Tear-free self-adhesive rubber waterstop belt and preparation method thereof

A rubber waterstop, self-adhesive technology, used in chemical instruments and methods, adhesives, adhesive types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

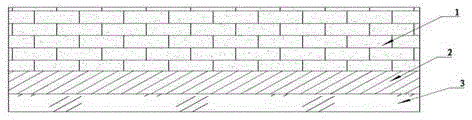

Image

Examples

preparation example Construction

[0041] The preparation steps of the above-mentioned peel-off rubber waterstop:

[0042] In the first step, the preparation of the rubber base material includes: according to the rated component ratio, the traditional extrusion process is used to produce a rubber base material with a thickness of 8-10 mm;

[0043] The second step, the preparation of the polymer self-adhesive adhesive layer includes: first adding softening oil, tackifying resin, filler and antioxidant into the reaction kettle and heating, the temperature is controlled at 170-180 °C, and at the same time, the agitator is started to stir ;After the above materials are all melted, add thermoplastic elastomer, the main material of the self-adhesive layer, and keep the temperature between 170°C and 190°C. self-adhesive;

[0044] In the third step, the pretreatment process of the isolation layer includes:

[0045] Put the natural zeolite, metakaolin and wollastonite inorganic particles and stearic acid into the ...

Embodiment 1

[0051] Embodiment 1: by the SBS of 50 parts by weight, the softening oil of 20 parts by weight, the C5 petroleum resin of 34 parts by weight, the coumarone resin of 15 parts by weight, the rutile titanium dioxide of 3 parts by weight and the antioxidant of 0.2 parts by weight Agent 1010 composition;

Embodiment 2

[0052] Embodiment 2: by the SBS of 48 parts by weight, the SIS of 20 parts by weight, the softening oil of 15 parts by weight, the carbon nine petroleum resin of 32 parts by weight, the coumarone resin of 12 parts by weight, the rutile titanium dioxide of 2.5 parts by weight and The antioxidant 1010 of 0.3 parts by weight constitutes;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com