Camellia nitidissima type structure main tower construction method

A construction method, golden camellia technology, applied to bridge parts, erecting/assembling bridges, bridges, etc., can solve problems such as structural deviation, deformation, and numerous construction procedures in the design of the main tower structure, so as to overcome horizontal displacement, ensure safety, The effect of ensuring overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following examples.

[0057] A construction method for a golden camellia type structure main tower, comprising the following steps:

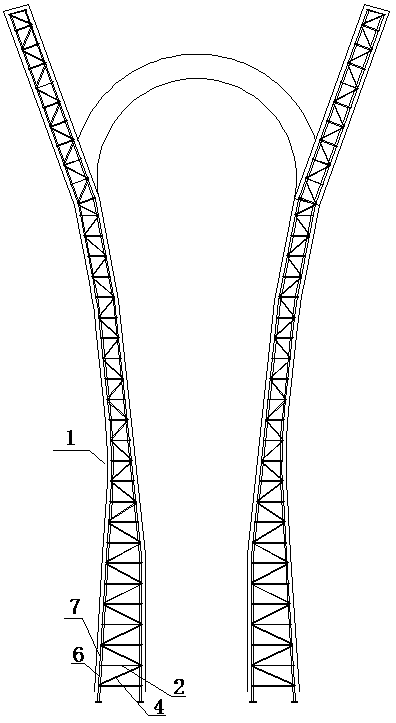

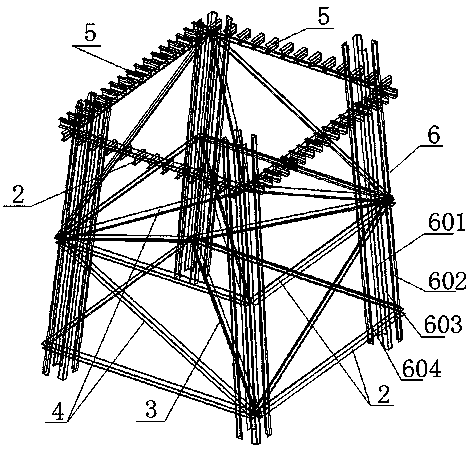

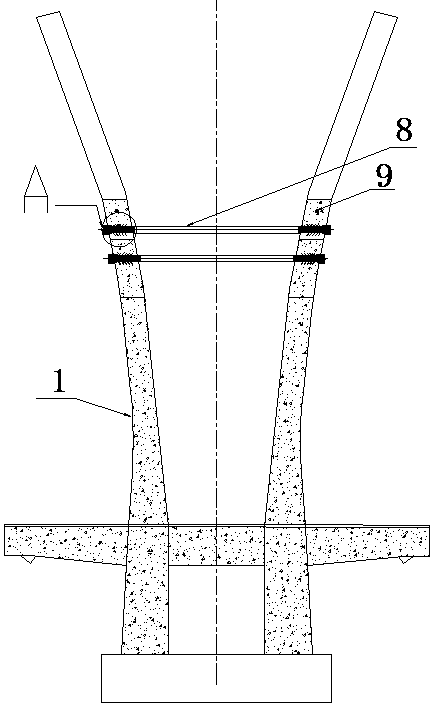

[0058] S1. Establish a three-dimensional model according to the coordinates of the main tower of the Camellia-style structure given by the design. The main tower of the Camellia-style structure includes two symmetrically designed petal-shaped tower columns 1, such as figure 1 As shown, each column 1 is correspondingly divided into H 1 、H 2 ......H N Tower segment, T 1 , T 2 ...T M Each tower arch section and closing section will divide the section of each section to export the section drawing, determine the position of each section formwork and reinforcement, calculate the size of each section formwork and skeleton, and process the formwork of each section and skeleton; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com