Assembled prestressed construction waste recycled aggregate road and construction method thereof

A technology of construction waste and recycled aggregates, applied in roads, roads, buildings, etc., can solve problems such as the impact of rescue work, the pressure brought by traffic operation, and the difficulty of construction, so as to achieve sustainable development and prevent road accidents. The effect of arch damage and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

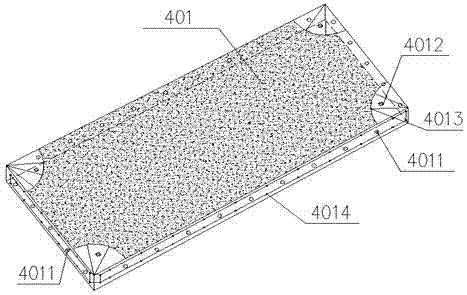

[0040] Example 1: A prefabricated multi-lane road with recycled aggregate from construction waste

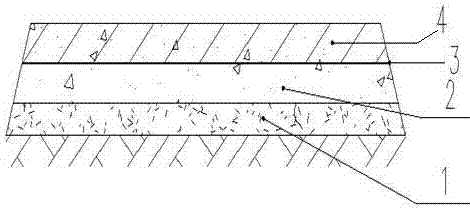

[0041] (1) According to the different geological conditions and environment of the construction site, adopt the corresponding roadbed construction method. Make the subgrade meet the design requirements; (see figure 1 )

[0042] (2) Pave construction waste regenerated fine aggregate on the roadbed as the cushion layer (1). The width of the cushion layer (1) is the same as that of the roadbed, and the designed thickness is 150 mm. The loose paving coefficient is determined through experiments during paving. . At the same time meet the urban road construction technology; (see figure 1 )

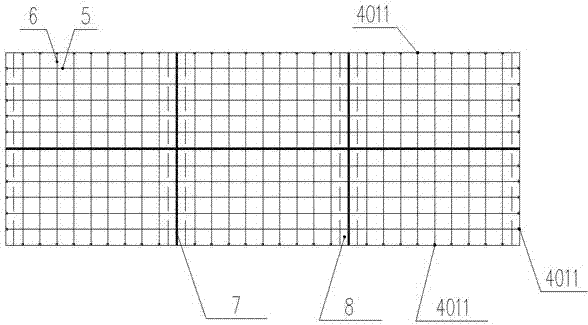

[0043] (3) Design a corbel (8) every 10000mm on the paved cushion (1). The height of the corbel (8) is the same thickness as that of the base (2), and the width is designed to be 1000mm, and the binding steel mesh is placed at its corresponding place. Simultaneously every 3 to 5 corbel beams...

Embodiment 2

[0056] Example 2: An assembled prestressed construction waste recycled aggregate single-lane road

[0057] (1) According to the different geological conditions and environment of the construction site, adopt the corresponding subgrade construction method. Make the subgrade meet the design requirements; (see figure 1 )

[0058] (2) Pave construction waste regenerated fine aggregate on the roadbed as the cushion layer (1). The width of the cushion layer (1) is the same as that of the roadbed, and the designed thickness is 150mm. The loose paving coefficient is determined through experiments during paving. . At the same time meet the urban road construction technology; (see figure 1 )

[0059] (3) Design a corbel (8) every 10000mm on the paved cushion (1). The height of the corbel (8) is the same thickness as that of the base (2), and the width is designed to be 1000mm, and the binding steel mesh is placed at its corresponding place. Simultaneously every 3 to 5 corbel beams...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com