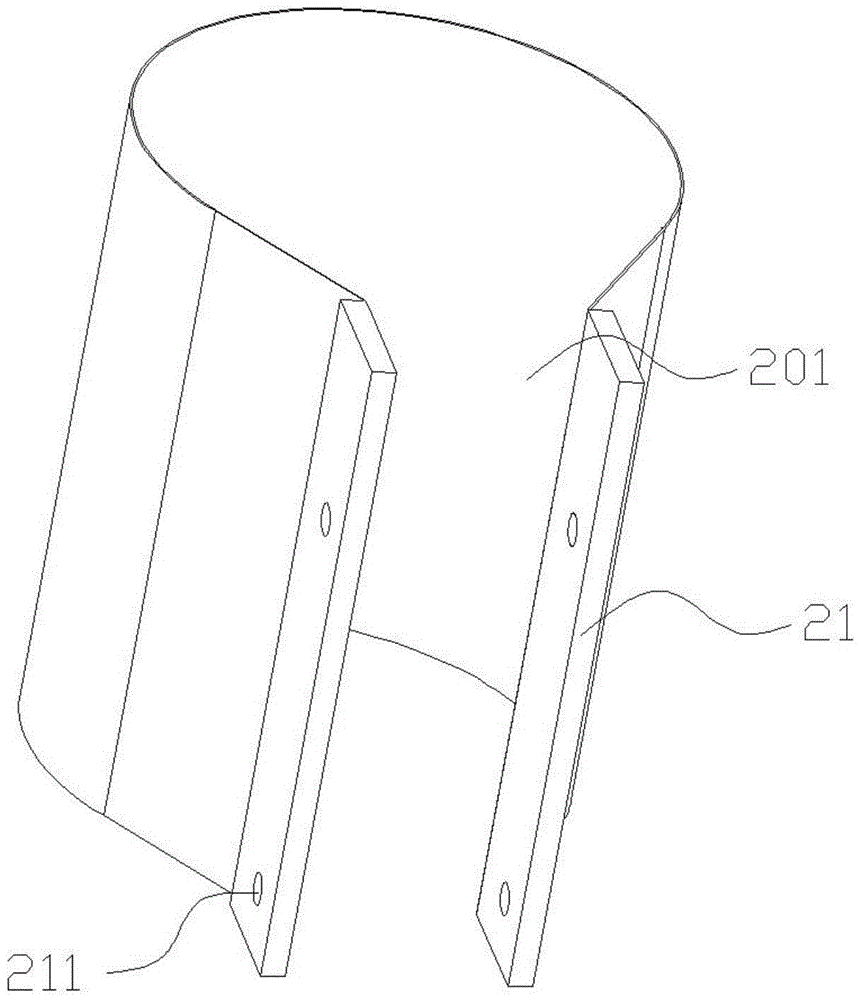

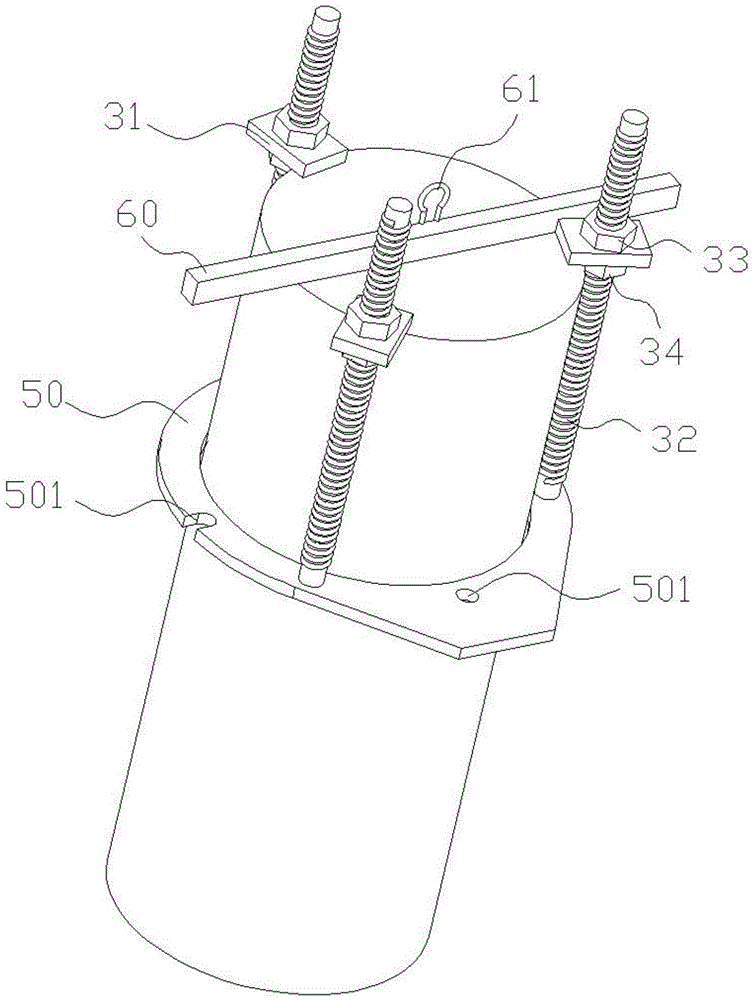

Epoxy casting mold with height-adjustable upper end cover

InactiveCN104149245APrecise positioningAvoid horizontal displacementInductances/transformers/magnets manufactureEpoxyCasting mold

The invention discloses an epoxy casting mold with a height-adjustable upper end cover. The epoxy casting mold comprises a bottom plate (10), an outer mold (20), an inner mold (30), a branching terminal mold (40) and the upper end cover (50), wherein protrusion parts (31) are fixedly mounted on the top surface of the inner mold (30); a through hole is formed in each protrusion part (31); a thread rod (32) is inserted into each through hole; nuts (33 and 34) are connected to each thread rod (32) through threads and are positioned above and below the corresponding protrusion part (31); the lower end of each thread rod (32) is fixedly connected with the upper end cover (50); the upper end cover (50) sleeves the inner mold (30) and can lift along the outer side surface of the inner mold (30). According to the technical scheme, the phenomenon that molds with the corresponding casting heights are prepared due to the difference of the casting heights of epoxy resin is avoided, the production cost is greatly reduced, and the production efficiency is improved.

Owner:AQ ELECTRIC SUZHOU

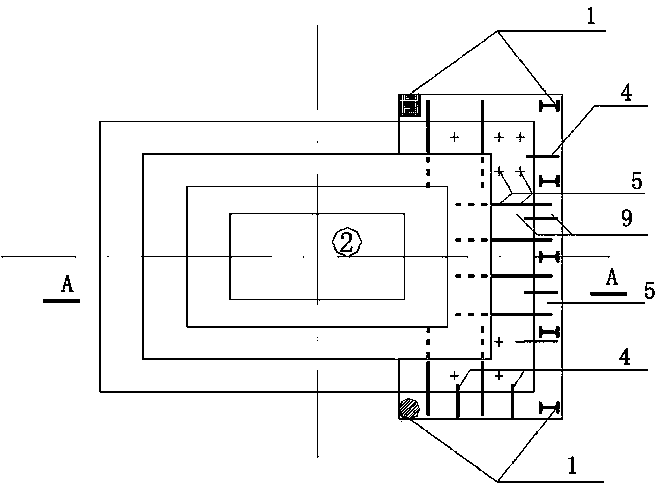

Pile foundation underpinning method for building foundation adjacent to deep foundation pit

ActiveCN104179204AMeet bending resistanceMeet punching resistanceFoundation repairArchitectural engineeringShear resistance

The invention relates to the technical field of civil engineering foundation reinforcing of industrial and civil construction projects, in particular to a pile foundation underpinning method for a building foundation adjacent to a deep foundation pit. The method includes the steps of firstly, investigating and designing, to be more specific, investigating the existing building, selecting foundation underpinning pile types according to building foundation size, buried depth, distance between the building foundation and the deep foundation pit and the depth of the deep foundation pit, calculating to determine the required length and number of foundation underpinning piles according to bearing capacity, allowing the foundation underpinning piles to exceed the depth of the bottom of the deep foundation pit, and completing ring beam design; secondly, pressing the piles at the edges of the building foundation; thirdly, performing pile foundation underpinning on the building foundation. The method has the advantages that the building foundation satisfies the requirements of bending resistance, punching resistance and shearing resistance by the aid of pile foundation underpinning, natural foundation bearing of the building foundation is changed into pile foundation bearing, additional load of the building foundation to the deep foundation pit is lowered greatly, sedimentation and horizontal displacement of the building foundation adjacent to the deep foundation pit are solved, and factory building safety is guaranteed.

Owner:山西钢铁建设(集团)有限公司

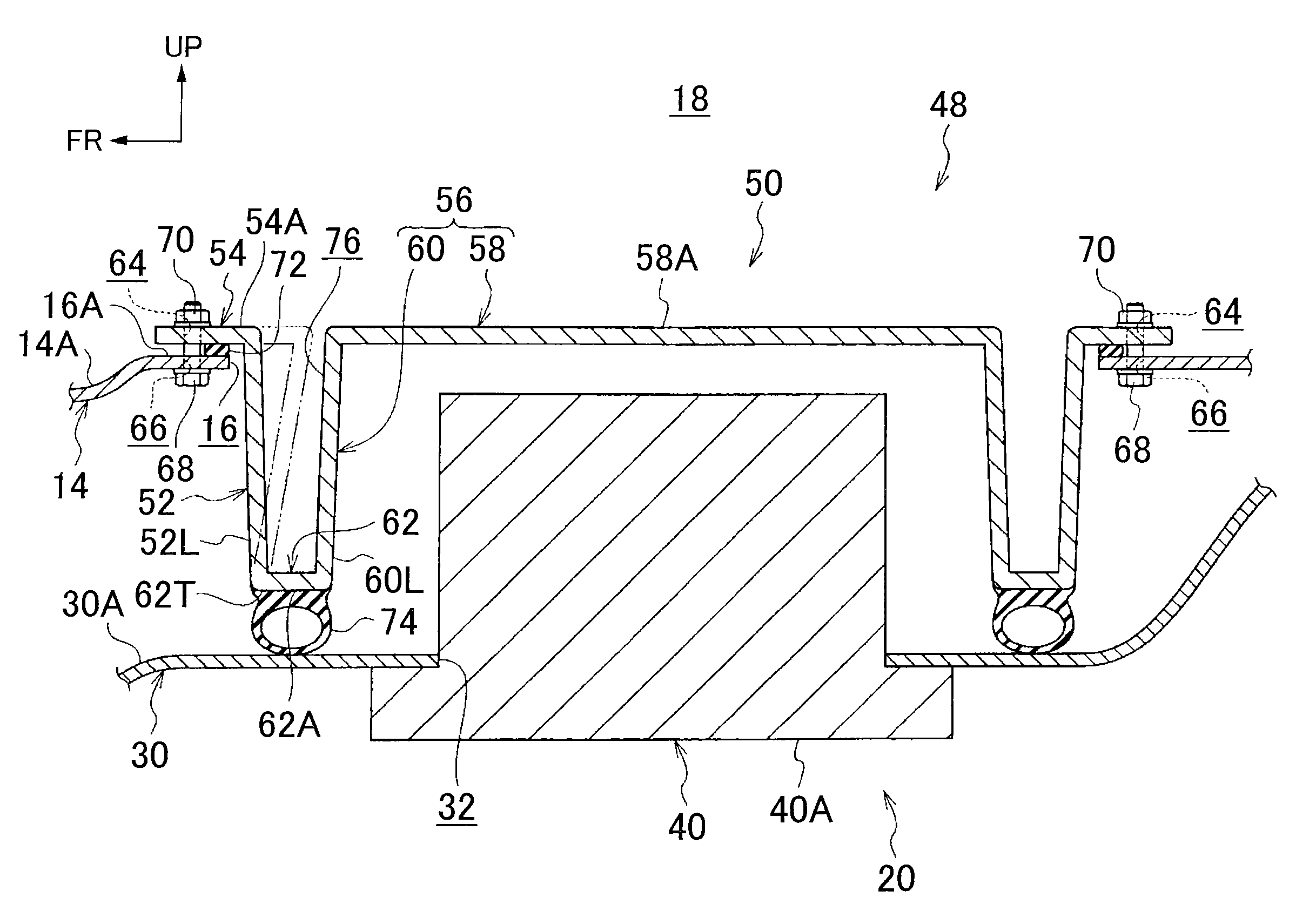

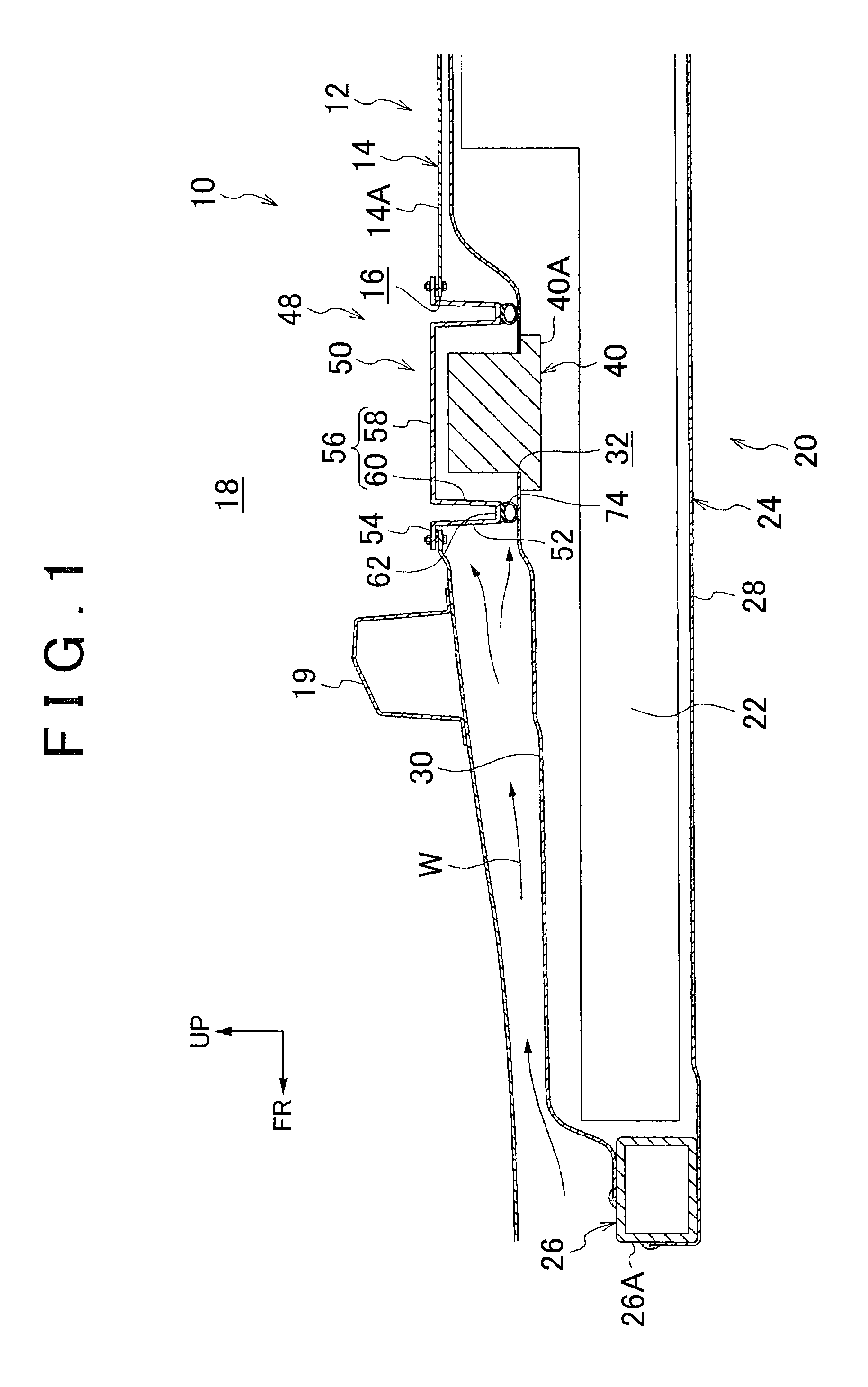

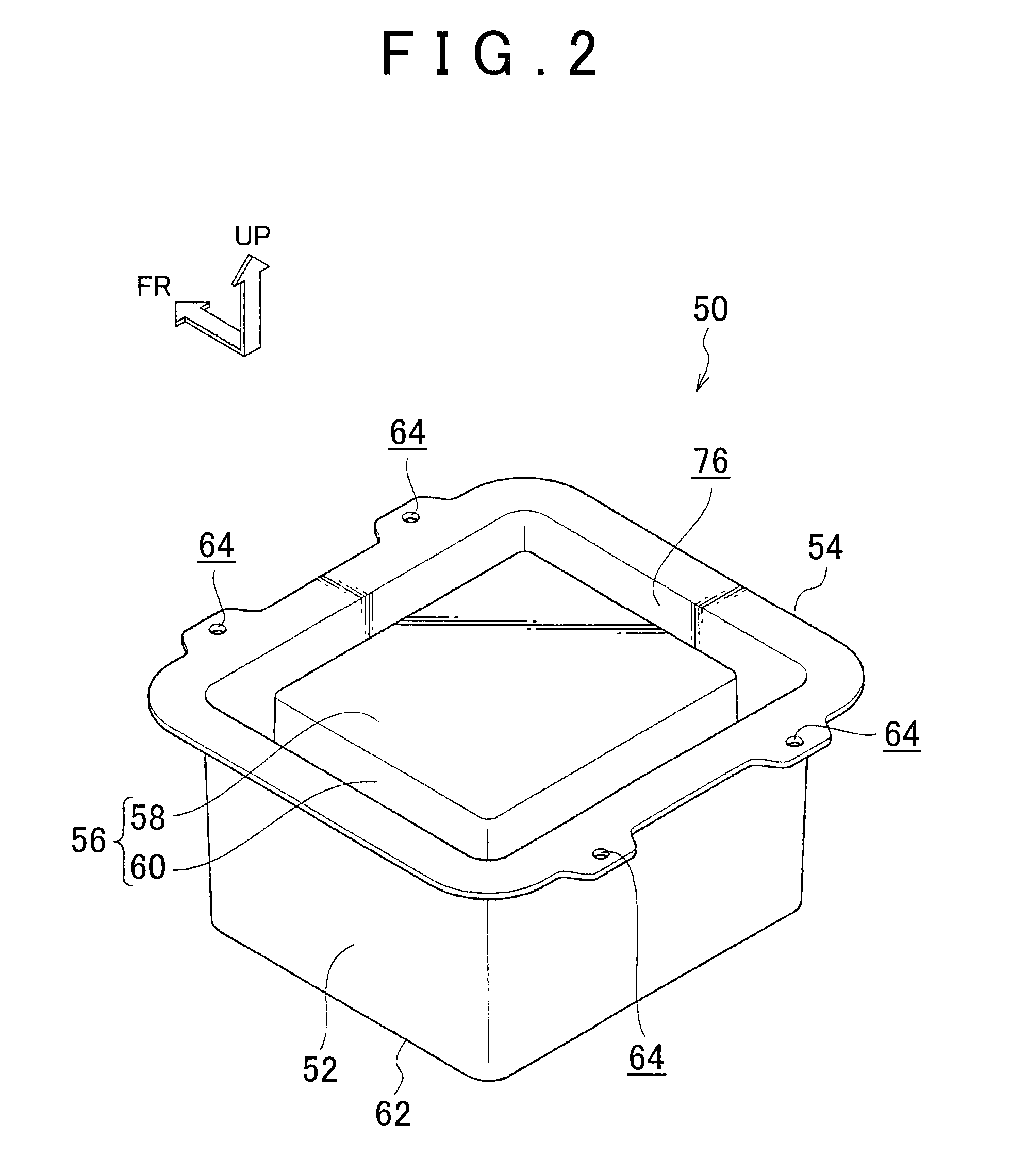

Service hole cover mounting structure, and vehicular battery mounting structure provided therewith

ActiveUS8910737B2Increased durabilityAvoid enteringPassenger spaceElectric propulsion mountingEngineeringMechanical engineering

A service hole cover has a housing recessed portion that has been brought from above the vehicle floor toward the battery unit through the service hole through a service hole formed in a floor panel from inside a vehicle cabin, and that covers an upper portion of a power supply circuit interrupting device from the floor panel side. An extended portion that extends toward an outside of the housing recessed portion is provided on a lower end portion of an inner peripheral wall portion of this housing recessed portion. Also, a bent-back portion that is bent back toward the floor panel side is provided on an outer peripheral side end portion of the extended portion. This bent-back portion will easily deform toward the inner peripheral wall portion side of the housing recessed portion with the outer peripheral side end portion of the extended portion as the fulcrum.

Owner:TOYOTA JIDOSHA KK

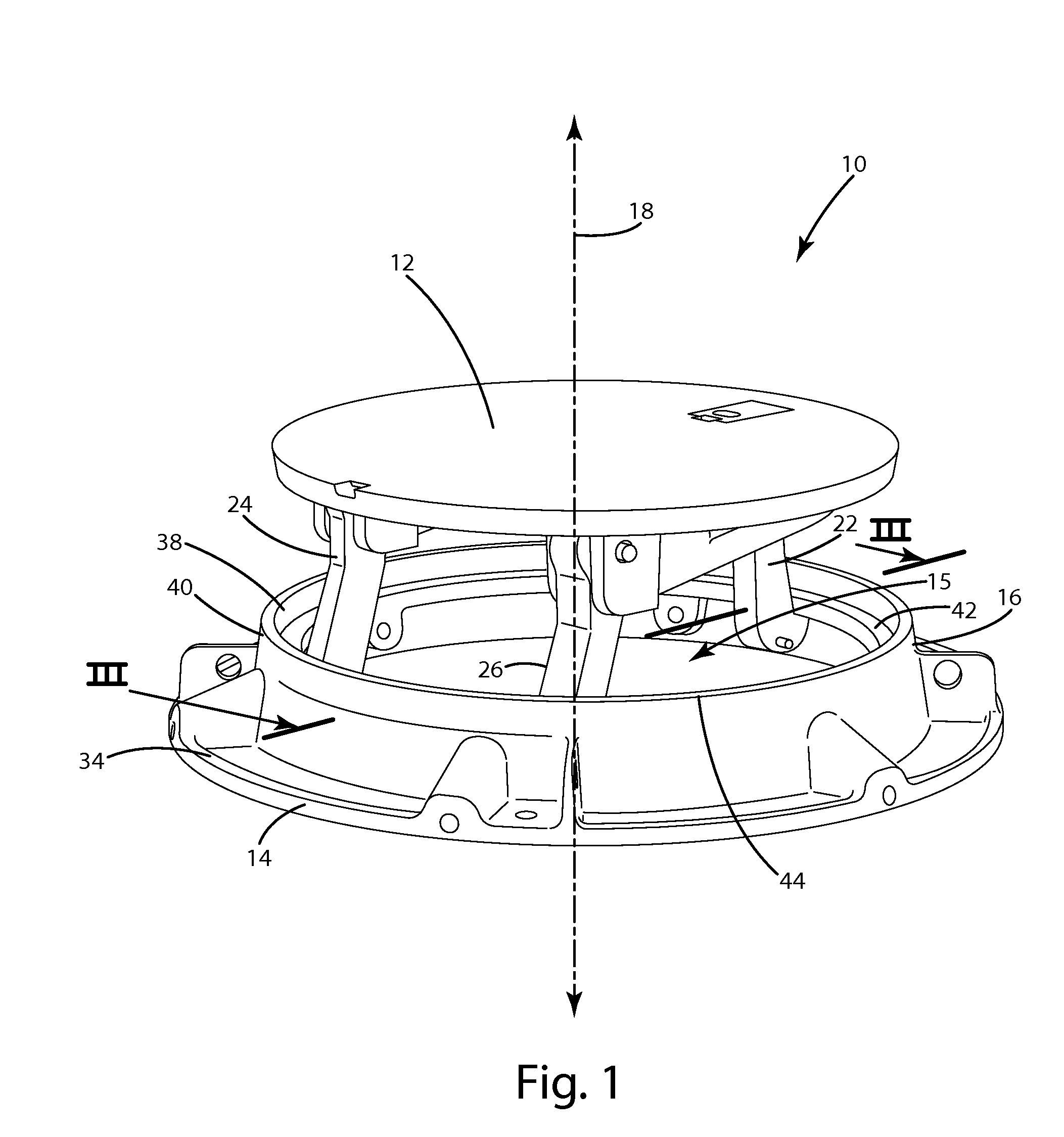

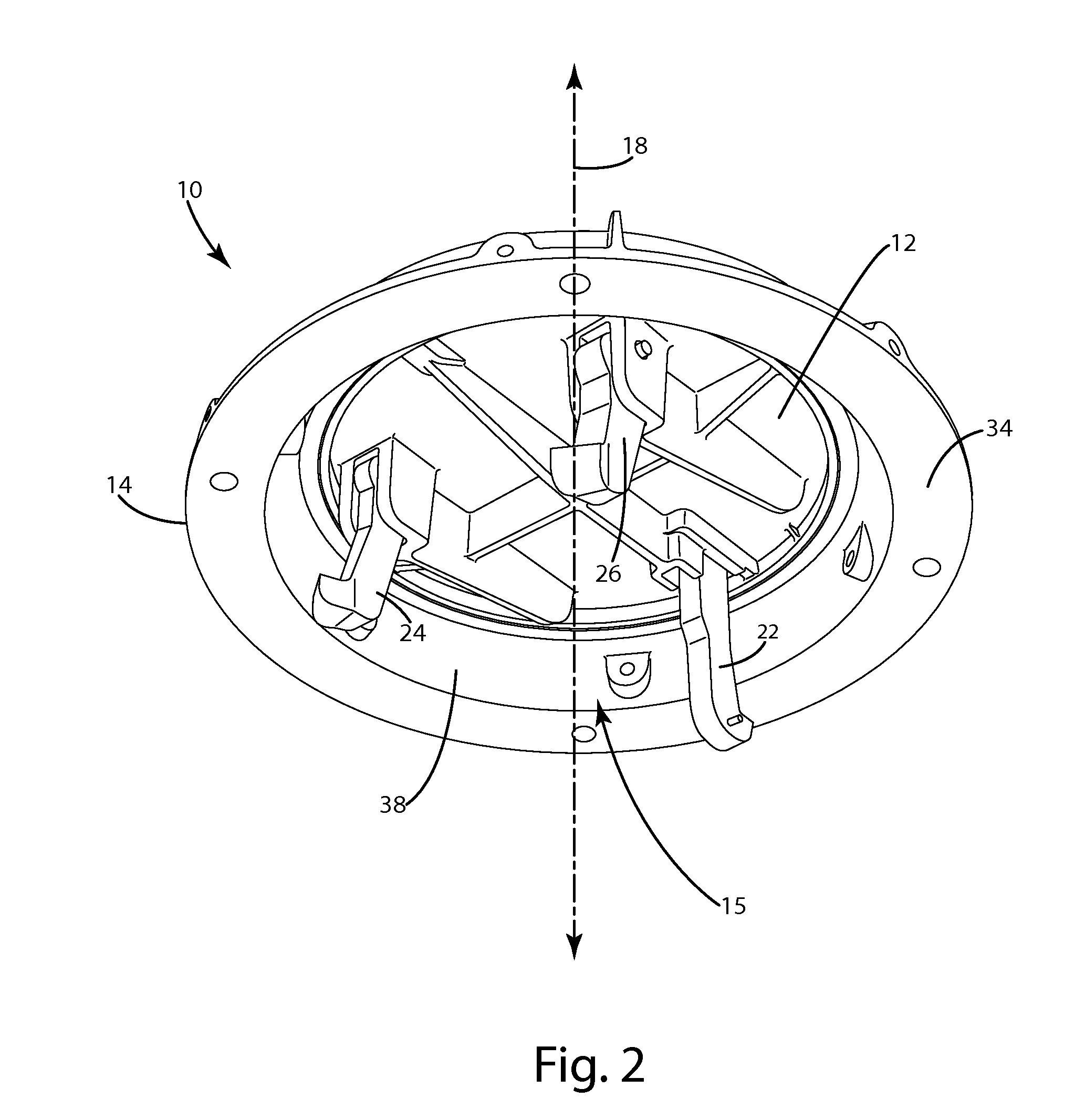

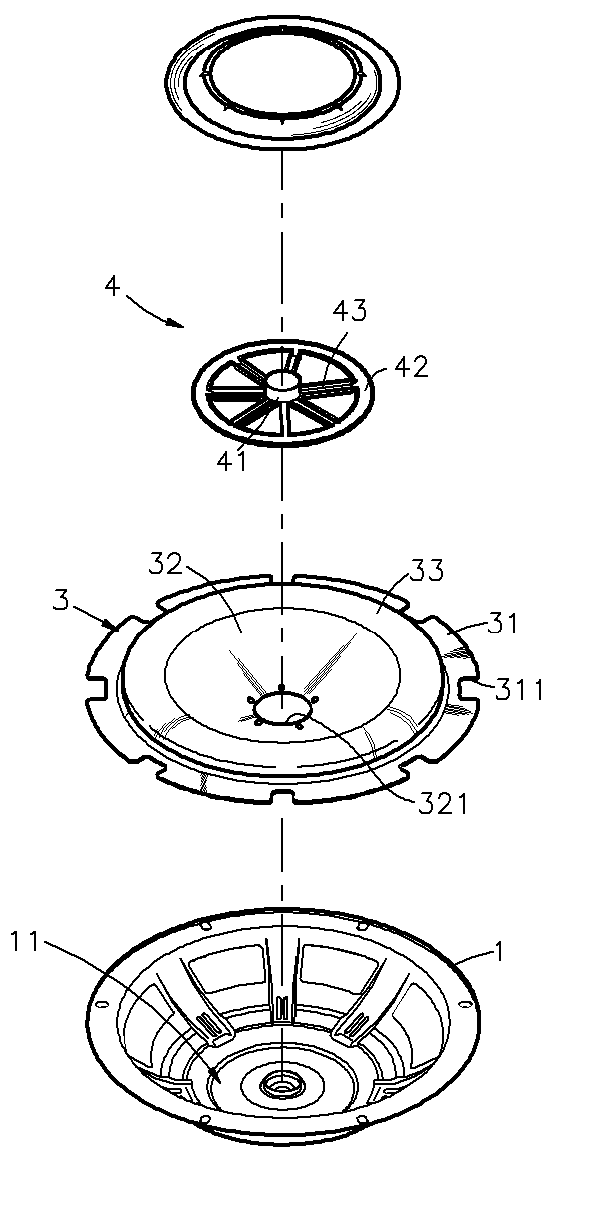

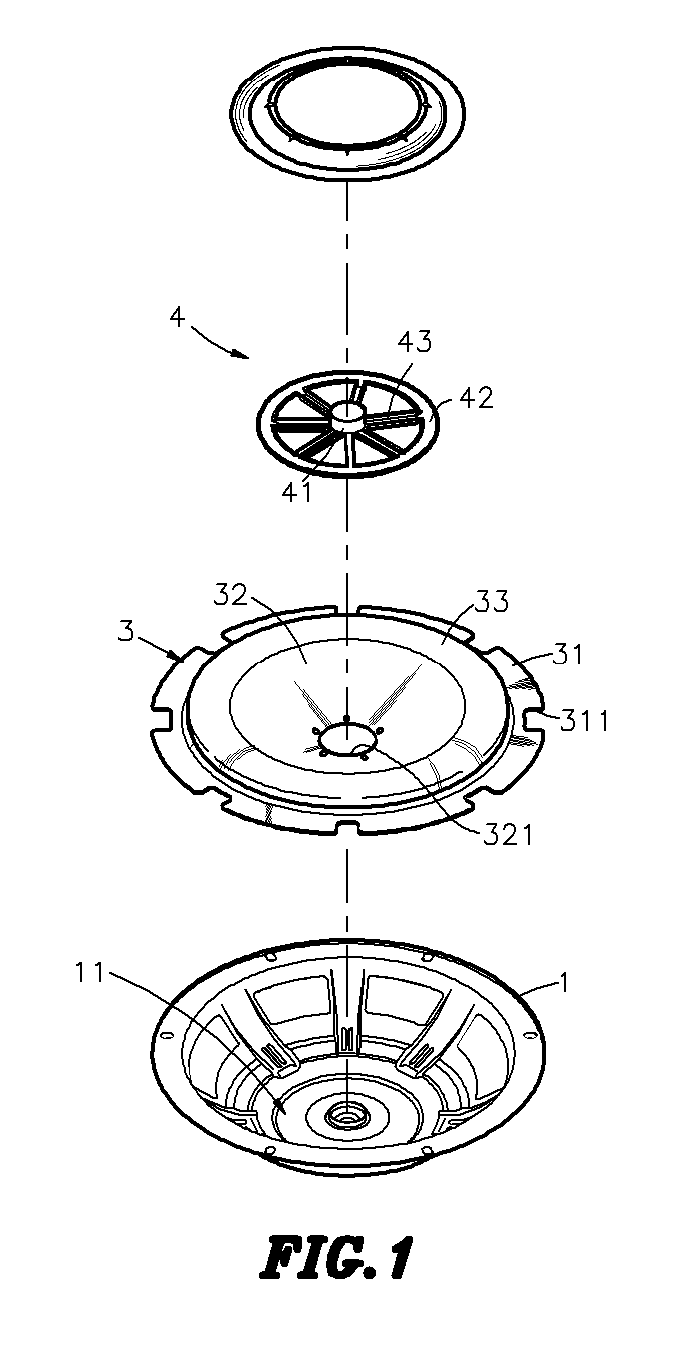

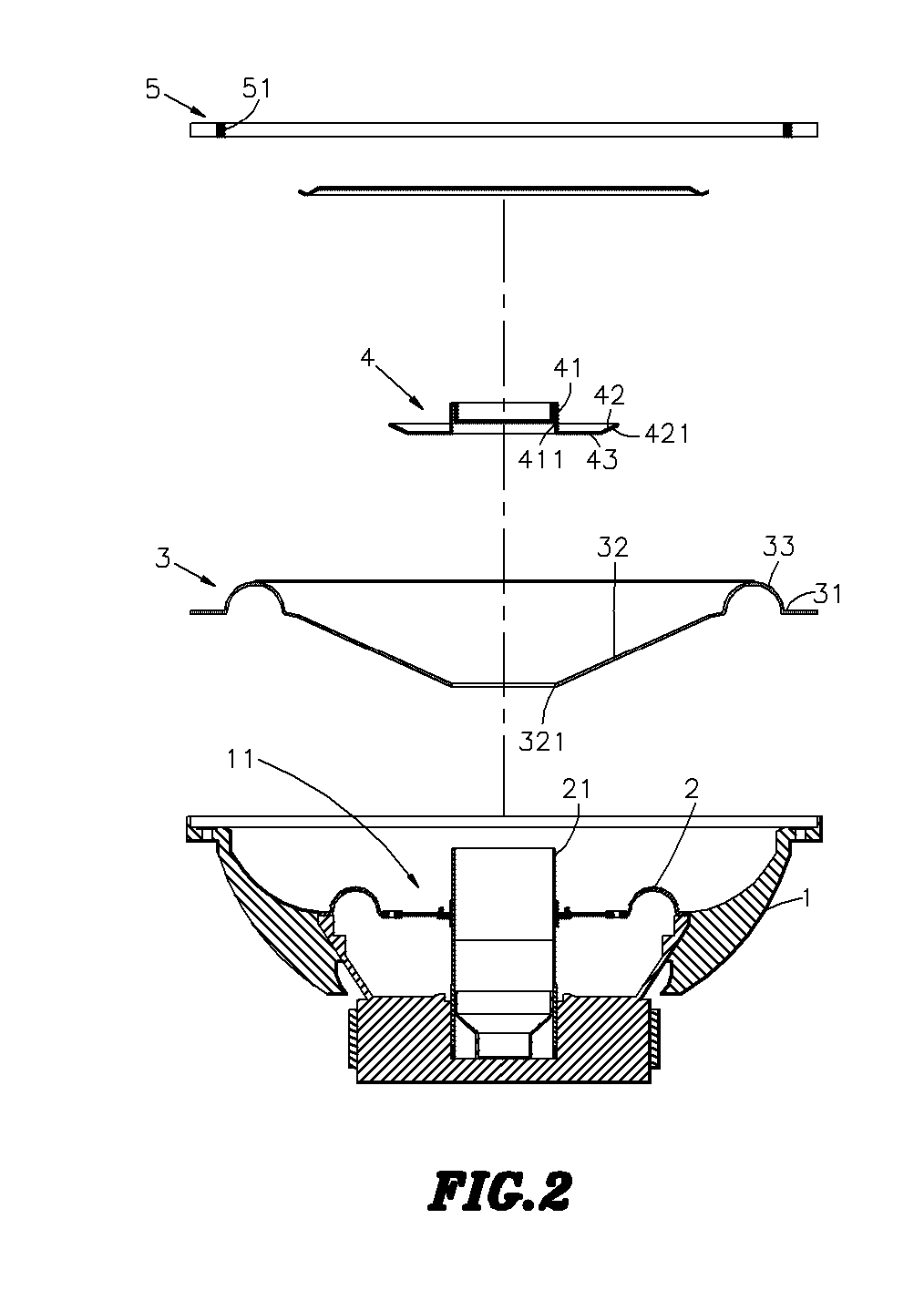

Structure of speaker

ActiveUS20070127765A1Avoid horizontal displacementAvoid sound distortionTransducer casings/cabinets/supportsDeaf-aid setsLoudspeakerBearing surface

A speaker, which includes a basket holding an exciter, a holding down ring fastened to the basket to hold down a diaphragm, which has an annular suspension and a cone fastened to the inner diameter of the annular suspension and coupled to the exciter, and a locating plate capped on an annular positioning portion of the exciter and pressed on the center area of the cone with a beveled outer bearing surface to hold down the center area of the cone against vibration in transverse direction to prevent a distortion of sound.

Owner:CHAN YEN CHEN

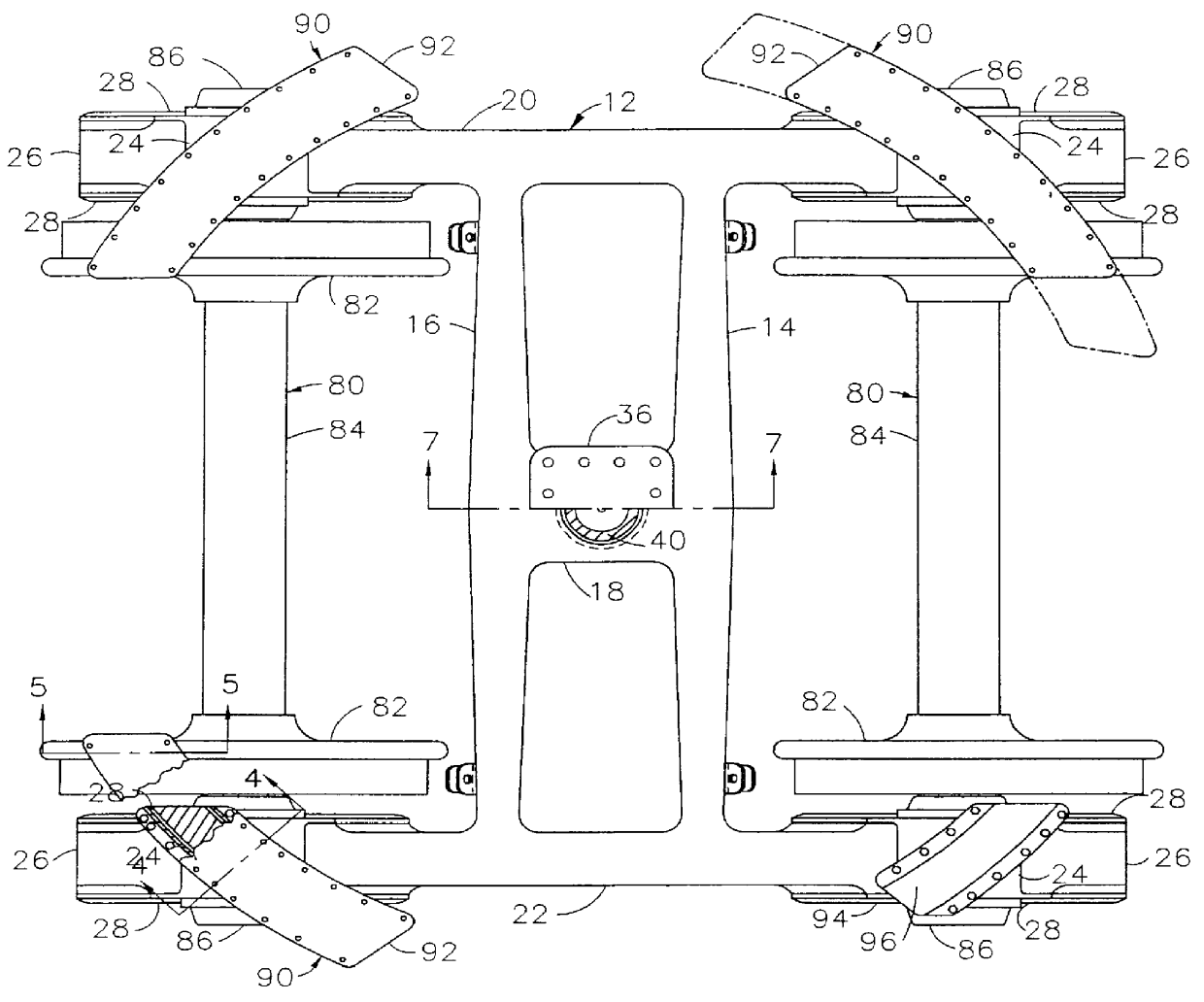

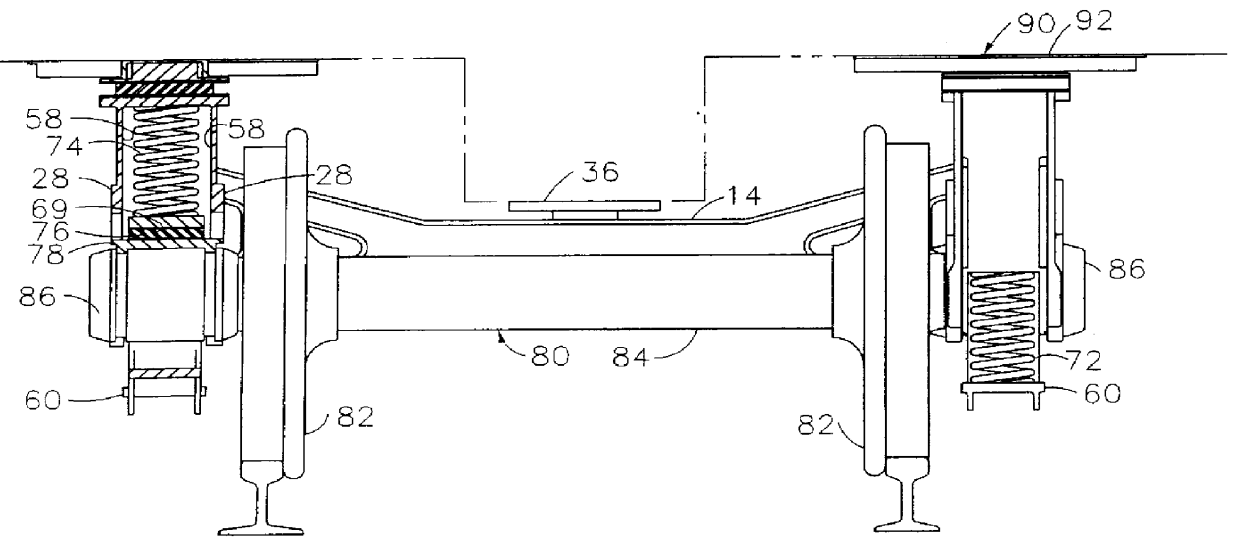

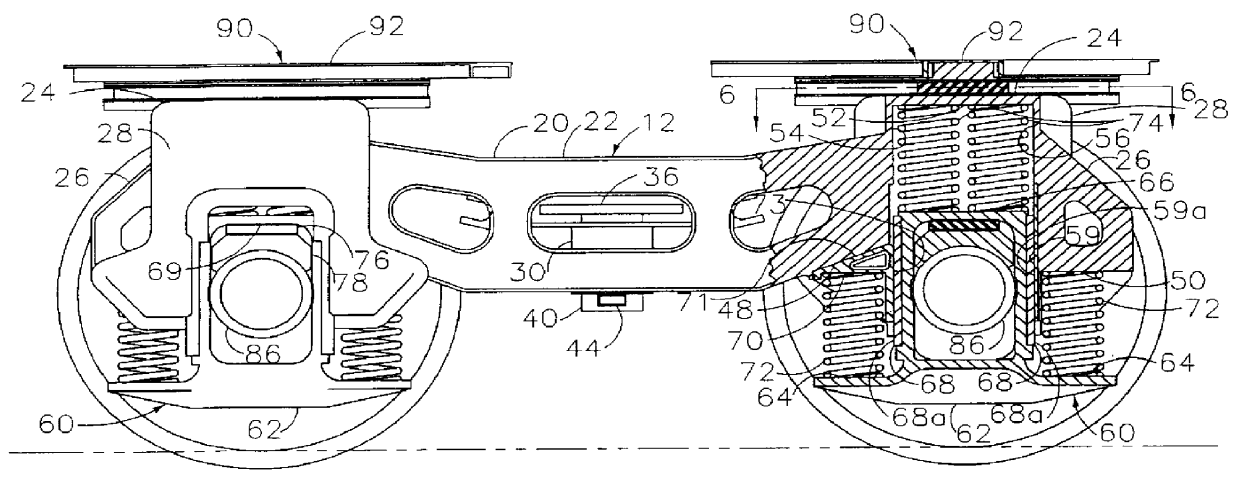

Radially side mounted railway car truck

InactiveUS6092469AIncreased wheelset hunting controlReduced wheel wearUnderframesPassenger carriagesTruckEngineering

An improved railroad car wheel truck assembly comprises four arcuate weight bearing surfaces, one above each axle bearing, providing a direct load path such that a light weight frame can be used, each weight bearing surface being received within a matching arcuate channel mounted on the underside of the rail car body, the channels having a greater arc length that the corresponding weight bearing surface such that the wheel truck is allowed to rotate relative to the rail car body, about a central pivot pin, the wheel truck assembly further comprising a two part spring assemblies for each wheel with long springs that are always under compression and shorter springs that are compressed only when the car is under a load, each wheel spring assembly having one long spring that urges a wedge between the wheel truck frame and wheel set axle holding saddle to urge the wheel set and axle into alignment.

Owner:MONSELL DALE

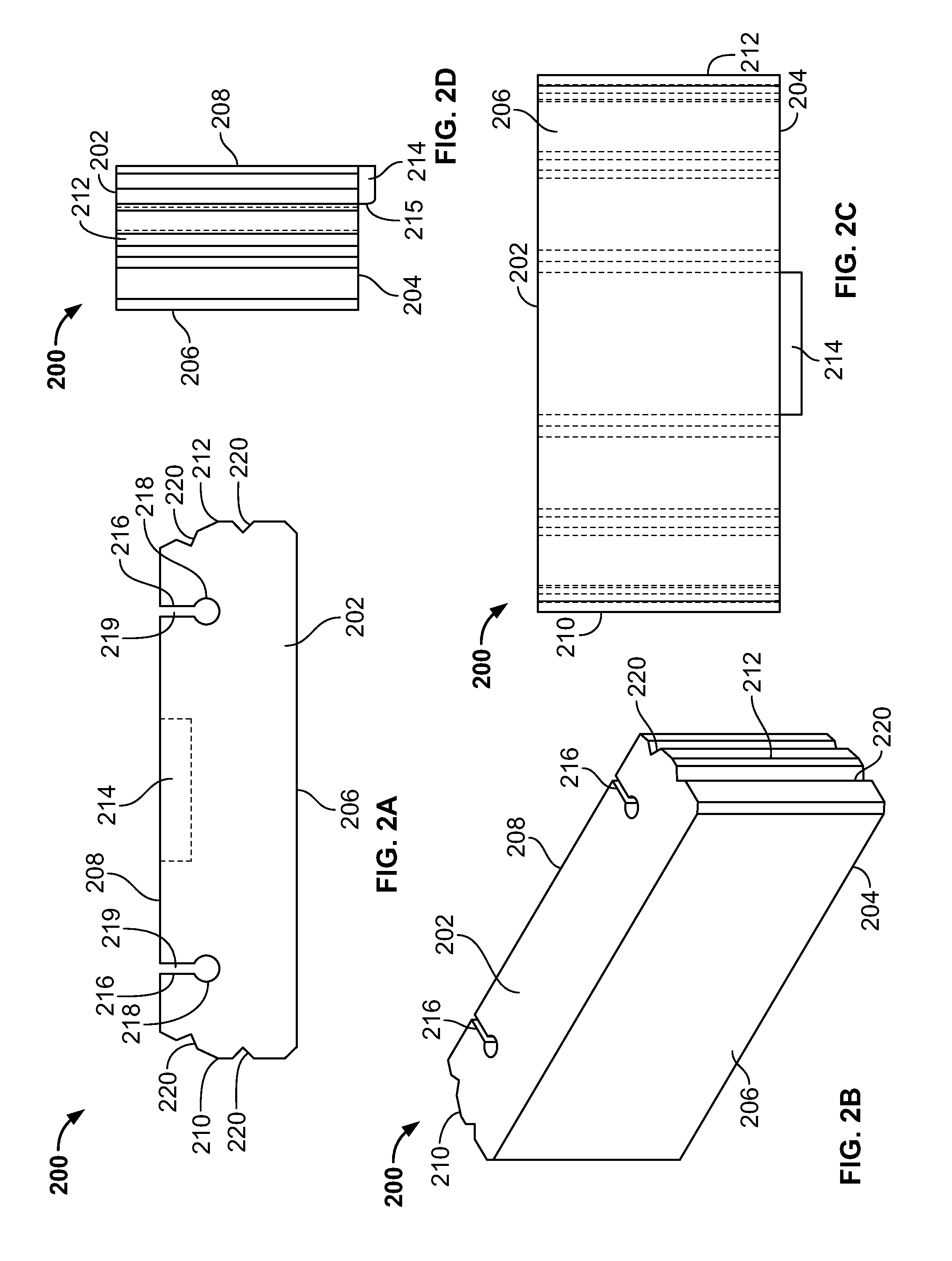

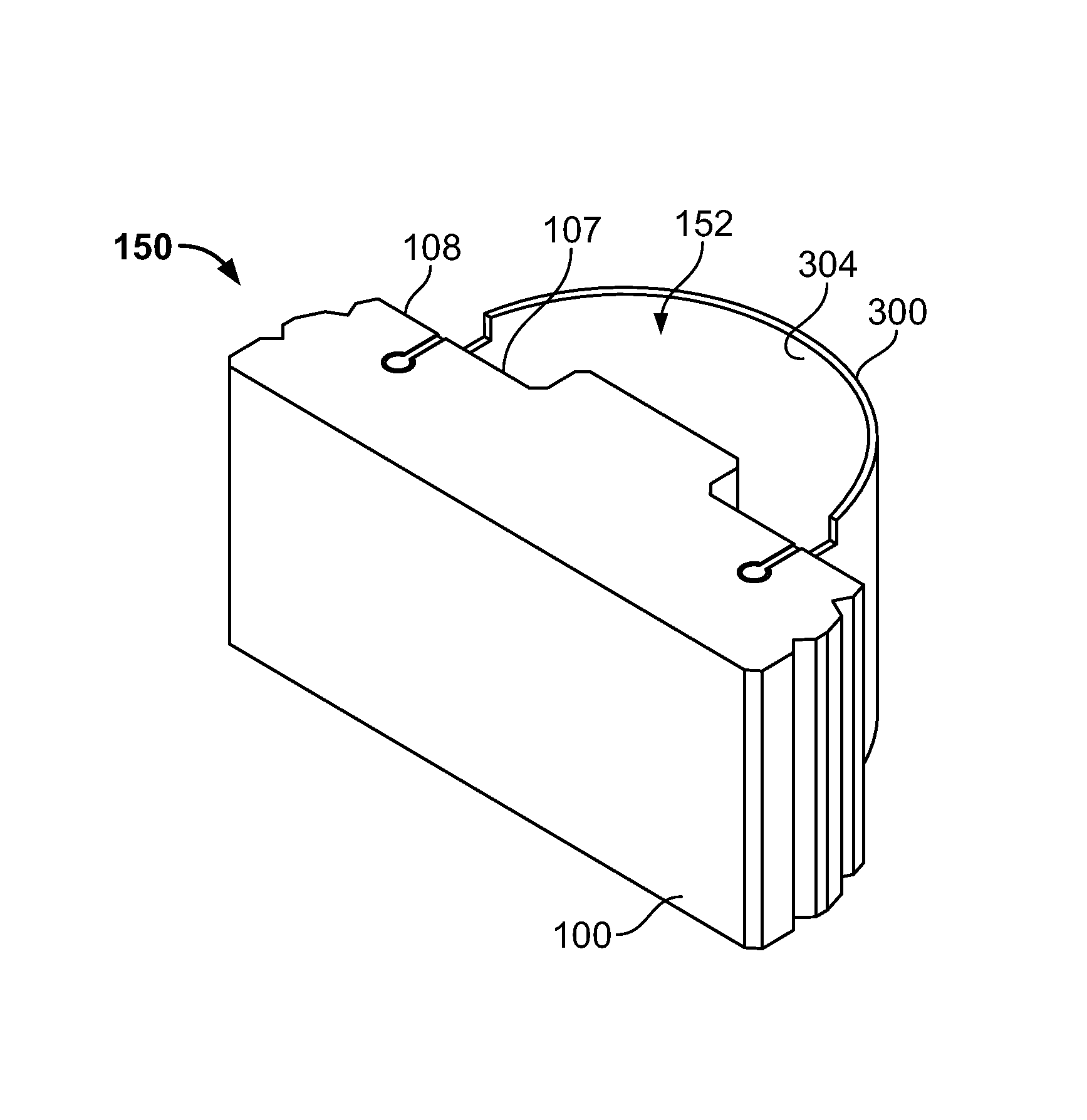

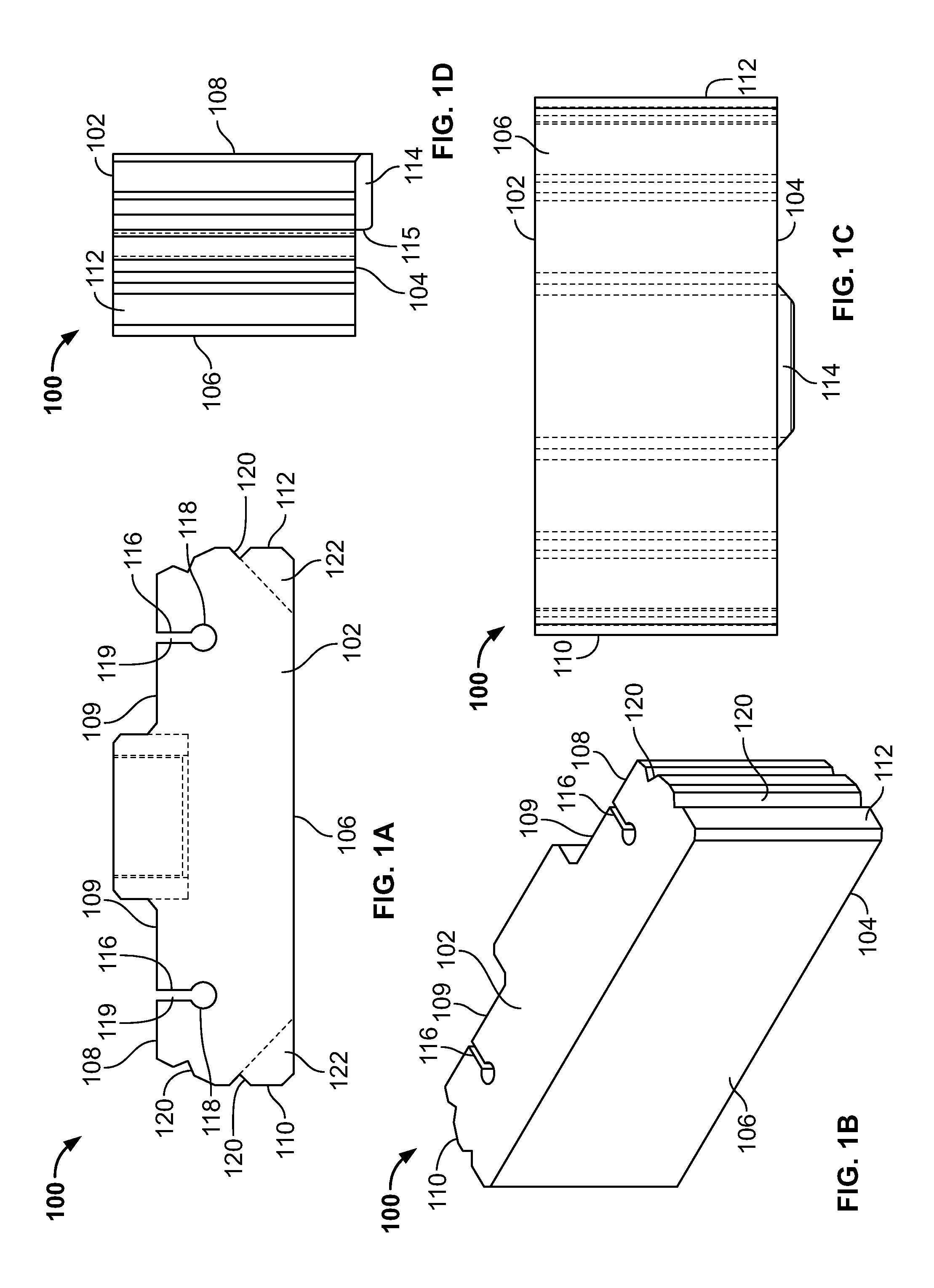

Wall block with barrier member

ActiveUS8430603B2Avoid horizontal displacementArtificial islandsConstruction materialFilling materialsMechanical engineering

A retaining wall block can include a top surface and opposing bottom surface, a front surface and opposing rear surface, and first and second opposing side surfaces. A projection can extend downwardly from the bottom surface and can include a forwardly facing indexing surface oriented generally parallel with the front surface of the block. The indexing surface can be configured to engage a rearwardly facing surface of a block in a lower course of blocks. The block can also include a pair of spaced apart key slots defined in the rear surface. Each key slot can include an enlarged interlocking portion and a throat portion extending from the interlocking portion to the rear surface. An assembly can be created whereby a pair of correspondingly shaped keys of an elongate barrier member are engaged with key slots of block so as to inhibit rearward horizontal displacement of the keys within the key slots. Elongate barrier member can include a body presenting an inner surface and an outer surface and a pair of opposing ends, each opposing end defined one of the keys. The inner surface of the barrier member and the rear surface of the block can together define a core region for receiving fill material.

Owner:MORTARLESS TECH

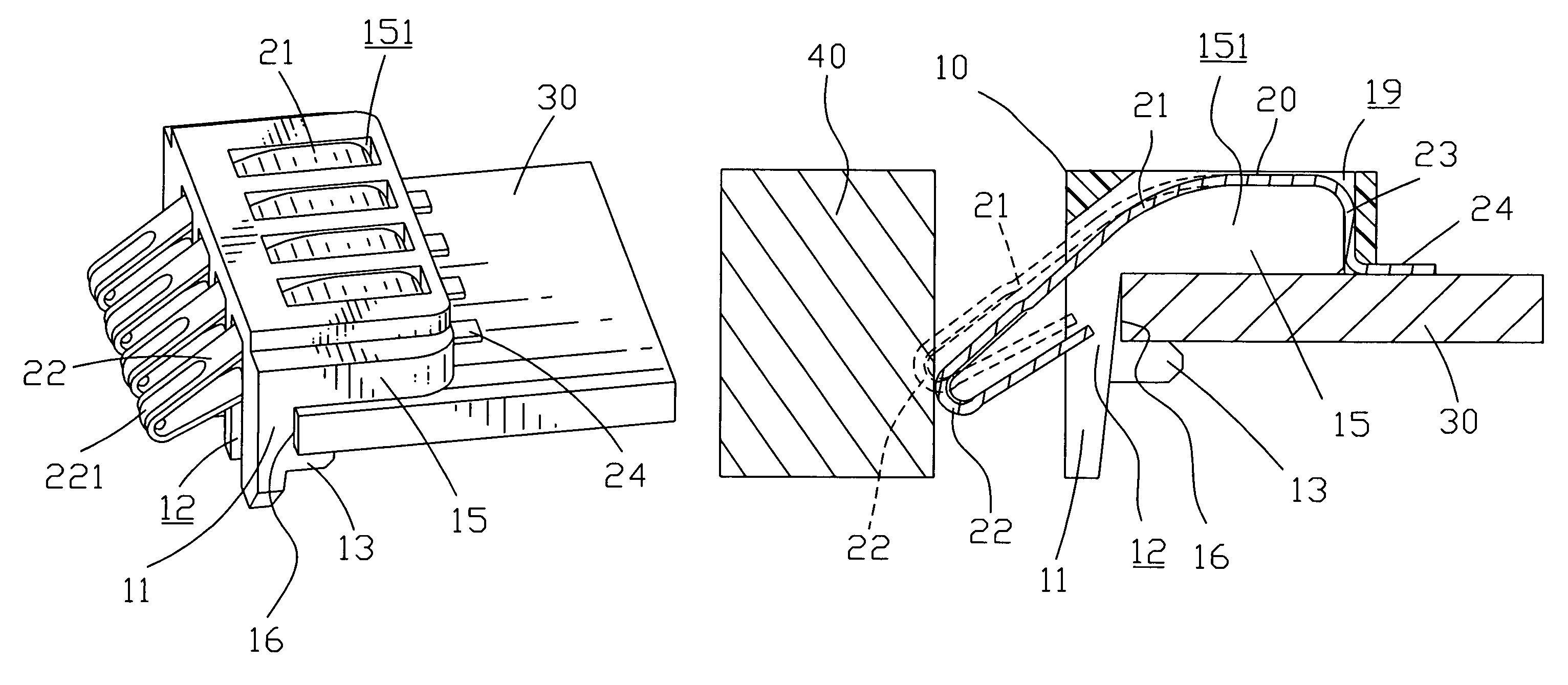

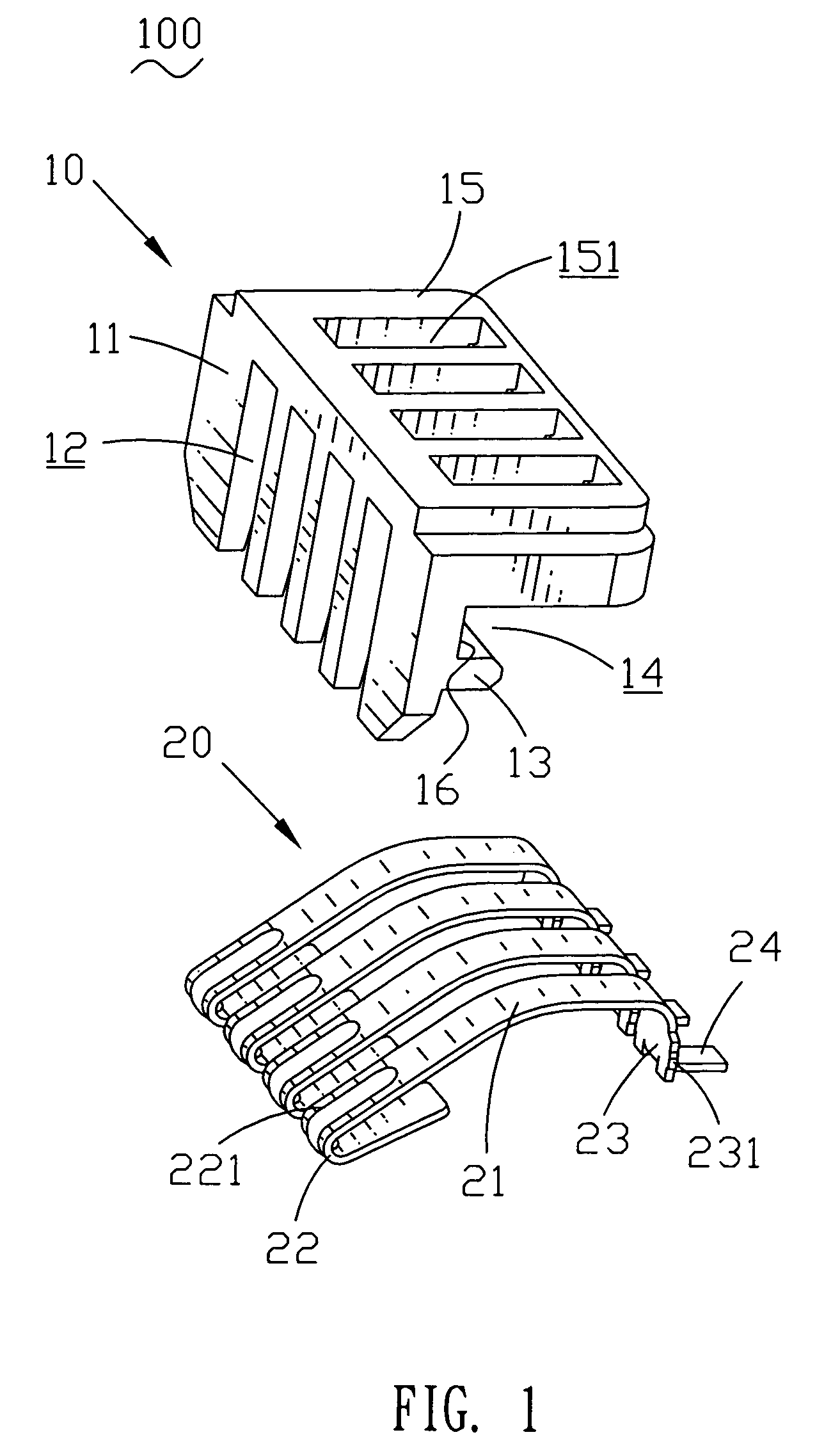

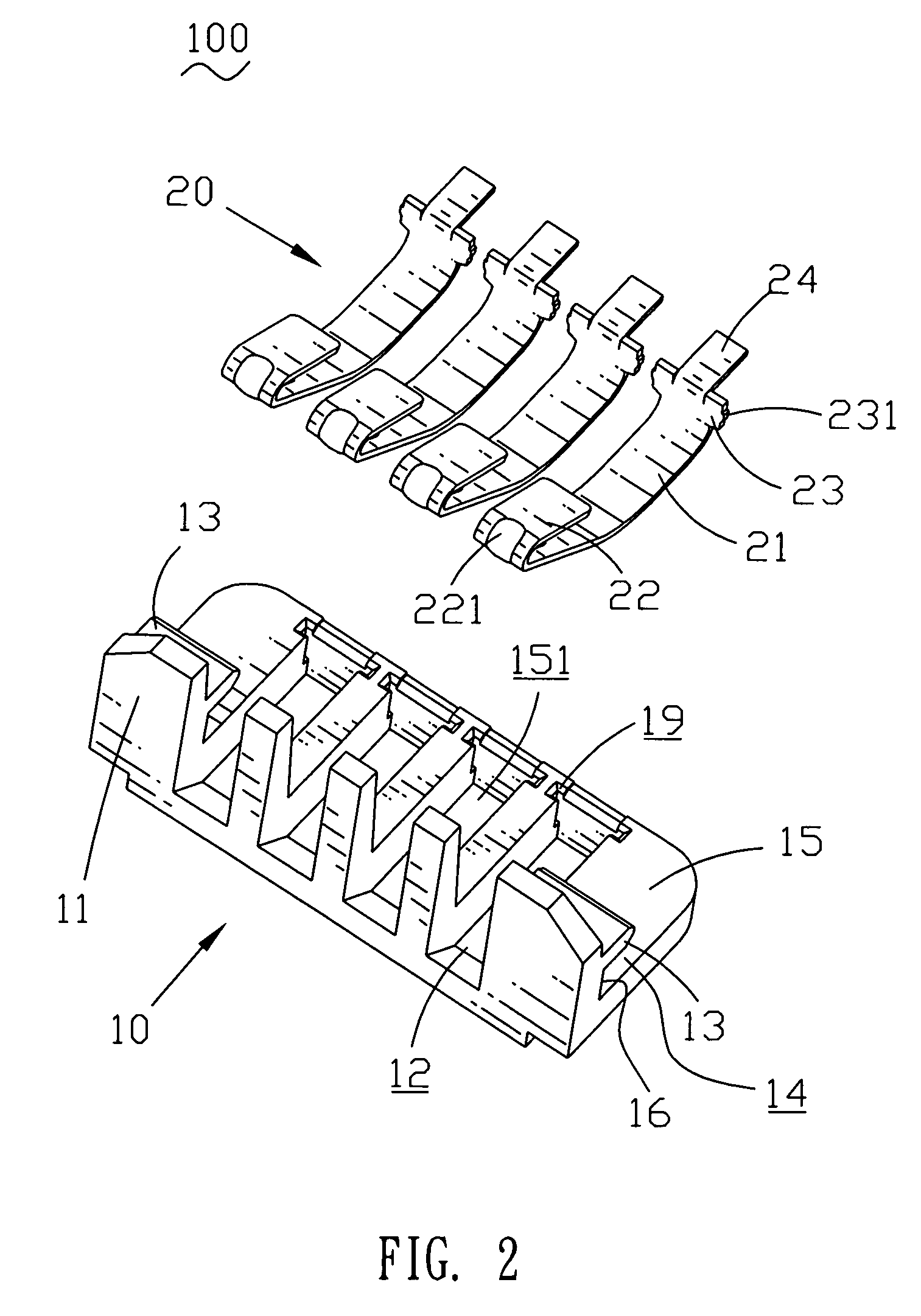

Battery connector with retaining board

InactiveUS7258571B1Electrical connectionAvoid horizontal displacementCoupling contact membersElectric connection structural associationsElectrical connectionEngineering

A battery connector with retaining board includes an insulating housing and a plurality of terminals received in the insulating housing. Each terminal includes a connecting portion, a contacting portion and a soldering portion. The insulating housing has a vertical cooperating wall. A top wall and a retaining board backward extend from the backside of the vertical cooperating wall, thereby a retaining space is formed therebetween. The backside of the cooperating wall defines a contacting side formed between the top wall and the retaining board. A printed circuit board is retained in the retaining space and one end of the printed circuit board is depressed against the contacting side of the insulating housing whereby a firmly engagement is between the printed circuit board and the battery connector. Therefore, an electrical connection therebetween is stable.

Owner:CHENG UEI PRECISION IND CO LTD

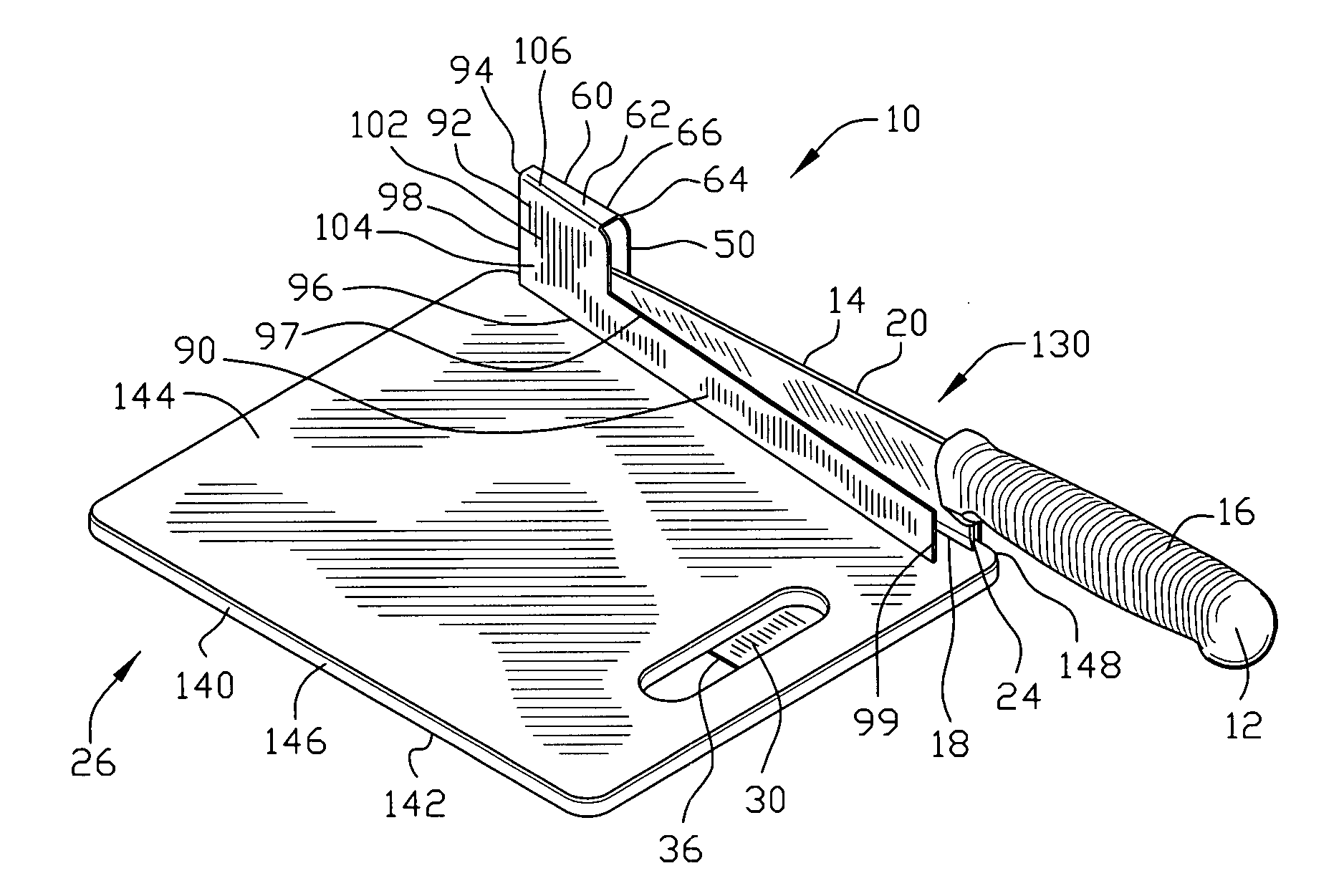

Cutlery receptacle

InactiveUS20080041757A1Avoid vertical displacementAvoid horizontal displacementStands/trestlesContainer/bottle contructionEngineeringSupport surface

An improved receptacle is disclosed for retaining a cutlery instrument, the cutlery instrument has a blade and a handle. The receptacle comprises a base having a base support surface and a base engaging surface. A wall member is secured to the base engaging surface extending substantially perpendicular from said base. A coupling member is secured to the wall member extending substantially parallel and above said base. An arm member is secured to the coupling member extending substantially parallel to the wall member and above the base. A slit is defined between the wall member and the arm member for receiving and maintaining the blade of the cutlery instrument in a static position. A slot is defined between the arm member and the base engaging surface for exposing the wall member.

Owner:NELSON GARY W

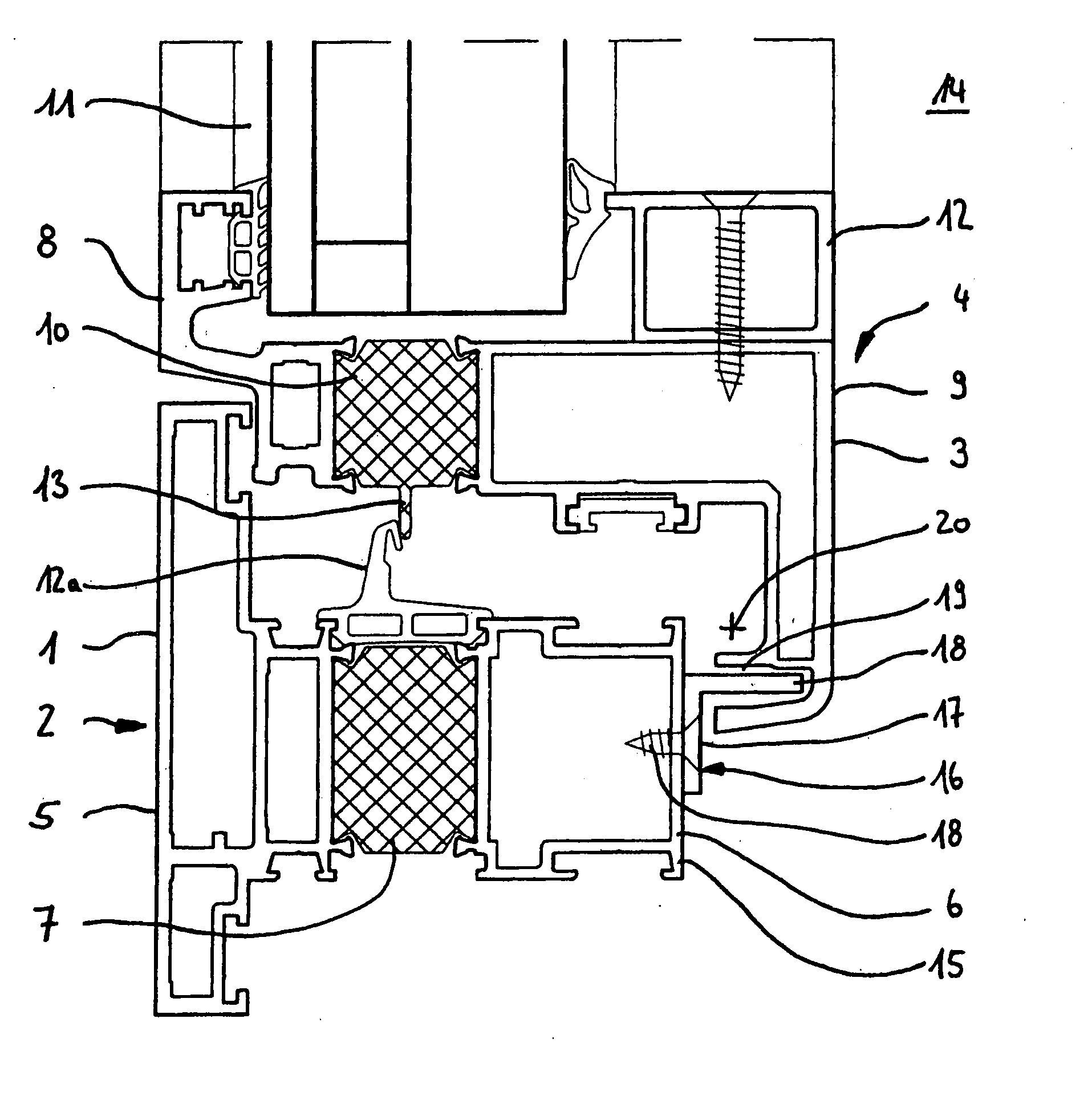

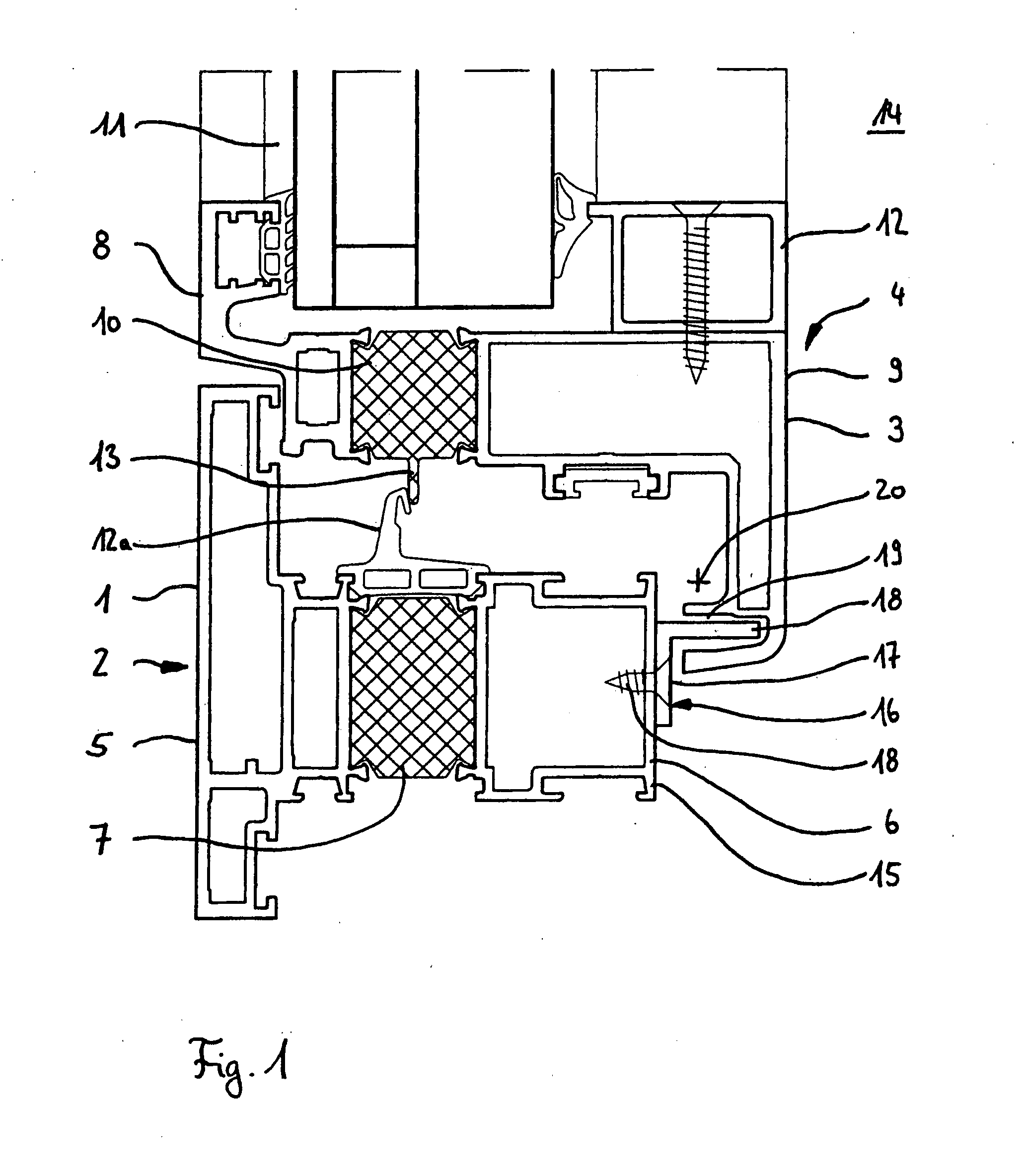

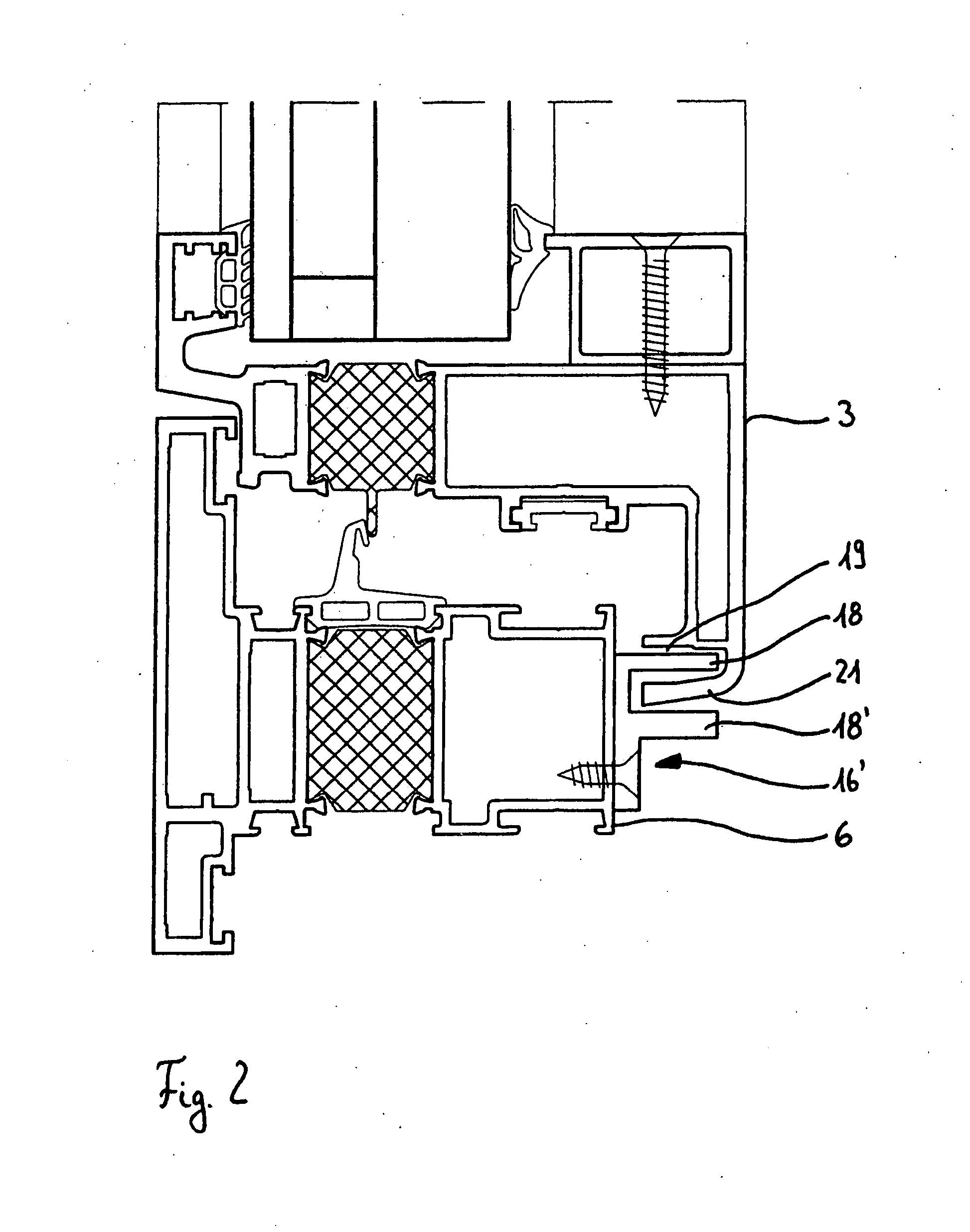

Security window or security door with burglar-retardant features

InactiveUS20080040976A1Improve suppression propertiesImprove securityBurglary protectionFixed grillesEngineeringSash window

Owner:SALZER SICHERHEITSTECHN

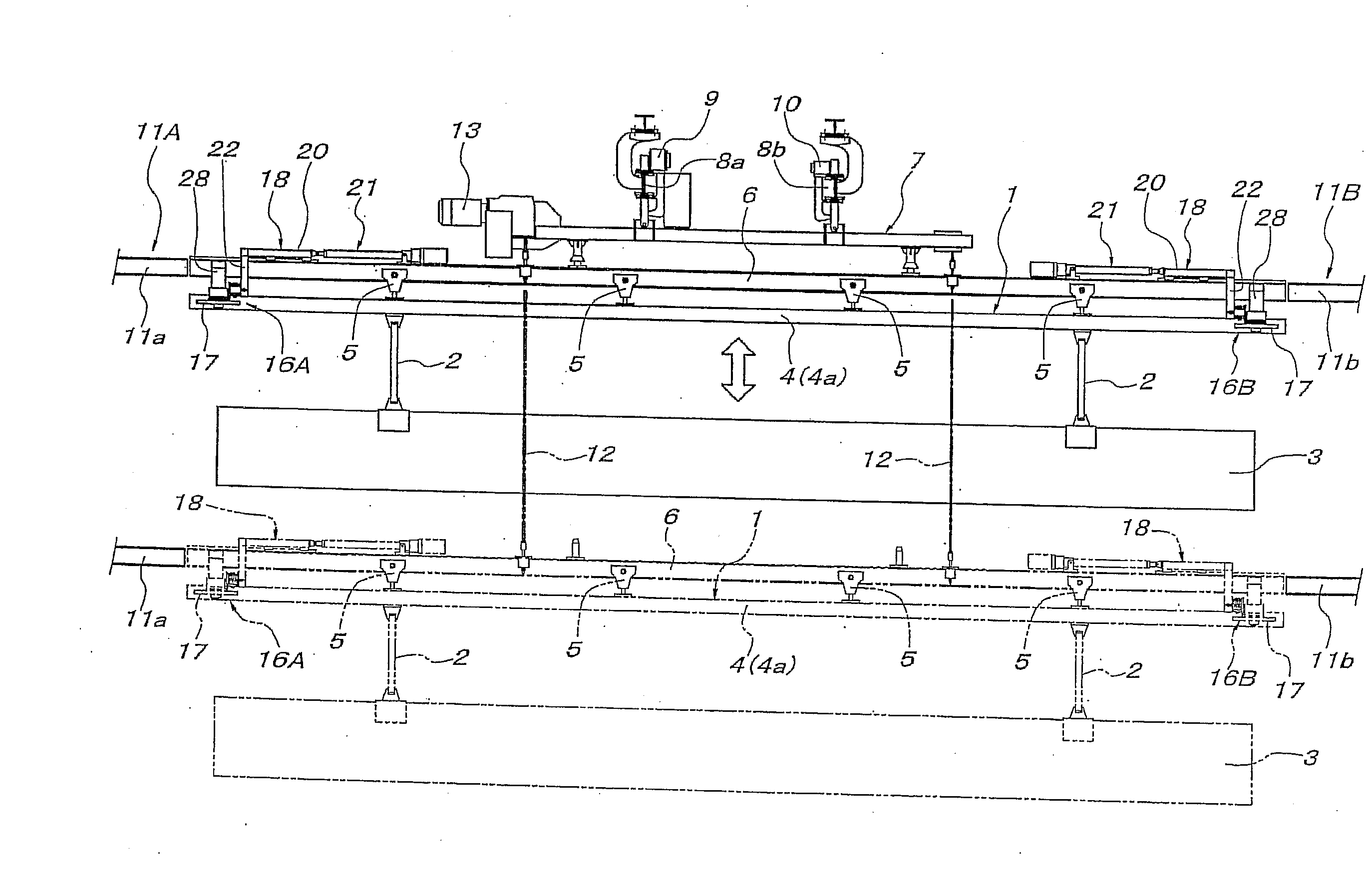

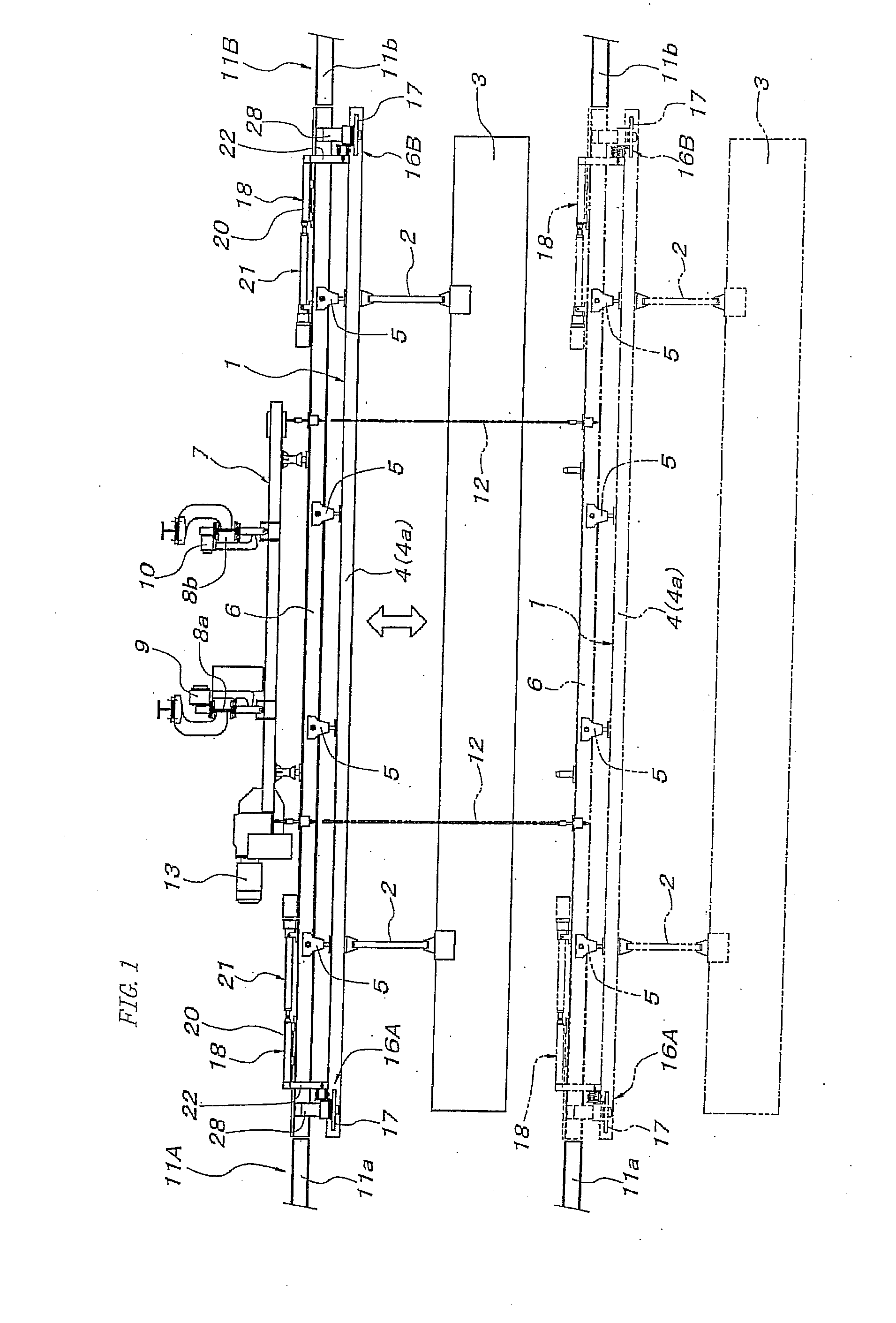

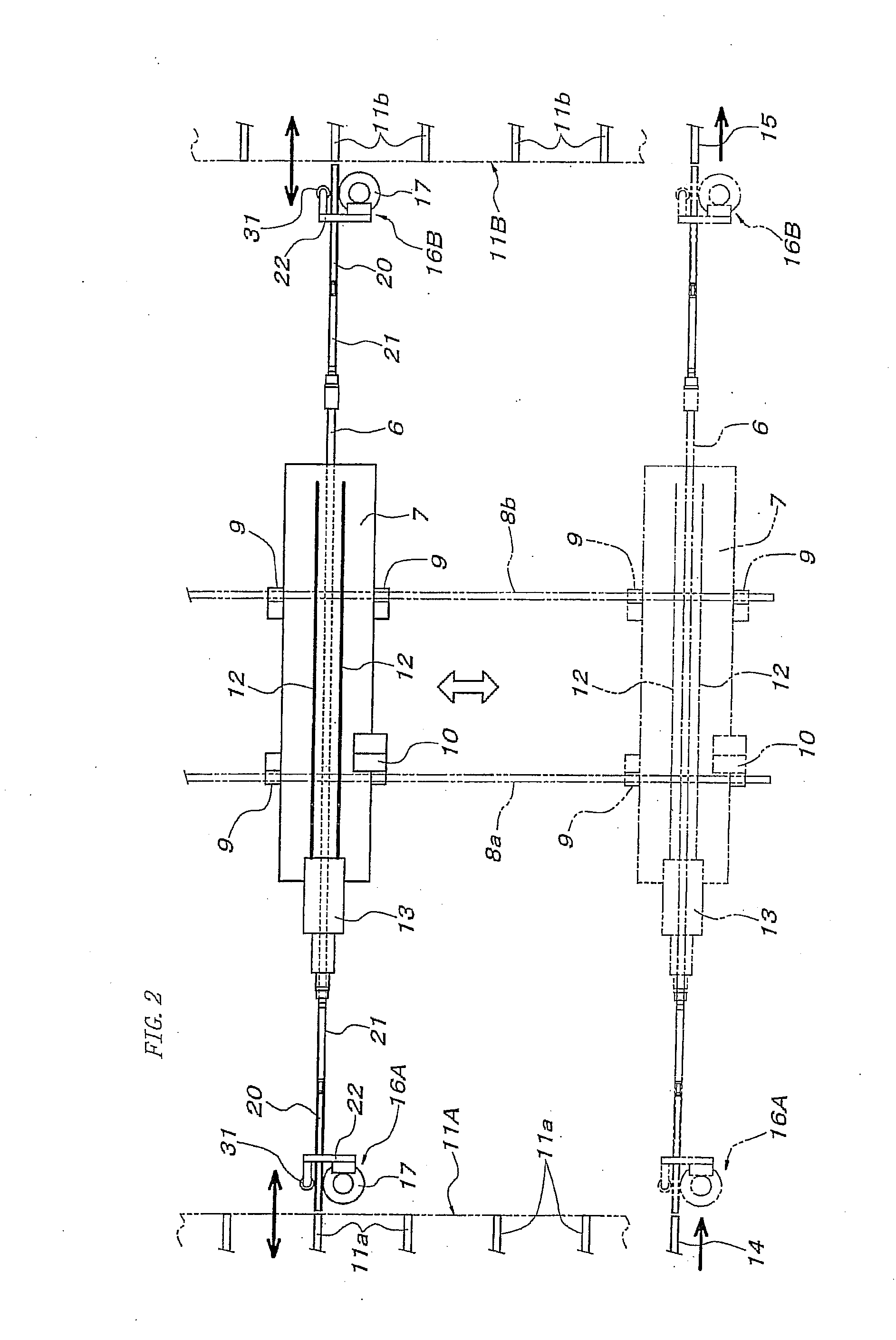

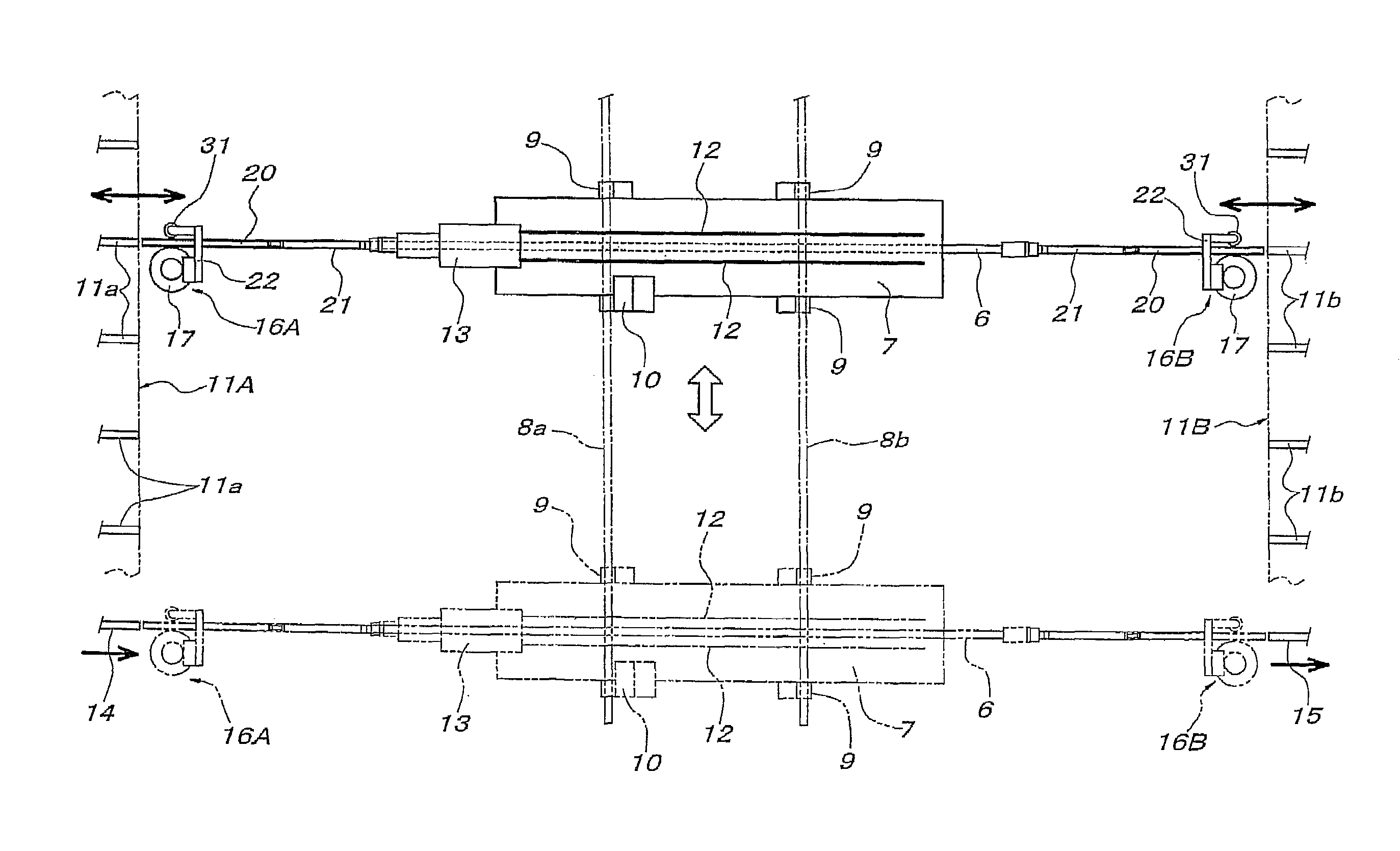

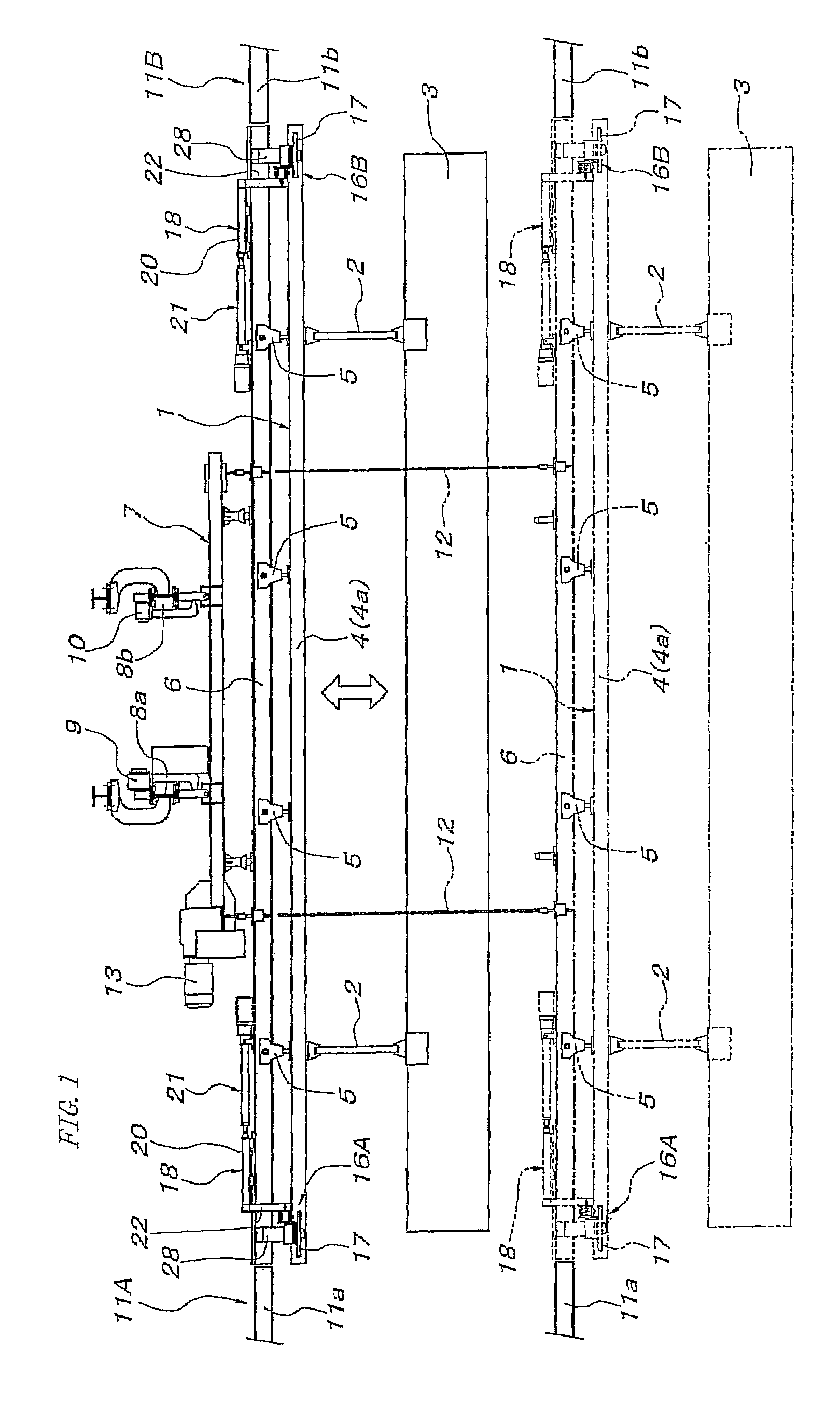

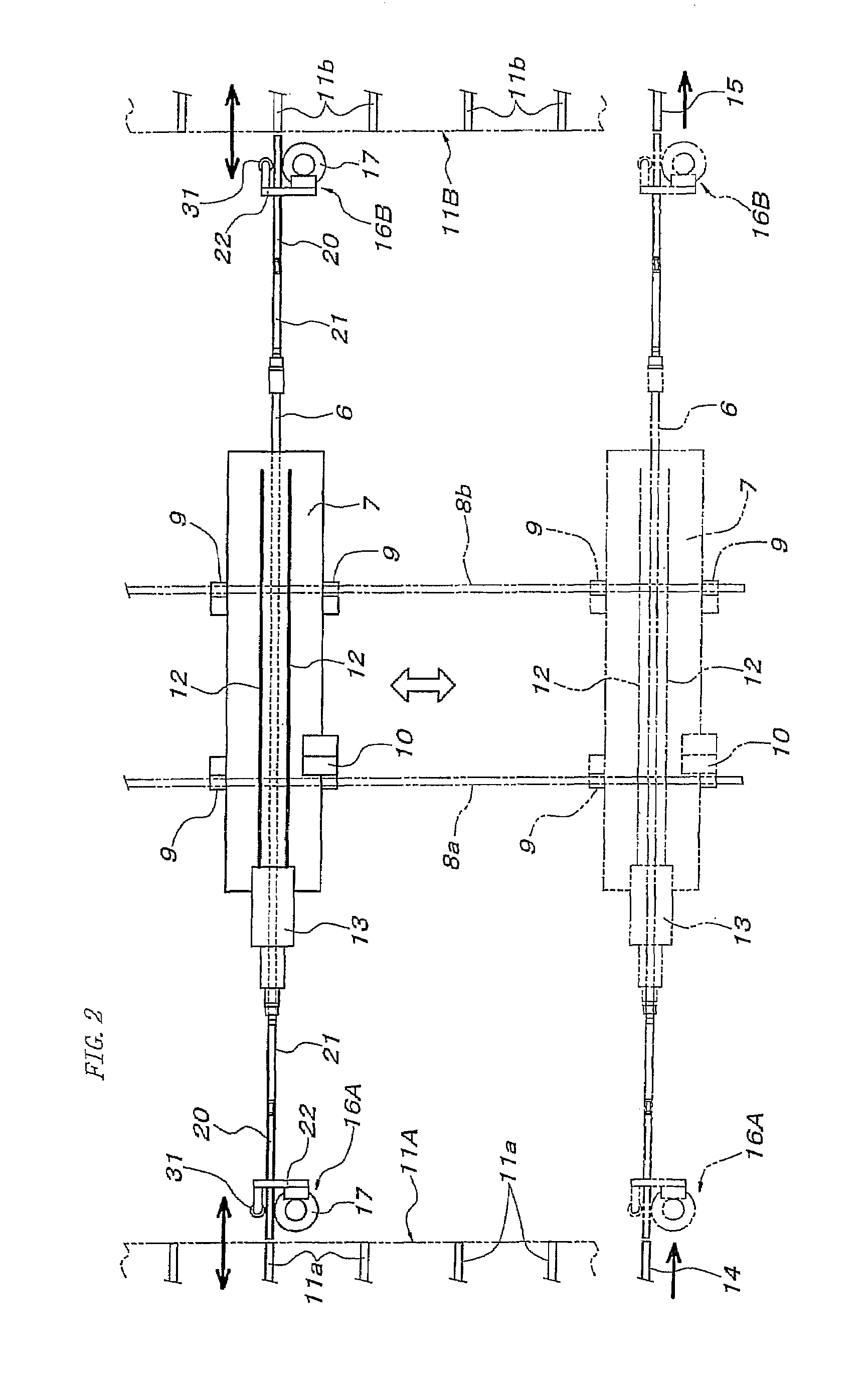

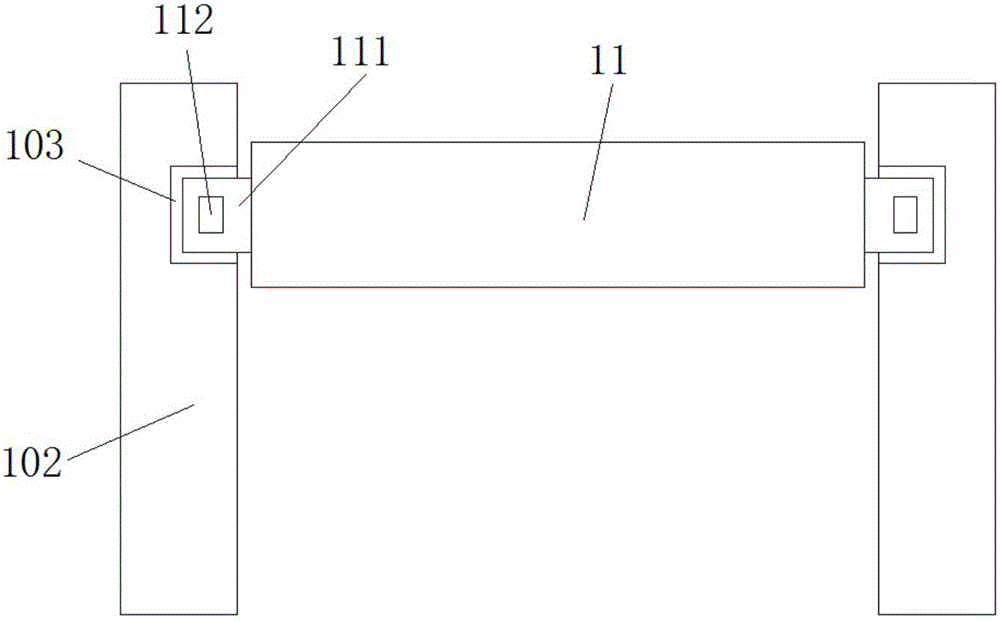

Travelling carrier delivery equipment

InactiveUS7721871B2Avoid horizontal displacementAvoid contactRailway componentsControl devices for conveyorsDrive wheelReciprocating motion

Travelling carrier delivery equipment includes a delivery unit for transferring a travelling carrier that has no self-running means between a movable rail and a main rail by means of external friction-driven, and the travelling carrier is provided with a friction driving surface across its entire length, the delivery unit has a friction drive wheel and friction drive wheel moving means, the friction drive wheel is provided on the movable rail and is switchable between a driving state, in that it propels the travelling carrier via the friction driving surface and a driving release state, and the friction drive wheel moving means reciprocates the friction drive wheel between a retreating position (R), at which the friction drive wheel can be made to contact with the friction driving surface of the travelling carrier supported on the movable rail and a forwarding position (F), at which the friction drive wheel can be made to contact with the friction driving surface of the travelling carrier supported on the main rail.

Owner:DAIFUKU CO LTD

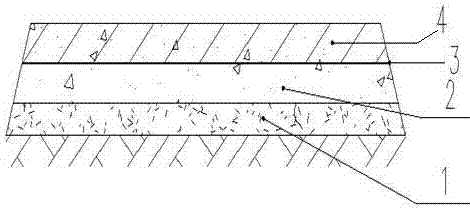

Assembled prestressed construction waste recycled aggregate road and construction method thereof

PendingCN107083730AHigh strengthIncreased durabilitySingle unit pavingsPaving detailsArchitectural engineeringStructural engineering

The invention discloses an assembled prestressed construction waste recycled aggregate road and a construction method thereof. The recycled aggregate road comprises a cushion layer, a base layer, a sliding layer and a surface layer, wherein the surface layer is formed by splicing a plurality of precast recycled concrete road slabs with reserved prestressed bar holes, sleeper beams are placed below transverse joints of the precast recycled concrete road slabs, and waterproof rubber strips are embedded in the transverse joints and longitudinal joints; and the precast recycled concrete road slabs at two ends are stretched so as to be connected with the sleeper beams through telescopic components. The road structure manufactured by the construction waste recycled aggregate is convenient and fast in overall manufacturing and high in economic benefit, the carrying capacity of the road structure is enhanced, the deformation performance of the road structure is improved, the ductility of the road structure is increased, and the construction time is greatly shortened. The construction method is suitable for road structures, such as town roads and post-disaster emergency repair roads.

Owner:NANCHANG UNIV

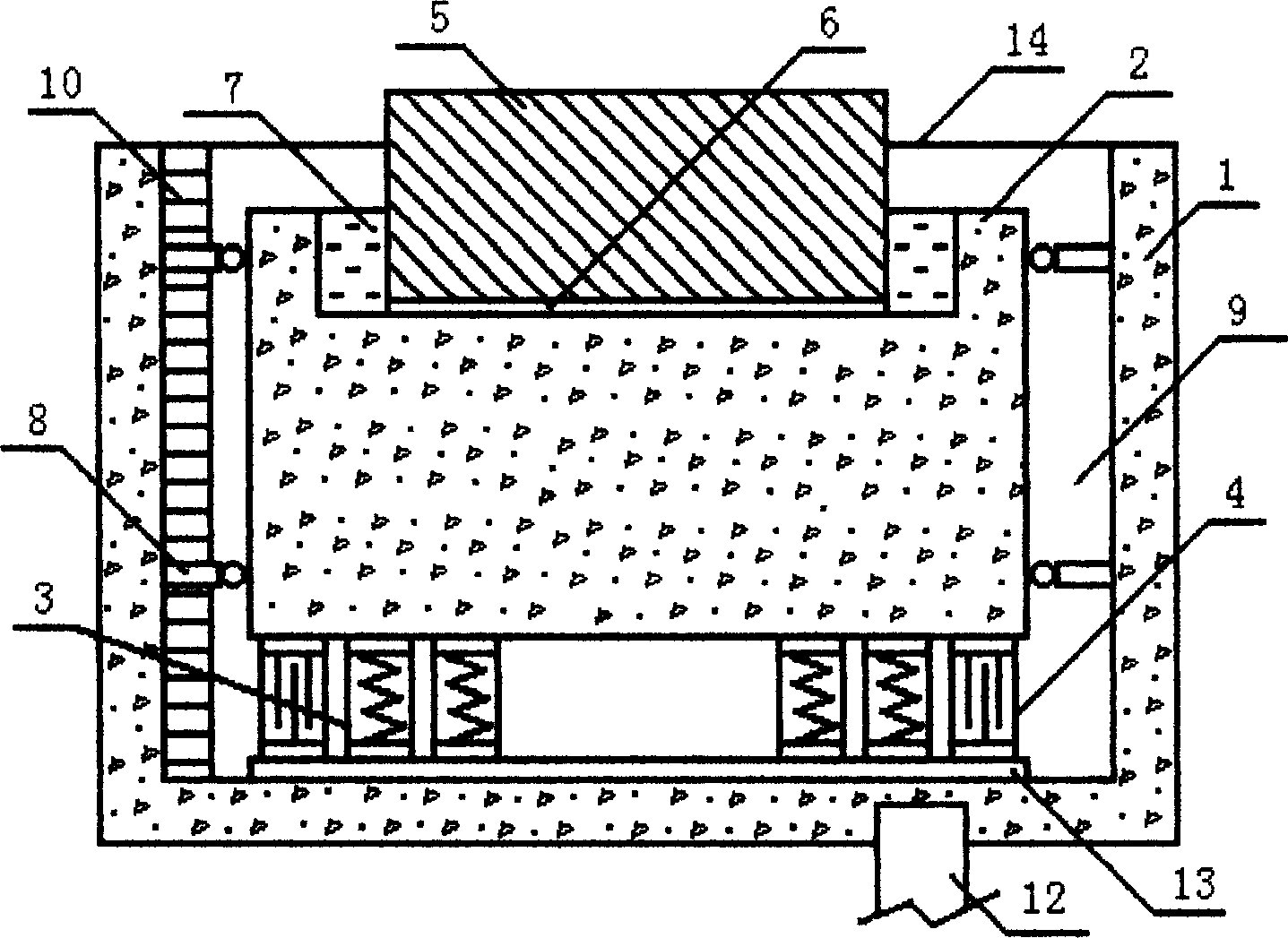

Shock absorbing system for forging hammer

The invention discloses to a forge damping system, which relates to the damping technique of large force device. It combines the large base, the small base, the buffer, the damper and the rubber cushion, and it arranges a maintaining well and a water collecting hole. It has better damping effect and easy maintenance to apply the impact vibration device with large tonnage.

Owner:HUBEI TRI RING FORGING

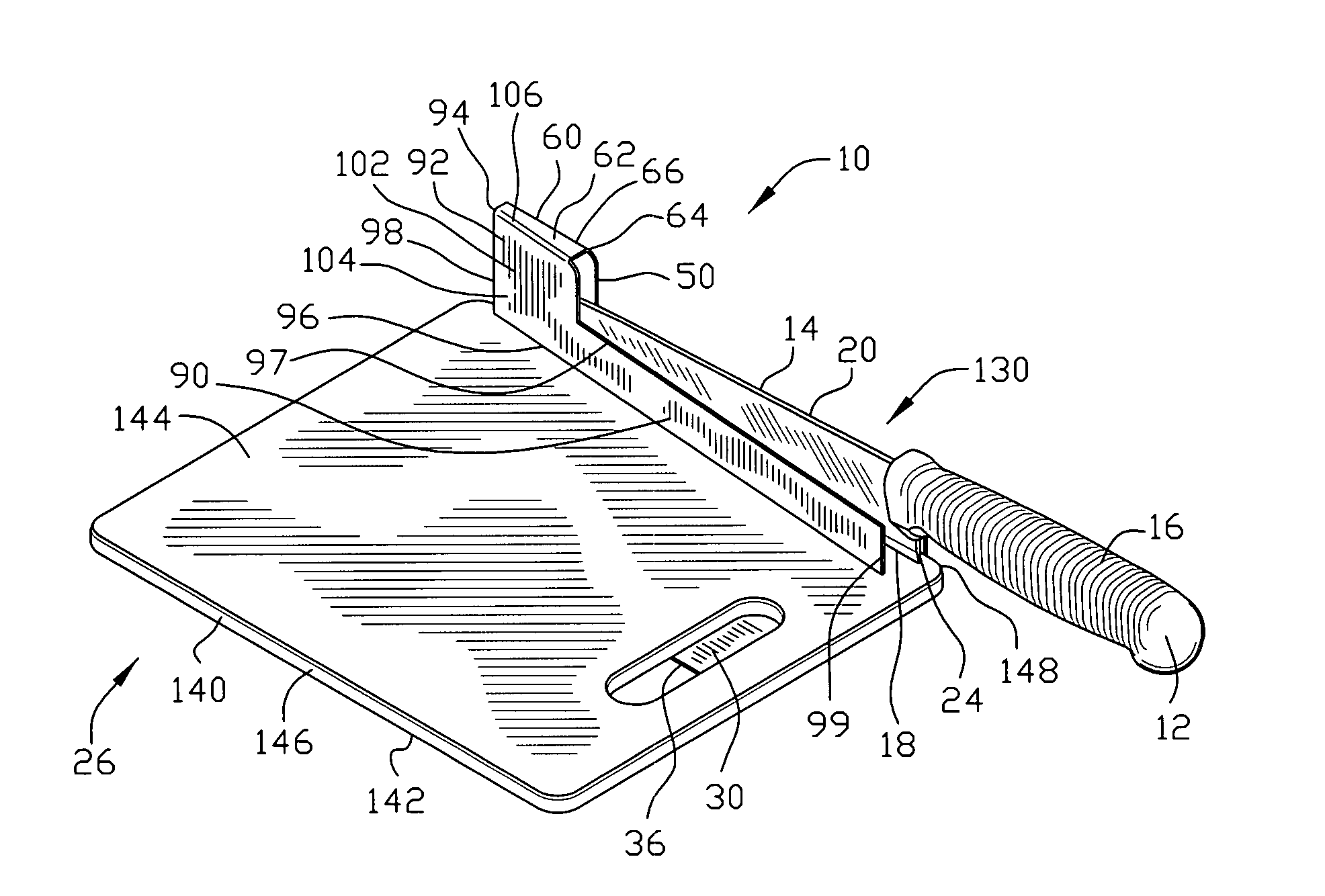

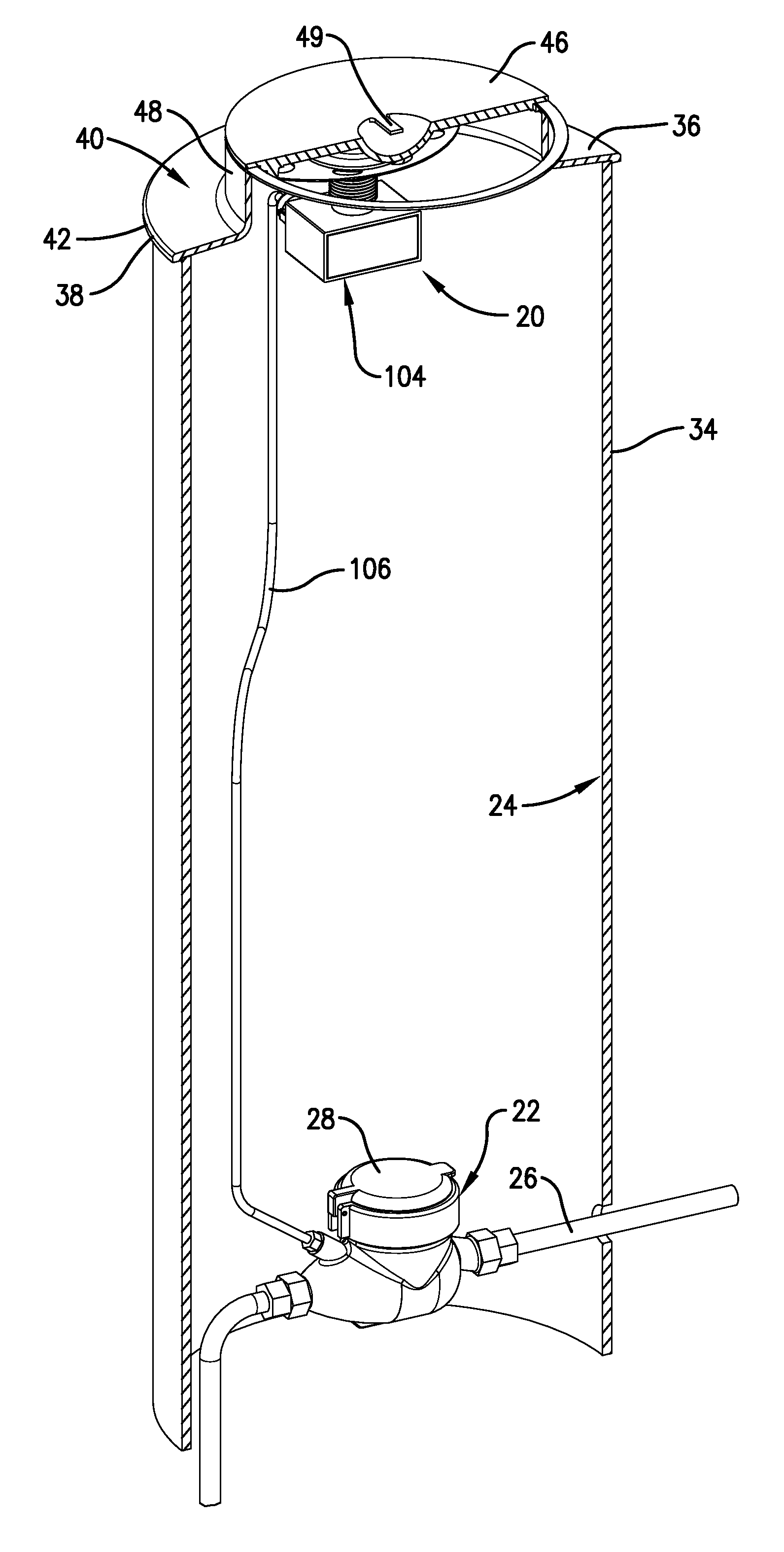

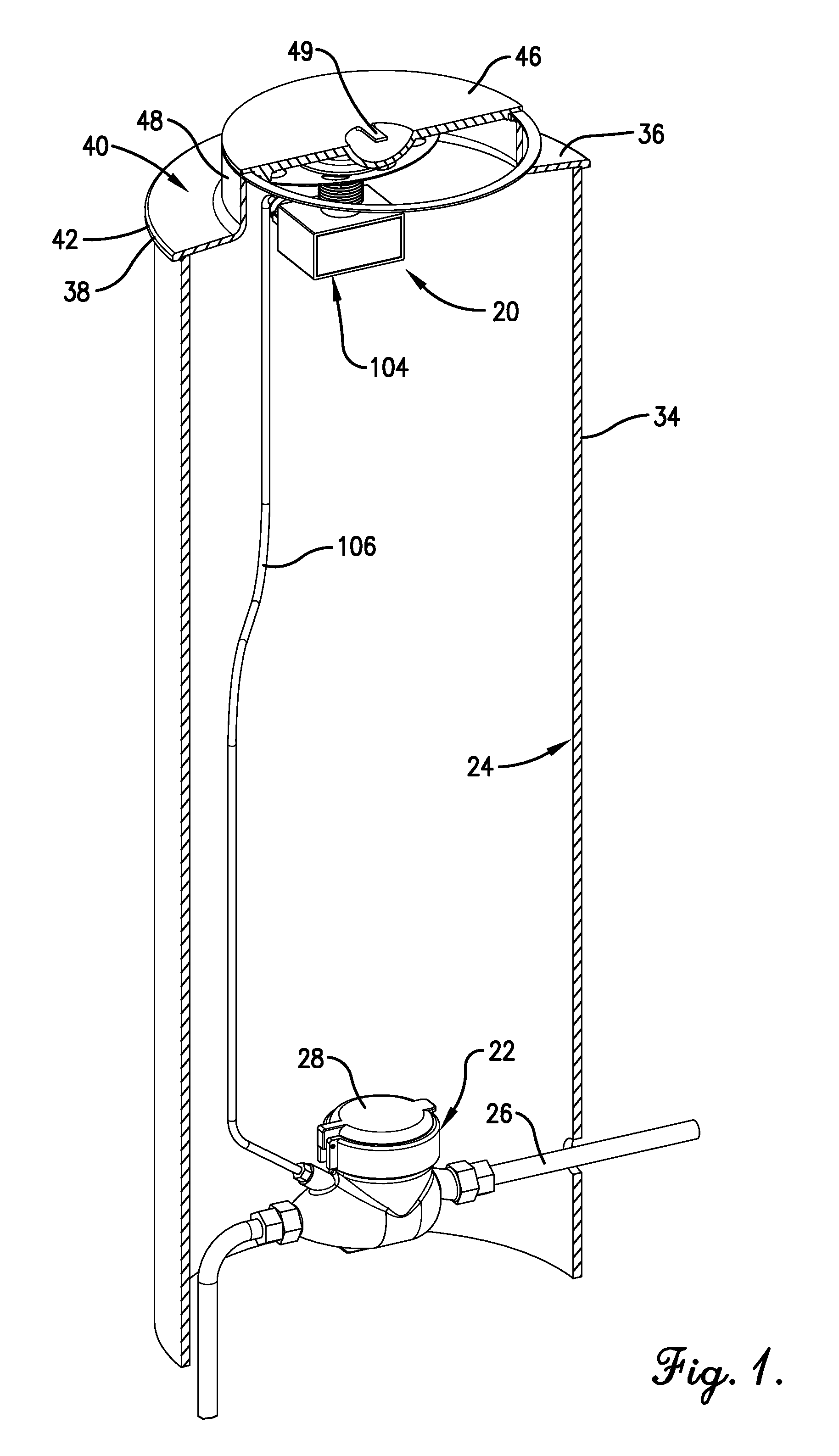

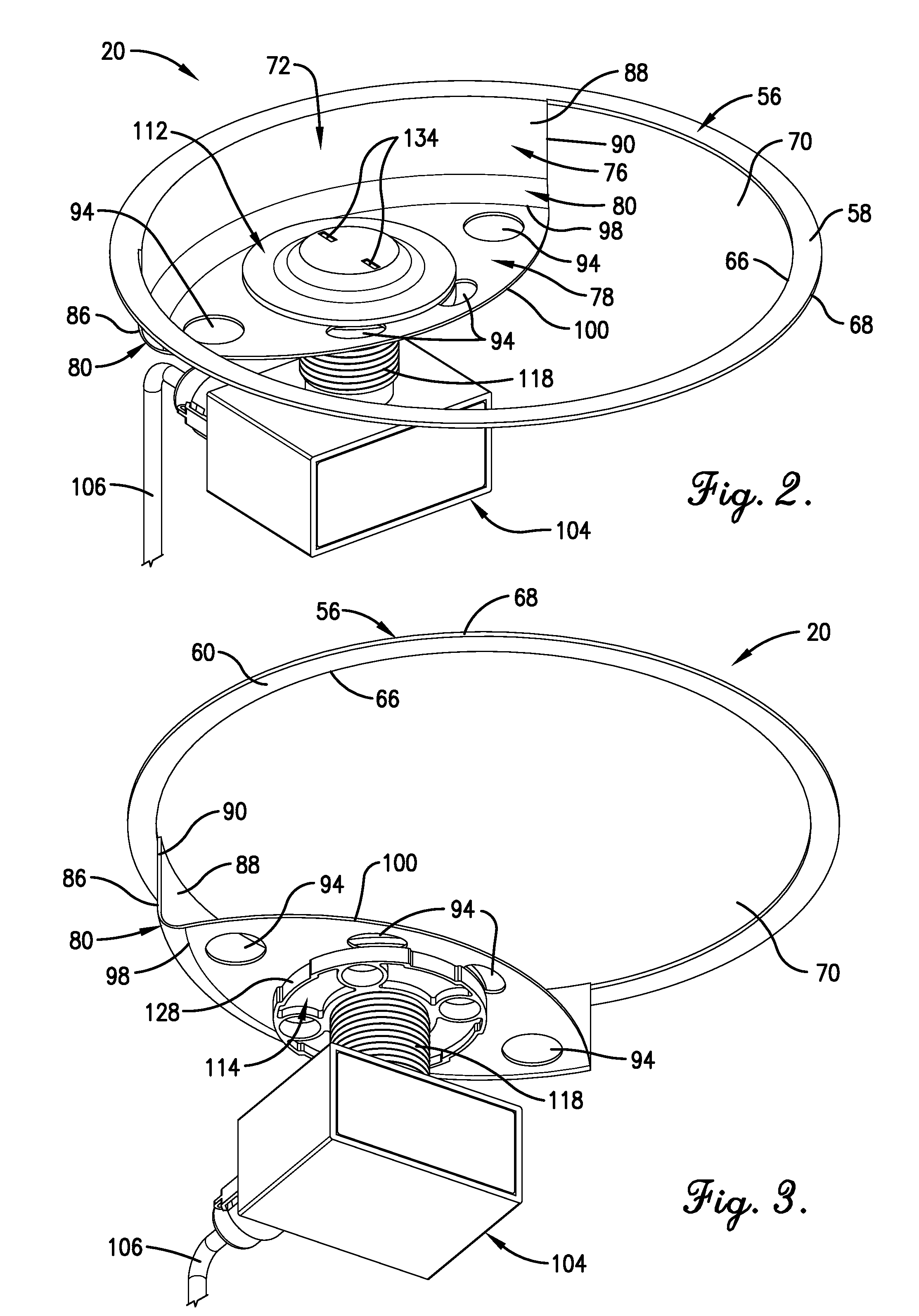

Water meter mounting bracket system and method

ActiveUS20120211615A1Avoid vertical displacementUniform supportDecorative coversCandle holdersEngineering

A bracket system and method to retrofit a subsurface water meter enclosure with a mount so as to provide secure positioning means suitable for components related to a water meter such as water-usage monitoring equipment. The system is only removable from the water meter enclosure via disassembling the water meter enclosure.

Owner:RINALDI DAVID C +1

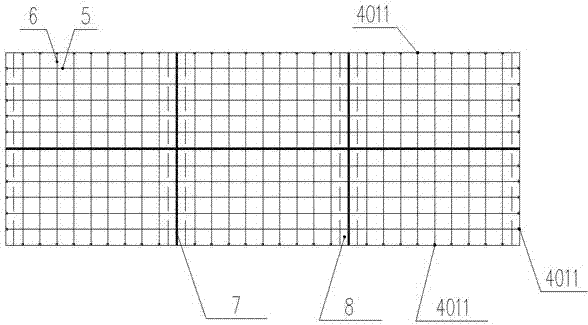

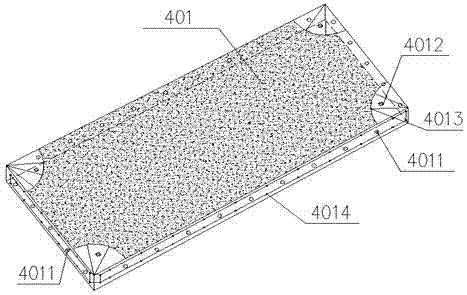

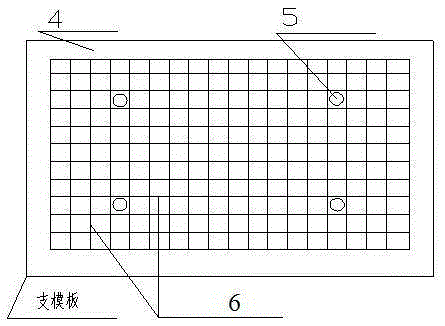

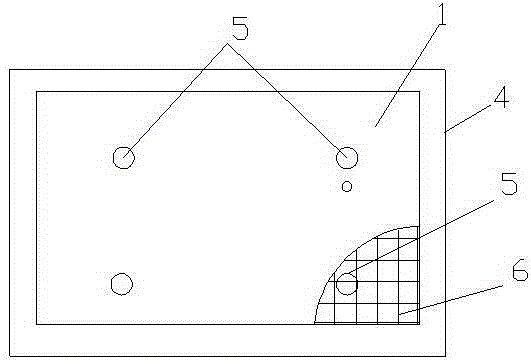

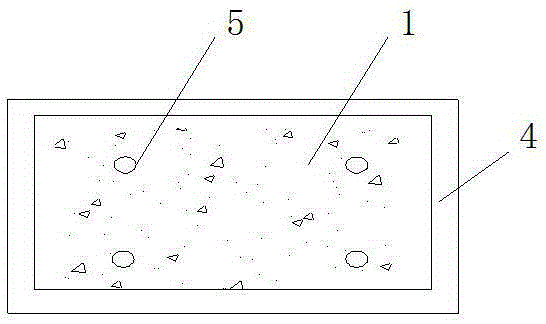

Single-bar, single-mesh and anti-crack type precast concrete pavement slab convenient to carry, disassemble and assemble and using method of precast concrete pavement slab

The invention discloses a single-bar, single-mesh and anti-crack type precast concrete pavement slab convenient to carry, disassemble and assemble. The single-bar, single-mesh and anti-crack type precast concrete pavement slab comprises a slab surface main body, a bottom layer, a surface layer, pre-buried angle steel, pre-buried steel pipes and concrete and is characterized in that the slab surface main body is constructed by pouring concrete; a pipeline is laterally pre-buried in the slab surface main body in the length direction; the surface layer is arranged above the bottom surface; the four sides and edge and corner parts of the slab surface main body are wrapped and covered by the pre-buried angle steel; the outer side face of the pre-buried angle steel is flush with a concrete surface; reservation holes of the four pre-buried steel pipes are uniformly formed in the slab surface main body; a steel bar is inserted into each pre-buried steel pipe.

Owner:YONGSHENG CONSTR GRP

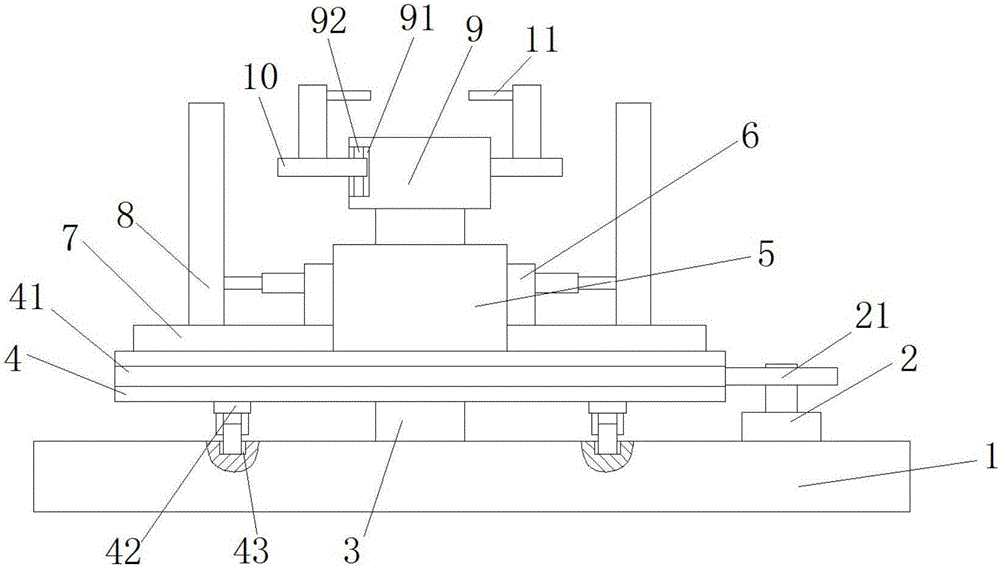

Production clamp for automobile wheel steel ring trimming

ActiveCN106825744AAvoid horizontal displacementDisplacement does not occurShearing machine accessoriesHydraulic cylinderPiston rod

The invention relates to the technical field of automobile wheel steel ring production clamps, in particular to a production clamp for automobile wheel steel ring trimming. The production clamp comprises a base, a stand column is arranged on the base, a rotating disc is mounted on the stand column through a bearing, a sleeve is mounted on the rotating disc, the sleeve and the stand column are coaxially arranged, a plurality of hydraulic cylinders are arranged on the outer wall of the sleeve, a linear guide rail is arranged between each hydraulic cylinder and the rotating disc, and connecting rods are arranged at the ends of the piston rods of the hydraulic cylinders, and are mounted in the linear guide rails in a sliding manner; a round bearing table is arranged at the end of the stand column, a plurality of first grooves are formed in the outer wall of the bearing table, rotating shafts are erected in the first grooves, the rotating shafts are sleeved with a connecting plate in clearance fit with the rotating shafts, two parallel sliding grooves are formed in the upper surface of the connecting plate, sliding rods are arranged in the sliding grooves in a sliding manner, the opposite inner side tops of the two sliding rods are rotatably connected with a baffle, and a bolt hole is formed in the end of the baffle. The production clamp can be applied to multiple automobile steel rings, and it is ensured that during automobile wheel steel ring machining, displacement is not generated, and errors are avoided.

Owner:大楚神驰车轮股份有限公司

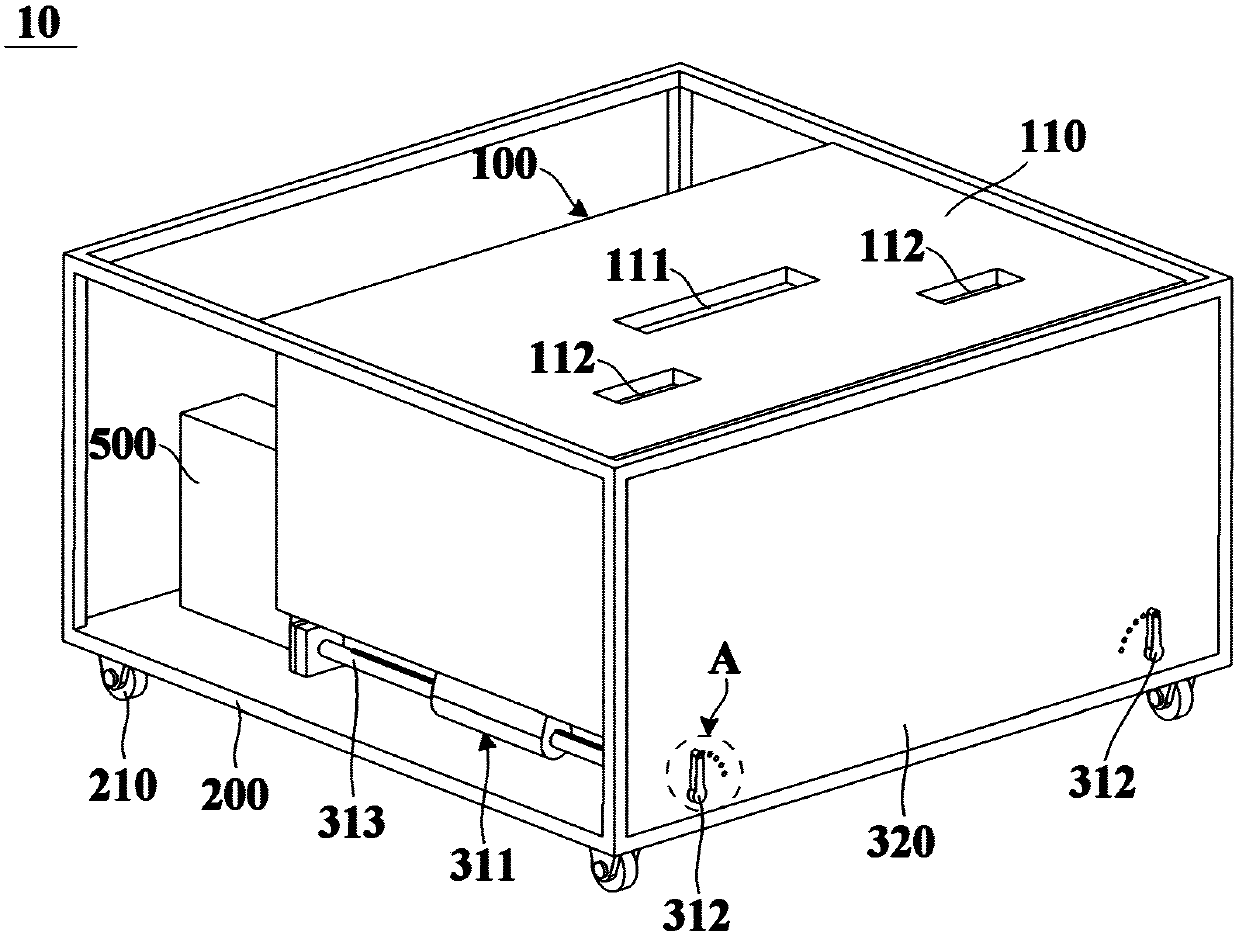

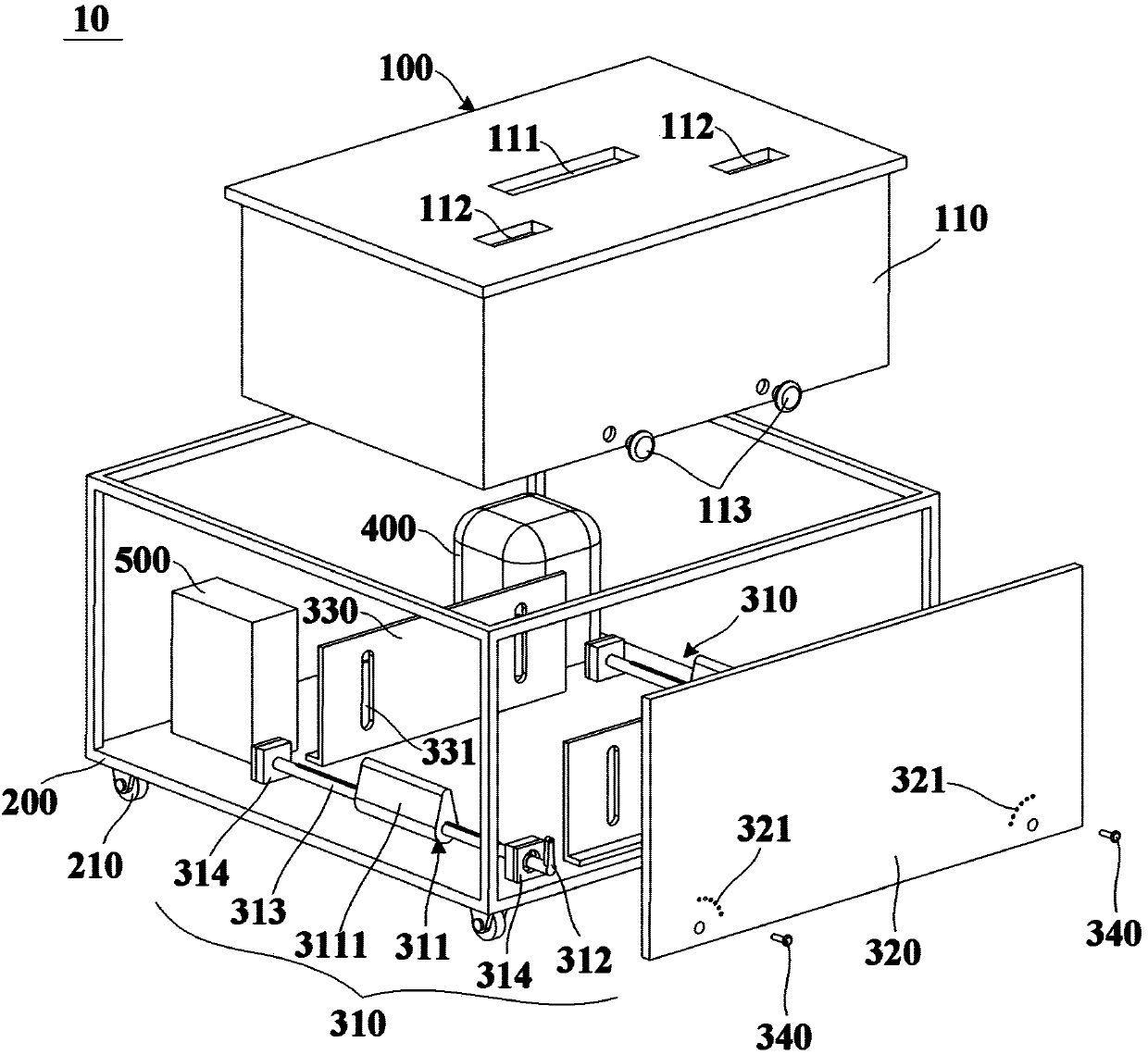

Refrigeration module for cold storage and refrigerating device and cold storage and refrigerating device

InactiveCN107664377AEasy to seal the connectionAchieve separationLighting and heating apparatusDomestic refrigeratorsVertical planeEngineering

The invention relates to a refrigeration module for a cold storage and refrigerating device and the cold storage and refrigerating device. The refrigeration module comprises an evaporator box assembly, a bottom support plate and a lifting mechanism. The top of the evaporator box assembly is provided with an air supply opening and an air return opening. The bottom support plate is used for bearingthe evaporator box assembly. The lifting mechanism is provided with at least one lifting unit. Each lifting unit comprises a cam located under the evaporator box assembly, the circumferential curved face of the cam abuts against the bottom of the evaporator box assembly, and the cam is arranged to operationally rotate in the vertical plane relative to the bottom support plate so as to lift and / ordrop the evaporator box assembly. The cold storage and refrigerating device comprises at least one storage module, a rack used for supporting at least one storage module, and the refrigeration module.At least one storage module is arranged on the rack, and the refrigeration module is arranged in the rack and is located below at least one storage module. The refrigeration module can be in seal connection with the storage module and is convenient to disassemble and assemble independently.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

Cutlery receptacle

InactiveUS7441659B2Avoid vertical displacementAvoid horizontal displacementStands/trestlesContainer/bottle contructionCutleryEngineering

An improved receptacle is disclosed for retaining a cutlery instrument, the cutlery instrument has a blade and a handle. The receptacle comprises a base having a base support surface and a base engaging surface. A wall member is secured to the base engaging surface extending substantially perpendicular from said base. A coupling member is secured to the wall member extending substantially parallel and above said base. An arm member is secured to the coupling member extending substantially parallel to the wall member and above the base. A slit is defined between the wall member and the arm member for receiving and maintaining the blade of the cutlery instrument in a static position. A slot is defined between the arm member and the base engaging surface for exposing the wall member.

Owner:NELSON GARY W

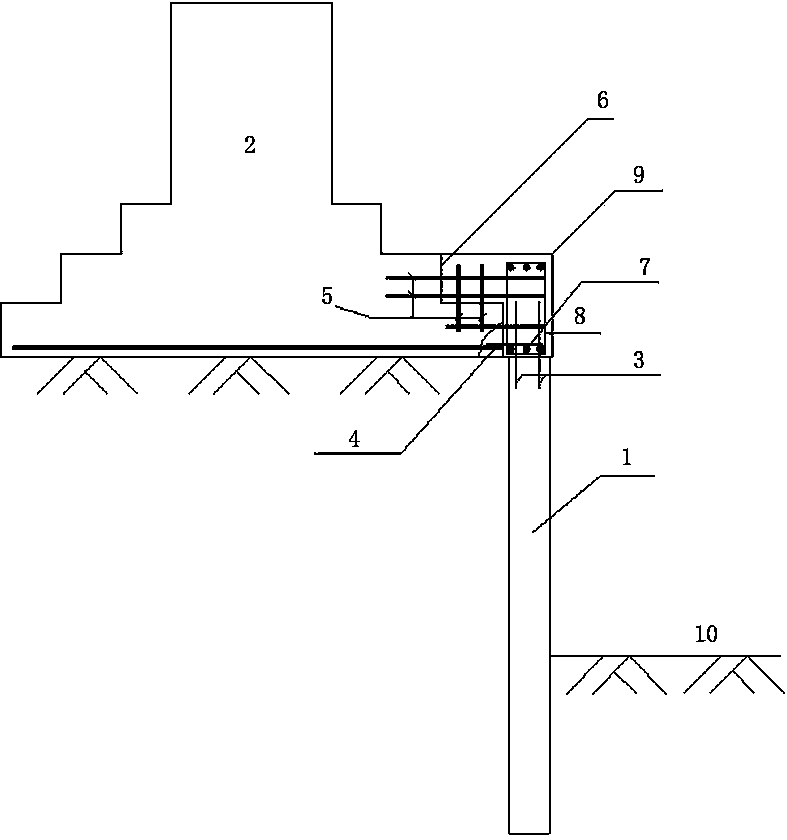

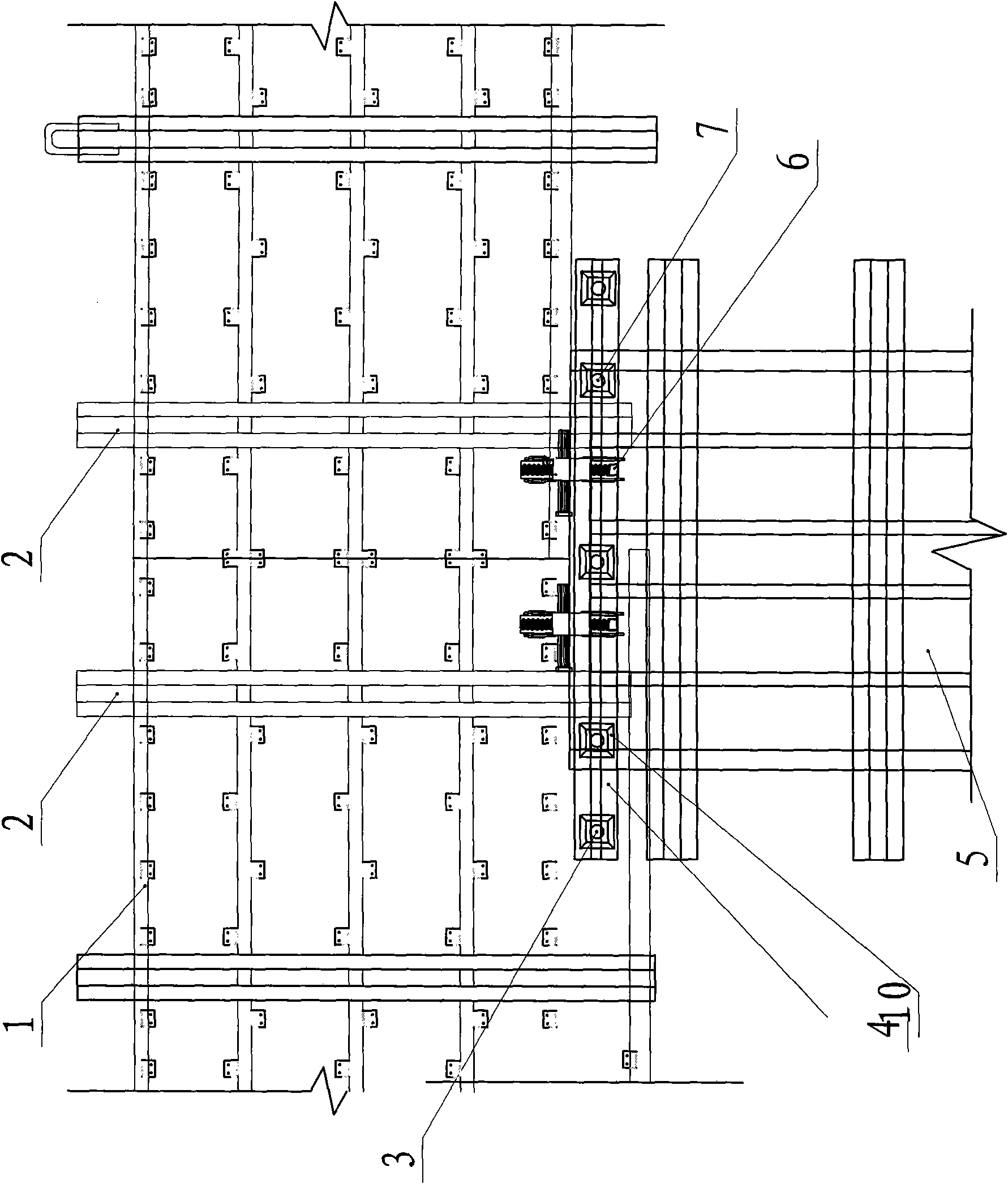

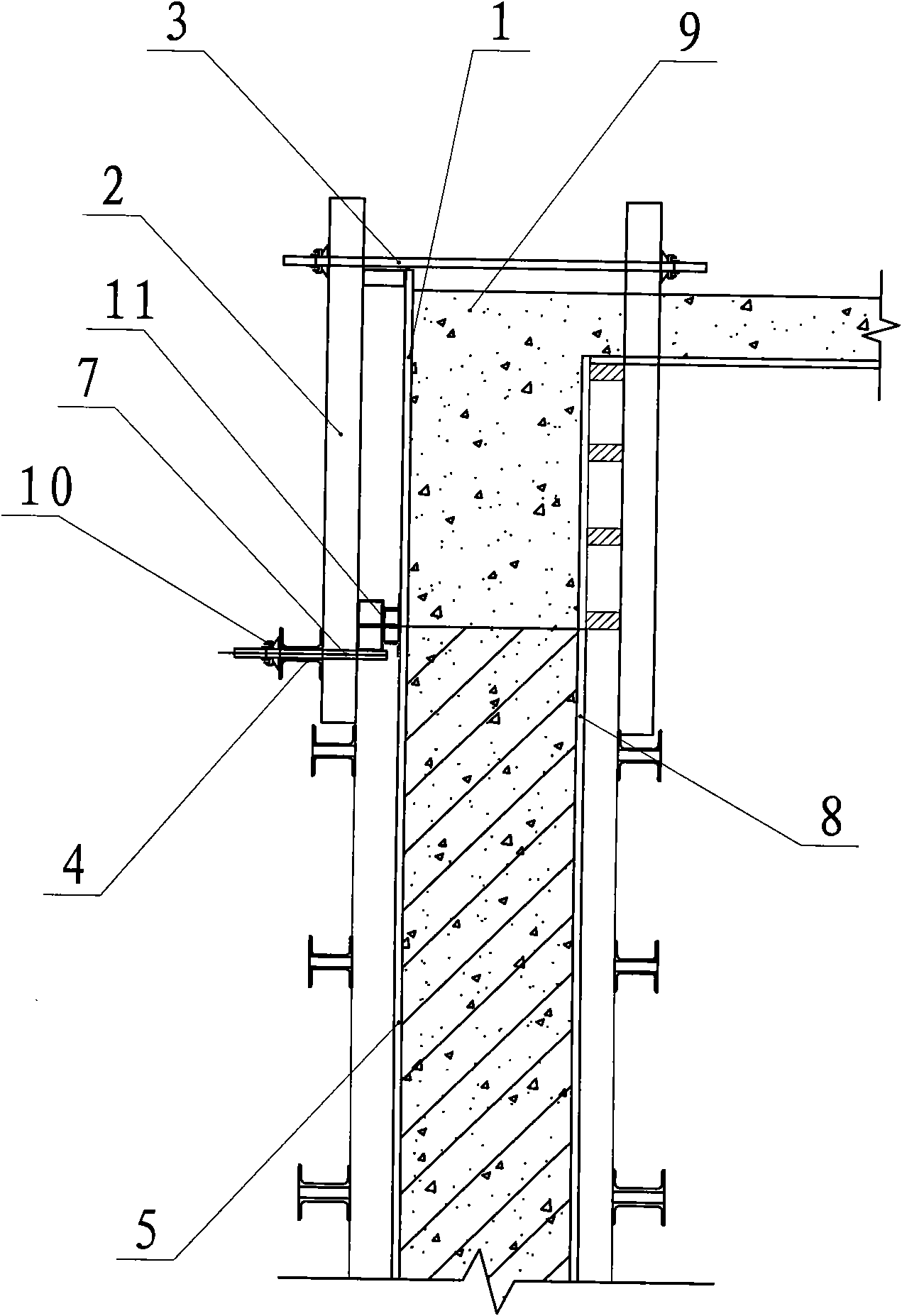

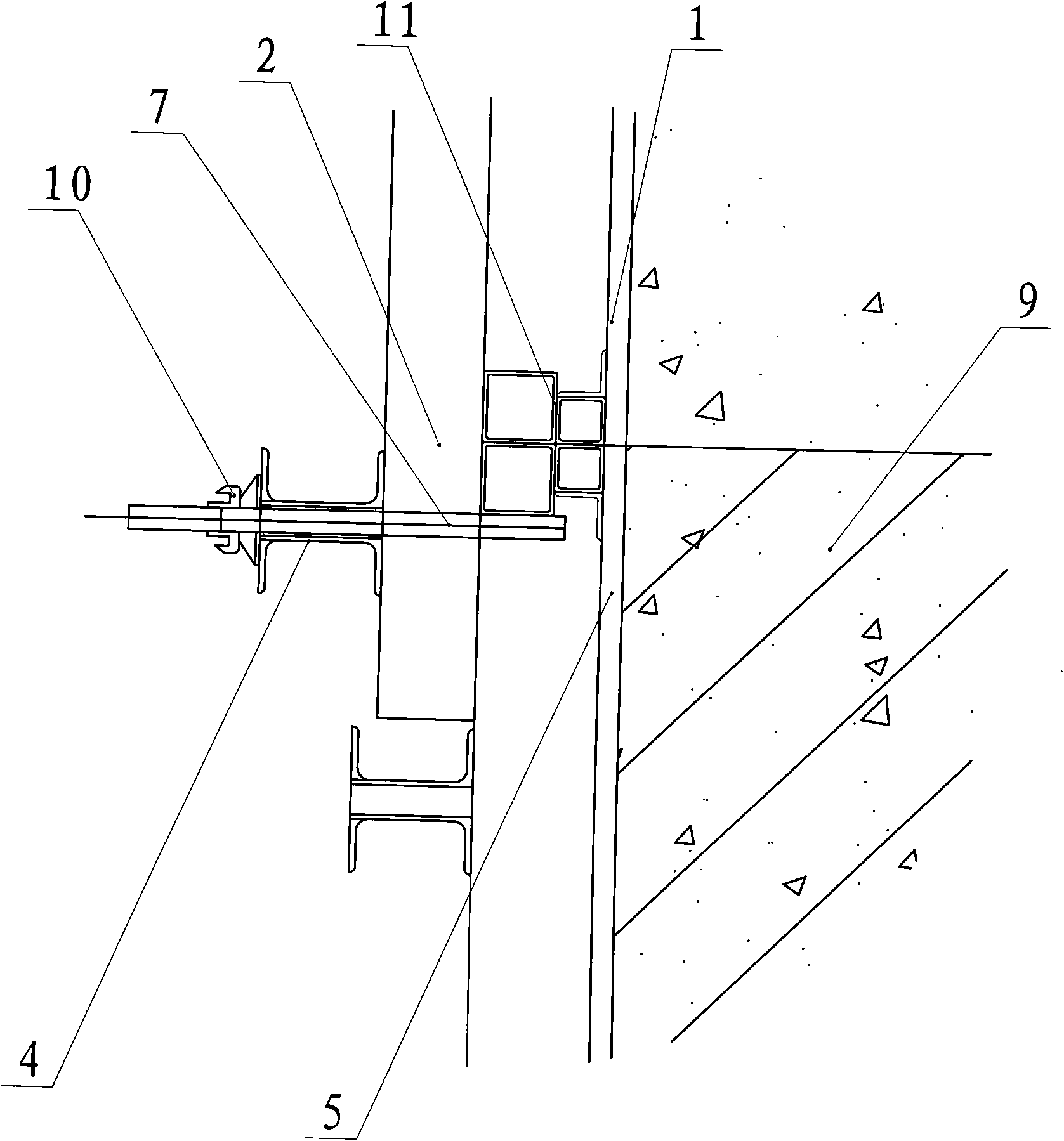

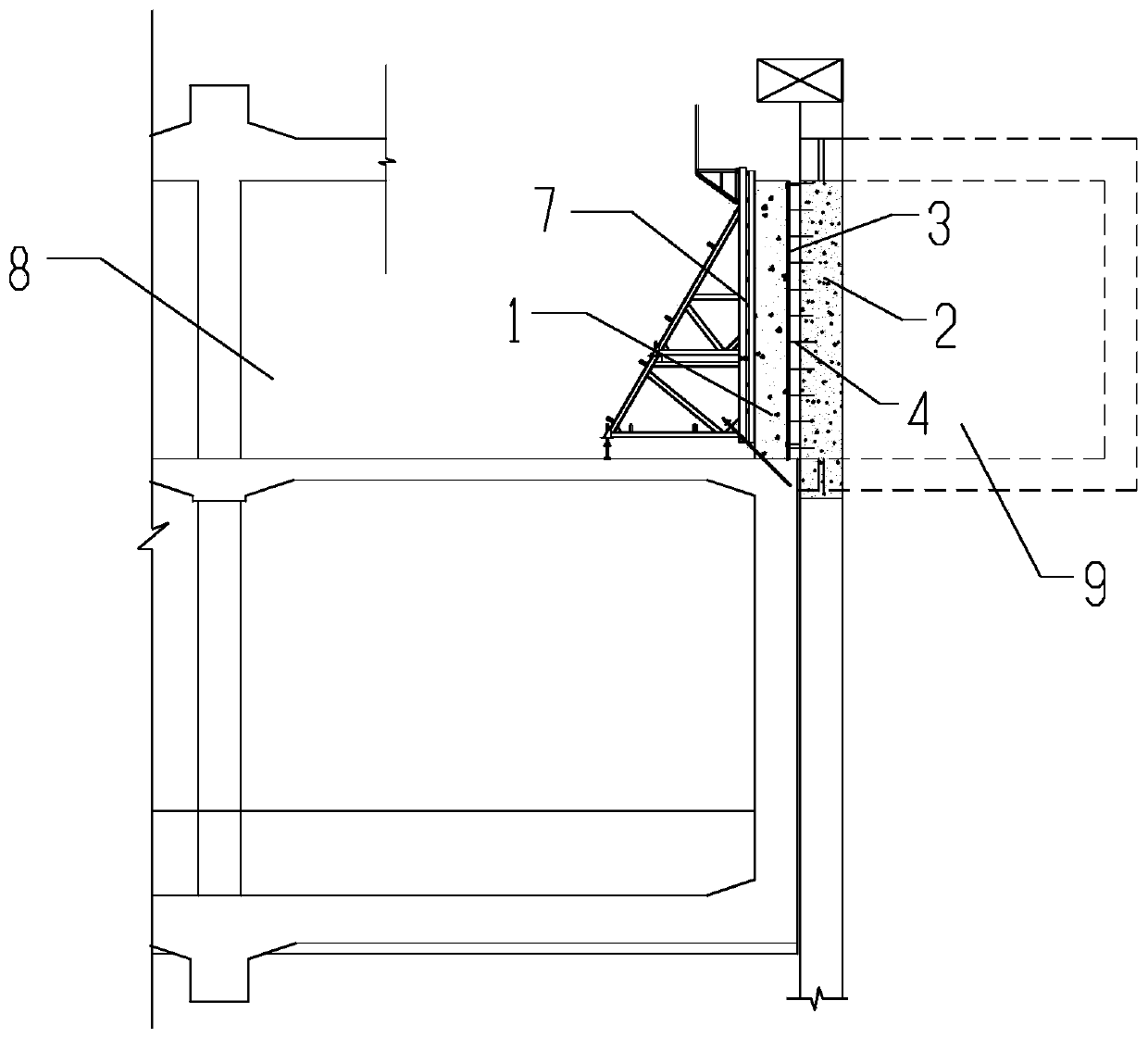

Fair-faced concrete structure beam and column joint formwork reinforcement system

ActiveCN102003067AAvoid vertical displacementAvoid horizontal displacementForms/shuttering/falseworksBeam columnBuilding construction

The invention discloses a fair-faced concrete structure beam and column joint formwork reinforcement system, which comprises a column formwork and a beam formwork. The backs of the column formwork and the beam formwork are provided with back dorsal ribs. The fair-faced concrete structure beam and column joint formwork reinforcement system is characterized in that: frameworks mutually matched are arranged on the back of a joint edge of the column formwork and the beam formwork; the frameworks of the column formwork and the beam formwork are clamped through a fixture for seaming; the dorsal ribs of the column formwork are vertical dorsal ribs; at least two dorsal ribs of the beam formwork above the column formwork extend the lower end heads to the back of the column framework, and horizontal pressure levers are pressed outside the dorsal ribs; the framework of the column formwork is welded with a plurality of lead screws vertical to a main formwork; and the lead screws extend out of the pressure levers and the end parts of the lead screws are provided with nuts. The fair-faced concrete structure beam and column joint formwork reinforcement system is easy to operate, has low investment, can effectively ensure the flatness of a construction joint at a beam and column joint when the fair-faced concrete structure beam and column are simultaneously poured, and ensures the construction quality of the fair-faced concrete construction joint.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

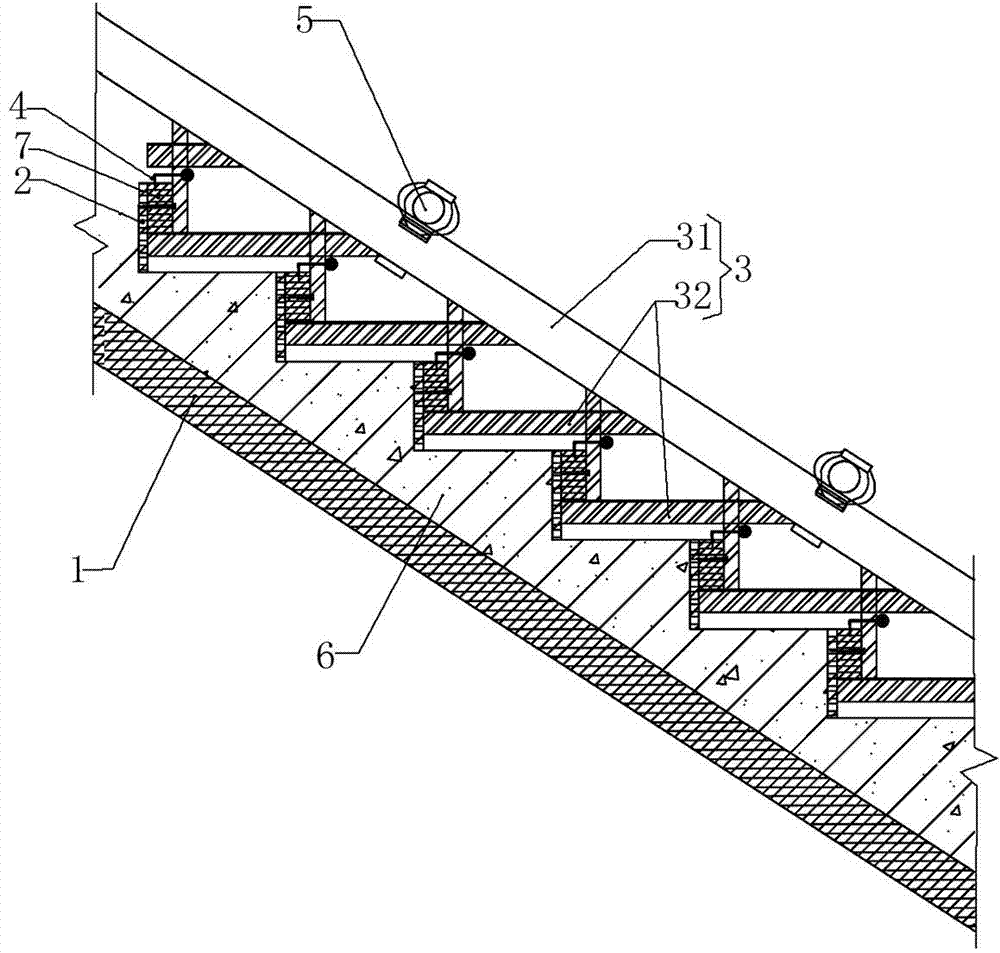

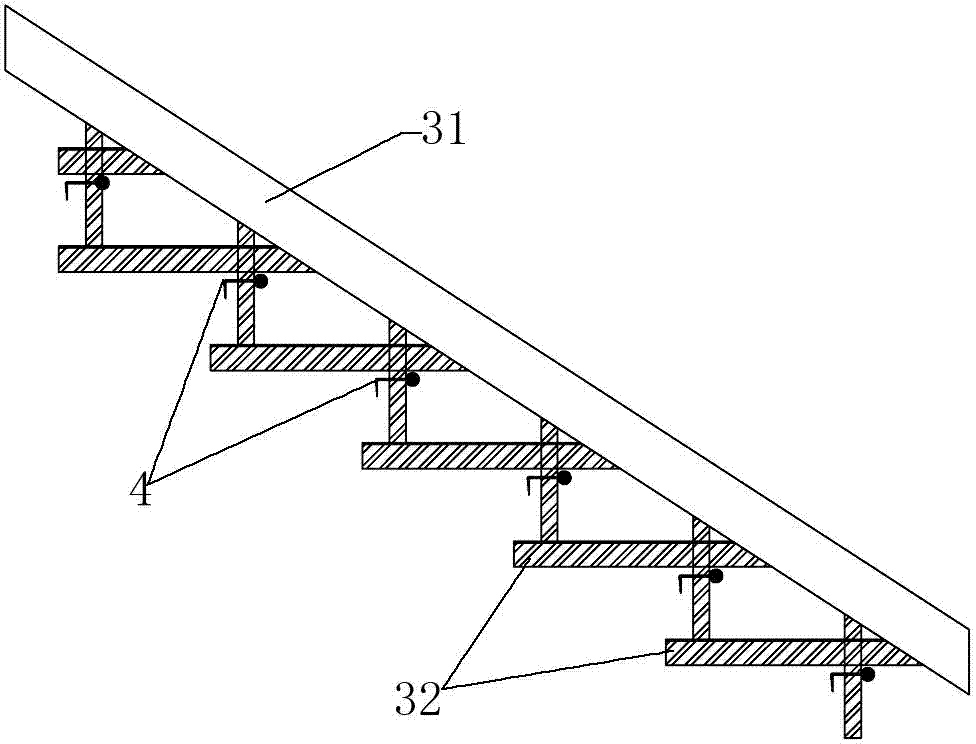

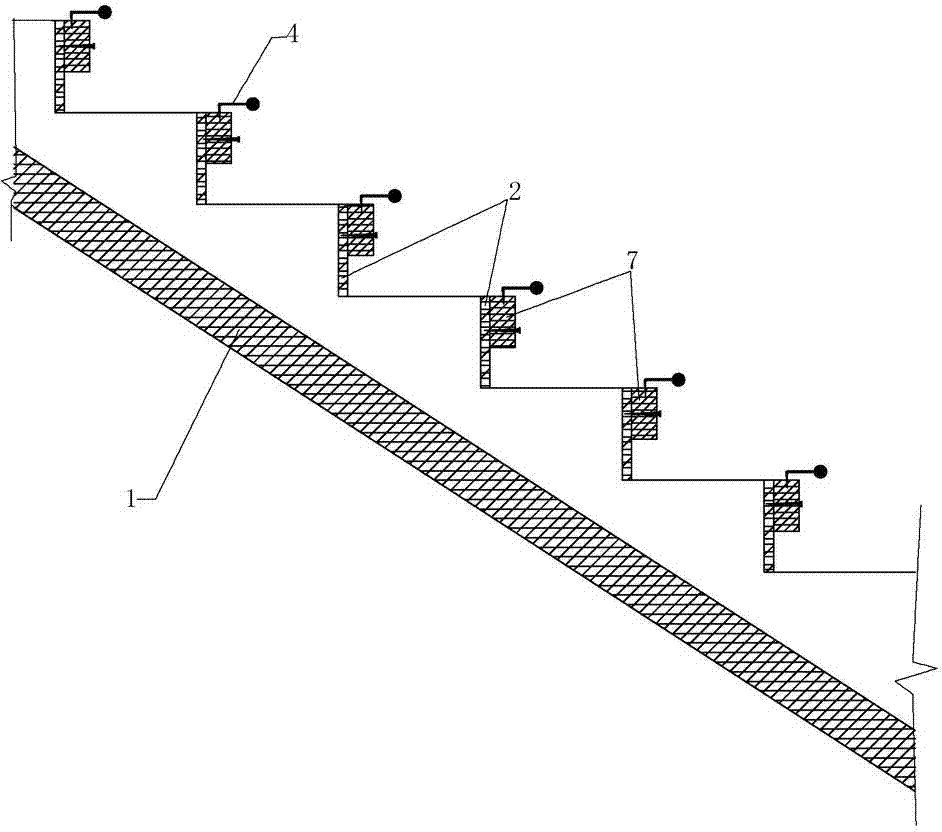

Forming-tool-type staircase formwork system and constructing method thereof

InactiveCN104120880AGuaranteed section sizeGuarantee molding qualityForms/shuttering/falseworksBuilding material handlingForming faceRear quarter

Disclosed are a forming-tool-type staircase formwork system and a constructing method thereof. A steel support is arranged between lateral formworks of the forming-tool-type staircase formwork system, and the steel support comprises two supporting frames and transverse main joist steel tubes for connecting the supporting frames. The supporting frames comprise longitudinal main joist steel tubes and angle steel supporting frame bodies on the bottom surfaces. The angle steel supporting frame bodies are arranged in the mode that the angle steel supporting frame bodies correspond to stepping lateral plates one to one, and vertical angle steel of the angle steel supporting frame bodies are connected with the stepping lateral plates through self-made connecting pieces. According to the forming-tool-type staircase formwork system, the axis of a staircase is located accurately, the geometric dimension of the staircase and the flatness of the forming face of the staircase are effectively controlled, the problems that in traditional construction, a stair formwork is prone to deflecting and the concrete forming quality is poor are solved, and the problems that in a fully-closed staircase formwork, concrete construction and vibration are inconvenient, many air bubbles exist on the surface after forming and the cost is high are also solved. The method is simple, construction is convenient, the quality is reliable, the cost is low and the method is suitable for formworks of high-rise building concrete-slab-type staircases.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

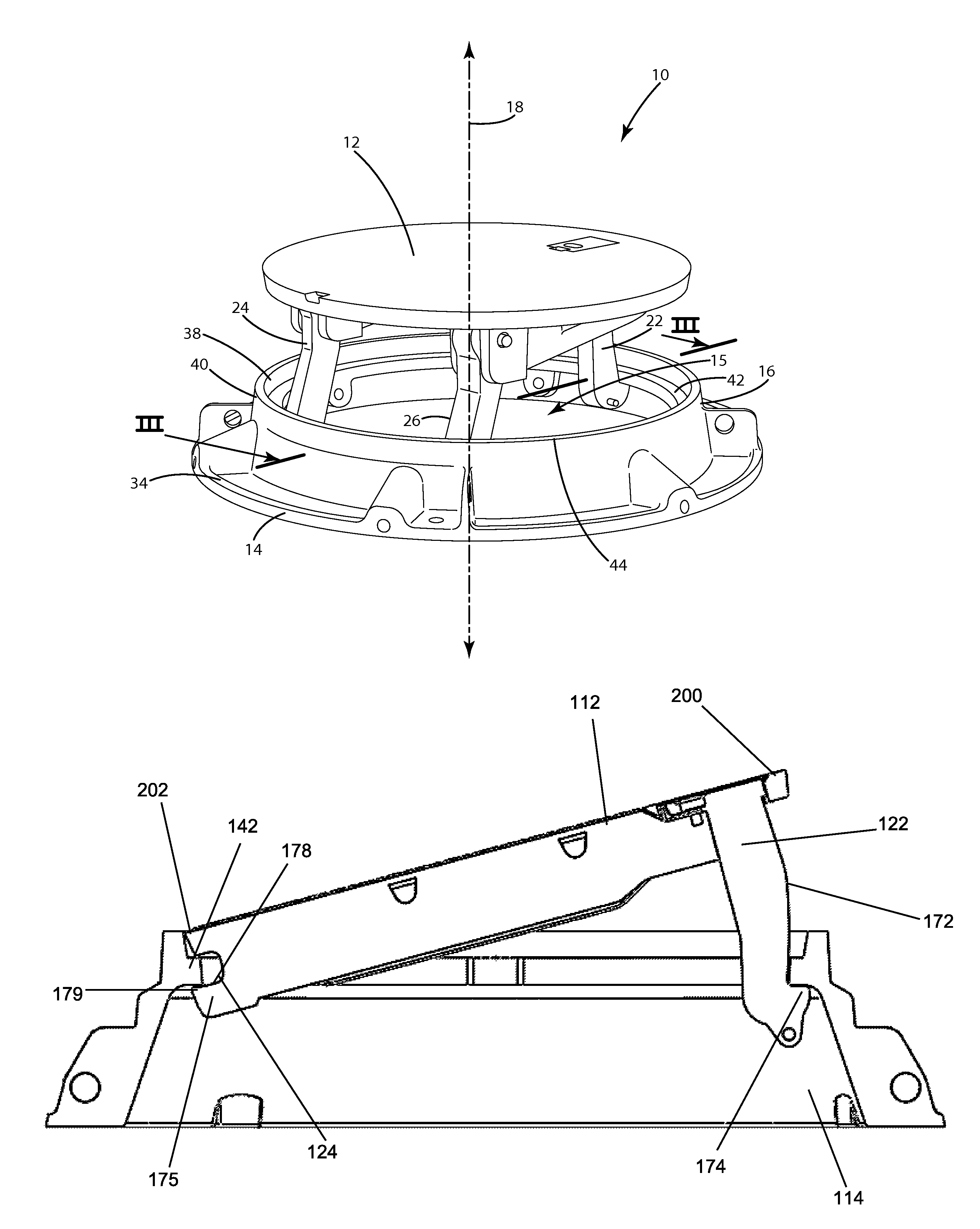

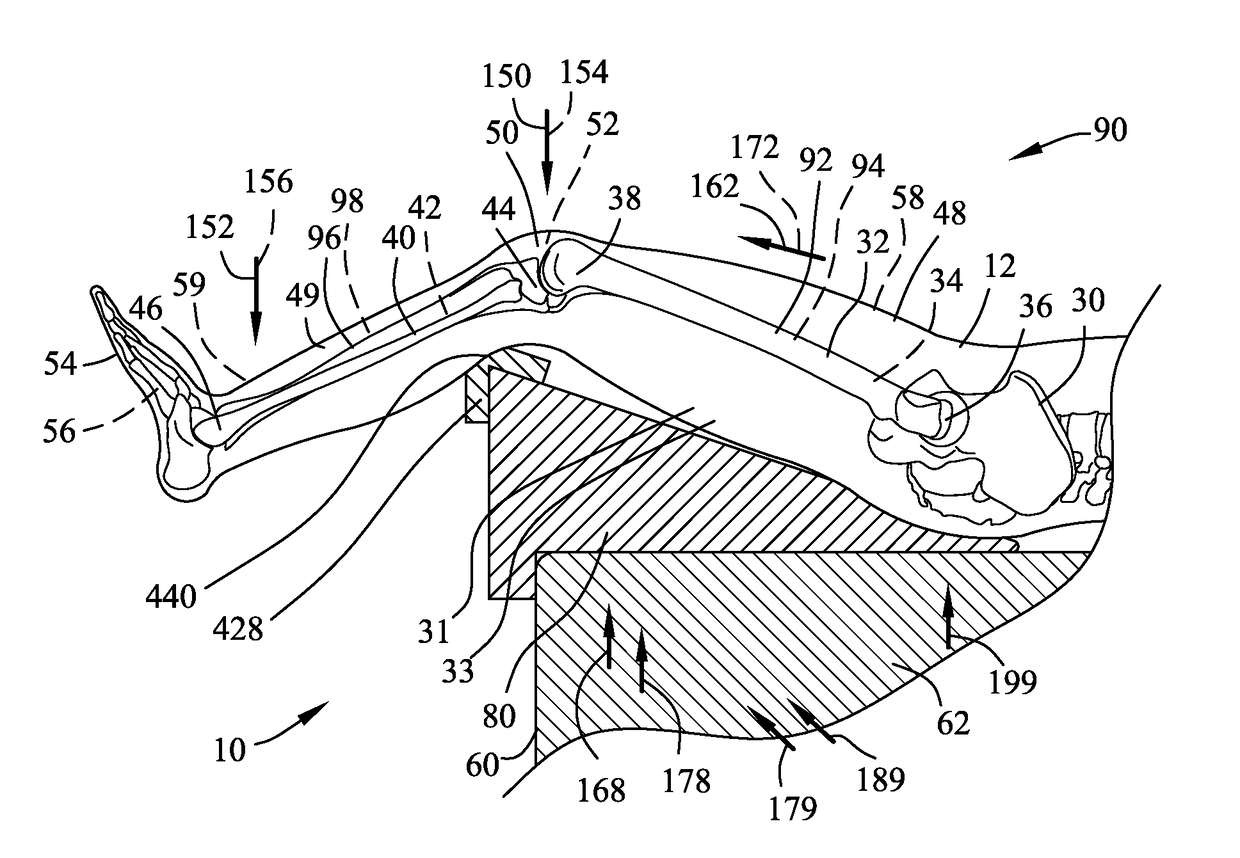

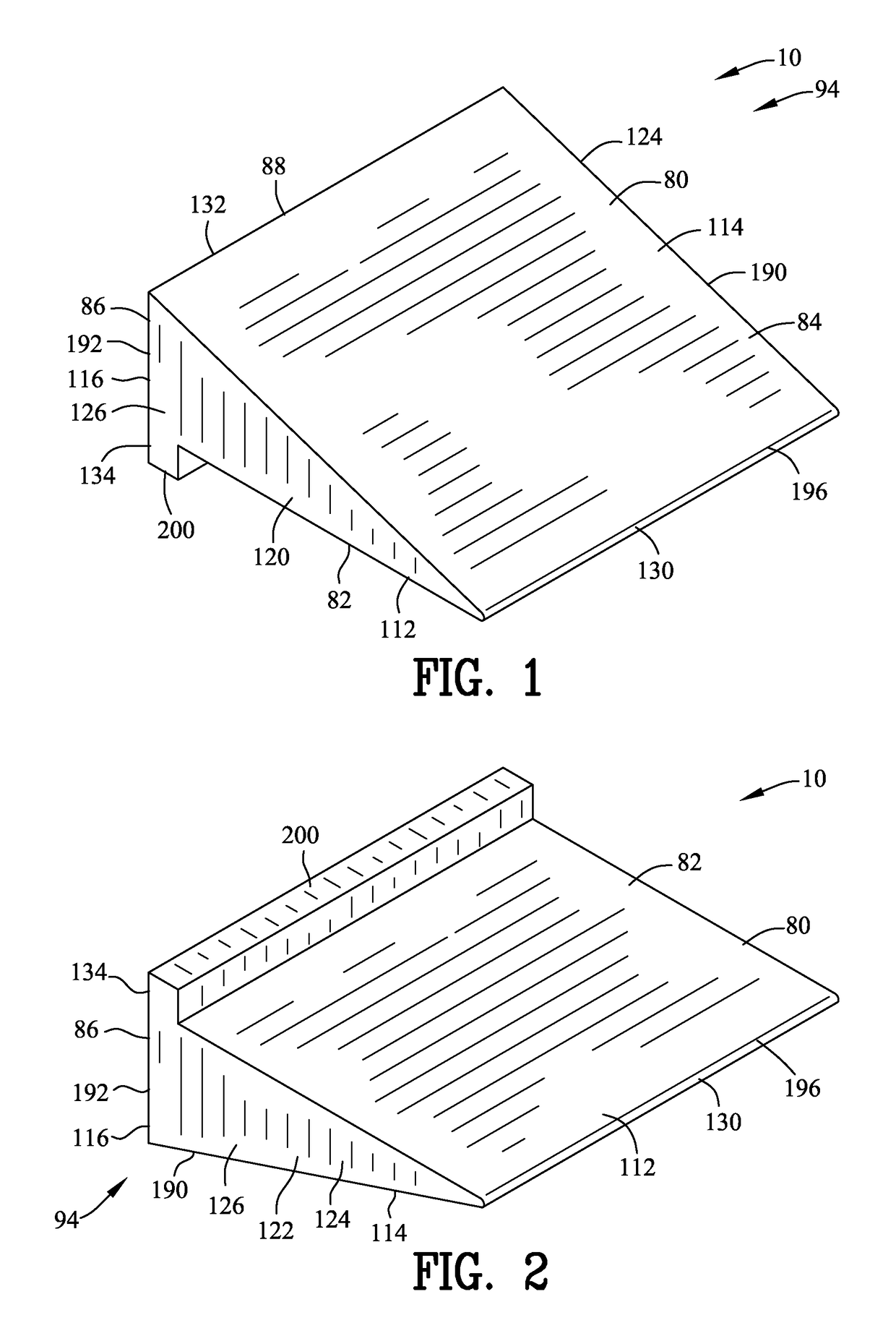

Vertebral column traction device and method

ActiveUS9717640B1Avoid horizontal displacementChiropractic devicesPatient positioning for diagnosticsFemurCantilever

A vertebral column traction device is disclosed for expanding the vertebral column of an individual. The vertebral column traction device comprises a support body having a front surface generally adjacent to a first femur and a second femur for creating a first inclined orientation and a second inclined orientation respectively. A rear surface of the support body is distanced from a first tibia and a second tibia for creating a first cantilever orientation and a second cantilever orientation respectively. A pivot area of the support body is generally adjacent to the first tibia and the second tibia for defining a first fulcrum and a second fulcrum respectively. A first lever and the second lever are defined about the first fulcrum and the second fulcrum respectively for expanding the vertebral column.

Owner:PLEASANTS DONALD A

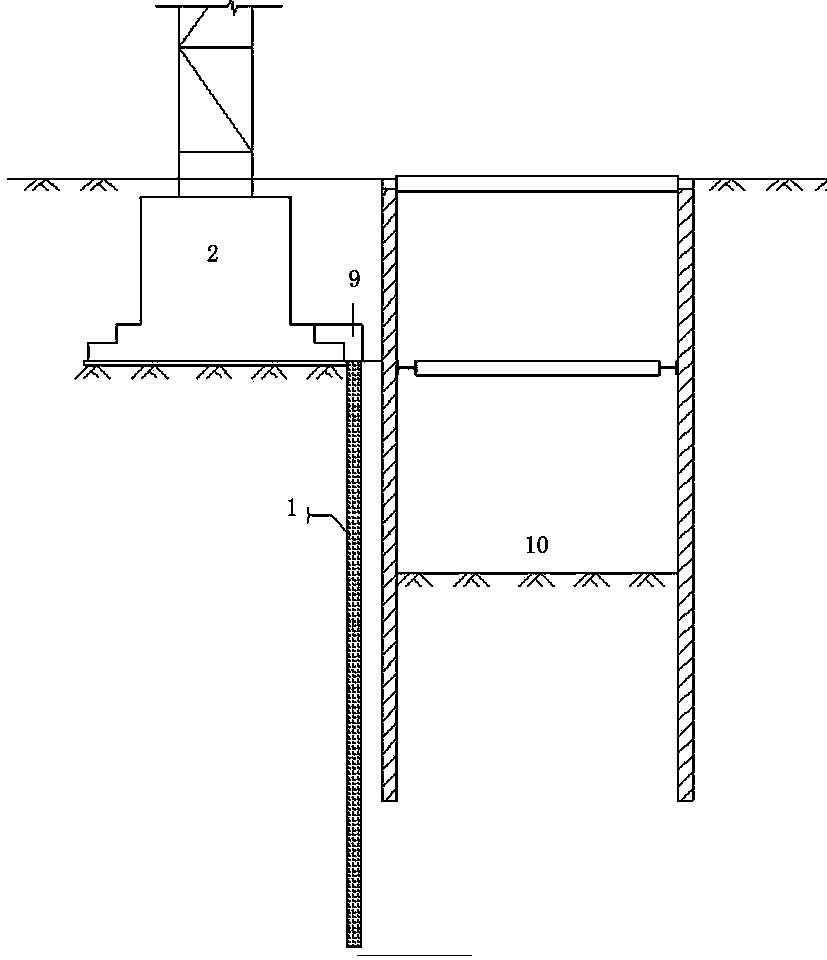

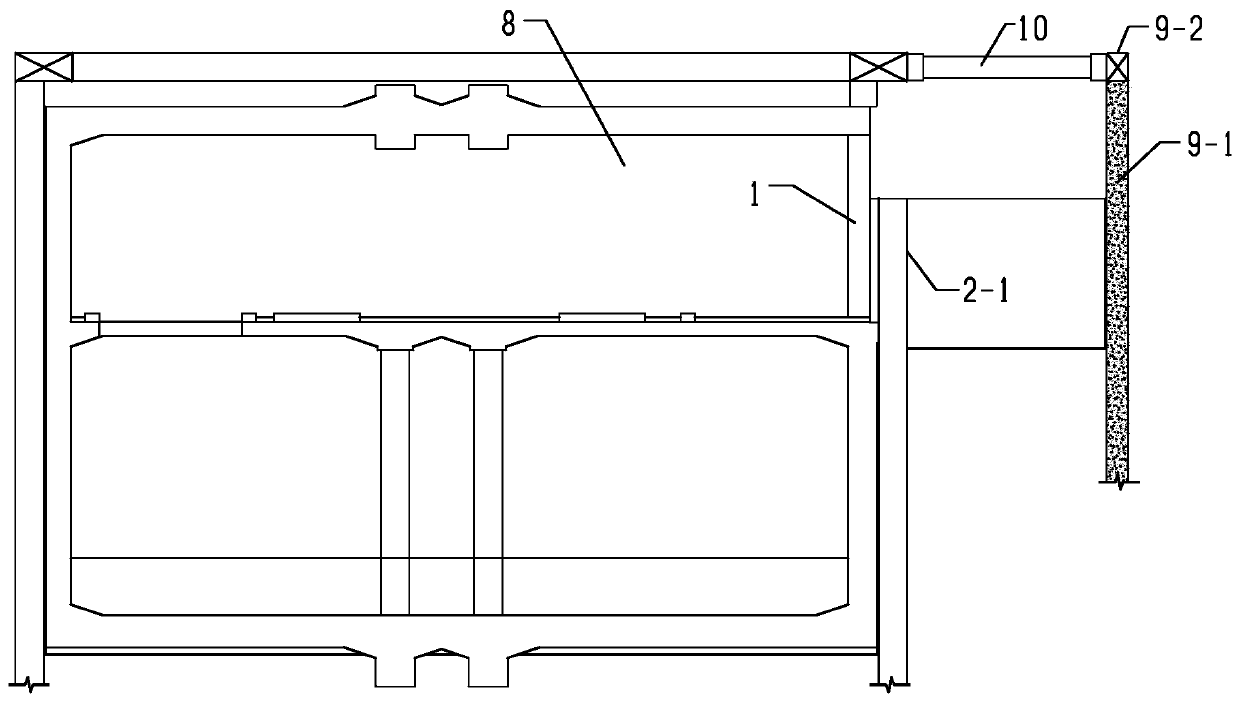

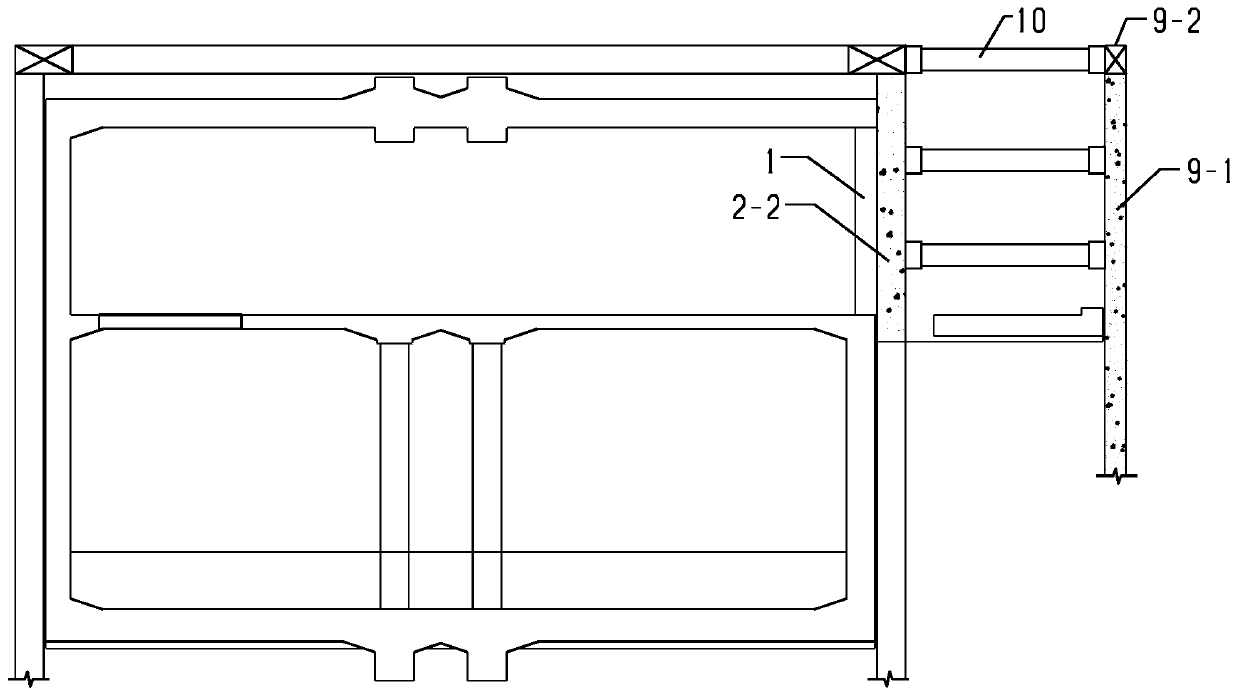

Construction method of air duct structure sharing side wall together with subway station

PendingCN110499779AReduce the amount of demolition worksVersatileArtificial islandsCellarsRebarInstability

The invention provides a construction method of an air duct structure sharing a side wall together with a subway station. The construction method of the air duct structure sharing the side wall together with the subway station specifically comprises the steps of firstly, adopting a mode of erecting templates on the two sides to construct the side wall shared by the air duct structure and the subway station; secondly, breaking station fender posts in a shared side wall area according to a mode of breaking one post every 2-4 posts; finishing excavation of earthwork and construction of an air duct bottom plate, wherein the air duct bottom plate is connected with a station middle plate through a fender post breaking area to form a temporary support; after a station main body structure is constructed, breaking the rest fender posts, and pouring micro-expansion concrete in the breaking area; and fixing the template on the air duct side of the shared side wall on a supporting net sheet by embedding a steel reinforcement anchor bolt in the station building envelope and welding the supporting net sheet on the exposed end of the steel reinforcement anchor bolt. The construction method of theair duct structure sharing the side wall together with the subway station can be widely used for construction of the air duct structure when the station and an air duct share the side wall; the apparent mass of concrete of a shared side wall cast-in-place structure is guaranteed; and the occurrence of foundation pit instability accidents is avoided.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

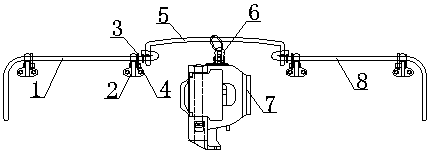

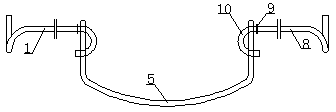

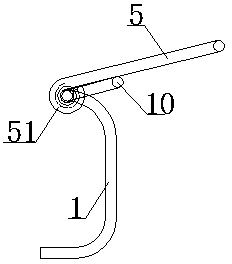

Novel locomotive upper action car coupler opening device

InactiveCN104176084AAvoid horizontal displacementCompact structureRailway coupling accessoriesDiesel locomotiveIndustrial engineering

The invention relates to the technical field of diesel locomotives, in particular to a novel locomotive upper action car coupler opening device. The novel locomotive upper action car coupler opening device comprises a car coupler, a coupler pin chain, lifting rod seats, a left lifting rod, a middle lifting rod and a right lifting rod. The coupler pin chain is inserted into the car coupler, the middle lifting rod is arranged in the coupler pin chain in a penetrating mode, and the left lifting rod and the right lifting rod are installed on the lifting rod seats and connected to the two ends of the middle lifting rod respectively. The left lifting rod, the middle lifting rod and the right lifting rod are designed to be parts which are independent. The split car coupler lifting rods are compact in structure, small in occupied area and capable of being installed in narrow space, the left lifting rod and the right lifting rod are rotated to transmit force to the middle lifting rod according to the lever principle, the car coupler is opened through the coupler pin chain, the opening stroke is short, operation is flexible, and use is convenient.

Owner:CRRC QISHUYAN CO LTD

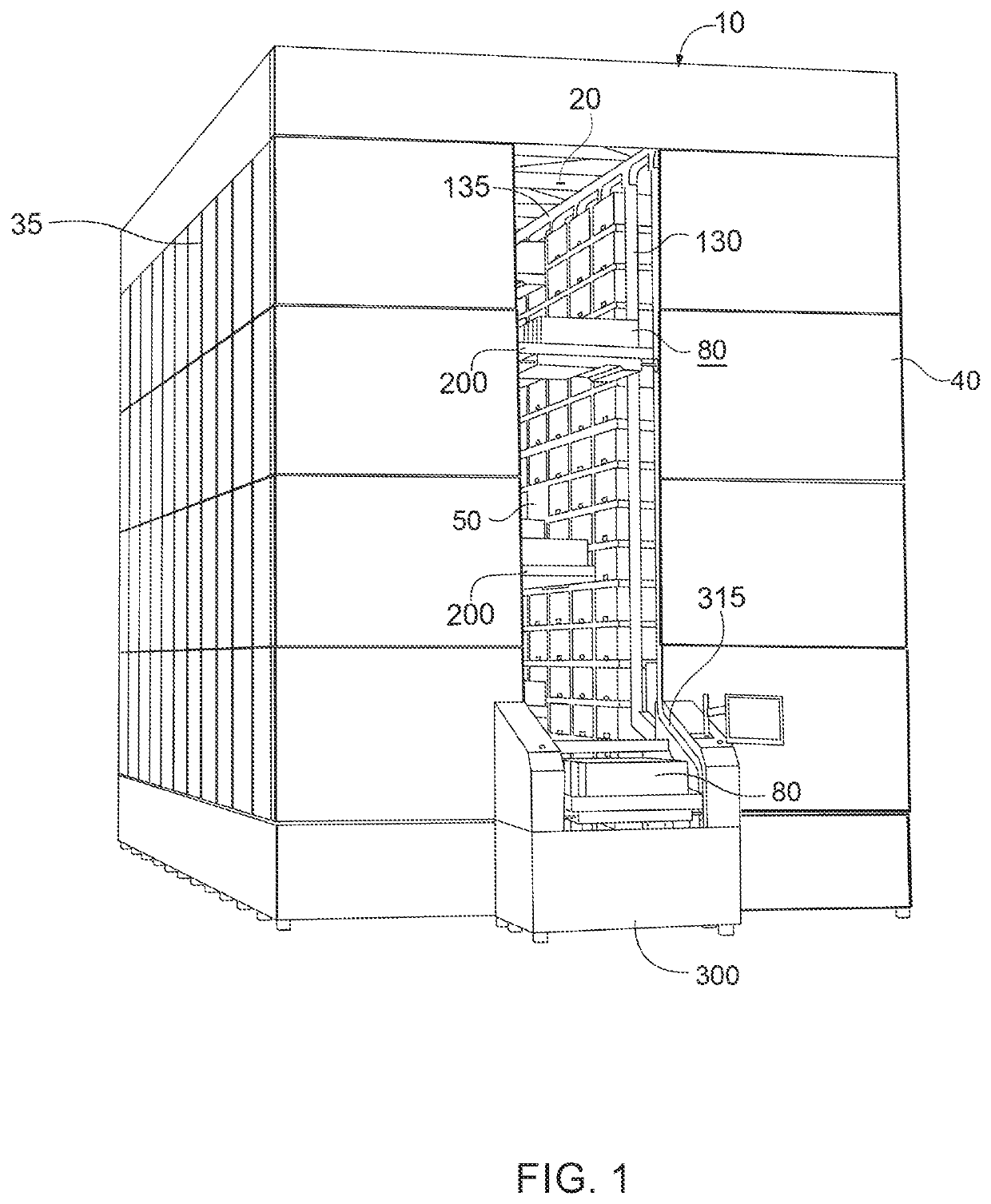

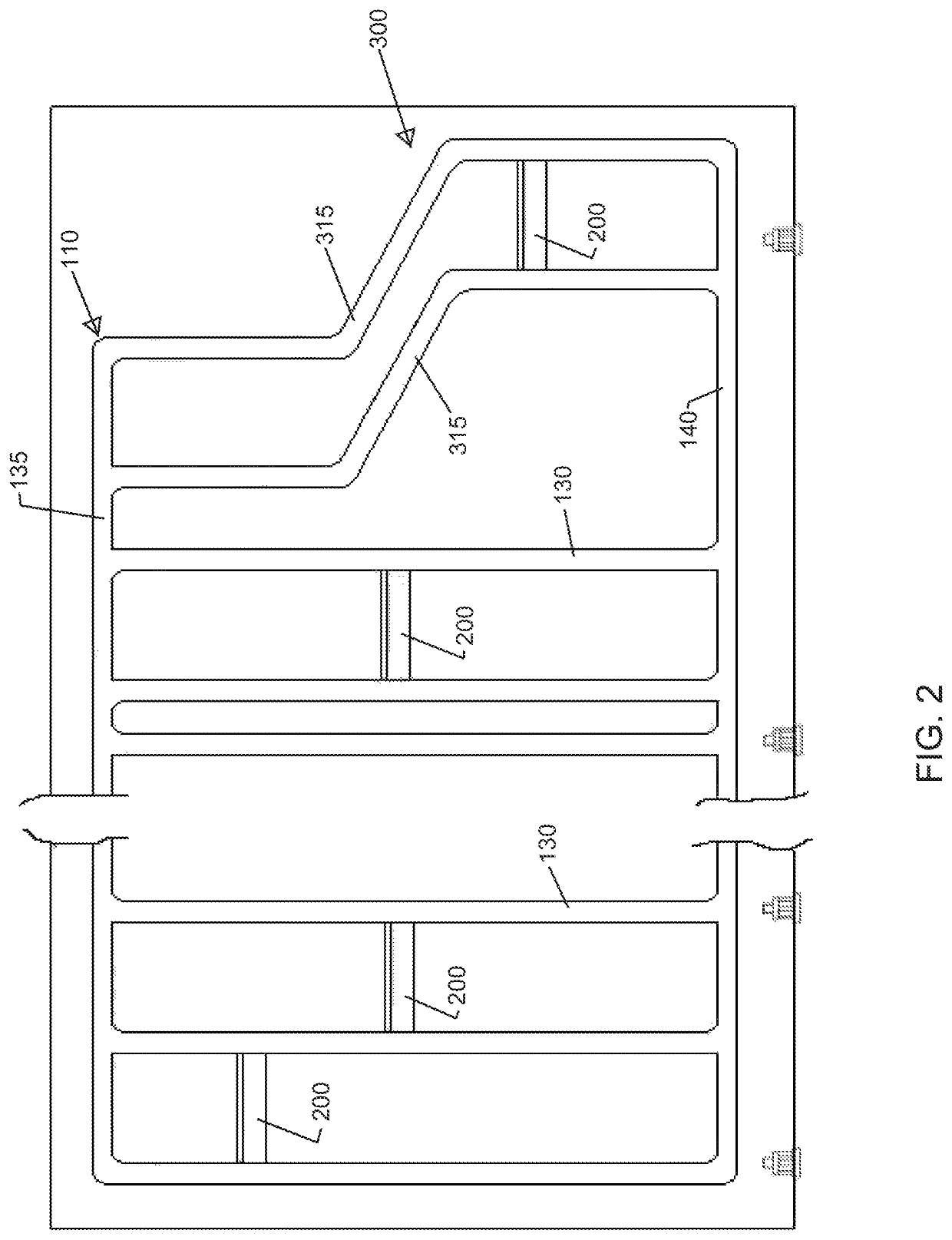

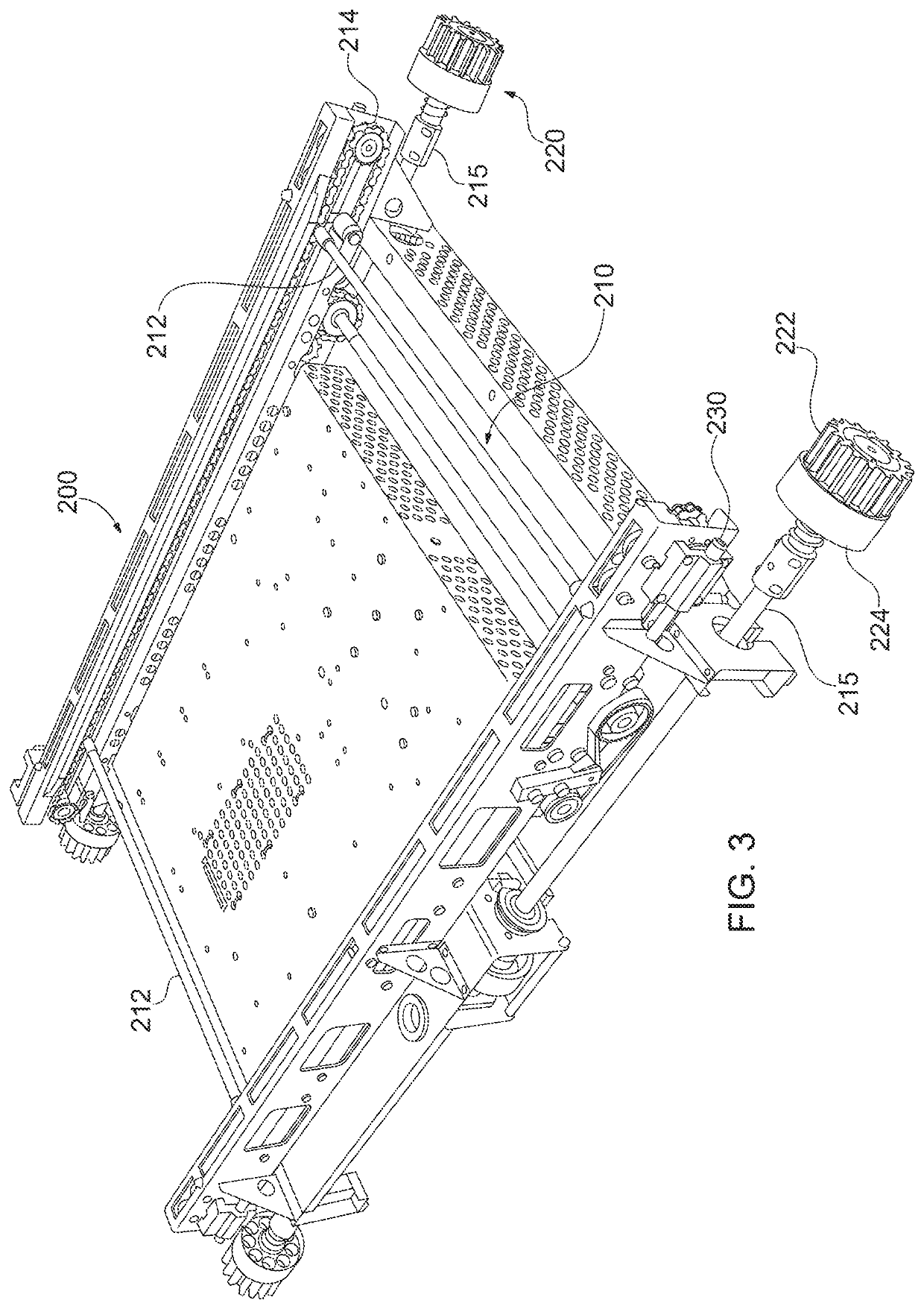

Automated storage and retrieval system

ActiveUS10940998B2Avoid horizontal displacementConveyorsDigital data processing detailsDelivery vehicleDatabase

A method and apparatus are provided for storing or retrieving items to / from a plurality of destinations areas. The items are loaded onto one of a plurality of independently controlled delivery vehicles. The delivery vehicles follow a path to / from the destination areas that are positioned along the path. The destination areas are configured such that the destination areas have a depth to accommodate a plurality of containers in a horizontal line one behind another. The containers may be releasable interconnected so that retrieving one of the interconnected containers displaces one or more connected containers.

Owner:OPEX

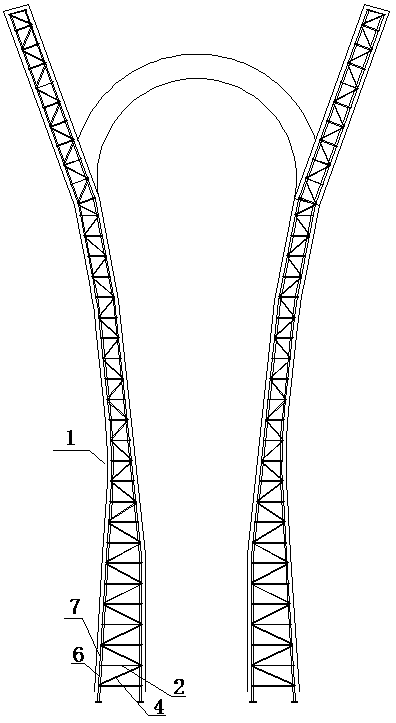

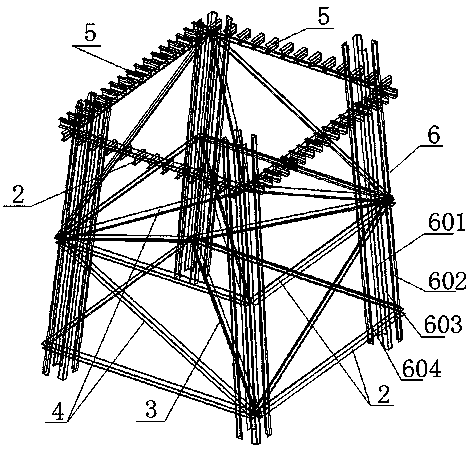

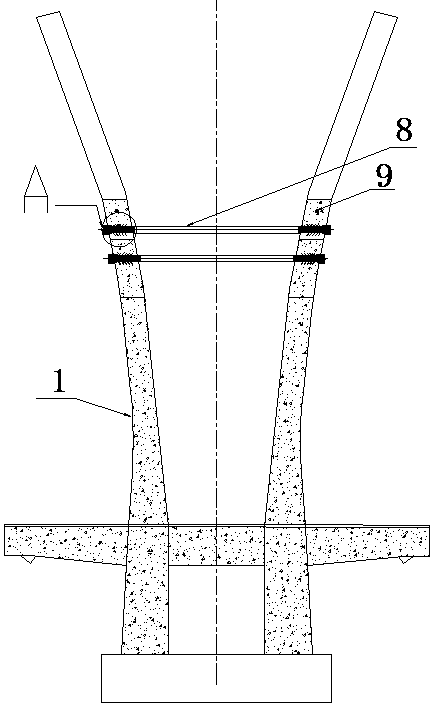

Camellia nitidissima type structure main tower construction method

ActiveCN110983984AAvoid horizontal displacementEnsure safetyBridge structural detailsBridge erection/assemblyArchitectural engineeringSteel frame

The invention provides a camellia nitidissima type structure main tower construction method which comprises the following steps: correspondingly dividing each tower column into a plurality of tower body sections, tower arch sections and closure sections according to a three-dimensional model, and calculating and processing a template and a framework of each section; pouring the tower body sections, and for the tower body sections which incline outwards by more than or equal to 5 degrees in the transverse bridge direction and the longitudinal bridge direction, mounting a tower body longitudinaltensioning device between every two tower bodies, and mounting tower body transverse tensioning devices in the tower bodies so as to ensure the line type control of the tower bodies; pouring the tower arch sections and the closure sections; installing a tower arch longitudinal restraining device between every two tower arches; and installing and tensioning stay cables, and dismantling the tower body longitudinal tensioning devices, the tower body transverse tensioning devices, the tower arch longitudinal restraining devices and a supporting steel frame after tensioning is completed. By meansof the method, it is guaranteed that the line type of the main tower meets the design requirement, and the stability of the main tower structure can be guaranteed in the construction process.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com