Patents

Literature

77results about How to "Achieve chemical bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photosensitive PRP (platelet-rich plasma) gel and preparation method and application thereof

ActiveCN106822183ATightly boundSeamless integrationSurgical adhesivesAerosol deliveryChemical reactionBlood plasma

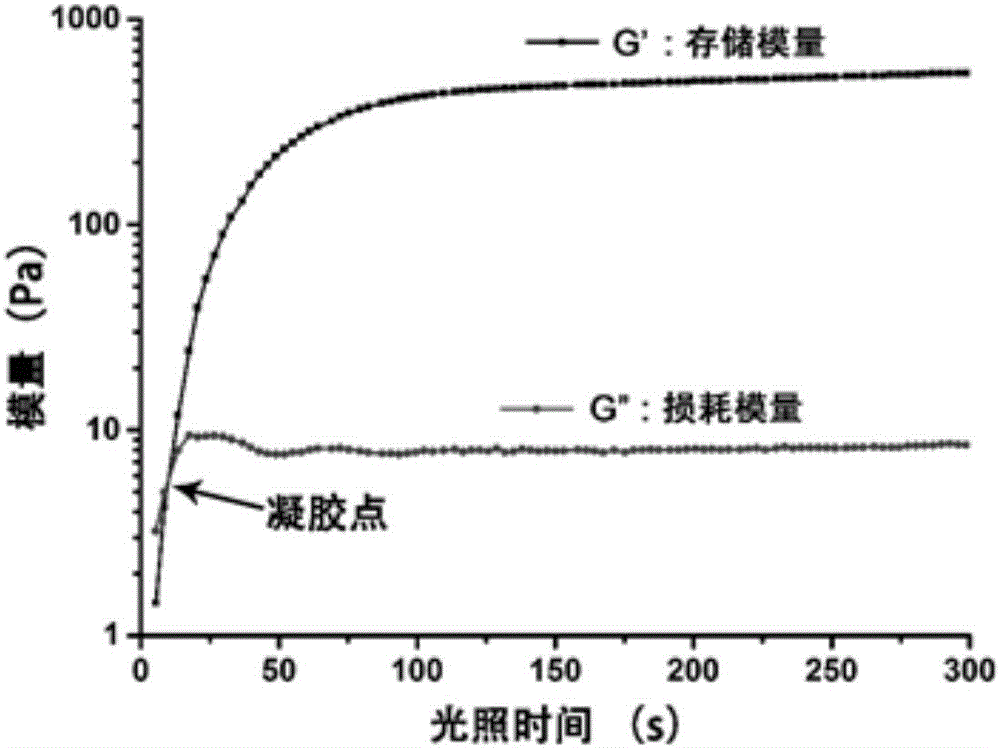

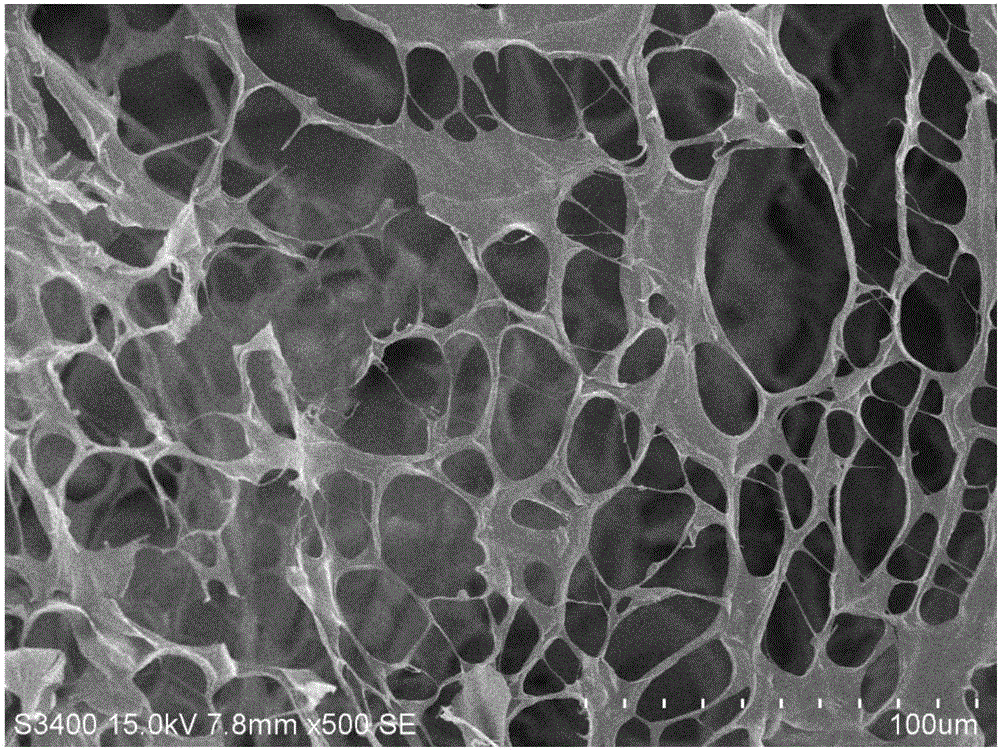

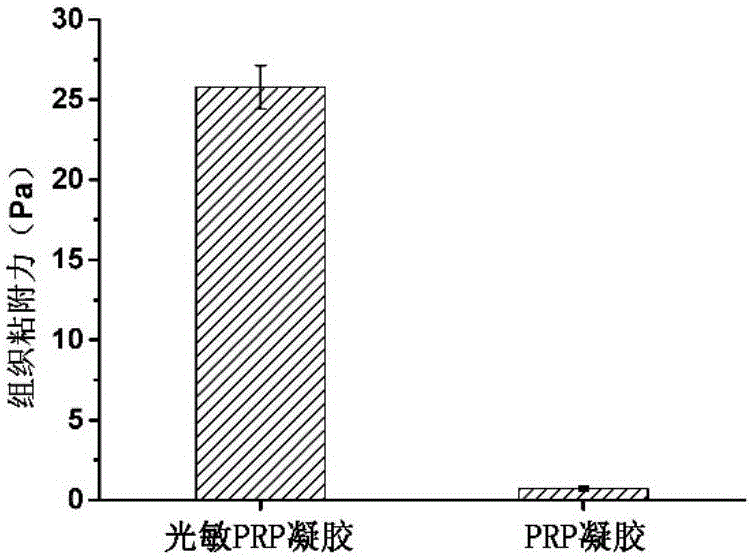

The invention relates to a photosensitive PRP (platelet-rich plasma) gel and a preparation method and application thereof. The preparation method comprises the following steps of mixing a biocompatible medium solution of a macromolecule modified by an o-nitrobenzyl photo response group and an extracted PRP according to a certain ratio, so as to form a gel precursor solution; then, radiating the gel precursor solution by light, and enabling the o-nitrobenzyl group in the macromolecule modified by the o-nitrobenzyl photo response group to generate photochemical reaction under the excitation action of a light source, so as to produce an aldehyde functional group; generating coupling reaction with amino distributed at the surface of the protein in the PRP to form an imine bond, so as to realize the preparation of the photosensitive PRP gel. Compared with the prior art, the photosensitive PRP gel prepared by the method has the advantages that the internal cell factors can be slowly released, and the tight and seamless bonding between the PRP gel and wounds is realized.

Owner:ZHONGSHAN GUANGHE MEDICAL TECH CO LTD

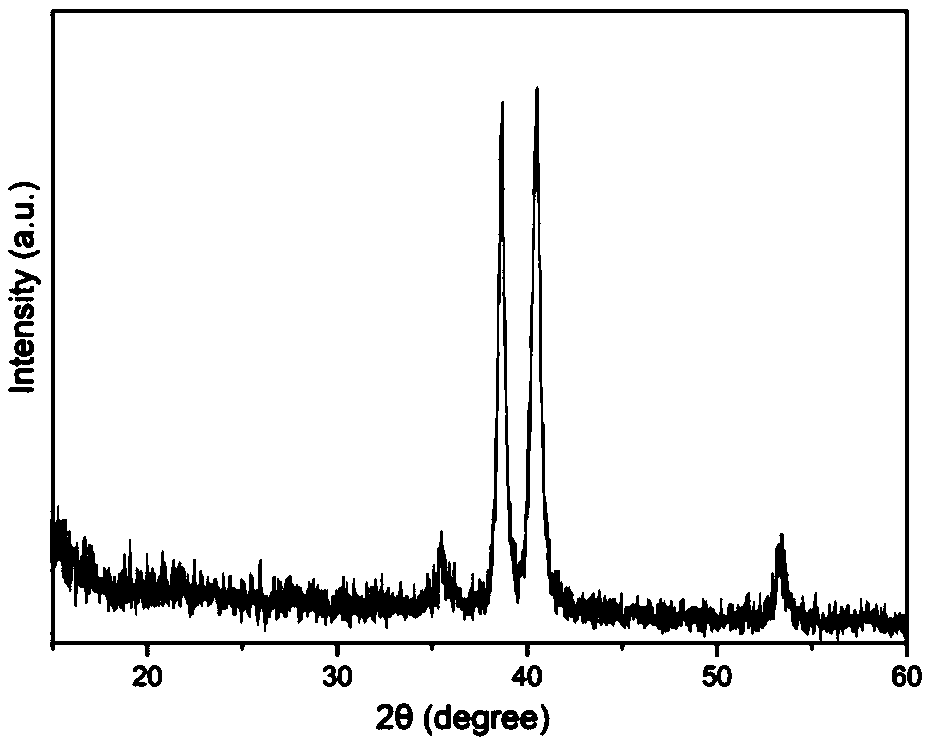

Vacuum brazing connection technology for tungsten copper composite block

ActiveCN103658904AImprove wettabilityImprove bindingWelding/cutting media/materialsWelding/soldering/cutting articlesButt jointTungsten

The invention belongs to the technical field of heterogeneous material welding, and particularly relates to a method for vacuum brazing connection of tungsten and copper. The method is applied to connection of a tungsten copper composite block of a high-heating-load component of a fusion device. The method comprises the following steps that (1) brazing connection materials and brazing filter metal are determined; (2) a welding surface is preprocessed, a tungsten block and a chromium-zirconium-copper alloy block are cleaned, impurities, oil contamination and an oxidation film of the welding surface are removed, and dewatering and drying are conducted; (3) the ribbon copper-based brazing filter metal is cleaned; (4) assembly is conducted, connection is conducted in a butt-joint mode, the copper-based brazing filter metal is placed between the preprocessed surface to be welded of the tungsten and the preprocessed surface to be welded of copper alloy, assembly is conducted through a clamp and the pressure of 0.01MPa-0.1MPa is perpendicularly exerted; (5) welding is conducted, the assembled tungsten block-ribbon copper-based brazing filter metal-chromium copper alloy welding piece is placed in a vacuum brazing device for welding. According to the technical scheme, the obtained pure tungsten and the chromium-zirconium-copper alloy are welded in a butt joint mode, welding-seam forming is good, deformation of the welding piece is avoided, and shortages of microscopic cracks, air holes and impurities and the like are avoided.

Owner:SOUTHWESTERN INST OF PHYSICS

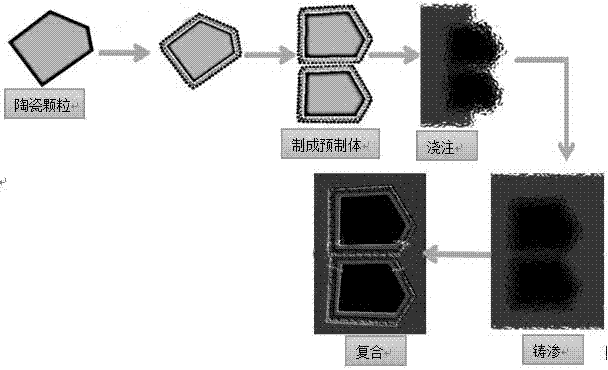

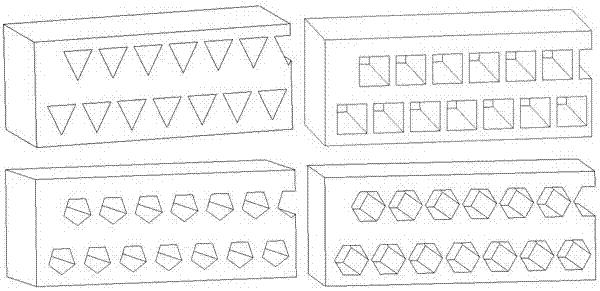

Method for preparing non-sintered ceramic preform composite materials

The invention relates to a method for preparing non-sintered ceramic preform composite materials, and belongs to the technical field of composite materials. The method includes uniformly mixing ceramic micro-powder and adhesive with each other to obtain mixtures A; adding ceramic particles into the mixtures A, uniformly mixing the ceramic particles and the mixtures A with one another and carrying out preparation molding and dehydration treatment to obtain ceramic preforms; pouring metal matrix liquid on the ceramic preforms to obtain the ceramic preform composite materials. The method has the advantages that spatial distribution structures of the ceramic particles, in metal matrixes, of the ceramic particle enhancement metal-based composite materials prepared by the aid of the method can be designed as needed, metal liquid can be advantageously subjected to cast-infiltration in the ceramic preforms, binding of the ceramic particles in the obtained non-sintered ceramic preform composite materials and the metal matrixes can be improved, the abrasion resistance can be improved, and accordingly the service lives of the non-sintered ceramic preform composite materials can be prolonged.

Owner:KUNMING UNIV OF SCI & TECH

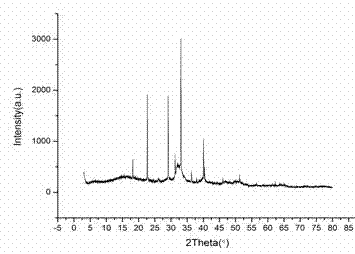

Method for polylactic acid high polymer material surface modified hydroxyapatite coating

InactiveCN102504311AAchieve chemical bondingGood osteoinductivityCoatingsProsthesisPolymer scienceApatite

The invention discloses a method for a polylactic acid high polymer material surface modified hydroxyapatite coating, and aims to design a method for the polylactic acid high polymer material surface modified hydroxyapatite coating, which has the advantages of simple and feasible preparation method, low cost and suitability for surface modification of various degradable polylactic acid high polymer material scaffolds. The method for the polylactic acid high polymer material surface modified hydroxyapatite coating comprises the following steps of: soaking a polylactic acid high polymer material with the molecular weight of 10,000-200,000 in an activating solution for activating, covalently introducing -OH, -COOH or -NH2 active groups onto the surface, soaking the activated polylactic acid high polymer material in a Ca<2+> ionic solution, soaking in a PO4<3-> alkaline solution, and repeatedly circulating the steps for 3-50 times to grow a layer of uniform and compact hydroxyapatite coating on the surface of the material finally. The method is environment-friendly, has the advantages that the coating preparation period is short and the cost is low, and is suitable for preparing degradable biological material hydroxyapatite coatings.

Owner:HENAN NORMAL UNIV

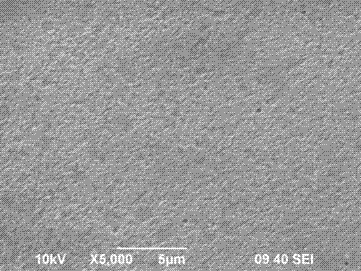

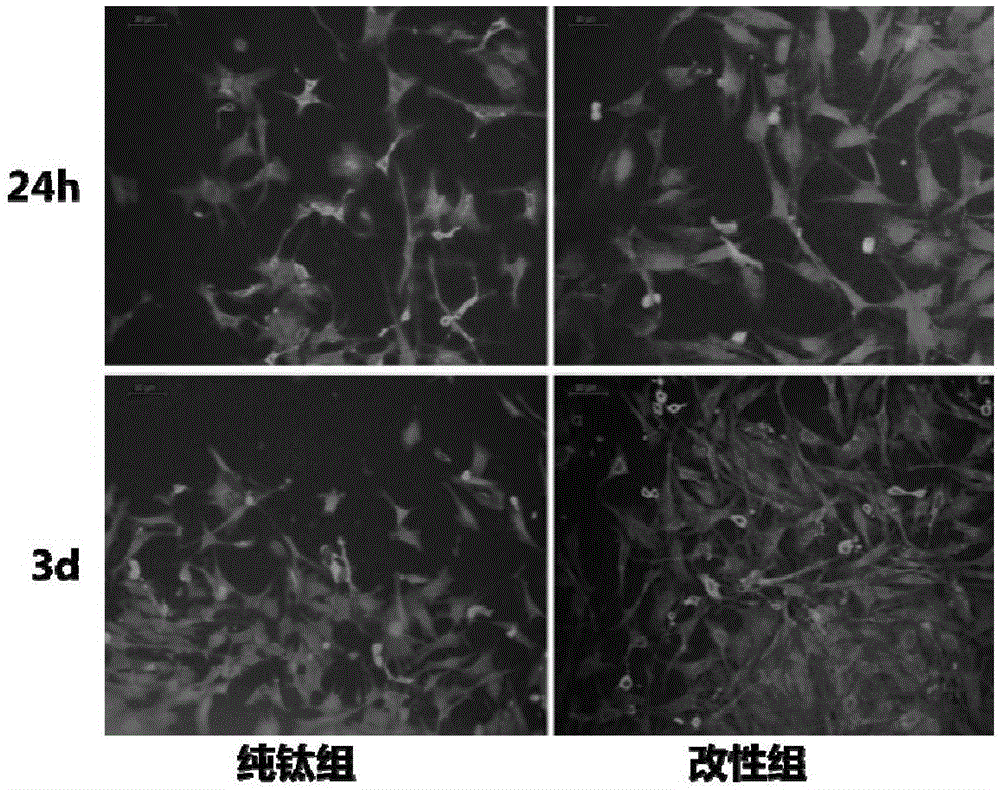

Surface modified medical metal material and preparation method thereof

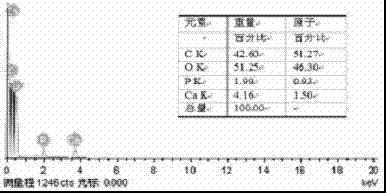

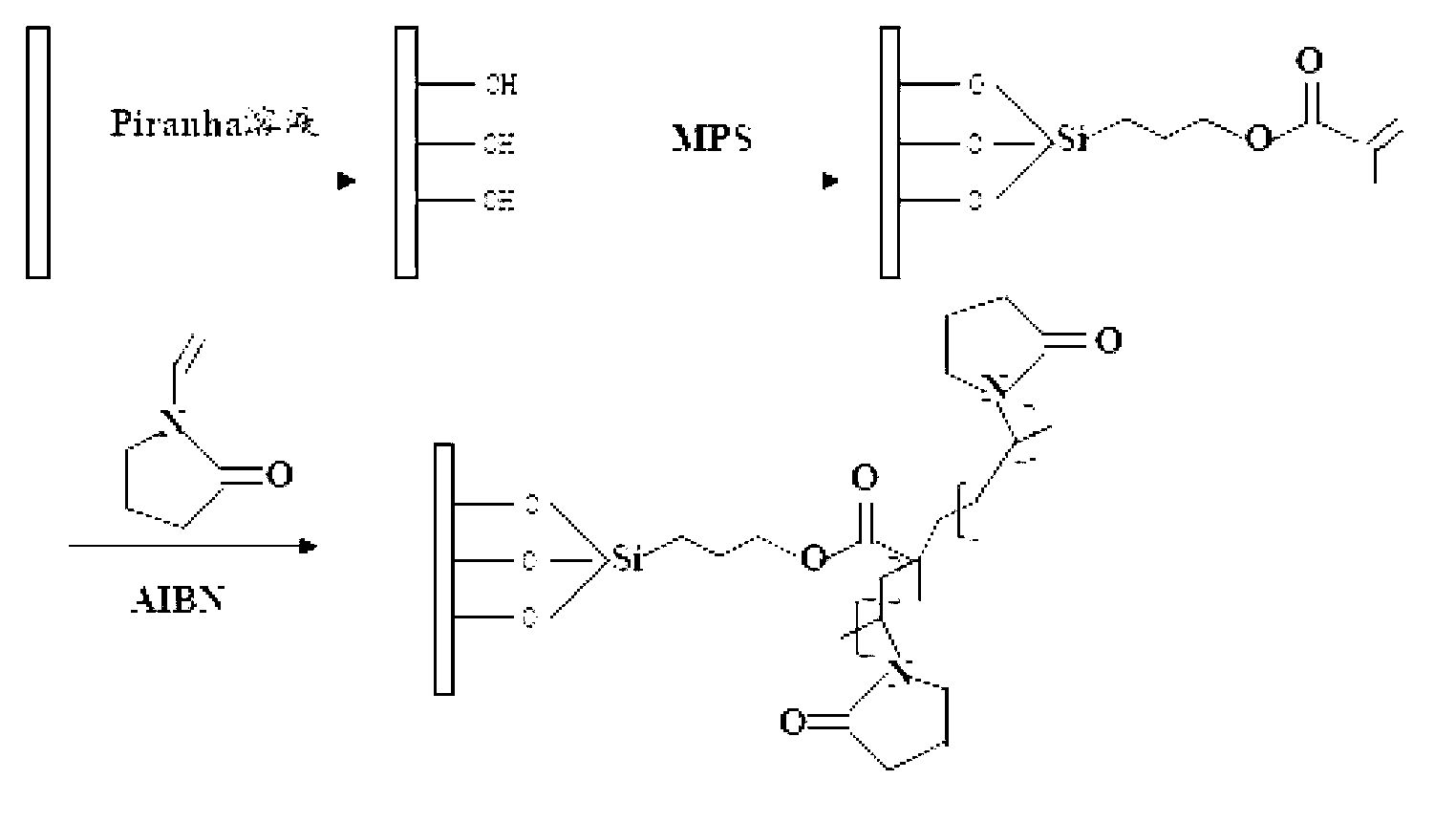

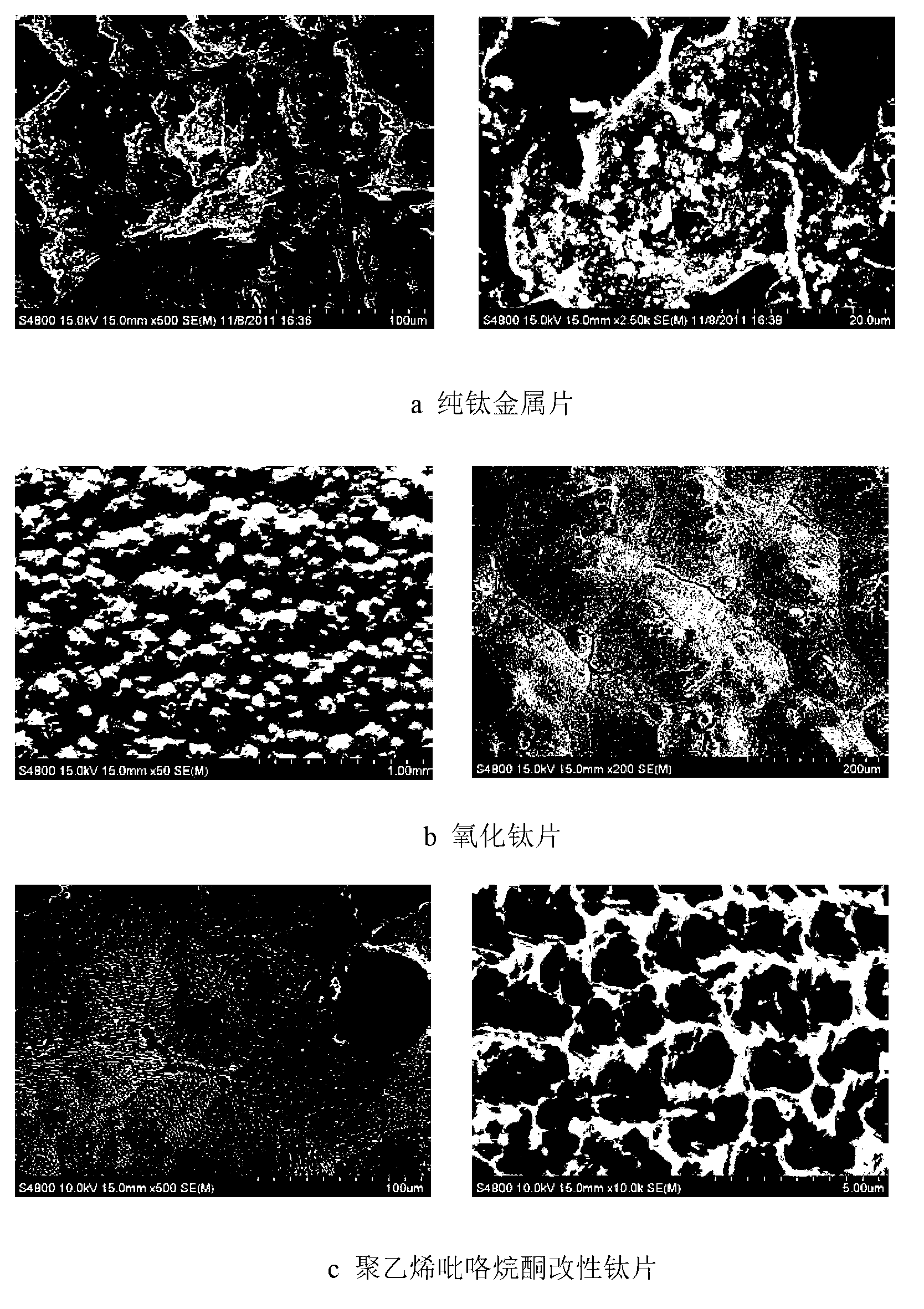

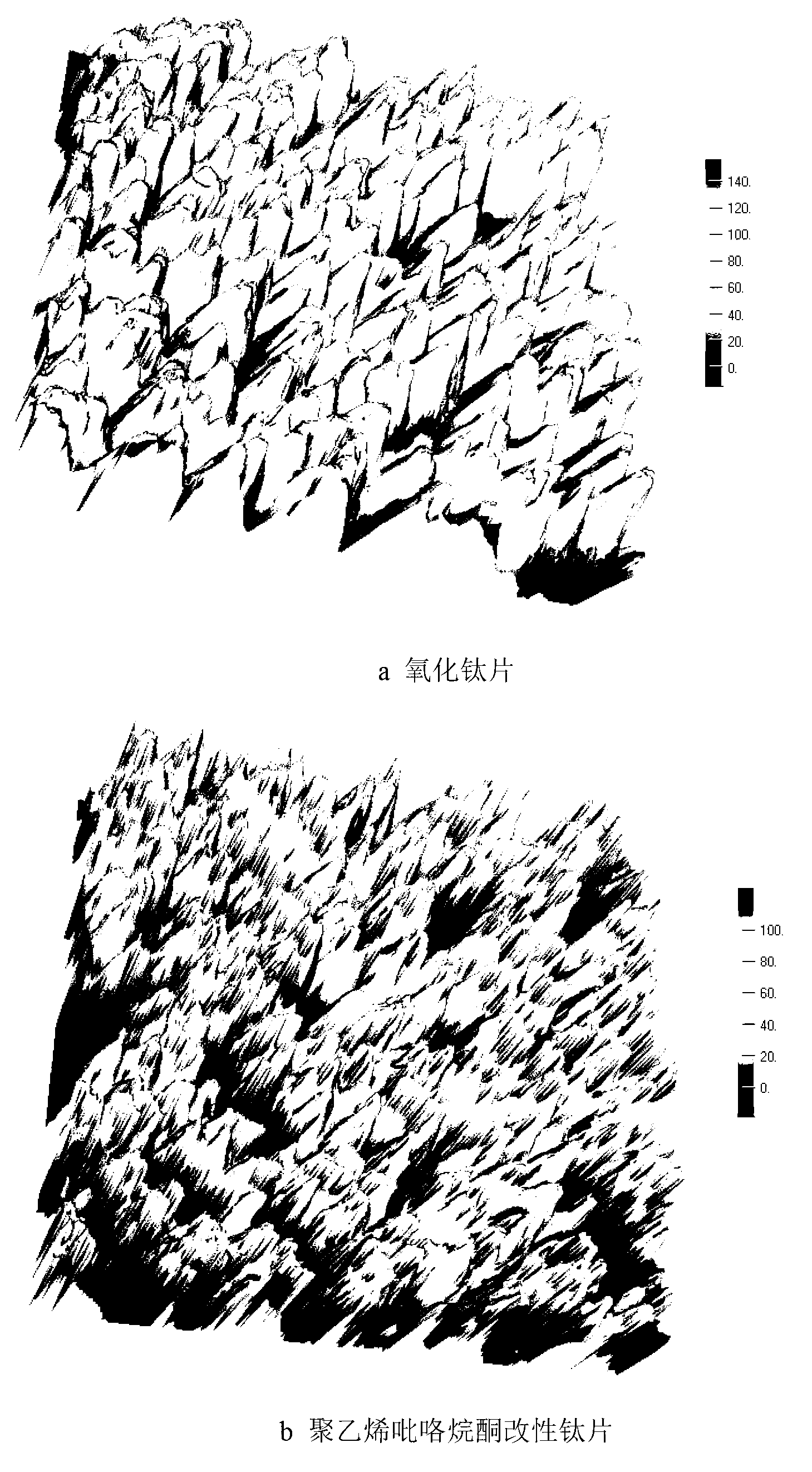

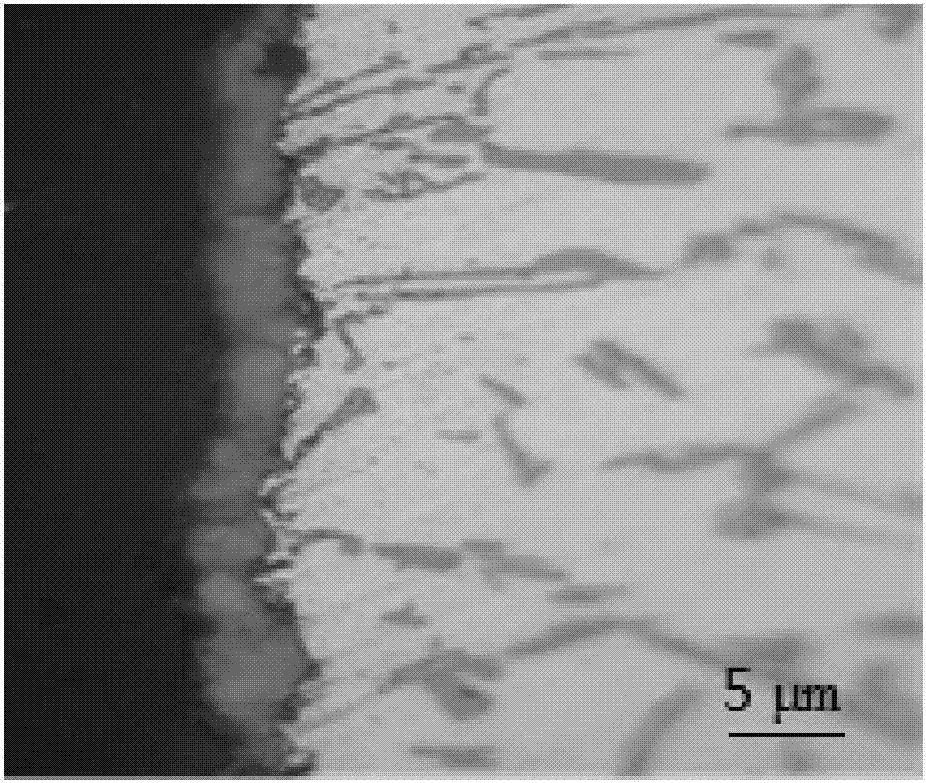

InactiveCN102912335AAchieve chemical bondingImprove antibacterial propertiesMetallic material coating processesEscherichia coliMicron scale

The invention discloses a surface modified medical metal material (titanium, titanium alloy, magnesium and magnesium alloy) and a preparation method of the surface modified medical metal material. Medical metal is firstly oxidized in a piranha solution, and an oxide layer is formed on the metal surface; a coupling reagent is used for coupling, and double bonds are led on the surface in a covalence mode; and finally a free radical polymerization method is adopted to cause copolymerization between the medical metal and vinylpyrrolidone monomers so as to lead in polyvinylpyrrolidone macromolecules on the surface of the medical metal in a covalence mode. A surface modified layer of the medical metal material is located on the oxide layer of the medical metal surface, and thickness of the modified layer is located in a micron scale. After the surface modified layer absorbs silver ions, the surface modified layer has a good antibiosis capability on escherichia coli and staphylococcus aureus, and antibiosis rate can achieve higher than 98%. The surface modified medical metal material prepared by the method has a good biological activity, stability and an antibacterial property and is simple in preparation method, free of needs of special equipment, low in production cost and applicable to industrial production.

Owner:HENAN UNIV OF SCI & TECH

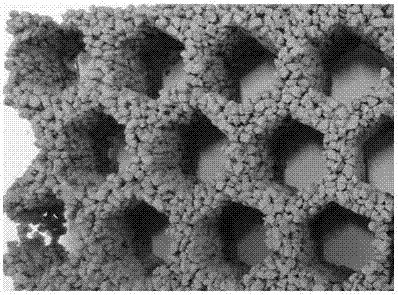

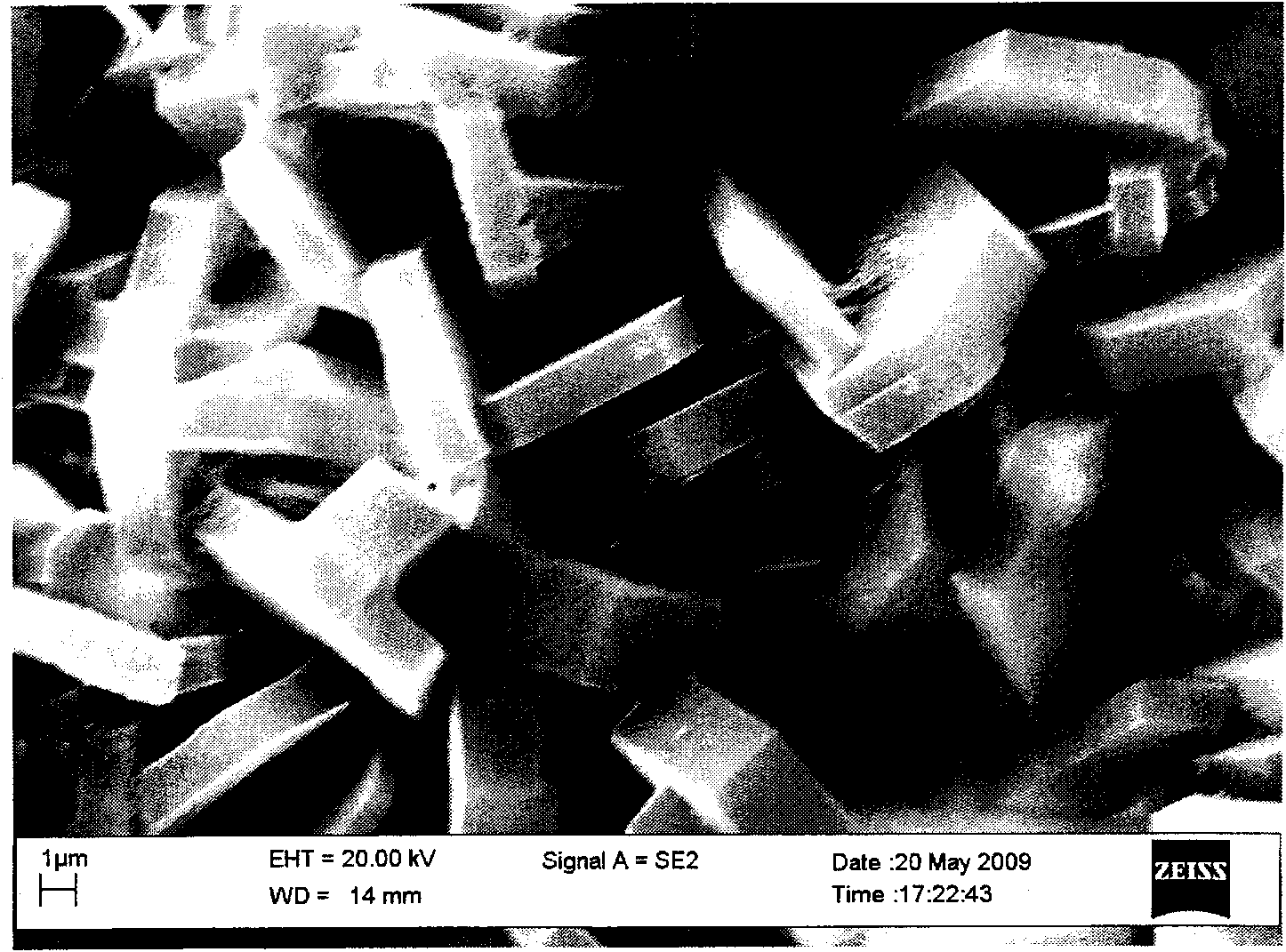

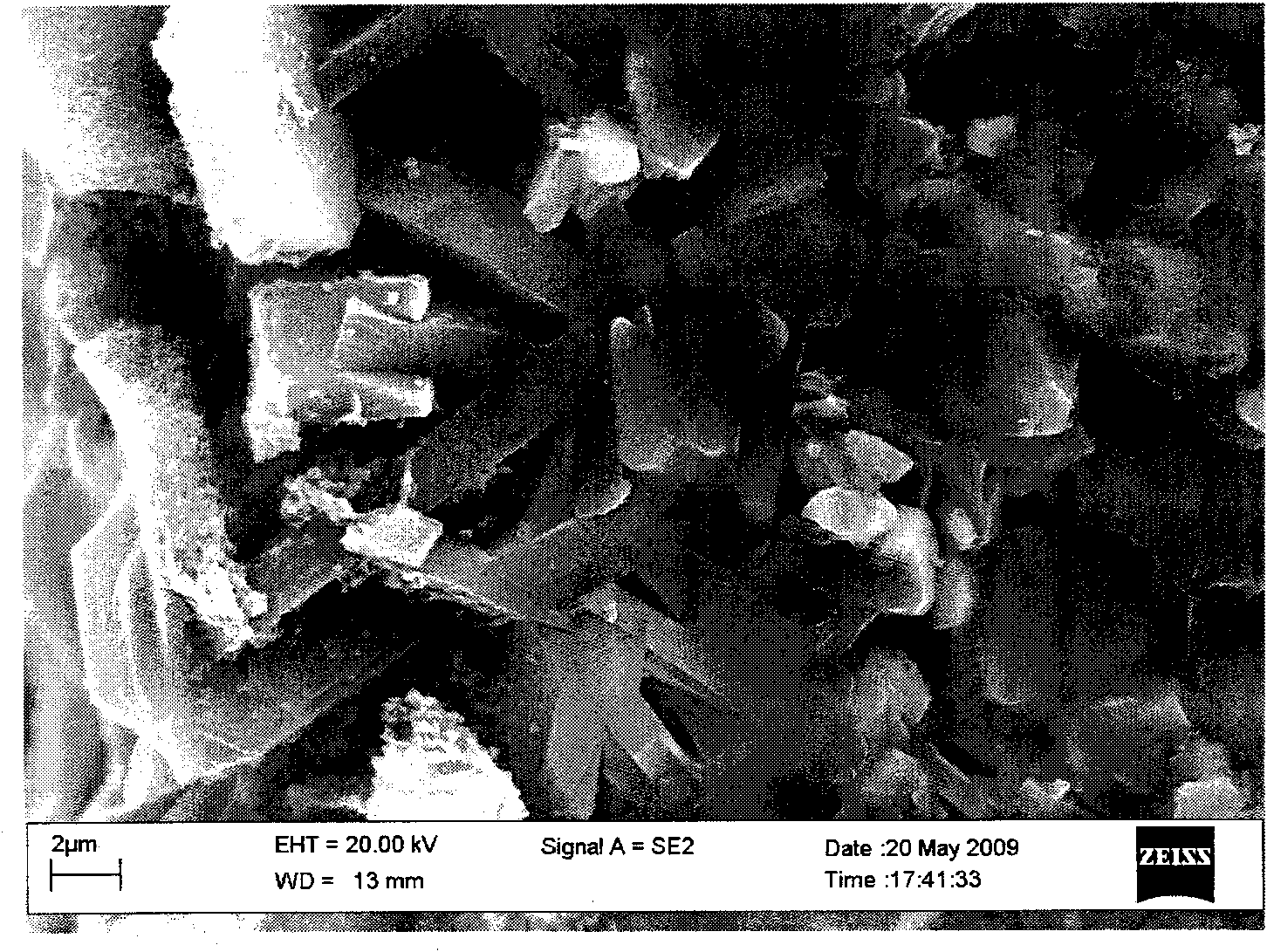

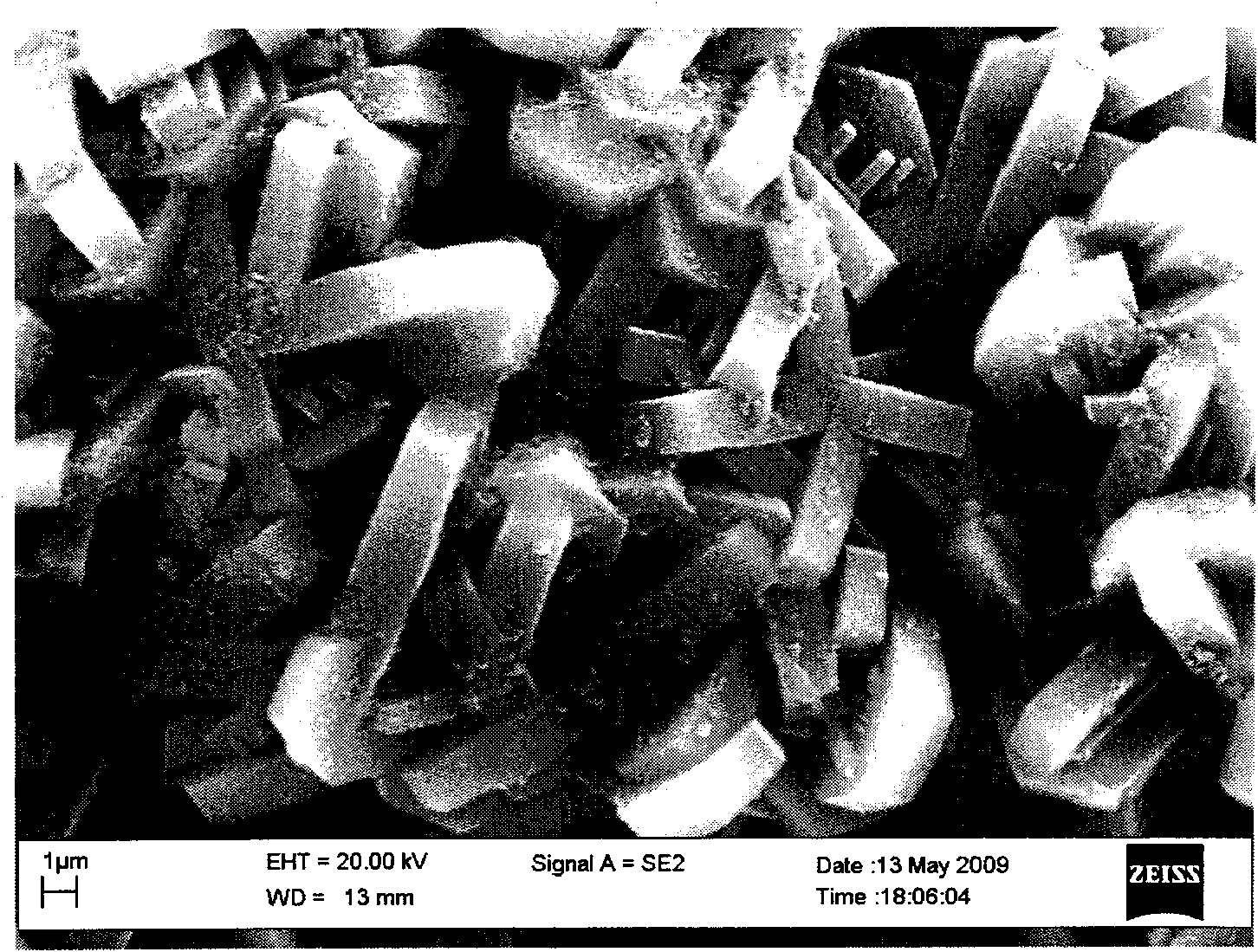

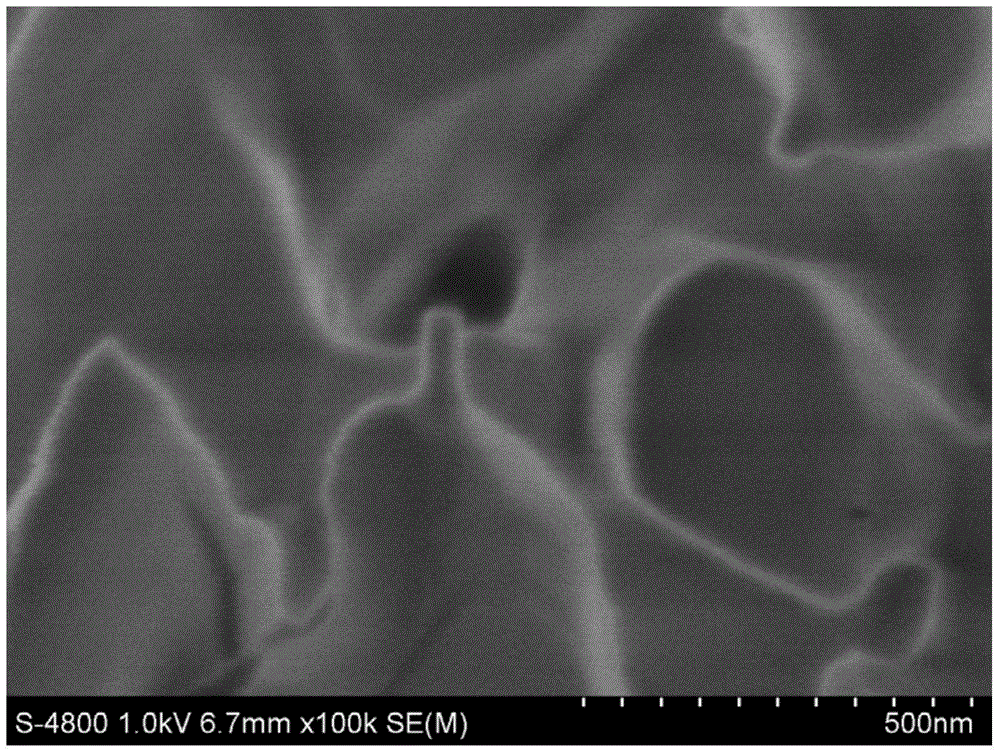

Porous zeolite molecular sieve coating material on surface of silicon carbide ceramics and preparation method thereof

ActiveCN101992126AIncrease profitEnhanced mass transferMolecular sieve catalystsCatalyst activation/preparationMolecular sieveAmmonium hydroxide

The invention belongs to the field of catalysis of zeolite crystals, in particular to a porous zeolite molecular sieve coating material on a surface of silicon carbide ceramics and a preparation method thereof. The zeolite molecular sieve coating is uniformly loaded on the surface of a porous silicon carbide ceramics carrier, and the zeolite molecular sieve coating has a double-pore canal structure composed of micropores of zeolite molecular sieves and macropores formed by mutual overlapping of zeolite crystals. The preparation method comprises the following steps: coating a zeolite precursor sol layer on the surface of porous silicon carbide ceramics, wherein the mol ratio of ethyl orthosilicate, tetrapropyl ammonium hydroxide and de-ionized water is 1:0.1-1.0:29; and growing in a secondary growth solution, wherein the mol ratio of ethyl orthosilicate, tetrapropyl ammonium hydroxide and de-ionized water is 1:0.05-1.0:110. Micron-sized pore canals are formed among the zeolite crystals in the coating, thereby improving the utilization efficiency of the zeolite coating. At the same time, the method has the advantages of simple process and low energy consumption, and the prepared zeolite molecular sieve coating is uniformly loaded and stably combined.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

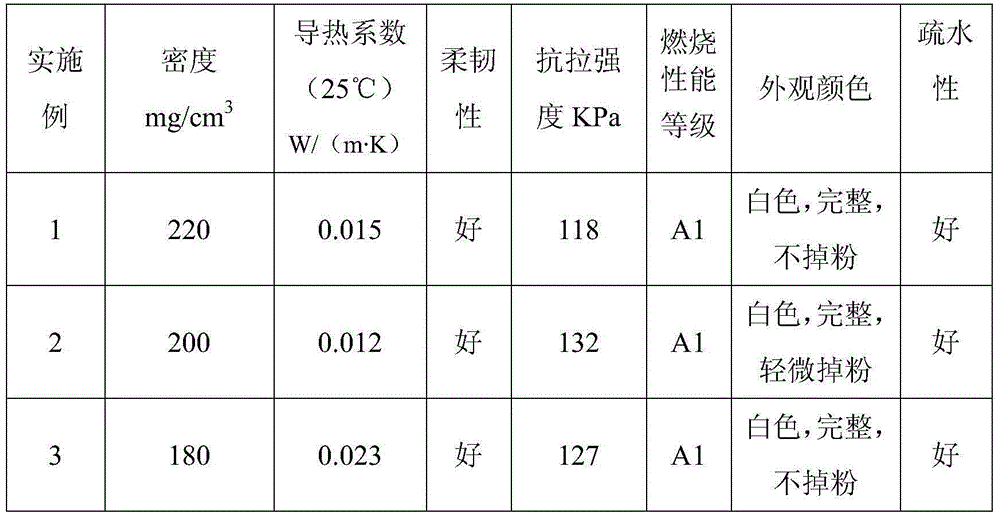

Thermal insulation silicon dioxide aerogel/hydroxylation glass fiber felt composite and preparation method thereof

The invention discloses a thermal insulation silicon dioxide aerogel / hydroxylation glass fiber felt composite and a preparation method thereof. The thermal insulation silicon dioxide aerogel / hydroxylation glass fiber felt composite is characterized in that silicon dioxide aerogel accounts for 50-80 weight parts of a matrix, and hydroxylation glass fiber felt accounts for 70-120 weight parts of a reinforcing body. The thermal insulation silicon dioxide aerogel / hydroxylation glass fiber felt composite is prepared by preparing a silica sol system of an MQ structure (M represents (CH3)3SiO1 / 2, Q represents SiO4 / 2) through raw materials including absolute ethyl alcohol, deionized water, hexamethyldisiloxane and the like under the acid catalysis environment, then adding gel catalysts, submerging preprocessed glass fiber in the silica sol system to form a wet gel and fiber felt composite, conducting soaking through normal hexane after ageing is conducted for 12-24 h so that water in the system can be removed, and conducting drying to obtain the silicon dioxide aerogel / hydroxylation glass fiber felt composite at temperature of 50-120 DEG C and pressure of 0.01-5 Pa for 1-5 h.

Owner:四川中蓝基业新材料科技有限公司

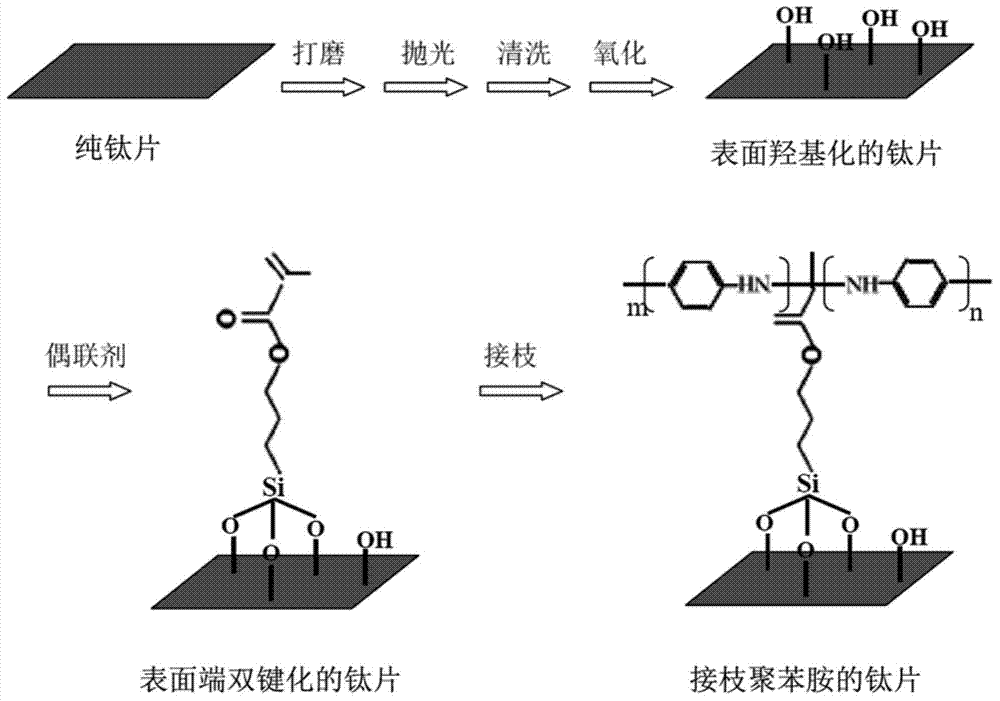

Modified medical titanium metal material and preparation method thereof

InactiveCN103751841AGood biocompatibilityGood antibacterial effectCoatingsProsthesisEscherichia coliTitanium metal

The invention discloses a modified medical titanium metal material and a preparation method thereof. The modified medical titanium metal material comprises a medical titanium metal, wherein a bioactive coating is applied to the surface of the medical titanium metal, and is formed by performing surface hydroxylation on the medical titanium metal, introducing silane coupling agent molecules with terminal double bonds and covalently grafting polyaniline in an in-situ polymerization manner. The modified medical titanium metal material has excellent biocompatibility, bacteriostasis and stability because the bioactive coating is applied to the surface of the medical titanium metal, and has an excellent bacteriostatic capability to common strains, such as escherichia coli and staphylococcus aureus, with the bacteriostasis rate of over 90 percent; the bioactive coating is in chemical bonding with a matrix material, is high in bonding strength and can not easily fall off, so that the stability of an implant can be improved, and the service life of the implant can be prolonged.

Owner:HENAN UNIV OF SCI & TECH

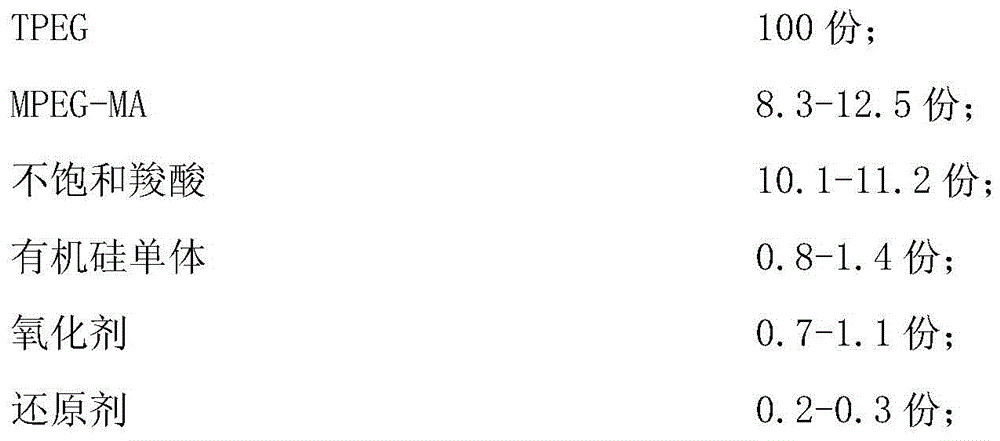

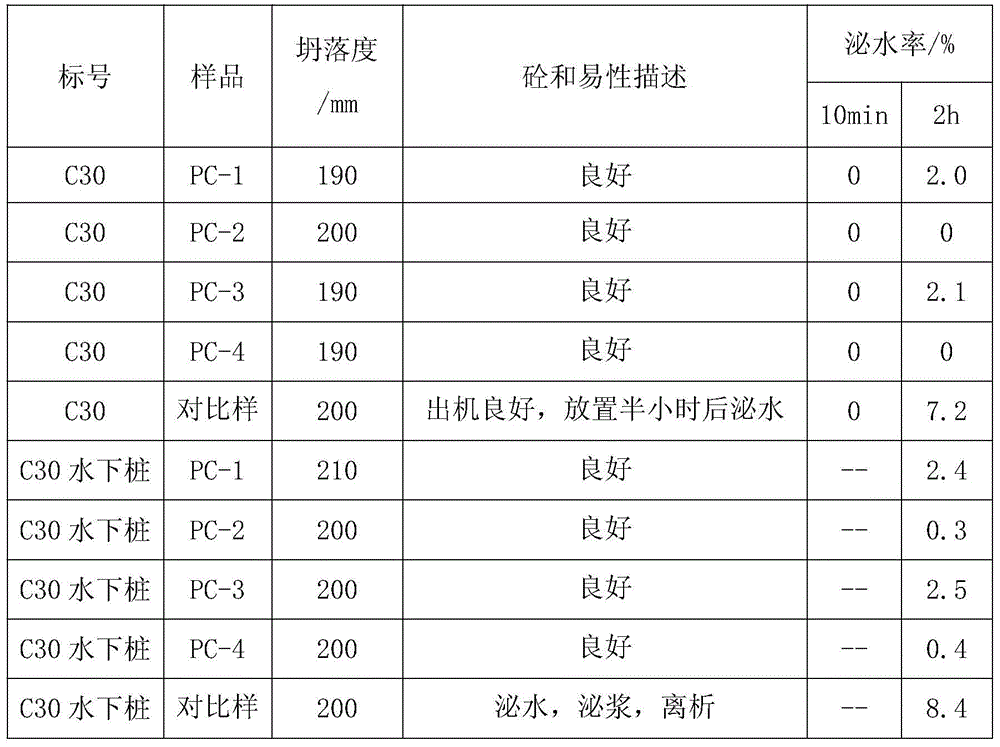

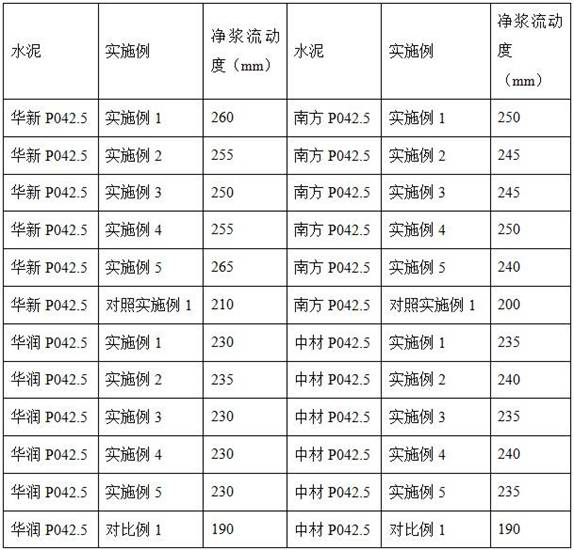

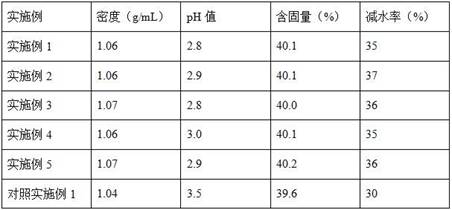

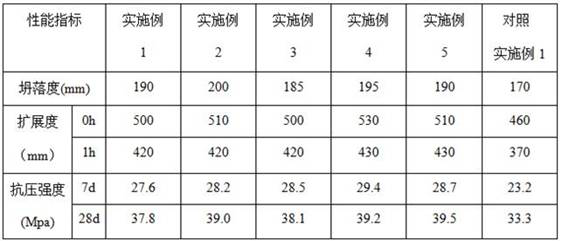

Polycarboxylate superplasticizer with high water retention and preparation method thereof

The invention discloses a polycarboxylate superplasticizer with high water retention and a preparation method thereof. The polycarboxylate superplasticizer with high water retention is prepared from, by weight, 100 parts of TPEG, 8.3-12.5 parts of MPEG-MA, 10.1-11.2 parts of unsaturated carboxylic acid, 0.8-1.4 parts of organosilicone monomer, 0.7-1.1 parts of an oxidizing agent, 0.2-0.3 part of a reducing agent, 0.3-0.4 part of a chain transfer agent, 163-172 parts of deionized water and liquid alkali for making pH to 5.5-6. The polycarboxylate superplasticizer with high water retention has high slump under the condition of low dosage, workability of concrete can be improved, and water-retention and tackifying effects are achieved. Meanwhile, reaction condition is suitable, the reaction is normal-temperature reaction without heat source, and the technology is concise, environmentally friendly and highly efficient and is suitable for a large-scale industrial production method.

Owner:厦门路桥翔通建材科技有限公司

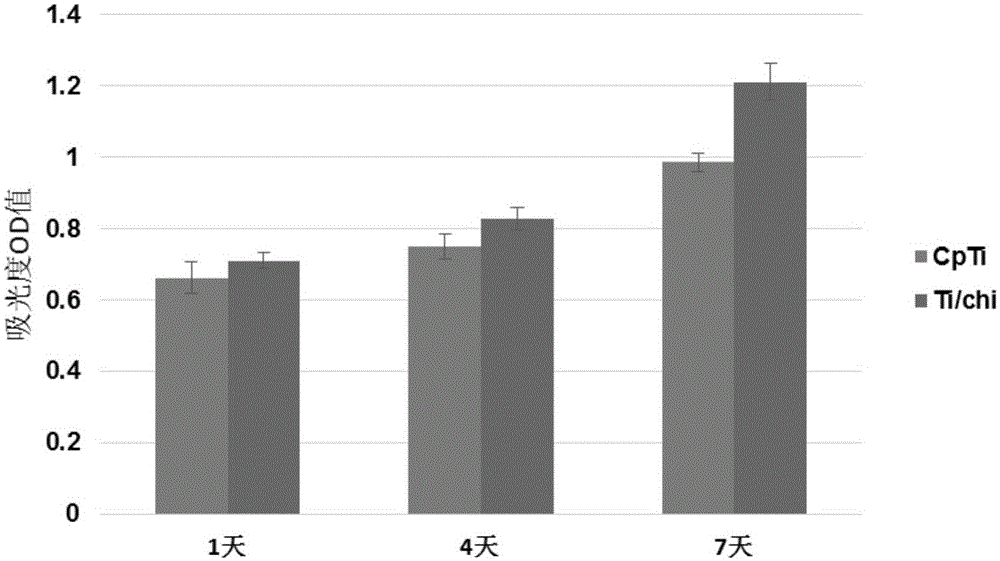

Titanium dental implant material and preparing method and application of titanium dental implant material

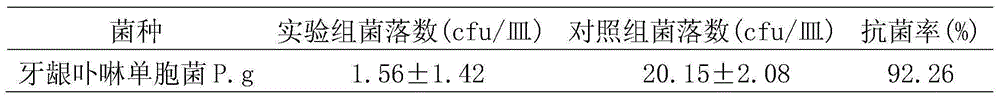

InactiveCN105126165AGood biocompatibilityStrong proliferative activityProsthesisBiocompatibility TestingAntimicrobial peptides

The invention discloses a titanium dental implant material and a preparing method and application of the titanium dental implant material. The titanium dental implant material prepared through the preparing method of the titanium dental implant material comprises a base body, a cationic polymer layer, an anion polysaccharide layer-chlorination chitosan-polypeptide A conjugate composite layer and an anion polysaccharide layer-antimicrobial peptide layer composite layer. The titanium dental implant material has good biocompatibility, bacterium resistance, apoptosis resistance and angiogenesis promoting activity, can support adhesion, survival, proliferation and differentiation of various cells, promotes survival, proliferation and migration of vascular endothelial cells, forms a lumen structure of a capillary tube sample and meanwhile inhibits adhesion and survival of periodontal common pathogenic bacteria. The titanium dental implant material has durable and efficient sterilizing and infection resisting capabilities, healing of peripheral bone wounds of the implant can be accelerated, chemical bonding of an implant-bone interface can be achieved, the success rate of oral implantology is increased, the treatment time is shortened, in addition, the preparing method is simple, and a good application prospect is achieved in the oral implantology field.

Owner:AFFILIATED HOSPITAL CHINA ACADEMY OF MILITARY MEDICAL SCI

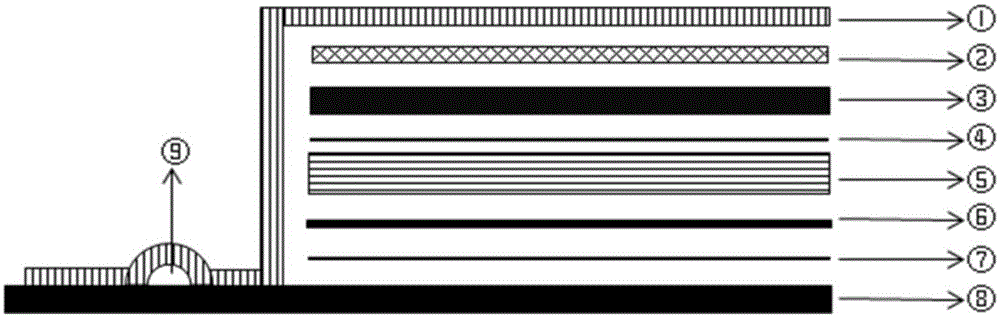

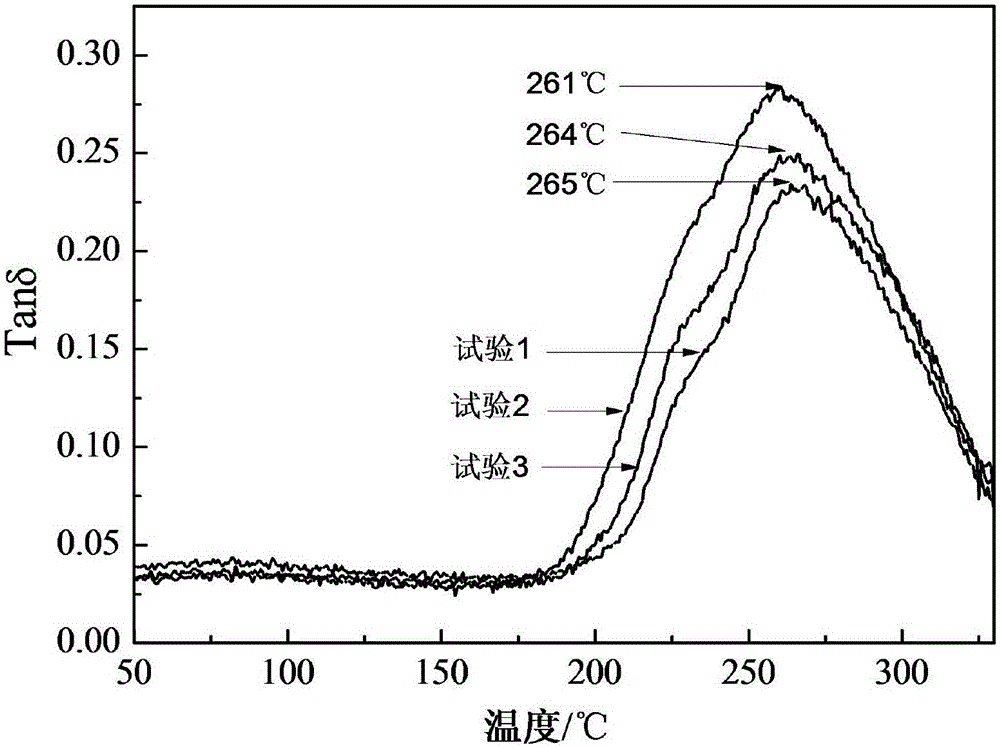

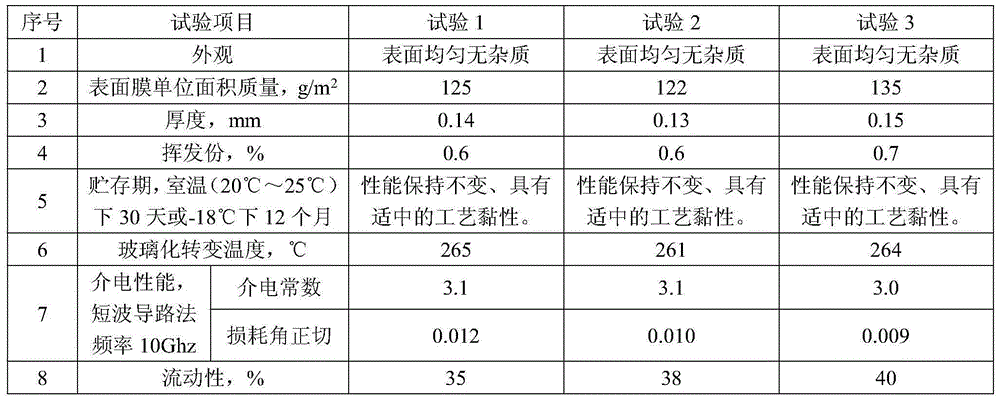

Modified cyanate ester resin surface film and preparation method thereof

ActiveCN105131827ALow dielectric constantImprove the bonding strength of the interfaceCoatingsAdhesiveToughening

The invention provides a modified cyanate ester resin surface film and a preparation method thereof, relates to a resin surface film and a preparation method thereof, and solves the problems that an existing epoxy composite surface film and cyanate ester resin prepreg are not matched well, as a result, the curing temperature is inconsistent, the long-term working service temperature is low, the dielectric property of a workpiece cannot meet the standard and the like. The cyanate ester resin surface film comprises cyanate ester resin, a polymerization process modifier, a toughening modifier, a curing accelerator, a coupling agent, inorganic filler, UV (ultraviolet) stabilizer and a carrier. The preparation method of the cyanate ester resin surface film comprises steps as follows: cyanate ester resin and the modifier are kneaded, and copolymerized and modified cyanate ester resin is obtained; the toughening modifier, the coupling agent, the inorganic filler and the UV stabilizer are added and mixed, and a modified cyanate ester resin surface film adhesive is obtained; a three-roller rotating coating film making machine is adopted for film forming. The modified cyanate ester resin surface film is used for improving the surface quality of a cyanate ester resin composite structural member.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

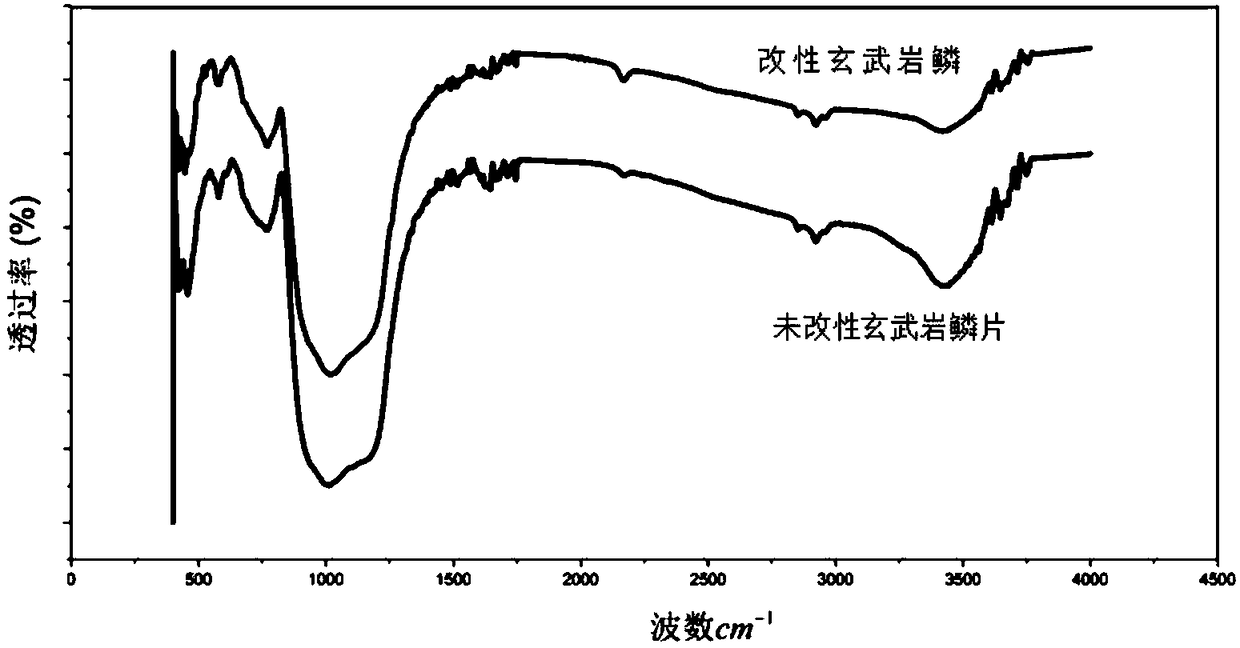

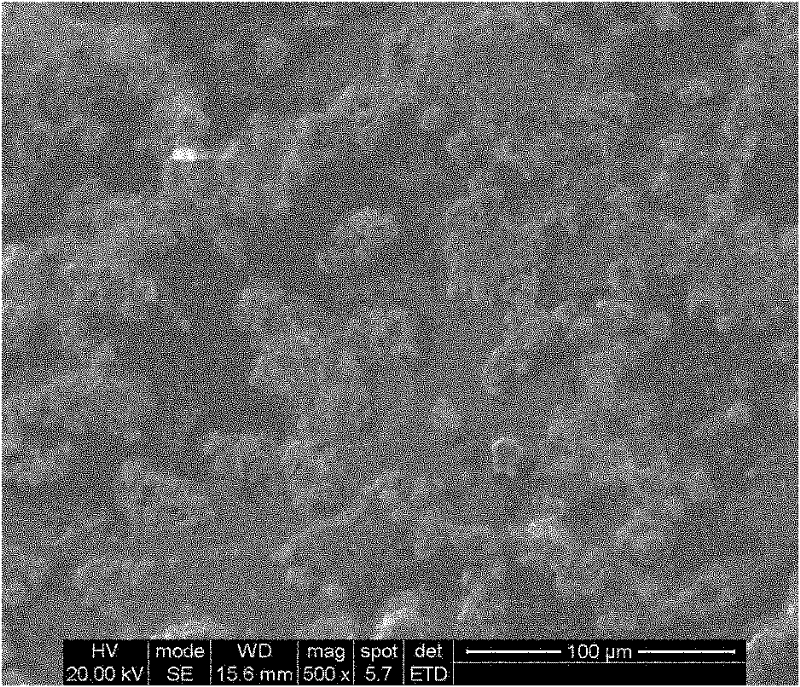

Basalt scale solvent-free heavy anticorrosive coating and method for preparing same

InactiveCN108441083AEnhance the interface forceAchieve chemical bondingAnti-corrosive paintsEpoxy resin coatingsPolymer scienceSolvent free

The invention provides basalt scale solvent-free heavy anticorrosive coating. The basalt scale solvent-free heavy anticorrosive coating comprises, by weight, 7-15 parts of modified basalt fiber scales, 45-55 parts of epoxy resin, 28-40 parts of curing agents, 2-6 parts of activated diluents, 1-3 parts of defoaming agents and 1-4 parts of coalescing agents. A method for preparing the modified basalt fiber scales includes steps of mixing basalt scales and silane coupling agent solution with one another, and ultrasonically dispersing the basalt scales and the silane coupling agent solution for 25-35 min to obtain dispersion; carrying out solid-liquid separation on the dispersion, and carrying out heat treatment on obtained solid materials at the temperatures of 110-130 DEG C for 50-70 min toobtain the modified basalt fiber scales. The basalt scale solvent-free heavy anticorrosive coating has the advantages of excellent performance and environmental friendliness.

Owner:BEIHANG UNIV +1

High-temperature ceramic/metal riveting-glass sealing combination connection method

InactiveCN104909795AHigh temperature and high reliability sealed connectionAchieving tightnessElectrical resistance and conductanceThermal insulation

The invention provides a high-temperature ceramic / metal riveting-glass sealing combination connection method and relates to a connection method of high-temperature ceramic / metal. The connection method solves the technical problems of poor joint intensity and low usage temperature of a present connection method when a high-temperature ceramic / metal structural member has a large size. The method comprises steps: first, pretreatment of ceramic and metal is carried out; second, glass sealants and binders are mixed and stirred, and coating is carried out; third, assembling, nail placing and rivet application are carried out; fourth, the product is placed in an electric resistance furnace for thermal insulation. Glass systems with different ratios are selected as sealing materials according to different ceramic / metal and usage temperatures. The glass sealants can match ceramic and metal in the thermal expansion coefficients, and can keep certain viscosity during high temperature usage, and high-temperature high-reliability sealing connection of ceramic / metal connection members is achieved. The connection method is used for obtaining high-temperature ceramic / metal riveting-glass sealing combination high-reliability connection.

Owner:HARBIN INST OF TECH

Tear-free self-adhesive rubber waterstop belt and preparation method thereof

ActiveCN104789148AWith self-adhesive functionEasy to processMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesPolymer scienceAdhesive

The invention belongs to the technical field water-proof materials of buildings and particularly discloses a tear-free self-adhesive rubber waterstop belt and a preparation method of the tear-free self-adhesive rubber waterstop belt. The invention adopts the major technical scheme that the rubber waterstop belt comprises a rubber base material, as well as a high polymer self-adhesive layer and an isolation layer that are pasted on one side face of the base material. The rubber base material is prepared from natural rubber, ZnO, stearic acid, an antiager, a reinforcing agent, operating oil, functional filling and a valcanizer via an extrusion technology, the high polymer self-adhesive layer is formed by melting SBS (styrene-butadiene-styrene) or / and SIS (styrene isoprene styrene) resin softening oil, an antiager, an reinforcing agent, operating oil, functional filling and an antioxidant via a stirrer, and the isolation layer is formed by stirring and mixing natural zeolite, metakaolin, wollastonite and stearic acid, and then the prepared high polymer self-adhesive layer and the isolation layer are applied on the rubber base material for calendering to form the belt. The waterstop belt has the self-adhesive layer which is securely connected with a concrete boundary layer, greatly improves adhesion between the rubber waterstop belt and concrete, and effectively solves the problems of water leakage and dampening of an expansion joint, a deformation joint and a construction joint.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER

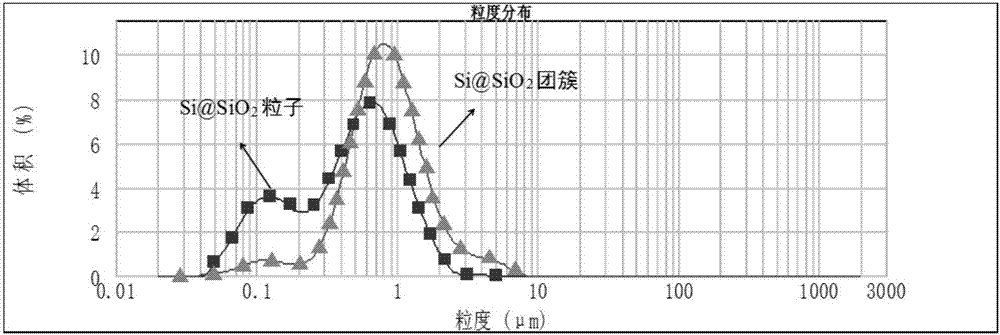

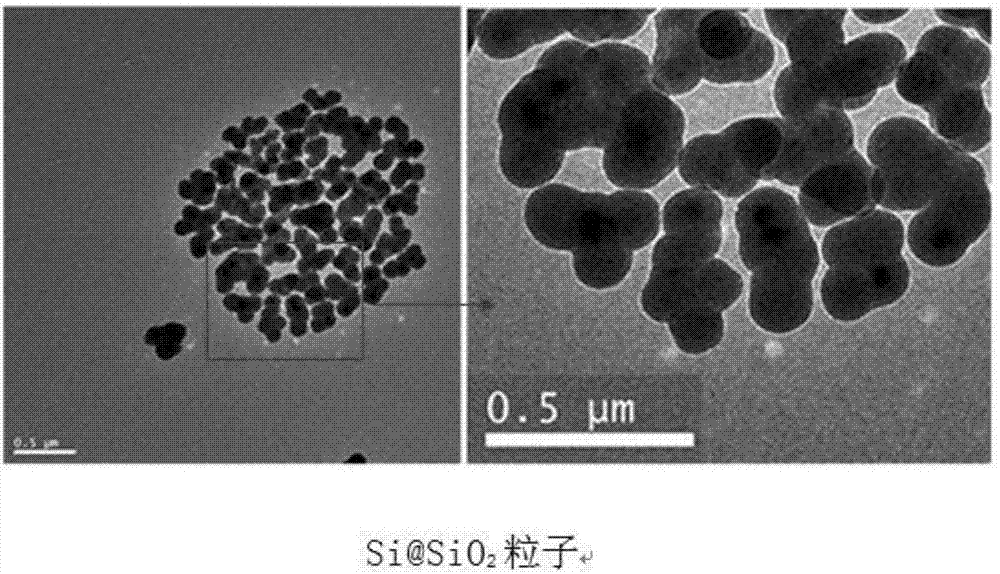

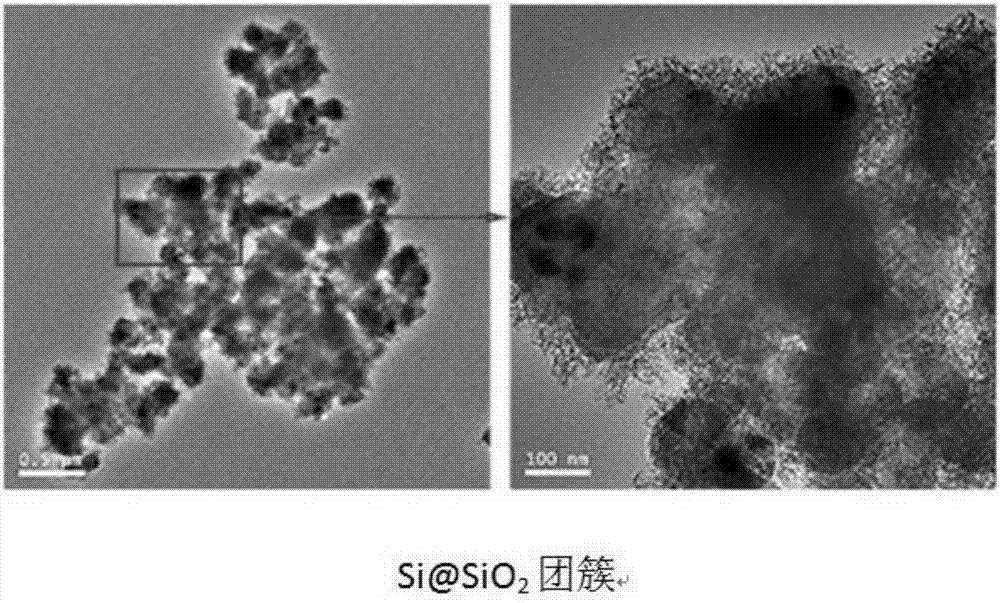

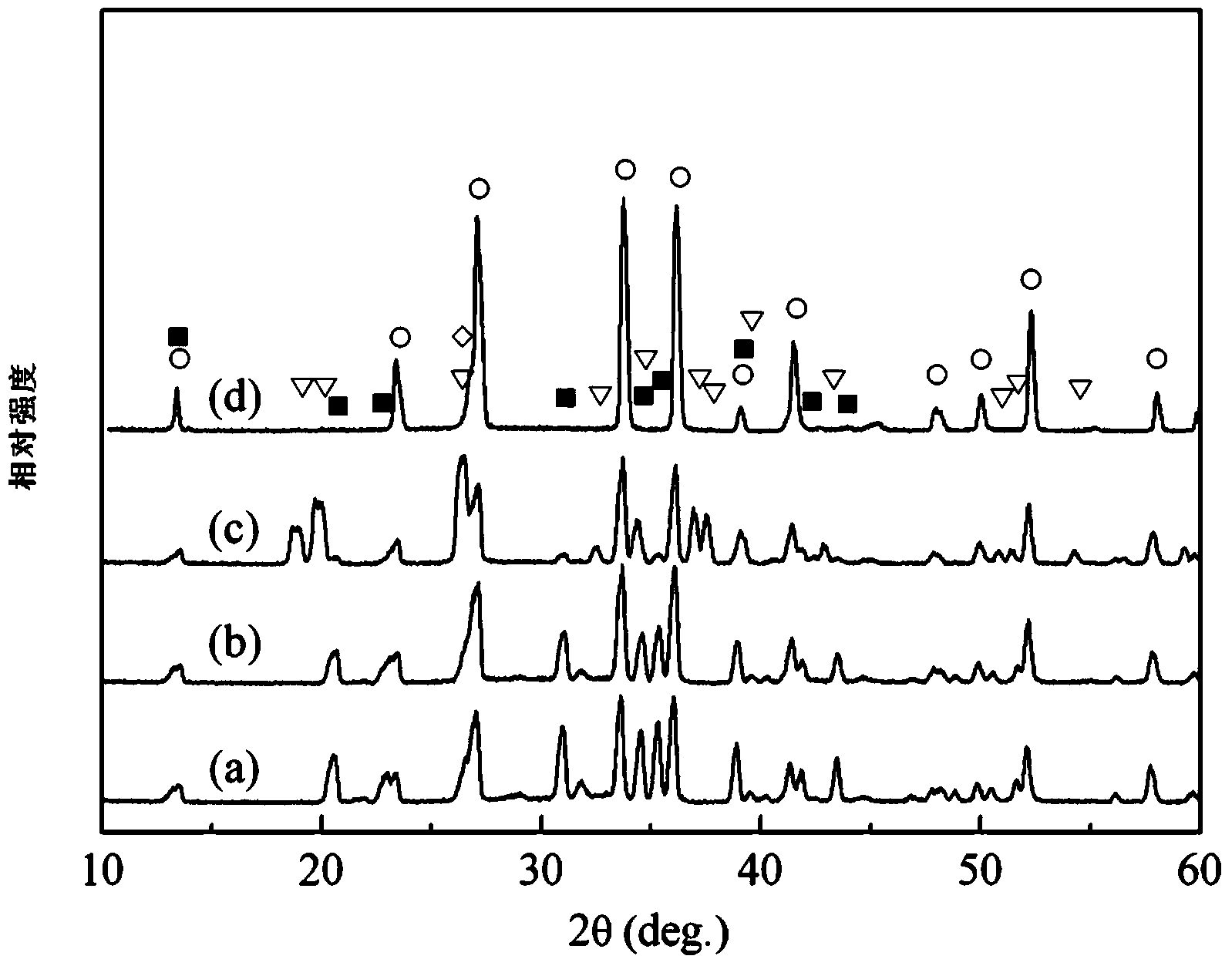

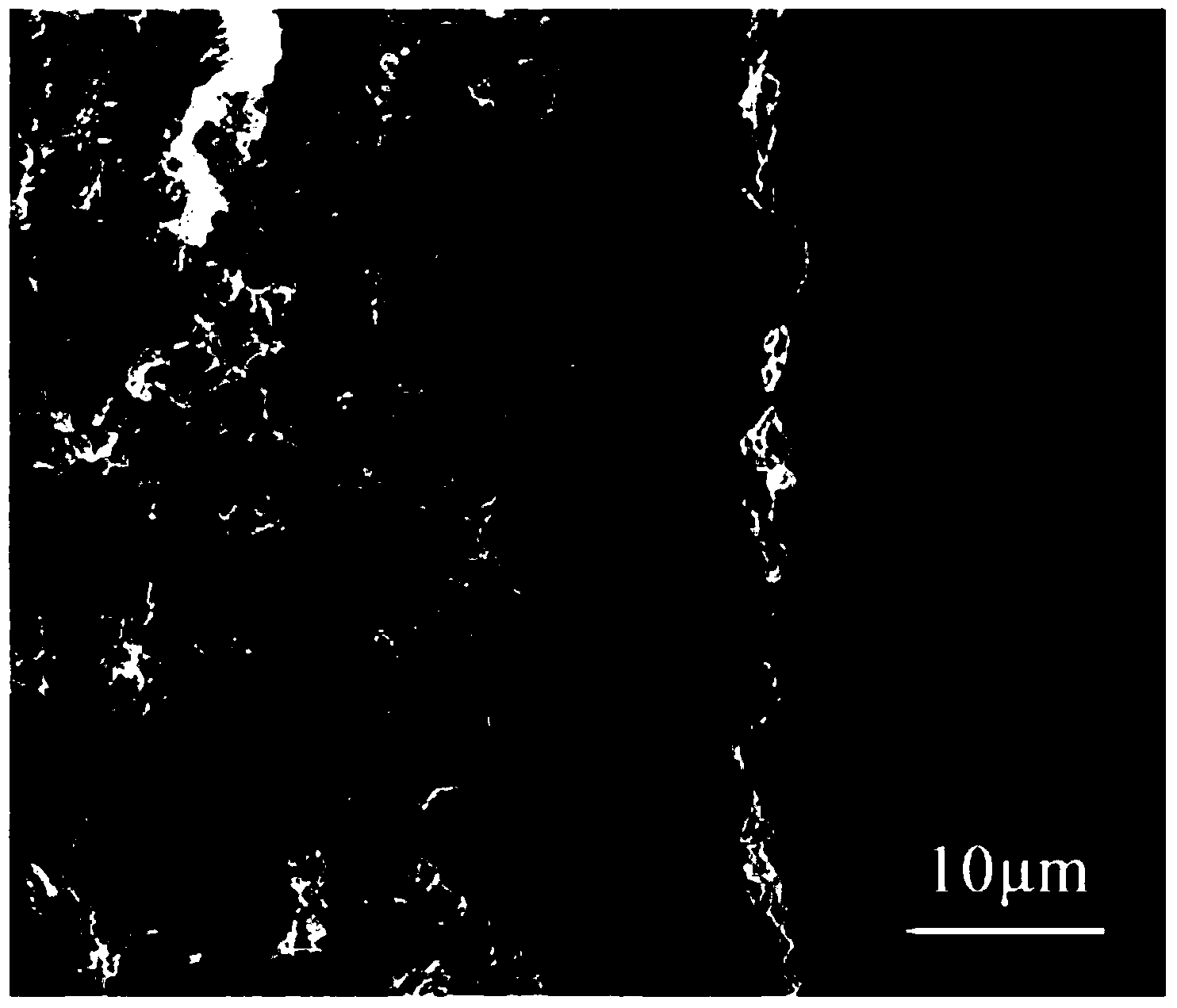

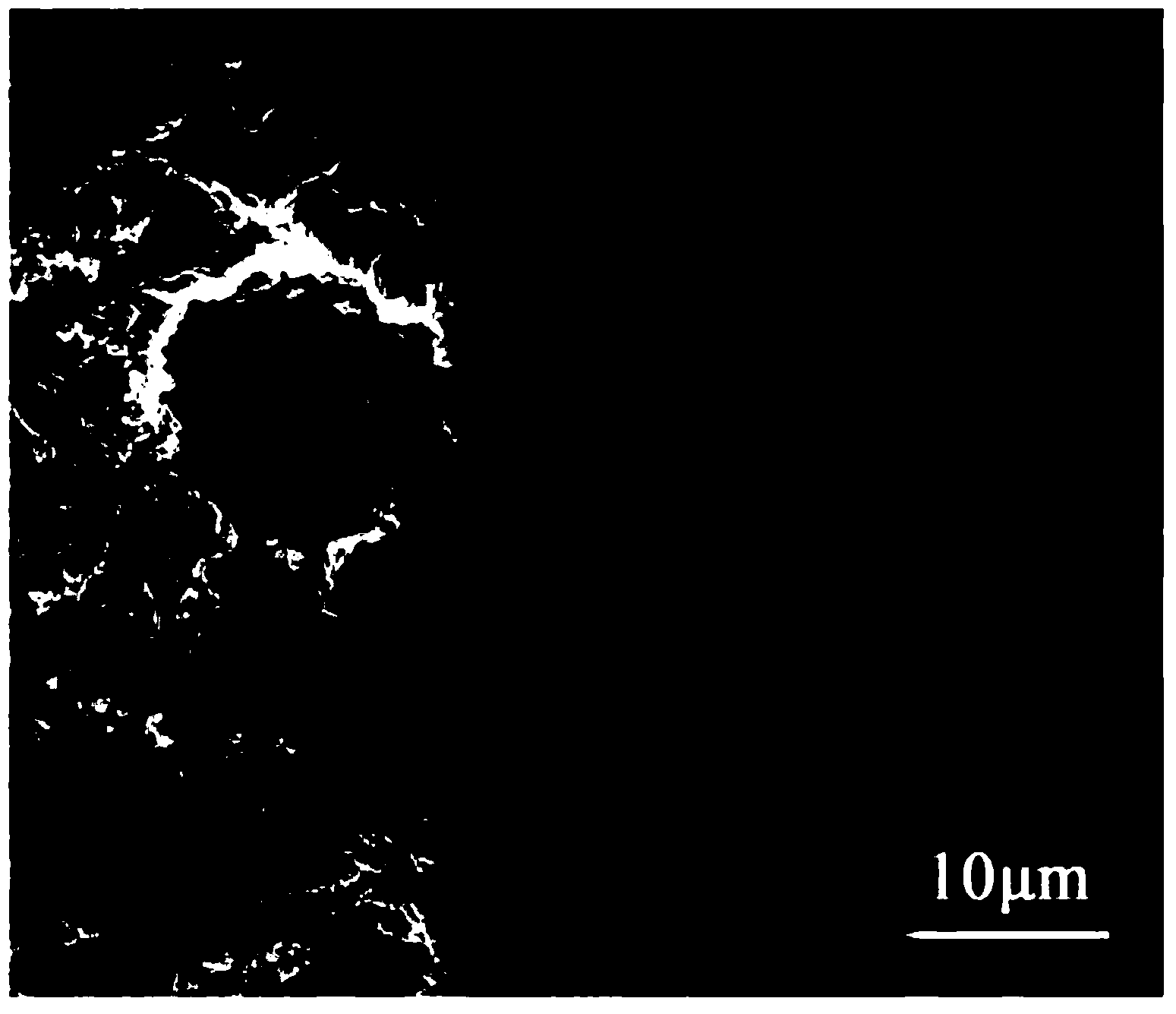

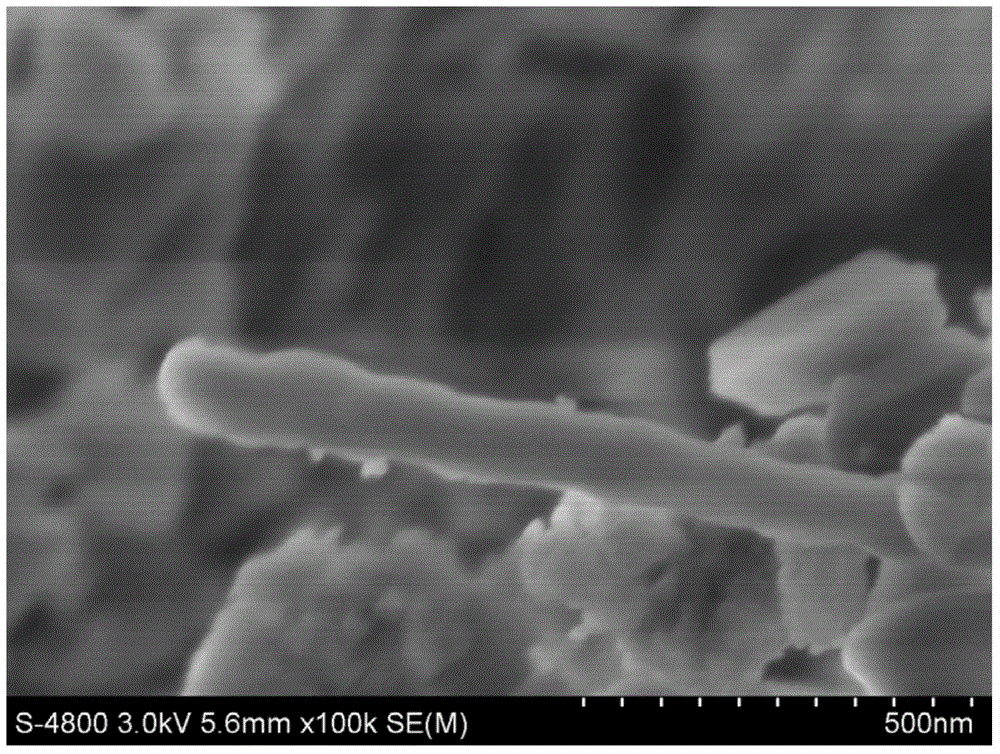

Preparation method for silicon-based negative electrode material with secondary cluster structure and used for lithium ion battery

ActiveCN106935817AImprove bindingReduce manufacturing costCell electrodesSecondary cellsSolventLithium electrode

The invention relates to a preparation method for a silicon-based negative electrode material with a secondary cluster structure and used for a lithium ion battery. In a preparation process of a Si@SiO<2> cluster, a solvothermal method is adopted; a compound is generated on the surfaces of Si@SiO<2> particles in an in-situ manner to realize chemical bonding between the Si@SiO<2> particles, so that the bonding force between the Si@SiO<2> particles in the Si@SiO<2> cluster is greatly improved; in addition, subsequent high-temperature heat treatment is not needed, so that production cost is lowered; and in addition, the surface of the Si@SiO<2> cluster is further coated with carbon, and hydrofluoric acid treatment is carried out to obtain the material with the secondary cluster structure, wherein the material has high cycling performance and rate capability.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of porous BN/Si3N4 composite ceramic hole sealing layer

The invention discloses a preparation method of a porous BN / Si3N4 composite ceramic hole sealing layer. The invention relates to a surface hole sealing technology of porous BN / Si3N4 composite ceramic. The problems that the existing porous BN / Si3N4 composite wave-transmitting ceramic hole sealing layer material is large in effect on the dielectric property of the overall material and high temperature operating requirements are hard to meet are solved. The method comprises the following steps: 1, weighing the raw materials according to the ratio; 2, preparing hole sealing slurry; 3, preparing a hole sealing layer by adopting a vacuum impregnation method; 4, carrying out drying treatment and thermal treatment. The preparation method disclosed by the invention is simple in technology, and uniform and compact in thickness of the hole sealing layer; the hole sealing layer is formed by Si3N4 and Si2N2O composite ceramics; the control on phase composition of the hole sealing layer can be achieved by controlling the ratio of the Si3N4 to the SiO2; the porous BN / Si3N4 composite ceramic subjected to hole sealing treatment can be used as bearing, wave-transparent and thermal protection materials, and can be applied to the fields of aerospace and mechanical industry.

Owner:HARBIN INST OF TECH

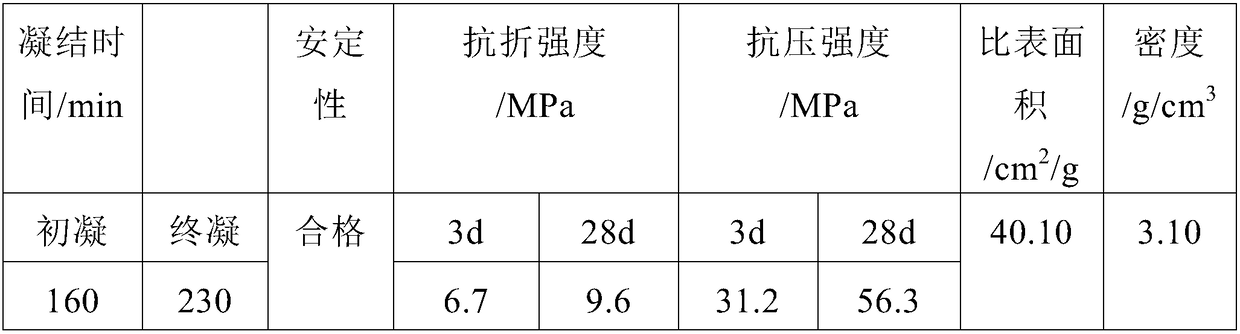

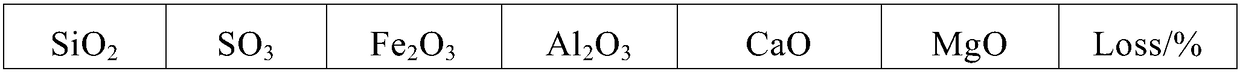

Impervious cement mortar

Owner:南京嘉怡装饰设计有限公司

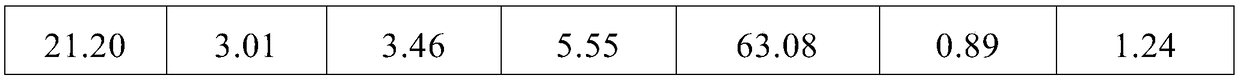

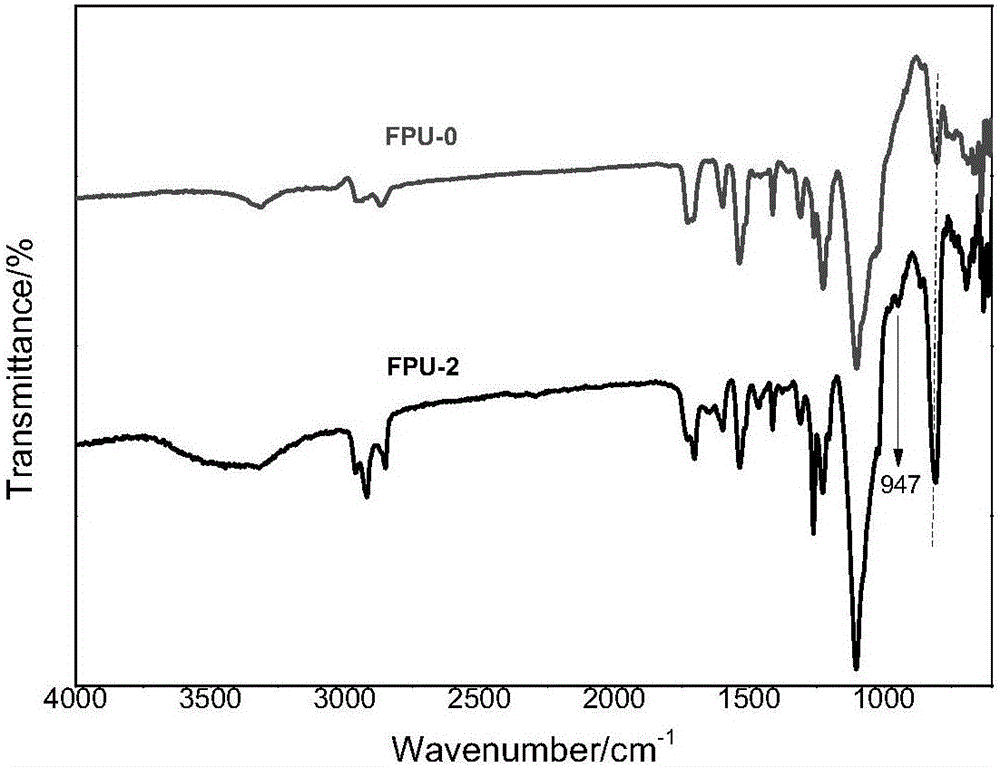

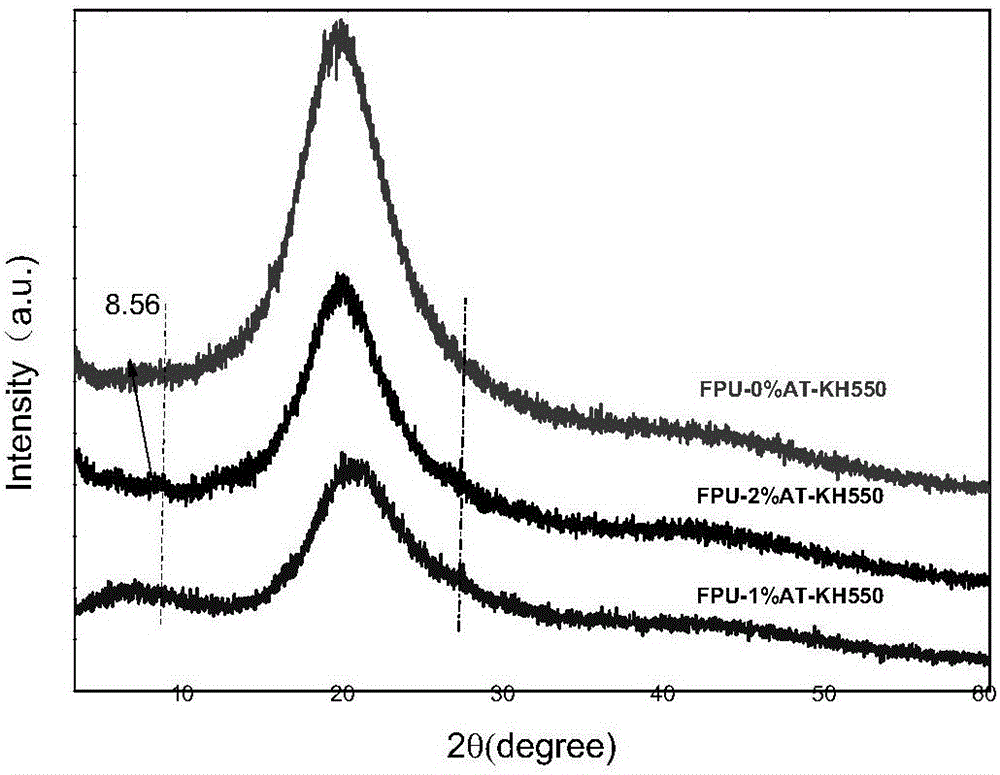

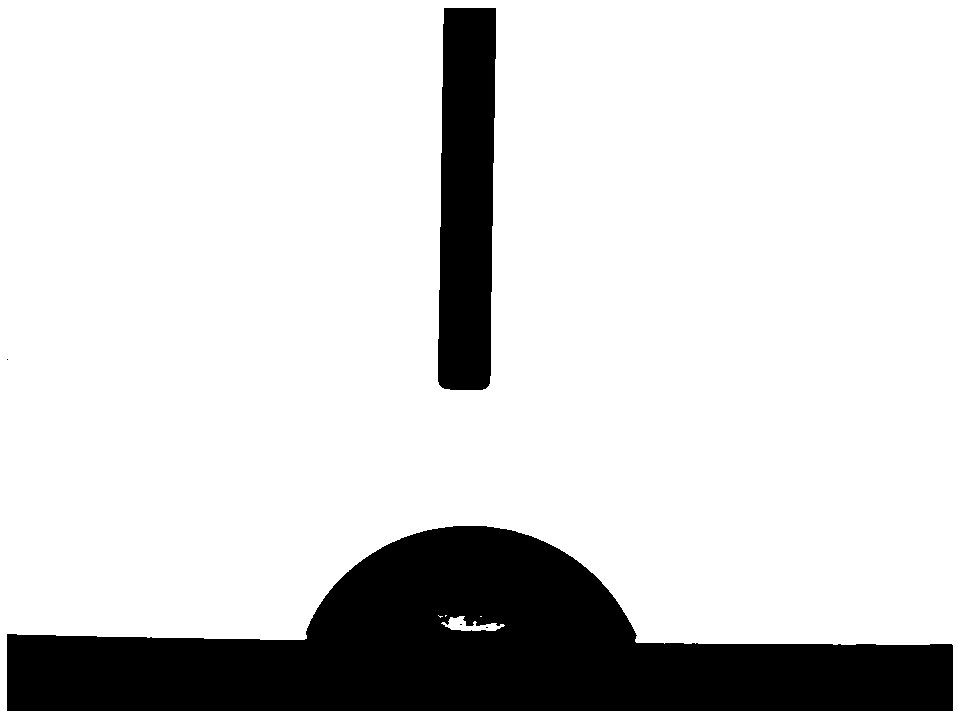

Preparation method of attapulgite/fluorinated polyurethane nanocomposite

The invention relates to a preparation method of an attapulgite / fluorinated polyurethane nanocomposite. The method comprises the steps of firstly, carrying out pretreatment on attapulgite, specifically, dispersing the attapulgite into deionized water, adding a dispersing agent-sodium hexametaphosphate into the deionized water, stirring and then centrifuging, drying and then grinding, acidizing the purified attapulgite, and then carrying out centrifugal drying and sieving; secondly, carrying out organic modification on the attapulgite, specifically, firstly hydrolyzing a silane coupling agent KH550, then adding alcohol and the pretreated attapulgite, carrying out a reflux reaction and then filtering, drying the obtained filter cake, grinding and sieving to obtain modified attapulgite; finally, evenly mixing fluorinated polyether polyol and the modified attapulgite in a nitrogen atmosphere condition, then adding isocyanate into the mixture, heating, carrying out a reaction and then vacuumizing, removing bubbles, adding a chain extender-triethanolamine, stirring and then molding by vacuum solidification. The preparation method is mild in conditions, simple and convenient in operation, easy in control of conditions and low in cost.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for raising heat-resistance property of organic silicon resin adopting polyheadral oligo-sesqui silione

This is the method of improving the thermal stability of organosilicon resin adopting polyhedral oligomeric silsesquioxane (POSS). It relates to a kind of method of improving the thermal stability of organosilicon resin. The invention solves the problem of reducing the wave-transmissivity of the organosilicon resin by all the methods that changes the structure of the pendent groups of polysiloxane or changes the structure of main chain or adds thermostable padding to improve the thermal stability of the organosilicon resin. It includes following steps: a. adopt methyl methoxy silane monomer as raw material, prepare organosilicon resin through hydrolyzation and polyesterification reaction; b. add alcohol solvent into the prepared organosilicon resin to prepare the organosilicon resin with alcohol as solvent; besides it also includes Step c.: add 0.5 -10% POSS of the weight of the organosilicon resin into the organosilicon resin produced in Step b., the reaction temperature is 60 -90 Deg. C, the reaction time is 4 -8 hours, and vacuum membrane distillation. The modified organosilicon resin produced by the method has high heat-resisting performance.

Owner:HARBIN INST OF TECH

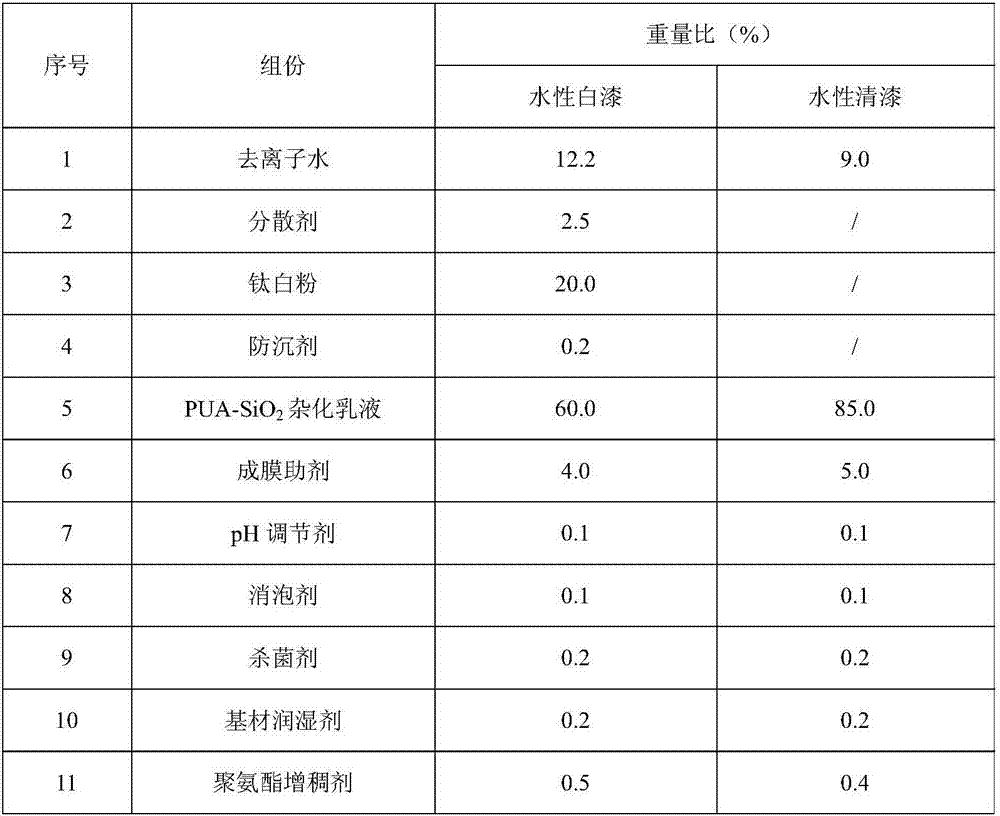

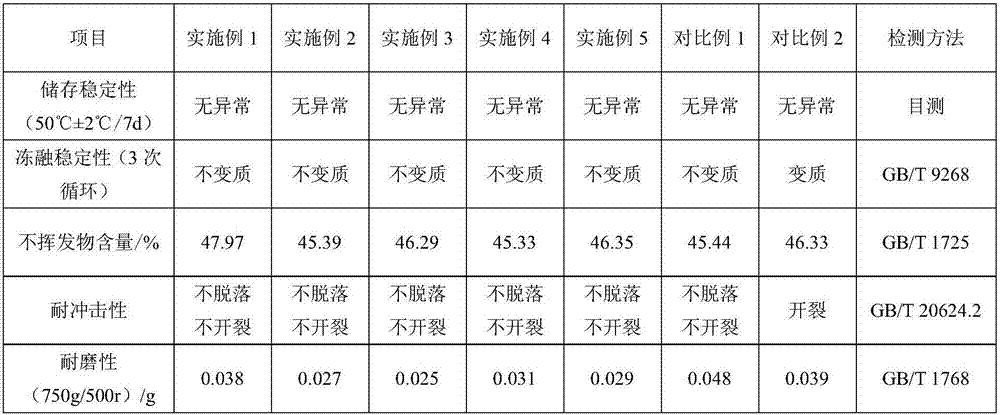

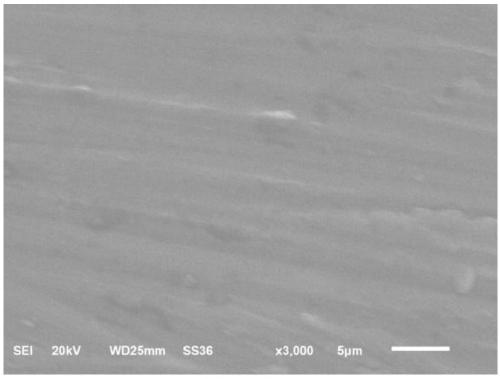

Room temperature self-crosslinking type PUA-SiO2 hybrid emulsion and preparation method thereof

The invention discloses a room temperature self-crosslinking type PUA-SiO2 hybrid emulsion and a preparation method thereof. The hybrid emulsion consists of a core-shell type waterborne polyurethane-polyacrylate copolymer, functional nanosilicon dioxide and water. Different from traditional blend doping, the PUA-SiO2 hybrid emulsion disclosed by the invention realizes filler reinforcing through chemical bonding generated by self-crosslinking. In the film-forming stage of the hybrid emulsion, a firm organic-inorganic hybrid network is formed among organic and inorganic components through coupled reactions of acetylacetic ester units and primary amines, so that the hybrid emulsion has the excellent characteristics of high film hardness, scratch resistance, water resistance, chemical product resistance, heat resistance and the like. The hybrid emulsion is applicable for high-performance water-based coatings, and is particularly applicable for product preparation of water-based wood coatings.

Owner:NANJING CHANGJIANG PAINT

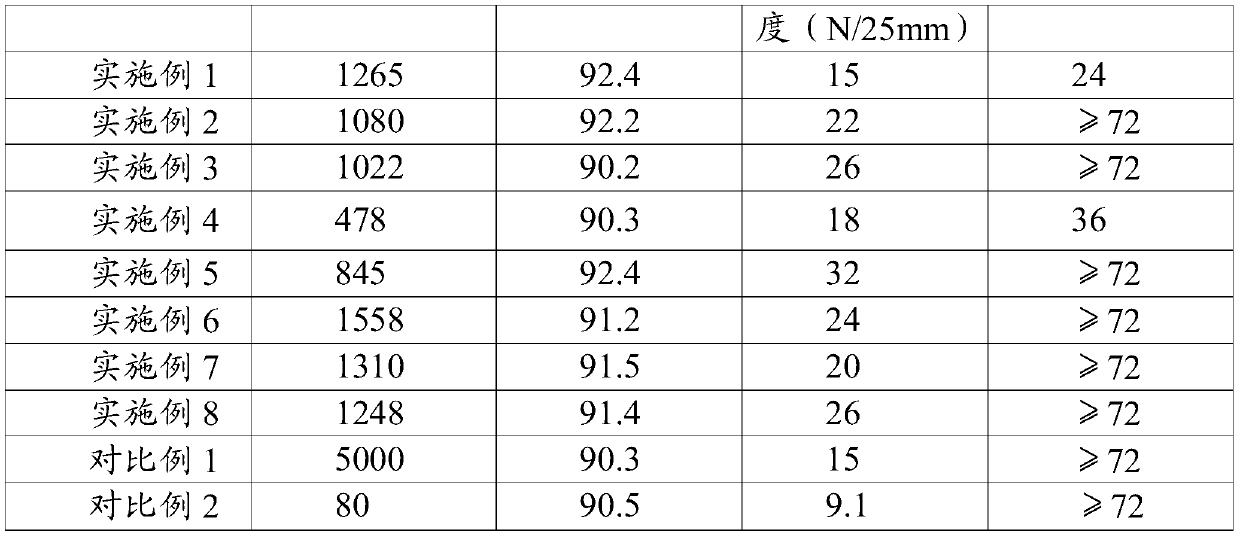

UV-LED curing modified acrylate pressure-sensitive adhesive and preparation method thereof

ActiveCN110396370AImprove cohesionGood adhesionOrganic non-macromolecular adhesiveTemperature resistanceHigh heat

The invention relates to the technical field of pressure-sensitive adhesives, in particular to a UV-LED curing modified acrylate pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive comprises the following components in percentage by mass: 20%-60% of acrylate monomer diluent, 1%-4% of photoinitiator and 36%-79% of modified acrylate pressure-sensitive prepolymer, wherein the modified acrylate pressure-sensitive prepolymer is prepared by polymerizing various acrylate monomers terminated by hydrogenated rosin glyceride, hydrogenated rosin glyceride tackifying resin is introduced into a molecular chain of the modified acrylate pressure-sensitive prepolymer to obtain the acrylate pressure-sensitive adhesive with a self-tackifying effect, and the initialadhesion and peel strength of the acrylate pressure-sensitive adhesive are obviously improved; the pressure-sensitive adhesive prepared from the prepolymer has good light aging resistance and high temperature resistance, can be used for preparing an optical pressure-sensitive adhesive with the light transmittance of more than 90%, and satisfies the use requirements of electronic products on the optical pressure-sensitive adhesive. No water or organic solvent participates in the whole production process of the pressure-sensitive adhesive, and the purposes of low energy consumption, safety and environmental protection are achieved.

Owner:JINAN NORTH TAIHE NEW MATERIAL

Tantalum atom doped bioactive ceramic coating prepared on titanium alloy surface and preparation method thereof

ActiveCN109680266AGood biocompatibilityPromote proliferationSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingMicro arc oxidationPlasma electrolytic oxidation

The invention provides a tantalum atom doped bioactive ceramic coating prepared on a titanium alloy surface and a preparation method thereof, and belongs to the technical field of surface modificationof metal materials. The invention provides a method for preparing a functional element tantalum (Ta) doped bioactive ceramic coating on the surface of a medical titanium alloy by a sol-gel-micro-arcoxidation method. The method is characterized in that tantalum oxide containing sol is dipped to uniformly coat the surface of the titanium alloy by a sol-gel method, and then the high spark dischargeeffect of micro-arc oxidation is utilized to further improve so as to form a dense ceramic film on the sol-gel layer on the surface, and thus the coating is prevented from separating. The Ta-containing coating prepared by the method is uniformly distributed on the surface of the titanium alloy, so that the adhesion and multiplication of osteoblast can be improved, and as a result, the bioactivityof the titanium alloy can be improved; and the method has a good application prospect in the field of medical implant materials

Owner:JILIN UNIV

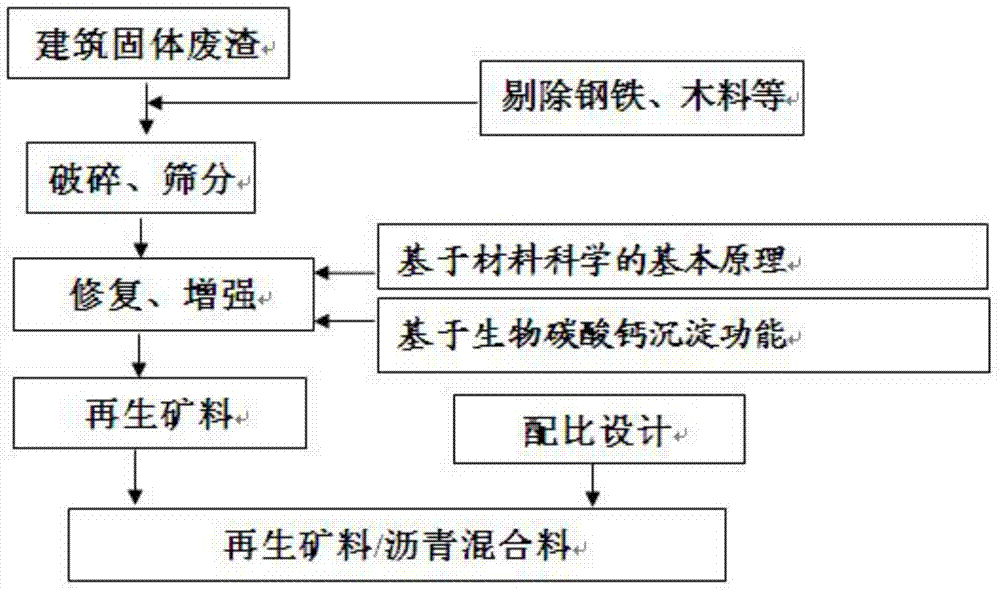

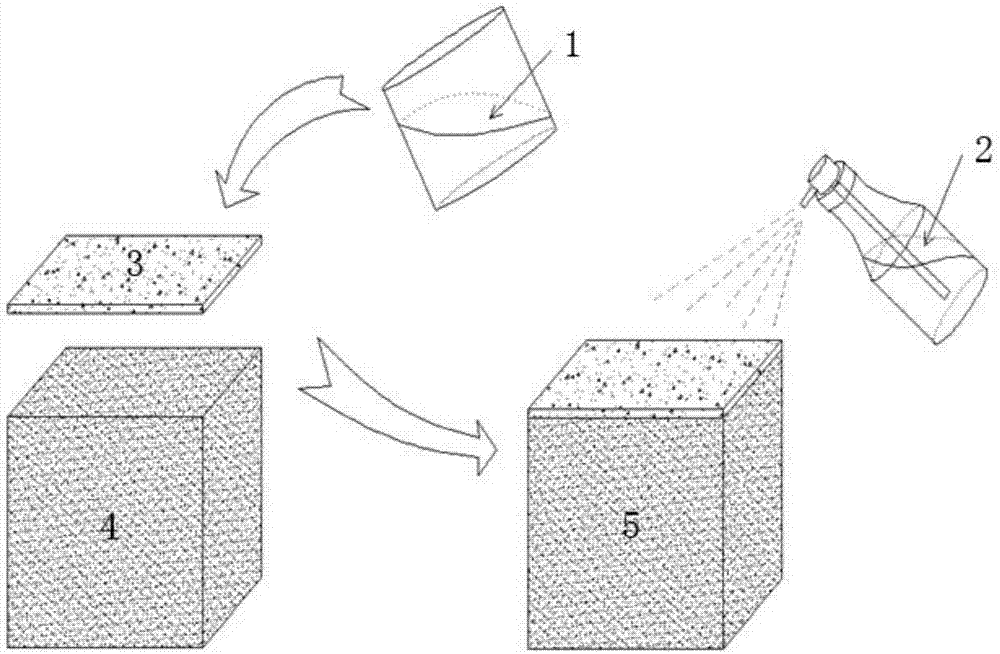

High content regenerated mineral aggregate/asphalt mixture and preparation method thereof

The invention relates to a high content regenerated mineral aggregate / asphalt mixture and a preparation method thereof. Building solid waste residues and petroleum asphalt are adopted as main raw materials, Bacillus pasteurii is adopted as a biological modifier, a microbial chemical deposition product calcium carbonate generated by the Bacillus pasteurii is used as a physical filler and a chemical adhesive, and the performances of regenerated mineral aggregates are restored and enhanced by adopting a microbial chemical deposition technology. The mixture is a novel asphalt mixture with building industrial solid waste slag as main mineral aggregate, a green restoration technology is adopted, and the regenerated mineral aggregate is processed through a microbial technology to realize recycling of building solid waste slag with severe pollution, so the exploitation of raw materials is greatly reduced, the cost is low, and the regenerated mineral aggregate / asphalt mixture has excellent performances.

Owner:SHANTOU UNIV

High-water-reducing high-adaptability polycarboxylate superplasticizer and preparation method thereof

ActiveCN111808244AImprove adaptabilityBarrier adsorptionSolid waste managementMeth-Vinyltriethoxysilane

Owner:湖南加美乐素新材料股份有限公司

Treatment method of phenol-containing wastewater from power generation from rice husk pyrolysis

InactiveCN110437508ALow in phenolic concentrationNot easy to recyclePigment treatment with macromolecular organic compoundsChemical industryCross-link

The invention provides a treatment method of phenol-containing wastewater from power generation from rice husk pyrolysis, and belongs to the field of biomass energy chemical industry. The treatment method of the phenol-containing wastewater from power generation from rice husk pyrolysis comprises the following steps of (1) conducting rice husk pyrolysis to produce pyrolysis gas and pyrolysis carbon, subjecting the pyrolysis gas to spraying, washing and purifying to generate phenol-containing tar wastewater, and crushing the pyrolysis carbon through a crusher to produce 5-10-[mu]m silicon carbon black powder; (2) carrying out an acid-catalyzed reaction on the phenol-containing wastewater and formaldehyde to produce a biomass phenolic resin aqueous solution, and adding a cross-linking agentto promote polymerization of other tar; (3) modifying the silicon carbon black with resin; and (4) mixing modified silicon carbon black and rubber, conducting kneading and mixing through an internal mixer, and conducting extrusion and granulation to produce silicon carbon black / rubber master batch. By means of the proposed method, not only is the phenol-containing wastewater from power generationfrom rice husk pyrolysis treated, but also the silicon carbon black powder is modified, used as a reinforcing agent and applied into various rubber products, so that the proposed method is a rice huskresourceful and comprehensive utilization method with power generation by pyrolysis, production of the phenolic resin from the wastewater, modification of the silicon carbon black and production of the rubber master batch achieved.

Owner:JILIN UNIV

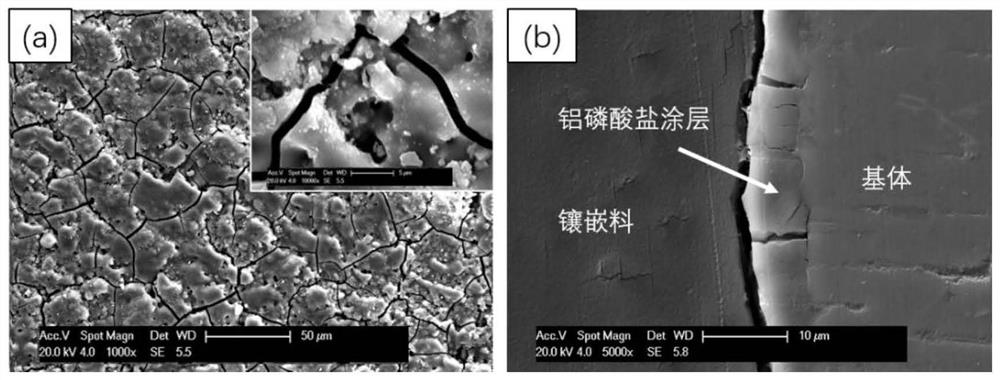

Paint for preparing aluminum phosphate coating on surface of aluminum alloy and use method of paint

InactiveCN107164749AAchieve chemical bondingAccelerated corrosionMetallic material coating processesChemical reactionWater vapor

The invention provides paint for preparing an aluminum phosphate coating on the surface of an aluminum alloy and a use method of the paint. The paint comprises the following raw materials, by weight, 10-70 parts of Al(H2PO4)3, 30-80 parts of pure water, 1.1-1.3 times of the total chemical reaction required amount of pure water and Al(H2PO4)3 of Al2O3 powder. The use method of the paint comprises the following steps: 1) the raw materials are weighed proportionally, and are mixed uniformly and the paint is obtained; 2) an aluminum alloy sample is placed in an alkaline solution for alkaline washing, and then is washed with the pure water, finally the aluminum alloy sample is subjected to natural drying for use; and 3) the surface of the dried aluminum alloy is coated with the paint, then the aluminum alloy is placed in a water vapor environment, and an aluminum alloy casting provided with the aluminum phosphate coating is obtained. The aluminum phosphate coating can be formed on the surface of the aluminum alloy, the corrosion resistance of the aluminum alloy can be improved, the technical treatment temperature is lower than the aging heat treatment temperature usually used for the aluminum alloy, and the use method can act as a final treatment technology to be applied to product production.

Owner:SOUTHEAST UNIV

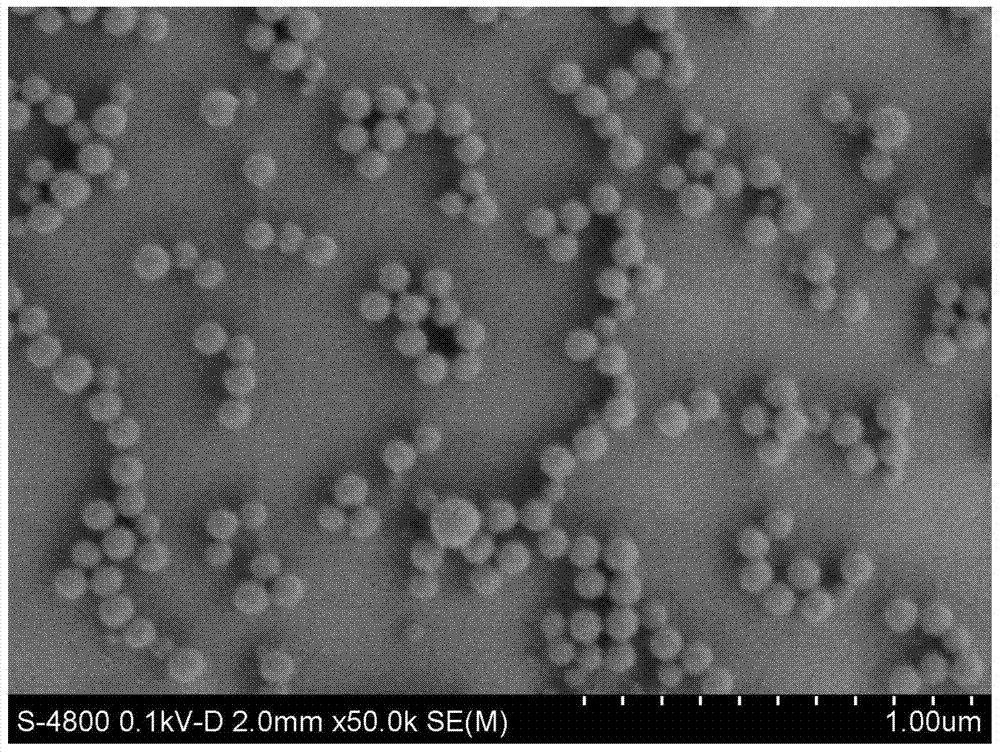

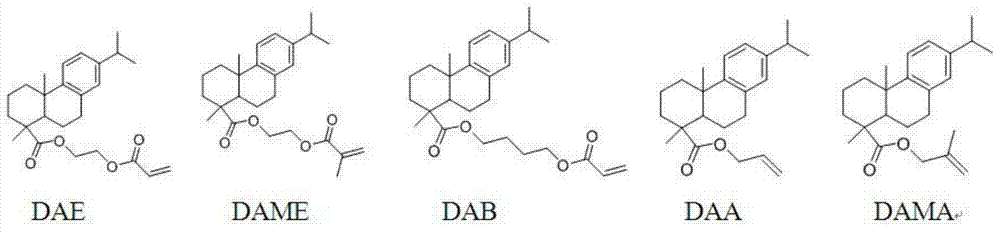

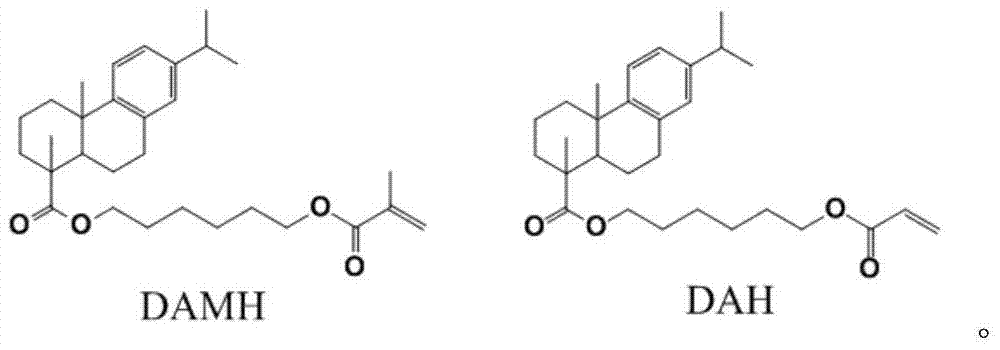

Preparation method for rosinyl composite nano polymer micro-sphere

The invention relates to a preparation method for a rosinyl composite nano polymer micro-sphere. The preparation method comprises the following steps: by taking a polymerizable rosinyl monomer as a stabilizing agent, carrying out an in-situ polymerization reaction with an allyl monomer under the common effect of an emulsifying agent to prepare the rosinyl composite nano polymer micro-sphere. The preparation method comprises the following steps: step 1, by taking the allyl monomer as a solvent, dissolving the polymerizable rosinyl monomer to prepare a polymerizable rosinyl monomer composite solution; step 2, adding the polymerizable rosinyl monomer composite solution into a water solution containing the stabilizing agent and agitating and dispersing; step 3, homogenizing and dispersing at a high speed to prepare a rosinyl composite monomer nano polymer micro-sphere; and step 4, adding an initiator and carrying out in-situ polymerization to prepare the novel rosinyl composite nano micro-sphere. The novel rosinyl composite nano micro-sphere is uniform in size; the grain diameter is about 50nm-200nm and the novel rosinyl composite nano micro-sphere has a very good application prospect in the aspects of adhesives, coatings and the like.

Owner:中国林科院林产化工研究所南京科技开发有限公司

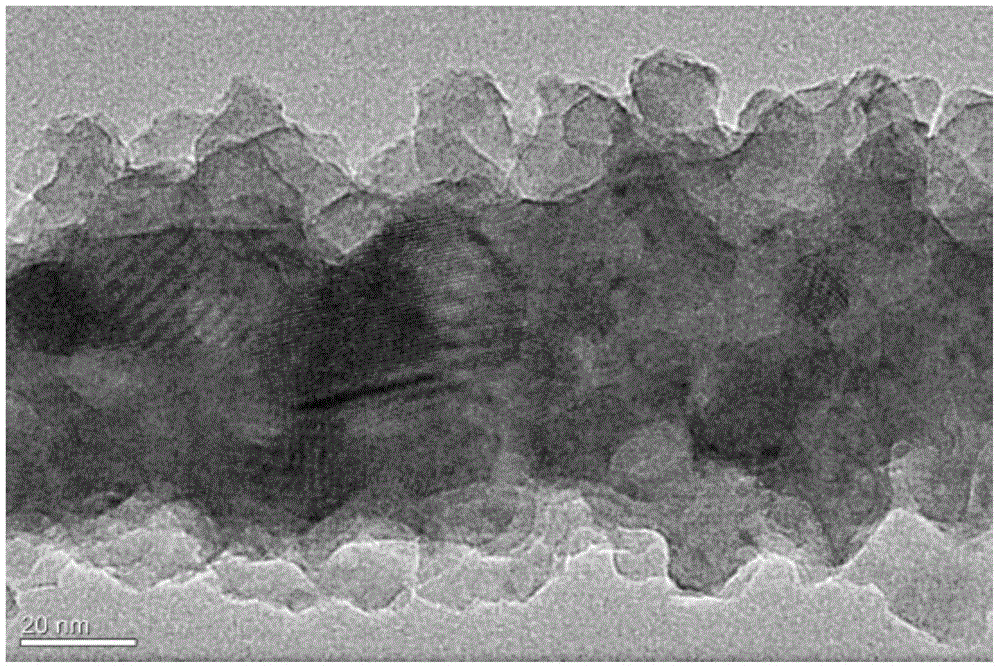

Double in-situ synthesis method for preparing carbon nano tube reinforced hydroxyapatite composite materials

InactiveCN104692348AHighlight substantiveOvercoming contact problemsPhosphorus compoundsSol-gelCarbon nanotube

The invention relates to composite materials for prosthesis materials, in particular to a double in-situ synthesis method for preparing carbon nano tube reinforced hydroxyapatite composite materials. The method comprises the steps that 1, in-situ synthesis of carbon nano tube-hydroxyapatite in-situ mixed powder is carried out; 2, double in-situ synthesis of carbon nano tube-hydroxyapatite in-situ composite powder is carried out; 3, the carbon nano tube reinforced hydroxyapatite composite materials are prepared. On the basis of preparing the carbon nano tube-hydroxyapatite in-situ composite powder, a hydroxyapatite layer which is dense in coating and controllable in structure is synthesized on the surface of the carbon nano tube through a sol-gel process, the carbon nano tube reinforced hydroxyapatite composite materials are prepared, the prefect structure of a carbon nano tube and the good biocompatibility of the hydroxyapatite composite materials are both achieved, meanwhile, the dispersion effect of the carbon nano tube and the interface combination effect are obviously improved, the carbon nano tube reinforced hydroxyapatite composite materials with the excellent mechanical property and the biocompatibility are made, and the carbon nano tube reinforced hydroxyapatite composite materials are widely applied to the bio-medical field.

Owner:HEBEI UNIV OF TECH

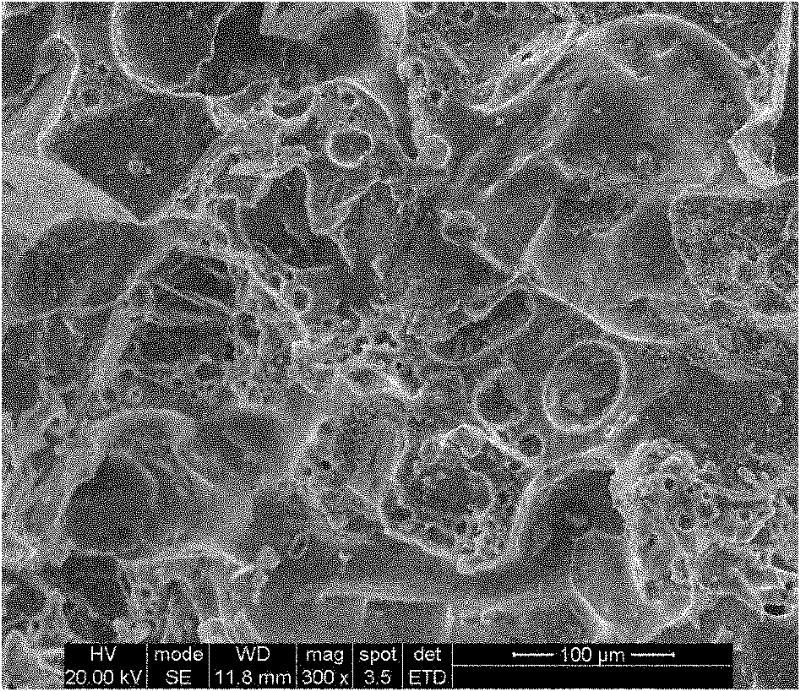

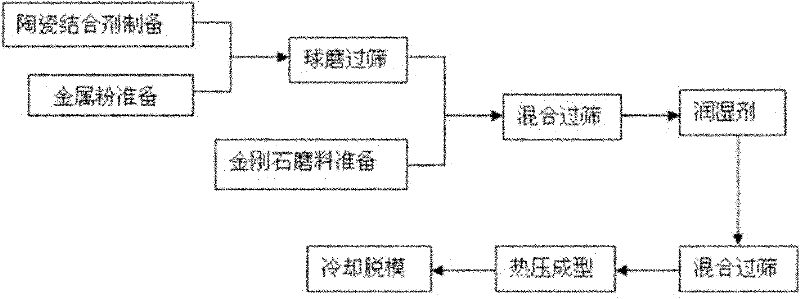

Diamond grinding tool of ceramic-metallic bond and preparation method of grinding tool

ActiveCN102152248BImprove toughnessHigh strengthAbrasion apparatusGrinding devicesLithium oxideMixed materials

The invention discloses a diamond grinding tool of a ceramic-metallic bond and a preparation method of the grinding tool. The preparation method comprises the following steps of: firstly, preparing the ceramic-metallic bond by ball milling the following components in percentage by weight: 40 to 50 percent of silicon dioxide (SiO2), 8 to 15 percent of aluminium oxide (Al2O3), 12 to 20 percent of diboron trioxide (B2O3), 3 to 6 percent of lithium oxide (Li2O), 6 to 12 percent of sodium oxide (Na2O), 3 to 6 percent of potassium oxide (K2O), 2 to 8 percent of zinc oxide (ZnO), 1 to 10 percent of titanium (Ti) and 1 to 5 percent of aluminium (Al); secondly, mixing the ceramic-metallic bond with a diamond abrasive to obtain a mixed material, and then adding 3 to 5 mass percent of wetting agent into the mixed material to obtain a raw material of the grinding tool; and finally, carrying out hot-forming and cooling de-moulding on the raw material of the grinding tool respectively to obtain thediamond grinding tool of the ceramic-metallic bond. The diamond grinding tool of the ceramic-metallic bond provided by the invention has the advantages of the diamond grinding tool of a metallic bondand the grinding tool of a ceramic bond.

Owner:长沙百通新材料科技有限公司

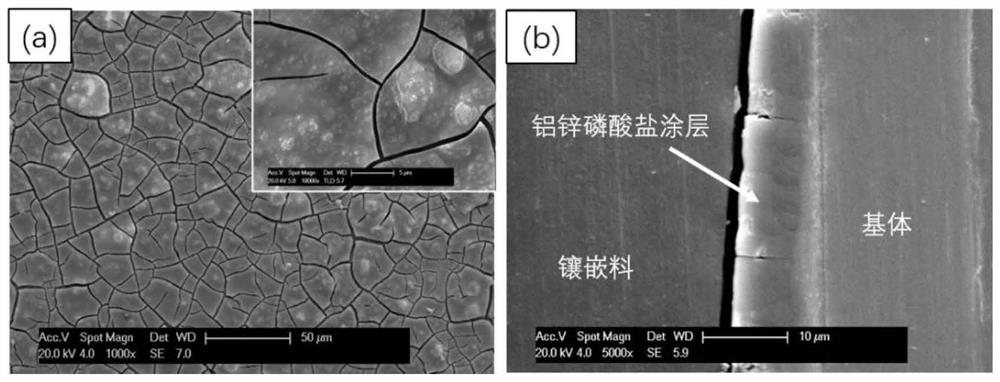

Aluminum-zinc phosphate coating and use method thereof

ActiveCN113174150AHigh reactivityIncrease crosslink densityAnti-corrosive paintsZinc phosphatePhysical chemistry

The invention discloses an aluminum-zinc phosphate coating and a use method thereof. The coating is prepared from the following components in parts by weight: 10 to 50 parts of Al(H2PO4)3, 1 to 20 parts of Zn(H2PO4)3, 1 to 10 parts of TEOS, 60 to 90 parts of H2O and 10 to 70 parts of Al2O3 powder. The modified aluminum-zinc phosphate coating is prepared on the surface of a cast aluminum alloy through a steam-assisted heat treatment method. According to the invention, Al(H2PO4)3 and Zn(H2PO4)3 are used as composite binders, so the reaction activity of the coating and a cast aluminum matrix is improved; as the TEOS is added as a modifier, the compatibility of nano-SiO2 and the composite binders can be improved, and the crosslinking density of the coating is improved; and the prepared modified aluminum zinc phosphate coating is uniform and flat, is tightly combined with the matrix, mainly comprises Zn3(PO4)2, AlPO4, AlPO4. 2H2O and SiO2, and can remarkably improve the corrosion resistance of an aluminum alloy casting.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com