Patents

Literature

188results about How to "Enhance the interface force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

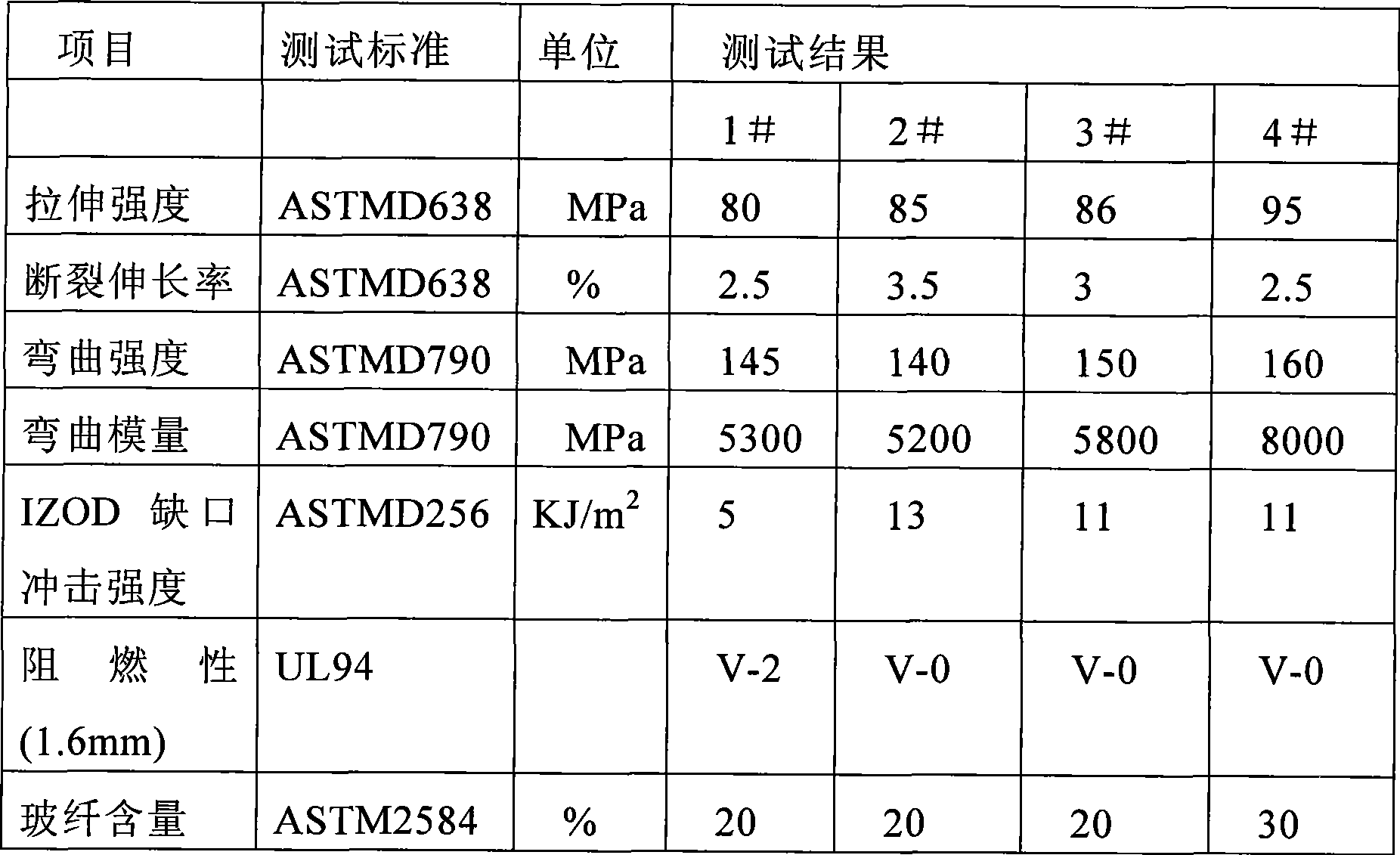

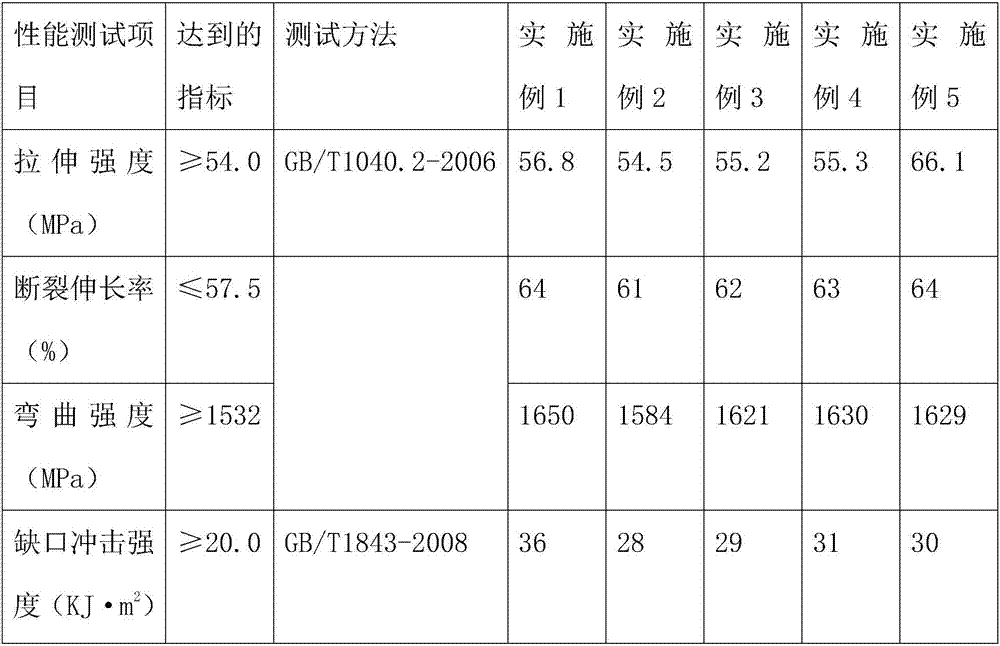

High tenacity halogen-free flame-retardant glass fiber reinforced polycarbonate composition

InactiveCN101469112AImprove mechanical propertiesImprove notched impact strengthPolycarbonateHalogen

The invention relates to a high-tenacity, halogen-free and flame-retardant fiber glass reinforced polycarbonate composition, which comprises the following components by weight portion: 300 to 800 portions of polycarbonate, 100 to 400 portions of fiber glass, 30 to 150 portions of toughening compatilizer, 10 to 100 portions of organosilicon flame retardant, 10 to 150 portions of nano silicic acid inorganic substances, 1 to 10 portions of antioxidant A, 1 to 15 portions of antioxidant B, 1 to 15 portions of coupling agent, and 0 to 20 portions of other assistants. Compared with the prior art, the composition has the characteristics of good processing property, high impact strength, environmental protection due to free halogen and flame retardance, and the like.

Owner:HEFEI GENIUS NEW MATERIALS

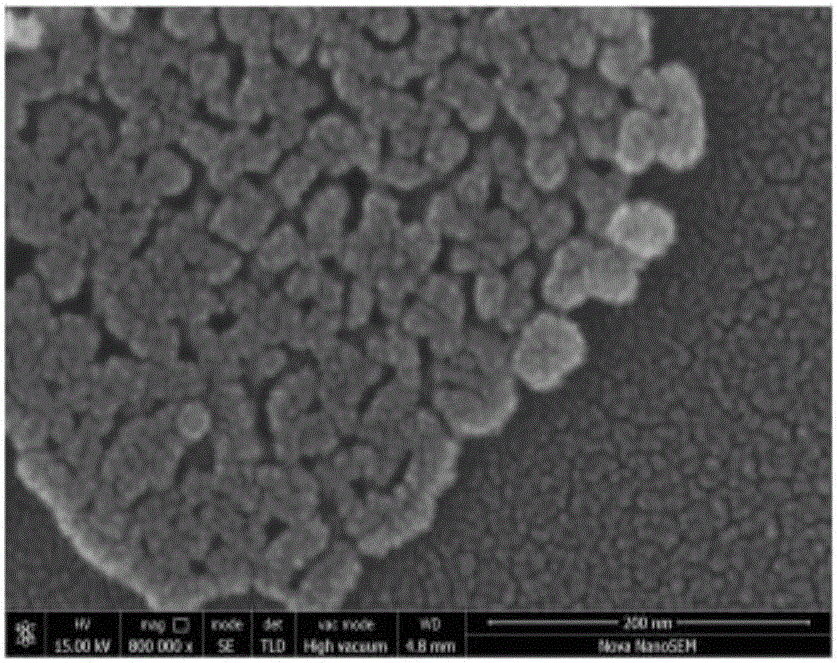

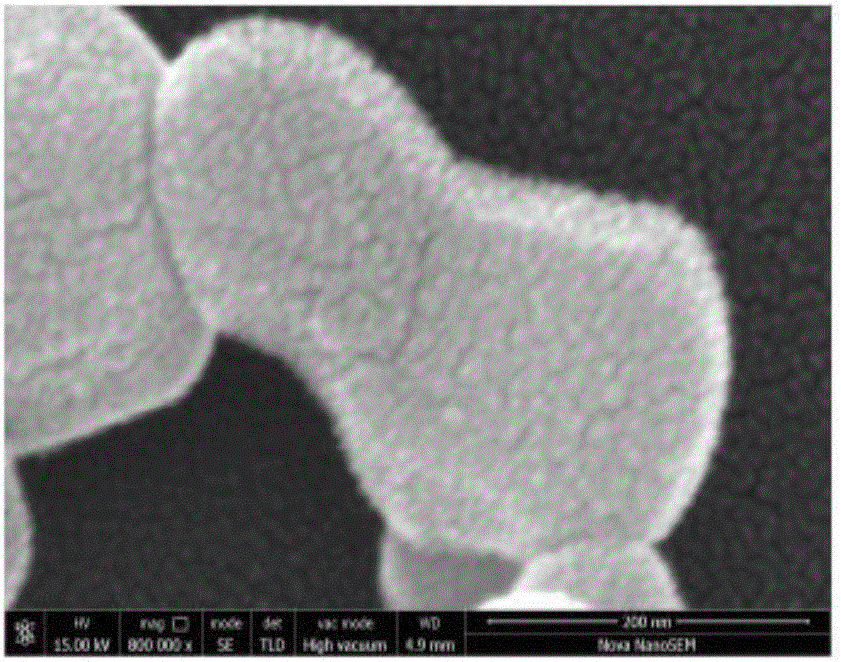

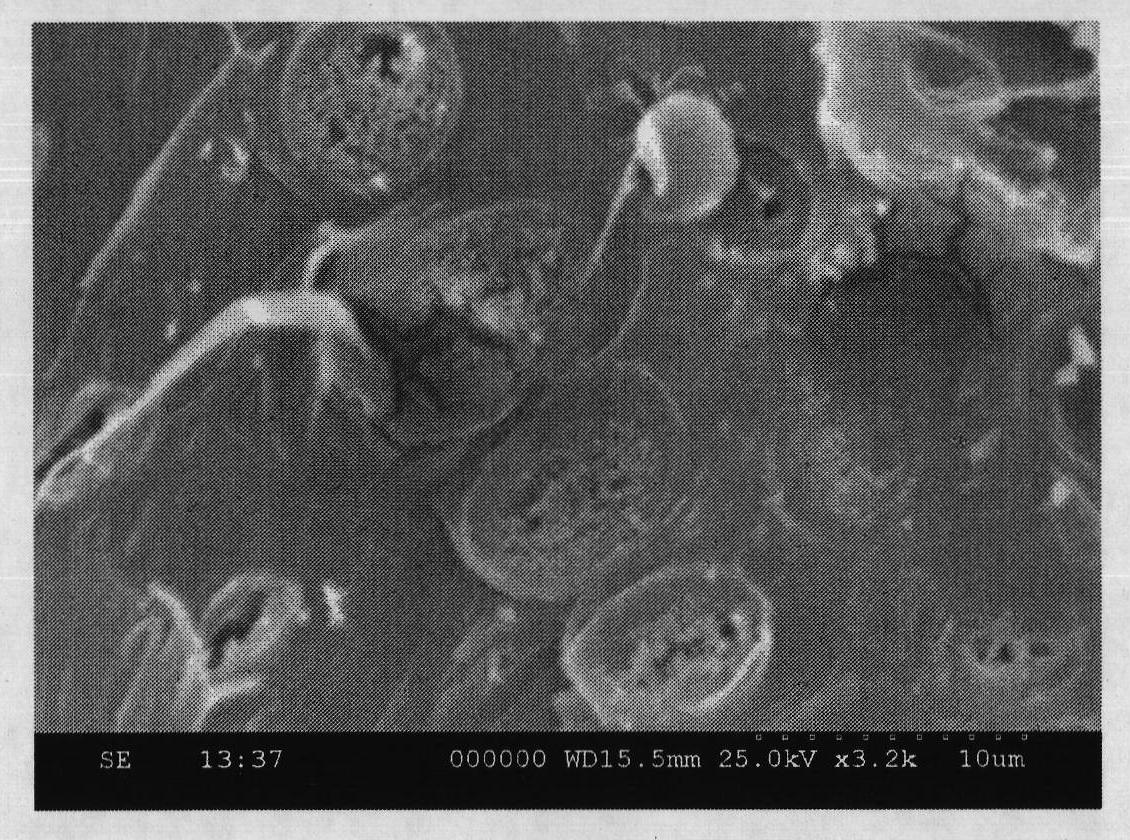

Phase change microcapsule, preparation method and applications thereof

InactiveCN108276854AImprove hydrophilicityAvoid problems such as loss of strengthHeat-exchange elementsCoatingsDispersion stabilityPhase change

The invention discloses a phase change microcapsule and a preparation method thereof. The phase change microcapsule comprises an outer shell and a capsule core wrapped in the outer shell, wherein thecapsule wall of the outer shell contains the polymer material of a repeating monomer unit formed from the following monomer: (A) 40-80 wt% of more than one selected from C1-C24 alkyl acrylate or C1-C24 alkyl methacrylate, and (B) 20-60 wt% of a long-chain monomer with a general formula of CH2=CR1COO(CH2CH2O)m-(CH3CHCH2O)nR2, a weight ratio of the outer shell to the capsule core is 1:1-9, and the capsule core is an organic phase change material. According to the present invention, the product has good dispersion stability in practical application, especially in the application of aqueous matrixes or inorganic materials, so as to further improve the energy storage property; and with the long-chain hydrophilic group, the interfacial action force between the phase change microcapsule and the matrix can be enhanced, and the problems of the reduced strength and the like in the application of the material can be avoided.

Owner:NANOSPHERE SHANGHAI +1

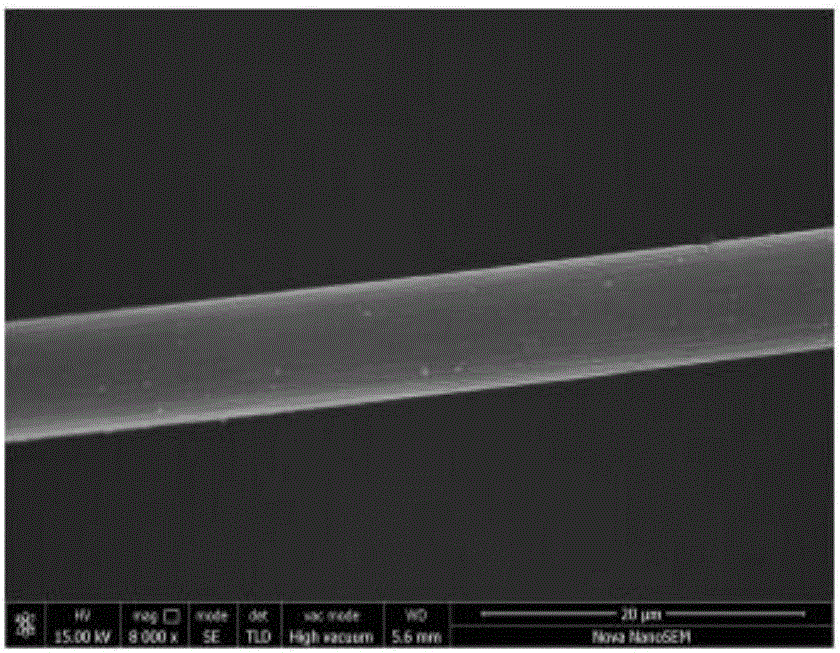

Bamboo fiber reinforced polylactic acid composite material used for 3D printing and preparation method for bamboo fiber reinforced polylactic acid composite material

ActiveCN104927320AImprove the shortcoming of brittle fractureRaise the ratioAdditive manufacturing apparatusPolymer sciencePlasticizer

The invention discloses a bamboo fiber reinforced polylactic acid composite material used for 3D printing and a preparation method for the bamboo fiber reinforced polylactic acid composite material. The material is a co-mixture comprising modified bamboo fibers, polylactic acid, polypropylene, a compatilizer and a plasticizer. The invention further provides the preparation method for the bamboo fiber reinforced polylactic acid composite material, wherein the preparation method comprises the following steps: preparing the modified bamboo fibers; co-mixing the bamboo fibers, the polylactic acid, the polypropylene, the compatilizer and the plasticizer by a high-speed mixer to form co-mixed materials; fusing, co-mixing, extruding and pelletizing the co-mixed materials by a twin-screw extrusion method, and repeating the extruding twice; processing the composite material particles into monofilaments by a single screw extruder after drying. According to the bamboo fiber reinforced polylactic acid composite material, on the basis of keeping the excellent performance of the polylactic acid, elongation at break and impact resistance of the material are improved. The method is more liable to realize industrialization, and the material has unique color of natural bamboo fibers, and color master batch is not required to add in a processing process for coloring.

Owner:琪恒泰新材料科技(深圳)有限公司

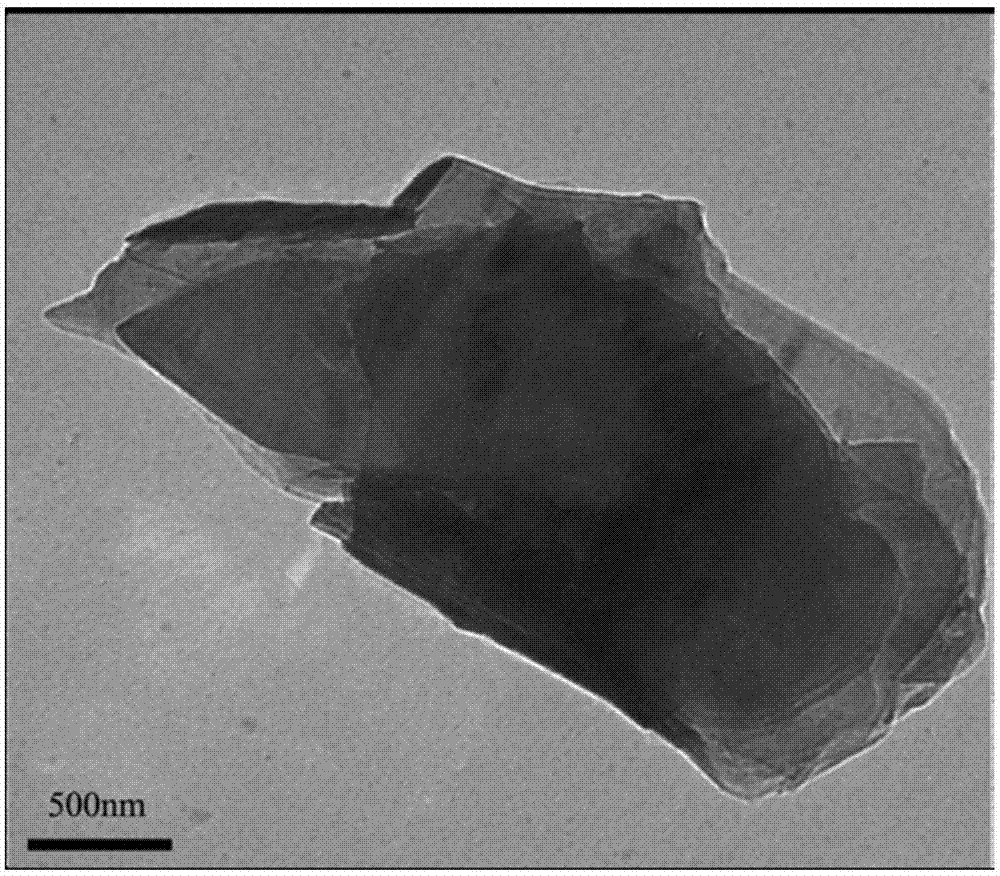

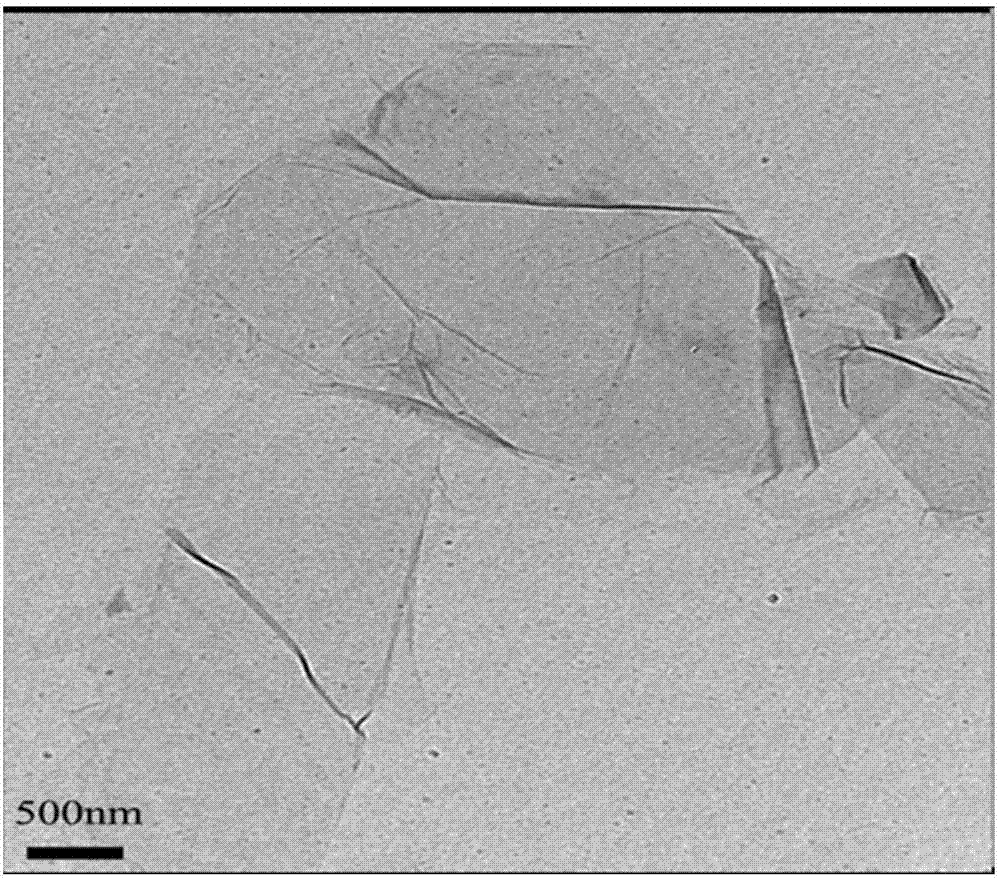

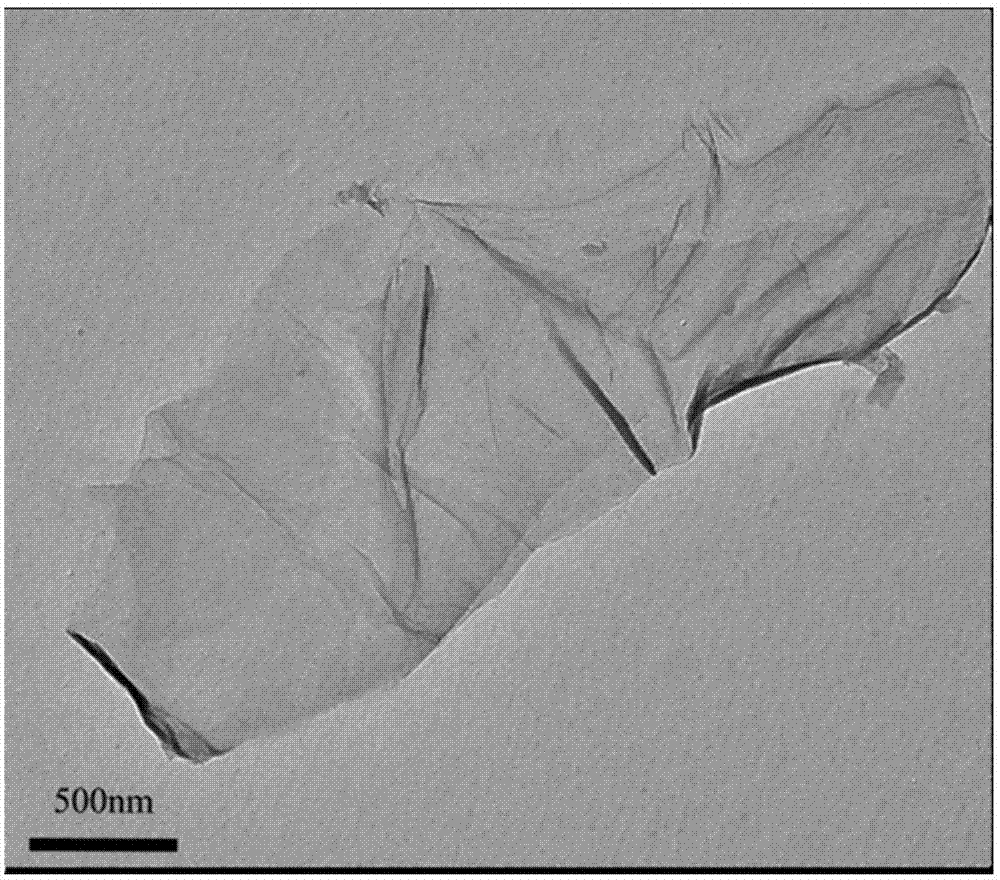

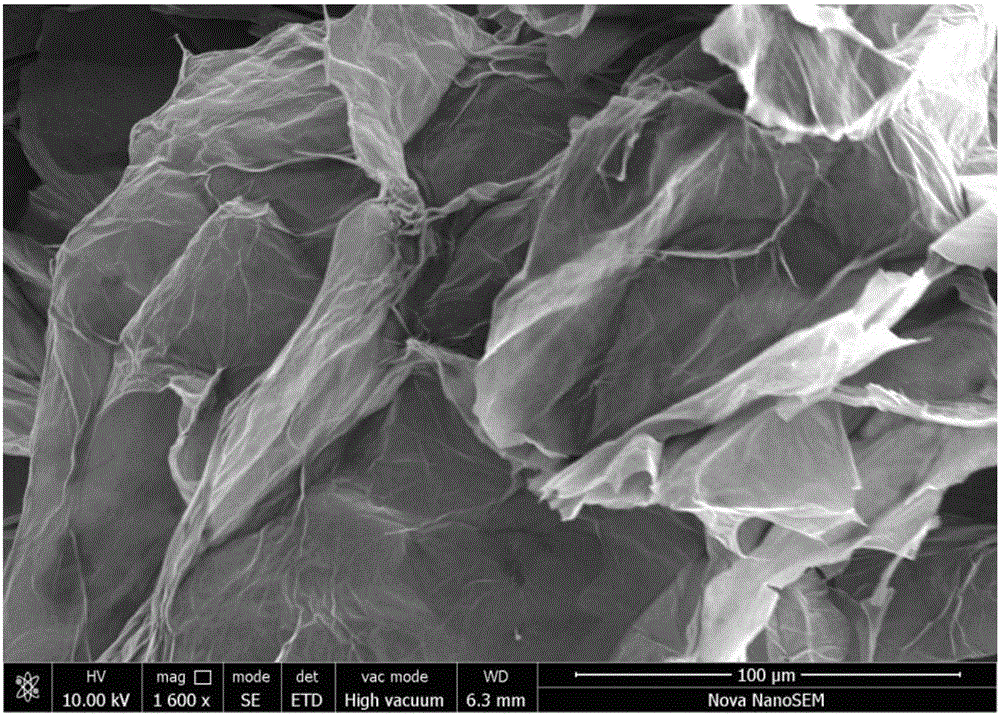

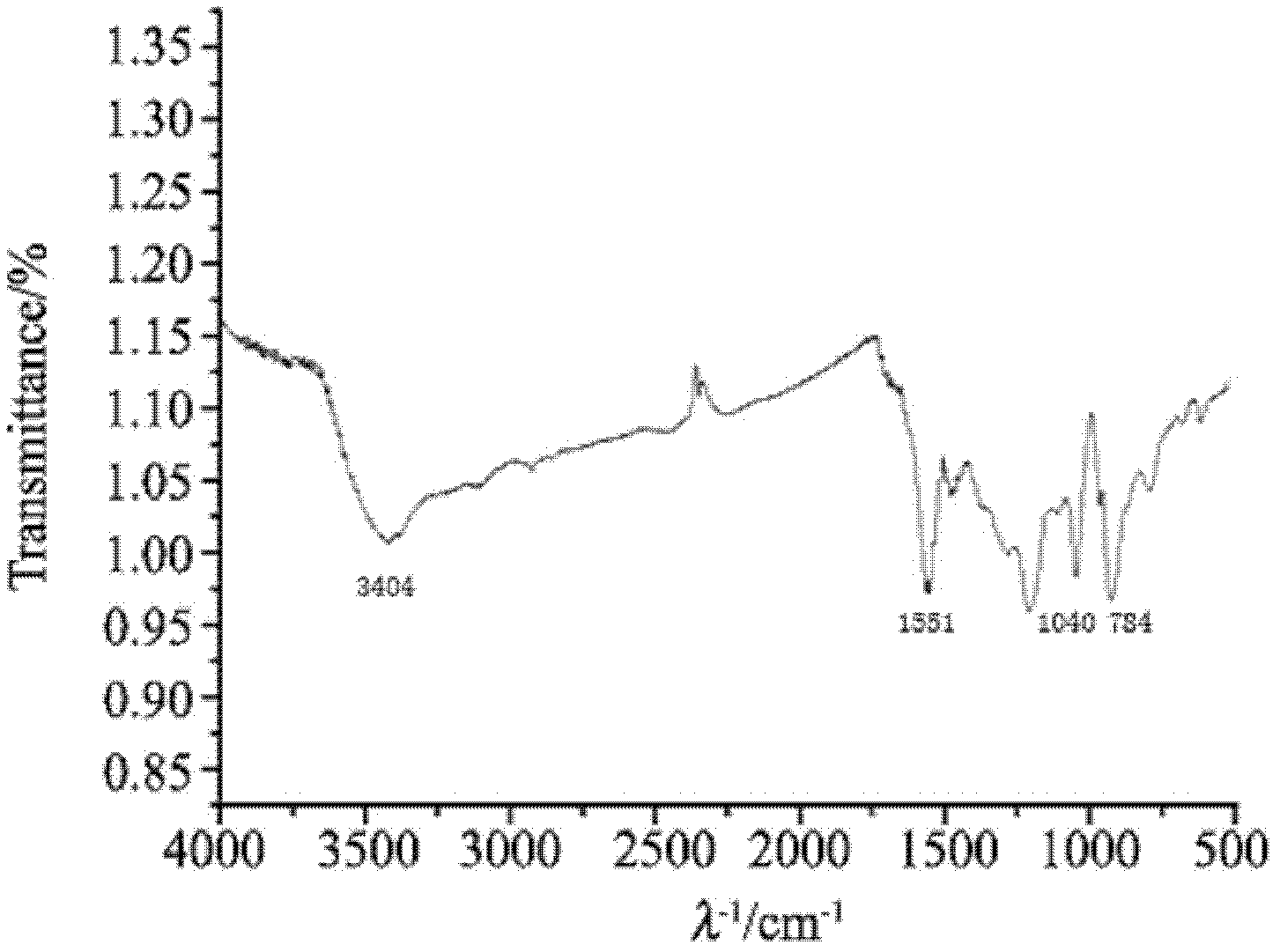

Method for carrying out graft modification on graphene by virtue of styrene-maleic anhydride copolymer

The invention discloses a method for carrying out graft modification on graphene by virtue of a styrene-maleic anhydride copolymer. The method comprises the following steps: taking graphite powder as a raw material, preparing graphene oxide (GO) by utilizing an improved Hummers' process, then grafting maleic anhydride to the GO by adopting a monomer grafting way, then taking a free radical initiator, styrene and maleic anhydride as functional modification reagents, carrying out in situ polymerization, solvent washing and centrifugal separation, and drying, so that styrene-maleic anhydride copolymer grafted graphene oxide is obtained. Grafting ratio of the obtained SMAFG is 20-50%. The styrene-maleic anhydride copolymer grafted graphene oxide can be well dispersed and form stable chemical bonding in a process of preparing a styrene-maleic anhydride copolymer grafted graphene oxide / polymer matrix composite material with the polymer matrix and has the effect of better improving mechanical and thermal properties of a polymer.

Owner:TIANJIN POLYTECHNIC UNIV

Anti-oxidization and high-intensity 3D printing material for building engineering and preparation method of printing material

InactiveCN107141799AImprove oxidation resistanceHigh strengthAdditive manufacturing apparatusSodium BentonitePolyvinyl chloride

The invention discloses an anti-oxidization and high-intensity 3D printing material for building engineering. The anti-oxidization and high-intensity 3D printing material is prepared from the following raw materials: modified polyphenylene sulfide, polyethylene sulfone, polycarbonate, polyvinyl chloride resin, diisocyanate, trimethyl phosphate, chlorinated polyethylene, polytetrafluoroethylene fine powder, hydroxypropyl methyl cellulose, nano titanium dioxide, zinc borate, antimonous oxide, organic bentonite, glass fiber, nano-zinc oxide, basalt plain fiber cloth, nanosilicon dioxide, tetraethoxysilane, a silane coupling agent KH-570, glycerinum, a defoaming agent, an anti-oxidization modifier and a modifier filler. The invention further provides a preparation method of the anti-oxidization and high-intensity 3D printing material for building engineering. The prepared 3D printing material is excellent in oxidization resistance and intensity.

Owner:HEFEI SKE INTELLIGENT TECH

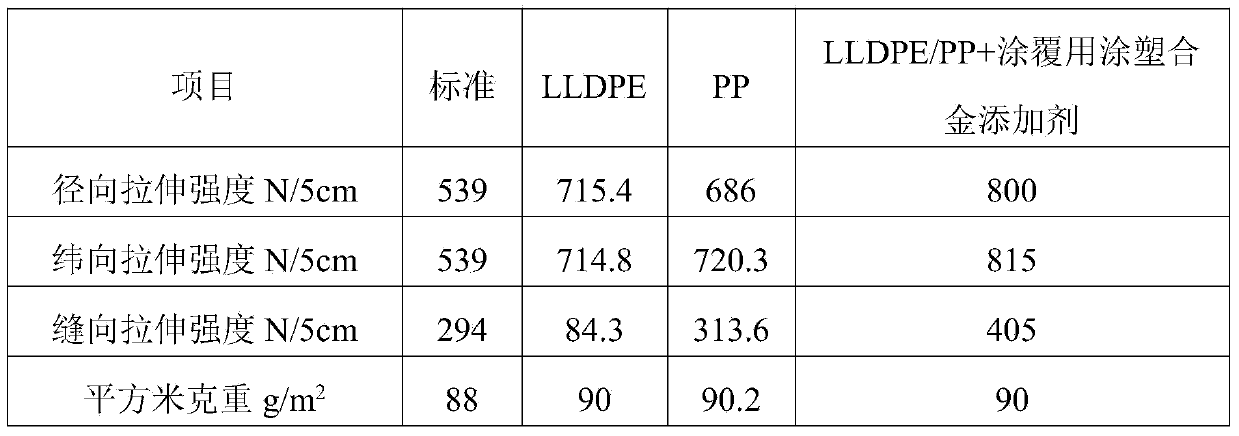

Preparation method of plastic woven bag

The invention relates to a preparation method of a plastic woven bag. The invention aims at solving the problems of poor bursting strength, poor tearing strength and poor tensile strength of an existing plastic woven bag taking a polypropylene material as a base fabric. The preparation method comprises the following steps: 1, preparing a mixture from a coating plastic coated alloy additive, an LLDPE (linear low density polyethylene) resin, a PP (propene polymer) resin antioxidant and an ultraviolet light absorber; 2, extruding the mixture by using an extruder and cooling and forming to obtain a coating woven fabric used for producing the woven bag; 3, putting the coating woven fabric used for producing the woven bag into a screw extruder and extruding to obtain ribbon-like filaments of the coating fiber of the woven bag; 4, using a cylinder loom to woven the ribbon-like filaments of the coating fiber of the woven bag through a flat die method, and sequentially cutting, tailoring and sewing to obtain the plastic woven bag. The preparation method of the plastic woven bag is mainly used to prepare the plastic woven bag.

Owner:哈尔滨盛洋塑胶材料有限公司

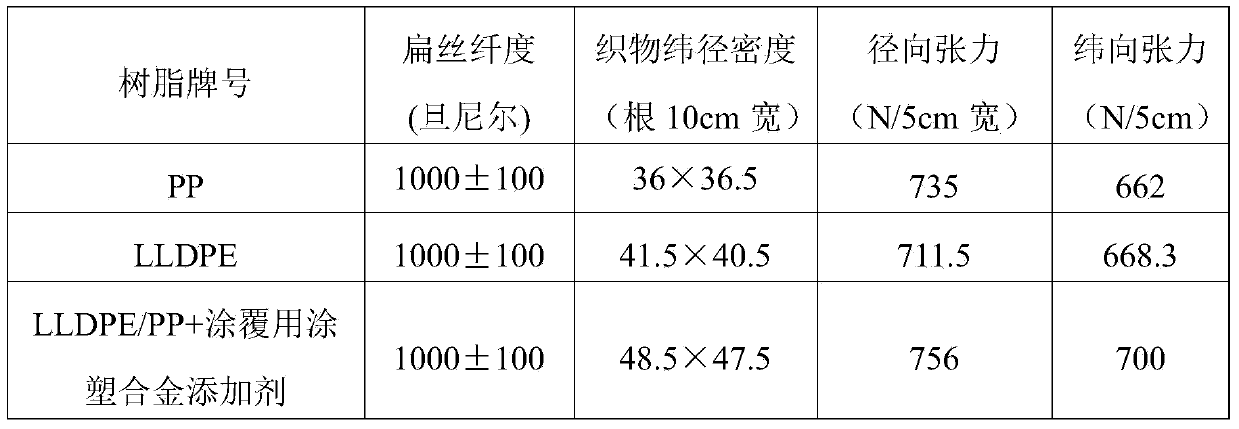

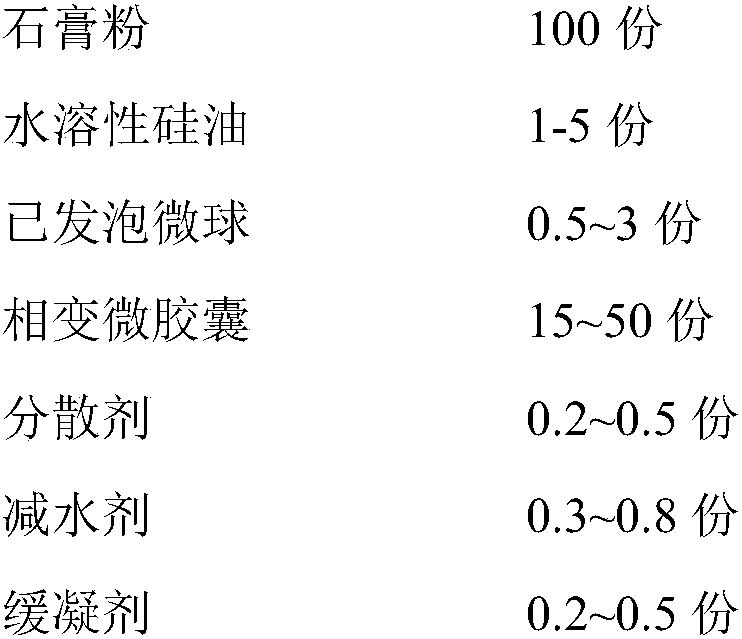

Ultra-light energy-storing gypsum board and preparation method thereof

The invention discloses an ultra-light energy-storing gypsum board and a preparation method thereof. The ultra-light energy-storing gypsum board is prepared from the following components in parts by weight: 100 parts of gypsum powder, 0.5 to 7 parts of water soluble silicon oil, 0.1 to 5 part of foamed microsphere and 10 to 60 parts of phase change microcapsule. By adopting the ultra-light energy-storing gypsum board, the weight of the gypsum board is lowered remarkably; meanwhile, the heat-insulation performance is achieved; under the synergistic effect with phase change microcapsules, the temperature control effect is improved further, and the dispersion property, the flowing performance and the combination strength of foamed microspheres in the gypsum powder are improved; meanwhile, thefoamed microspheres are very light, and can be premixed with the phase change microcapsules, so that subsequent machining operation is facilitated; moreover, the foamed microspheres have certain strength, and the dispersing property in the gypsum powder of the phase change microcapsules and interface action force with the gypsum powder are improved by hydrophilic long-chain monomers in the phasechange microcapsules, so that the requirement on the strength of the gypsum board product is met; gaps in the gypsum board can be filled with the foamed microspheres, so that the water absorbing rateis lowered; the ultra-light energy-storing gypsum board can be applied to a high-moisture environment.

Owner:NANOSPHERE SHANGHAI +1

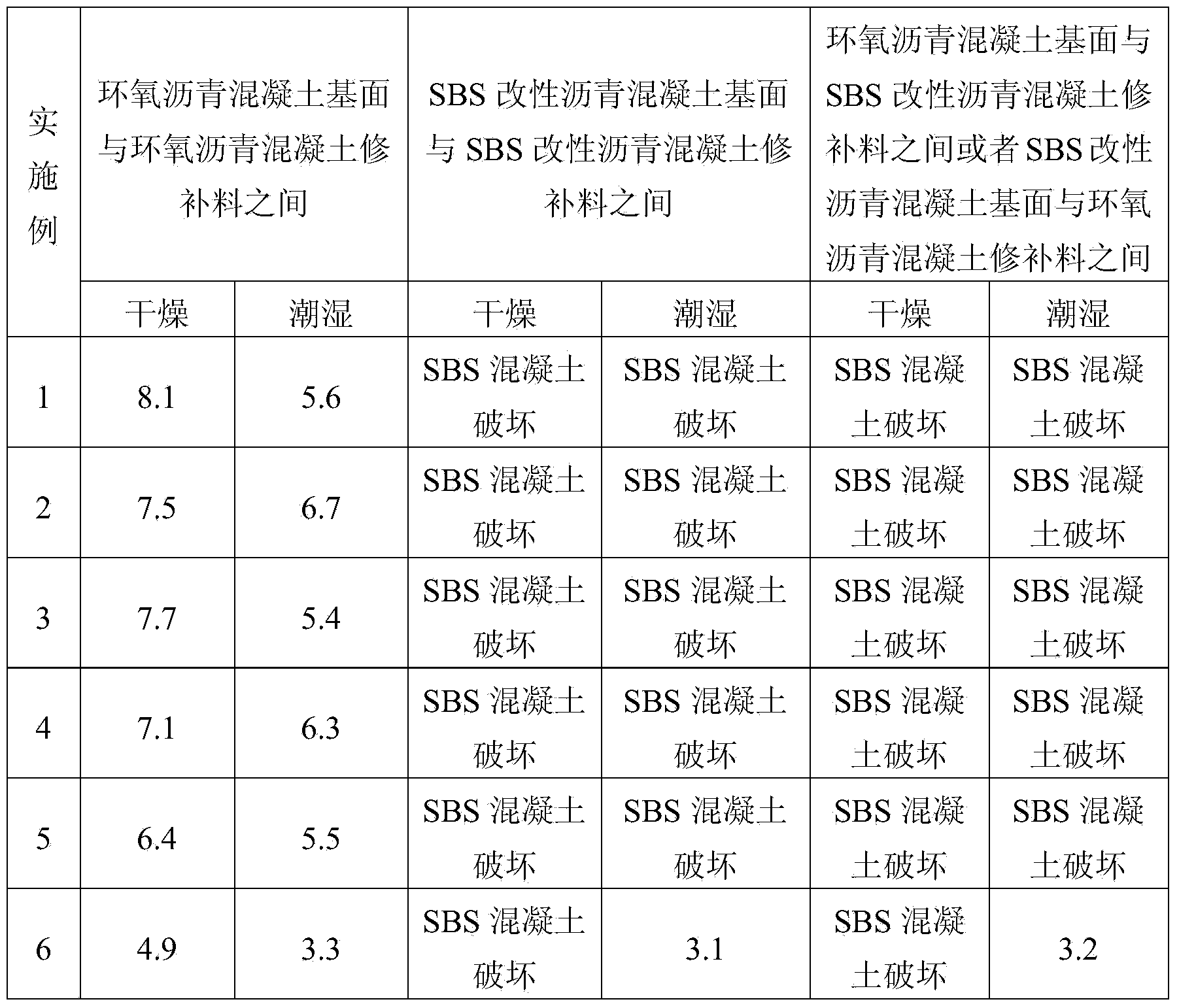

Binding material for bituminous concrete base-surfaces and preparation method thereof

InactiveCN103627368AImprove permeabilityImprove adhesionNon-macromolecular adhesive additivesOil/fat/wax adhesivesEpoxySynthetic resin

The invention provides a binding material for bituminous concrete base-surfaces, which is composed of a matrix component and a hardening component, wherein the mass ratio of the matrix component to the hardening component is 100: (8-60); the matrix component is composed of the following raw materials in parts by weight: 10-80 parts of bitumen, 14-65 parts of a synthetic resin, 2-20 parts of a thinner, and 1.5-5 parts of a solubilizer, and the part sum of the raw materials of the matrix component is 100; the hardening component is composed of the following raw materials in parts by weight: 80-99 parts of an amine curing agent, and 1-20 parts of a penetrating agent, and the part sum of the raw materials of the hardening component is 100. The binding material disclosed by the invention can improve the binding performance thereof, and increase the durability of repair of epoxy bituminous concrete paved layers.

Owner:CHANGAN UNIV

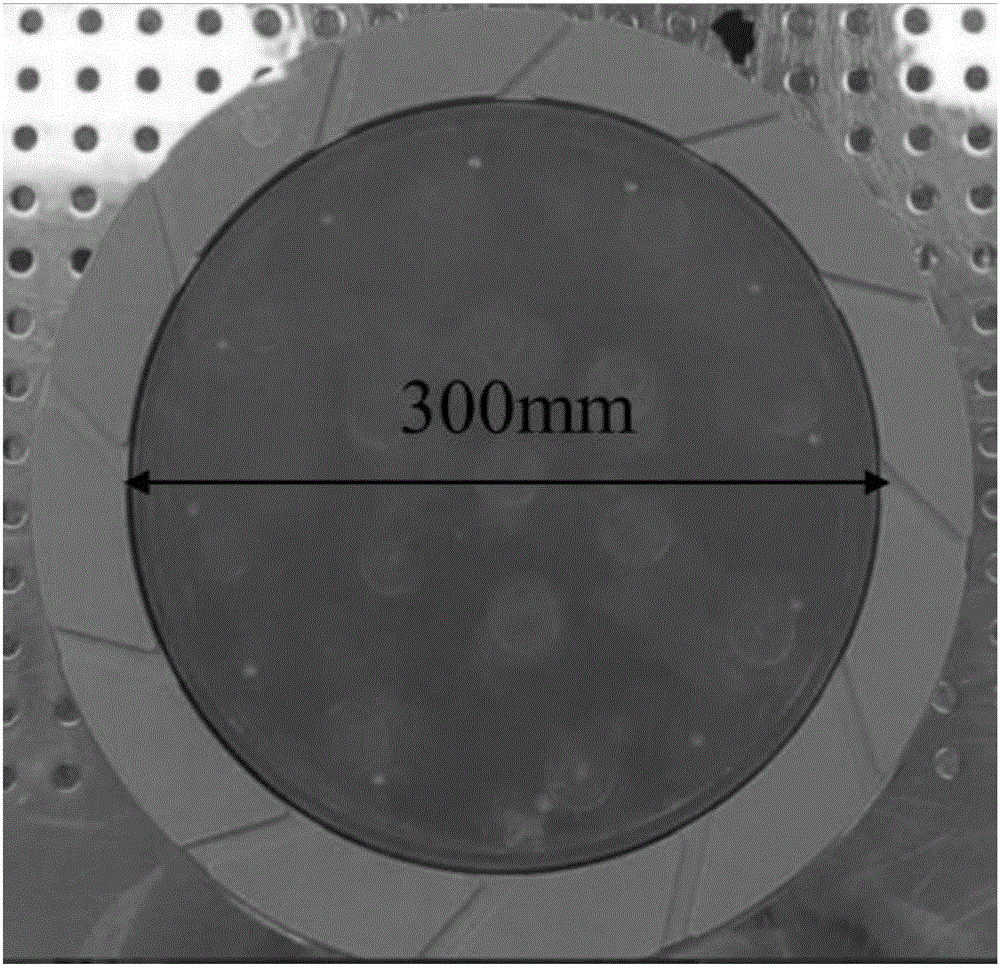

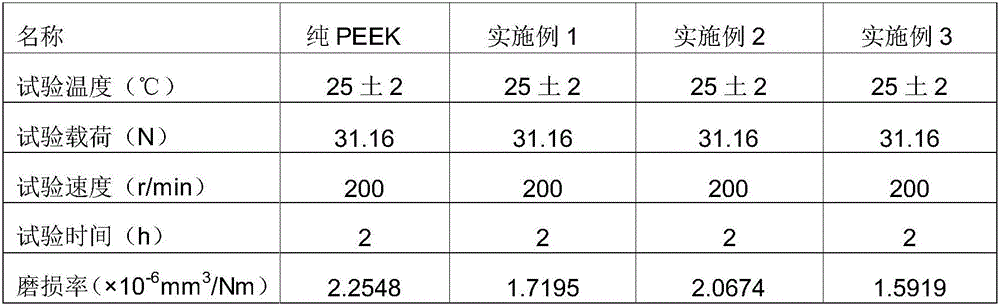

Polyether-ether-ketone/nanometer zinc oxide/carbon fiber wear-resistant composite material and preparation method thereof, and application of composite material to mechanical polishing of retaining rings

The invention provides a polyether-ether-ketone / nanometer zinc oxide / carbon fiber wear-resistant composite material and a preparation method thereof, and application of the composite material to mechanical polishing of retaining rings, belonging to the technical field of polymer-based composite materials. The composite material is composed of, by mass, 75 to 90% of polyether-ether-ketone resin, 5 to 20% of carbon fibers coated by polyethersulfone and 2.5 to 7.5% of nanometer zinc oxide modified by a coupling agent, summing to 100%. To improve dispersibility of zinc oxide nanoparticles and reduce the agglomeration degree of the zinc oxide nanoparticles, the coupling agent is employed for surface modification of the zinc oxide nanoparticles; and polyethersulfone is used for physical coating of the surfaces of the carbon fibers so as to improve compatibility between the carbon fibers and polyether-ether-ketone. Compared with a polyether-ether-ketone composite material without any treatment, the wear-resistant composite material provided by the invention has more excellent strength, wear resistance and antifriction performance, is low in processing cost and is applicable to mechanical polishing of retaining rings.

Owner:JILIN UNIV

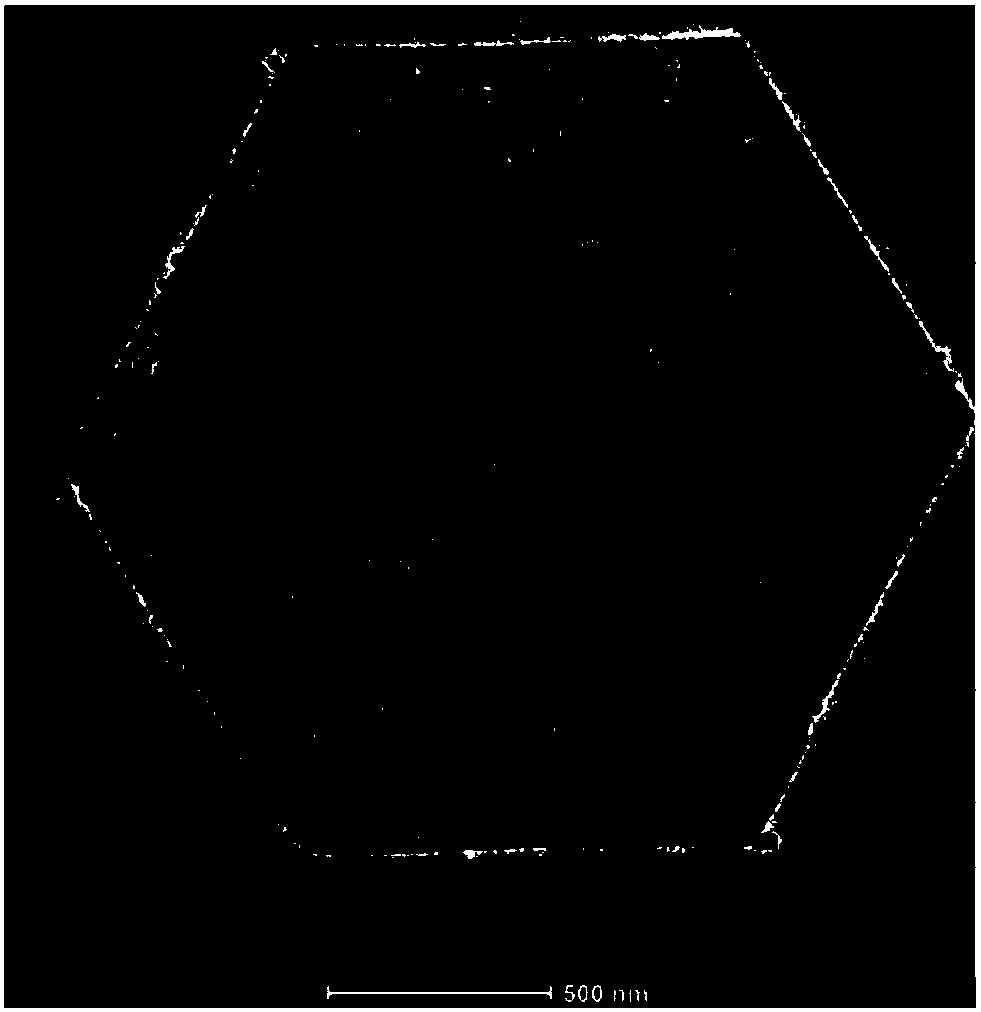

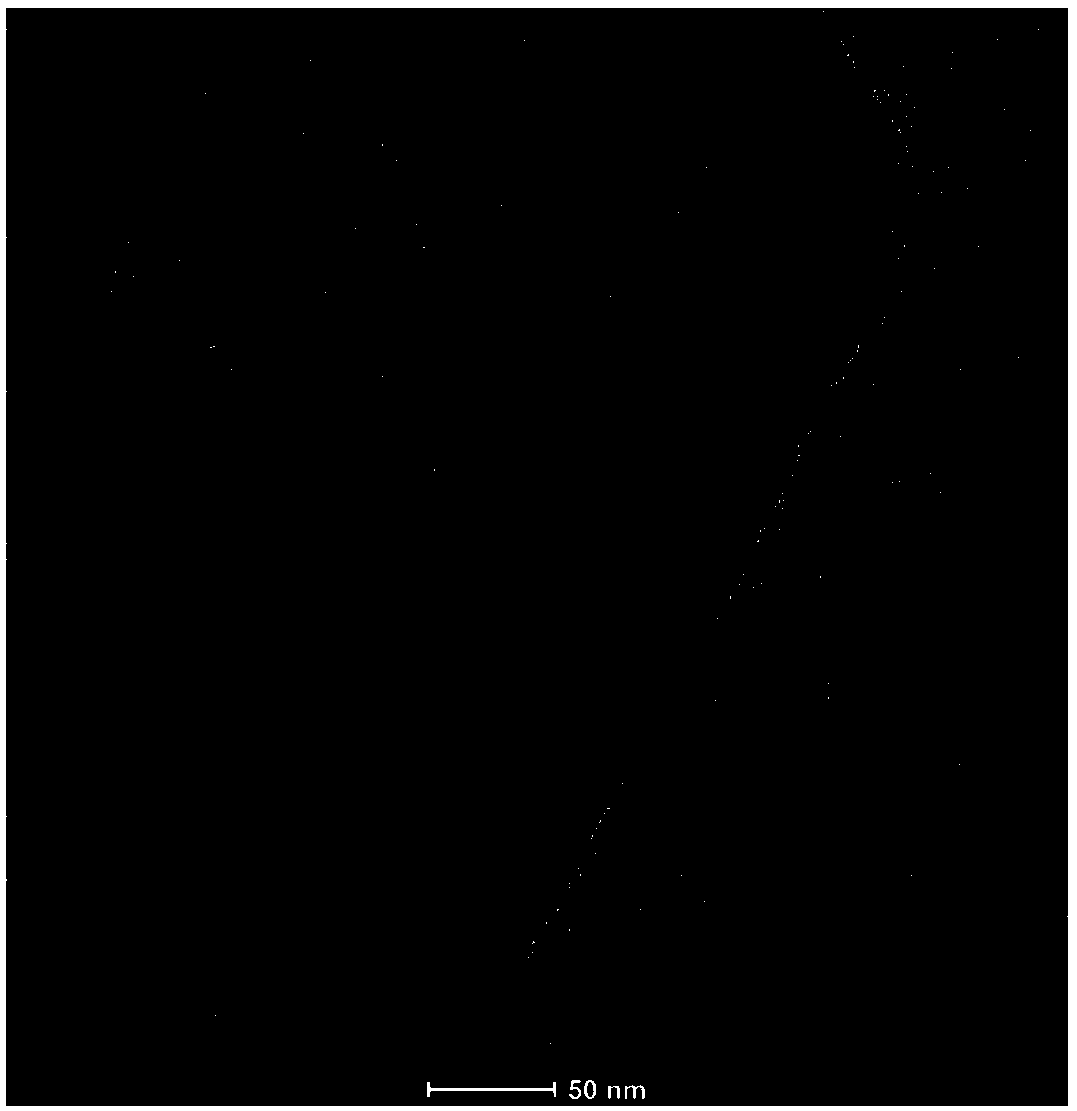

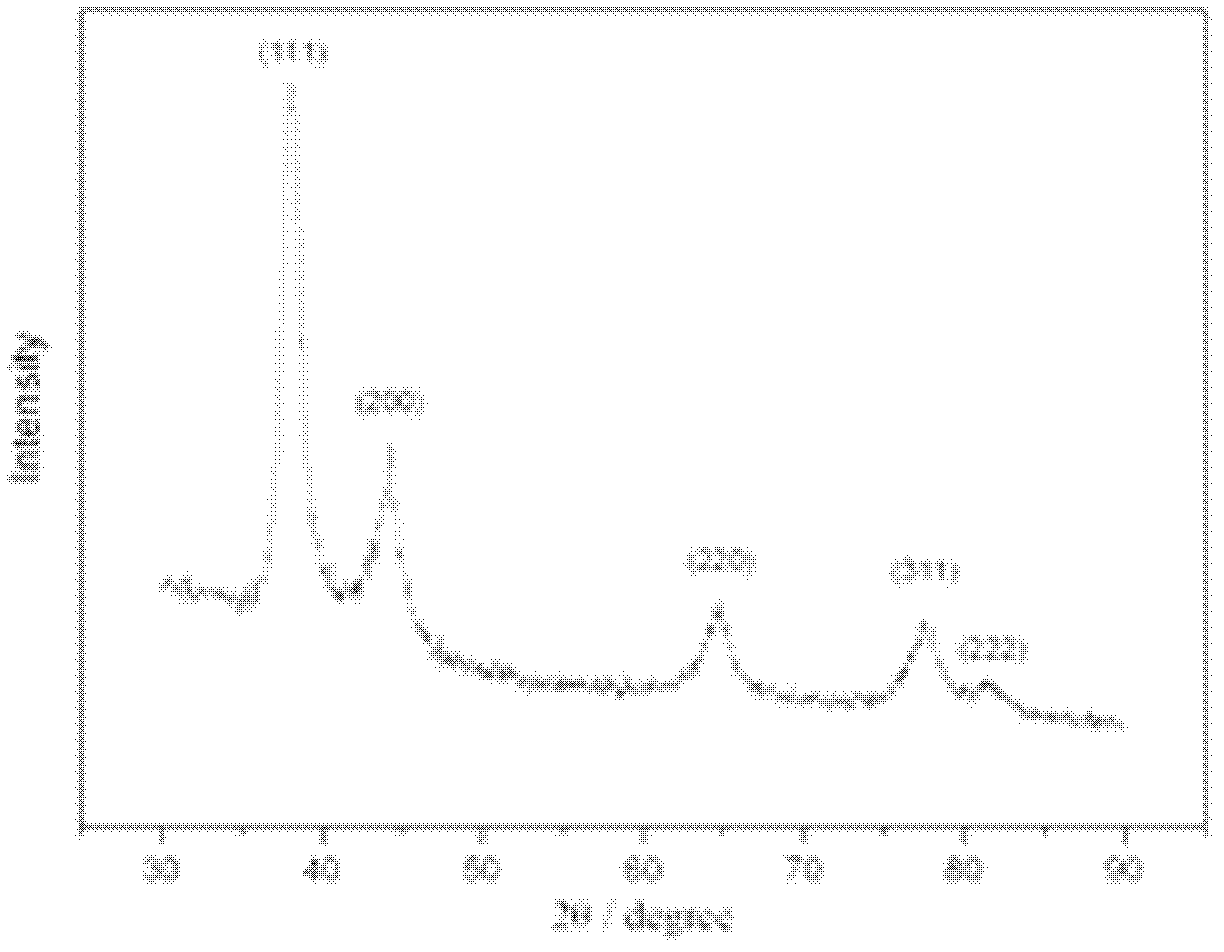

Polyether-ether-ketone wear resistant composite material, preparation method and application thereof in mechanical polishing retaining rings

InactiveCN105754288AGood compatibilityEnhance the interface forceWear resistantPolyether ether ketone

Belonging to the technical field of polymer composite materials, the invention relates to a polyether-ether-ketone wear resistant composite material, a preparation method and application thereof in mechanical polishing retaining rings. The polyether-ether-ketone wear resistant composite material is composed of, by mass percentage, 90-99.99% of polyether-ether-ketone resin and the balance coupling agent modified graphene oxide, and is prepared by a melt blending process. In order to improve the dispersibility of graphene oxide, the coupling agent is employed to perform surface treatment on graphene oxide. The polyether-ether-ketone wear resistant composite material prepared by the method provided by the invention has the characteristics of good wear resistance, high strength, high temperature resistance and the like, the processing technology is simple, the processing cost is low, and the polyether-ether-ketone wear resistant composite material meets the material requirement of mechanical polishing retaining rings. The material greatly reduces the processing cost of mechanical polishing retaining rings, and prolongs the service life of mechanical polishing retaining rings.

Owner:JILIN UNIV

3D printing polylactic acid /leather powder composite materials and preparation method thereof

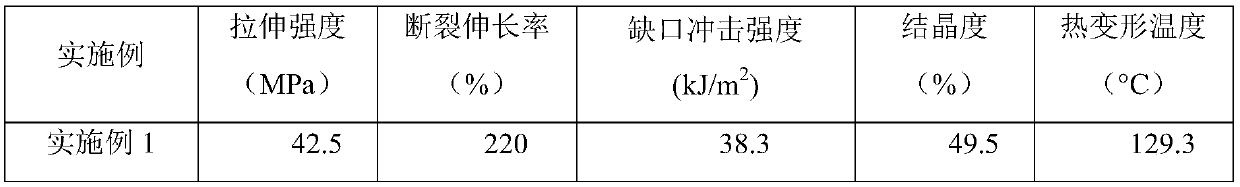

InactiveCN105647137AIncrease profitSelf-performance has not declinedHeat deflection temperatureDistortion

3D printing polylactic acid / leather powder composite materials comprise the components in parts by weight: 70-85 parts of polylactic acid, 1-5 parts of a chain extender, 1-5 parts of a coupling agent, 0.5-1 part of a nucleating agent, 0-25 parts of leather powder, 5-10 parts of a flexibilizer, 1-5 parts of a reinforcing agent, and 0-0.1 part of an antioxidant. According to the 3D printing polylactic acid / leather powder composite materials, an in-situ melt grafting blending technology is utilized, polylactic acid is subjected to modified processing, the toughness, the impact strength and the heat distortion temperature of the polylactic acid are improved to a large extent, a series of 3D printing polylactic acid / leather powder composite materials which can be completely biodegradable are prepared, and thus the polylactic acid can have wider application prospects in 3D printing materials.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

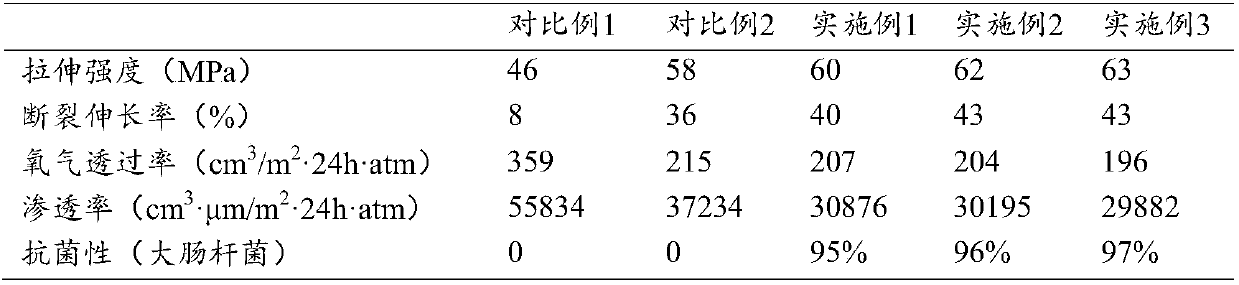

Polylactic acid antibacterial thin film and preparation method thereof

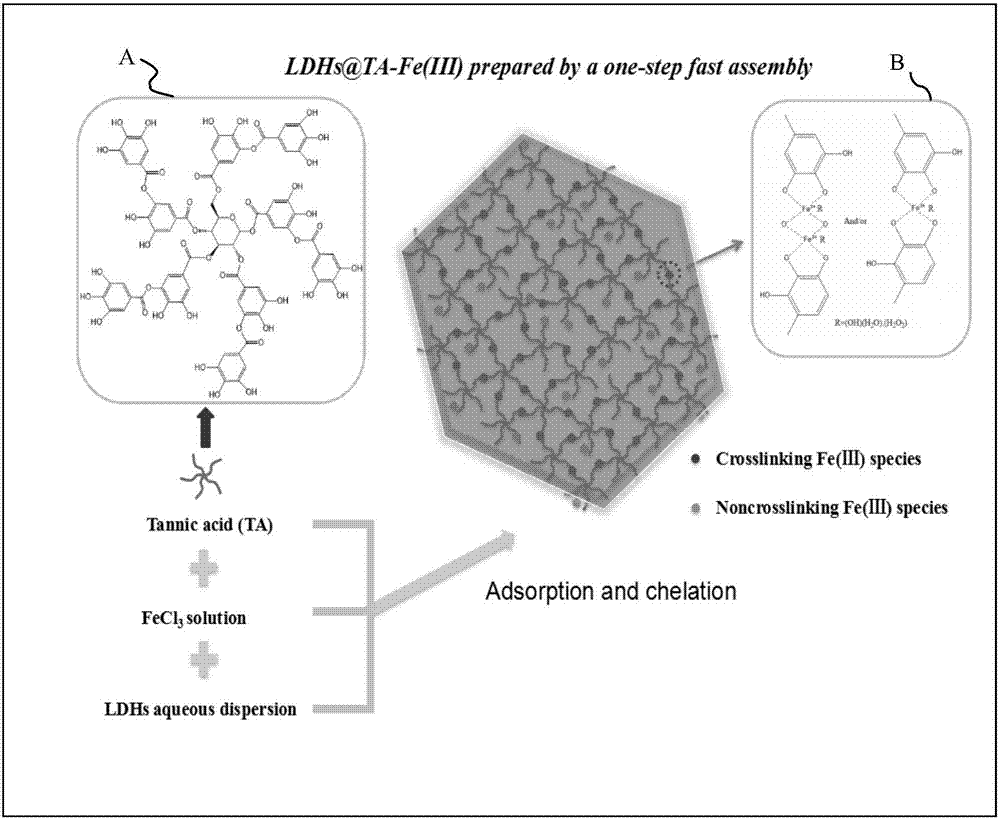

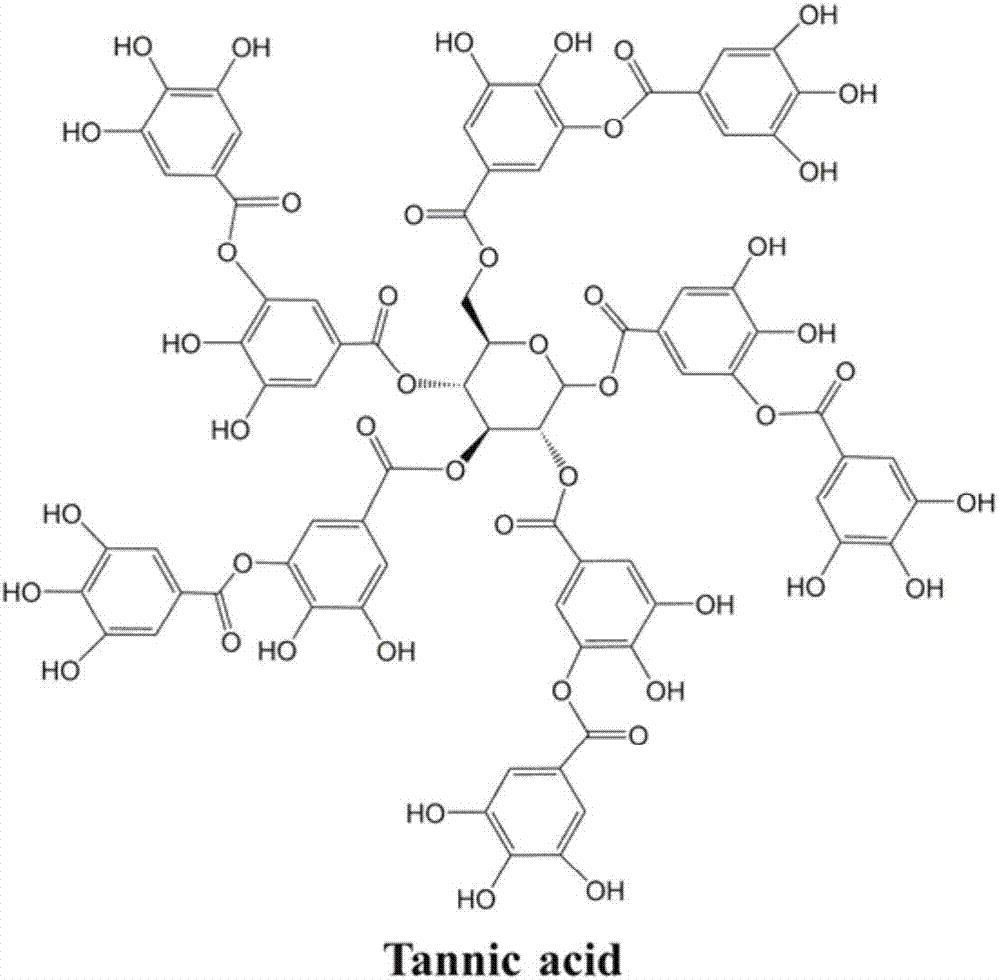

The invention provides a polylactic acid antibacterial thin film and a preparation method thereof, and relates to the technical field of polymer materials. The preparation method includes the steps: carrying out acid activation treatment of layered clay LDHs; then forming an organic coating material of tannic acid and ferric ions on the surface of the acid activated LDHs, to obtain LDHs@TA-Fe (III); adding glutathione to a silver nitrate solution to obtain a nano silver precursor, and carrying out a reaction of the LDHs@TA-Fe (III) with the nano silver precursor to obtain nano silver loaded modified layered clay; and finally, mixing the nano silver loaded modified layered clay and polylactic acid to form a film, and thus obtaining the polylactic acid antibacterial thin film which has excellent mechanical properties, barrier properties and antibacterial properties.

Owner:XIAMEN AMESON NEW MATERIAL INC

Degradable composite material and preparation method thereof

The invention discloses a degradable composite material and a preparation method thereof, and belongs to the technical field of polymer processing and modification. The degradable composite material comprises the following components in parts by weight: 50-90 parts of polylactic acid A, 0.1-10 parts of polylactic acid B (the polylactic acid A and the polylactic acid B are optical isomers), 1-20 parts of a degradable polyester C, 1-50 parts of a polylactic acid B-degradable polyester C copolymer and 0.1-5 parts of a functional additive. The degradable composite material disclosed by the invention not only has excellent toughness, but also has excellent heat resistance, is completely biodegradable, and can be widely applied to the fields of plastic structural parts, plastic packages, automotive upholstery, medical consumables and the like.

Owner:JIANGNAN UNIV

Soybean protein-calcium carbonate nano-adhesive as well as preparation method and application thereof

InactiveCN101962529AHigh strengthImprove waterproof performanceNon-macromolecular adhesive additivesProtein adhesivesFiberAdhesive

The invention provides a soybean protein-calcium carbonate nano-adhesive as well as a preparation method and application thereof, aiming at overcoming the defects of low bonding strength and poor water resistance existing in the traditional soybean protein-calcium carbonate adhesive. The preparation method has the advantages of simple and convenient process, low production cost, no pollution and suitability to industrialized production. The adhesive can be used for bonding wood, bamboo, vines, straws and papers and other fiber materials and is convenient to apply with good bonding performance. The soybean protein-calcium carbonate nano-adhesive of the invention comprises the following components in parts by weight: 80-95 parts of soybean protein matrixes (1) and 1-15 parts of inorganic calcium carbonate particles (2) dispersed in the (1) in nano sizes.

Owner:NANJING LAIBU TECH IND CO LTD

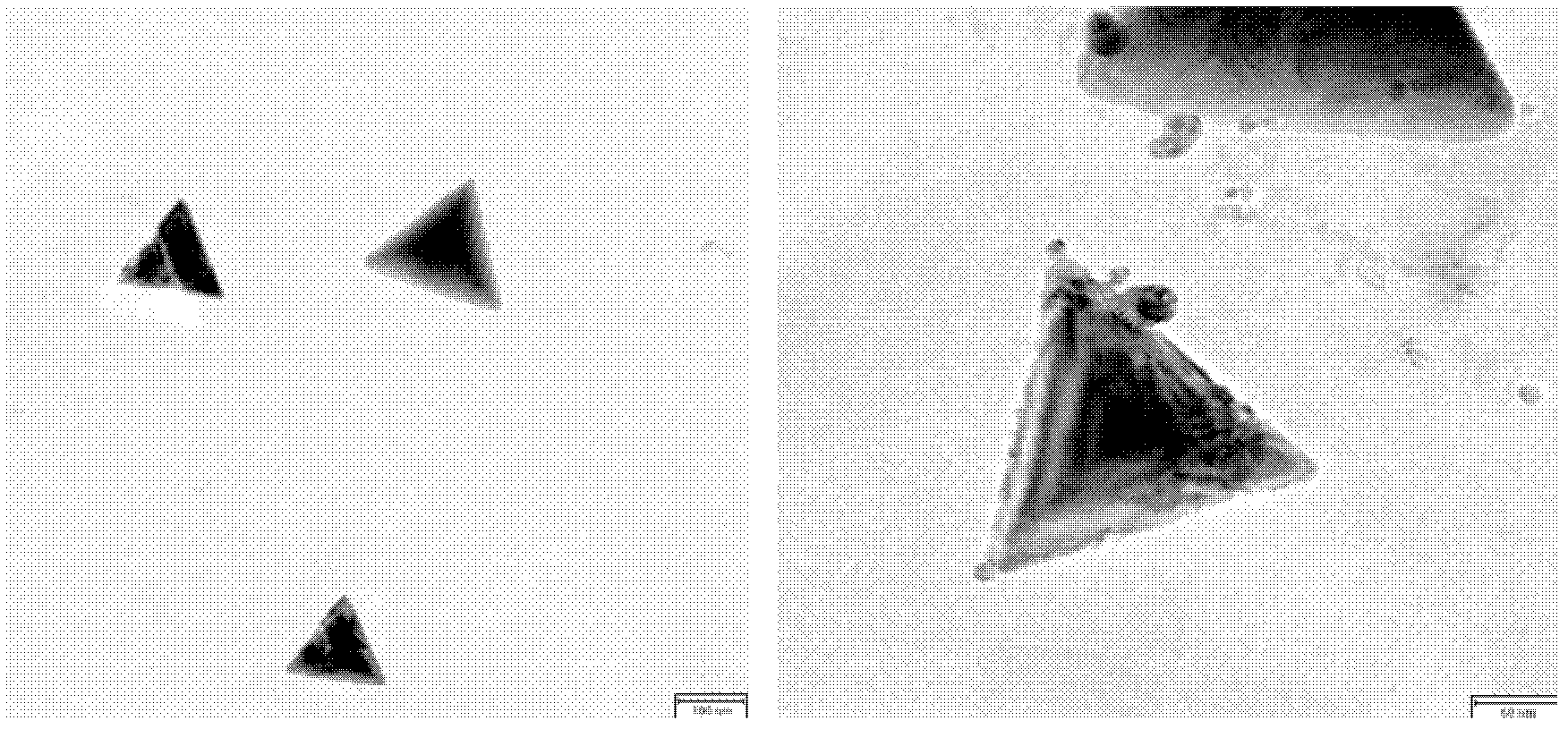

Method for preparing polypyrrole/gold nano composite

The invention relates to a method for preparing a polypyrrole / gold nano composite, belonging to the technical field of material, comprising the following steps: uniformly stirring deionized water, surfactant and cosurfactant at room temperature, adding pyrrole in the system, and adding certain concentrated hydrochloric acid to adjust the PH value to 0.8-1.3; adding auric chloride acid solution slowly to react for 3-6h; after the reaction, carrying out demulsification, centrifugation and drying to obtain polypyrrole / gold nano composite particles. The polypyrrole / gold nano composite particles prepared by the invention are in a good dispersion and regular tetrahedron morphology, have good conduct electricity, good electrical conductivity, and are capable of being used in the fields of electrode material, luminescent material, electromagnetic shielding material, anticorrosion paint and the like of secondary battery. Simultaneously, the preparation method has the advantages of simple process, low reaction environmental requirement, and easy to control experiment parameters.

Owner:SHANDONG UNIV

Potassium hexatitanate whisker reinforced PTFE composite material

InactiveCN1401699AImprove performanceImprove wear resistanceHeat deflection temperaturePolymer science

A teflon composite material reinforced by the crystal whisker of potassium hexatitanate, which has 0.5-2 microns of diameter and whose surface has been treated by silane or titanate coupling agent, is disclosed. Its advantages are high impact strength, high temp for thermal deformation, high elongation for break, high tension strength and high antiwear nature.

Owner:NANJING UNIV OF TECH

Aramid fiber reinforced high temperature resistance nylon composite material and preparation method thereof

The invention belongs to the field of high temperature resistance nylon composite materials, and relates to an aramid fiber reinforced high temperature resistance nylon composite material and a preparation method thereof. The composite material is prepared from the following components by weight: 100 parts of a nylon salt, 1-13 parts of aramid fibers, 0.1-1 part of a capping agent, 0.2-1 part of montmorillonite, 0.1-0.6 part of a catalyst, and 30-60 parts of deionized water. According to the present invention, the in situ polymerization method is adopted to improve the interface adhesion between the aramid fibers and the nylon matrix and improve the mechanical property of the composite material; the prepared reinforced high temperature resistance nylon composite material has characteristics of good mechanical property, high heat distortion temperature and low water absorption compared with the pure nylon matrix; and the method is simple and is easy to perform, and is suitable for large scale industrial production.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Cellulose fiber modification method, modified cellulose fibers and application

ActiveCN106283641AImprove hydrophobicityEnhance the interface forceFibre treatmentDispersityPolymer science

The invention discloses a cellulose fiber modification method, modified cellulose fibers prepared according to the method and application of the modified cellulose fibers. The method includes: pretreating cellulose fibers with alkoxide, drying, mixing with epoxy monomers, stirring, allowing reaction under heating, removing the epoxy monomers in a reaction system after reaction is finished, cleaning residues, and drying to obtain the modified cellulose fibers. The modified cellulose fibers are applied to filling modification of polymer materials. The cellulose fiber modification method has advantages of simplicity, safety, low cost and improvement of interfacial compatibility and interfacial force between the modified cellulose fibers and the polymer materials. The modified cellulose fibers are excellent in fiber dispersity, and the polymer materials adopting the modified cellulose fibers for filling modification are remarkably improved in water resistance.

Owner:BEIJING UNIV OF CHEM TECH

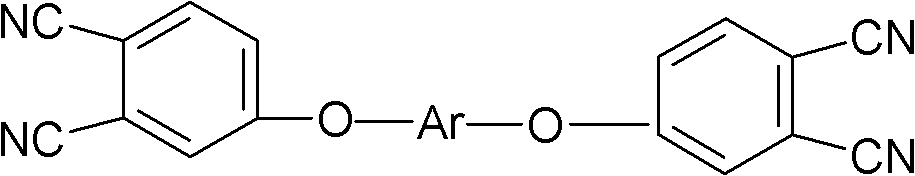

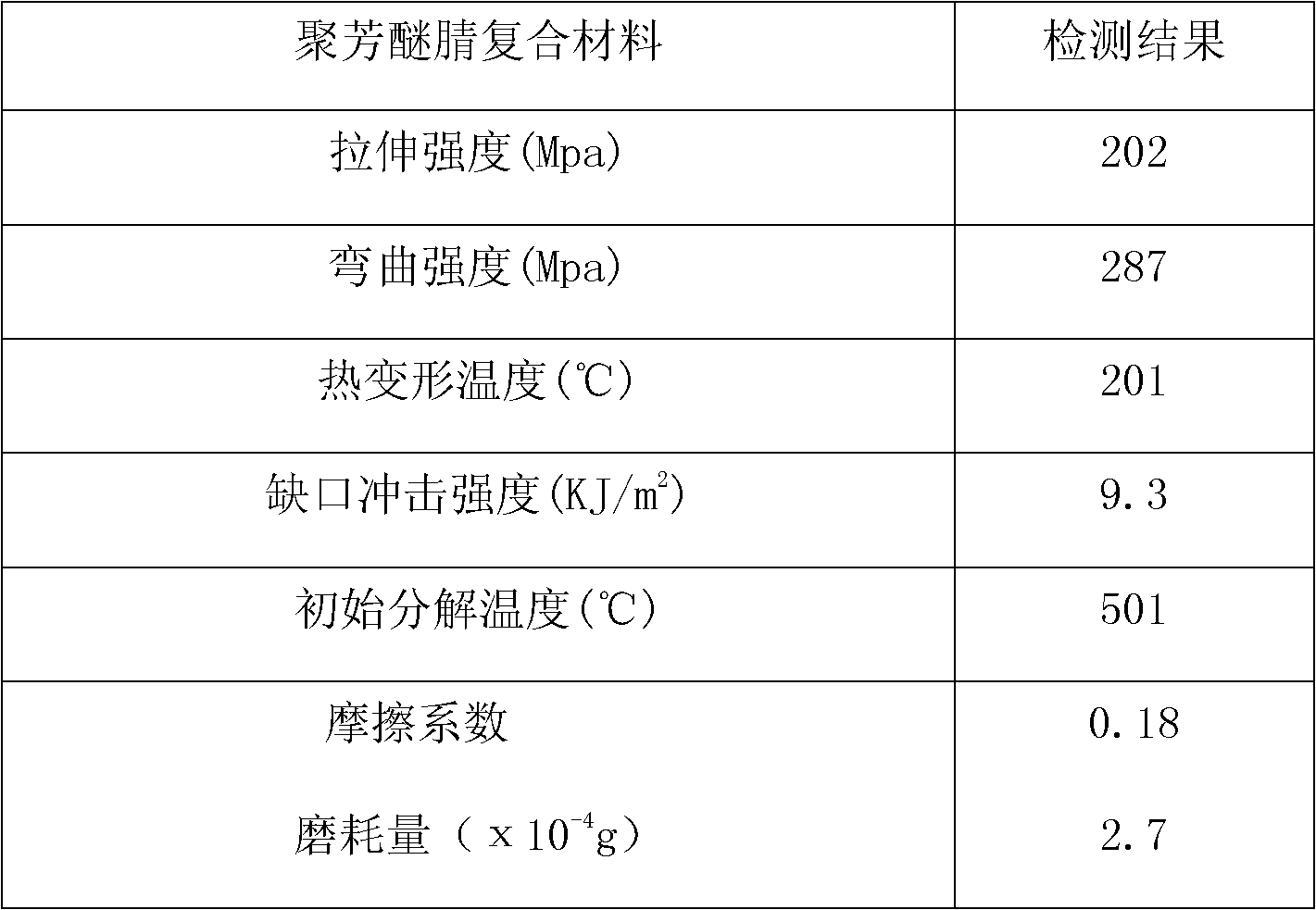

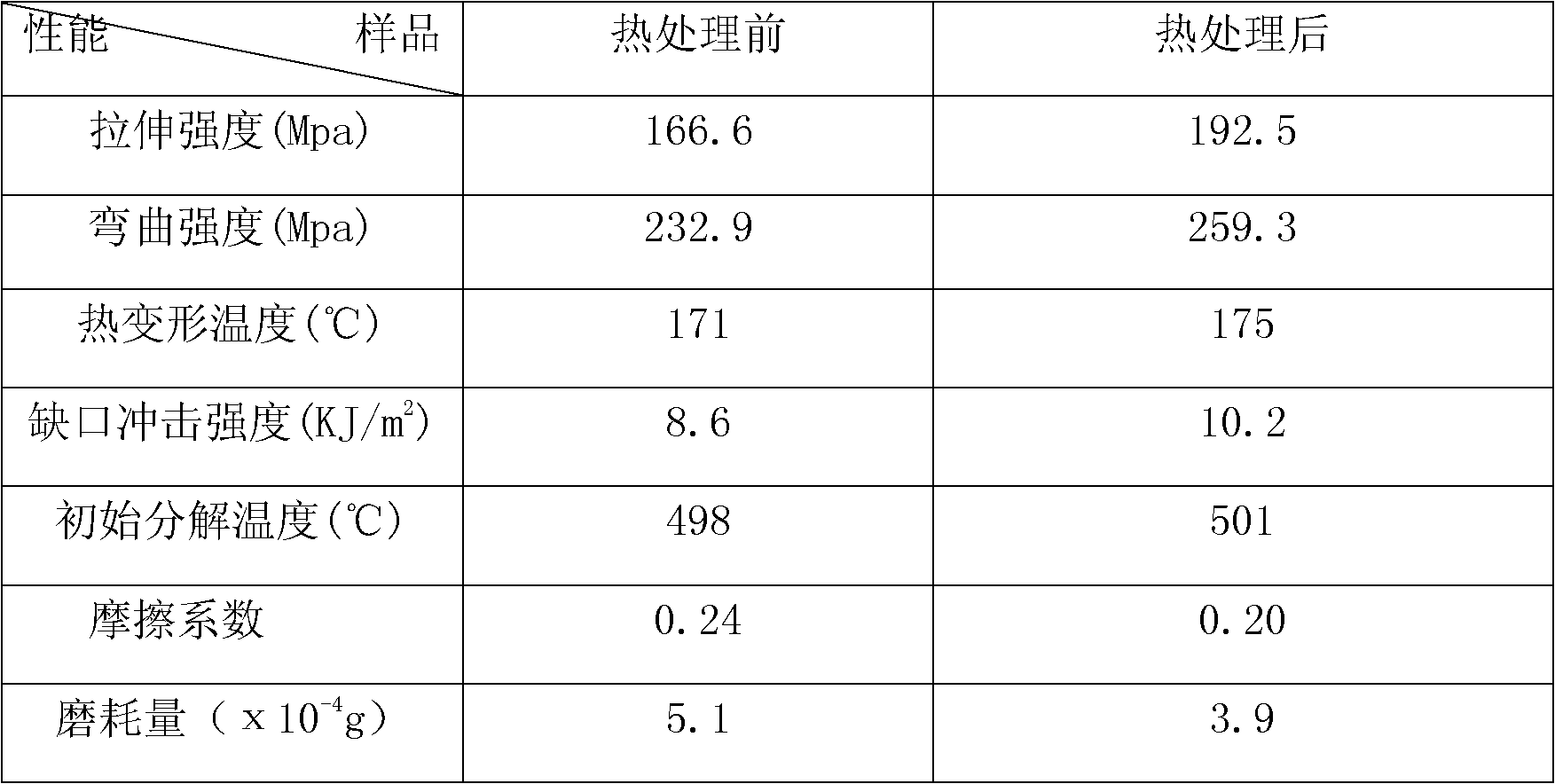

Poly (arylene ether nitrile) composite material and preparation method thereof

ActiveCN101891947AProduction conditions are easy to achieveThe production process is easy to controlFiberPolymer science

The invention belongs to the field of high polymer materials, particularly relating to a poly (arylene ether nitrile) composite material and a preparation method thereof. The invention aims to solve the first technical problem of providing the poly (arylene ether nitrile) composite material with high performance and wear resistance. The poly (arylene ether nitrile) composite material of the invention comprises the following components in parts by weight: 40-70 parts of poly (arylene ether nitrile), 10-40 parts of filling, 3-10 parts of phthalocyanine prepolymer and 0-7 parts of anti-wear additive. The phthalocyanine prepolymer of the invention has the effect of plastification and improve the interface action between a resin system and fibers and between the resin system and the anti-wear additive, and the mechanical strength, abrasive resistance and abrasive resistance of the composite material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

High-barrier property toughening polylactic acid film and preparation method thereof

The invention provides a high-barrier property toughening polylactic acid film and a preparation method thereof, and relates to the field of high polymer materials. The preparation method comprises the following steps: preparing laminar double-hydroxyl metal oxides (LDHs) with a high-temperature hydrothermal method; dispersing the LDHs in water, adding a tannin solution, performing adsorption, further adding a ferric salt solution to obtain a reaction liquid, and rapidly obtaining modified LDHs (LDHS@TA-FE (III)); dispersing the modified LDHs in dimethyl formamide, adding polylactic acid, performing heating stirring dissolution, transferring into filming equipment, and performing drying filming; performing adsorption deposition and chelation on tannin (TA) and ferrous ions on the surfaces of the LDHs, thereby obtaining a core-shell structure of LDHs coated with Ta-Fe<3+>. The obtained polylactic acid film is remarkable in barrier property and toughening function, LDHS@TA-FE (III) and PLA (Polylactic Acid) are in good compatibility and play a relatively good interface function, and thus the use performance of PLA is improved.

Owner:XIAMEN AMESON NEW MATERIAL INC

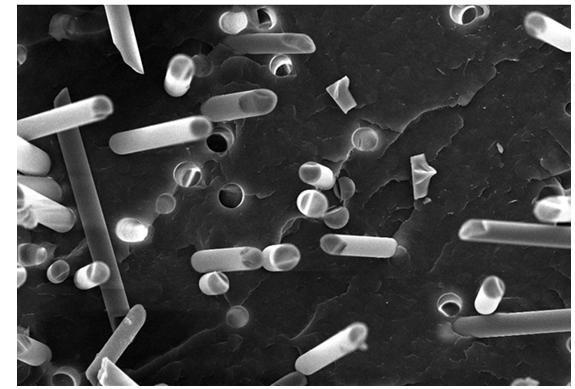

Preparation method of nano calcium carbonate suspension used for natural rubber latex reinforcement

InactiveCN102888131AEnhance the interface forcePigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsAlcoholRoom temperature

A preparation method of nano calcium carbonate suspension used for natural rubber latex reinforcement comprises the following steps: mixing pure concentration of organic alcohol and silane coupling agent, and fully and uniformly stirring to prepare a complexing agent, the weight ratio of the organic alcohol and silane coupling agent being 1 : 0.8-1.4; weighing 100 parts by weight of surface-modified nano calcium carbonate by stearic acid to slowly mix with 45 to 60 parts by weight of the complexing agent to prepare a mixed liquid; sealing the mixed liquid in a container, allowing the container to stand at room temperature, so that the complexing agent is slowly penetrated into the surface of the nano calcium carbonate until a layer of water film is observed to appear on the surface of the nano calcium carbonate, then adding 800 to 950 parts of water, and uniformly stirring to prepare the nano calcium carbonate suspension used for natural rubber latex reinforcement. The method uses relatively little amount of the complexing agent, and can ensure a uniform contact of the complexing agent with the stearic acid on the surface of the modified nano calcium carbonate particles.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

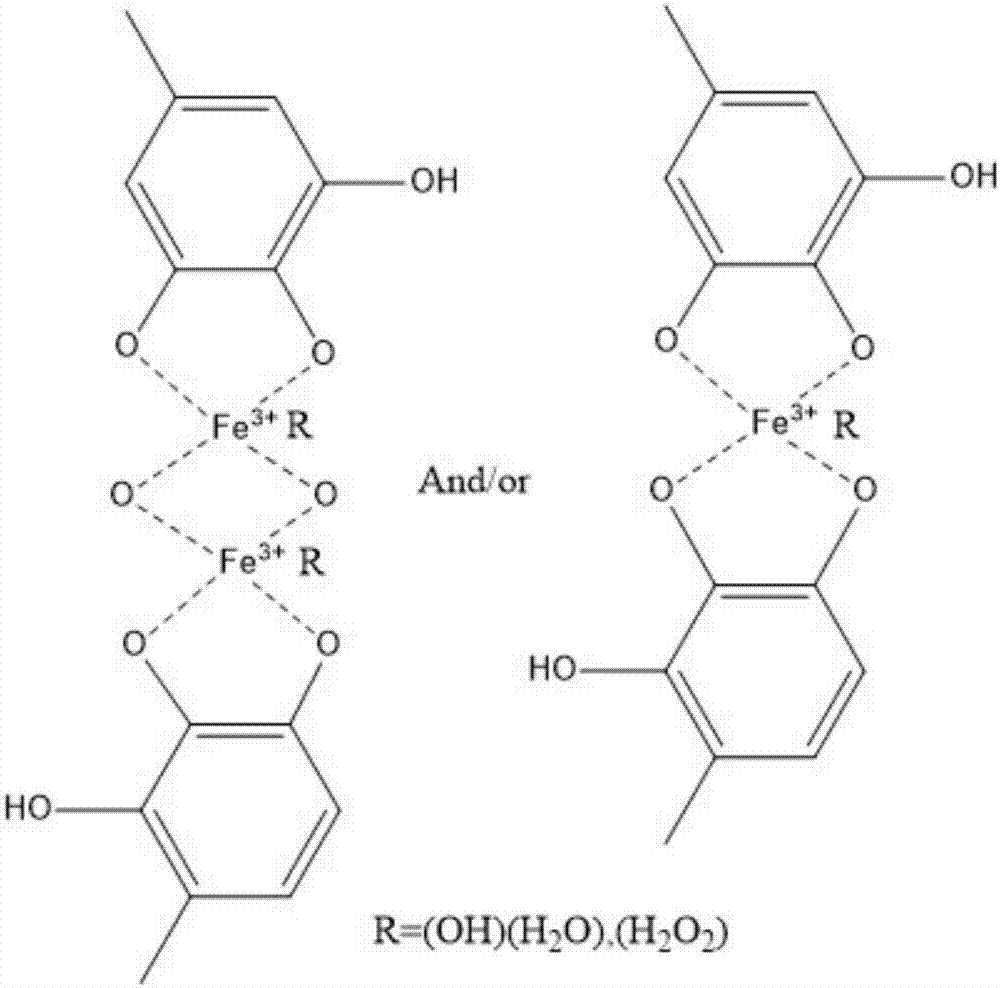

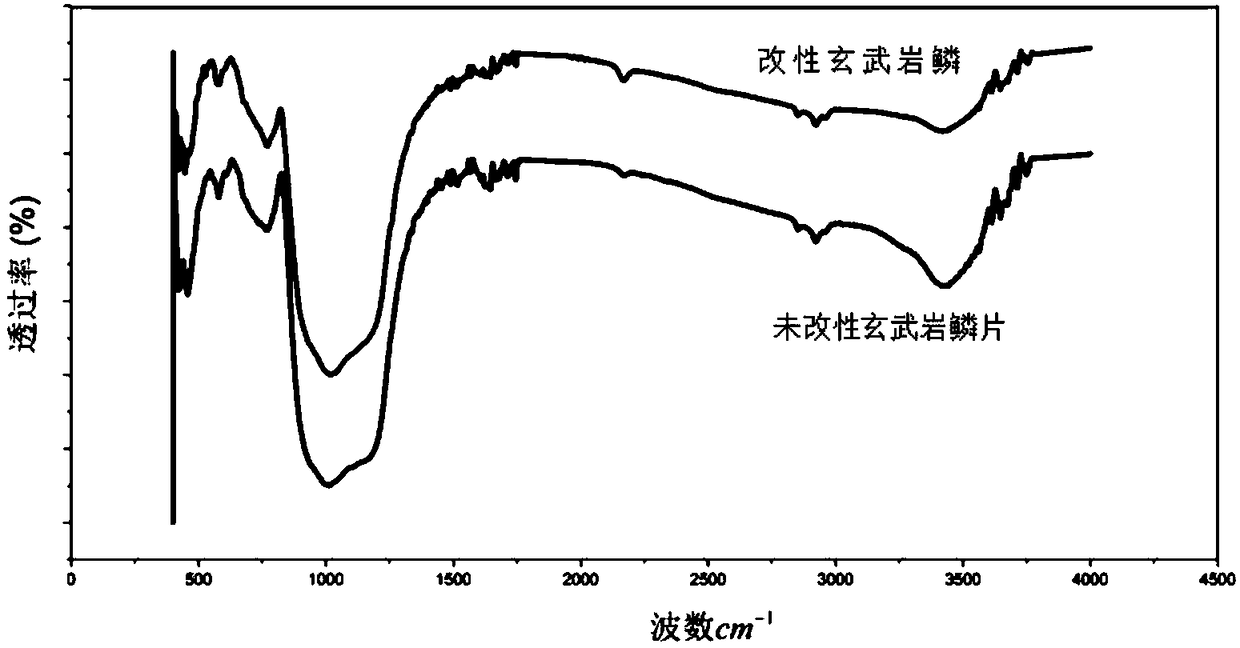

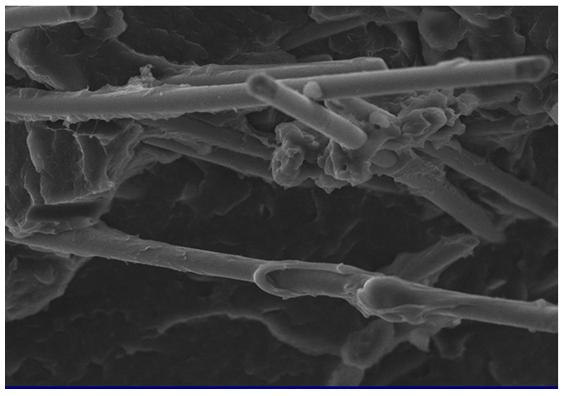

Basalt scale solvent-free heavy anticorrosive coating and method for preparing same

InactiveCN108441083AEnhance the interface forceAchieve chemical bondingAnti-corrosive paintsEpoxy resin coatingsPolymer scienceSolvent free

The invention provides basalt scale solvent-free heavy anticorrosive coating. The basalt scale solvent-free heavy anticorrosive coating comprises, by weight, 7-15 parts of modified basalt fiber scales, 45-55 parts of epoxy resin, 28-40 parts of curing agents, 2-6 parts of activated diluents, 1-3 parts of defoaming agents and 1-4 parts of coalescing agents. A method for preparing the modified basalt fiber scales includes steps of mixing basalt scales and silane coupling agent solution with one another, and ultrasonically dispersing the basalt scales and the silane coupling agent solution for 25-35 min to obtain dispersion; carrying out solid-liquid separation on the dispersion, and carrying out heat treatment on obtained solid materials at the temperatures of 110-130 DEG C for 50-70 min toobtain the modified basalt fiber scales. The basalt scale solvent-free heavy anticorrosive coating has the advantages of excellent performance and environmental friendliness.

Owner:BEIHANG UNIV +1

Thermal conductive carbon fiber reinforced PET (polyethylene terephthalate)/polyester alloy and preparation method thereof

The invention discloses a thermal conductive carbon fiber reinforced PET (polyethylene terephthalate) / polyester alloy and a preparation method thereof. The PET / polyester alloy is composed of the following components in percentage by weight: 30-40% of PET, 4-10% of polyester, 2-4% of a nucleating agent, 30-45% of thermal conductive filler, 5-20% of carbon fiber, 1-2% of a coupling agent, 0.5-1% of an antioxidant and 0.5-1% of a lubricant. The preparation method of the PET / polyester alloy comprises the following steps: firstly, mixing the PET, the polyester, the nucleating agent, the thermal conductive filler, the coupling agent, the antioxidant and the lubricant for 3-5 minutes in a high-speed mixing machine; then, adding the obtained mixture from a first-section barrel of a twin-screw extruder, and then adding the carbon fiber from a fourth-section barrel of the twin-screw extruder; and through controlling the rotating speed of the twin-screw extruder to be 1050-1200rpm and controlling the temperature at 240-250 DEG C, carrying out extrusion granulating, thus obtaining the thermal conductive carbon fiber reinforced PET / polyester alloy which has the advantages of high mechanical property, short molding cycle and good product appearance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Glass fiber-reinforced polypropylene resin composition formula and preparation method

The invention discloses a glass fiber-reinforced polypropylene resin composition formula and a preparation method, wherein the glass fiber-reinforced polypropylene resin composition formula comprises the following components by weight parts: 95-100 parts of mixtures of polypropylene and glass fiber, 1-10 parts of unsaturated resins, 0.01-0.2 part of cross-linking agent and 0.1-1 part of antioxidant. The preparation method uses unsaturated polyester as an interface compatilizer to prepare polypropylene graft which has the functions of crosslinking and coupling and can form a grafting monomer when melted with polypropylene to be extruded so that the surface activity of the polypropylene is enhanced, a reactive group at one end of the polypropylene and the surface of the glass fiber form an ionic bond, a long chain at the other end and the polypropylene generate strong tangling function so that the interface acting force is obviously improved, and then the polypropylene graft with high strength and good stability is obtained.

Owner:国家复合改性聚合物材料工程技术研究中心

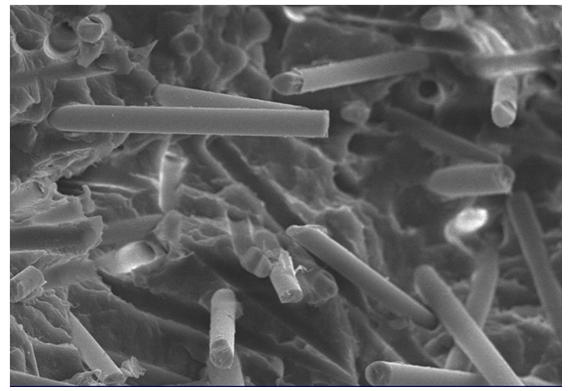

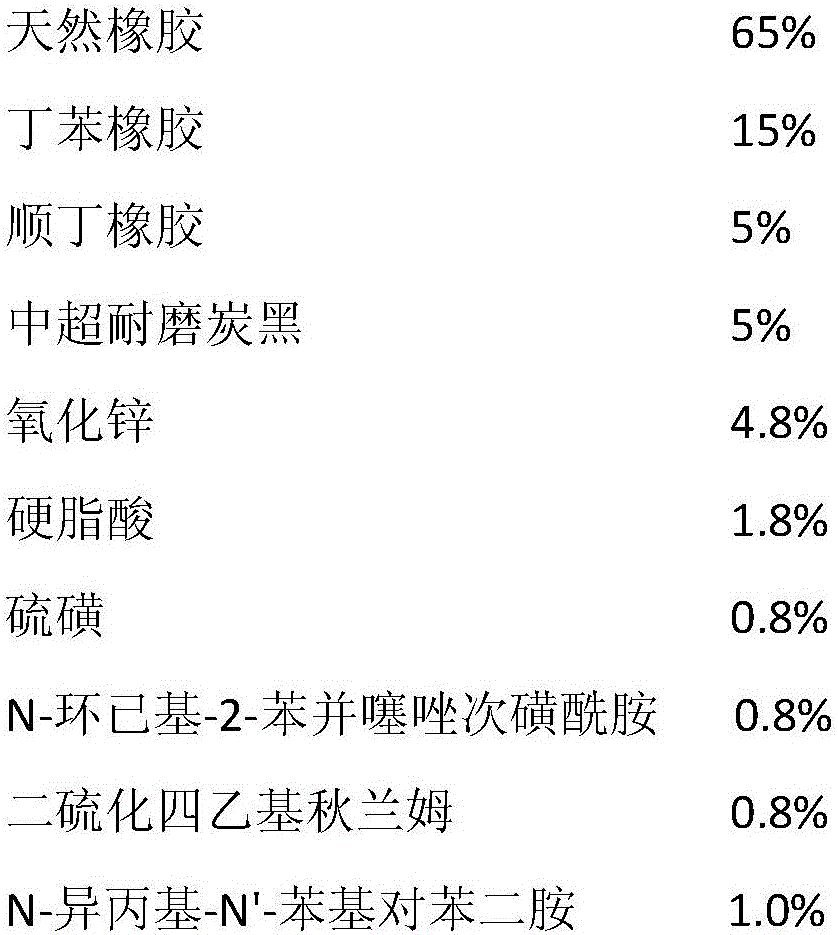

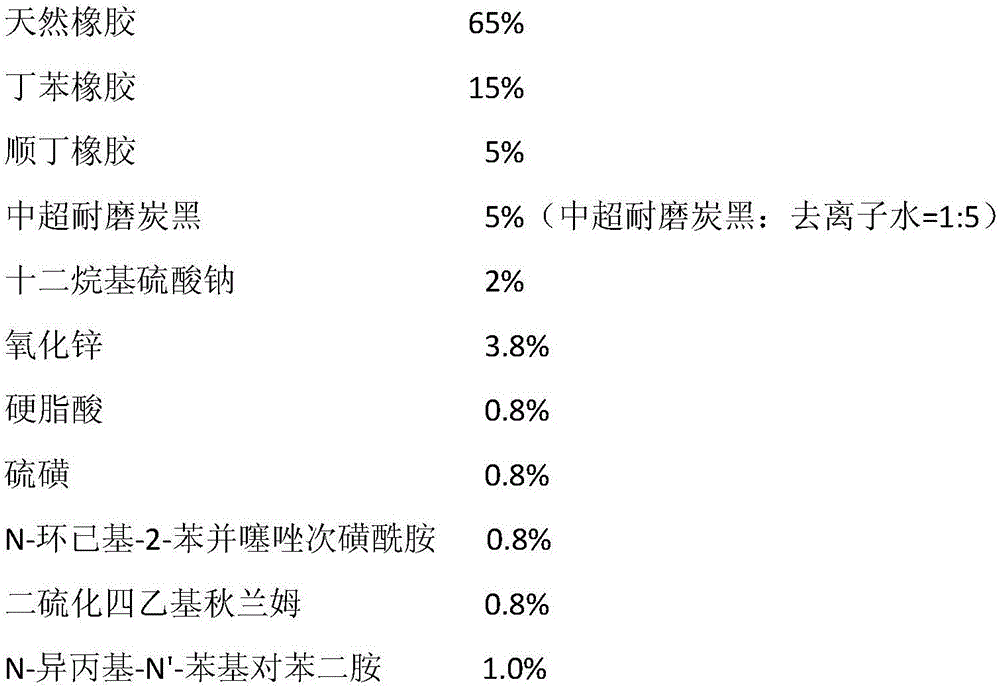

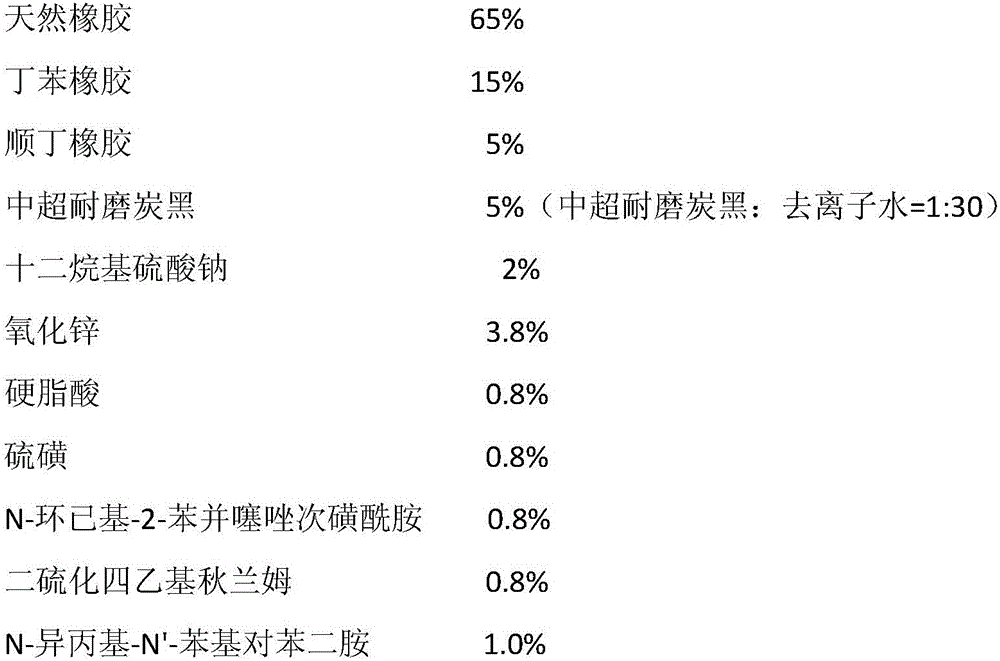

Preparation method of olefin rubber/filler blend vulcanized rubber

The invention discloses a preparation method of olefin rubber / filler blend vulcanized rubber. The method comprises the following steps: preparing a filler predispersion solution; plasticizing unvulcanized natural rubber by a rubber Banbury mixer, mixing with styrene-butadiene rubber and cis-1,4-polybutadiene rubber, increasing the temperature of the Banbury mixer to 110-160 DEG C, adding the filler predispersion solution into the rubber Banbury mixer, compounding, evaporating to remove water, and drying with hot air to obtain an olefin rubber / filler mixture; adding zinc oxide, stearic acid, a vulcanizing agent, an accelerator and an anti-aging agent into a rubber open mill or Banbury mixer, compounding uniformly, discharging, and standing to obtain the olefin rubber / filler compounded rubber; and vulcanizing the olefin rubber / filler compounded rubber on a flat vulcanizing machine to obtain the olefin rubber / filler blend vulcanized rubber. The method has the advantages of simple technique, no solvent pollution and no flying dust, is green and environment-friendly, and can be widely used for mixing multiple fillers and rubber.

Owner:SOUTH CHINA UNIV OF TECH

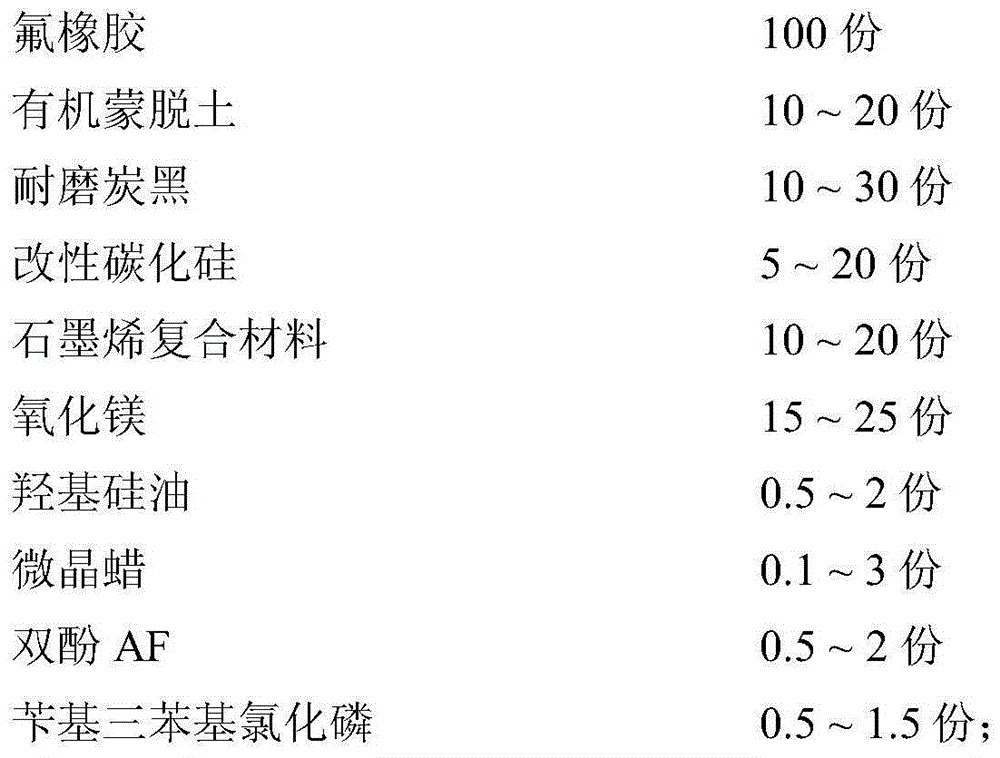

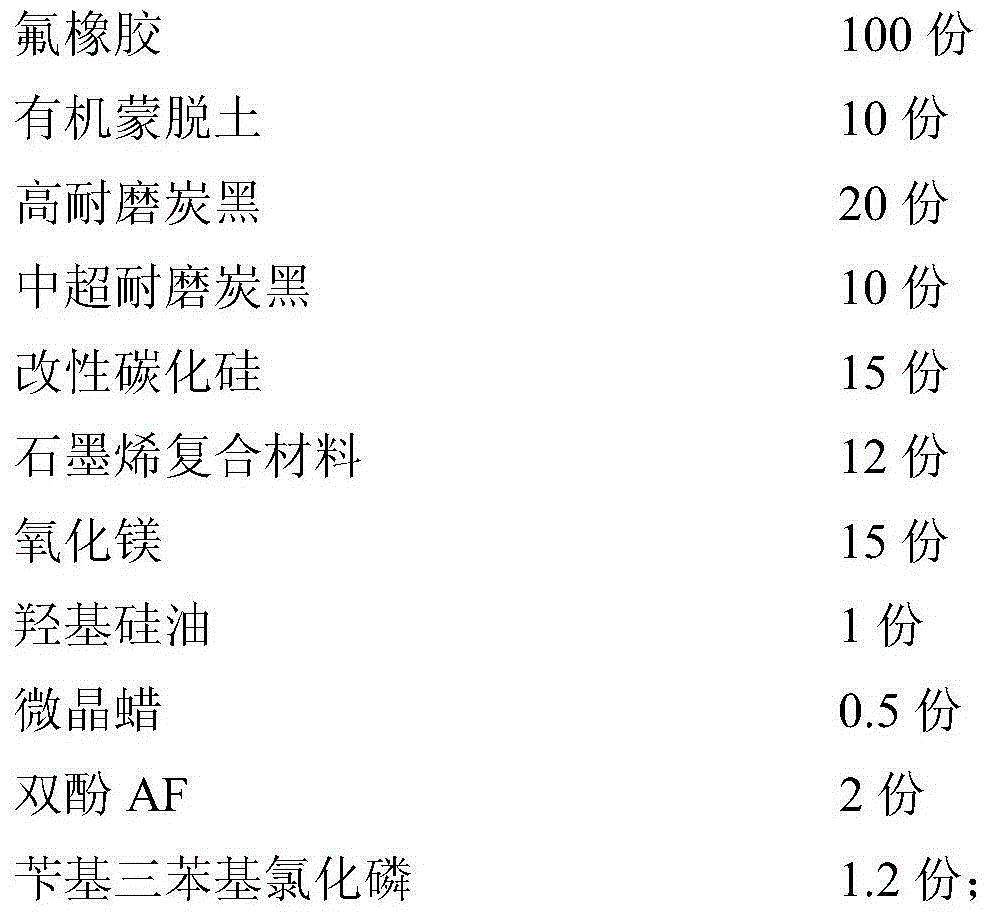

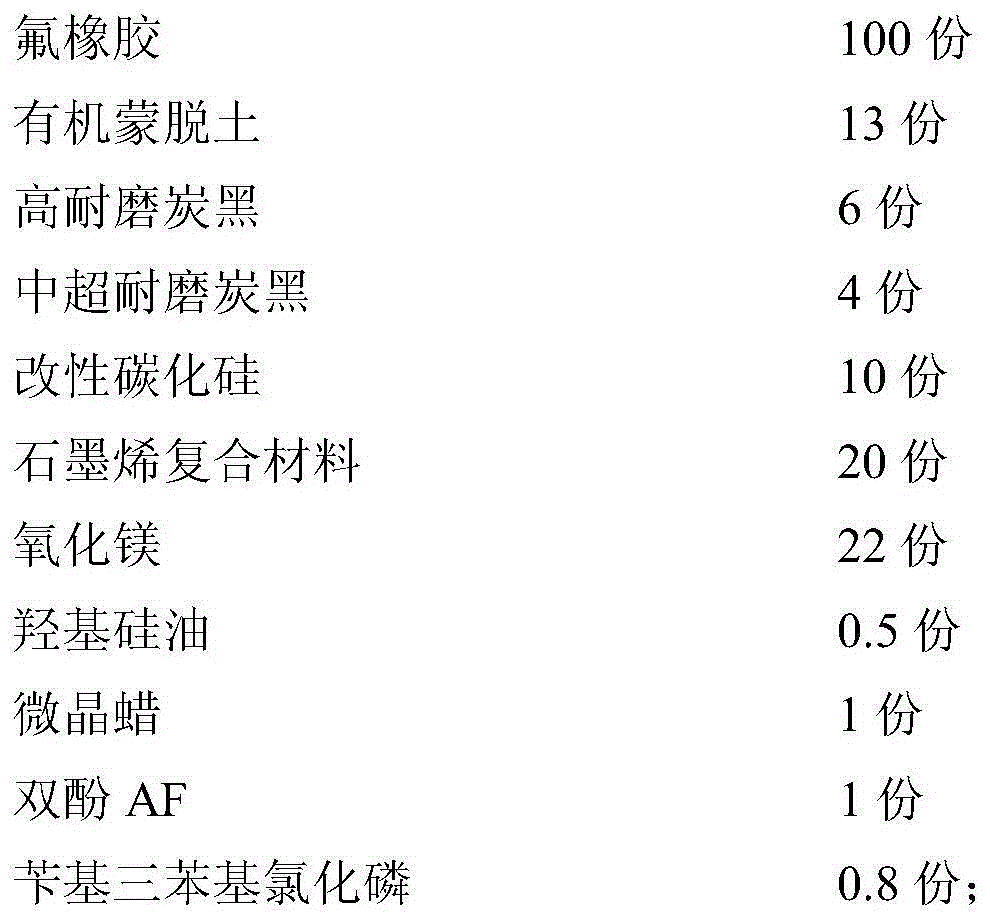

Grinding roller sealing ring materials and preparation method thereof

ActiveCN104530611ASolve difficult peelingSolve densityOther chemical processesMicrocrystalline waxBisphenol AF

The invention relates to grinding roller sealing ring materials. The grinding roller sealing ring materials are characterized by comprising, by weight, 100 parts of fluororubber, 10-20 parts of organic montmorillonite, 10-30 parts of wear-resisting carbon black, 5-20 parts of modified silicon carbide, 10-20 parts of graphene composites, 15-25 parts of magnesium oxide, 0.5-2 parts of hydroxyl silicone oil, 0.1-3 parts of microcrystalline wax, 0.5-2 parts of bisphenol AF and 0.5-1.5 parts of benzyl triphenyl phosphoric chloride. The graphene composites are graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction. The graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction are added, the graphene composites are dispersed easily, the problems of difficult stripping of graphene and difficult addition caused by low apparent density in the prior art are resolved, graphene can be evenly dispersed in the grinding roller sealing ring materials, the function of the graphene is fully played, and the wear resistance and heat resistance of the grinding roller sealing ring materials are effectively improved.

Owner:宁波佳乐特橡塑机电有限公司

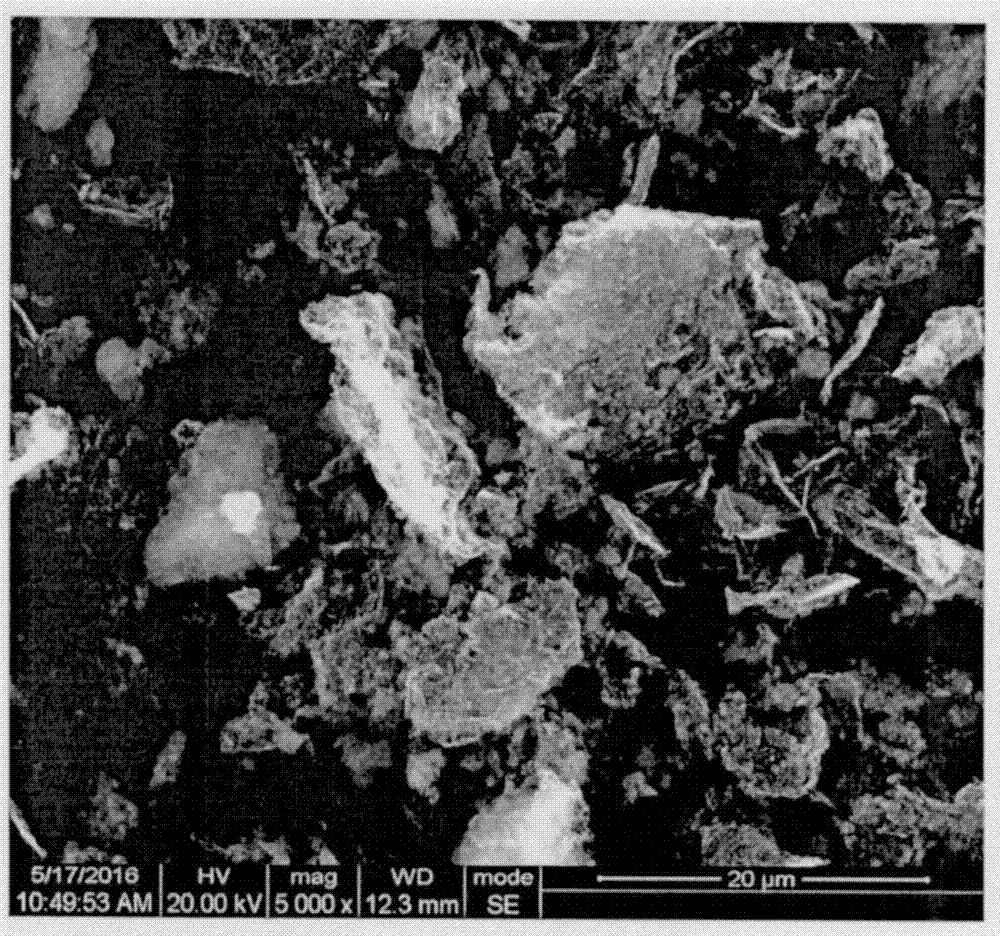

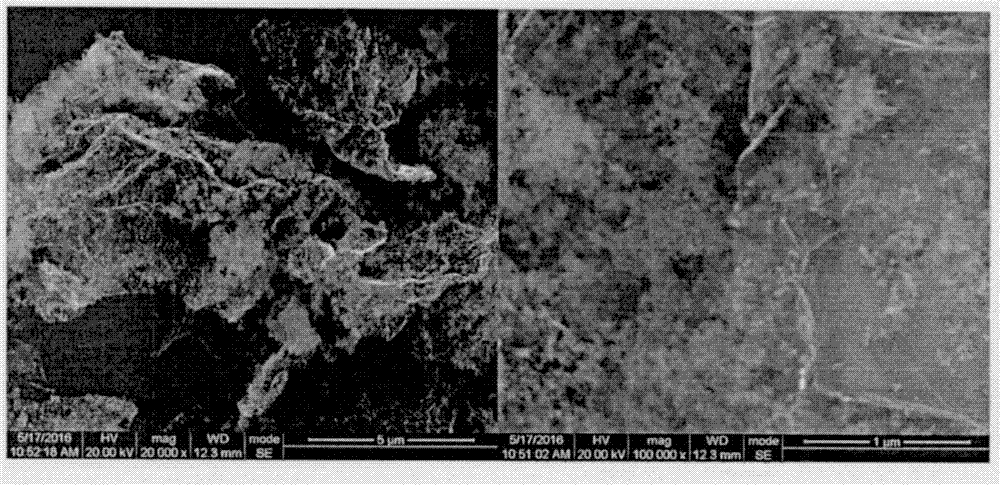

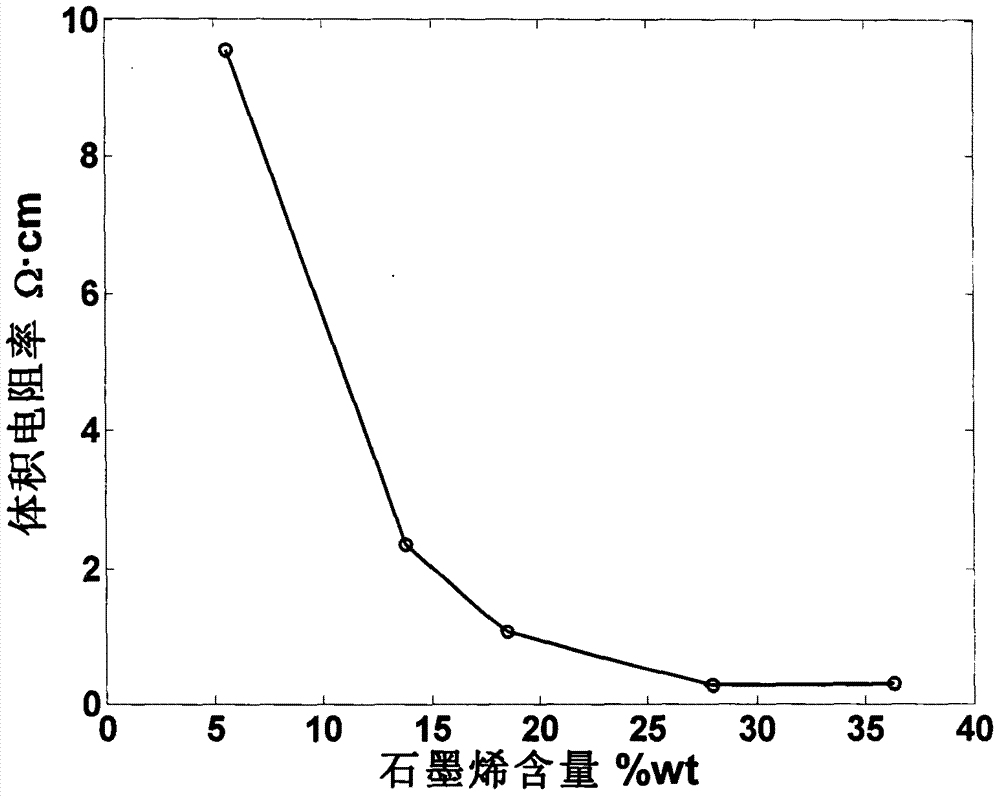

Graphene-white carbon black composite powder and preparation technology thereof

InactiveCN107541096AMaintain Monolayer DispersionImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersitySlurry

The invention relates to graphene-white carbon black composite powder and a preparation technology thereof. The preparation technology comprises dispersing a graphene oxide aqueous solution and whitecarbon black powder in water at a high speed to obtain uniform mixed aqueous slurry, adding a gelling agent and a surfactant into mixed aqueous slurry, adjusting pH of the solution so that graphene oxide-white carbon black hydrogel is obtained, filtering and drying the graphene oxide-white carbon black hydrogel to obtain graphene oxide-white carbon black aerogel and calcining the graphene oxide-white carbon black aerogel at a high temperature in the inert atmosphere to reduce the graphene oxide so that the graphene-white carbon black composite powder is obtained. The preparation technology issimple and reliable and realizes a low cost. The graphene-white carbon black composite powder has powder resistivity less than 100 omega. cm, graphene in the composite material has good single layer dispersity, rich pore structures are formed through layer enwinding, the white carbon black nano-particles are uniformly dispersed on the surface of the graphene layer, and the composite material has excellent electrical conductivity and thermal conductivity and can be widely used in the fields of coatings, rubber products and plastic.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

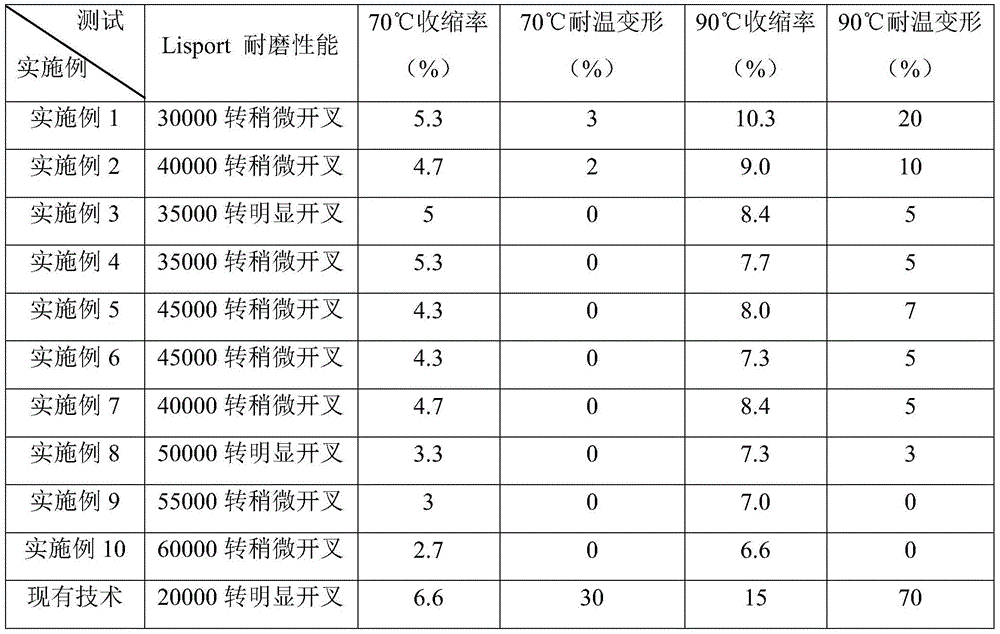

Wear-resistant and temperature-resistant artificial turf and preparation method thereof

ActiveCN105568425AImprove wear resistanceImprove performanceGround pavingsConjugated synthetic polymer artificial filamentsFiberWear resistant

The invention discloses a wear-resistant and temperature-resistant artificial turf. The wear resistance of the artificial grass fiber is improved; meanwhile, the temperature resistance of the artificial turf fiber is improved; the acting force between the artificial grass fiber and a bottom back is improved; the artificial grass fiber falling phenomenon is avoided. The wear-resistant and temperature-resistant artificial turf comprises the artificial grass fiber, wherein the artificial grass fiber is prepared from the following ingredients in parts by weight: 35 to 90 parts of base body resin, 5 to 30 parts of thermoplastic elastomer, 5 to 20 parts of wear-resistant and temperature-resistant master batch, 0.01 to 5 parts of anti-aging agents and 0.5 to 10 parts of master batch.

Owner:COCREATION GRASS CO LTD

Ultraviolet curing transfer adhesive for glass substrate

ActiveCN106281198AAvoid overall performance degradationReasonable compositionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventChemistry

The invention discloses an ultraviolet curing transfer adhesive for a glass substrate. The ultraviolet curing transfer adhesive comprises aliphatic polyurethane acrylate, an acrylate active diluent, a photoinitiator, an acrylate aid and a silane coupling agent. The ultraviolet curing transfer adhesive for a glass substrate, disclosed by the invention, has good mechanical property, wear resistance, solvent resistance and cold / hot impact resistance while the adhesion between the adhesive layer and the substrate is good; and particularly, after water boiling test, the adhesion between the adhesive layer and the substrate is still greater than 4B, and little environmental pollution is caused. The problems that existing ultraviolet curing transfer adhesive has low adhesion and is not resistant to water boiling and solvent are solved; and the ultraviolet curing transfer adhesive disclosed by the invention meets the industry requirements, reduces the production cost of an enterprise and brings profit to the enterprise.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

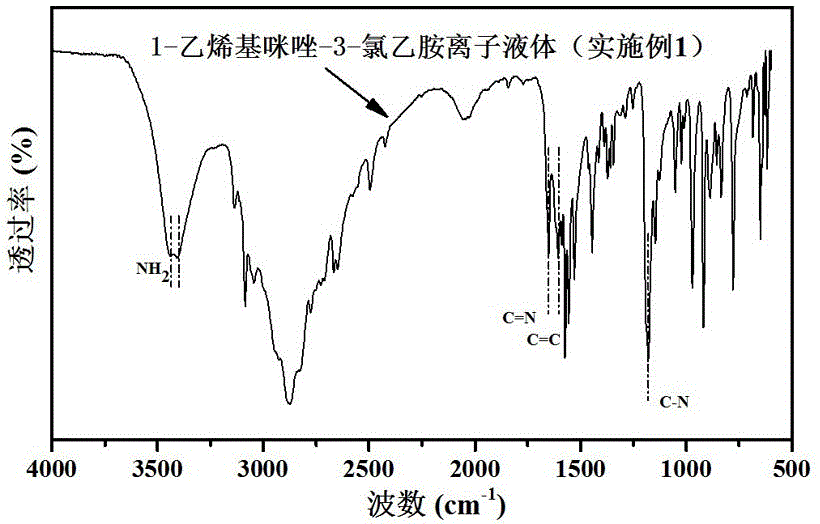

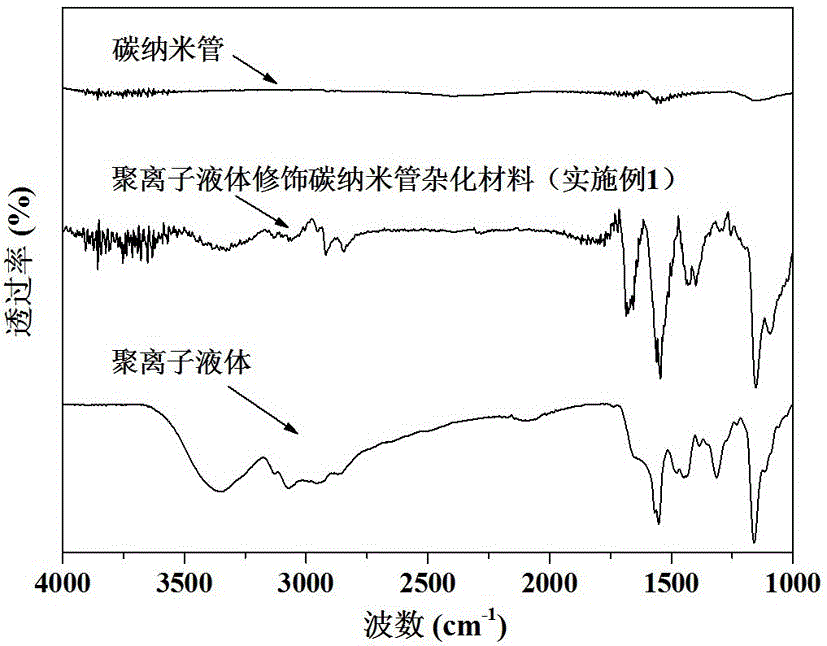

Polyion liquid-modified carbon nano-tube hybrid material and preparation method thereof

The invention discloses a polyion liquid-modified carbon nano-tube hybrid material and a preparation method thereof. The preparation method comprises the following steps: under the protection of nitrogen, mixing and heating vinyl N-heterocycle and 2-chloroethylamine hydrochloride; performing Menshutkin reaction to obtain an ionic liquid hydrochloride; neutralizing to obtain ion liquid monomers; reacting a certain ratio of monomers and a metal salt under a heating condition to obtain an ion liquid which contains an amino end group and a transition metal; dissolving obtained ion liquid in water, adding a fixed amount of carbon nano-tubes, performing ultrasonic dispersing, adding an initiator to perform surface-initiated polymerization, and filtering and drying a product to obtain the polyion liquid-modified carbon nano-tube hybrid material. According to the polyion liquid-modified carbon nano-tube hybrid material and the preparation method thereof, the hybrid material is prepared by coating the carbon nano-tubes with polyion liquid; the hybrid material has toughening and catalyzing functions; the preparation method has the characteristics of simple process and easiness in control.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com