Patents

Literature

101results about How to "Increase ultimate bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

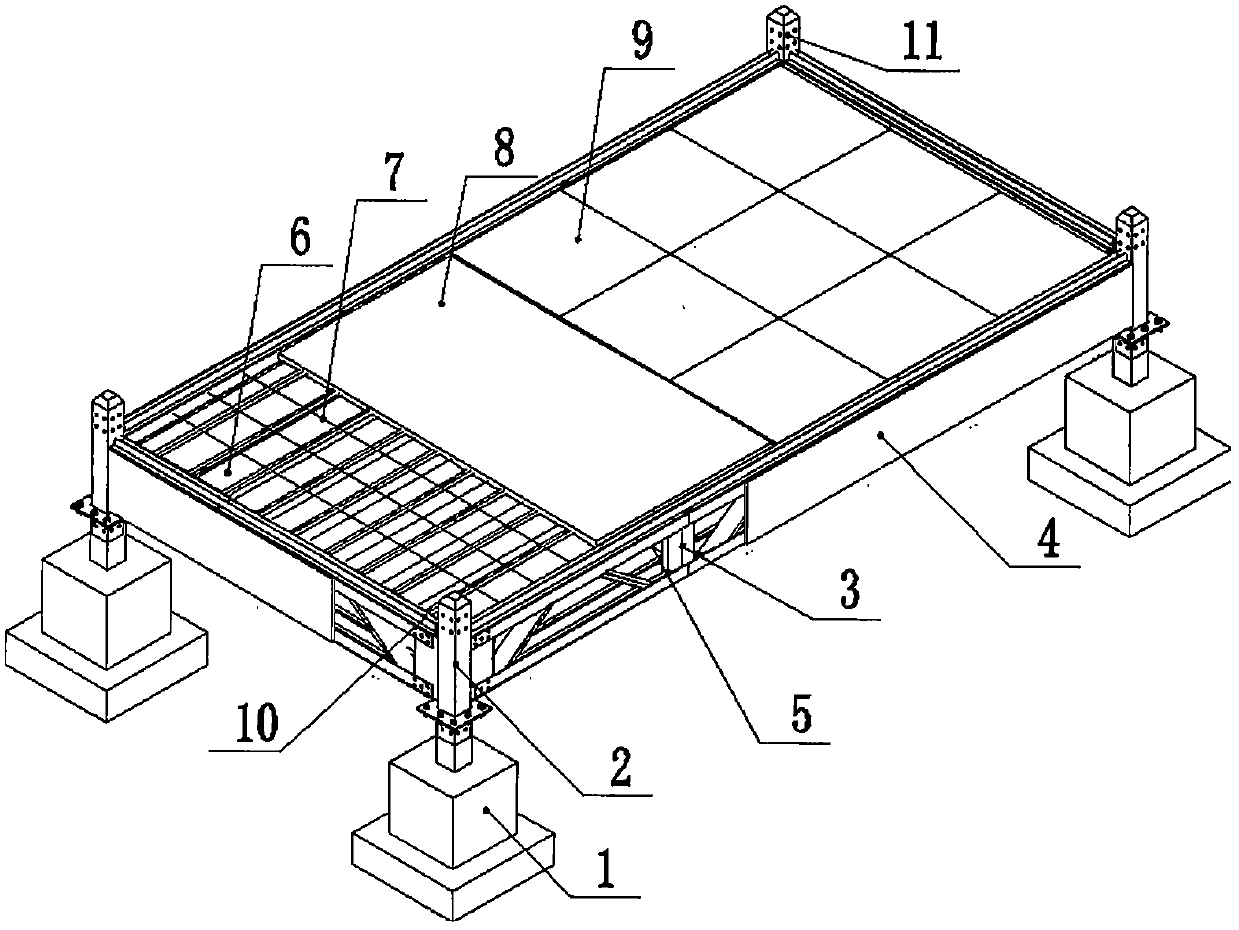

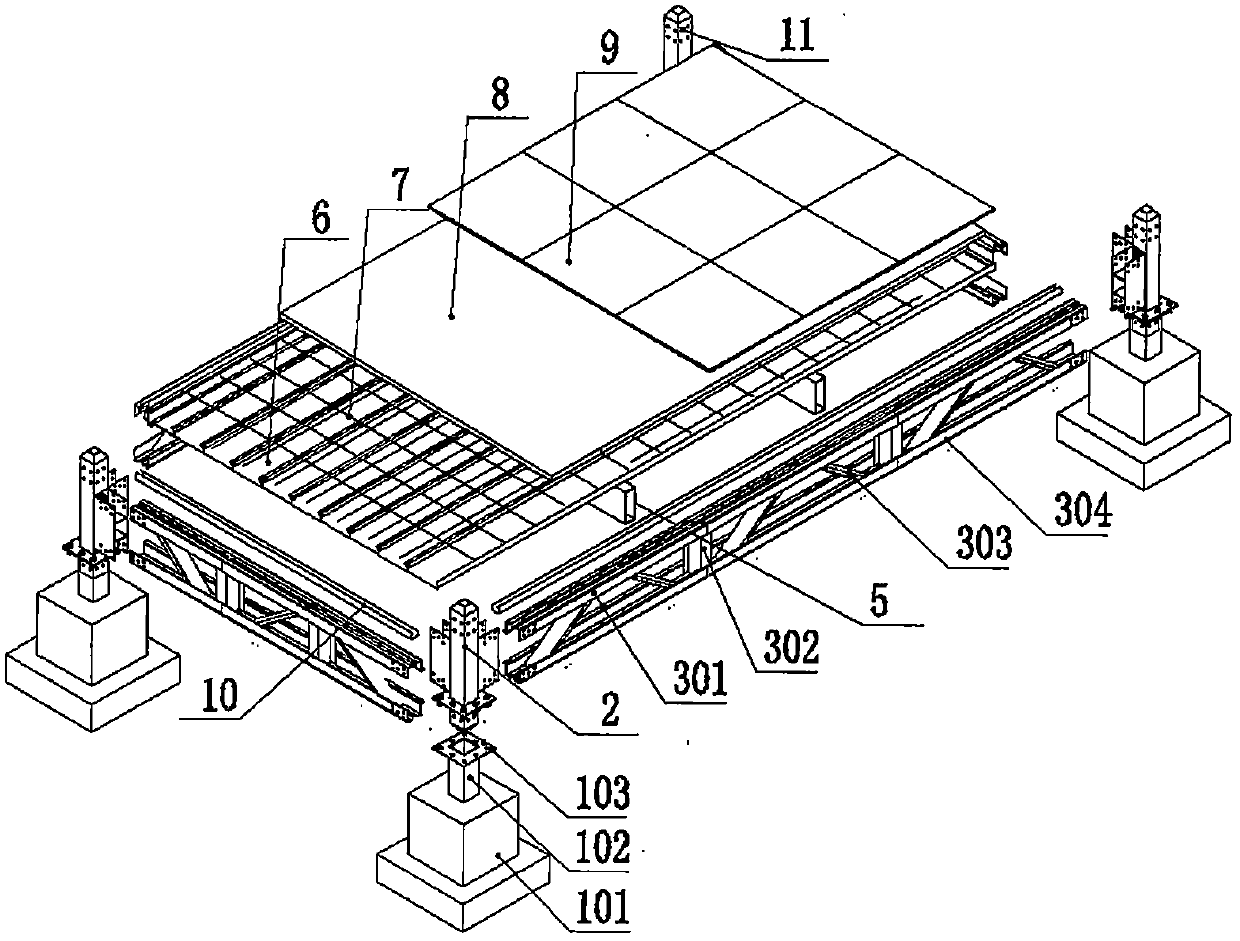

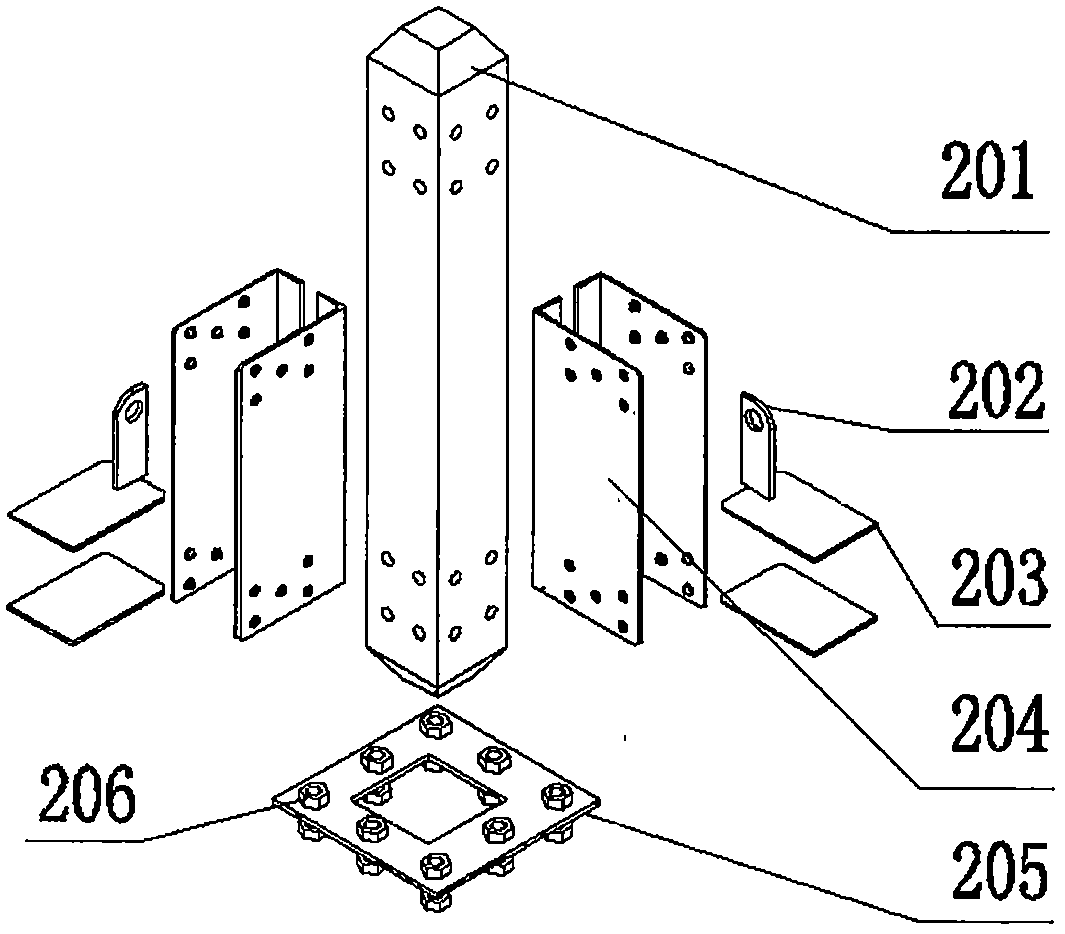

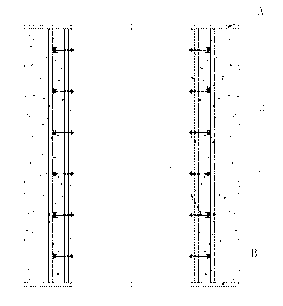

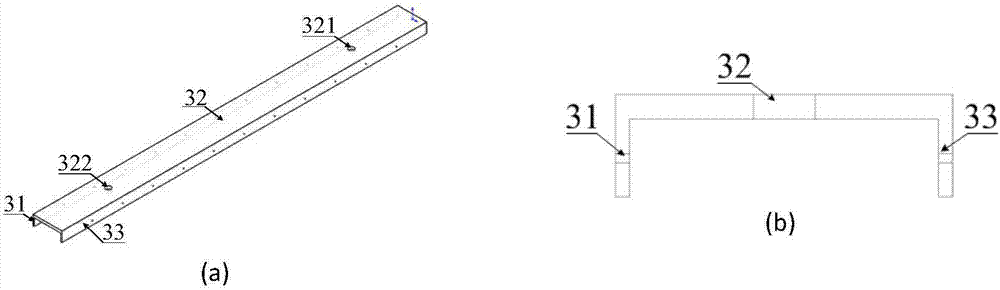

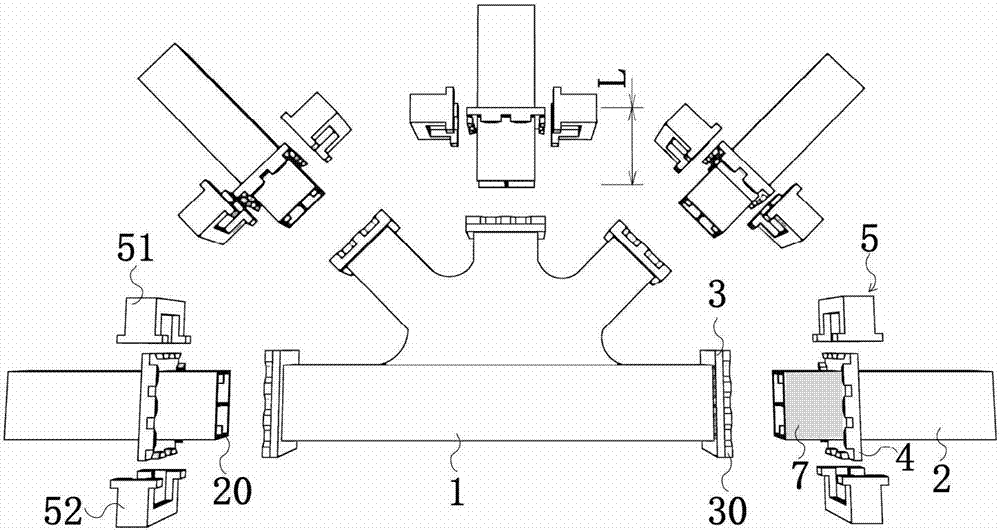

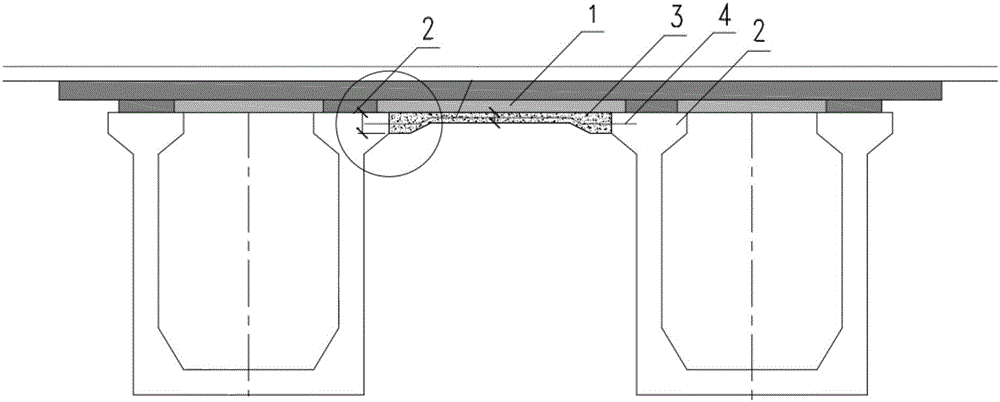

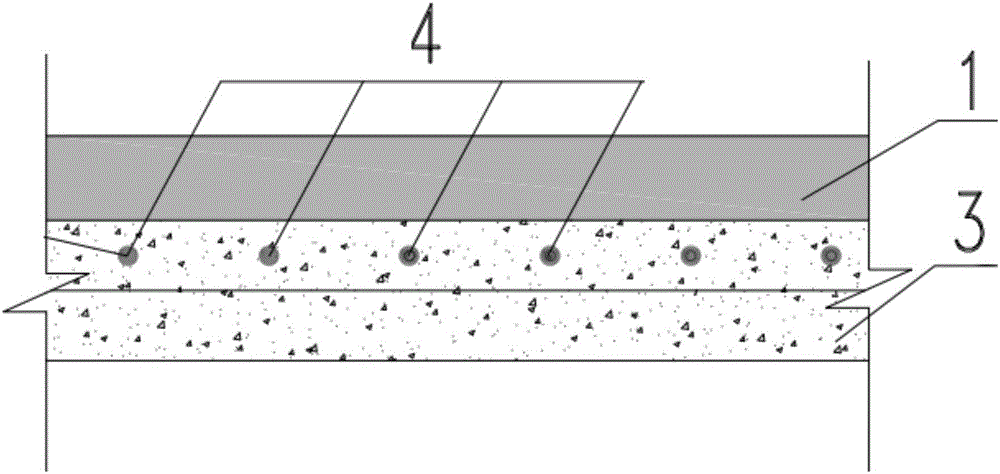

Assembly-type building bottom-layer composite floor and connection mode thereof

PendingCN107780576AImprove prefabrication rateReduce pollutionFloorsGirdersReinforced concreteMortise and tenon

Provided are an assembly-type building bottom-layer composite floor and a connection mode thereof. Factory-fabricated reinforced concrete with embedded parts is used as independent basis, square headshort columns are factory-prefabricated connection components and connected with upper chord members and lower chord members of main beams through pulling rivets to form outer frames of floors; on thebasis of the outer frames, secondary beams, profiled steel sheets and reinforcing meshes are laid horizontally, a surface course is poured, a decorative layer is attached to the surface course, and thus a mortise and tenon joint type connection mode of the floors and basic nodes is formed by combing insertion, pulling rivet connection and flange connection. According to the assembly-type buildingbottom-layer composite floor and the connection mode, the building mode of a traditional bottom-layer floor can be changed, the assembly type can be achieved, and the defects of poor vibration performance and soundproof effect and the like of an assembly-type light steel composite floor can also be overcome; meanwhile, the assembly-type building bottom-layer composite floor also has the advantages that the floor is assembled rapidly and subjected to industrial production easily and is high in strength and high in production speed, and has large actual project significance and market values topromotion and development of assembly-type buildings.

Owner:谢志强 +1

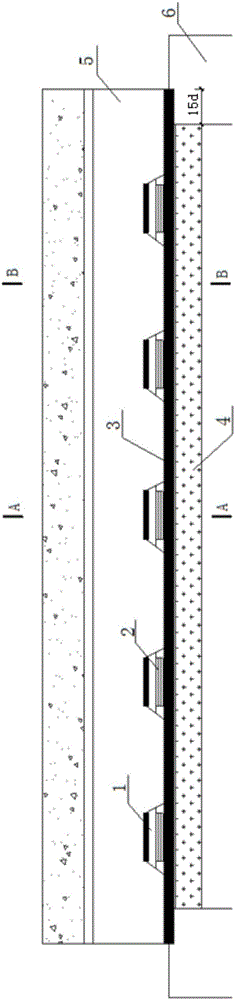

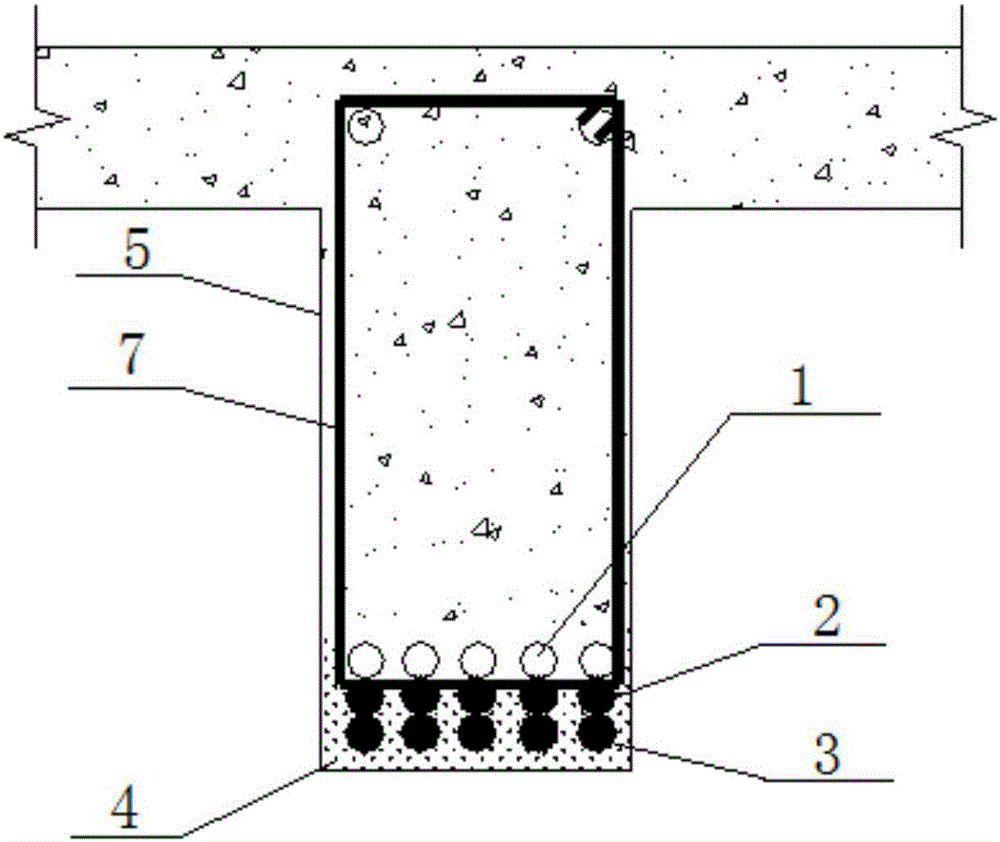

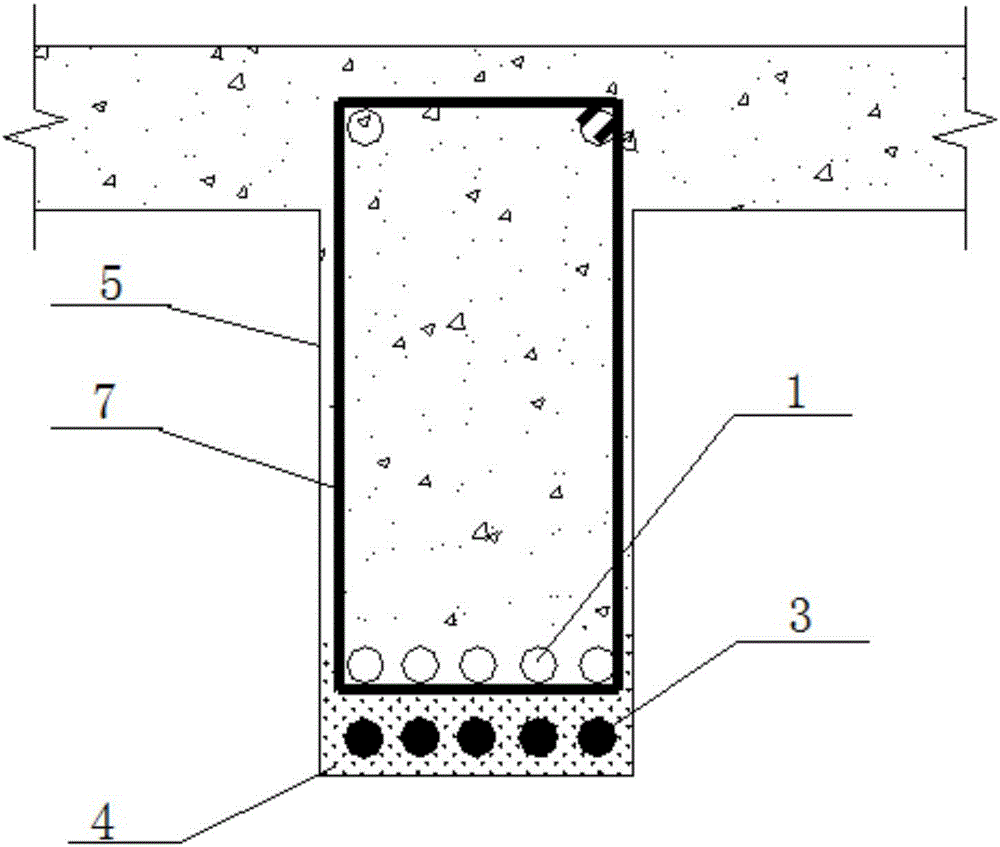

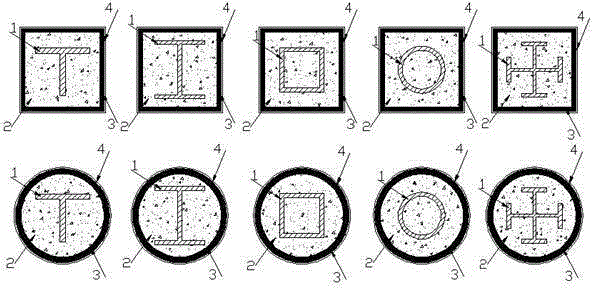

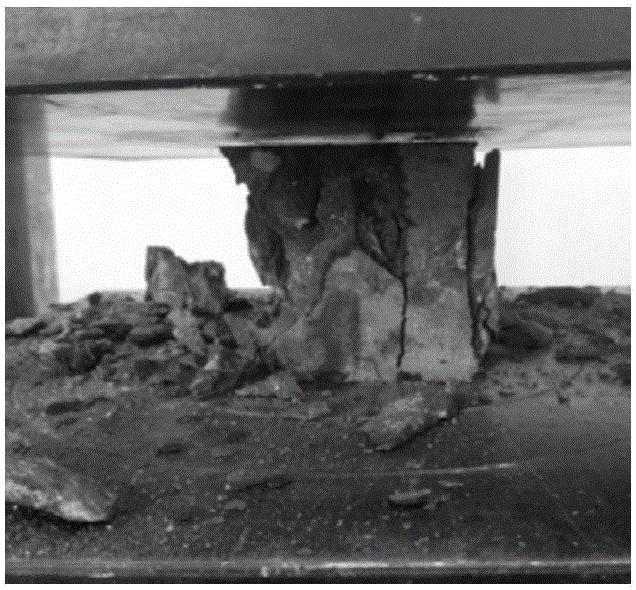

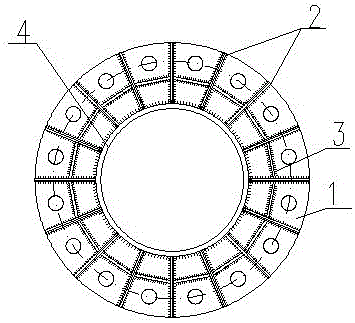

Steel plate and steel reinforced concrete well wall

ActiveCN103075158AIncrease ultimate bearing capacityReduce thicknessShaft liningSteel platesSheet steel

The invention discloses a steel plate and steel reinforced concrete well wall, which is mostly suitable for deep vertical shafts for bearing high ground pressure and high water pressure. A steel plate cylinder, an annular steel rib, inside vertical steel ribs, outside vertical steel ribs and radial connecting pieces are arranged and concrete is poured to form a cylindrical well wall. The steel plate cylinder and the annular steel rib are respectively positioned on the inner surface of the well wall and in the well wall, and are respectively fixed to the inside and outside vertical steel ribs; the steel plate cylinder and the annular steel rib are connected through the radial connecting pieces to form a spatial structure; and concrete is poured into an annular space formed by the steel plate cylinder and a well wall template or surrounding rock to coat the annular steel rib, the inside and outside vertical steel ribs and the like, and the cylindrical well wall structure is formed. The steel ratio on the inner side of the well wall is high, the concrete between the steel plate cylinder and the annular steel rib is positioned in a three-directional stress state, the compressive strength can be obviously improved, a core bearing area is formed, and the ultimate bearing capacity of the well wall is greatly improved. The steel plate and steel reinforced concrete well wall is used for building deep vertical shafts, the thickness of the well wall can be greatly reduced and the cost is reduced; and the steel plate and steel reinforced concrete well wall is reasonable in structure and easy and convenient to construct and has wide applicability.

Owner:CHINA UNIV OF MINING & TECH

Outer casing pipe constraint folding steel plate energy consumption support

ActiveCN105507445AIncrease stiffnessIncrease ultimate bearing capacityShock proofingOuter CannulaEarthquake disaster

The invention discloses an outer casing pipe constraint folding steel plate energy consumption support. The support comprises an outer casing pipe, a core barrel arranged in the outer casing pipe, end bearing plates arranged at barrel openings of the two sides of the core barrel and outer casing pipe seal plates arranged at the ends of the two side of the outer casing pipe; the end bearing plates are connected with cross-shaped node plates penetrating through the outer casing pipe seal plates, and the core barrel is formed by sequentially connecting multiple energy consumption units. The support reduces earthquake responses of buildings through the good post-yielding energy consumption capacity, is easy to manufacture and convenient to install and can be applied to structural earthquake resisting and effectively reduce earthquake disasters.

Owner:SOUTHEAST UNIV

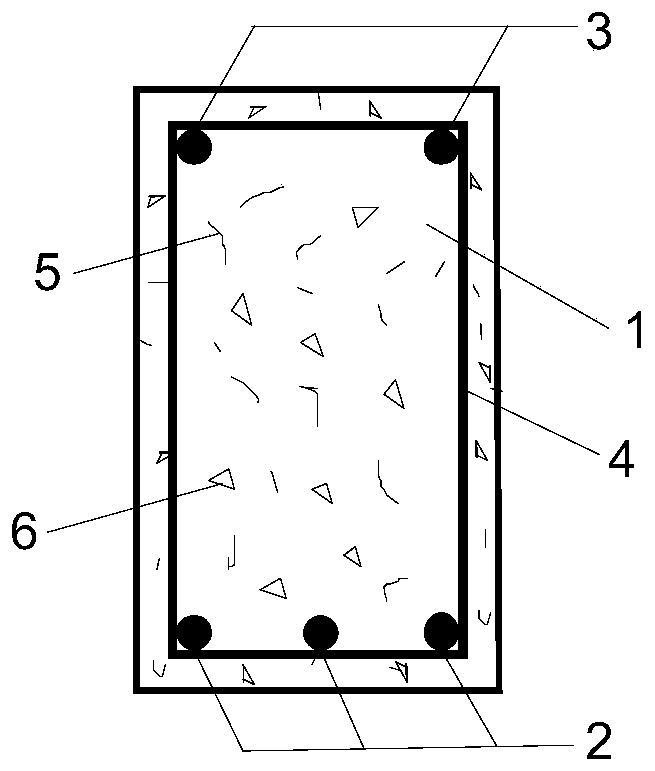

High-ductility fiber concrete and construction method for reinforcing beam by using high-ductility fiber concrete

The invention discloses high-ductility fiber concrete and a construction method for reinforcing a beam by using the high-ductility fiber concrete. The concrete is prepared from cement, coal ash, limestone powder, water, common riversand, a water reducing agent and PVA fibers. The construction method comprises the following steps: chiseling away a bottom reinforcement protective cover of an original concrete beam to enable load-bearing rebars to be exposed, welding added load-bearing main rebars to original load-bearing main rebars through short rebars, and then pouring the high-ductility fiber concrete to the surface. The construction method aims to solve the problem that the existing reinforcement construction technological method is low in operability. By the use of the mechanical property of the high-ductility fiber concrete as well as high joint work performance and integrality of an added structure and an original structure which are reinforced, the bearing capacity of the original concrete beam can be substantially improved; the reinforcement process is simple, the construction is convenient and quick, and the added section is relatively small in size; the high-ductility fiber concrete is safe in structure and relatively high in applicability.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for additionally anchoring reinforced concrete beam strengthened with FRP cloth material in anti-bending way

InactiveCN101691817AIncrease the bonding surface areaIncrease profitBuilding repairsConcrete beamsRebar

The invention discloses a method for additionally anchoring a reinforced concrete beam strengthened with an FRP cloth material in an anti-bending way, which belongs to the technical field of structural engineering. In the method, an internally-locking anchoring system is formed by opening a groove on the bottom surface of the reinforced concrete beam and embedding the FRP cloth material into the groove. The method comprises the following steps: opening the groove on the bottom surface of the reinforced concrete beam according to a required size and clearing groove dust; pre-treating the bottom surface of the reinforced concrete beam, grinding the bottom surface smoothly and grinding corners of the bottom surface into smooth chamfer angles; cutting the FRP cloth material as required, painting primers on the bottom surface of the reinforced concrete beam and in the groove and treating unsmooth parts by flattening glue; pasting two layers of unidirectional FRP cloth materials on the end parts of the bottom surface of the beam respectively, and then painting surface glue; and embedding the FRP cloth material on the bottom surface of the reinforced concrete beam and filling the groove with the surface glue so as to form the internally-locking anchoring system. The method is suitable for additionally anchoring the reinforced concrete beam strengthened with the FRP cloth material in the anti-bending way.

Owner:EAST CHINA JIAOTONG UNIVERSITY

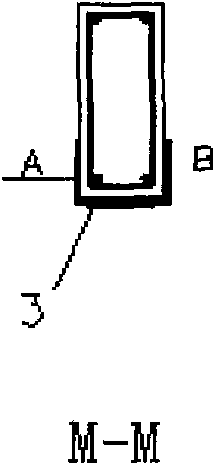

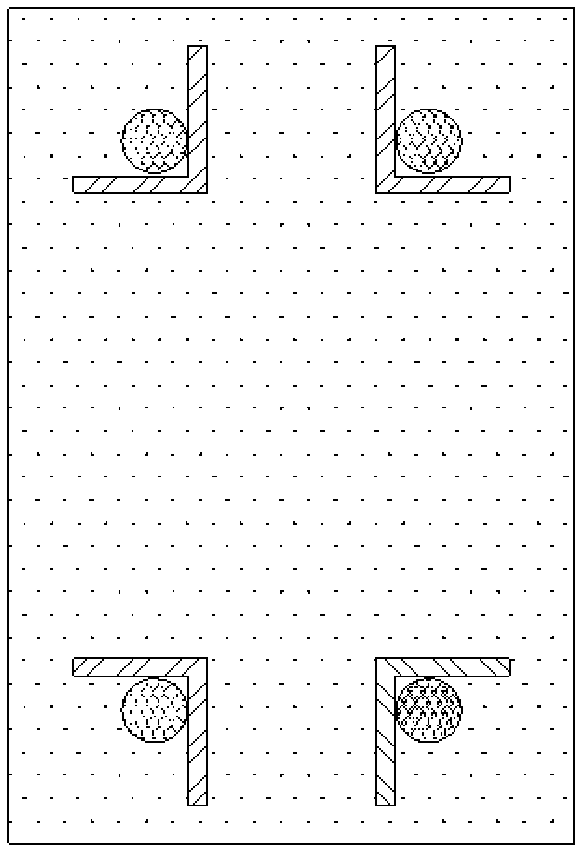

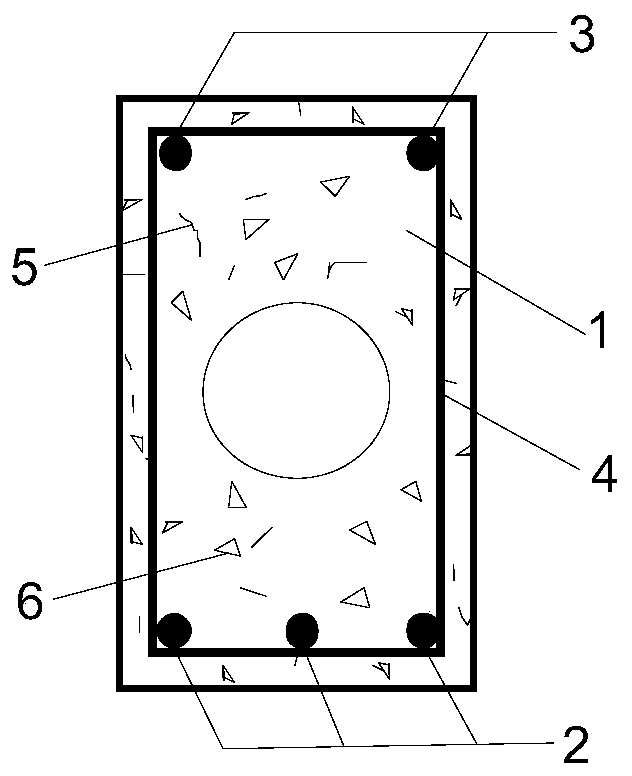

Carbon fiber thin-wall steel tube concrete composite column with internal FRP sectional material and method

InactiveCN105201143AImprove brittlenessIncrease ultimate bearing capacityStrutsPillarsFiberCarbon fibers

The invention aims to provide a carbon fiber thin-wall steel tube concrete composite column with an internal FRP sectional material and a method. The carbon fiber thin-wall steel tube concrete composite column comprises the FRP sectional material, a thin-wall steel tube, an outer protection layer and concrete, wherein the FRP sectional material is arranged at the center of the thin-wall steel tube; the space between the FRP sectional material and the thin-wall steel tube is filled with concrete; the thin-wall steel tube is covered by the outer protection layer in a winding manner; the outer protection layer is carbon fiber reinforced plastic; the cross section of the FRP sectional material is crisscross, I-shaped, T-shaped, circular or square; the cross section of the thin-wall steel tube is circular or polygonal; the ratio of the cross-sectional area of the internal FRP sectional material to the integral cross-sectional area of the composite column is not greater than 15%. The manufacturing method of the composite column comprises the following specific steps: 1, putting the FRP sectional material into the steel tube, and fixing the FRP sectional material at the center of the steel tube; 2, covering the outer layer of the steel tube with the carbon fiber reinforced material layer; 3, pouring concrete inside the steel tube; 4, performing periodical maintenance.

Owner:SHENYANG JIANZHU UNIVERSITY

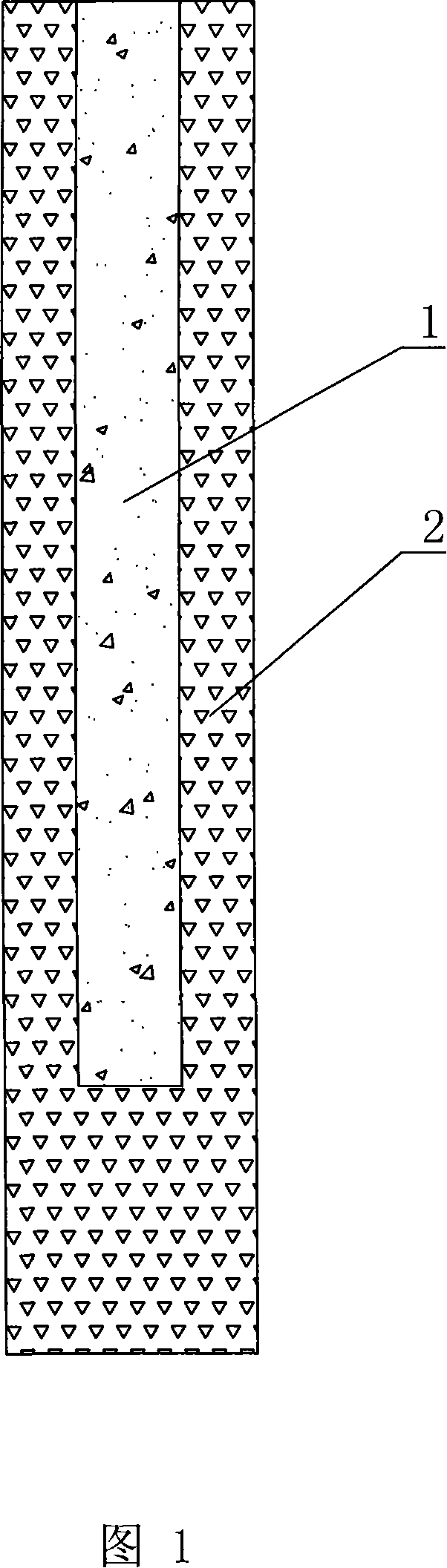

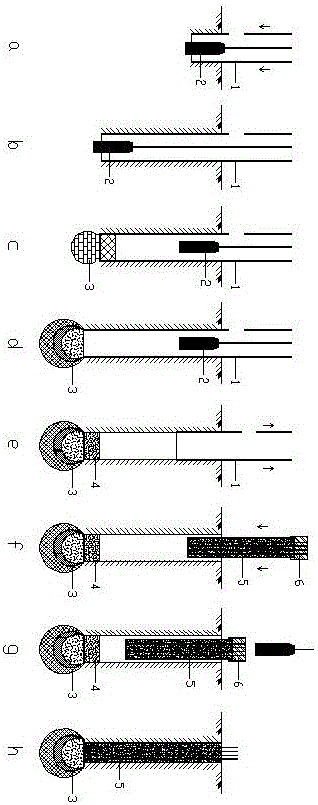

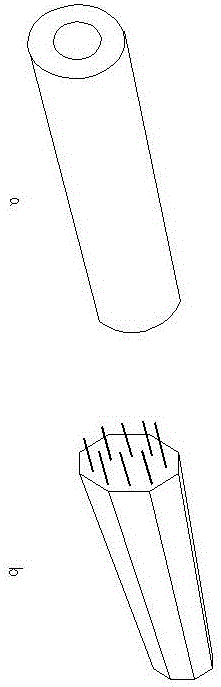

Large load composite pile and construction method thereof

InactiveCN101148876AIncrease ultimate bearing capacityReduce dosageBulkheads/pilesPre stressPre stressing

The present invention discloses one kind of heavy load composite pile comprising one pile core of high strength pre-stressed concrete pipe and one outer layer pile of plain concrete coating the pile core and its construction process. The construction process includes the following steps: 1. long auger boring and pump pressurizing concrete to form the in-situ deposited plain concrete pile; and 2. hoisting the high strength pre-stressed concrete pipe pile and inserting or pressurizing into the center of the plain concrete pile until reaching the designed depth. The composite pile has the vertical load borne by the high strength pre-stressed concrete pipe pile and the plain concrete pile, the side friction force increased by the plain concrete pile with relatively great cross section. It has great limit bearing capacity from the high strength pre-stressed concrete pipe pile.

Owner:山东省机械施工有限公司

Basalt and polypropylene hybrid fiber reinforced concrete and preparing method

The invention provides basalt and polypropylene hybrid fiber reinforced concrete and a preparing method. Basalt fibers accounting for 0.1-0.5 part of the weight of a concrete matrix and polypropylene fibers accounting for 0.01-0.08 part of the weight of the concrete matrix are doped into the concrete matrix. (1) at the normal temperature, sand and stone are put into a blender to be blended for 60 s; (2) cement is put into the blender to be blended for 60 s; (3) water is added into the blender to be blended for 90 s to 120 s, and a concrete matrix is obtained; and (4) two kinds of fibers including the basalt fibers and the polypropylene fibers are mixed, and are scattered into the concrete matrix obtained in the step (3) to be blended for 120 s after the two kinds of fibers are highly scattered, and then the basalt and polypropylene hybrid fiber reinforced concrete is obtained. Compared with traditional concrete, the basalt and polypropylene hybrid fiber reinforced concrete can better adapt to complex environments such as high temperature, high heat, corrosion and the like, can be widely applied to roads, bridges, buildings, undergrounds and oceanographic engineering, and the concrete application scope is greatly expanded.

Owner:HARBIN ENG UNIV

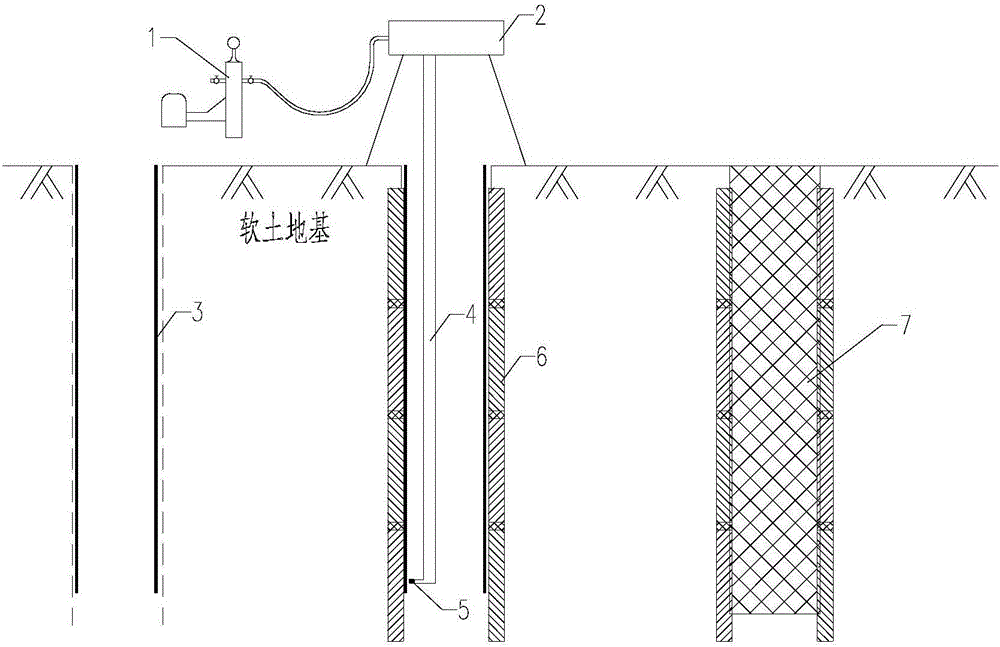

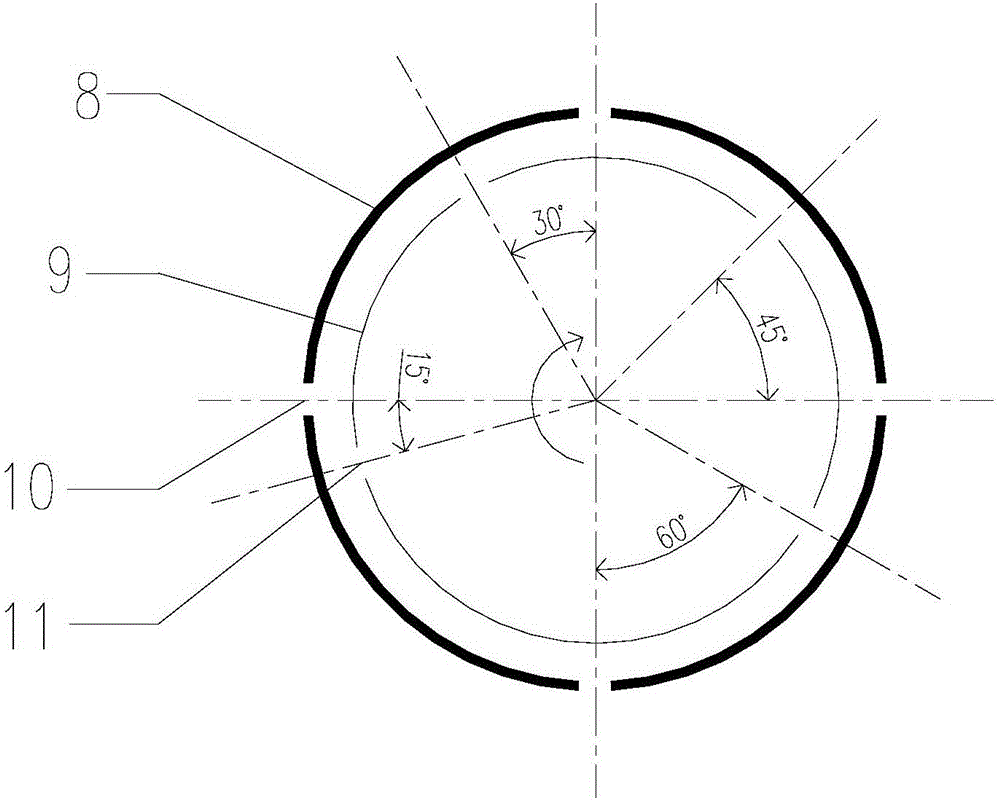

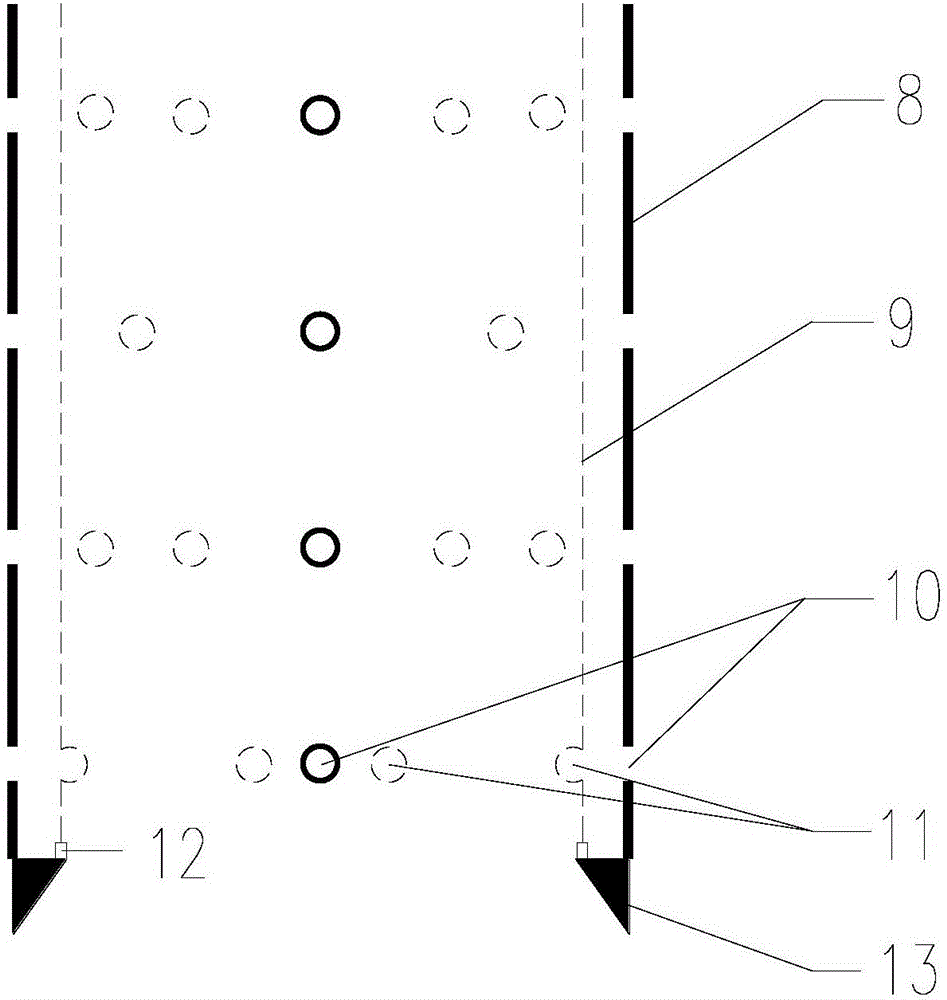

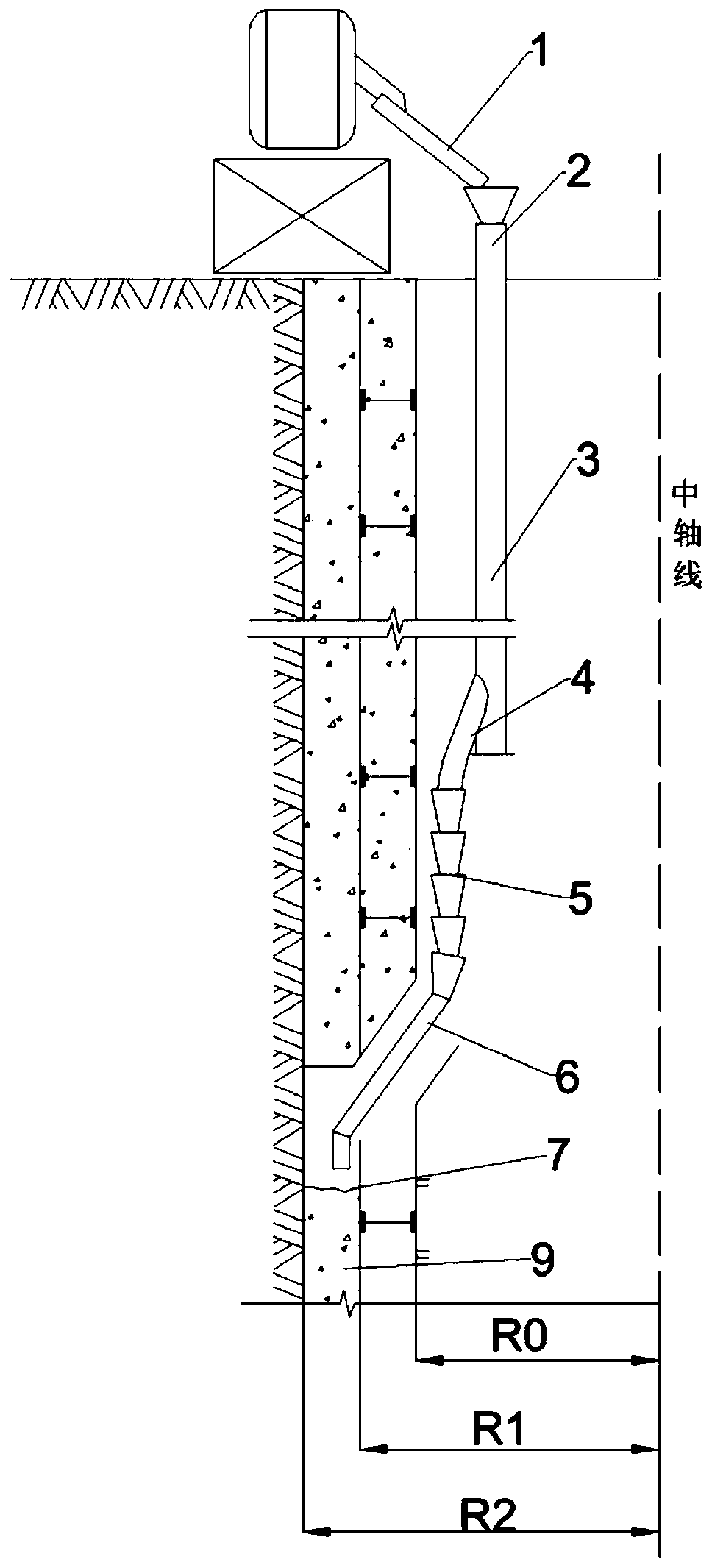

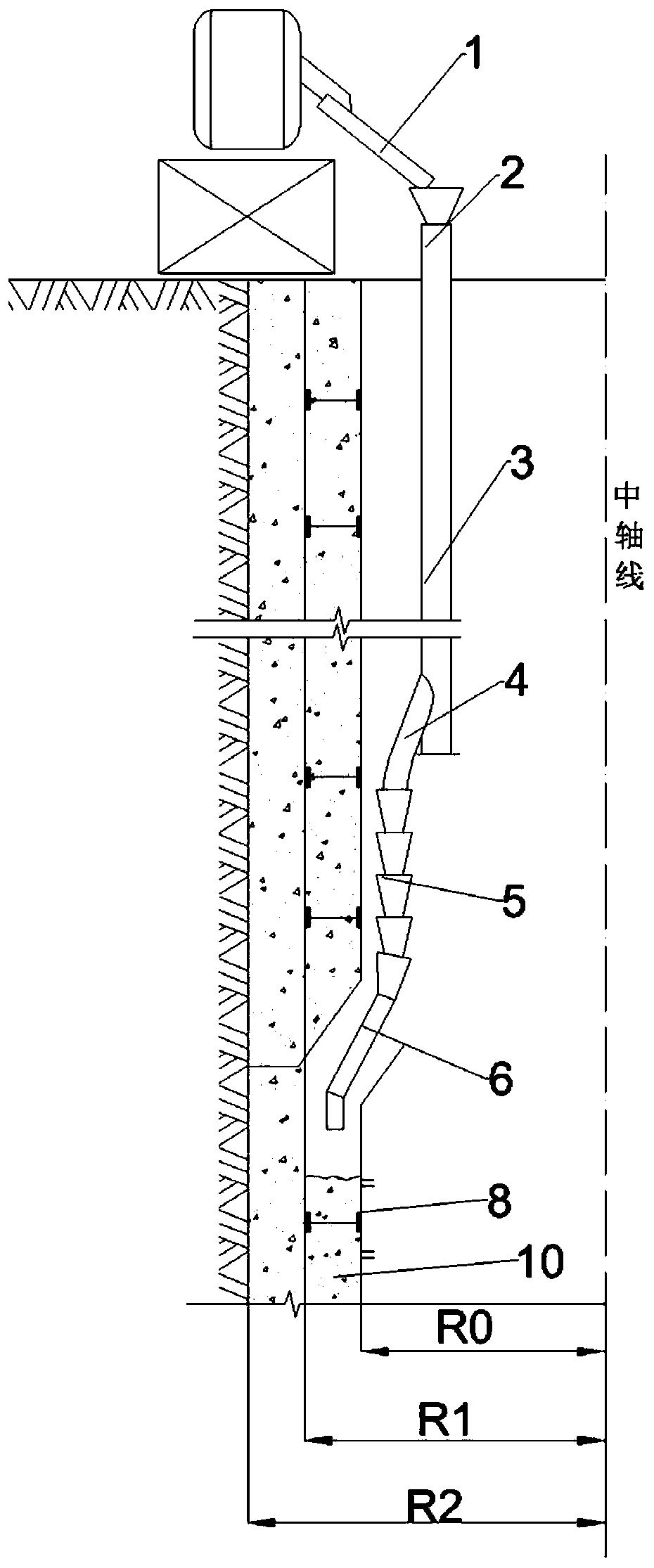

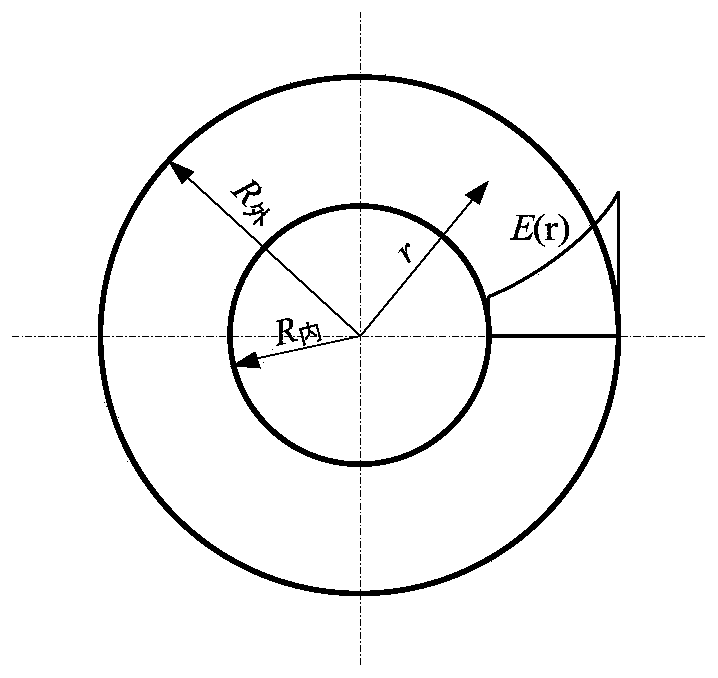

Equipment and method for improving bearing capacity of cast-in-place pile under soft soil foundation condition

The invention belongs to the field of foundation engineering and relates to equipment and method for improving a bearing capacity of a cast-in-place pile under a soft soil foundation condition. The equipment comprises a cement paste pumping device, an injection grouting pipe position control device, am injection grouting pipe and a rotatable three-directional nozzle, wherein the injection grouting pipe is arranged on the injection grouting pipe position control device and the position of the injection grouting pipe in a pile hole of the cast-in-place pile through the injection grouting pipe position control device; the cement paste pumping device is connected with the rotatable three-directional nozzle through the injection grouting pipe; the rotatable three-directional nozzle is used for carrying out slurry spraying work on an injection grouting reinforcing region in the pile hole of the cast-in-place pile. The equipment and method for improving the bearing capacity of the cast-in-place pile under the soft soil foundation condition, provided by the invention, are simple in structure and are convenient to control and implement; soft soil at the periphery of a pile body is reinforced by adopting an injection grouting manner and the strength of a soil body is improved, so that the aims of guaranteeing the pile forming quality of the cast-in-place pile under the soft soil foundation condition and improving the friction resistance of a pile foundation side and a total bearing capability are realized.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

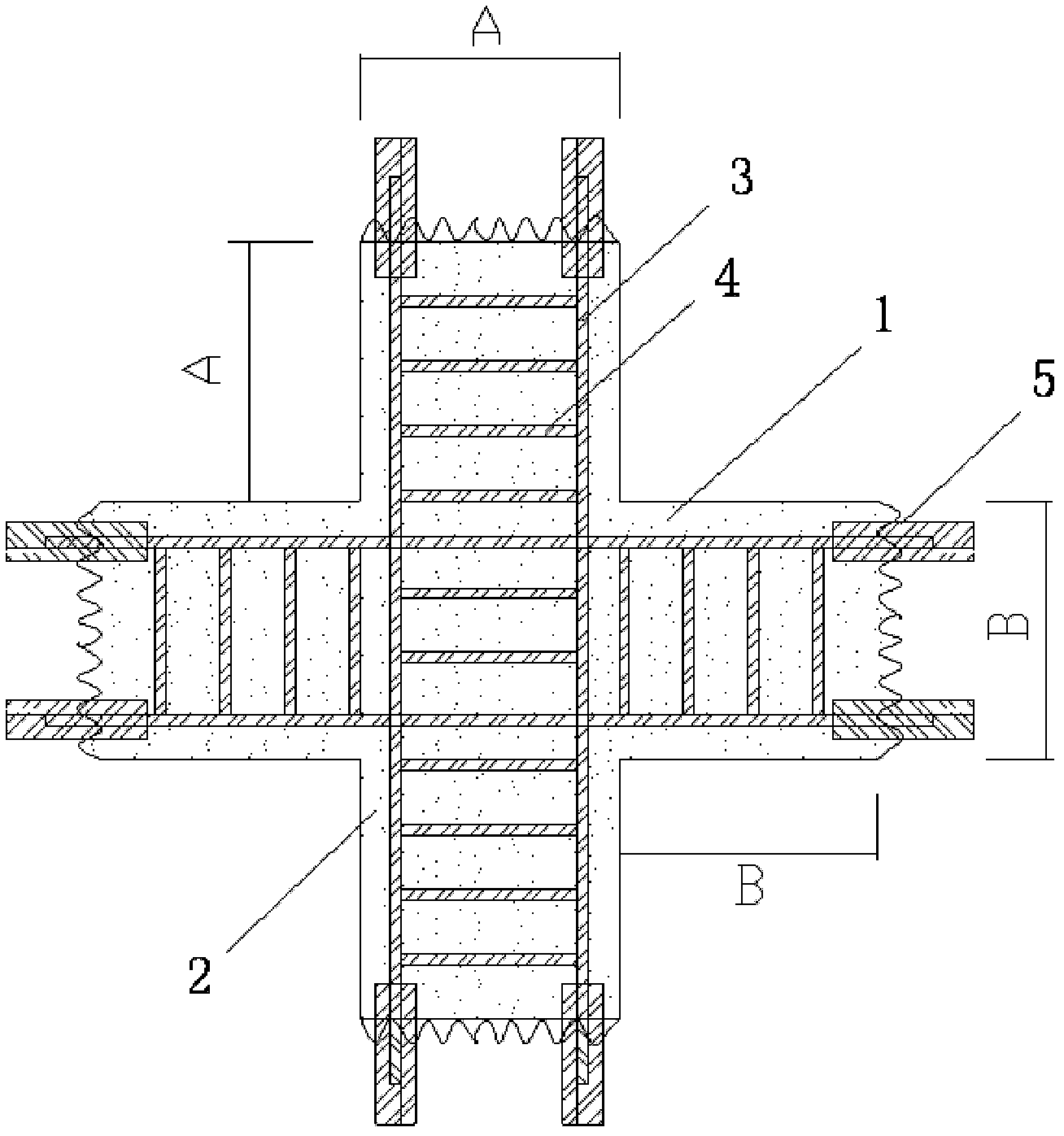

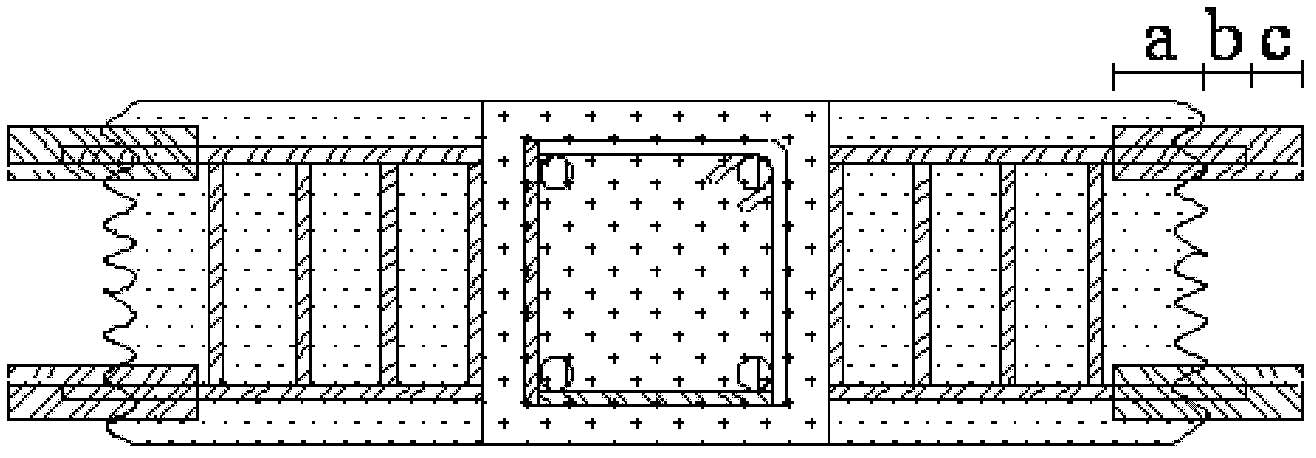

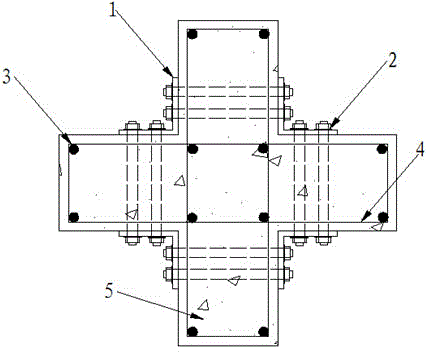

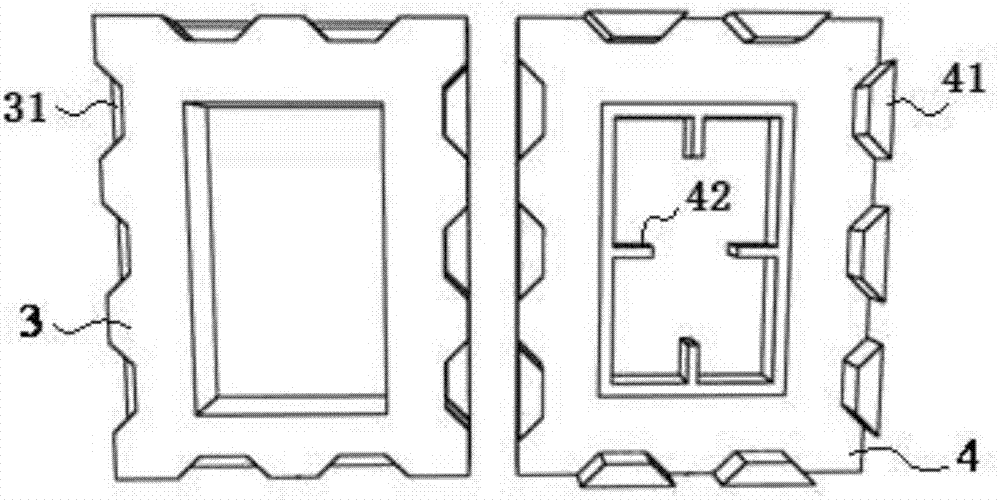

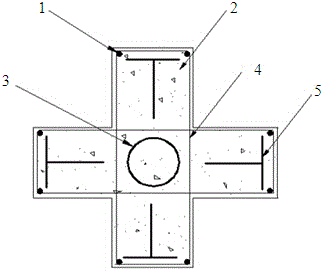

Prefabricated combined beam and column node member

InactiveCN102505760AGuaranteed stiffnessGuarantee welding qualityClimate change adaptationShock proofingReinforced concreteSteel bar

The invention relates to a prefabricated combined beam and column node member. The prefabricated combined beam and column node member comprises a cross beam and a vertical column which are intersected, wherein the cross beam as well as the vertical column comprises an ECC (engineered cementitious composite) material, longitudinal bars and stirrups, and a rectangular region where the cross beam and the vertical column are intersected and superposed is in the transverse width of A and the longitudinal height of B; the cross beam is in the transverse width of 2B plus A and the longitudinal height of B, and the longitudinal bars penetrate the full length of the cross beam and extend out of two beam ends by 10cm-15cm; and the vertical column in the longitudinal height of 2A plus B, and the longitudinal bars penetrate the full length of the vertical column and extend out of the two column ends by 10cm-15cm. The prefabricated combined beam and column node member disclosed by the invention is the prefabricated member which is formed by casting the steel bar-reinforced ECC material and is applied to an anti-seismic key part, in particular to a key node. Compared with an ordinary reinforced concrete member, the prefabricated combined beam and column node member can significantly improve the ductility and the anti-seismic performance of the structure, greatly reduce the use of the stirrups at the node under the condition of meeting the anti-seismic requirement and solve the difficult problem in construction caused by too dense stirrups in a node region.

Owner:SOUTHEAST UNIV

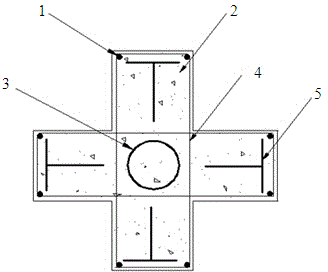

Star-section reinforced concrete combination column with reinforced with external angle steel

InactiveCN104358357AConstrained Lateral DeformationImprove carrying capacityStrutsPillarsStress concentrationReinforced concrete

The invention relates to a star-section reinforced concrete combination column with reinforced with external angle steel. The star-section reinforced concrete combination column with reinforced with external angle steel comprises external angle steel, bolt connecting parts, longitudinal ribs, stirrups and concrete, wherein the stirrups are bent to be a cross shape; the external angle steel is arranged at the turning corner where two branches of the cross intersect with each other; two adjacent pieces of external angle steel are connected through the bolt connecting parts; the external angle steel is fixed with a bottom plate in a welded manner or through the bolt connecting parts; the concrete is arranged inside a cross fence formed by the bent stirrups; the longitudinal ribs are arranged on the corners. Due to the adoption of the external angle steel, the situation that the stress is centralized at two adjacent corners is changed, the external angle steel and the star-section reinforced concrete combination column are connected together through bolts and stressed and deformed together, and the star-section reinforced concrete combination column is a main component of a frame structure in a high-rise and large-span building, and has the advantages that the bearing property is high, the rigidity is high, the weight is light, the plasticity and the toughness are good, the impact resistance and the anti-fatigue property are good, the anti-shaking property is good, and the durability is good.

Owner:SHENYANG JIANZHU UNIVERSITY

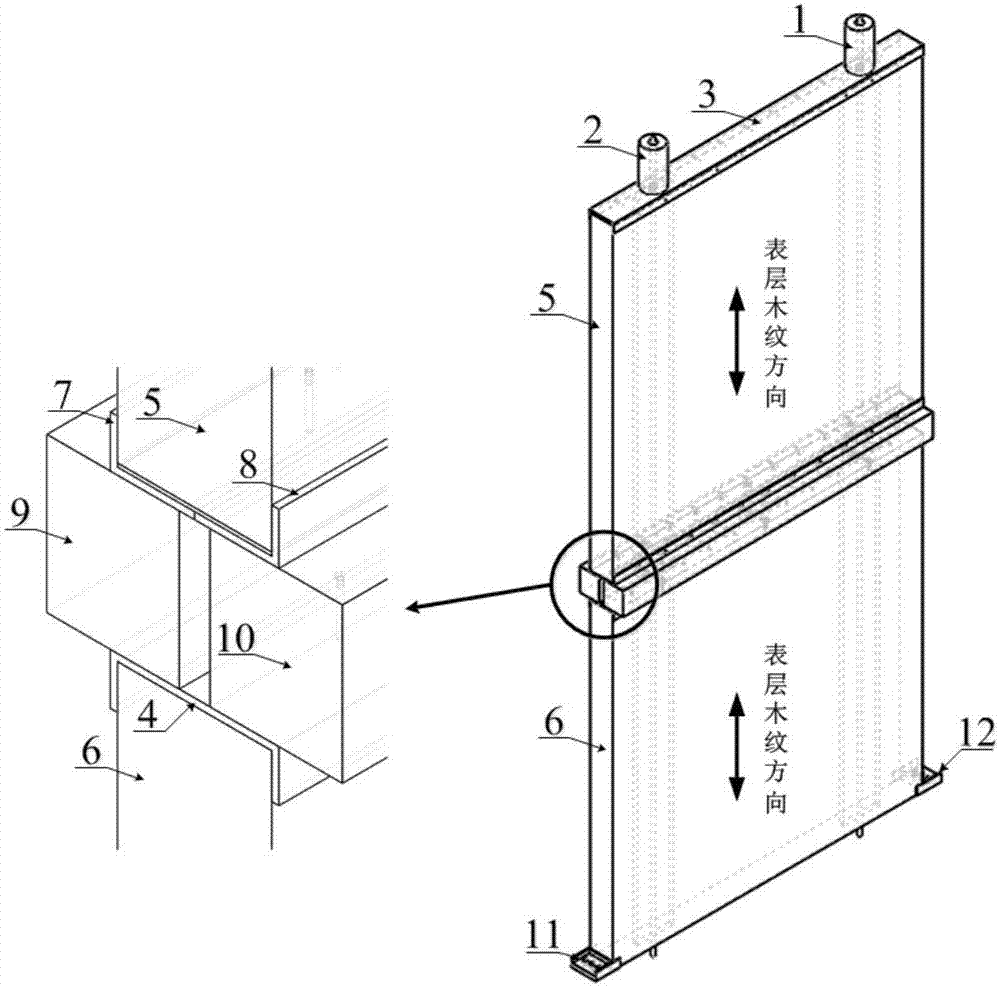

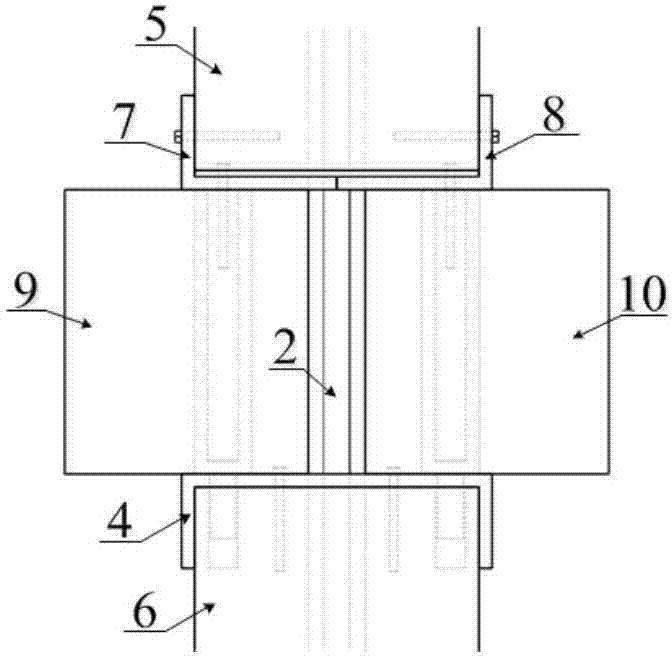

Assembling prestress orthogonal laminated wood shear wall

ActiveCN107574953AIn line with the structural design conceptImprove lateral force resistanceWallsProtective buildings/sheltersPre stressSelf recovery

The invention discloses an assembling prestress orthogonal laminated wood shear wall. The assembling prestress orthogonal laminated wood shear wall comprises bond-free prestress bars, bearing beams, CLT wall plates, slab supporting frames and limiting steel components. The two limiting steel components are connected with a base. The CLT wall plates on the lower layer tightly abut against the basethrough the bond-free prestress bars. The bearing beams on the lower layer are connected with the CLT wall plates on the lower layer. The slab supporting frames on the lower layer are connected with the CLT wall plates on the lower layer and then put on the top of the bearing beams on the lower layer. The CLT wall plates on the upper layer are connected with the two slab supporting frames on the lower layer. The bearing beams on the upper layer are connected with the CLT wall plates on the upper layer. The two bond-free prestress bars penetrate through the CLT wall plates on the upper layer and the lower layer. The CLT shear wall has high initial rigidity, high ultimate bearing capacity and a certain self-recovery characteristic under lateral loads after the bond-free prestress bars are applied, and the common damage mode of weak joints and strong components of a common CLT shear wall is avoided. The assembling prestress orthogonal laminated wood shear wall is high in assembling degree, and prestress loss caused when CLT slabs have big creep deformation under the band stress action can be reduced obviously due to the arrangement of the slab supporting frames on the lower layer.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

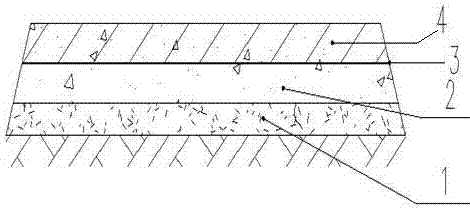

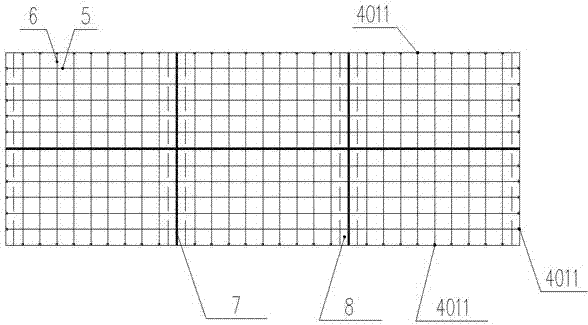

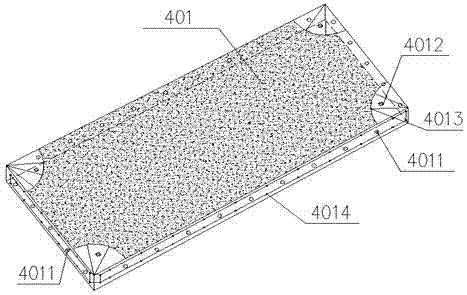

Assembled prestressed construction waste recycled aggregate road and construction method thereof

PendingCN107083730AHigh strengthIncreased durabilitySingle unit pavingsPaving detailsArchitectural engineeringStructural engineering

The invention discloses an assembled prestressed construction waste recycled aggregate road and a construction method thereof. The recycled aggregate road comprises a cushion layer, a base layer, a sliding layer and a surface layer, wherein the surface layer is formed by splicing a plurality of precast recycled concrete road slabs with reserved prestressed bar holes, sleeper beams are placed below transverse joints of the precast recycled concrete road slabs, and waterproof rubber strips are embedded in the transverse joints and longitudinal joints; and the precast recycled concrete road slabs at two ends are stretched so as to be connected with the sleeper beams through telescopic components. The road structure manufactured by the construction waste recycled aggregate is convenient and fast in overall manufacturing and high in economic benefit, the carrying capacity of the road structure is enhanced, the deformation performance of the road structure is improved, the ductility of the road structure is increased, and the construction time is greatly shortened. The construction method is suitable for road structures, such as town roads and post-disaster emergency repair roads.

Owner:NANCHANG UNIV

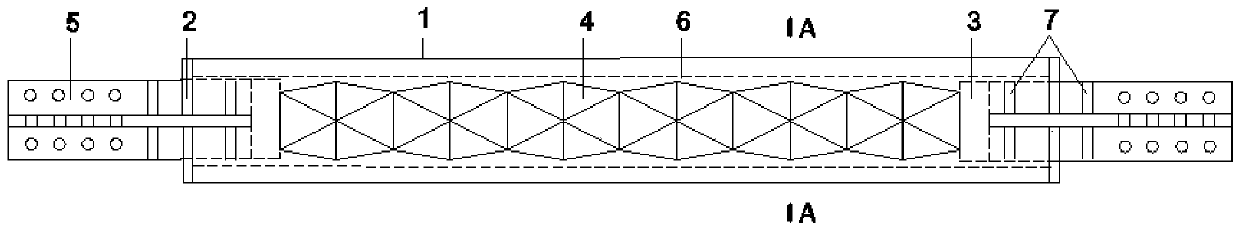

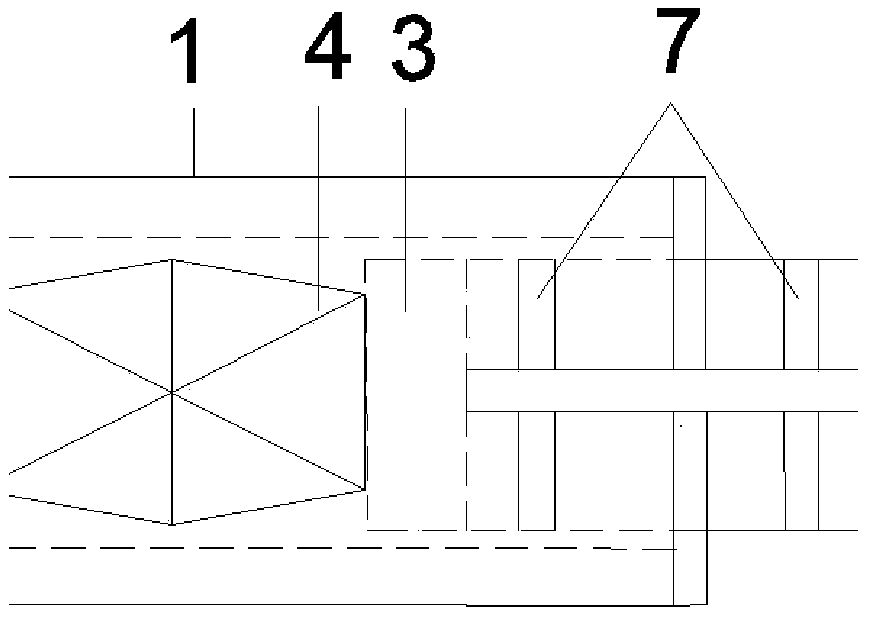

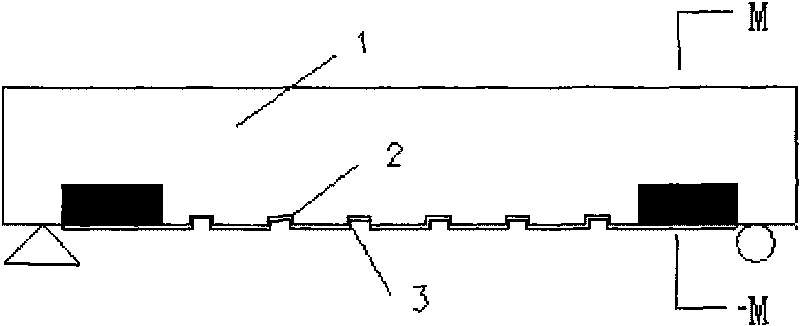

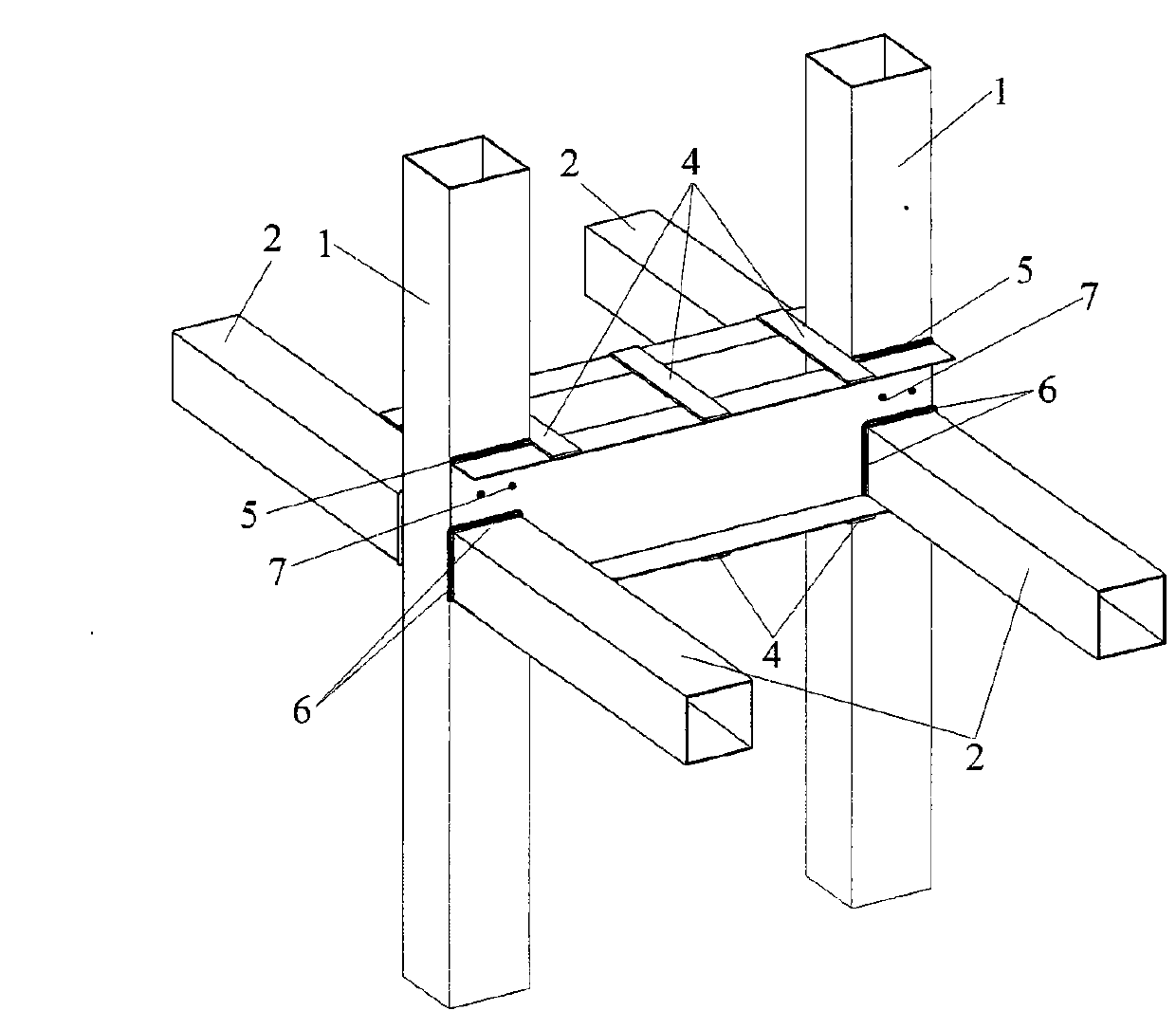

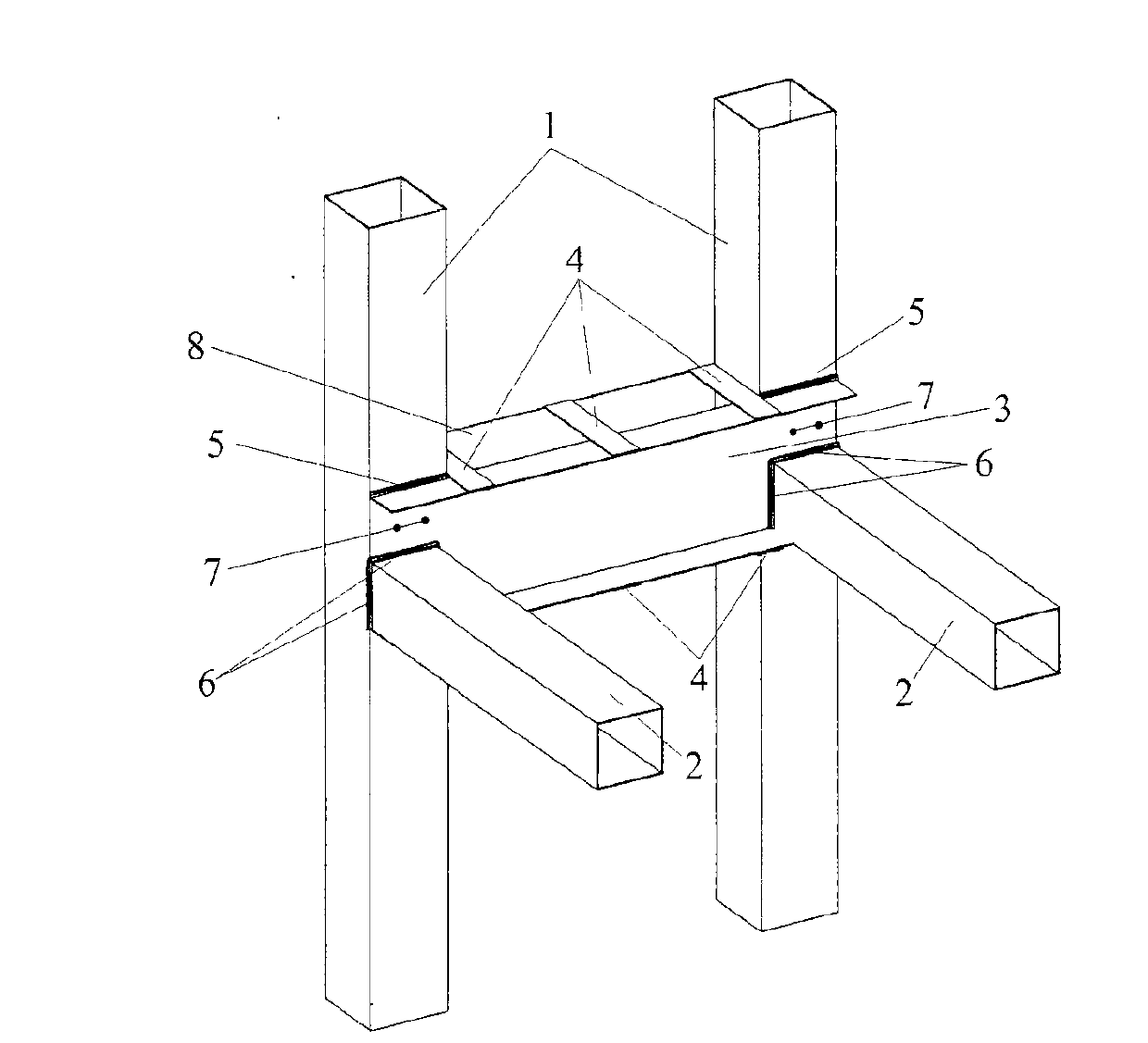

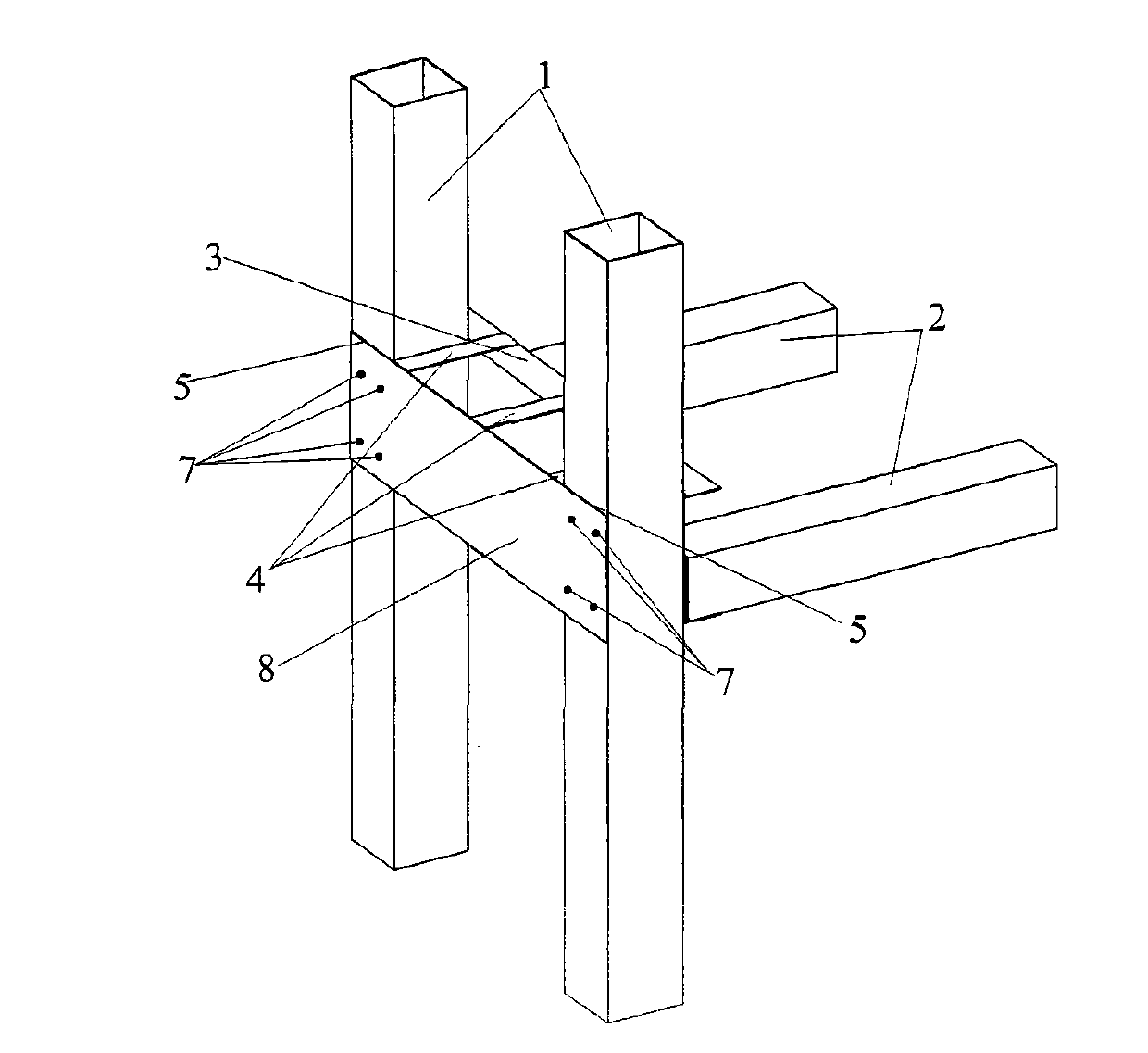

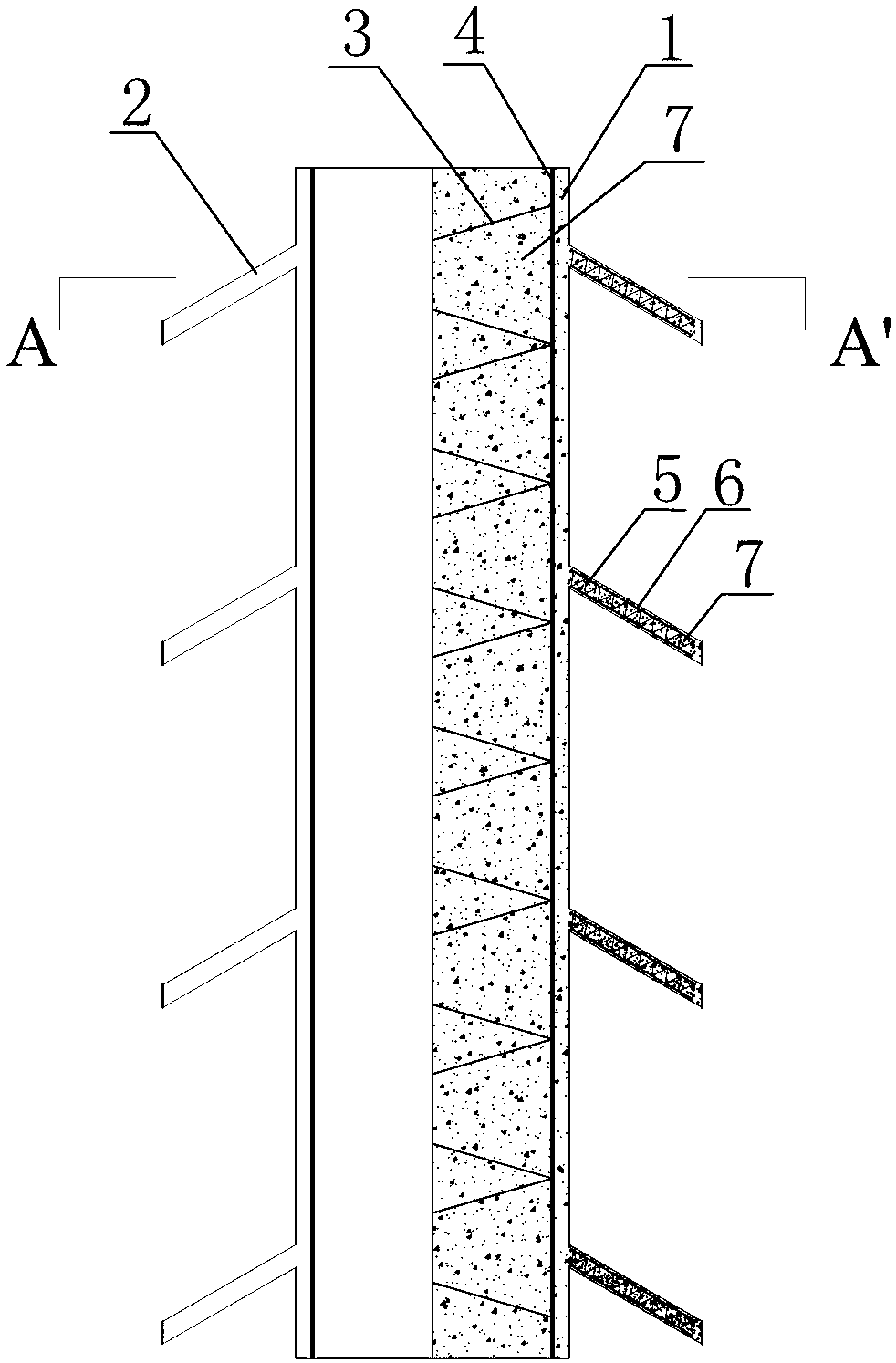

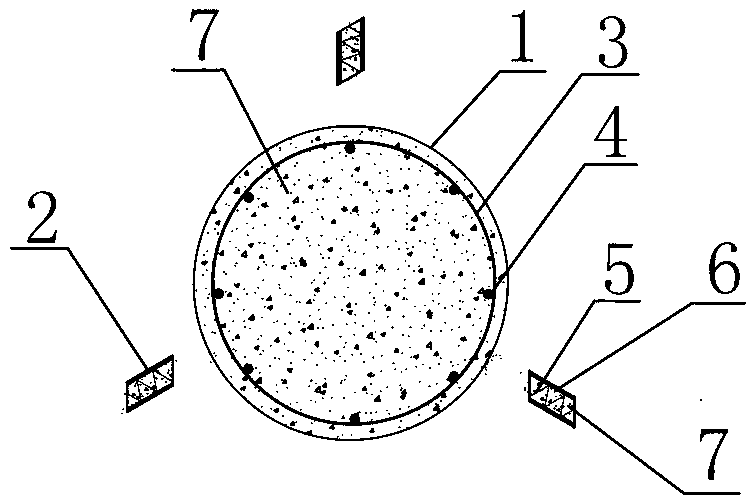

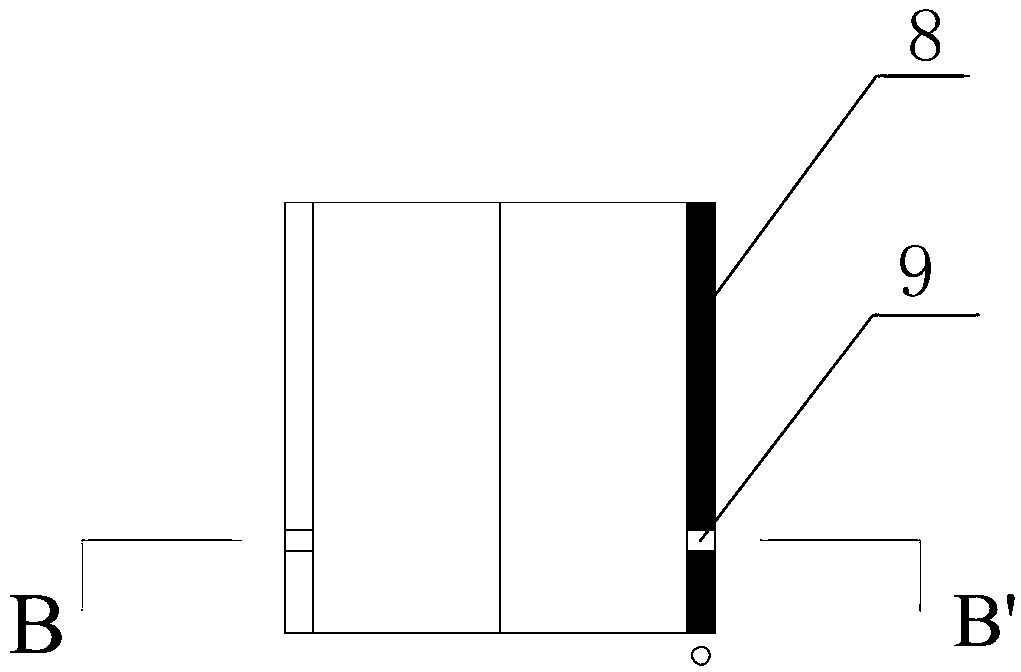

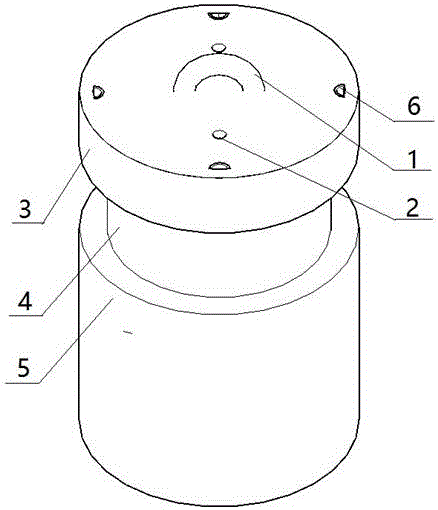

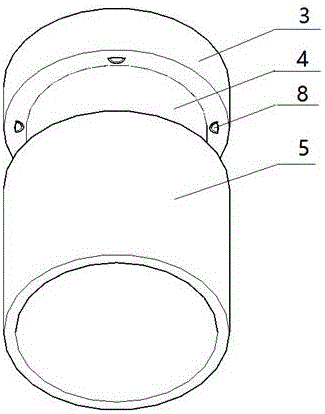

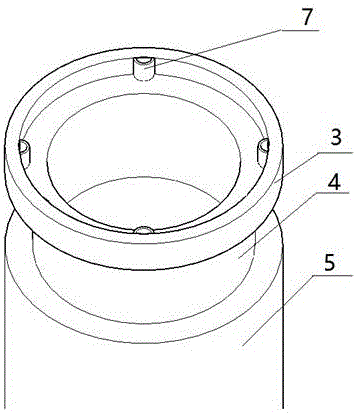

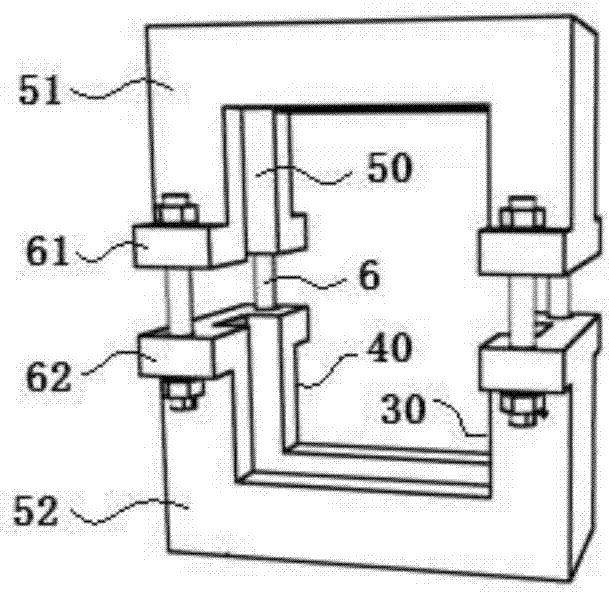

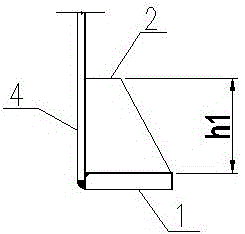

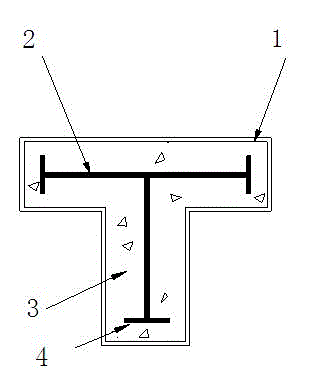

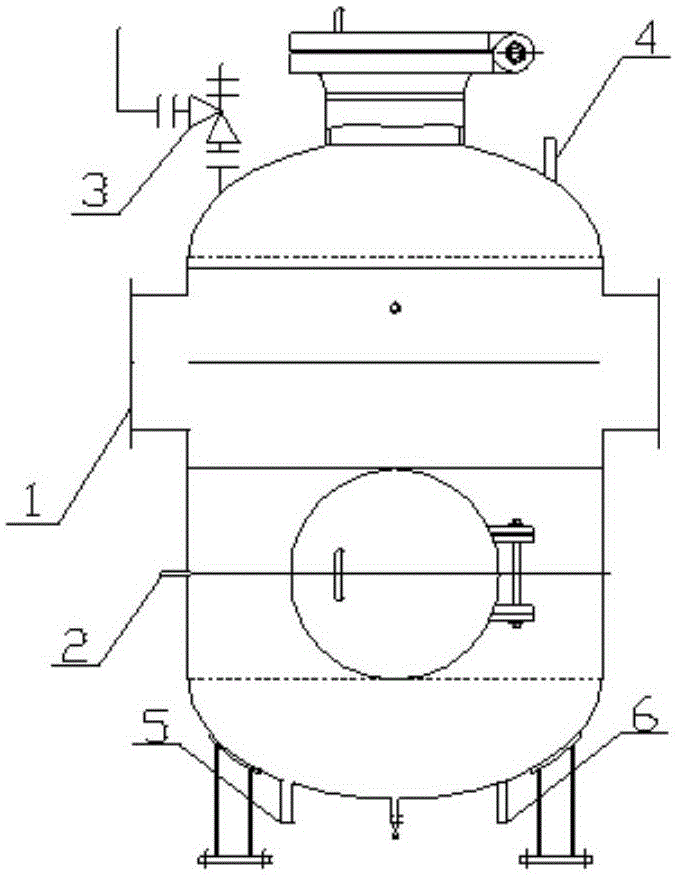

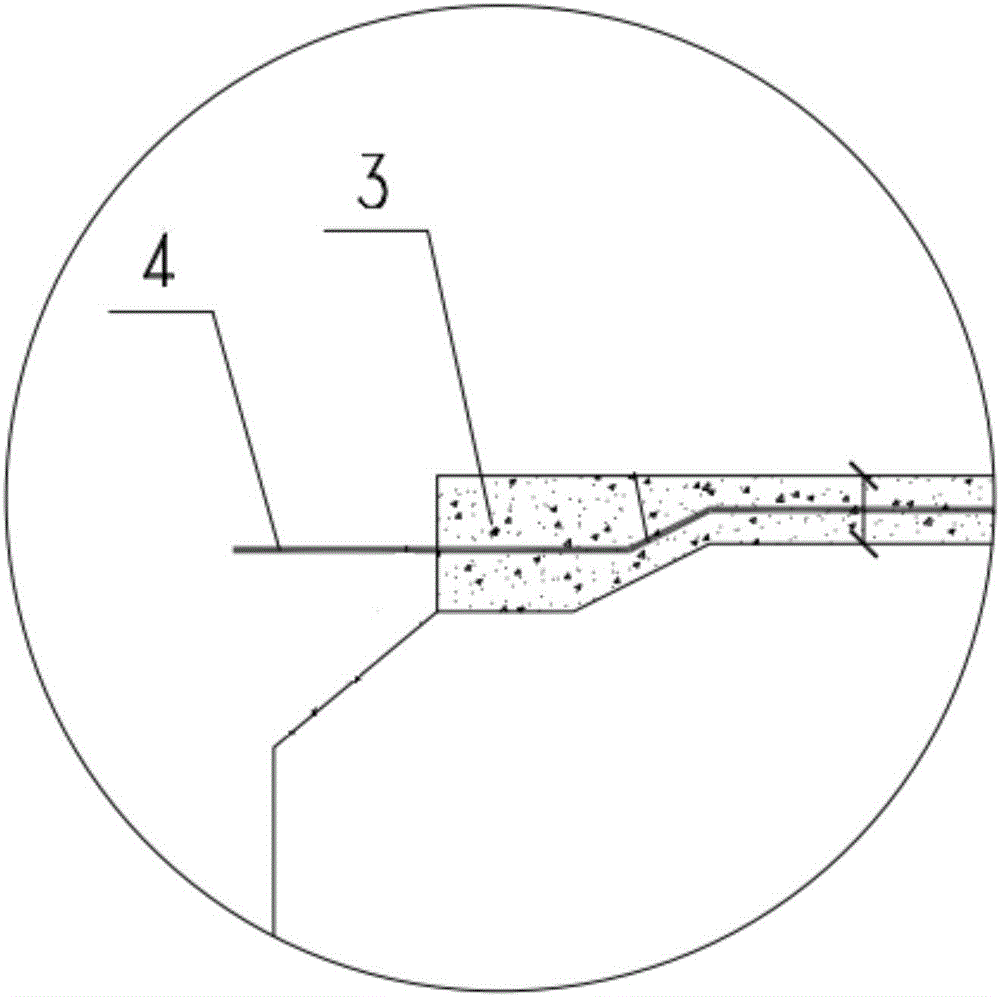

Cold bending thin-wall steel beam column node

InactiveCN101793059AImprove ductilityIncrease ultimate bearing capacityBuilding constructionsEarthquake resistanceStructural system

The invention discloses a cold bending thin-wall steel beam column node, which comprises a square steel tubular column (1), a square steel tubular beam (2) and a C-shaped steel beam (3). The steel beam column node is characterized in that the C-shaped steel beam (3) is welded on the square steel tubular column (1), and the square steel tubular beam (2) is welded on the C-shaped steel beam (3). The C-shaped steel beam (3) and the square steel tubular column (1) can be connected by self-tapping screws (7). The cold bending thin-wall steel beam column node overcomes the defect of the conventional cold bending thin-wall steel beam column node connection; and the node has the advantages of definite stress transfer pathway, predominant earthquake resistance and simple and feasible construction operation, can be widely applied to connection of sections of various cold bending thin-wall steel rods, and is particularly suitable for a structural system adopting a plug-in retaining wall.

Owner:SOUTHWEAT UNIV OF SCI & TECH

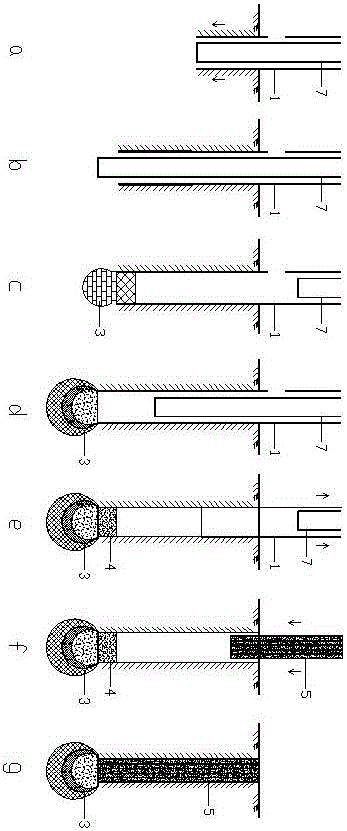

Manual hole digging pile and construction method thereof

ActiveCN103233464AImprove bearing capacityReduce load capacityBulkheads/pilesEngineeringUltimate tensile strength

The invention discloses a manual hole digging pile and a construction method thereof. The manual hole digging pile is characterized by comprising a cylinder-shaped trunk pile body and a plurality of cylinder-shaped branch pile bodies. The branch pile bodies are fixedly distributed on the external wall of the trunk pile body and are distributed on a circumferencial section of the trunk pile body in a regular triangle way; a trunk spiral stirrup and a plurality of trunk force bearing ribs are arranged inside the trunk pile body; the trunk spiral stirrup is arranged on the inner wall of the trunk pile body along pile long spirals; the trunk force bearing ribs are uniformly distributed along the circumference of the inner surface of the trunk spiral stirrup; every branch pile body is provided with a branch spiral stirrup and a plurality of branch force bearing ribs; the branch force bearing ribs are arranged on the inner wall of every branch pile body along pile long spirals; a soil body which is corresponding to the trunk pile body is manually dug mainly in a cylinder-shaped trunk steel pile casing; and soil bodies which are corresponding to the branch pile bodies are manually dug mainly in cylinder-shaped branch steel pile casings. The manual hole digging pile and the construction method of the manual hole digging pile have the advantages of improving the side friction resistance, ultimate bearing capacity of the pile bodies and strength and stiffness of soil bodies around the pile and being capable of being widely applied to coastal soft soil areas.

Owner:宁波市产城生态建设集团有限公司

Construction method of precast concrete pile body carrier pile

The invention aims to provide a construction method of a precast concrete pile body carrier pile. According to the construction method, a precast concrete pile body is imbedded after a pile end carrier is manufactured by various methods, and the close combination of the precast pile body and the pile end carrier is guaranteed. The construction method comprises the following steps: 1) sinking a pile casing in various ways such as hammering or vibrating; 2) performing reinforcing treatment of a pile end by various methods such as filler ramming; 3) repeating the operation in step 3) to form the pile end carrier, and detecting the compactness according to a penetration degree or filler quantity control standard; 4) filling the pile casing with flowing concrete and then lifting out the pile casing; and 5) imbedding the precast pile body by one of the methods of hammering, static pressure and vibrating, and selecting a corresponding imbedding method according to the type of the precast pile body.

Owner:王继忠

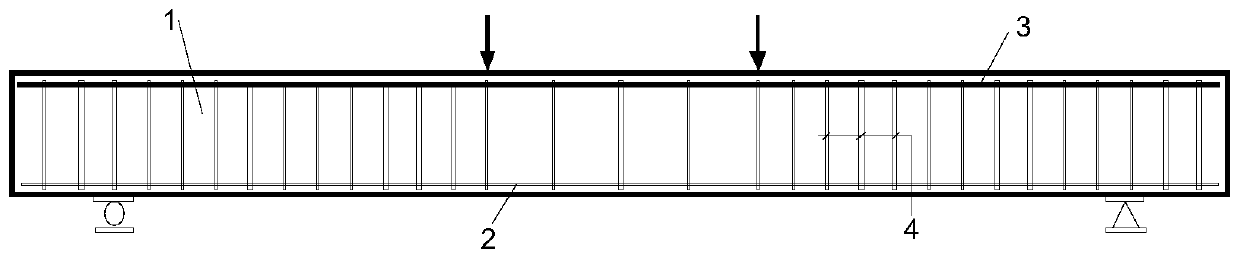

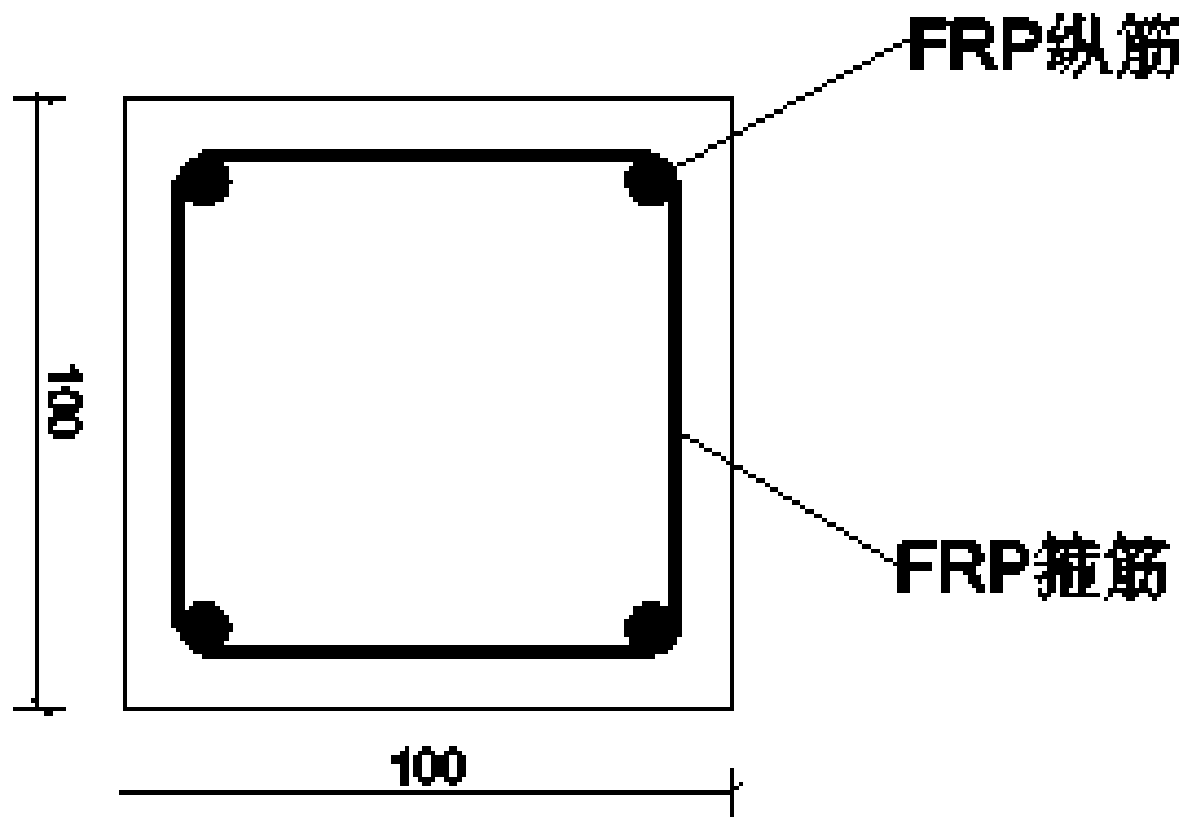

Fiber reinforce plastic (FRP) rib fiber high-strength light-weight aggregate concrete beam member and manufacturing method

InactiveCN110005129AImprove bending performanceIncrease ultimate bearing capacityBridge structural detailsGirdersRebarDuctility

The invention discloses a fiber reinforce plastic (FRP) rib fiber high-strength light-weight aggregate concrete beam member and a manufacturing method. Fiber is doped in fiber light-weight aggregate concrete, the flexural performance of a FRP rib fiber high-strength light-weight aggregate concrete beam can be effectively improved, the ultimate bearing force of the member can be improved, the flexural rigidity of the member is increased, so that the deflection of the beam is reduced, and the beam fundamentally meets the normal using state requirements; the crack width under the load effect further can be reduced; and compared with a steel bar light-weight aggregate concrete sample, after the fiber is doped, the ductility is greatly improved. According to a rib cage formed by a FRP rib, a longitudinal erection steel bar and a stirrup, a longitudinal tension rib is the FRP rib, and the corrosion resistance of the FRP rib can obviously improve the durability of the member during crack developing.

Owner:CHANGAN UNIV

Grouting suction anchor and installation method thereof

InactiveCN106240749APrevent pull upImprove ultimate pull-out capacityAnchorsBulkheads/pilesEngineeringCement mortar

The invention discloses a grouting suction anchor comprising a cylinder body; the cylinder body has an integral structure comprising an upper part, an intermediate part and a lower part; the diameter of the upper cylinder body is identical to that of the lower cylinder body; the diameter of the intermediate cylinder body is less than those of the upper cylinder body and the lower cylinder body; the upper, the intermediate and the lower cylinder body share a same center line; a top part of the upper cylinder body is provided with multiple grouting inlets and scuppers; the grouting inlets are communicated with a grouting channel inside a side wall of the upper cylinder body; the grouting channel extends downwards to a lower end surface of the upper cylinder body; an outlet of a lower end of the grouting channel is positioned between the outer lateral surface of the upper cylinder body and the outer lateral surface of the intermediate cylinder body; the grouting channel and the cylinder body inner chamber are separated from each other. The invention also discloses an installation method of the suction anchor. After downward penetration of the suction anchor is completed, the intermediate cylinder body and soil body interspace are filled with cement mortar which can improve the lateral bearing capacity of the suction anchor. After the cement mortar is solidified, the friction coefficient between surrounding soil body and anchor cylinder contact surface is increased and the limit bearing capacity of the suction anchor is increased.

Owner:OCEAN UNIV OF CHINA

Method for connecting resin-based composite material tube and metal material

InactiveCN101799095AIncreased shear strengthHigh strengthPipe connection arrangementsInterference fitAdhesive

The invention relates to a method for connecting a resin-based composite material tube. The technical scheme of the invention is that: the outer surface of a joint of the resin-based composite material tube is provided with threads to match threads on the inner wall of a metal sleeve; and the metal sleeve of which the outside diameter is same as the inside diameter of the composite material tube is inserted into the joint of the resin-based composite material tube. The method overcomes respective defects of the conventional composite material connecting modes such as adhesion, bolt connection and adhesive and bolt mixed connection. The metal sleeve is connected with the composite material tube through the threads; the composite material tube is applied with radial pressure by an annular high-strength bolt or an interference fit method, the ultimate bearing capacity of the joint is improved, and the member stress reaches 700MPa; the shearing resistance of helical teeth and the interface friction transmit force together, so the connecting method has the advantages of difficult ageing, good fatigue resistance and multiple suitable section forms; and single or dual lug joints between composite material truss units, ball joints of composite material space trusses, anchorage devices with composite material ribs and cables can be manufactured and applied to truss bridges, space grids and prestressed bridges.

Owner:赵启林

Post-grouting technology adopting manual hole digging and all-casing construction method, and adopting manner of installing rubber capsule (cavity) at bottom of cast-in-place pile

InactiveCN109056716AEliminate settlementIncrease ultimate bearing capacityBulkheads/pilesRebarUltimate tensile strength

The invention discloses a post-grouting technology adopting a manual hole digging and all-casing construction method, and adopting a manner of installing a rubber capsule (cavity) at the bottom of a cast-in-place pile. The post-grouting technology is applicable to the technical field of foundation and underground space engineering. The background technology is that with regard to a borehole usinga mud protection wall at present, if a steel plate capsule is installed at the bottom of a reinforcement cage, the collapse of the hole wall of the borehole is easily caused, so that the sediment of the bottom of the hole exceeds the standard, and silt collapsing from the hole wall is easily accumulated on a steel plate, so that the quality of the cast-in-situ bored pile is influenced. The post-grouting technology has the most prominent characteristic that the limit conditions and the application conditions of closed grouting adopting a manner of installing a grouting container at the bottom of a pile are found; and the main content is that a manual hole digging method or an all-casing construction method is utilized for hole formation for the cast-in-place pile, the mud protection wall isnot used in a hole formation process, a grouting pipe is bound on the reinforcement cage, the steel plate is installed at the bottom of the reinforcement cage, the rubber capsule is installed on thebottom surface of the steel plate, and the grouting pipe penetrates through the steel plate and communicates with the rubber capsule. After the hole is formed by virtue of the construction method, thereinforcement cage is descended to reach the bottom of the hole, then concrete starts to be poured, and after the strength of the body of the pipe meets requirements, pressure grouting is carried outon the rubber capsule at the bottom of the pile through the grouting pipe.

Owner:高永光 +1

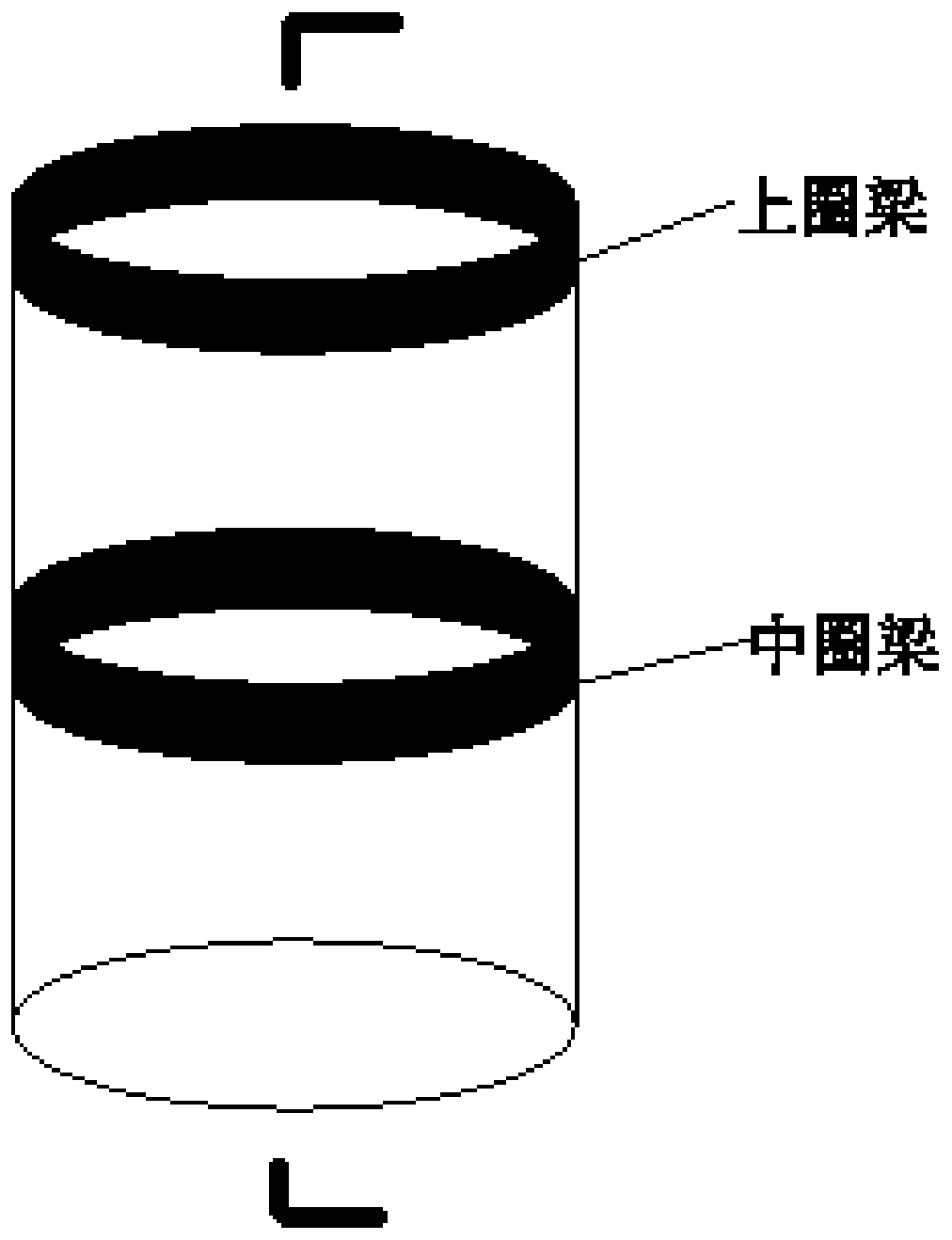

Method for reinforcing electric power tunnel by means of fiber grid enhanced polymer mortar and material

ActiveCN110952996AImprove crack resistanceIncrease ultimate bearing capacityUnderground chambersTunnel liningCelluloseGlass fiber

The invention discloses a method for reinforcing an electric power tunnel by means of fiber grid enhanced polymer mortar and a material, and belongs to the technical field of fiber grid enhanced cement-based composite material reinforcing. Raw material components comprise cement, polymers, polyvinyl alcohol fibers, alkali-resistant glass fibers, sand, water, a water reducer, starch ether, cellulose ether and the like. The method comprises the steps that pre-repairing such as filling and blocking is conducted on masonry or concrete tunnel wall cracks with the polymer mortar, and the mortar is embedded into the cracks; the surfaces of rusted steel bars are painted with a steel bar corrosion remover, and the tunnel wall is painted with one or two layers of an interface agent; and structural reinforcing is conducted on the tunnel and the well wall through multiple layers of the fiber grid enhanced polymer mortar. In order to improve the anti-seismic overall property, 1-3 fiber rib enhancedconcrete ring beams are arranged; and pretreatment is conducted firstly, and then reinforcing is conducted.

Owner:BEIJING UNIV OF TECH

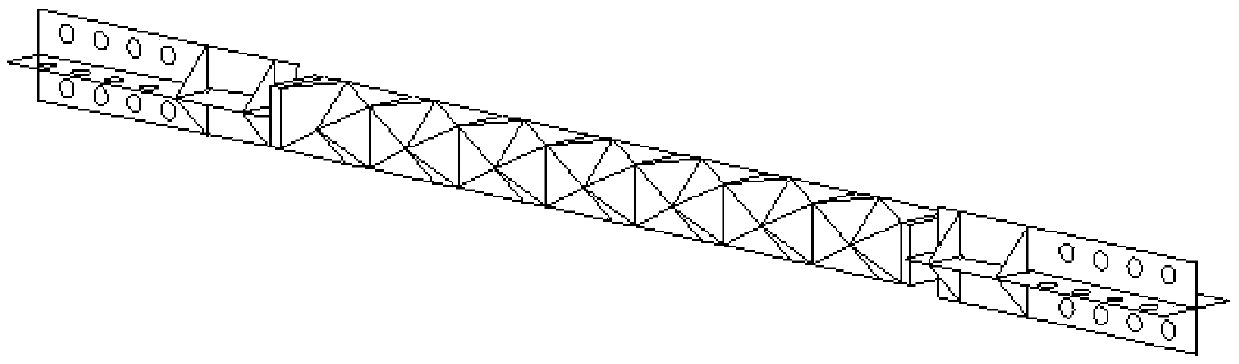

Inserted-type steel truss joint construction for building bridge or building structure

ActiveCN107165289AImprove connection reliabilityIncrease ultimate bearing capacityBridge structural detailsBuilding constructionsAdhesiveEngineering

An inserted-type steel truss joint construction comprises a steel truss joint, truss frame rod parts, fasteners, structural adhesives and bolts, wherein at least one be-inserted opening is formed in the steel truss joint, and a be-inserted end flange is arranged at the end of each be-inserted opening; each truss frame rod part is provided with an inserting end which can be in clearance fit with the be-inserted end of the steel truss joint, wherein an inserting end flange is arranged on the tail, opposite to the end of the truss frame rod part, of the inserting end; each fastener is composed of two half parts, a groove is formed in each fastener, and each groove is matched with the peripheries of the corresponding be-inserted end flange and the corresponding inserting end flange, upper half bosses are arranged at the two ends of a closing line of the first half parts of the fasteners, and upper half bolt holes are formed in each upper half boss, while a lower half bosses is arranged at the two ends of a closing line of the second half parts of the fasteners, and lower half bolt holes are arranged on the lower half bosses; structural adhesives are arranged in installing clearances; and the bolts enable the upper half bolt holes to be connected with the lower half bolt holes. The truss frame joint construction is high in construction efficiency, good in reliability, and long in service life.

Owner:BEIJING JIAOTONG UNIV

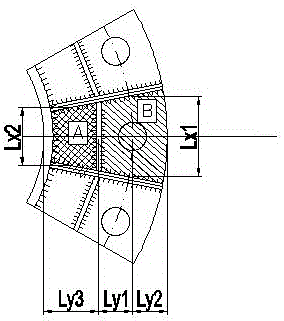

Combinational design method for radial and circumferential stiffening ribs of flange joints of tower feet of steel tube tower

ActiveCN106599365AReduce stress concentrationIncrease ultimate bearing capacityGeometric CADDesign optimisation/simulationStress concentrationElement analysis

The invention relates to a construction design method for flanged connections of steel tube towers or steel pipe poles applied in electric transmission lines, in particular to a combinational design method for radial and circumferential stiffening ribs of flange joints of tower feet of a steel tube tower. The method comprises following steps: adding circumferential stiffening ribs on original flange joints and designing original radial stiffening ribs in a combinational mode; taking a fan shape enclosed by the radial and circumferential stiffening ribs as a calculation unit and taking the ratio of limit value and design value borne by a flange bottom plate as references to adjust configurations of all parameters of flange joints with finite element analysis as a calculation basis; finally obtaining new flange joint construction. The combinational design method for radial and circumferential stiffening ribs of flange joints of tower feet of the steel tube tower has following beneficial effects: the overall calculation is largely close to actual value; stress concentration degree of the flange bottom plate is reduced to the maximum; uniform stress degree is increased; extreme bearing capabilities of flange joints are greatly improved; and strength of all regions of steel material is effectively applied.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +3

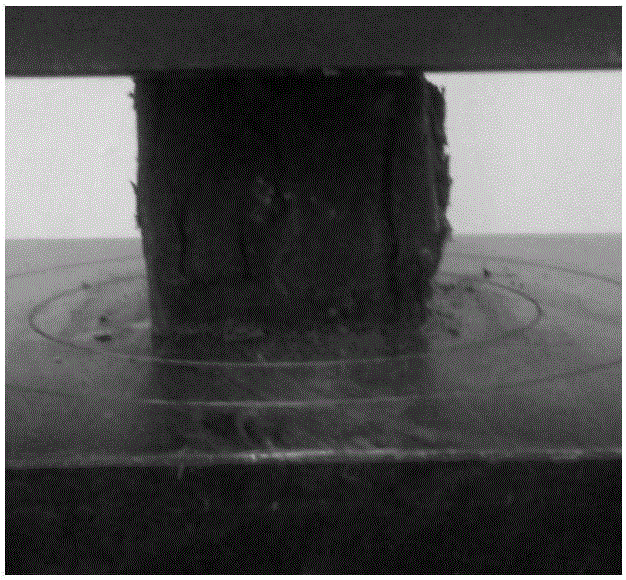

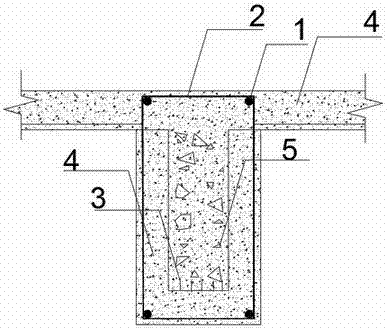

Steel rib-steel pipe regenerated-concrete combined column with cross-shaped section

A related steel rib-steel pipe regenerated-concrete combined column with a cross-shaped section is composed of a steel rib, a steel pipe, a steel skeleton and concrete; the steel rib is formed by welding steel plates, and is disposed on a limb of the cross-shaped column formed by stirrups in a circle; the steel pipe is at the core of the cross-shaped column; concrete is regenerated concrete and is at the interior and the exterior of the steel pipe and the interior of the cross-shaped column limb formed by stirrups in a circle; the steel rib is T-shaped by welding the steel plates; and corners of the cross-shaped column formed by stirrups in a circle are provided with vertical steel bars. Due to the fact that the regenerated concrete is at the interior and the exterior of the steel pipe, resource is saved and environment is protected. The steel skeleton constrains concrete and enhances the bearing capability of the column. The combined column is a main member of a framework structure of high-rise and wide-span buildings, and has the characteristics of high bearing capacity, high rigidity, light weight, good plasticity and toughness, good impact resistance and fatigue resistance, excellent earthquake-proof performance, good endurance, energy saving, environment friendliness and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

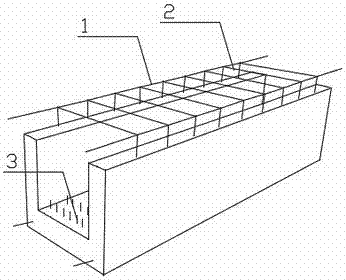

T-shaped steel pipe-steel rib recycled concrete combination column

The invention relates to a T-shaped steel pipe-steel rib recycled concrete combination column. The T-shaped steel pipe-steel rib recycled concrete combination column is composed of a steel rib, a steel pipe and recycled concrete, wherein the steel rib is formed by welding steel plates; the recycled concrete is located in the steel pipe; the concrete covers the steel rib; the steel pipe is in a T shape surrounding the concrete; the steel rib is welded to form the T shape and is distributed in the T shape; the steel rib which is distributed in the T shape is located at the center of the T-shaped steel pipe and is coaxial to the T-shaped steel pipe; the inner steel rib and the steel pipe are fixedly connected with a bottom plate through welding or bolt connection. The T-shaped steel pipe-steel rib recycled concrete combination column is good for improving the stress performance of a limb part of the T-shaped column; the concrete in the steel pipe is in a three-directional stressing state so that the deformation of the concrete is restricted and the application of fragile and high-strength concrete in the T-shaped column is accelerated; the T-shaped steel pipe-steel rib recycled concrete combination column is a main part of a framework structure in a high-rise and large-span building and has the characteristics of high bearing capability, high rigidity, light weight, good plasticity and toughness, good anti-impact and anti-fatigue performances, excellent anti-seismic property, good durability, energy conservation, environment friendliness and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

High-strength building waste regeneration concrete composite beam and construction method thereof

The invention discloses a high-strength building waste regeneration concrete composite beam and a construction method thereof. A high-strength building waste regeneration concrete composite beam body comprises a high-strength regeneration aggregate concrete prefabricated groove, cast-in-place regeneration block body concrete filled in the high-strength regeneration aggregate concrete prefabricated groove, a plurality of longitudinal bars arranged on a high-strength building waste regeneration aggregate concrete composite beam in the beam-length direction, a plurality of closed stirrups vertically arranged in the groove-length direction and bottom plate steel nails. According to the high-strength building waste regeneration concrete composite beam and the construction method thereof, overall manufacturing is convenient and quick, and the economic benefits are high; according to design of the bottom plate steel nails, adhering between the high-strength regeneration aggregate concrete prefabricated groove and the cast-in-place regeneration block body concrete can be tighter, integrality of the beam is improved, the bearing capacity of the structure is effectively improved, and the deformation property of the beam is improved; and ductility of components is increased, and the high-strength building waste regeneration concrete composite beam and the construction method thereof are applicable to beam structures such as heavy loads, industrial factory buildings, high-rise buildings and the large spans.

Owner:NANCHANG UNIV

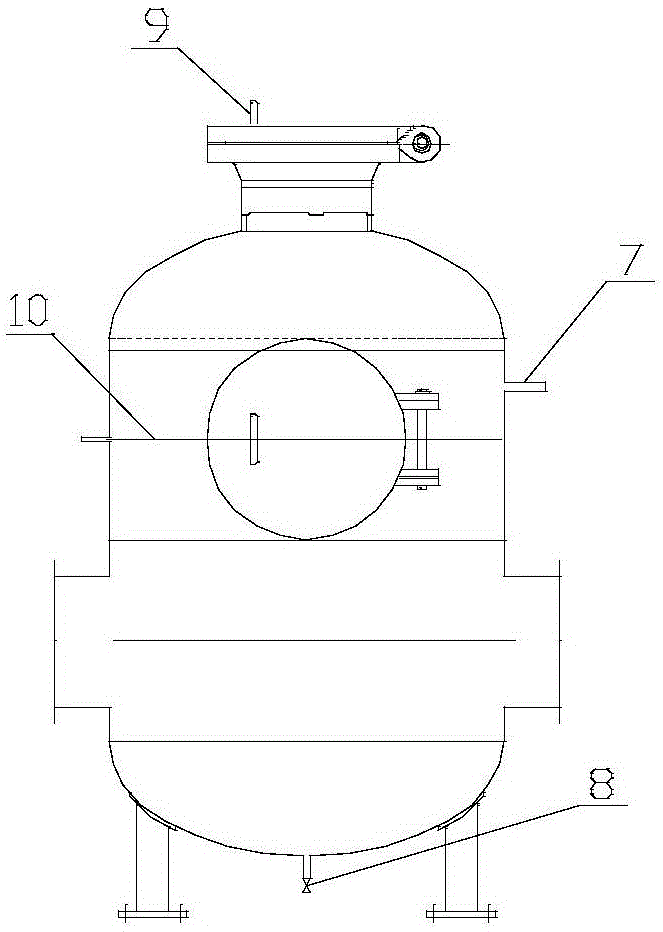

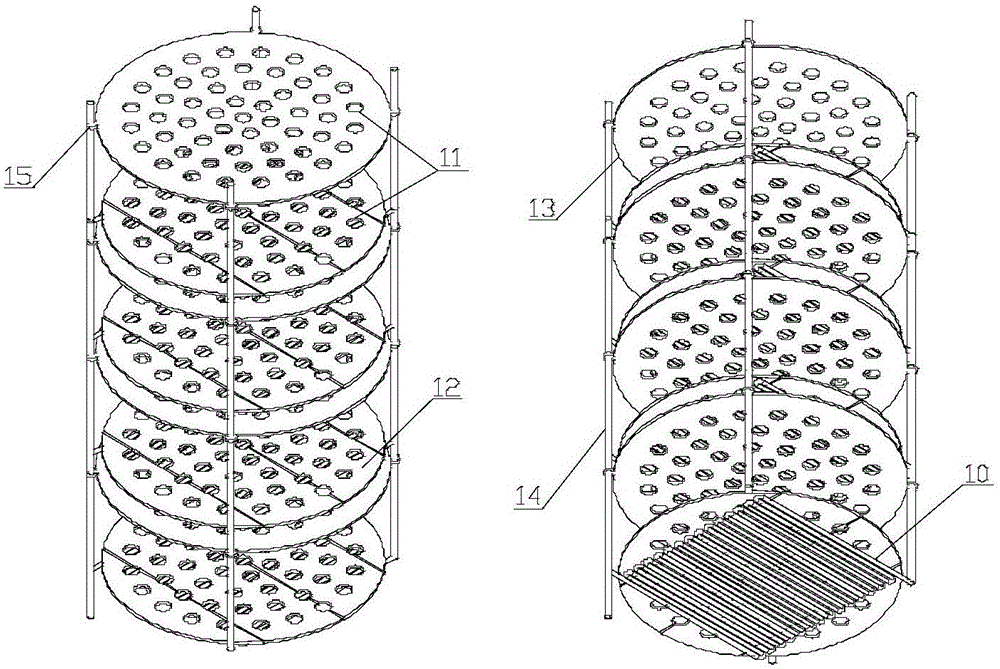

Adsorptive natural gas transporting tank for storing and transporting natural gas

InactiveCN105090742ATemperature balanceImprove adsorption efficiencyContainer filling methodsFixed capacity gas holdersActivated carbonThermodynamics

The invention discloses an adsorptive natural gas transporting tank for storing and transporting natural gas. A constant temperature system and a support structure are arranged at the inner part of the transporting tank, wherein the constant temperature system comprises heat dissipation holes and a constant temperature coiler; the support structure comprises support plates, more than two fixing plates and vertical pipes; the constant temperature coiler is communicated with the vertical pipes, the fixing plates are fixed through the vertical pipes, the constant temperature coiler is arranged on the fixing plates, and the support plates is arranged on the constant temperature coiler; activated carbon is placed on the one support plate, and another fixing plate is arranged on the activated carbon; the heat dissipation holes are formed in the support plate. Four hand holes are also formed in the transporting tank, so that the activated carbon is convenient to take out and exchange, and the transporting tank is convenient to maintain. In addition, high temperature N2 can also be directly connected with an air inlet pipe, the activated carbon does not need to be taken out, and regeneration is directly performed. The adsorptive natural gas transporting tank disclosed by the invention has the characteristics of being convenient to operate, good in applicability, high in safety and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Steel skeleton-steel pipe fiber concrete cross shaped section composite column

InactiveCN104100041AImprove fire resistanceImprove corrosion resistanceStrutsPillarsHigh strength concreteFiber

The invention relates to a concrete member, particularly to a cross shaped section composite column used for civil engineering. The steel skeleton-steel pipe fiber concrete cross shaped section composite column is composed of steel skeletons, a steel pipe, steel bars and fiber concrete. The steel skeletons are on the limbs of the cross shaped column, and are in favor of improving the stress performance of the limbs of the T-shaped column; the steel pipe is located at the intersecting core part of the column limbs, thus effectively limiting the brittle deformation of high-strength concrete and promoting application of high-strength concrete in the cross shaped column; the fiber concrete is arranged inside and outside the steel pipe, and the characteristics of the fiber material are fully utilized to improve the low brittleness, tensile strength, shearing resistance, bending strength and other disadvantages of high-strength concrete; the steel bar skeletons have a restriction effect on the fiber concrete and strengthen the bearing capacity of the column. The steel skeleton-steel pipe fiber concrete cross shaped section composite column provided by the invention is a main member of the frame structure in high-rise and large span buildings, and has the characteristics of high bearing capacity, high stiffness, light weight, good plasticity and toughness, good impact and fatigue resistance, excellent seismic performance, and good durability, etc.

Owner:SHENYANG JIANZHU UNIVERSITY

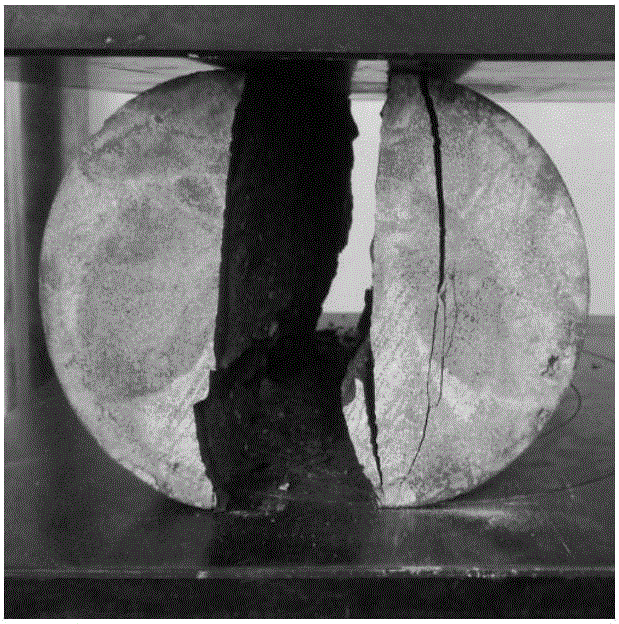

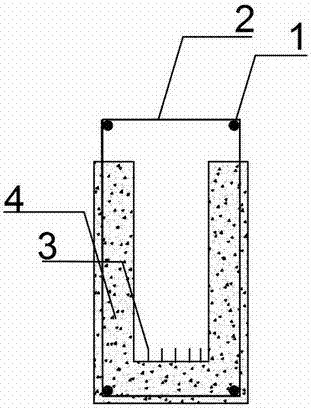

Function gradient concrete composite well wall and manufacturing method

InactiveCN111287754AReduced strength requirementsReduce wall thicknessShaft liningHigh strength concreteStructural engineering

The invention discloses a function gradient concrete composite well wall and manufacturing method and belongs to the technical field of vertical well construction. The function gradient concrete composite well wall is manufactured by adopting a prefabricating or cast-in-place manner. The function gradient concrete composite well wall comprises multiple layers of concrete well walls, wherein the concrete well walls are combined coaxially and closely, and elastic moduli of the concrete well walls are different. Damping material layers are arranged among the layers. All the well walls are arranged with different thicknesses. The concrete material performance is utilized fully, and the function gradient concrete composite well wall with the low requirement for concrete strength, small wall thickness and low project manufacture cost is manufactured. The elastic limit bearing capacity of a thick-wall cylinder is improved remarkably, and high-strength concrete does not need to be used. The well wall thickness is reduced, the material use amount is reduced, and the project manufacturing cost is reduced substantially.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for implanting steel bar to reinforce groove-type beam bridge face plate through UHPC thin layer

InactiveCN106836017ALow input costSimplify construction stepsBridge structural detailsBridge erection/assemblyThin layerEconomic benefits

The invention relates to a method for implanting steel bars to reinforce a groove-type beam bridge face plate through a UHPC thin layer. Particularly, super-high-strength performance of UHPC is utilized, by implanting the steel bars and pouring the UHPC, poured concrete and an original structure becomes a whole and bear force jointly. The UHPC has ultra-low permeability and high corrosion resistance, high cohesiveness with an interface, and the UHPC can form a good whole with the implanted steel bars after poured and can protect the steel bars against being rusted. The reinforced groove-type beam bridge face plate is light in self-weight and high in bend-tensile resisting strength; the ultimate bearing capacity of the reinforced structure can be improved greatly, no exposed steel bars or steel plate exist after reinforcing; later maintenance is easy, the maintenance cost is low, and a special maintenance means is not needed; early stage strength forming is fast; and the influence on traffic is little, the traffic does not need to be closed to conduct construction so that social and economic benefits are high.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com