Patents

Literature

2031 results about "Basalt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Basalt (US: /bəˈsɔːlt, ˈbeɪsɒlt/, UK: /ˈbæsɔːlt, ˈbæsəlt/) is a mafic extrusive igneous rock formed from the rapid cooling of magnesium-rich and iron-rich lava exposed at or very near the surface of a terrestrial planet or a moon. More than 90% of all volcanic rock on Earth is basalt. Basalt lava has a low viscosity, due to its low silica content, resulting in rapid lava flows that can spread over great areas before cooling and solidification. Flood basalt describes the formation in a series of lava basalt flows.

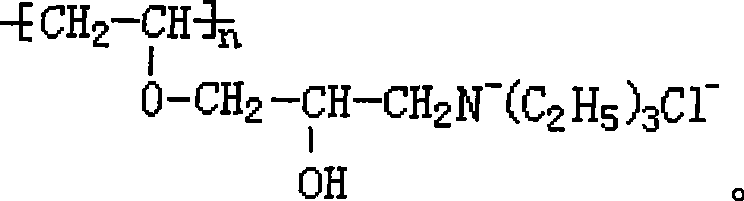

Basalt fiber surface modification impregnating compound and preparation method thereof

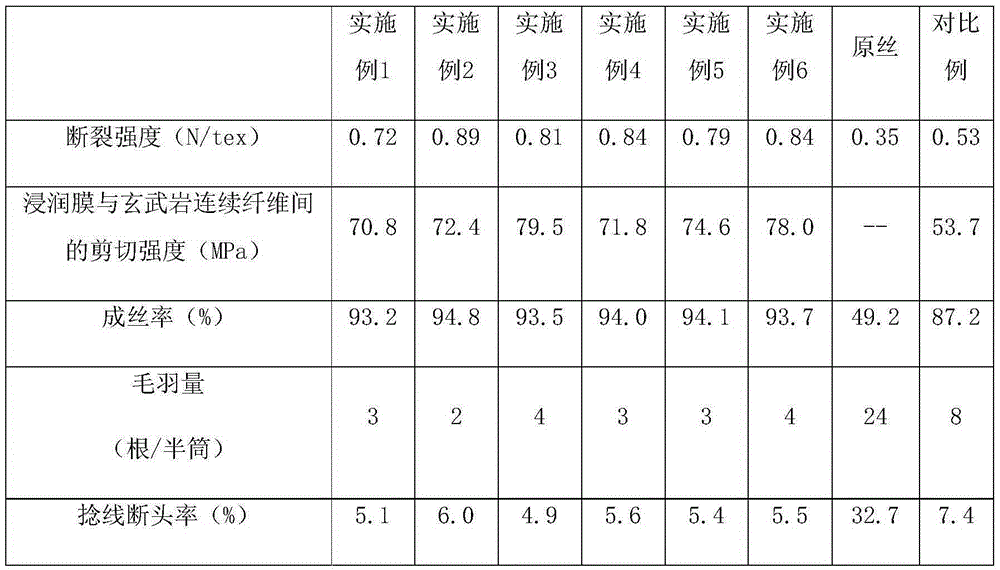

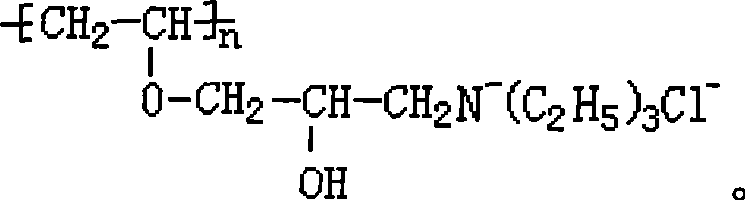

The invention discloses a basalt fiber surface modification impregnating compound and a preparation method thereof, and belongs to a basalt fiber impregnating compound. The impregnating compound comprises the following components in percentage by weight: 0.2-0.6% of organic silane coupling agent, 0.05-0.3% of pH (potential of hydrogen) conditioning agent, 3.0-10.0% of polyvinyl acetate emulsion, 0.2-2.0% of polyurethane emulsion, 0.5-3.0% of water-borne epoxy resin film forming matter, 1.0-5.0% of polyolefin emulsion, 0.1-1.0% of organic silicon emulsion, 0.1-1.0% of antistatic agent and the balance of water. The basalt fiber surface modification impregnating compound prepared according to the rated mass ratio is directly coated on the surface of basalt fiber in the basalt producing and wiredrawing process, and the surface modification is finished after the basalt fiber surface modification impregnating compound is dried, thereby being convenient to use. Meanwhile, the preparation method for the basalt fiber surface modification impregnating compound, which is disclosed by the invention, is simple, is suitable for industrial production and is easy for popularizing.

Owner:SICHUAN AEROSPACE TUOXIN BASALT IND

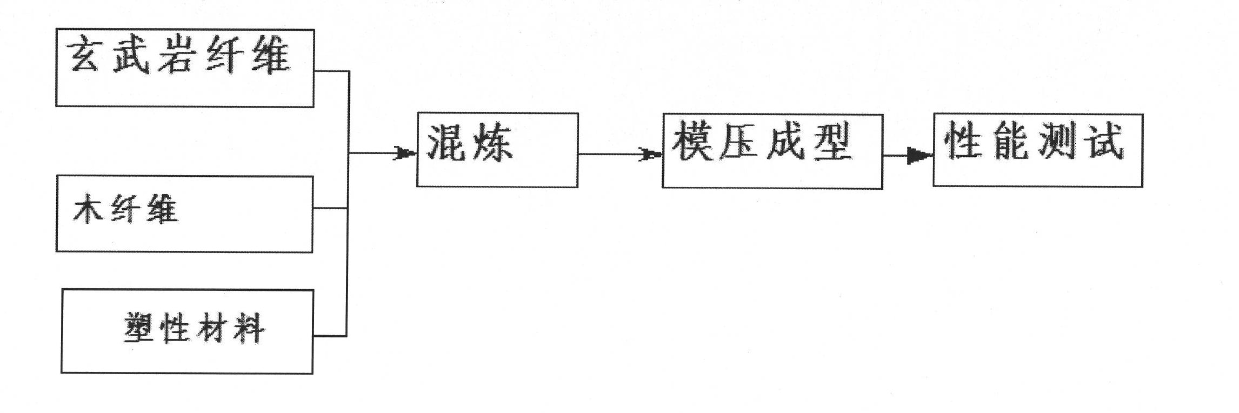

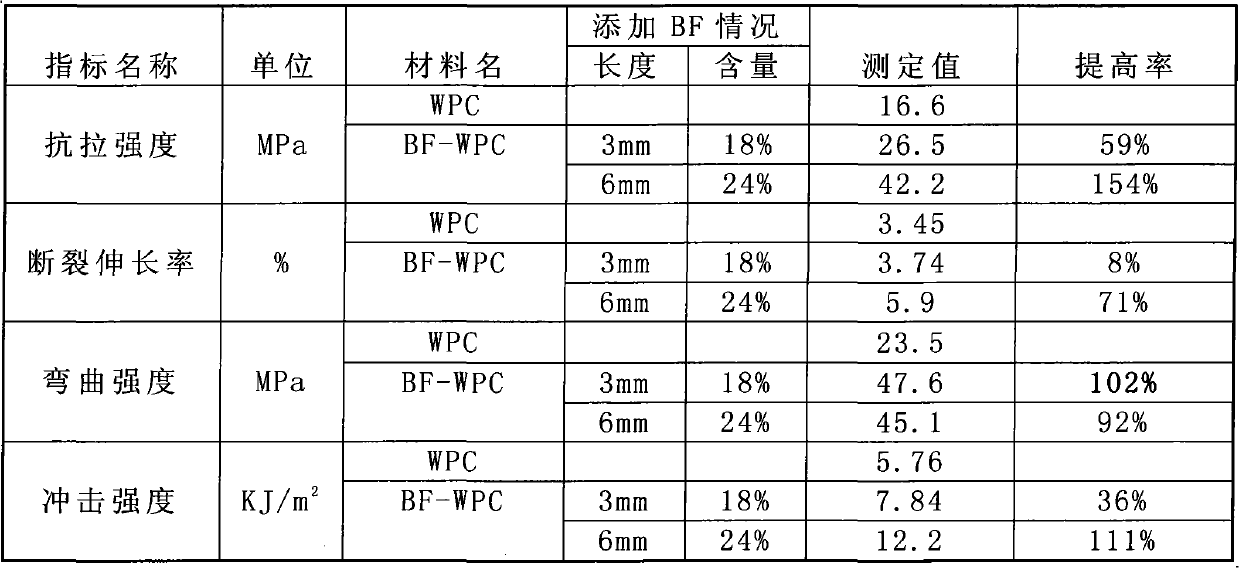

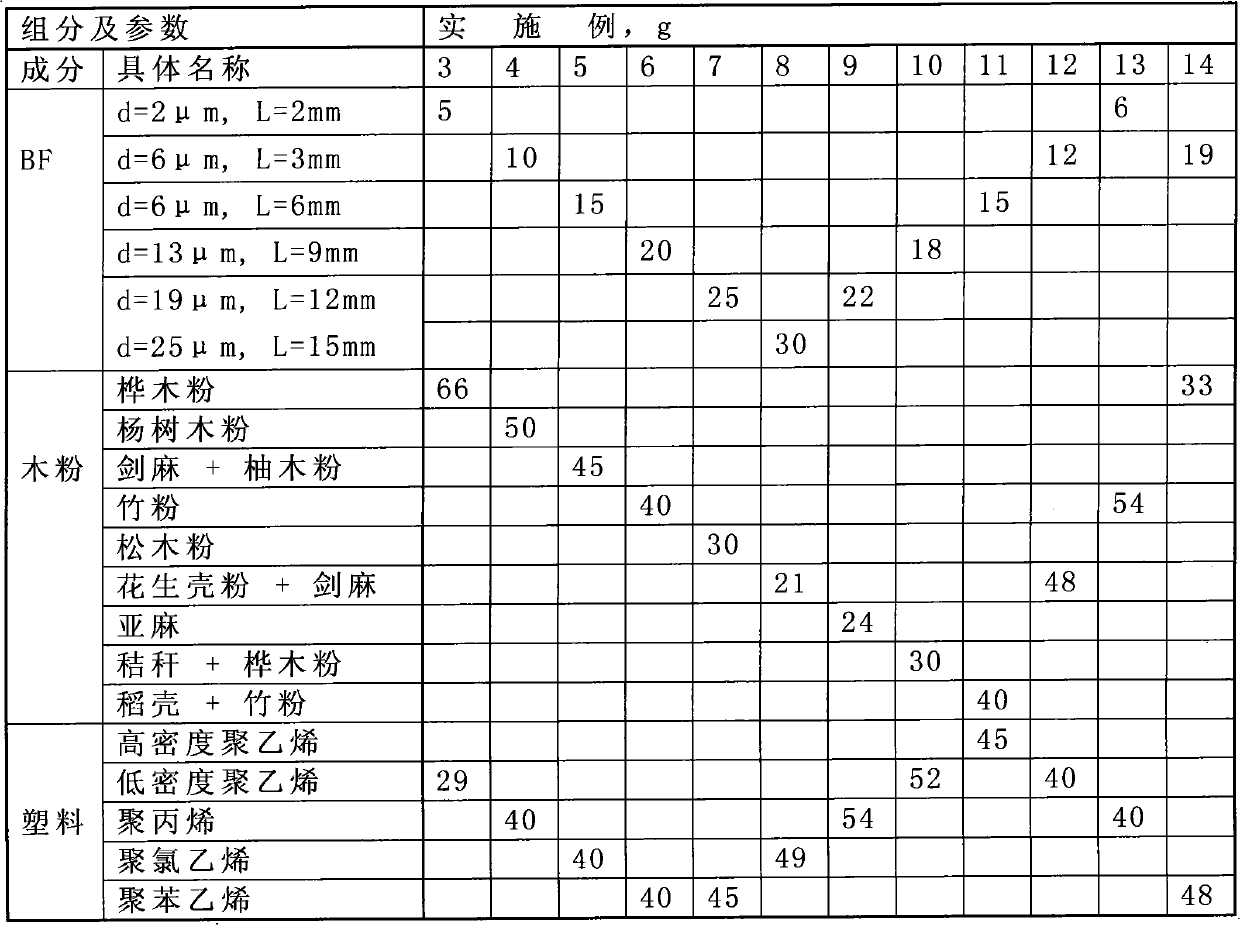

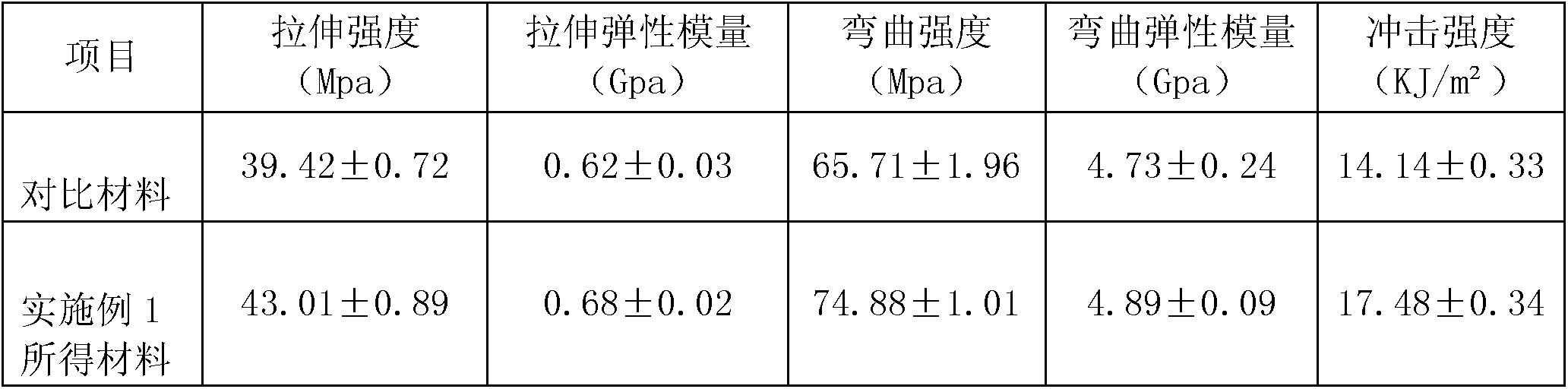

Basalt fiber reinforced wood-plastic composite material and preparation method thereof

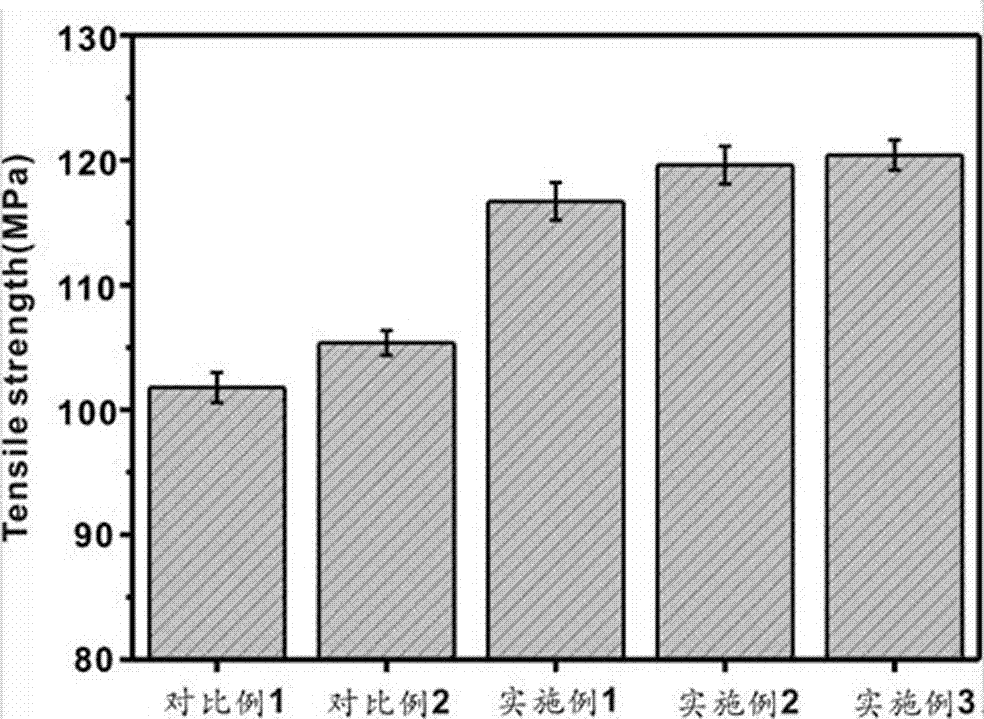

The invention relates to a basalt fiber reinforced wood-plastic composite material. The composite material is characterized by comprising 5 to 30 parts of chopped basalt fiber with length of 2 to 15 millimeters and diameter of 2 to 25 microns, 21 to 66 parts of wood fiber and 21 to 66 parts of plastic material in part by weight. A preparation method comprises the following steps of: weighing each component according to a proportion, mechanically mixing the components and then feeding the mixture into a double-roll open mill to perform plasticizing and mixing, controlling the temperatures of front and rear rolls at 160 DEG C and 170 DEG C respectively, and mixing the components for 10 minutes till the system is mixed uniformly, namely no BF is observed from the surface; crushing the uniformly plasticized material by using a crusher till the diameters of the particles of the material are not more than 20 millimeters; and heating, mold-pressing and molding the crushed material by using a flat vulcanizing machine to obtain a plate sample. The tensile strength, bending strength and impact strength of the basalt fiber reinforced wood-plastic composite material obtained by the method are improved by over two times, and the composite material has good economic and social benefits.

Owner:SOUTHEAST UNIV

Basalt fiber high temperature compositing filter material

InactiveCN101053718AImprove high temperature resistanceMeeting the needs of the high temperature filtration industryFiltration separationThermal energyIndustrial gas

The invention provides a basalt fibre high-temperature composite filter material. The high-temperature composite filter material is formed by weaving or needling, using the basalt fibre or the mixture of basalt fibre and other high temperature material which is one or more of the glass fibre, stainless-steel fibre and ceramic fibre. The invention can effectively improve the resistance to high temperature of filter material, extending the useful life, and also recycle heat energy, which saves energy source, has a excellent filter effect, and meet the need in the industry of industrial gases filter in high temperature.

Owner:江苏正大森源集团

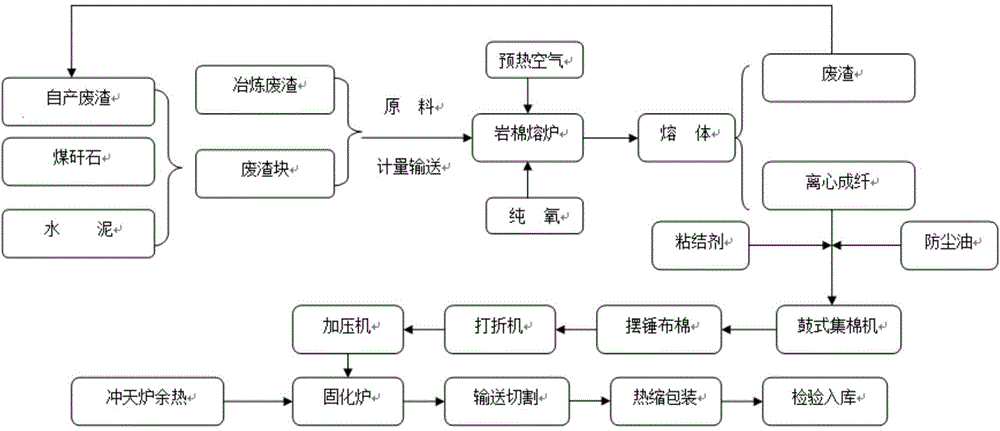

Method for producing rock wool

The invention relates to a method for producing rock wool, which comprises the following steps: 1) selecting slag as a principle raw material, adding basalt or silica, and melting in a melting furnace; 2) under the action of a centrifugal machine, drawing the melted materials into fibers, utilizing high-pressure air to blow the fibers into a wool collecting machine, separating out slag balls during a blowing process, and meanwhile, applying a binder onto the surfaces of the fibers; 3) forming the fibers into a primary wool layer under the action of the wool collecting machine, conveying the primary wool layer to a conveyer under the action of a pendulum bob machine, and forming a wool felt of a multilayer folding structure on a conveying belt of the conveyer; 4) preparing the wool felt into structural wool under the action of a pressing pleating machine; and 5) feeding the structural wool into a curing furnace for pressing and forming, and meanwhile, blowing 220-300 DEG C hot air, and curing a water-soluble phenolic resin solution which is used as a binder. The rock wool produced according to the method has the advantage of high compression strength. The method provided by the invention belongs to the field of the manufacturing of an inorganic nonmetallic material.

Owner:HUZHOU LINGJIA THERMAL INSULATION MATERIALS

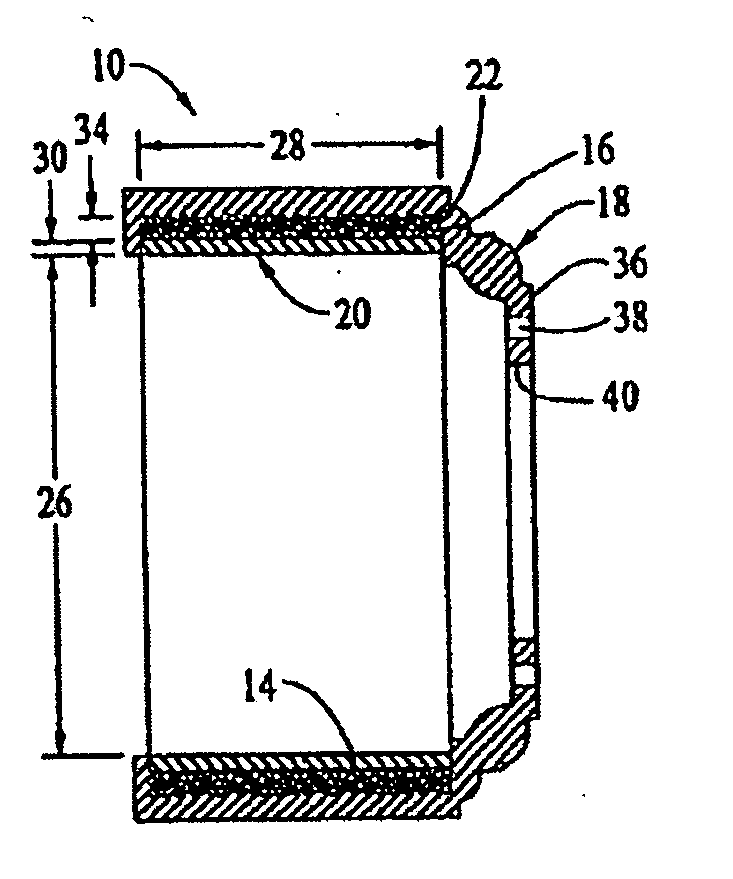

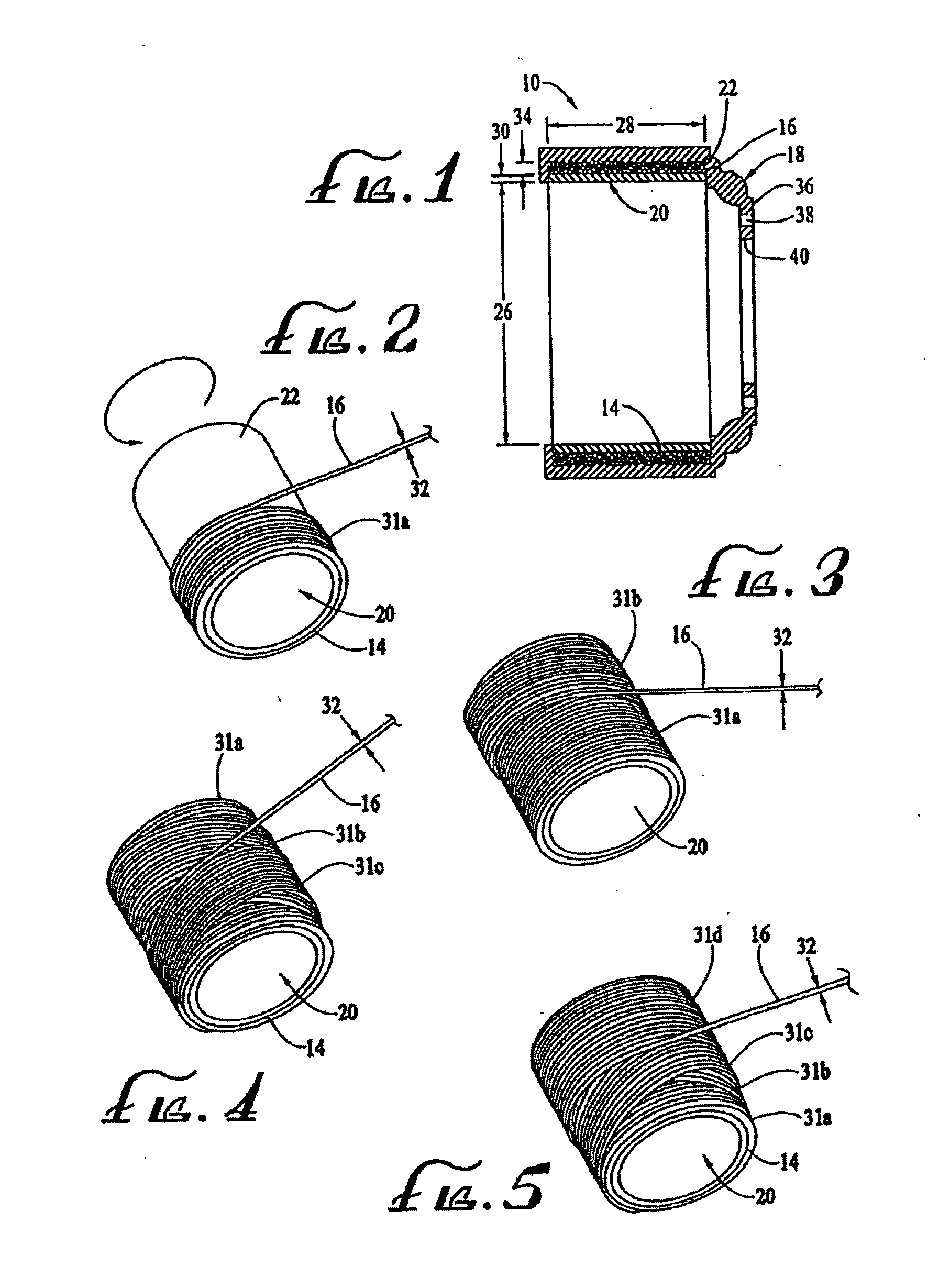

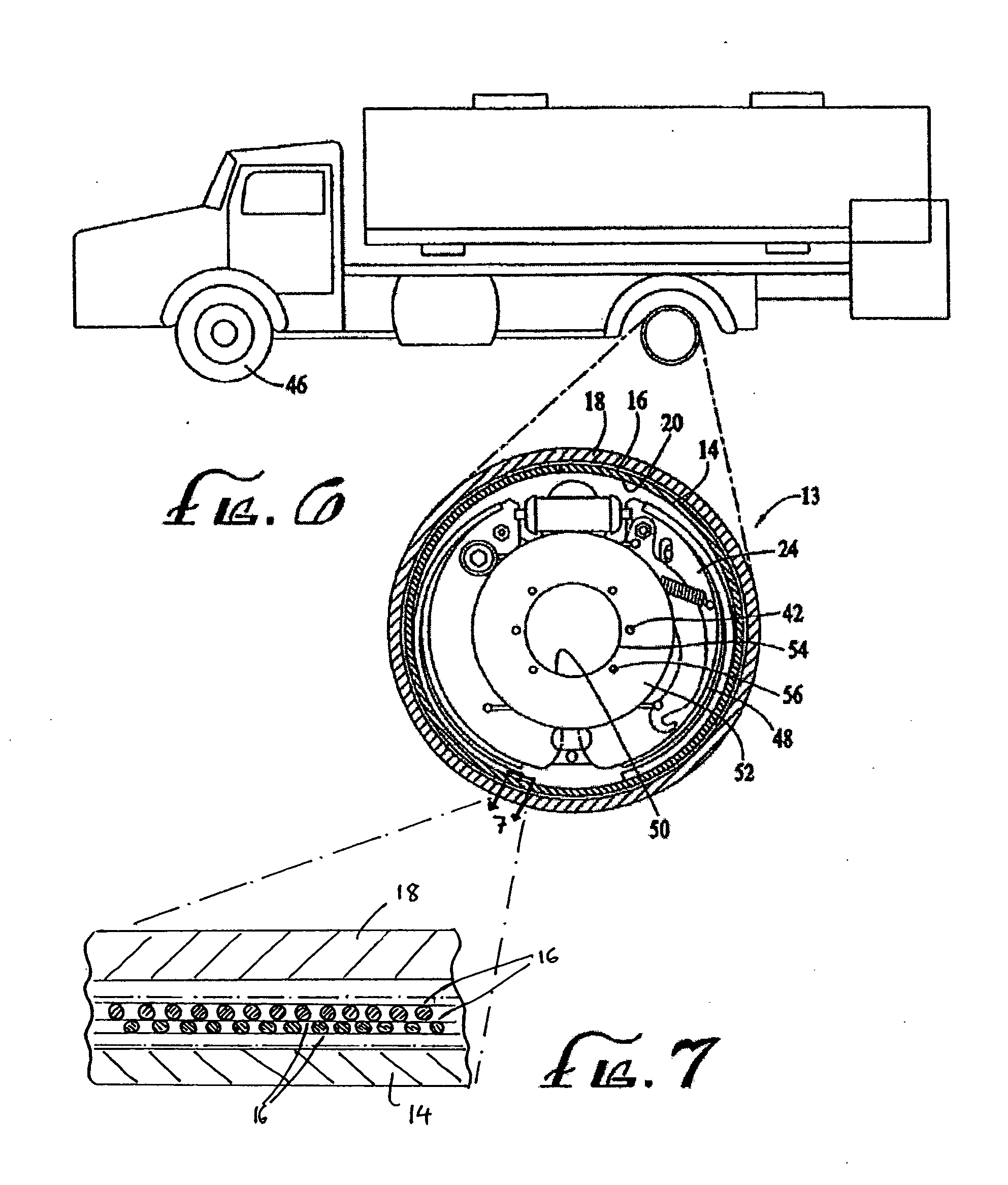

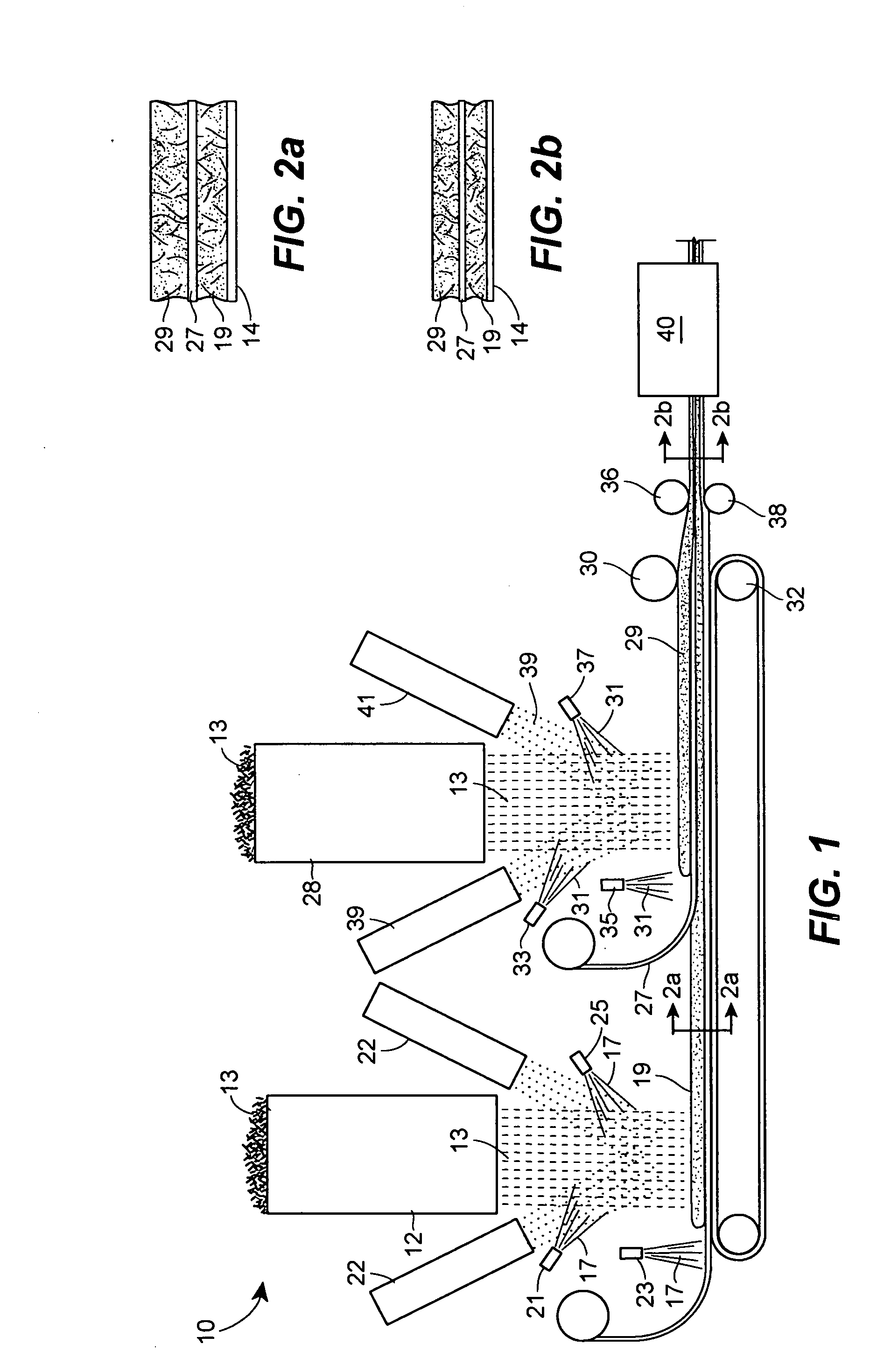

Lightweight reinforced brake drum and method for making same

InactiveUS20050217950A1Reduce manufacturing costAdd supportBraking drumsCoatingsCarbon graphiteEngineering

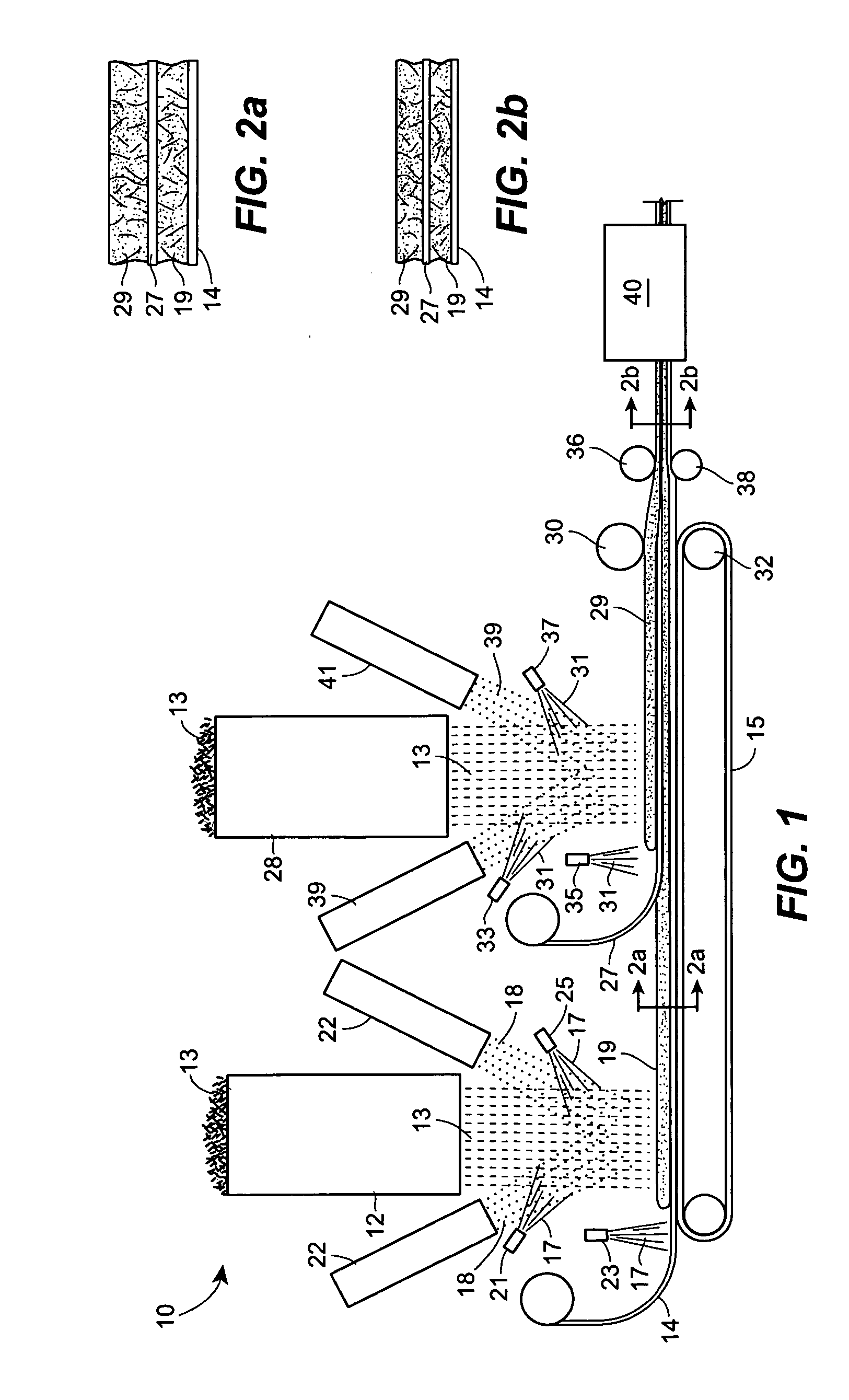

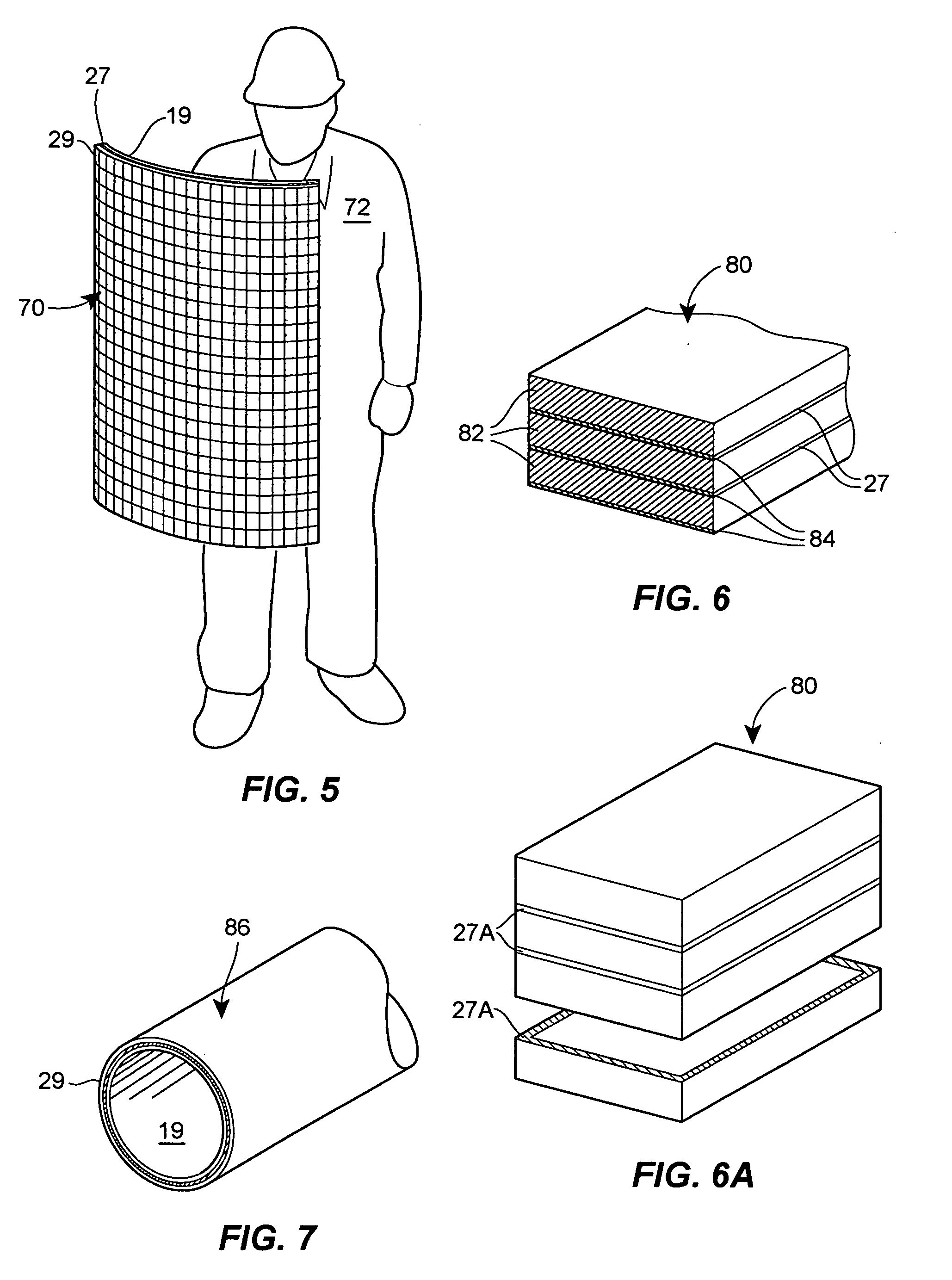

The invention provides a lightweight brake drum (10) comprising a lightweight, tubular inner member (14) having a reinforcement wrapping retention pattern (e.g., groove) cast in the exterior surface thereof, a length of reinforcement material (e.g., wrapped wire, cable, mesh, fibers, etc.) (16) in communication with a reinforcement retention pattern (e.g., a groove around the inner member) (14), the drum including an outer shell (18). The inner member (14) and the outer shell (18) are made of lightweight materials. Single, or multiple layers of reinforcement material (e.g. wrapping) are applied (e.g., wrapped) around the inner member (14) to support and inhibit expansion of the inner member (14). Because the reinforcement material (16) provides support against expansion, the inner member (14) and the outer shell (18) can be made of lightweight materials. In preferred embodiments, a bonding layer (66) is applied to the exterior surface of the inner member prior to application of the reinforcement material thereon. In preferred embodiments the reinforcement material comprises a low-impedance material such as copper along with another material that has good tensile strength characteristics (e.g., steel, composite fibers, Basalt-fibers, etc.). Preferably, the inner member comprises at least one material selected from the group consisting of a aluminum-based metal matrix composite (MMC) with a particulate reinforcement, ceramic matrix composite (CMC), and carbon graphite foam.

Owner:BENMAXX

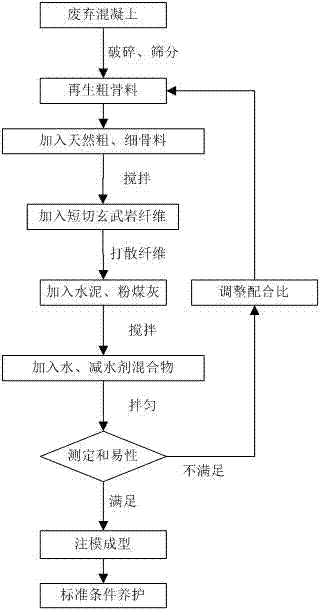

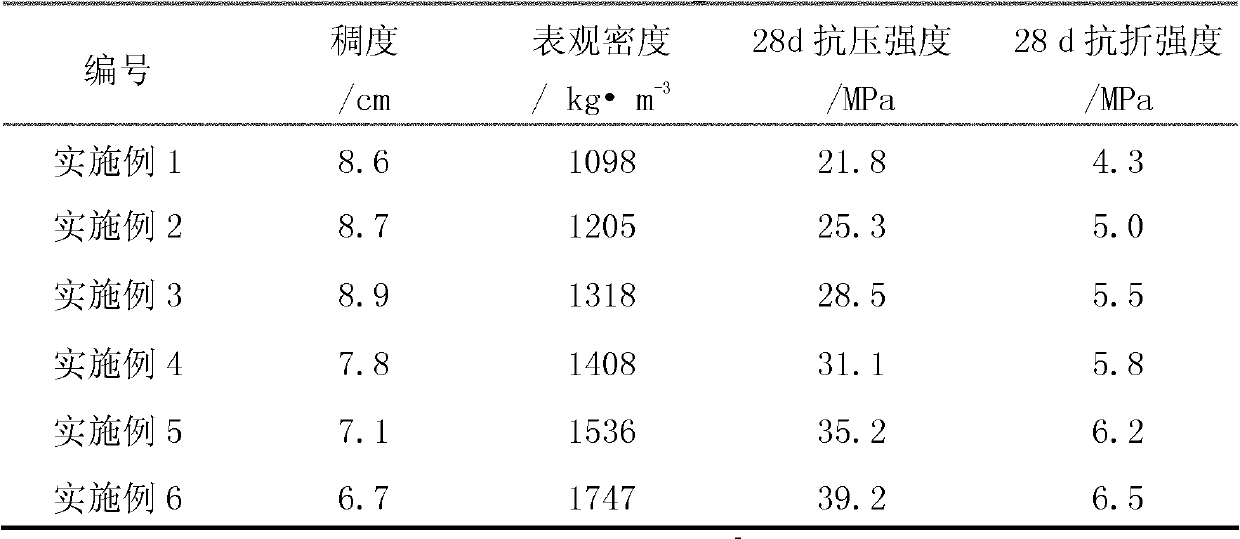

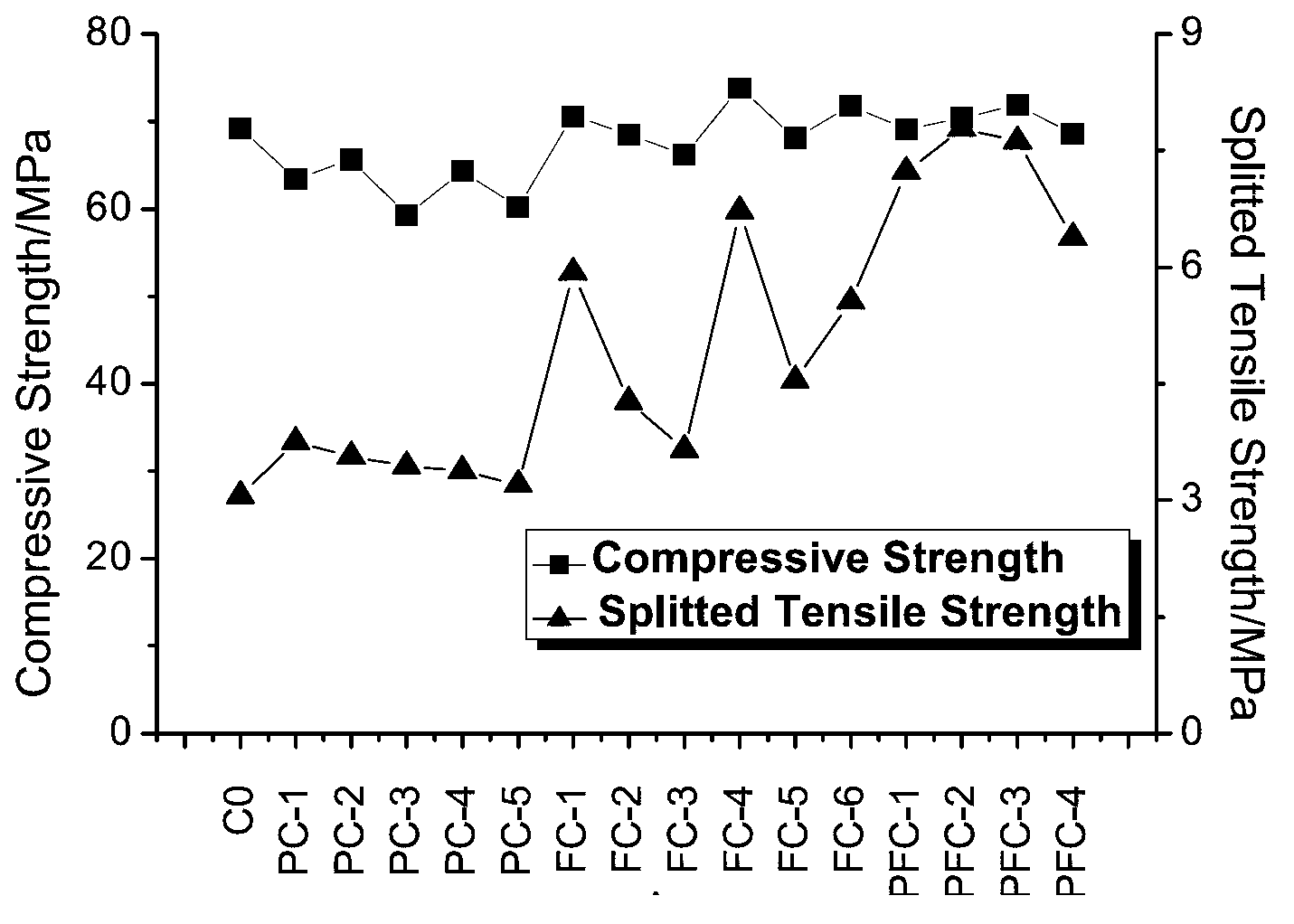

Recycled concrete doped with short-cut basalt fibers and recycled coarse aggregate

The invention belongs to the field of building materials and in particular relates to recycled concrete doped with short-cut basalt fibers and recycled coarse aggregate. The recycled concrete is prepared from the following raw materials in parts by weight: 100-300 parts of water, 300-500 parts of ordinary Portland cement, 500-700 parts of medium sand, 500-650 parts of natural gravels, 500-650 parts of recycled coarse aggregate, 30-50 parts of fly ash, 1-5 parts of a water reducing agent and 1-6 parts of short-cut basalt fibers. The recycled concrete provided by the invention is low in preparation cost, and the obtained concrete has high temperature resistance, corrosion resistance, tensile strength, crack resistance and better durability property.

Owner:FUZHOU UNIV

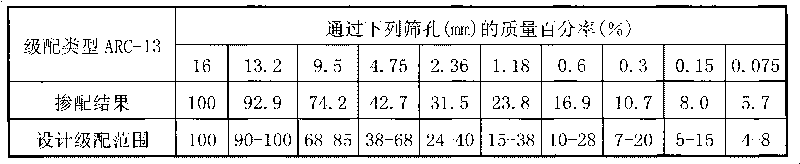

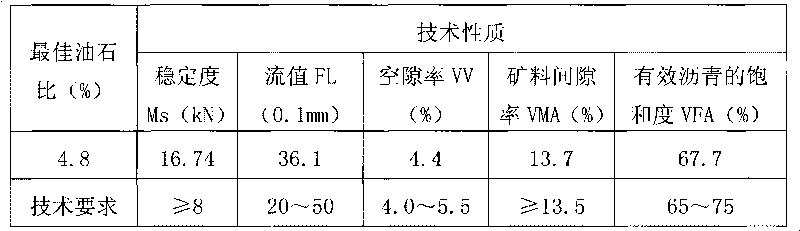

Method for enhancing bituminous mixture by adopting chopped basalt fibers

InactiveCN101712803AImprove high temperature stabilityFix rutsBuilding insulationsCrack resistanceWhole-life cost

The invention relates to a method for enhancing bituminous mixtures by adopting chopped basalt fibers, belonging to the technical field of novel compound materials. According to the invention, continuous basalt protofilaments or twistless rovings the surfaces of which are expanded into fibers in certain length, and then the fibers are used for enhancing the bituminous mixtures in a certain doping proportion and can be respectively used for maintaining the bituminous mixtures used for new construction and reconstruction and extension of highways and SMA and OGFC bituminous mixtures as well as fiber seals. In addition, the fibers can also be used for the enhancement of high-speed railway packing layer CA mortar and relevant hydraulic architectures. The chopped basalt fiber plays roles of enhancing, toughening and elasticizing the cracking prevention, crack resistance and reinforcement and 'bridging' in the enhanced bituminous mixtures, can obviously increase the anti-rutting ability of highways of the enhanced bituminous mixtures and reduces the whole life costs of the enhanced bituminous mixtures; if the fibers are used for high-speed railway plate-type ballastless tracks and CA mortar, the bending strength and the deformation resistance can be increased, i.e. the fibers play a role of crack prevention and crack resistance; in addition, the fibers have better anti-water leakage action if being used for Hydraulic and Hydro-Power Engineering.

Owner:ZHEJIANG GBF BASALT FIBER +1

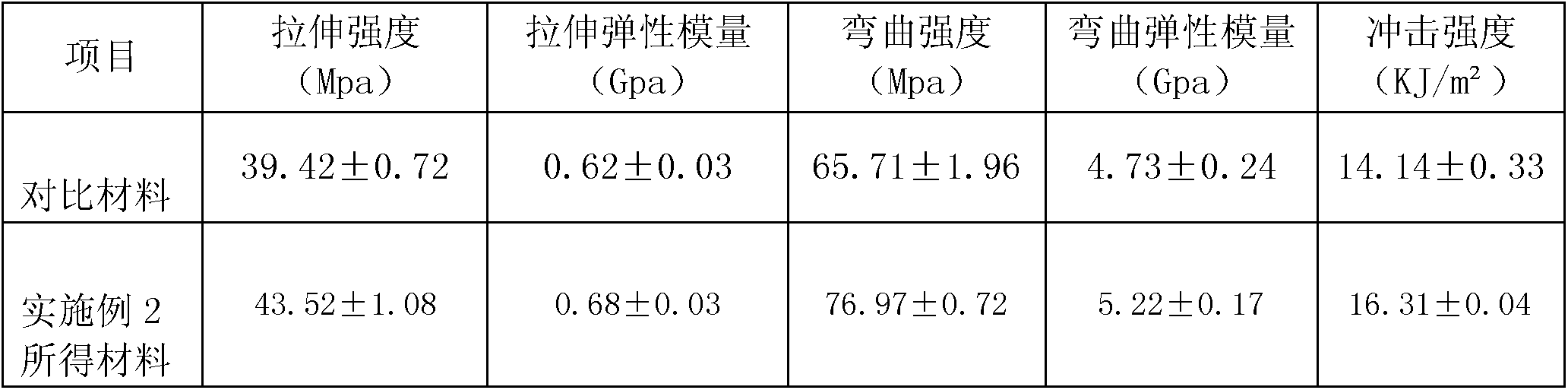

Basalt fiber reinforced wood-plastic composite material and preparation method thereof

The invention discloses a basalt fiber reinforced wood-plastic composite material and a preparation method thereof, and relates to a wood-plastic composite material and the preparation method thereof. The problem of bad comprehensive mechanical property of the current wood-plastic composite material is solved. The material is prepared from thermoplastic plastic, a wood fiber material, modified basalt fibers, a bulking agent and a lubricant. The preparation method comprises the following steps: 1. pre-treating the wood fiber material; 2. sequentially putting the raw materials in a high-speed mixer to be stirred, discharging the materials into a low-speed cold mixer to be stirred, and cooling the materials to obtain premix; and 3. carrying out extrusion forming on the premix. Beside keeping the advantages of good weather fastness, thermal insulation, water resistance, corrosion resistance, and the like, the basalt fiber reinforced wood-plastic composite material provided by the invention has the advantages that the mechanical property is greatly improved compared with common wood-plastic composite materials, and the problems of low mechanical strength and large brittleness of traditional wood-plastic composite material products are well solved. Leftover materials generated in the production process of the basalt fiber reinforced wood-plastic composite material provided by the invention can be entirely recycled, few additives are added, and the basalt fiber reinforced wood-plastic composite material is environment-friendly, thereby being a typical environment-friendly material.

Owner:JILIN HABOD NEW MATERIALS TECH

High-strength basalt fibre reinforced nylon composition and preparation method thereof

The invention discloses high strength basalt fiber reinforcing nylon composition, which comprises the following components and contents (parts by weight): 50-70 percent of nylon, 20-40 percent of basalt fiber, 3-12 percent of toughening agent, 1-5 percent of antioxidant, 0.3-1 percent of coupling agent and 0-15 percent of other accessory ingredient. Compared with the common glass fiber reinforcing nylon composition in the present market, the high strength basalt fiber reinforcing nylon composition has the advantages of high intensity, high impact strength and good temperature resistance, etc.

Owner:SHENZHEN KEJU NEW MATERIAL

High-iron ground steel slag lightweight high-toughness wave absorption concrete and preparation method thereof

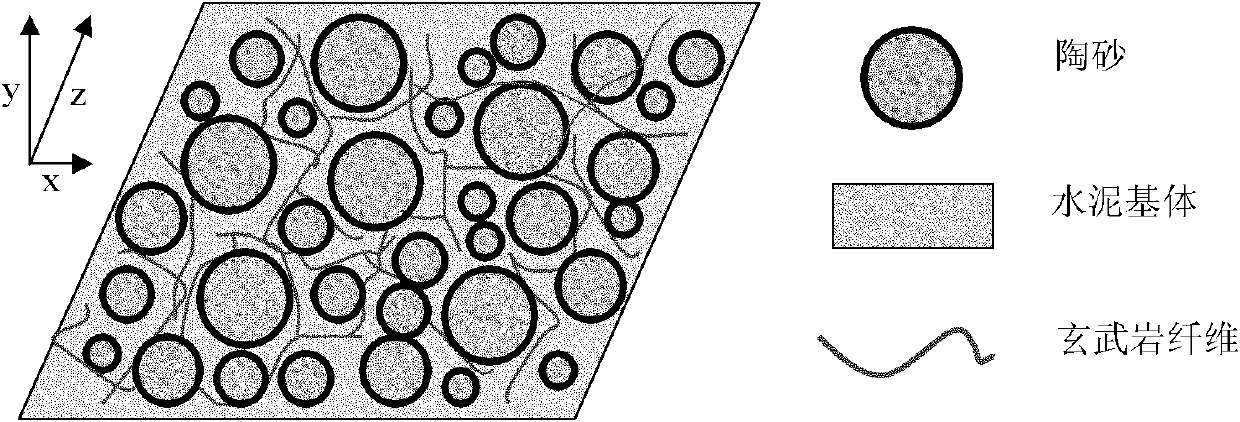

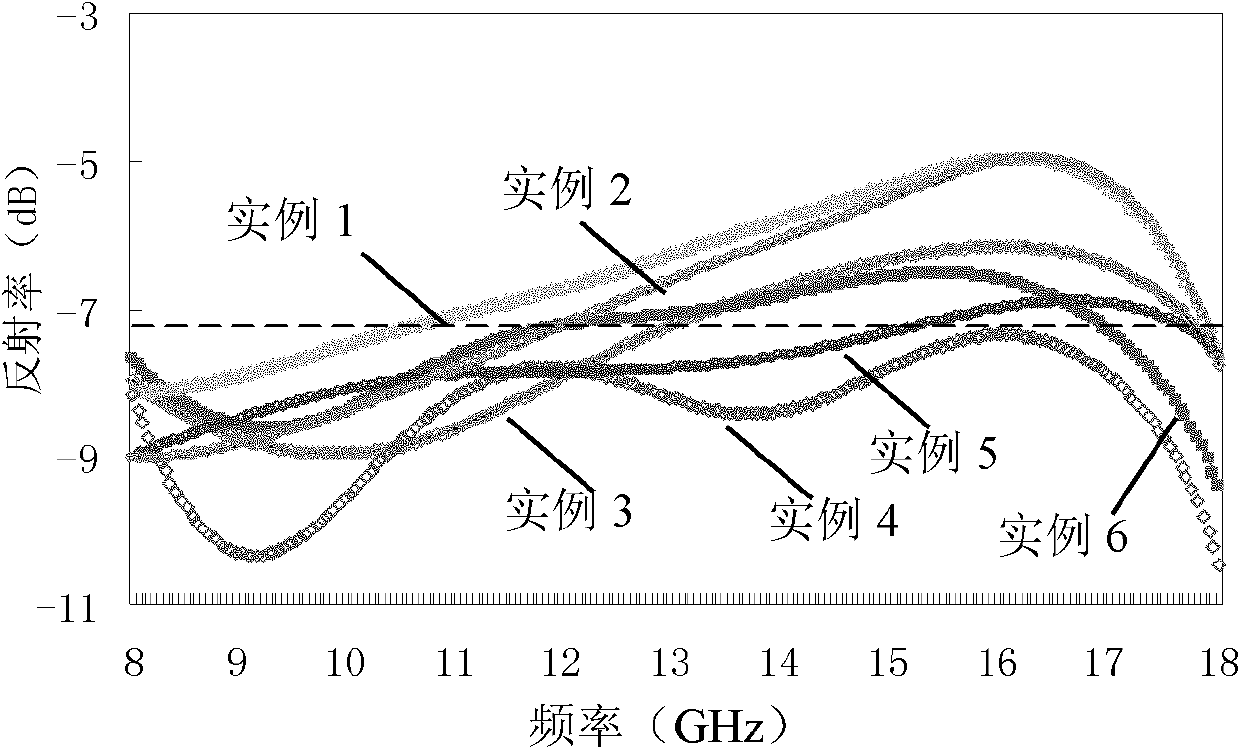

The invention relates to wave absorption concrete and a preparation method thereof. High-iron ground steel slag lightweight high-toughness wave absorption concrete is characterized in that the concrete is prepared from powder, aggregate and admixture, wherein the powder consists of silicate cement, fly ash and high-iron ground steel slag; the aggregate is ceramic sand; the admixture consists of efficient water reducing agent, basalt fiber and water; and the concrete comprises the following raw materials in a ratio (kg / m<3>): 110 to 300 kg / m<3> of silicate cement, 80 to 120 kg / m<3> of fly ash, 70 to 140 kg / m<3> of high-iron ground steel slag, 600 to 1,500 kg / m<3> of ceramic sand, 3.0 to 4.5 kg / m<3> of efficient water reducing agent, 30 to 50 kg / m<3> of basalt fiber and 150 to 180 kg / m<3> of water. The wave absorption concrete has the characteristics of energy conservation, environmental protection and low price.

Owner:WUHAN HAIJIAN ENVIRONMENTAL PROTECTION MATERIALS CO LTD

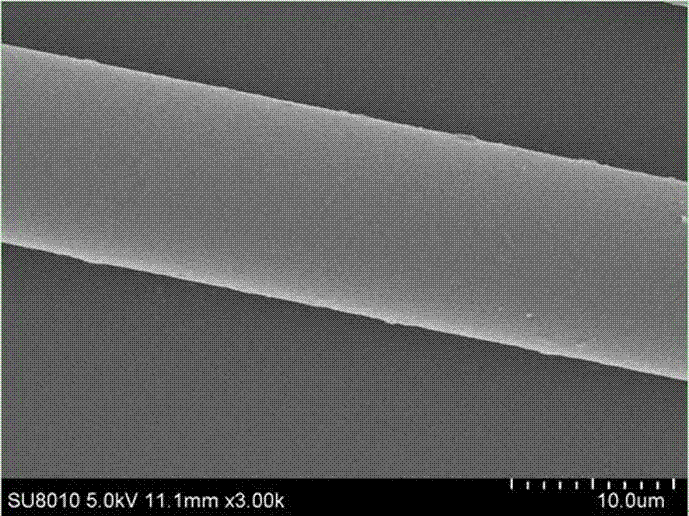

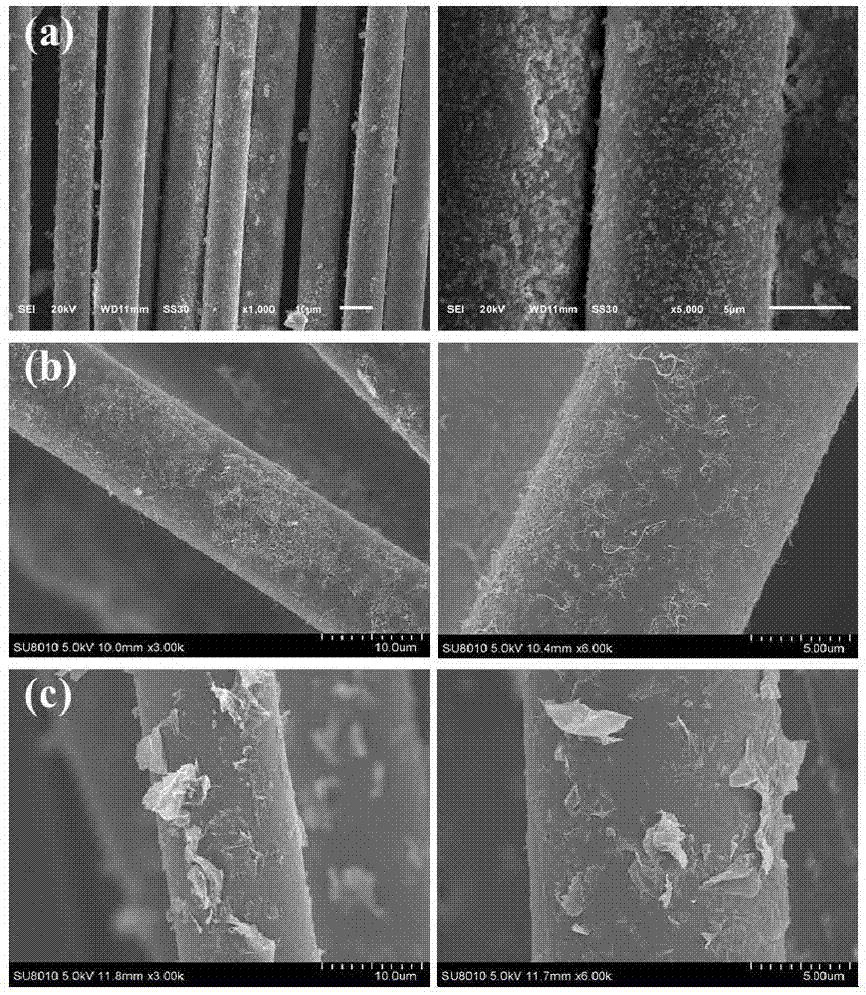

Preparation method and application of basalt fiber surface nano-coated multi-scale reinforcement

The invention belongs to the field of fiber-reinforced composite materials, and in particular relates to a preparation method and application of a basalt fiber surface nano-coated multi-scale reinforcement. According to the preparation method, functional nanoparticles are added into basalt fibers by using a surface coating method, and the basalt fibers are subjected to surface modification, so that the surfaces of the basalt fibers are successfully coated with the nanoparticles, and the multi-scale reinforcement having a nanoparticle and basalt fiber composite structure is further prepared. After the surfaces of the basalt fibers are coated with the nanoparticles, the wetting property of the basalt fibers is obviously improved, and the roughness of the basalt fibers is obviously increased, so that the interface compatibility between the basalt fibers and a matrix in a composite material is facilitated to be improved, stress concentration is effectively relieved, the interface damage to the composite material is inhibited, and the comprehensive performance of the composite material is further improved.

Owner:ZHONGBEI UNIV

Special nano-modified impregnating compound for basalt continuous fiber and preparation method of special nano-modified impregnating compound

The invention provides a special nano-modified impregnating compound for basalt continuous fiber and a preparation method of the special nano-modified impregnating compound. The preparation method comprises specific operation steps as follows: (1), citric acid is added to a deionized aqueous solution, the PH (potential of hydrogen) value of a citric acid aqueous solution is adjusted to range from 3 to 4, the mixture is stirred at a high speed, a silane coupling agent is slowly and dropwise added, the mixture is stirred until the silane coupling agent is completely hydrolyzed, and a clear and transparent hydrolyzed coupling agent is obtained; (2), organosilicone-modified acrylic ester and a polyester resin emulsion are diluted by 10-20 times with deionized water respectively and then are mixed and uniformly stirred, and a diluted film forming agent is obtained, monodispersed nano-silica and titanium dioxide particles are added, the mixture is heated, stirred and cooled at the room temperature, and the film forming agent containing nano particles is obtained; (3), fatty acid amide acetate, aliphatic ester sulfate and a quaternary ammonium salt cationic antistatic agent are added to deionized water, the PH value of the solution is adjusted, the hydrolyzed coupling agent and the film forming agent containing the nano particles are added respectively, the mixture is stirred uniformly and left to stand to be defoamed, and the special nano-modified impregnating compound for the basalt continuous fiber is obtained.

Owner:江门市新会区美亚化工有限公司

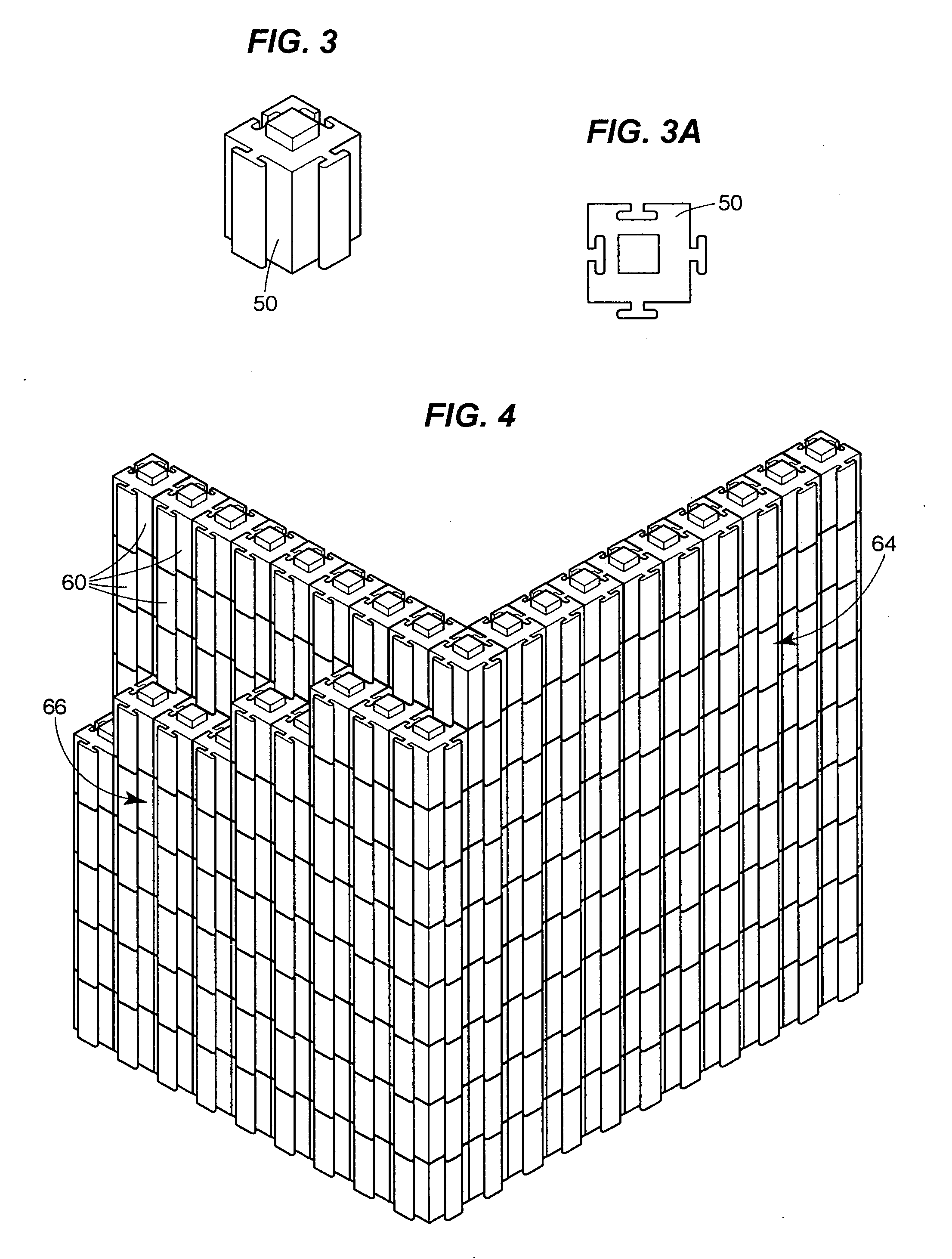

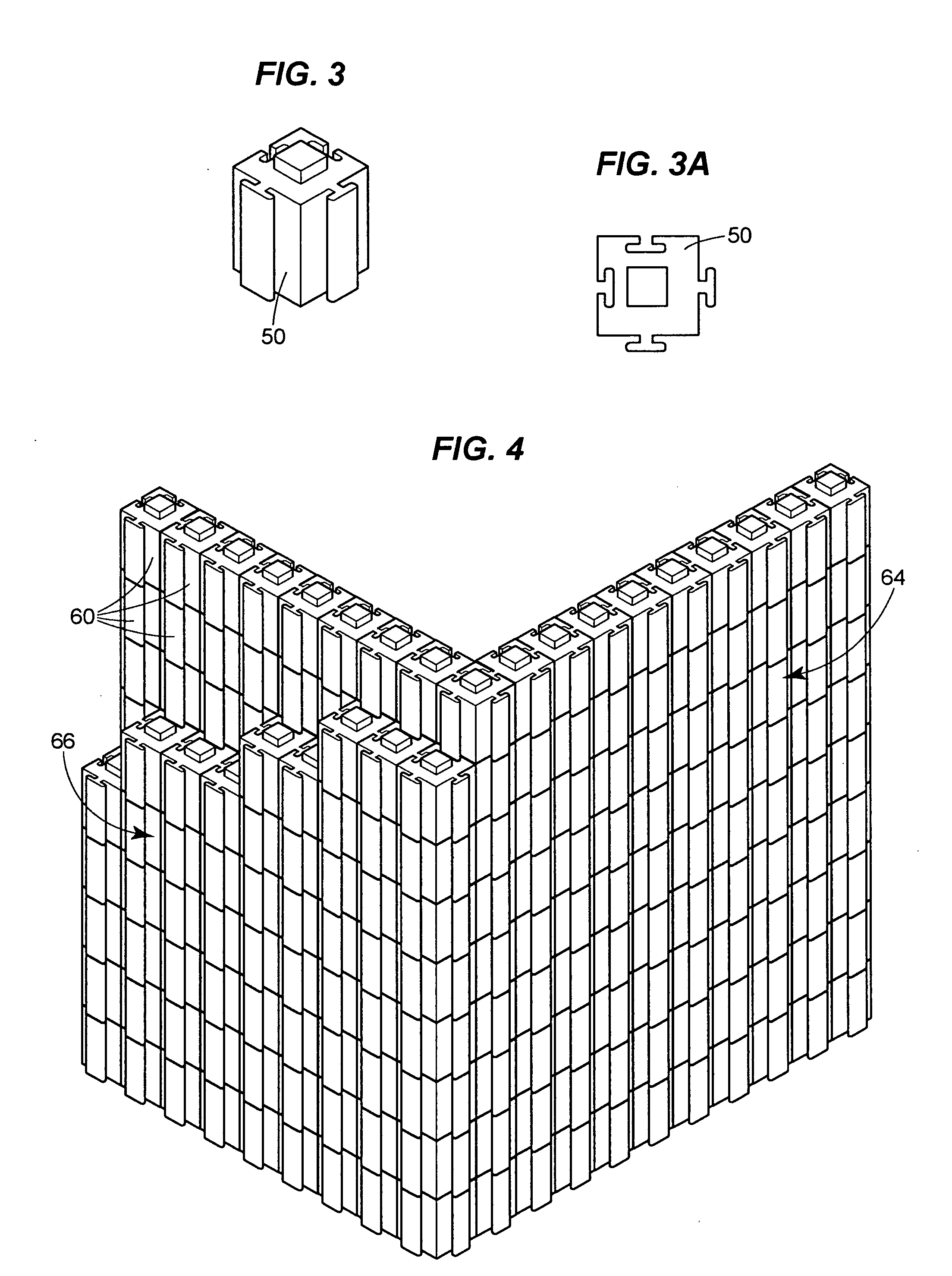

Basalt particle-containing compositions and articles for protective coatings and ballistic shield mats/tiles/protective building components

It has been found that basalt particles, when combined with a resin binder and a reinforcing material, such as fiberglass, provide unexpected strength, fire-resistance, radiation impermeability, and projectile shielding for ballistic armor / shields, fire-resistant building panels, construction blocks and protective coatings on substrates. The armor panels can be worn, as in a bullet-proof vest, or can be used as a shield to protect a vehicle, aircraft or other structures as projectile penetration-resistant and fire and radiation resistant materials.

Owner:U S WIND FARMING

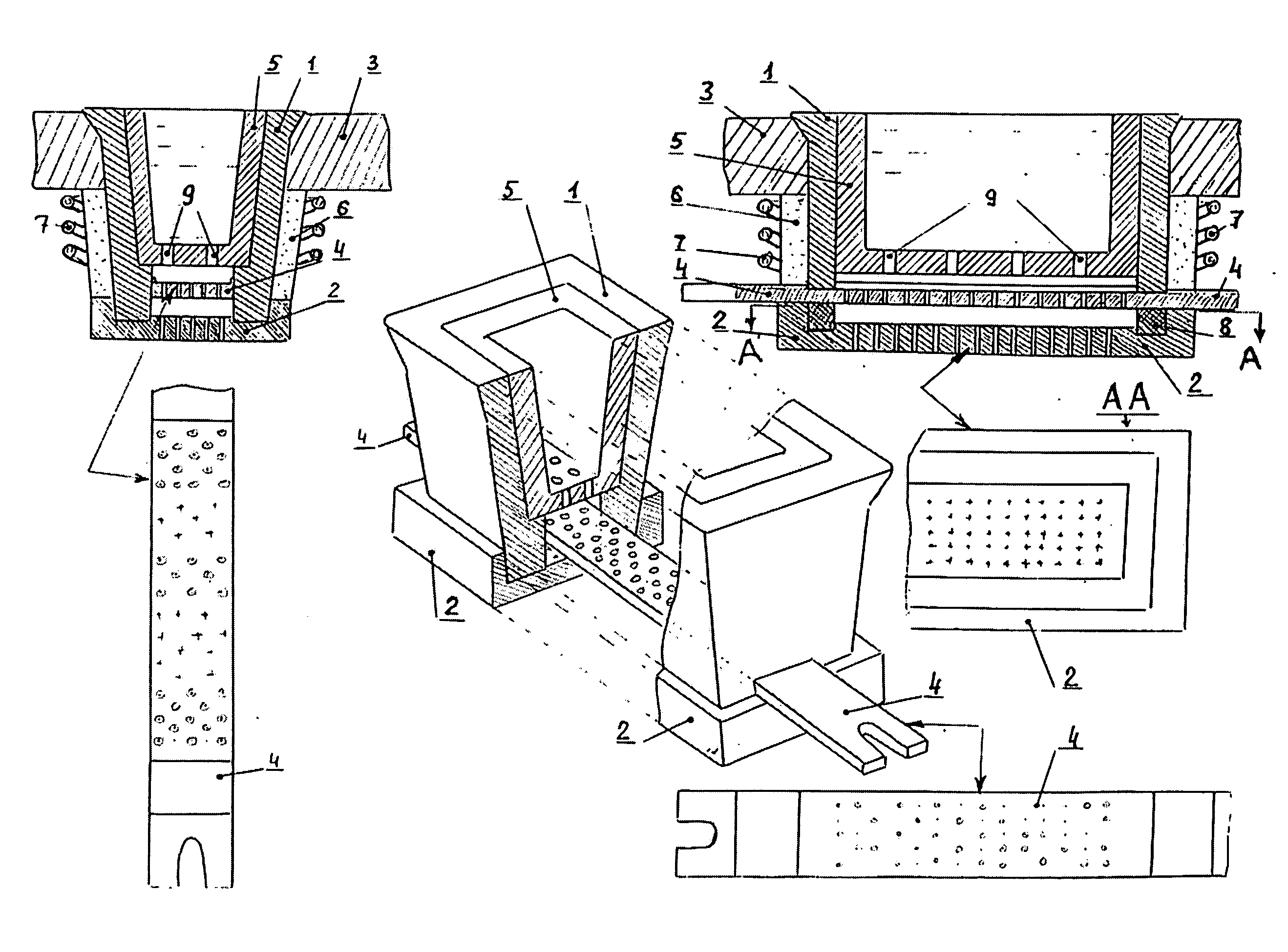

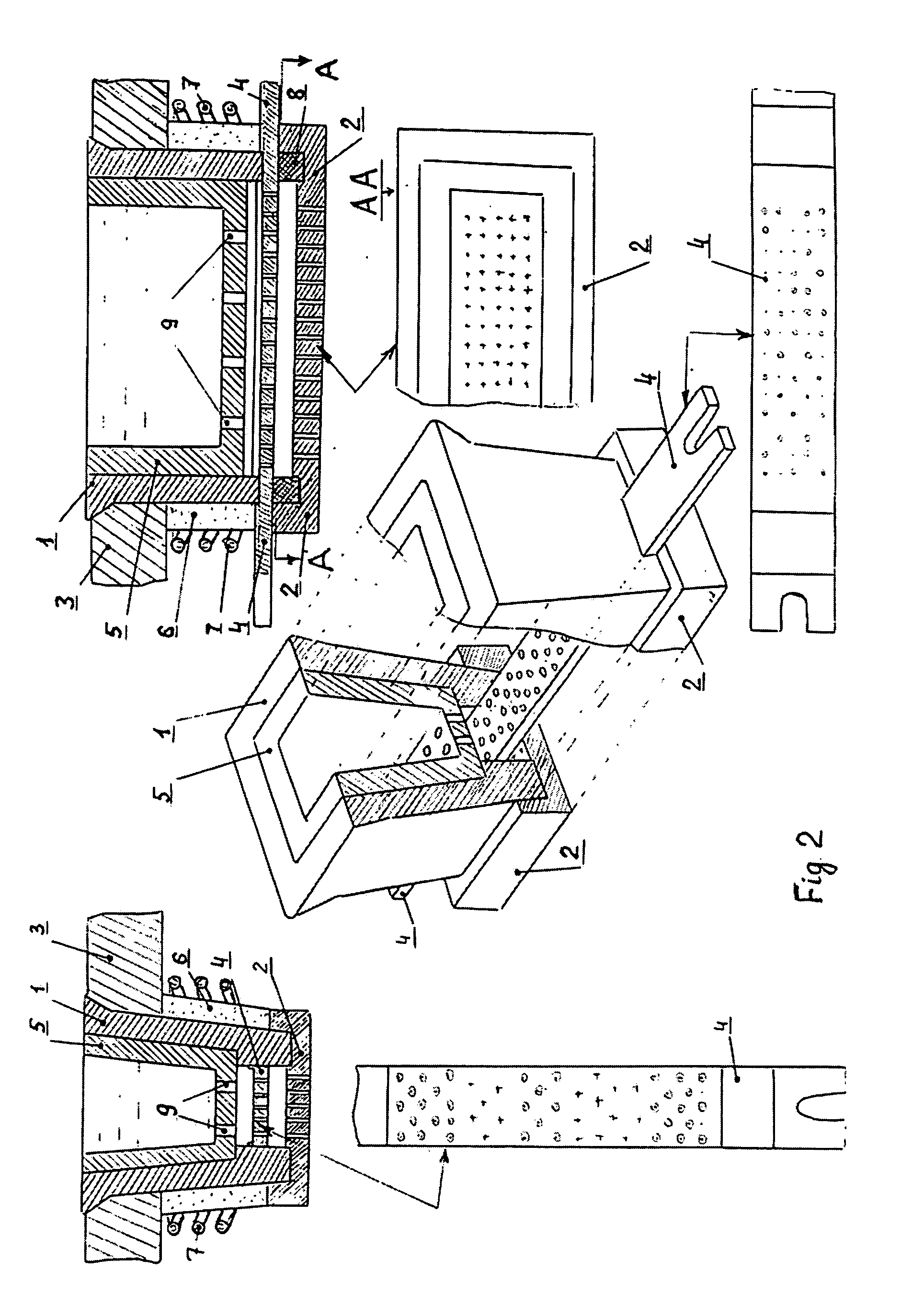

Apparatus integrated with ceramic bushing for manufacturing mineral/basalt fibers

ActiveUS20060218972A1Low costImprove stabilityGlass furnace apparatusRotary drum furnacesComposite applicationMicrometer

The apparatus integrated with ceramic bushing / s for manufacturing mineral / basalt fibers from natural basalt rocks is disclosed. The apparatus and the ceramic bushing / s are integrated into one unit capable provide all operations which are needed: melt basalt rock materials, homogenize basalt glass body suitable for forming fibers to be drawn / attenuated into continuous fibers and gathered into a strand of elemental fibers from 7 to 20 micrometers (μm) in diameter. Also the coarse fibers at the diameters from 20 μm to 100 micrometers (μm) having amorphous structural state which exhibit ductile / flexible properties. The ceramic bushing / s are designed to eliminate precious Pt, Rd metals using instead corrosion resistant ceramic materials to reduce basalt fiber products cost and to increase its commercial compatibility when compared to the other fibers currently been on the market in reinforced concrete / composite applications, including Three Dimension Fiber Reinforced Concrete-3D FRC.

Owner:BLACKBULL IND INC +1

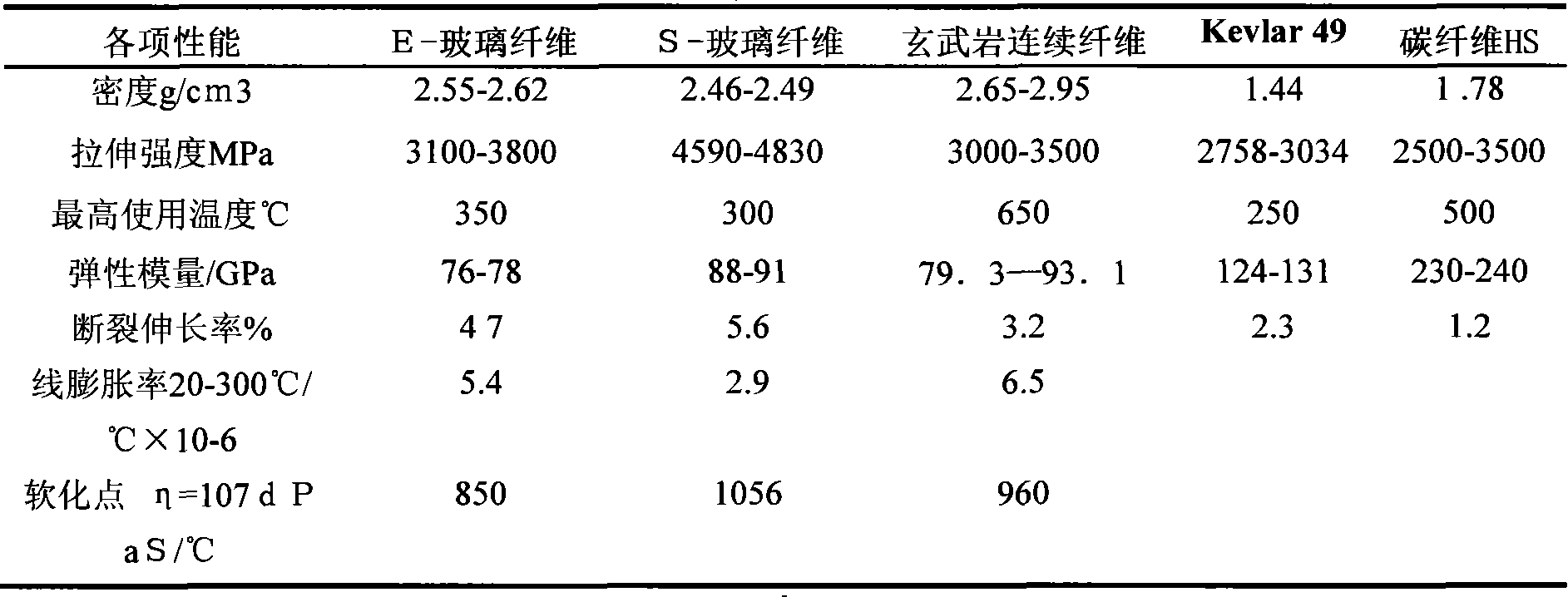

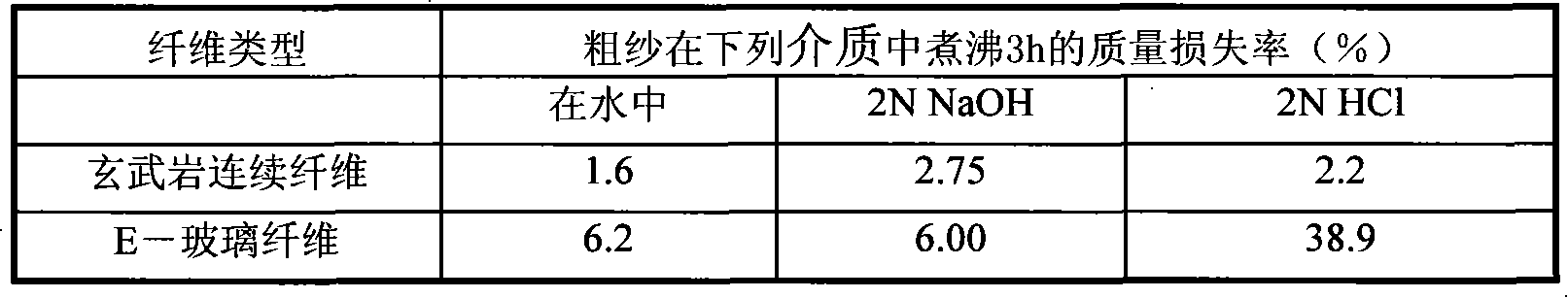

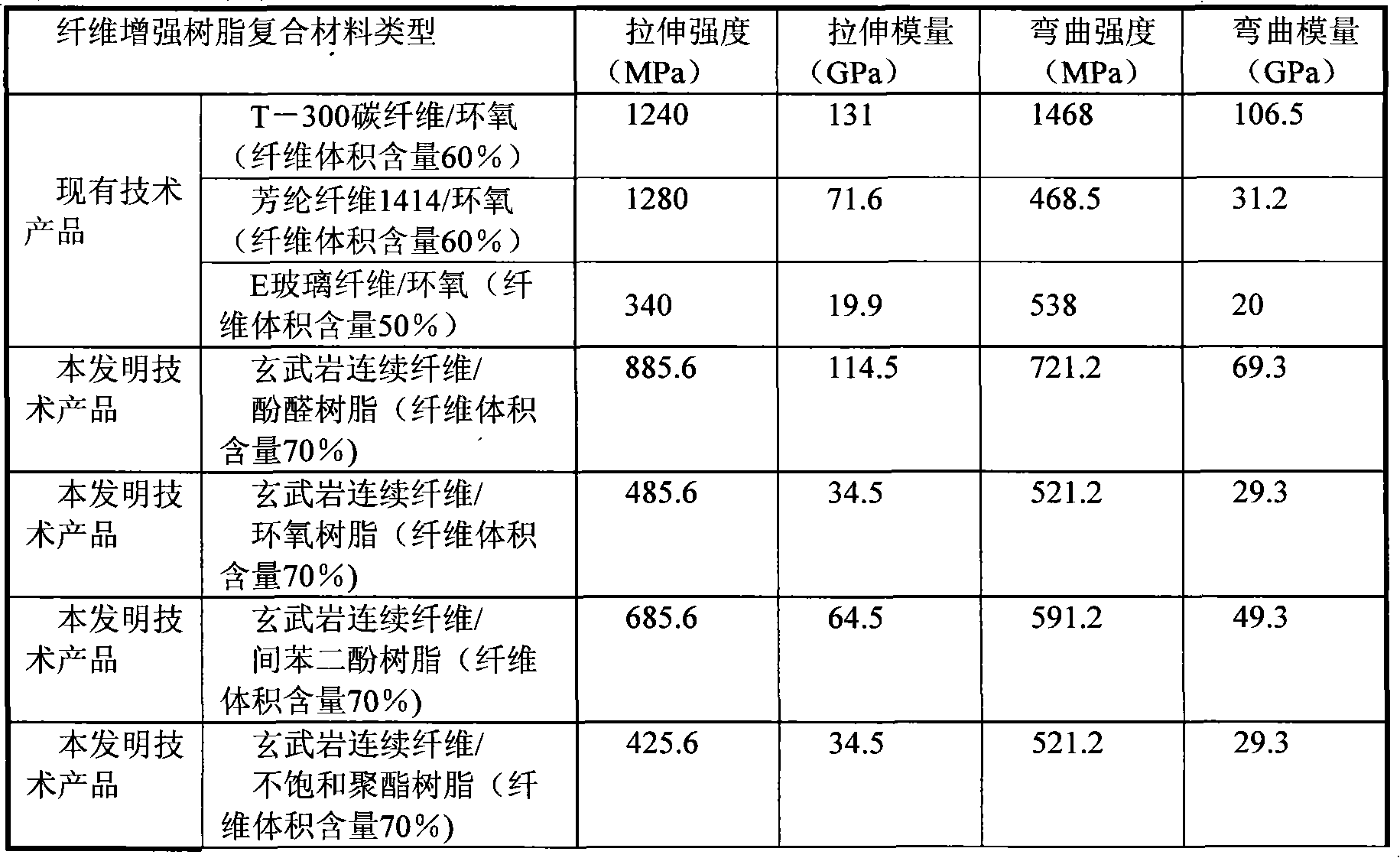

Basalt continuous fibre enhancement resin composite material and manufacturing method thereof

The invention discloses a basalt continuous fiber reinforced resin composite material and a relative production method, which uses basalt continuous fiber as reinforce material, uses the chemical material containing the silane compounds as coupling agent, and uses unsaturated polyester resin, phenol resin, epoxy resin, resorcinol resin, amino resin and vinyl resin, or modified unsaturated polyester resin, phenol resin, epoxy resin, resorcinol resin, amino resin and vinyl resin as substrate, to produce basalt continuous fiber reinforced resin composite material. The physical properties of the basalt continuous fiber reinforced resin composite material are better than glass fiber reinforced resin, and the hydrolysis resistance and corrosion resistance of basalt continuous fiber are better than glass fiber, with better performance price ratio than carbon fiber and Kevlar fiber. The basalt continuous fiber has better high temperature resistance, fireproof property, better combination property and low cost.

Owner:BEIJING FORESTRY UNIVERSITY

Chicken manure fermented fertilizer

InactiveCN102924185ASave resourcesAvoid pollutionBio-organic fraction processingClimate change adaptationNutrientPlant Alkaloids

The invention belongs to the technical field of bio-organic fertilizer, and particularly discloses chicken manure fermented fertilizer, which is prepared through normal temperature fermenting, three-time mixing and separating adding of dry chicken manure, rice bran powder, flue curing straw, EM (Effective Microorganisms), basalt powder and camellia shell powder, and has the benefits that the nutrient in the agricultural waste is utilizes, so as to avoid environmental protection; the plant alkaloid and the perfume oil in the flue curing straw and the camellia shell powder are utilized to kill the pest in the field; the EM can produce microorganisms beneficial to the growth of organisms, so as to accelerate the fertility releasing and the crop growth; and the basalt powder can provide the rich elements necessary for the crop as calcium, magnesium, sulfur, iron, copper, zinc and cobalt. Through practice, the chicken manure fermented fertilizer is applicable to all sorts of food crop and fruit and vegetables, enables the soil fertilizer efficiency to last 4 months with one-time fertilization, and enables the average increase of the crop to be 15%, as a result, not only is the labor intensity during agricultural production reduced, but also the soil ecological balance can be adjusted and the soil permeability is improved as well.

Owner:重庆润绿生物有机肥有限公司

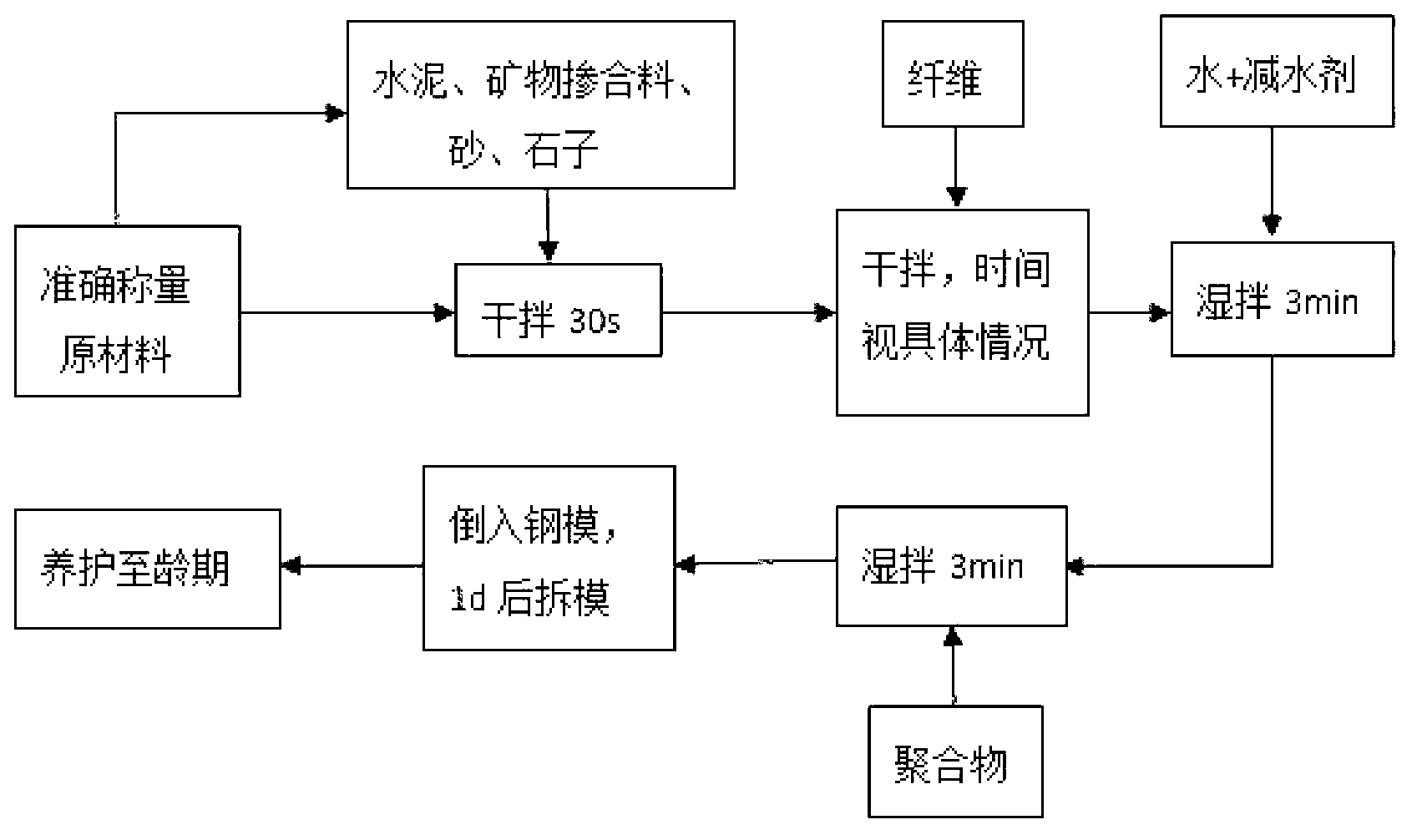

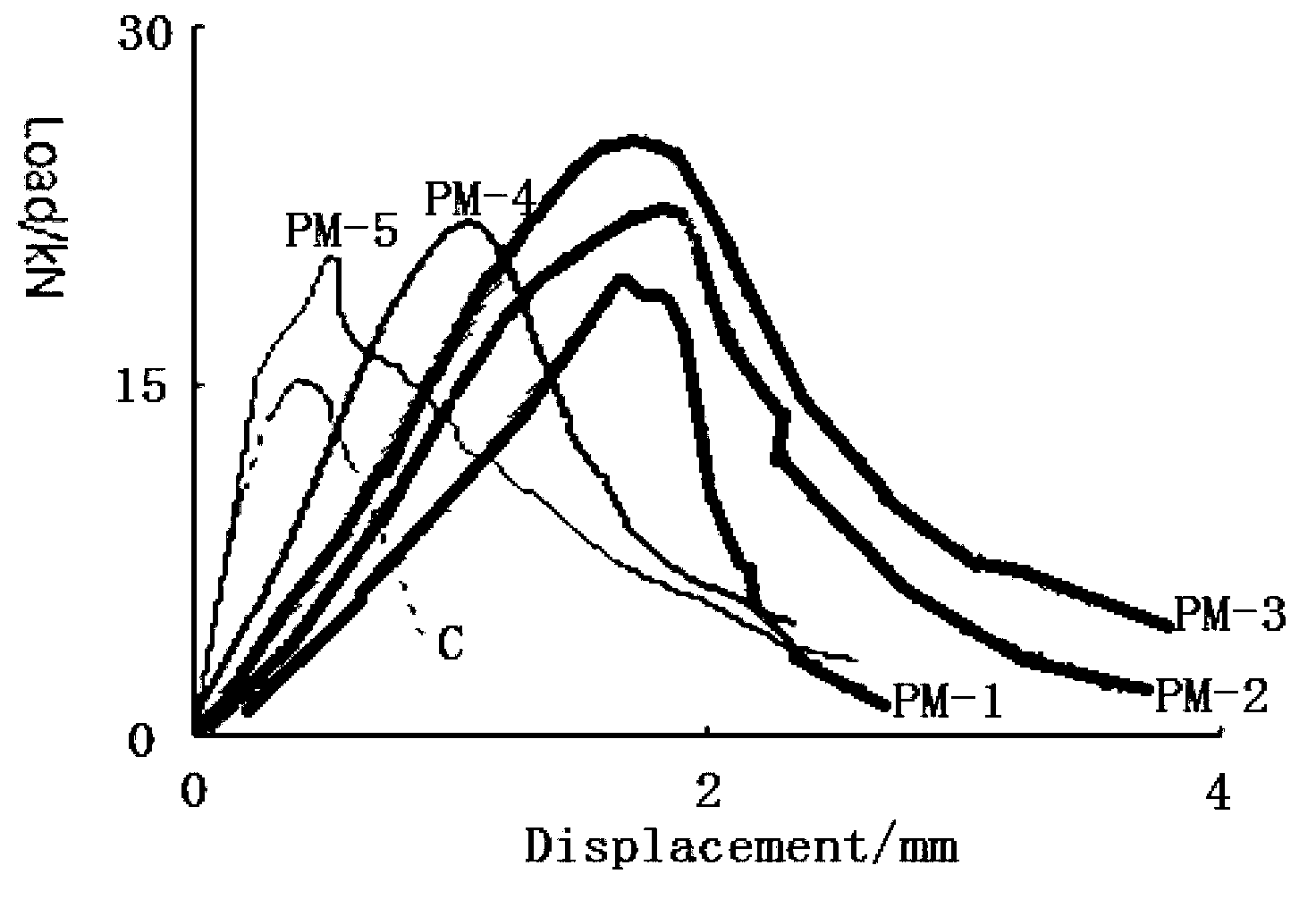

Fibre-polymer compound toughened concrete and preparation method for same

The invention discloses a fibre-polymer compound toughened concrete and a preparation method for the same. The basic raw materials of the concrete are coarse aggregate, fine aggregate, portland cement, fly ash and a polycarboxylic water reducer; moreover, fibres and a polymer are added, the fibres are any one of end-hook type steel fibres, superfine type steel fibres, modified polyester fibres, polyvinyl alcohol fibres, basalt fibres and cellulose fibres, and are doped in a ratio that the volume doped amount in per 1 m<3> concrete is 0.08%; and the polymer is any one of ethylene-vinyl acetate copolymer, ethyl acrylate, styrene-acrylate copolymer, vinyl acetate-acrylate copolymer and organosilicone acrylate, and the doped amount of each polymer is 10% based on the mass of the portland cement and the fly ash. The preparation method comprises the following steps of: pouring stone, sand, a gelling material, fibres, and water dissolved with a water reducer, and then stirring according to a blending mode of pouring dry materials at first and then pouring wet materials; and pouring the polymer, and stirring and forming.

Owner:SOUTHEAST UNIV

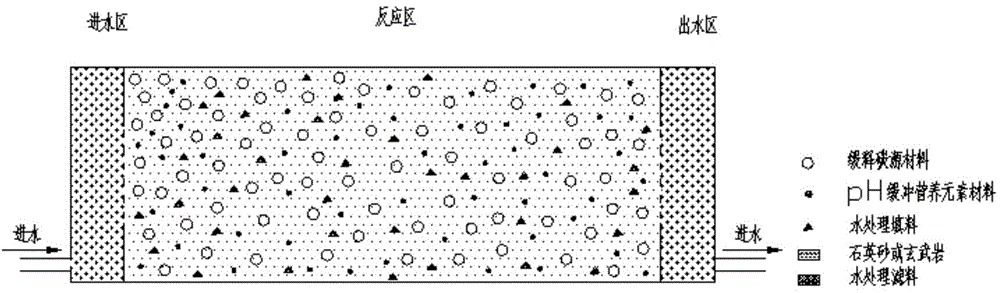

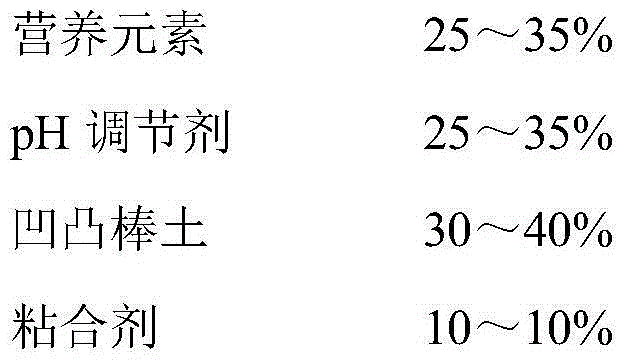

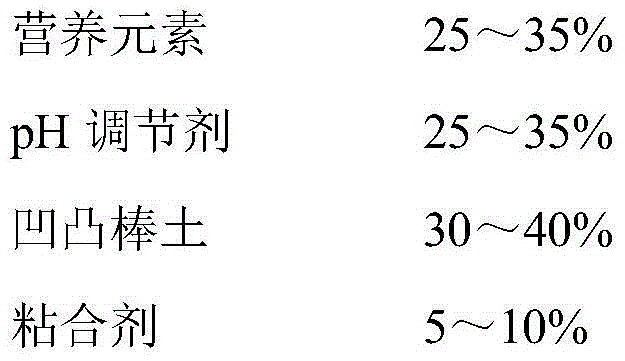

Permeable reactive filler for removing nitrate organisms from underground water, system and filling method thereof

ActiveCN104150613AAvoid mixing modes that are fixed in one materialEasy to controlTreatment with anaerobic digestion processesGroundwater nitratePollution

The invention discloses a permeable reactive filler for removing nitrate organisms from underground water, a system and a filling method thereof, and belongs to the field of underground water pollution remediation. The filler for the permeable reactive barrier system is formed by the mixture of biological slow release carbon source materials, pH buffer nutrient element materials and bacteria enrichment water treatment fillers, the process inlet and outlet areas of the permeable reactive barrier system are filled with water treatment filters, a process reaction area is filled with the mixture of quartz sand or basalt and fillers, and the bacteria enrichment water treatment fillers inoculated with acclimatized native denitrifying bacteria. According to the invention, slow release carbon source materials, slow release pH nutrient element materials and water treatment fillers can be flexibly added, and the shortcomings that the carbon source materials are inoculated with hang membrane materials and native microorganisms in the remediation area are insufficient are avoided. The water treatment filters in the water outlet area are capable of preventing secondary pollution.

Owner:NANJING UNIV

High temperature resistance basalt fiber composite filter material and preparation method thereof

InactiveCN101612496AStable structureHigh filtration precisionLayered productsFiltration separationFiltrationPore diameter

The invention relates to a high temperature resistance basalt fiber composite filter material and a preparation method thereof; the composite filter material comprises basalt fiber base fabric and high-performance fiber mesh in a weight ratio of 7:1-2:1; the preparation method comprises the following steps: forming high-performance fiber mesh on the basalt fiber base fabric, combining and strengthening the material more by spunlaced process, hot rolling the material, then soaking the material in water repellent oil-proofing agent, sizing and obtaining the finished product. The filter material of the invention has the advantages of stable structure, high filtration accuracy, small bore diameter, concentrated pore diameter distribution and high temperature resistance, can bear 450 DEG C of instantaneous high temperature and can be used stablely for long time below 280 DEG C.

Owner:DONGHUA UNIV

Concrete with functions of crack resistance and infiltration resistance

InactiveCN104386959AReduce porosityImprove pore structureSolid waste managementCrack resistanceDiethylenetriamine

The invention discloses concrete with the functions of crack resistance and infiltration resistance. The concrete comprises the following raw materials in part by weight: 70-100 parts of cement, 400-500 parts of macadam, 50-70 parts of river sand, 40-50 parts of fly ash, 30-60 parts of mine residues, 5-20 parts of coal slack, 20-50 parts of basalt fibers, 5-15 parts of polypropylene fibers, 5-20 parts of glass fibers, 6-13 parts of expanded perlite, 20-80 parts of nanometer silicon dioxide, 5-15 parts of nano calcium carbonate, 1-3 parts of sodium dodecyl sulfate, 3-6 parts of zinc stearate, 2-5 parts of zinc borate, 3-7 parts of sodium citrate, 0.5-1.4 parts of acetyl tributyl citrate, 0.7-1.3 parts of diethylenetriamine, 3-10 parts of a water reducing agent, and 80-100 parts of water. The concrete disclosed by the invention has the advantages of good crack resistance, excellent infiltration resistance and good durability.

Owner:WUWEI HENGJI COMML CONCRETE

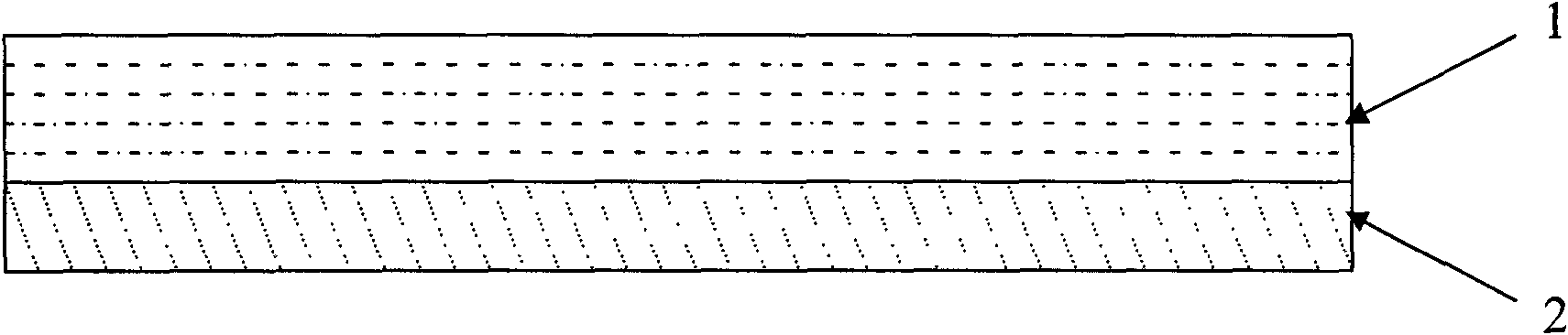

Basalt particle-containing articles for ballistic shield mats/tiles/protective building components

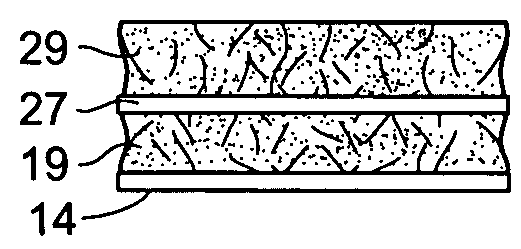

A spaced, multi-layer article of manufacture comprising a first layer comprising about 10% to about 80% by weight basalt particles, about 2% to about 50% by weight reinforcing fibers, and about 5% to about 50% by weight of an adhesive resin binder; a second layer comprising about 10% to about 80% by weight basalt particles, about 2% to about 50% by weight reinforcing fibers, and about 5% to about 50% by weight of an adhesive resin binder; and an intermediate spacing layer that separates the first and second layers.

Owner:U S WIND FARMING

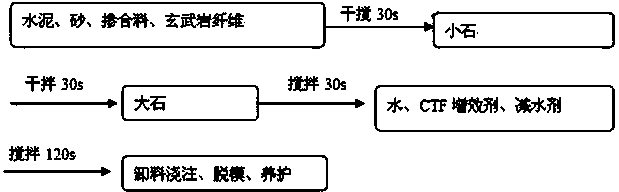

Basalt fiber concrete and preparation method thereof

The invention discloses basalt fiber concrete and a preparation method thereof, and belongs to concrete. The concrete consists of the following components in percentage by weight: 14-19 parts of cement, 29-39 parts of sand, 35-44 parts of stones, 1-4 parts of active admixture, 0.05-0.8 part of basalt short fiber, 0.05-1 part of other short fiber, 6-8.5 parts of water, 0.05-0.15 part of CTF synergist and 0.05-0.2 part of a water reducing agent. Through the addition of the basalt fiber that is in net-form distribution to the concrete, both toughness and anti-cracking performance of the concrete are effectively improved; the concrete, which is prepared depending on the proportions and by the preparation method, has the advantages that the maximum crack width is reduced by 44.8-89.7%, the average cracking area is reduced by 19.7-92.6%, the crack quantity in unit area is reduced by 22.7-25.2%, the total cracking area in the unit area is reduced by 1.7-94.5%, the frost resistance is enhanced by 37-50% and the shock resistance is improved by more than twice; the concrete can be used for effectively avoiding various defects of existing conventional concrete.

Owner:SICHUAN AEROSPACE TUOXIN BASALT IND

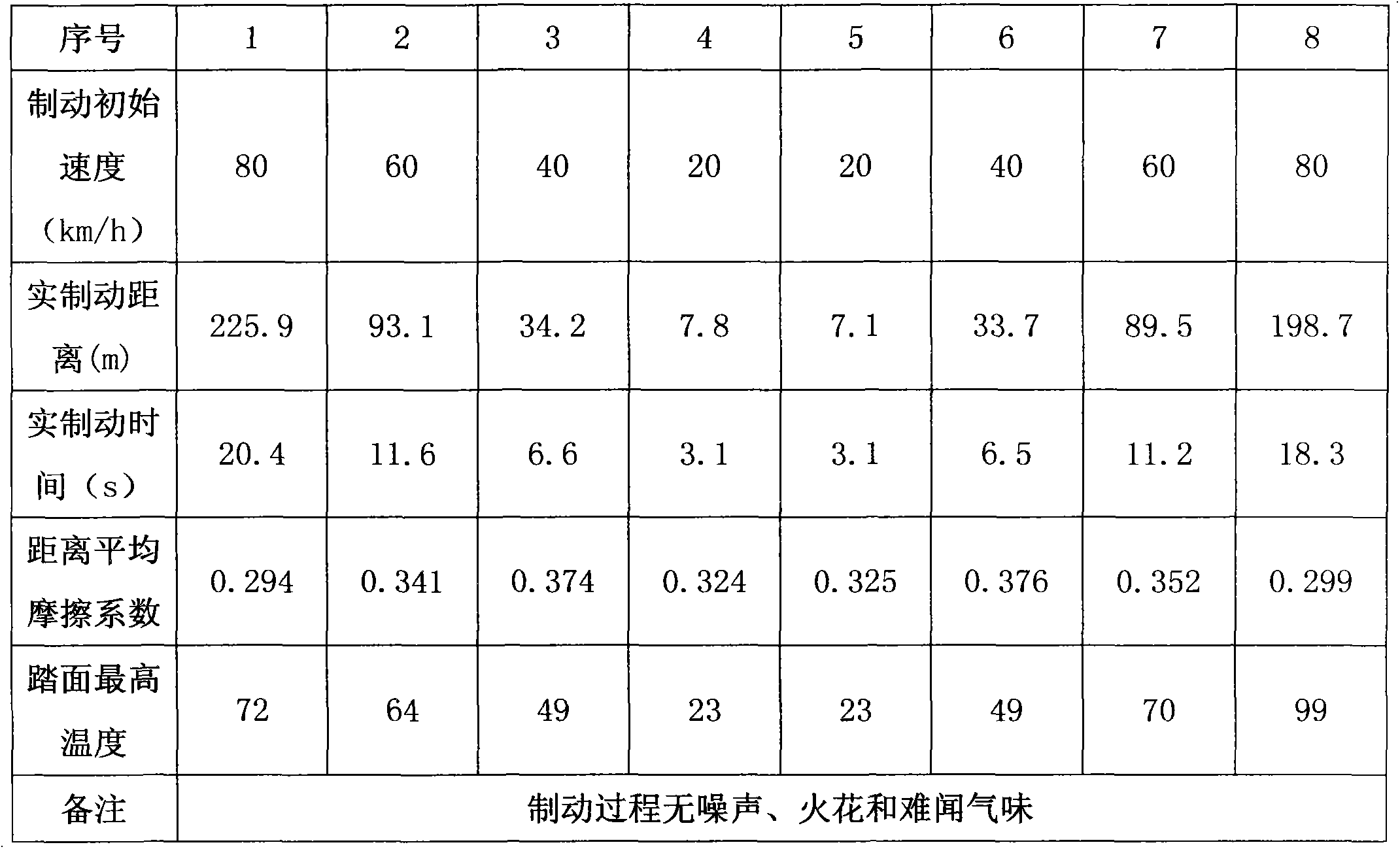

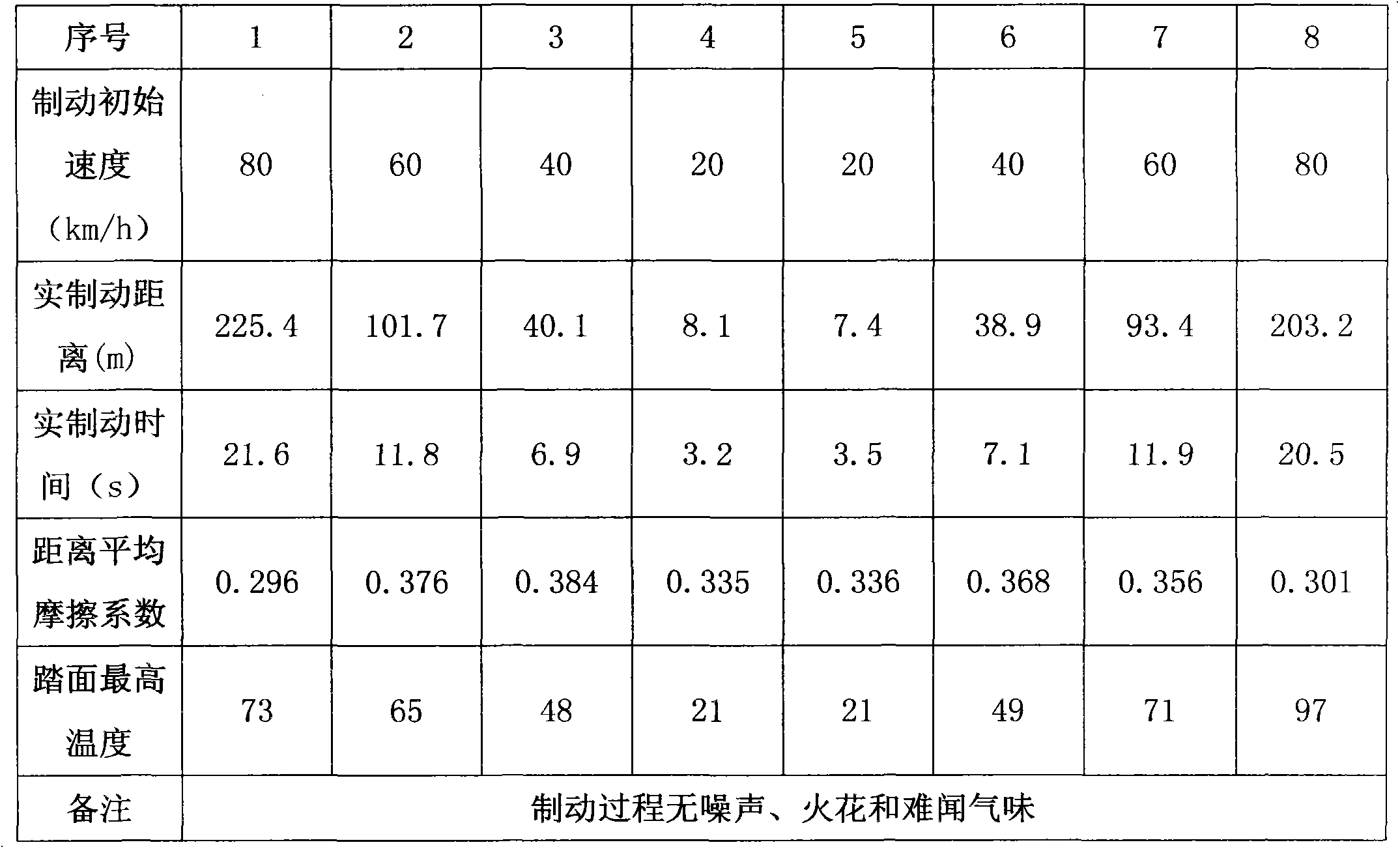

Composition brake shoe for urban rail vehicle and manufacturing method thereof

ActiveCN103410893AImprove brittlenessImprove heat resistanceFriction liningCarbon fibersHexamethylenetetramine

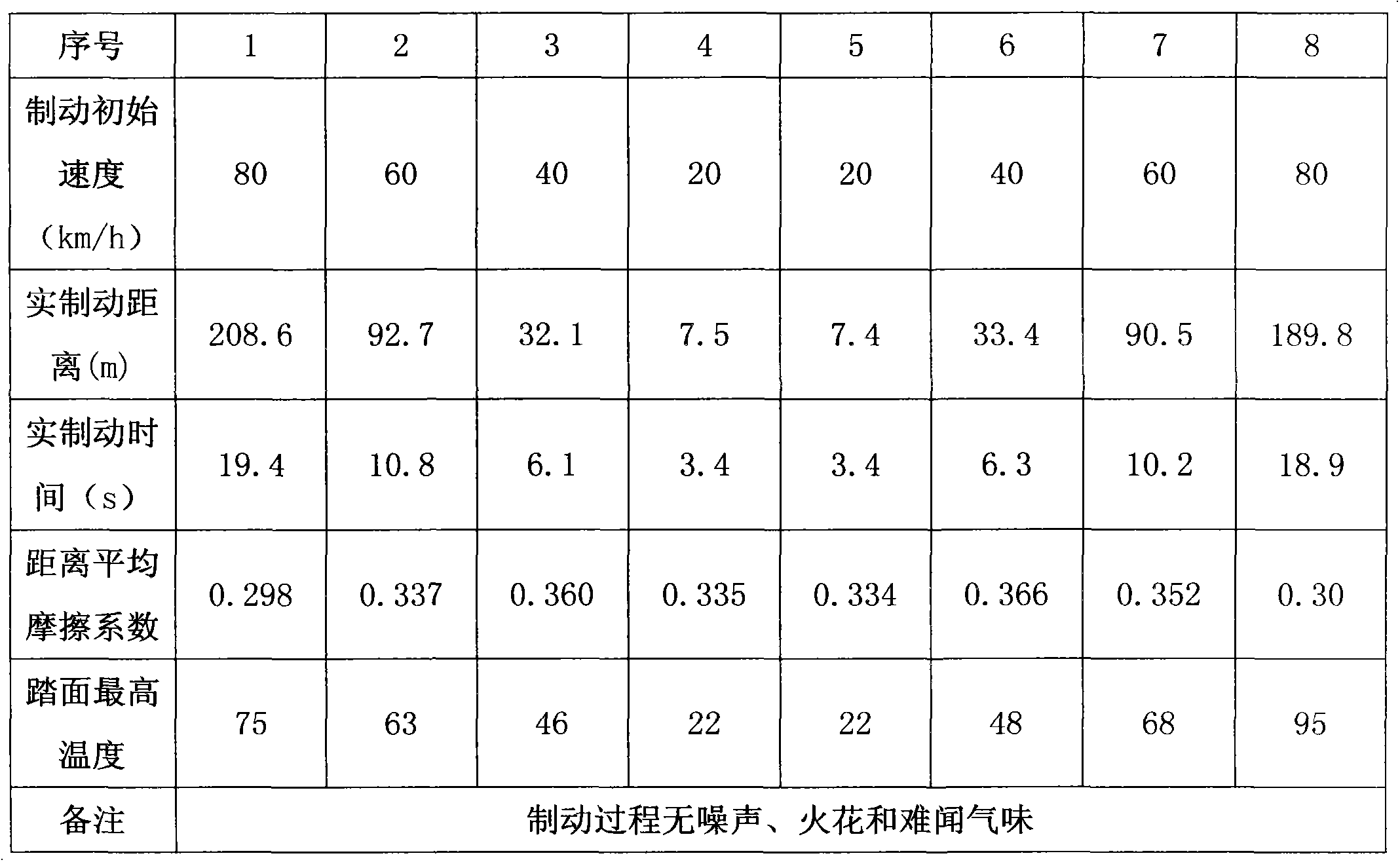

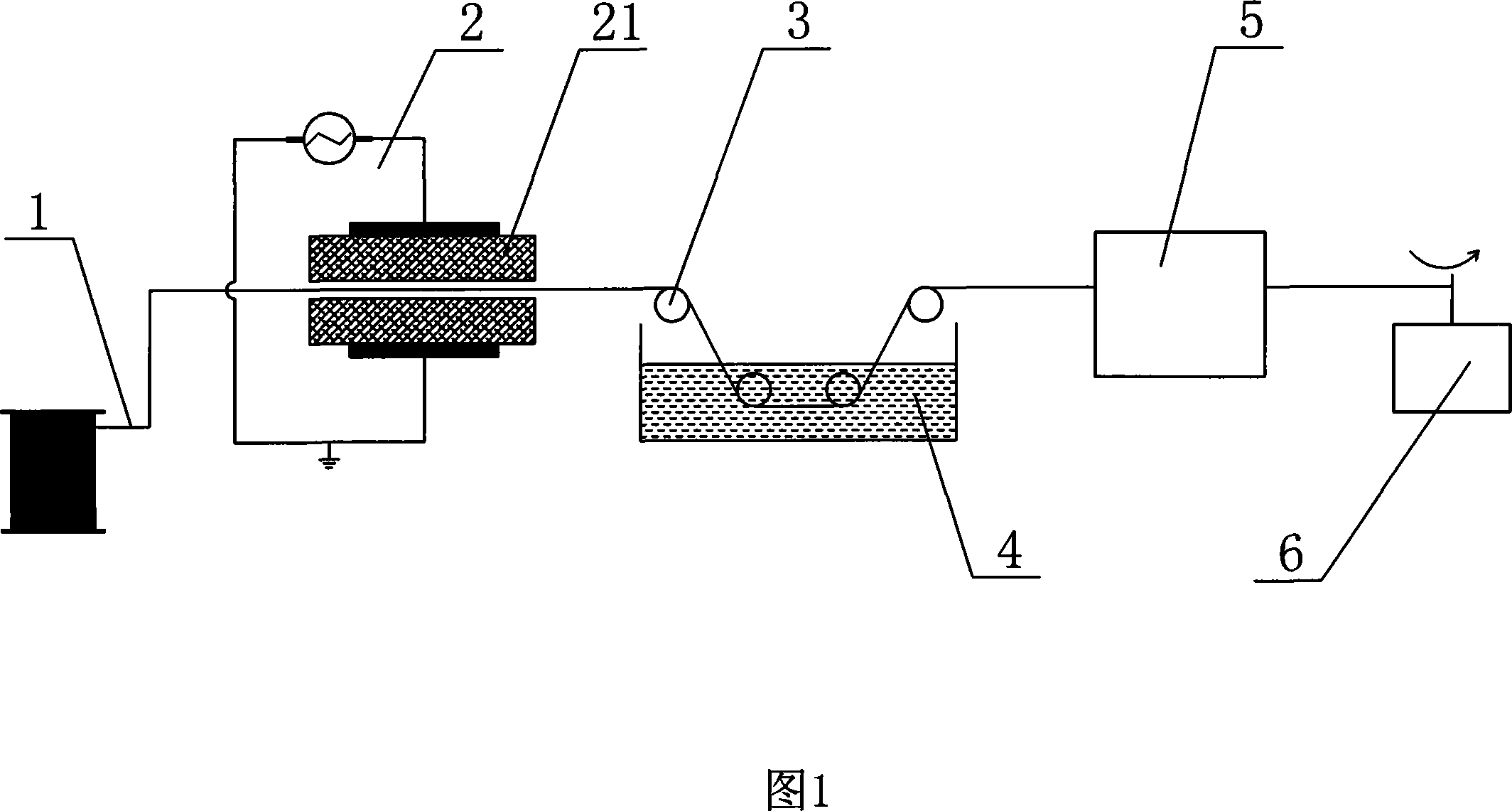

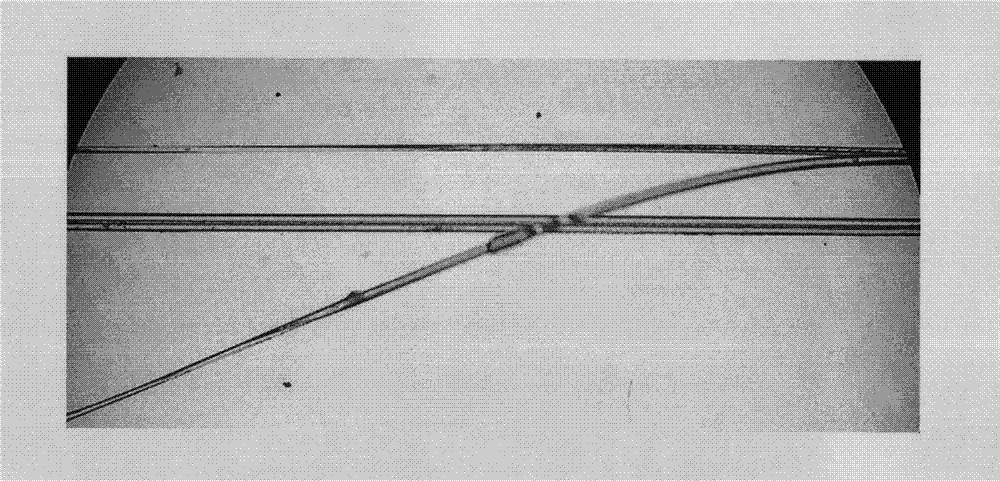

The invention relates to a composition brake shoe for an urban rail vehicle and a manufacturing method of the composition brake shoe for the urban rail vehicle. The composition brake shoe comprises the following components of, by weight, 10-15 parts of butadiene-acrylonitrile rubber, 10-20 parts of cashew nut shell oil modified phenolic resin, 6-10 parts of basalt fibers, 4-8 parts of carbon fibers, 8-15 parts of steel fibers, 5-8 parts of sepiolite fibers, 2-6 parts of hexamethylenetetramine, 5-8 parts of iron oxide powder, 5-7 parts of crystalline flake graphite, 5-7 parts of chromite, 6-9 parts of barium sulfate, 3-6 parts of potassium feldspar and 5-8 parts of frictional powder. The manufacturing method of the composition brake shoe is a dry method production technology, and comprises the steps of steel back production, abrasive blasting processing, shaping, burdening, mixing, hot compacting, heat processing, subsequent processing, finished product forming and inspection. The manufactured composition brake shoe is inspected through the 1:1 rack test, is excellent in friction and abrasion resisting performance, stable in brake performance, safe and environmentally friendly, and solves the problem that the friction coefficient drops too fast under the conditions of damascene of the composition brake shoe for the urban rail vehicle, hot cracks, hot spots and rain and snow weather.

Owner:GUANGXI UNIV FOR NATITIES

Surface treatment method for basalt fibre

InactiveCN101125738ANot easy to cause pollutionComposite improvementTreatment effectPlasma generator

The invention discloses a treatment method for treating the surface of basalt fiber with simple technique, good treatment effect and low cost and is characterized in that a discharge electrode in a plasma generator device is caused to generate plasma and then basalt fiber goes through the plasma, thereby, the surface of the basalt fiber is modified. The composition performance of the basalt fiber after being treated through the method of the invention with organic substrate materials is greatly improved.

Owner:ZHANGJIAGANG ZHONGLIAN TECH +1

Method for manufacturing micro-hollow and micro-bubble rock wool by using basalt as a main ingredient and product of the method

InactiveCN102757178AImprove toughnessImprove thermal insulationGlass making apparatusCentrifugationHigh pressure

The invention relates to a method for manufacturing a micro-hollow and micro-bubble rock wool by using basalt as a main ingredient and a product of the method. The method comprises the following steps of: 1, firing; 2, preparation of materials: pulverizing basalt, dolomite or limestone (which serves as a fluxing agent) to be a lump material with the diameter being 3-10CM, pulverizing fluorite andsilica (which serve as regulators) to be a lump material with the diameter being 0.5-2CM, processing combustion-supporting carbon to be a lump material with the grain diameter being 5-15Cm, and preparing the materials according to the weight proportion of 60-85 percent of basalt, 10-28 percent of dolomite or 10-28 percent of limestone, 5-15 percent of fluorite and 0-10 percent of silica and according to the volume ratio that aggregated rocks to combustion-supporting carbon is 4.5-6 to 3-4; 3, charging: charging the prepared combustion-supporting carbon and the prepared aggregated rocks in sequence into a smelting furnace according to a laminated circular charging way until the furnace is filled up; 4, smelting: smelting the basalt, the regulator and the aggregated rocks serving as combustion-supporting agents to form smelted streams; and 5, fiber-making: performing high speed centrifugation on the smelted streams, continuously air-blowing the smelted streams at high pressure and cooling to prepare a rock wool fiber having a micro-hollow and micro-bubble structure. By the method, the defect of technology prejudice is overcome, the method is simple in process and low in cost, and the product has high quality.

Owner:牡丹江超越新材料科技有限公司

Open-gradation storage type asphalt mixture for patching of draining asphalt pavement

The invention belongs to the technical field of building materials in road engineering and particularly relates to an open-gradation storage type asphalt mixture for patching of a draining asphalt pavement. The mixture comprises aggregate, a filler, a fiber stabilizer and diluted asphalt, and the largest nominal grain size of the mixture is 13.2mm. The aggregate comprises coarse aggregate and fine aggregate, the coarse aggregate is made of basalt or diabase, the fine aggregate is made of limestone, and the largest nominal grain size of the aggregate is 13.2mm. The filler is made of limestone ore powder. The fiber stabilizer is made of a lignin fiber or a basalt mineral fiber or a mixed fiber of the lignin fiber and the basalt mineral fiber, and the dosage of the fiber stabilizer is 0.1%-0.6% of mass of the mixture. The diluted asphalt is diluted polymer modified asphalt, and a modifier in the diluted asphalt is a patented product RST modifier produced by Shanghai Pudong Road and Bridge Construction Co., Ltd. The asphalt mixture has the advantages of being long in storage time, convenient and quick to construct and the like.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

Inorfil softening intensifier and preparation thereof

InactiveCN101503280AGood flexibilityHigh strengthInorganic fibres/flakesGlass fiberPolyvinyl alcohol

The invention relates to an inorganic fiber softening reinforcing agent and a preparation method thereof. The method is to lead H2O2, polyvinyl alcohol and potassium hydroxide to react for 2 to 4 hours at a temperature between 50 and 60 DEG C, adds an etherifying agent after the reaction to react for 4 to 8 hours at a temperature between 50 and 70 DEG C, and regulates the pH value of the solution to 7 to 8 so as to obtain the inorganic fiber softening reinforcing agent. The softening reinforcing agent is applicable to various inorganic fiber materials produced by physical or hot melt method, including basalt fibers, aedelforsite fibers, meerschaum fibers, gypsum fibers, flyash fibers and glass fibers. The softening reinforcing agent can improve the softness and strength of inorganic fibers, improve the defect of easy fracture of the inorganic fibers in processes of pulping, dispersing and transporting, change the charge property of the inorganic fiber surface, reinforce the bonding force of the inorganic fibers and plant fibers, and greatly improve application performance of the inorganic fibers in making paper, insulating wool boards and the like by wet method.

Owner:鹤壁洁联新材料科技有限公司

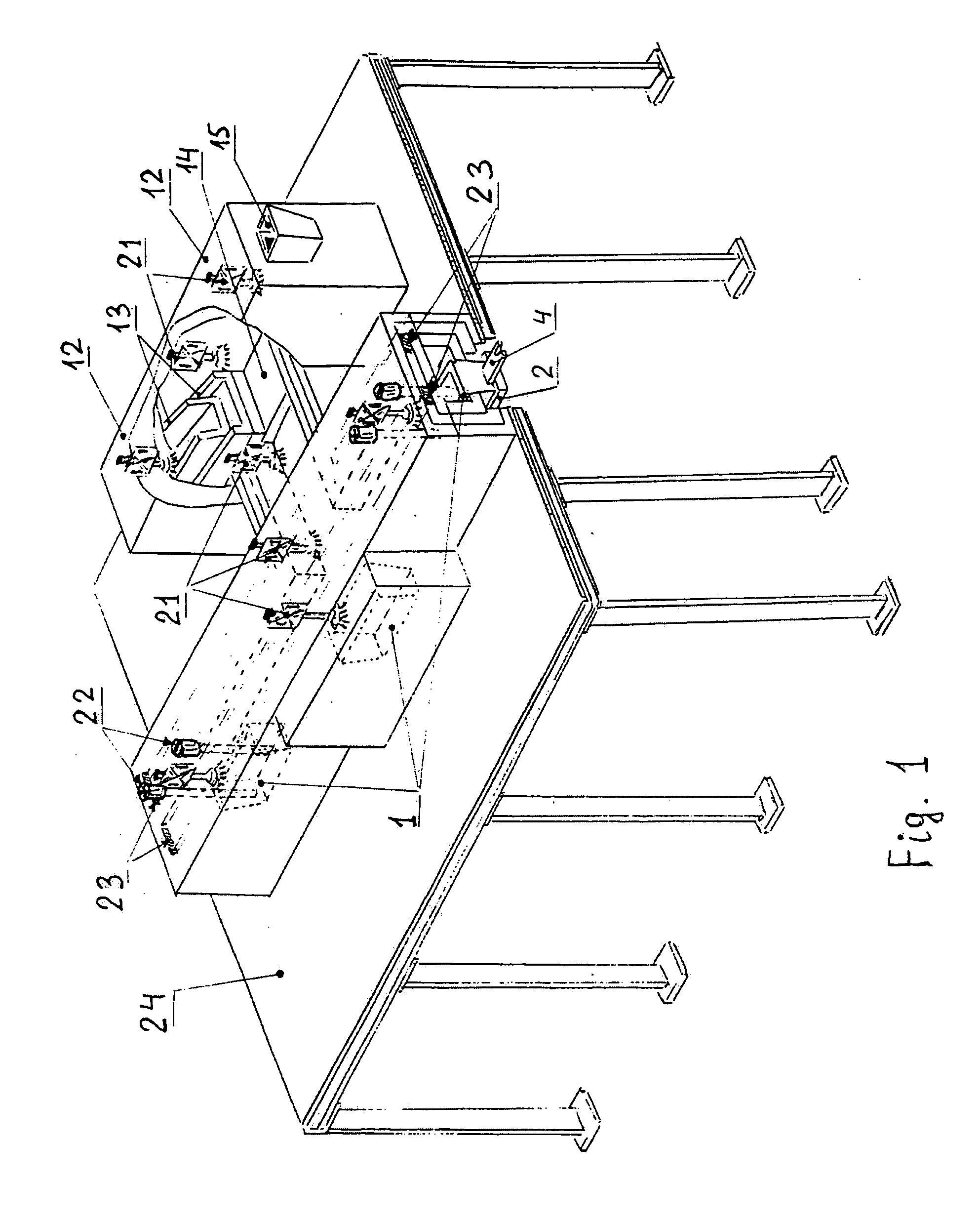

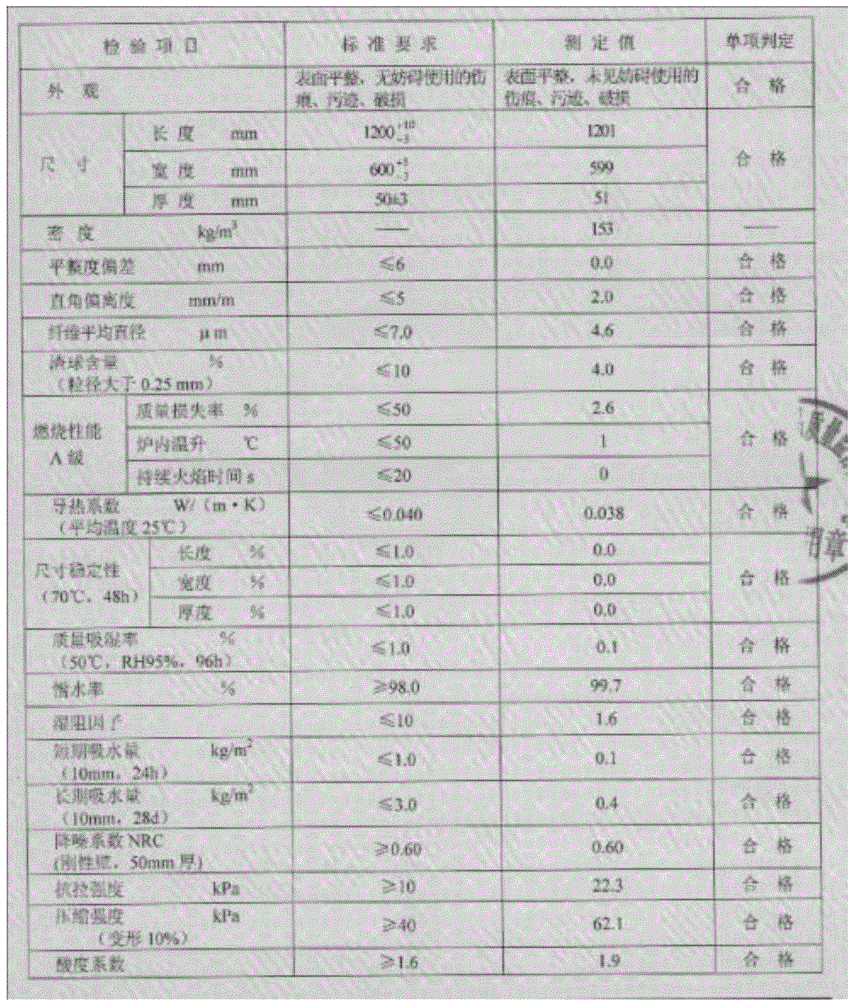

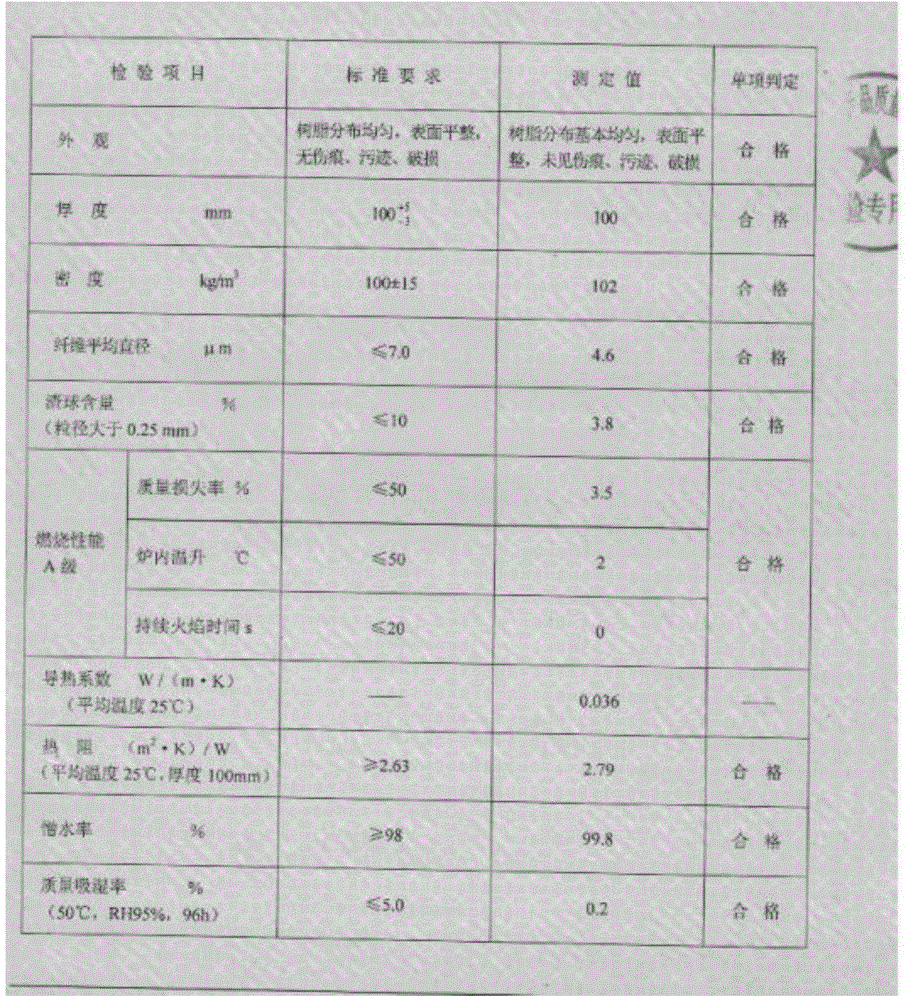

Method and system for producing rock wool by comprehensively utilizing solid wastes

ActiveCN104692648AReduce consumptionLower melting temperatureGlass making apparatusGlass productionFiberAdhesive

The invention discloses a method and system for producing rock wool by comprehensively utilizing solid wastes. The method comprises the following steps: a) uniformly mixing rock wool waste residue, coal gangue and cement in a mass ratio of (50-70):(20-35):(10-20) to prepare an autoclaved waste residue block; b) uniformly mixing the autoclaved waste residue block and smelting waste residue in a mass ratio of (60-80):(20-40) to obtain a mixture; c) melting the mixture at high temperature, and centrifuging at high speed for fiber formation, thereby obtaining fibers; and d) spraying an adhesive, a water repellent and a coupling agent on the fibers, and carrying out wool accumulation, solidification and cutting to obtain the rock wool plate. The method has the advantages of simple technological equipment, low energy consumption and recoverable heat source, is convenient to operate, comprehensively utilizes the solid wastes instead of the traditional basalt and dolomite to produce the rock wool product, and thoroughly solves the problem of solid wastes in the rock wool enterprise.

Owner:TAISHI ROCK WOOL

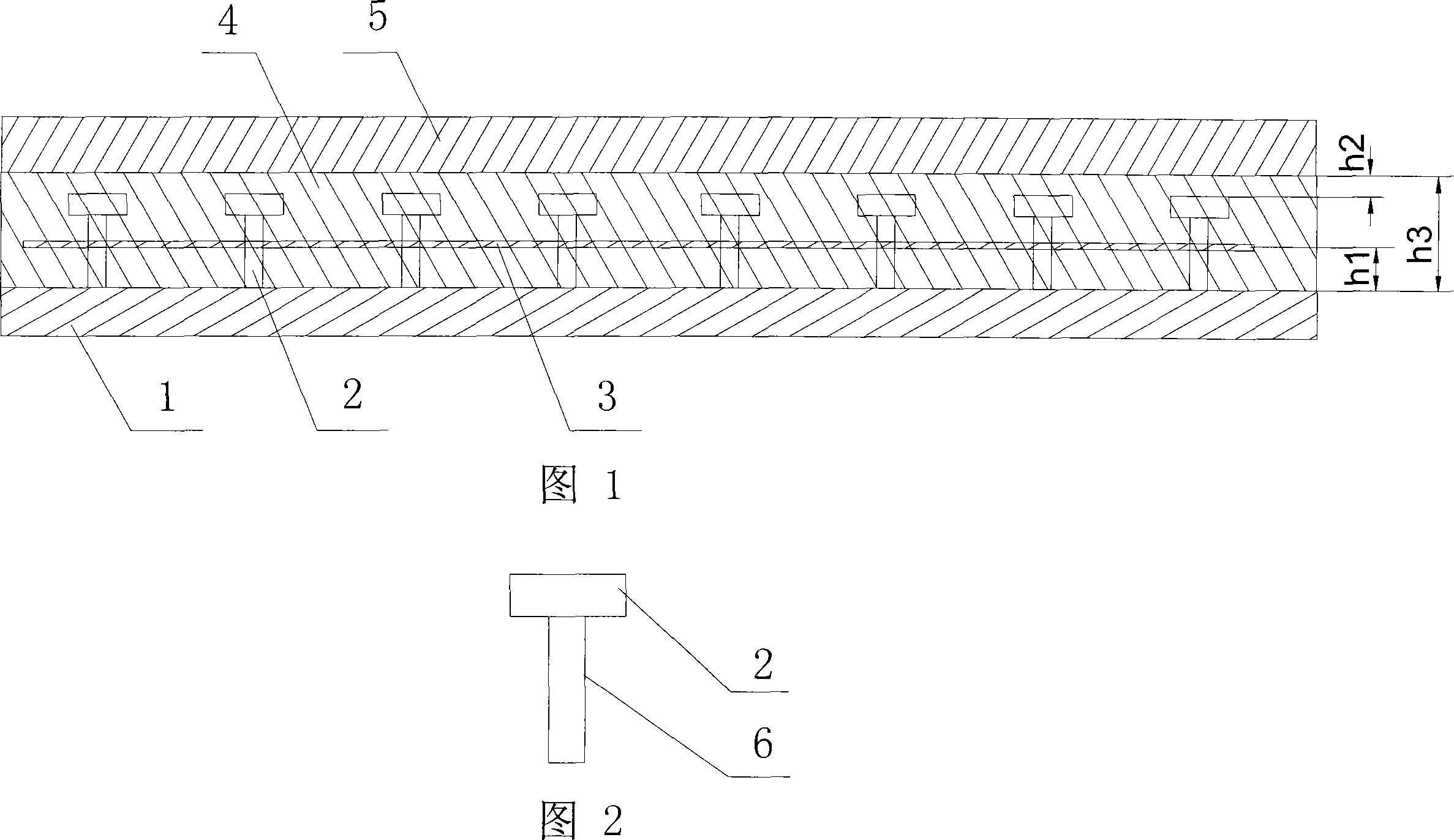

Method for preparing antiskid wearable lightweight steel box girder bridge floor paving layer

ActiveCN101234876AWear-resistantWith wear resistanceSolid waste managementWear resistantMesh reinforcement

The invention relates to an anti-sliding, wear-resistant and light steel box girder bridge deck pavement and a preparation method thereof, which is characterized in that the method includes the following steps: 1) preparation of high toughness and high strength lightweight aggregate concrete and cement paste on a basalt bare stone surface layer: a. the high toughness and high strength lightweight aggregate concrete is prepared; b. the cement paste on the basalt bare stone surface layer is prepared; 2) pretreatment of the steel box girder bridge deck; 3) welding of shear key: the shear key is welded on the steel box girder bridge deck one by one according to mutual spacing of the shear keys with (30-60)cm plus (30-60)cm; the shear key is stud; 4) lashing of mesh reinforcement; 5) paving of the high toughness and high strength lightweight aggregate concrete layer: thickness of the high toughness and high strength lightweight aggregate concrete layer is 50-80cm; 6) paving of the surface layer of the basalt bare stone; then maintenance is carried out. The bridge deck pavement prepared by the method can effectively prevent disease occurrence of the steel box girder, prolong service life of the bright deck and simultaneously has the functions of anti-sliding, wear-resistant and noise reduction and has good pavement performance.

Owner:WUHAN MUNICIPAL CONSTR GROUP

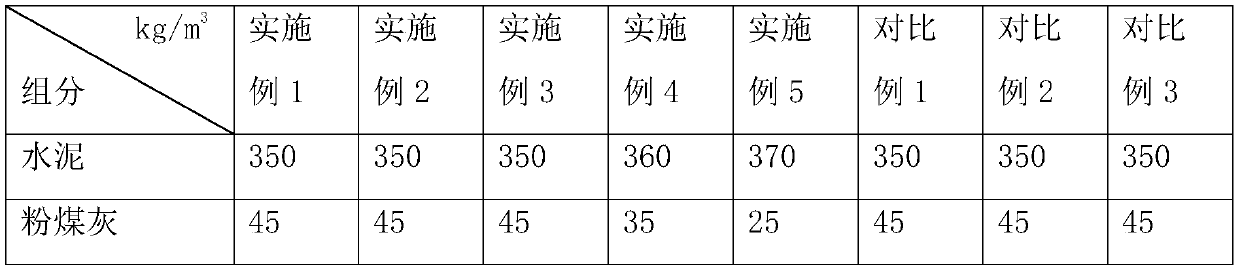

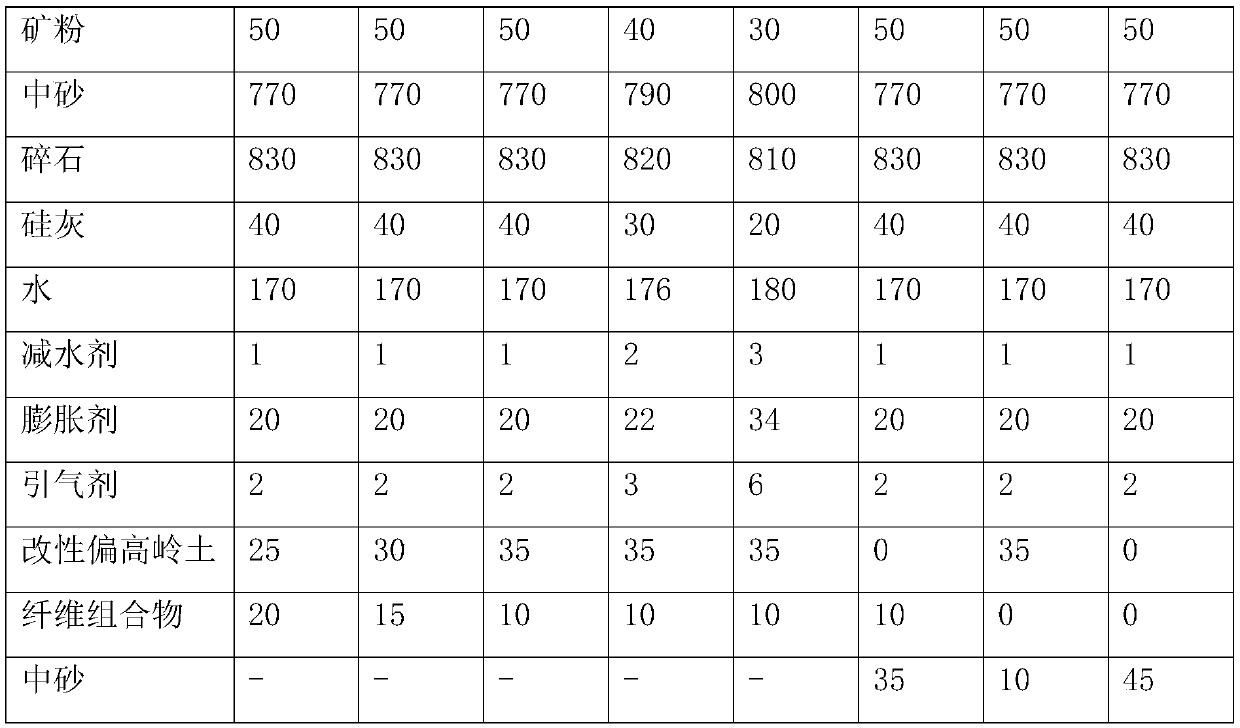

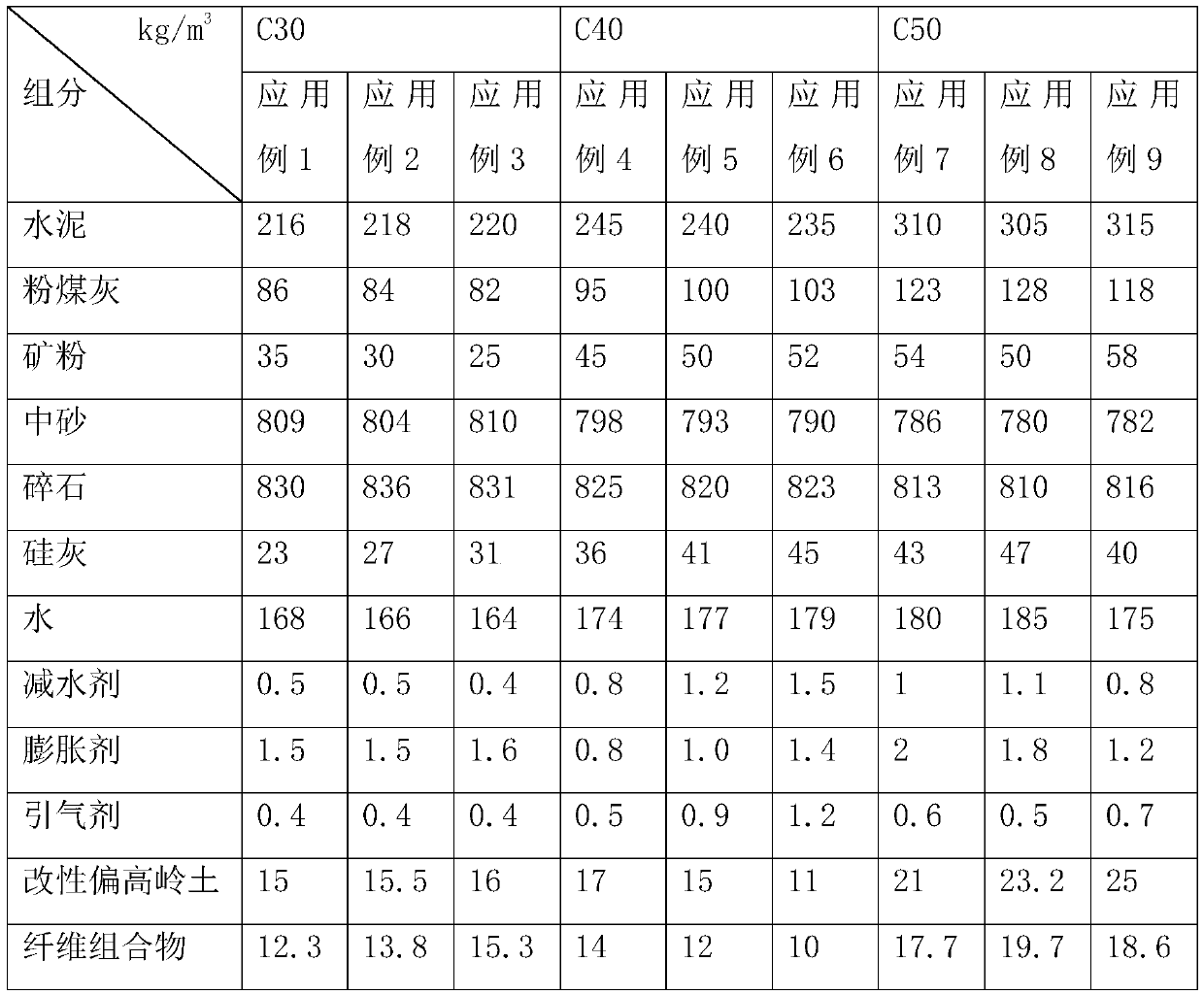

Anti-seepage, anti-freeze-thaw self-compacting concrete and preparation method thereof

The invention discloses anti-seepage, anti-freeze-thaw self-compacting concrete and a preparation method thereof. The anti-seepage, anti-freeze-thaw self-compacting concrete comprises the following components in parts by weight: 350-370 parts of cement, 25-45 parts of fly ash, 25-35 parts of modified metakaolin, 30-50 parts of mineral powder, 770-800 parts of medium sand, 810-830 parts of crushedstone, 20-40 parts of silica fume, 170-180 parts of water, 1-3 parts of a water reducing agent, 20-34 parts of an expansion agent, 2-6 parts of an air entraining agent, and 10-20 parts of a fiber composition, wherein the fiber composition is prepared by mixing a modified polyester fiber, a basalt fiber and a polyacrylonitrile fiber in a mass ratio of 1:0.6-0.9:0.3-0.6. The anti-seepage, anti-freeze-thaw self-compacting concrete has the advantages of good workability and fluidity, and excellent anti-seepage performance and anti-freezing performance.

Owner:西安新意达建筑制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com