Inserted-type steel truss joint construction for building bridge or building structure

A steel truss and plug-in technology, applied in building construction, bridge construction, bridges, etc., can solve problems such as difficult to break through technical bias, durability affects connection reliability, etc., achieve remarkable technical effects and meet the requirements of mechanical properties , to ensure the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

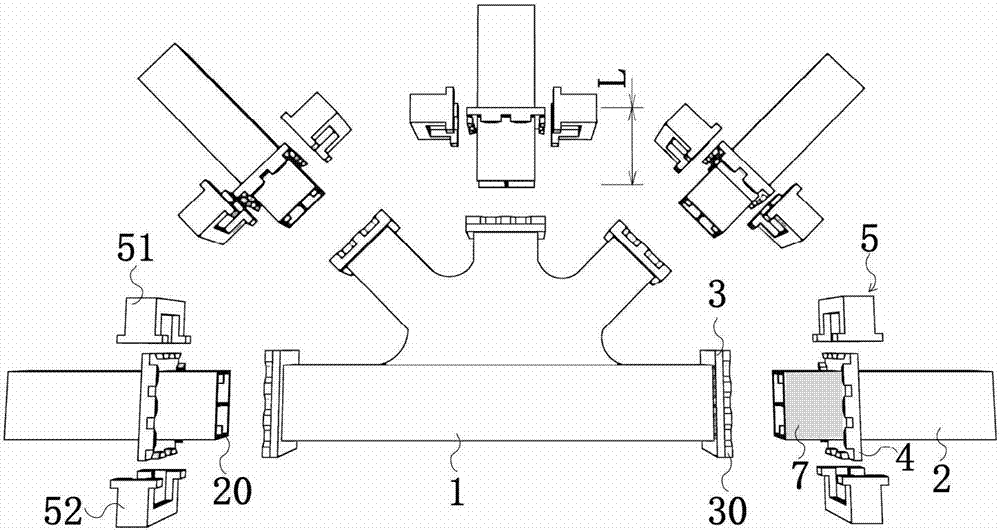

[0028] Such as Figure 1-3 As shown, according to an embodiment of the present invention, the plug-in steel truss node construction includes:

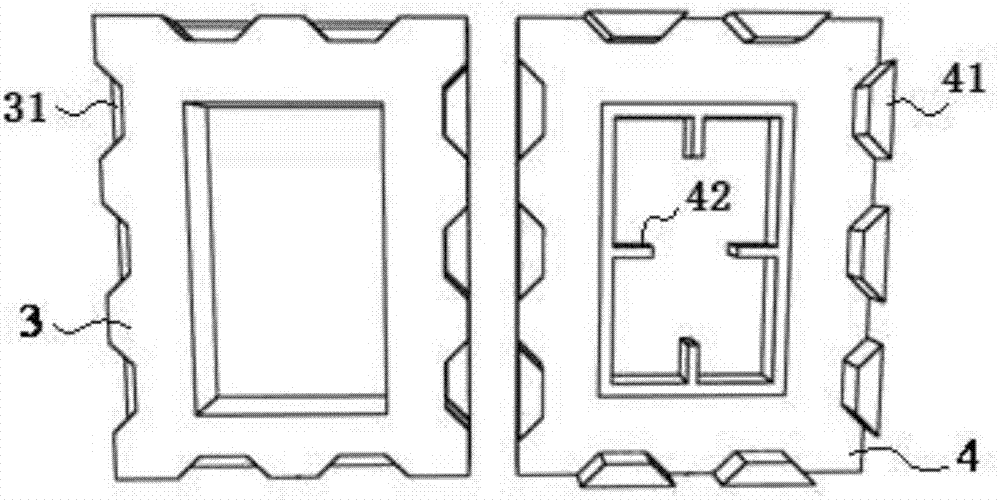

[0029] Steel truss node 1, which has at least one inserted opening, and the end 30 of each inserted opening is provided with an inserted end flange 3;

[0030] A truss member 2, which has an insertion end capable of clearance fit with the inserted end of the steel truss node 1, at the tail of the insertion end opposite to the end 20 of the truss member 2 (with the end 20 The distance is L) there is an insertion end flange 4;

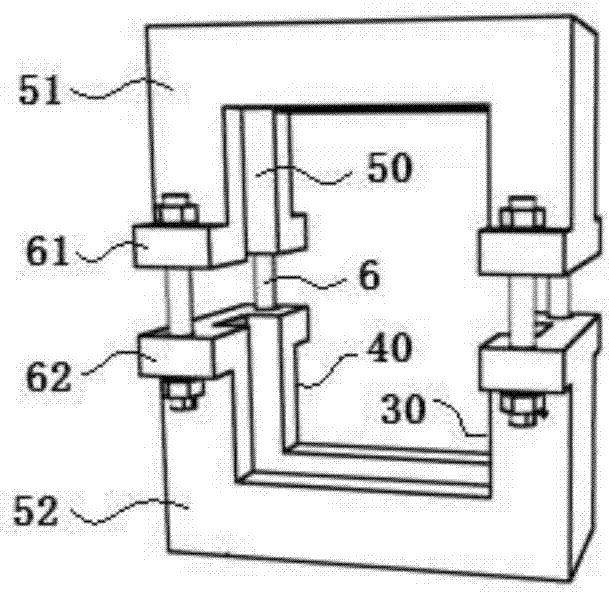

[0031] A fastener 5, which is composed of two halves 51, 52, the fastener 5 is provided with a groove 50 matching the periphery of the inserted end flange 3 and the insertion end flange 4, the groove 50 The width is the sum of the width of the inserted end flange 3 and the width of the inserted end flange 4, and one side of the fastener 5 has an inserted end matched with the inserted end of the steel truss node...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com